Rare earth magnet and manufacturing method thereof

A magnet and rare earth technology, applied in the field of rare earth magnets and their manufacture, can solve the equal problems of no fluorine compound, it is difficult to achieve a low concentration of rare earth elements with magnetic properties, and it is difficult to form fluorine, and achieves high magnetic flux density, low The effect of coercive force and low iron loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Made as NdFeB powder with Nd 2 Fe 14 B-based quenching powders form fluorine compounds on their surfaces. Formation of DyF on the surface of quenched powder 3 In the case of Dy(CH 3 COO) 3 with H 2 O dissolved and HF was added. Gelatin-like DyF can be formed by adding HF 3 ·XH 2 O or DyF 3 ·X(CH 3 COO) (X is a positive number). This was centrifuged, the solvent was removed, and it was mixed with the above-mentioned NdFeB powder as a translucent solution. The solvent of the mixture was evaporated, and the water of hydration was evaporated with heating. The coating film thus formed was studied by XRD. As a result, when the heating temperature is lower than 200° C., the half width of the X-ray diffraction peak is twice or more than the peak width after the subsequent heat treatment, including a broad peak. The half-value width of this broad peak is 1 degree or more. By heat treatment at a temperature higher than 200°C, the crystal structure of the fluorine co...

Embodiment 2

[0043] Made as NdFeB powder with Nd 2 Fe 14 B-based quenching powders form fluorine compounds on their surfaces. Formation of DyF on the surface of quenched powder 3 In the case of Dy(CH 3 COO) 3 with H 2 O dissolved and HF was added. Gelatin-like DyF can be formed by adding HF 3 ·XH 2 O. It was centrifuged and the solvent was removed. The concentration of rare earth fluoride in the gel state is 10g / dm 3 As mentioned above, the transmittance of the treatment liquid with an optical path length of 1 cm at a wavelength of 700 nm is 5% or more. This light-transmitting solution is mixed with the above-mentioned NdFeB powder. The solvent of the mixture was evaporated, and the water of hydration was evaporated with heating. It was found that by heat treatment at 500°C, the crystal structure of the fluorine compound was changed from NdF 3 Structure, NdF 2 structure etc.

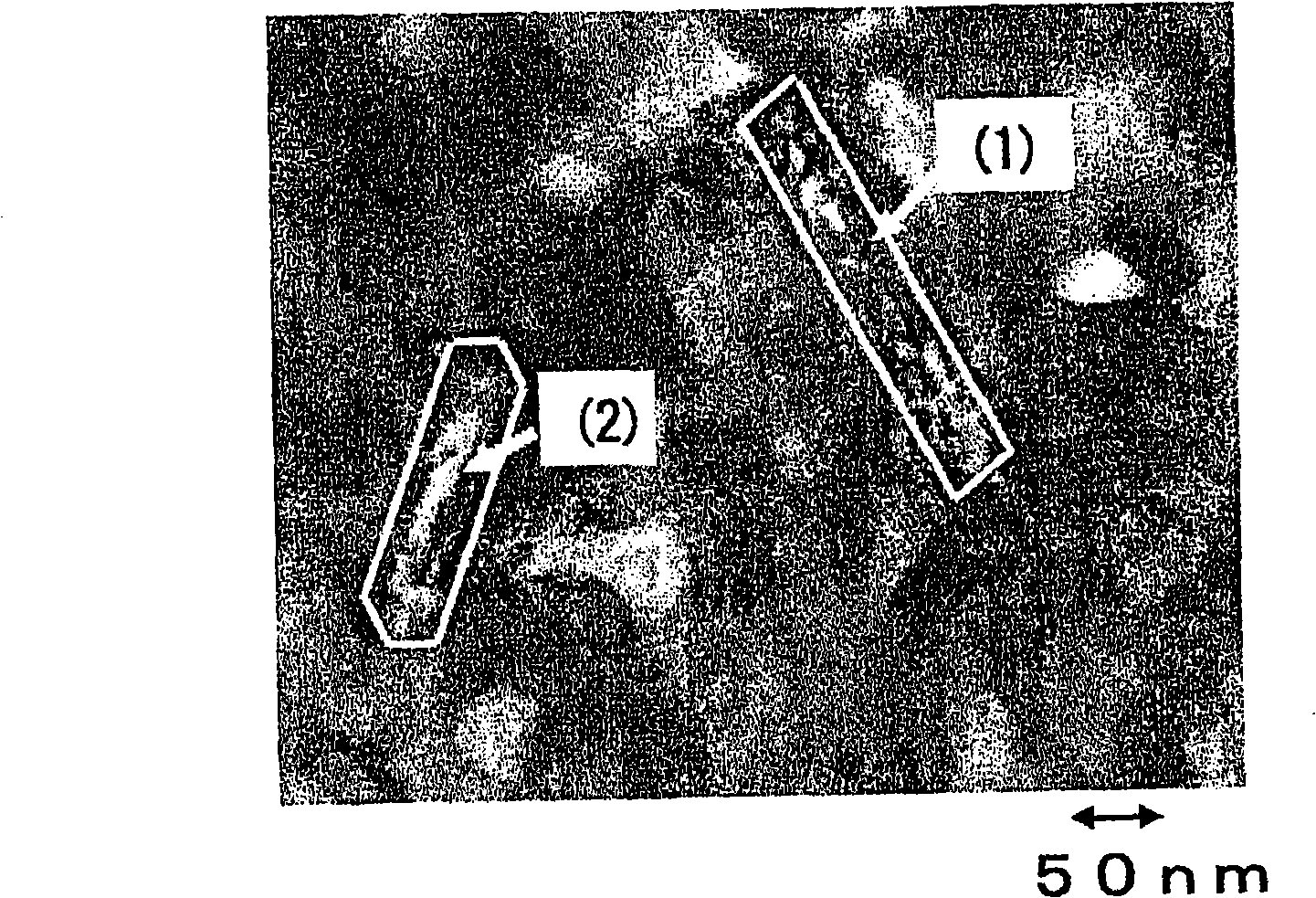

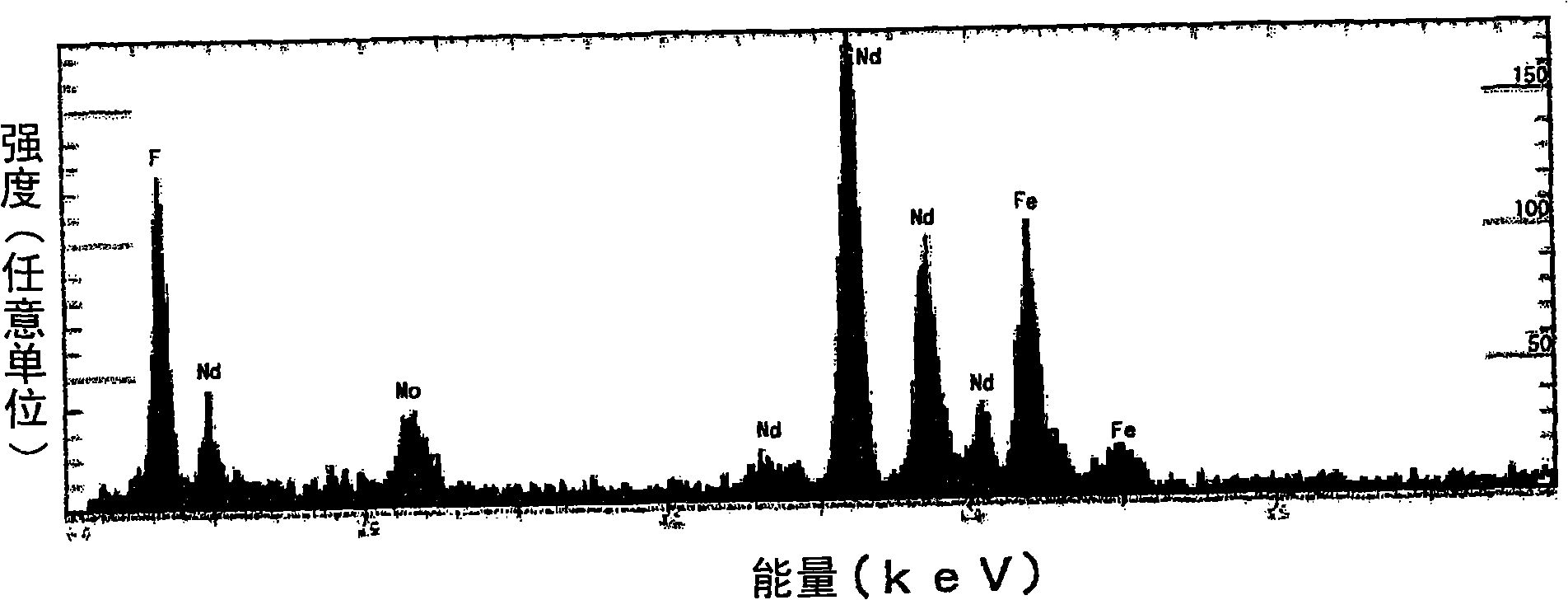

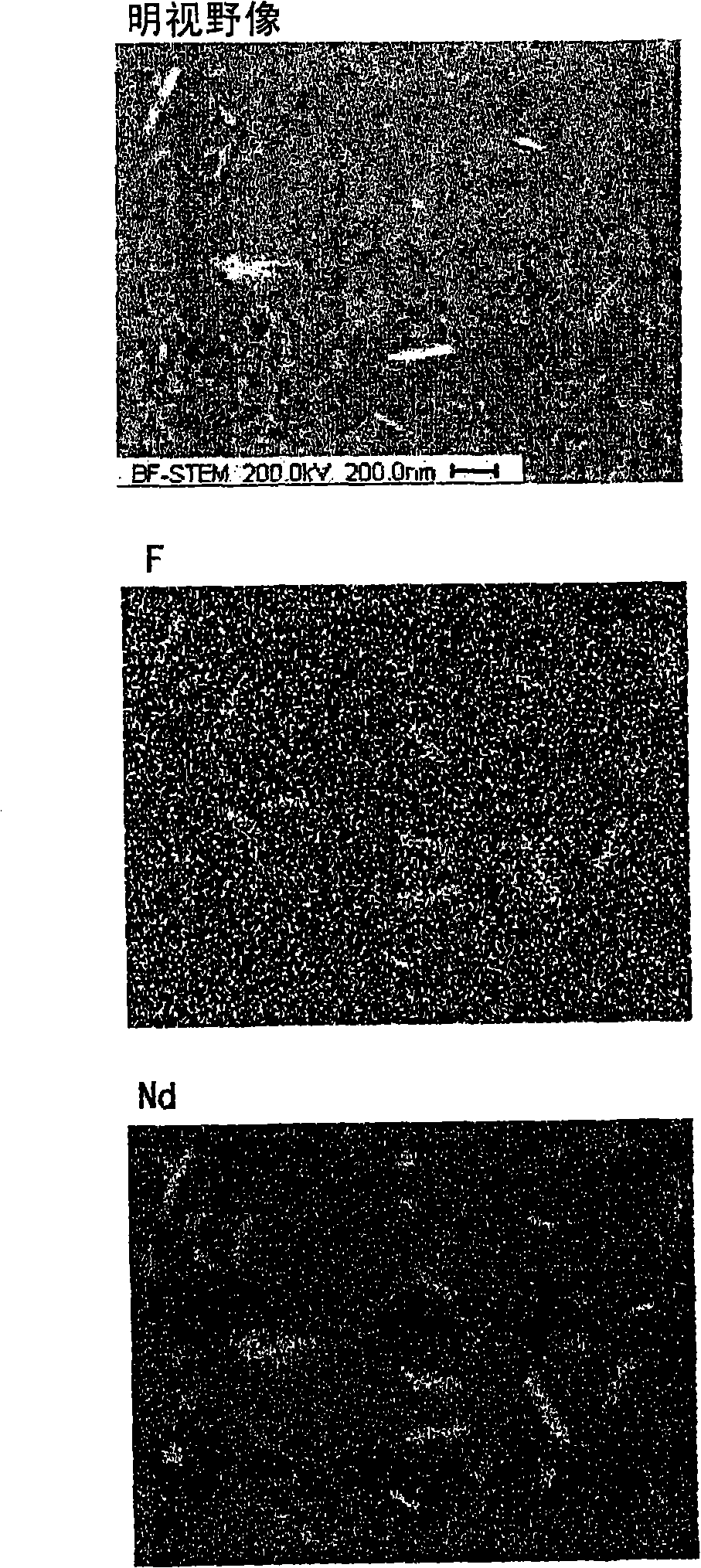

[0044] The cross-section of the heat-treated magnetic powder was observed with a transmission elect...

Embodiment 3

[0051] The rare earth fluoride or alkaline earth metal fluoride coating film forming treatment liquid is obtained by dissolving rare earth acetate or alkaline earth metal acetate in water, and then gradually adding diluted hydrofluoric acid. The solution of the fluorine compound or the oxyfluorine compound or the oxyfluorocarbon that produced the gel-like precipitate was stirred using an ultrasonic stirrer, and after centrifugation, methanol was added, and after stirring the gel-like methanol solution, the anion was removed and the Its transparent. Anions are removed until the transmittance of the treatment solution under visible light reaches 5% or more. This solution was coated on magnetic powder, and the solvent was removed. Made as NdFeB powder with Nd 2 Fe 14 B-based quenching powders form Dy fluorine compounds on their surfaces. After mixing the above-mentioned translucent solution with the above-mentioned NdFeB powder, the solvent of the compound was evaporated. By...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com