Variable-speed winch and foldable type onboard crane with same

A variable-speed hoist and hoist technology, which is applied in hoisting devices, cranes, mechanical equipment, etc., can solve the problem that the speed of the reducer cannot meet the special requirements of light, heavy, lifting, lowering, and speed transmission mechanisms, and increase the additional load of vehicles. Problems such as its own cost and the unoptimized design of the crane force can achieve the effect of good speed change effect, light weight and strong lifting ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

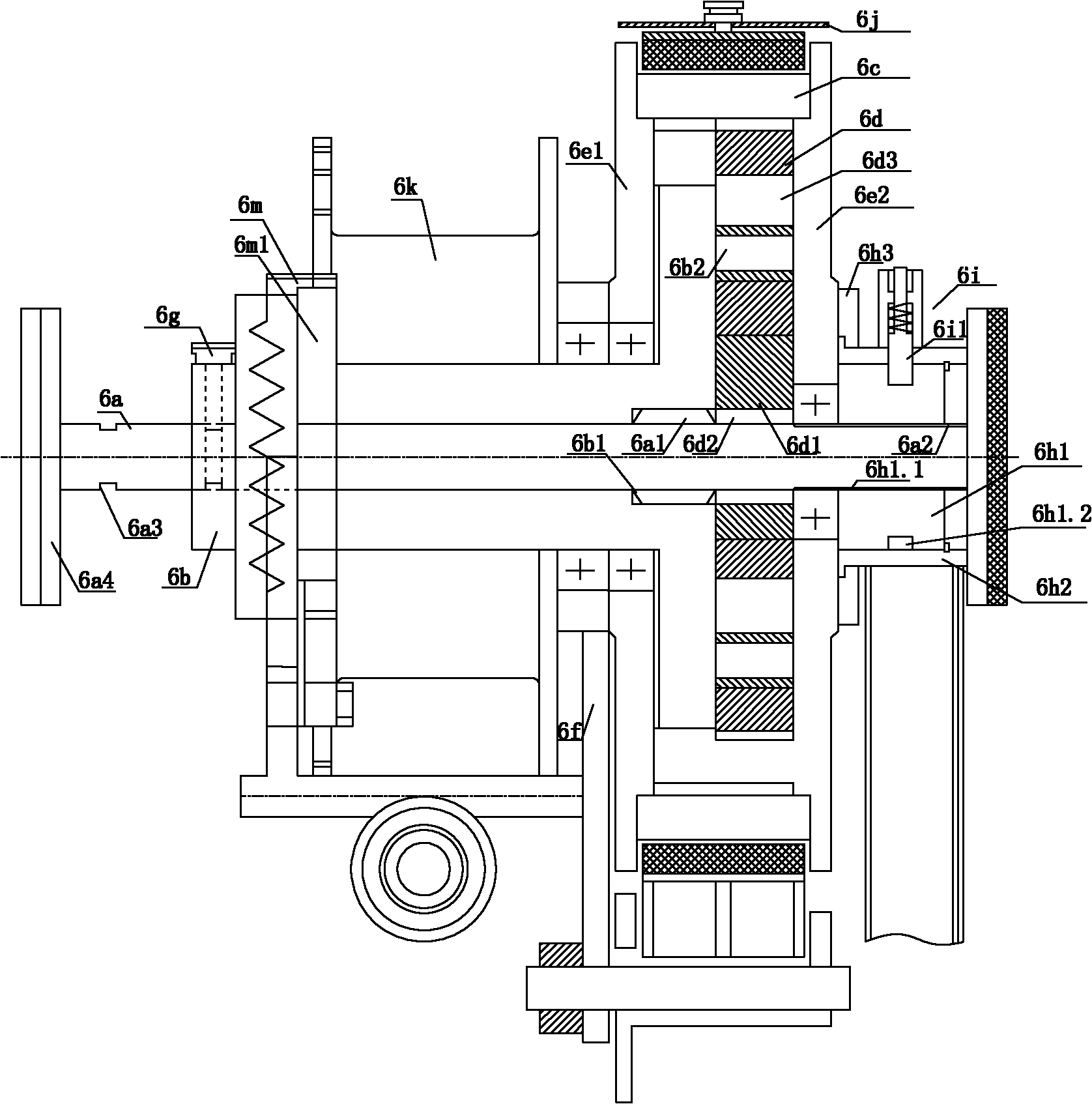

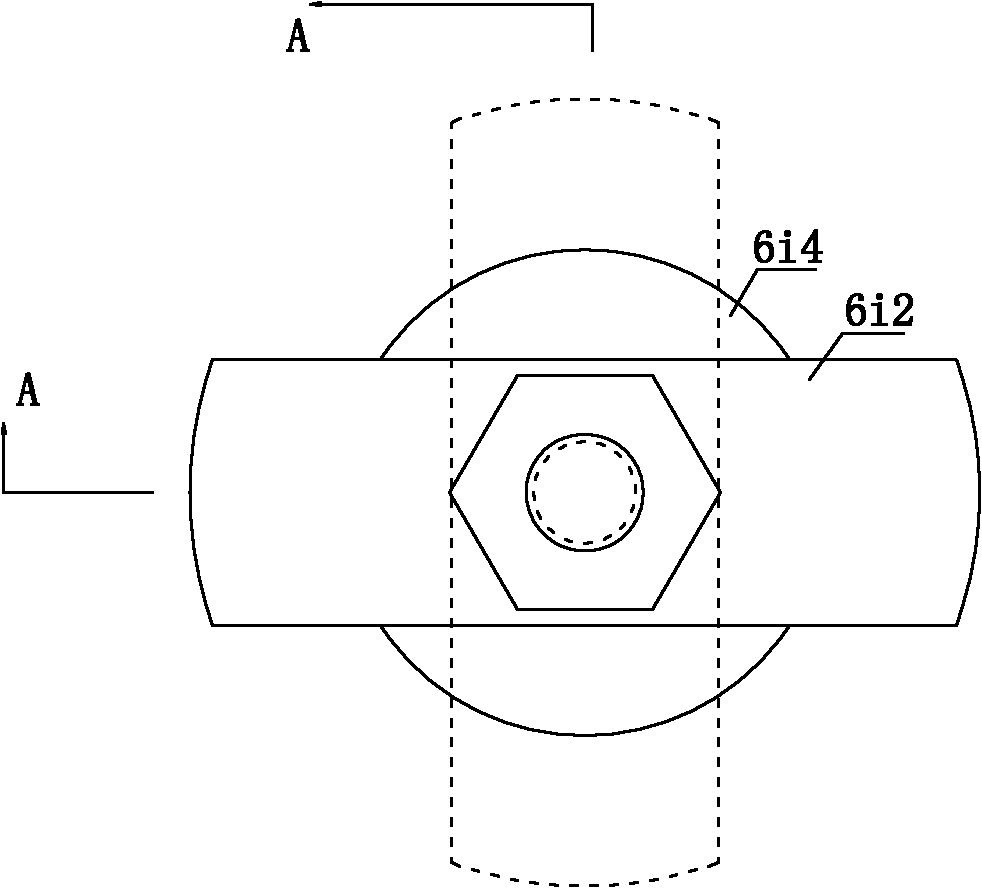

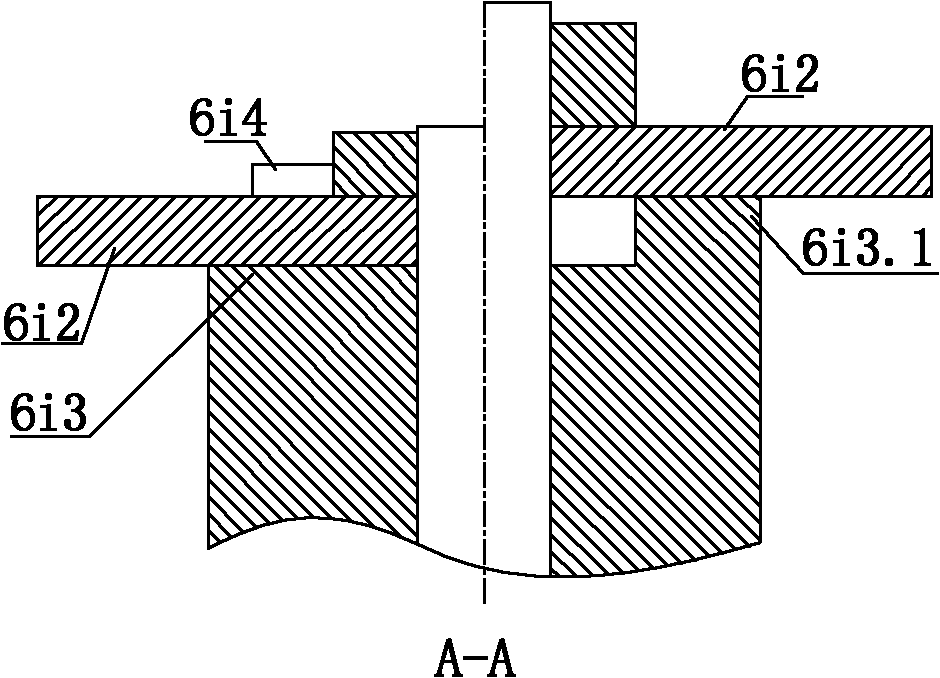

[0051] figure 1 The variable-speed hoist is a variable-speed hoist that adopts K-H-V planetary gear transmission with small tooth difference. The winch includes a drive shaft 6a, a driven shaft 6b and a speed change mechanism. The driven shaft 6b is mounted on the frame 6f of the winch through a bearing. The driven shaft 6b is sleeved on the outside of the drive shaft 6a. The drive shaft 6a runs through the entire The power output end of the driving shaft 6a is provided with a gear position positioning groove 6a3, and the corresponding driven shaft 6b is provided with a positioning pin 6g. When the positioning pin 6g is set in different positioning grooves 6a3, different positions can be realized. stage transmission. Limiting push blocks 6a4 are fixed at both ends of the drive shaft 6a. The transmission mechanism includes a planetary gear 6d, and the planetary gear 6d includes a rotating arm eccentric sleeve 6d1. An internal gear 6c is arranged outside the planetary gear 6d,...

Embodiment 2

[0072] The collapsible truck-mounted crane of the present invention can also be applicable to flatbed trucks without a rainproof roof. Such as Figure 14 to Figure 17 As shown, now the upper bearing seat 3.2 of the vertical rod is connected with the front fender barrier bar 1.5 through the connector 3.2.1, and the limit support member 3.3 in the middle of the column is fixed on the front fender 1.4. A rainproof cover 16.1 is installed on the top of the upper bearing seat 3.2, and the rainproof cover 16.2 is inlaid on the inside of the downturned edge of the rainproof cover 16.1, and the opening of the rainproof cover 16.2 is connected by a gluing button 16.3 or other methods, a belt or an elastic Rigging 16.4 is installed on a side of rainproof cover 16, and the other end of belt or flexible rigging 16.4 is fixed on opposite sign buckle or hangs on the nose 16.5, rainproof cover and folded and locked crane are locked.

[0073]The bar 1.5 tops on both sides of the front baffle...

Embodiment 3

[0076] Figure 19 and Figure 20 It is another embodiment of the variable-speed winch 6 of the K-H-V type planetary gear transmission with less tooth difference. The difference from Embodiment 1 is that the outer diameters of the baffles on both sides of the internal gear are enlarged, so that the baffles on both sides of the internal gear are aligned with the internal gear. The outer wall constitutes the reel 6k. At this time, a ratchet 6n3 with rectangular teeth is fixed on the driven shaft on the side of the power output end of the driving shaft, and a positioning pin 6n2 is fixed on the side plate 6f1 of the hoist frame, and the axis of the positioning pin 6n2 is aligned. The central line of the driven shaft 6b, the positioning pin 6n2, the ratchet 6n3 and the reel 6k form a power output component. When hoisting heavy cargo, push the driving shaft 6a to make the outer spline 6a1 mesh with the inner spline 6d2 of the eccentric sleeve of the arm, and when the positioning pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com