Patents

Literature

705 results about "Rare-earth magnet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rare-earth magnets are strong permanent magnets made from alloys of rare-earth elements. Developed in the 1970s and 1980s, rare-earth magnets are the strongest type of permanent magnets made, producing significantly stronger magnetic fields than other types such as ferrite or alnico magnets. The magnetic field typically produced by rare-earth magnets can exceed 1.4 teslas, whereas ferrite or ceramic magnets typically exhibit fields of 0.5 to 1 tesla.

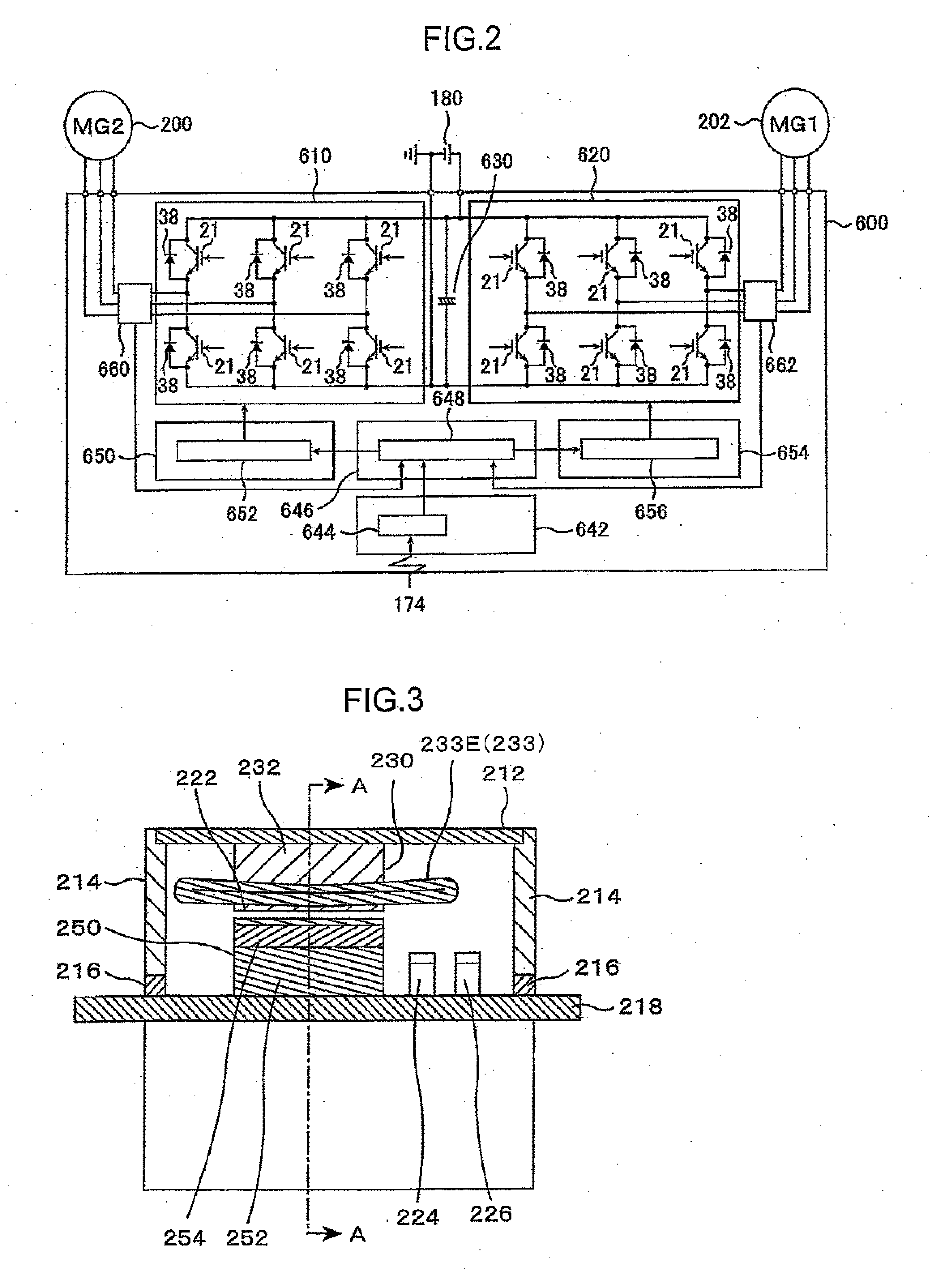

Magnetic connector for electronic device

ActiveUS7311526B2Coupling contact membersElectric connection structural associationsRare-earth magnetElectrical contacts

Owner:APPLE INC

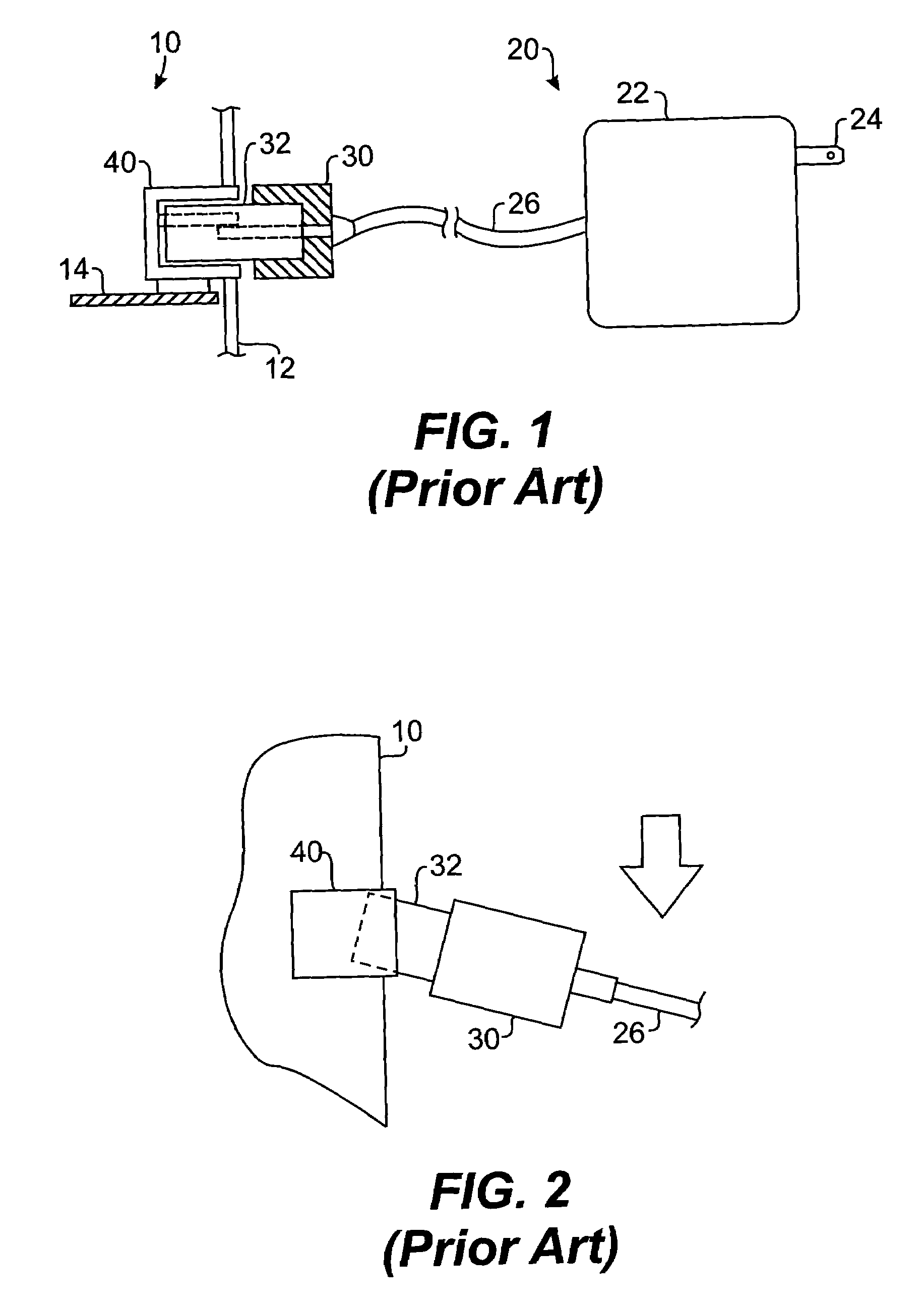

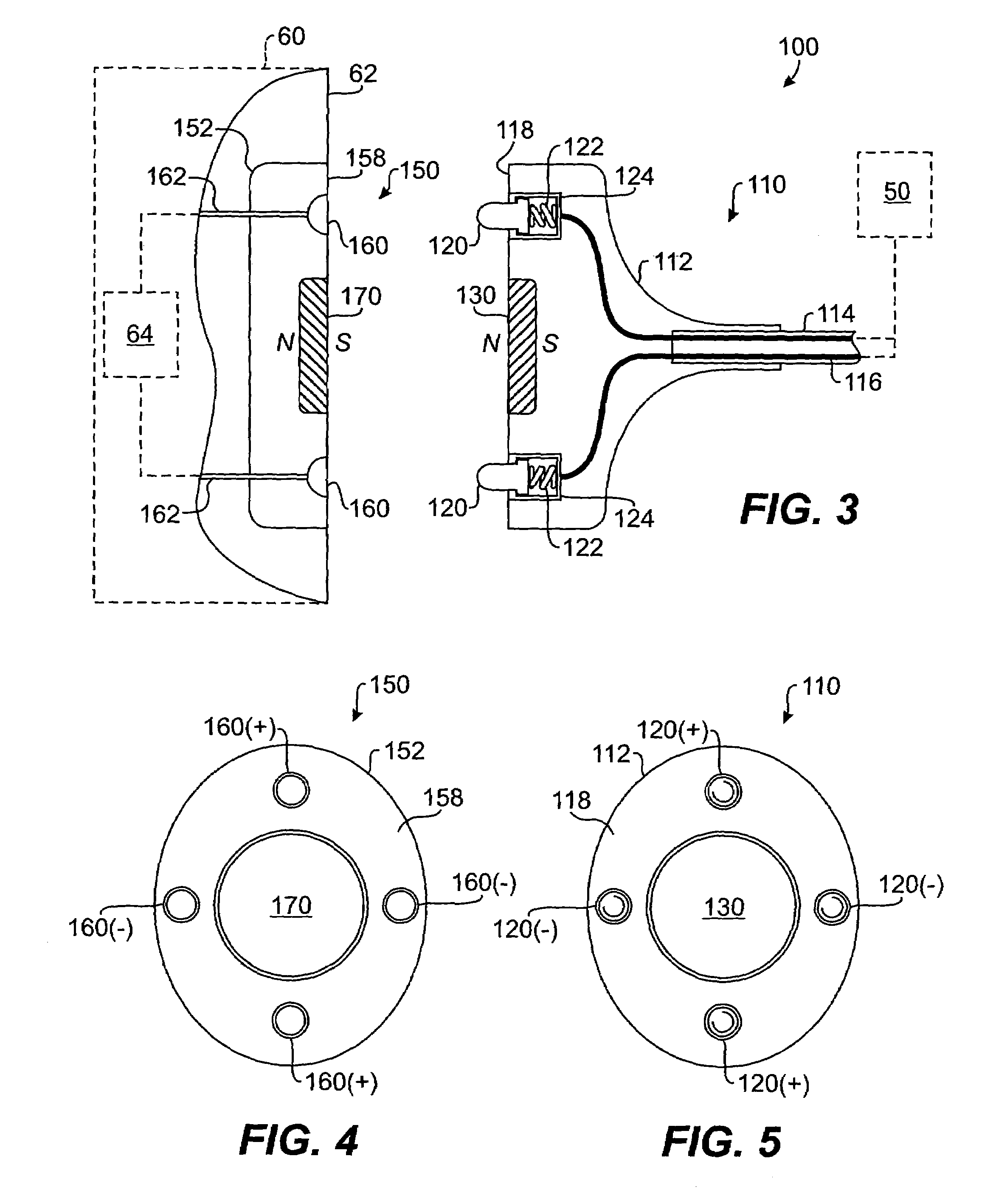

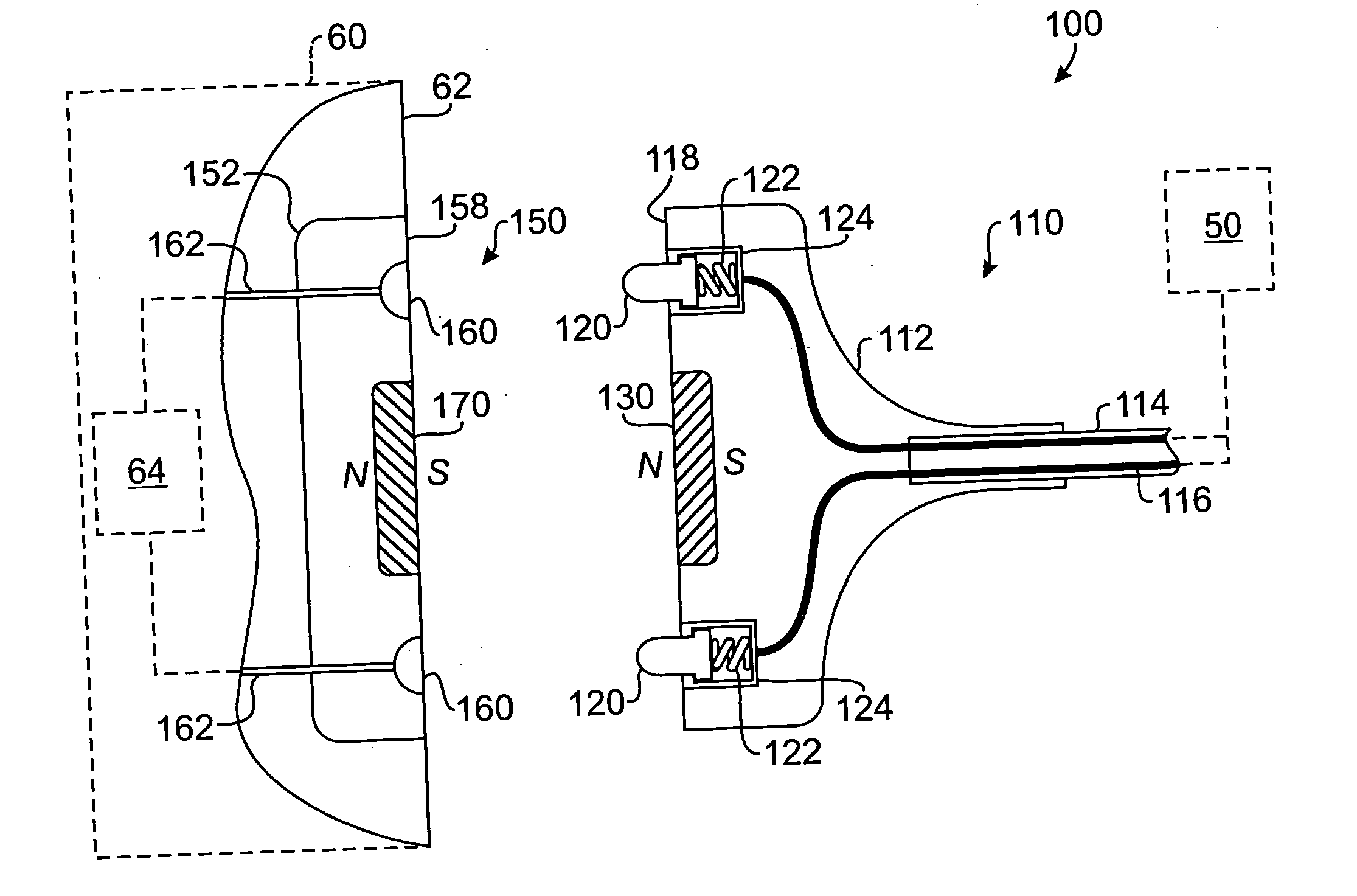

Magnetic connector for electronic device

ActiveUS20070072443A1Coupling contact membersElectric connection structural associationsEngineeringRare-earth magnet

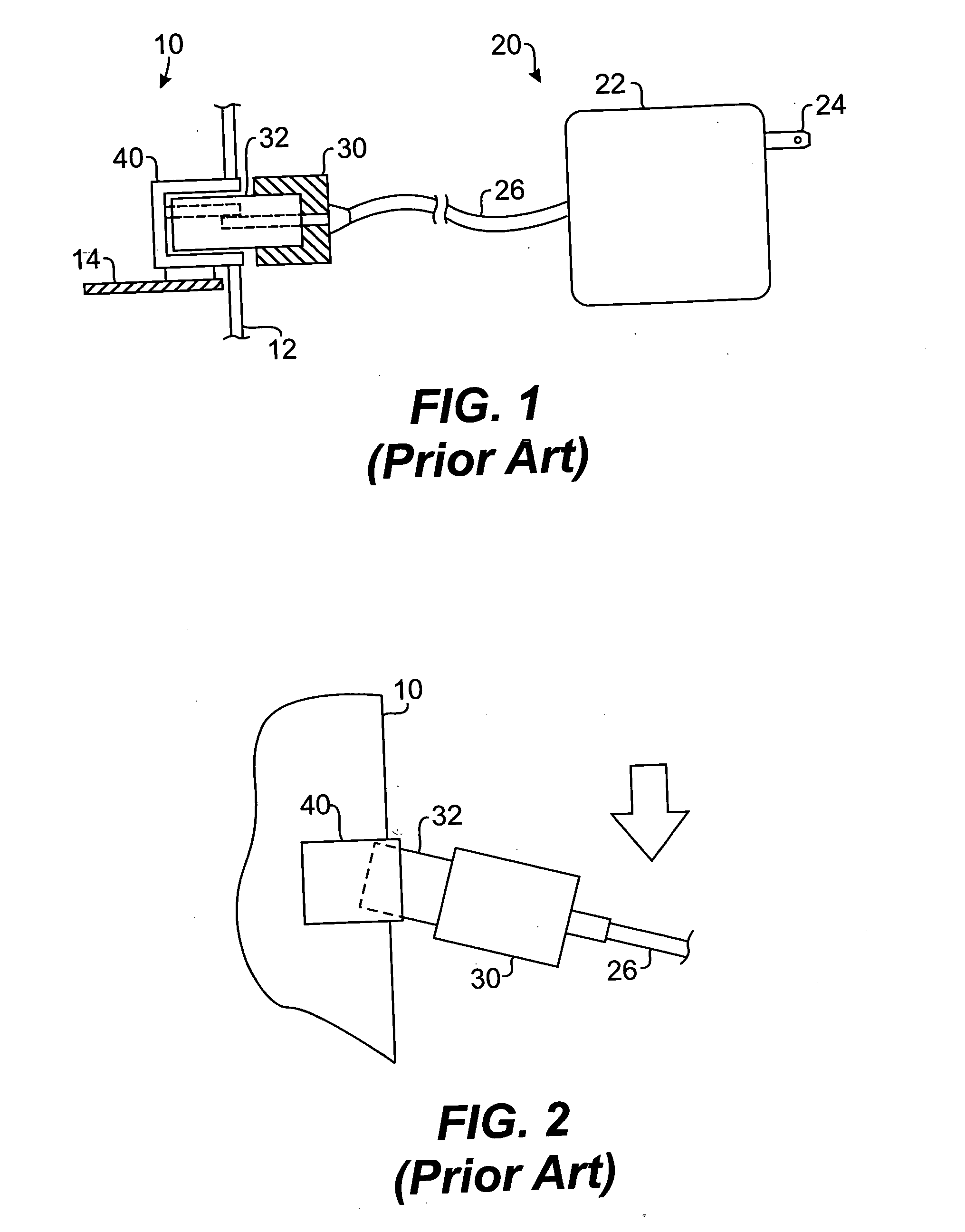

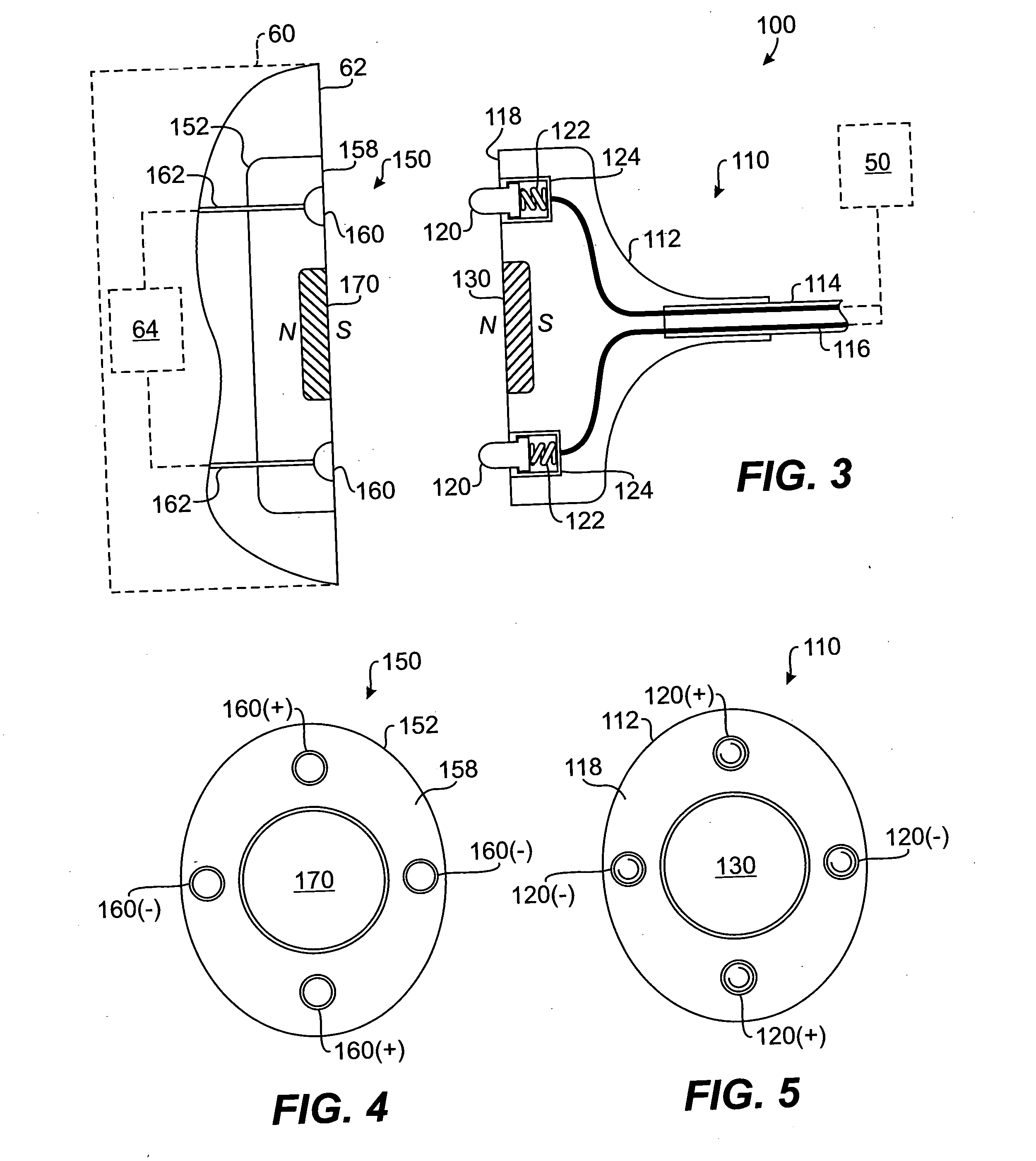

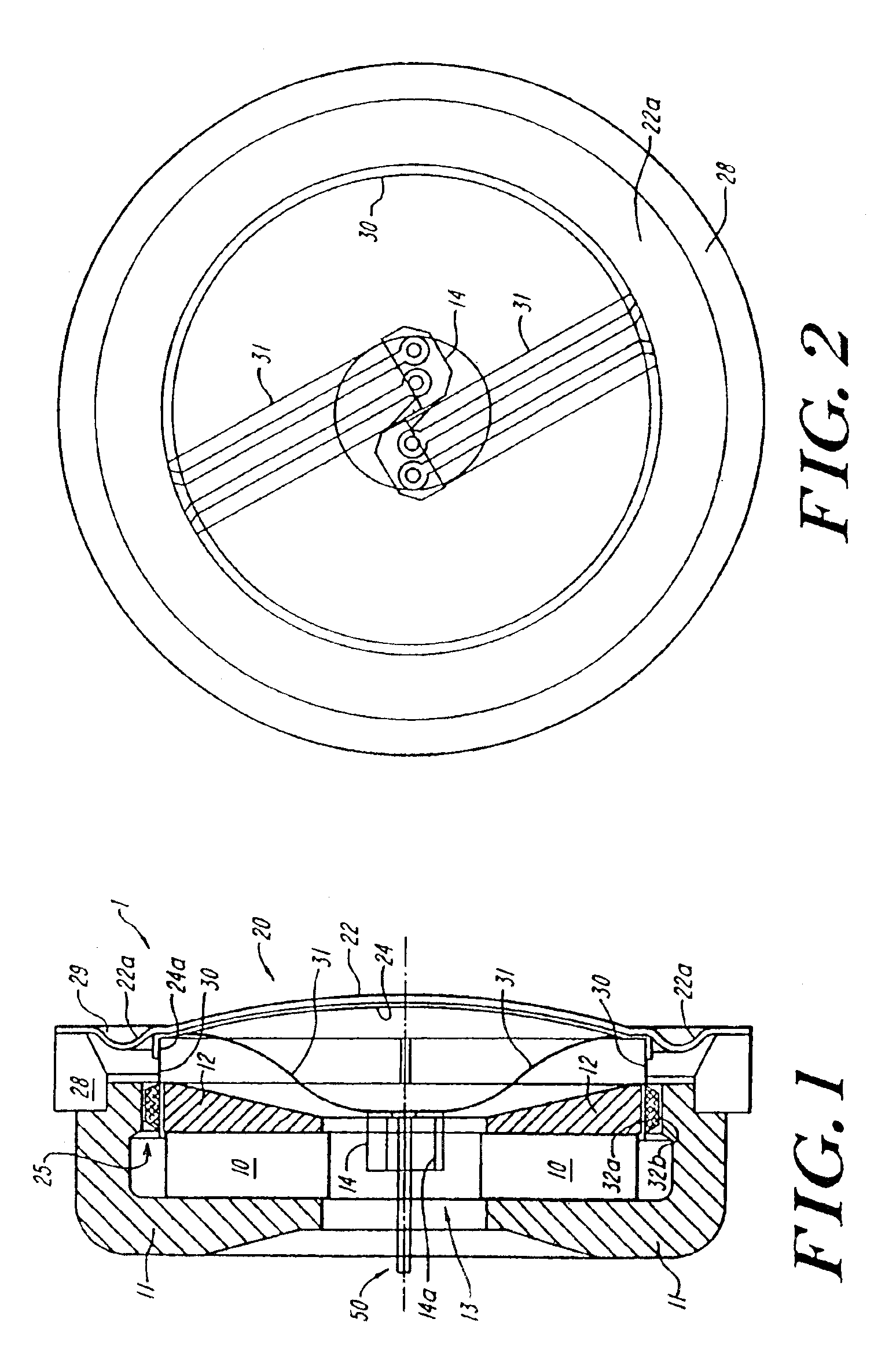

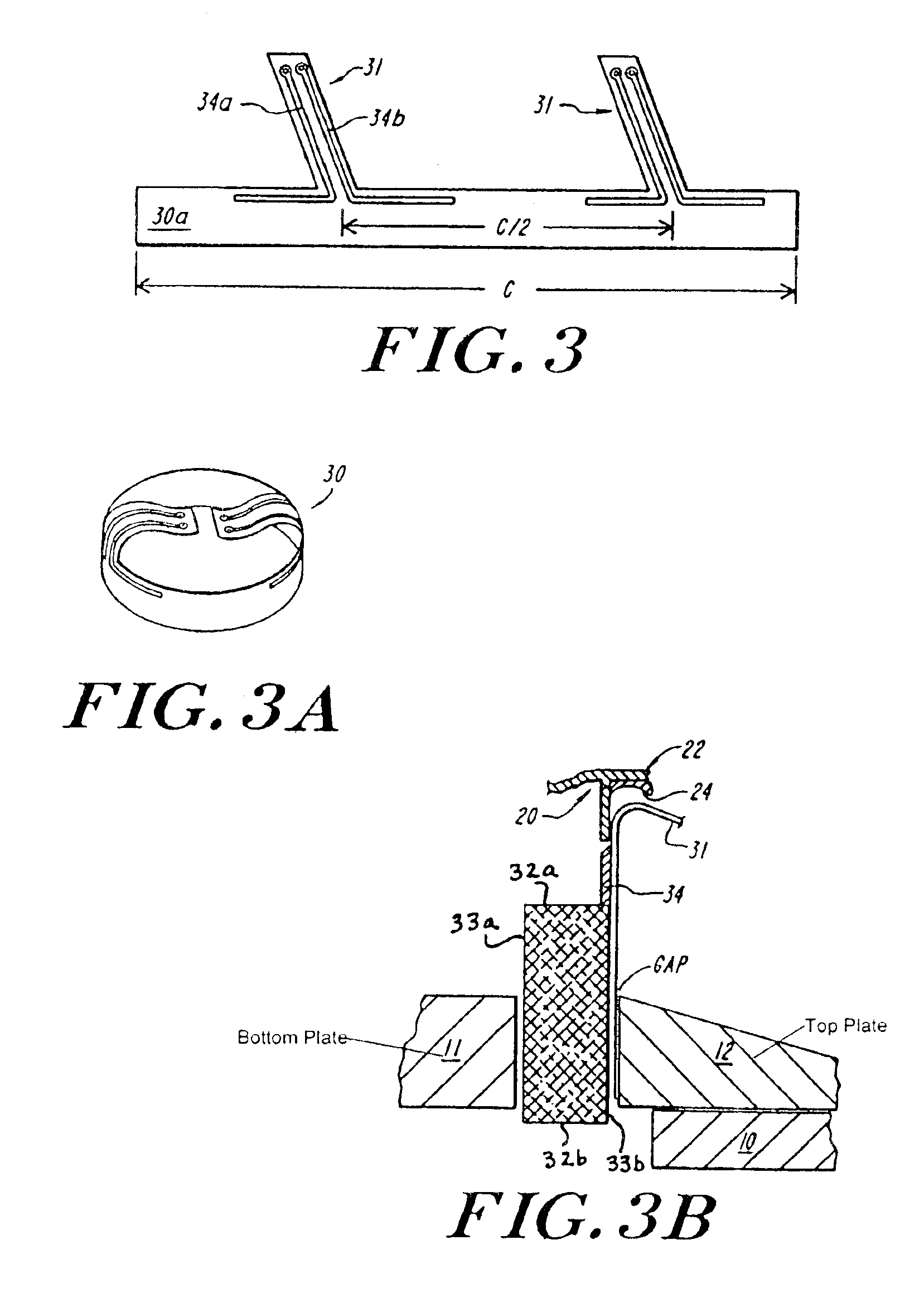

An electrical plug and receptacle relying on magnetic force to maintain contact are disclosed. The plug and receptacle can be used as part of a power adapter for connecting an electronic device, such as a laptop computer, to a power supply. The plug includes electrical contacts, which are preferably biased toward corresponding contacts on the receptacle. The plug and receptacle each have a magnetic element. The magnetic element on one or both of the plug and receptacle can be a magnet, which is preferably a permanent rare earth magnet although electromagnets may also be used. The magnetic element on the plug or receptacle that does not include a magnet is composed of ferromagnetic material. When the plug and receptacle are brought into proximity, the magnetic attraction between the magnet and its complement, whether another magnet or a ferromagnetic material, maintains the contacts in an electrically conductive relationship.

Owner:APPLE INC

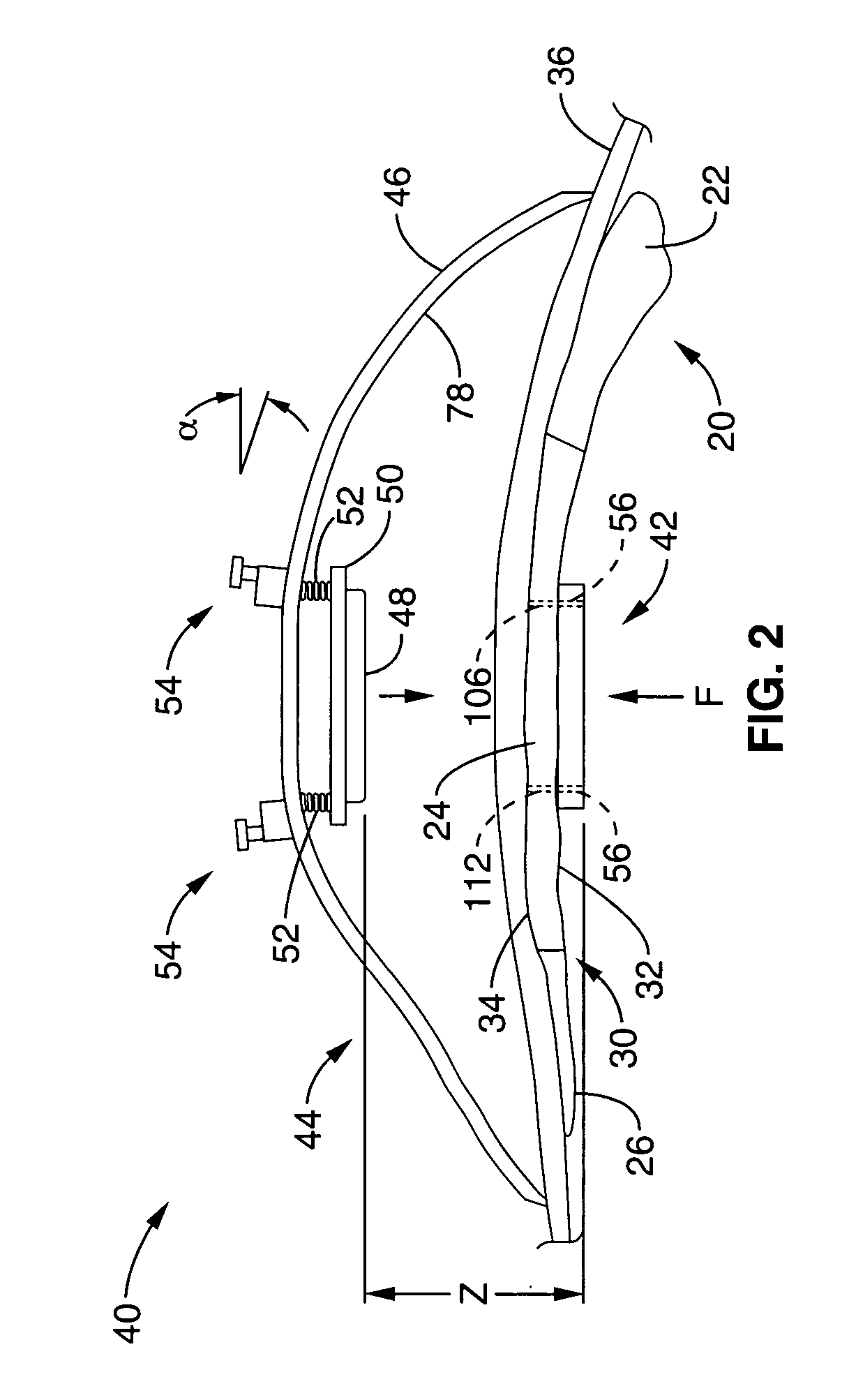

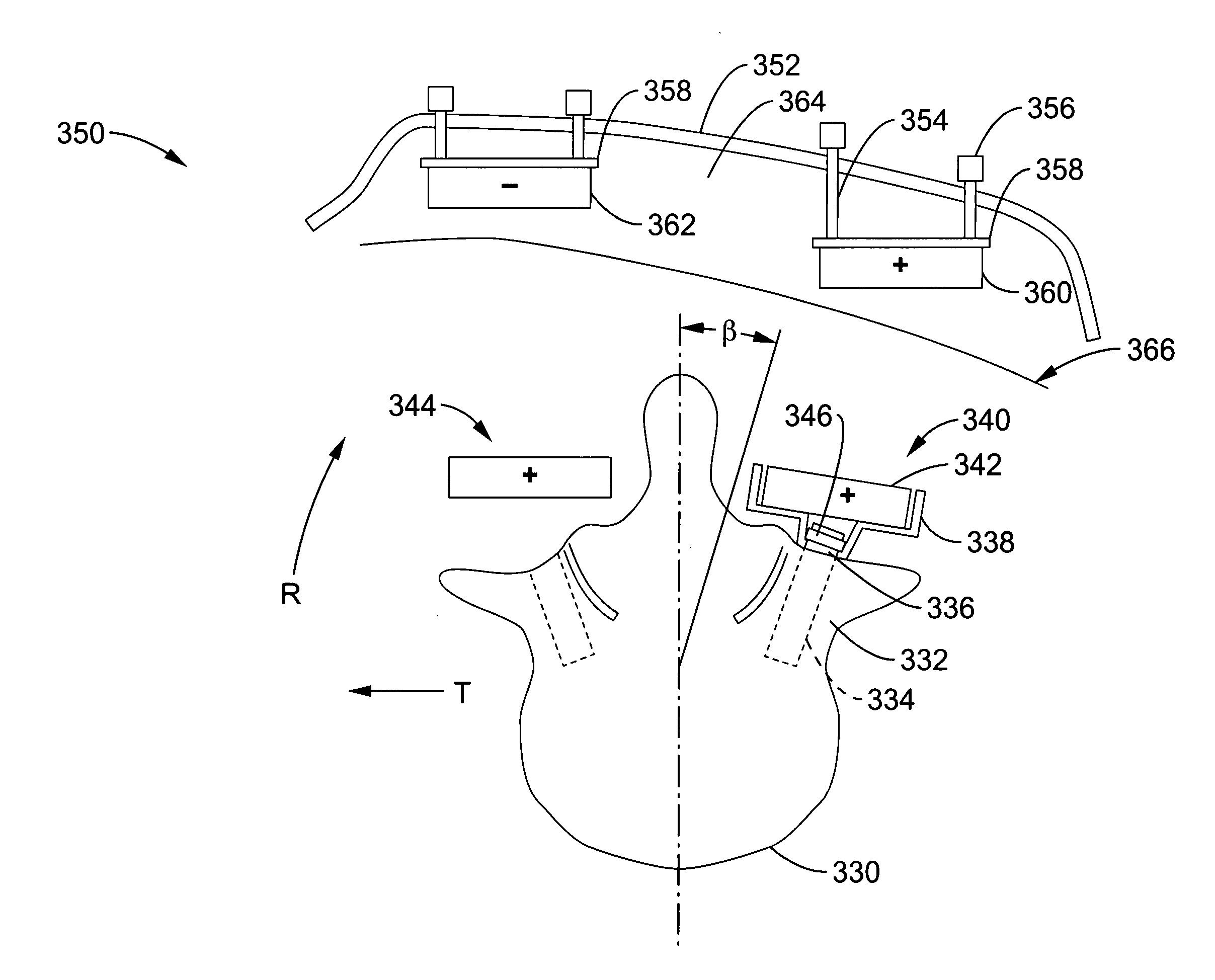

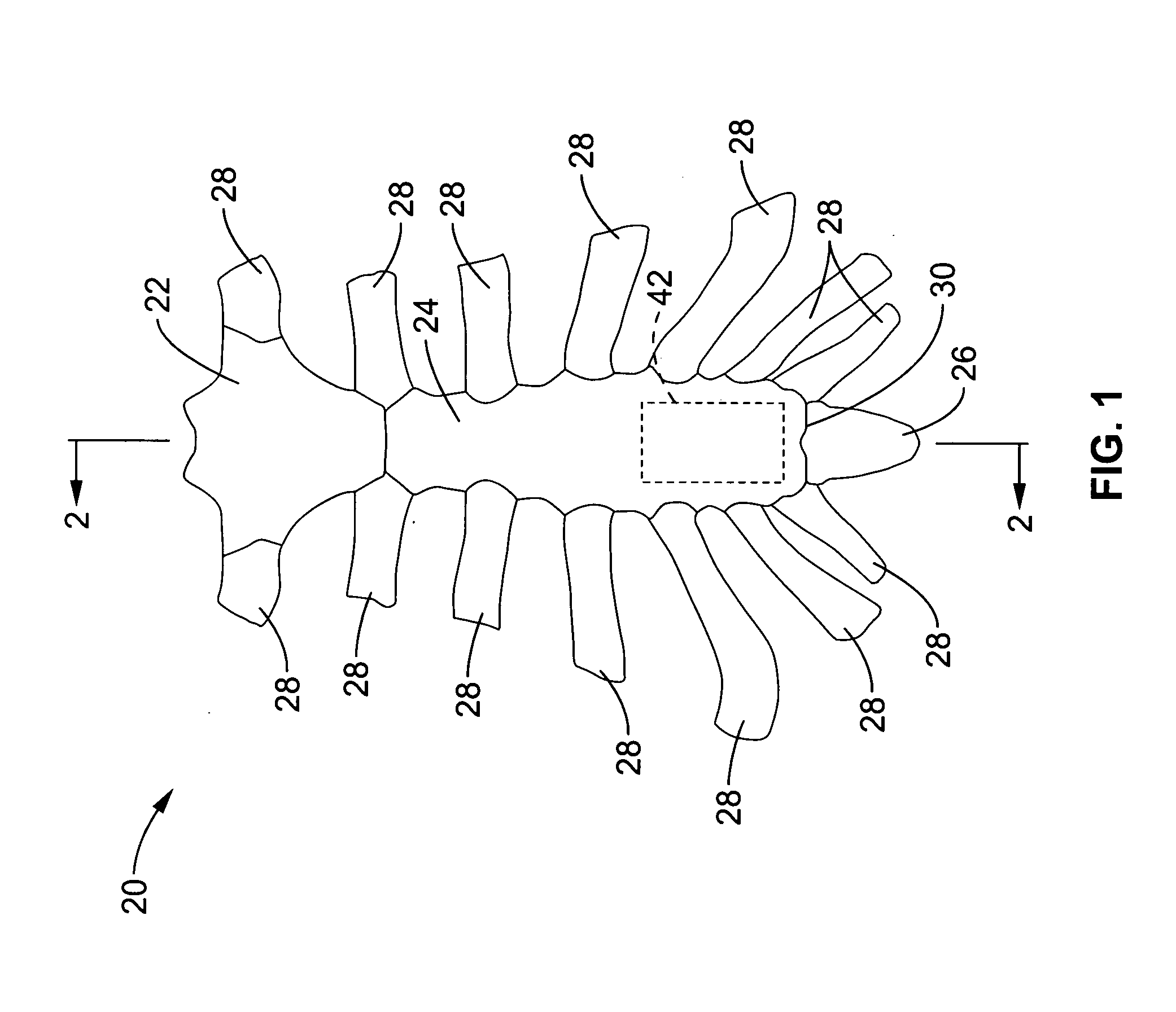

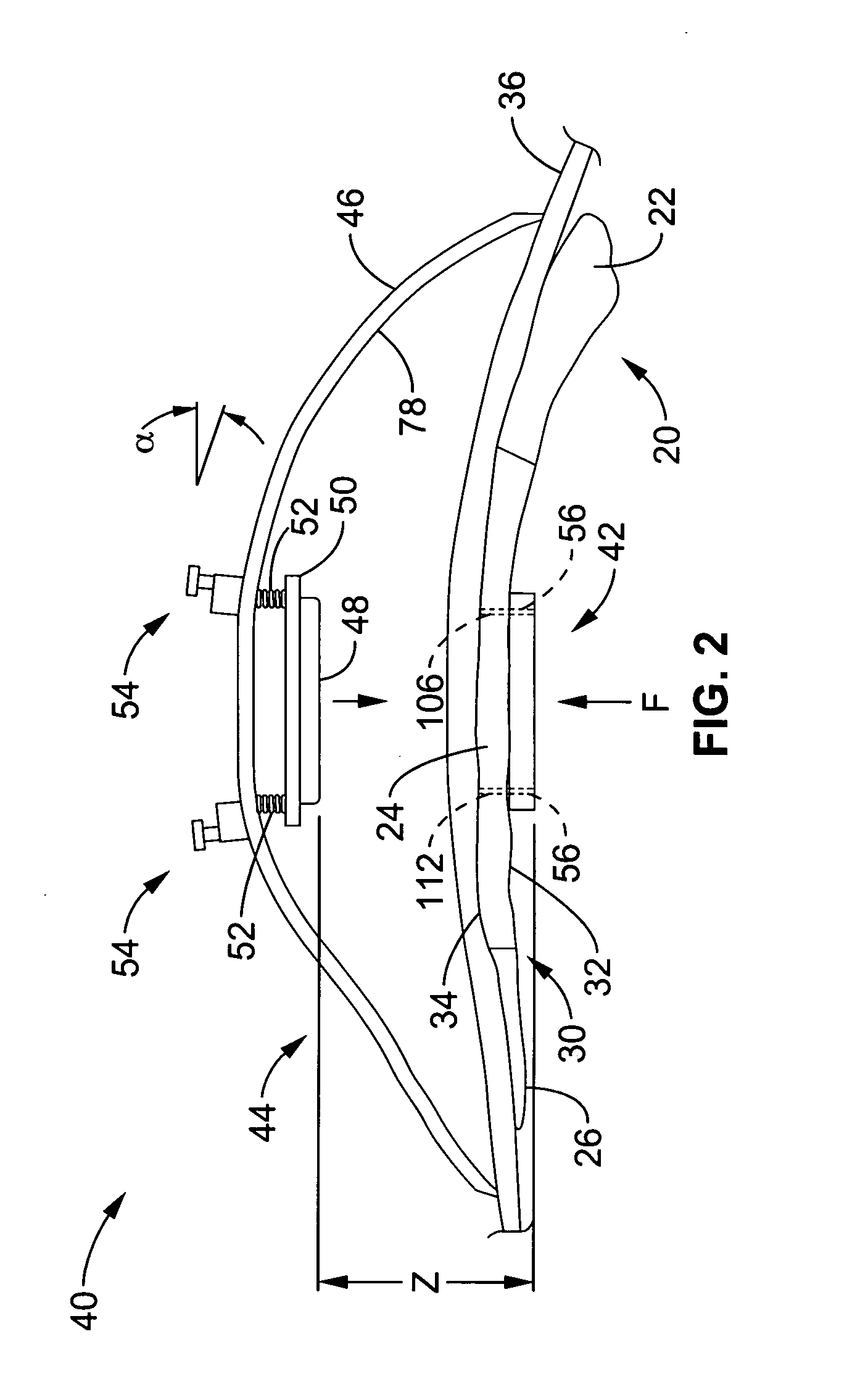

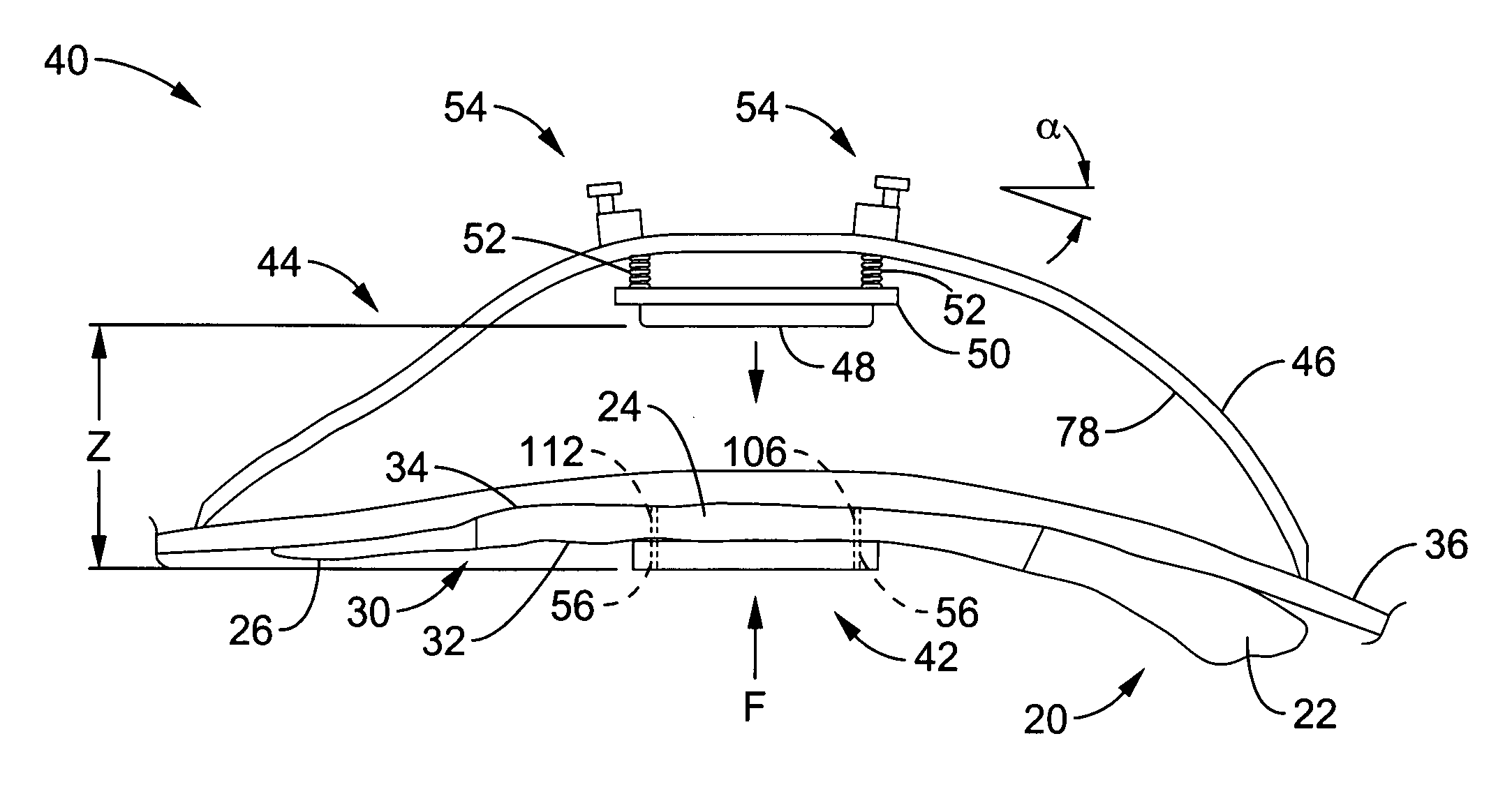

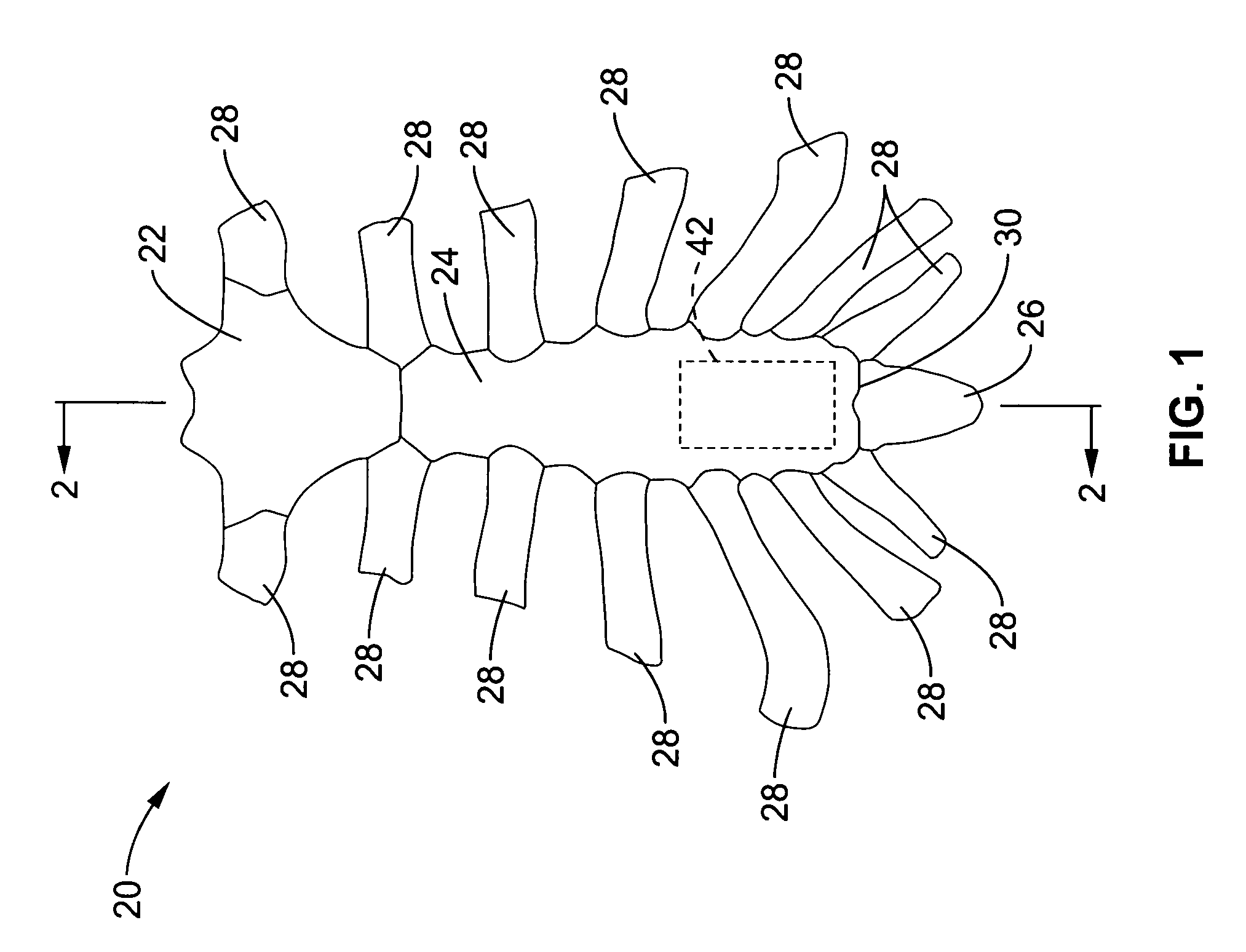

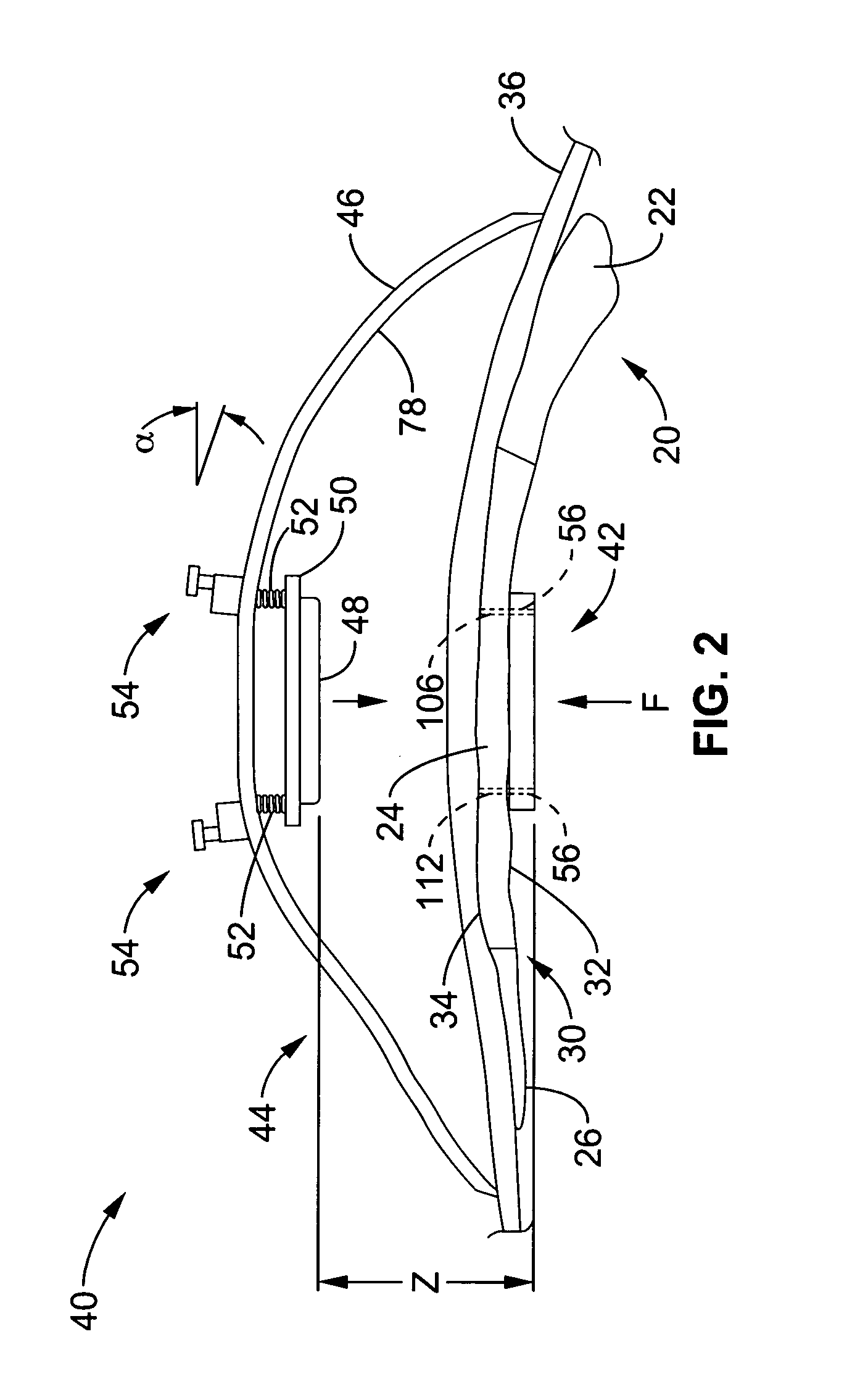

Apparatus and methods for magnetic alteration of anatomical features

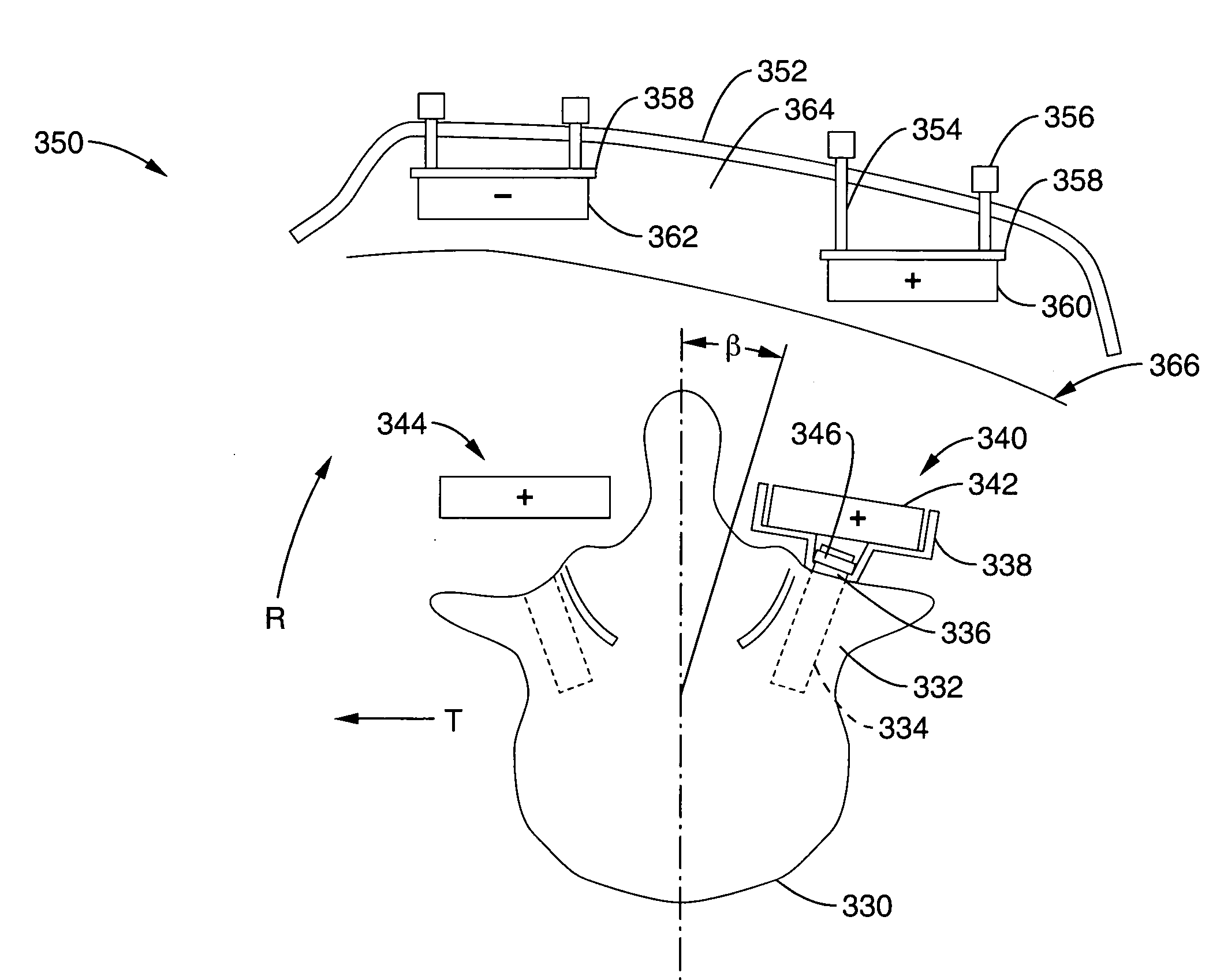

Methods and apparatus for incrementally manipulating a body member of a patient are disclosed. The apparatus has a magnetic implant adapted to be received on a location of the body member, a form external to the patient, and a magnetic member coupled to the form, wherein the magnetic member generates a magnetic force between the implant and the form to incrementally manipulate the body member. The implant and external magnetic member are preferably rare earth magnets or an array of rare earth magnets, and are configured to generate an attractive or repulsive force between the implant and the platform to reposition, reorient, deform, or lengthen the body member.

Owner:RGT UNIV OF CALIFORNIA

Apparatus and methods for magnetic alteration of deformities

Methods and apparatus for incrementally manipulating an internal body member of a patient are disclosed. The apparatus has a magnetic implant adapted to be received on a location of the body member, a platform external to the patient, and a magnetic member coupled to the platform, wherein the magnetic member generates a magnetic force between the implant and the platform to incrementally manipulate the body member. The implant and external magnetic member are preferably rare earth magnets or an array of rare earth magnets, and are configured to generate an attractive or repulsive force between the implant and the platform to reposition, reorient, deform, or lengthen the body member.

Owner:RGT UNIV OF CALIFORNIA

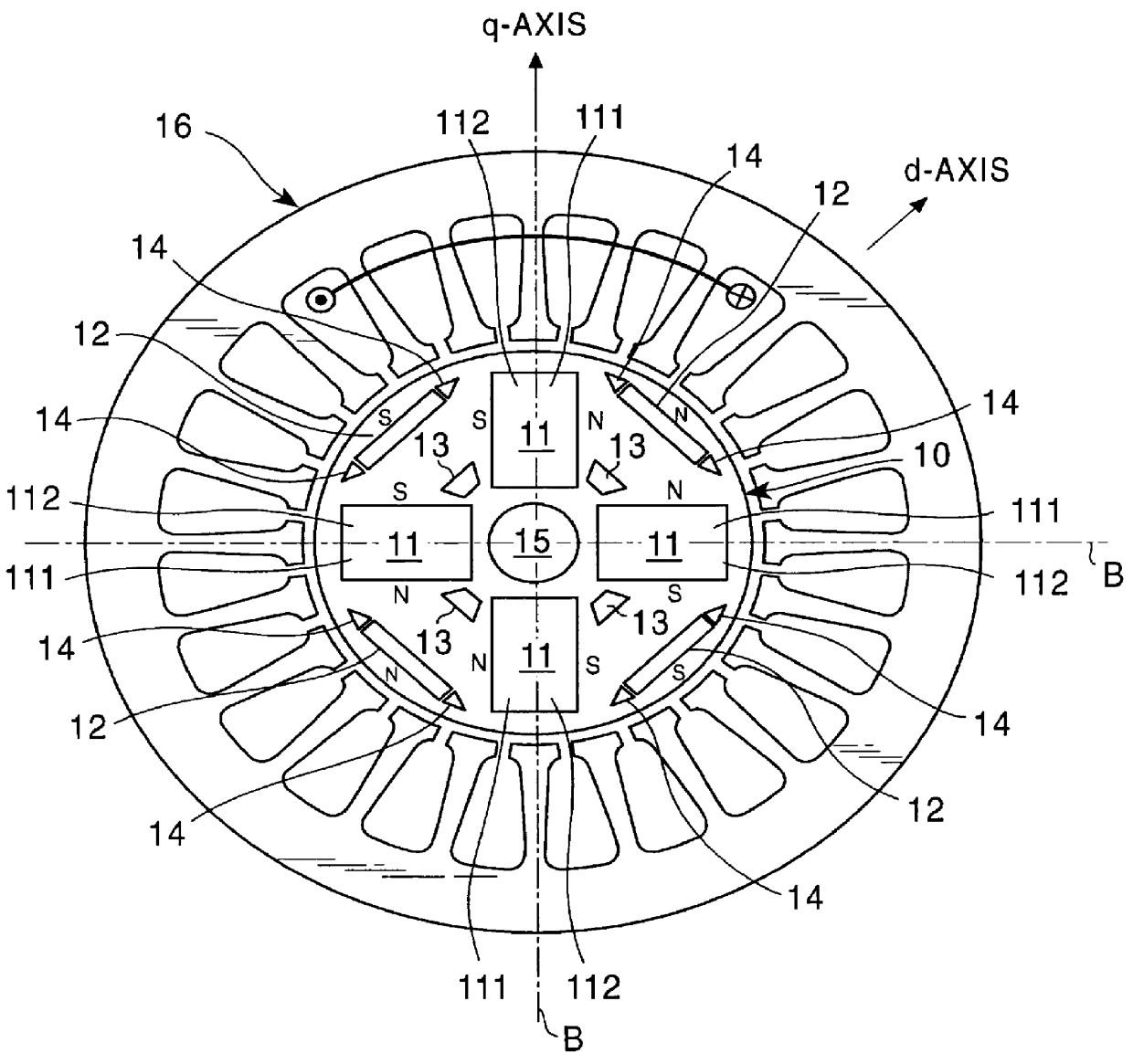

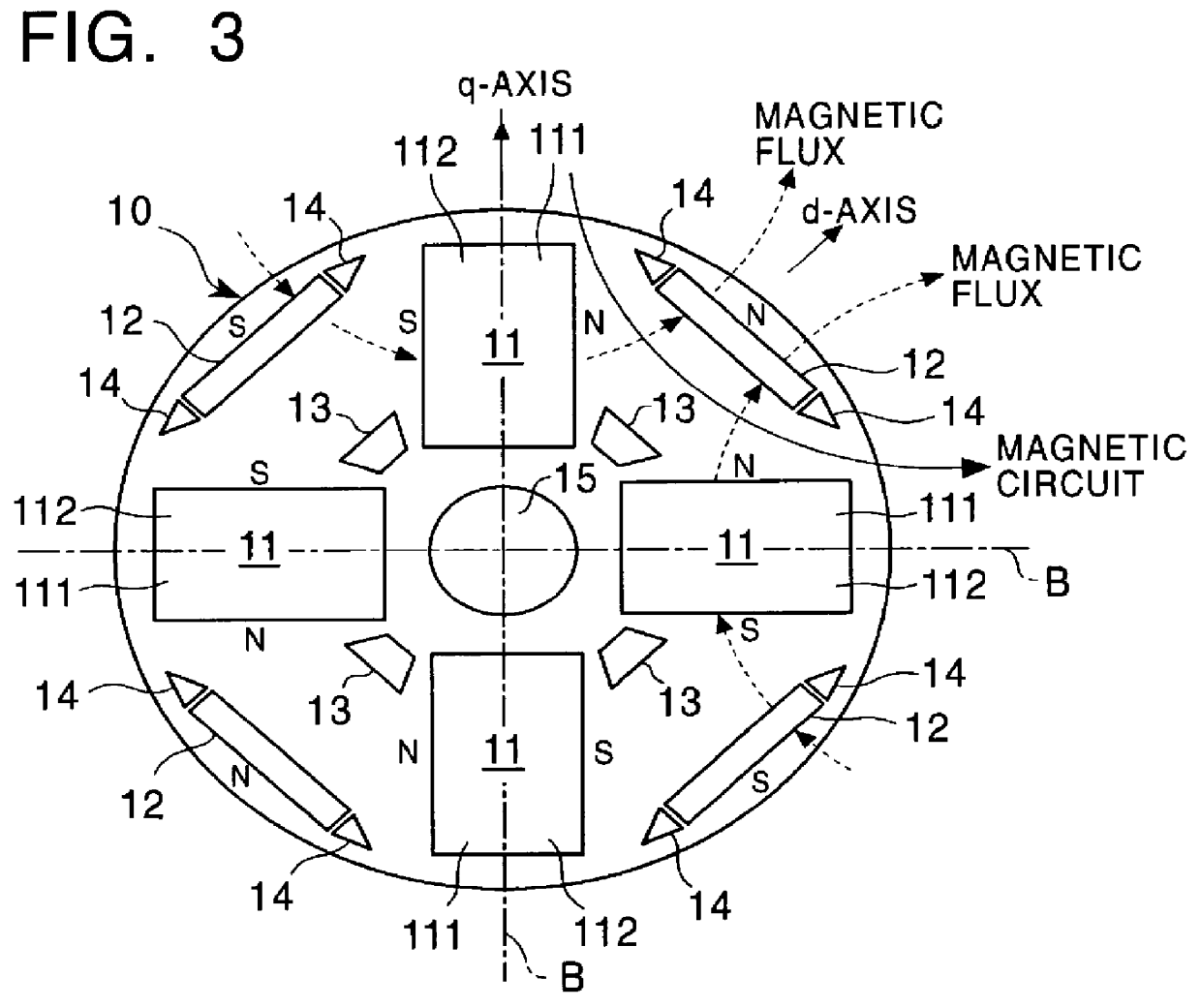

Permanent magnet rotor type electric motor with different permanent magnet materials

InactiveUS6025667AMagnetic circuit rotating partsManufacturing stator/rotor bodiesBrushless motorsPermanent magnet rotor

In an electric motor, such as a DC brushless motor or the like, having a permanent magnet in a rotor, each magnetic pole is formed of three permanent magnets, and the permanent magnets are made of at least two kinds of magnetic materials represented by ferrite magnet and rare-earth magnet. Thus, in a permanent magnet rotor type electric motor, a reluctance torque and a magnetic flux density can be selectively established, and cost is reasonable, corresponding to the quality.

Owner:FUJITSU GENERAL LTD

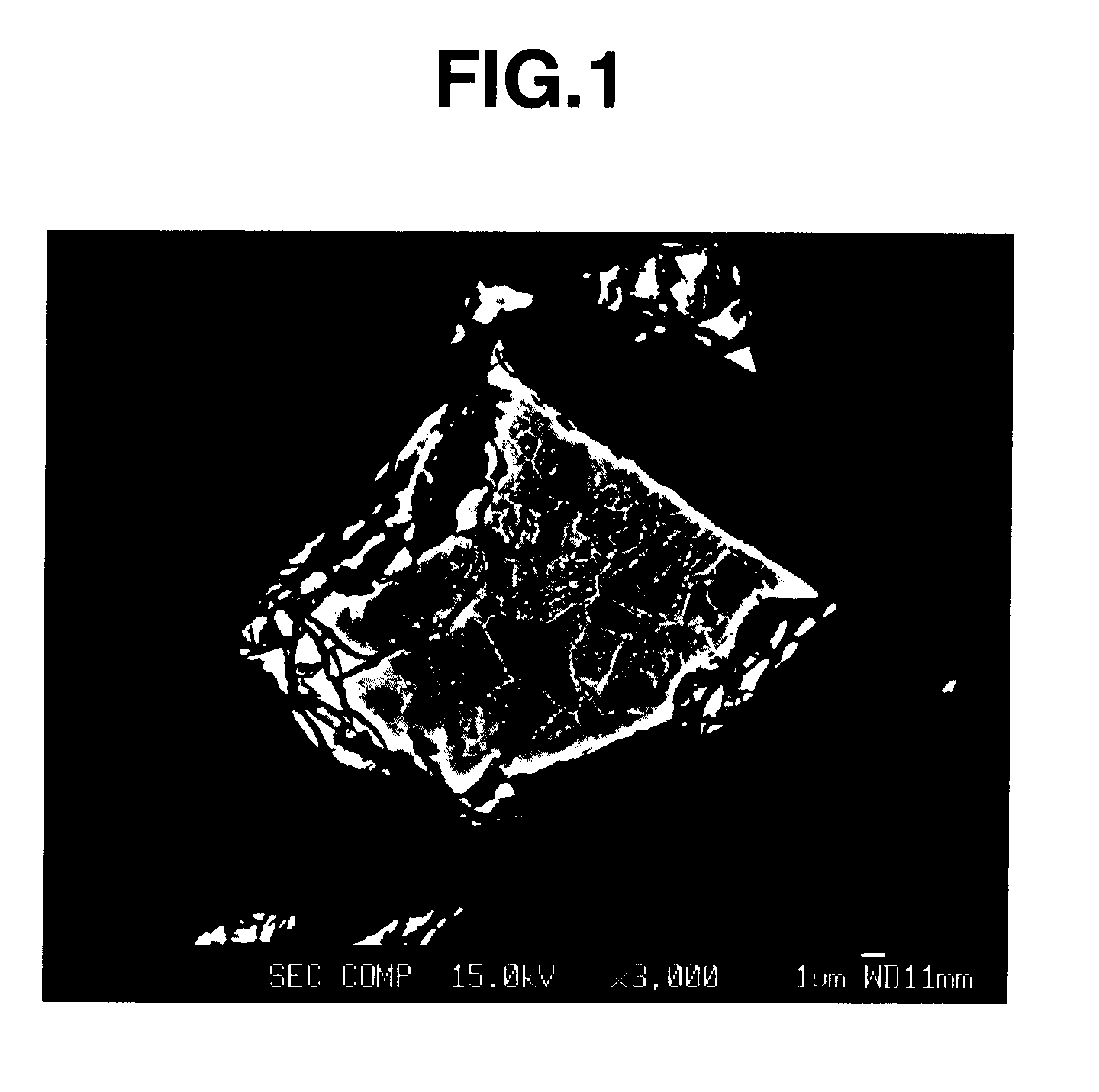

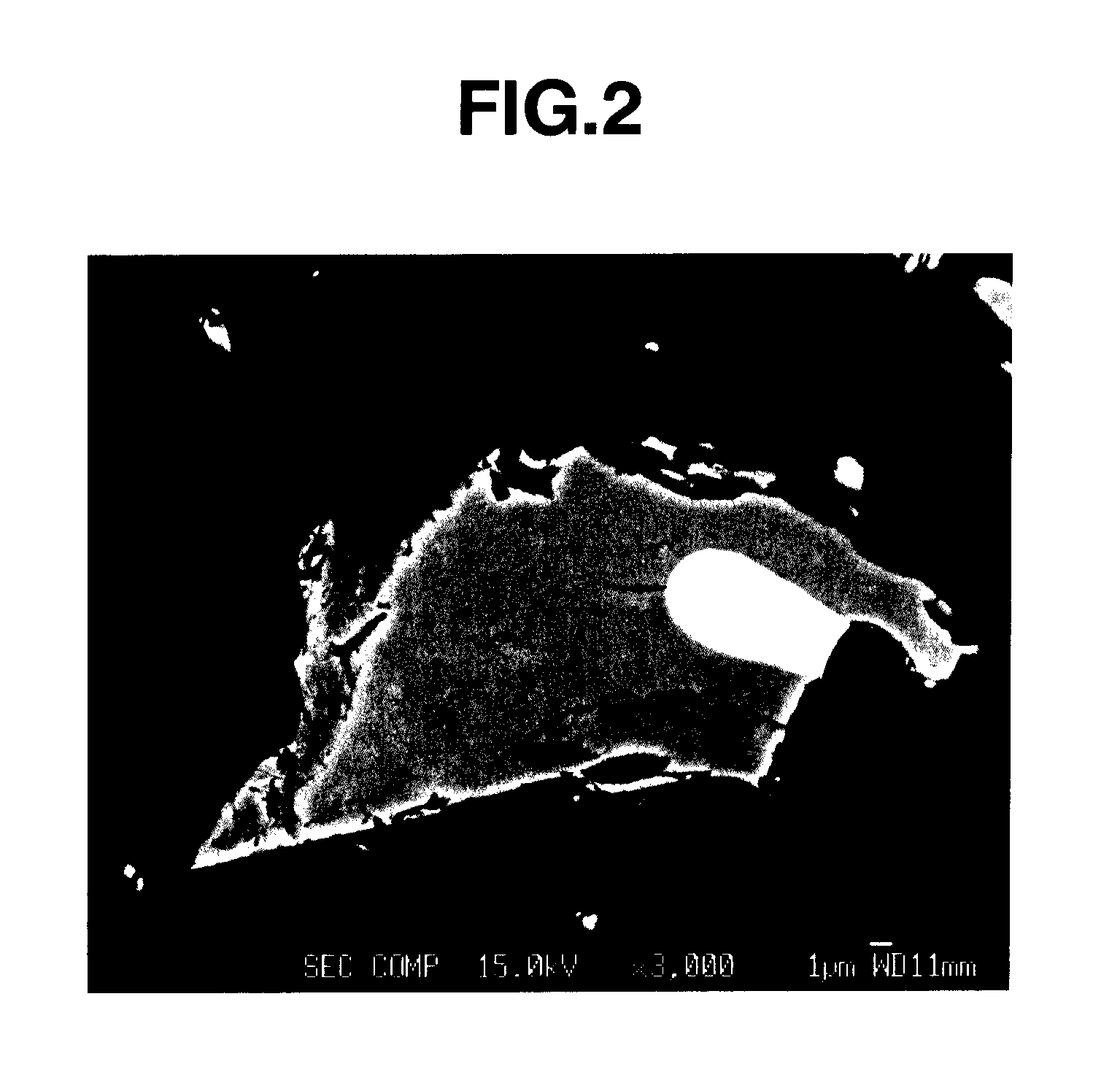

Rare earth magnet and method therefor

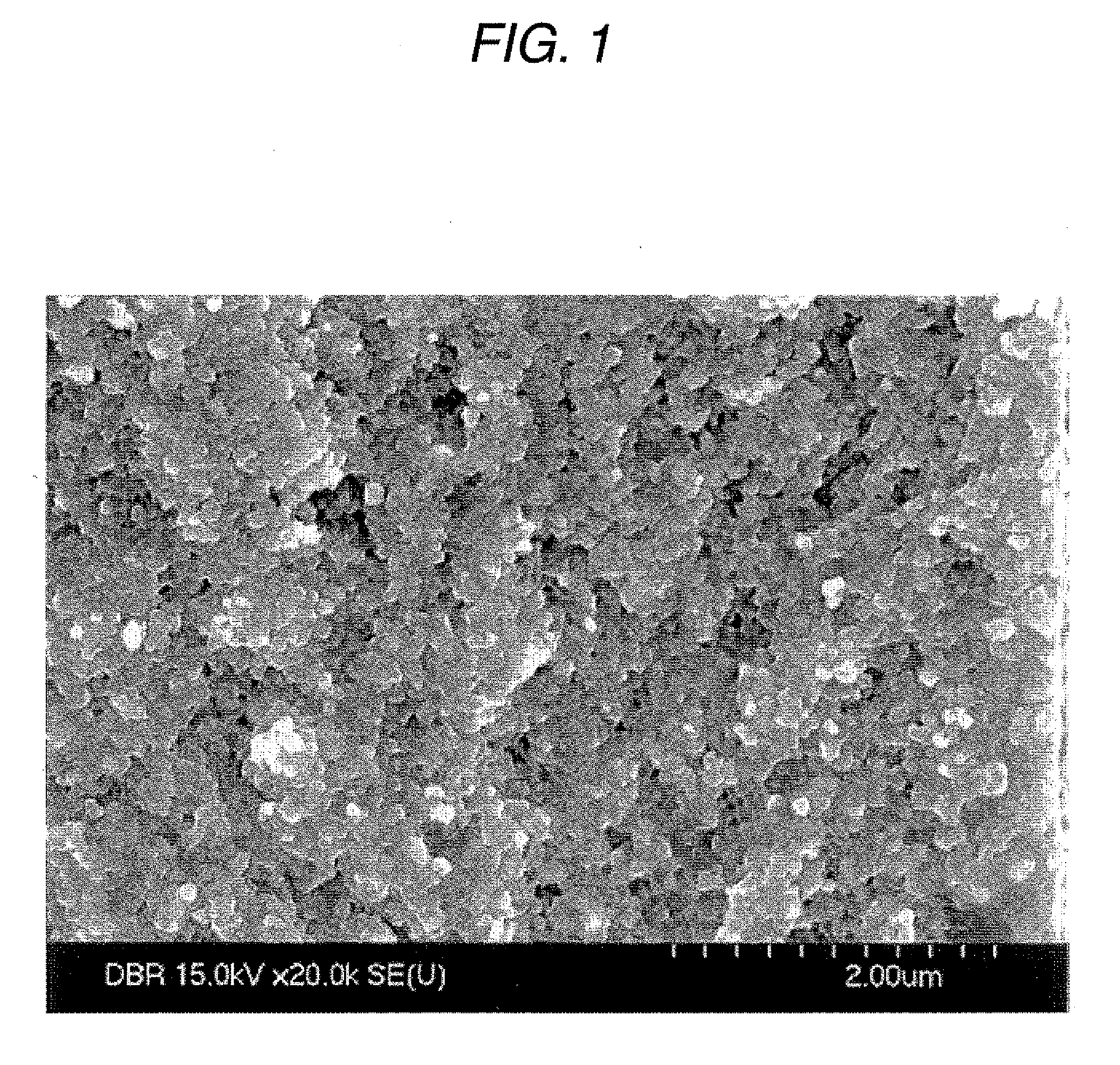

InactiveUS20050133117A1Increase resistanceReduced characteristicsMagnetic circuit rotating partsInorganic material magnetismEddy currentRare-earth magnet

A rare earth magnet includes rare earth magnet particles; and amorphous and / or crystalline terbium oxide present at the boundary of the rare earth magnet particles and represented by the formula: TbOn, wherein 1.5<n≦2. The rare earth magnet prevents decrease eddy current effectively.

Owner:NISSAN MOTOR CO LTD

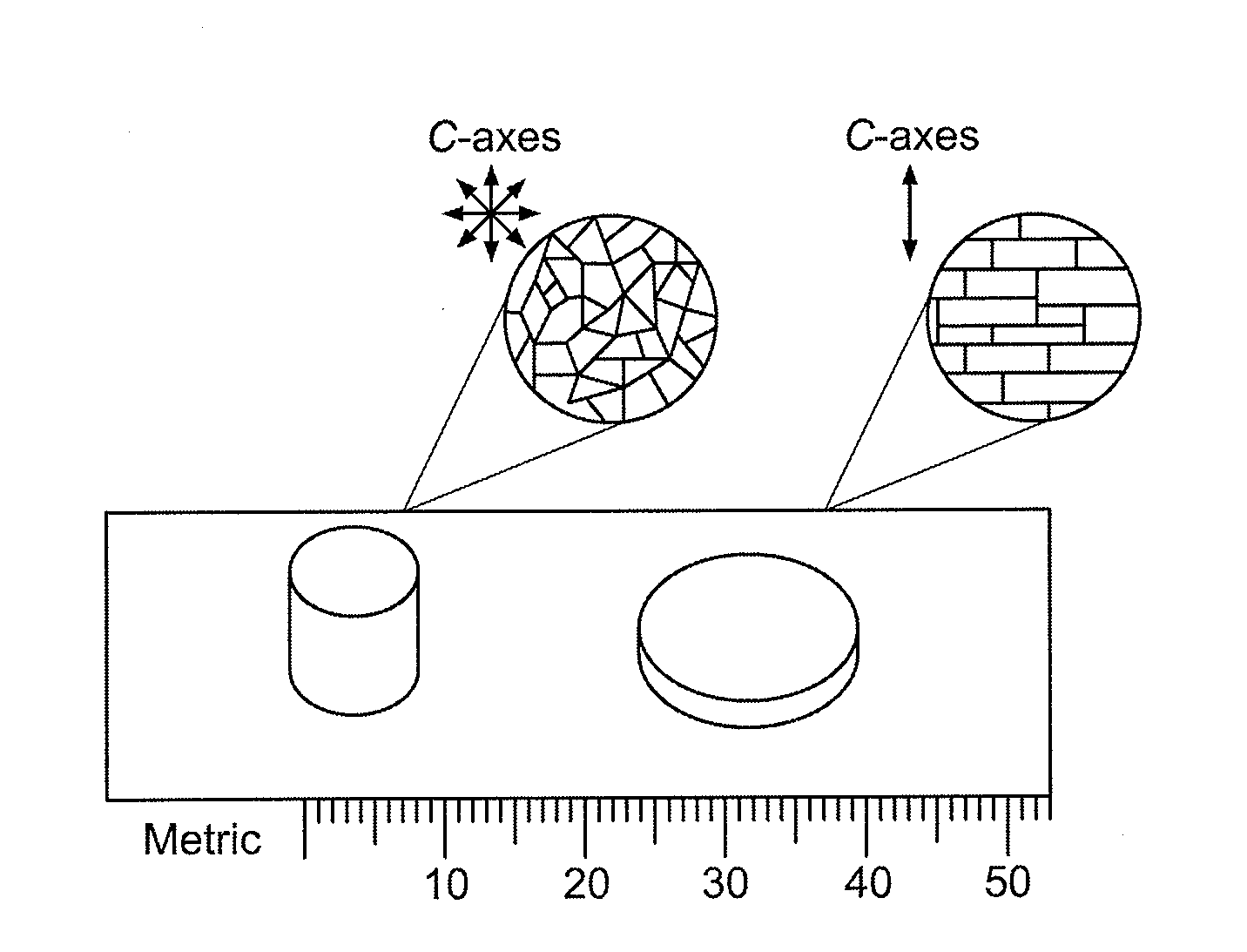

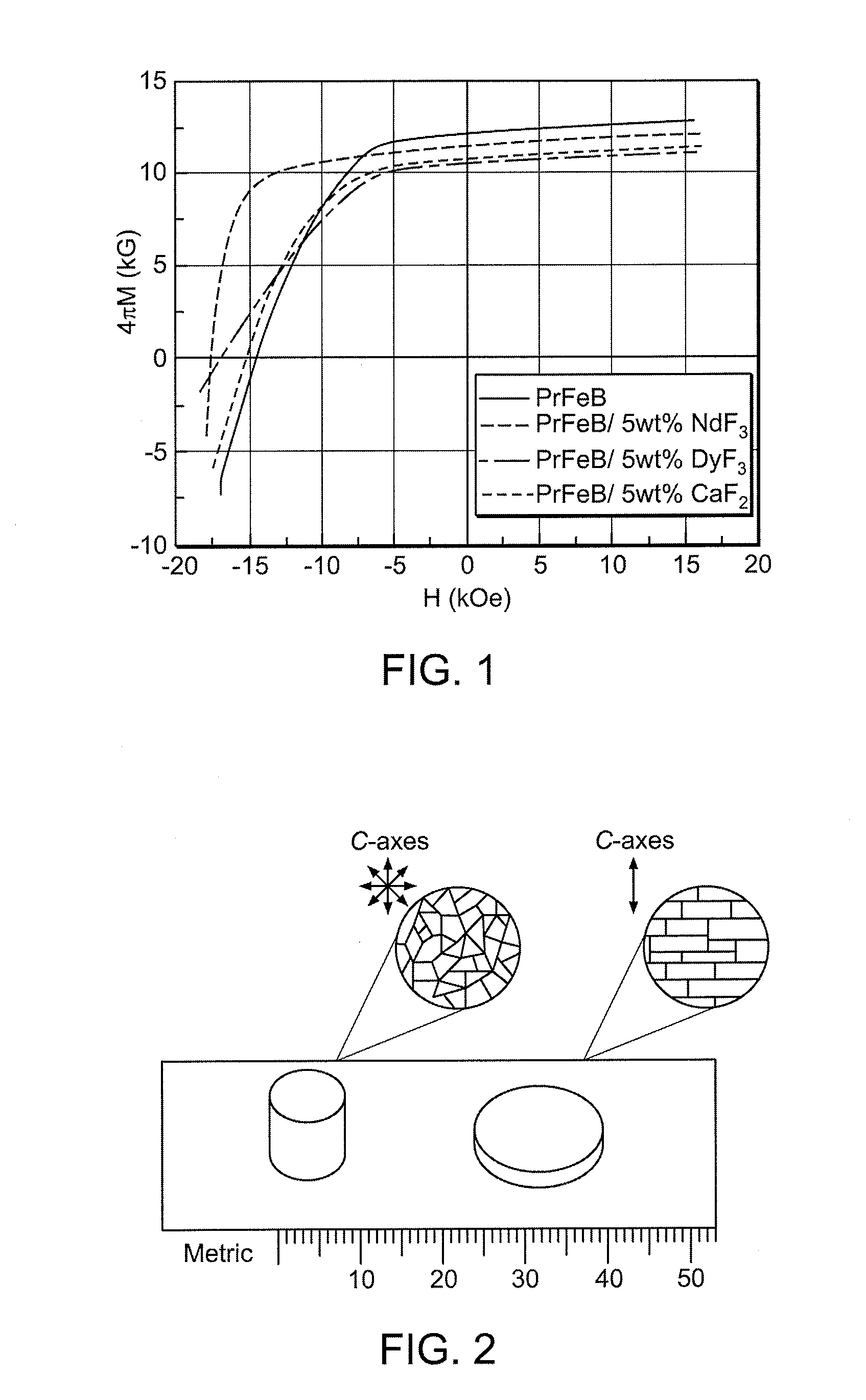

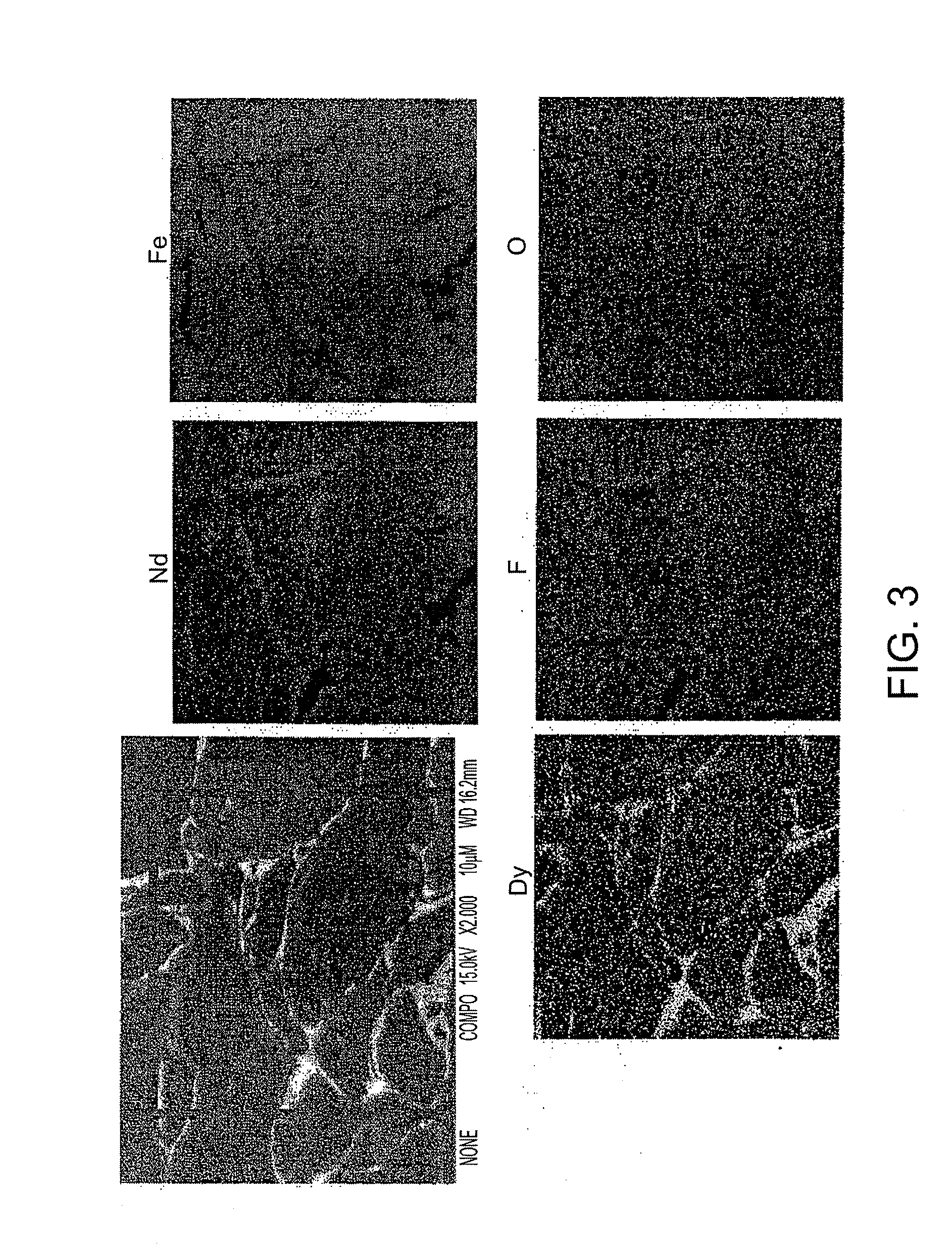

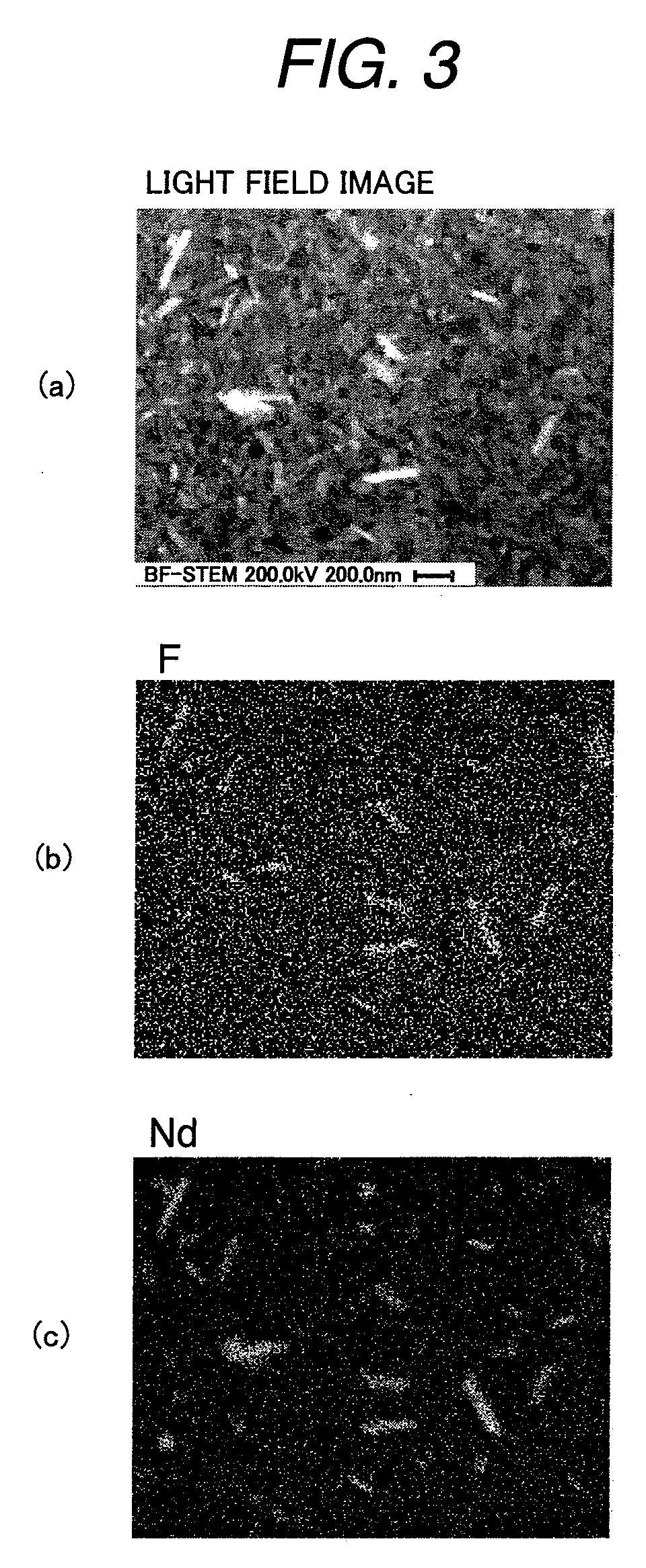

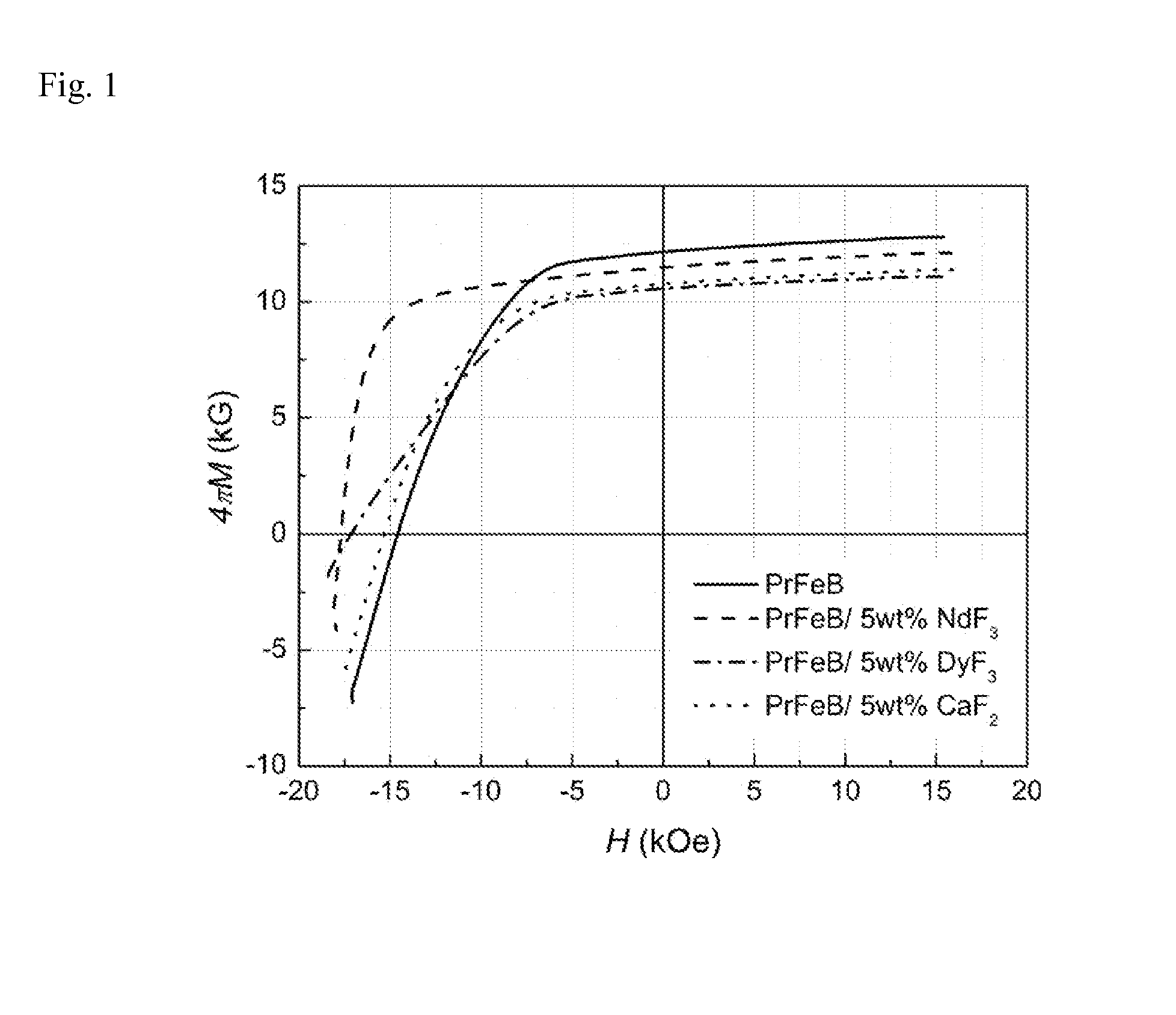

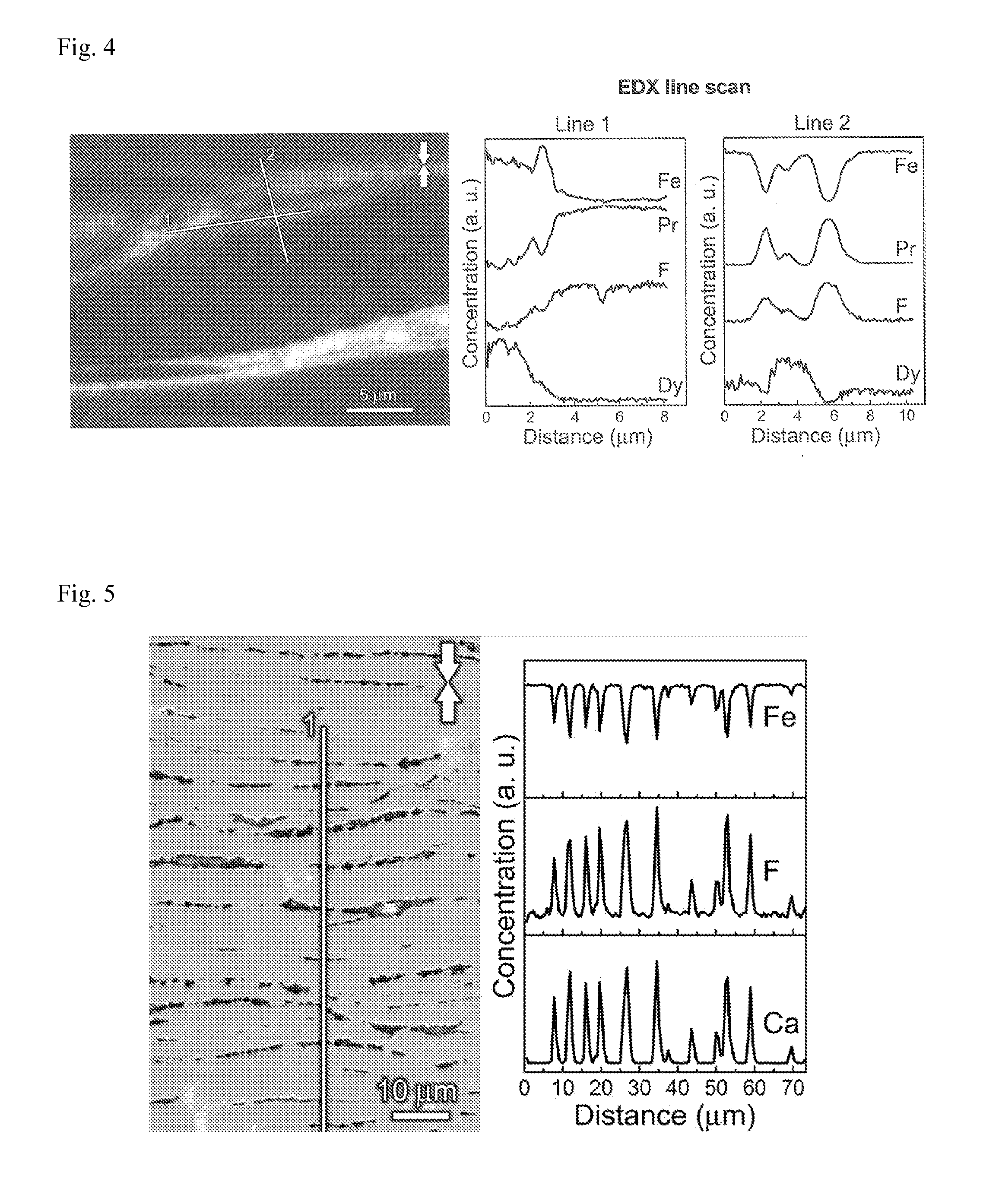

Rare Earth Composite Magnets with Increased Resistivity

InactiveUS20110057756A1Increased electrical resistivityReduce eddy current lossTransportation and packagingMetal-working apparatusDielectricHigh resistivity

Dielectric rare earth fluorides are blended with rare earth magnet powders to produce high-resistivity fluoride composite rare earth magnets.

Owner:ELECTRON ENERGY CORP +1

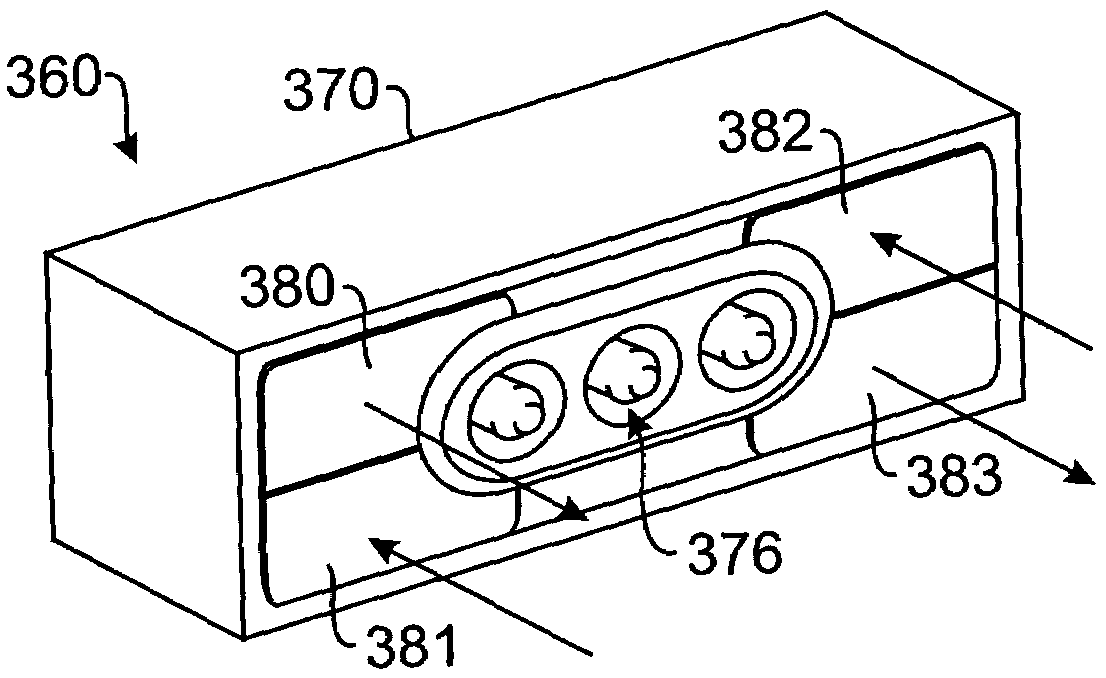

Apparatus and methods for magnetic alteration of deformities

Methods and apparatus for incrementally manipulating an internal body member of a patient are disclosed. The apparatus has a magnetic implant adapted to be received on a location of the body member, a platform external to the patient, and a magnetic member coupled to the platform, wherein the magnetic member generates a magnetic force between the implant and the platform to incrementally manipulate the body member. The implant and external magnetic member are preferably rare earth magnets or an array of rare earth magnets, and are configured to generate an attractive or repulsive force between the implant and the platform to reposition, reorient, deform, or lengthen the body member.

Owner:RGT UNIV OF CALIFORNIA

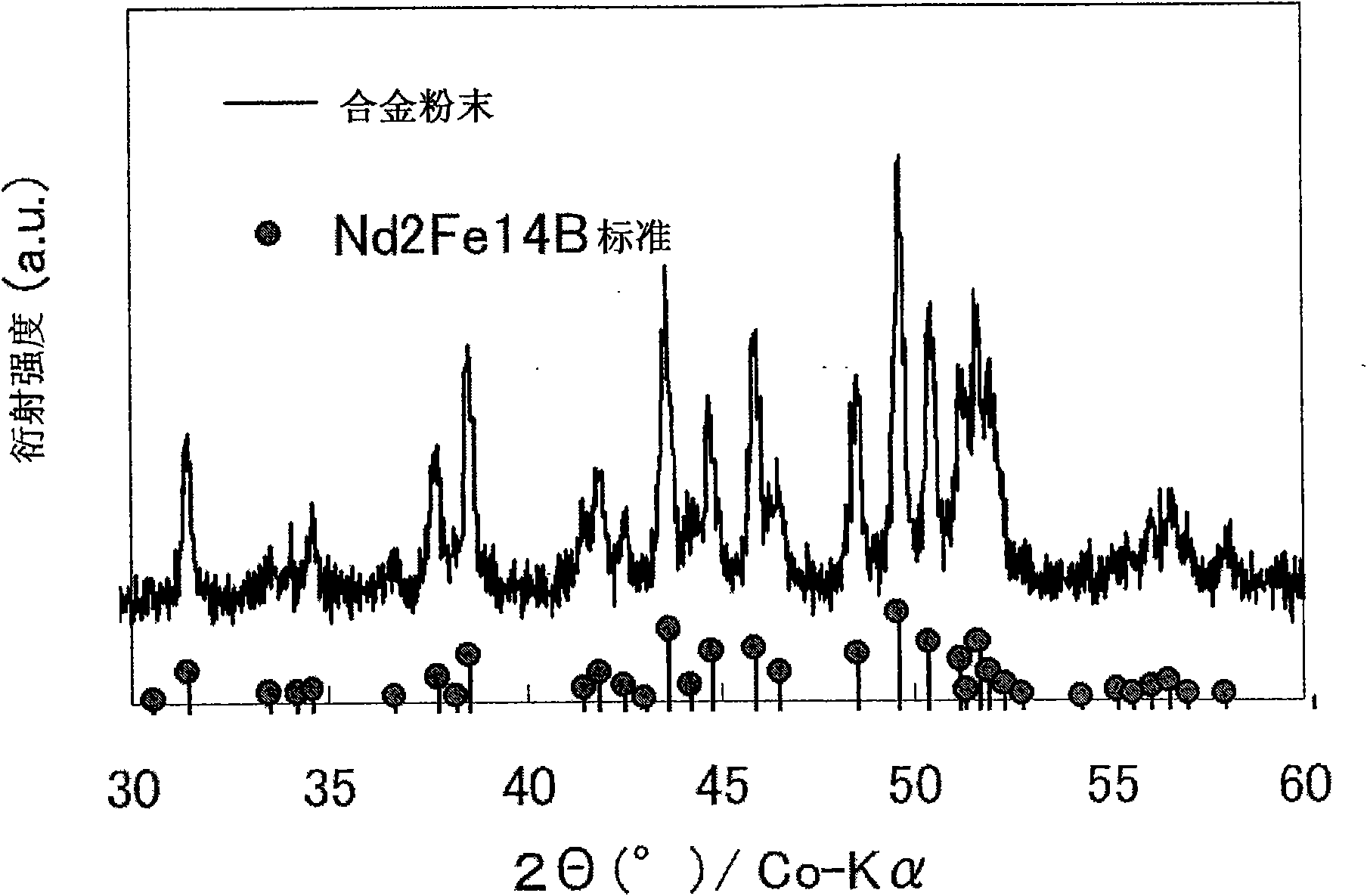

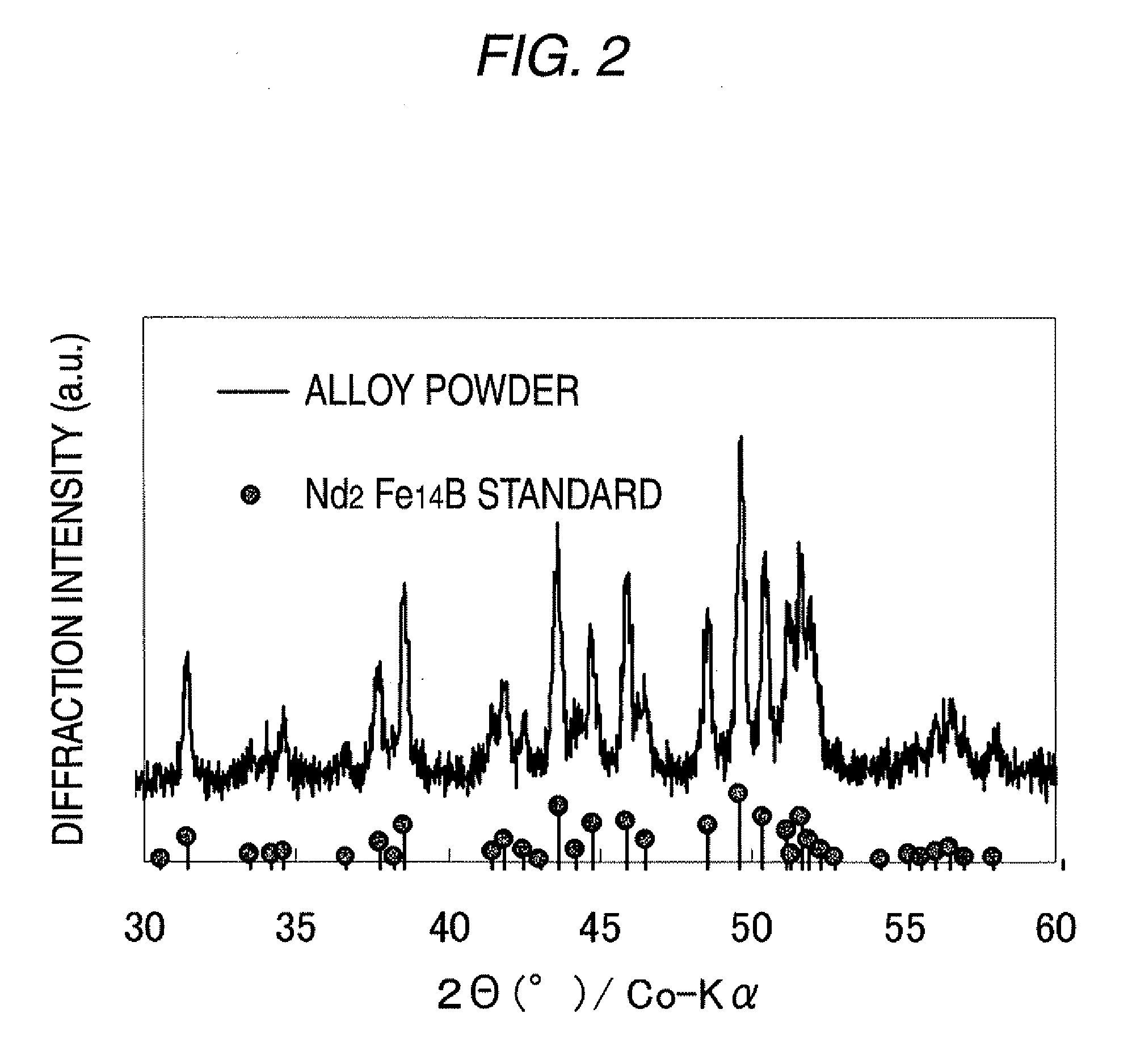

Method of making material alloy for iron-based rare earth magnet

InactiveUS6695929B2Good reproducibilityUniform structureNanomagnetismInorganic material magnetismRare-earth elementRare-earth magnet

A melt of an iron-based rare earth material alloy, represented by (Fe1-mTm)100-x-y-zQxRyMz, is prepared, wherein T is Co and / or Ni; Q is B and / or C; R is selected from Y (yttrium) and the rare earth elements; M is selected from Al, Si, Ti, V, Cr, Mn, Cu, Zn, Ga, Zr, Nb, Mo, Ag, Hf, Ta, W, Pt, Au and Pb; 10<=x<=30 at %; 2%<=y<10 at %; 0<=z<=10 at % and 0<=m<=0.5. The melt is fed onto a guide to form a flow of the melt thereon and move the melt onto a melt / chill roller contact region, where the melt is rapidly cooled by the chill roller to make a rapidly solidified alloy. An oxygen concentration of the melt yet to be fed onto the guide is controlled at about 3,000 ppm or less in mass percentage.

Owner:SUMITOMO SPECIAL METAL CO LTD

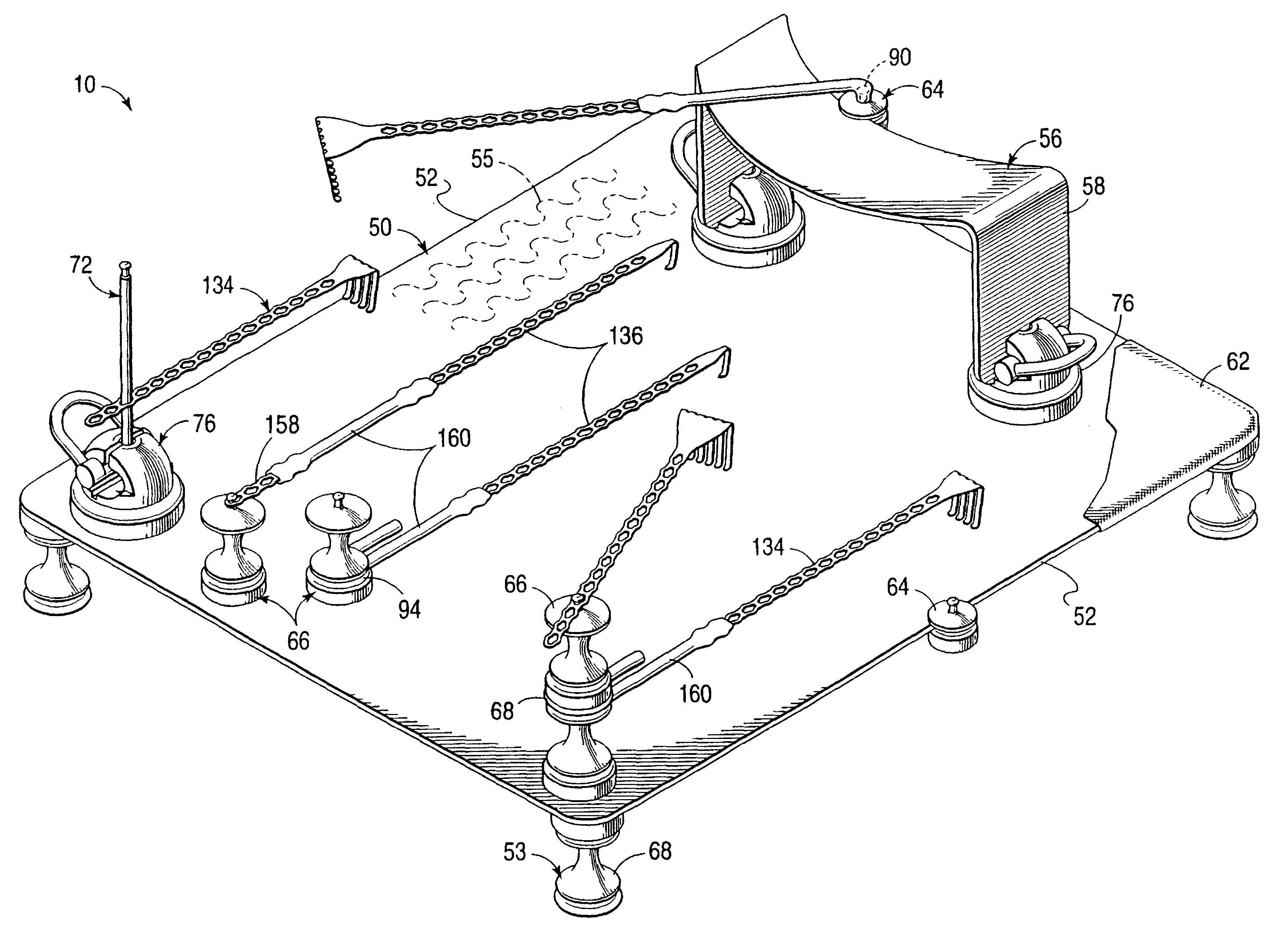

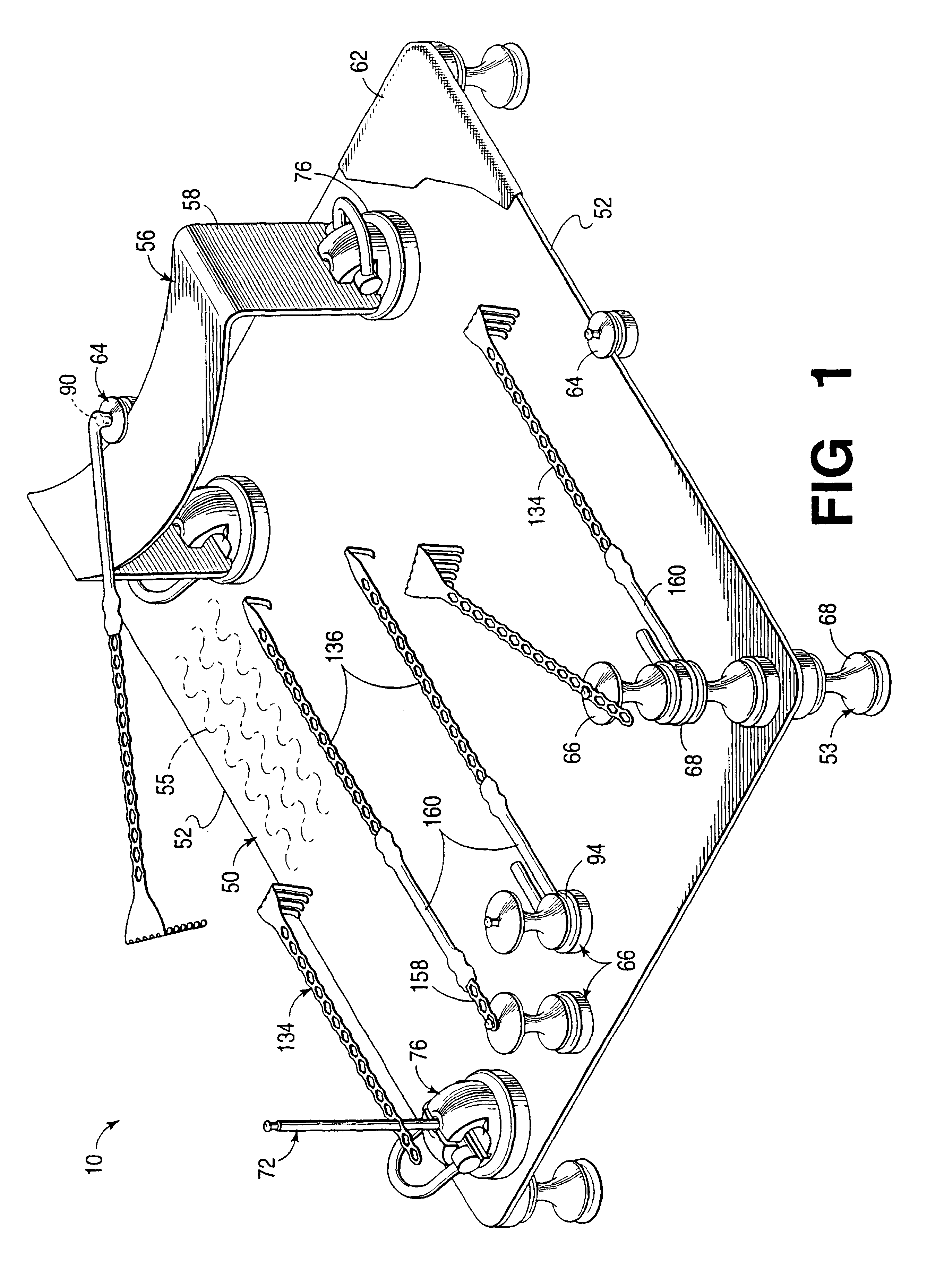

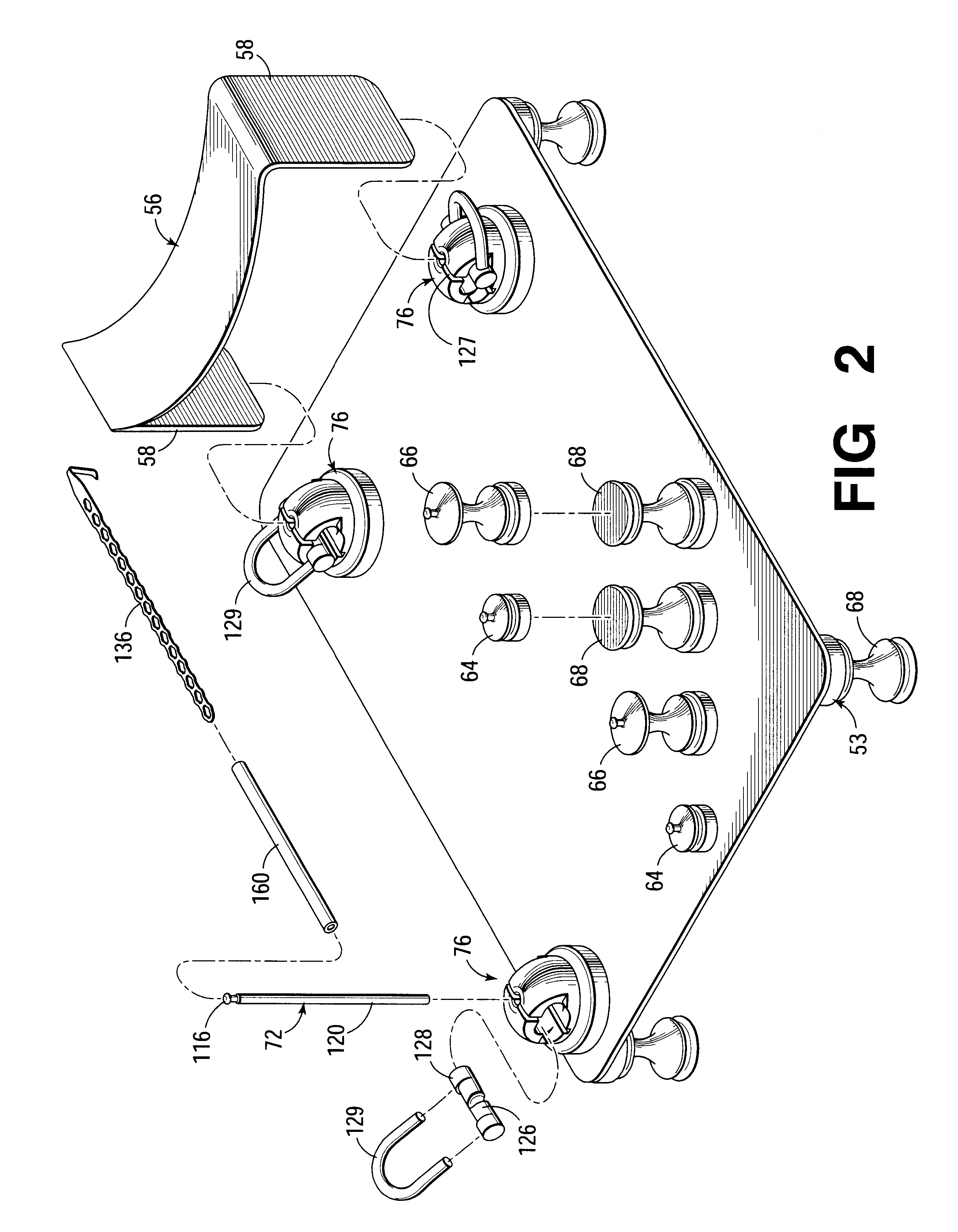

Surgical fixation and retraction system

A fixation and retraction system utilizing base components to which shielded magnet components attach in order to locate movable fixation and retraction components or other operating theater devices, such as surgical drapes. Use of rare earth magnets permits system components to be attached quickly, easily and securely in almost an infinite number of configurations.

Owner:CANICA DESIGNE

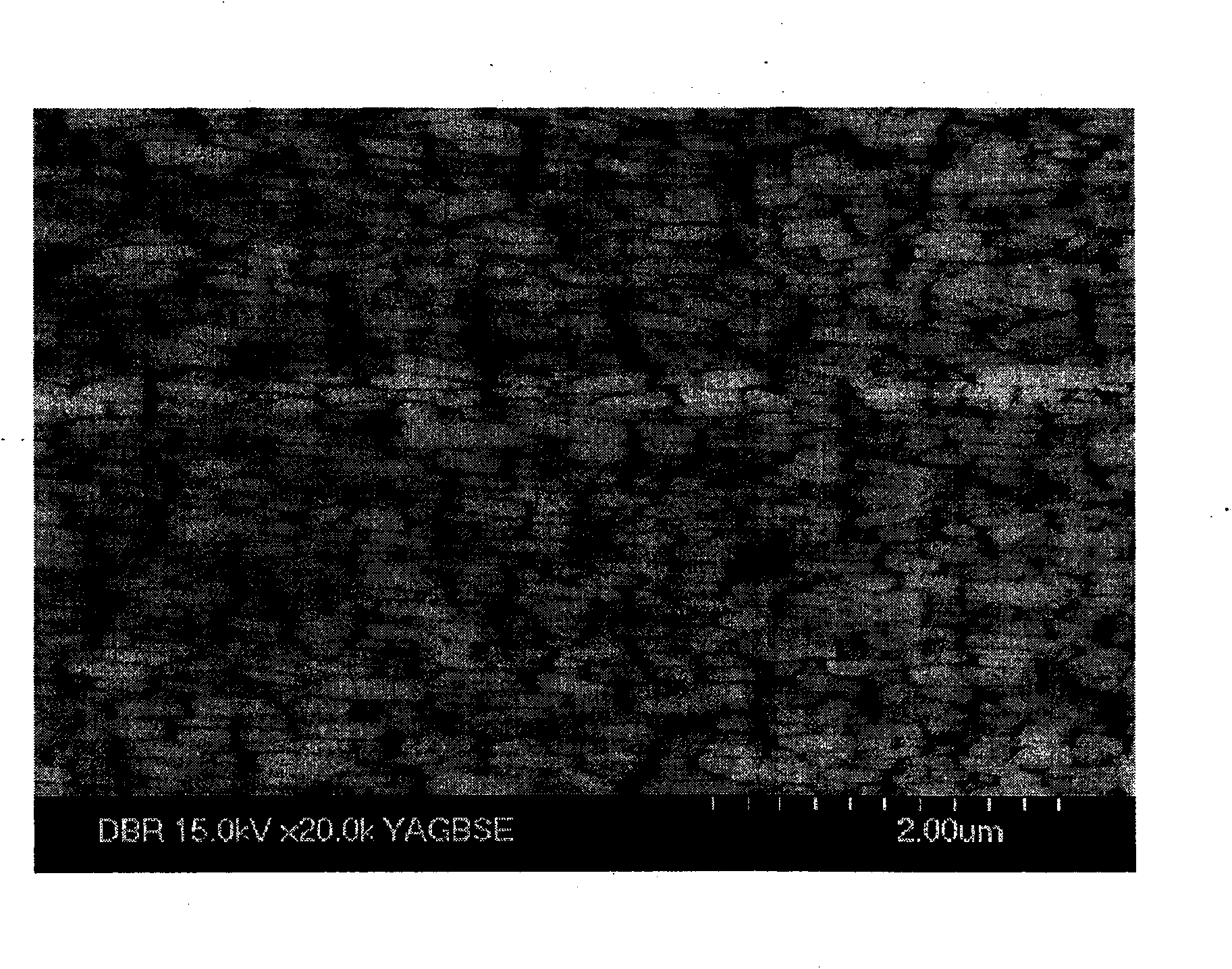

Rare earth magnet and production process thereof

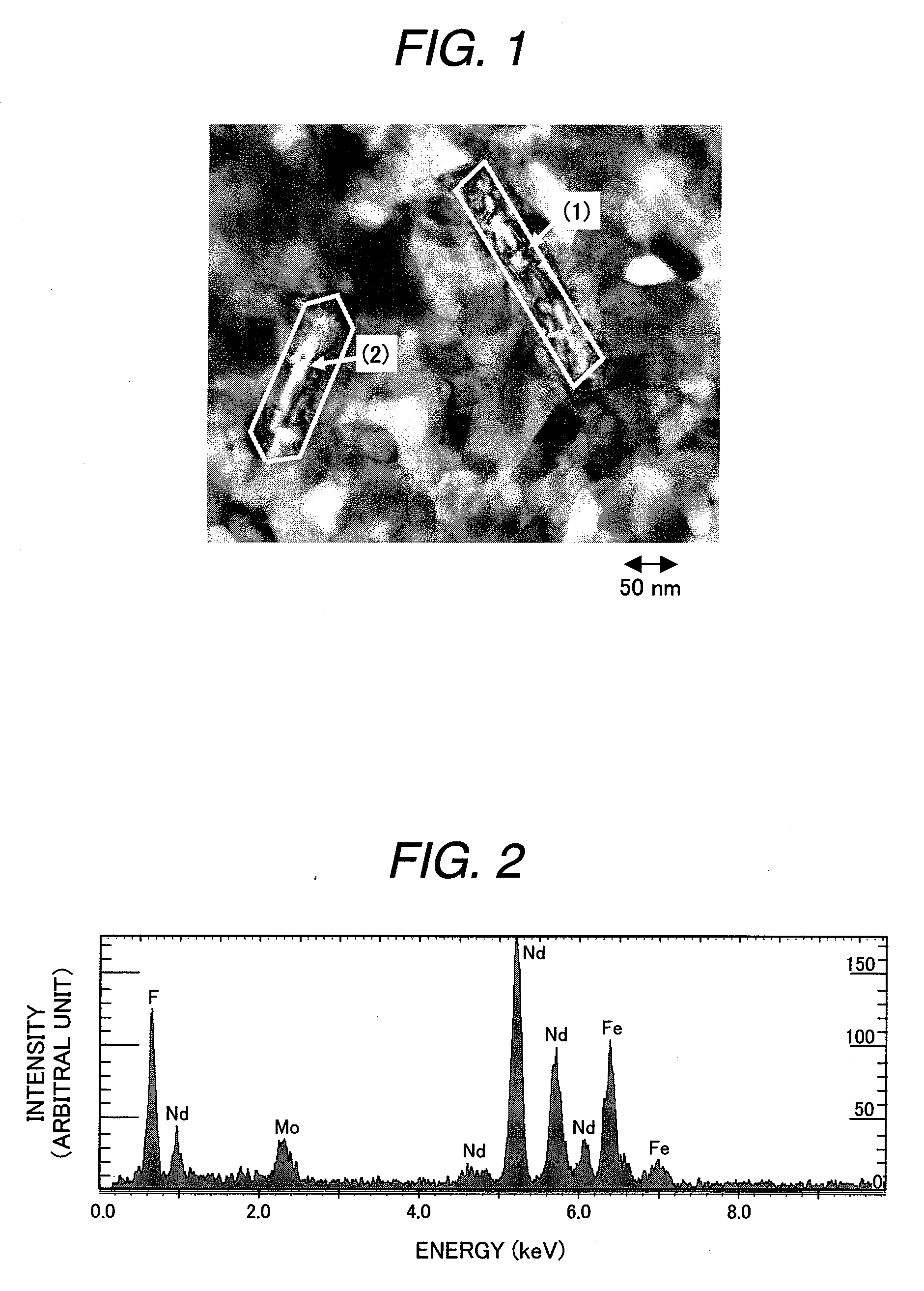

InactiveCN101640087ATransportation and packagingMetal-working apparatusRare-earth magnetGrain boundary

The present invention provides a rare earth magnet, which is formed through at least hot molding, the rare earth magnet containing grains including an R 2 X 14 B phase as a main phase, and a grain boundary phase surrounding peripheries of the grains, in which R is at least one element selected from the group consisting of Nd, Pr, Dy, Tb and Ho, and X is Fe or Fe with a part being substituted by Co; in which an element RH is more concentrated in the grain boundary phase than in the grains, in which the element RH is at least one element selected from the group consisting of Dy, Tb and Ho; and the element RH is present with a substantially constant concentration distribution from the surface part of the magnet to the central part of the magnet.

Owner:DAIDO STEEL CO LTD

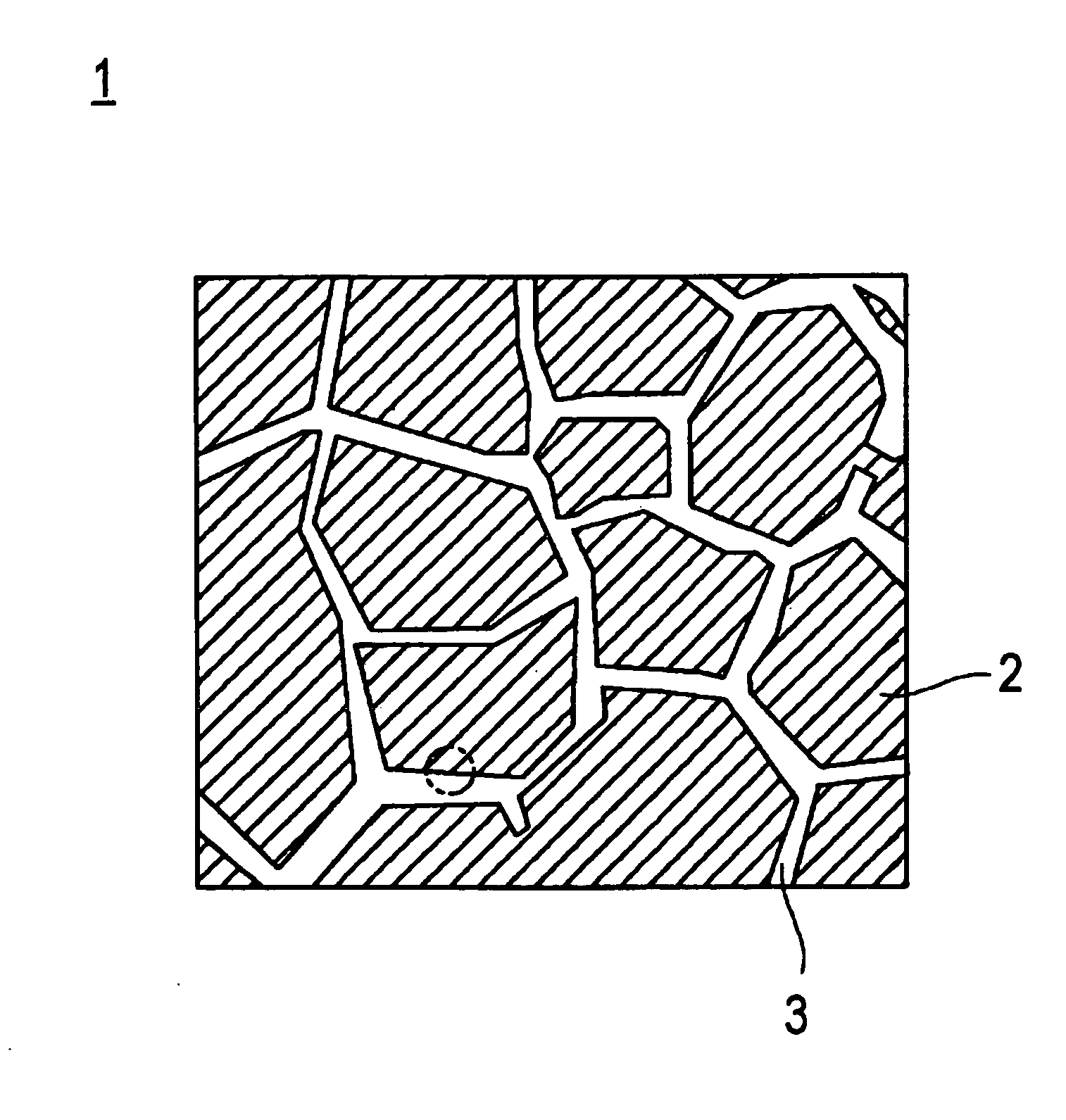

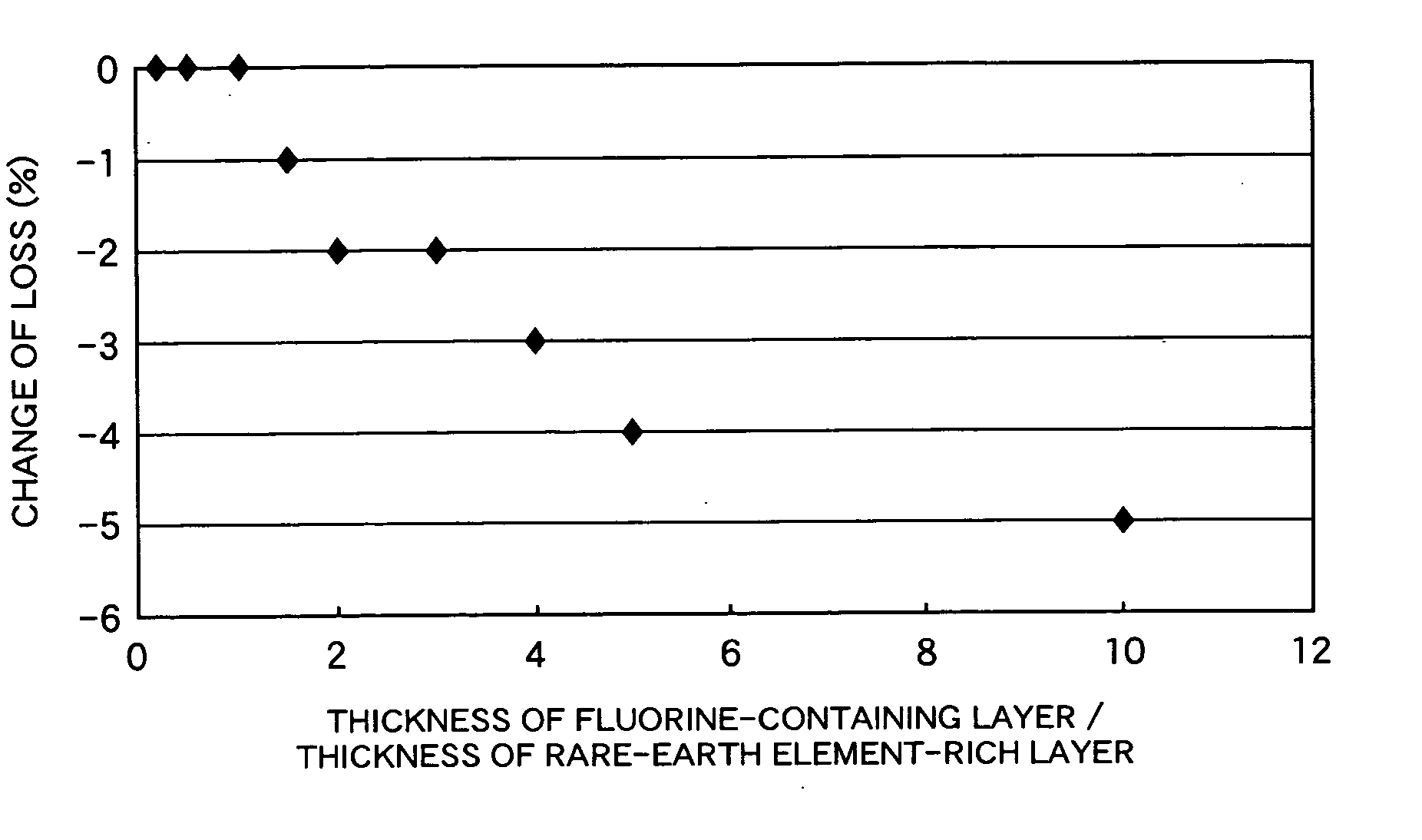

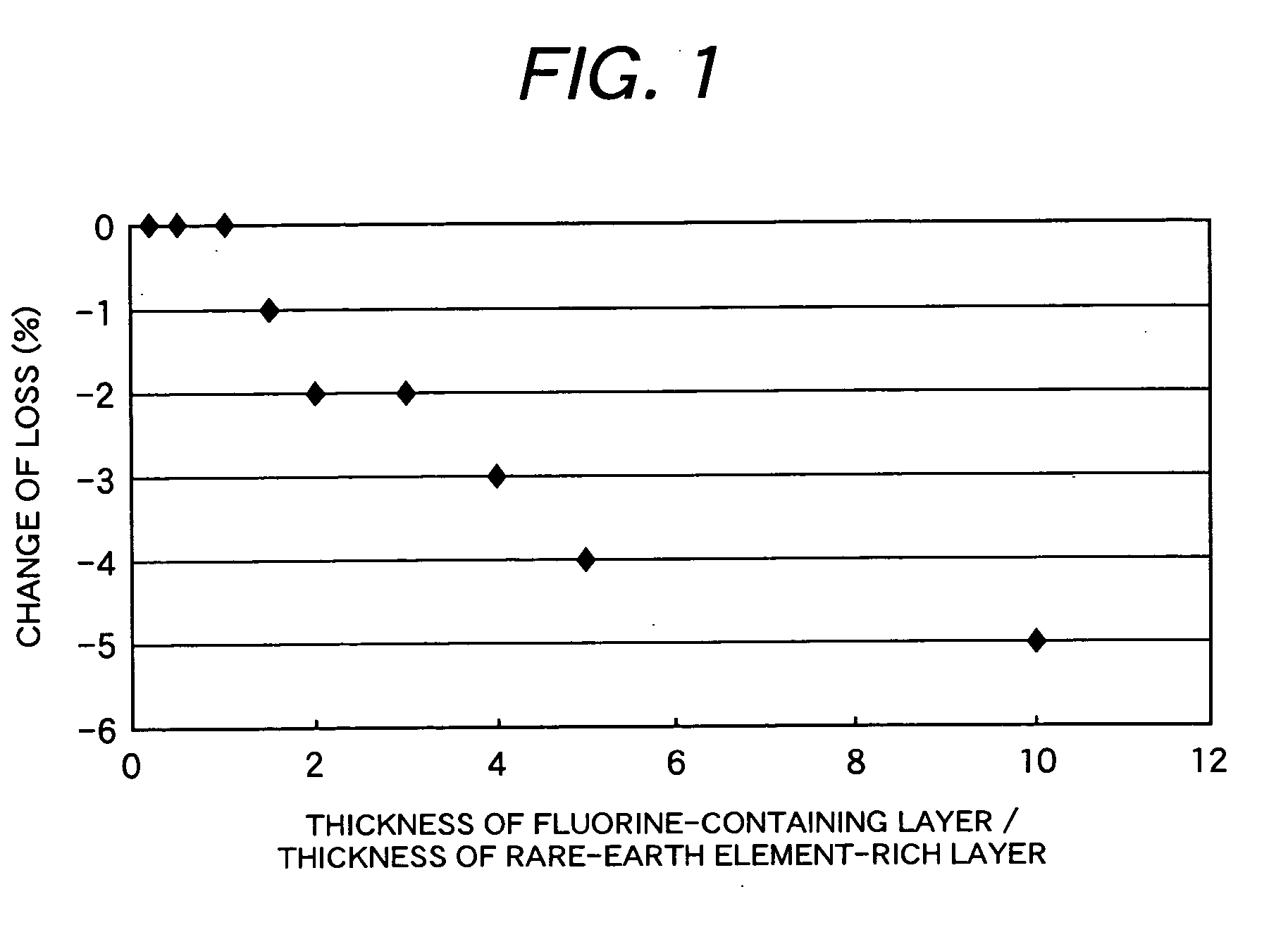

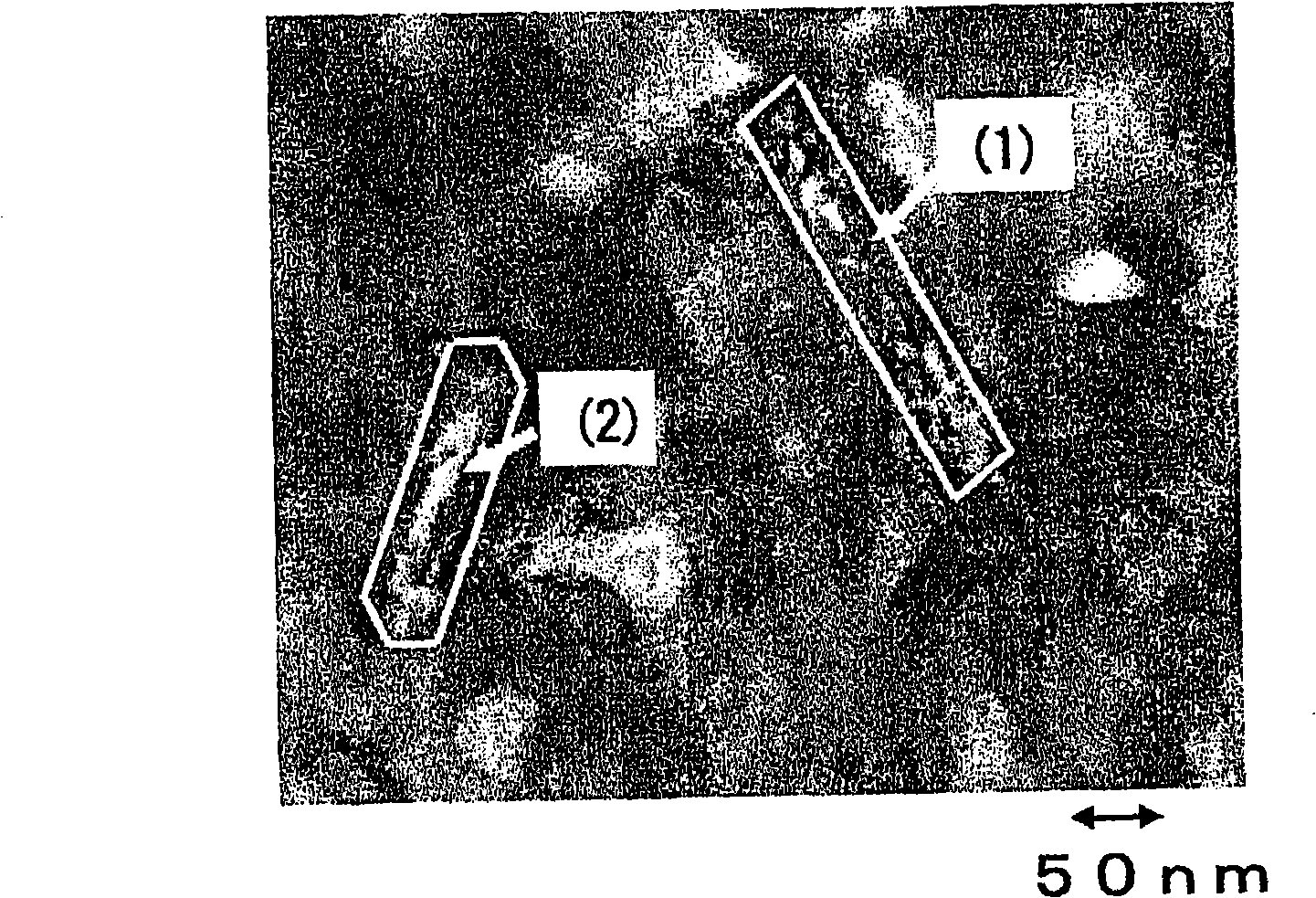

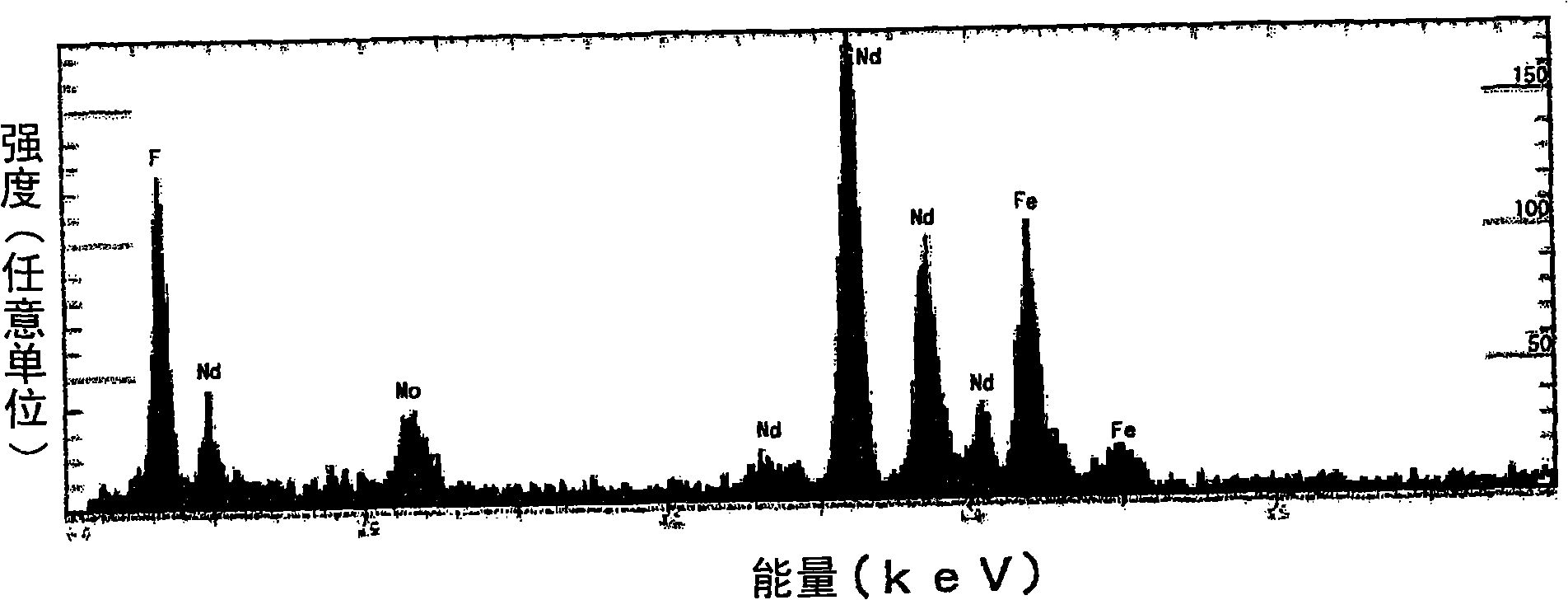

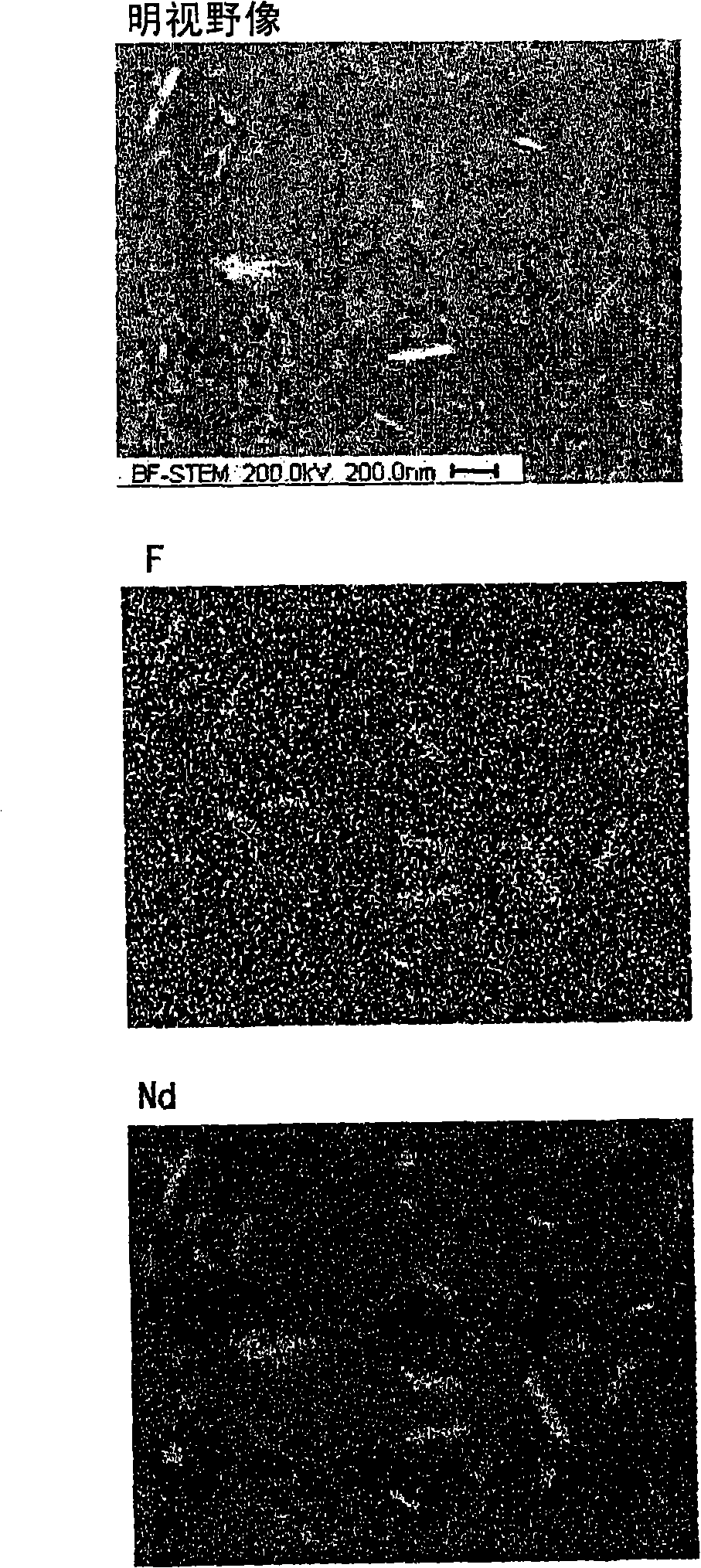

Rare-earth magnet

InactiveUS20060022175A1Improve efficiencyReduce magnetic noiseConductive materialInductances/transformers/magnets manufactureRare-earth elementRare-earth magnet

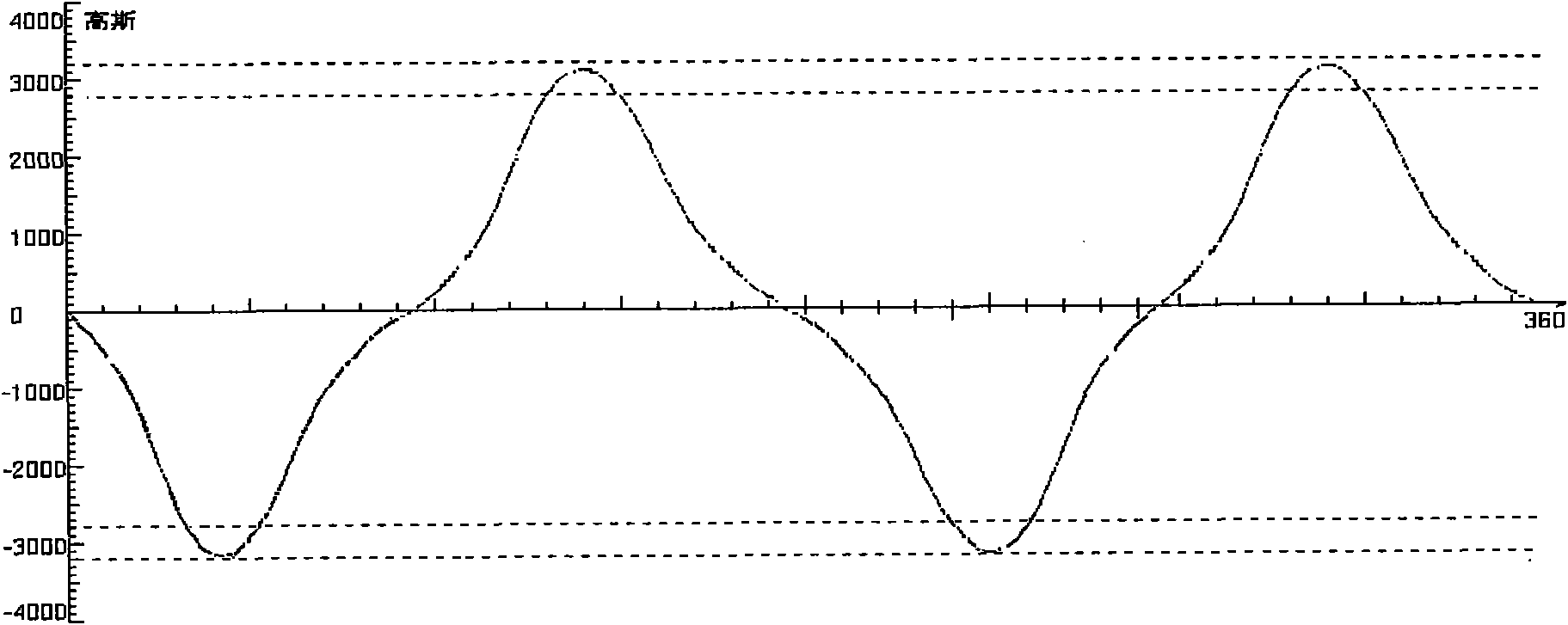

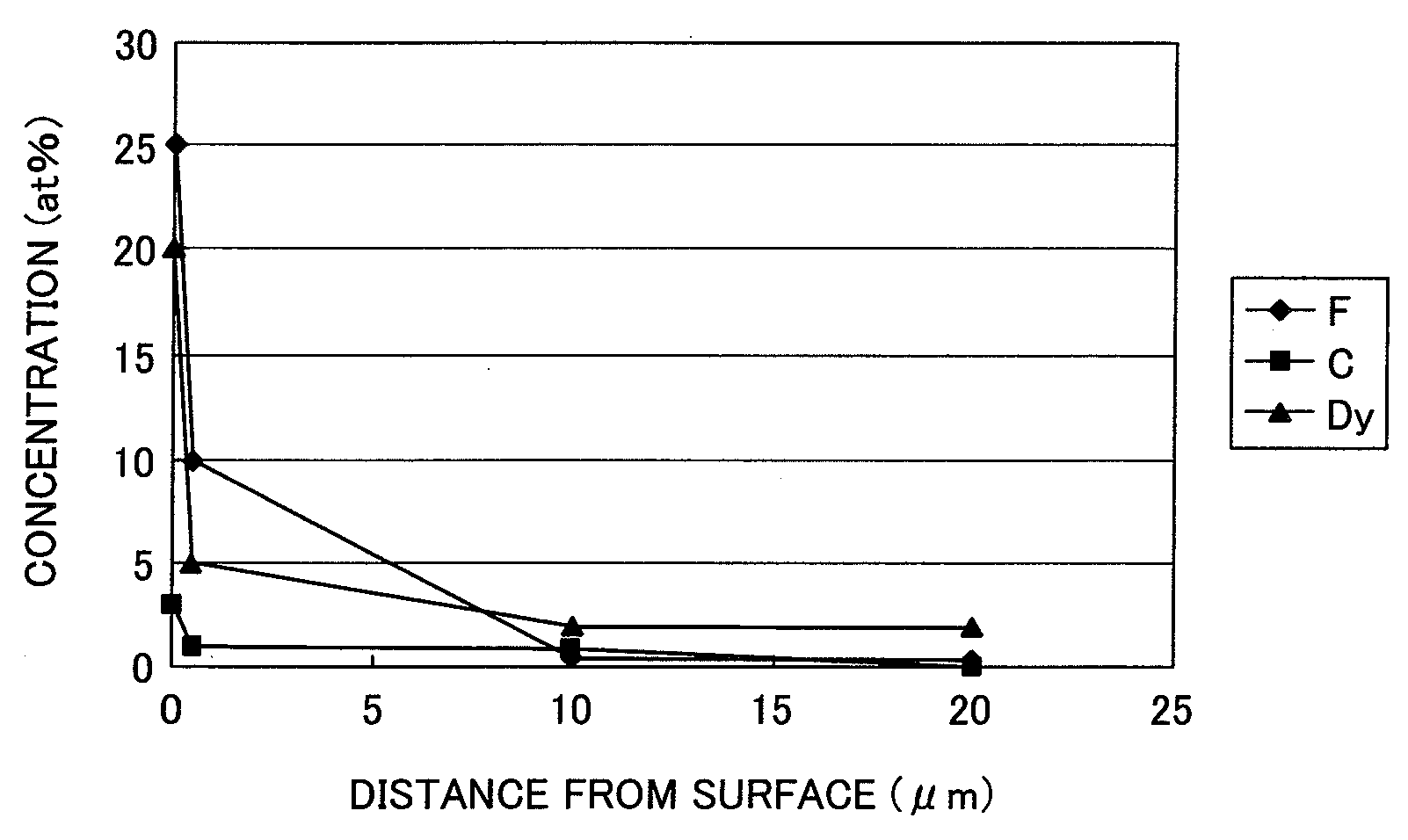

In a ferromagnetic material containing at least one kind of rare-earth element, a layer containing at least one kind of alkaline earth element or rare-earth element and fluorine is formed at the grain boundary or near the powder surface of the ferromagnetic material. A further layer containing at least one kind of rare-earth element, having a fluorine concentration lower than that of the layer described first and having a rare-earth element concentration higher than that of the host phase of the ferromagnetic material, or an oxide layer containing a rare-earth element is formed in adjacent with a portion of the layer described first.

Owner:HITACHI LTD

Rare earth magnet and production process thereof

InactiveUS20100003156A1Suppressing substitutionRestraining reduction of remanenceTransportation and packagingMetal-working apparatusRare-earth magnetGrain boundary

The present invention provides a rare earth magnet, which is formed through at least hot molding, the rare earth magnet containing grains including an R2X14B phase as a main phase, and a grain boundary phase surrounding peripheries of the grains, in which R is at least one element selected from the group consisting of Nd, Pr, Dy, Tb and Ho, and X is Fe or Fe with a part being substituted by Co; in which an element RH is more concentrated in the grain boundary phase than in the grains, in which the element RH is at least one element selected from the group consisting of Dy, Tb and Ho; and the element RH is present with a substantially constant concentration distribution from the surface part of the magnet to the central part of the magnet.

Owner:DAIDO STEEL CO LTD

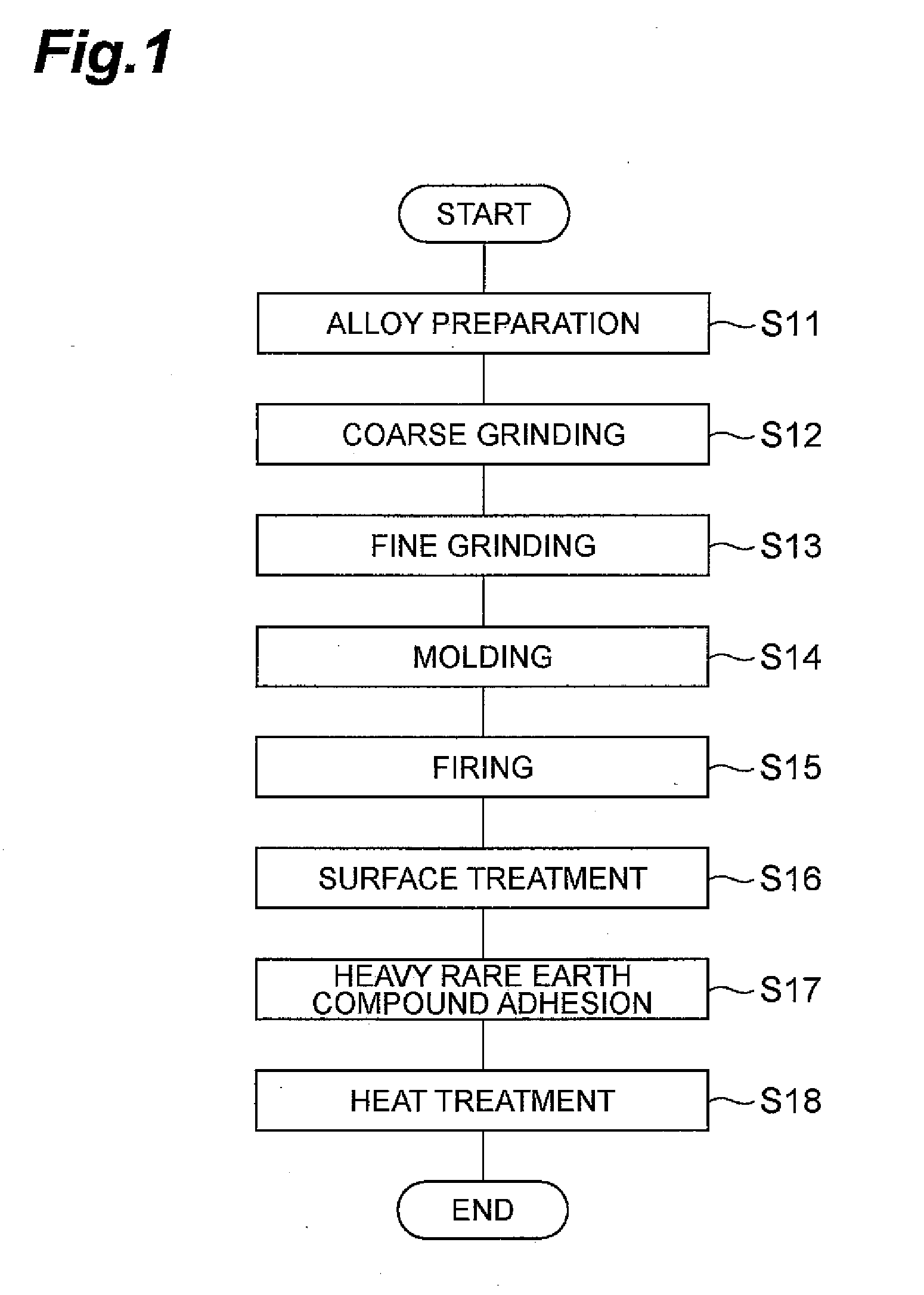

Process for producing magnet

ActiveUS20090297699A1Excellent high magnetic propertyEvenly bondedSpecial surfacesCoatingsRare-earth elementRare-earth magnet

The process for producing a magnet according to the invention is characterized by comprising a first step in which a heavy rare earth compound containing Dy or Th as a heavy rare earth element is adhered onto a sintered compact of a rare earth magnet and a second step in which the heavy rare earth compound-adhered sintered compact is subjected to heat treatment, wherein the heavy rare earth compound is a Dy or Th iron compound.

Owner:TDK CORPARATION

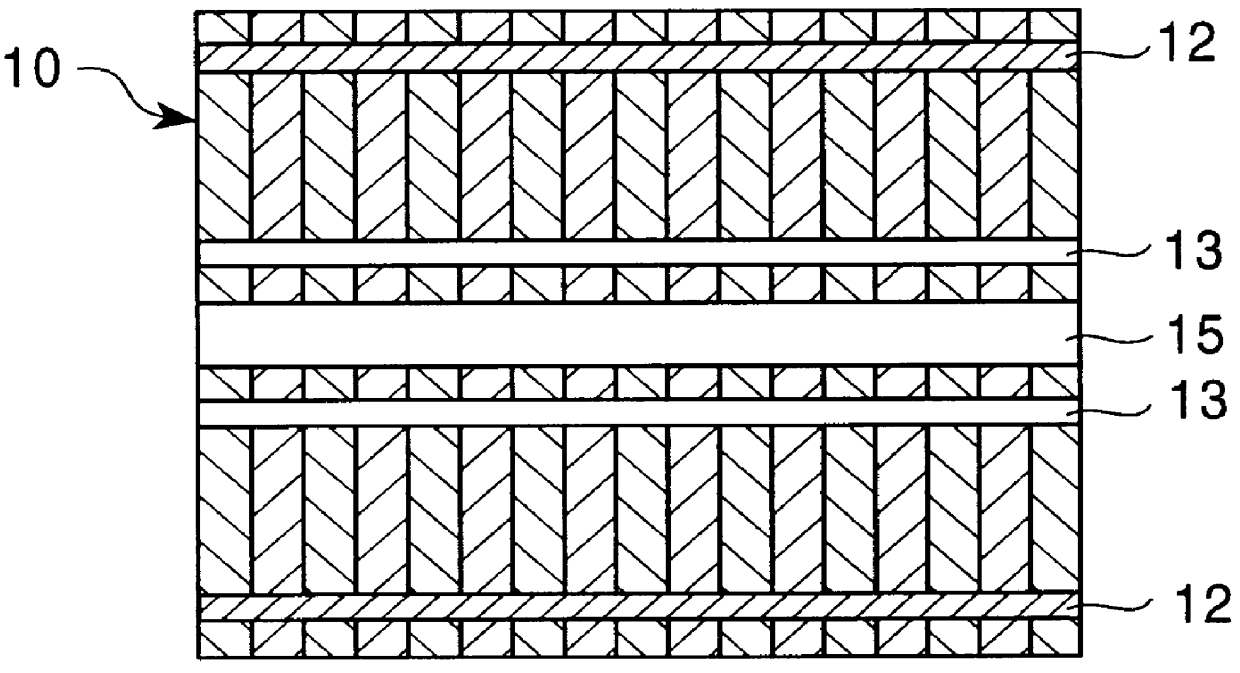

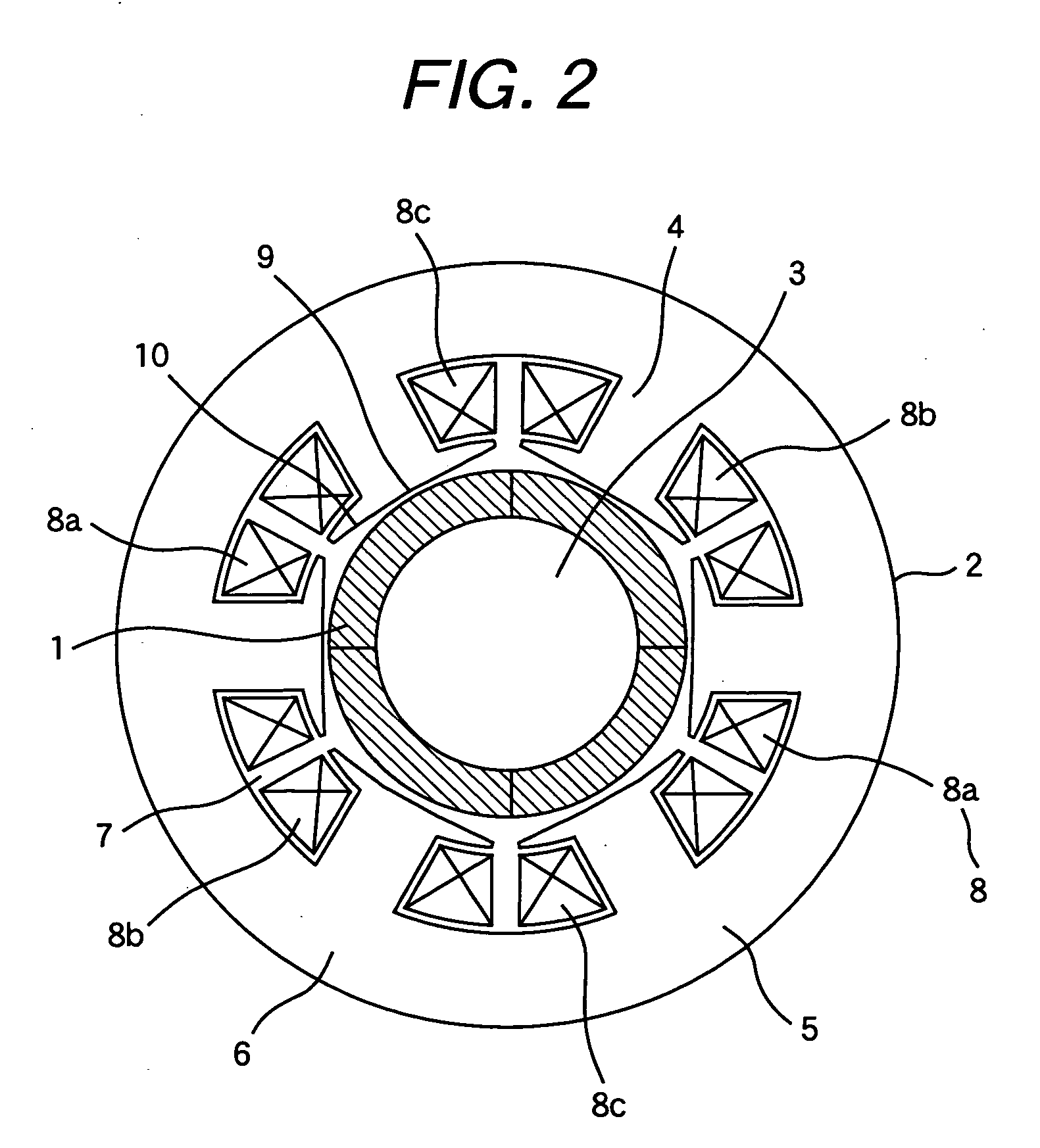

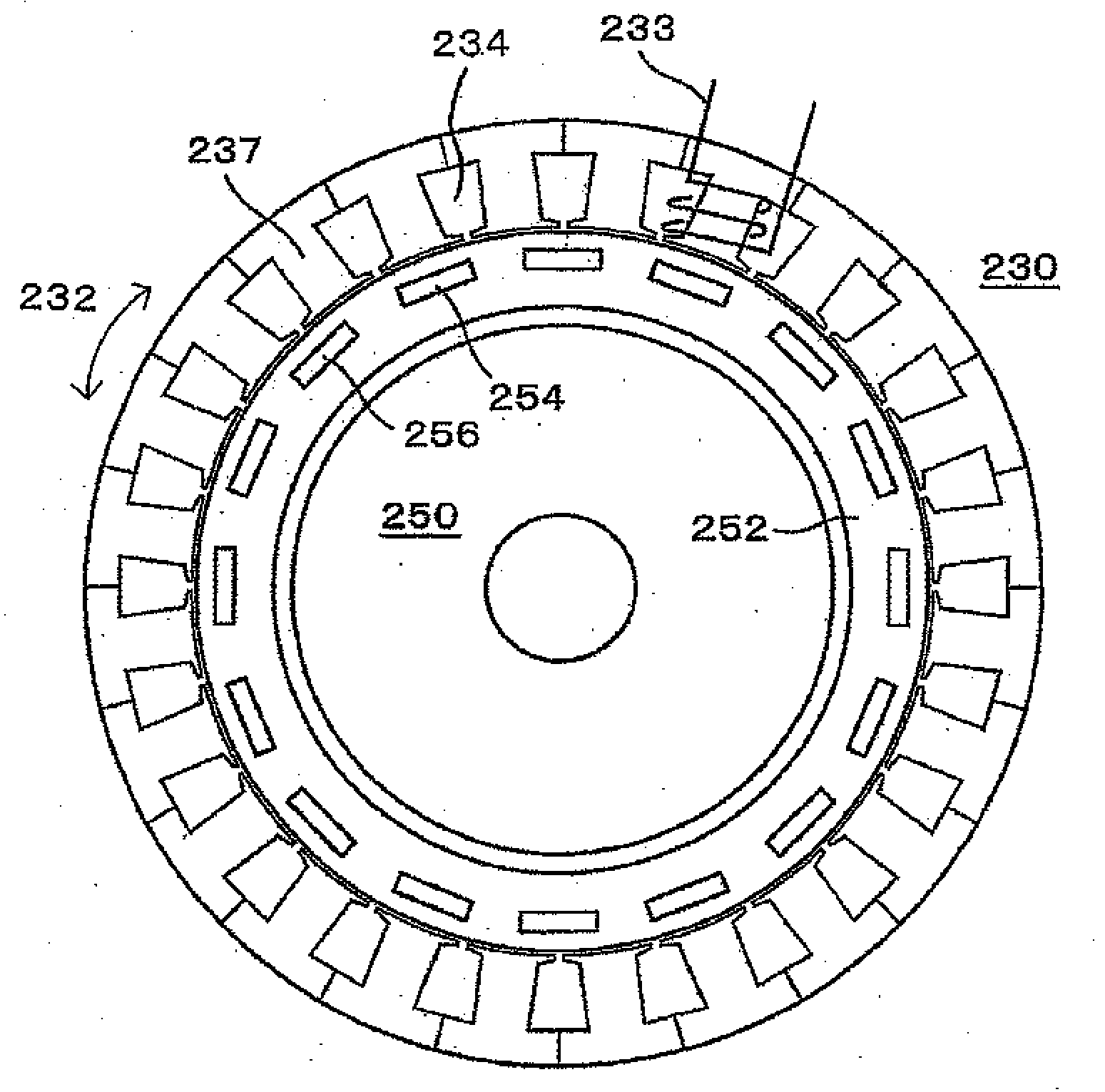

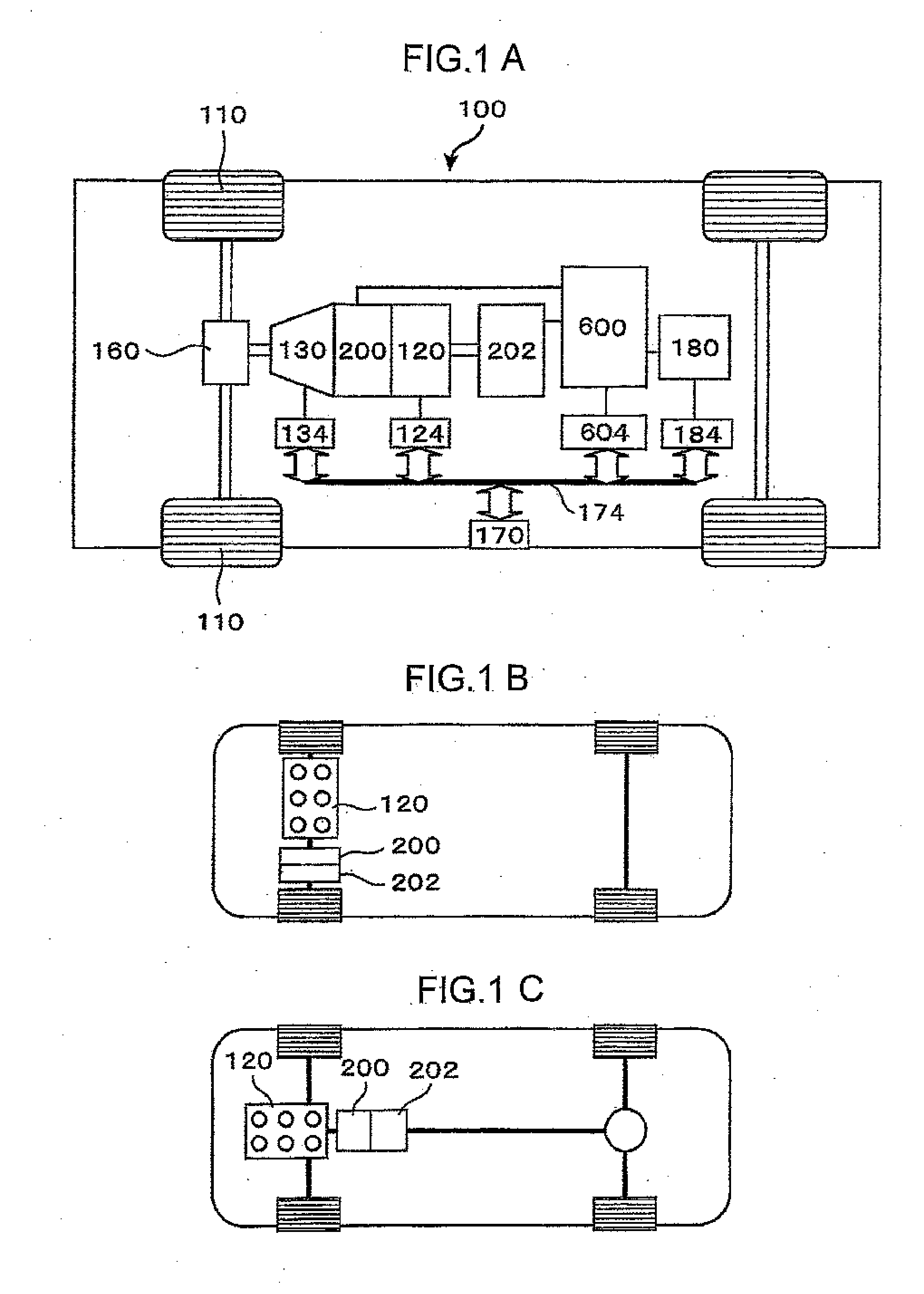

Electric Rotating Machine and Automobile Equipped with It

InactiveUS20090072647A1Improve magnetic propertiesInhibit currentHybrid vehiclesWindingsEngineeringRare-earth magnet

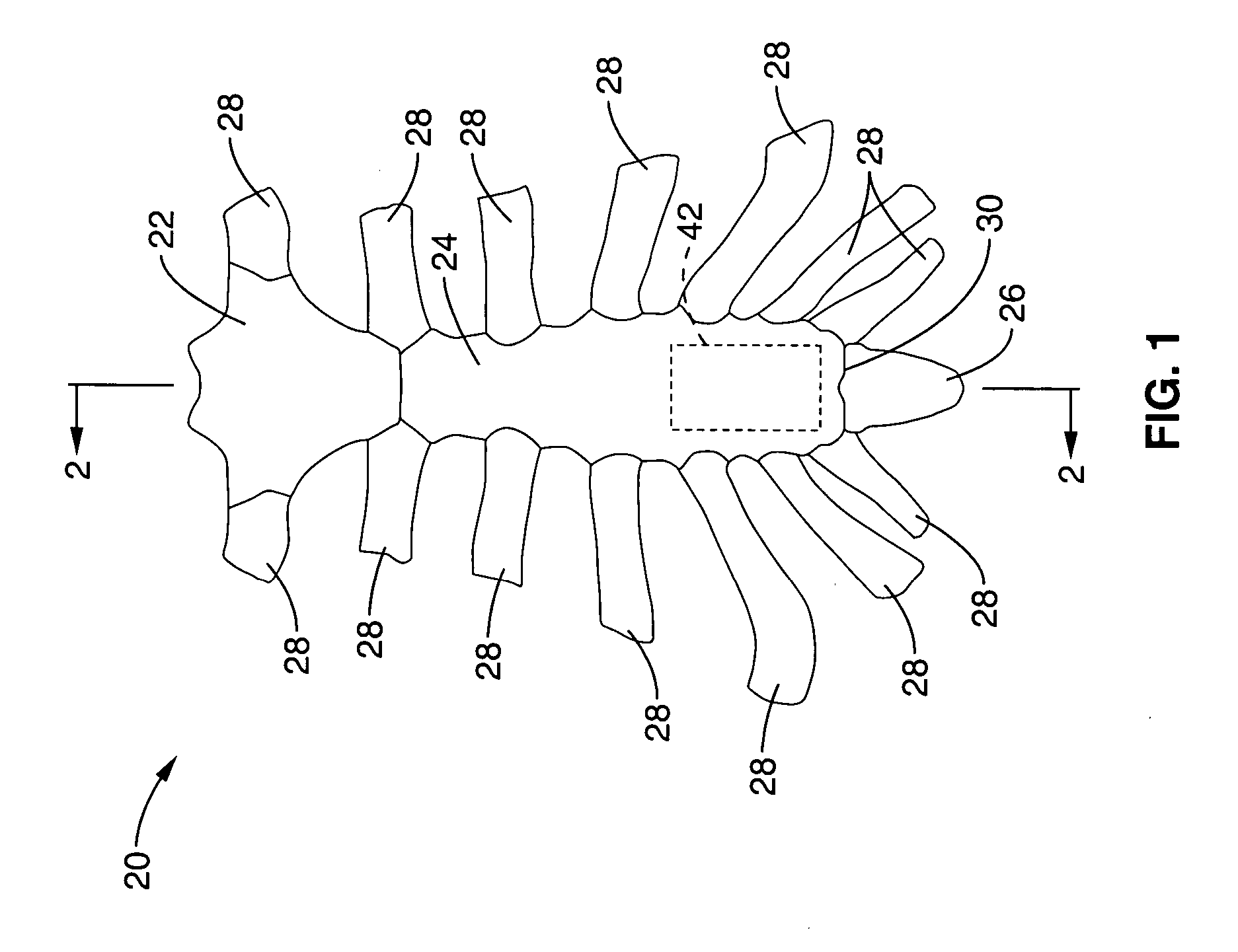

An electric rotating machine includes a stator having a stator core provided with a teeth unit and a coil wound around each tooth in the teeth unit in a concentrated fashion and a rotor rotatably supported with air gap against the teeth unit of the stator, the rotor having a rotor core and a plurality of permanent magnets held by the rotor core, wherein the permanent magnet is a rare earth magnet made of rare earth magnetic particles bound with SiO2. Also disclosed is an automobile that includes the electric rotating machine in which the permanent magnet in the rotor is a rare earth magnet made of rare earth magnetic particles bound with SiO2, and the stator in the electric rotating machine has a stator core provided with a teeth unit and a coil wound around each tooth in the teeth unit in a concentrated fashion.

Owner:HITACHI LTD

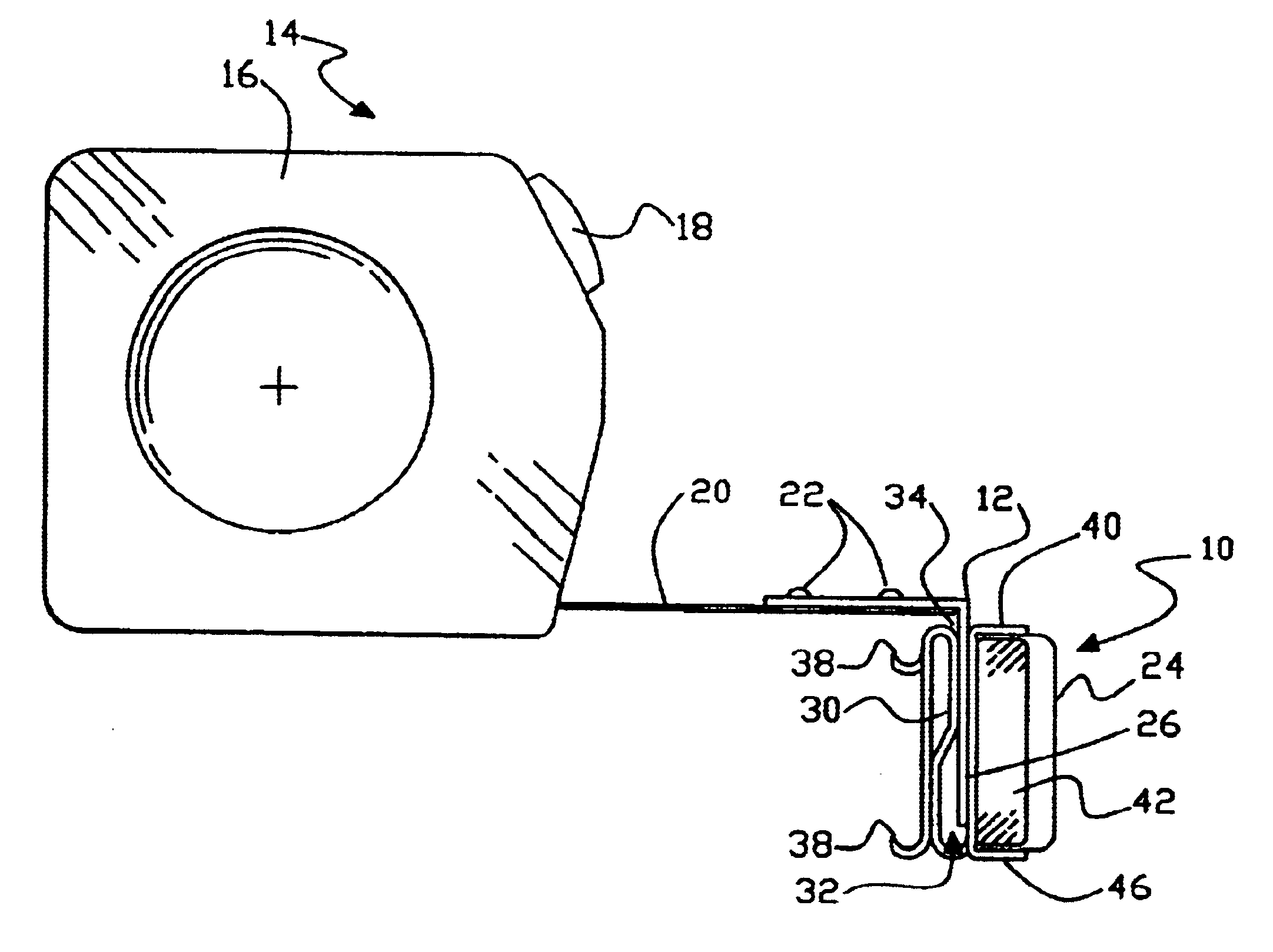

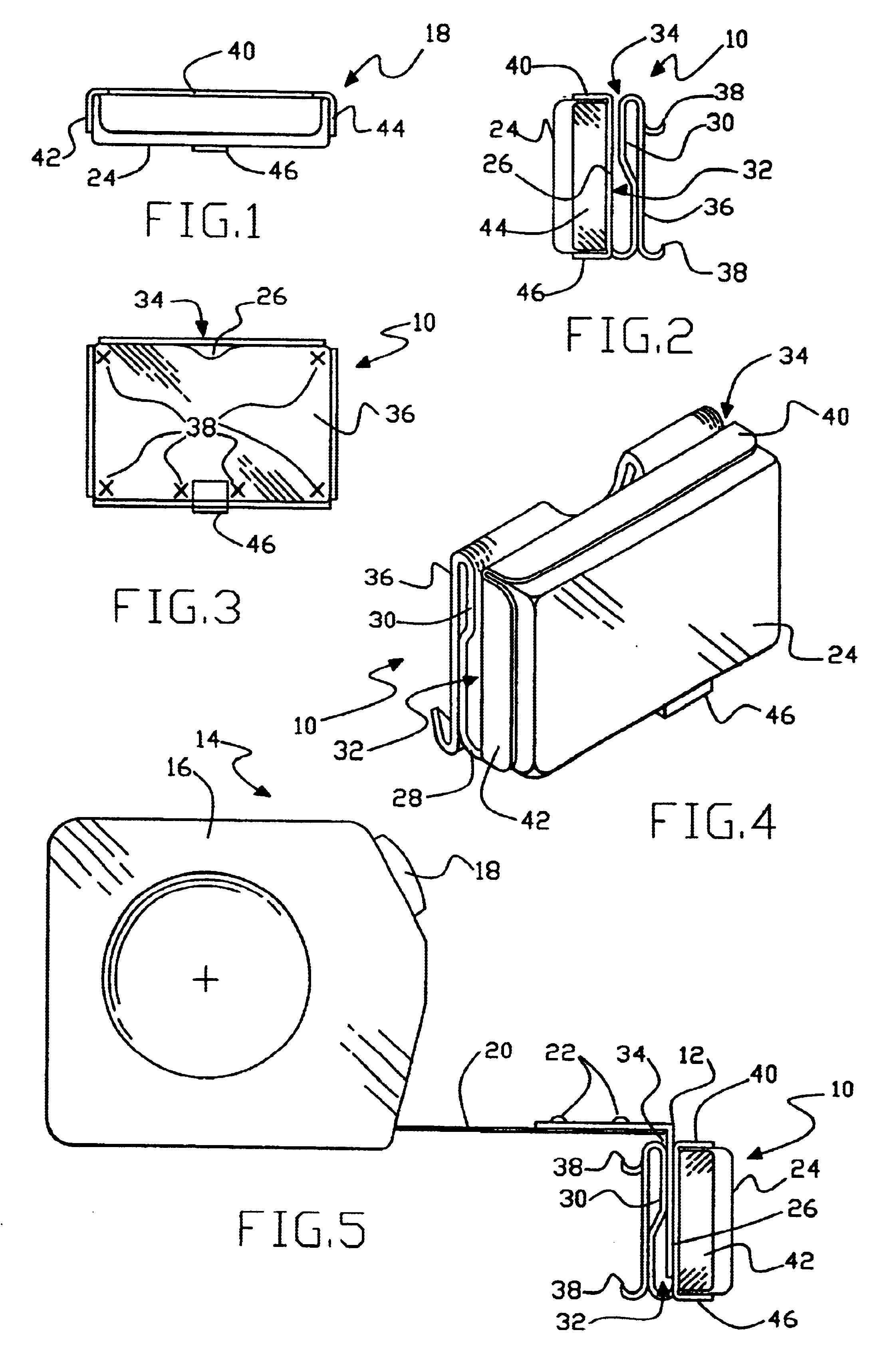

Removable attachment device for tape measure

A compact, lightweight and small removable device enhances the operation and utility of a tape measure when measuring metallic or nonmetallic structures. The device comprises a flat base, a small, powerful rare earth magnet secured to one side of the base, and a spring clip that extends from a bottom edge of the base and up its other side and includes a curved surface normally contacting the base to provide a pocket having an entrance slot for insertion of the zero hook. The zero hook is clamped between the base and the spring clip when inserted through the entry slot into the pocket. The small powerful magnet enables use with metallic surfaces behind wallboard, and above, below and beside the zero hook. A plurality of friction enhancing tangs extend from the spring clip in a direction opposite the magnet for gripping nonmetallic surfaces. The device can also be used to retrieve remote metal tools and other objects. The device is selectively and easily manually attached to and removed from the zero hook, and easily stored in a worker's pocket.

Owner:BRUNSON MARK E

Method for manufacturing injection-molding rare-earth radial magnetic ring

InactiveCN101552132AIncrease the areaIncrease expansionInductances/transformers/magnets manufactureMagnetic materialsQuadrupoleMagnetic characteristic

A method for manufacturing injection-molding rare-earth radial magnetic ring belongs to the technical field of rare earth magnet preparing. The method of the invention comprises the following technical processes: mixing and drying the rare-earth magnetic powder which is coated by the coupling agent and antioxidant in negative pressure until the dissolvent and the absorbed gas is totally released, then placing the thermoplastic organic resin powder into a mixing machine for mixing to uniform in inert protective atmosphere, then placing a double-screw extruder with protective atmosphere, fully compounding the thermoplastic organic binding agent with magnetic powder, granulating for obtaining the granulate for rare-earth anisotropic bonded permanent magnet, placing the granulate into a magnetic field injector with magnetic field mold for preparing into the magnetic ring oriented along the radial direction, wherein the magnetic ring comprises radially oriented magnetic ring and multipole magnetic ring. The method of the invention has the advantage that the granulate manufactured by organic resin has excellent oxidation resistance, fluidity and magnetic characteristic. The radiating, quadrupole and multipole oriented magnetic field which is obtained by matching the permanent magnet repulsive permutation and combination and magnetic material is higher than the permanent magnetic field in which N and S are alternately permutated and combined. An energy saving effect is obtained.

Owner:BEIJING BEILILONG MAGNETIC MATERIALS TECH

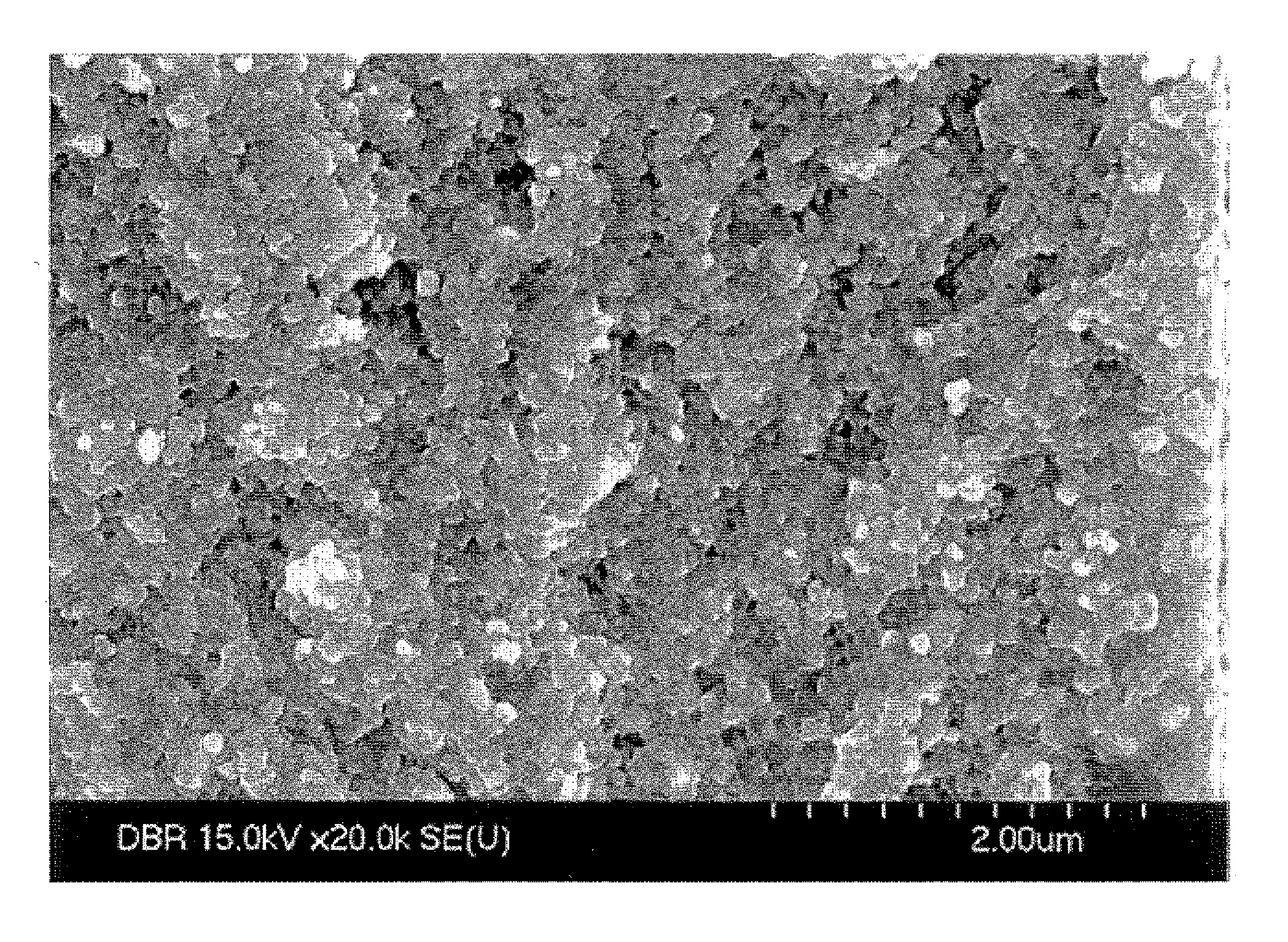

Rare earth magnet and manufacturing method thereof

InactiveUS20080241513A1Increase in coercivityLayered productsInductances/transformers/magnets manufactureOxygenRare-earth magnet

A structure of a magnet wherein a magnet consisting of a magnetic body including iron and rare earths, a plurality of fluorine compound layers or oxyfluorine compound layers are formed interior of the magnetic body, and the fluorine compound layer or oxyfluorine compound layer has a major axis which is greater than the mean particle size of the crystal grains of the magnetic body.

Owner:HITACHI LTD

Rare Earth Composite Magnets with Increased Resistivity

InactiveUS20150132174A1High resistivityReduce eddy current lossTransportation and packagingMetal-working apparatusDielectricHigh resistivity

Owner:ELECTRON ENERGY CORP

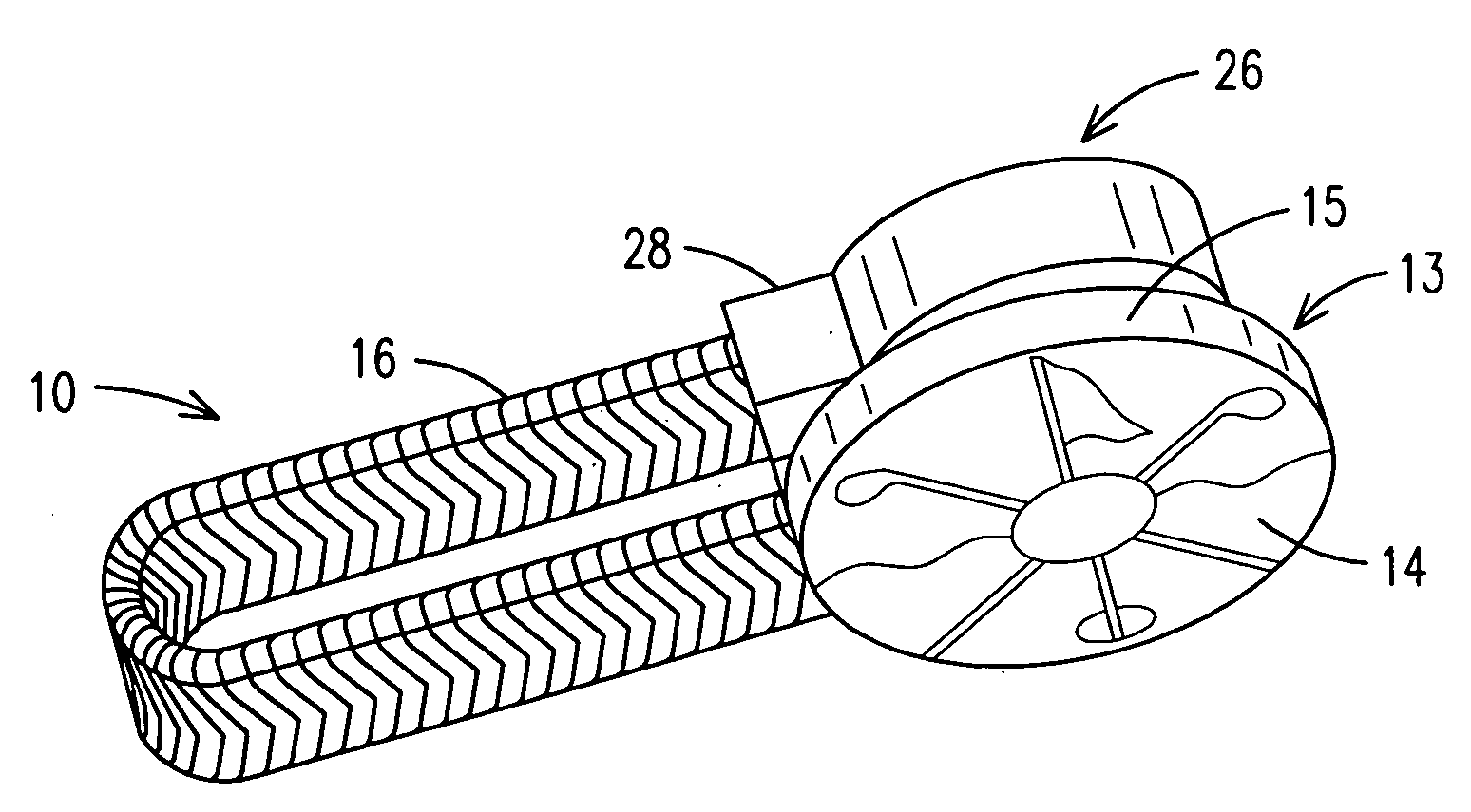

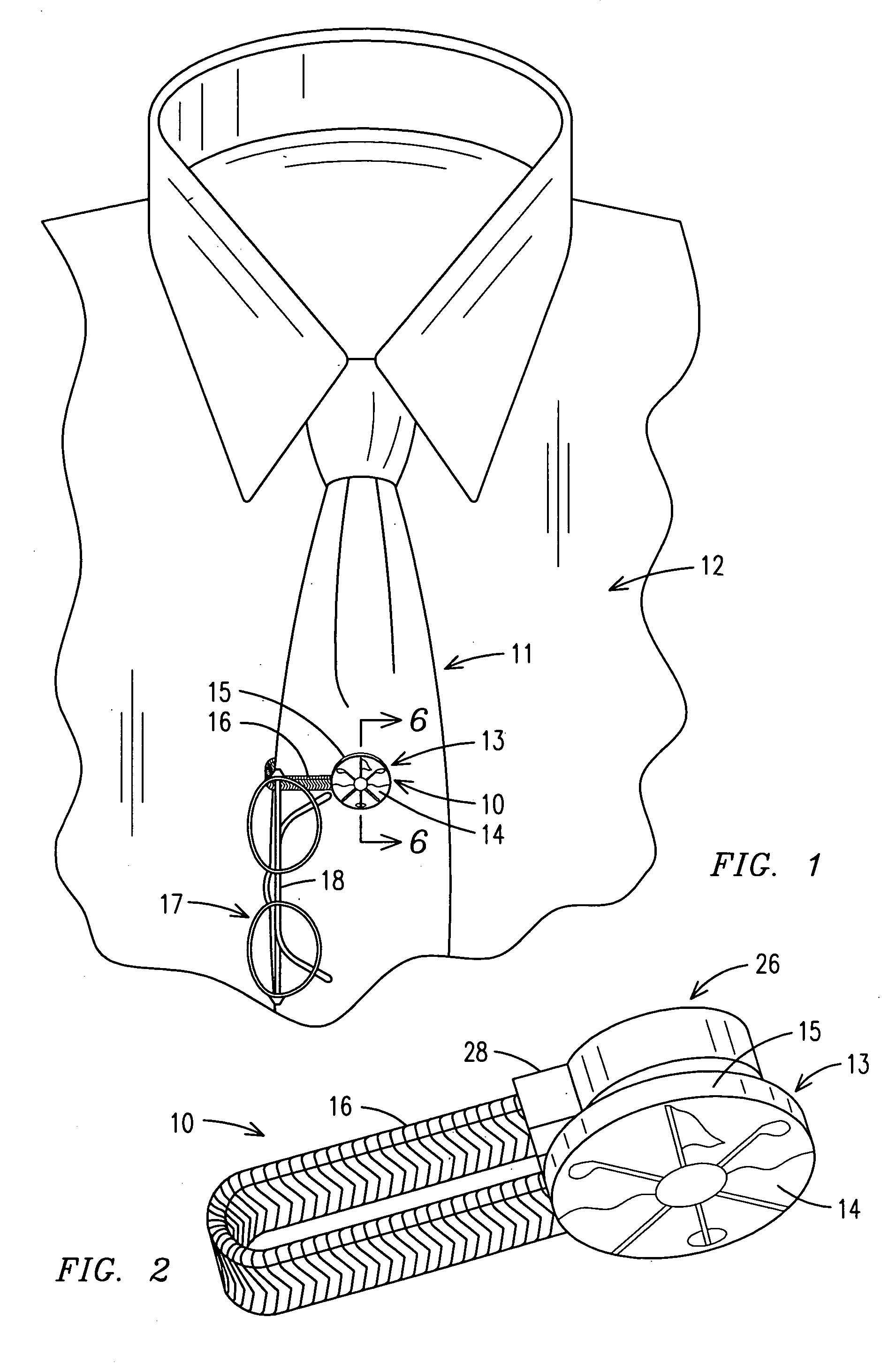

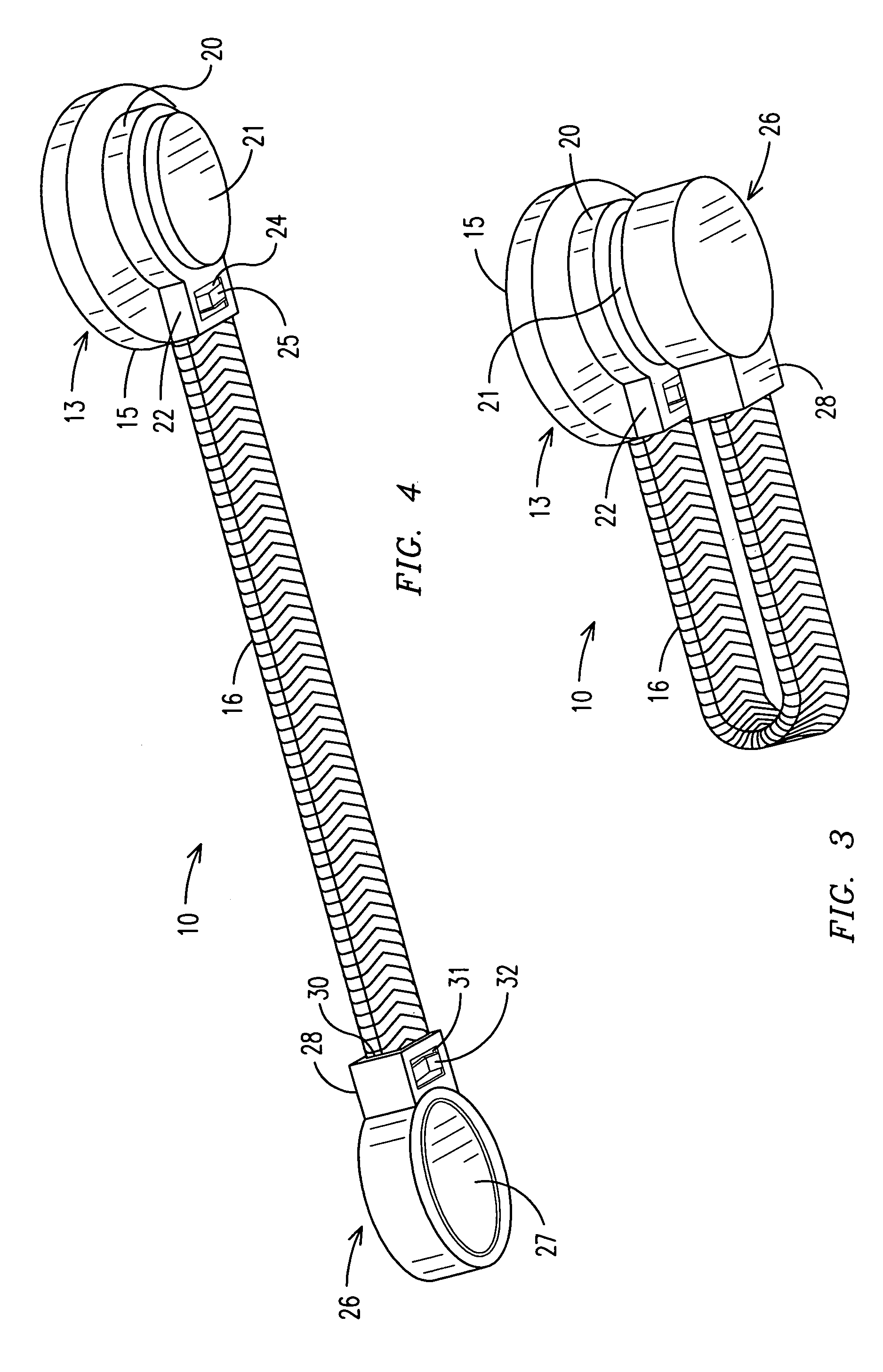

Article holding jewelry apparatus and process

InactiveUS20100083699A1Strong magnetic fieldStronger magnetic fieldSnap fastenersGarment suspendersEngineeringRare-earth magnet

A jewelry apparatus and process for holding an article to a person's clothing. A rare earth magnet is attached to one side of a piece of jewelry and connected with a chain or cord to a second rare earth magnet. The two magnets are magnetically held together through a person's clothing allowing eyeglasses or another article to be removably hung on the chain or cord.

Owner:CONIGLIARO ARACELIS

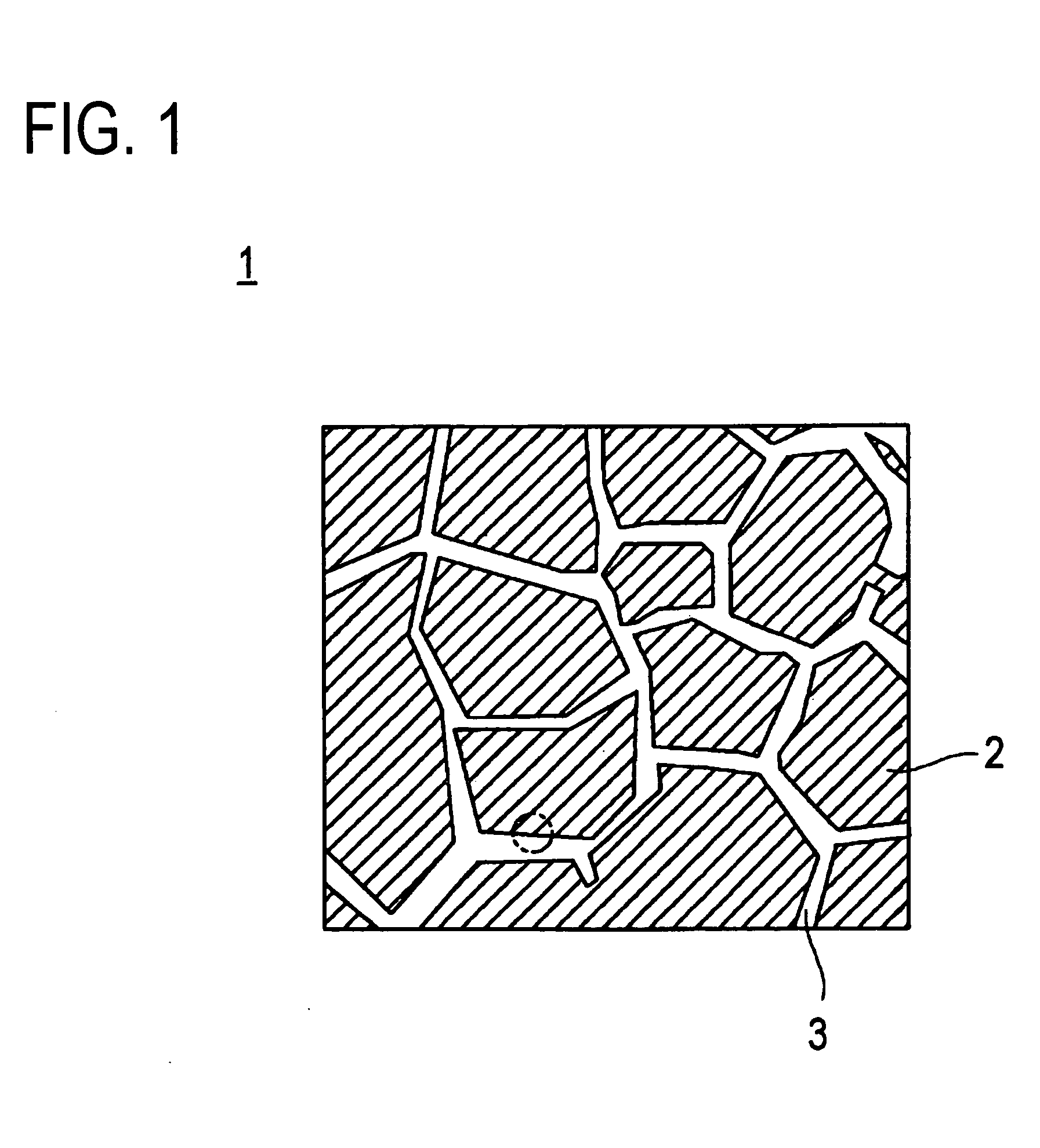

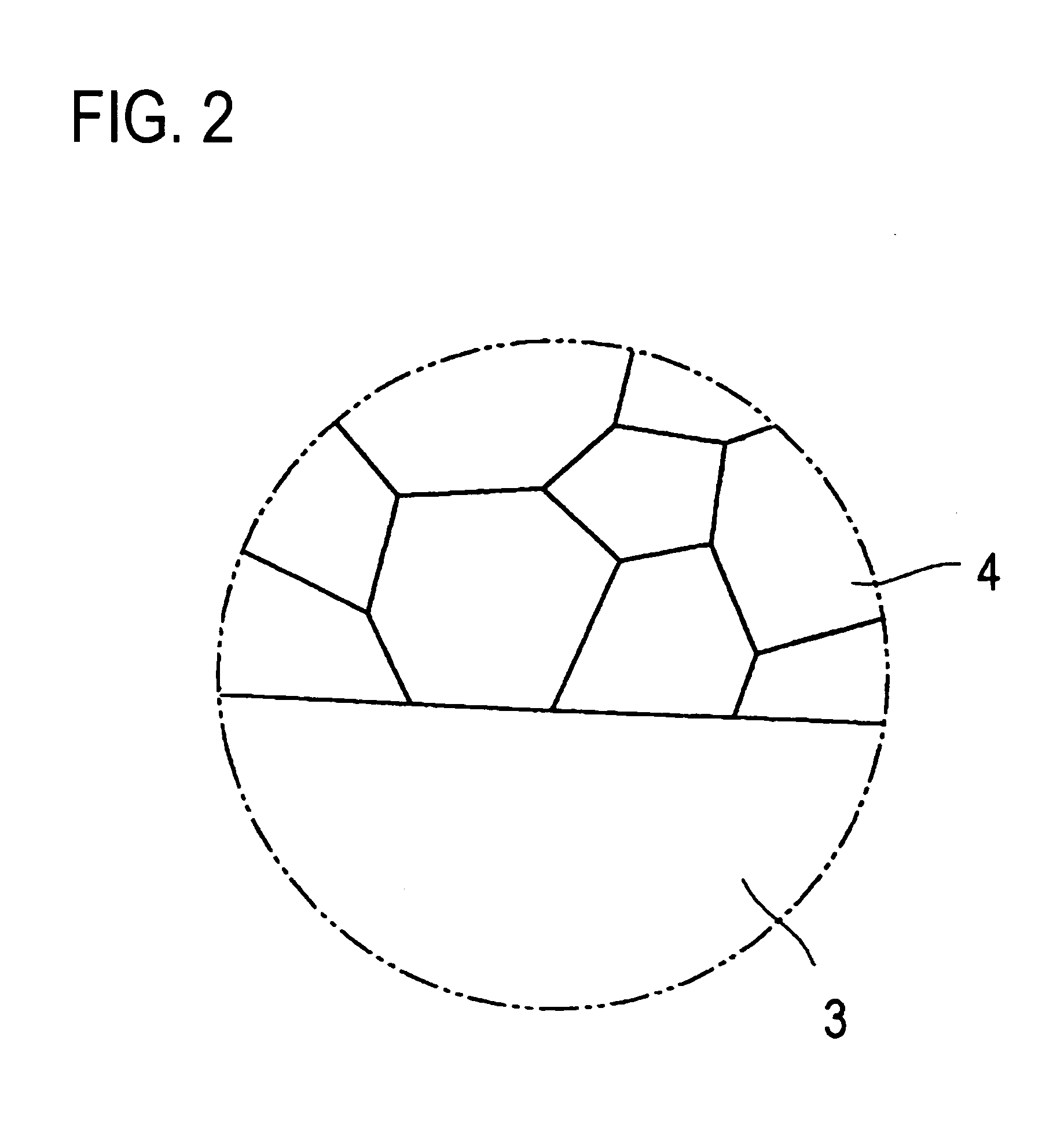

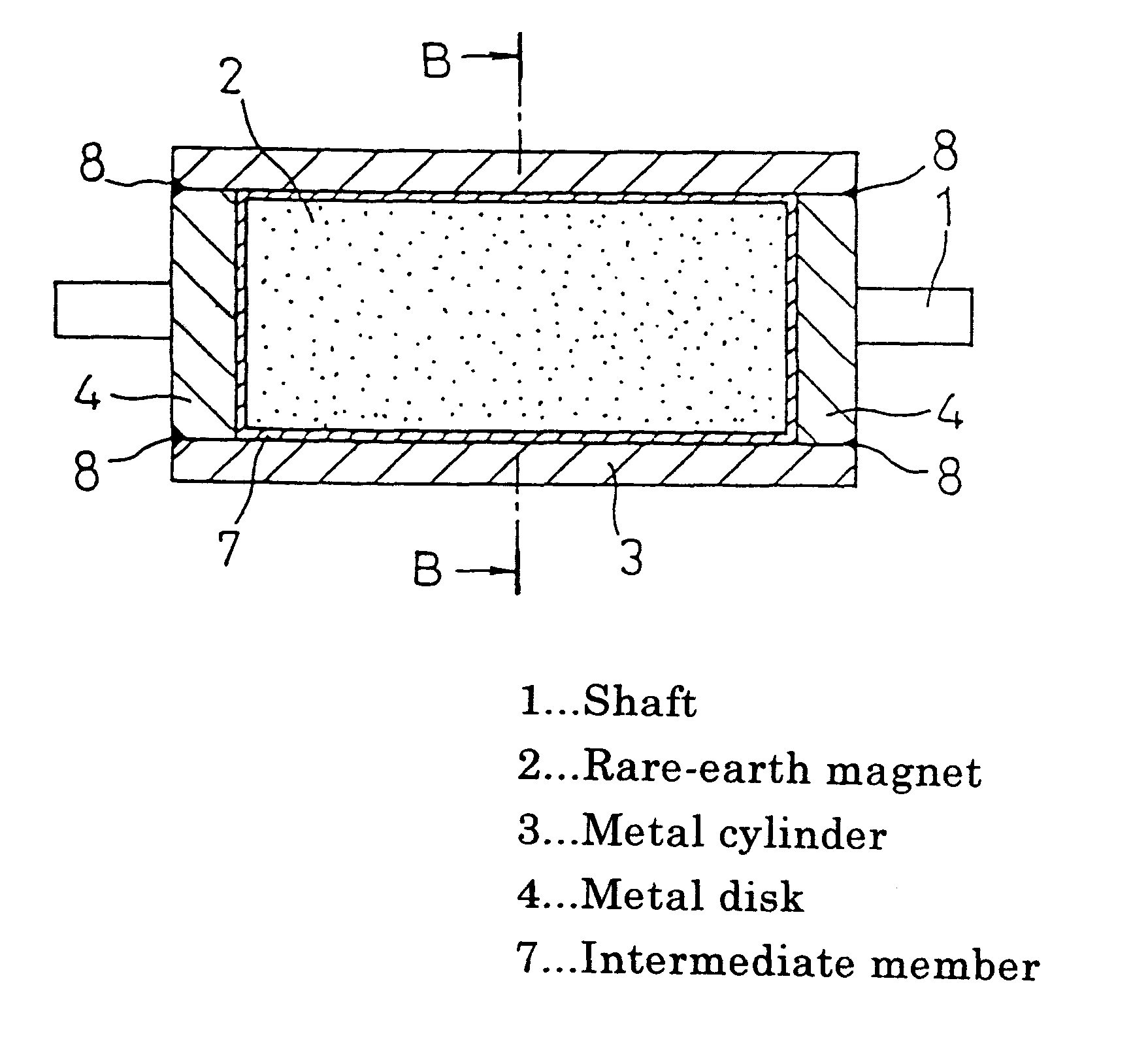

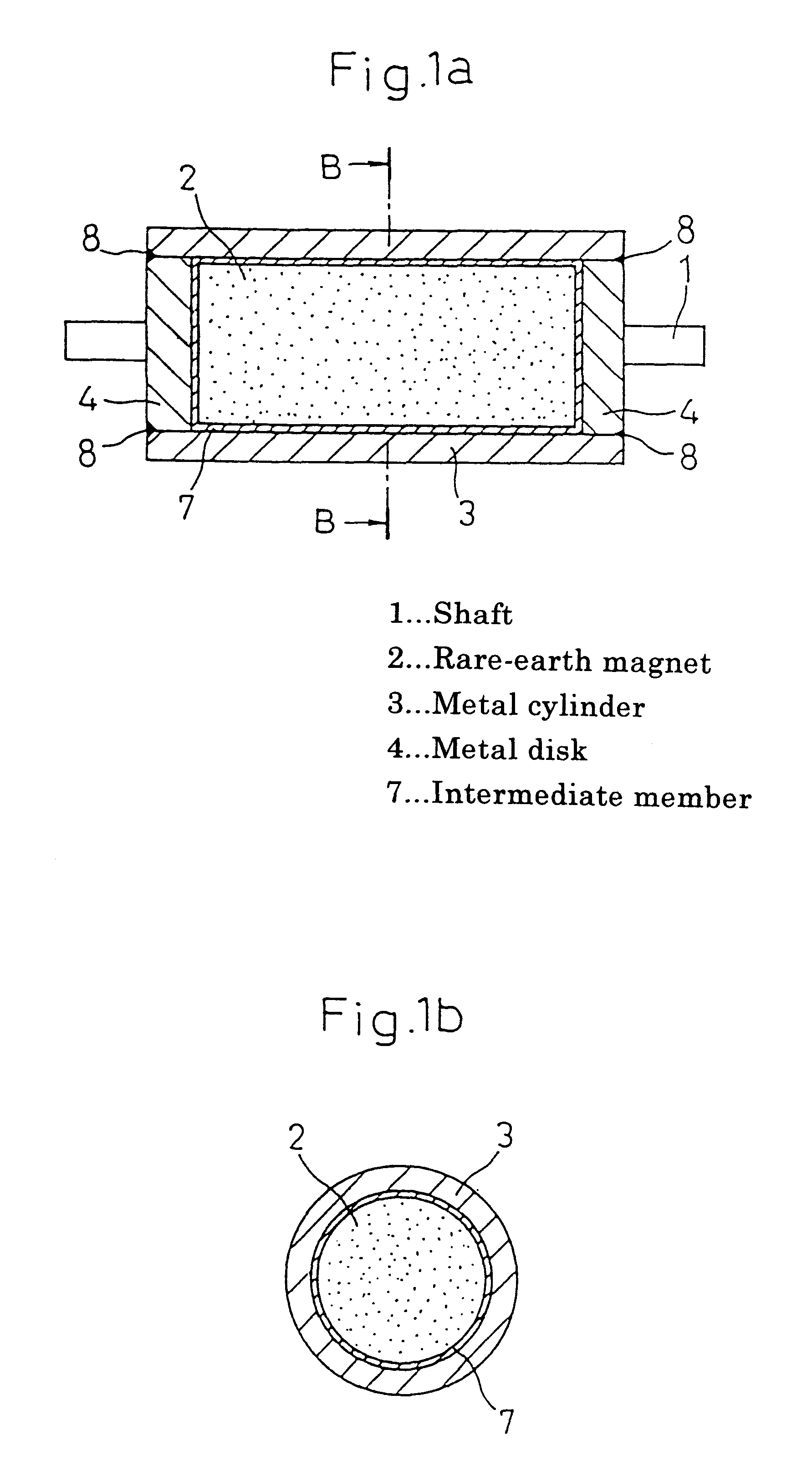

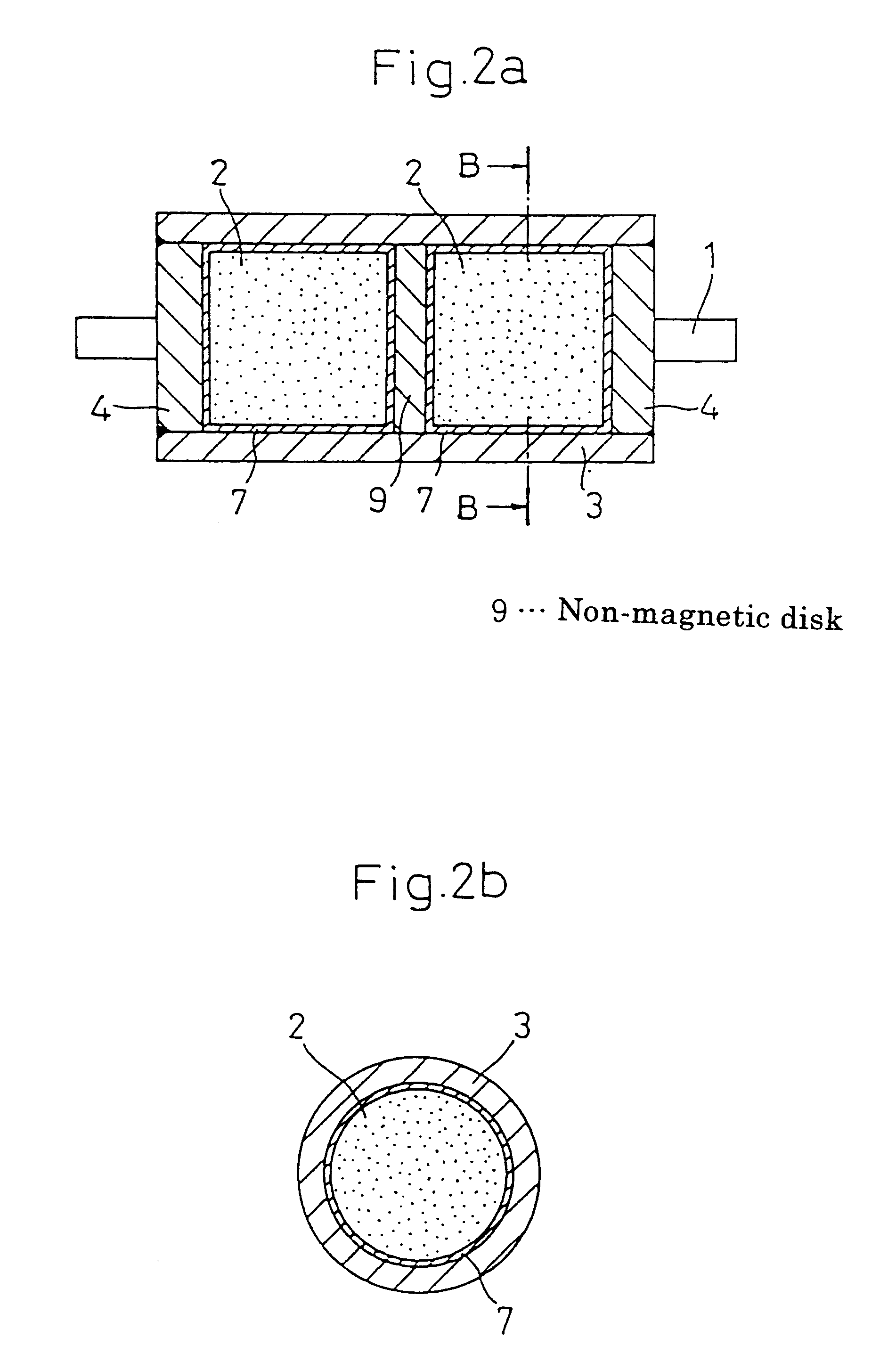

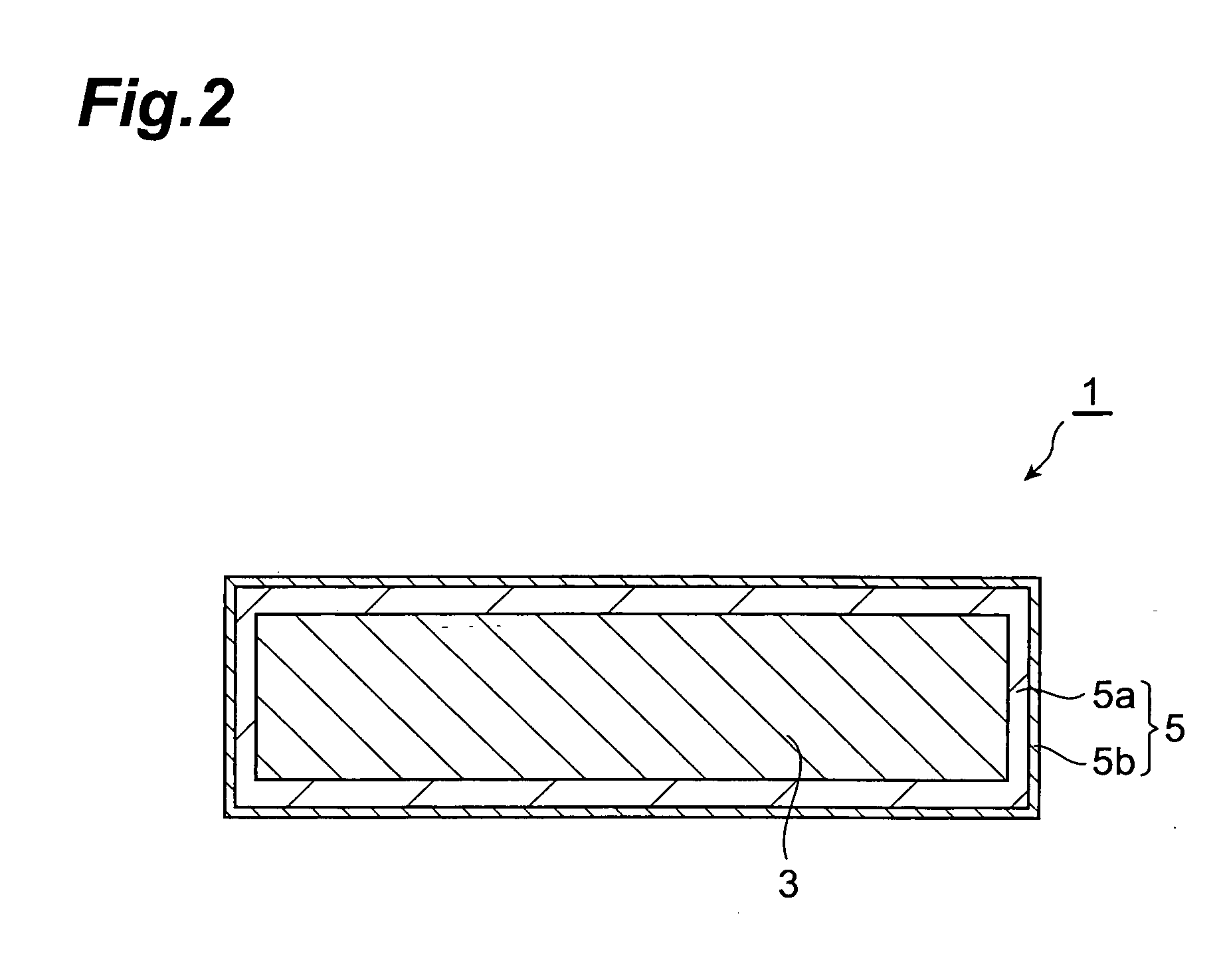

Monolithically bonded construct of rare-earth magnet and metal material and method for bonding same

InactiveUS6331214B1Manufacturing stator/rotor bodiesThin material handlingMetallic materialsHigh pressure

Its basic means is a monolithically bonded construct prepared by monolithically bonding together a rare-earth magnet 2 and a an alloy material that is a high melting point metal or a high specific-tenacity material through the solid phase diffusion bonding by the hot isostatic pressing treatment, and a monolithically bonded construct with an interposal of a thin layer of the high melting point metal between a rare-earth magnet 2 and an alloy material 3, 4 that is a high specific-tenacity material. As a method for the bonding, there is used a hot isostatic pressing treatment method in which a rare-earth An magnet and a high melting-point metal are laminated together, thereby to prepare an object to be treated, then the object is put into a hermetic-type high pressure container having an inner wall portion equipped with a heater, then the object is uniformly pressurized in all directions by a synergistic effect caused by pressure and temperature, while the object is maintained for a certain period of time under a certain pressure and temperature condition in an atmosphere of an inert gas, thereby to monolithically bond the object. With this, it is possible to obtain a bonded construct in which a magnet can monolithically be bonded with another metal member with a high strength, without deteriorating magnetic characteristics, such that the rare-earth magnet's insufficiency in brittleness, rigidity, tenacity and the like is compensated.

Owner:MEIDENSHA ELECTRIC MFG CO LTD +1

Rare Earth Magnet and Method for Manufacturing Same

InactiveUS20080050581A1Solve the lack of corrosion resistanceSolve the lack of resistancePermanent magnetsRecord information storageRare-earth elementHybrid compound

The object of the present invention is to provide a rare-earth magnet having a sufficient corrosion resistance, and a method of manufacturing the same. The rare-earth element in accordance with a preferred embodiment comprises a magnet body containing a rare-earth element, and a protective layer formed on a surface of the magnet body. The protective layer in accordance with a preferred embodiment includes a first layer covering the magnet body and containing a rare-earth element, and a second layer covering the first layer and containing substantially no rare-earth element. Another protective layer in accordance with a preferred embodiment comprises an inner protective layer and an outer protective layer successively from the magnet body side. The outer protective layer is any of an oxide layer, a resin layer, a metal salt layer, and a layer containing an organic-inorganic hybrid compound.

Owner:TDK CORPARATION

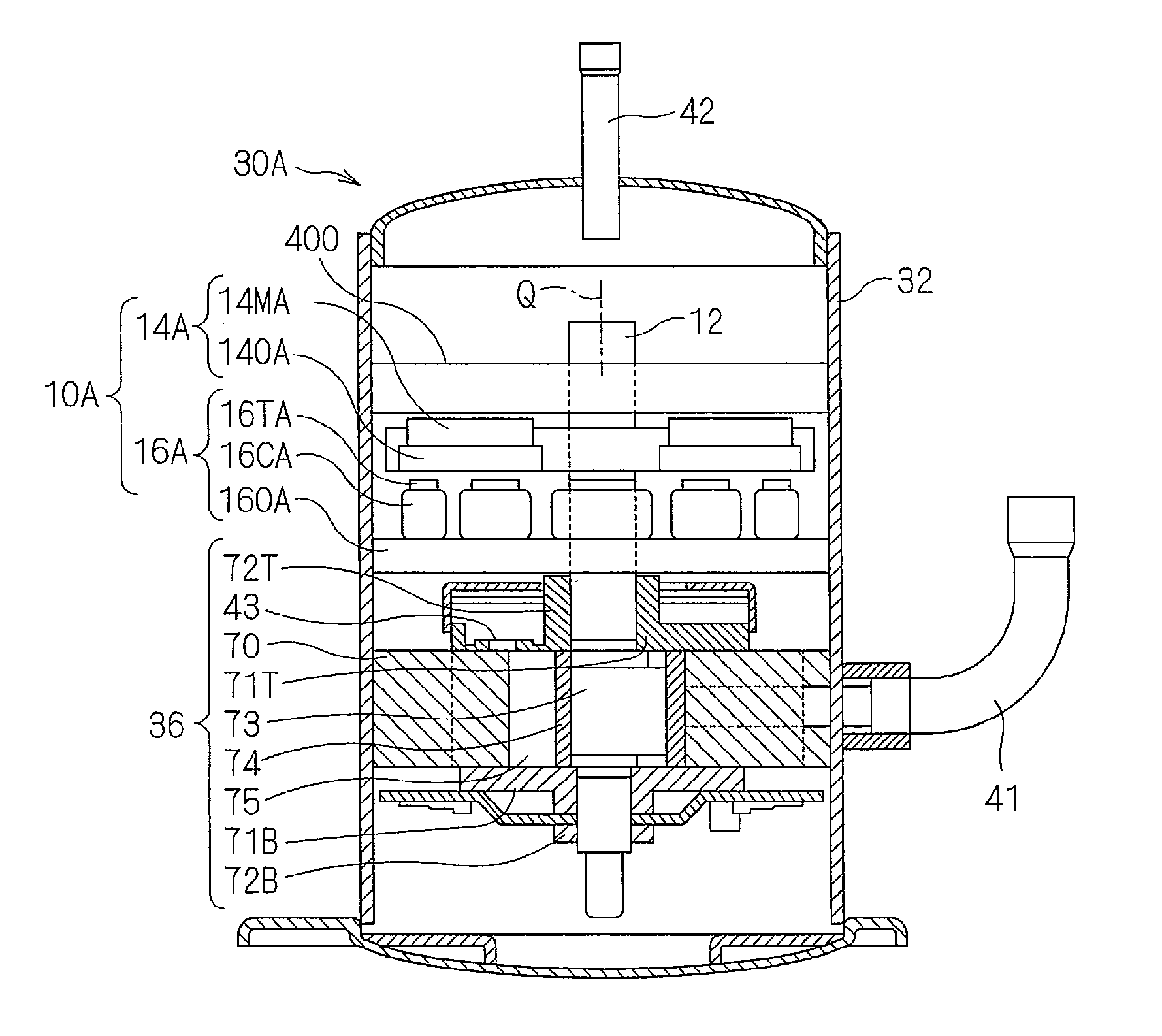

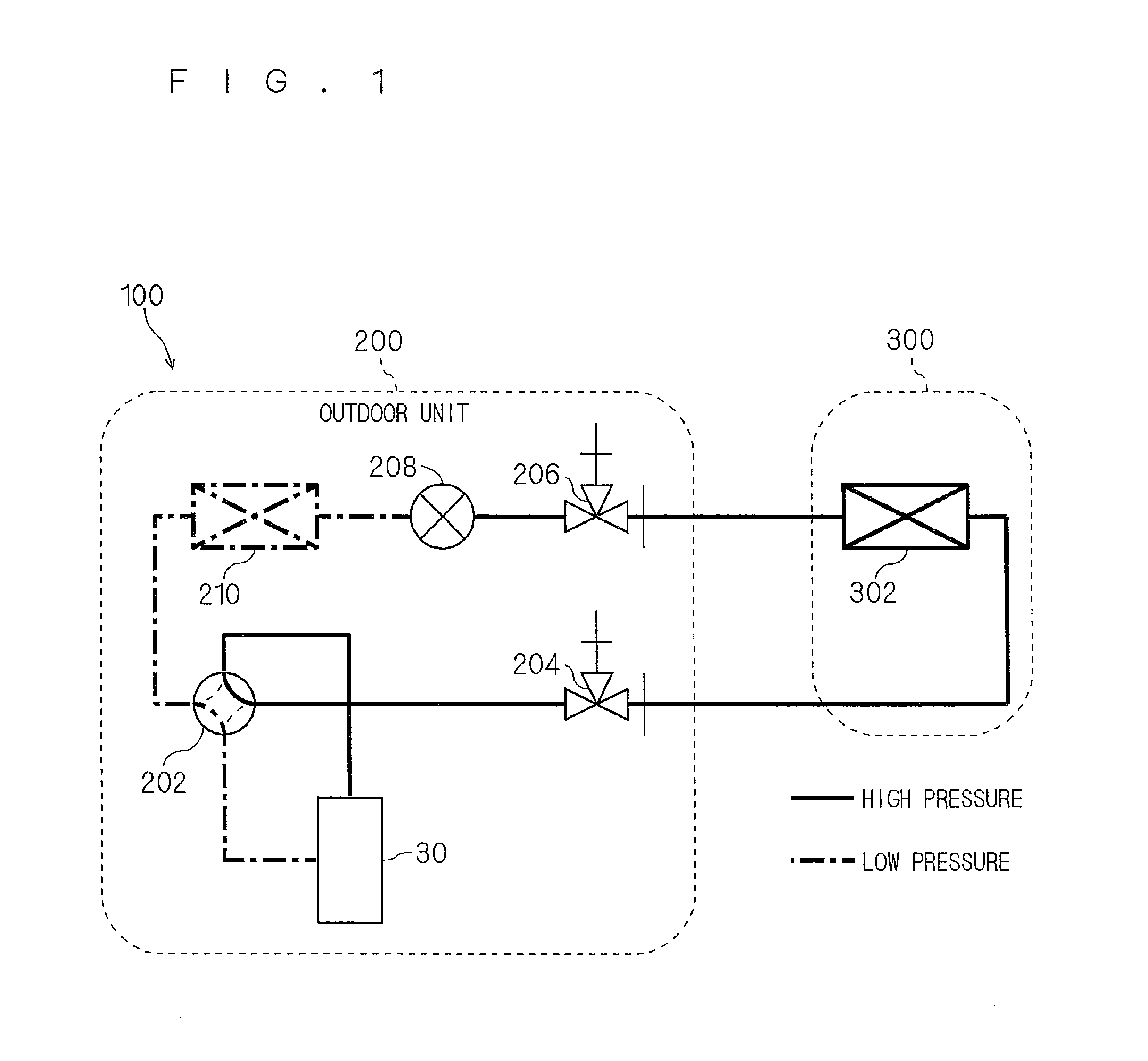

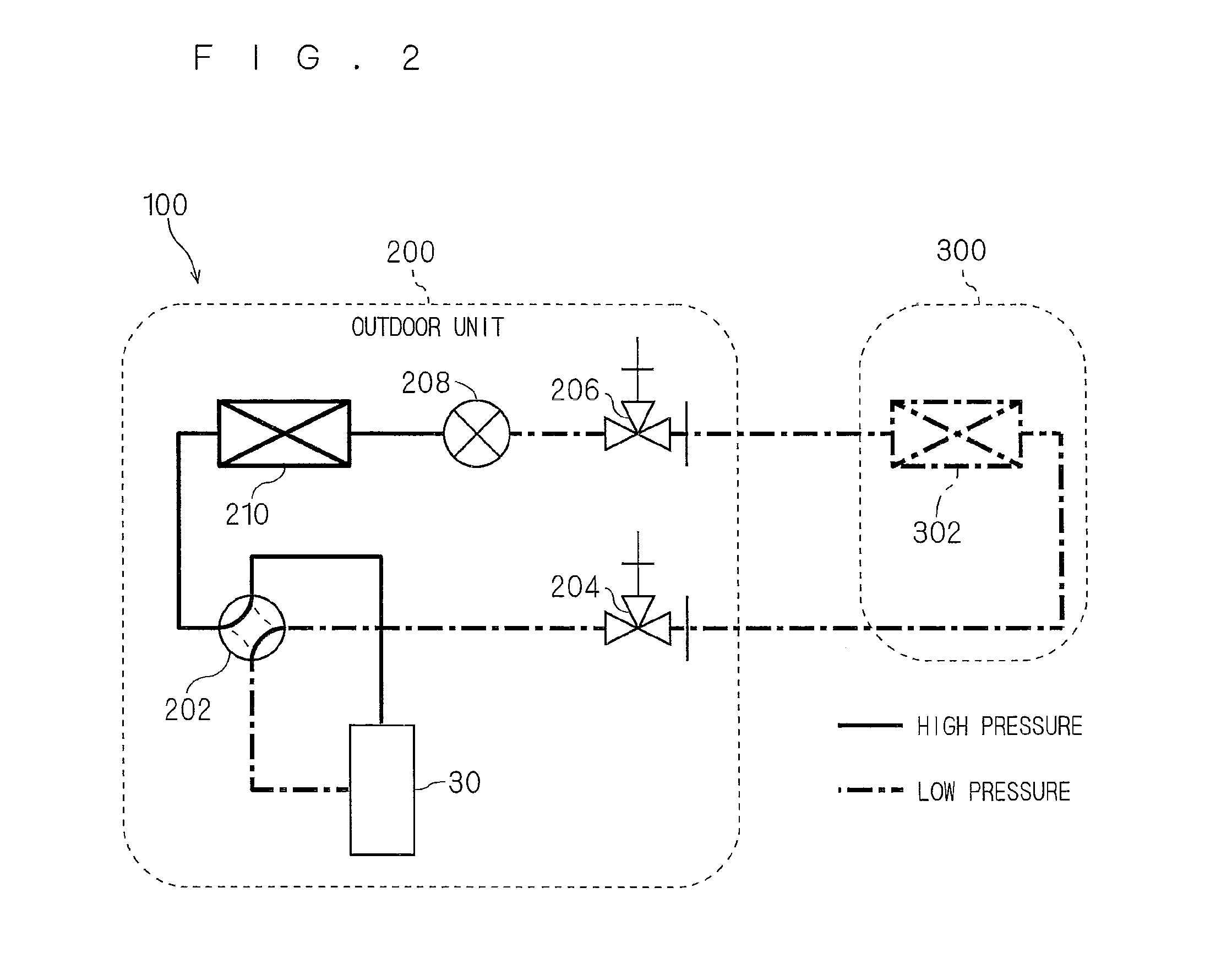

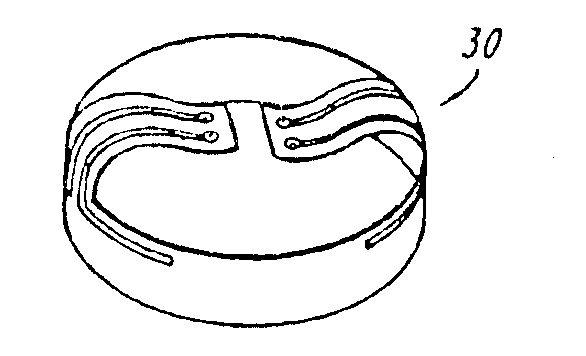

Air conditioner, air conditioner manufacturing method, and compressor

ActiveUS20110083467A1Increased number of spinsHigh voltageWindingsSpace heating and ventilationPower flowPower conditioner

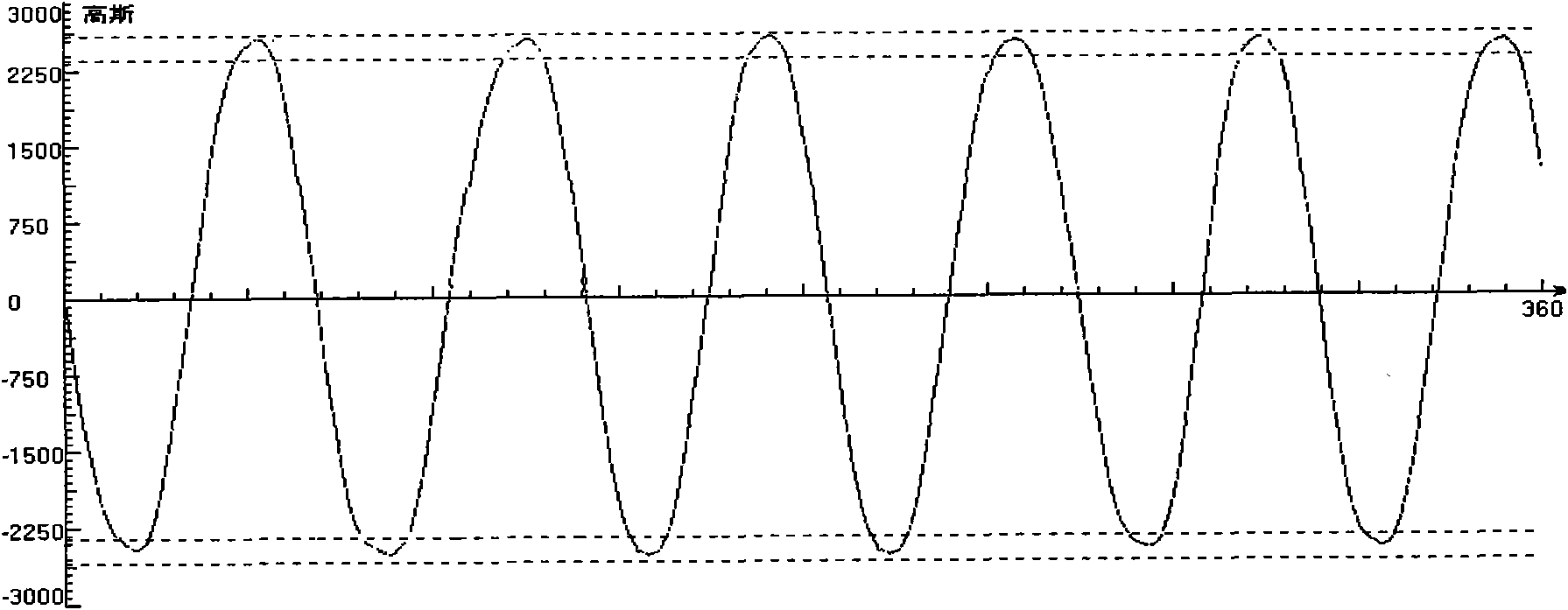

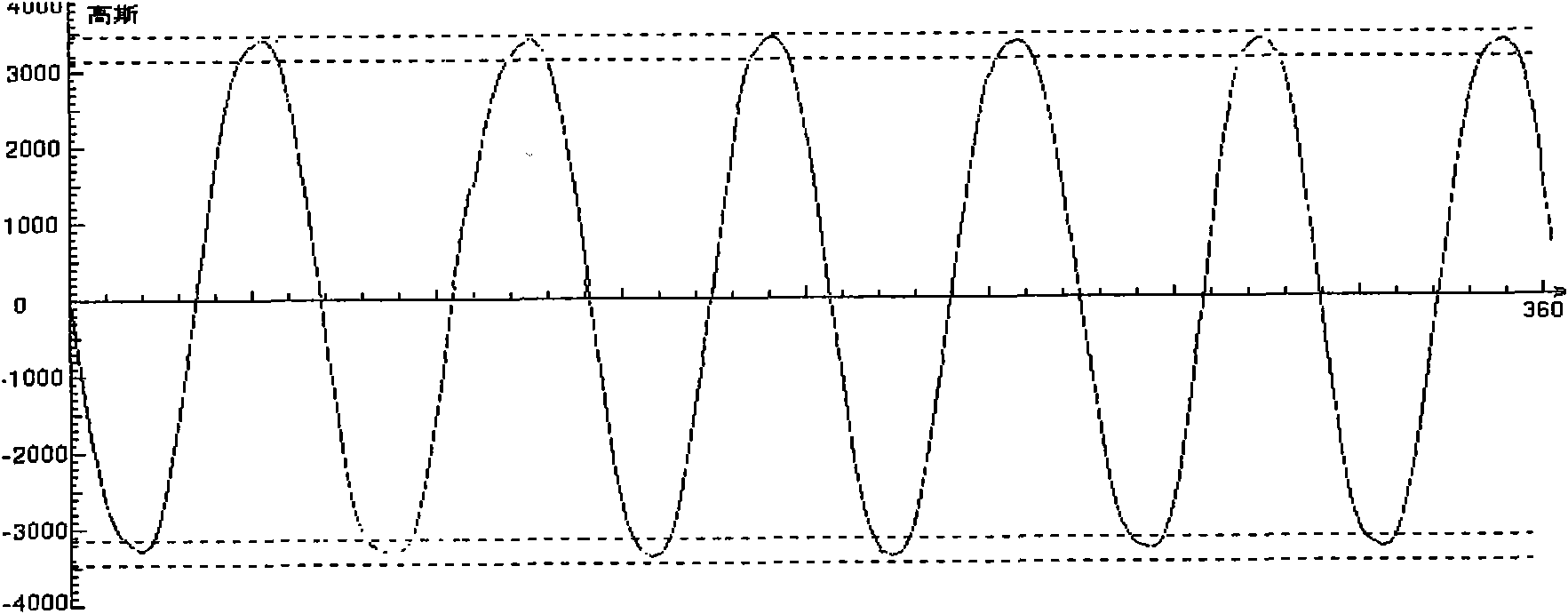

At a time of a heating high-load operation, a harmonic current is flown in an armature winding to induction-heat rare-earth magnets, thus reducing a residual magnetic flux density. Thereby, the number of rotations of a radial gap type motor is improved. The rare-earth magnets are provided near a cooling medium passage extending substantially in parallel with a flow line of a cooling medium, so that the cooling medium recovers heat of the heated rare-earth magnets. At a time of a cooling high-load operation, a greater number of rotations are obtained with respect to the same torque command value, by a field weakening control by means of a current-phase advance.

Owner:DAIKIN IND LTD

Rare earth magnet and its preparation

ActiveUS20110000586A1Prevent oxidationMinimal hazardTransportation and packagingMetal-working apparatusRare-earth elementRare-earth magnet

A rare earth magnet is prepared by disposing a R1-T-B sintered body comprising a R12T14B compound as a major phase in contact with an R2-M alloy powder and effecting heat treatment for causing R2 element to diffuse into the sintered body. The alloy powder is obtained by quenching a melt containing R2 and M. R1 and R2 are rare earth elements, T is Fe and / or Co, M is selected from B, C, P, Al, Si, Ti, V, Cr, Mn, Fe, Co, Ni, Cu, Zn, Ga, Ge, Zr, Nb, Mo, Ag, In, Sn, Sb, Hf, Ta, W, Pt, Au, Pb, and Bi.

Owner:SHIN ETSU CHEM IND CO LTD

Low cost broad range loudspeaker and system

InactiveUS6993147B2Low costGood value for moneyTransducer detailsDeaf-aid setsBobbinElectrical conductor

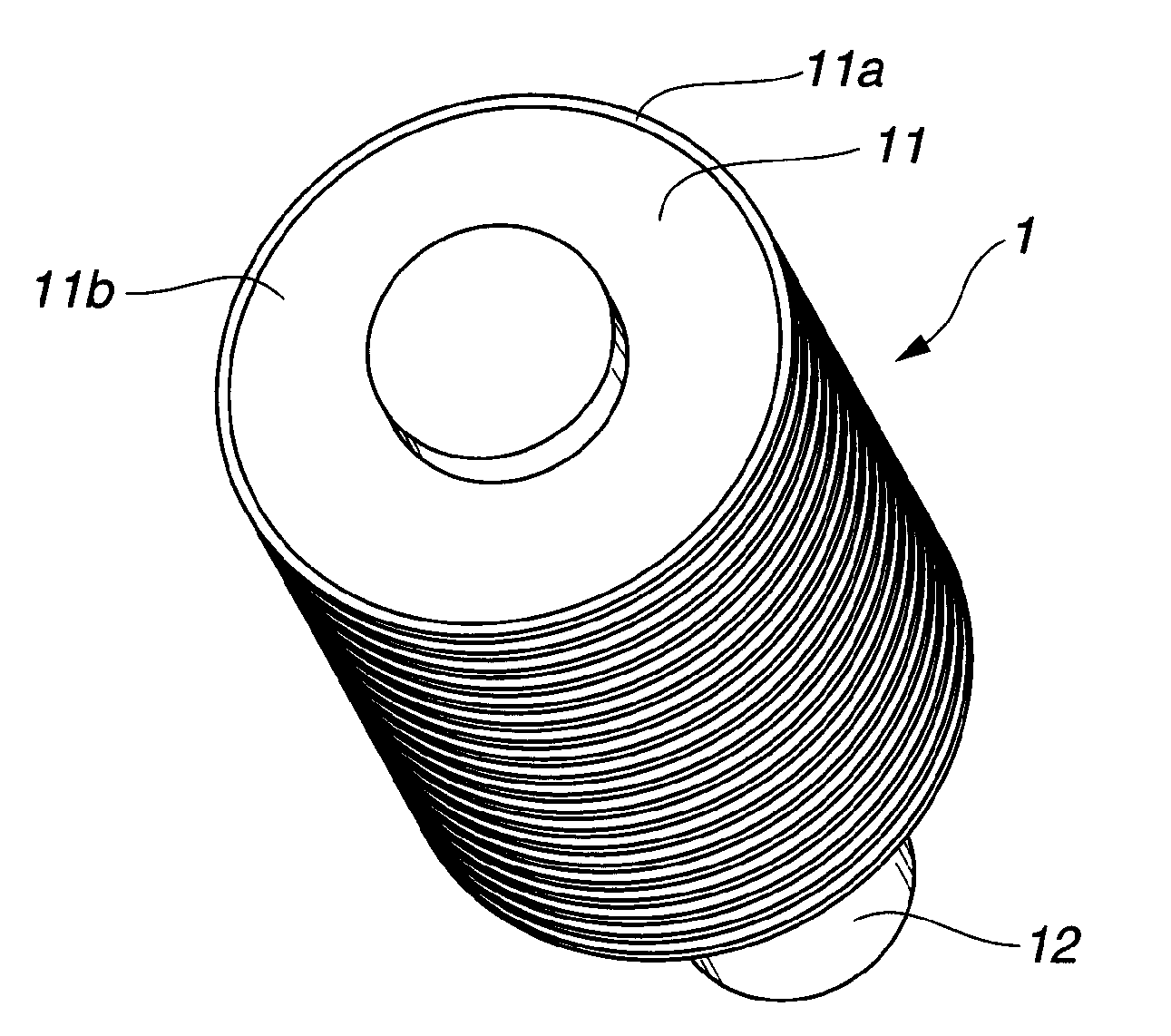

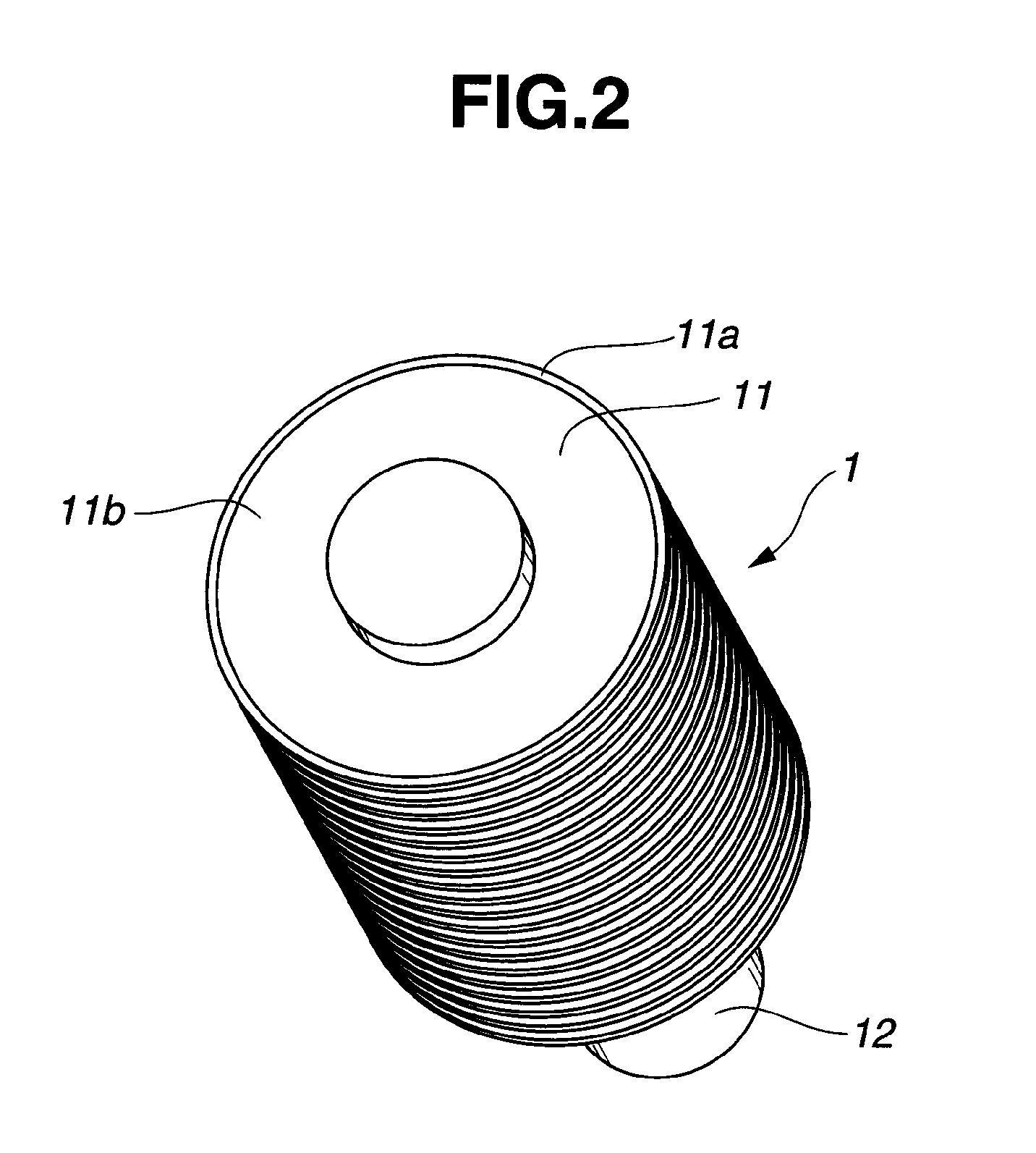

A loudspeaker has a diaphragm with a voice coil disposed about its perimeter and extending in a gap into which the flux of an annular rare earth magnet is focused. An opening behind the diaphragm communicates through the speaker frame. The voice coil may have two or more windings that are connected in parallel, and may, e.g., be layered on top of one another, so that the impedance of the coil, as well as its depth in the front / back direction of motion, are low. The voice coil is preferably implemented using a polyamide form or bobbin, which has patterned lead-in conductors embedded therein to bring power to wire windings on the perimeter of the coil. The lead-in conductors extend to, or through, the central opening of a ring magnet, providing a robust ribbon input connection.

Owner:NUTTER MCCLENNEN & FISH

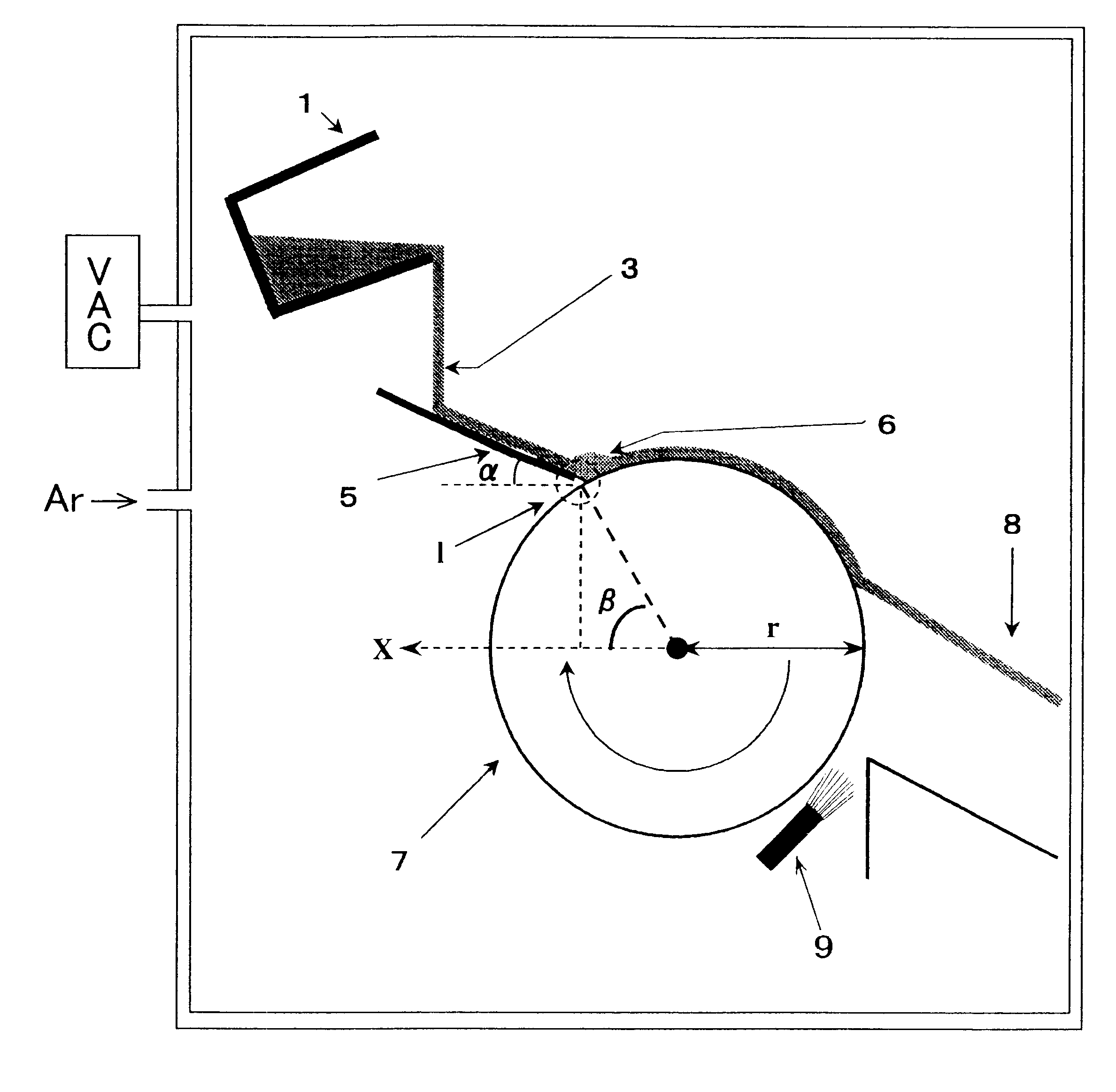

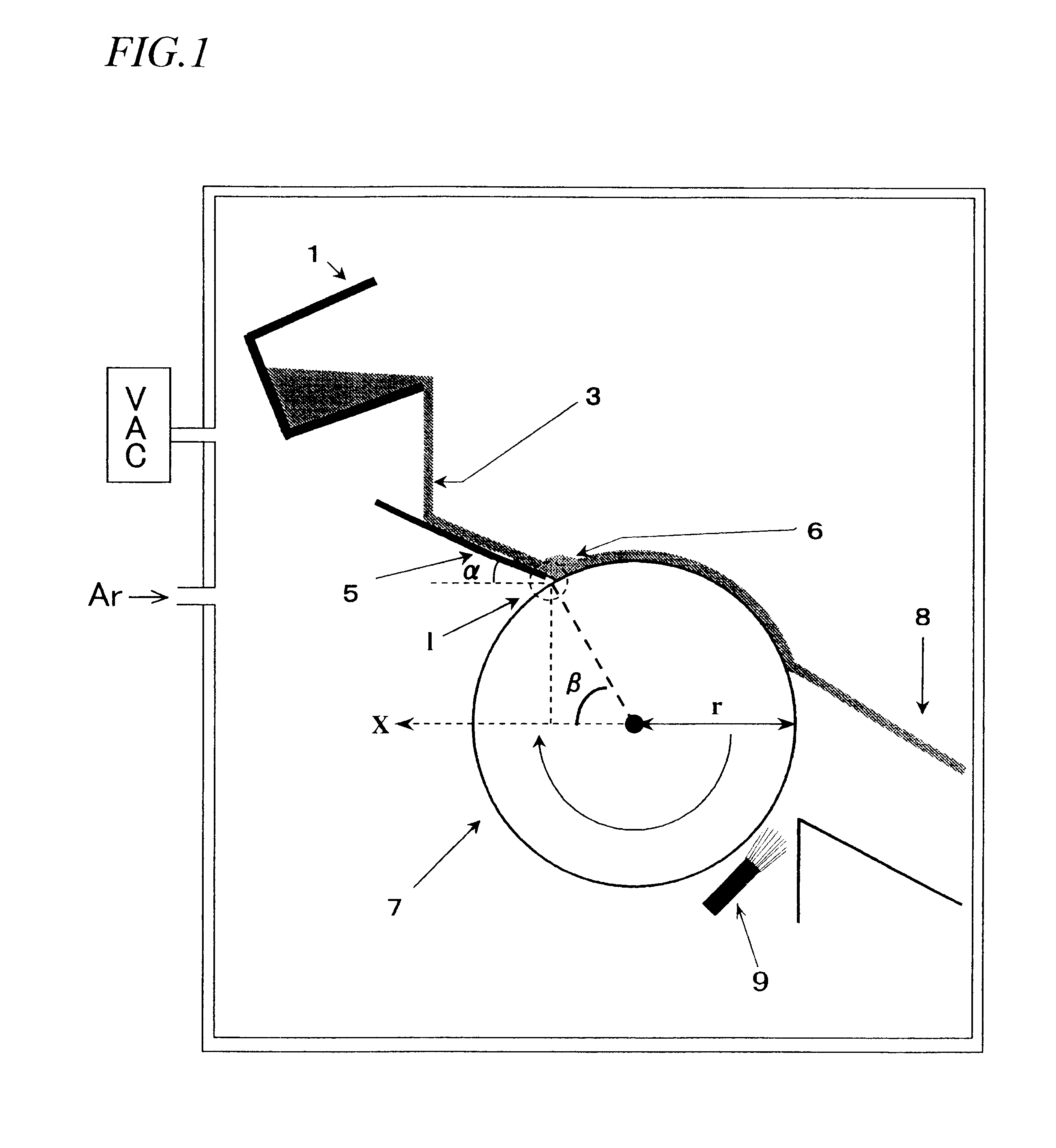

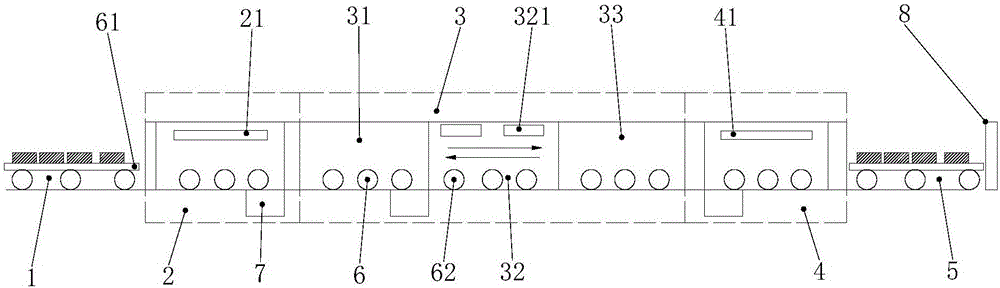

Coating method, coating system and method for preparing rare-earth magnet

ActiveCN106282948AImprove consistencyEffective thickness controlVacuum evaporation coatingSputtering coatingSputteringCoating system

The invention discloses a coating method, a coating system and a method for preparing rare-earth magnets. In the method and the system disclosed by the invention, magnets are arranged on a conveying device in a plurality of rows in a horizontal direction; the magnets which are arranged in the plurality of rows sequentially pass through a sputtering area of sputter coating equipment to complete coating; a vertical distance between the sputter coating equipment and the upper surface of the magnets is 10mm to 200mm. The method and the system disclosed by the invention adopt continuous pass type magnetron sputtering equipment to sputter heavy rare earth such as Dy and Tb onto the surfaces of the magnets, the thickness of the sputtering layer is effectively controlled, the uniformity of the sputtering layer is guaranteed, thereby the uniformity of the magnetic property of magnetic sheets obtained by performing grain boundary diffusion to the sputtered magnets is guaranteed, and the rapid and continuous production of magnets by adopting the grain boundary diffusion technique can be realized.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH +1

Remelting of rare earth magnet scrap and/or sludge, magnet-forming alloy, and sintered rare earth magnet

InactiveUS6960240B2Improve efficiencyIncrease productionPermanent magnetsInorganic material magnetismMischmetalAlkaline earth metal

Rare earth magnet scrap and / or sludge is remelted for reuse. Once a rare earth-free magnet-constituent metal feed is loaded in a melting furnace and heated into a melt, a rare earth-containing metal feed and the rare earth magnet scrap and / or sludge are added to the melt, a particulate flux of an alkali metal, alkaline earth metal or rare earth metal halide and having an average particle size of 1-50 μm, preferably wrapped in a metal foil, is added to the melt, and the resulting mixture is melted, from which an alloy ingot is obtained. The valuable elements in the scrap and / or sludge can be recycled. Better separation between the slag and the molten metal ensures that the ingot is obtained from the melt in a high yield.

Owner:SHIN ETSU CHEM IND CO LTD

Rare earth magnet and manufacturing method thereof

InactiveCN101276665AHigh reluctanceHigh magnetic flux densityInorganic material magnetismEddy currentOxygen

A structure of a magnet wherein a magnet consisting of a magnetic body including iron and rare earths, a plurality of fluorine compound layers or oxyfluorine compound layers are formed interior of the magnetic body, and the fluorine compound layer or oxyfluorine compound layer has a major axis which is greater than the mean particle size of the crystal grains of the magnetic body.

Owner:HITACHI LTD

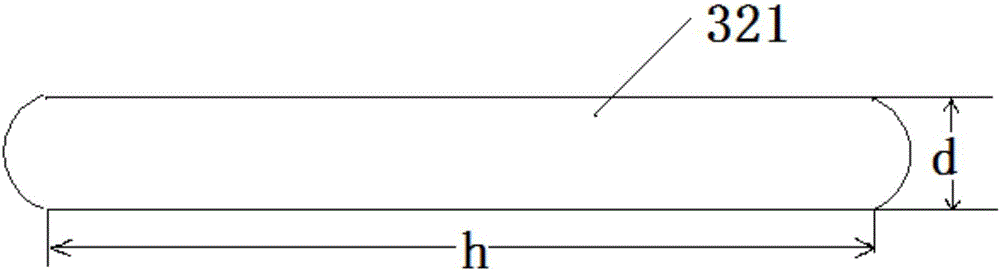

Method for multiple cutoff machining of rare earth magnet

InactiveUS20110312255A1Reduce effective diameterLarge heightBonded abrasive wheelsInductances/transformers/magnets manufactureEngineeringRare-earth magnet

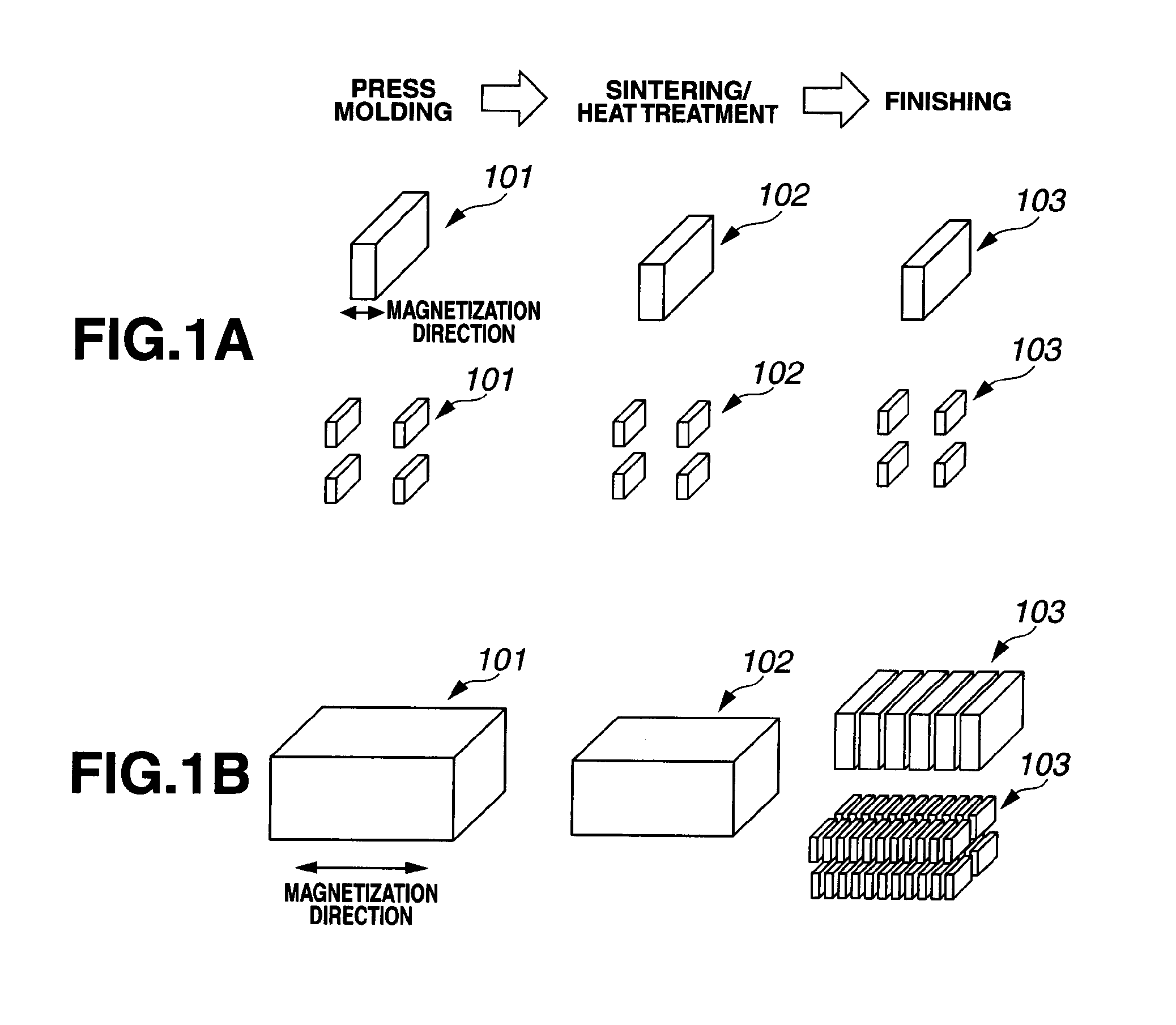

A rare earth magnet block is cutoff machined into pieces by rotating a plurality of cutoff abrasive blades. Improvements are made by starting the machining operation from the upper surface of the magnet block downward, interrupting the machining operation, turning the magnet block upside down, placing the magnet block such that the cutoff grooves formed before and after the upside-down turning may be aligned with each other, and restarting the machining operation from the upper surface of the upside-down magnet block downward until the cutoff grooves formed before and after the upside-down turning merge with each other.

Owner:SHIN ETSU CHEM IND CO LTD

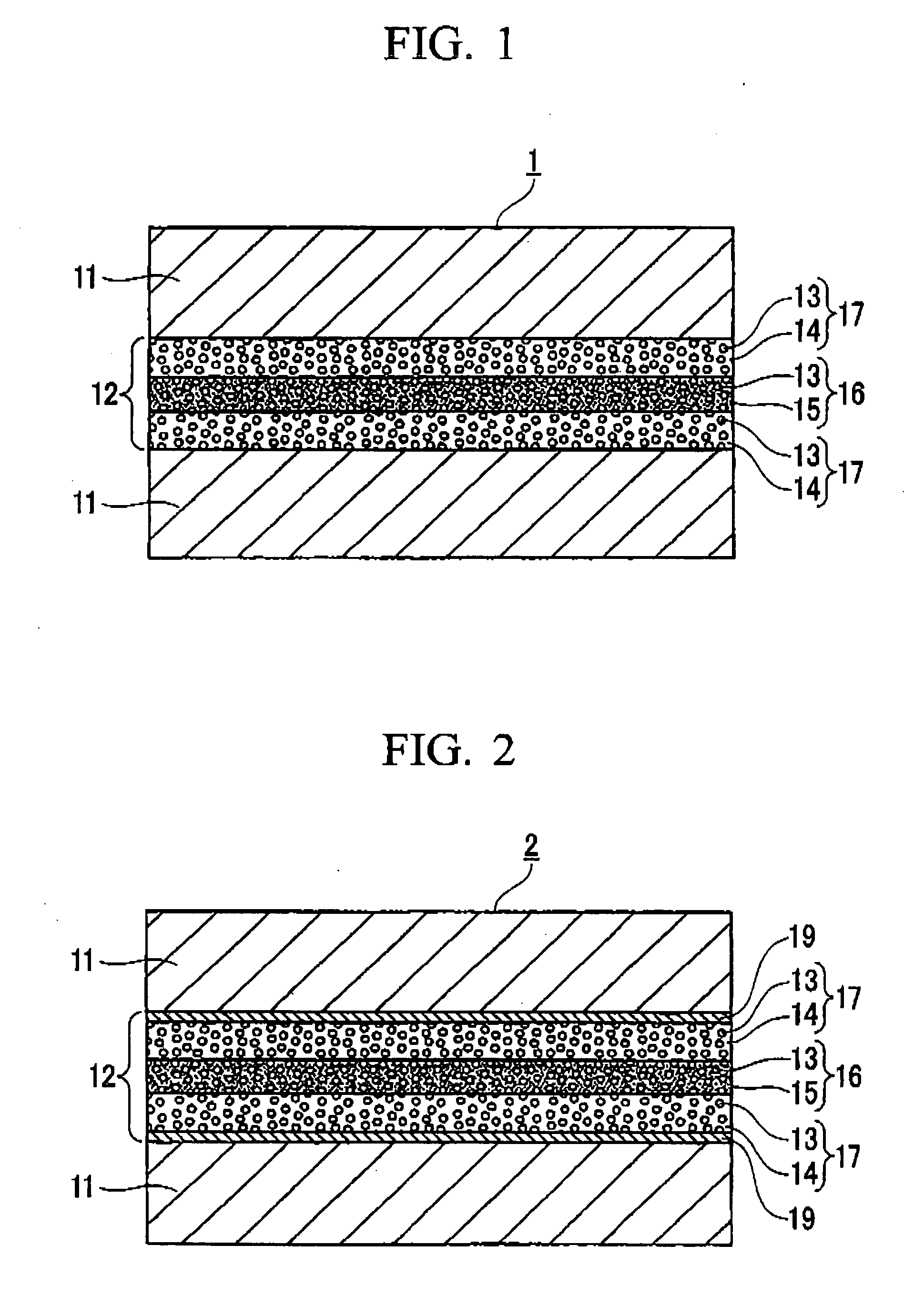

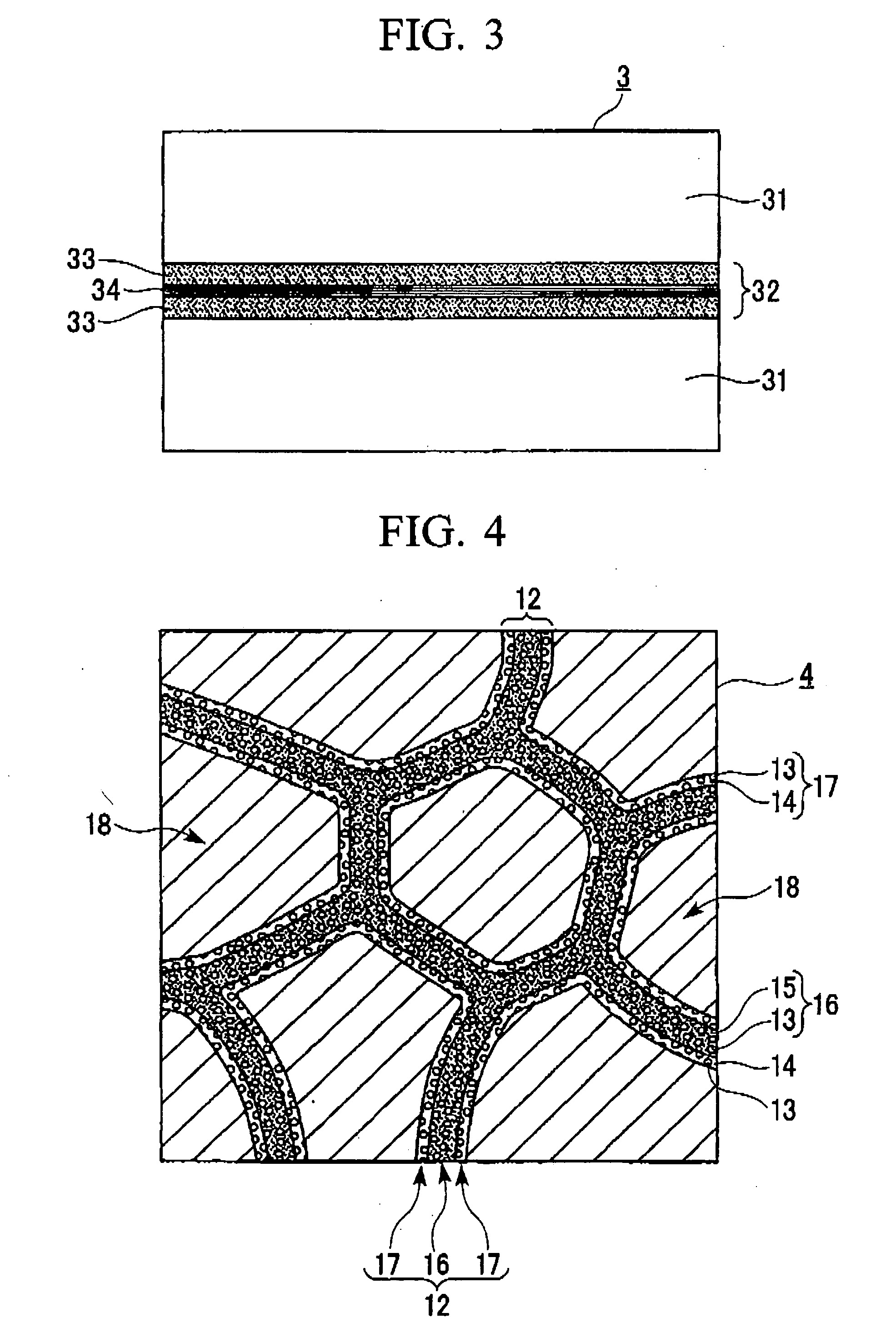

Rare earth magnet having high strength and high electrical resistance

InactiveUS20060292395A1Improve permanent magnet performanceHigh strengthInductances/transformers/magnets manufactureThin magnetic filmsHigh intensityRare-earth magnet

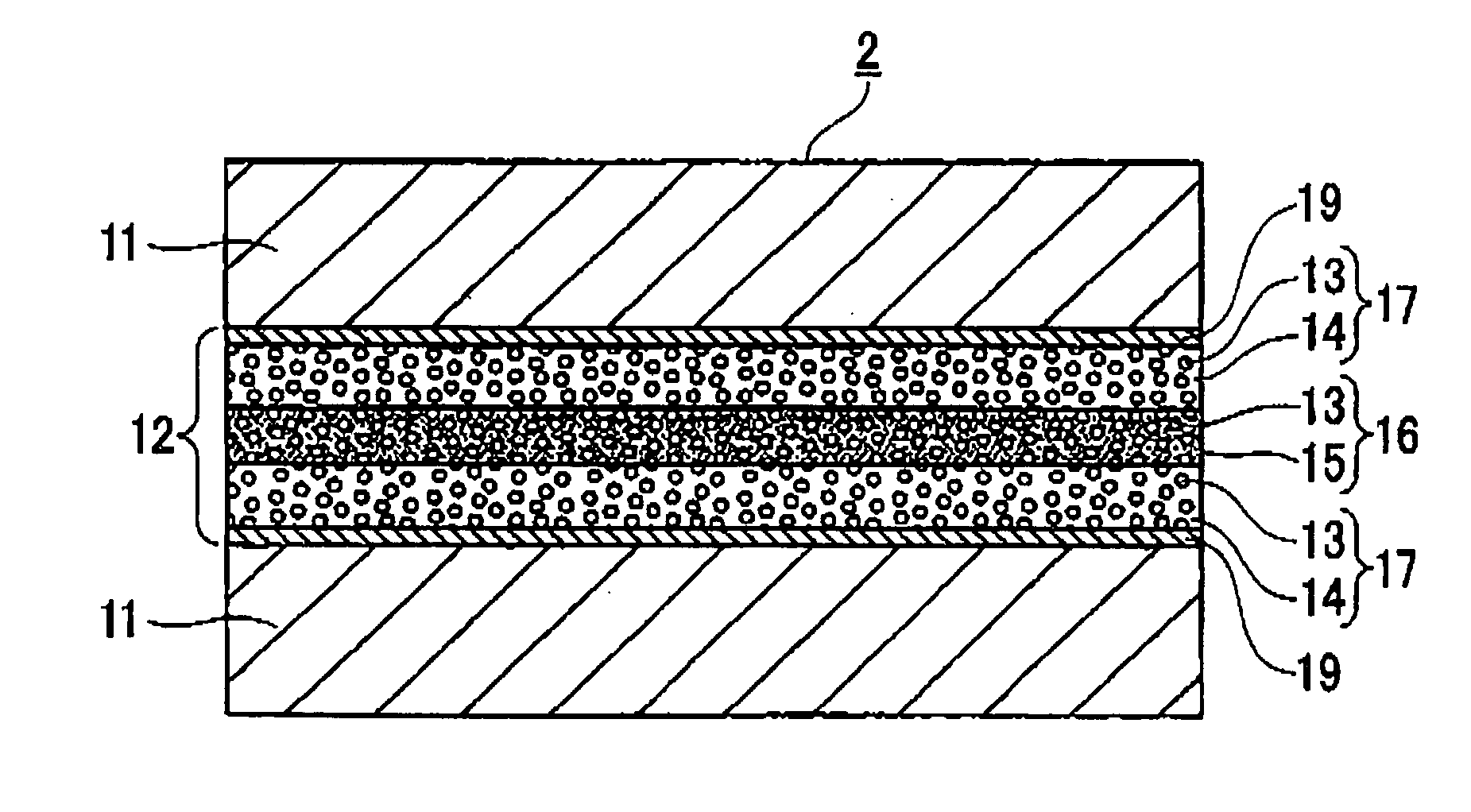

This rare earth magnet having high strength and high electrical resistance has a structure including an R—Fe—B-based rare earth magnet particles 18 which are enclosed with a high strength and high electrical resistance composite layer 12. The high strength and high electrical resistance composite layer 12 is constituted from a glass-based layer 16 that has a structure comprising a glass phase or R oxide particles 13 dispersed in glass phase, and R oxide particle-based mixture layers 17 that are formed on both sides of the glass-based layer 16 and contain an R-rich alloy phase 14 which contains 50 atomic % or more of R in the grain boundary of the R oxide particles.

Owner:NISSAN MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com