Stator and rotating linear two-degree-of-freedom permanent magnet motor with modular structure

A permanent magnet motor, modular technology, applied in the shape/pattern/structure of magnetic circuit, shape/pattern/structure of winding conductor, magnetic circuit, etc., can solve the problem of complex structure of auxiliary transmission, low torque/thrust density, Problems such as limited linear motion stroke, to achieve the effect of modular structure design, high torque density, and easy independent control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

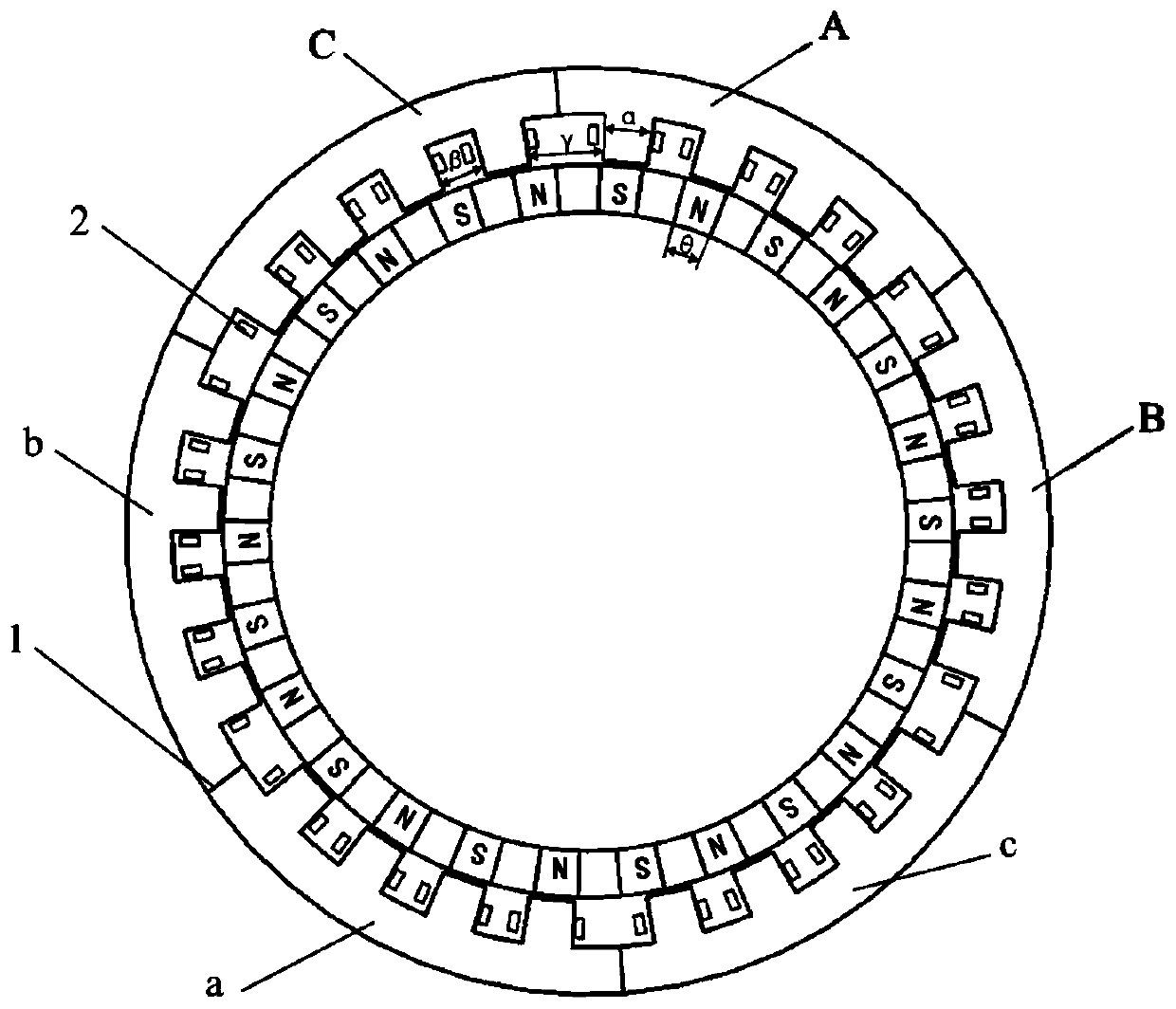

[0053] A stator in this embodiment includes a stator core, a rotating winding and a linear winding;

[0054] The stator core is composed of several identical modular core units in a three-phase form on the circumference;

[0055] Stator slots are simultaneously opened along the axial and circumferential directions of the inner surface of the stator core, so that the stator teeth are distributed in an array and evenly distributed on each modular core unit;

[0056] The rotary motion winding is wound on the stator teeth arranged axially along the inner surface of the stator core along the direction of linear motion to form a phase-group centralized winding that drives the rotary motion; the linear motion winding is wound along the circumferential direction along the inner surface of the stator core. On the stator teeth arranged in the circumferential direction on the surface, a phase-group concentrated winding for driving linear motion is formed.

[0057] Such as image 3 As s...

Embodiment 2

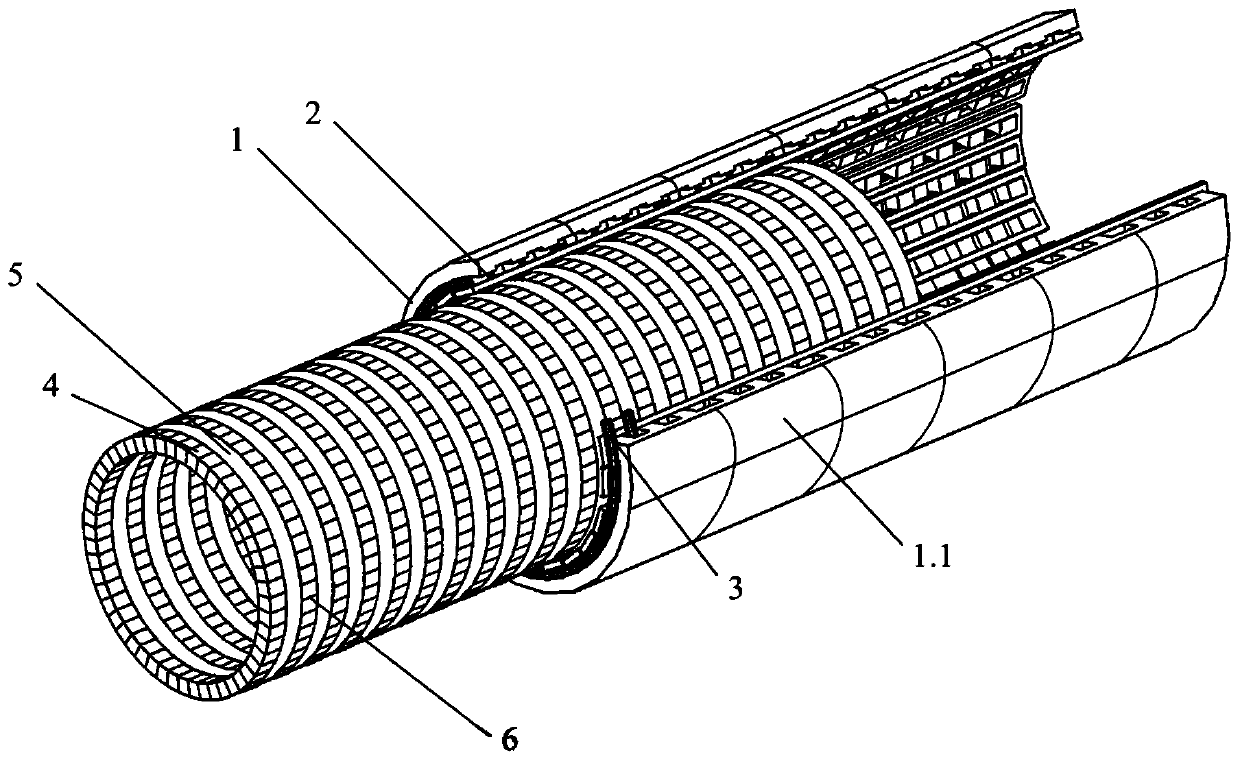

[0061] Such as figure 1 As shown, a rotary linear two-degree-of-freedom permanent magnet motor of a modular structure in this embodiment includes:

[0062] The stator as described in Embodiment 1;

[0063] Mover.

[0064] In specific implementation, the iron core parts of the stator and the mover can be die-cast with SMC soft magnetic material, and the iron core loss is small.

[0065] For example: the stator includes a stator core 1, a rotary motion winding 2, and a linear motion winding 3. Both the rotary motion winding and the linear motion winding adopt a phase group centralized winding; the stator core 1 is composed of 36 stator core module units 1.1. The stator core module unit 1.1 is as Figure 5 shown.

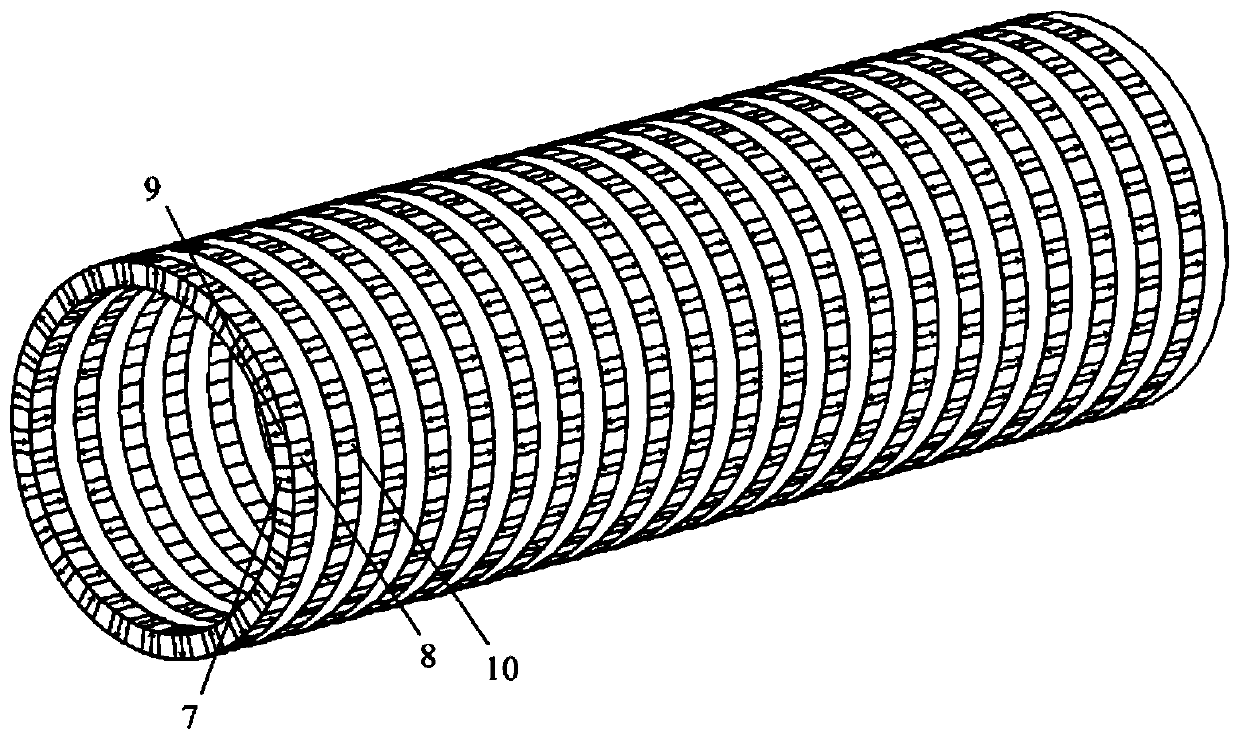

[0066] Such as Figure 4 As shown, the first permanent magnet block ring 4, the mover iron yoke ring 5 and the second permanent magnet block ring 6 on the mover are assembled alternately in the axial direction, through the magnetization effect of the spoke structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com