Patents

Literature

36results about How to "Improve the winding factor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Brushless double-feedback motor of winding rotor

InactiveCN102412684AIncrease profitFlexible adjustmentAsynchronous induction motorsWindings conductor shape/form/constructionPhysicsWinding factor

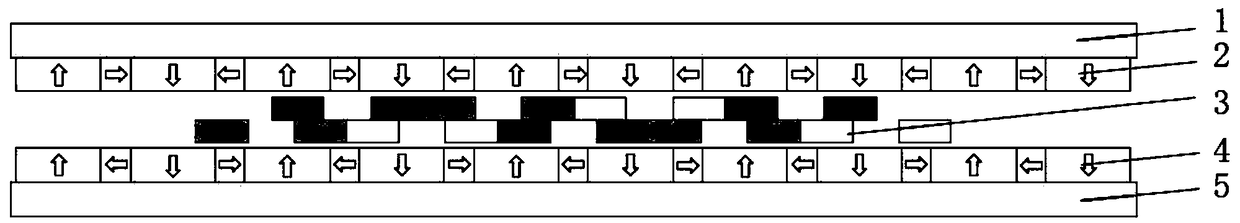

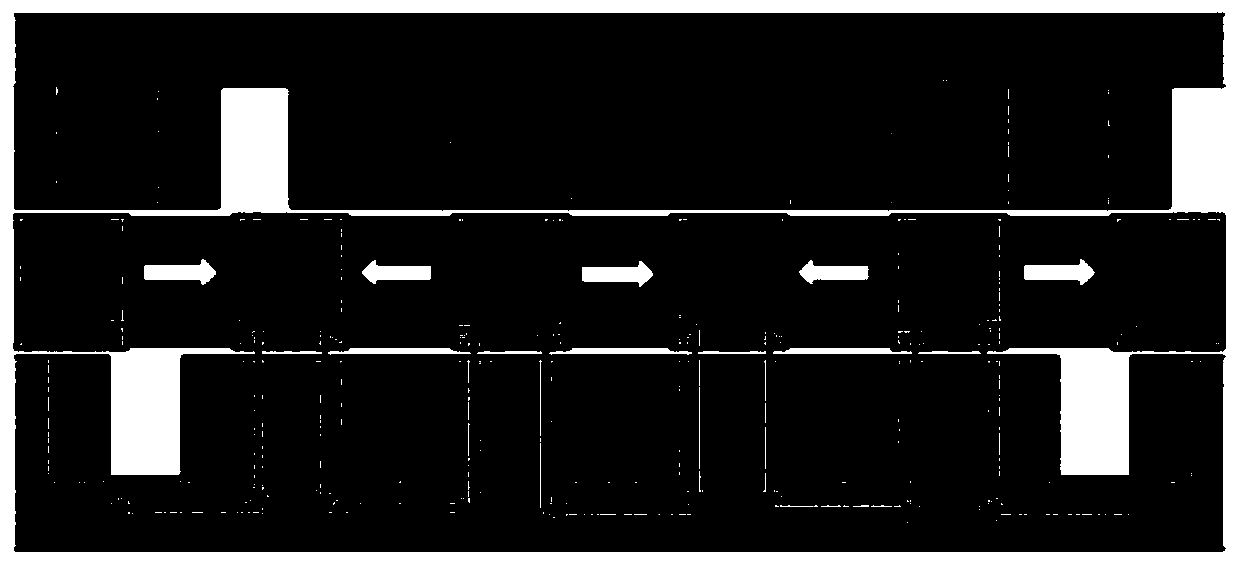

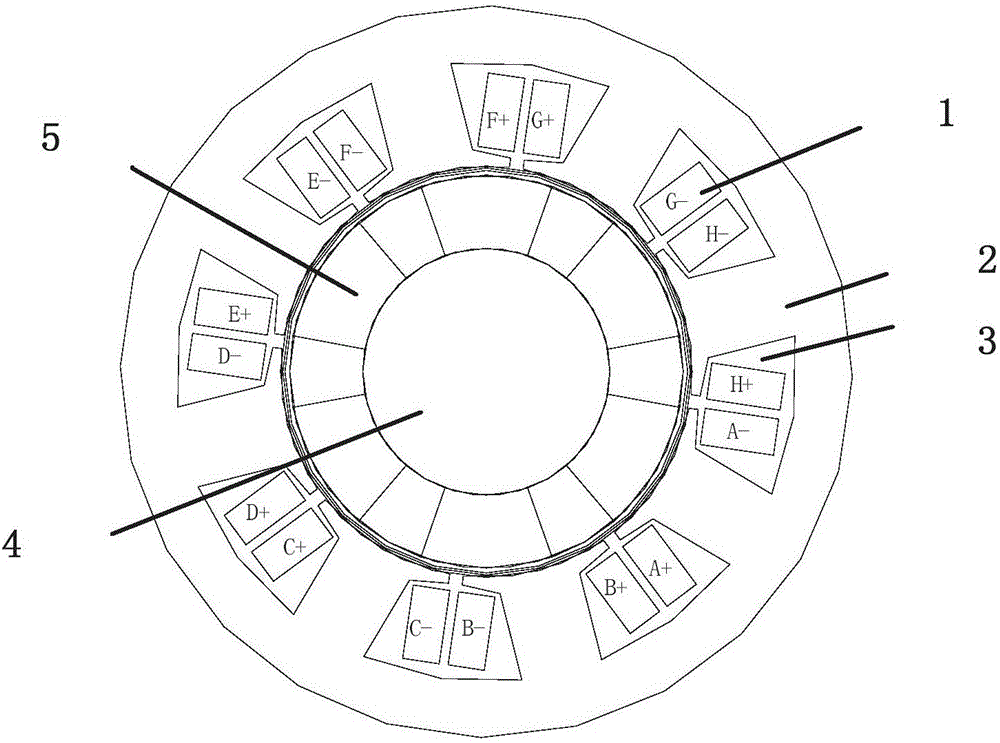

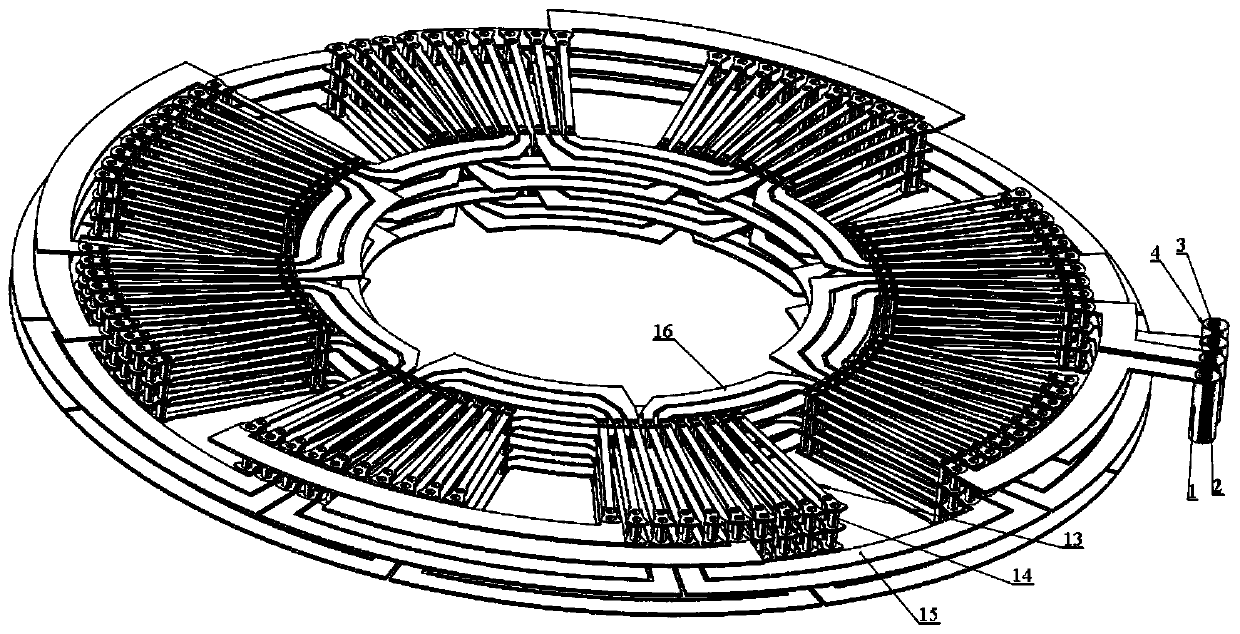

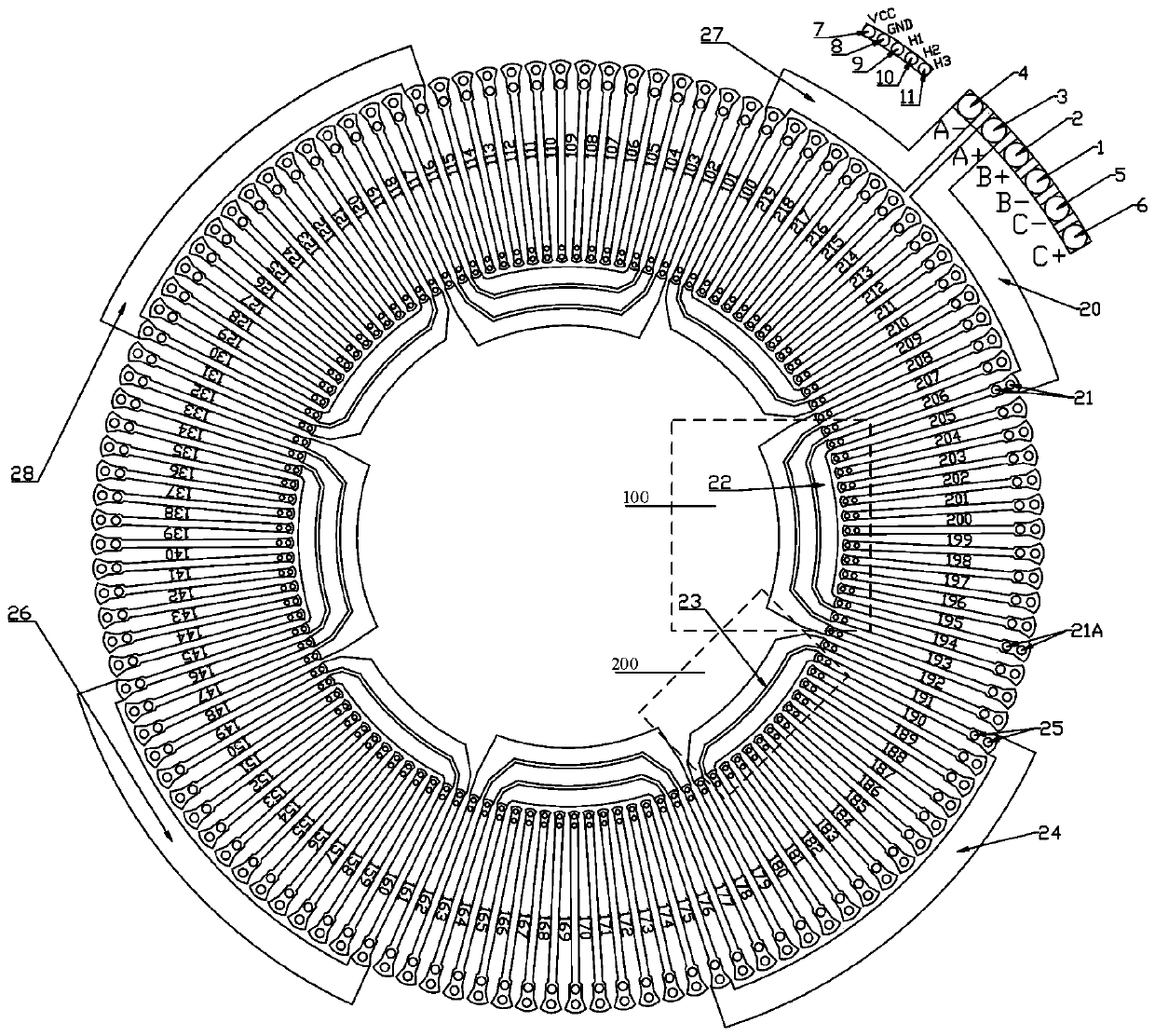

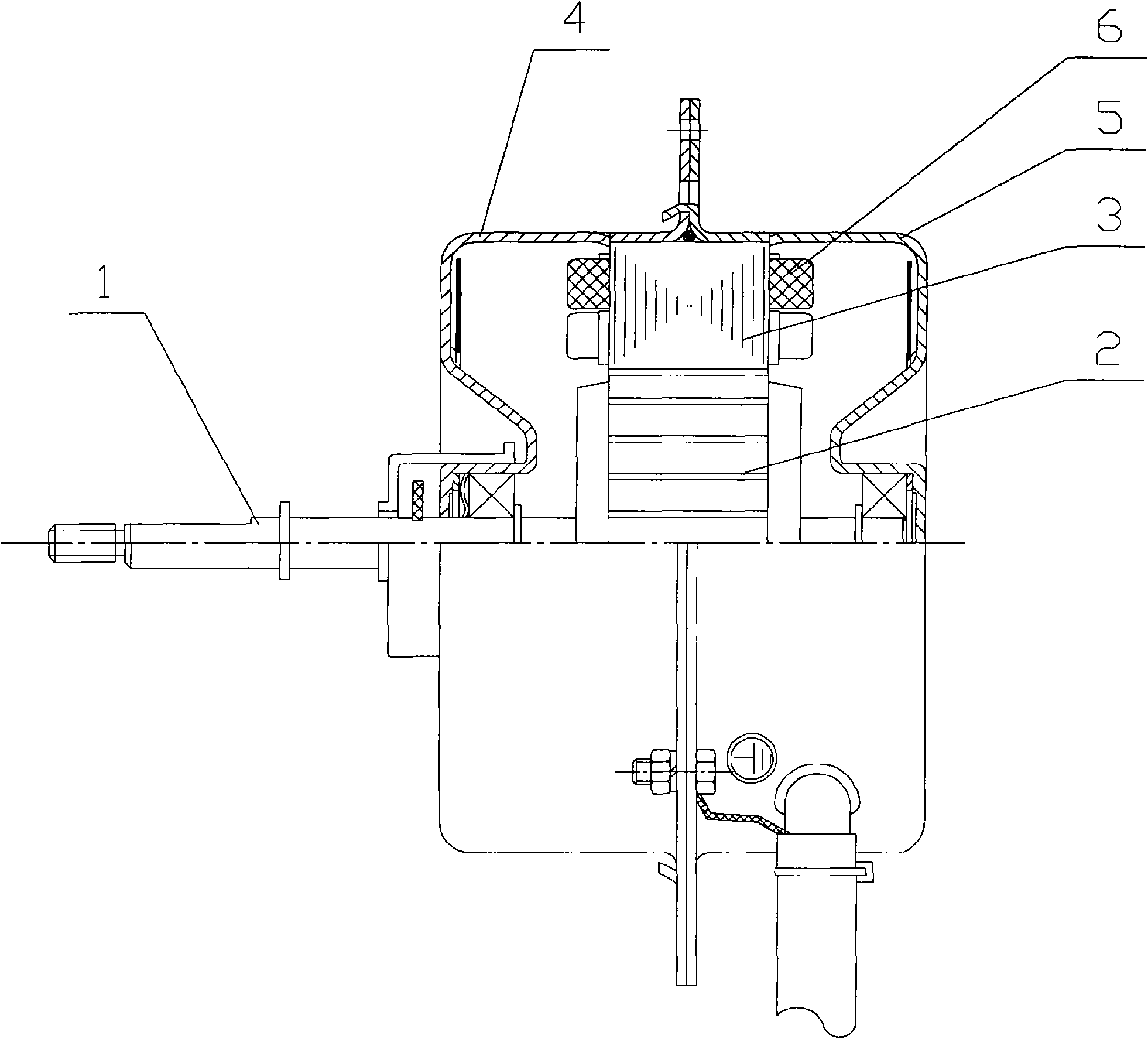

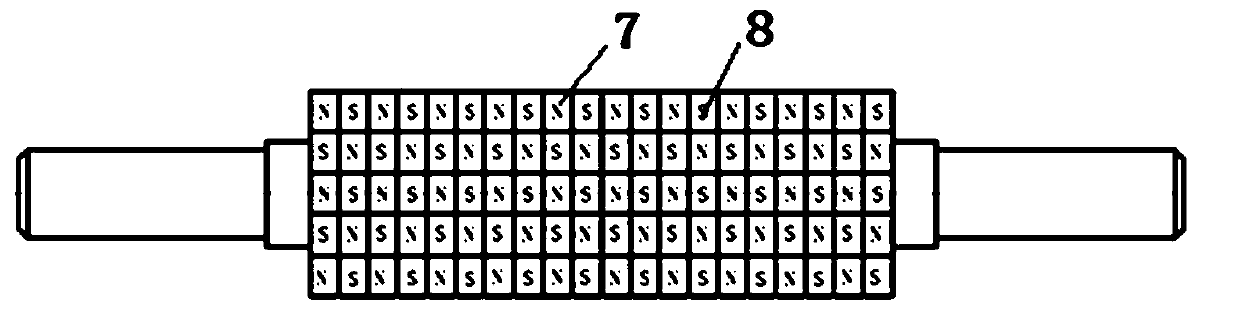

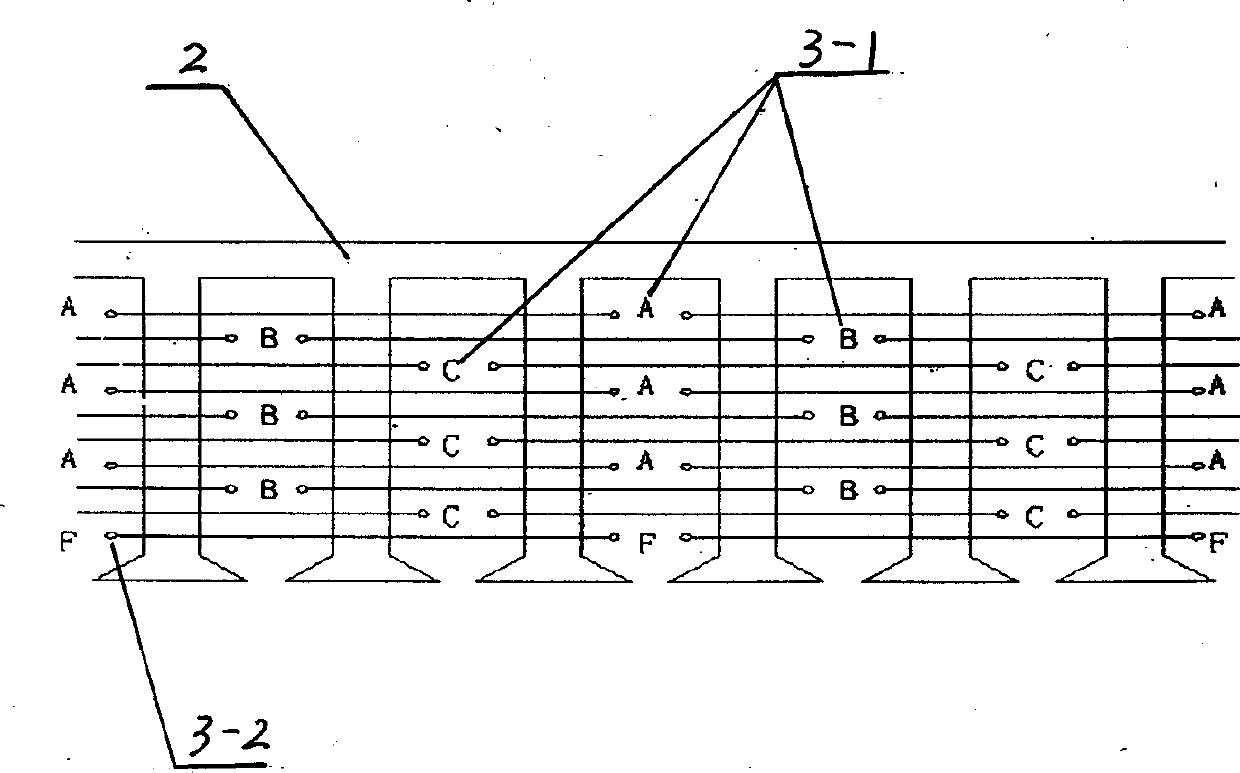

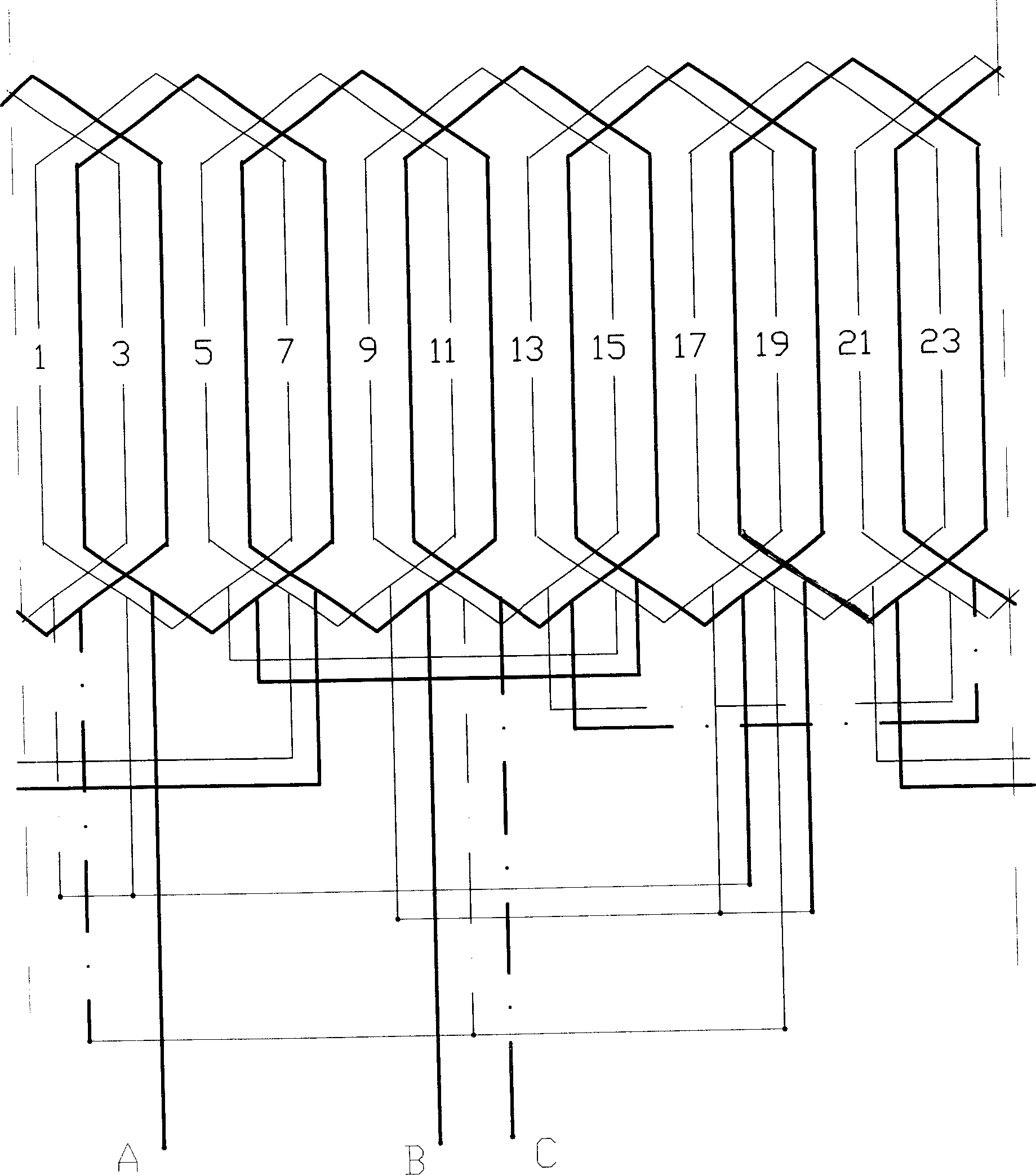

The invention discloses a brushless double-feedback motor of a winding rotor, which belongs to winding rotor motors. The problems of low slot space utilization rate, effective conductor utilization rate of a rotor winding and winding coefficient of a traditional brushless double-feedback motor of the winding rotor are solved. A power winding and a control winding which are mutually independent are arranged on a stator; Z rotor slots and m phase rotor windings are distributed on a rotor core; each phase rotor winding is provided with a parallel branches; each parallel branch consists of two or three coil groups; first, second and third pitches which are different are respectively adopted in coils with different turn numbers in the first, second and third coil groups; the coils in each coil group are connected in series; and each coil group is in short-circuit connection. The turn number of each winding coil can be flexibly adjusted; the slot space utilization rate, the effective conductor utilization rate of the rotor winding and the winding coefficient can be improved by 5 to 15 percent; and other harmonic waves are inhibited and the content of the harmonic waves is reduced to the maximal degree.

Owner:HUAZHONG UNIV OF SCI & TECH

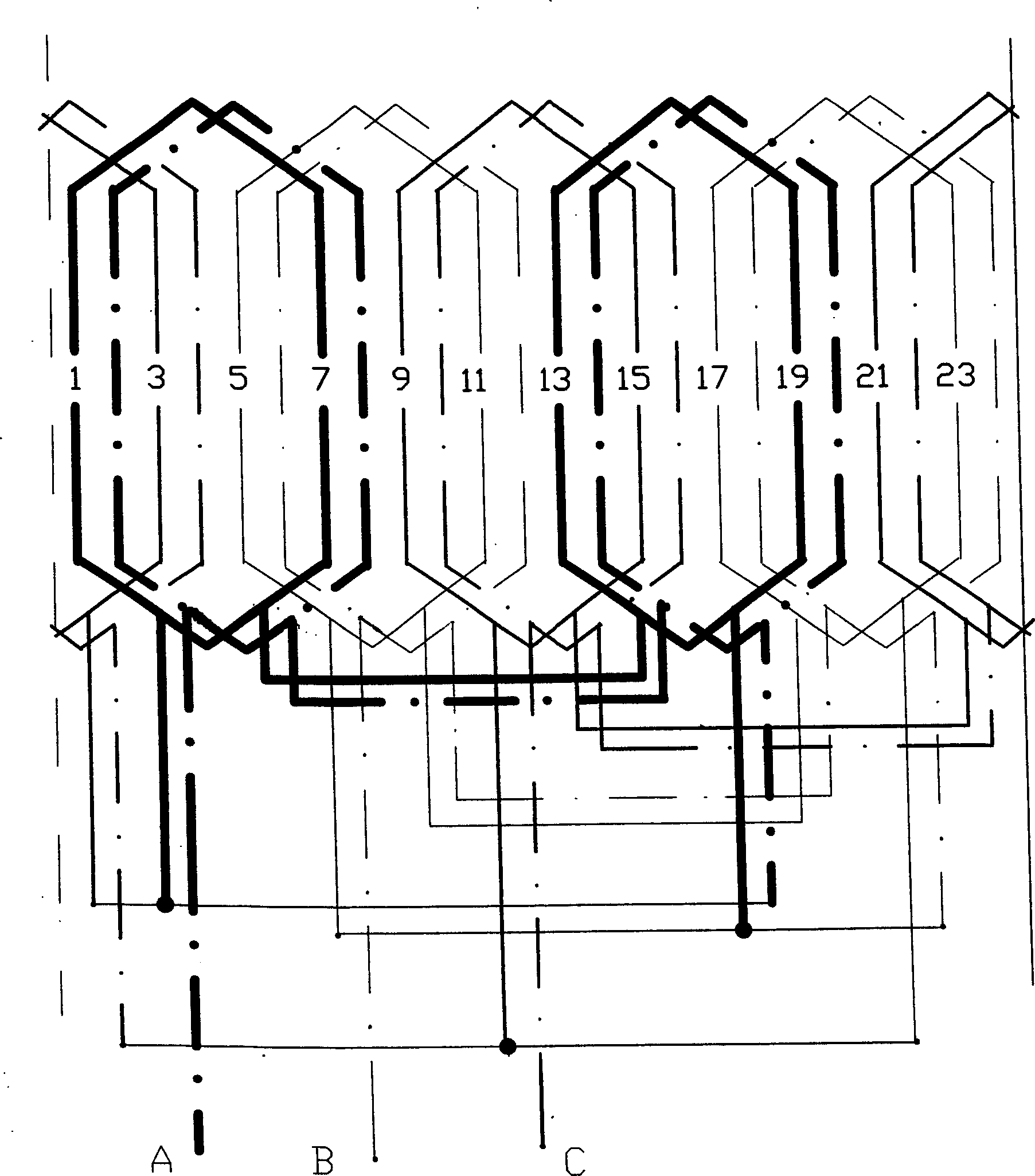

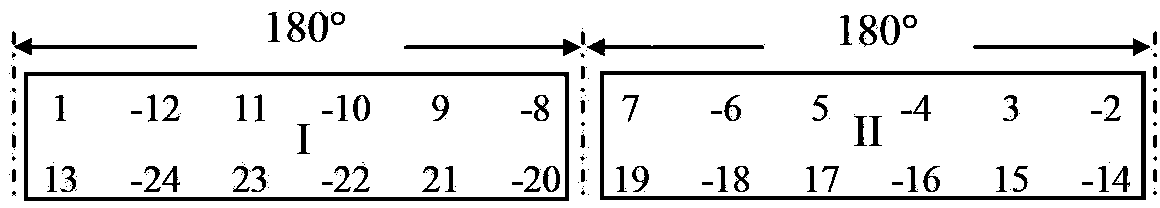

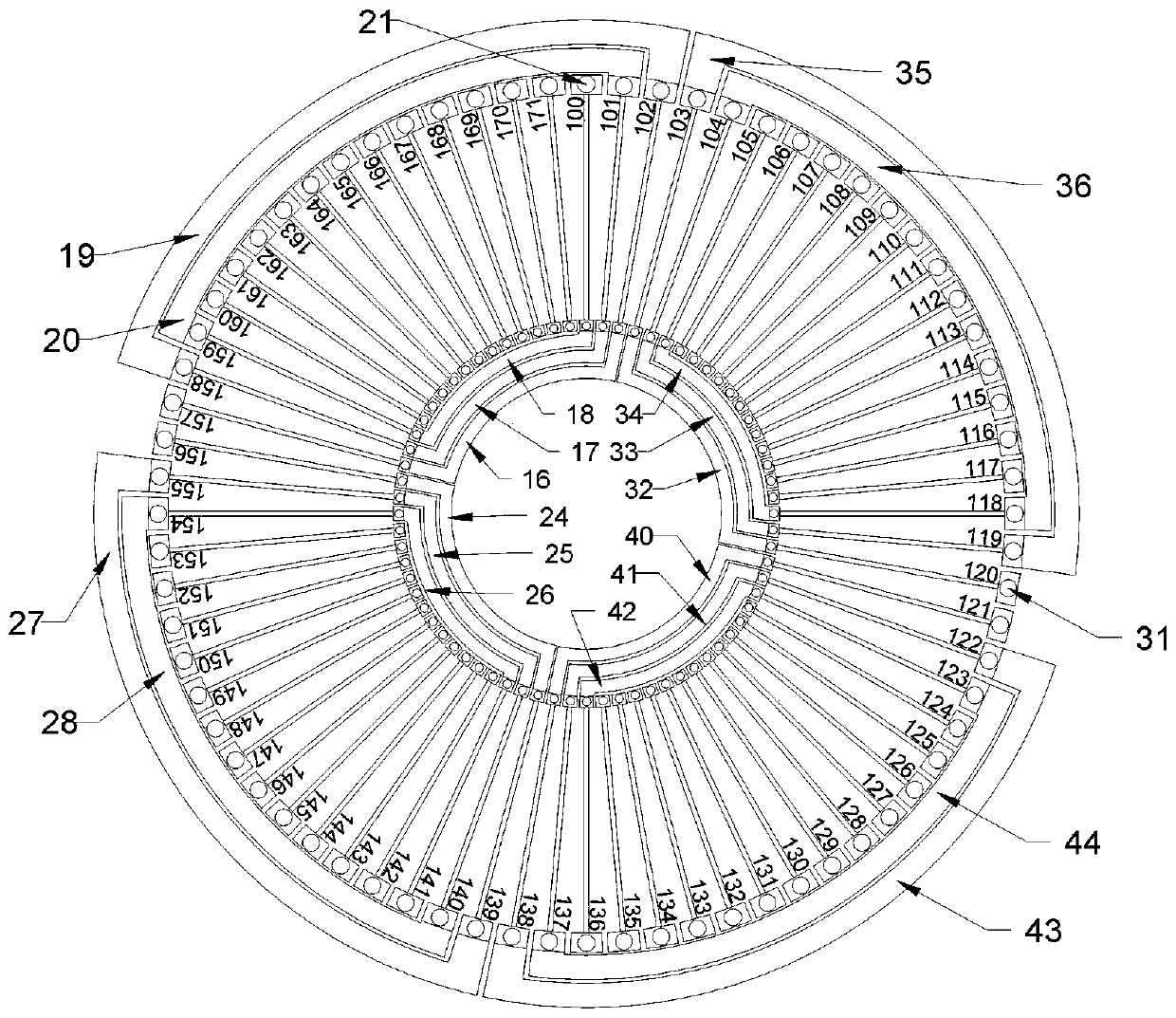

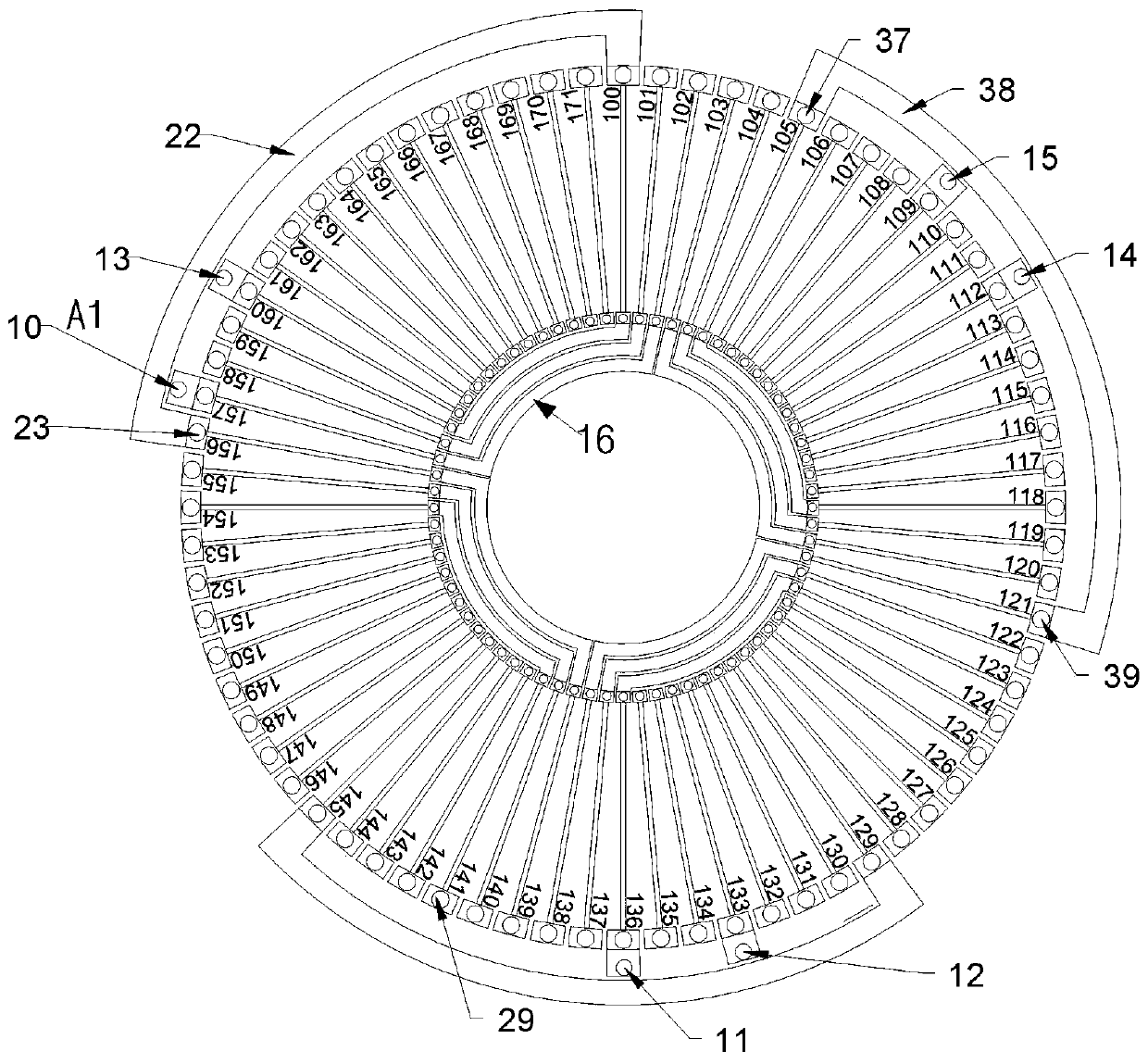

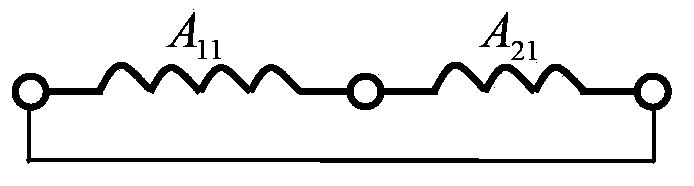

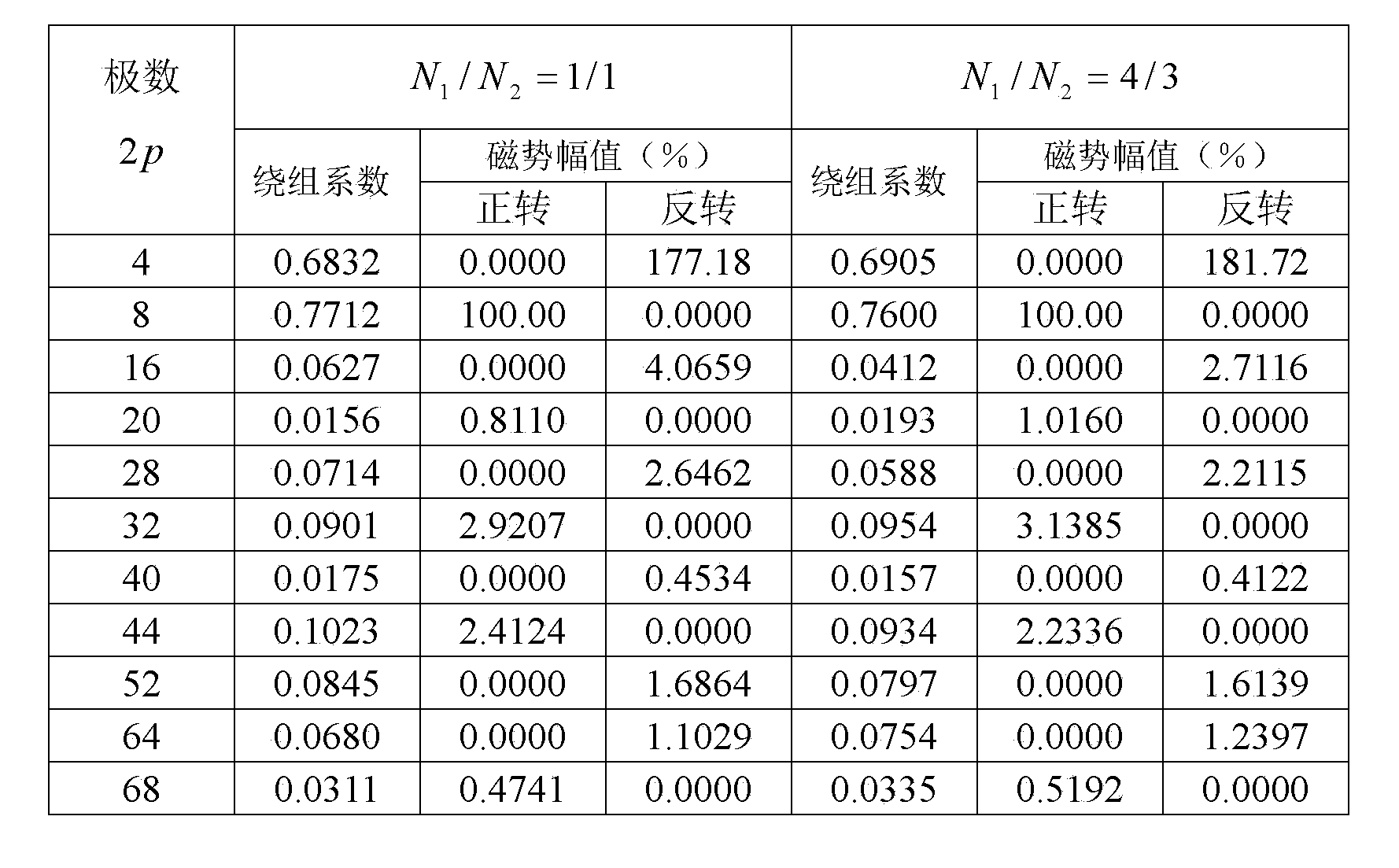

Brushless double-fed motor wound rotor winding and manufacturing method thereof

ActiveCN102801266AImprove the winding factorHarmonic reductionAsynchronous induction motorsManufacturing dynamo-electric machinesElectrical conductorHarmonic

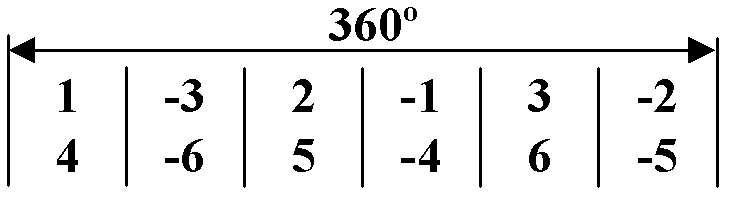

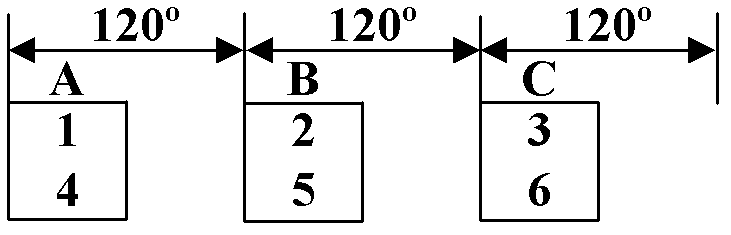

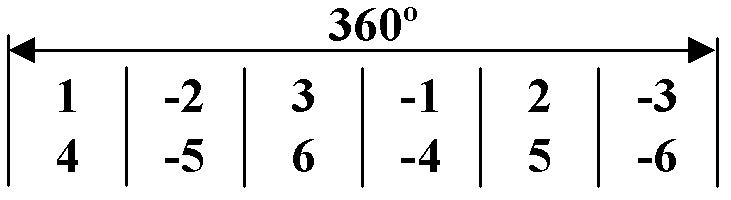

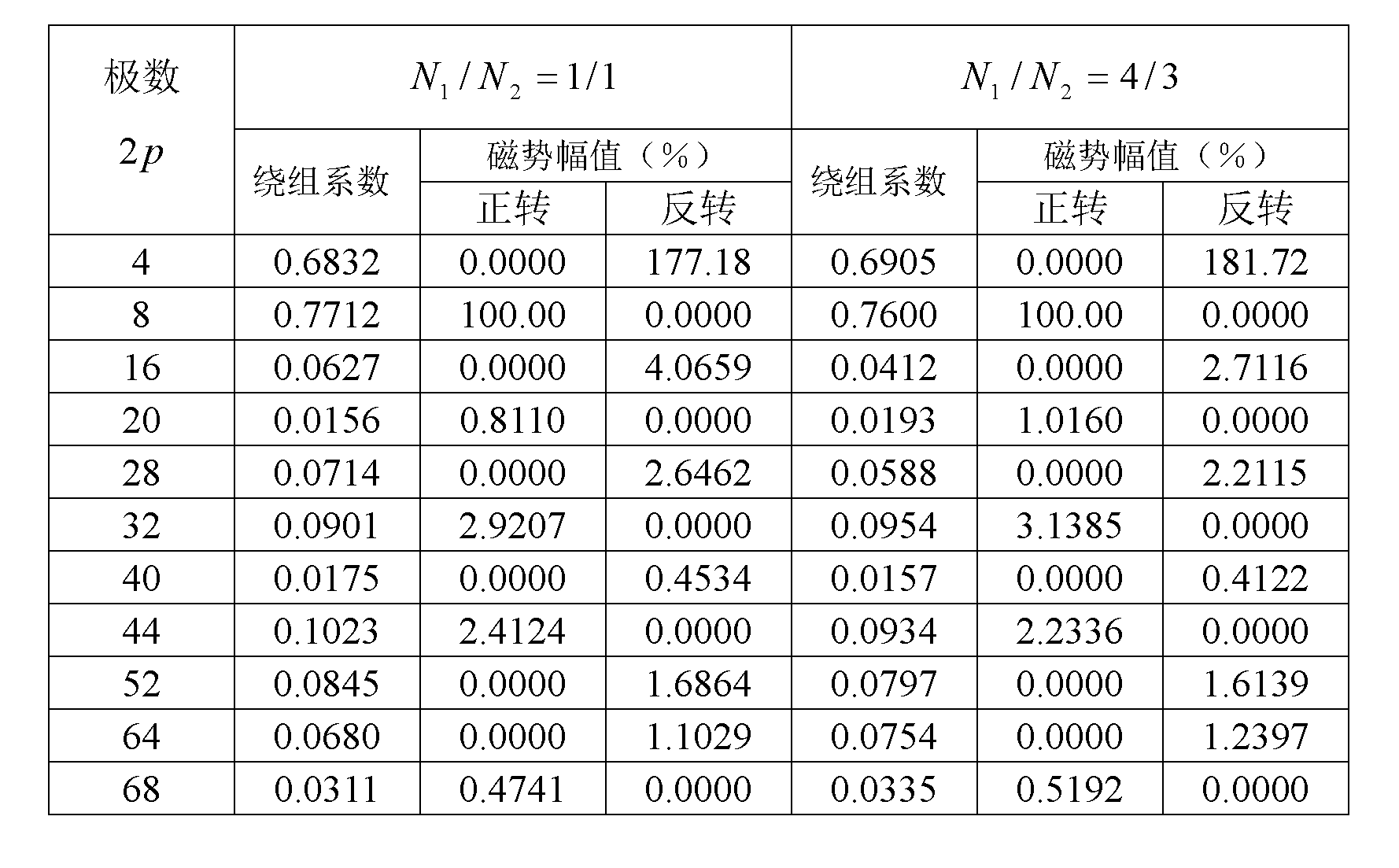

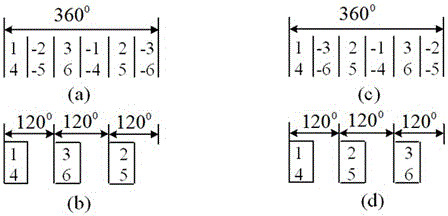

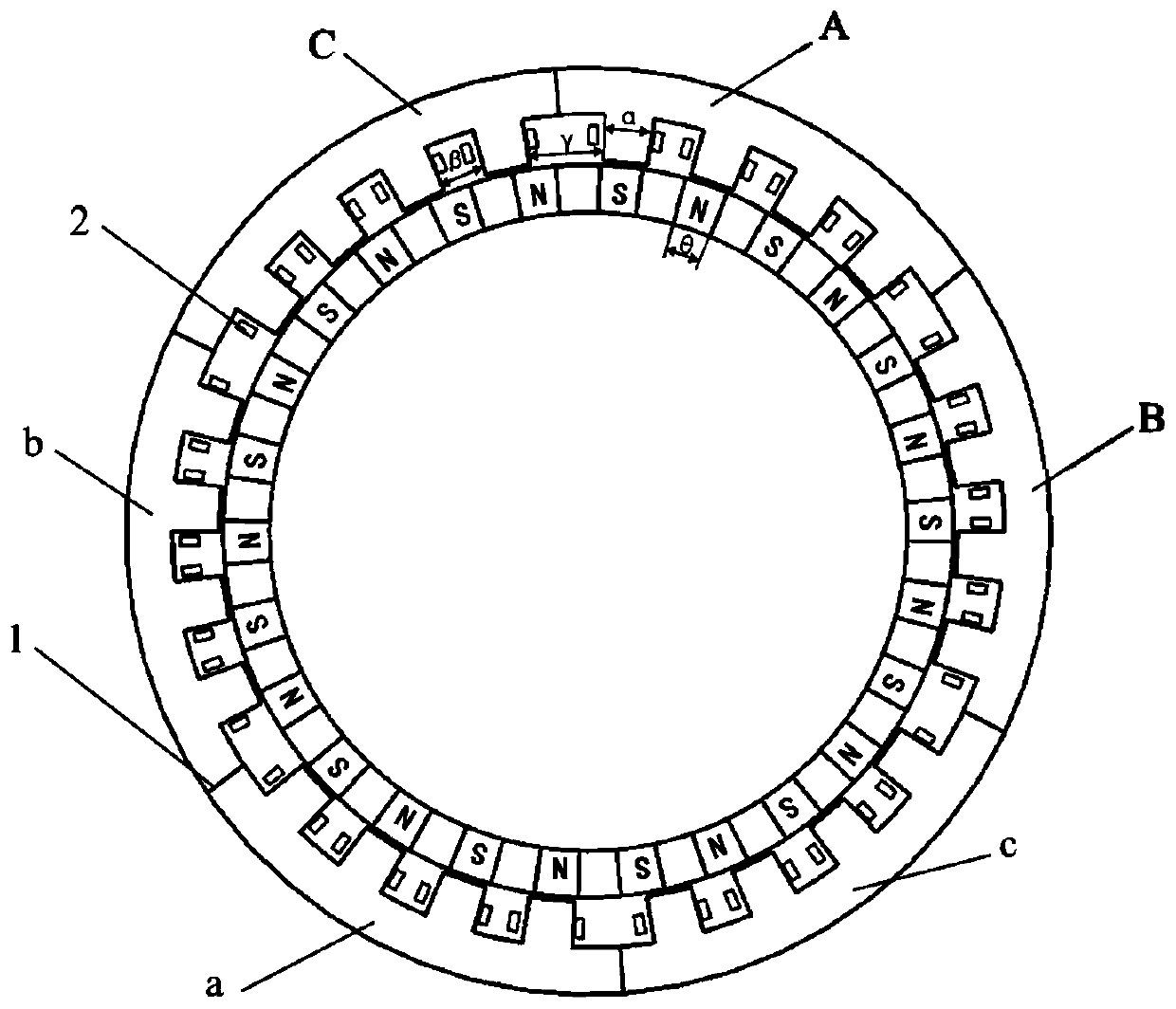

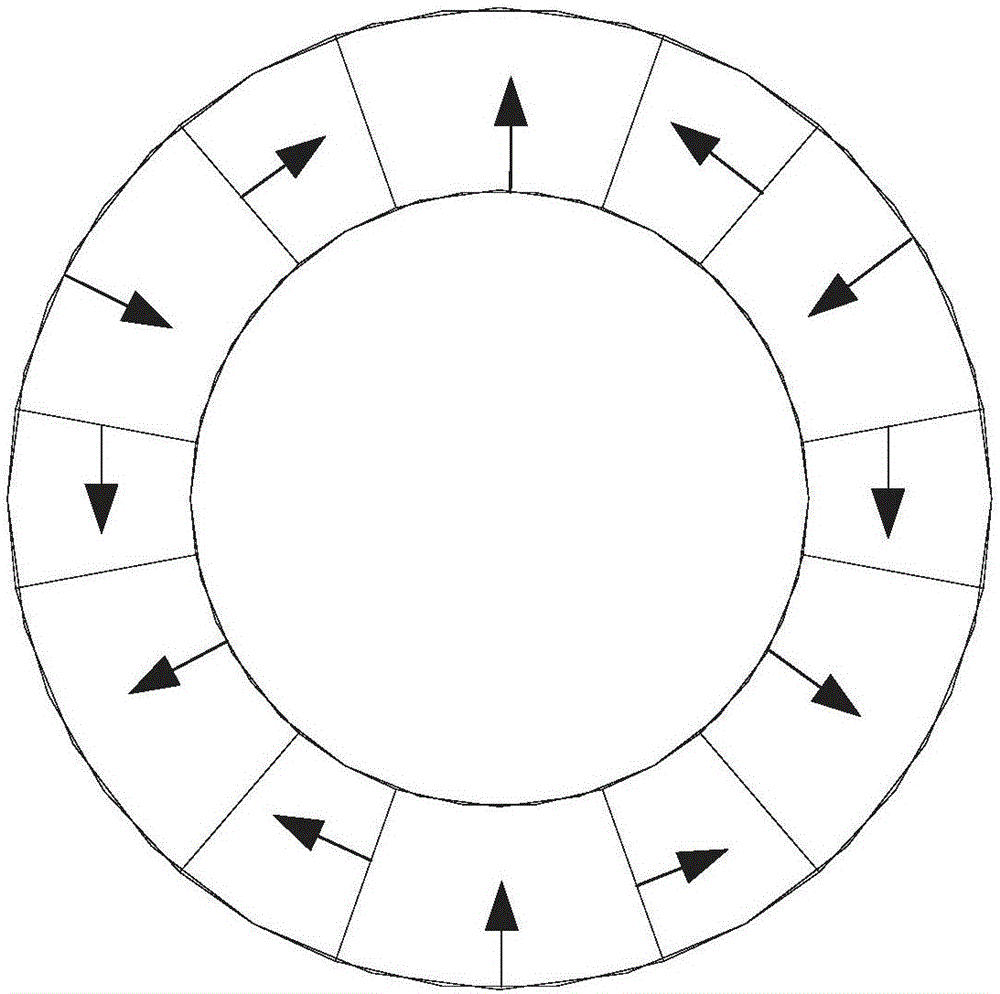

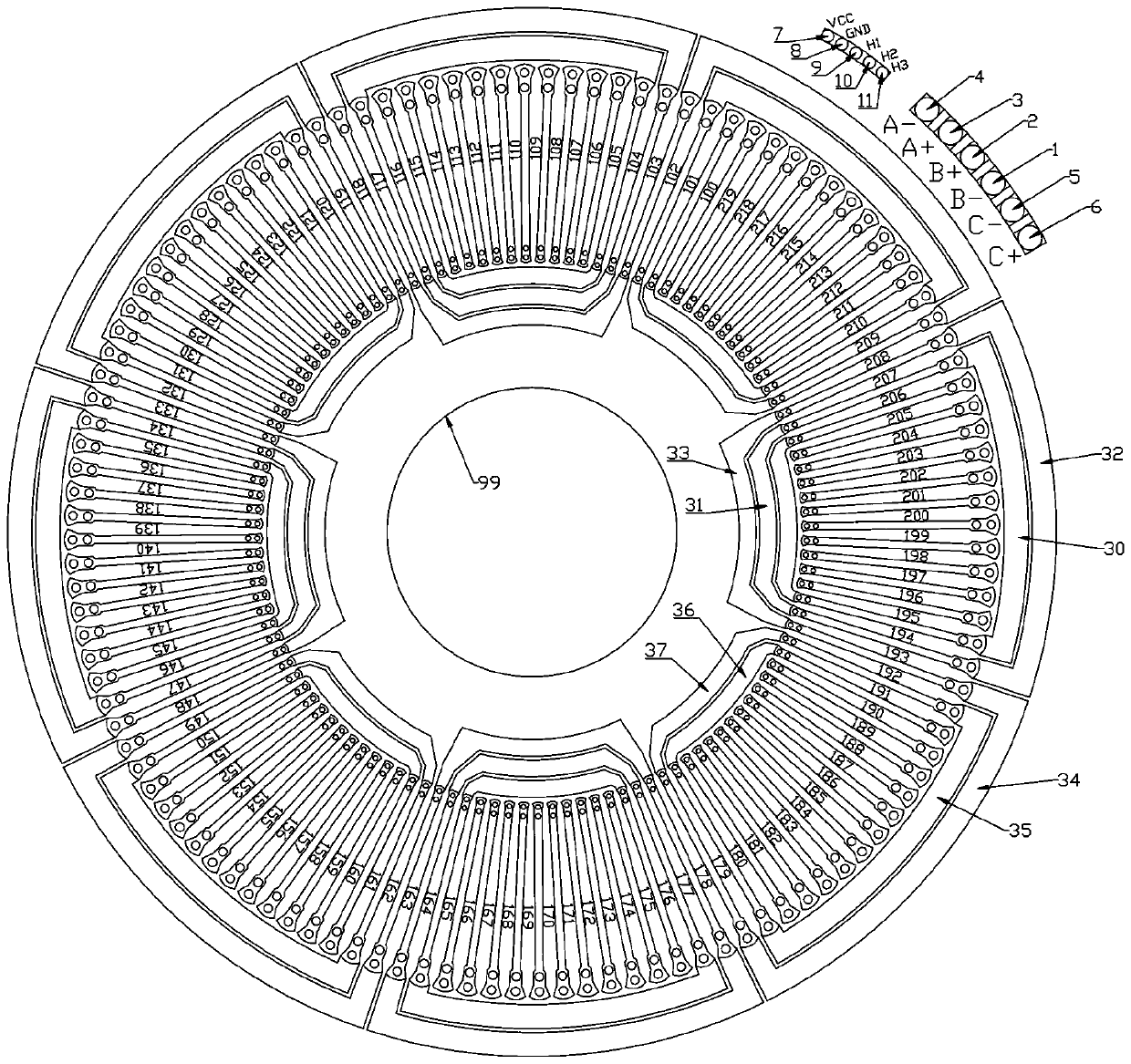

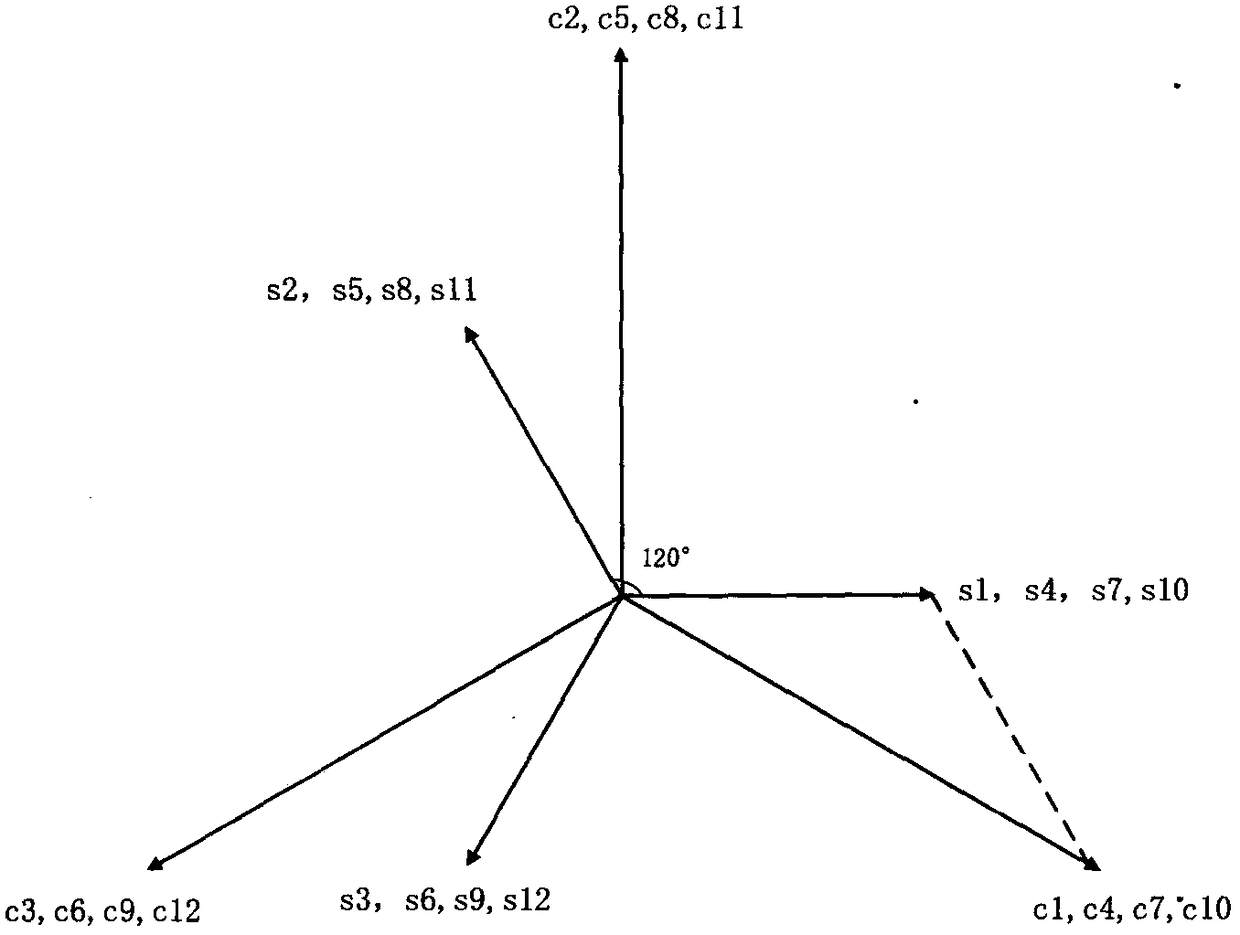

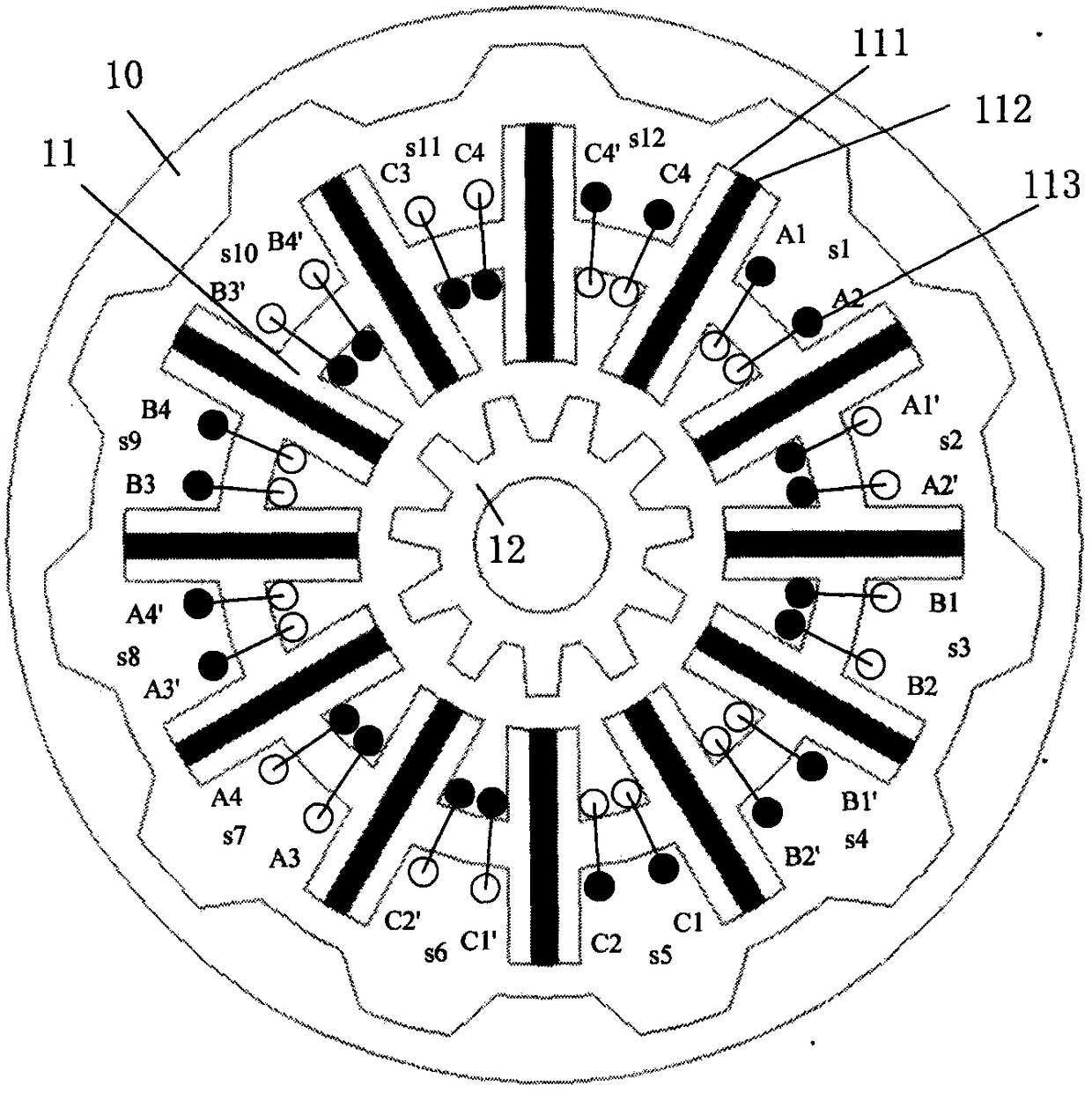

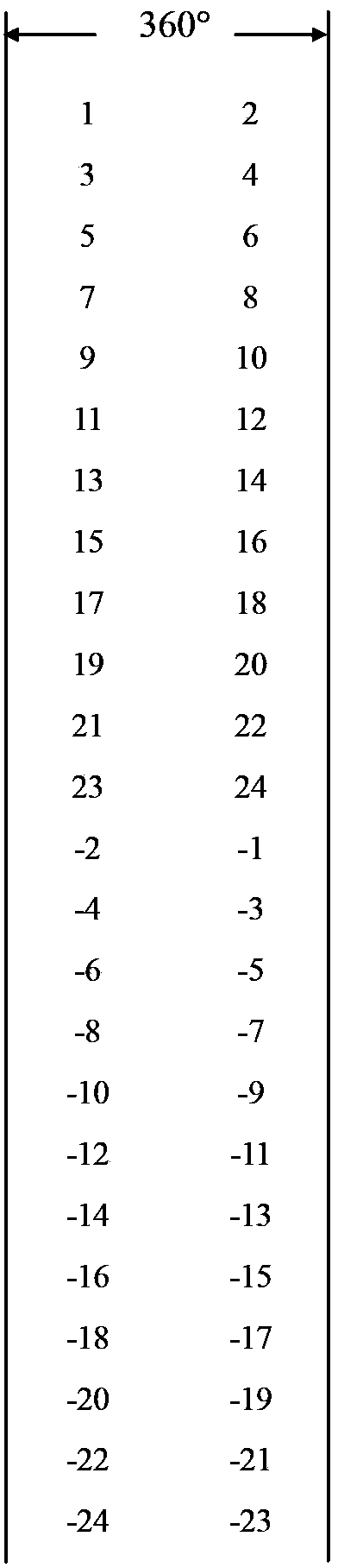

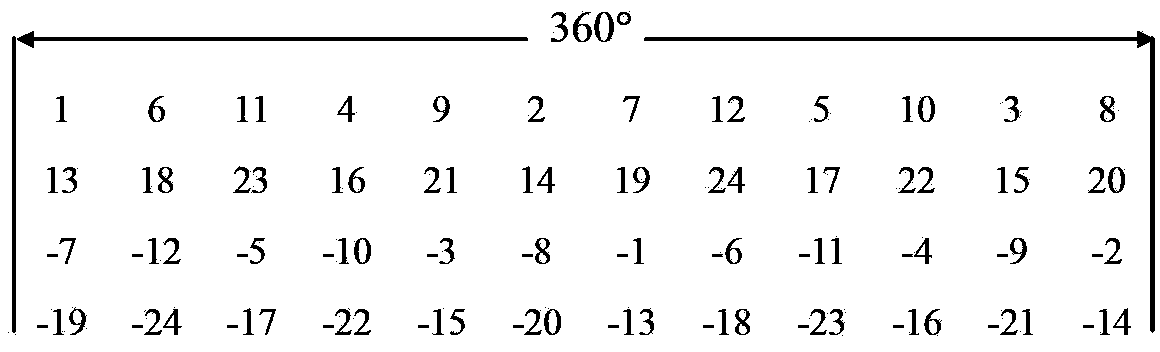

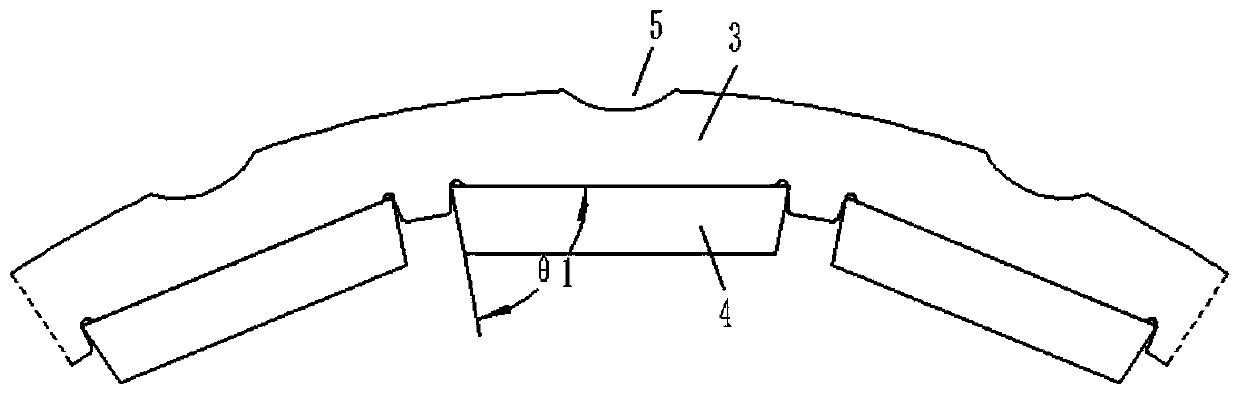

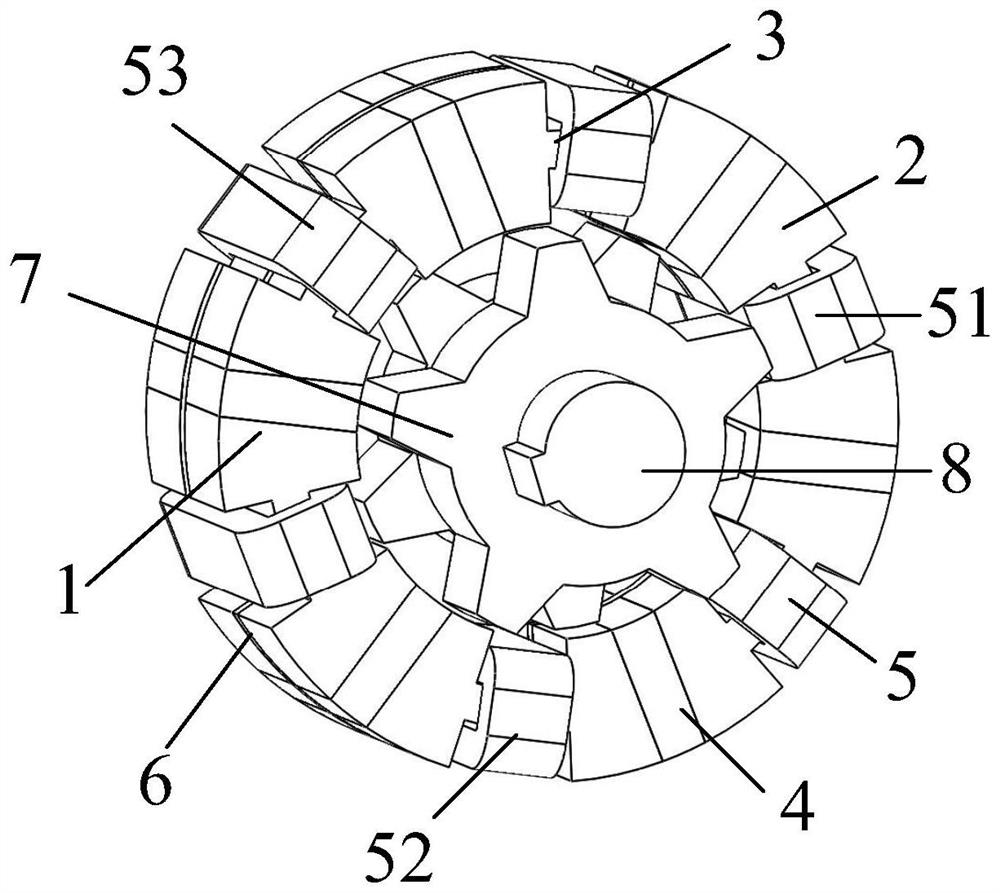

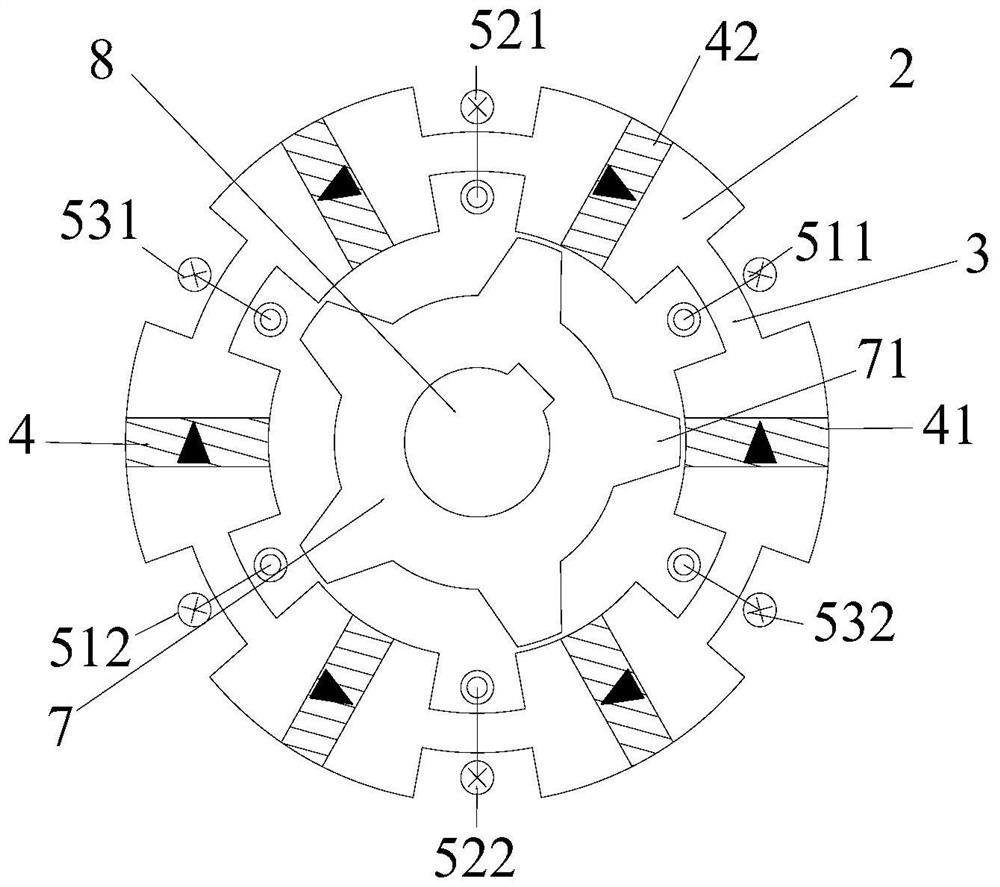

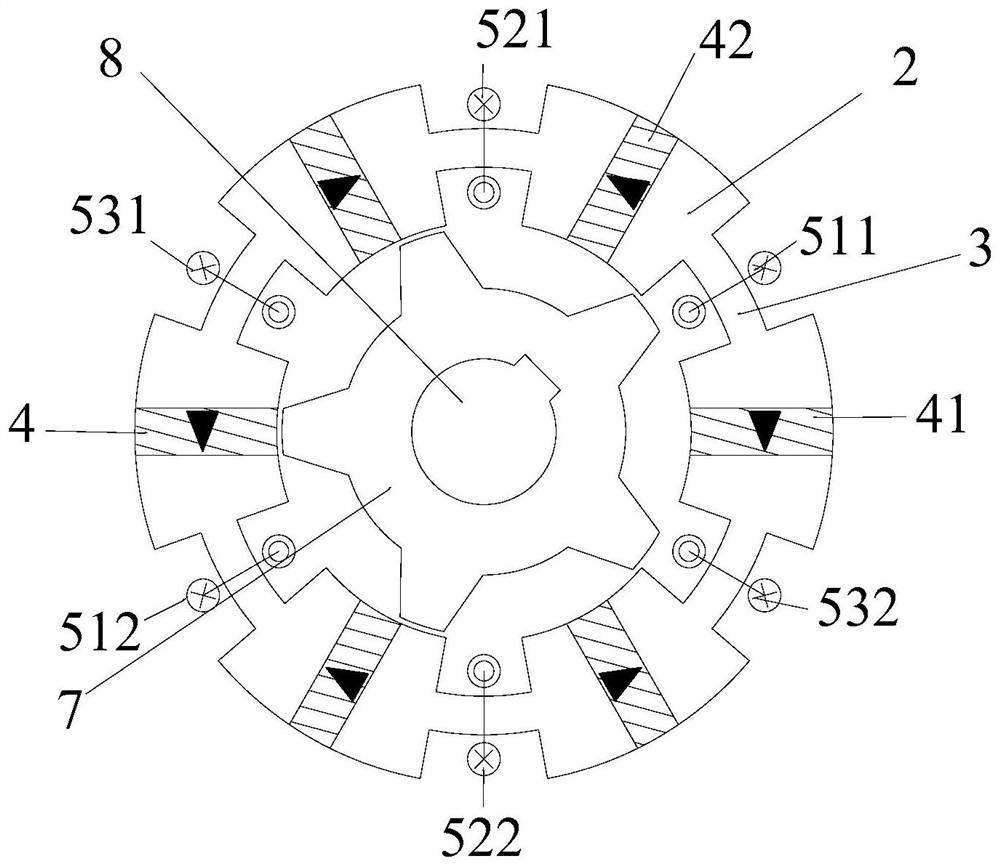

The invention relates to a brushless double-fed motor wound rotor winding and a manufacturing method thereof, and adopts two sets of multiphase sub windings to form a multiphase winding type winding in a stacking and overlapping way. The two sets of multiphase sub windings are respectively comprise coils and pitches, wherein the numbers of the coils and the numbers of the pitches of the two sets are respectively different, one of the two sets of multiphase sub windings comprises m phases of sub windings, each phase the m phases of sub windings is composed of n 1 serial-connection coils which have N1 turns and are numbered in order or is in a double-layer or a single-layer manner, and a coil pitch is y1; the other set of m phases of sub windings is in a single-layer manner, each phase is composed of n 2 serial-connection coils which have N2 turns and are numbered in order, a coil pitch is y 2, and the n 2 and the y 2 meet a relation that n2= z / (p1+p2)-y2; after the two sets of multiphase sub windings are synthetized, the all coils (in each phase) n= n 1+ n 2 are successively connected in series and then are connected from a short circuit, and the relative positions of the two sets of multiphase sub windings is shifted through regulating the numbers pitches or relative turns of the coils; and the optimum matching is realized so as to generate a superimposed effect, thereby achieving the purpose of improving fundamental wave utilization ratio of a winding coil conductor and weakening a harmonic wave.

Owner:HUAZHONG UNIV OF SCI & TECH +1

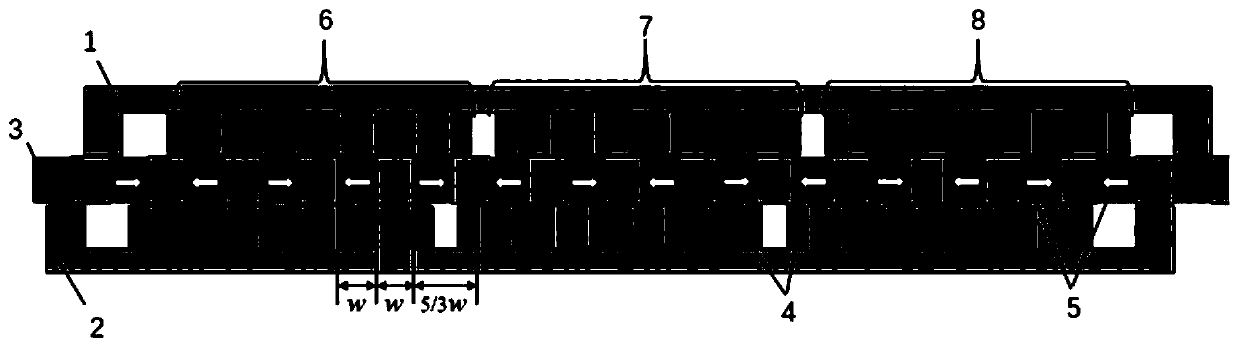

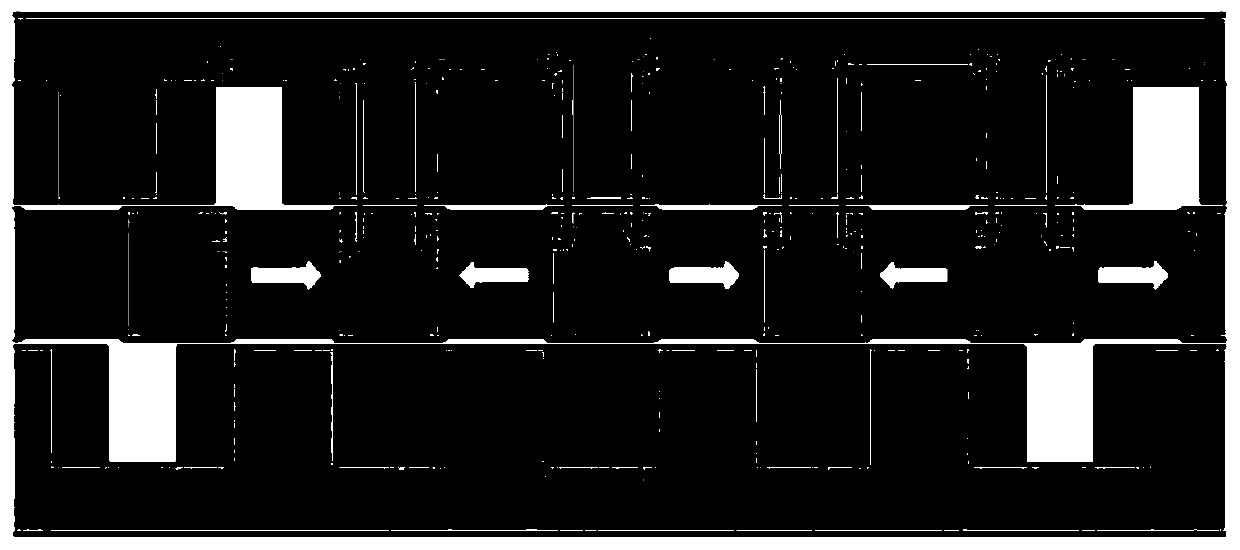

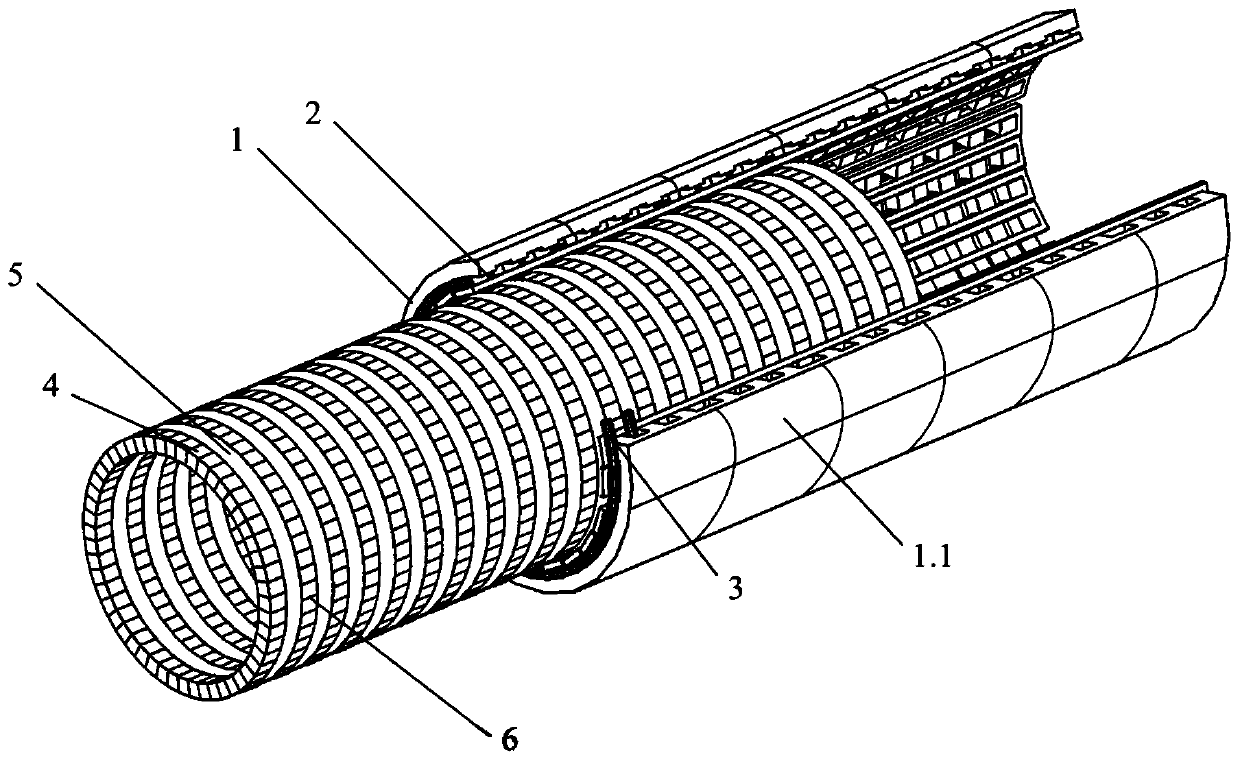

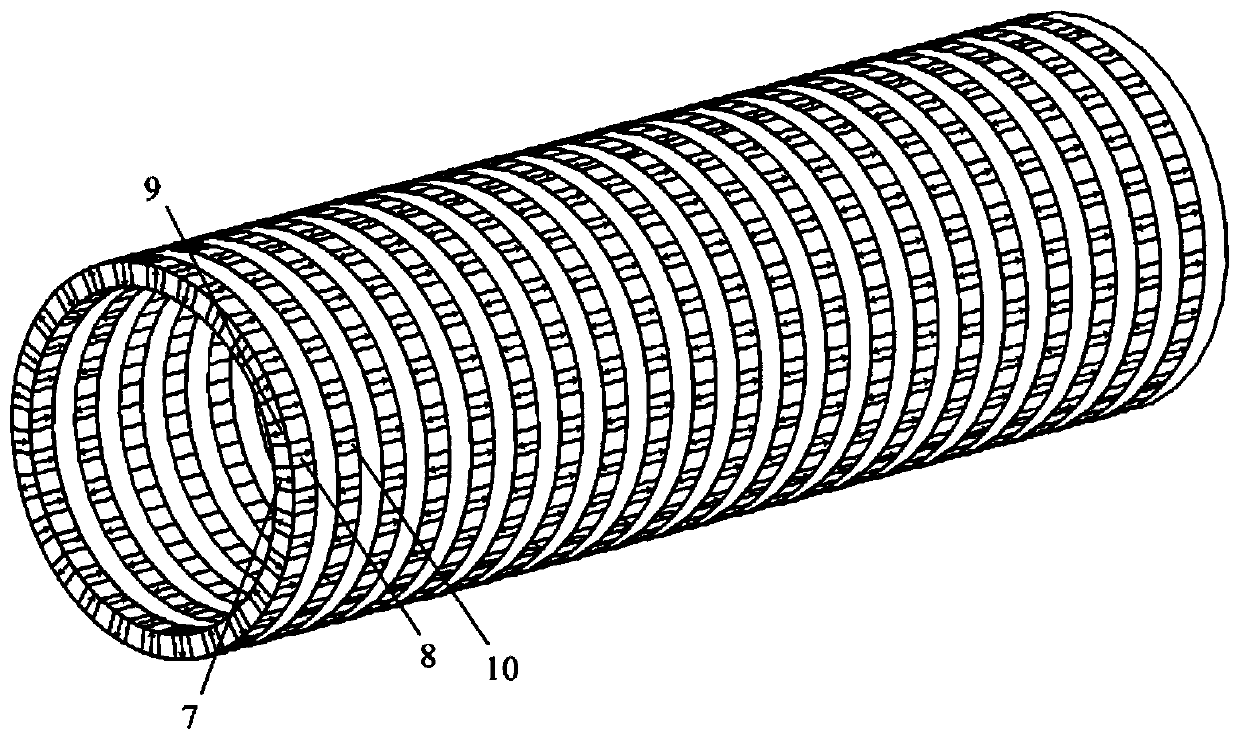

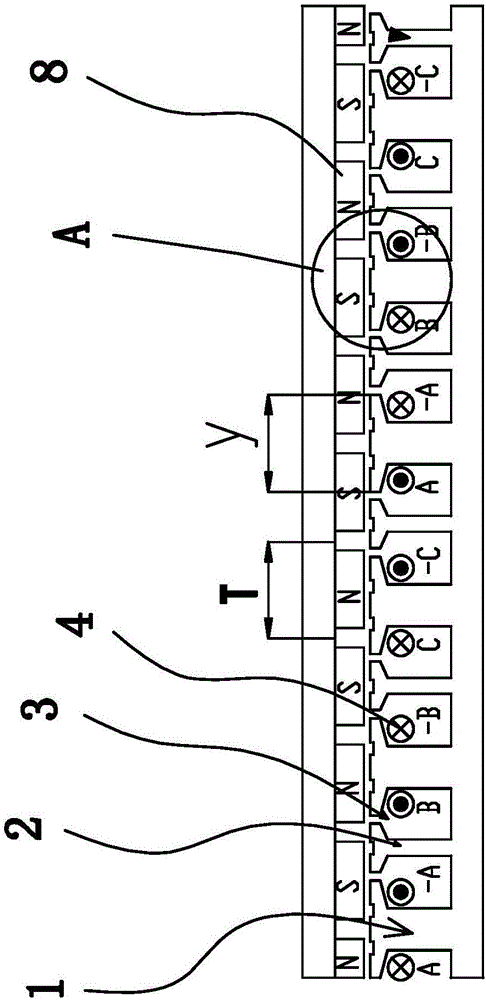

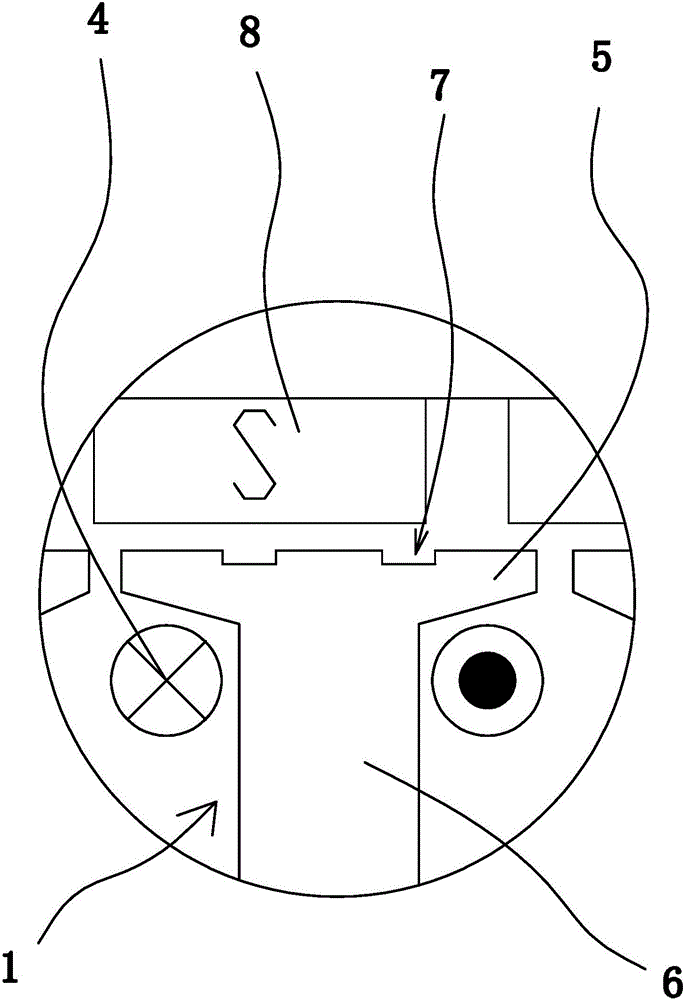

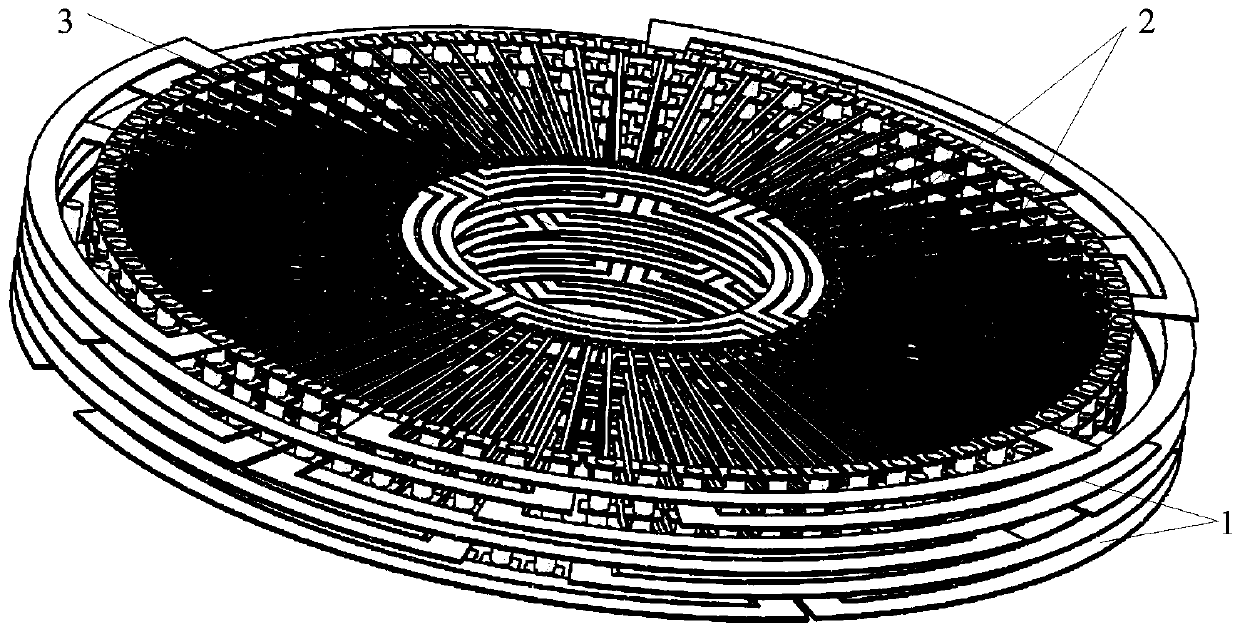

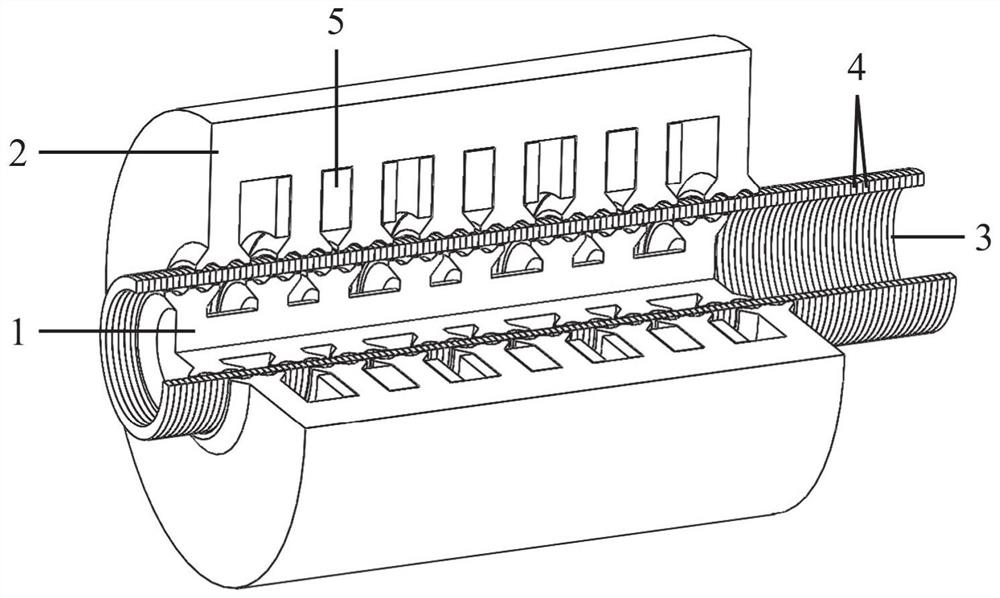

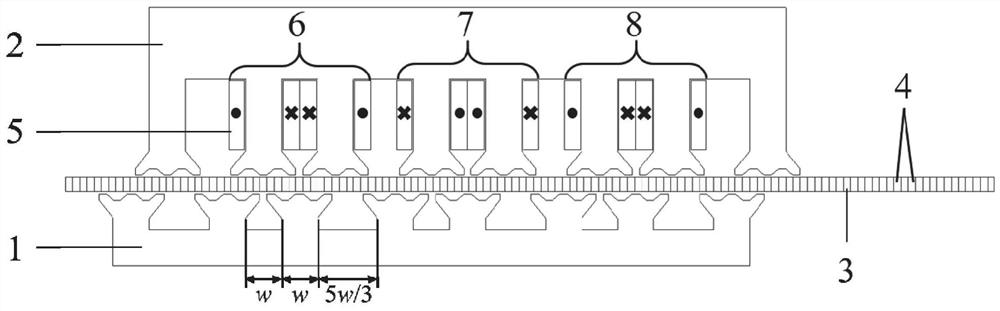

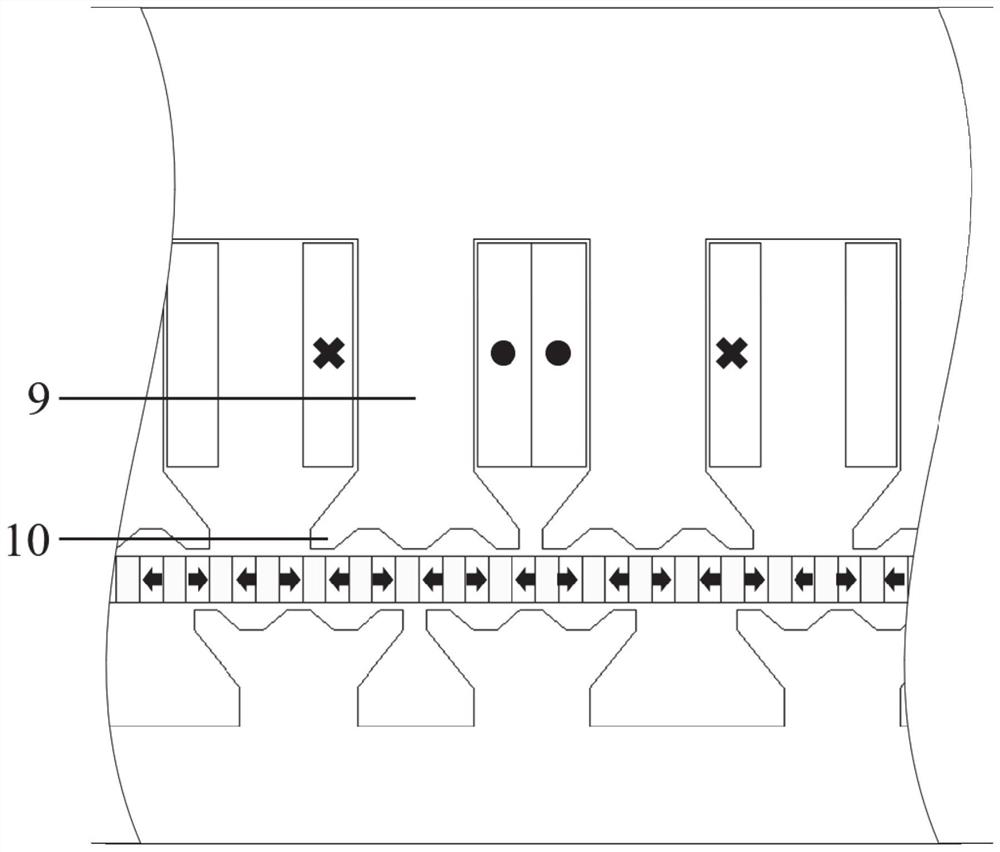

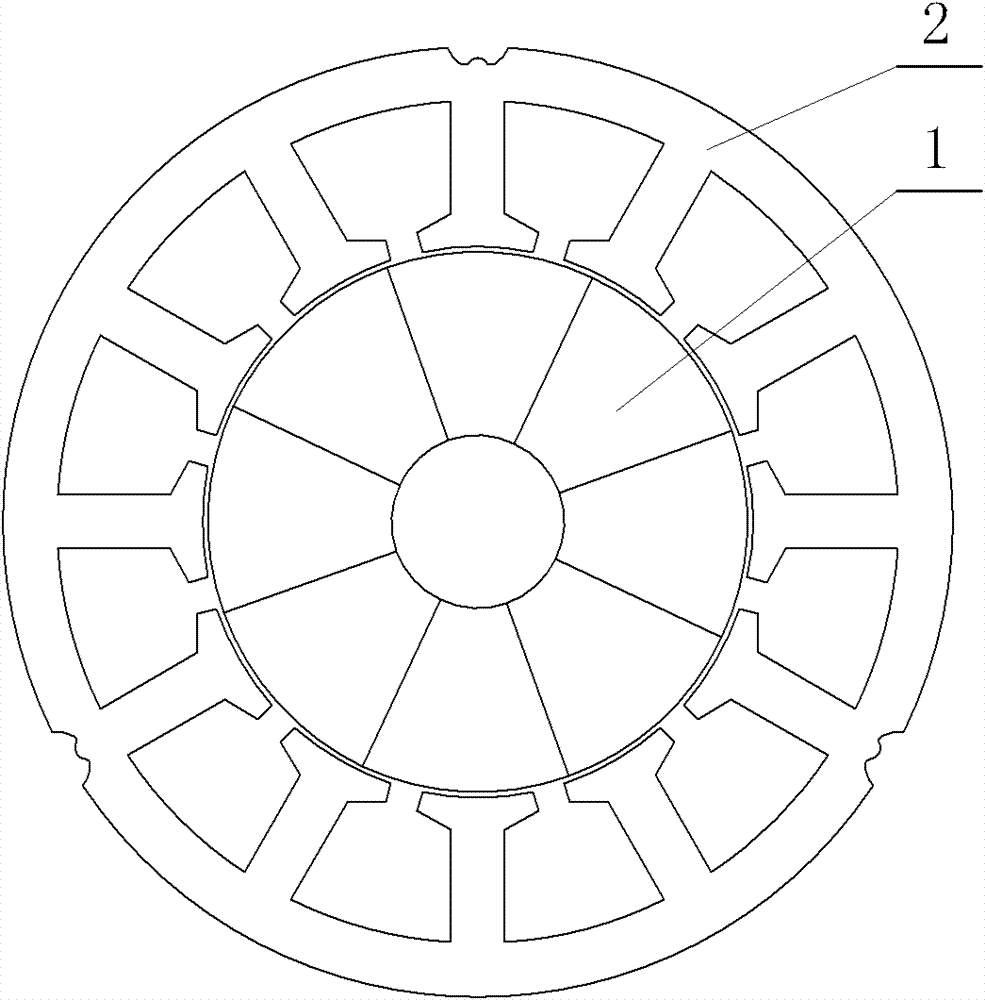

Winding-type linear brushless doubly-fed generator

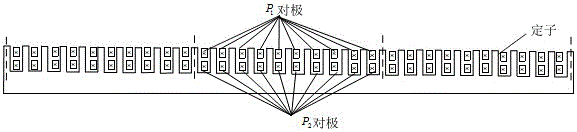

ActiveCN104993629AImprove power densityLow failure rateWindings conductor shape/form/constructionFailure rateEngineering

The invention discloses a winding-type linear brushless doubly-fed generator, and proposes a unit motor according to a unit motor concept, wherein the total number of pole-pairs of a stator power winding and a control winding of the unit motor is N times. Meanwhile, a rotor winding employs a mode of symmetric distribution like a sine rule according to the principle of tooth harmonic, thereby reducing coils of different phases of a power winding P1 and a control winding P2. The rotor winding can achieve the coupling of a control winding and another winding well, and the air-gap magnetic density harmonic is lower. The generator can enable a magnetic field with a lower moving speed to be modulated into a high-speed magnetic field, and effectively improves the power density. The control winding is placed at a stator side, and a sliding ring and a brush are removed. The generator is low in motor failure rate, is long in service life, eliminates the higher harmonic of a magnetomotive force of a rotor to the maximum degree through the adjustment of the span and turns of a rotor coil, achieves the higher winding coefficients of the pole pairs of power windings P1 and P2, and achieves the high efficiency and energy saving.

Owner:黄山市开发投资集团有限公司

Coreless permanent magnet synchronous linear motor based on double-layer winding structure

The invention discloses a coreless permanent magnet synchronous linear motor based on a double-layer winding structure. The coreless permanent magnet synchronous linear motor comprises a two-sided long secondary stage and a short primary stage; the long secondary stage is of a two-sided Halbach permanent magnet array structure; permanent magnets are mounted oppositely to provide an air-gap magnetic field; and the short primary stage is encapsulated by double-layer integrated coils, and is mounted in an air gap via a sliding guide rail. The motor provided by the invention has many characteristics of the coreless permanent magnet synchronous linear motor; moreover, the volume of the primary stage of the motor is reduced, the usage of a coil material is reduced, the winding coefficient of thecoils is improved, the average thrust density of the coreless motor is improved and the advantages of a concentrated winding and a distributed winding are combined well; and thus, the coreless permanent magnet synchronous linear motor is applied to an accurate positioning system that operates continuously for a long time as well as a precision machining platform.

Owner:ZHEJIANG UNIV

Special-winding energy-saving three-phase asynchronous motor

InactiveCN101409486AEliminate the magnetic potentialMagnetic potential increaseAsynchronous induction motorsWindings conductor shape/form/constructionShortest distanceThree phase asynchronous motor

The invention discloses an energy-saving three-phase asynchronous motor of a special winding, comprising a stator winding which is embedded in a stator channel; the stator winding is an unequal-turn winding, with single-layer winding for whole distance and dual-layer winding for short distance; the turn of the upper layer and the lower layer of the coils of the dual-layer winding is unequal. By adopting the structure, the motor can weaken and eliminate the magnetic potential of high harmonic, reduces the electromagnetic noise, decreases the single-side magnetic pulling force, so as to reduce the vibration, can improve the magnetic potential of fundamental wave and reduce the additional loss; the reduction of the pitch leads the starting performance of the motor to be better, reduces the copper dosage, reduces the copper loss, lowers the temperature increment of the winding and improves the usage efficiency of the motor.

Owner:JIANGSU DAZHONG ELECTRIC MOTOR

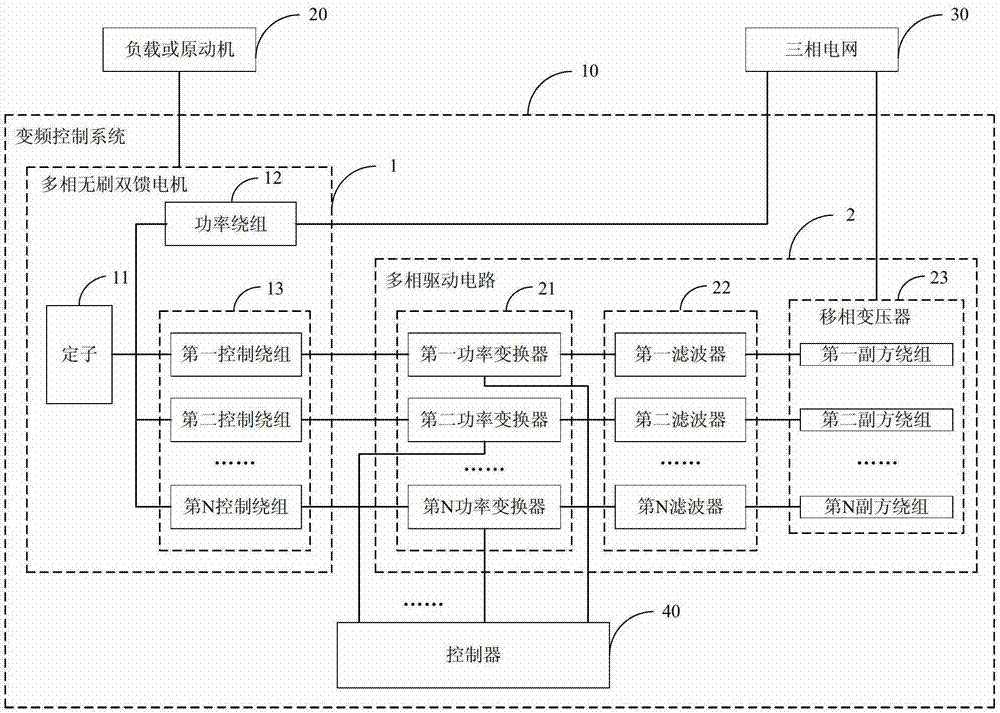

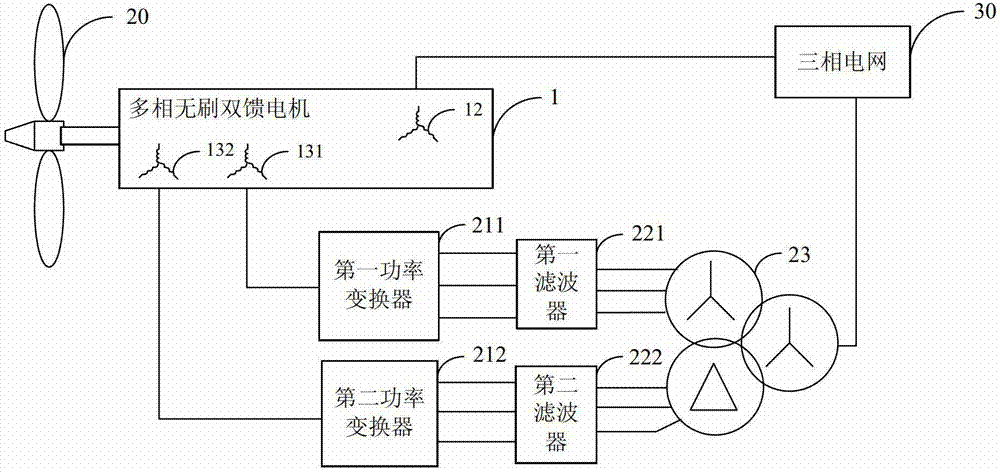

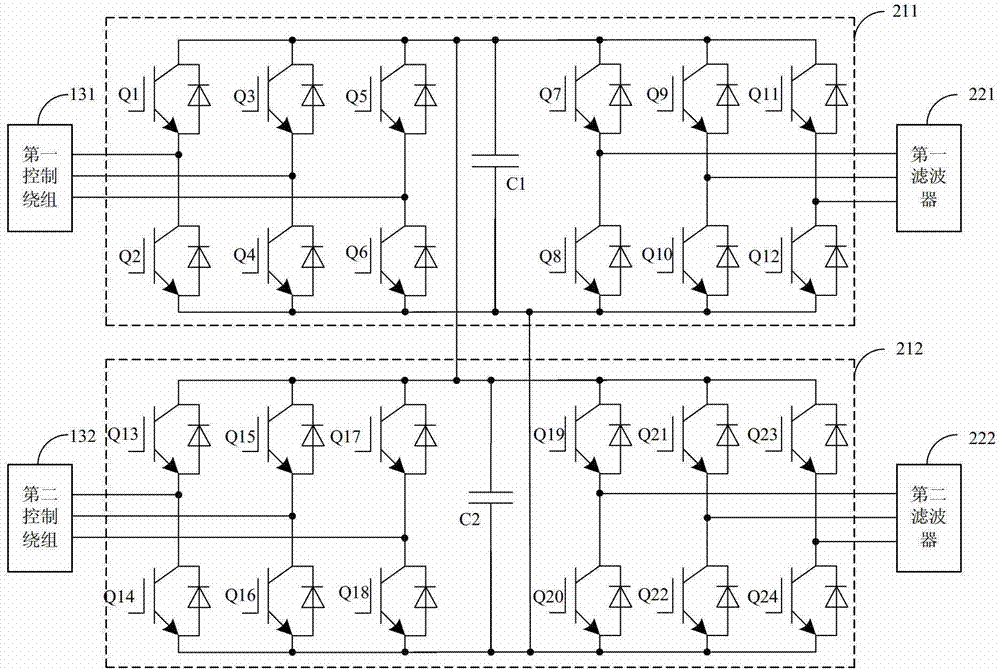

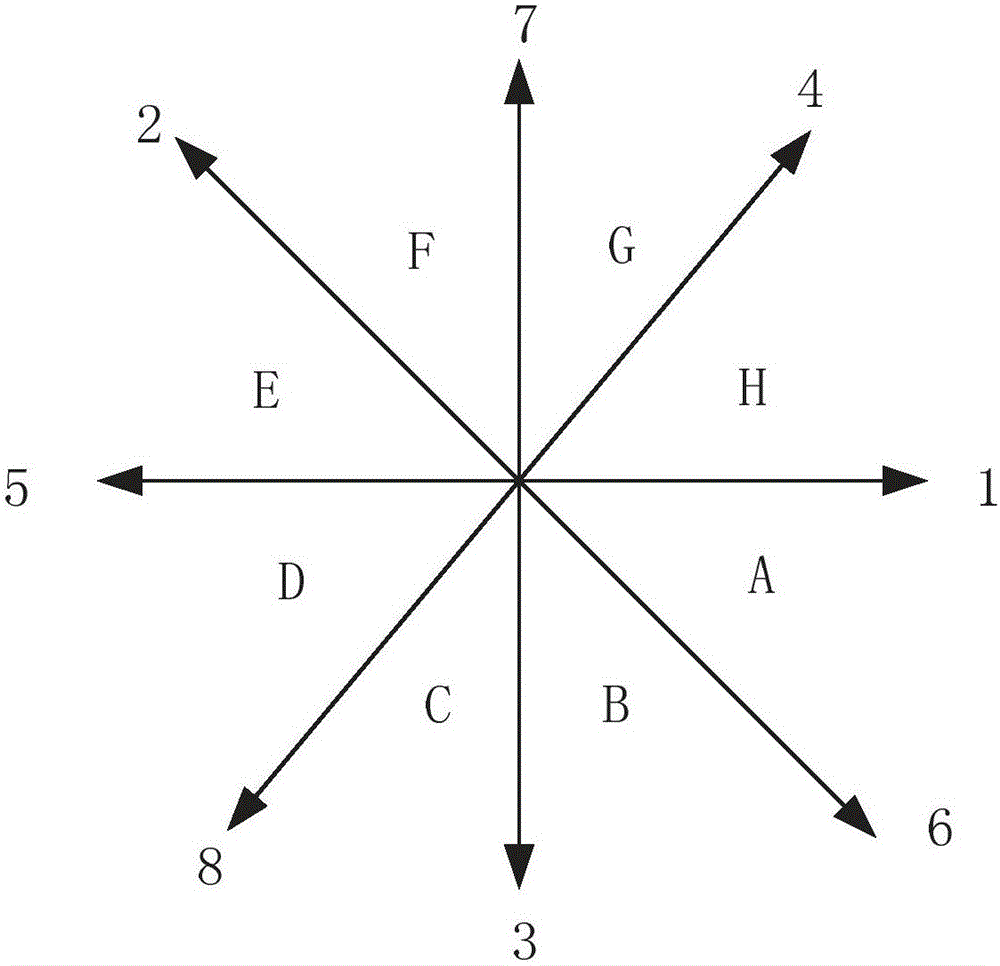

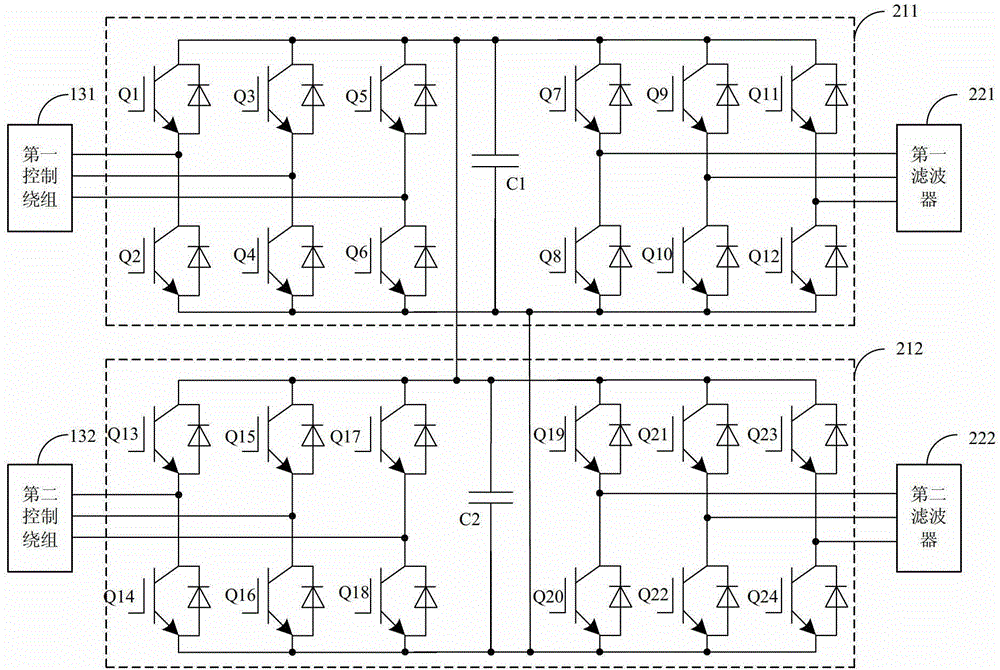

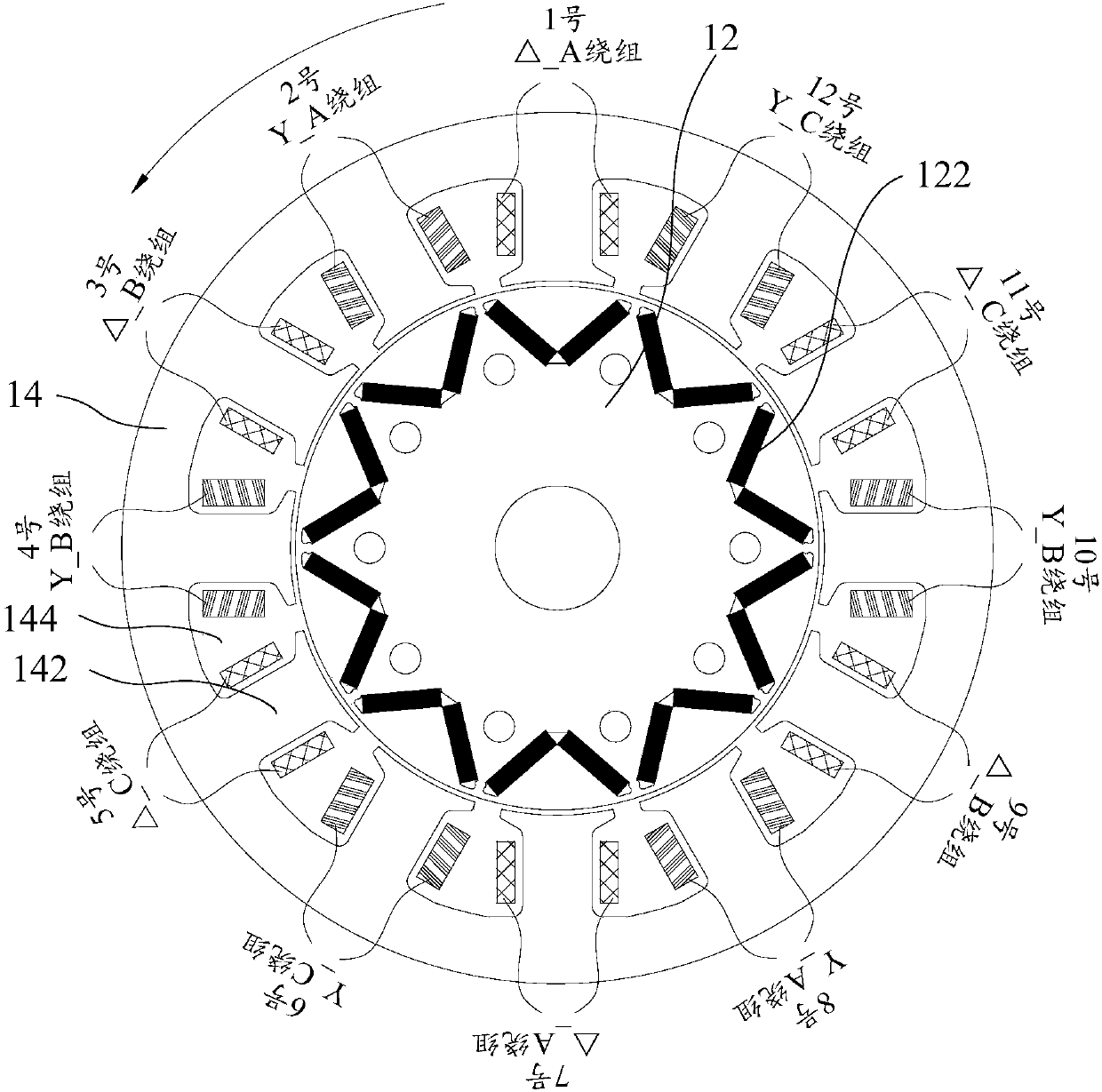

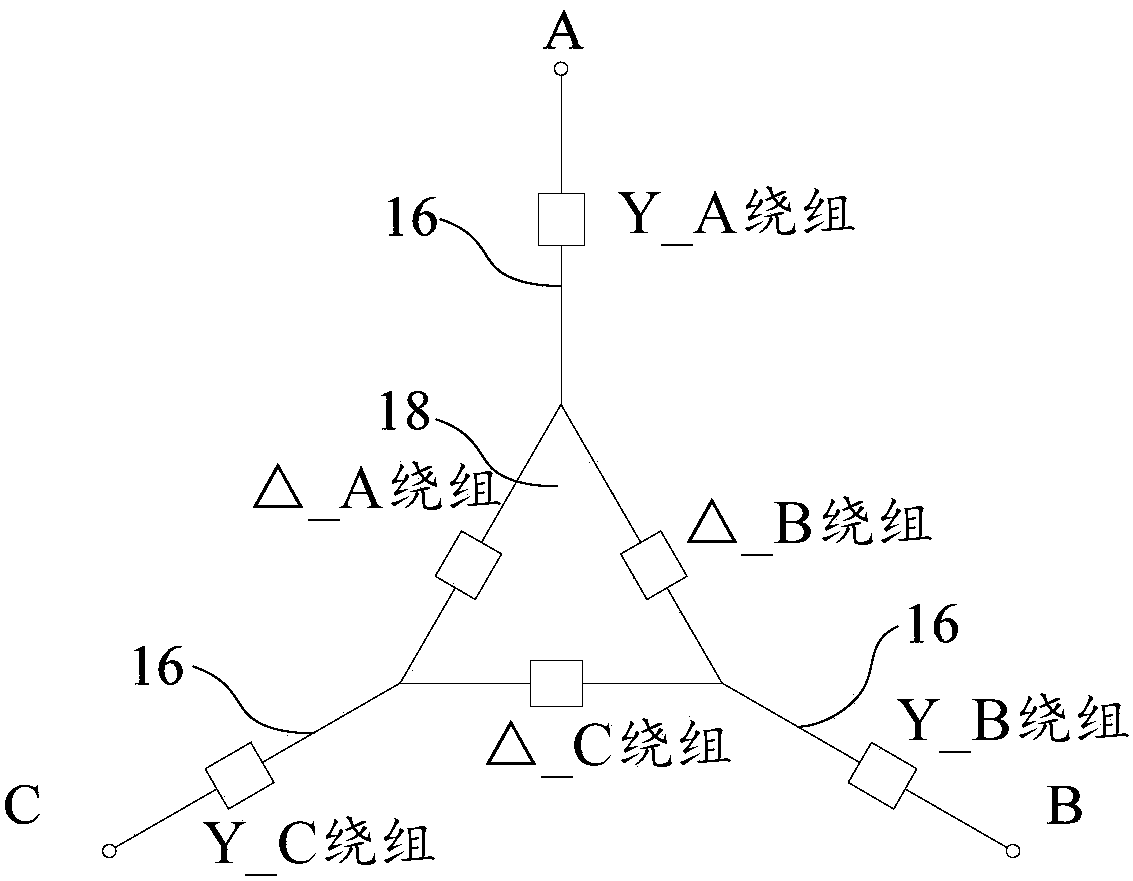

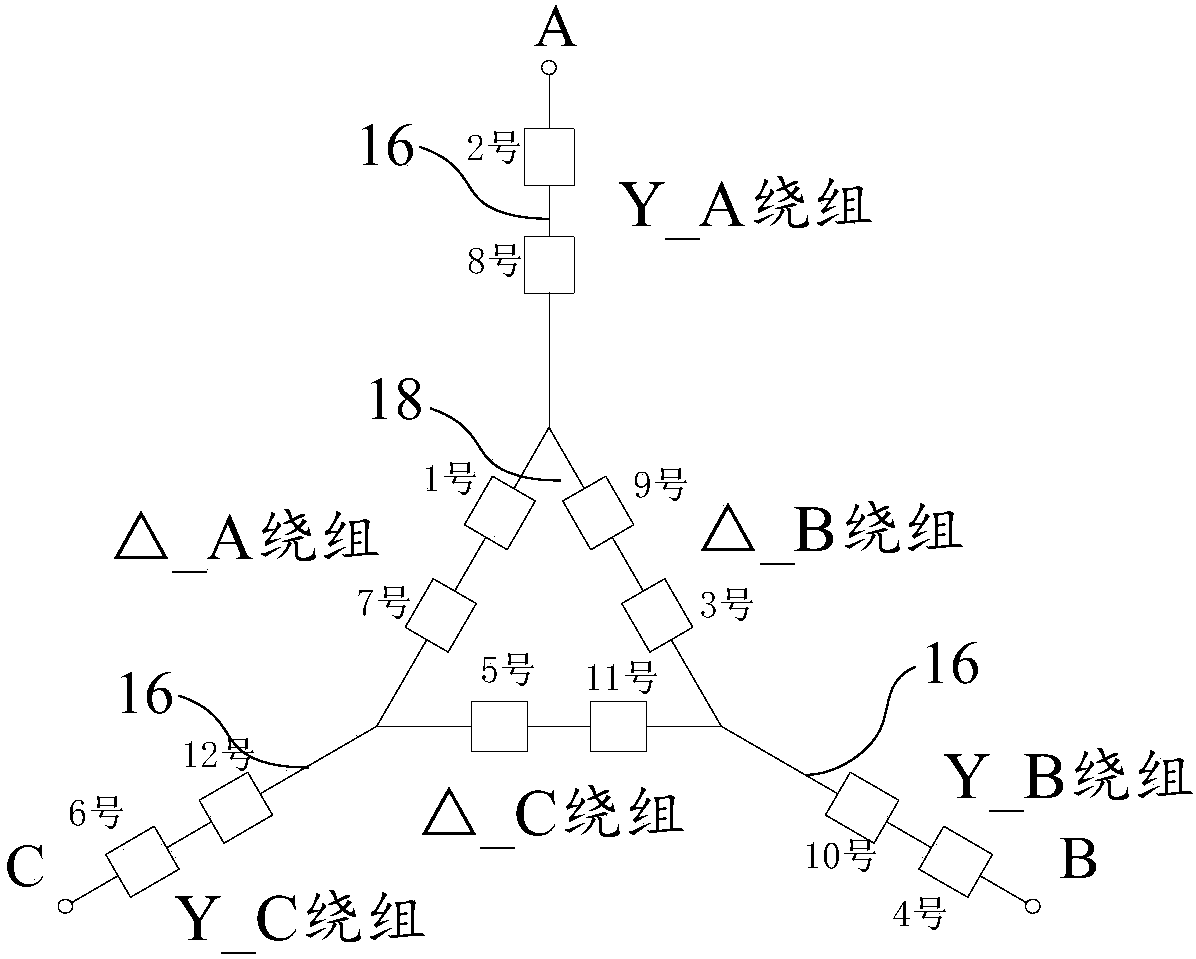

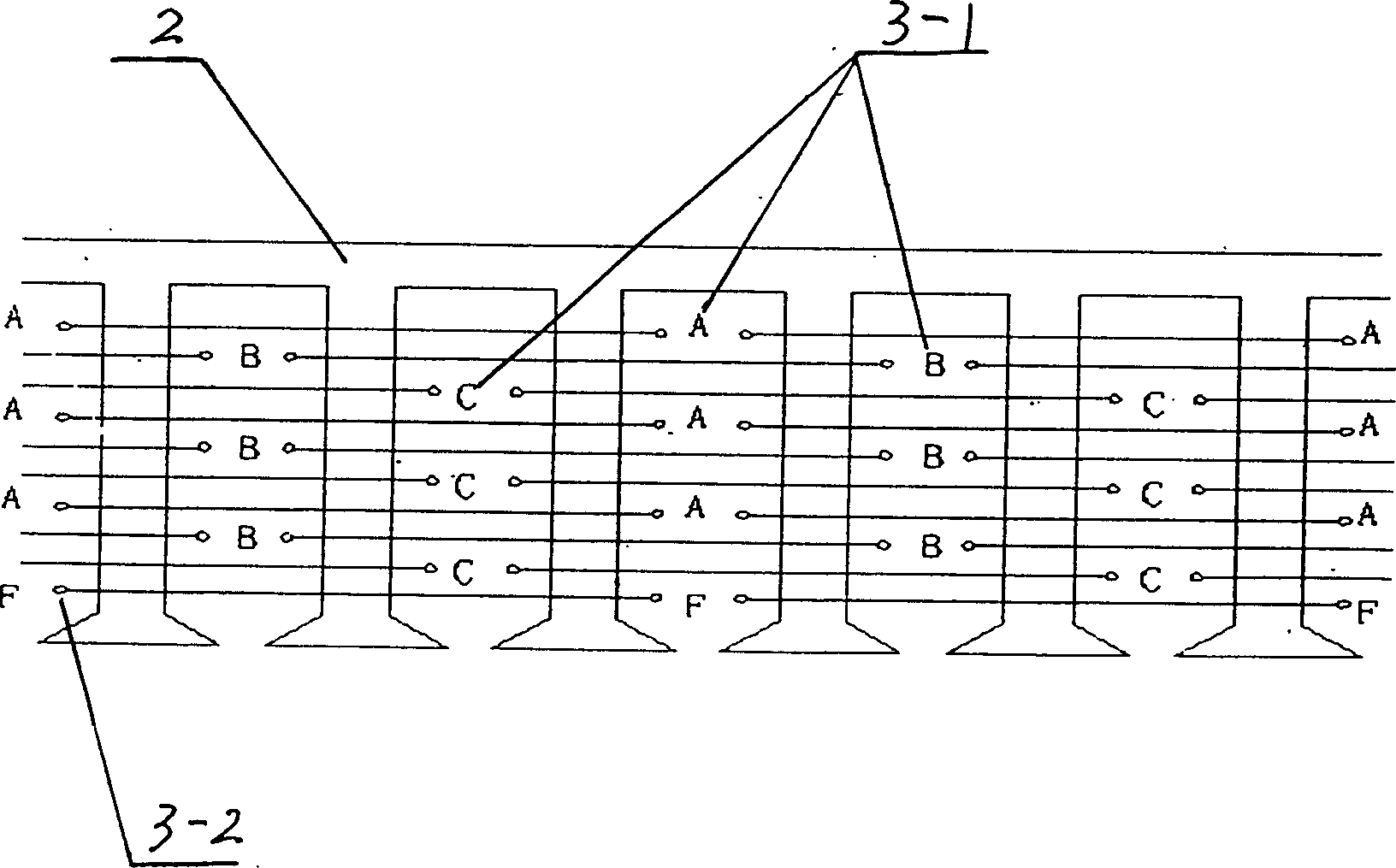

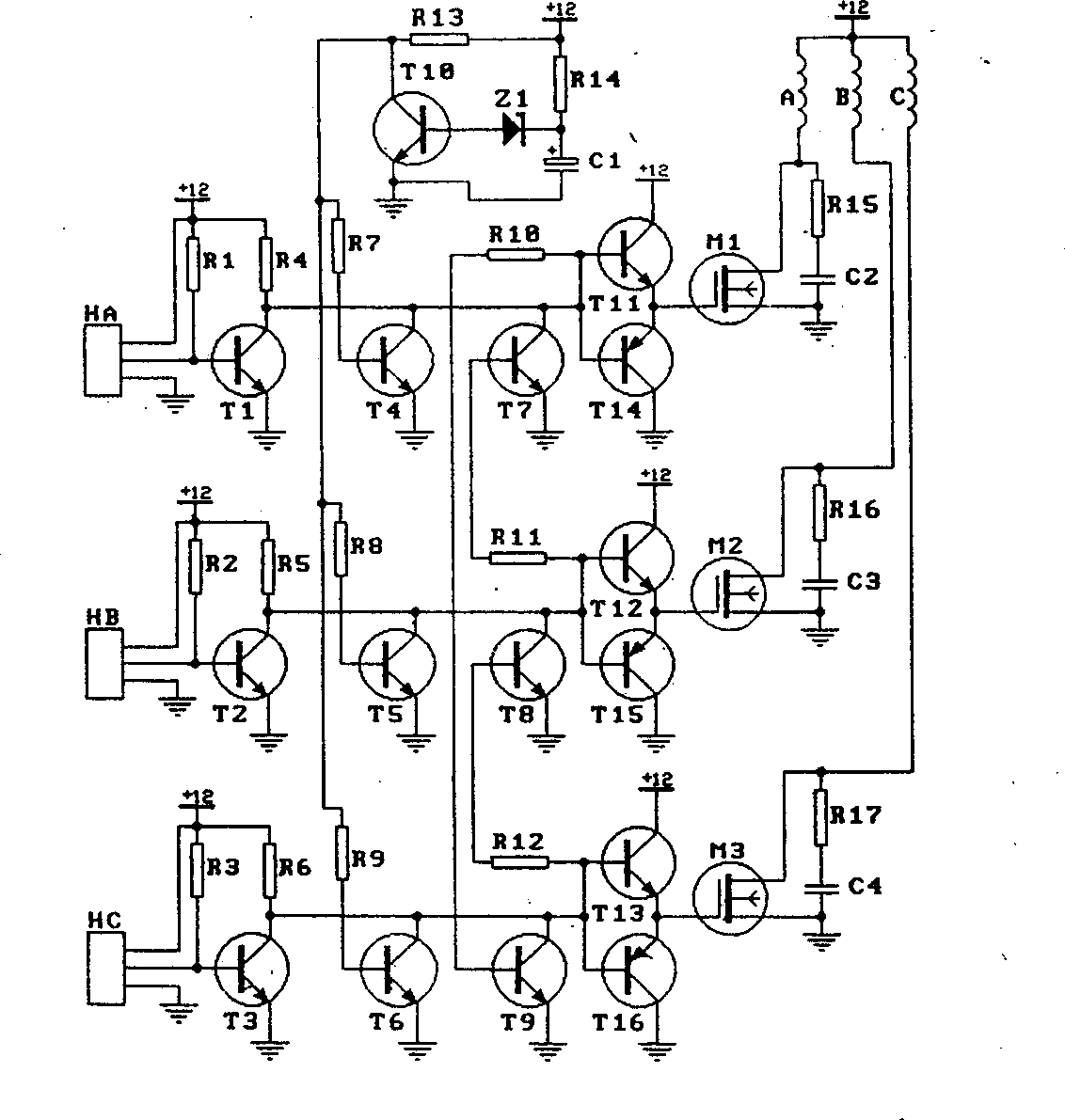

Multi-phase brushless double-fed motor and frequency converting control system

InactiveCN102969860AImprove efficiencyImprove the winding factorAC motor controlWindings conductor shape/form/constructionTransformerConductor Coil

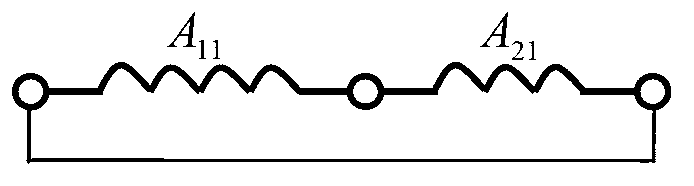

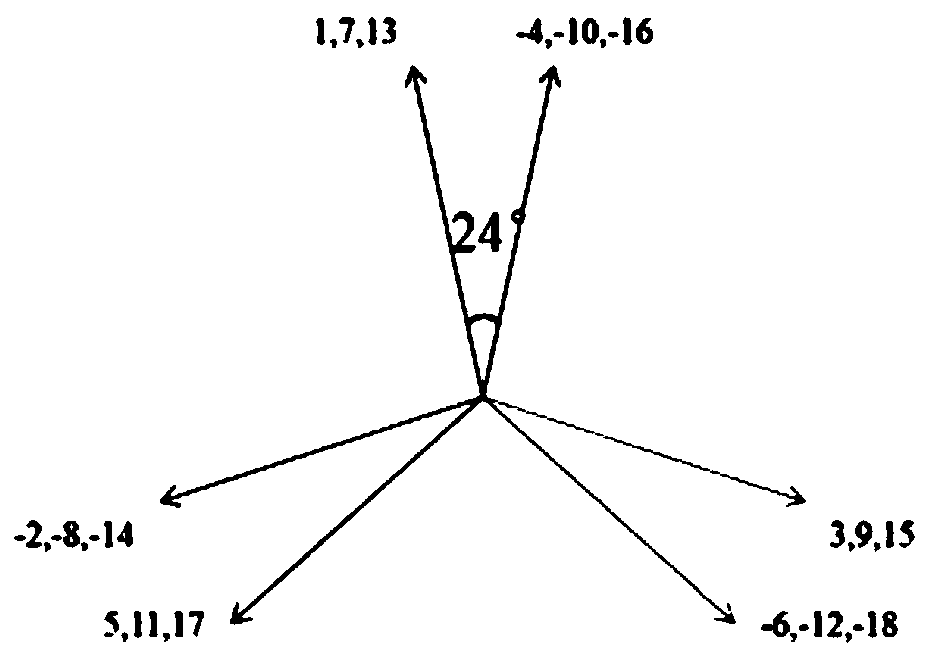

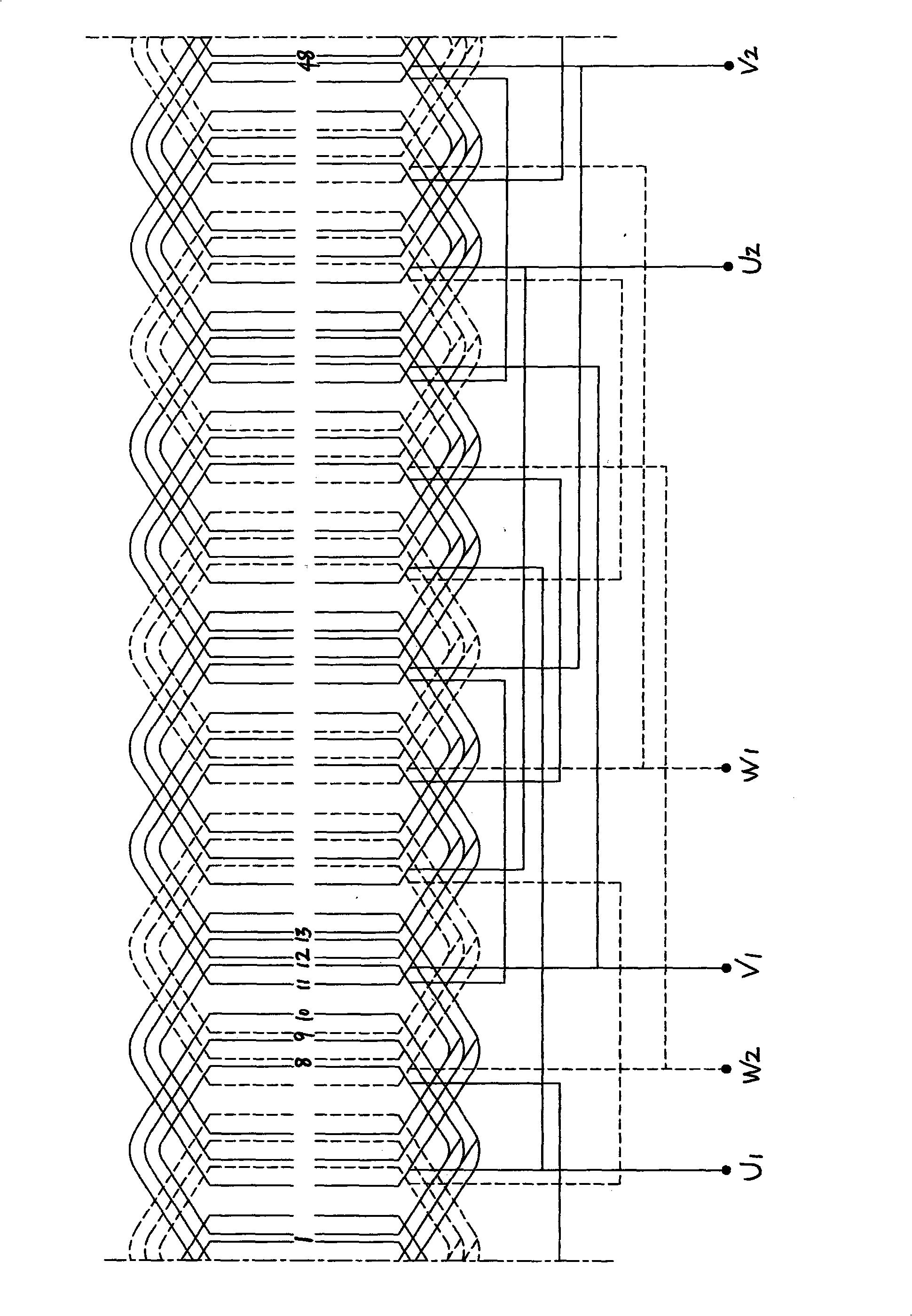

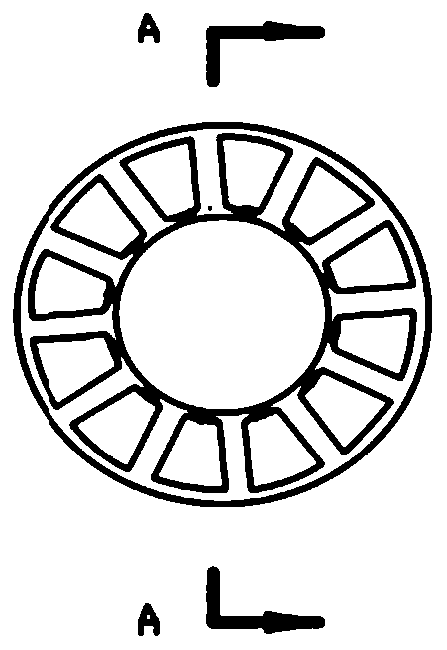

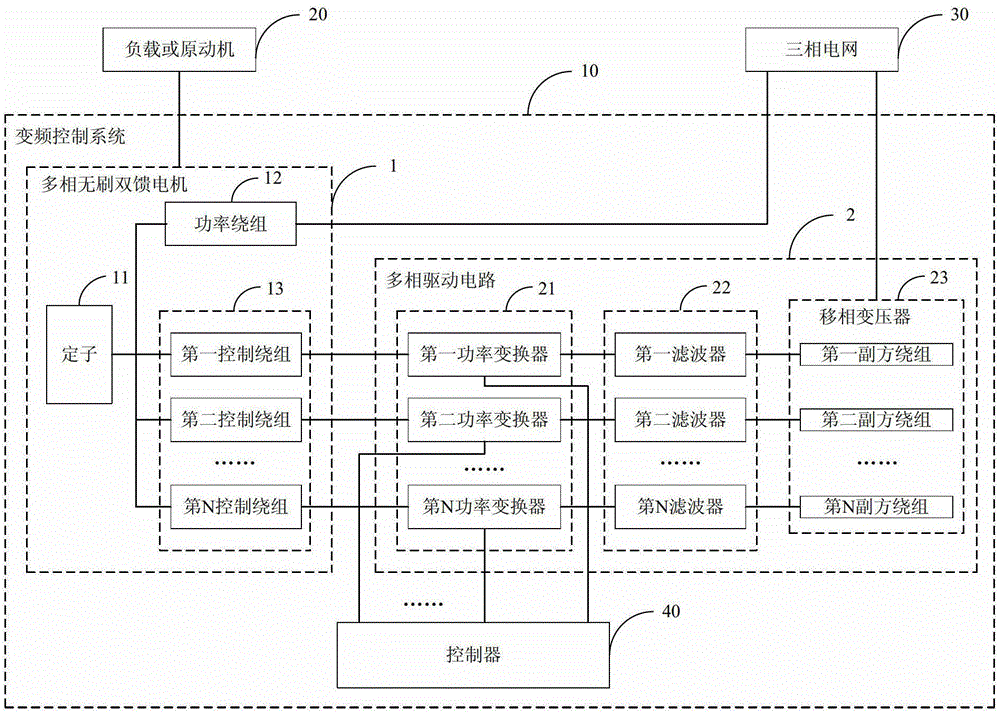

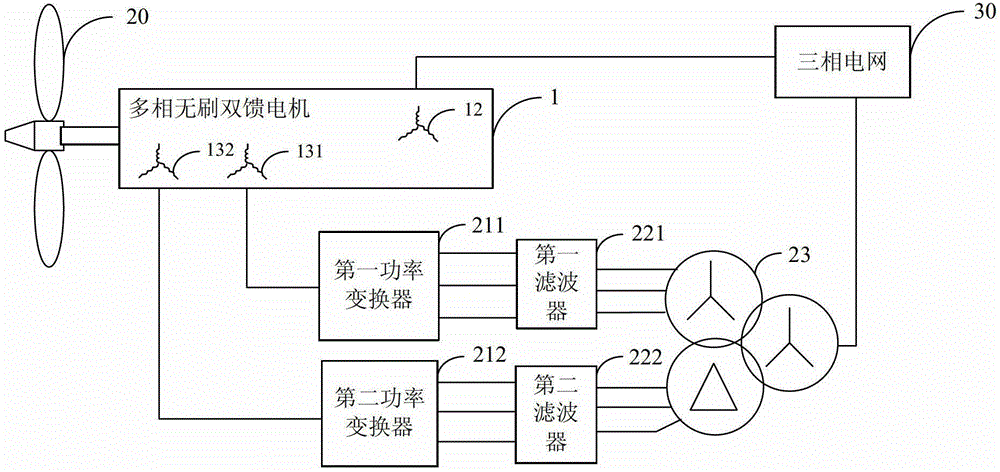

The invention discloses a multi-phase brushless double-fed motor and a frequency converting control system. The frequency converting control system comprises the multiphase brushless double-fed motor and a multi-phase driving circuit, wherein a set of power winding and N sets of control windings are arranged in a stator of a multi-phase brushless double-fed motor, and every set of control winding in the N sets of control windings controls the windings to be distributed with a phase of 60 / N electricity degree. The multi-phase driving circuit comprises N power converters respectively connected with the N sets of control windings, N filters respectively connected with N power converters and a phase-shifting transformer. The phase-shifting transformer comprises N auxiliary square windings and N original square windings, wherein the N auxiliary winding square windings are respectively connected with the N filters, and the original square windings are connected with a three-phase power grid. The control windings of the multi-phase brushless double-fed motor is demounted into a plurality of sets from one set, the phase belt width is changed into 30 degrees or less from the conventional 60 degrees, therefore, winding coefficients of fundamental waves of the control windings are improved, harmonic wave magnetic potential is reduced, and efficiency of a motor is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

Dual-stator magnetism-gathering permanent magnet linear motor with concentrated winding of phase windings

ActiveCN110165852AImprove performanceReduce manufacturing costPropulsion systemsWindings conductor shape/form/constructionPermanent magnet linear motorMagnetization

The invention provides a dual-stator magnetism-gathering permanent magnet linear motor with concentrated winding of phase windings, which comprises a mover and two single-sided stators arranged at twosides of the mover face to face, wherein the mover is a magnetism-gathering permanent magnet mover structure, permanent magnets are horizontally magnetized along the movement direction of the mover,and two adjacent permanent magnets are opposite in magnetization direction; at least one of the single-sided stators is provided with windings and has a mode of concentrated winding of the phase windings. Each single-sided stator is a certain air gap distance away from the mover, the two air gap distances are equal, and the two single-sided stators has an offset of one stator tooth width along themovement direction of the mover. The permanent magnet linear motor provided by the invention has high power density and output thrust, and effectively suppresses the magnetic resistance and thrust fluctuation.

Owner:SHANDONG UNIV

Stator and rotating linear two-degree-of-freedom permanent magnet motor with modular structure

ActiveCN111082551AImprove the winding factorReduced end windingMagnetic circuit rotating partsElectric machinesLinear motionElectric machine

The invention provides a stator and a rotating linear two-degree-of-freedom permanent magnet motor with a modular structure. The rotating linear two-degree-of-freedom permanent magnet motor with the modular structure comprises a stator and a rotor, and the stator comprises a stator core, a rotating motion winding and a linear motion winding; the stator iron core is formed by a plurality of same modular iron core units in a three-phase mode on the circumference. Stator grooves are formed in the axial direction and the circumferential direction of an inner surface of the stator iron core at thesame time, so that stator teeth are distributed in an array mode and evenly distributed on all the modular iron core units. The rotating motion winding is wound on stator teeth which are axially arranged along an inner surface of the stator core along the linear motion direction to form a phase group centralized winding for driving rotary motion; and the linear motion winding is wound on the stator teeth arranged along the circumferential direction of the inner surface of the stator iron core along the circumferential direction to form a phase group centralized winding for driving linear motion. The structure is simple, the manufacturing is easy, and the material utilization rate is increased.

Owner:SHANDONG UNIV

High-winding-factor permanent magnet brushless motor and design and fault-tolerant control method

ActiveCN106357073AReduce volumeReduce weightAC motor controlElectric motor controlBrushless motorsElectric machine

The invention discloses a high-winding-factor permanent magnet brushless motor and a design and fault-tolerant control method. The high-winding-factor permanent magnet brushless motor comprises a stator, an armature winding, a rotor and a permanent magnet, wherein an armature groove is formed in the stator, and the armature winding is placed in the armature groove; double-layer winding is adopted. An air gap is arranged between the stator and the rotor, and a permanent magnet is attached to the surface of the rotor, and is magnetized by using a Halbach array structure. The motor is an eight-phase motor, and phases are evenly distributed at a phase belt angle of 45 degrees; after the phases are distributed, four phase line terminals and a common neutral point are led out. The single-phase open-circuit fault-tolerant algorithm of the motor of the invention solves the problem that the fault-tolerant algorithm can be implemented only by utilizing the phase which and the fault phase has a difference of 180 degrees when the ordinary four-phase motor is in a single-phase open-circuit fault state, and the capacity of an inverter and the insulation rating of the motor winding can be reduced by the fault-tolerant control strategy of the motor. Finally, the motor of the invention and the control algorithm have good fault-tolerant effects, and the average torque after fault tolerance is basically consistent with that in the normal operation.

Owner:JIANGSU UNIV

Stator structure based on disc type permanent-magnetism motor winding

PendingCN109842229ALower resistanceReduce copper consumptionWindings conductor shape/form/constructionEngineeringConductor Coil

The invention discloses a stator structure based on a disc type permanent-magnetism motor winding. The stator structure comprises a PCB with at least 6 or 6N layers, and a Hall sensor; each PCB layeris provided with outer end portions, a winding setting part and inner end portions; each PCB layer is provided with at least three windings, and each winding is provided with two wiring ends correspondingly; the wiring ends are arranged in the outer end portions; each winding coil is printed and arranged in the corresponding outer end portion; the winding coil is uniformly printed on the winding set part along the circumferential direction, and the length of the winding coil is arranged and printed in parallel along the radial direction without overlapping; the same phase of winding coils on the PCB layers are connected via the outer and inner end portions; the Hall sensor is arranged in the outer end portions with an angle; and the layers in the PCB are connected via through holes.

Owner:上海崴崖实业有限公司

Single-phase capacitor-operated motor

InactiveCN101557148AIncrease productivityThe amount of copper used is obviousWindingsMagnetic circuit rotating partsCapacitanceCopper

The invention provides a single-phase capacitor-operated motor, comprising a motor shaft, a rotor, a stator, a front end cover and a rear end cover; wherein, the rotor is sheathed on the motor shaft and the stator is sheathed at the outer side of the rotor; mutually snap-fit front end cover and rear end cover are arranged at the outer side of the stator; the two ends of the motor shaft are installed on the front end cover and rear end cover via bearings; a stator core of the stator is provided with double-row grooves including a deep-row groove and a shallow-row groove; stator winding is concentrated winding comprising first winding and second winding; coils of the first winding and the second winding are respectively wound in the deep-row groove and the shallow-row groove of the stator core; the adjacent coils of the first winding, which are wound in the deep-row groove, are wound forward and reverse; the adjacent coils of the second winding, which are wound in the shallow-row groove, are wound forward and reverse; the first winding is in parallel connection with the second winding after series connection with capacitance or the second winding is in parallel connection with the first winding after series connection with capacitance. The single-phase capacitor-operated motor can save wires by about 20%; motors with thin iron core and large winding span witness more obvious saving of copper content for windings; in addition, the winding shortens the axial length of the motor; manufacturing of the stator winding achieves machine winding, simplifies the processing flows and improves the production efficiency of the stator; besides, the concentrated stator winding adopted by the invention has high coefficient and good motor property and is suitable for motors with different poles and power.

Owner:MIDEA GRP CO LTD

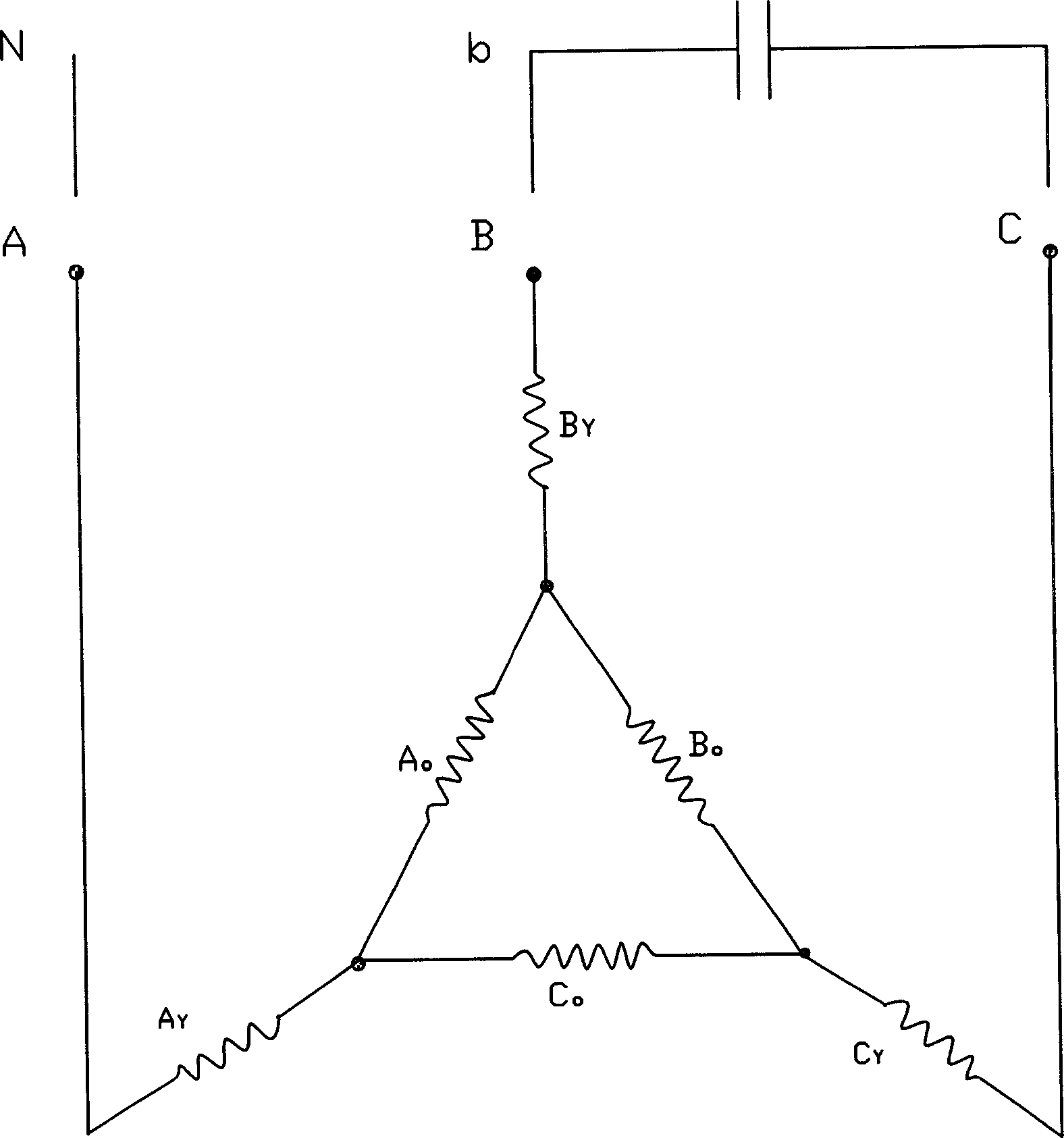

Light power three-phase motor

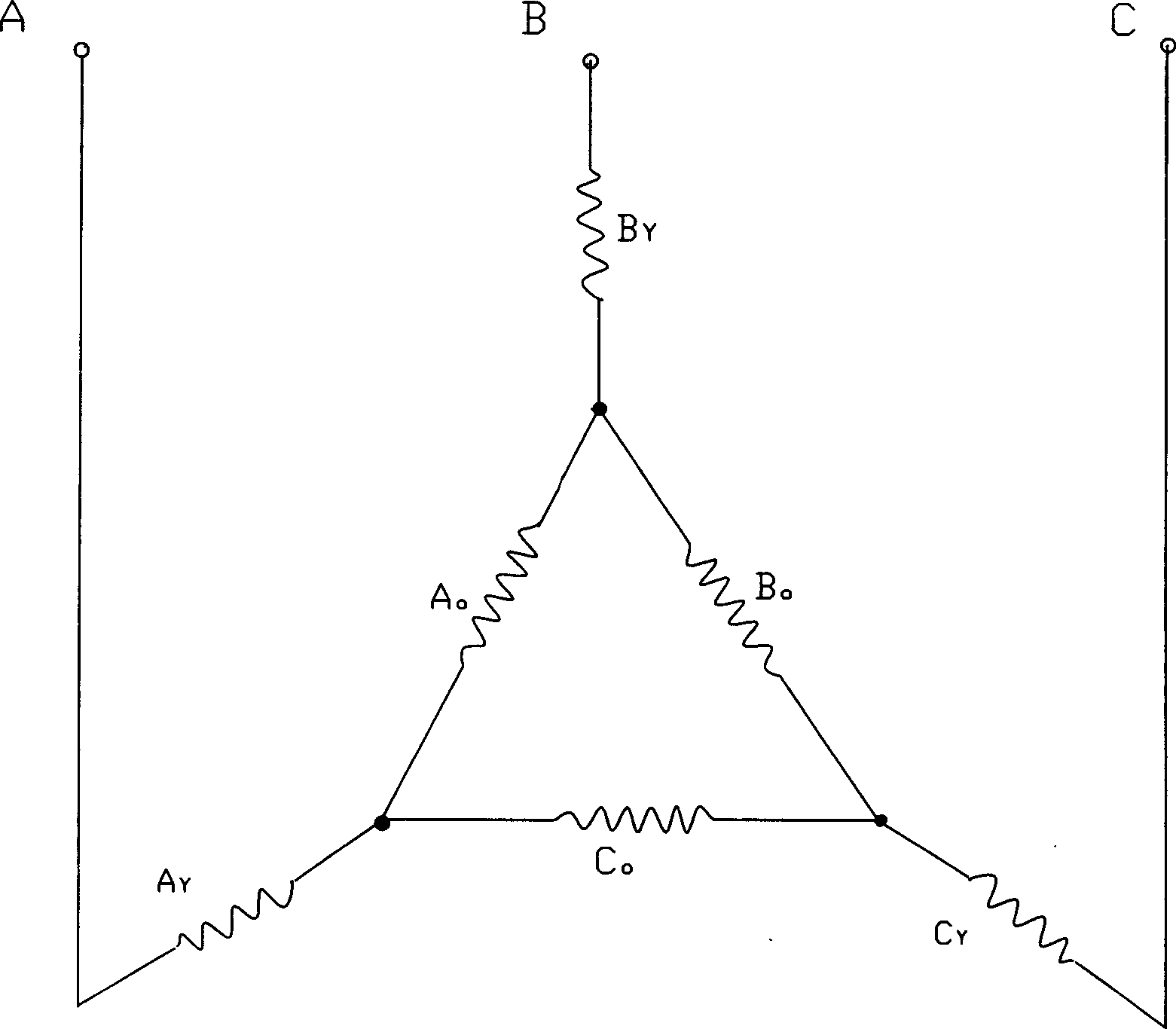

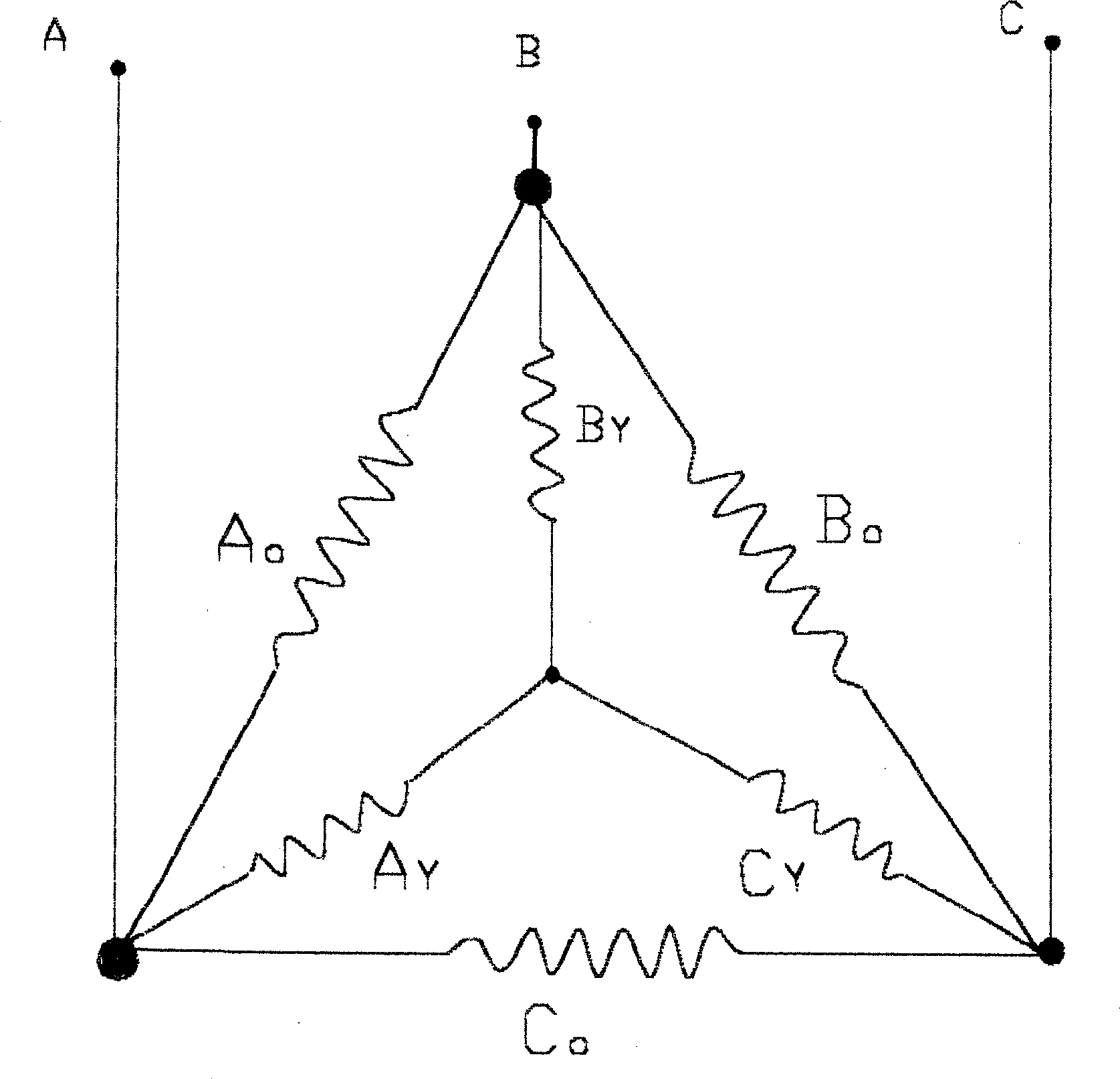

InactiveCN1756042AImprove the winding factorEliminate higher harmonicsWindings conductor shape/form/constructionPhysicsWinding factor

The invention relates to a low power three phase motor. Wherein, the stator has a star winding and a triangle winding; the phase bands of said two windings are alternatively distributed while the electrical angle distance of central space of nearby phase bands is ªð / 6; the invention is characterized in that: the stator has 4 electrodes and 24 grooves while it is consequent pole single-phase winding, the edge of star winding and the edge of triangle winding individually takes up 12 grooves while said two windings are alternatively distributed along the grooves; the number of turn of triangle winding is the 1.73 times of the number of turn of star winding while its wire diameter is the 0.76 times of the wire diameter of star winding; according to the phase sequence, the initial terminal of each phase of star winding is connected to the power source and every linear terminal of triangle winding is connected to the end terminal of relative phase of star winding or the initial terminal of each phase of star winding and every linear terminal of triangle winding are connected to the power source while the end terminals of each phase of star winding are connected each other. Compared to the present technique, the invention can improve the coefficient of winding and weaken higher harmonic to improve the property, reduce the cost, improve the start property and reduce the electromagnetic vibration noise.

Owner:JINLING ELECTRICAL CO LTD

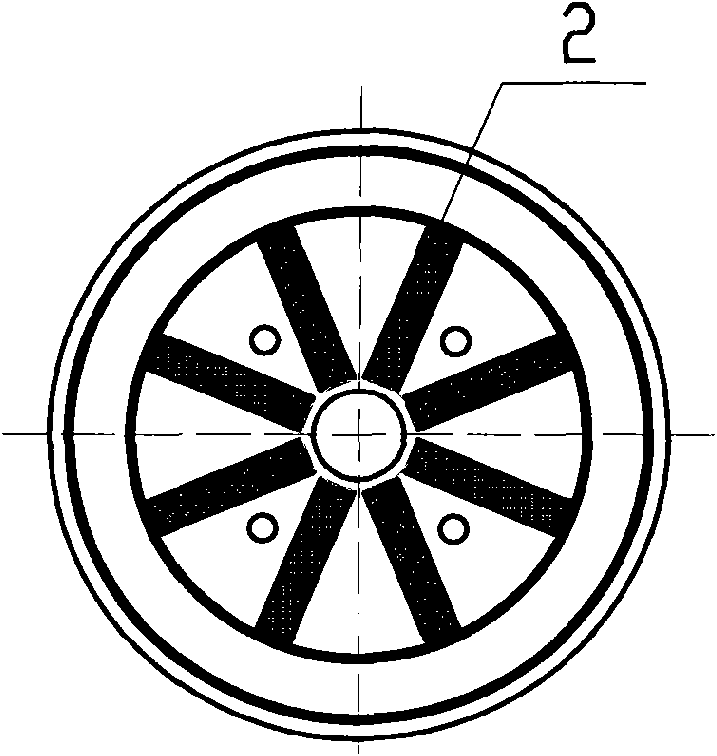

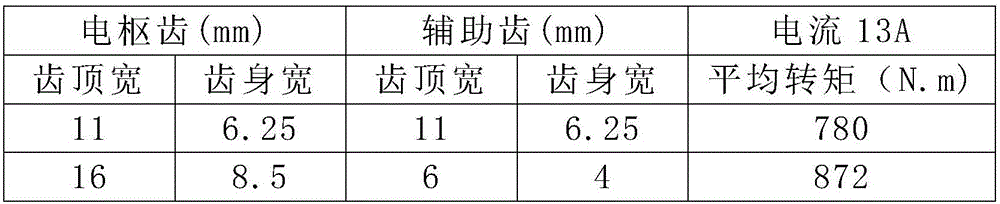

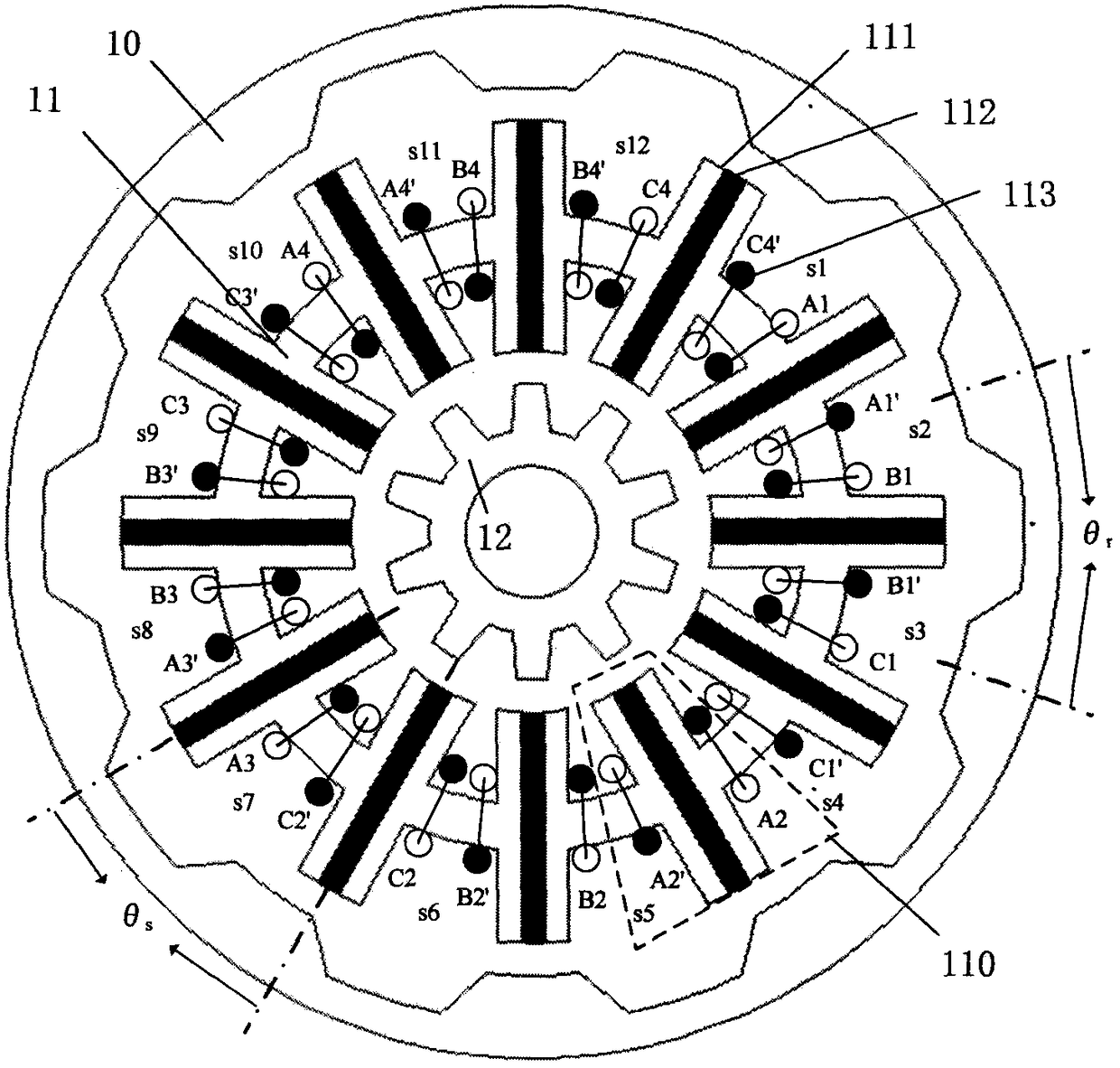

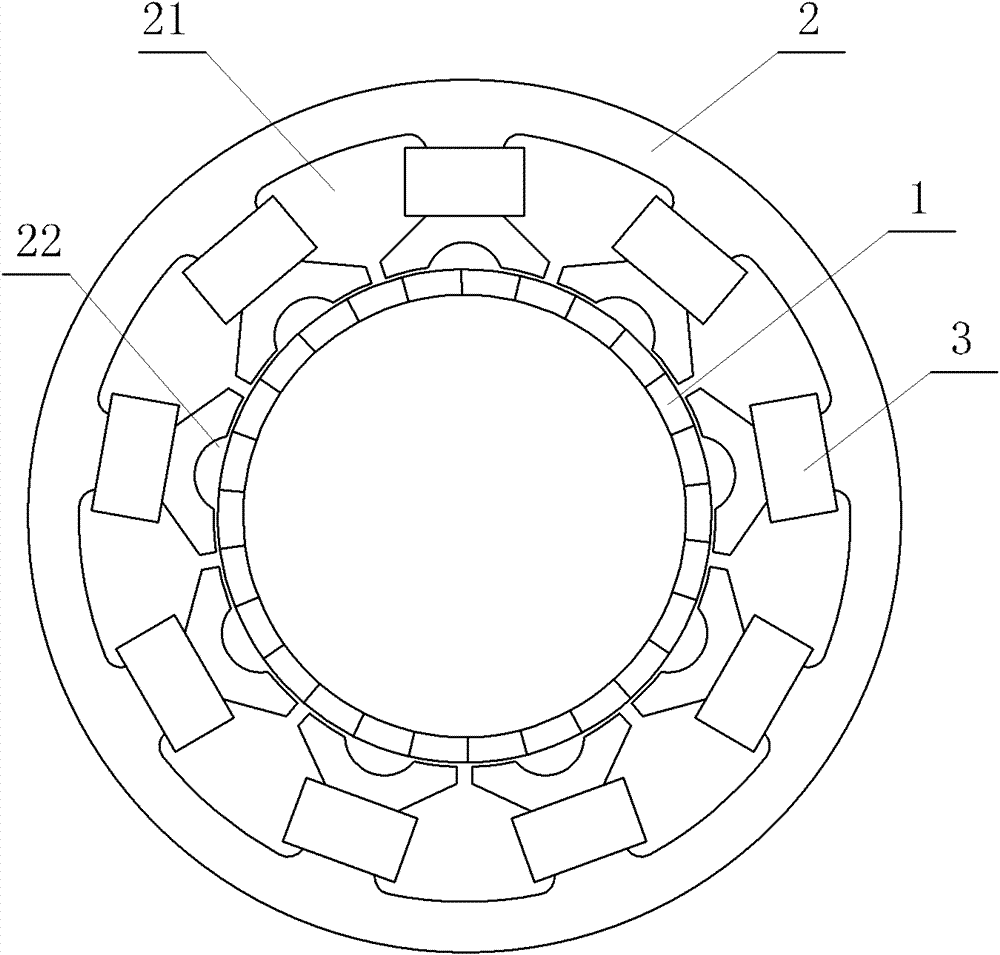

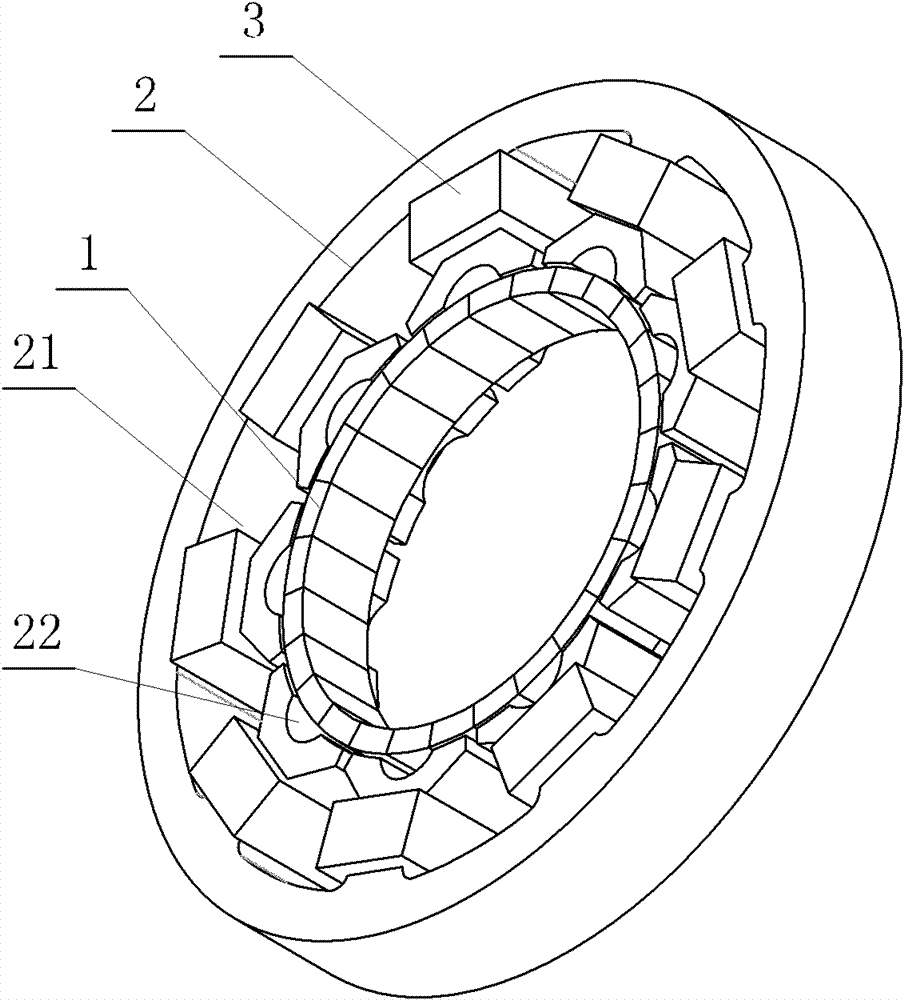

Rotor-stator structure of permanent magnet brushless DC motor

InactiveCN105978182AImprove the winding factorReduce magnetic saturationMagnetic circuit stationary partsElectric machineTorque density

The invention provides a rotor stator structure of a permanent magnet brushless DC motor, which belongs to the technical field of motors. It solves the problems of low torque density and control precision of the existing permanent magnet brushless DC motor. The stator structure of the permanent magnet brushless DC motor includes stator teeth, stator slots and stator windings. The stator teeth include a number of armature teeth and auxiliary teeth. The width of the top and teeth, a number of armature teeth and a number of auxiliary teeth are spaced apart from each other in turn, a stator slot is formed between adjacent armature teeth and auxiliary teeth, the stator winding is embedded in the stator slot and each armature tooth Both are wound with a stator winding. The motor adopts the unequal tooth width design of the armature teeth and auxiliary teeth, which improves the winding coefficient of the motor. At the same time, by rationally designing the tooth width of the armature teeth and auxiliary teeth, the distribution of the magnetic density of the teeth is optimized to avoid saturation of the teeth and improve The output torque of the motor is improved, and the control accuracy of the motor is improved.

Owner:ZHEJIANG ZOBOW MECHANICAL & ELECTRICAL TECH

Single-stator spiral motion multi-phase permanent magnet synchronous motor capable of fault-tolerant operation

InactiveCN110994819AImprove efficiencyIncrease powerMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machinePermanent magnet synchronous motor

The invention relates to a permanent magnet synchronous motor, in particular to a single-stator spiral motion multi-phase permanent magnet synchronous motor capable of fault-tolerant operation. The motor comprises a stator and a rotor, the rotor is positioned on the inner side of the annular stator; the rotor comprises a magnetic conductive rotating shaft and permanent magnet sheets which are alternately distributed on the surface of the magnetic conductive rotating shaft and have polarities of N and S, the stator comprises a stator iron core and a stator winding, the stator iron core is provided with a spiral tooth groove, the spiral direction of the spiral tooth groove and the positive direction of the axis of the motor are in a right-handed spiral relation, six-phase windings A, D, C, F, B and E are sequentially arranged in the spiral tooth groove in the clockwise direction, and the six-phase windings adopt a six-phase double-Y-shift 30-degree winding structure. Materials are saved,the cost is low, the fault-tolerant capability is high, and the working stability of the motor is improved.

Owner:SHANDONG UNIV OF TECH +1

Frequency converting control system

InactiveCN102969860BImprove efficiencyImprove the winding factorAC motor controlWindings conductor shape/form/constructionTransformerConductor Coil

The invention discloses a multi-phase brushless double-fed motor and a frequency converting control system. The frequency converting control system comprises the multiphase brushless double-fed motor and a multi-phase driving circuit, wherein a set of power winding and N sets of control windings are arranged in a stator of a multi-phase brushless double-fed motor, and every set of control winding in the N sets of control windings controls the windings to be distributed with a phase of 60 / N electricity degree. The multi-phase driving circuit comprises N power converters respectively connected with the N sets of control windings, N filters respectively connected with N power converters and a phase-shifting transformer. The phase-shifting transformer comprises N auxiliary square windings and N original square windings, wherein the N auxiliary winding square windings are respectively connected with the N filters, and the original square windings are connected with a three-phase power grid. The control windings of the multi-phase brushless double-fed motor is demounted into a plurality of sets from one set, the phase belt width is changed into 30 degrees or less from the conventional 60 degrees, therefore, winding coefficients of fundamental waves of the control windings are improved, harmonic wave magnetic potential is reduced, and efficiency of a motor is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

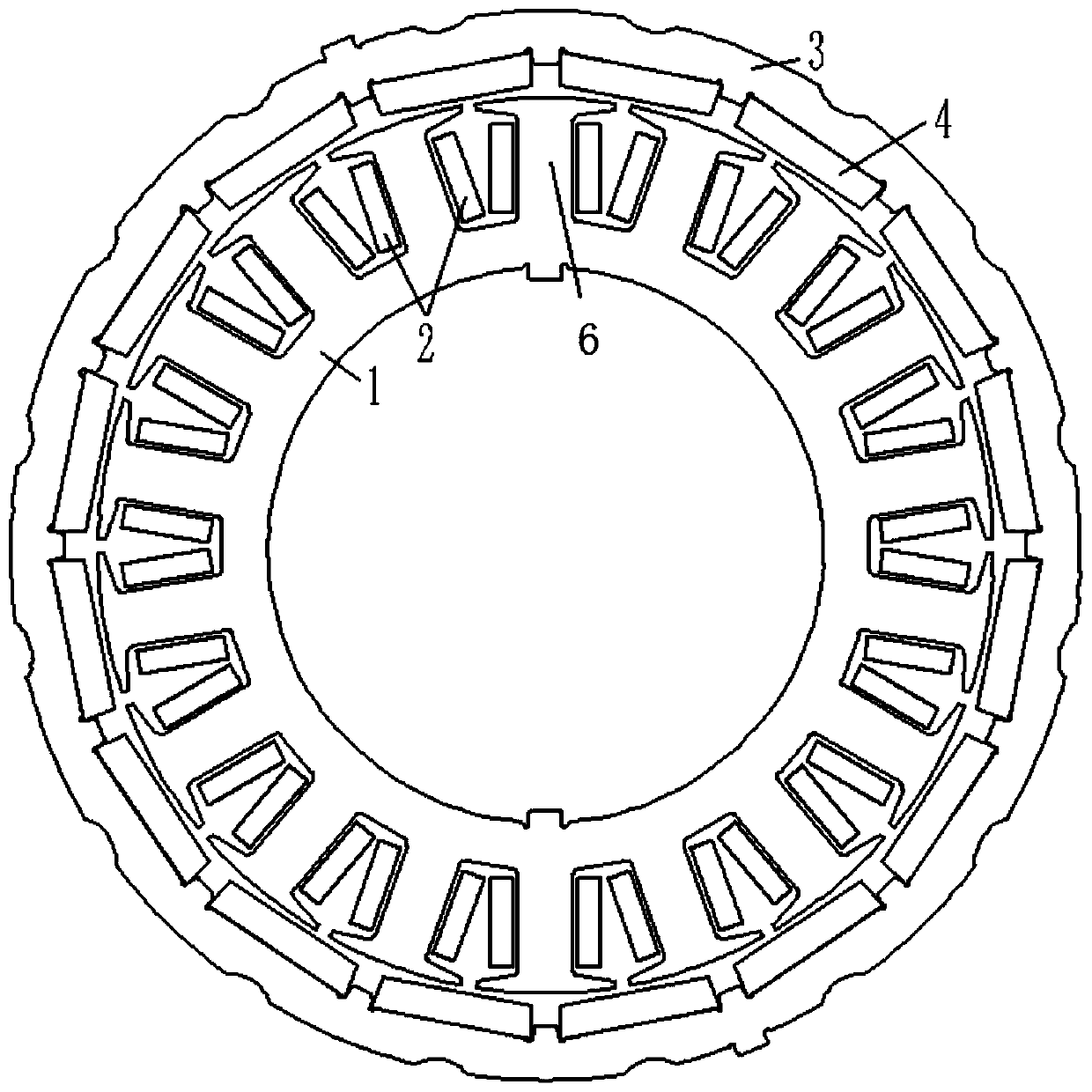

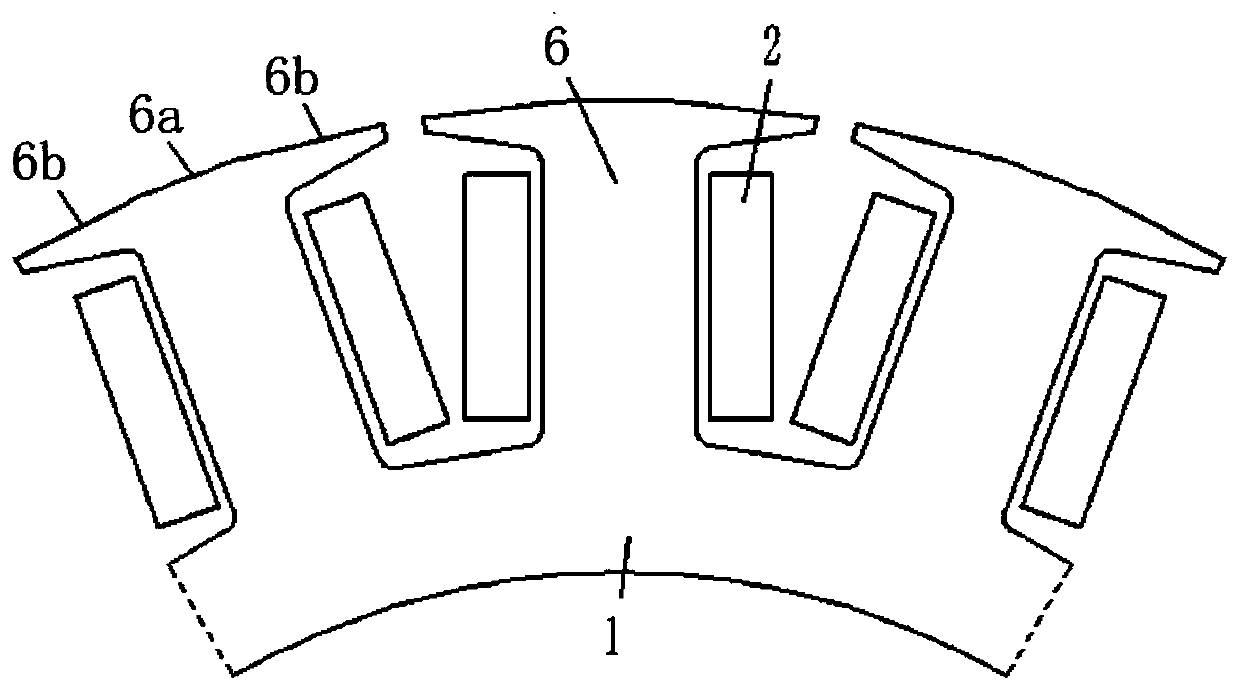

Permanent magnet synchronous motor and compressor

PendingCN108539943AImprove power densityImprove operational efficiencyMagnetic circuit rotating partsMagnetic circuit stationary partsPermanent magnet synchronous motorMagnetic poles

The present invention provides a permanent magnet synchronous motor. The permanent magnet synchronous motor comprises: a rotor which is provided with ten magnetic poles; a stator core provided with arotor hole configured to allow the rotor to pass through and 12 double wedges distributed around the rotor hole, wherein one winding groove is formed between each two adjacent double wedges; three-phase stator windings arranged in the winding grooves, wherein each phase stator winding in the three-phase stator windings comprises two sets of coils, each coil comprises one first-class coil and one second-class coil which are adjacently distributed to each other, the first-class coils are advanced to the second-class coils in the coils, and the diameters of naked wires of the first-class coils are the same as these of the second-class coils; each three-phase stator winding comprises one angle connection portion and one star connection portion, wherein each angle connection portion comprises aplurality of second-class coils which are connected end to end, and each star connection portion comprises first-class coils directly or indirectly connected with points of intersection of the second-class coils; and in each phase stator winding, there is at least one first-class coil connected with a supply wire of a corresponding phase.

Owner:GUANGDONG WELLING AUTO PARTS CO LTD

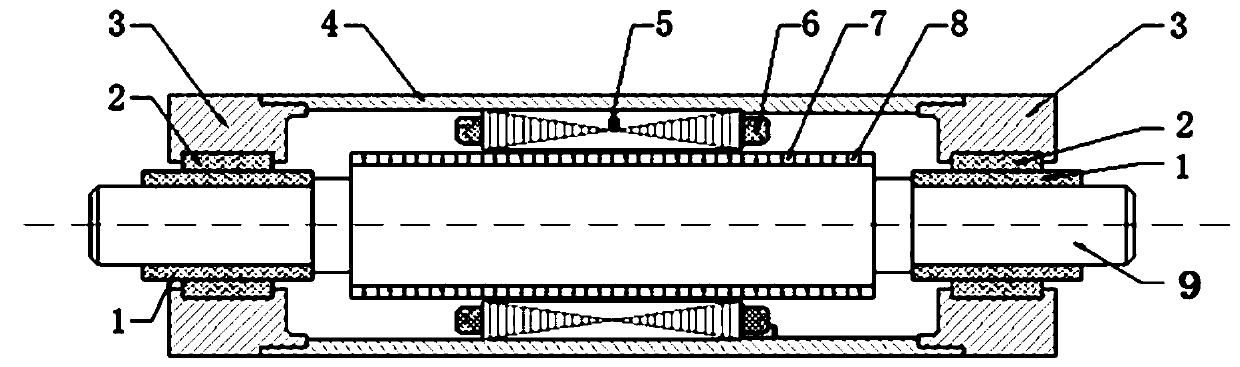

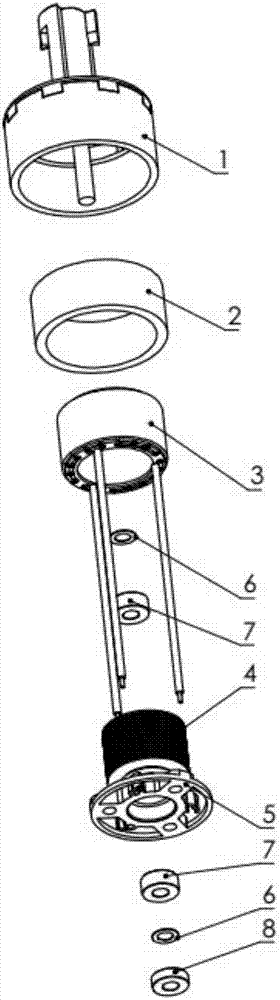

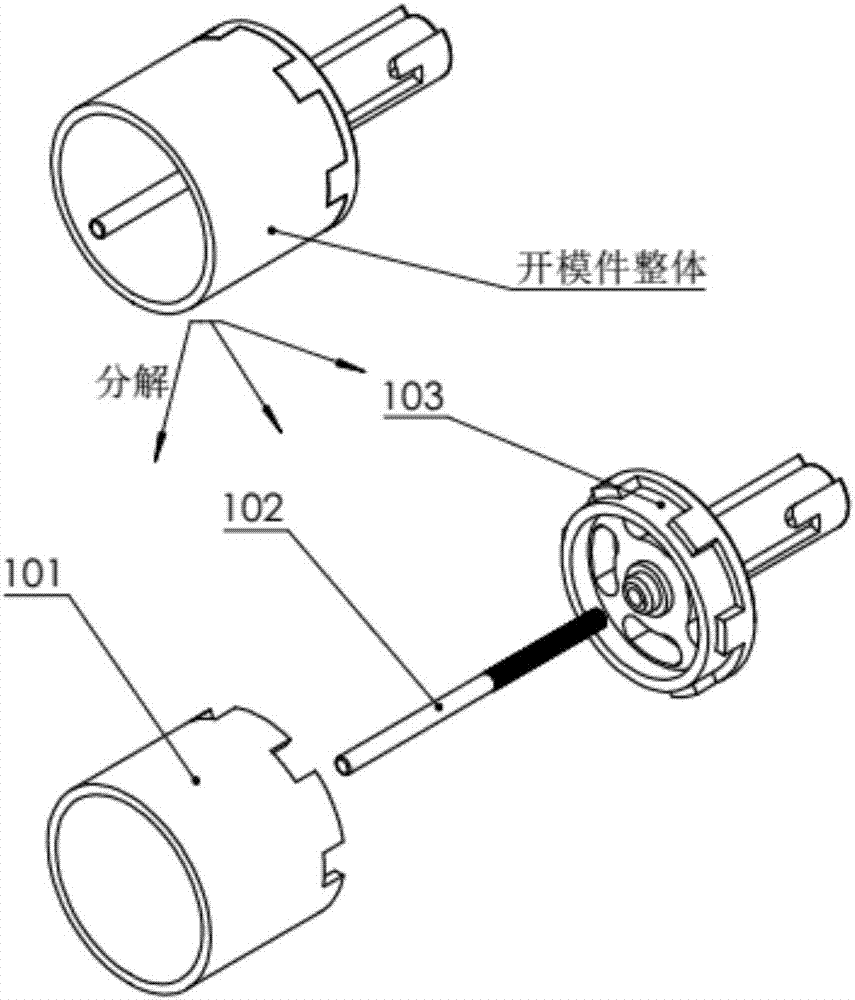

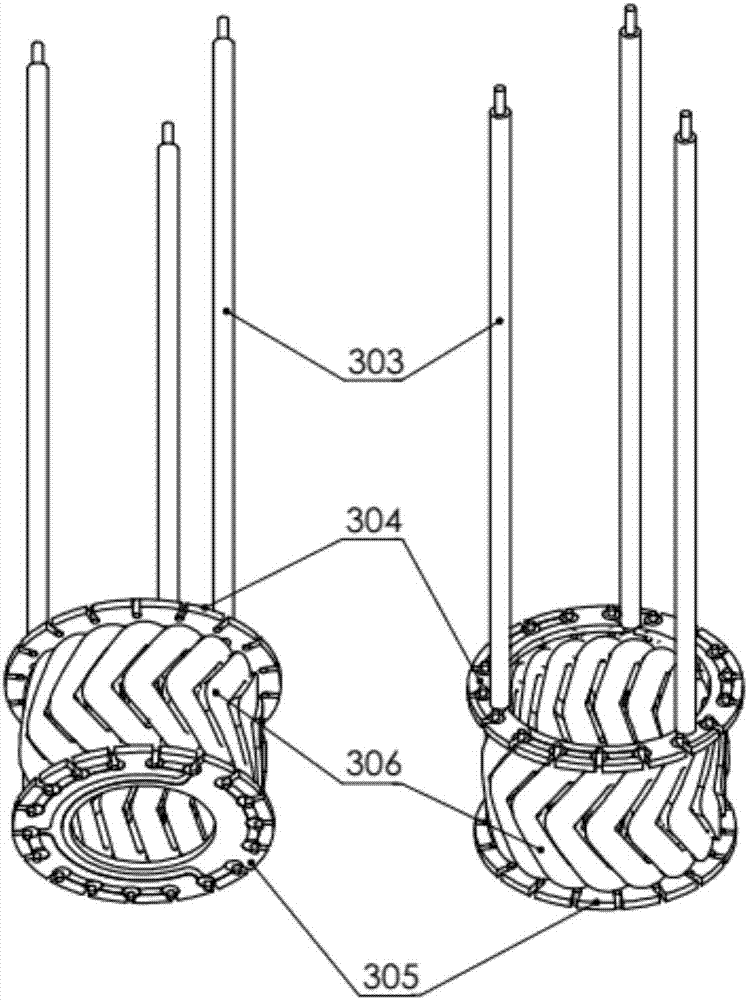

High-efficiency precise DC brushless motor

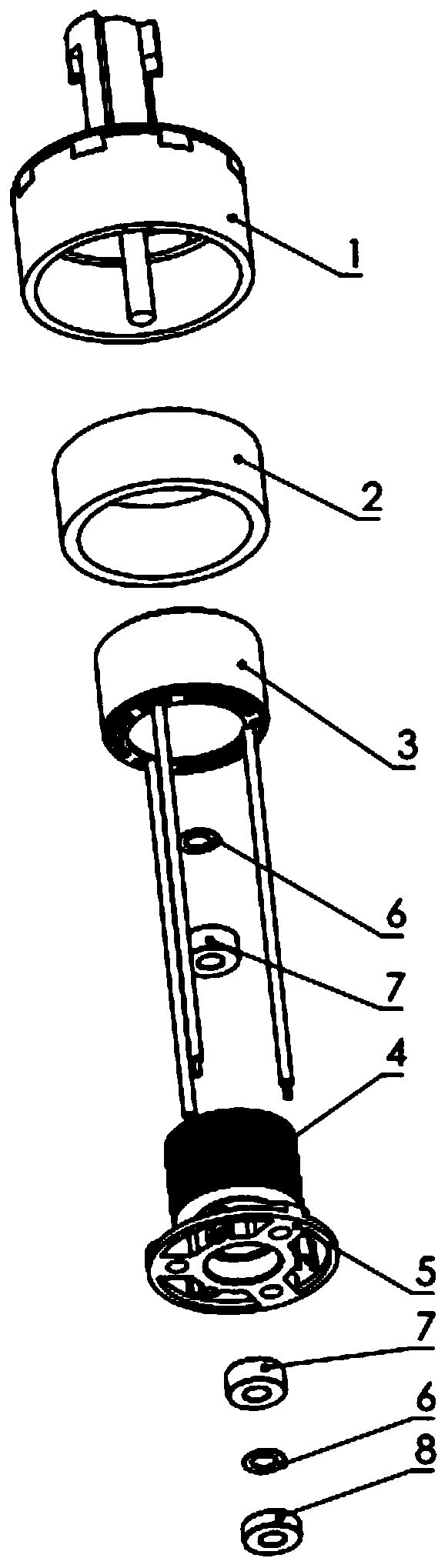

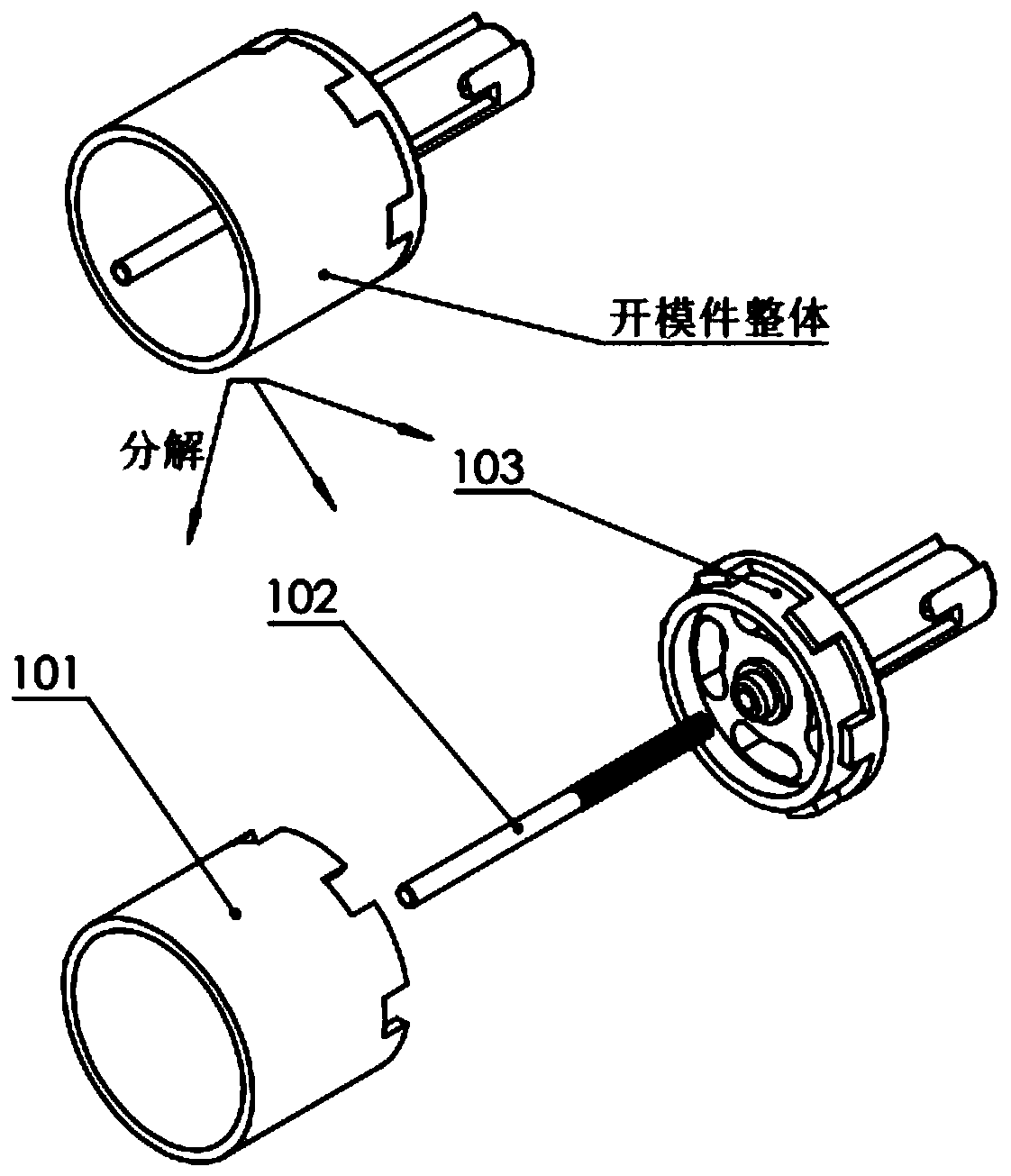

ActiveCN107979202AImprove assembly accuracyImprove structural strengthWindingsMagnetic circuit rotating partsBrushless motorsEngineering

The invention discloses a high-efficiency precise DC brushless motor. The motor comprise an outer rotor assembly, a circular magnet, an armature winding assembly, a laminated stator and a motor base assembly, wherein the outer rotor assembly, the circular magnet, the armature winding assembly, the laminated stator and the motor base assembly are sequentially installed on the same axis from the topto the bottom. The outer rotor assembly comprises a front end cover, a motor case and a rotating shaft, wherein the motor case and the rotating shaft are integrated with the front end cover in a mold-opening poured manner. The armature winding assembly comprises a hollow cup armature winding, a winding wire head connection board, and a terminal wire. The laminated stator is installed on a centralcylinder of the motor base assembly, and is formed by the lamination of a plurality of silicon steel pieces of a toothless groove structure. The motor base assembly comprises a flange, a baring, a gasket and a central cylinder disposed above the flange, wherein the bearing and the gasket are disposed in the flange. According to the invention, the assembly precision of the motor is improved, the assembly technology is simple and the cost is reduced. The operation of the motor is more stable, and the vibration and noise are reduced. Moreover, the utilization rate of space is higher, the reduction of the size of the motor is facilitated, and the power density of the motor is improved. The output efficiency of the motor is remarkably improved.

Owner:ONCE TOP MOTOR MFG

Non-overlapping winding tooth slot type dual-rotor permanent magnet synchronous motor

PendingCN108258820AImprove the winding factorShorten the lengthMagnetic circuit stationary partsWindings conductor shape/form/constructionHigh power densityPhysics

The invention discloses a non-overlapping winding tooth slot type dual-rotor permanent magnet synchronous motor, which comprises a stator, an inner rotor and an outer rotor; an air gap is arranged between the stator and the rotor. A primary grade comprises m*k*n basic units, m is a phase number, k is a positive integer, and n is a motor unit number; every basic unit comprises two half-H shaped permeability magnetic materials and a permanent magnet arranged between the half-H shaped permeability magnetic materials; the magnetizing directions of the permanent magnet of adjacent basic units are opposite to each other, the winding is encircled at a yoke part of the basic unit; the inner and outer rotors are tooth slot structures. The motor is featured by simple rotor structure, short winding end part, non-overlapping winding, high power density, and others; the motor can be applied to electric automobile, wind power generation, and other occasions.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Salient-pole pole-changing synchronous motor

InactiveCN104184289APole changeKeep the structureMagnetic circuit rotating partsSynchronous motorsSynchronous motorPhysics

The invention relates to the motor technical field and especially to a salient-pole pole-changing synchronous motor. The salient-pole pole-changing synchronous motor comprises a stator three-phase winding with two different numbers of pole-pairs p1 and p2, wherein the p1 is greater than p2. Magnetic poles arranged on a rotor are configured in salient-pole non-equidistant structure and have same sizes and widths. A DC excitation coil is wound around each magnetic pole. All the magnetic poles are divided into two groups. When the directions of current flowing through the excitation coils in the two groups are same, the number of pole-pairs of the rotor is p1. When the directions of current flowing through the excitation coils in the two groups are opposite, the number of pole-pairs of the rotor is p2. Based on a concept of virtual multiple grooves, a salient-pole rotor is converted into a non-salient-pole rotor by means of a groove number phase diagram so as to be analyzed such that a novel design principle is formed. Therefore, a clear and visualized basis is provided for the establishment of a pole-changing scheme.

Owner:SHANGHAI ELECTRIC TIMAC

Stator structure based on iron-core-free disc type motor

PendingCN109842228AImprove output performanceMake full use of spaceWindings conductor shape/form/constructionEngineeringConductor Coil

The invention provides a stator structure based on an iron-core-free disc type motor. The stator structure comprises a PCB including 6 or 6N layers; each layer of the PCB is provided with an outer endportion, a winding setting portion and an inner end portion successively from outside to inside; each layer is also provided with at least three phase of windings, and each phase of winding is provided with a terminal correspondingly; the terminal is arranged in an external through hole in the winding setting portion; each phase of winding coil is printed and arranged in the corresponding terminal position; the winding coil is uniformly printed on the winding setting portion along the circumferential direction, the length of the winding coil is arranged side by side along the radial direction, and the winding coil is printed without overlapping; the same phase of winding coils arranged in the layers of the PCB are connected via the outer and inner portions; and the layers in the PCB are connected via through holes. The structure of the stator winding is arranged along the circumferential direction of the PCB, the radial length is not increased, space of a stator board can be used morefully, the structure is more compact, the size of the stator board can be reduced, and the output performance of the motor is improved.

Owner:上海崴崖实业有限公司

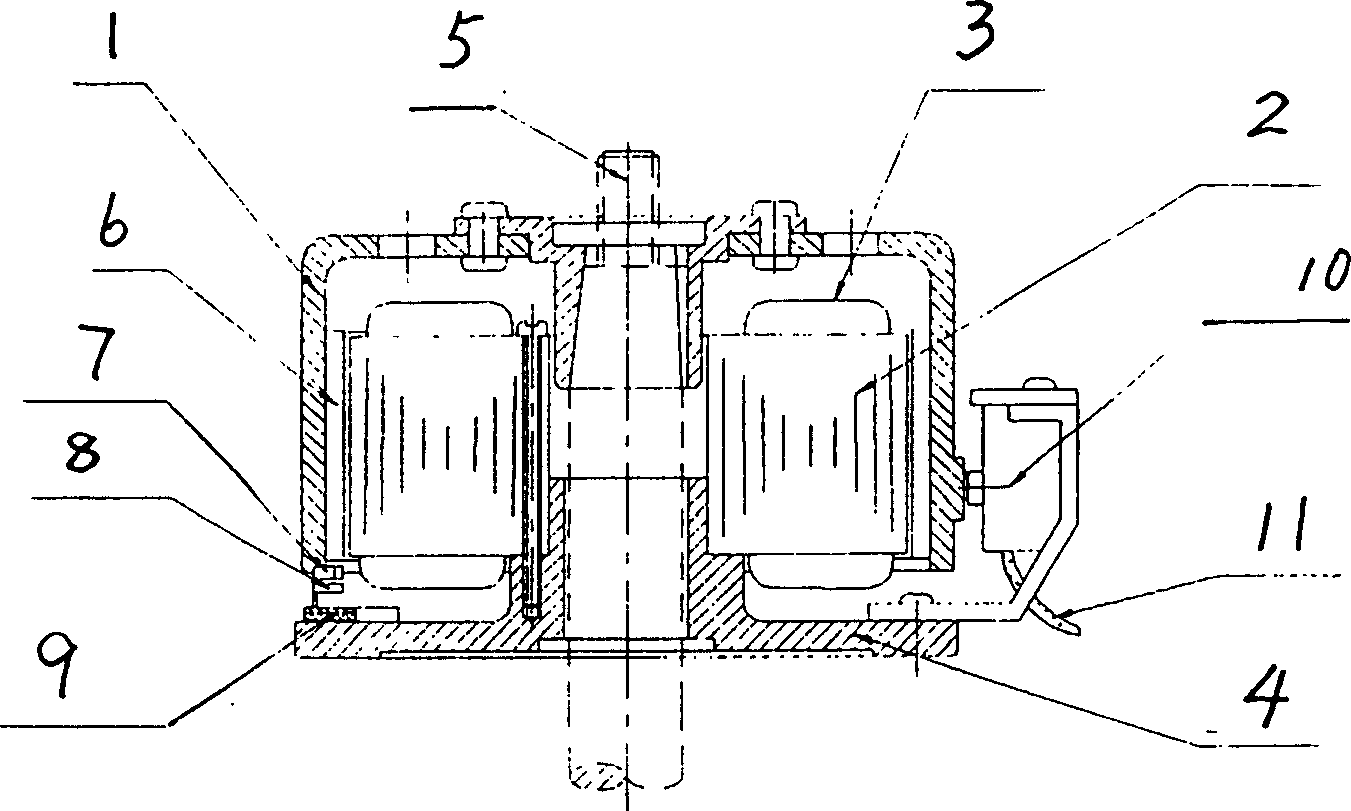

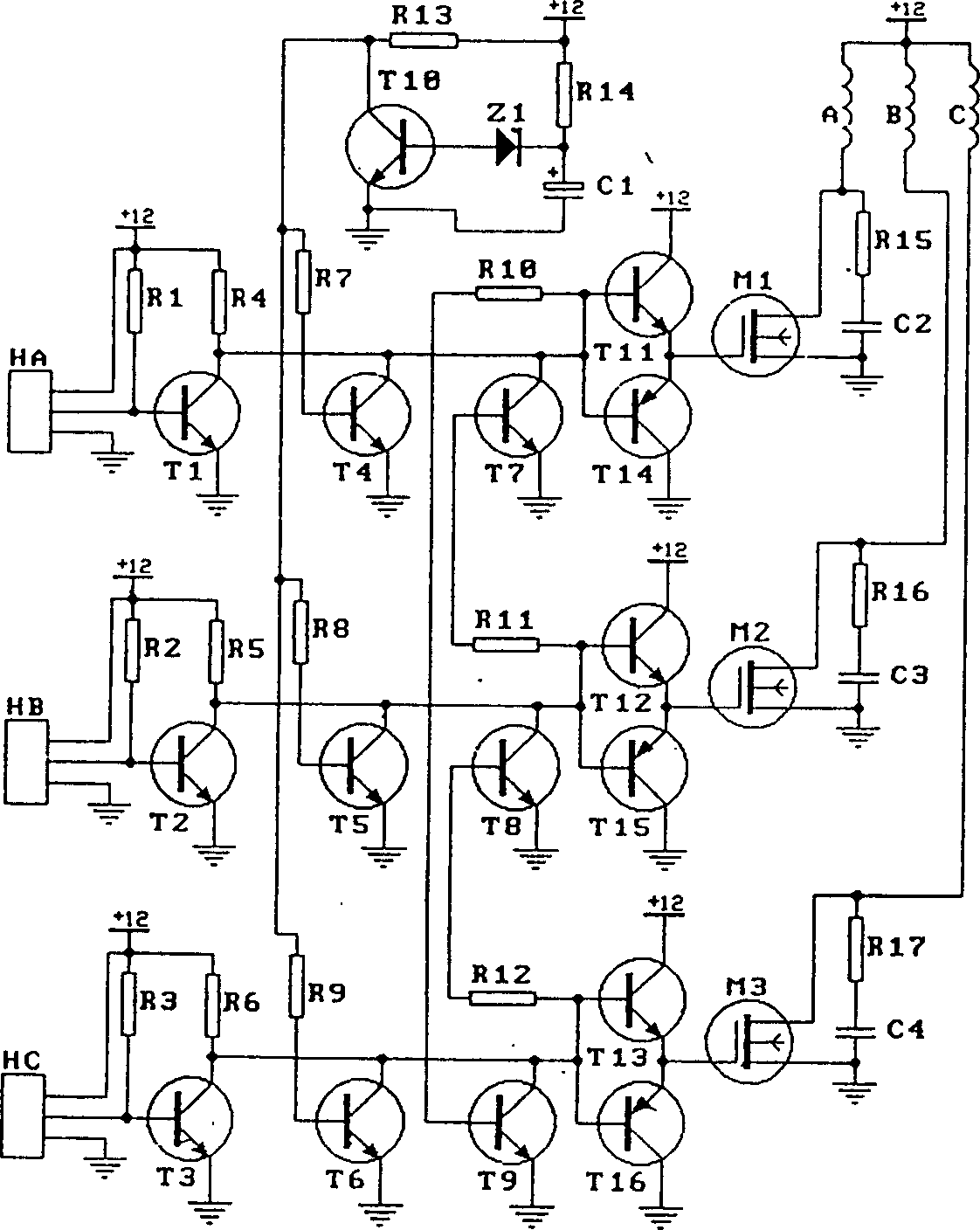

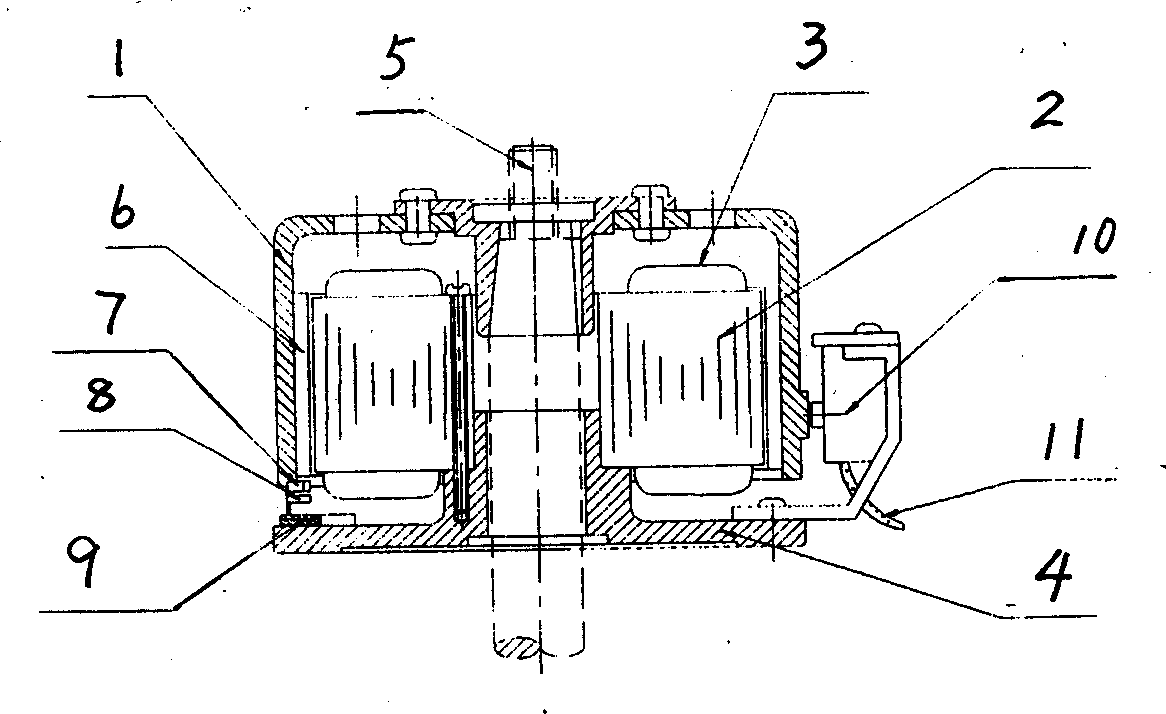

Starting brushless DC magnetor for motorcycle

The invention discloses a DC brushless starting magnetor used in motorcycle. The magnetor includes bottom seat of electrical motor, flywheel of out rotor, rotating shaft, internal stator and starting driving circuit. Cheap material of ferrite magnet steel is adopted in the invention. Three-phase starting coil group with spanning slots and integral interval as well as single-phase coil of generating electricity with spanning slot and integral interval is installed in the coil slot of internal stator. In said three-phase coil and under each pole, the coils with same phase have same turn number and are laid on layers in same slot, and the connection between coils is in parallel or in serial. Out of phase coils are laid on layers in different slot in sequence, and the connection between coils is in parallel or in serial. Number of turns in serial of each parallel branch circuit in each phase coil is equal. Said single-phase coil is located on outside layer of said three-phase coil. The connection between single-phase coils is in serial. The invention reduces cost greatly, but without reducing starting performance of electrical motor so as to provide good economical effect.

Owner:TIANJIN UNIV

Starting brushless DC magnetor for motorcycle

InactiveCN1360390ALower the altitudeIncrease profitDynamo-electric machinesDriver circuitElectricity

The invention discloses a DC brushless starting magnetor used in motorcycle. The magnetor includes bottom seat of electrical motor, flywheel of out rotor, rotating shaft, internal stator and startingdriving circuit. Cheap material of ferrite magnet steel is adopted in the invention. Three-phase starting coil group with spanning slots and integral interval as well as single-phase coil of generating electricity with spanning slot and integral interval is installed in the coil slot of internal stator. In said three-phase coil and under each pole, the coils with same phase have same turn number and are laid on layers in same slot, and the connection between coils is in parallel or in serial. Out of phase coils are laid on layers in different slot in sequence, and the connection between coilsis in parallel or in serial. Number of turns in serial of each parallel branch circuit in each phase coil is equal. Said single-phase coil is located on outside layer of said three-phase coil. The connection between single-phase coils is in serial. The invention reduces cost greatly, but without reducing starting performance of electrical motor so as to provide good economical effect.

Owner:TIANJIN UNIV

Single-phase capacitor motor

InactiveCN1756043AImprove the winding factorEliminate higher harmonicsAsynchronous induction motorsWindings conductor shape/form/constructionCapacitancePhase angle difference

The invention relates to a single-phase capacity motor. Wherein, its stator has a three phase winding, two input terminals connected to the two electrodes of single-phase power source and the second input terminal via the capacitor connected to one electrode of said single-phase power source. And the invention is characterized in that: said three phase winding comprises a star winding with a star connection to said three input terminals and a triangle winding with a triangle connection to said three input terminals; the phase band of said star wind and the phase band of triangle winding are alternatively distributed in the stator groove while the electrical angle distance of central space between nearby phase band is ªð / 6; And the current time phase angle difference of said nearby phase bands has the same sign with the electrical angel distance of central space of phase band. Compared to the present technique, the invention can improve the coefficient of winding and weaken higher harmonic to improve the property, reduce the cost, improve the start property and reduce the electromagnetic vibration noise.

Owner:JINLING ELECTRICAL CO LTD

A High Efficiency and Precision DC Brushless Motor

ActiveCN107979202BImprove assembly accuracyImprove structural strengthWindingsMagnetic circuit rotating partsBrushless motorsElectric machine

The invention discloses a high-efficiency precise DC brushless motor. The motor comprise an outer rotor assembly, a circular magnet, an armature winding assembly, a laminated stator and a motor base assembly, wherein the outer rotor assembly, the circular magnet, the armature winding assembly, the laminated stator and the motor base assembly are sequentially installed on the same axis from the topto the bottom. The outer rotor assembly comprises a front end cover, a motor case and a rotating shaft, wherein the motor case and the rotating shaft are integrated with the front end cover in a mold-opening poured manner. The armature winding assembly comprises a hollow cup armature winding, a winding wire head connection board, and a terminal wire. The laminated stator is installed on a centralcylinder of the motor base assembly, and is formed by the lamination of a plurality of silicon steel pieces of a toothless groove structure. The motor base assembly comprises a flange, a baring, a gasket and a central cylinder disposed above the flange, wherein the bearing and the gasket are disposed in the flange. According to the invention, the assembly precision of the motor is improved, the assembly technology is simple and the cost is reduced. The operation of the motor is more stable, and the vibration and noise are reduced. Moreover, the utilization rate of space is higher, the reduction of the size of the motor is facilitated, and the power density of the motor is improved. The output efficiency of the motor is remarkably improved.

Owner:ONCE TOP MOTOR MFG

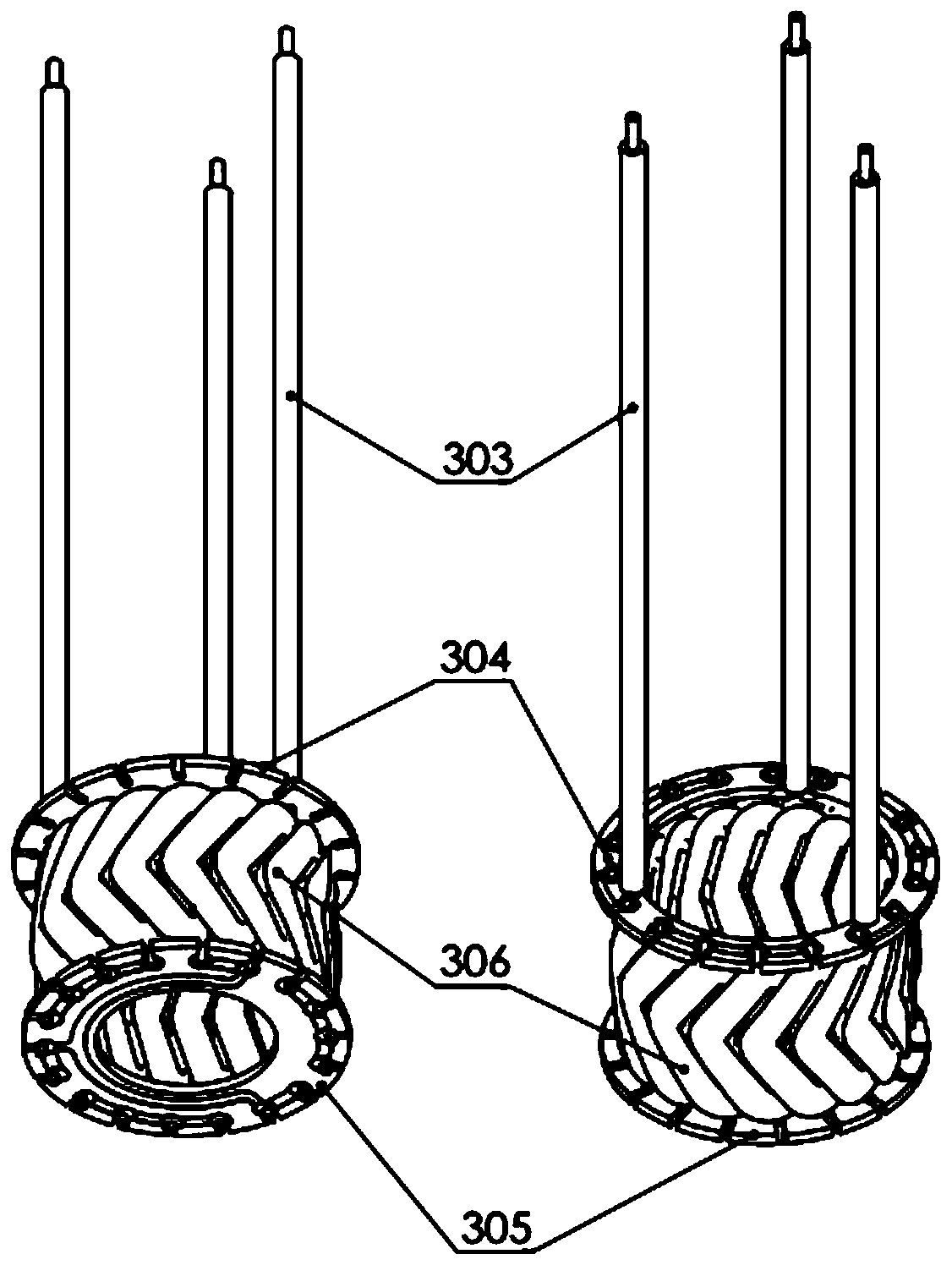

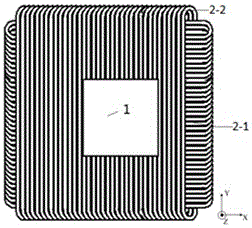

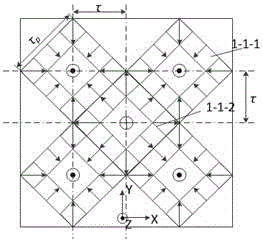

Multi-phase nested winding permanent magnet synchronous planar motor

ActiveCN104218770BImplementation driveRemove constraintsPropulsion systemsRange of motionPermanent magnet synchronous motor

The invention discloses a multi-phase nested winding type permanent magnet synchronous planar motor. It includes the permanent magnet excitation part and the armature winding part. After the two parts are superimposed, there is an air gap; the permanent magnet excitation part includes a two-dimensional permanent magnet array and a yoke composed of N pole and S pole excitation modules. The excitation modules have the same size. And all include a vertically excited main magnetic pole at the center, auxiliary magnetic poles at four sides and auxiliary magnetic poles at four corners; the armature winding includes windings placed along the X direction and along the Y direction, along X and along Y The windings placed in each direction are divided into two parts based on the Y-direction and X-direction centerlines. The windings between the four parts are independent of each other. According to the relative position between the armature winding and the two-dimensional permanent magnet array, the current of each part of the winding can be controlled. Separate control to realize driving and positioning of five degrees of freedom. The invention has the advantages of high winding utilization rate, light weight, fast response speed, wide range of movement, etc., and can be used in the occasions requiring multi-degree-of-freedom driving and positioning.

Owner:ZHEJIANG SCI-TECH UNIV

Brushless double-fed motor wound rotor winding and manufacturing method thereof

ActiveCN102801266BImprove the winding factorHarmonic reductionAsynchronous induction motorsManufacturing dynamo-electric machinesElectrical conductorHarmonic

The invention relates to a brushless double-fed motor wound rotor winding and a manufacturing method thereof, and adopts two sets of multiphase sub windings to form a multiphase winding type winding in a stacking and overlapping way. The two sets of multiphase sub windings are respectively comprise coils and pitches, wherein the numbers of the coils and the numbers of the pitches of the two sets are respectively different, one of the two sets of multiphase sub windings comprises m phases of sub windings, each phase the m phases of sub windings is composed of n 1 serial-connection coils which have N1 turns and are numbered in order or is in a double-layer or a single-layer manner, and a coil pitch is y1; the other set of m phases of sub windings is in a single-layer manner, each phase is composed of n 2 serial-connection coils which have N2 turns and are numbered in order, a coil pitch is y 2, and the n 2 and the y 2 meet a relation that n2= z / (p1+p2)-y2; after the two sets of multiphase sub windings are synthetized, the all coils (in each phase) n= n 1+ n 2 are successively connected in series and then are connected from a short circuit, and the relative positions of the two sets of multiphase sub windings is shifted through regulating the numbers pitches or relative turns of the coils; and the optimum matching is realized so as to generate a superimposed effect, thereby achieving the purpose of improving fundamental wave utilization ratio of a winding coil conductor and weakening a harmonic wave.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Double-stator split tooth type cylindrical linear motor

PendingCN112688524AImprove performanceReduce manufacturing costMagnetic circuit rotating partsMagnetic circuit stationary partsPermanent magnet rotorElectric machine

The invention provides a double-stator split tooth type cylindrical linear motor. The double-stator split tooth type cylindrical linear motor comprises an inner stator, a rotor and an outer stator; the rotor is of a magnetism gathering type permanent magnet rotor structure, the permanent magnets are horizontally magnetized in the moving direction of the rotor, and the magnetization directions of every two adjacent permanent magnets are opposite; the outer stator is provided with a phase group concentrated winding, and the inner stator is not provided with a winding; the inner stator and the outer stator are both of a split tooth structure; and a certain air gap distance exists between each stator and the rotor, the two air gap distances are equal, and the two stators have the offset of the width of one main stator tooth in the moving direction of the rotor. According to the scheme, high power density and high output thrust are achieved, and magnetic resistance and thrust fluctuation are effectively restrained.

Owner:SHANDONG UNIV

Novel inner rotor permanent magnet motor

ActiveCN102185447BGuaranteed uptimeImprove craftsmanshipMagnetic circuit stationary partsSynchronous machines with stationary armatures and rotating magnetsSlot insulationElectric machine

The invention belongs to the technical field of motors, and in particular relates to a novel inner rotor permanent magnet motor with permanent magnet. The inner rotor permanent magnet motor comprises a stator assembly and a shaft type inner rotor inside the inner rotor, wherein the rotor assembly comprises a stator iron core and a stator coil which is wound on the stator iron core; the stator iron core is of a big and small slot structure which comprises big slots and small slots; the number of the small slots is equal to the number of the big slots; the small slots are correspondingly distributed on the top of the each tooth of the stator iron core; the ratio of the number of the big slots to the number of poles of the rotor is in a fractional slot design; the ratio of the number of the big slots to the number of poles of the rotor meets the following formula: the ratio is equal to (2p+ / -1) / 3: 2p, wherein p represents pole pairs of the motor; and the total number of the stator iron core is (2p+ / -1) / 3*2. On the basis of keeping higher processing property, slot insulation materials of the inner rotor permanent magnet motor are reduced, the winding coefficients are high, the harmonic content is small and the efficient running of the motor can be ensured. The inner rotor permanent magnet motor can be widely applied to an axial flow fan and other electrical equipment, thus ensuring preferable usability of the axial flow fan and the other electrical equipment.

Owner:FANS TECH ELECTRIC CO LTD

External rotor permanent magnet motor

InactiveCN110752682AImprove performanceReduce manufacturing costMagnetic circuit rotating partsElectric machinesFlywheel energy storageElectric machine

The invention discloses an external rotor permanent magnet motor. The external rotor permanent magnet motor includes a stator and an external rotor; the external rotor includes a rotor iron core and aplurality of rotor steel magnets fixed inside the rotor iron core; the stator includes a stator iron core and a stator winding embedded into a stator groove; a stator tooth includes a tooth body anda tooth boot located on left and right sides of the tooth body; the tooth body and top surfaces of the tooth boots on the left and right sides form a segmented type structure; and a relationship between the number of stator grooves Q and the number of poles of the external rotor 2P meets Q=(2P+ / -1):2P, wherein the P is the number of pole pairs of the rotor. According to the external rotor permanent magnet motor, on the basis of improving performance of the motor, the difficulty of a machining process is reduced, and the manufacturing cost of the motor is reduced; and the external rotor permanent magnet motor has the advantages of high winding coefficient, small harmonic content, low torque pulsation and high torque / power density, and the like, and can be widely applied to fields such as flywheel energy storage, electromobile and electric propulsion.

Owner:江苏迈吉易威电动科技有限公司

Radial and axial dual-modular magnetic flux switching motor

ActiveCN113178963ALess odd harmonic contentSuppresses unilateral magnetic pullWindingsMagnetic circuit rotating partsElectric machineEngineering

The invention relates to a radial and axial dual-modular magnetic flux switching motor. The radial and axial dual-modular magnetic flux switching motor comprises a stator and a rotor; the stator comprises an armature winding and at least one stator module arranged in the axial direction, each stator module comprises two stator units, and magnetic isolation rings are embedded between the two stator units of each stator module and between the two adjacent stator units of the two adjacent stator modules; each stator unit comprises a permanent magnet and a plurality of stator iron cores which are arranged in a circumferential manner, and the permanent magnet is embedded between two adjacent stator iron cores; the same armature coil of the armature winding is wound on the magnetic conductive bridge arms of the stator cores at the same positions of all the stator units along the axial direction of the motor; and the rotor comprises rotor modules with the same number as the stator modules, each rotor module comprises two rotor units, and the difference between the central angles of the installation positions of the two rotor units of each rotor module is 180 DEG. The harmonic waveform of the permanent magnet flux linkage of the motor is closer to sine waves, pulsation of output torque of the motor is reduced, and vibration and noise are reduced.

Owner:HEBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com