Formula and machining method of resin grinding wheel angle abrasive disc

A technology of resin grinding wheel and angle grinding disc, which is applied in the direction of bonded grinding wheel, metal processing equipment, abrasives, etc., can solve the problems of low surface precision of the processed workpiece, small amount of grinding removal, and poor grinding feel, etc. Effects of tissue homogeneity, increased porosity, and good lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

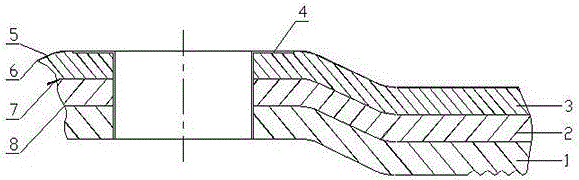

[0045] see figure 1 , in an embodiment of the present invention, a formulation of a resin grinding wheel angle grinding disc, including three layers of coarse material layer 1, coarse material layer 2 and fine material layer 3 compounded in sequence,

[0046] The raw materials of the coarse material layer are composed by weight: 40 parts of SG abrasive, 30 parts of AZ40 zirconium corundum, 30 parts of white corundum, 3 parts of liquid phenolic resin, 0.75 parts of liquid epoxy resin, 15 parts of 325 mesh powdered phenolic resin , 2 parts of 400-mesh potassium fluoroborate, 2 parts of 600-mesh electrolytic copper powder, 0.5 part of 600-mesh talcum powder;

[0047] Wherein, the viscosity of the liquid phenolic resin in the raw material of the coarse material layer is 500mPa·s (25 ℃), and the particle size numbers of the three kinds of abrasives of the SG abrasive, AZ40 zirconium corundum, and white corundum are all 24 meshes, and the total of the three abrasives The number of ...

Embodiment 2

[0060] see figure 1 , in an embodiment of the present invention, a formulation of a resin grinding wheel angle grinding disc, including three layers of coarse material layer 1, coarse material layer 2 and fine material layer 3 compounded in sequence,

[0061] The raw materials of the coarse material layer are composed by weight: 50 parts of SG abrasive, 25 parts of AZ40 zirconium corundum, 25 parts of white corundum, 4.8 parts of liquid phenolic resin, 1.2 parts of liquid epoxy resin, 17.2 parts of 325 mesh powdered phenolic resin , 5 parts of 500-mesh potassium fluoroborate, 1 part of 800-mesh electrolytic copper powder, 1 part of 800-mesh talcum powder;

[0062] Among them, the viscosity of the liquid phenolic resin in the raw material of the coarse material layer is 650mPa·s (25°C), the particle size numbers of the three abrasives of SG abrasive, AZ40 zirconium corundum, and white corundum are all 36 mesh, and the total number of parts of the three abrasives Keep 100 parts...

Embodiment 3

[0075] see figure 1 , in an embodiment of the present invention, a formulation of a resin grinding wheel angle grinding disc, including three layers of coarse material layer 1, coarse material layer 2 and fine material layer 3 compounded in sequence,

[0076] The raw materials of the coarse material layer are composed by weight: 60 parts of SG abrasive, 20 parts of AZ40 zirconium corundum, 20 parts of white corundum, 6 parts of liquid phenolic resin, 1.5 parts of liquid epoxy resin, 20 parts of 400 mesh powdered phenolic resin , 8 parts of 600-mesh potassium fluoroborate, 0.5 parts of 800-mesh electrolytic copper powder, 2 parts of 800-mesh talcum powder;

[0077] Among them, the viscosity of the liquid phenolic resin in the raw material of the coarse material layer is 800mPa·s (25°C), the particle size numbers of the three abrasives of SG abrasive, AZ40 zirconium corundum, and white corundum are all 46 mesh, and the total number of parts of the three abrasives Keep 100 parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com