Environment-protection dry type vibrating material and production method thereof

A dry vibrating material and environment-friendly technology, applied in the field of unshaped refractory materials, can solve the problems of irritating the respiratory tract and eyes, affecting physical health, increasing product cost, etc., achieving high strength at low and medium temperatures, without affecting slag resistance and The effect of oxidation resistance, excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

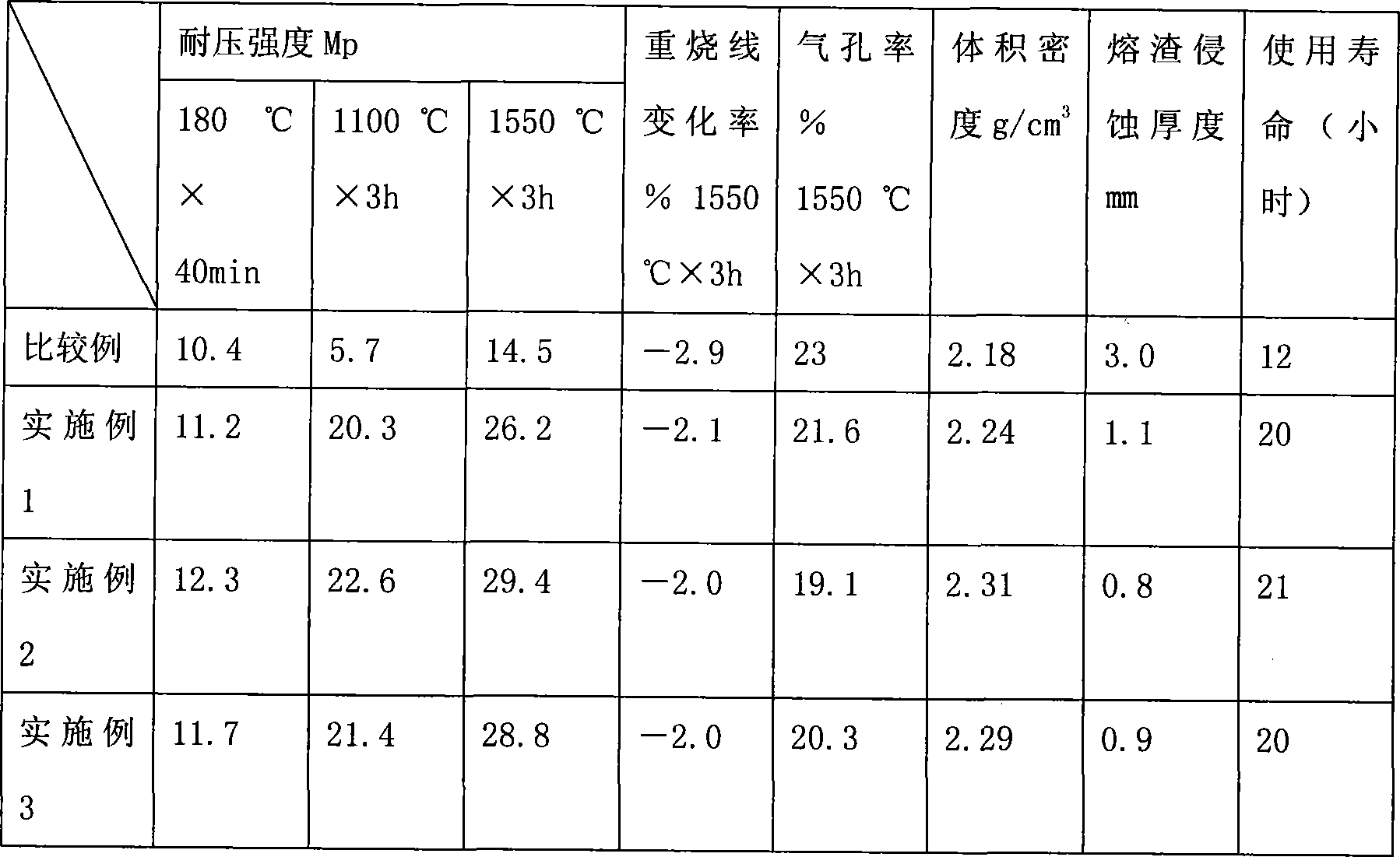

Examples

Embodiment 1

[0063] The mass percent content of each chemical composition of the environment-friendly dry vibrating material provided by the invention is: MgO70.20%, CaO2.14%, Al 2 o 3 3.28%, C 15.30%, SiO 2 3.31%, SiC1.73%, Fe 2 o 3 1.81%.

[0064] The specific ratio (percentage by weight) of each raw material is: 55% of waste magnesia-carbon brick sand with a particle size of 5-1mm, 20% of waste magnesia-carbon brick sand with a particle size of 3-0mm, 25% of waste magnesia-carbon brick powder with a particle size of ≤0.088mm, metal Al powder (extra) 1.2%, metal Si powder (extra) 1.0%, SiC powder (extra) 2%, α-Al 2 o 3 powder (extra) 0.5%, borax (extra) 1.8%, silica powder (extra) 0.2%, inorganic salt binder (extra) 3.8%.

[0065] Weigh according to the above weight percentage, then put the fine powder into a small mixer and mix for 15 minutes, then put it into a small bag for later use. Put the coarse particles and binder into the planetary mixer for 4 minutes, then add the mi...

Embodiment 2

[0067] The mass percent content of each chemical composition of the environment-friendly dry vibrating material provided by the invention is: MgO5.33%, CaO2.18%, Al 2 o 3 71.24%, C 12.54%, SiO 2 3.60%, SiC1.80%, Fe 2 o 3 1.31%.

[0068] The specific ratio (percentage by weight) of each raw material is: 63% of waste aluminum-magnesia-carbon sand with a particle size of 5-1mm, 12% of waste aluminum-magnesia-carbon brick sand with a particle size of 3-0mm, and 25% of waste aluminum-magnesia-carbon brick powder with a particle size of ≤0.088mm , metal Al powder (extra) 1.0%, metal Si powder (extra) 0.8%, 94SiC powder (extra) 2.0%, α-Al 2 o 3 Powder (extra) 0.5%, borax (extra) 2.2%, silica powder (extra) 0.2%. Inorganic salt binder (additional) 3.5%. The 94SiC-based SiC material with a SiC content of 94% is referred to as an abbreviation.

[0069] Weigh according to the above weight percentage, then put the fine powder into a small mixer and mix for 20 minutes, then put ...

Embodiment 3

[0071] The mass percent content of each chemical composition of the environment-friendly dry vibrating material provided by the invention is: MgO56.00%, CaO2.04%, Al 2 o 3 25.33%, C 8.72%, SiO 2 2.78%, SiC1.39%, Fe 2 o 3 1.74%.

[0072] The specific ratio (percentage by weight) of each raw material is: 12% of waste aluminum magnesia carbon brick sand with a particle size of 5-1mm, 20% of waste magnesia carbon brick sand with a particle size of 5-1mm, and waste aluminum magnesia carbon brick with a particle size of 3-0mm Sand 17%, waste magnesia carbon sand with a particle size of 3-0mm 26%, particle size ≤ 0.088mm, waste aluminum magnesia carbon brick powder 10%, waste magnesia carbon brick powder 15%, metal Al powder (additional) 1.0%, metal Si Powder (extra) 0.8%, 94SiC powder (extra) 2.0%, α-Al 2 o 3 Powder (extra) 0.5%, borax (extra) 2.2%, silica powder (extra) 0.2%. Inorganic salt binder (additional) 3.5%.

[0073] Weigh according to the above weight percentag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com