Patents

Literature

604results about How to "Suppress Diffuse" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

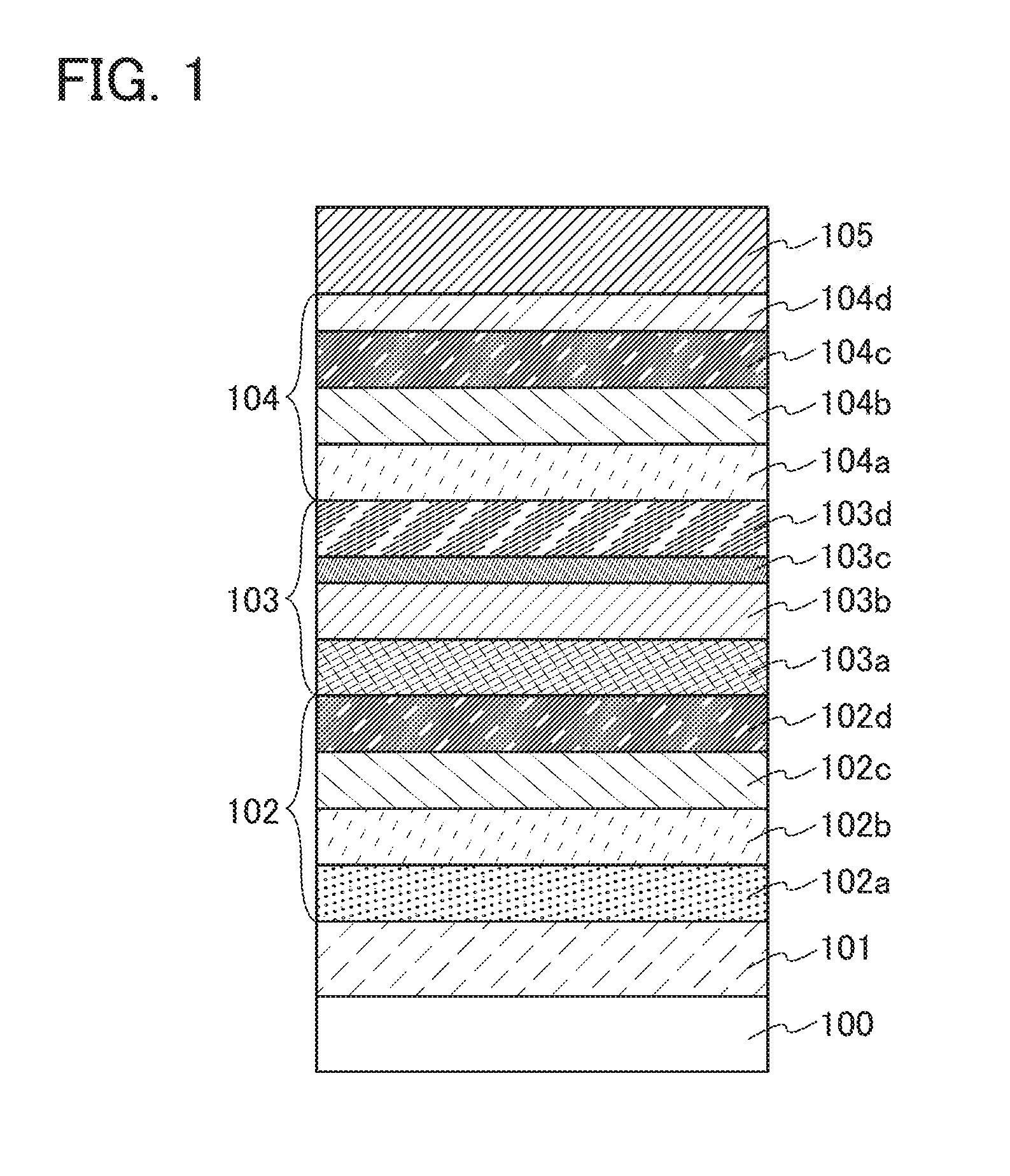

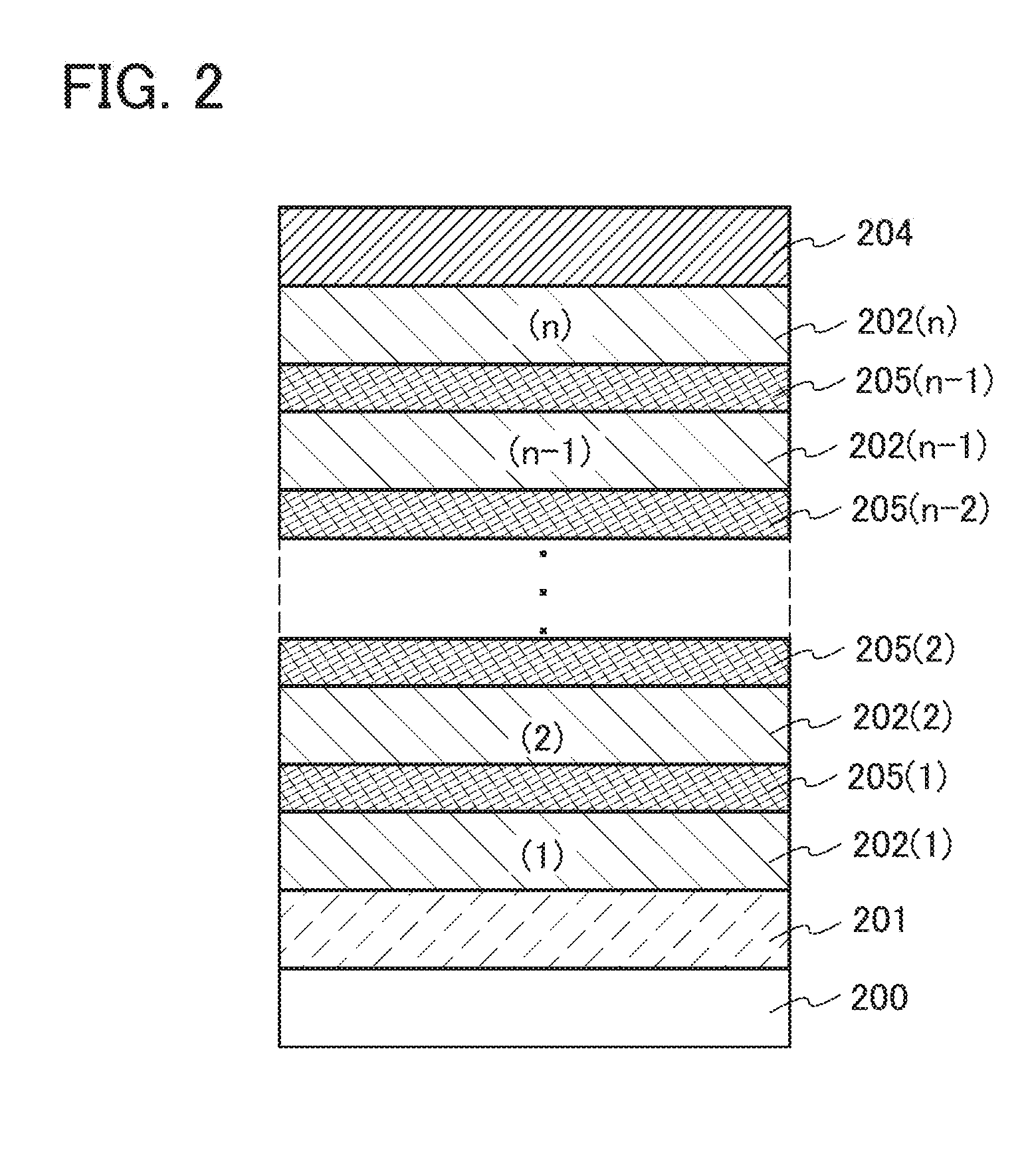

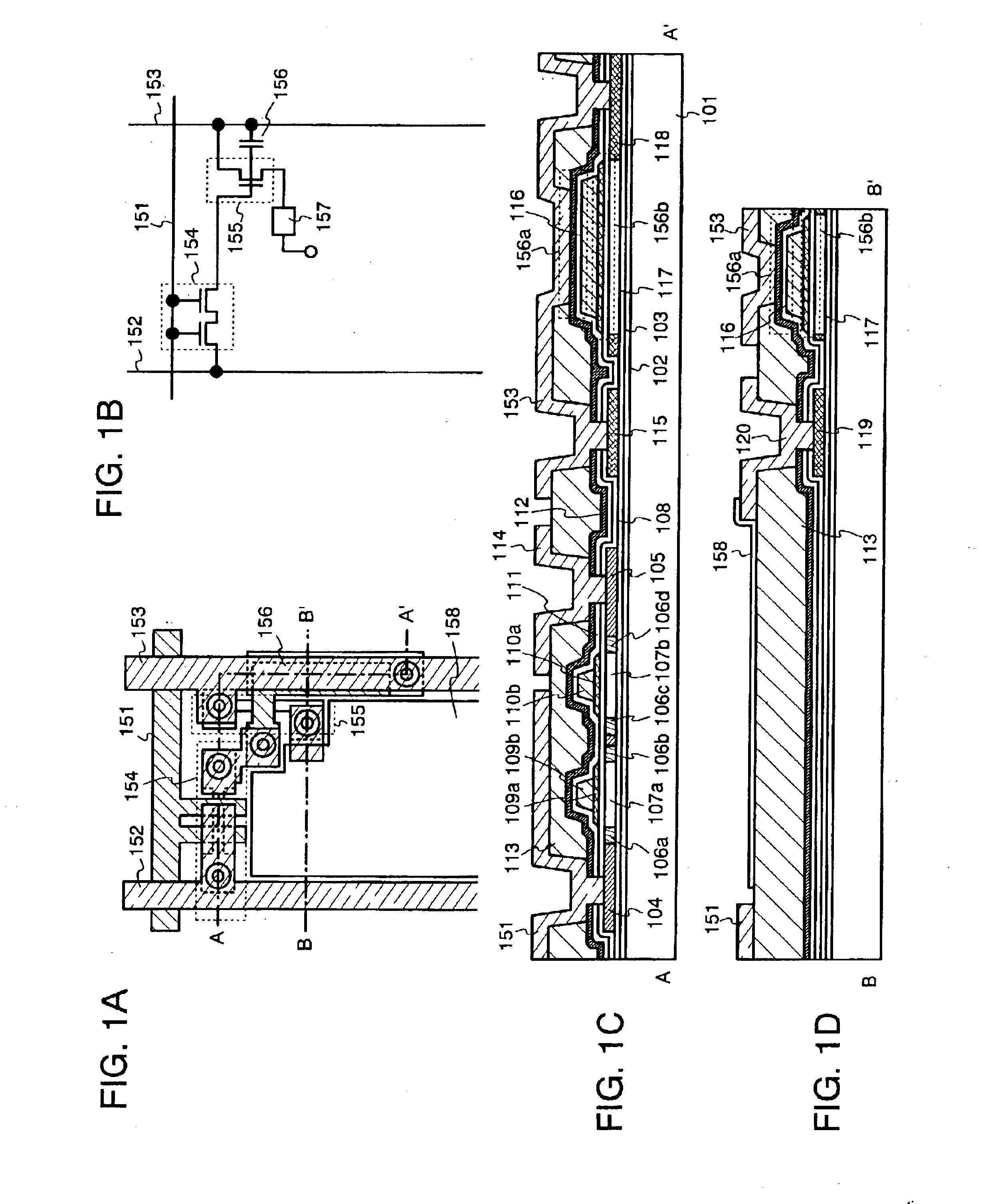

Light-emitting element, lighting device, and electronic appliance

ActiveUS20170012232A1Element characteristicIncrease the driving voltageMechanical apparatusDomestic lightingAlkaline earth metalEngineering

A tandem light-emitting element employing an inverted-structure is provided. The light-emitting element includes a cathode, a first EL layer over the cathode, a second EL layer over the first EL layer, an anode over the second EL layer, and an intermediate layer. The intermediate layer is between the first EL layer and the second EL layer. The intermediate layer includes a first layer, a second layer over the first layer, and a third layer over the second layer. The first layer includes a hole-transport material and an electron acceptor. The third layer includes an alkali metal or an alkaline earth metal. The second layer includes an electron-transport material.

Owner:SEMICON ENERGY LAB CO LTD

Semiconductor device and manufacturing method of the same

InactiveUS6930360B2High activation rateSuppress DiffuseTransistorSolid-state devicesNear neighborSite location

A semiconductor device having a semiconductor layer, includes: a first impurity atom having a covalent bond radius larger than a minimum radius of a covalent bond of a semiconductor constituent atom of a semiconductor layer; and a second impurity atom having a covalent bond radius smaller than a maximum radius of the covalent bond of the semiconductor constituent atom; wherein the first and second impurity atoms are arranged in a nearest neighbor lattice site location and at least one of the first and second impurity atoms is electrically active.

Owner:KK TOSHIBA

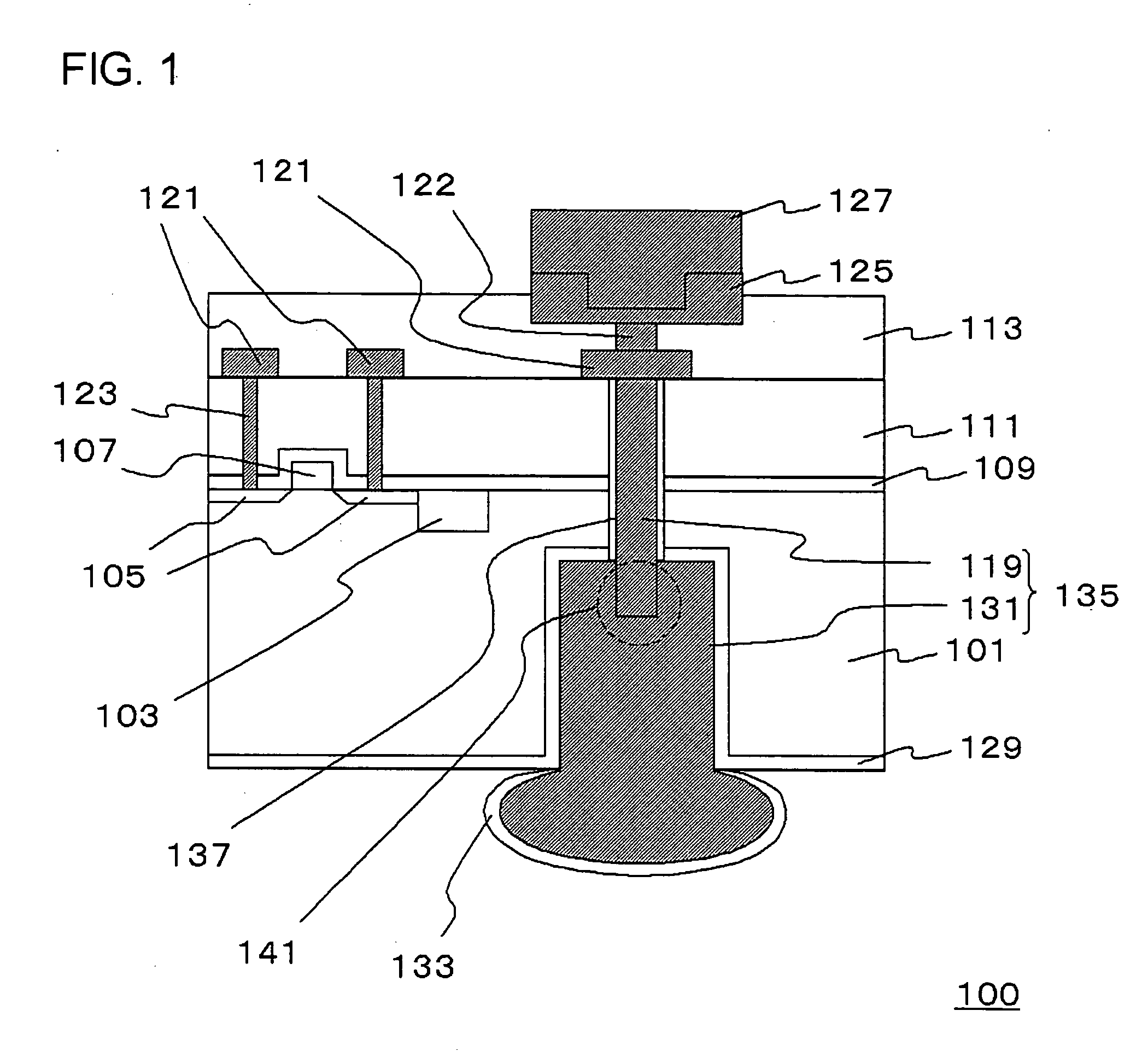

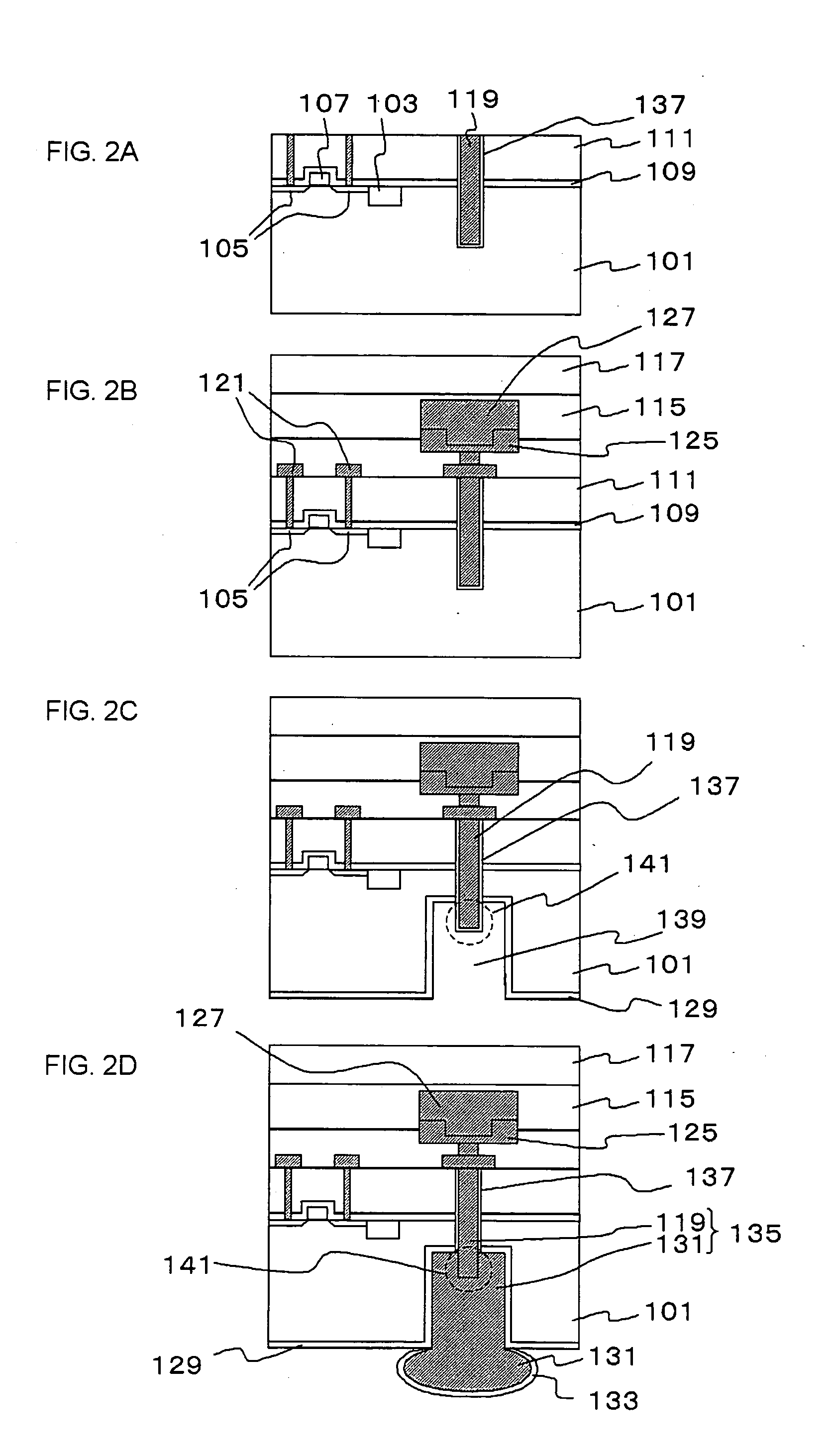

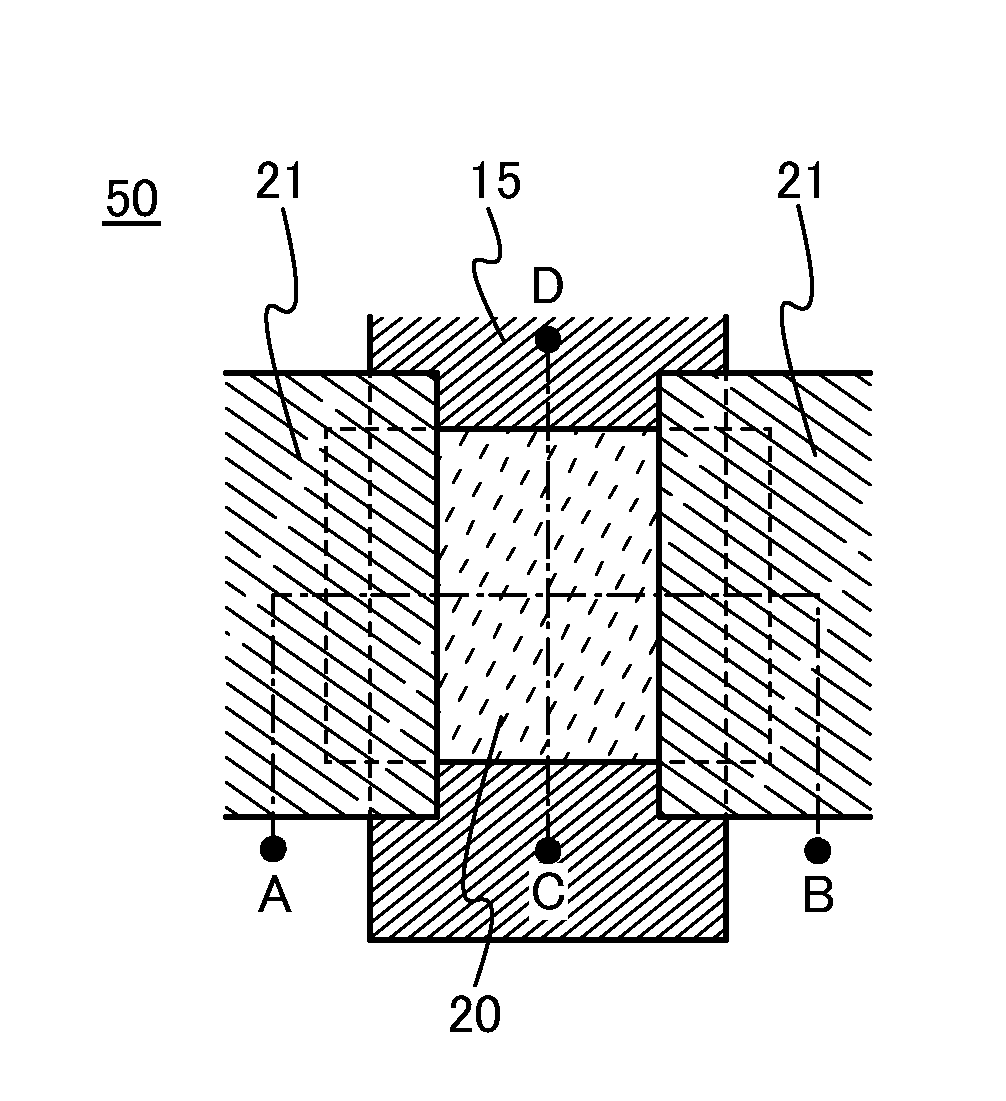

Semiconductor device and method for manufacturing the same

ActiveUS20050221601A1Improve featuresSimple processSemiconductor/solid-state device detailsSolid-state devicesDevice materialEngineering

A semiconductor device having a through electrode excellent in performance as for an electrode and manufacturing stability is provided. There is provided a through electrode composed of a conductive small diameter plug and a conductive large diameter plug on a semiconductor device. A cross sectional area of the small diameter plug is made larger than a cross sectional area and a diameter of a connection plug, and is made smaller than a cross sectional area and a diameter of the large diameter plug. In addition, a protruding portion formed in such a way that the small diameter plug is projected from the silicon substrate is put into an upper face of the large diameter plug. Further, an upper face of the small diameter plug is connected to a first interconnect.

Owner:RENESAS ELECTRONICS CORP

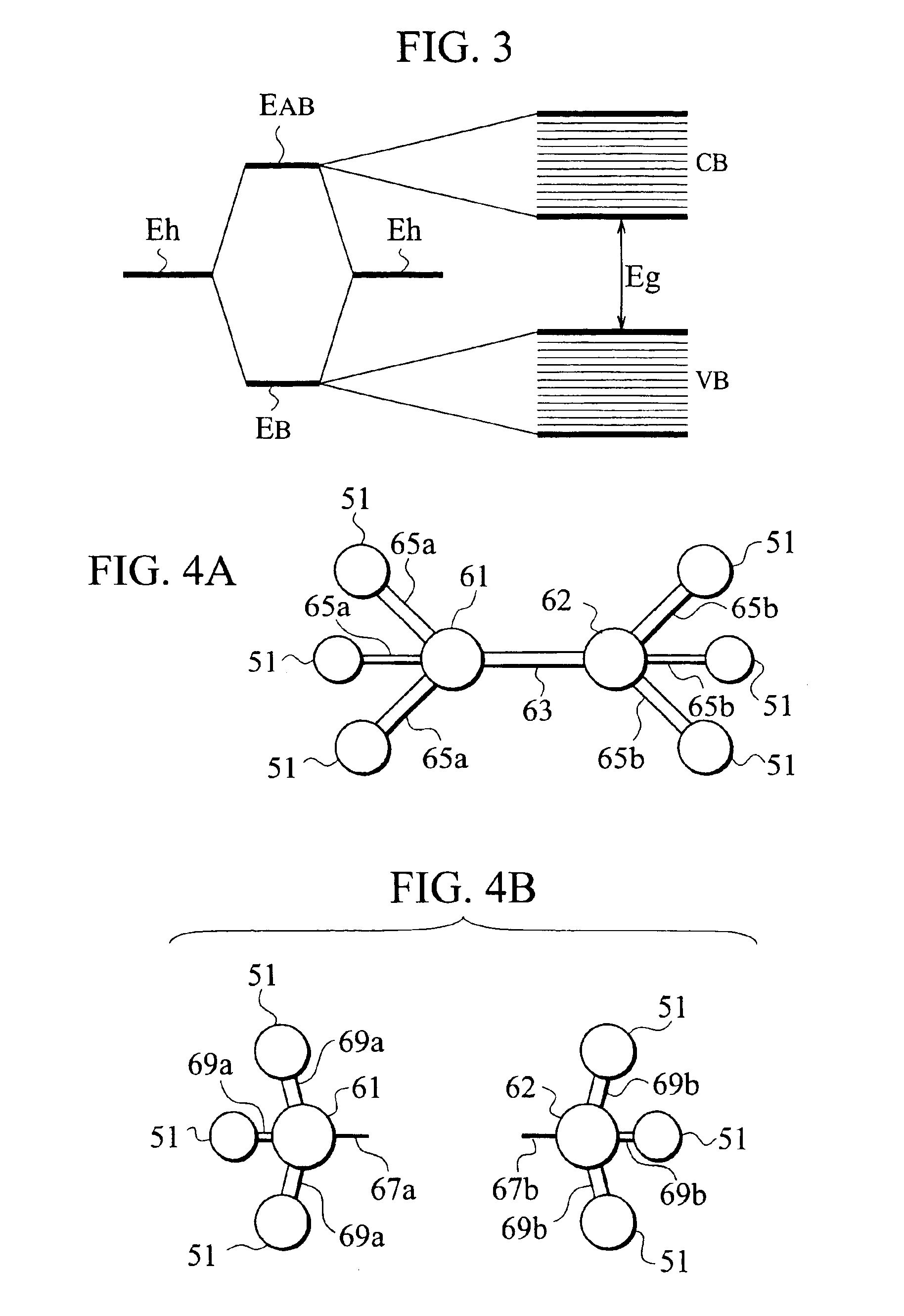

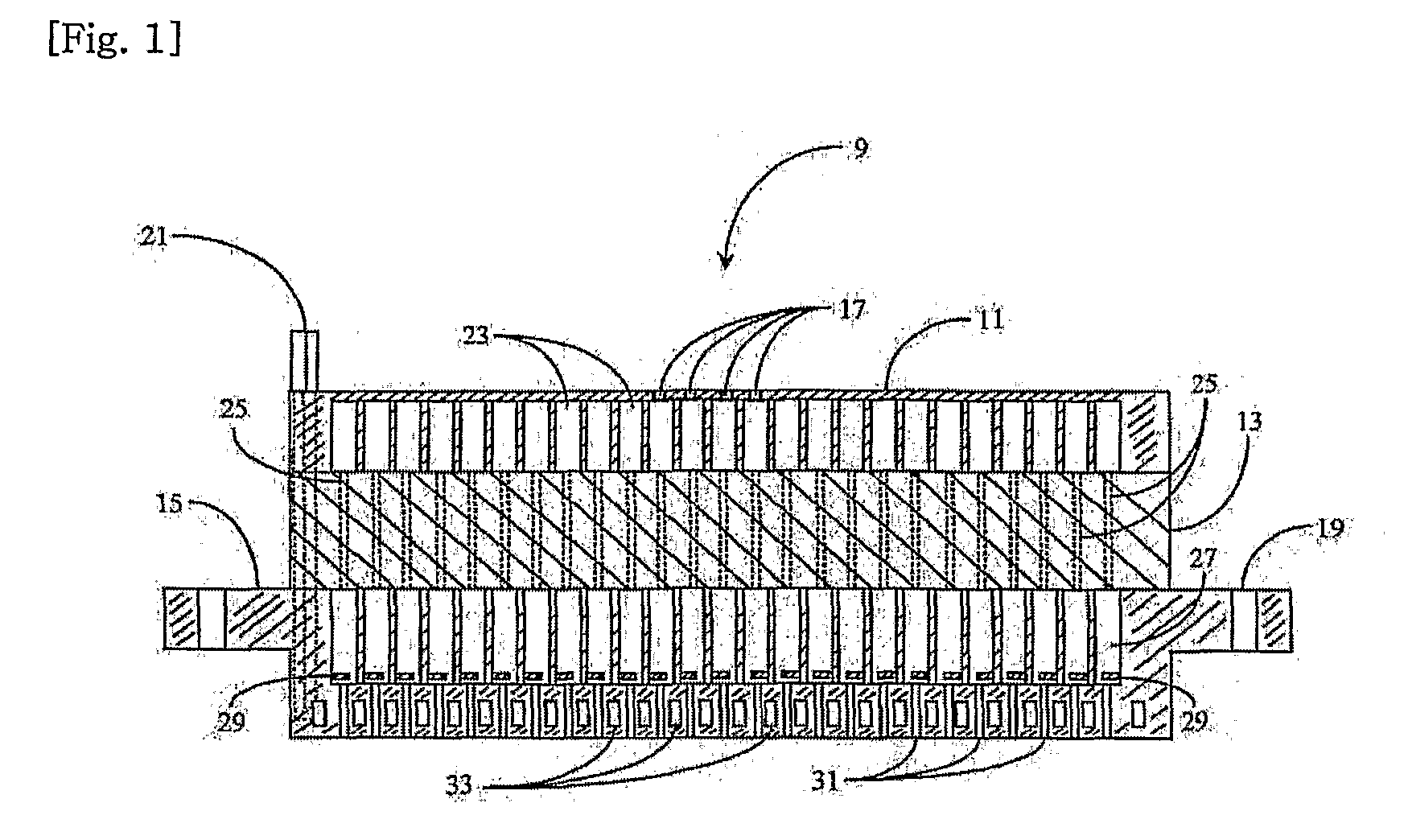

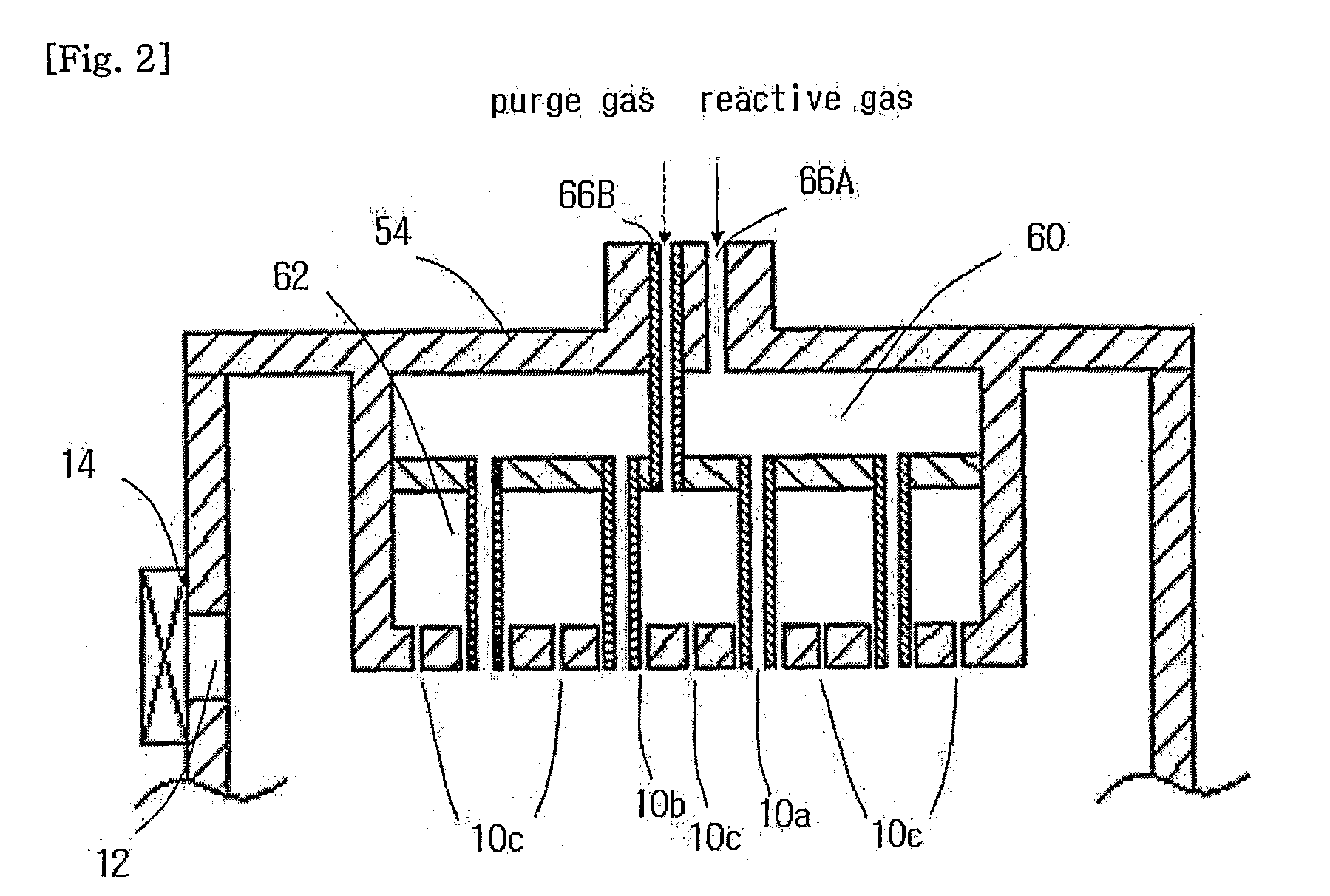

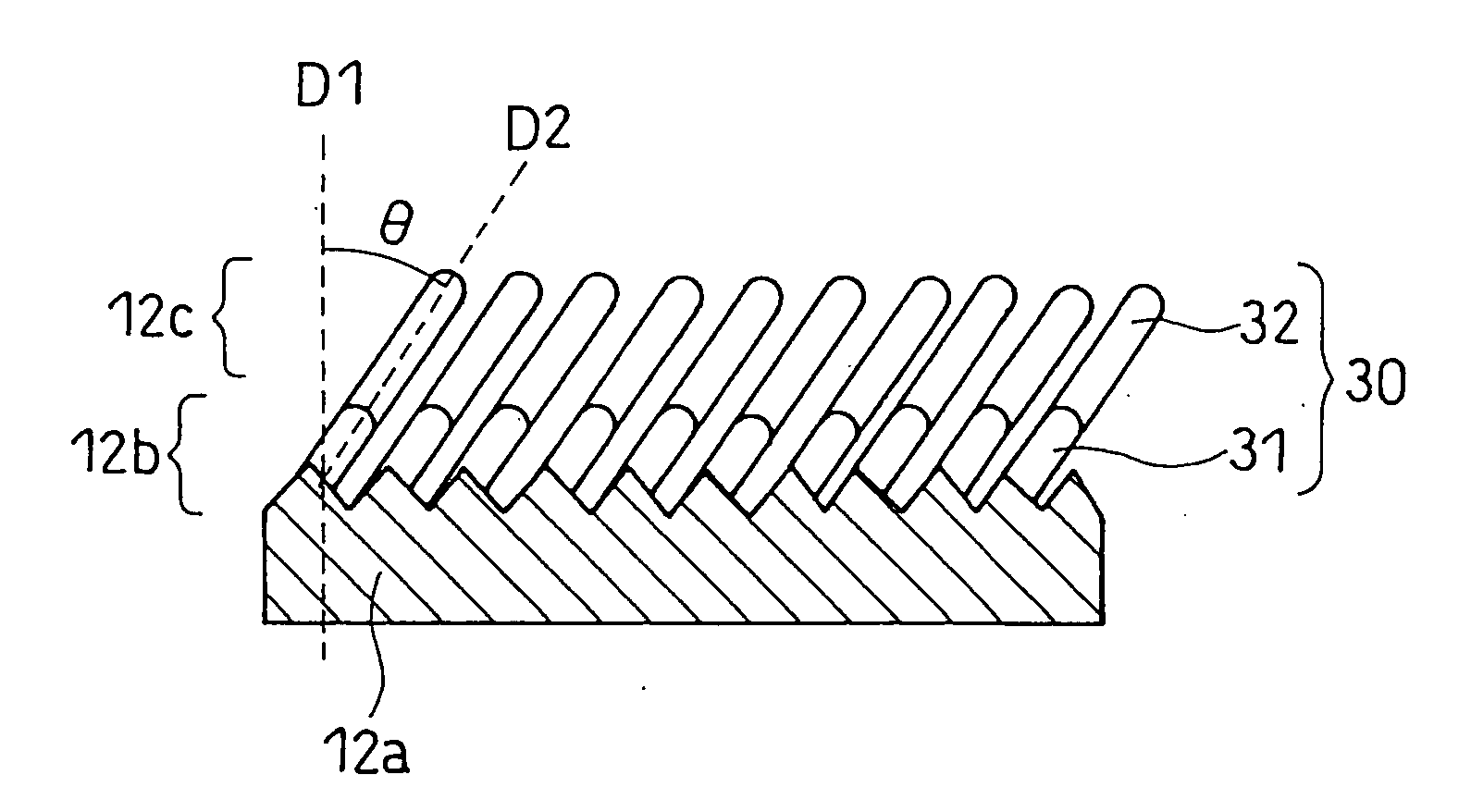

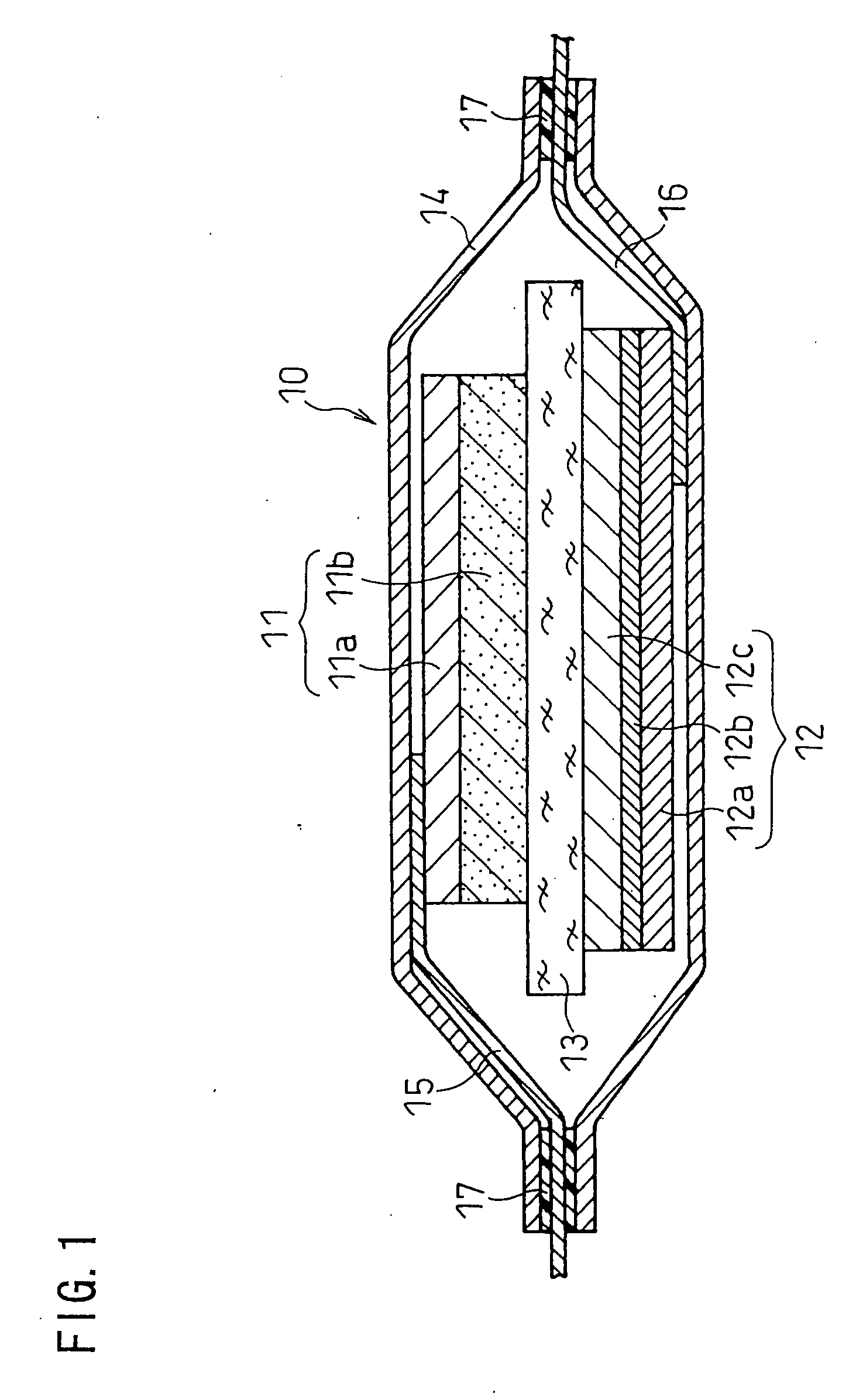

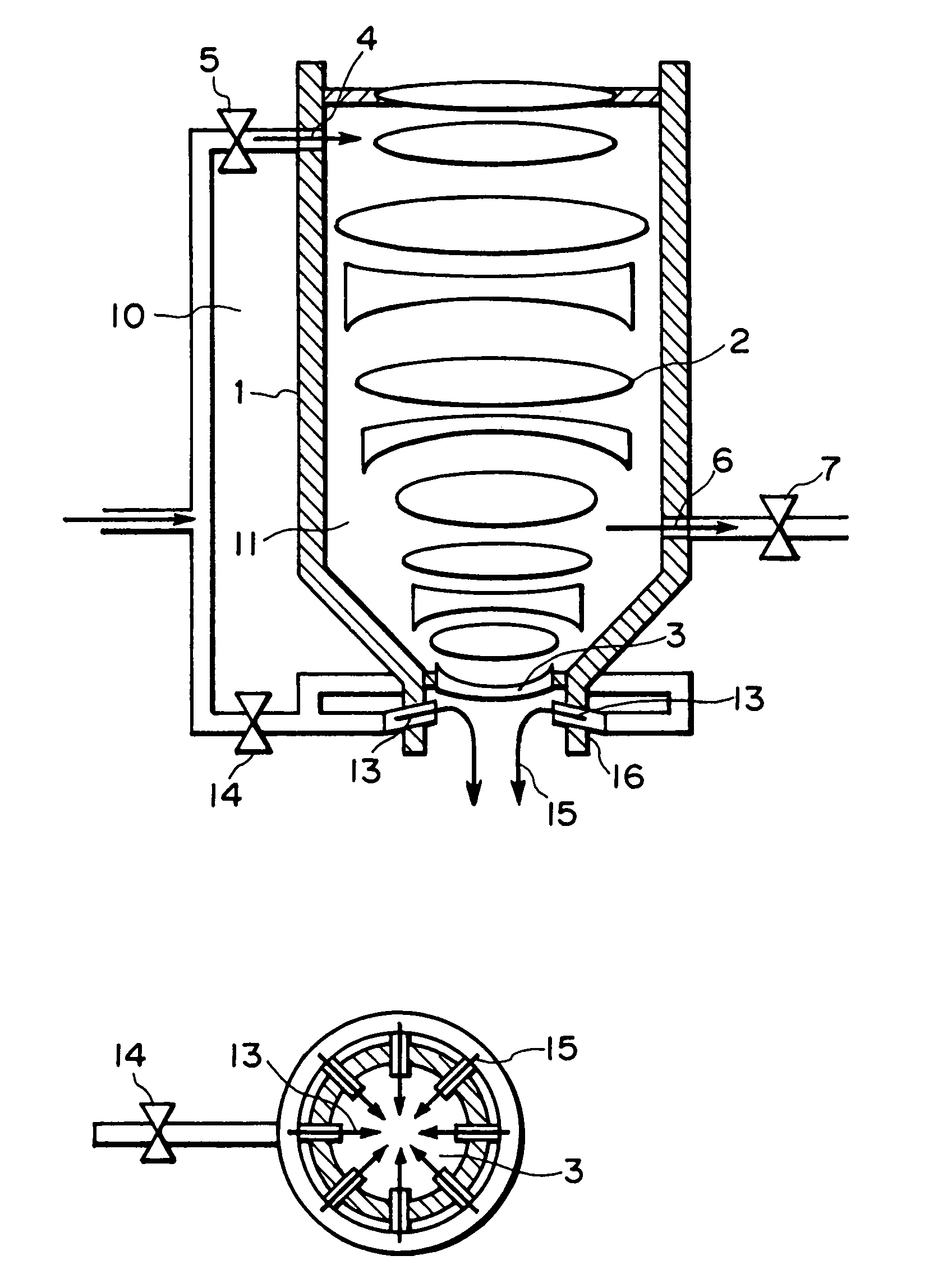

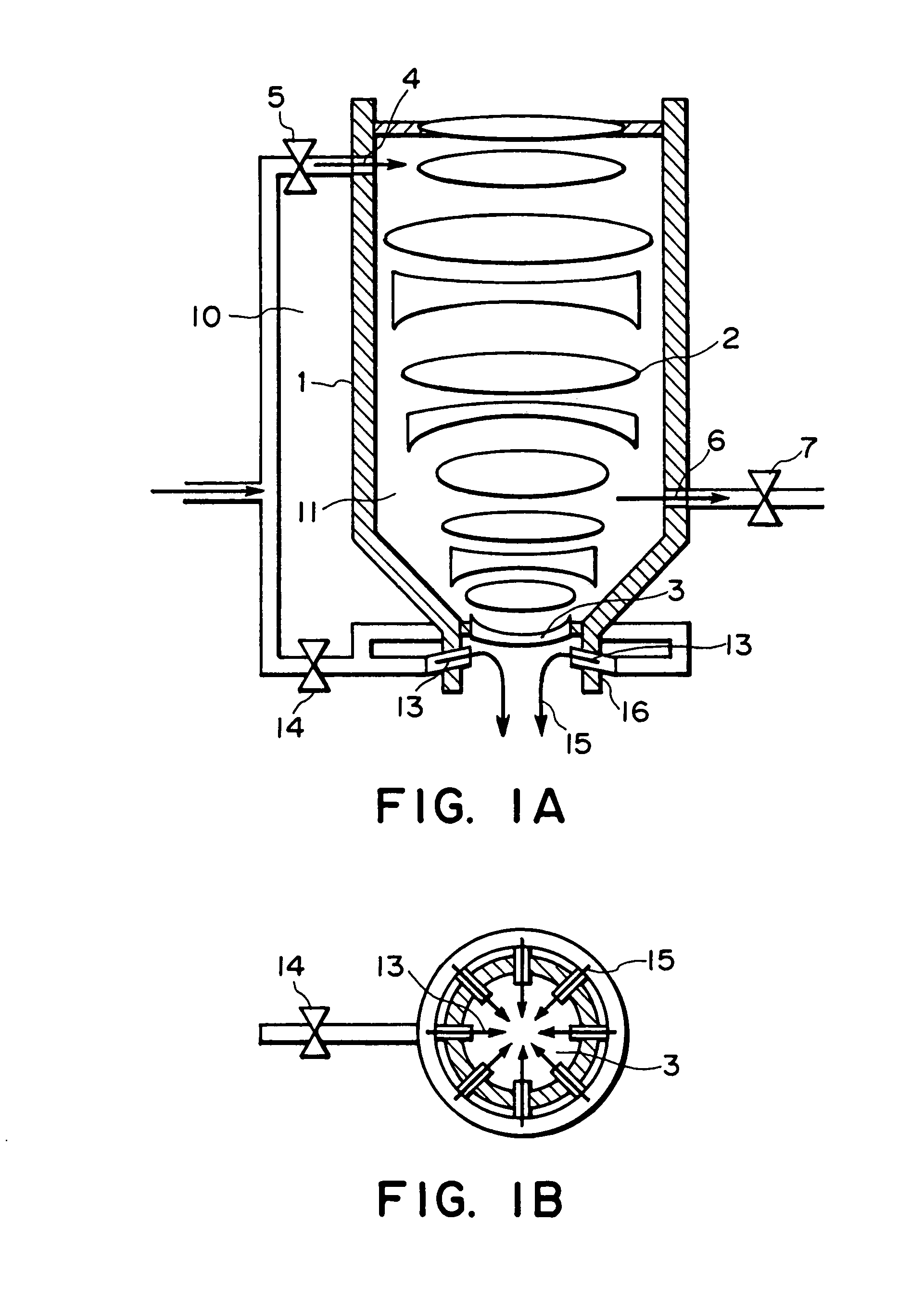

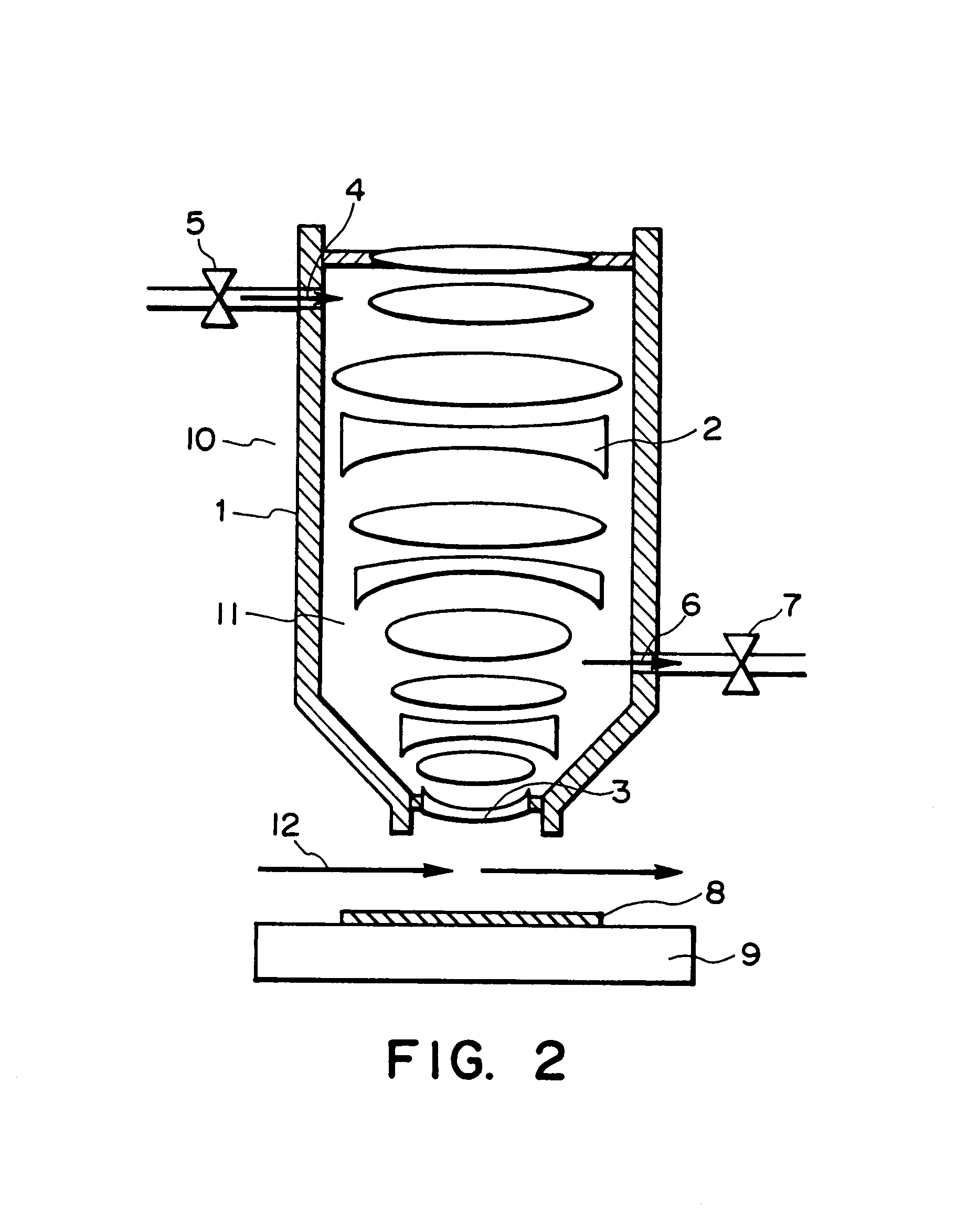

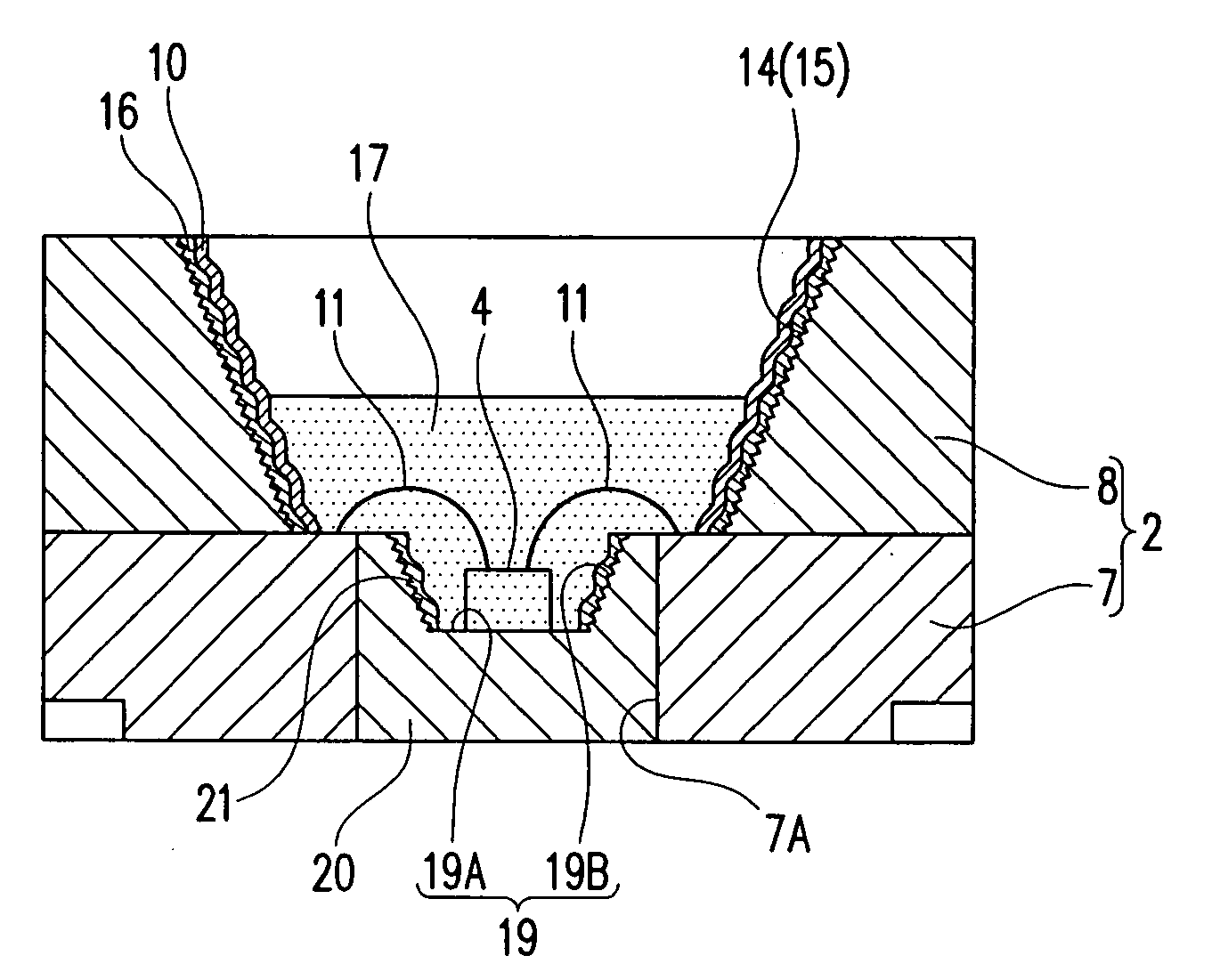

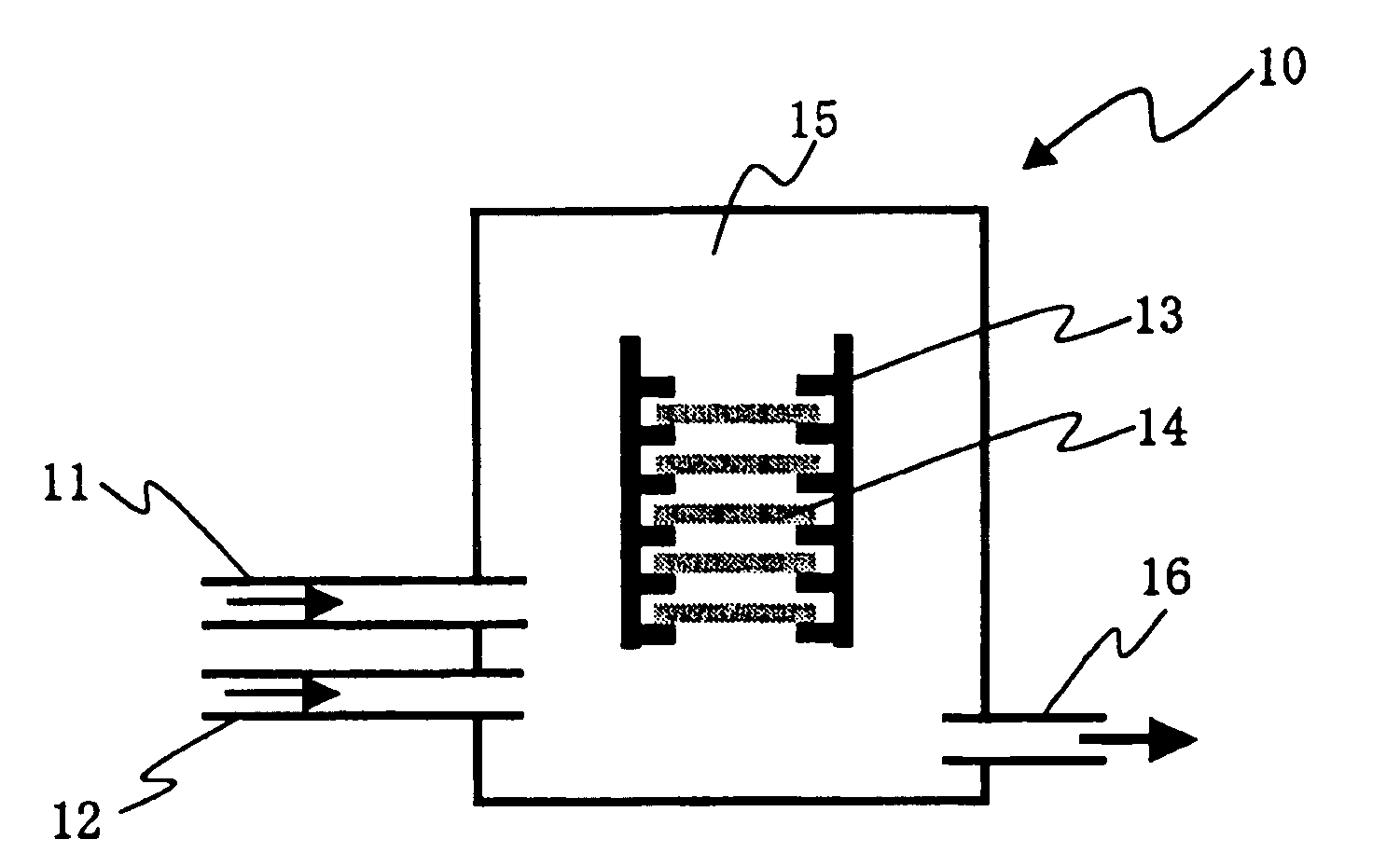

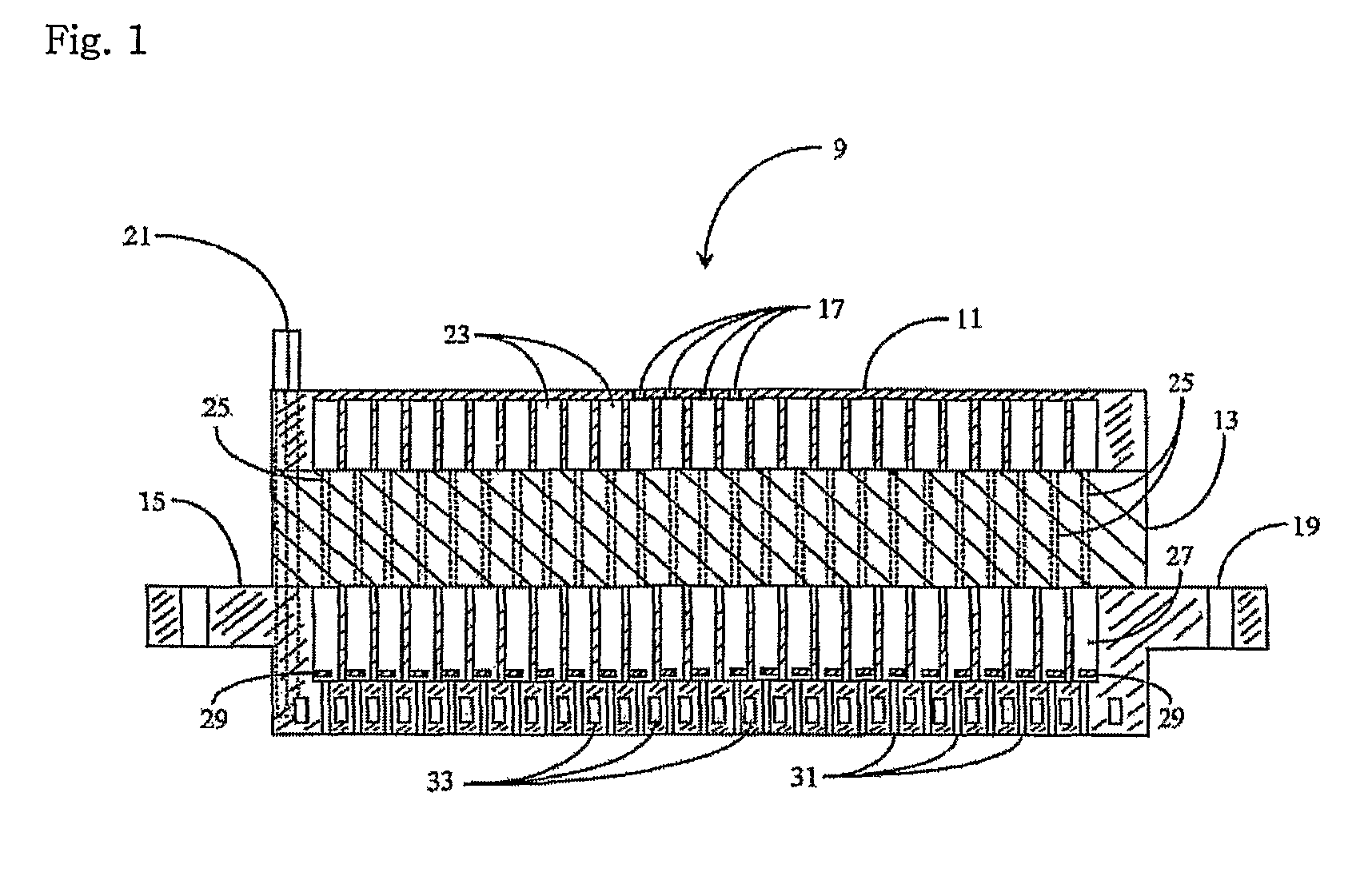

Apparatus of chemical vapor deposition with a showerhead regulating injection velocity of reactive gases postively and method thereof

ActiveUS20090169744A1Suppress DiffuseAvoid pollutionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingReactive gasGas phase

The present invention is related to an apparatus and a method for chemical vapor deposition (CVD) using a showerhead through which a reactive gas of at least one kind and a purge gas is injected over a substrate on which a film is growing. A plural number of reactive gas showerhead modules are laid on a purge gas showerhead module. Each reactive gas is injected from a bottom of the showerhead after flowing through the showerhead as separated, thereby preventing the reactive gases from causing homogeneous gas phase reactions and from generating unwanted particles at the inside of the showerhead. And purge gas is injected from the bottom surface of the showerhead by forming a protective curtain, thereby suppressing diffusion of the reactive gas injected backwardly. Each reactive gas is mixed with an injection support gas which is a kind of inert gas in a mixing zone at inside of the showerhead, where the injection velocity of each reactive gas is regulated positively by the amount of the injection support gas mixed. The present invention further includes an apparatus and a method, wherein the showerhead is cooled by a cooling jacket which keeps the temperature of the showerhead at proper levels to prevent both the condensation and the thermal decomposition of the reactive gas used.

Owner:KOREA INST OF IND TECH +1

Semiconductor substrate for solid-state image sensing device as well as solid-state image sensing device and method for producing the same

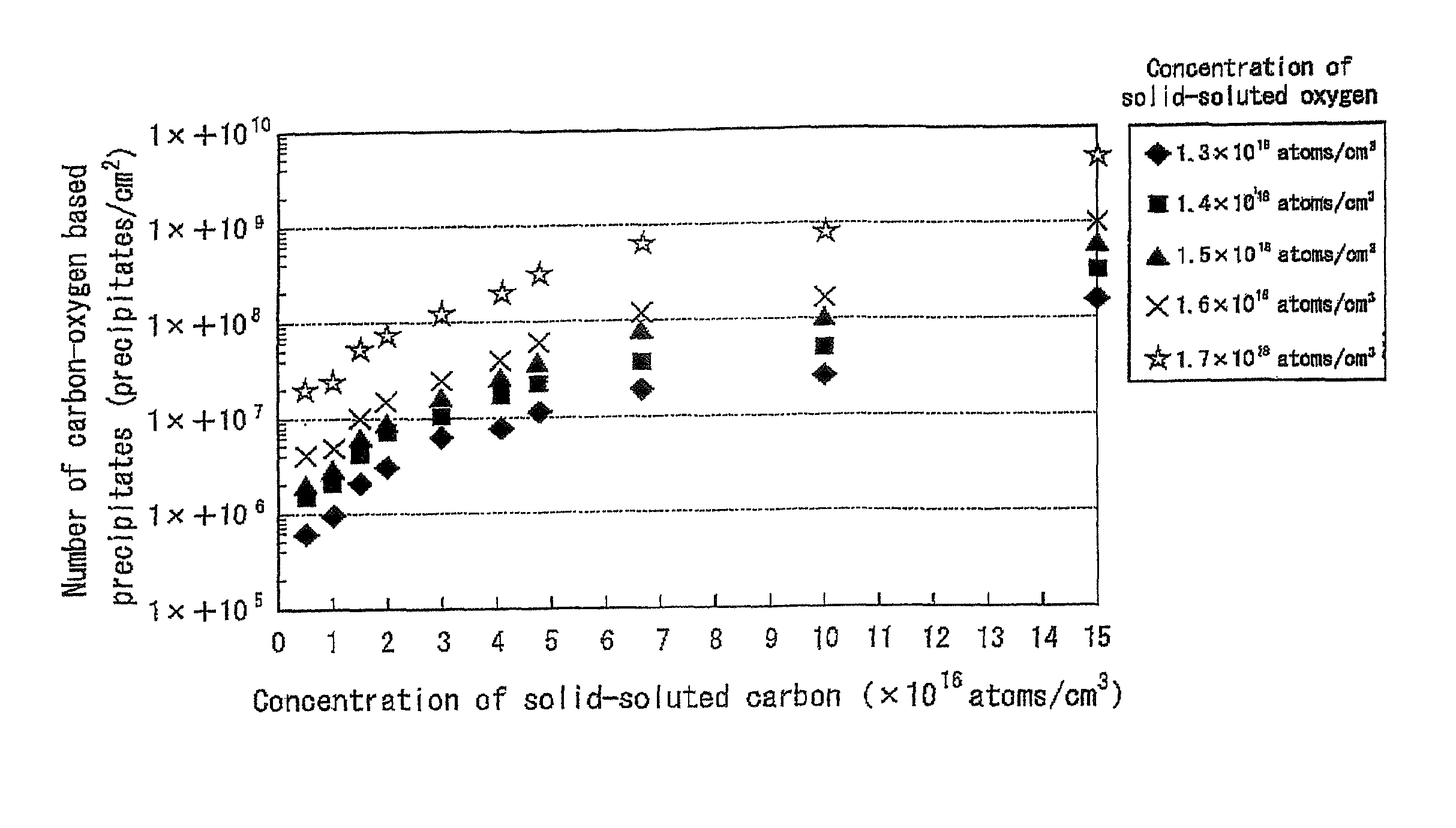

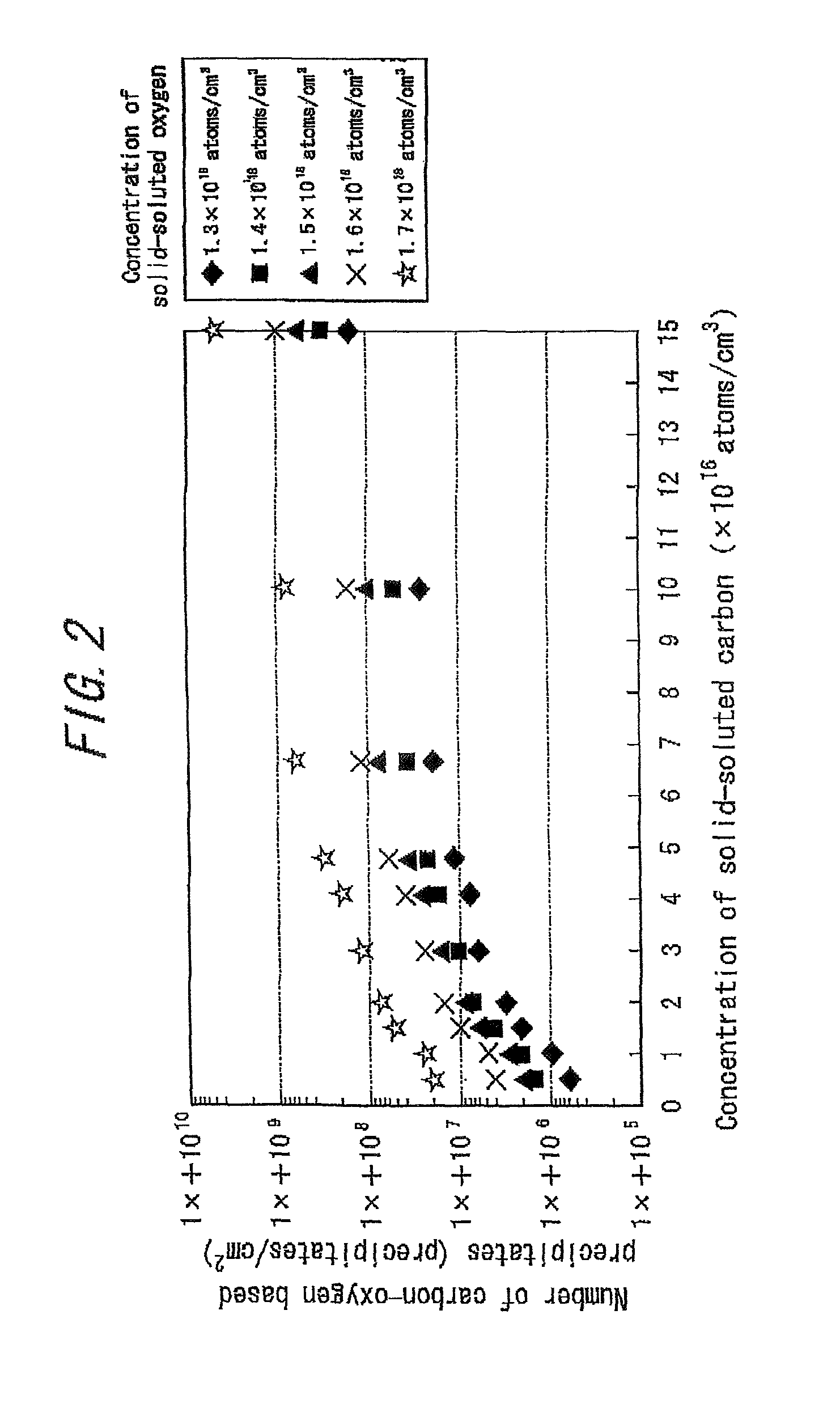

ActiveUS8063466B2Improve inhalation effectGood electric characteristicPolycrystalline material growthAfter-treatment detailsCarbon ionOxygen

There is provided a semiconductor substrate for solid-state image sensing device in which the production cost is lower than that of a gettering method through a carbon ion implantation and problems such as occurrence of particles at a device production step and the like are solved.Silicon substrate contains solid-soluted carbon having a concentration of 1×1016-1×1017 atoms / cm3 and solid-soluted oxygen having a concentration of 1.4×1018-1.6×1018 atoms / cm3.

Owner:SUMCO CORP

High performance FET devices and methods therefor

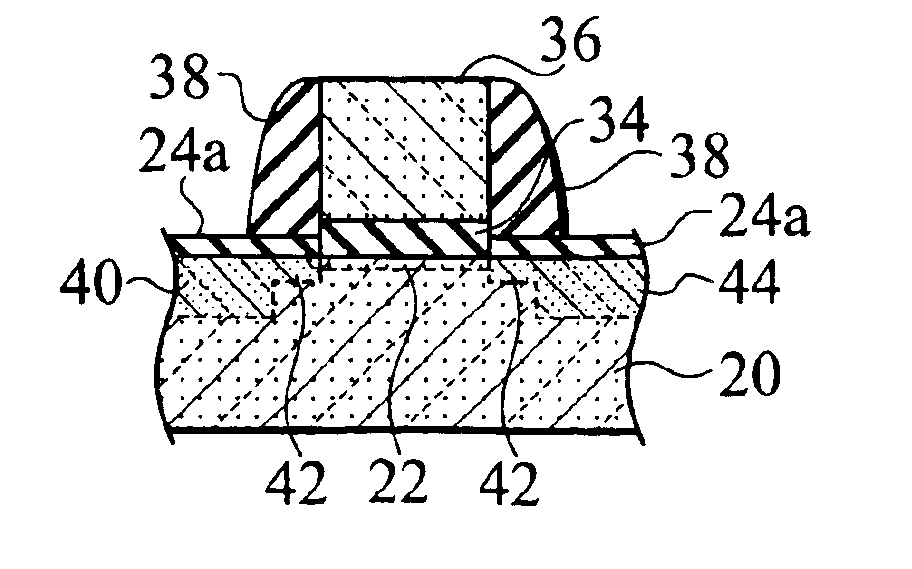

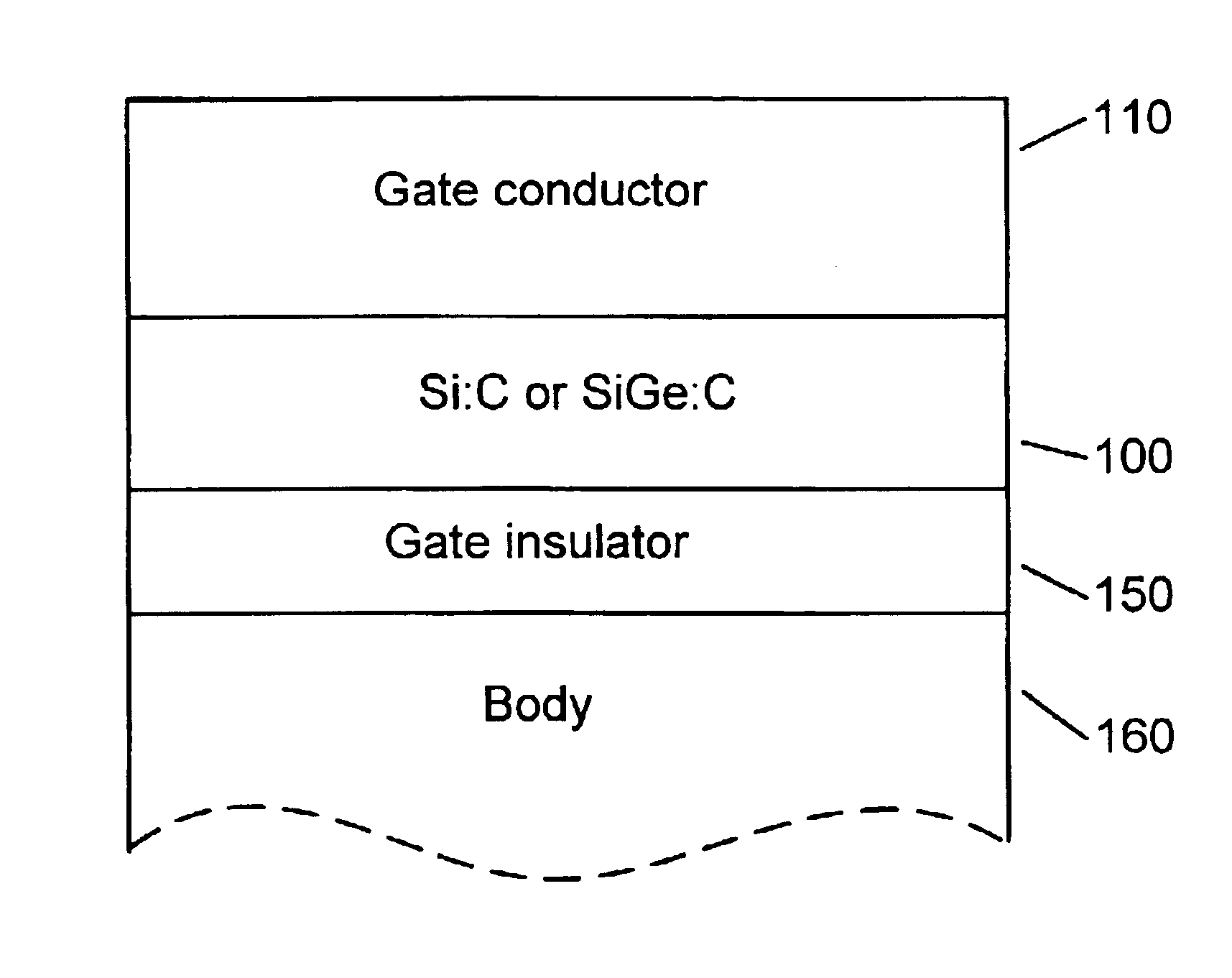

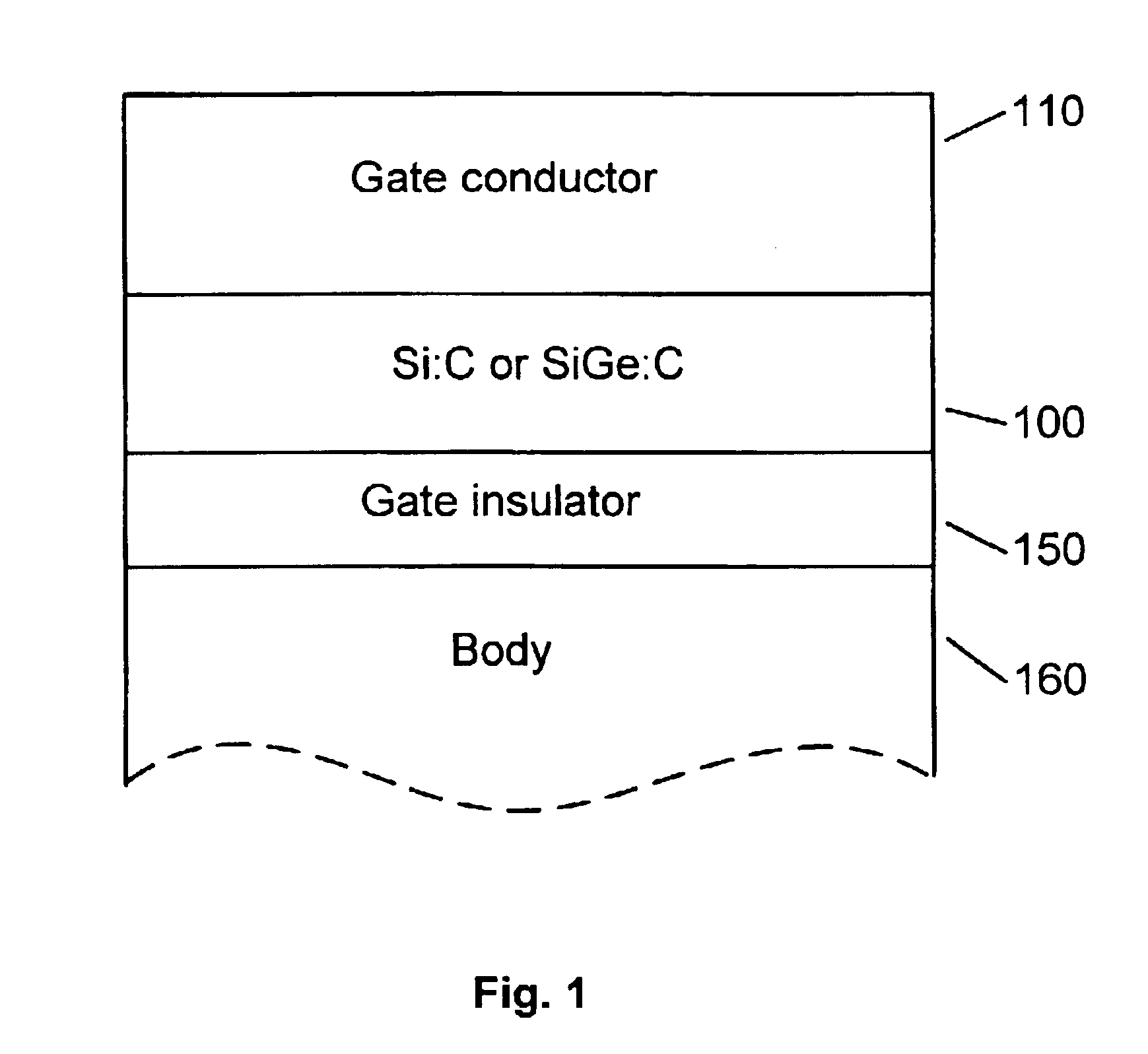

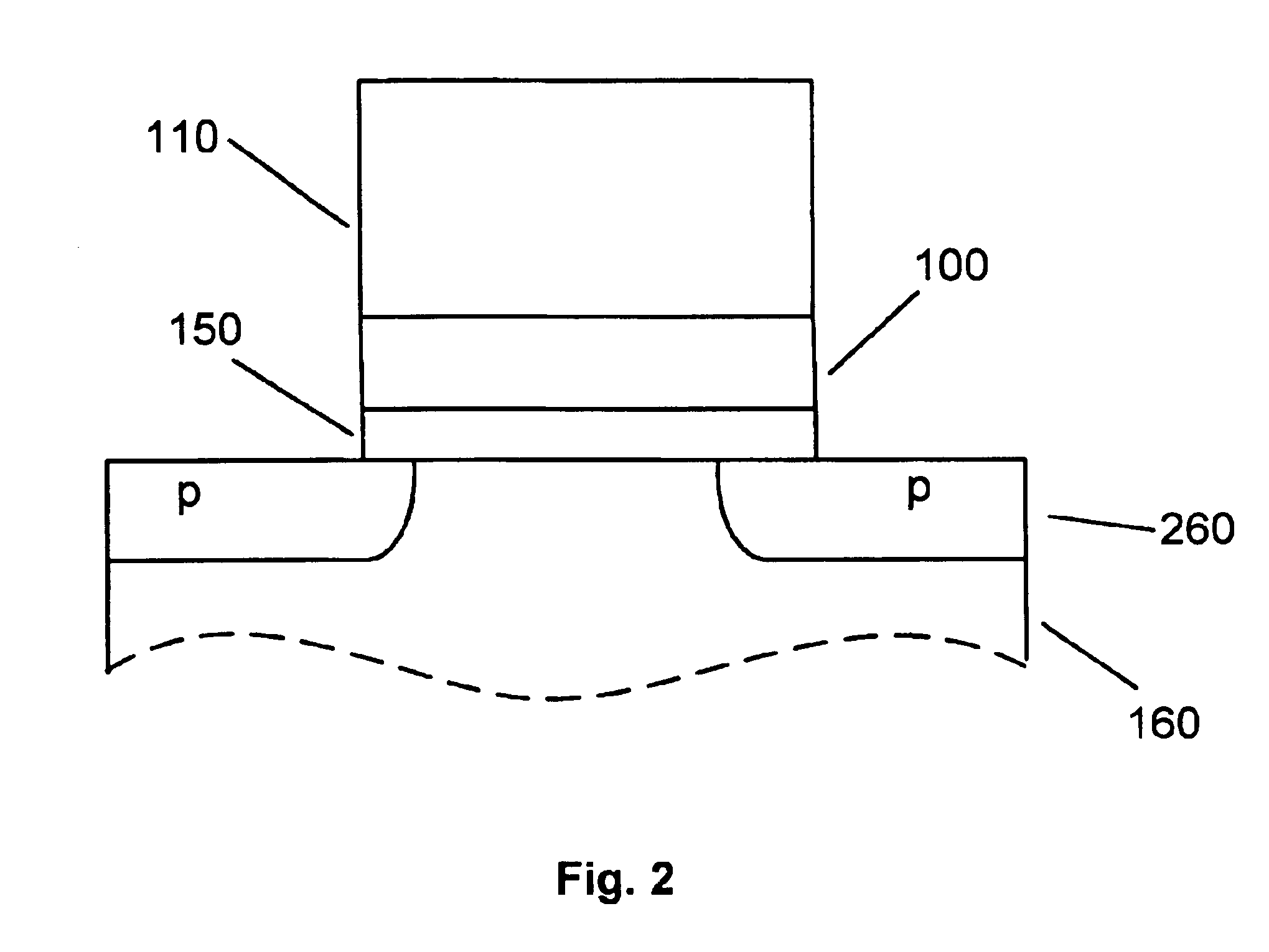

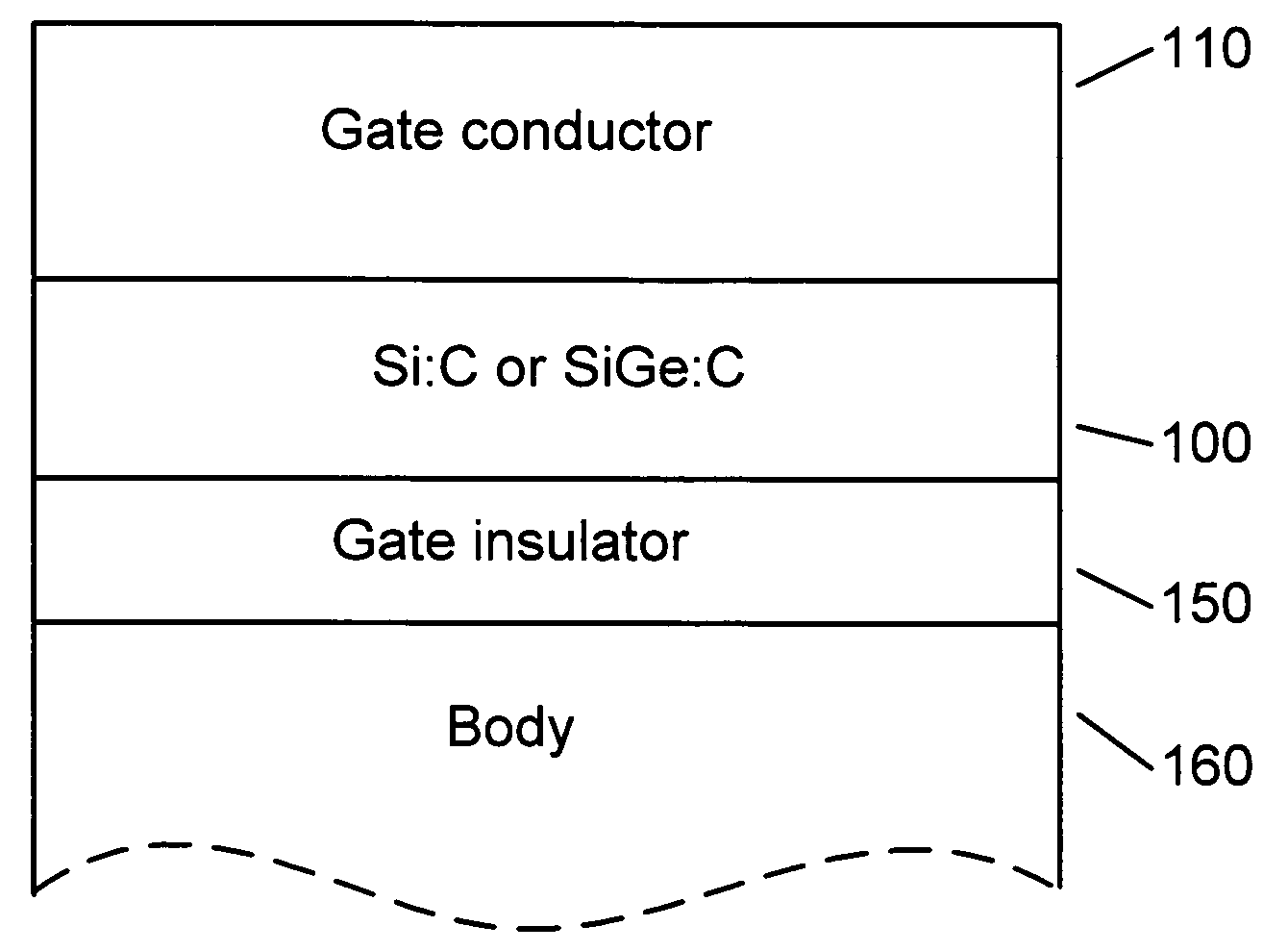

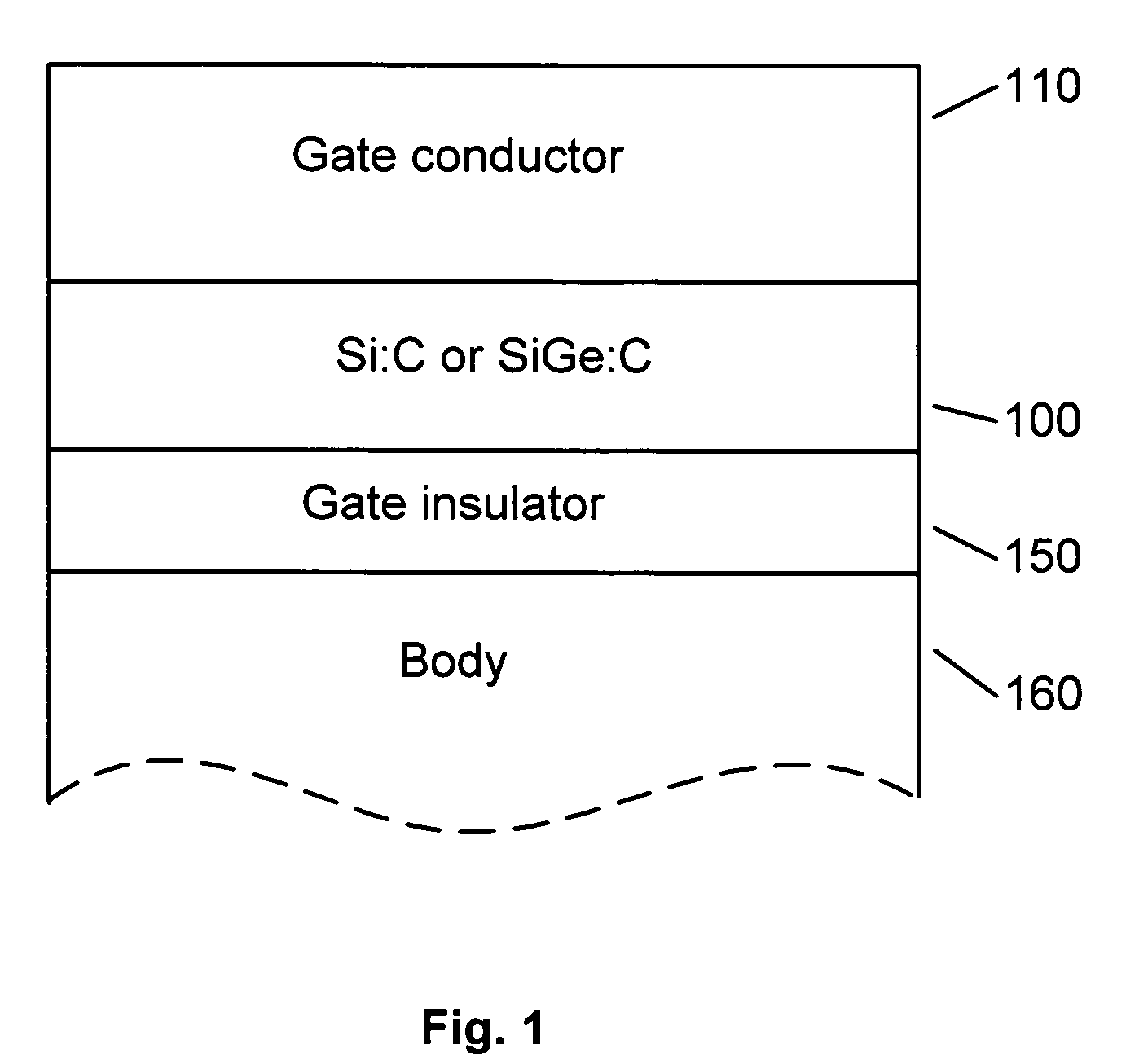

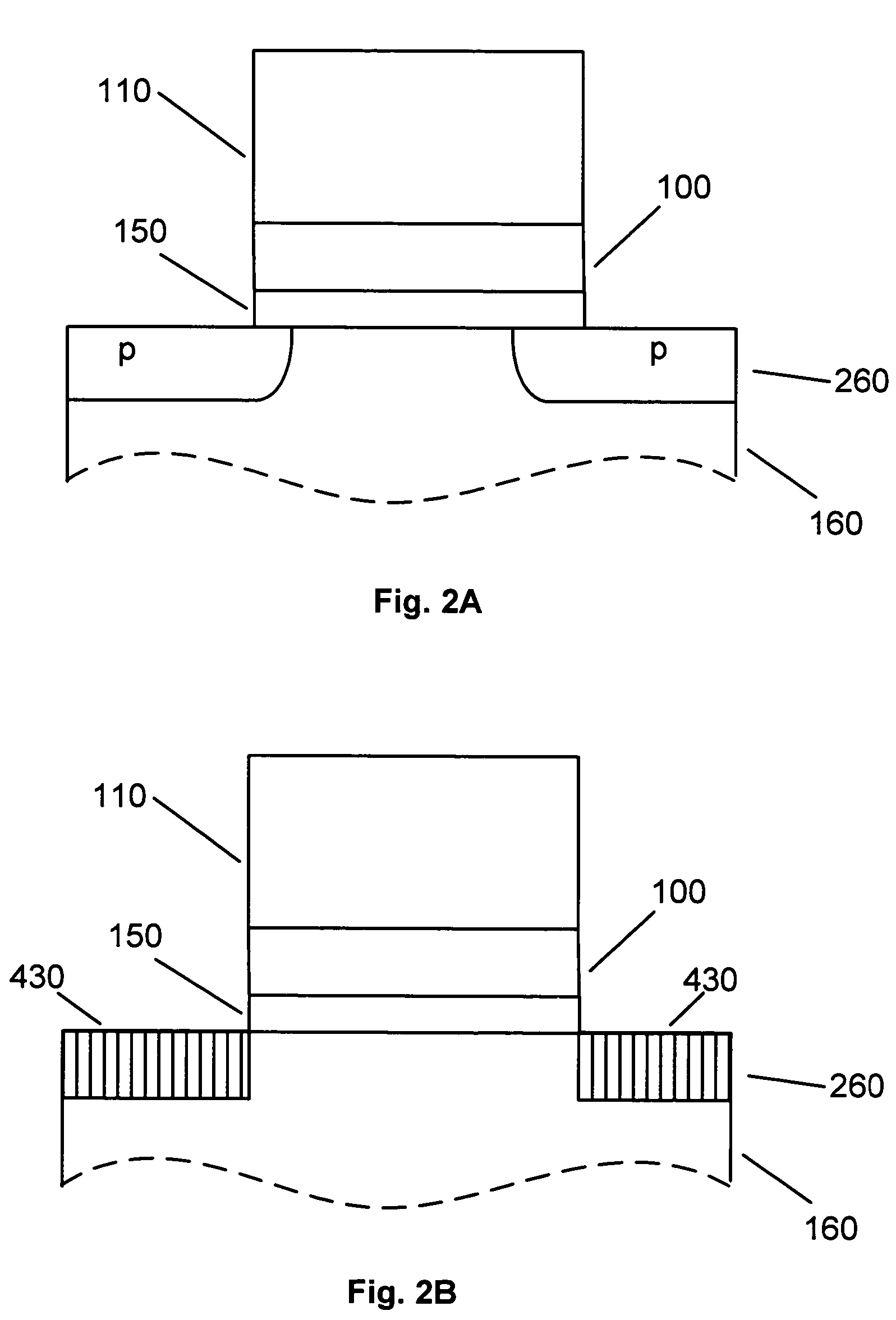

InactiveUS6909186B2Suitable for low temperature operationIncrease the areaTransistorSemiconductor/solid-state device detailsDopantGate insulator

Structure and methods of fabrication are disclosed for an enhanced FET devices in which dopant impurities are prevented from diffusing through the gate insulator. The structure comprises a Si:C, or SiGe:C, layer which is sandwiched between the gate insulator and a layer which is doped with impurities in order to provide a preselected workfunction. It is further disclosed how this, and further improvements for FET devices, such as raised source / drain and multifaceted gate on insulator, MODFET on insulator are integrated with strained Si based layer on insulator technology.

Owner:IBM CORP

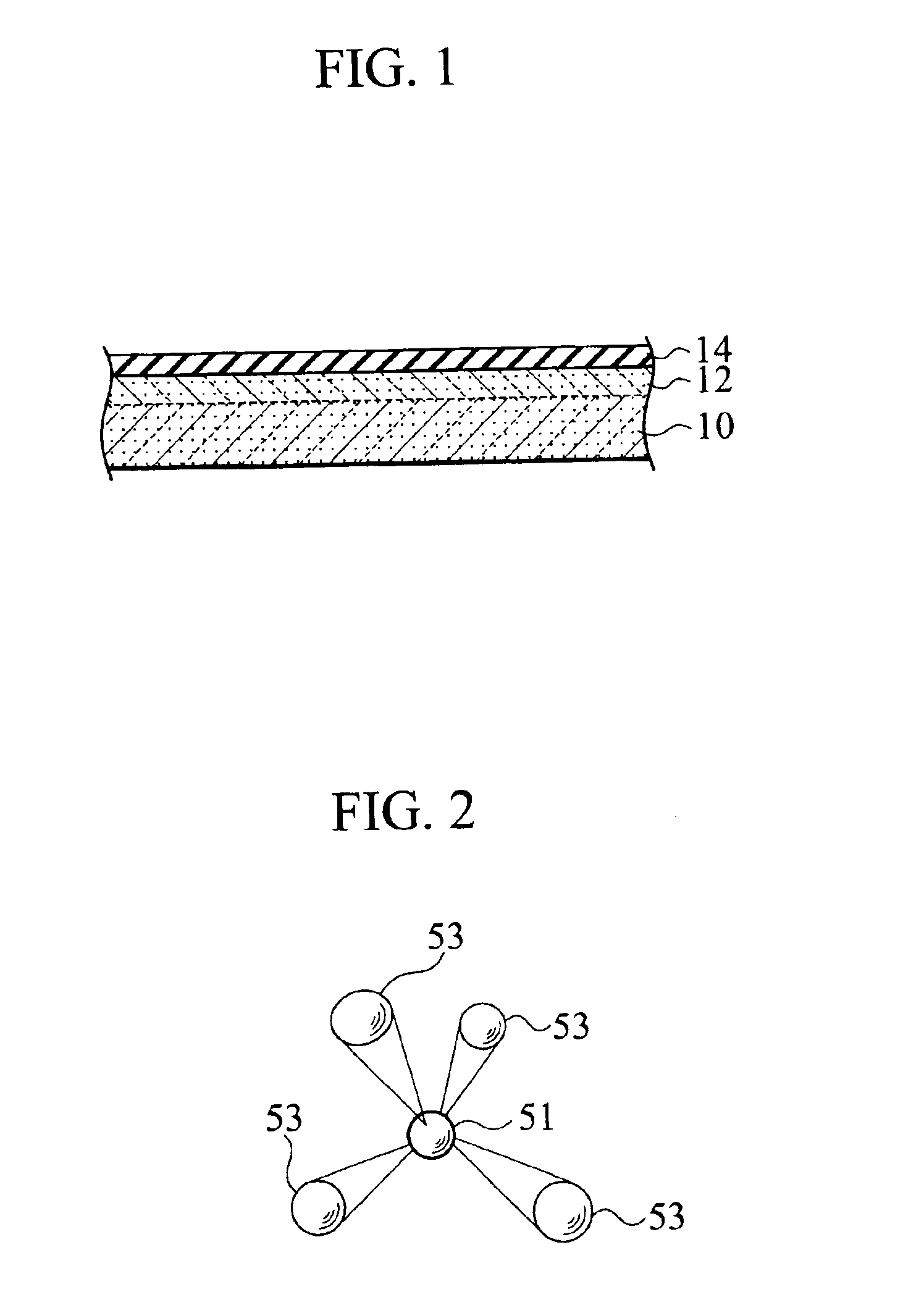

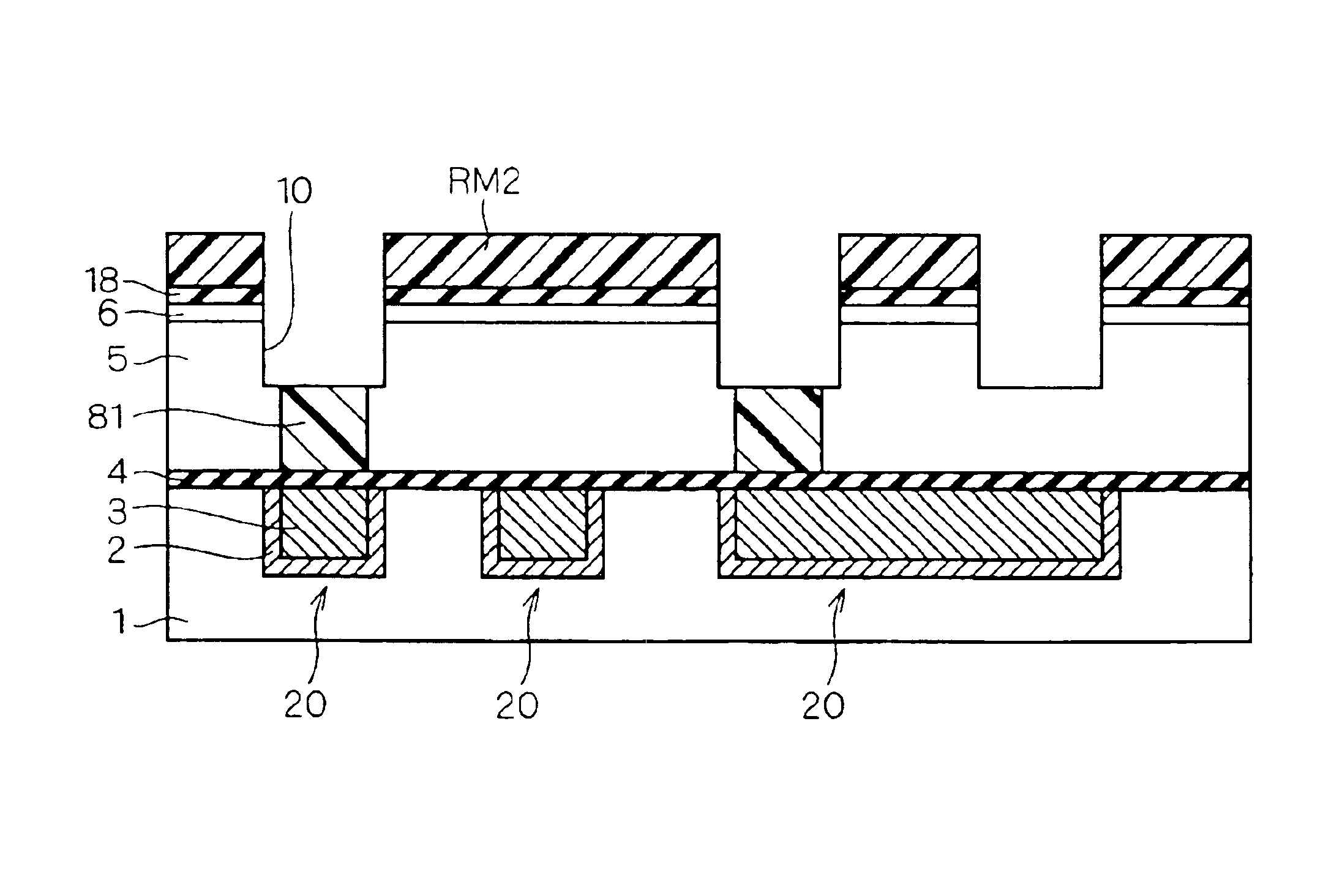

Negative electrode for lithium ion secondary battery, method for producing the same, and lithium ion secondary battery

ActiveUS20080020281A1Inhibited DiffusionSuppress DiffuseFinal product manufactureElectrode carriers/collectorsLithiumOxygen

A negative electrode for a lithium ion secondary battery includes a current collector, an intermediate layer formed on a surface of the current collector, and an active material layer formed on the intermediate layer. The current collector includes a metal capable of being alloyed with silicon. The active material layer includes an active material including silicon. The intermediate layer includes silicon and oxygen. The intermediate layer prevents the metal capable of being alloyed with silicon from diffusing into the active material layer. The diffusion of the constituent element of the current collector into the active material layer is suppressed.

Owner:PANASONIC CORP

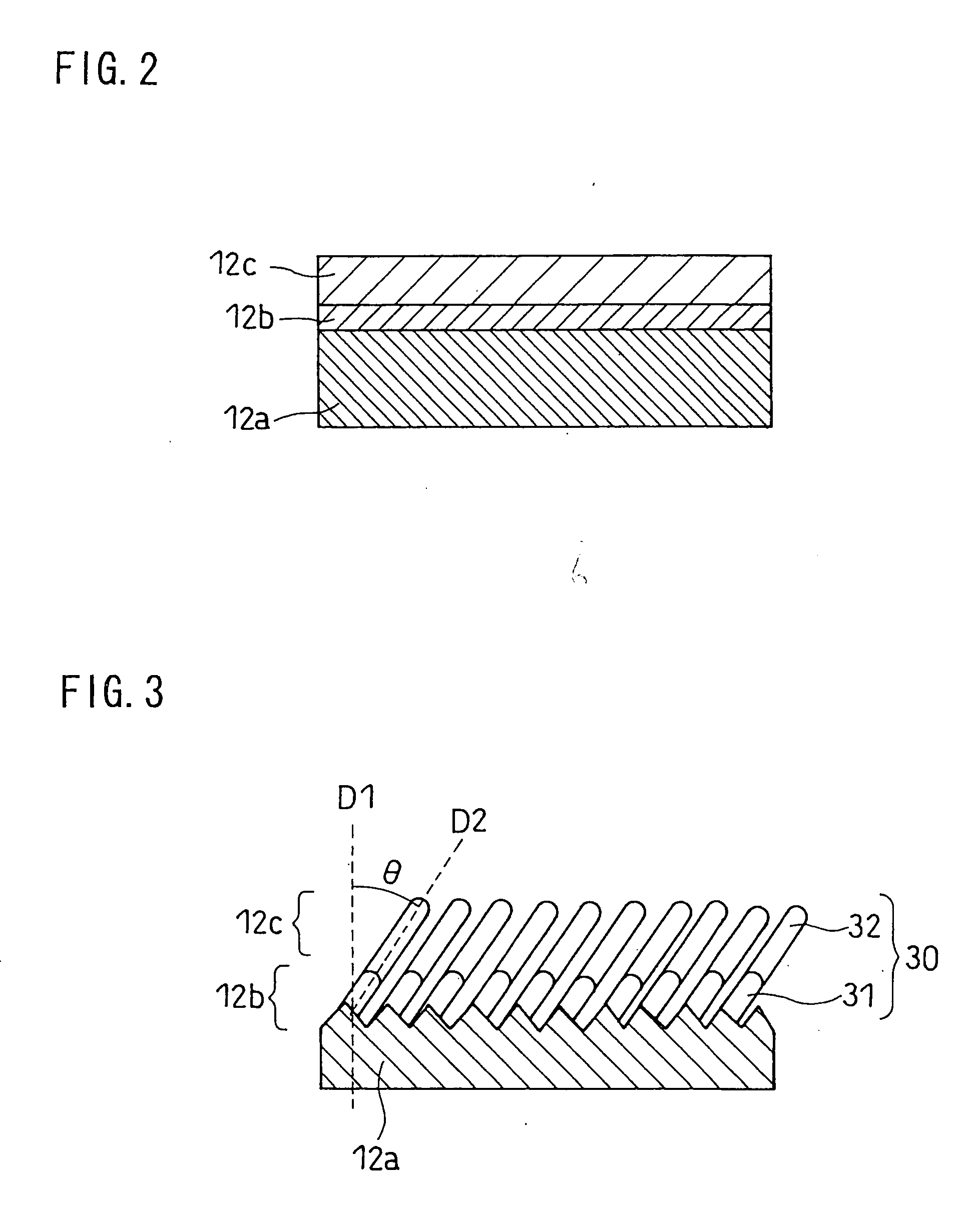

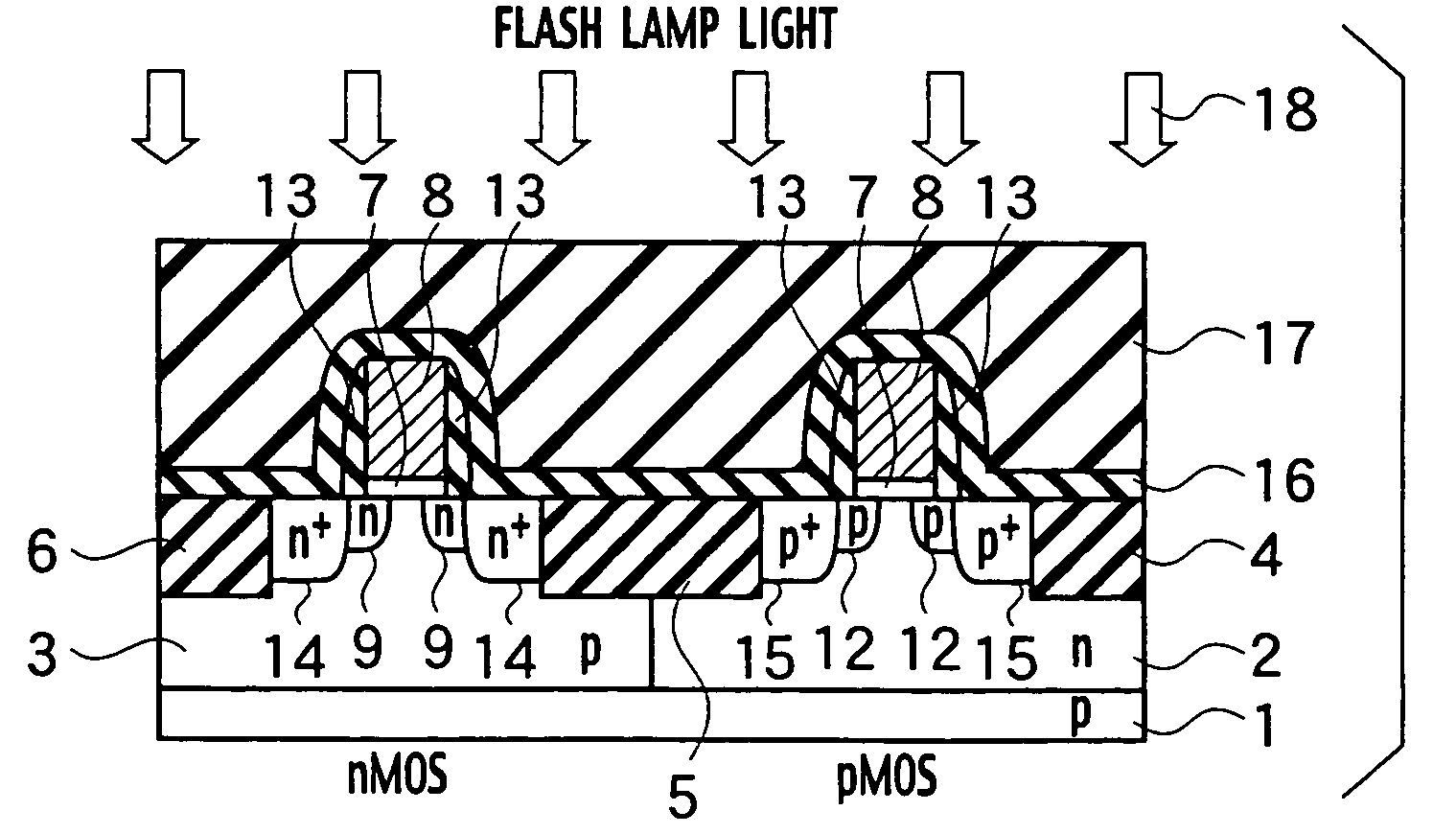

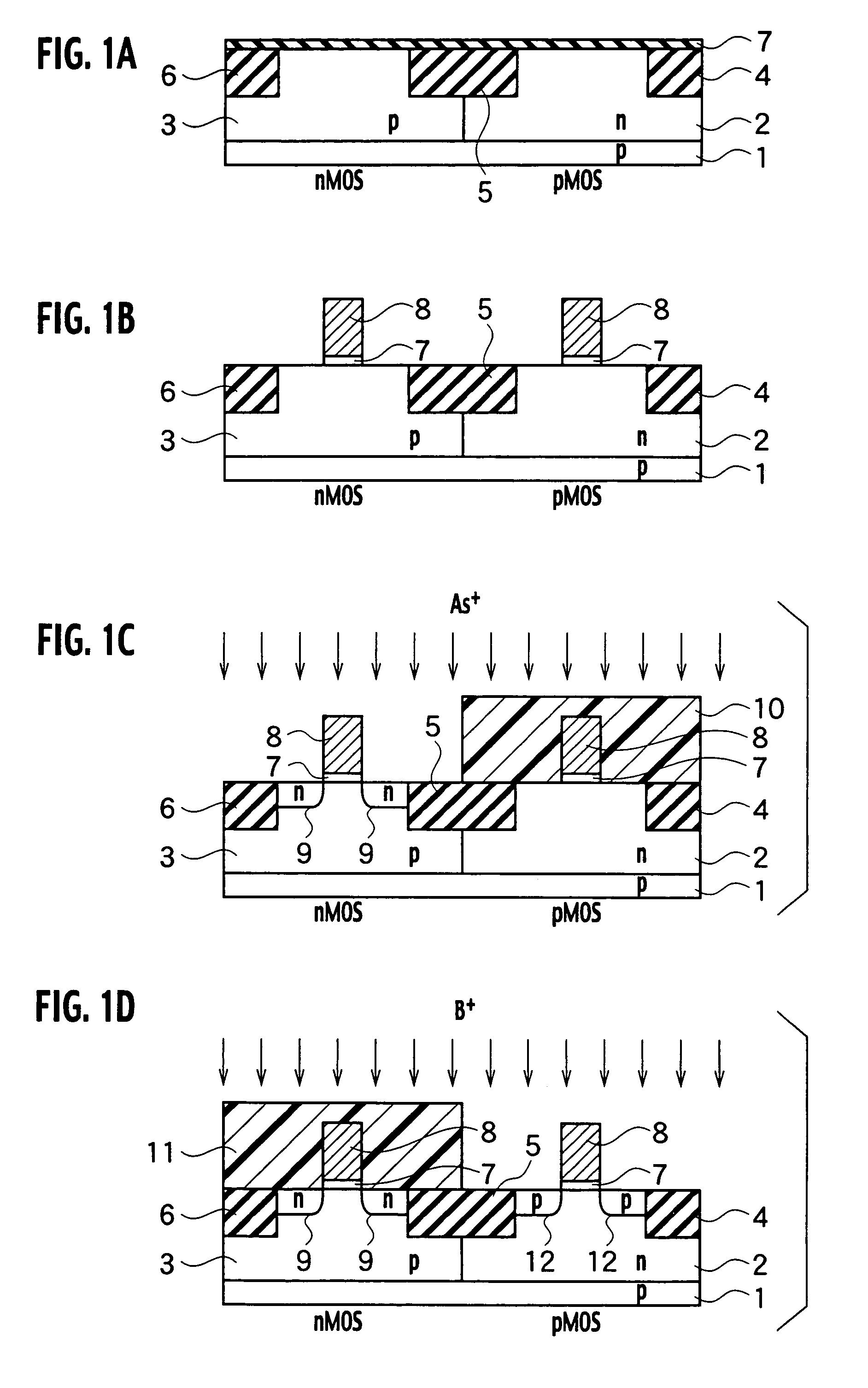

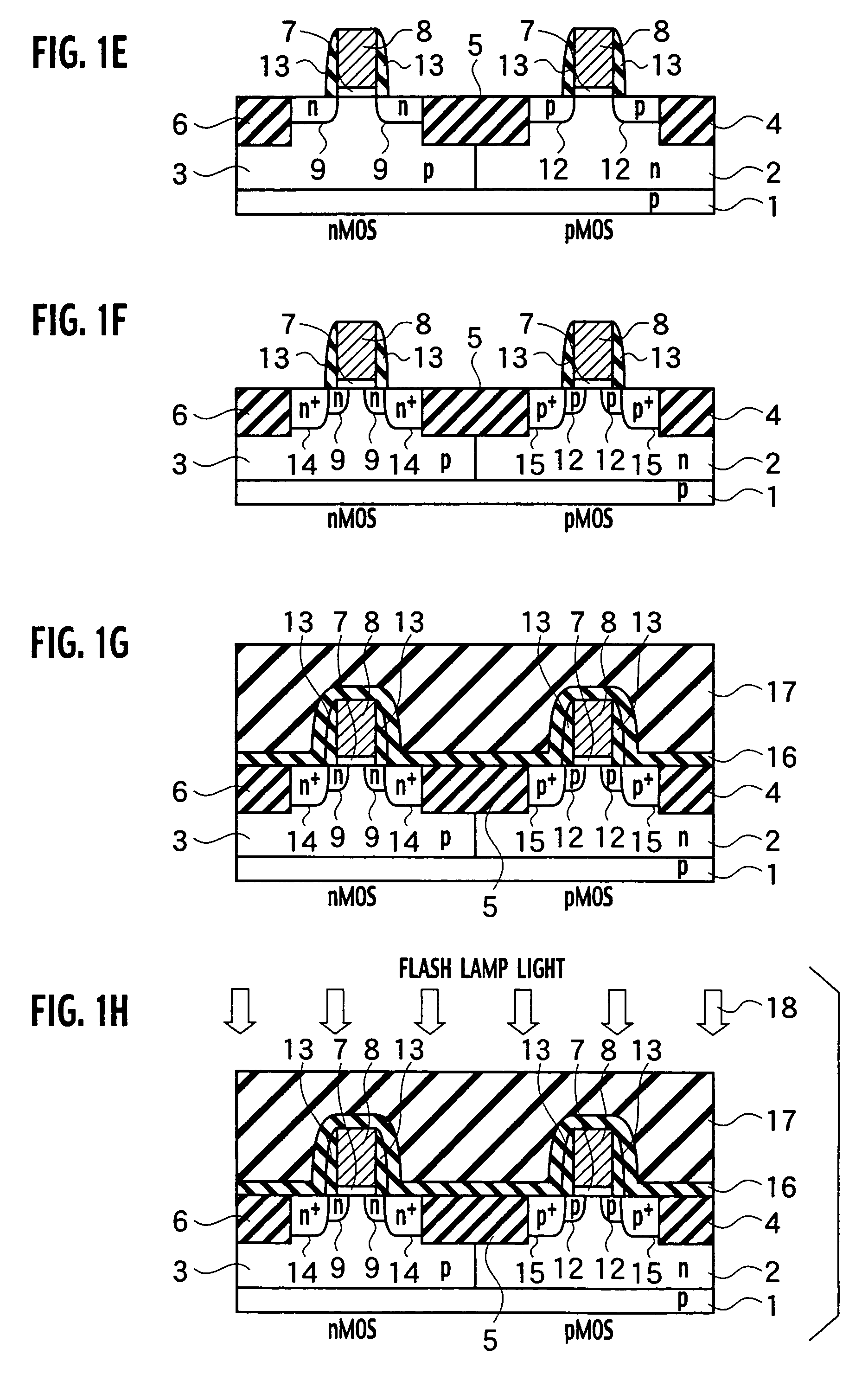

Fabrication method for a semiconductor device including a semiconductor substrate formed with a shallow impurity region

A method of manufacturing a semiconductor device includes forming isolation regions, a gate insulator film and gate electrodes, implanting in the silicon substrate with impurity ions, annealing to recover crystallinity of the implanted silicon substrate without diffusing the impurity ions, depositing an interlayer insulator film on the isolation regions, the silicon substrate, and the gate electrodes, and heating the silicon substrate by irradiating a light having a wavelength that the light is absorbed by the silicon substrate without being absorbed by the interlayer insulator film, activating the impurity ions so as to form source and drain regions.

Owner:KK TOSHIBA

High performance FET devices and methods thereof

ActiveUS20050156169A1Facilitated DiffusionAvoid impuritiesTransistorSemiconductor/solid-state device detailsDopantGate insulator

Structure and methods of fabrication are disclosed for an enhanced FET devices in which dopant impurities are prevented from diffusing through the gate insulator. The structure comprises a Si:C, or SiGe:C, layer which is sandwiched between the gate insulator and a layer which is doped with impurities in order to provide a preselected workfunction. It is further disclosed how this, and further improvements for FET devices, such as raised source / drain and multifaceted gate on insulator, MODFET on insulator are integrated with strained Si based layer on insulator technology.

Owner:INT BUSINESS MASCH CORP

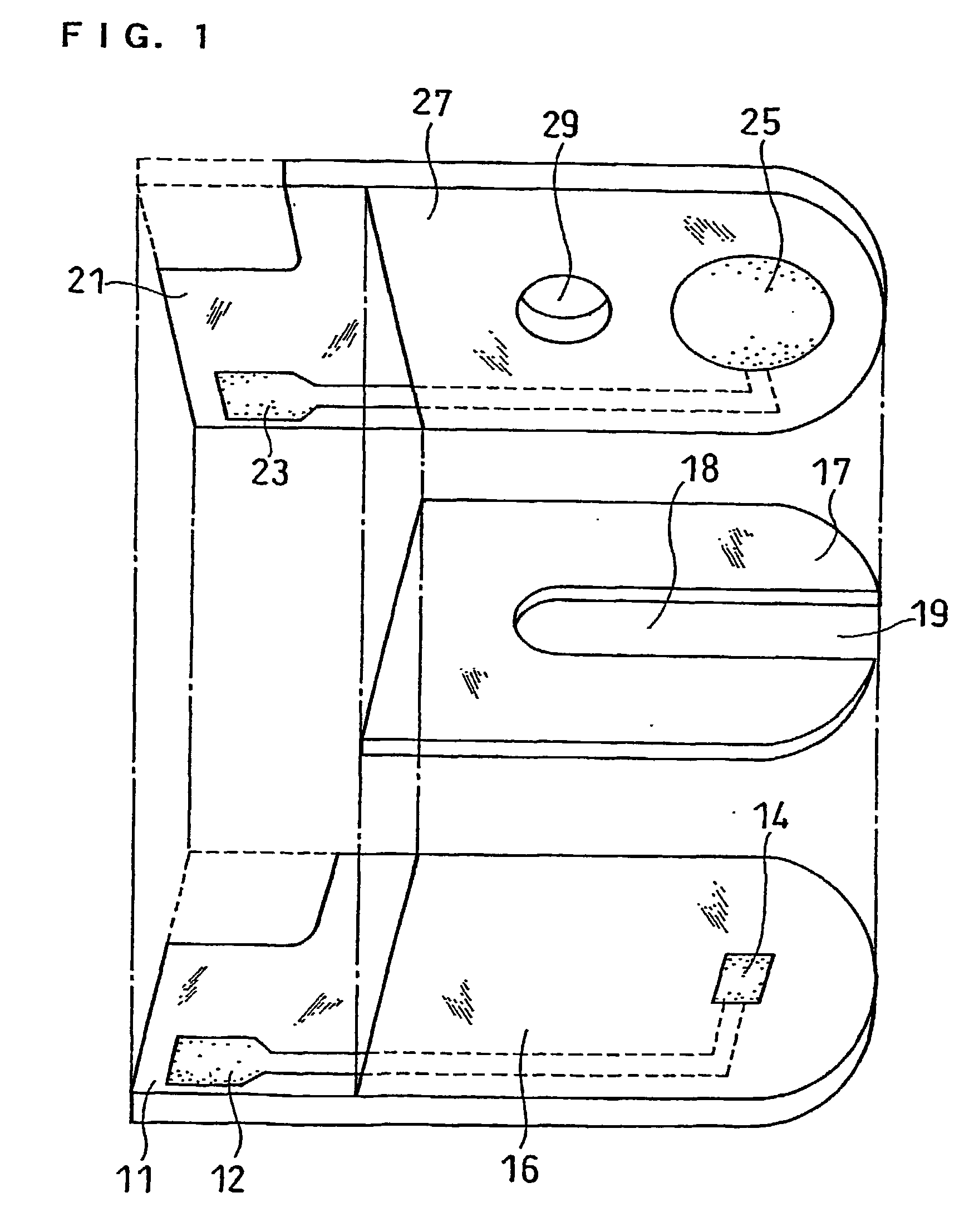

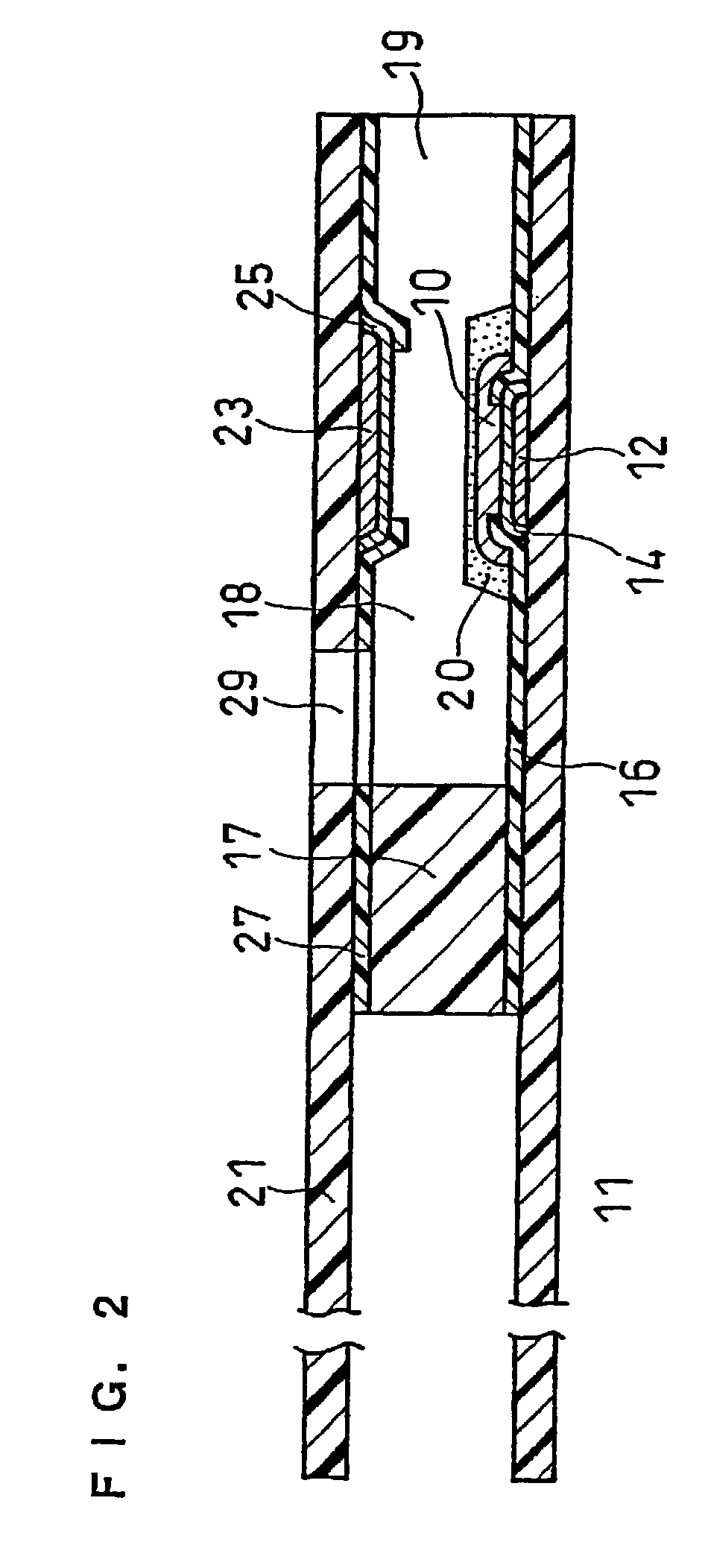

Biosensor

InactiveUS20030032875A1Reduce sample volumeAmount of sample can be reducedImmobilised enzymesBioreactor/fermenter combinationsOptoelectronicsOxidoreductase

The present invention provides a highly sensitive biosensor that needs a smaller amount of sample for measurement. The biosensor comprises a first insulating base plate having a working electrode, a second insulating base plate having a counter electrode opposed to the working electrode, a reagent layer comprising at least an oxidoreductase, and a sample supply pathway formed between the first and second insulating base plates, wherein the working electrode, counter electrode and reagent layer are exposed to an inside of the sample supply pathway, and the distance between the working electrode and the counter electrode is 150 mum or less.

Owner:PHC HLDG CORP

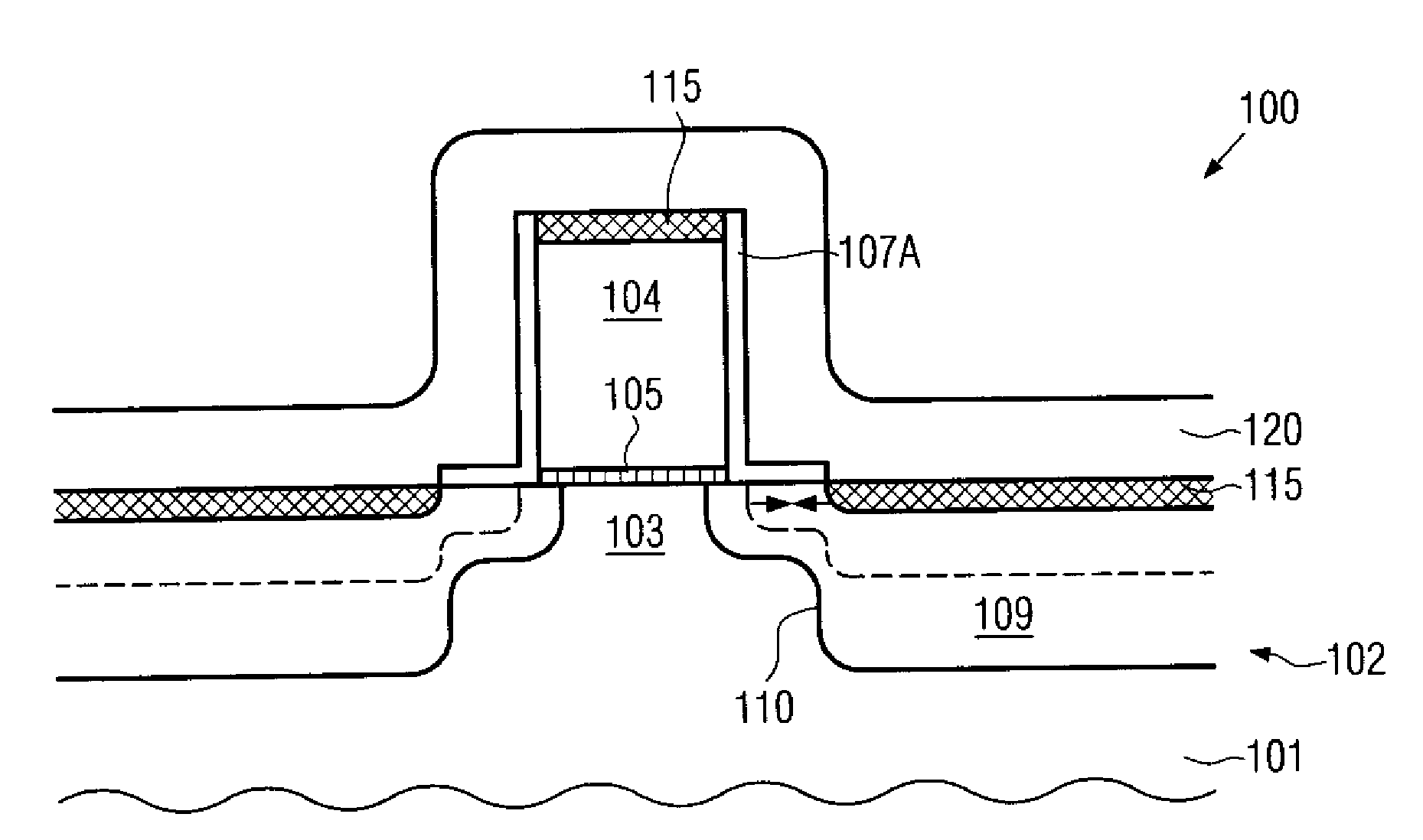

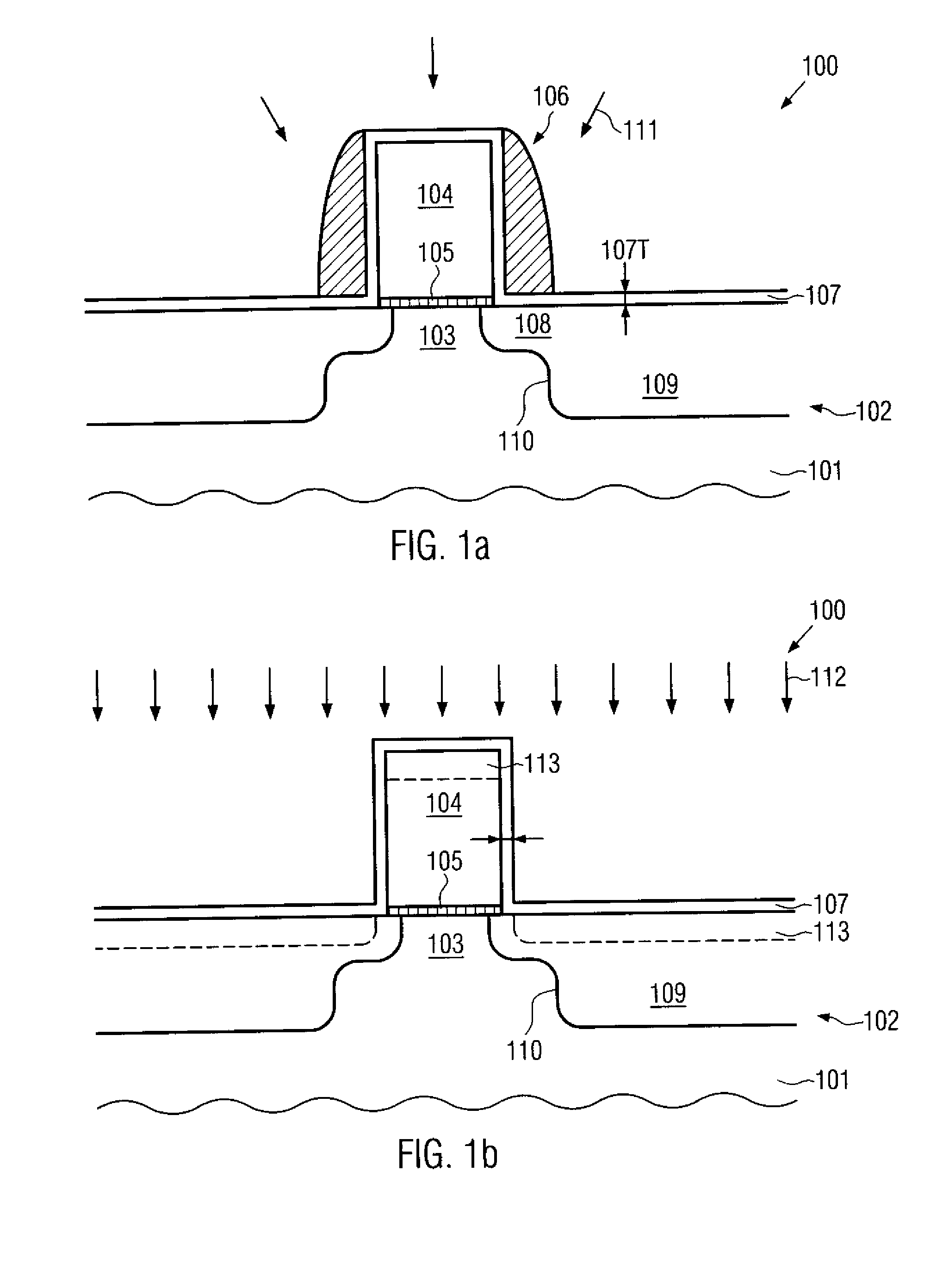

Transistor having an embedded tensile strain layer with reduced offset to the gate electrode and a method for forming the same

ActiveUS20070254461A1Increase strainIncrease flexibilityTransistorSemiconductor/solid-state device manufacturingTensile strainSalicide

By incorporating carbon by means of ion implantation and a subsequent flash-based or laser-based anneal process, strained silicon / carbon material with tensile strain may be positioned in close proximity to the channel region, thereby enhancing the strain-inducing mechanism. The carbon implantation may be preceded by a pre-amorphization implantation, for instance on the basis of silicon. Moreover, by removing a spacer structure used for forming deep drain and source regions, the degree of lateral offset of the strained silicon / carbon material with respect to the gate electrode may be determined substantially independently from other process requirements. Moreover, an additional sidewall spacer used for forming metal silicide regions may be provided with reduced permittivity, thereby additionally contributing to an overall performance enhancement.

Owner:GLOBALFOUNDRIES US INC

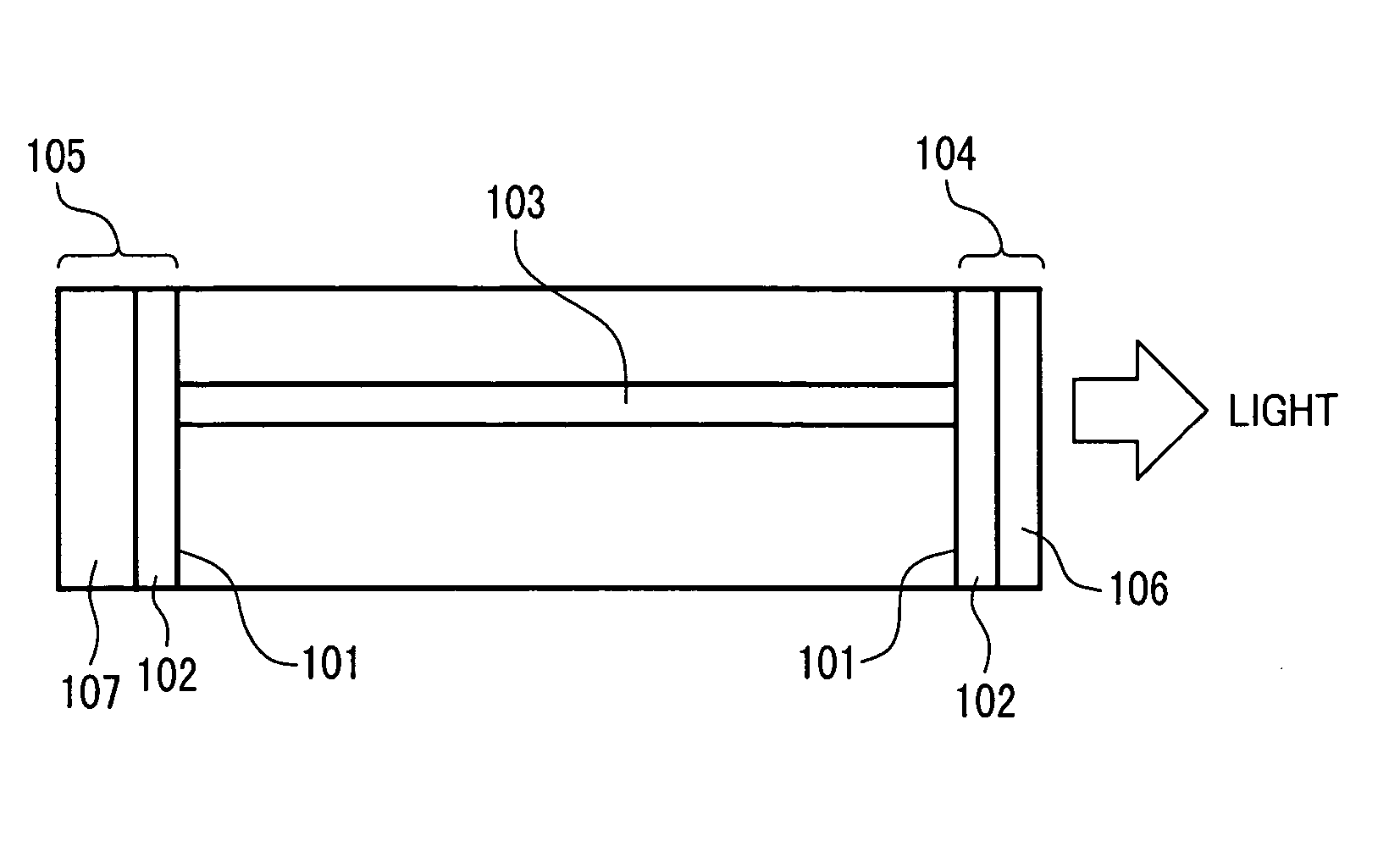

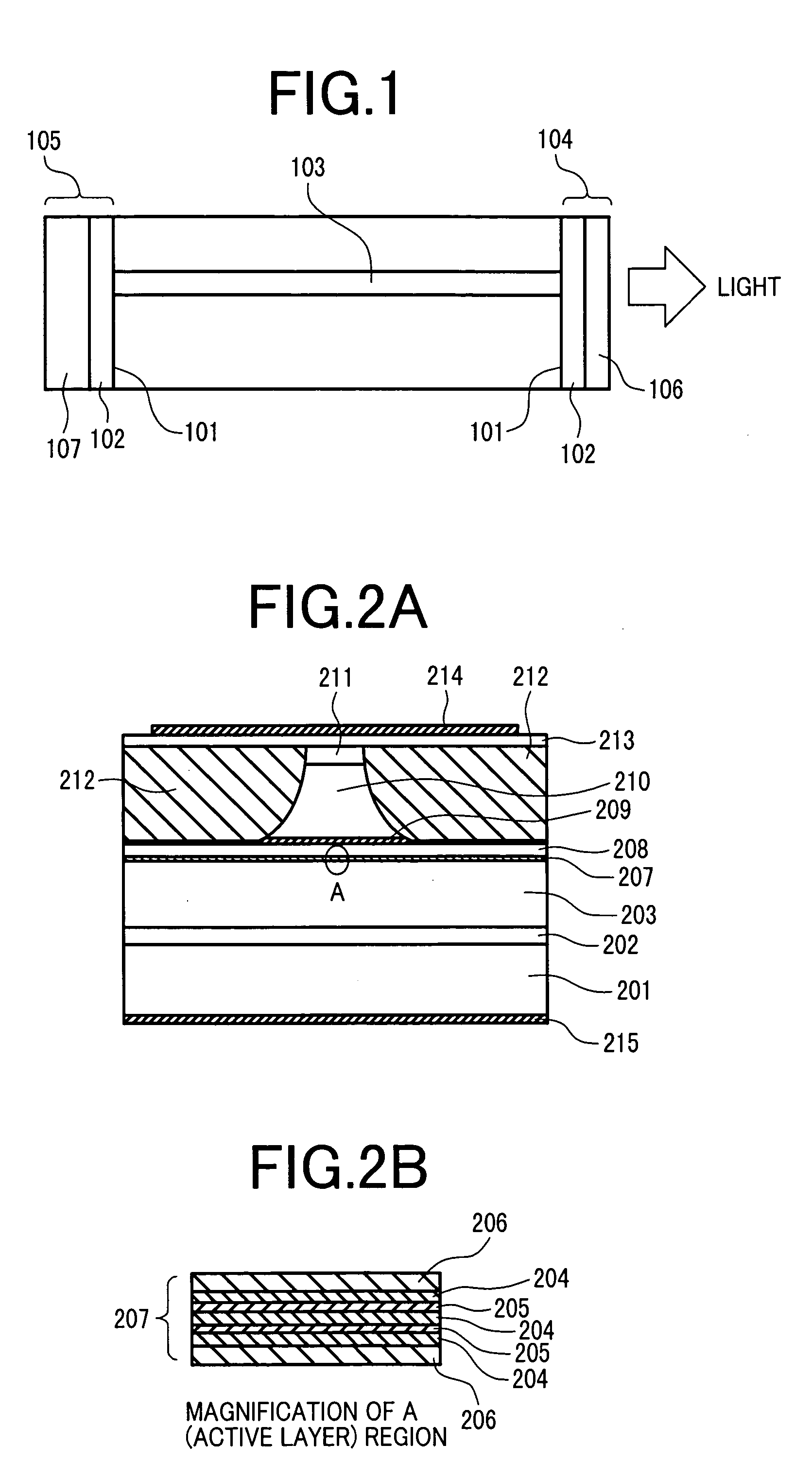

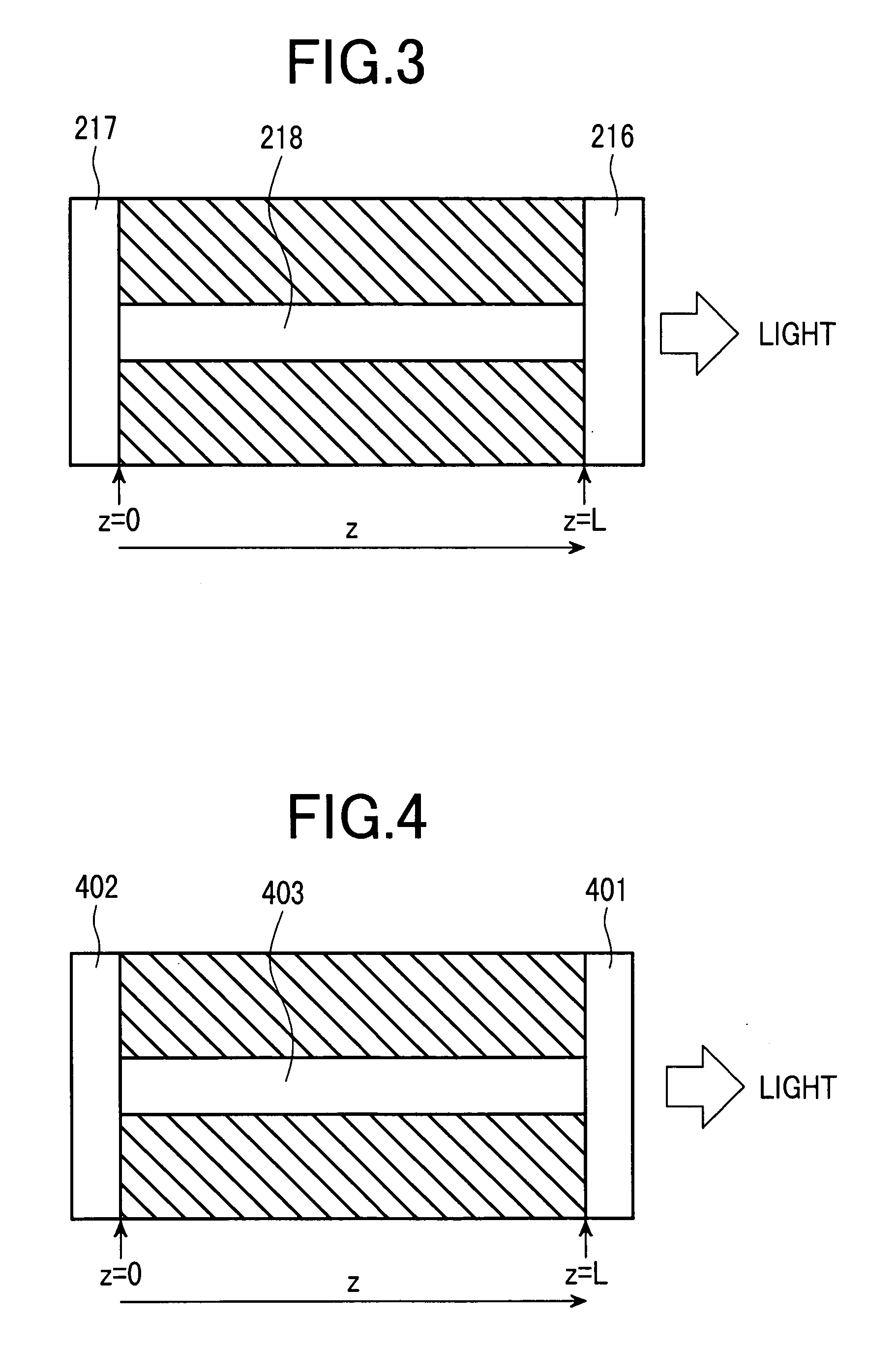

Laser diode and manufacturing method thereof

ActiveUS20050127383A1Lower resistanceLight increaseLaser detailsLaser optical resonator constructionPhysicsResonator

Laser diodes containing aluminum at high concentration in an active layer have been usually suffered from remarkable facet deterioration along with laser driving operation and it has been difficult for the laser diodes to attain high reliability. An aluminum oxide film lacking in oxygen is formed adjacent to the semiconductor on an optical resonator facet, by which facet deterioration can be minimized and, accordingly, the laser diode can be operated with no facet deterioration at high temperature for long time and a laser diode of high reliability can be manufactured at a reduced cost.

Owner:LUMENTUM JAPAN INC

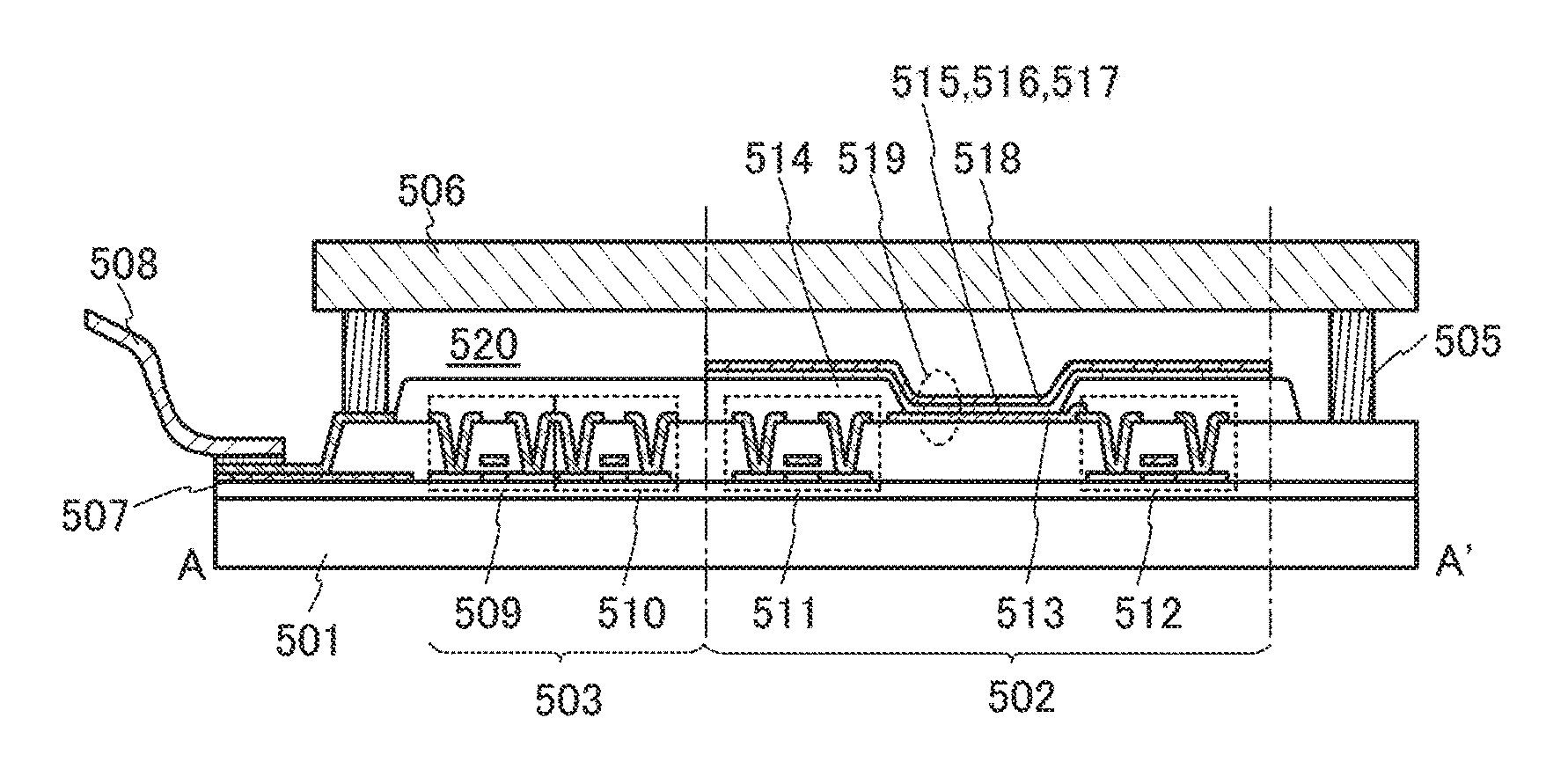

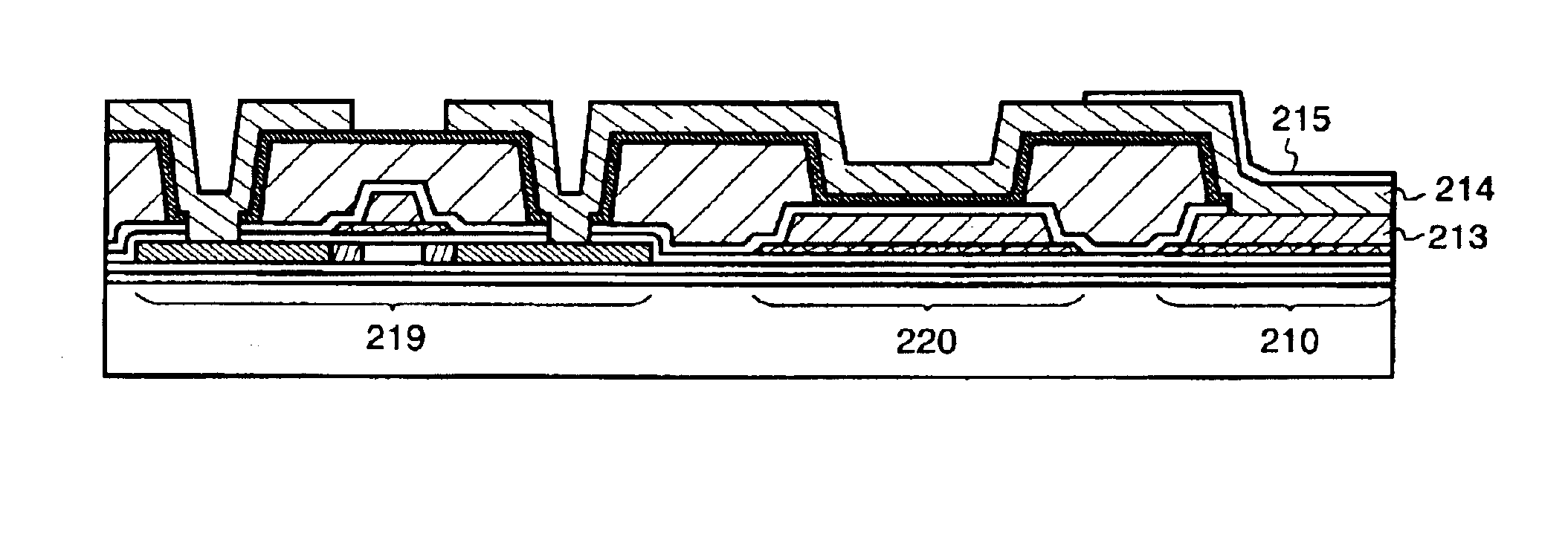

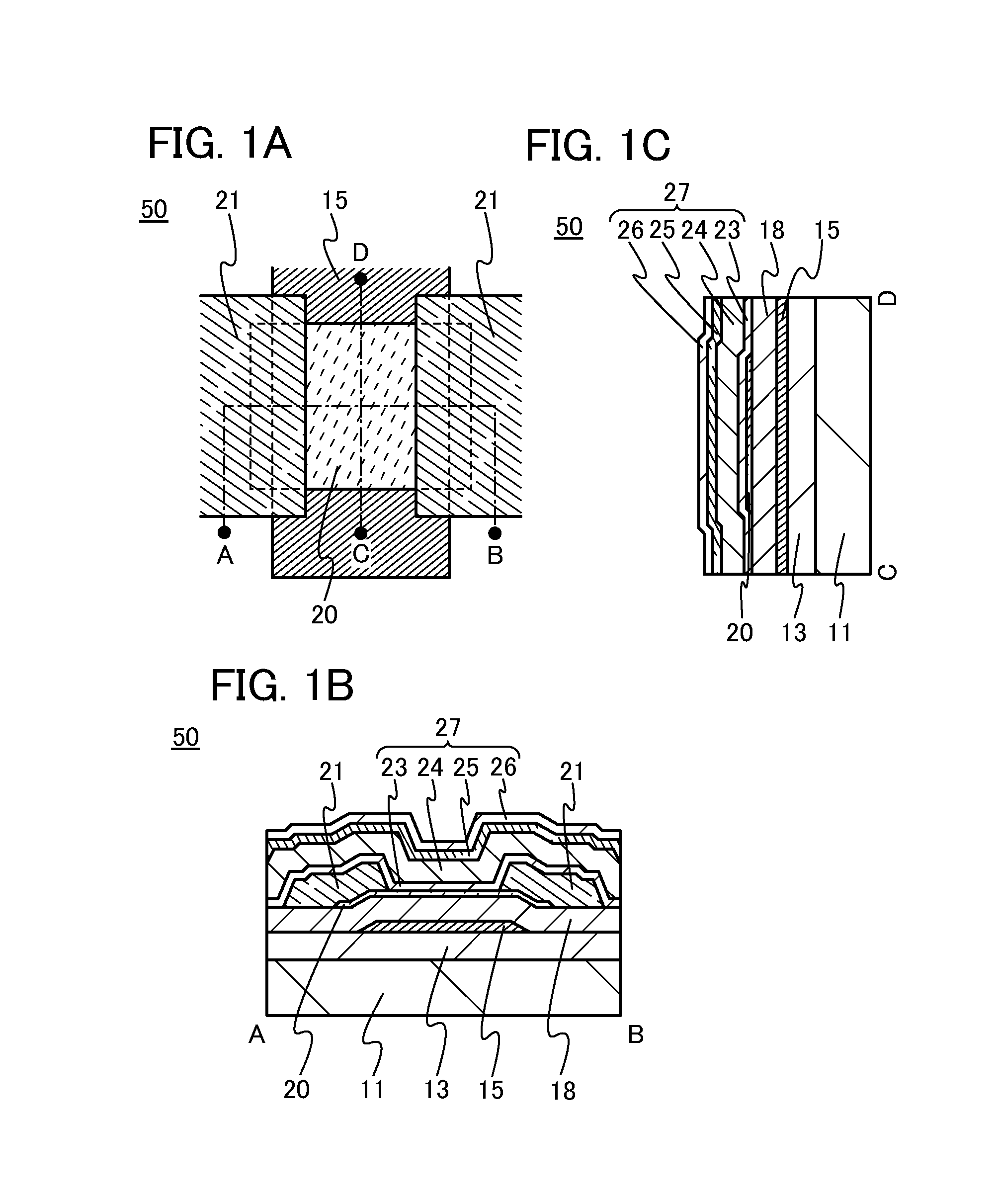

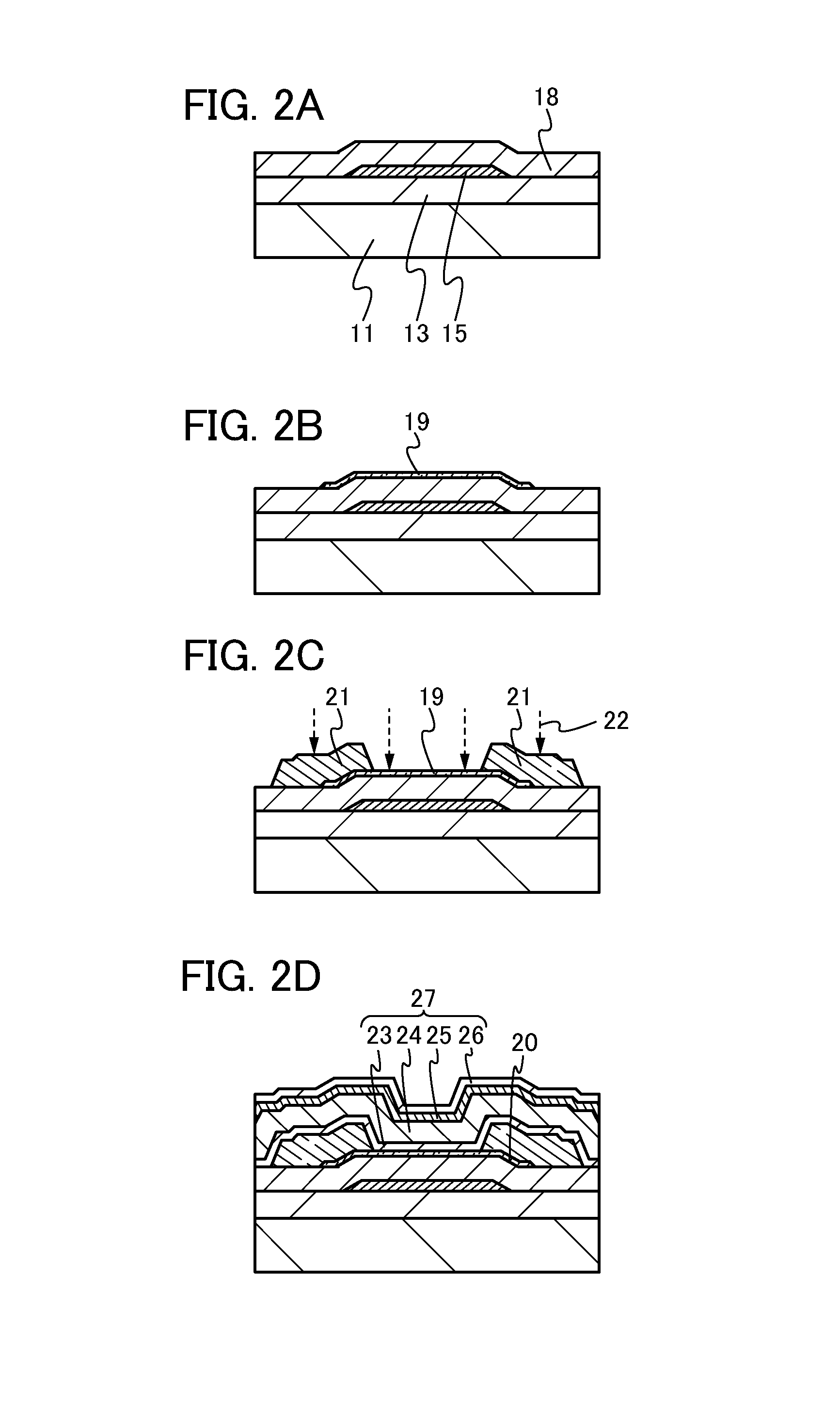

Display device

InactiveUS6960786B2Reduce impactSuppress mutationTransistorElectroluminescent light sourcesDisplay deviceOptoelectronics

Owner:SEMICON ENERGY LAB CO LTD

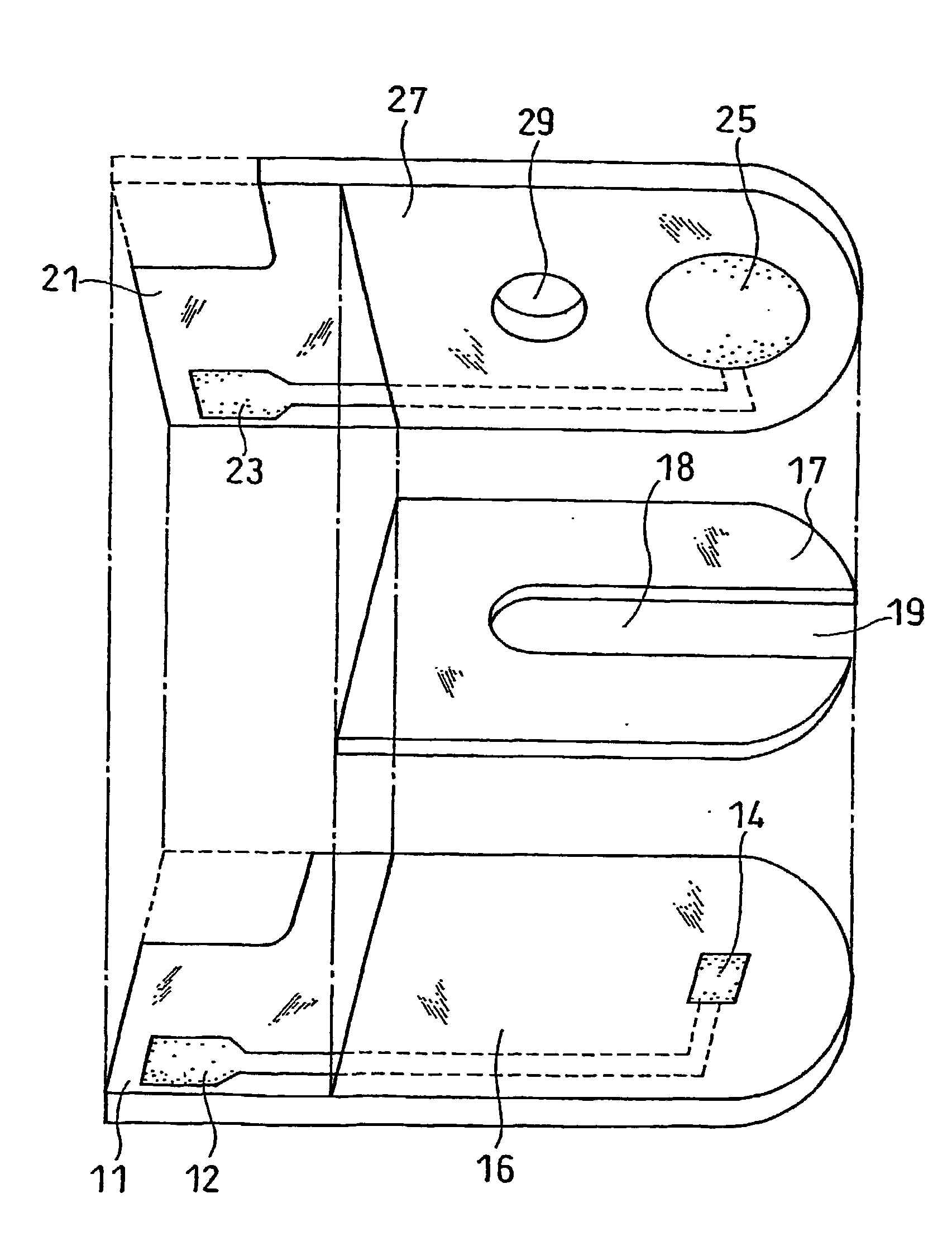

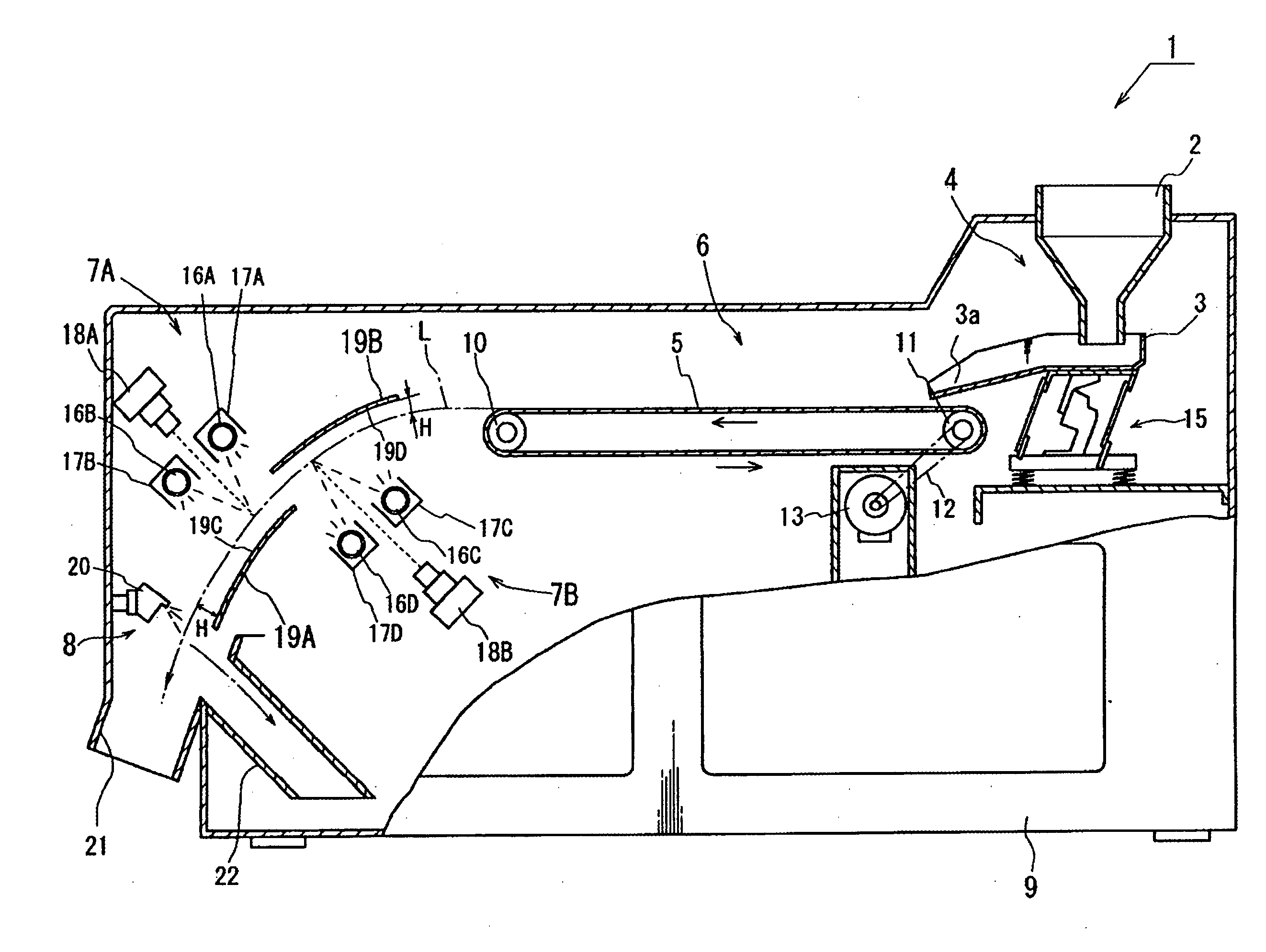

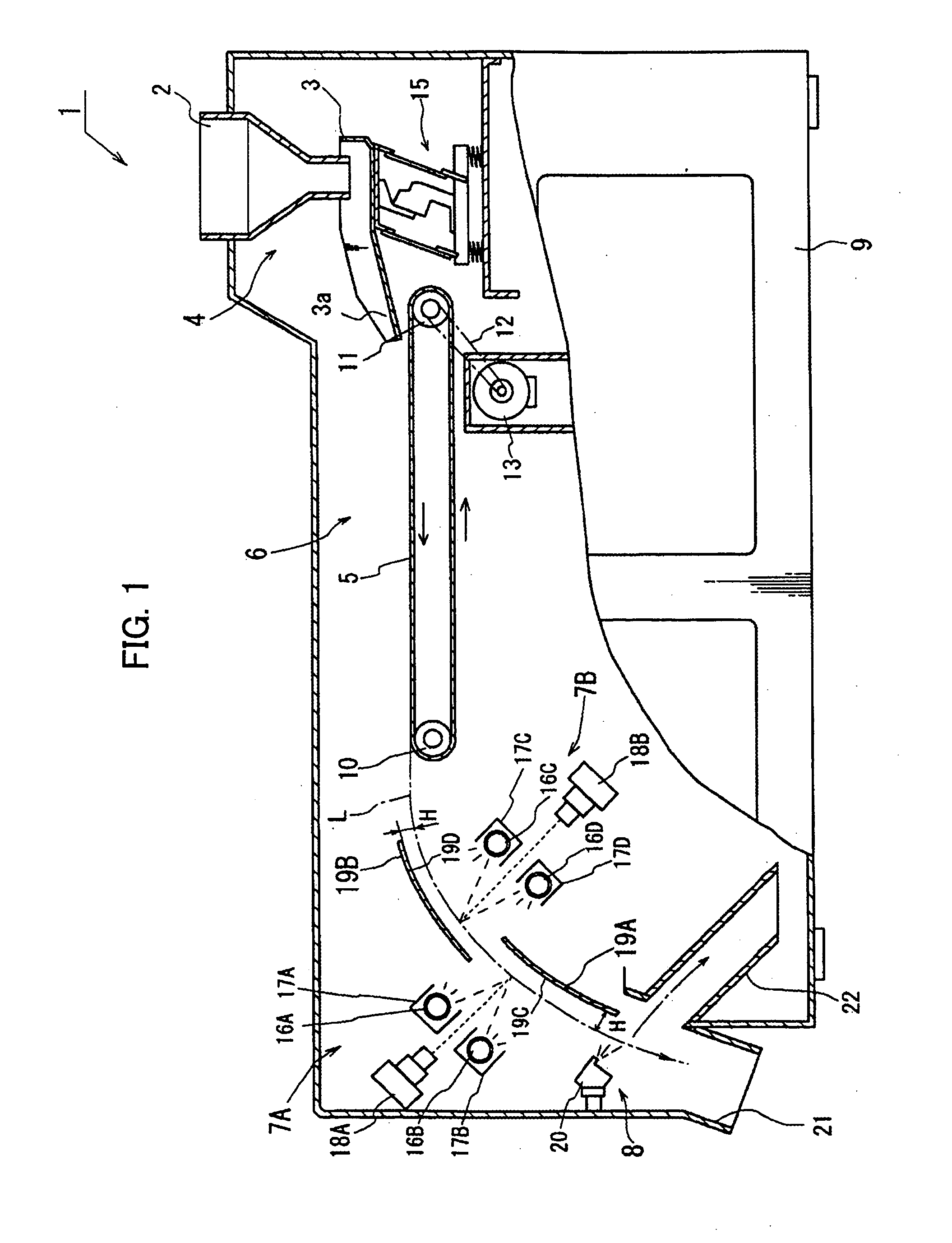

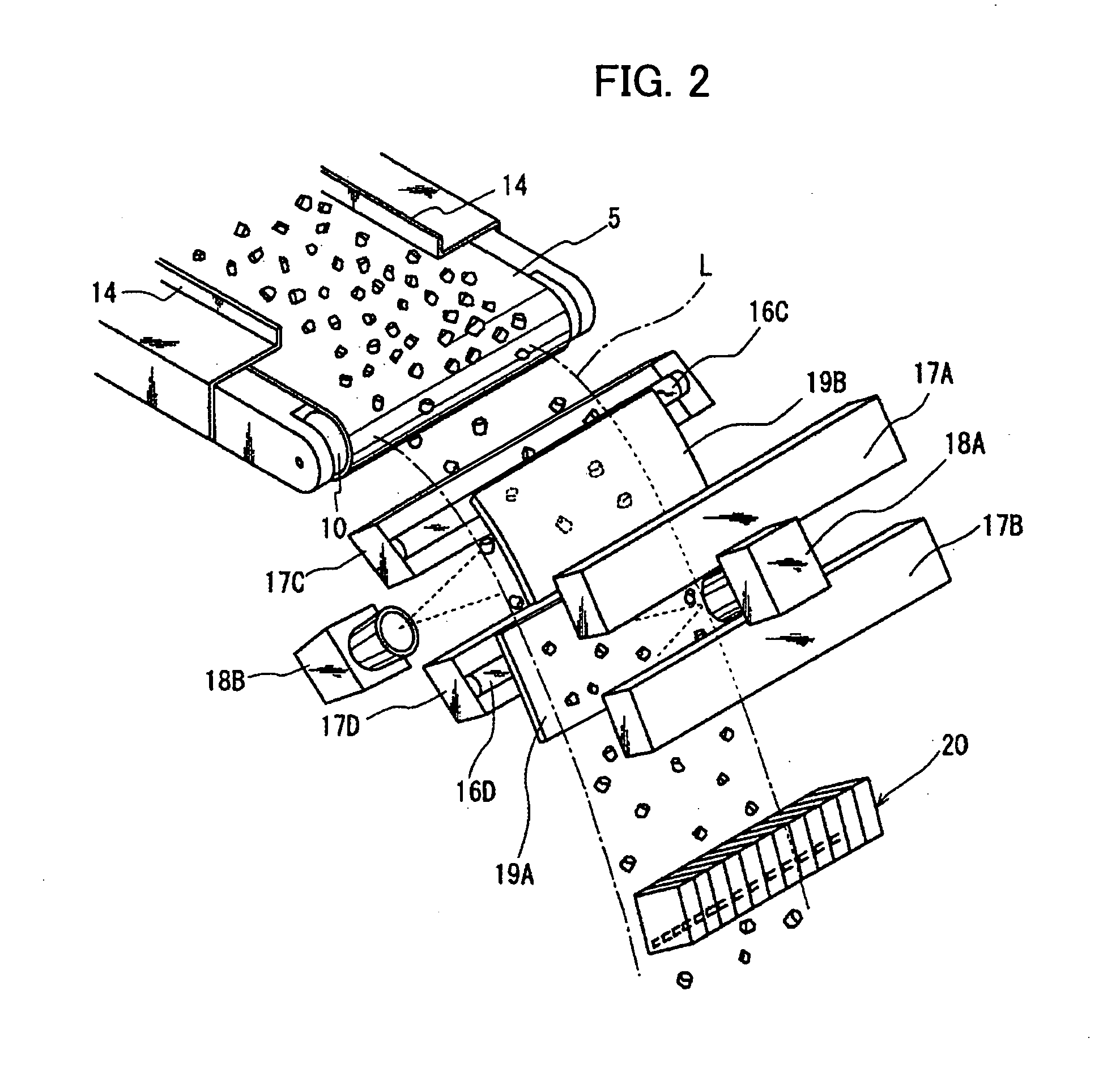

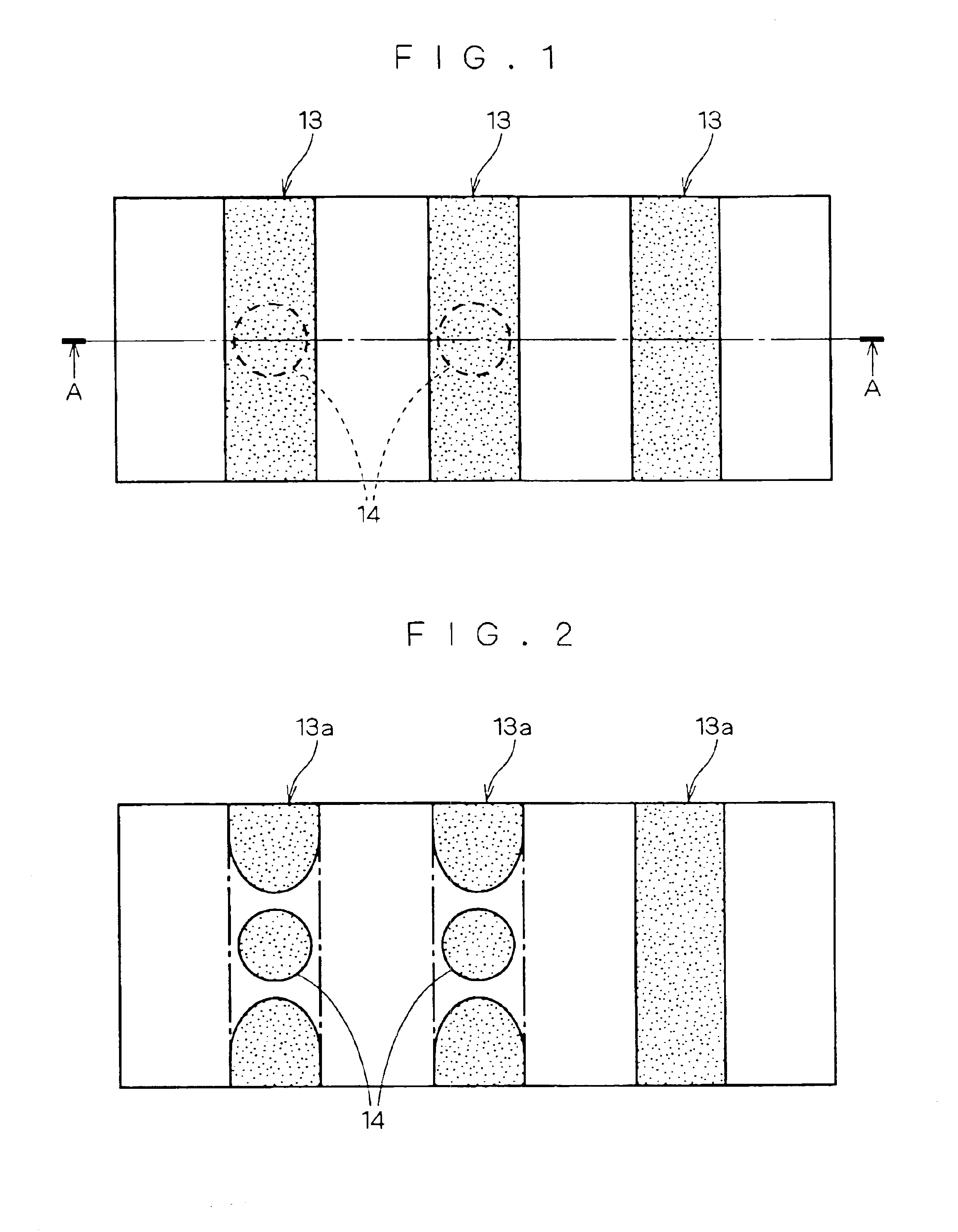

Pellet separator

InactiveUS20060016735A1Suppress DiffuseAccurately sorting and removingSortingEngineeringDiffuse reflection

A pellet separator capable of accurately sorting and removing defective pellets without generating false identifications of nondefective pellets as defective pellets by suppressing diffused reflection inside even resin pellets of high transparency. A first background and a second background of the pellet separator are formed in the vicinity of a parabolic trajectory and shaped to be curved along the parabolic trajectory in the downstream direction thereof.

Owner:SATAKE CORPORATION

Mosfet having a high stress in the channel region

InactiveUS20090174002A1Improve etch uniformityEasy to controlTransistorSemiconductor/solid-state device manufacturingDopantMOSFET

Source and drain extension regions are selectively removed by a dopant concentration dependent etch or a doping type dependent etch, and an embedded stress-generating material such as SiGe alloy or a Si:C alloy in the source and drain extension regions is grown on a semiconductor substrate. The embedded stress-generating material may be grown only in the source and drain extension regions, or in the source and drain extension regions and in deep source and drain regions. In one embodiment, an etch process that removes doped semiconductor regions of one conductivity type selective to doped semiconductor regions of another conductivity type may be employed. In another embodiment, a dopant concentration dependent etch process that removes doped semiconductor regions irrespective of the conductivity type selective to undoped semiconductor regions may be employed.

Owner:GLOBALFOUNDRIES INC

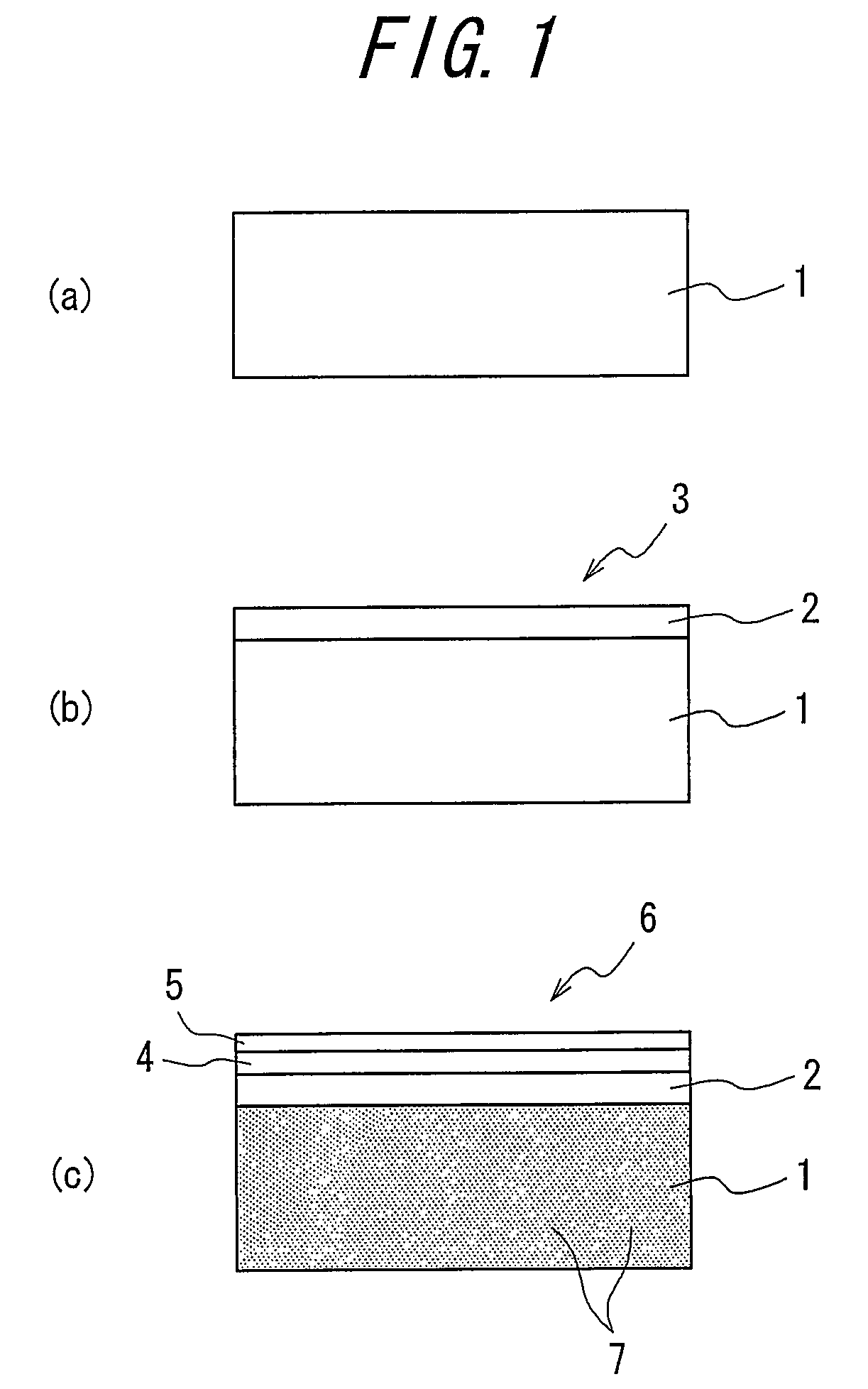

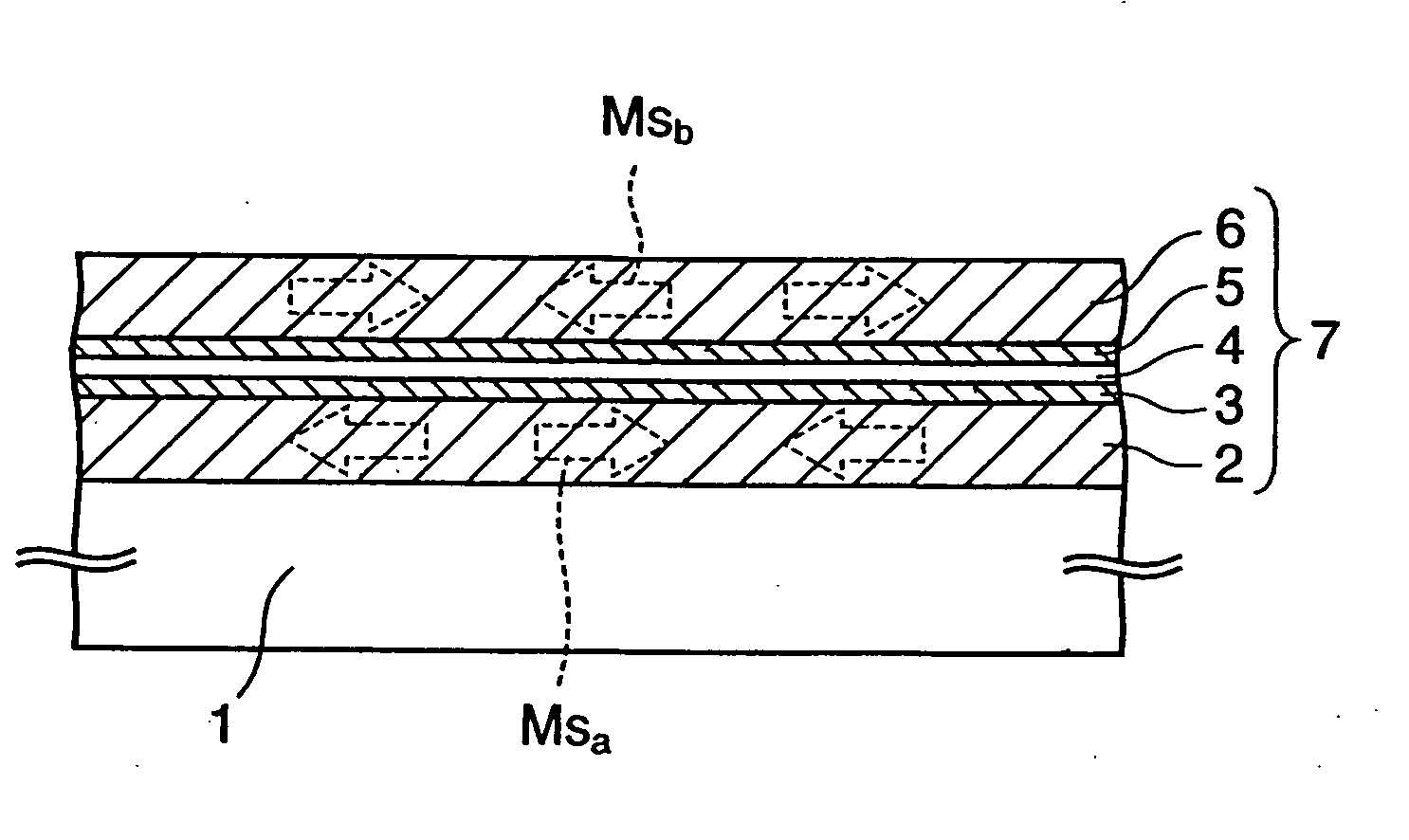

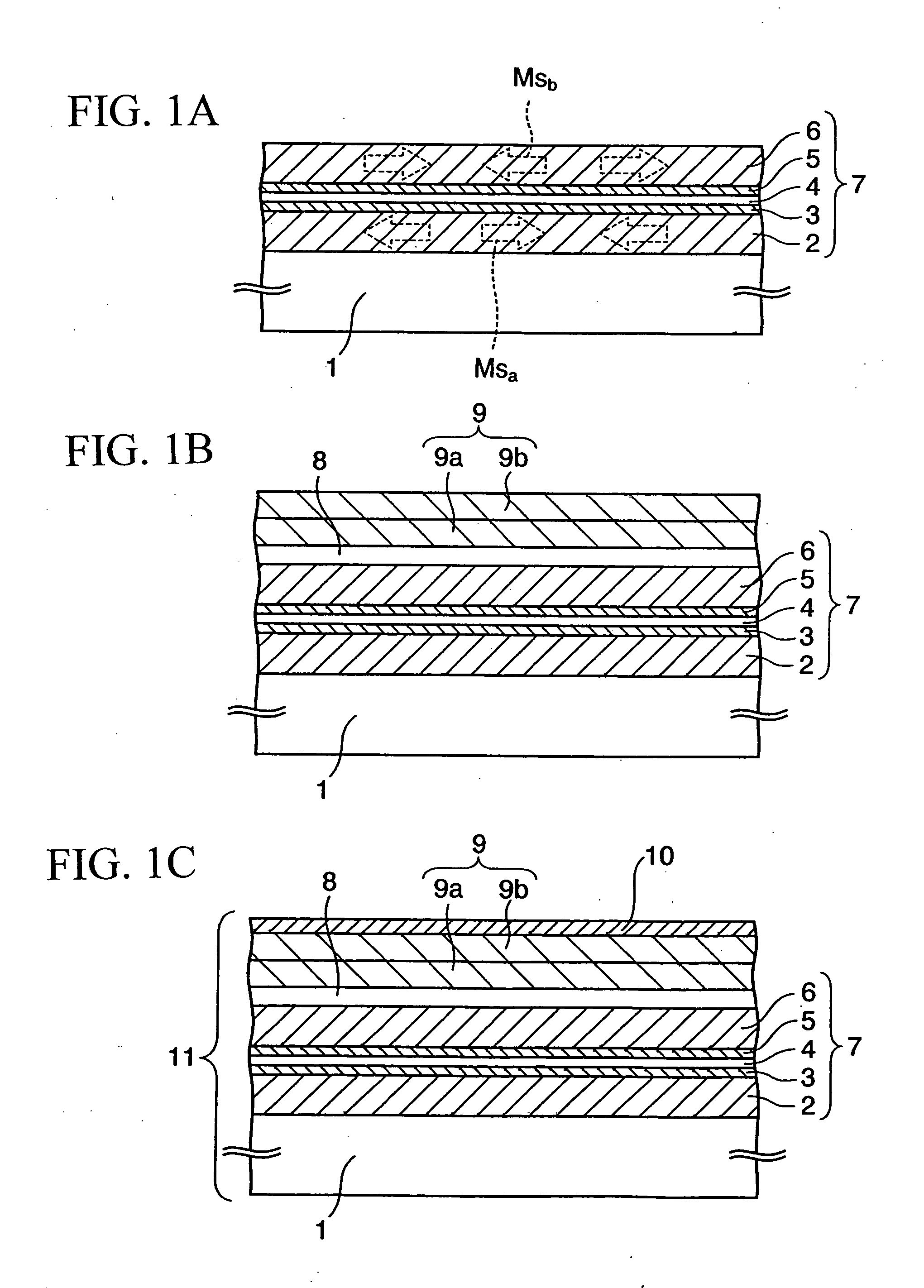

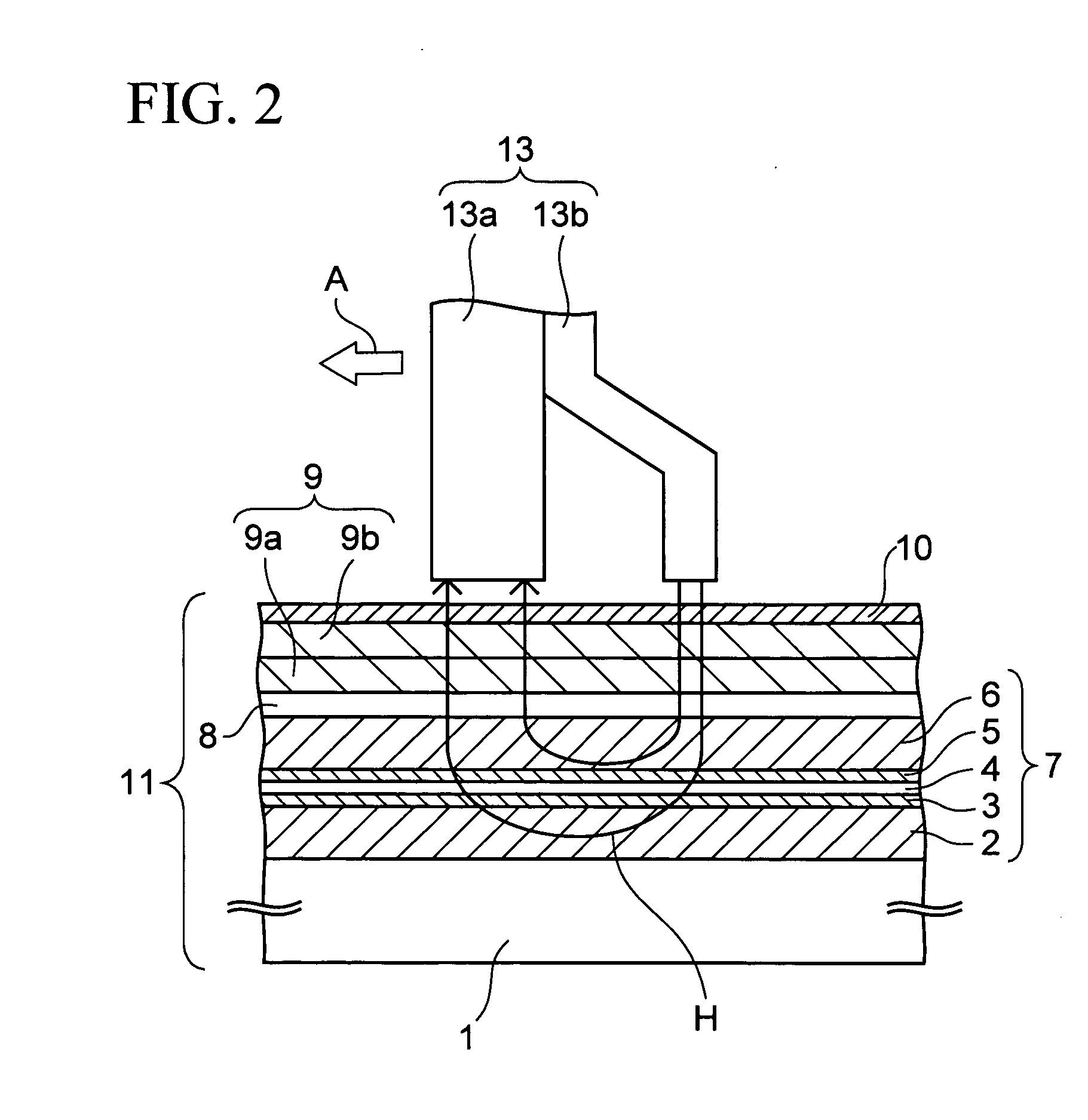

Magnetic recording medium, method of manufacturing the same, and magnetic recording apparatus

InactiveUS20070217071A1Improve film qualitySuppression of Leakage FluxRecord information storageDisk carriersRecording layerNon magnetic

According to the present invention, provided is a magnetic recording medium 11 comprising: a non-magnetism base member 1; a lower soft magnetic underlying layer 2 formed on the non-magnetism base member 1; a non-magnetic layer 4 formed on the lower soft magnetic underlying layer 2; an upper soft magnetic underlying layer 6 formed on the non-magnetic layer 4; and a recording layer 9 having a perpendicular magnetic anisotropy, the recording layer 9 being formed on the upper soft magnetic underlying layer 6, wherein crystalline magnetic layers 3 and 5 are formed between the lower soft magnetic underlying layer 2 and the non-magnetic layer 4 or between this non-magnetic layer 4 and the upper soft magnetic underlying layer 6.

Owner:SHOWA DENKO KK

Contamination prevention in optical system

InactiveUS7061573B2Avoid stickingEasy to cleanSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusOptical surfaceOptic system

An exposure apparatus for illuminating a pattern with light from a light source and for exposing a predetermined surface with light from the pattern includes (i) a projection optical system for projecting the pattern onto the predetermined surface, the projection optical system having at least one optical element having optical surfaces, and (ii) a gas supplying device for locally supplying a gas to the at least one optical element. In one aspect, the gas supplying device directly blows the gas toward one of the optical surfaces of the at least one optical element, which is closest to the predetermined surface, from the predetermined surface side.

Owner:CANON KK

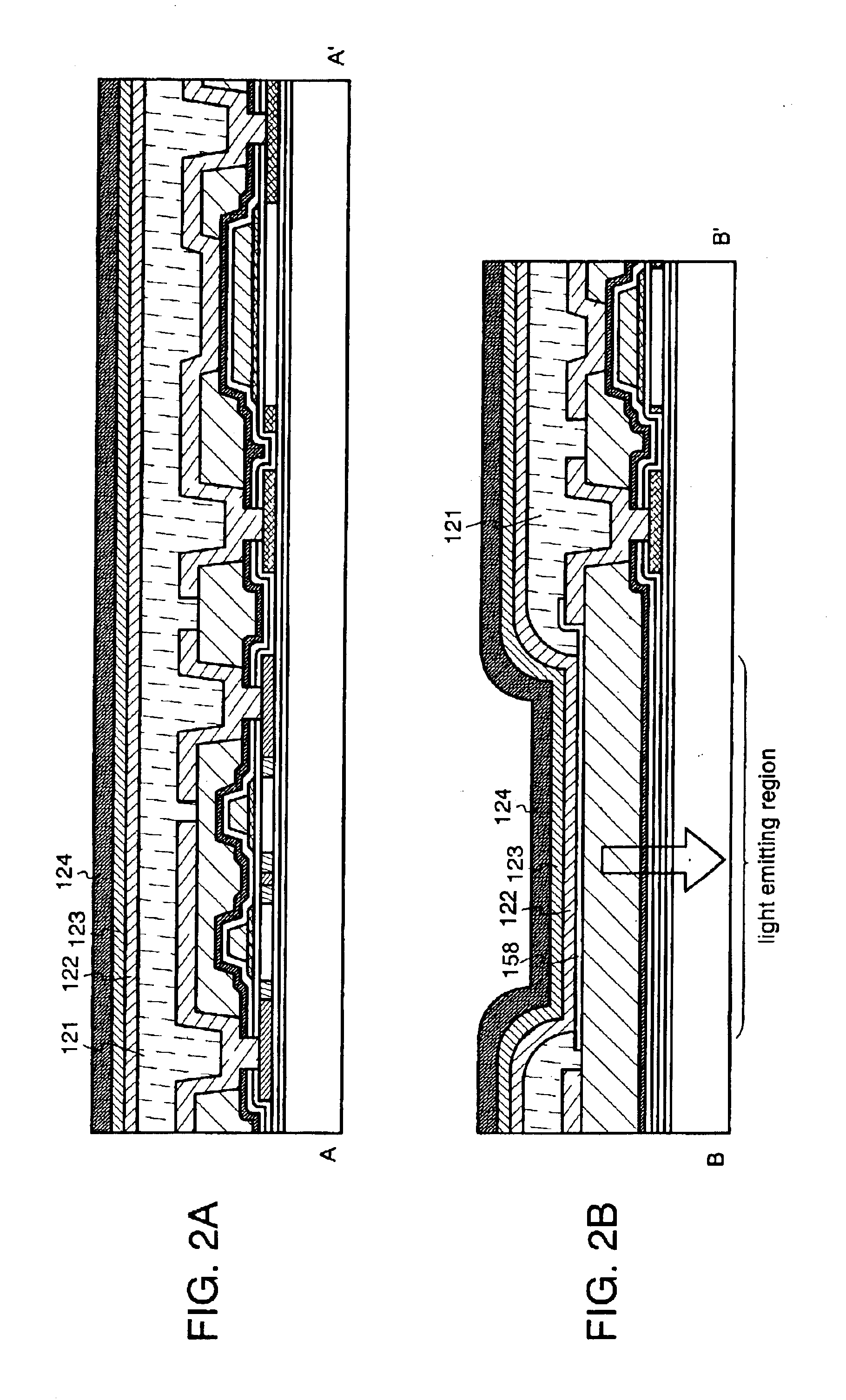

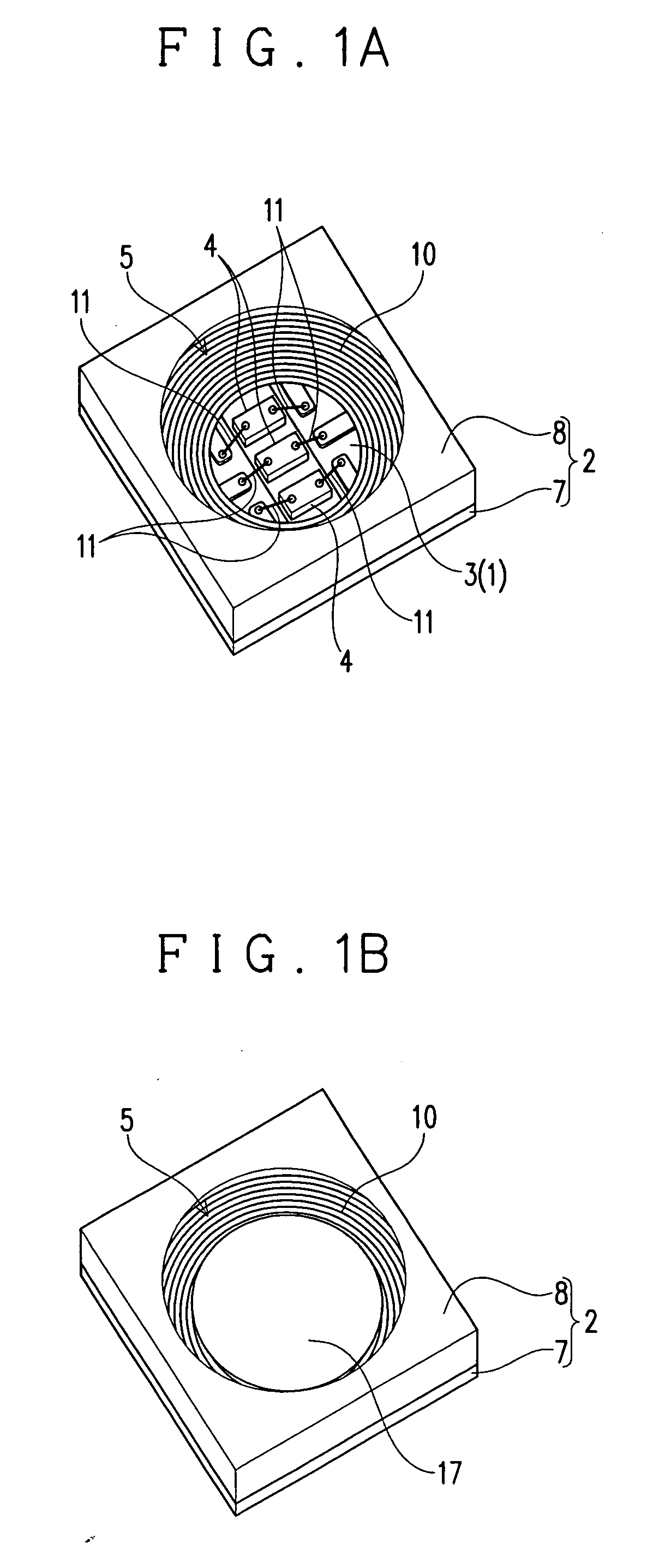

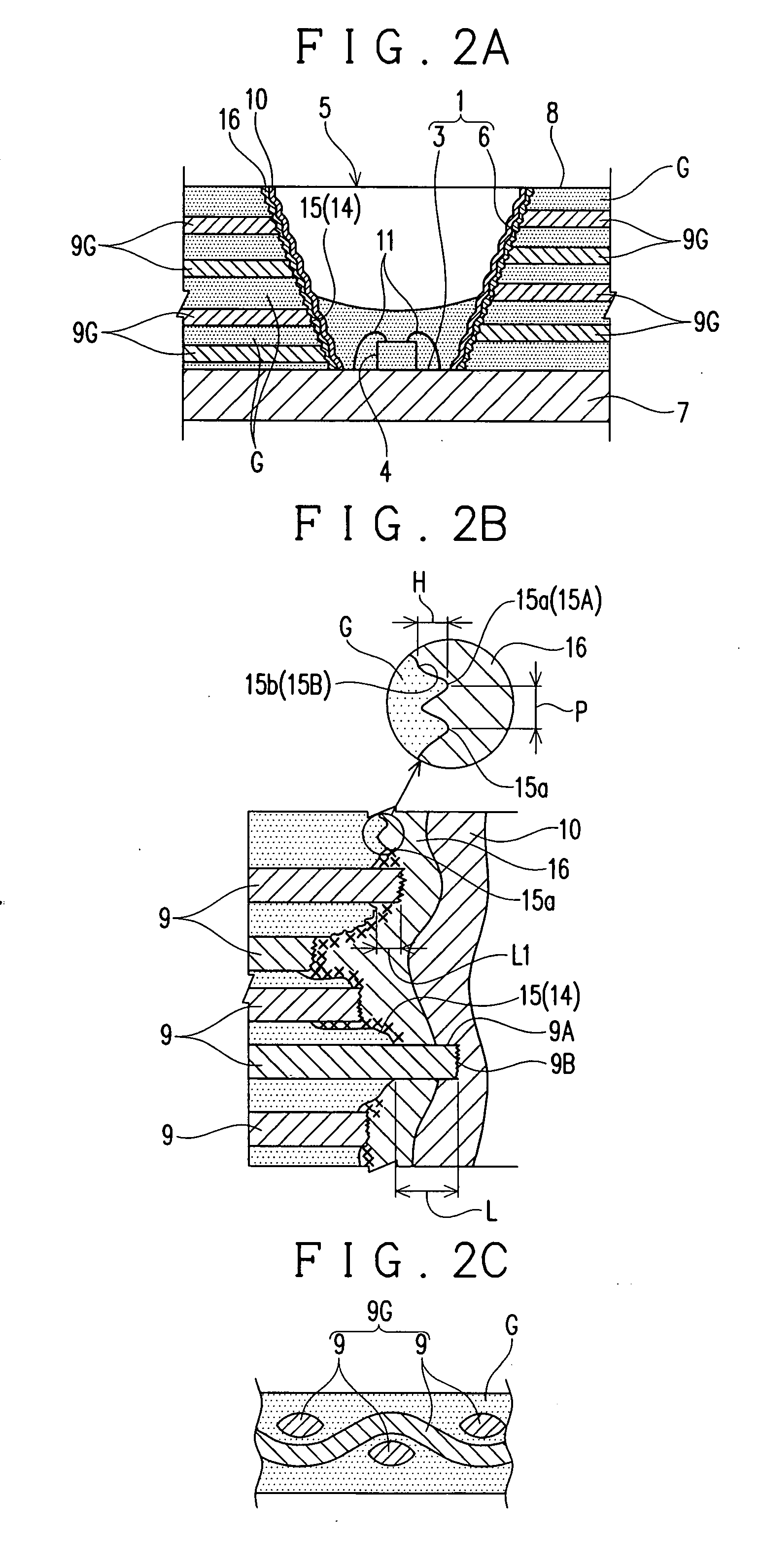

Light emitting device

InactiveUS20070262336A1Small height differenceImprove adhesionDischarge tube luminescnet screensLamp detailsFiberLight emitting device

A light emitting device includes a package having a recessed portion defined by a bottom surface and a side surface and a light emitting element mounted on the bottom surface of the recessed portion, in which the package has fibrous fillers, and at least some of the fillers are projected outwards through the side surface and coated with a reflection film made of metal.

Owner:NICHIA CORP

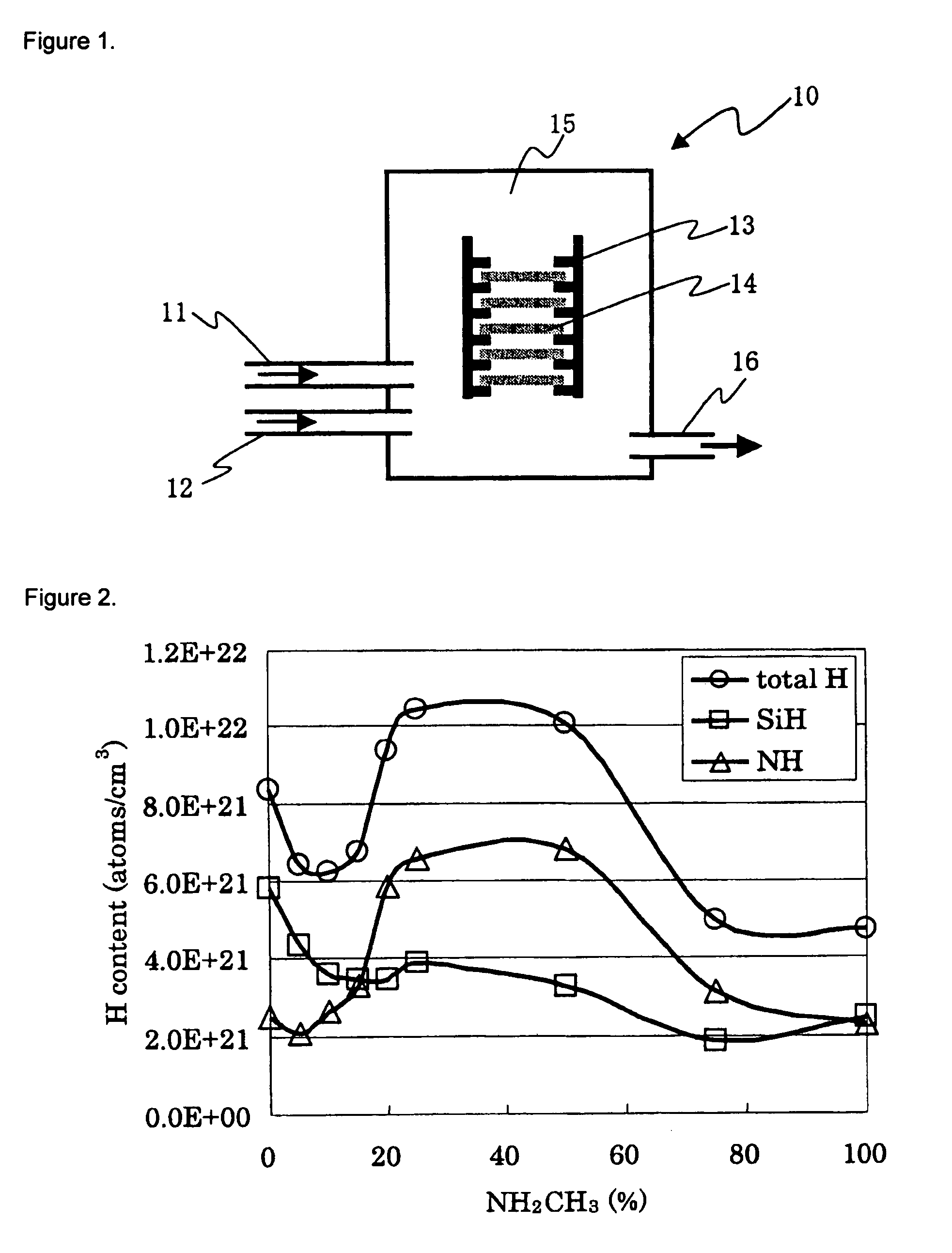

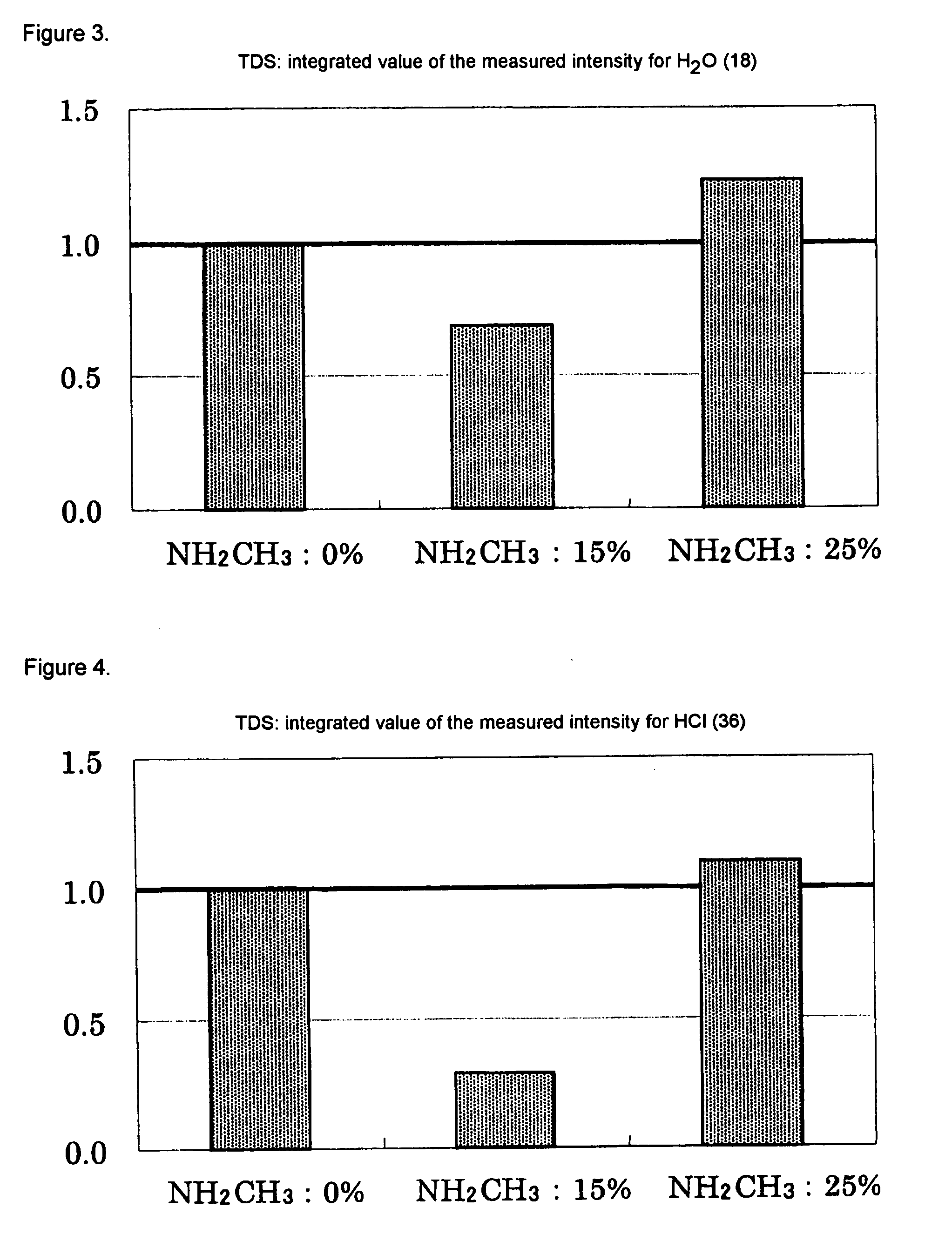

Method for producing silicon nitride films and process for fabricating semiconductor devices using said method

InactiveUS20050158983A1Reduction in thermal budgetImprove film propertiesSemiconductor/solid-state device manufacturingChemical vapor deposition coatingNitrogen sourceAmmonia

Silicon nitride film is formed on a silicon wafer mounted in a boat in an LPCVD tool by feeding a silicon source (SiH2Cl2, SiCl4, Si2Cl6, etc.) from an injector and feeding a mixed gas of monomethylamine (CH3NH2) and ammonia (NH3) as the nitrogen source from an injector. This addition of monomethylamine to the source substances for film production makes it possible to provide an improved film quality and improved leakage characteristics even at low temperatures (450-600° C.).

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

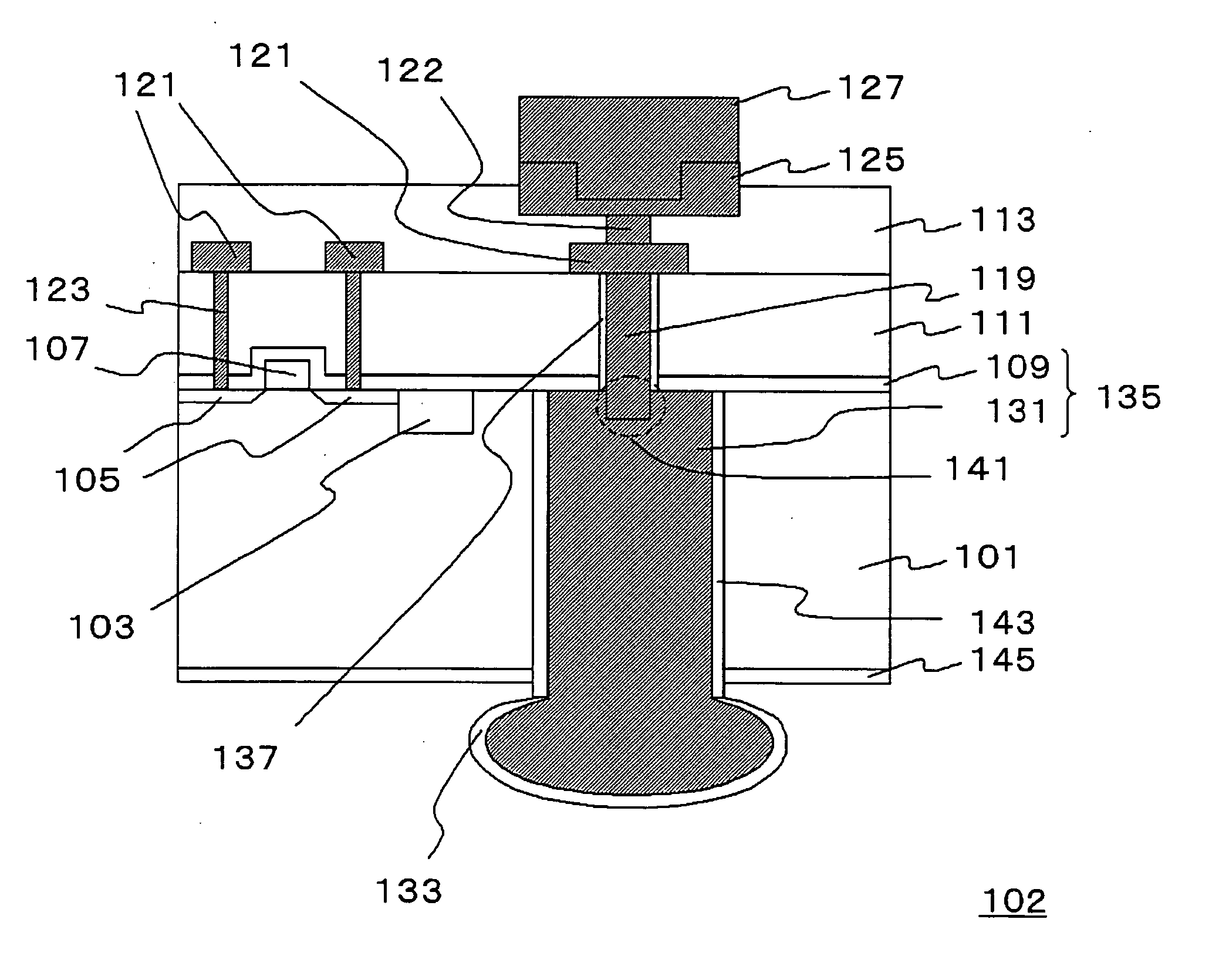

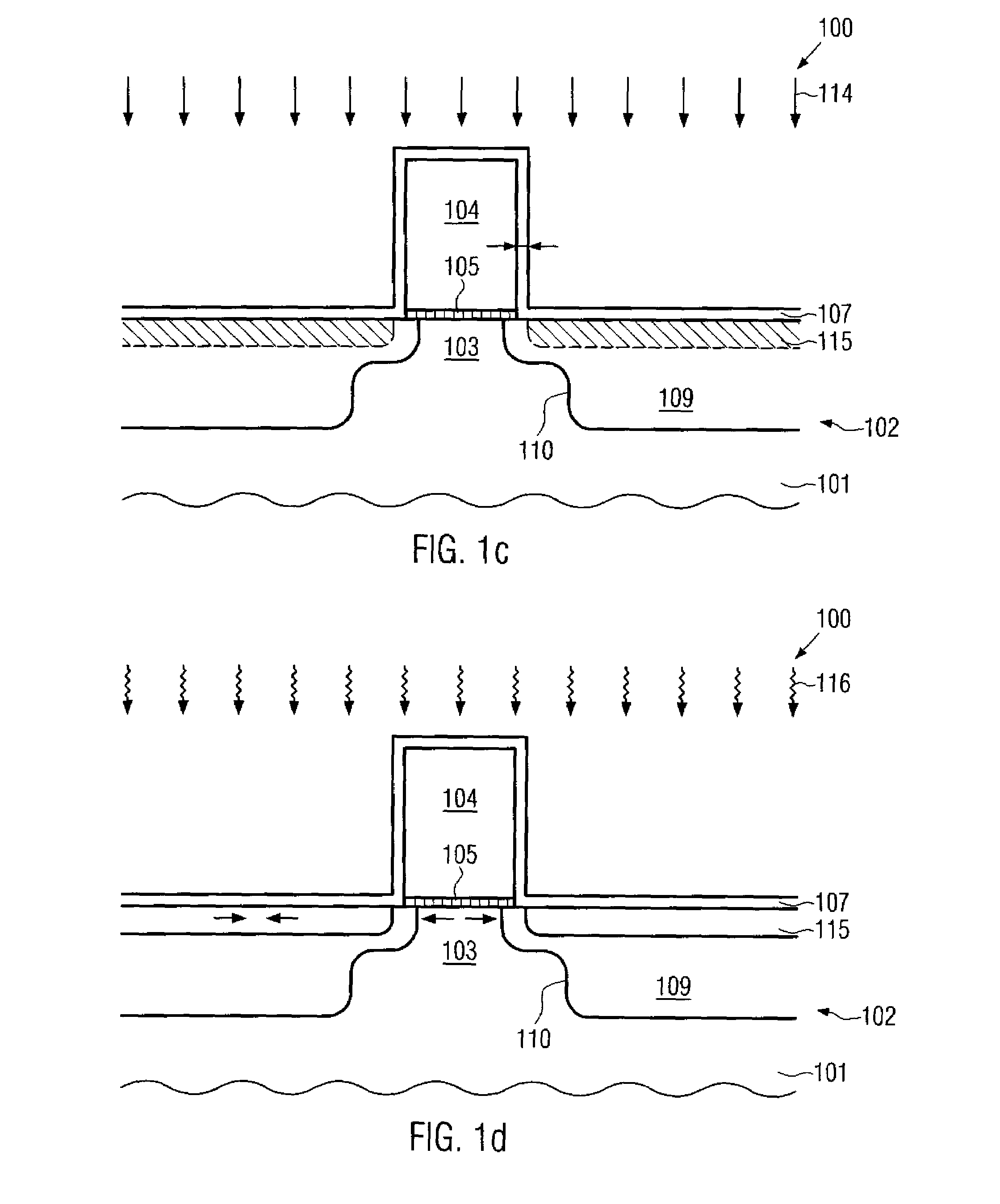

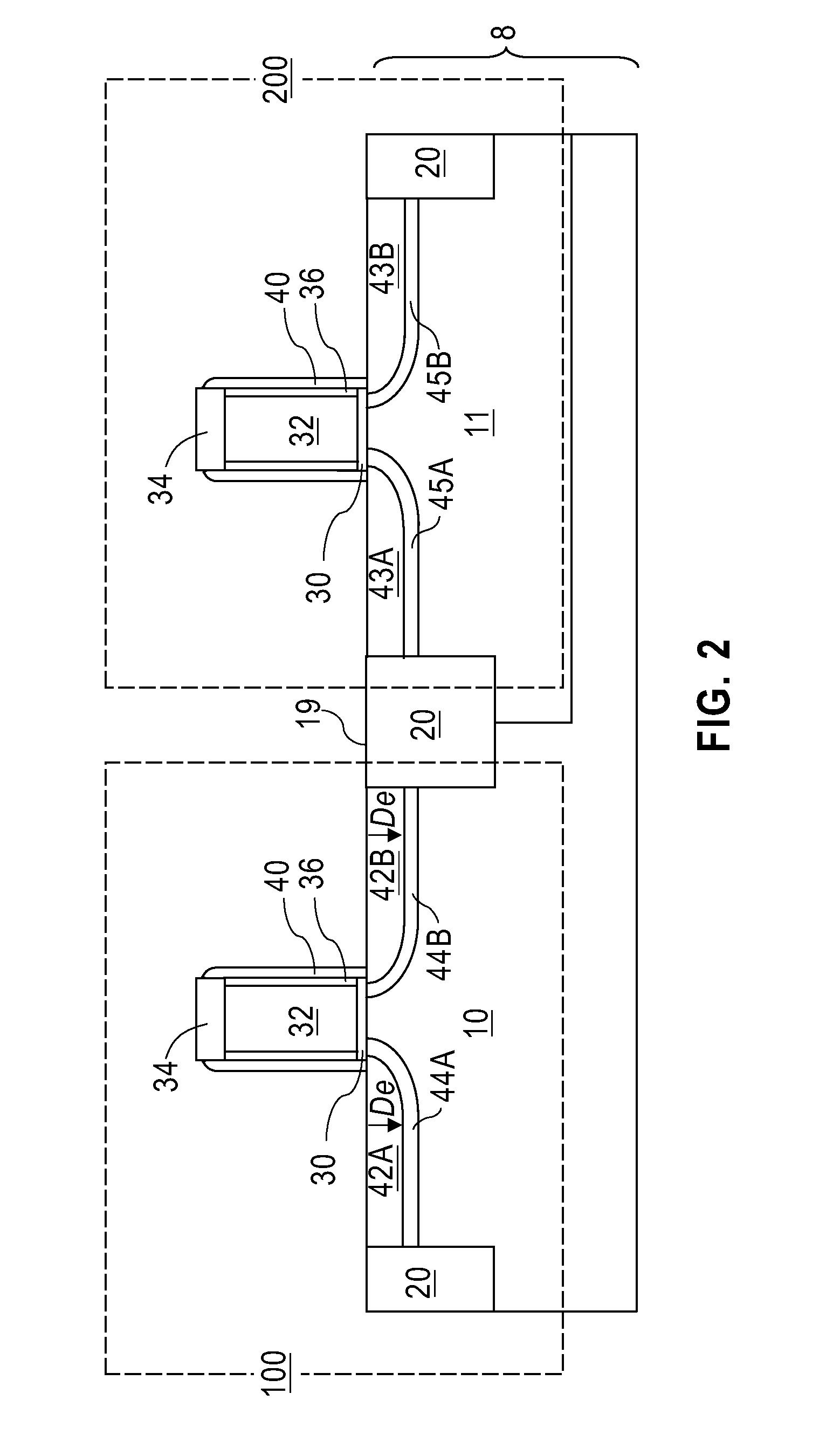

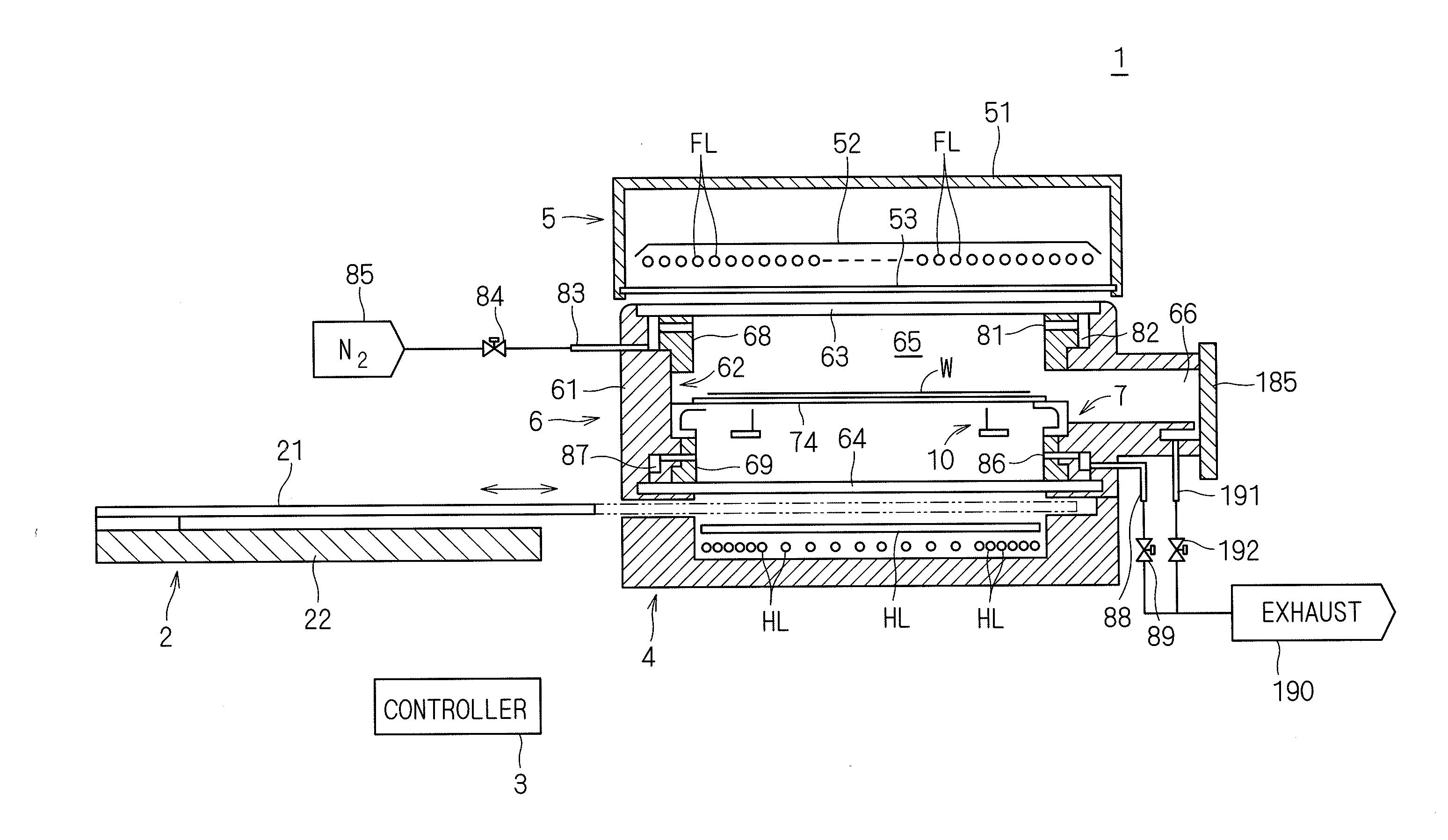

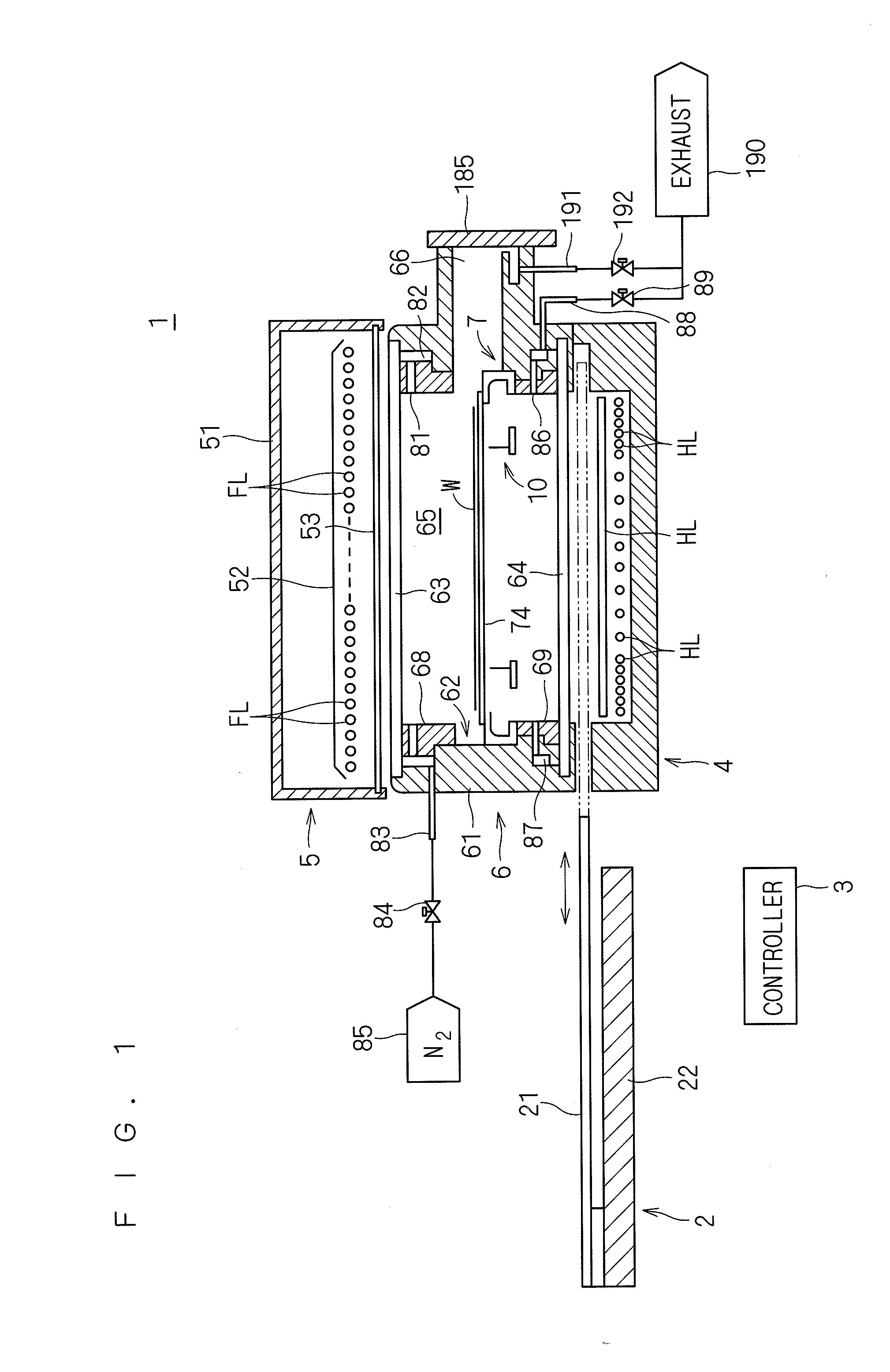

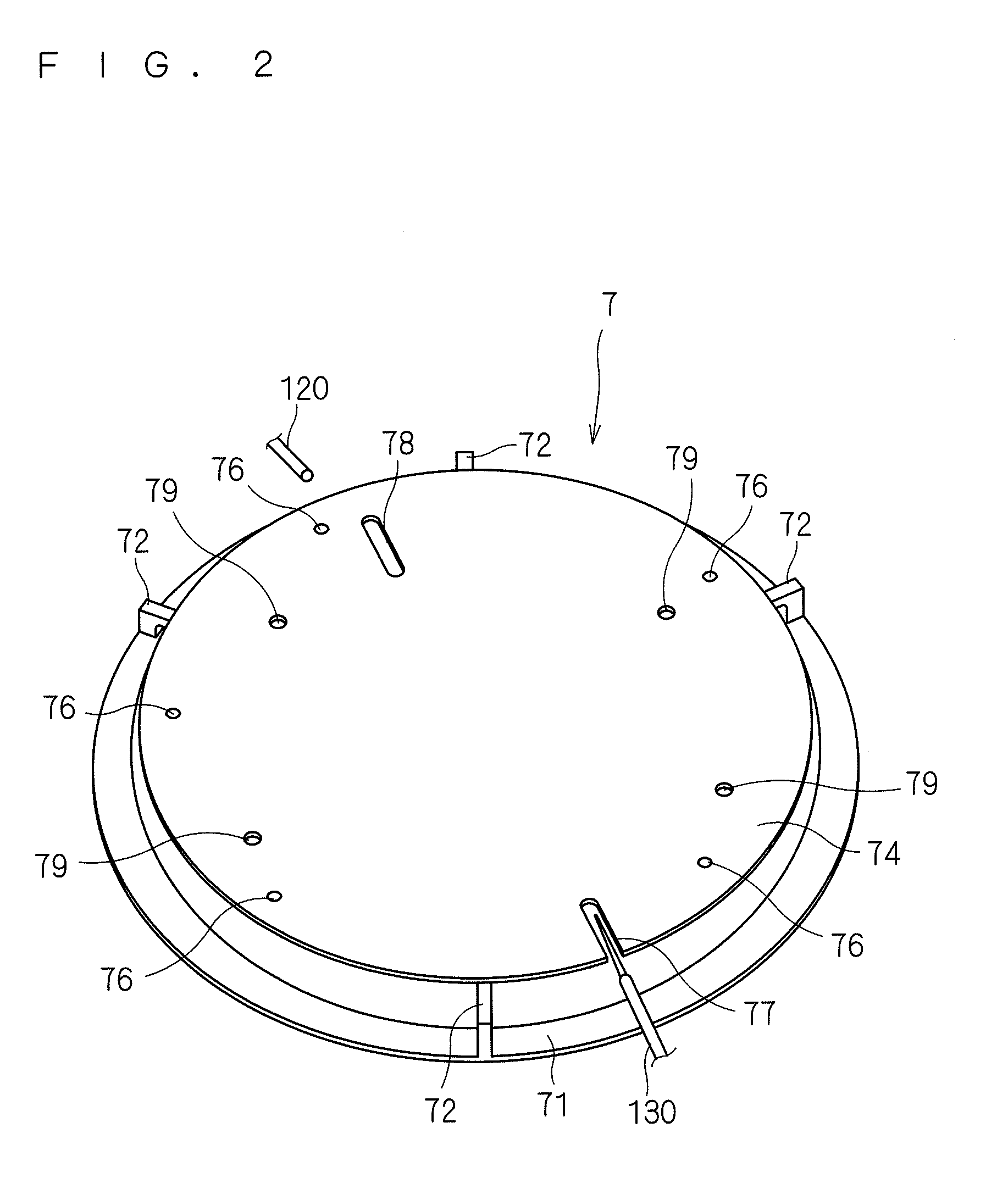

Heat treatment method and heat treatment apparatus for heating substrate by irradiating substrate with light

ActiveUS20120244725A1Avoid it happening againSuppress DiffuseRotary drum furnacesSemiconductor/solid-state device manufacturingEngineeringIrradiation

First irradiation which causes an emission output from a flash lamp to reach its maximum value over a time period in the range of 1 to 20 milliseconds is performed to increase the temperature of a front surface of a semiconductor wafer from a preheating temperature to a target temperature for a time period in the range of 1 to 20 milliseconds. This achieves the activation of the impurities. Subsequently, second irradiation which gradually decreases the emission output from the maximum value over a time period in the range of 3 to 50 milliseconds is performed to maintain the temperature of the front surface within a ±25° C. range around the target temperature for a time period in the range of 3 to 50 milliseconds. This prevents the occurrence of process-induced damage while suppressing the diffusion of the impurities.

Owner:DAINIPPON SCREEN MTG CO LTD

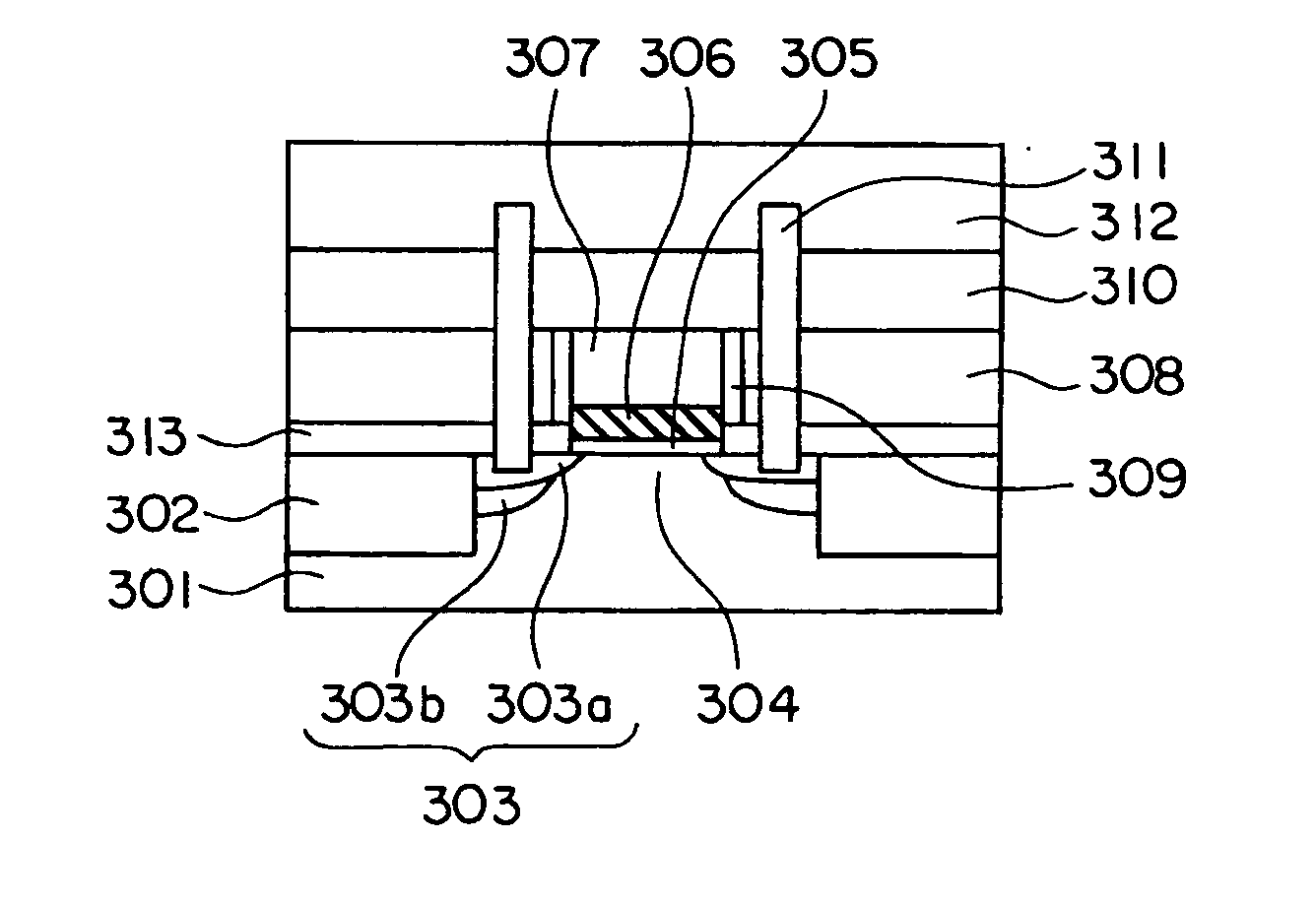

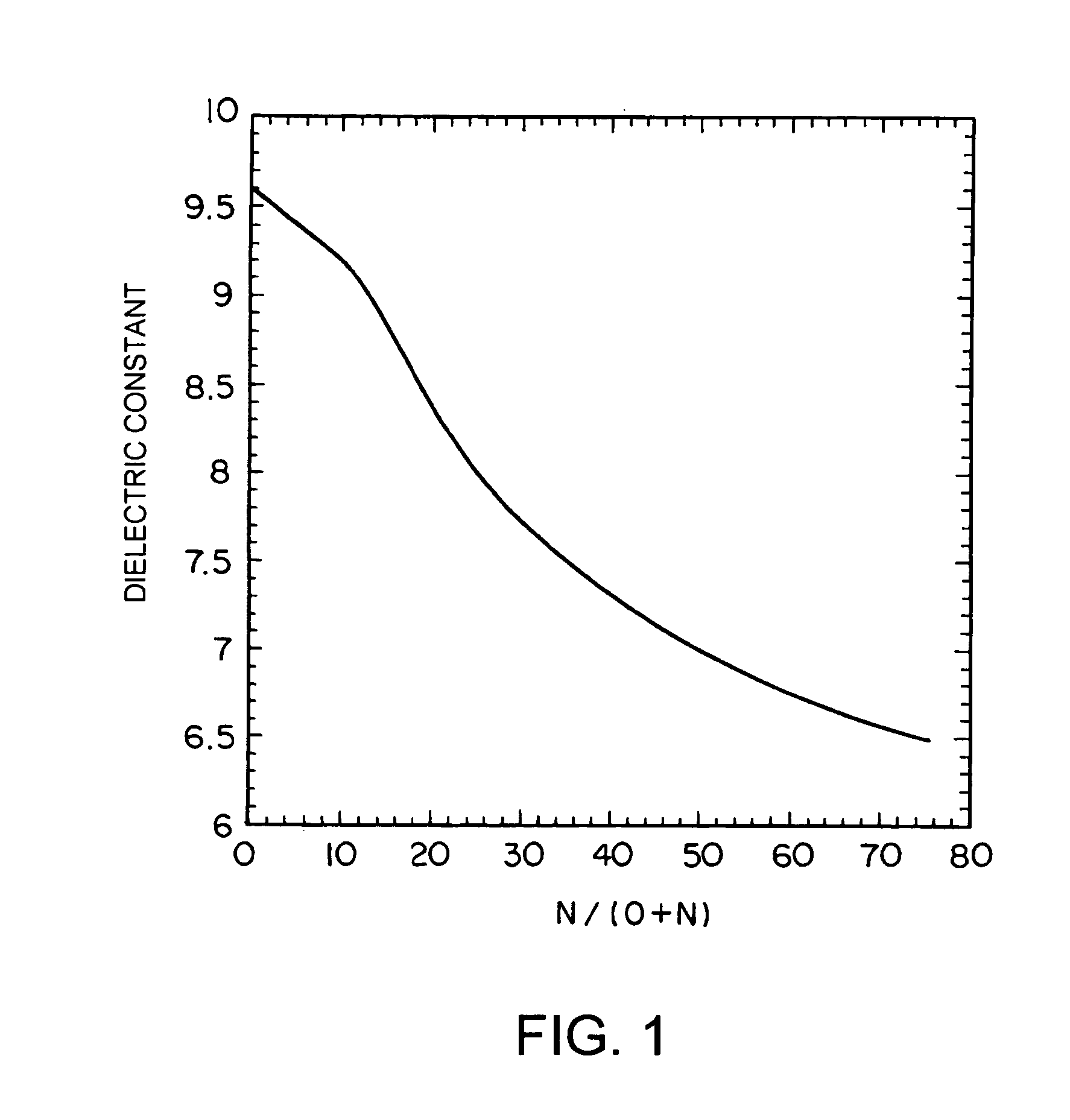

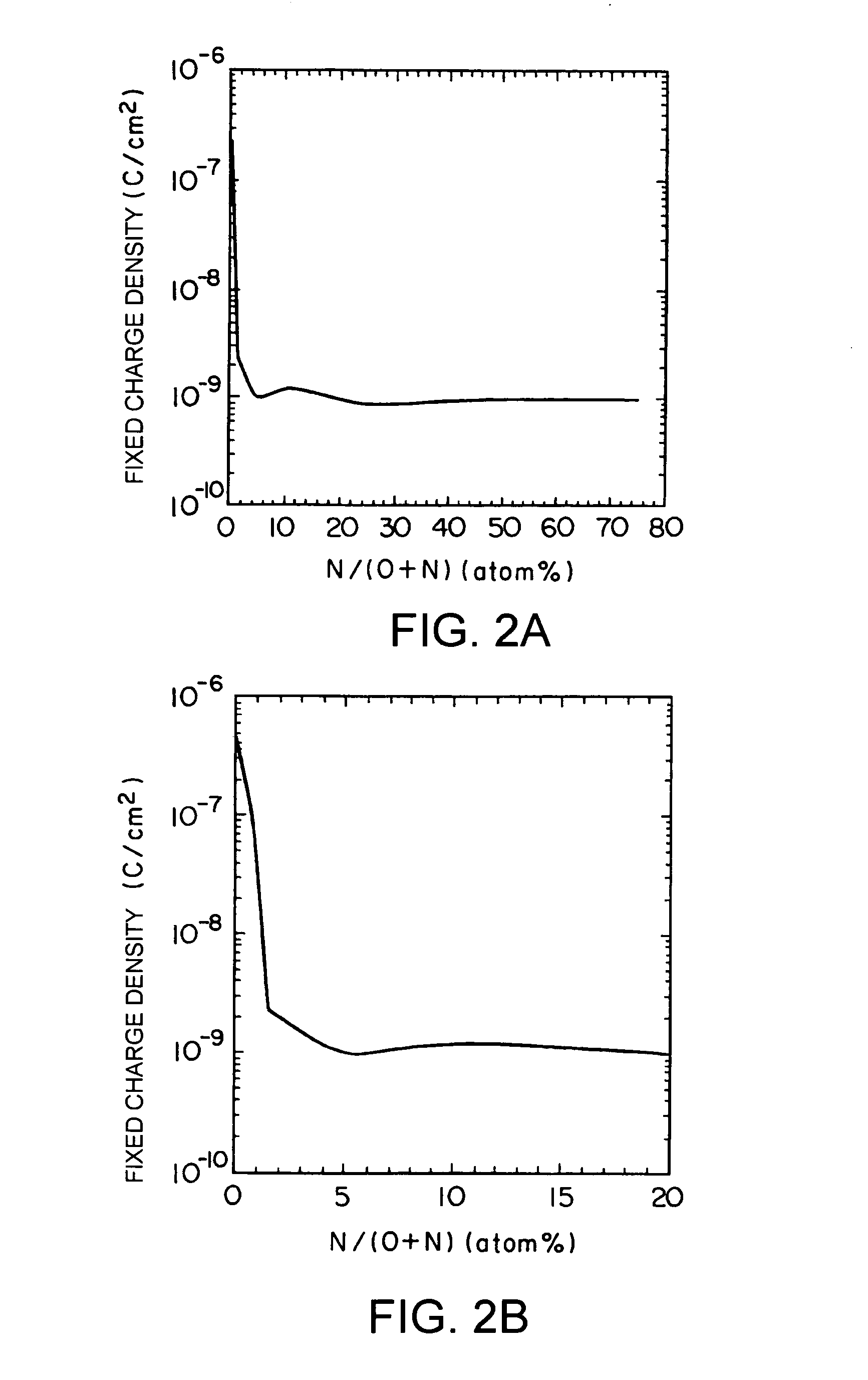

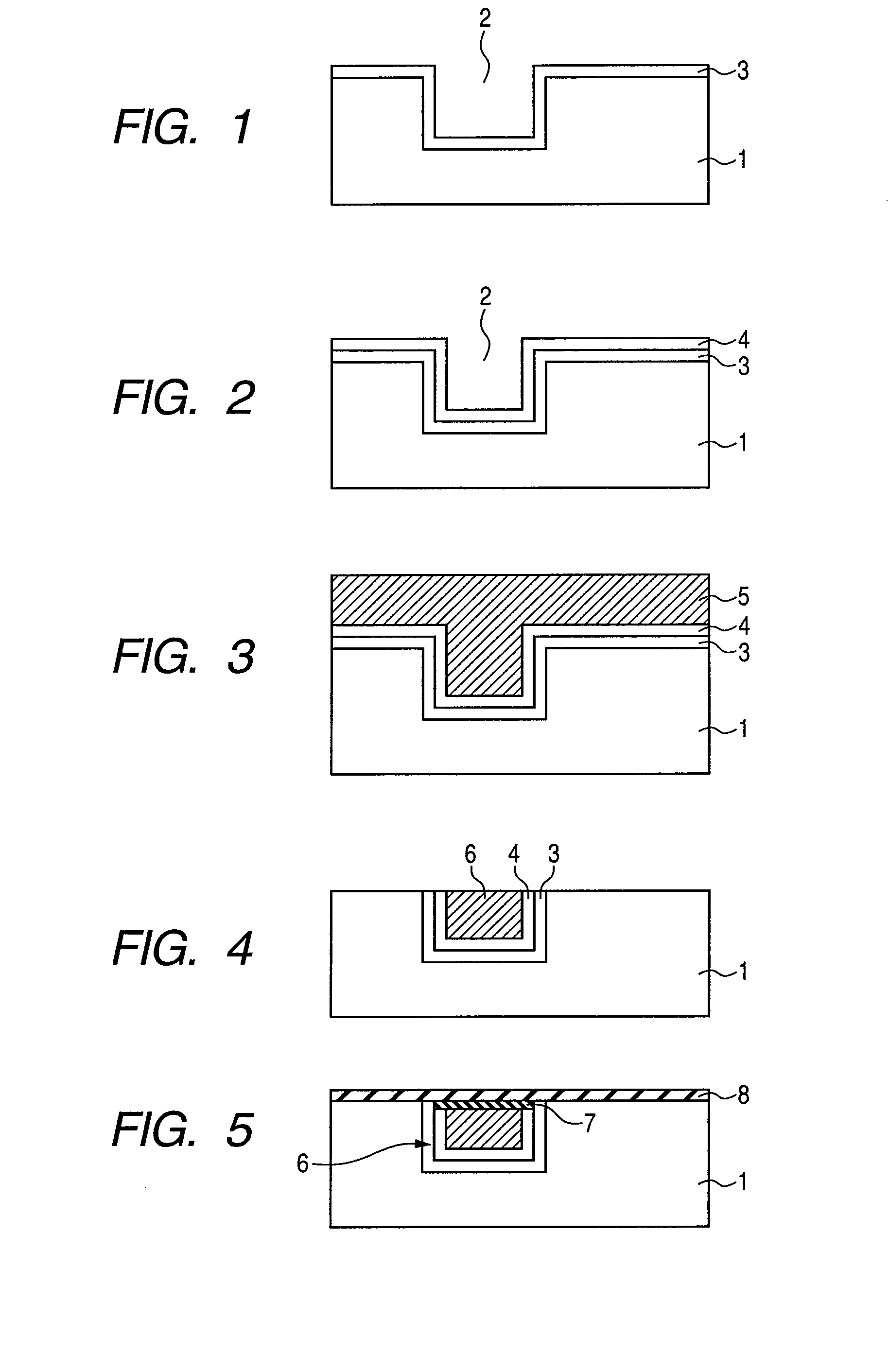

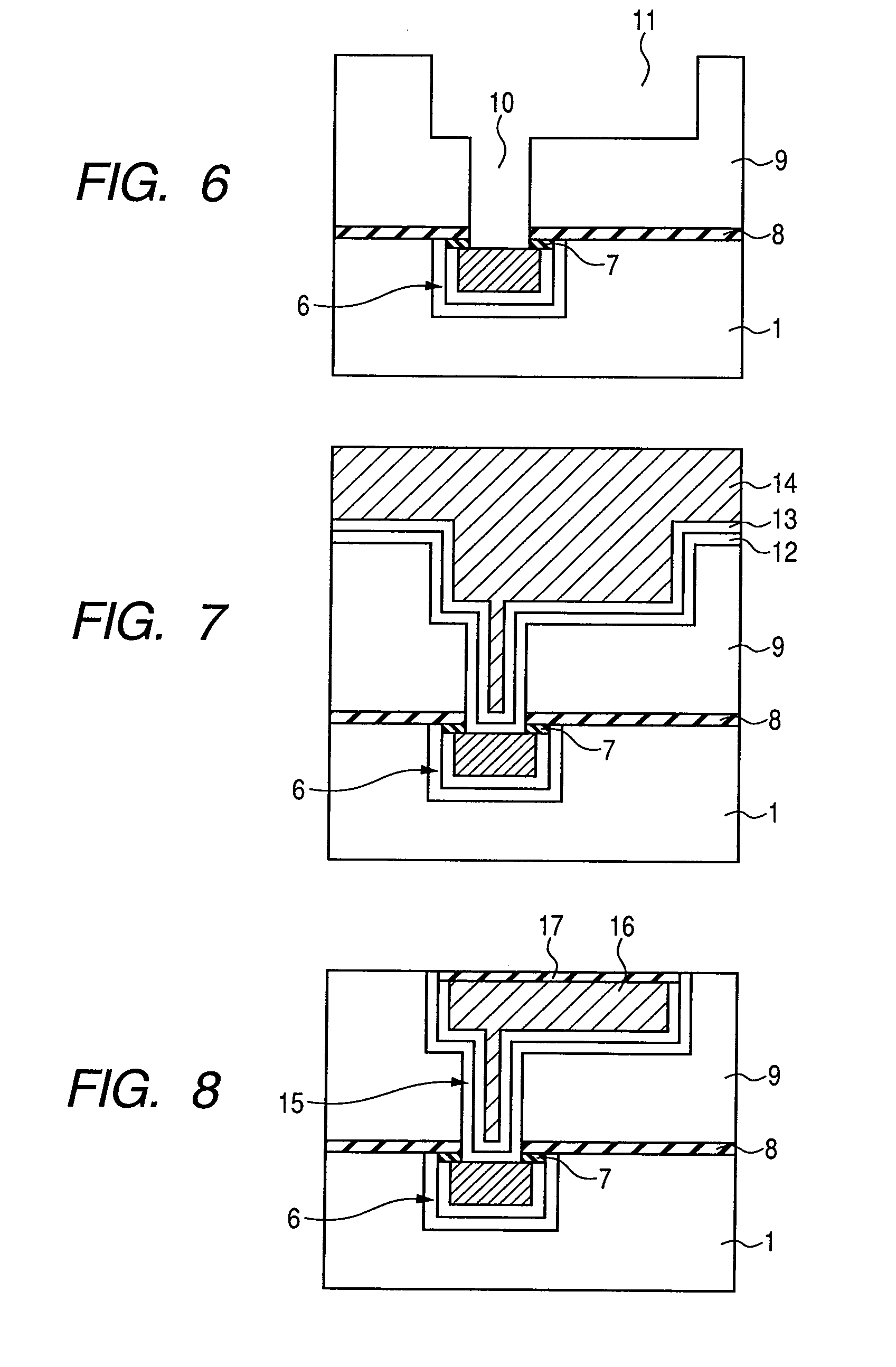

Semiconductor device and production method therefor

InactiveUS20050017319A1Improve responseVoltageSemiconductor/solid-state device manufacturingSemiconductor devicesImpurity diffusionDevice material

A semiconductor device has an MIS (metal-insulating film-semiconductor) structure, and a film mainly containing Al, O, and N atoms is used on a semiconductor. Alternatively, a semiconductor device has an MIS structure, and a film mainly containing Al, O, and N atoms is provided as a gate insulating film on a channel region between a source and a drain. Characteristics required of a gate insulating film of a 0.05 μm-gate-length-generation semiconductor transistor are satisfied. In particular, no fixed charge is included in the film, and impurity diffusion is reduced.

Owner:GK BRIDGE 1

Apparatus of chemical vapor deposition with a showerhead regulating injection velocity of reactive gases positively and method thereof

ActiveUS8882913B2Suppress DiffuseAvoid pollutionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseReactive gas

The present invention is related to an apparatus and a method for chemical vapor deposition (CVD) using a showerhead through which a reactive gas of at least one kind and a purge gas is injected over a substrate on which a film is growing. A plural number of reactive gas showerhead modules are laid on a purge gas showerhead module. Each reactive gas is injected from a bottom of the showerhead after flowing through the showerhead as separated, thereby preventing the reactive gases from causing homogeneous gas phase reactions and from generating unwanted particles at the inside of the showerhead. And a purge gas is injected from the bottom surface of the showerhead by forming a protective curtain, thereby suppressing diffusion of the reactive gas injected backwardly. Each reactive gas is mixed with an injection support gas which is a kind of inert gas in a mixing zone at inside of the showerhead, where the injection velocity of each reactive gas is regulated positively by the amount of the injection support gas mixed. The present invention further includes an apparatus and a method, wherein the showerhead is cooled by a cooling jacket which keeps the temperature of the showerhead at proper levels to prevent both the condensation and the thermal decomposition of the reactive gas used.

Owner:KOREA INST OF IND TECH +1

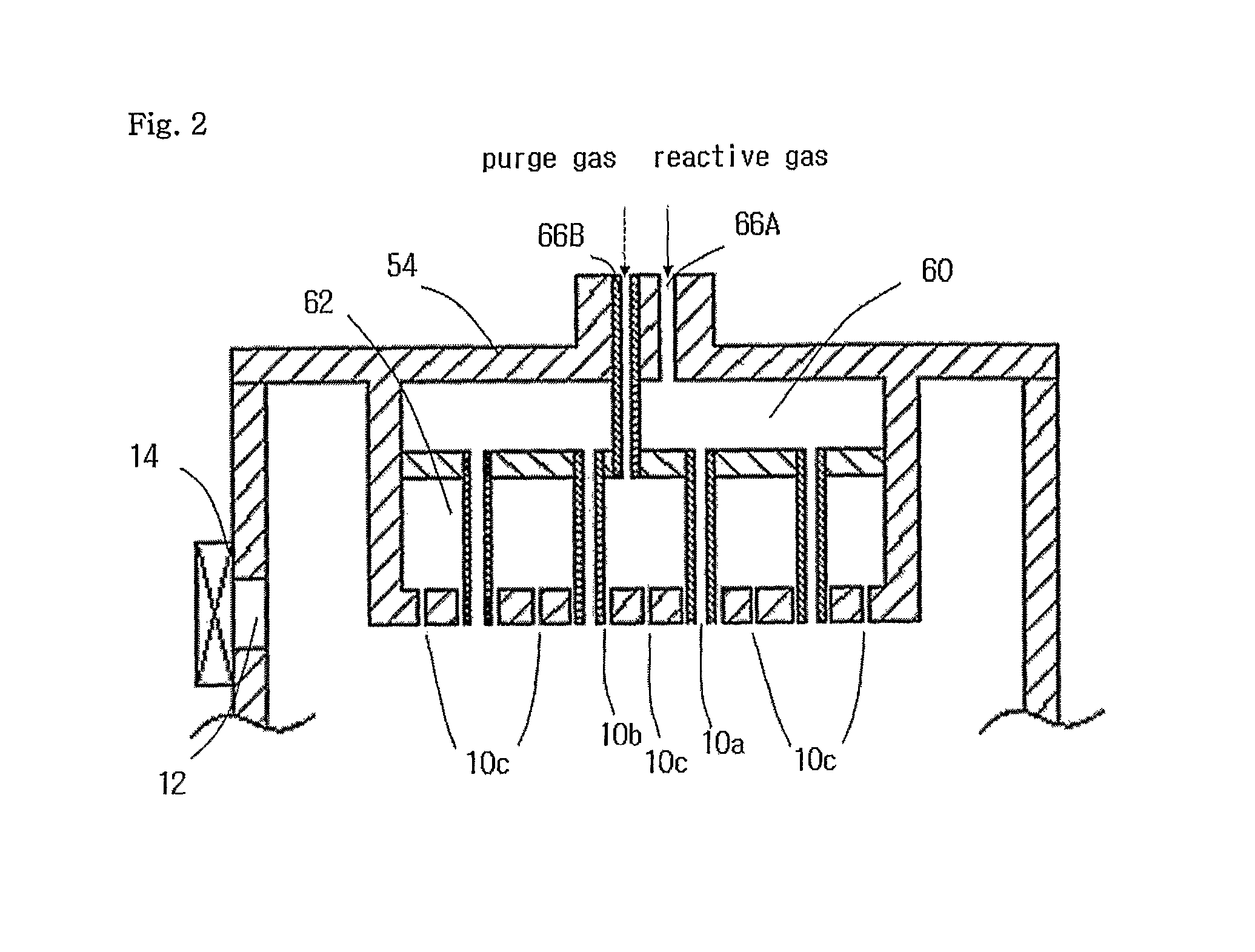

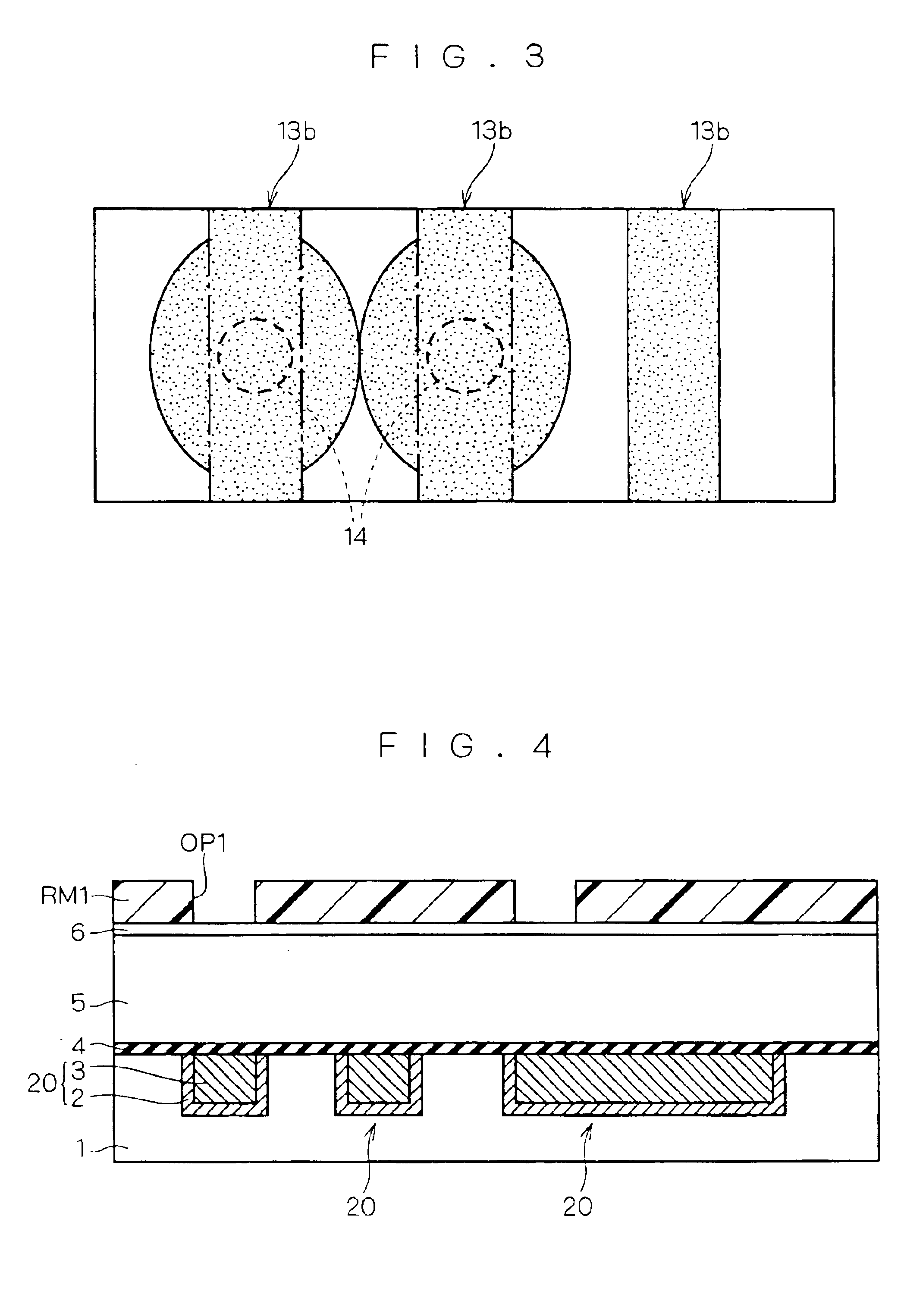

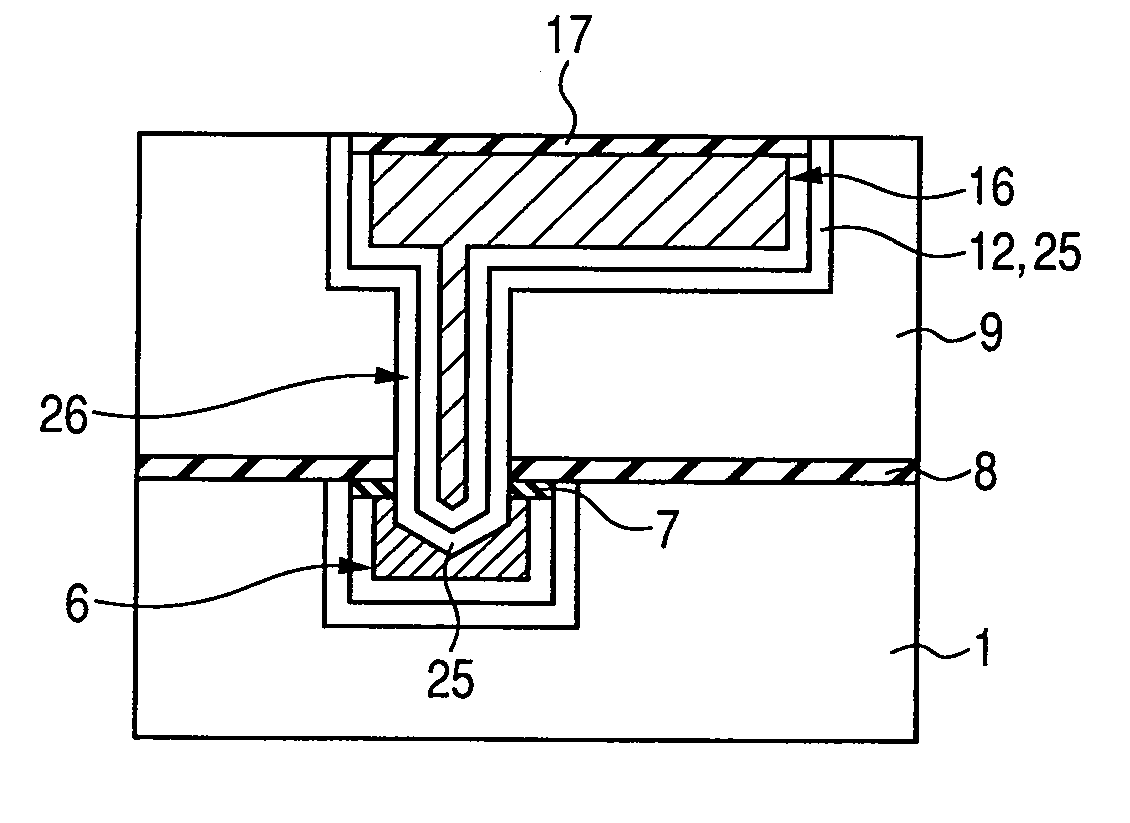

Electronic device manufacturing method

InactiveUS6898851B2Reduce generationDefective resolutionPrinted circuit assemblingLine/current collector detailsResistImage resolution

It is an object to provide a semiconductor device having a buried multilayer wiring structure in which generation of a resolution defect of a resist pattern is suppressed and generation of a defective wiring caused by the resolution defect is reduced. After a via hole (7) reaching an etching stopper film (4) is formed, annealing is carried out at 300 to 400° C. with the via hole (7) opened. As an annealing method, it is possible to use both a method using a hot plate and a method using a heat treating furnace. In order to suppress an influence on a lower wiring (20) which has been manufactured, heating is carried out for a short time of approximately 5 to 10 minutes by using the hot plate. Consequently, a by-product staying in an interface of an upper protective film (6) and an interlayer dielectric film (5) having a low dielectric constant and a by-product staying in an interface of the etching stopper film (4) and the interlayer dielectric film (5) having a low dielectric constant are discharged so that an amount of the residual by-product can be decreased.

Owner:RENESAS ELECTRONICS CORP +1

Method of manufacturing semiconductor device, and semiconductor device

ActiveUS20100044864A1Suppress diffusion of copperRetard diffusion of copperTransistorSemiconductor/solid-state device detailsCopper platingDevice material

The present invention aims at providing a method of manufacturing a semiconductor device capable of suppressing metal diffusion from the upper face of wiring.In the present invention, a copper seed film containing copper and a first metal element is formed in a groove formed in a first interlayer film over a semiconductor substrate. After that, a copper plating treatment is performed. After that, a first heat treatment is performed in a first atmosphere in which the copper layer is not oxidized. Then, an excess metal layer of copper alloy is removed and copper alloy wiring is formed in the groove. After that, a second heat treatment is performed in a second atmosphere containing oxygen to form an oxide layer being the oxide of the first metal element over the surface of the copper alloy wiring.

Owner:RENESAS ELECTRONICS CORP

Flux for soldering and circuit board

InactiveUS20060147683A1High bonding strengthSuppress DiffuseBlast furnace componentsBlast furnace detailsSolventCopper complex

A flux contains resin having film forming ability, activator, solvent, and at least one complex selected from silver complex and copper complex. The flux is used when soldering is performed onto a circuit having electroless nickel plating or further having gold plating on the electroless nickel plating. Allowing a barrier layer of silver or copper to deposit on the surfaces of lands suppresses the diffusion of nickel into the melted solder alloy during soldering, and also prevents phosphorous concentration. This improves the bonding strength of soldering and suppresses the reduction deposition of silver and / or copper to portions other than circuit patterns.

Owner:HARIMA CHEM INC

Semiconductor device

InactiveUS20140001467A1Low reliabilityAvoid changeTransistorNon-linear opticsPower semiconductor deviceNitrogen

To provide a semiconductor device including an oxide semiconductor in which a change in electrical characteristics is suppressed or whose reliability is improved. In a semiconductor device including an oxide semiconductor film in which a channel formation region is formed, an insulating film which suppresses entry of water and contains at least nitrogen and an insulating film which suppresses entry of nitrogen released form the insulating film are provided over the oxide semiconductor film. As water entering the oxide semiconductor film, water contained in the air, water in a film provided over the insulating film which suppresses entry of water, or the like can be given. Further, as the insulating film which suppresses entry of water, a nitride insulating film can be used, and the amount of hydrogen molecules released by heating from the nitride insulating film is smaller than 5.0×1021 molecules / cm3.

Owner:SEMICON ENERGY LAB CO LTD

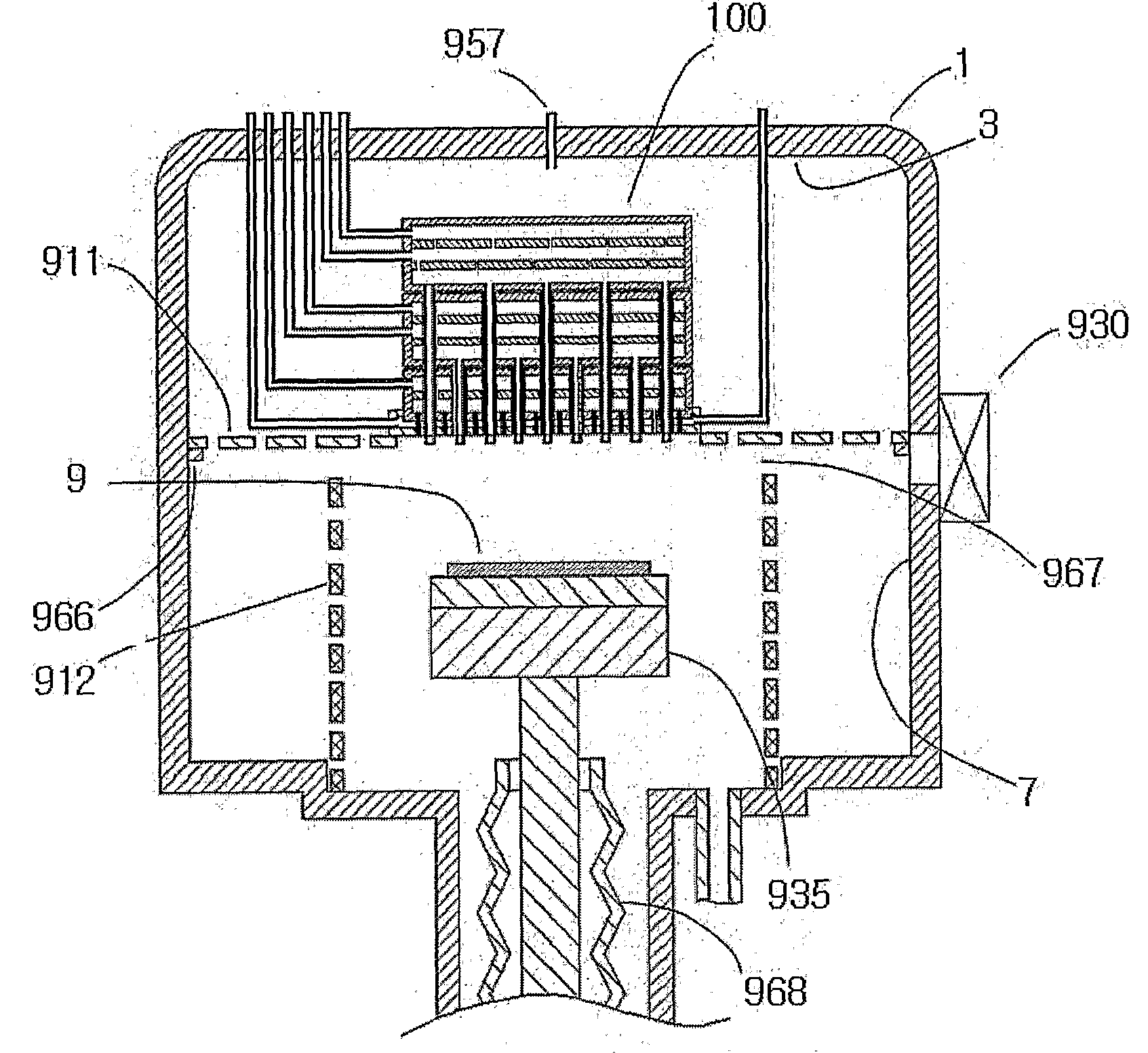

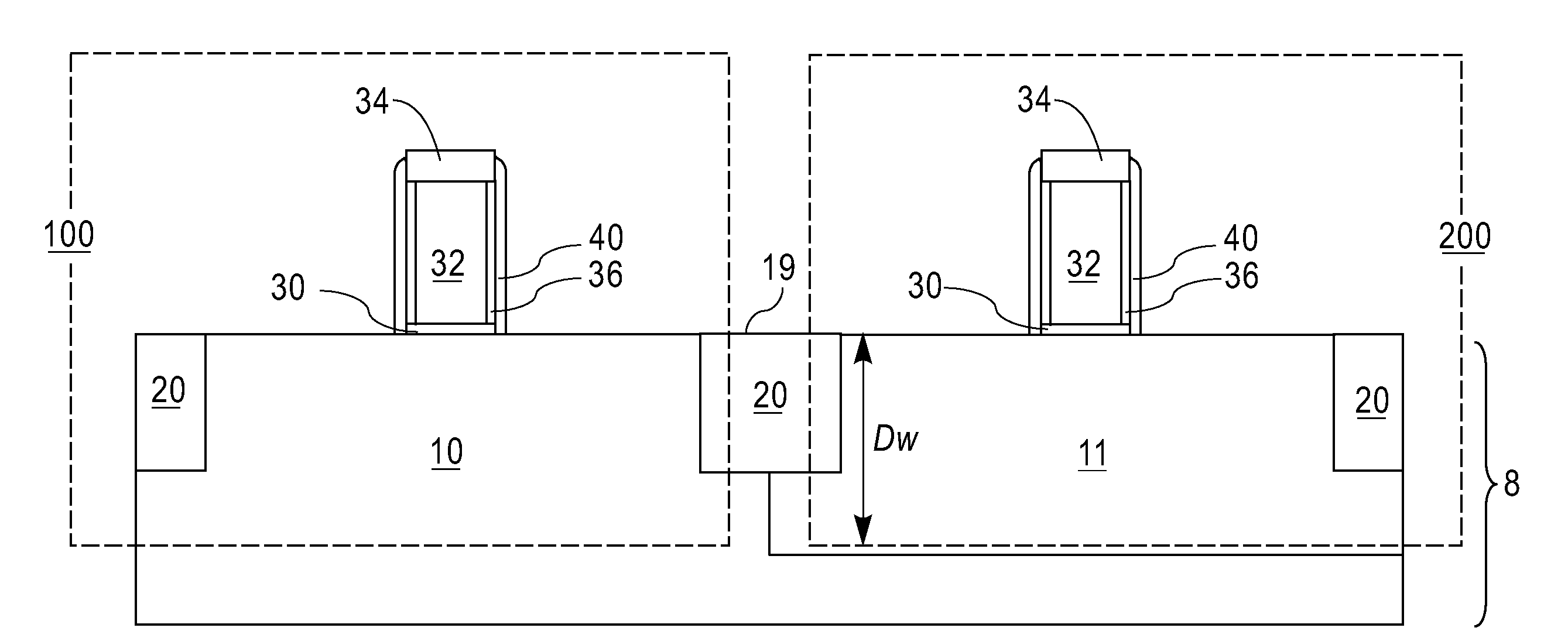

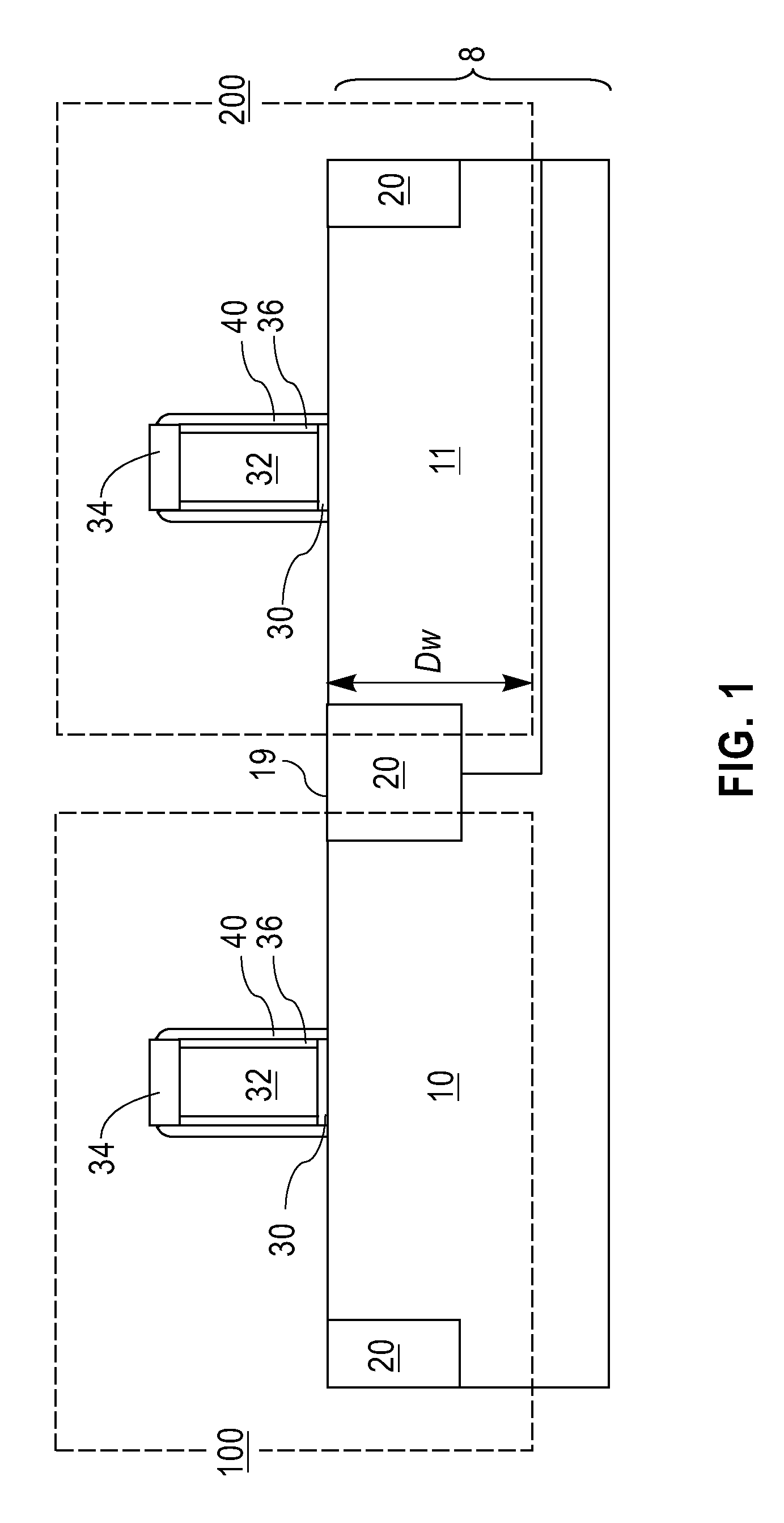

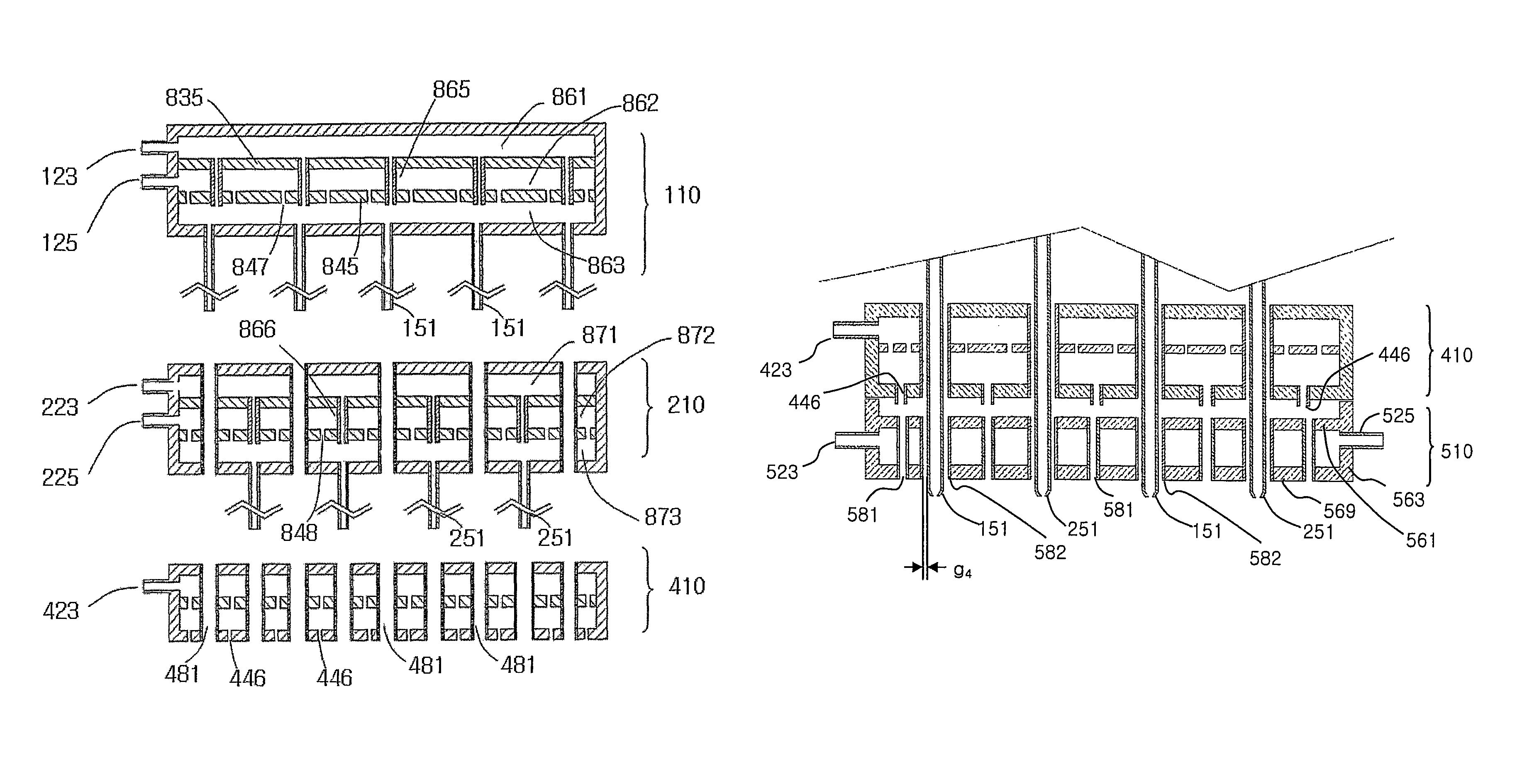

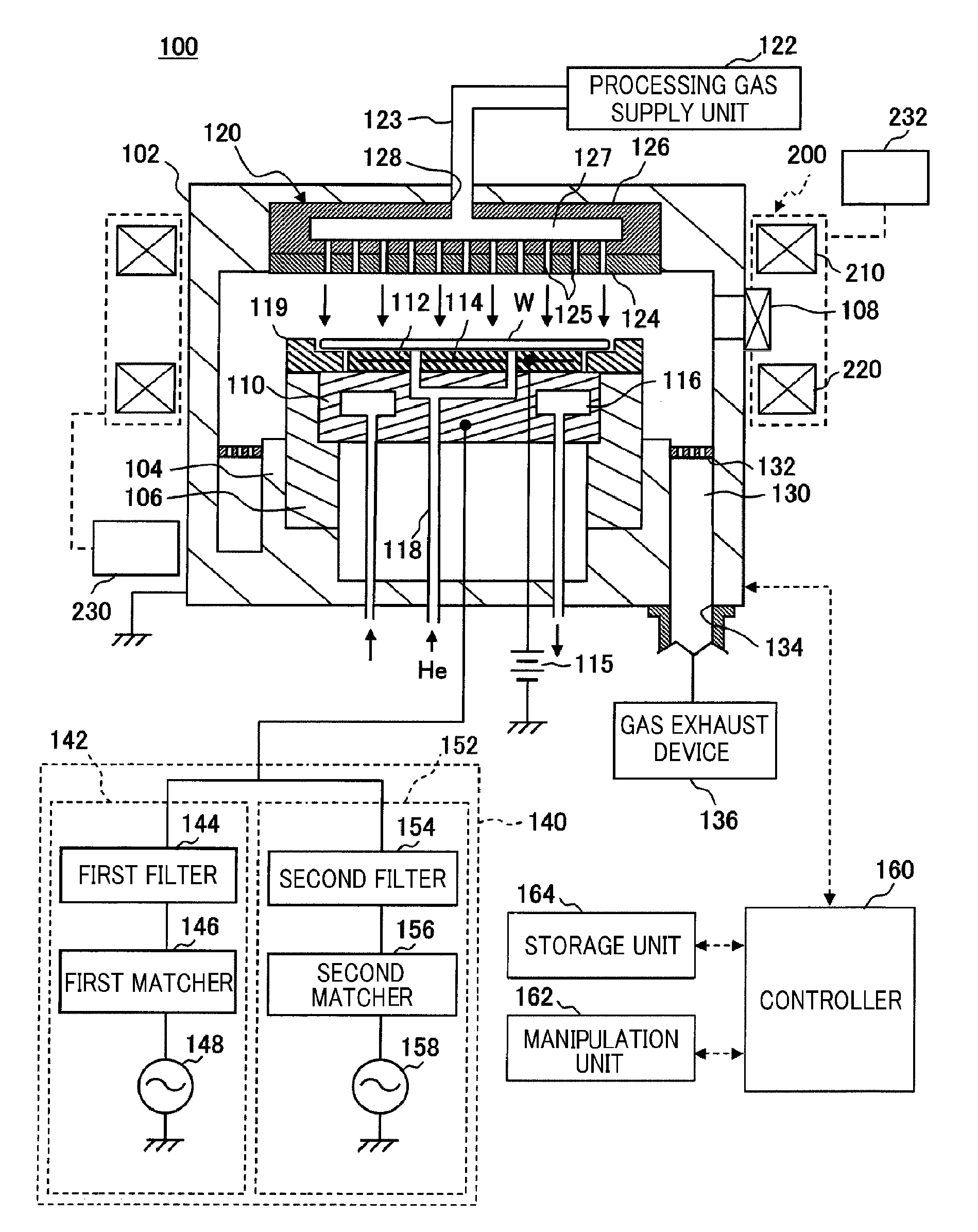

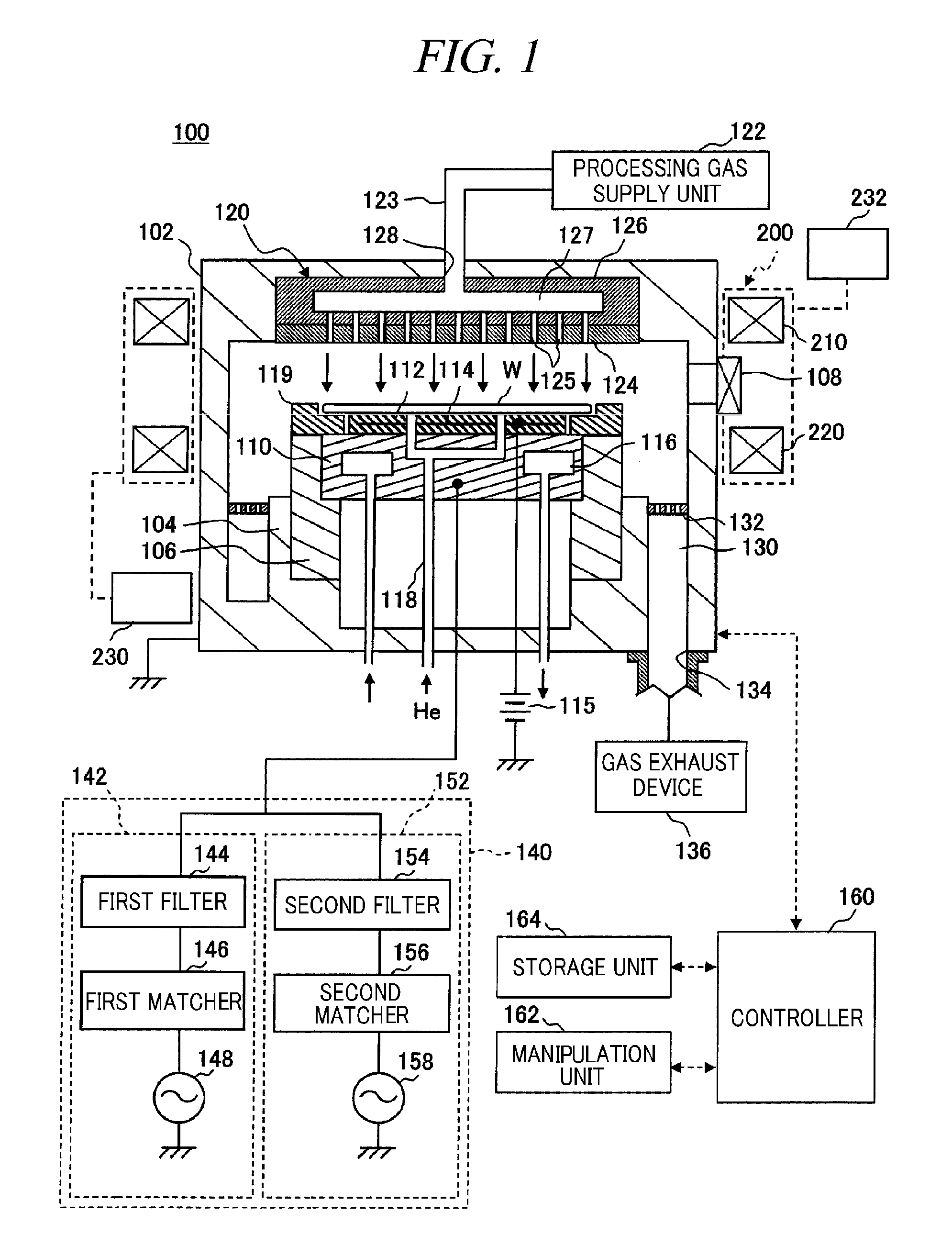

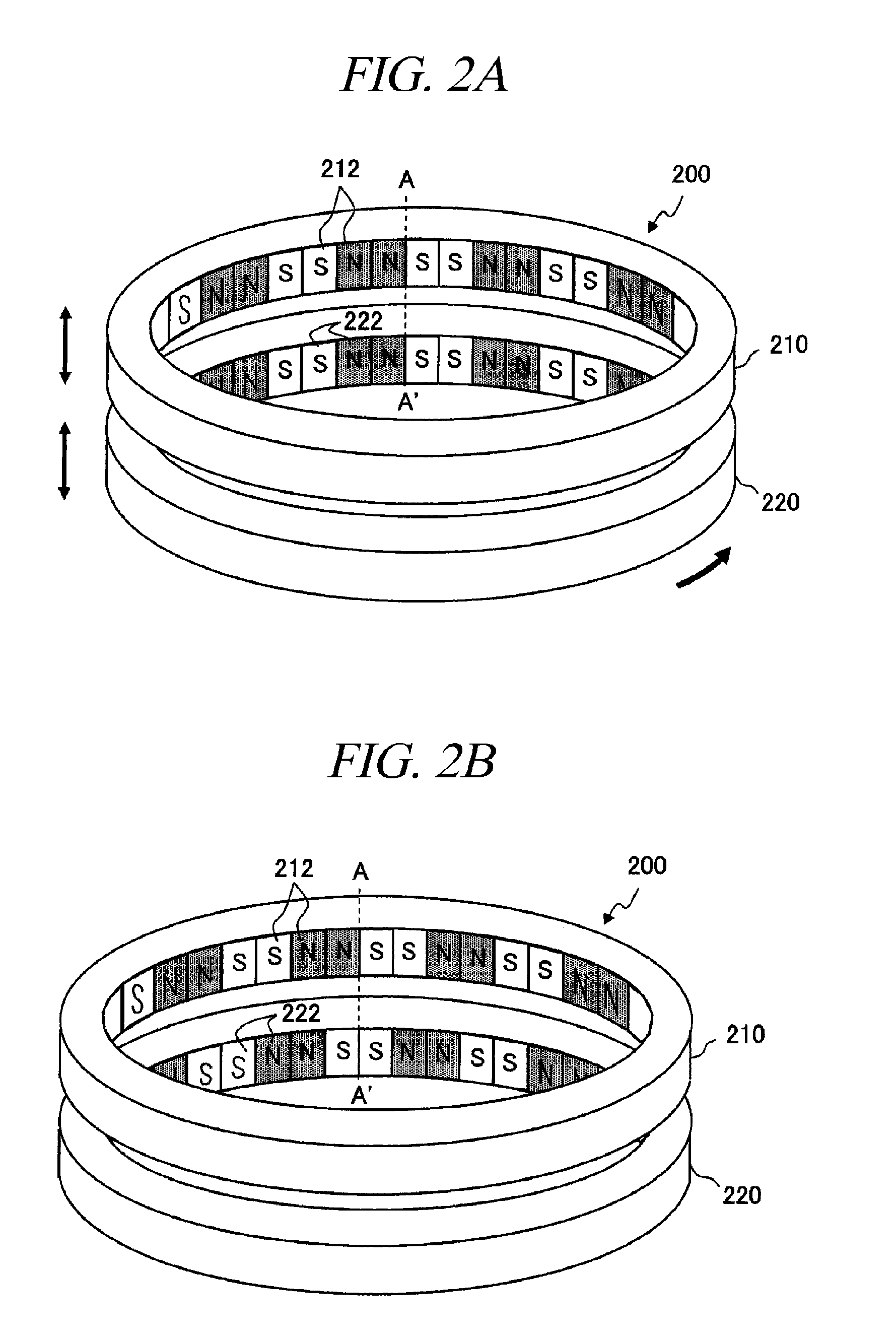

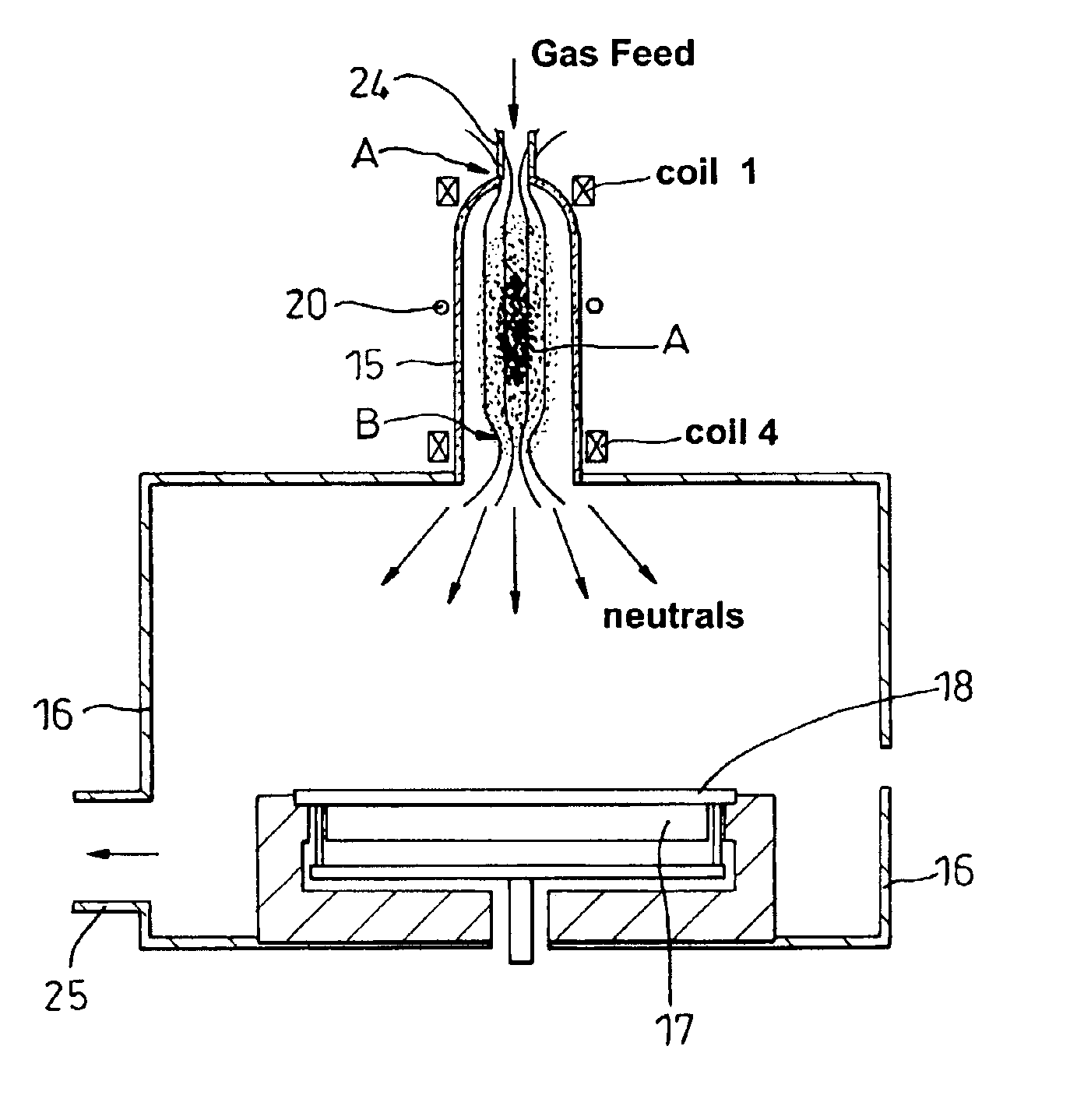

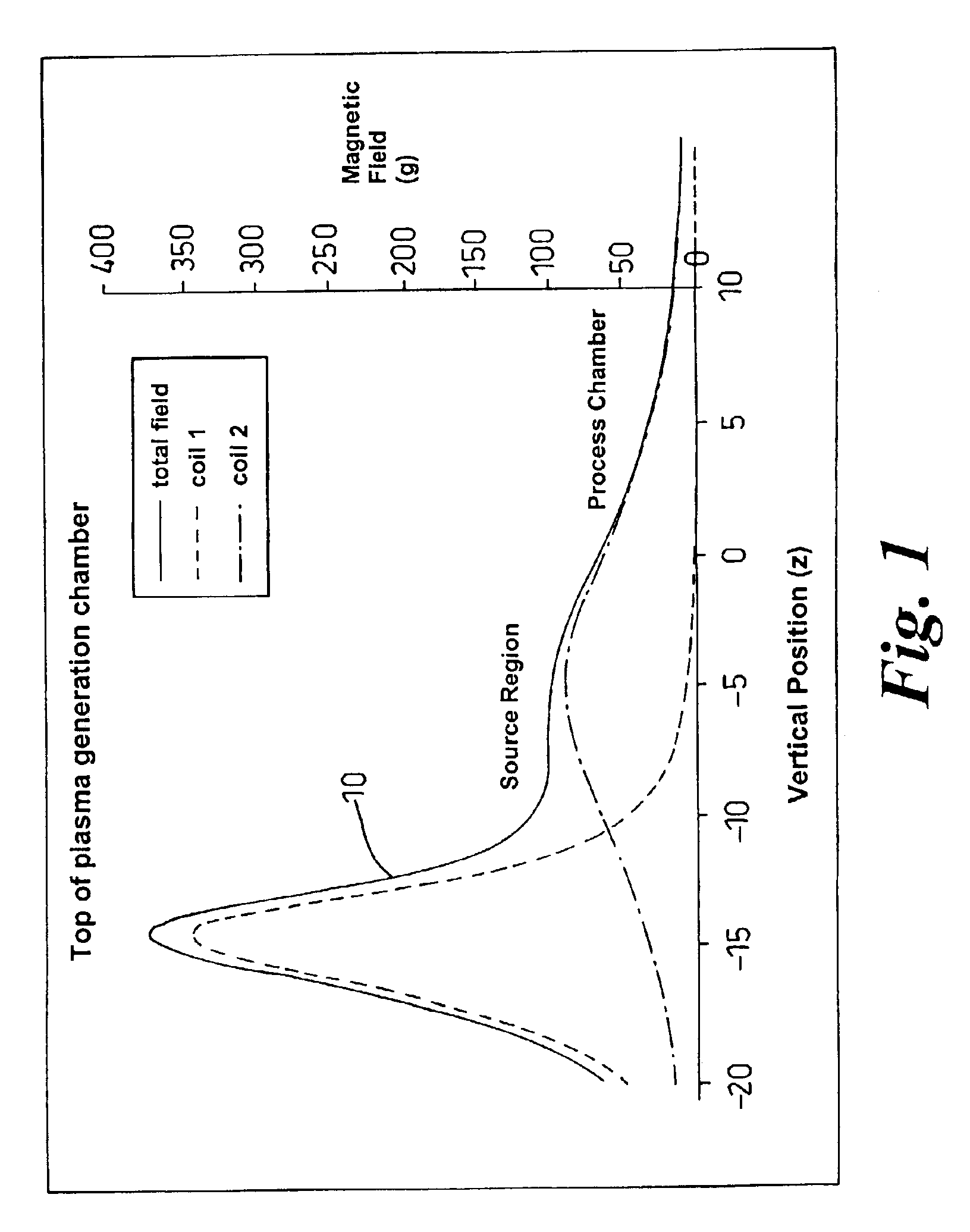

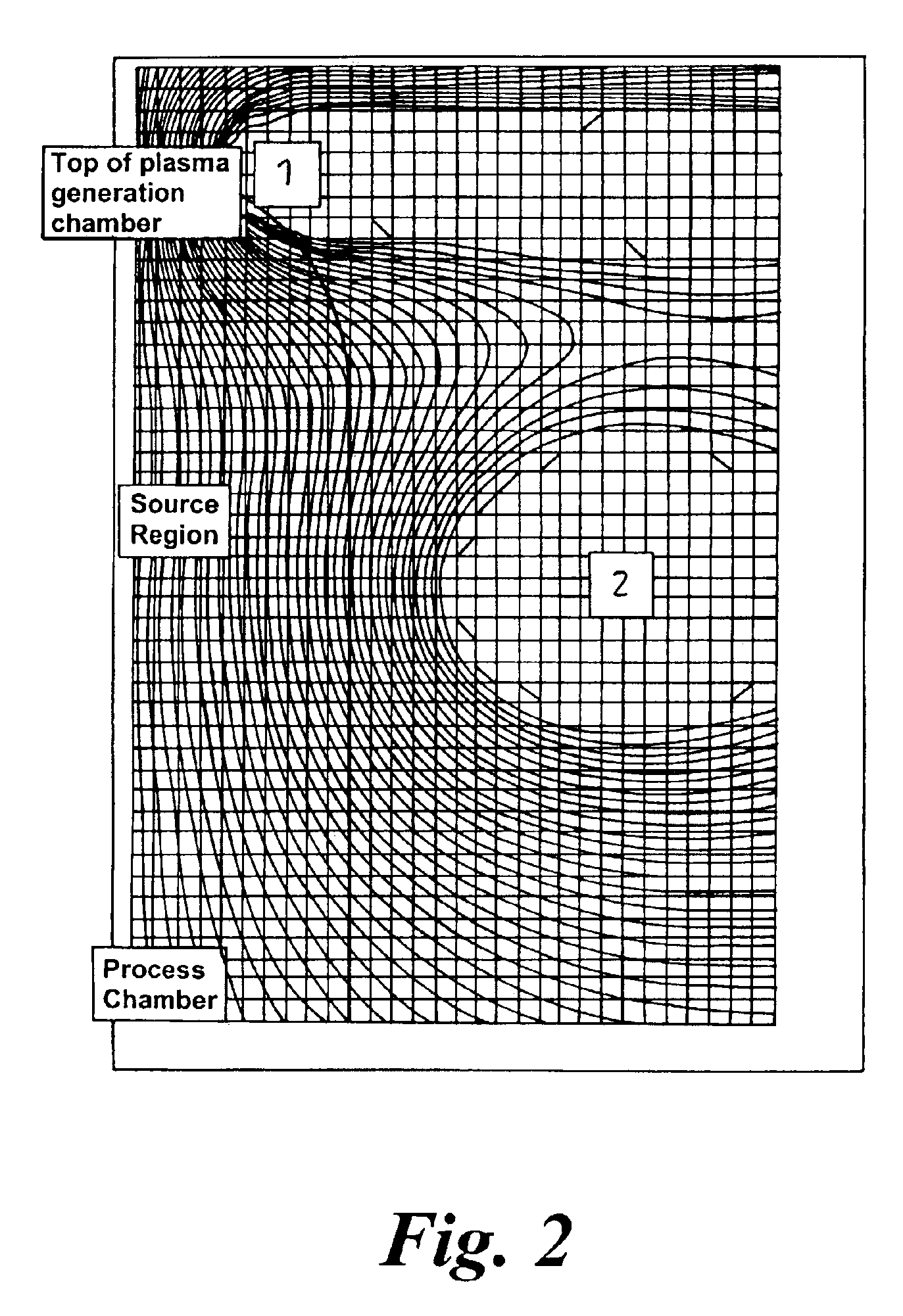

Plasma processing apparatus and plasma processing method

InactiveUS20110056912A1Suppress DiffuseReduce processLiquid surface applicatorsVacuum evaporation coatingPhysicsPlasma processing

Uniformity in a plasma process can be increased by increasing a plasma confining effect by a cusp magnetic field over the whole circumference. There is provided a plasma processing apparatus which performs a process on a substrate by generating plasma of a processing gas in a depressurized processing chamber. The apparatus includes a magnetic field generation unit 200 including two magnet rings 210 and 220 vertically spaced from each other and arranged along a circumferential direction of the processing chamber. Each of the magnet rings includes multiple segments 212 and 222 of which magnetic poles are alternately reversed two by two along a circumferential direction of an inner surface of the magnet ring. In the magnetic field generation unit 200, arrangement of upper and lower magnetic poles is changed by rotating the lower magnet ring 220 in a circumferential direction with respect to the upper magnet ring 210.

Owner:TOKYO ELECTRON LTD

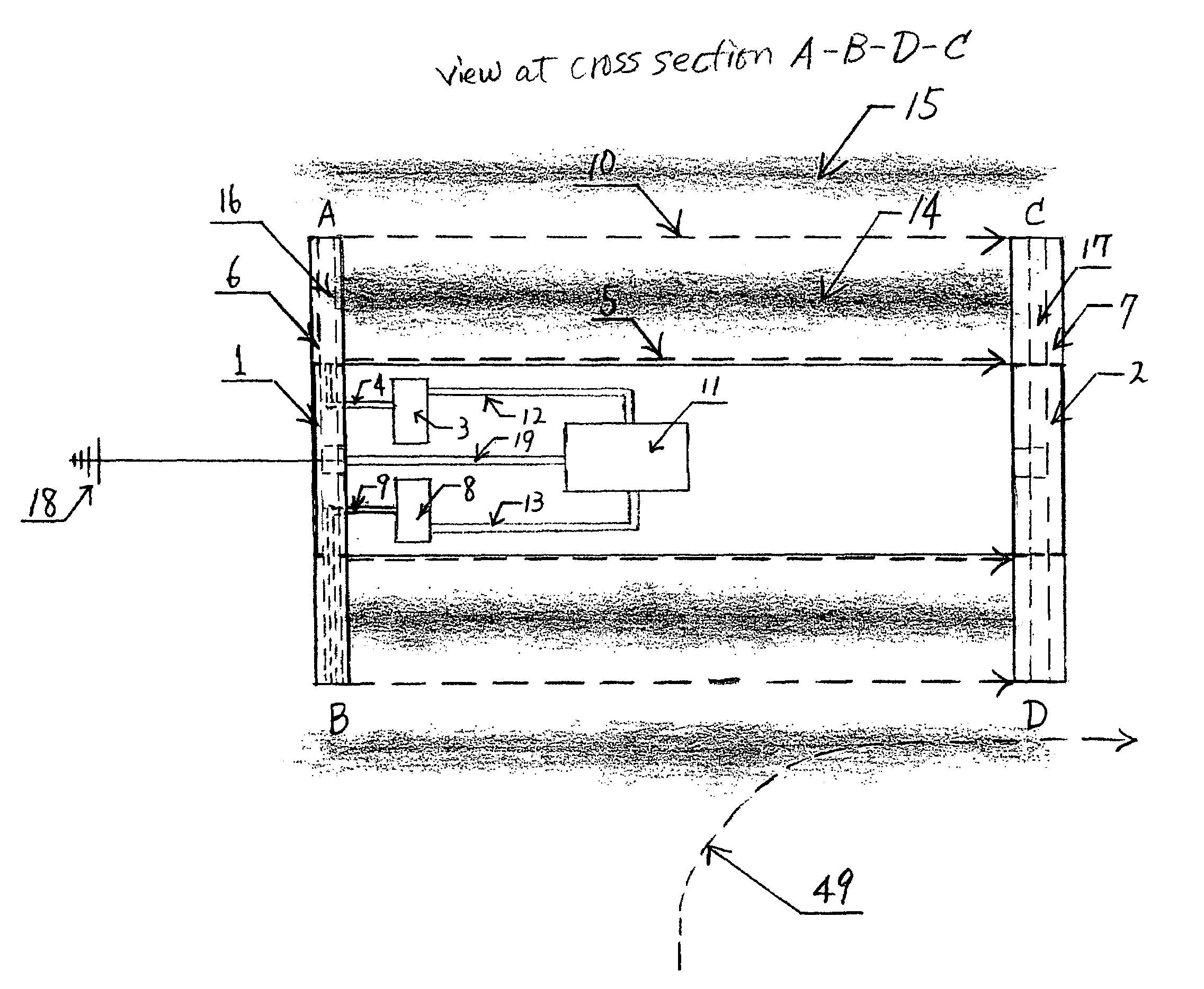

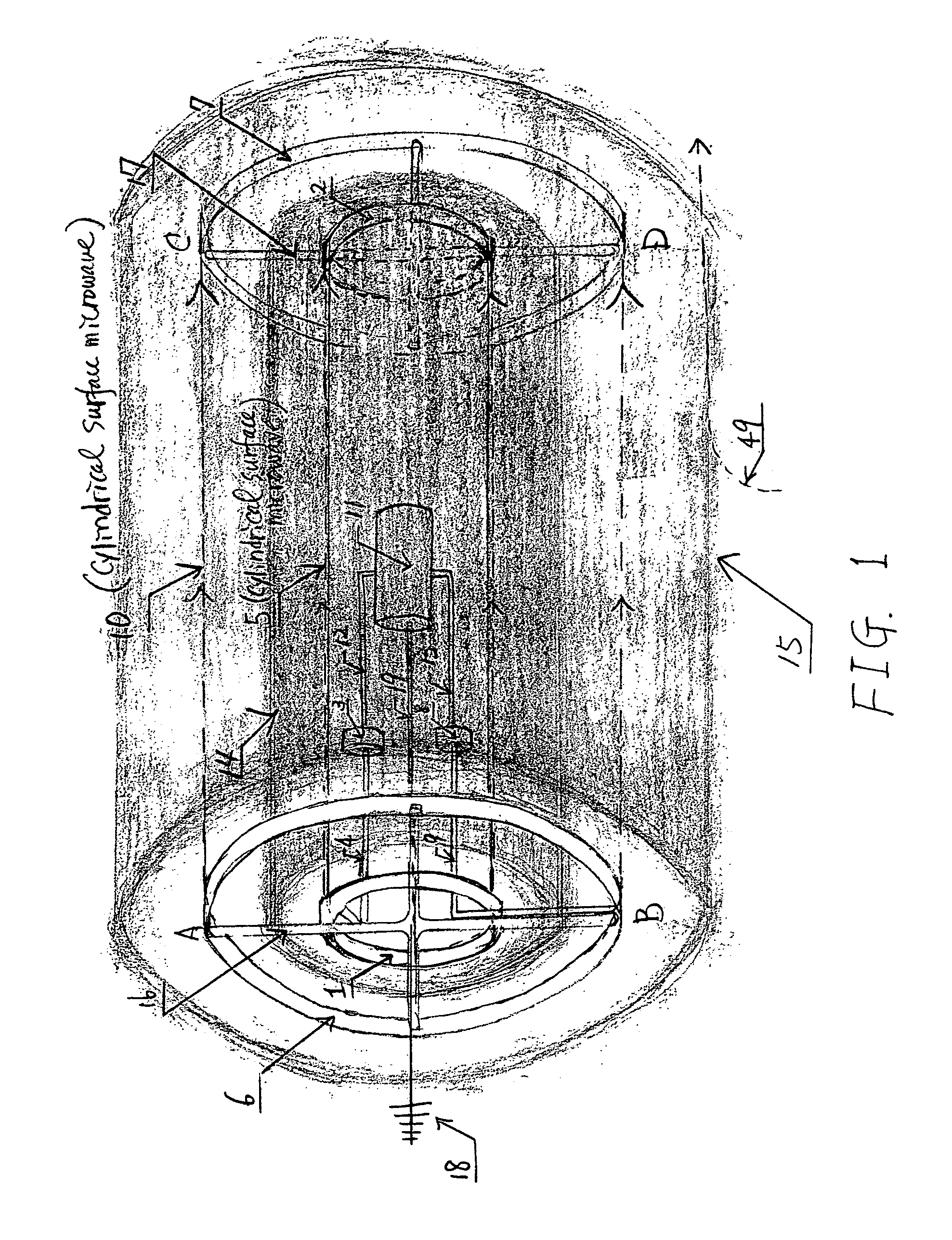

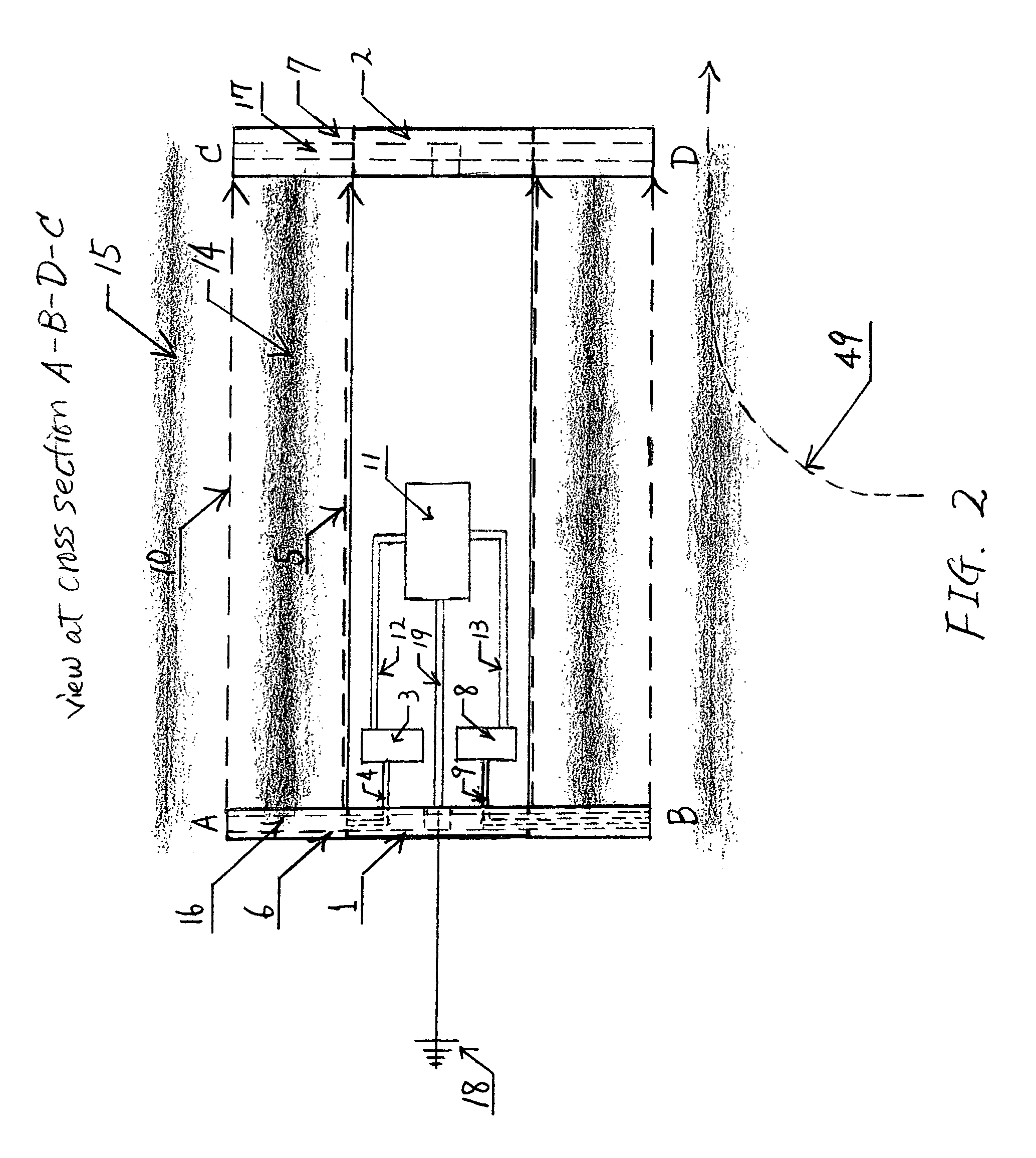

Pseudo surface microwave produced plasma shielding system

ActiveUS7255062B1Increase the magnetic field strengthSuppress DiffuseElectric discharge tubesElectric arc lampsPlasma densityCombustion chamber

A pseudo surface microwave produced plasma shielding system is a simple device that creates a prescribed plasma environment with a prescribed plasma density gradient, and protects an object surrounded by this environment as a shield. Pseudo surface microwaves interacting with an artificial intelligence equipped on board are used to create and to adjust this plasma environment for a particular application. This plasma environment provides potential capabilities of military applications of the plasma in the system. Examples of military applications include a stealth system from RADAR and SONAR, a protection system from WMD, and a weapon system to generate and launch plasmoids as a plasma gun. The scope of this invention extends to commercial applications of this plasma shielding system as a conditioned and controlled flow field, for example, a boundary layer and turbulence control system, and a lift control system to improve flight performance and flight economy of aircrafts. It further extends to develop a concept of a new type of engine using this plasma shielding system as a heating method alternative to the conventional combustion method that uses petroleum based fuel in the combustion chamber of an engine.

Owner:HIGMAN KUMIKO I

Plasma processing apparatus

ActiveUS6876154B2Zero net effectIncrease controlElectric arc lampsSolid cathode detailsPlasma processingMagnetic mirror

This invention relates to plasma processing apparatus and in particular, but not exclusively, to inductively coupled plasma helicon or electron cyclotron resonance apparatus. A plasma generation chamber is sat above a process chamber, in which is located a workpiece support. A plasma generation or source region exists and coils are provided to create magnetic mirrors above and below the plasma generation zone, whereby electrons will be reflected back towards the plasma zone and there is no electrical conductive path extending around or through at least the upper mirror.

Owner:SPTS TECH LTD

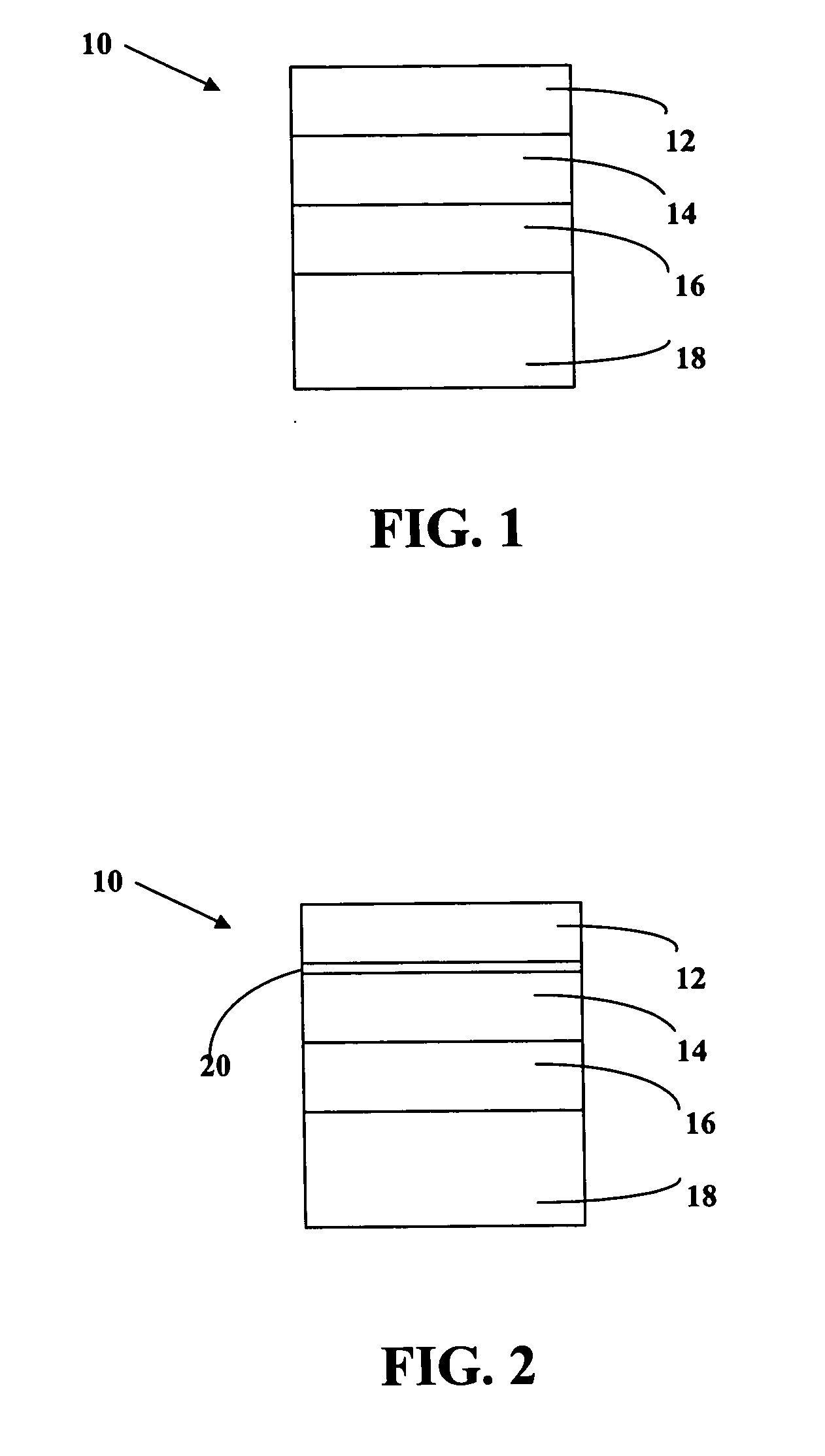

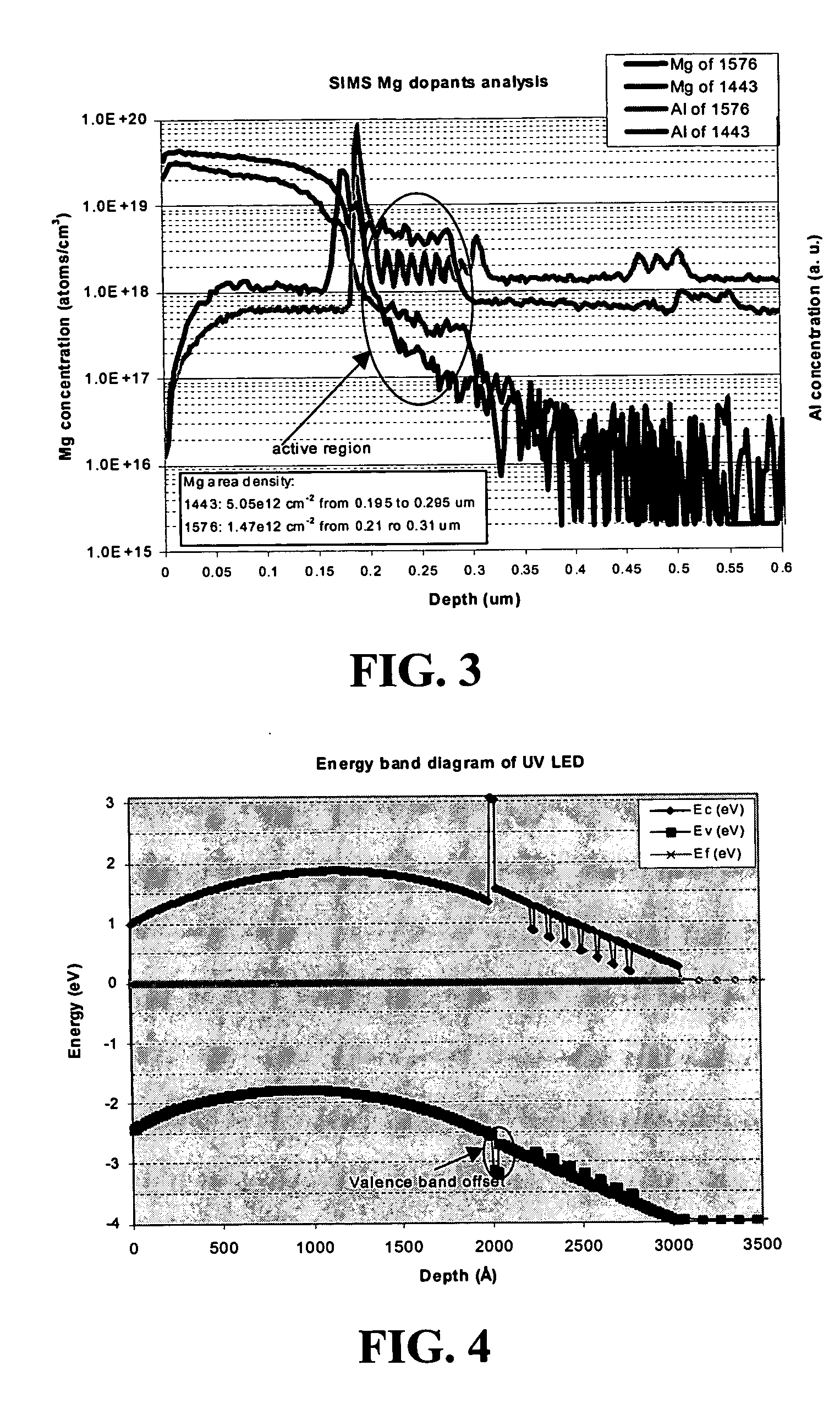

III-nitride optoelectronic device structure with high Al AlGaN diffusion barrier

ActiveUS20040222431A1Suppressing migrationSuppress DiffuseSemiconductor devicesDopantDiffusion barrier

A III-nitride electronic device structure including doped material, an active region and a barrier material arranged to suppress transport of dopant from the doped material into the active region, wherein the barrier material comprises high-Al content AlxGayN, wherein x+y=1, and x>=0.50. In a specific aspect, AIN is used as a migration / diffusion barrier layer at a thickness of from about 5 to about 200 Angstroms, to suppress flux of magnesium and / or silicon dopant material into the active region of the III-nitride electronic device, e.g., a UV LED optoelectronic device.

Owner:CREELED INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com