Fast ceramic flame-resistant cable and its production method

A fire-resistant cable, ceramic technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of complex production process, difficult construction, easy damage, etc., and achieve the effect of simple process, convenient construction and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A rapid ceramization refractory cable material, its raw material ratio is as follows:

[0030] Ethylene-vinyl acetate copolymer 60 parts

[0031] Linear low density polyethylene (DJM1820) 40 parts

[0032] GA 26 copies

[0033] GC 39 copies

[0034] 0.7 parts of 3-methacryloxypropyltrimethoxysilane

[0035] Magnesium hydroxide 80 parts

[0036] 20 parts melamine

[0037] 1 part stearic acid

[0038] Antioxidant 1010 1 part

[0039] Add GA, GC and 3-methacryloxypropyltrimethoxysilane into a high-speed mixer at 60°C, mix for 10 minutes, and discharge for later use. Add ethylene-vinyl acetate copolymer, linear low-density polyethylene, antioxidant, flame retardant, porcelain-forming filler, and lubricant into the high-speed mixer in sequence, mix at room temperature for 2 to 3 minutes, and then granulate with twin-screw, extrude The temperature of each section of the machine is as follows: the first zone is 125°C, the second zone is 135°C, the third zone is 145°C, ...

Embodiment 2

[0042] A rapid ceramization refractory cable material, its raw material ratio is as follows:

[0043] Ethylene-vinyl acetate copolymer 65 parts

[0044] Linear low density polyethylene (DJM1820) 35 parts

[0045]GA 40 copies

[0046] GC 40 copies

[0047] Isopropyl dioleate (dioctyl phosphate acyloxy) titanate 1.2 parts

[0048] Magnesium hydroxide 90 parts

[0049] 15 parts melamine

[0050] 1.5 parts of stearic acid

[0051] Antioxidant 300 1.5 parts

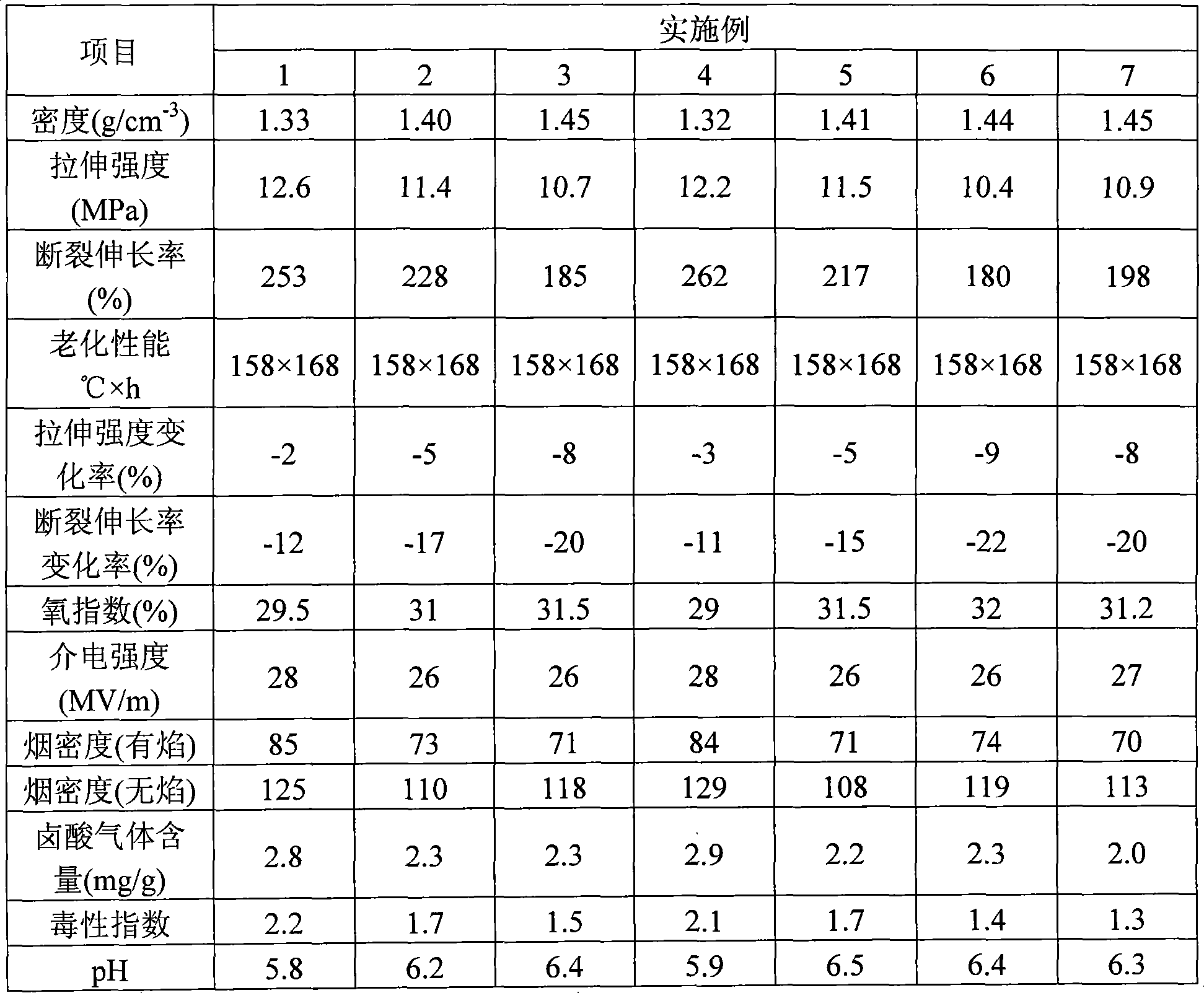

[0052] The preparation method of the above-mentioned cable material is the same as that of Example 1, and the performance test results are shown in Table 1.

Embodiment 3

[0054] A rapid ceramization refractory cable material, its raw material ratio is as follows:

[0055] Ethylene-vinyl acetate copolymer 70 parts

[0056] Linear low density polyethylene (DJM1820) 30 parts

[0057] GA 54 copies

[0058] GC 36 copies

[0059] 1.2 parts of γ-methacryloxypropyltrimethoxysilane

[0060] Magnesium hydroxide 95 parts

[0061] 10 parts melamine

[0062] Zinc stearate 1.8 parts

[0063] Antioxidant 300 2 parts

[0064] The preparation method of the above-mentioned cable material is the same as that of Example 1, and the performance test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com