Patents

Literature

124results about How to "Easy to control independently" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

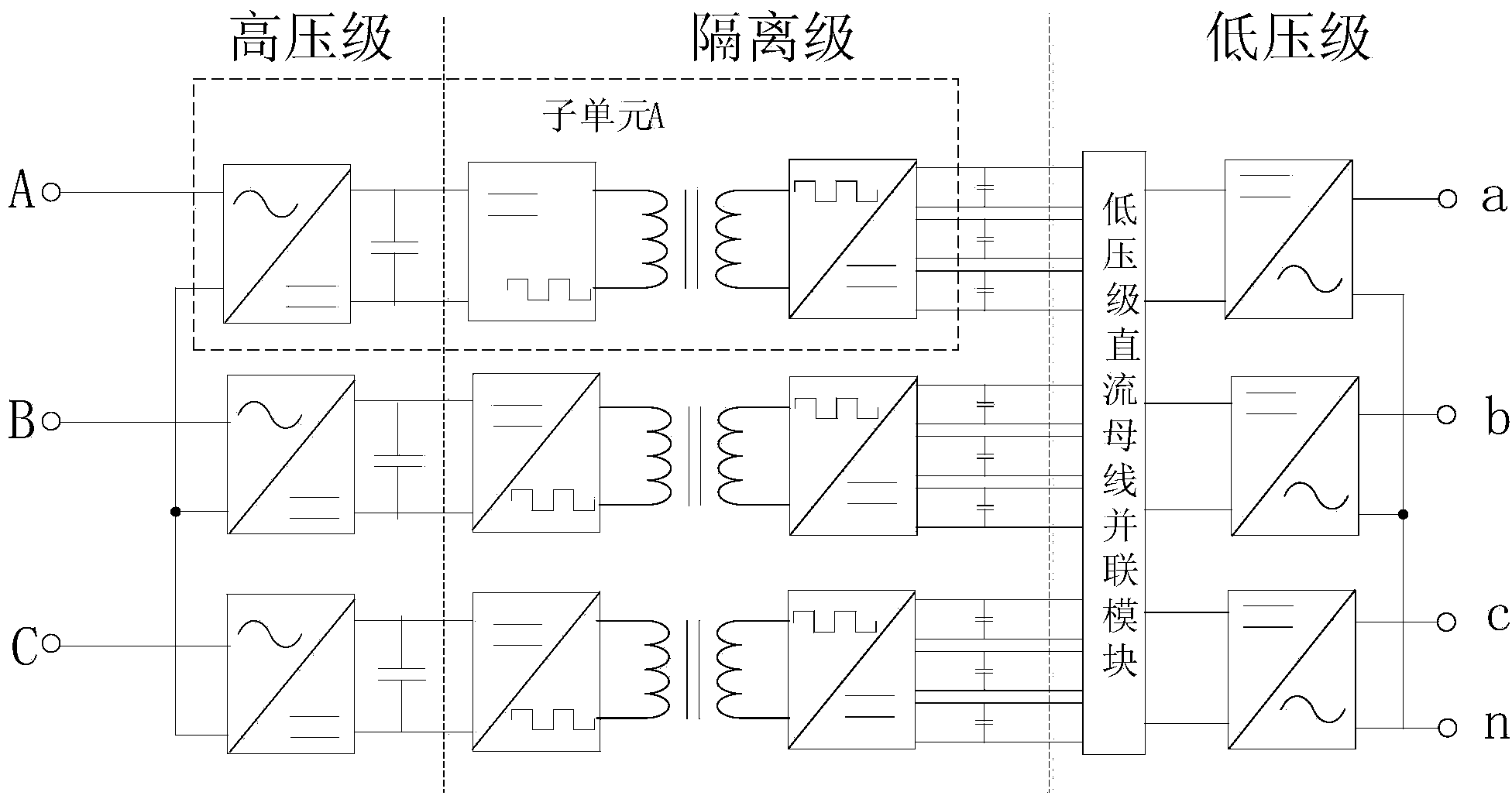

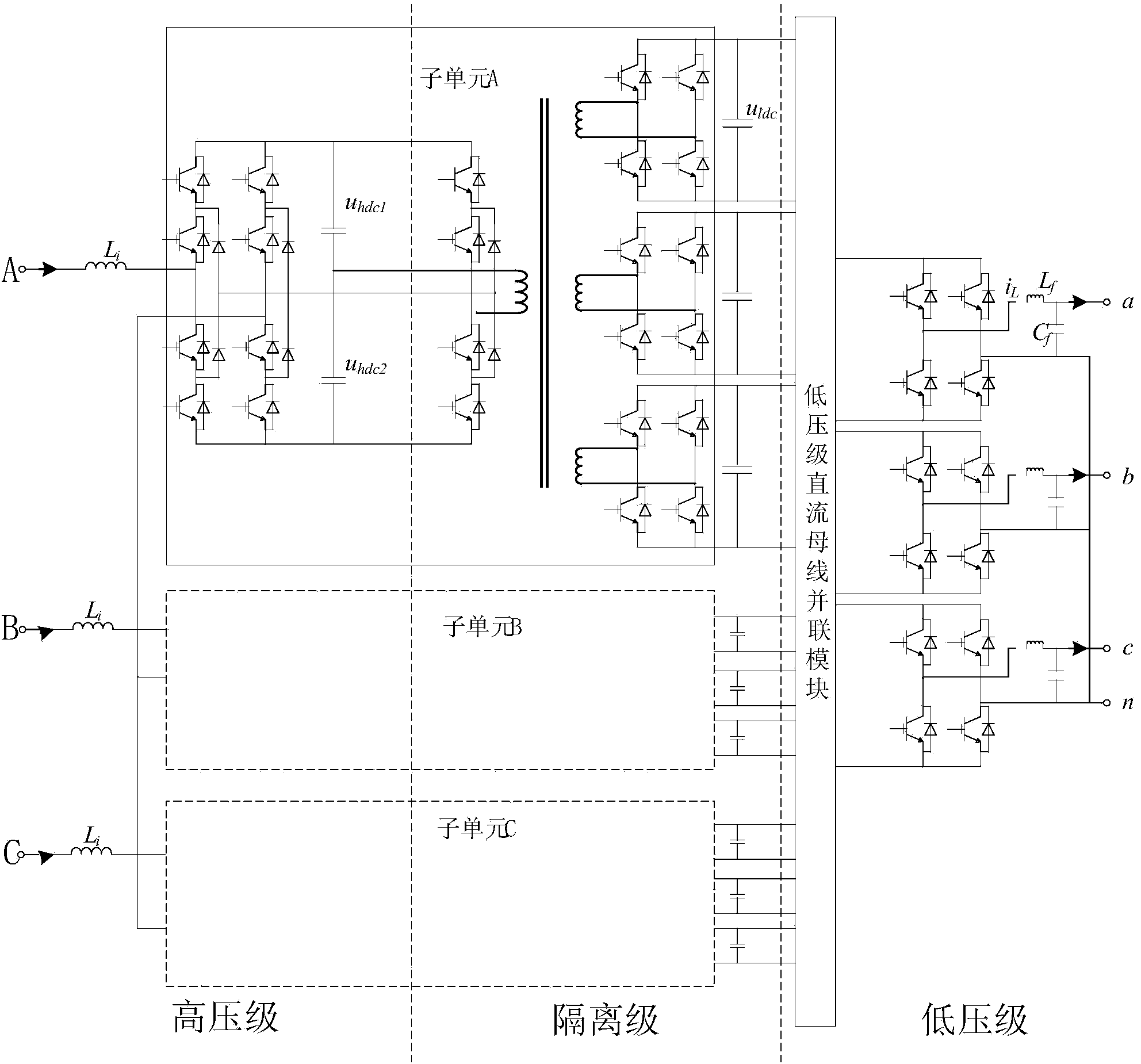

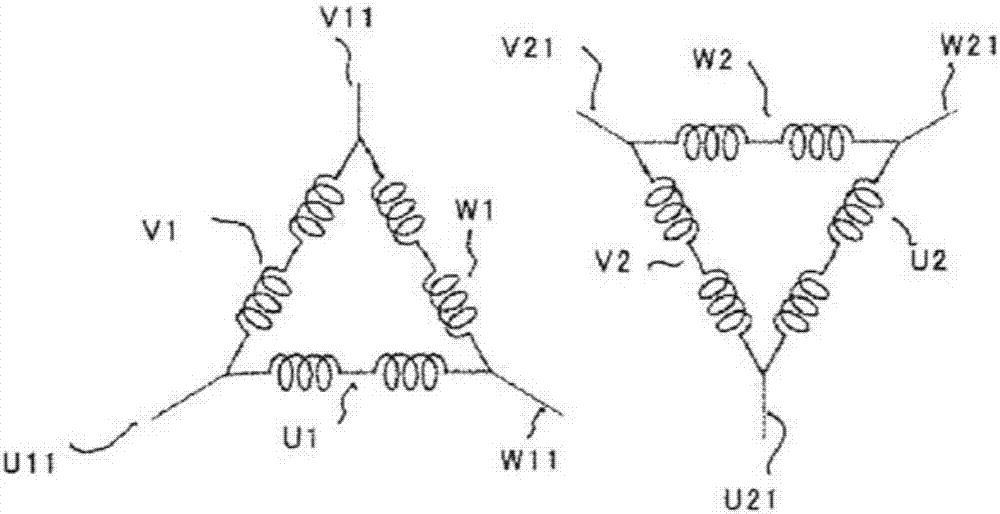

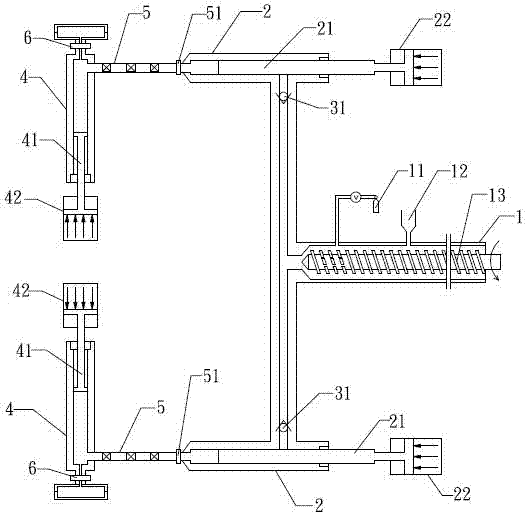

Modularized H-bridge cascade multilevel mutual-balance power electronic transformer

InactiveCN103956911AReduce usageReduce harmonic effectsAc-dc conversionAc-ac conversionPower qualityLow voltage

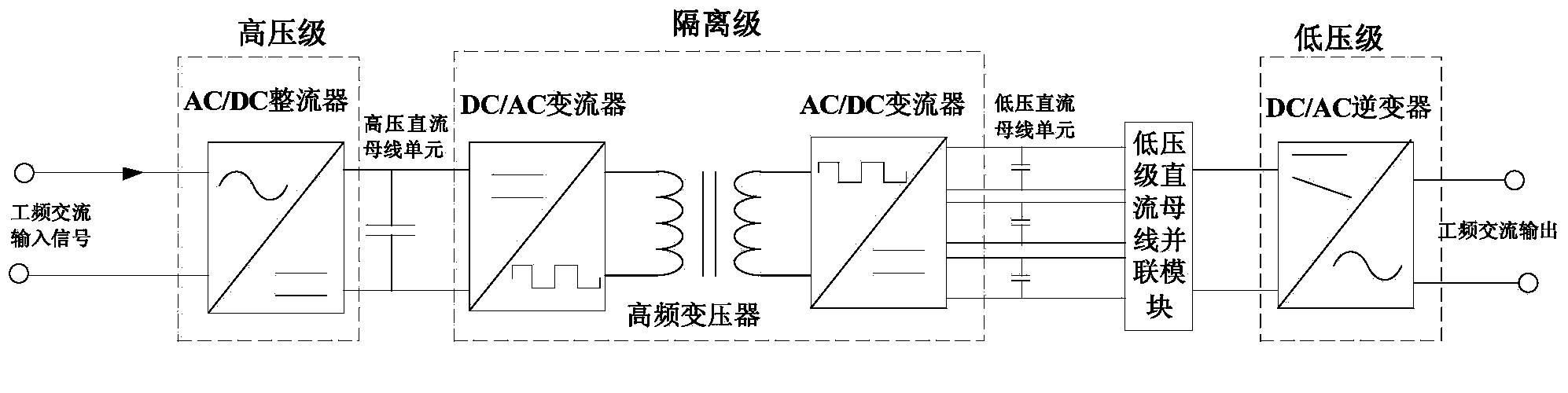

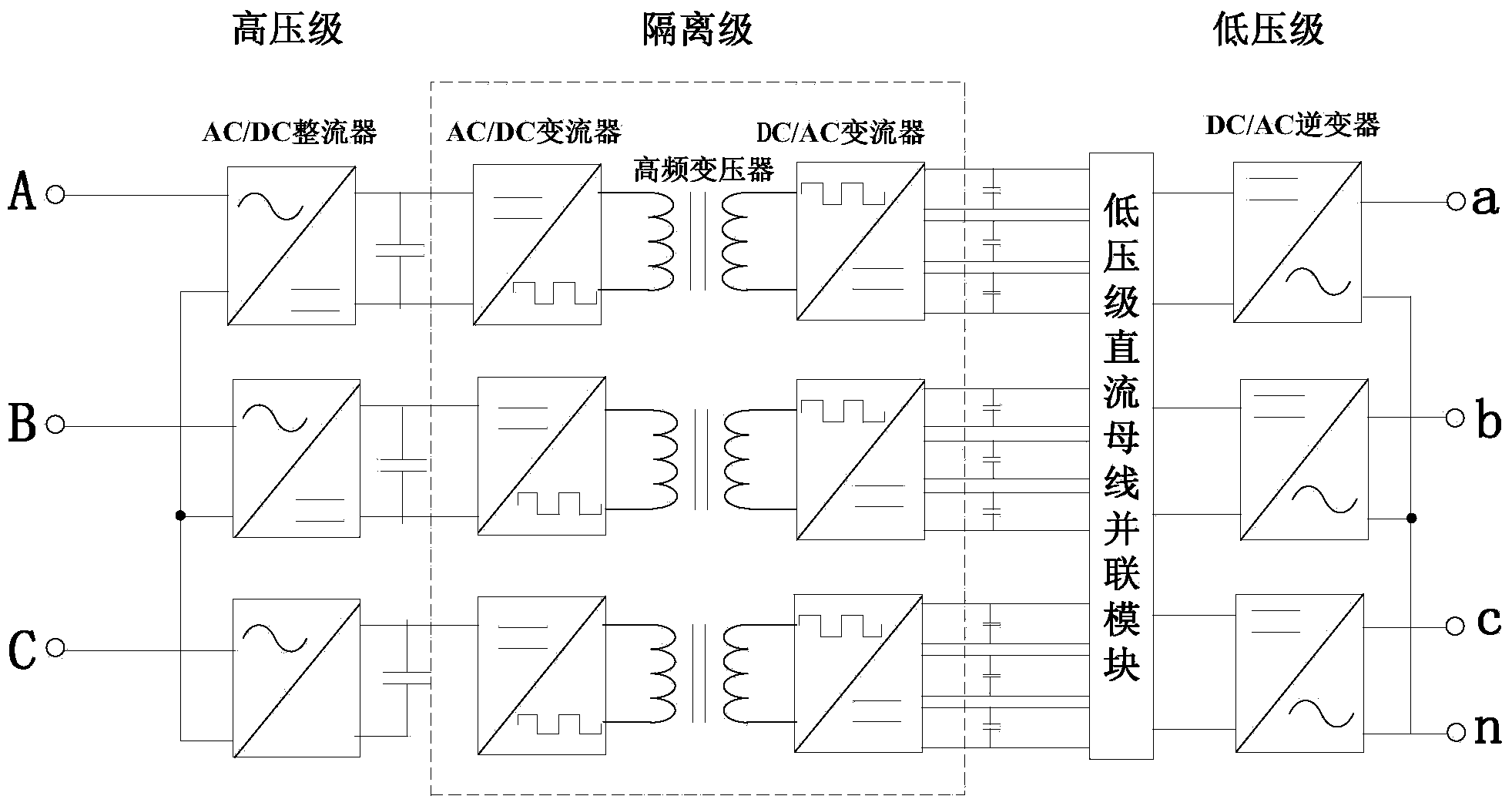

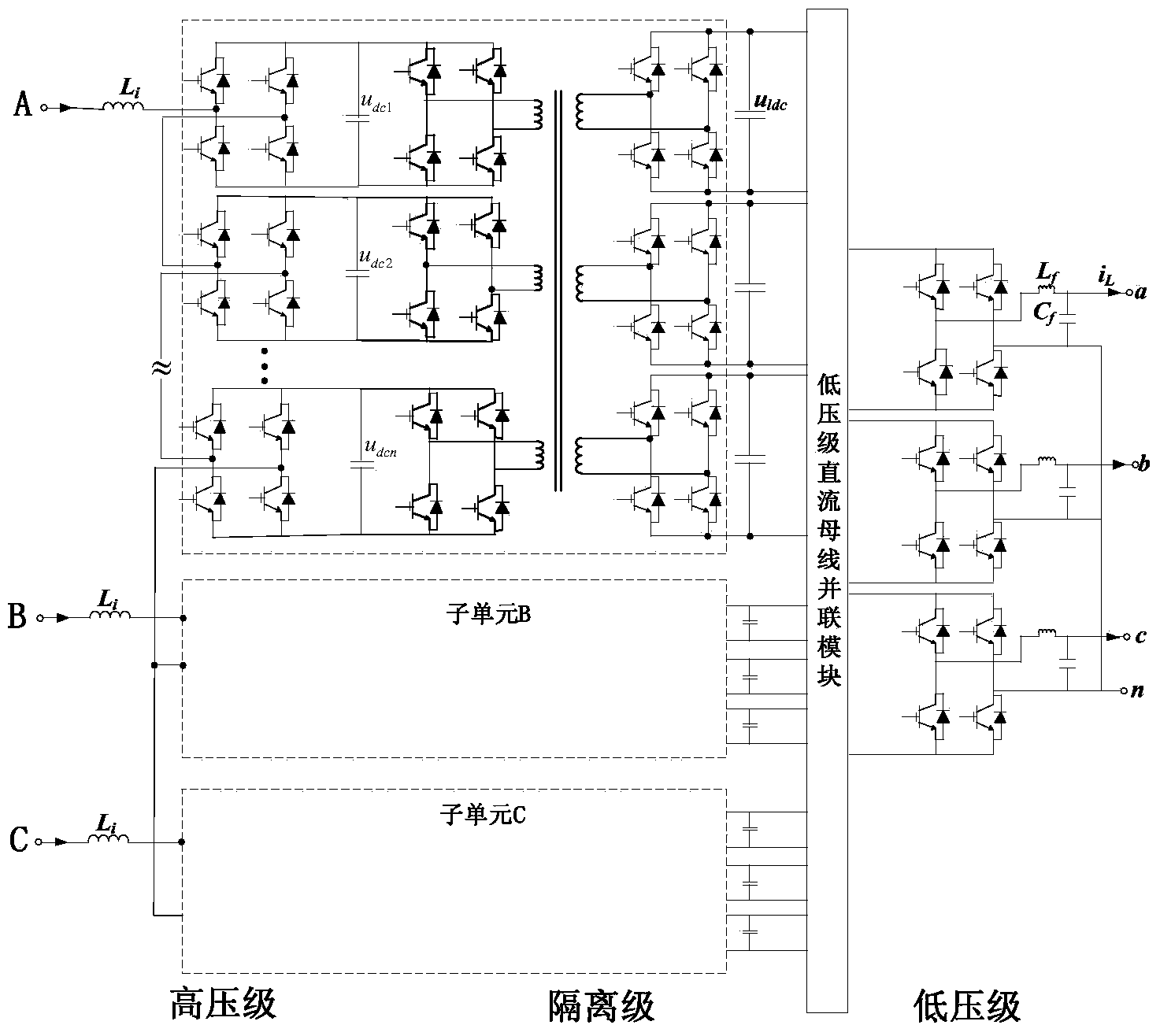

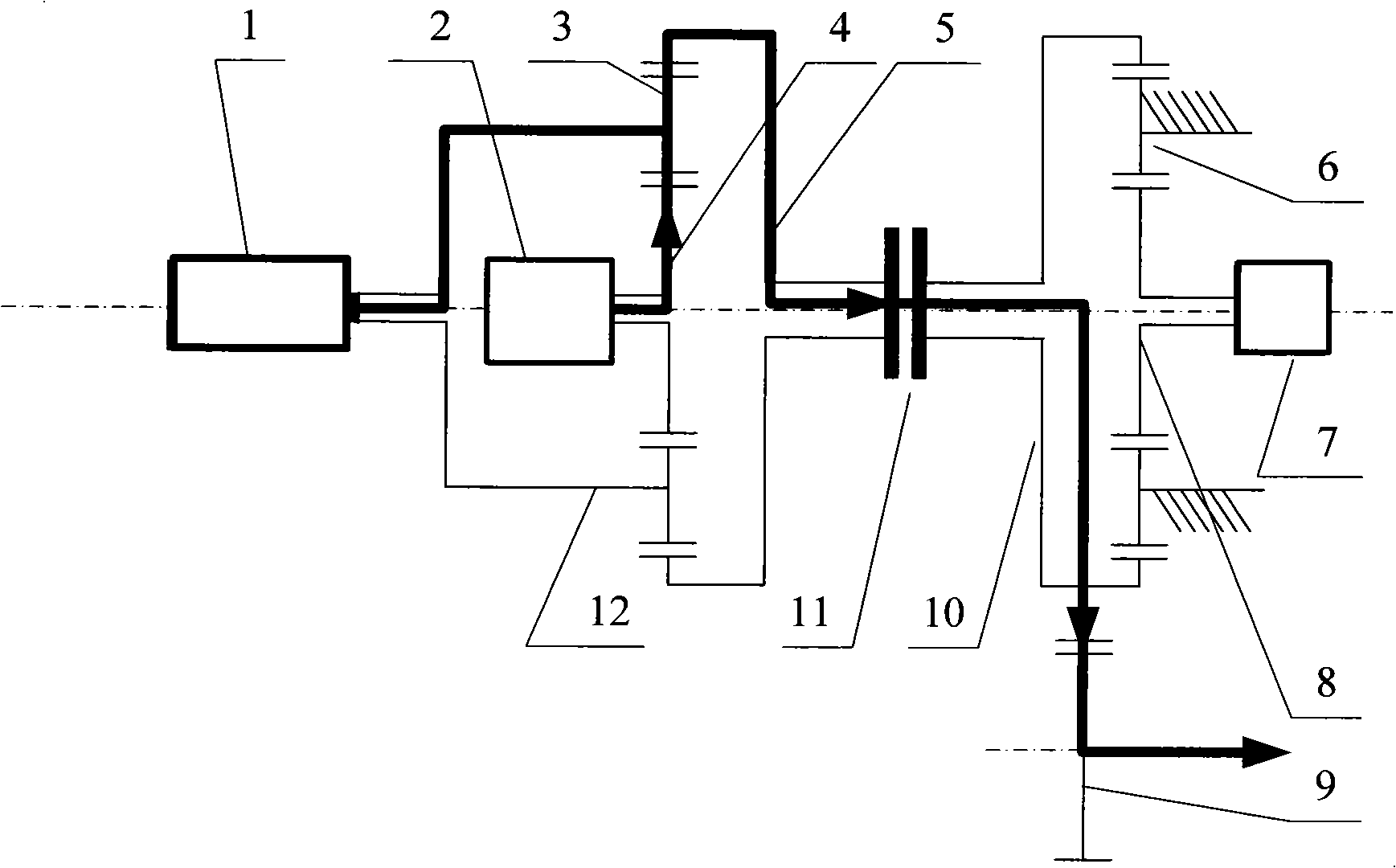

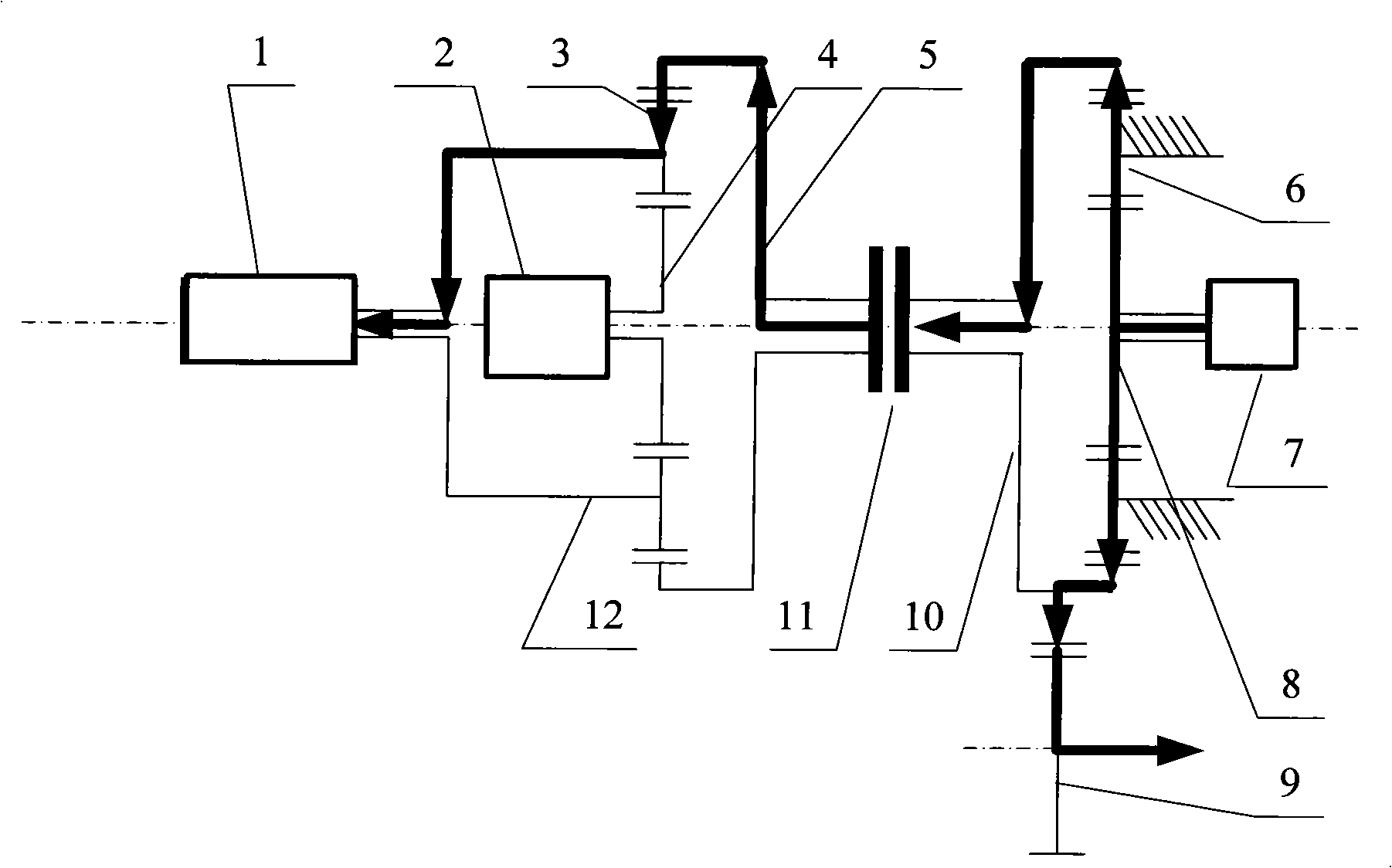

The invention provides a modularized H-bridge cascade multilevel mutual-balance power electronic transformer. Power electronic devices are formed on the basis of IGBTs, the power electronic transformer can achieve four-quadrant controlled operation through an effective control strategy, two-way power flow control can be performed, a H-bridge cascade multilevel modularized structure is adopted for a main circuit, large-scale modularized production is facilitated, actual high-voltage class application can be performed, the harmonic content of output voltage is lower, the switching frequency of the power electronic devices is low, loss is lower, and the voltage-sharing problem is avoided. The system structure of the modularized H-bridge cascade multilevel mutual-balance power electronic transformer is in an AC / DC / AC mode, the high-voltage stage, the isolation stage and the low-voltage stage are achieved, and while the voltage transformation function, the isolation function, the energy transmission function and the like of a conventional transformer are completed, the power flow control and the function of control over the quality of electric energy can be completed.

Owner:STATE GRID CORP OF CHINA +1

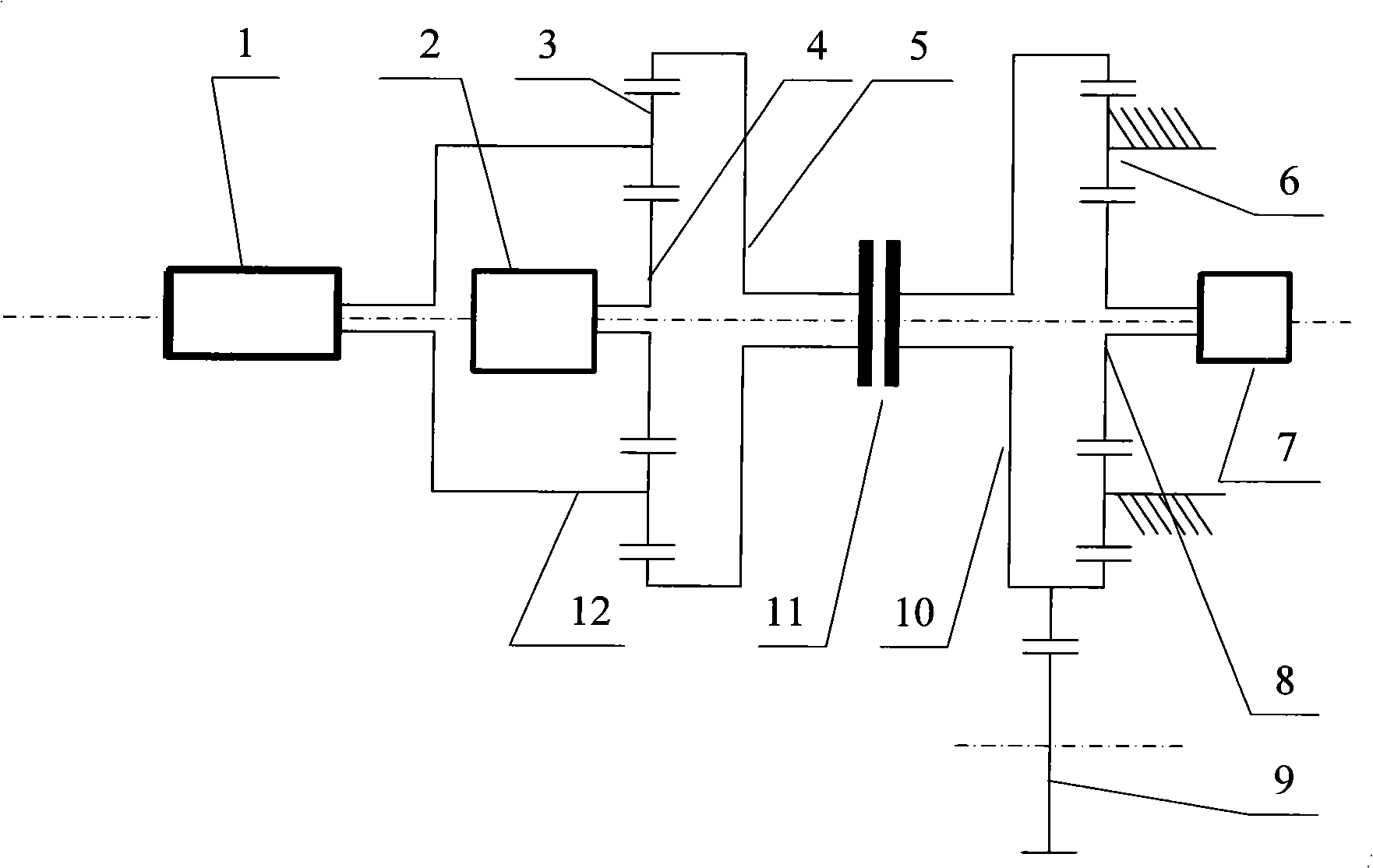

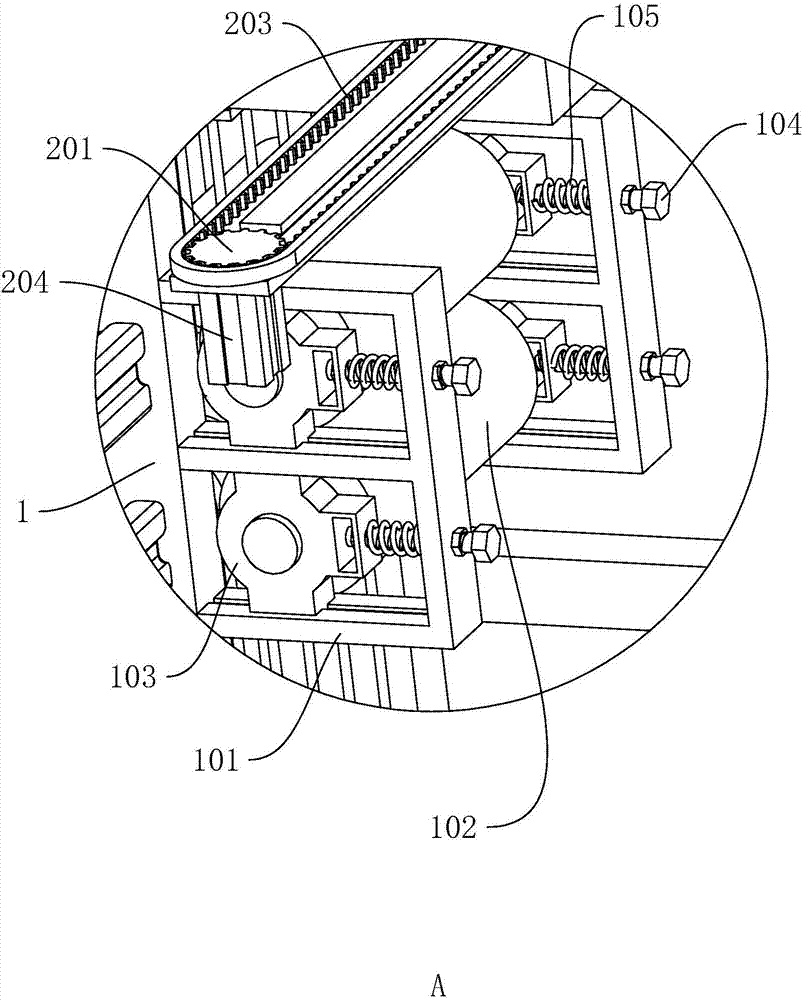

Hybrid power vehicle double row planetary gear electromechanical coupling driving mechanism

InactiveCN101323242AEasy to control independentlyLower requirementHybrid vehiclesGas pressure propulsion mountingVehicle frameGear wheel

The invention discloses a two-planet-row electromechanical coupling driving device of a hybrid vehicle in the technical field of machinery. The device is provided with a front planet row and a back planet row; each of the two planet rows is provided with a planet wheel, a sun gear and a row gear ring; the two planet row gear rings are connected with each other by a clutch. An engine is connected with the planet wheel of the front planet row; an ISG motor is connected with the sun gear of the front planet row; the gear ring of the front planet row is connected with the driving disk of the clutch; the driven disk of the clutch is connected with the gear ring of the back planet row; the planet carrier of the planet wheel of the back planet row is arranged fixedly on a car frame; the sun gear of the back planet row is connected with a drive motor; the outside gear of the gear ring of the back planet row is normally engaged with a power take-off gear. The two-planet-row electromechanical coupling driving device of the hybrid vehicle has the advantages of compact structure, large transmission ratio, large load support capability, stable driving, and high transmission efficiency, thereby realizing power dividing and infinite variable speed at the same time.

Owner:SHANGHAI JIAO TONG UNIV

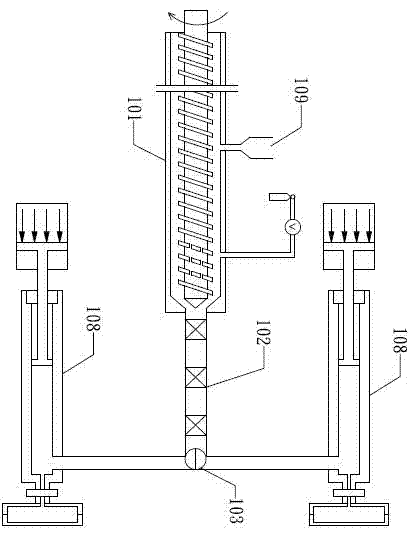

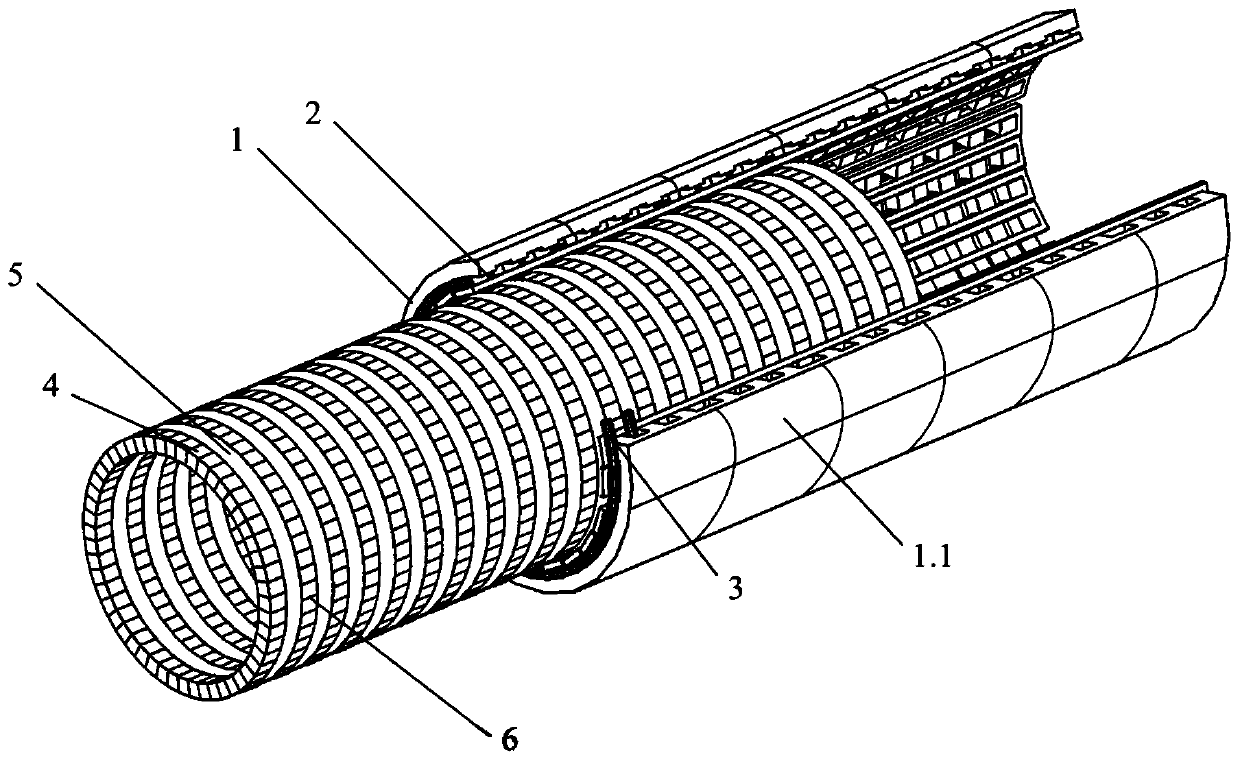

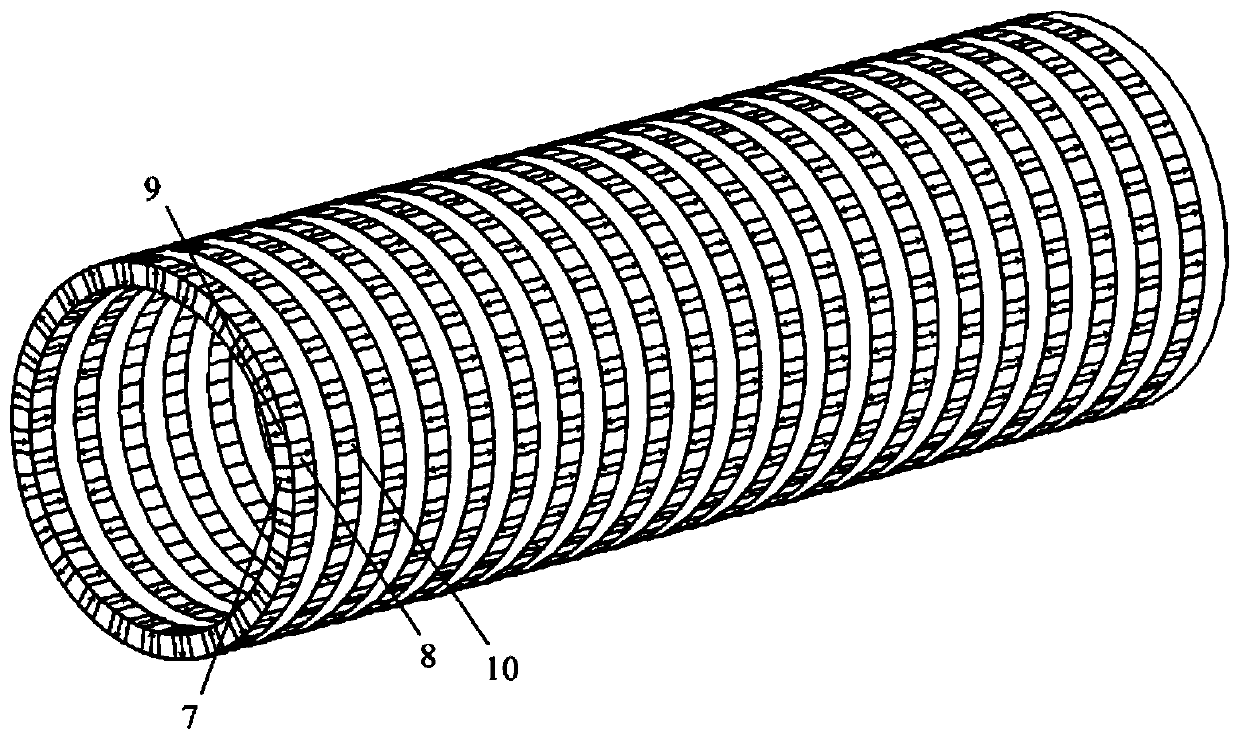

Spinning technology applied to semi-continuous high-speed spinning machine with spinning roller arranged horizontally

InactiveCN103290496ASmooth rotationNo shakingArtificial filaments from viscoseWet spinning methodsYarnSpinning

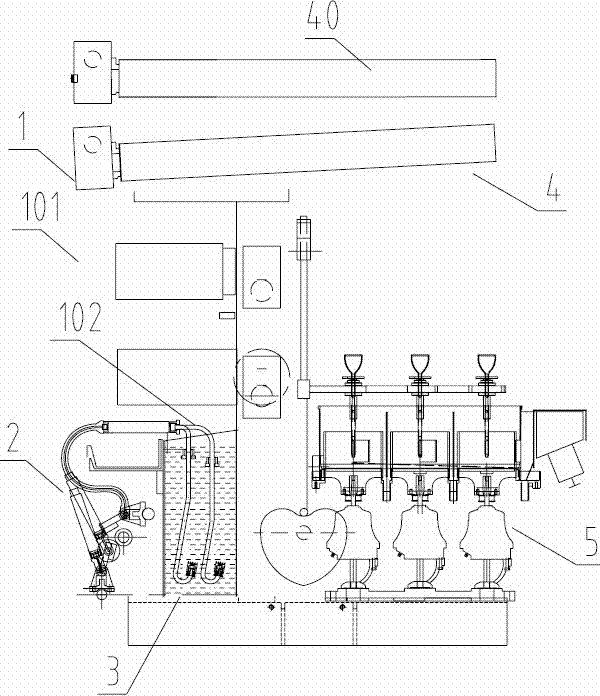

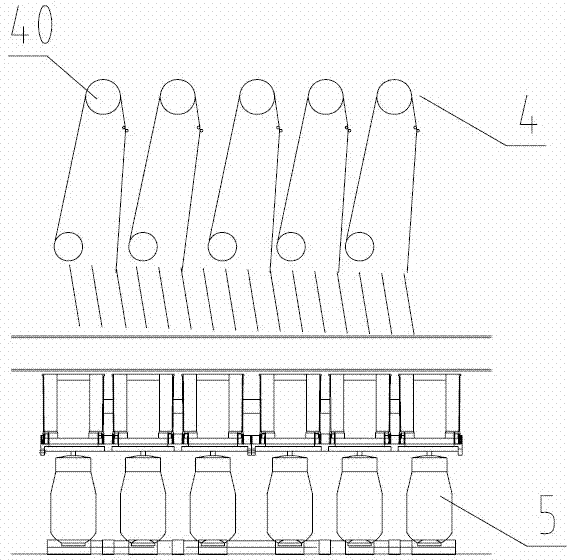

The invention relates to a spinning technology applied to a semi-continuous high-speed spinning machine with a spinning roller arranged horizontally. The spinning technology comprises glue measurement and supply, pre-spinning filtering, yarn strip forming, spinning and winding. The spinning technology aims at the specific semi-continuous high-speed spinning machine with the spinning roller arranged horizontally, under the mutual action of all processes and control of technological parameters, the spinning speed is ensured to be improved, independent walking of single yarn strips can be achieved, operations are simplified, the problems of doubling, burrs, breakage and the like are solved, the yarn strips are fully reacted and good in uniformity, the product quality is guaranteed, meanwhile, operations of workers are facilitated, and equipment maintenance is easy, overhaul costs are low, so that product costs are greatly reduced while the production efficiency is effectively improved.

Owner:YIBIN HIEST FIBER +2

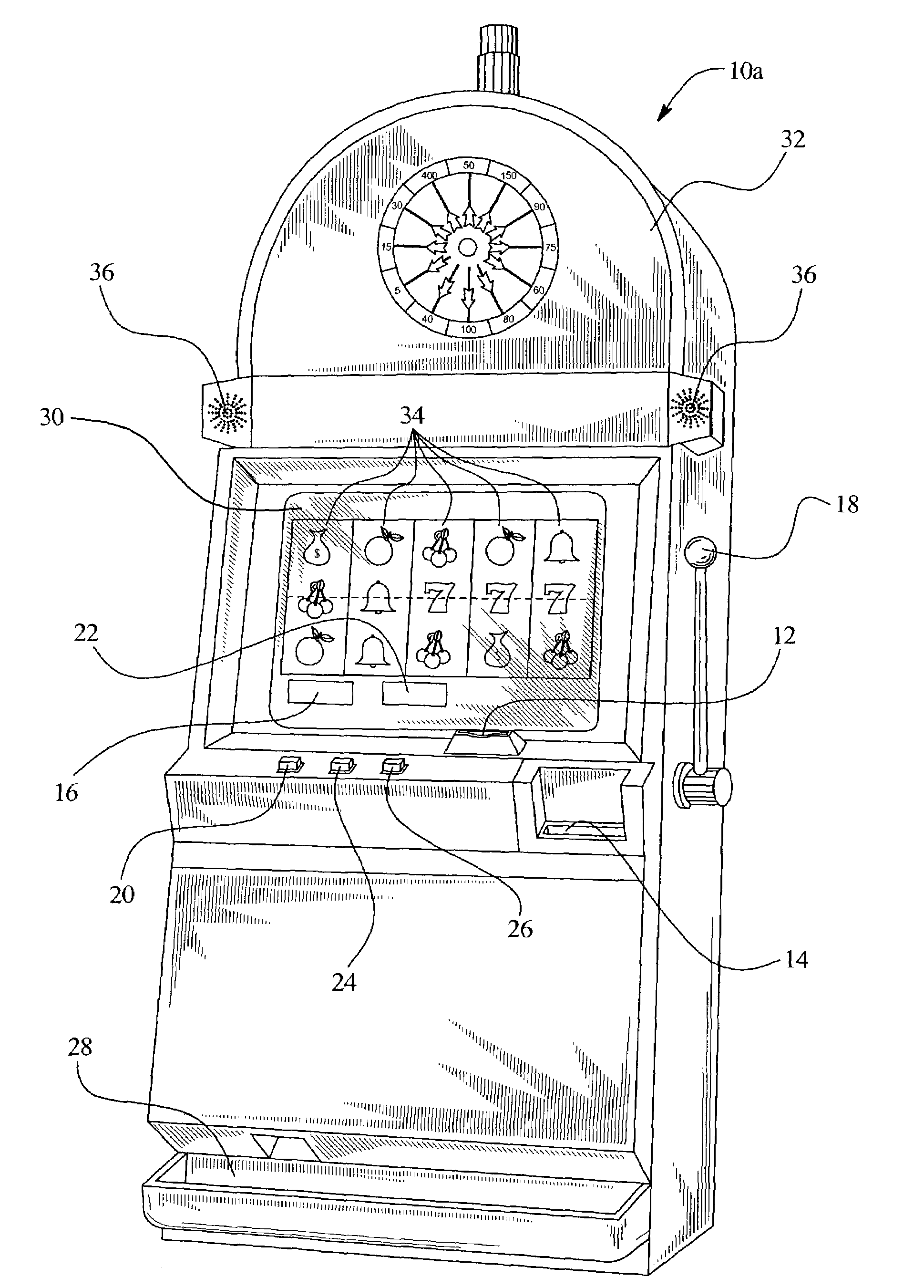

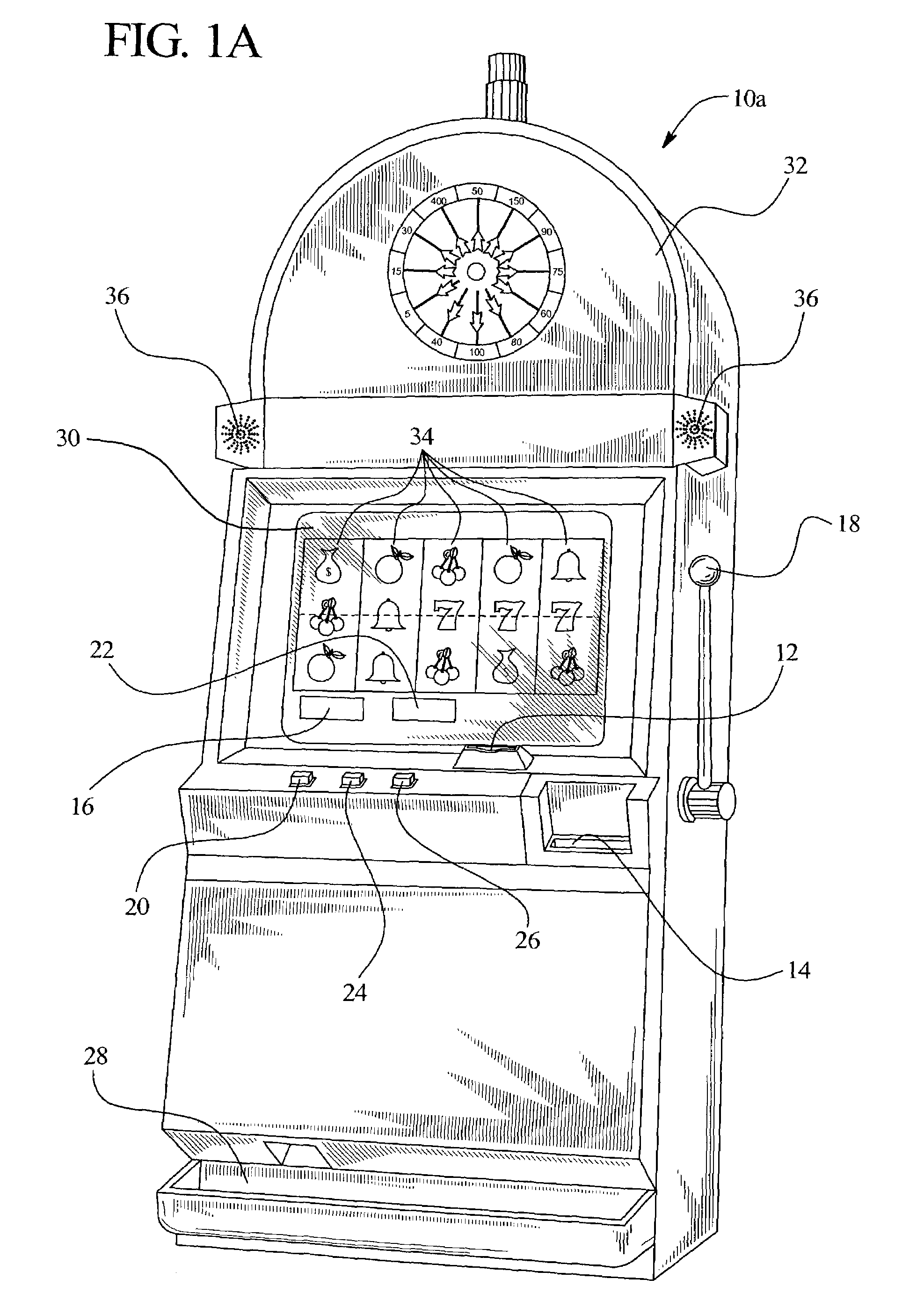

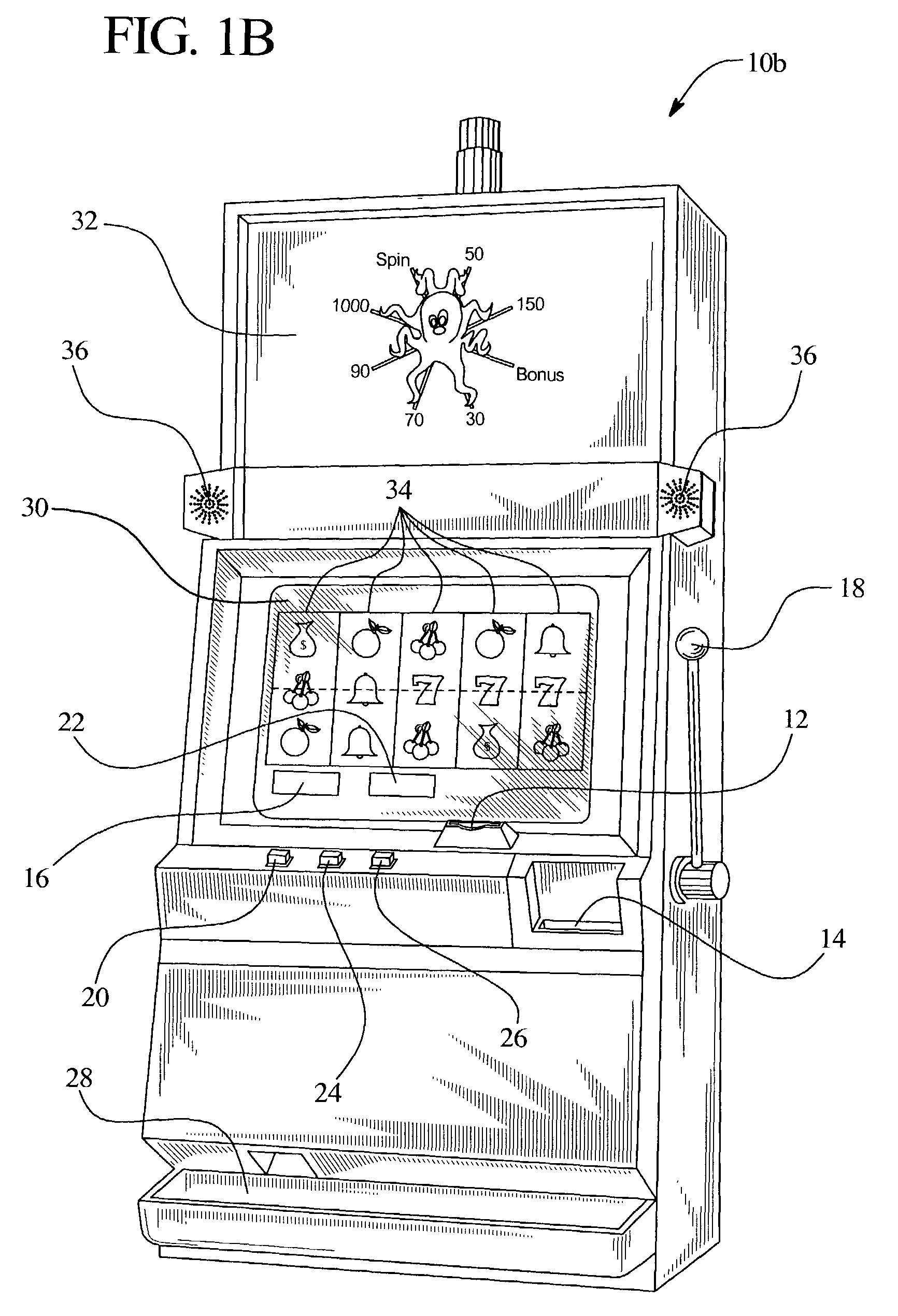

Gaming device having display with multiple radially translating indicators

InactiveUS7258609B2Easy to control independentlyEasy to changeCard gamesApparatus for meter-controlled dispensingDisplay deviceVisual perception

Owner:IGT

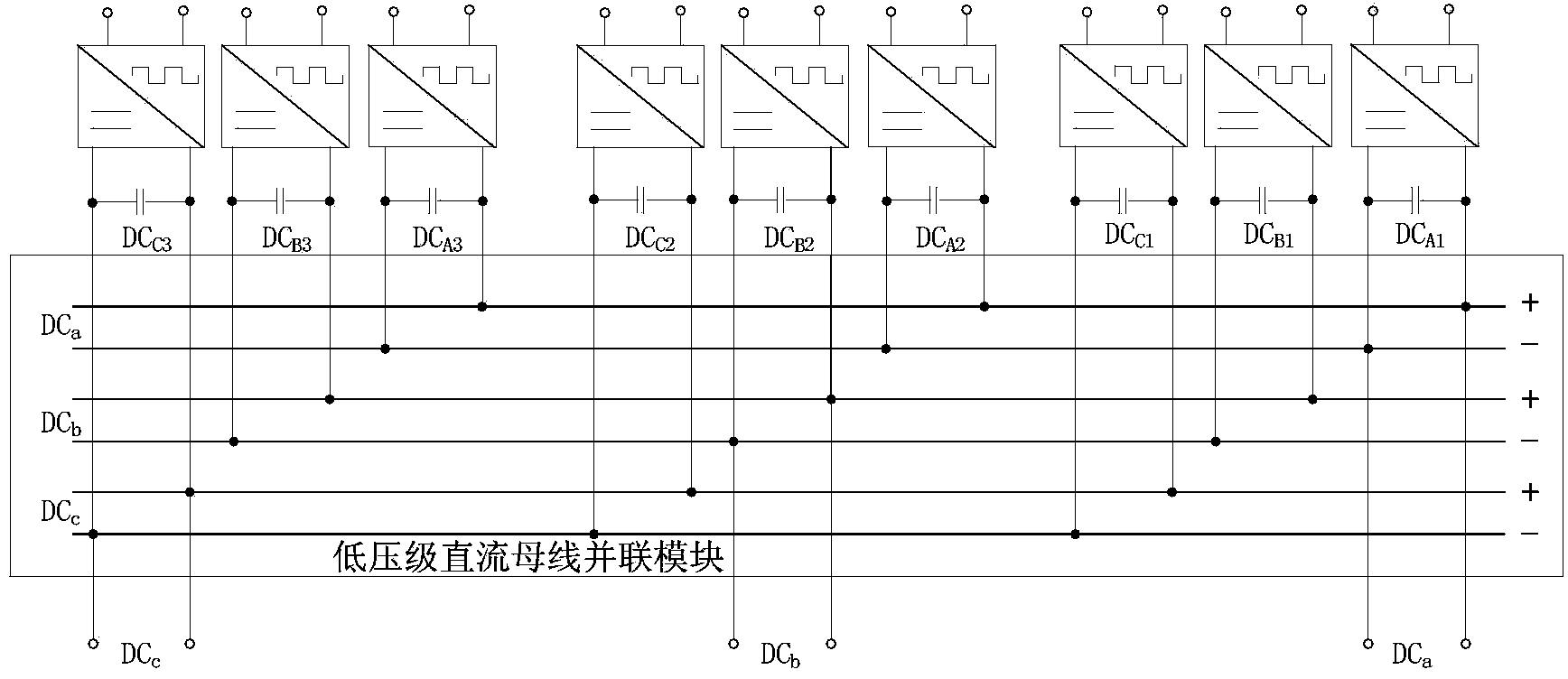

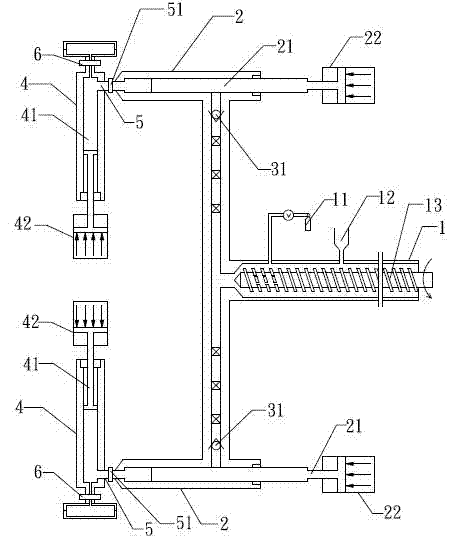

Bi-directional power flow controlled multi-level mutual balance solid state transformer and realization method thereof

ActiveCN103516230ASolve the high voltage problem of demandEasy to controlAc-dc conversionAc-ac conversionLow voltageEngineering

The invention relates to a bi-directional power flow controlled multi-level mutual balance solid state transformer and a realization method thereof. The solid state transformer is a three-phase solid state transformer which is designed by using a mutual balance structure, and uses an AC-DC-AC three step type transform structure. A high voltage level, an isolation level and a low voltage level are comprised. The high voltage level and the isolation level are transformers with the same three-phase structure and are composed of sub units. The low voltage level is a single whole module which realizes an automatic mutual balance structure. Three-phase sub units of the high voltage level are connected in a star mode. The low voltage level is an alternating current output end with a three-phase four-wire wiring mode. The solid state transformer can realize power bi-directional flow. The whole three-phase system uses an independent structure, which is convenient for three-phase independent control and modular production. Through the direct current bus parallel module of the low voltage level, a three-phase electric power automatic mutual balance function is realized, so that the practical problem of the solid state transformer is solved.

Owner:STATE GRID CORP OF CHINA +1

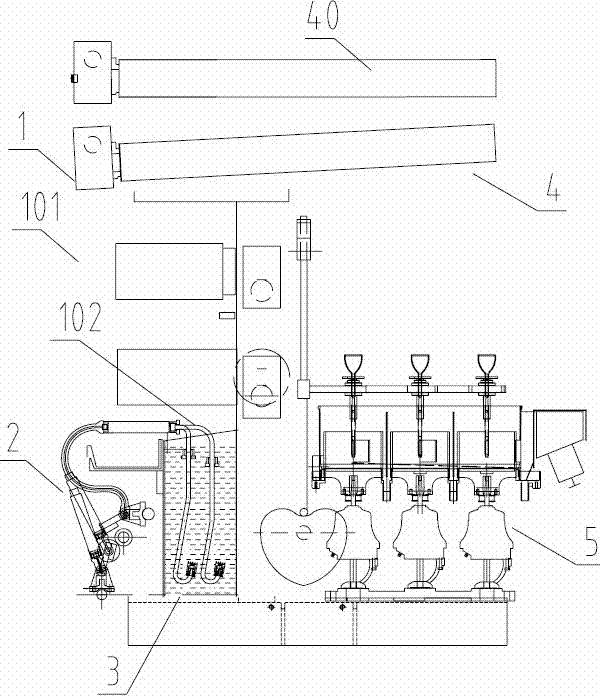

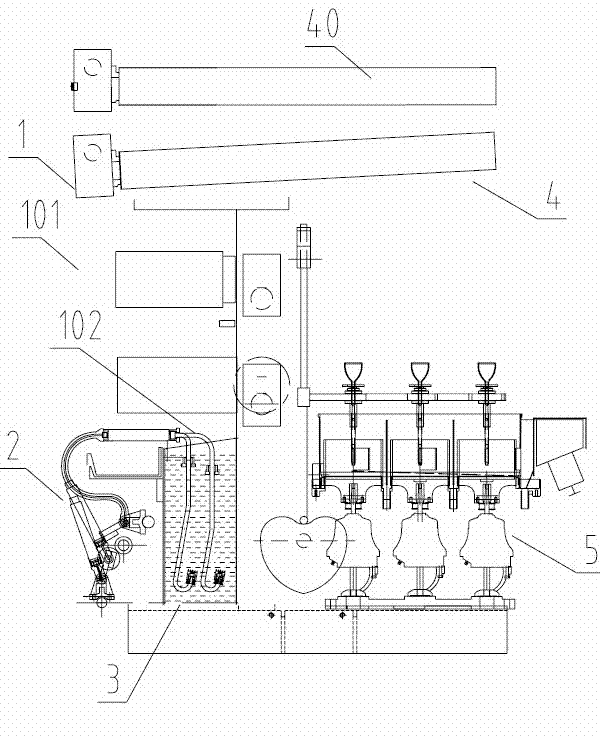

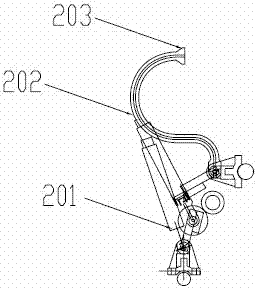

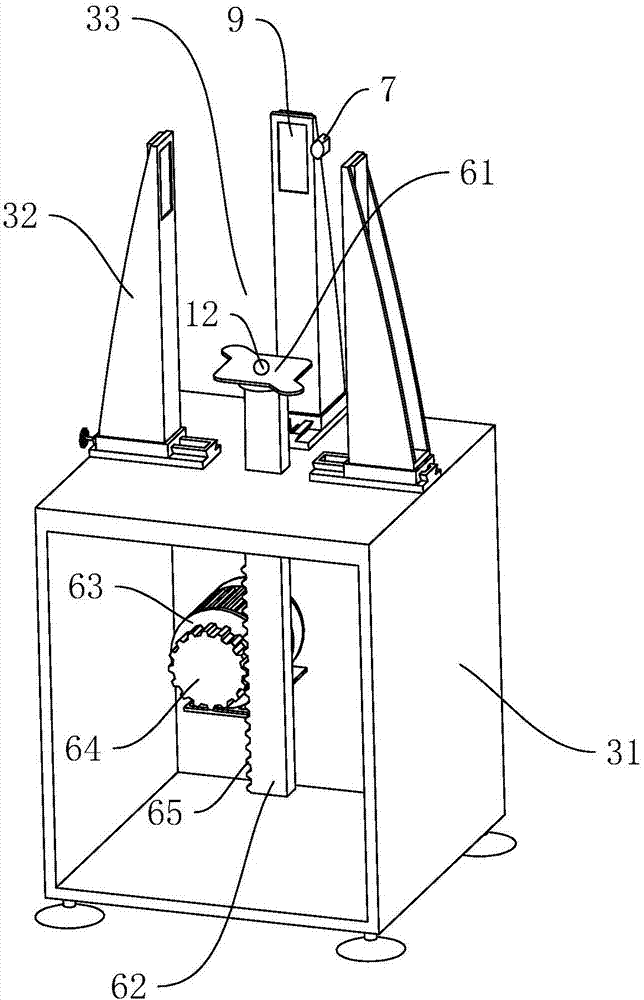

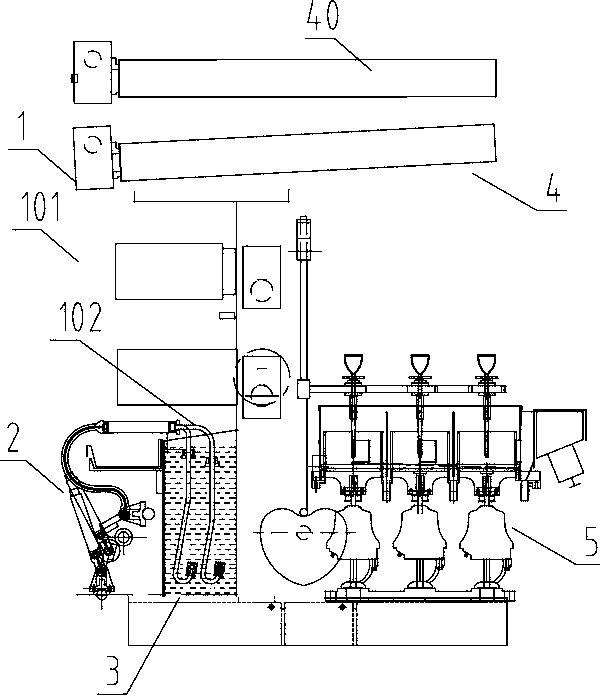

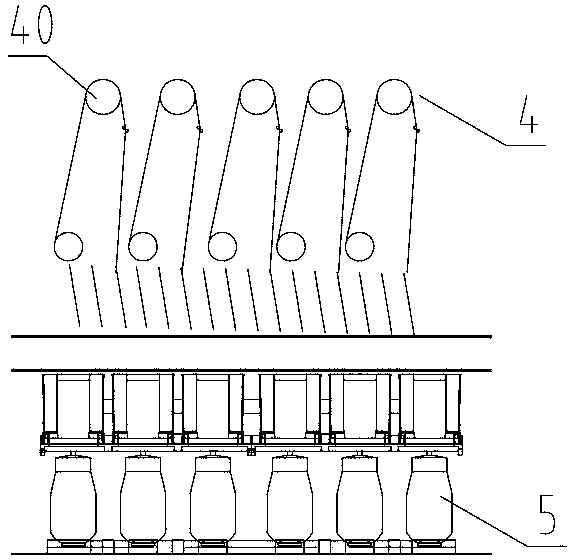

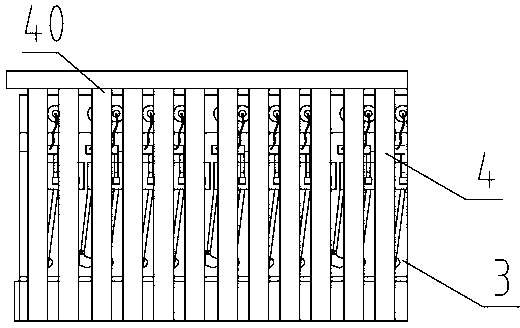

Semi-continuous high-speed spinning machine

ActiveCN103290501AEasy to operateControllableNew-spun product collectionArtificial thread manufacturing machinesEngineeringMechanical engineering

The invention relates to spinning equipment, in particular to a semi-continuous high-speed spinning machine. The semi-continuous high-speed spinning machine comprises a rack, a glue supply device, a strip forming device, a spinning device and a winding device, wherein a spinning roller of the spinning device is horizontally arranged relative to an operating surface of a spinning surface. The operating surface of the spinning surface is a horizontal working surface in a spinning surface area, and the fact that the spinning roller is horizontally arranged relative to the operating surface of the spinning surface refers to that the spinning roller is horizontally installed relative to spinning workers when the spinning workers face towards the winding device. According to the semi-continuous high-speed spinning machine, the spinning roller is horizontally arranged relative to the operating surface of the spinning surface, and two ends of the horizontally arranged spinning roller are fixed, so that the spinning speed can be increased on the basis of the semi-continuous high-speed spinning machine, the spinning roller is ensured to rotate stably without shaking, and the problems of intertwining and breakage of strips caused by shaking of the spinning roller during spinning are solved.

Owner:YIBIN HIEST FIBER +2

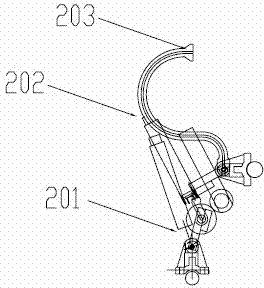

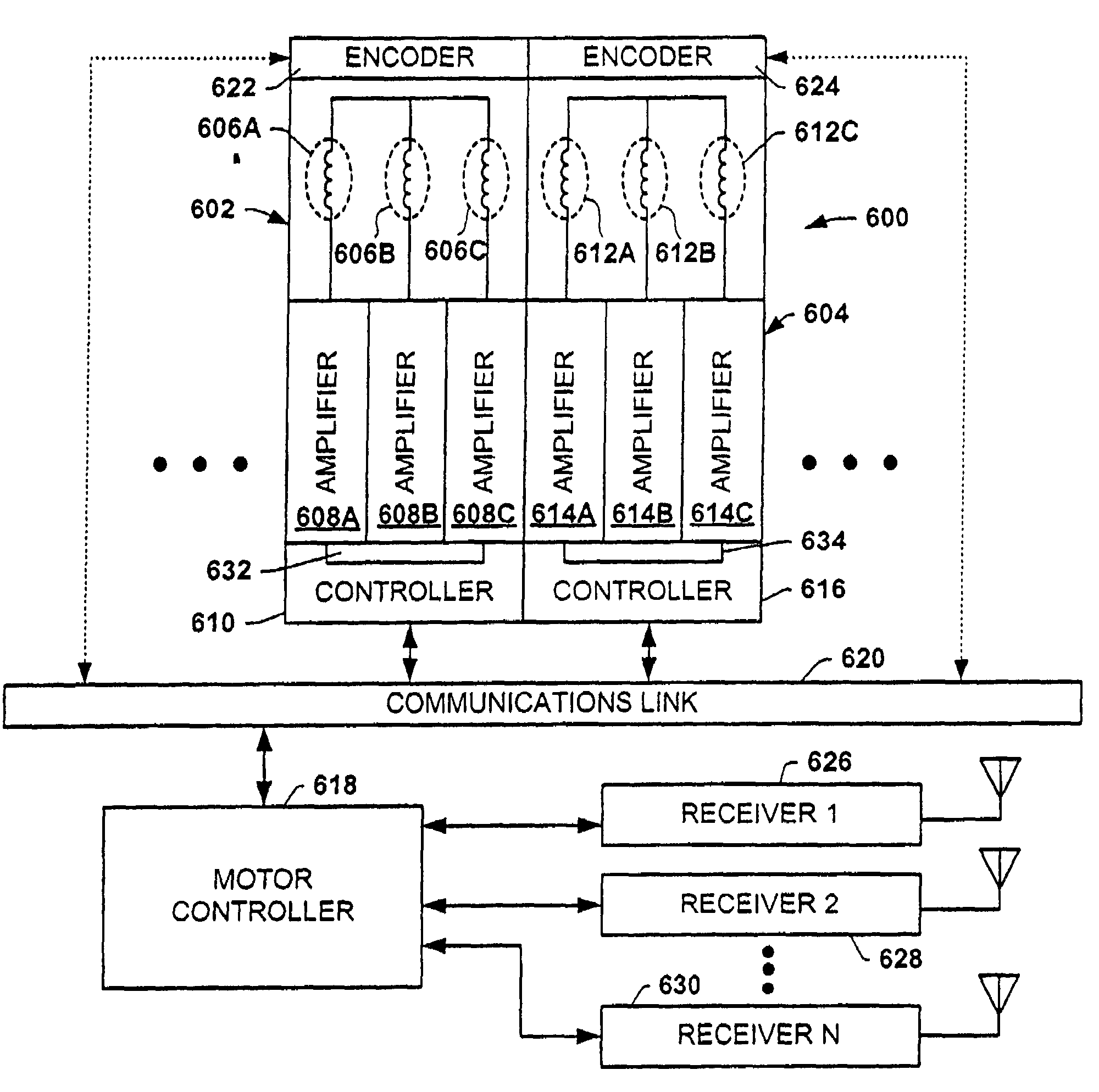

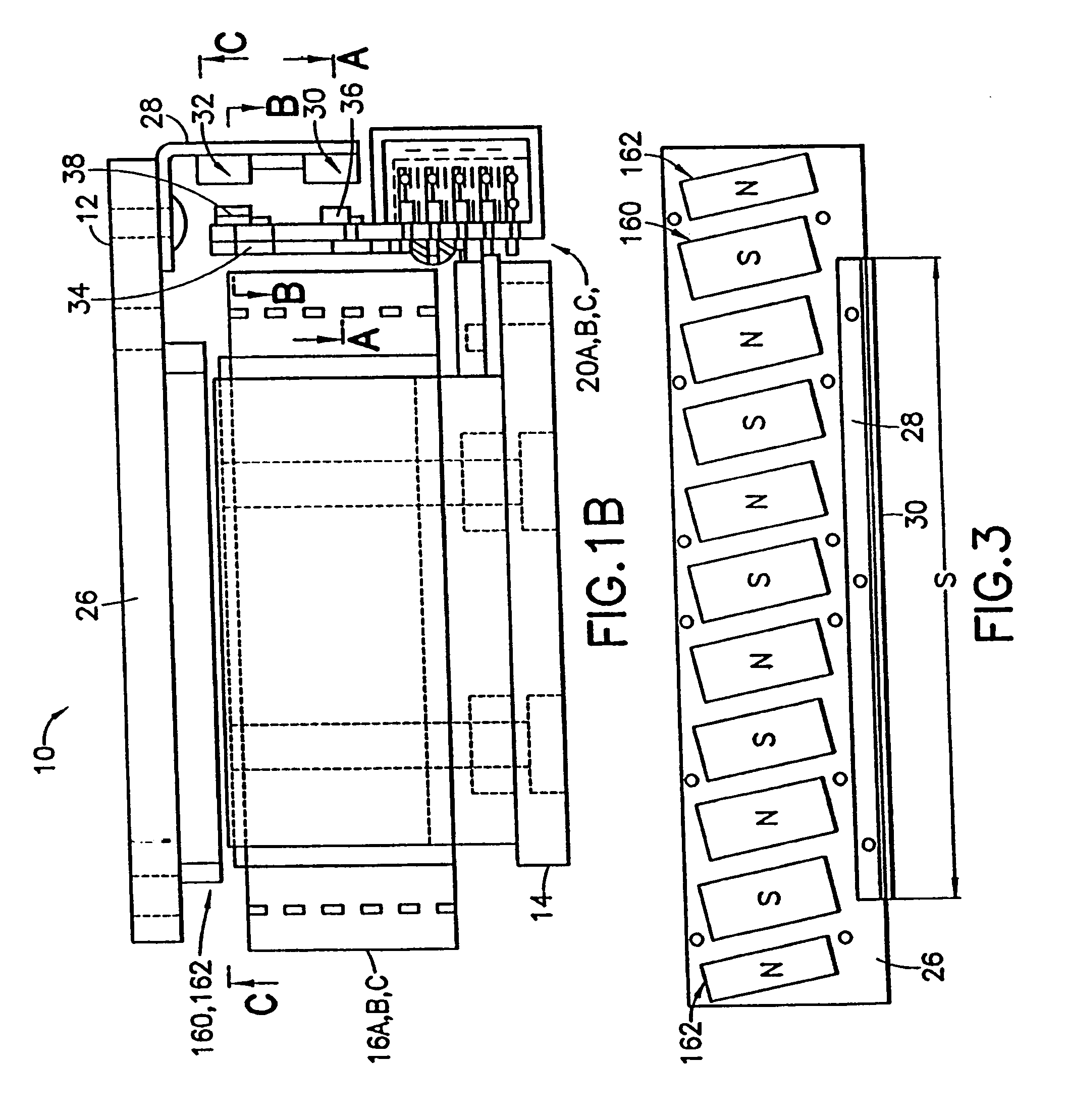

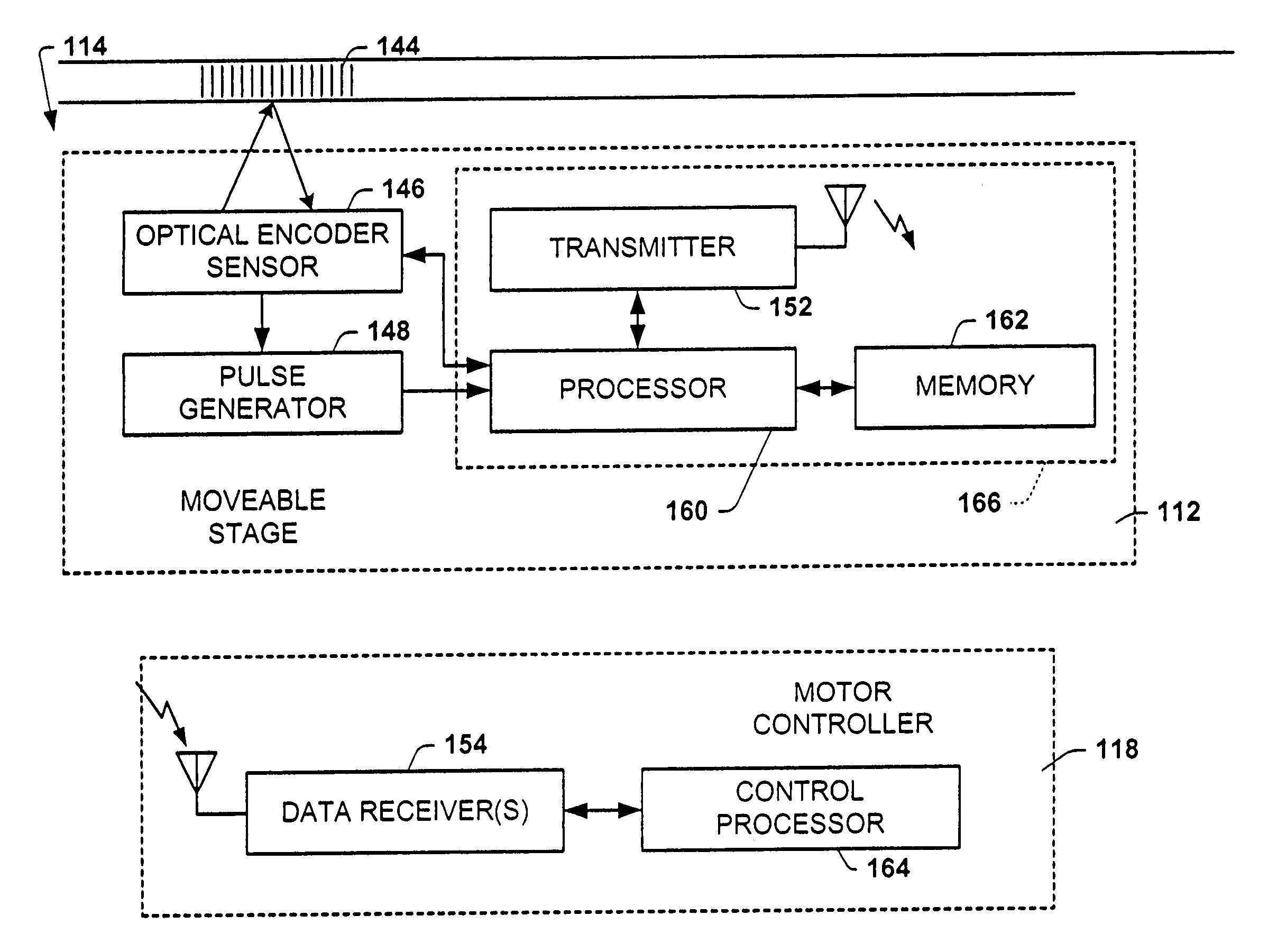

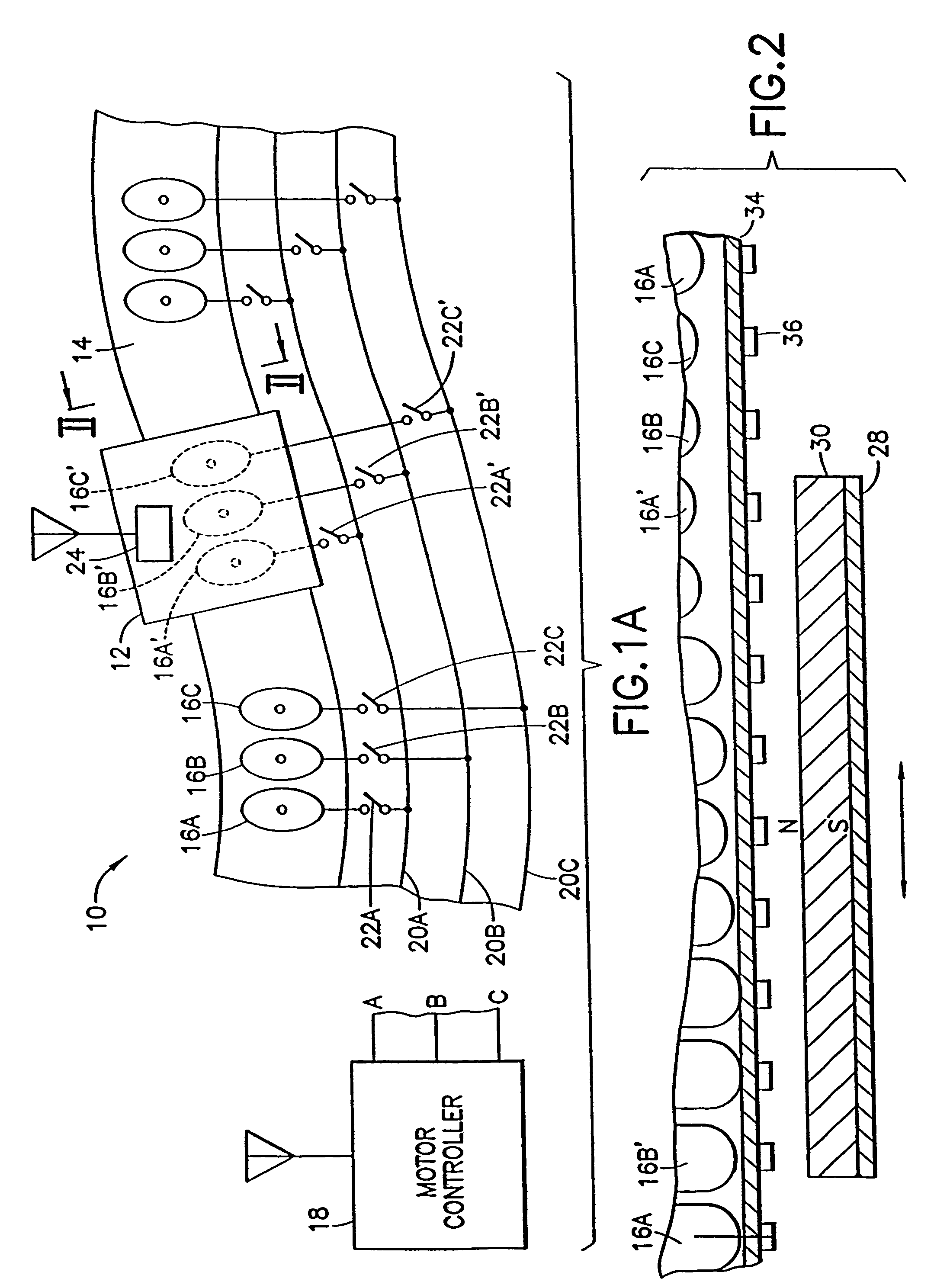

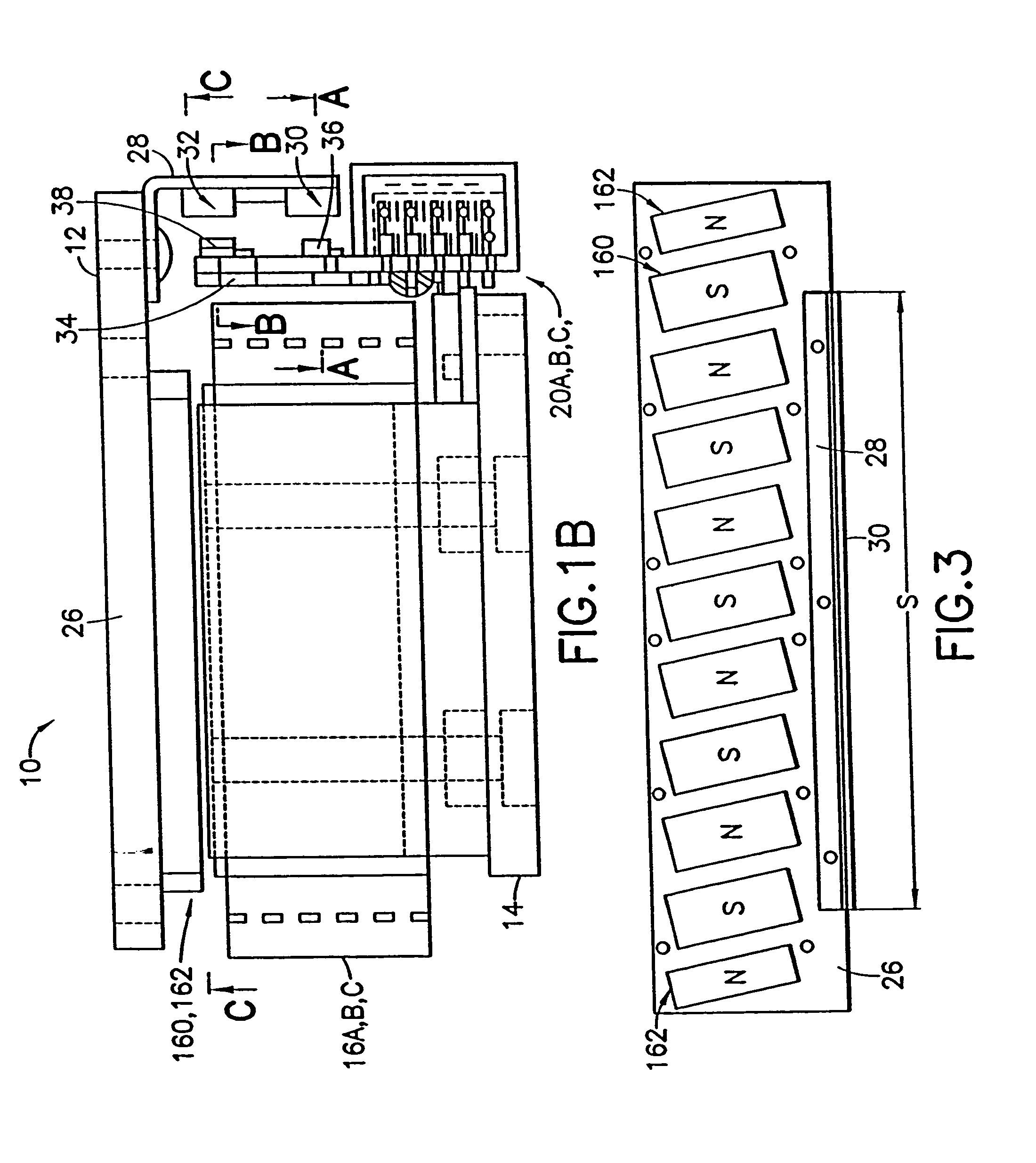

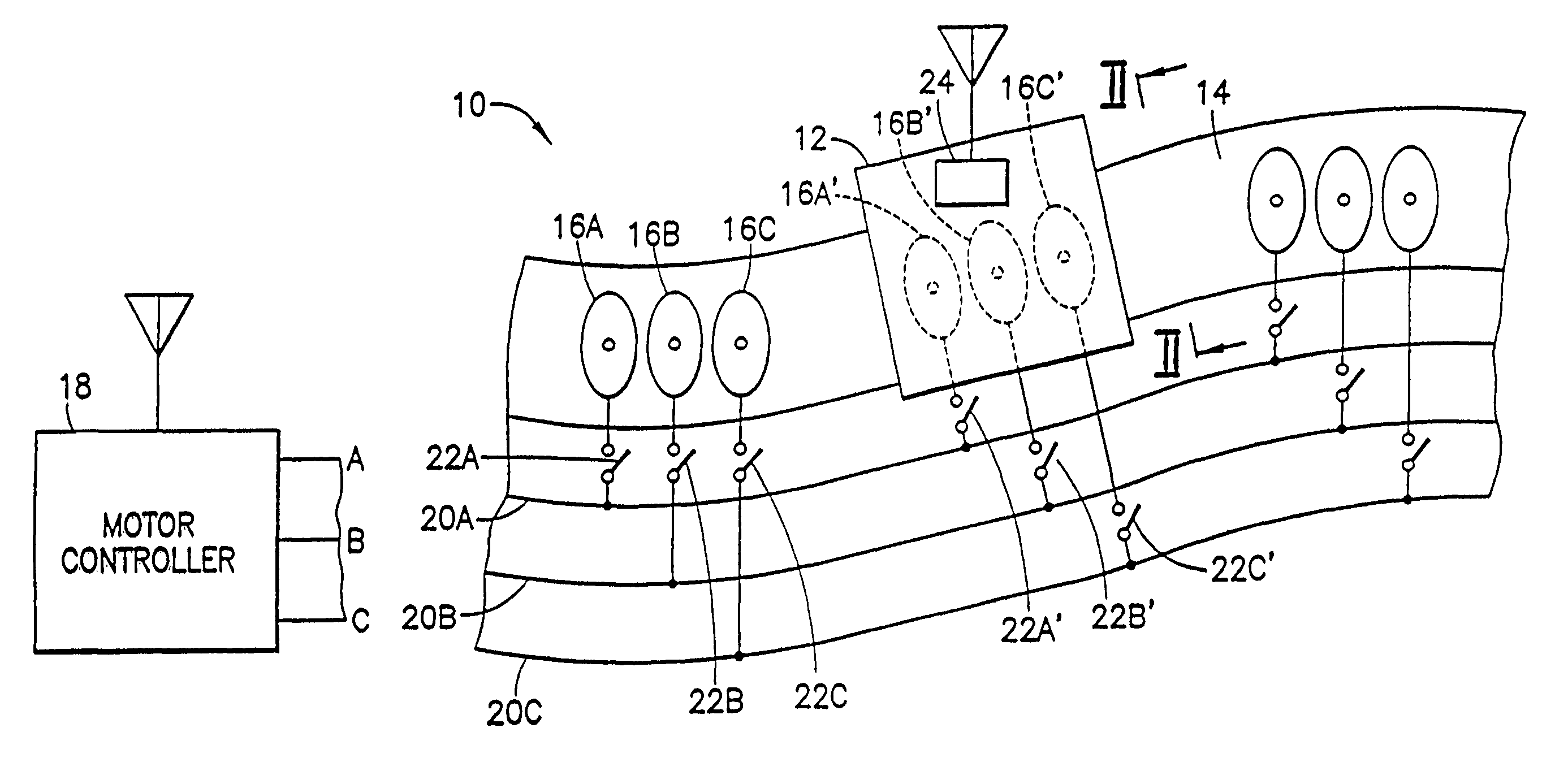

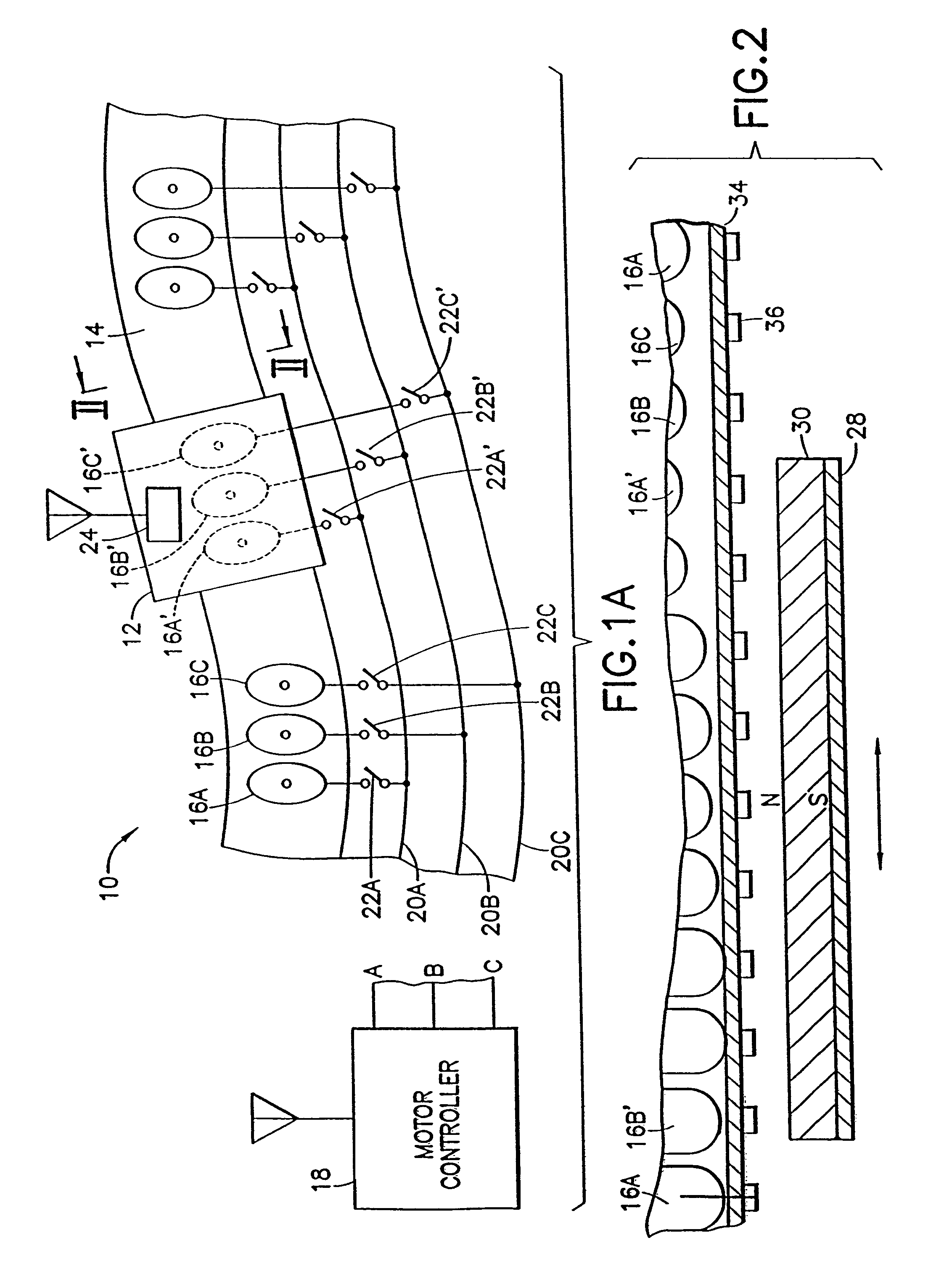

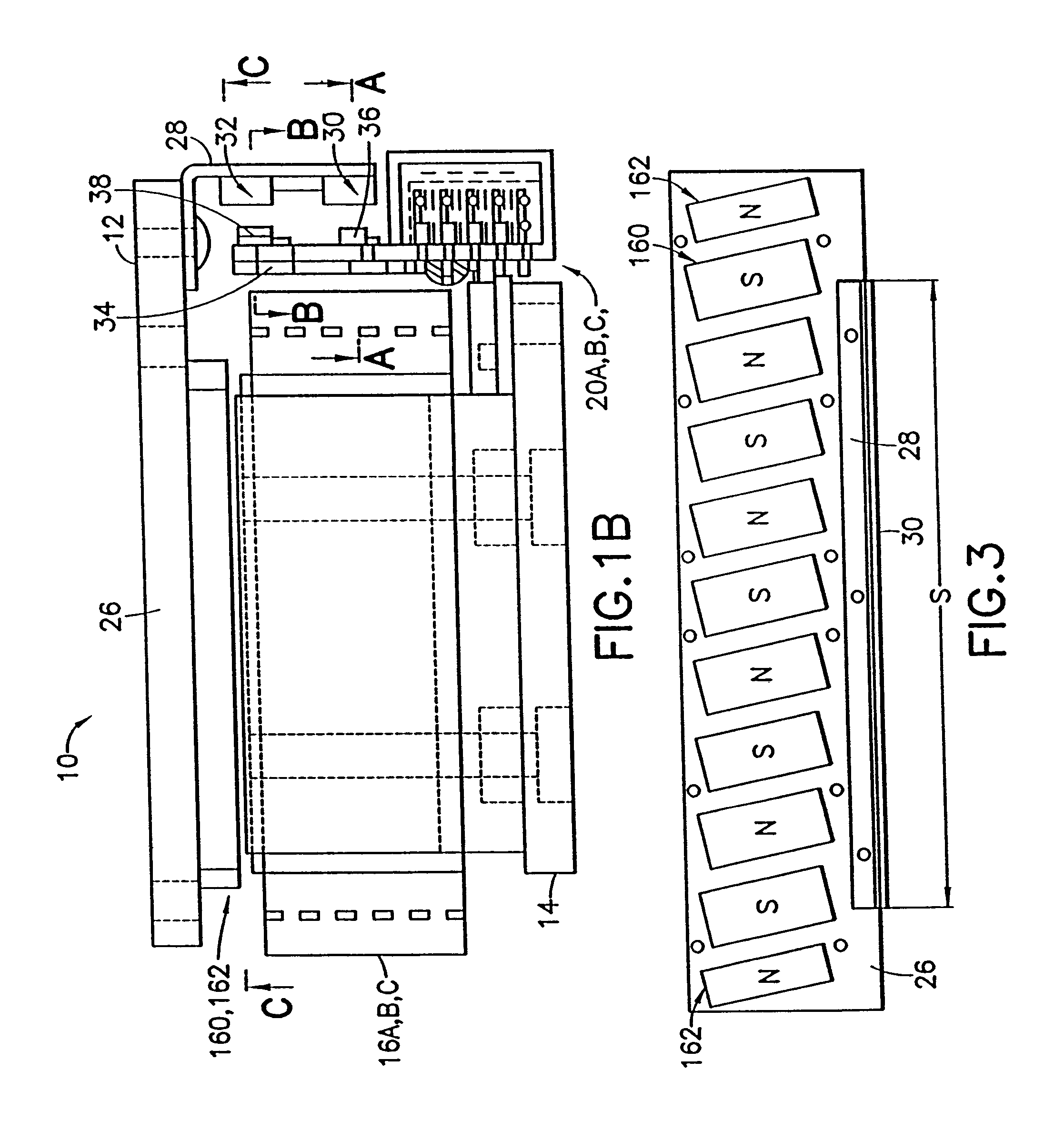

Path module for a linear motor, modular linear motor system and method to control same

InactiveUS7170241B1Facilitates independent controlEasy to control independentlyMotor/generator/converter stoppersDC motor speed/torque controlTelecommunications linkConductor Coil

A path module for a linear motor system includes a controller coupled to one or more amplifiers that are operative to control associated windings in the module. The controller receives control information via a communications link. The controller controls the amplifier based on the received control information so as to selectively energize the associated windings in the module. In one aspect, a plurality of such modules may be connected together to form a path along which one or more stages are moveable according to energization of the windings in the path.

Owner:ROCKWELL AUTOMATION

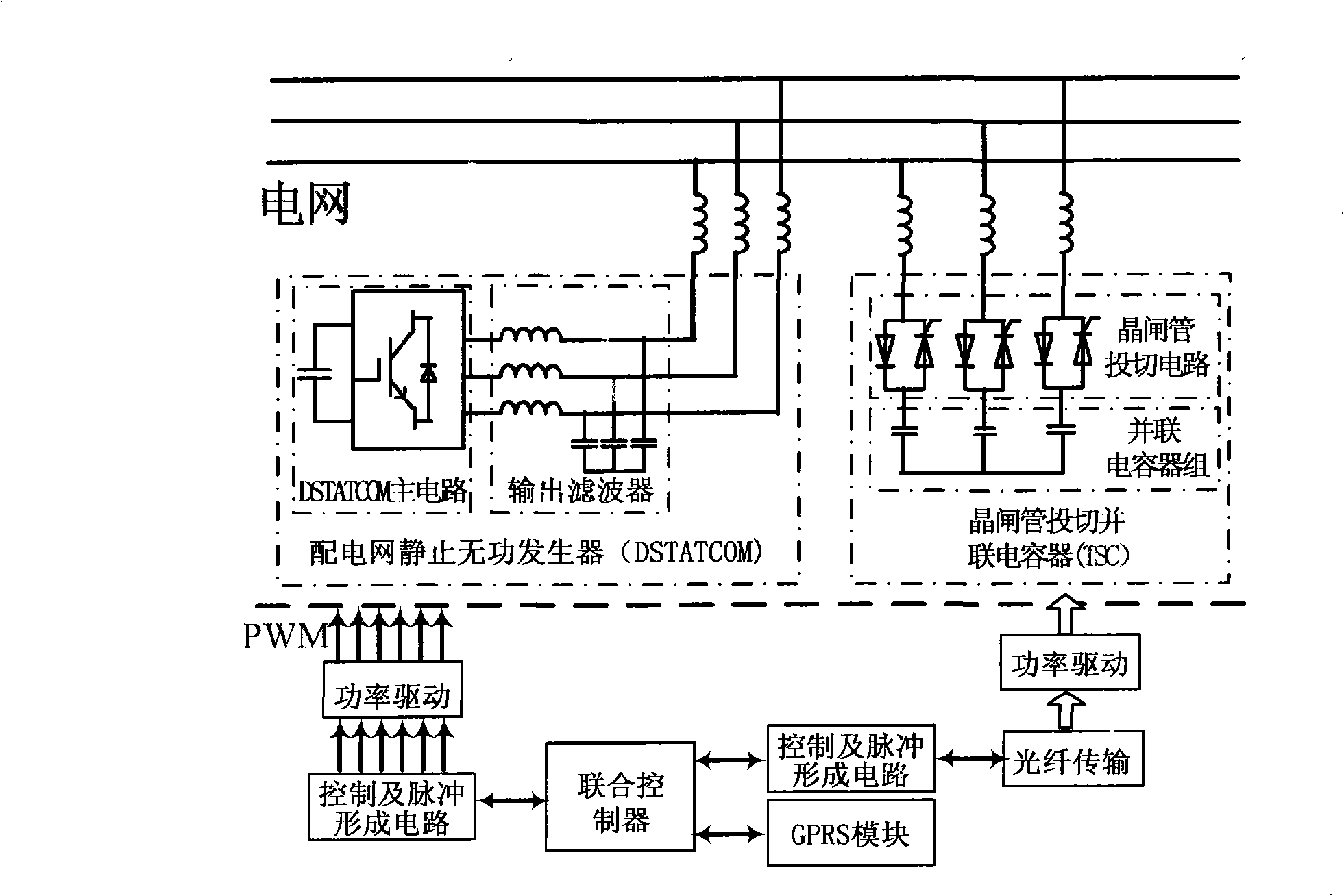

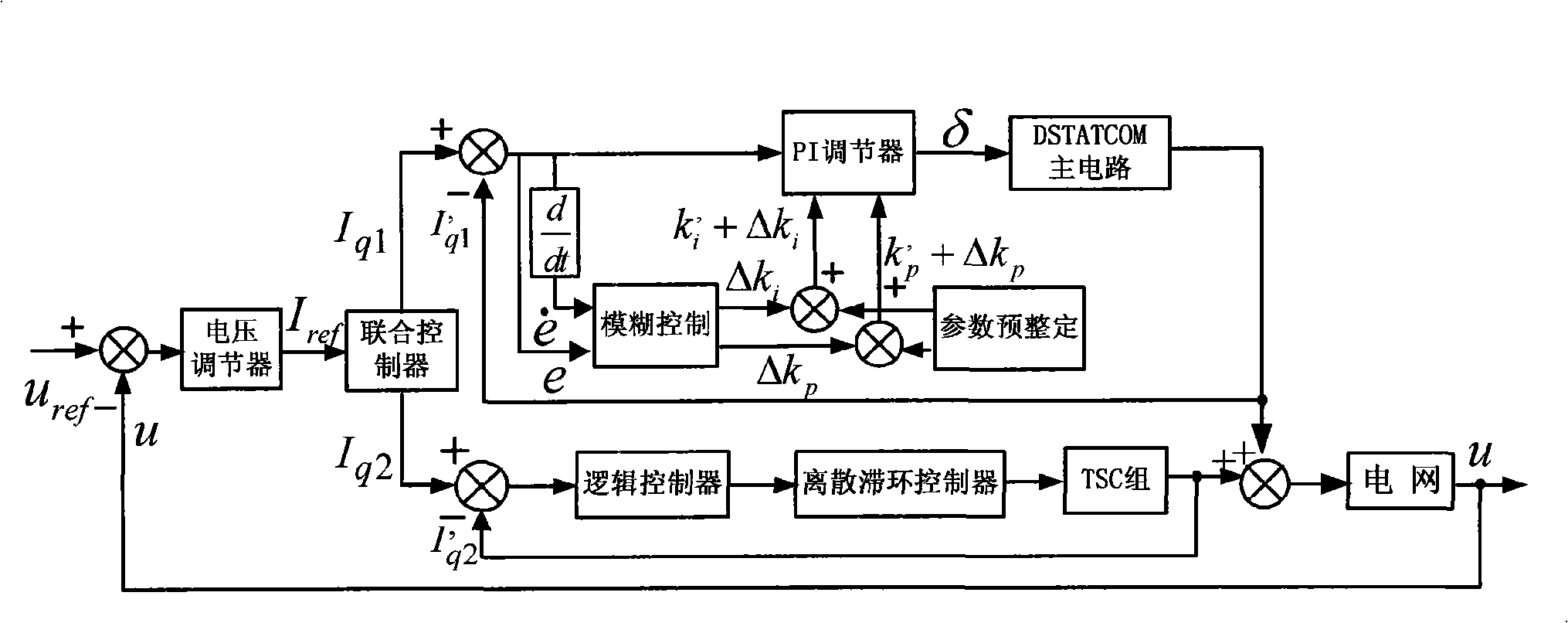

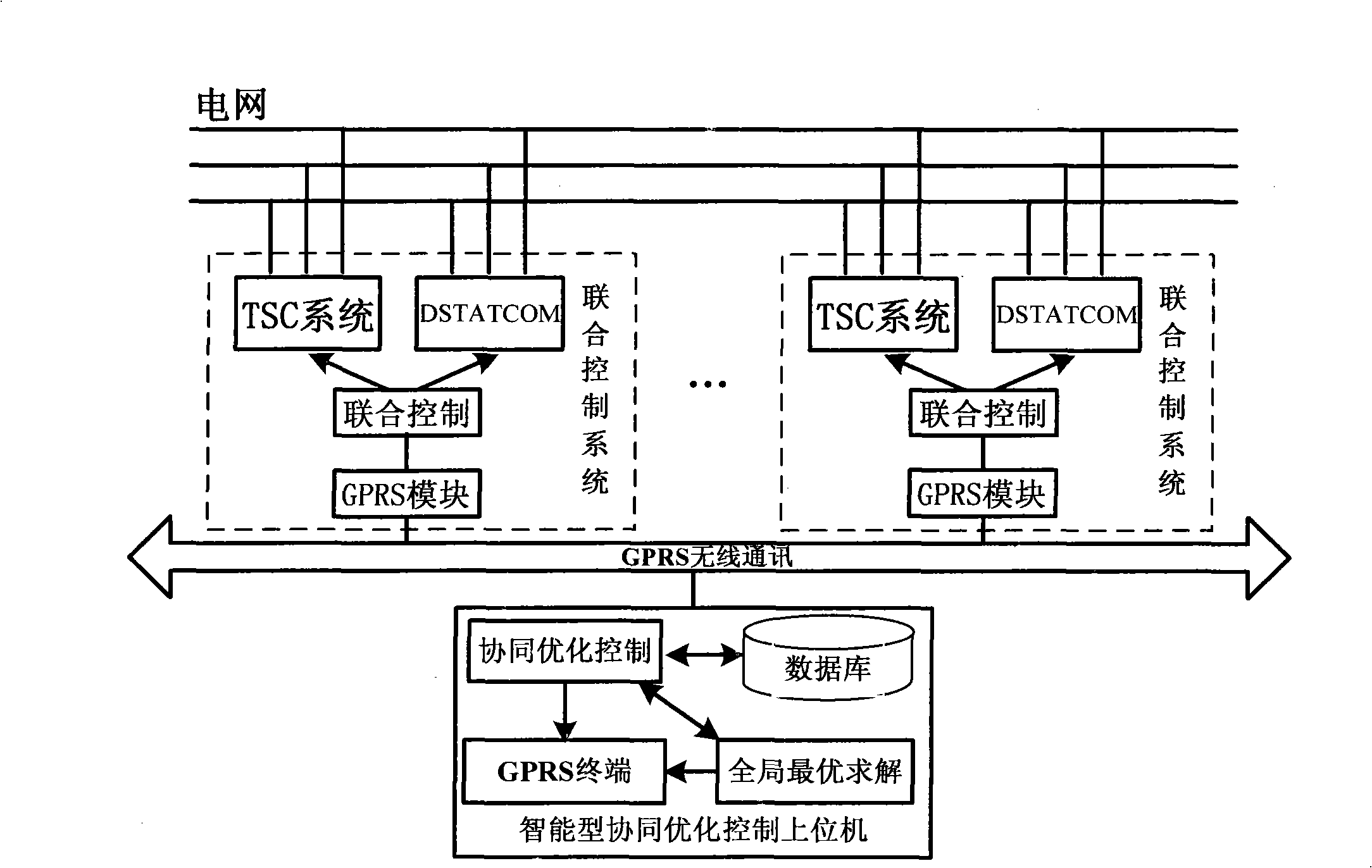

Power distributing reactive optimizing compensation system based on GPRS and control method thereof

InactiveCN101335456ALarge capacityLow costReactive power adjustment/elimination/compensationReactive power compensationPower compensationCapacitance

The invention discloses a reactive power optimum compensation system and a control method thereof of a GPRS-based distribution network. The compensation system of the invention comprises a combination control system and an intelligent upper computer (industrial computer) with collaborative optimization control, wherein, the combination control system coordinately controls TSC and DSTATCOM on the same compensation node by a hybrid dynamic control method, and can also realize the data remote-transmission of the system parameters of the node to the intelligent upper computer with collaborative optimization control by a GPRS wireless communication network; the intelligent upper computer with collaborative optimization control searches the optimum compensation node and the compensation capacity by utilizing a multi-machine collaborative reactive power compensation method and also sends an optimum control command to a combination compensation system which then realizes the local large-capacity and continuous reactive power compensation by classified TSC capacitance switching and continuous DSTATCOM compensation. The reactive power optimum compensation system of the invention effectively solves the defects of poor capacity of resisting disturbance and difficult networking, etc. of the existing reactive power compensation system, and also reduces the operation cost.

Owner:HUNAN UNIV

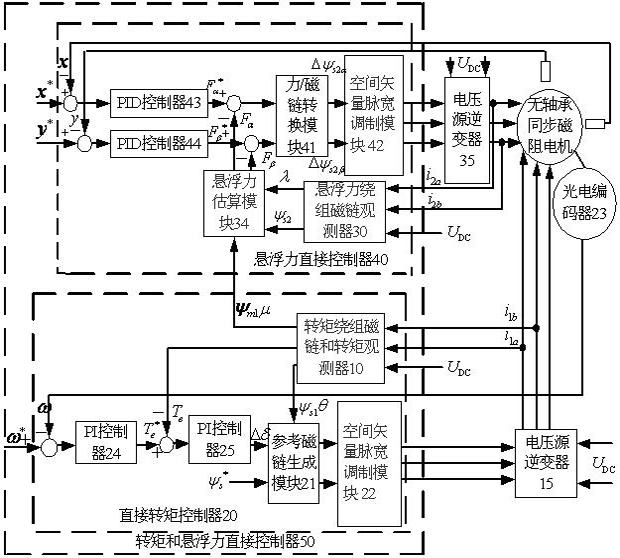

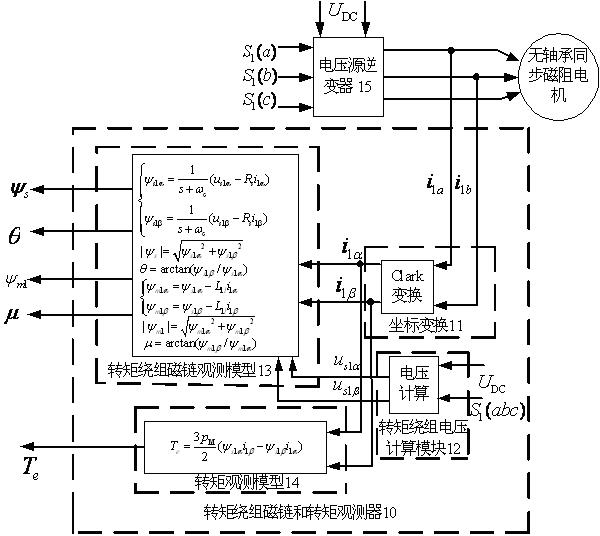

Bearingless synchronous reluctance motor torque and suspension force direct controller and construction method thereof

InactiveCN102082544AGuaranteed uptimeEasy to control independentlyElectronic commutation motor controlAC motor controlSynchronous reluctance motorClassical mechanics

The method discloses a bearingless synchronous reluctance motor torque and suspension force direct controller and a construction method thereof. The bearingless synchronous reluctance motor torque and suspension force direct controller consists of a direct torque controller with a rotating speed and torque double closed loop and a suspension force direct controller with a rotor displacement and suspension force double closed loop, wherein the direct torque controller consists of two proportional plus integral (PI) controllers, a torque winding flux linkage and a torque observer, a reference flux linkage generating module and a space vector pulse width modulation module; and the suspension force direct controller consists of two proportional plus integral plus derivative (PID) controllers, a torque winding flux linkage and torque observer, a suspension force winding flux linkage observer, a suspension force estimation module, a force / flux linkage conversion module and a space vector pulse width modulation module. By the controller and the construction method, motor torque and radial suspension force are independently controlled, stable suspension and operation of a motor rotor are ensured and high motor operating performance is achieved.

Owner:JIANGSU UNIV

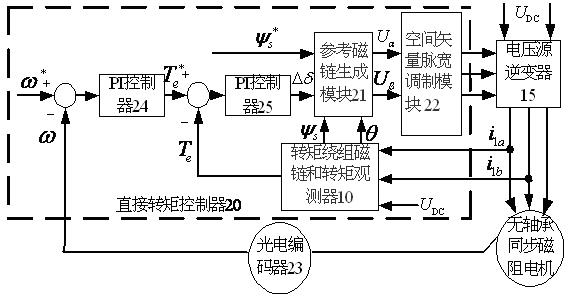

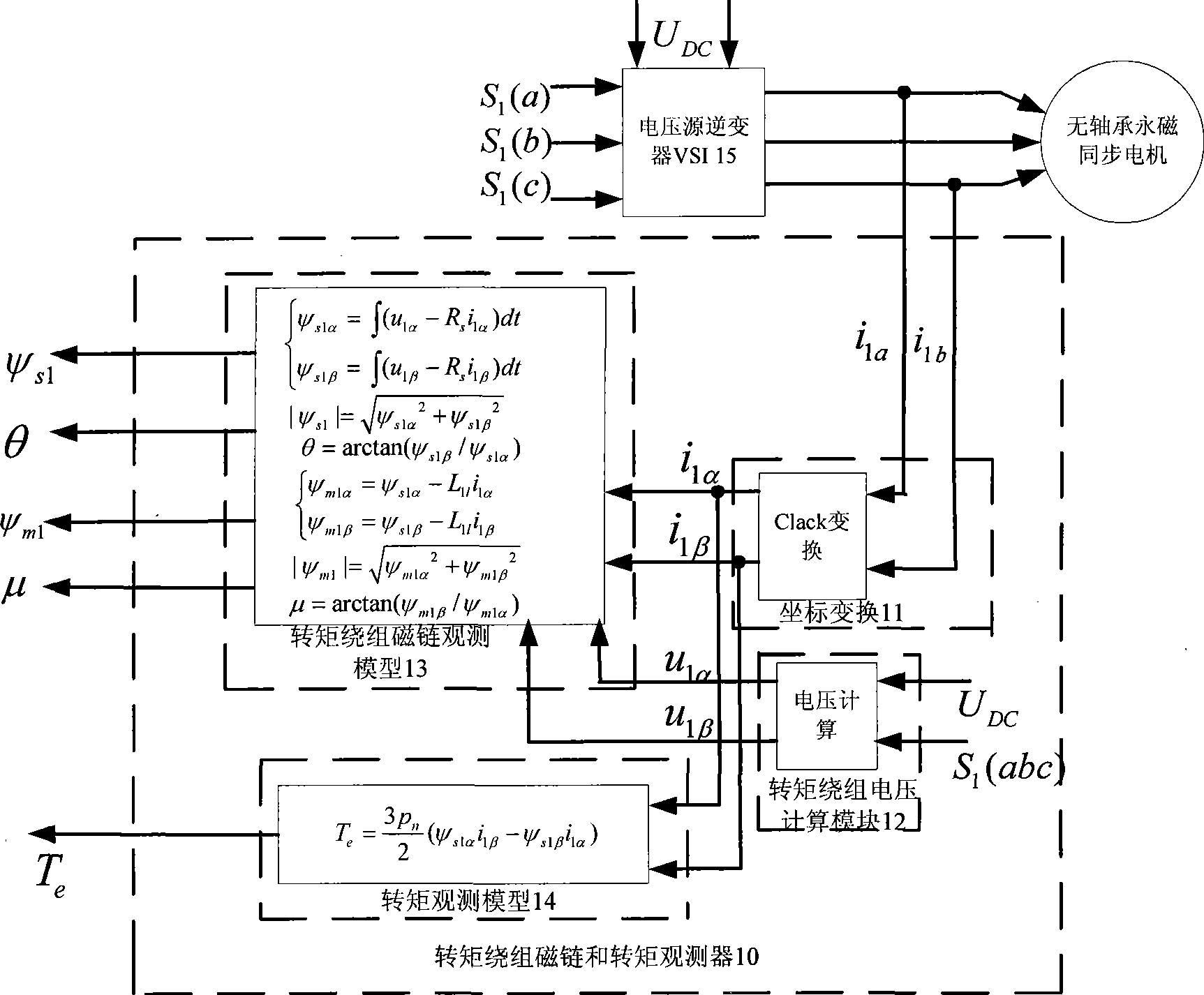

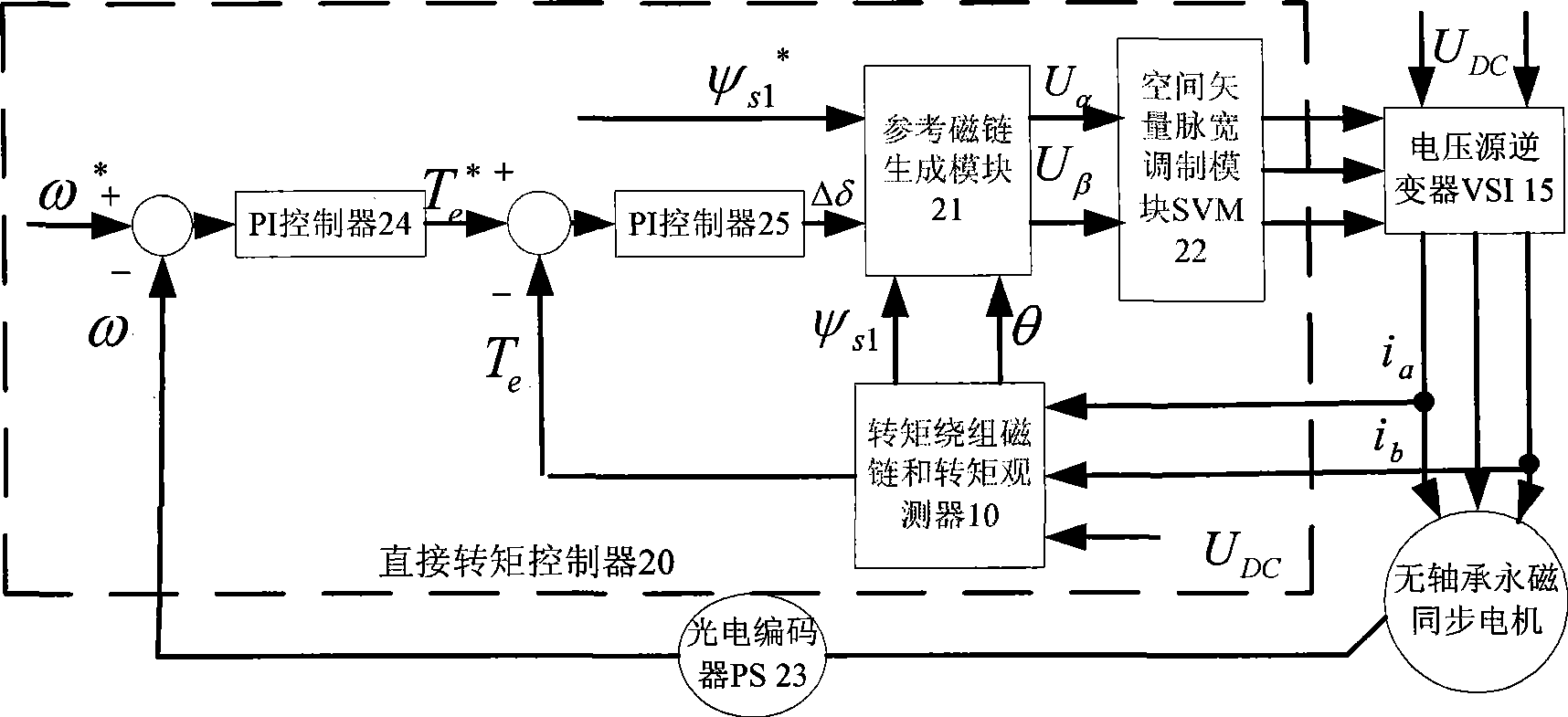

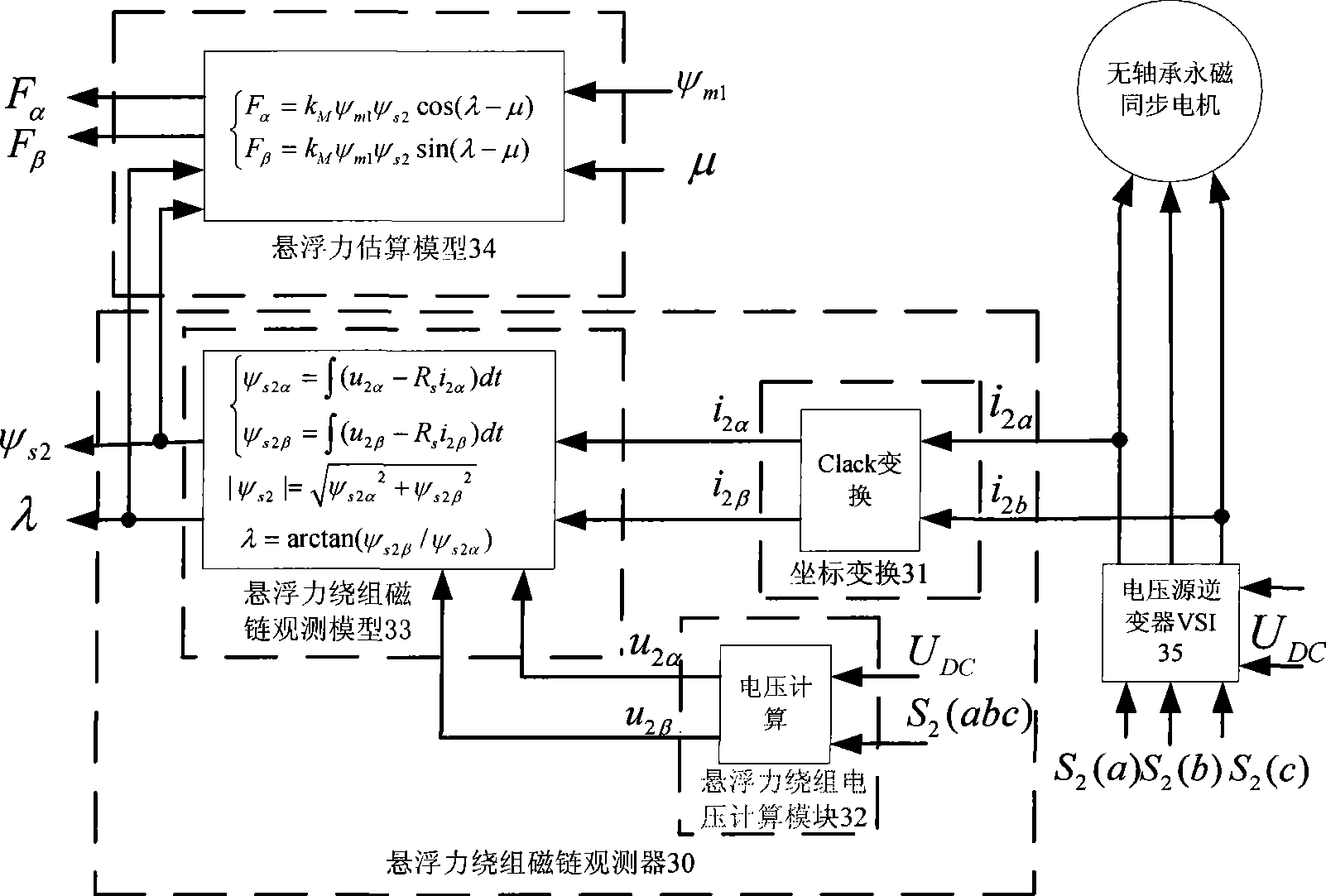

Controller and controlling method for non-bearing permanent magnet synchronous electric motor

InactiveCN101425775AExcellent motor running performanceSimple control structureElectronic commutation motor controlAC motor controlSynchronous motorVoltage source inverter

The invention relates to a controller and a controlling method of a no-bearing permanent-magnetic synchronous motor. The controlling method comprises the following steps: a direct torque controller calculates magnetic linkage and a torque by torque winding magnetic linkage, a double-closing loop of a rotating speed and the torque is constructed, the increment of the phase angle of the magnetic linkage is generated by the comparing difference value of the instruction value and the real-time value of the rotating speed and the torque through double-P1 modulation, and a switch signal of an inverter of a power supply source is obtained by the modulation of SVM and a reference magnetic linkage generating module; a suspending power direct controller calculates the magnetic linkage by a winding magnetic linkage observer of the suspending power, the double-closing ring of rotor shift and the suspending power is constructed, the comparing difference value of the rotor shift generates a suspending power instruction value by PID modulation, and the switch signal of an inverter of a power supply is obtained by the rotor shift comparing difference value and the comparing difference value of the real-time value thereof after the modulation of SVM and a power / magnetic linkage converting module. The direct torque controller and the suspending power direct controller are used for forming the torque and suspending power direct controller to control the no-bearing permanent magnetic synchronous motor, and the controlling method has the advantages of simplicity and good effect.

Owner:JIANGSU UNIV

Spinning process of bamboo-like flat filaments produced by semi-continuous high-speed spinning machine

ActiveCN103290495AEasy maintenanceLow cost of spinningArtificial thread manufacturing machinesArtificial filaments from viscoseFrequency changerPolymer science

The invention relates to a spinning process of bamboo-like flat filaments produced by a semi-continuous high-speed spinning machine and belongs to the technical field of spinning of semi-continuous spinning machines. The spinning process comprises glue supply, filament strip forming, spinning and winding. The spinning process is characterized in that the glue supply is achieved through a glue supply device which comprises a metering pump, a glue supply tube and a filter; the metering pump is connected with a frequency converter which is used for controlling the amount of the glue supply of the metering pump; the frequency converter controls the metering pump to perform intermittent glue supply; the spinning is achieved through a spinning device which comprises at least one spinning roller which is horizontally arranged relative to an operating surface of a spinning surface; and filament strips surround the spinning roller to achieve drafting, solidification and deacidification in the spinning processes under the rotation of the spinning roller. The spinning process of the bamboo-like flat filaments produced by the semi-continuous high-speed spinning machine has the advantages of solving the problems that the filament strips of the semi-continuous spinning machines are inadequate in response, so that the spinning speed cannot be improved and the production efficiency and product quality cannot be integrated, enabling the arrangement direction of the spinning roller to be changed to enable the spinning speed of the spinning machine to be improved and enabling the high quality bamboo-like flat filaments to be spun out.

Owner:YIBIN HIEST FIBER +2

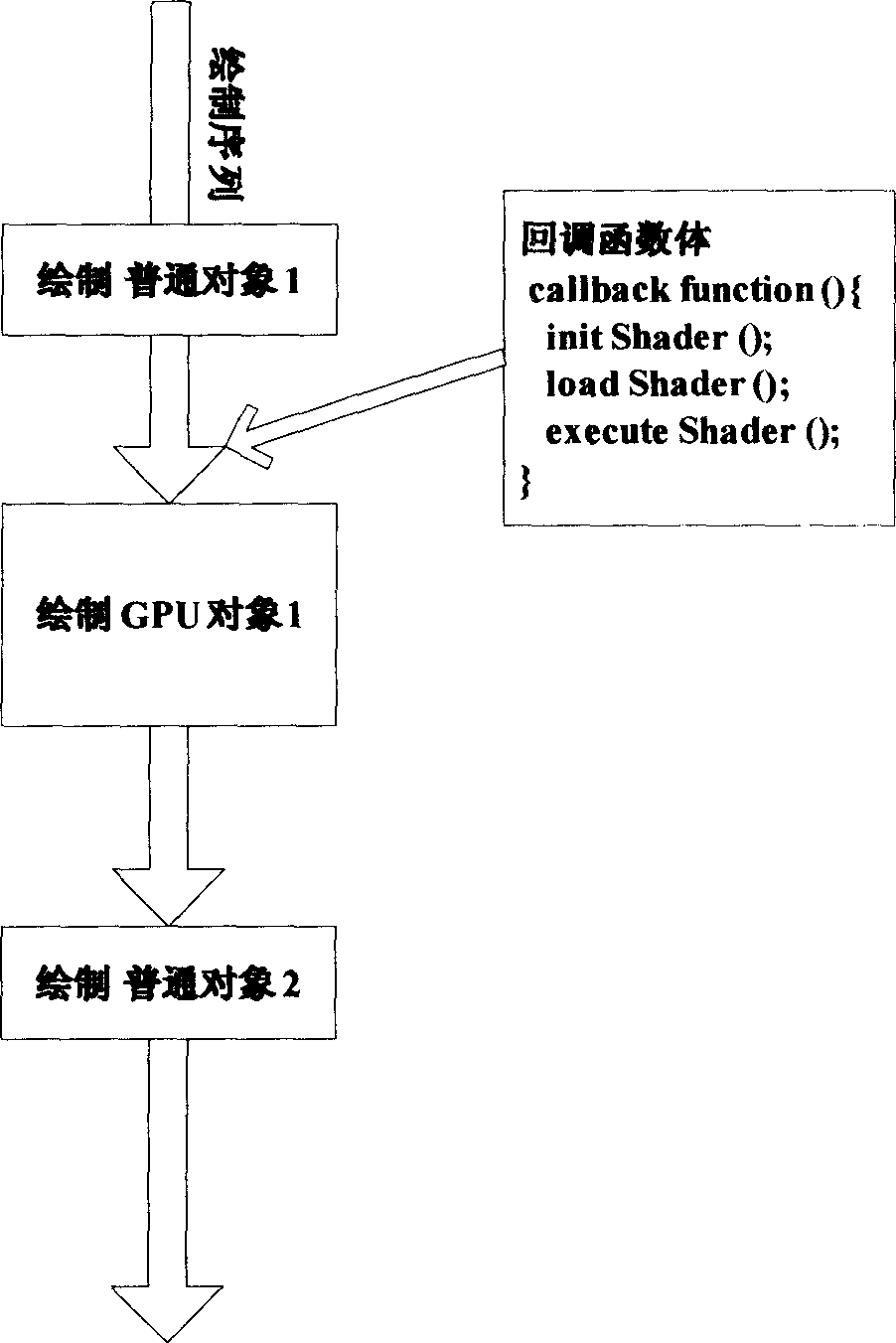

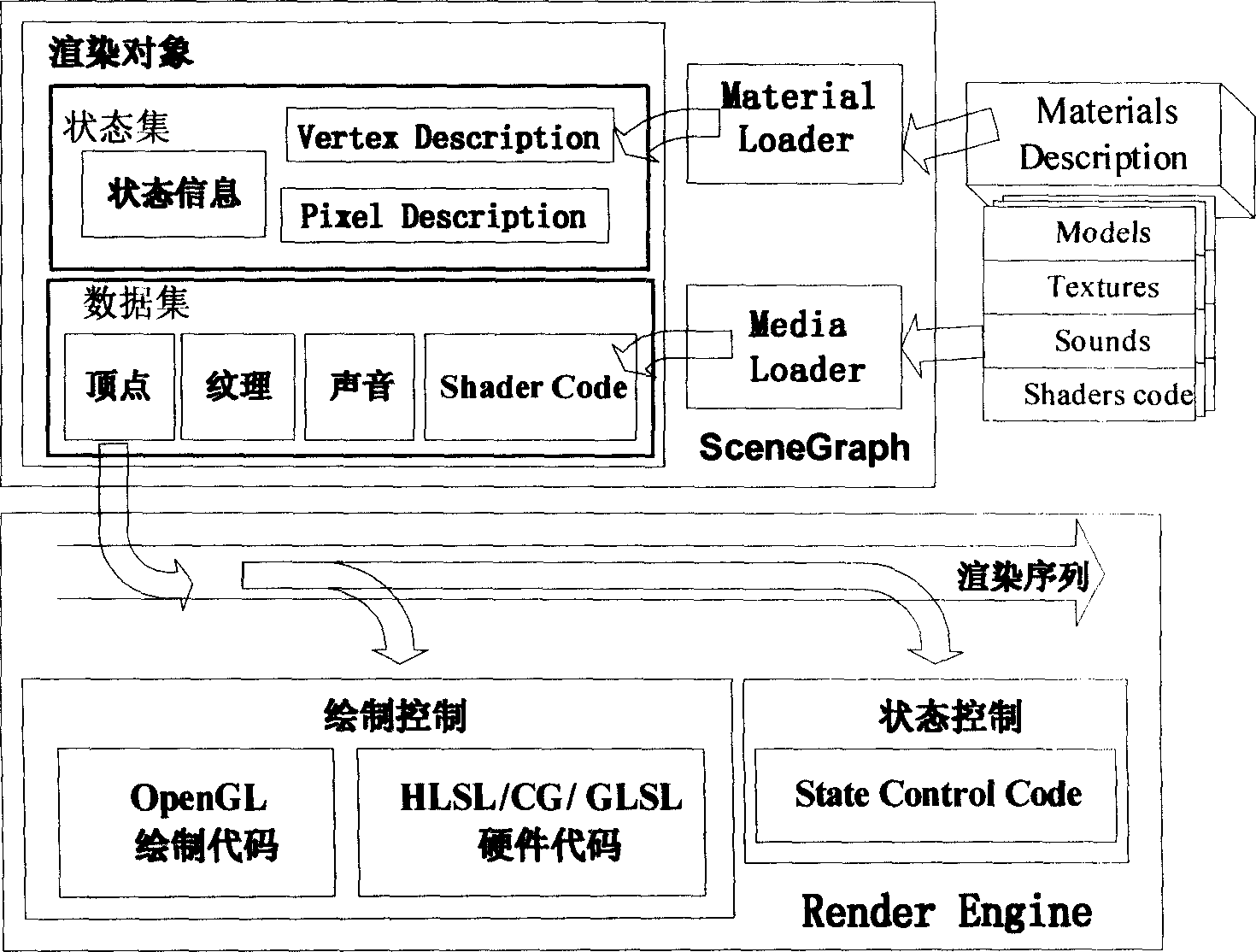

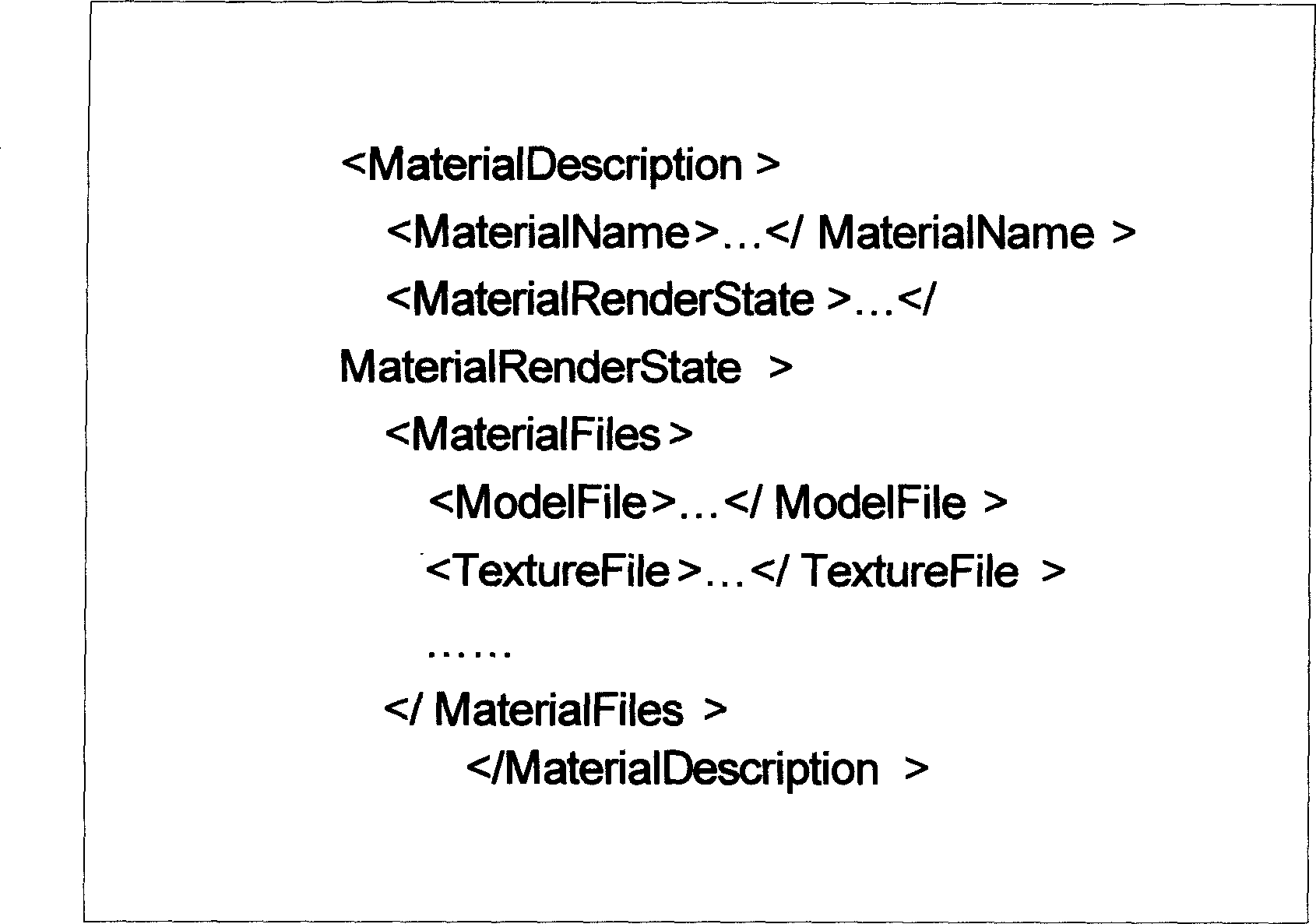

State set based shader three-dimensional graph drawing frame and drawing method

InactiveCN1851753AImprove integrityImprove acceleration performance3D-image renderingDynamical optimizationMaterial Description

The present invention uniformly package and descript the drawing object model information, texture information, voice message relevant Shader code in Materials Description file before tuning in scene chart, and tuning in shown off object through Material Loader and Media Loader in scene chart data store organization, also according to Shader information sorting and to proceed static and dynamic optimization, then using optimized drawing status information loading to engine to proceed drawing, drawing engine consisting of drawing control and state control, both combined to complete one drawing object drawing process. The present invention makes effective management to Vertex Shader and Pixel Shader, fully utilizing state package and sorting function, simplifying interface calling.

Owner:BEIHANG UNIV

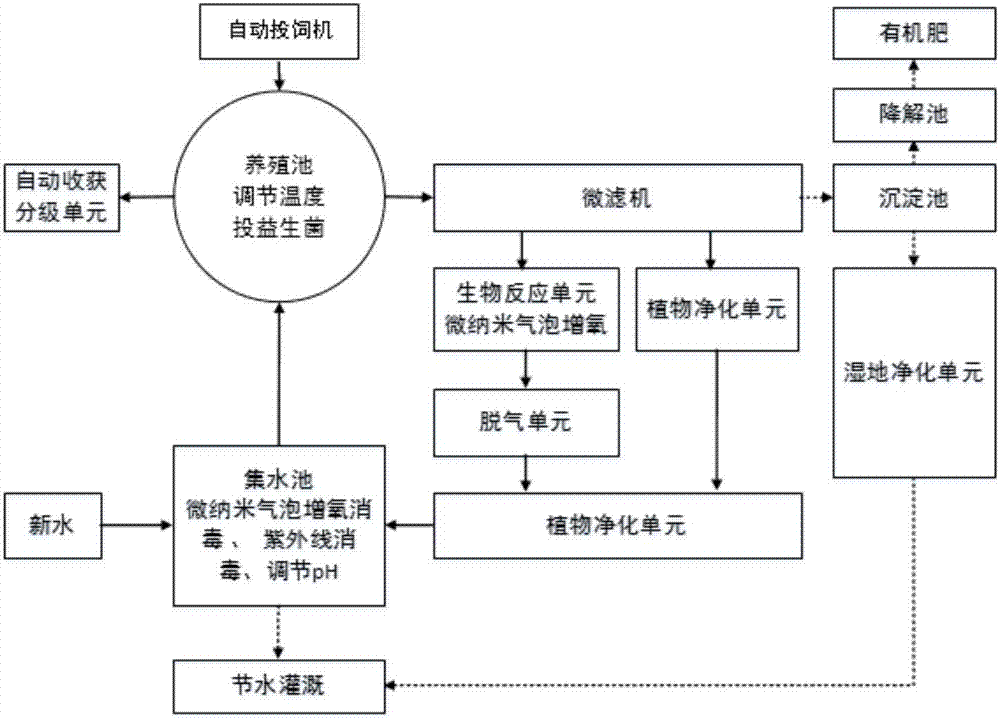

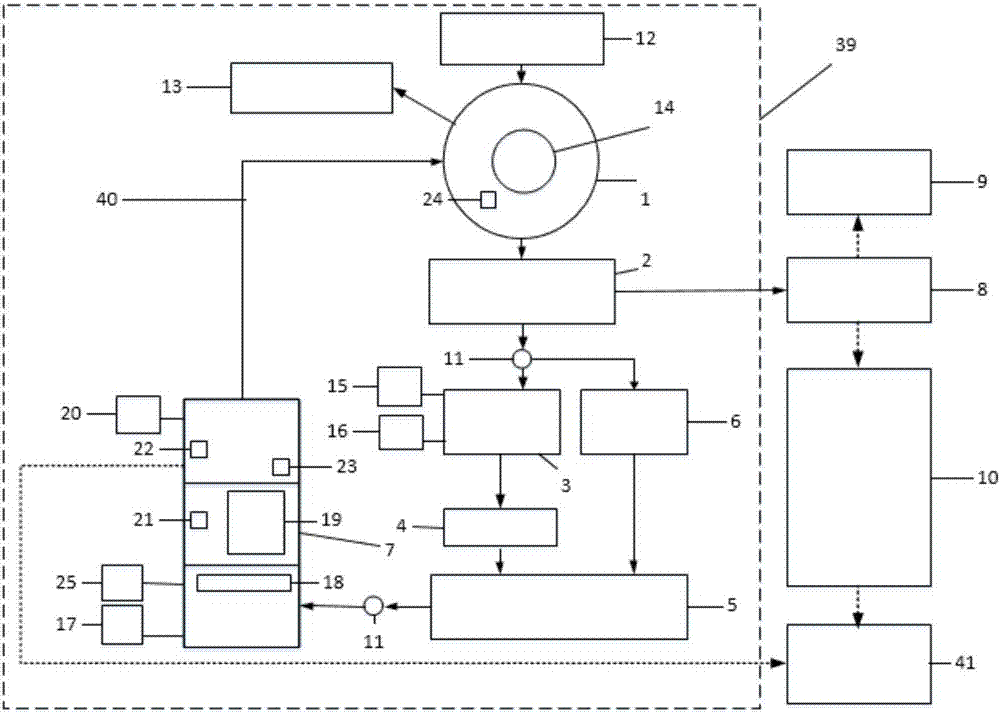

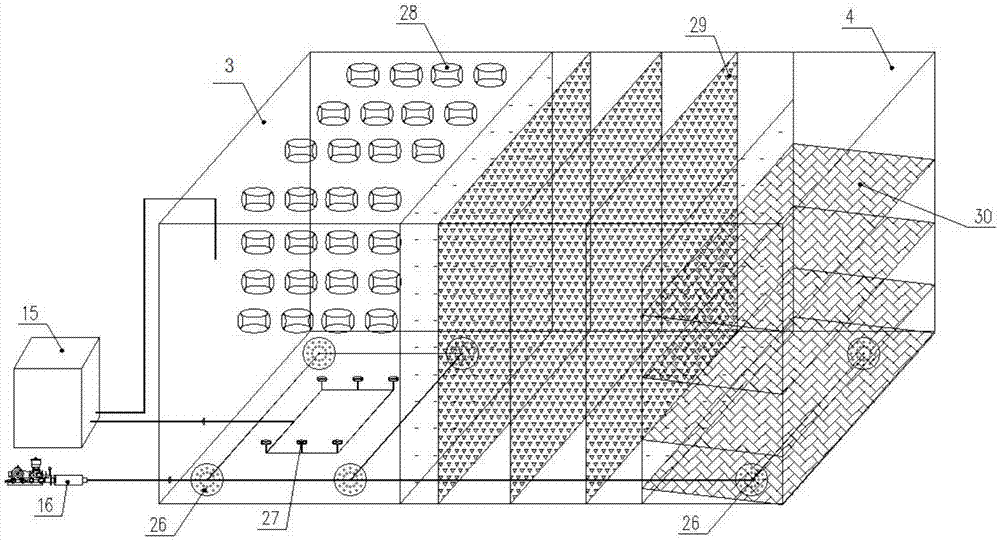

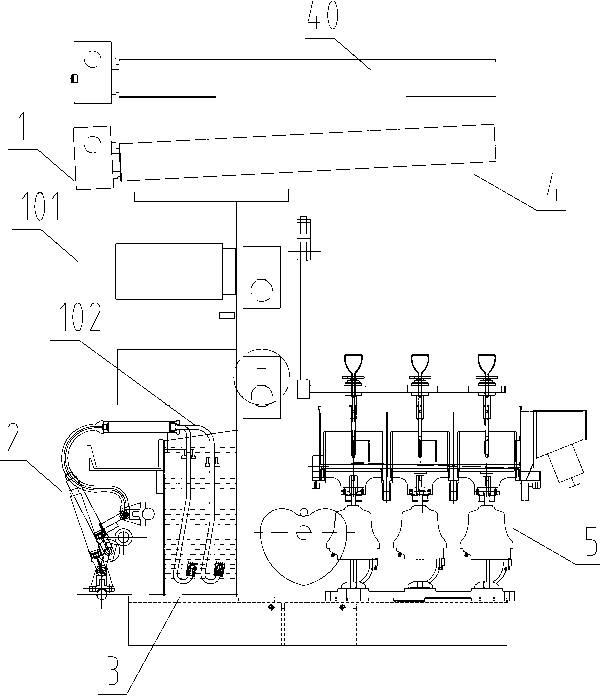

Circulation aquaculture process and system

ActiveCN107251830AEasy to installEasy to moveClimate change adaptationWaste water treatment from animal husbandryMicro nanoSludge

The invention discloses a circulation aquaculture process and system. The aquaculture system includes a breeding unit, a filtering unit, a biological reaction unit, a degassing unit, a plant cleaning unit, an oxygenation disinfection unit, a water feeding and drainage unit, and an intelligent control unit; the breeding unit, the filtering unit, the biological reaction unit, the degassing unit, the plant cleaning unit, and the oxygenation disinfection unit are successively connected through a pipe of the water feeding and drainage unit to form a circulation system. The beneficial effects of the invention are that the micro-nano bubble aeration technology has a good oxygenation effect, and can improve the biological activity of cells and the breeding density; micro-nano ozone bubbles and ultraviolet light can improve the disinfection effect, can reduce chemicals, and can ensure food safety; water feeding and drainage, temperature control, pH control, oxygenation, disinfection and feeding can be achieved automatically, and labors can be saved; processed waste water can be used for watering or enter to the system to be used; sludge becomes an organic fertilizer, a closed ecological chain is formed, and zero emission, a water saving, energy saving, and environment protection effect can be achieved.

Owner:BEIJING ZHONGNONG TIANLU MICRO NANO BUBBLE WATER S&T

Spinning technology of semi continuous high speed spinning machine

InactiveCN103305935AThe transmission mechanism is simpleEasy to maintainArtificial thread manufacturing machinesWet spinning methodsPhysicsSpinning

The invention relates to a spinning technology of a semi continuous high speed spinning machine, belongs to the technical field of semi continuous spinning machine spinning, and comprises the steps of glue supplying, filament forming, spinning and winding, wherein the spinning is accomplished by a spinning device which comprises one or more spinning rollers arranged on an operating surface corresponding to the spinning surface, the filament winds around the spinning roller, the drafting, solidification and deacidification of the spinning step are accomplished under the rotation of the spinning roller. According to the spinning technology provided by the invention, the problems that the spinning speed can not be accelerated and dual attention to the working efficiency and the product quality cannot be given, caused by the insufficiency reaction of the semi continuous high speed spinning machine filament, are solved, the changing of the spinning roller distribution direction enables the spinning machine to accelerate spinning speed and reserve the structure of other parts of the conventional device, the filament to walk farther, and the reaction of the filament and the acid bath to be more efficient, both the working efficiency and the product quality are considered.

Owner:YIBIN HIEST FIBER +2

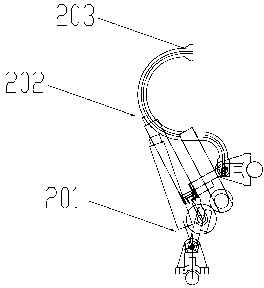

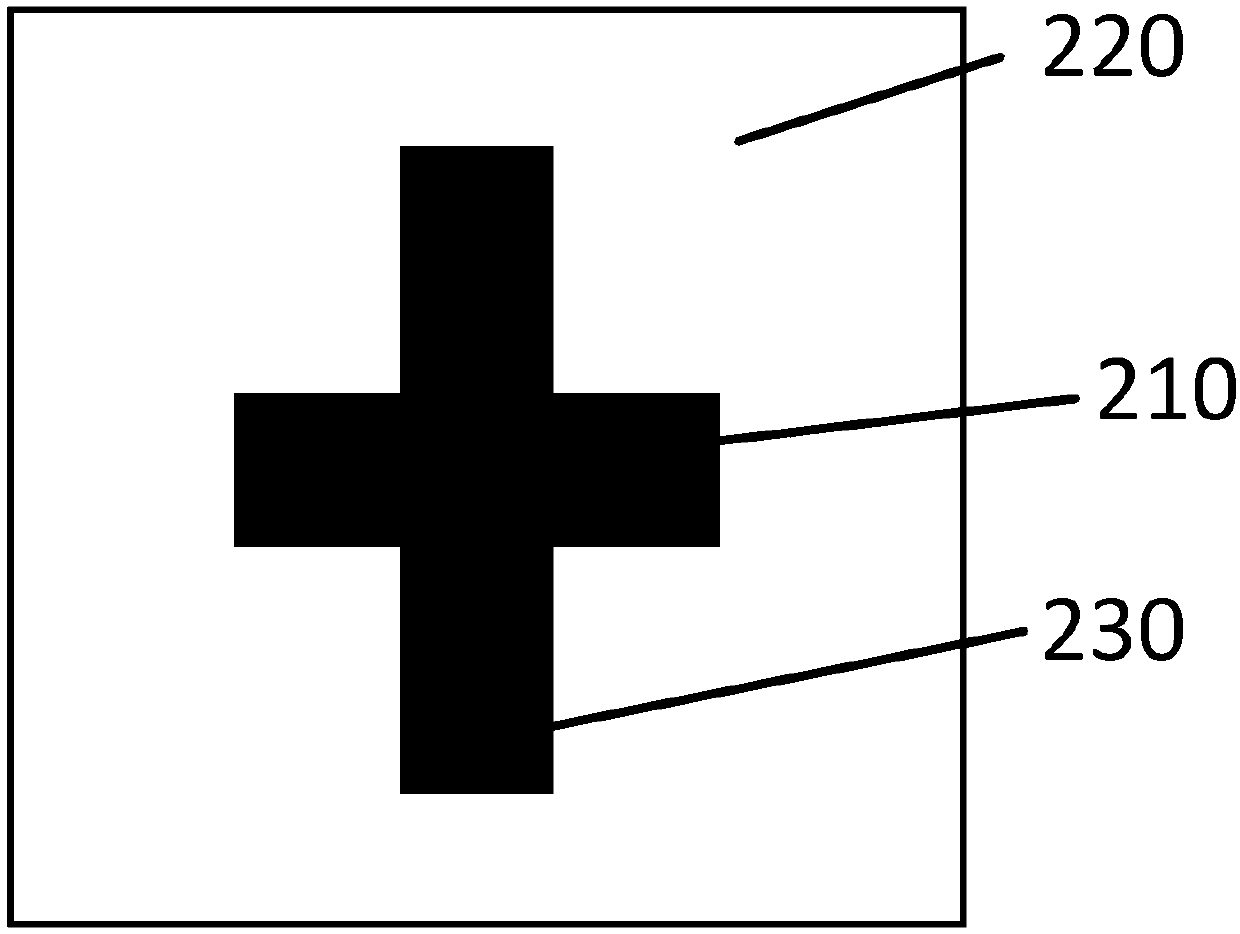

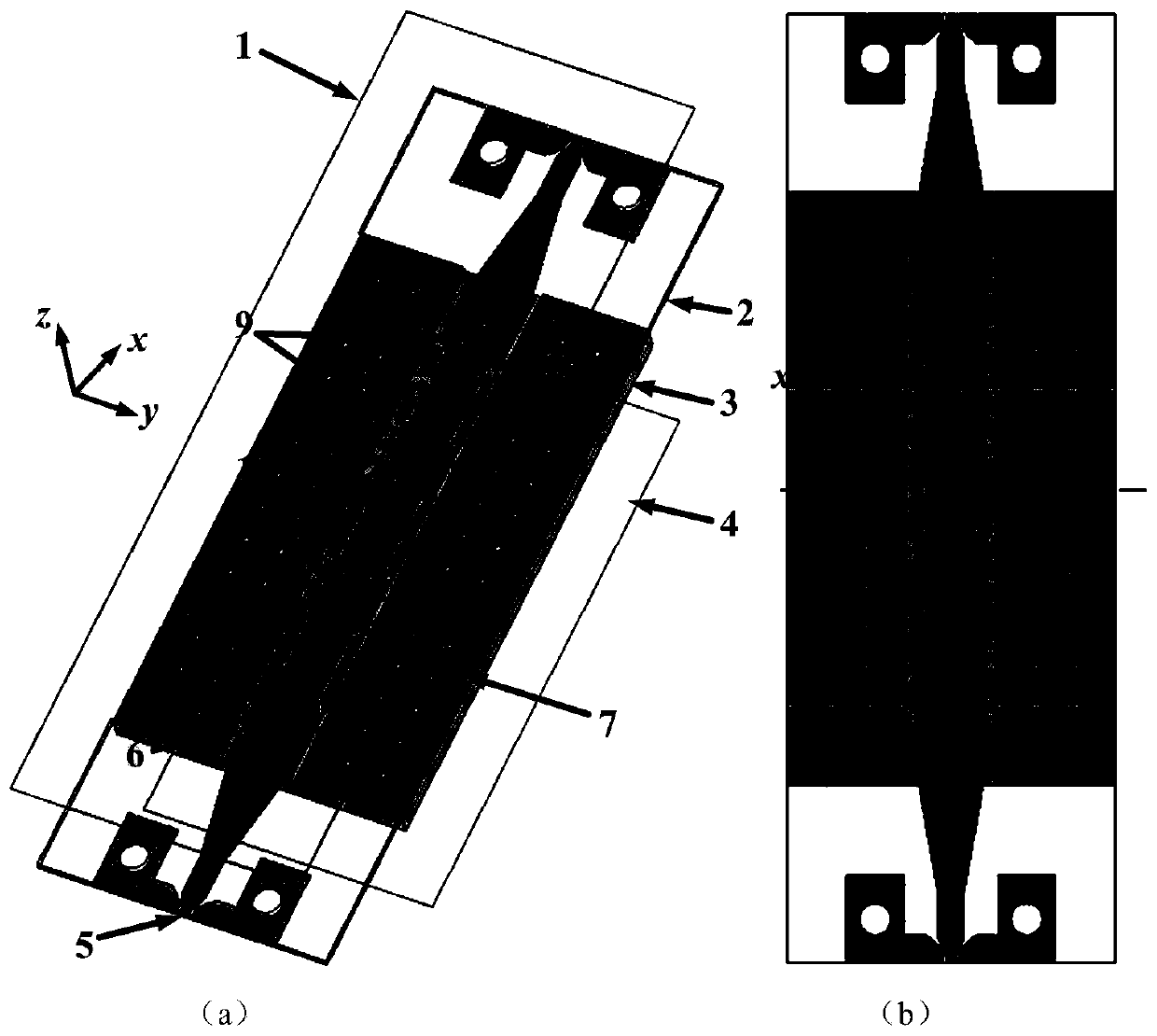

Antenna unit and antenna array

ActiveCN109935964AGood phase shiftEasy to control independentlyRadiating elements structural formsIndividually energised antenna arraysPhase shiftedDielectric substrate

The invention provides an antenna unit and an antenna array. The antenna unit comprises M cross-shaped metal patches, M dielectric substrates and a metal ground layer, wherein M is an integer which isgreater than 1; the ith cross-shaped metal patch and the (i+1)th cross-shaped metal path are provided with the ith dielectric substrate therebetween; the ith cross-shaped metal patch, the ith dielectric substrate and the (i+1)th cross-shaped metal patch are sequentially arranged in a laminated manner, and i is an integer between 1 and (M-1); and the Mth cross-shaped metal patch, the Mth dielectric substrate and the metal ground layer are sequentially arranged in a laminated manner. The antenna unit provided by the invention and the antenna array formed by the unit provided by the invention can have good polarization characteristics, wide operation bandwidth and good phase shift characteristics.

Owner:HUAWEI TECH CO LTD

Path module for a linear motor, modular linear motor system and method to control same

InactiveUS6975081B1Facilitates independent controlEasy to control independentlyMotor/generator/converter stoppersDC motor speed/torque controlModularityTelecommunications link

A path module for a linear motor system includes a controller coupled to one or more amplifiers that are operative to control associated windings in the module. The controller receives control information via a communications link. The controller controls the amplifier based on the received control information so as to selectively energize the associated windings in the module. In one aspect, a plurality of such modules may be connected together to form a path along which one or more stages are moveable according to energization of the windings in the path.

Owner:ROCKWELL AUTOMATION

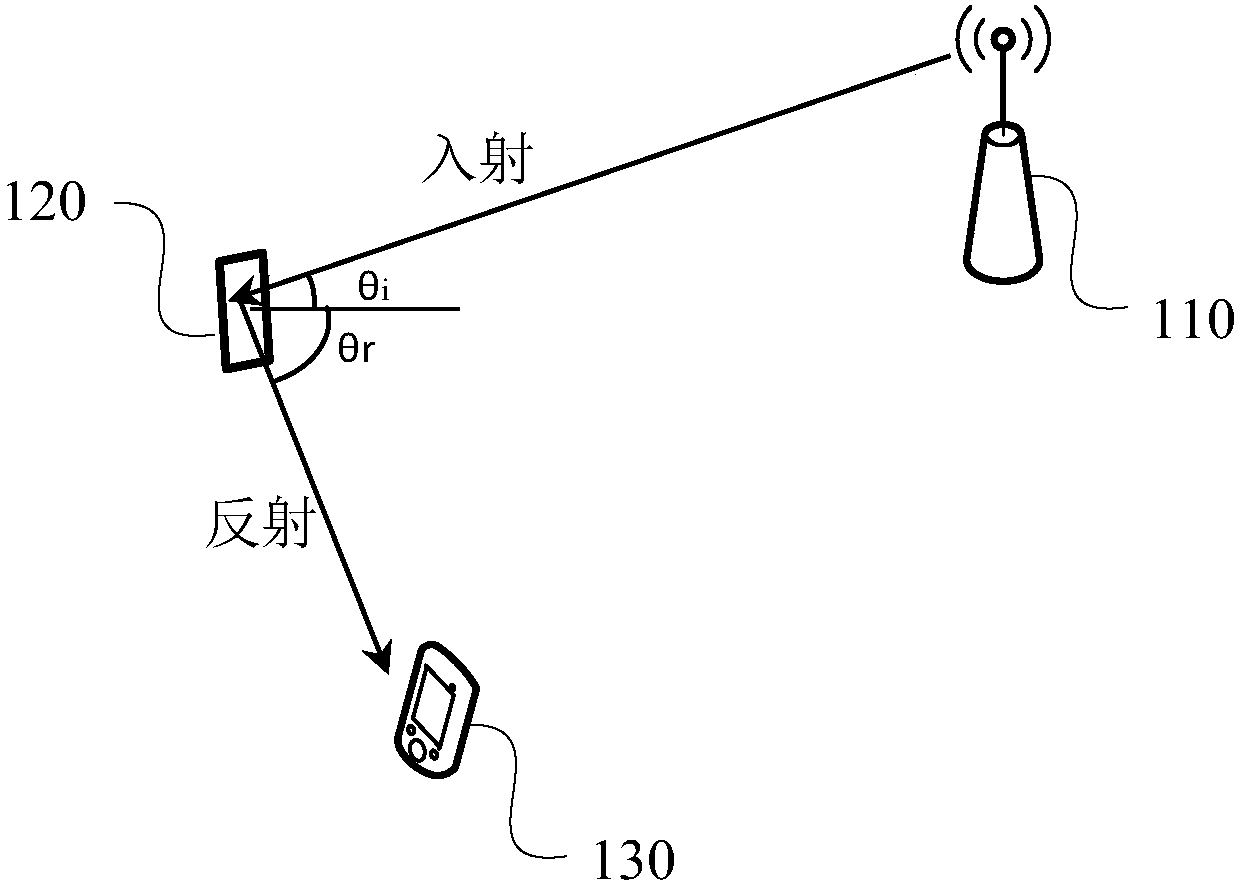

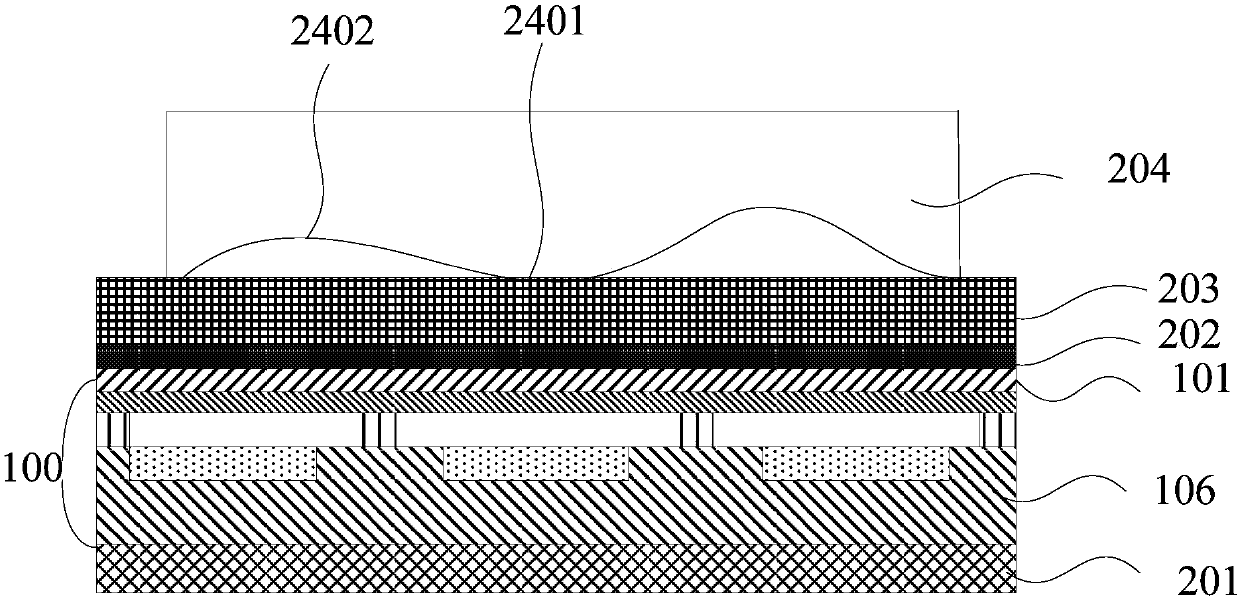

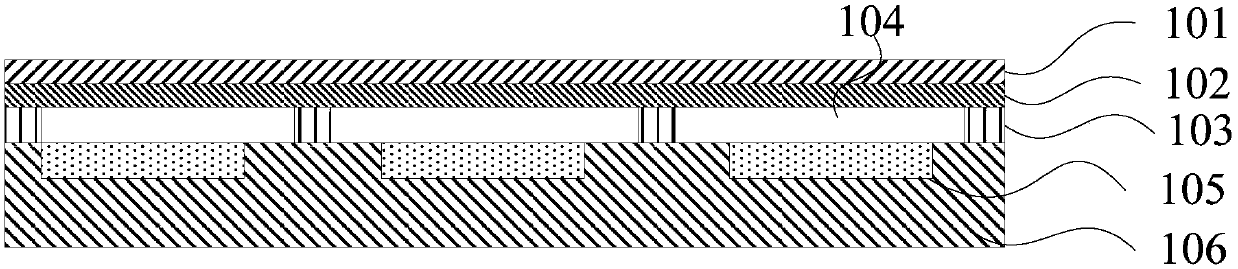

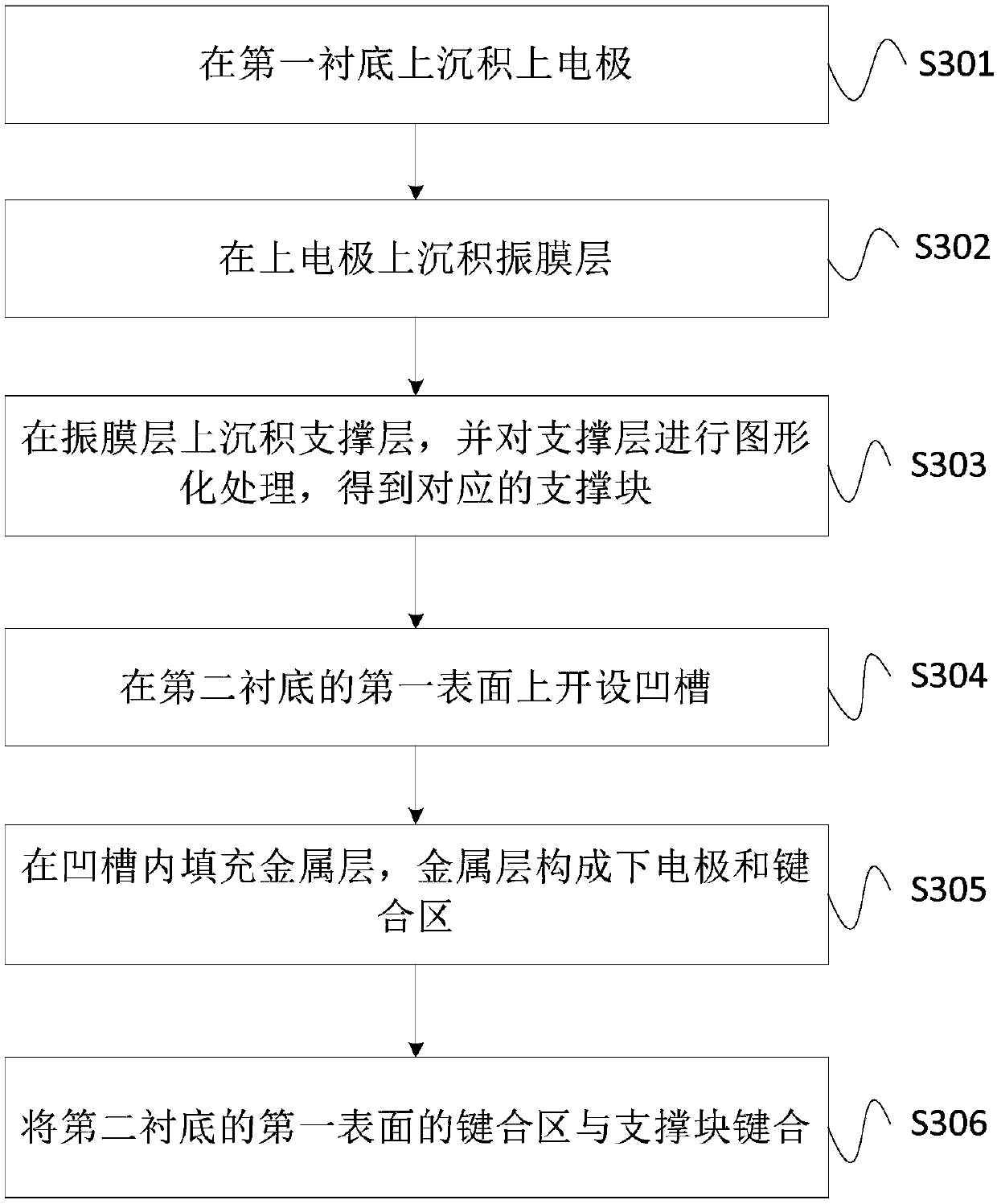

Ultrasonic transducer and manufacturing method thereof

InactiveCN109561876ARealize arrayizationEasy to control independentlyUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsClosed cavityUltrasonic transducer array

The invention provides an ultrasonic transducer and a manufacturing method thereof. The ultrasonic transducer comprises a substrate (106), a lower electrode (105), a support block (103), a diaphragm layer (102), and an upper electrode (101) arranged sequentially in a stacked manner, wherein a groove is arranged on a surface of the substrate near the diaphragm layer, and the lower electrode is filled in the groove, the support block (103) separates the space between the diaphragm layer (102) and the substrate (106) into a closed cavity (104), and the cavity (104) corresponds to the position ofthe lower electrode (105). Therefore, arraying of the low electrode is realized, the lead mode is simpler, and the transmission and reception of ultrasonic transducer array elements are conveniently controlled independently.

Owner:SHENZHEN GOODIX TECH CO LTD

Path module for a linear motor, modular linear motor system and method to control the same

InactiveUS7781993B1Easy to control independentlyMotor/generator/converter stoppersDC motor speed/torque controlInformation controlTelecommunications link

A path module for a linear motor system includes a controller coupled to one or more amplifiers that are operative to control associated windings in the module. The controller receives control information via a communications link. The controller controls the amplifier based on the received control information so as to selectively energize the associated windings in the module. In one aspect, a plurality of such modules may be connected together to form a path along which one or more stages are moveable according to energization of the windings in the path.

Owner:ROCKWELL AUTOMATION

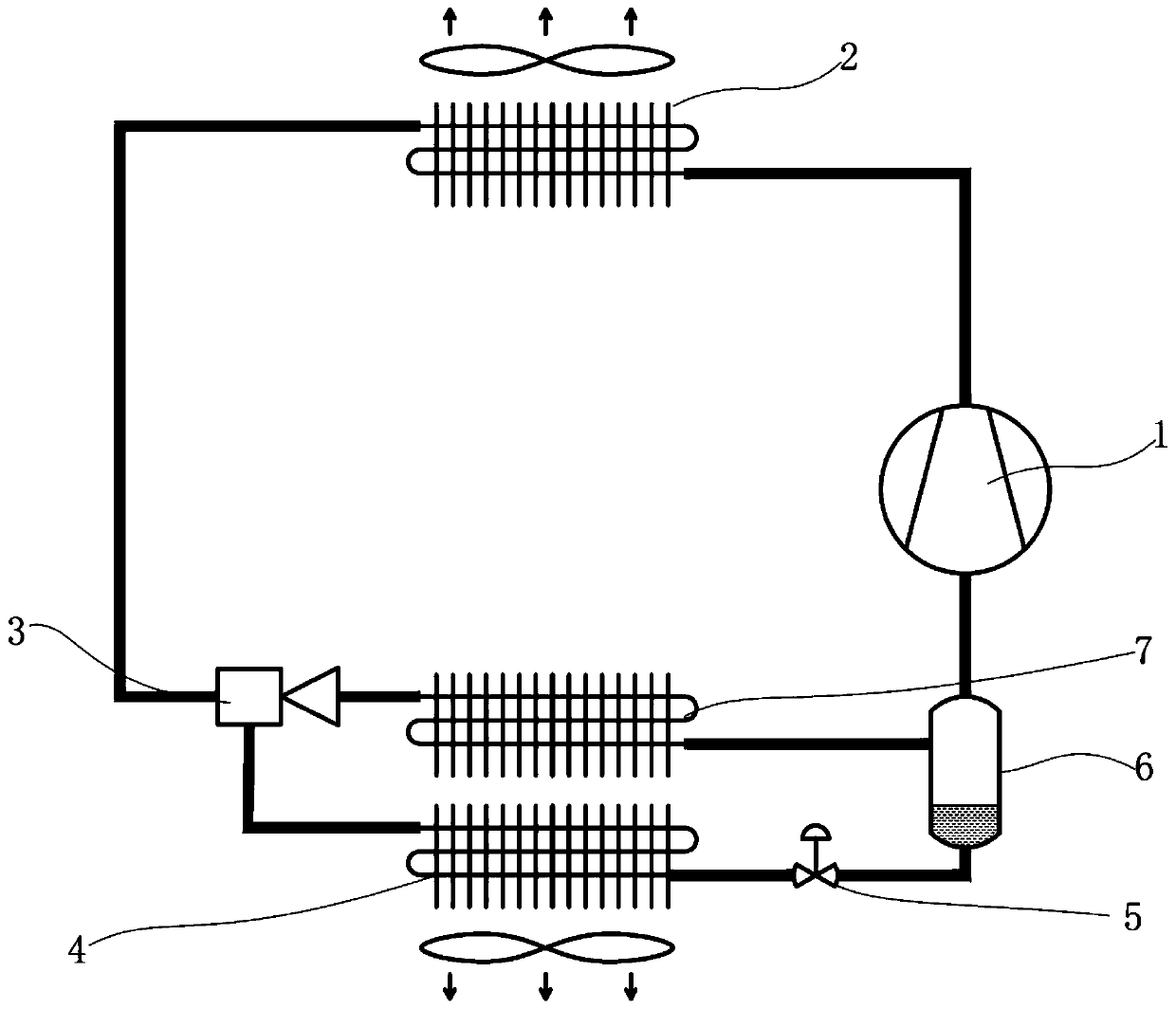

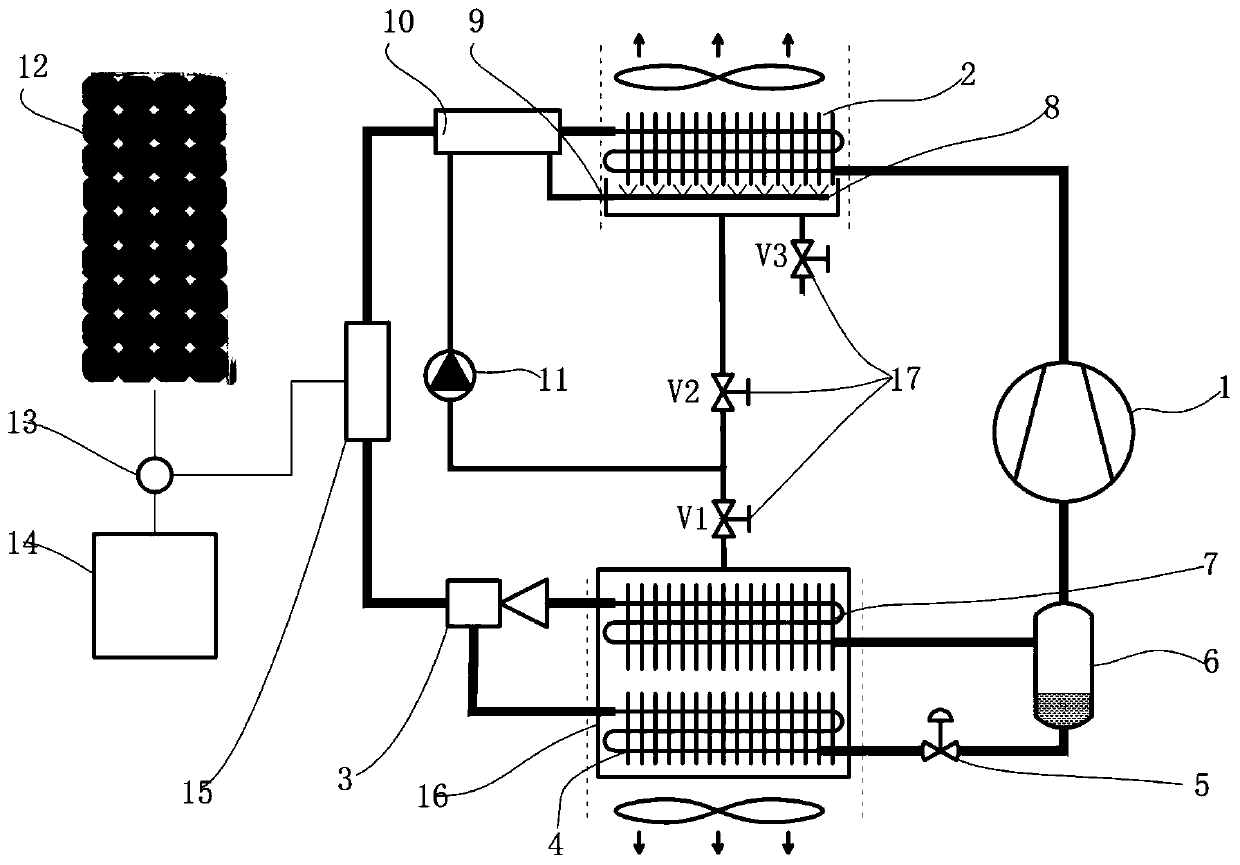

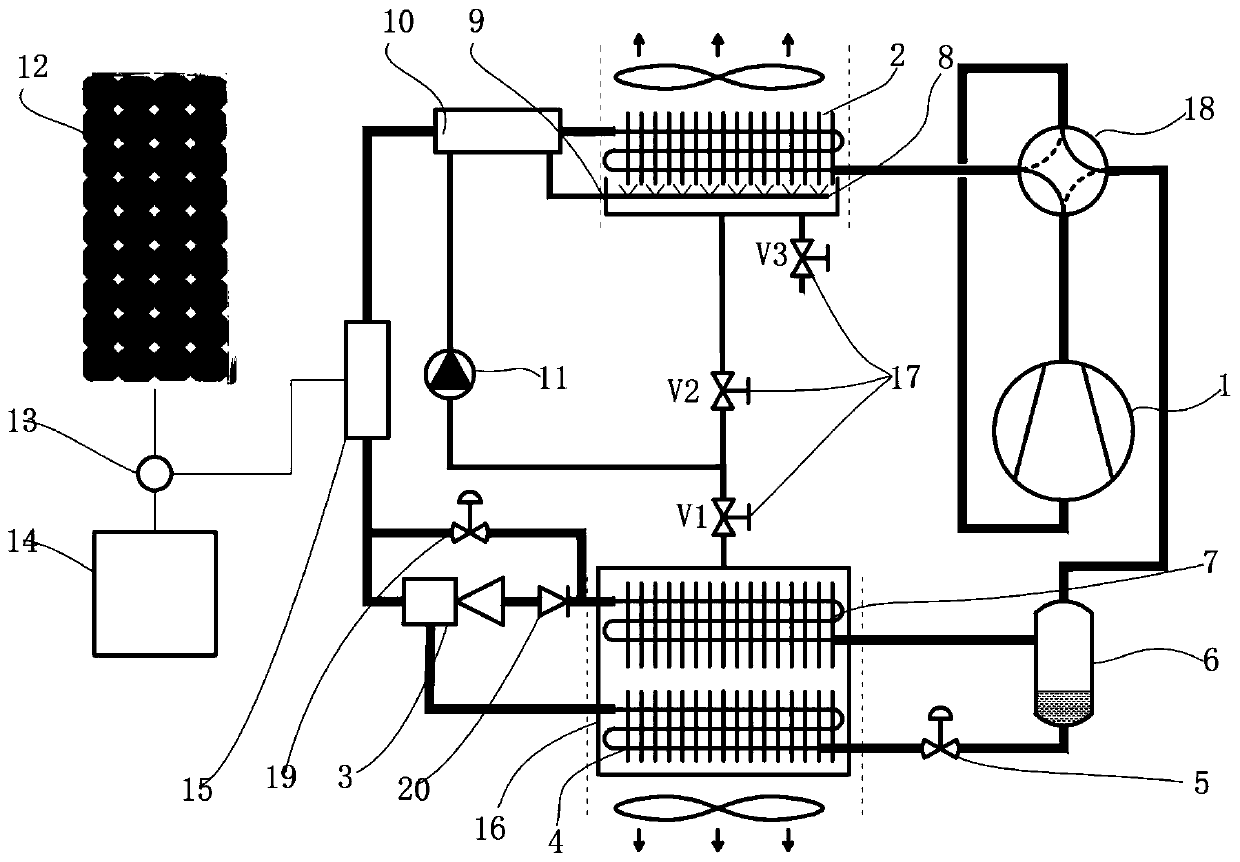

Temperature and humidify independent control air conditioning system with compactness and high performance

InactiveCN110410904AAvoid remix delivery problemsSimple structureMechanical apparatusBatteries circuit arrangementsVapor–liquid separatorEngineering

The invention belongs to the field of air conditioning and energy-saving related equipment, and discloses a temperature and humidify independent control air conditioning system with compactness and high performance. The system comprises a compressor, an outdoor unit condenser, a liquid-air sprayer, a cooling evaporator, an air-liquid separator, a throttling mechanism, a dehumidifying evaporator and the like, wherein the pressure energy of high-pressure refrigerant liquid is recovered through introduction of such modules as the sprayer, so that a refrigerating system can work at two different evaporation temperatures; specific connecting modes of key modules are further optimally designed to greatly simplify the whole structure correspondingly; an additional air-liquid separator is not needed, the air sucking pressure of the compressor is improved, and the energy consumption of the compressor is reduced, so that the system achieves higher circulating performance and reliability; and inaddition, such aspects as condensed water collection and utilization of the evaporator and solar photovoltaic driving are transformed and upgraded.

Owner:HUAZHONG UNIV OF SCI & TECH

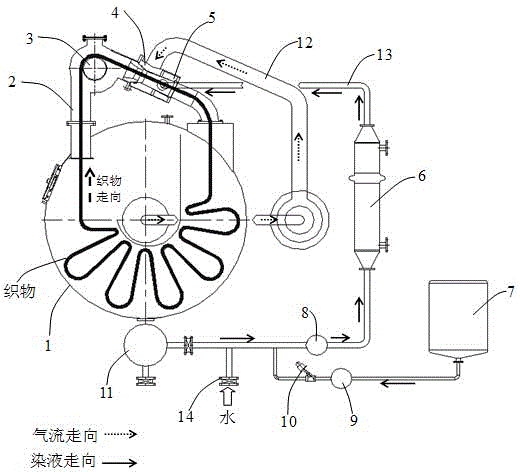

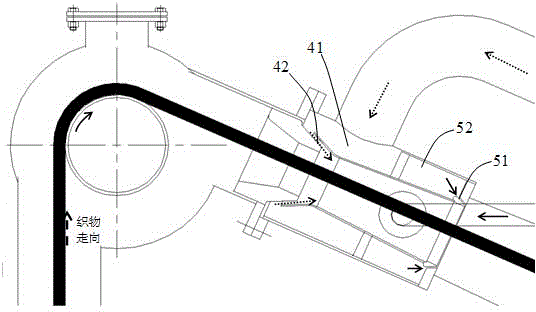

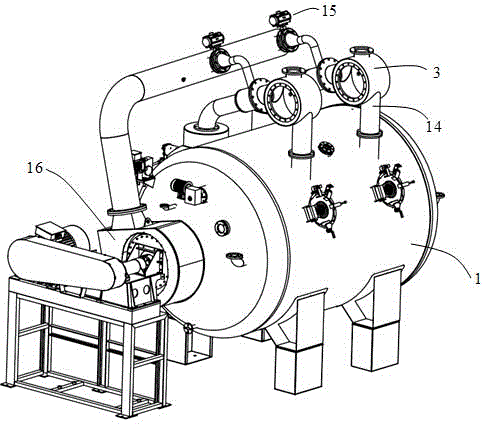

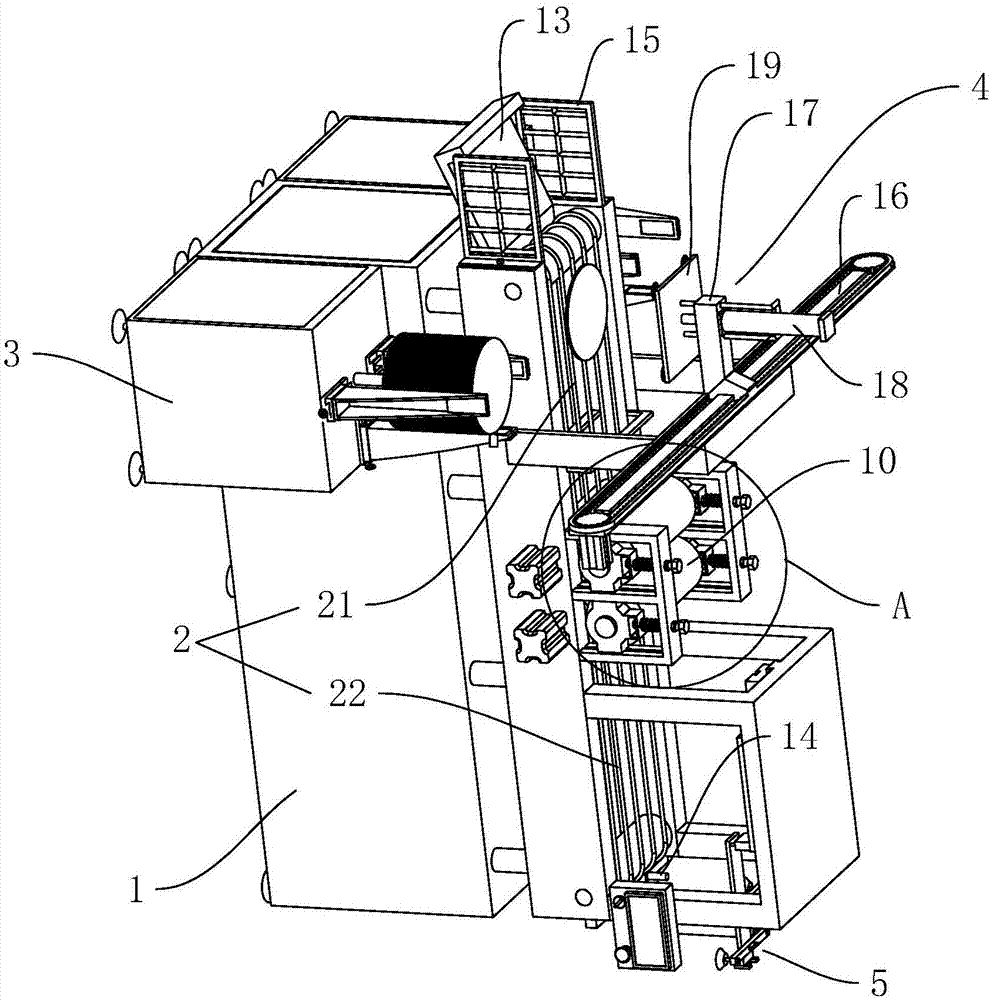

High-temperature high-pressure gas-liquid dyeing machine and control method thereof

ActiveCN104099734AReduce energy consumptionConvenient and fast independent controlTextile treatment machine arrangementsTextile treatment by spraying/projectingProcess engineeringMechanical engineering

The invention discloses a high-temperature high-pressure gas-liquid dyeing machine and a control method thereof. The high-temperature high-pressure gas-liquid dyeing machine comprises a main cylinder, a cloth lifting wheel, an airflow nozzle, a dyeing liquid nozzle, a heat exchanger, a main dyeing liquid pump and a fan component, and the airflow nozzle and the dyeing liquid nozzle are separated and can conveniently and quickly control parameters of airflow and dyeing liquid flow independently according to characteristics of to-be-dyed fabric. The airflow nozzle is positioned in front of the dyeing liquid nozzle, so that the wound fabric can be blown fluffily by high-pressure airflow, dyeing liquid spraying and penetrating is performed afterwards, using efficiency of dyeing liquid is improved greatly, leveling performance and dye yield rate of dyeing are improved, dyeing time is reduced, total consumption of auxiliaries and dye is lowered, and total COD quantity is lowered effectively. By the high-temperature high-pressure gas-liquid dyeing machine, more uniformity in dyeing can be realized, energy consumption of a gas-liquid split-flow dyeing machine is lowered, and the objectives of energy conservation and environment protection are achieved.

Owner:高勋绿色智能装备(广州)有限公司

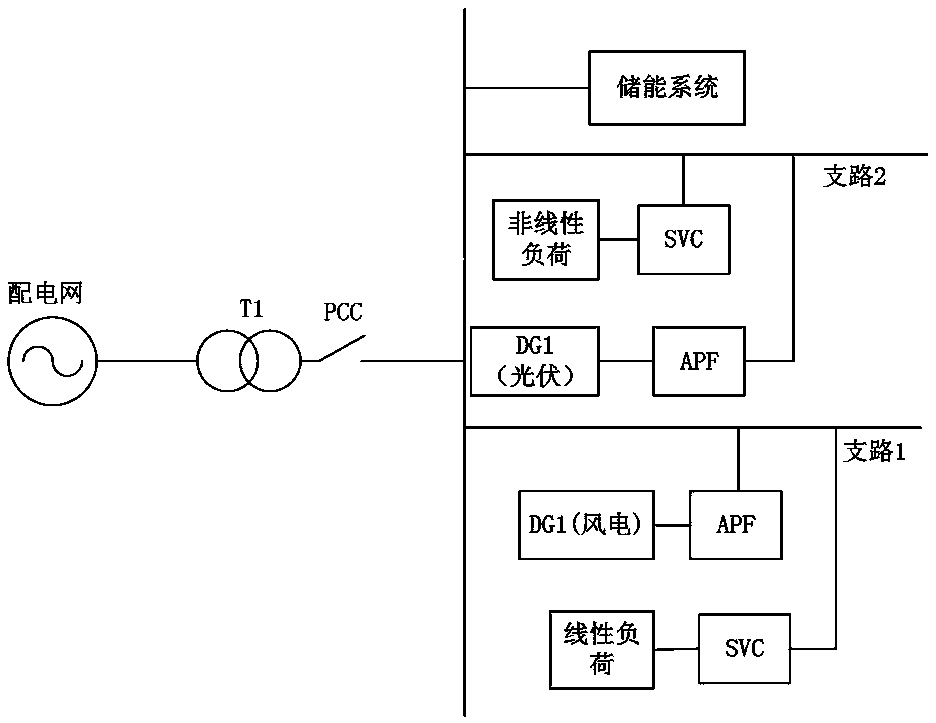

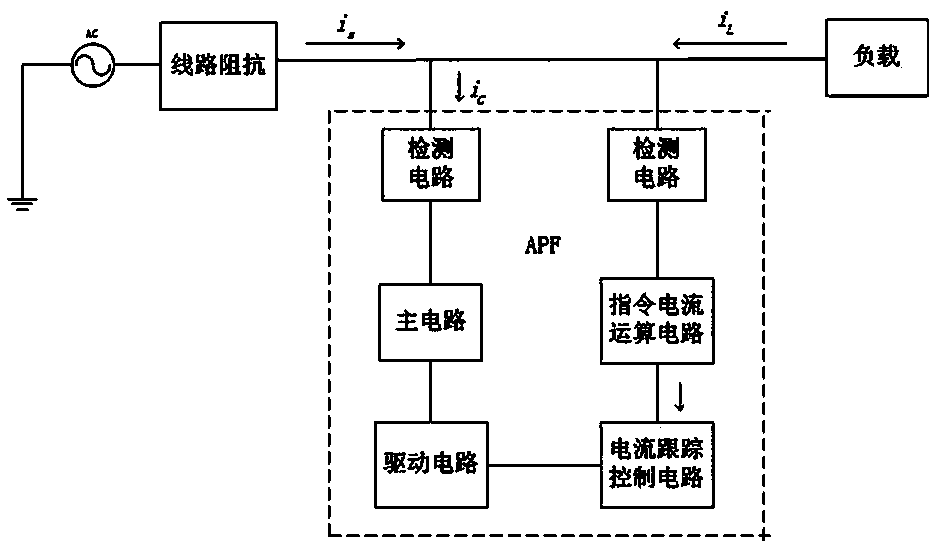

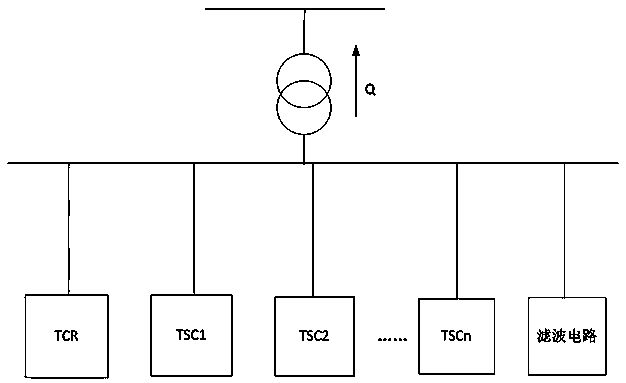

APFs and SVCs combined power quality control method based on micro-power grid energy storage system

InactiveCN108075491ARealize unionGood effectFlexible AC transmissionActive power filteringBusbarPower Balance

The invention relates to an APFs and SVCs combined power quality control method based on a micro-power grid energy storage system. A micro-power grid busbar is connected with an energy storage system,loads, SVCs and a distributed power supply device; the energy storage system is composed of a PCS and an energy storage battery, and the energy storage battery achieves energy exchange with the micro-power grid through the PCS and outputs a proper amount of active power and reactive power to ensure the power balance of the micro-power grid from the system level, so that the system voltage and frequency are maintained relatively stable; the PCS is connected to the micro-power grid busbar; the loads include the linear load and the non-linear load, and both loads are connected to two branches through the corresponding SVCs respectively; the distributed power supply device includes a solar photovoltaic plate and a wind power generation device, and the solar photovoltaic plate and the wind power generation device are connected to two branches through corresponding parallel-type APFs respectively. Through overall coordinated use of the energy storage system, the APFs and the SVCs, the battery energy storage system not only can effectively maintain the power balance of the micro-power grid, but also can improve the power quality of the micro-power grid, and the stable operation of the system in various states is achieved.

Owner:JIANGSU FRONT NEW ENERGY +1

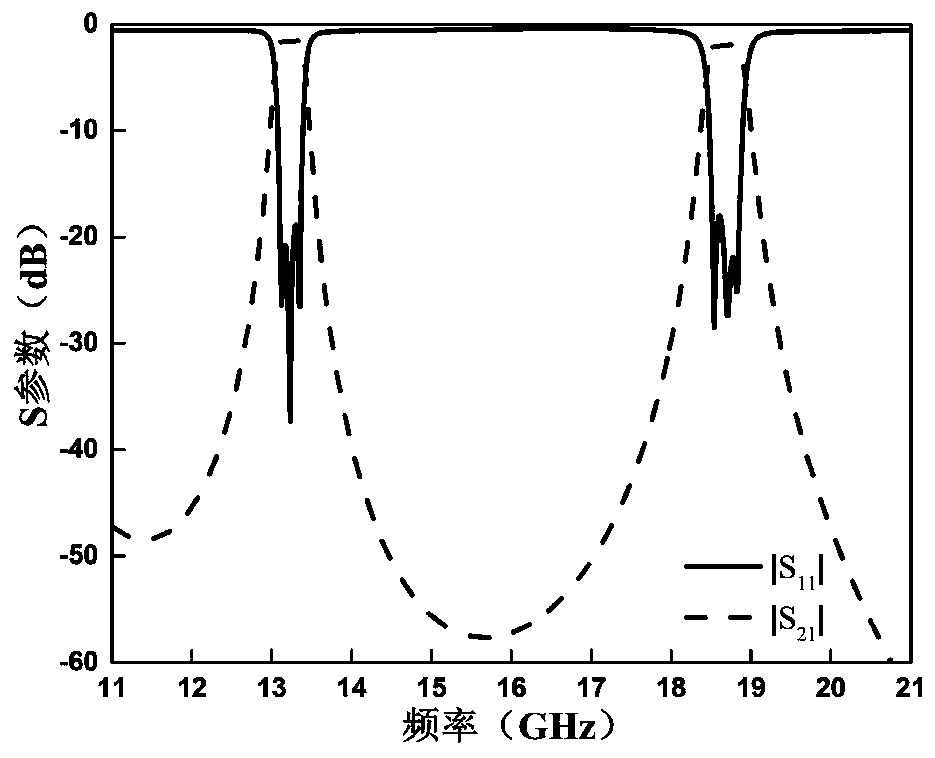

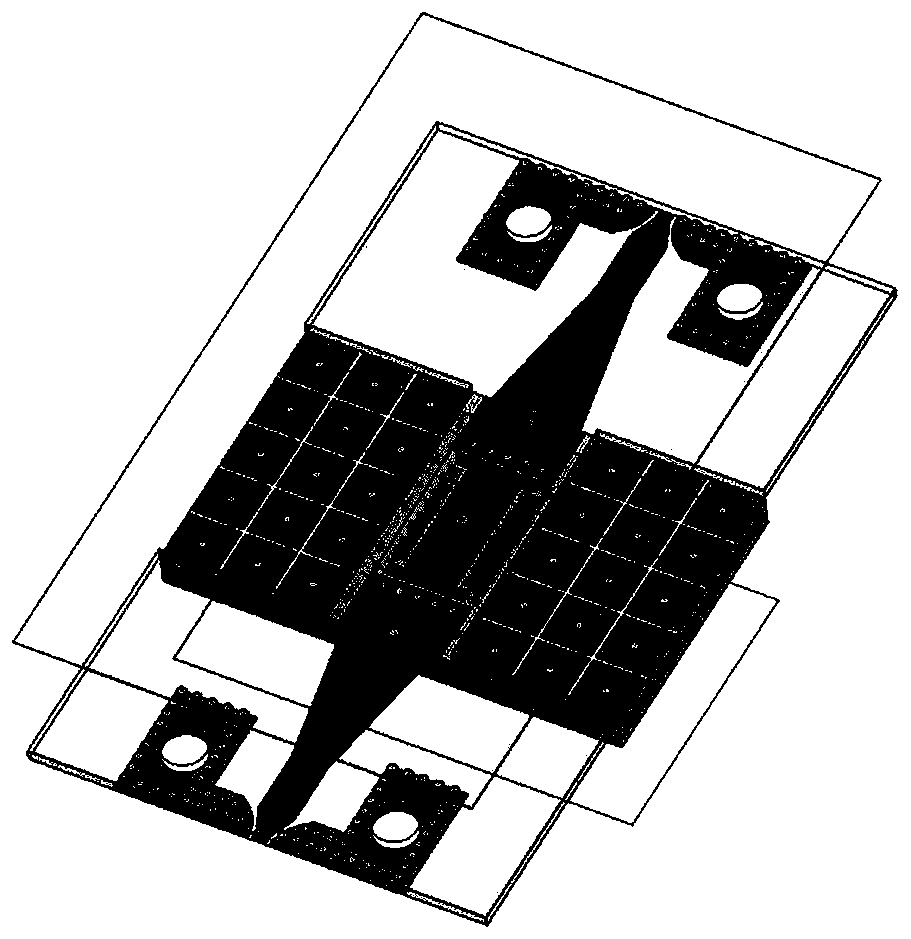

Double-frequency three-order band-pass filter based on microstrip ridge gap waveguide

ActiveCN111244587AEasy to control independentlyCompact sizeResonatorsFrequency bandCoplanar waveguide

The invention belongs to the technical field of microwave devices, and discloses a double-frequency three-order band-pass filter based on microstrip ridge gap waveguides. A metal floor is arranged onthe upper surface of an upper dielectric plate, metalized via holes are embedded in the two sides and the middle of the dielectric plate respectively, and a grounded coplanar waveguide-microstrip gapwaveguide transition structure is loaded on the lower surface of the dielectric plate. A metal ridge is loaded on the upper surface of the lower dielectric plate, mushroom-shaped EBG structures are loaded at the two sides of the metal ridge, and a metal floor is arranged on the lower surface of the lower dielectric plate. Three microstrip ridge gap waveguide dual-mode resonators are embedded in the metal ridge, and two sections of metal ridges are loaded between the microstrip ridge gap waveguide dual-mode resonators on the upper surface of the lower dielectric plate and are of a coupling structure. According to the invention, the double-frequency three-order band-pass filter is realized, the double-frequency filter is compact in structure, and the frequencies of the two passbands are easyto control independently. The double-frequency band-pass filter based on the microstrip ridge gap waveguide is realized for the first time, so that the application of the microstrip ridge gap waveguide is wider.

Owner:XIDIAN UNIV

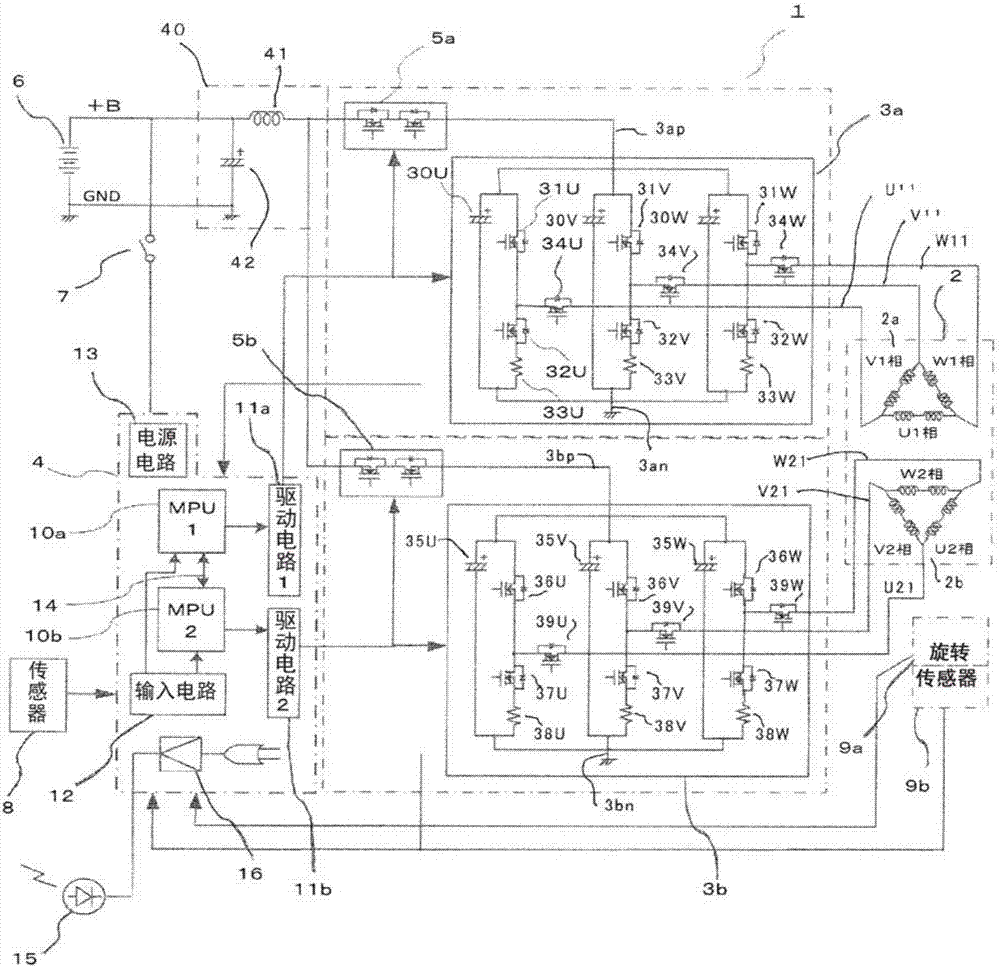

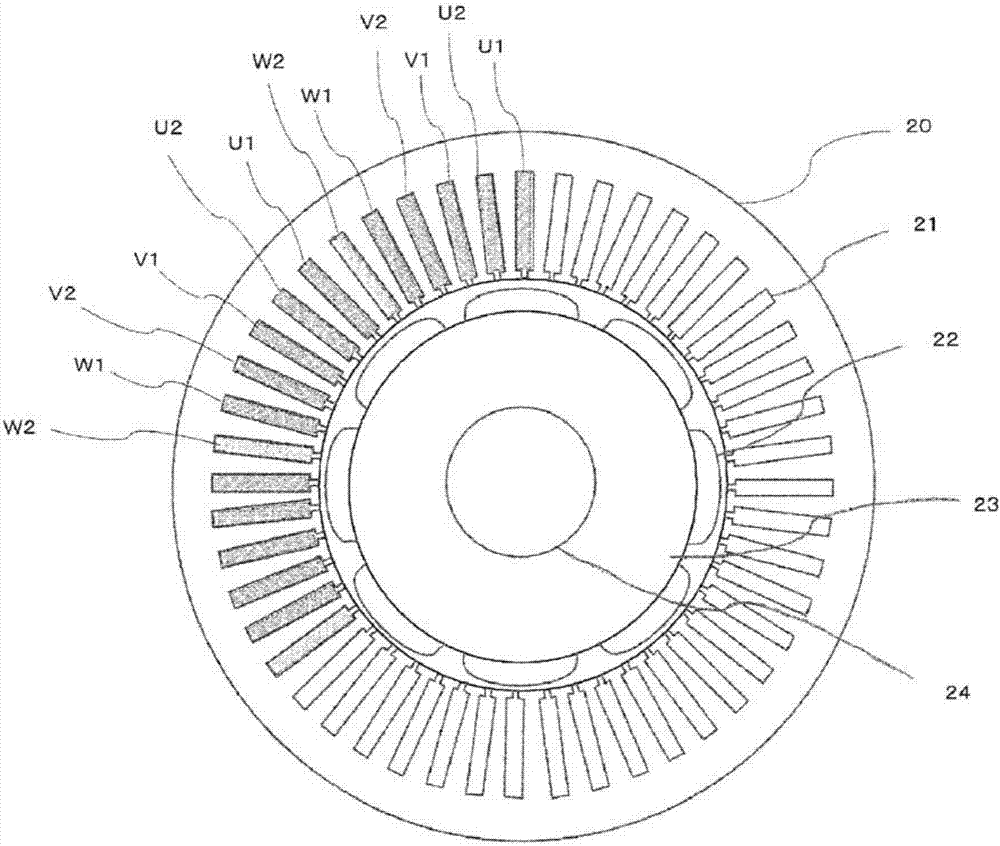

Electric drive device, and electric power steering device

ActiveCN107343389AEasy to control independentlyAC motor controlElectric motor controlElectric power steeringControl signal

The present invention is configured from an electric motor (2), and a control unit (1) for driving the motor. The motor (2) has, provided to a single rotor (23), a stator (20) provided with two independent coil winding groups. The control unit (1) is mainly configured from: an input circuit (12) for inputting various pieces of information; output circuits for driving the coil winding groups of the motor (2); and MPUs (10a, 10b) which calculate control quantities on the basis of the information from the input circuit (12), and output control signals to the output circuits. The MPUs are provided as two separate independent units, and are configured so as to be capable of supplying and turning off currents to the respective winding groups of the motor. The MPUs are respectively provided with integrated CPUs (10c, 10d), and trigger circuits (17) which use prescribed periods as trigger signals. Both of the CPUs are configured so as to synchronize and output at least control commands in accordance with the trigger signals.

Owner:MITSUBISHI ELECTRIC CORP

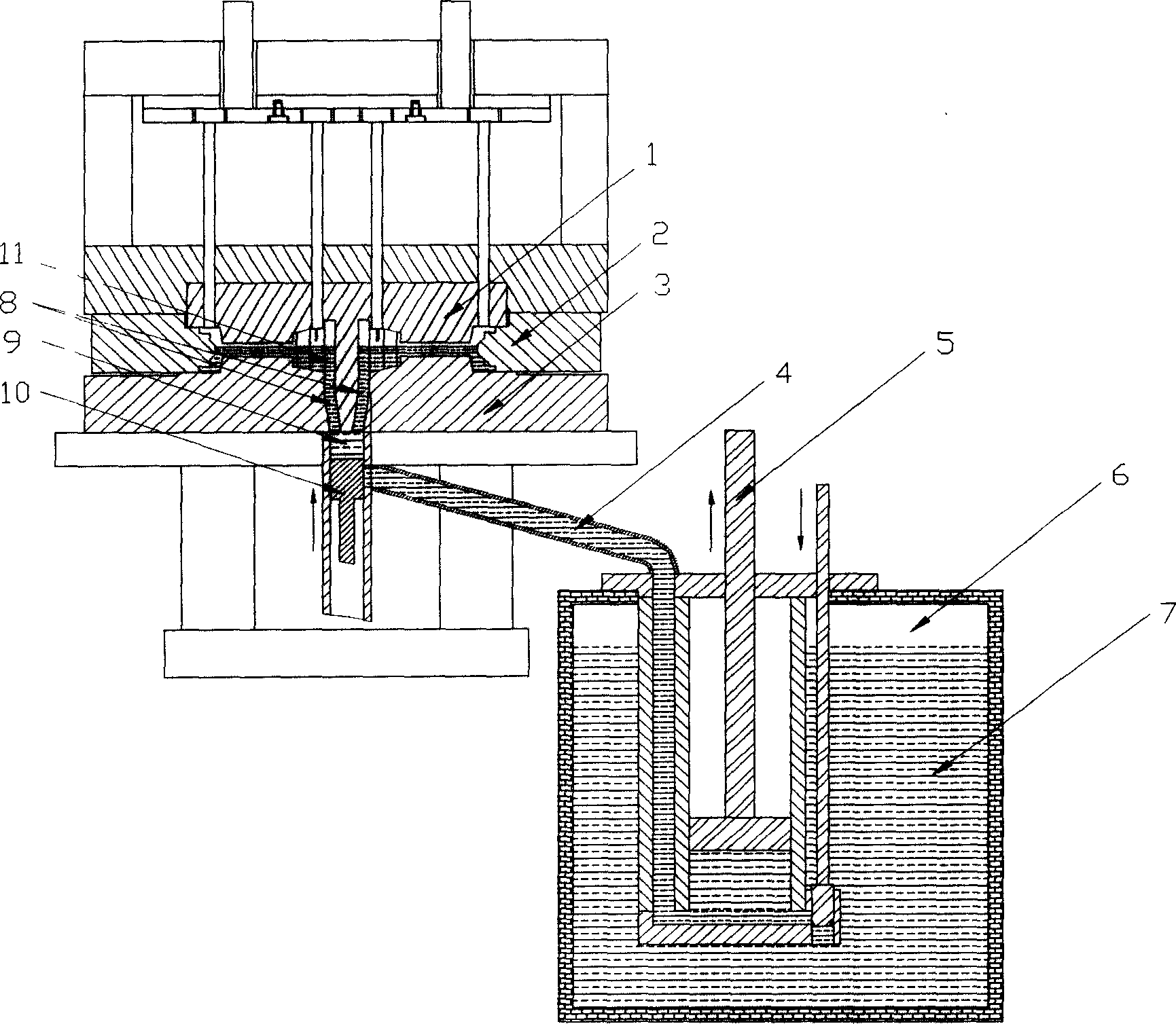

Indirect extrusion casting process

The indirect extrusion and casting method is used in producing non-ferrous alloy casting. It is realized through low pressure filling of alloy melt via casting pipes, and extrusion with extruding head to make alloy melt solidify and crystallize under certain pressure to form extruded non-ferrous alloy casting in high yield.

Owner:龙思远

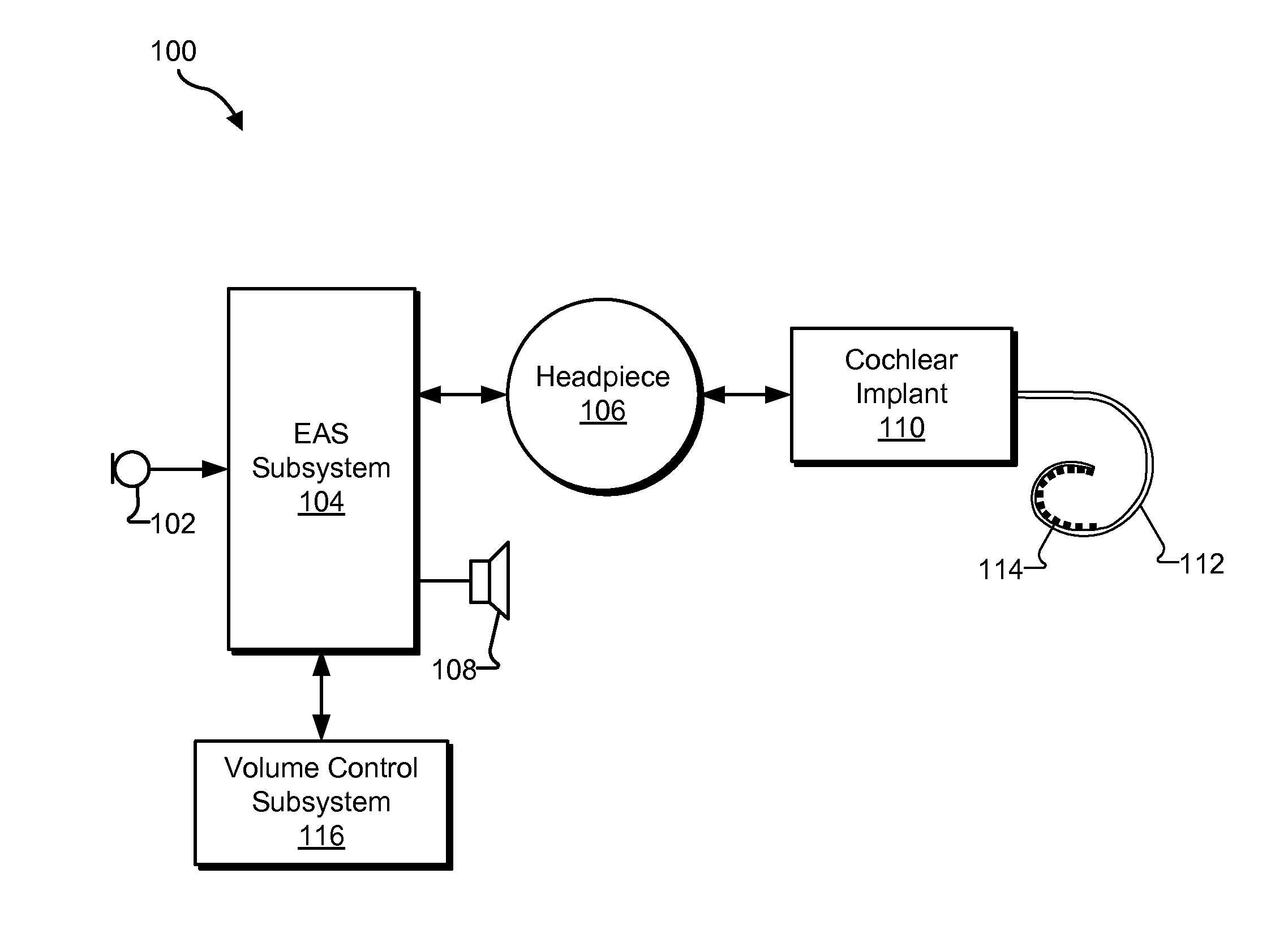

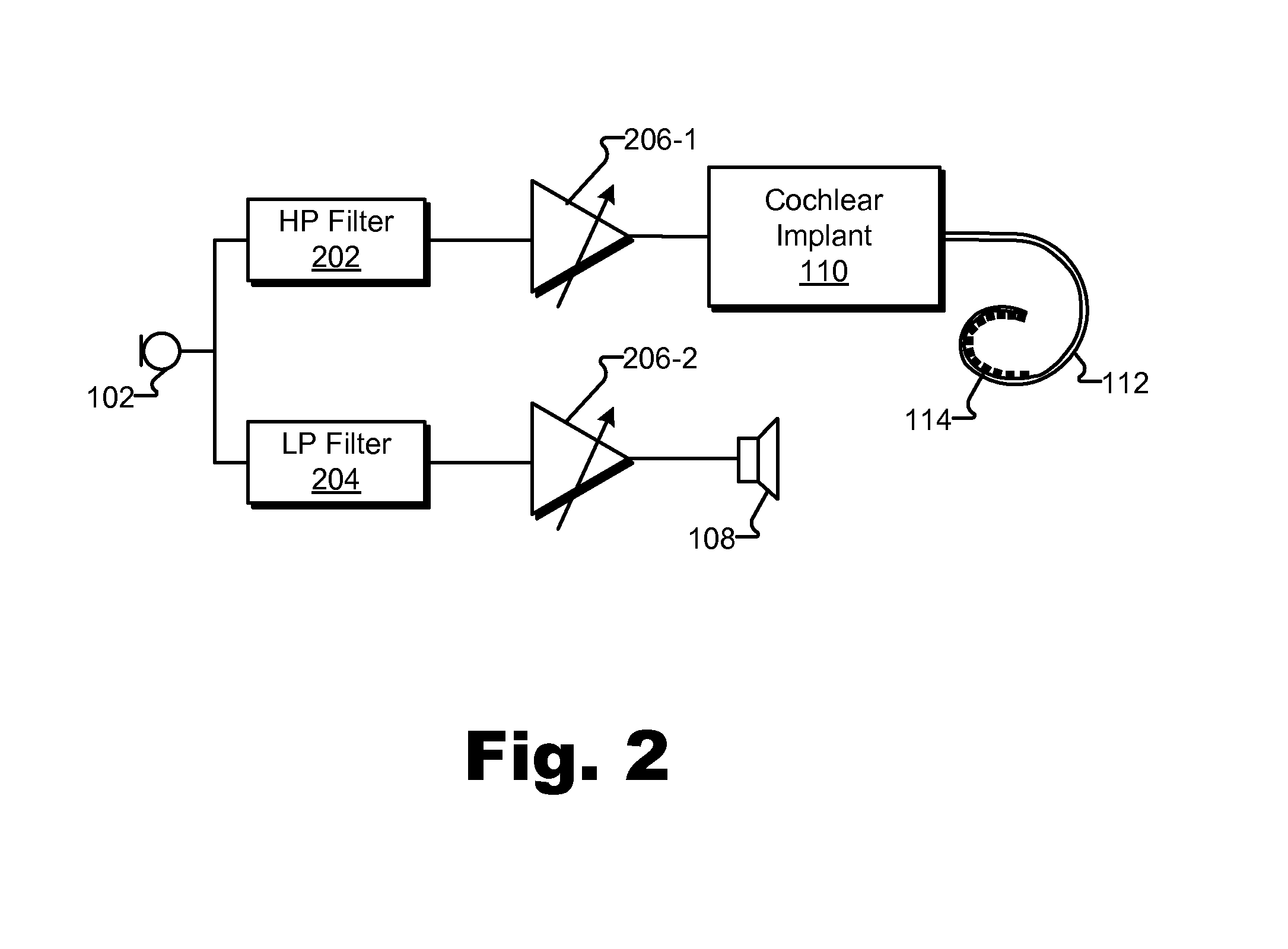

Independent Volume Control in Electro-Acoustic Stimulation Systems

InactiveUS20130345767A1Easy to control independentlyElectrotherapySignal processingElectrical stimulationsAudio frequency

An exemplary system includes an electro-acoustic stimulation (EAS) subsystem and a volume control subsystem communicatively coupled to the EAS subsystem. The EAS subsystem is configured to direct a cochlear implant to apply electrical stimulation representative of audio content included in a first frequency band to a patient and to direct a receiver to apply acoustic stimulation representative of audio content included in a second frequency band to the patient. The volume control subsystem is configured to facilitate independent control of a volume associated with the electrical stimulation and a volume associated with the acoustic stimulation. Corresponding systems, devices, and methods are also disclosed.

Owner:ADVANCED BIONICS AG

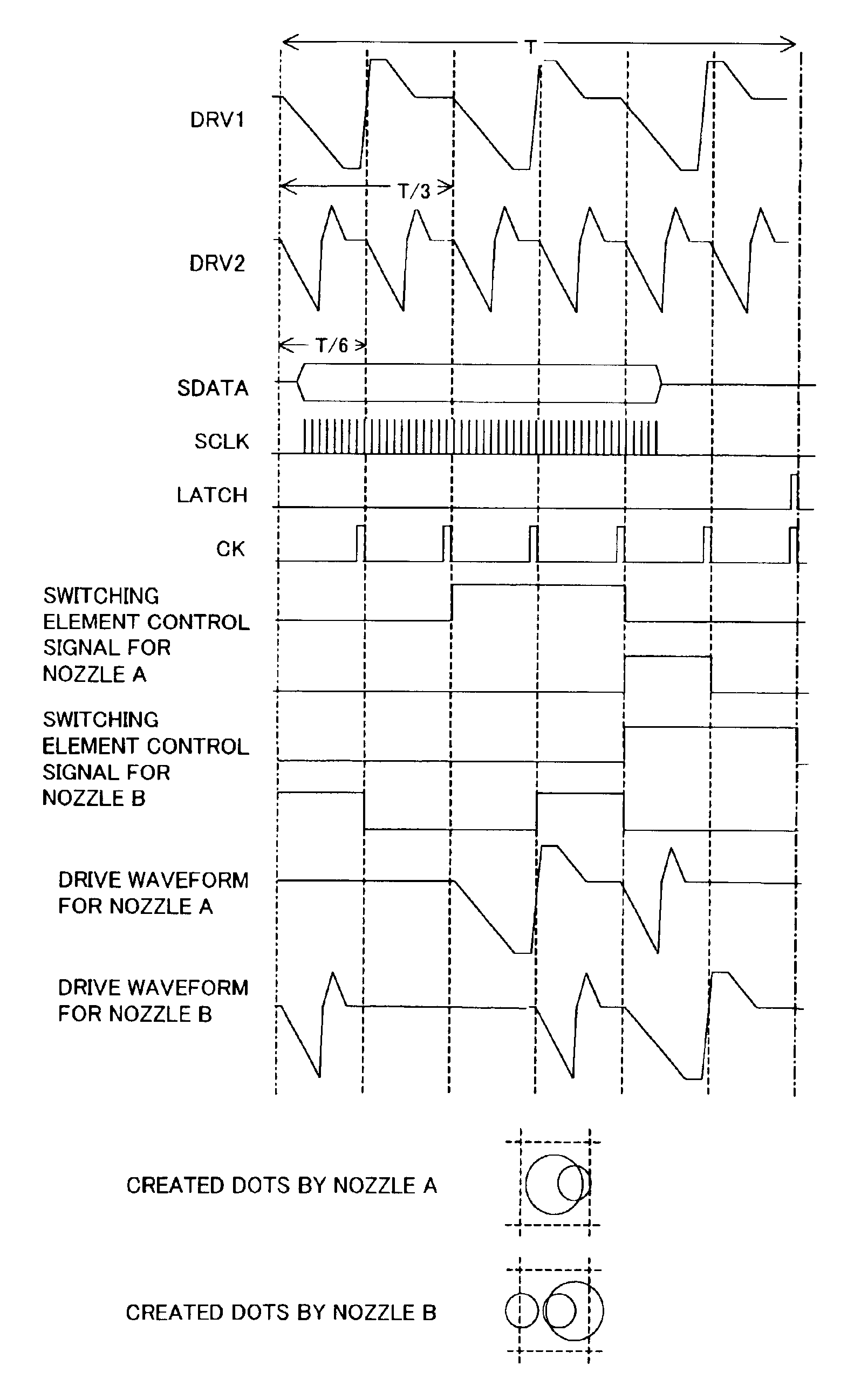

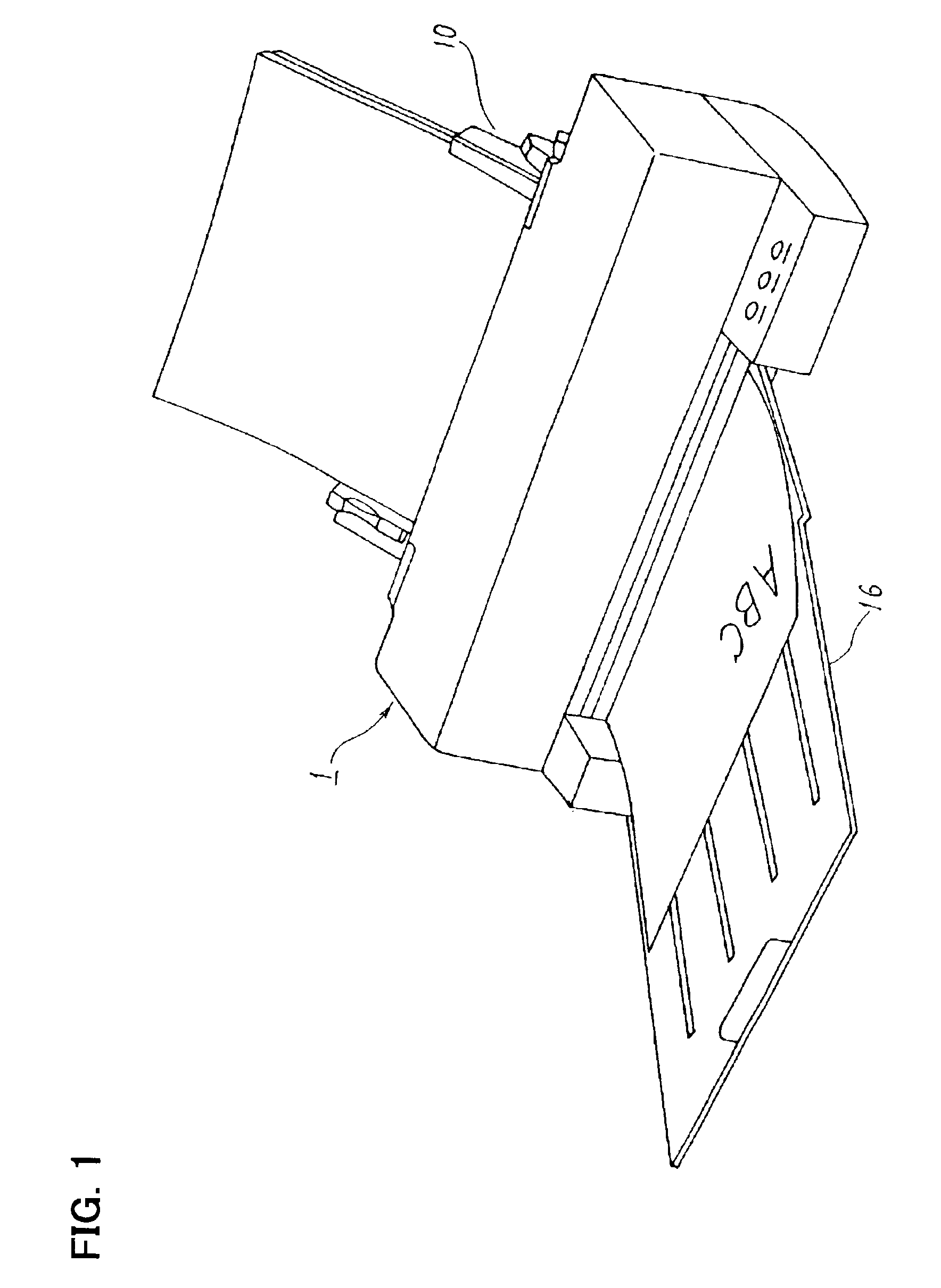

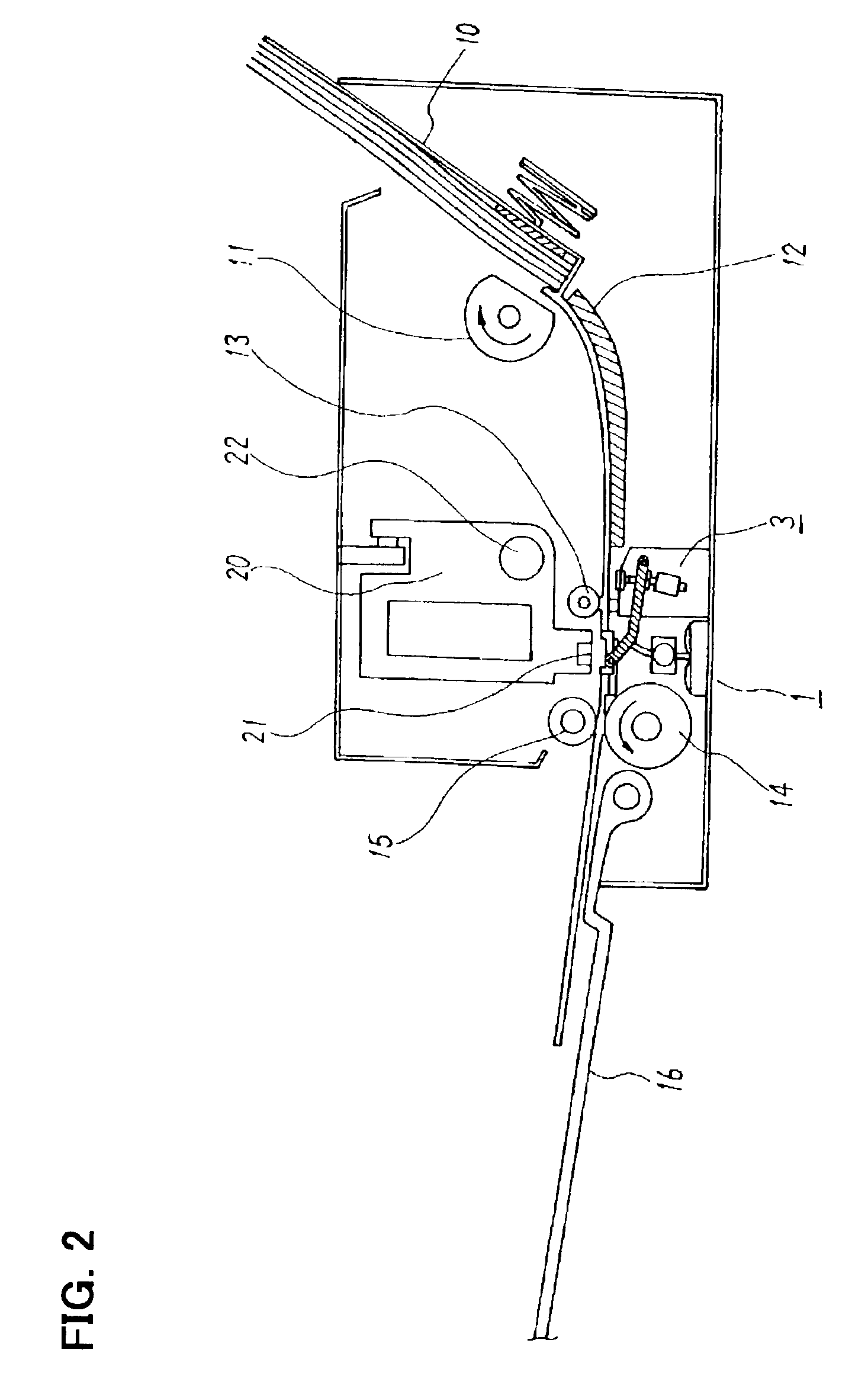

On-demand inkjet printer and drive method and drive circuit for same

In an inkjet head, both tones and smoothing can be represented suitably through use of a small number of drive waveforms. A drive waveform generator unit (46) generates drive waveforms for emitting a ink particle to form dots of a same size within one cycle that is an integral fraction of the cycle for one pixel, a print data generator unit (42) generates print data of a plurality of bits for selecting said drive waveform in said cycle for one pixel, and a head drive unit (47) drives the nozzles of said head by selecting said drive waveform in accordance with said print data. Thereby, tones and smoothing can be represented suitably, through use of a small number of different waveforms.

Owner:FUJIFILM HLDG CORP

Method for forming foam products and system thereof

InactiveCN102173056AAt the same time of pressure, the resistance of the feeding screw is lowRelieve pressurePolymer scienceFoaming agent

The invention discloses a method for injecting single-phase solution in a mold to form foam products, which comprises the steps of foaming agent introducing, buffering in feed liquid conveying and single-phase solution obtaining. The method for forming foam products comprises the steps of: in a polymer processing system, conveying polymer material to a mold cavity with an inlet from the upper stream of a polymer processing space through a selectable path, wherein the inlet of the mold cavity is connected with a tail end outlet in lower stream direction; introducting the foaming agent that is gaseous in environment condition into the polymer material; and forming the foam products with the polymer material. The system for forming foam products consists of a processing device with a screw rod, at least two material storage cylinders, at least one discharge cylinder, and at least one mold cavity with an inlet, wherein the inlet of the mold cavity is connected with the corresponding tail end outlet of the discharge cylinder. The invention has the advantages of being capable of keeping the single-phase solution at high pressure continuously and not influencing the introducing of the foaming agent; in addition, resistance of a feeding screw rod is small and for the bearing pressure of the cylinder is small.

Owner:UNION PLASTIC HANGZHOU MACHINERY

Double-station feeding device and oil press with same

ActiveCN107244094AHigh degree of automationAvoid safety accidentsMetal-working feeding devicesPositioning devicesEngineeringFuselage

The invention discloses a double-station feeding device and an oil press with the same. The double-station feeding device is technically characterized in that the double-station feeding device comprises a machine base; a conveying mechanism is arranged on the machine seat in the length direction; a loading mechanism for loading workpieces to be machined is arranged at the front end of the machine base; a material fetching robot is arranged at the front end of the machine base and used for grabbing the workpieces in the loading mechanism to the conveying mechanism to be conveyed; a feeding robot is arranged at the rear end of the machine base and used for grabbing the workpieces at the tail end of the conveying mechanism to the next procedure; and the loading mechanism comprises a machine body arranged at the front end of the machine base, and at least two baffles vertically arranged on the upper end face of the machine body, the baffles form a feeding station matched with the workpieces, and the feeding station is provided with a lifting assembly which is used for guaranteeing the effect that the workpieces on the uppermost layer are located at the same height all the time. According to the double-station feeding device and the oil press with the same, the automation degree can be improved, and the labor cost is reduced.

Owner:浙江佶福智能科技有限公司

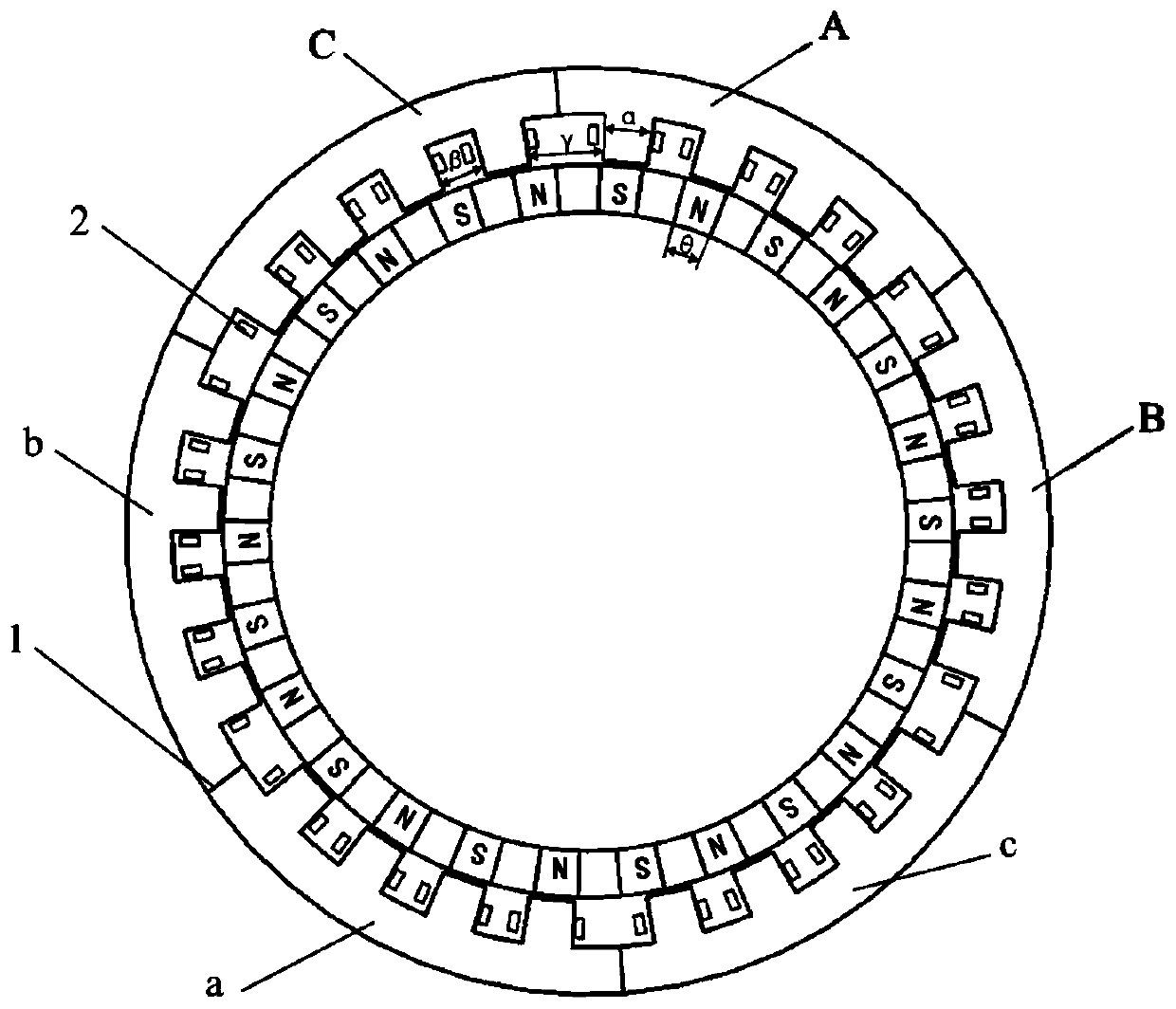

Stator and rotating linear two-degree-of-freedom permanent magnet motor with modular structure

ActiveCN111082551AImprove the winding factorReduced end windingMagnetic circuit rotating partsElectric machinesLinear motionElectric machine

The invention provides a stator and a rotating linear two-degree-of-freedom permanent magnet motor with a modular structure. The rotating linear two-degree-of-freedom permanent magnet motor with the modular structure comprises a stator and a rotor, and the stator comprises a stator core, a rotating motion winding and a linear motion winding; the stator iron core is formed by a plurality of same modular iron core units in a three-phase mode on the circumference. Stator grooves are formed in the axial direction and the circumferential direction of an inner surface of the stator iron core at thesame time, so that stator teeth are distributed in an array mode and evenly distributed on all the modular iron core units. The rotating motion winding is wound on stator teeth which are axially arranged along an inner surface of the stator core along the linear motion direction to form a phase group centralized winding for driving rotary motion; and the linear motion winding is wound on the stator teeth arranged along the circumferential direction of the inner surface of the stator iron core along the circumferential direction to form a phase group centralized winding for driving linear motion. The structure is simple, the manufacturing is easy, and the material utilization rate is increased.

Owner:SHANDONG UNIV

Novel semi-continuous high-speed spinning machine

ActiveCN103409825AEasy to operateControllableArtificial thread manufacturing machinesWet spinning methodsEngineeringSpin speed

The invention relates to a novel semi-continuous high-speed spinning machine which comprises a rack, a glue supply device, a filament strip forming device, a spinning device and a winding device. The spinning device comprises a spinning roller which is transversely arranged relative to the operating surface of a spinning face, and the two ends of the spinning roller are fixed on the rack. The novel semi-continuous high-speed spinning machine improves spinning speed, ensures that filament strips are sufficiently reacted, and then achieves the purposes of ensuring the quality of the filament strips, improving production efficiency and reducing spinning cost.

Owner:YIBIN HIEST FIBER +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com