Patents

Literature

1113results about How to "Large transmission ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

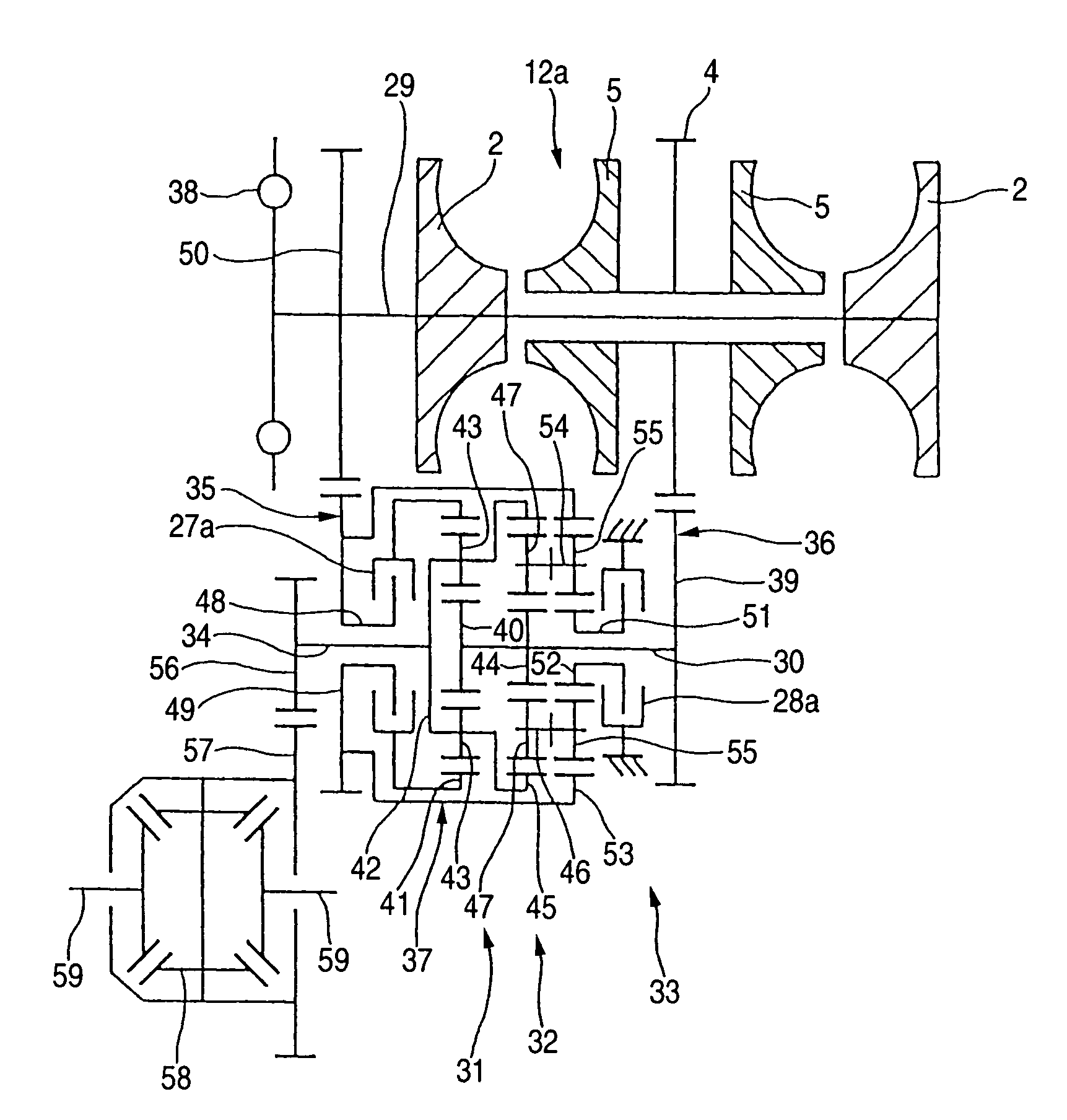

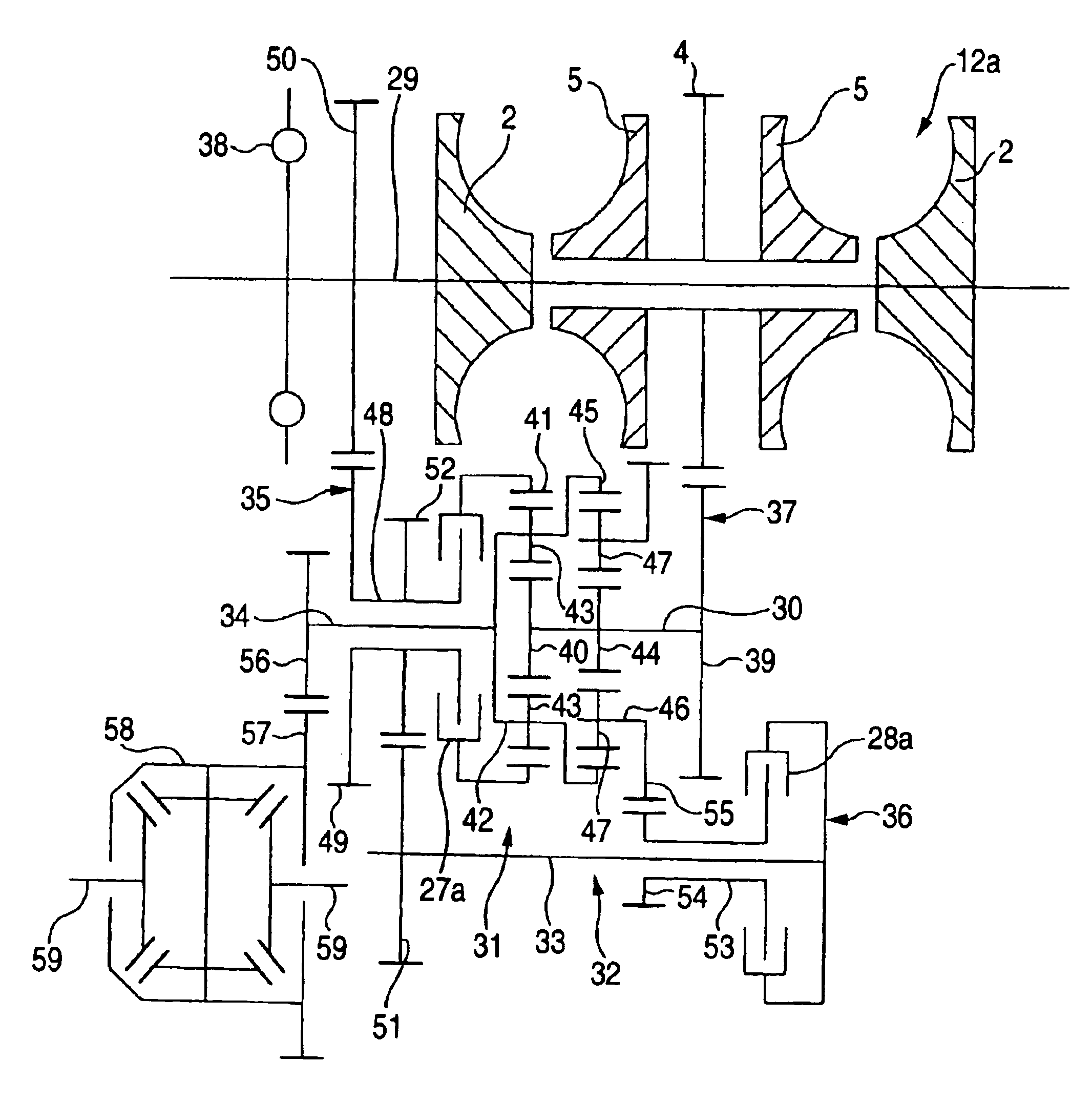

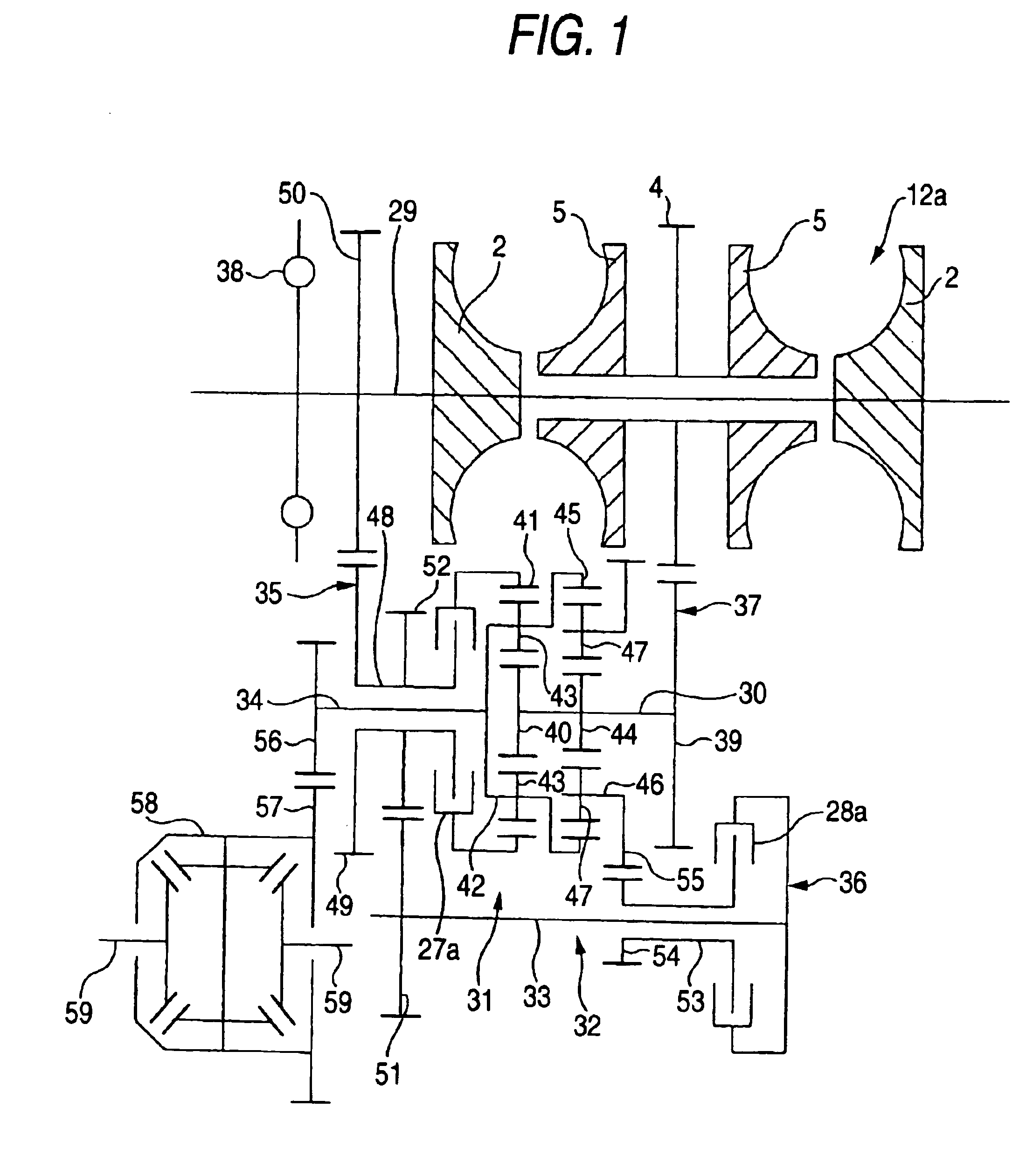

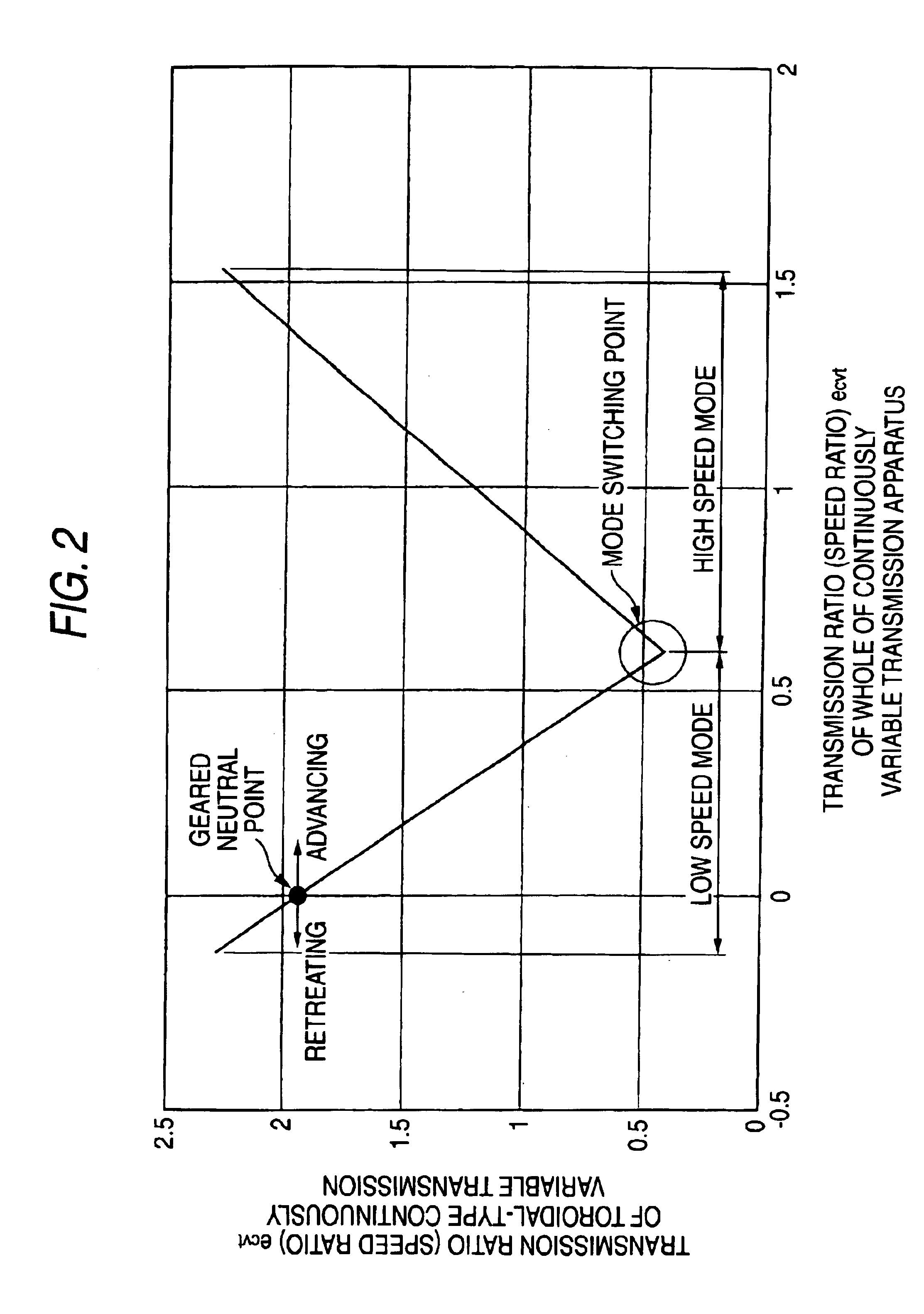

Continuously variable transmission apparatus

ActiveUS7094171B2Save spaceAxial-direction dimension can be reducedFriction gearingsGear wheelDrive shaft

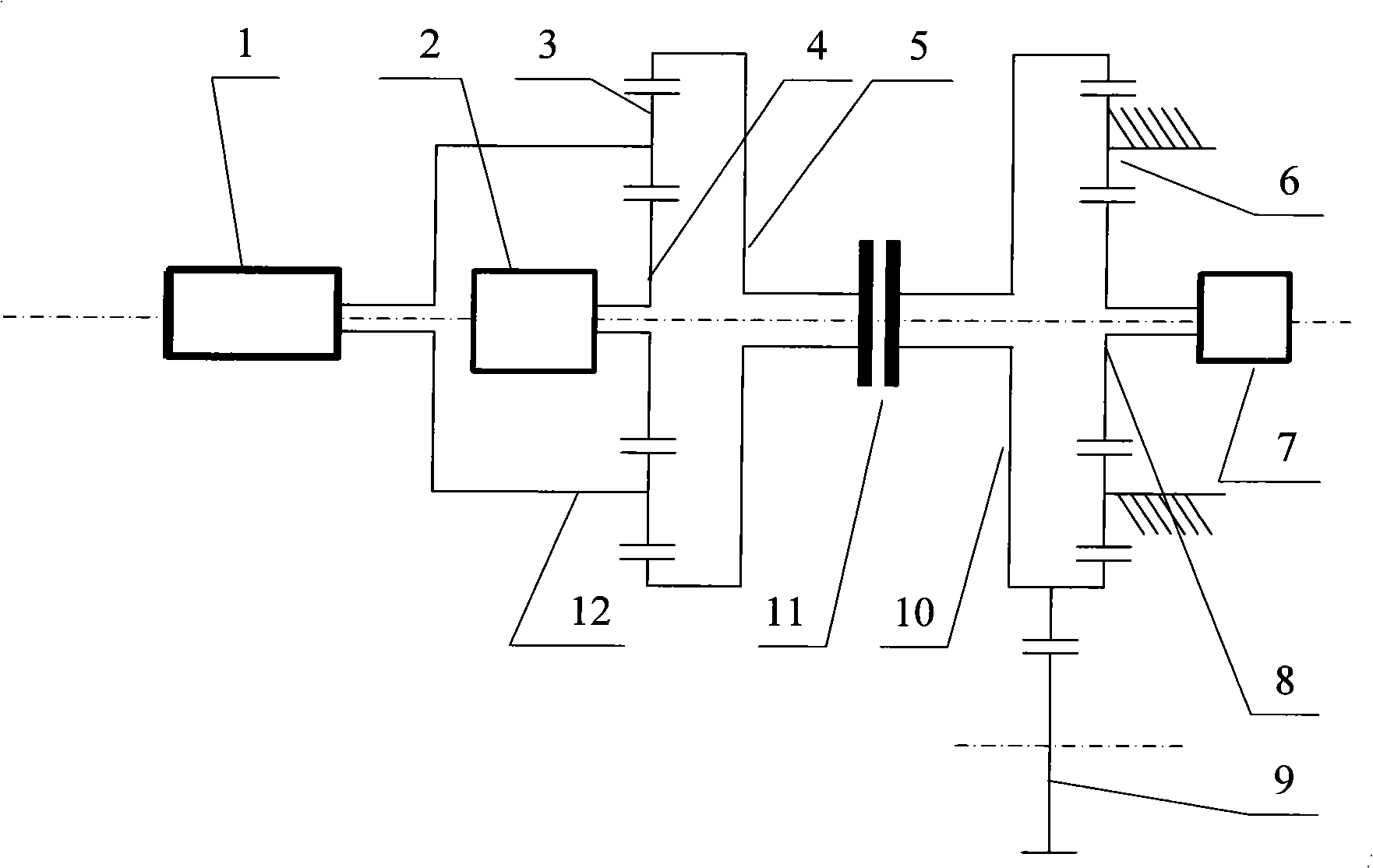

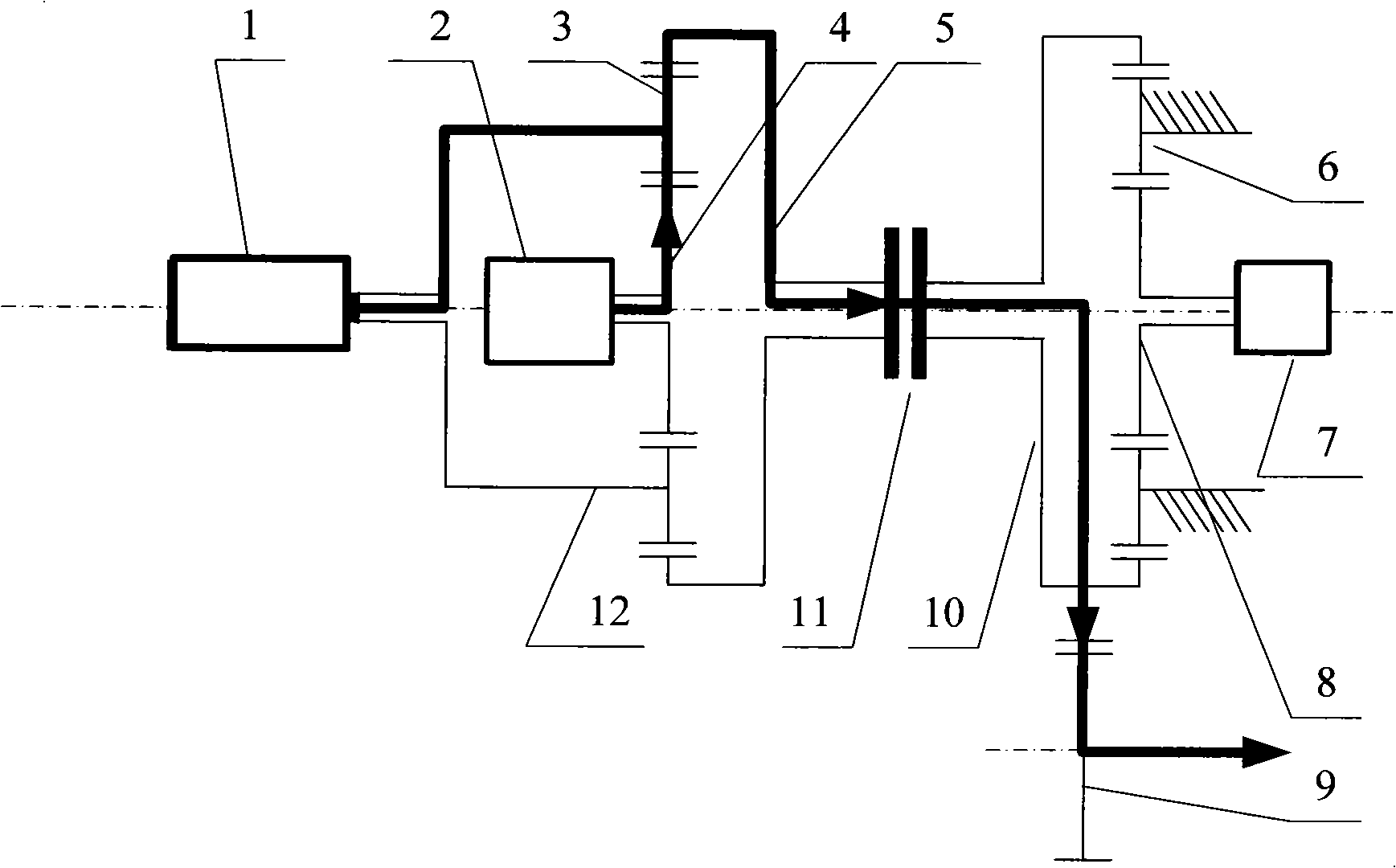

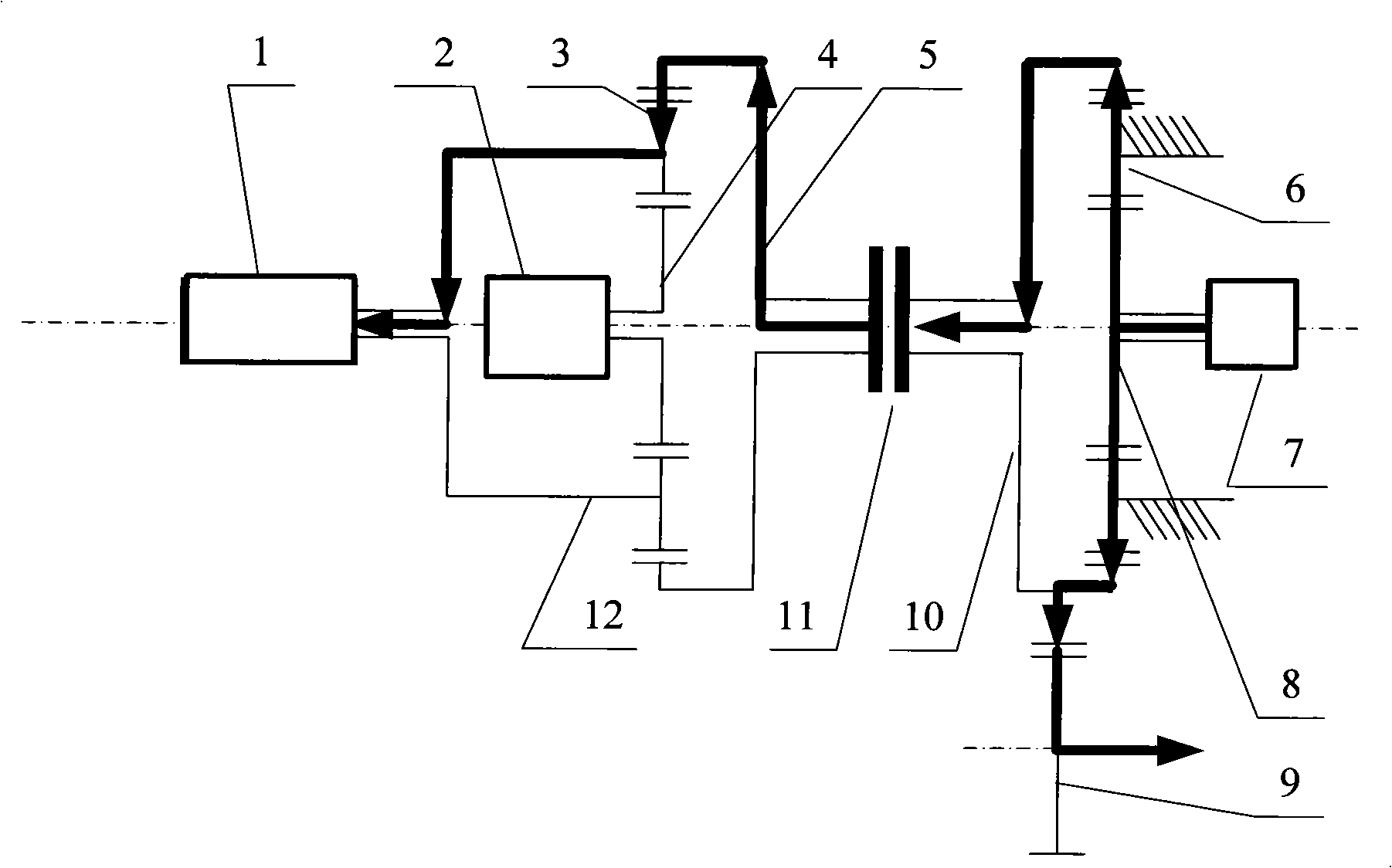

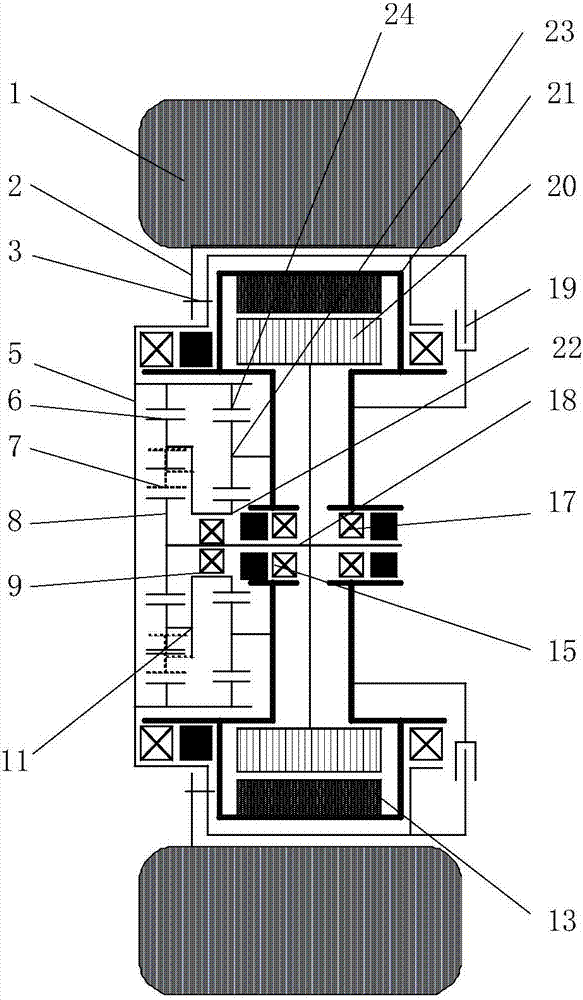

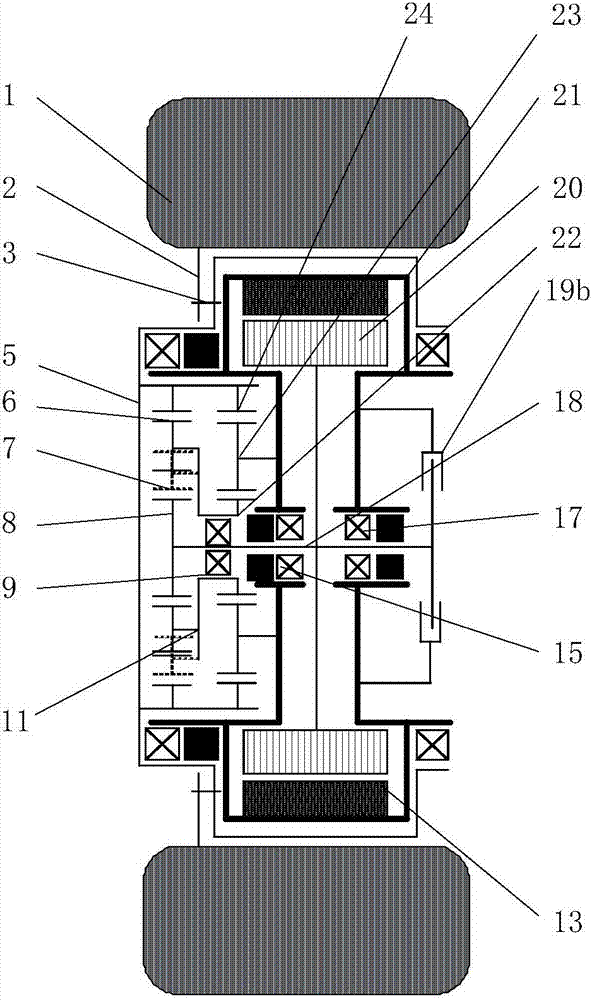

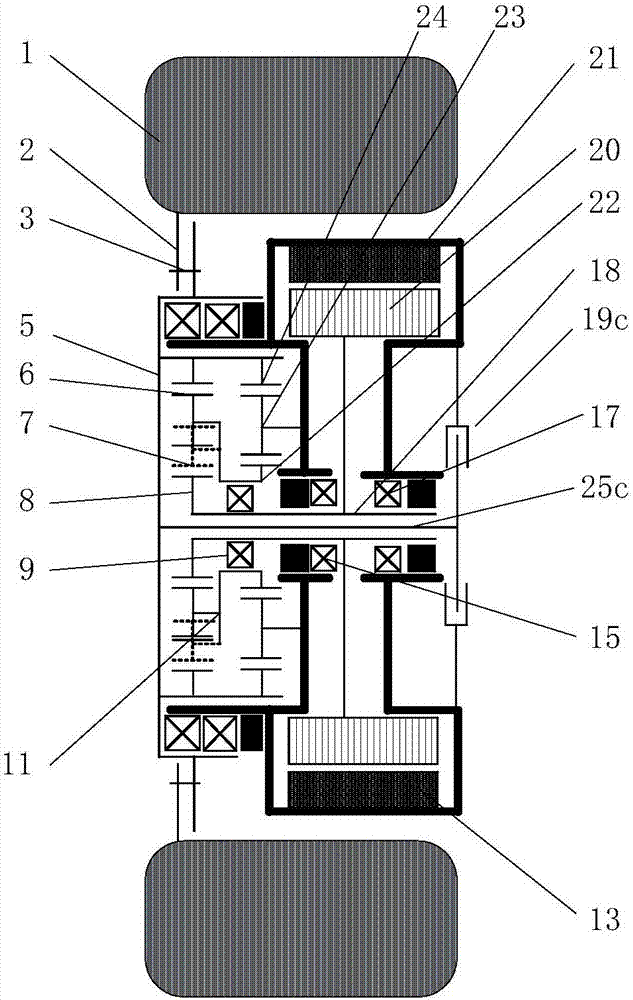

A continuously variable transmission apparatus, has: an input shaft; a toroidal-type continuously variable transmission; a rotation transmission shaft; first, second and third planetary-gear-type transmissions; a first power transmission mechanism; a second power transmission mechanism; a third power transmission mechanism; and, a switching mechanism, wherein the second sun gear and one of the first and third sun gears are rotated together with the rotation transmission shaft to thereby execute the power transmission through the rotation transmission shaft and one of the first and second planetary-gear-type transmissions, and, in a state where the power transmission through the third planetary-gear-type transmission is cut off, in accordance with the control of the transmission ratio of the toroidal-type continuously variable transmission, the output shaft is stopped while the input shaft is rotating.

Owner:NSK LTD

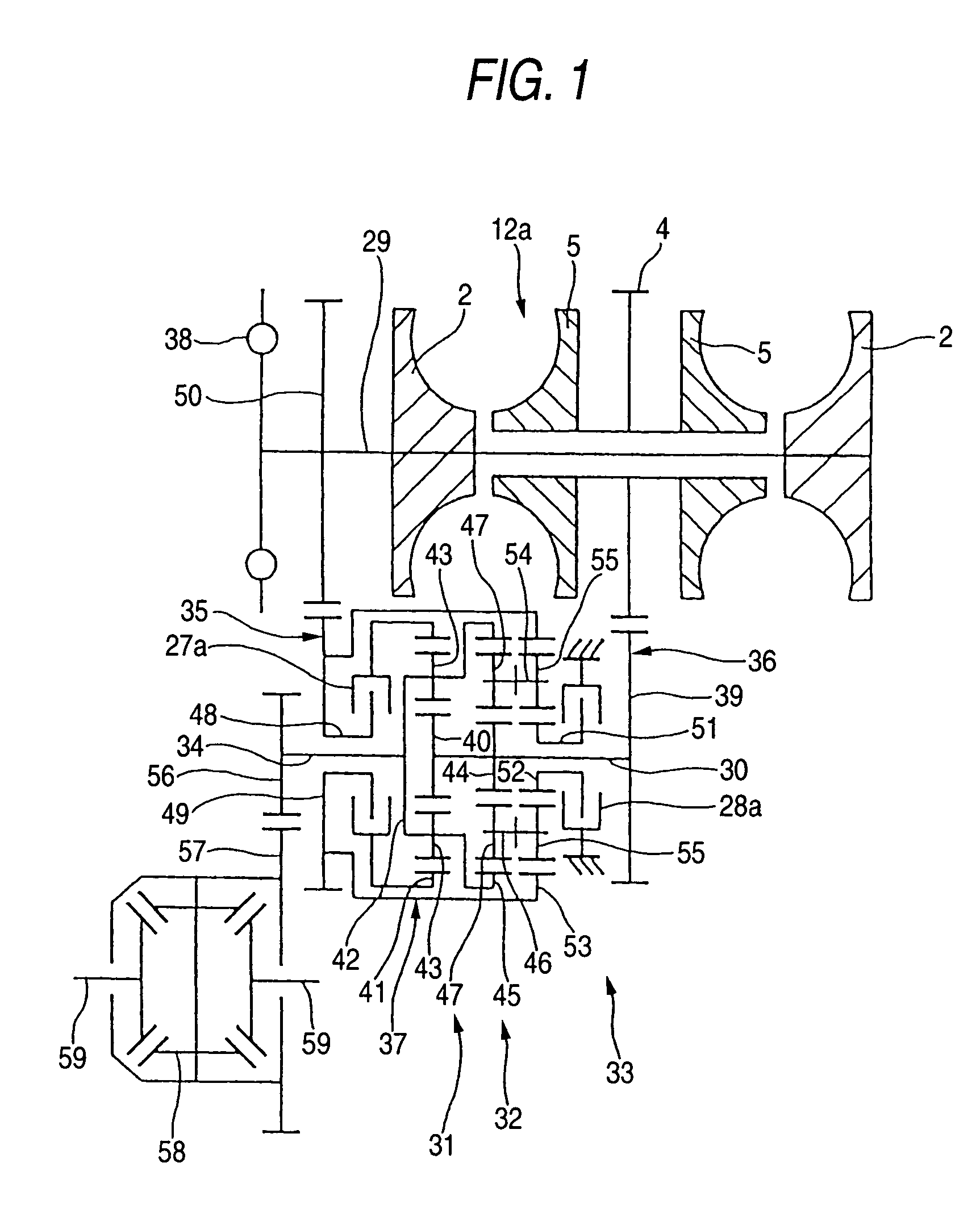

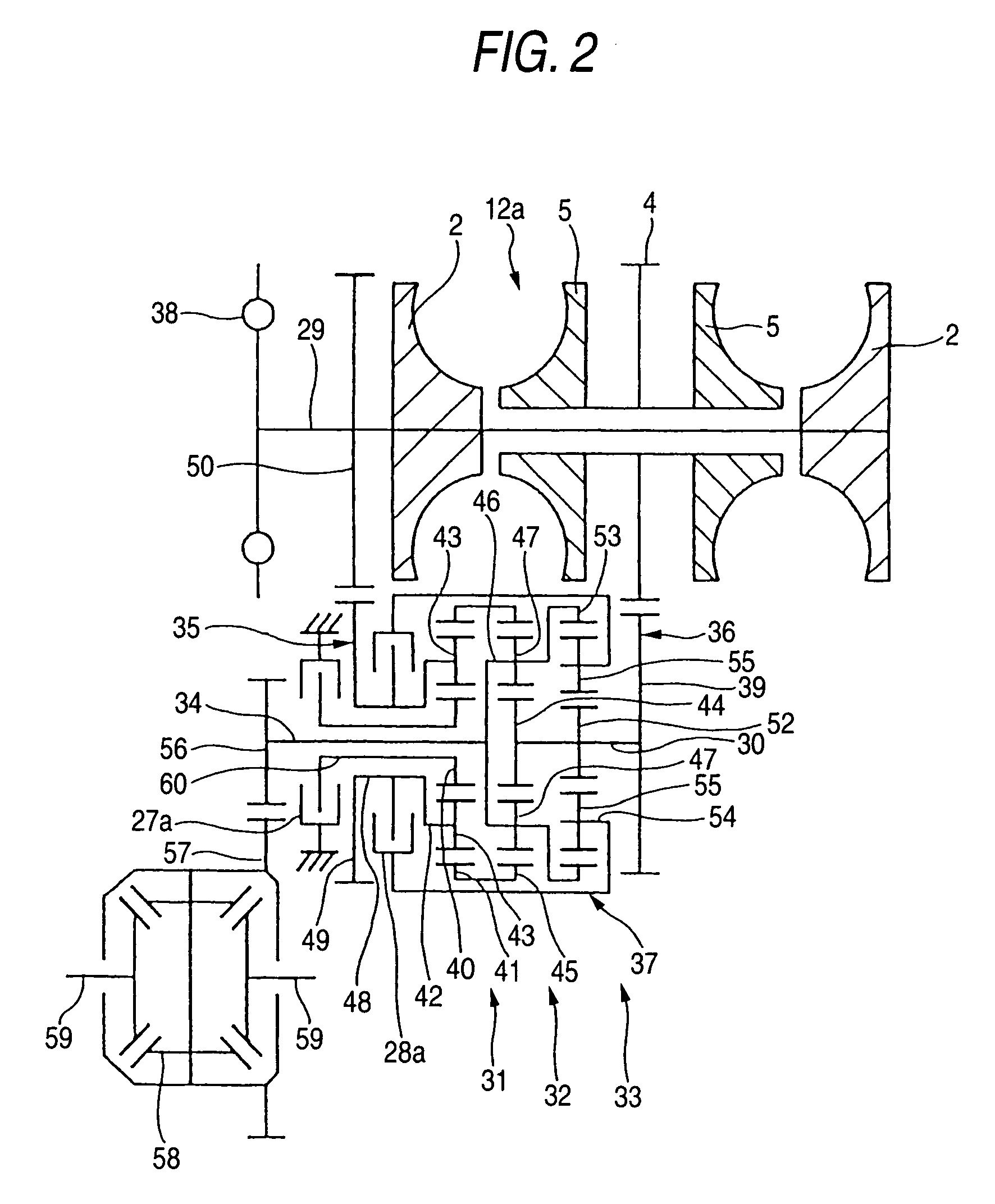

Continuously variable transmission apparatus

A continuously variable transmission apparatus, has: an input shaft; a toroidal-type continuously variable transmission; a first rotation transmission shaft; a first planetary-gear-type transmission; a second planetary-gear-type transmission; a second rotation transmission shaft; an output shaft; a first power transmission mechanism; a second power transmission mechanism; and a switching mechanism, wherein, in a state where the power transmission through the first power transmission mechanism is allowed and the power transmission through the second power transmission mechanism is cut off, in accordance with the control of the transmission ratio of the toroidal-type continuously variable transmission, the output shaft be stopped while leaving the input shaft rotating.

Owner:NSK LTD

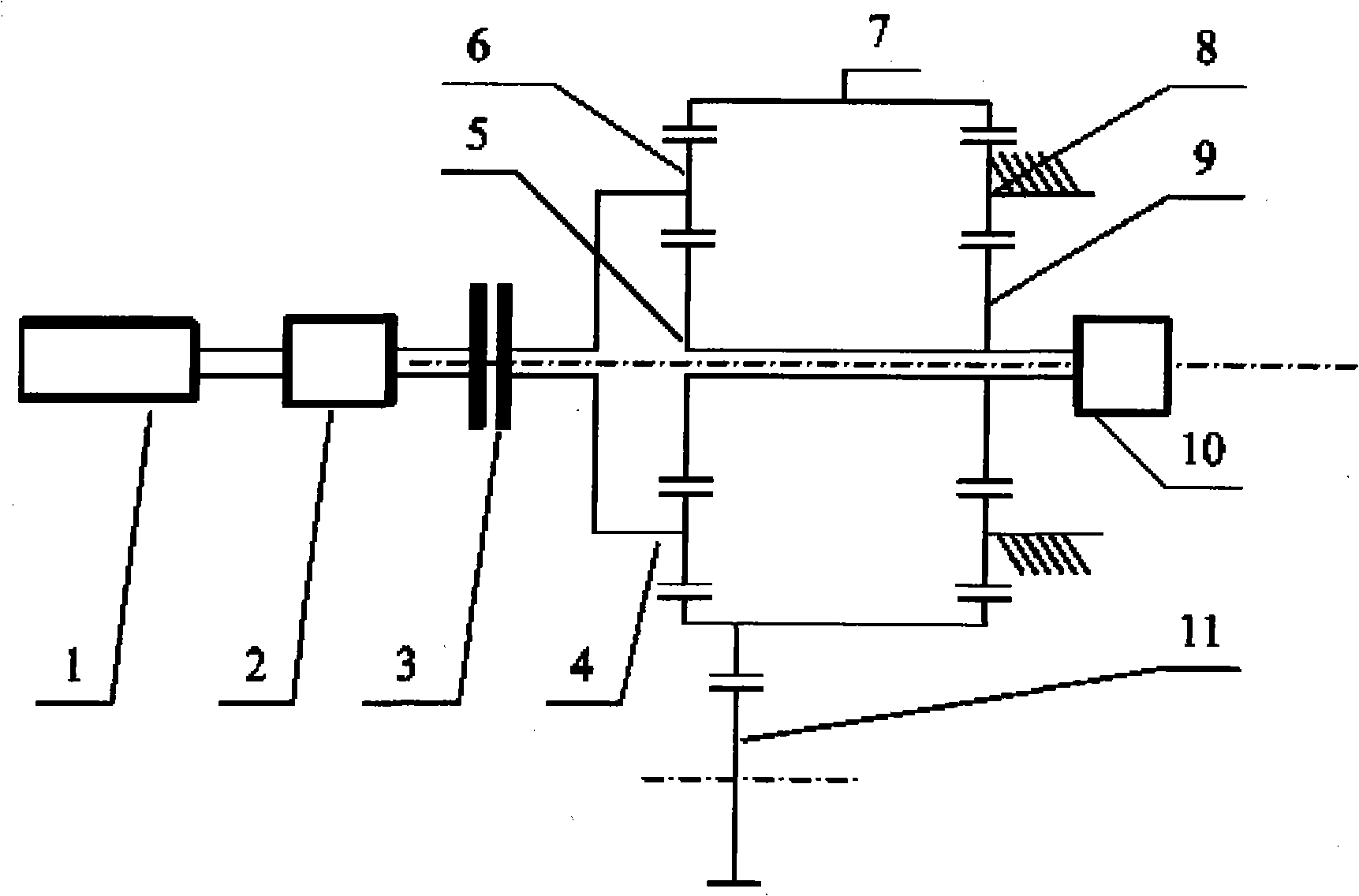

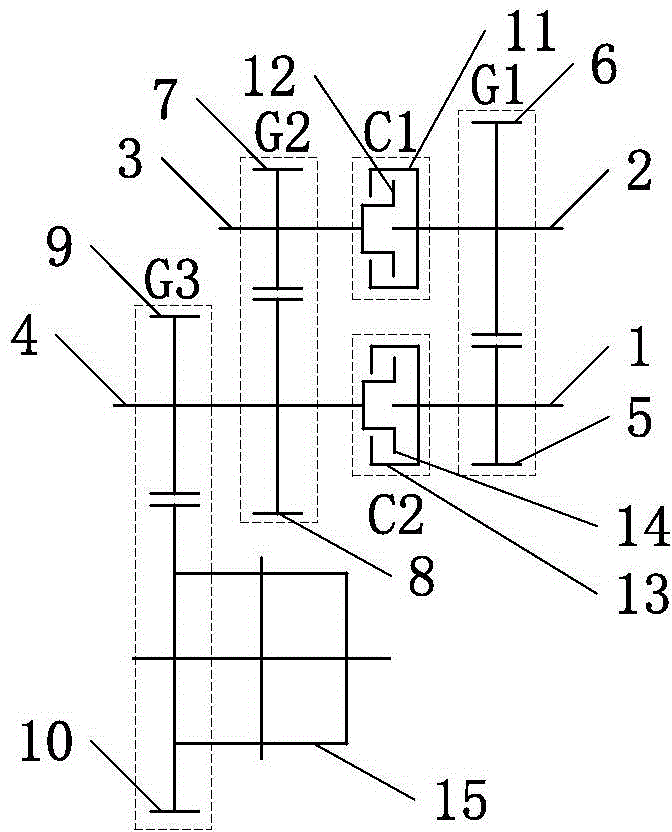

Hybrid power vehicle double electric machine double row planetary gear single clutch drive apparatus

InactiveCN101323243ALower requirementIncrease profitHybrid vehiclesGas pressure propulsion mountingStarter generatorVehicle frame

The invention discloses a twin-motor two-planet-row and single clutch driving device of a hybrid vehicle in the technical field of machinery. The device is provided with a front planet row and a back planet row; the front planet row is provided with a front planet row planet wheel and a front planet row sun gear; the back planet row is provided with a back planet row planet wheel and a back planet row sun gear; the front planet row and the back planet row share a gear ring. The output shaft of an engine is connected with the input end of an integrated starter generator; the output end of the integrated starter generator is connected with the driving disk of the clutch; the driven disk of the clutch is connected with the planet wheel of the front planet row through a planet carrier; the sun gear of the front planet row is connected with a drive motor; the planet carrier of the planet wheel of the back planet row is arranged fixedly on a car frame; the sun gear of the back planet row is also connected with the drive motor; the outside gear of the gear ring is normally engaged with a power take-off gear. The twin-motor two-planet-row and single clutch driving device of the hybrid vehicle has the advantages of compact structure, large transmission ratio, large load support capability, stable driving, and high transmission efficiency, thereby realizing power dividing and infinite variable speed at the same time.

Owner:SHANGHAI JIAO TONG UNIV

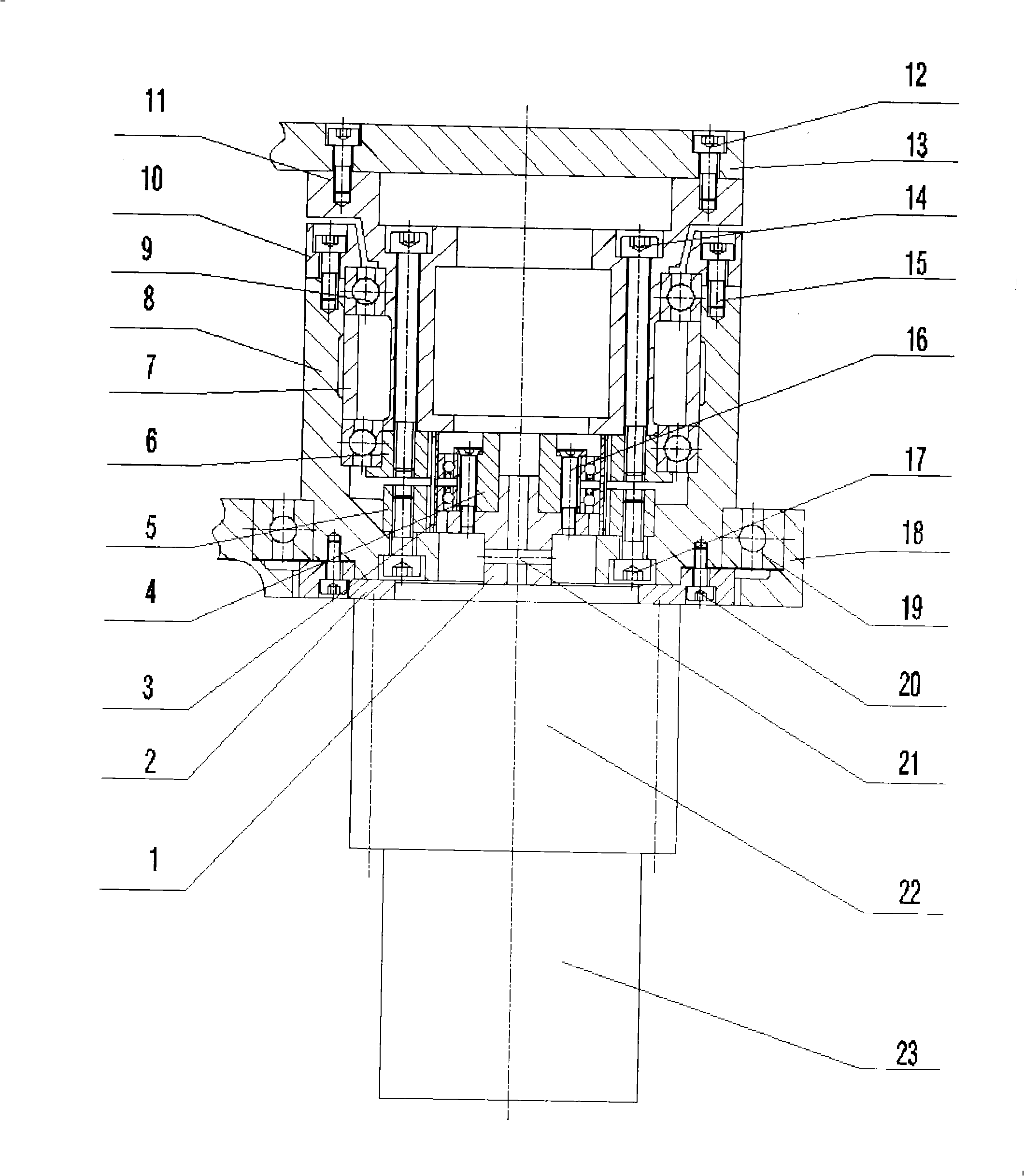

Robot joint based on harmonic wave speed reducer

The invention relates to a robot joint based on harmonic reducers, which comprises a motor, an encoder connected with the motor, a harmonic reducer connected with a rotor of the motor, and a transmission mechanism connected with the harmonic reducer; wherein, the harmonic reducer comprises a wave generator, a flexible wheel outside the wave generator, a fixed steel wheel outside the flexible wheel and a rotary steel wheel; the transmission mechanism comprises a housing fixedly connected with the fixed steel wheel of the harmonic reducer and an end cover fixedly connected with the rotary steel wheel of the harmonic reducer; a bearing is arranged between the housing and the end cover. The robot joint has the advantages of high drive ratio, high reliability, compact structure, ability to substitute the robot joint in the prior art, gradual decrease with the size of the harmonic reducer, higher applicability to joint transmission of miniature robots, and wide application prospect.

Owner:HARBIN ENG UNIV

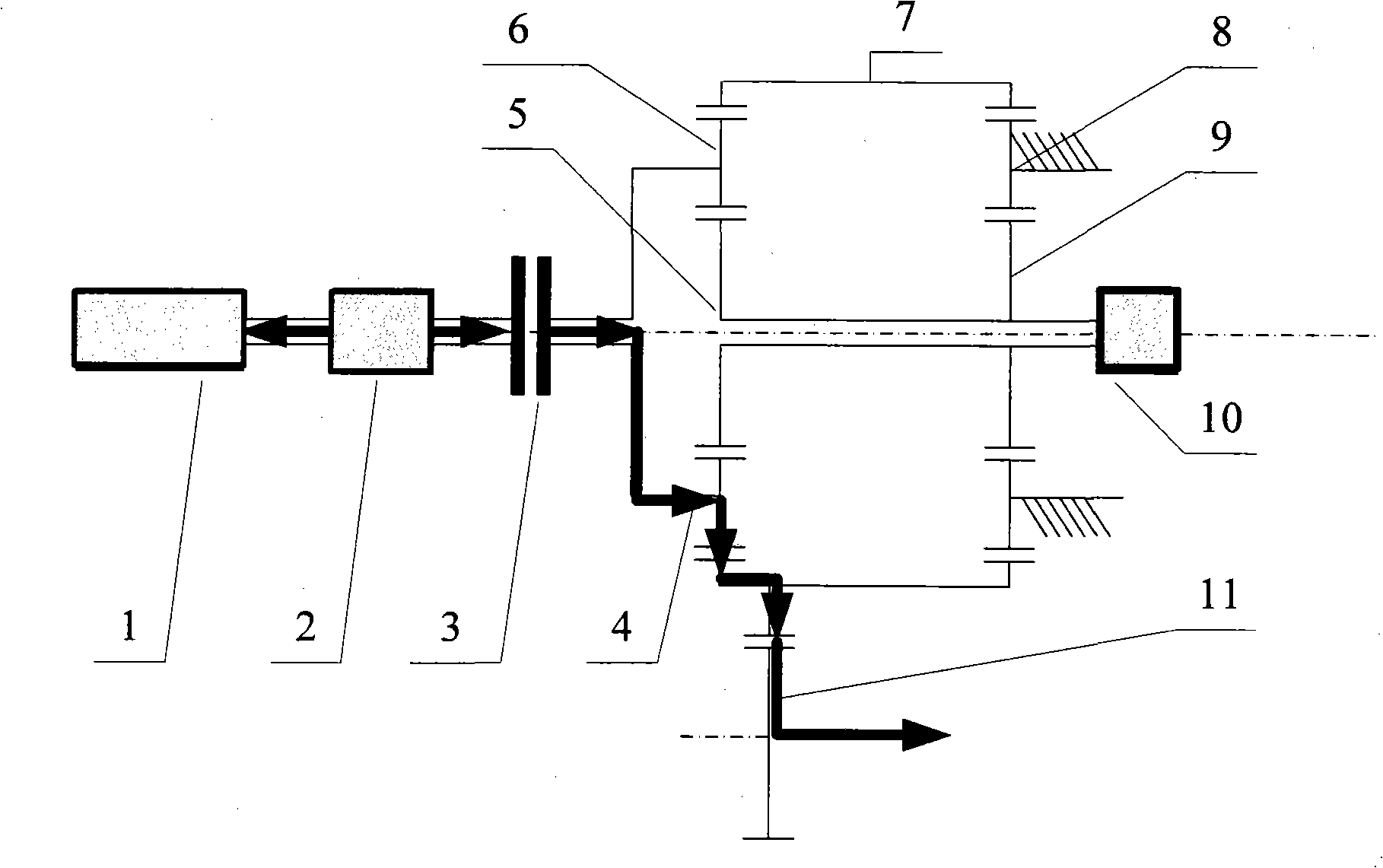

Hybrid power vehicle double row planetary gear electromechanical coupling driving mechanism

InactiveCN101323242AEasy to control independentlyLower requirementHybrid vehiclesGas pressure propulsion mountingVehicle frameGear wheel

The invention discloses a two-planet-row electromechanical coupling driving device of a hybrid vehicle in the technical field of machinery. The device is provided with a front planet row and a back planet row; each of the two planet rows is provided with a planet wheel, a sun gear and a row gear ring; the two planet row gear rings are connected with each other by a clutch. An engine is connected with the planet wheel of the front planet row; an ISG motor is connected with the sun gear of the front planet row; the gear ring of the front planet row is connected with the driving disk of the clutch; the driven disk of the clutch is connected with the gear ring of the back planet row; the planet carrier of the planet wheel of the back planet row is arranged fixedly on a car frame; the sun gear of the back planet row is connected with a drive motor; the outside gear of the gear ring of the back planet row is normally engaged with a power take-off gear. The two-planet-row electromechanical coupling driving device of the hybrid vehicle has the advantages of compact structure, large transmission ratio, large load support capability, stable driving, and high transmission efficiency, thereby realizing power dividing and infinite variable speed at the same time.

Owner:SHANGHAI JIAO TONG UNIV

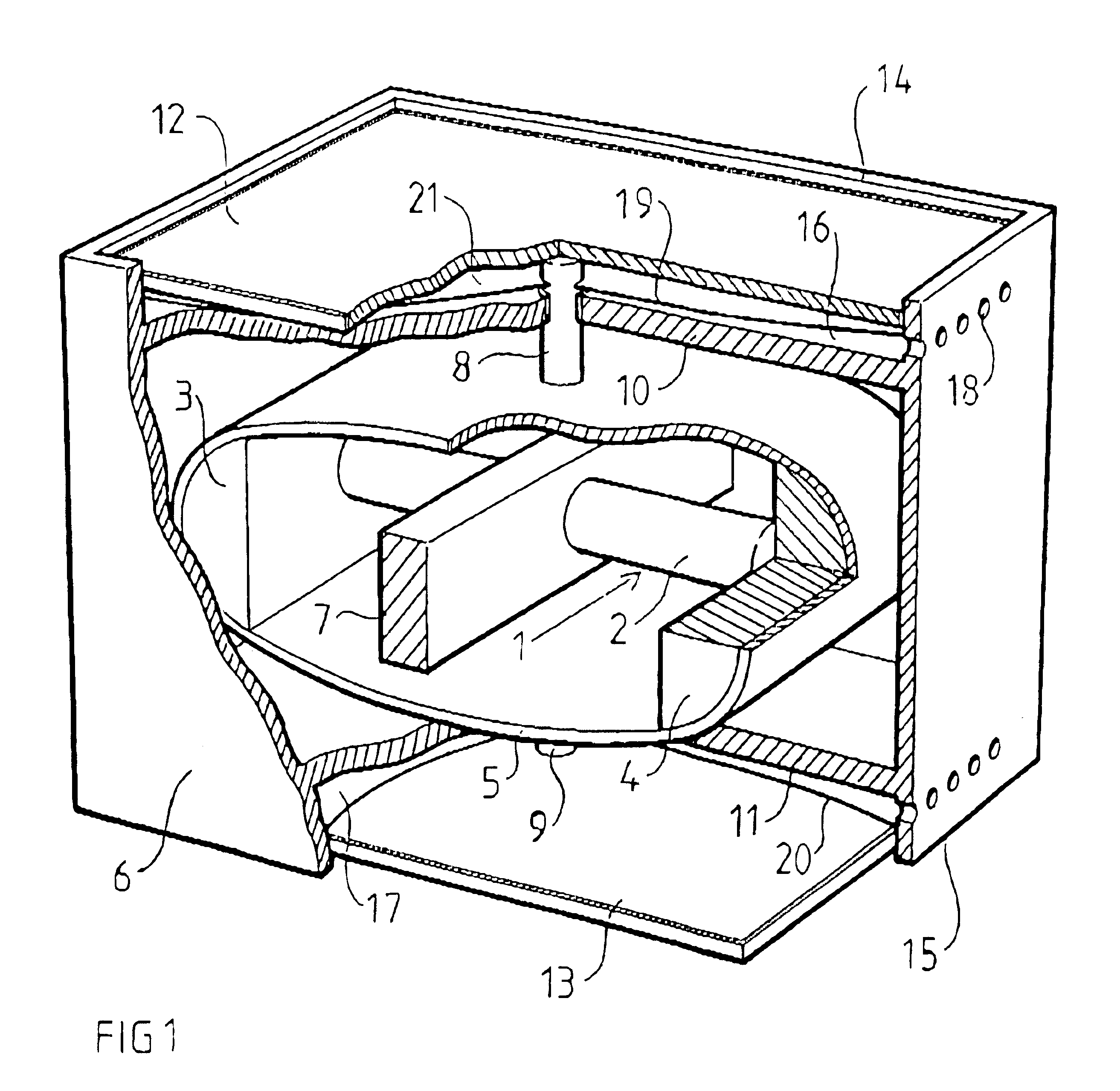

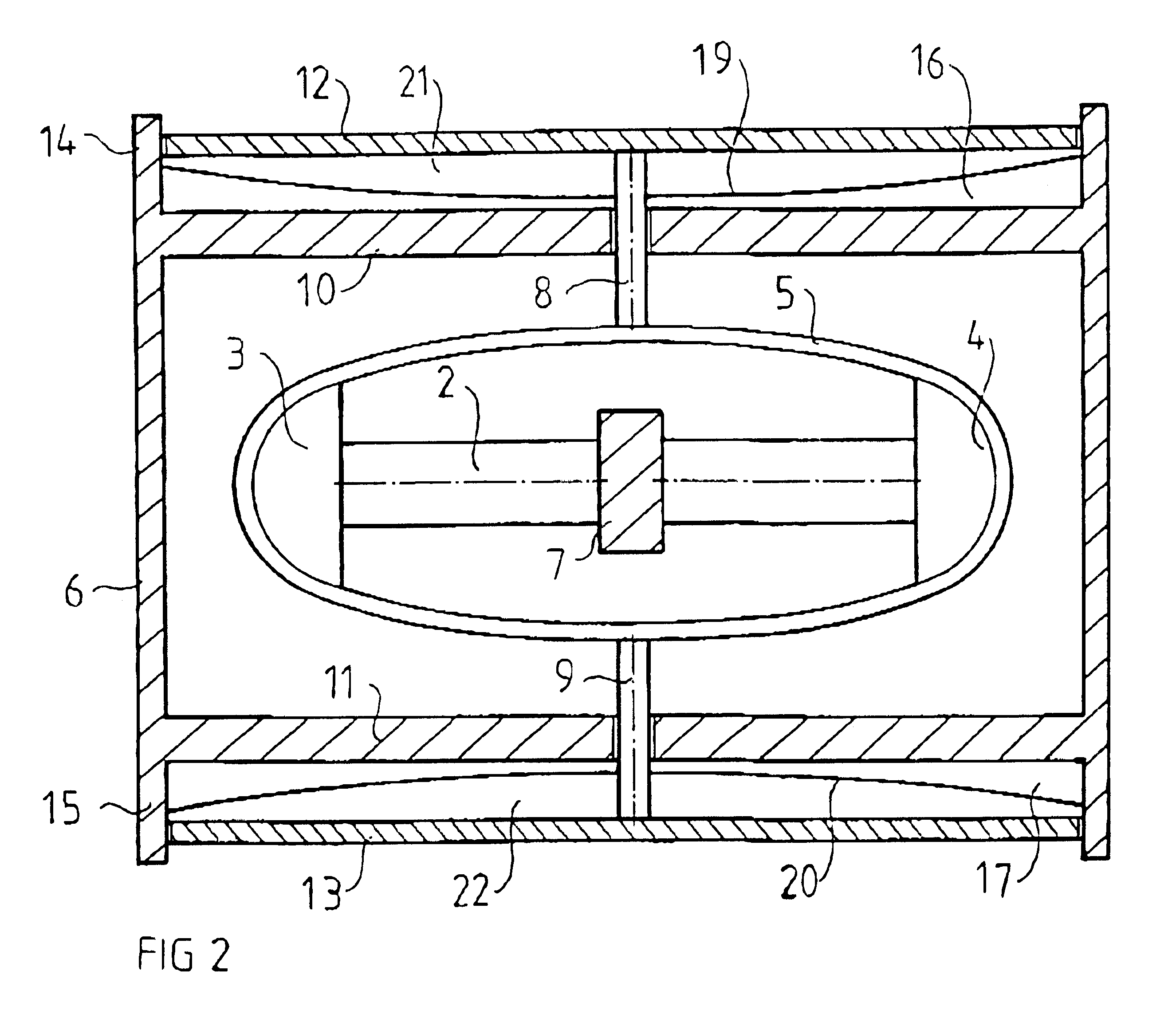

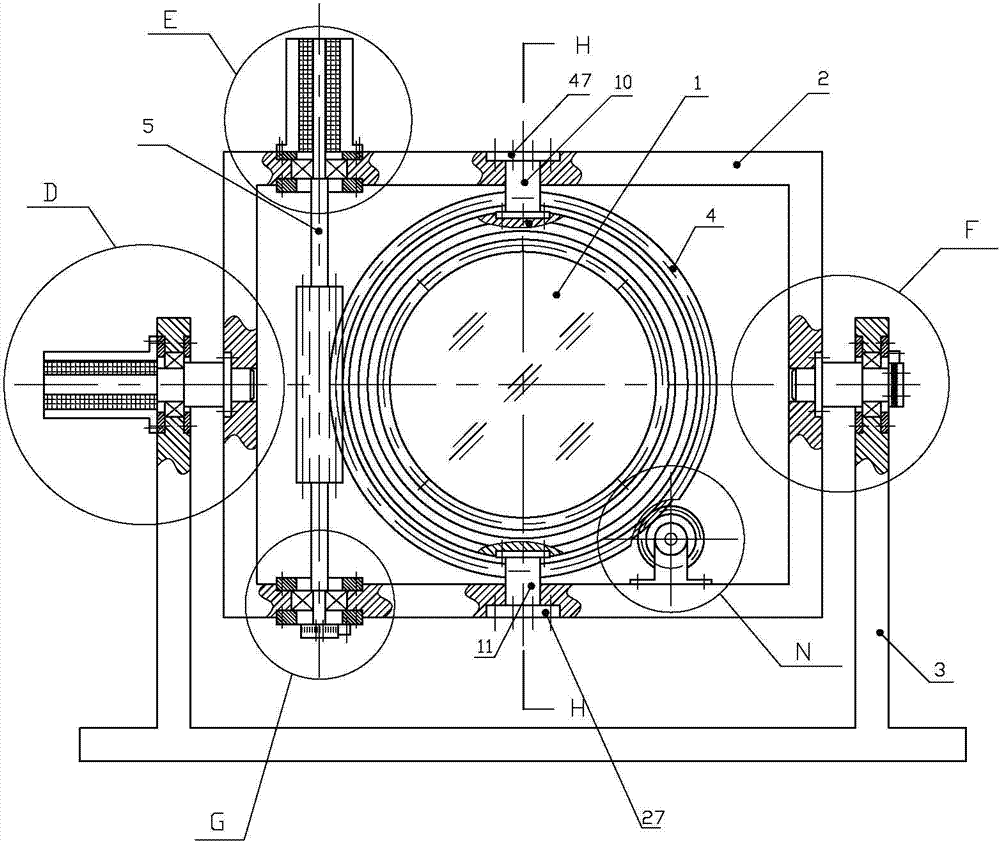

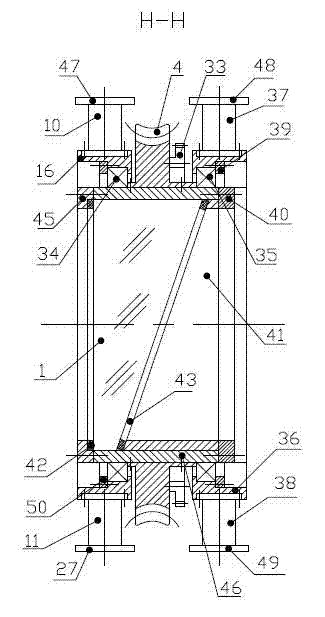

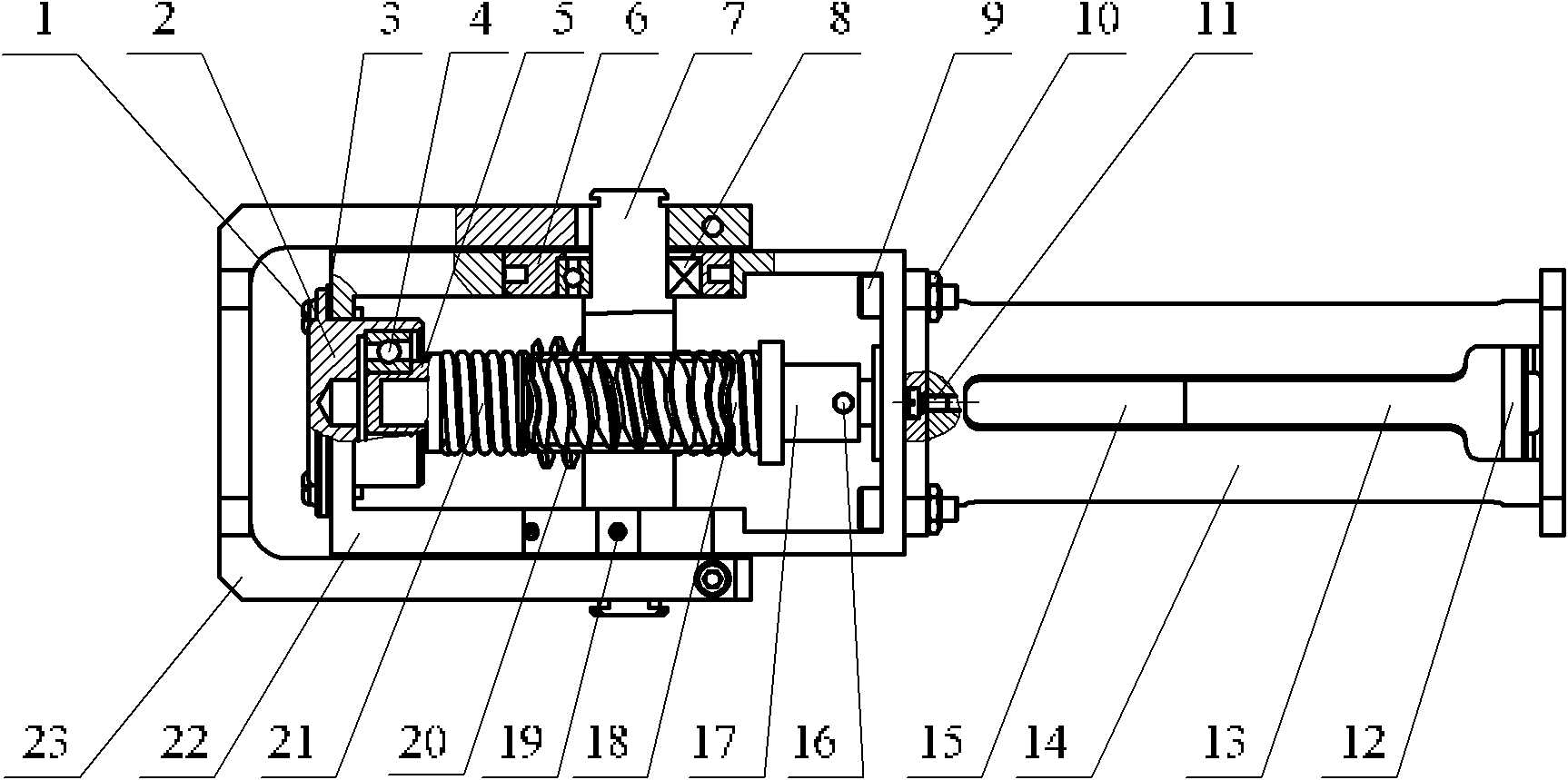

Driving device for a hydroacoustic transmitter

InactiveUS6711097B1Large transmission ratioInterference problemMechanical vibrations separationSound producing devicesReciprocating motionEngineering

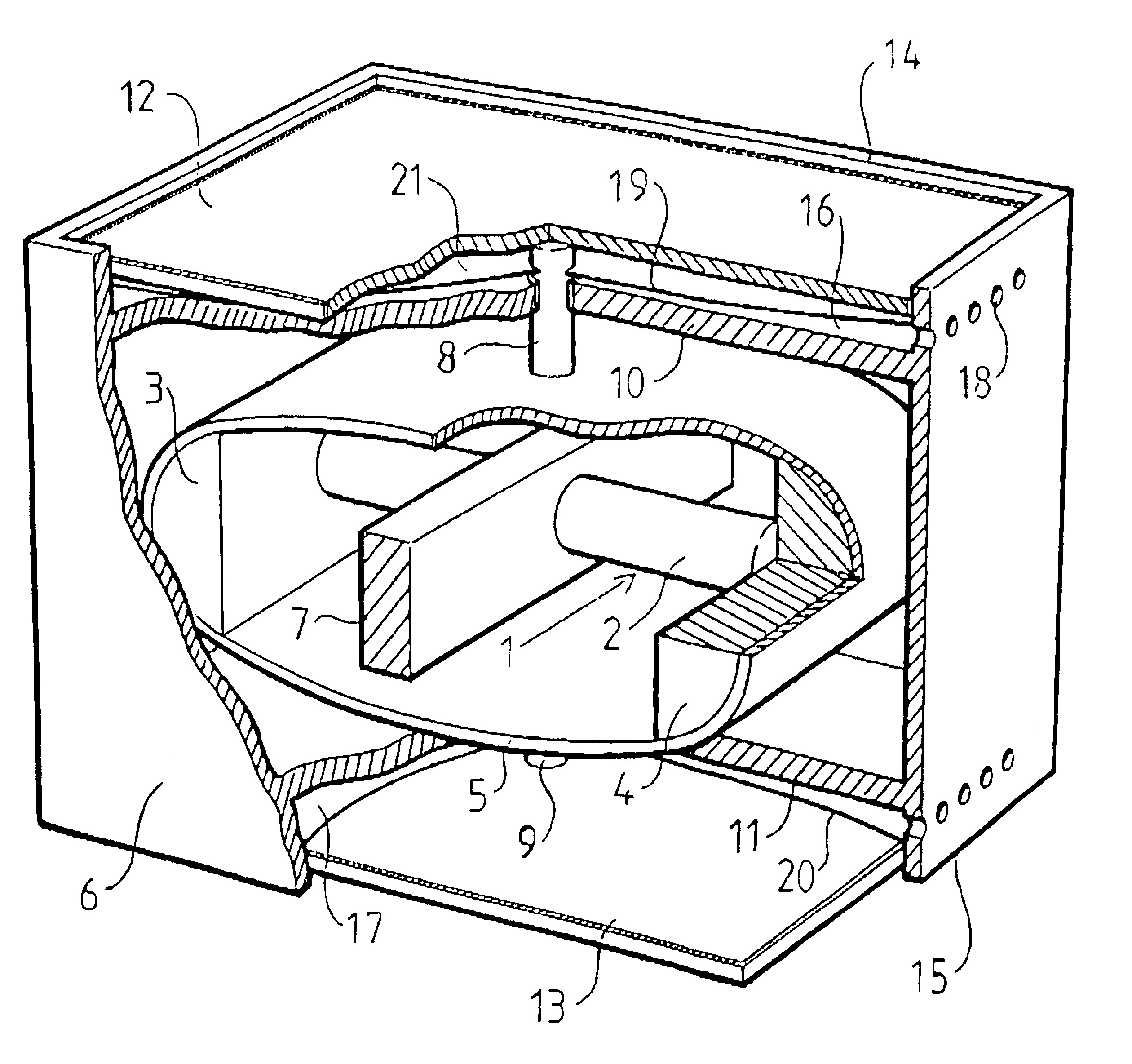

The invention refers to a driving device for hydroacoustic transmitters, including at least one actuating element (1), arranged to execute a reciprocating movement, wherein the movement of the actuating element (1) includes an increase and a decrease of the distance between two ends thereof, and at least one spring member (5, 27) which is connected to the actuating element (1) at said ends and which extends along a curved line between said ends, wherein the increase and the decrease of the distance between said ends result in a change of the curve of the spring member (5, 27) and thereby a movement of it. The device includes an element (12, 13, 28) for displacement of a mass, which displacement element (12, 13, 28) is connected to the spring member (5, 27) so that the movement of the latter is transmitted to the displacement element (12, 13, 28) and generates a displacement thereof, resulting in said mass displacement. Furthermore, the invention refers to the use of such a device for transmitting hydroacoustic waves in a liquid.

Owner:CETUS CORP

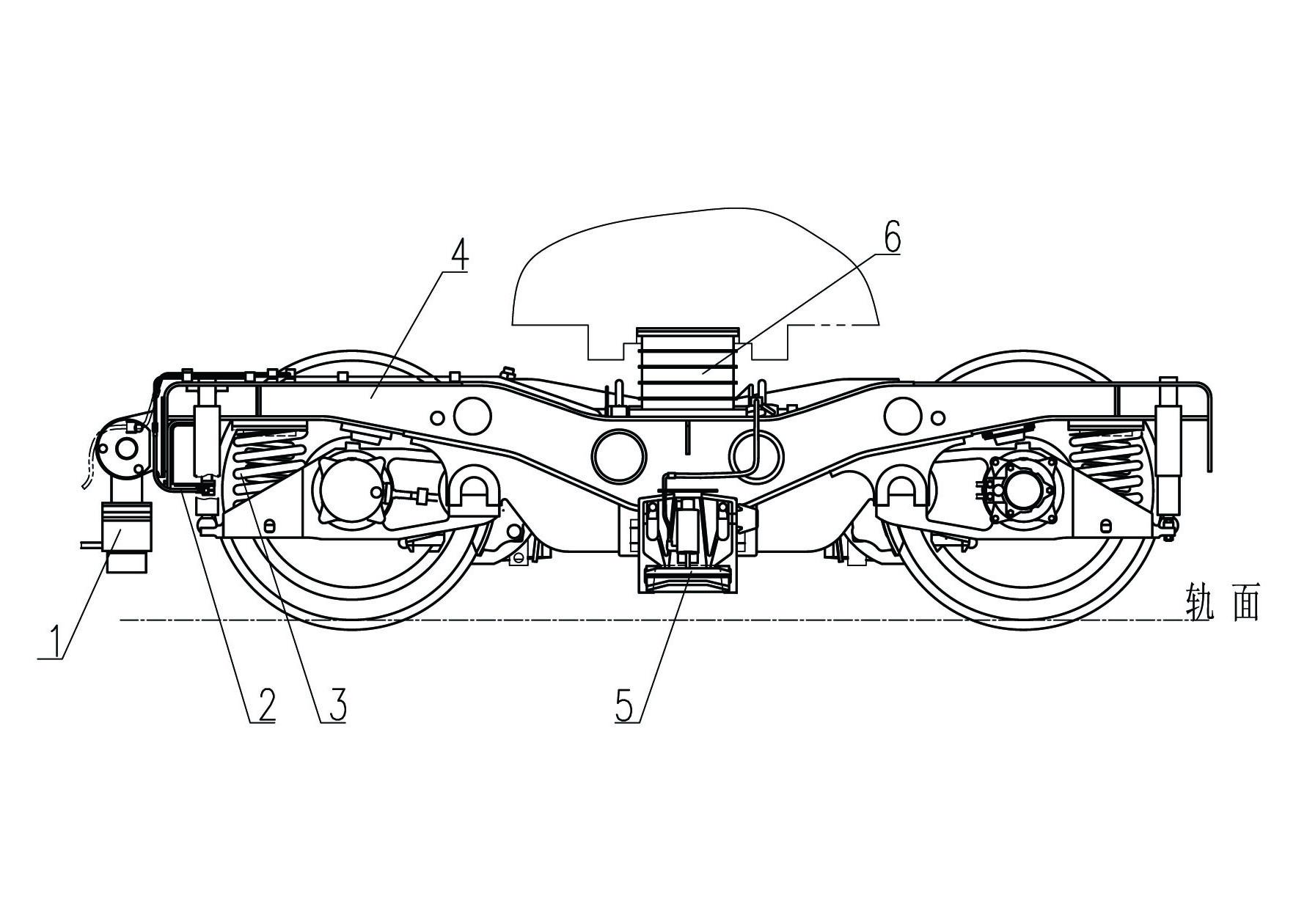

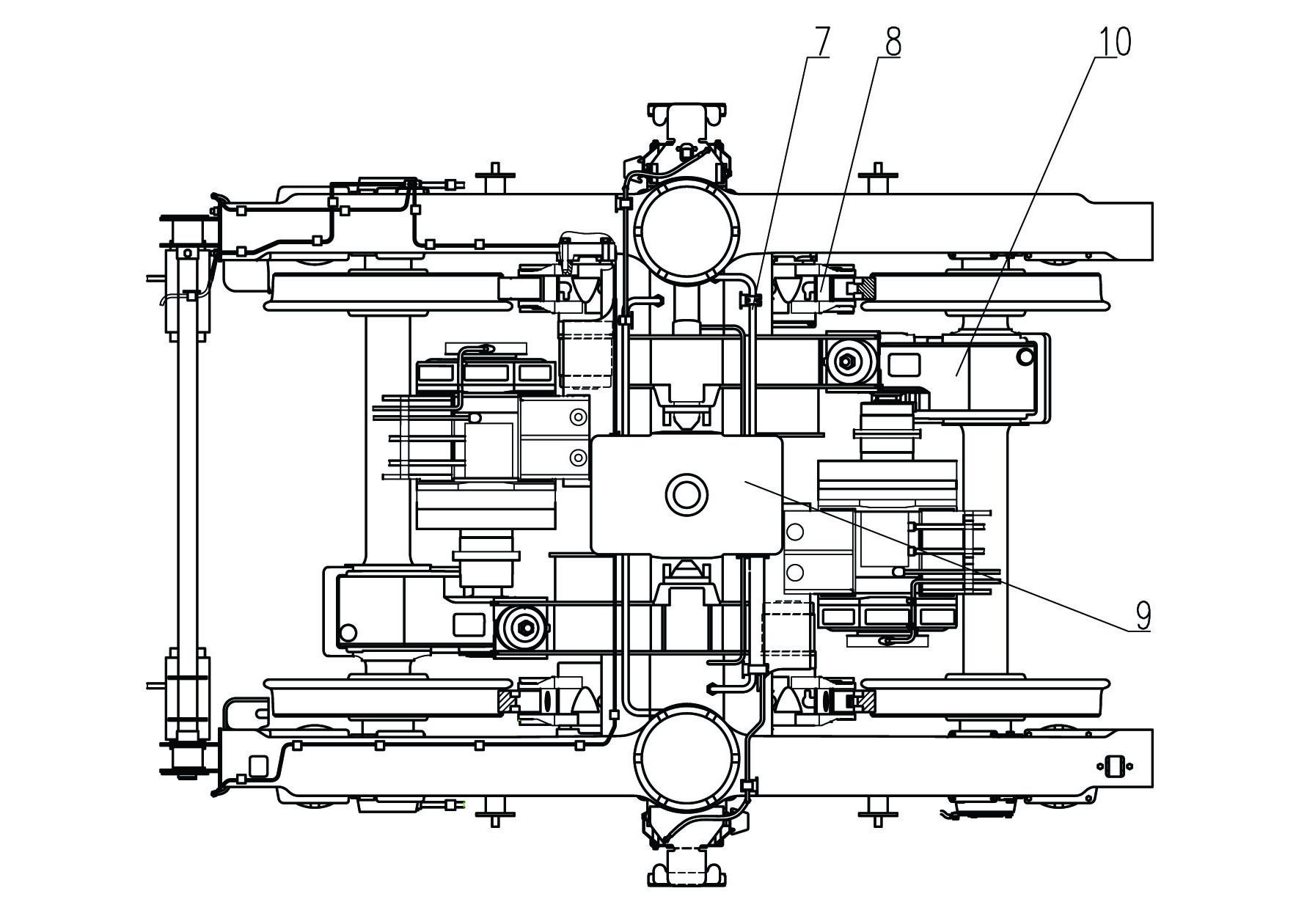

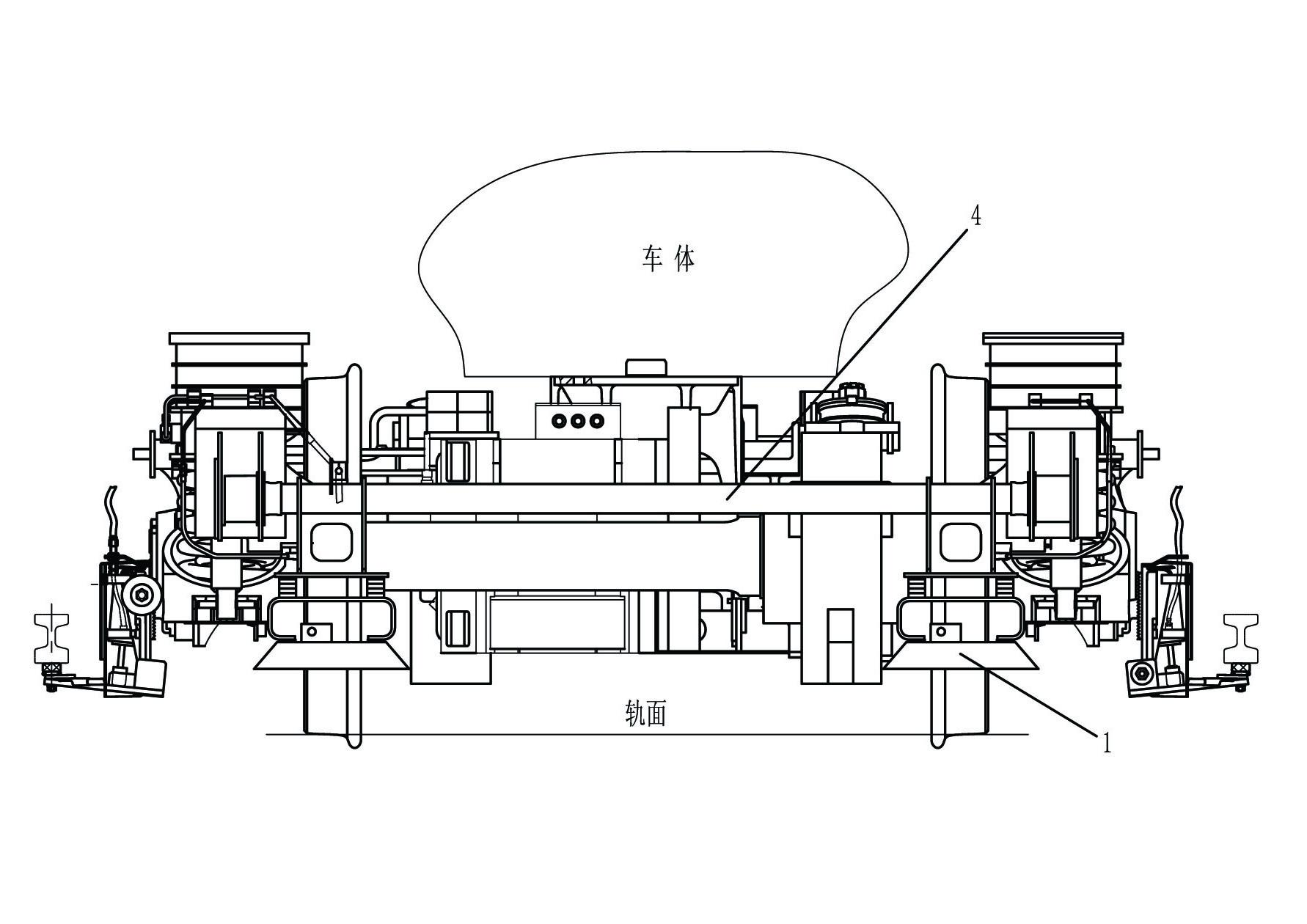

Rail engineering truck steering frame

ActiveCN102114851AEasy to disassembleEasy maintenanceBogiesBogie-underframe connectionsLower limitBogie

The invention discloses a rail engineering truck steering frame belonging to the field of rail vehicle steering frames. Aiming at the defects of large turning radius and incapability of meeting the low-speed operation working conditions of the traditional rail engineering truck, the steering frame comprises an H-type frame, ATP (Array Transform Processor) induction coil devices arranged at end parts of two lateral beams of the frame, rim lubricating devices arranged at two ends of a locomotive, a primary suspension device, a secondary suspension device, a third rail current collector arranged at the middles of the lateral beams of the frame, a basic brake device transversely arranged on the lateral beams of the frame, and a traction device connected with the frame by adopting a full-suspension manner; and a gear box is hung on a cross beam of the frame and is internally provided with two stages of gear transmissions with total transmission ratio of (7.63-10.03):1. The rail engineering truck steering frame has the highest operation speed of 90km / h, the continuous speed of about 18km / h and the lowest operation speed of below 5km / h and has the advantages of small turning radius, high low limit, simpler structure, convenience for maintenance and high reliability.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

Coarse and fine scanning rotating prism device

InactiveCN102955251ASatisfy rough scan requirementsMeet fine scanning requirementsOptical elementsElectric machineGear wheel

The invention relates to a coarse and fine scanning rotating prism device, which comprises a prism and an inner and outer prism frame assembly, a worm and gear movement mechanism, a rotary motor, a yaw motor and a rotating half shaft assembly, an anti-backlash motor and an anti-backlash gear assembly, a rotary encoder assembly, a deflection encoder assembly, a rectangular frame and a base, wherein the rotary motor drives the prism and the inner and outer prism frame assembly through the worm and gear mechanism to realize full circumferential rotation, and the yaw motor is directly coupled with the rectangular frame to realize the yaw movement of the prism and the inner and outer prism frame assembly; and the whole device is arranged on the base. The prism is driven by the worm and gear mechanism to realize the full circumferential large-range rotation, and the coarse scanning requirements of dynamic beams are met; and a rotary movement mechanism and a yaw movement mechanism are nested to be combined, so that the integration of coarse and fine scanning functions is skillfully realized in a single set of devices, and the problems that the dispersal spatial structure is brought by a coarse and fine scanning separation design and the coarse and fine error term of the system is difficult to separate and traceably amend are avoided.

Owner:TONGJI UNIV

Automatic two-gear transformer for pure electric automobile

InactiveCN104595450ACompact structureLight in massElectric propulsion mountingToothed gearingsElectricityAutomatic transmission

An automatic two-gear transformer for a pure electric automobile comprises an input shaft, a first middle shaft, a second middle shaft, a third middle shaft, a first cylindrical gear pair, a second cylindrical gear pair, a third cylindrical gear pair, a first torque transmission device, a second torque transmission device and a differential assembly; rotation center lines of the input shaft, the third middle shaft and the differential assembly are mutually parallel. According to the automatic two-gear transformer for the pure electric automobile, automatic two-gear speed change is adopted, the transmission ratio range is expanded, the performance requirement on a drive motor can be reduced greatly, an efficient and light drive motor is allowed to be used, and the total size, the total mass and the total cost of an electric drive system of the pure electric automobile are further reduced.

Owner:BEIHANG UNIV

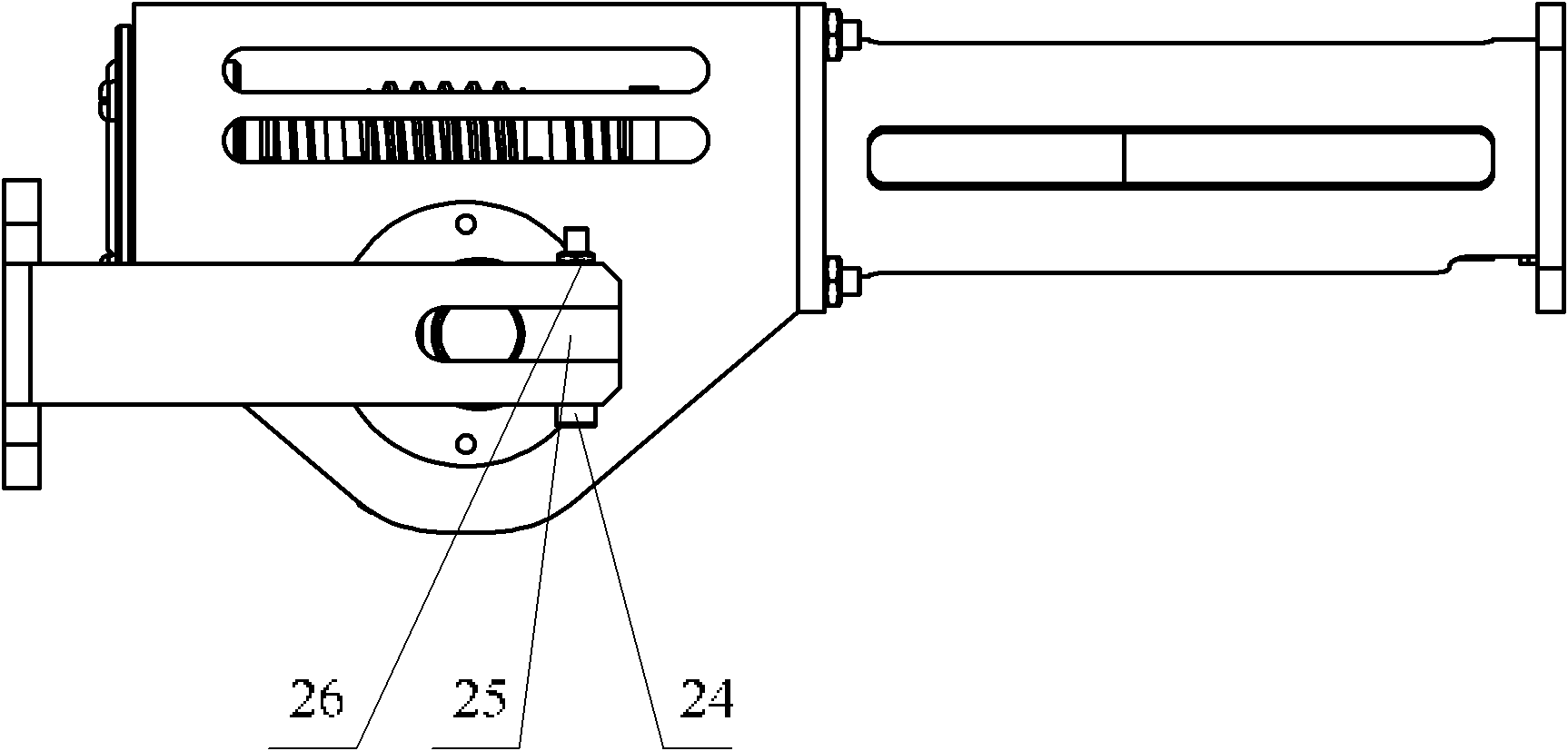

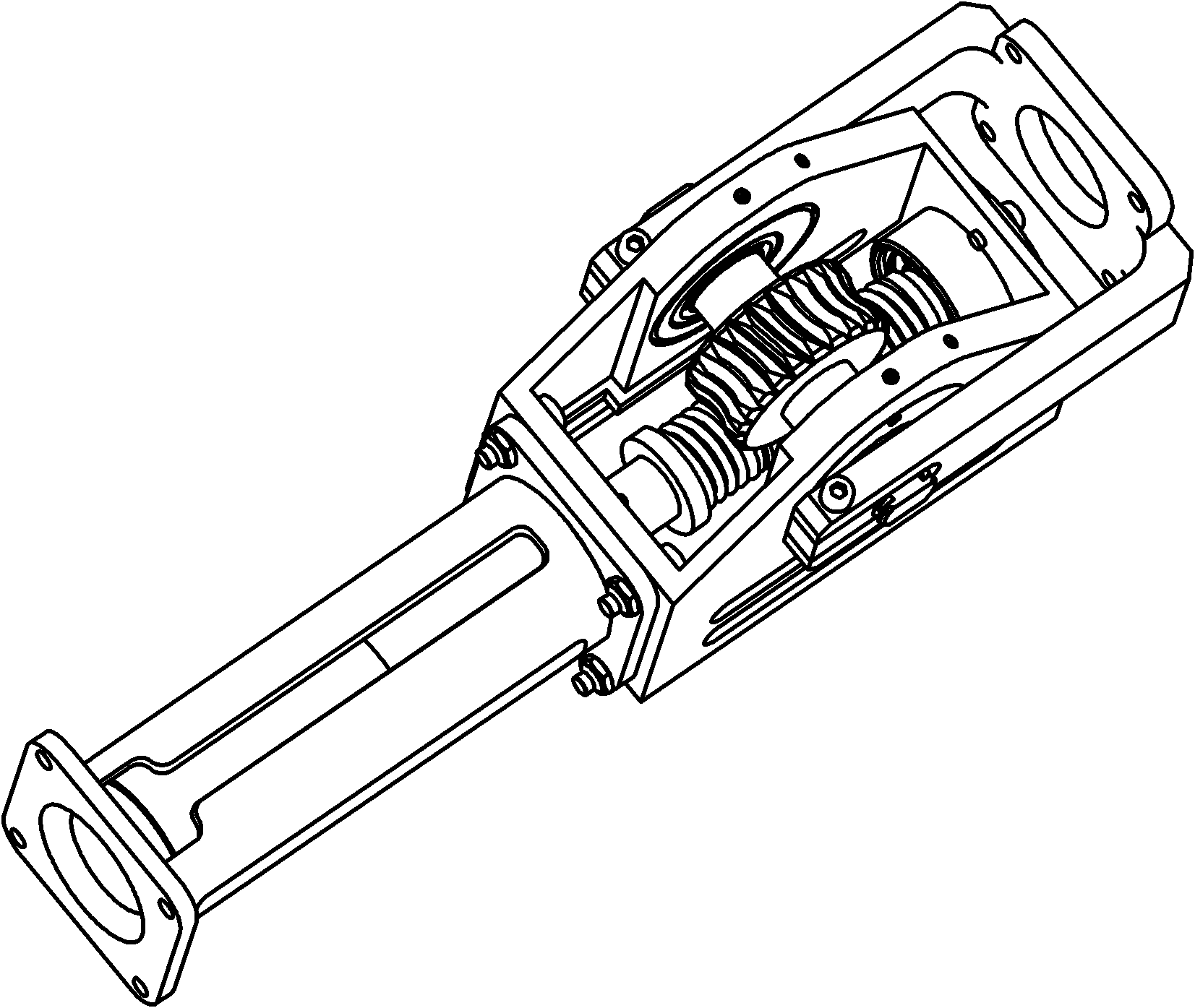

Elastically-driven rotational joint

InactiveCN102152319ALarge transmission ratioHigh requirements for external dimensionsJointsSelf lockingEngineering

The invention aims at providing an elastically-driven rotational joint which comprises a motor frame, a box body, an output frame, a U-shaped slot check block, a coder, a direct current motor, a reduction box, a spline shaft, springs, a worm wheel, and a worm, wherein the box body is fixedly connected with the motor frame; the output frame is mounted on the box body through the U-shaped slot check block; the coder, the direct current motor, and the reduction box are arranged in the motor frame in sequence; the spline shaft is arranged in the box body; an output shaft of the reduction box is connected with the spline shaft; the springs also comprise a first spring and a second spring; the first spring, the worm, and the second spring are sheathed on the spline shaft in sequence; the worm wheel is arranged on the box body and is matched with the worm; and flat shaft ends at two ends of the worm wheel are matched with the U-shaped slot check block. The elastically-driven rotational joint has small size, large transmission ratio, self-locking, impact resistance, large output angle, strong commonality, and convenience for installation and maintenance. The elastically-driven rotational joint has broad application prospect in the field of microminiature bionic robots, in particular to occasions which require high appearance sizes on the robots and large transmission ratio, and exist rigid impact.

Owner:HARBIN ENG UNIV

Variable-speed winch and foldable type onboard crane with same

ActiveCN102001596ASimple structureEasy loading and unloadingToothed gearingsWinding mechanismsLifting capacityDrive shaft

The invention relates to a variable-speed winch and a foldable type onboard crane comprising the same, relating to the field of winches. The variable-speed winch comprises a variable-speed mechanism, a driving shaft and a driven shaft, wherein the driven shaft is arranged on a stand of the variable-speed winch through a bearing and at the outer side of the driving shaft and is provided with a power output mechanism; the power output end of the driving shaft is provided with a gear locating slot, and the corresponding driven shaft is provided with a locating pin; the locating pin is arranged on the end part of the driving shaft or in the gear locating slot; the variable-speed mechanism comprises a center wheel and a planet wheel; the part of the driving shaft, which is close to the planet wheel, is provided with a radially outwards raised outer spline, and the inner surface of the corresponding variable-speed mechanism is provided with an inner spline; the inner wall of the driven shaft is provided with an inner spline in clearance fit with the outer spline of the driving shaft; and the outer spline of the driving shaft is respectively meshed with the inner spline of the variable-speed mechanism and the inner spline of the driven shaft to form multi-gear variable-speed transmission. The variable-speed winch can realize variable speed of at least two gears and has the advantages of simple structure, convenience for operation, good speed varying effect, small mass and high transmission ratio; and in addition, the foldable type onboard crane with the variable-speed winch has small size and high lifting capacity.

Owner:姜启胜

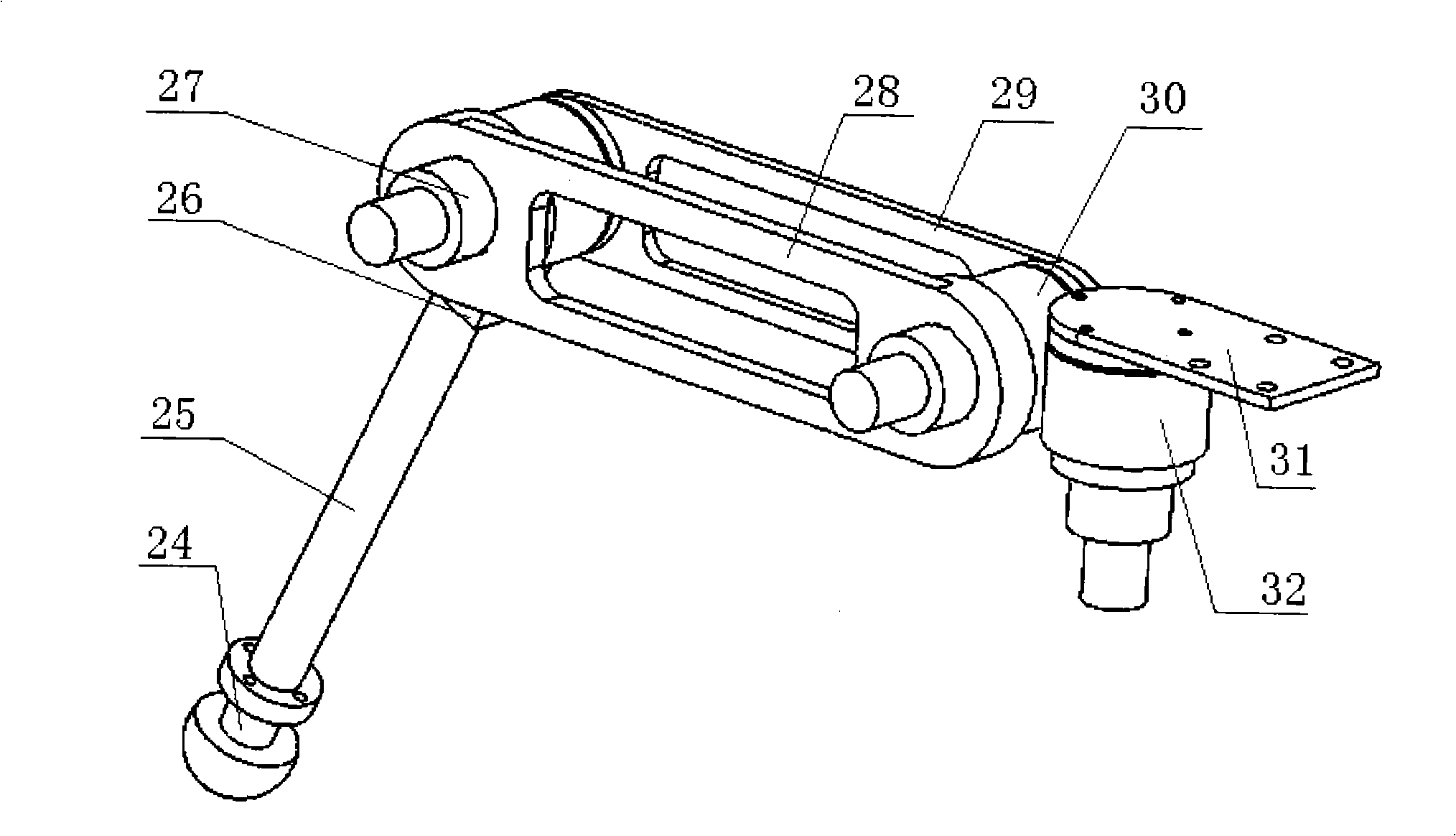

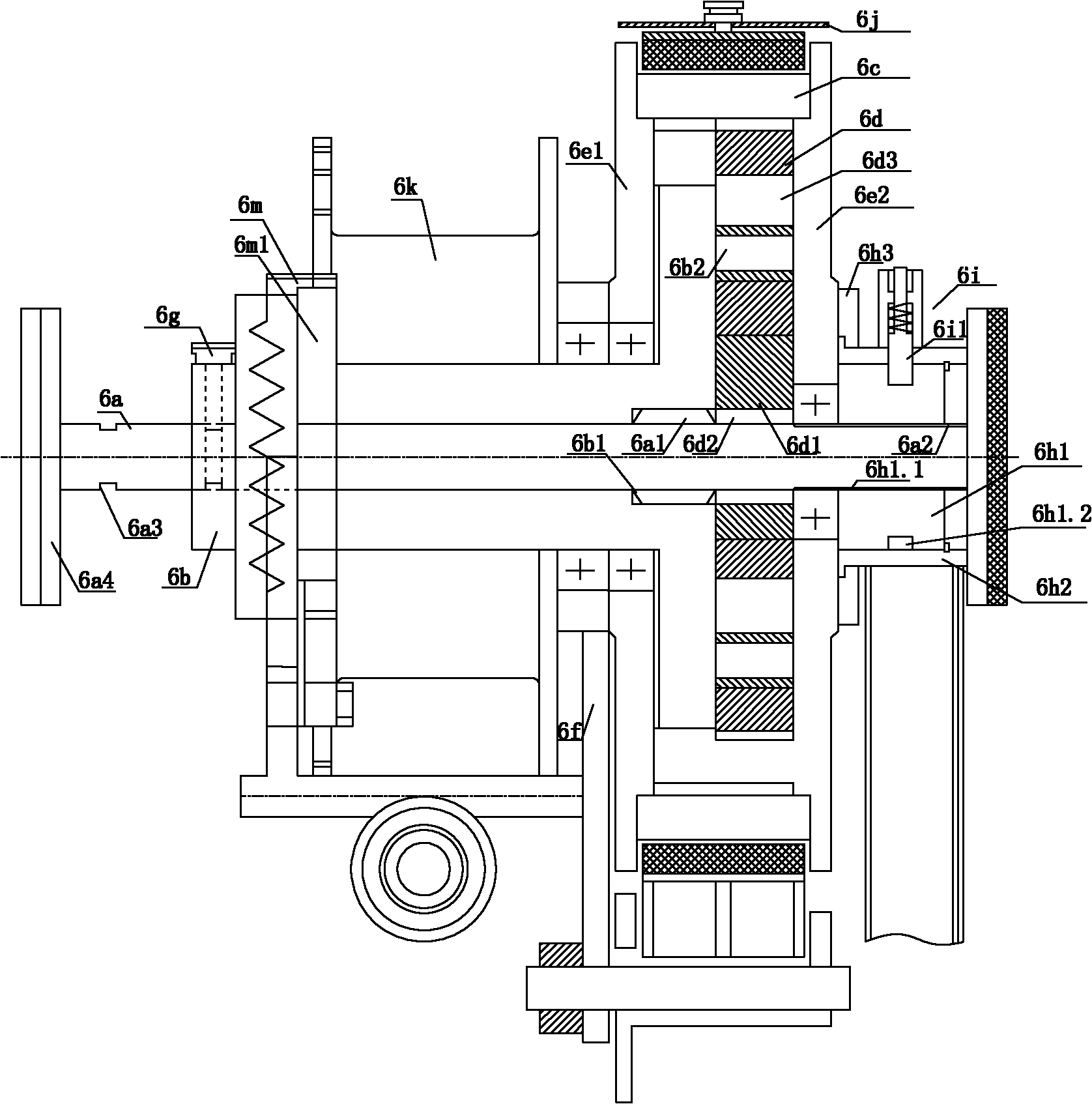

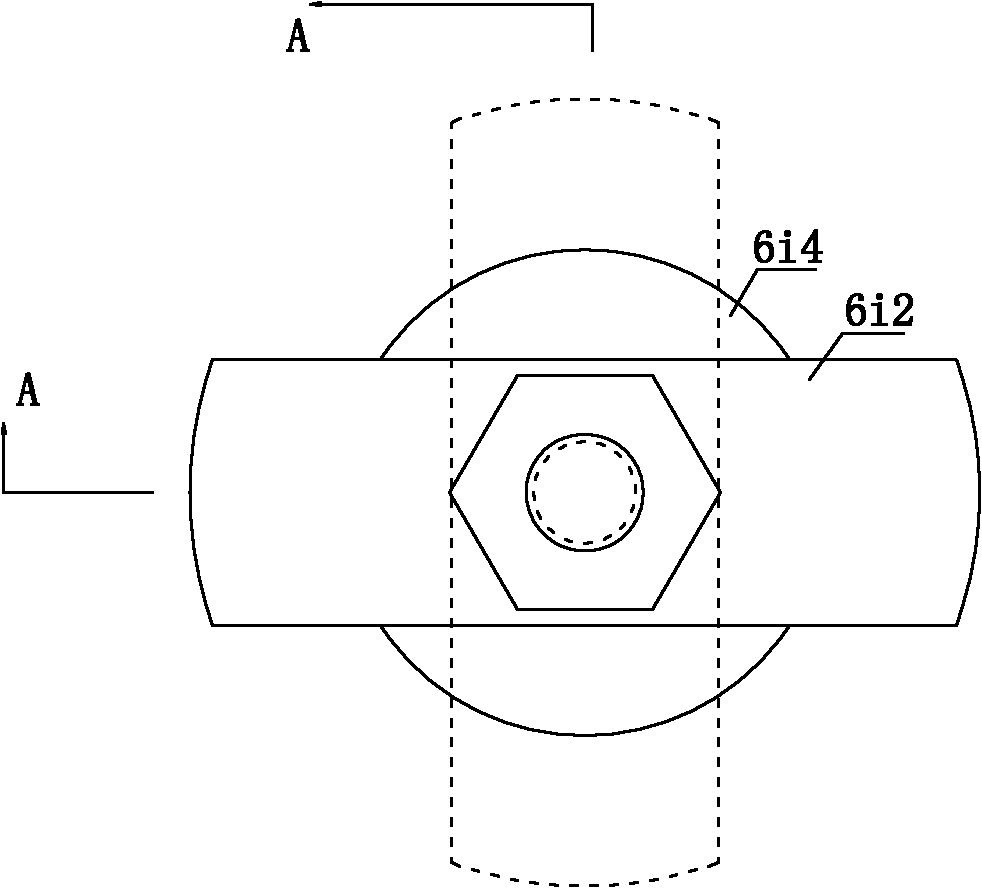

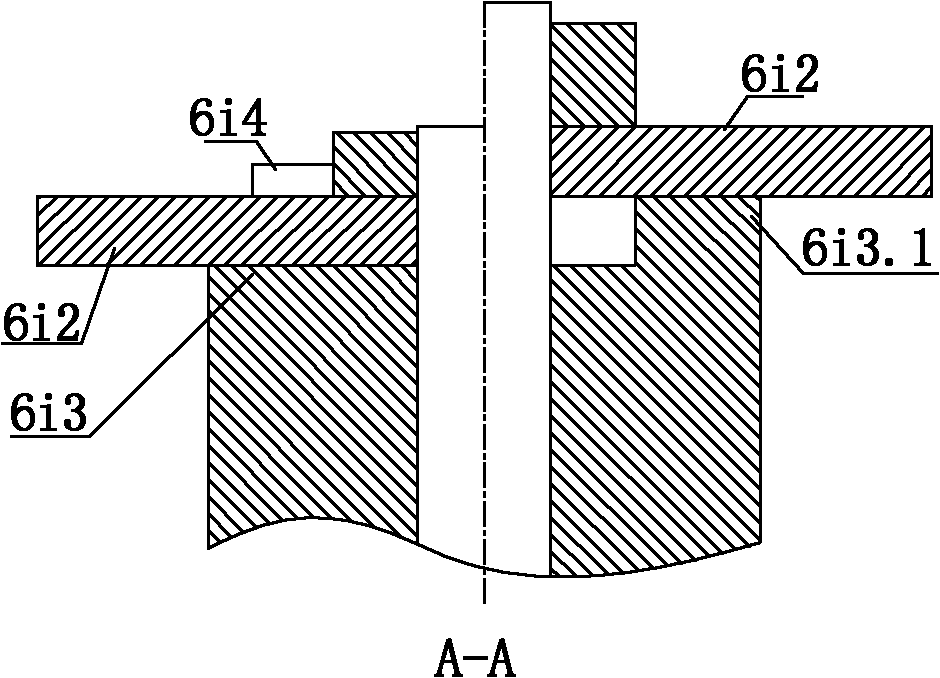

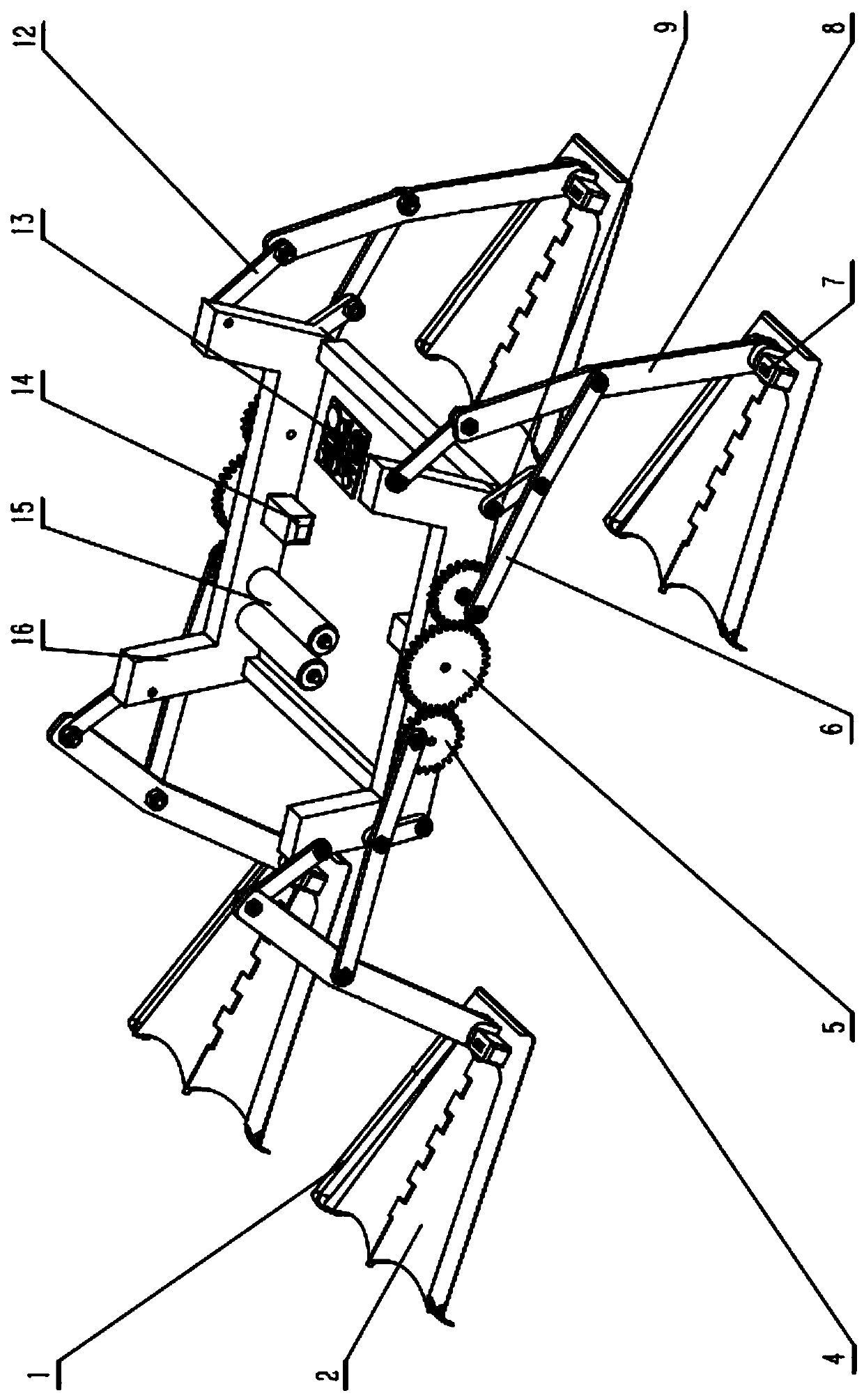

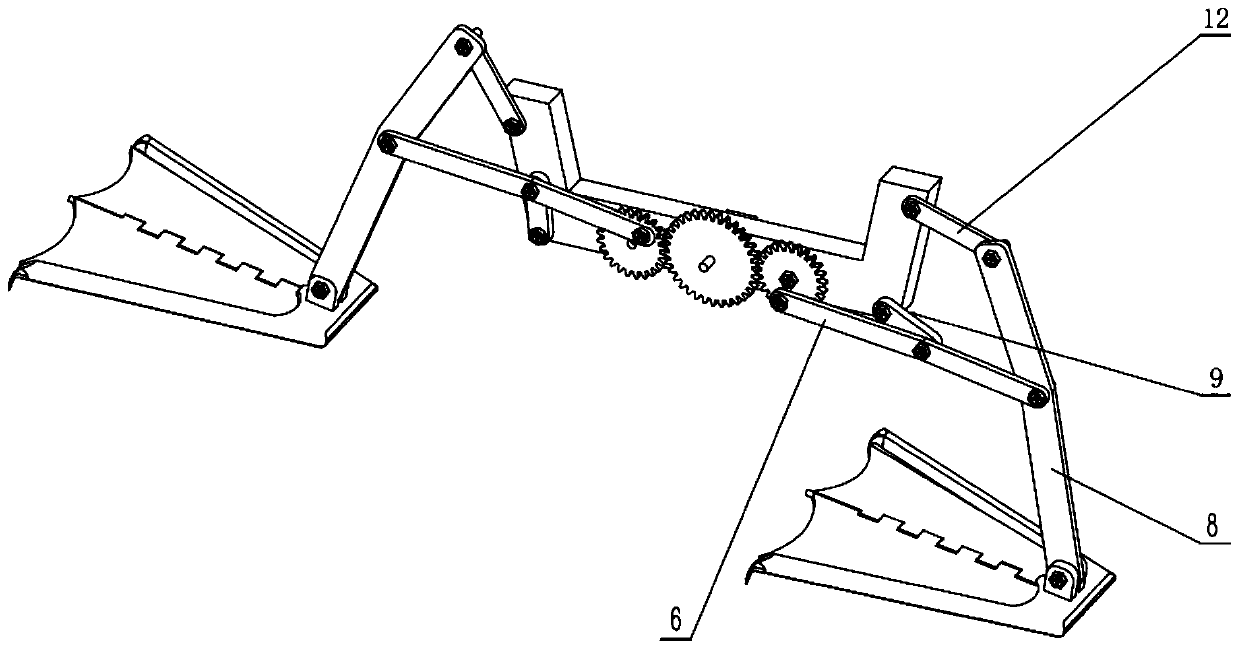

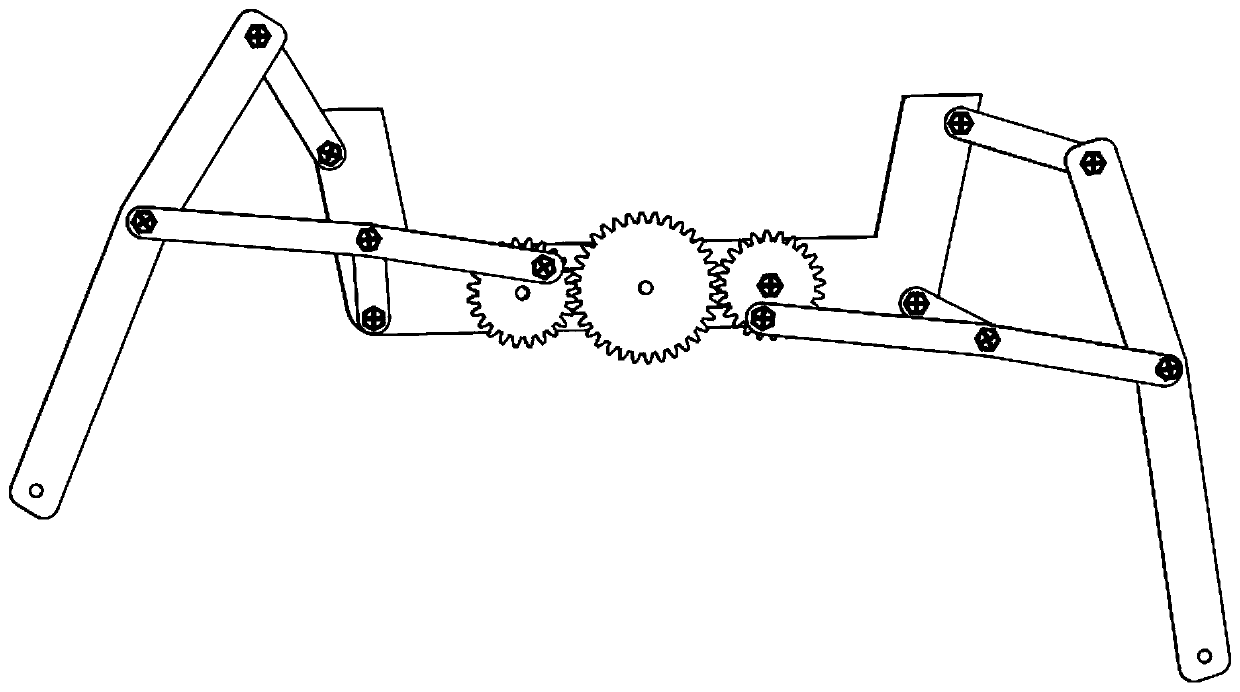

Duck web imitating climbing and swimming type propelling robot

PendingCN109733136AMovement is intuitive and reliableLarge transmission ratioAmphibious vehiclesPropulsive elements of non-rotary typeMotor driveComputer module

The invention relates to the technical field of a robot, and aims at providing a duck web imitating climbing and swimming type propelling robot. The robot needs to have the characteristics of high maneuverability and capability of meeting propelling requirements in two environments including a water environment and a land environment. The duck web imitating climbing and swimming type propelling robot has the technical scheme that the duck web imitating climbing and swimming type propelling robot is characterized by comprising a machine frame, a control module, a power supply, two motors, fourKlann connecting rod mechanisms, gear mechanisms and webs, wherein the control module, the power supply and the two motors are arranged in the machine frame; the four Klann connecting rod mechanisms are arranged on the periphery of the machine frame; the gear mechanisms are used for transmitting the motor power to drive the Klann connecting rod mechanisms to move; the webs are arranged on the Klann connecting rod mechanisms; the two motors are arranged at the left side and the right side of the machine frame; each motor drives the two (front and back) Klann connecting rod mechanisms to move atthe same time through one gear mechanism; each gear mechanism comprises a driving gear and two driven gears; the driving gear is fixed to an output shaft of the motor; and the driven gears are engaged with the driving gear and are used for driving the two (front and back) Klann connecting rod mechanisms.

Owner:ZHEJIANG SCI-TECH UNIV

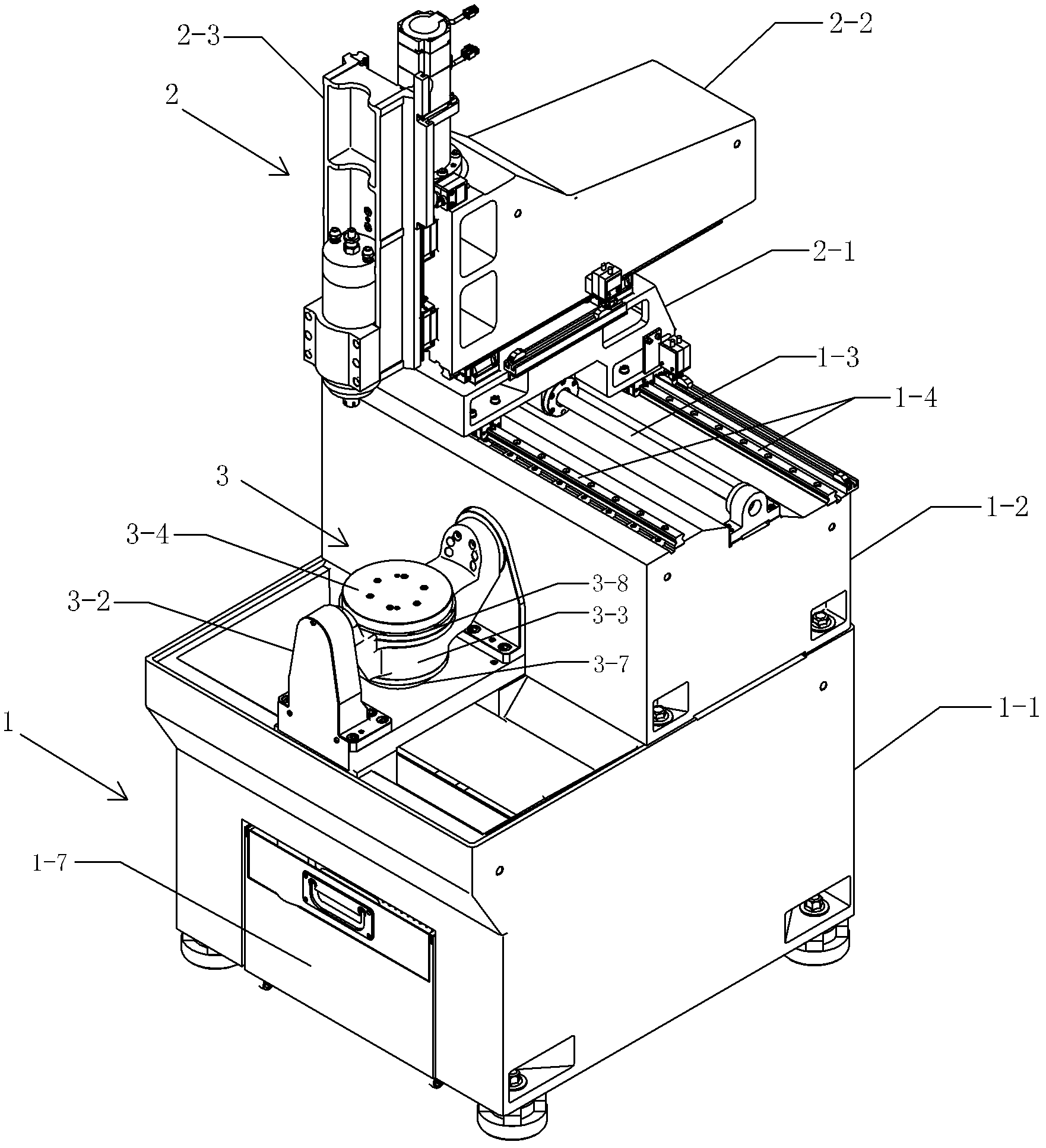

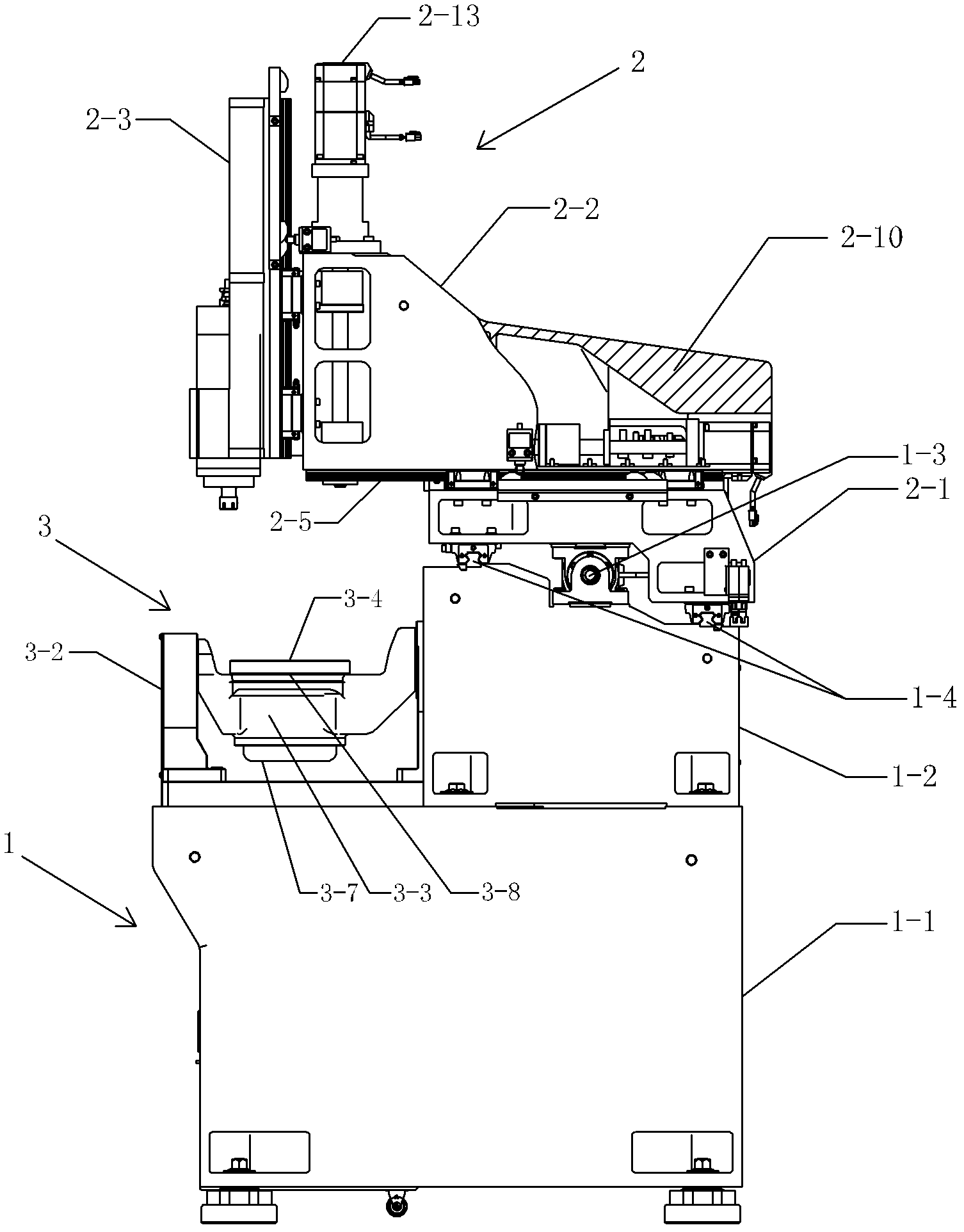

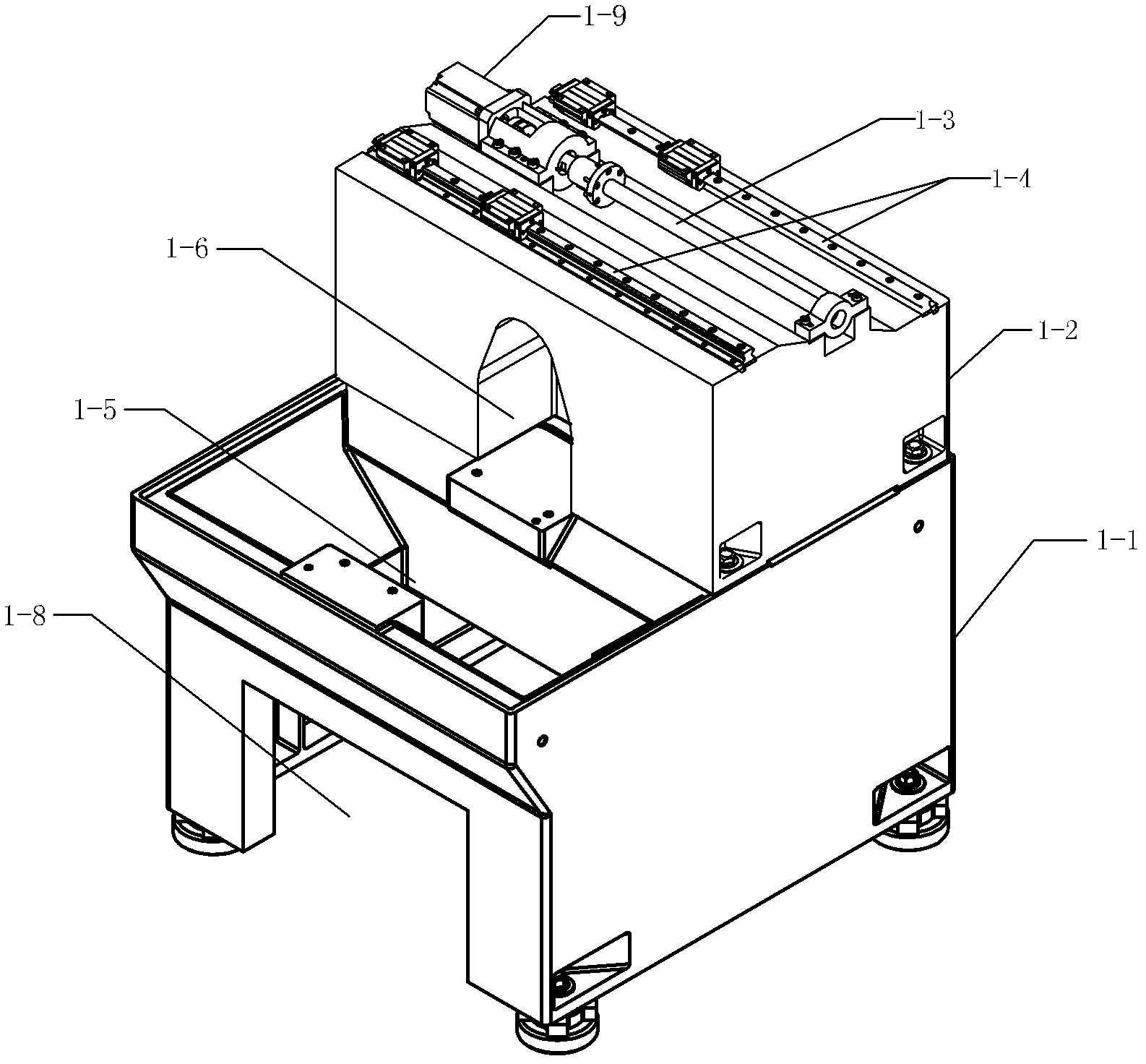

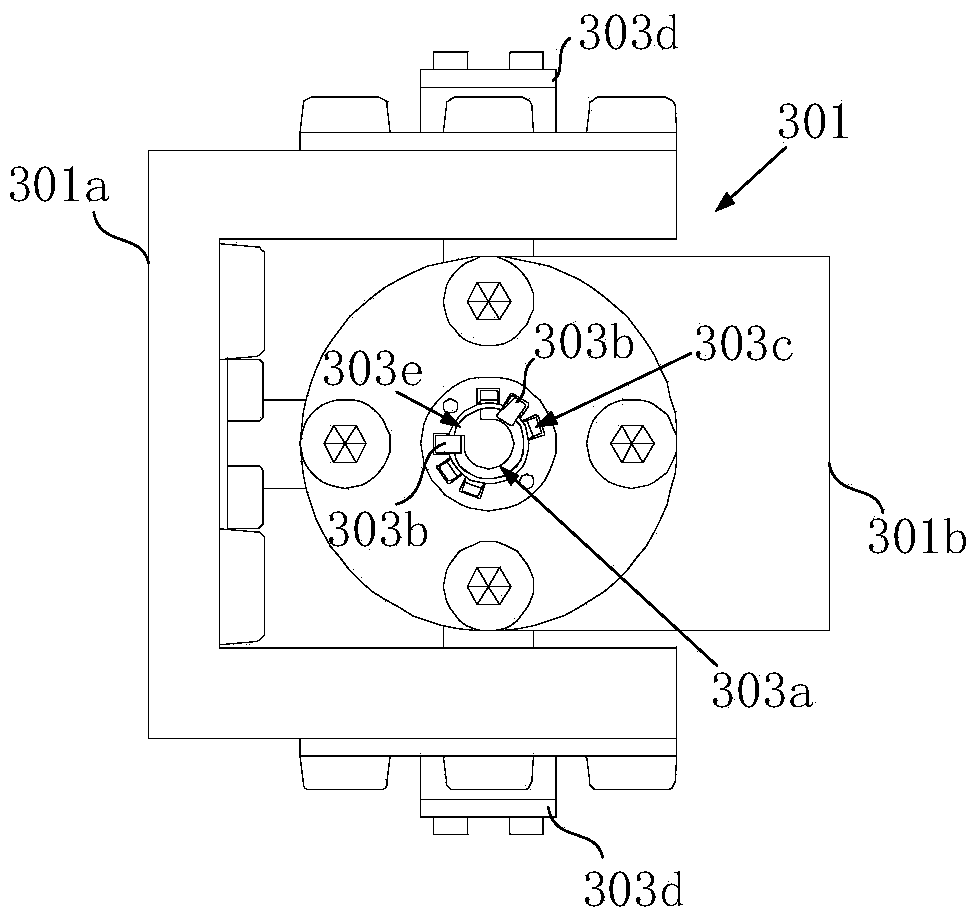

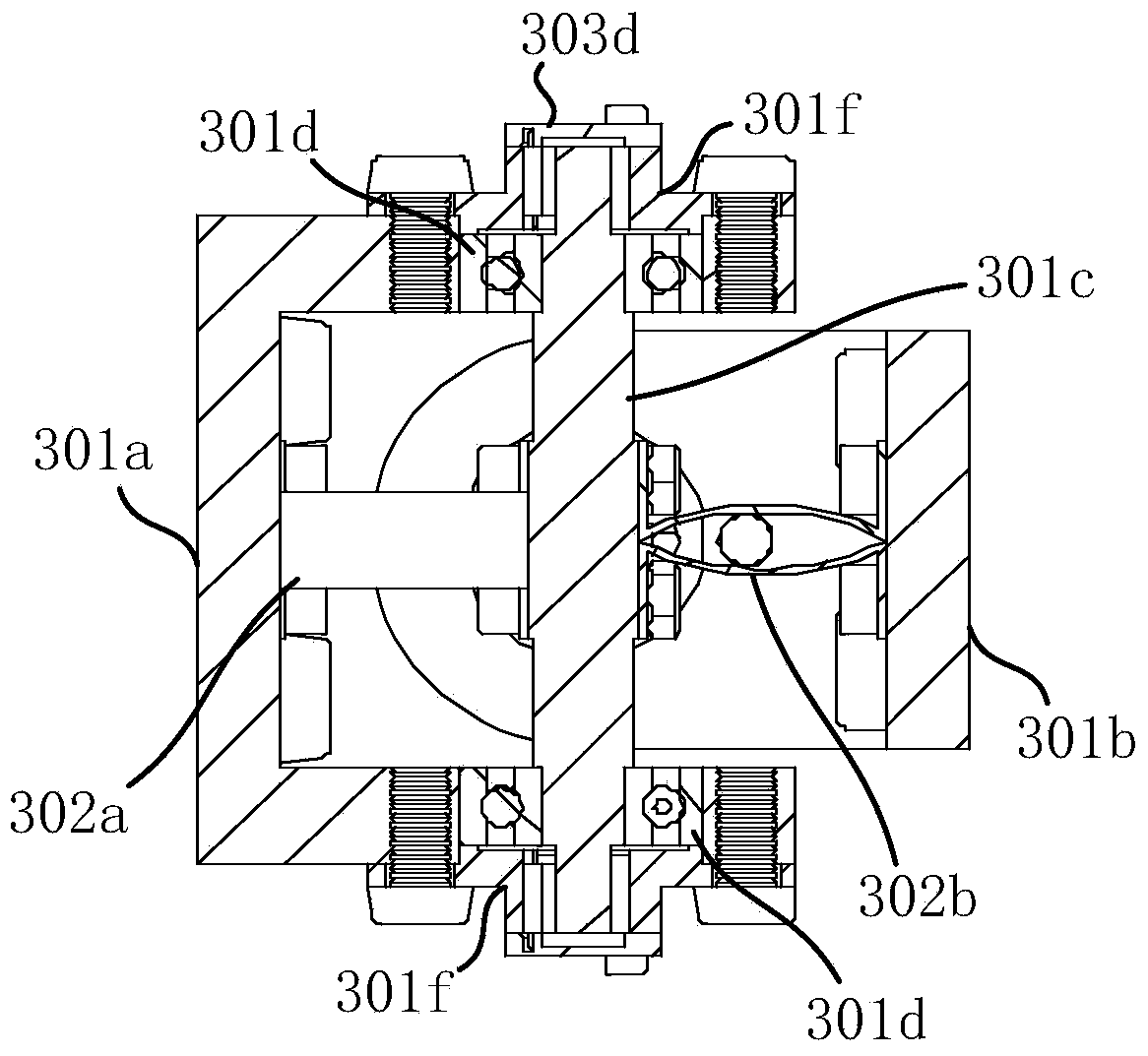

Small-sized five-axis machining center

InactiveCN102672472AReduce weightEasy to planLarge fixed membersMetal working apparatusBall screwEngineering

The invention relates to a small-sized five-axis machining center which comprises a base structure (1), an XYZ vertical shaft structure (2) and a BC rotary table (3). The small-size five-axis machining center is characterized in that the base structure (1) is L-shaped and comprises an X-axis substrate (1-2) and an internally hollow machine tool base (1-1); the X-axis substrate (1-2) is arranged on the machine tool base (1-1) and the X-axis substrate and the machine tool base are of integral structures or fixation connection molding structures; an X-axis ball screw (1-3), a Y-axis ball screw (2-6), a Z-axis ball screw (2-4), two X-axis guide tracks (1-4), two Y-axis guide tracks (2-7) and two Z-axis guide tracks (2-5) are arranged on the X-axis substrate (1-2); the BC rotary table (3) is arranged on a table plate of the machine tool base (1-1) and is arranged beside the positive plane of the X-axis substrate (1-2); a funnel-shaped structure chip discharge port (1-5) is arranged on the table plane of the machine tool base (1-1); and a connecting hole (1-6) of the BC rotary table (3) is arranged at the positive plane of the X-axis substrate (1-2). The small-sized five-axis machining center has the characteristics of being convenient to operate, high in production efficiency, low in cost and attractive and harmonious.

Owner:广州市技师学院

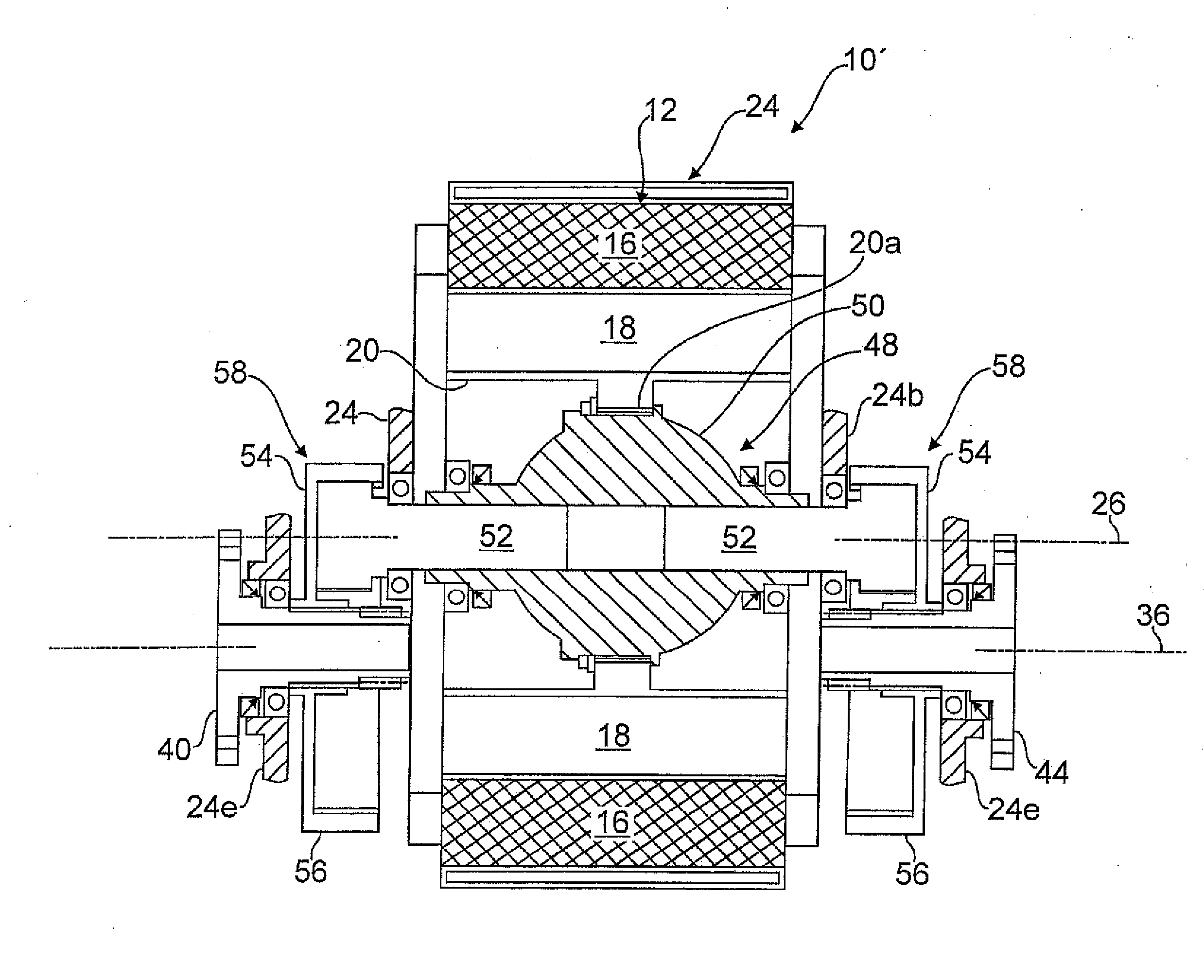

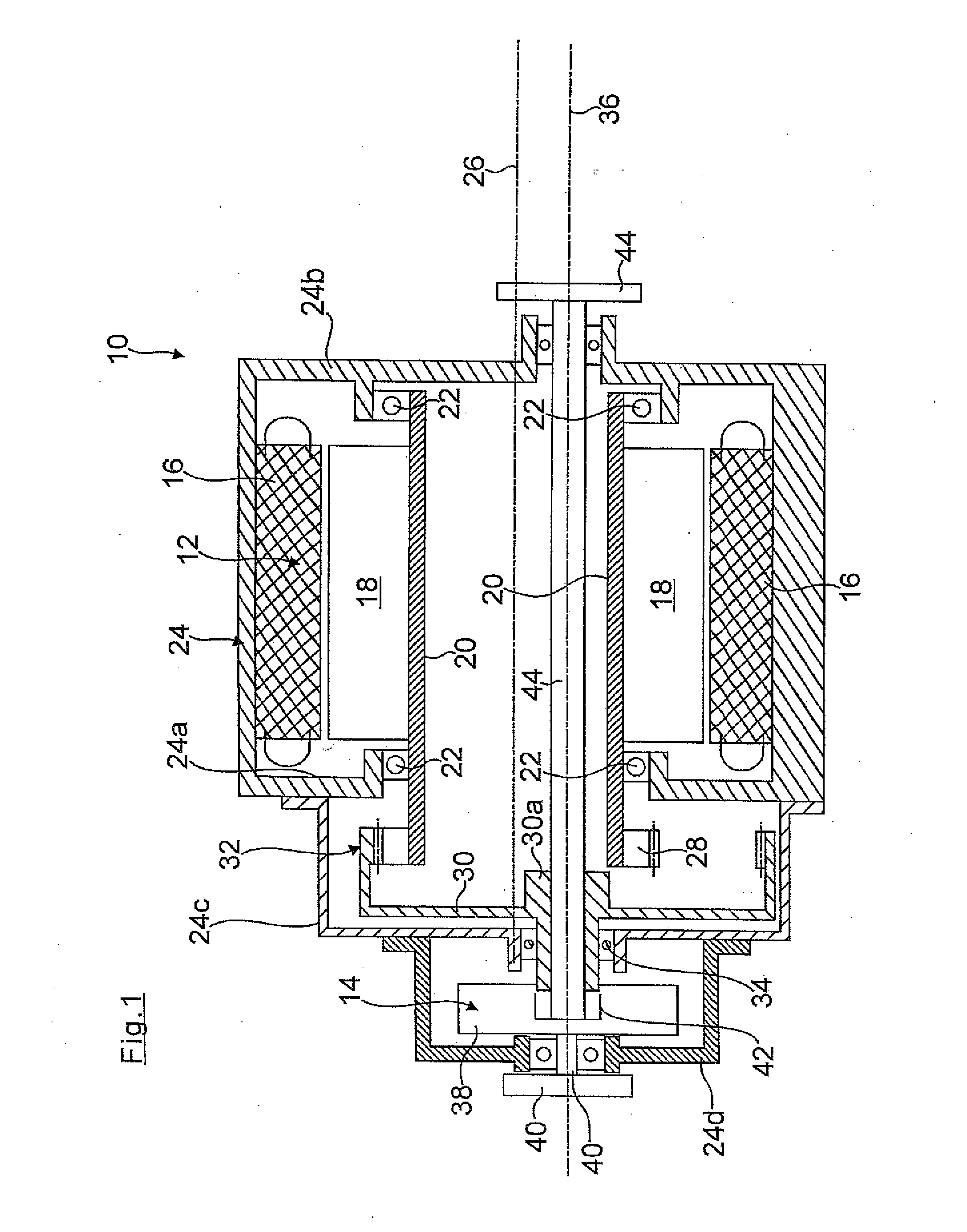

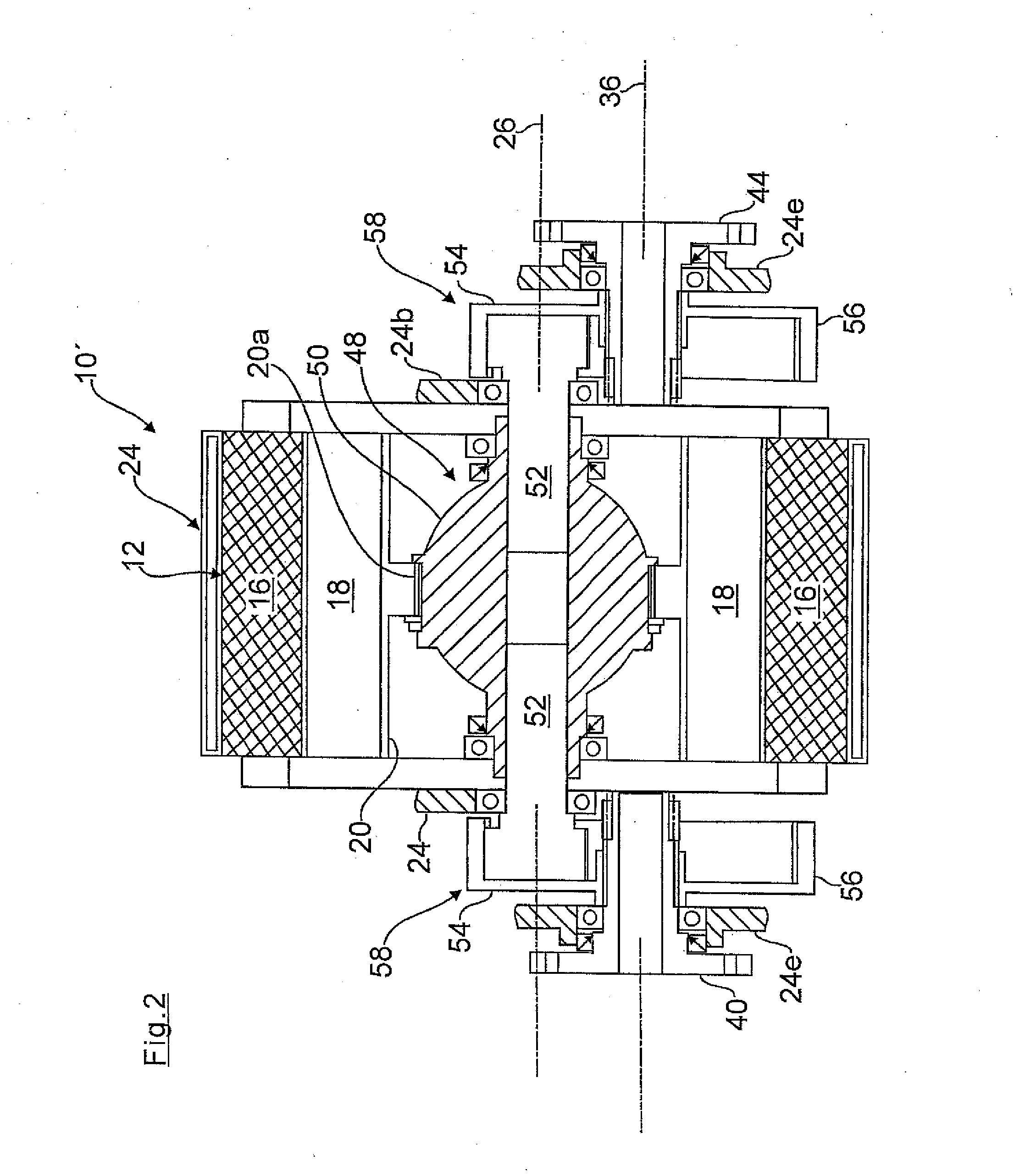

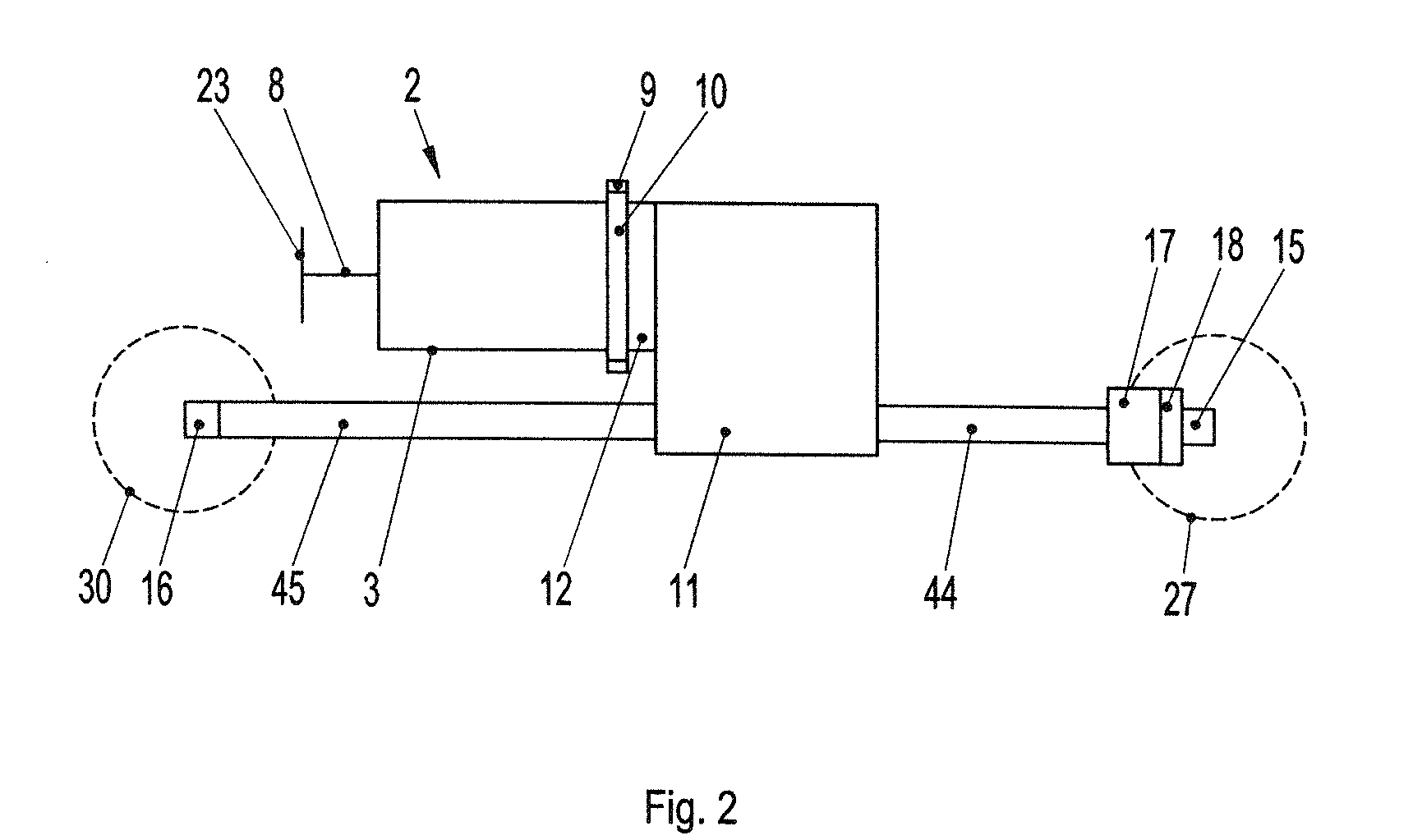

Drive arrangement

InactiveUS20130123057A1Increase gear ratioHigh drive torqueElectric propulsion mountingDifferential gearingsElectric machineControl theory

In a drive arrangement for wheels of a motor vehicle which are driven by means of an electric machine via a differential, the electric machine includes a rotor and a stator and drives a drive element of the differential whose output shafts output to the wheels of the motor vehicle. In order to achieve a structurally compact construction which enables favorable transmission ratios the rotor outputs to the drive element of the differential and that by interposing a gear mechanism, the drive element and / or the output shafts are supported offset to the rotation axis of the rotor.

Owner:AUDI AG

Wheel hub motor driving device

ActiveCN106864251AIncrease speedImprove power densityMotor depositionControl devicesMotor driveElectric machine

The invention belongs to the technical field of electric cars and particularly relates to a power transmission technology. A wheel hub motor driving device comprises a shell (21), a motor, a two-stage planetary reducer, wheel rims (2) and tires (1); and the motor and the two-stage planetary reducer are coaxially arranged, the wheel rims (2) are connected with the output end (5) of the two-stage planetary reducer, and the tires (1) are installed on the wheel rims (2), so that power from the two-stage planetary reducer is transmitted to the tires (1). According to the wheel hub motor driving device, a planetary reducing mechanism is adopted, the manufacturability is good, transmission efficiency is high, the large transmission ratio can be obtained, the rotating speed of the motor can be increased, and thus the power density of the wheel hub motor driving device is improved; output of the reducer serves as a rotating shell and is directly connected with the wheel rims, and wheel detaching and installing are convenient; and brakes are arranged inside the wheels, the outer diameters are large, and thus heat dissipation and thermal capacity guaranteeing are facilitated.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

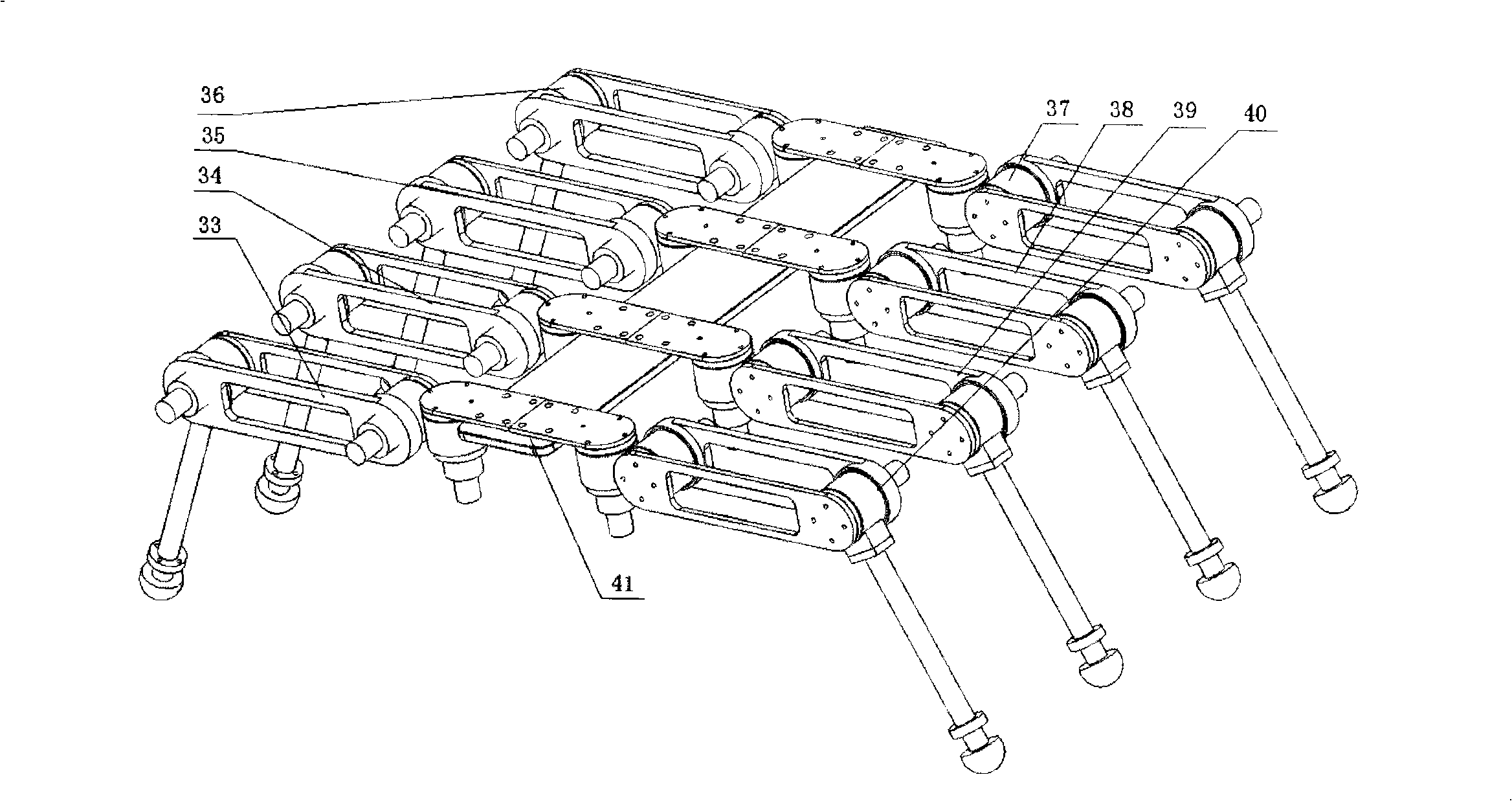

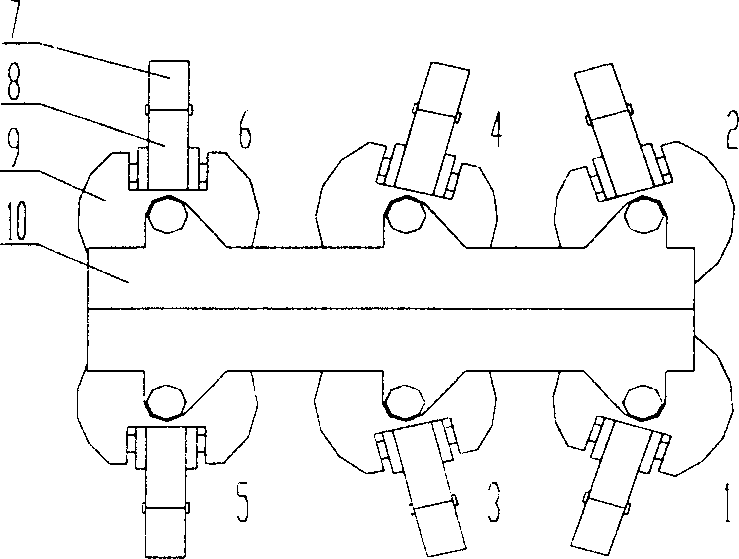

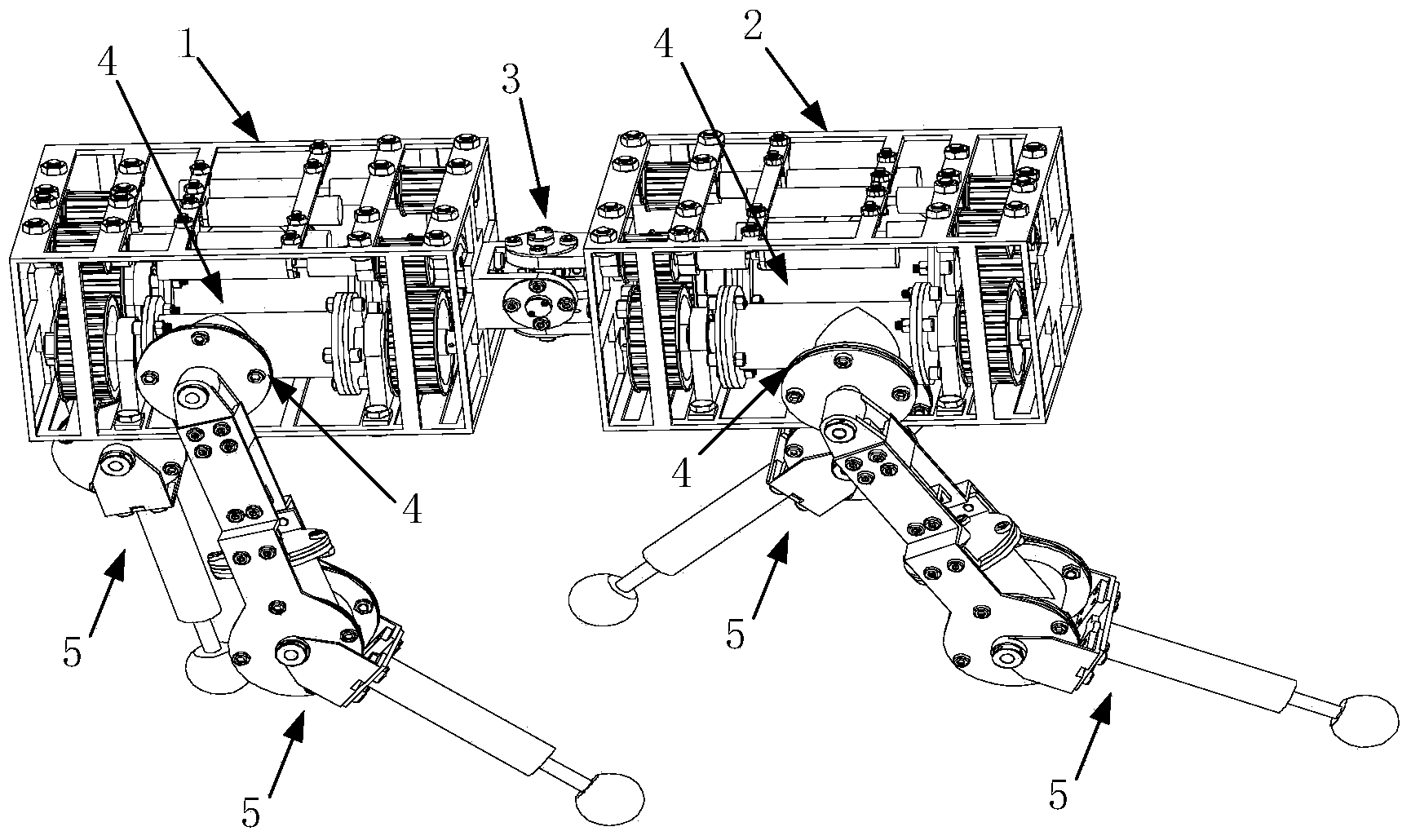

Multifeet walking robot and its control device

A multi-lag walking robot has two front, two middle and two rear legs arranged in left and right two rows. Each leg is composed of foot, shank, thigh, innominate part and drive unit consisting of servo motors, gear pairs and steel wire-pulley drive pairs. Its controller comprises central axles of innominate parts, potentiometers on the drive axle of joints, contact switches and pressure sensors on feet, range sensor in the front of frame and visual sensor. A computer is used to control the operation of robot. Its advantages are compact structure, big rotary range of joint, and high flexibility and impact resistance.

Owner:HUAZHONG UNIV OF SCI & TECH

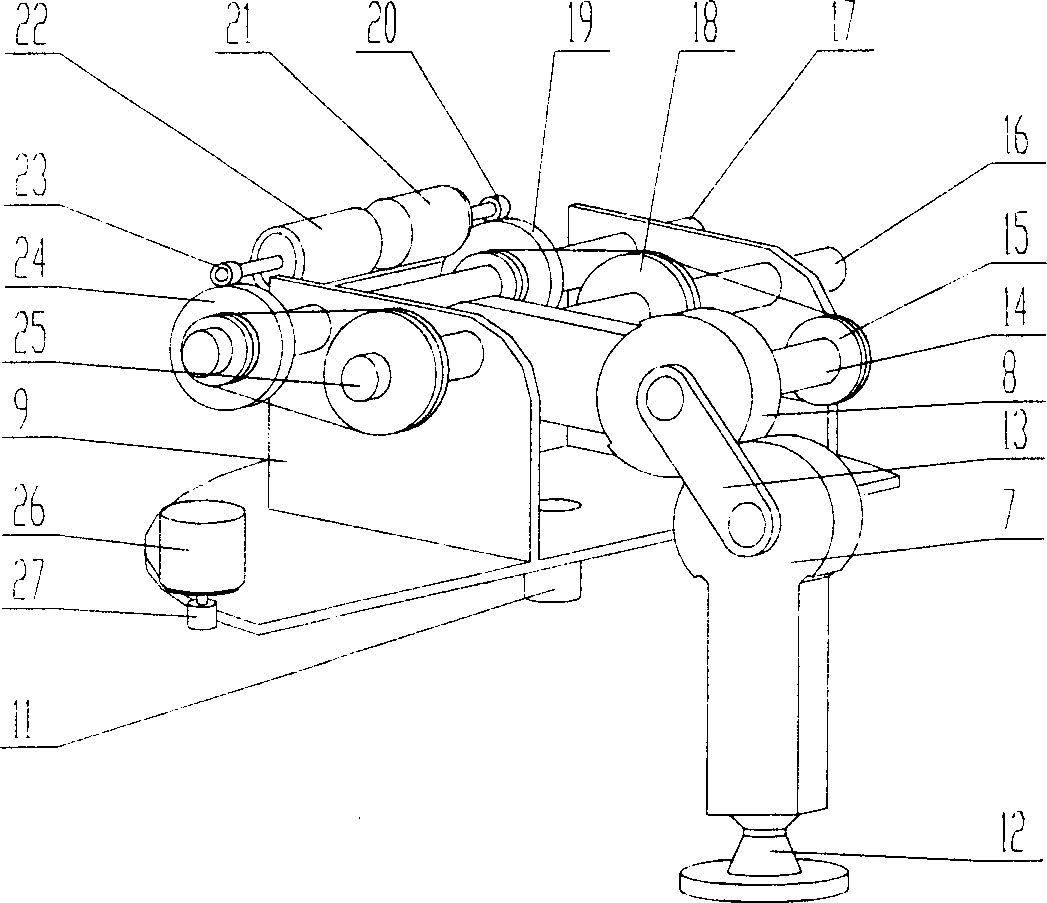

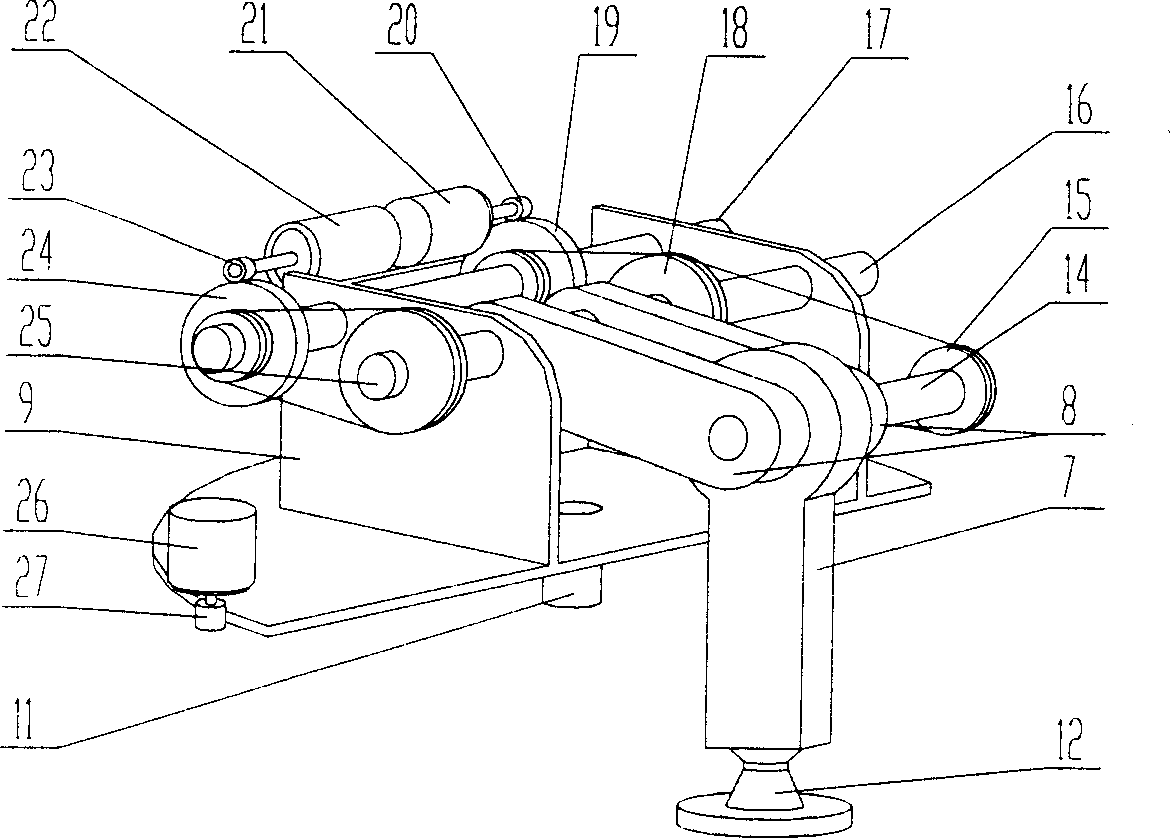

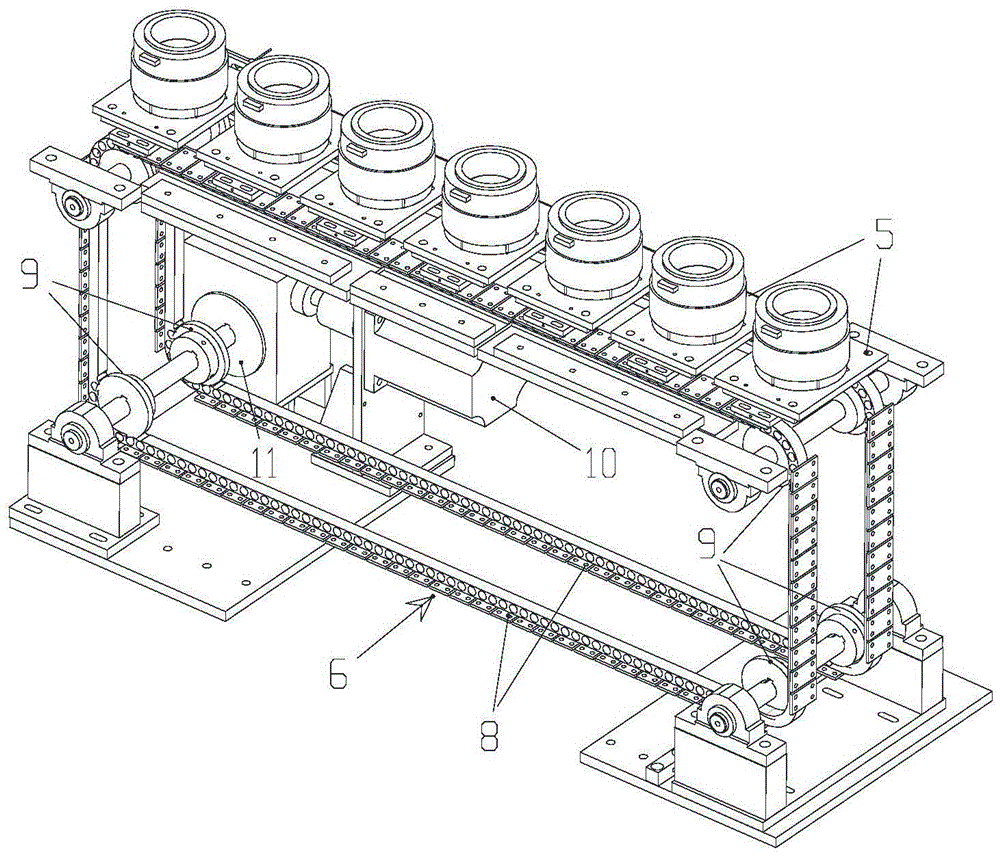

Robot-assisting motor stator carrying system

InactiveCN105537899ALarge transmission ratioIncrease carrying capacityProgramme-controlled manipulatorMetal working apparatusEngineeringAssembly line

The invention relates to machinery manufacturing automation assembly lines, in particular to a motor manufacturing assembly line assisted by an industrial robot. A robot-assisting motor stator carrying system comprises a robot, a three-jaw finger, a delivering mechanism and jig bodies. The robot is fixedly connected to the delivering mechanism. The three-jaw finger is movably connected to the executing tail end of the robot. The jig bodies are fixedly connected to the delivering mechanism. The jig bodies are fixedly connected to a chain. The chain can perform long-distance delivery so that stators can be delivered far. The stators are fixedly connected to the jig bodies through flanks of threads of the stators, so that connecting is stable and stationary. The robot grasps the stators and enables the stators to get rid of threaded connection from the jig bodies. Then, the robot moves the stators to the needed position.

Owner:戴毅

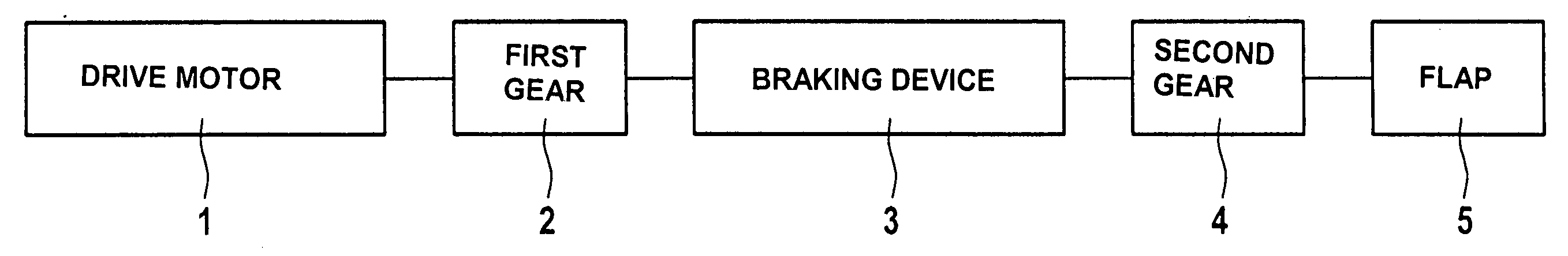

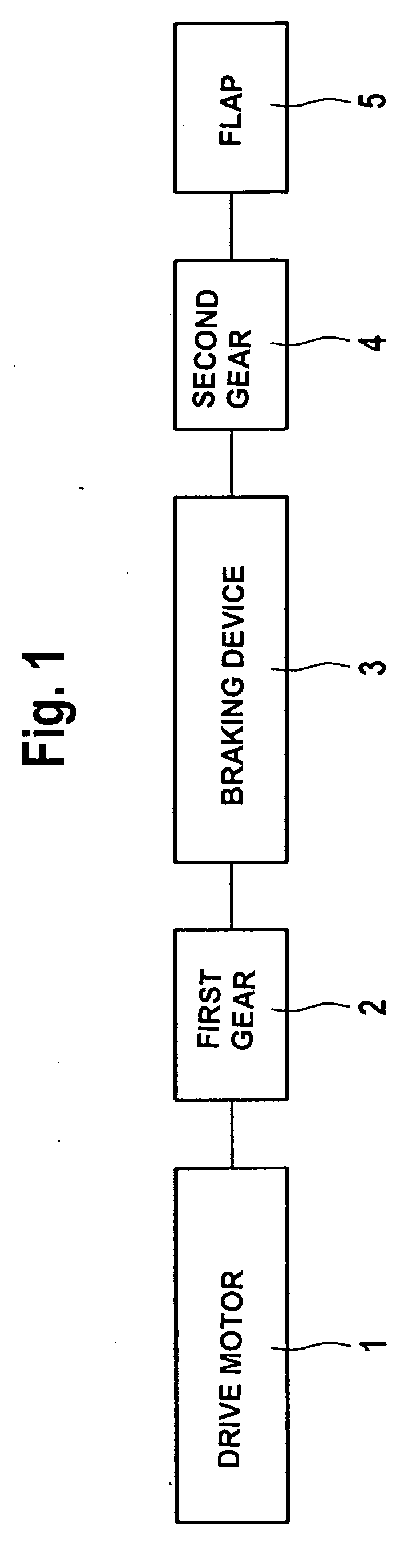

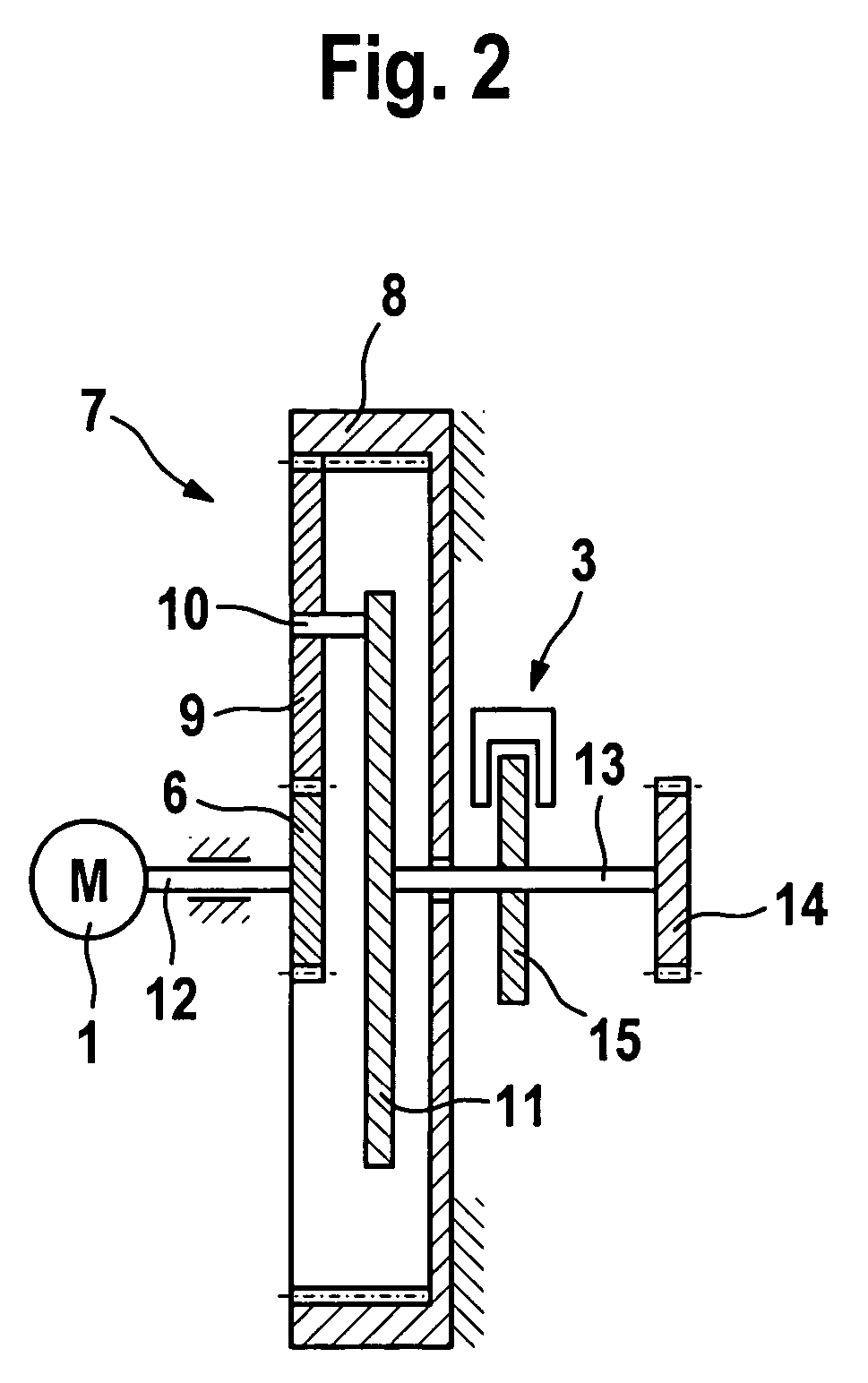

Drive for pivoting a flap arranged on a vehicle body

InactiveUS20060289821A1Large transmission ratioSimple and cost-effectiveOperating means/releasing devices for valvesBuilding braking devicesDrive motorSelf locking

A drive for pivoting a flap arranged on a vehicle body about a pivot axis includes a non-self locking electric motor and a drive train connecting the motor to the flap. The motor can be switched between a driving active state and a non-driving inactive state, the motor being moveable in the inactive state at least substantially without any resistance. A braking device blocks the drive train in the inactive state of the drive motor and unblocks the drive train in the active state of the motor.

Owner:STABILUS

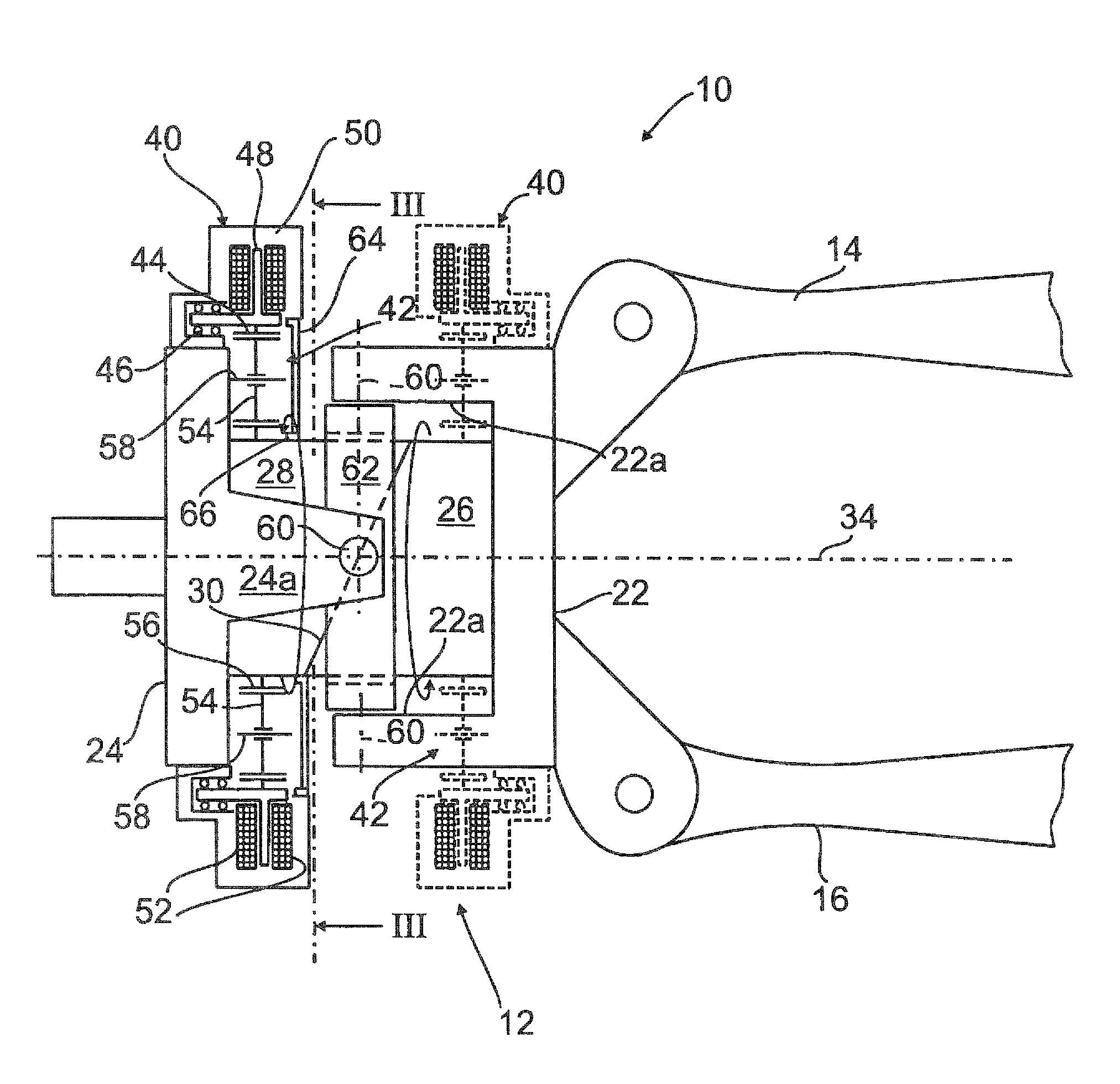

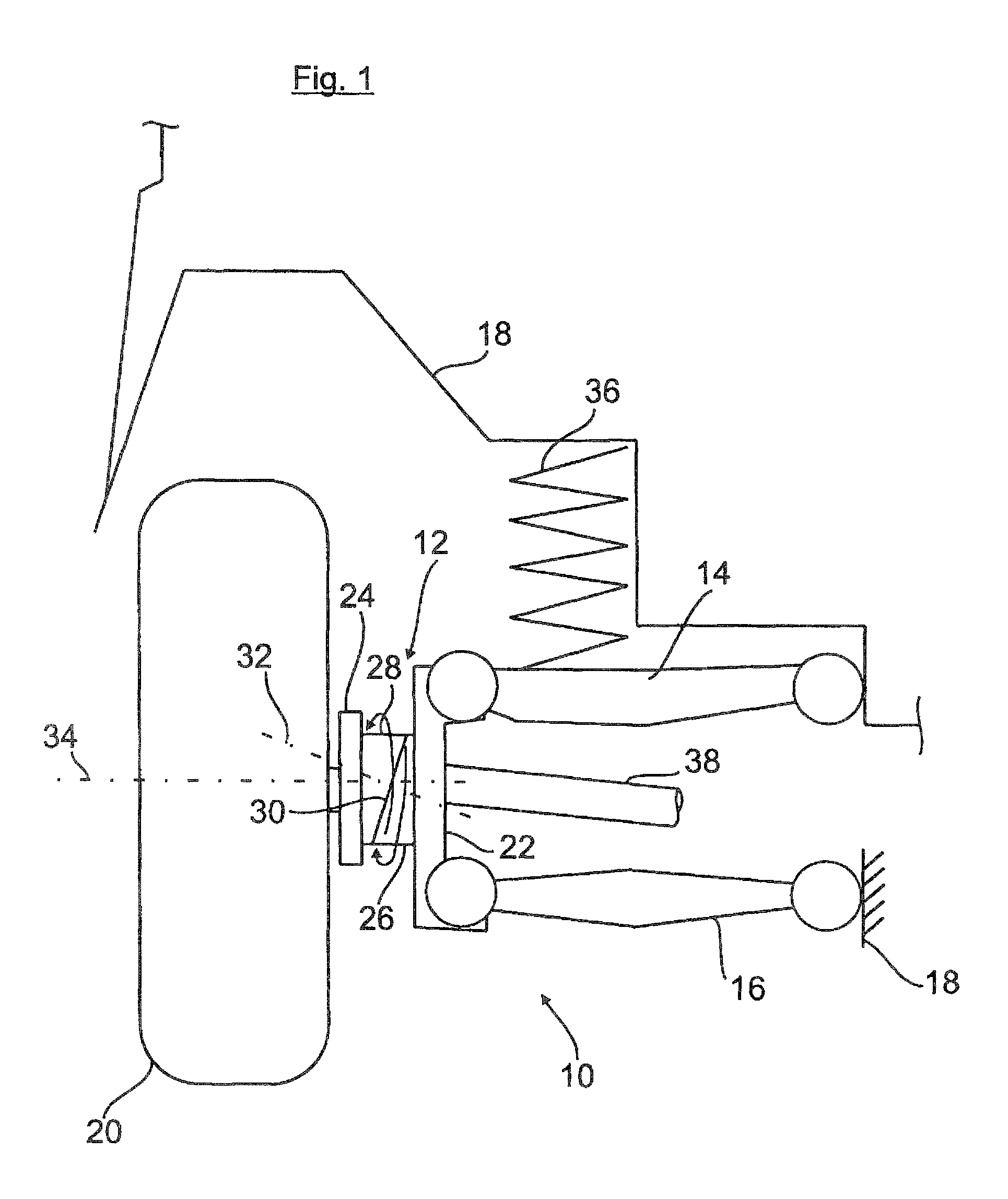

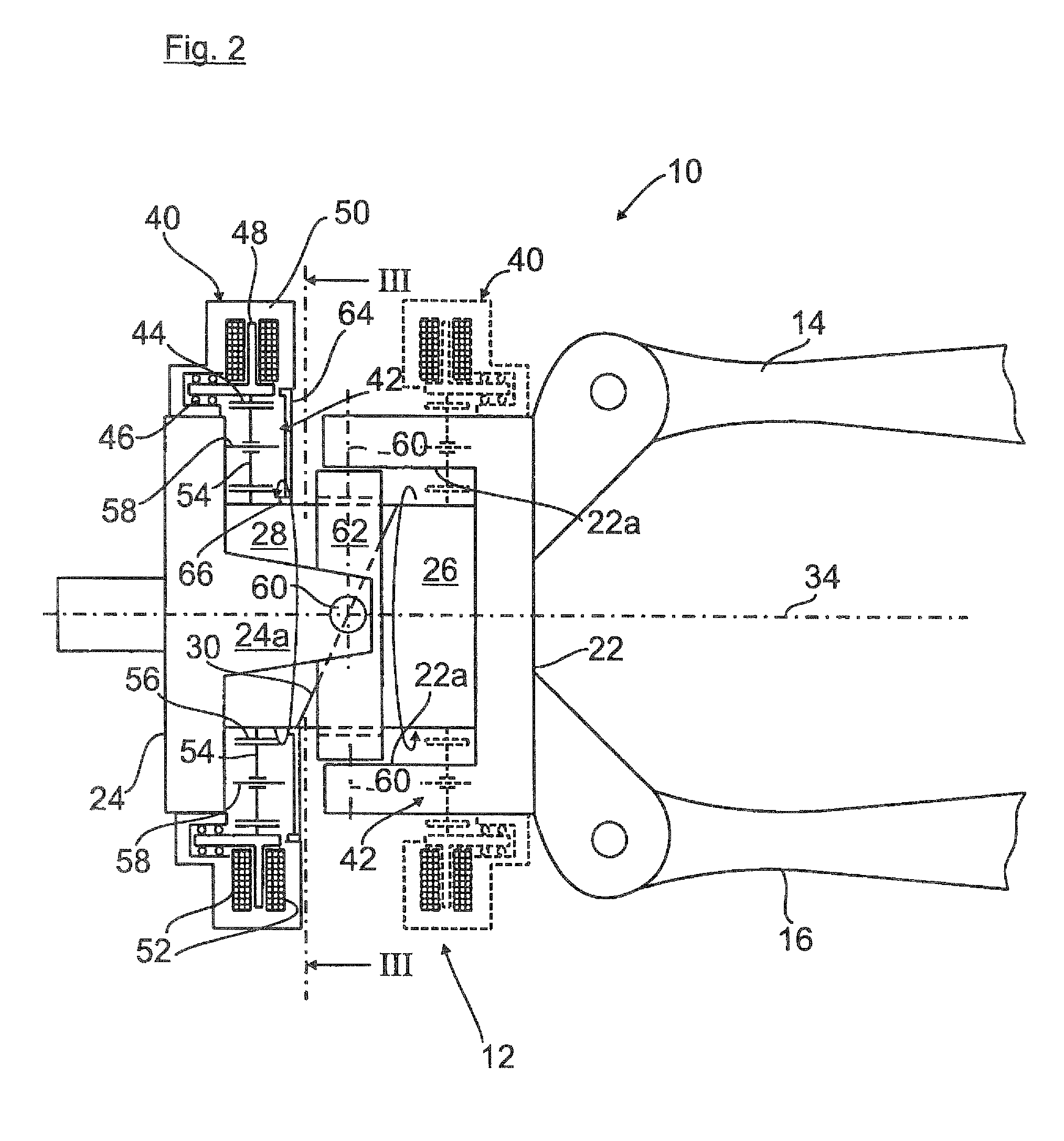

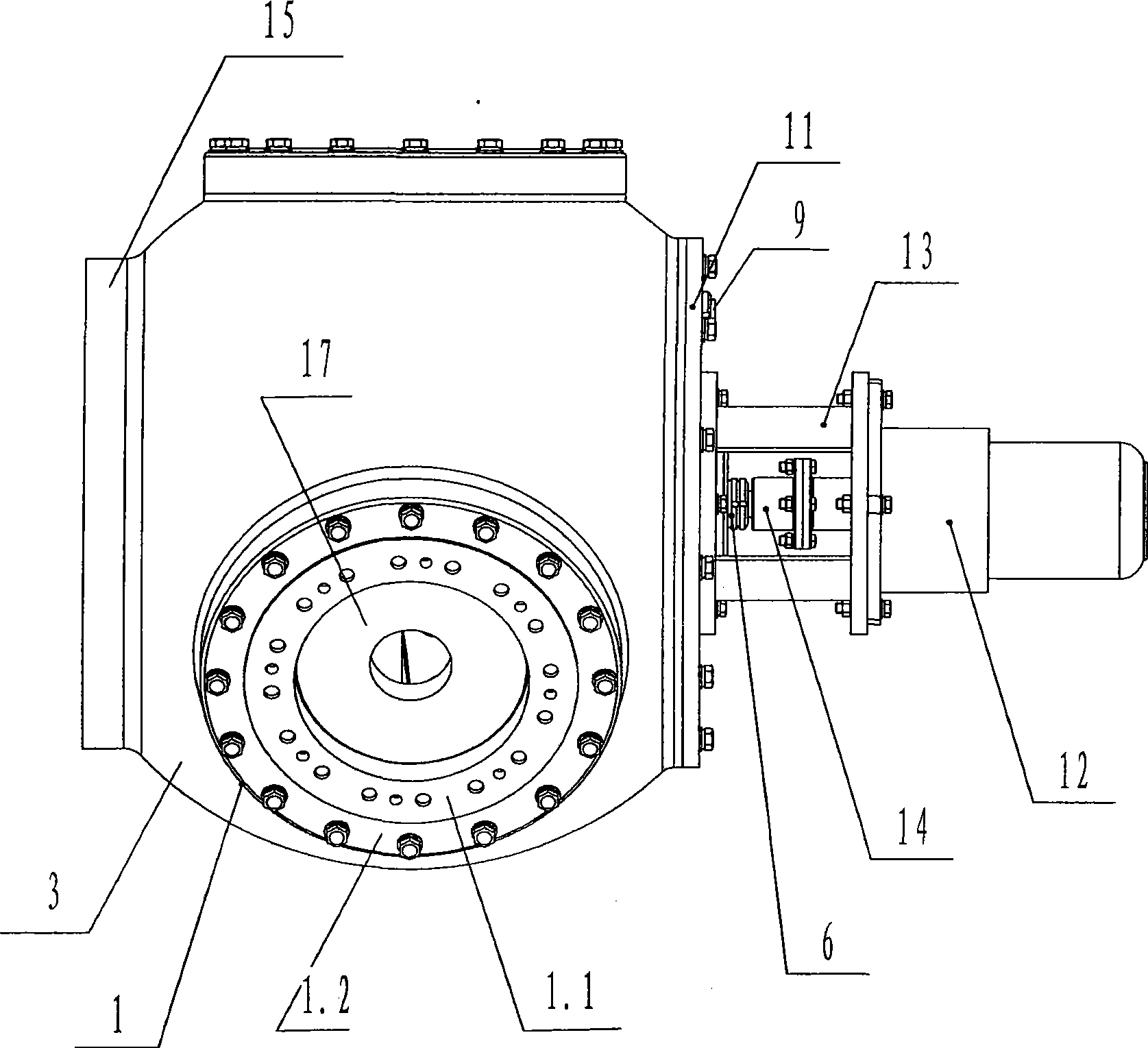

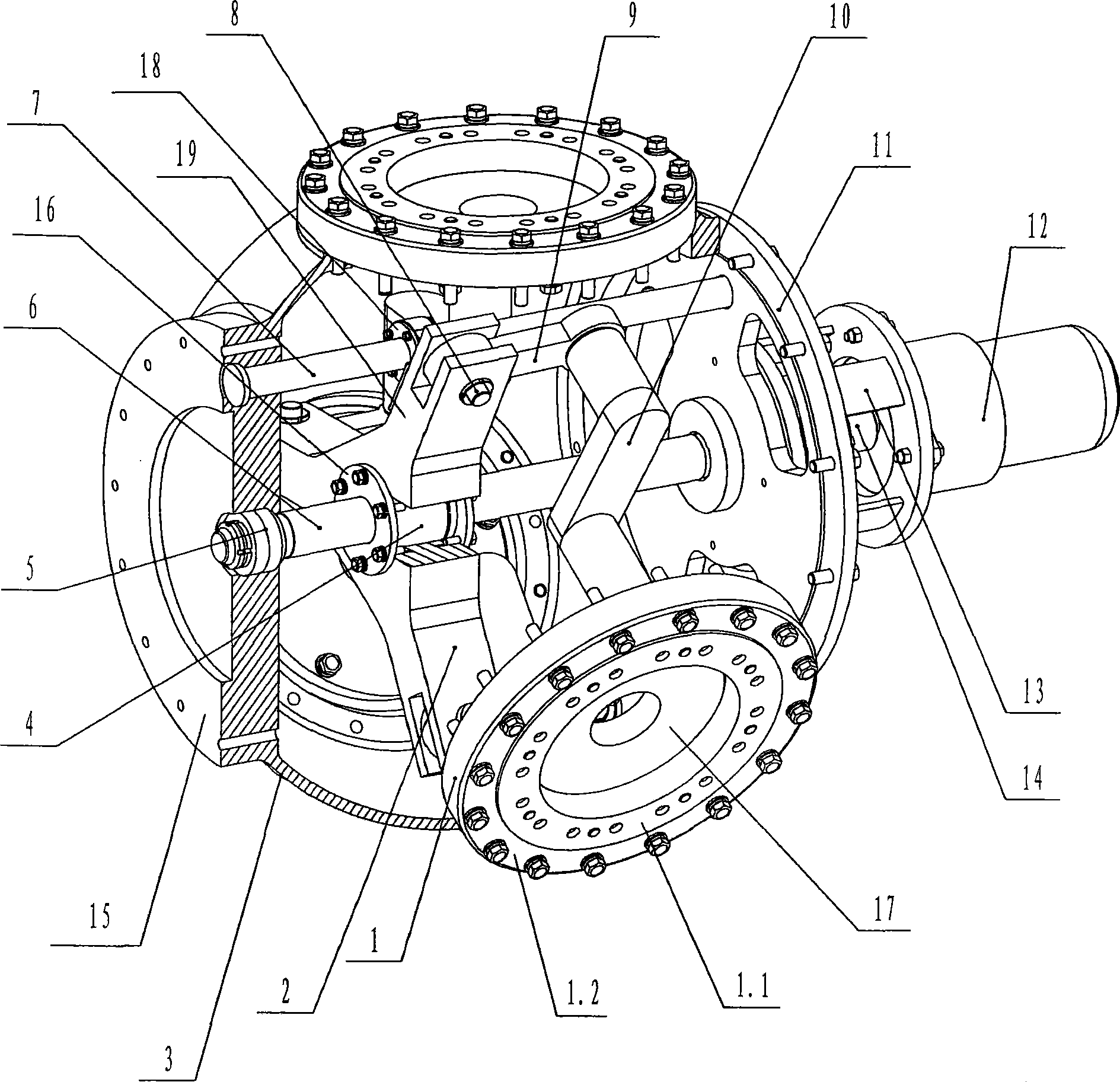

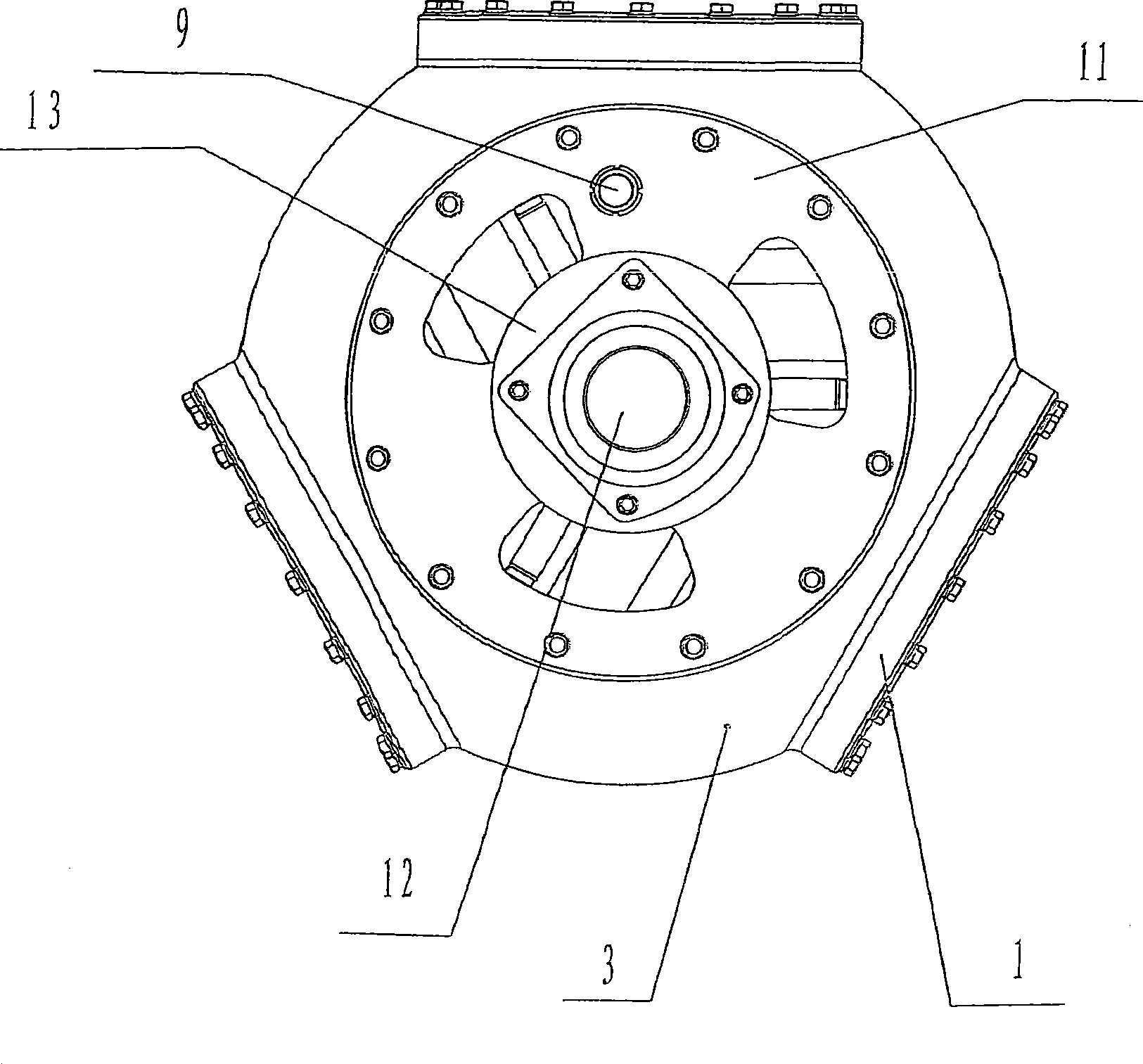

Device for adjusting camber and/or toe

ActiveUS8322729B2Robust transmissionIncreased tooth meshingSteering partsResilient suspensionsEngineeringMechanical engineering

The invention relates to a device for adjusting the camber and / or toe of the wheels (20) of wheel suspensions (10), especially for motor vehicles, including a wheel carrier (12) on which the respective wheel (20) is rotatably mounted and which is subdivided into a carrier part (24) receiving the wheel, a guide part (22) connected to the wheel suspension (10), and two rotary parts, especially control cylinders (26, 28), arranged between the carrier part and the guide part and rotatable in relation to each other, to the carrier part (24) and to the guide part (22) about a common rotation axis (32). Each of the rotary parts can be moved by a drive (40) and a servo drive (42) in both directions of rotation. According to the invention, the servo drive (42) is designed for at least one of the rotary parts (26, 28) as a planetary gear train (42), and the planetary gear train (42) is especially radially externally arranged around the rotary part (26, 28).

Owner:AUDI AG

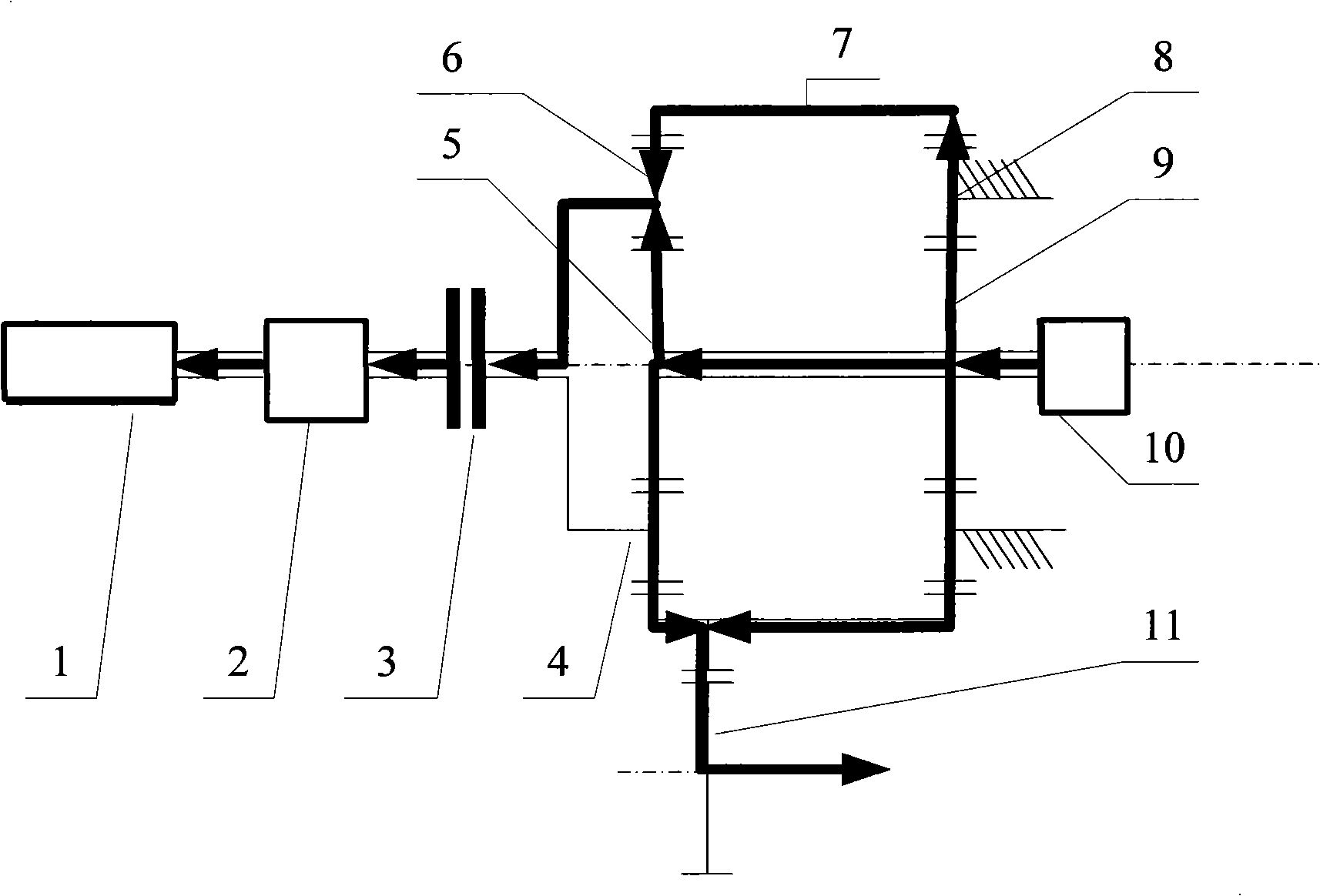

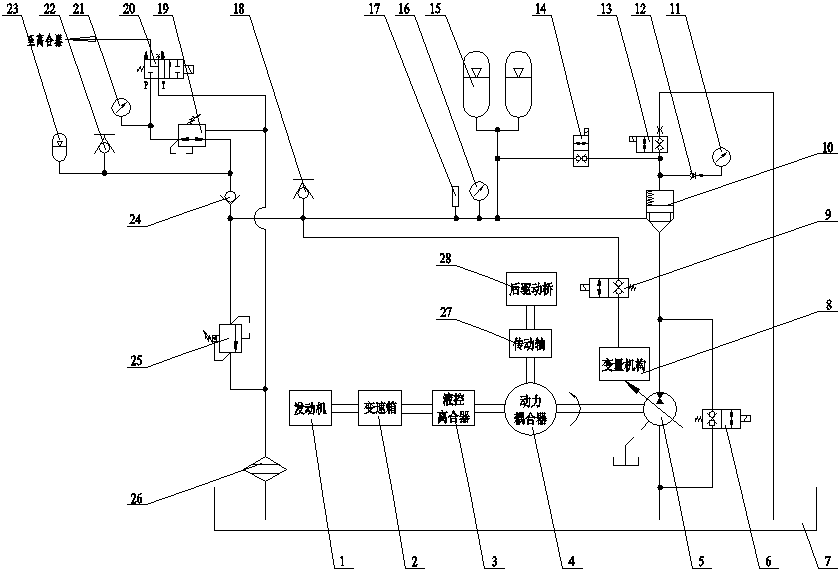

Parallel hydraulic hybrid driving system of vehicle

InactiveCN103223849ASimple structureReduce lossesGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingHigh pressureHydraulic pressure

The invention relates to a parallel hydraulic hybrid driving system of a vehicle, which comprises a mechanical transmission system and a hydraulic regenerative brake system, wherein the mechanical transmission system comprises an engine, a gearbox, a hydraulic control clutch, a power coupler, a two-way variable pump / motor, a transmission shaft and a rear driving axle; and the hydraulic regenerative brake system comprises a two-way variable pump / motor, a first stop valve, an oil tank, a variable mechanism of the two-way variable pump / motor, a plugin valve, a high pressure accumulator, a high pressure accumulator pressure gauge, a pressure sensor, a reducing valve, a two-position two-way reversing valve, an overflow valve and a filter. A charging / discharging major loop of the driving system adopts a controllable plugin valve, the plugin valve is controlled by controlling a pilot valve of the driving system, and the driving system responses rapidly. The driving system is convenient to operate and high in reliability, the power source switching is smooth, the power performances of the vehicle are improved, and the driving system has significant effects in recovering energy of the vehicle and improving fuel economy. The driving system meets the intermittent and high-power requirements and is used for the heavy vehicle requiring frequent start and parking operations.

Owner:TONGJI UNIV +1

Smart quadruped robot with flexible waist

The invention discloses a smart quadruped robot with a flexible waist. The smart quadruped robot with the flexible waist comprises a front body, a rear body, a waist mechanism, crotch mechanisms and leg mechanisms. The front body and the rear body are connected through a split Hooke joint, so that relative deflection and pitching of the front body and the rear body are realized. The front body and the rear body are respectively provided with two crotch mechanisms, wherein output shafts of the crotch mechanisms are made to face the outer side of the bodies so that the leg mechanisms can be installed; the output shafts are meshed with bevel gears between transmission shafts for transmission, so that the output shafts are driven through rotation. A fixed shaft is fixed to each crotch mechanism, and the fixed shafts are driven to rotate to rotate a gearbox; in this way, the leg mechanisms can swing front and back as well as up and down. Each leg mechanism comprises a thigh part and a calf part, wherein each thigh part and each calf part are connected through a knee joint; transmission of the knee joints is realized through two bevel gears, so that the calf part made to swing front and back relative to the thigh part. The smart quadruped robot with the flexible waist has the advantages that the capability of passing through a mountain environment of the robot can be improved, the turning radius in the advancing process is reduced, rotational inertia of legs of the robot is reduced, and the energy utilization rate is increased.

Owner:BEIHANG UNIV

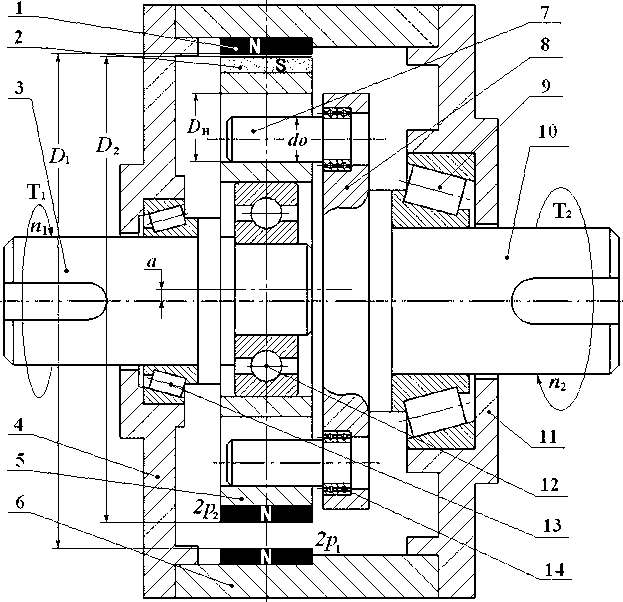

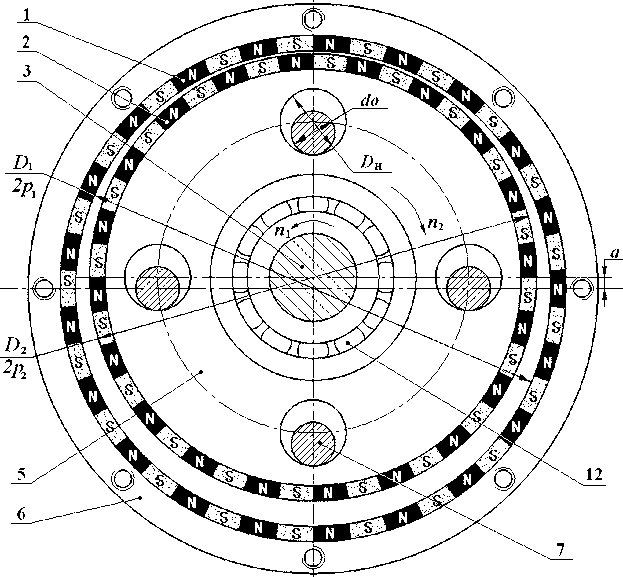

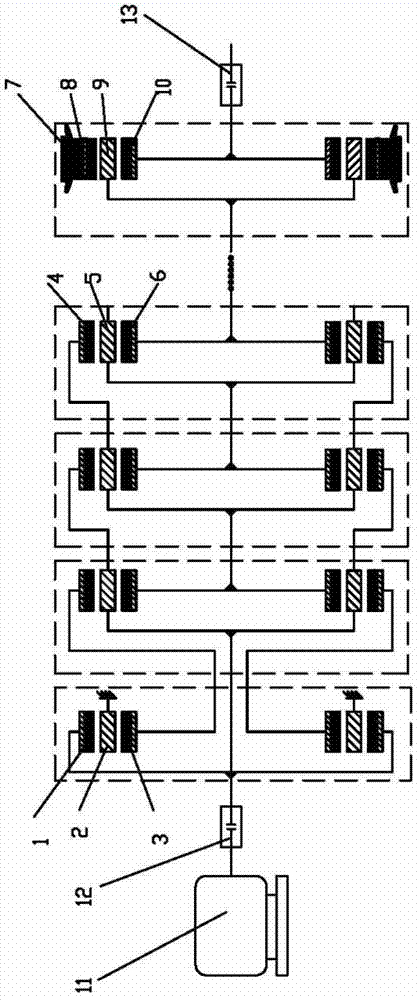

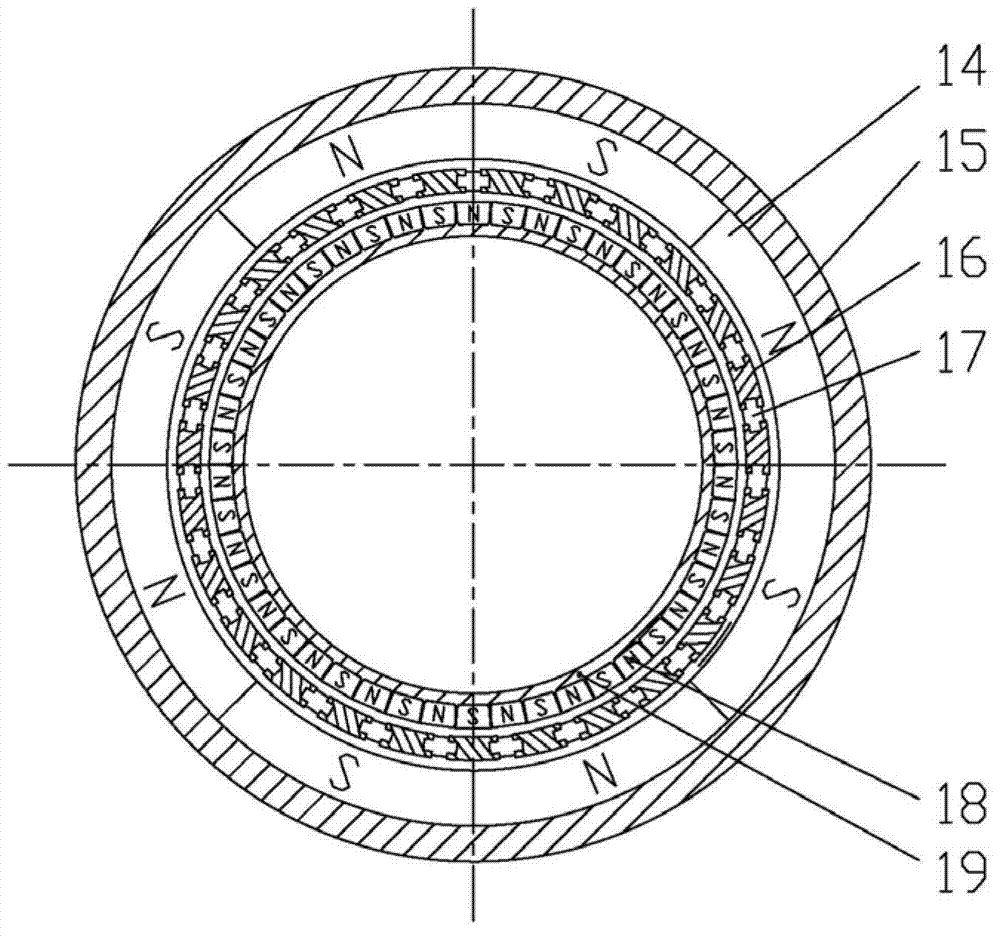

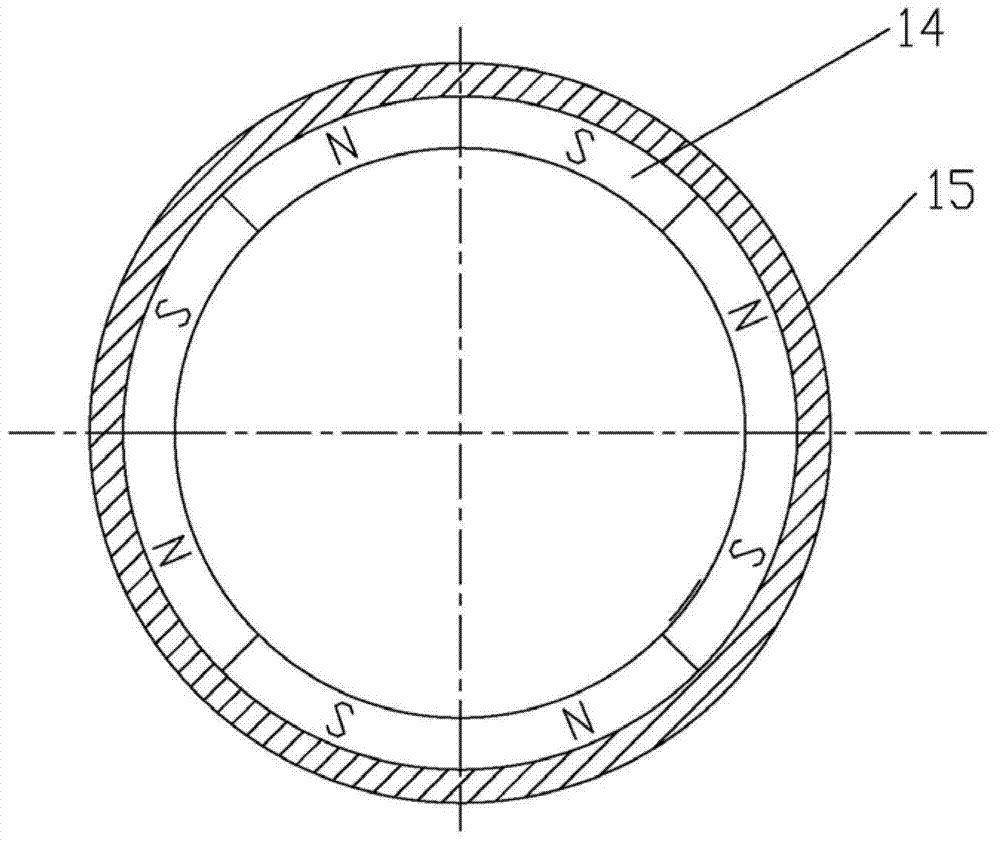

Little pole difference magnetic field coupling type magnetism transmission eccentricity gear pair of novel radial direction magnetic field

InactiveCN103107676ATo achieve technical and economic effectReduce lossDynamo-electric brakes/clutchesElectric machinesLow speedMagnetic field coupling

Disclosed is a little pole difference magnetic field coupling type magnetism transmission eccentricity gear pair of a novel radial direction magnetic field. The little pole difference magnetic field coupling type magnetism transmission eccentricity gear pair of the novel radial direction magnetic field can be applied widely in the field of industry transmissions of wind power generation, electric automobile, vessel driving and the like. The little pole difference magnetic field coupling type magnetism transmission eccentricity gear pair of the novel radial direction magnetic field is characterized in that a stator with a 2p1 stator permanent magnet 1 are distributed in the inner hole of a machine shell 6. A magnetism transmission gear pairs are formed by planet rotors of 2p2 planet rotor permanent magnet 2 are distributed on the excircle of a planet rotor iron core5. A number difference between the pole number 2p1 and 1p2 is small. The permanent magnets on the two magnetic gear pairs penetrate through an air gap magnetic field coupling of the radial direction eccentricity, and are connected to an eccentricity structure by the little pole difference two magnetic gear pairs. A second bearing 12 and a third bearing 13 are installed on an eccentricity input shaft 3. The planet rotor iron core 5 is driven by the eccentricity input shaft 3 to revolve in autogiration around the axis. A low speed autogiration of the planet rotor is output through a pin hole type output structure.

Owner:余虹锦

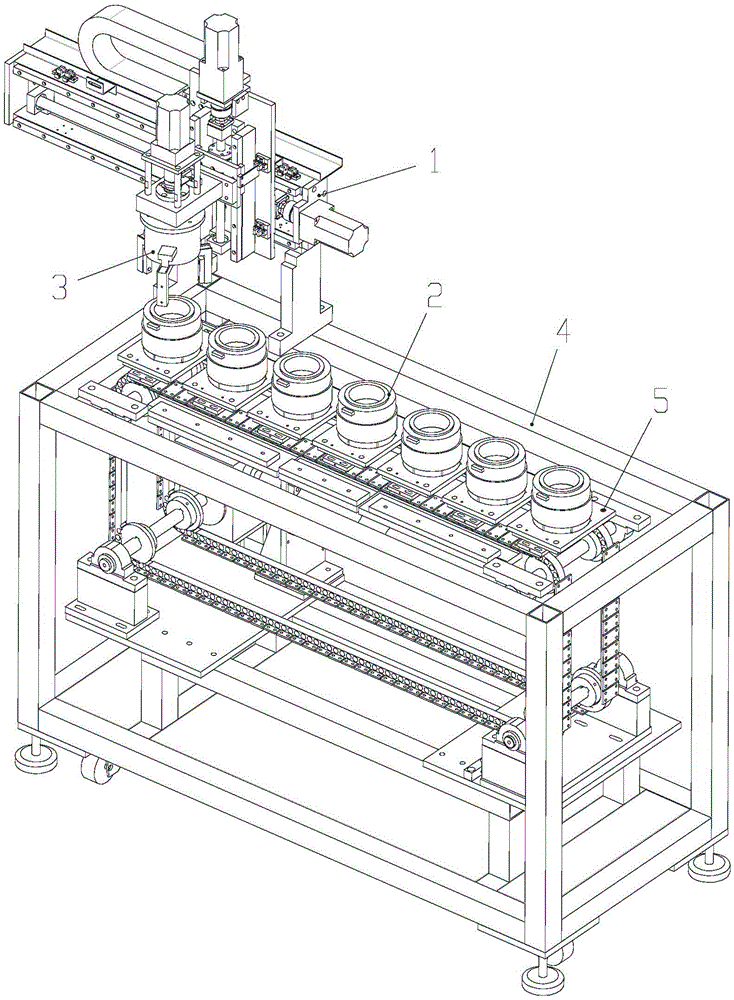

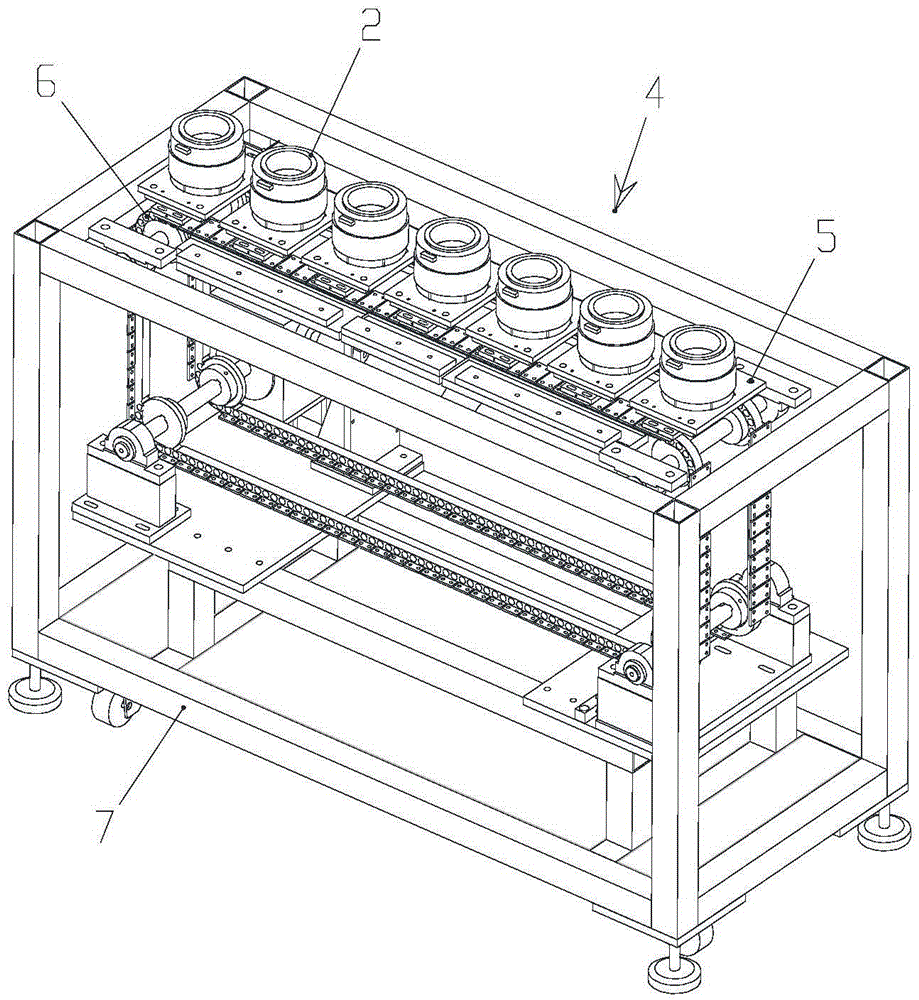

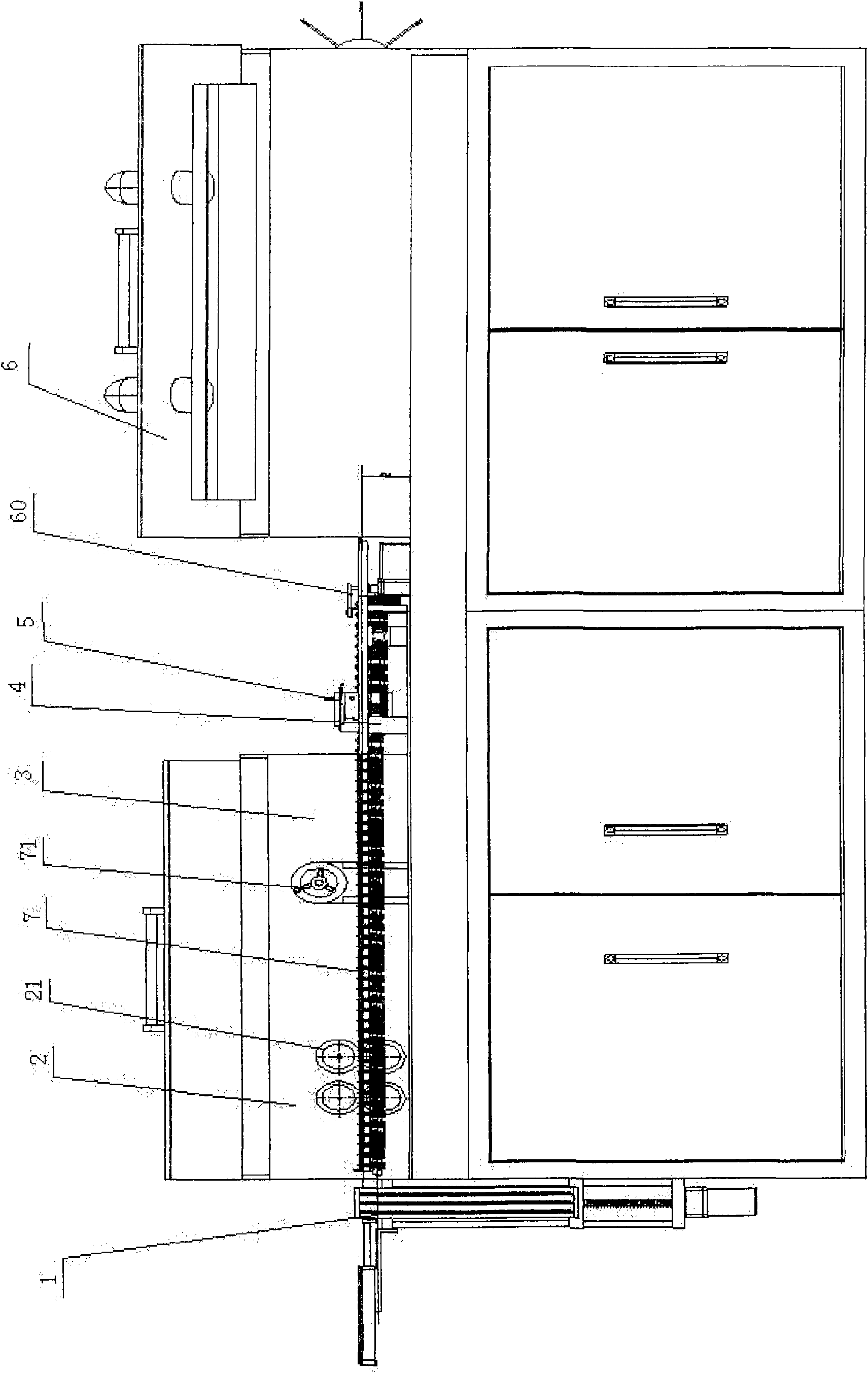

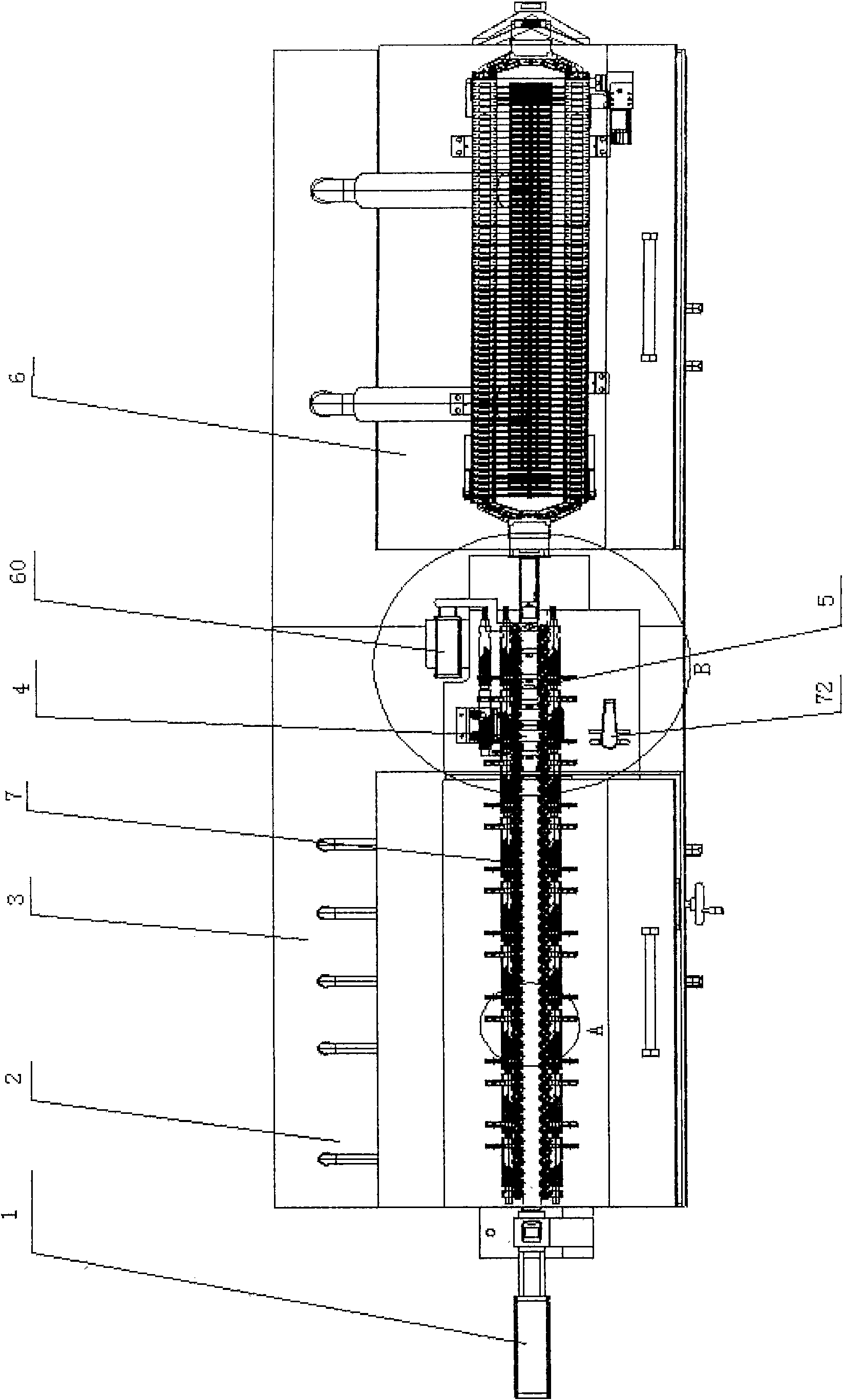

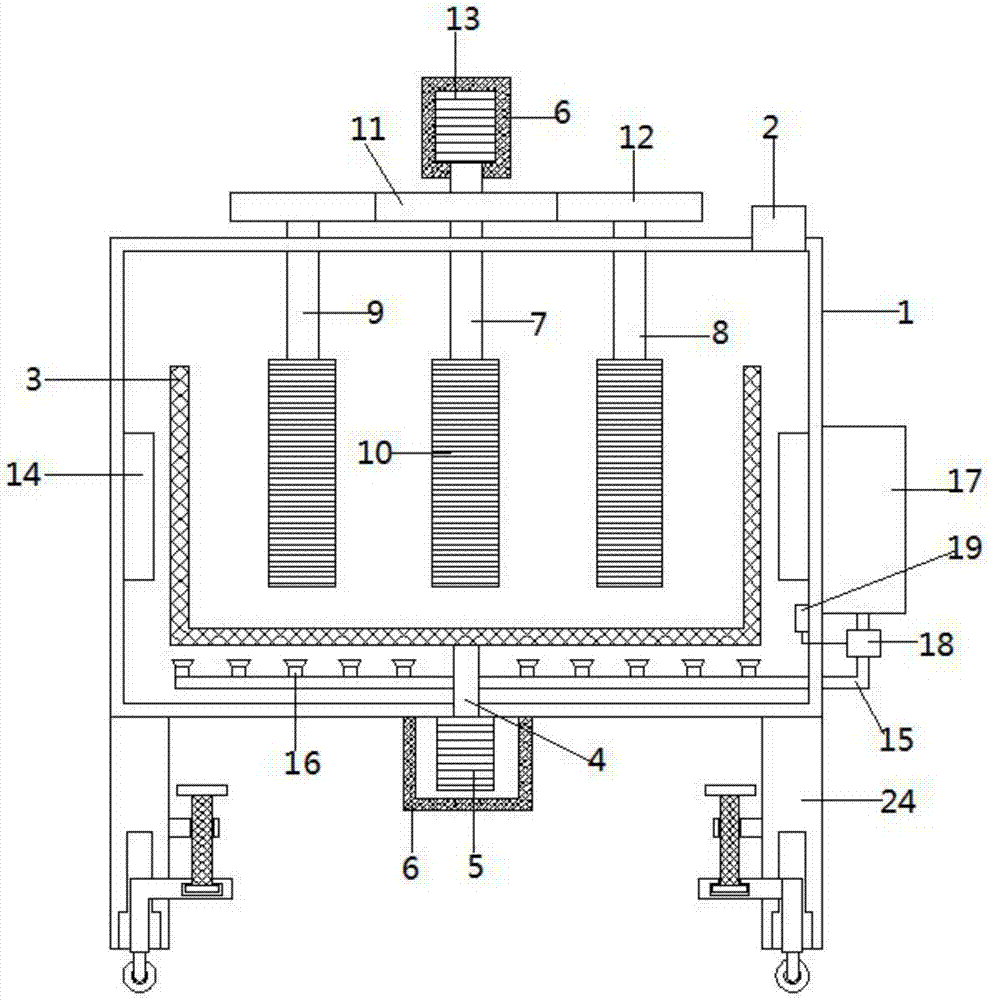

Mobile phone lens cleaning production line device

InactiveCN101596531AReduce bump damageLarge transmission ratioToothed gearingsFlexible article cleaningProduction lineMobile phone

The invention discloses a mobile phone lens cleaning production line device, which comprises a feed mechanism, a cleaning mechanism and a drying mechanism, and is characterized in that: the inside of at least one of the feed mechanism, the cleaning mechanism and the drying mechanism is provided with a worm and worm gear transmission device for transmitting lenses of mobile phones. The mobile phone lens cleaning production line device has the characteristics of good cleaning effect, high drying efficiency and stable transmission.

Owner:苏州开石精密电子有限公司

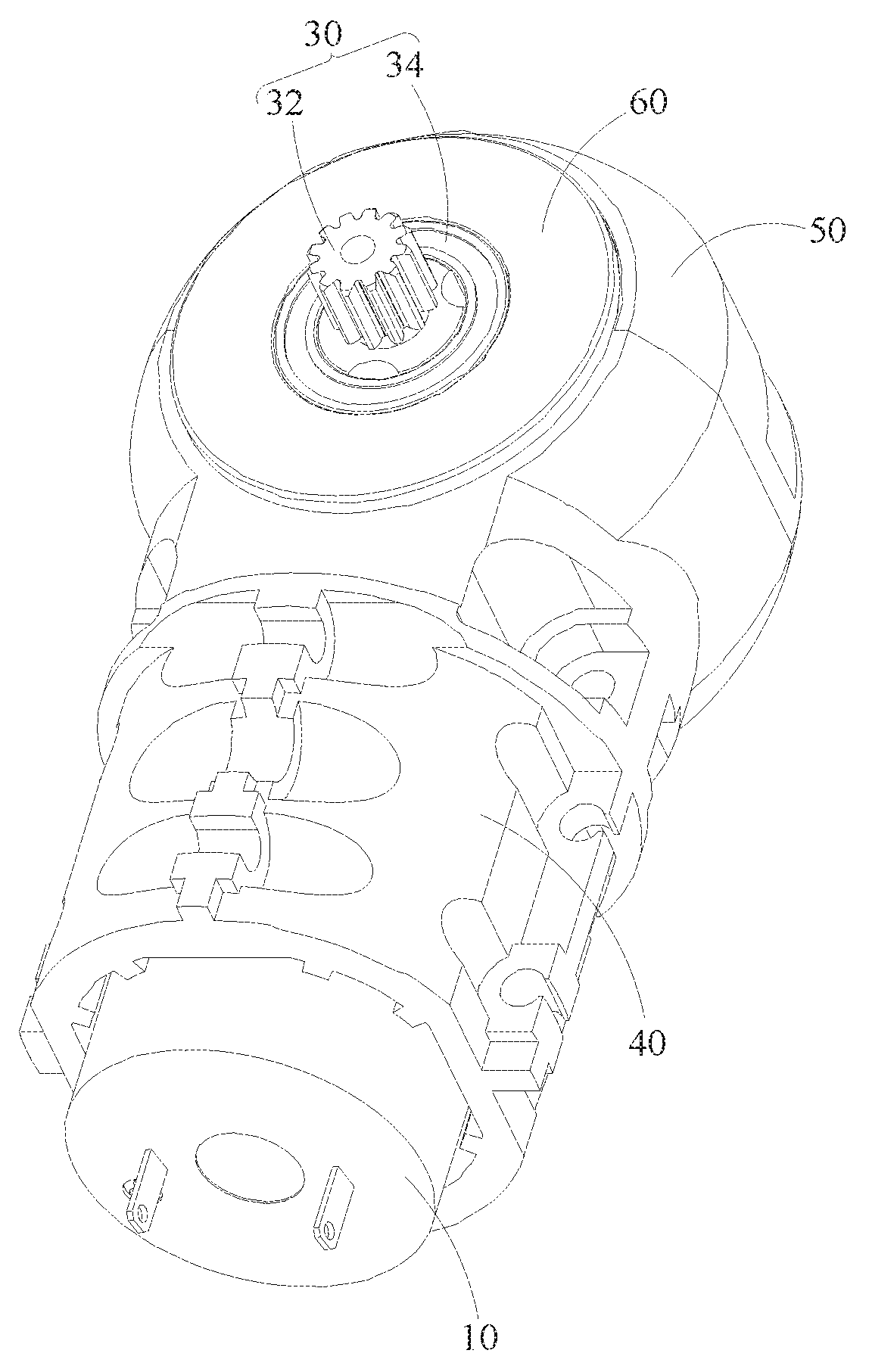

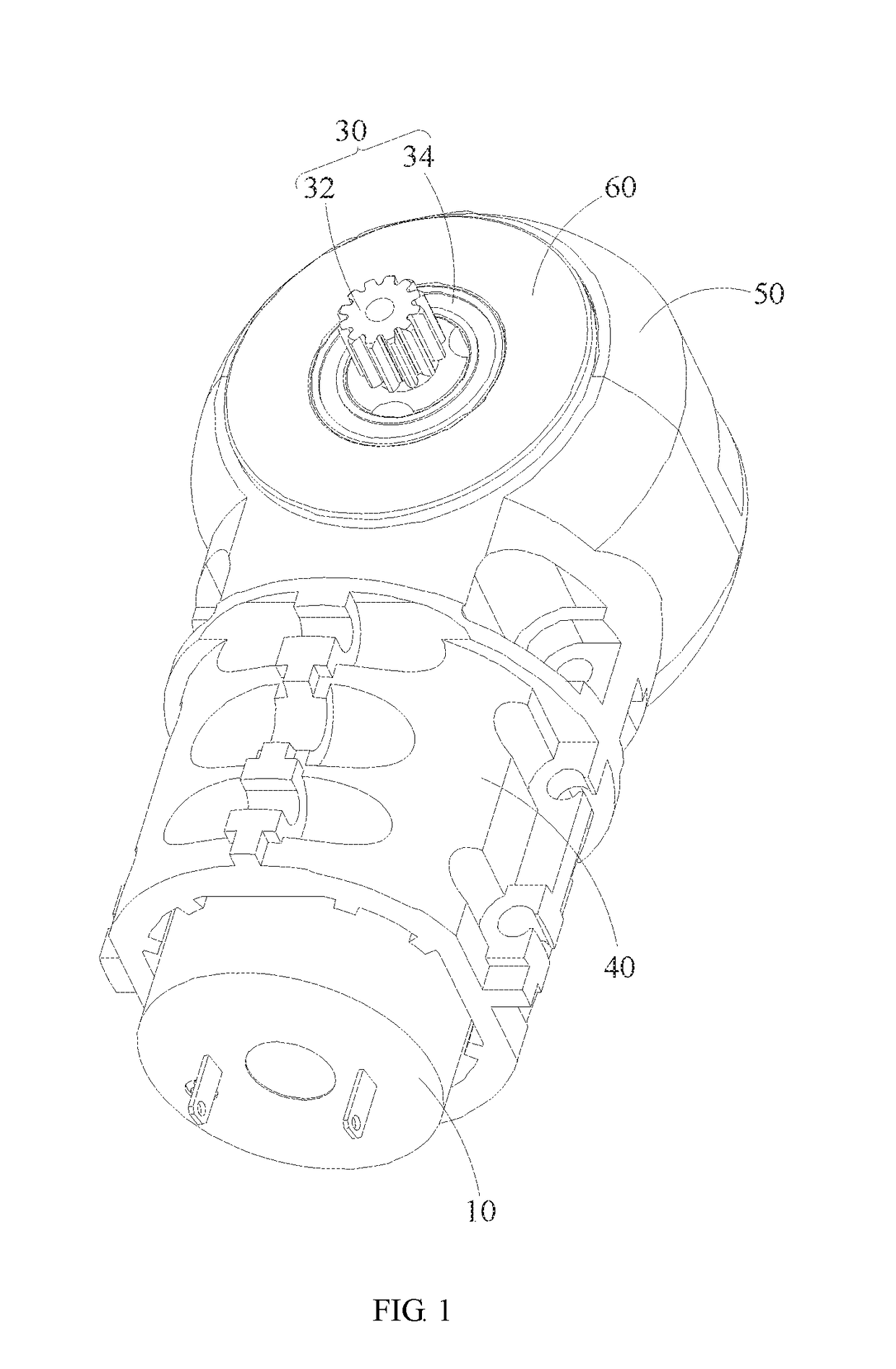

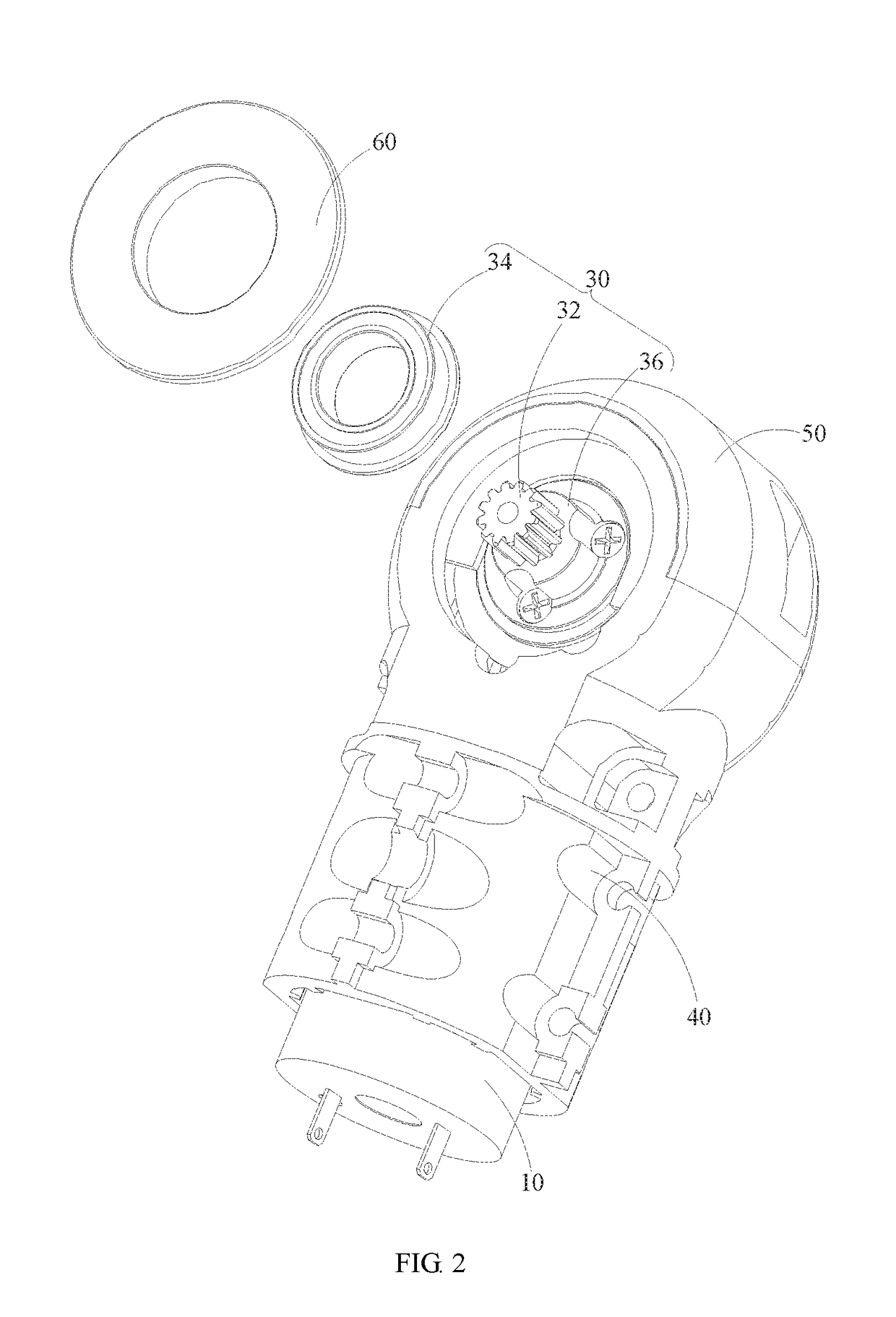

Servo and robot with servo

ActiveUS9815192B1Compact structureIncrease contactProgramme-controlled manipulatorJointsEngineeringServomechanism

A servo and a robot with the servo are provided. The servo comprises a power input apparatus with a first output shaft, a deceleration apparatus, and a power output mechanism. The deceleration apparatus comprises a first-stage deceleration mechanism and a second-stage deceleration mechanism. The power output mechanism comprises a second output shaft and an output bearing fixedly installed on the second output shaft, wherein the second output shaft is an external spline output shaft. Through the external spline output shaft and the output bearing disposed on the power output mechanism, the servo could directly connect with an exterior component through the external spline output shaft, and the strength is improved. As a result, the friction between the servo and the exterior component is reduced, and the lifetime is therefore increased.

Owner:UBTECH ROBOTICS CORP LTD

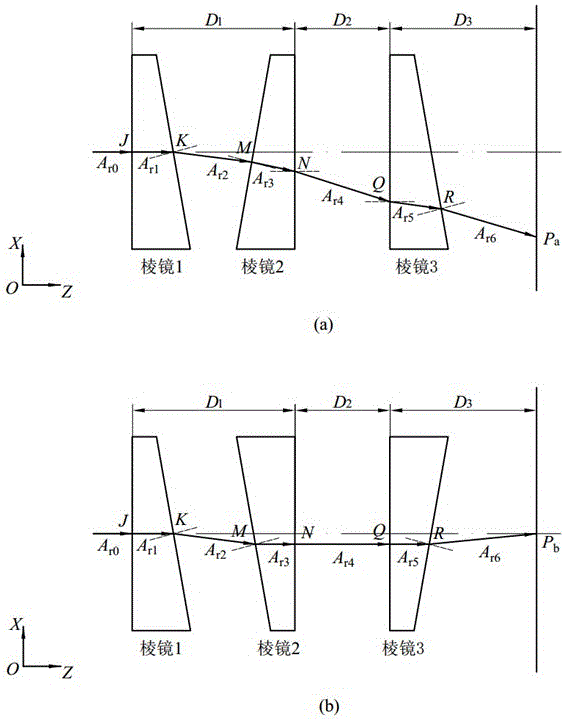

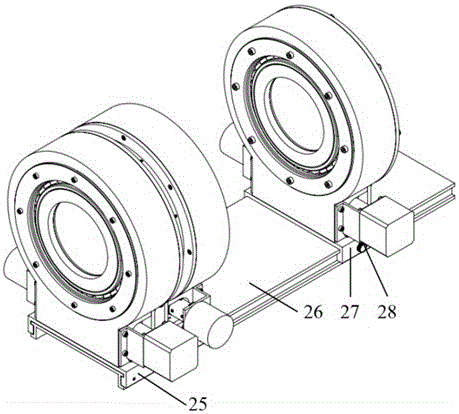

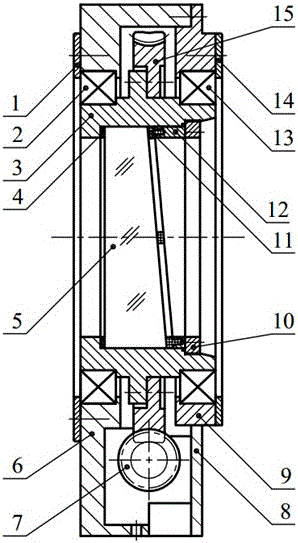

Rotating triple-prism beam scanning device

InactiveCN106249405AControl rotation angleAvoid empty backOptical elementsCouplingRolling-element bearing

The invention relates to a rotating triple-prism beam scanning device comprising a rotating double-prism system, a rotating single-prism system, a guide rail, an adjustable support, and a fixed support. The rotating single-prism system comprises a base component, a prism and frame assembly, and a worm-and-gear mechanism. The prism and frame assembly comprises a flat washer, a wedge prism, a rubber pad, a wedge retainer ring, a threaded retainer ring, and a frame. The base component comprises a base, a base baffle, and a base insert. The worm-and-gear mechanism comprises a rotary motor, a motor stand, a coupling, a worm, a bearing support, a rolling bearing, a worm gear, an encoder support, and a rotary encoder. The rotating double-prism system is formed by assembling two rotating single-prism systems together. In the invention, the three wedge prisms are driven by the worm-and-gear mechanisms to do full-circumferential rotation, transmission is stable and accurate, and the scanning precision and stability of dynamic beams can be ensured; the prisms are independent of one another in rotation control, and diversified scanning modes can be achieved; and by introducing the third prism to the double-prism system, the scanning field of beams is enlarged significantly, and the problem that a double-prism system has scanning blind areas and control singular points is solved effectively.

Owner:TONGJI UNIV

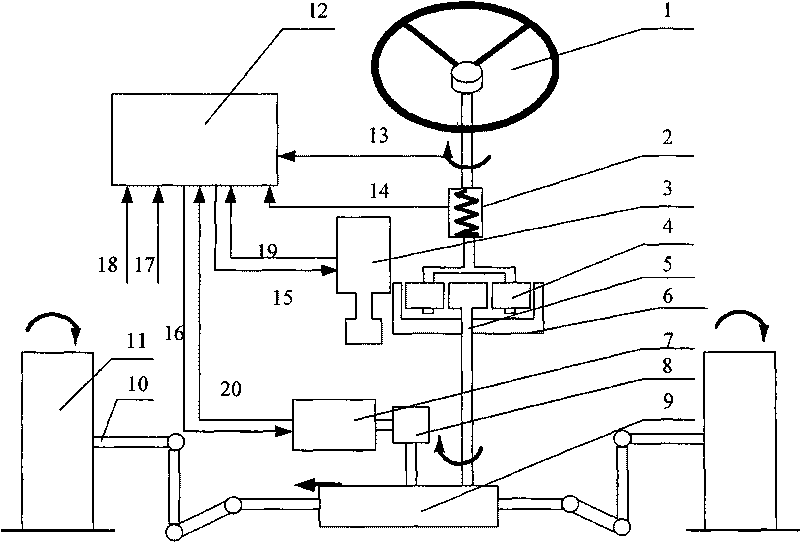

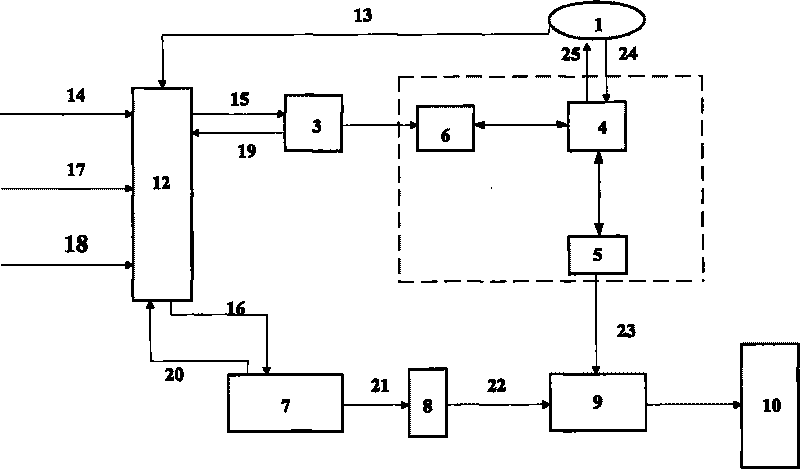

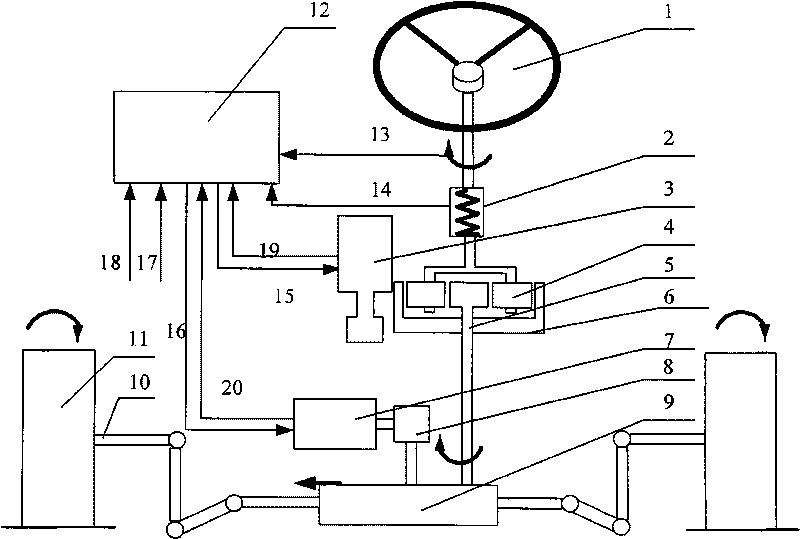

Electric power-assisted steering system with variable transmission ratio and method for controlling transmission ratio thereof

InactiveCN101722983ARealize variable transmission ratio controlRealize functionSteering linkagesAutomatic steering controlElectric power steeringElectric power system

The invention relates to an electric power-assisted steering system with a variable transmission ratio and a method for controlling transmission ratio thereof, and belongs to an electric power-assisted steering system. A planetary gear mechanism and a steering motor are arranged between a torque sensor and a gear rack; and on the basis of completing the conventional electric power-assisted steering, the electric power-assisted steering system can realize the functions of variable transmission ratio control and active steering interference.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Pulp distance varying mechanism of wind power generator

InactiveCN101392726AQuick responseAvoid adaptationWind motor controlMachines/enginesPower componentWind force

The invention discloses a variable-pitch mechanism for an aerogenerator, which comprises a wheel hub, a power component, a plurality of variable-pitch bearings, wherein the wheel hub consists of a curved surface formed by the axes around the wheel hub, a front cover and a back cover which are vertical to the axes of the wheel hub; the outer circle of the variable-pitch bearing is fixedly connected with the curve surface of the wheel hub, and the variable-pitch bearing is evenly distributed on the curve surface of the wheel hub. The device also comprises a screw-driven component, a synchronous mounting rack, a connecting piece and a rotating component, wherein the screw-driven component is rotationally matched with central holes of the front cover and the back cover, and the screw-driven component is connected with the power component; the screw-driven component is fixedly connected with the synchronous mounting rack; the synchronous mounting rack is rotationally connected with each connecting piece, each connecting piece is evenly distributed on the circumference taking the center of the synchronous mounting rack as circle center, and circumference plane is vertical to the axes of the wheel hub; and the connecting piece is also rotationally connected with the rotating component, and the rotating component is fixedly connected with the inner circle of the variable-pitch bearing.

Owner:宁波欣达(集团)有限公司

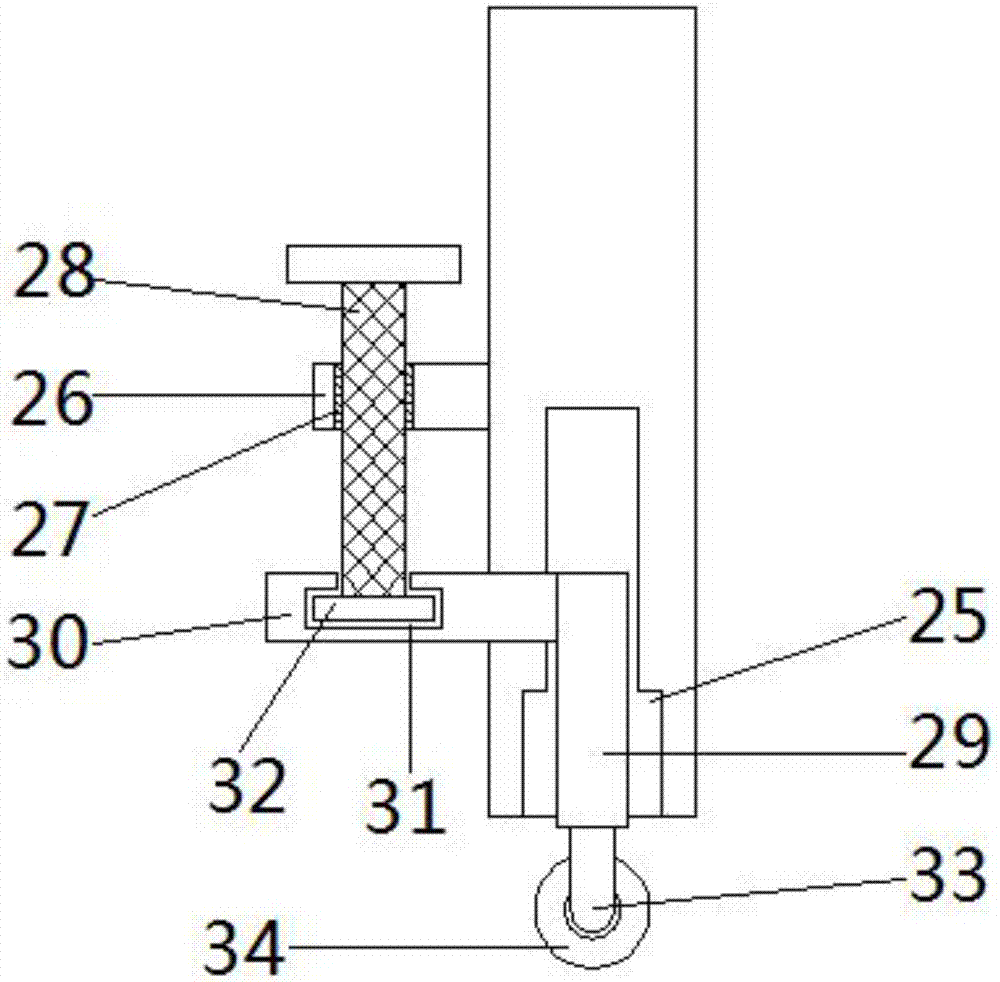

Hydraulic part cleaning device convenient to use

InactiveCN107442452AEasy to fixGood effectCleaning using toolsCleaning using liquidsInfrared lampGear wheel

The invention discloses a hydraulic part cleaning device convenient to use. The device comprises a cleaning box, a liquid feeding pipe is connected to the right end of the upper side of the cleaning box, a cleaning groove is arranged on the lower side inside the cleaning box, a rotating shaft is connected to the center of the bottom end of the cleaning groove, the bottom end of the rotating shaft is connected with a first driving motor, a first cleaning rotating shaft, a second cleaning rotating shaft and a third cleaning rotating shaft are vertically arranged in the cleaning box, and the second cleaning rotating shaft and the third cleaning rotating shaft are arranged on the left side and the right side of the first cleaning rotating shaft correspondingly. According to the hydraulic part cleaning device convenient to use, hydraulic parts are cleaned in a brushing or ultrasonic cleaning mode, the cleaning effect is good, the efficiency is high, the three cleaning rotating shafts are driven by gear transmission to work, the transmission ratio is large, working is stable, noise is low, the cleaned hydraulic parts can be spin-dried and heated through an infrared lamp to be dried, the drying efficiency is high, the drying effect is good, bolts are screwed to ascend to drive rollers to be contracted into groove in the bottom of supporting legs, the cleaning device can be conveniently cleaned, and stability is improved.

Owner:WUHU ZHONGYI HYDRAULIC TECH

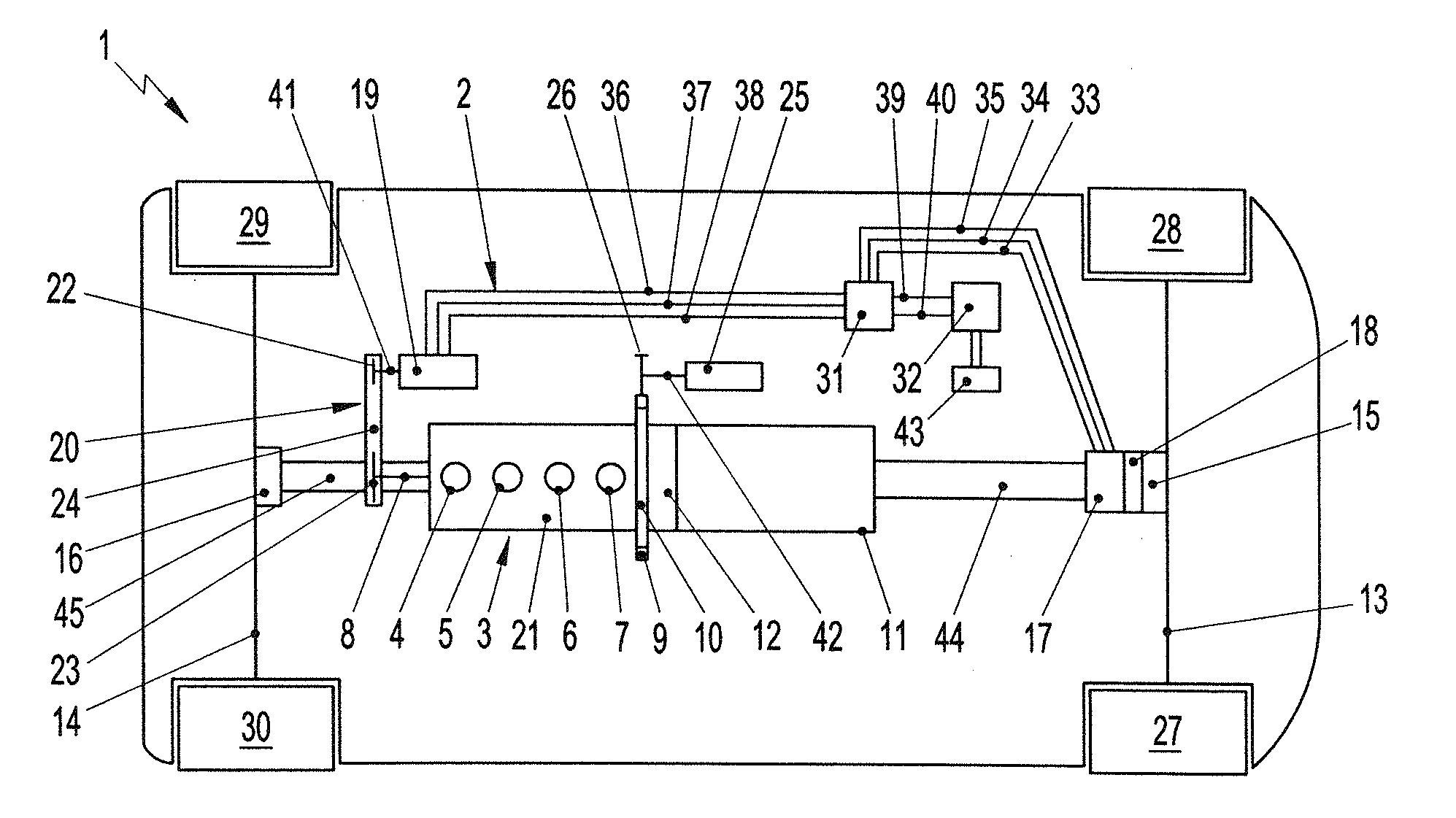

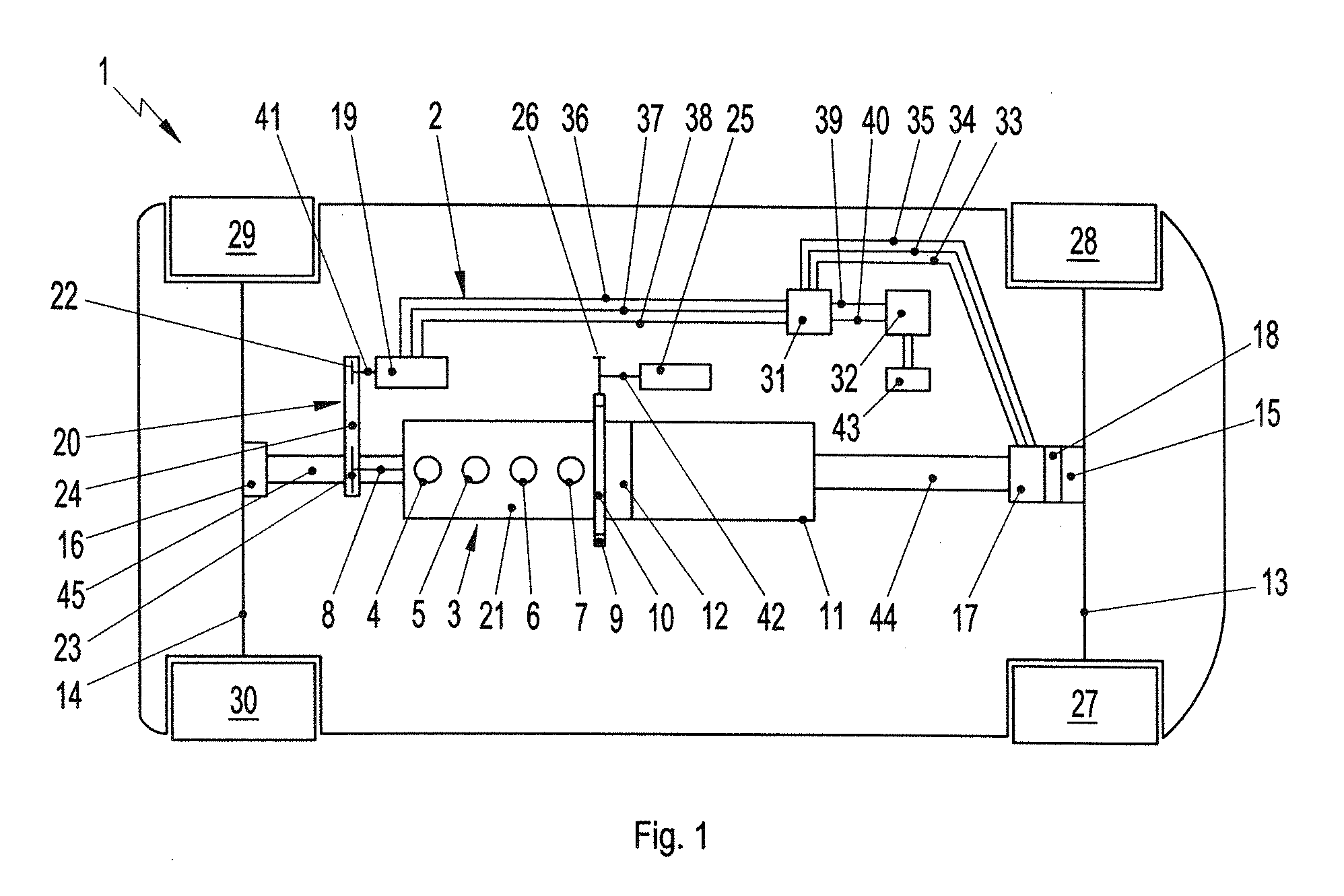

Drive system for a motor vehicle and motor vehicle having such a drive system

ActiveUS20120006152A1Reduced space requirementsAvoid friction lossGearingGas pressure propulsion mountingInternal combustion engineMotorized vehicle

A drive system (2) for a motor vehicle (1) has a transmission (11) for driving at least one drive axle (13, 14) of the motor vehicle (1). An internal combustion engine (3) optionally is connected operatively to the transmission (11) or decoupled therefrom. A first electric machine (17) optionally is connected operatively to the at least one drive axle (13, 14) or to an output shaft (39) of the transmission (11) or decoupled therefrom. A second electric machine (19) is connected operatively to the internal combustion engine (3).

Owner:DR ING H C F PORSCHE AG

Magnetic transmission speed-transformation device

InactiveCN102780381AControl load speedFine tune the valueDynamo-electric gearsCouplingComputer module

The invention discloses a magnetic transmission speed-transformation device, which comprises an input module, connecting modules and an output module; the input module is connected with the connecting modules through double-layer couplers; the connecting modules is connected with the output module through the double-layer couplers; cascading number of the connecting modules is one or more than one; and when the cascading number of the connecting modules is more than one, the connecting modules are connected in series through double-layer couplers. According to the invention, the input module is connected with a power input source through an input coupler; power P is output through the input module, the connecting modules and the output module after being input through an input end of the power input source; N connecting modules can be in series according to the load situation to realize shunting transmission of N magnetic speed-transformation mechanisms, and power borne by each magnetic speed-transformation mechanism at P / N; and an output end synthesizes power of the N speed-transformation mechanisms to total power P through an output coupler for output. According to the invention, the quantity of the cascading modules is reasonably changed, so as to change systematic transmission ratio.

Owner:DALIAN JIAOTONG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com