Patents

Literature

160results about How to "Effective thickness control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

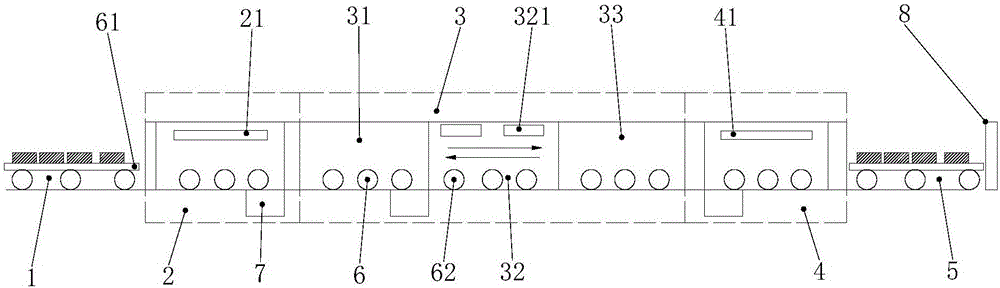

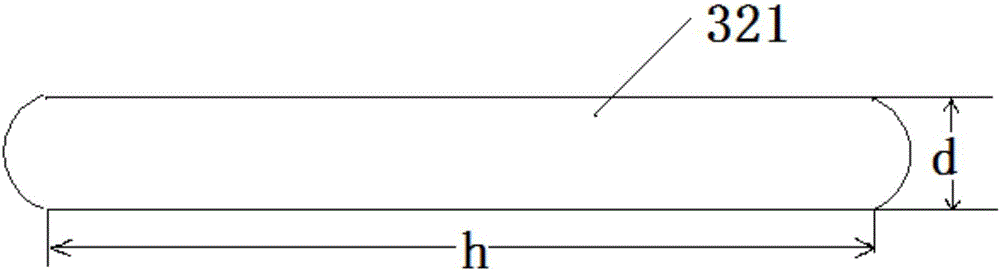

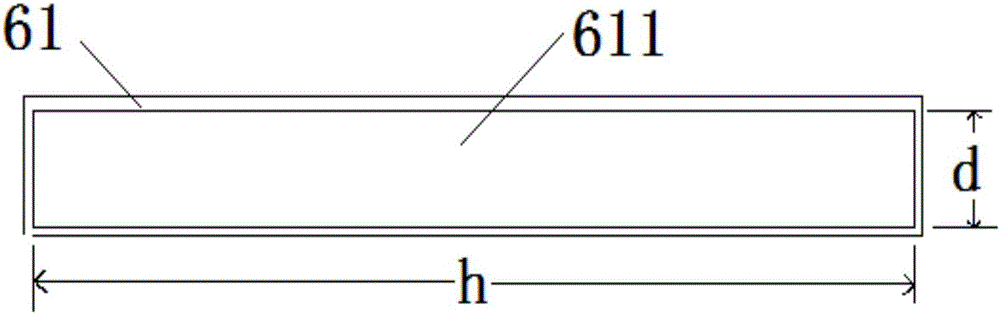

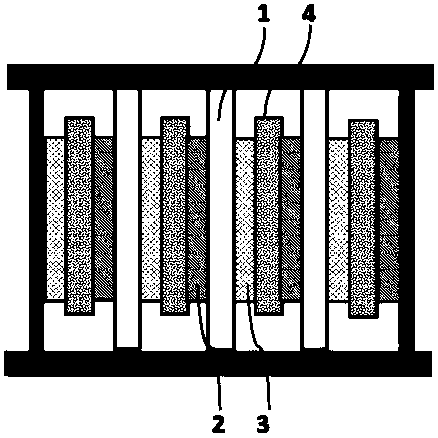

Coating method, coating system and method for preparing rare-earth magnet

ActiveCN106282948AImprove consistencyEffective thickness controlVacuum evaporation coatingSputtering coatingSputteringCoating system

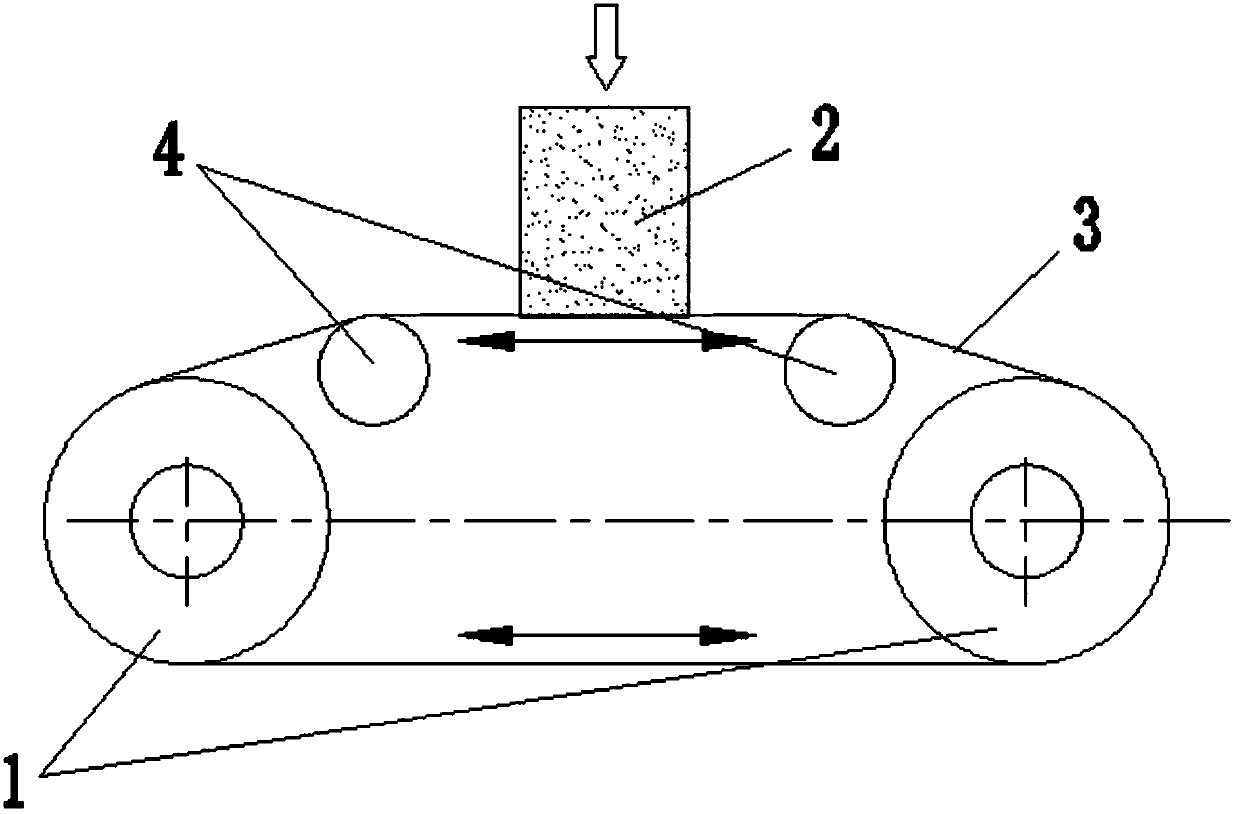

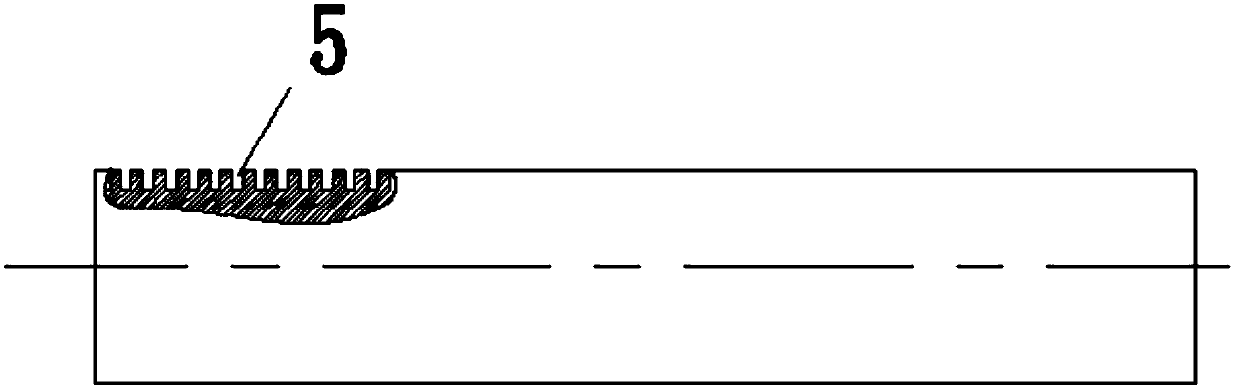

The invention discloses a coating method, a coating system and a method for preparing rare-earth magnets. In the method and the system disclosed by the invention, magnets are arranged on a conveying device in a plurality of rows in a horizontal direction; the magnets which are arranged in the plurality of rows sequentially pass through a sputtering area of sputter coating equipment to complete coating; a vertical distance between the sputter coating equipment and the upper surface of the magnets is 10mm to 200mm. The method and the system disclosed by the invention adopt continuous pass type magnetron sputtering equipment to sputter heavy rare earth such as Dy and Tb onto the surfaces of the magnets, the thickness of the sputtering layer is effectively controlled, the uniformity of the sputtering layer is guaranteed, thereby the uniformity of the magnetic property of magnetic sheets obtained by performing grain boundary diffusion to the sputtered magnets is guaranteed, and the rapid and continuous production of magnets by adopting the grain boundary diffusion technique can be realized.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH +1

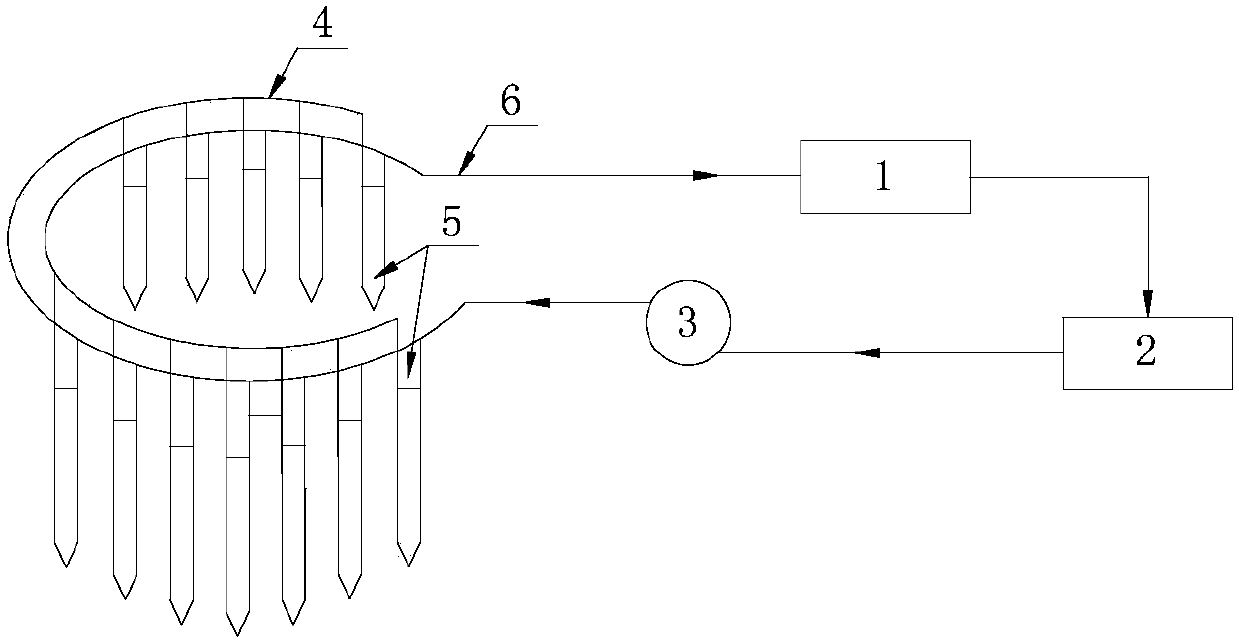

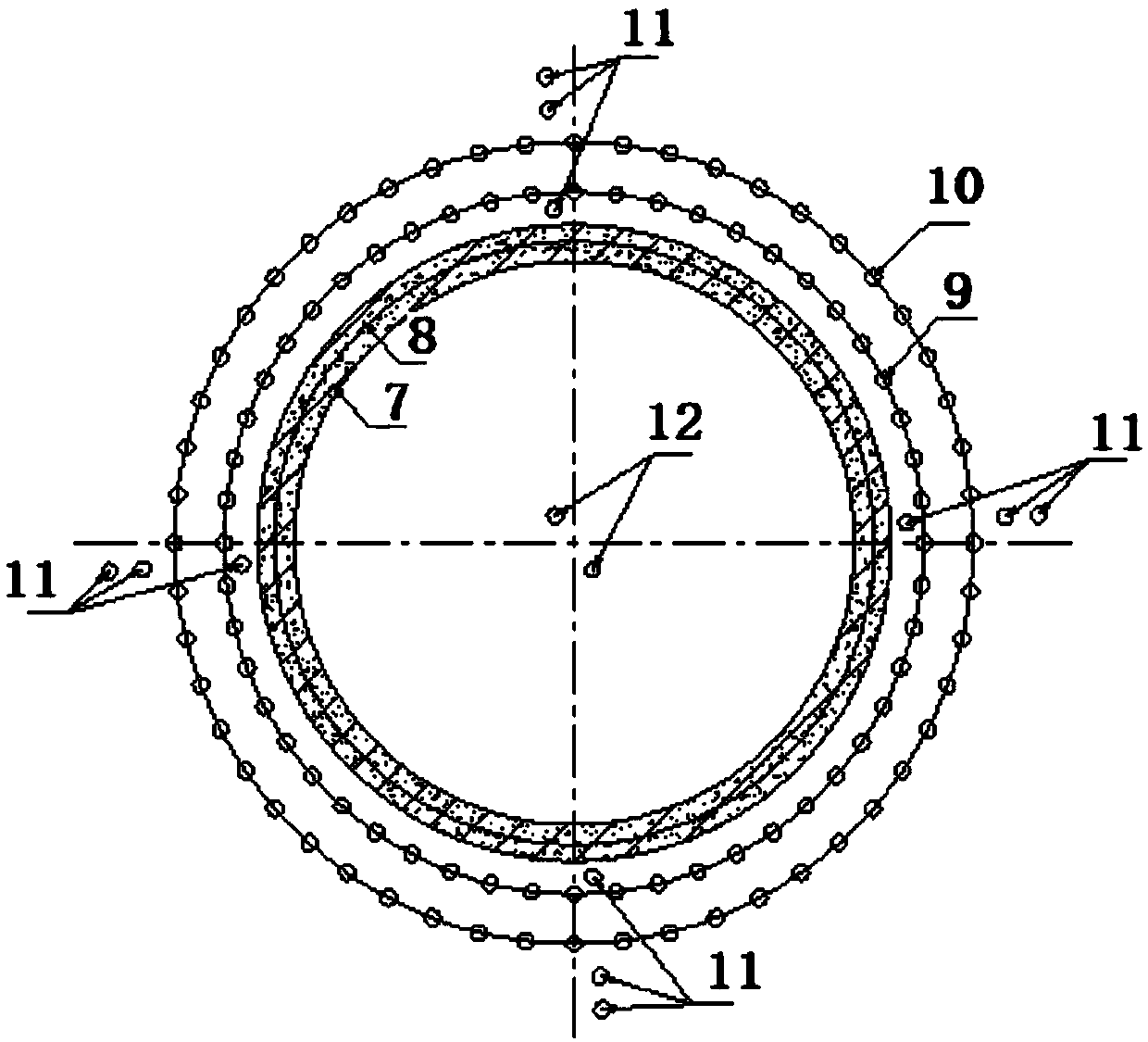

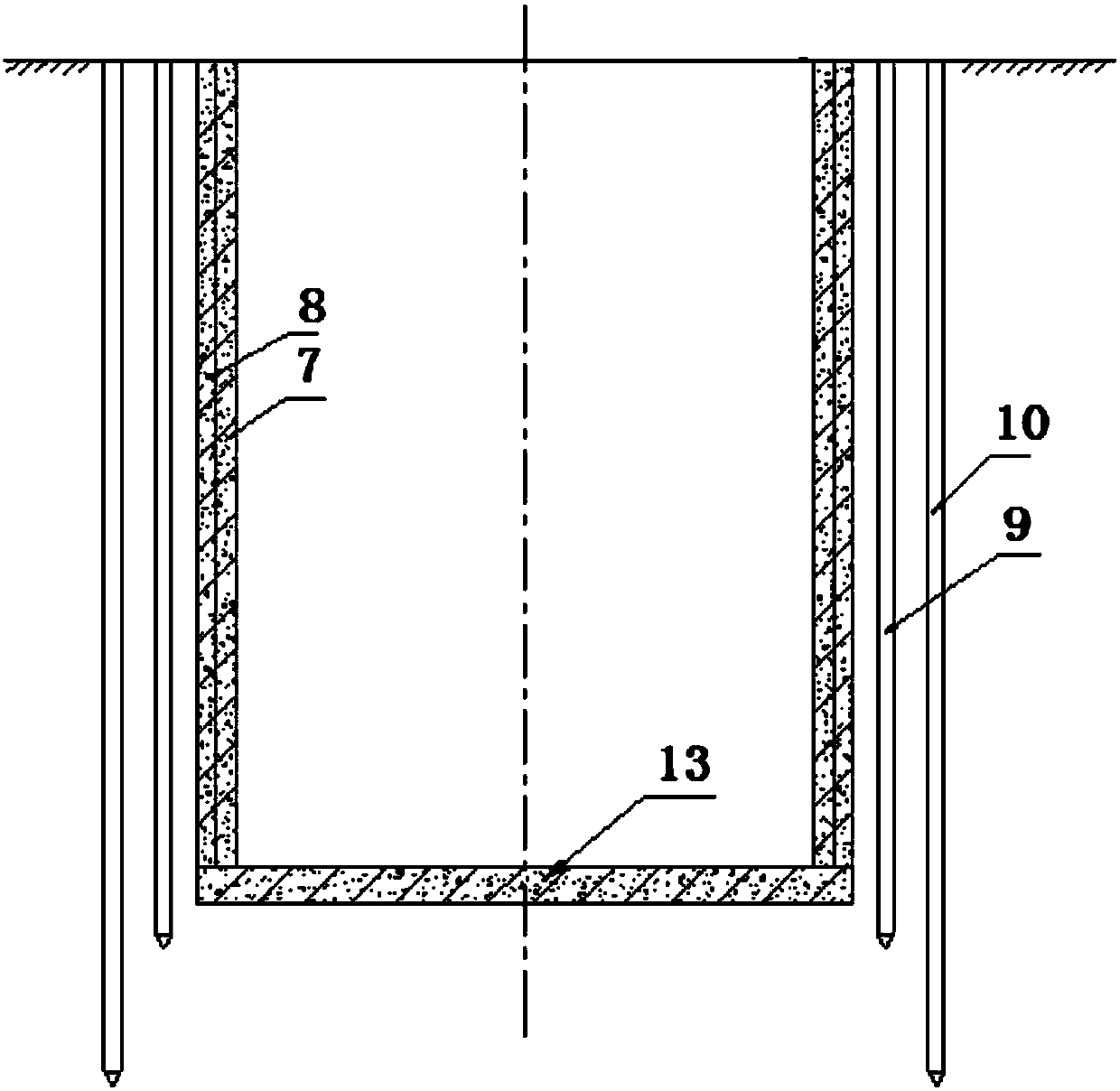

Freeze construction method for wellbore type underground parking garage

ActiveCN108035335AUnlimited construction depthAdapt to a wide rangeArtificial islandsUnderwater structuresTowerWellbore

The invention discloses a freeze construction method for wellbore type underground parking garage. A circular wellbore is built underground by sequentially using freeze construction, excavation construction, grouting and thaw grouting, and an elevator type and intelligent tower type stereo garage system currently applied at home and abroad is installed in the wellbore for operation. Before construction of the wellbore, an artificial freezing method is applied, water-bearing strata around the wellbore is frozen, a frozen wall having temporary load bearing and water isolating functions and meeting construction safety requirements is formed, and wellbore excavation is performed under protection of the frozen wall; the frozen wall is formed by mutual matching mutual complementing of inner ringfreezing holes and outer ring freezing holes; a cap beam is firstly constructed at the top of the wellbore; excavation construction of the outer wall of the wellbore, concrete pouring on the bottom plate of the wellbore and construction of the inner wall of the wellbore are performed in sequence; after freezing of the wellbore, lining is performed, and grouting and strata thaw are performed for grouting compensation.

Owner:CHINA COAL NO 5 CONSTR

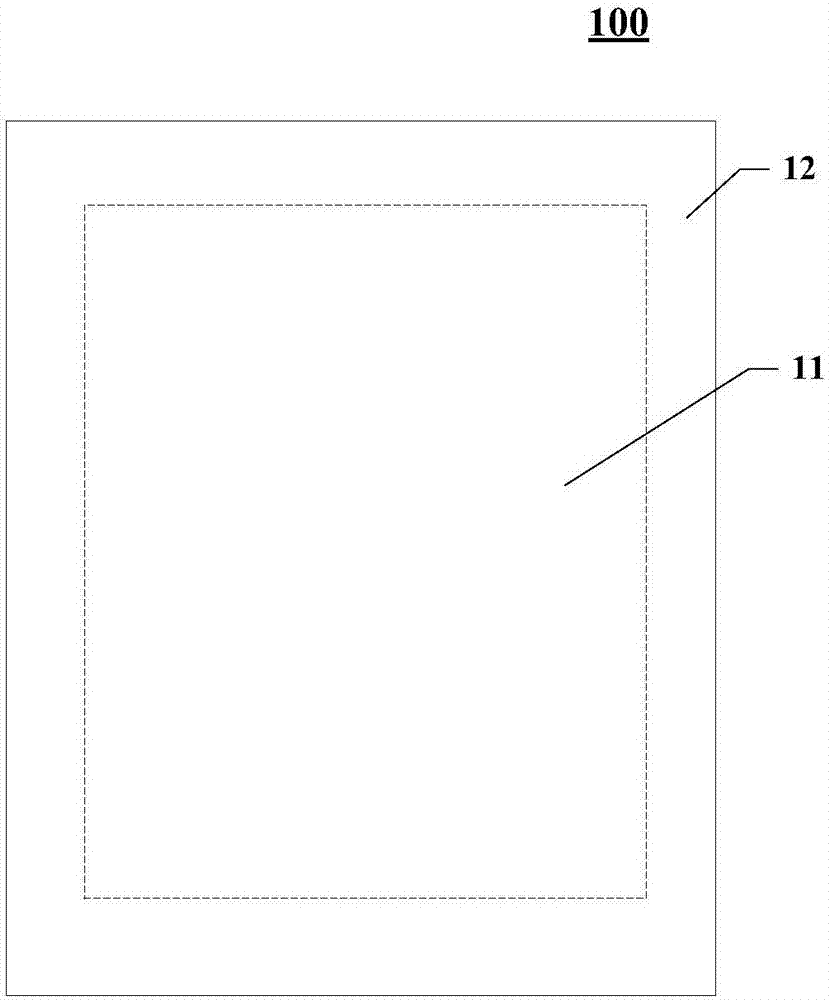

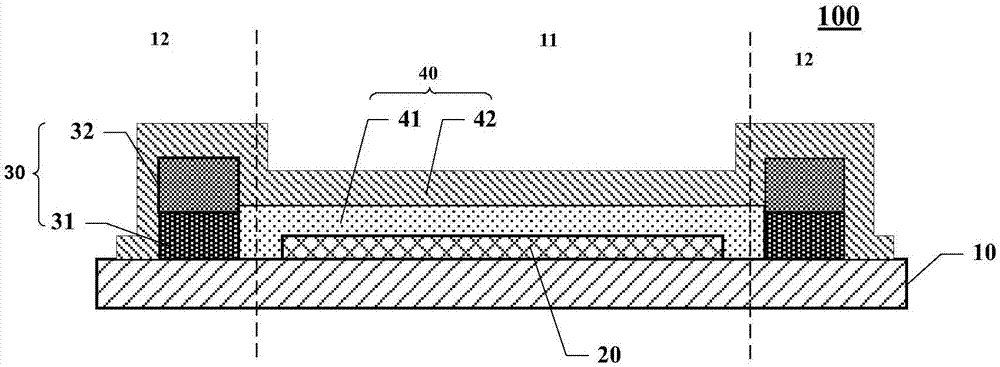

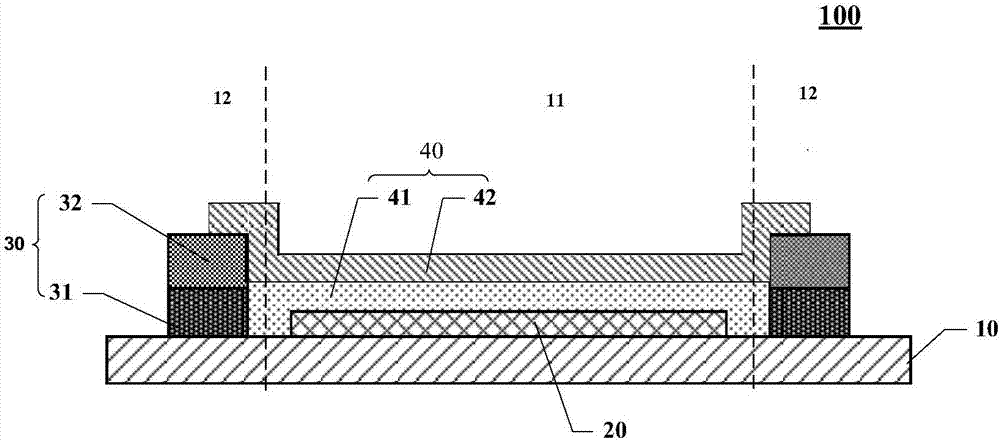

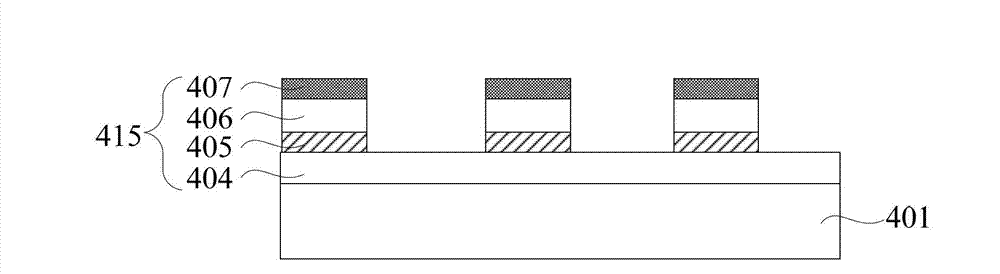

Organic electroluminescence device

ActiveCN107204404AIncrease the speed of diffusionAvoid exceedingSolid-state devicesSemiconductor/solid-state device manufacturingOrganic filmEngineering

The invention discloses an organic electroluminescence device which comprises the components of a substrate; an electroluminescent structure which is arranged on the substrate and is located in a displaying area; at least one retaining wall which is arranged on the substrate and is arranged in a non-displaying area, wherein the retaining wall surrounds the displaying area; at least one retaining wall is successively arranged in a direction of departing from the displaying area, and the retaining walls comprise a first retaining wall which is adjacent with the displaying area; the first retaining wall comprises at least one stack structure, the stack structure comprises an organophilic material layer and an organo-hydrophobic material layer, the organo-hydrophobic material layer is arranged on one side, which is far from the substrate, of the organophilic material layer; and a thin-film packaging layer which comprises an organic film layer and an inorganic film layer, wherein the organic film layer is arranged in a space which is formed through surrounding the displaying area by the first retaining wall, and the inorganic film layer is arranged on the surface, which is far from the electroluminescent structure, of the organic film. According to the organic electroluminescence device, a good boundary of the organic film layer is formed and furthermore thickness at the boundary of the organic film layer is effectively controlled.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

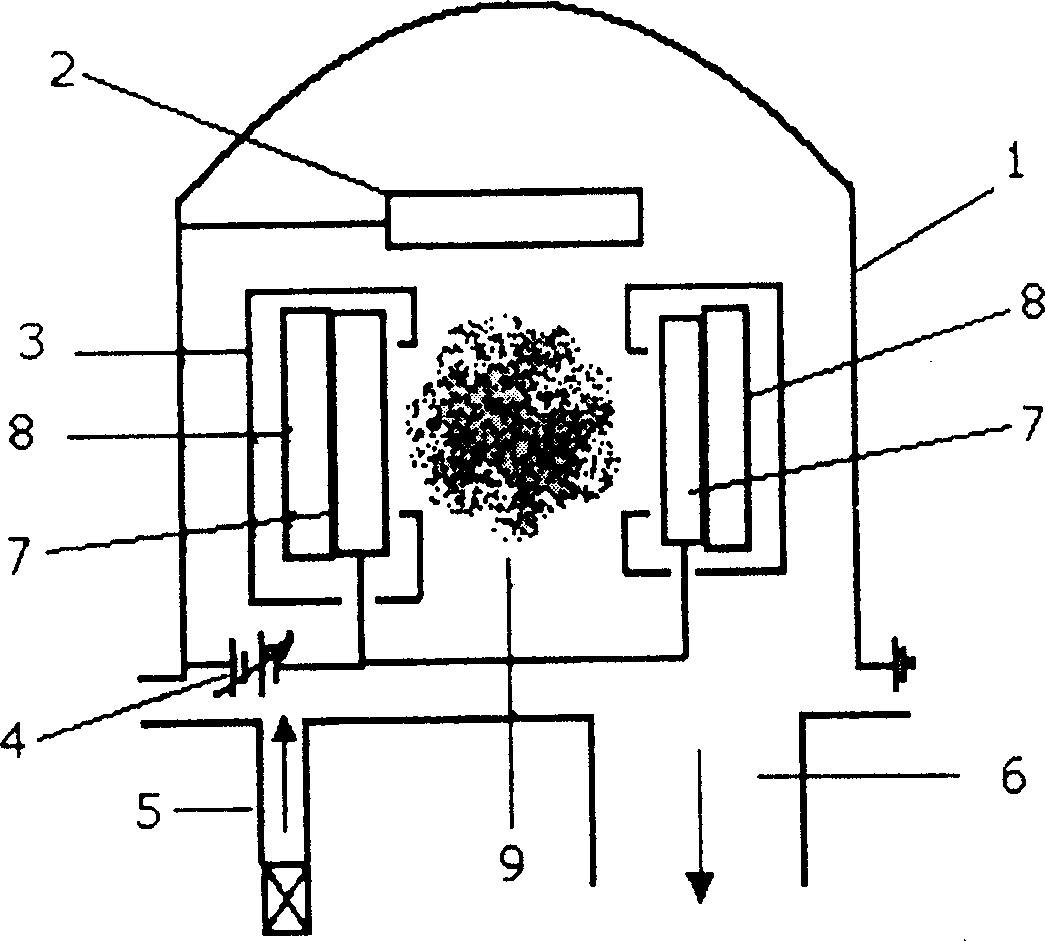

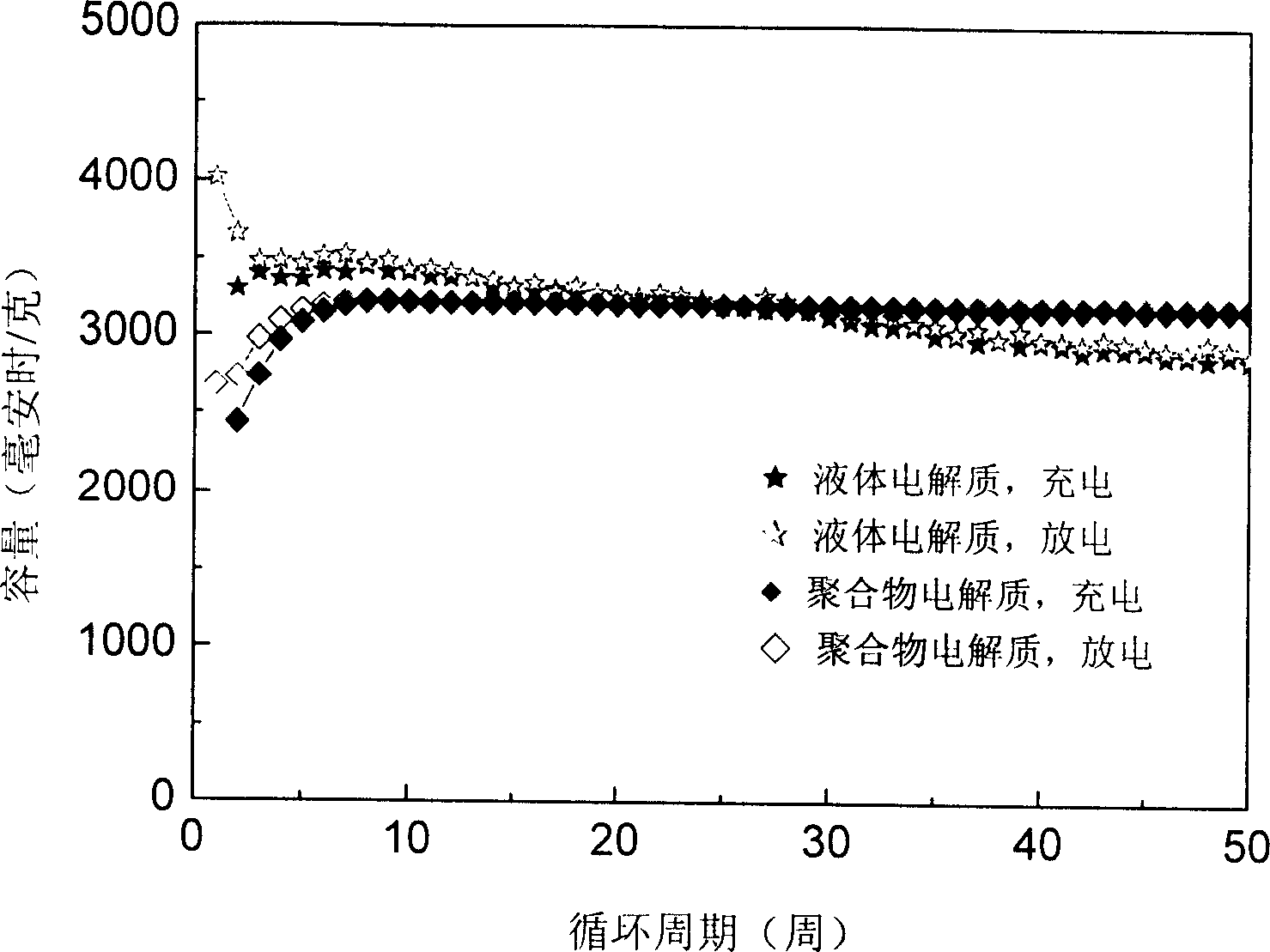

Secondary battery negative pole (anode) and making method

ActiveCN1731599AImprove overall lifespanEffective thickness controlElectrode manufacturing processesSecondary cellsLithiumMain group element

The invention discloses a negative / positive pole for lithium secondary battery and polymer secondary battery and method for making same. The inventive pole is prepared by covering Si or Si1-xMx on copper foil, nickel foil, coppering base or / and nickel iron foil coated base with magnetron sputtering process, wherein M is main group element of subgroup element. By controlling target source and power, the components of electrode can be controlled. The inventive method has the advantage of controlling the thickness of electrode active materials effectively.

Owner:TIANJIN B&M SCI & TECH

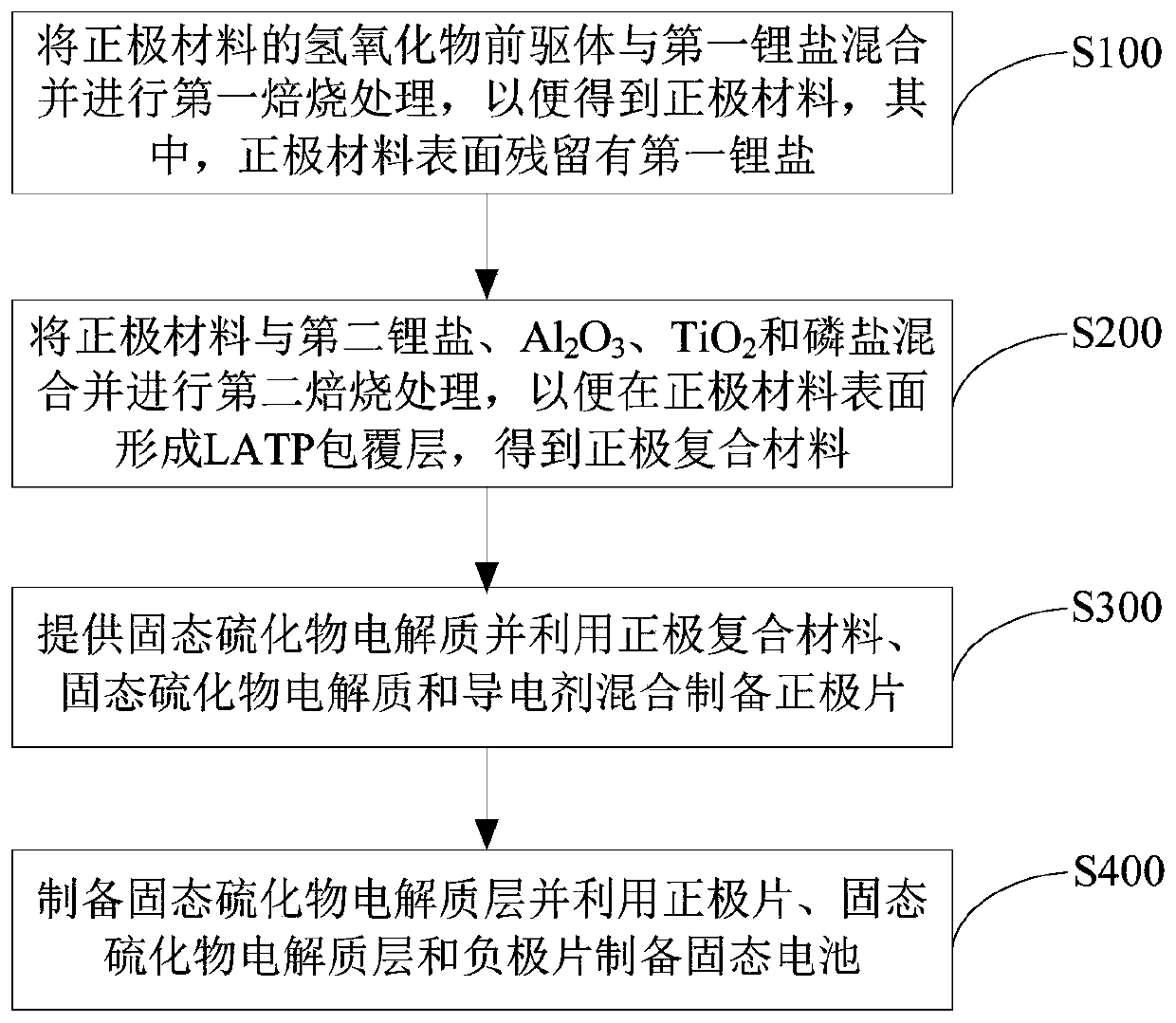

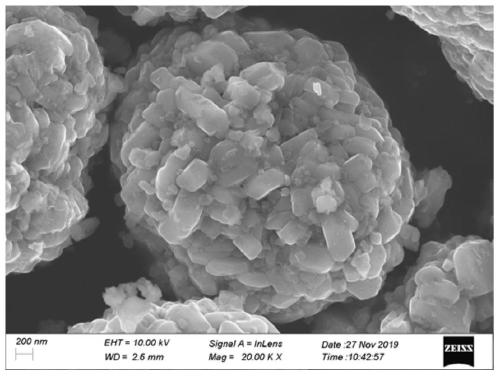

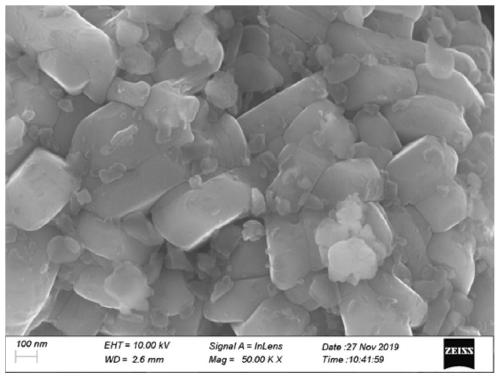

Solid-state battery and preparation method and application thereof

InactiveCN111430688AHigh charge and discharge capacityImprove the first effectSolid electrolytesCell electrodesPhysical chemistrySulfide compound

The invention discloses a solid-state battery and a preparation method and application thereof. The solid-state battery comprises a positive plate, a solid-state sulfide electrolyte layer and a negative plate. The positive plate comprises a positive composite material, a solid-state sulfide electrolyte and a conductive agent, the positive composite material comprises a positive material and an LATP coating layer formed on the surface of the positive material, and the solid sulfide electrolyte layer is arranged between the positive plate and the negative plate, wherein the LATP coating layer isobtained by taking the residual lithium salt on the surface of the positive electrode material as a guiding agent and the lithium source and inducing the lithium source, an aluminum source, a titanium source and a phosphorus source through an in-situ synthesis method. The solid-state battery has better rate capability and cycle performance at room temperature and a high temperature (70 DEG C).

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

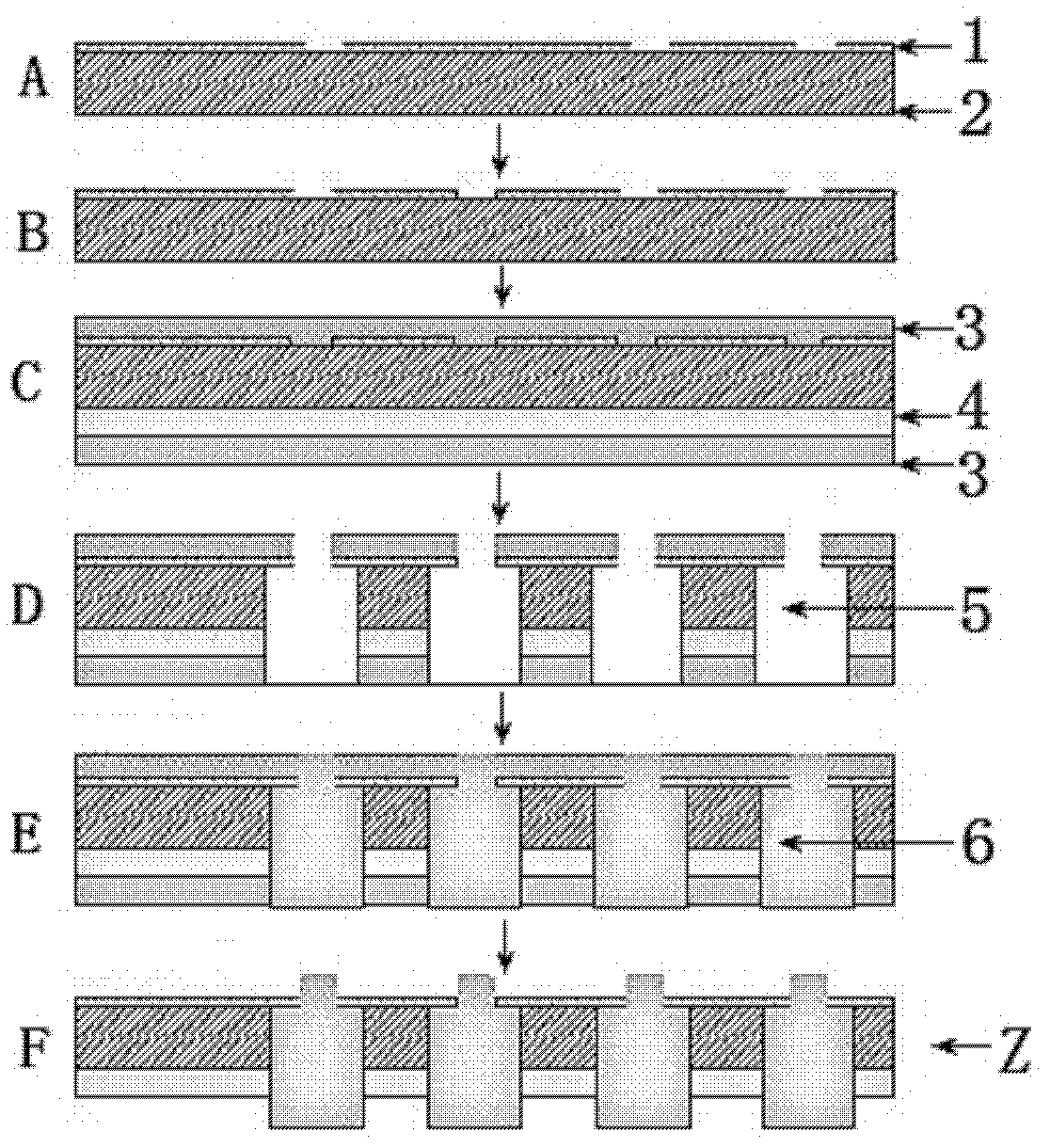

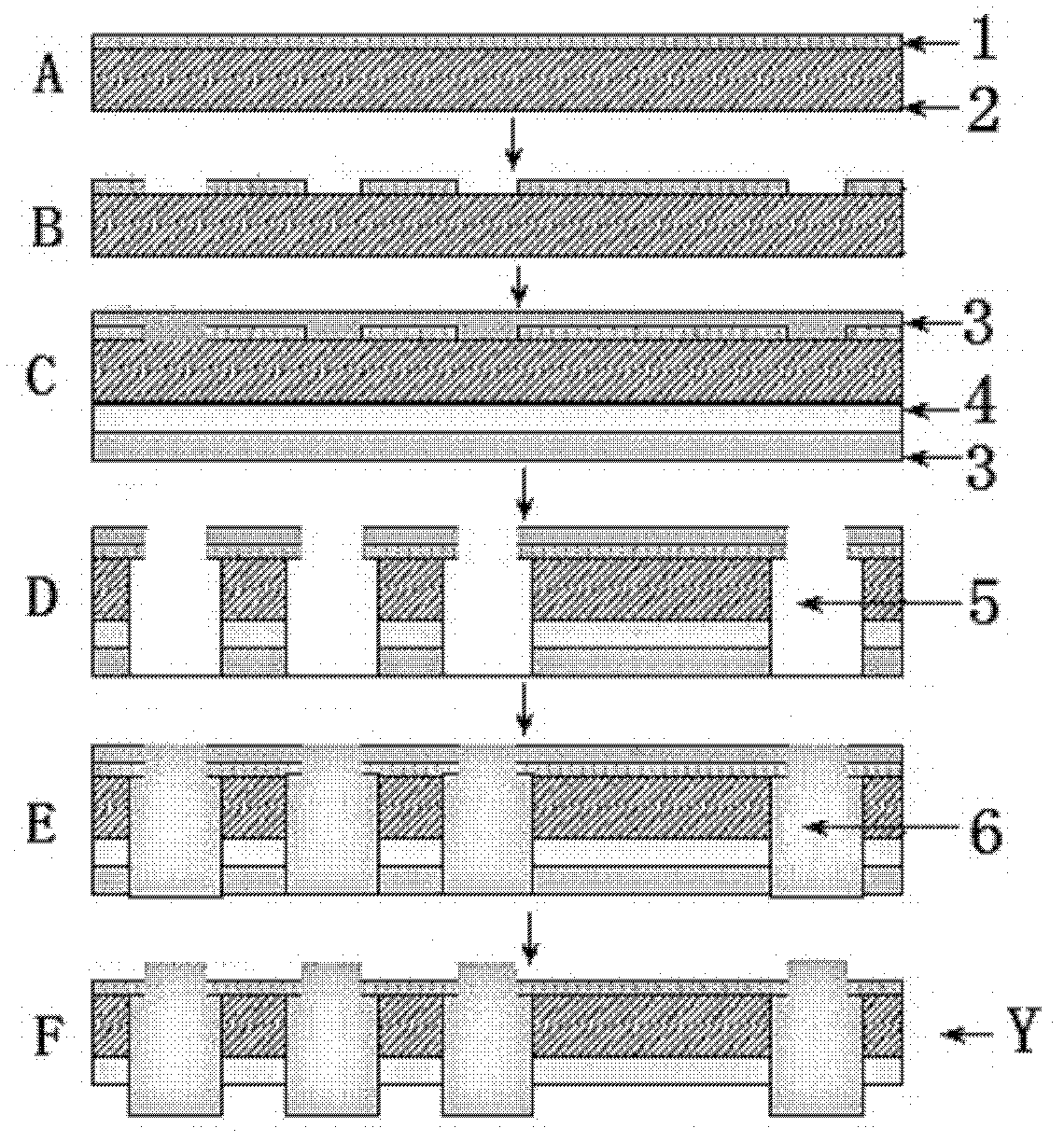

Manufacturing method of high-density interconnected printed circuit board

ActiveCN102595799AAvoid damageAvoid pollutionNon-metallic protective coating applicationPrinted element electric connection formationTectorial membraneConductive paste

The invention discloses a manufacturing method of a high-density interconnected printed circuit board, which mainly comprises the following steps that: the high-density interconnected printed circuit board is divided into a core layered structure, an outer layered structure and a plurality of middle layered structures which are respectively manufactured and finally pressed in; and the method for manufacturing the core layered structure, the outer layered structure and each middle layered structure is to press protective films onto copper foil base plates with made lines, drill through holes, fully fill conductive paste into the through holes and remove the protective films, so that the conductive paste is protruded out of the surfaces of the copper foil base plates. According to the method, the processing procedures are simple, the repeat of electroplating and hot pressing is reduced, the energy is saved, the environment is protected, and the production efficiency and the yield are high.

Owner:PLOTECH TECH KUNSHAN CO LTD

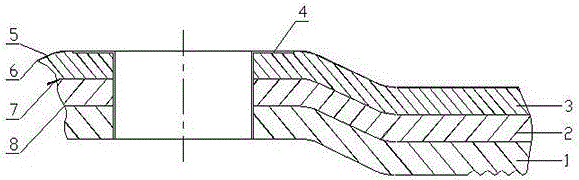

Connecting method for sintering/welding titanium-steel dissimilar metal

ActiveCN103480846ALittle controllabilityEffective thickness controlWelding/soldering/cutting articlesWelding apparatusExpansion factorTitanium

The invention discloses a connecting method for sintering / welding titanium-steel dissimilar metal. The differences of physical properties of the titanium and the steel which are dissimilar metal are large, and the titanium and the steel are hard to connect through conventional methods. According to the connecting method, firstly, the titanium or titanium alloy, V-Cu gradient alloy powder C1, C2 and C3 and stainless steel are placed in a die one by one to be pressed in advance, and secondly, the die is placed in a sintering device to be sintered in a spark plasma mode, wherein the V-Cu gradient alloy powder C1, C2 and C3 are composed of mixed powder which is formed by mixing a plurality of kinds of metal powder according to different proportions, and the expansion factor gradient of the V-Cu gradient alloy powder C1, the expansion factor gradient of the V-Cu gradient alloy powder C2 and the expansion factor gradient of the V-Cu gradient alloy powder C3 are matched with one another. The titanium or the titanium alloy and the stainless steel are directly connected and formed at a time in a sintering mode, the method of spark plasma sintering is particularly suitable for sintering molding of V-Cu gradient connectors of the titanium and the stainless steel, and a titanium-steel dissimilar metal sintering / welding connector can have a high mechanical property.

Owner:NANJING UNIV OF SCI & TECH

Preparation method of active graphene/active carbon composite electrode plate

ActiveCN105551830ALarge specific surface areaIncrease energy densityHybrid capacitor electrodesHybrid/EDL manufactureCarbon filmMass ratio

The invention particularly relates to a preparation method of an active graphene / active carbon composite electrode plate, and belongs to the technical field of new energy storage devices. The preparation method comprises the following steps: mixing reduced graphene oxide with a pore-forming agent evenly at the mass ratio of 1 to (5-10); carrying out equivalent-volume impregnation in water for 8-24 hours, carrying out activating treatment at 600-1,000 DEG C in an inert atmosphere for 0.5-4 hours after drying, and cleaning and drying the product to obtain active graphene after activating; carrying out modified treatment on the active graphene; mixing the modified active graphene with the active carbon at the mass ratio of (10%-90%) to (10%-90%), mixing an active graphene / active carbon mixture, a conductive agent and an adhesive at the mass ratio of (75%-93%) to (2%-10%) to (5%-15%) and then laminating the mixture to form a carbon film; and pasting the carbon film and a current collector through a conductive adhesive, and carrying out heating and solidifying to obtain the active graphene / active carbon composite electrode plate. According to the preparation method of the active graphene / active carbon composite electrode plate, the thickness and the density of the final electrode plate are controllable; continuous mass preparation can be carried out; the capacity can also be improved when the prepared electrode plate is applied to a super capacitor; the internal resistance is reduced; the power density is improved; and the voltage endurance capability of the super capacity is improved.

Owner:NINGBO CRRC NEW ENERGY TECH CO LTD

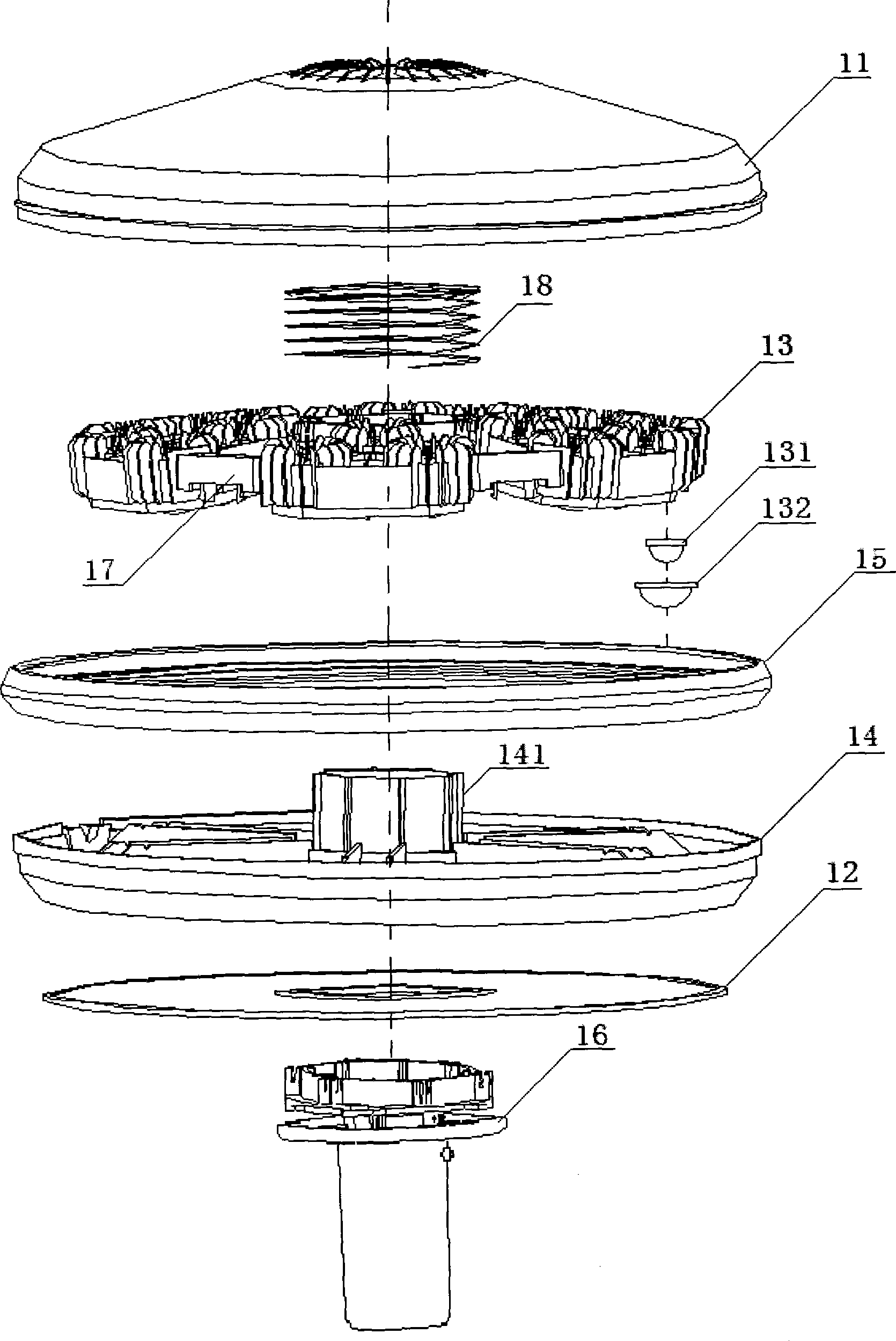

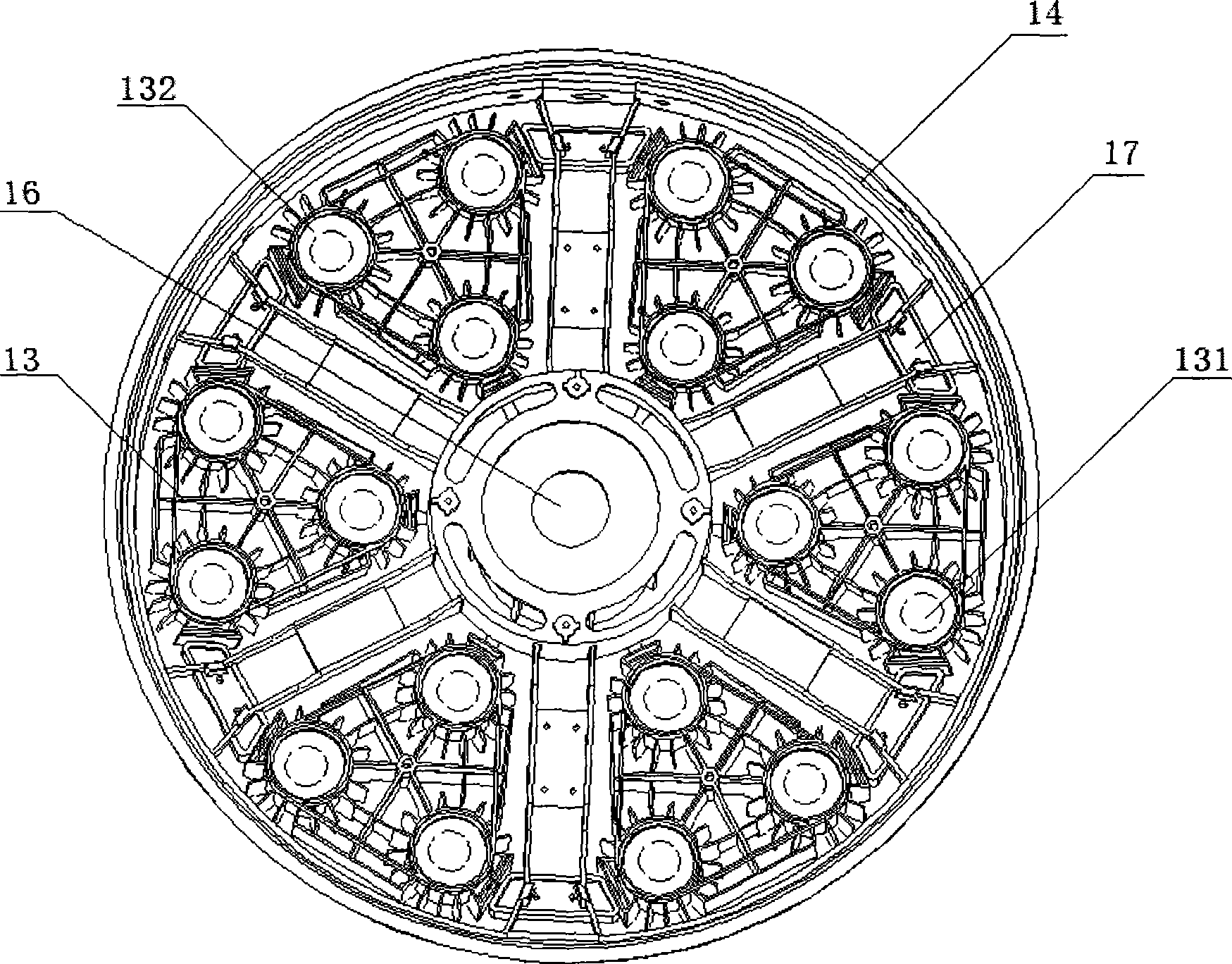

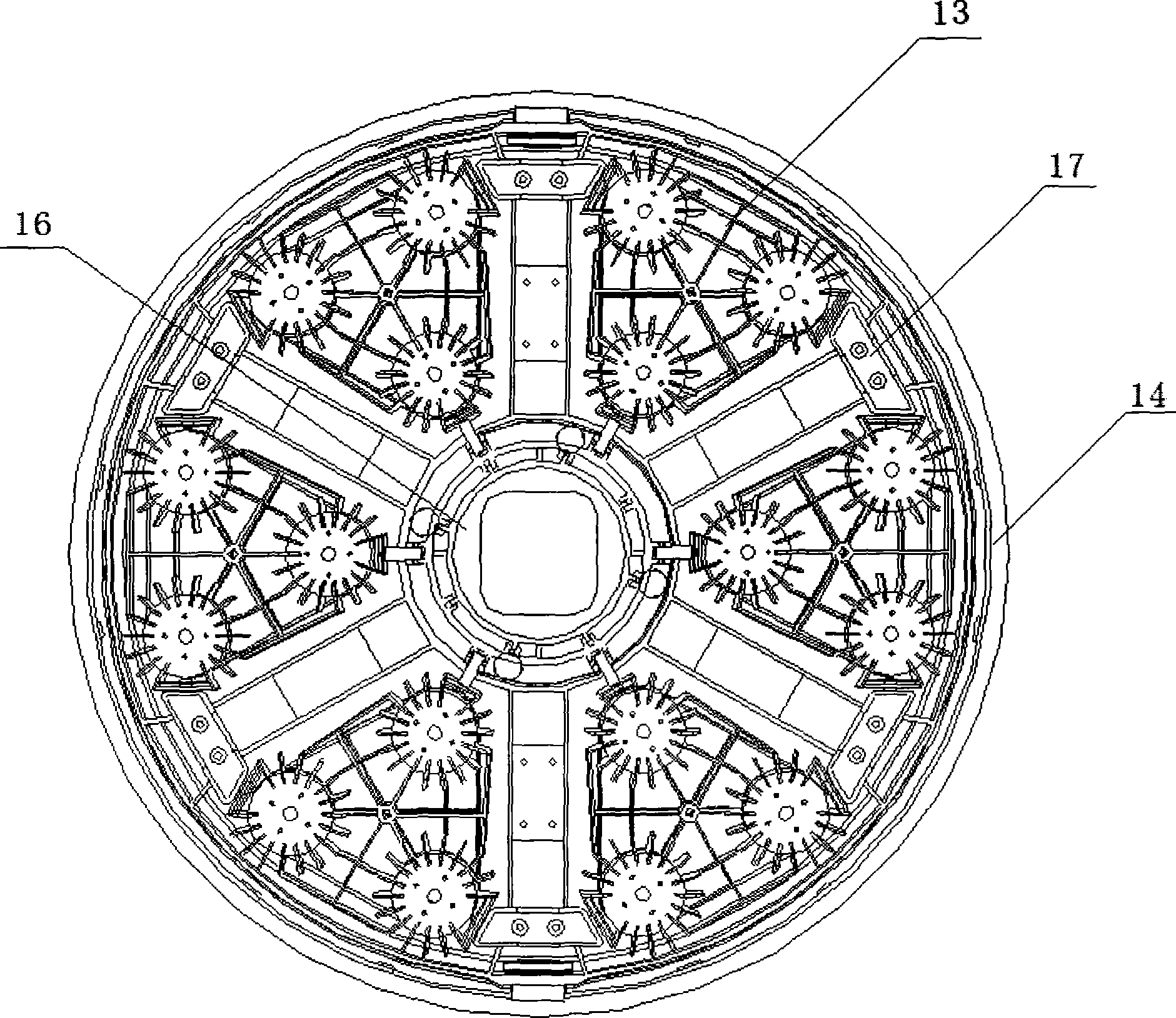

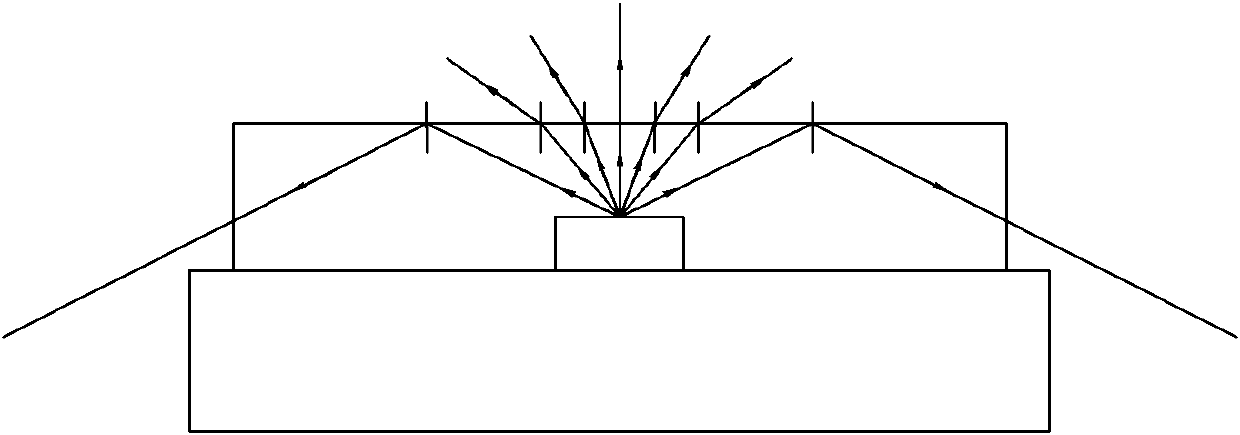

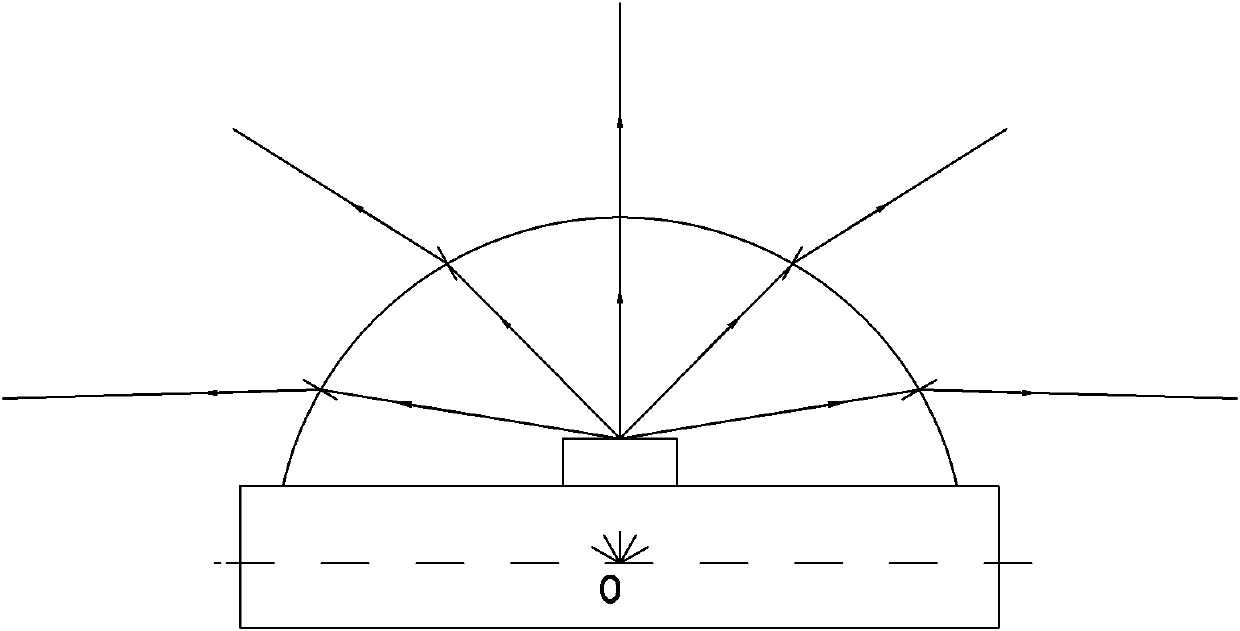

Operating astral lamp

InactiveCN101382250AEffective thickness controlLow costPoint-like light sourceTreatment roomsLight beamEngineering

The invention provides an operating shadowless lamp, comprising at least a cover body, a lens, a plurality of light source components which are arranged between the cover body and the lens, and a bearing frame which is used for arranging the power components, wherein, the light source component is provided with a plurality of LED light sources and a plurality of convergence lenses which correspondingly cover the LED light sources; furthermore, the light beam emitted by the LED light source is directly projected to the operating position by the lens and a softening mirror; the bearing frame is provided with an exes part; a plurality of light source components are arranged in the bearing frame by surrounding the axes part; compared with the prior art, as the operating shadowless lamp adopts the LED light source, the operating shadowless lamp has the advantages of no frequency flashing, uniform luminance, ultra-long service life, safe usage, adjustable brightness, environmental protection and green energy resource, quick response speed and the like; furthermore, the operating shadowless lamp can avoid the reflector (reflector bowl), thus effectively controlling the thickness of the lamp body and reducing the production cost.

Owner:SHANGHAI PINXING SCI & TECH

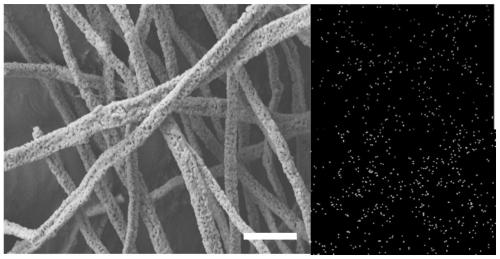

Polymer-based composite solid electrolyte film and preparation method thereof

ActiveCN111403804AShorten the transmission pathFast transferSolid electrolytesSecondary cellsSolid state electrolyteFiber

The invention relates to a polymer-based composite solid electrolyte film adopting magnetic composite fibers as filler and a preparation method of the polymer-based composite solid electrolyte film. The polymer-based composite solid electrolyte film comprises the magnetic composite fibers and a polymer matrix in which lithium salt is dissolved, the volume ratio of the magnetic composite fibers is0.5%-2%, the volume ratio of the polymer is 99.5%-98%, and the magnetic composite fibers are arranged in the polymer matrix in a vertical orientation mode. The preparation method comprises the following steps: 1) preparing precursor sol into magnetic composite fibers by an electrostatic spinning method and a calcining process; and 2) compounding the polymer matrix in which the lithium salt is dissolved and the magnetic composite fibers again to form a film, and introducing a magnetic field to carry out orientation regulation and control. According to the process, the distribution and orientation of the filler in the composite film can be controlled, so that the mechanical and electrical properties of the composite film can be improved by regulating and controlling the distribution structure of the filler, and finally, the room-temperature ionic conductivity of the solid electrolyte film is improved.

Owner:WUHAN UNIV OF TECH

Fabrication method of dual-polarity solid-state lithium secondary battery

InactiveCN109768334AIncrease energy densityAvoid internal short circuit problemsFinal product manufactureElectrode carriers/collectorsSolid state electrolyteEngineering

The invention discloses a fabrication method of a dual-polarity solid-state lithium secondary battery, and belongs to the technical field of a chemical power supply. The used bipolarity current collector is a bipolarity aluminum-plated copper current collector obtained by a physical or chemical deposition method, the thickness and the weight of the bipolarity current collector are controllable; and the used solid-state electrolyte is a high-ion conductivity solid-state electrolyte, and room-temperature or low-temperature working can be achieved. A solid-state electrolyte system is used in thebipolarity structure battery, the problem of internal short circuit brought by a liquid-state electrolyte is effectively prevented, the bipolarity solid-state lithium secondary battery fabricated according to the method proposed by the invention has the remarkably advantages of voltage controllability and high safety, and large-scale production is easy.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

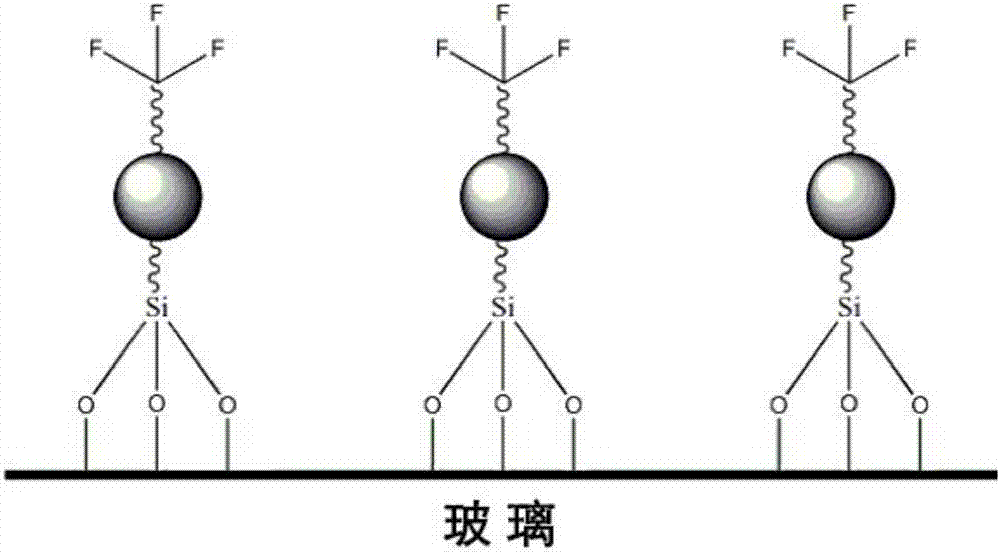

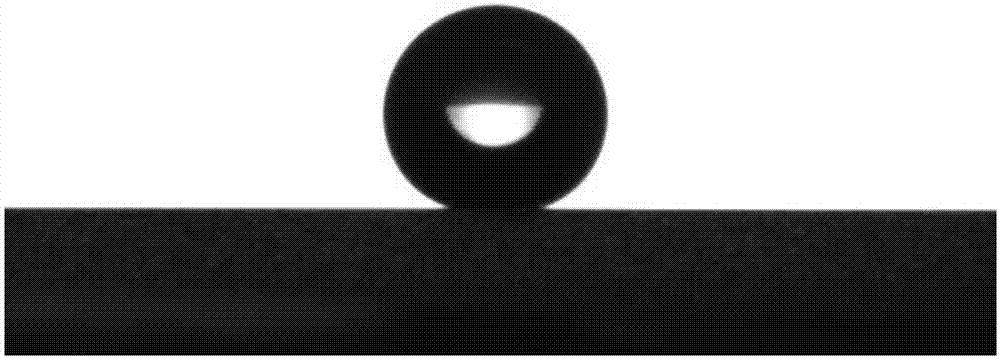

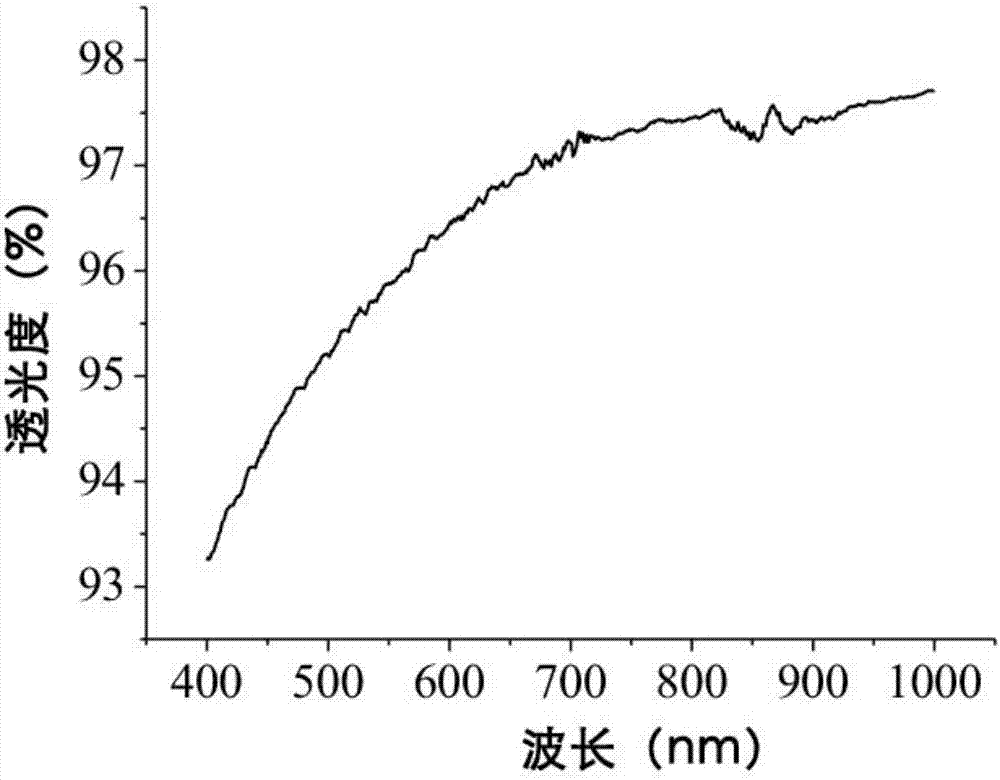

Ultraviolet light polymerization super-hydrophobic transparent wear-resistant coating and preparation method thereof

ActiveCN107254207AImprove wear resistanceHigh hardnessPretreated surfacesCoatingsWear resistantNanoparticle

The invention discloses an ultraviolet light polymerization super-hydrophobic transparent wear-resistant coating and a preparation method thereof, and belongs to the technical field of the photocureable coating. The preparation method comprises the following steps: activating and pre-processing a transparent base material, and preparing dispersion liquid containing active nano-particles; and adding active fluorine monomers, an active diluent and a light initiator to the dispersion liquid containing the active nano-particles, and uniformly coating on the transparent base material activated and pre-processed in the first step, to obtain the super-hydrophobic transparent wear-resistant coating by the solidification of ultraviolet light energy action. The preparation method has the characteristics of efficiency, extensive adaptability, economies, energy-saving and environment-friendliness. The prepared ultraviolet light polymerization super-hydrophobic transparent wear-resistant coating has the characteristics of surface self-cleaning, surface corrosion prevention, dewatering, antifogging, freeze resistance, and good adhesive force to the base material.

Owner:BEIHANG UNIV

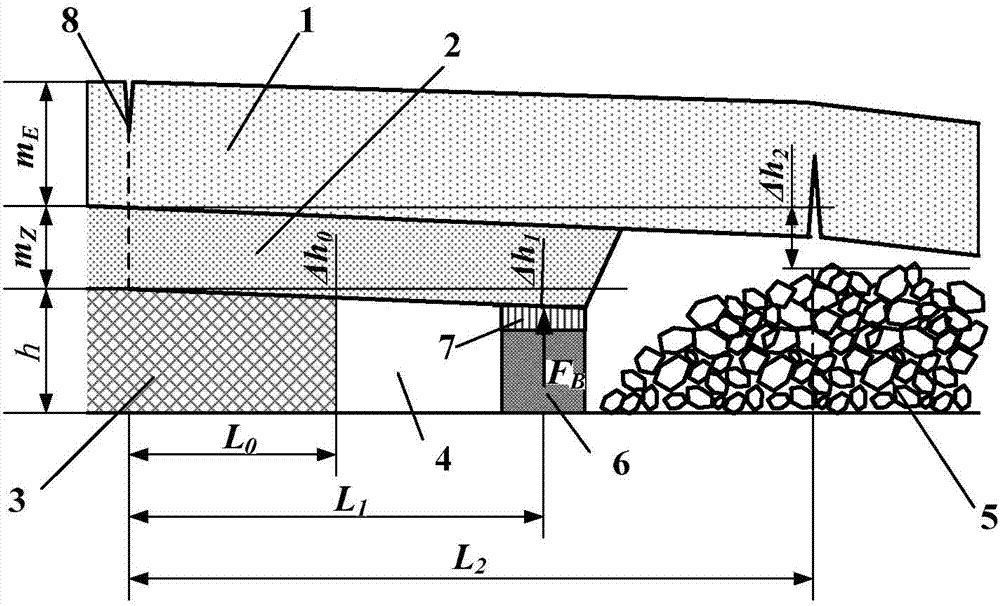

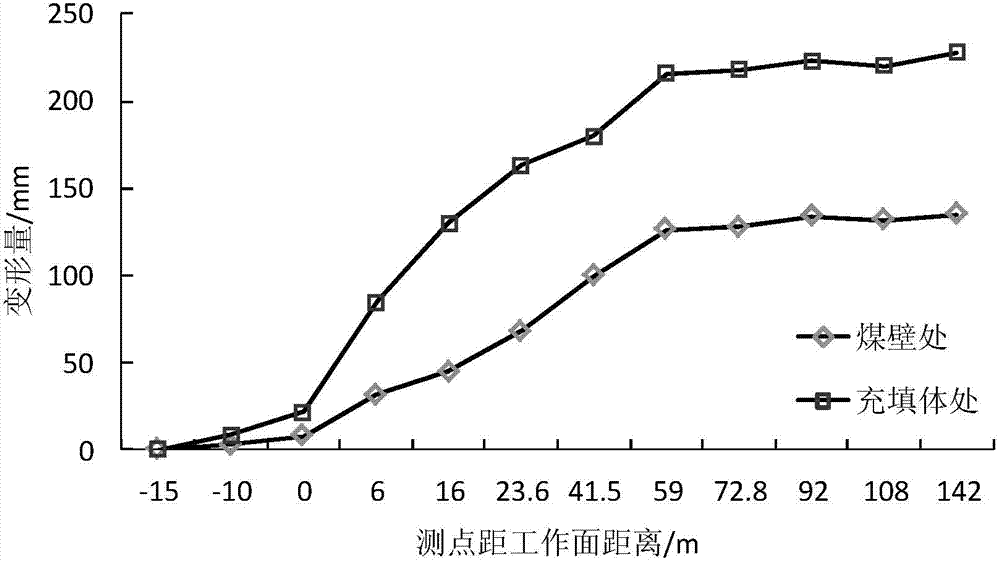

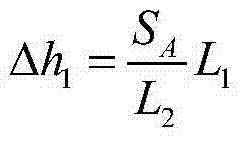

Method for determining thickness of flexible material of roadside flexible-strength double-layer composite support in gob-side entry retaining

ActiveCN103573287ARelieve pressureGive full play to the bearing roleMaterial fill-upCompressibilityEngineering

The invention discloses a method for determining the thickness of a flexible material of a roadside flexible-strength double-layer composite support in gob-side entry retaining. According to the structure of the roadside flexible-strength double-layer composite support in gob-side entry retaining, a flexible filling material is adopted by an upper layer and a high-strength filling material is adopted by a lower layer. When the thickness of the flexible filling material is determined, the sinking amount generated when a main rock-abutting beam of the working face in the side direction is in contact with gangue is used for determining the early-stage compression amount of a roadside filling body; due to the fact that the rigidity of the flexible filling material is equal to the initial rigidity of the high-strength filling material, the coefficient of compressibility of the flexible filling material is reckoned; early-stage deformation of the high-strength filling material can be ignored and due to the fact that the compression amount of the flexible filling material is equal to the early-stage compression amount of the roadside filling body, the thickness of the flexible filling material can be determined. According to the method, the flexible filling material is made to effectively control a top board to move, the best yielding effect is achieved, and the filling cost optimization is achieved.

Owner:SHANDONG UNIV OF SCI & TECH

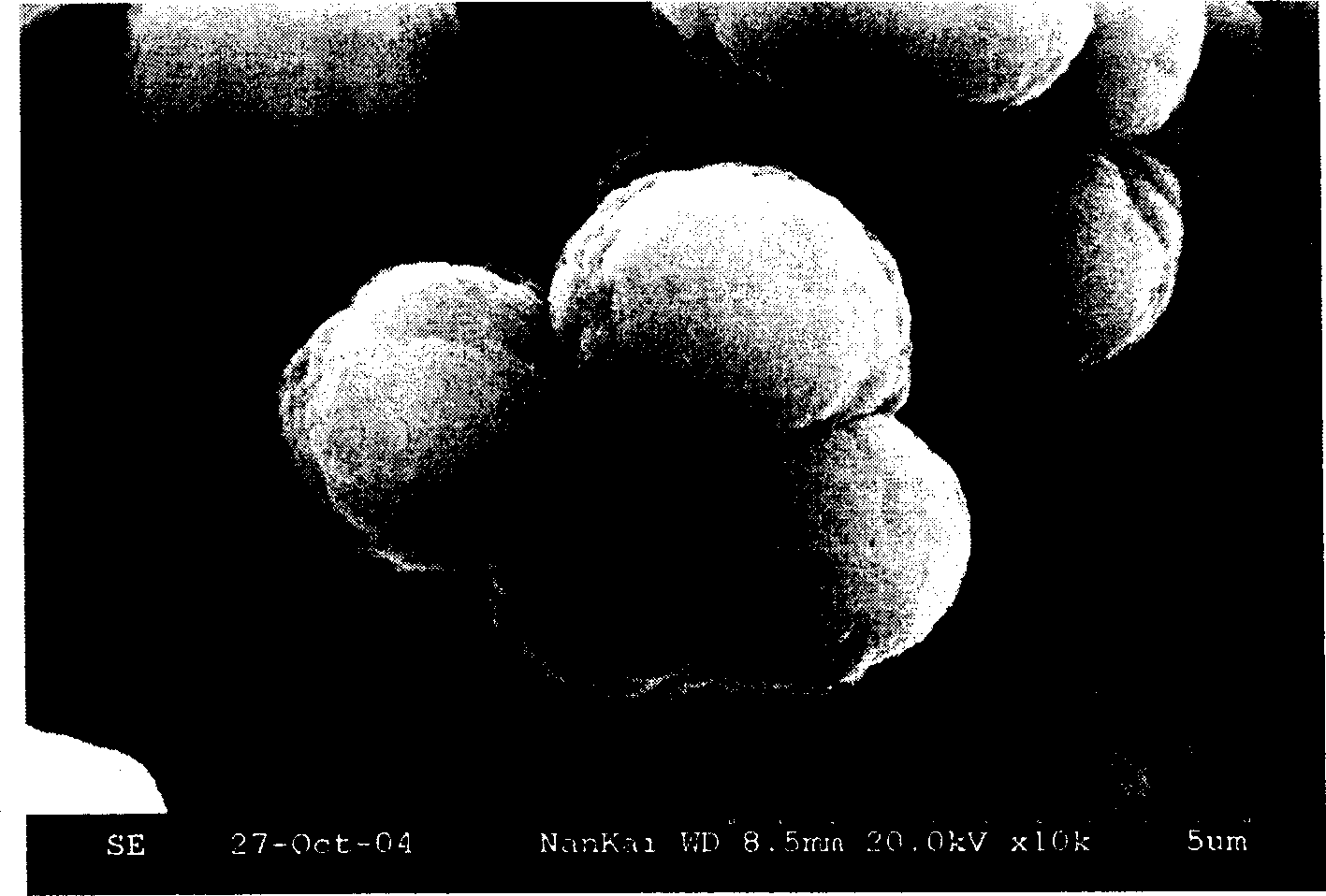

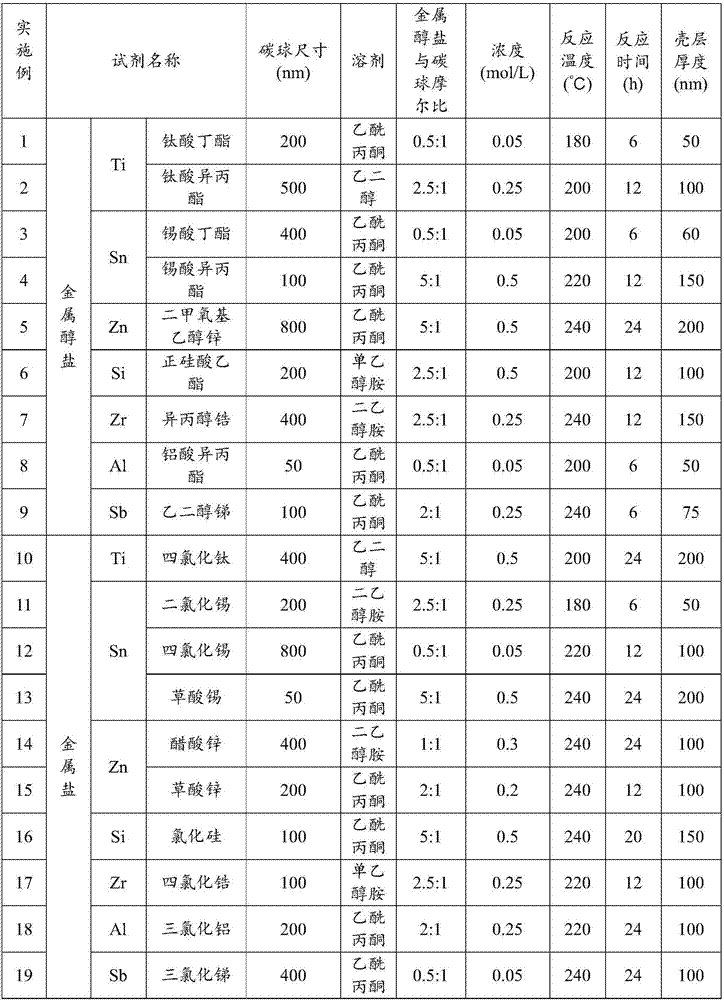

Preparation method of hollow oxide microspheres

ActiveCN107140606AReduce in quantityGood application prospectOxygen/ozone/oxide/hydroxideSilicaSolventMetal alkoxide

The invention discloses a preparation method of hollow oxide microspheres. The preparation method includes the following steps that 1, carbon spheres serve as templates, the surfaces of the carbon spheres adsorb water, then, the carbon spheres are dispersed in solvent with the coordination effect with metal alkoxide, and carbon sphere template suspension is obtained; 2, metal alkoxide is added into the carbon sphere template suspension, the solvent with the coordination effect with metal alkoxide is added to enable the concentration of metal alkoxide to be 0.05-0.5 mol / L, and stirring reaction is conducted; 3, after a solution obtained in the step 2 is subjected to high-temperature and high-pressure reaction, and through washing and separation, C / oxide microspheres with core-shell structures are obtained; 4, after the C / oxide microspheres obtained in the step 3 are dried and subjected to heat treatment, the hollow oxide microspheres are obtained. According to the preparation method of the hollow oxide microspheres, the solvent with the coordination effect is adopted, the water is limited to the surfaces of the carbon spheres, the quantity of homogeneous nucleation can be greatly reduced, the thicknesses of the shell layers of the hollow oxide microspheres are effectively controlled, and the preparation method of the hollow oxide microspheres has good application prospects.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

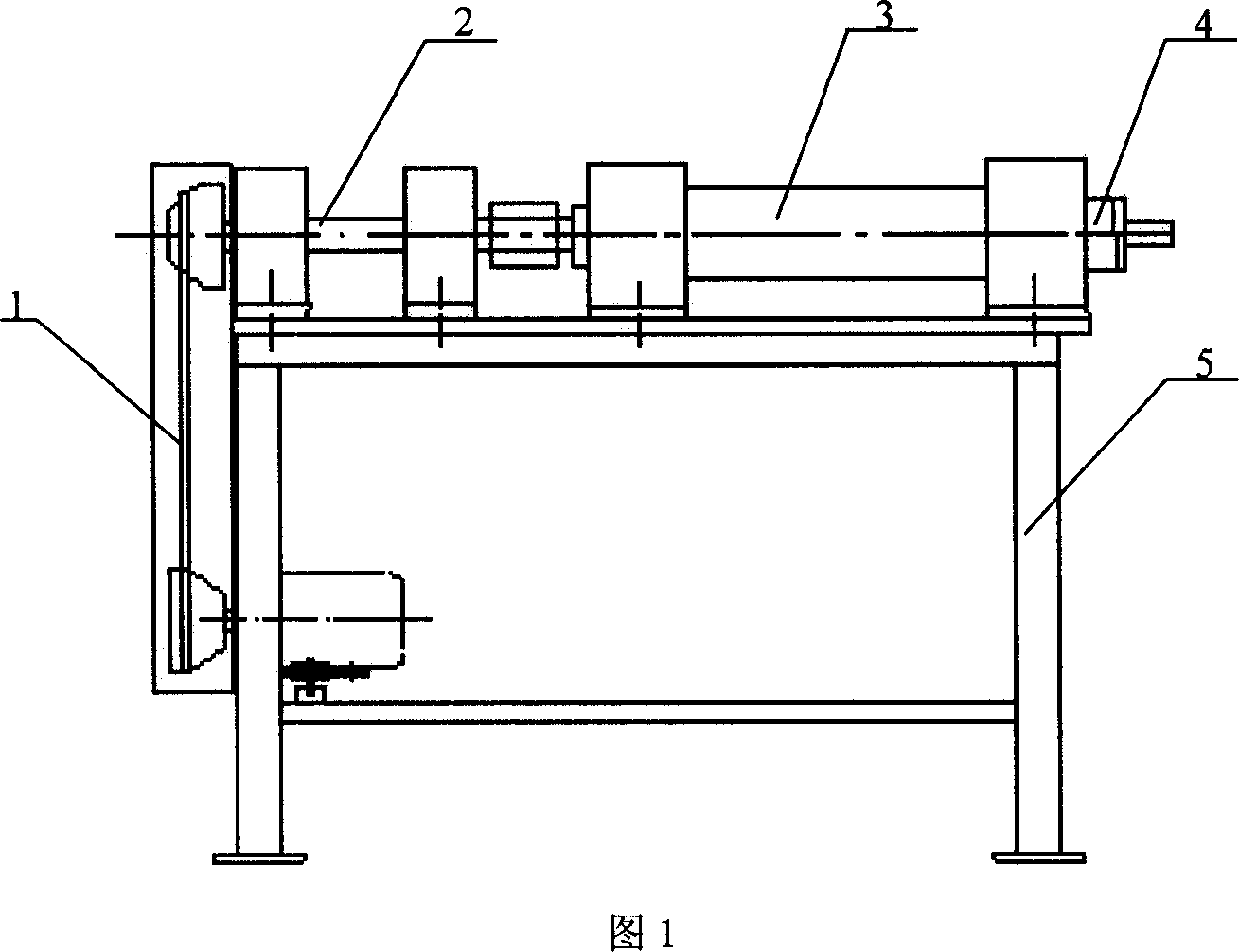

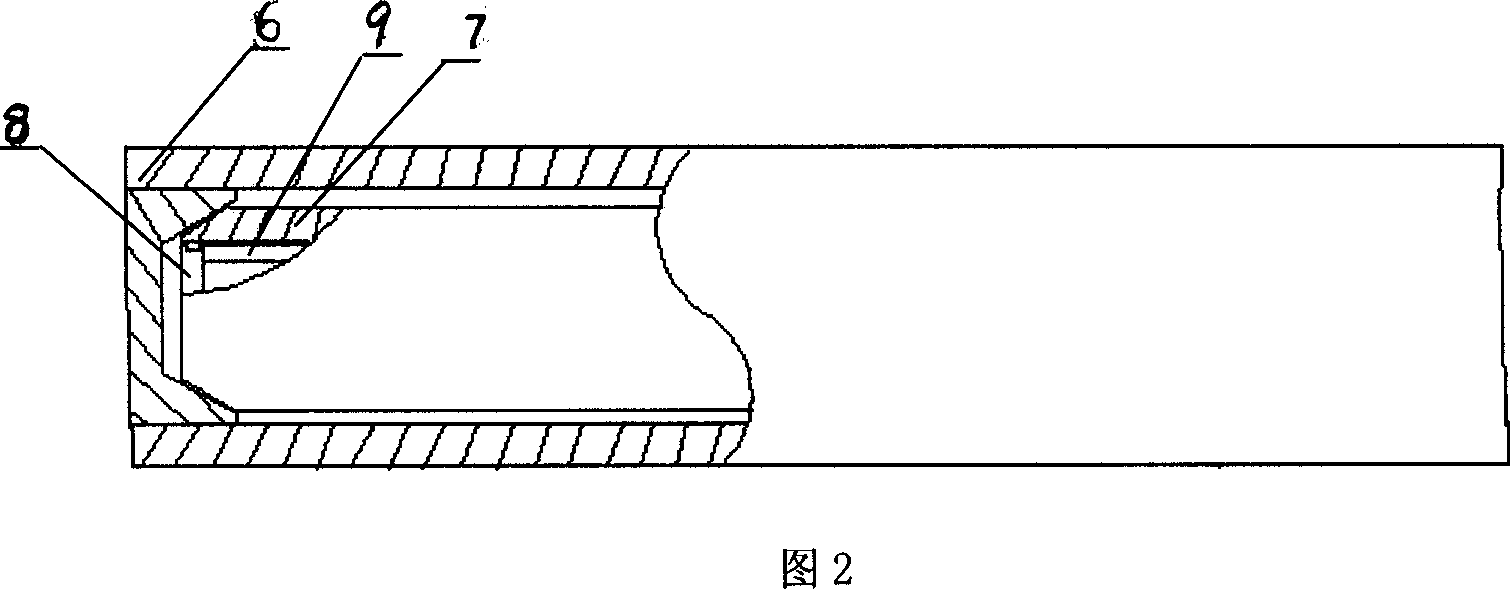

Micro-porous metal film prepn. method

InactiveCN1947861AEffective thickness controlEffective control of uniformityLiquid surface applicatorsCoatingsPorous substrateMetallurgy

A process for preparing millipore metallic film used for filter, separator, catalyzing, fluid distributor and mass or heat transfer includes such steps as providing a centrifugal drum with a porous substrate fixed on its inner surface, preparing slurry from raw powder, loading the slurry in the centrifugal drum, and high-speed rotating to centrifugally form a gradient millipore film on the inner surface of said porous substrate.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

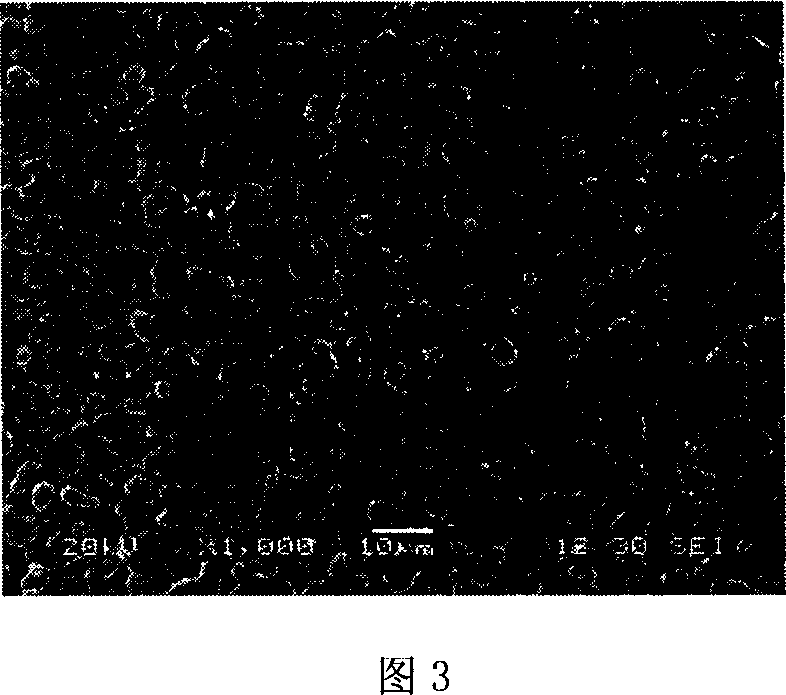

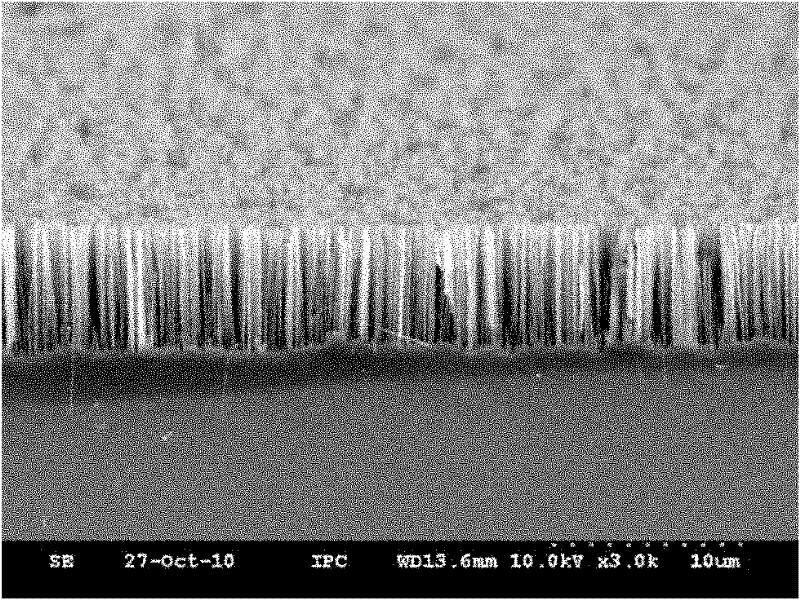

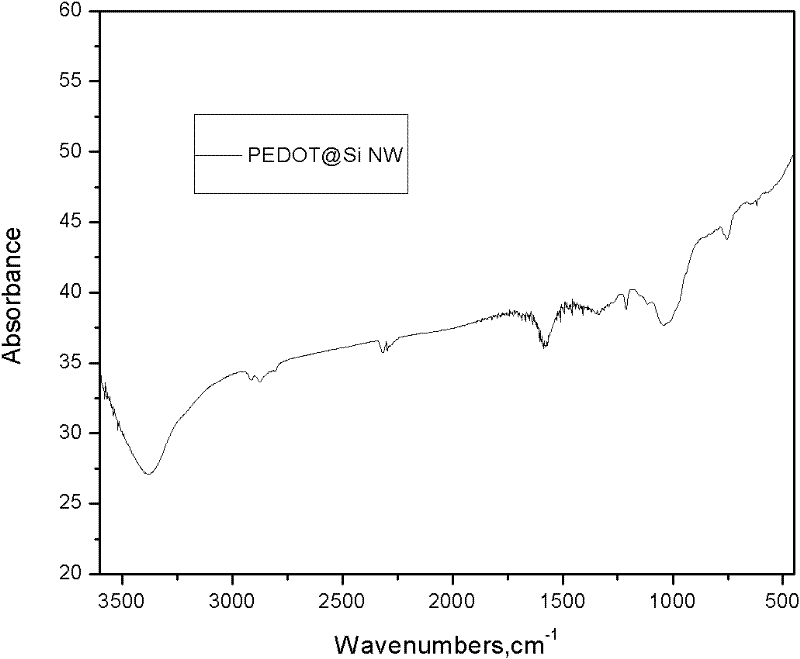

Silicon nanometer wire-conductive polymer compound as well as preparation method and application thereof

InactiveCN102249238AImprove catalytic performanceMild reaction conditionsElectrolysis componentsElectrolytic organic productionEtchingElectronic band structure

The invention discloses a silicon nanometer wire-conductive polymer PEDOT (polyethylenedioxythiophene) compound as well as a preparation method and an application thereof. The preparation method comprises the following steps: 1) using an HF (Hydrogen Fluoride) solution to treat the surface of a silicon nanometer wire array structure which is acquired by using a metal nanometer particle catalyzing auxiliary etching method, thereby acquiring a treated silicon nanometer wire array structure; and 2) using a cyclic voltammetry to enable a polymer monomer EDOT (ethylenedioxythiophene) to have electrochemical polymerization on the surface of the treated silicon nanometer wire array structure, thereby acquiring a silicon nanometer wire-conductive polymer compound. The preparation method has a mild reaction condition, is easily operated and can be used for efficiently controlling the thickness of functional polymers on the silicon nanometer wire surface, the band structure and the conductivity. The preparation method is an effective method for constructing a compound structure of the silicon nanometer wire-conductive polymer functional compound. The application of the acquired compound structure in the field of photocatalytic hydrogen production is researched and a result shows that the compound structure has high catalytic property.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

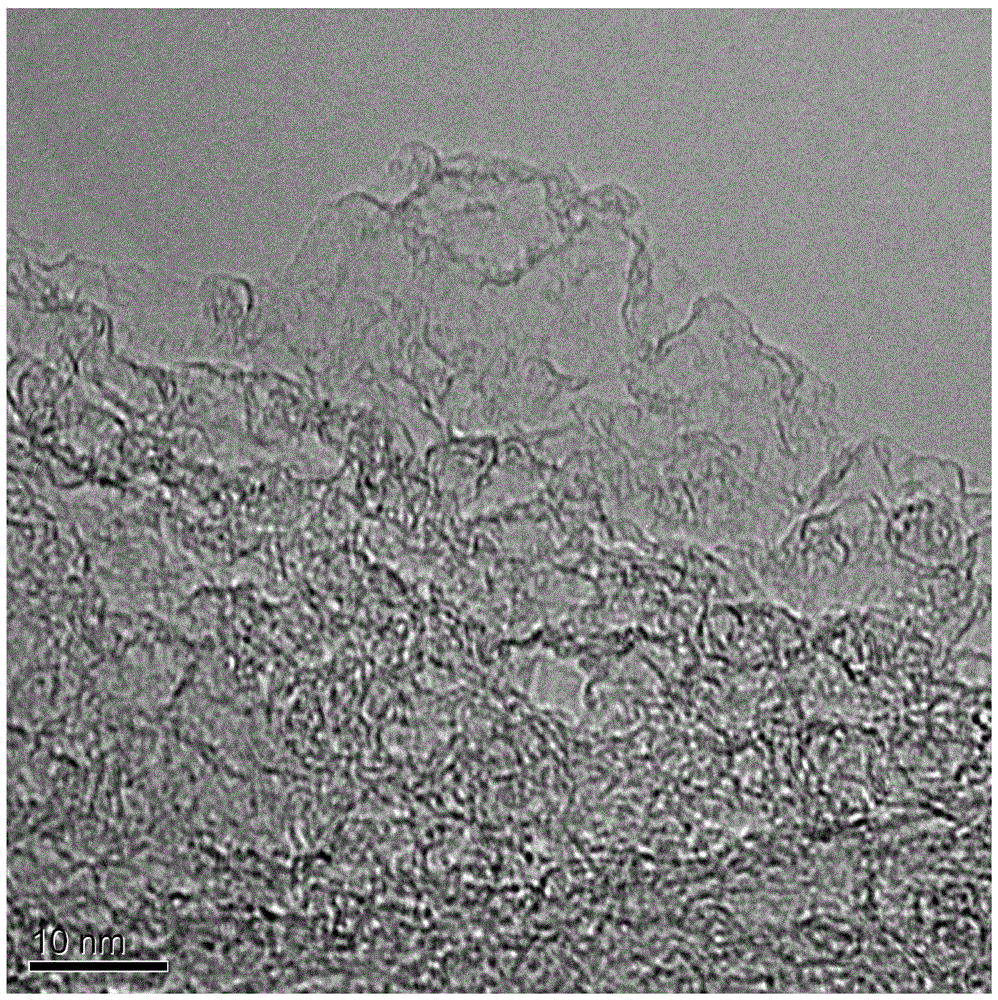

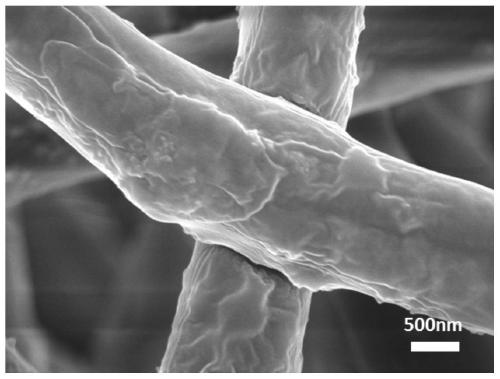

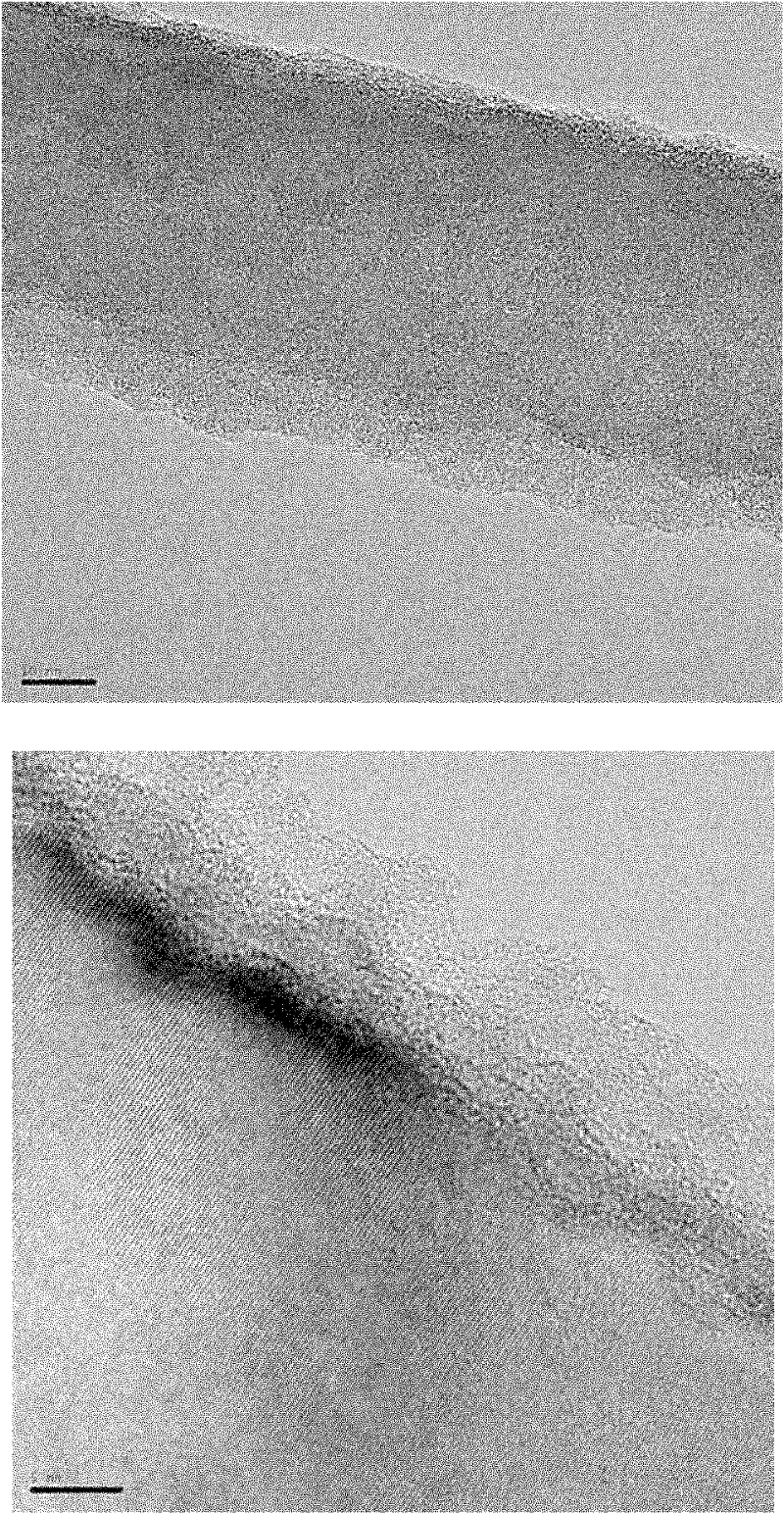

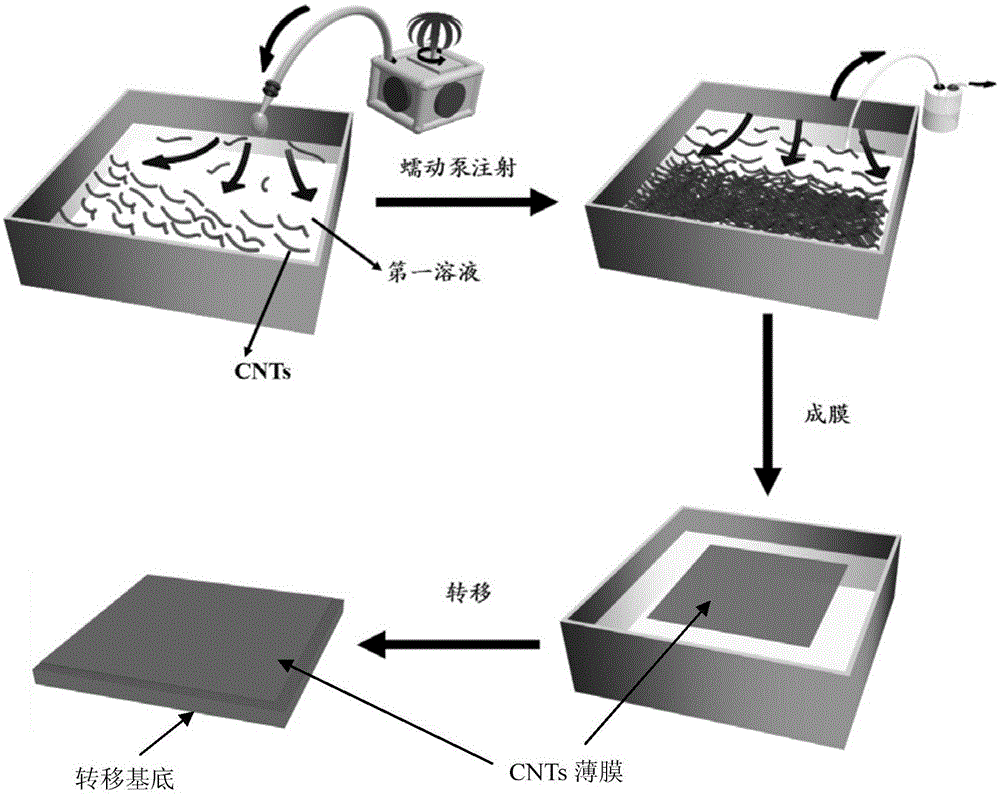

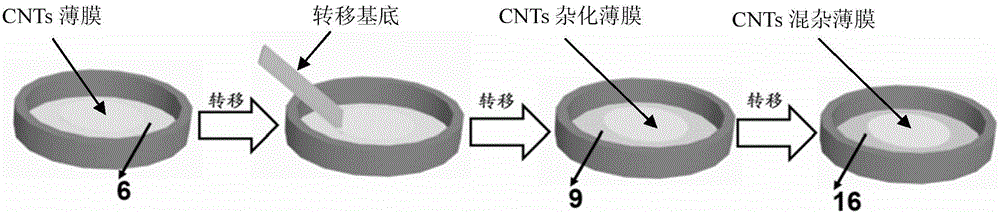

Self-supported ultra-thin transparent conductive carbon nanotube film and preparation method and application thereof

ActiveCN106409428ASimple preparation processShort timeCarbon-silicon compound conductorsCable/conductor manufactureHigh volume manufacturingSelf assemble

The invention discloses a self-supported ultra-thin transparent conductive carbon nanotube film and a preparation method and application thereof. The method obtains a carbon nanotube film by transferring a carbon nanotube dispersion liquid to the surface of a selected solution and removing the selected solution; and forms a carbon nanotube hybridized film by transferring the carbon nanotube film to an ink interface to be self assembled. The self-supported ultra-thin transparent conductive carbon nanotube film has good comprehensive properties, such as a thickness of about 20 nm to 100 nm, surface roughness less than 1.5 nm, light transmittance more than 86%, surface resistance of less than 1500ohm / M2. The preparation process is simple, easy to operate, low in environmental requirements, and does not adversely affect the surrounding environment, and meets the large-scale industrial production and mass production needs.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Preparation method of Sn-base composite solder sheet based on porous Ni/Cu alloy

ActiveCN109848611AControl thicknessChange sintering timeWelding/cutting media/materialsSoldering mediaComposite solderUltimate tensile strength

The invention relates to a preparation method of a Sn-base composite solder sheet based on a porous Ni / Cu alloy. The preparation method comprises the steps that first of all, a layer of Cu is preparedon the surface of porous Ni metal, and then high-temperature sintering is carried out, so that mutual diffusion between Ni and Cu is facilitated, and bonding of Ni and Cu is further tight; and then the porous Ni / Cu alloy is immersed into the molten Sn-base solder, and finally is rolled into a foil. In the porous Ni / Cu alloy subjected to high-temperature sintering treatment, the bonding strength of Ni and Cu is higher and the oxidation resistance is better through the mutual diffusion between Ni and Cu, and the relatively high strength, good plasticity, high corrosion resistance and high ductility are shown. Along with change of sintering parameters and electroplating parameters, concentration distribution gradients of Ni and Cu in the porous Ni / Cu alloy are different, reaction between theporous Ni / Cu alloy and the Sn-base solder is rapider in the brazing process, and the soldering reliability is high.

Owner:无锡继平新材料科技有限公司

Formula and machining method of resin grinding wheel angle abrasive disc

ActiveCN106346379AImprove high temperature strengthImprove adhesionBonded abrasive wheelsGrinding devicesEpoxyPotassium

The invention discloses a formula of a resin grinding wheel angle abrasive disc. The resin grinding wheel angle abrasive disc comprises a coarse material layer, another coarse material layer and a fine material layer which are composited in sequence. Raw materials of the coarse material layers include SG adhesive materials, AZ40 fused alumina zirconia, white corundum, liquid phenolic resin, liquid epoxy resin, 325-400-mesh powdery phenolic resin, 400-600-mesh potassium fluoborate, 600-800-mesh electrolytic copper powder and 600-800-mesh talcum powder. Raw materials of the fine material layer include brown fused alumina, white corundum, liquid phenolic resin, liquid epoxy resin, 325-400-mesh powdery phenolic resin, 400-600-mesh potassium fluoborate and 600-800-mesh talcum powder. The made resin grinding wheel angle abrasive disc is good in hand feeling, free of edge breakage, large in grinding removal quantity, high in grinding efficiency and adaptability and capable of meeting the requirements for rapid coping of tracks and weld joints, and machined workpieces are high in surface precision.

Owner:东莞市金利威磨料磨具有限公司

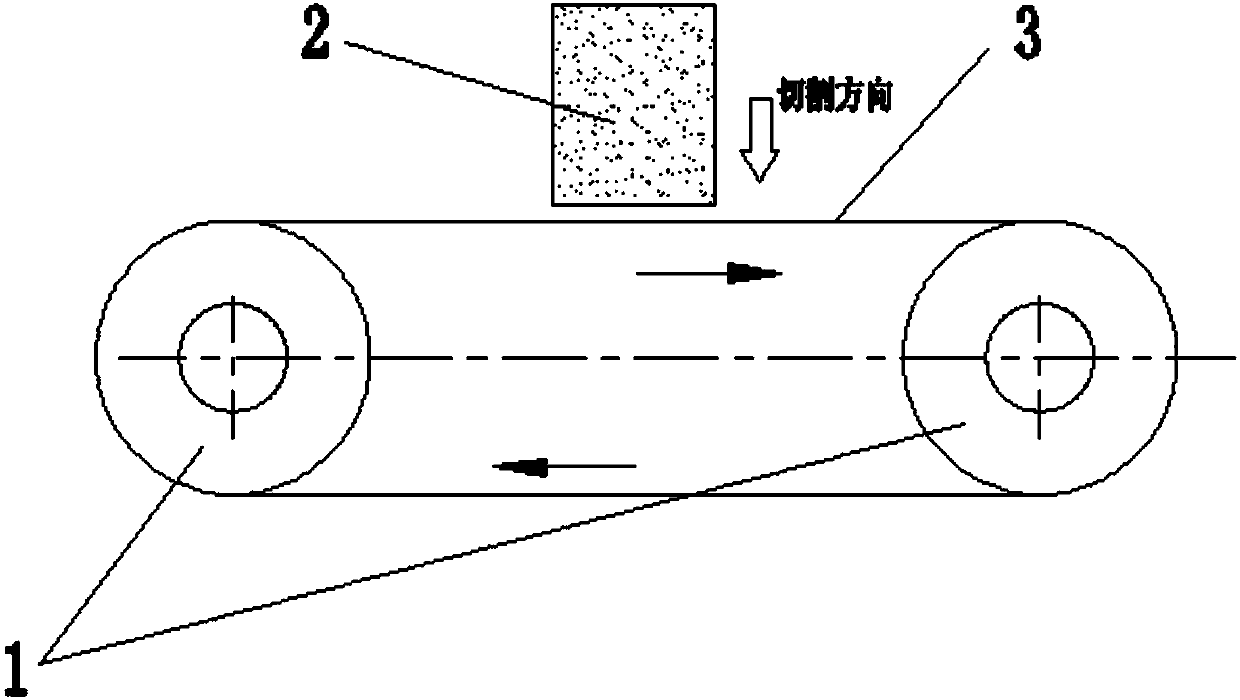

Device for cutting polycrystalline silicon wafer through diamond wires and cutting method

ActiveCN107901256AControl thicknessReduce dosageFine working devicesSpray coolingPolycrystalline silicon

The invention discloses a device for cutting a polycrystalline silicon wafer through diamond wires and a cutting method. The device for cutting the polycrystalline silicon wafer through the diamond wires comprises a cutting machine. The cutting machine comprises two large guide wheels arranged in a spaced manner, the multiple diamond wires arranged between the two large guide wheels in a surrounding manner, and a cooling liquid nozzle for spraying cooling liquid. The device is characterized in that two small guide wheels with the diameter smaller than the diameter of the large guide wheels arearranged at the positions above the two large guide wheels in parallel, the two small guide wheels are located on the inner side between the two large guide wheels, and the upper surfaces of the twosmall guide wheels are flush; a plurality of wire grooves are formed in the surfaces of the small guide wheels at intervals, the diamond wires are wound around the upper surfaces of the two small guide wheels and are located in the wire grooves in the small guide wheels, the part between the two small guide wheels is a cutting area, and the diamond wires can move in both directions. According to the device, wire and net balance is achieved in the cutting process, wire breakage is not likely to happen in the cutting process, and the silicon wafer yield can be increased.

Owner:SHANDONG DAHAI NEW ENERGY DEV

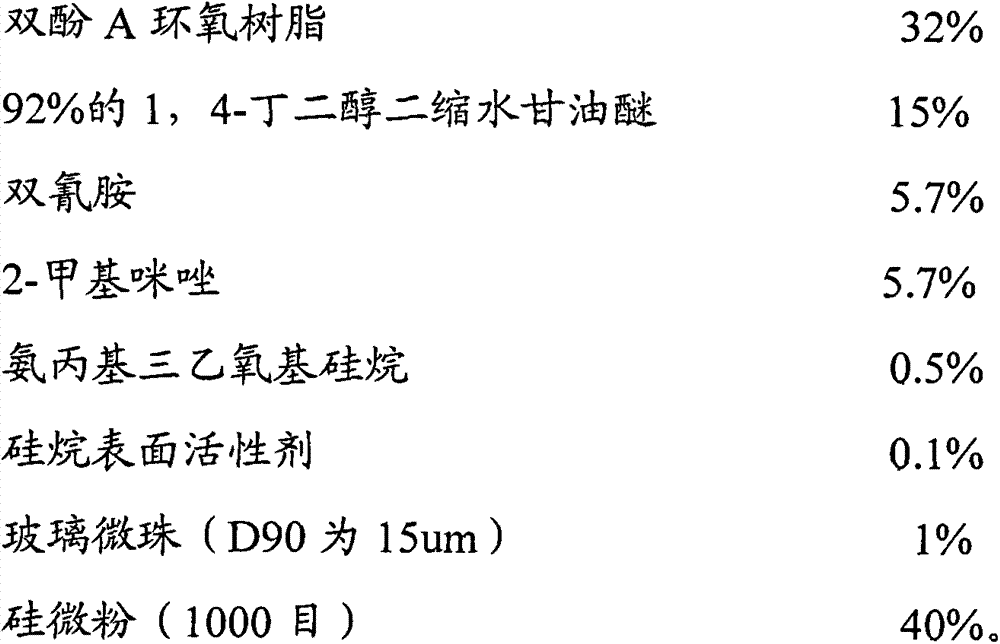

Epoxy resin adhesive used for encapsulating smart cards

ActiveCN103540285ASuppress overflowEffective thickness controlNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxySmart card

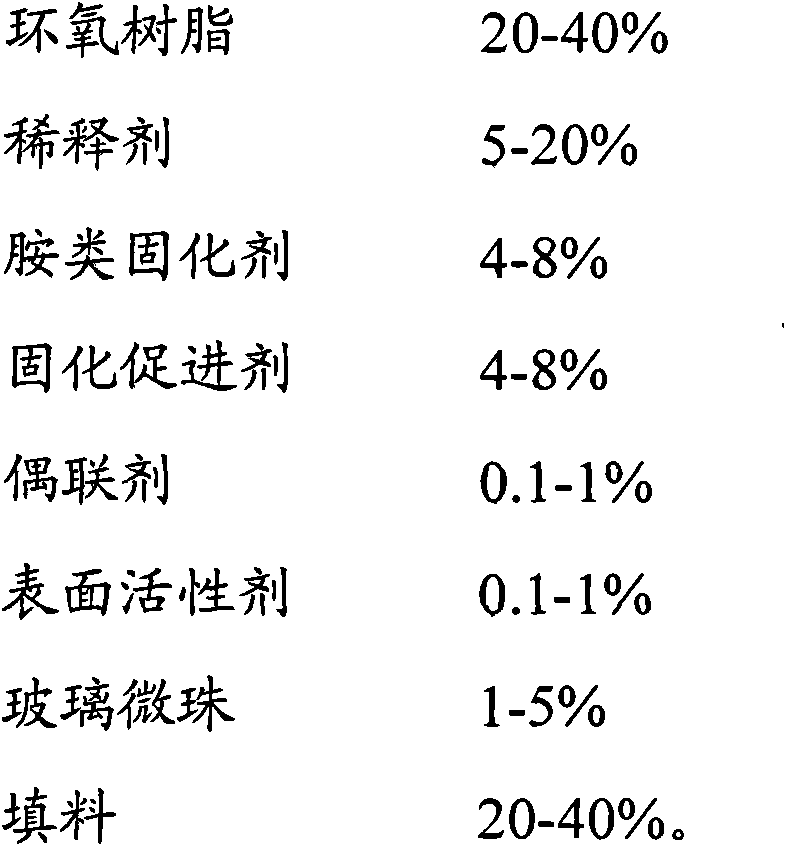

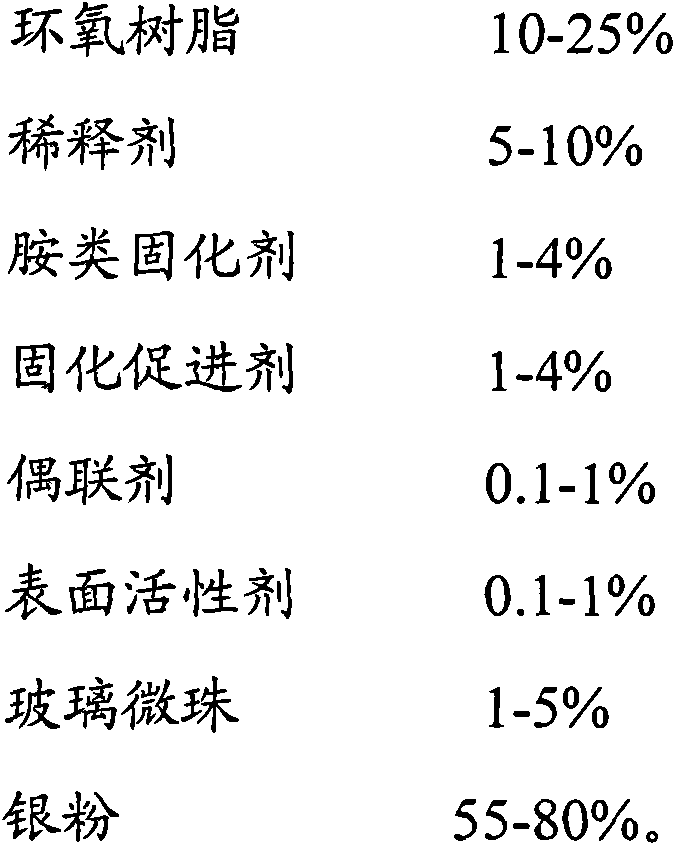

The invention discloses an epoxy resin adhesive used for encapsulating smart cards. The epoxy resin adhesive is non-conductive adhesive and conductive adhesive and comprises the following components in percentage by weight: 20-40% of epoxy resin, 5-20% of diluent, 4-8% of amine curing agent, 4-8% of curing accelerator, 0.1-1% of coupling agent, 0.1-1% of surfactant, 1-5% of glass microspheres and 20-40% of fillers. The epoxy resin adhesive is prepared in a special preparation sequence. The surfactant is added to effectively inhibit the resin overflow, improve the routing yield and ensure the reliability of the product at the same time, the glass microspheres are added to effectively control the thickness of the adhesive layer, prevent the adhesive layer from becoming excessive thin or thick after being pasted, ensure the reliability of the encapsulated product, and meanwhile, reduce the height difference of four corners and improve the routing yield and efficiency.

Owner:CHANGCHUN YONGGU TECH

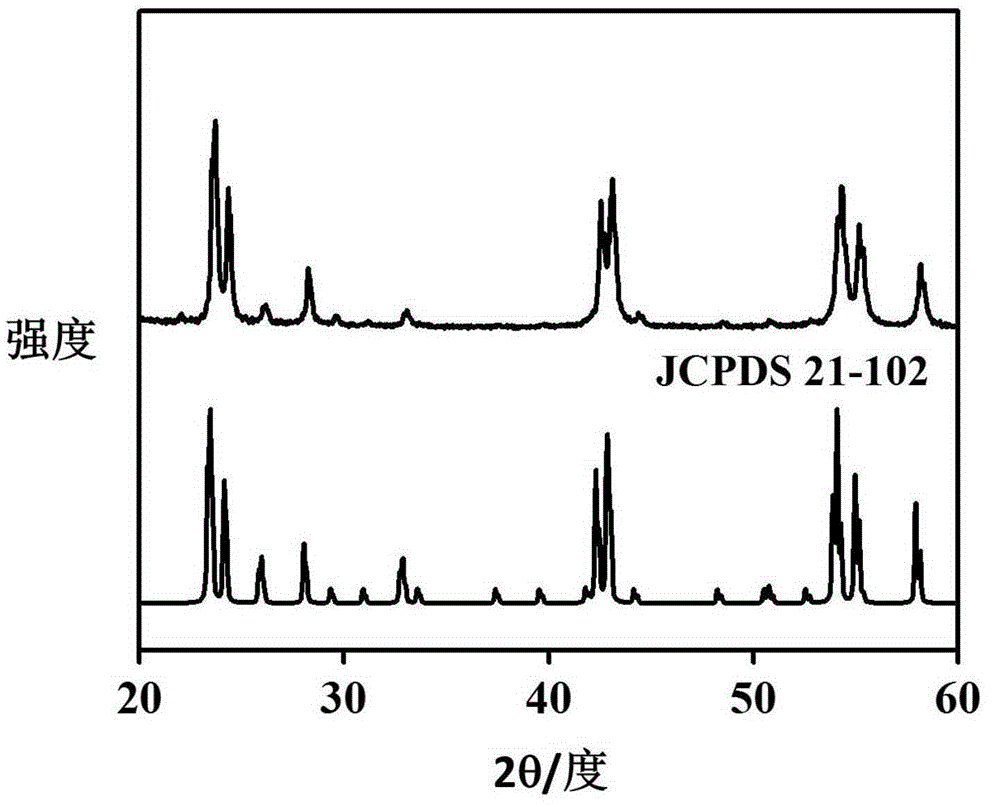

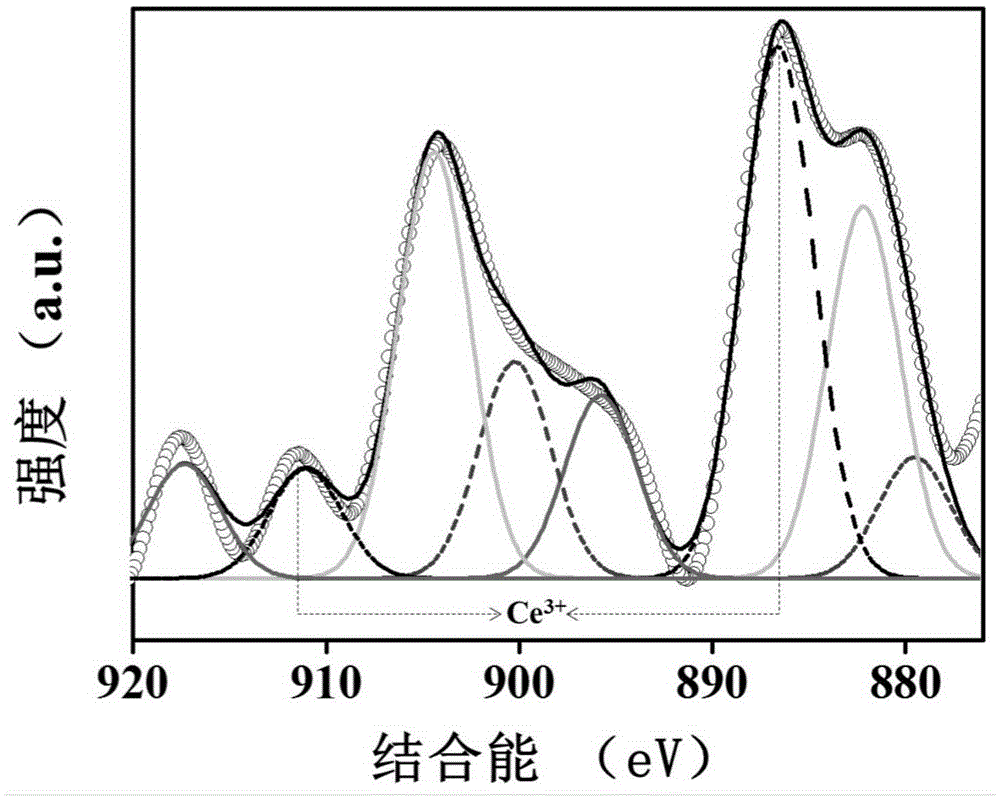

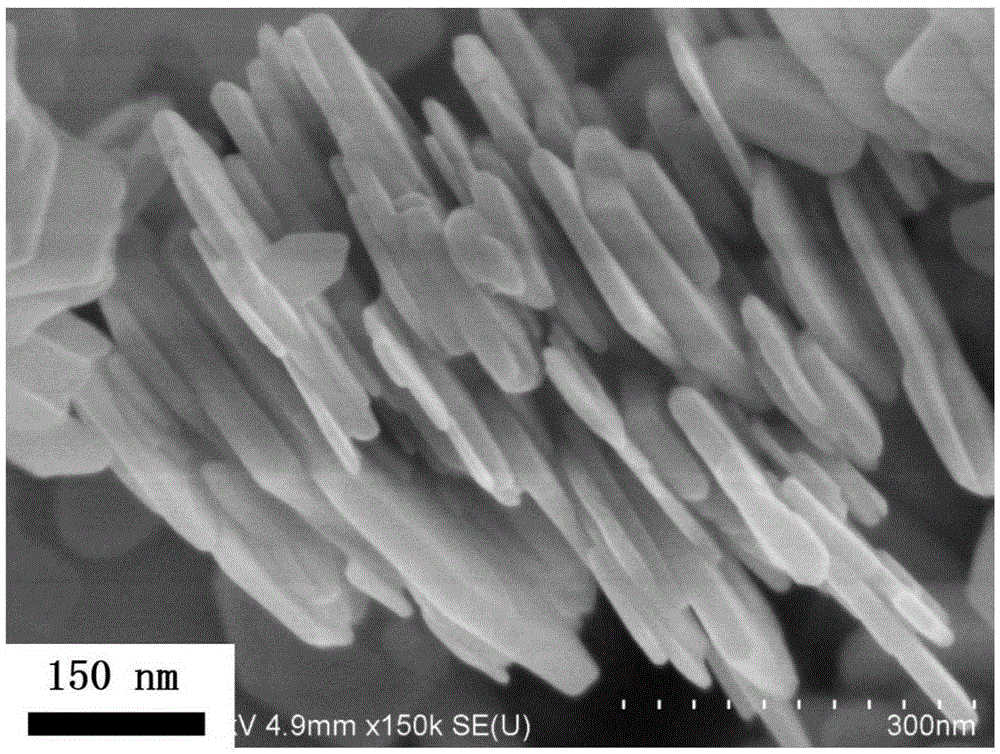

Nanometer flake cerium-doped bismuth molybdate catalyst, as well as preparation method and application thereof

InactiveCN105289579AEffective thickness controlSimple preparation processBiocideMaterial nanotechnologyDyeing wastewaterLight response

The invention discloses a preparation method of a nanometer flake cerium-doped bismuth molybdate catalyst. A simple one-step hydrothermal method is adopted; the PH of reaction liquor is free from being adjusted; the method is green and is free from acid-base pollution. A nanometer flake cerium-doped bismuth molybdate material can be served as a visible light response photocatalyst and has a uniform flake appearance with the average thickness being 20-30nm; a relatively thin flake structure and cerium ions are introduced, so that the absorption for photons is promoted, the high-efficient separation for a photon-generated carrier is realized and the ultrahigh photocatalytic performance is shown under the irradiation of visible light; the catalyst has relatively high catalytic activity at the aspects of degradation of dye wastewater and killing of water bacteria; the application prospect is wide.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

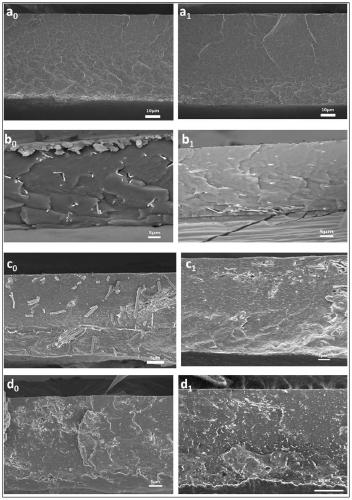

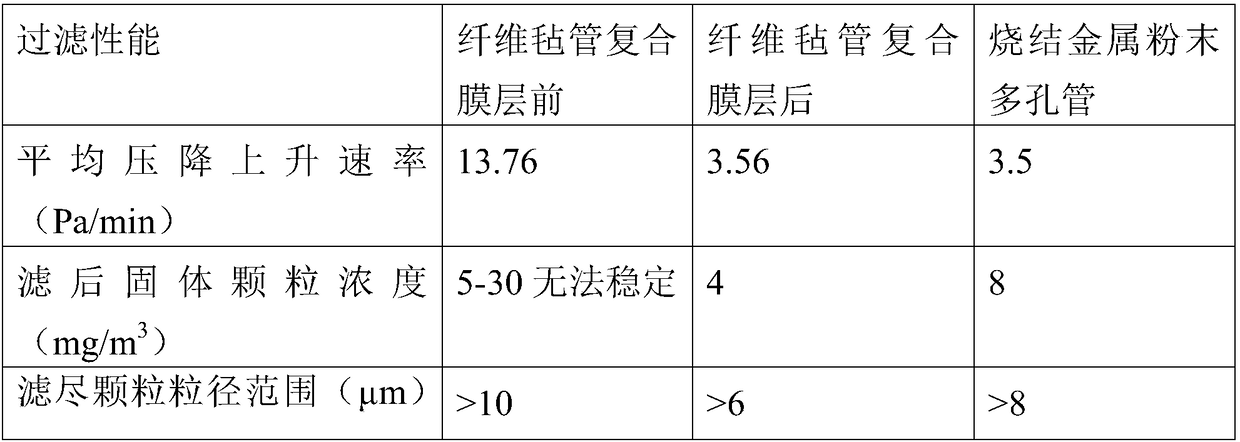

Low-resistance-drop filtering material and preparation method thereof

PendingCN108079666AImprove blowback effectMake up for the disadvantage of poor blowback performanceMembrane filtersFiltration separationFilter materialFlue gas

The invention relates to a low-resistance-drop filtering material and a preparation method thereof, and belongs to the technical field of high temperature flue gas, porous materials and high-flux filtering materials. The material is formed by compounding a metal fibrofelt base material and a metal powder film layer attached to the surface of the metal fibrofelt base material; and the metal powderfilm layer comprises the following raw materials: a Fe-Al series intermetallic compound and / or a NiCrAlFe intermetallic compound. The preparation method of the material comprises the following steps:firstly, mixing the intermetallic compound powder with a glue solution, and fully stirring to obtain metal powder suspension liquid; secondly, spraying the surface with high filtering precision of themetal fibrofelt base material with the metal powder suspension liquid to obtain a sprayed material; and finally, drying the sprayed material and then carrying out sintering treatment to obtain the low-resistance-drop filtering material finally. By the material, the problems that flux is low, resistance drop is high, high temperature resistance and sulfur attack resistance are poor, and the structural mode is single are solved, the thickness of a spraying layer and the filtering precision are controllable, and the cost is low.

Owner:AT&M ENVIRONMENTAL ENG TECH CO LTD +1

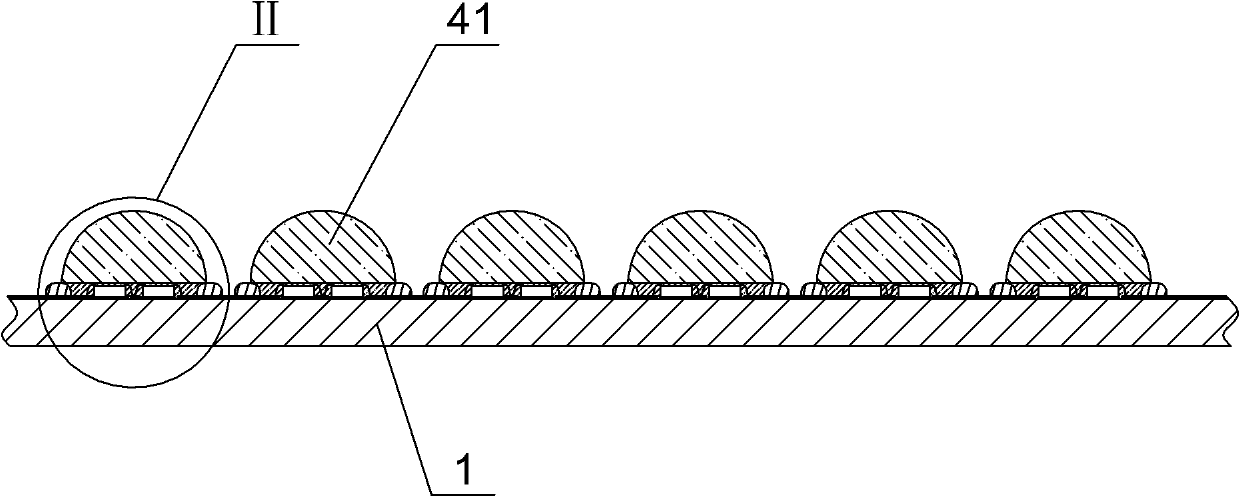

LED integrated light source board and manufacturing method thereof

ActiveCN101949521ASimple processIncrease productivityLighting heating/cooling arrangementsLight fasteningsElectricityHeat conducting

The invention discloses an LED integrated light source board with low cost, simple structure and process, high production efficiency and high color temperature precision and a manufacturing method thereof. The light source board comprises a heat-conducting insulation substrate (1) and an LED light source unit (30), wherein, the LED light source unit (30) comprises a plurality of LED modules (31) formed by integrating a plurality of LED chips (3) or composed of the separate LED chip (3); a circuit connecting wire (21) and a radiating foil (22) which are composed of metal layers are laid on the surface of the heat-conducting insulation substrate (1); the LED modules (31) are electrically connected with the circuit connecting wire (21); the LED chips (3) are connected with a radiating foil (22) for conducting heat; and a white colloid coffer (4) the height of which is 0.3-1.5mm is coated around the LED modules (31), and silica gel or resin (6) is filled in the colloid coffer (4) to cover the LED chips (3). The manufacturing method comprises the following steps: die-bonding, forming the colloid coffer, filling the silica gel or the resin (6), and curing. The invention can be applied to the LED integrated light source field.

Owner:NANKER GUANGZHOU SEMICON MFG

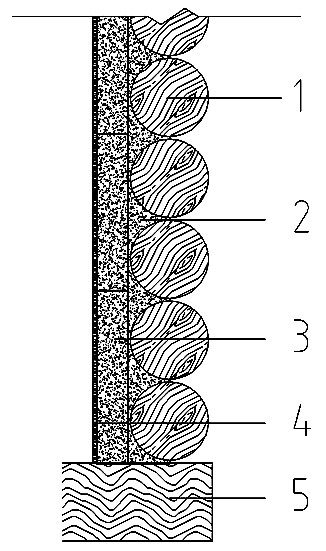

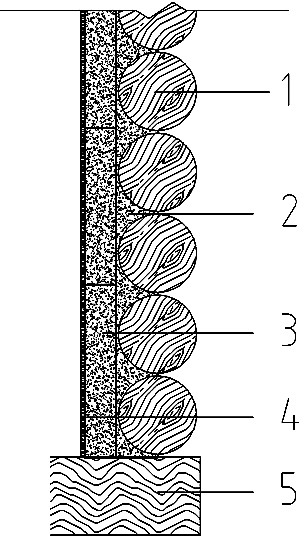

Method for enhancing thermal-insulation performance of well-frame wall body by adopting light raw soil material and composite thermal-insulation wall body

InactiveCN102505780AImprove thermal performance defectsReduce gapWallsClimate change adaptationSurface finishEnvironmental resource management

The invention provides a method for enhancing the thermal-insulation performance of a well-frame wall body by adopting a light raw soil material and a composite thermal-insulation wall body, and belongs to the technical field of buildings. The method comprises the following steps: light clay slurry formed by mixing raw soil, cement and plant fiber is used for filling slits on the well-frame wall body, so as to form a flatting layer; pre-cast light clay building blocks are built on the surface of the flatting layer; and slurry formed by mixing raw soil and cement or a surface finishing material such as board is adopted as a surface layer. The composite thermal-insulation wall body mainly comprises a beam, a wood ridge, a light clay flatting layer filled in the slits on the surface of the wood ridge, and a light clay building block thermal-insulation layer built on the surface of the flatting layer. The invention has the advantages that the materials are mainly local construction materials; the building block building method is adopted; the thickness of the thermal-insulation layer of the wall body can be designed according to local conditions; the slits in the wall body are reduced; the poor thermotechnical performance of a well-frame building is improved effectively; the construction is simple; the construction cost is low; the purpose of ecological and environmental protection is realized; and the local advantages can be played.

Owner:KUNMING UNIV OF SCI & TECH

Method for chemically plating Ni-Mo-P on silicon dioxide

InactiveCN101235495AImprove bindingImprove performanceLiquid/solution decomposition chemical coatingElectroless platingChemistry

The invention relates to a method for chemically plating Ni-Mo-P on silicon dioxide (SiO2), which belongs to the electroless plating application field. The method comprises: firstly, carrying out former treatment such as cleaning, coupling, activating and the like for a substrate (SiO2Si), then, arranging the substrate into chemical plating liquid which is heated in water bath, happening redox reaction in the chemical plating liquid, and rapidly depositing on the surface of the silicon dioxide (SiO2) to obtain Ni-Mo-P film. The Ni-Mo-P film which is prepared by the technique has bright, compact, and flat surface, strong binding force with the substrate and excellent barrier property. The method is convenient for preparing solution, production procedure is easy, and the cost is low, which is one of the best choices for integrating electric circuit copper interconnected wire barrier layers in the future.

Owner:TSINGHUA UNIV

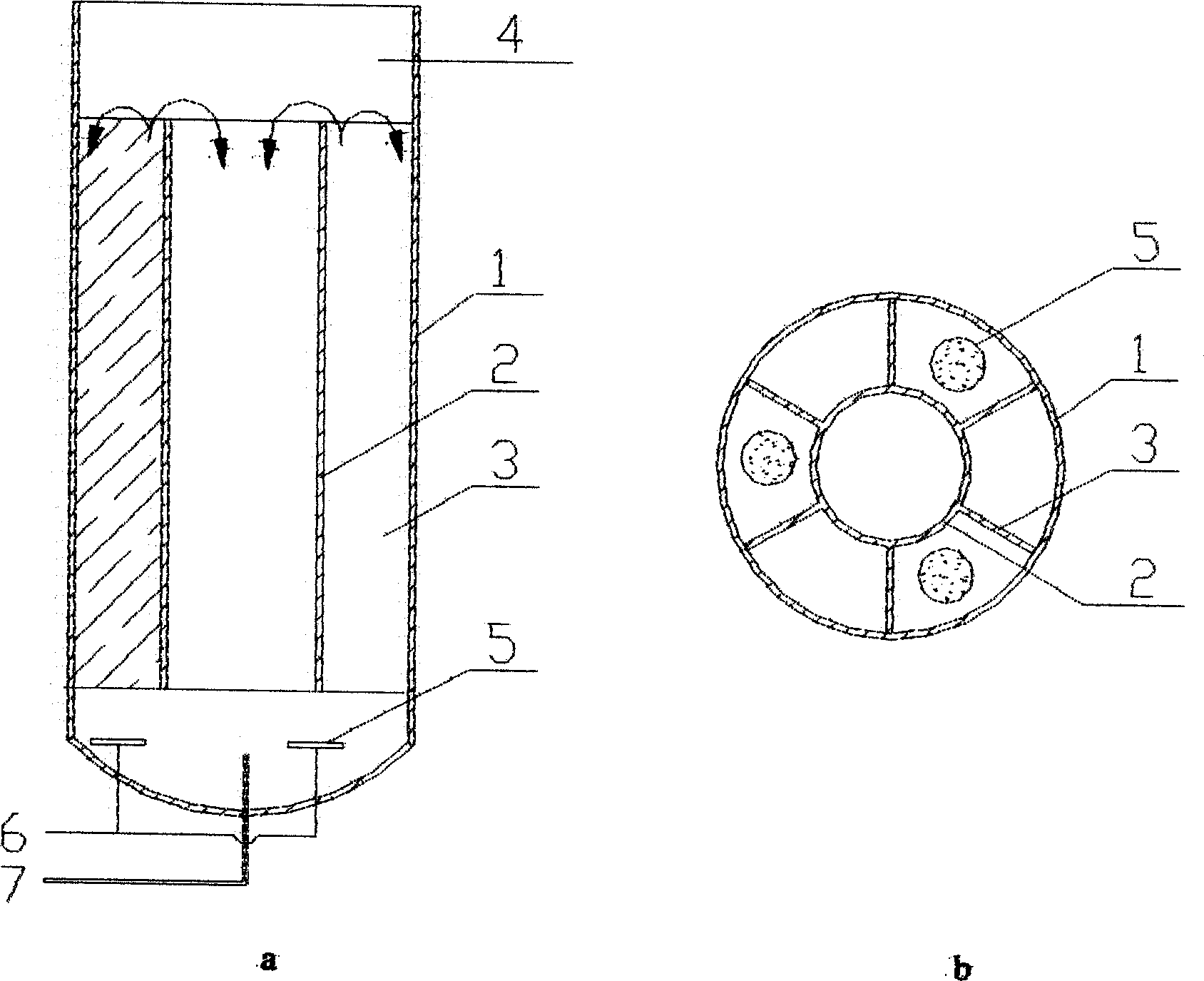

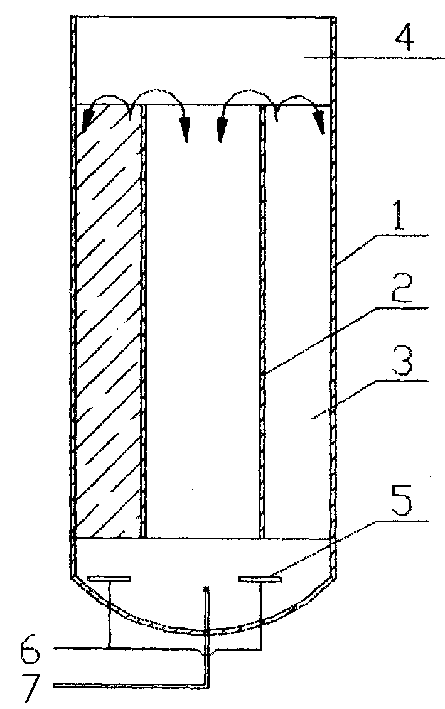

Honeycombed section biological fluidized composite reactor

InactiveCN1460651AReduce the cross-sectional areaEffective thickness controlTreatment using aerobic processesSustainable biological treatmentHoneycombProcess engineering

The biofluidized composite reactor adopts honeycomb section structure, the internal cylinder of said reactor is positioned in the centre of interior of external cylinder of said reactor, in the annular space between external cylinder and internal cylinder of the reactor even number of partion boards can be added, and the separated adjacent annular space zones are successively used as flow-lifting zone and flow-falling zone, said flow-lifting zone and flow-falling zone are limited by said honeycomb section structure, and the section area of single flow-lifting zone is reduced, so that it can better uniformly fluidize, reduce energy consumption and raise oxygen-transferring efficiency.

Owner:TSINGHUA UNIV

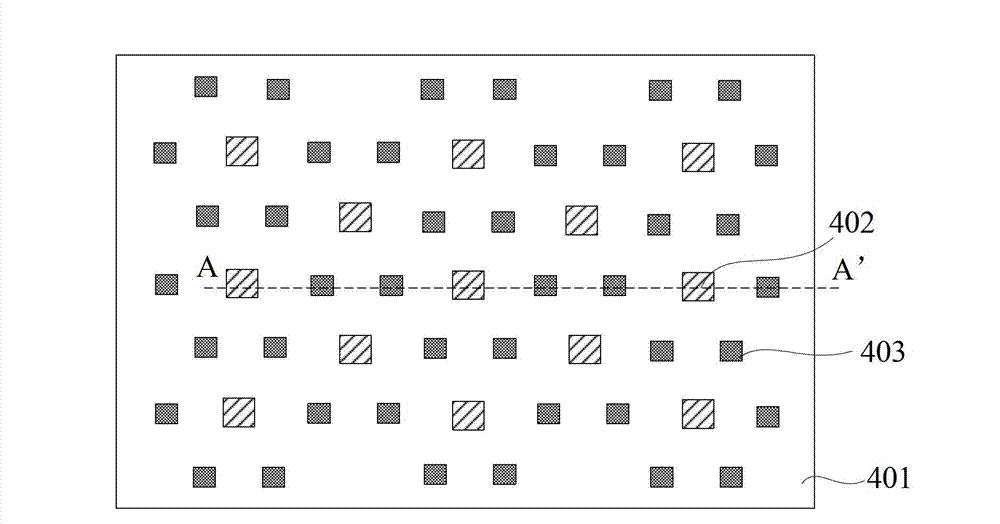

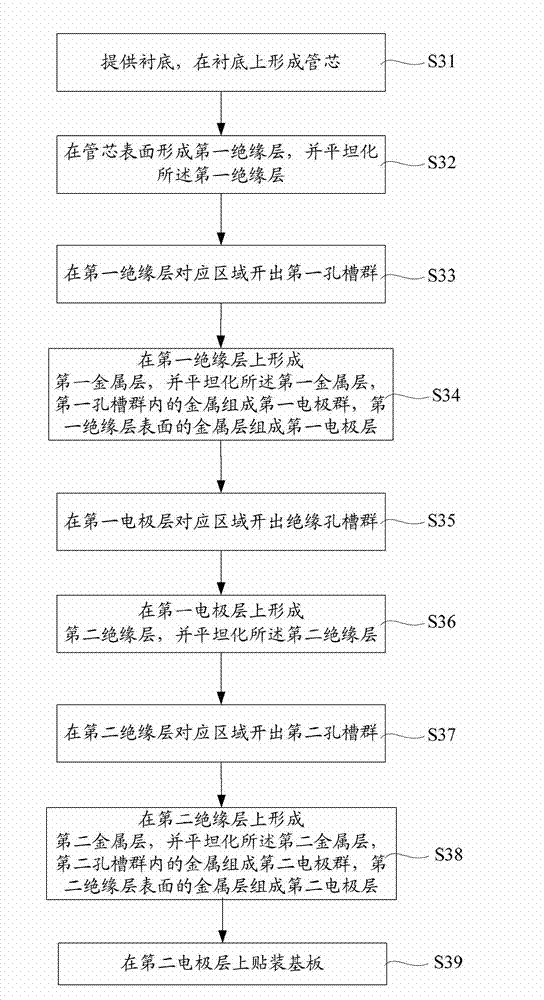

LED (Light-Emitting Diode) chip and manufacturing method of LED chip

InactiveCN102931297AEffective thickness controlSimple processSemiconductor devicesPower flowEngineering

The invention discloses an LED (Light-Emitting Diode) chip and a manufacturing method of the LED chip. The manufacturing method of the LED chip comprises the steps of continually generating structures comprising an electrode layer and an insulating layer and the like after an electrode group is generated, and two steps of the traditional flip chip process are optimized; and meanwhile, the method can effectively control the thickness of the LED chip. A pair of traditionally-arranged electrodes into a first electrode group and a second electrode group which are distributed at the corresponding regions of a pipe core; and sufficient current expansion can be obtained by the structure to uniformly distribute current, so that the uniform device has good luminous efficiency and uniform luminous rate, thereby meeting the requirement of further increasing the chip size.

Owner:ENRAYTEK OPTOELECTRONICS

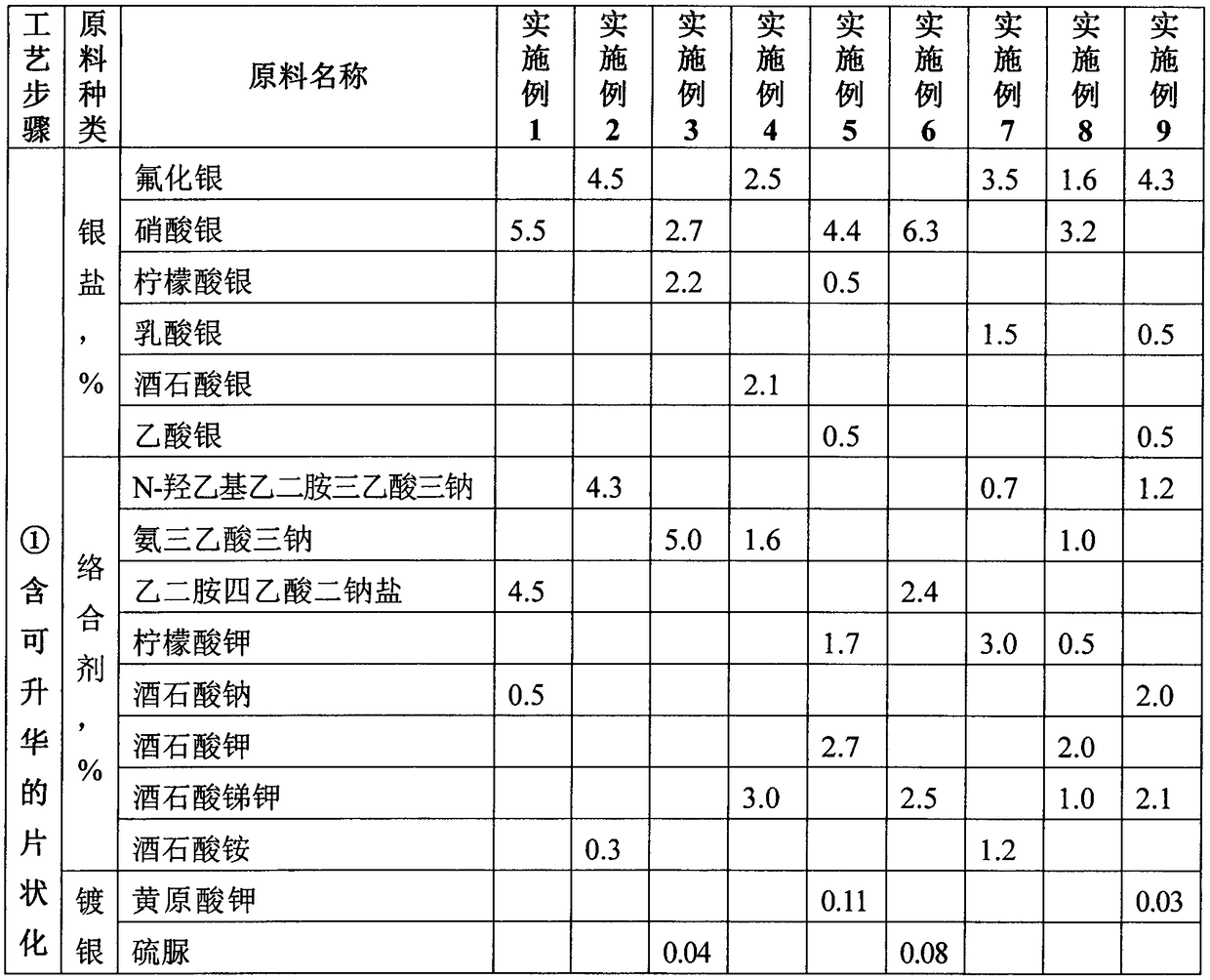

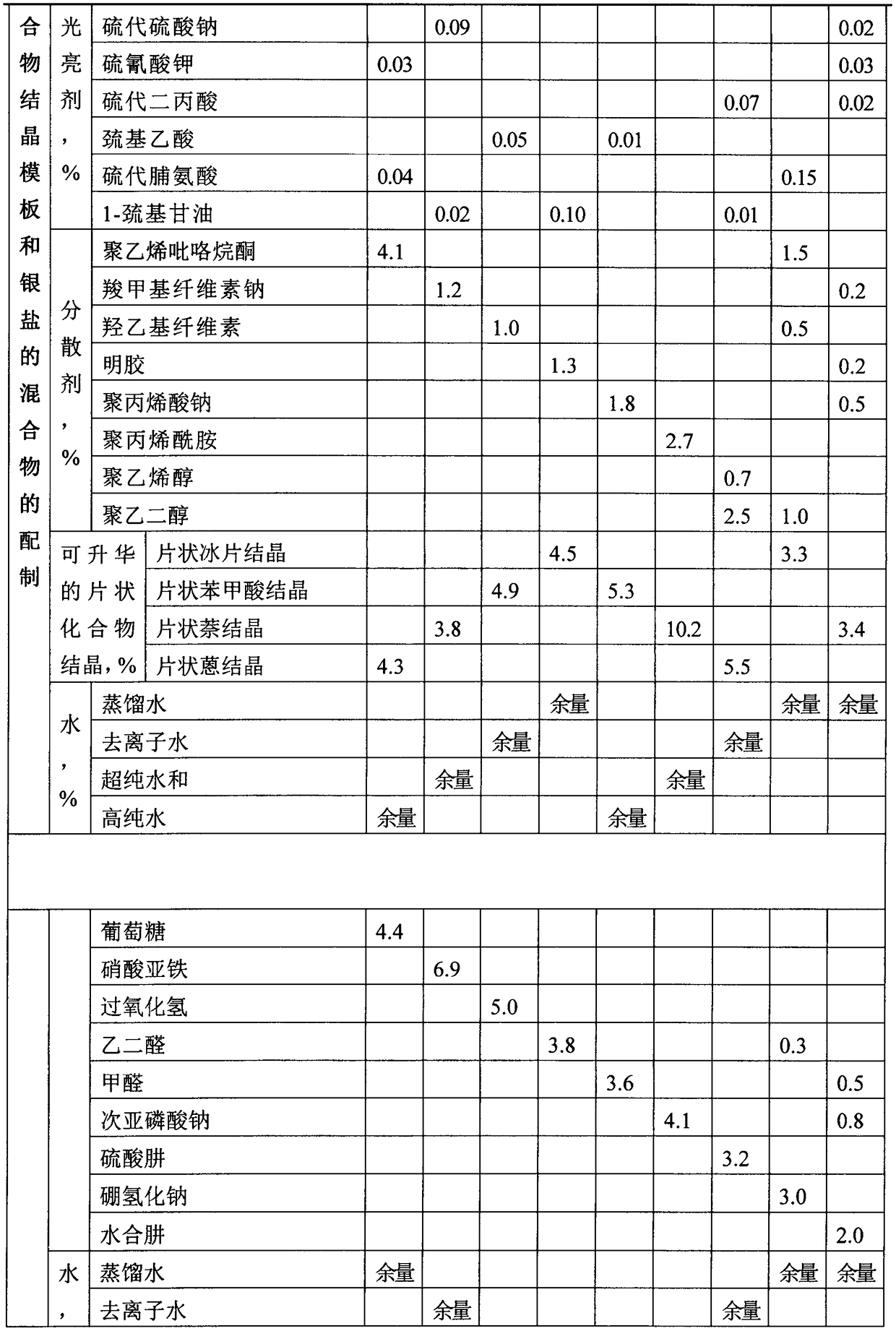

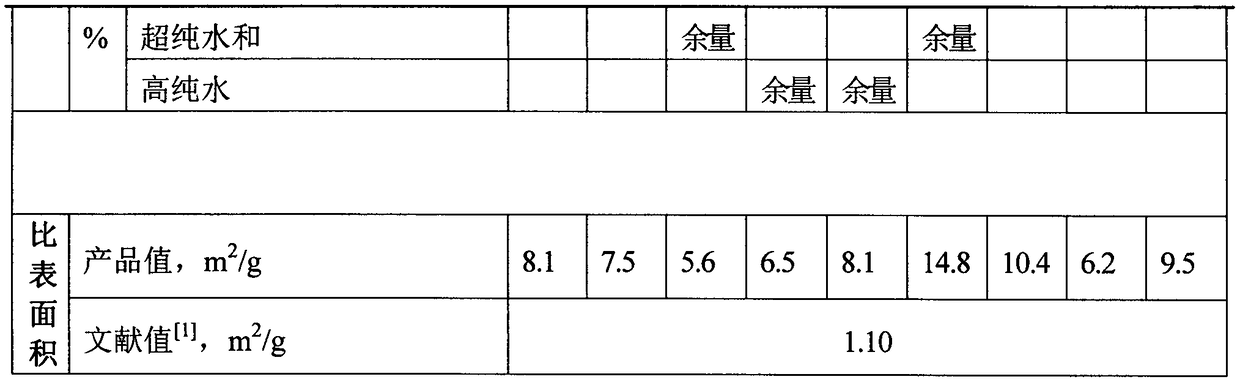

Preparation method of flake silver powder

InactiveCN108580920ASimple purification processHigh product purityMaterial nanotechnologyTransportation and packagingChemical platingEnergy consumption

The invention provides a preparation method of flake silver powder. The method comprises the steps that water, silver salt, a complexing agent, a silver-plated brightener, a dispersing agent, sublimated flake compound crystals and a reducing agent are adopted as raw materials, a chemical plating method is adopted, silver is plated on the surface of the sublimated flake compound crystal until silver ions react completely, and after the reaction is finished, the flake silver powder is directly obtained through separation and purification and processing treatment processes without ball milling. The preparation method has a series of advantages of being low in energy consumption, small in environmental pollution, simple in production process, short in process route, low in the large-scale production equipment investment, high in production efficiency, lower in production cost, good in product dispersion performance, good in product conductivity and the like, the method is suitable for large-scale production, the problems existing in the process of preparing the sheet-like silver powder by a ball milling method are solved, and the method has the good industrialization prospects.

Owner:NANJING FORESTRY UNIV

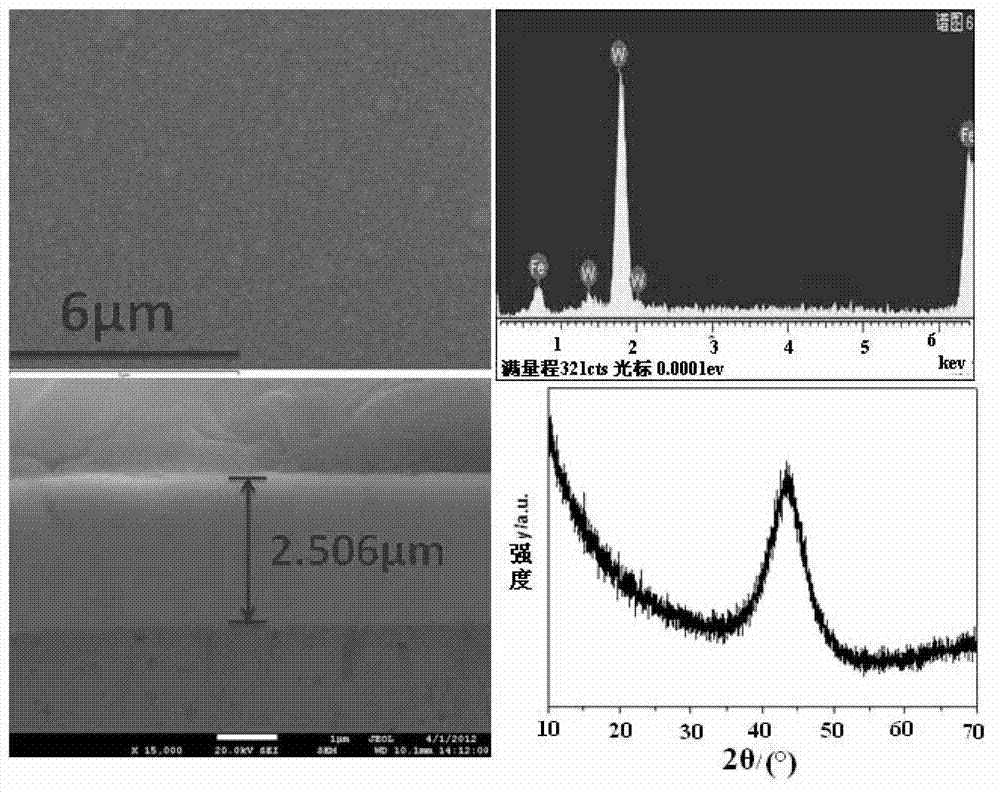

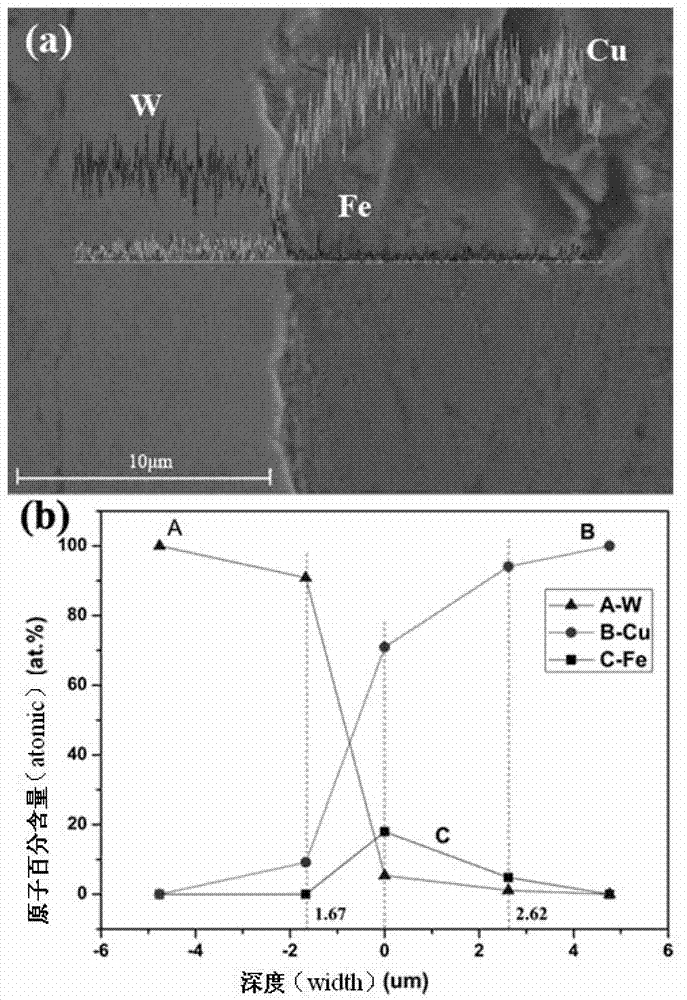

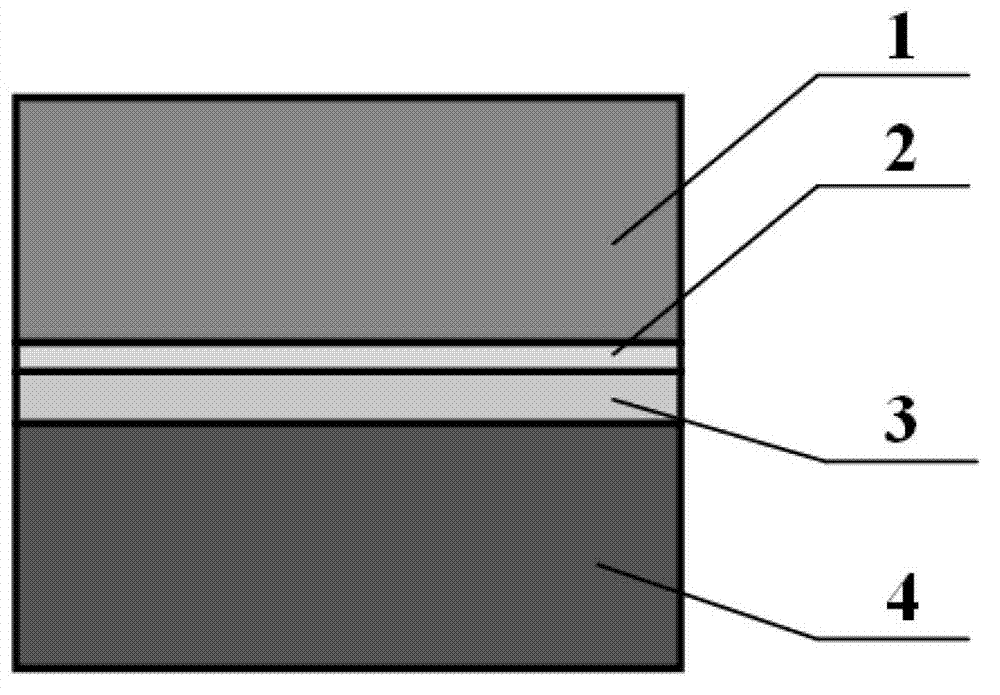

Diffusion bonding method for tungsten and copper dissimilar metal

InactiveCN103706939AEffective thickness controlImprove bindingNon-electric welding apparatusCopper foilElectrochemistry

The invention provides a diffusion bonding method for tungsten and copper dissimilar metal. The diffusion bonding method includes steps of (1), electrochemically polishing copper sheets and copper foils; (2), encapsulating the surface of one side of each electromechanically polished copper foil, then electroplating the copper foils in electroplate liquid and acquiring an amorphous Fe-W coating on the surface of the other side of each copper foil; (3), sequentially overlapping each copper sheet, the corresponding copper foil and a tungsten sheet from bottom to top to obtain a combination, and performing vacuum hot-pressed sintering on the combinations so as to implement diffusion bonding on the tungsten and copper dissimilar metal. The electroplate liquid comprises sodium tungstate, ferrous sulfate, ammonium tartrate and water. The side surfaces of the amorphous Fe-W coatings of the copper foils are in contact with the tungsten sheets. The diffusion bonding method has the advantages of simplicity in technological operation, low cost, high applicability, good connection performance and tensile strength which is higher than 146MPa.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com