Patents

Literature

1764results about "Blast furnace components" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

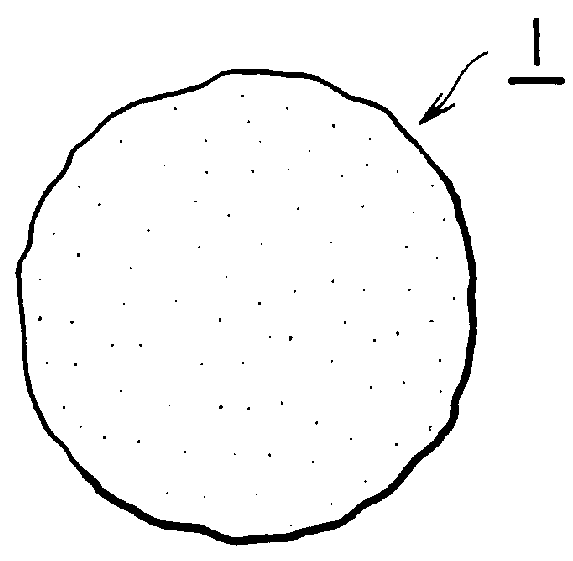

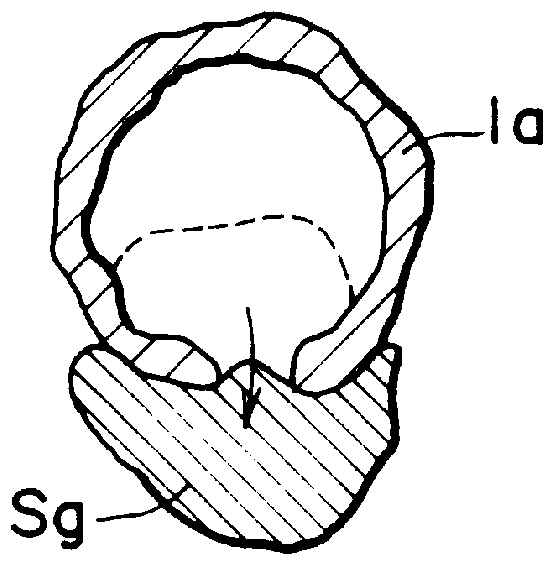

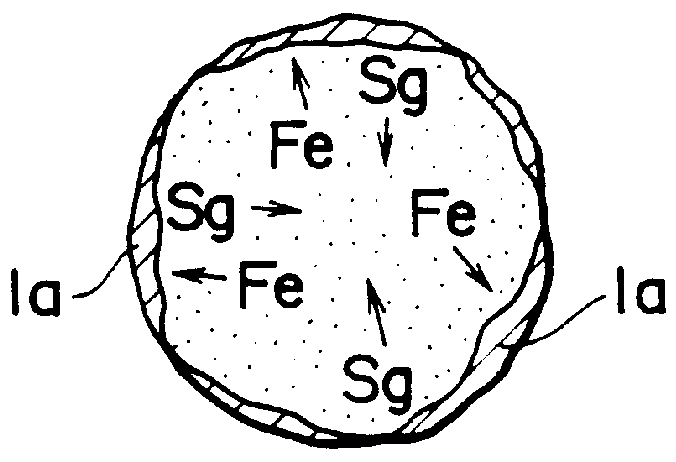

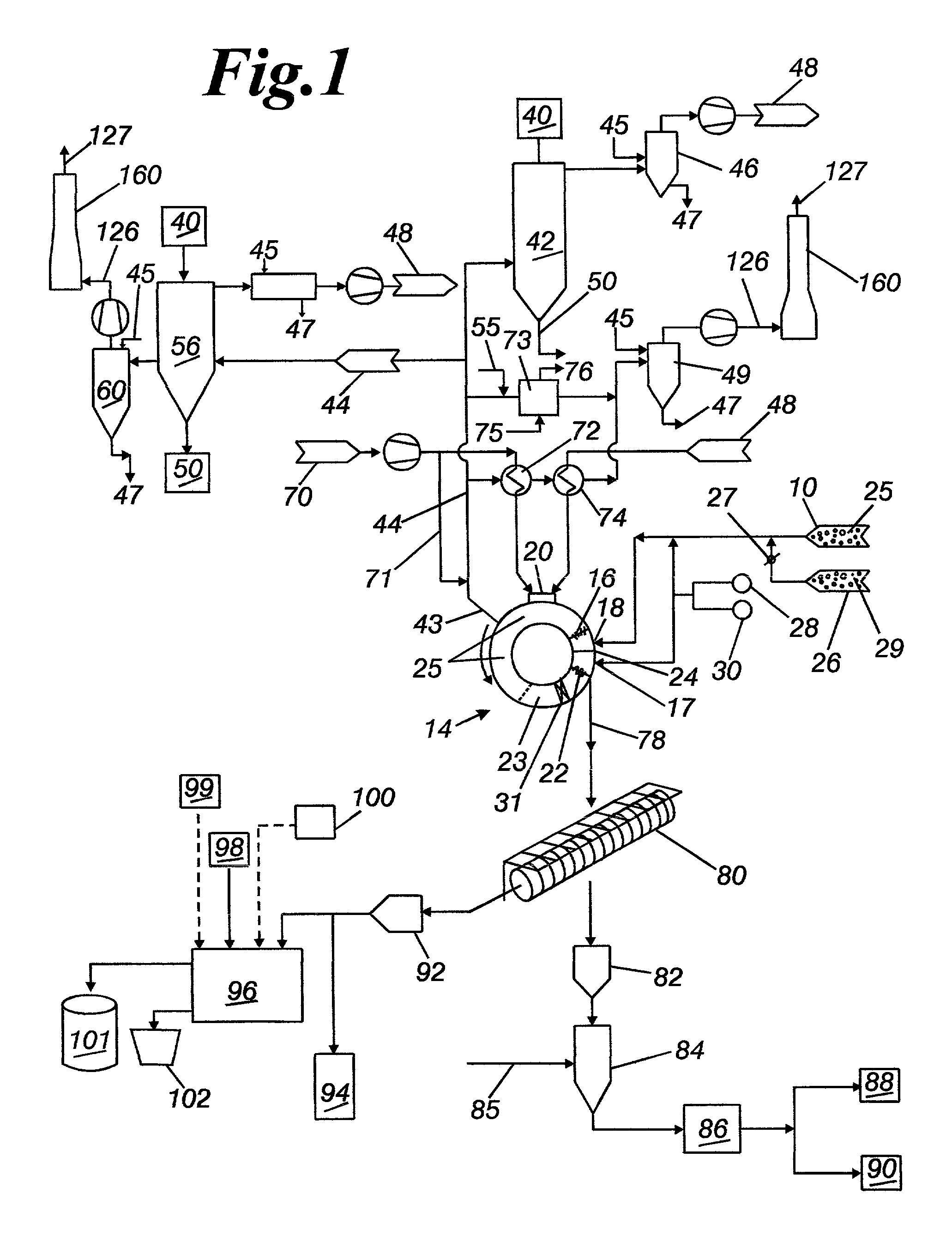

Method and apparatus for making metallic iron

InactiveUS6036744AHigh purityReadily and efficiently madeBlast furnace componentsRotary drum furnacesMolten slagCoal

A method of making metallic iron in which a compact, containing iron oxide such as iron ore or the like and a carbonaceous reductant such as coal or the like, is used as material, and the iron oxide is reduced through the application of heat, thereby making metallic iron. In the course of this reduction, a shell composed of metallic iron is generated and grown on the surface of the compact, and slag aggregates inside the shell. This reduction continues until substantially no iron oxide is present within the metallic iron shell. Subsequently, heating is further performed to melt the metallic iron and slag. Molten metallic iron and molten slag are separated one from the other, thereby obtaining metallic iron with a relatively high metallization ratio. Through the employment of an apparatus for making metallic iron of the present invention, the above-described method is efficiently carried out, and metallic iron having a high iron purity can be made continuously as well as productively not only from iron oxide having a high iron content but also from iron oxide having a relatively low iron content.

Owner:KOBE STEEL LTD

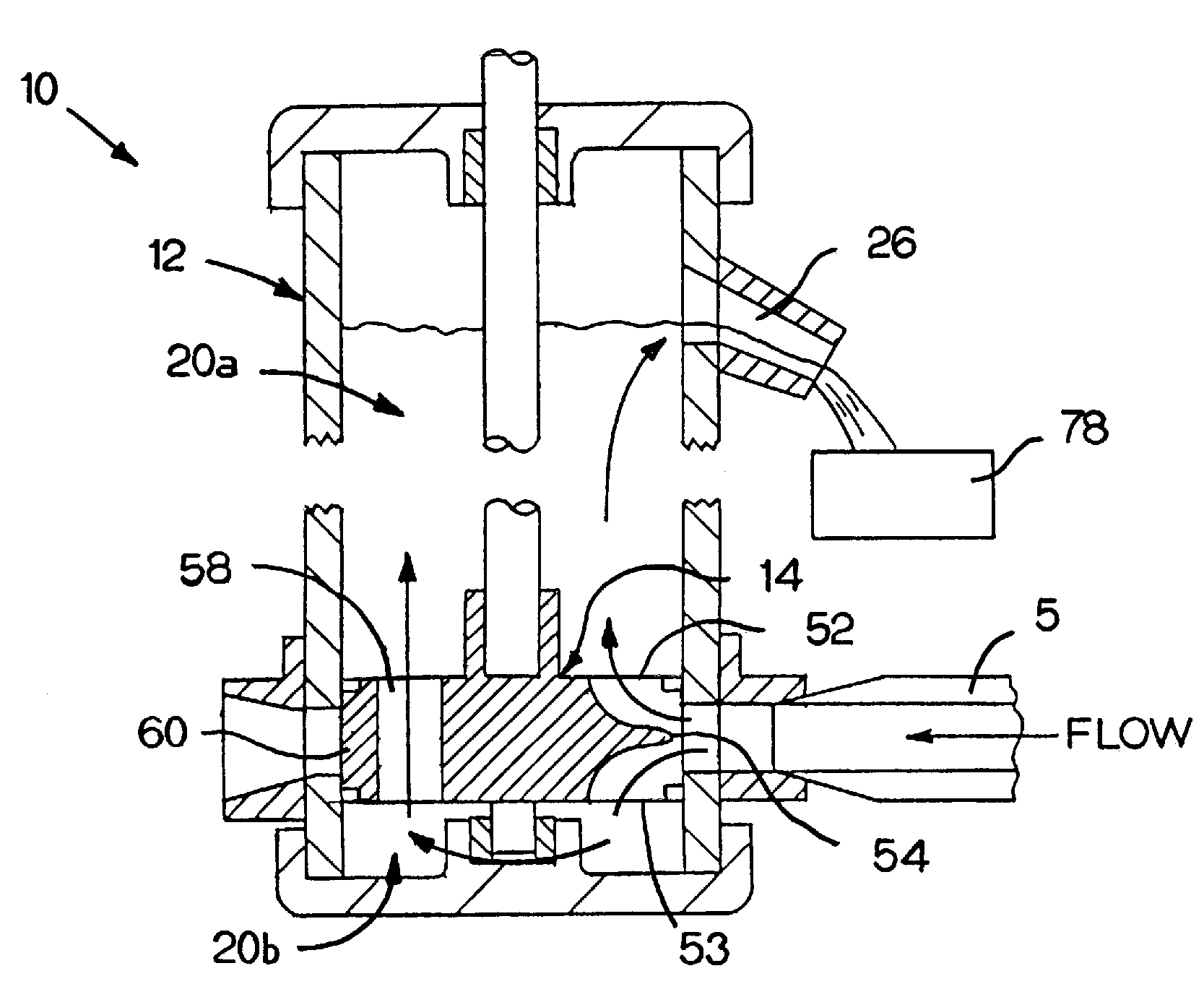

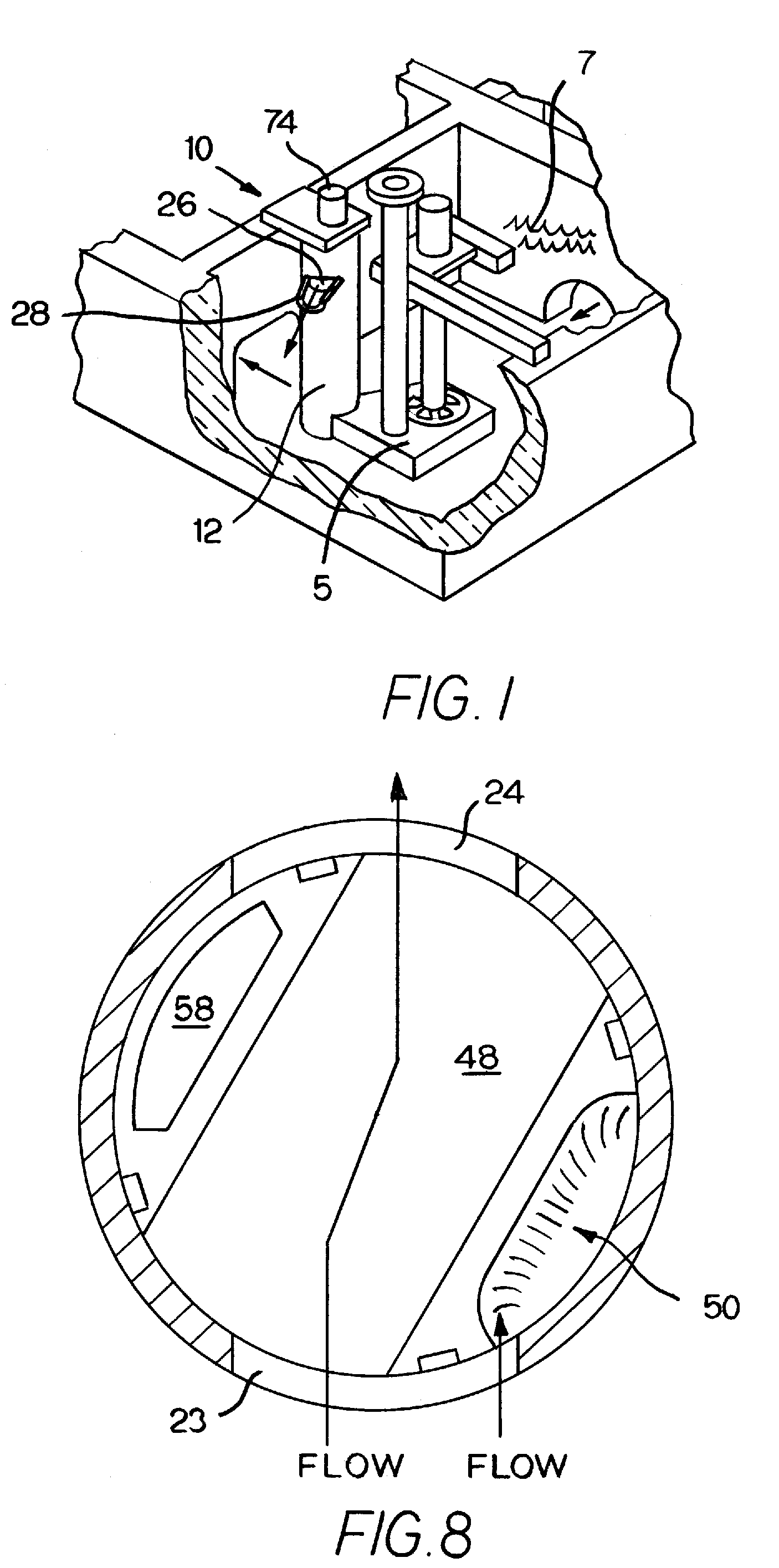

Scrap melter and impeller therefore

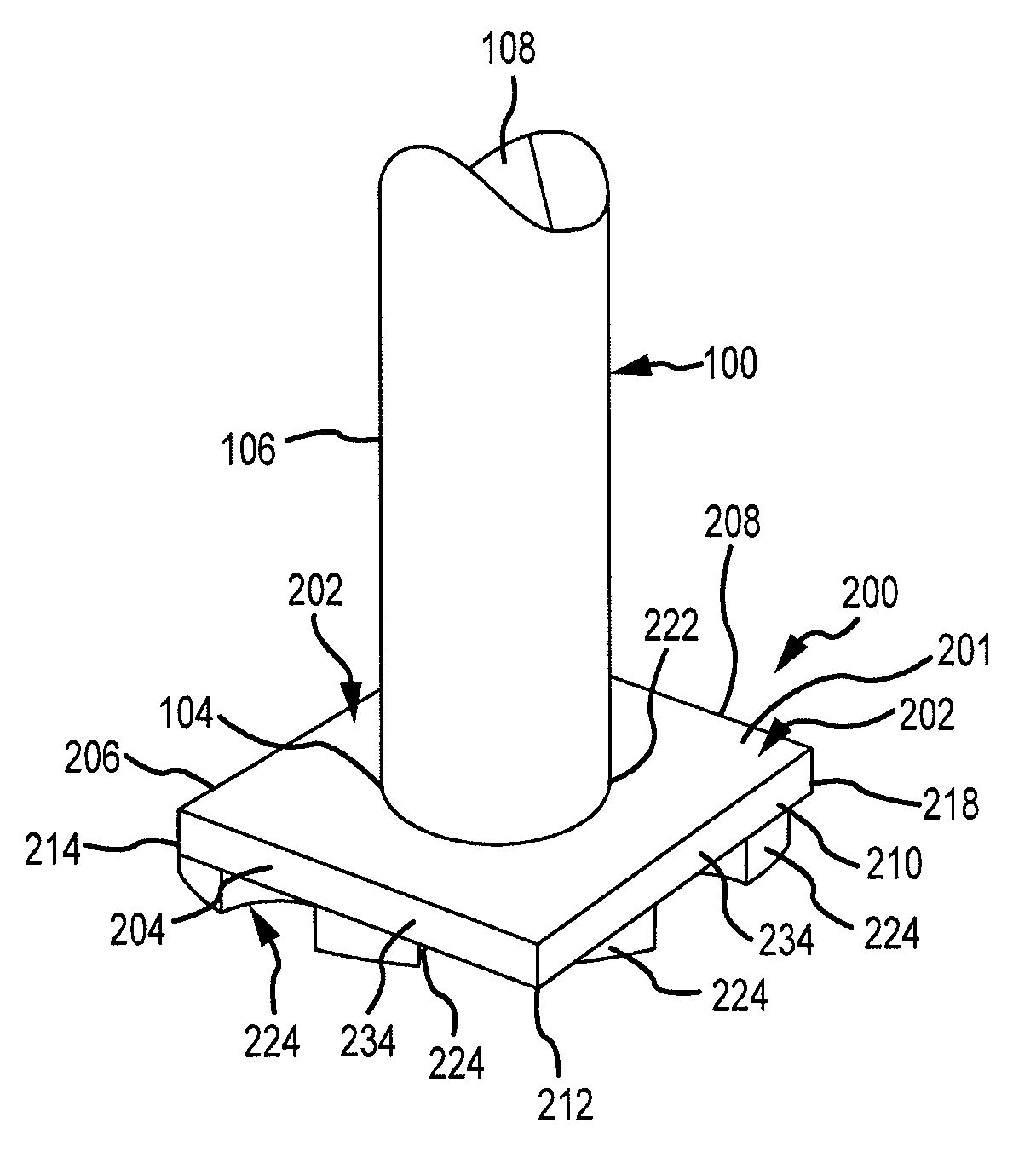

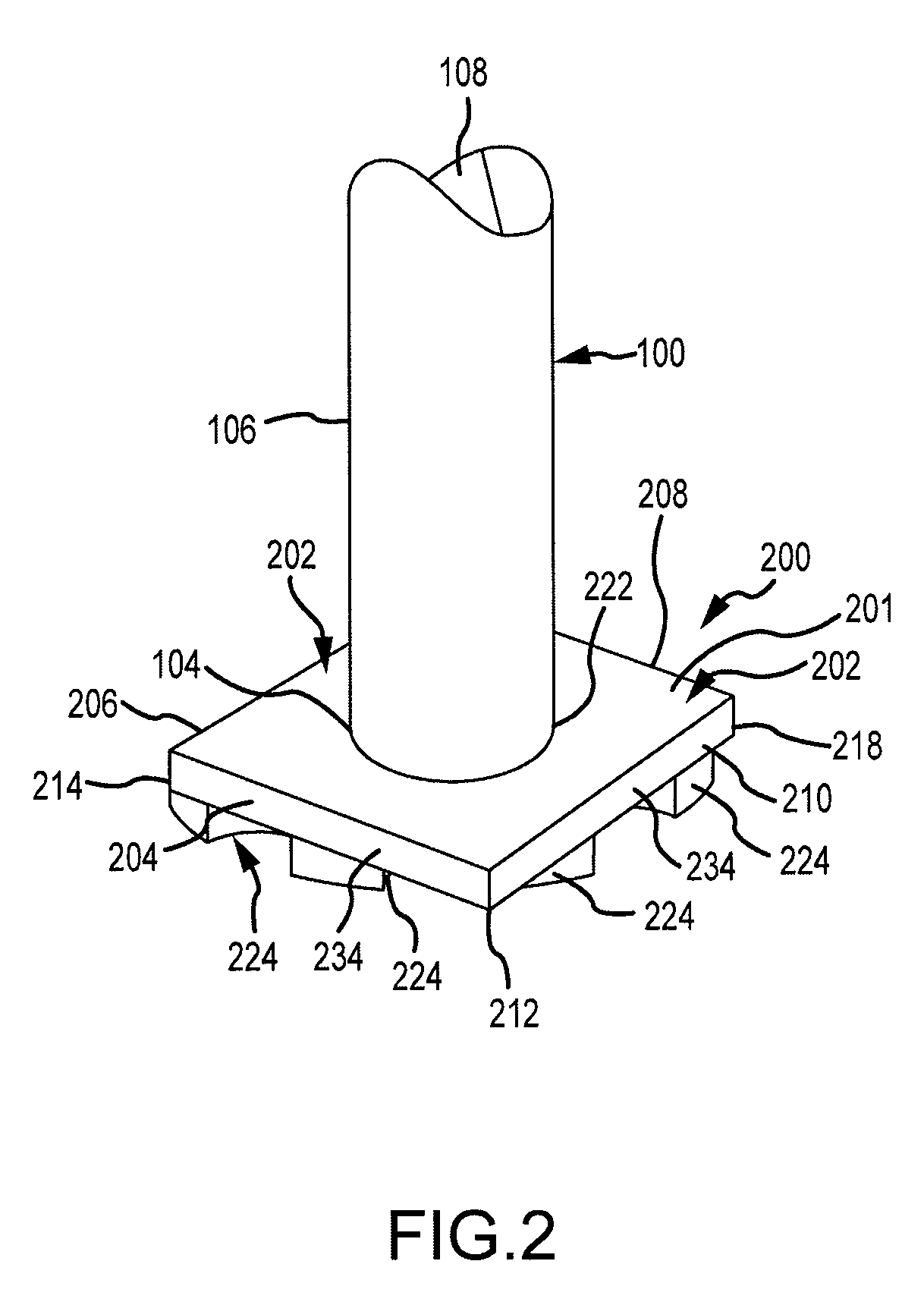

InactiveUS20080230966A1Reduce jammingReduce cloggingMelt-holding vesselsStirring devicesImpellerDrive shaft

A device for submerging scrap metal includes: (a) a drive source, (b) a drive shaft having a first end and a second end, the first end being connected to the drive source, and (d) an impeller connected to the second end of the drive shaft, the impeller preferably having two or more outwardly-extending blades. Preferably, each of the blades has a portion that directs molten metal at least partially downward. The impeller design leads to lower operating speeds, lower vibration, longer component life and less maintenance. Additionally, the impeller preferably has a connective portion. The connective portion is used to connect the impeller to the shaft and preferably comprises a nonthreaded, tapered bore extending through the impeller.

Owner:COOPER PAUL V

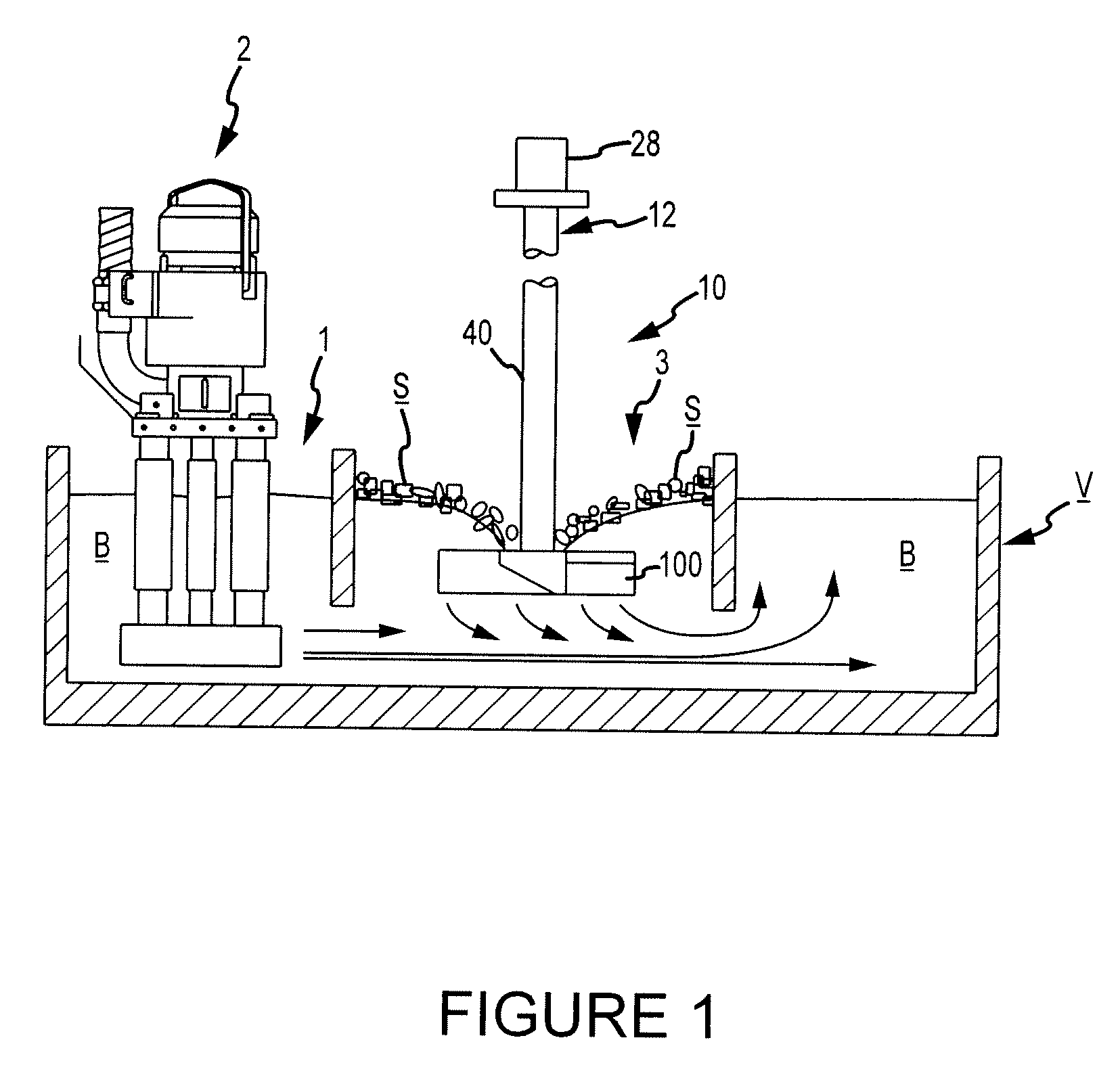

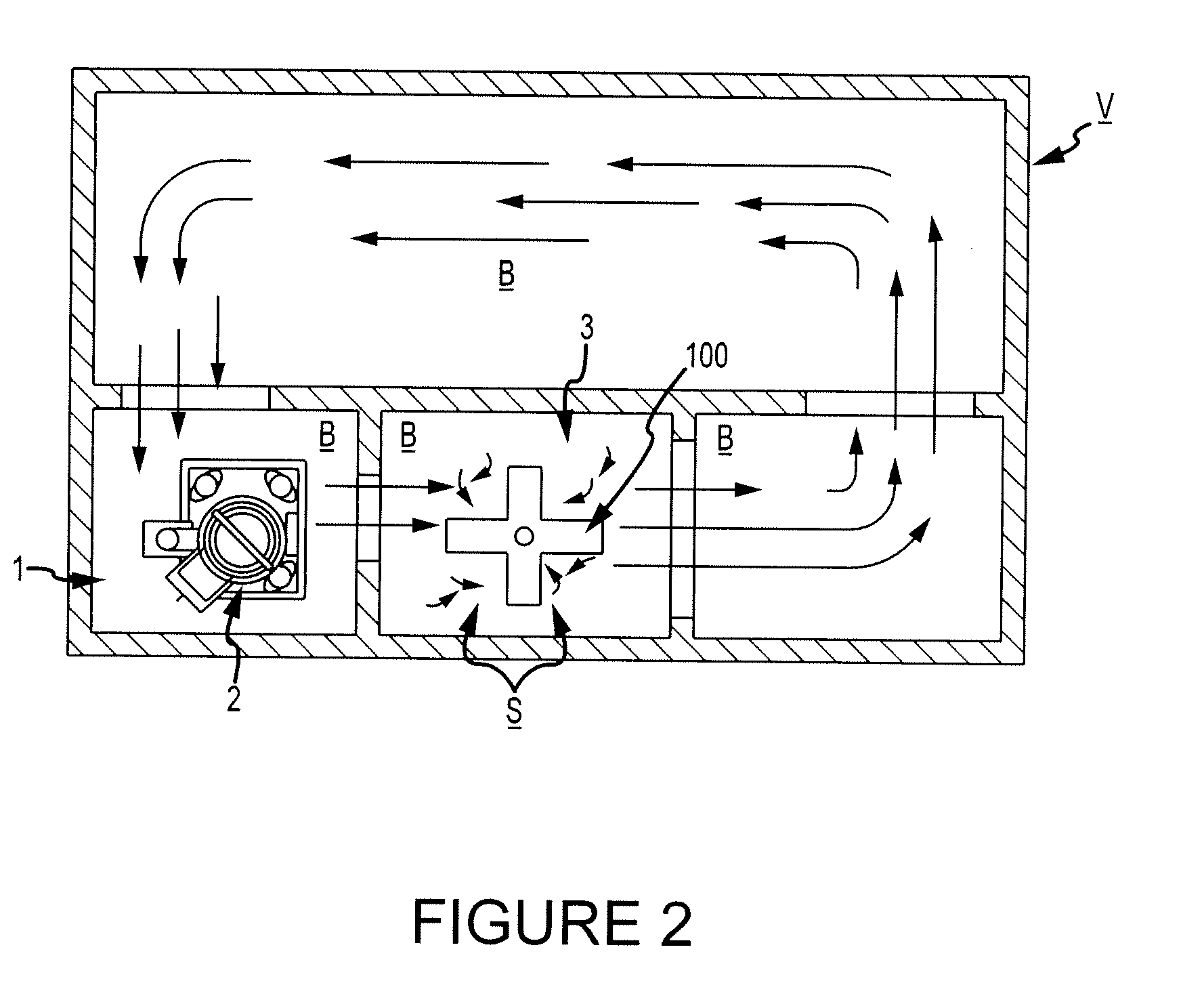

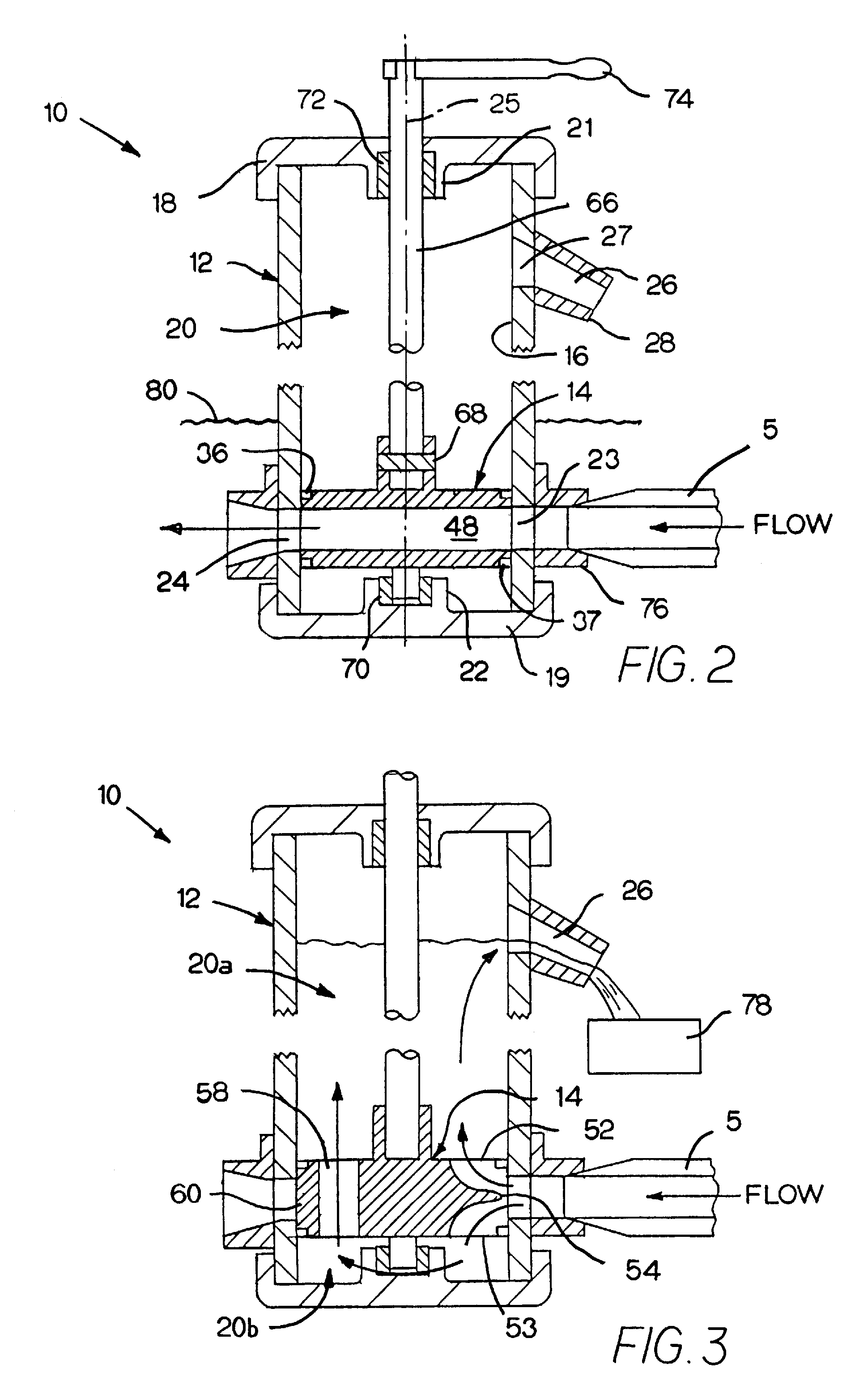

Dual recycling/transfer furnace flow management valve for low melting temperature metals

InactiveUS7543605B1Eliminate needIncrease flow rateMelt-holding vesselsMolten metal pouring equipmentsControl valvesFlow management

A furnace flow control valve for use within a bath of molten metal. The flow control valve includes a vertically-disposed elongated tubular stator, which is configured to receive flow from a molten metal pump. The valve has a rotor which is sealing rotatable within the stator between: a full re-circulation position, where flow from the pump passes un-hindered through the valve; a full transfer position, where flow from the pump is redirected into the vertically disposed stator and out of the valve; and a partial re-circulation / partial transfer position where flow from the pump both passes through the valve and is transferred up and out of valve through the stator.

Owner:MORANDO JORGE A

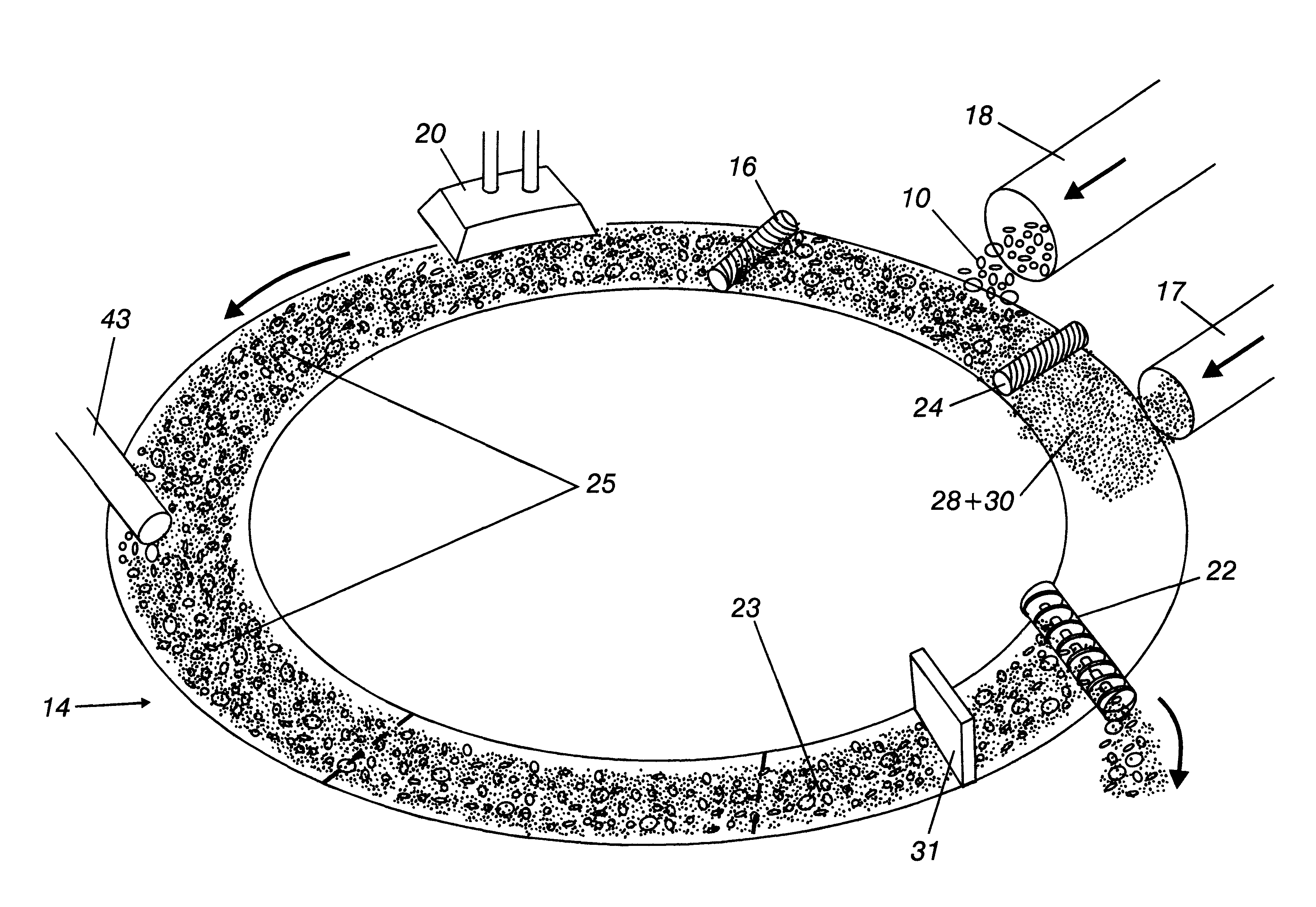

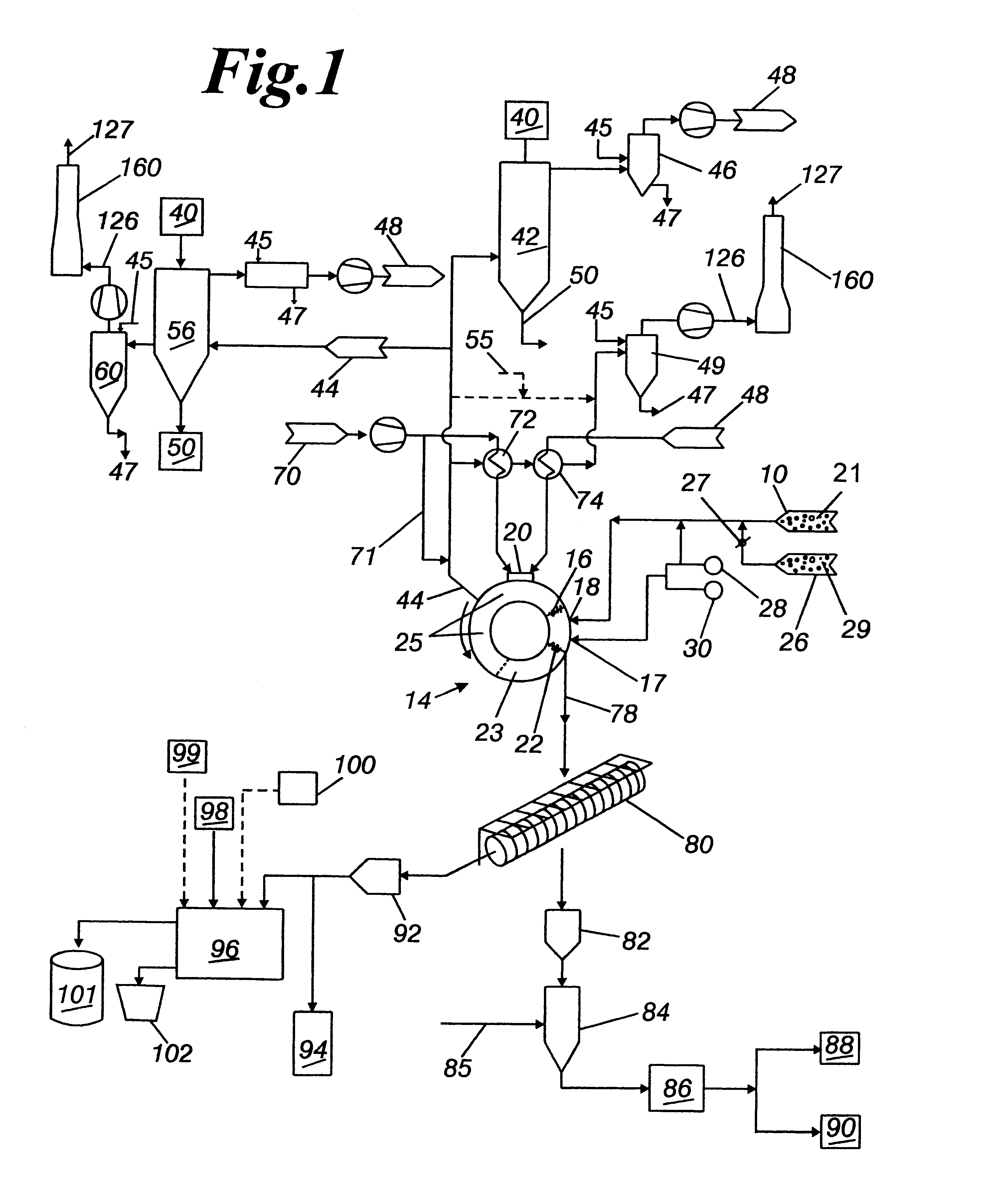

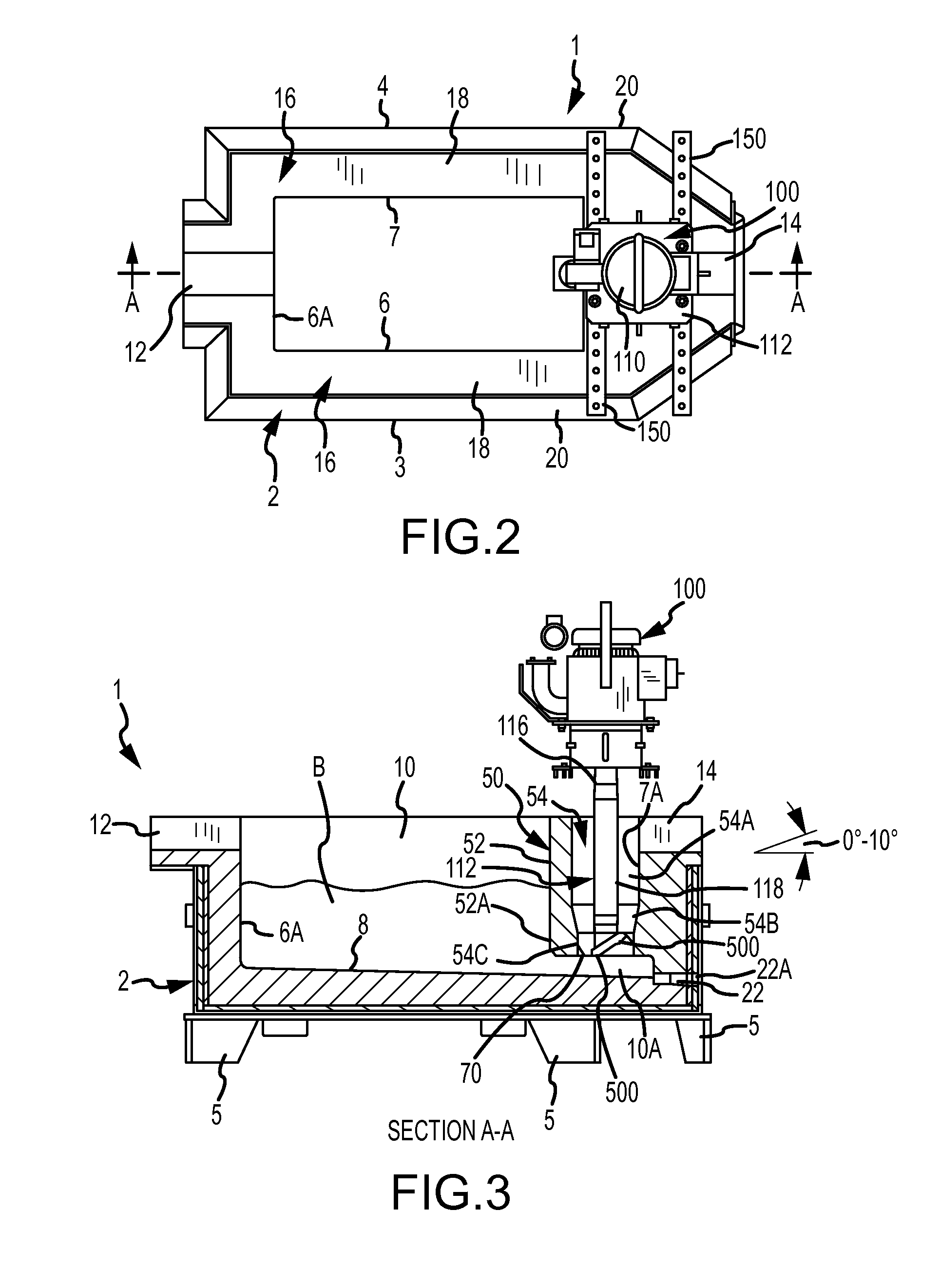

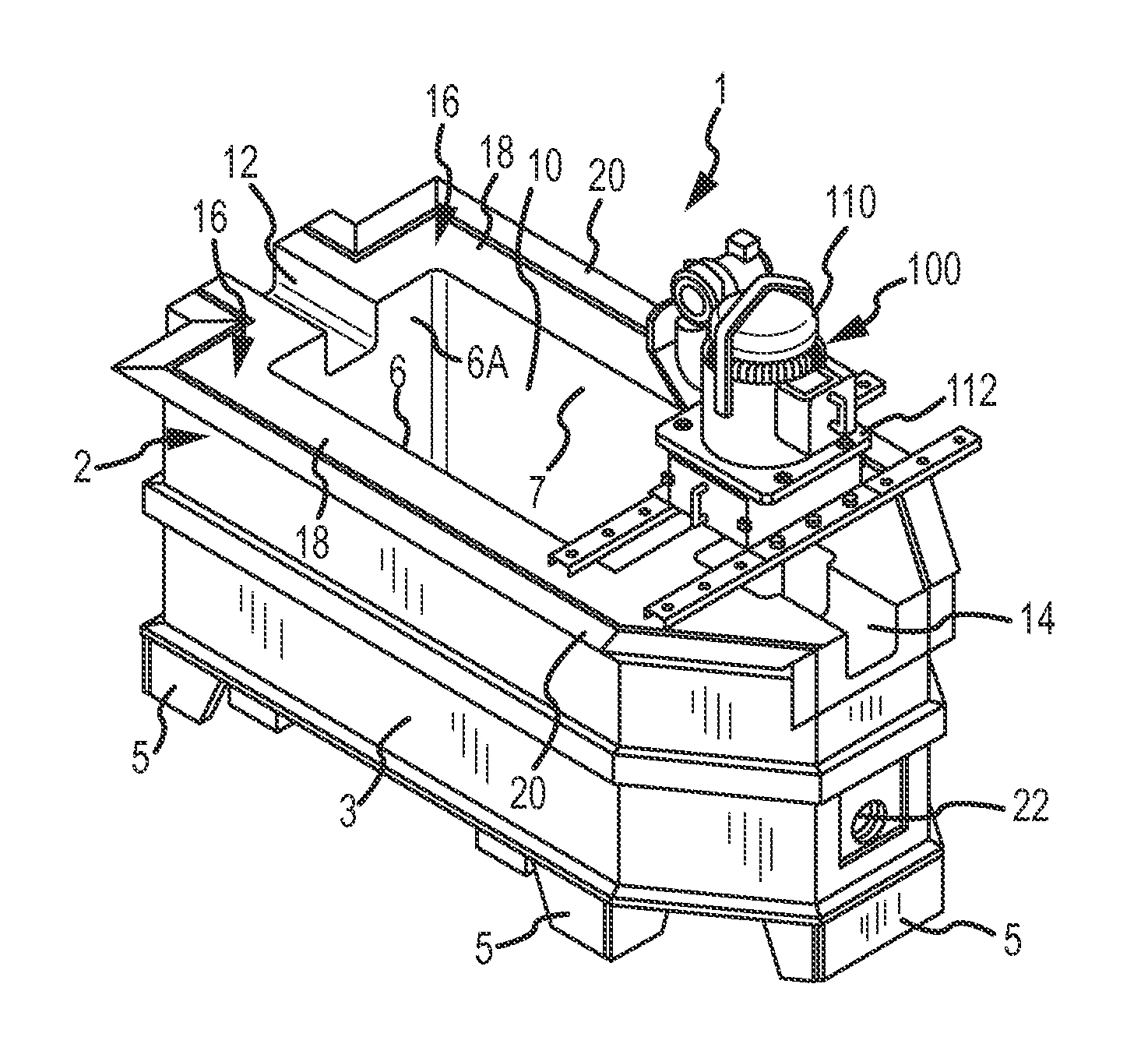

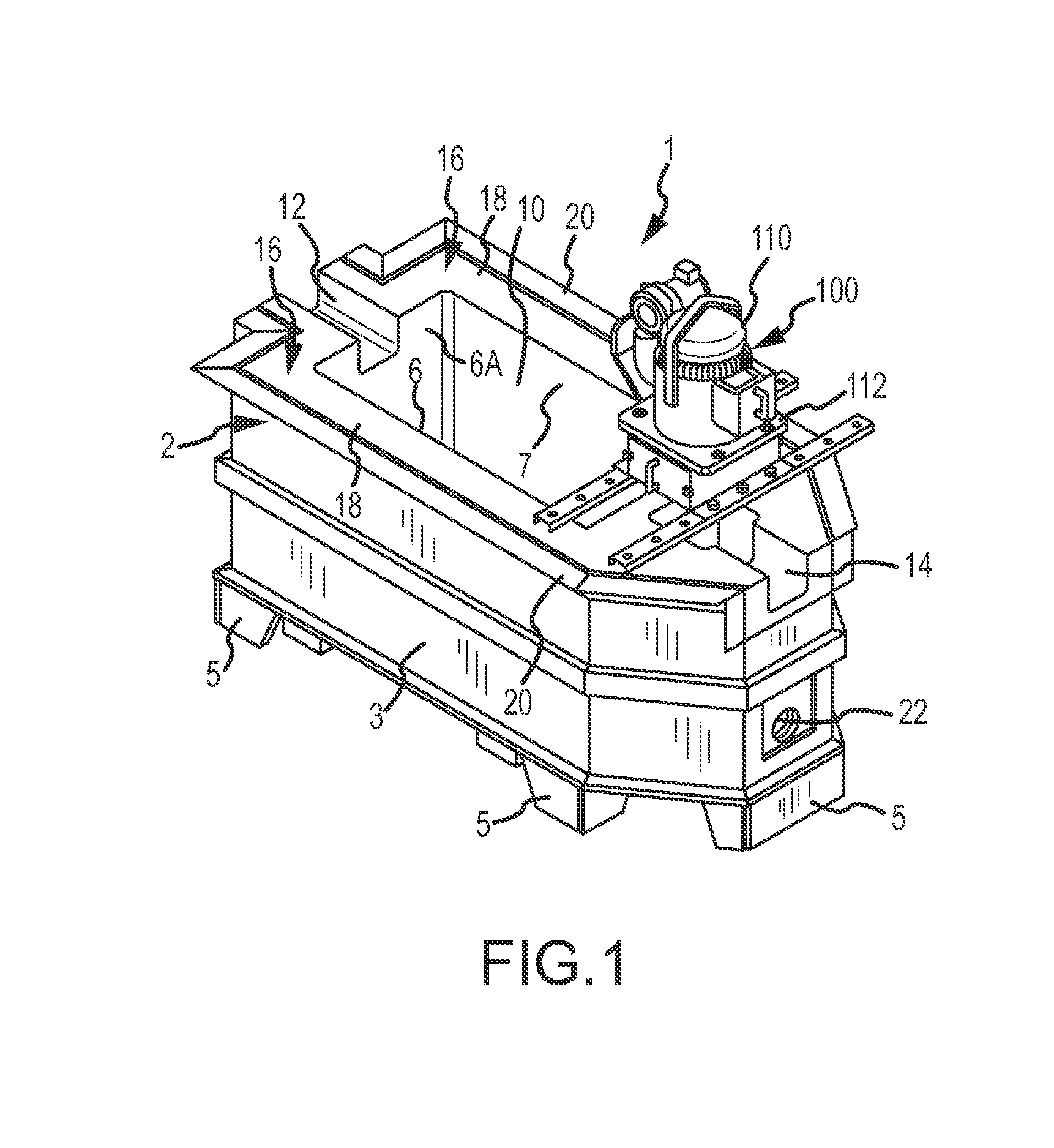

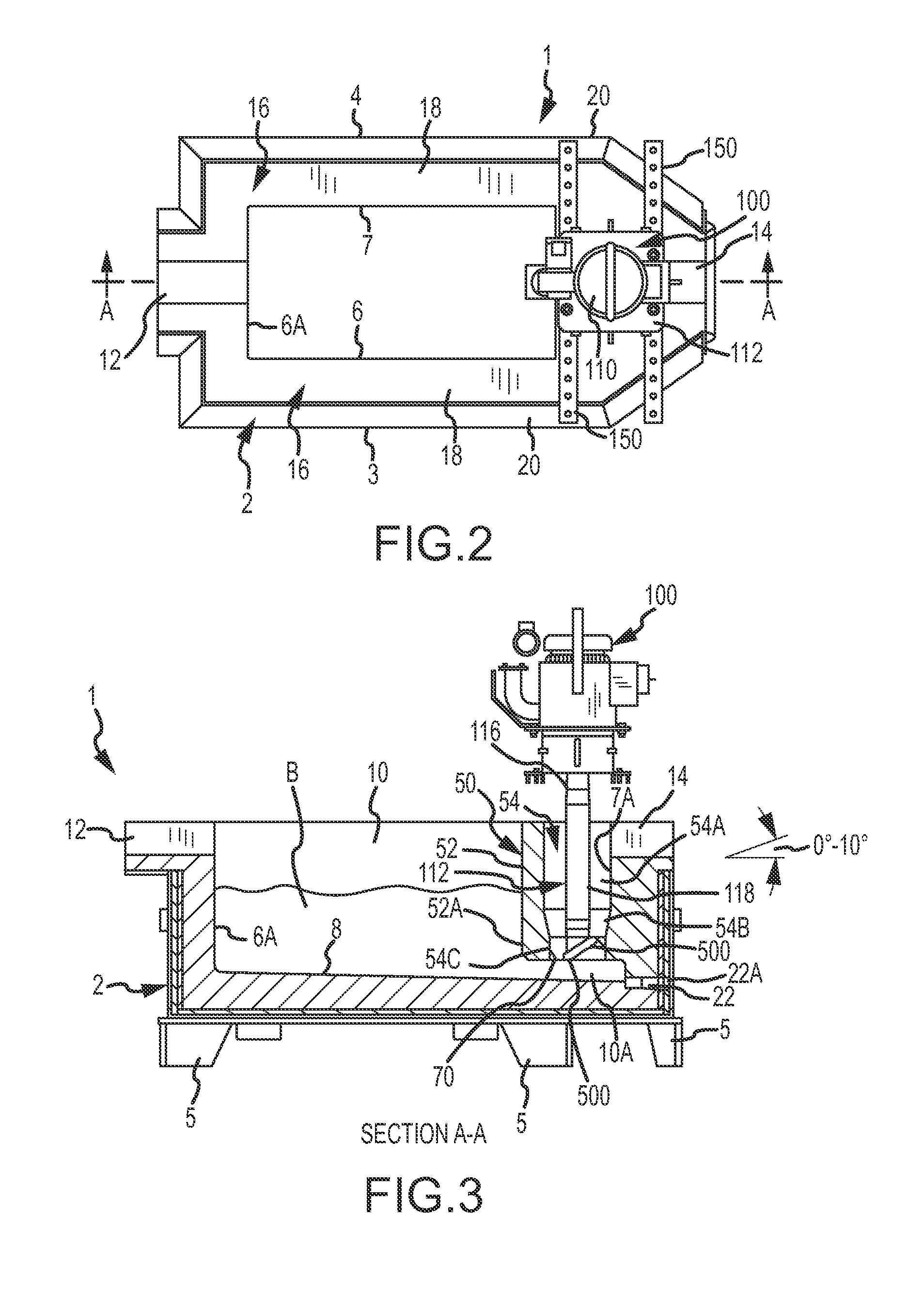

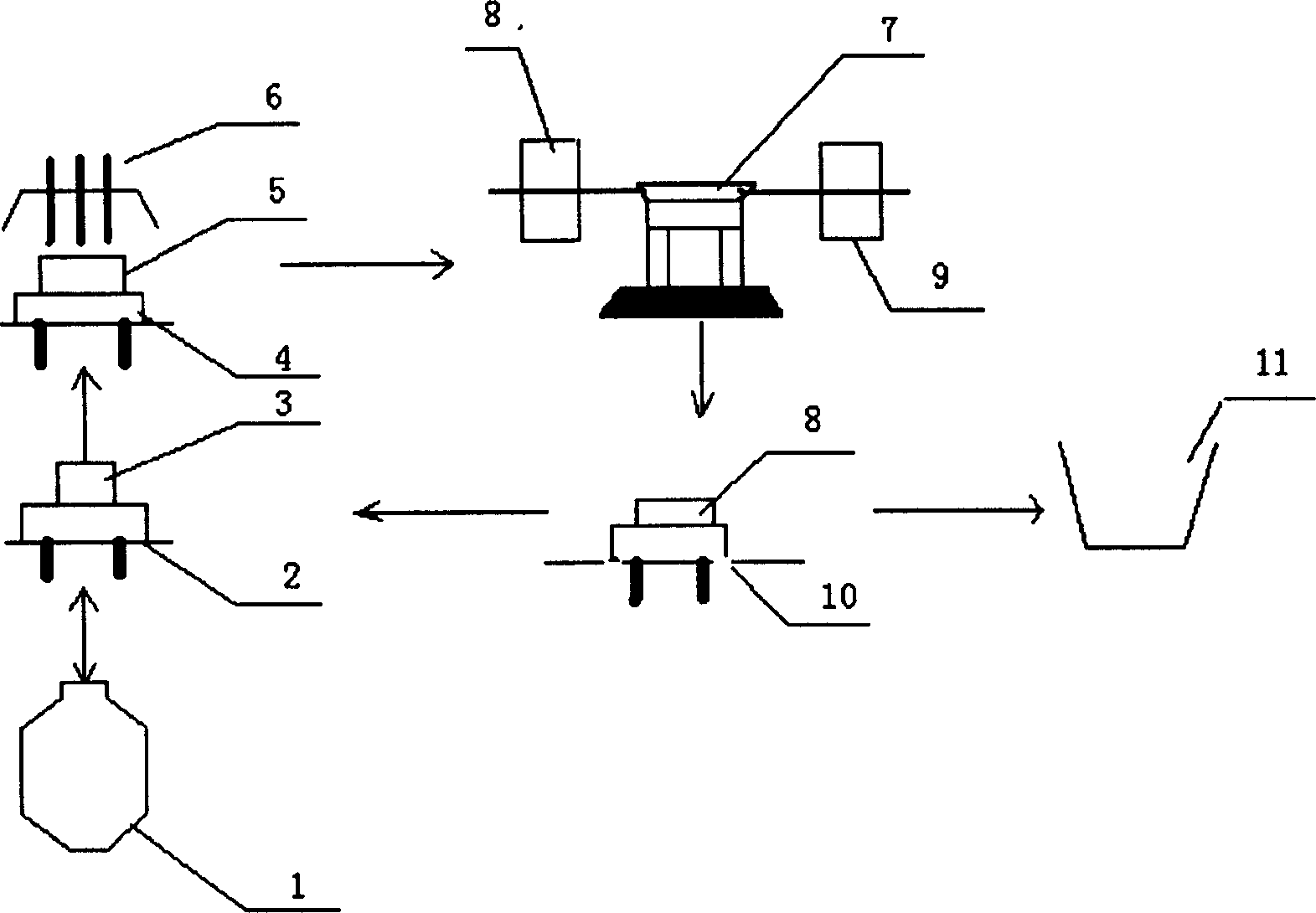

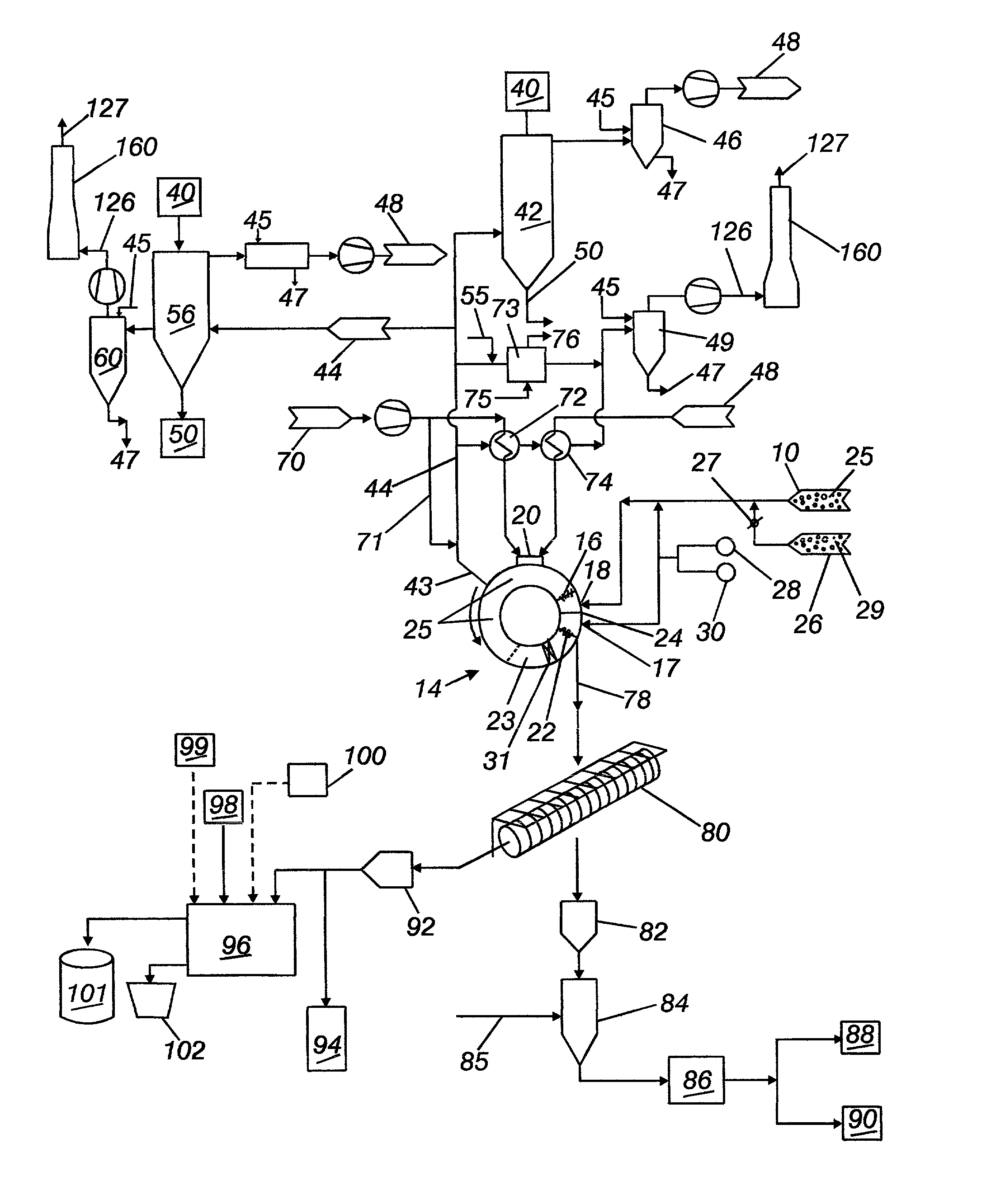

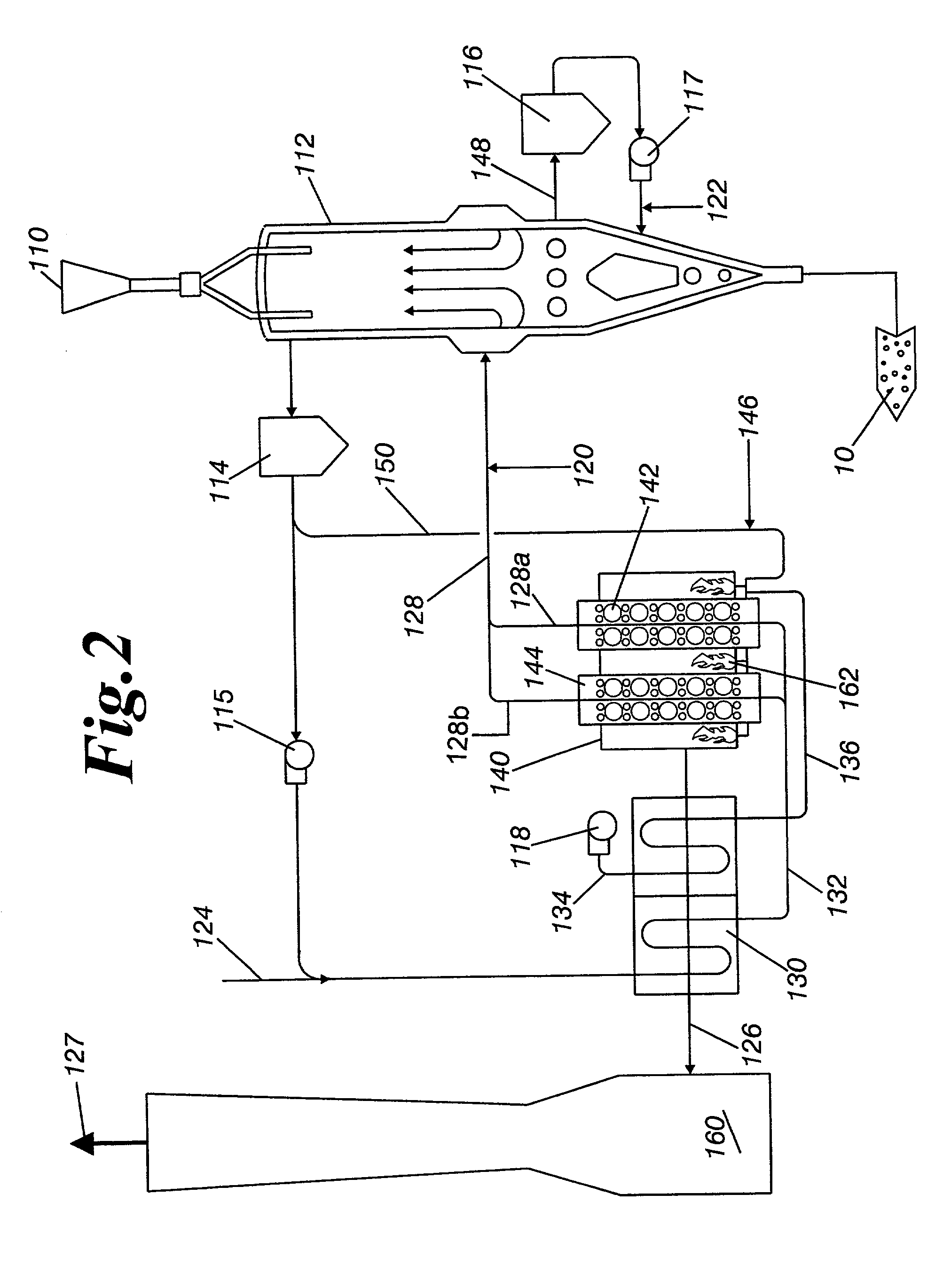

Method of direct iron-making / steel-making via gas or coal-based direct reduction and apparatus

The invention is a method and apparatus for iron-making / steel-making using a modified rotary hearth furnace, that is a finisher-hearth-melter (FHM) furnace. In the method the refractory surface of the hearth is coated with carbonaceous hearth conditioners and refractory compounds, where onto said hearth is charged with pre-reduced metallized iron. The pre-reduced metallized iron is leveled, then heated until molten, and then reacted with the carbon and reducing gas burner gases until any residual iron oxide is converted to iron having a low sulfur content. Nascent slag separates from the molted iron forming carburized iron nuggets. The nuggets are cooled, and then the iron nuggets and the hearth conditioners, including the refractory compounds, are discharged onto a screen, which separate the iron nuggets from the hearth conditioner. The hearth conditioner is recycled, and the iron nuggets are either prepared for sale or for additional treatment, such as alloying, in a final melter, where the final melter is preferably an electric furnace. Exhaust gases from the FHM furnace are recovered for calcining coal into fuel gases and coke.

Owner:KOBE STEEL LTD

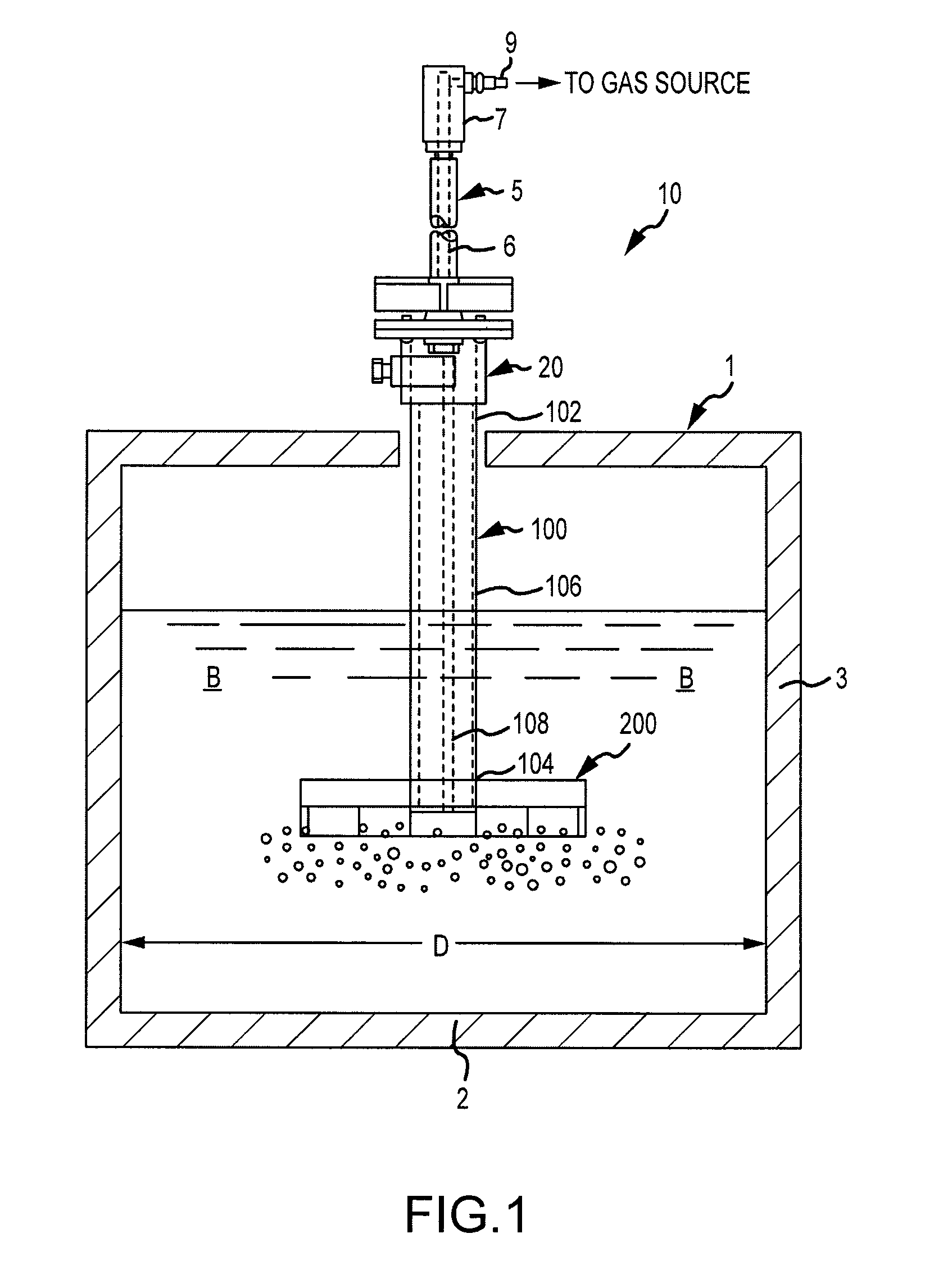

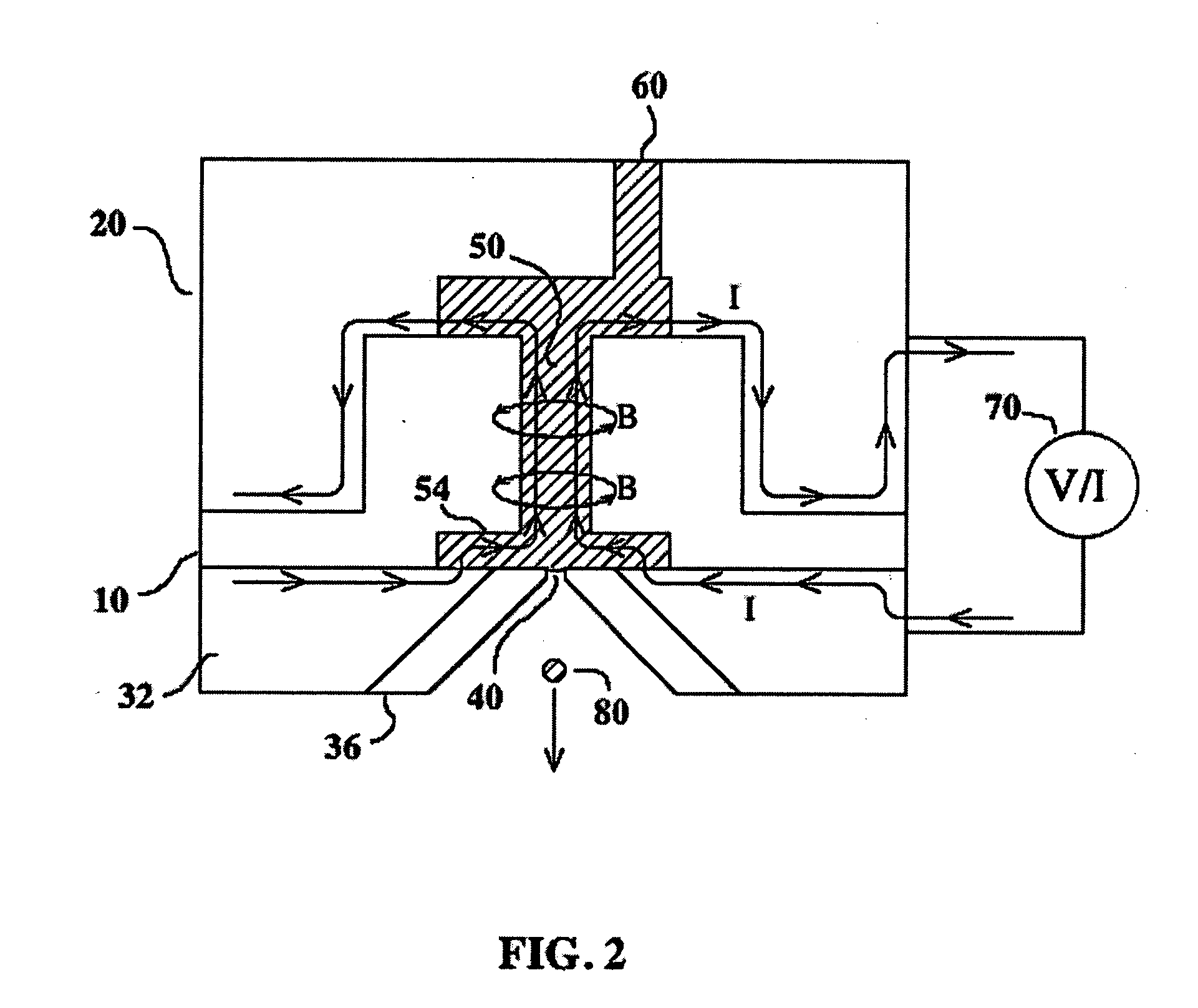

Rotary degasser and rotor therefor

ActiveUS8535603B2Efficiently circulatedWell mixedMelt-holding vesselsStirring devicesImpellerDegasser

A device for dispersing gas into molten metal includes an impeller, a drive shaft having a gas-transfer passage therein, and a first end and a second end, and a drive source. The second end of the drive shaft is connected to the impeller and the first end is connected to the drive source. The impeller includes a first portion and a second portion with a plurality of cavities. The first portion covers the second portion to help prevent gas from escaping to the surface without entering the cavities and being mixed with molten metal as the impeller rotates. When gas is transferred through the gas-transfer passage, it exits through the gas-release opening(s) in the bottom of the impeller. At least some of the gas enters the cavities where it is mixed with the molten metal being displaced by the impeller. Also disclosed are impellers that can be used to practice the invention.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

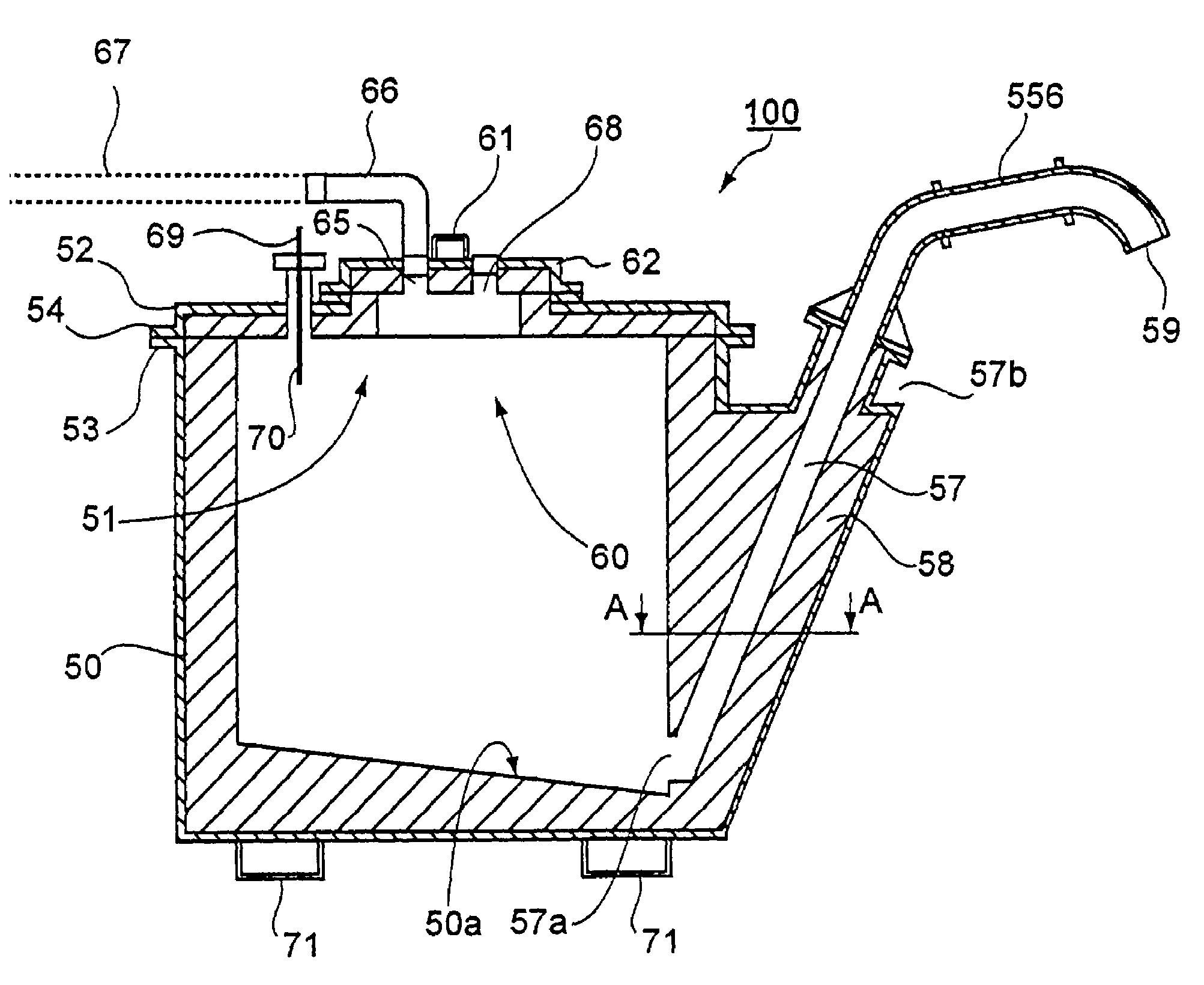

Transfer well system and method for making same

ActiveUS20130292426A1Melt-holding vesselsMolten metal pouring equipmentsMarine engineeringMolten metal

The invention relates to systems for transferring molten metal from one structure to another. Aspects of the invention include a transfer chamber constructed inside of or next to a vessel used to retain molten metal. The transfer chamber is in fluid communication with the vessel so molten metal from the vessel can enter the transfer chamber. A powered device, which may be inside of the transfer chamber, moves molten metal upward and out of the transfer chamber and preferably into a structure outside of the vessel, such as another vessel or a launder.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Molten metal transfer system and rotor

The invention relates to systems for transferring molten metal from one structure to another. Aspects of the invention include a transfer chamber constructed inside of or next to a vessel used to retain molten metal. The transfer chamber is in fluid communication with the vessel so molten metal from the vessel can enter the transfer chamber. A powered device, which may be inside of the transfer chamber, moves molten metal upward and out of the transfer chamber and preferably into a structure outside of the vessel, such as another vessel or a launder.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Molten metal transfer and degassing system

ActiveUS20130306687A1Keep the flowReduce the possibilityMelt-holding vesselsMolten metal pouring equipmentsEngineeringMolten metal

Aspects of the invention include a transfer chamber constructed inside of or next to a vessel used to retain and degas molten metal. The transfer chamber is in fluid communication with the vessel so molten metal from the vessel is pulled through the vessel by the pump as it is degassed. This helps maintain a generally constant flow of molten metal through the degassing vessel. Other aspects relate to a system and method for efficiently performing maintenance on components positioned in a vessel.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Transfer well system and method for making same

The invention relates to systems for transferring molten metal from one structure to another. Aspects of the invention include a transfer chamber constructed inside of or next to a vessel used to retain molten metal. The transfer chamber is in fluid communication with the vessel so molten metal from the vessel can enter the transfer chamber. A powered device, which may be inside of the transfer chamber, moves molten metal upward and out of the transfer chamber and preferably into a structure outside of the vessel, such as another vessel or a launder.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Container

InactiveUS7204954B2High heat conductivityObstructing flow passageMelt-holding vesselsBlast furnace componentsMetallurgyOperability

A container does not need a member such as a stoke and the like that are exposed to the molten metal therein, thus the necessity to replace the parts such as the stoke and the like can be eliminated. In addition, there is no structure like the stoke in the container, the operability for the preheating is improved thus the preheating can be performed effectively. In addition, since a flow passage is formed inside the lining with high heat conductivity, inner heat of the container is easily conducted to the flow passage. Thus, the decrease in temperature of the molten metal that flows inside the flow passage can be suppressed to the utmost.

Owner:HOEI SHOKAI CO LTD

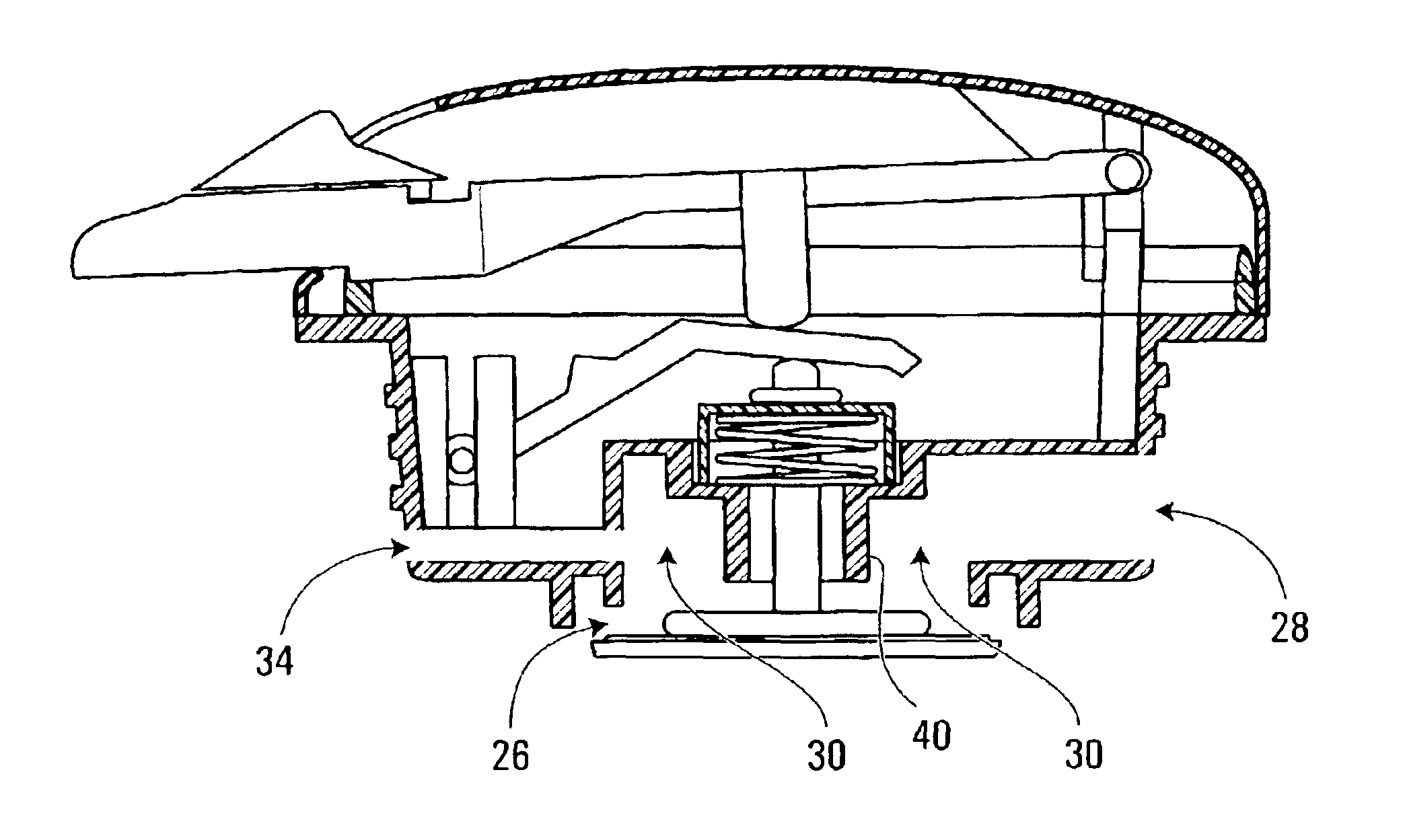

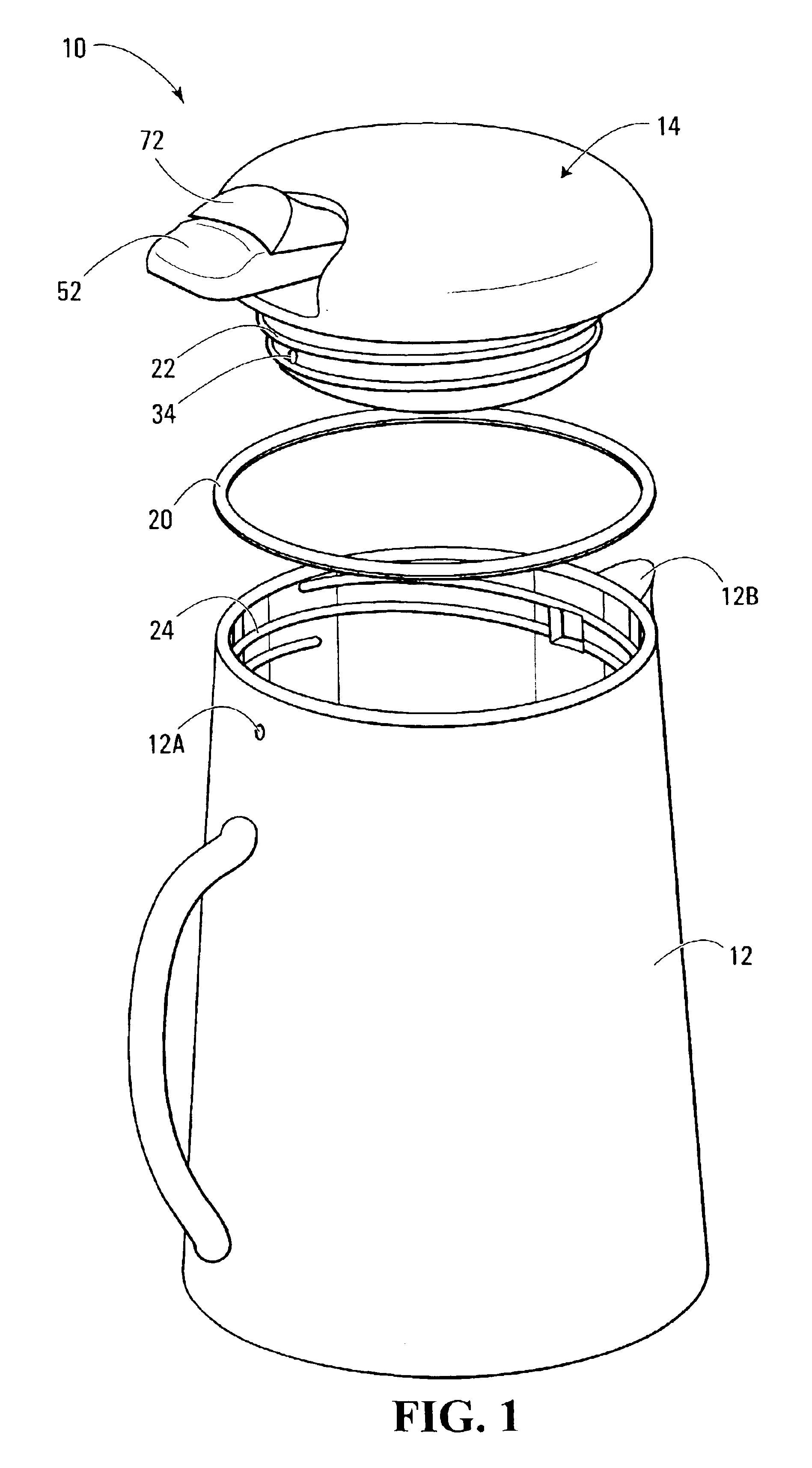

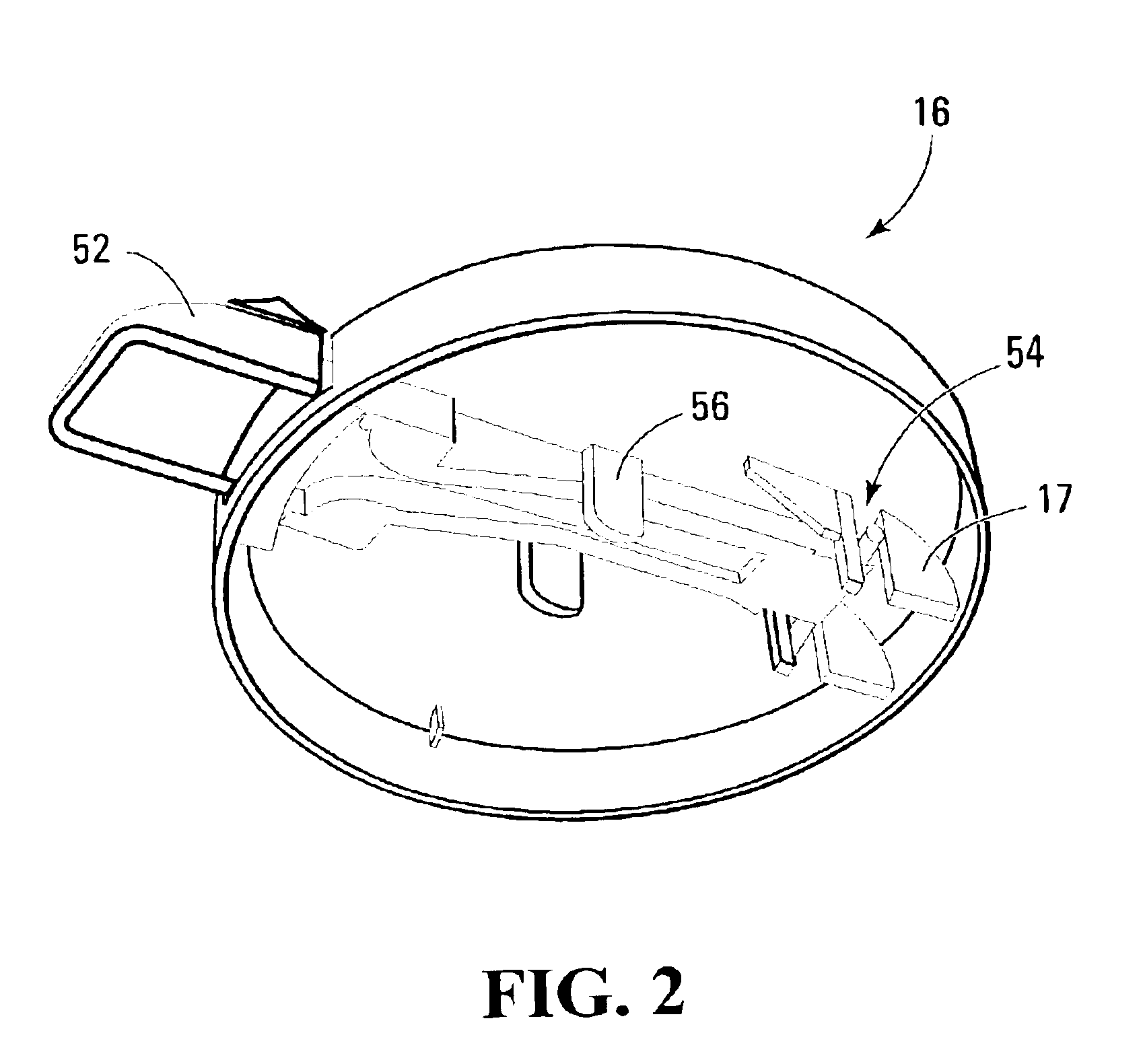

Cap for a container

InactiveUS6935536B2Reduce probabilityAvoid accidental dischargeMelt-holding vesselsMolten metal pouring equipmentsEngineeringActuator

Cap for a container, including a body having an inlet, a spout and a passageway therebetween. The cap also includes a valve movable between a first position wherein the passageway is blocked and a second position wherein the passageway is at least partly unblocked, the valve being biased towards the first position. Furthermore, the cap includes an actuator mounted to the body and engaging the valve. Selective control of the state of the valve is associated with movement of the actuator in a different direction than for securing the valve in the open position. The combination of movements required to lock the valve in the open position is sufficiently complex to reduce its probability of opening unintentionally. Meanwhile, the combination of movements is simple enough to be performed by a single finger.

Owner:TRUDEAU 1889

Exothermic feeder

An exothermal feeder mass is described, containing aluminum and magnesium, at least one oxidizing agent, a SiO2-containing filler, and an alkali silicate as the binder; it is characterized in that it contains roughly 2.5 to 20% by weight of a reactive aluminum oxide with a specific surface of at least roughly 0.5 m2 / g and an average particle diameter (d50) from roughly 0.5 to 8 microns and is essentially free of fluoride-containing fluxes.

Owner:AS LINGEN GMBH & CO KG

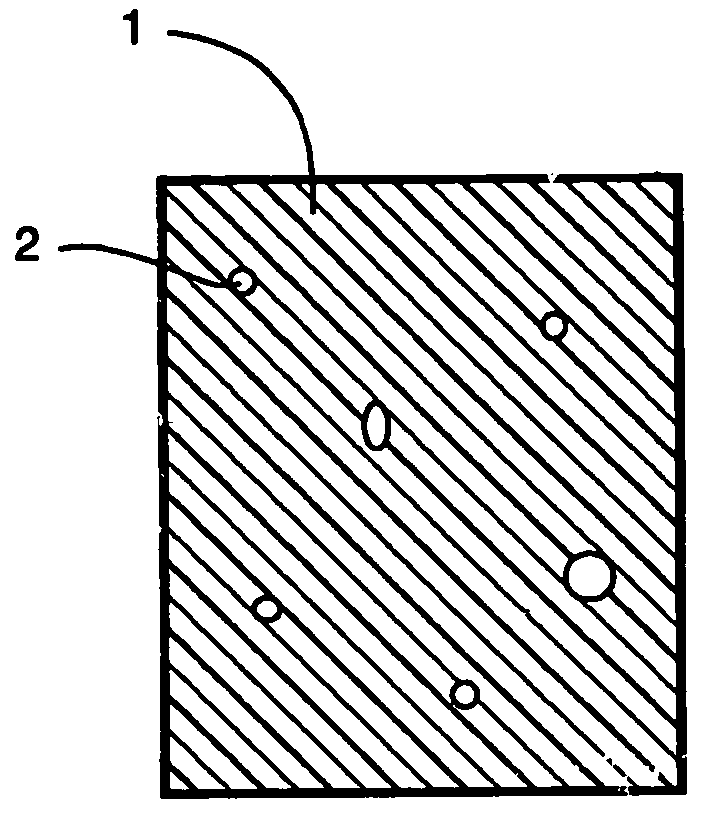

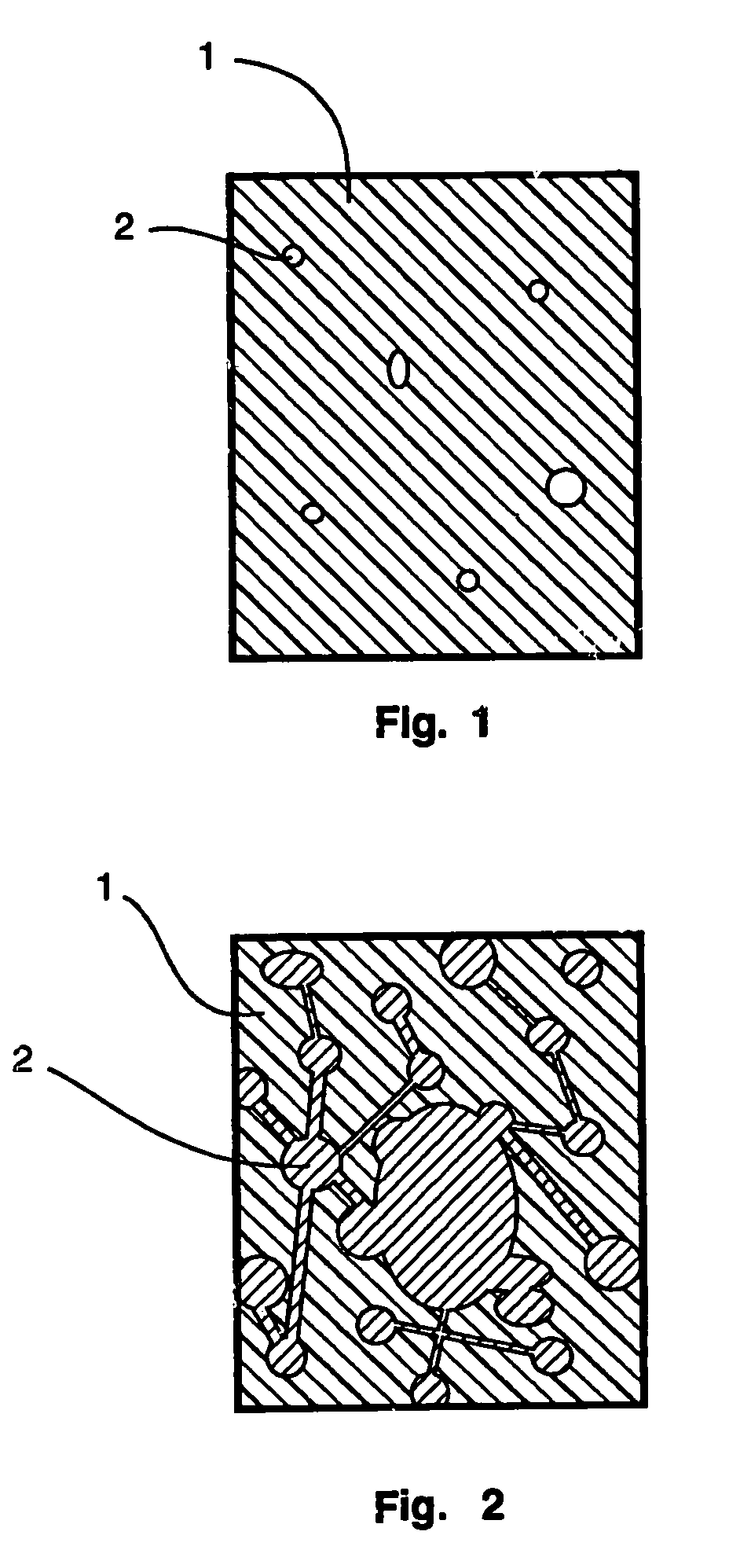

Cast iron inoculant and method for production of cast iron inoculant

InactiveUS6102983AEliminate segregationIncrease the number ofBlast furnace componentsBlast furnace detailsCeriumManganese

The invention relates to an inoculant for the manufacture of cast iron with lamellar, compacted or spheroidal graphite. The inoculant comprises between 40 and 80% by weight of silicon, between 0.5 and 10% by weight of calcium and / or strontium and / or barium, between 0 and 10% by weight of cerium and / or lanthanum, between 0 and 5% by weight of magnesium, less than 5% by weight of aluminium, between 0 and 10% by weight of manganese and / or titanium and / or zirconium, between 0.5 and 10% by weight of oxygen in the form of one or more metal oxides, the balance being iron, said inoculant further comprising between 0,1 and 10% by weight of sulphur in the form of one or more metal sulphides. The invention further relates to a method for the production of the inoculant.

Owner:ELKEM

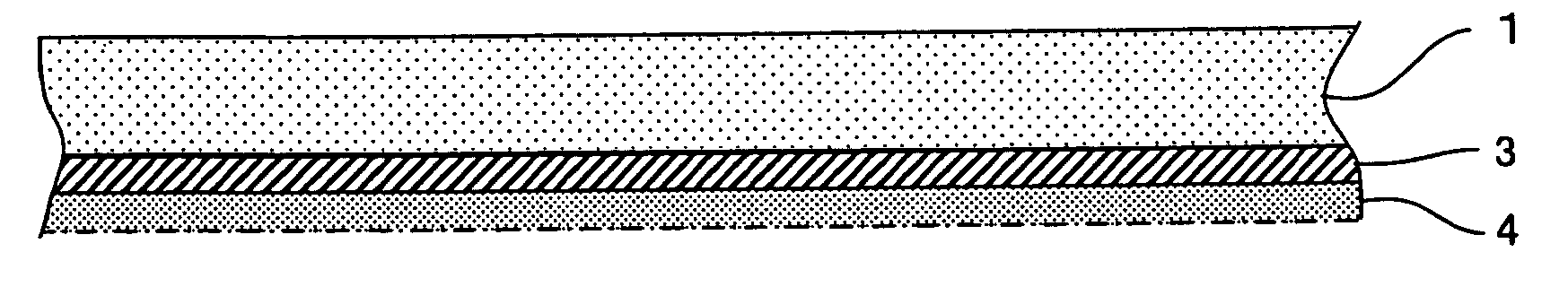

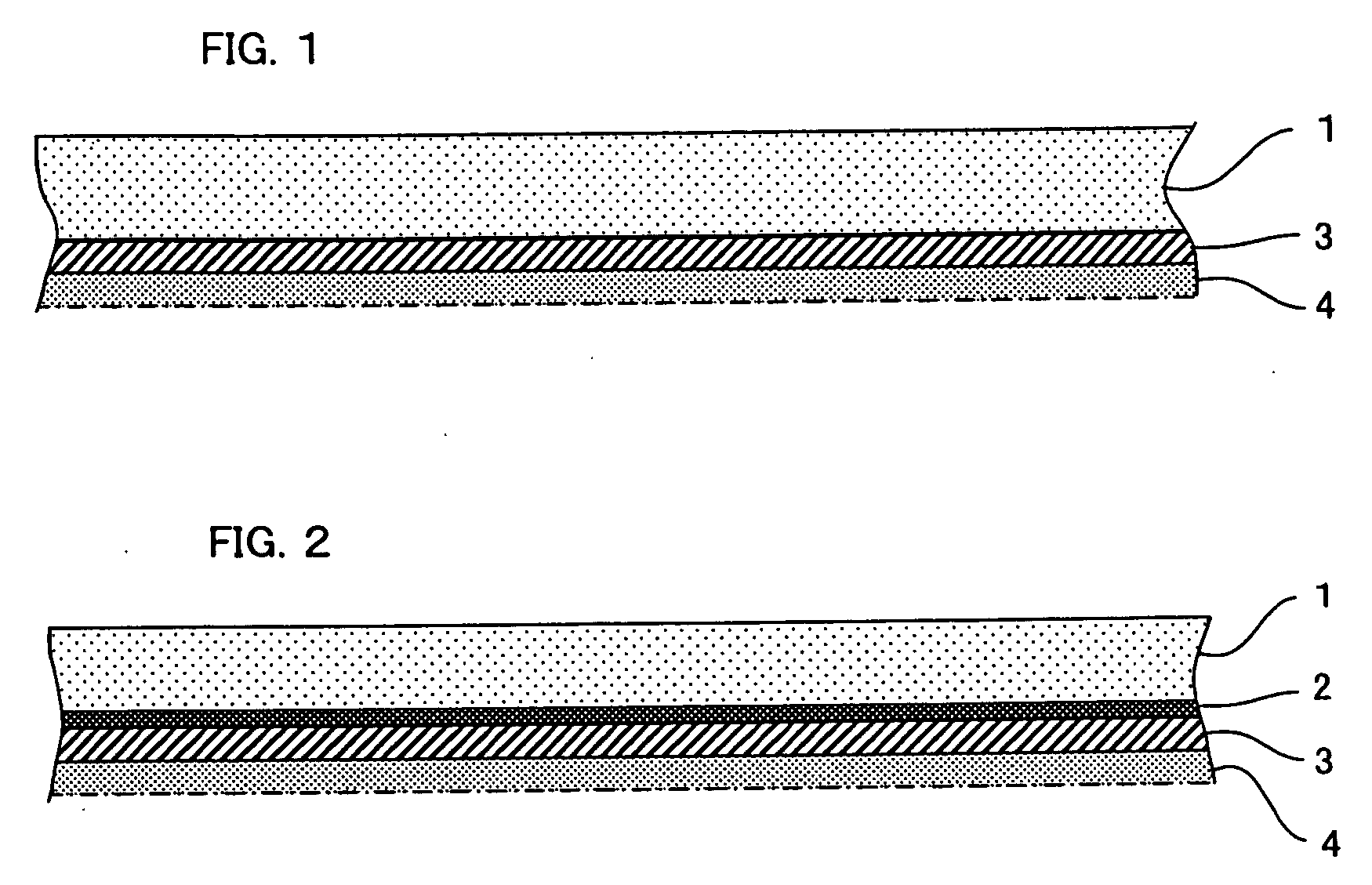

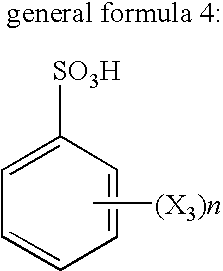

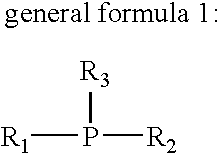

Adhesive composition, adhesive optical film and image display device

ActiveUS20060188712A1Improve adhesionImprove heat resistanceBlast furnace componentsSynthetic resin layered productsPolymer scienceMeth-

To provide an adhesive composition which shows high adhesion with a glass substrate and has excellent heat resistance, moisture resistance and moist heat resistance, an adhesive optical film comprising an adhesive layer made of the adhesive composition, which shows high adhesion between the adhesive layer and an optical film and effectively suppresses the occurrence of adhesive residue and lack of adhesive and also has excellent heat resistance, moisture resistance and moist heat resistance, and an image display device comprising the adhesive optical film, the adhesive optical film comprises an optical film 1, an adhesive layer 3 made of a water dispersible adhesive composition comprising, as raw monomers, an alkyl(meth)acrylate ester whose alkyl group has 4 to 18 carbon atoms, a carboxyl group-containing vinyl monomer, a phosphoric acid group-containing vinyl monomer, and a copolymerizable vinyl monomer which is optionally copolymerizable with the above monomers, wherein a carboxyl group concentration is from 0.05 to 1.50 mmol / g and a phosphoric acid group concentration is from 0.01 to 0.45 mmol / g in the raw monomers, an under coat layer 2 containing an oxazoline group-containing polymer, and being interposed between the optical film 1 and the adhesive layer 3, and the adhesive optical film is applied onto an image display device.

Owner:NITTO DENKO CORP

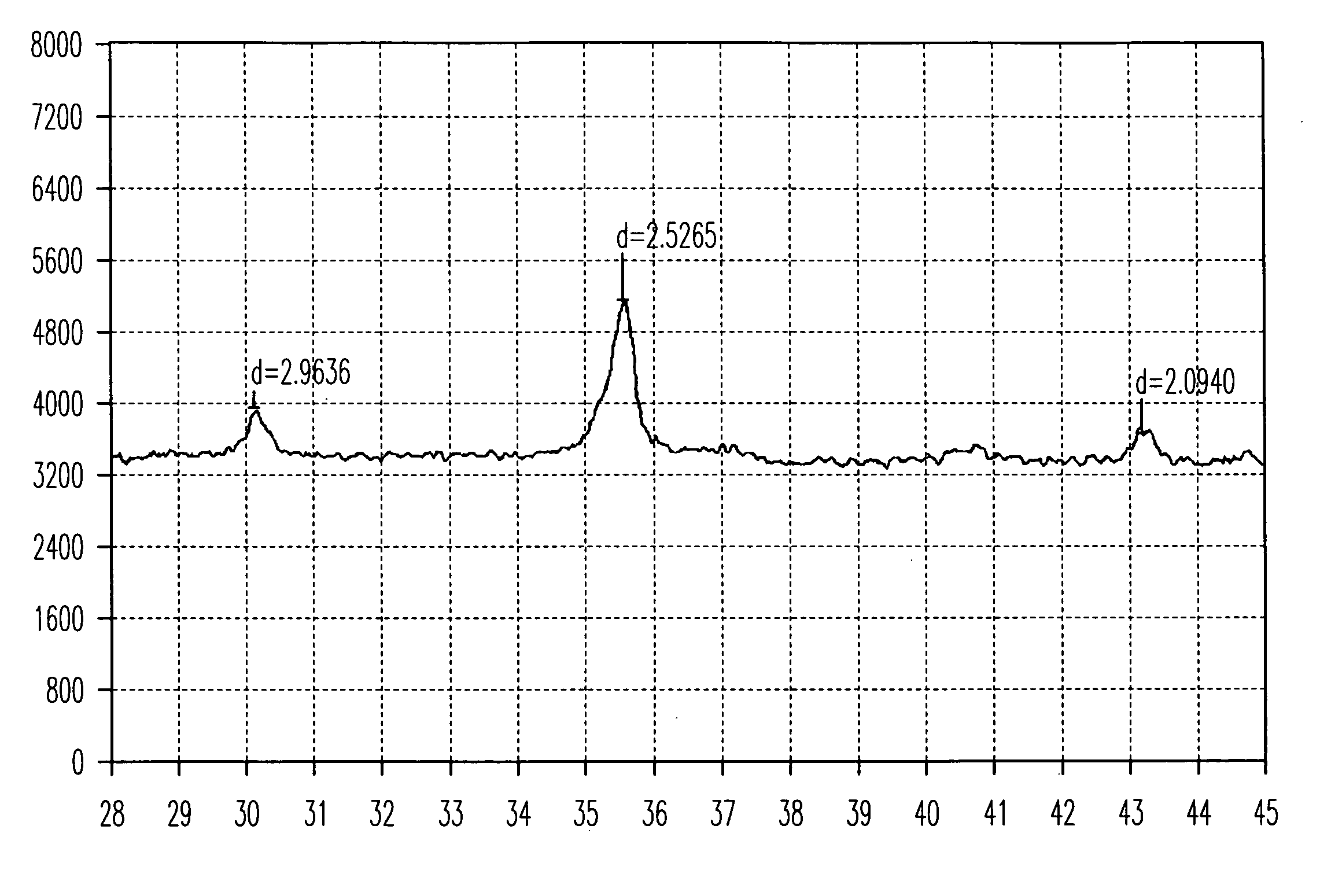

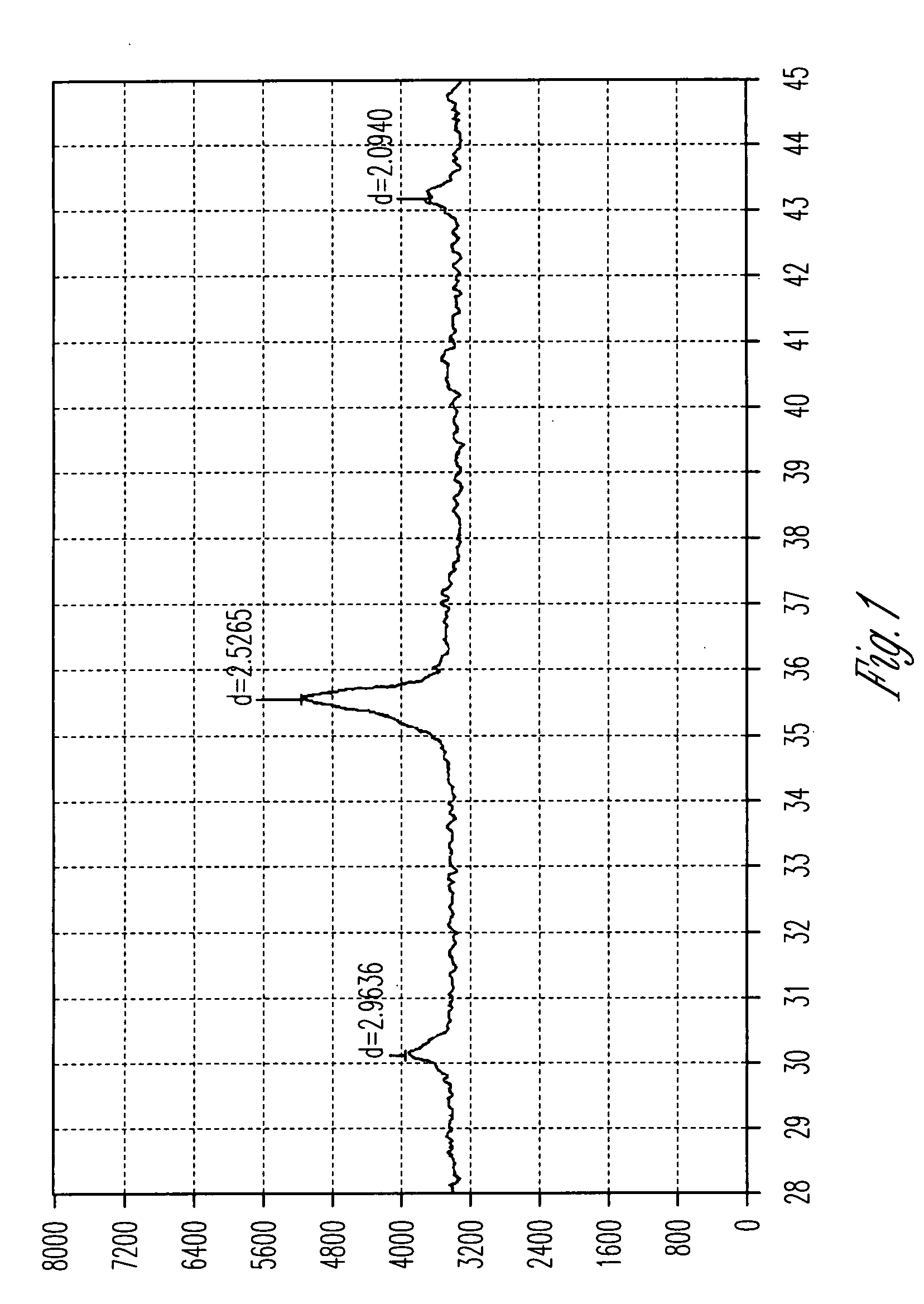

Composition for a desulfurizer with a high sulfur capacity and the process of making the same

ActiveUS20080047395A1Quality improvementEasy to operateGas treatmentBlast furnace componentsActive componentLiquid state

The present invention discloses a composition for a desulfurizer with a high sulfur capacity and a process for making the same. The composition comprises the active components of three kinds of iron oxides and is used in the desulfurizer to remove hydrogen sulfide from the gaseous and liquid state feed stocks. The above-mentioned composition comprises cubic ferroferric oxide in the form of crystalline phase (Fe3O4), amorphous ferric oxide (Fe2O3) and amorphous ferric oxide monohydrate (Fe2O3.H2O). The composition has a sulfur capacity of at least 40%. The process for preparing the composition comprises the following steps: (1) mixing a solid ferrous compound with a solid hydroxide at a molar ratio of iron to hydroxyl being in the range from 1:2 to 1:3; (2) kneading the mixture feeds obtained in step (1) and making them react completely; (3) drying the products obtained in step (2) in the air; (4) washing and filtering the feeds obtained in the step (3); (5) naturally drying or baking the solids obtained in step (4) to form a composition for a desulfurizer with a high sulfur capacity. The process of the present invention is simple and easy to operate, consumes less energy and produces the products with a stable quality.

Owner:BEIJING HAIXIN ENERGY TECH CO LTD

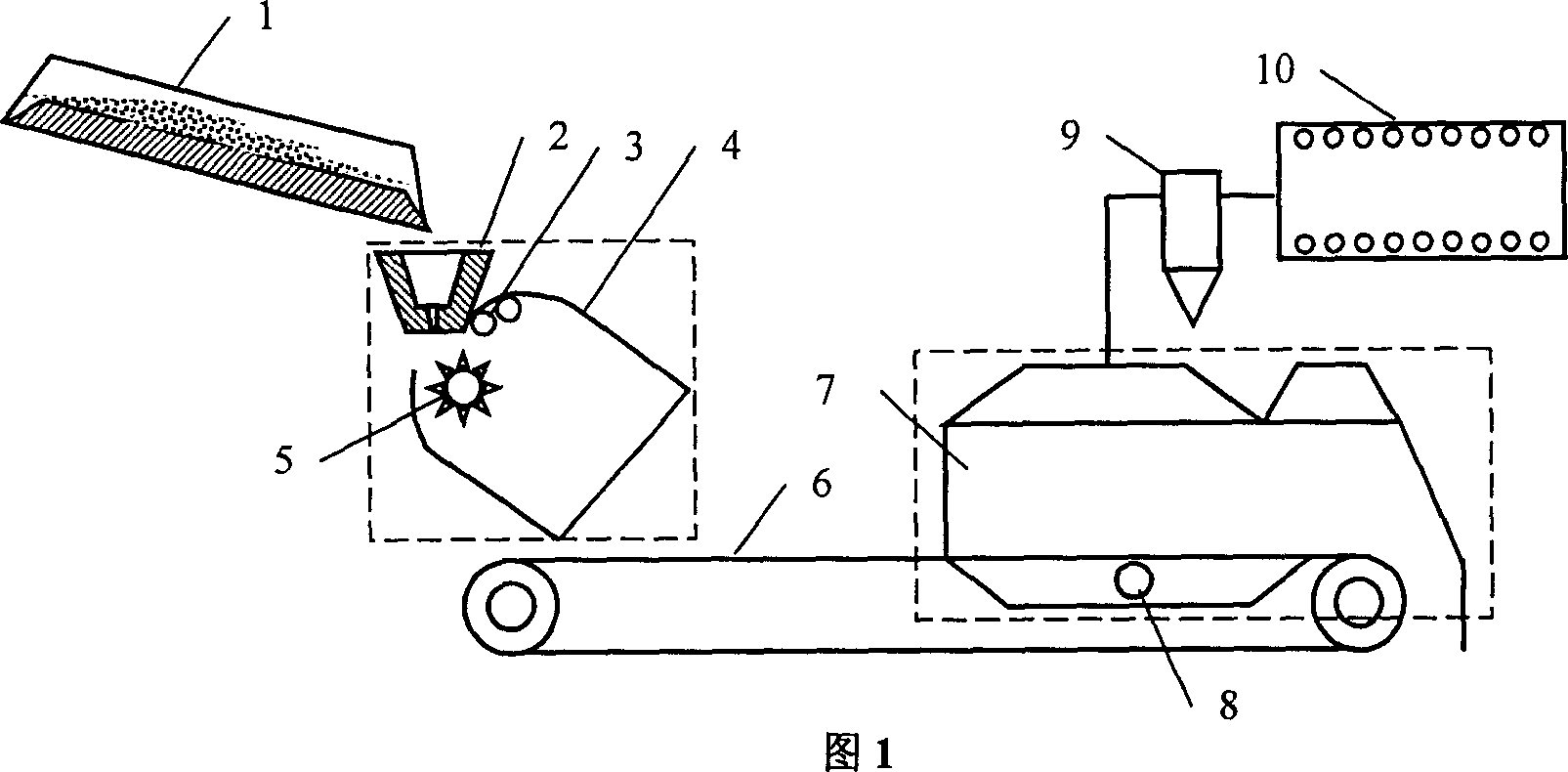

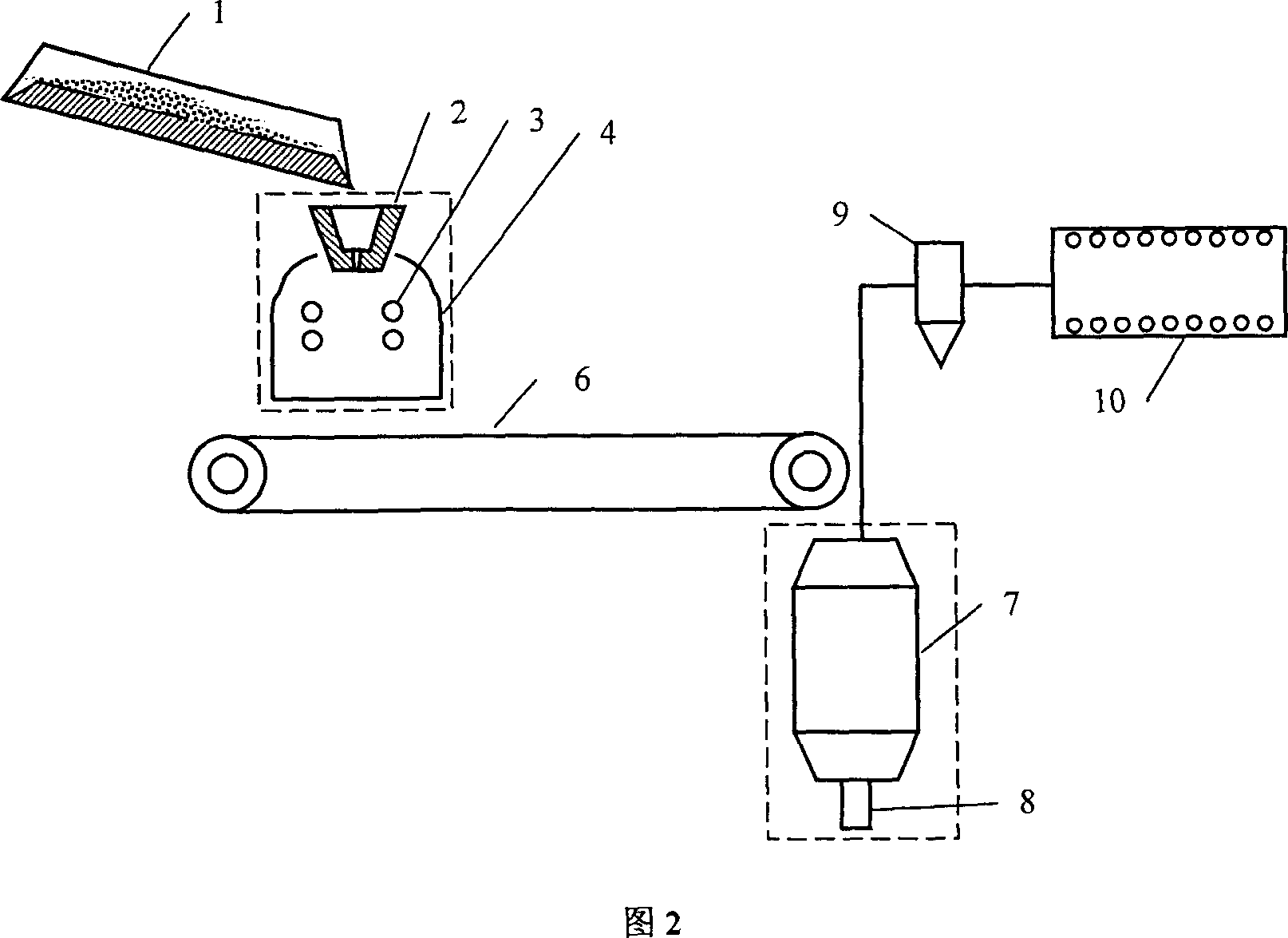

Blast-furnace cement sensible heat recovery system and its production process

InactiveCN1920380AReduce focal ratioRaise the hot air temperatureOther heat production devicesBlast furnace componentsSlagProduct gas

The invention relates to a blast furnace slag heat recycle system and relative production, wherein it is formed by cooling-breaking, gas-slag heat exchanger, and left-heat boiler units; the slag outlet has cooling-braking unit which will cool the slag to the solidify point 1200-1300Deg. C, to be broken into the slag particles whose diameter is less than 100mm; the transmitter is connected to the gas-slag heat exchanger to heat the air to 700-800Deg. C; the slag will be cooled under 150Deg. C; the heated air will be transmitted to the left-heat boiler; the water of heating tube of boiler will adsorb the heat of gas, to generate the steam whose pressure at 0.3-0.4MPa and temperature at 260-350Deg. C. The invention can improve the energy recycle efficiency more than 70%, to reduce the energy consumption of steel production, reduce the consumption of cooling water, and reduce the environment pollution.

Owner:ANGANG STEEL CO LTD +1

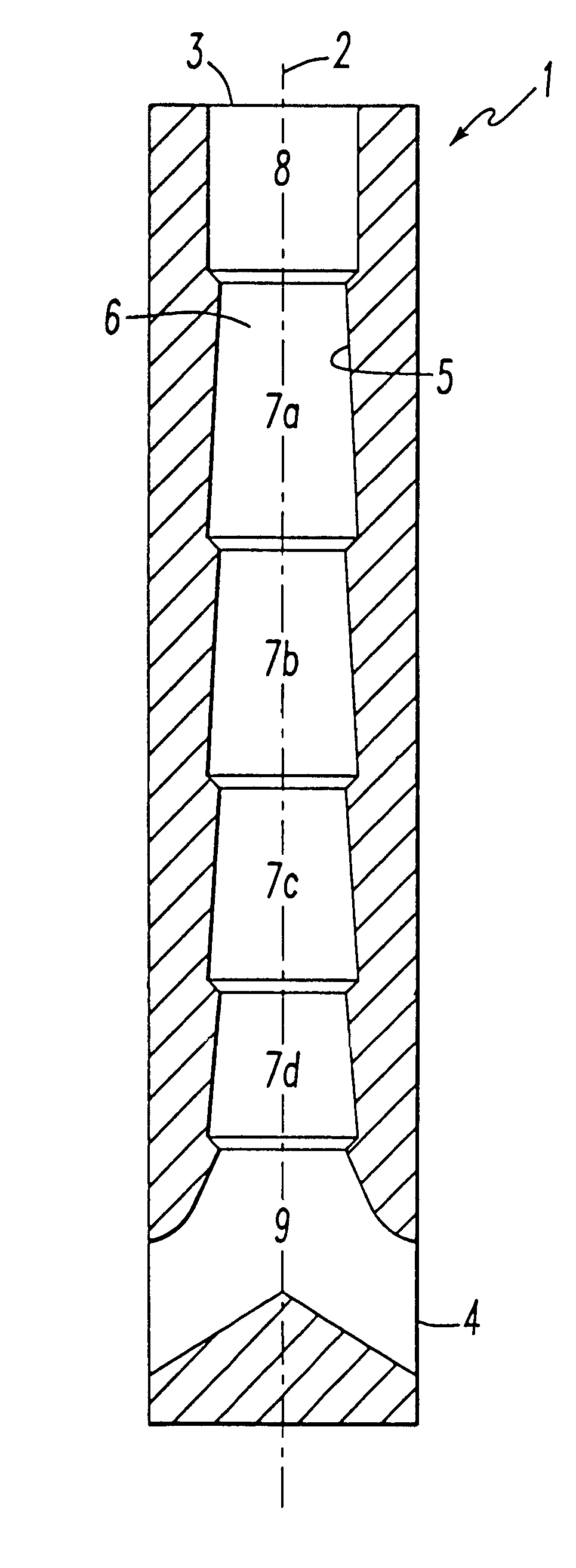

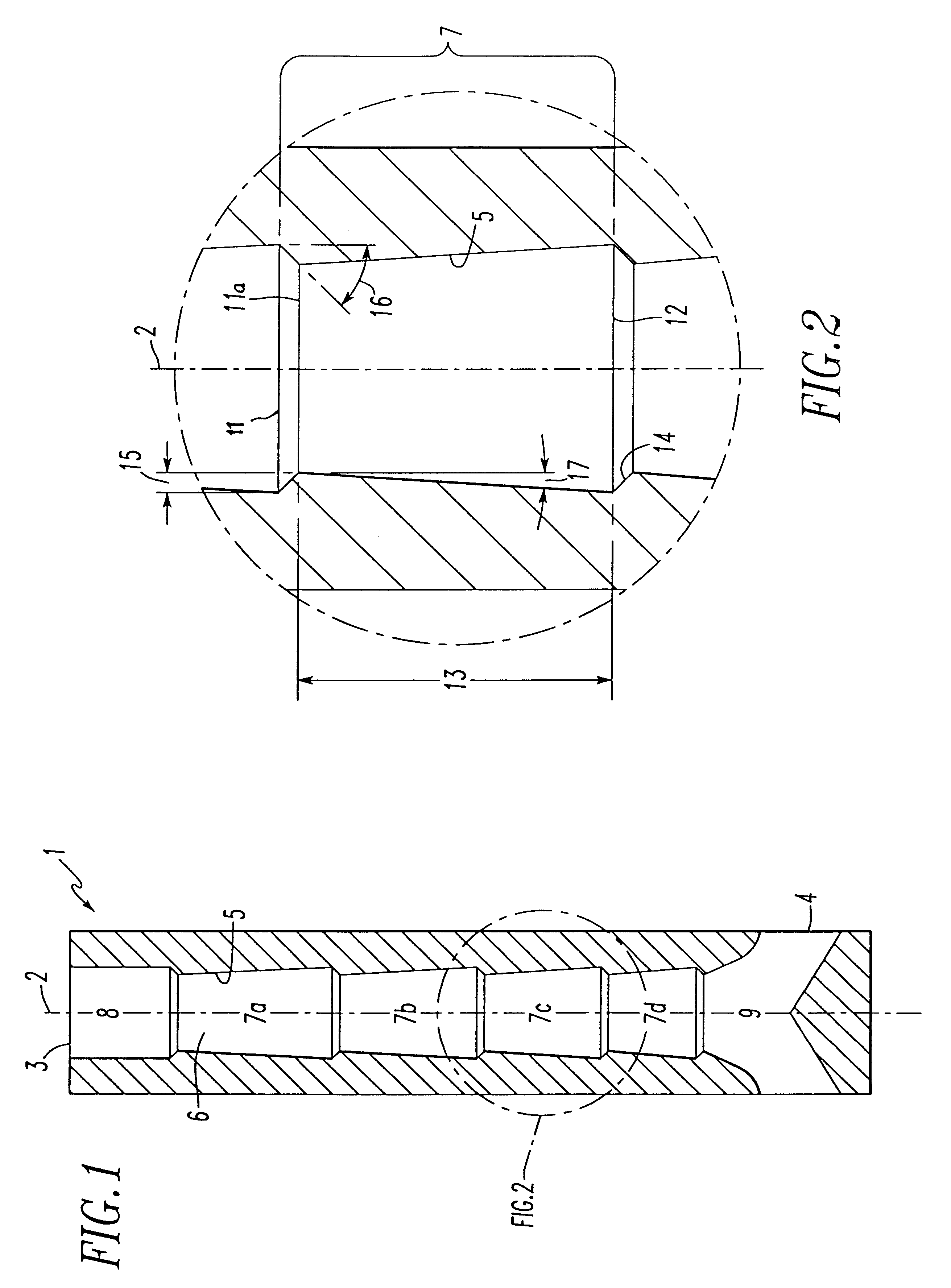

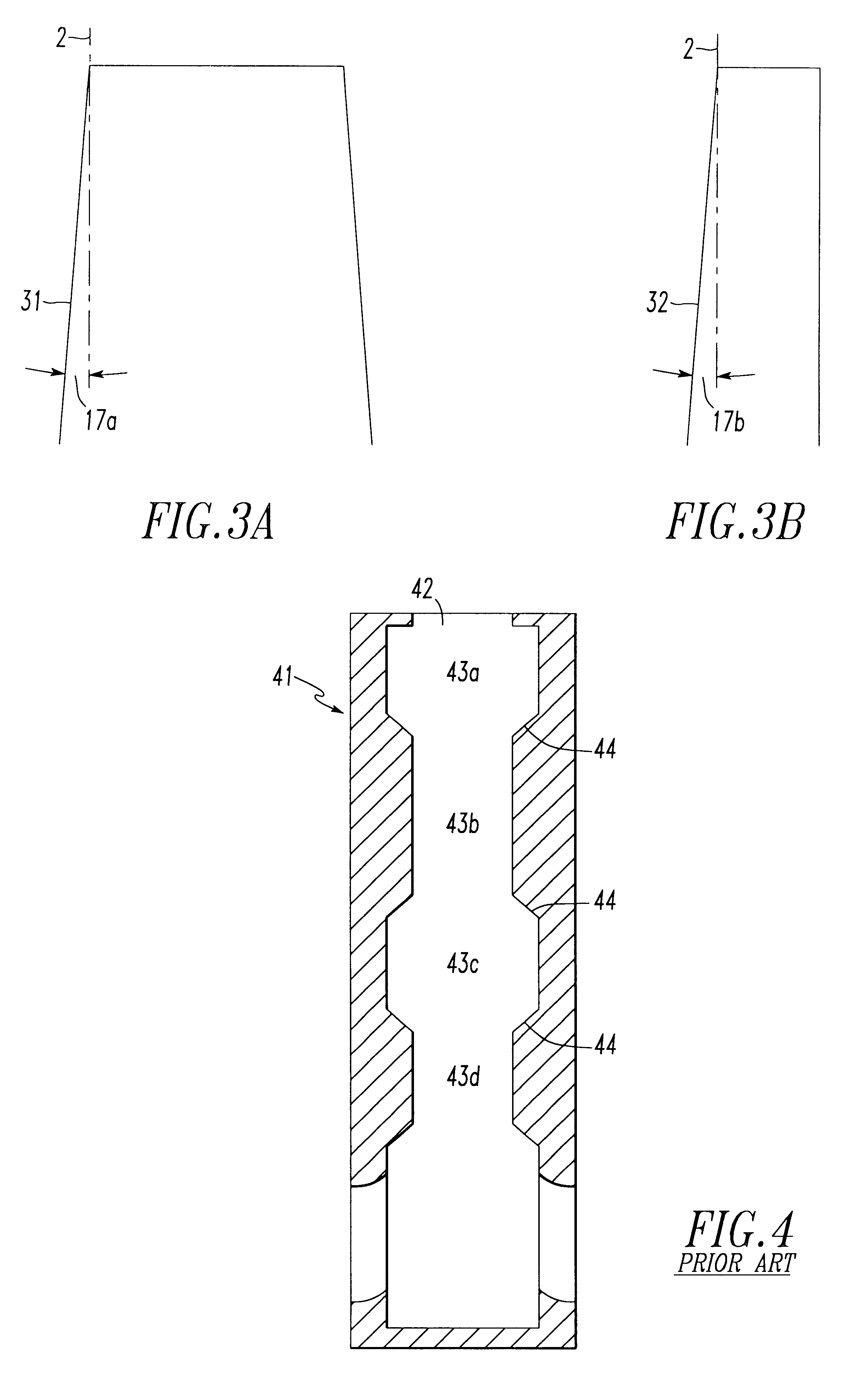

Pour tube with improved flow characteristics

A pour tube for use in the continuous casting of a stream of molten metal has a bore comprising a plurality of fluidly connected sections that improve the flow of molten metal through the bore. The sections reduce asymmetric flow of the molten metal stream and the likelihood of precipitates clogging the bore. Each section comprises a converging portion and a diverging portion. The converging portion deflects the stream toward the center of the bore, while the diverging portion diffuses the stream. The sections may comprise a plurality of frusto-conical sections. The cross-sectional areas of the sections may increase, decrease, or remain the same size from an upstream to a downstream position.

Owner:VESUVIUS USA CORP

Bleed hole stemming and method for producing the same

ActiveCN101219900AGood sintered strengthEasy to openBlast furnace componentsBlast furnace detailsPyrophylliteGraphite

The invention relates to a stemming at a taphole; the weight percentages of the components are the following: 20 to 40 of corundum, 10 to 20 of silicon carbide, 3 to 10 of silicon nitride, 10 to 23 of coke powders, 1 to 5 of graphite powders, 3 to 10 of sericite, 1 to 5 of active alumina micropowders, 5 to 15 of clay, 5 to 10 of pyrophyllite, 1 to 3 of metal powders, and +15 to 25 of water-free binder. The stemming adds a plurality of materials with plasticity and good cohesiveness to cause the stemming to easily block the hole and fill interspaces, with good binding performance of new stemming and old stemming; materials with medium and high temperature expansion are added to reduce the size of the stemming contraction at high temperature, and cracks can be avoided; materials with sintering function within different temperature areas are added, so the stemming has good sintering strength in different temperature scopes; materials with high-temperature resistance and good erosion resistance are added, and thus the stemming has high strength at high temperature, washing resistance and erosion resistance.

Owner:BAOSHAN IRON & STEEL CO LTD

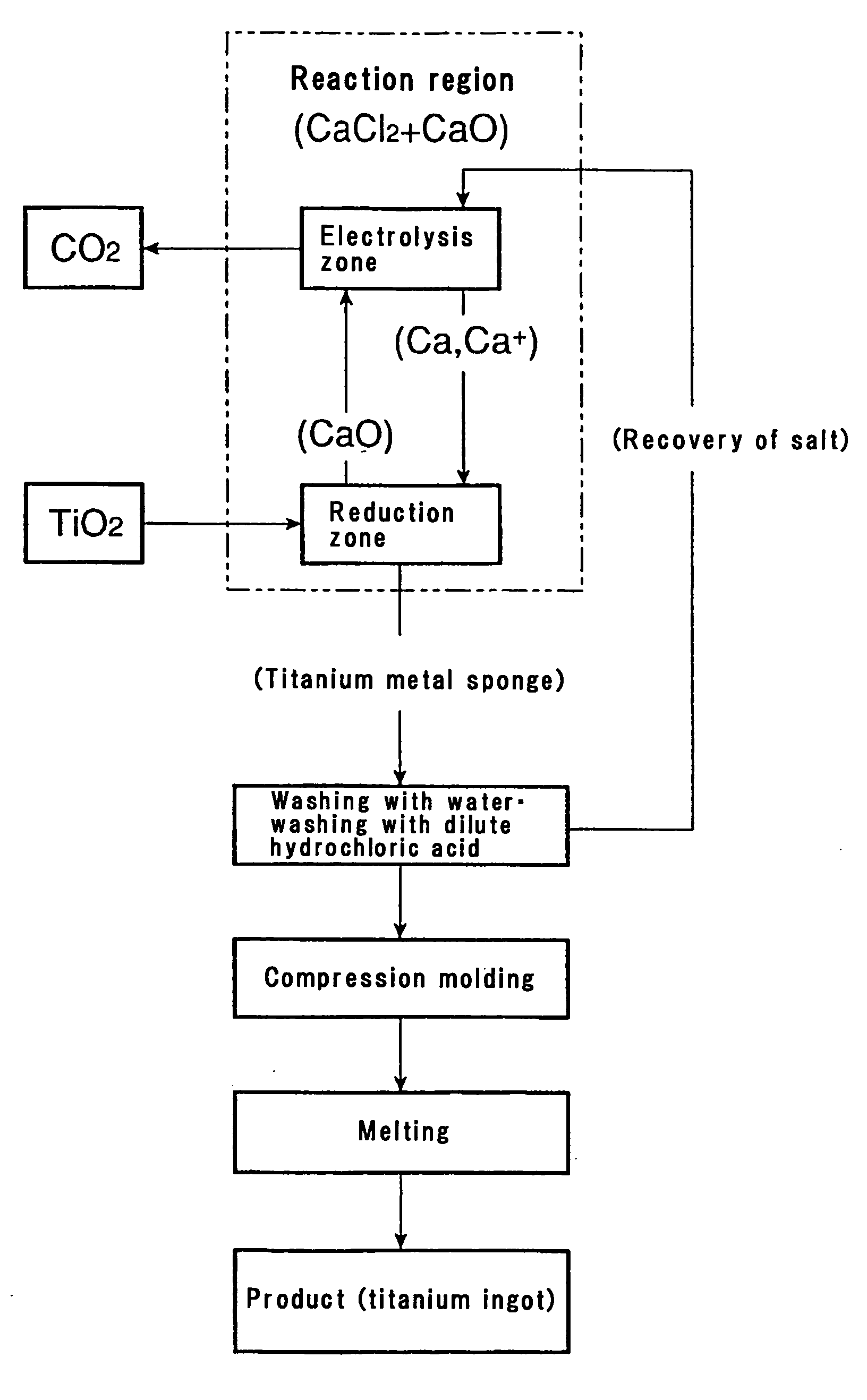

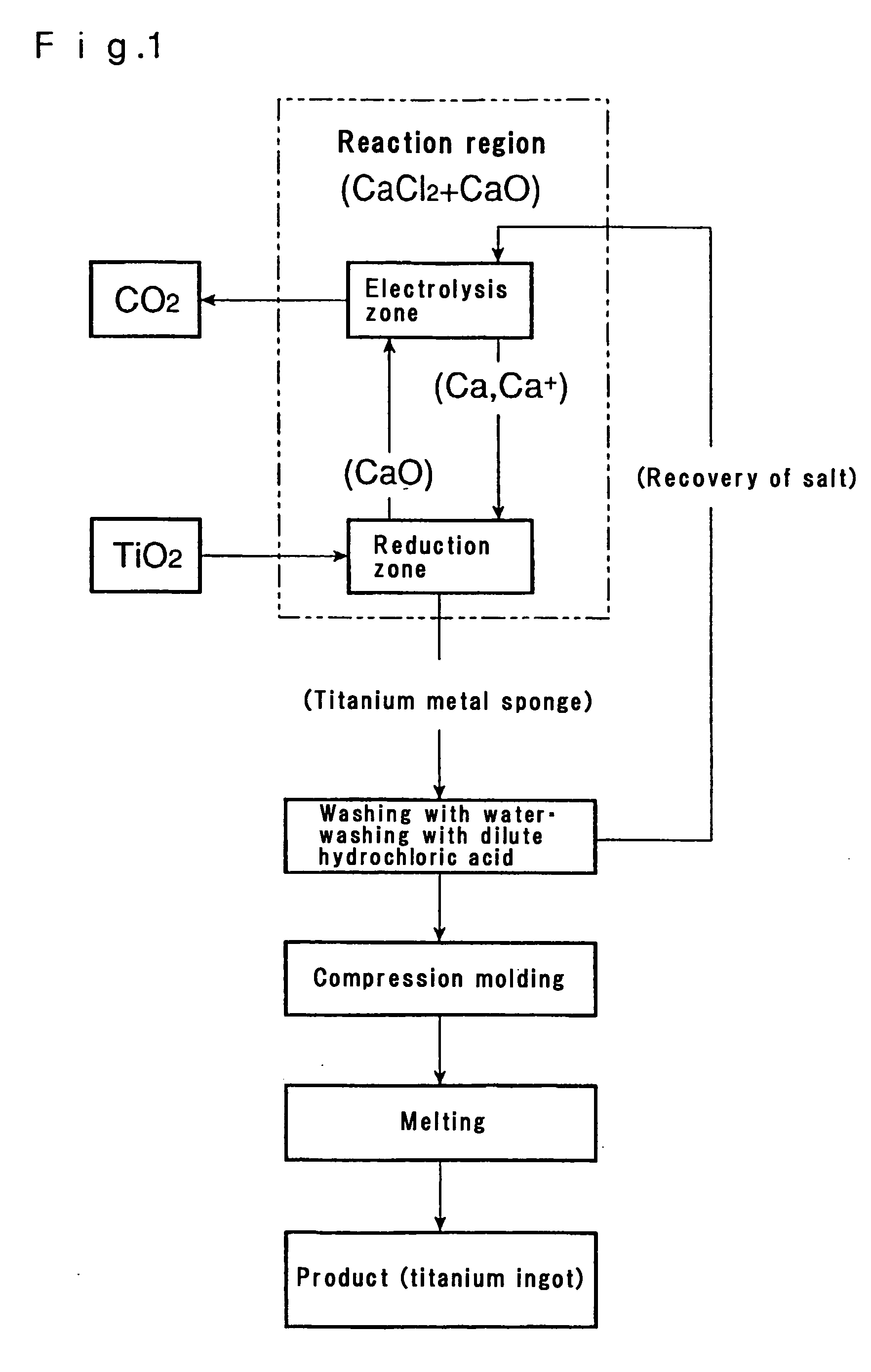

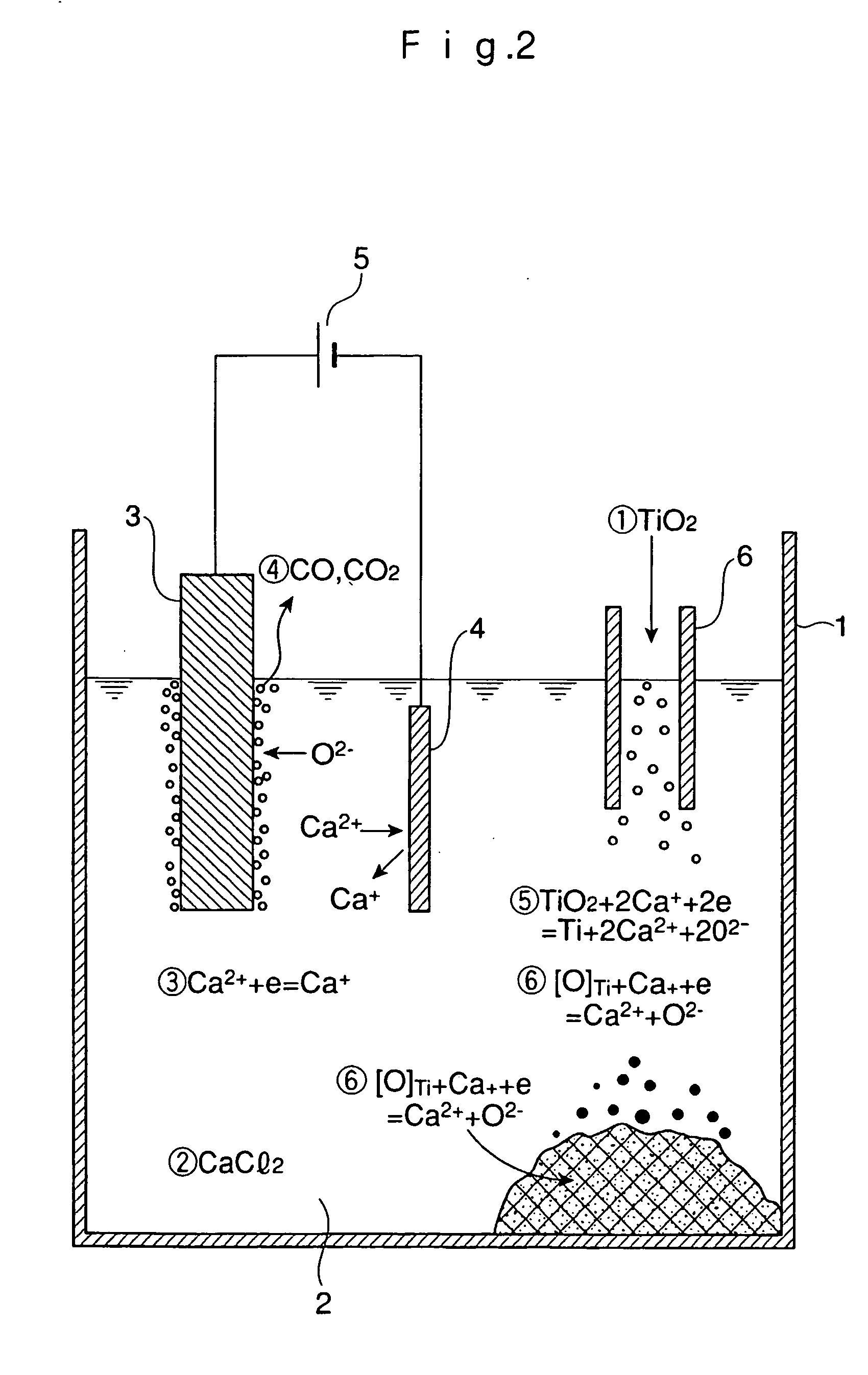

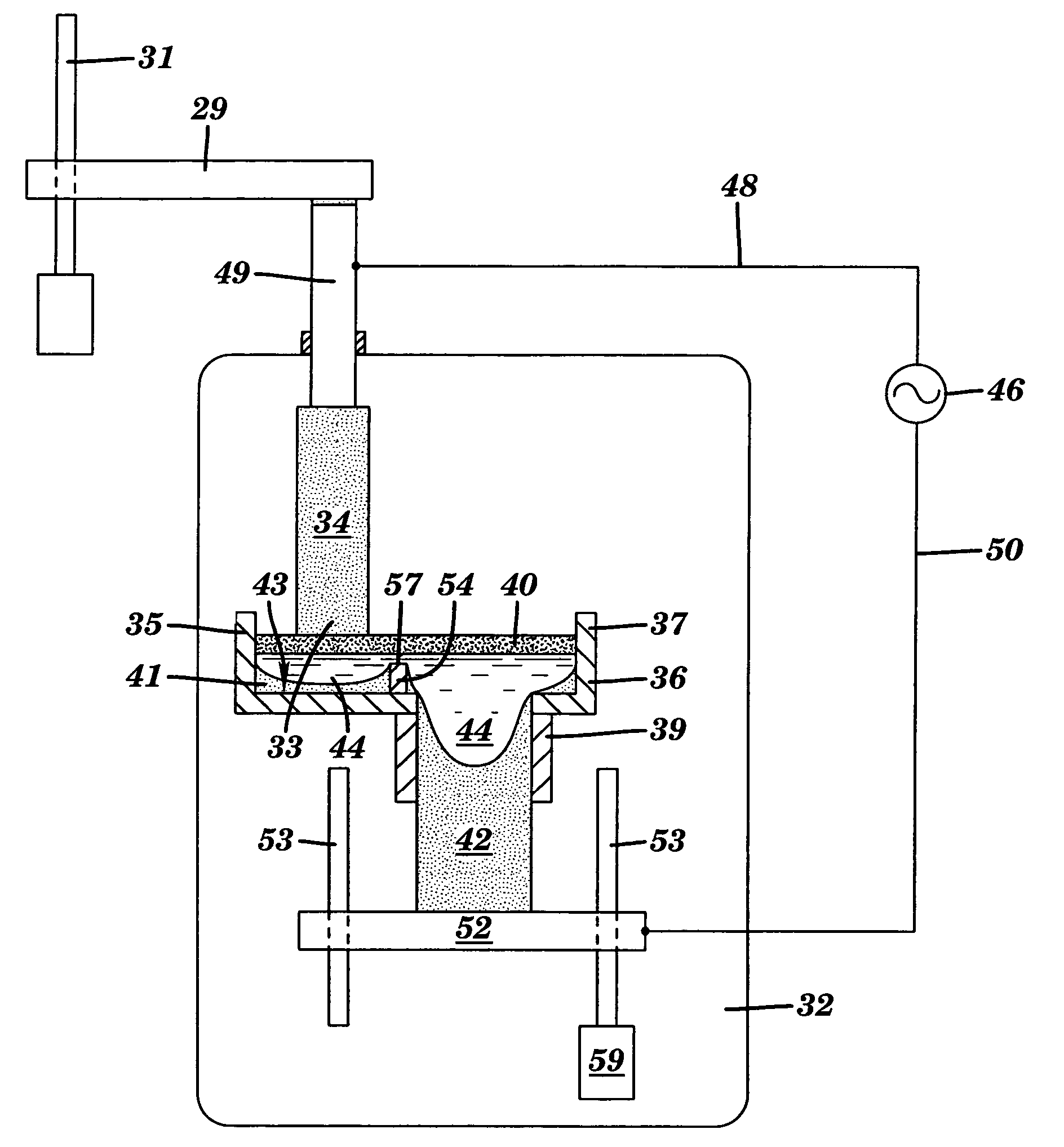

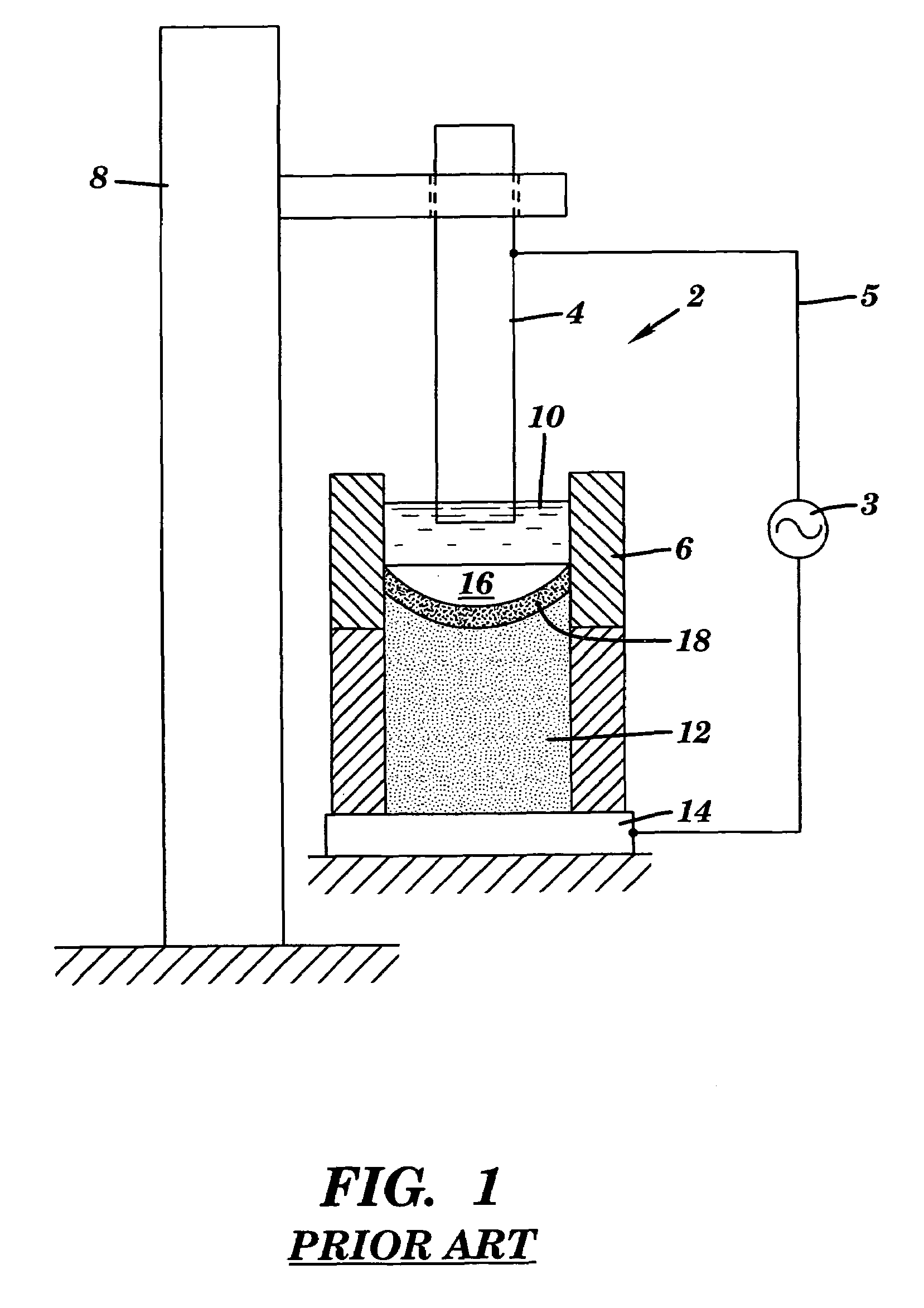

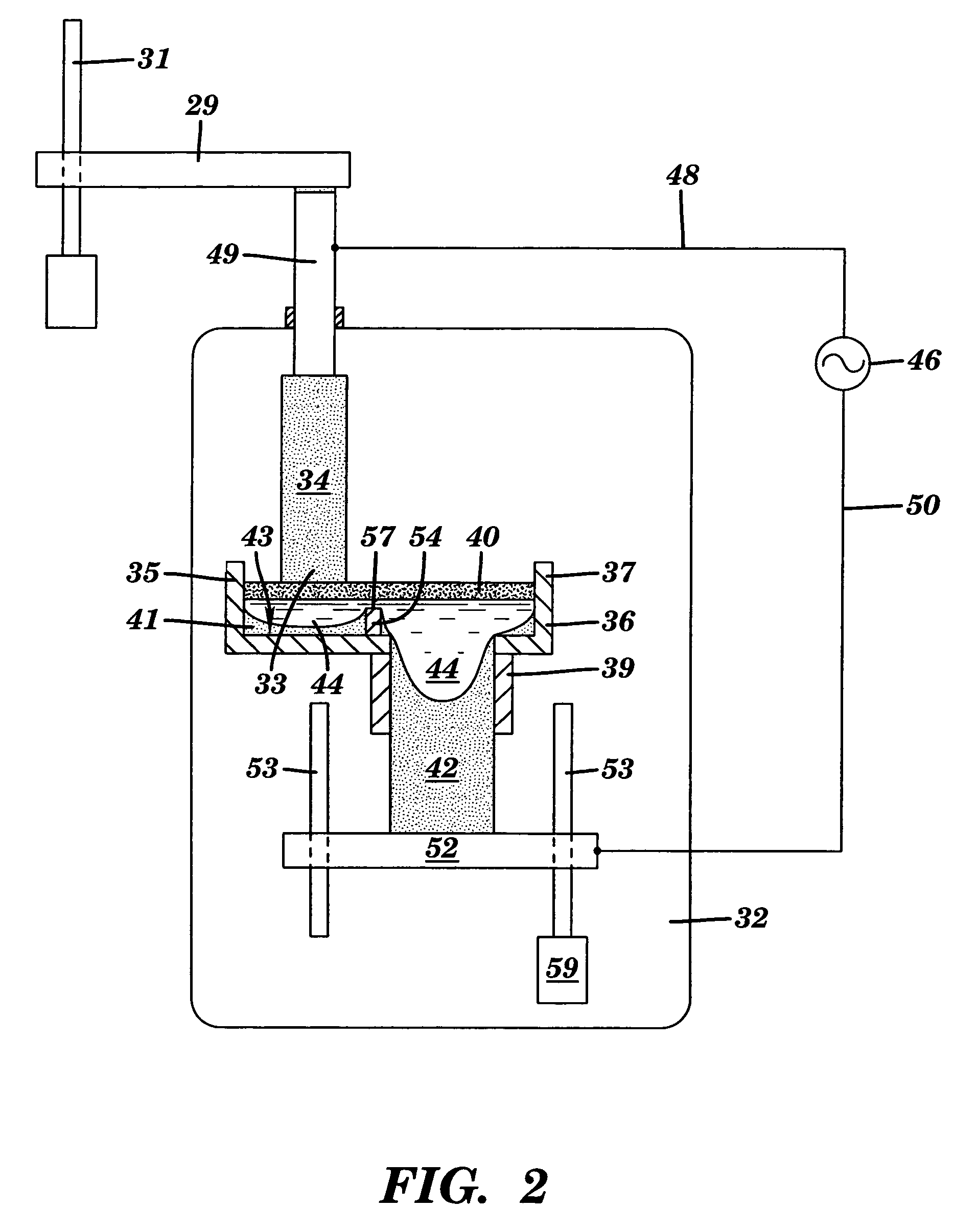

Method and apparatus for smelting titanium metal

This invention relates to a method and an apparatus for smelting titanium metal by the thermal reduction of titanium oxide (TiO2) to titanium metal (Ti); a mixed salt of calcium chloride (CaCl2) and calcium oxide (CaO) contained in a reaction vessel is heated to form a molten salt which constitutes a reaction region, the molten salt in the reaction region is electrolyzed thereby converting the molten salt into a strongly reducing molten salt containing monovalent calcium ions (Ca<+>) and / or calcium (Ca), titanium oxide is supplied to the strongly reducing molten salt and the titanium oxide is reduced and the resulting titanium metal is deoxidized by the monovalent calcium ions and / or calcium. The method and the apparatus make it feasible to produce commercially titanium metal suitable for a variety of applications from titanium oxide.

Owner:NIPPON LIGHT METAL CO LTD

Flux for soldering and circuit board

InactiveUS20060147683A1High bonding strengthSuppress DiffuseBlast furnace componentsBlast furnace detailsSolventCopper complex

A flux contains resin having film forming ability, activator, solvent, and at least one complex selected from silver complex and copper complex. The flux is used when soldering is performed onto a circuit having electroless nickel plating or further having gold plating on the electroless nickel plating. Allowing a barrier layer of silver or copper to deposit on the surfaces of lands suppresses the diffusion of nickel into the melted solder alloy during soldering, and also prevents phosphorous concentration. This improves the bonding strength of soldering and suppresses the reduction deposition of silver and / or copper to portions other than circuit patterns.

Owner:HARIMA CHEM INC

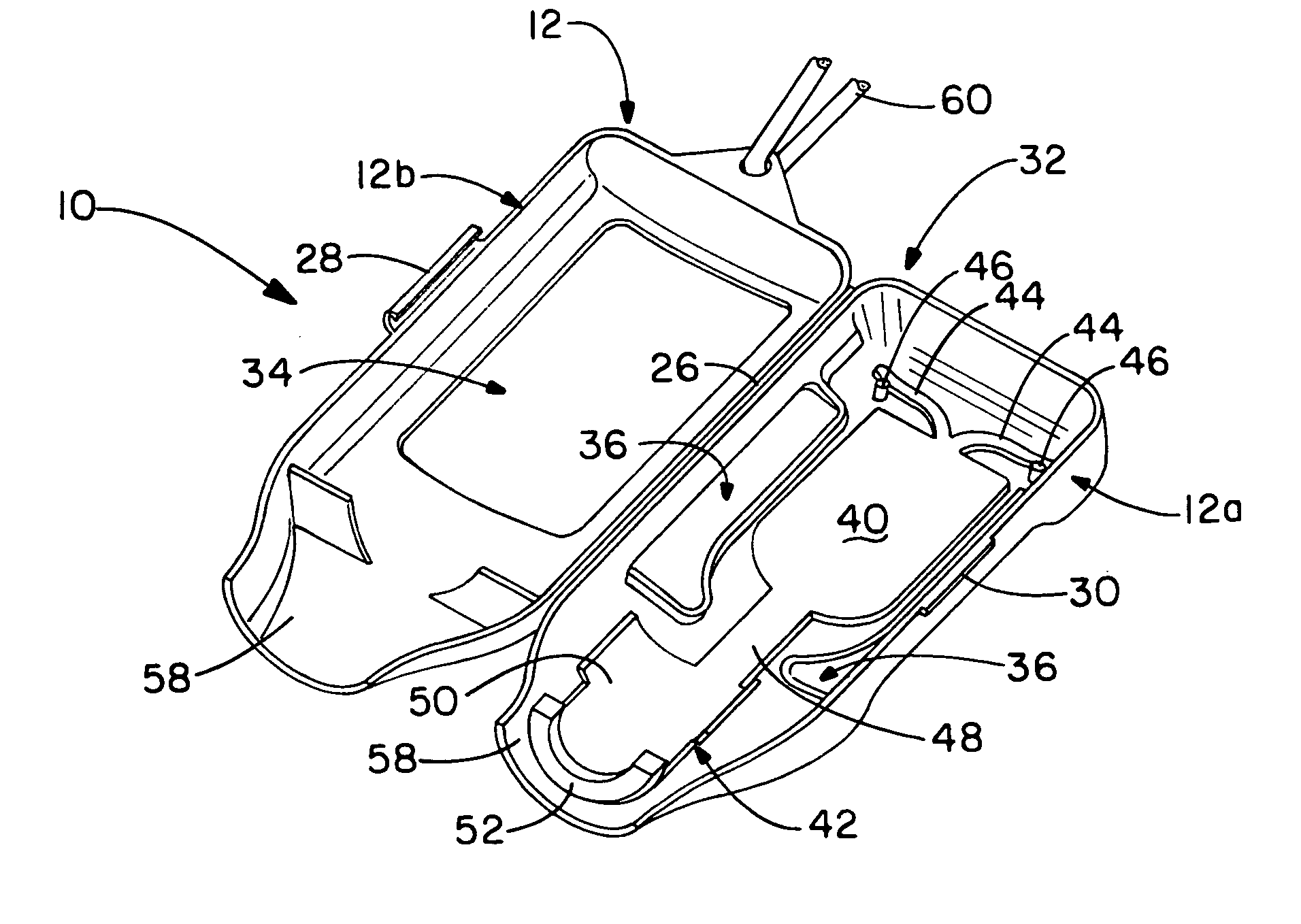

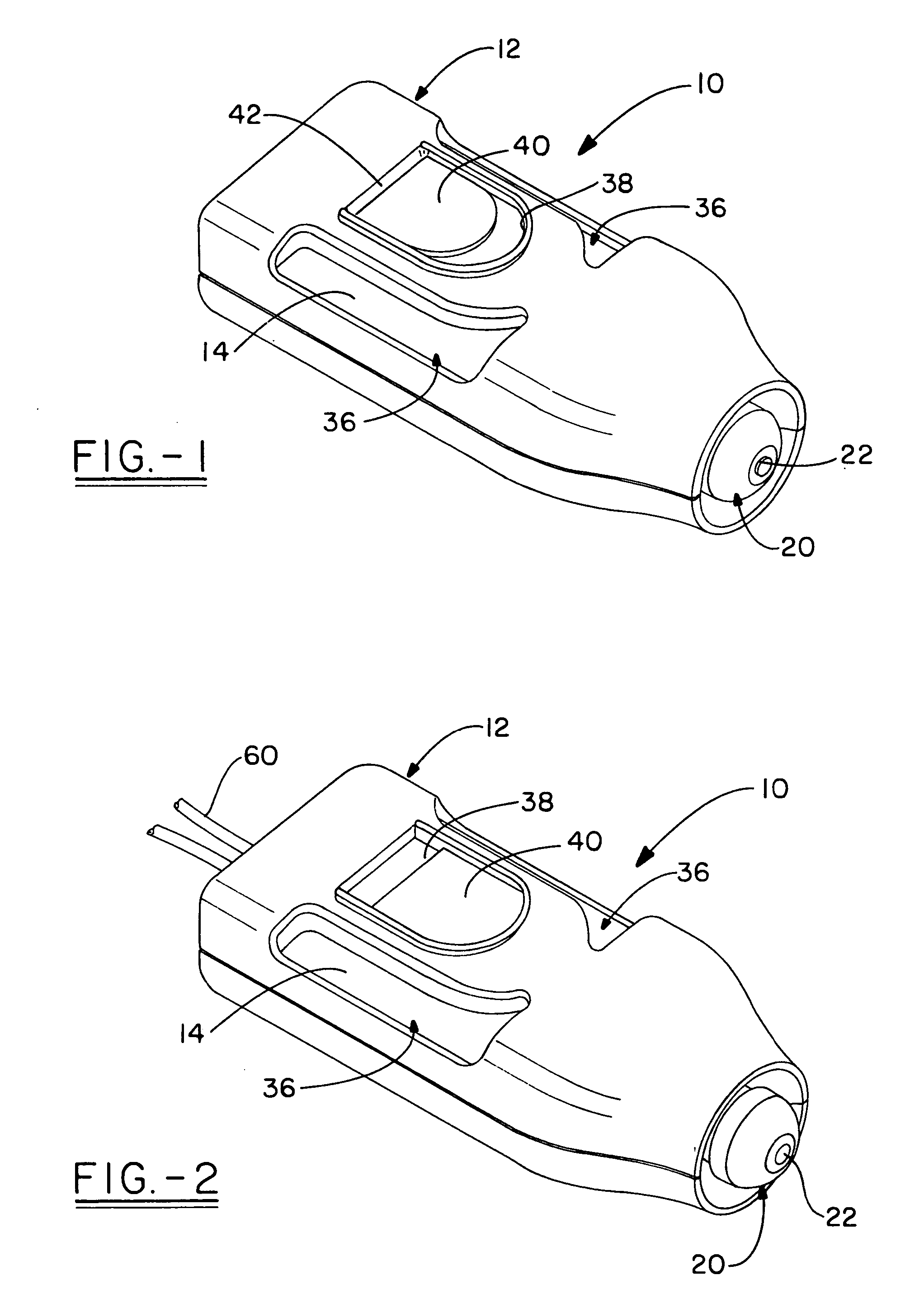

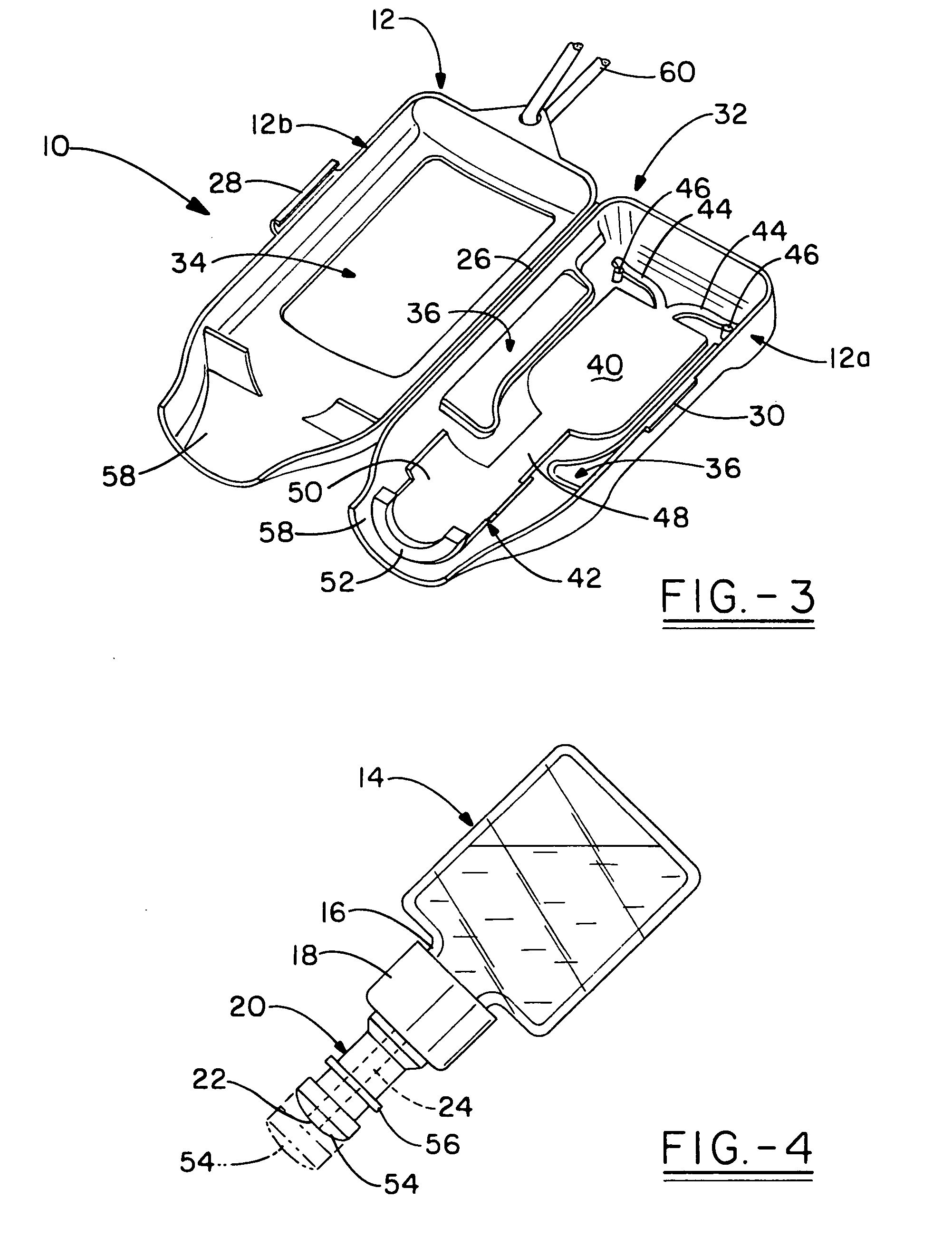

Personal squeeze bottle dispenser

A personal squeeze bottle dispenser has a clamshell housing adapted to receive a squeeze bottle having a push / pull dispensing valve. A slide mechanism is received within the housing and has a collar at one end engaging the push / pull valve, and a spring at the other end to effect automatic return of the slide mechanism upon termination of a dispensing cycle. The spring biases the push / pull valve to the closed position. The clamshell housing is configured with an opening for a thumb pad of the slide mechanism to achieve opening of the push / pull valve and accommodating pressure upon the squeeze bottle. An opening on the backside of the housing, opposite the thumb pad, is also provided to allow the user's fingers to access the squeeze bottle for the application of dispensing force.

Owner:KANFER JOSEPH S

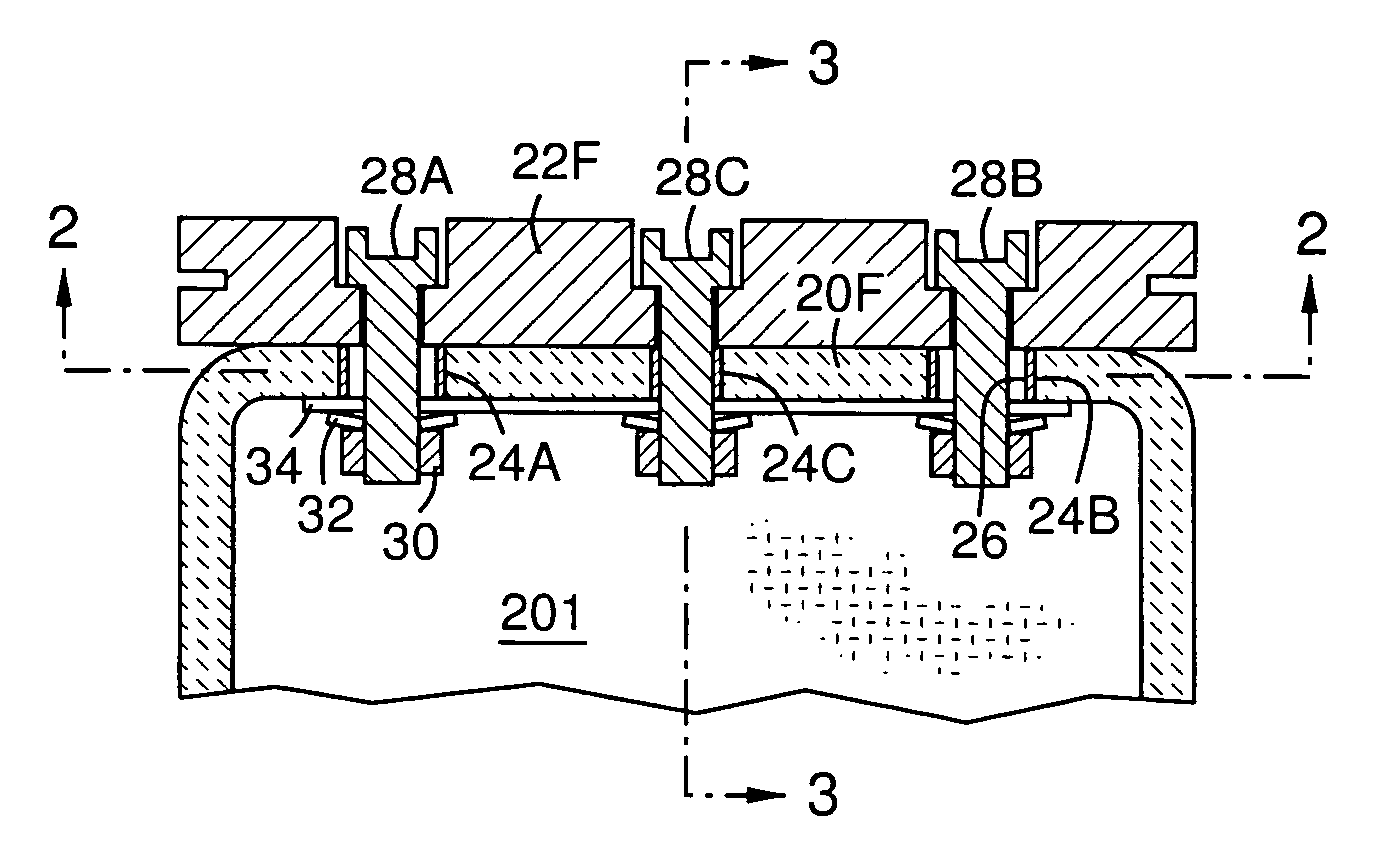

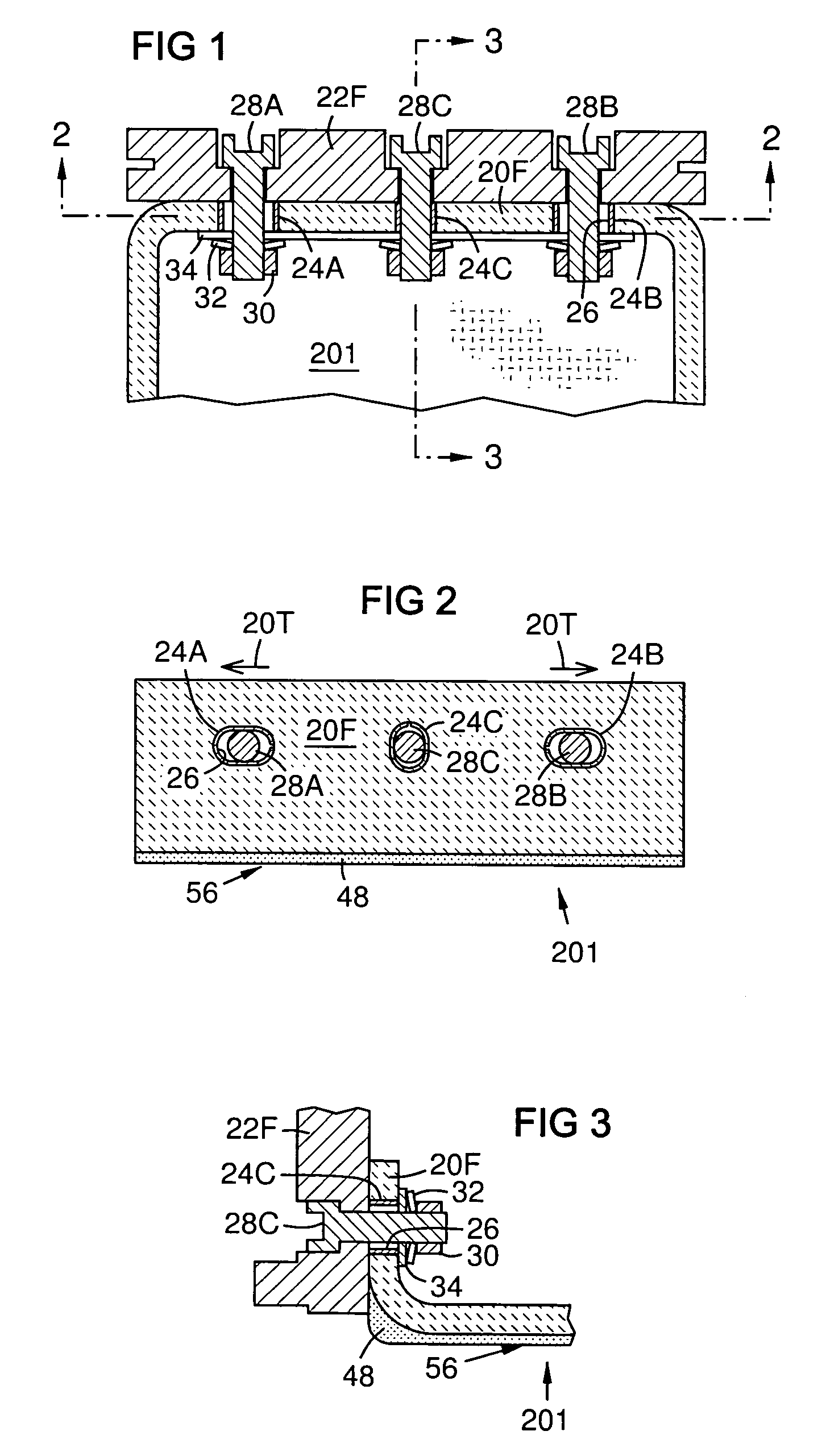

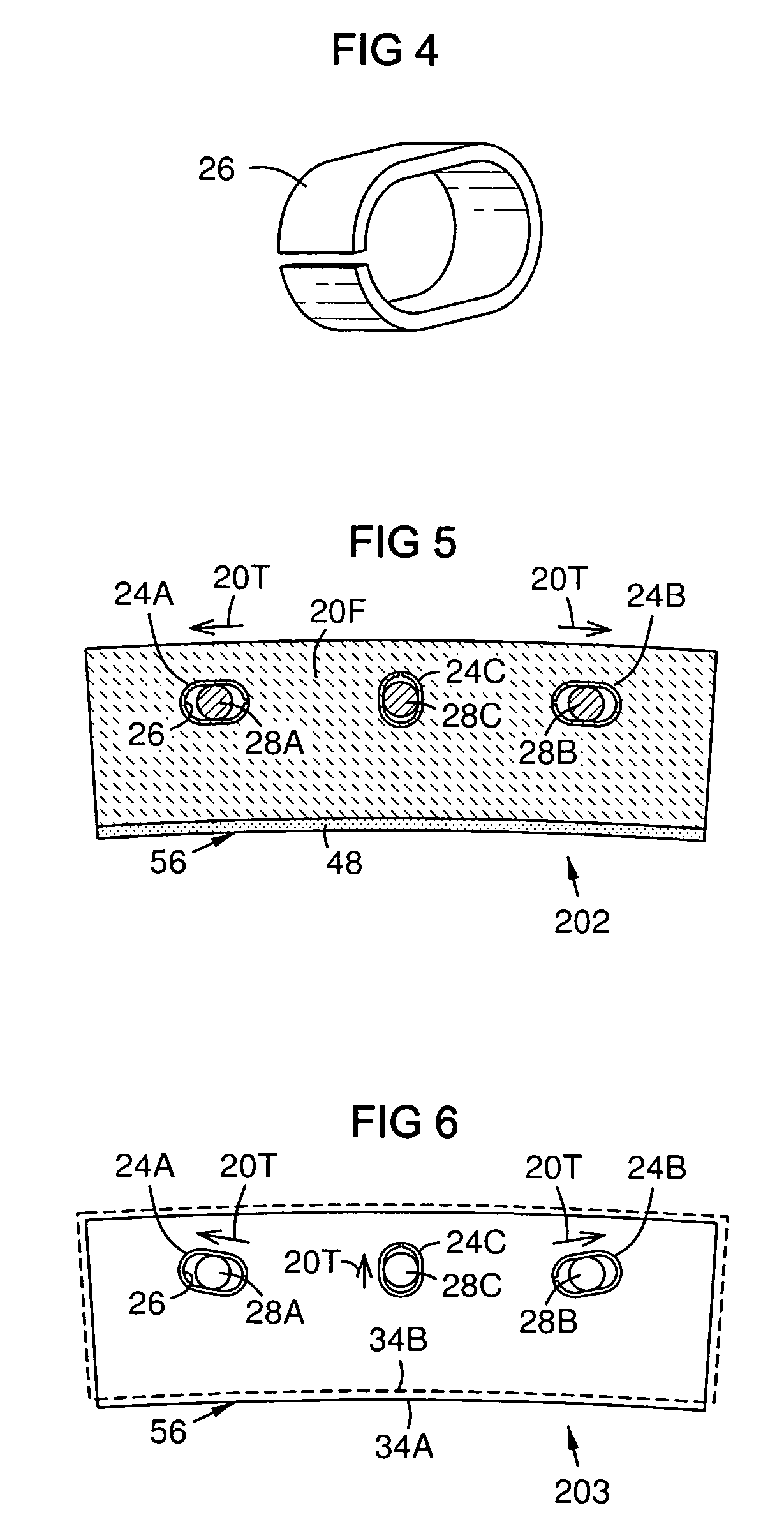

CMC to metal attachment mechanism

A CMC wall (20F) may be attached to a metal wall (22F) by a plurality of bolts (28A, 28B, 28C) passing through respective holes (24A, 24B, 24C) in the CMC wall (20F) and holes in the metal wall (22F), clamping the walls (20F, 22F) together with a force that allows sliding thermal expansion but does not allow vibrational shifting. Distal ones of the holes (24A, 24B) in the CMC wall (20F) or in the metal wall (22F) are elongated toward a central one of the bolts (24C) or at alternate angles to guide differential thermal expansion (20T) of the CMC wall (20F) versus the metal wall (22F) between desired cold and hot geometries. A second CMC wall (20R) may be mounted similarly to a second metal wall (22R) by pins (39A, 39B, 39C) that allow expansion of the CMC component (201) in a direction normal to the walls (20F, 20R).

Owner:SIEMENS ENERGY INC

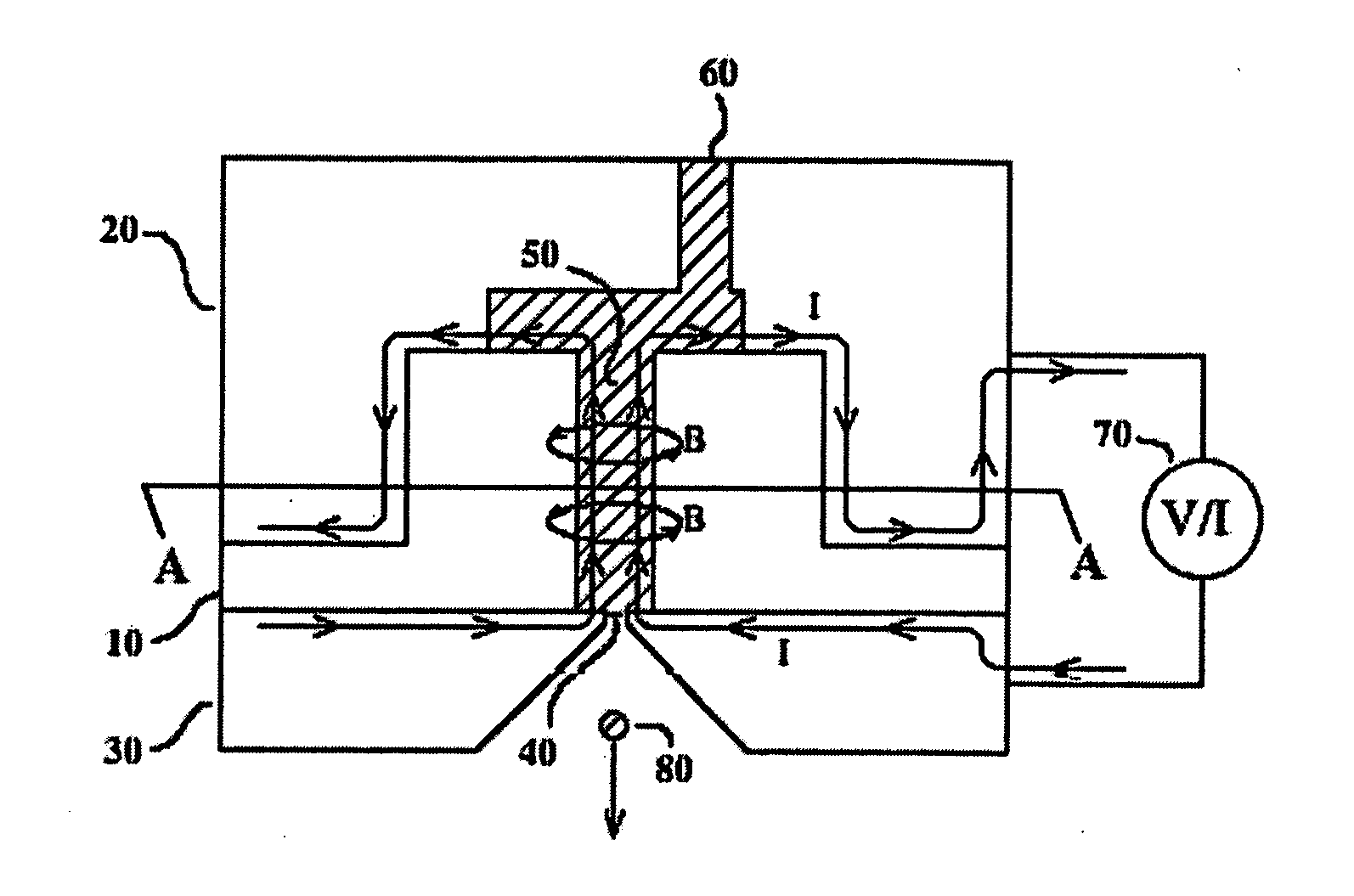

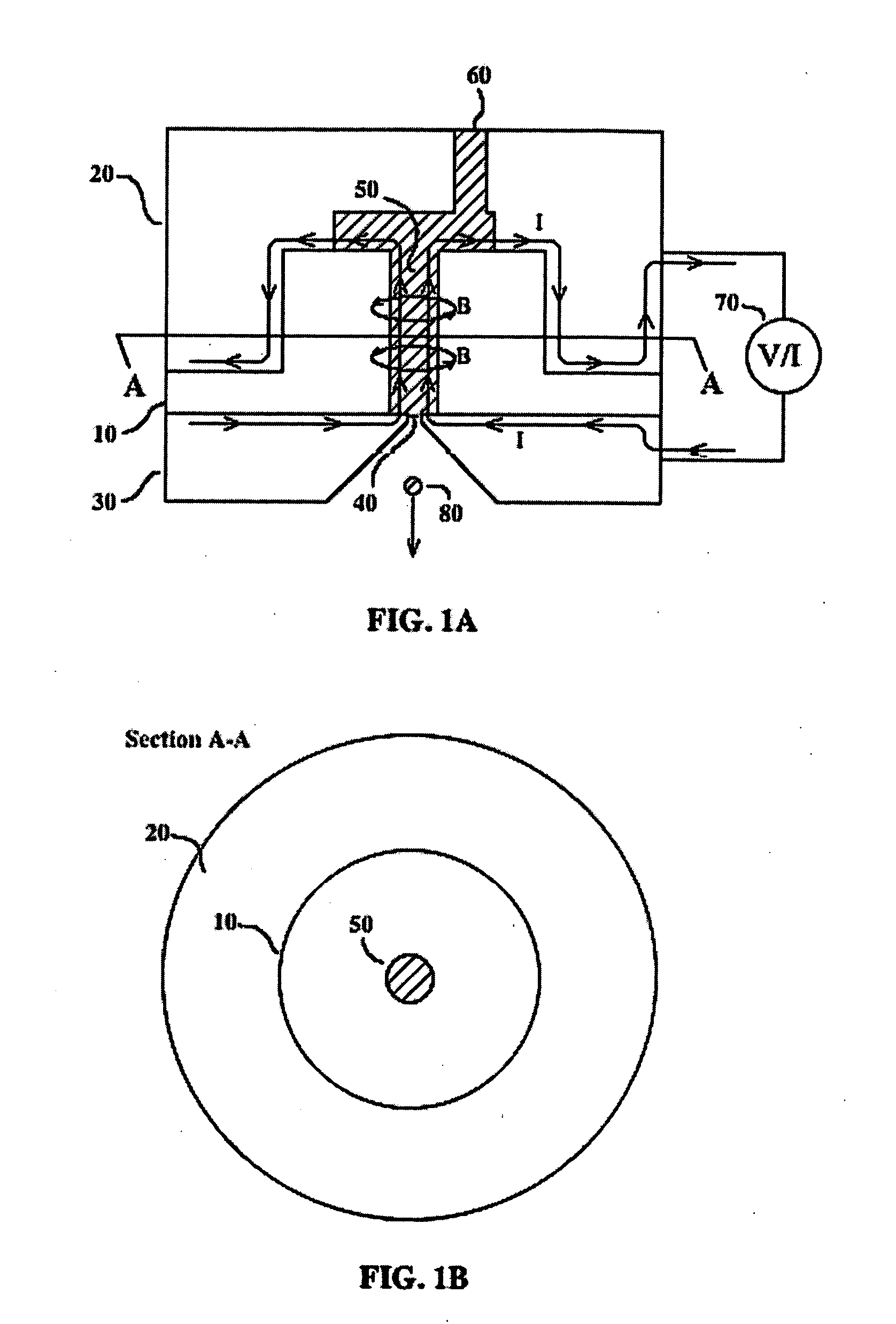

Apparatus for the production or refining of metals, and related processes

InactiveUS7381366B2Obstruct passageBlast furnace componentsBlast furnace detailsThermal energyForeign matter

An electroslag-cold hearth (ESCH) system for refining or producing a desired metal or metal alloy is described. The system includes at least one cold hearth vessel capable of holding a pool of molten liquid metal and an overlying slag layer, and an ingot mold laterally off-set from the cold hearth. A source of raw material, e.g., a feed electrode, is positioned above the cold hearth, and fed into the molten slag in a refining operation. A flow-over dam separates the ingot mold from the cold hearth, preventing the flow of inclusions and other foreign bodies into the ingot mold. In some instances, a non-consumable electrode provides additional thermal energy to the slag. In the production operation, the metal source can be a salt from which the desired metal can be electrochemically extracted. Related methods for refining or producing metals such as titanium alloys are also described.

Owner:GENERAL ELECTRIC CO

Method for reclaiming and cyclic utilizing residue molten steel slag in steel making

InactiveCN1804047AWell mixedReduce oxidationBlast furnace componentsBlast furnace detailsSulfurSludge

The method to pour residual hot steel sludge for recovery in steel production comprises: a. after casting, pouring the residual steel sludge into empty ladle; b. conveying the sludge to converter and tapping; c. refining; d. casting; repeating. This invention makes full use of the sulfur capacity and strong reducibility to absorb inclusion and improve liquid steel cleanness rapidly, overcomes the consumption for low-melting, and reduces pollution and cost.

Owner:HEBEI IRON AND STEEL

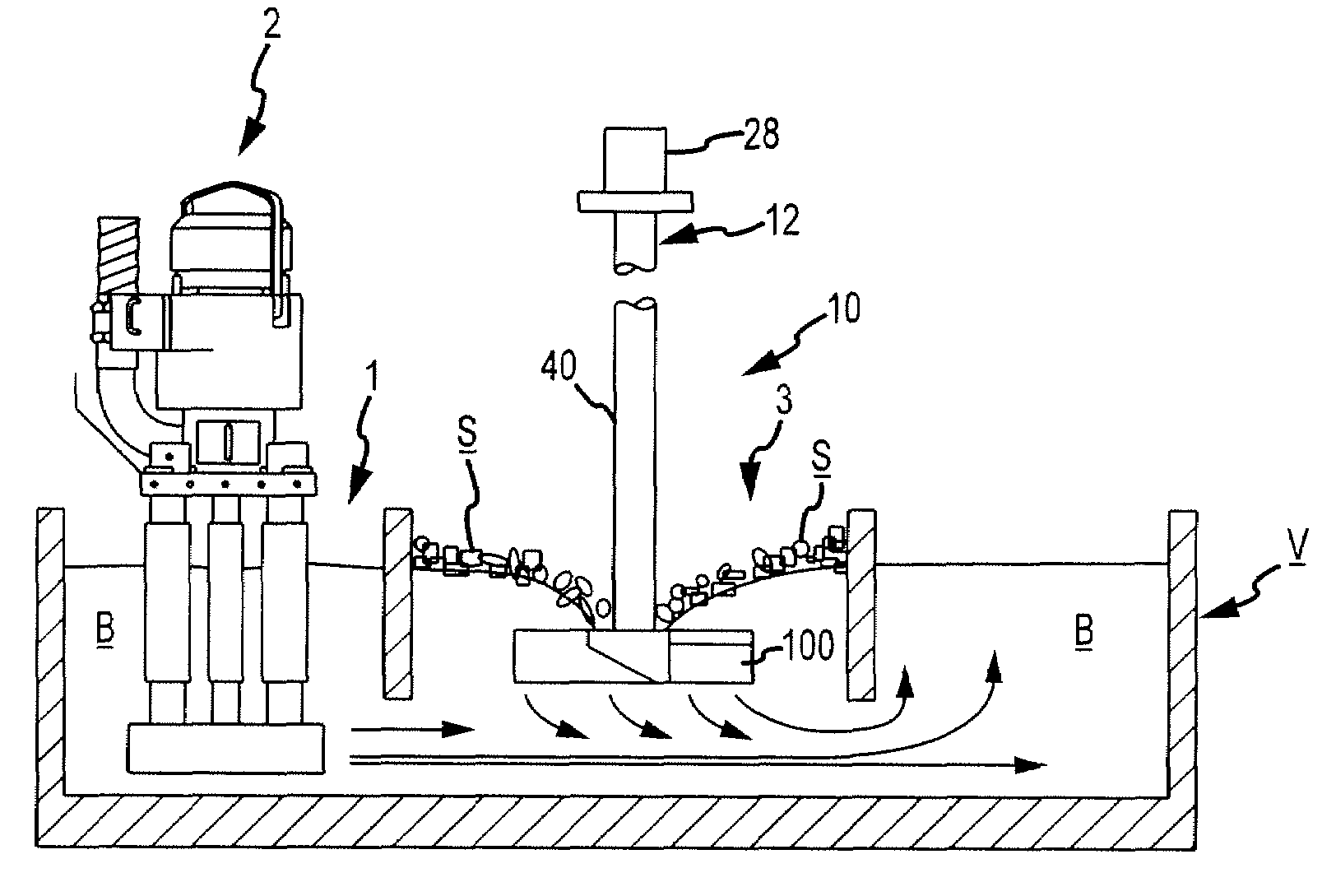

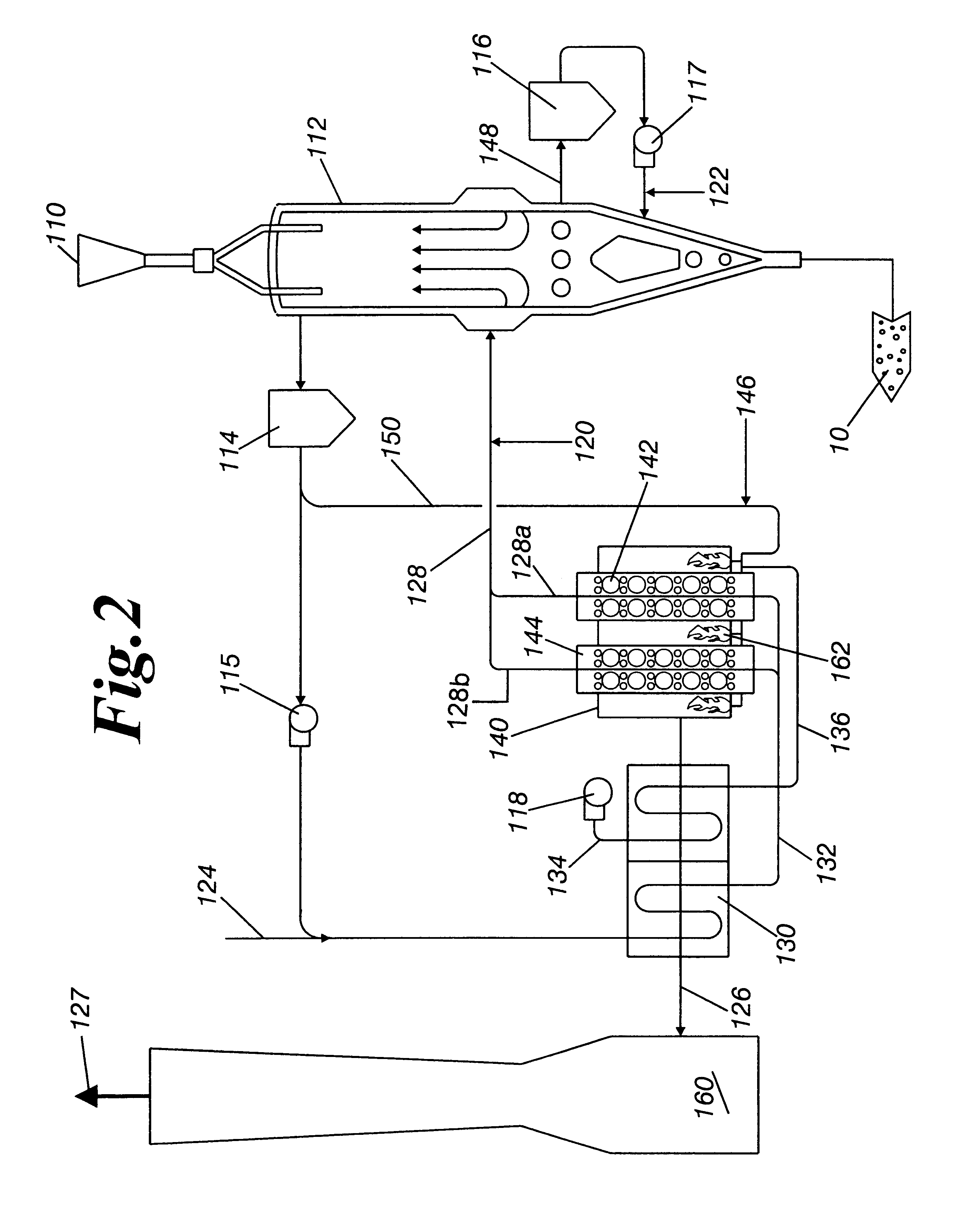

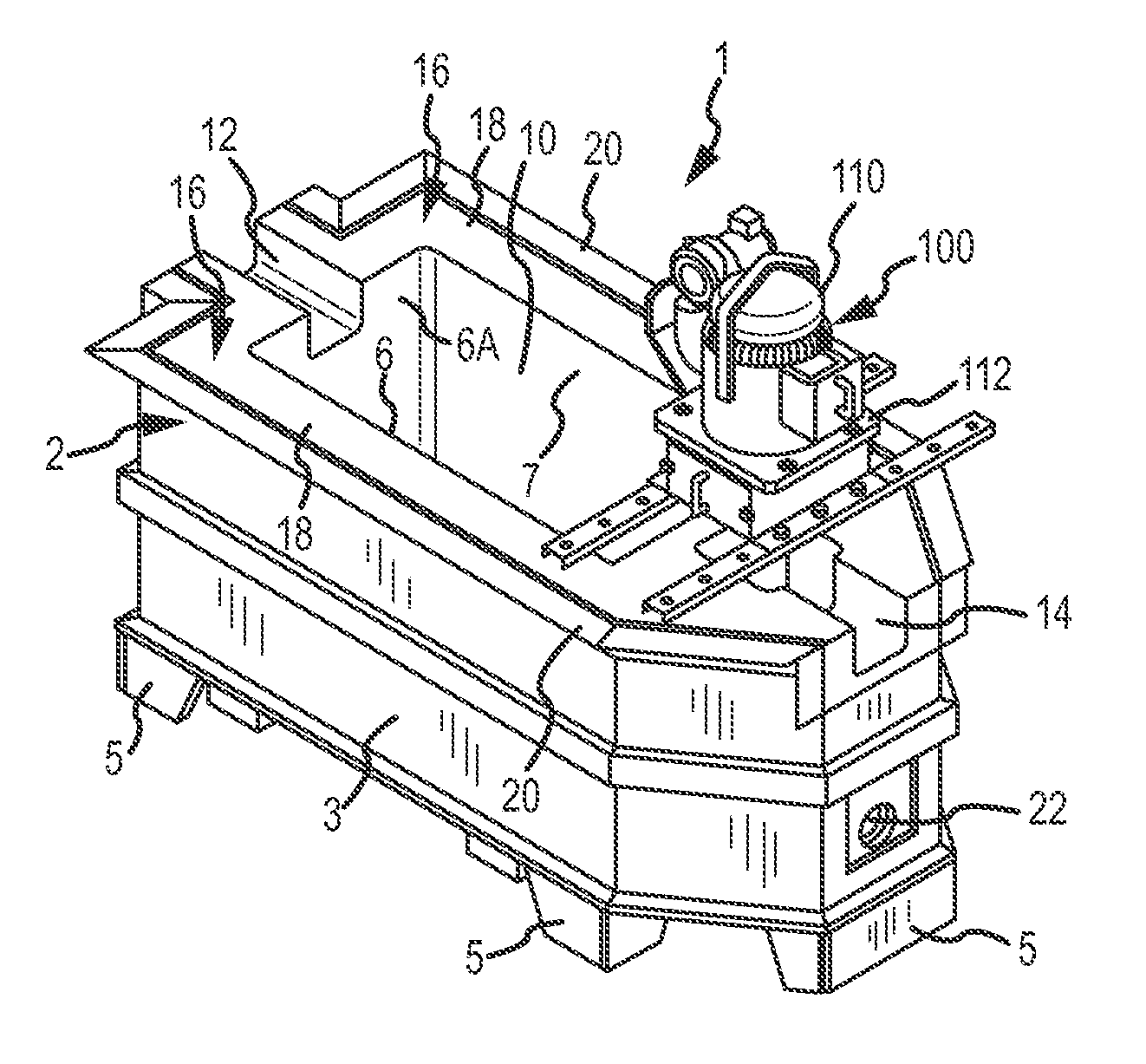

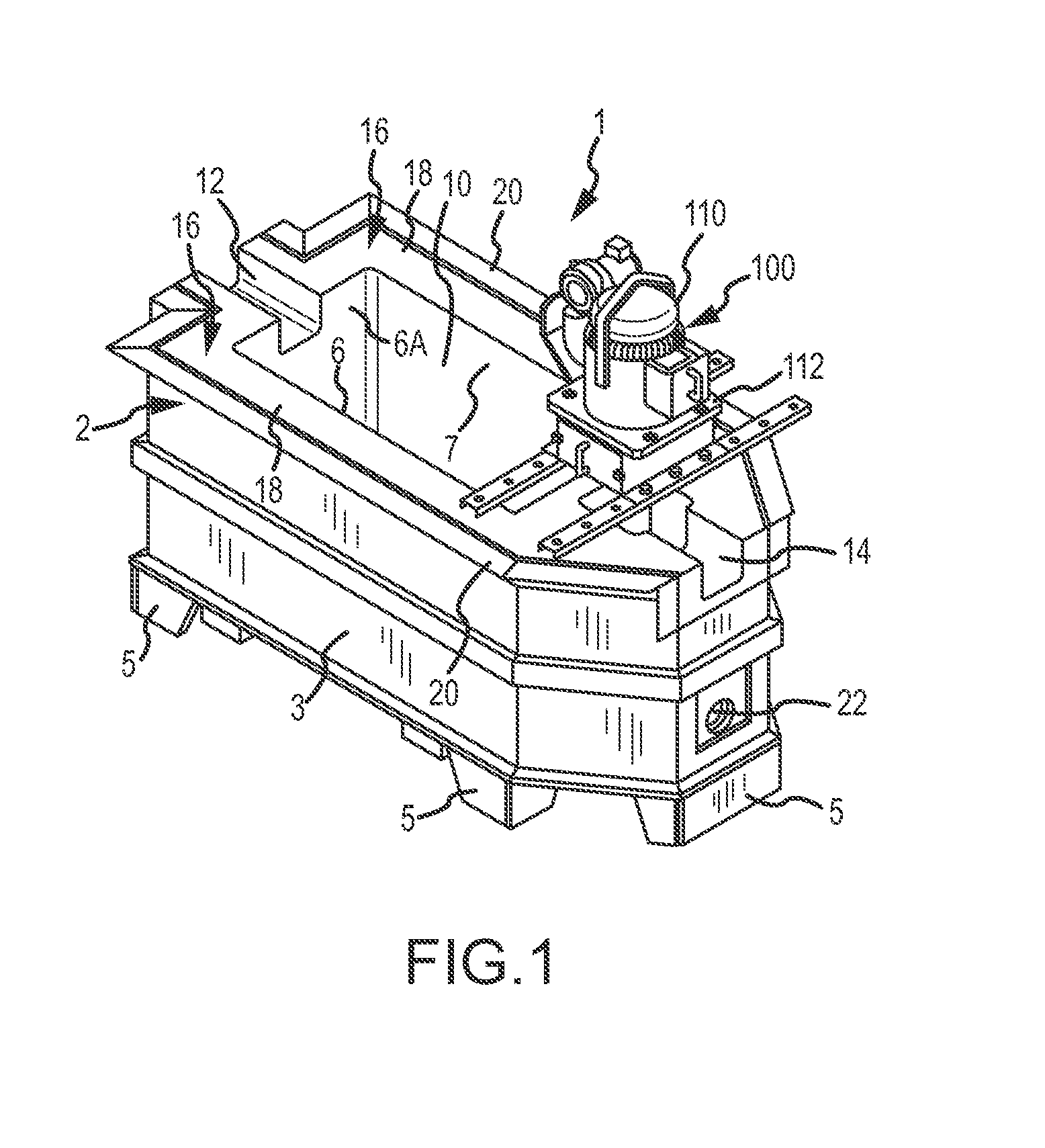

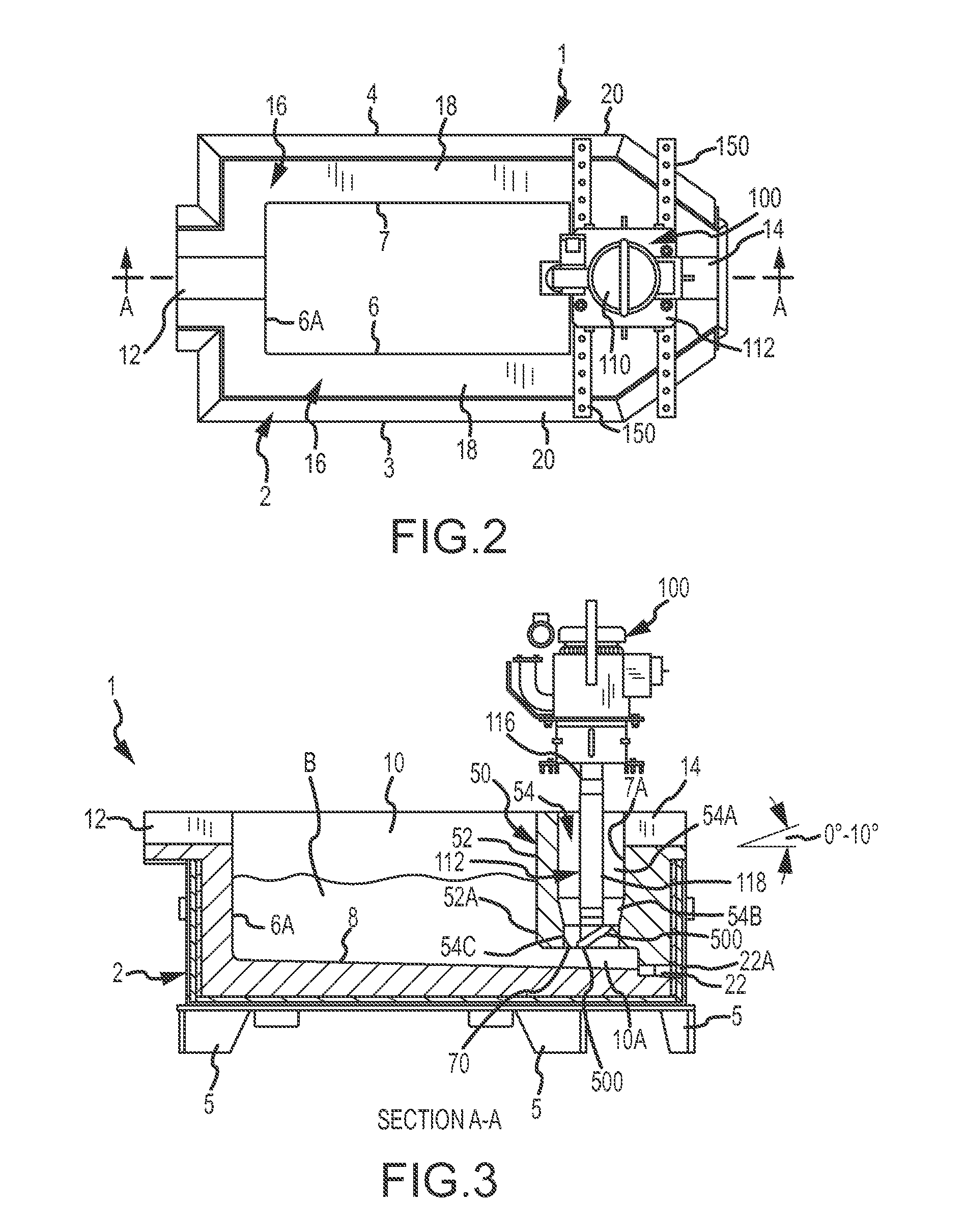

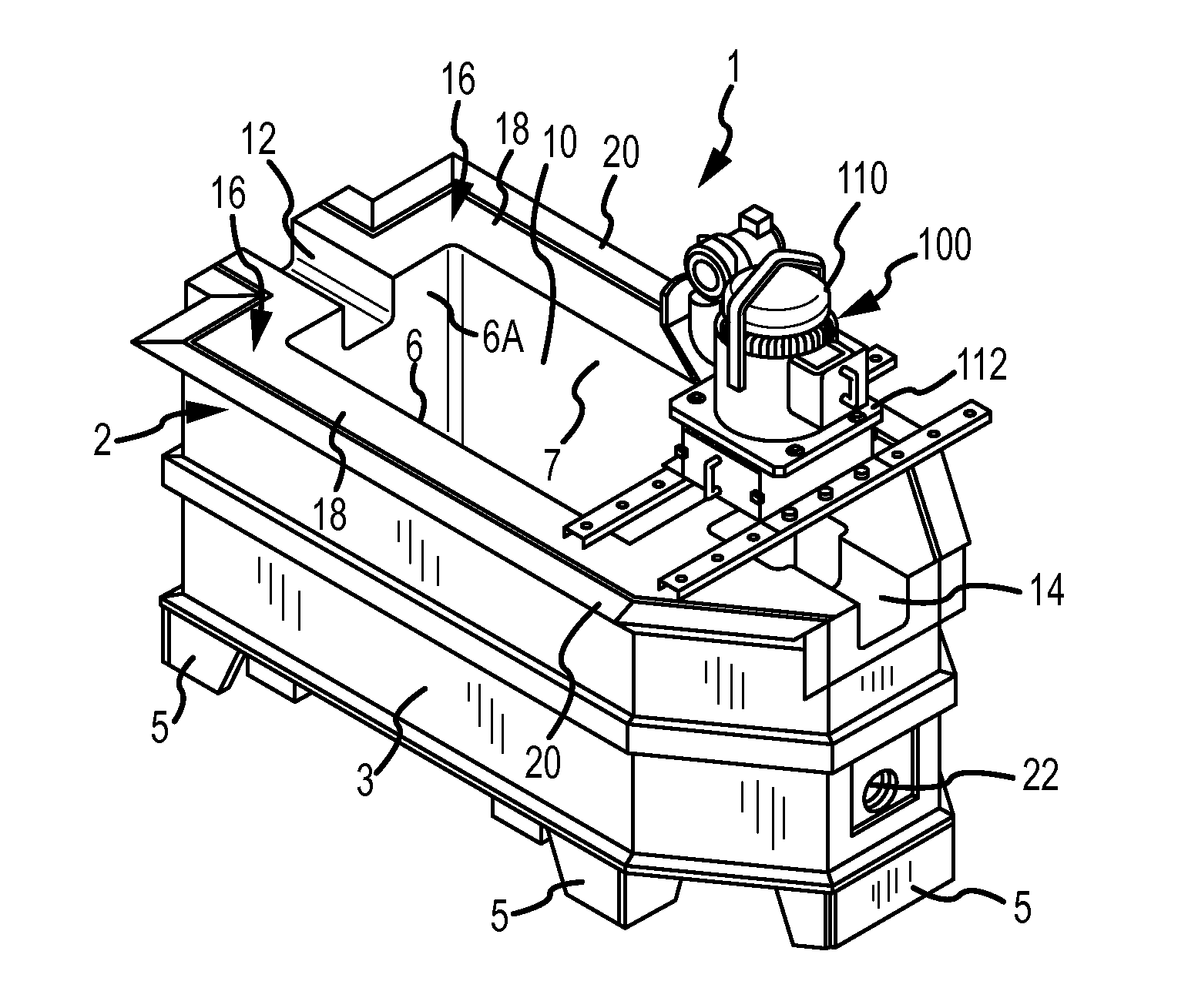

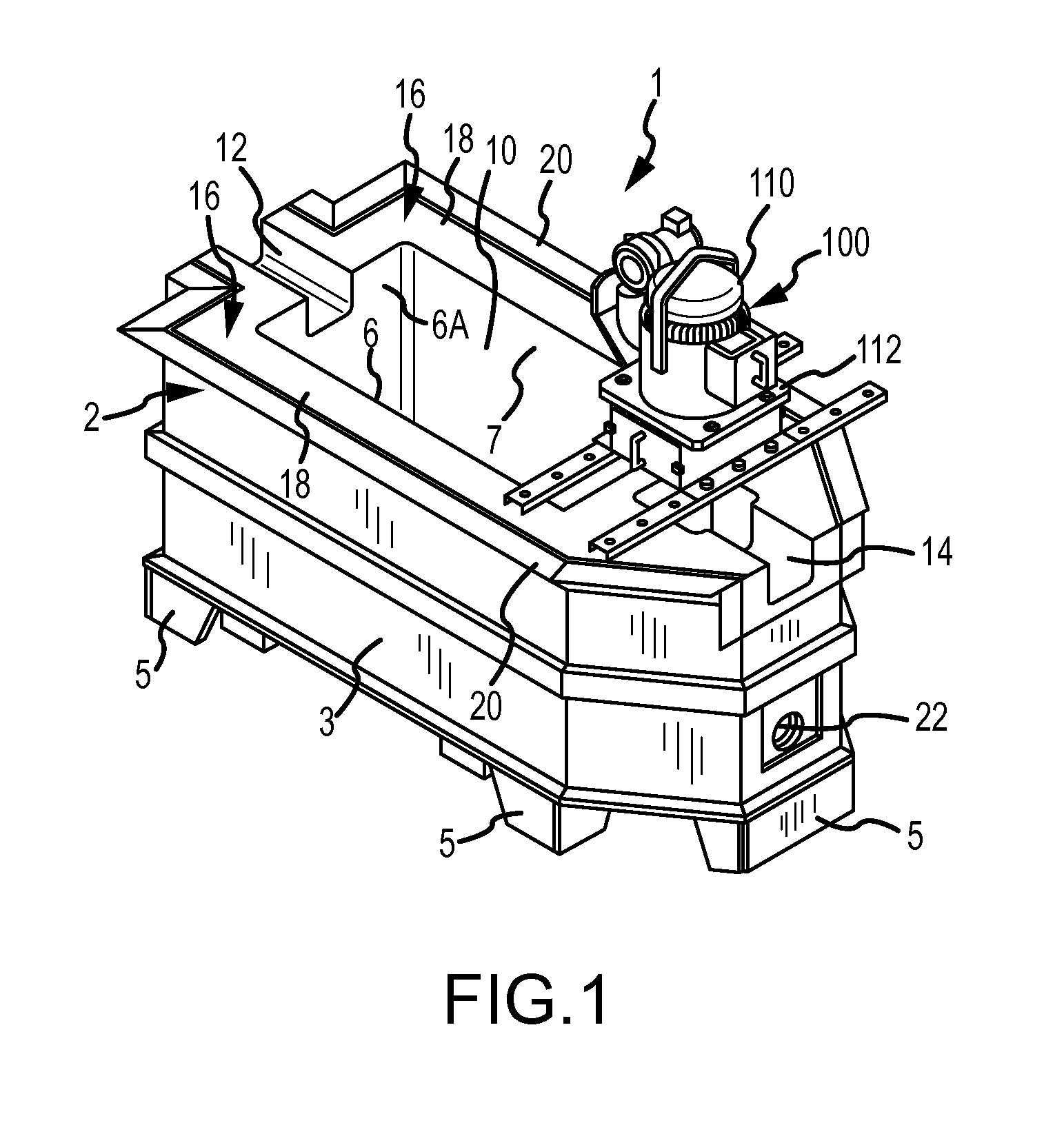

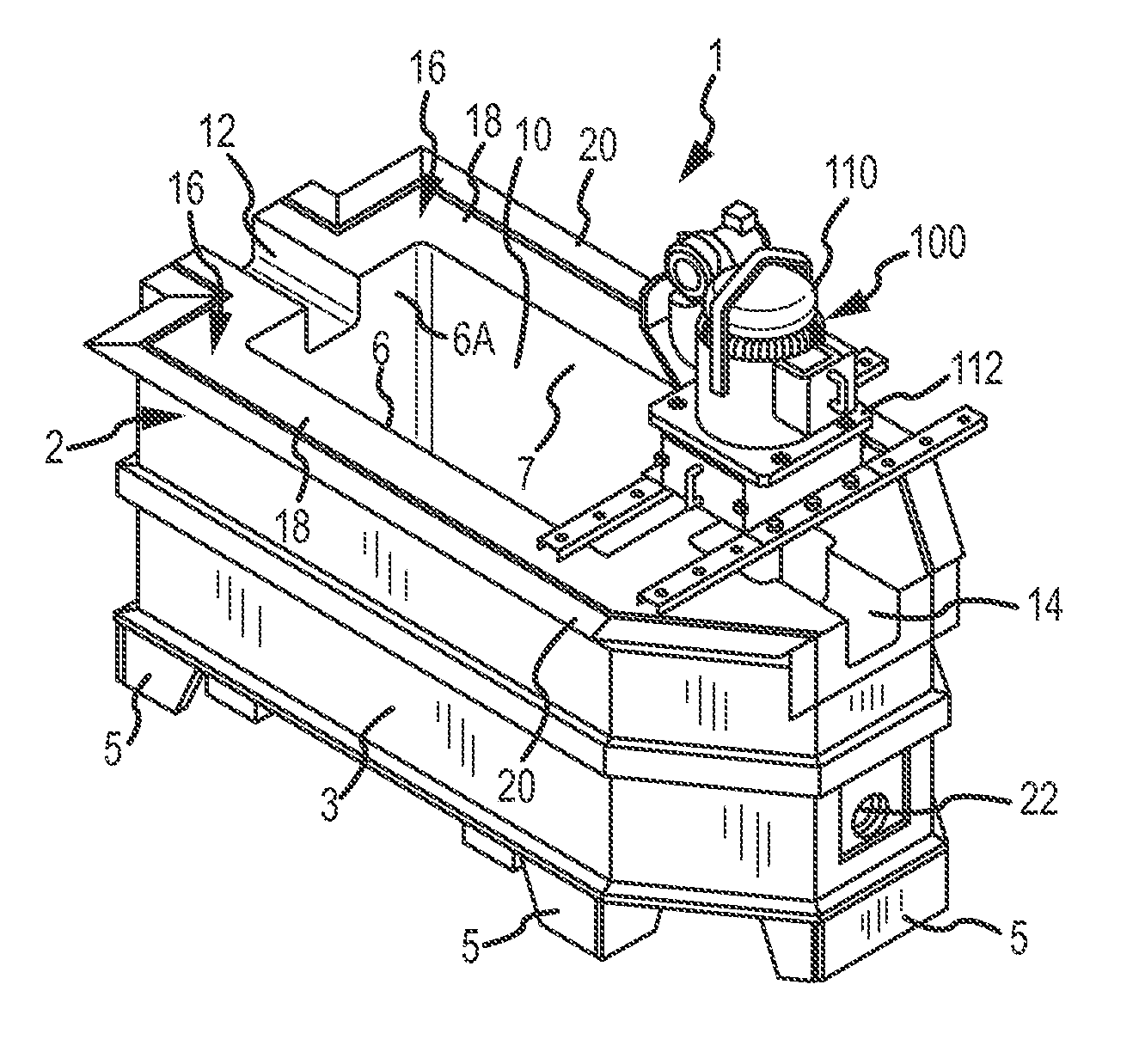

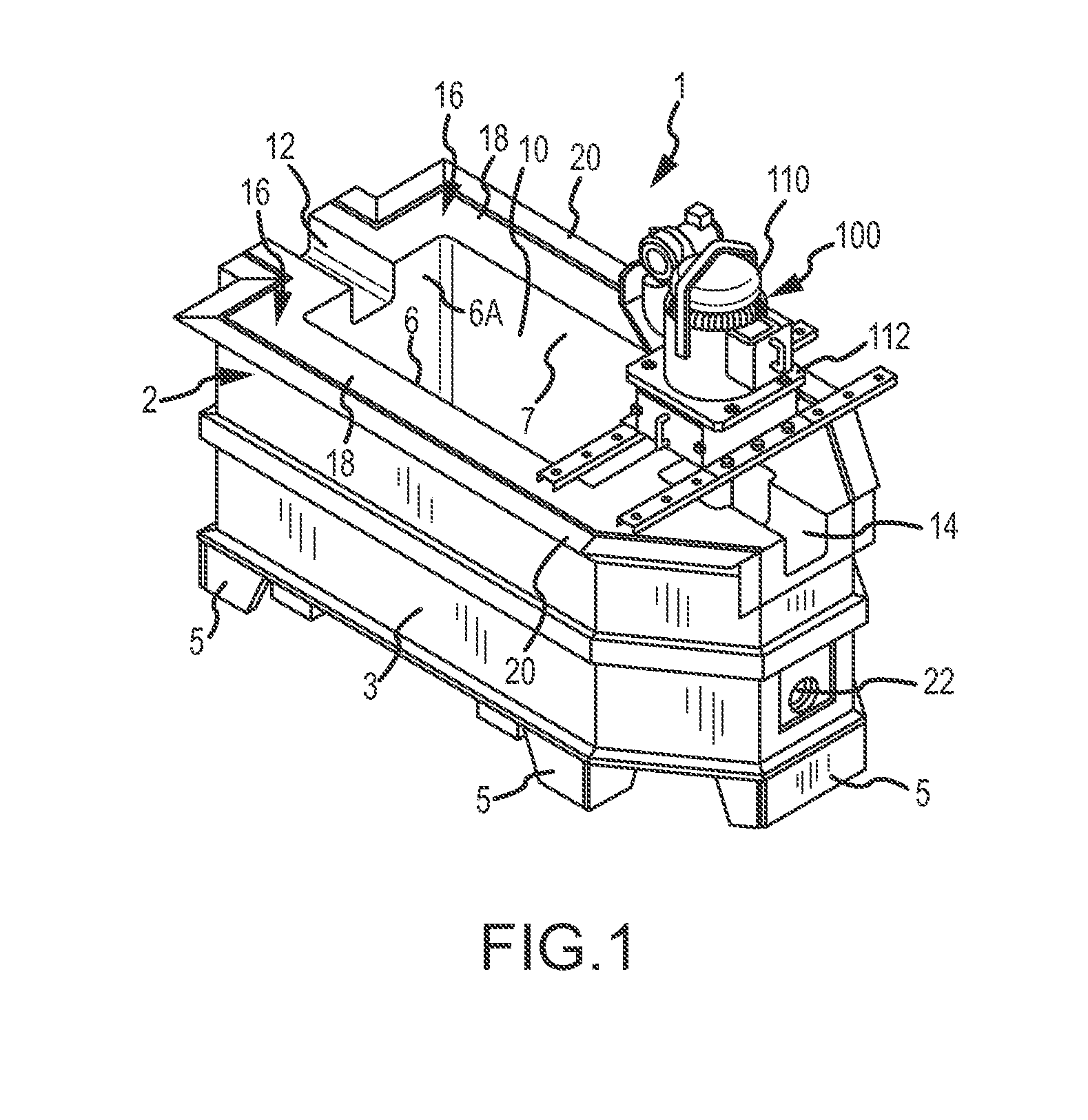

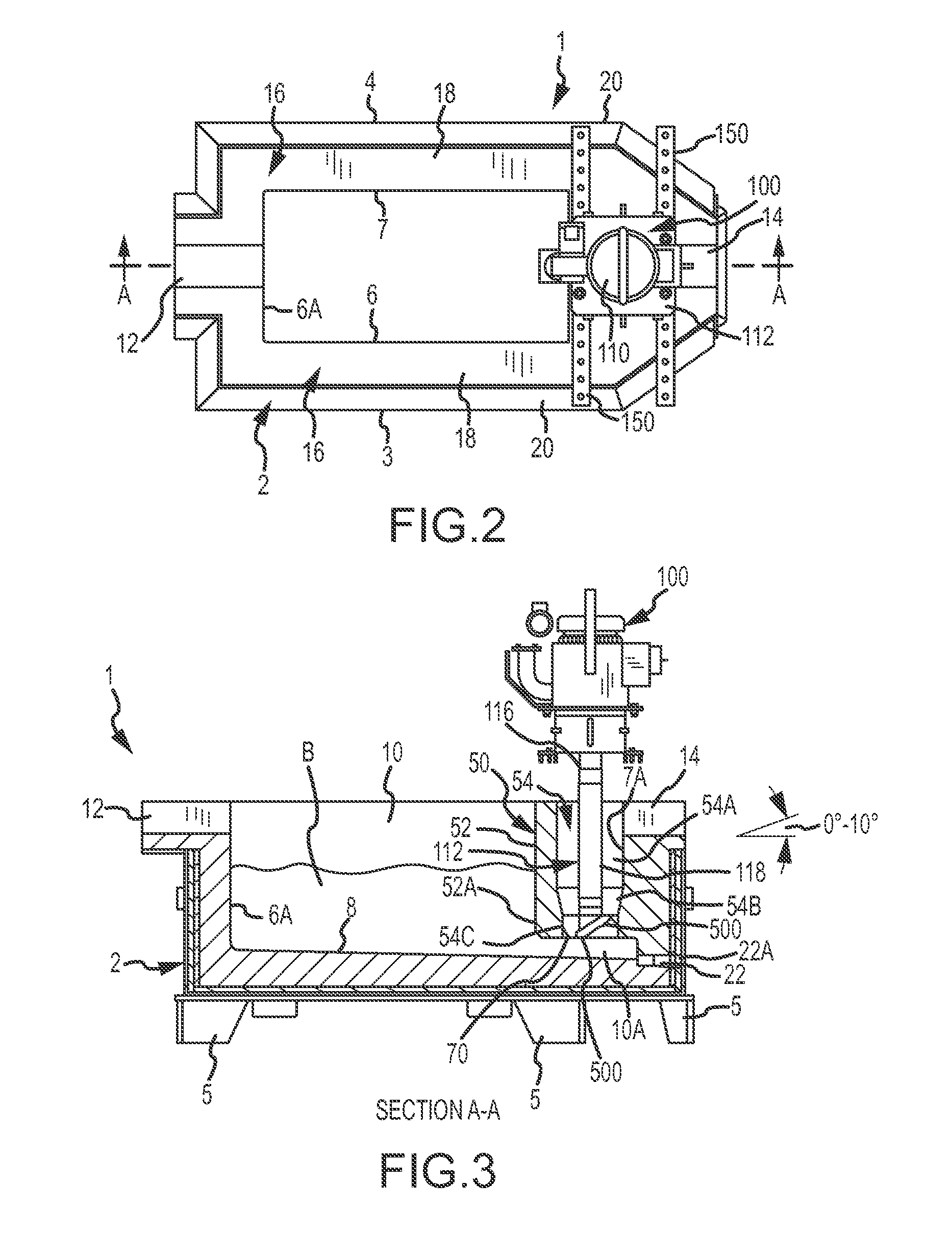

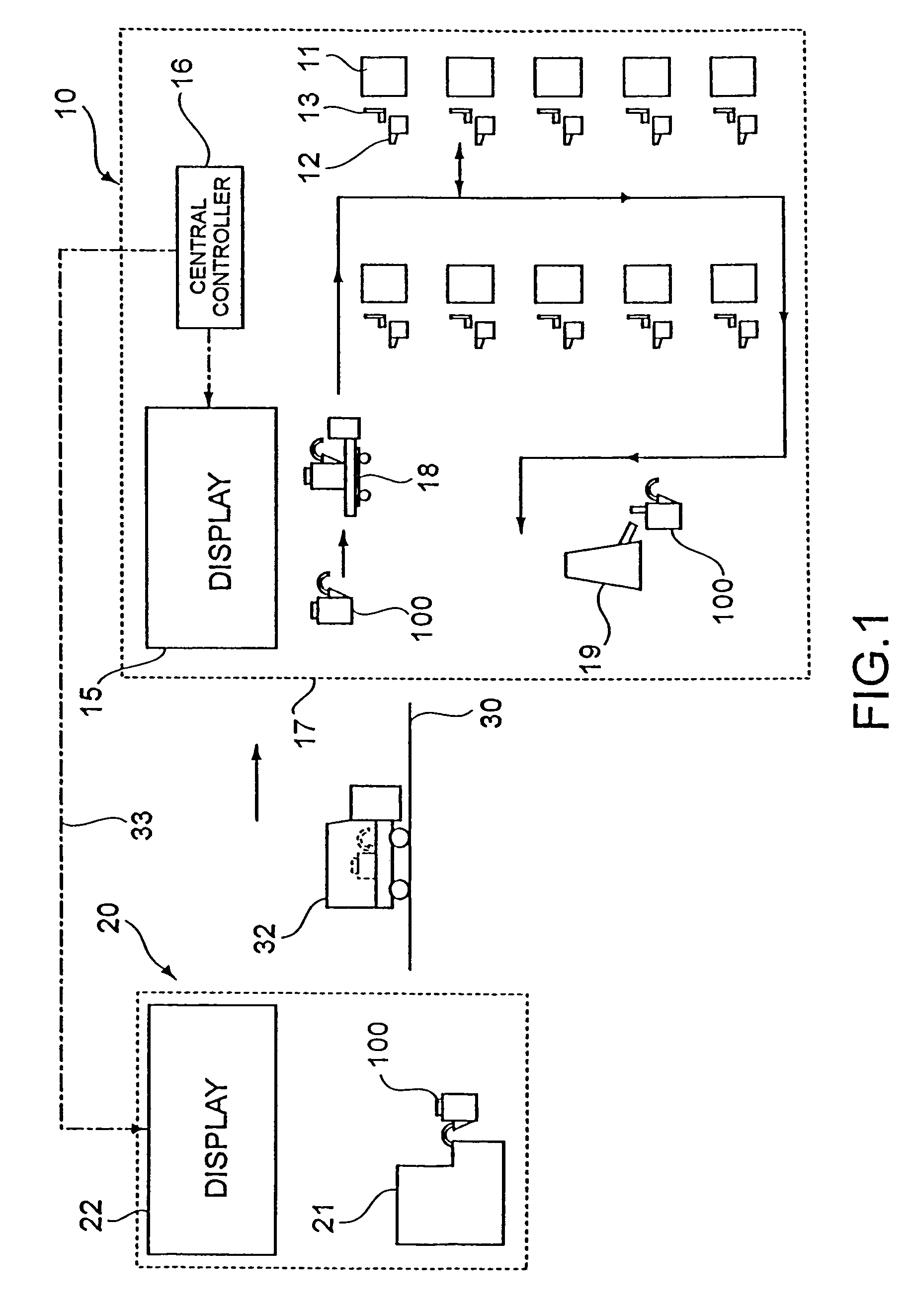

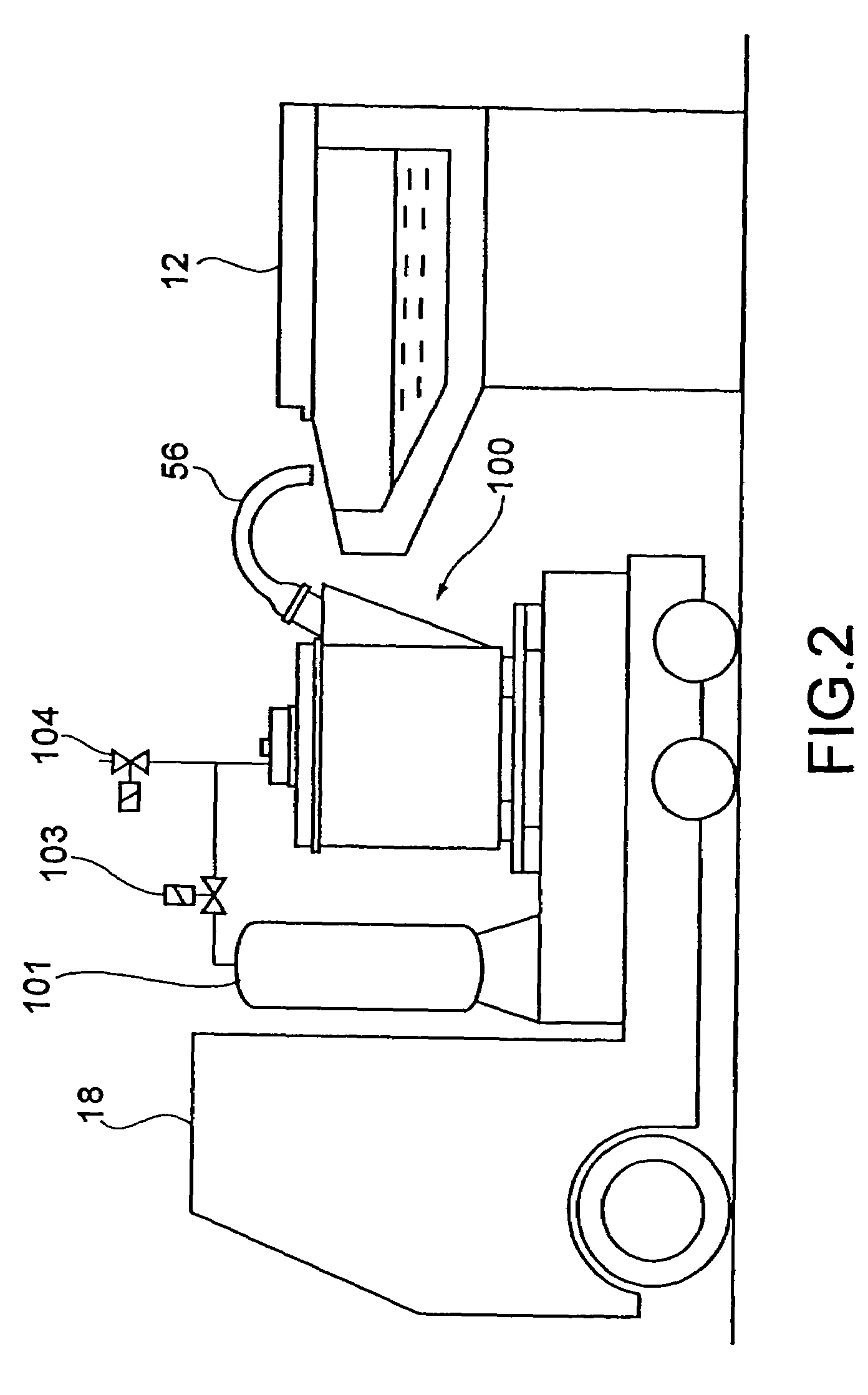

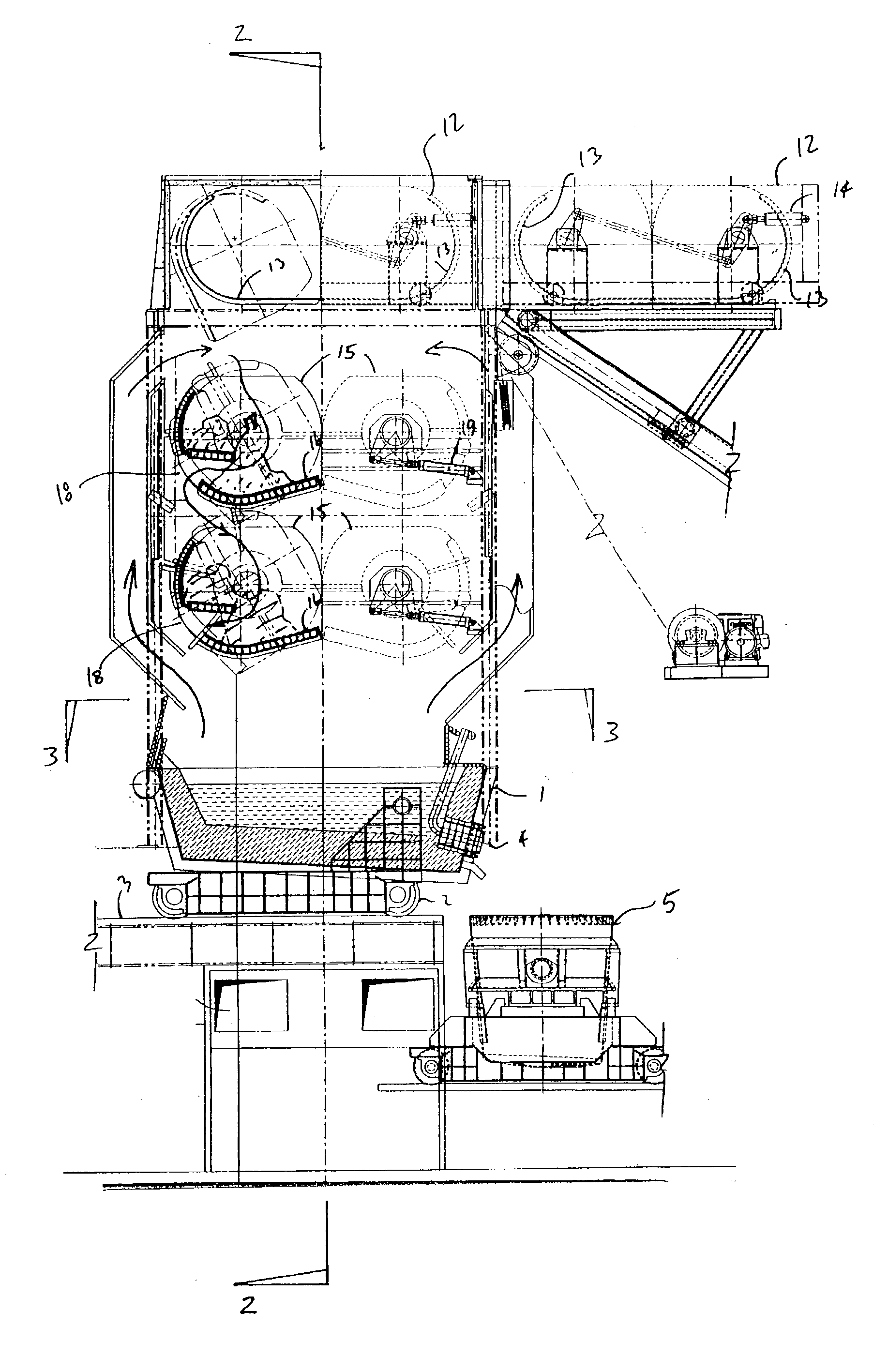

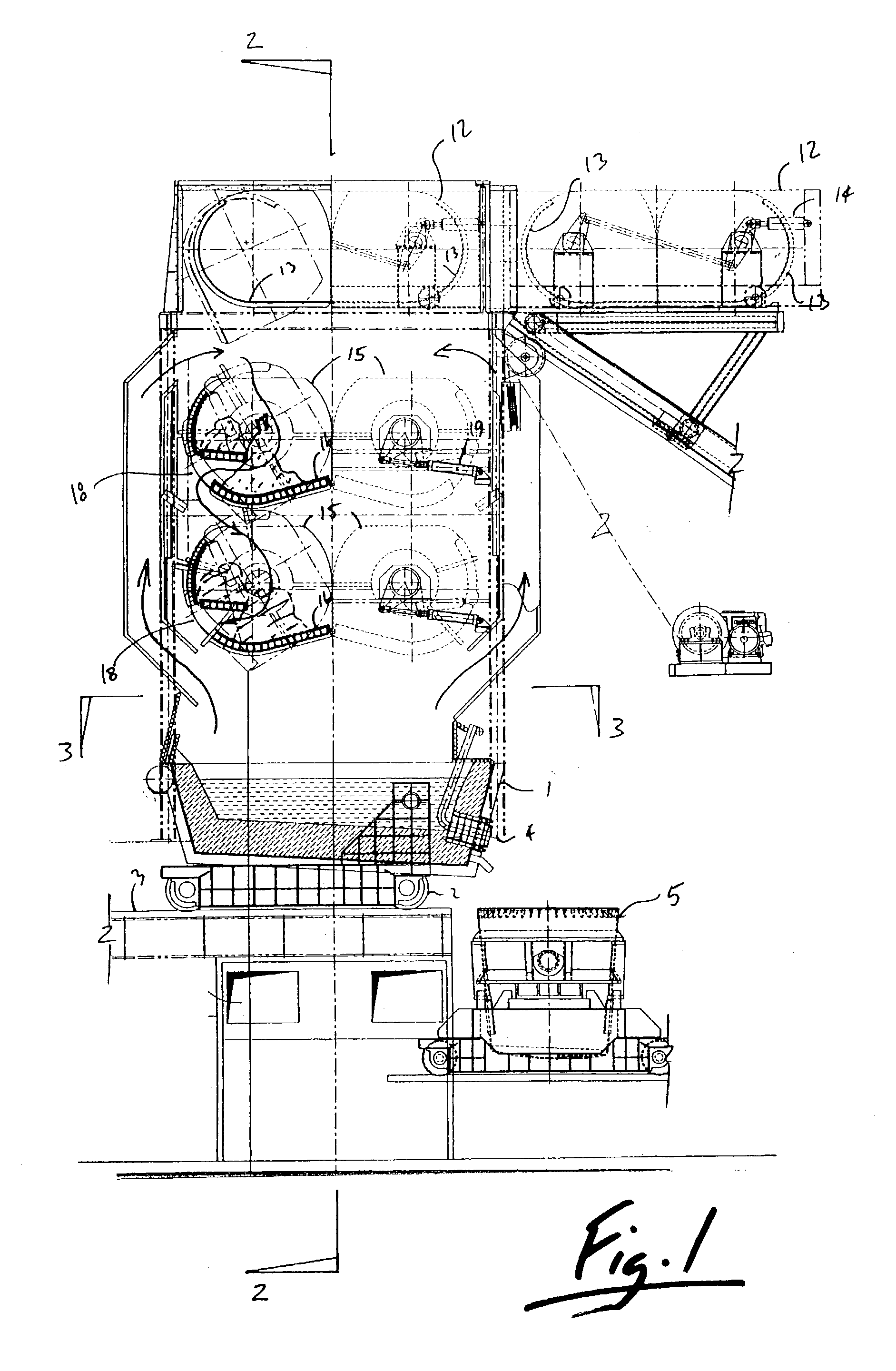

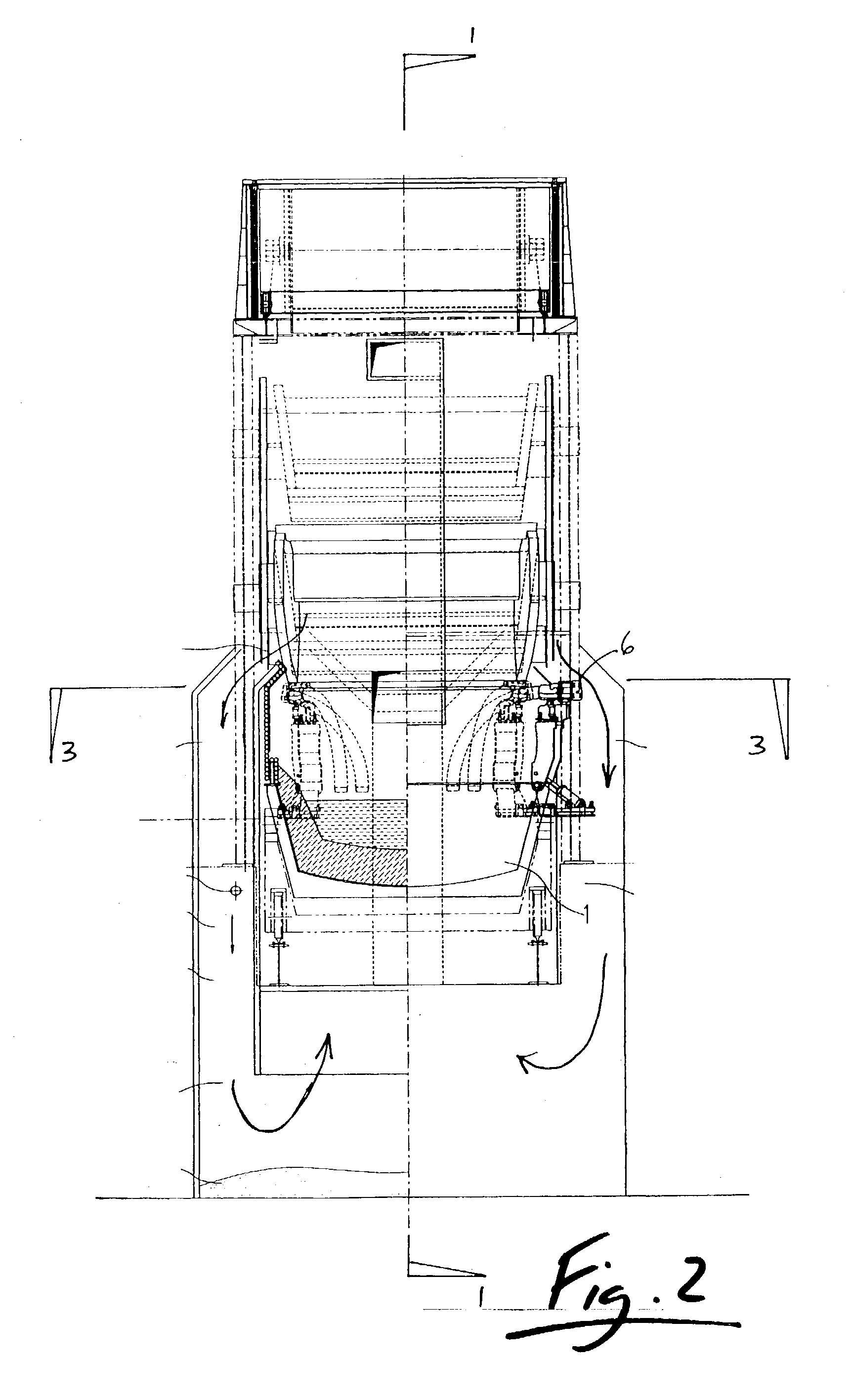

Metallurgical furnace with scrap metal preheater and dispenser

InactiveUS20030122290A1Reduce oxidationSimple and compact designBlast furnace componentsCharge supportsThermal energyProcess systems

A Preheater-Steelmaking Furnace and closed loop Process System for semi-continuous melting of integrally preheated recycled or virgin ferrous charge, by using highly energy efficient combustion process of natural gas combusted by oxygen as the main heat source, after preheating of the cold charge, by fully exploiting thermal energies of the melting process off-gases, in a gas tight, low noise, ecologically friendly PSF with scant CO and drastically reduced CO2 in exhaust gases for semi-continuous, batch self-charging, sealed pairs of eccentrically rotating quasi cylindrical, permeable half drums hoppers creating separate preheating chambers.

Owner:EMPCO (CANADA) LTD

Method of direct iron-making / steel-making via gas or coal-based direct reduction

The invention is a method and apparatus for iron-making / steel-making using a modified rotary hearth furnace, that is a finisher-hearth-melter (FHM) furnace. In the method the refractory surface of the hearth is coated with carbonaceous hearth conditioners and refractory compounds, where onto said hearth is charged with pre-reduced metallized iron. The pre-reduced metallized iron is leveled, then heated until molten, and then reacted with the carbon and reducing gas burner gases until any residual iron oxide is converted to iron having a low sulfur content. Nascent slag separates from the molted iron forming carburized iron nuggets. The nuggets are cooled, and then the iron nuggets and the hearth conditioners, including the refractory compounds, are discharged onto a screen, which separate the iron nuggets from the hearth conditioner. The hearth conditioner is recycled, and the iron nuggets are either prepared for sale or for additional treatment, such as alloying, in a final melter, where the final melter is preferably an electric furnace. Exhaust gases from the FHM furnace are recovered for calcining coal into fuel gases and coke.

Owner:KOBE STEEL LTD

Liquid metal droplet generator

Small, high velocity liquid metal droplets are produced for applications that require the accurate and remote placement of small quantities of a metal. The magnetic pressure of current flowing through liquid metal is used to force small quantities of liquid metal through an orifice. Examples of applications are to feed metal fuel into plasma extreme ultraviolet sources, and to place solder bumps on an integrated circuit prior to the attachment of connections.

Owner:PUREX

No-water stemming material for blast furnace taphole and its prepn

InactiveCN1810723AShorten the blasting timeExtend the tapping timeBlast furnace componentsBlast furnace detailsSlagRefractory

The present invention relates to amorphous refractory material, and is especially one kind of no-water stemming material for blast furnace taphole and its preparation process. The no-water stemming material is prepared with coke powder 15-25 wt%, clay 10-20 wt%, bauxite corundum 20-36 wt%, silicon carbide 10-20 wt%, asphalt 8-16 wt%, sericite 5-9 wt%, additive 1-5 wt% and binding agent 12-22 wt%, and through crushing, sieving, pre-mixing, rolling, kneading and extruding. The no-water stemming material has excellent plasticity and sintering performance, high strength at high and middle temperature and high slag and molten iron flush resistance, and can meet the requirement of high strength smelting in blast furnace.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

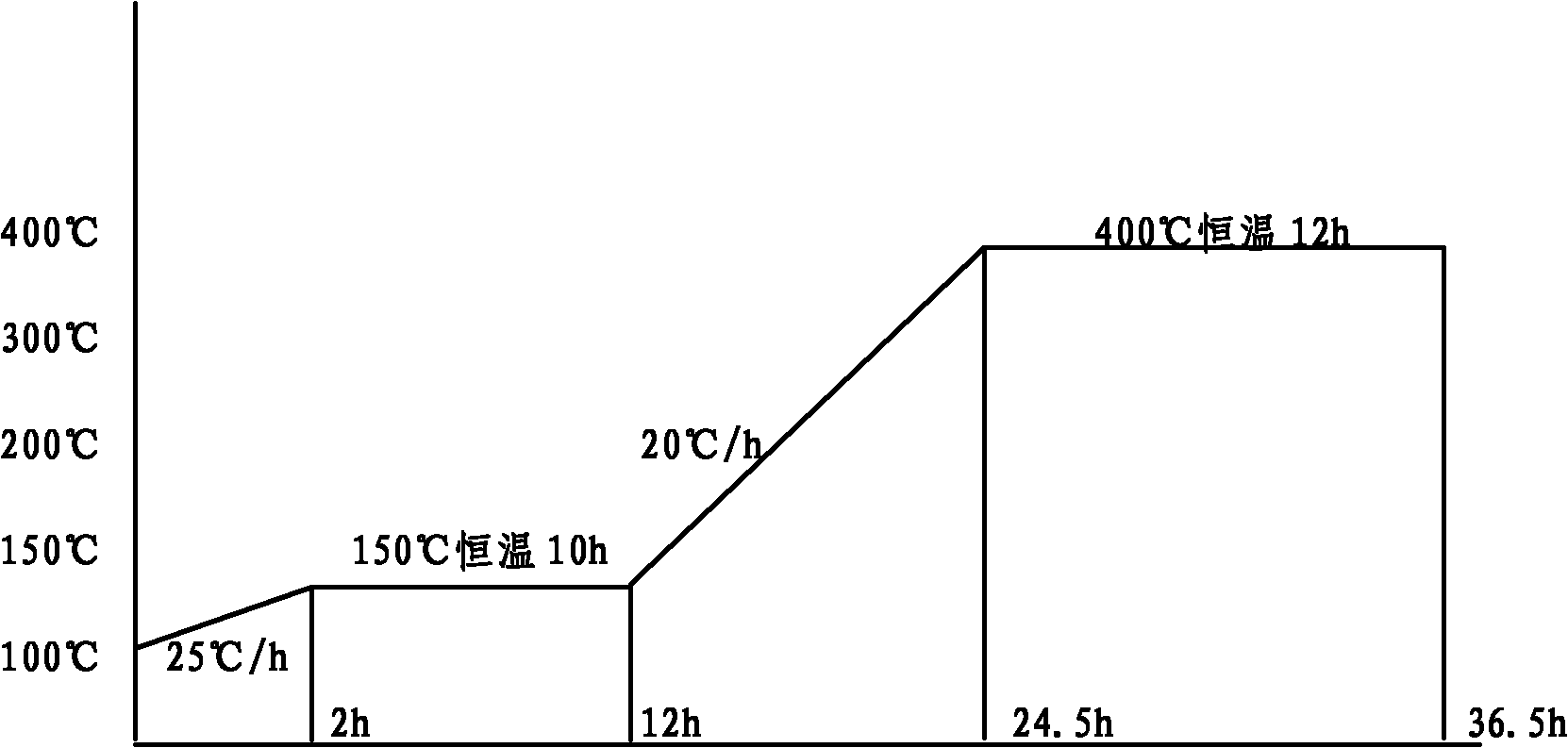

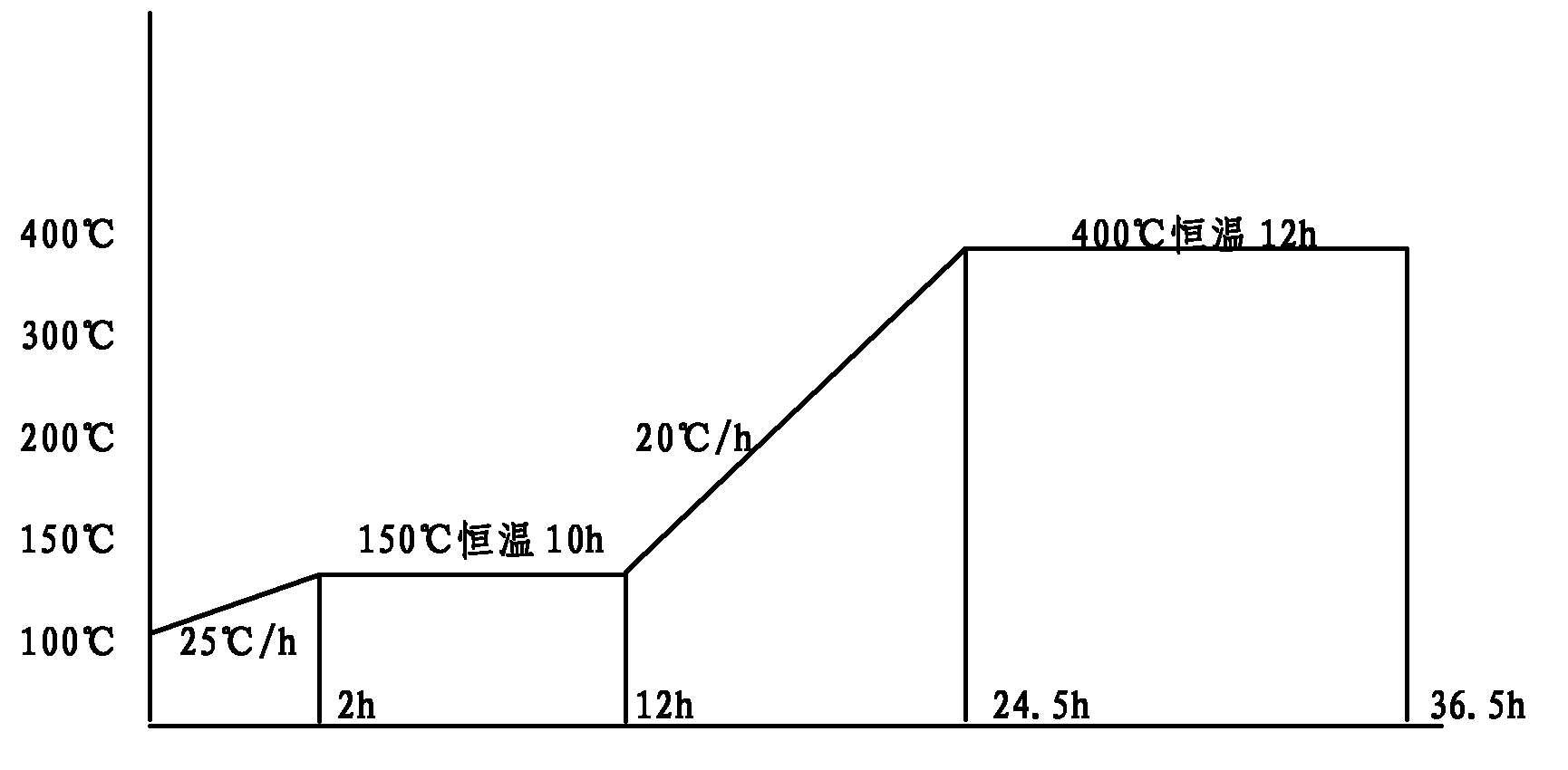

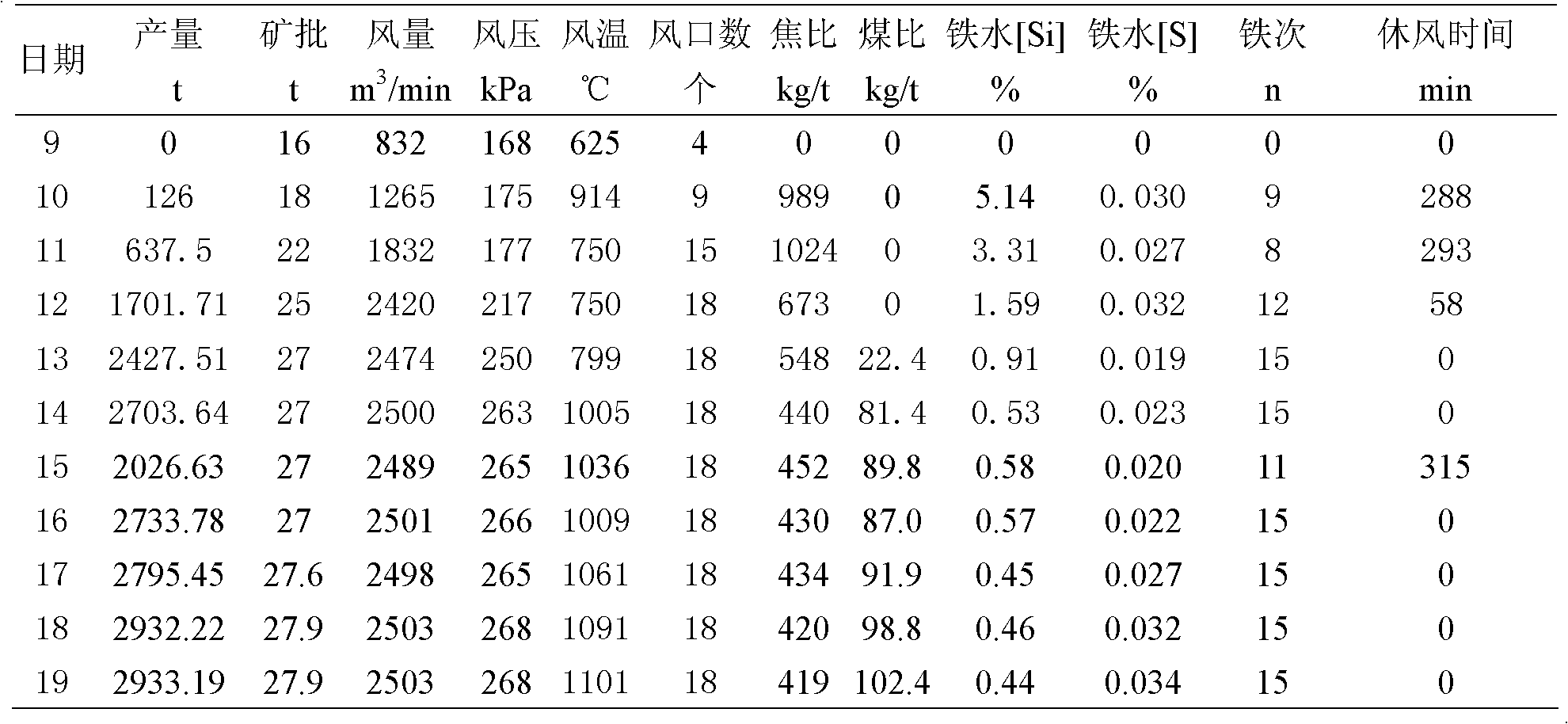

Method capable of rapidly reaching yield after small and medium maintenance of blast furnace

InactiveCN101818221ADischarge in timeOpen the furnace smoothlyBlast furnace componentsBlast furnace detailsSlagEconomic benefits

The invention relates to a method capable of rapidly reaching a yield after the small and medium maintenance of a blast furnace, mainly comprising the steps of adjusting a furnace condition before stopping the furnace, selecting relevant technological parameters in the process of running the furnace, and the like. The invention discharges iron slag in time and realizes the purpose of smooth furnace running and rapid yield reaching of the blast furnace through establishing a scientific furnace running scheme and sufficient preparation and adopting a reasonable air supply and loading system, and the yield reaching schedule achieves a satisfactory purpose. The whole production process of the invention is safe, sequential, scientific and high-efficient, the utilization factor of the blast furnace can achieve 2.253t / m3.d within 5 days, and in the whole process of furnace-running yield reaching, the blast furnace has the advantages of favorable iron slag fluidity, satisfactory quality of molten iron and less unplanned blast stoppage, greatly saves manpower and physical resources and obtains favorable effects and economic benefits.

Owner:CHONGQING IRON & STEEL CO LTD

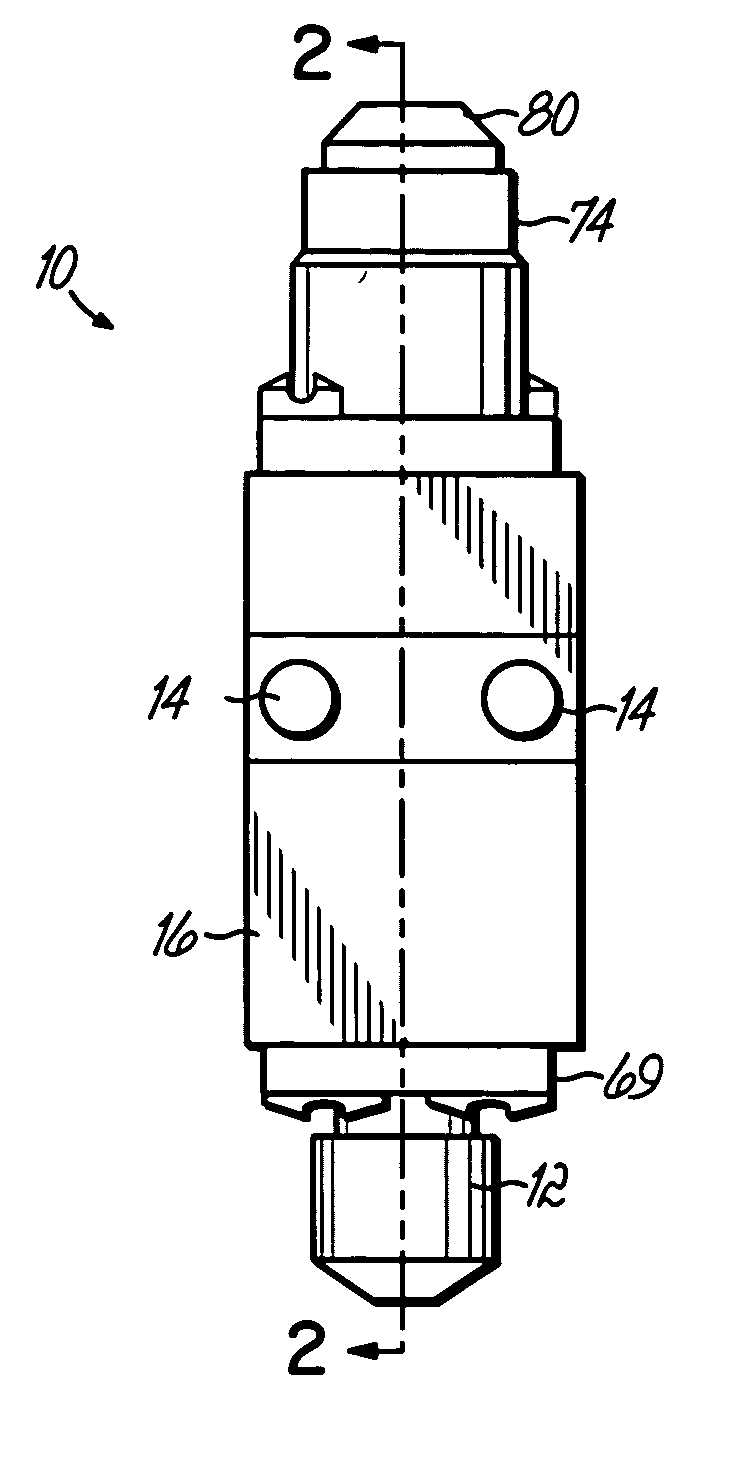

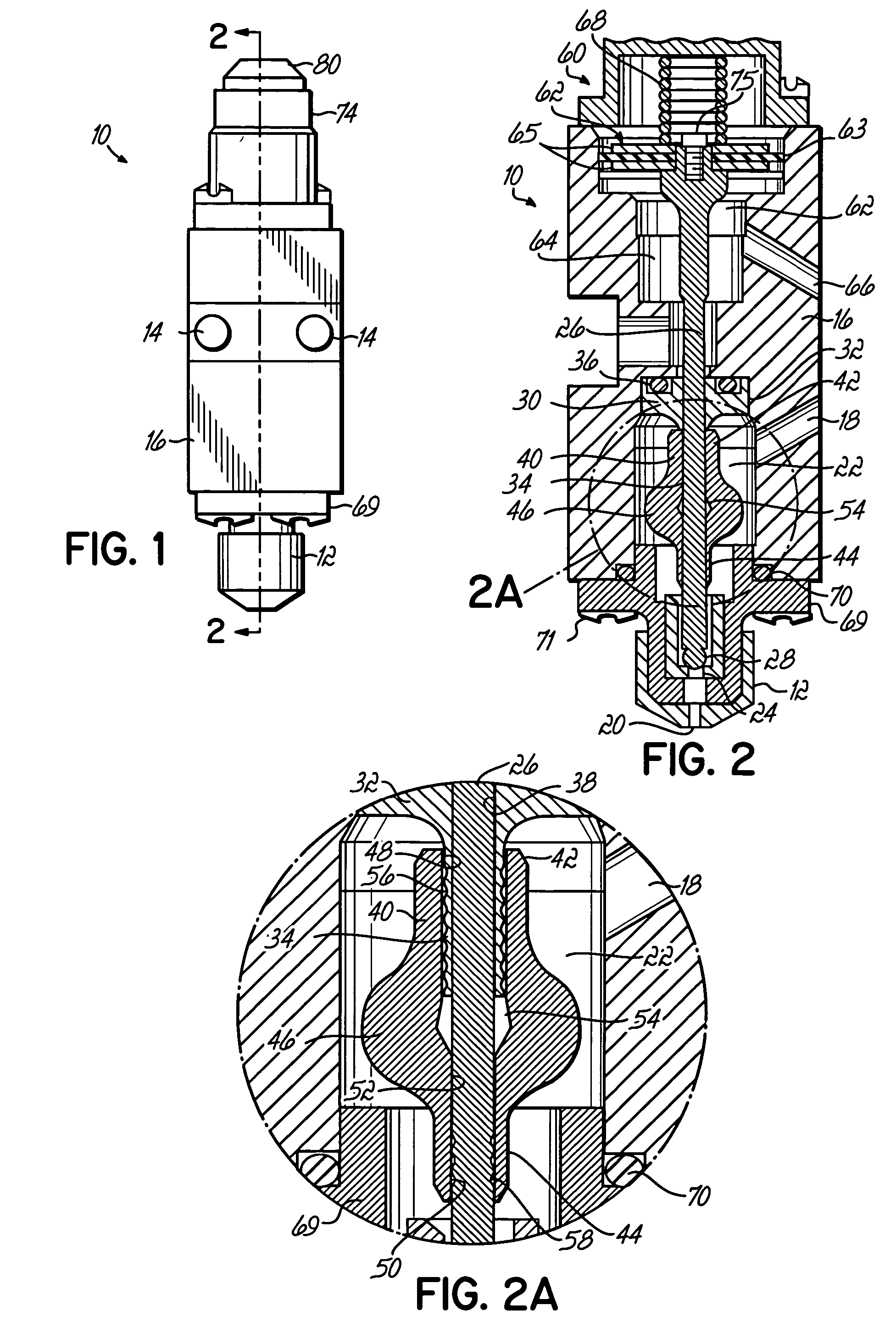

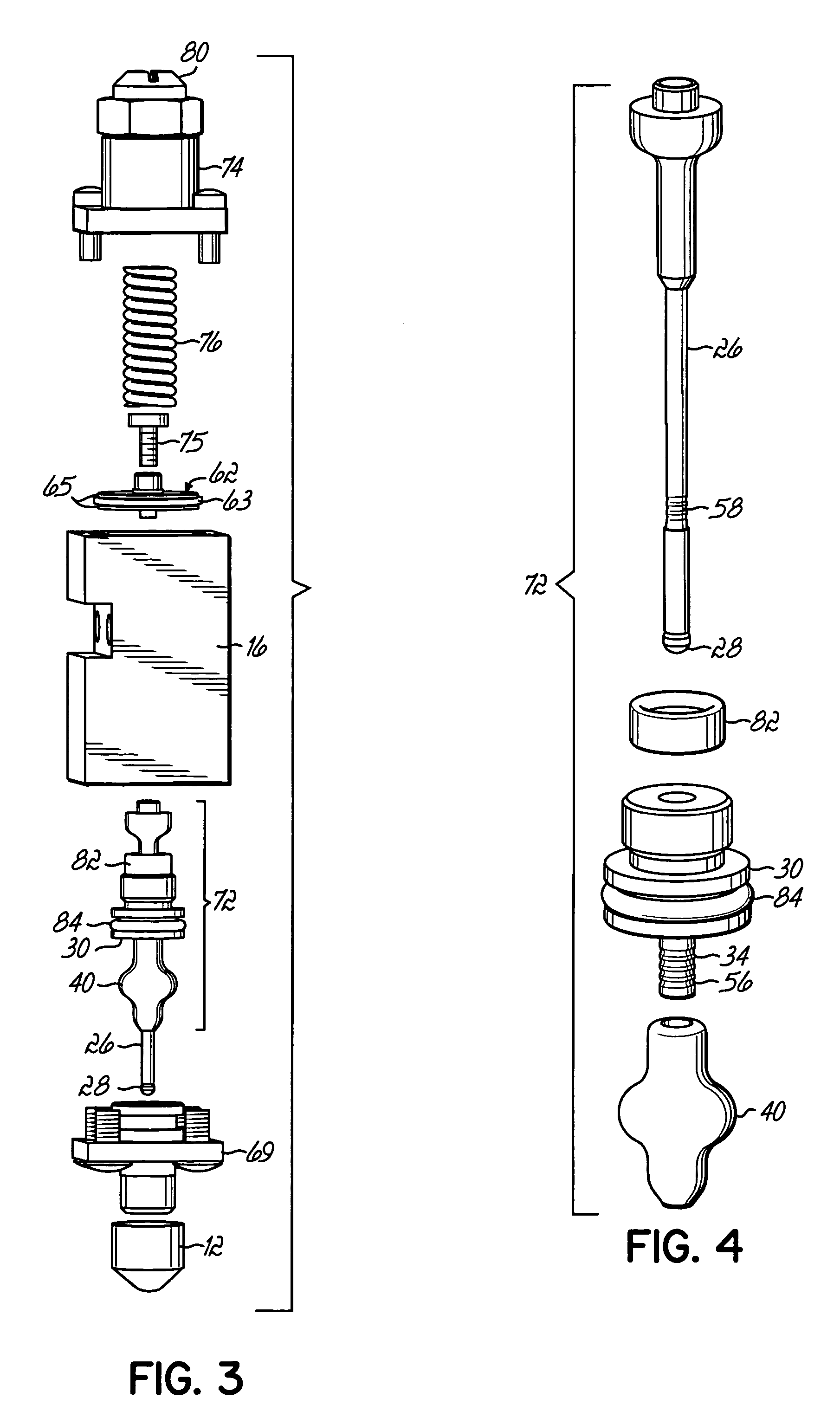

Method and system for dispensing liquid from a module having a flexible bellows seal

ActiveUS20060097015A1Prevent leakageImprove securityMelt-holding vesselsLiquid surface applicatorsReciprocating motionEngineering

A dispensing module for dispensing liquid includes a dispensing body having an inlet, a discharge outlet, and a flow channel therebetween having a valve seat. A needle having a valve element is mounted to the body and reciprocates therein between an open position, in which the valve element is disengaged from the valve seat thereby allowing liquid flow, and a closed position, in which the valve element is engaged with the valve seat thereby preventing liquid flow. A needle guide is mounted to the dispenser body and includes a passage for receiving a portion of the needle. A flexible seal includes a first end coupled to the needle guide and a second end coupled to the needle and moving therewith. An actuator is operatively coupled to the needle and moves the needle between the open and closed positions. The seal includes a central portion with an interior cavity that stretches and compresses as the needle reciprocates.

Owner:NORDSON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com