Patents

Literature

583results about How to "High magnetic flux density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

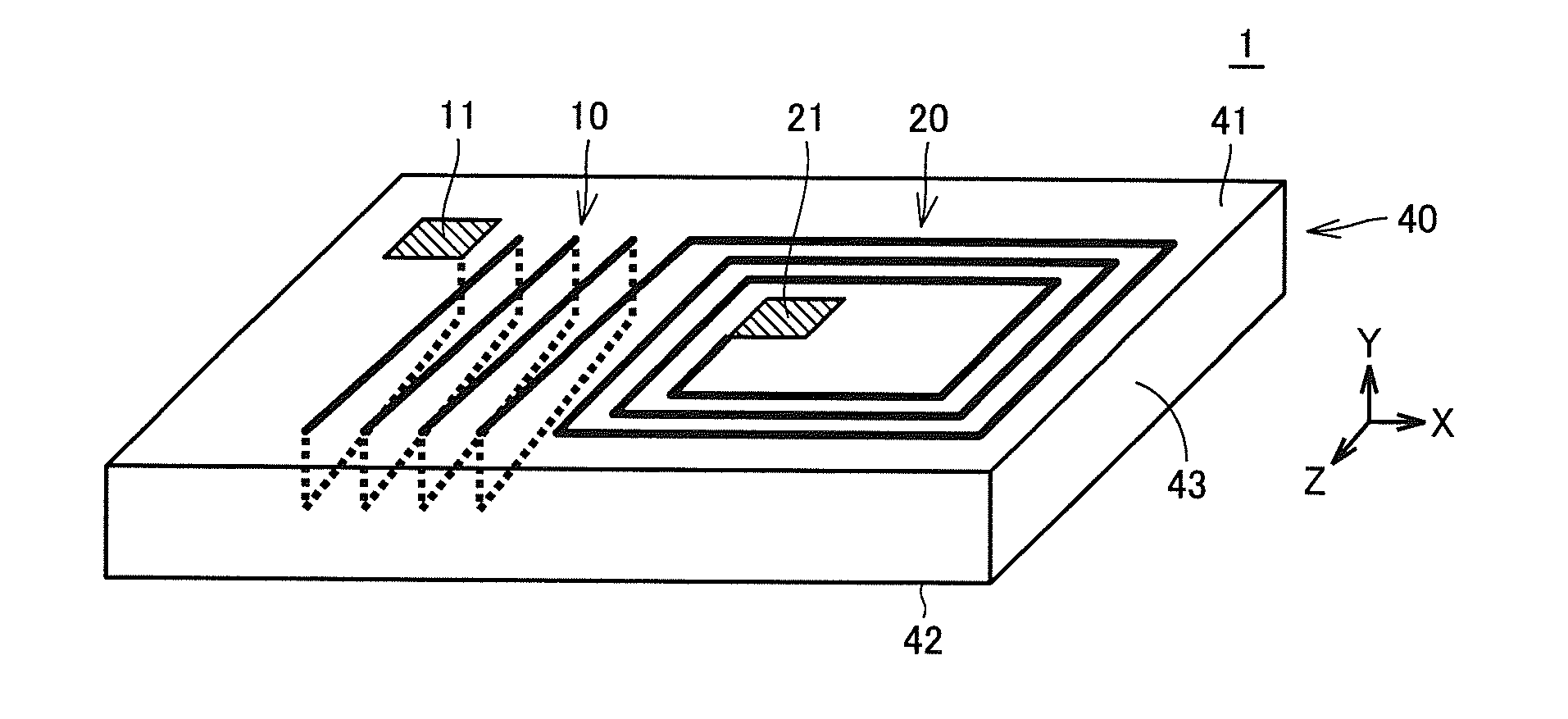

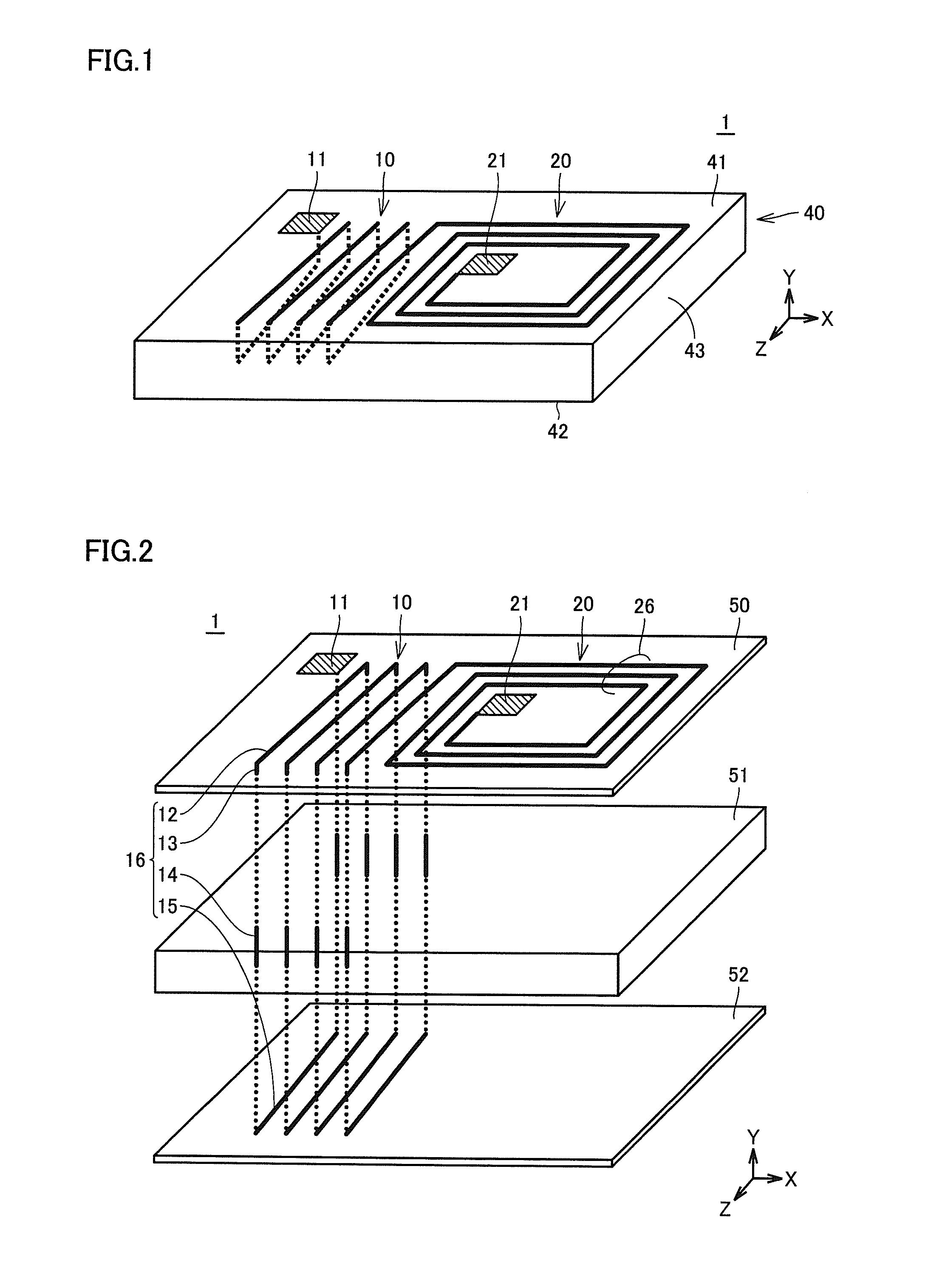

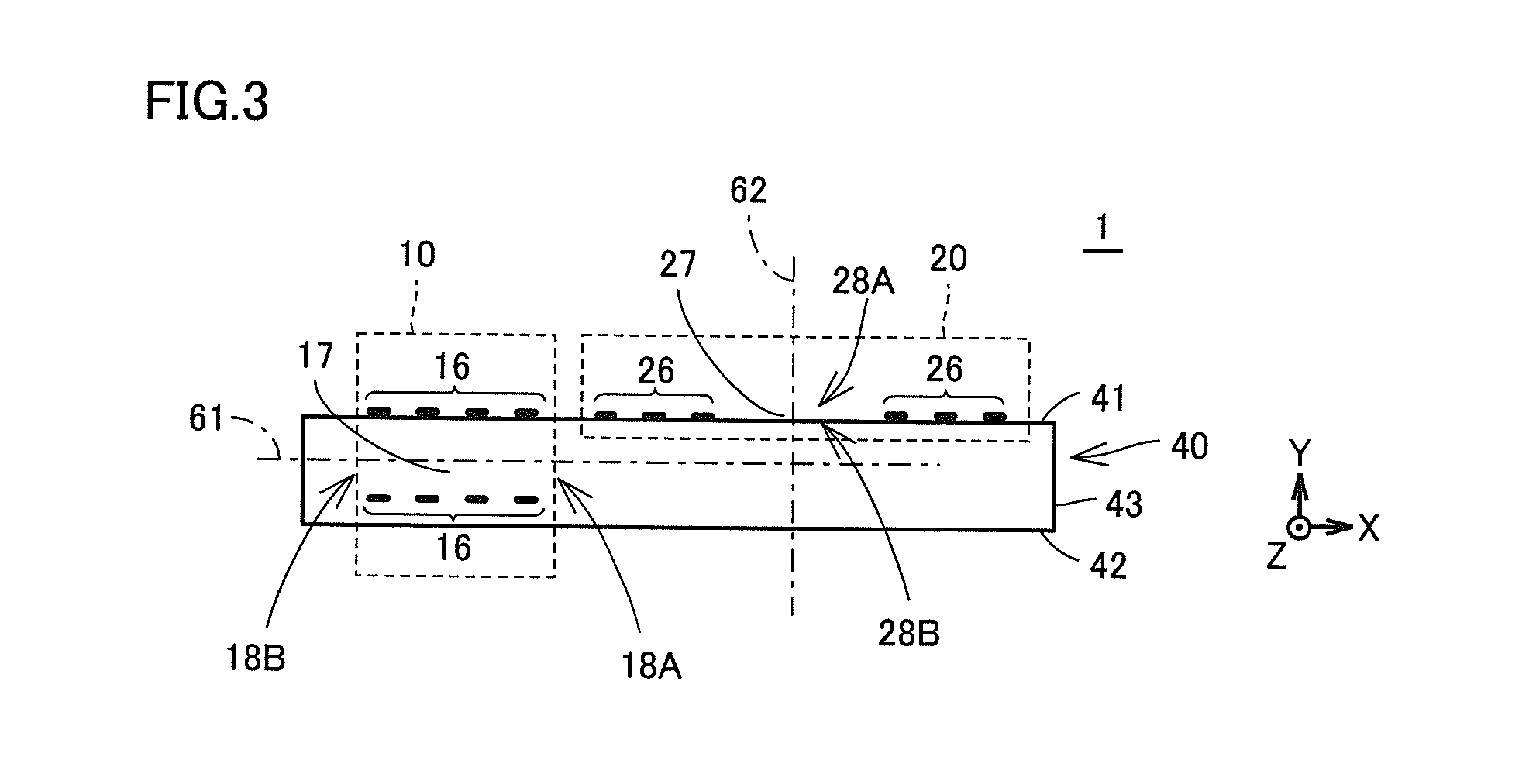

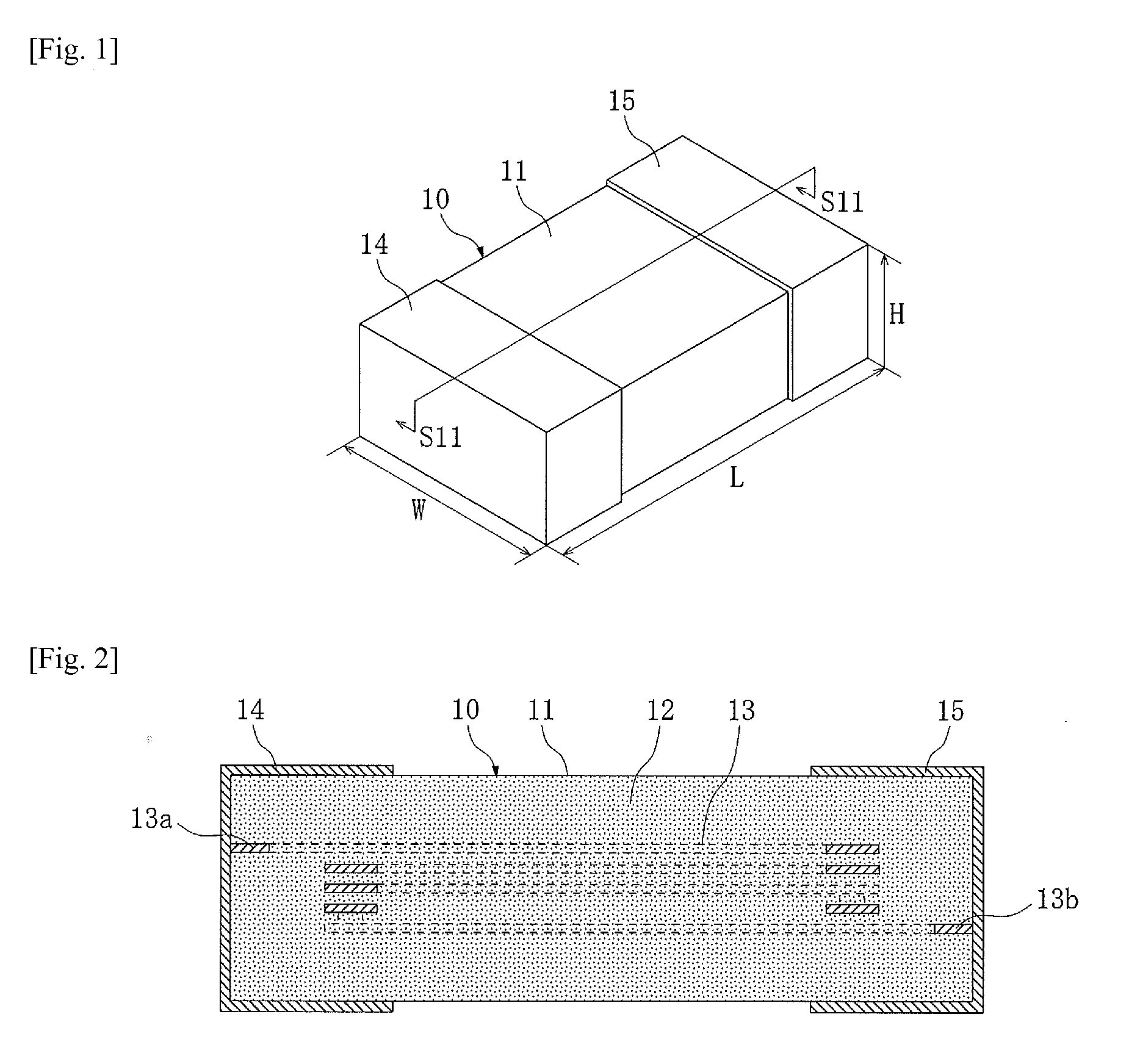

Antenna device and communication terminal apparatus

InactiveUS20140035793A1High magnetic flux densityLoop antennas with ferromagnetic coreRadiating elements structural formsElectrical conductorEngineering

Owner:MURATA MFG CO LTD

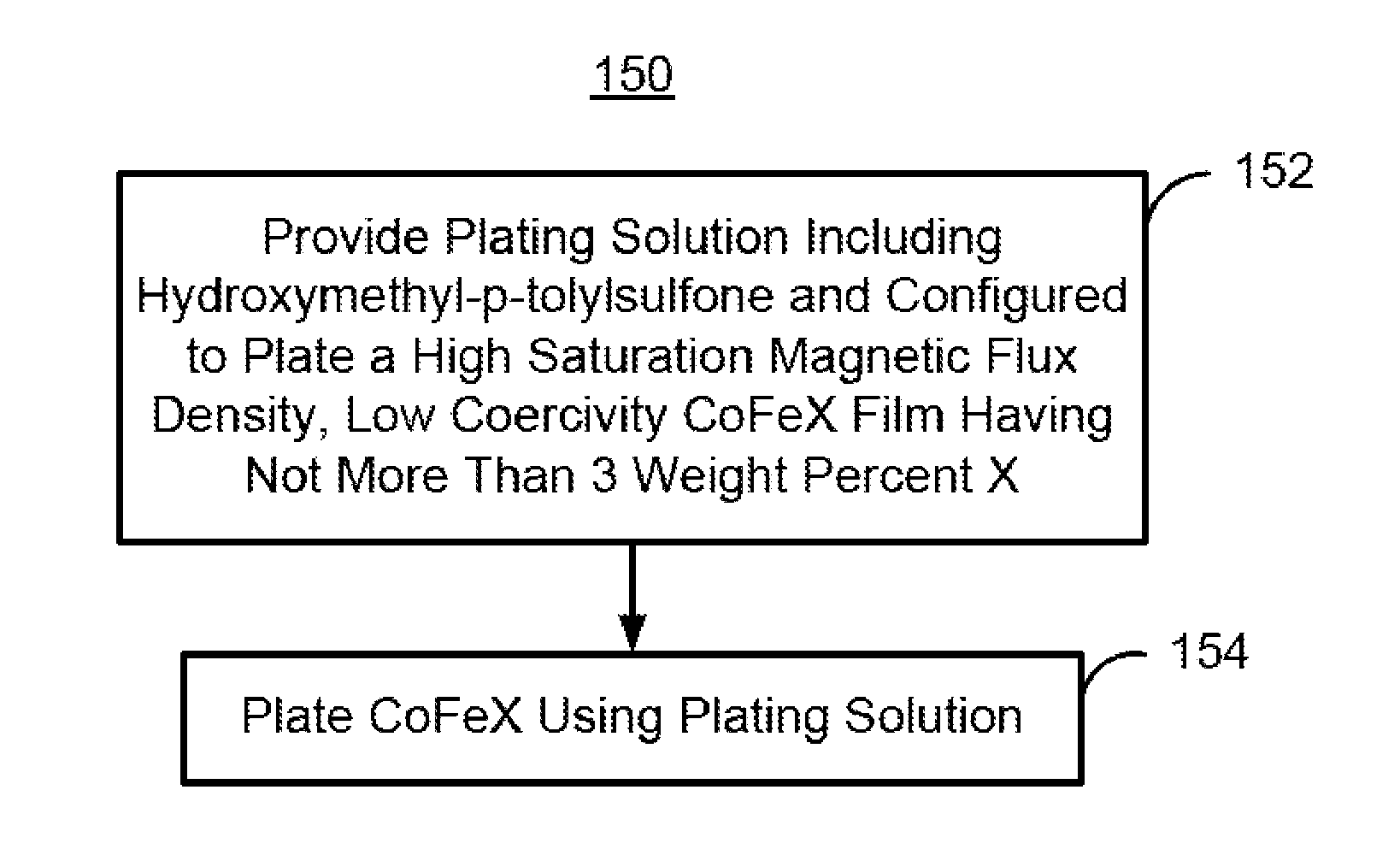

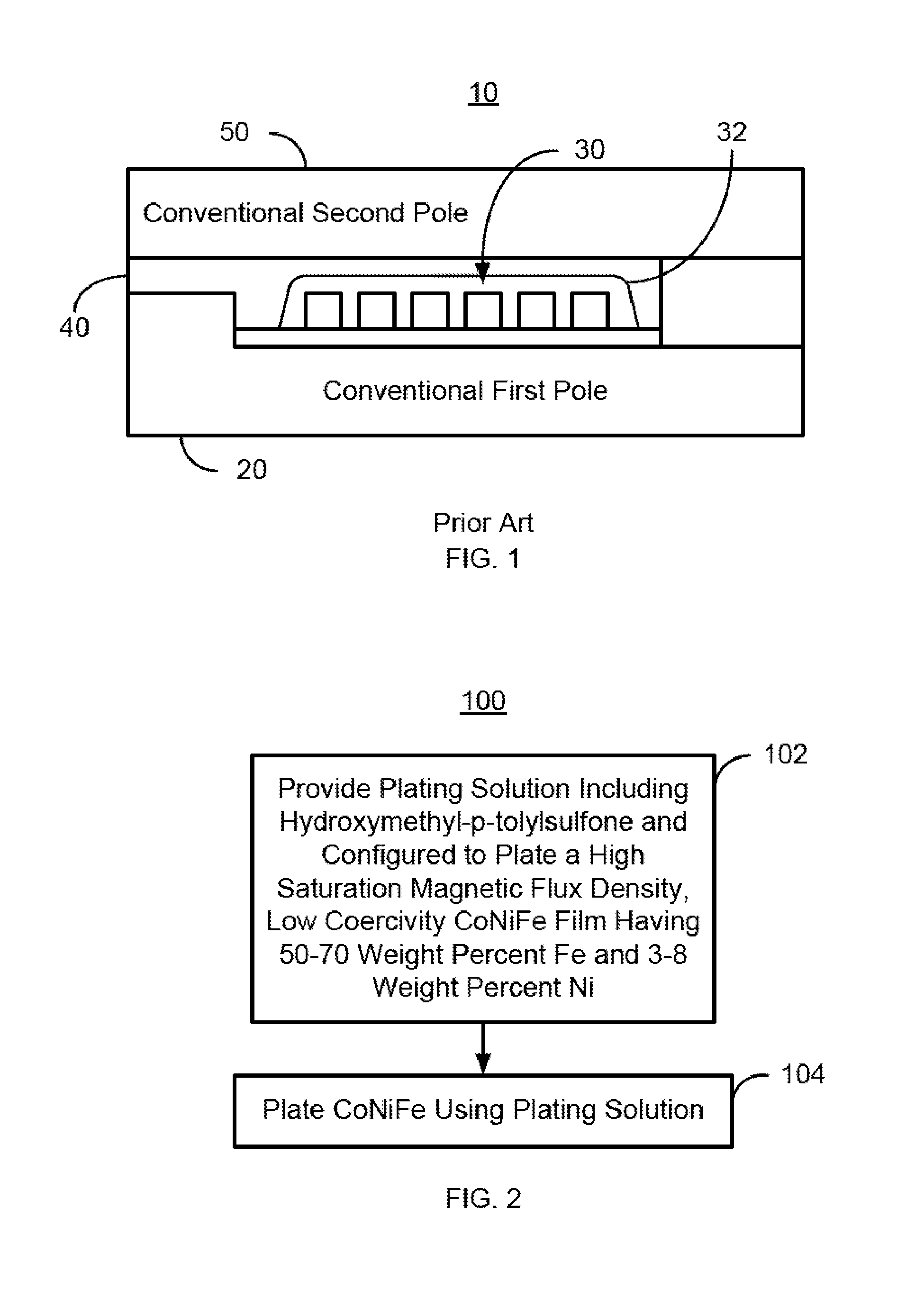

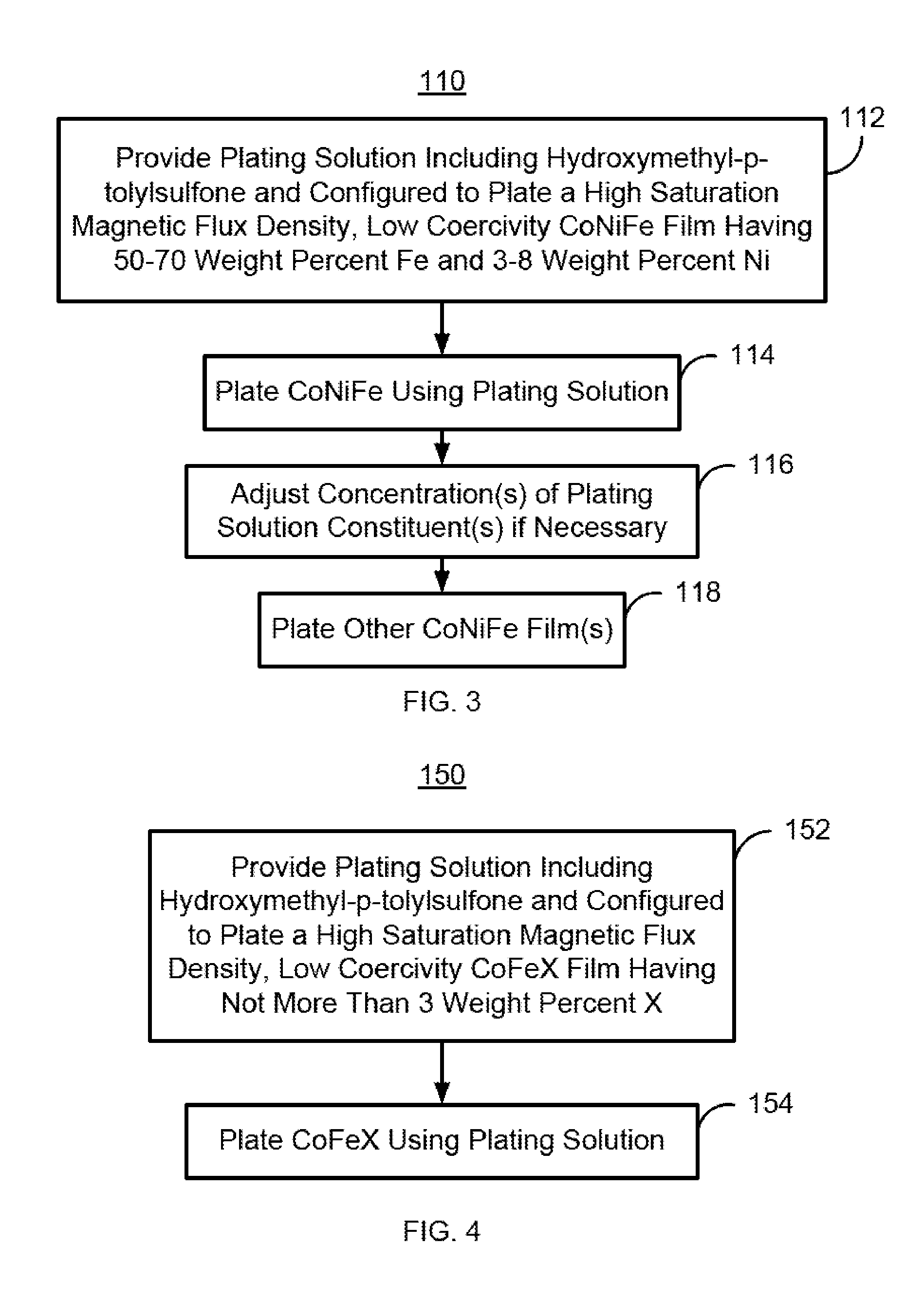

Method and system for providing high magnetic flux saturation CoFe films

InactiveUS8670211B1High magnetic flux densityLiquid applicationRecord information storageRecording headMagnetic flux

A method and system plates CoFeX, where X is an insertion metal. The method and system include providing a plating solution including hydroxymethyl-p-tolylsulfone (HPT). The plating solution being configured to provide a CoFeX film having a high saturation magnetic flux density of greater than 2.3 Tesla and not more than 3 weight percent of X. The method and system also include plating the CoFeX film on a substrate in the plating solution. In some aspects, the plated CoFeX film may be used in structures such as main poles of a magnetic recording head.

Owner:WESTERN DIGITAL TECH INC

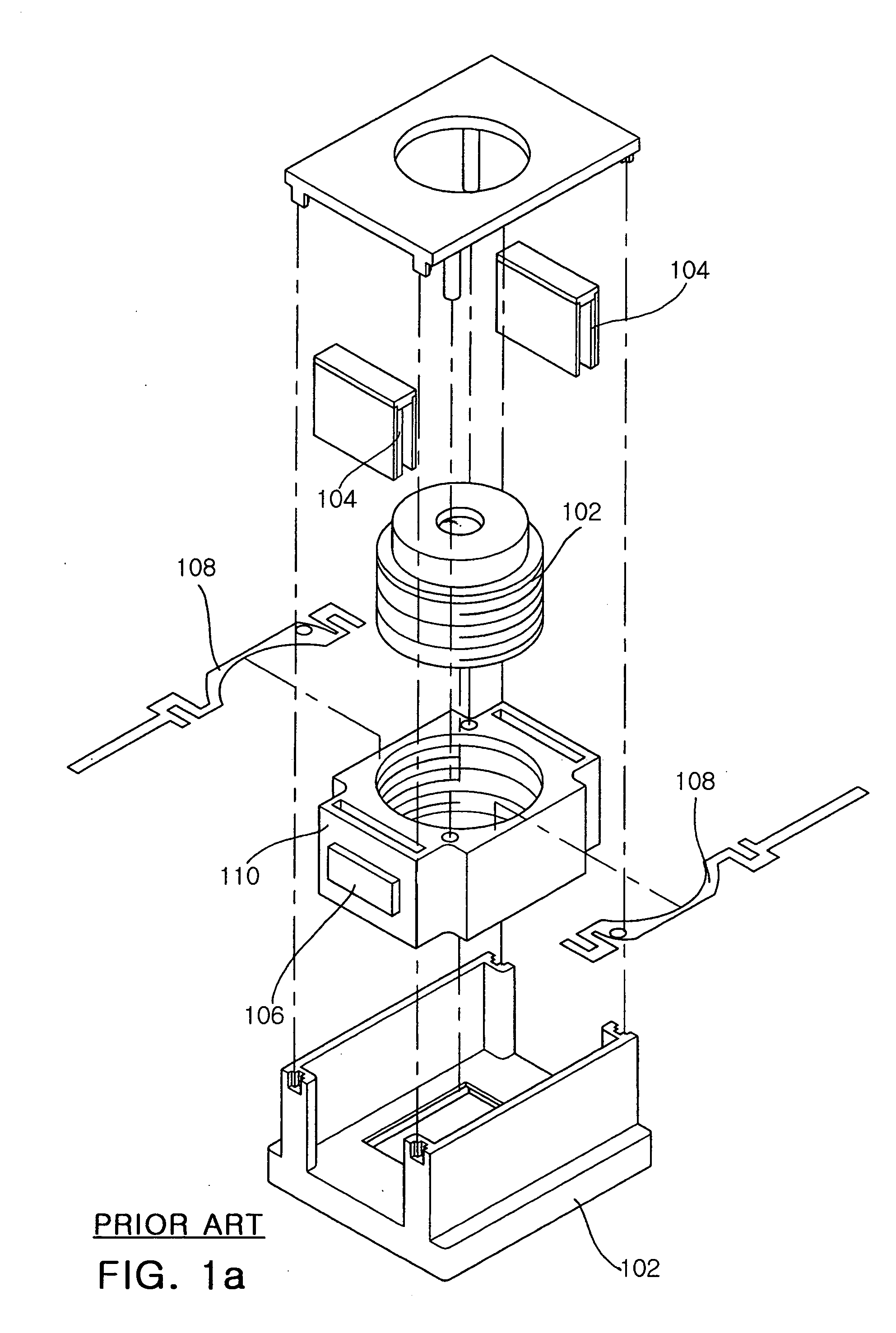

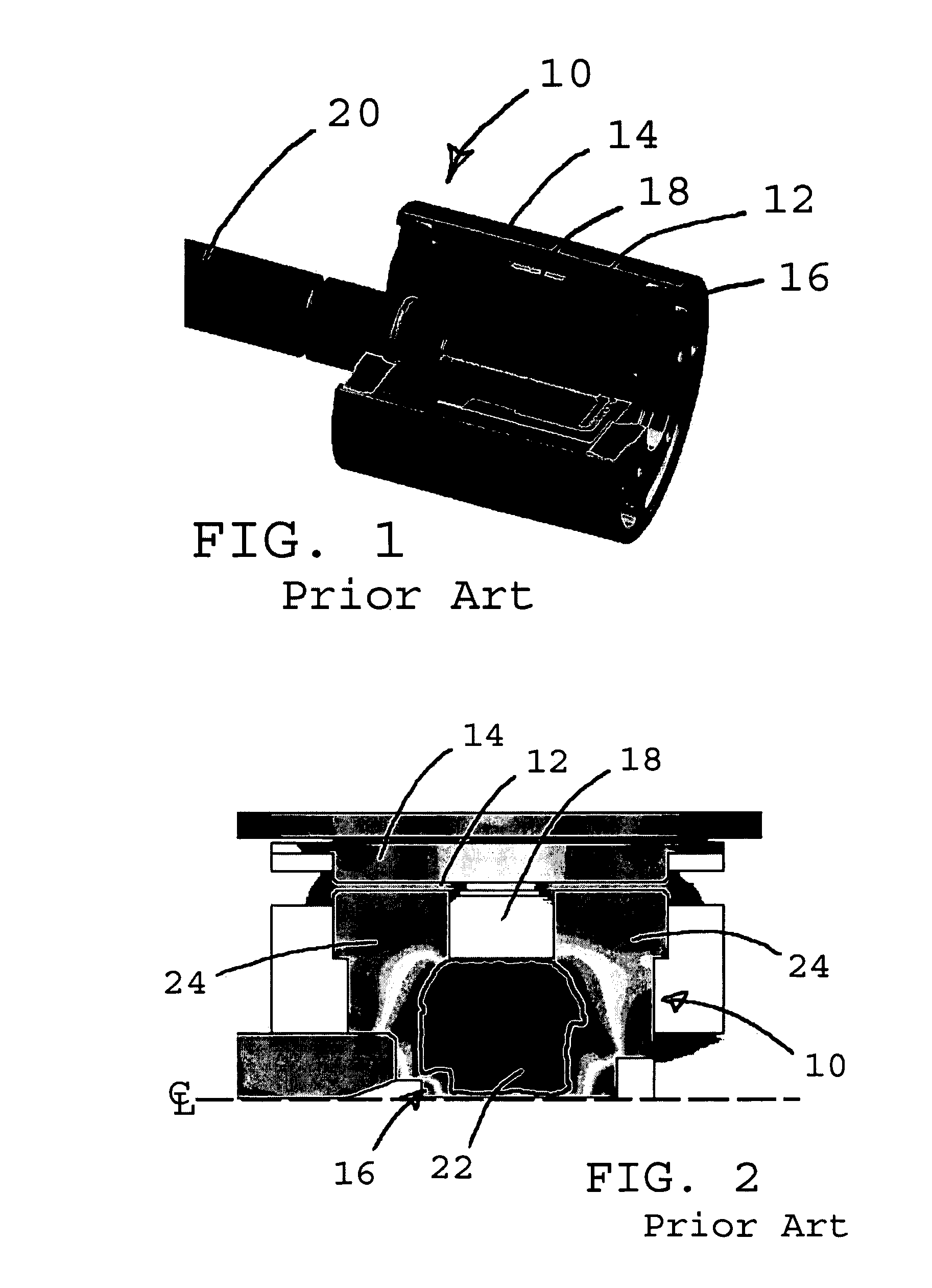

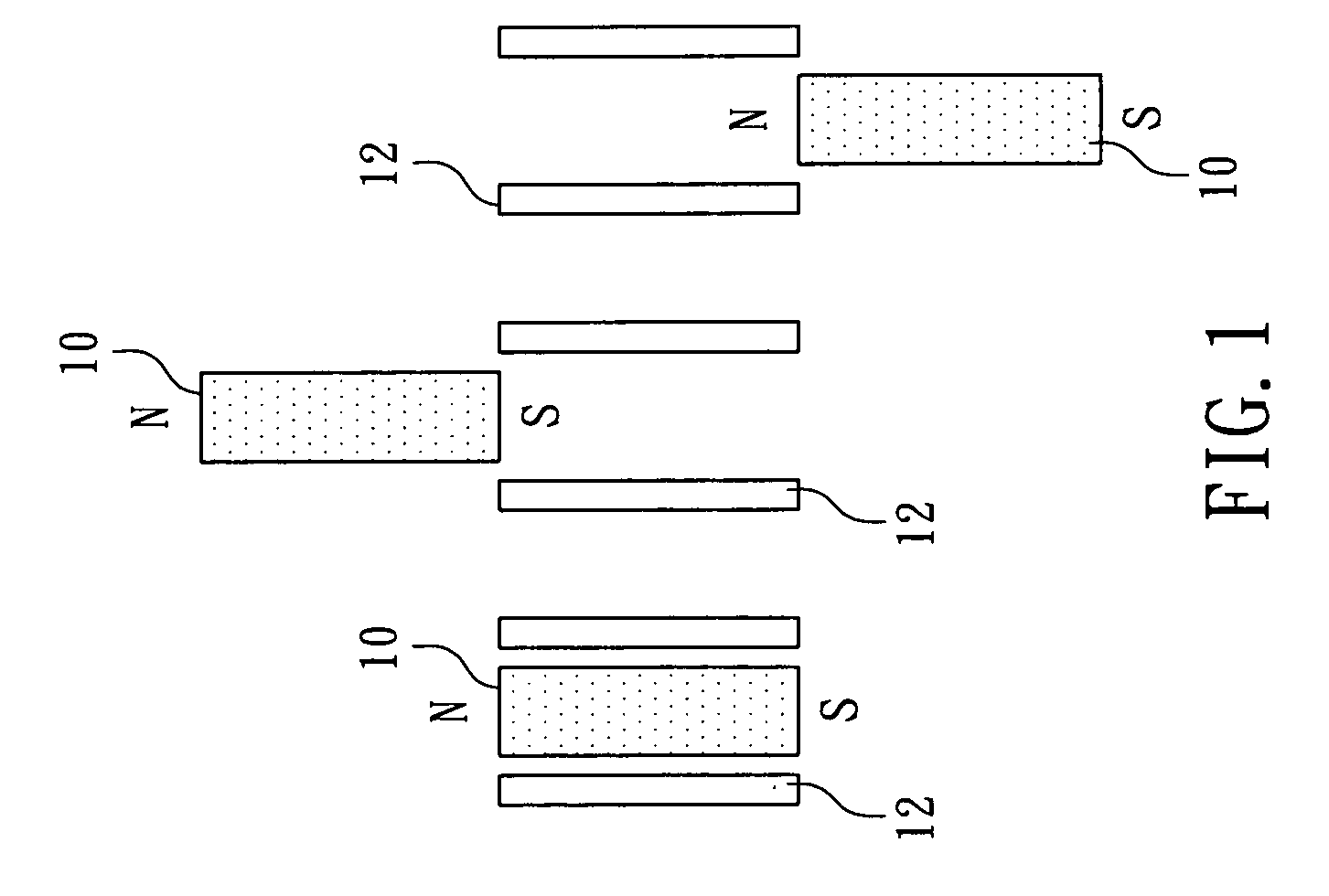

Auto-focusing device with voice coil motor for position feedback and method for using same

InactiveUS20070047942A1Simple configurationSmall sizeTelevision system detailsProjector focusing arrangementMagnetic tension forceAutofocus

An auto-focusing device with voice coil motor for position feedback comprises a lens holder, a sensor holder, a permanent magnet set, a yoke and a base. The lens holder holds a lens barrel and is wound around with at least two coils wound in opposite directions. The sensor holder holds an image sensor. The permanent magnet set includes at least two permanent magnets stacked together with opposing poles to form a multi-pole permanent magnet set. The permanent magnet set is furnished on the periphery of lens holder and corresponds to the two coils on lens holder. The permanent magnet set is disposed on the yoke to form a close-loop magnetism so as to increase the density of magnetic lines and the efficiency of magnetic force, save power consumption, and extend the service life of device.

Owner:POWERGATE OPTICAL INC

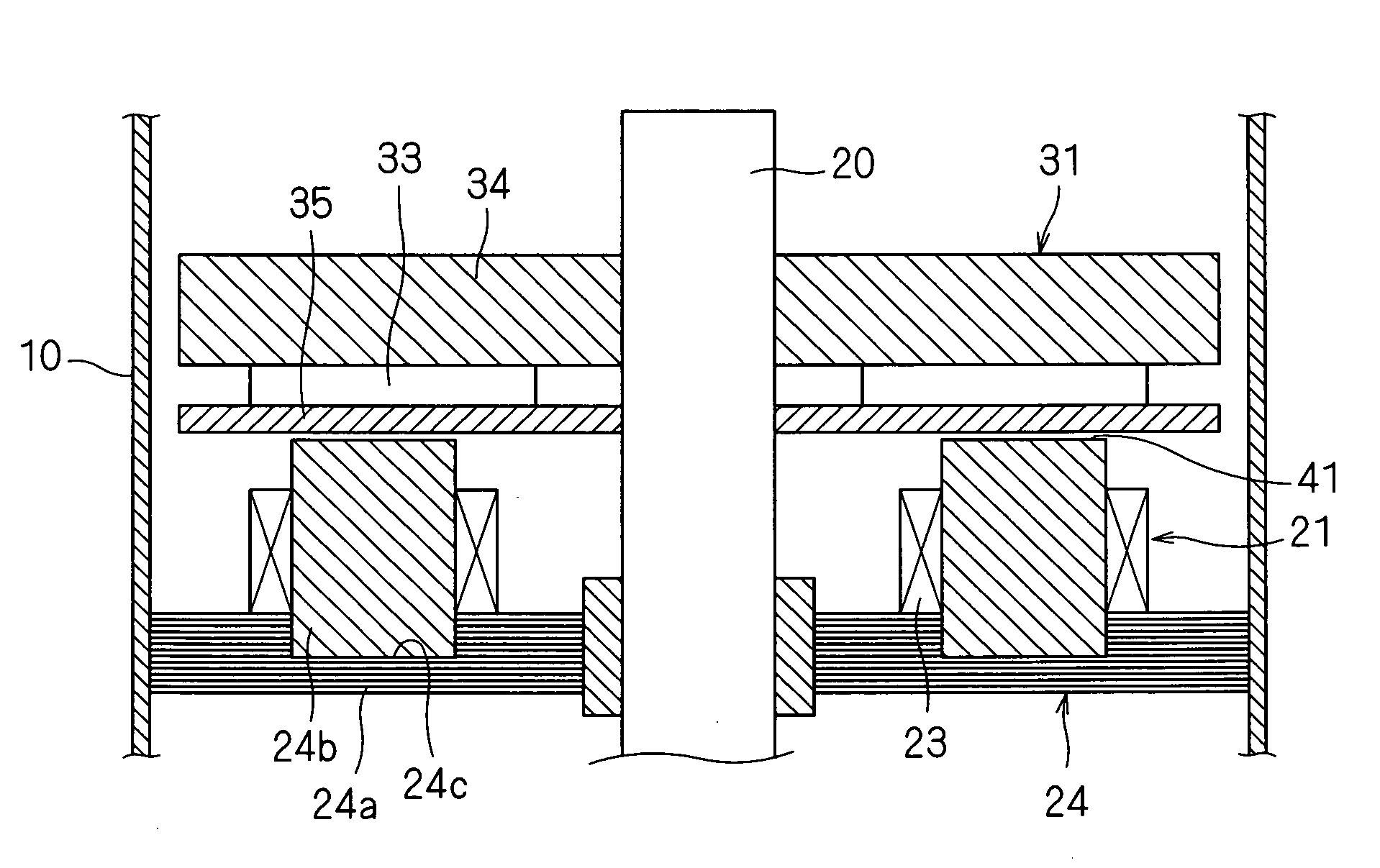

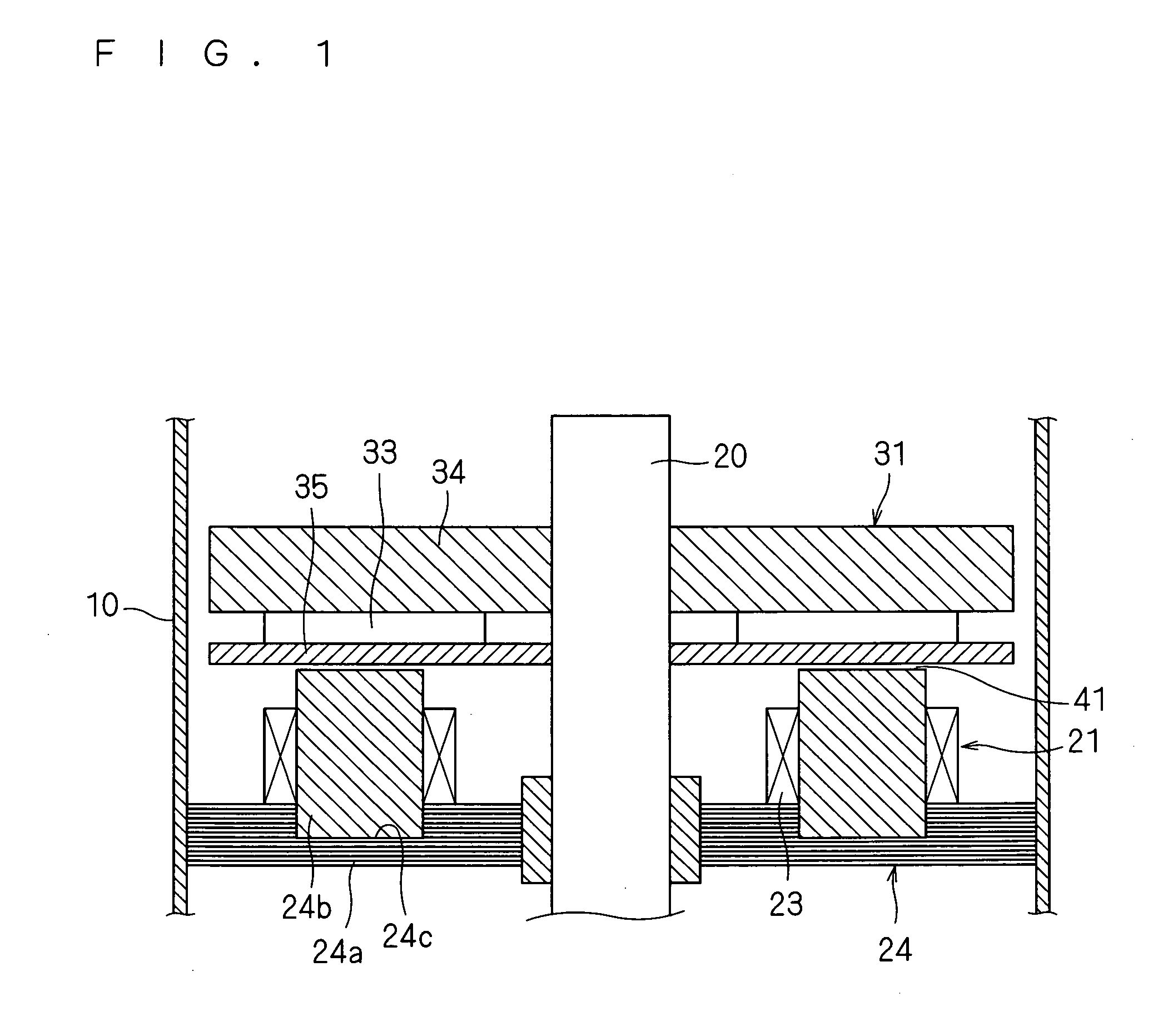

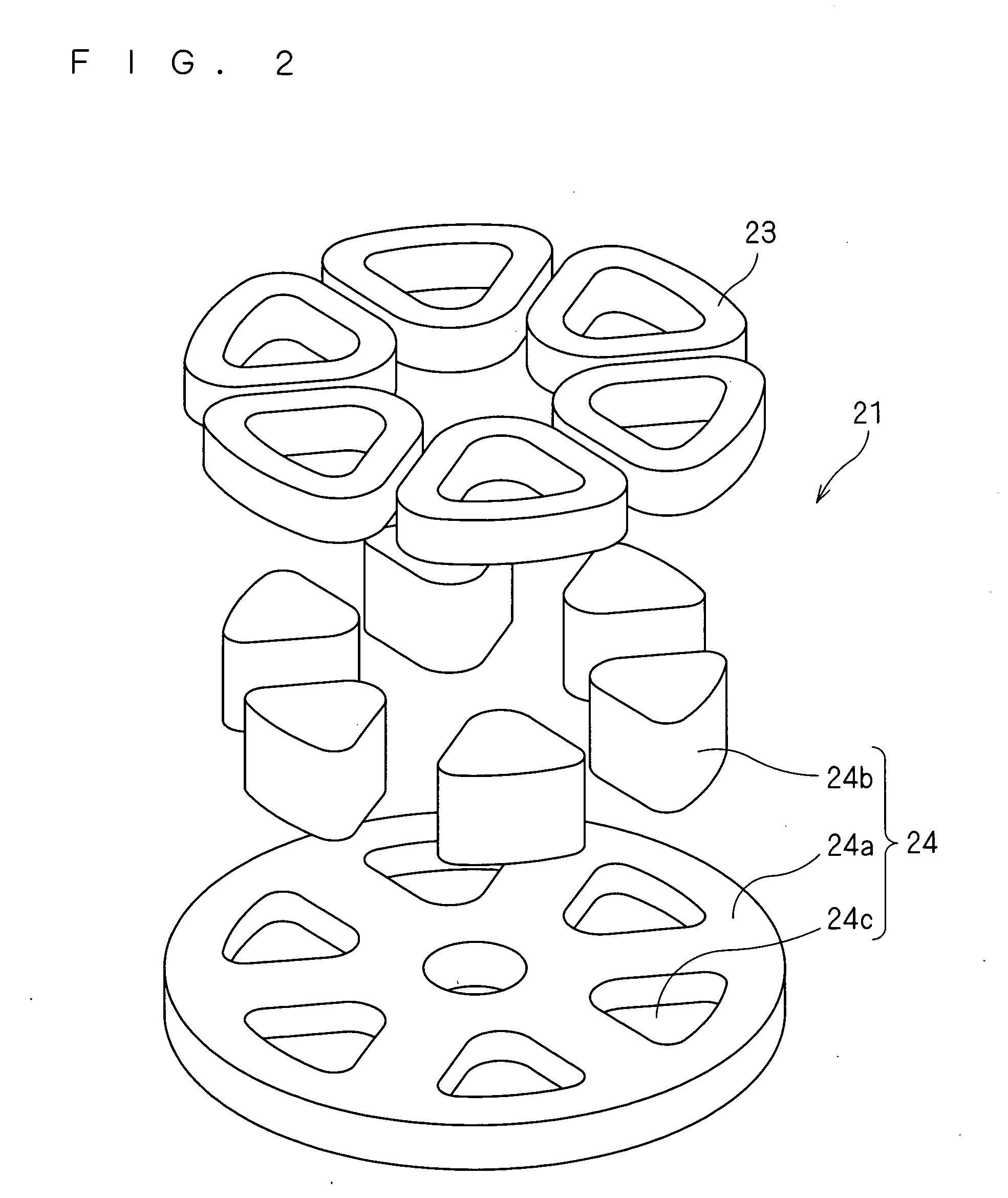

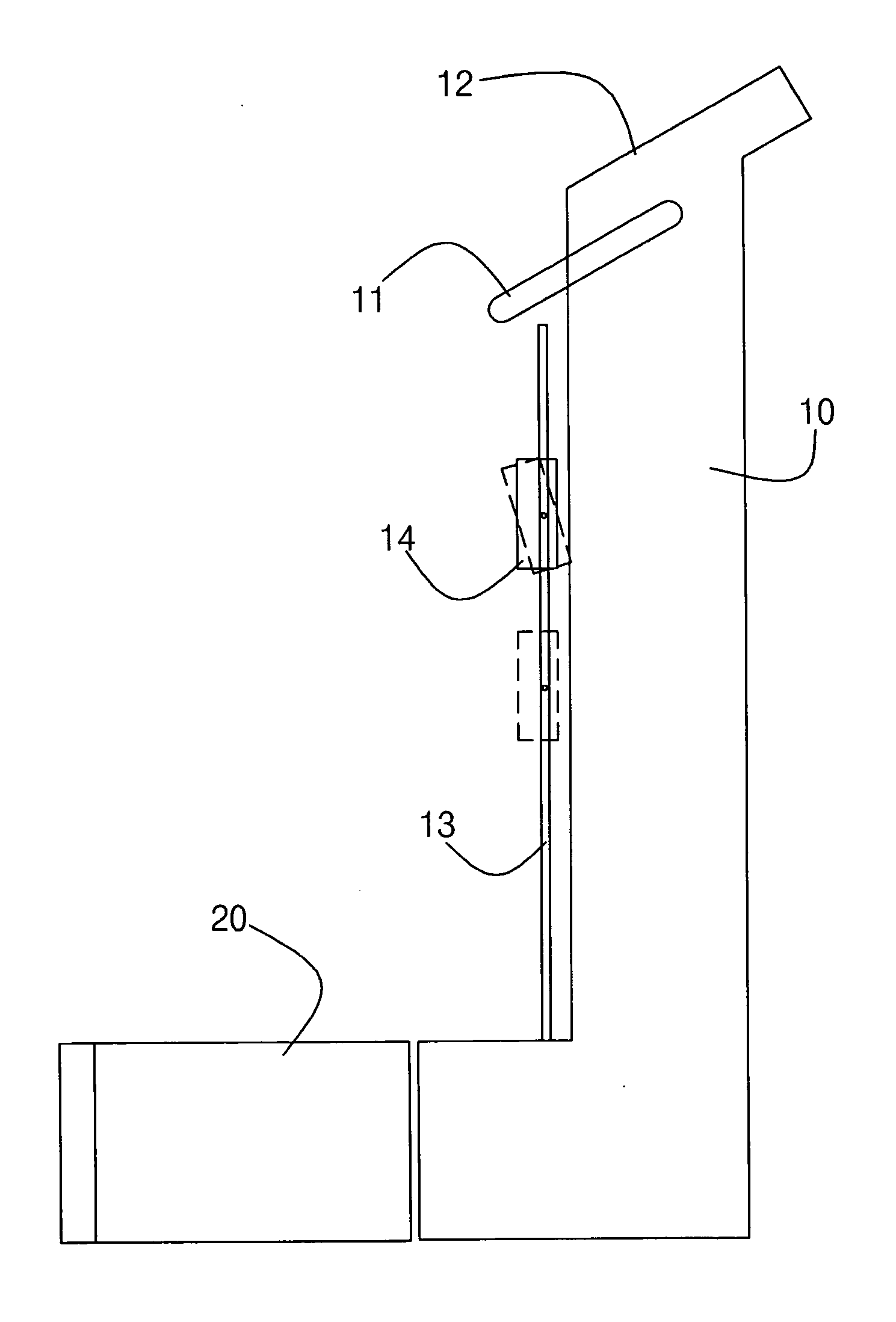

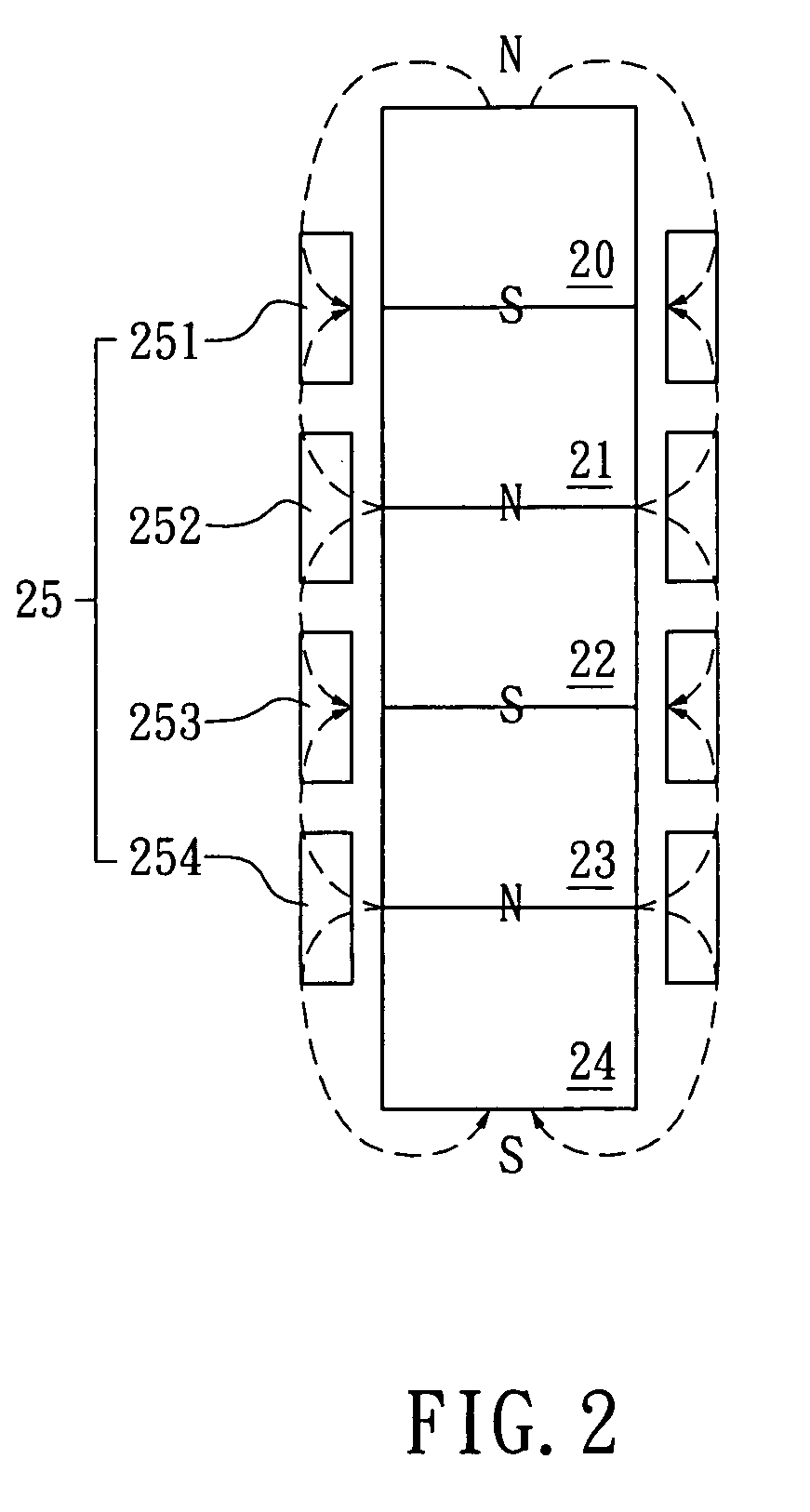

Hybrid-excited rotating machine, and vehicle with the hybrid-excited rotating machine

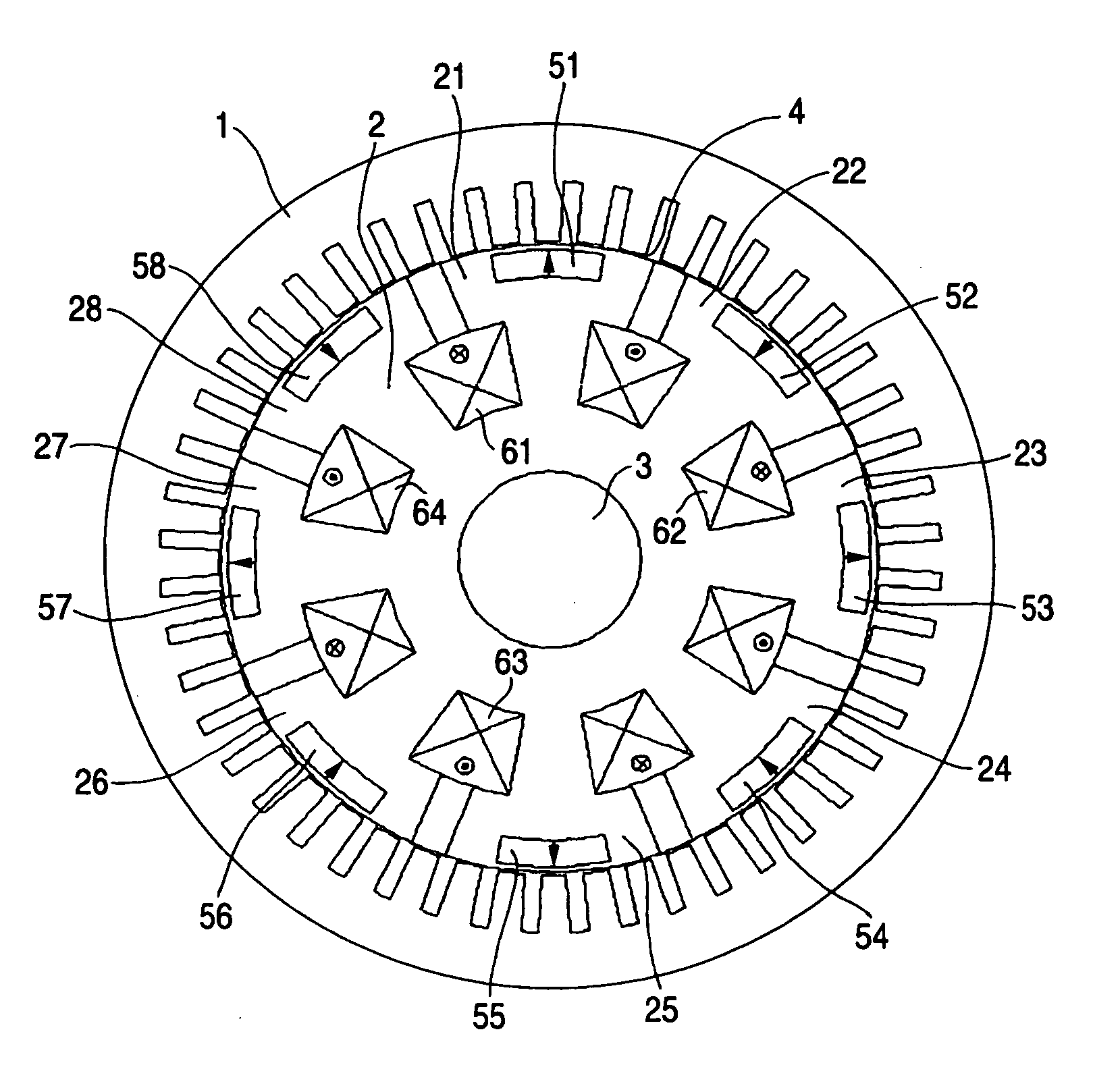

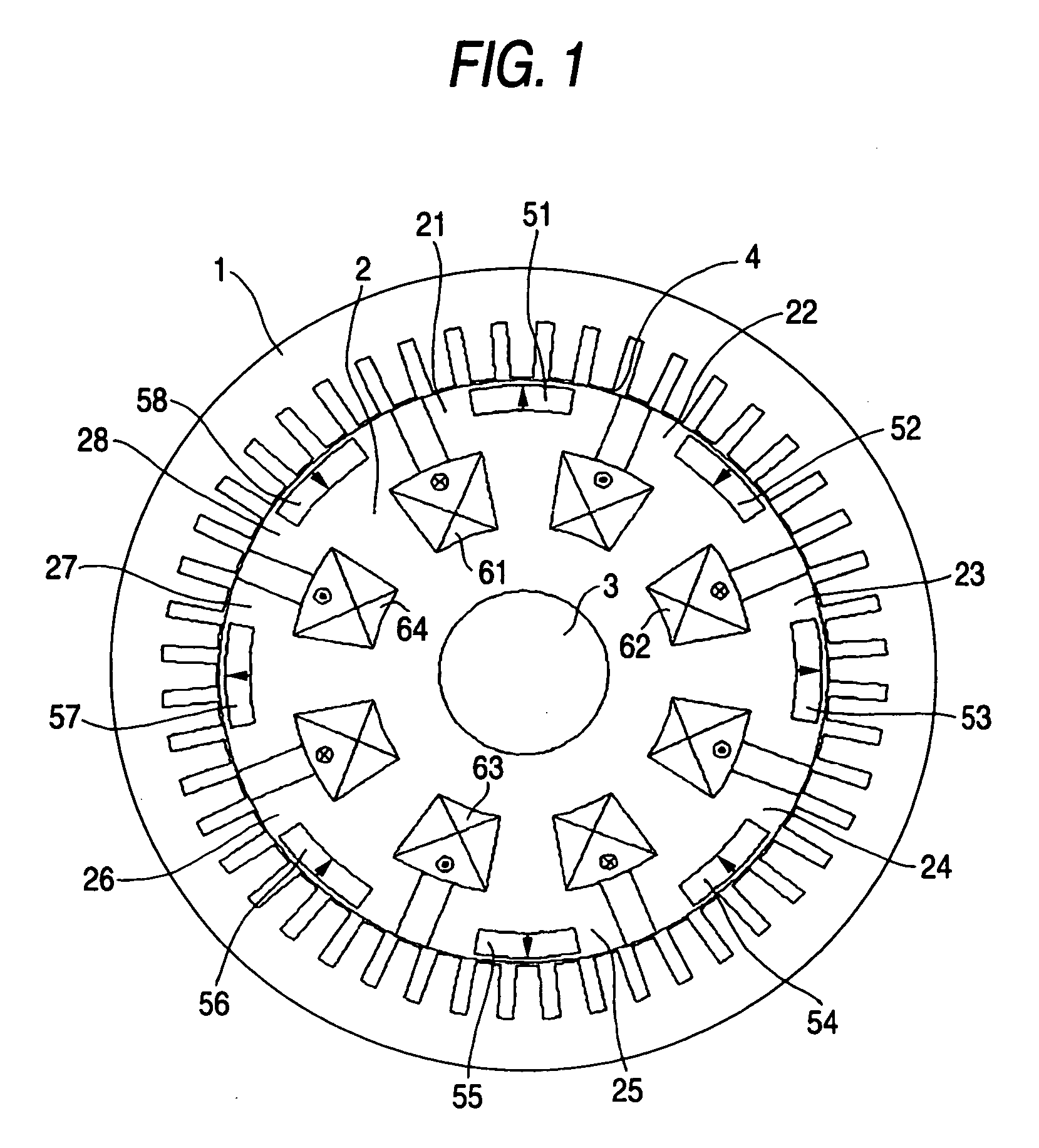

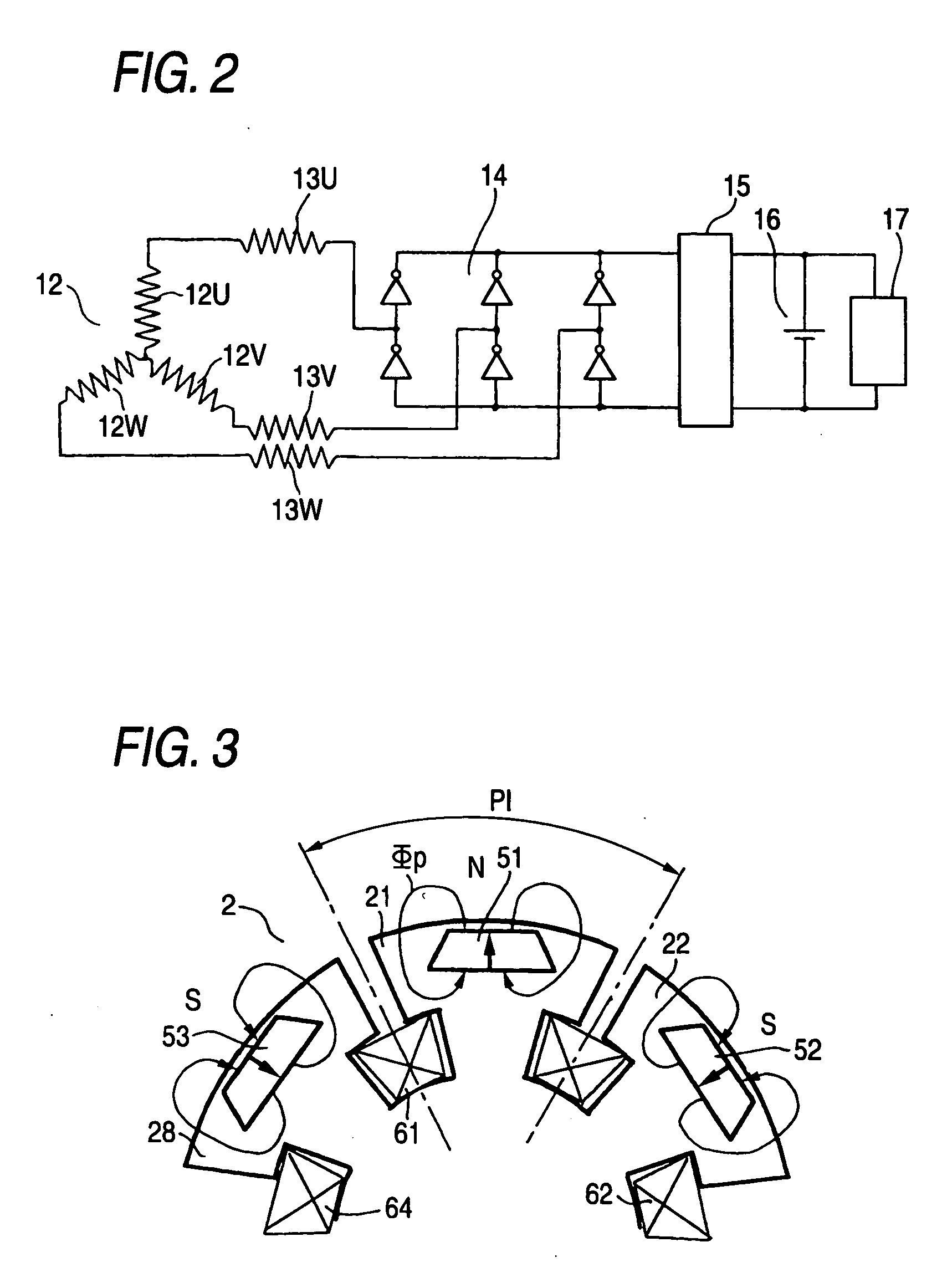

ActiveUS20070090713A1Increase total magnetic fluxIncrease torqueSynchronous generatorsWindingsEngineeringConductor Coil

A hybrid-excited rotating machine comprising: a stator winding 12 of a multi-phase Y-connection; a plurality of rotor magnetic poles 21, 22, 23, 24, 25, 26, 27, 28 fixed on a rotor shaft 3 at a predetermined spacing in the circumferential direction and confronting the inner circumference of said stator 1 through a air gap; a plurality of permanent magnets 51, 52, 53, 54, 55, 56, 57, 58 fixed at substantially central portions of said circumferential direction of said individual rotor magnetic poles and magnetized in the radial direction of said rotor shaft; and a plurality of field windings 61, 62, 63, 64, 65, 66, 67, 68 wound individually on said rotor magnetic poles.

Owner:MITSUBISHI ELECTRIC CORP

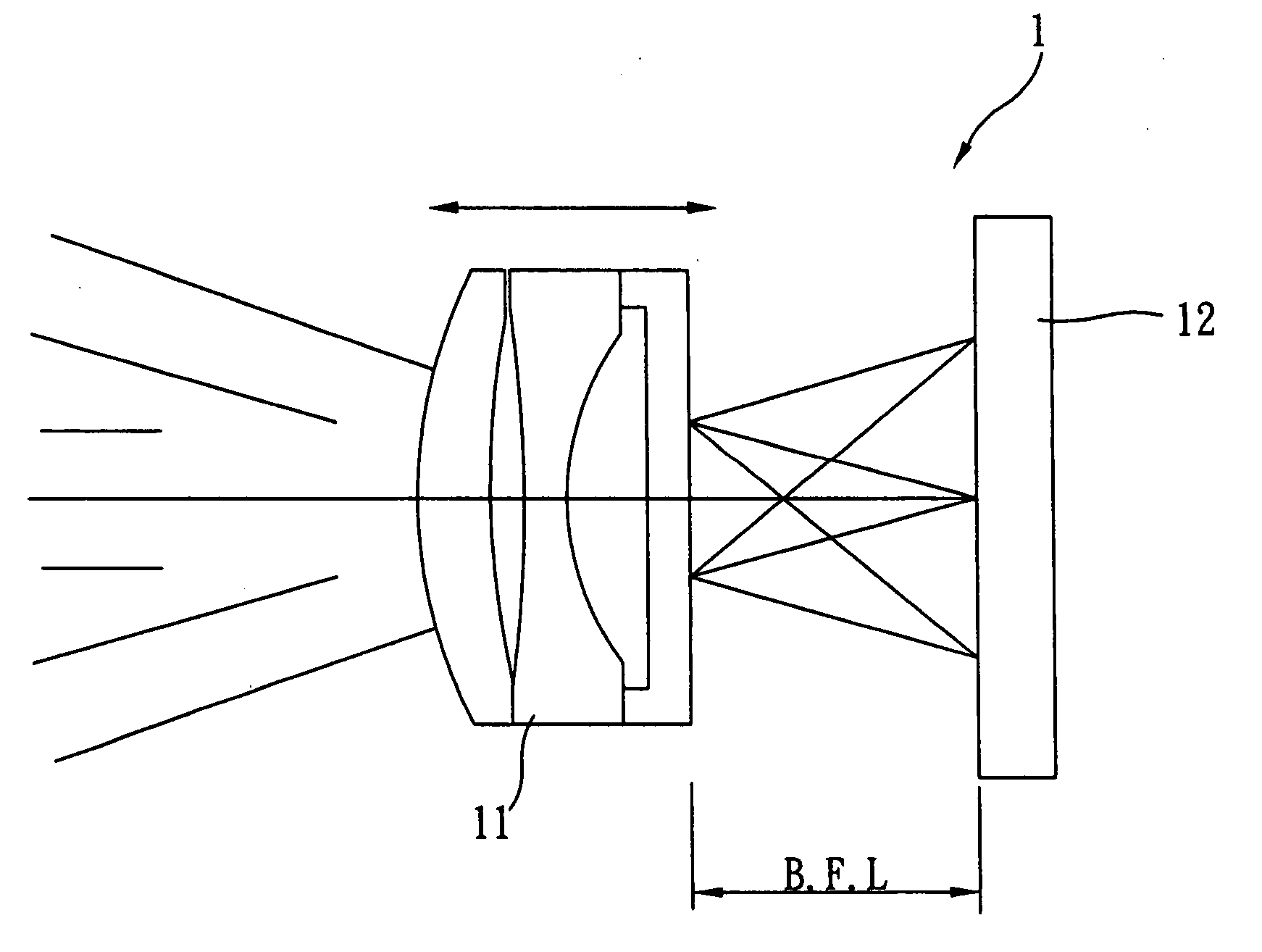

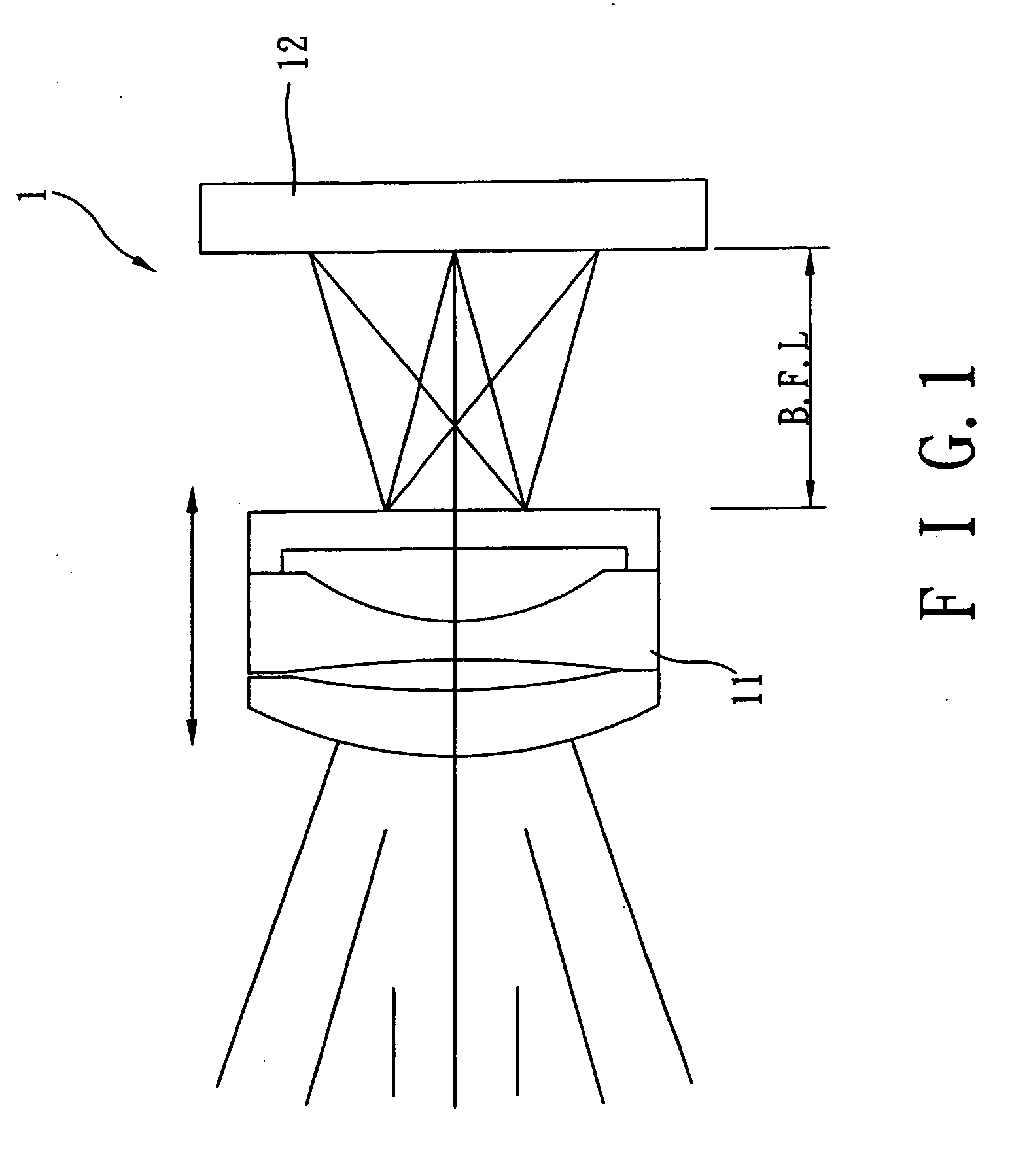

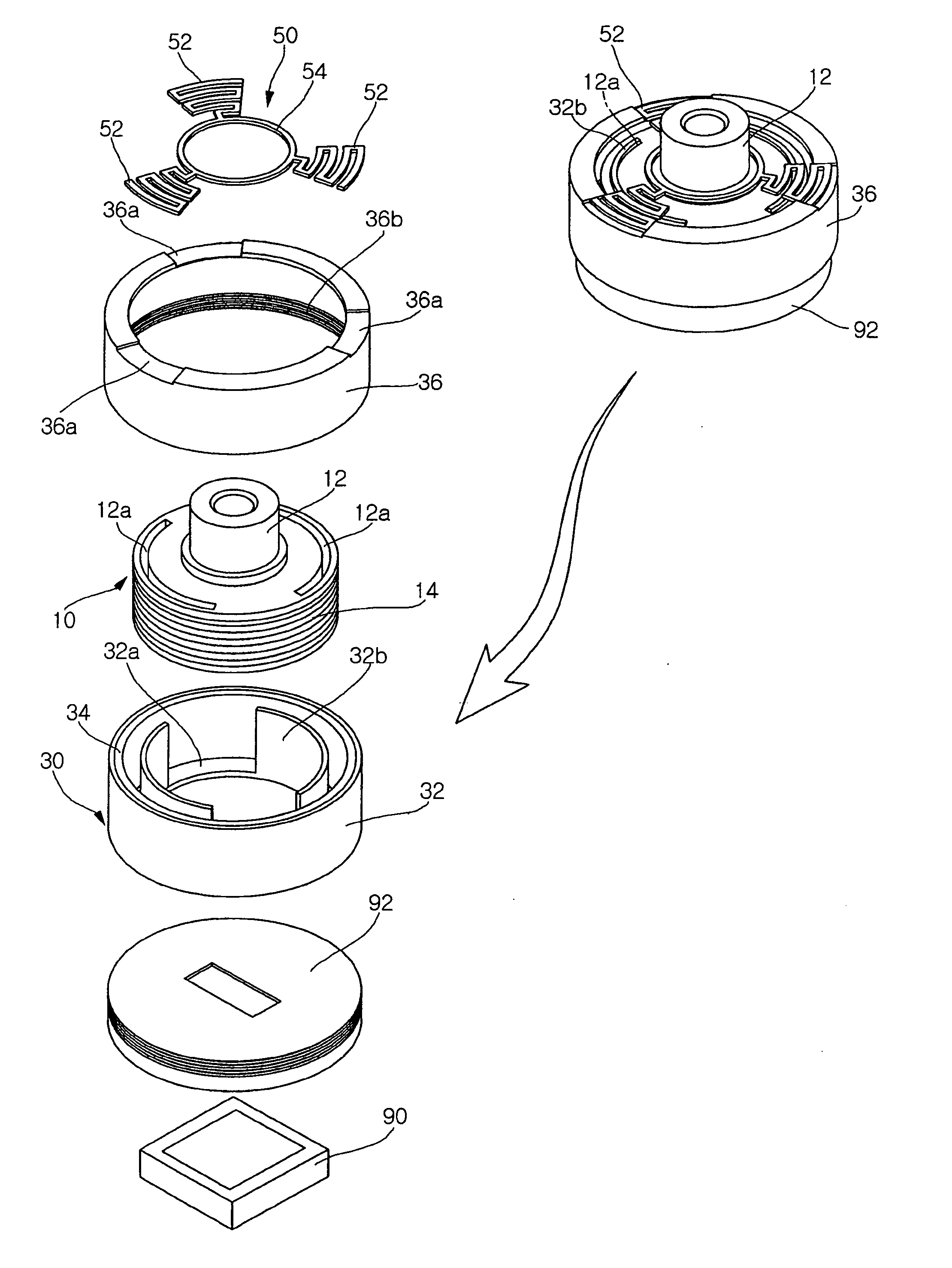

Focal length adjustment apparatus with improved vibration and impact-resistance properties

InactiveUS20060153556A1Improve damping effectHigh magnetic flux densityProjector focusing arrangementPliersUltrasound attenuationMagnetic flux

Disclosed herein is a focal length adjustment apparatus in which a magnetic fluid that serves as attenuation means is injected between a magnet and a coil to achieve an improvement in a magnetic flux density and damping effect. The apparatus comprises a moving unit including a lens barrel that contains at least one lens therein, and a coil arranged on an outer circumference of the lens barrel, a fixed unit including a yoke formed with an opening for receiving the lens barrel, a case into which the yoke is inserted and mounted, and a magnet affixed to the yoke to be arranged adjacent to the coil, a supporting member used to elastically support the moving unit relative to the case, and attenuation means interposed between the coil and the magnet to attenuate vibration of the moving unit.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

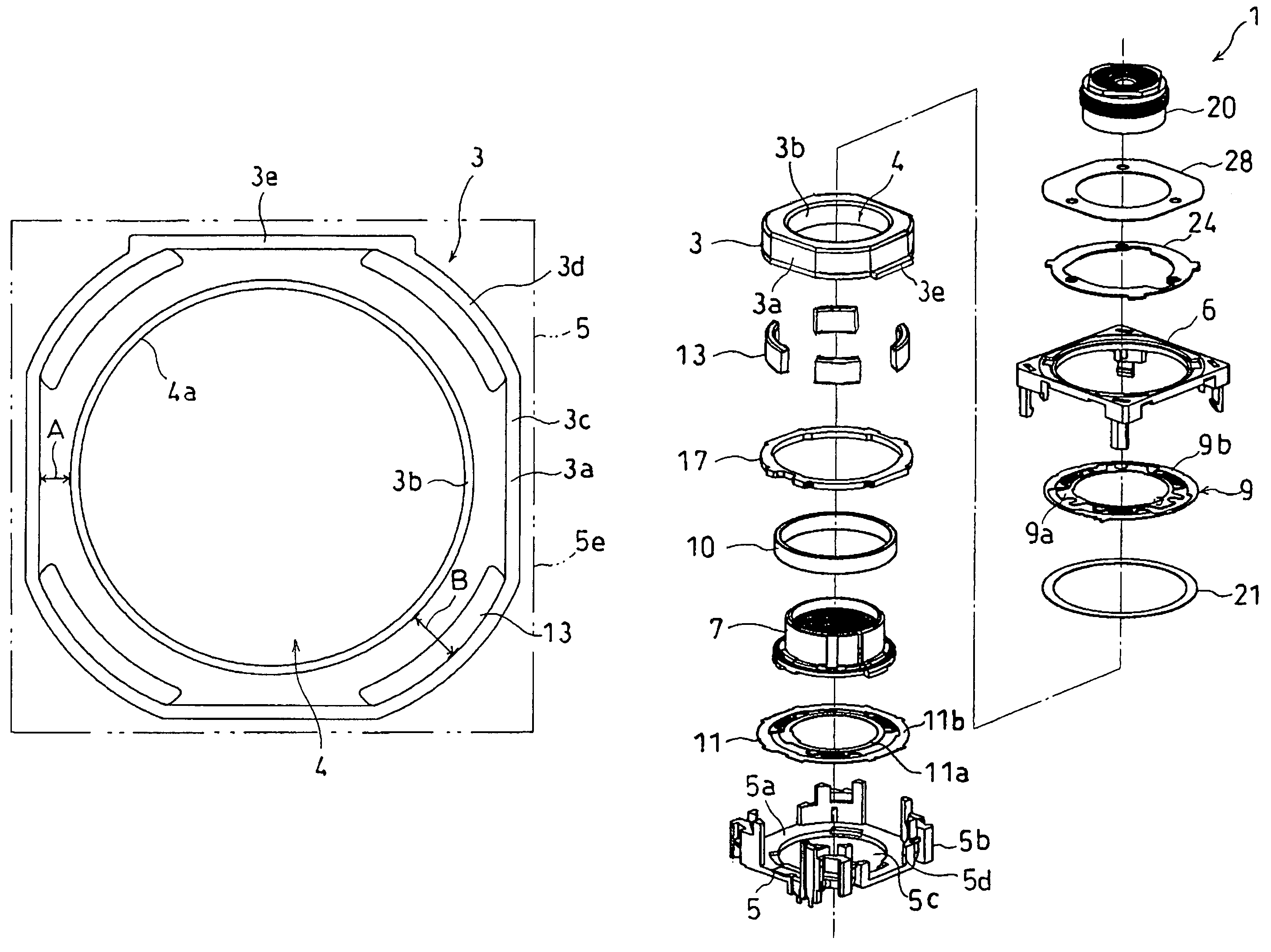

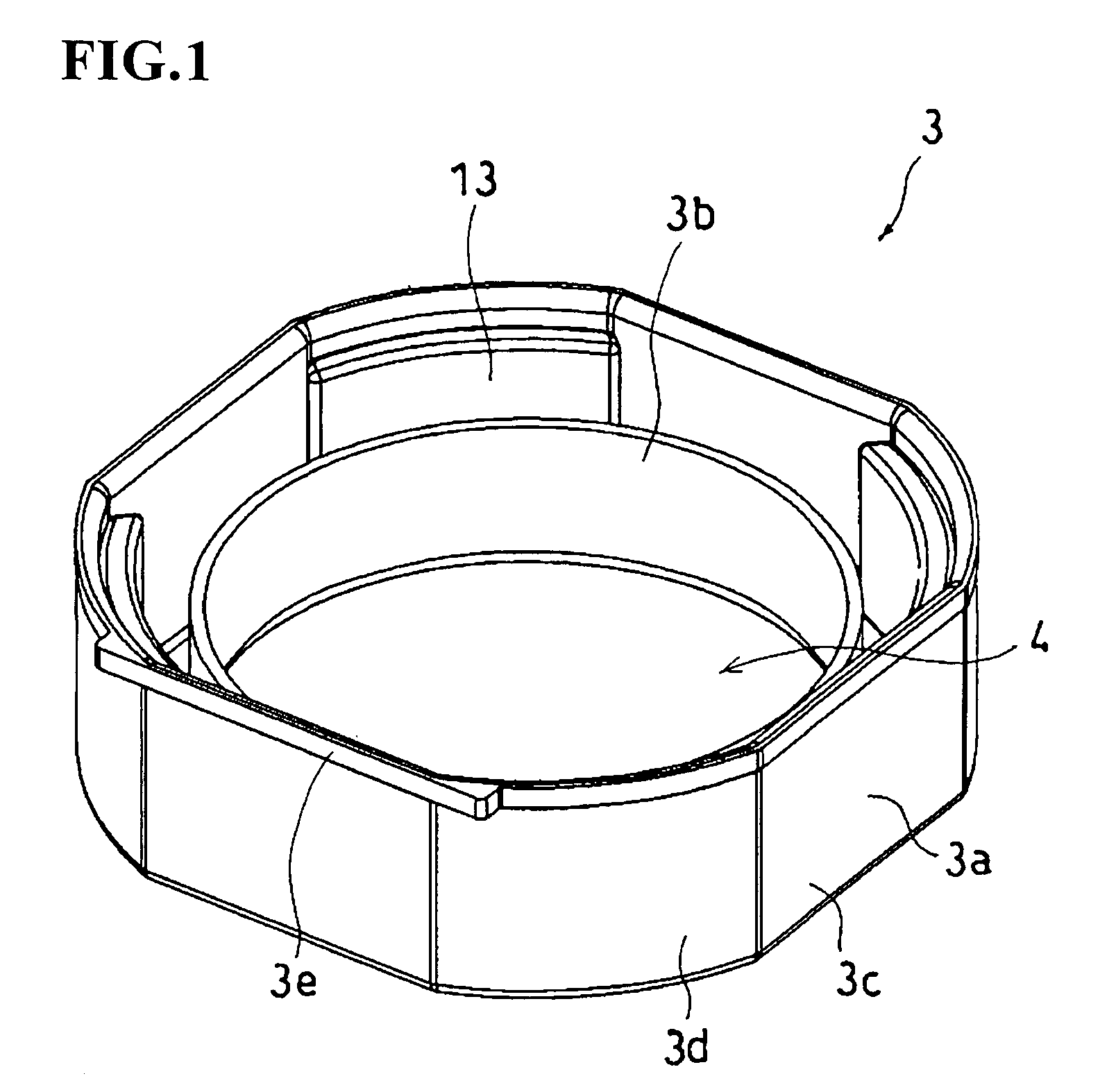

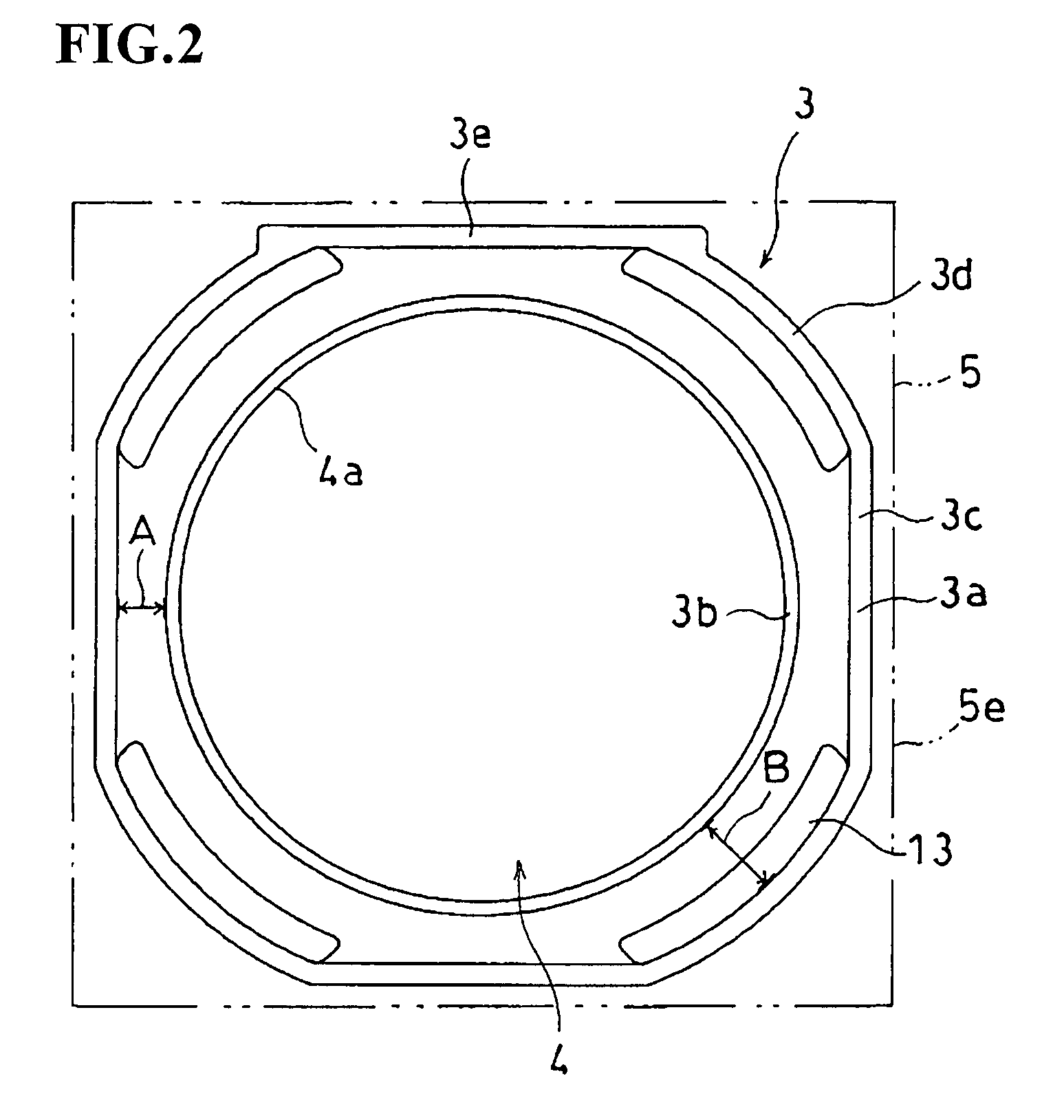

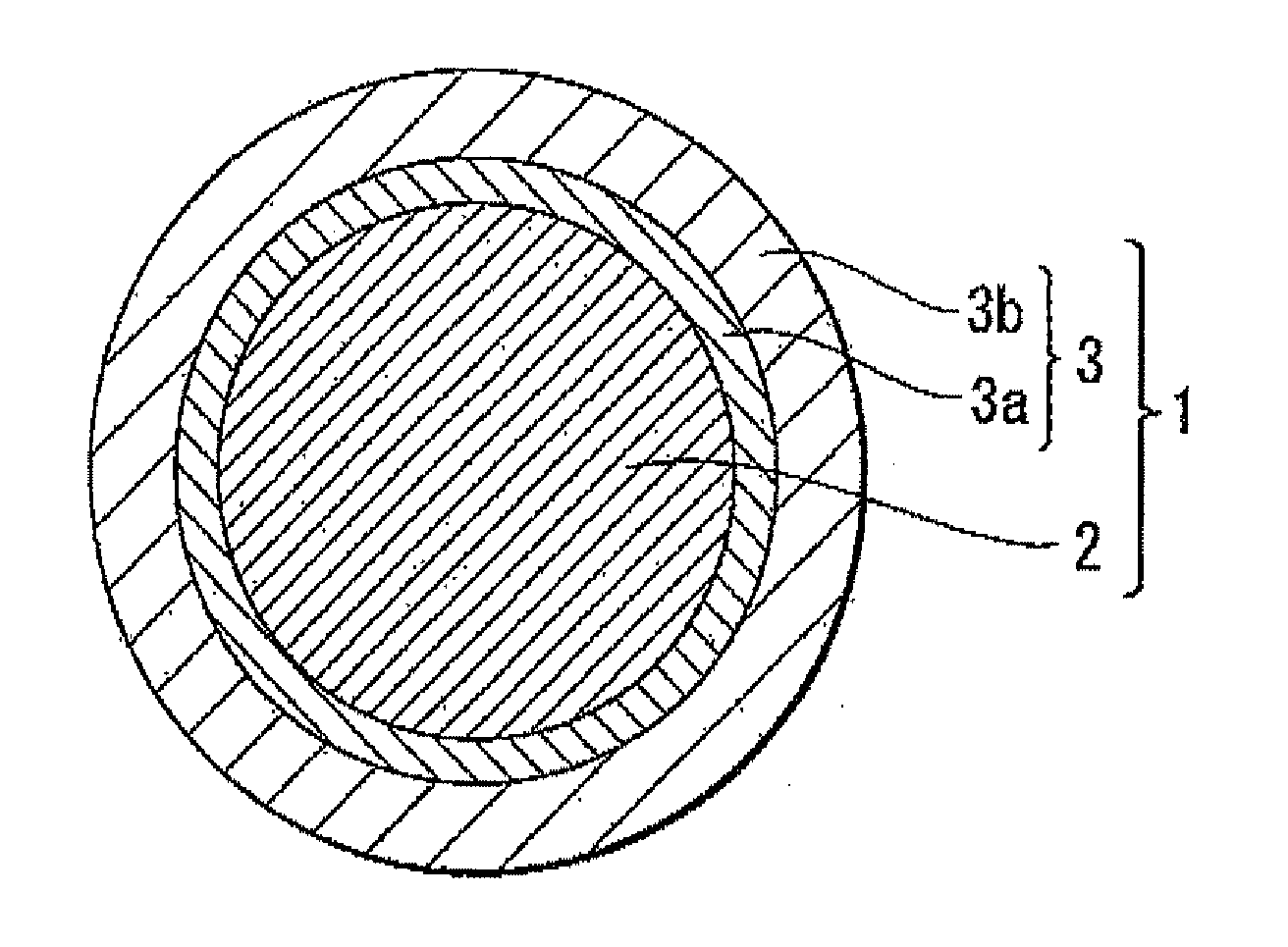

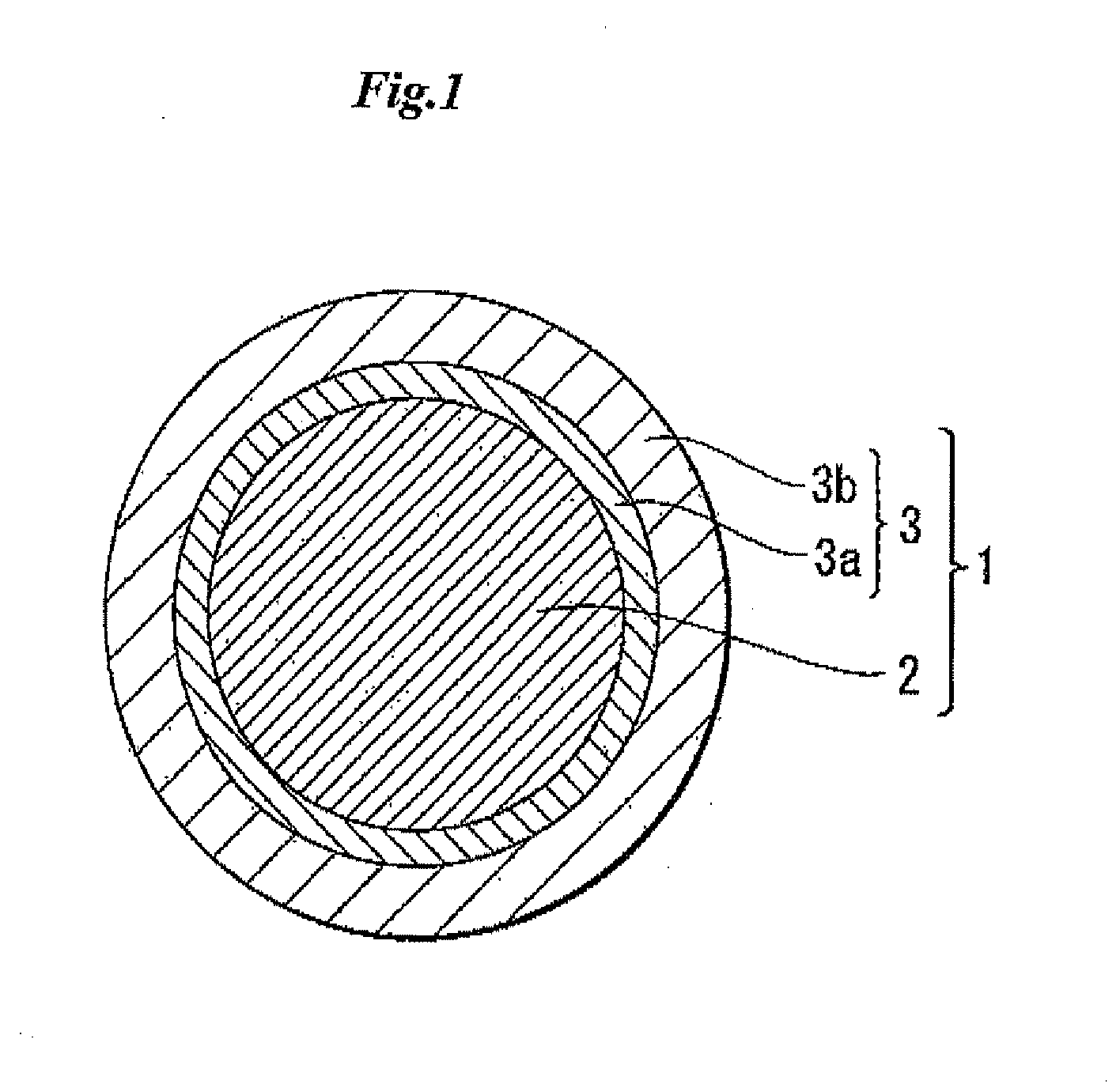

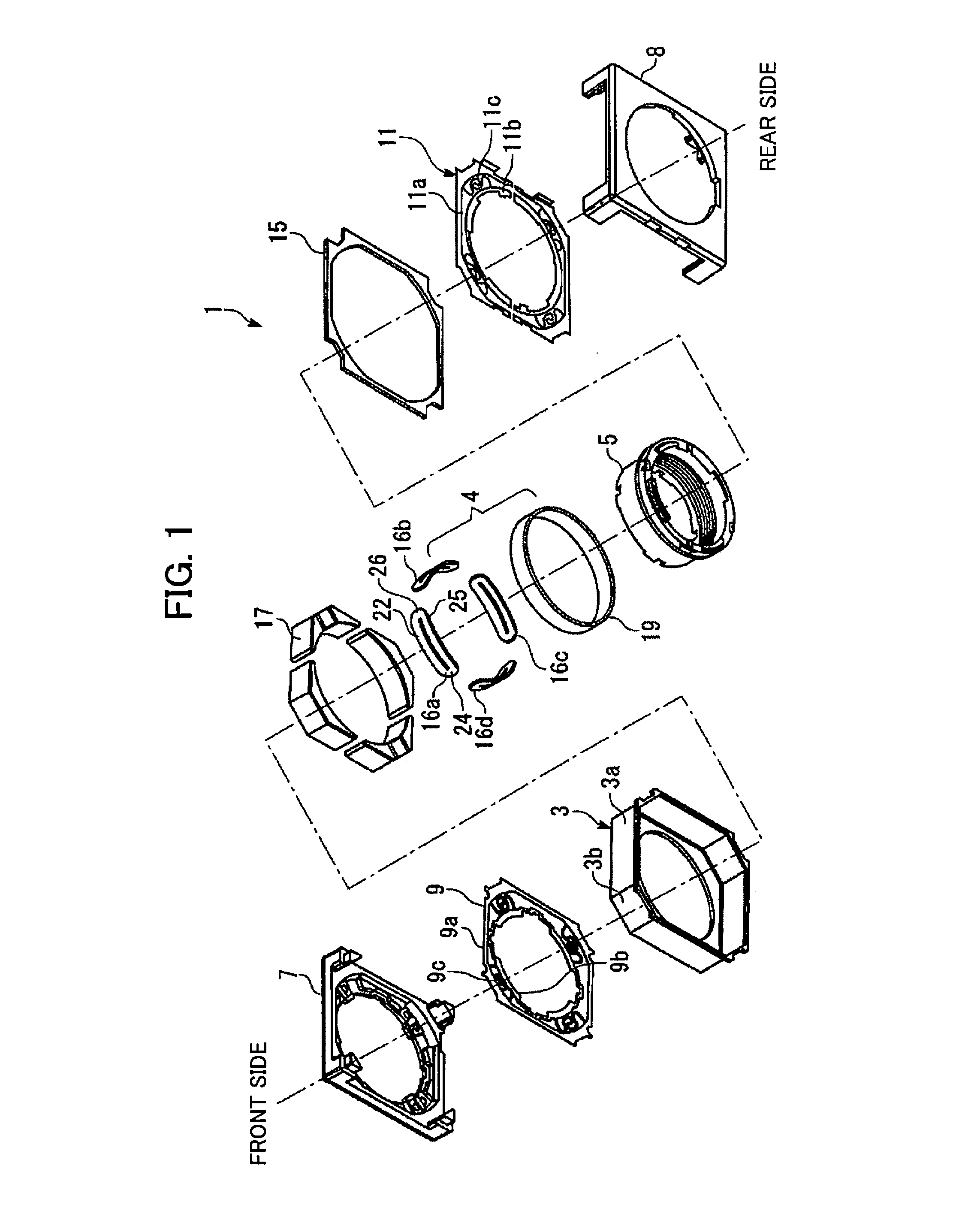

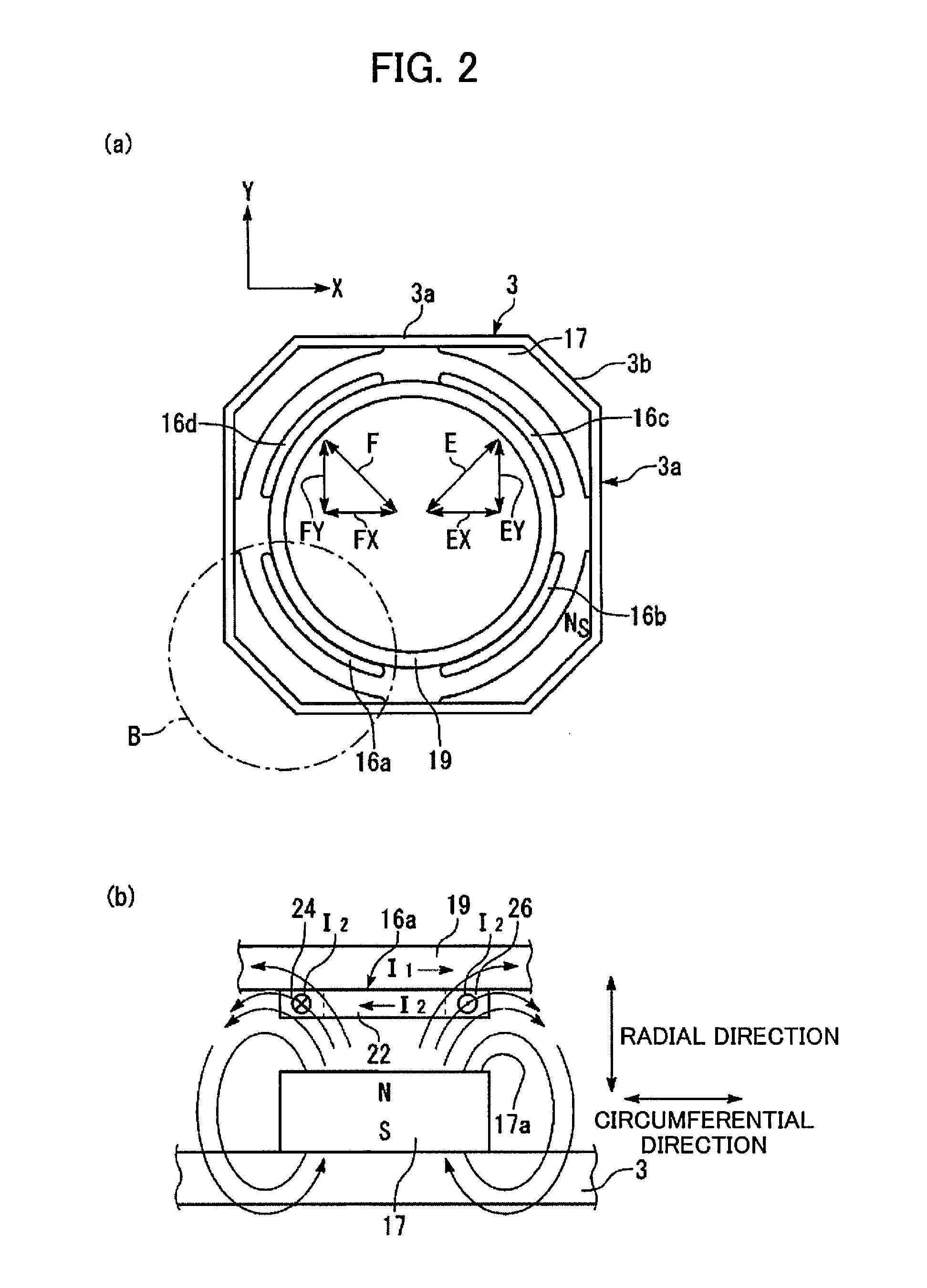

Lens driving apparatus

ActiveUS7649703B2Apparatus can be miniaturizedReduced external dimensionsTelevision system detailsProjector focusing arrangementCamera lensOptical axis

A lens driving apparatus 1 of the present invention includes a substantially cylindrical yoke 3; a base 5 to which the yoke 3 is attached; a carrier 7 having a lens; a coil 10; and a magnet 13, wherein the carrier 7 is moved in a direction of an optical axis of a lens by electromagnetic force generated by passing current through the coil 10, the base 5 is substantially square-shaped as viewed from a plane, the yoke 3 is placed at an inner position of the base 5, the yoke 3 has an outer peripheral wall 3a and an annular inner peripheral wall 3b to be spaced to each other, each magnet is placed between the outer peripheral wall and the inner peripheral wall and at a position corresponding to a base corner portion of the base 5, and a space between the outer peripheral wall 3a and the inner peripheral wall 3b positioned at a base side portion 3e is made narrower than a space between the outer peripheral wall 3a and the inner peripheral wall 3b positioned at the base corner portion.

Owner:NEW SHICOH MOTOR CO LTD

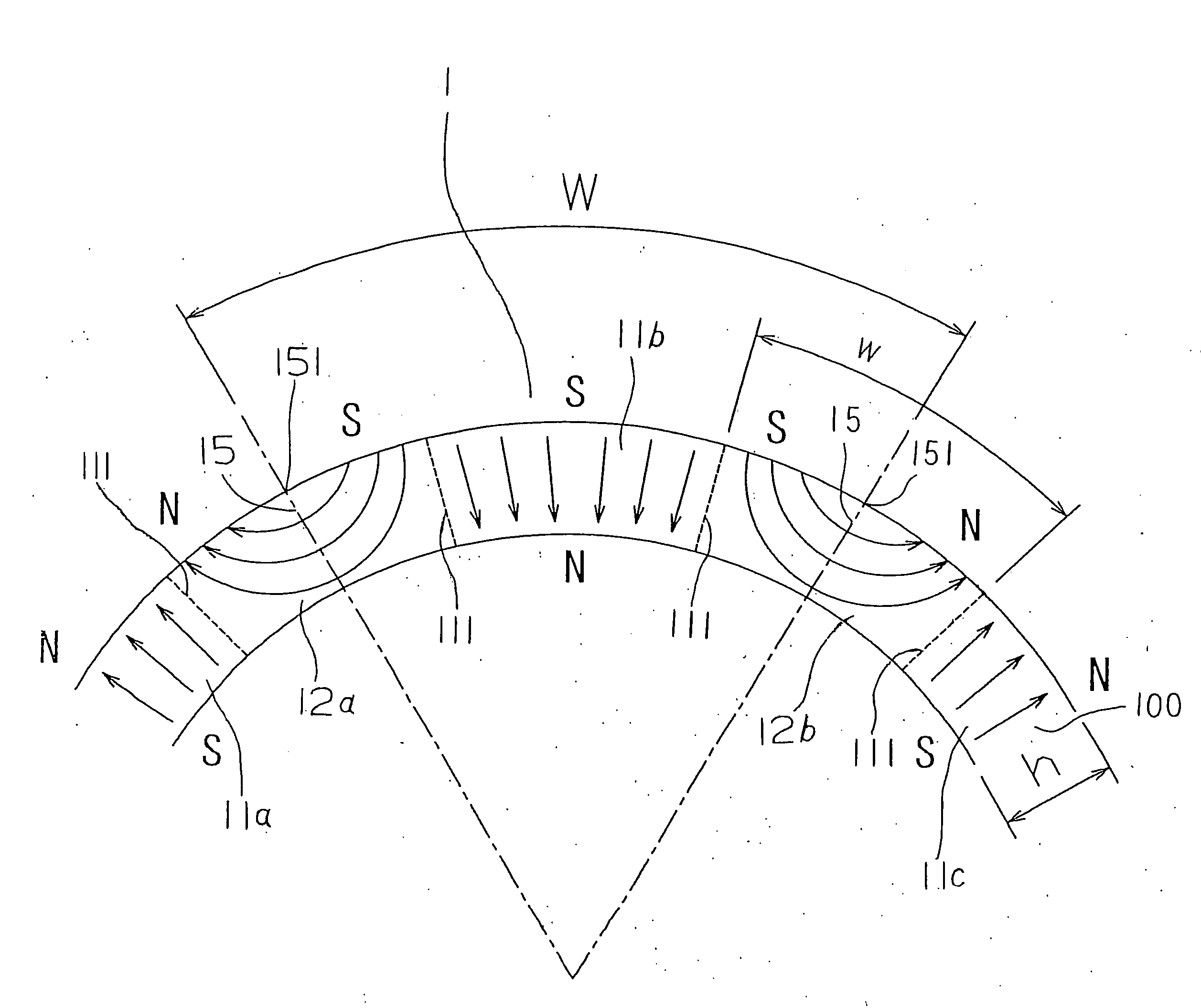

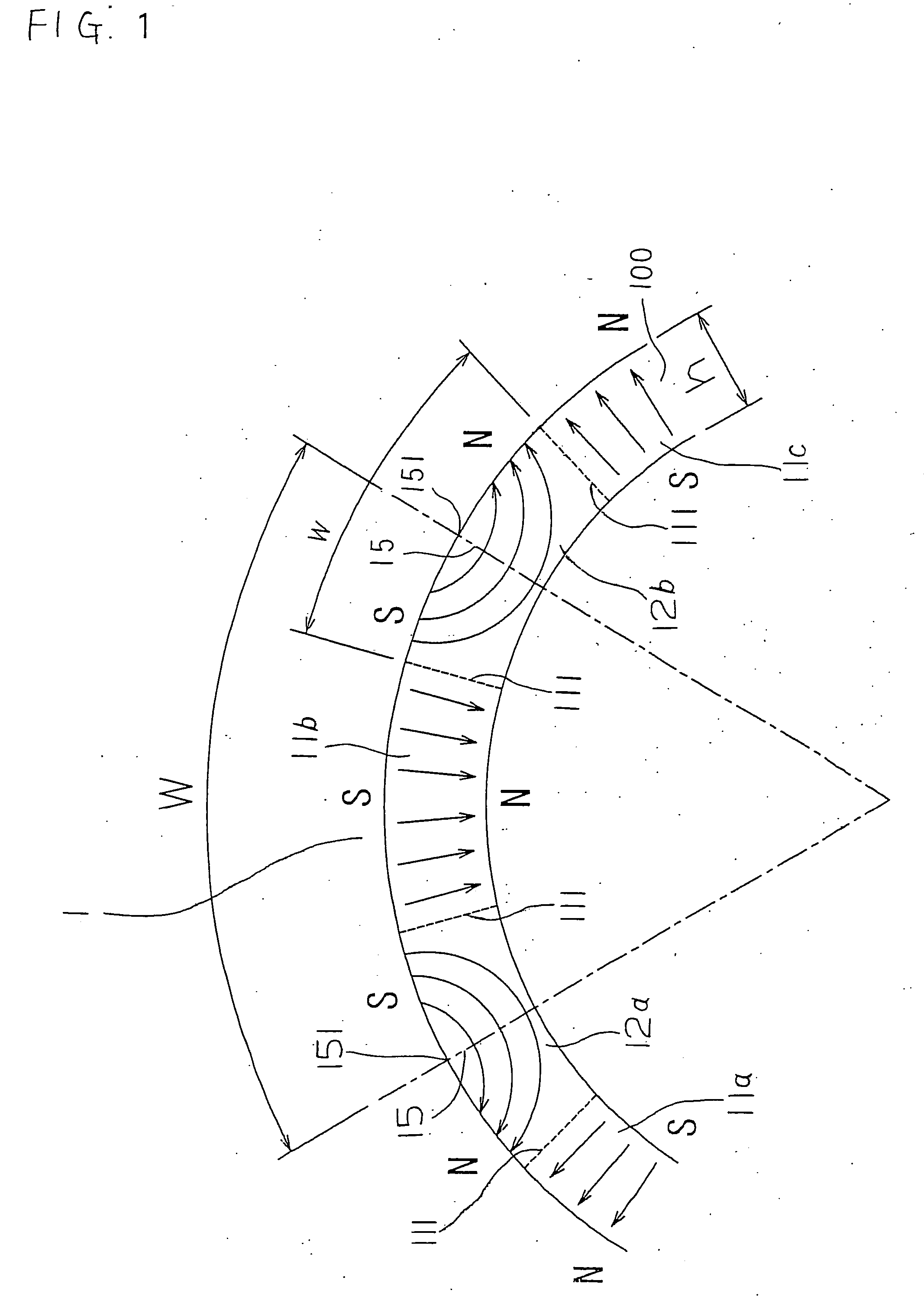

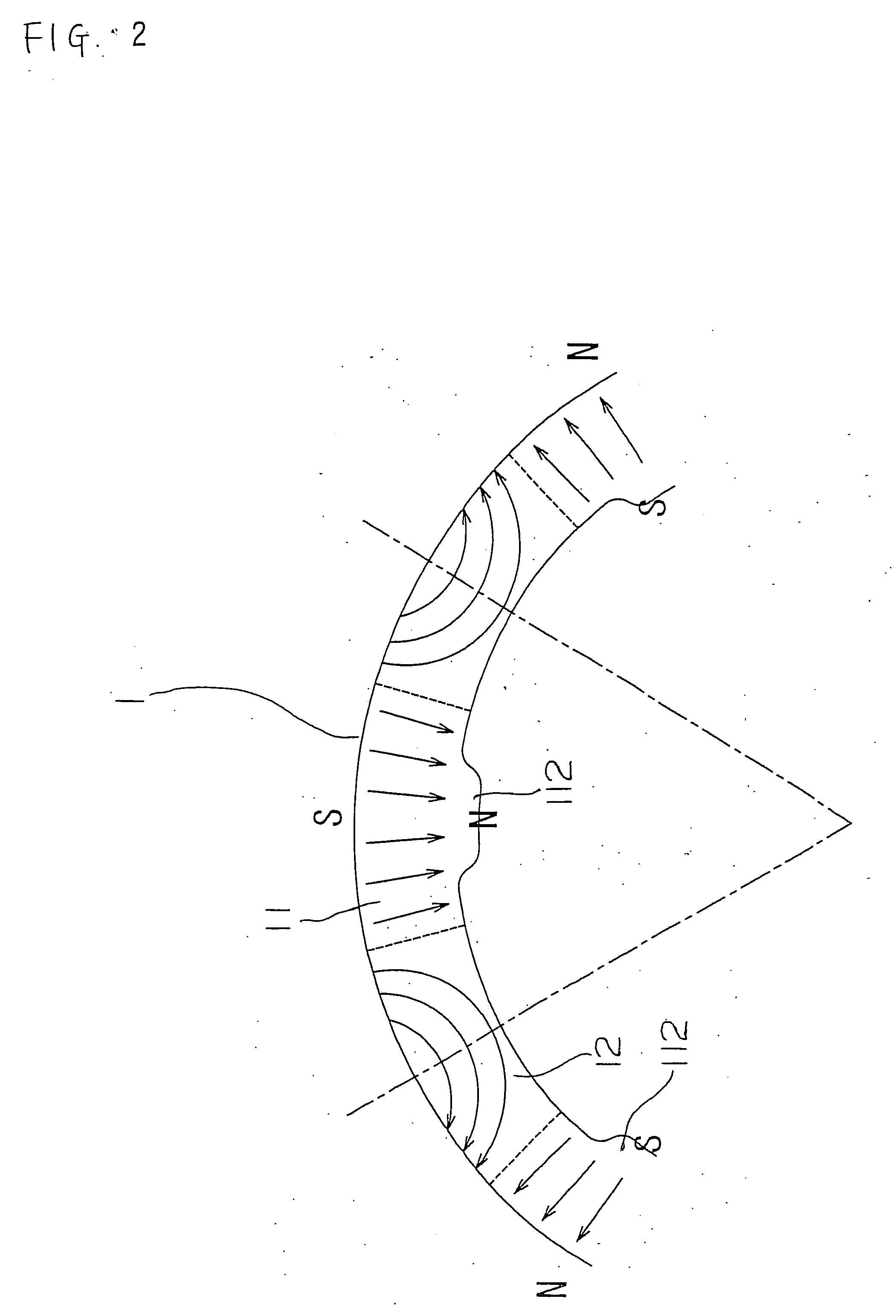

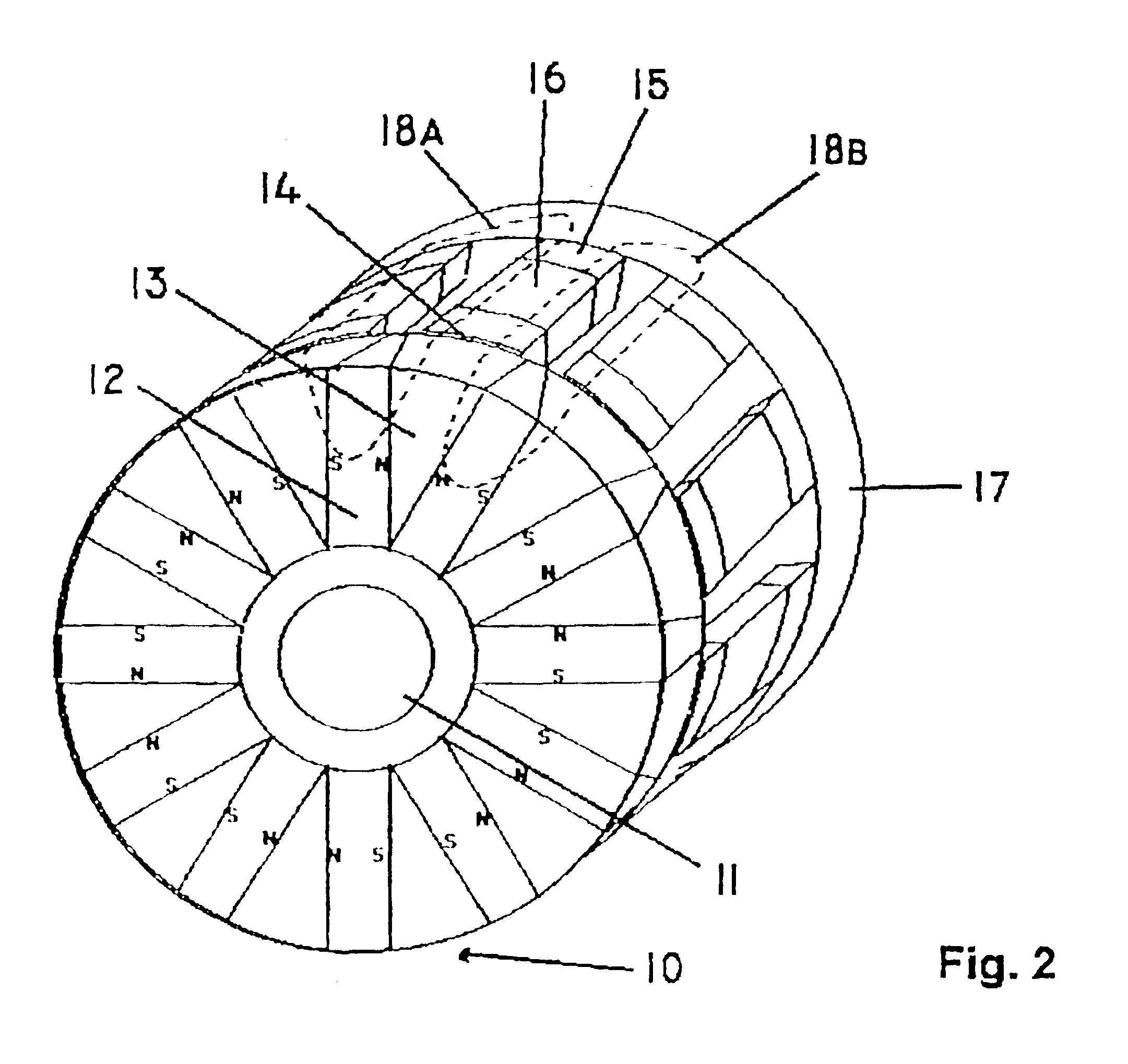

Thin hybrid magnetization type ring magnet, yoke-equipped thin hybrid magnetization type ring magnet, and brush-less motor

ActiveUS20060113857A1Decrease in cogging torqueIncrease in torque per unit volume of magnetMagnetic circuit rotating partsPermanent magnetsBrushless motorsMagnetization

The present invention provides miniaturization of brushless motors and brush motors used in electric devices, a ring magnet which simultaneously achieves both high torque and a reduction in cogging torque, a ring magnet with yoke, and a brushless motor. The thin hybrid magnetized ring magnet of the present invention is structured of, in a ring magnet comprised of a plurality of magnetic poles, a radially magnetized main pole and an interface for which the interface of the adjoining main pole is polar anisotropic. When the thin hybrid magnetized ring magnet structured in this manner is applied to a brushless motor, in the case of radial magnetizing, the abrupt change in magnetic flux of the interface between the magnetic poles becomes smooth and cogging torque is greatly reduced due to polar anisotropic magnetization of the interface. At the same time, by polar anisotropically magnetizing the interface between the magnetic poles, magnetic flux is concentrated on the radially magnetized main pole, and in comparison to only radial magnetization, maximum surface magnetic flux improves and it is possible to attain high torque.

Owner:AICHI STEEL

Electric multipole motor/generator with axial magnetic flux

InactiveUS6844656B1High magnetic flux densityReduce consumptionSynchronous generatorsWindingsPhysicsMaterial consumption

This invention relates to an electric multiple motor / generator with axial magnetic flux. Thus a generator / motor or electrical machine in which a magnetic flux path through one or more pole legs or pole cores surrounded by current windings or coils is provided. This allows a high density of the magnetic flux to be passed through the pole legs or cores, which results in a low consumption of material for the pole legs or pole cores compared with prior art machines, where for example a large stator diameter may be needed in order to conduct a high magnetic flux. Additionally the generator / motor or electrical machine is very efficient both at a low and a high number of revolutions. According to another aspect of the invention a multiple phase output without enlarging the diameter of the generator is provided.

Owner:MULTIPOLGENERATOR APS +1

Armature Core, Motor Using It, and Its Manufacturing Method

InactiveUS20100225195A1High magnetic flux densityPrevents impairment of motor characteristicMagnetic circuit rotating partsPositive displacement pump componentsMagnetic fieldElectric motor

An object is to enable simple manufacture of a motor, especially, a stator core or a field without impairment of motor characteristics. The motor includes a shaft, a rotor fixed to the shaft, and a stator including a stator core that faces the rotor with a certain space therebetween and coils that are attached to the stator core. The stator includes a back yoke, and the stator core having a plurality of teeth that are circumferentially placed in an axial end face of the back yoke so as to stand upright axially of the back yoke, and that are formed of a dust core made of pressed magnetic powder. The above-mentioned teeth are buried axially to a certain depth in the back yoke.

Owner:DAIKIN IND LTD

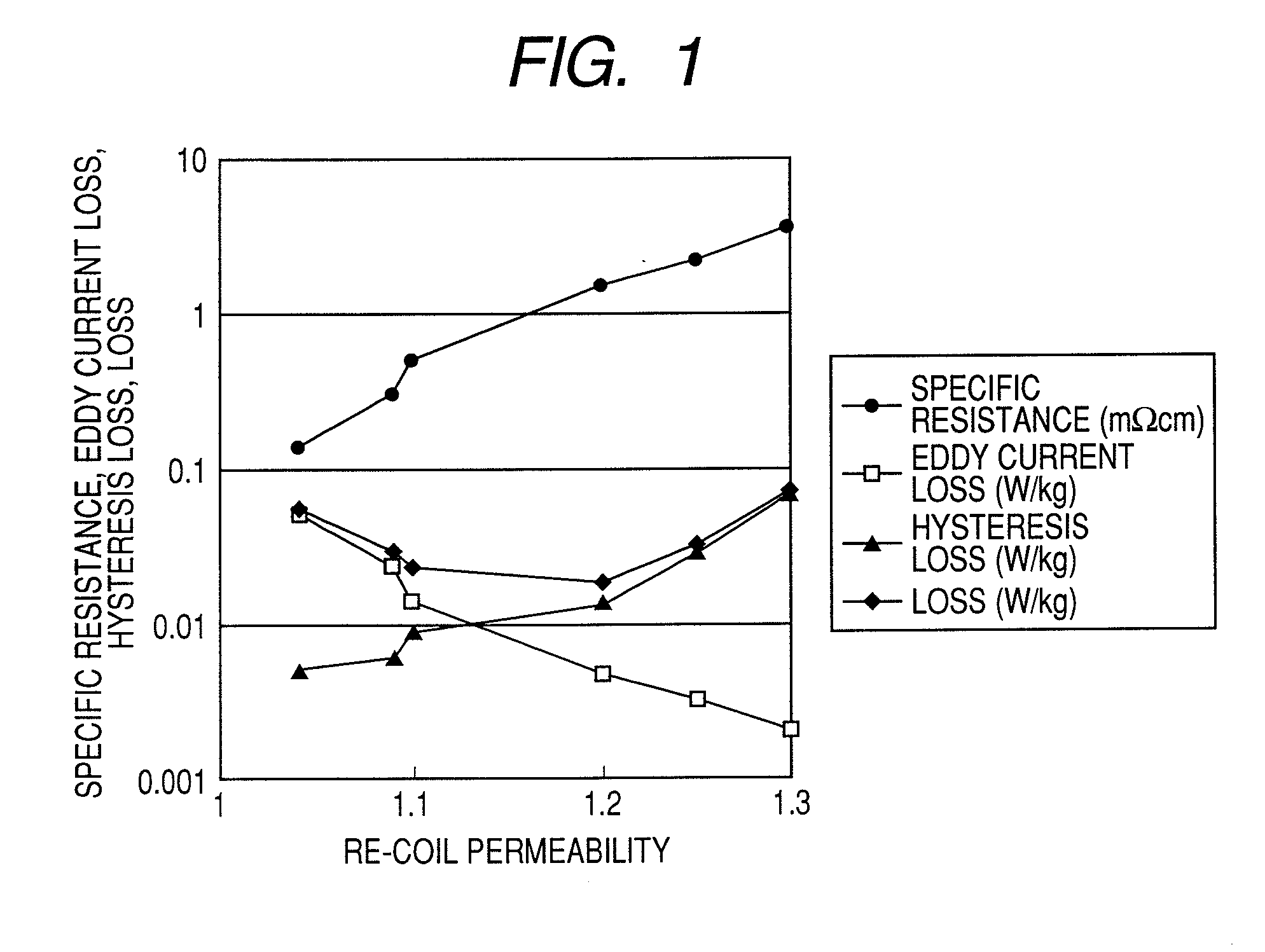

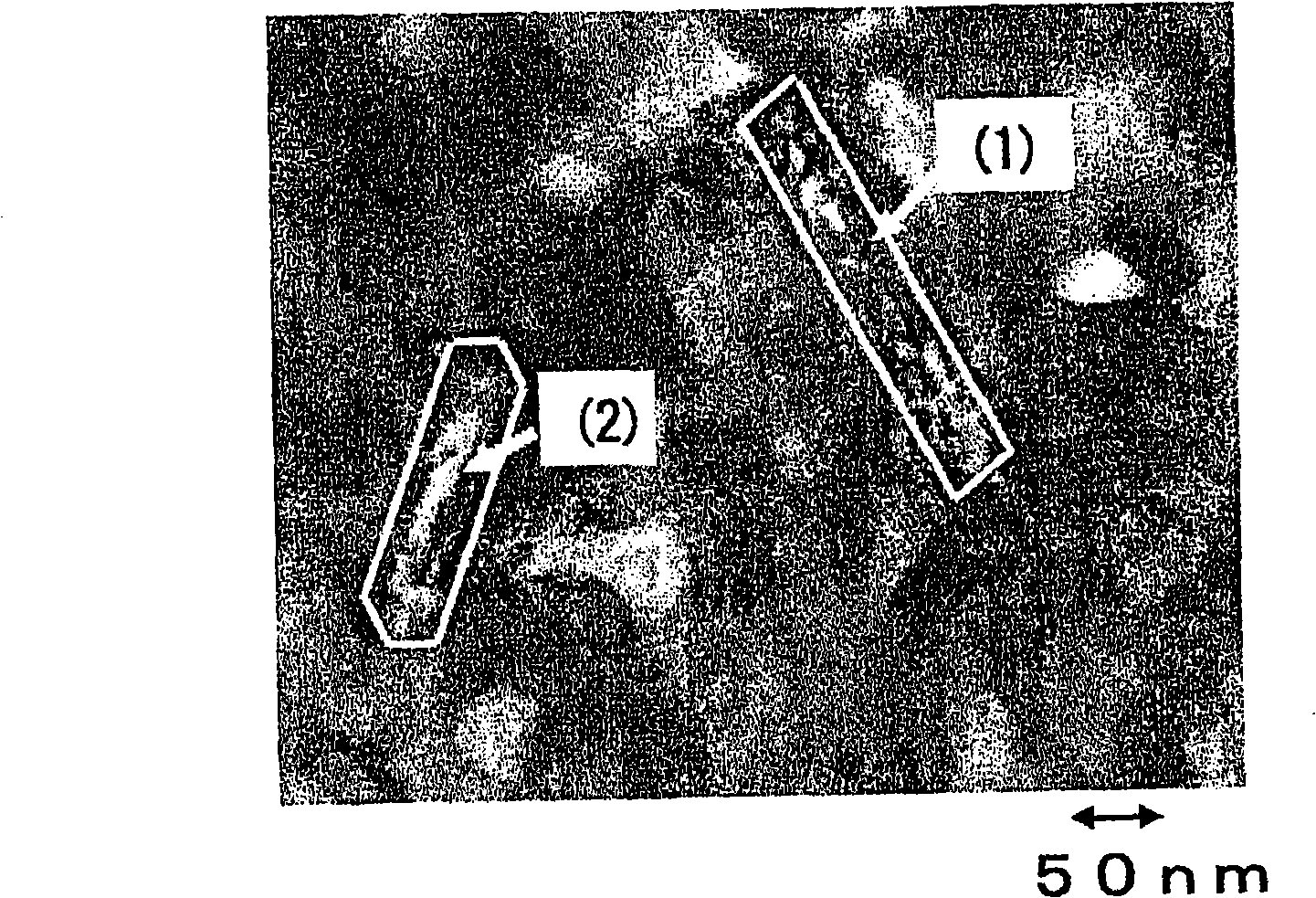

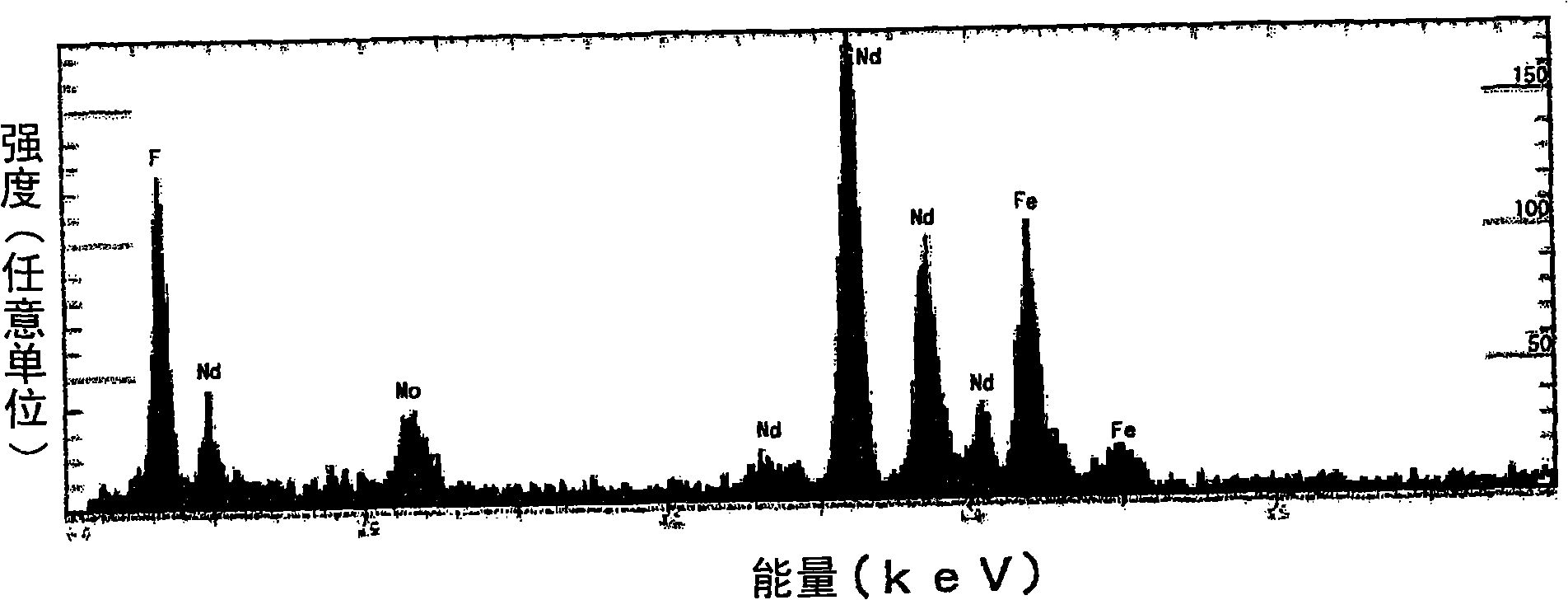

High resistance magnet and motor using the same

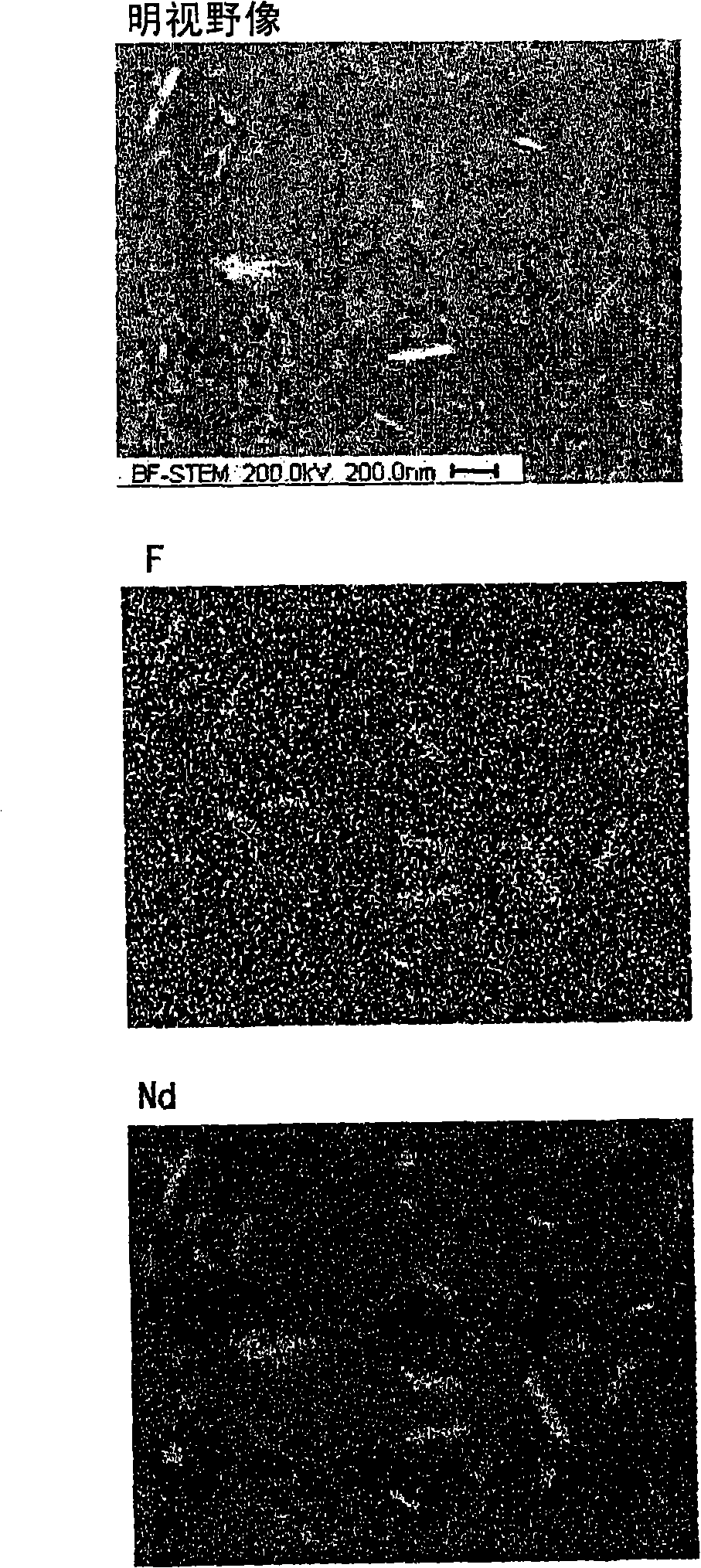

InactiveUS20080054738A1Improve magnetic propertiesImprove propertiesLayered productsNanoinformaticsRare-earth elementHigh resistance

A magnet comprising grains of a ferromagnetic material whose main component is iron and a fluorine compound layer or an oxy-fluorine compound layer of fluoride compound particles of alkali metals, alkaline earth metals and rare earth elements, present on the surface of the ferromagnetic material grains, wherein an amount of iron atoms in the fluorine compound particles is 1 to 50 atomic %.

Owner:HITACHI LTD

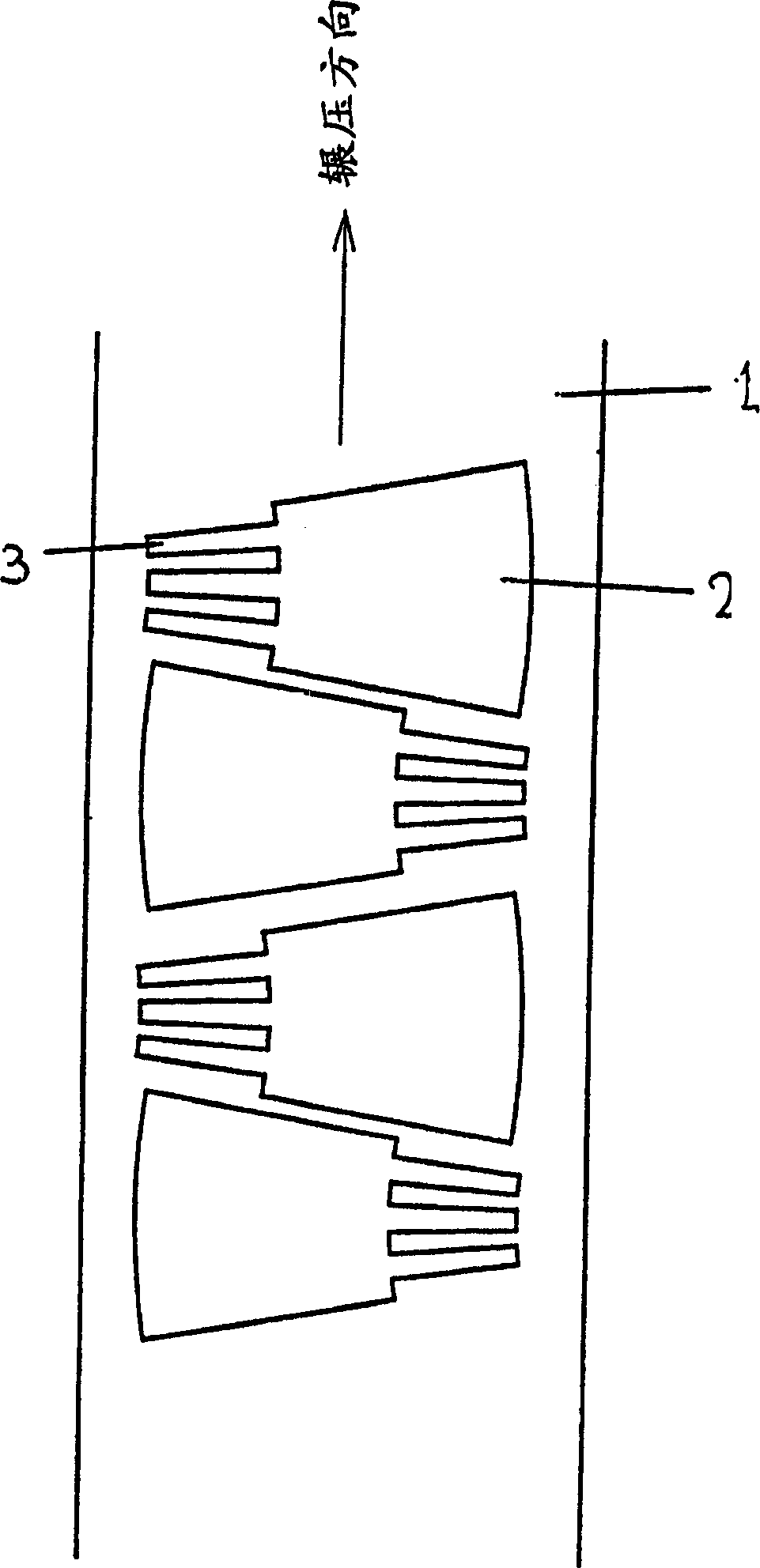

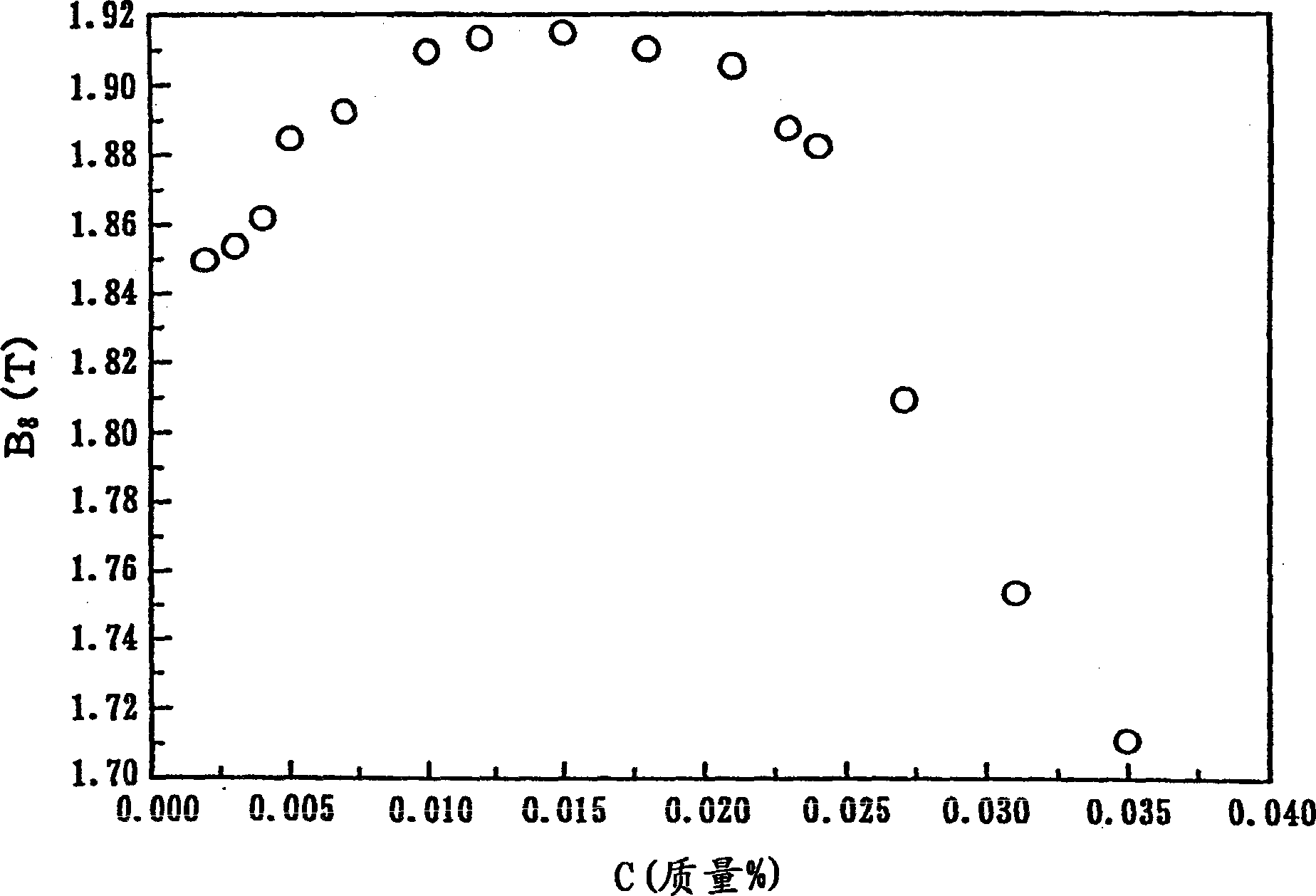

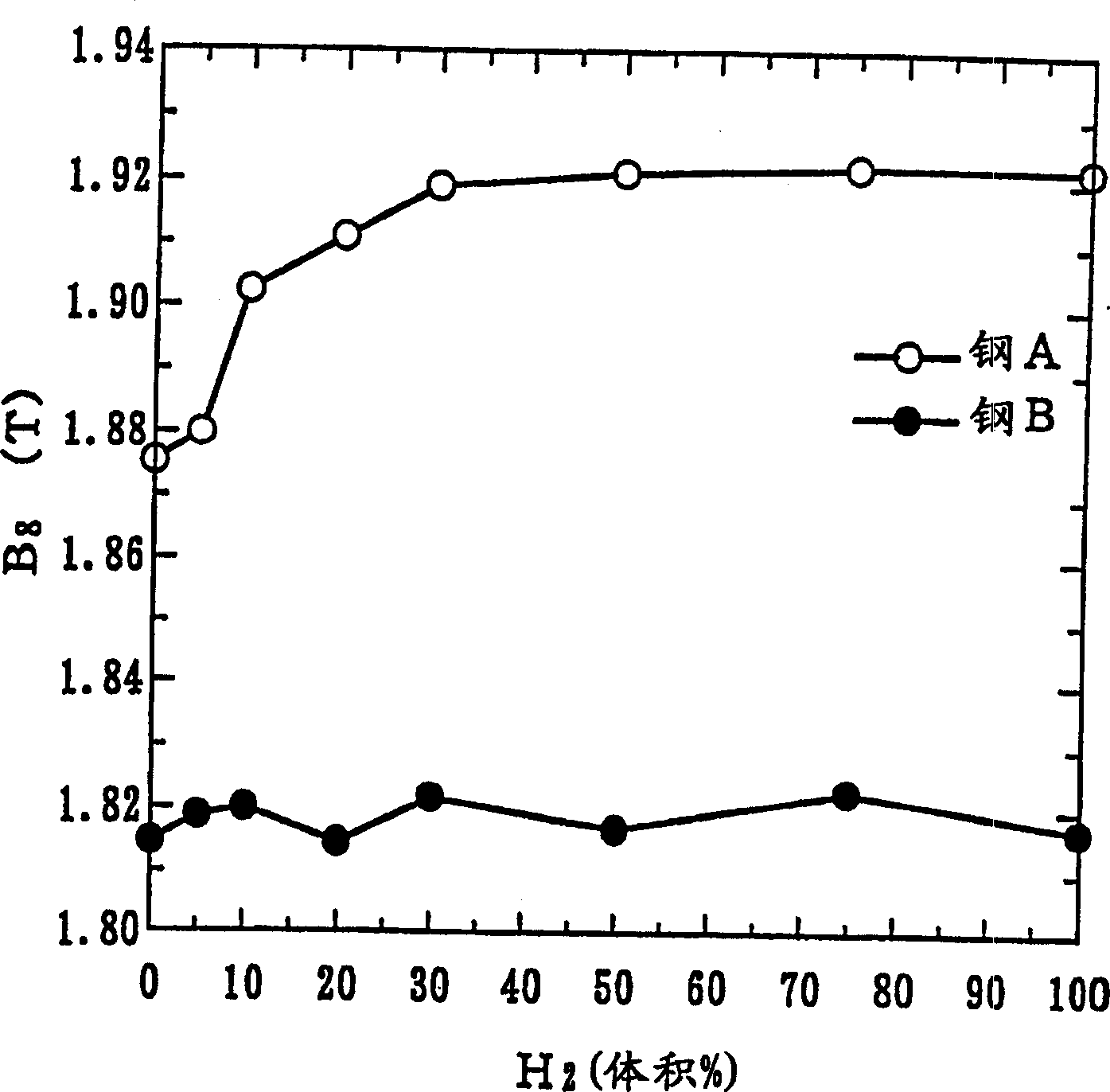

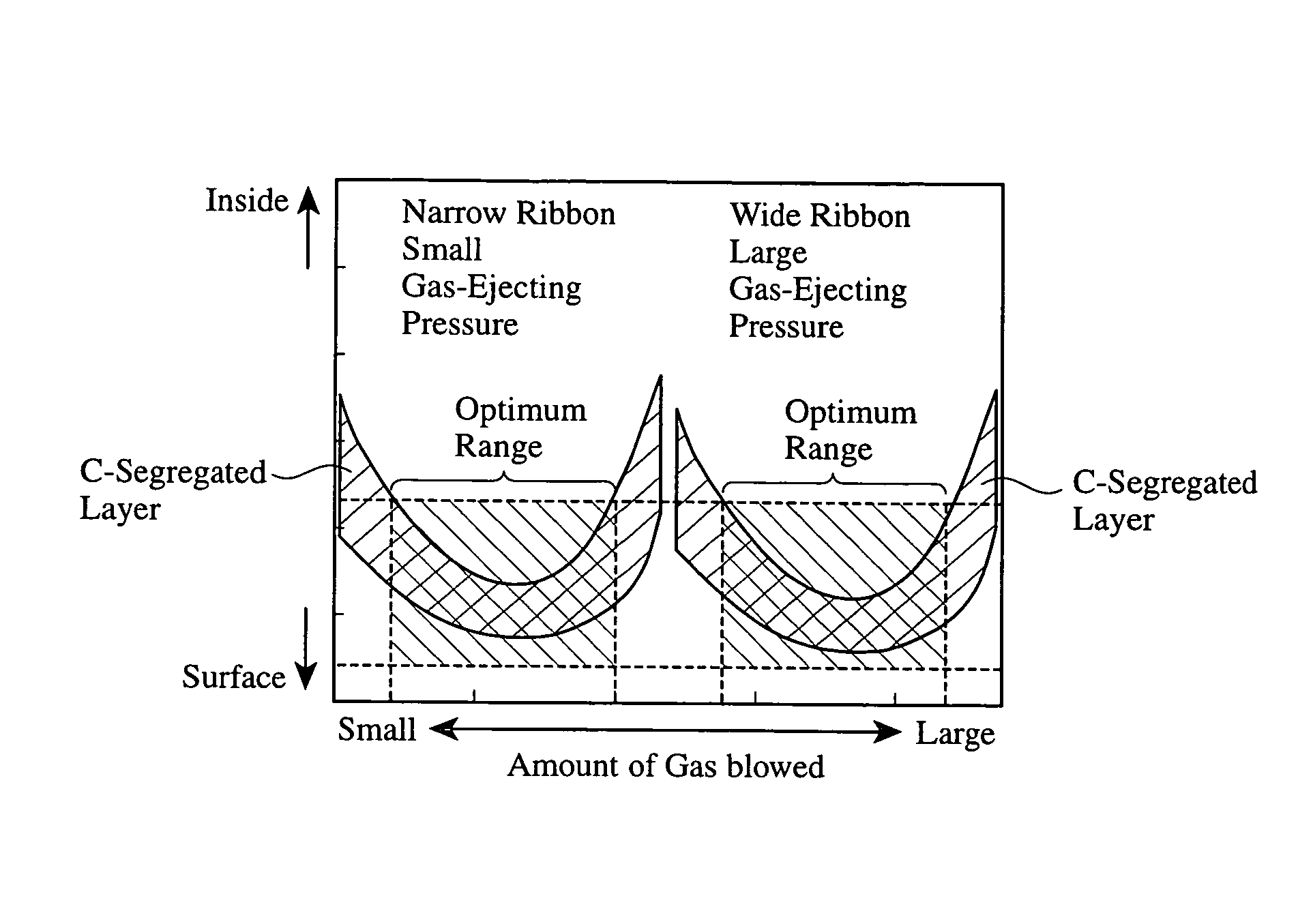

Manufacture of directional electromagnetic steel plate

A method of manufacturing a grain-oriented steel sheet including hot-rolling a slab prepared using molten steel containing, by mass%, C of not more than about 0.08 %, Si of about 1.0 to about 8.0 % and Mn of about 0.005 to about 3.0 %; optionally annealing the hot-rolled steel sheet; performing cold rolling once, or twice or more with intermediate annealing therebetween; performing primary recrystallization annealing in a low- or non-oxidizative atmosphere and adjusting the C content in the steel sheet after primary recrystallization annealing to be held in the range of about 0.005 to about 0.025 mass%; performing secondary recrystallization annealing; decarburization annealing; and, preferably, performing additional high-temperature continuous or batch annealing. A grain-oriented electrical steel sheet having a sufficiently high magnetic flux density and a low iron loss can be advantageously obtained even when it is manufactured without using an inhibitor.

Owner:JFE STEEL CORP

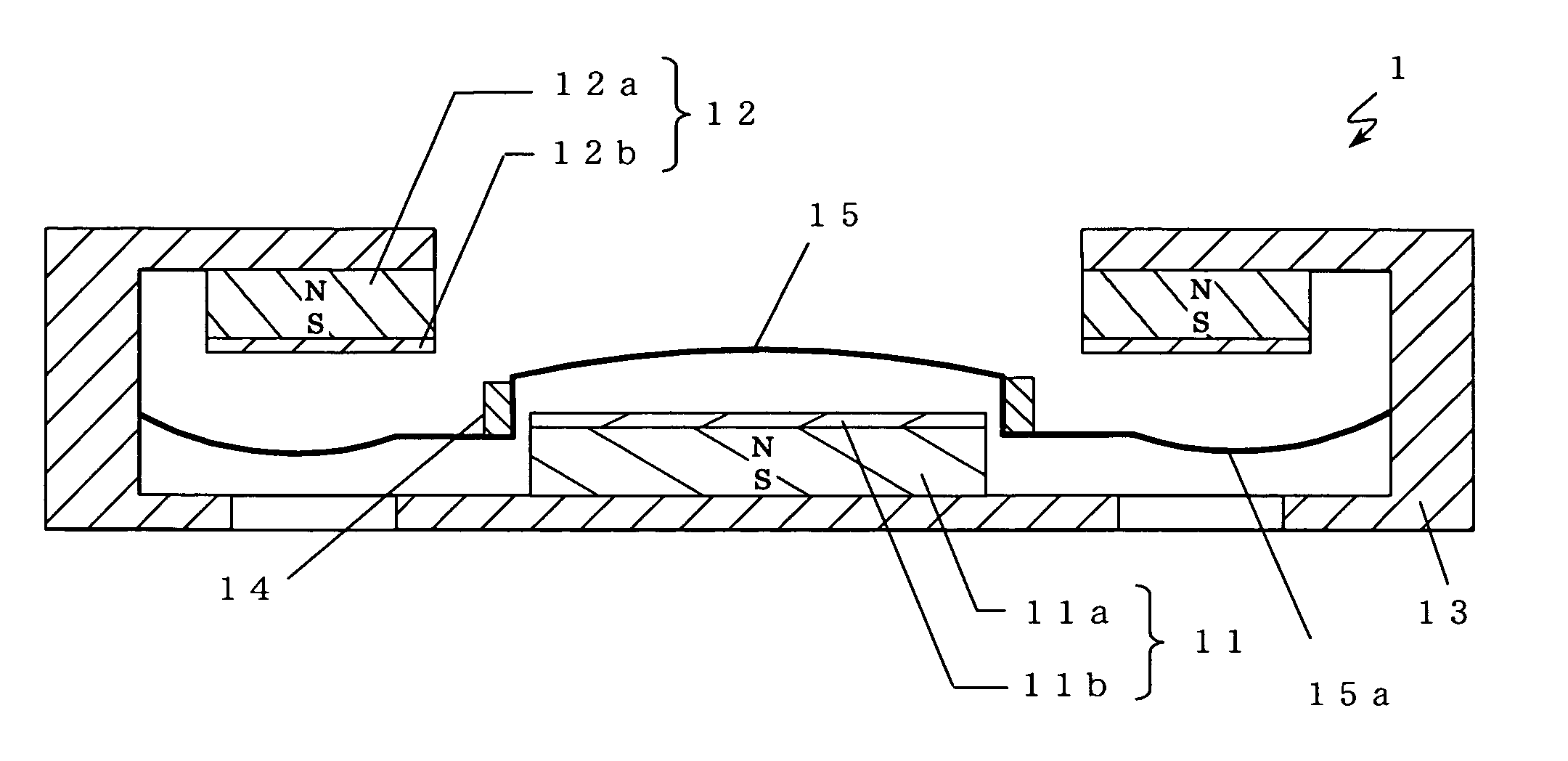

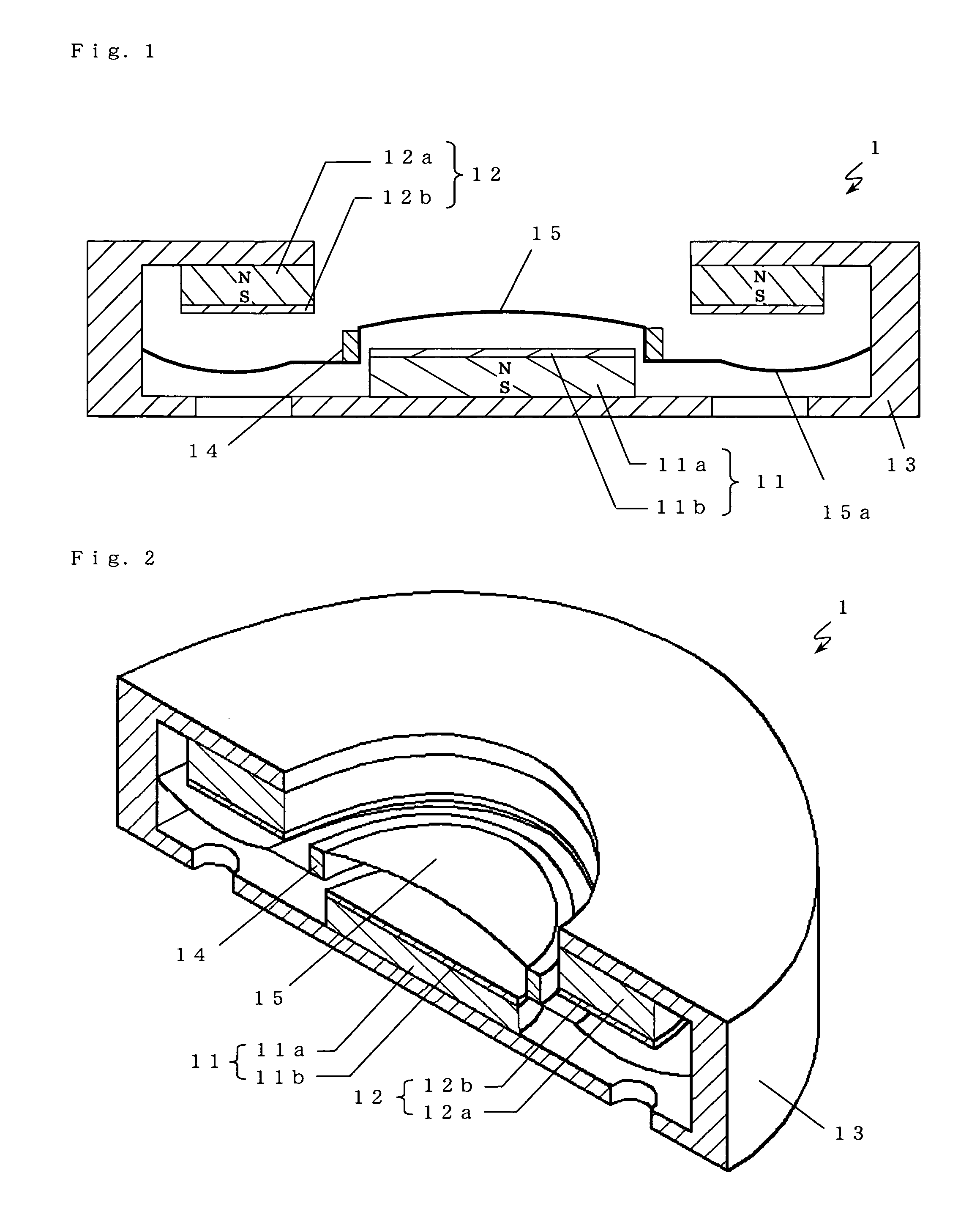

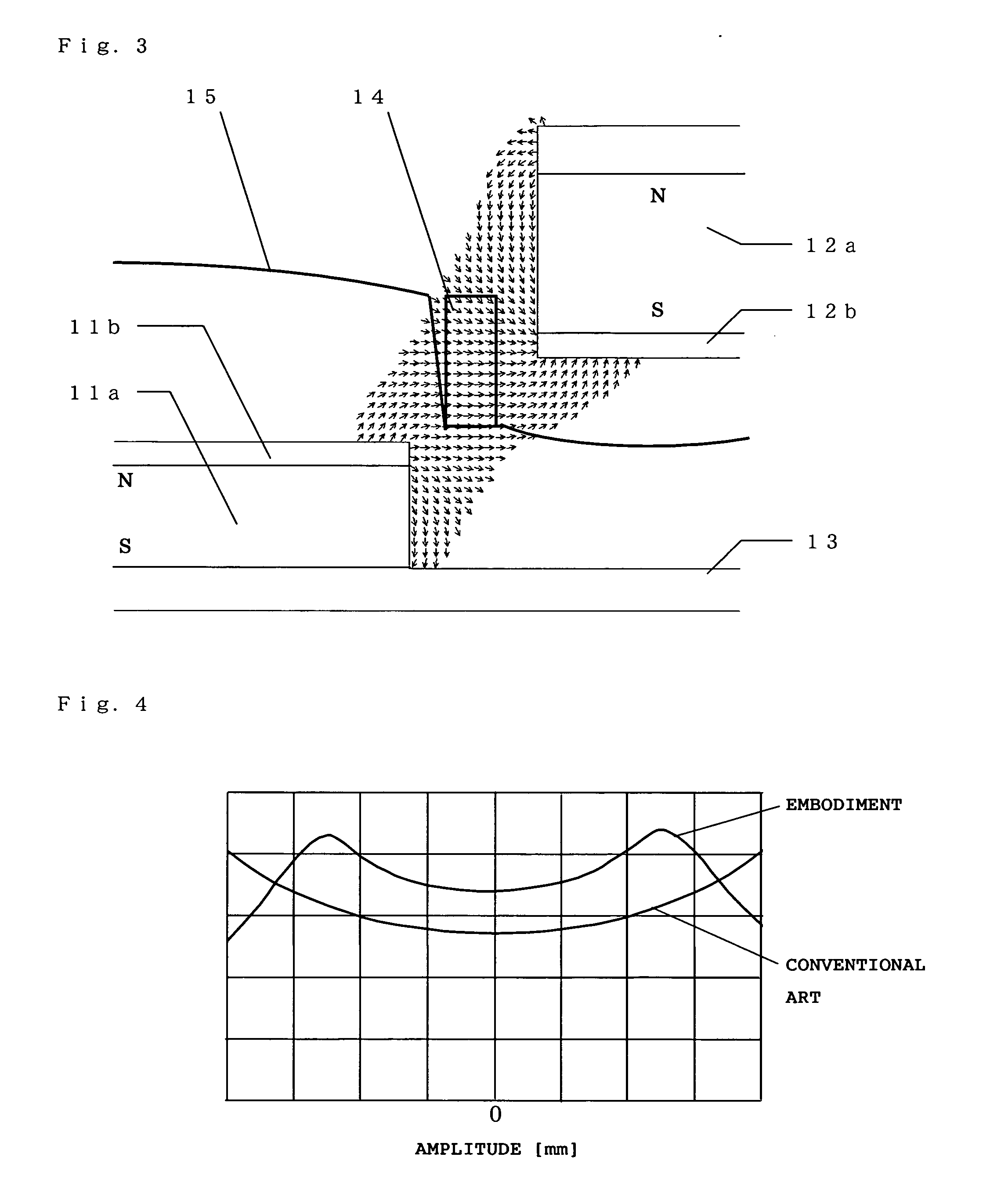

Electrodynamic electroacoustic transducer and electronic device

ActiveUS20070165902A1High magnetic flux densityImprove performanceTransducer detailsTransducerMagnetic poles

An electrodynamic electroacoustic transducer comprises: a first magnetic pole; a second magnetic pole that forms a magnetic gap between itself and the first magnetic pole and is arranged in a space excluding spaces in upper and lower face directions of the first magnetic pole; a yoke; a diaphragm; and a voice coil. The yoke magnetically couples one magnetic pole face of the first magnetic pole with one magnetic pole face of the second magnetic pole so as to support them. The diaphragm is arranged in a space in an upper face direction of the first magnetic pole and in a space in a lower face direction of the second magnetic pole, while its outer periphery is supported by the yoke. The voice coil is arranged in the magnetic gap and adhered to the diaphragm. At least one of the first magnetic pole part and the second magnetic pole part includes a magnet.

Owner:PANASONIC CORP

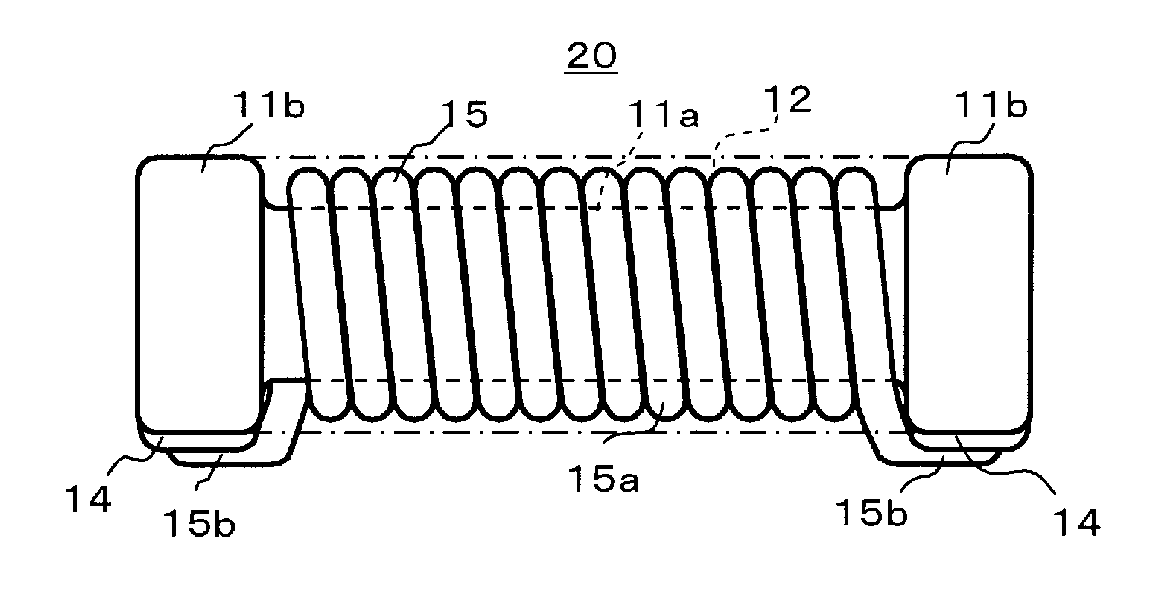

Coil component

ActiveUS20120188049A1High volume resistivityIncrease component densityTransportation and packagingMetal-working apparatusElectrical currentMaterials science

A coil component is of the type where a helical coil is directly contacting a magnetic body, which is still capable of meeting the demand for electrical current amplification. A coil component, comprising a magnetic body mainly constituted by magnetic alloy grains, and a coil formed on the magnetic body; wherein an oxide film of the magnetic alloy grains is present on the surface of each of the magnetic alloy grains, and based on grain size by volume standard, the magnetic alloy grains have a d50 in a range of 3.0 to 20.0 μm, d10 / d50 in a range of 0.1 to 0.7, and d90 / d50 in a range of 1.4 to 5.0.

Owner:TAIYO YUDEN KK

Fe-based amorphous alloy ribbon

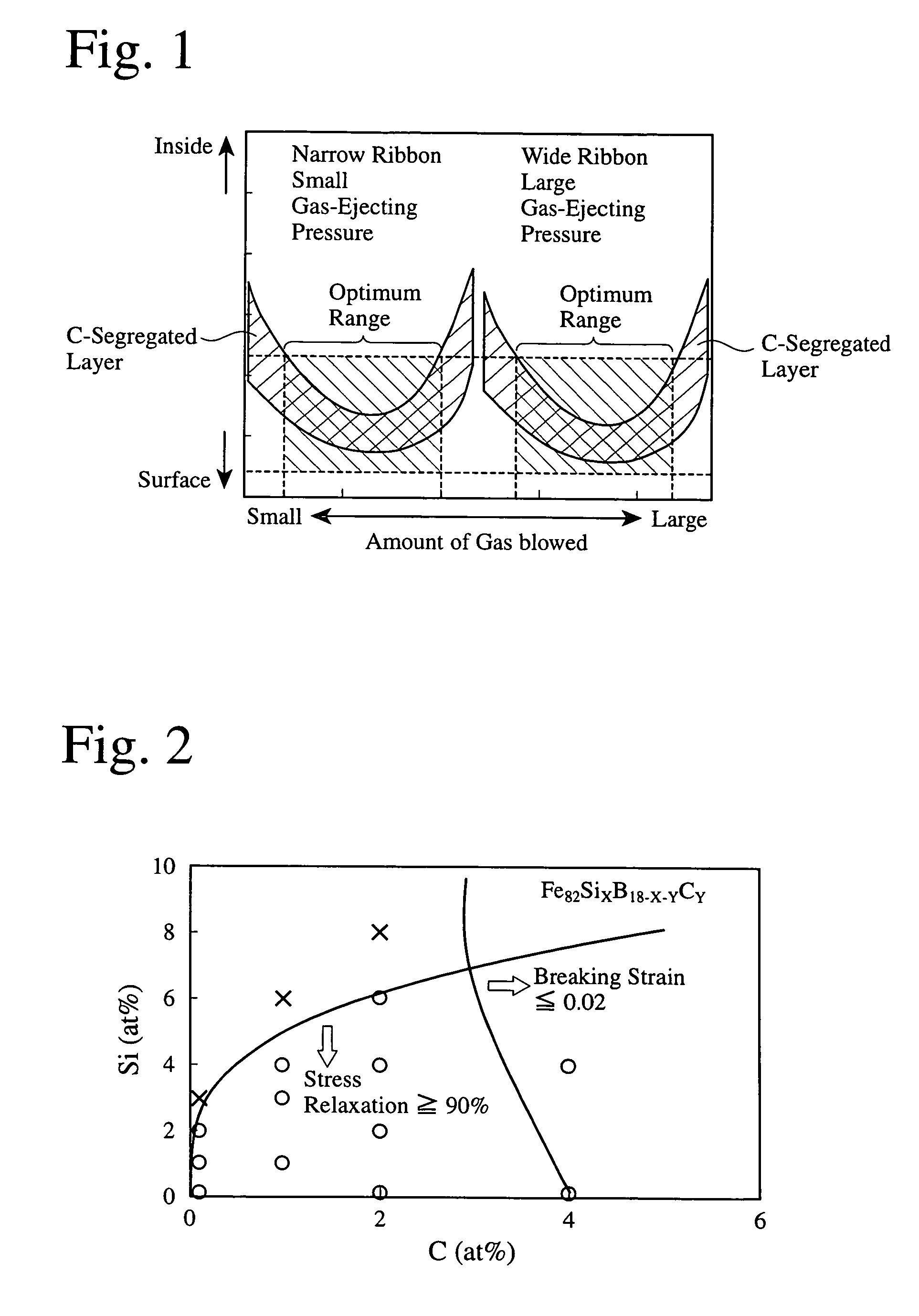

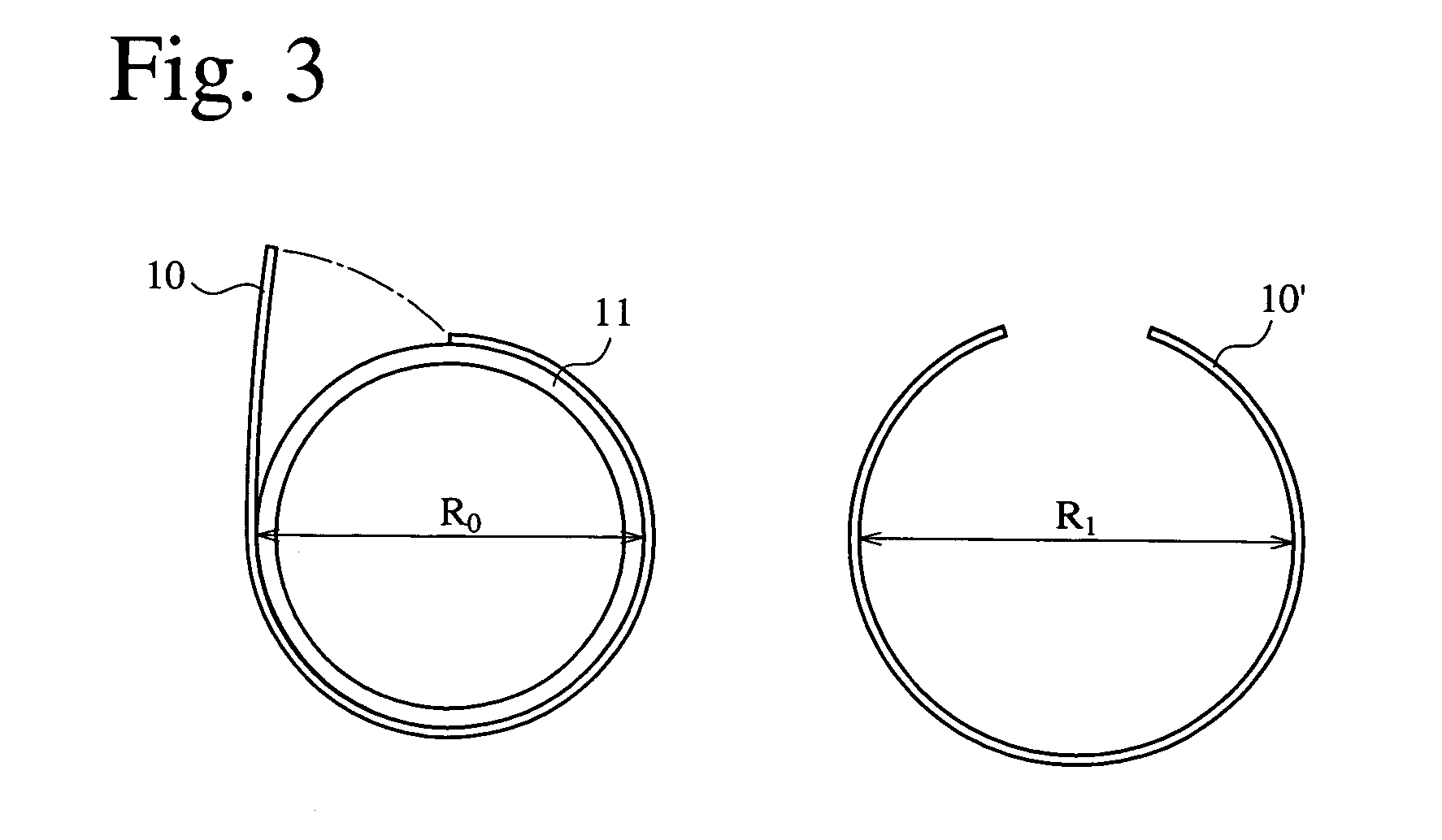

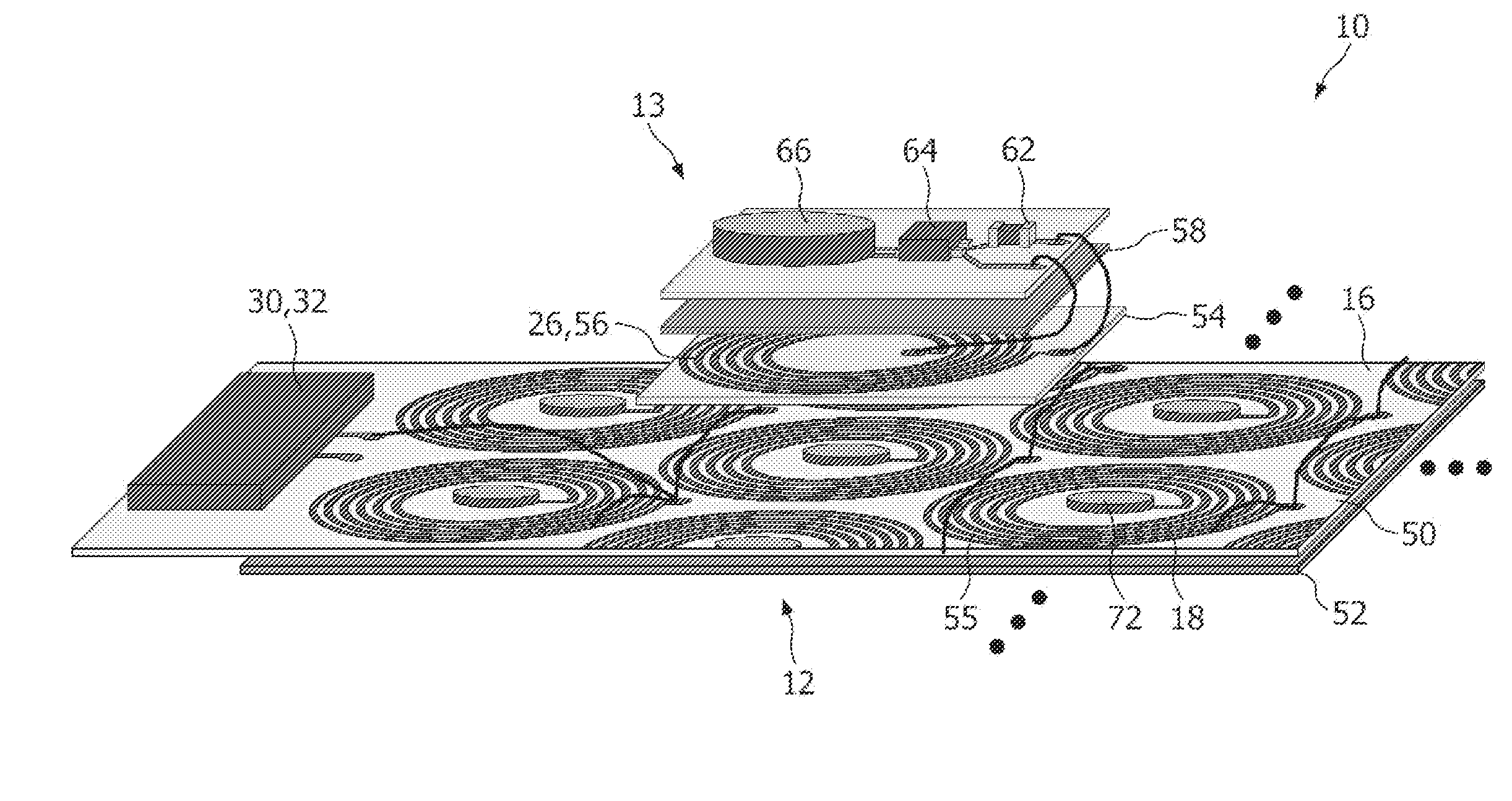

ActiveUS7425239B2High magnetic flux densityLow core lossInductances/transformers/magnets manufactureMagnetic materialsTO-18Impurity

An Fe-based amorphous alloy ribbon having a composition comprising FeaSibBcCd and inevitable impurities, wherein a is 80 to 83 atomic %, b is 0.1 to 5 atomic %, c is 14 to 18 atomic %, and d is 0.01 to 3 atomic %, the concentration distribution of C measured radially from both surfaces to the inside of said Fe-based amorphous alloy ribbon having a peak within a depth of 2 to 20 nm.

Owner:HITACHI METALS LTD

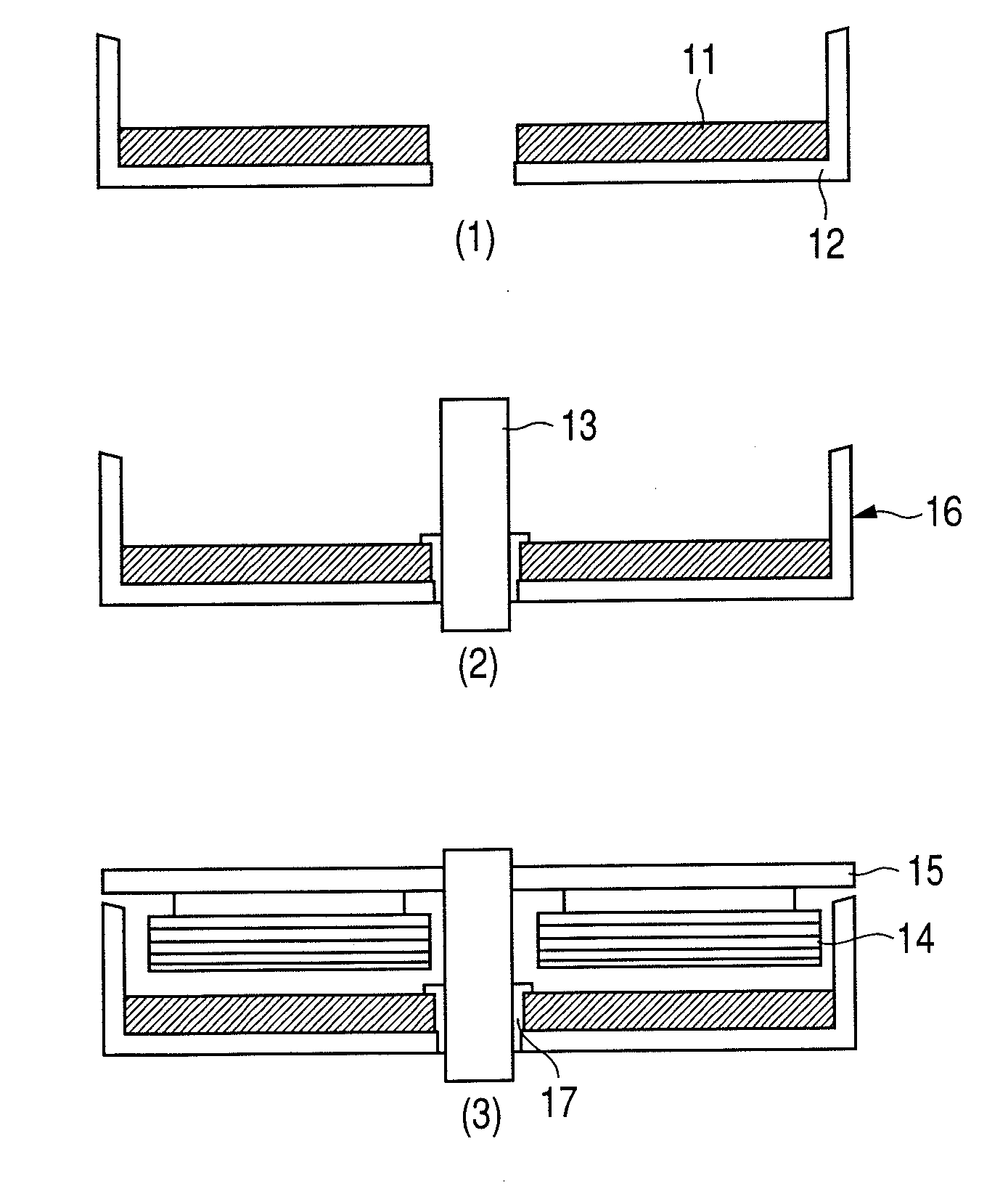

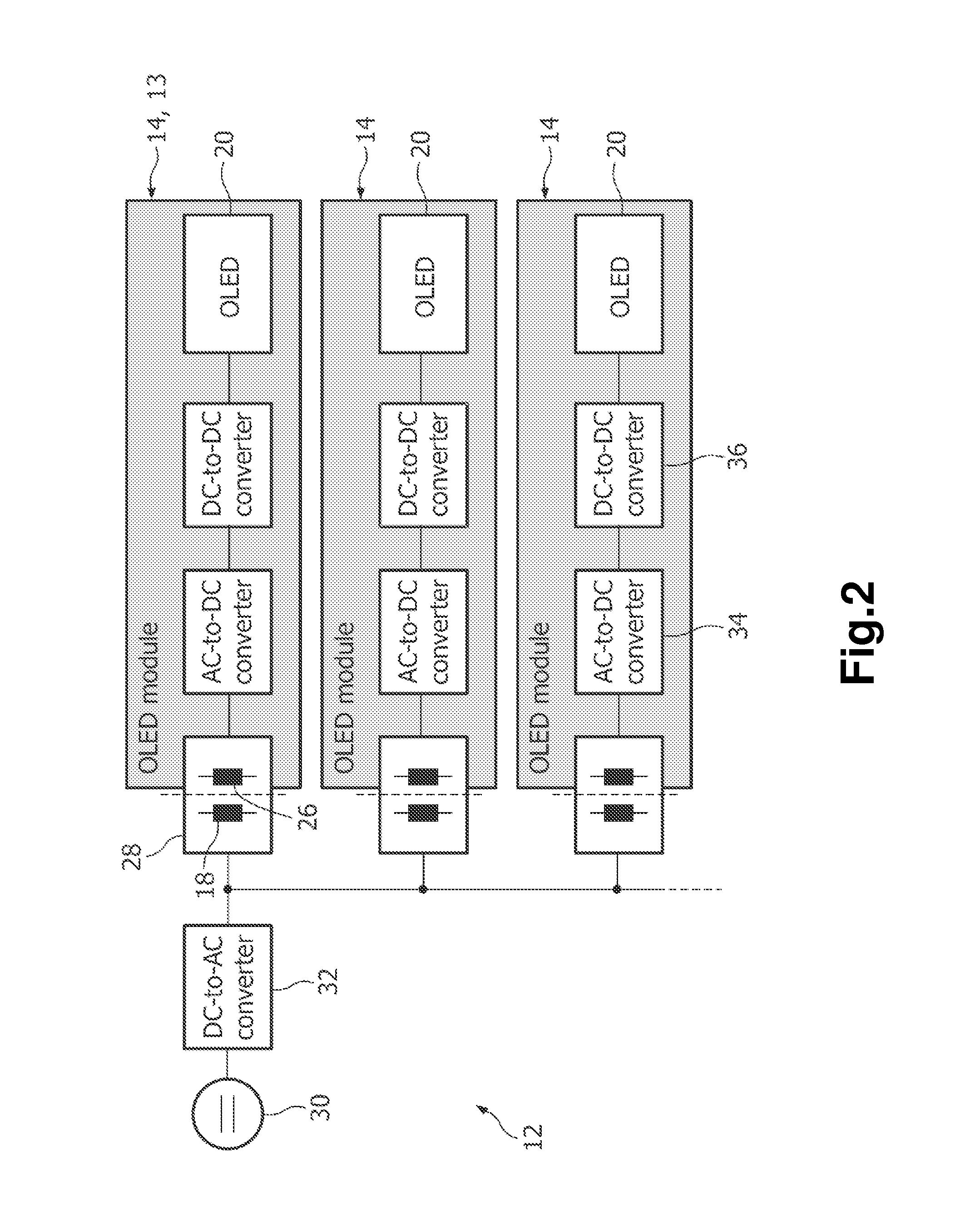

Lighting system

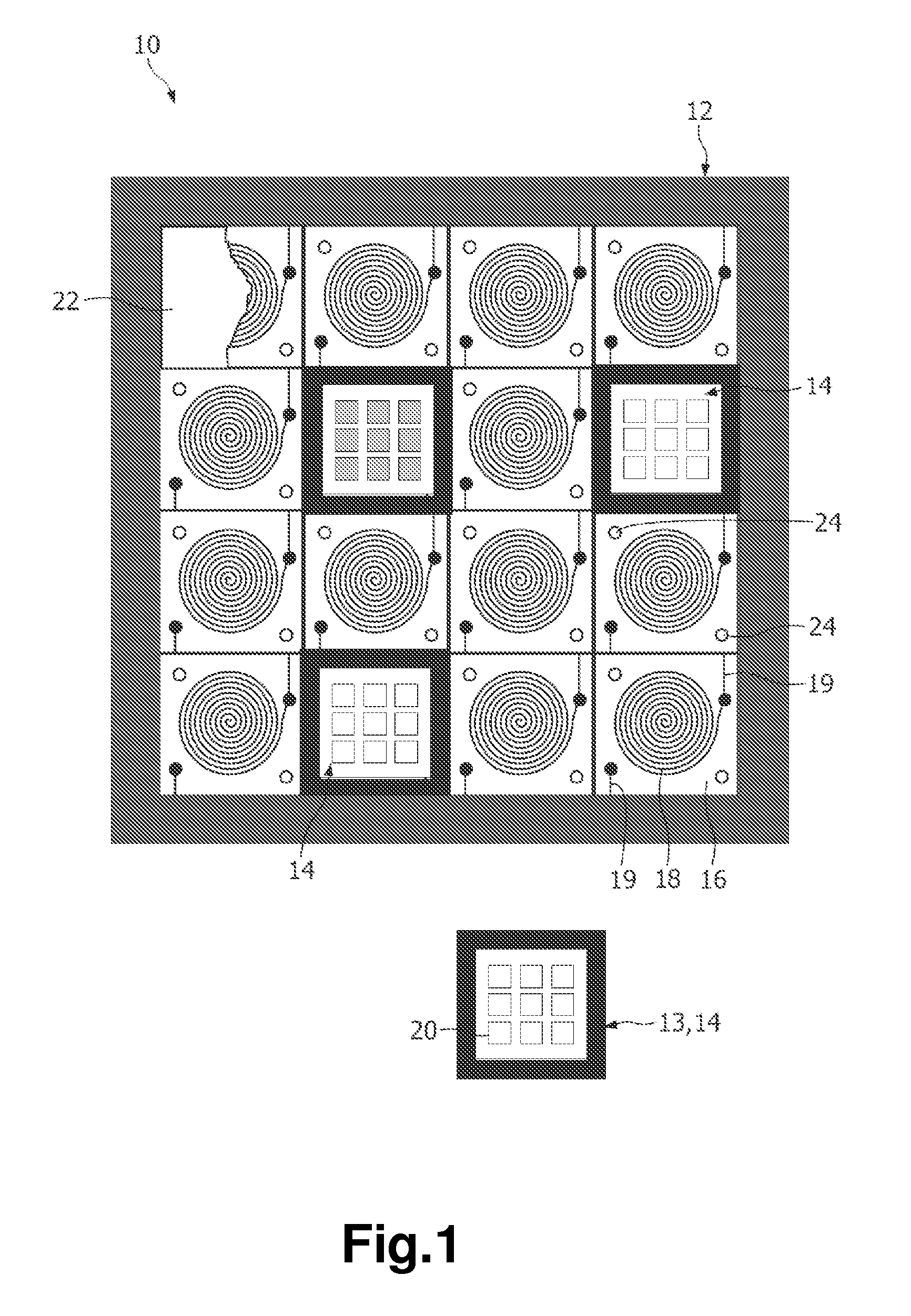

ActiveUS20090290332A1Compact formReduce restrictionsPlanar light sourcesBatteries circuit arrangementsEngineeringLighting system

The present invention relates to a lighting system comprising a base part (12) with at least one primary coil (18), and at least one light module (13, 14) with a secondary coil (26) adapted to inductively interact with the primary coil (18). The lighting system is characterized in that said base part (12) comprises a substrate (50) carrying said primary coil (18), the winding of which lying in one plane and forming a flat coupling area (16); the winding of the second coil (26) lies in one plane; and said light module (13, 14) comprises at least one light element (20) and a flat bottom surface, so that the light module (13, 14) is placeable with its flat surface on the flat coupling area (16).

Owner:SIGNIFY HLDG BV

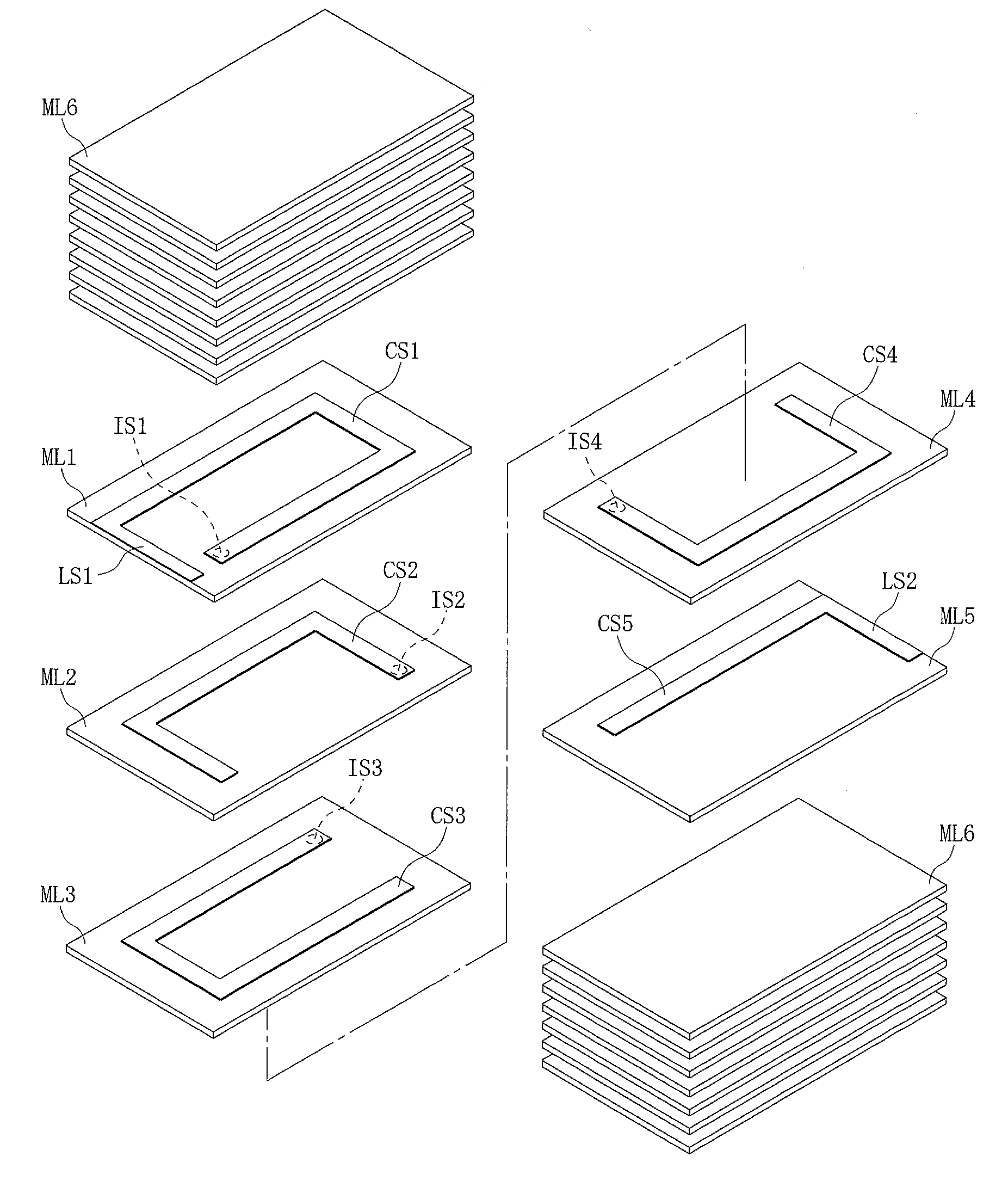

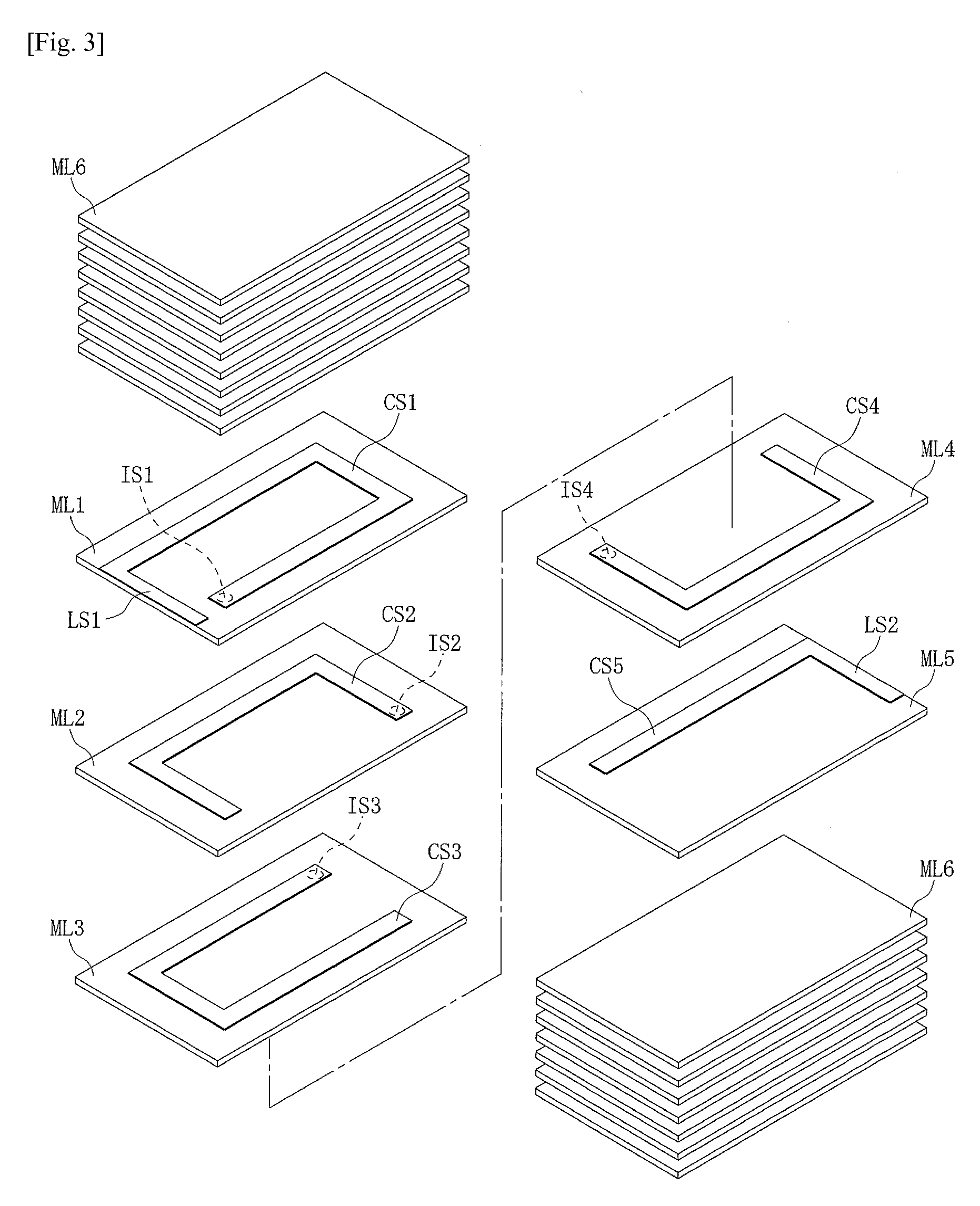

Coil-type electronic component and its manufacturing method

ActiveUS20120038449A1Low costHigh magnetic flux densityInorganic material magnetismInductances/transformers/magnets manufactureElectronic componentElectron

A coil-type electronic component has a coil inside or on an outer surface of its base material and is characterized in that: the base material is constituted by a group of grains of a soft magnetic alloy containing iron, silicon and other element that oxidizes more easily than iron; the surface of each soft magnetic alloy grain has an oxide layer formed on its surface as a result of oxidization of the grain; the oxide layer contains the other element that oxidizes more easily than iron by a quantity larger than that in the soft magnetic alloy grain; and grains are bonded with one another via the oxide layer.

Owner:TAIYO YUDEN KK

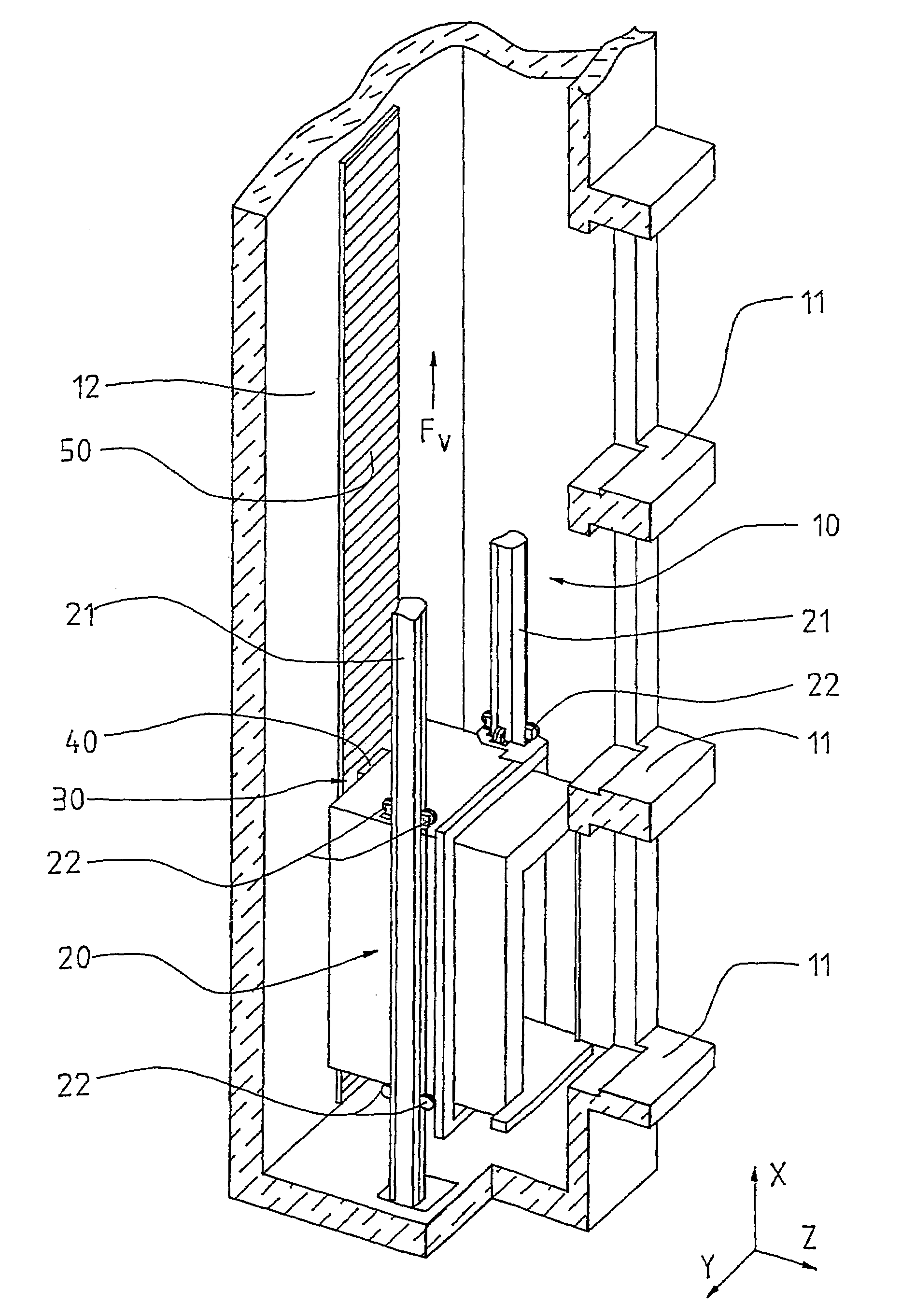

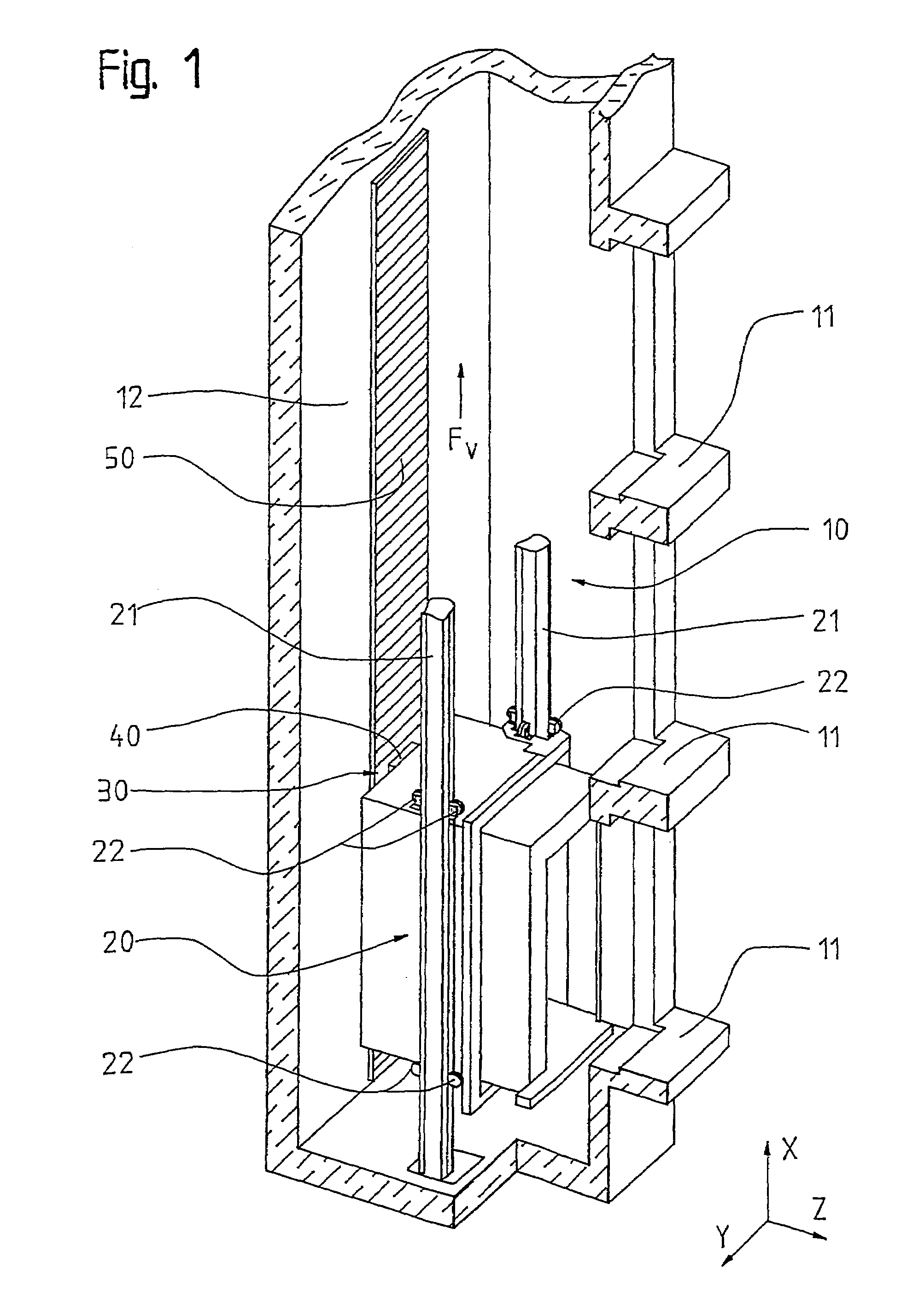

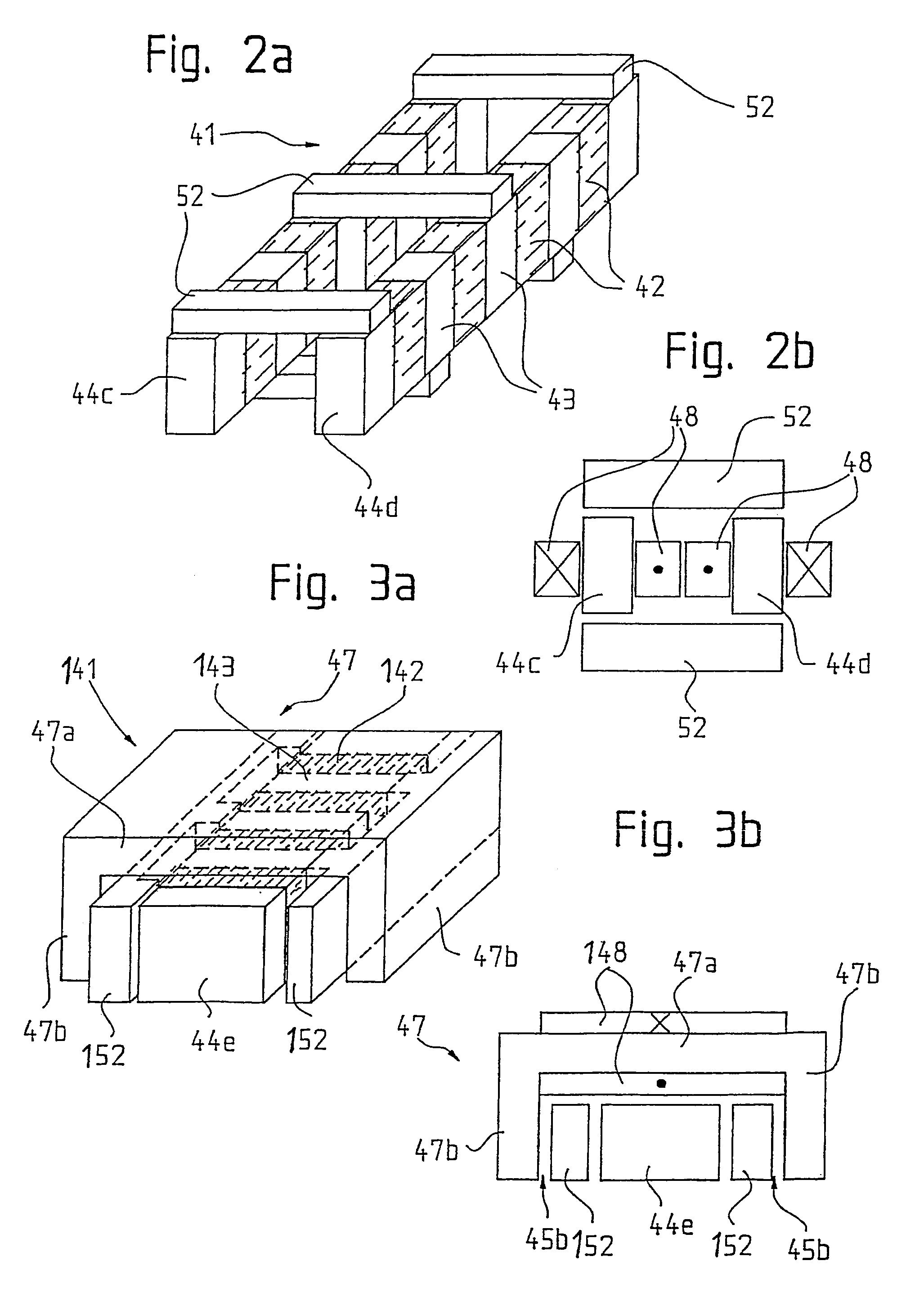

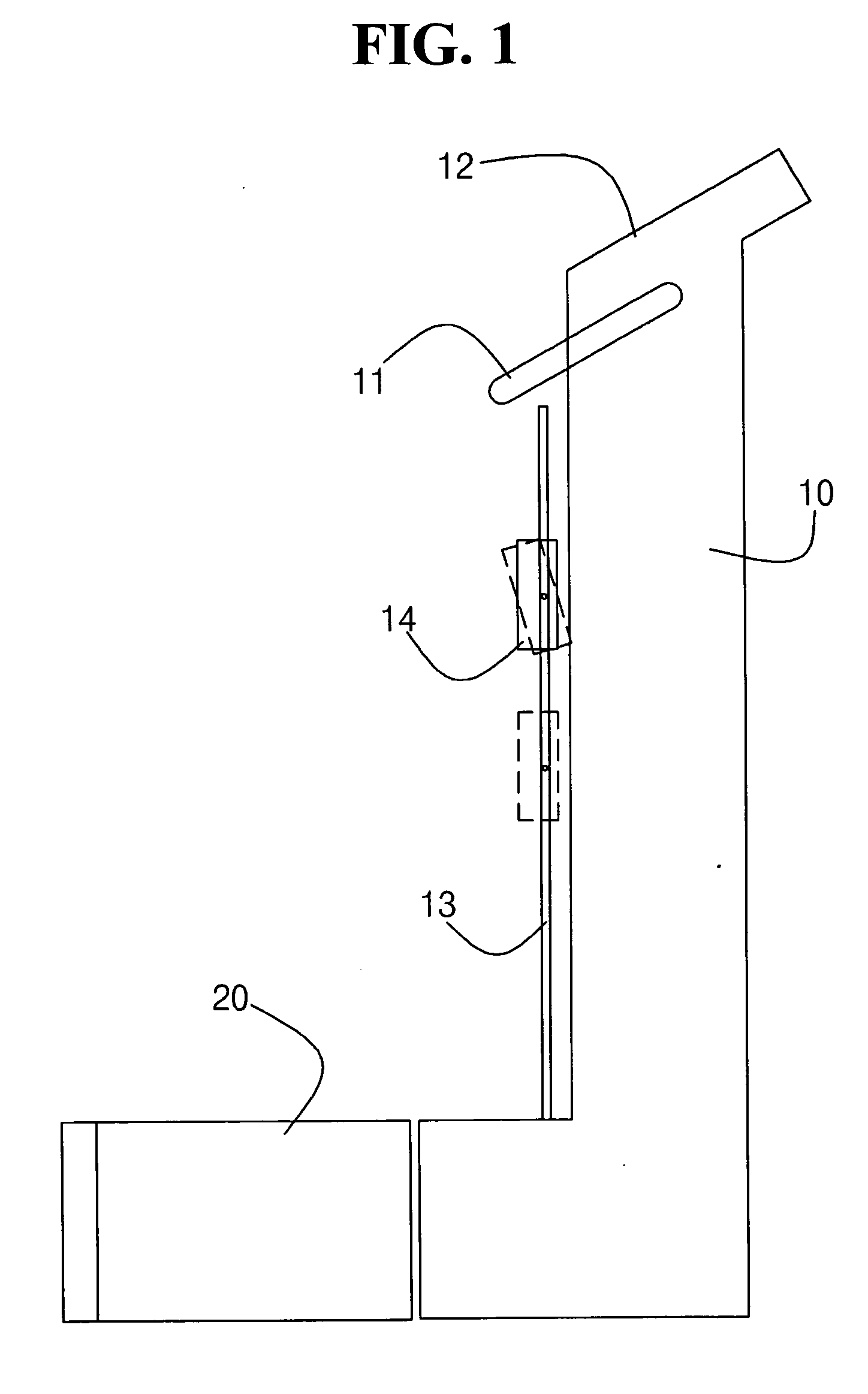

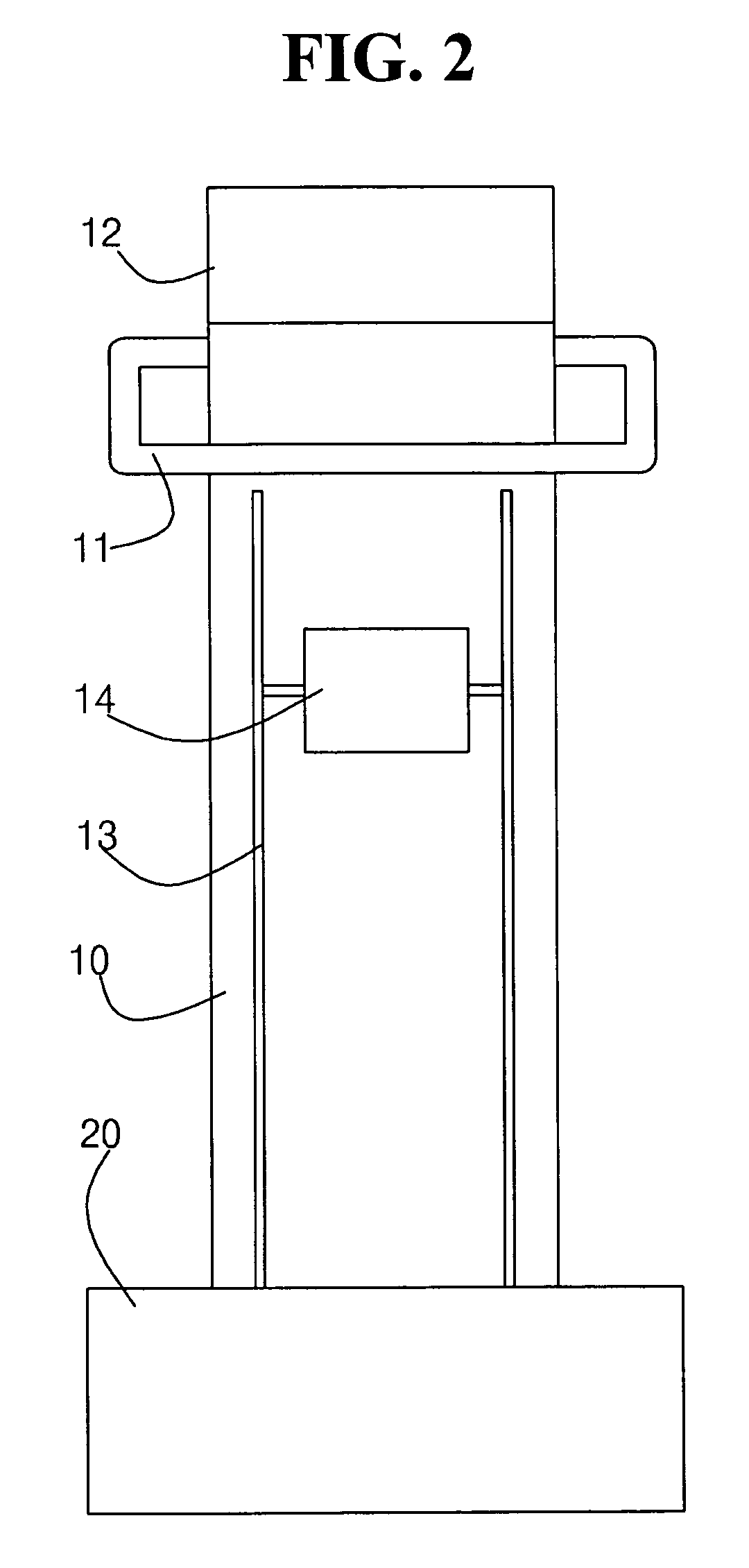

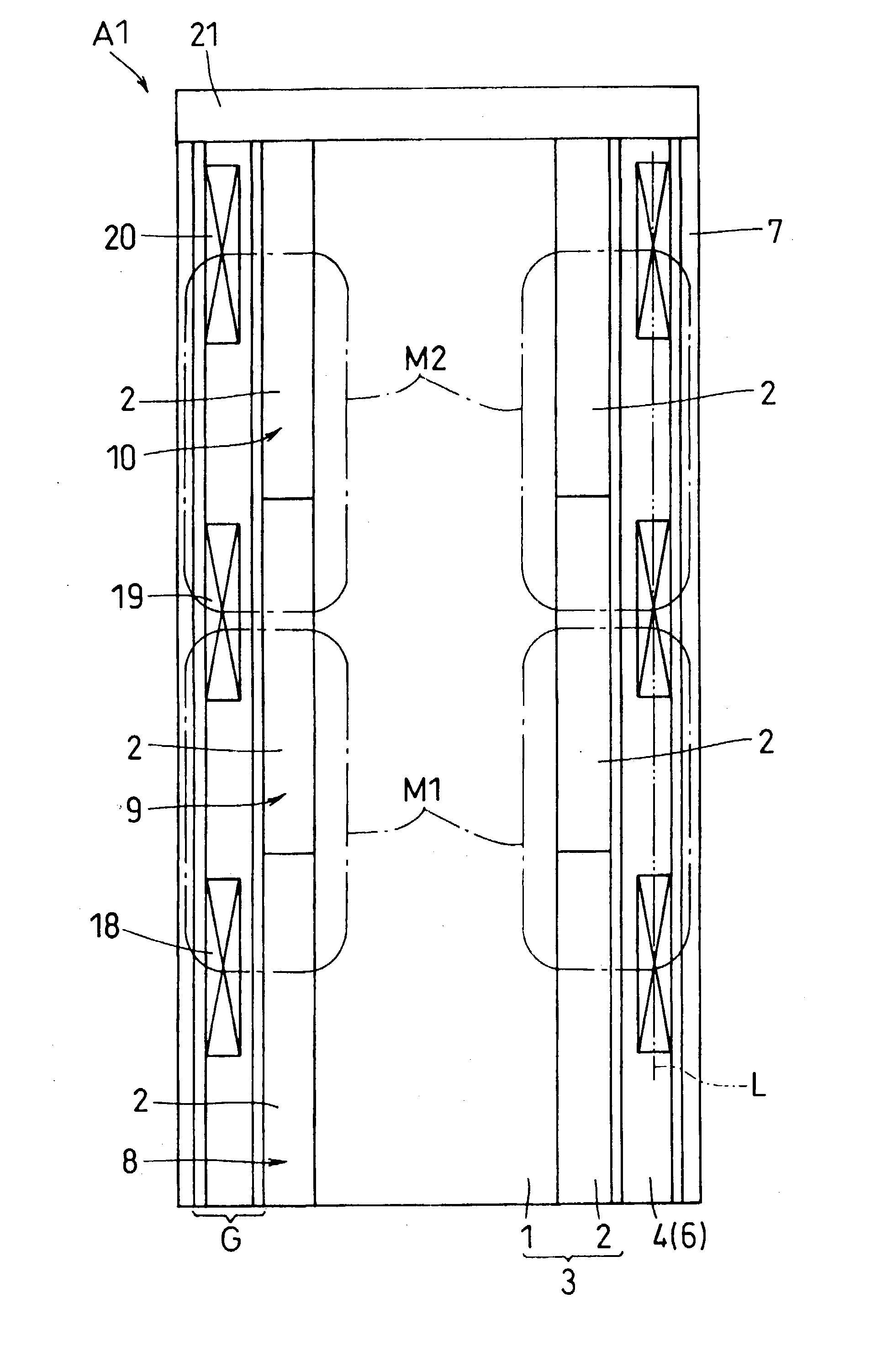

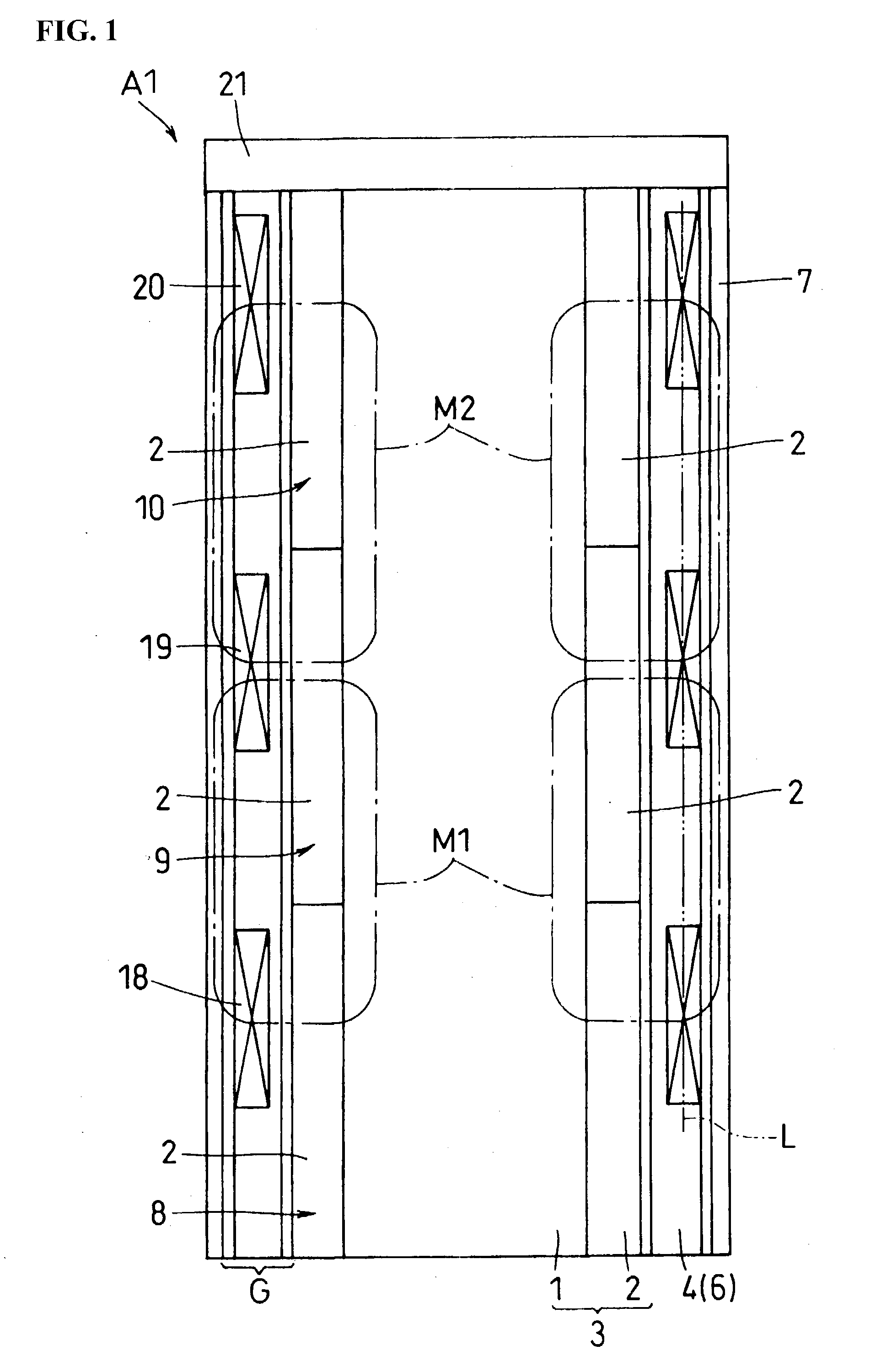

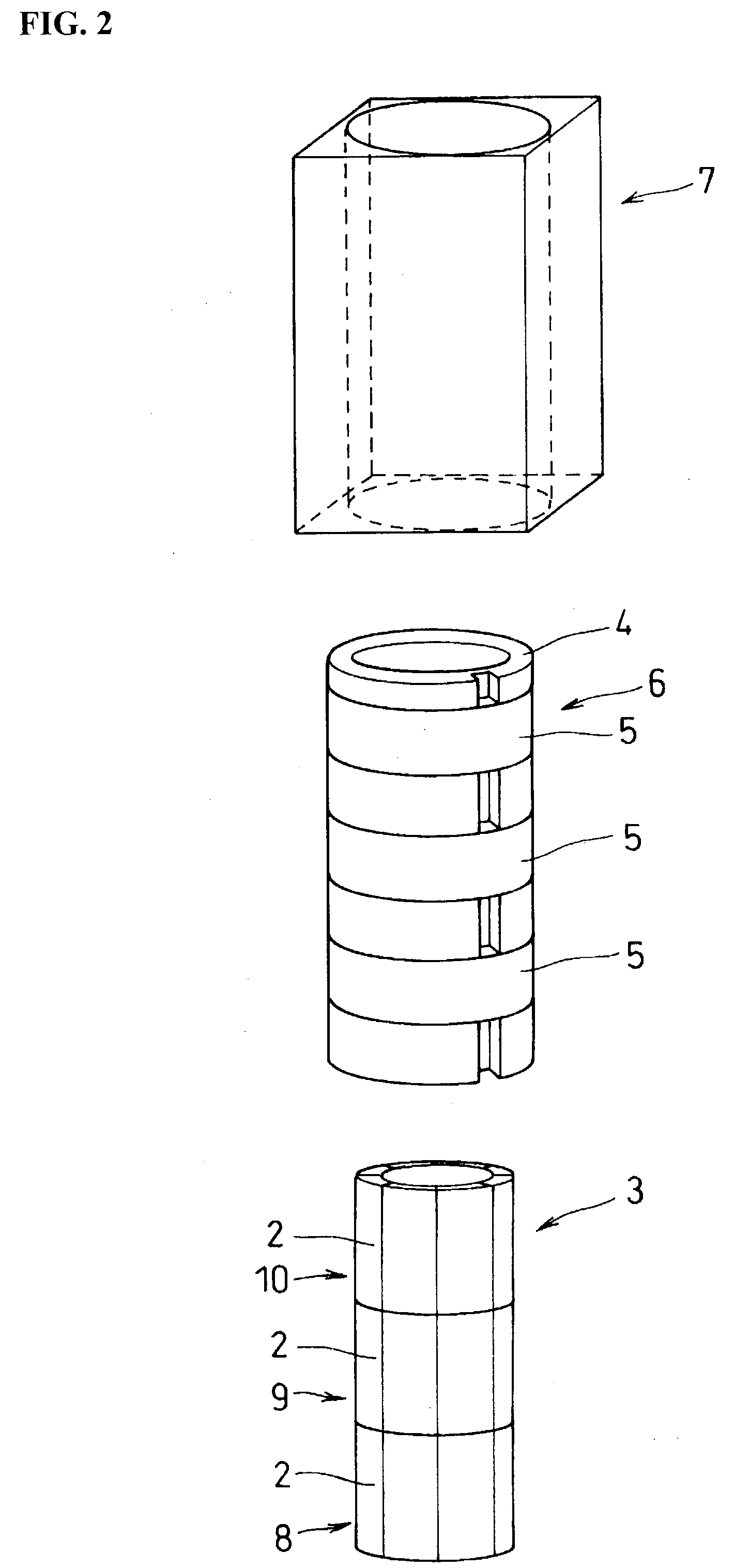

Elevator with transverse flux drive

InactiveUS7261186B2Improve power performanceLow production costMotor/generator/converter stoppersDC motor speed/torque controlTransverse fluxDrive motor

An elevator, particularly for transporting passengers, has an elevator car guided in an elevator shaft a direct drive motor. The drive motor includes an active primary part at the elevator car and a passive secondary part that is fixed in the elevator shaft and is spaced from the primary part by an air gap. In order to achieve a high power capability, the drive motor is configured as a transverse flux motor that moves the primary part linearly relative to the secondary part under the influence of an electromagnetic propulsive force. The secondary part has at least one rail made of a soft magnetic material and subdivided into a plurality of segments having a predetermined length. The segments are fixed to a wall of the elevator shaft by intermediate elements.

Owner:INVENTIO AG

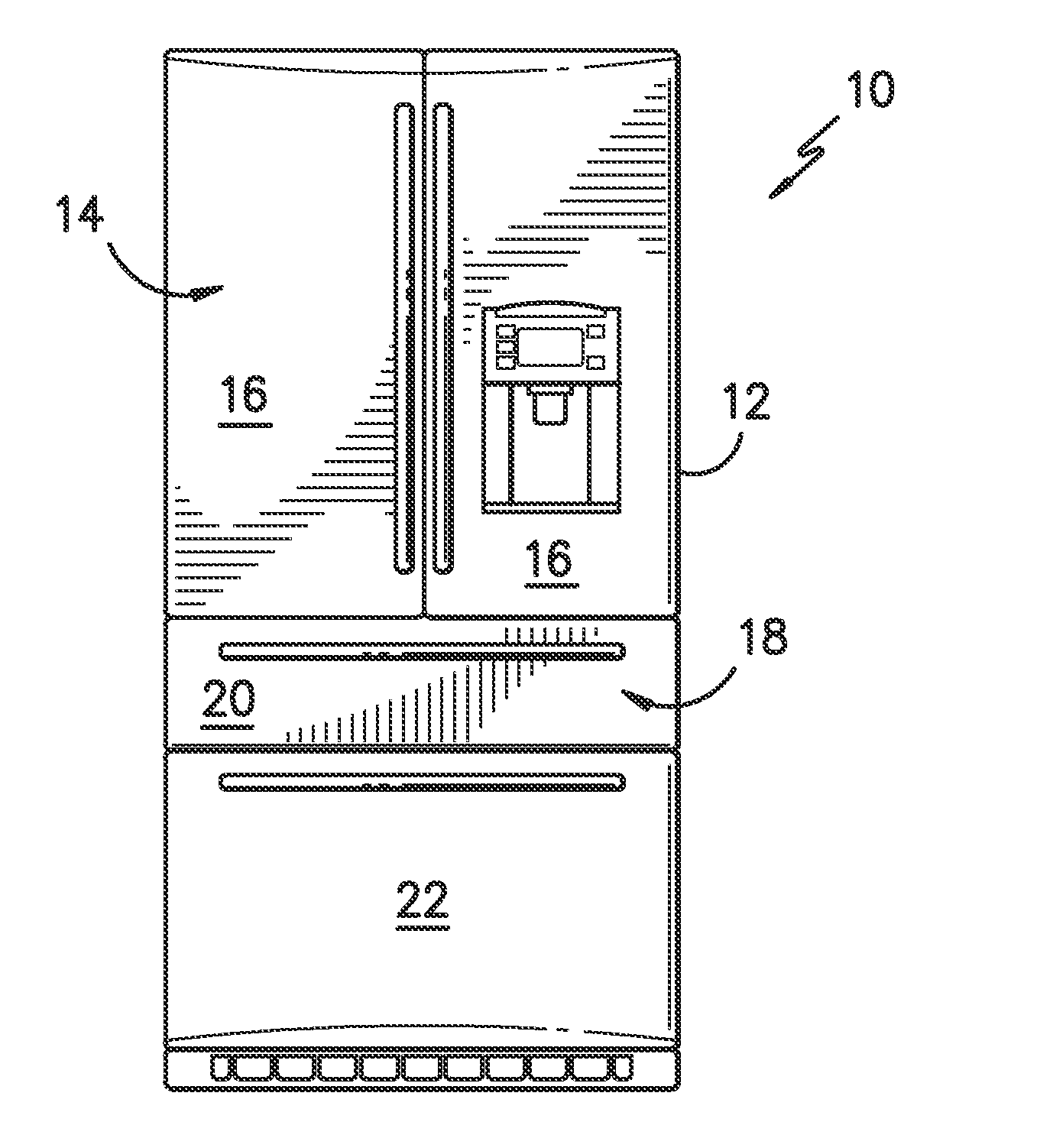

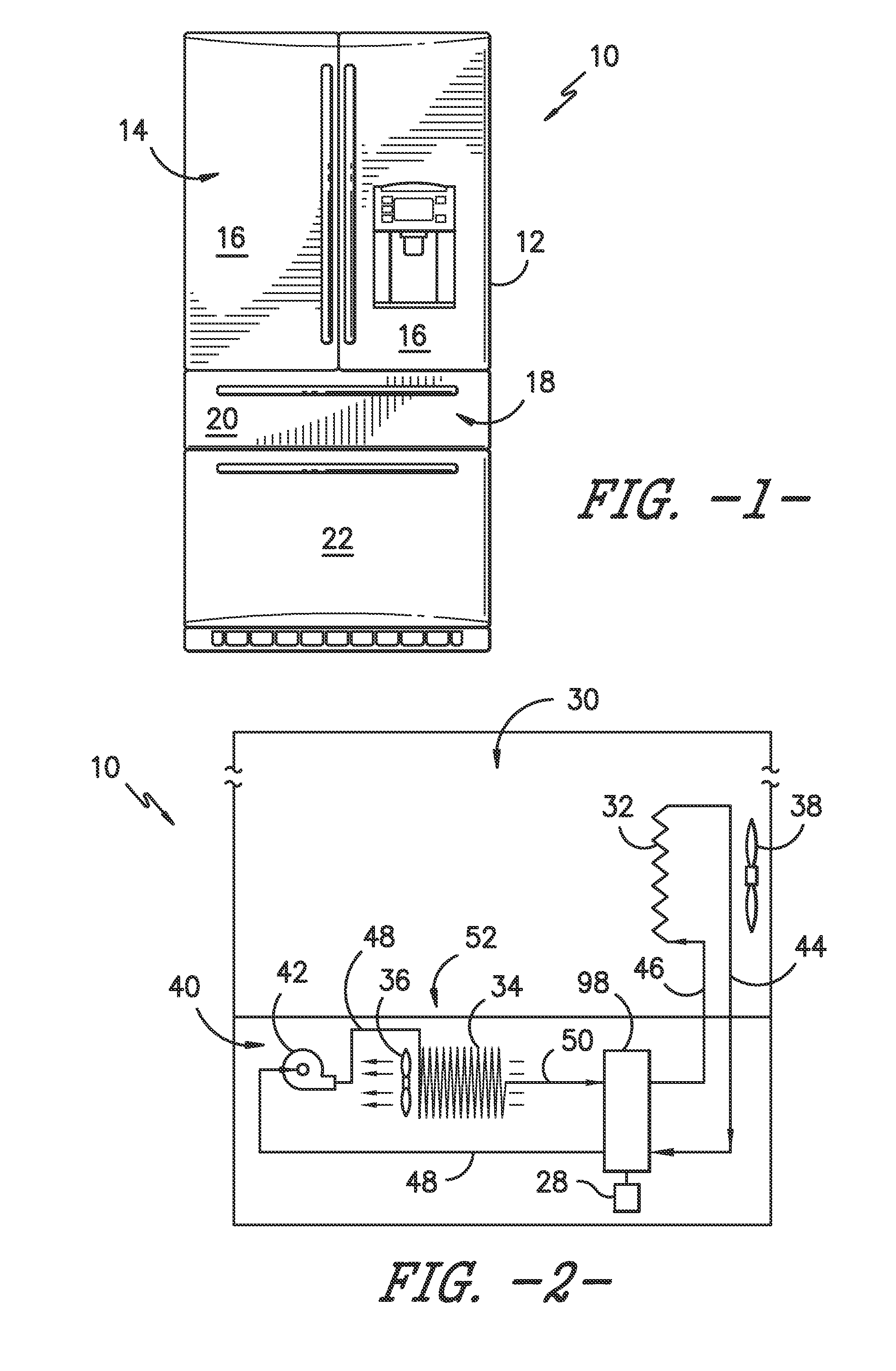

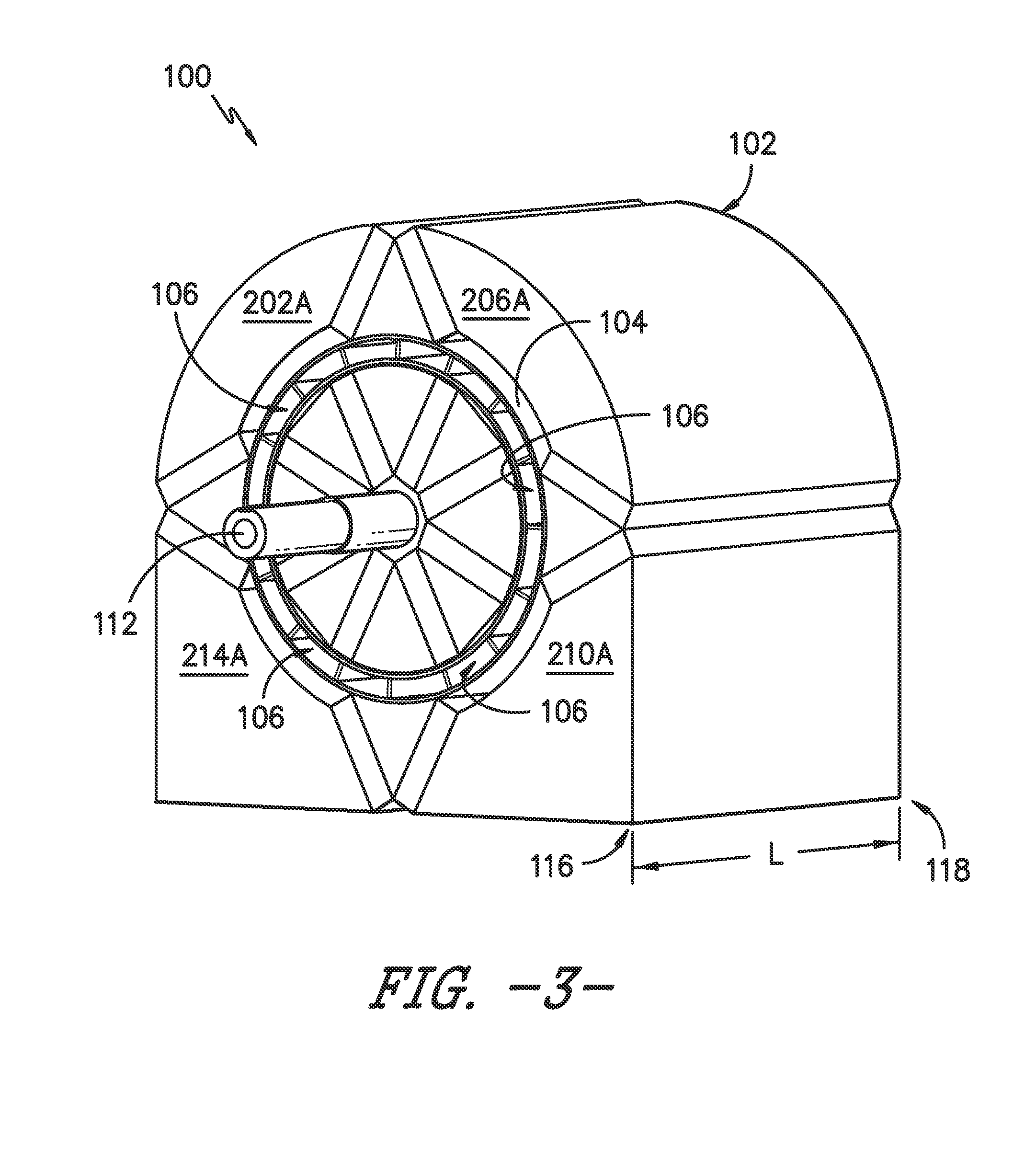

Magnetic device for magneto caloric heat pump regenerator

ActiveUS20160238287A1High magnetic flux densityDomestic refrigeratorsMachines using electric/magnetic effectsVolumetric Mass DensityMagnetic flux

A magnetic device is provided for a magneto caloric heat pump regenerator. Magnets are arranged within two magnetic flux circuits in a manner than that provides at least four fields of increased magnetic flux density. The regenerator can be used to move working units of magneto caloric material through the fields of increase magnetic flux to provide for heating and cooling as part of heat pump cycle. The orientation of the magnets provides concentrated fields of magnetic flux to induce the magneto caloric effect while optimizing the size of the magnets required to create the fields.

Owner:HAIER US APPLIANCE SOLUTIONS INC

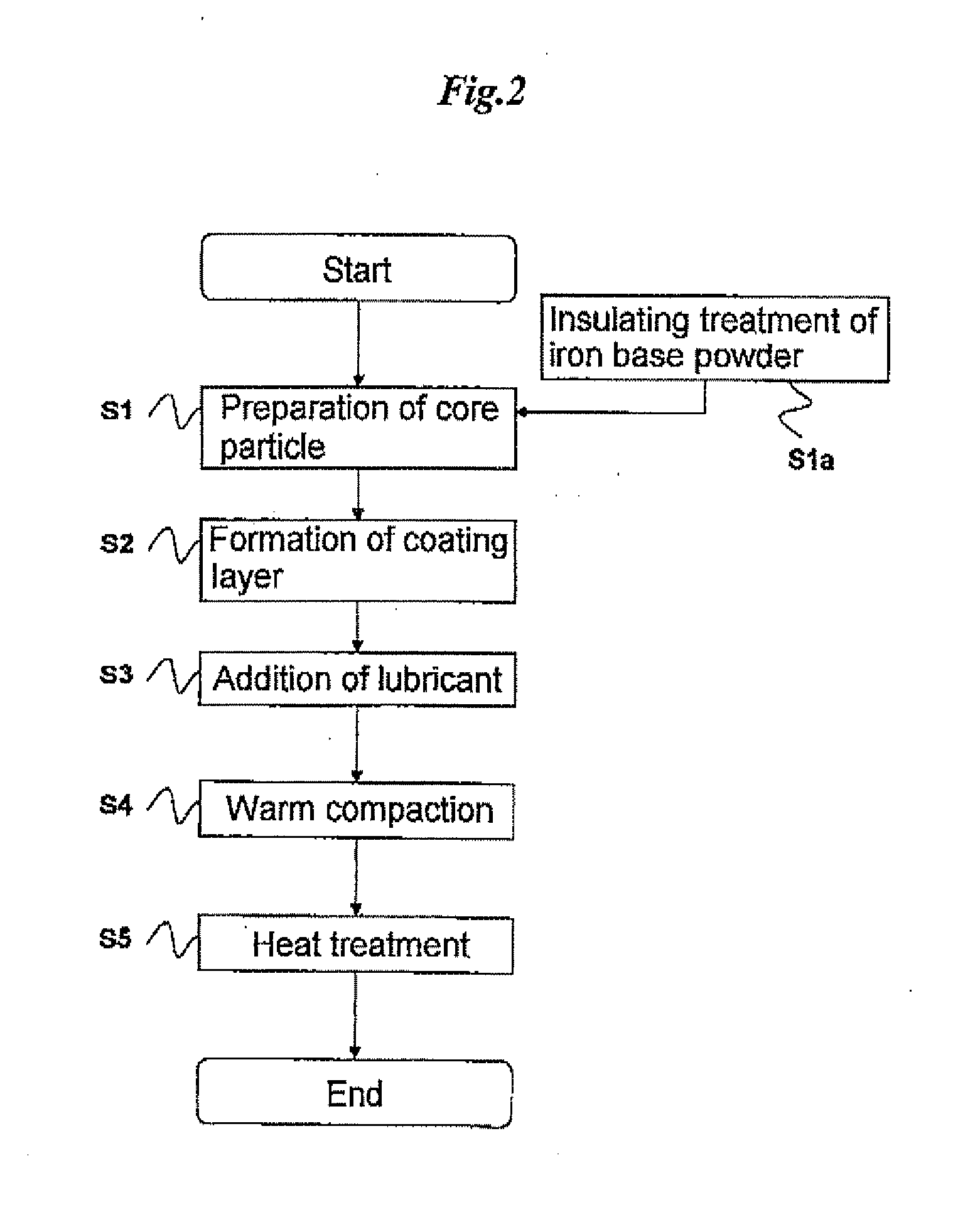

Powder magnetic core

ActiveUS20120082844A1High performanceHigh heat resistanceSynthetic resin layered productsMetal-working apparatusBrown iron oxideMagnetic core

A powder magnetic core having a high electrical resistivity and a high magnetic flux density, including at least a composite magnetic particle the composite magnetic particle including: a core particle containing iron as the main component; and an insulating passivation layer formed on the core particle, wherein: the insulating passivation layer at least has an inner layer formed on the core particle and the outermost layer formed on the inner layer; and the outermost layer contains iron oxide as the main component.

Owner:TDK CORPARATION

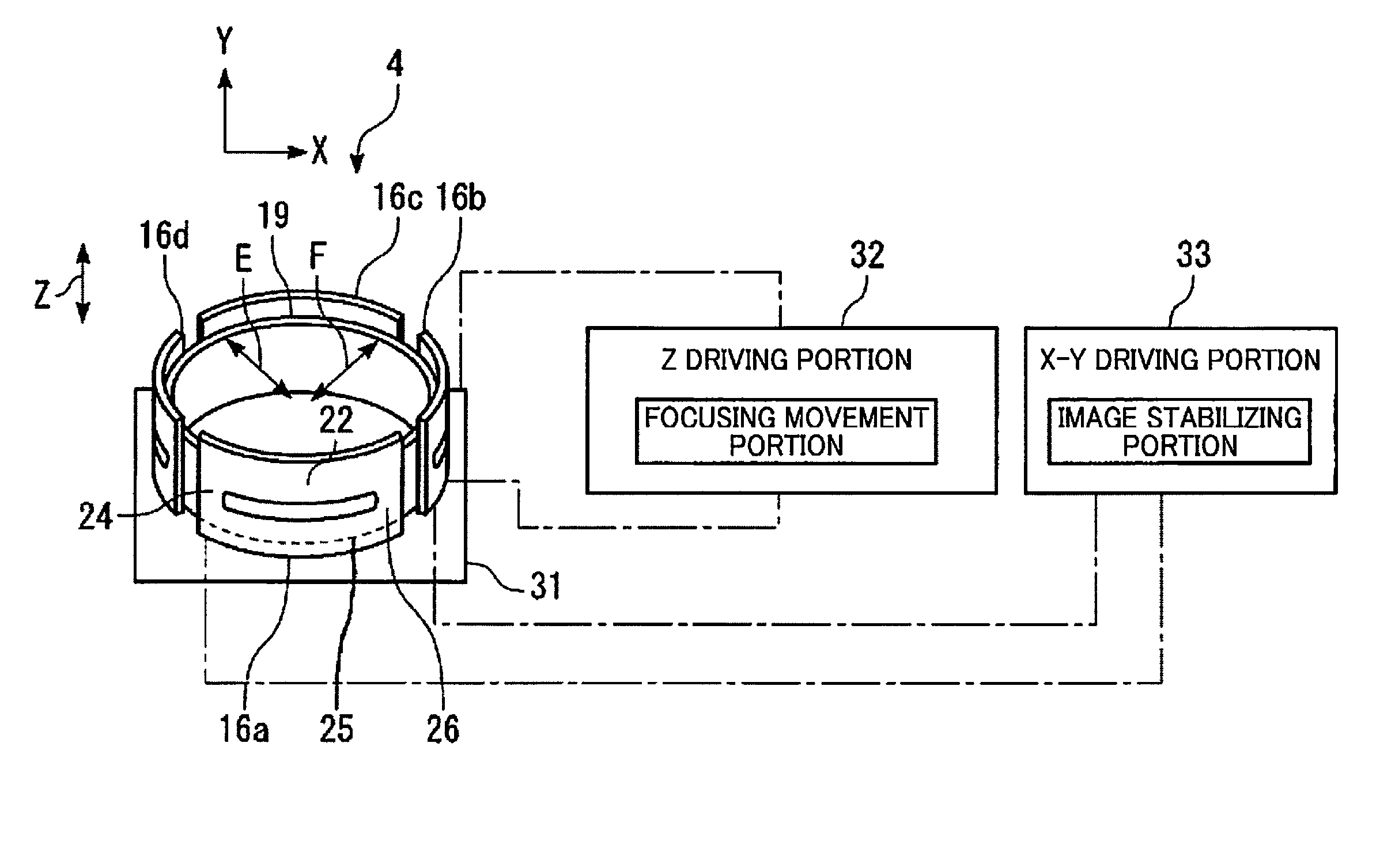

Lens driving device, autofocus camera and camera-equipped mobile terminal

ActiveUS20110286099A1Simple constitutionPossible to moveProjector focusing arrangementCamera focusing arrangementCamera lensPower flow

In the lens driving device of the present invention, at least two second coils are disposed at a 90 degree interval in a circumferential direction of a first coil wound around an outer circumference of a lens support in the circumferential direction, at least four magnets are provided at an inner circumferential side of a circumferential wall of a yoke and are provided at even intervals about the circumferential direction of the first coil, each magnet being provided so that an inner circumferential face is the same magnetic pole and opposes an outer circumferential face of the first coil, and in addition is opposite the second coil at the position of providing the second coil. When the lens support is moved in the optical axis direction, an electric current flows in the first coil, and when the lens support is moved in an X-Y direction orthogonal to the optical axis, a predetermined electric current flows in a predetermined second coil.

Owner:NEW SHICOH MOTOR CO LTD

Method for Manufacturing Grain-Oriented Electrical Steel Sheets Having Excellent Magnetic Properties

ActiveUS20130306202A1High magnetic flux densityLow core lossFurnace typesHeat treatment furnacesSheet steelElectrical steel

Provided is a method for manufacturing a grain-oriented electrical steel sheet, the method comprising: heating a grain-oriented electrical steel sheet slab; hot-rolling the heated slab; optionally annealing the hot-rolled steel sheet; subjecting the resulting steel sheet to one cold rolling or two or more cold rollings with intermediate annealing therebetween; subjecting the cold-rolled steel sheet to primary recrystallization annealing; and subjecting the annealed steel sheet to secondary recrystallization annealing, wherein the primary recrystallization annealing sequentially comprises an ultra-rapid heating process of heating the steel sheet at an average heating rate of 300° C. / sec or higher, a rapid heating process of heating the steel sheet at a lower average heating rate than the average heating rate of the ultra-rapid heating process, but not lower than 100° C. / sec, and a general heating process of heating the steel sheet at a lower average heating rate than the average heating rate of the rapid heating process.

Owner:POHANG IRON & STEEL CO LTD

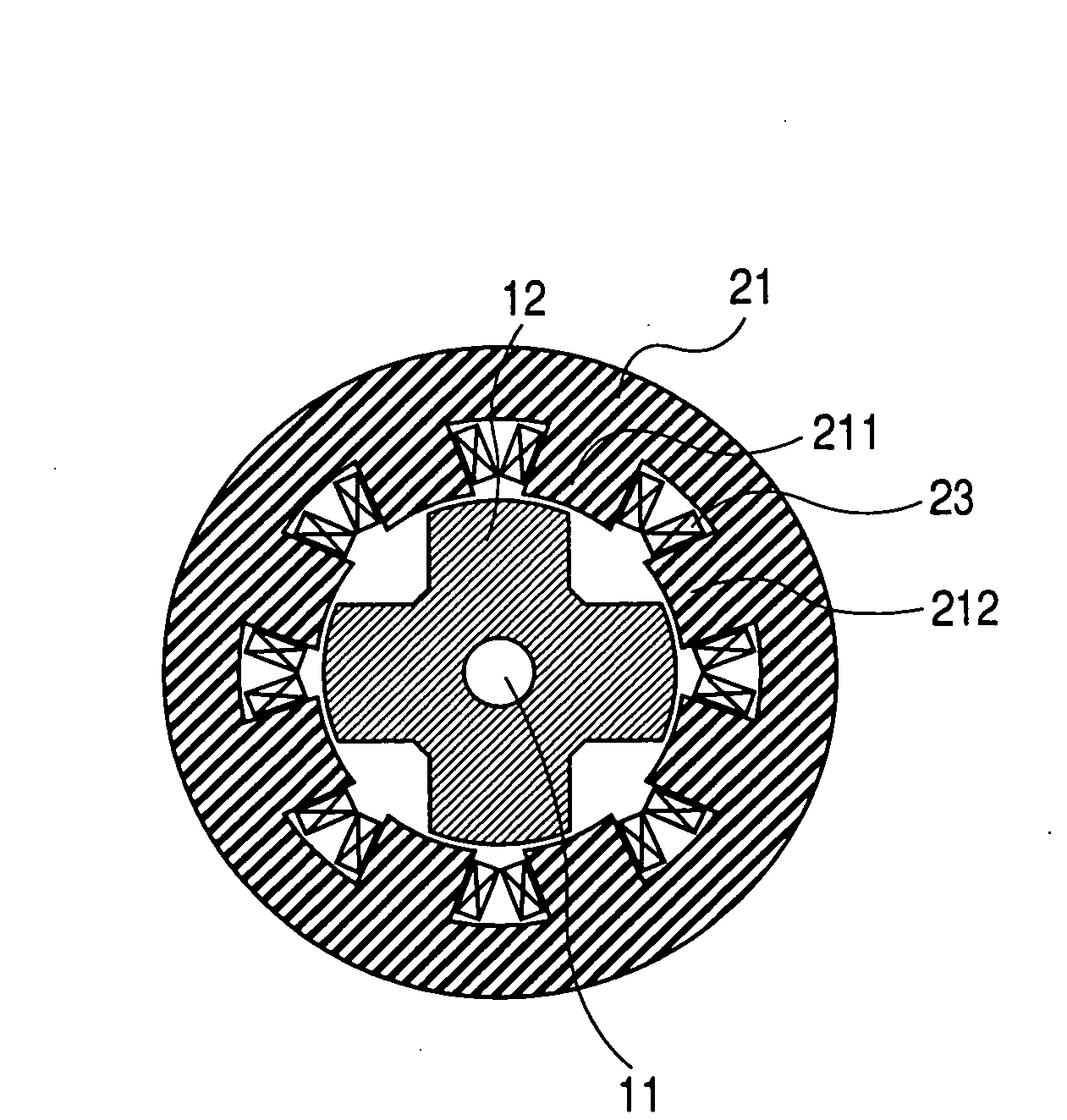

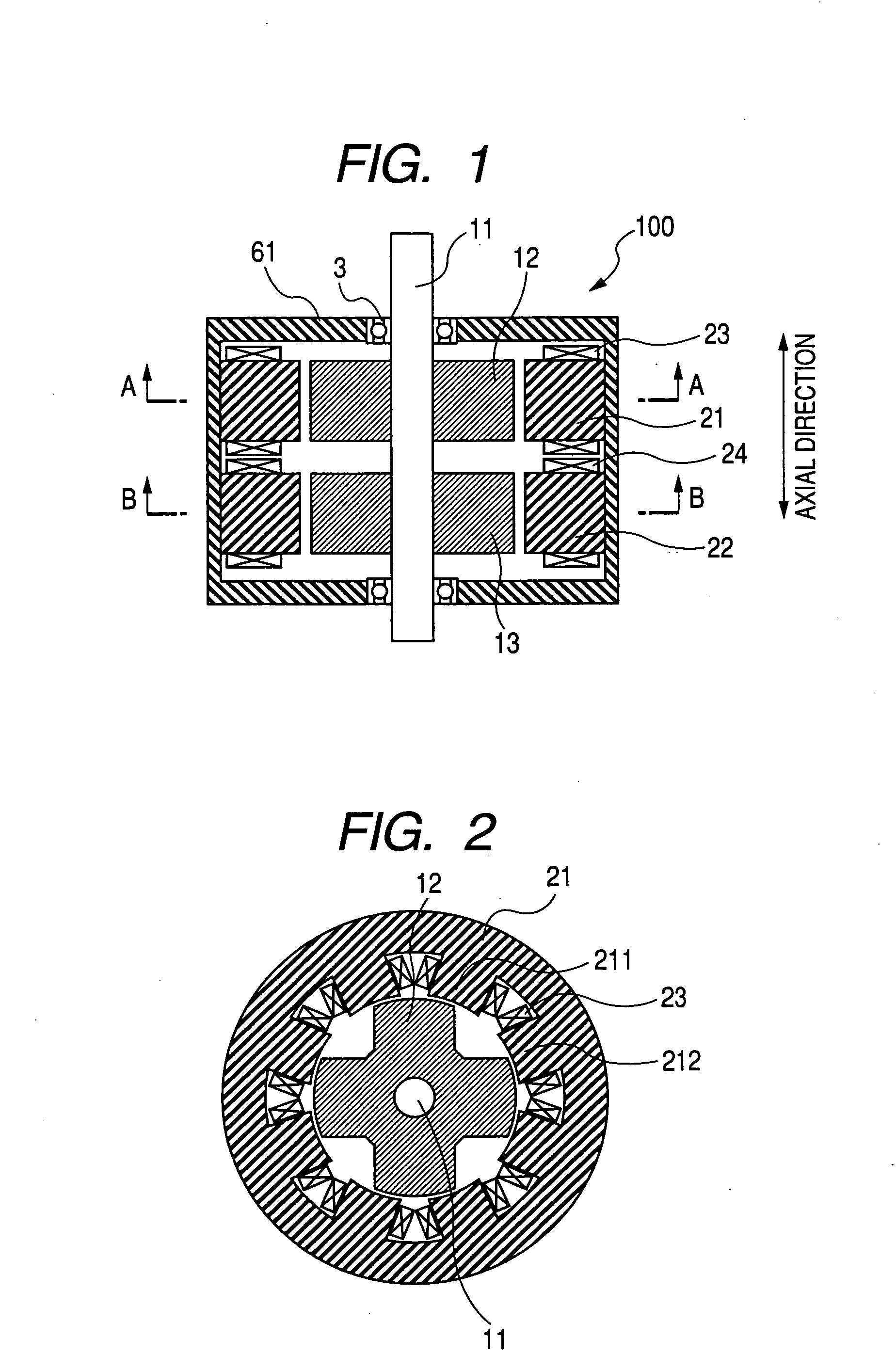

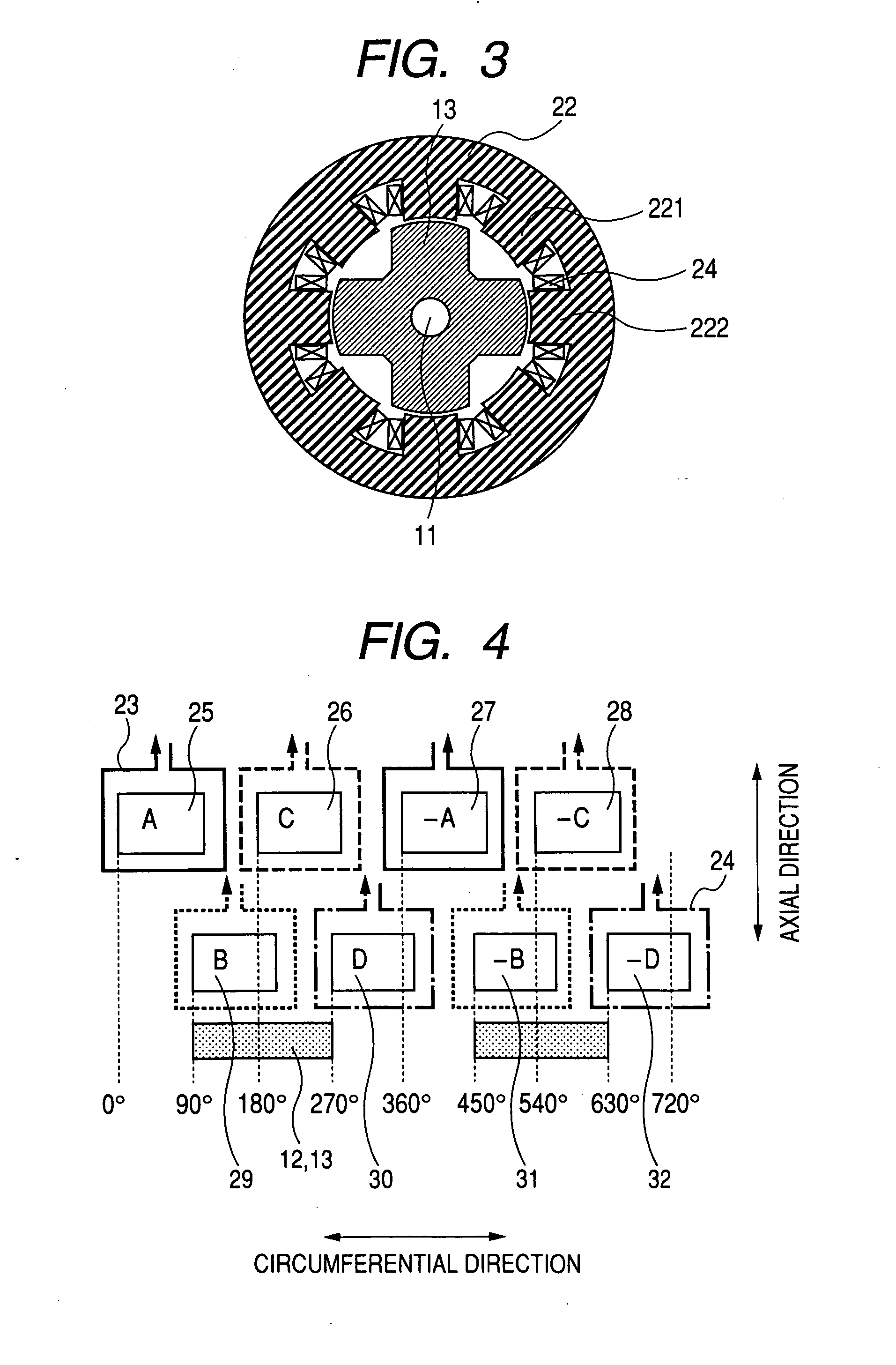

Switched reluctance motor

InactiveUS20080278010A1Reduce manufacturing costHigh magnetic flux densitySynchronous generatorsSynchronous motorsMagnetic polesReluctance motor

A switched reluctance motor has a rotor and a stator. The stator has first and second stator magnetic pole groups sequentially placed in an axial direction of the rotor. First and second stator magnetic poles in each group are alternately arranged on a same circumference. The first stator magnetic poles are placed every electrical angle 2π and reversely magnetized to each other. The second stator magnetic poles are placed every electrical angle 2π and reversely magnetized to each other. The first magnetic pole is apart from the second magnetic pole by electrical angle π. Each stator magnetic pole in the first stator magnetic pole group is apart from that in the second magnetic pole group by electrical angle π / 2 in the circumferential direction.

Owner:DENSO CORP

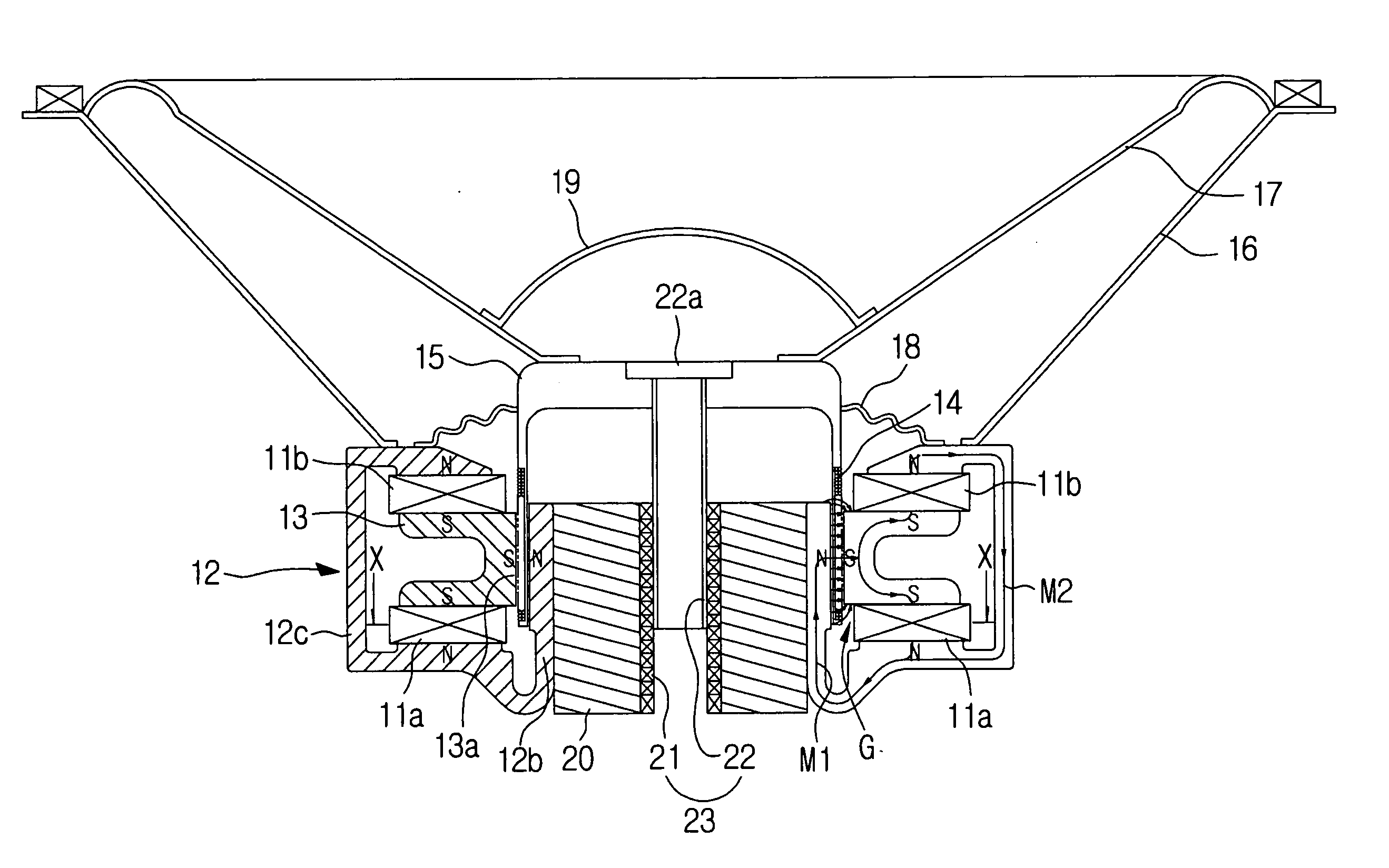

Vibratory apparatus of exercise

ActiveUS20060094990A1Good linear responseLow noise smallChiropractic devicesVibration massageVertical vibrationBobbin

A vibratory exercise apparatus capable of providing a sufficient vertical movement force is provided, which adopts a structure that a bobbin coil connected with a vibration plate is employed in a magnetic gap of a magnetic circuit using a permanent magnet which can generate a strong magnetic force. The vibratory exercise apparatus includes a magnetic gap type vertical vibrator which generates vertical vibration by a permanent magnet and a bobbin coil, a bobbin guide which is installed at the center of a yoke, a bobbin guide rod which is reciprocally movably coupled with the bobbin guide and whose one end is coupled with the upper portion of a bobbin, a joint whose one end is coupled with the upper portion of the bobbin, a vibration plate which is coupled with the other end of the joint, a guide which guides vertical movement of the vibration plate, and a spring which limits a range of movement of the vibration plate and absorbs impact when the vibration plate descends.

Owner:KIM SEONG BAE

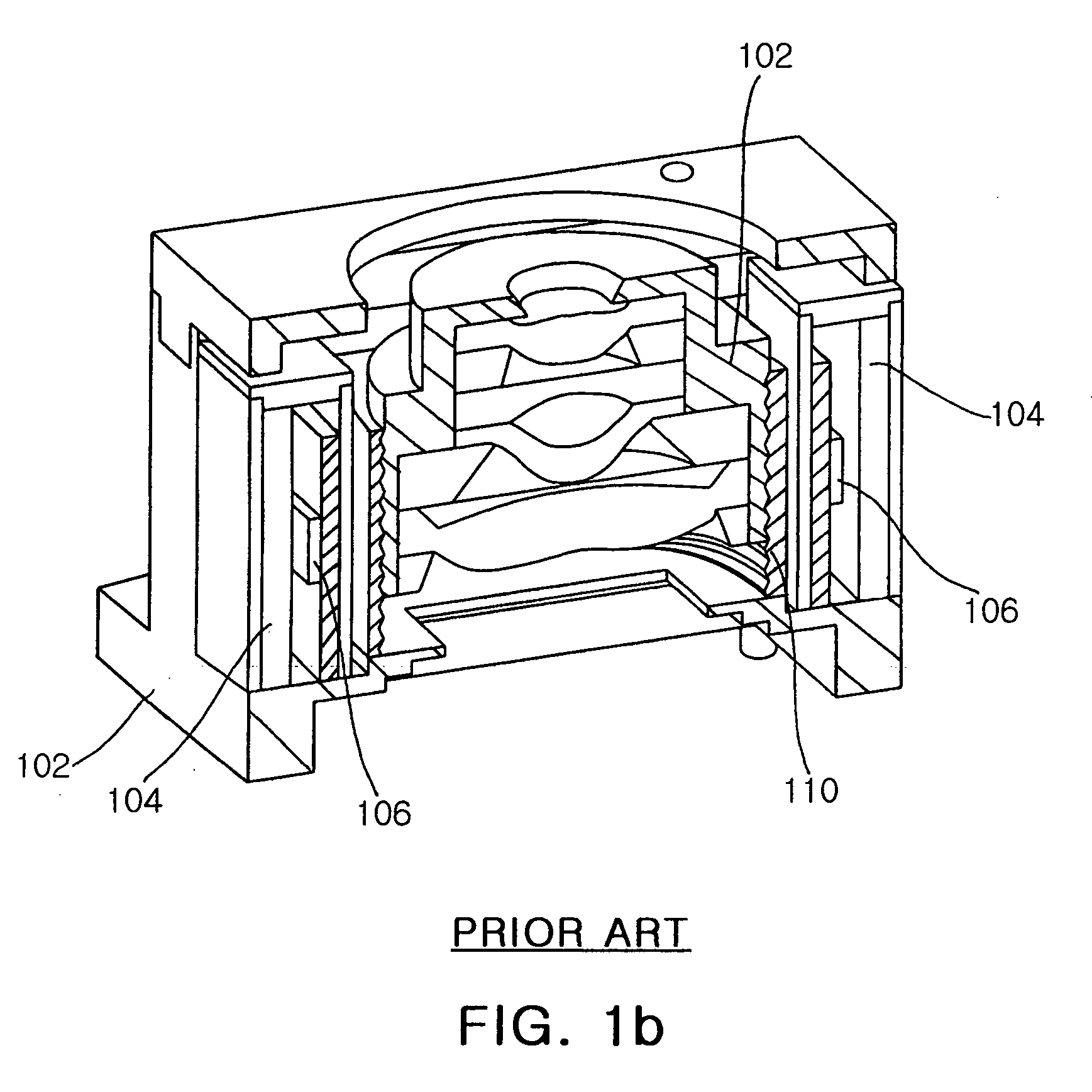

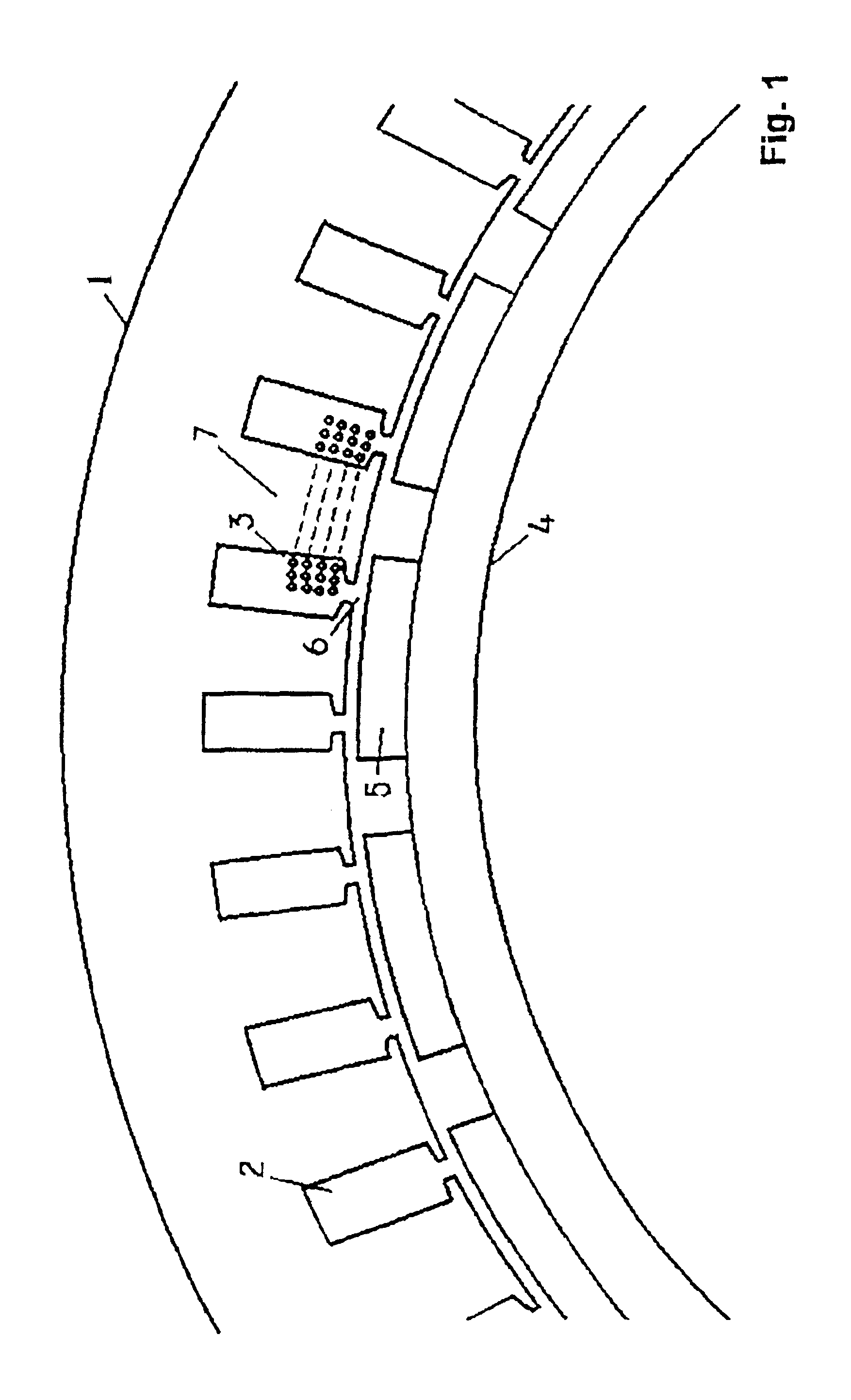

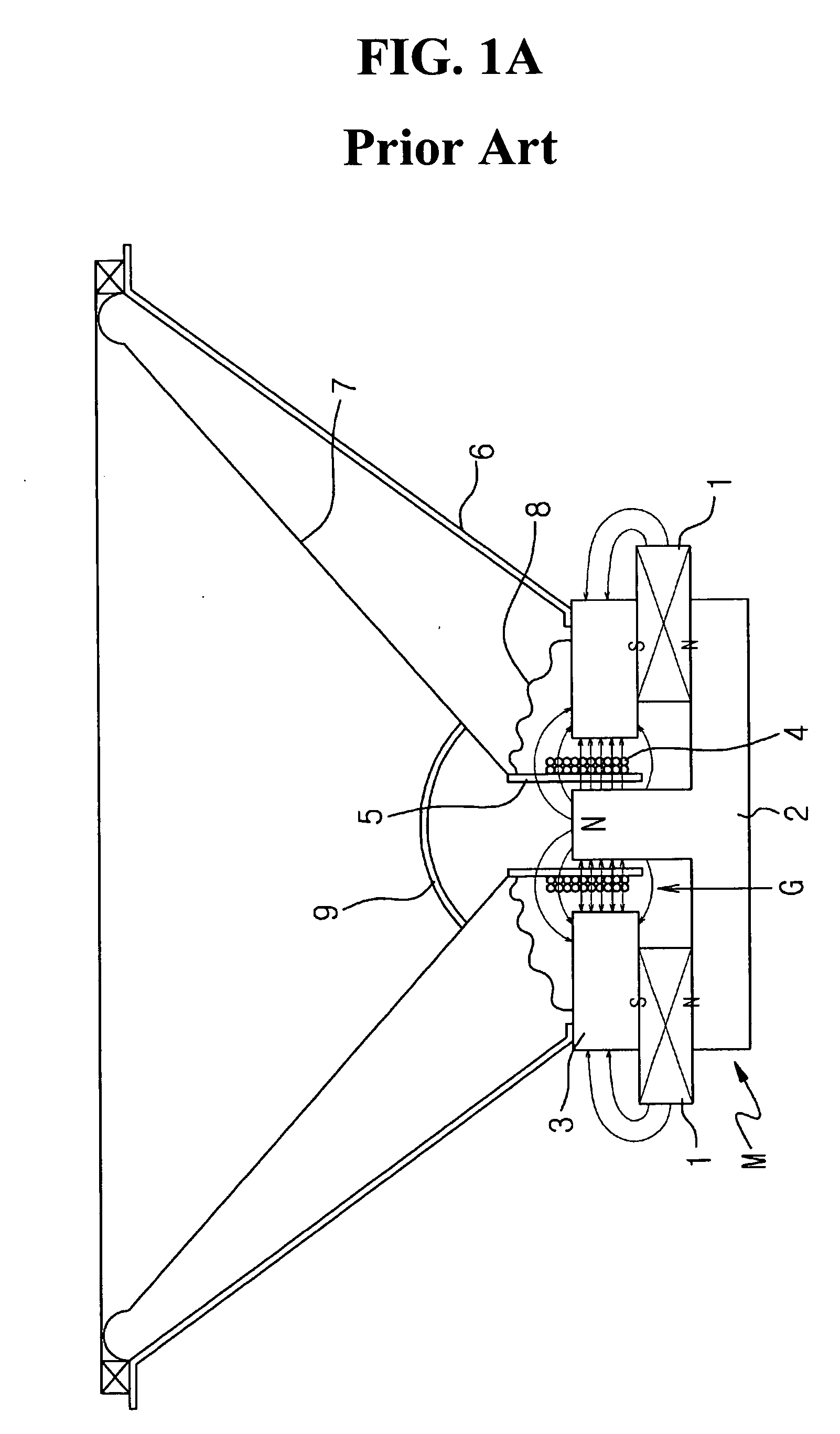

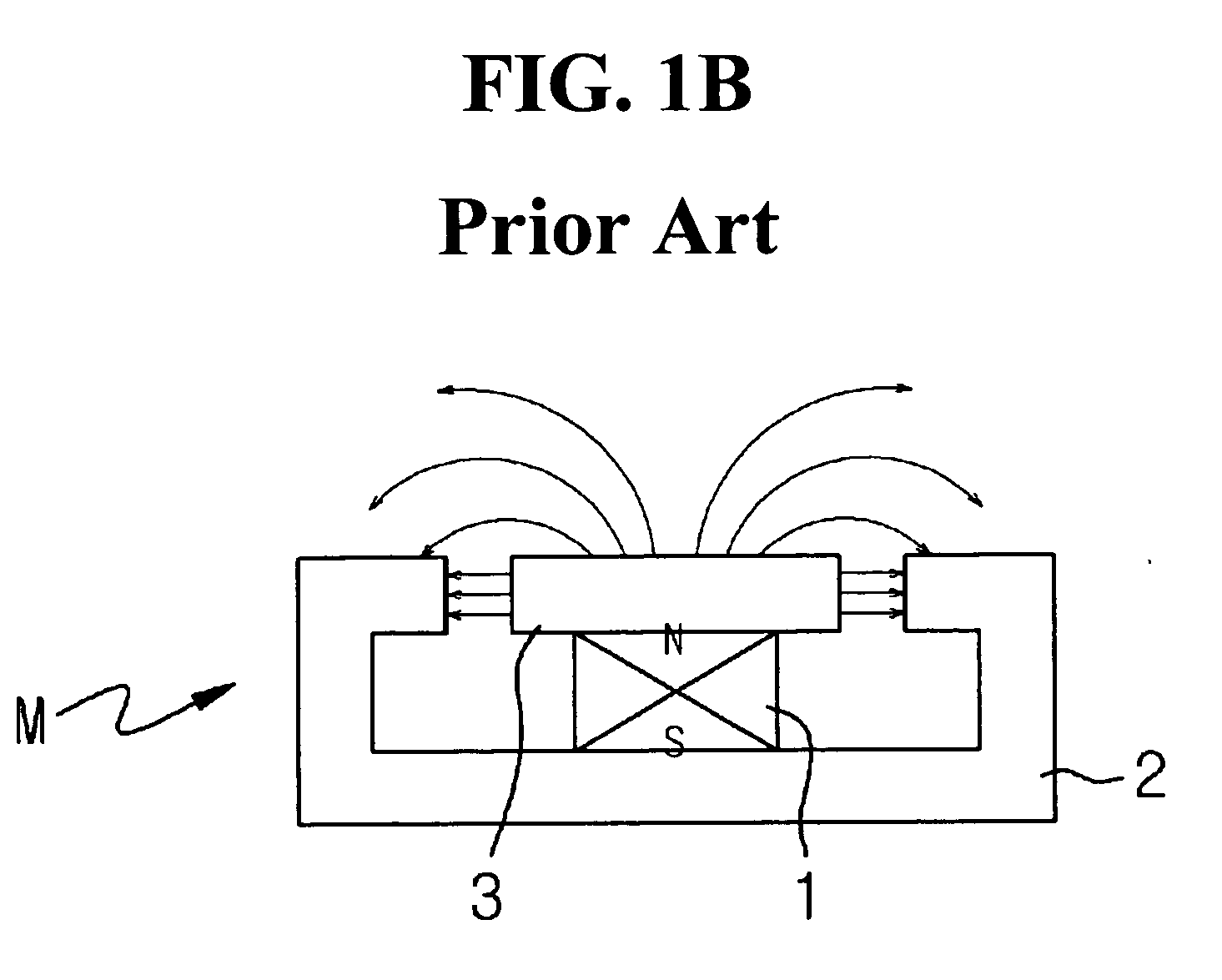

Magnetic circuit having dual magnets, speaker and vibration generating apparatus using the same

InactiveUS20060093180A1Good linear responseAvoid Flux LeakageTransducer detailsHearing device energy consumption reductionBobbinElectrical polarity

A magnetic circuit having a dual magnet, a speaker and a vibration generating apparatus using the same are provided. The magnetic circuit includes a magnetic gap having a small magnetic loss and an increasing magnetic flux density, in which a uniform distribution of a line of magnetic force can be realized on yoke surfaces facing each other. The speaker includes lower and upper magnets which are spaced so that mutually identical polarities oppose each other; a first yoke integrally having a loop-type circulating circuit portion extended from the lower magnet to the upper magnet and an extension portion which is extended perpendicularly upwards from the lower magnet; a second yoke which connects between the lower and upper magnets and forms a magnetic gap between the second yoke and the extension portion of the first yoke; a coil disposed in the magnetic gap and wound around a bobbin; a frame which is extended from the first yoke; a vibrating diaphragm generating an acoustic sound in correspondence to a drive signal; a damper limiting a vibration range of the bobbin; and a center cap covering the bobbin.

Owner:KIM SEONG BAE

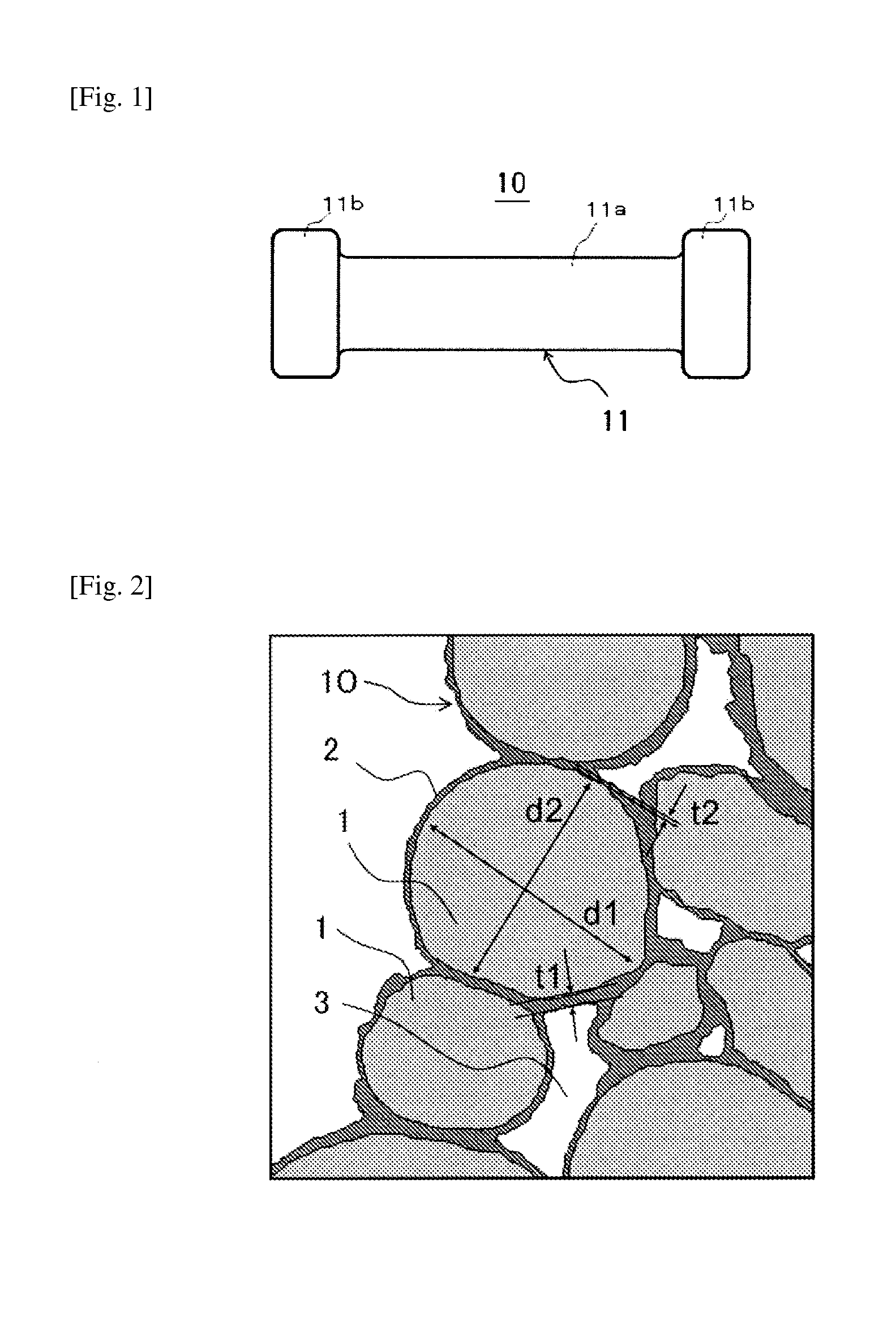

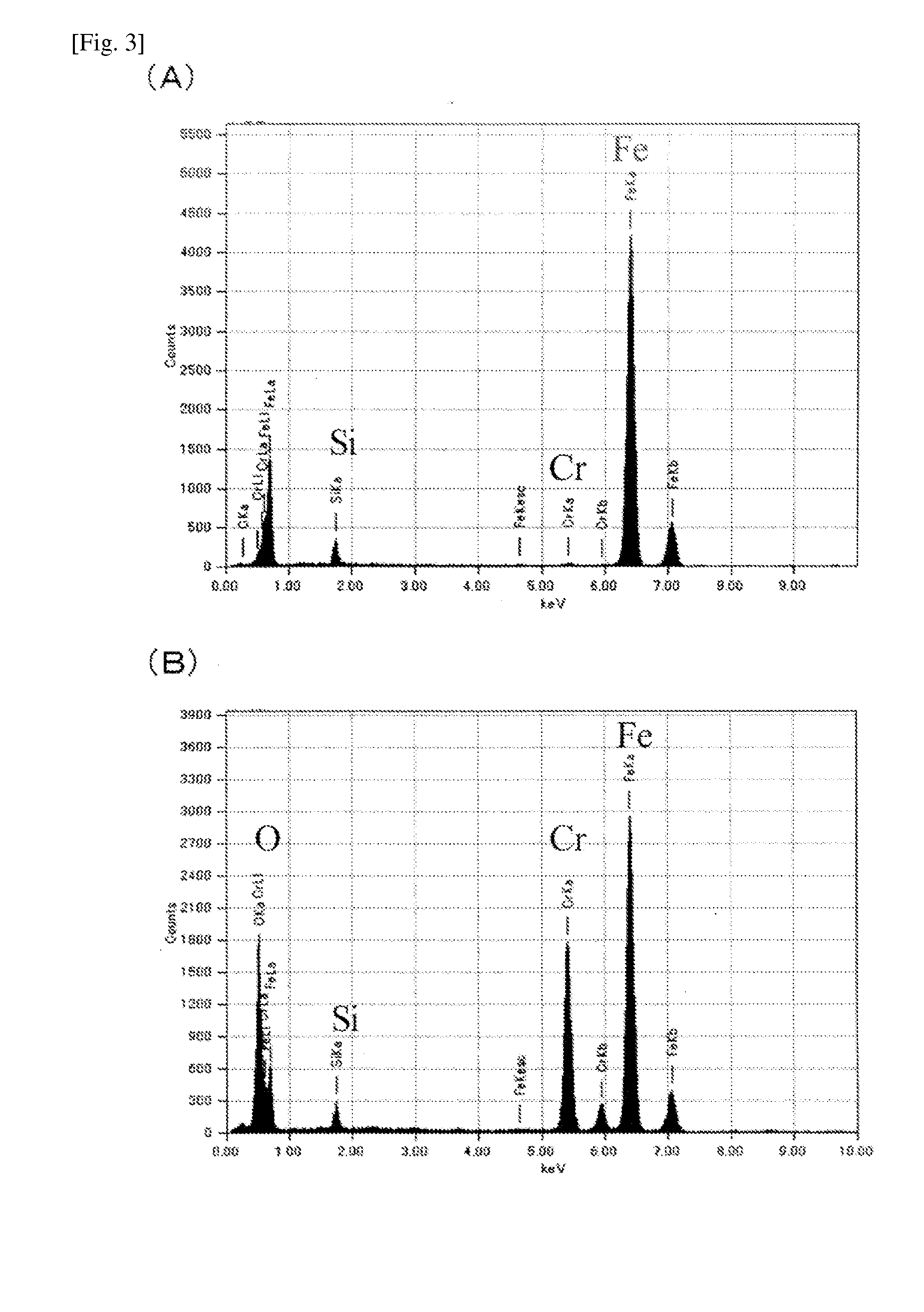

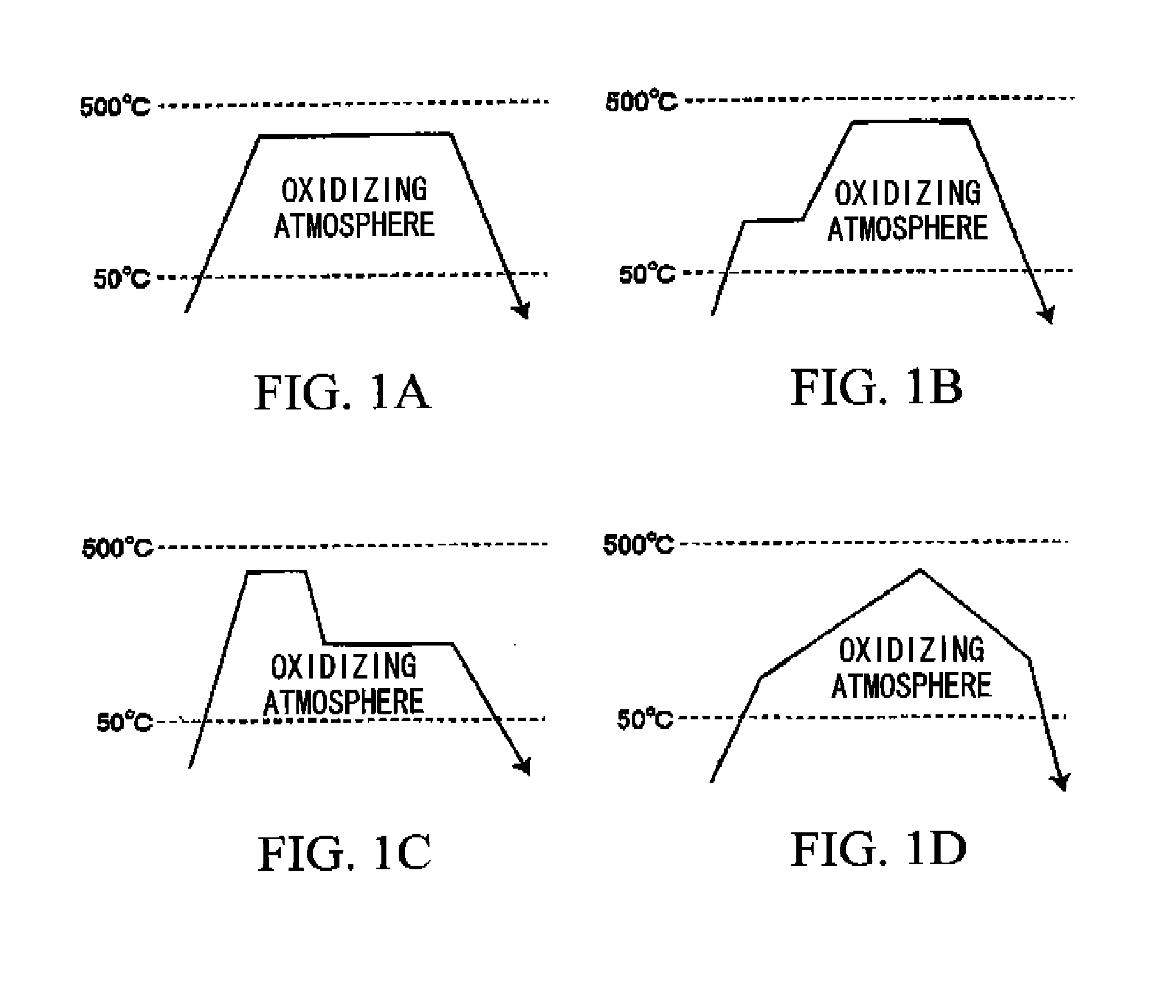

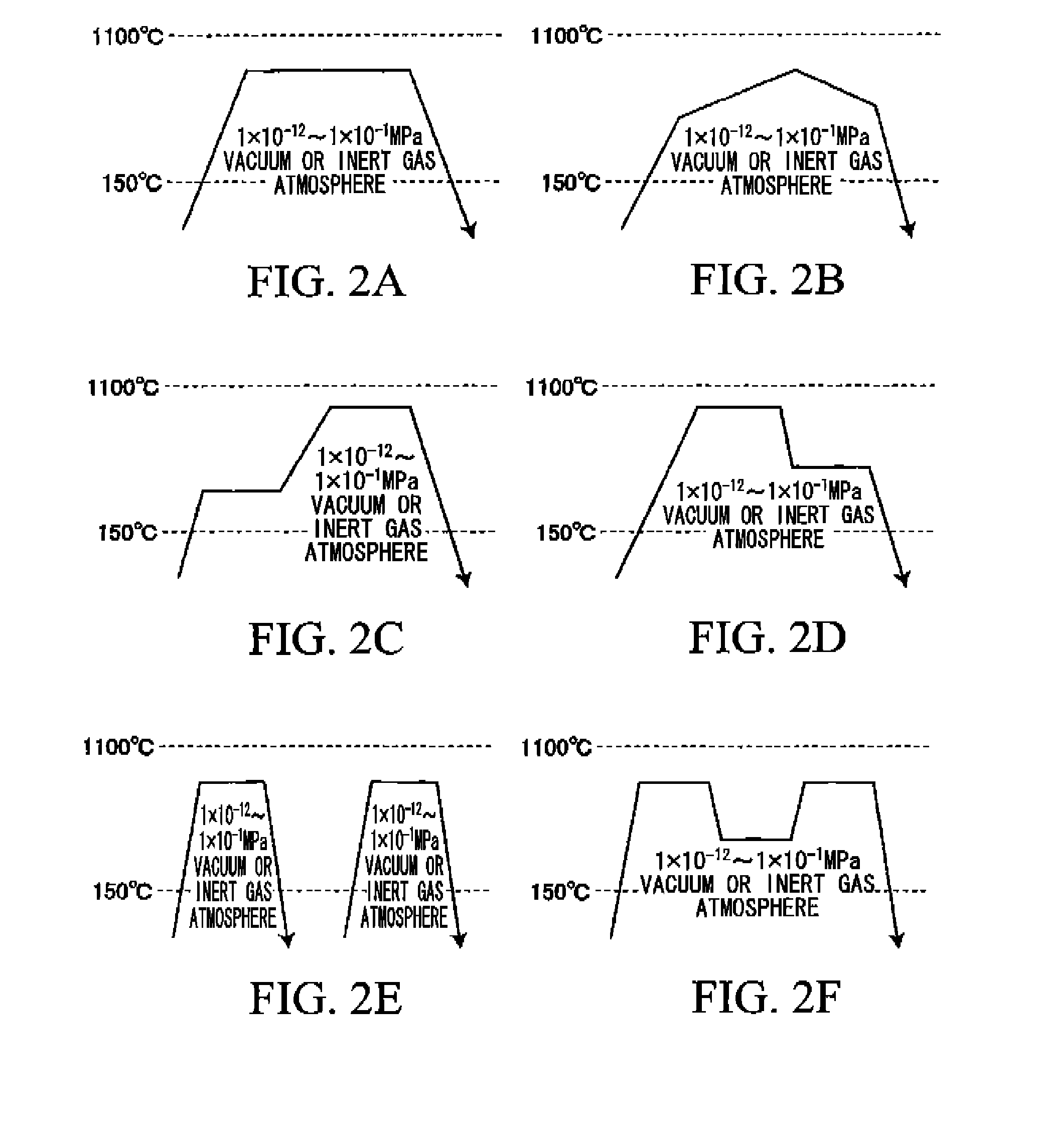

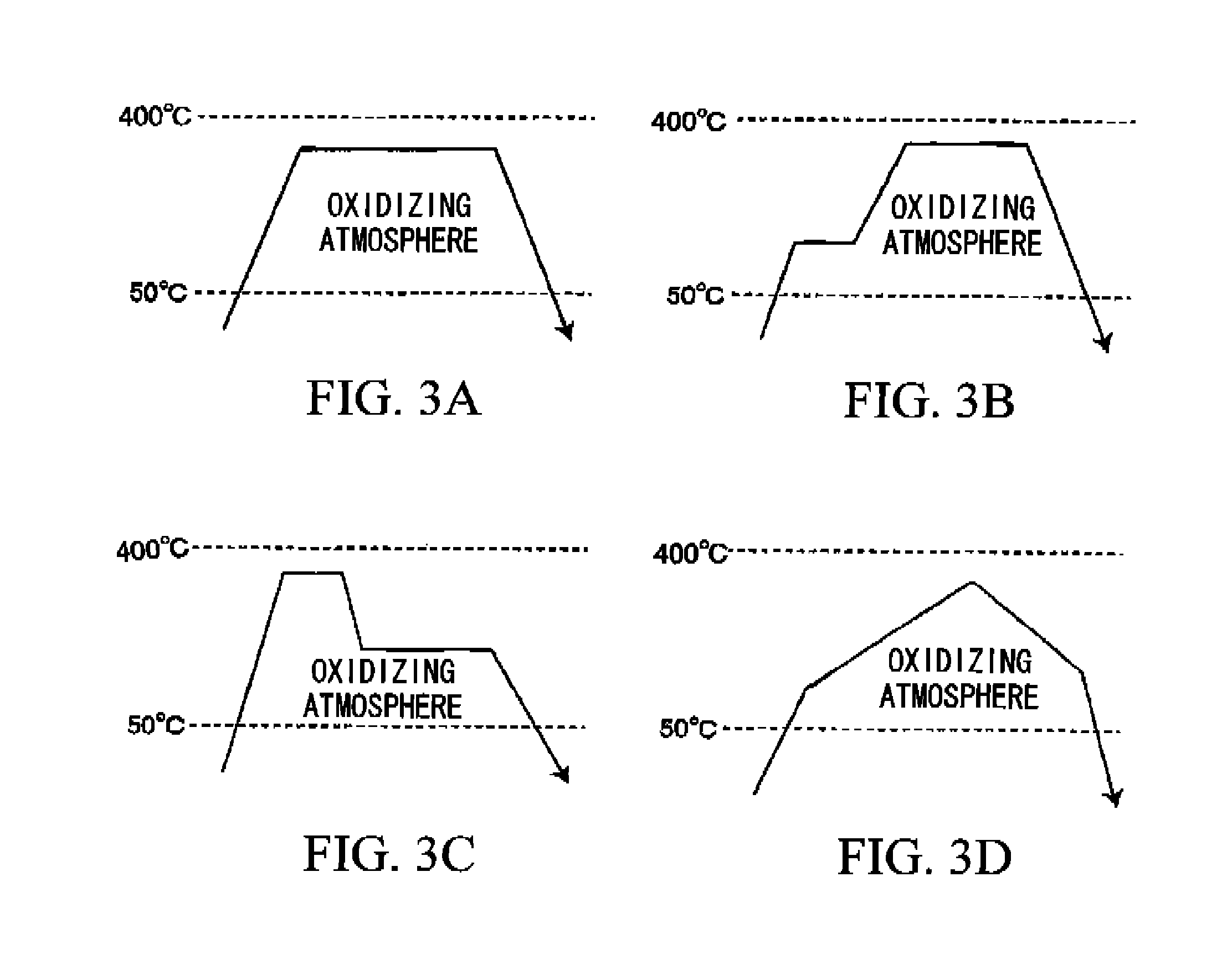

Method for Producing Soft Magnetic Metal Powder Coated With Mg-Containing Oxide Film and Method for Producing Composite Soft Magnetic Material Using Said Powder

InactiveUS20080003126A1High magnetic flux densityLow iron-lossTransportation and packagingMetal-working apparatusMetal powderThermal treatment

A method for producing a soft magnetic metal powder coated with a Mg-containing oxide film, comprising the steps of adding and mixing a Mg powder with a soft magnetic metal powder which has been subjected to heating treatment in an oxidizing atmosphere at a temperature of 40 to 500° C. to obtain a mixed powder, and heating the mixed powder at a temperature of 150 to 1,100° C. in an inert gas or vacuum atmosphere under a pressure of 1×10−12 to 1×10−1 MPa, while optionally tumbling; and a method for producing a composite soft magnetic material from the soft magnetic metal powder coated with a Mg-containing oxide film.

Owner:DIAMET CORP

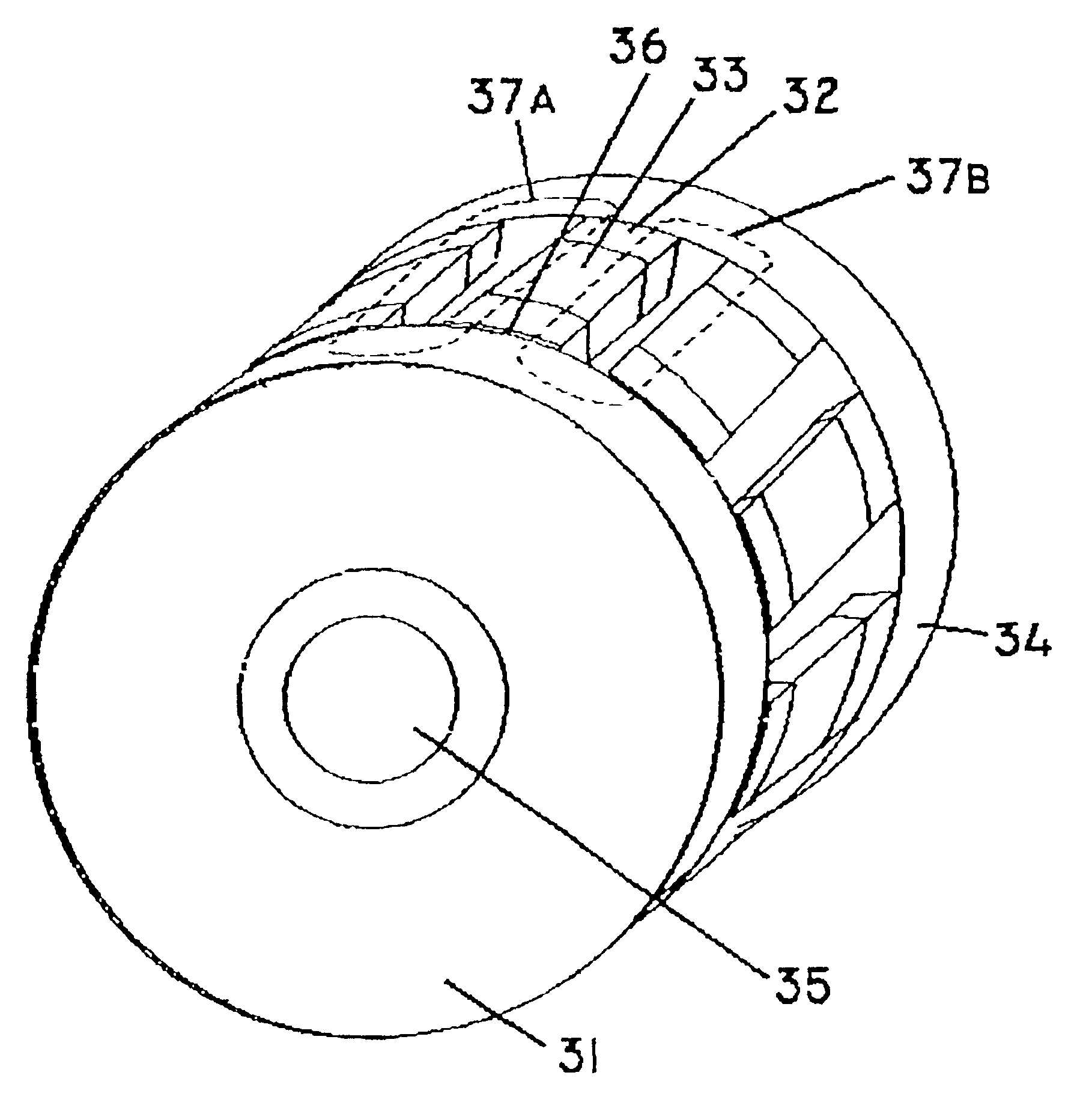

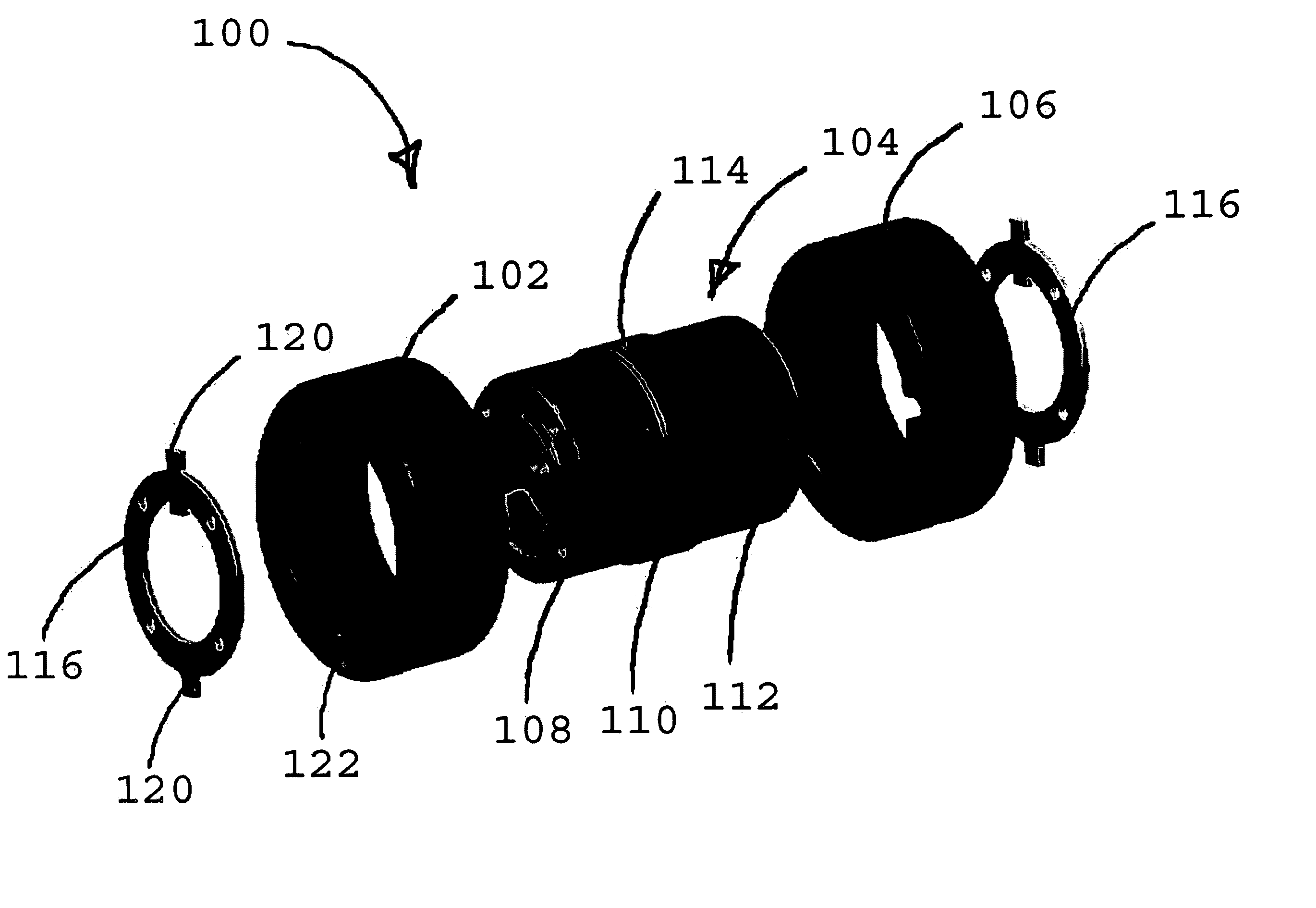

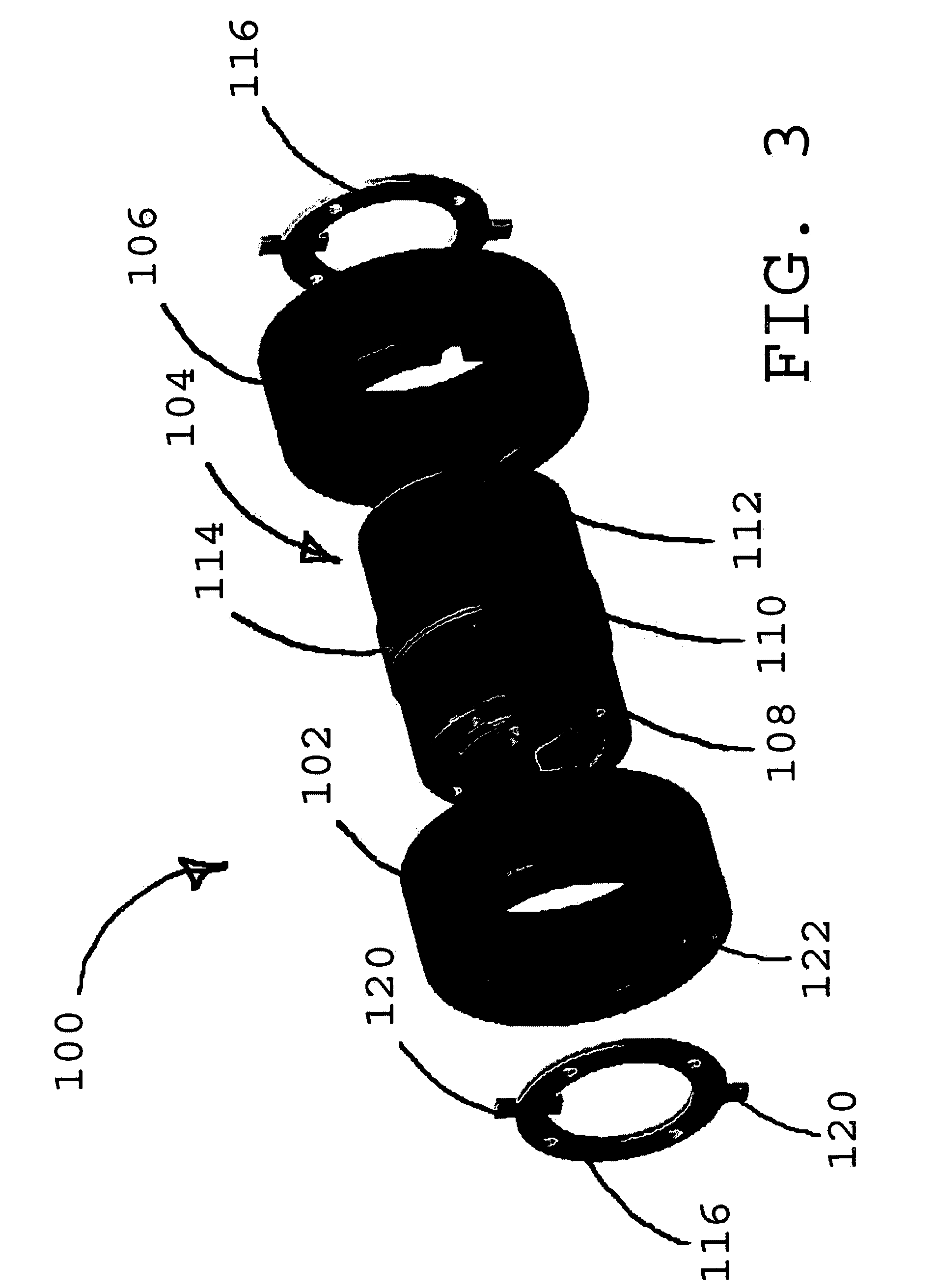

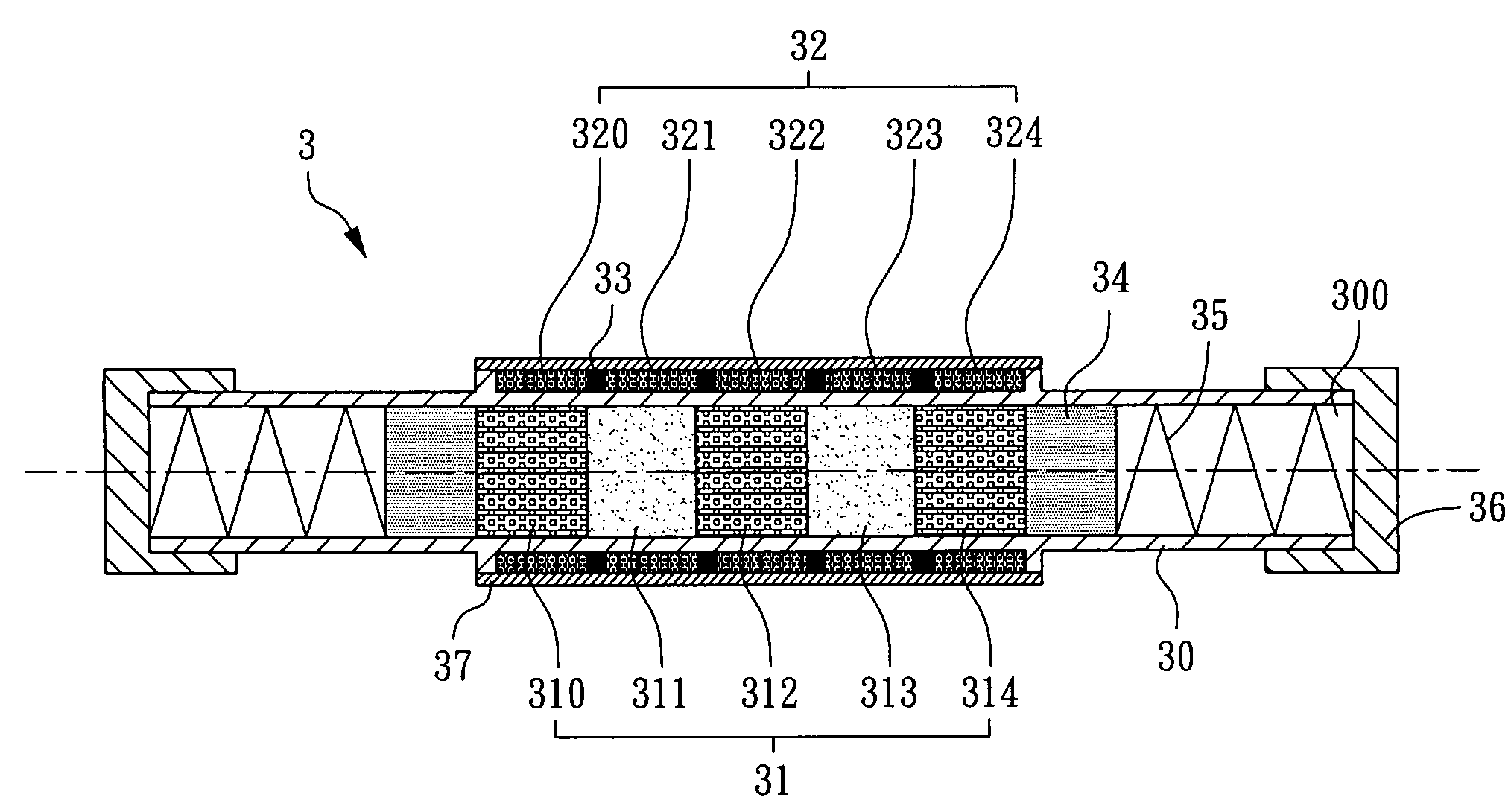

Voice coil linear actuator, apparatus using the actuator, and method for manufacturing the actuator

InactiveUS20030218391A1Reduce resistanceFew coilsElectrical transducersPropulsion systemsMagnetic polesEngineering

A voice coil linear actuator comprises: an axially-shaped center yoke formed of a ferromagnetic material; an armature coil concentrically disposed so as to move along the axial direction of the center yoke; and a plurality of ring-shaped permanent magnets which have N and S magnetic poles arranged in the radial direction thereof, and are disposed concentrically as to the armature coil. The armature coil has armature coil units distributed in at least three positions in the axial direction, with adjacent pairs of the armature coil units being arranged so that electric current flows through them in opposite directions, respectively. The permanent magnets are distributed in at least three positions in the axial direction at positions facing respective armature coil units in the radial direction. The respective directions of the N magnetic poles of adjacent permanent magnets are arranged facing in opposite directions.

Owner:MURATA MFG CO LTD

High-performance piston core for a magnetorheological damper

ActiveUS6948312B1High magnetic flux densityPrevent magnetic saturationSpringsNon-rotating vibration suppressionHigh fluxMagnetic reluctance

A high-performance piston core including a first piston cylinder and a second piston cylinder, with a piston center longitudinally disposed between and magnetically coupling the first piston cylinder and the second piston cylinder. The piston center is made of high-performance magnetic material, such as Cobalt steel (CoFe), Silicon steel (SiFe), Vanadium / Cobalt steel (Permendur), alloys thereof, or the like. The high-performance magnetic materials exhibit high magnetic permeability and reduce the magnetic reluctance of flux bottlenecks. In addition, high-performance magnetic materials typically saturate at a higher flux density than the conventional magnetic materials. The first piston cylinder and the second piston cylinder can be made of conventional magnetic material, such as low-carbon steel. The first piston cylinder can include a ring disposed about an end, where the end is longitudinally attached and magnetically coupled to the piston center.

Owner:DELPHI TECH INC +1

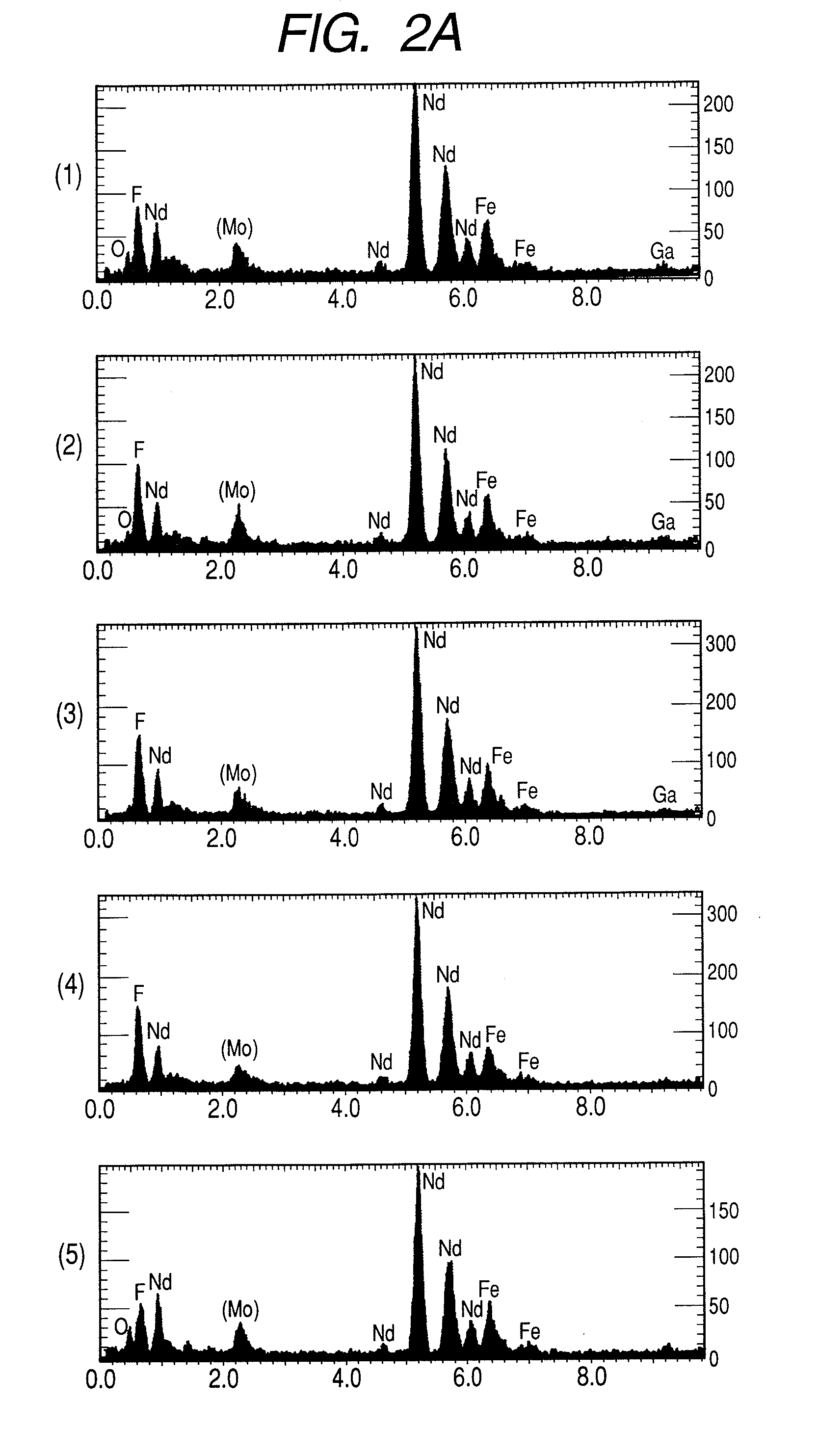

Rare earth magnet and manufacturing method thereof

InactiveCN101276665AHigh reluctanceHigh magnetic flux densityInorganic material magnetismEddy currentOxygen

A structure of a magnet wherein a magnet consisting of a magnetic body including iron and rare earths, a plurality of fluorine compound layers or oxyfluorine compound layers are formed interior of the magnetic body, and the fluorine compound layer or oxyfluorine compound layer has a major axis which is greater than the mean particle size of the crystal grains of the magnetic body.

Owner:HITACHI LTD

Reciprocating power generating module

InactiveUS20090146508A1High magnetic flux density utilizationHigh coil densityMechanical energy handlingSine waveMagnet

A reciprocating power generating module is disclosed, which comprises: a guide; a magnet, being an integrated unit composed of at least two magnetic elements connected with each other in a manner that poles of any one of the plural magnetic elements are orientated to repel poles of its neighboring magnetic elements; and a coil, being wound around the guide; wherein the magnet is capable of being driven to move linearly by the defining of the guide. The full sine-wave AC voltage output is obtained when the relative linear motion equals double of the length of the magnetic element.

Owner:IND TECH RES INST

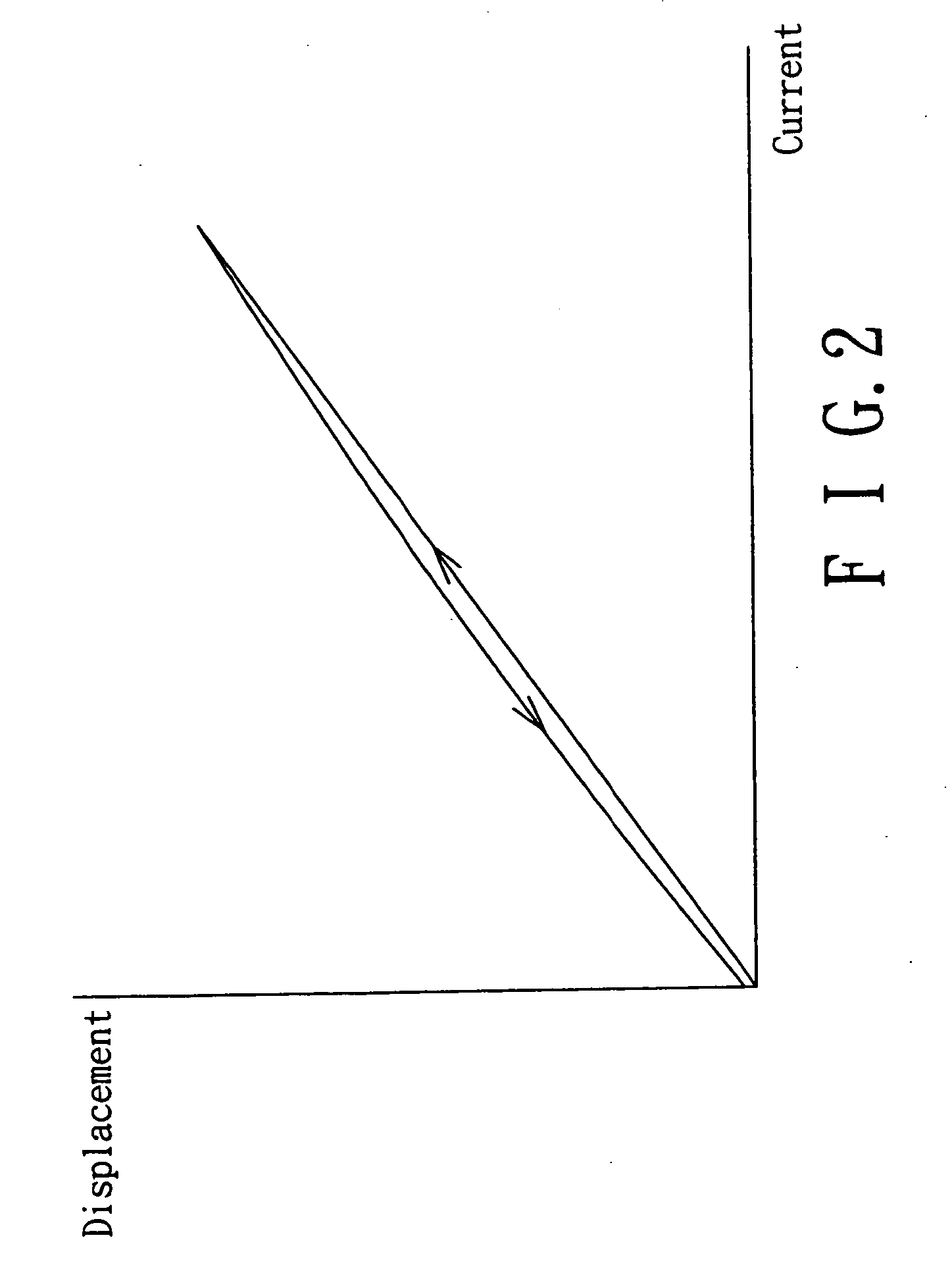

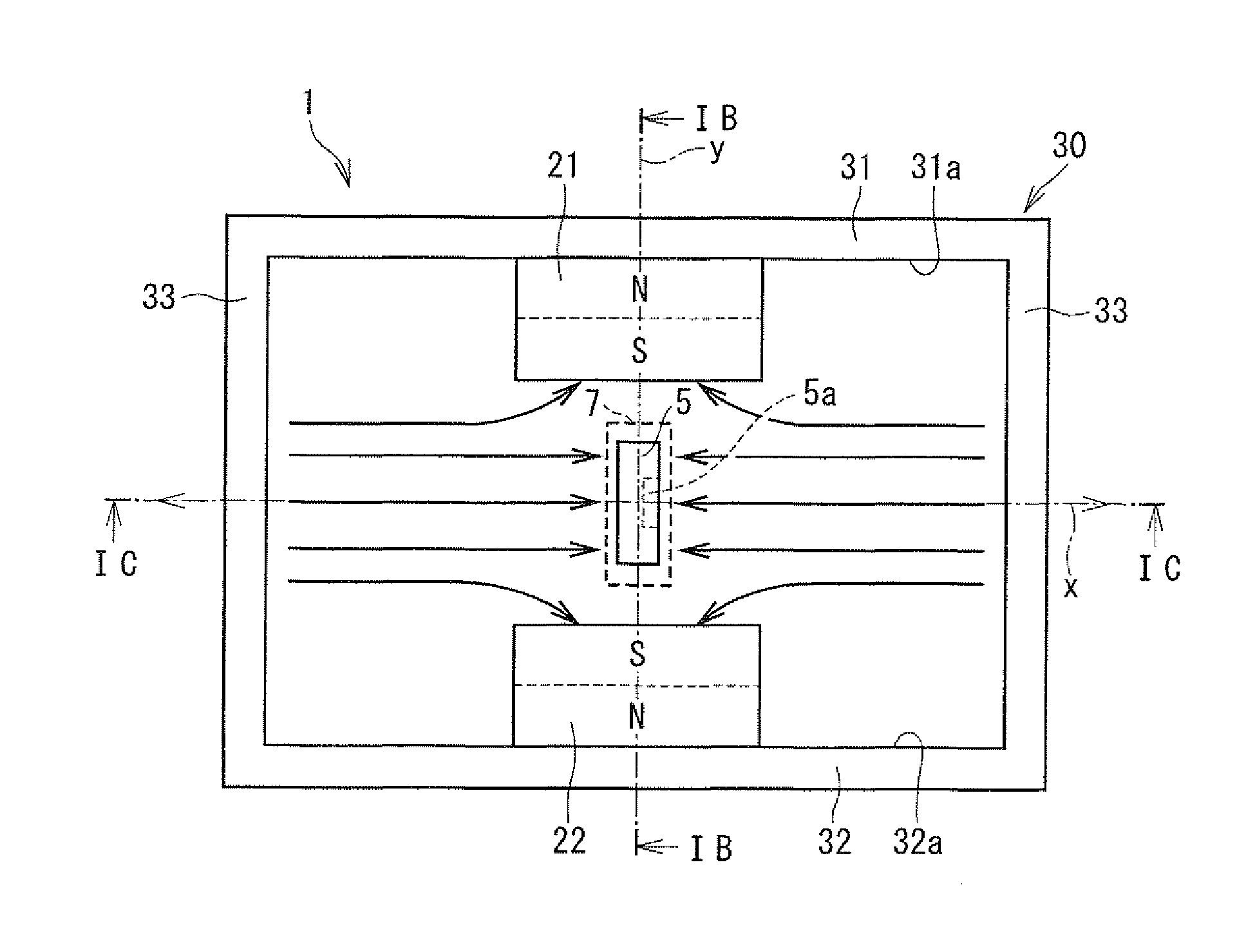

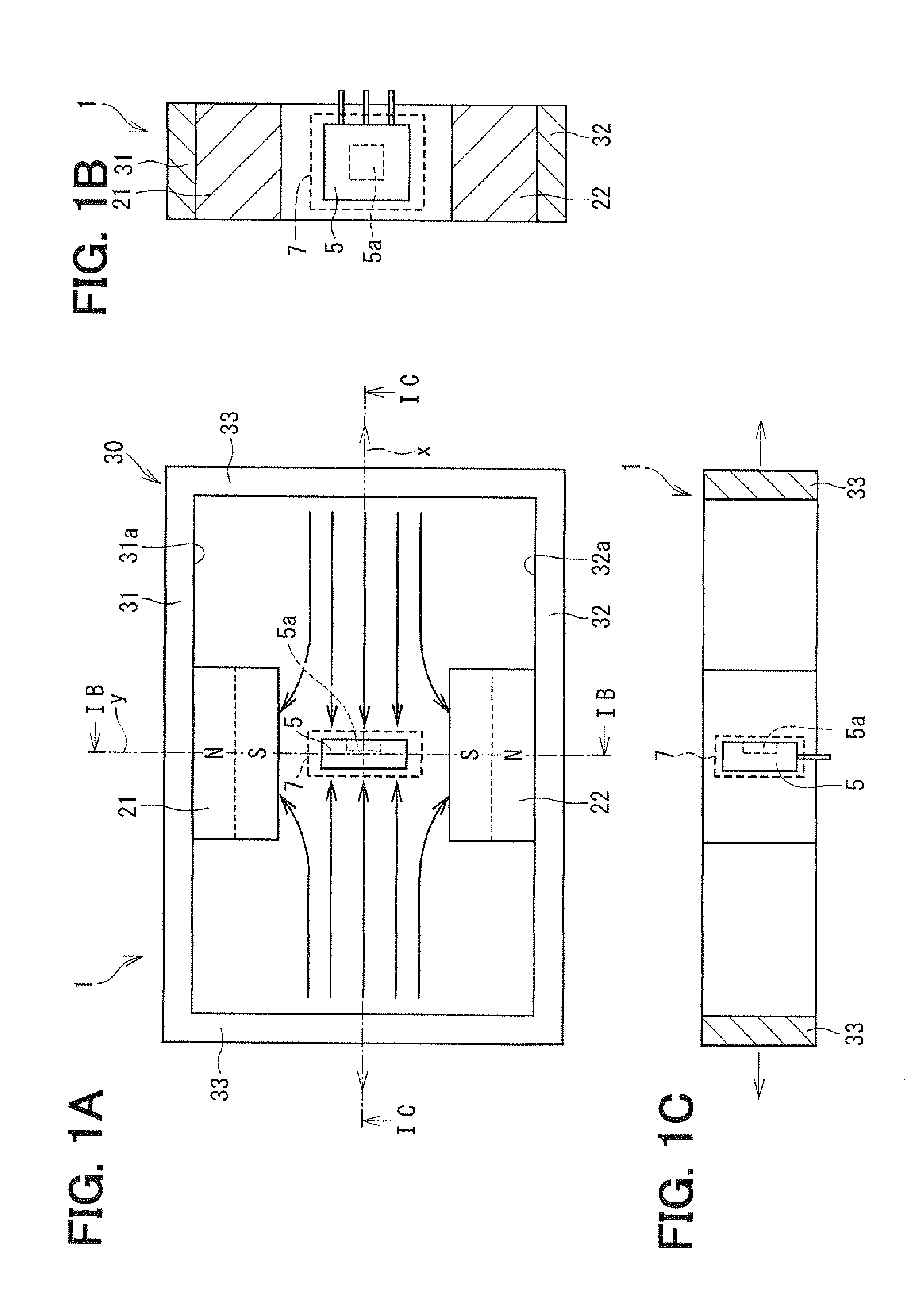

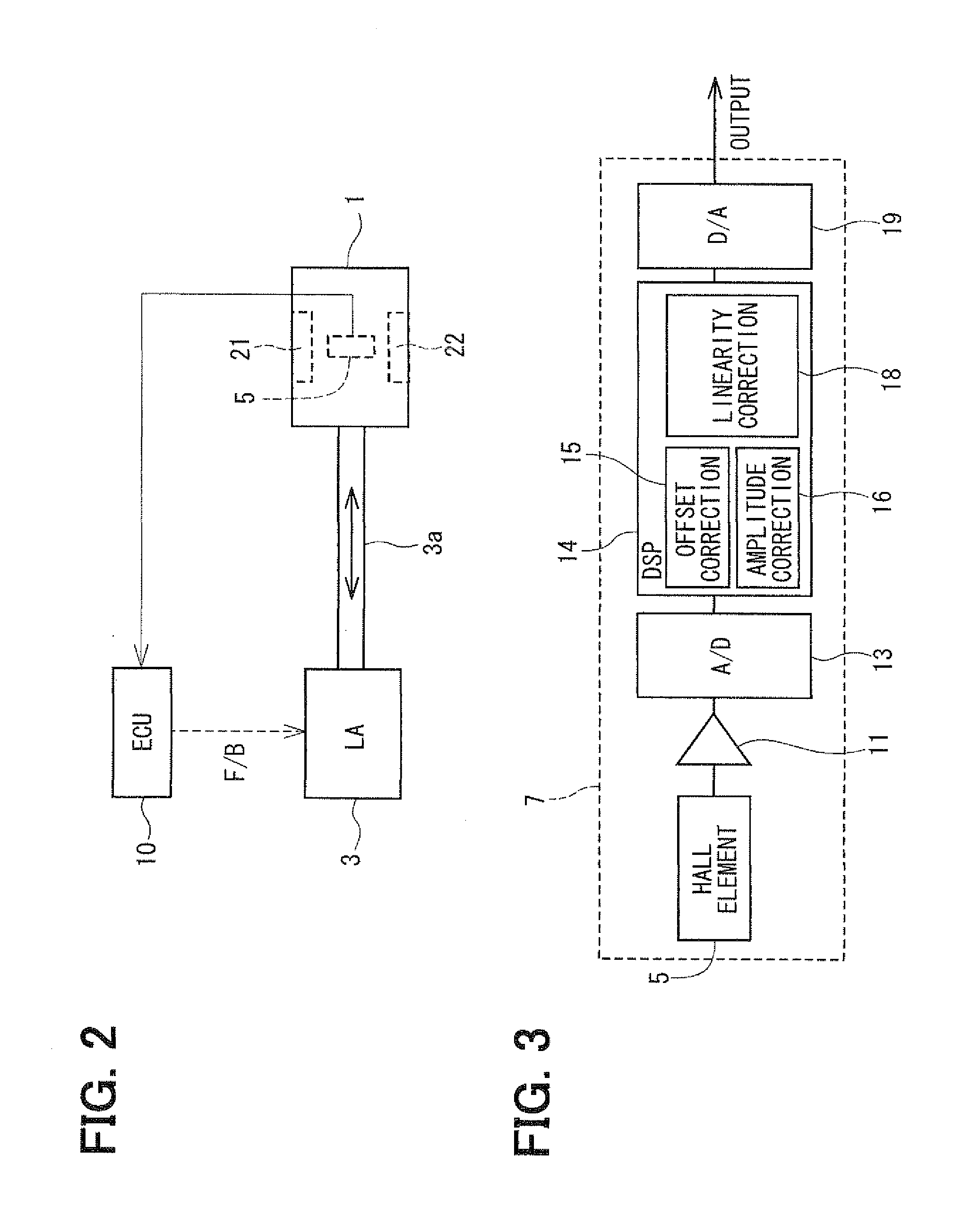

Stroke amount detecting device

ActiveUS20110248705A1Improve robustnessHigh magnetic flux densityMagnetic-field-controlled resistorsSolid-state devicesCondensed matter physicsMagnetic field

A stroke amount detecting device includes a first magnetic field generation member, a second magnetic field generation member, and a magnetic sensor unit. The first magnetic field generation member and the second magnetic field generation member are opposed to each other with respect to a direction perpendicular to a straight stroking axis of a stroking object, and magnetized in opposite directions. The magnetic sensor unit is movable in an area between the first magnetic field generation member and the second magnetic field generation member, along a straight traveling axis that is parallel to the straight stroking axis relative to the first magnetic field generation member and the second magnetic field generation member in accordance with a stroke motion of the stroking object. The magnetic sensor unit has a magnetosensitive surface facing a direction parallel to the traveling axis, thereby to detect an amount of stroke of the object.

Owner:DENSO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com