Salient-pole pole-changing synchronous motor

A technology of synchronous motors and salient poles, which is applied in the direction of synchronous motors for single-phase current, magnetic circuit shape/style/structure, magnetic circuit rotating parts, etc., which can solve the problem of reduced material utilization rate, low space or material utilization rate , It is difficult to accurately determine the magnetic pole position and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1, method steps are as follows:

[0047] 1. Select the number of pole pairs p of the front pole and the rear pole 1 =12 and p 2 =10;

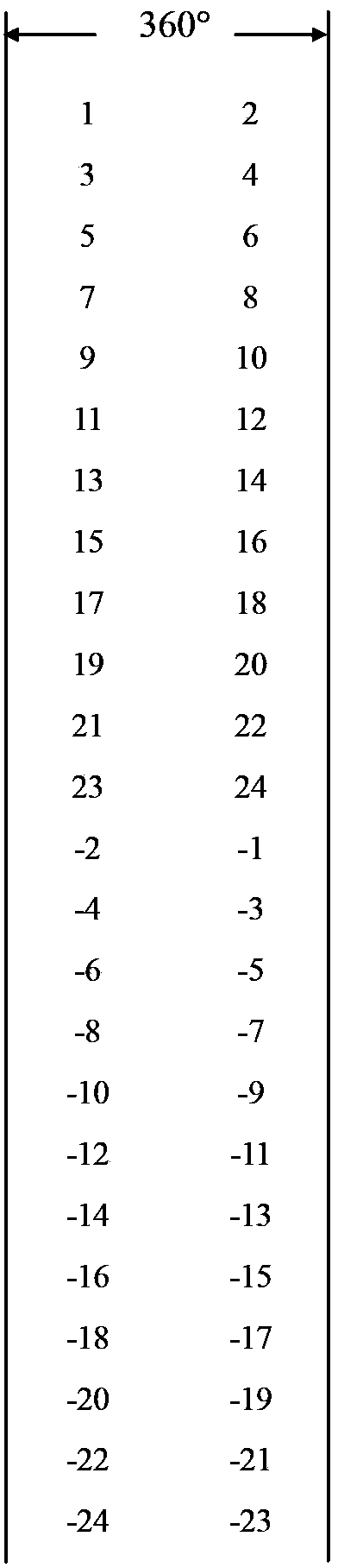

[0048] 2. Select the dense slot coefficient k=4, then the virtual slot number of the rotor is Z=2kp 1 =96

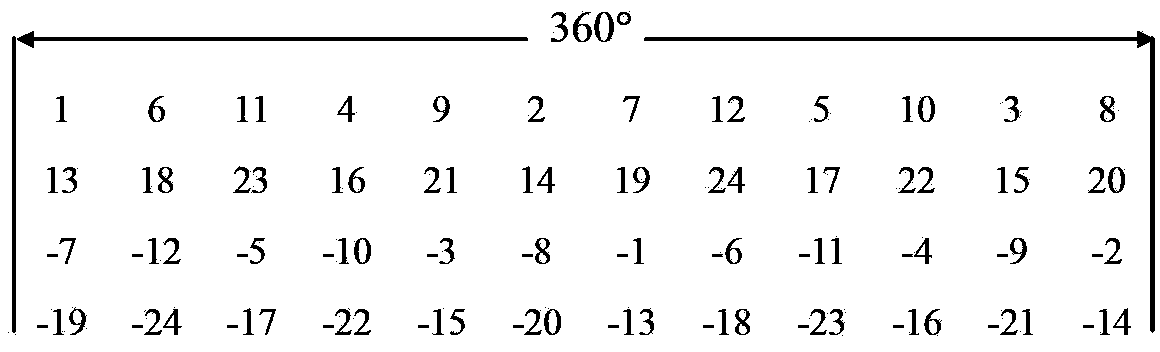

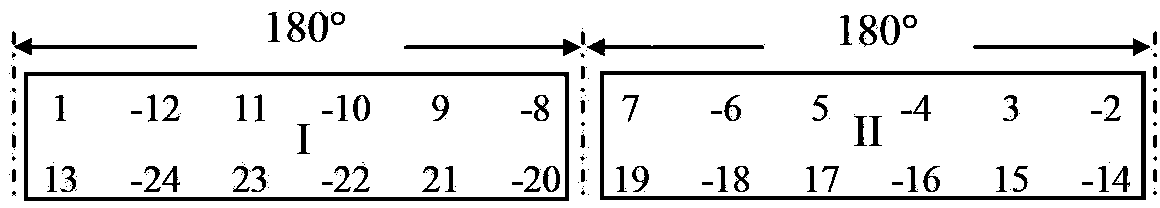

[0049] 3. According to the selected variable front pole p 1 and variable posterior pole p 2 The number of pole pairs, and the number of virtual slots Z, draw the variable front pole p 1 Slot number phase diagram and post pole p 2 Slot number phase diagram, such as image 3 with Figure 4a As shown, only the 180° range is drawn;

[0050] 4. Before changing pole p 1 Select the second column on the slot number phase diagram as the original magnetic pole column, see image 3 , the slot number contained in this column also represents the initial position of the original magnetic pole before the pole change;

[0051] 5. Select the first column and the third column adjacent to the original magnetic pole column as th...

Embodiment 2

[0056] Embodiment 2, in 1, can make k=5, at this moment Z=2kp 1 =120, a pole-changing scheme obtained, which is in the number of pole pairs p 1 =12 and p 2 =10 slot number phase distribution respectively as follows Figure 7a with Figure 7b as shown, Figure 8 A schematic diagram of the magnetic pole arrangement at this time. Still in accordance with general custom, Figure 8 The middle excitation poles are re-numbered according to the order of the slot numbers, that is, the numbers 1, 2, ..., 20 respectively represent the slot numbers 111, 116, 1, 7, 15, 21, 26, 31, 37, 45 in the figure , 51, 56, 61, 67, 75, 81, 86, 91, 97, 105. In the figure, the excitation poles still have unequal spacing. It can be seen that the distribution of magnetic poles along the rotor circumference is similar when k=5 and k=4, but the spacing is different. In the figure, for larger than normal polar distance k=τ 1 The intervals are still marked with 4 widths respectively The position of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com