Robot joint speed reducer based on nutation speed reduction and friction transmission and design method

A technology of robot joints and friction transmission, which is applied in the direction of friction transmission devices, transmission boxes, mechanical equipment, etc., can solve the problems of complex overall structure, limited service life, difficult assembly and maintenance, etc., and achieve high transmission accuracy, high positioning accuracy, and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

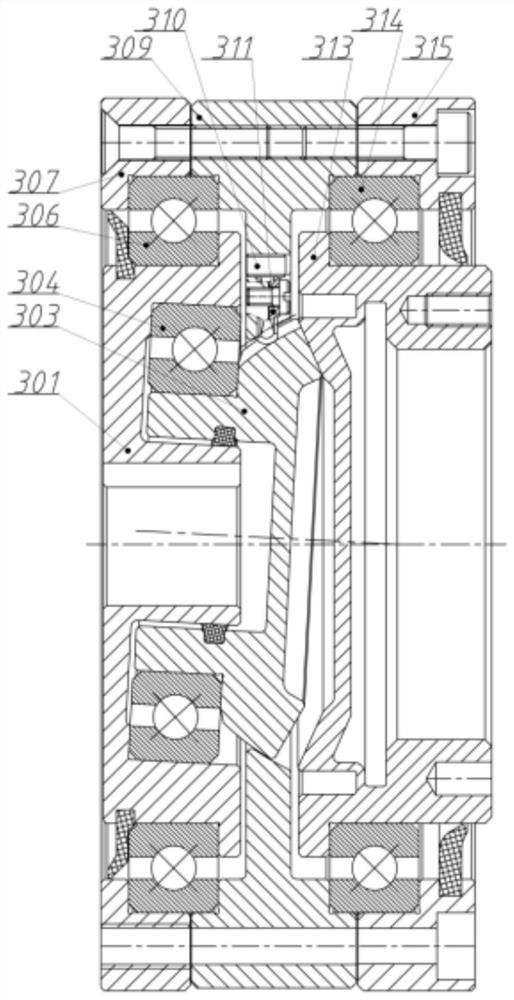

[0033] Such as figure 1 As shown, the present invention provides a technical solution: a robot joint reducer based on nutation deceleration and friction transmission, which is characterized in that it includes:

[0034] The shell, the shell is composed of the bearing base 309, the upper positioning ring 315, and the lower positioning ring 307. The shell is used as the installation reference of the reducer to position and install the reducer body. There are positioning pins 310 and small splints 311,

[0035] A nutating wheel seat 301, the nutating wheel seat 301 is installed on the lower positioning ring 307, and a nutating wheel 303 is installed on the nutating wheel seat 301;

[0036] It also includes an output flange 313 installed on the upper positioning ring 315 .

[0037] A pair of thin-walled four-point contact ball bearings or crossed roller bearings are installed in the housing, which are used as the rotation reference of the nutating wheel base 301 and the output f...

Embodiment 2

[0044] exist figure 1 The specific embodiment shown is a flat cylindrical precision reducer for the end joints of a small 6-joint manipulator, with a design reduction ratio of 40:1, a design power capacity of 100W, and a design maximum output torque of 20N·m.

[0045] Since the transmission parts of the reducer rely on rolling friction as the driving force, in order to ensure the life and performance of the core parts of the reducer, bearing steel or high manganese spring steel is generally used as the material of the parts. Under the condition of non-lubricated static friction, the friction coefficient between steel and steel is calculated as 0.15. The diameter of the large end of the inner cone surface of the primary selection output flange is 41mm, and the required static friction force is 1kN. According to the reduction ratio, the cone surface of the nutating wheel is larger The end diameter is 40mm.

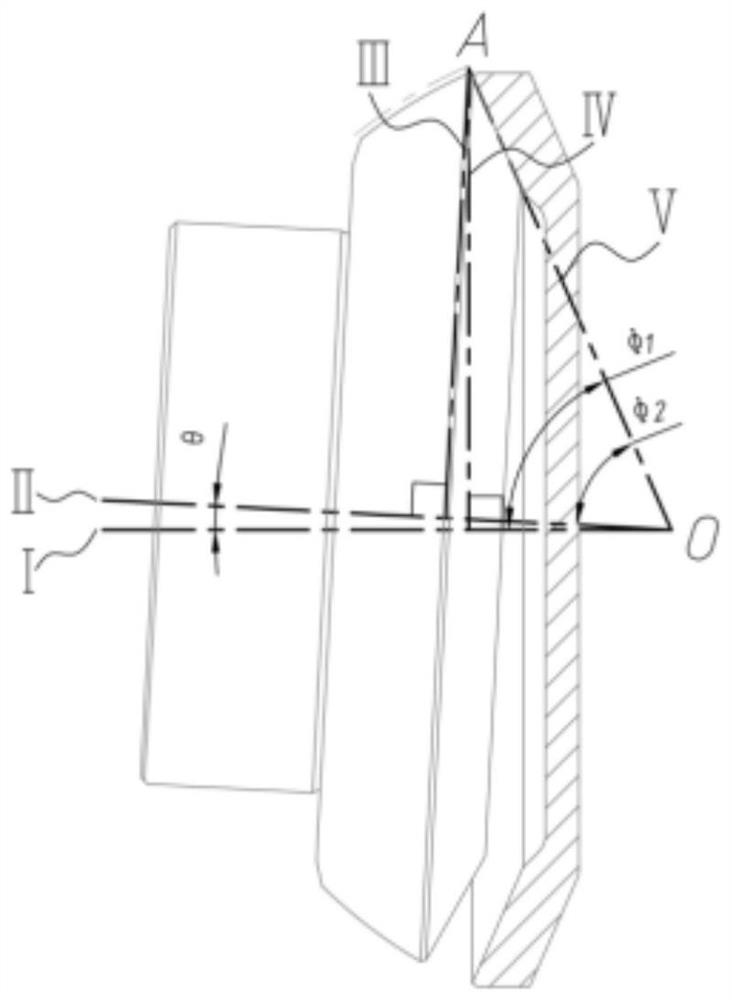

[0046] The primary nutation angle θ = 3°, and the cone angle of the nu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com