Patents

Literature

37results about How to "Suppression of Leakage Flux" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

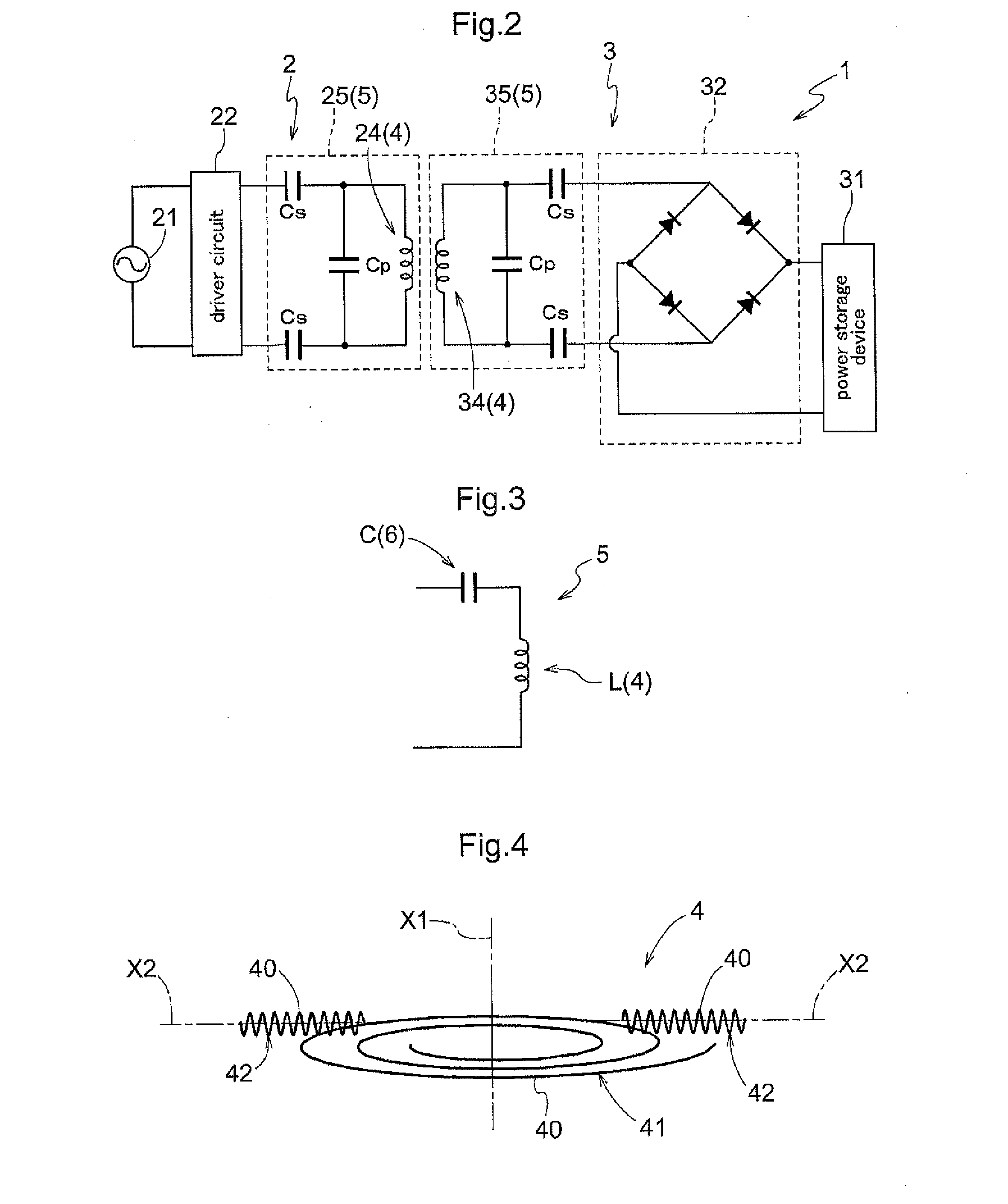

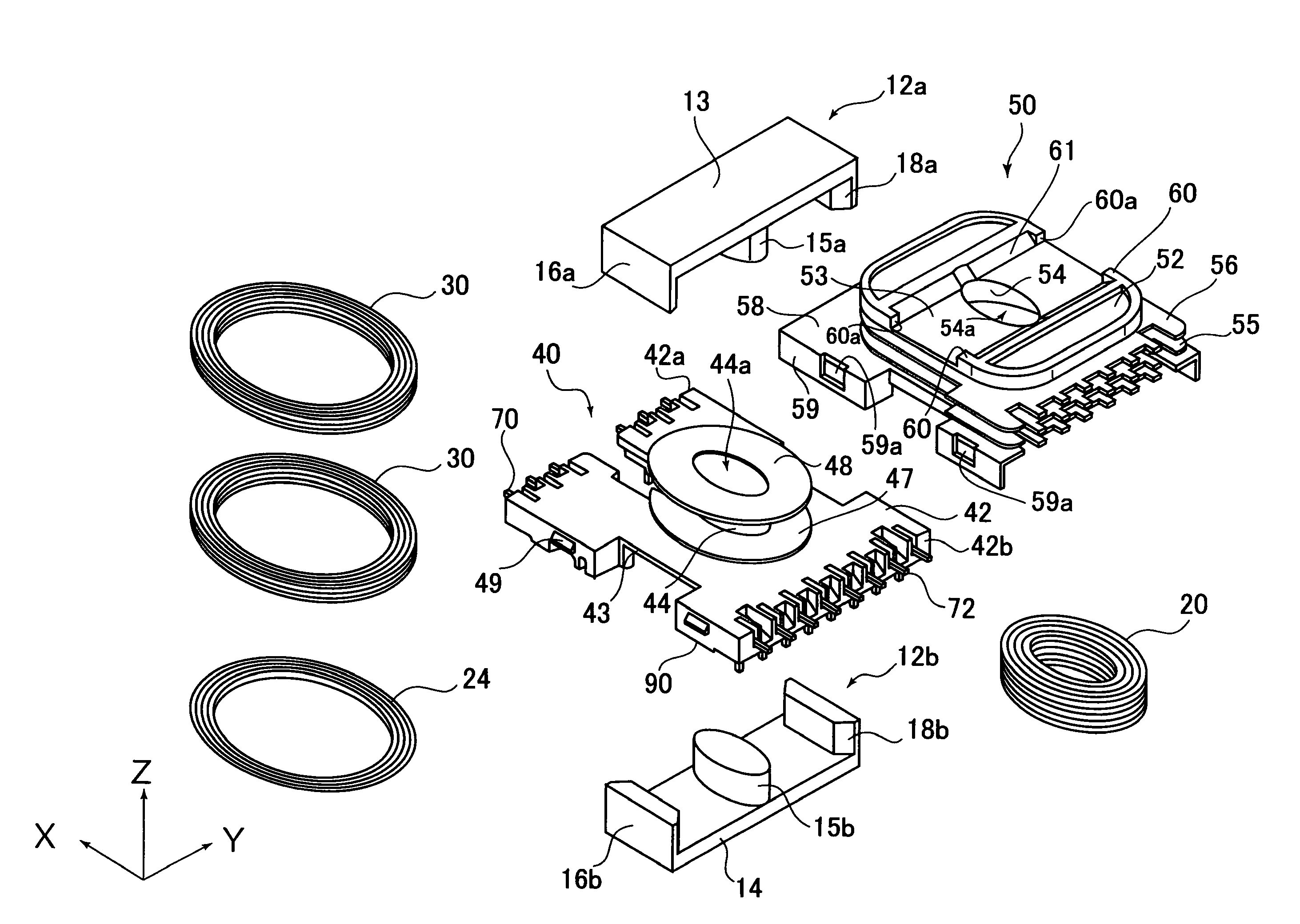

Antenna coil

InactiveUS20150137612A1Reduced strengthTransmission limitLoop antennas with ferromagnetic coreCharging stationsMagnetic fluxPhysics

Provided is an antenna coil capable of forming a magnetic field in a desired direction in an efficient manner, while suppressing leakage of magnetic flux into a space other than the space in which the magnetic field is formed. The antenna coil includes a main coil portion formed by winding a length of conductor wire around a first reference axis and an auxiliary coil portion formed by winding the conductor wire around a second reference axis. The second reference axis is set to intersect the magnetic flux of the main coil portion at an axial end of the auxiliary coil portion. The main coil portion and the auxiliary coil portion are connected to together form a closed circuit.

Owner:EQUOS RES

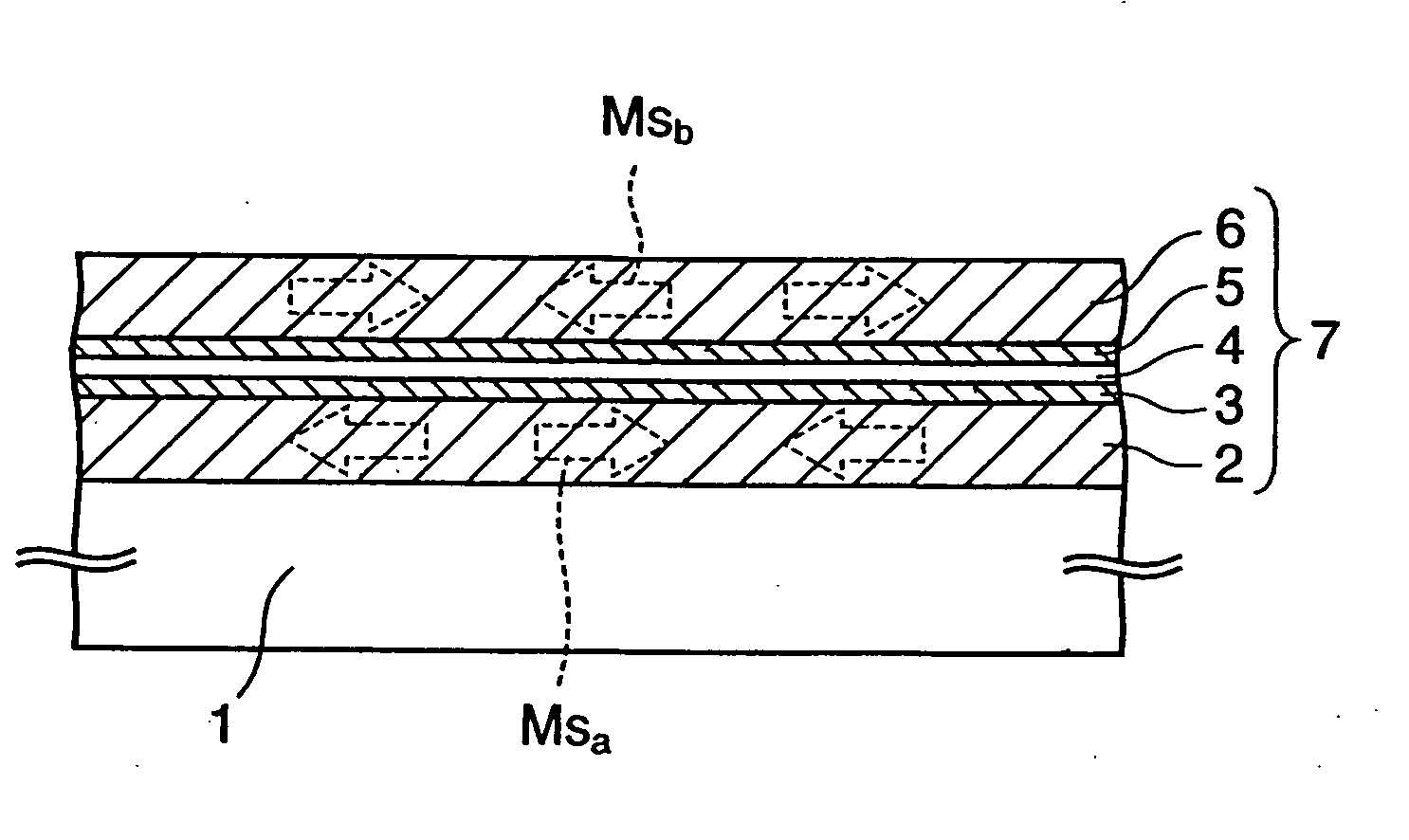

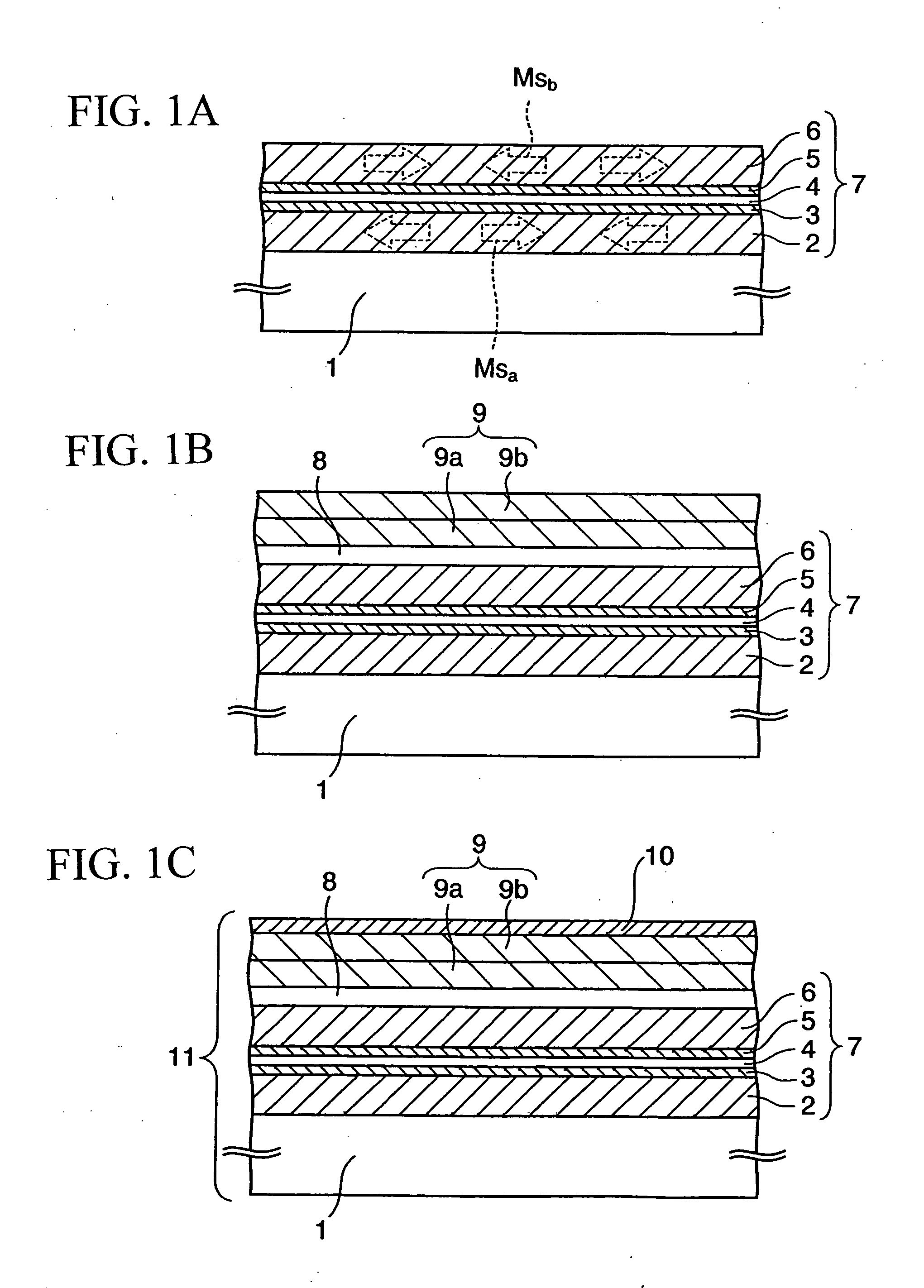

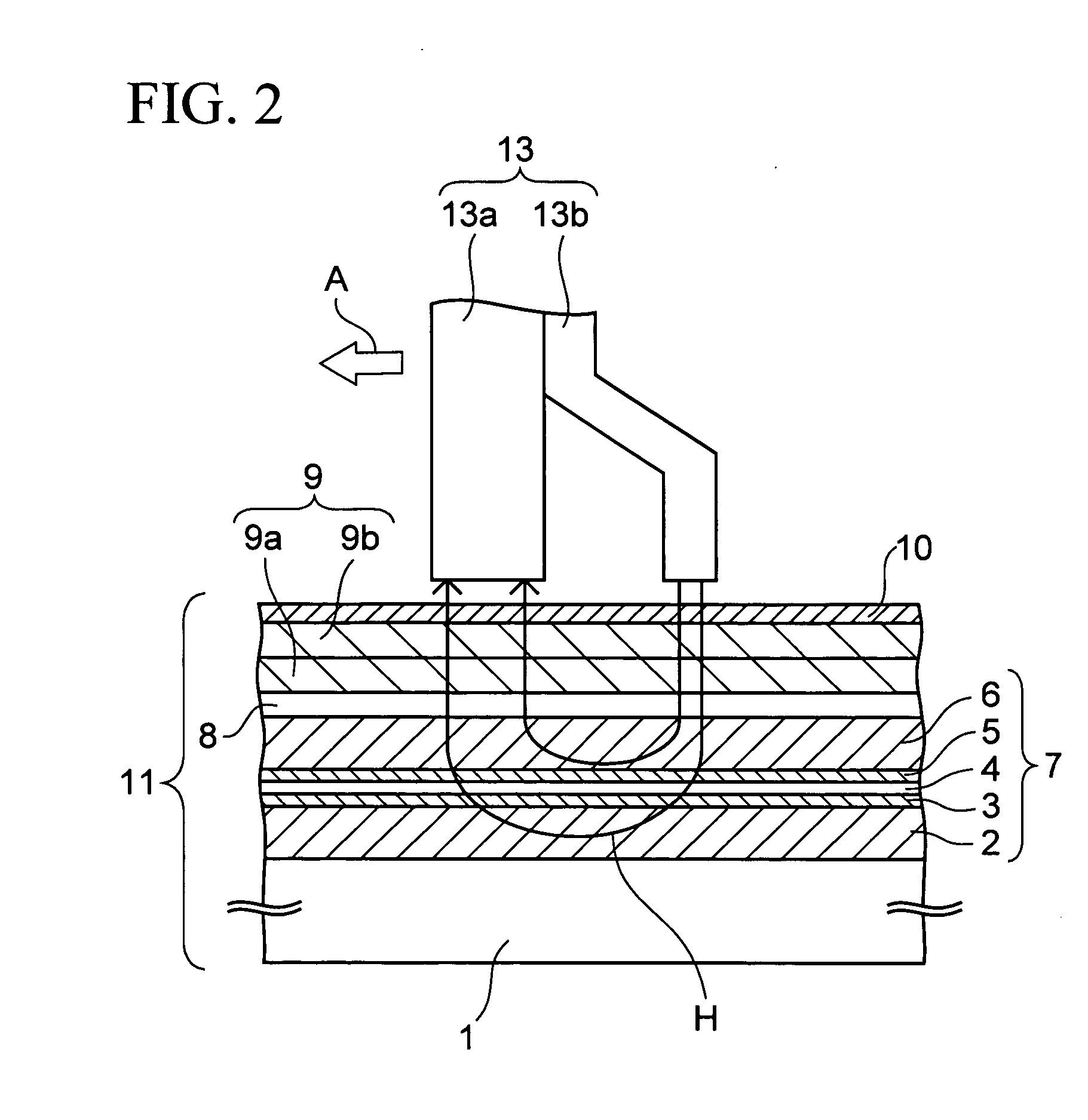

Magnetic recording medium, method of manufacturing the same, and magnetic recording apparatus

InactiveUS20070217071A1Improve film qualitySuppression of Leakage FluxRecord information storageDisk carriersRecording layerNon magnetic

According to the present invention, provided is a magnetic recording medium 11 comprising: a non-magnetism base member 1; a lower soft magnetic underlying layer 2 formed on the non-magnetism base member 1; a non-magnetic layer 4 formed on the lower soft magnetic underlying layer 2; an upper soft magnetic underlying layer 6 formed on the non-magnetic layer 4; and a recording layer 9 having a perpendicular magnetic anisotropy, the recording layer 9 being formed on the upper soft magnetic underlying layer 6, wherein crystalline magnetic layers 3 and 5 are formed between the lower soft magnetic underlying layer 2 and the non-magnetic layer 4 or between this non-magnetic layer 4 and the upper soft magnetic underlying layer 6.

Owner:SHOWA DENKO KK

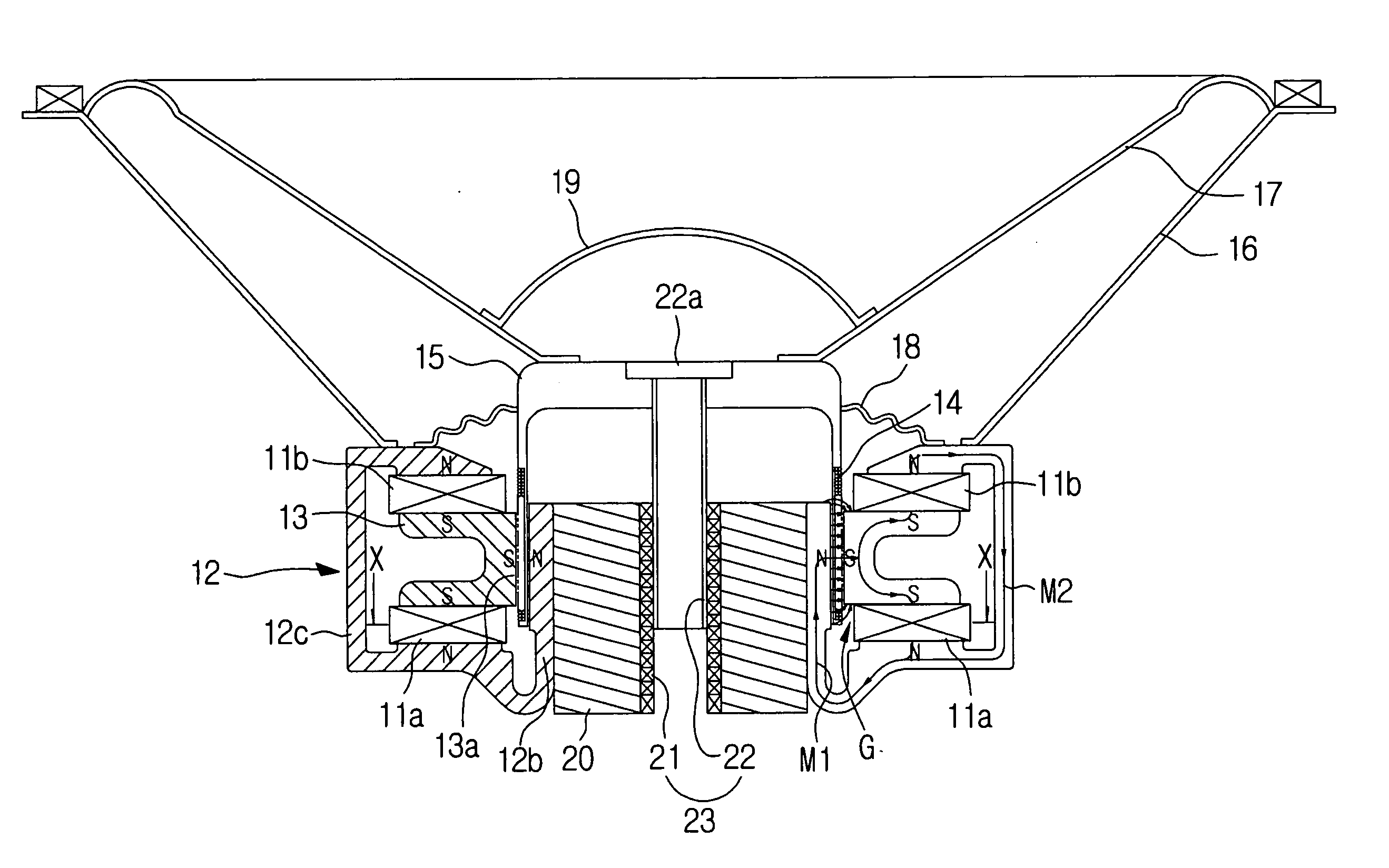

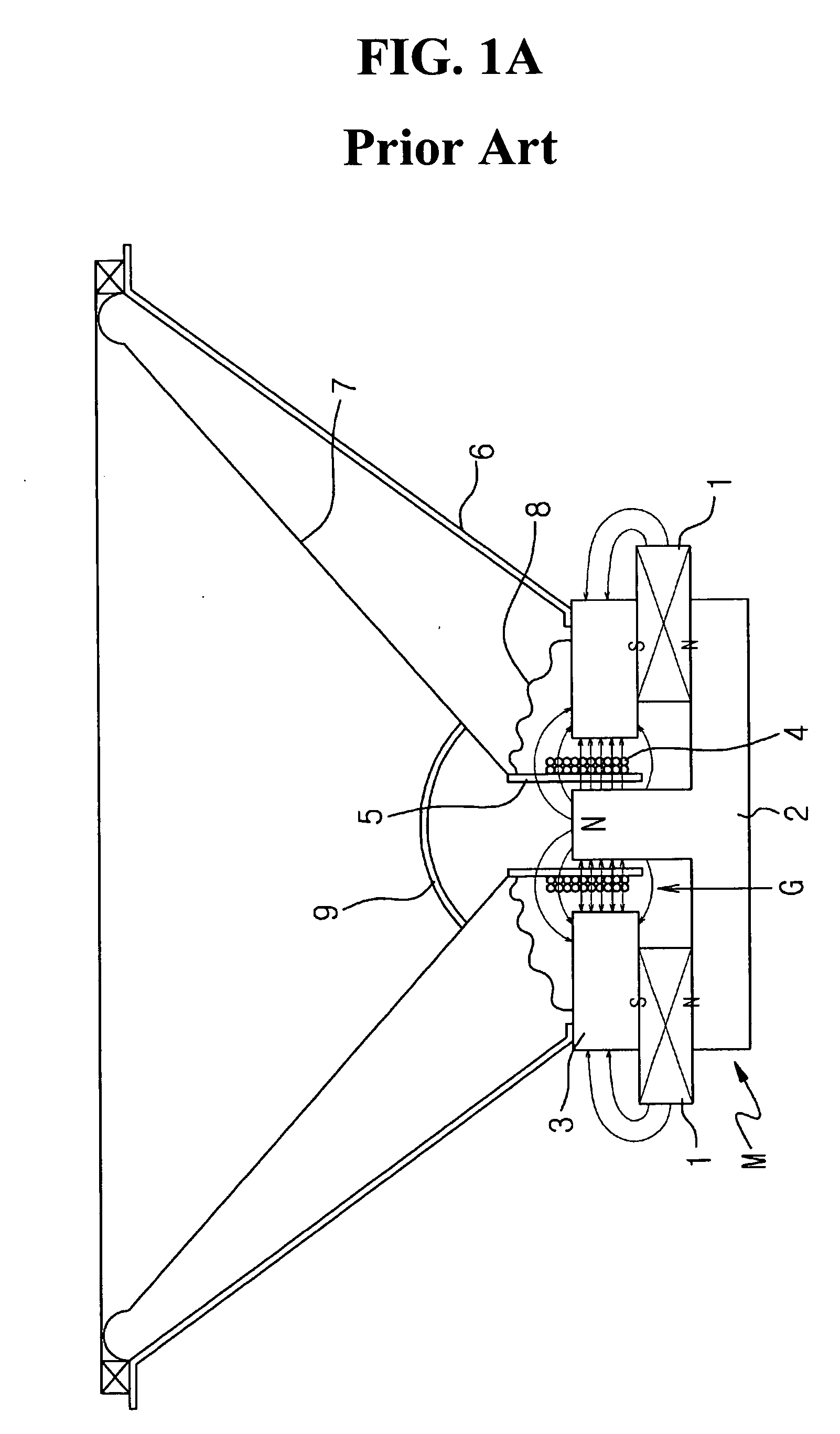

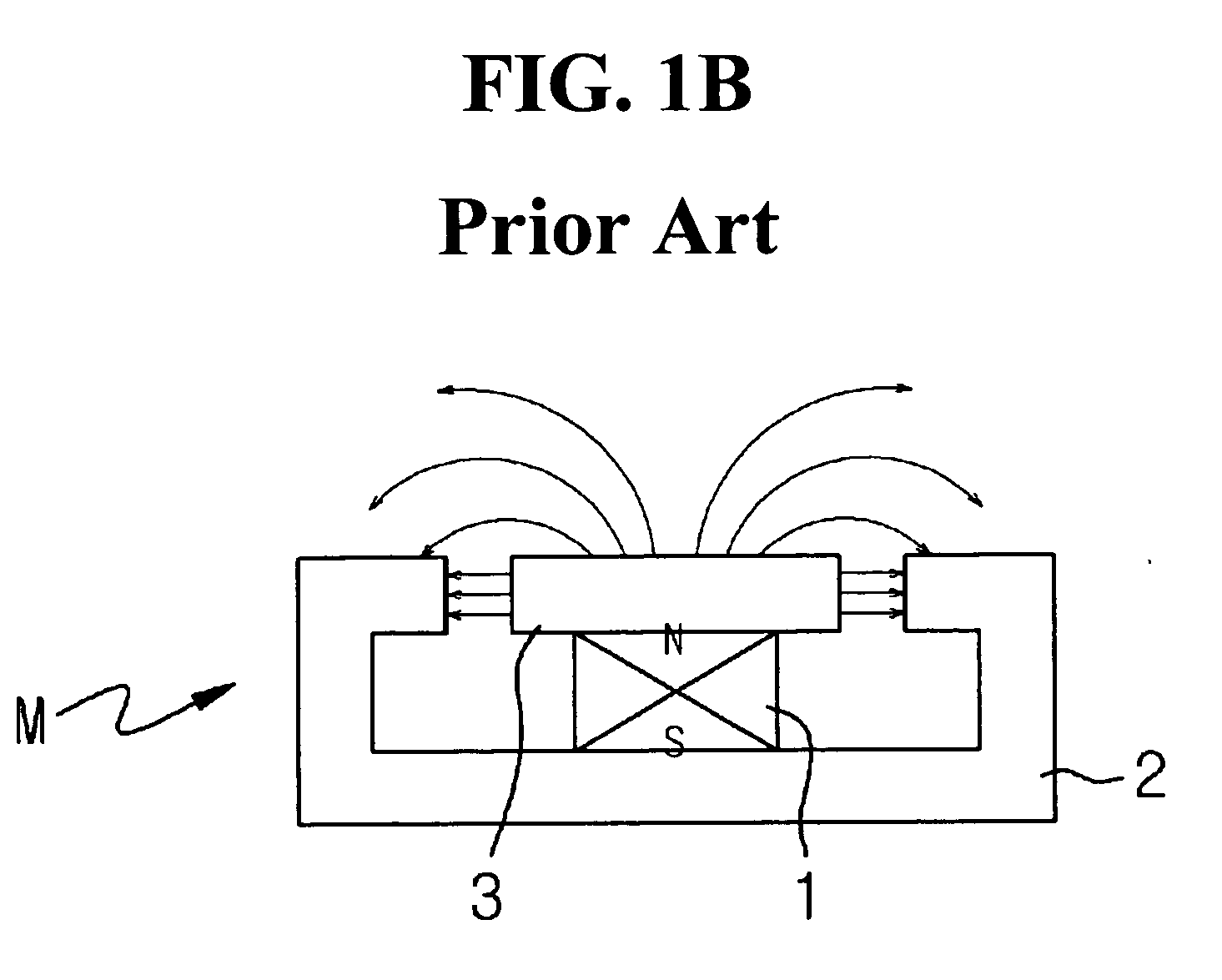

Magnetic circuit having dual magnets, speaker and vibration generating apparatus using the same

InactiveUS20060093180A1Good linear responseAvoid Flux LeakageTransducer detailsHearing device energy consumption reductionBobbinElectrical polarity

A magnetic circuit having a dual magnet, a speaker and a vibration generating apparatus using the same are provided. The magnetic circuit includes a magnetic gap having a small magnetic loss and an increasing magnetic flux density, in which a uniform distribution of a line of magnetic force can be realized on yoke surfaces facing each other. The speaker includes lower and upper magnets which are spaced so that mutually identical polarities oppose each other; a first yoke integrally having a loop-type circulating circuit portion extended from the lower magnet to the upper magnet and an extension portion which is extended perpendicularly upwards from the lower magnet; a second yoke which connects between the lower and upper magnets and forms a magnetic gap between the second yoke and the extension portion of the first yoke; a coil disposed in the magnetic gap and wound around a bobbin; a frame which is extended from the first yoke; a vibrating diaphragm generating an acoustic sound in correspondence to a drive signal; a damper limiting a vibration range of the bobbin; and a center cap covering the bobbin.

Owner:KIM SEONG BAE

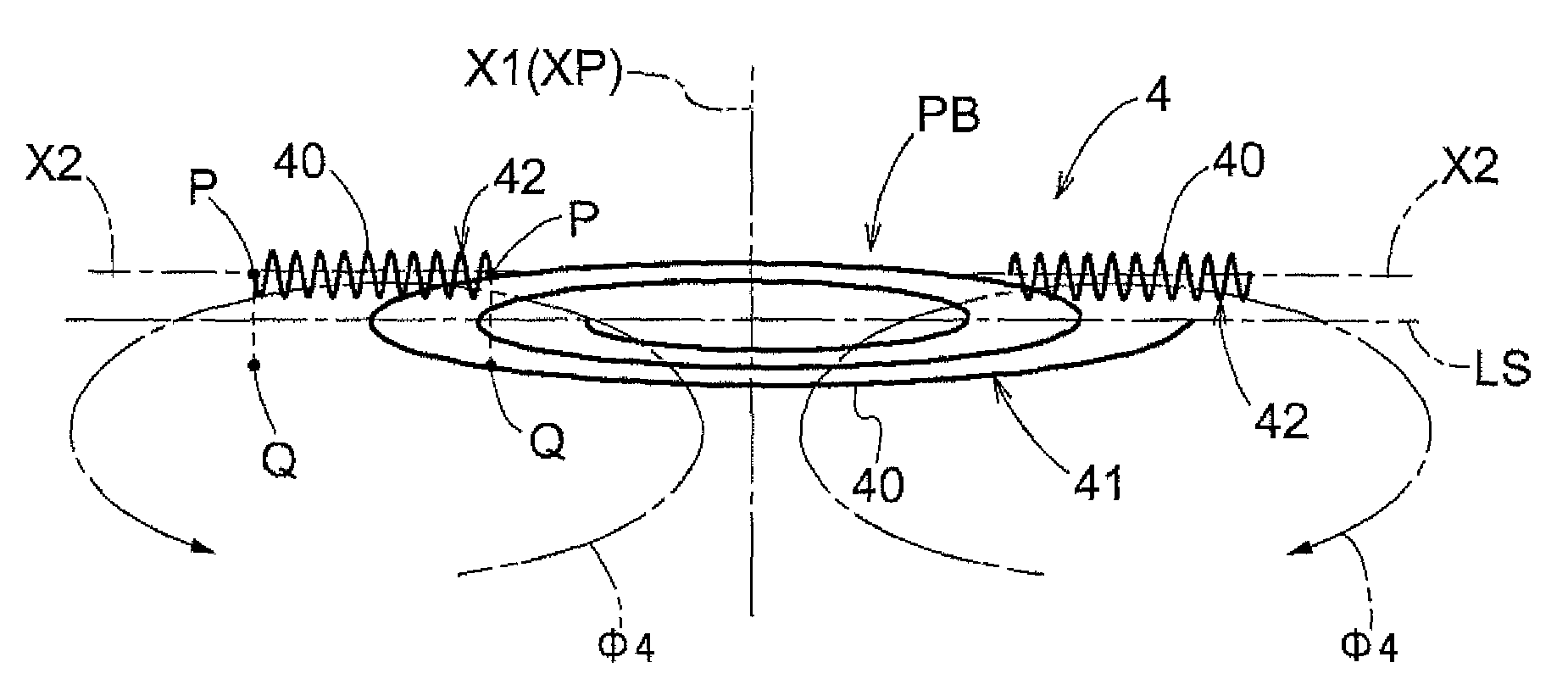

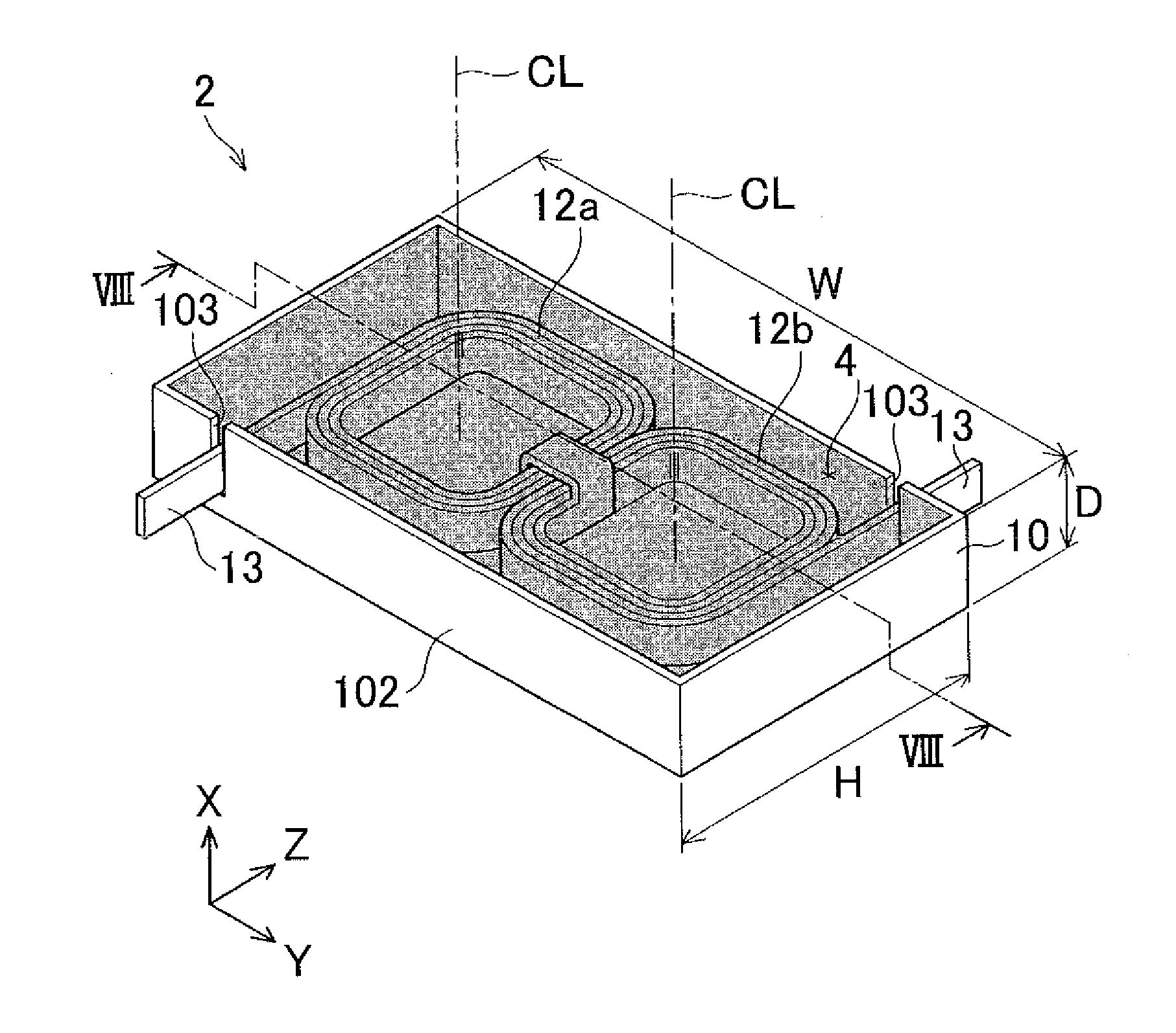

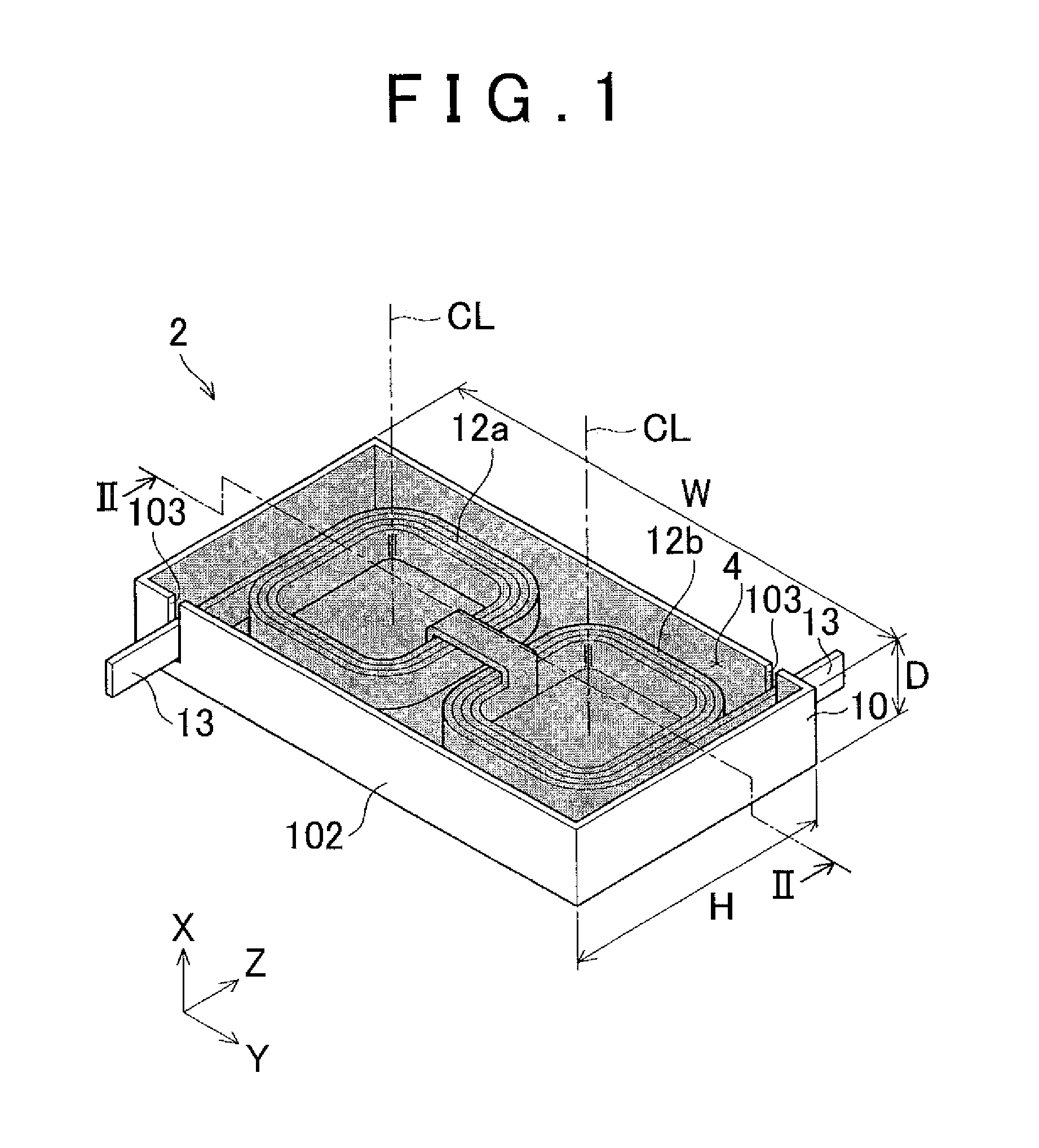

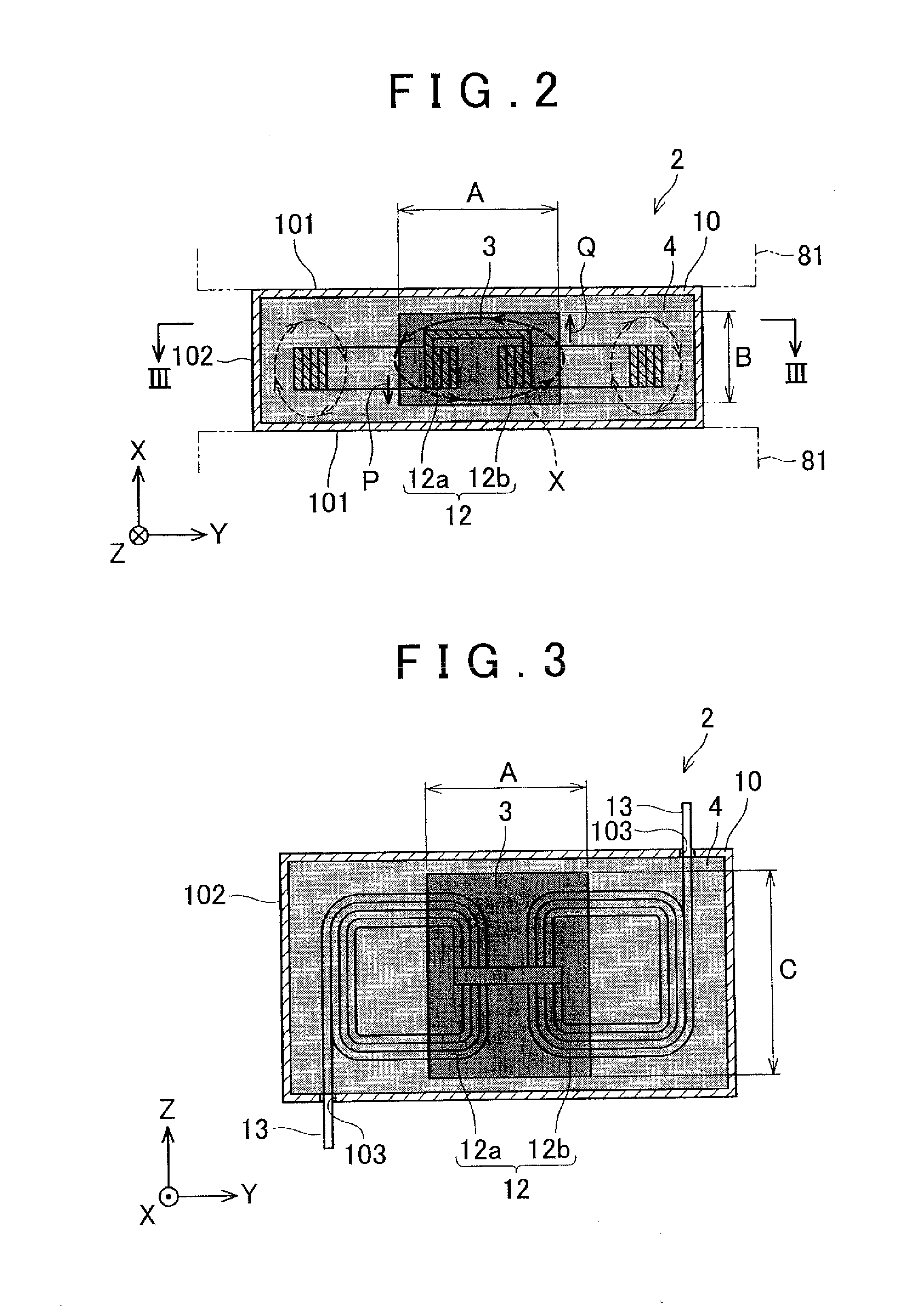

Antenna coil comprising plurality of coil portions

InactiveUS9318258B2Suppression of Leakage FluxEfficiently formedLoop antennas with ferromagnetic coreBatteries circuit arrangementsMagnetic fluxPhysics

Provided is an antenna coil capable of forming a magnetic field in a desired direction in an efficient manner, while suppressing leakage of magnetic flux into a space other than the space in which the magnetic field is formed. The antenna coil includes a main coil portion formed by winding a length of conductor wire around a first reference axis and an auxiliary coil portion formed by winding the conductor wire around a second reference axis. The second reference axis is set to intersect the magnetic flux of the main coil portion at an axial end of the auxiliary coil portion. The main coil portion and the auxiliary coil portion are connected to together form a closed circuit.

Owner:EQUOS RES

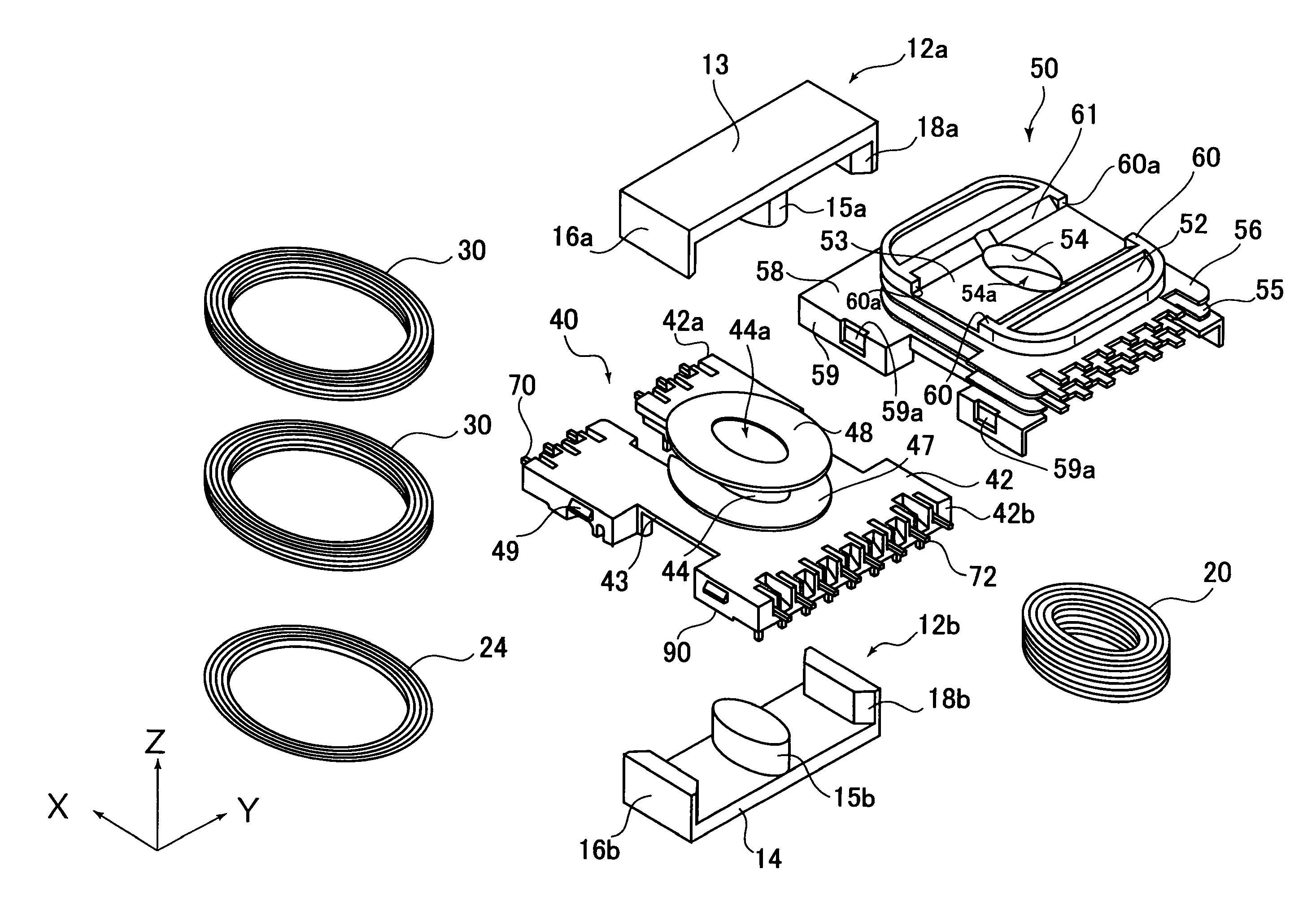

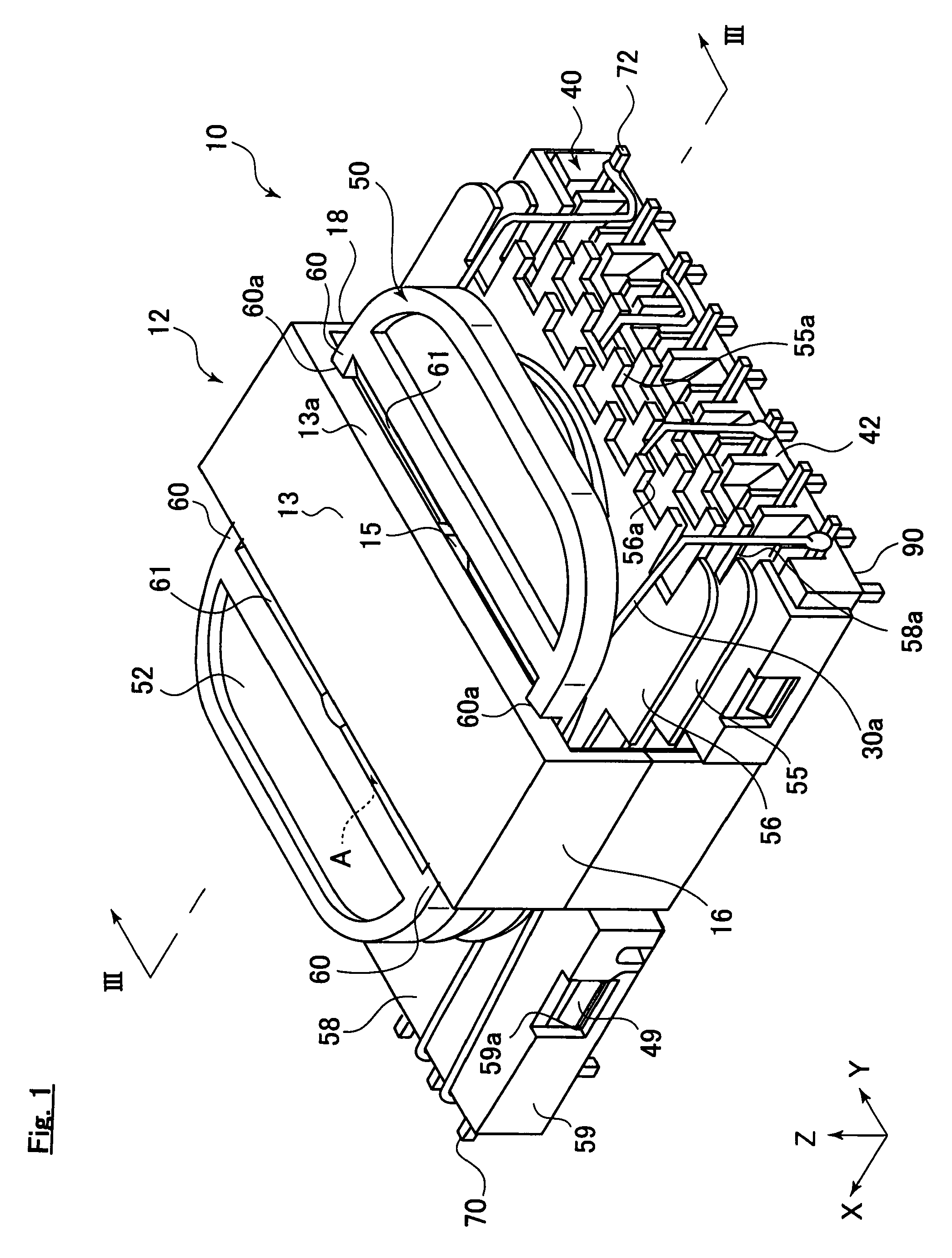

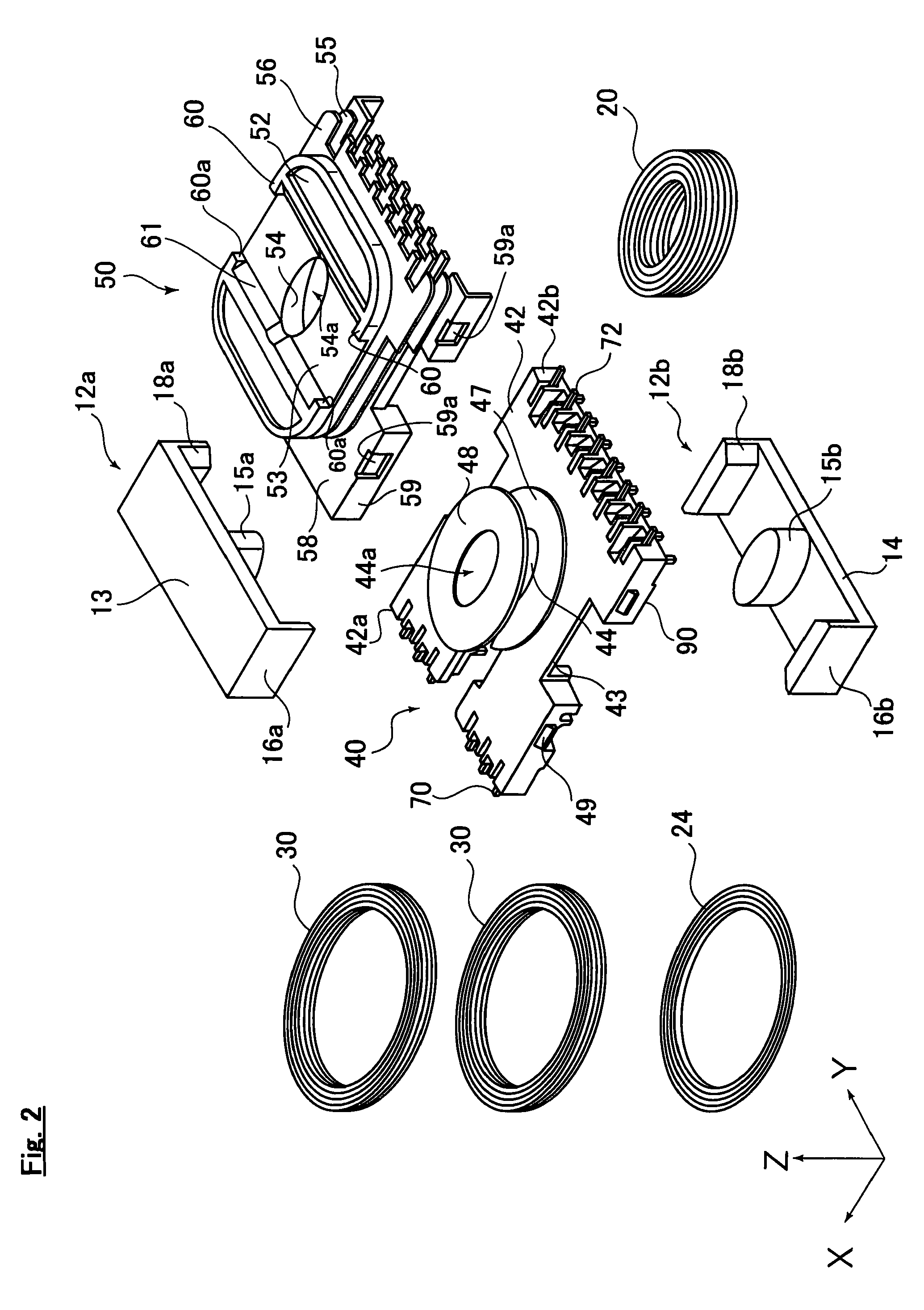

Reactor

InactiveUS20140320249A1Improve cooling effectIncrease inductanceTransformers/inductances coolingTransformers/inductances casingsNuclear engineeringEngineering

Owner:TOYOTA JIDOSHA KK

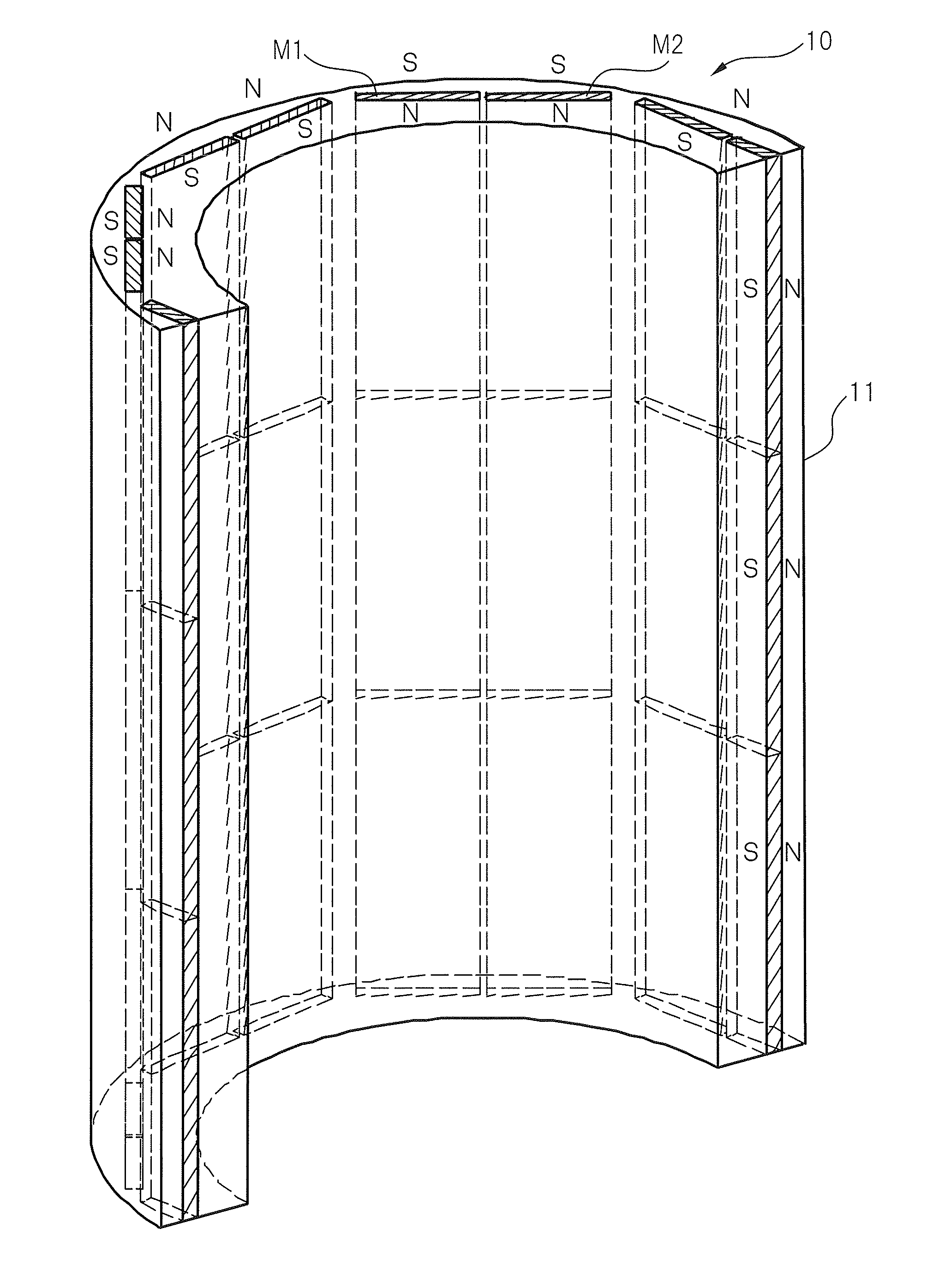

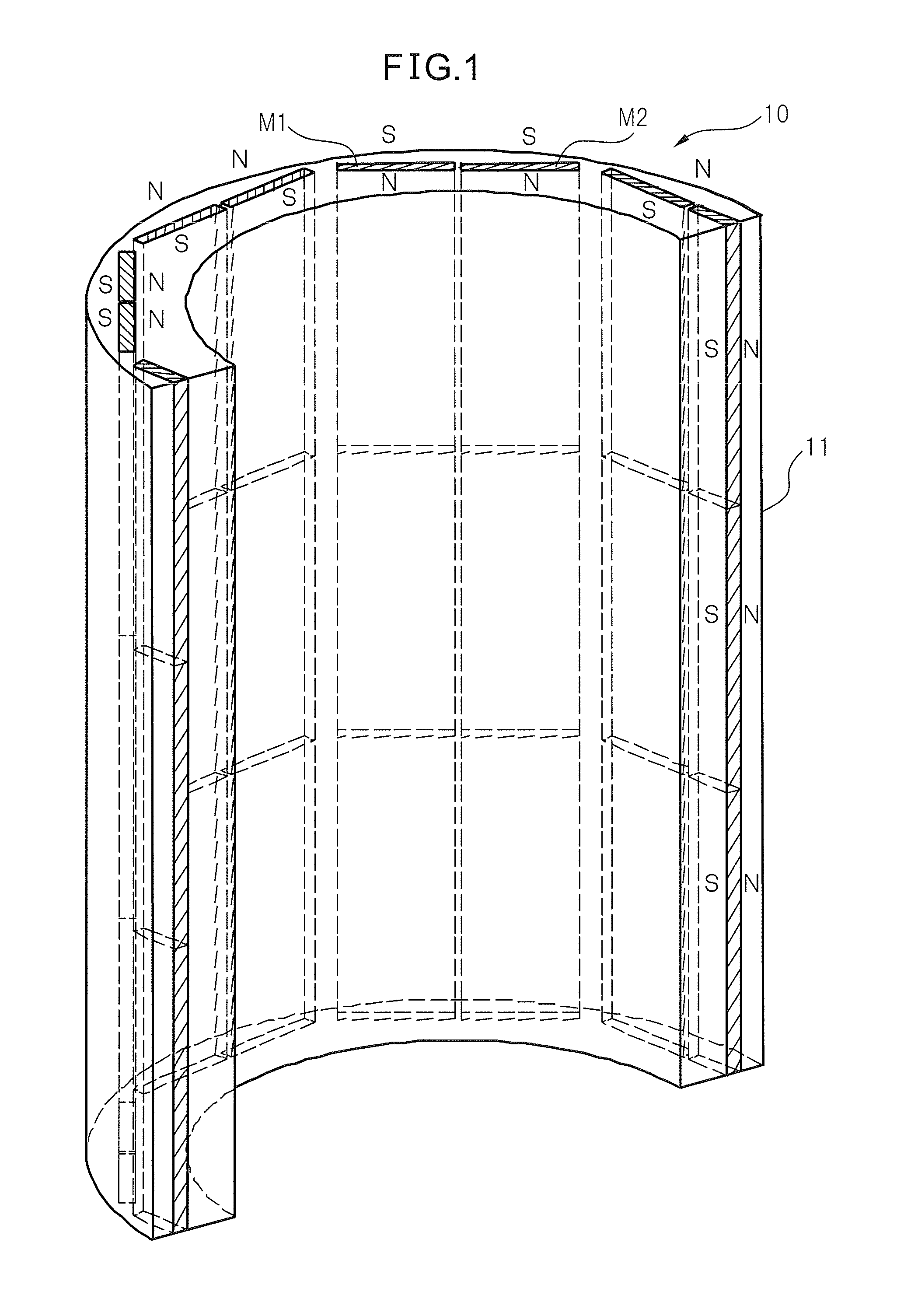

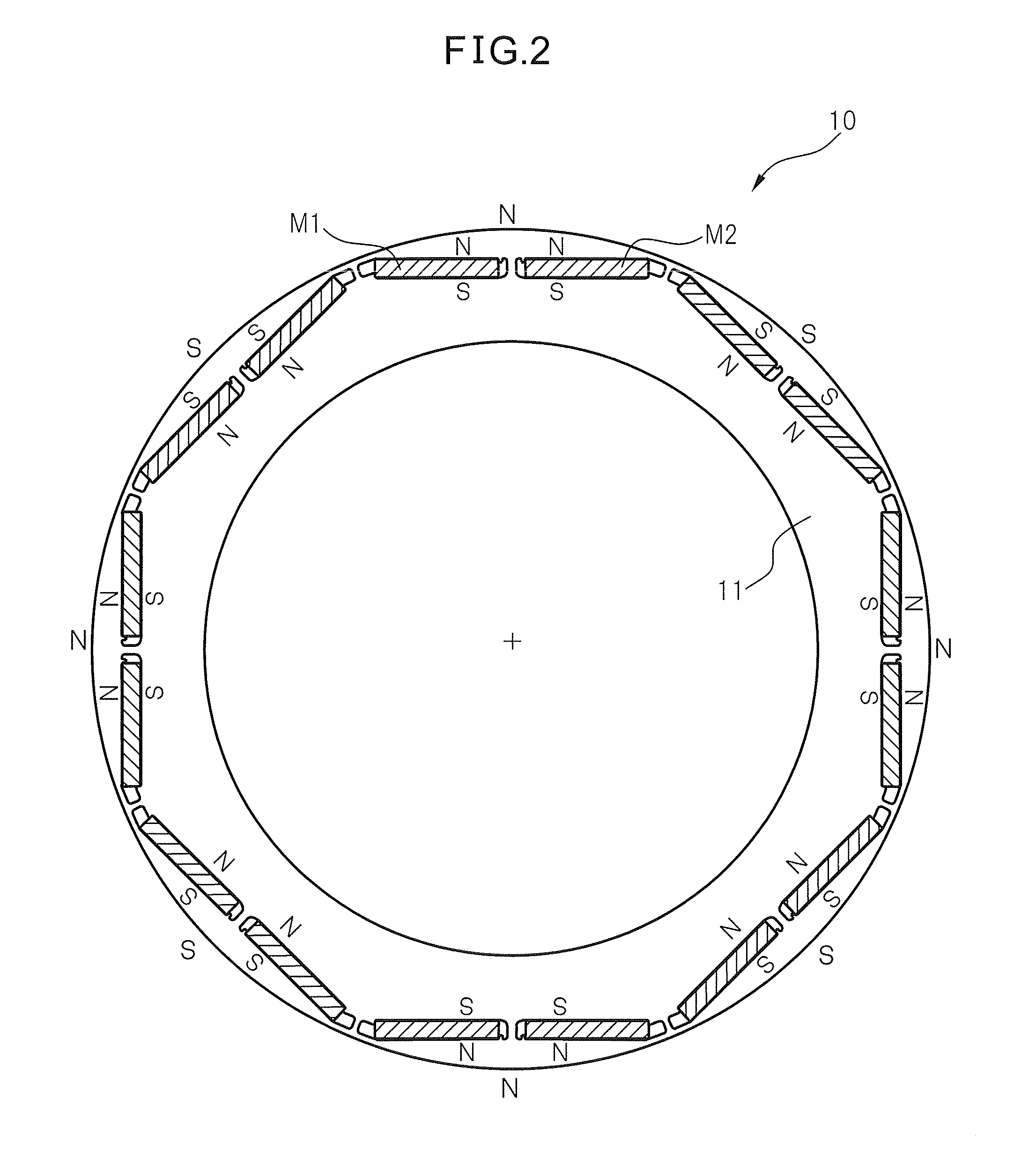

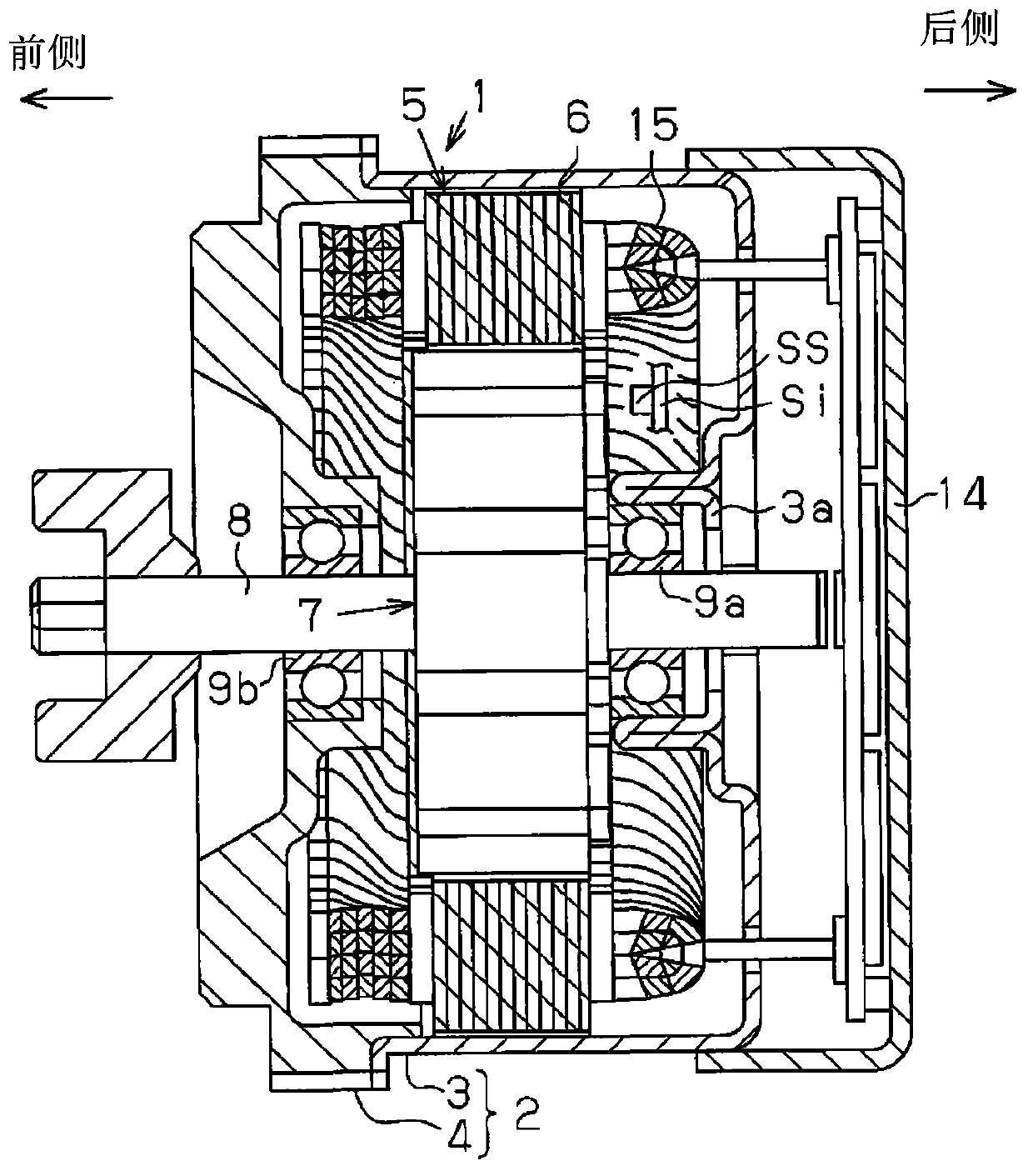

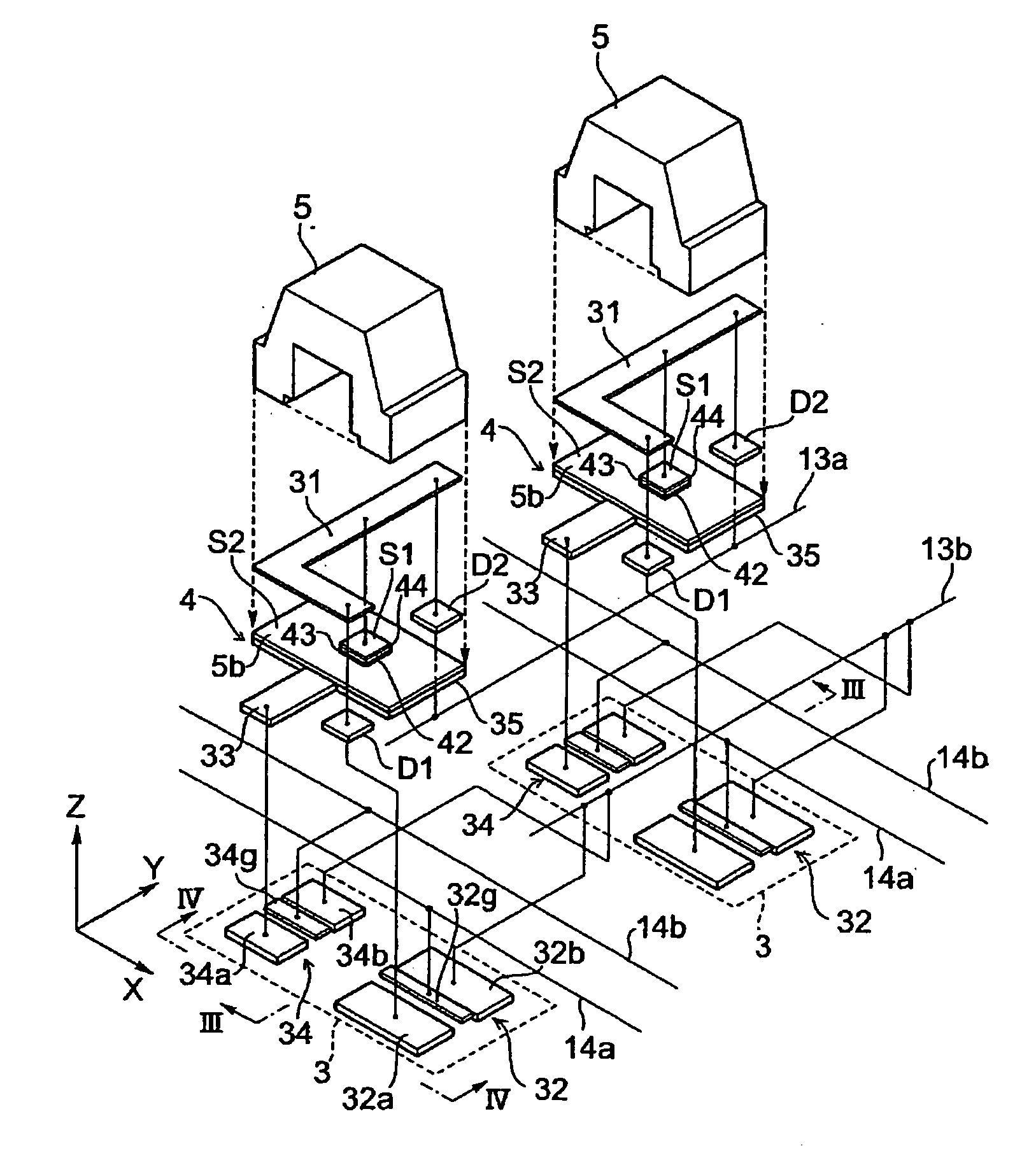

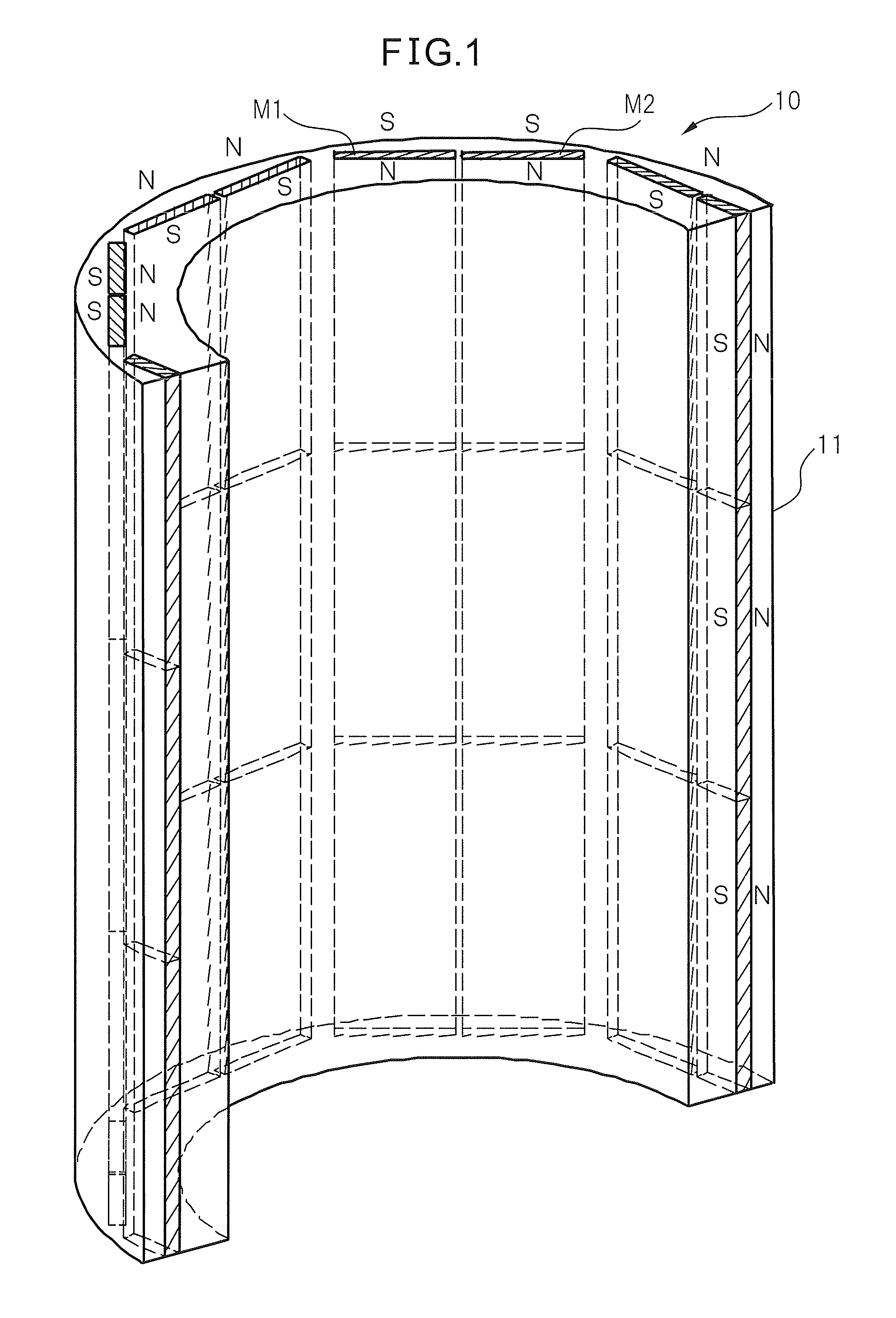

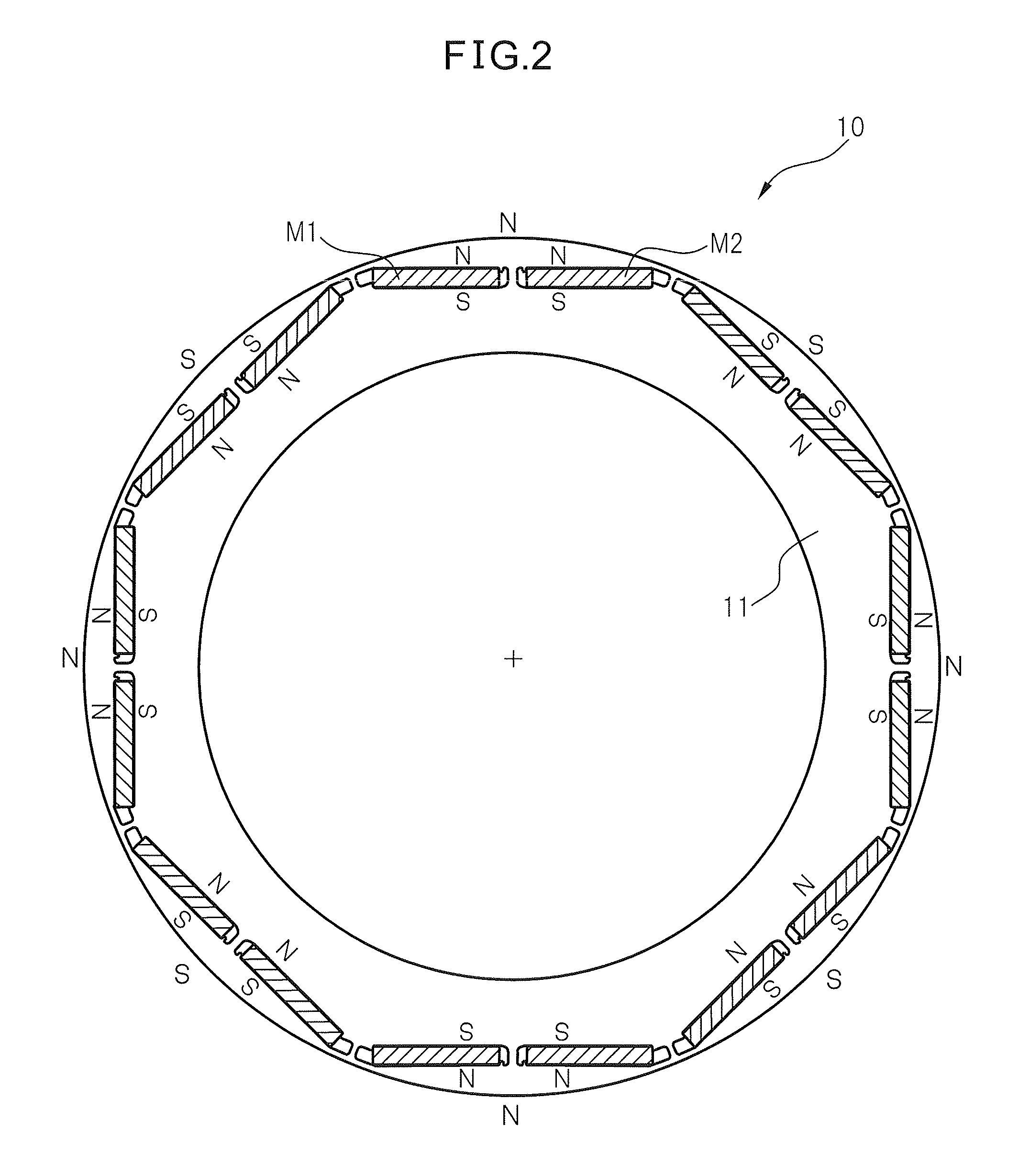

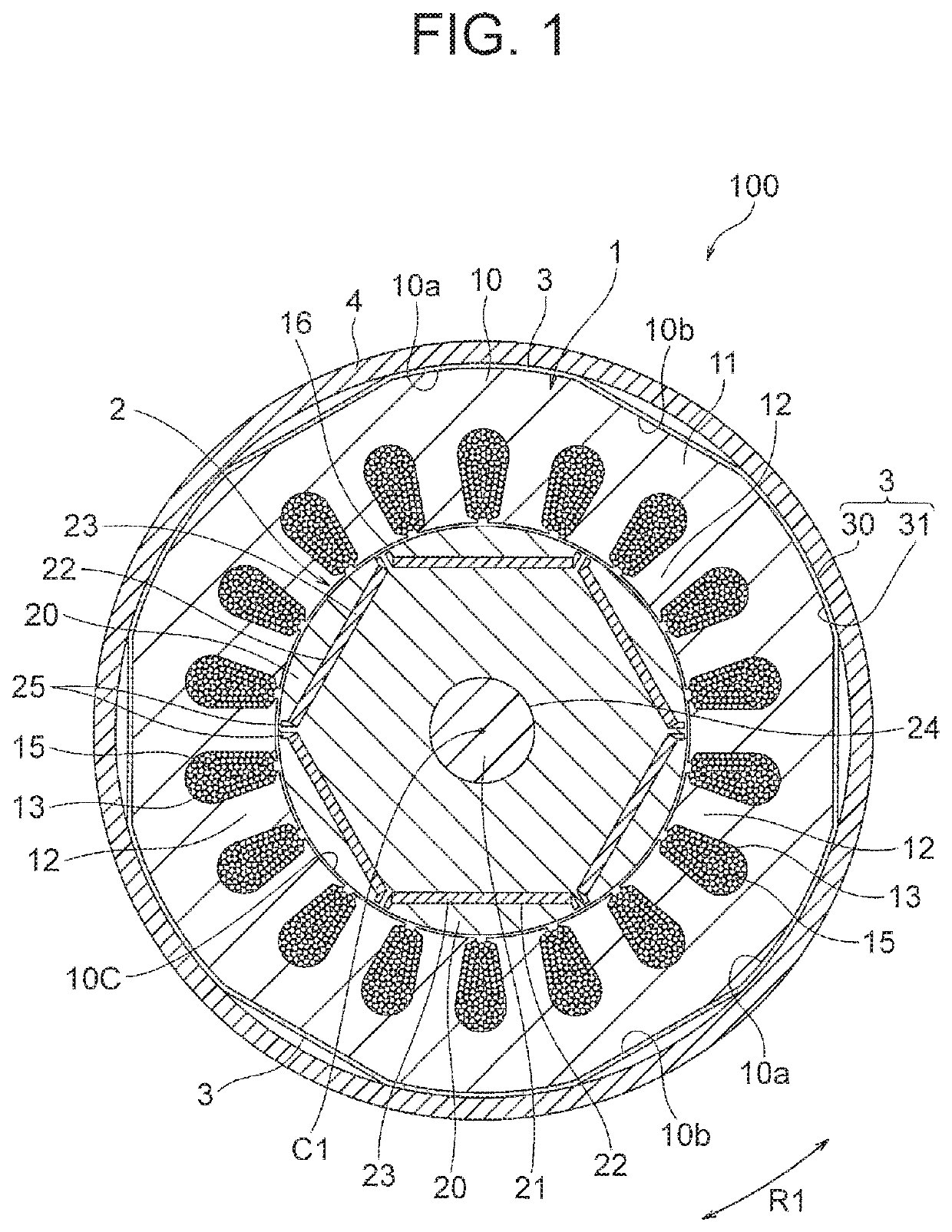

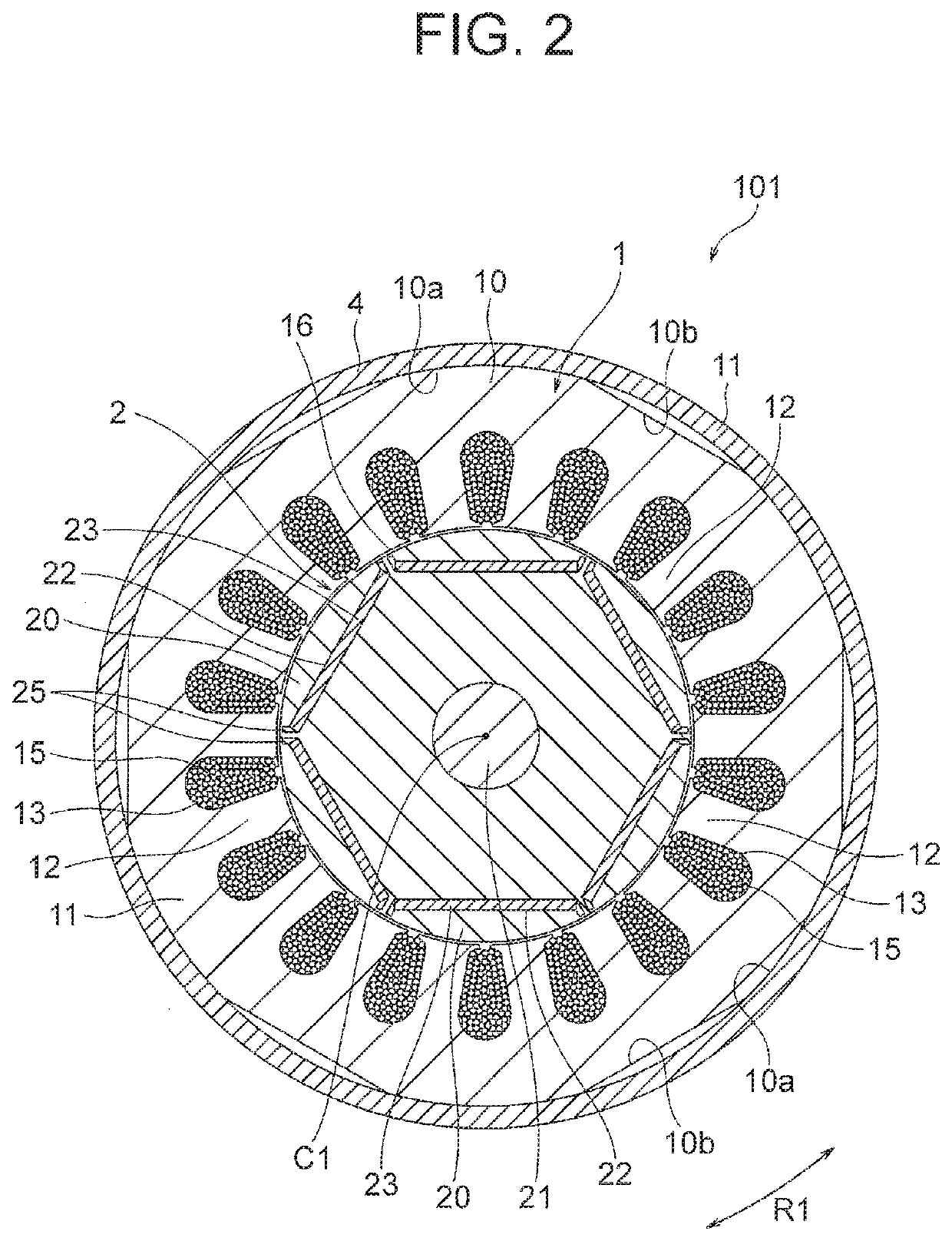

Rotor of permanent magnet synchronous motor, motor and machine tool

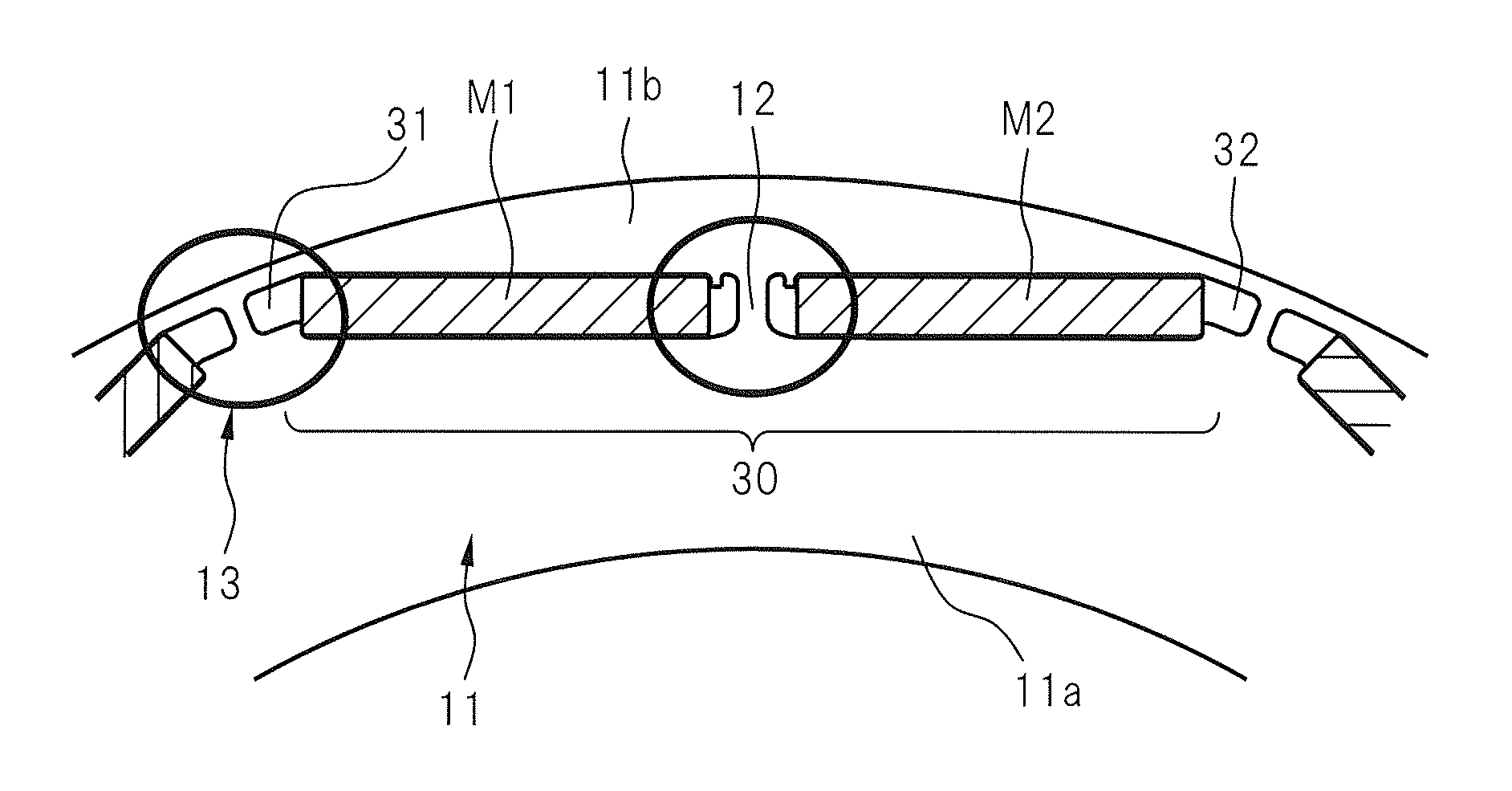

ActiveUS20130119817A1Suppression of Leakage FluxIncrease speedMagnetic circuit rotating partsPermanent magnet synchronous motorMagnetic poles

A rotor (10) of a buried magnet-type electric motor, wherein the magnetic poles thereof are each constituted by two rows of magnets (M1, M2) of the same pole, wherein a core portion (12) between magnet slots of the same pole is arranged between the magnet slots (31, 32) in which the two rows of magnets are arranged, and wherein, of the edges constituting said magnet slots, the portions connecting the edges (31a, 32a) on the inner side in the radial direction to the outer edges of the core portion between the magnet slots of the same pole, have curved portions (41, 42) that connect a curve of a small curvature to a curve of a large curvature starting from the edges on the inner side in the radial direction and heading toward the outer edges of the core portion between the magnet slots of the same pole.

Owner:FANUC LTD

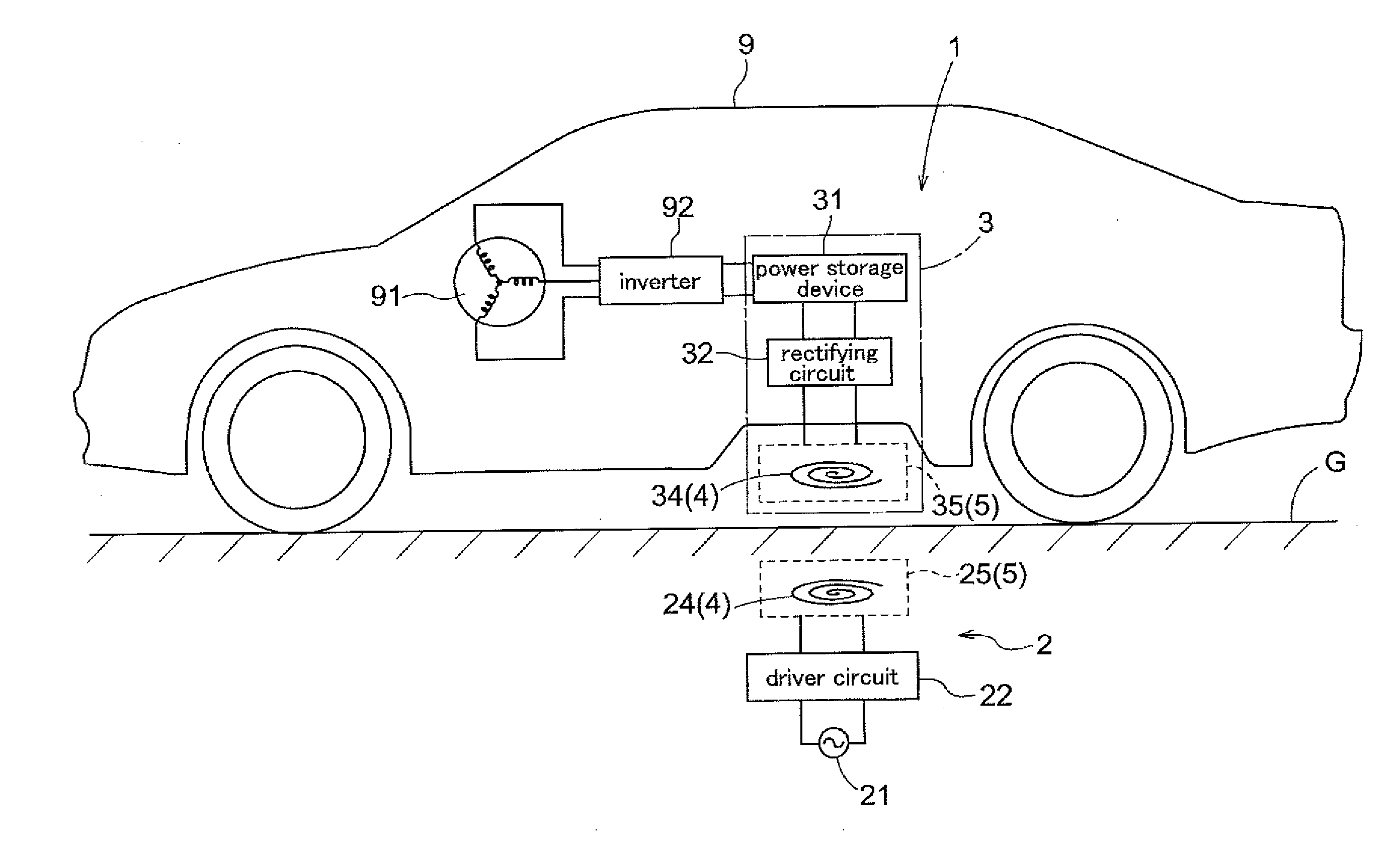

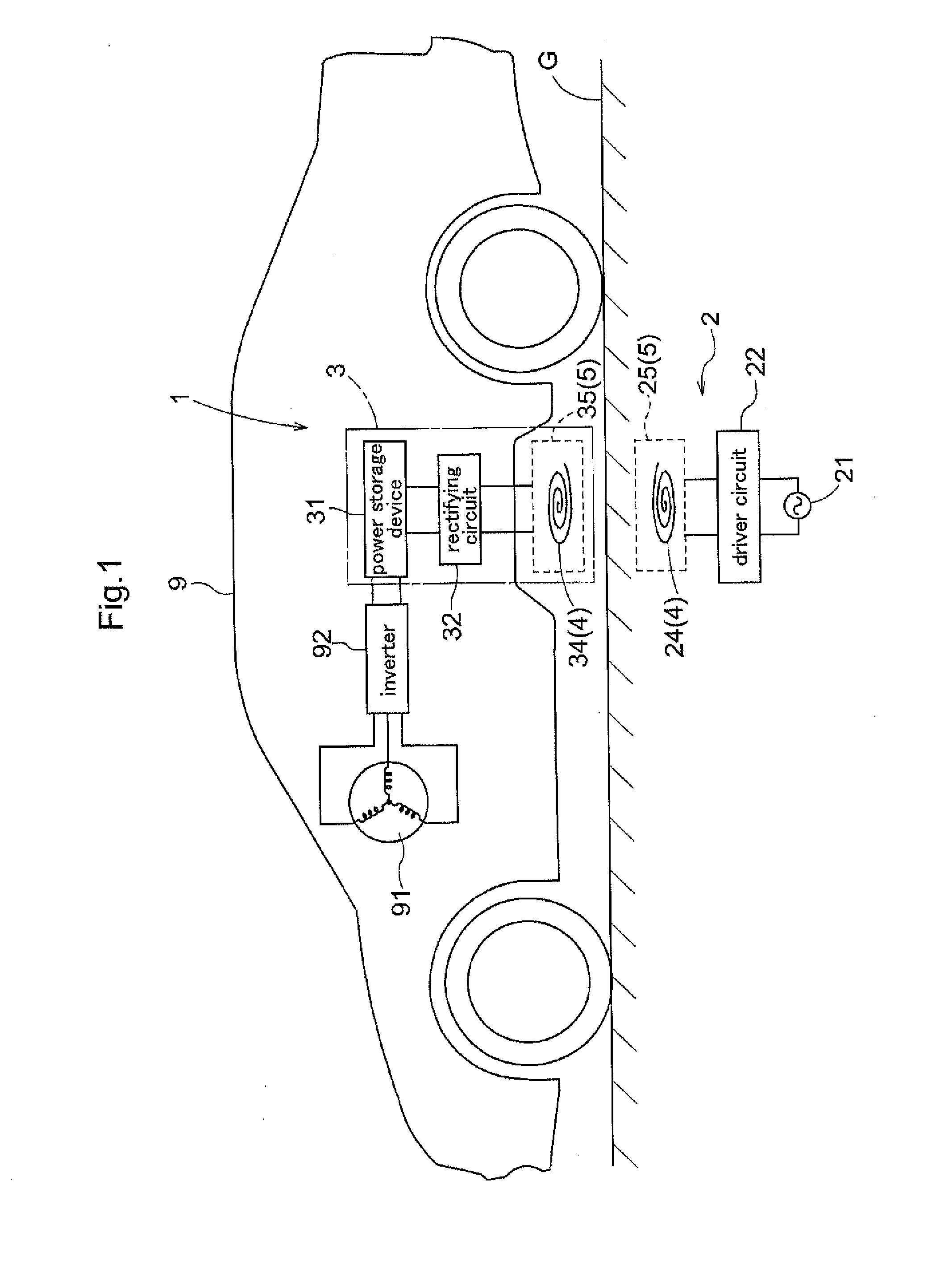

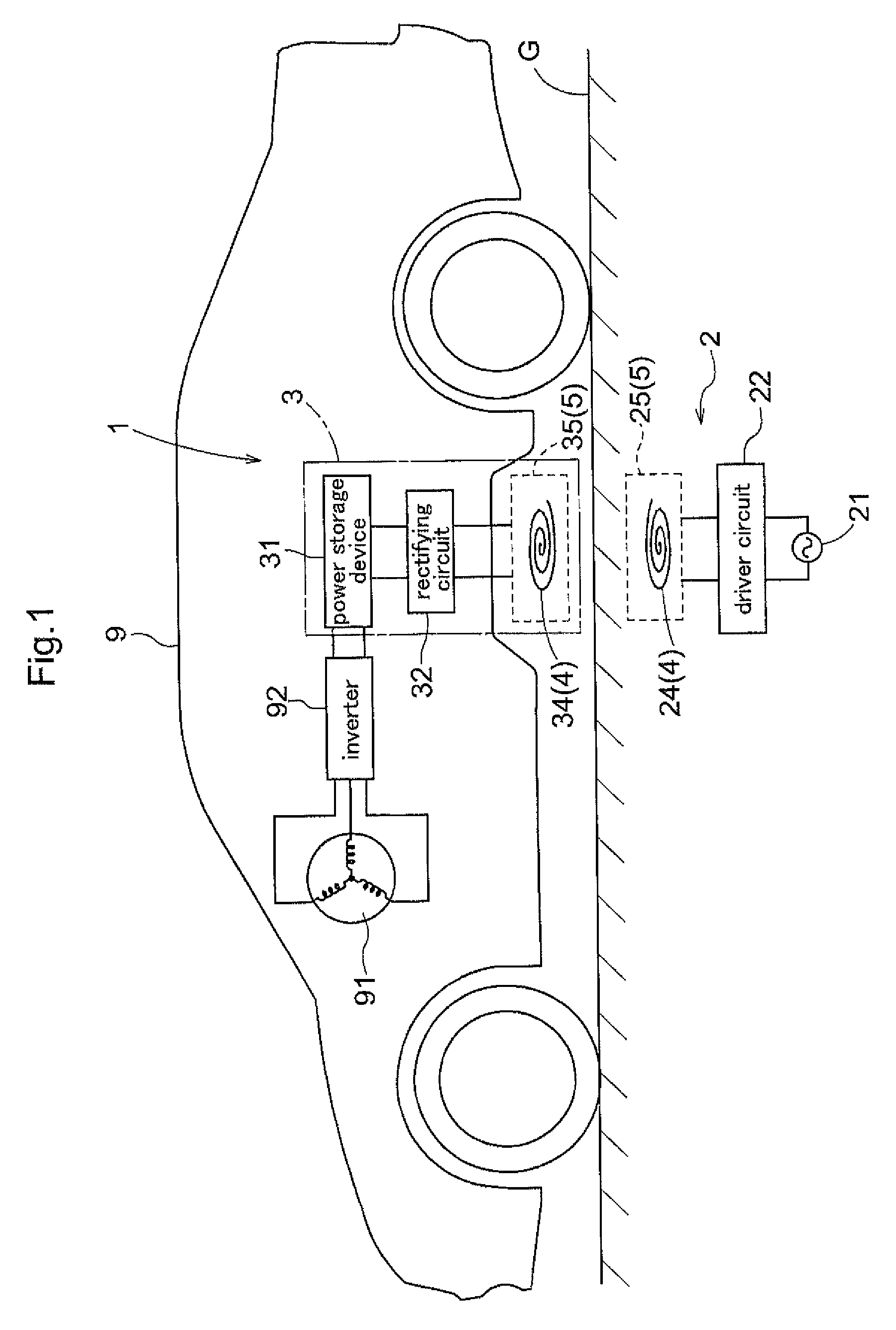

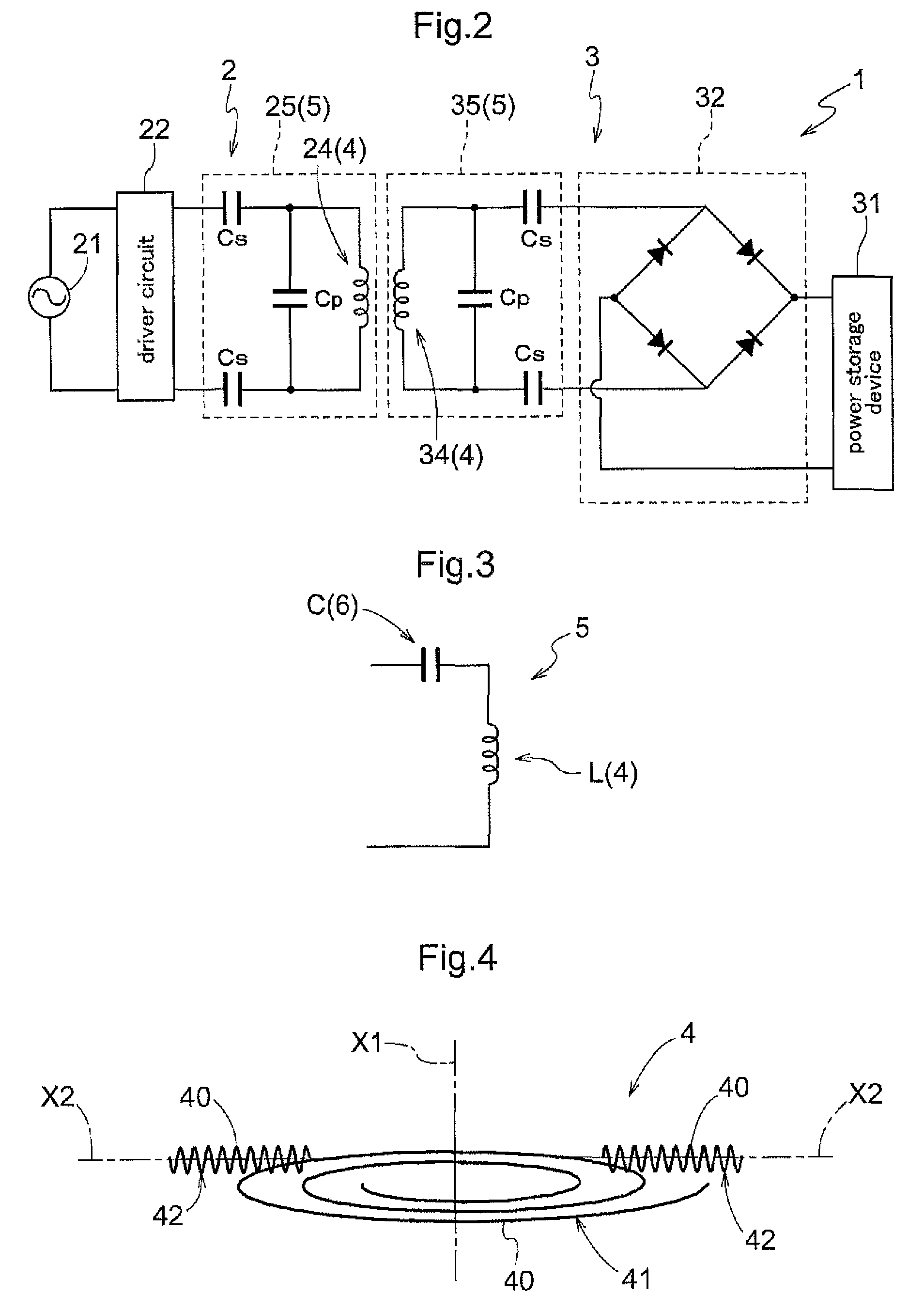

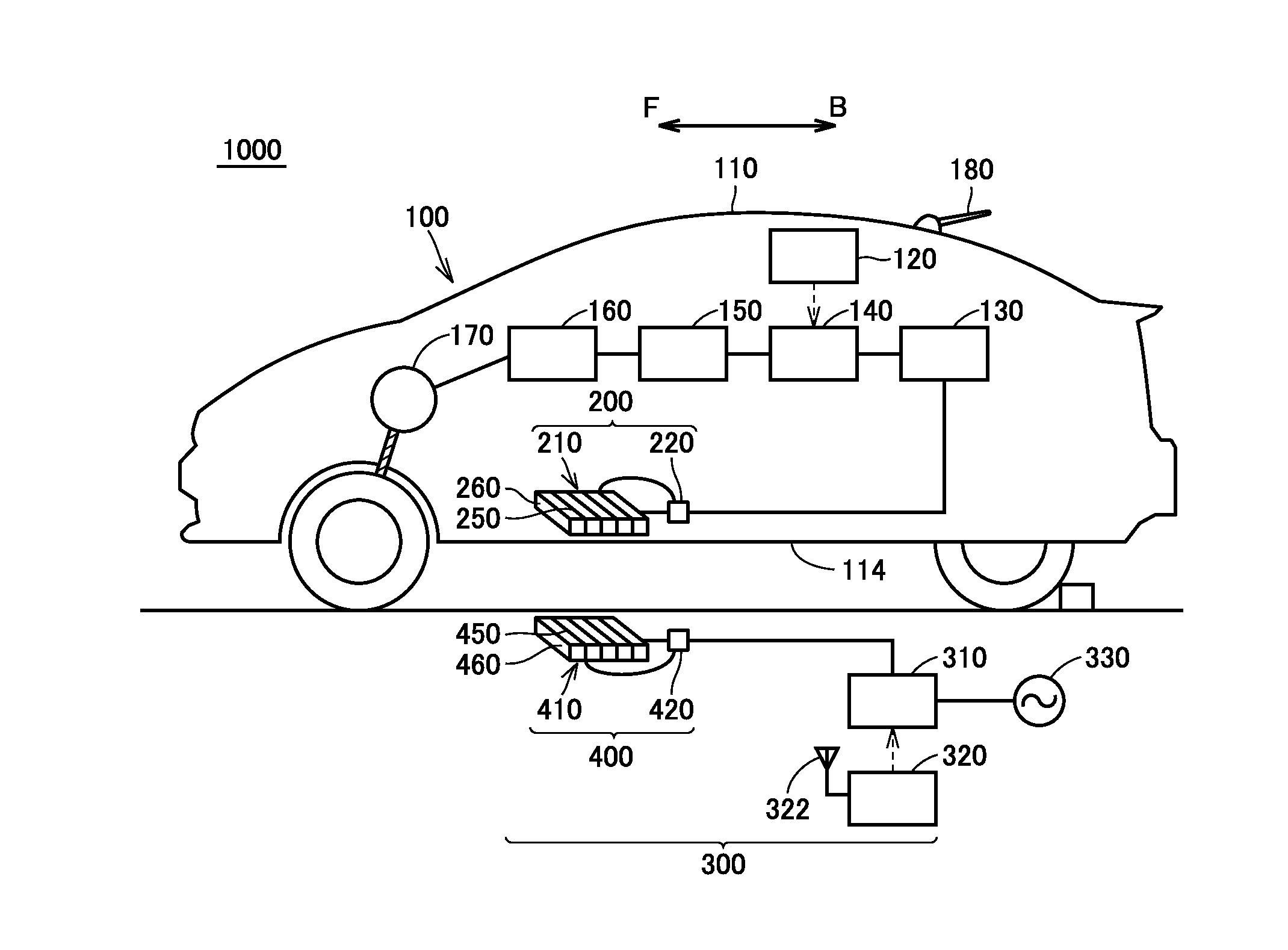

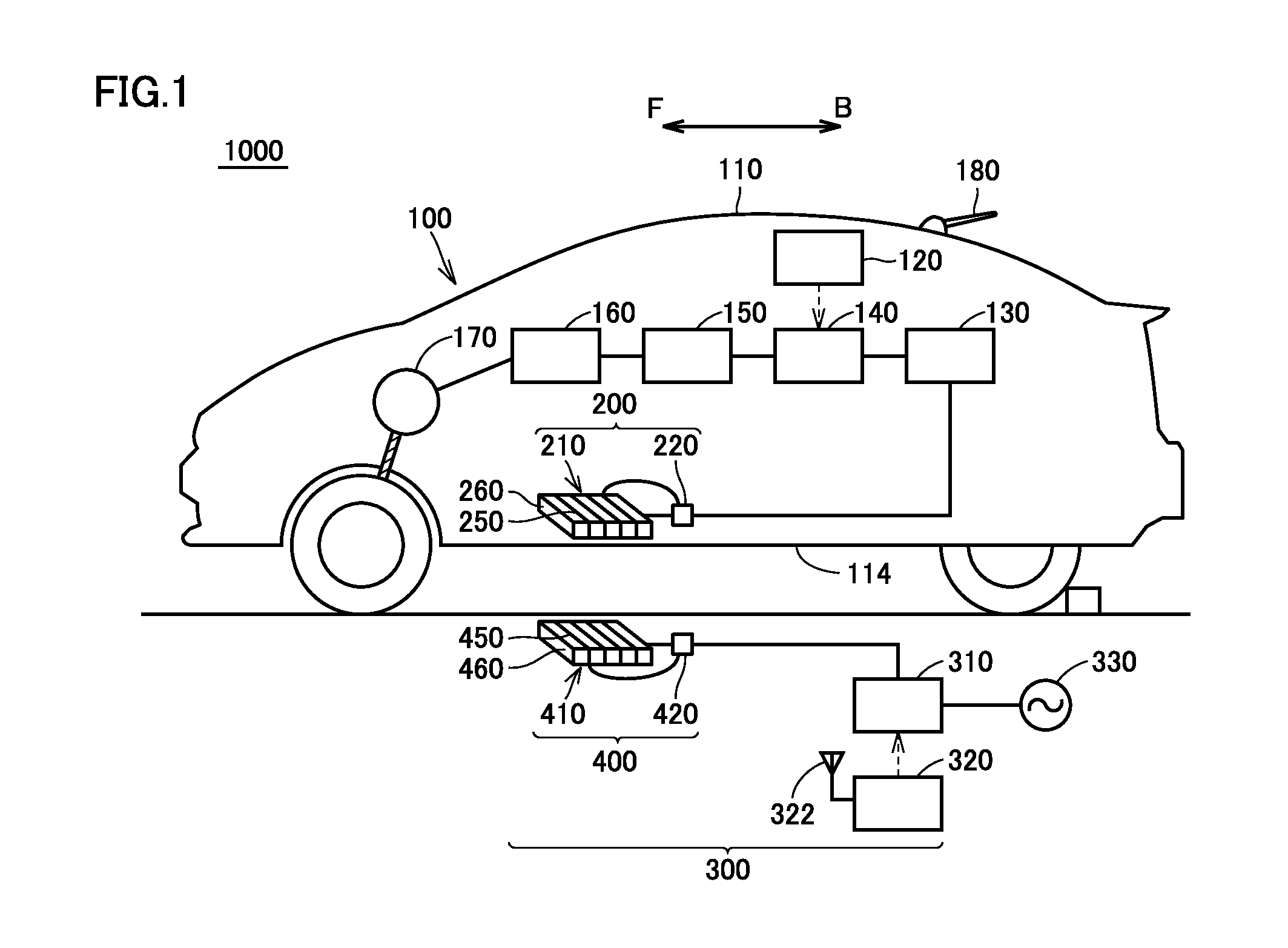

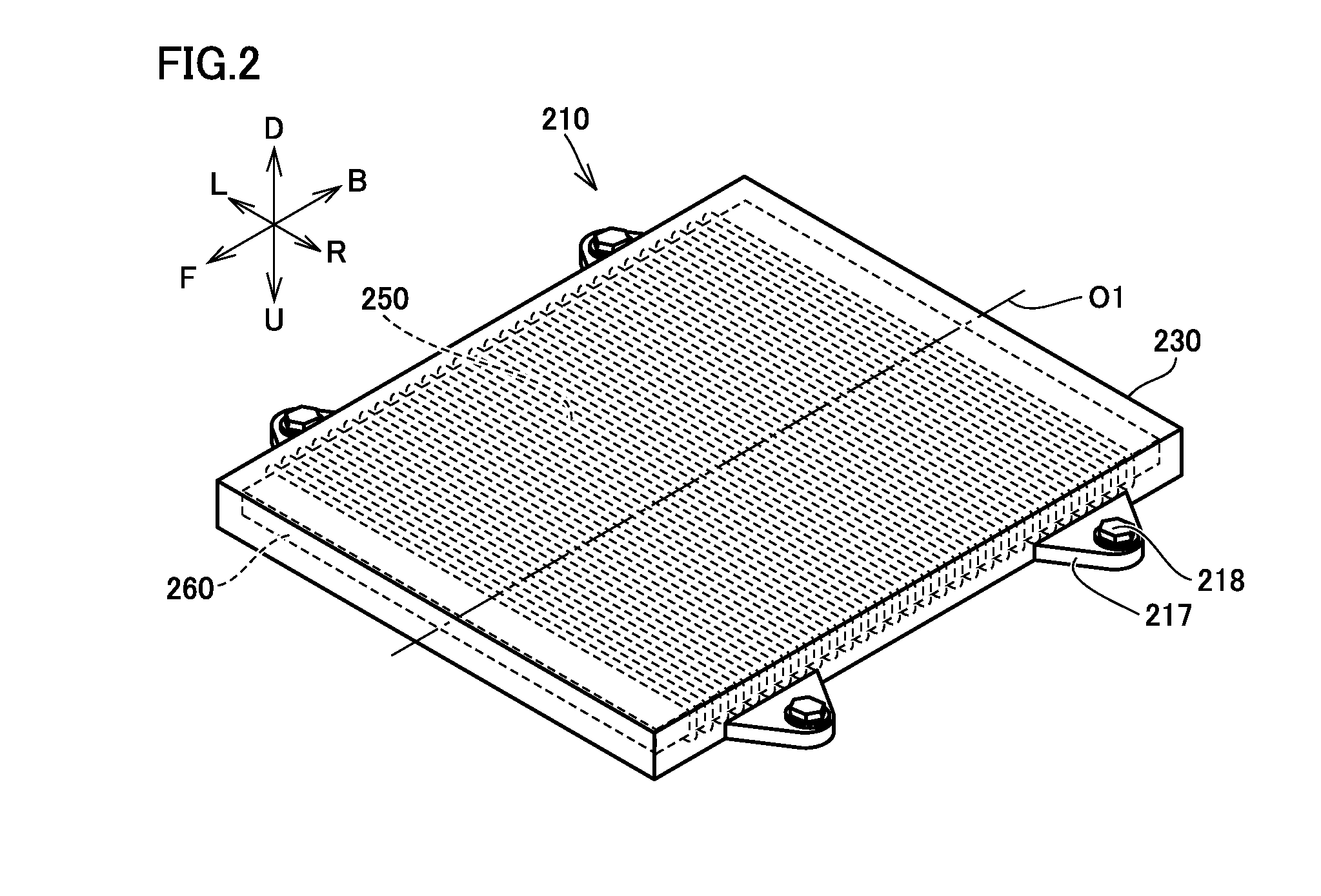

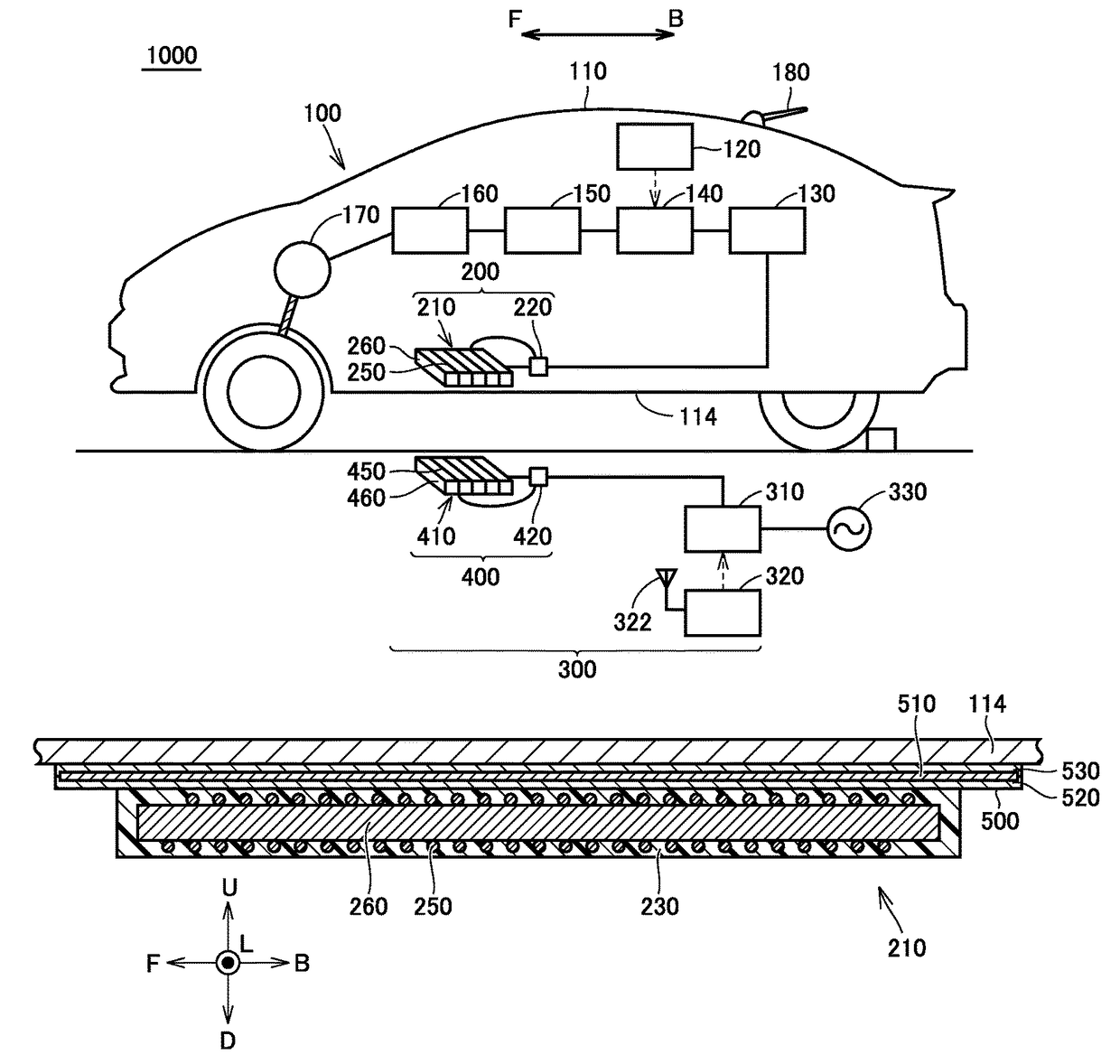

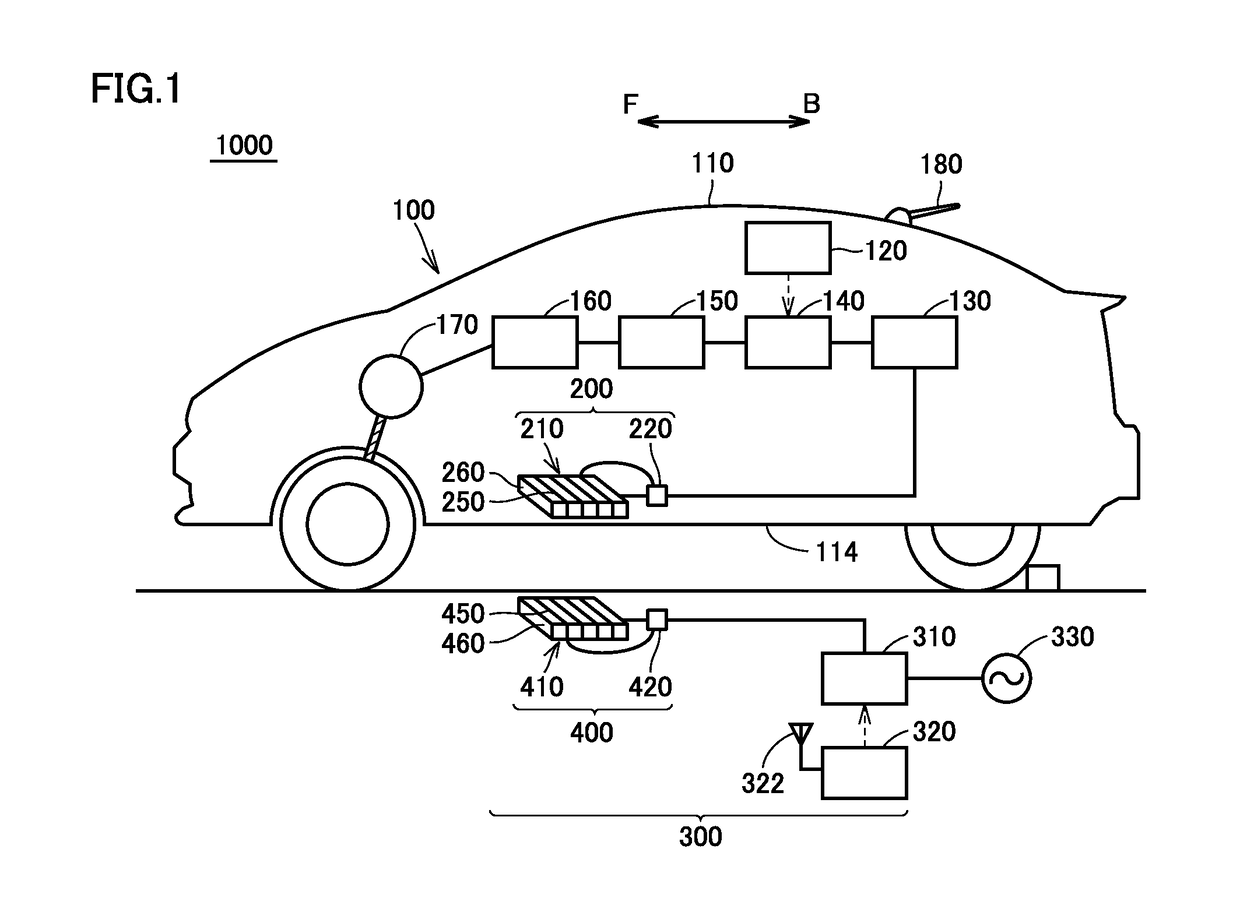

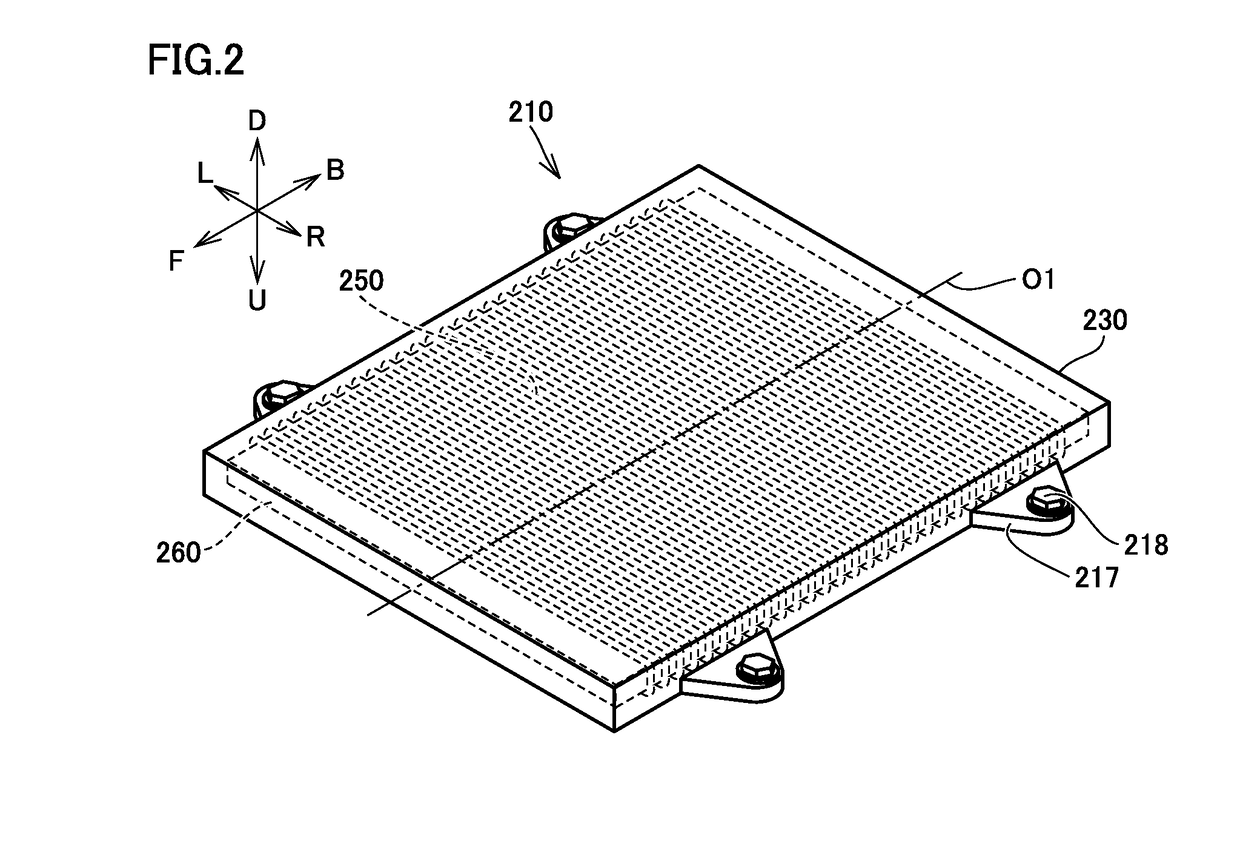

Power receiving device, vehicle, and power transmission device

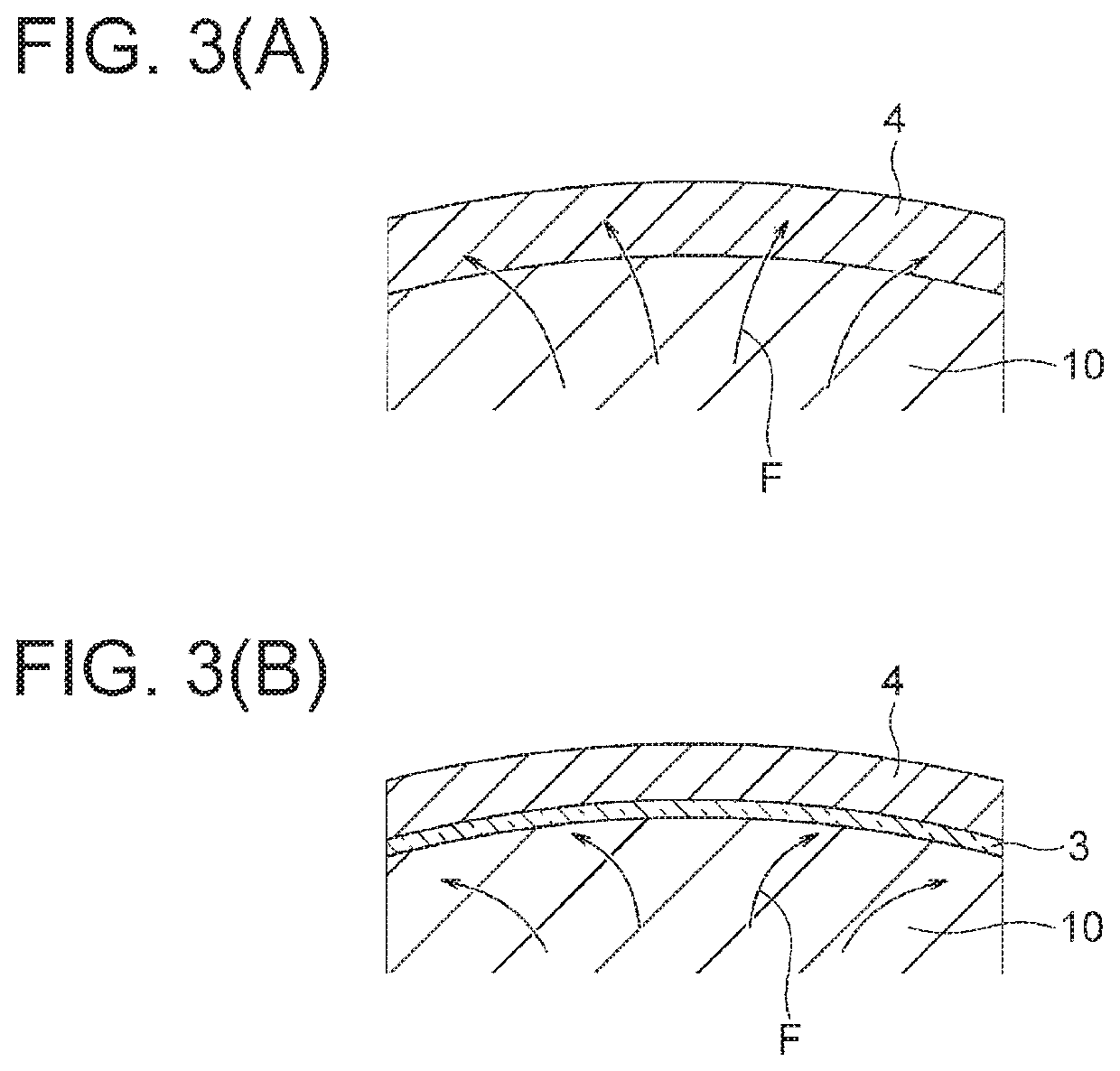

ActiveUS20150270717A1Suppression of Leakage FluxPrevent leakageCharging stationsTransformersElectric power transmissionElectricity

This power receiving device includes a magnetic shield, and the magnetic shield includes: a first magnetic sheet located beside the power receiving unit; a conductive sheet located opposite to the power receiving unit with the first magnetic sheet interposed therebetween; and a second magnetic sheet located opposite to the first magnetic sheet with the conductive sheet interposed therebetween.

Owner:TOYOTA JIDOSHA KK +1

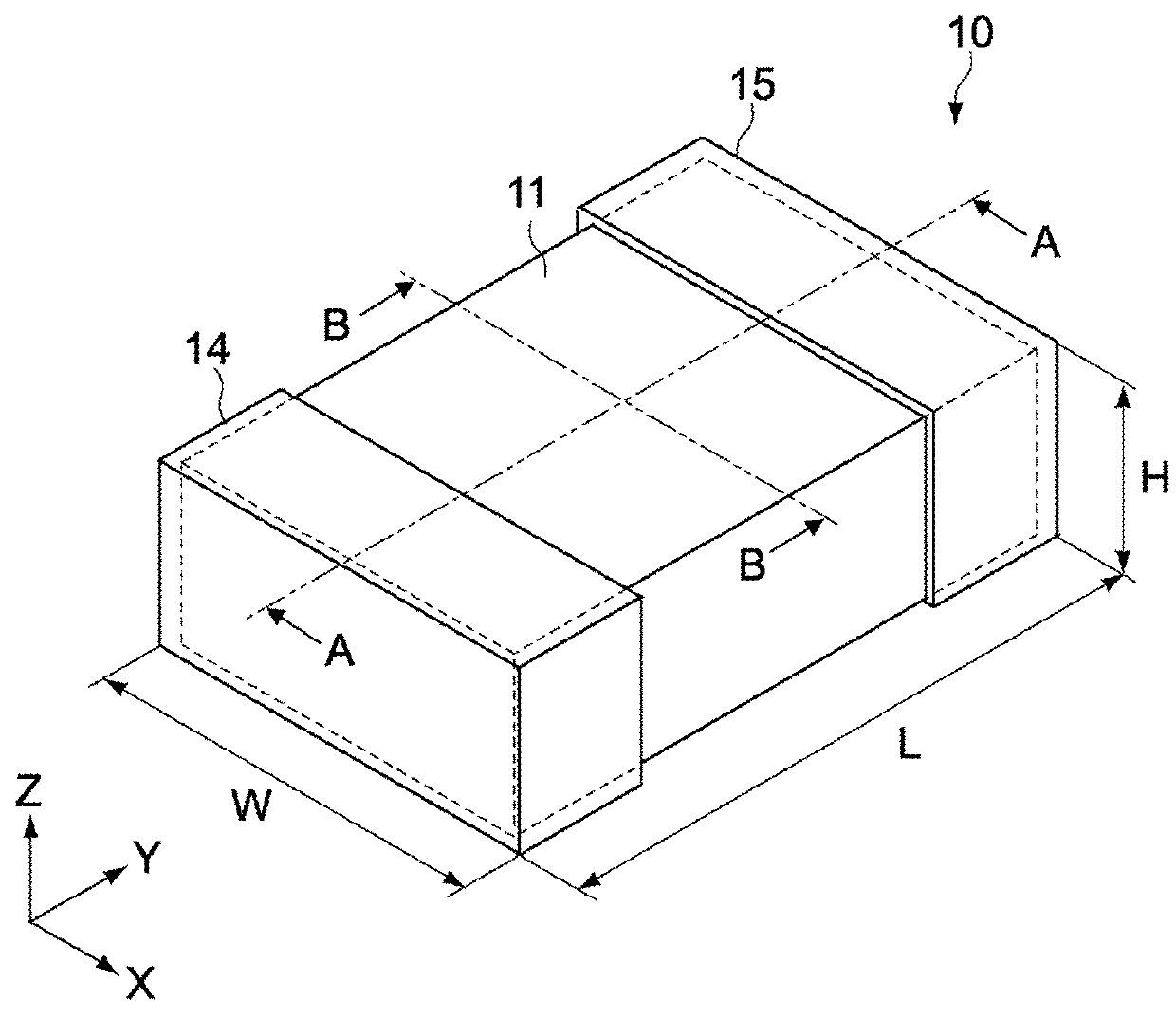

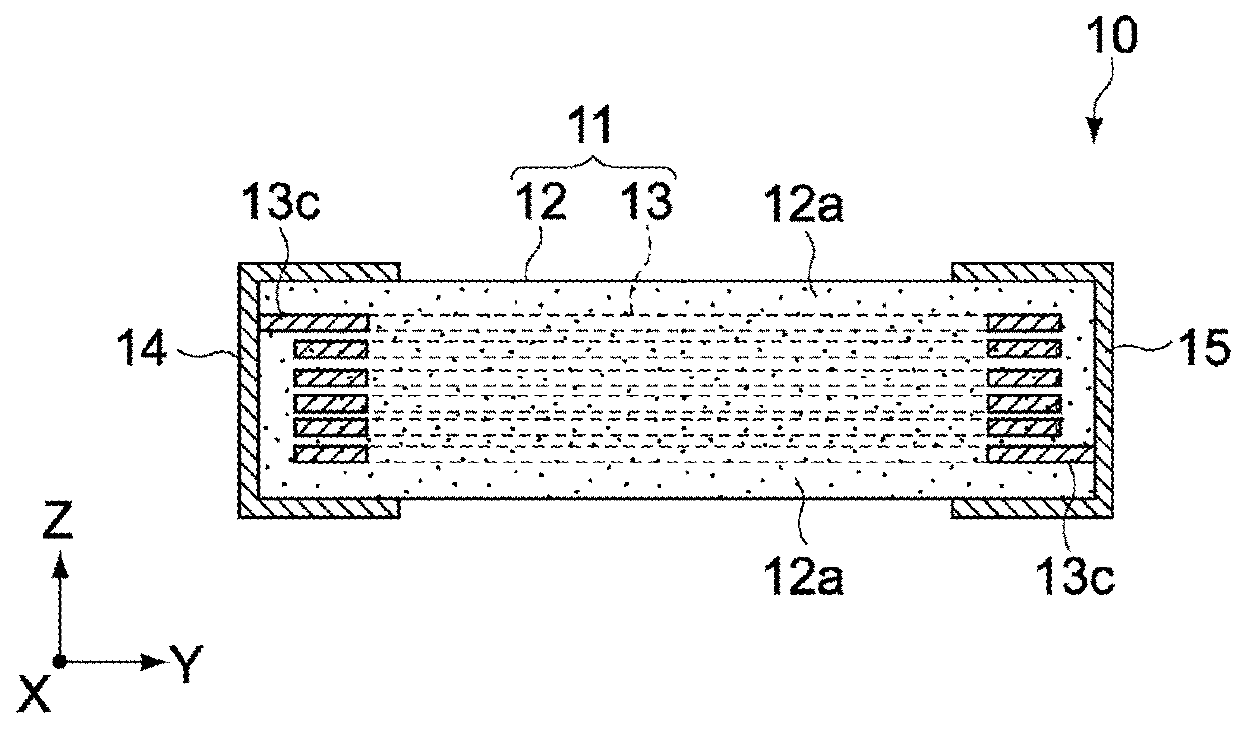

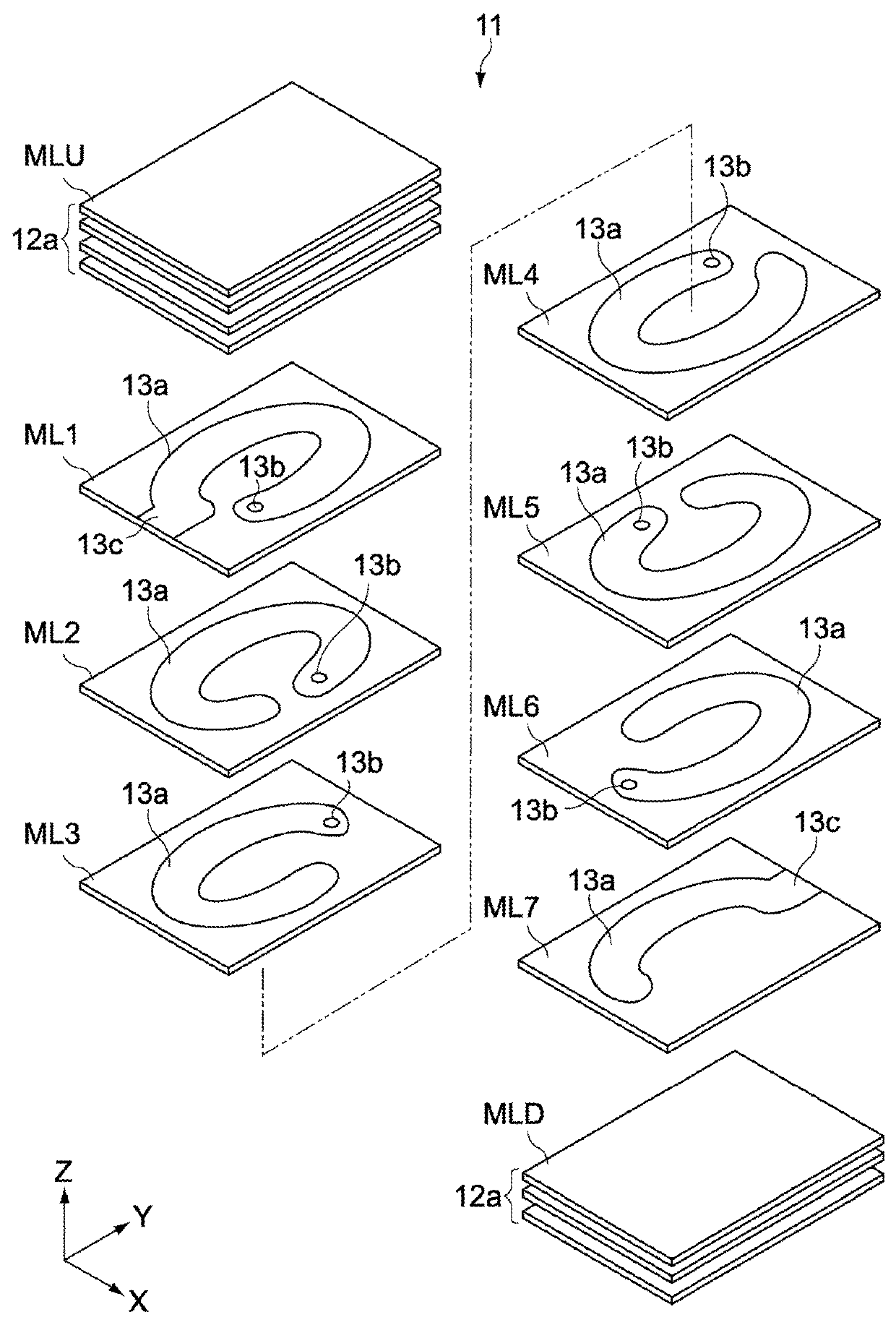

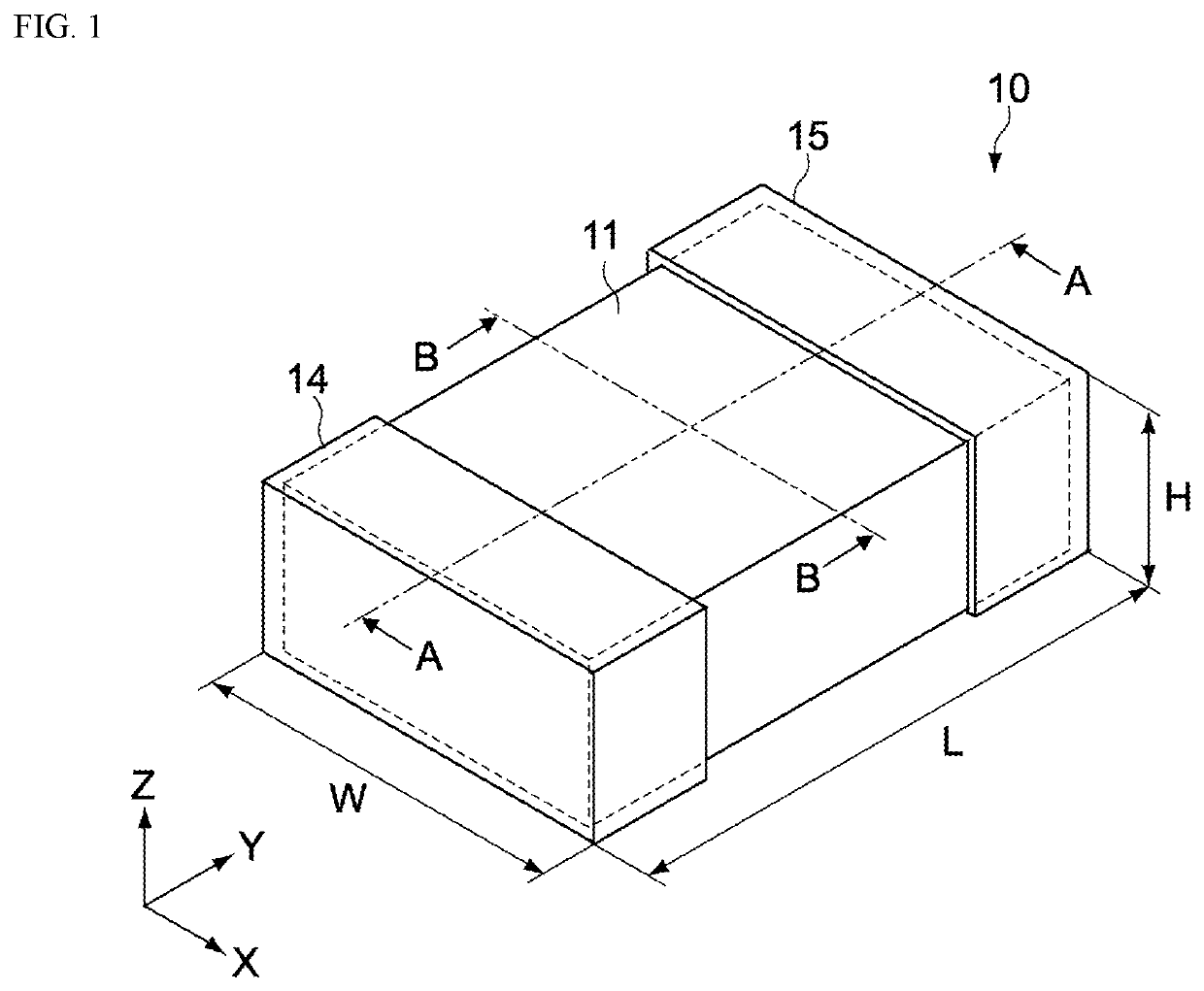

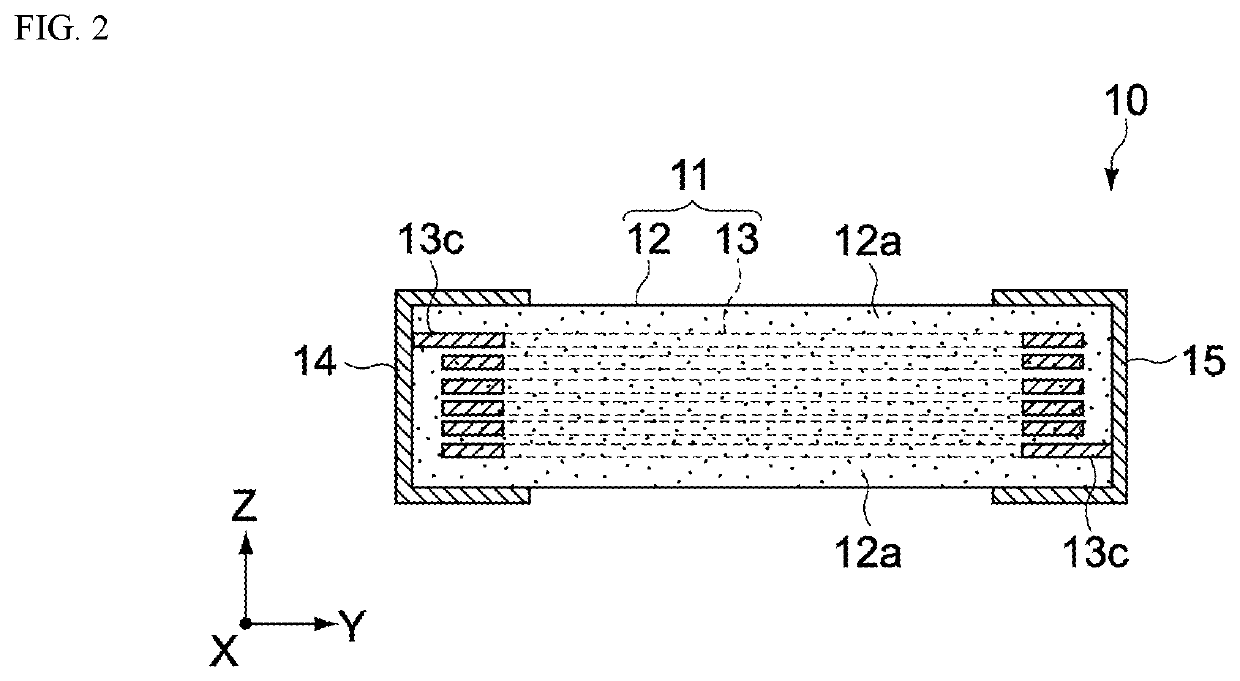

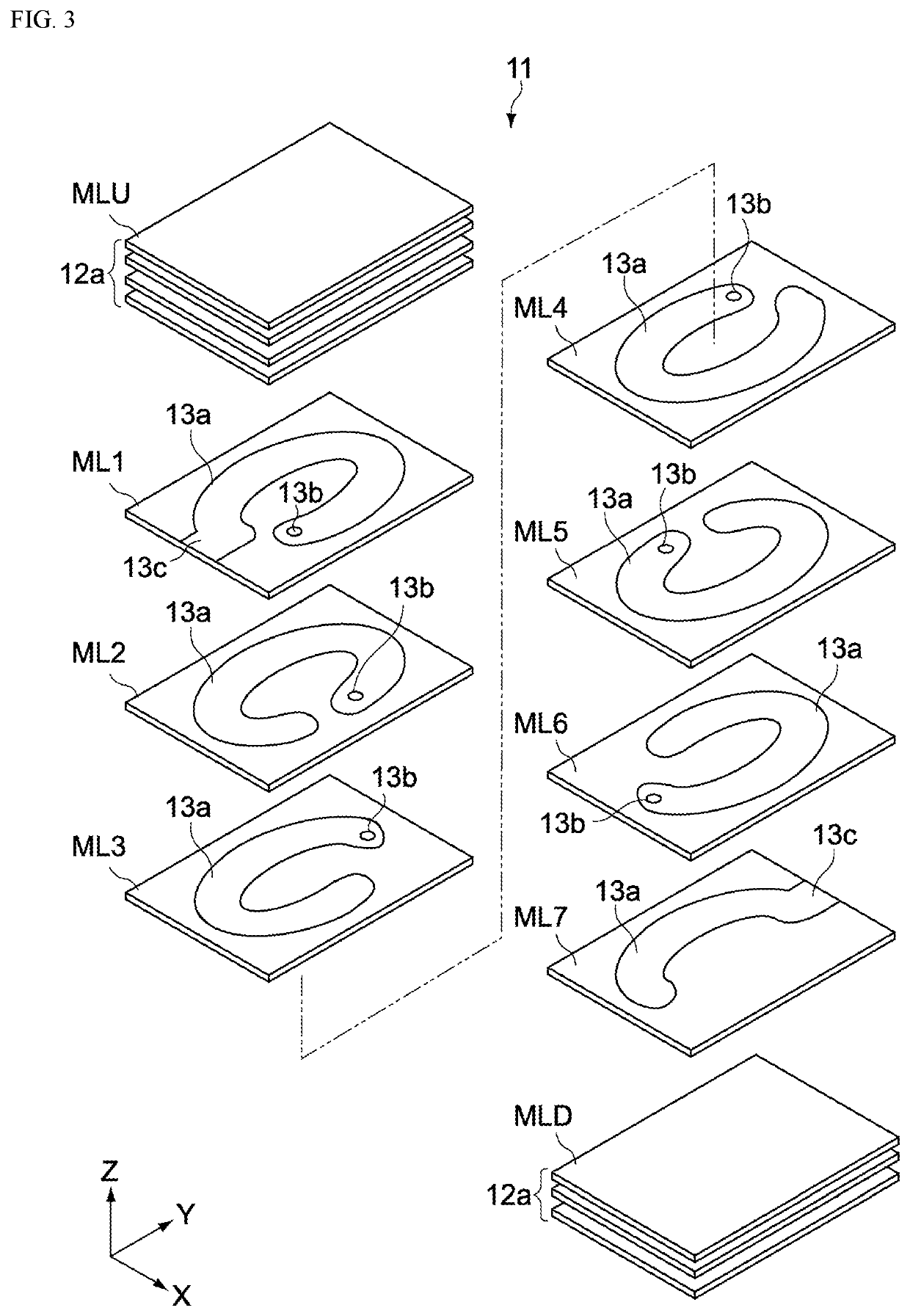

Coil component

ActiveUS20180166199A1Improve performanceAdditional componentTransportation and packagingTransformers/inductances coils/windings/connectionsElectrical conductorEngineering

A coil component includes a magnetic body part and a coil part. The magnetic body part has first and second magnetic layers stacked together alternately in one axis direction, and cover parts covering the first and second magnetic layers from the one axis direction. The coil part has conductor patterns provided on the second magnetic layers. The magnetic body part includes: oblate soft magnetic grain-containing layers extending over the entire range of the magnetic body part in the direction perpendicular to the one axis direction, exposed in the direction perpendicular to the one axis direction, and formed by oblate soft magnetic grains whose thickness direction is oriented in the one axis direction; and spherical grain-containing layers adjoining the oblate soft magnetic grain-containing layers in the one axis direction, and formed by insulative spherical grains.

Owner:TAIYO YUDEN KK

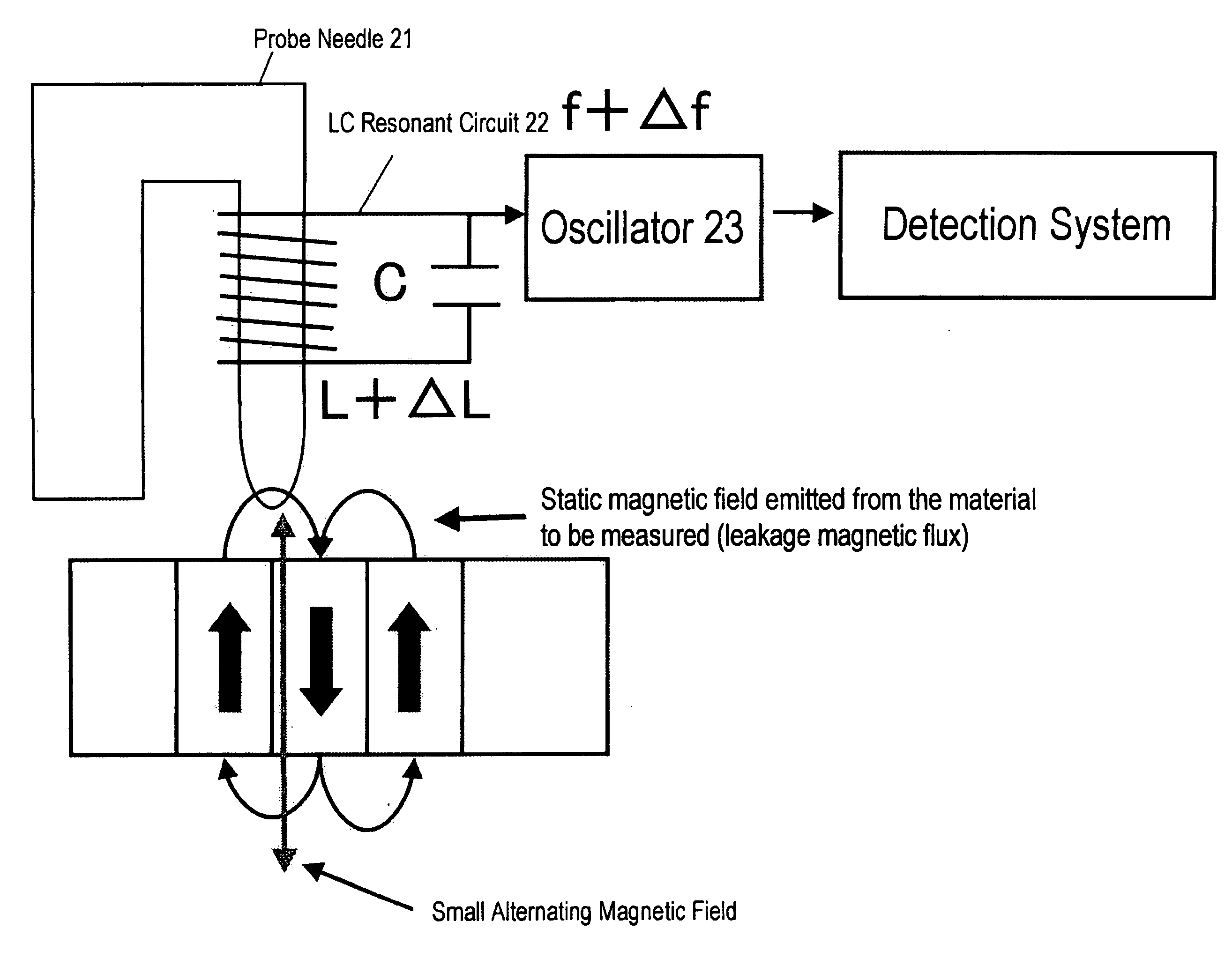

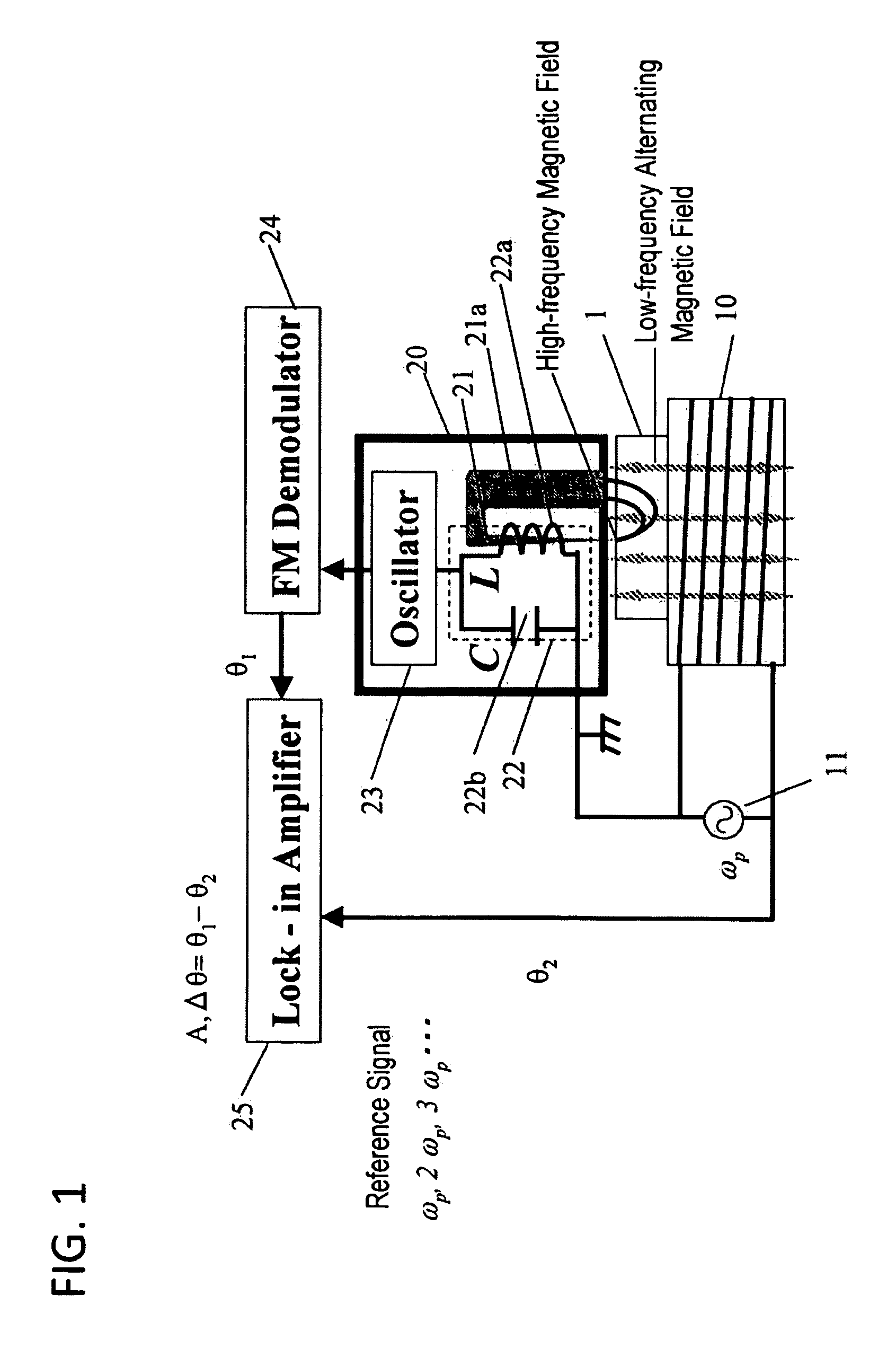

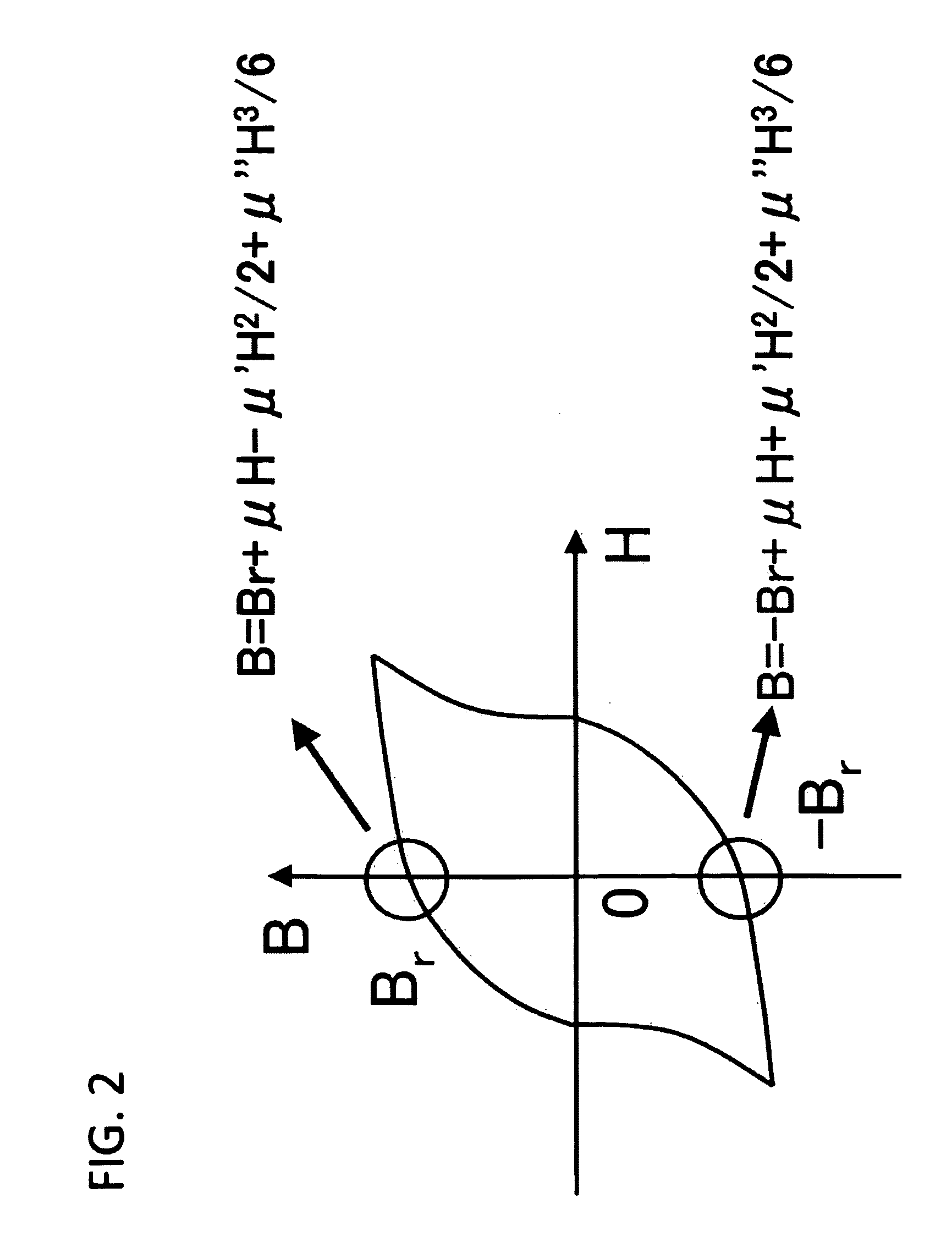

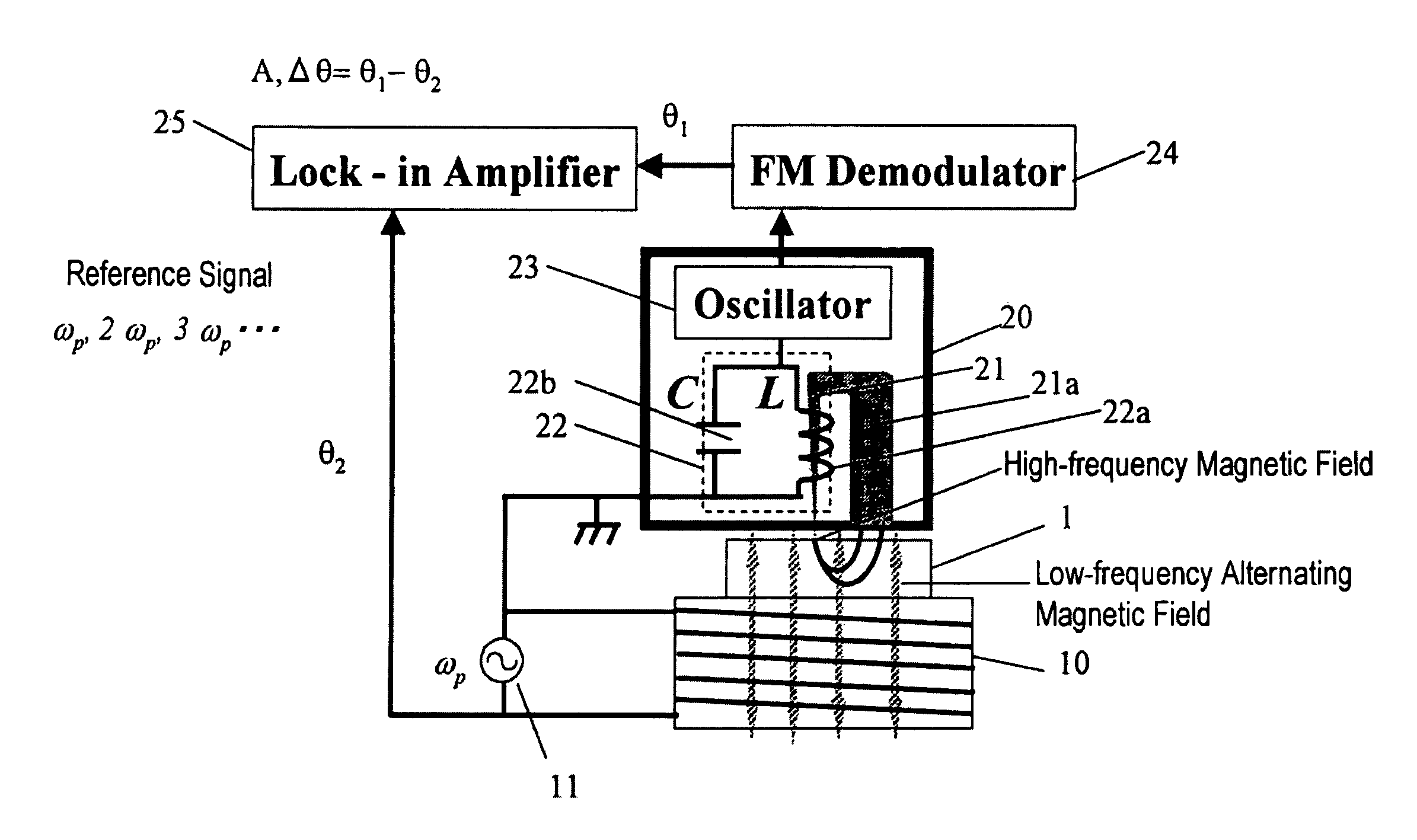

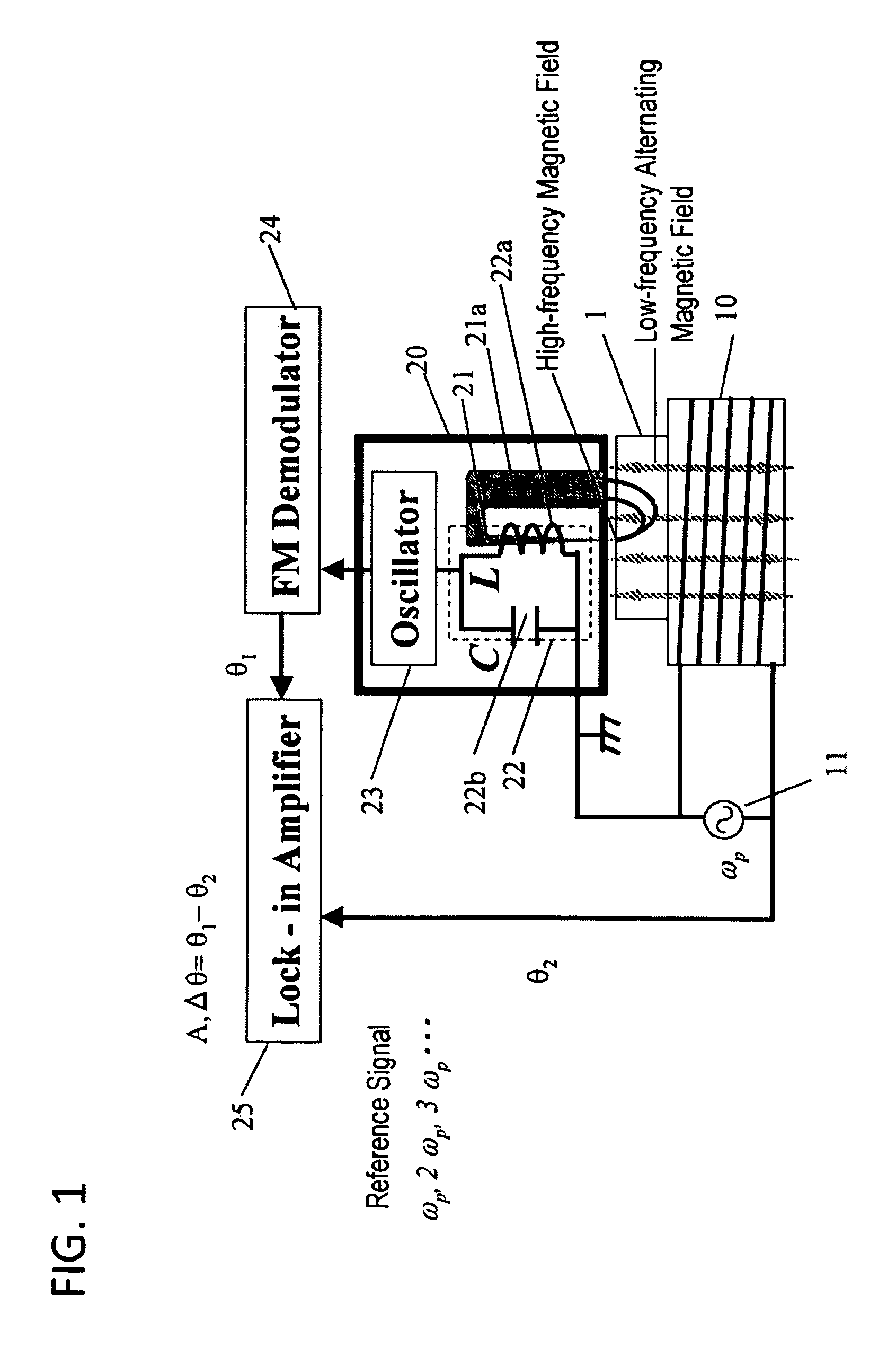

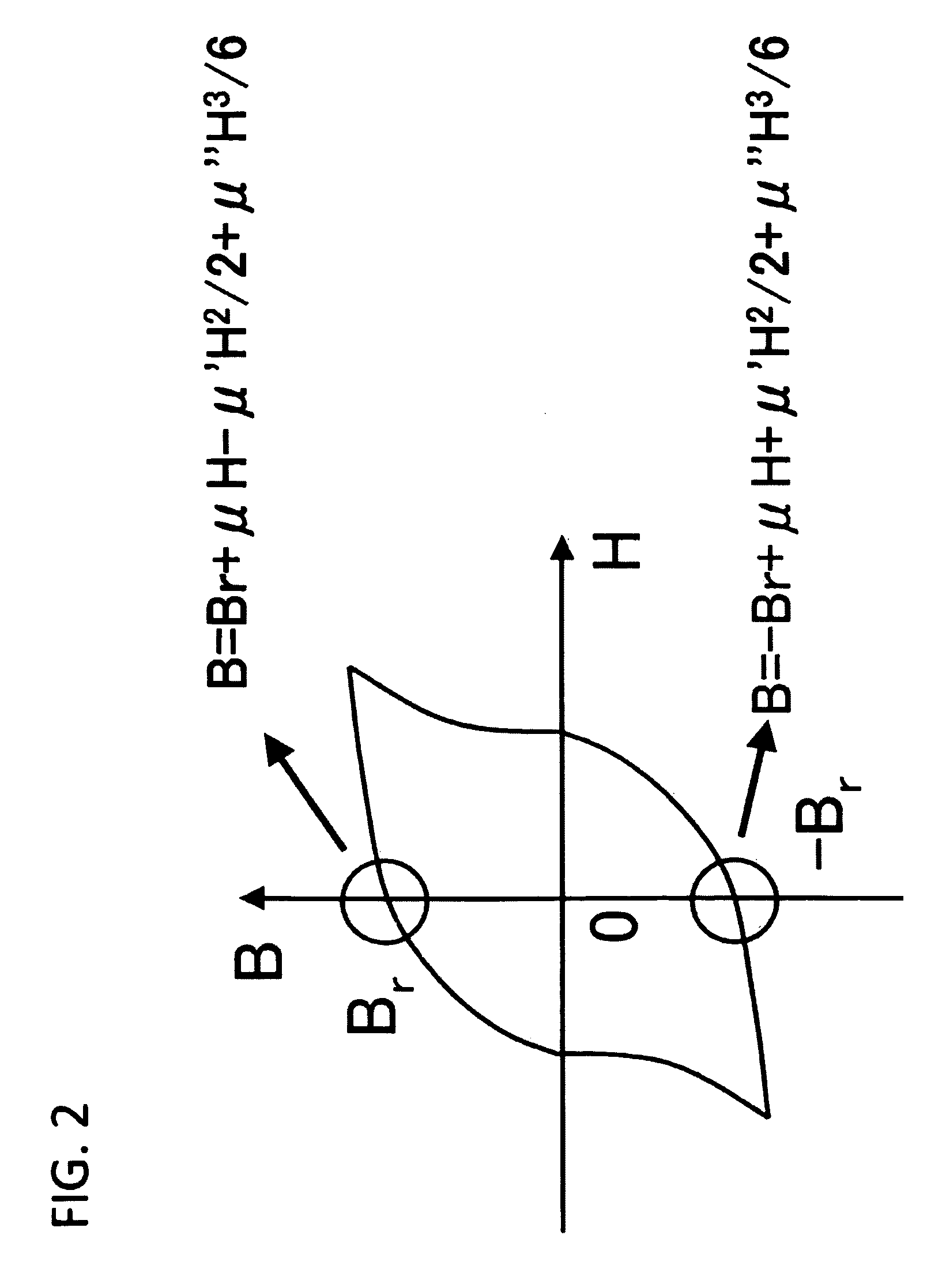

Permeability measurement apparatus

InactiveUS20080169805A1High sensitivitySuppression of Leakage FluxPermeability measurementsMeasurements using electron paramagnetic resonanceMeasurement deviceCoil inductance

A permeability measurement apparatus includes a magnetic field generation means applying an alternating magnetic field having a predetermined frequency to a magnetic substance to be measured; a probe needle placed in proximity or in contact to a microscopic area of the magnetic substance to be measured to which the alternating magnetic field is applied; a resonator including a coil wound on the probe needle, and generating a magnetic field having a resonant frequency higher than the frequency of the alternating magnetic field applied on the microscopic area having the probe needle in proximity or in contact thereto, and having an inductance of the coil varied as permeability in the microscopic area varies; and a measurement means measuring the permeability of the microscopic area of the magnetic substance to be measured based on the variation of the resonant frequency of the resonator according to the variation of the coil inductance.

Owner:TOHOKU UNIV

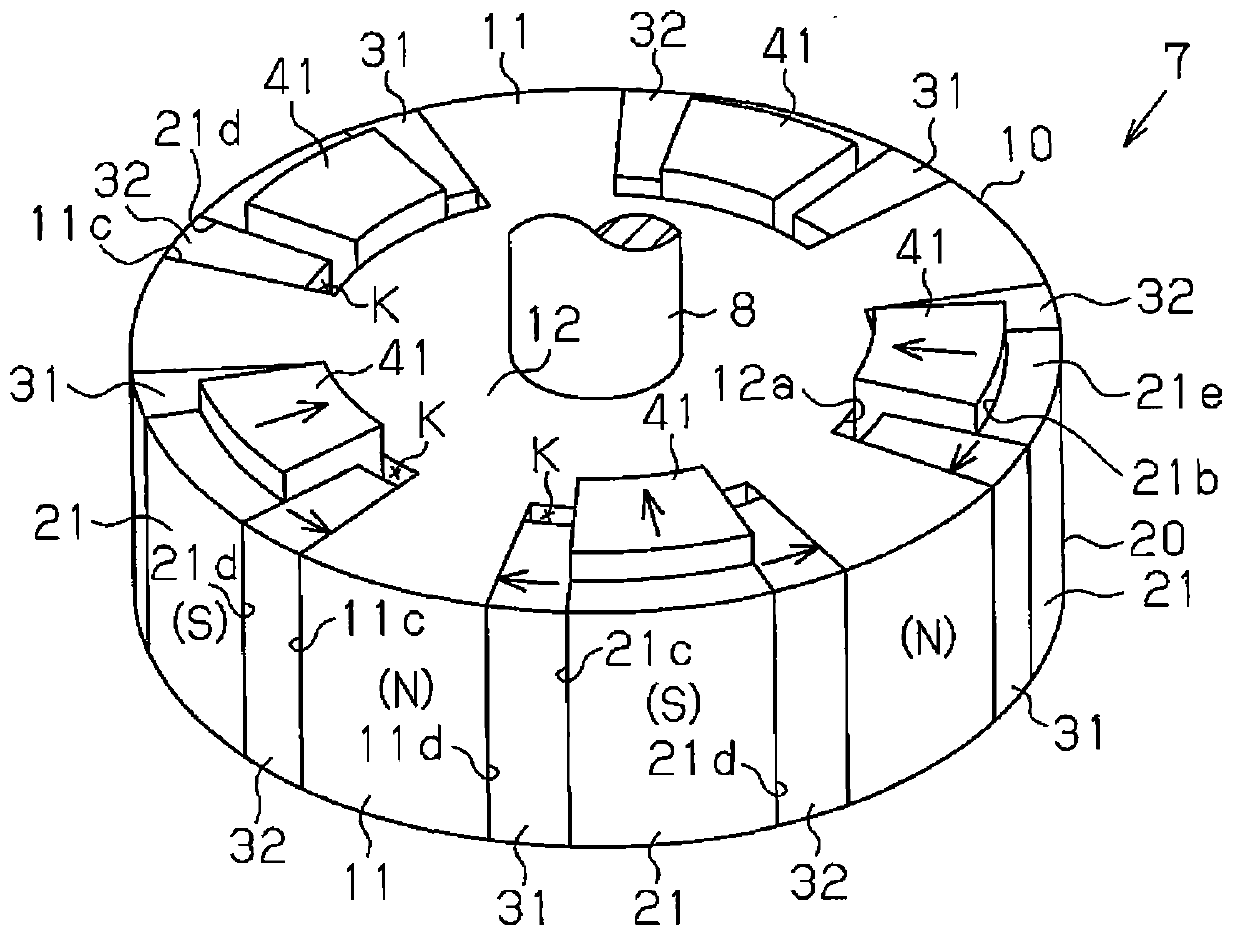

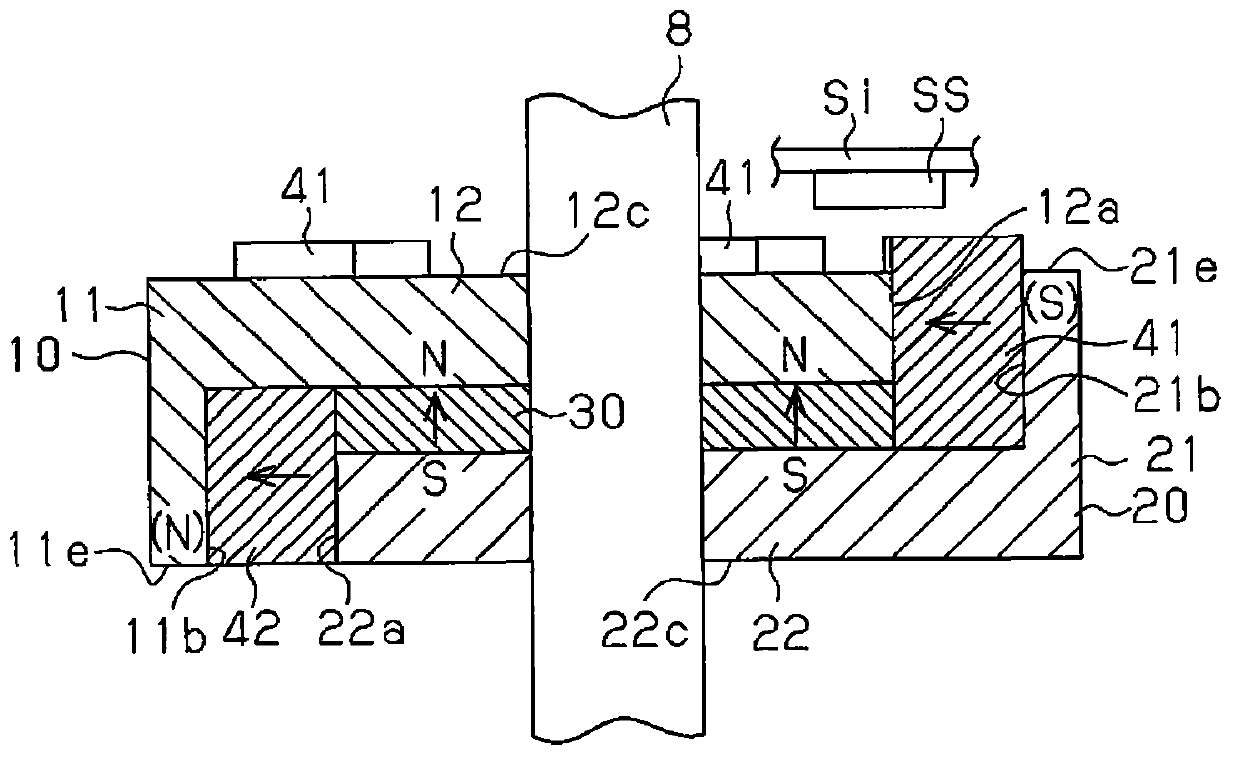

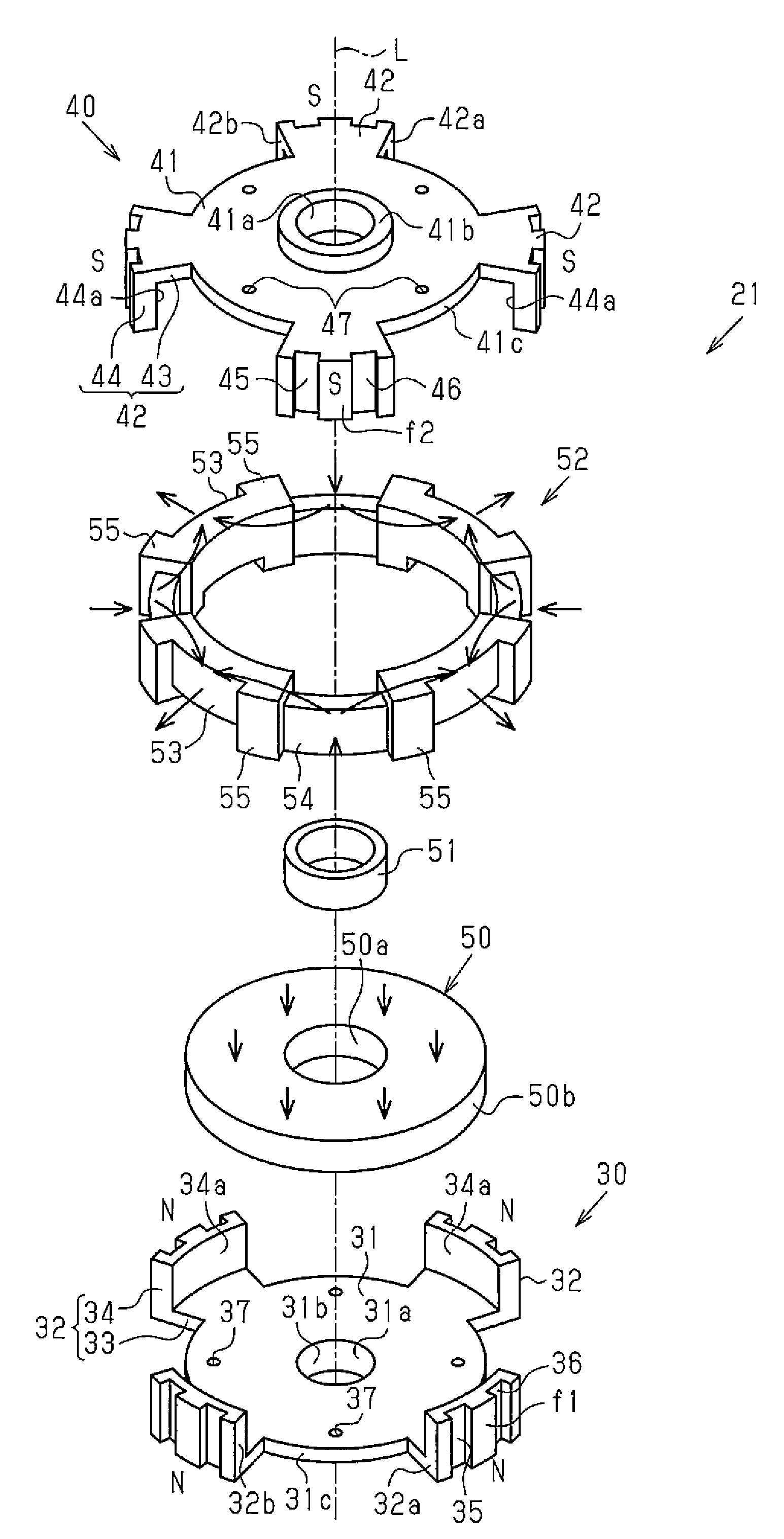

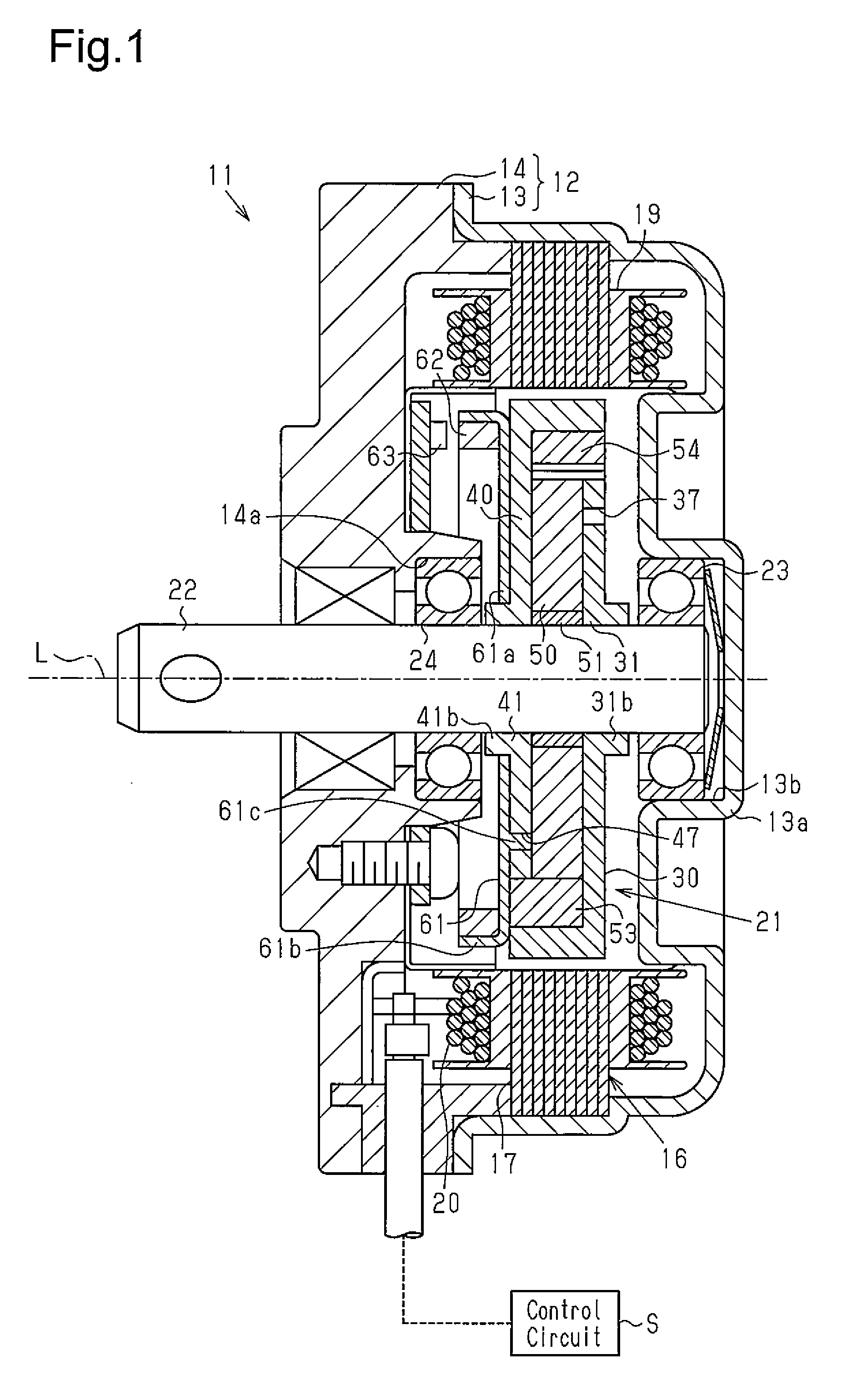

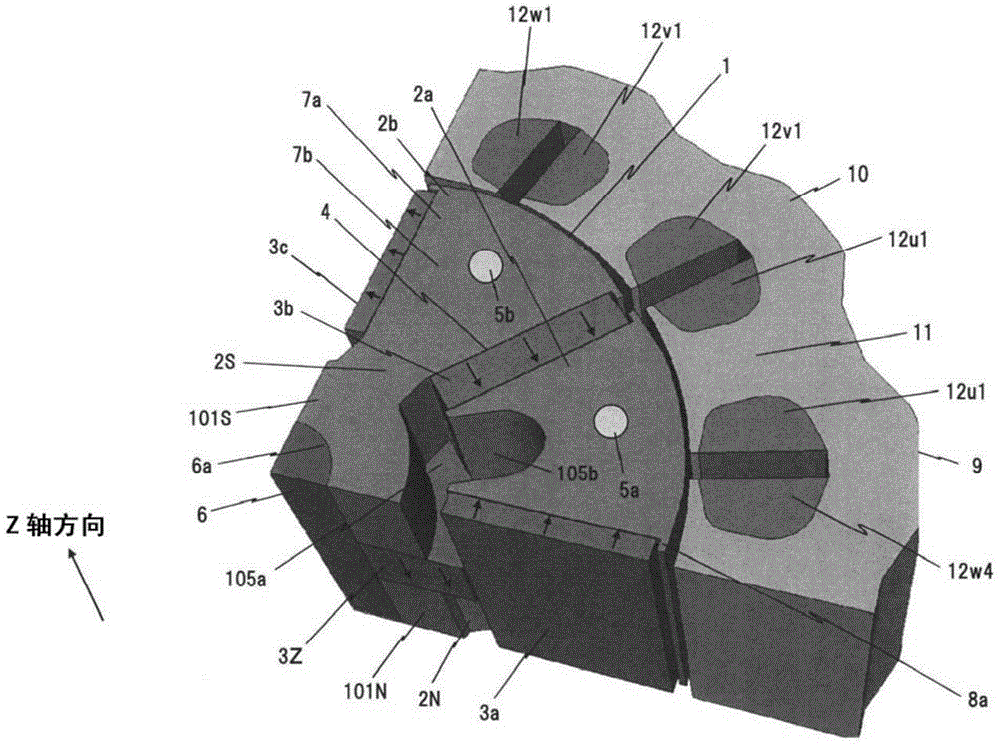

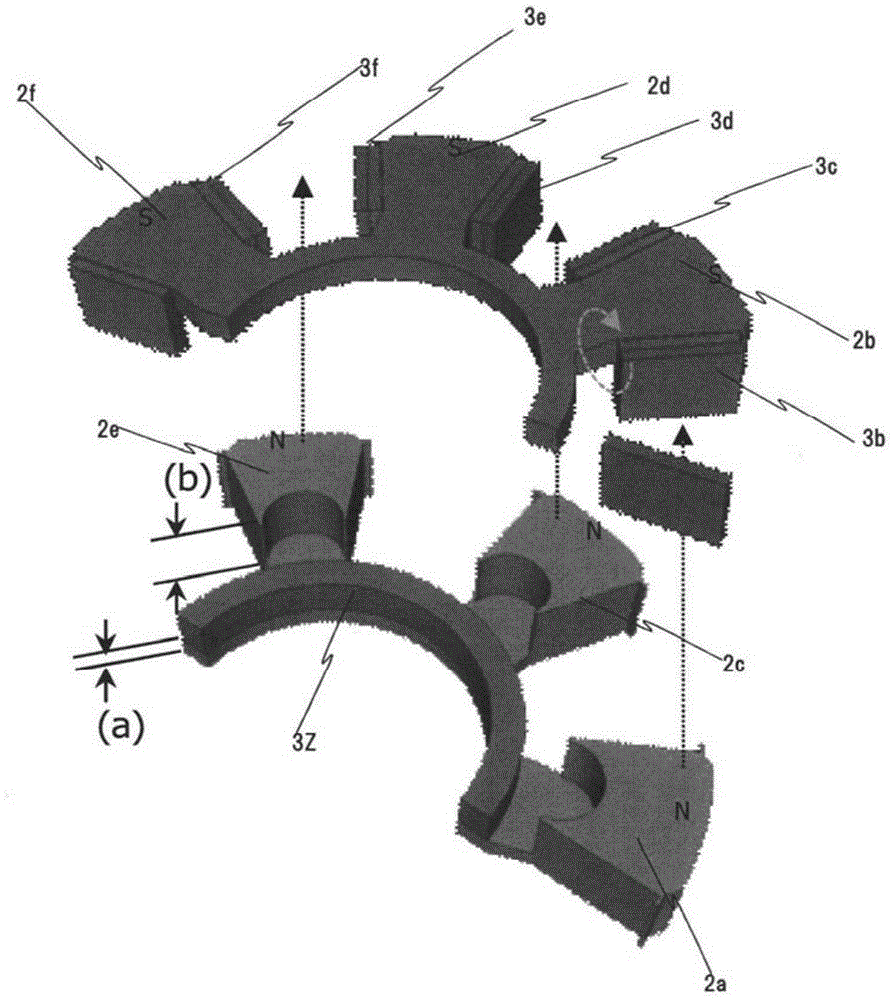

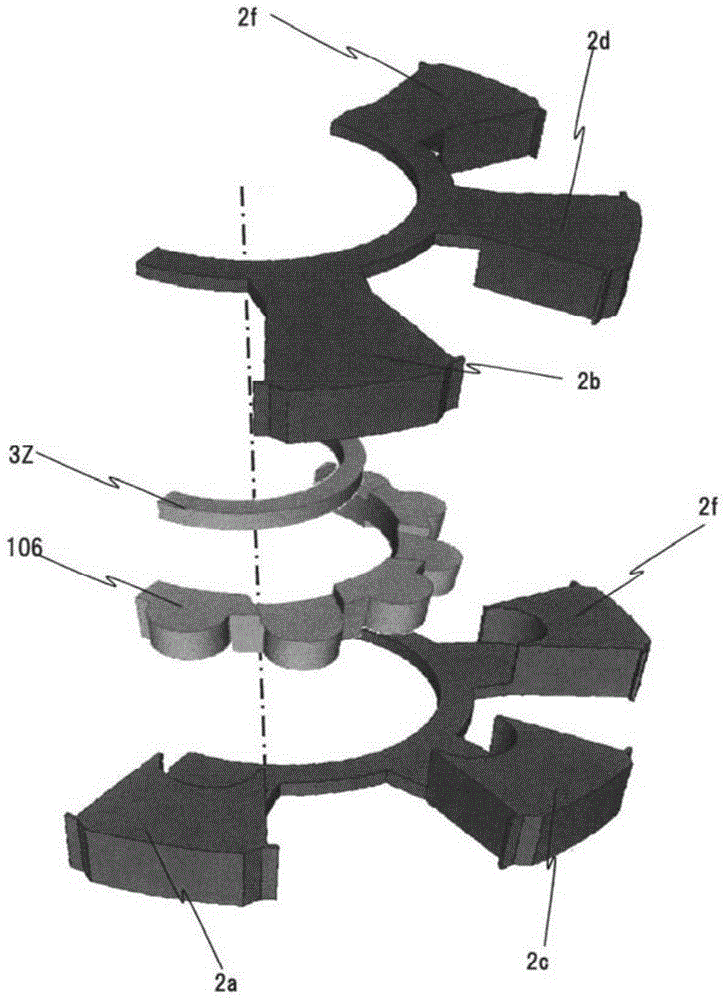

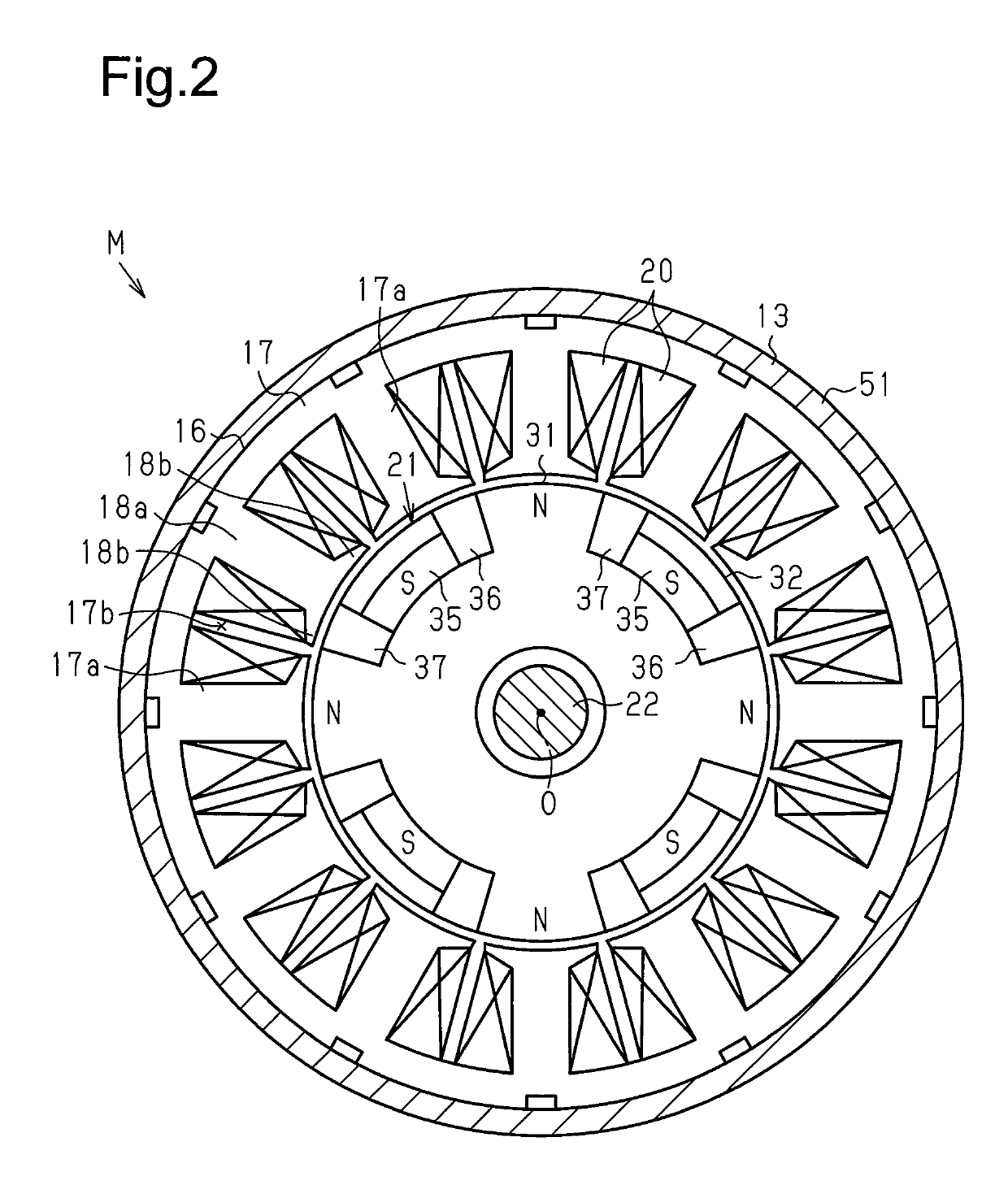

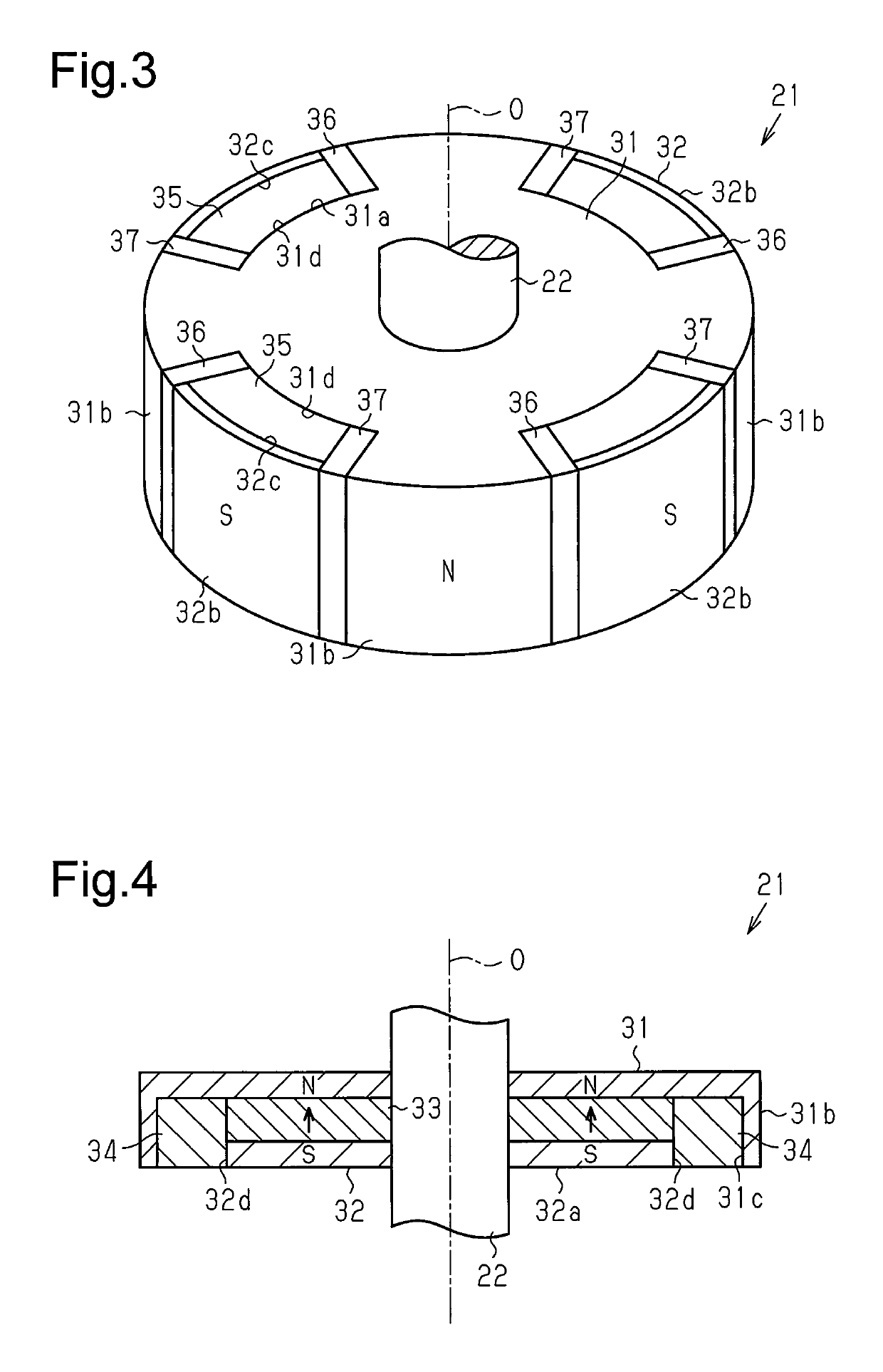

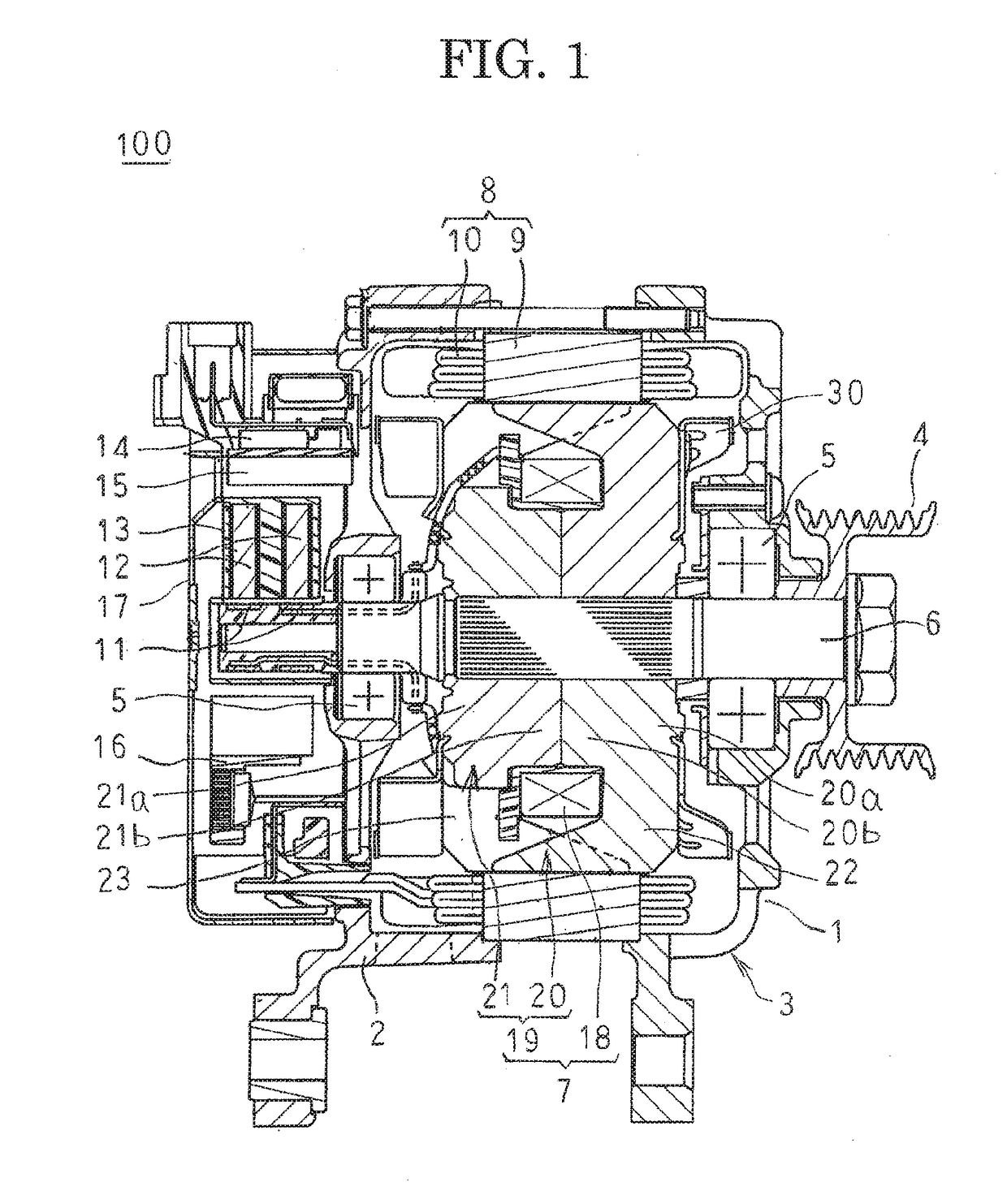

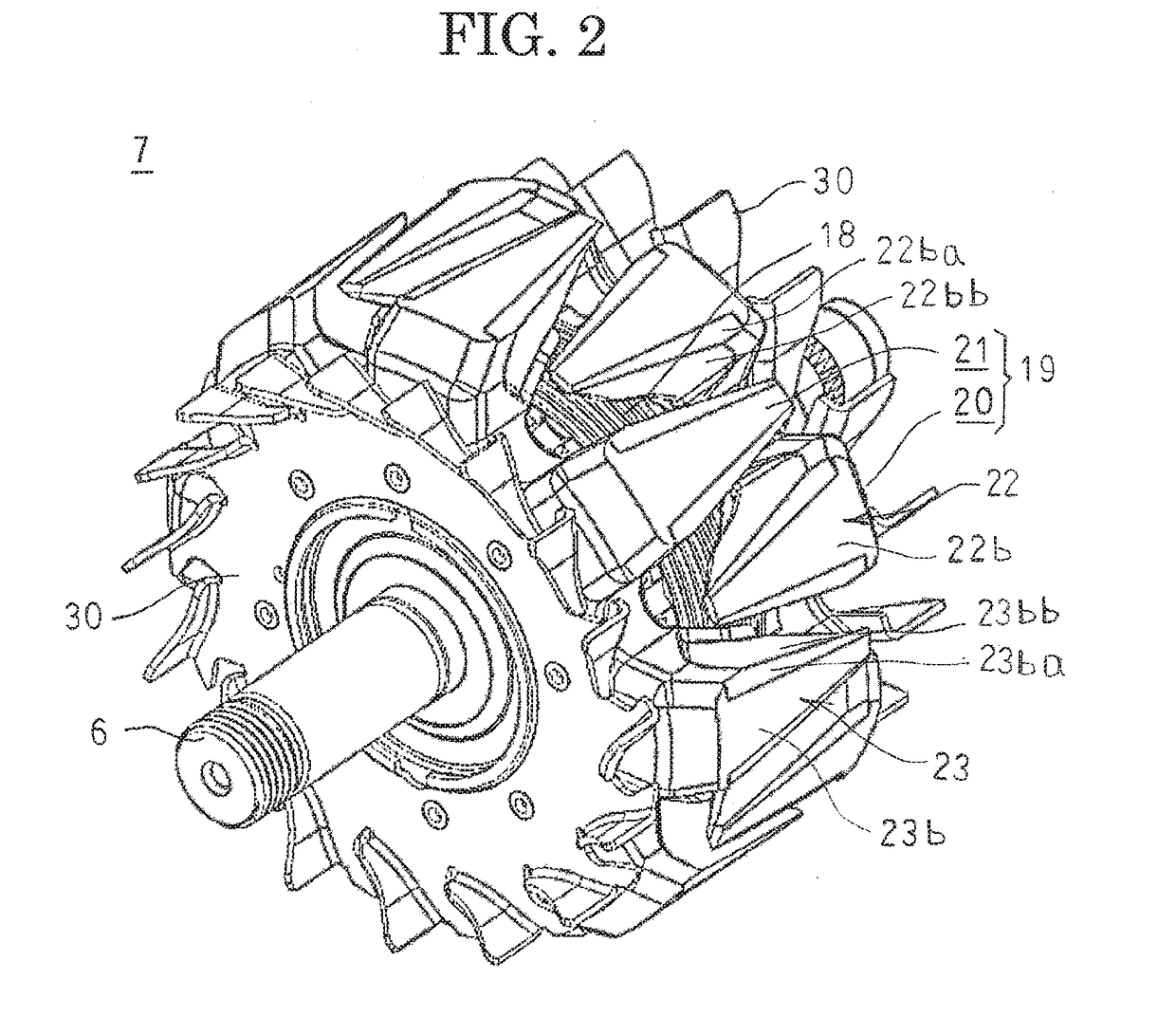

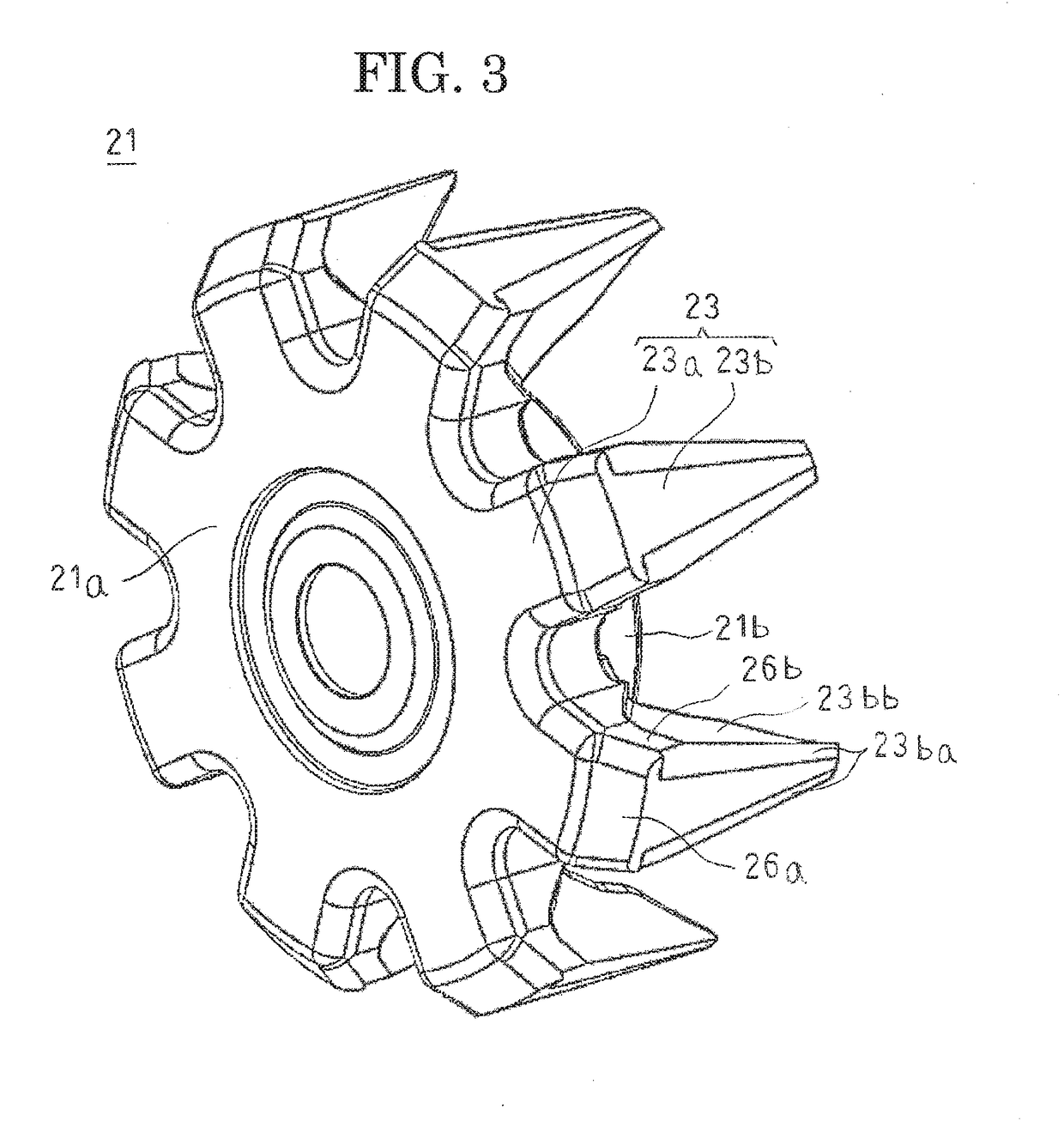

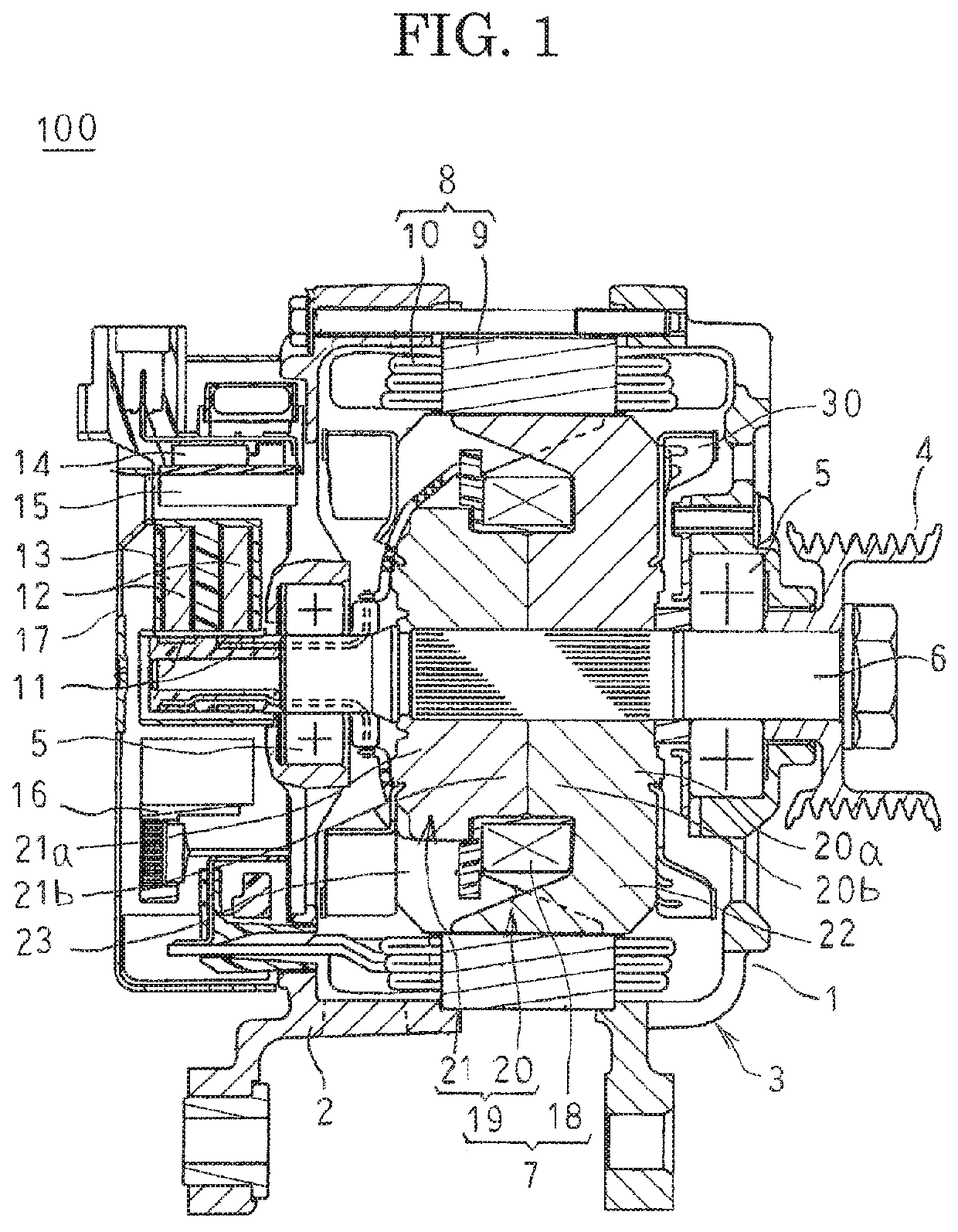

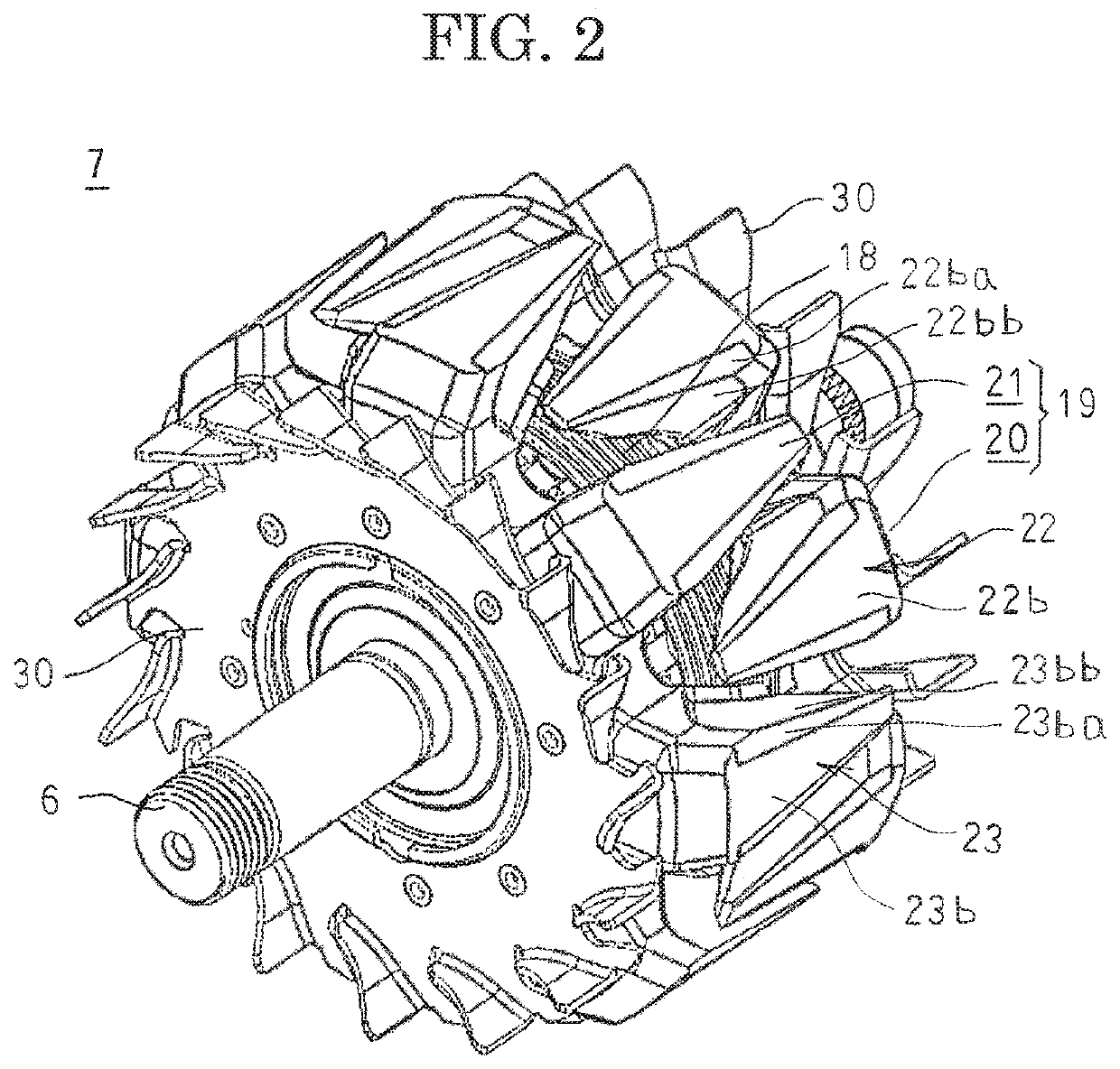

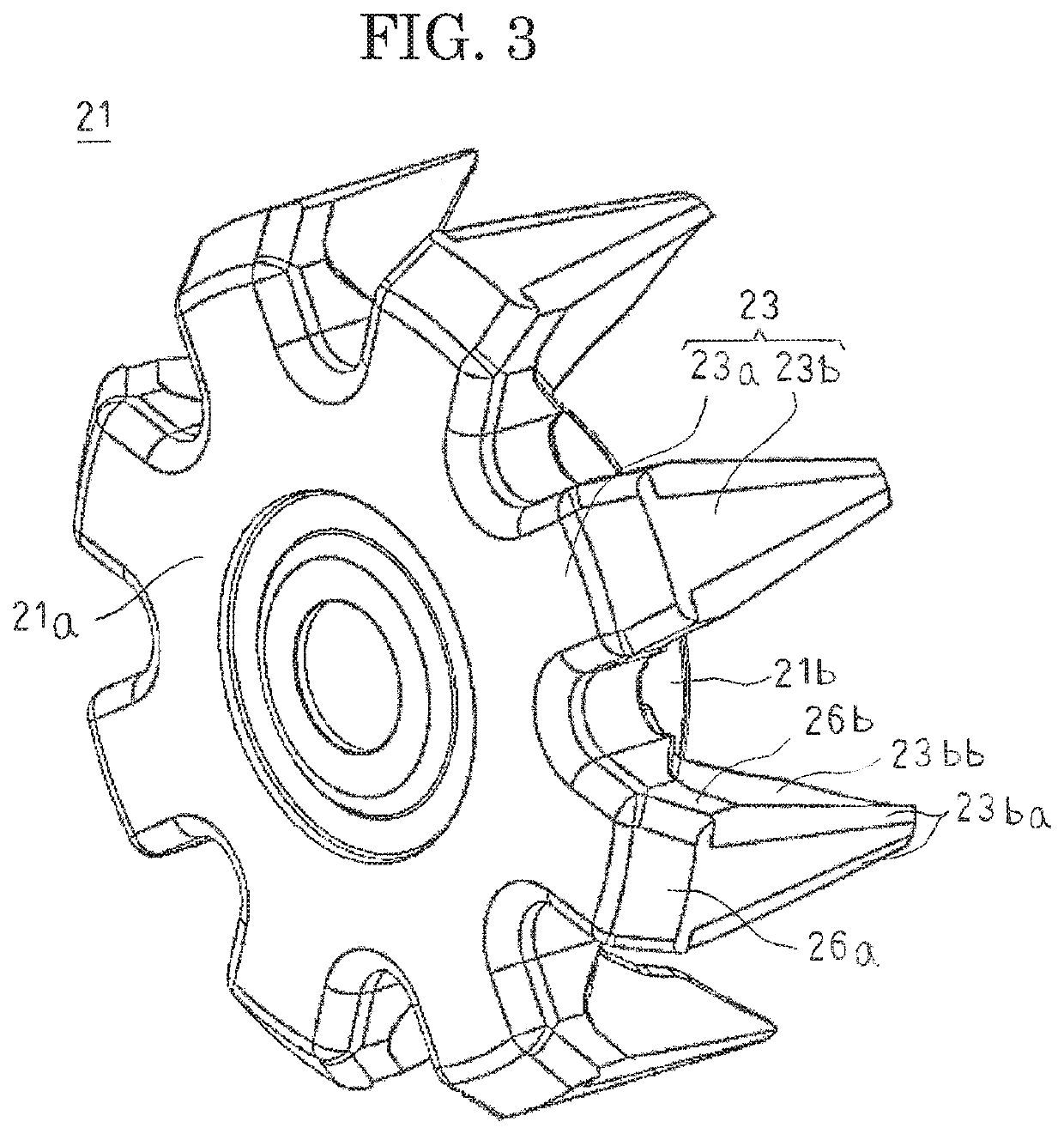

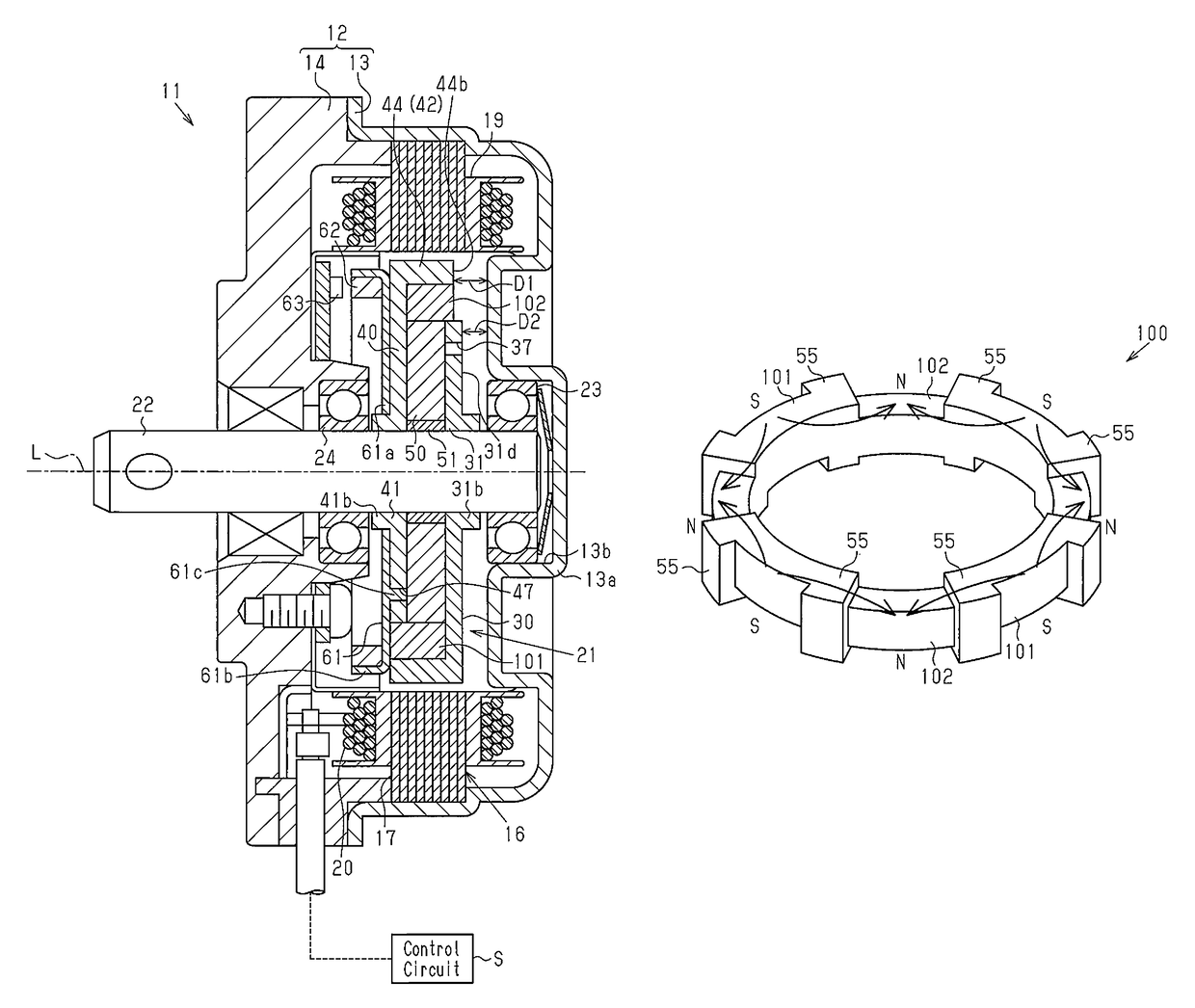

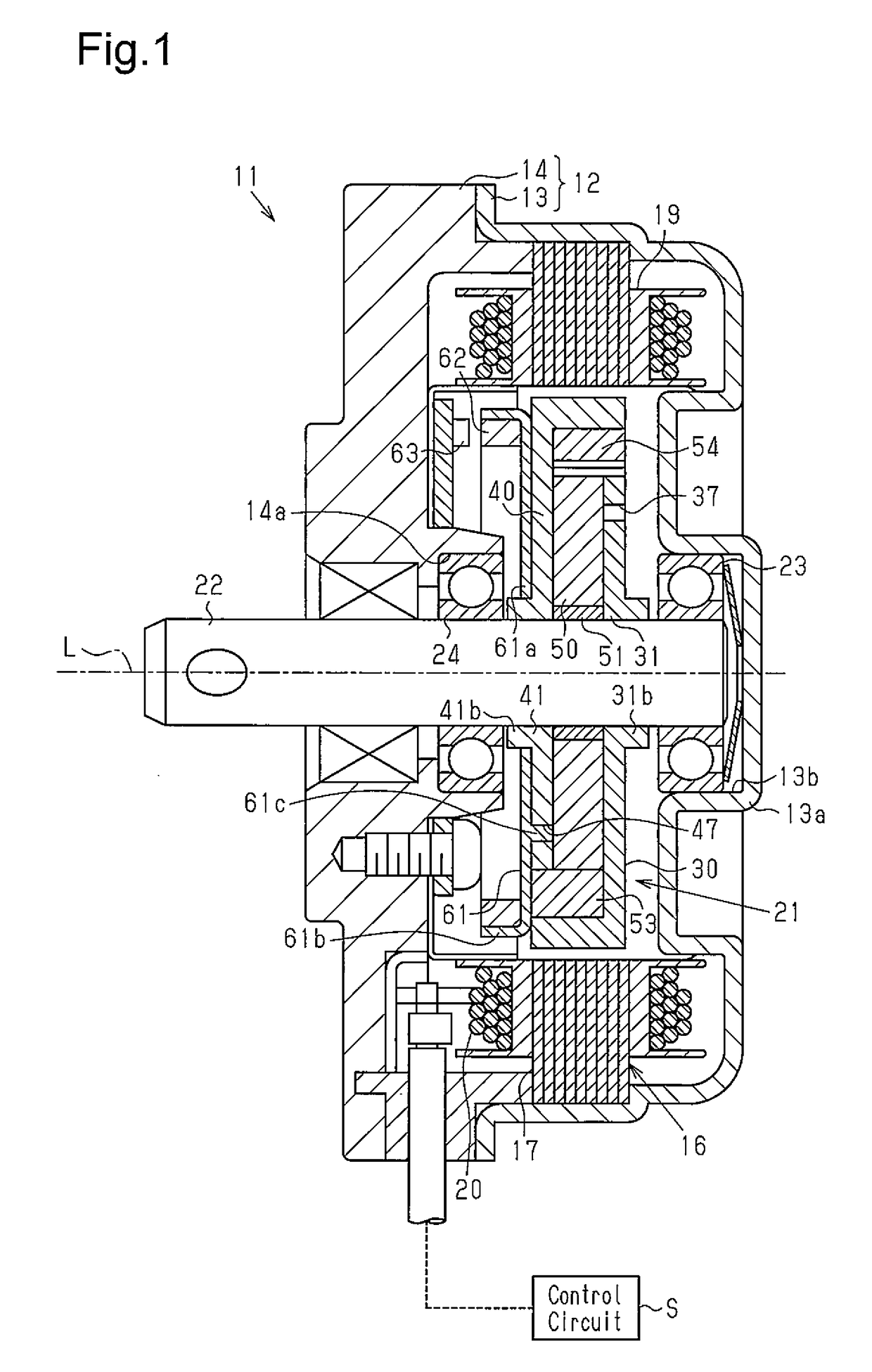

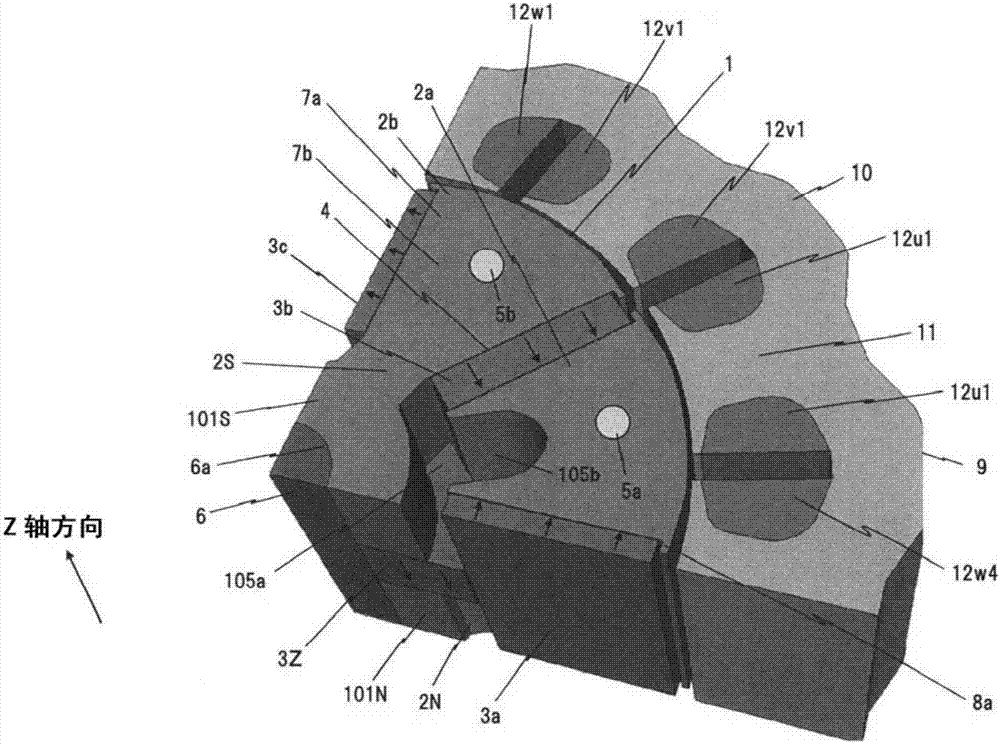

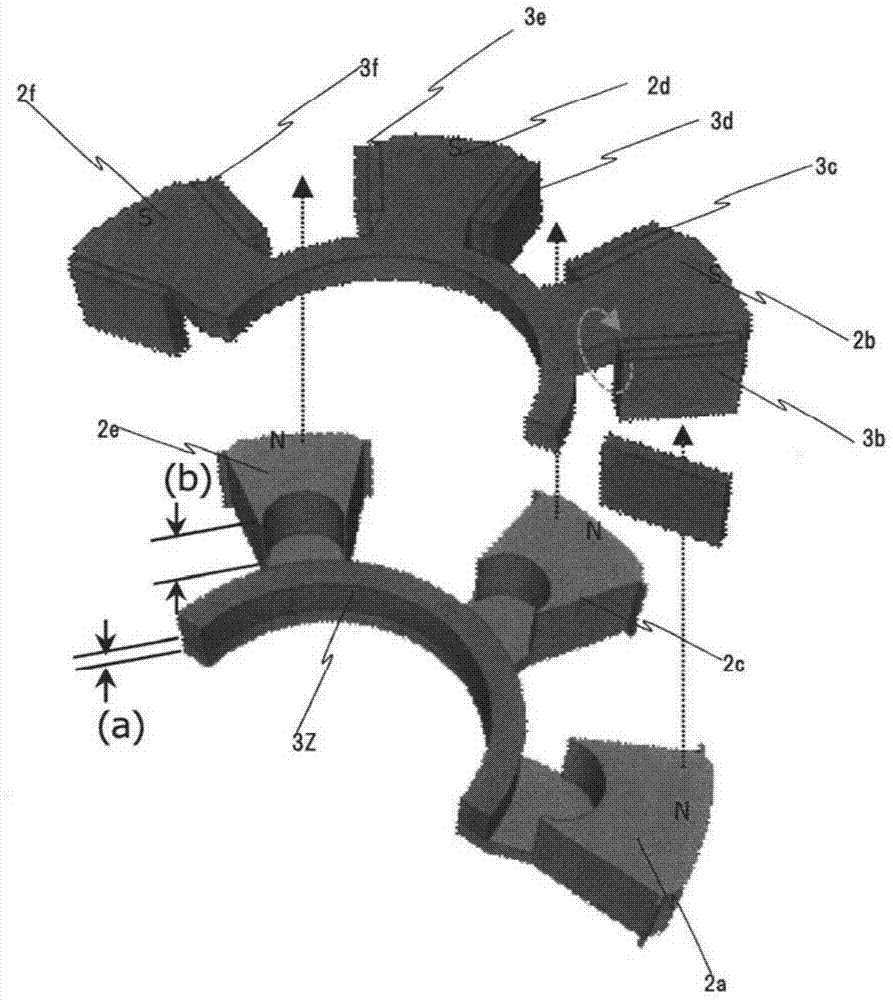

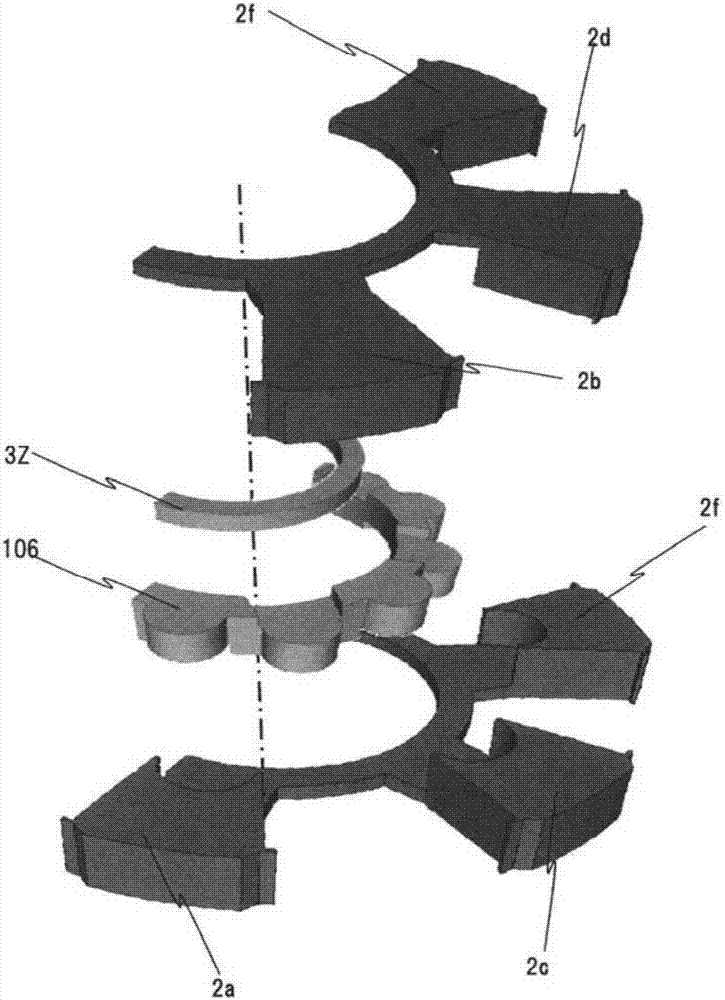

Rotor And Motor

ActiveCN103095014AReduce in quantitySuppression of Leakage FluxMagnetic circuit rotating partsMagnetic polesPhysics

A rotor includes at least one of a group of one or more auxiliary magnets that are located between first and second claw poles in a circumferential direction and magnetized to be magnetic poles of the same polarity as the first and second claw poles and another group of one or more auxiliary magnets that are located on a rear side of the first and second claw poles and magnetized to have radially outer portions of the same polarity as the first and second magnetic poles. The auxiliary magnets are arranged to protrude beyond at least one of axial end surfaces of the first and second core bases.

Owner:DENSO CORP

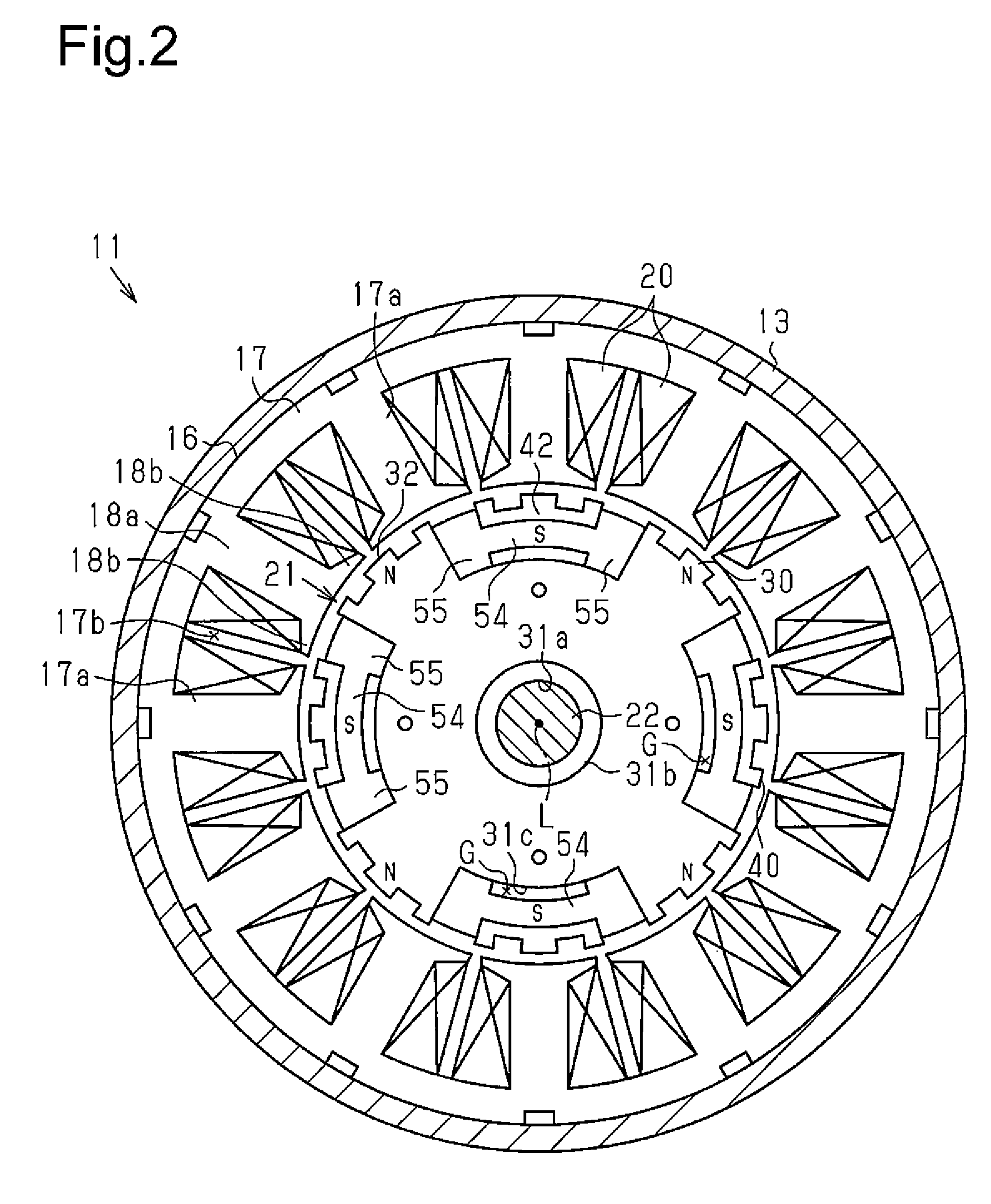

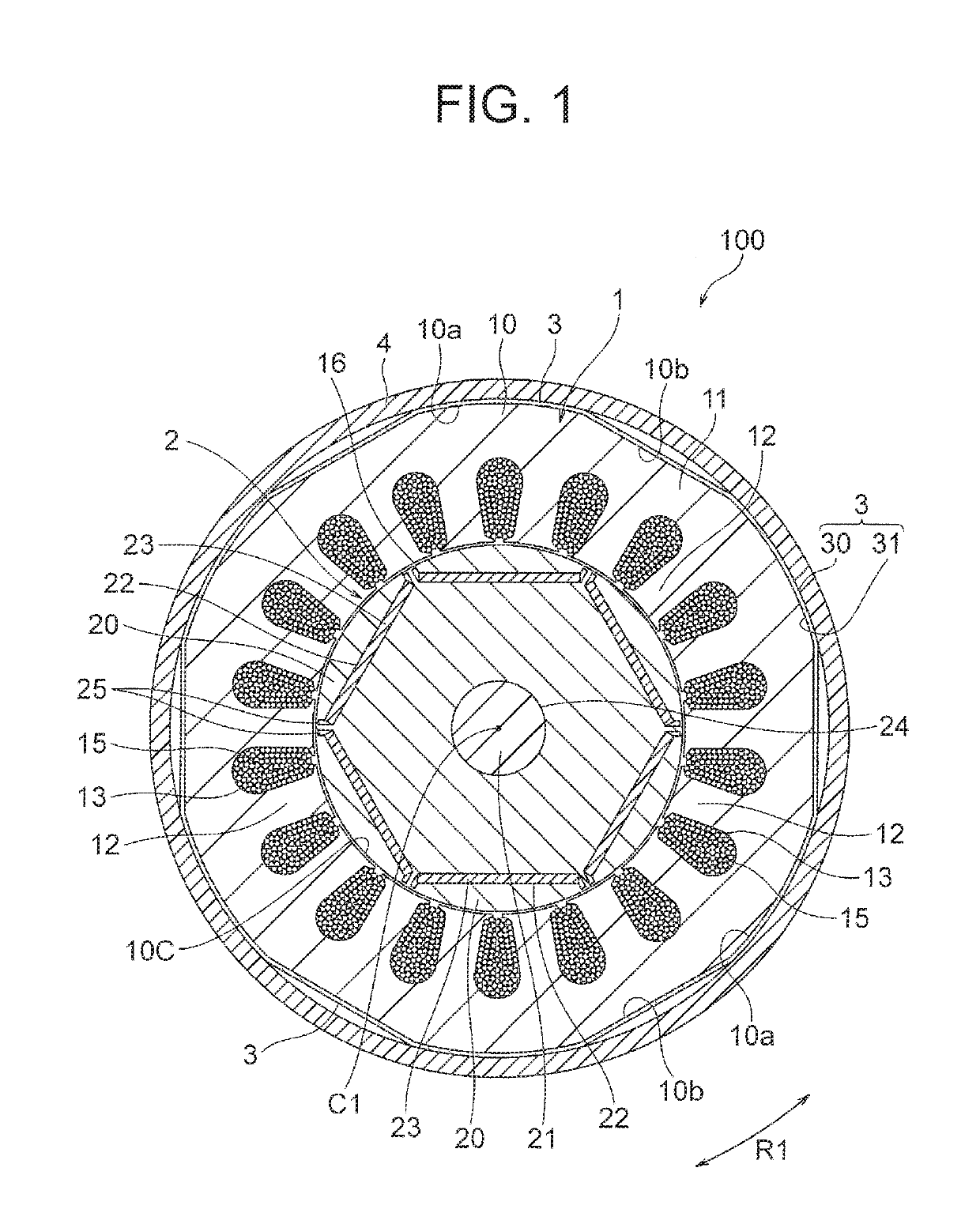

Motor

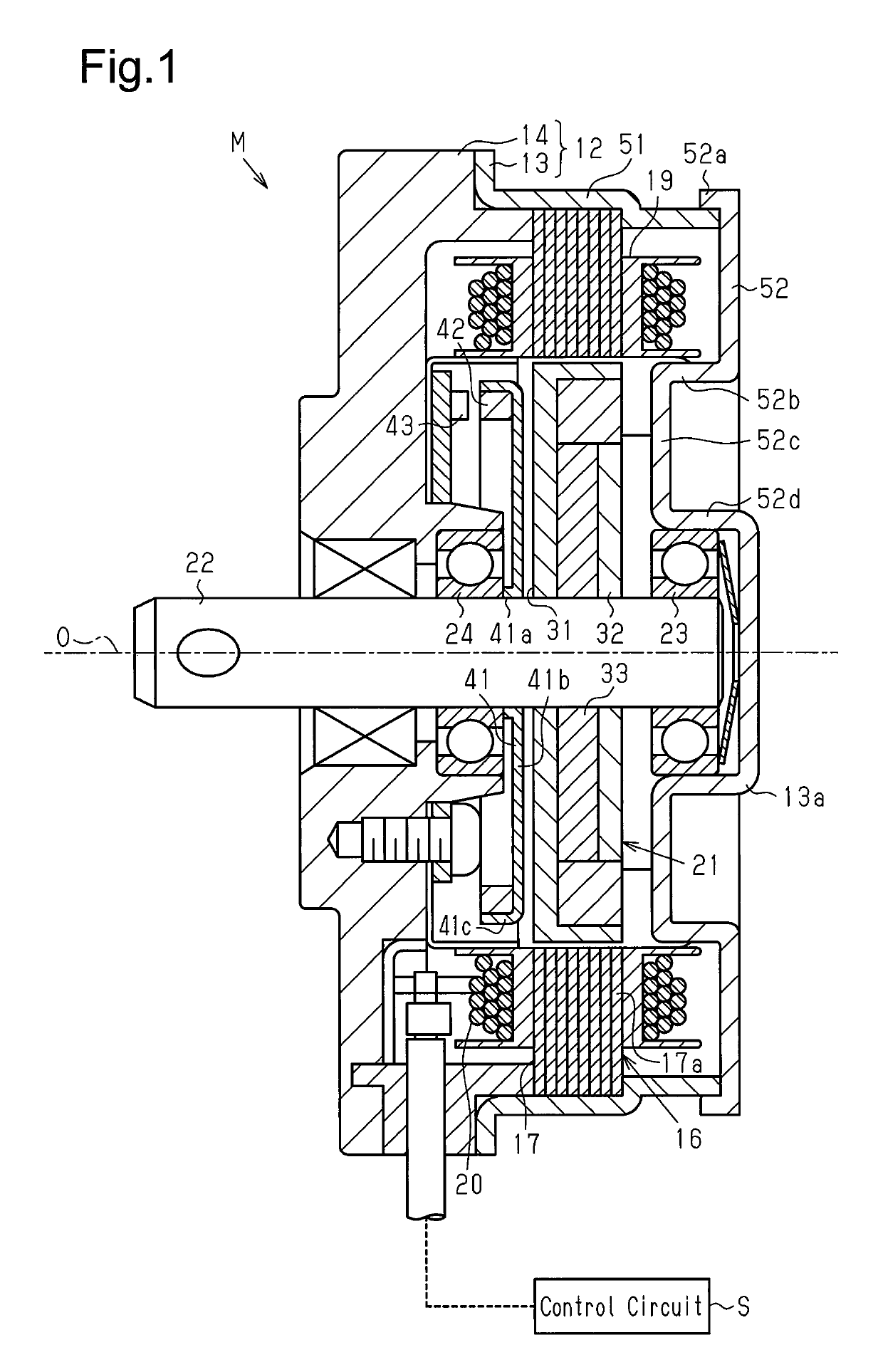

ActiveUS20150295458A1Suppression of Leakage FluxImprove output characteristicsMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsMagnetic polesPhysics

A motor includes a stator, a rotor, a case, and back-surface magnet portions. The rotor has a first rotor core, a second rotor core and a field magnet. Each of the first and second rotor cores has a core base and claw-shaped magnetic poles. The field magnet is sandwiched between the first rotor core and the second rotor core and causes the claw-shaped magnetic poles of the first rotor core and the second rotor core to function as different magnetic poles. The back-surface magnet portions include a second and a first back-surface magnet portions respectively provided on the back surfaces of the claw-shaped magnetic poles of the second rotor core and the first rotor core. Size of the second back-surface magnet portion differs from size of the first back-surface magnet portion are different from each other.

Owner:DENSO CORP

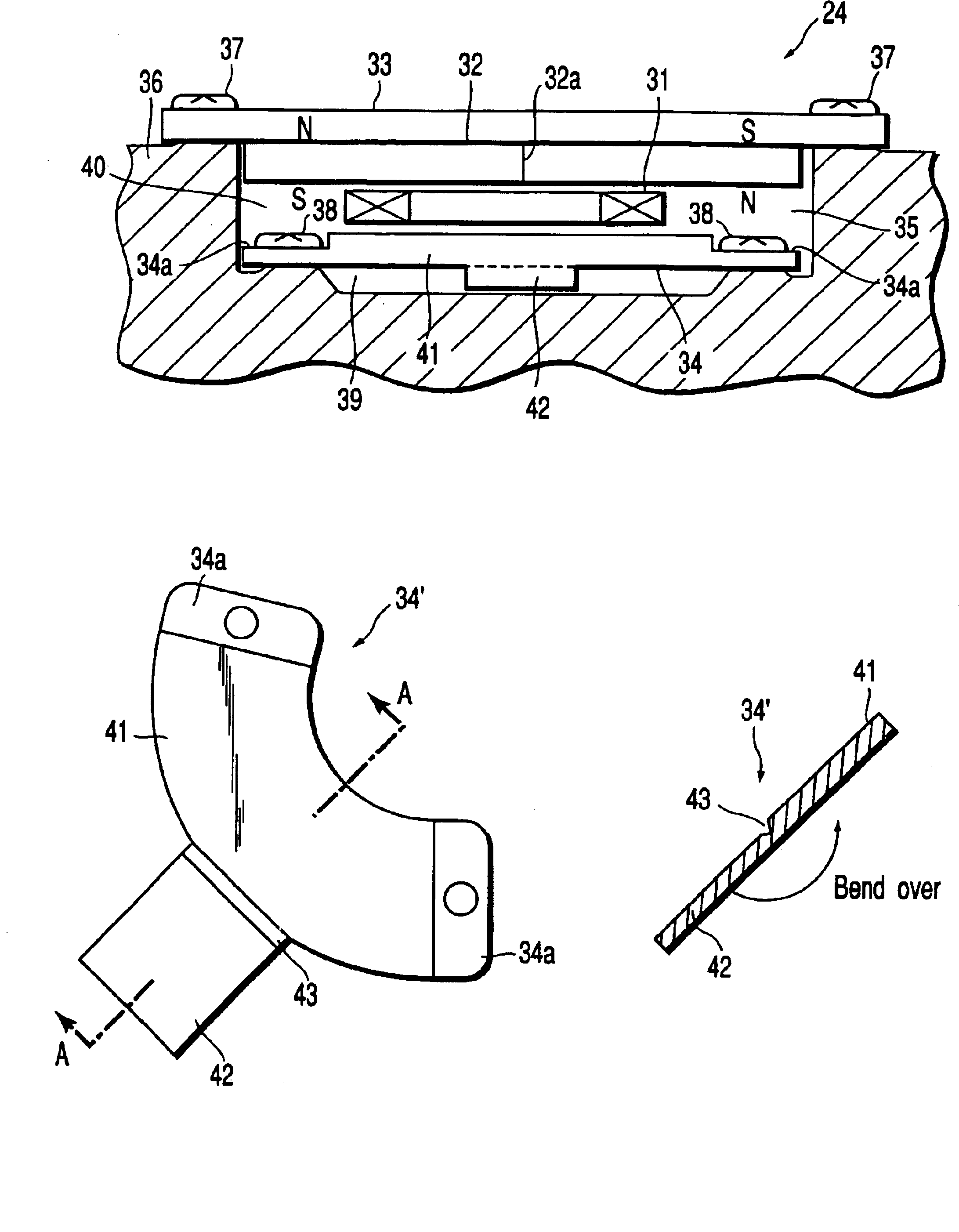

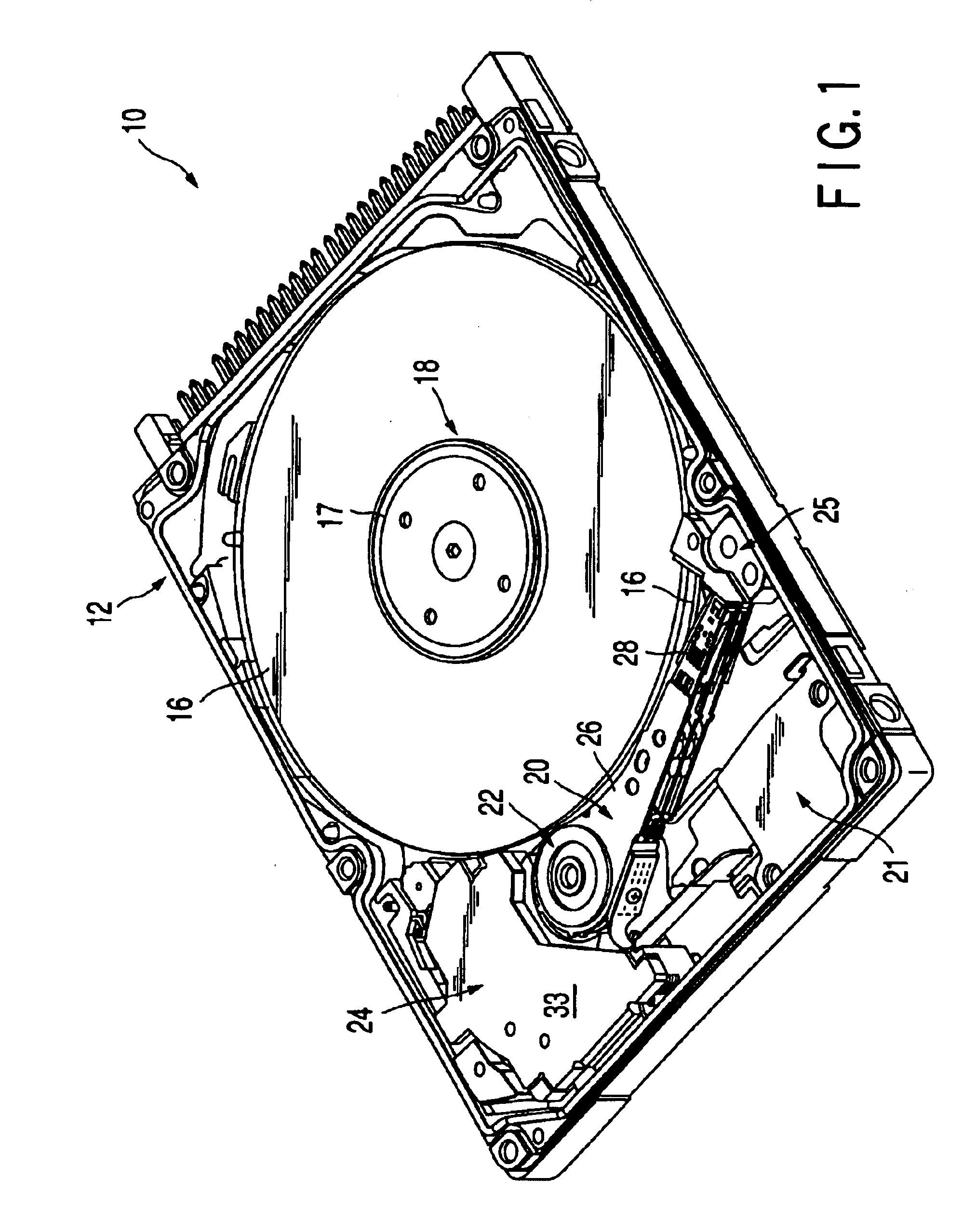

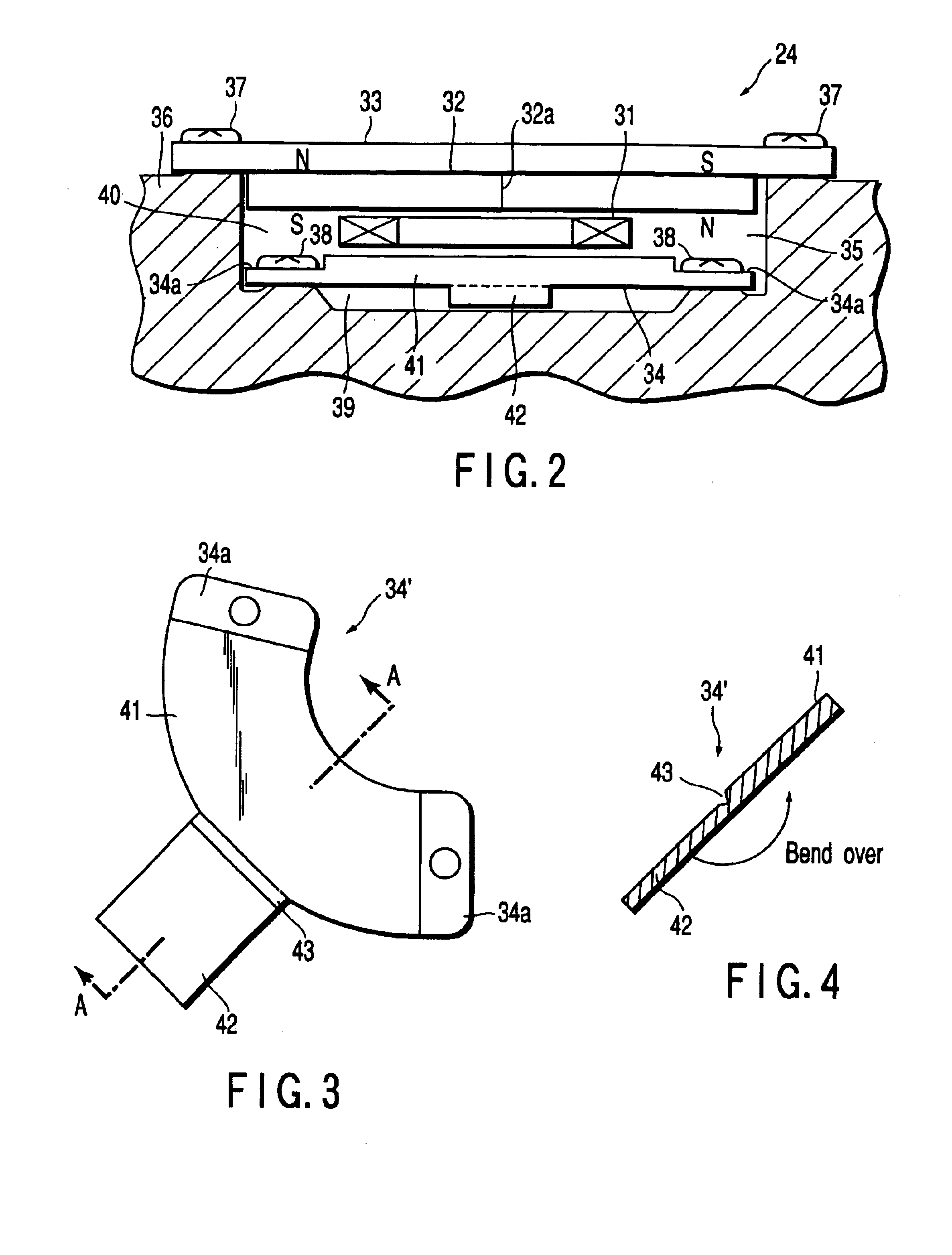

Disk unit, yoke built in disk unit and process of manufacturing same

InactiveUS6914755B2Suppression of Leakage FluxExercise sufficient performanceDisposition/mounting of recording headsRecord information storageEngineeringCantilever

A disk unit has a voice coil motor to oscillate a suspension arm mounted at the leading end of a head with respect to a disk. The voice coil motor has a voice coil integrally attached to the tail end of the suspension arm, a magnet to cause a magnetic field to act on the voice coil, and a pair of yokes provided in such a positional relationship that the voice coil and magnet are sandwiched therebetween. At least one yoke has a roughly fan-shaped main body and a plate piece portion provided in a condition extended from one end side of the main body. After the formation of the main body and plate piece portion by press working, the yoke is formed by folding the plate piece portion on the main body.

Owner:KK TOSHIBA

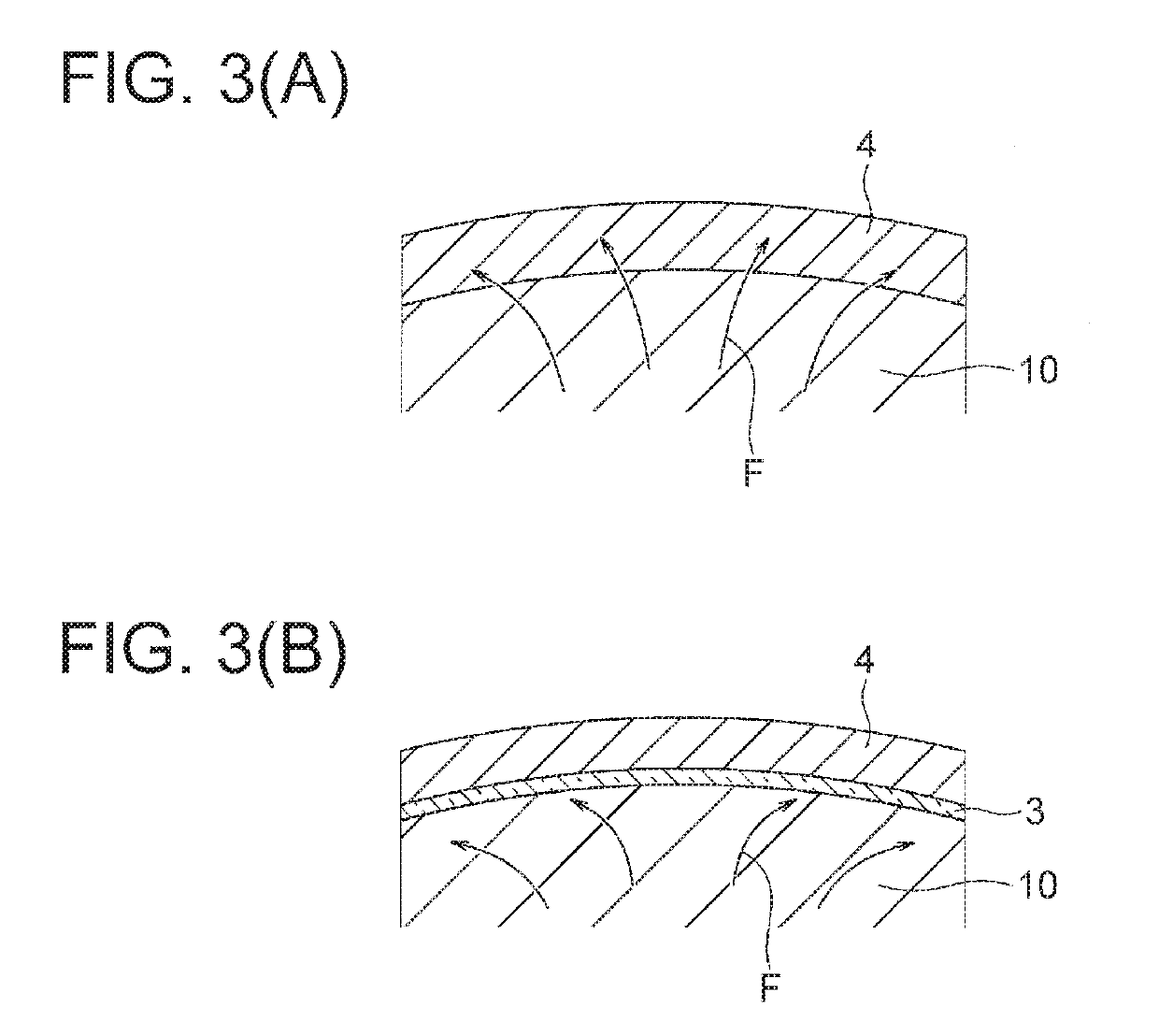

Motor, compressor, refrigerating and air conditioning apparatus, and method for manufacturing motor

ActiveUS20190319509A1Improve motor efficiencySuppression of Leakage FluxCompressorMagnetic circuitEngineeringAir conditioning

A motor is provided in a shell. The motor includes a stator having an outer peripheral surface facing an inner peripheral surface of the shell, a rotor rotatably disposed inside the stator, and a nonmagnetic film disposed between the outer peripheral surface of the stator and the inner peripheral surface of the shell.

Owner:MITSUBISHI ELECTRIC CORP

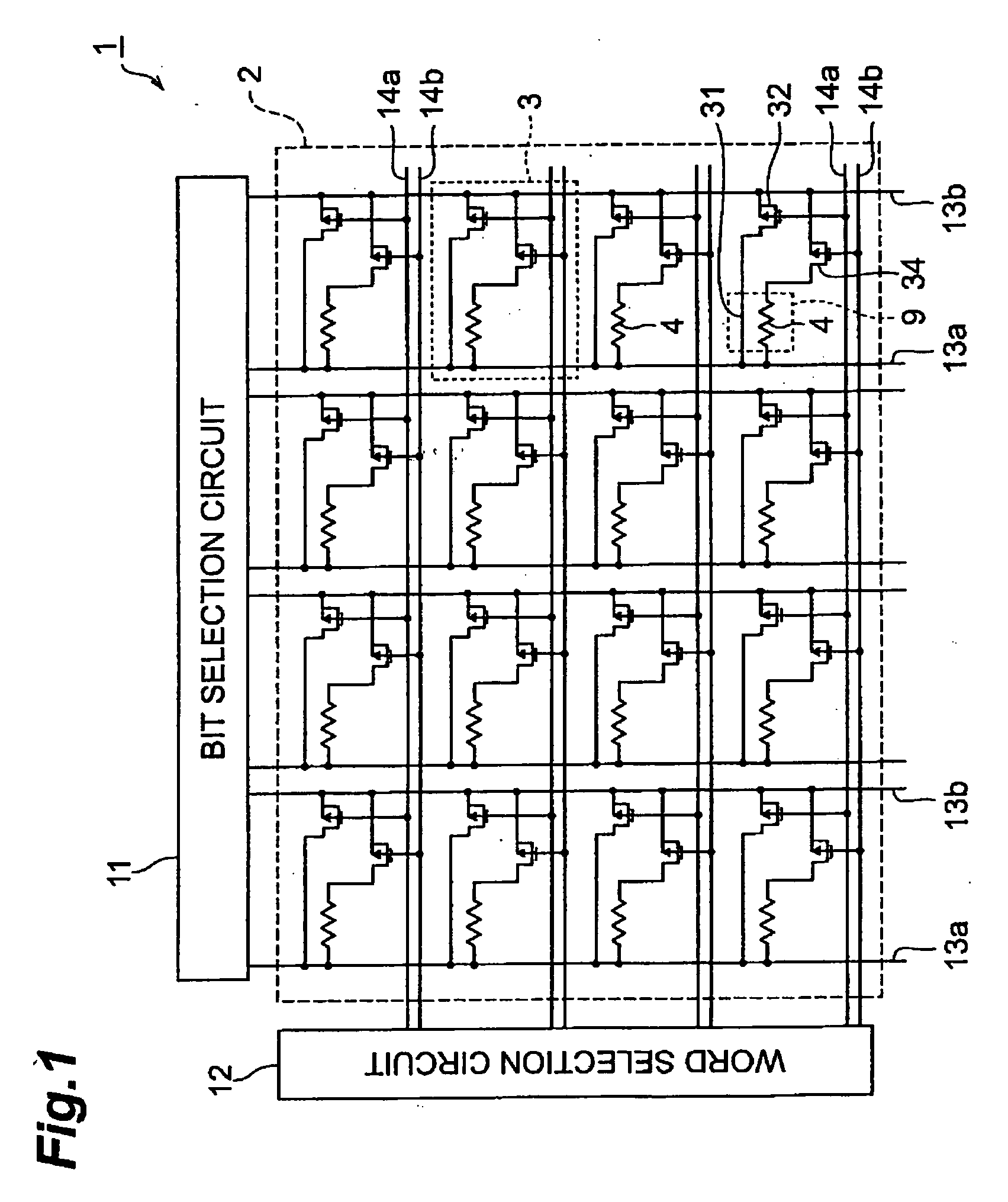

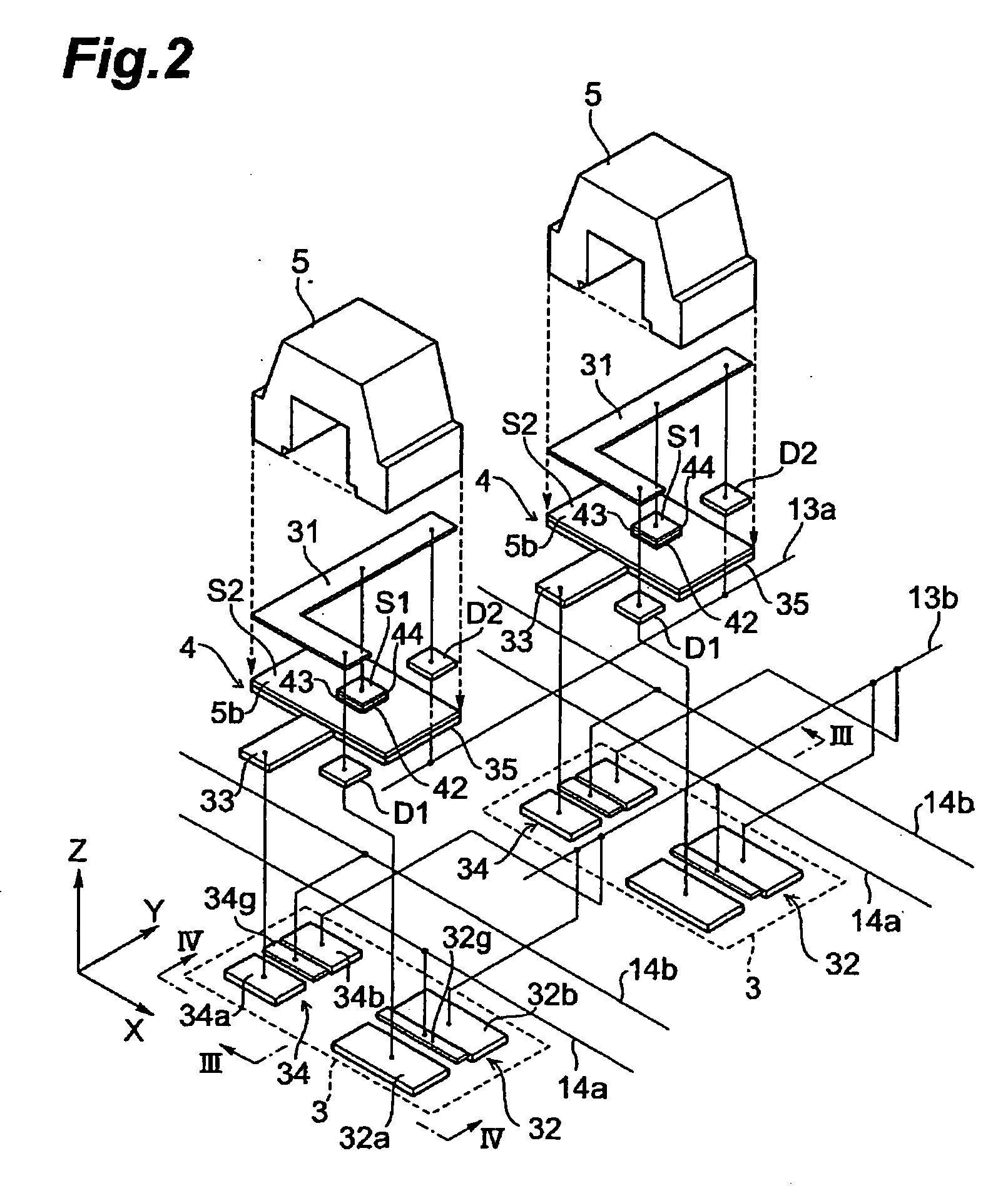

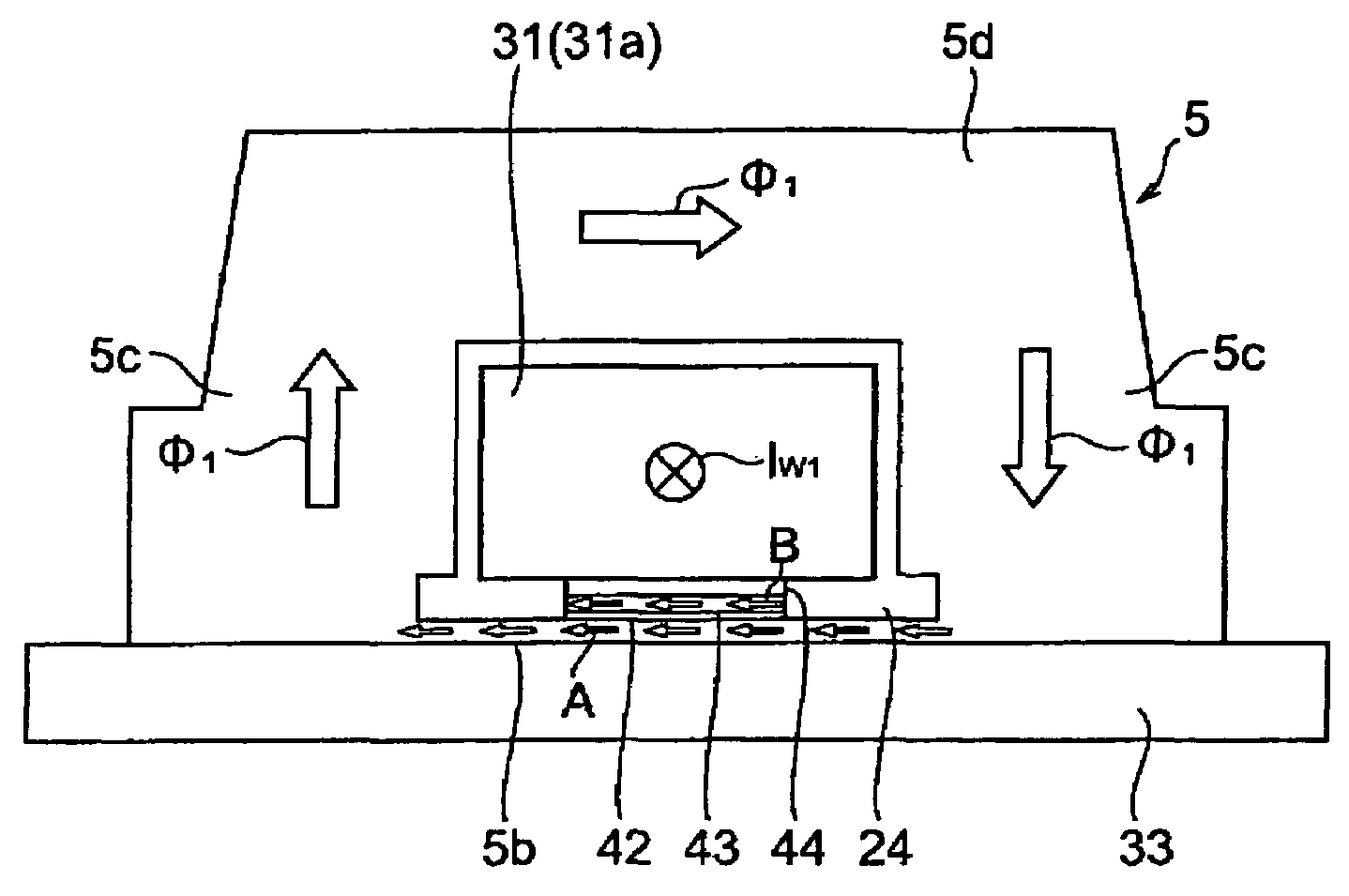

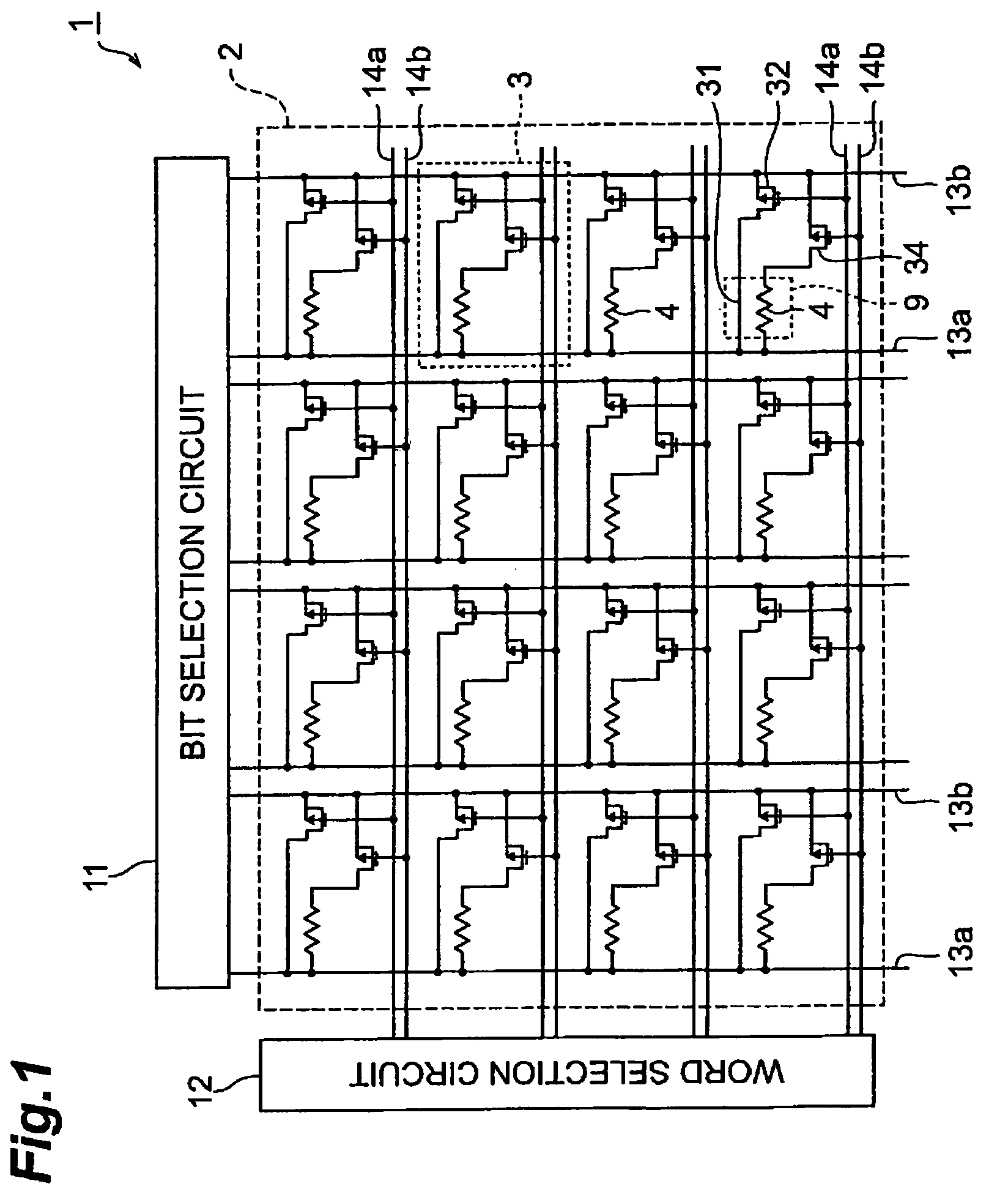

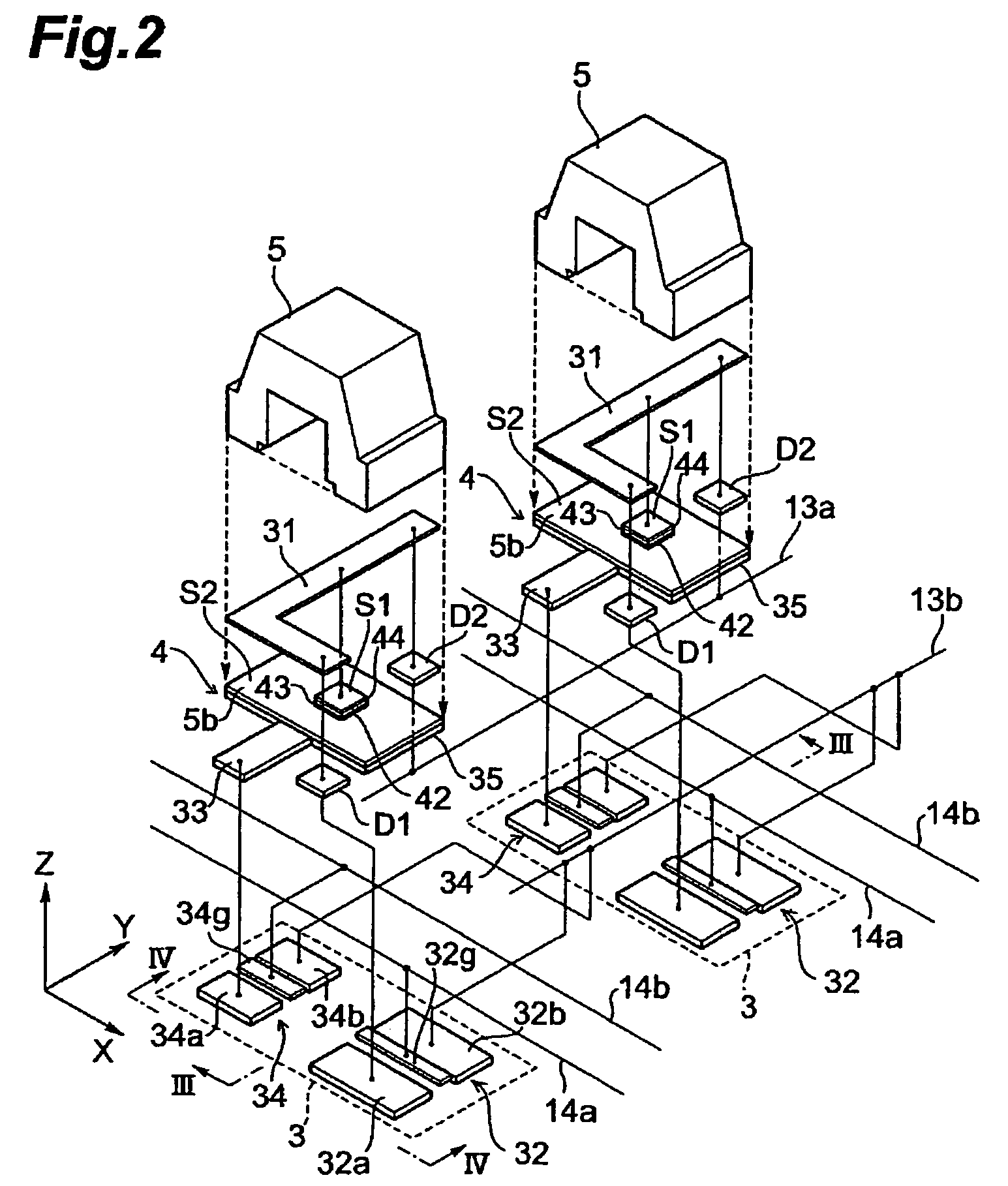

Magnetic memory and method of manufacturing same

InactiveUS20060266470A1High reliabilitySimple to manufactureLamination ancillary operationsNanoinformaticsMagnetic memory

A magnetization direction in a magnetosensing layer (5b) is perturbed near the magnetic connection between a magnetic yoke (5) and the magnetosensing layer (5b). If the magnetization direction of a region in the magnetosensing layer (5b) facing a fixed layer which functions during read is not perturbed, reliability is improved. In this magnetometric sensor, a surface area S1 of fixed layers (43, 44) is made smaller than a surface area S2 of the magnetosensing layer (5b) so that, in the region of the magnetosensing layer (5b) facing the fixed layer, the magnetization direction is perturbed less than in the surrounding region and reliability during data read is improved.

Owner:TDK CORPARATION

Coil component

ActiveUS10930420B2Increase inductanceImprove performanceTransportation and packagingTransformers/inductances coils/windings/connectionsElectrical conductorMagnetic layer

Owner:TAIYO YUDEN KK

Permanent magnet-type electric motor, compressor and refrigeration cycle device using the same

ActiveCN104426266ASuppression of Leakage FluxIncrease torqueMagnetic circuit rotating partsEngineeringRefrigeration

The present invention provides a permanent magnet-type electric motor with a spoke-shaped magnet, wherein the leakage flux of the permanent magnet is reduced and both the torque and the efficiency are improved. In order to achieve the above purposes, the permanent magnet-type electric motor comprises a stator having a plurality of teeth; and a rotor configured to be spaced from the stator radially at an interval. The rotor is composed of a magnetized S-pole core and a magnetized N-pole core combined togtether axially. The N-pole core is provided with N peripherally and outwardly extruding N lateral bulges, and the S-pole core is provided with N peripherally and outwardly extruding S lateral bulges. The N lateral bulges and the S lateral bulges are arranged in a mutually alien manner.

Owner:HITACHI JOHNSON CONTROLS AIR CONDITIONING INC

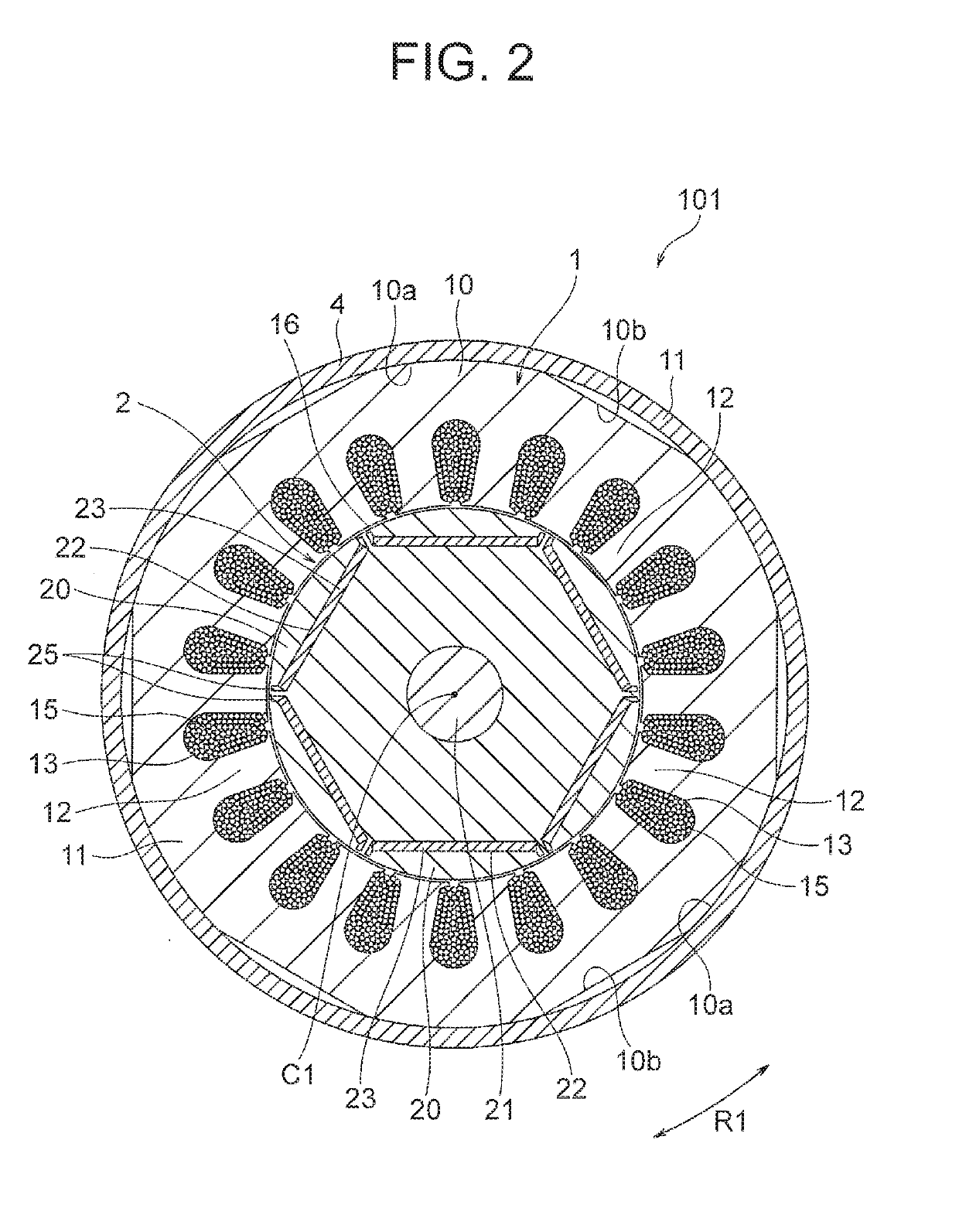

Motor and rotor

ActiveUS10270306B2Suppression of Leakage FluxMagnetic circuit rotating partsSupports/enclosures/casingsMagnetic polesNon magnetic

A motor includes a stator, a rotor, and a case. The stator includes a stator core and windings. The rotor is provided inside the stator. The rotor includes first and second rotor cores and a field magnet. The first and second rotor cores each includes a core base and claw-shaped magnetic poles. The core bases are opposed to each other and the claw-shaped magnetic poles of the first and second rotor cores are alternately disposed in a circumferential direction. The field magnet is disposed between the core bases in the axial direction. The field magnet is magnetized in the axial direction so as to cause the claw-shaped magnetic poles of the first rotor core and the second rotor core to function respectively as first magnetic poles and second magnetic poles. At least part of an end part of the case in the axial direction is made of a non-magnetic body.

Owner:DENSO CORP

Transformer

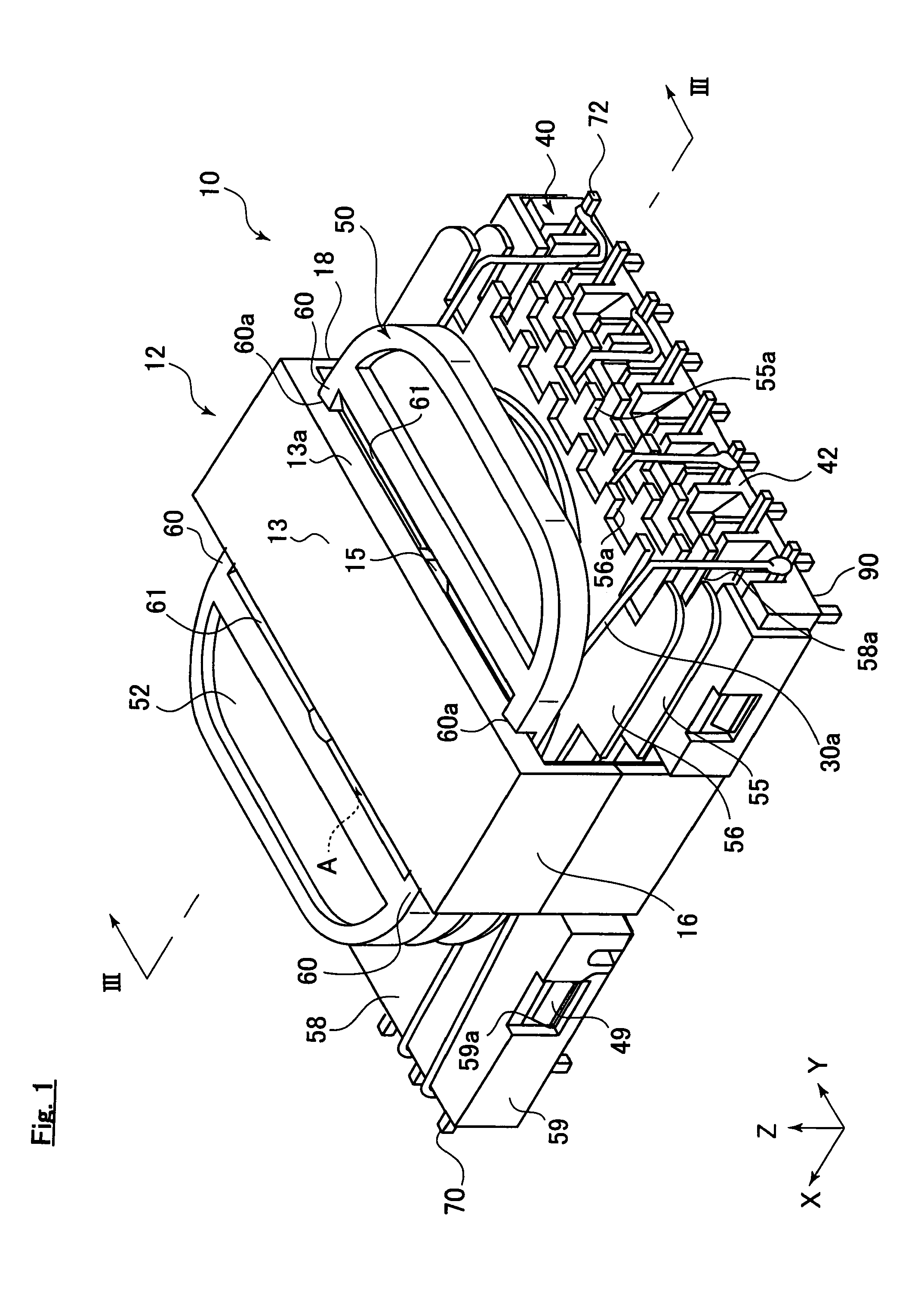

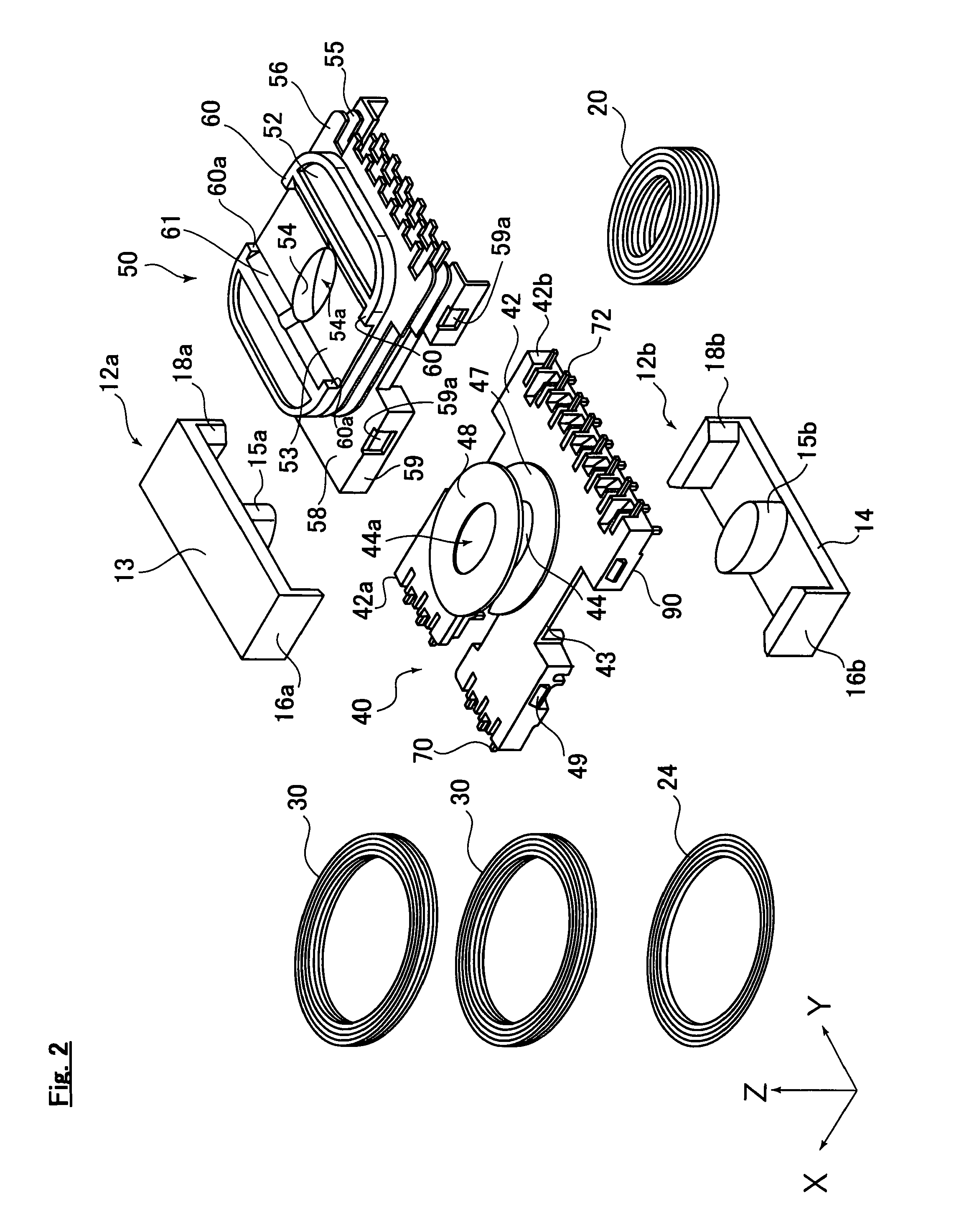

ActiveUS20130135073A1Firmly connectedShorten the lengthTransformers/inductances coils/windings/connectionsFixed transformersBobbinTransformer

A transformer is provided having good workability during production and good connection of the secondary main coil and the primary supportive coil. The transformer has a bobbin with a base part and first hollow cylinder part with a first through hole and a core projecting in a first positive direction from said base part, and a case having an upper collar part formed with a primary main coil wound around said first hollow cylinder part, a second through hole leading to said first through hole, and a second hollow cylinder part formed at the outer peripheral face. Said primary main coil is housed and projects in a first negative direction from said upper collar part. A lower collar part opposes said base part by extending approximately parallel to said mounting face. The primary supportive coil and secondary main coil are wound around said first and second sections, respectively.

Owner:TDK CORPARATION

Rotor of buried magnet-type electric motor, motor and machine tool having the rotor

ActiveUS9065314B2Suppression of Leakage FluxIncrease speedMagnetic circuit rotating partsMagnetic polesMachine tool

Owner:FANUC LTD

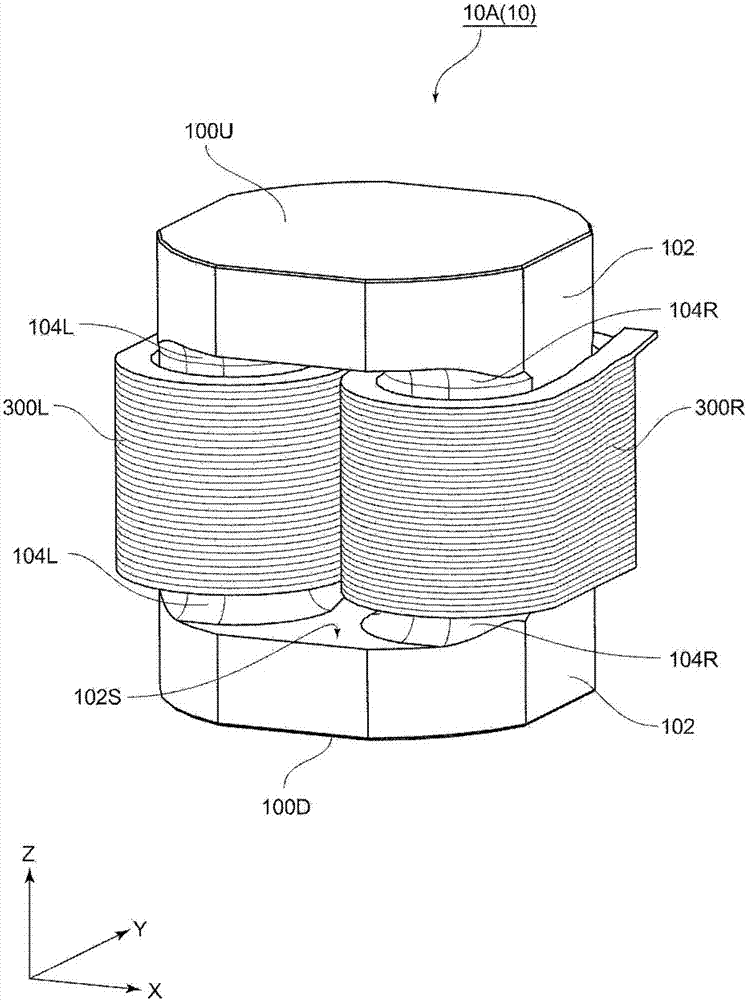

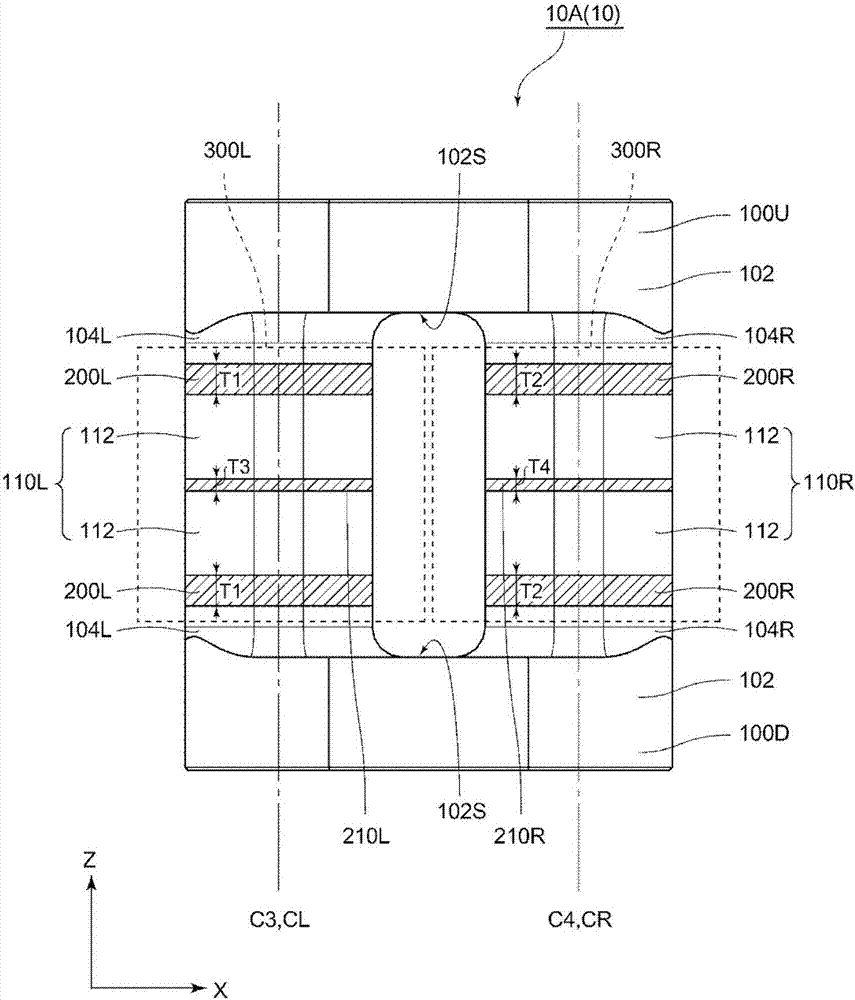

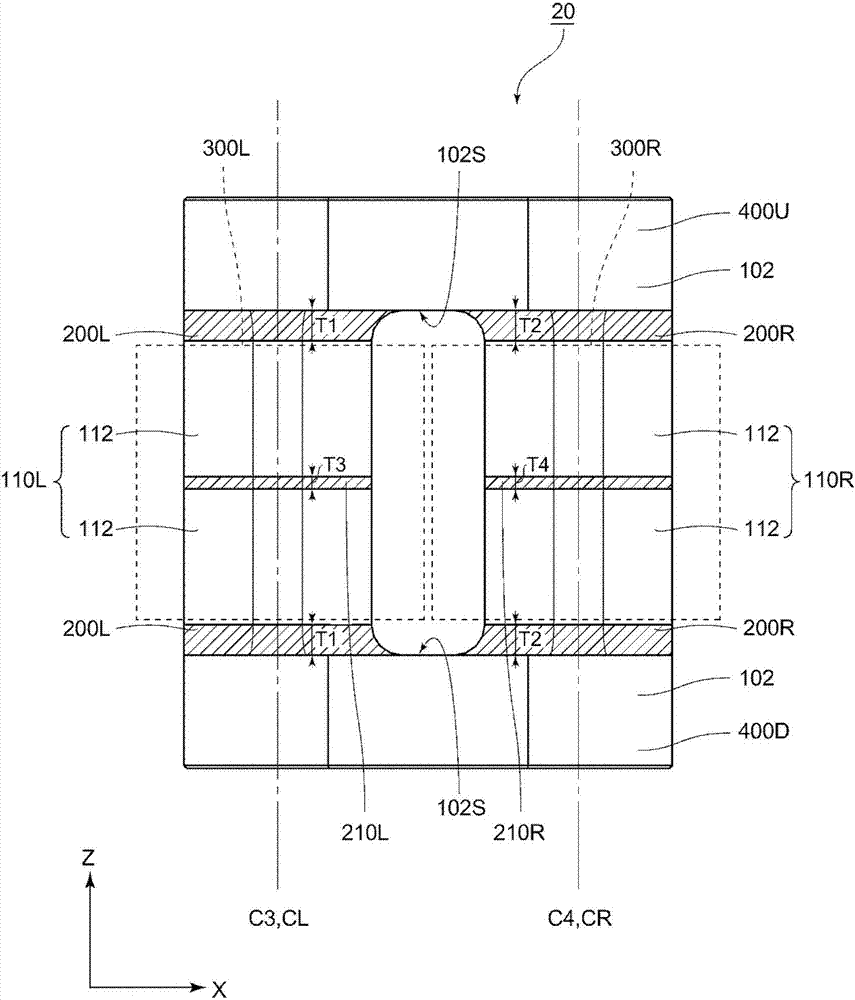

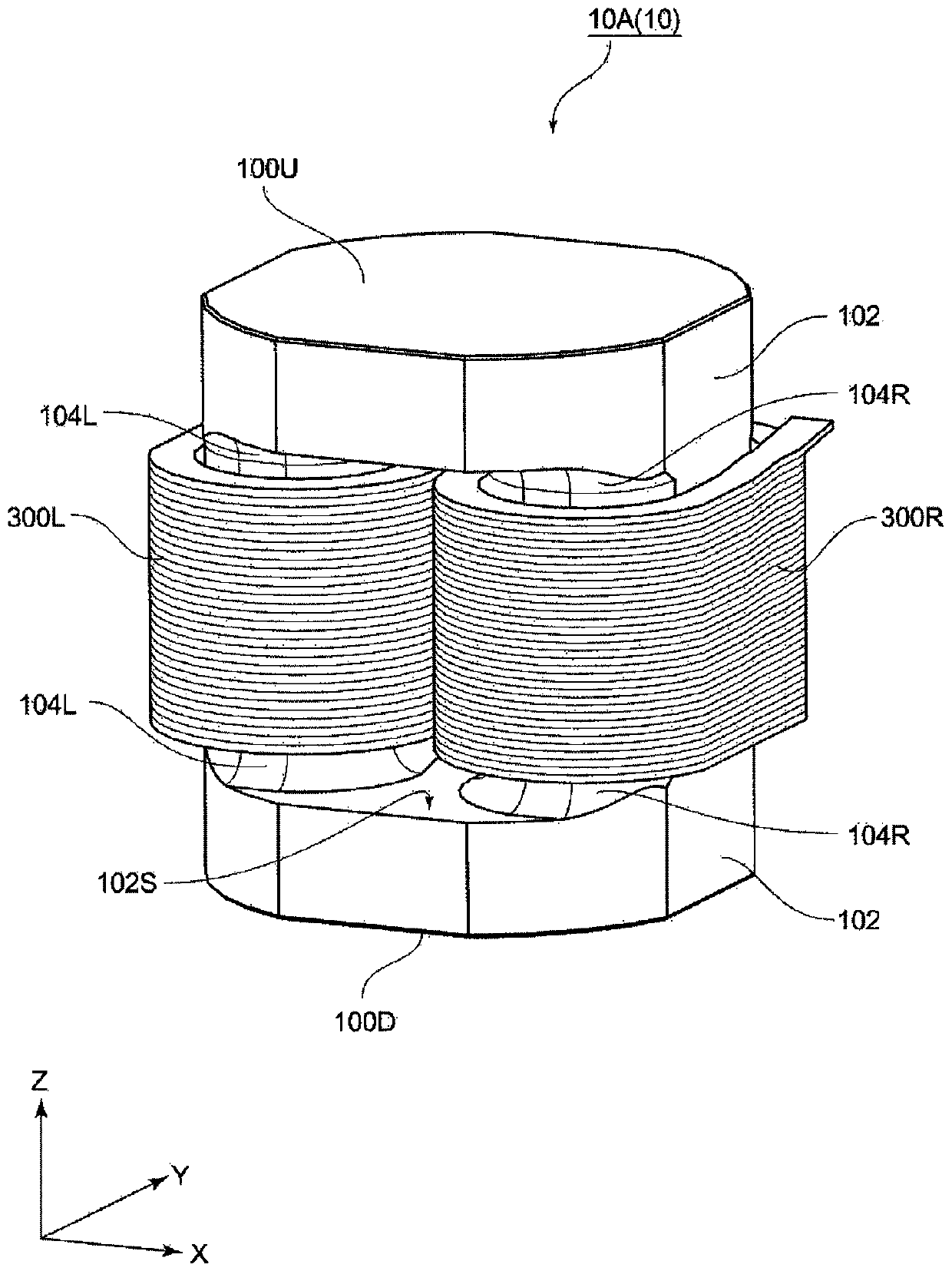

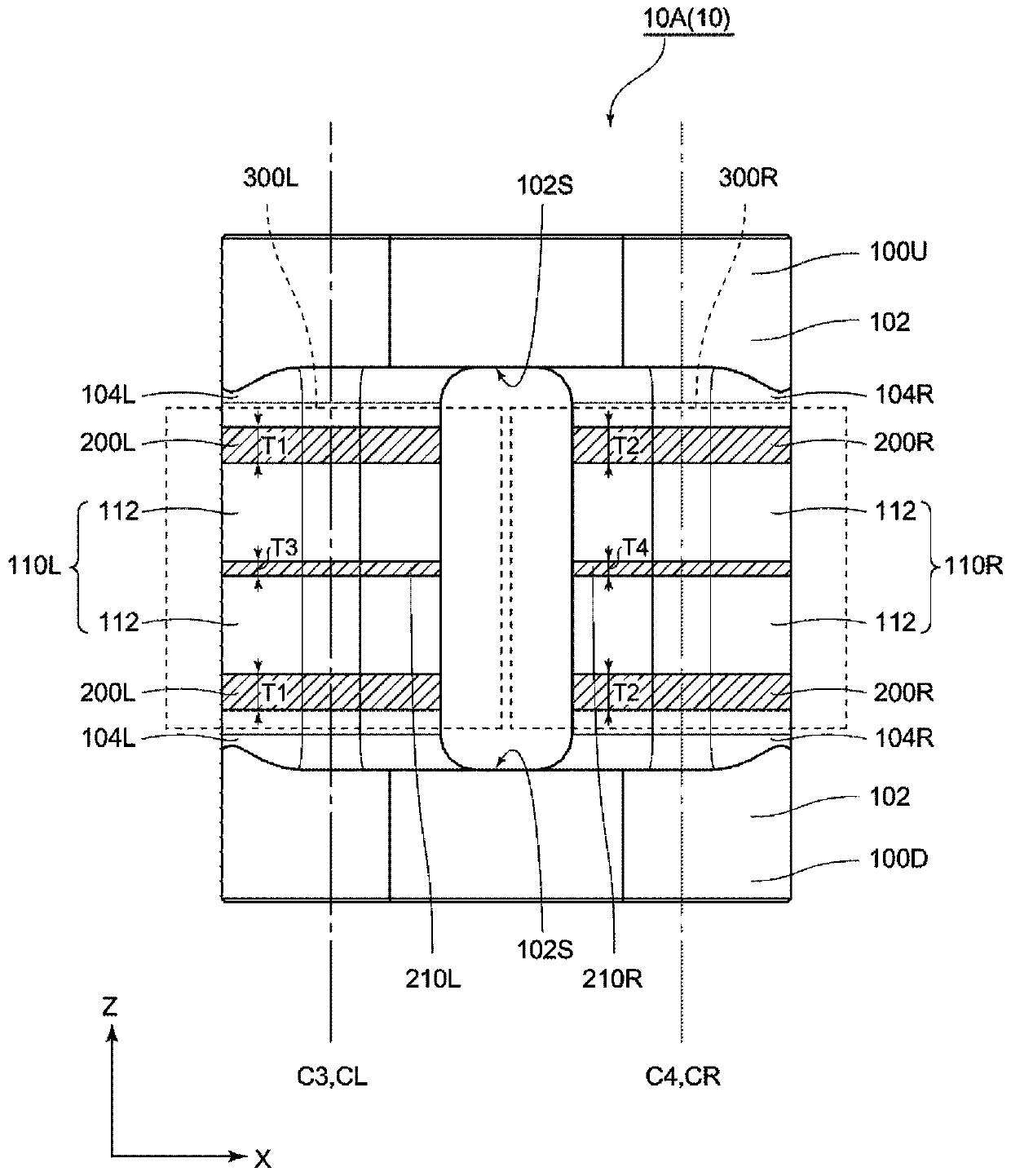

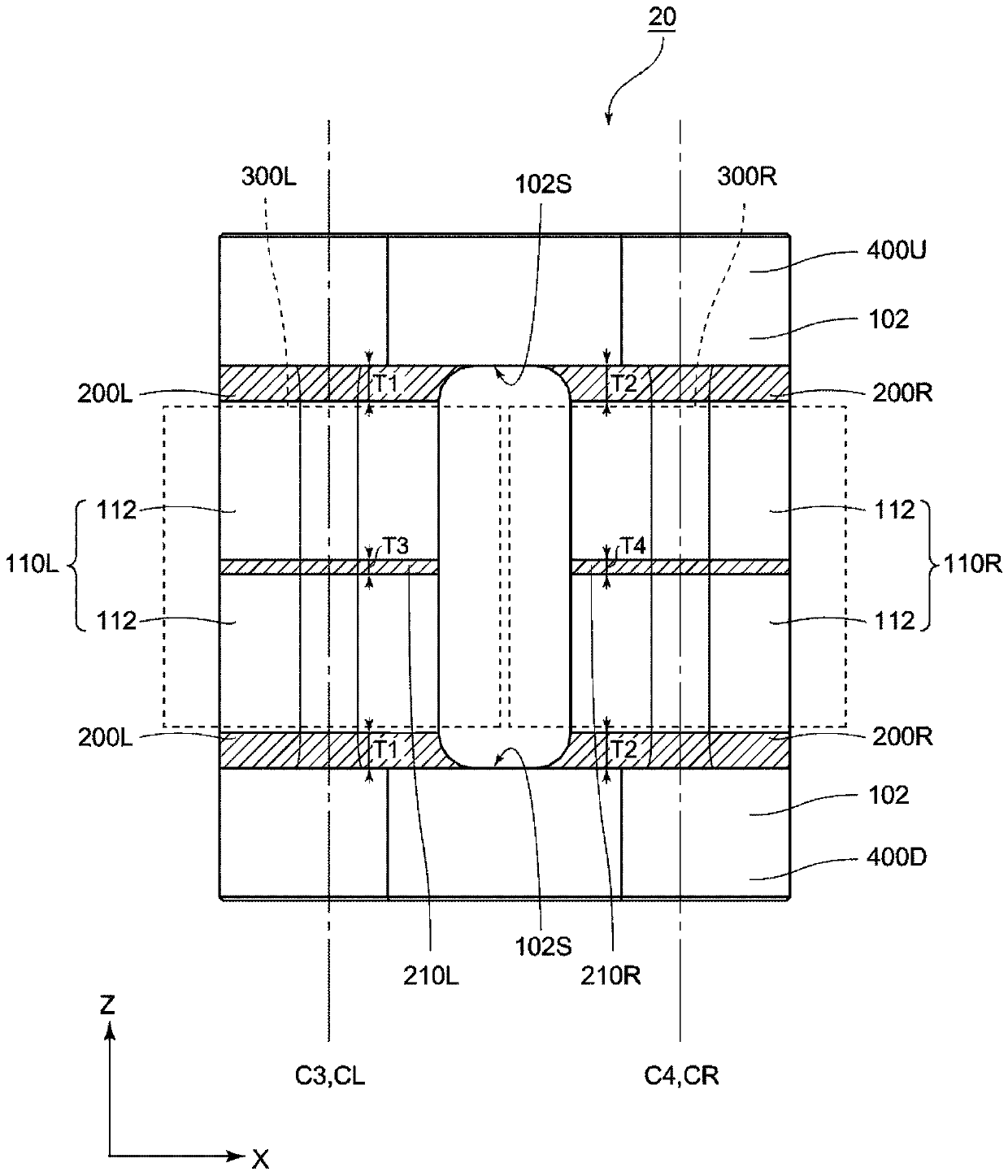

Magnetic component

ActiveCN107045927AExcellent DC superposition characteristicsSuppression of Leakage FluxTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresElectrical and Electronics engineeringFerrite core

A magnetic component is provided which has excellent DC overlay properties and is capable of suppressing leakage flux. The magnetic component includes: ferrite cores 100U, 100D each having two protruding components 104L, 104R; a ferrite core 110L disposed between one of the projecting members 104L of the ferrite cores 100U, 100D via the spacer 200L; a ferrite core 110R disposed via another spacer 200R between another of the protruding members 104R of the ferrite cores 100U, 100D; a coil 300L arranged so that the ferrite core 110L is located on an inner peripheral side thereof; and a coil 300R arranged so that the ferrite core 110R is located on an inner peripheral side thereof, the spacers 200L being located on the inner peripheral side of the coil 300L and the spacers 200R being located on the inner peripheral side of the coil 300R.

Owner:SUMIDA CORP

Automotive rotary electric machine

ActiveUS20180342915A1Increase volumeIncrease productionSynchronous generatorsAssociation with control/drive circuitsElectric machineMagnetic poles

Owner:MITSUBISHI ELECTRIC CORP

Permeability measurement apparatus

InactiveUS7816917B2High sensitivitySuppression of Leakage FluxPermeability measurementsMeasurements using electron paramagnetic resonanceMeasurement deviceCoil inductance

A permeability measurement apparatus includes a magnetic field generation means applying an alternating magnetic field having a predetermined frequency to a magnetic substance to be measured; a probe needle placed in proximity or in contact to a microscopic area of the magnetic substance to be measured to which the alternating magnetic field is applied; a resonator including a coil wound on the probe needle, and generating a magnetic field having a resonant frequency higher than the frequency of the alternating magnetic field applied on the microscopic area having the probe needle in proximity or in contact thereto, and having an inductance of the coil varied as permeability in the microscopic area varies; and a measurement means measuring the permeability of the microscopic area of the magnetic substance to be measured based on the variation of the resonant frequency of the resonator according to the variation of the coil inductance.

Owner:TOHOKU UNIV

Automotive rotary electric machine

ActiveUS10840752B2Increase volumeImprove compactnessSynchronous generatorsAssociation with control/drive circuitsElectric machineMagnetic poles

Owner:MITSUBISHI ELECTRIC CORP

Motor

ActiveUS9705365B2Improve balanceSuppression of Leakage FluxMagnetic circuit rotating partsSynchronous motorsMagnetic polesPhysics

A motor includes a stator, a rotor, a case, and back-surface magnet portions. The rotor has a first rotor core, a second rotor core and a field magnet. Each of the first and second rotor cores has a core base and claw-shaped magnetic poles. The field magnet is sandwiched between the first rotor core and the second rotor core and causes the claw-shaped magnetic poles of the first rotor core and the second rotor core to function as different magnetic poles. The back-surface magnet portions include a second and a first back-surface magnet portions respectively provided on the back surfaces of the claw-shaped magnetic poles of the second rotor core and the first rotor core. Size of the second back-surface magnet portion differs from size of the first back-surface magnet portion are different from each other.

Owner:DENSO CORP

Transformer

ActiveUS8773234B2Firmly connectedShorten the lengthTransformers/inductances coils/windings/connectionsFixed transformersBobbinTransformer

A transformer is provided having good workability during production and good connection of the secondary main coil and the primary supportive coil. The transformer has a bobbin with a base part and first hollow cylinder part with a first through hole and a core projecting in a first positive direction from said base part, and a case having an upper collar part formed with a primary main coil wound around said first hollow cylinder part, a second through hole leading to said first through hole, and a second hollow cylinder part formed at the outer peripheral face. Said primary main coil is housed and projects in a first negative direction from said upper collar part. A lower collar part opposes said base part by extending approximately parallel to said mounting face. The primary supportive coil and secondary main coil are wound around said first and second sections, respectively.

Owner:TDK CORPARATION

Motor, compressor, refrigerating and air conditioning apparatus, and method for manufacturing motor

ActiveUS10916989B2Improve motor efficiencySuppression of Leakage FluxCompressorMagnetic circuitElectric machineEngineering

A motor is provided in a shell. The motor includes a stator having an outer peripheral surface facing an inner peripheral surface of the shell, a rotor rotatably disposed inside the stator, and a nonmagnetic film disposed between the outer peripheral surface of the stator and the inner peripheral surface of the shell.

Owner:MITSUBISHI ELECTRIC CORP

Magnetic memory using spin injection flux reversal

InactiveUS7683446B2Suppression of Leakage FluxHigh magnetic flux densityNanoinformaticsSolid-state devicesMagnetizationMagnetic memory

Owner:TDK CORPARATION

magnetic parts

ActiveCN107045927BImprove DC Superposition CharacteristicsSuppression of Leakage FluxTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresEngineeringFerrite core

A magnetic component is provided which has excellent DC overlay properties and is capable of suppressing leakage flux. The magnetic component includes: ferrite cores 100U, 100D each having two protruding components 104L, 104R; a ferrite core 110L disposed between one of the projecting members 104L of the ferrite cores 100U, 100D via the spacer 200L; a ferrite core 110R disposed via another spacer 200R between another of the protruding members 104R of the ferrite cores 100U, 100D; a coil 300L arranged so that the ferrite core 110L is located on an inner peripheral side thereof; and a coil 300R arranged so that the ferrite core 110R is located on an inner peripheral side thereof, the spacers 200L being located on the inner peripheral side of the coil 300L and the spacers 200R being located on the inner peripheral side of the coil 300R.

Owner:SUMIDA CORP

Power receiving device, vehicle, and power transmission device

ActiveUS9876364B2Suppression of Leakage FluxPrevent leakageCharging stationsTransformersElectric power transmissionElectricity

This power receiving device includes a magnetic shield, and the magnetic shield includes: a first magnetic sheet located beside the power receiving unit; a conductive sheet located opposite to the power receiving unit with the first magnetic sheet interposed therebetween; and a second magnetic sheet located opposite to the first magnetic sheet with the conductive sheet interposed therebetween.

Owner:TOYOTA JIDOSHA KK +1

Permanent magnet motor, compressor using same, and refrigeration cycle device

ActiveCN104426266BSuppression of Leakage FluxIncrease torqueMagnetic circuit rotating partsEngineeringPermanent magnet motor

PROBLEM TO BE SOLVED: To improve torque and efficiency by reducing a leakage magnetic flux of a permanent magnet in a permanent magnet type motor employing a spoke-type magnet.SOLUTION: The permanent magnet type motor comprises a stator including a plurality of teeth and a rotor which is disposed via a gap in a radial direction relative to the stator. The rotor is configured by axially combining an S-pole core that is magnetized closer to an S pole, and an N-pole core that is magnetized closer to an N pole. In the S-pole core, a plurality of S-side protrusions are formed which protrude outside in a circumferential direction and in the N-pole core, a plurality of N-side protrusions are formed which protrude outside in a circumferential direction. By combining the S-pole core and the N-pole core, the S-side protrusions and the N-side protrusions are disposed alternately and between the alternately disposed S-side protrusion and the N-side protrusion, a protrusion permanent magnet is disposed in such a manner that a side of the S-side protrusion becomes the S pole and a side of the N-side protrusion becomes the N pole.

Owner:HITACHI JOHNSON CONTROLS AIR CONDITIONING INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com