Patents

Literature

311results about How to "Improve strength and toughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

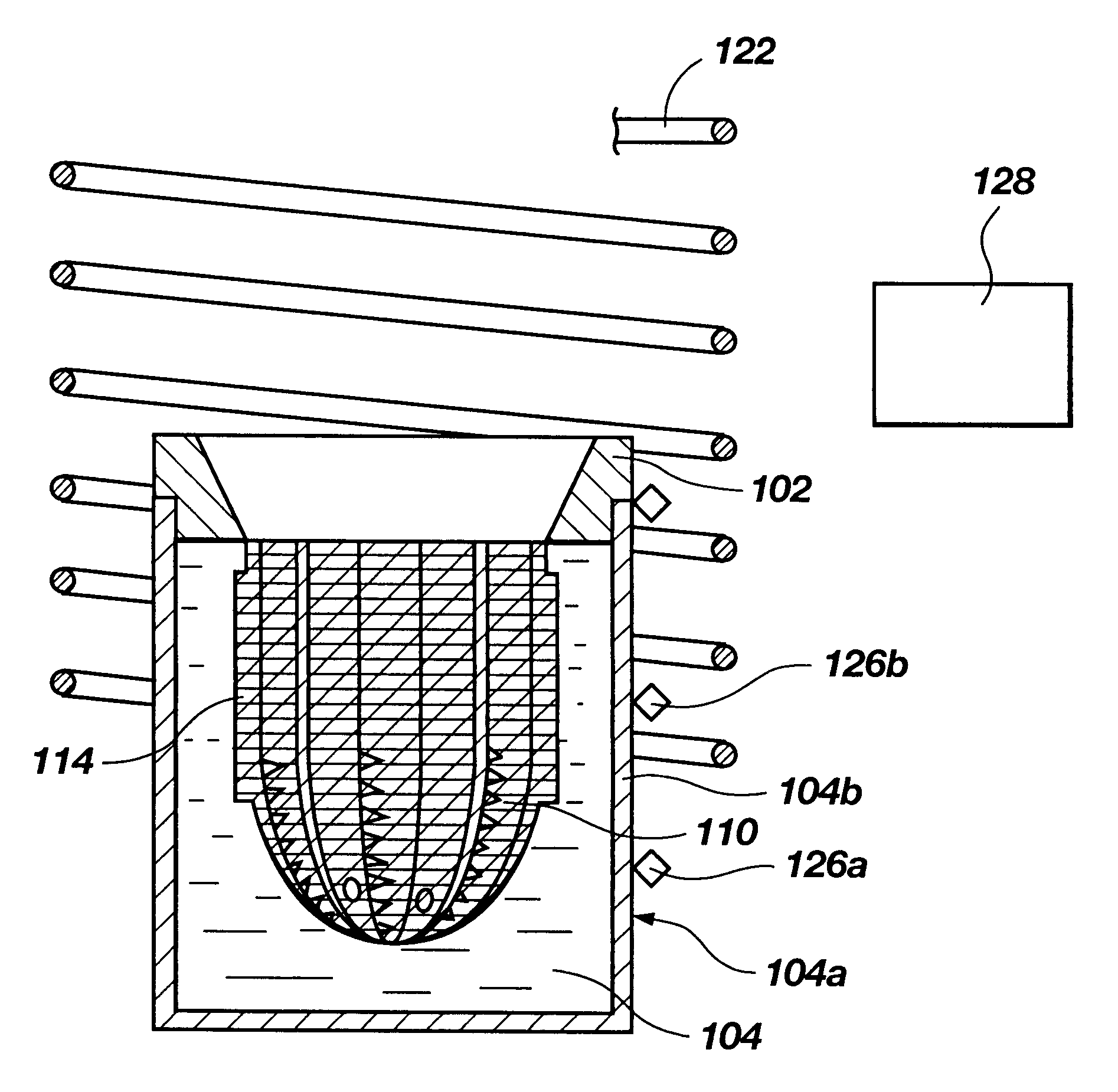

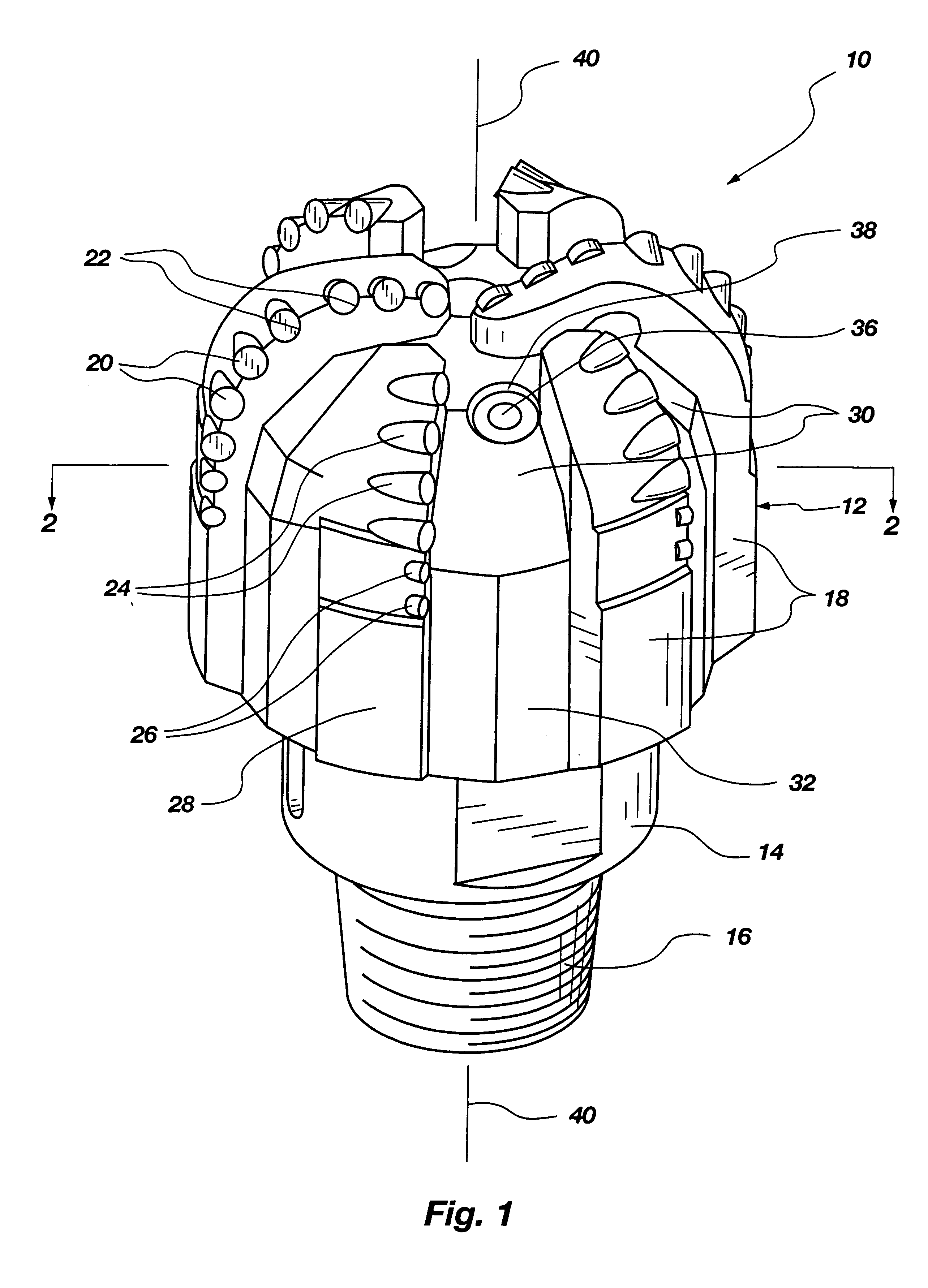

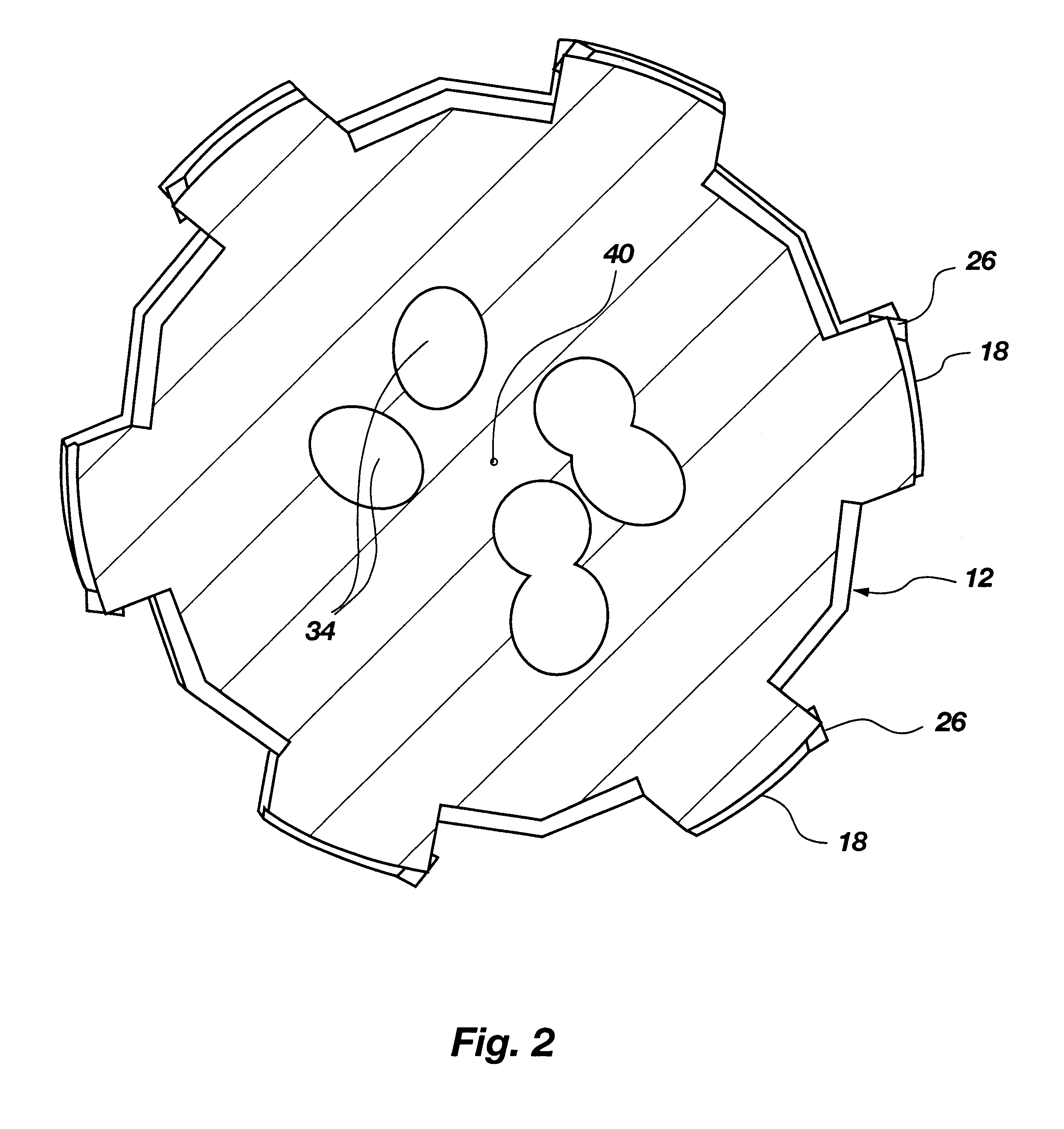

Methods of high temperature infiltration of drill bits and infiltrating binder

A method of manufacturing a bit body, other drilling-related component, or other article of manufacture, including fabricating a particulate-based matrix and infiltrating the particulate-based matrix with a binder that includes cobalt or iron. The binder may be a cobalt alloy or an iron alloy. The particulate-based matrix may be disposed within a non-graphite mold. The particulate-based matrix and binder are placed within an induction coil and an alternating current is applied to the induction coil in order to directly heat the binder, permitting the binder to infiltrate or otherwise bind the particles of the matrix together. The molten binder may then be directionally cooled by forming a cooling zone around an end portion of the bit body and increasing the size of the cooling zone relative to the bit body. The invention also includes a bit body, other drilling-related component, or other article of manufacture which includes a particulate-based matrix that is bound together with a binder that includes iron or cobalt.

Owner:BAKER HUGHES INC

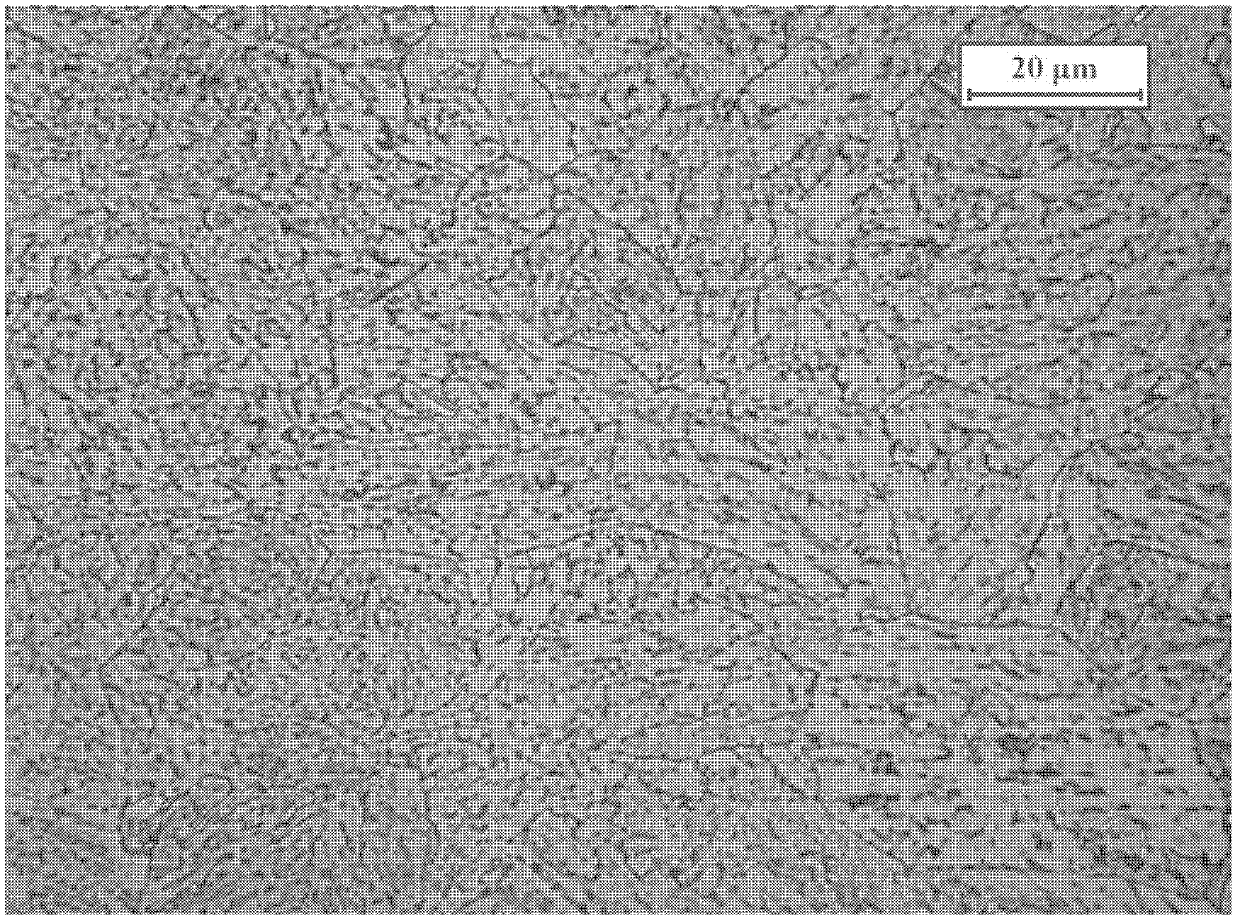

High-strength, high-toughness and high-plasticity martensitic stainless steel and preparation method thereof

ActiveCN103614649AImprove the level of toughness and plasticityImprove stabilityMartensitic stainless steelRoom temperature

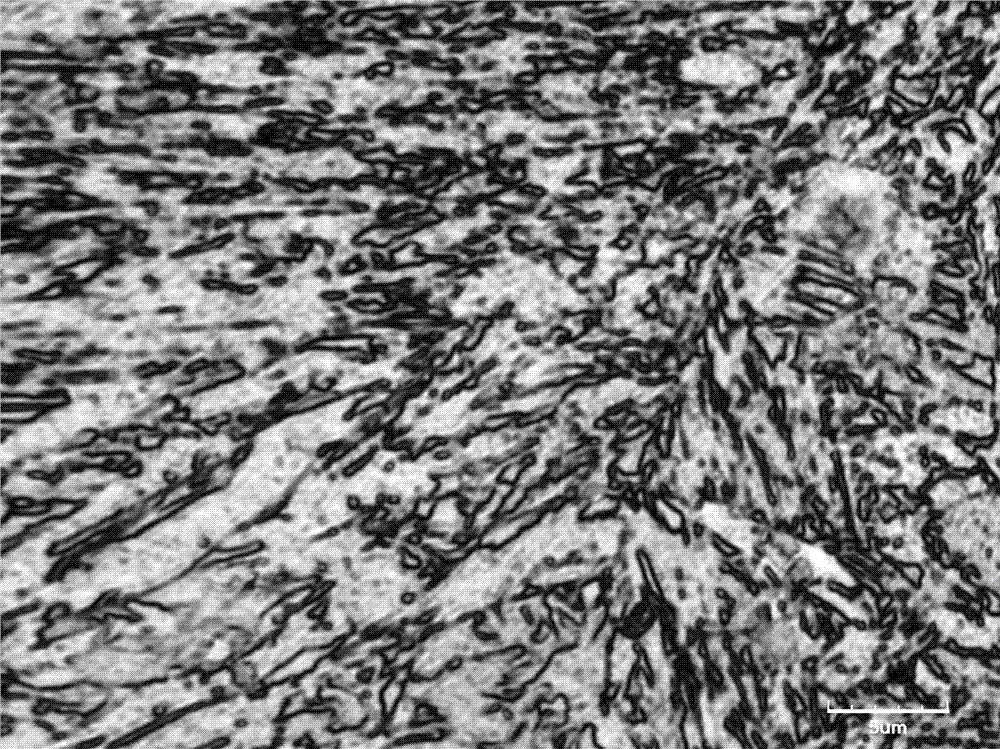

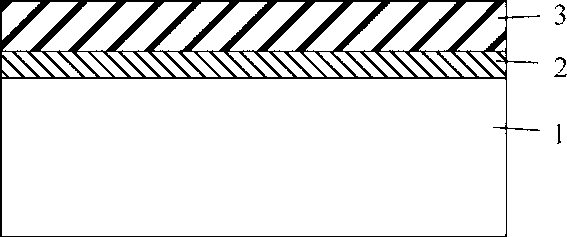

The invention discloses high-strength, high-toughness and high-plasticity martensitic stainless steel, and belongs to the technical field of metallurgy. The martensitic stainless steel comprises the following components in percentage by weight: 0.15 to 0.4 percent of C, 0 to 0.12 percent of N, 0.2 to 2.5 percent of Si, 0.4 to 3.0 percent of Mn, less than or equal to 0.02 percent of S, less than or equal to 0.02 percent of P, 13.0 to 17.0 percent of Cr, 0 to 5.0 percent of Ni, 0 to 2.0 percent of Mo, 0 to 0.3 percent of V, 0 to 0.2 percent of Nb, 0 to 0.05 percent of Ti, 0 to 0.8 percent of Al and the balance of Fe and inevitable impurities. A preparation method comprises the following steps of (1) smelting molten steel according to the set components, and solidifying the molten steel to form an ingot blank by using a continuous casting machine or a casting mold; (2) hot-rolling the ingot blank to form a hot-rolled plate blank; (3) heating the hot-rolled plate blank to 950 to 1100 DEG C, preserving heat for 0.5 to 2 hours, cooling the plate blank to 25 to 200 DEG C, heating the plate blank to 350 to 500 DEG C, preserving heat for 10 to 60 minutes, and air-cooling the plate blank to room temperature. According to the martensitic stainless steel prepared by the method, dispersed remaining martensite is introduced into a microscopic structure, so that the strength, toughness and plasticity of the martensitic stainless steel are greatly improved.

Owner:NORTHEASTERN UNIV

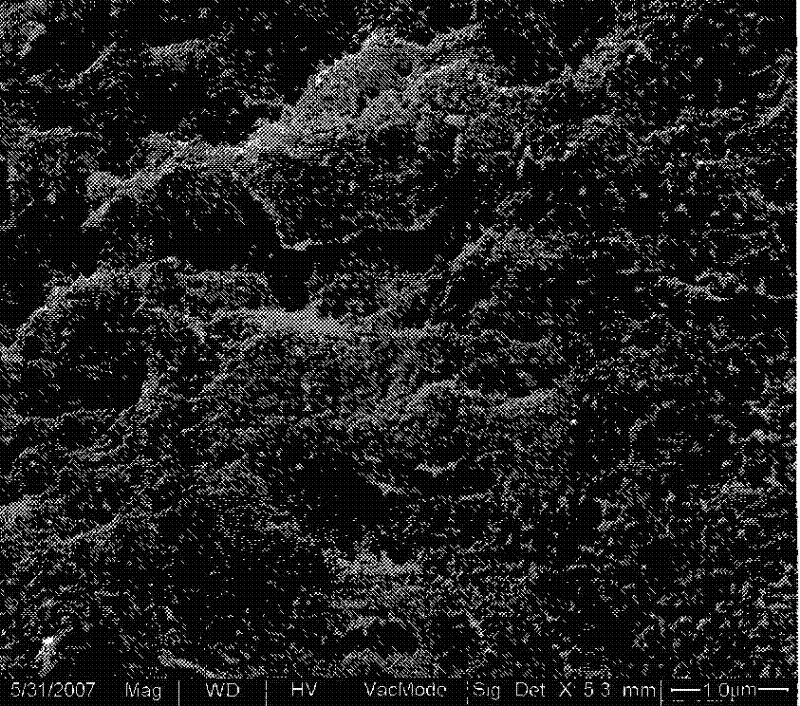

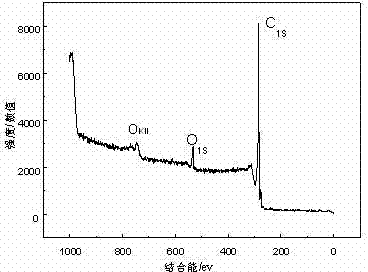

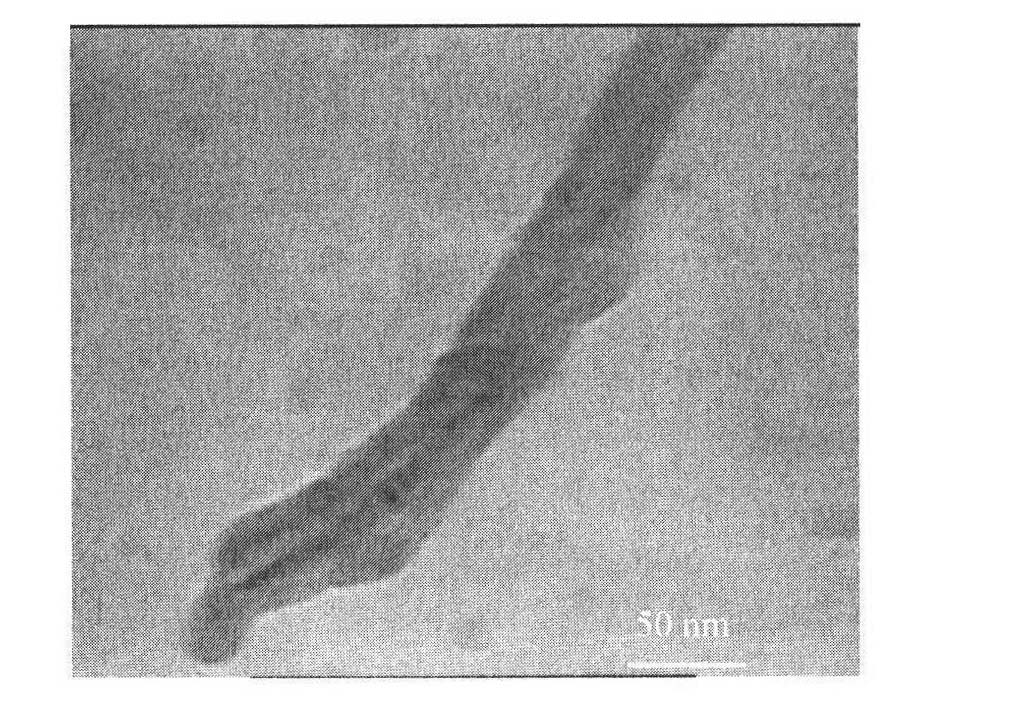

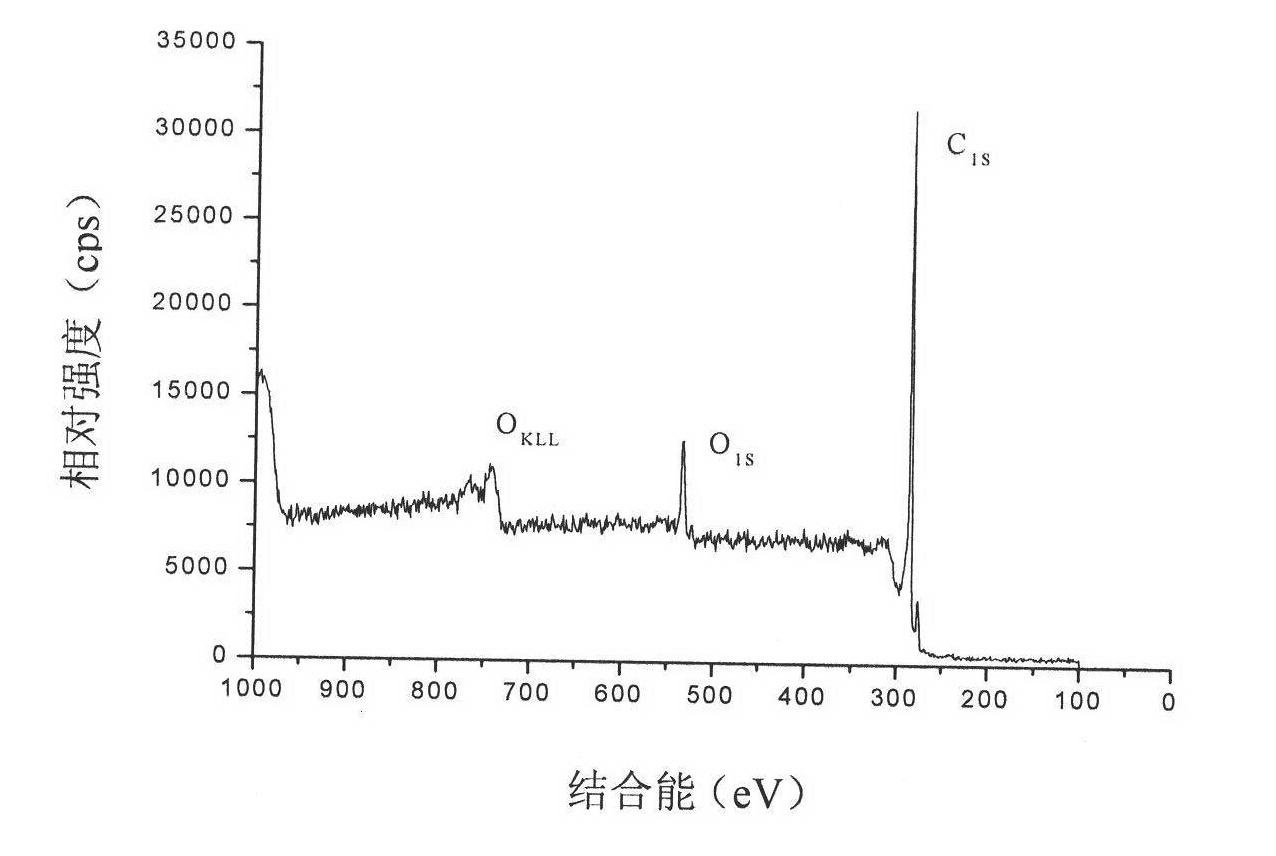

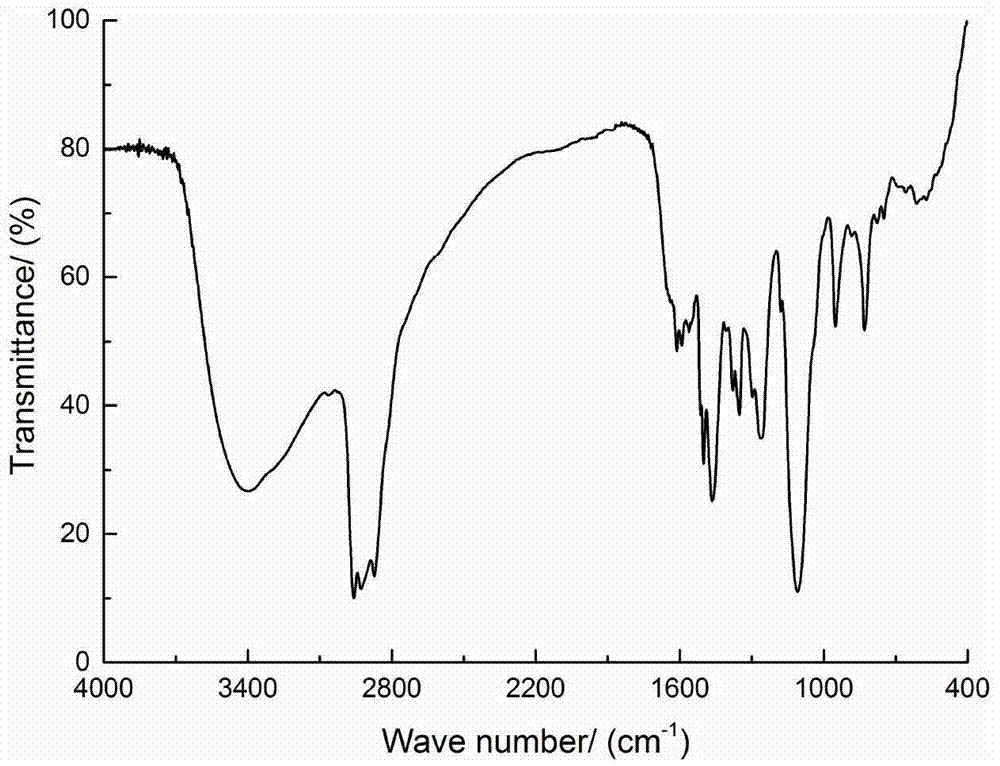

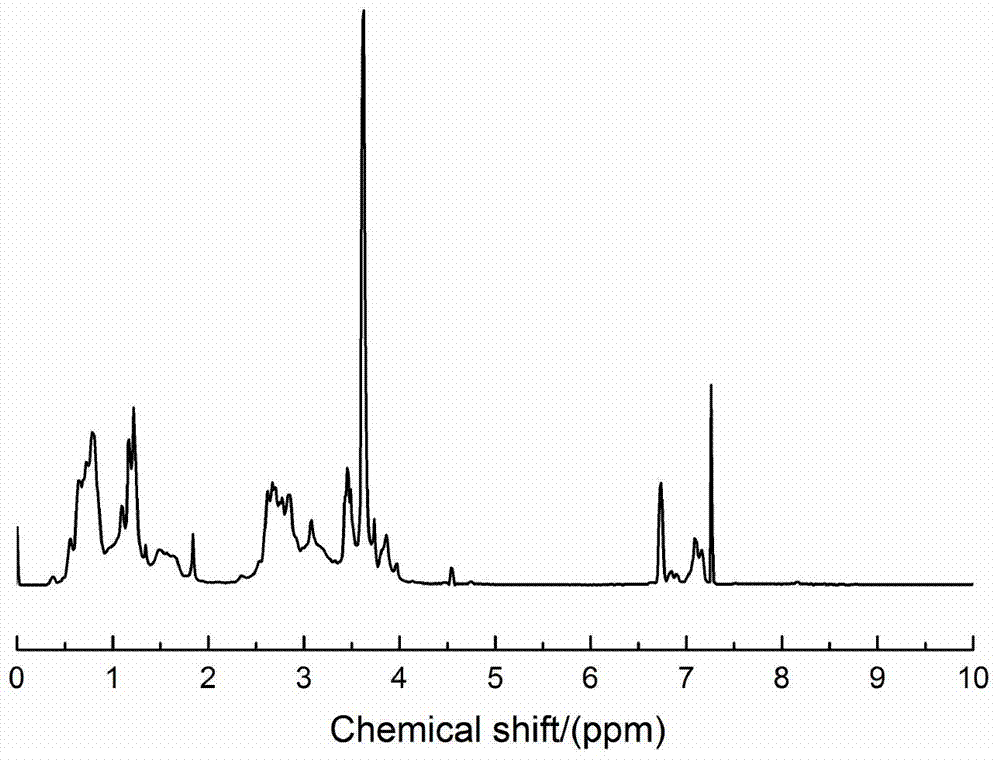

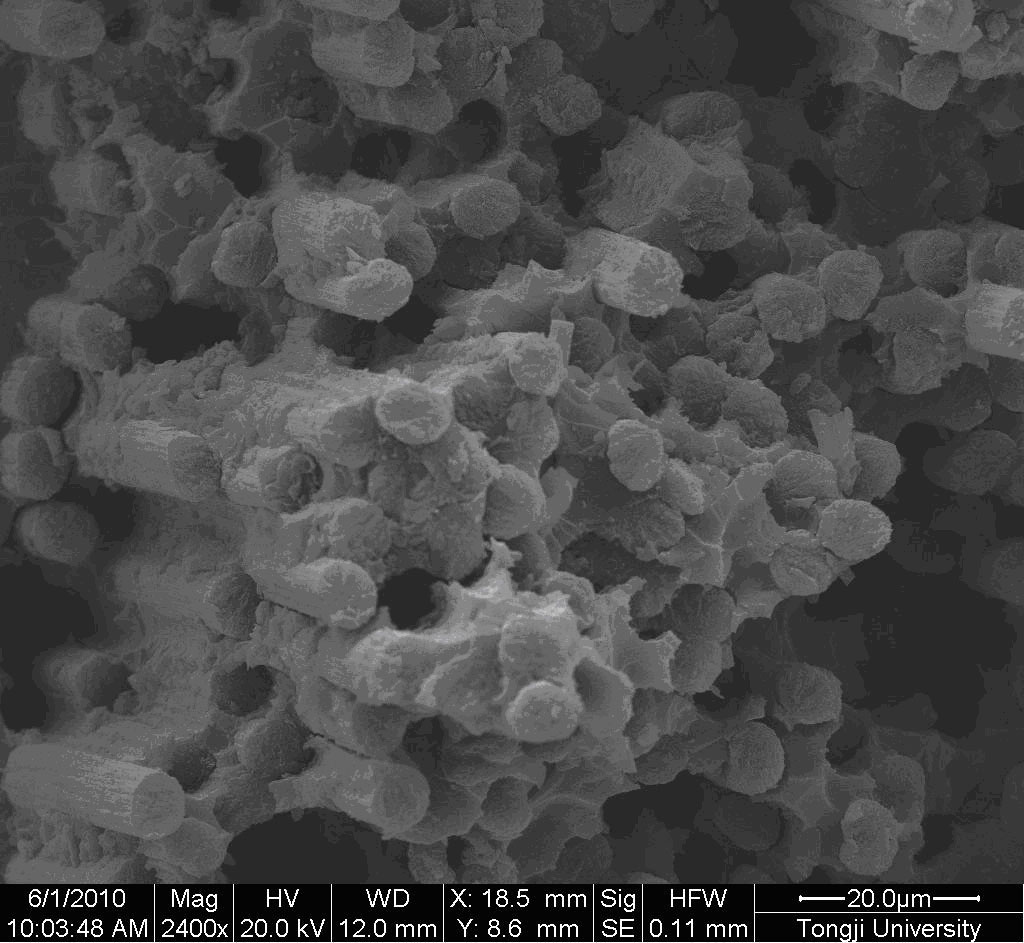

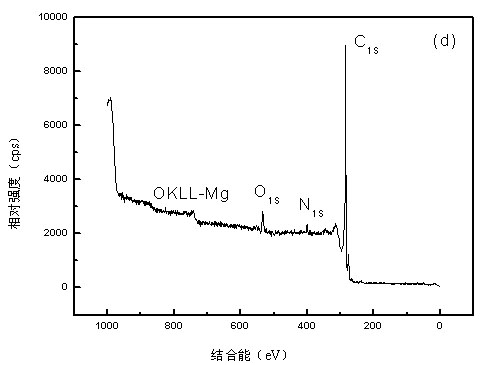

Preparation method of multidimensional hybrid composite of glass fibre/ grapheme- carbon nano tube/ epoxy resin

InactiveCN102304274AIncreased interlaminar shear strengthImprove interface strengthCarbon nanotubeResin matrix

The invention relates to a preparation method of multidimensional hybrid composite of glass fibre / grapheme-carbon nano tube / epoxy resin. In the method, after grapheme-carbon nano tube network structure is subjected to surface carboxylation, diamine or polyamine is introduced on the grapheme-carbon nano tube network structure; the grapheme-carbon nano tube connected with the amino is modified by micromolecule aromatic polybasic anhydride compound to prepare the carbon nano tube carried with an anhydride group; the grapheme-carbon nano tube is dispersed in the epoxy resin matrix by ultrasonic oscillation and high-speed stirring; organic acid anhydride curing agent is adopted for curing; and the obtained epoxy resin polymer containing the grapheme-carbon nano tube serves as the matrix to be compounded with glass fiber processed by silane coupling agent to form a multifunctional hybrid composite structure connected by covalent bonds. The multidimensional hybrid composite is convenient to prepare, the application range of the glass fiber, the grapheme, the carbon nano tube and the epoxy resin is widened, so that the hybrid composite can be widely applied on the aspects of aerospace, traffic transportation, electronic industry, civil facilities, building, chemical engineering and the like, can be industrially produced on a large scale, has low cost and is friendly to environment.

Owner:TONGJI UNIV

Sea water corrosion resistant steel for ocean drilling/production platform and preparation method thereof

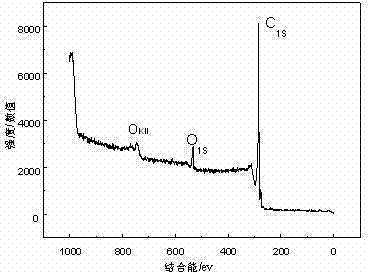

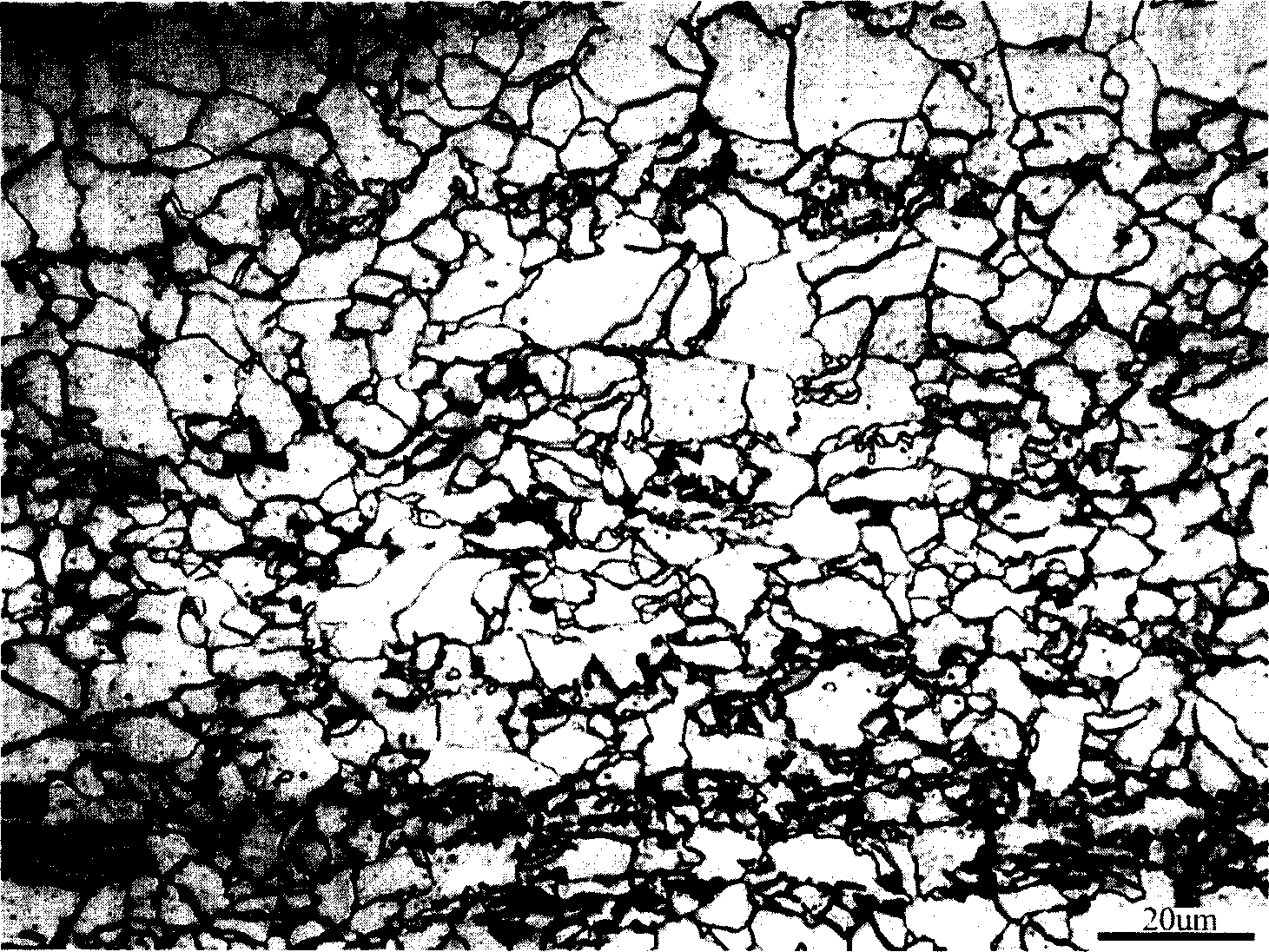

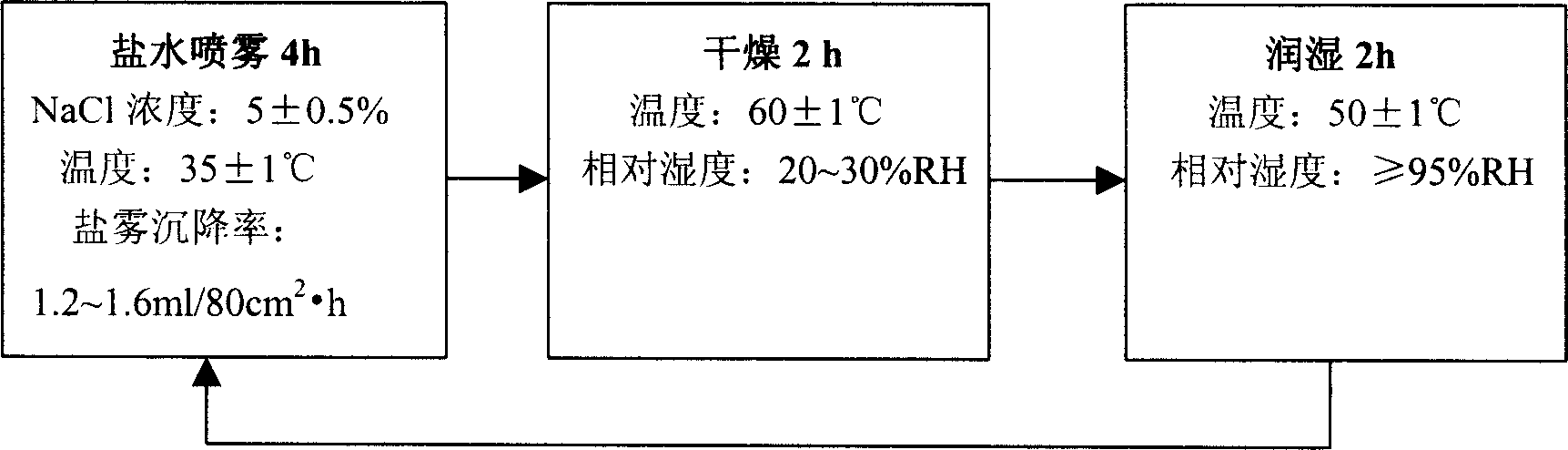

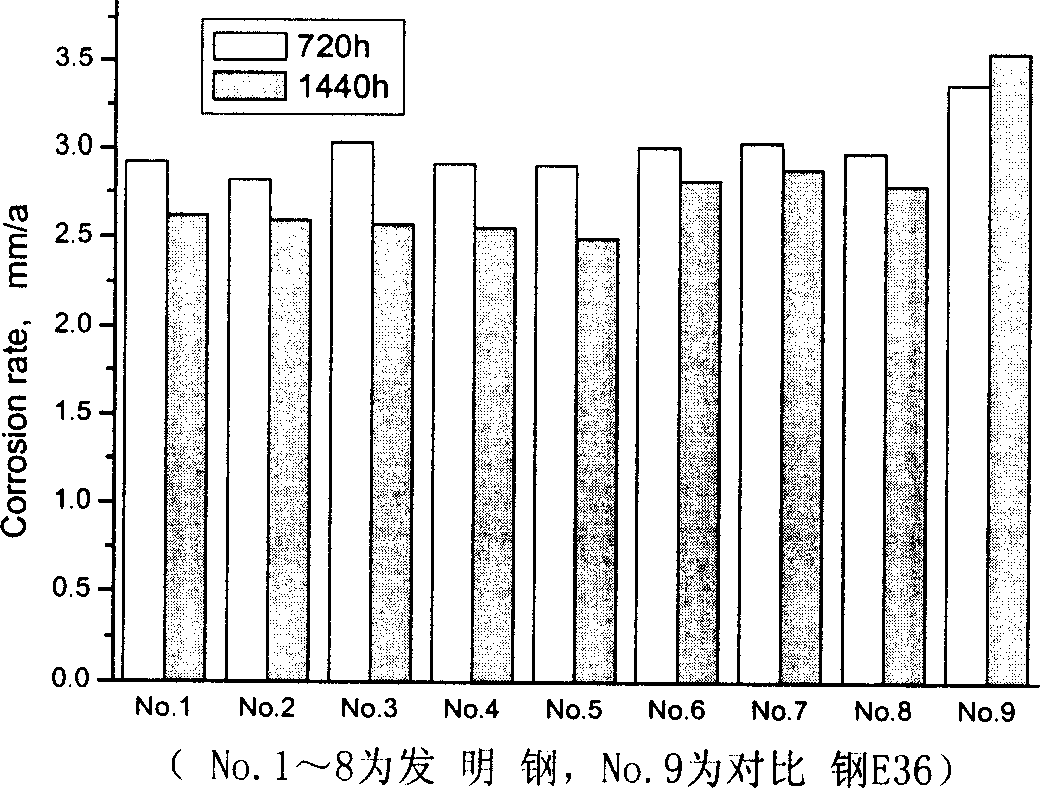

InactiveCN1908217AReduce unevennessAvoid corrosionRoll mill control devicesWelding/cutting media/materialsChemical compositionImpurity

the invention discloses a marine exploiting platform steel of erosion property of sea water resistance, which comprises the following parts: 0.03-0.09% C, 0.90-1.60% Mn, 0.10-0.50% Si, 0.006-0.020% P, 0.004-0.100% Cr, 0.02-0.40% Cu, 0.010-0.060% Als, 0.005-0.060% Nb, 0.005-0.030% Ti, Fe and impurity. the manufacturing method comprises the following steps: desulfurizing; blowing; disposing through vacuum; casting continually; rolling.

Owner:武钢集团有限公司

Elastic foamed material and preparation method of elastic foamed material

The invention discloses an elastic foamed material and a preparation method of the elastic foamed material, wherein the preparation method of the elastic foamed material comprises taking a thermoplastic elastomer material SEBS (styrene-ethylene-butylene-styrene) as a basic material and adding PP (polypropylene), EVA (ethylene-vinyl acetate) resin, an inorganic filler and a small amount of filling oil, a promoter, a cross-linking agent, a foaming agent and various auxiliary agents; the foamed material has uniform foamed holes, and the dosage of the cross-linking agent is small; and the foamed material is free from poison or odor, has good elasticity, is excellent anti-slipping property, low density which is as low as 0.040 grams per cubic centimeter.

Owner:CHINA PETROCHEMICAL CORP

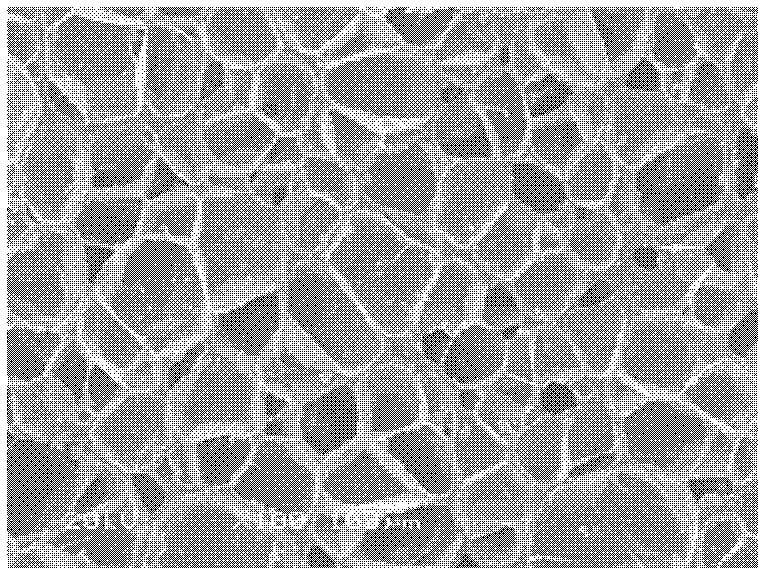

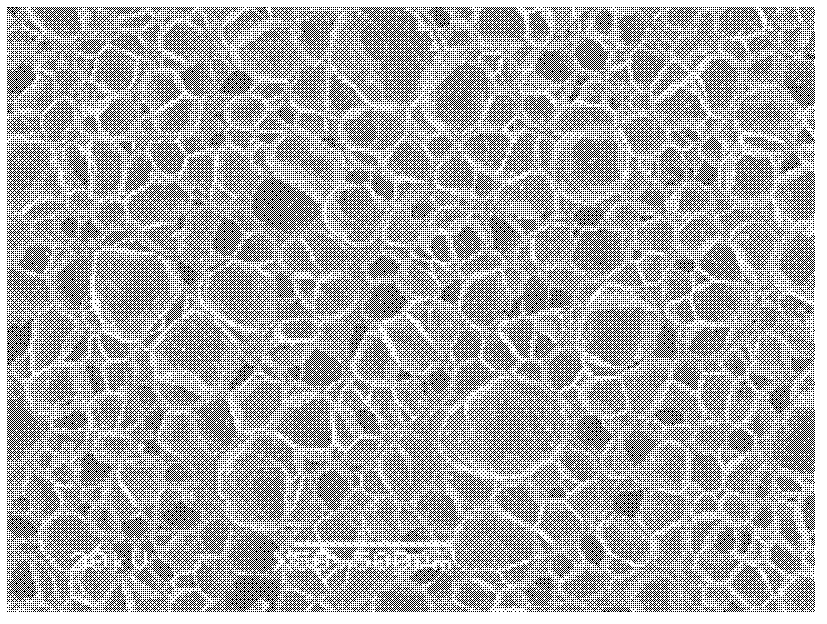

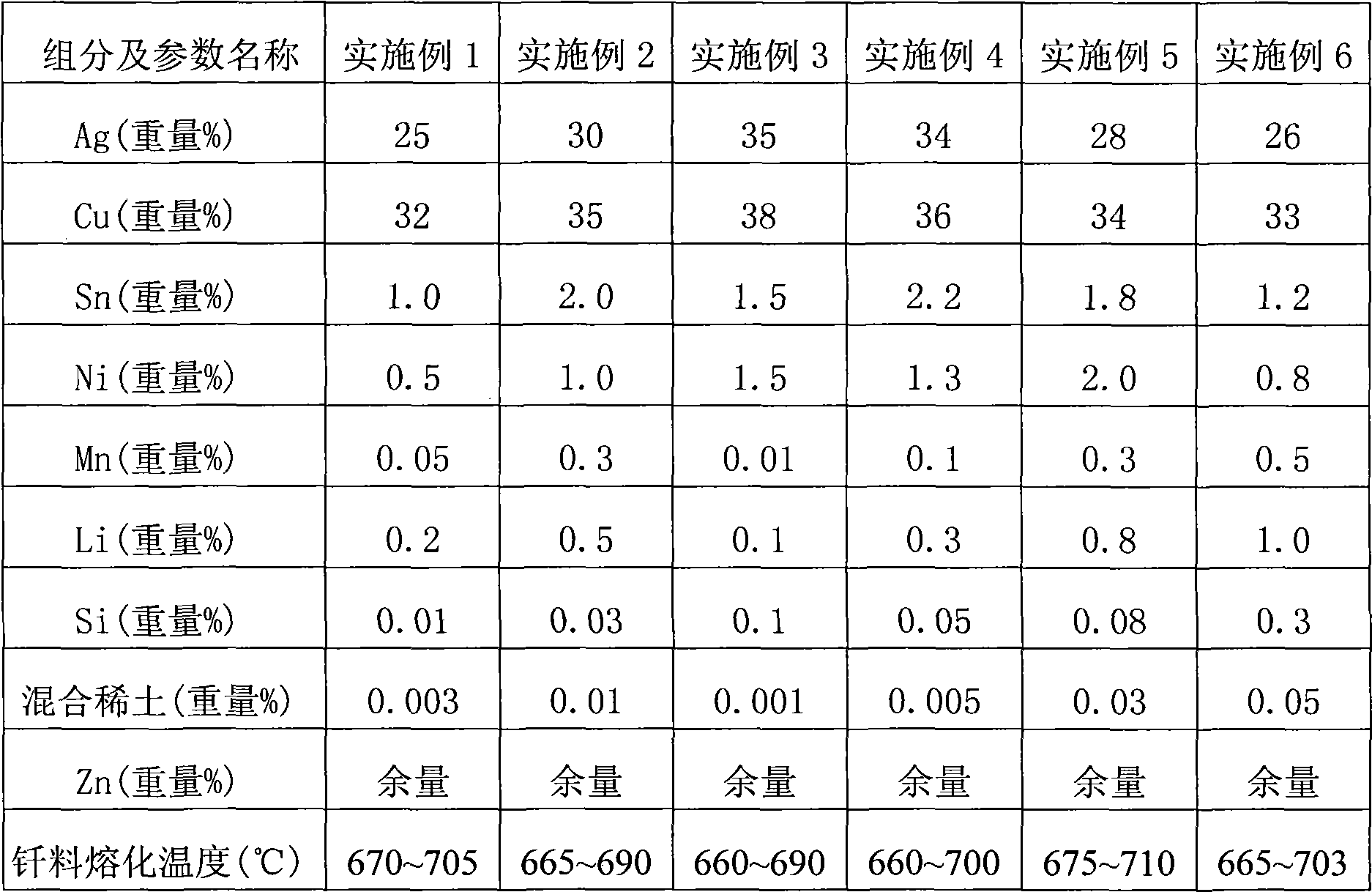

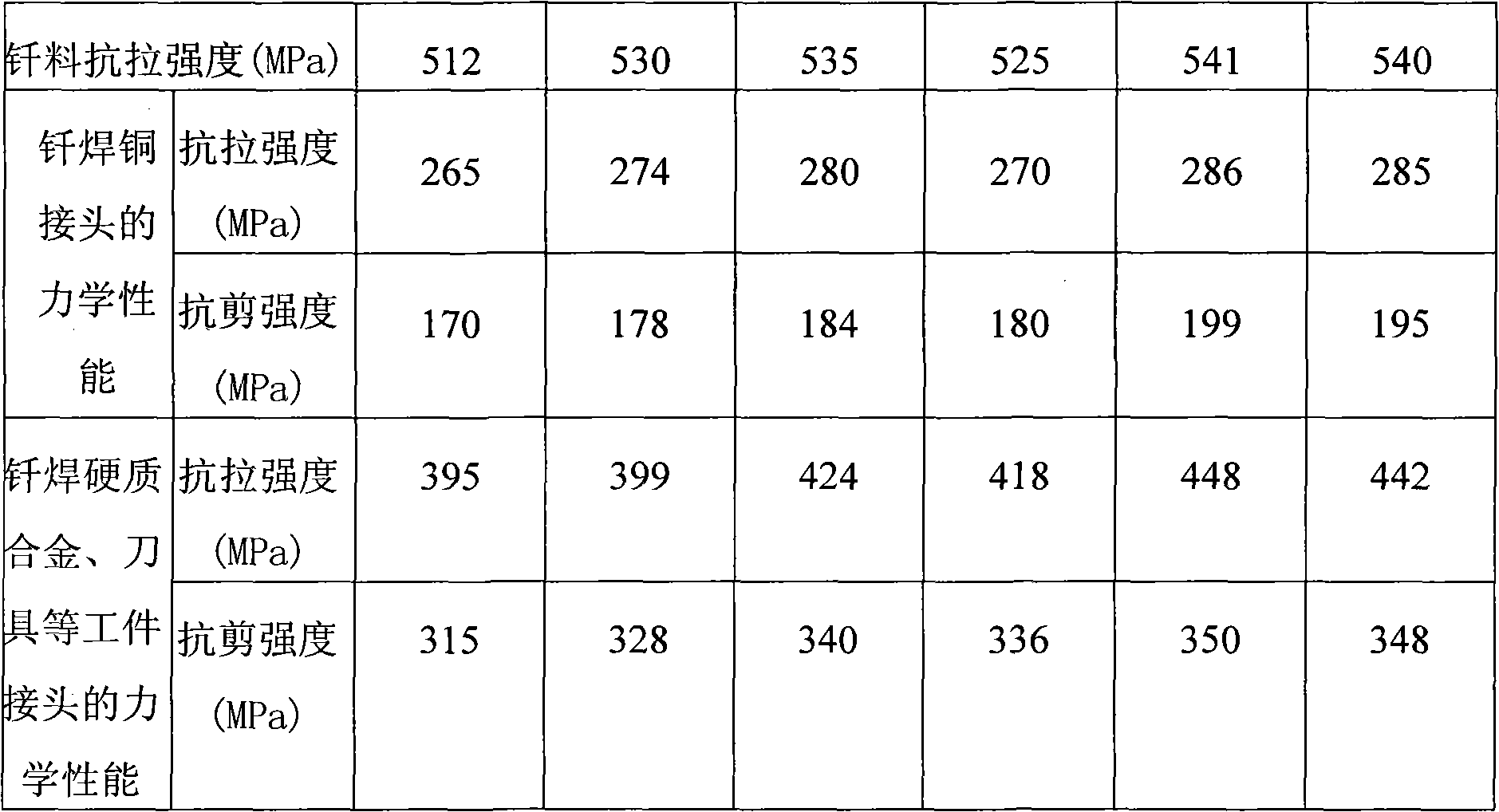

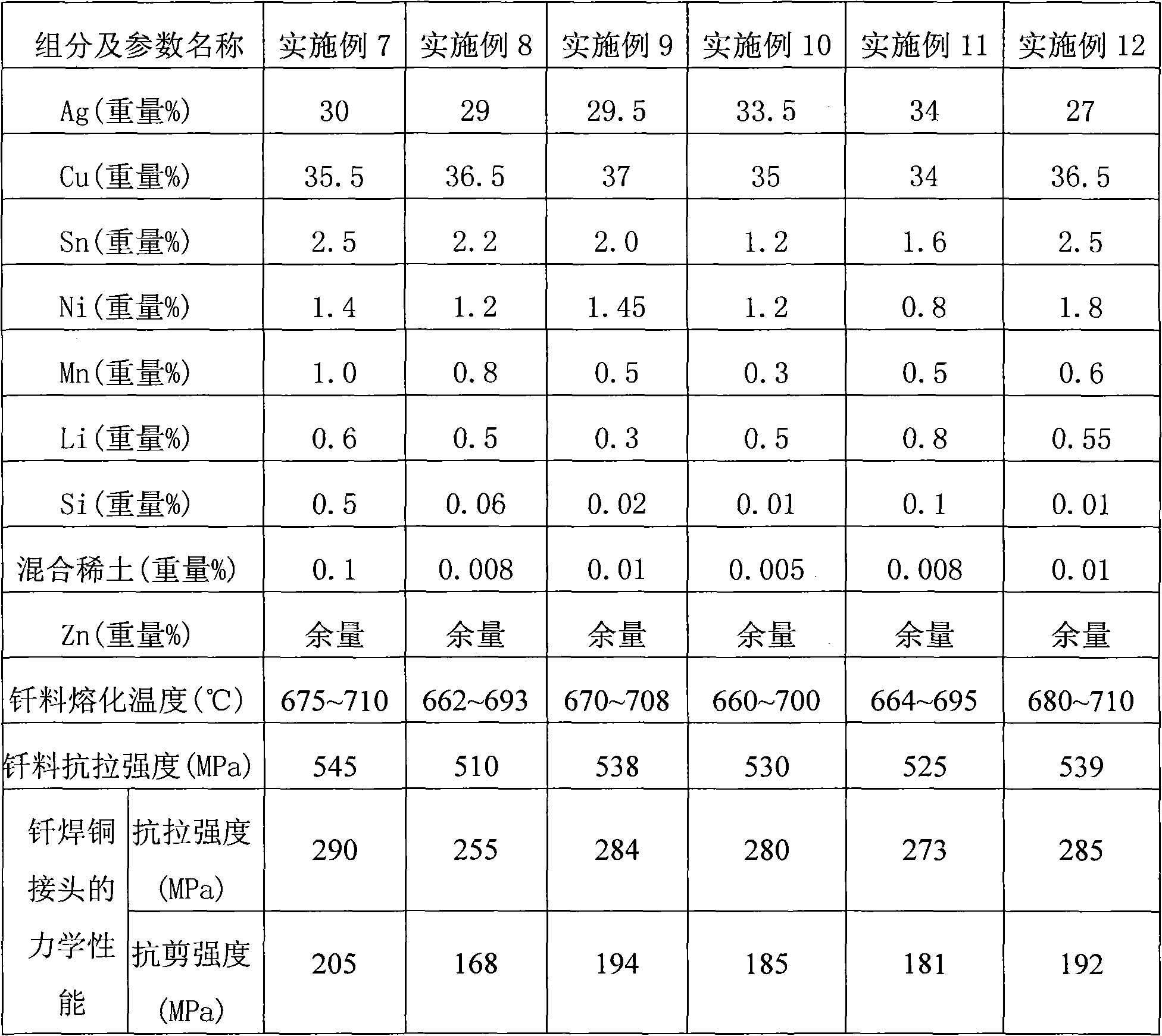

Special rare earth alloy silver-brazing filler metal

ActiveCN101780613AReduce dosageImprove plasticityWelding/cutting media/materialsSoldering mediaCeriumLanthanum

The invention relates to a special rare earth alloy silver-brazing filler metal applied to the brazing of the metal workpieces such as copper and copper alloy, cemented carbide, carbon steel, stainless steel, nickel-based alloy and the like, and belongs to a moderate temperature brazing material. At present, no silver-brazing filler metal has excellent performance and low price, so that the development of the brazing field is obstructed. The special rare earth alloy silver-brazing filler metal comprises the following components in percentage by weight: 25 to 35 percent of Ag, 32 to 38 percent of Cu, 1 to 2.5 percent of Sn, 0.5 to 2.0 percent of Ni, 0.01 to 1 percent of Mn, 0.1 to 1.0 percent of Li, 0.01 to 0.5 percent of Si, 0.001 to 0.1 percent of mixed rare earth, and the balance of Zn, wherein the mixed rare earth consists of lanthanum and cerium. The special rare earth alloy silver-brazing filler metal has the advantages of high cost performance, low fusion temperature of brazing filler metals, good wettability and fluidity, high mechanical strength of soldered joint, and good soldering technological property.

Owner:HANGZHOU HUAGUANG ADVANCED WELDING MATERIALS CO LTD

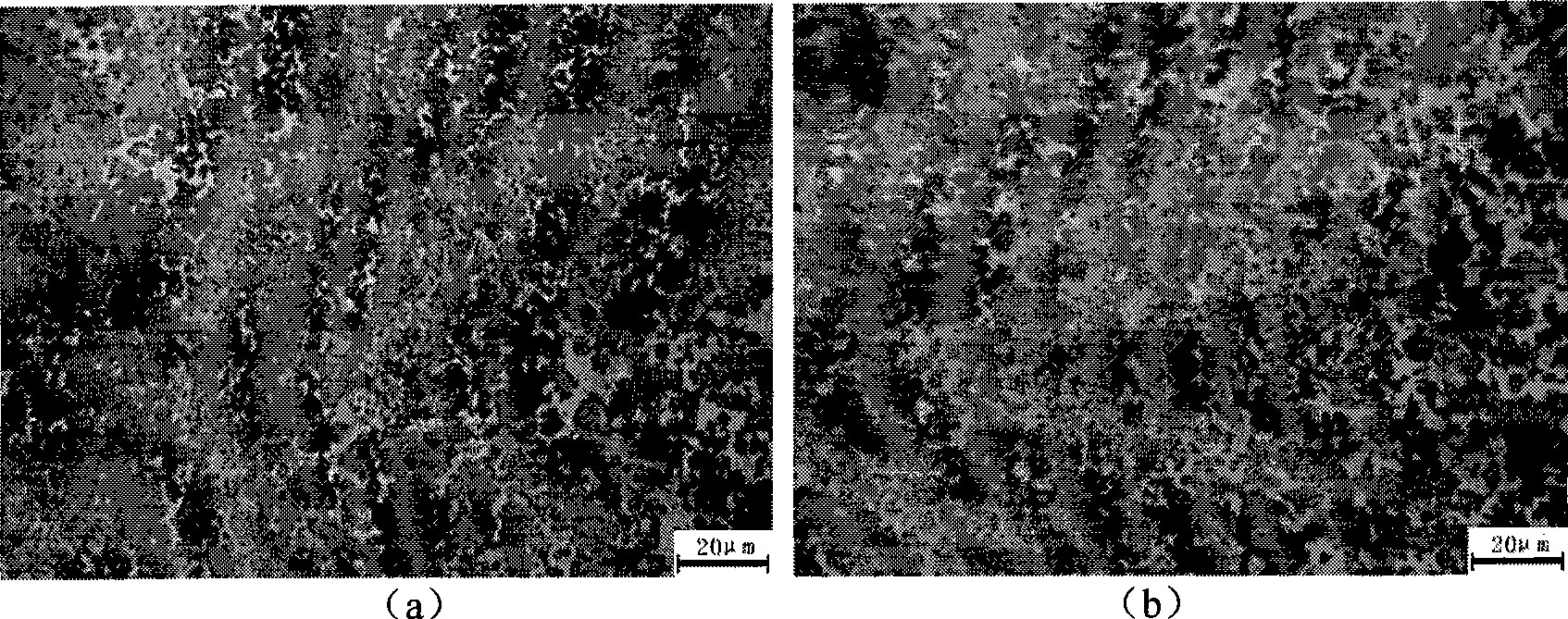

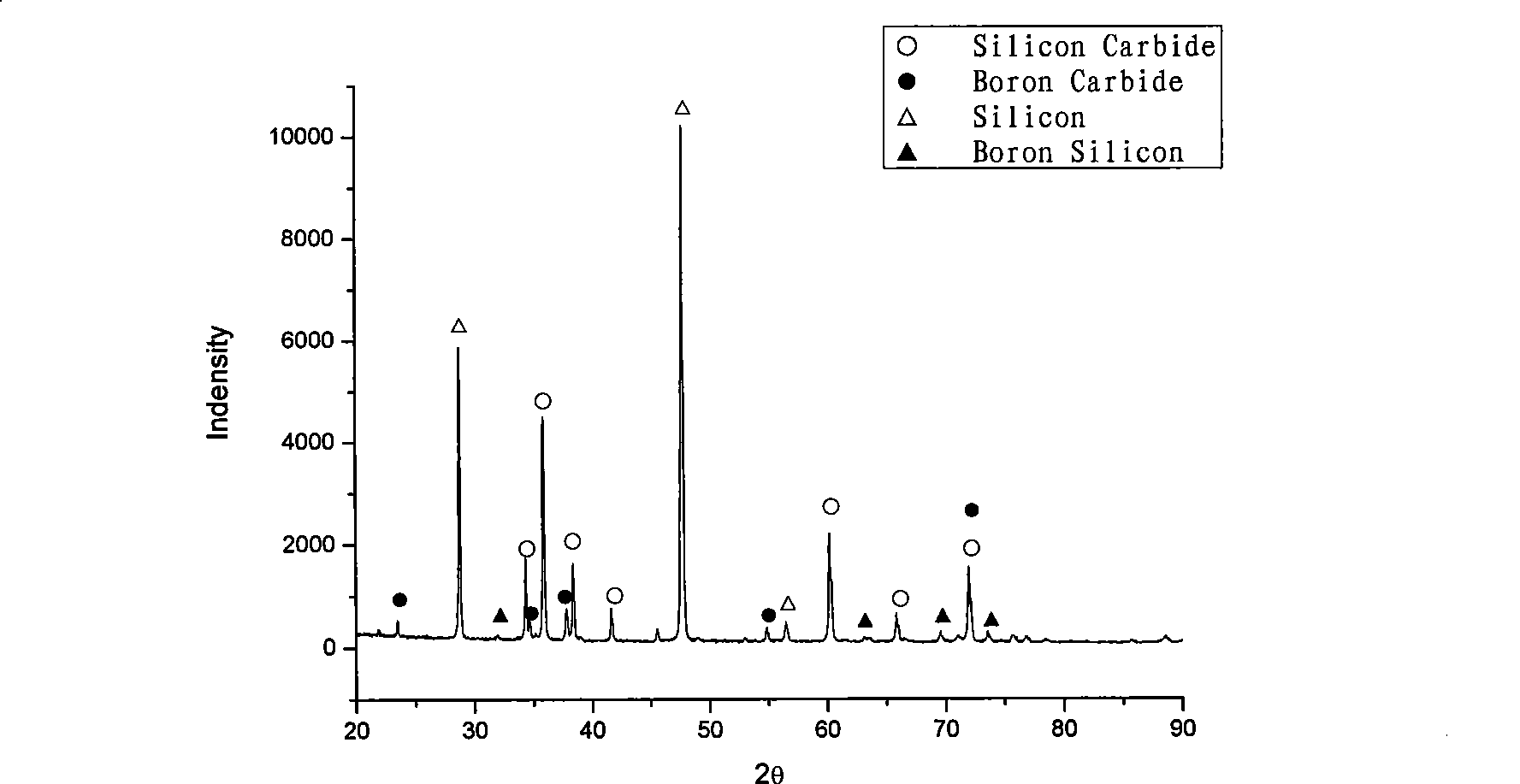

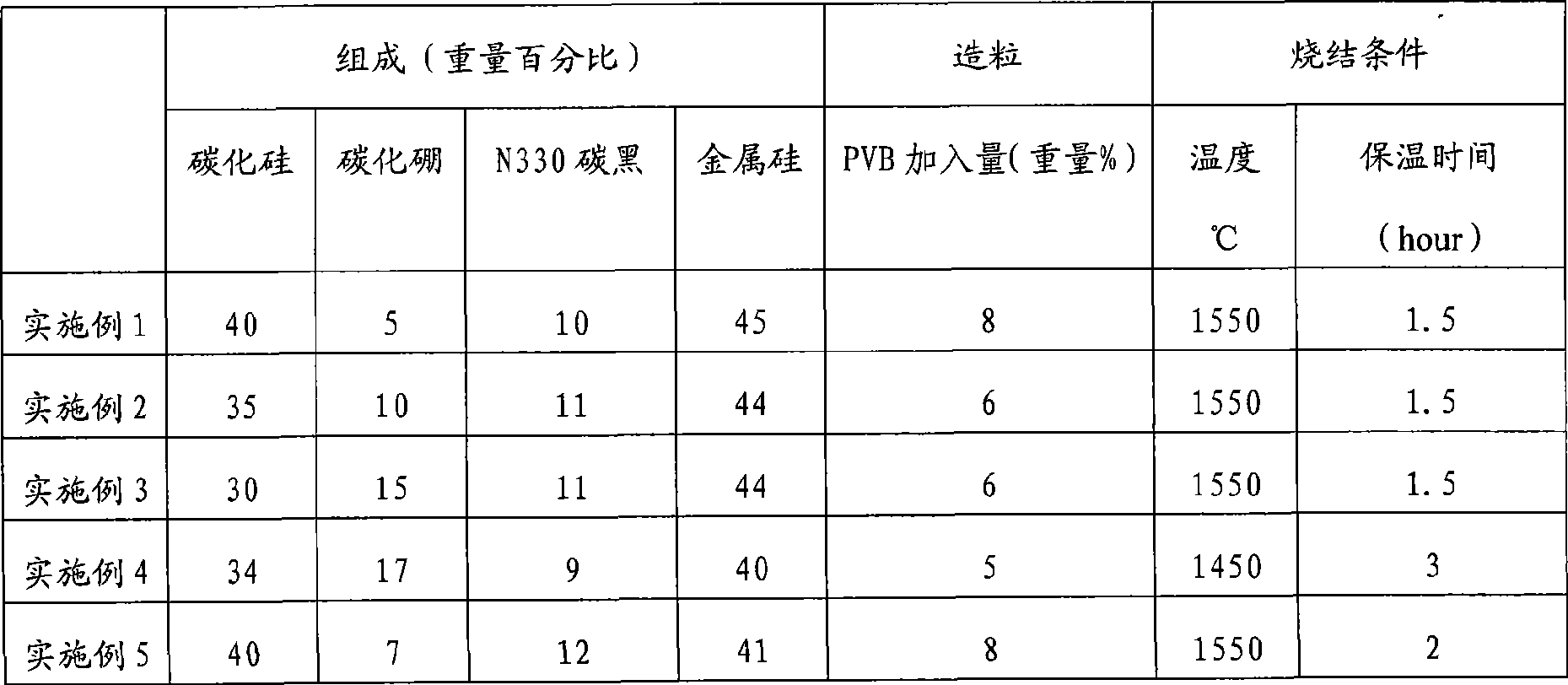

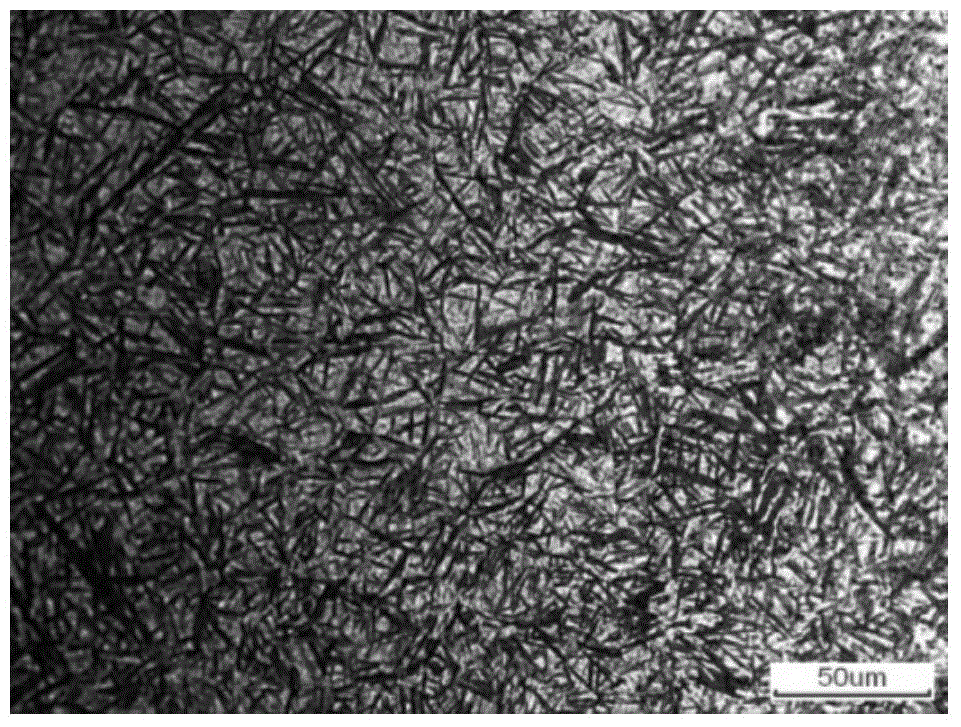

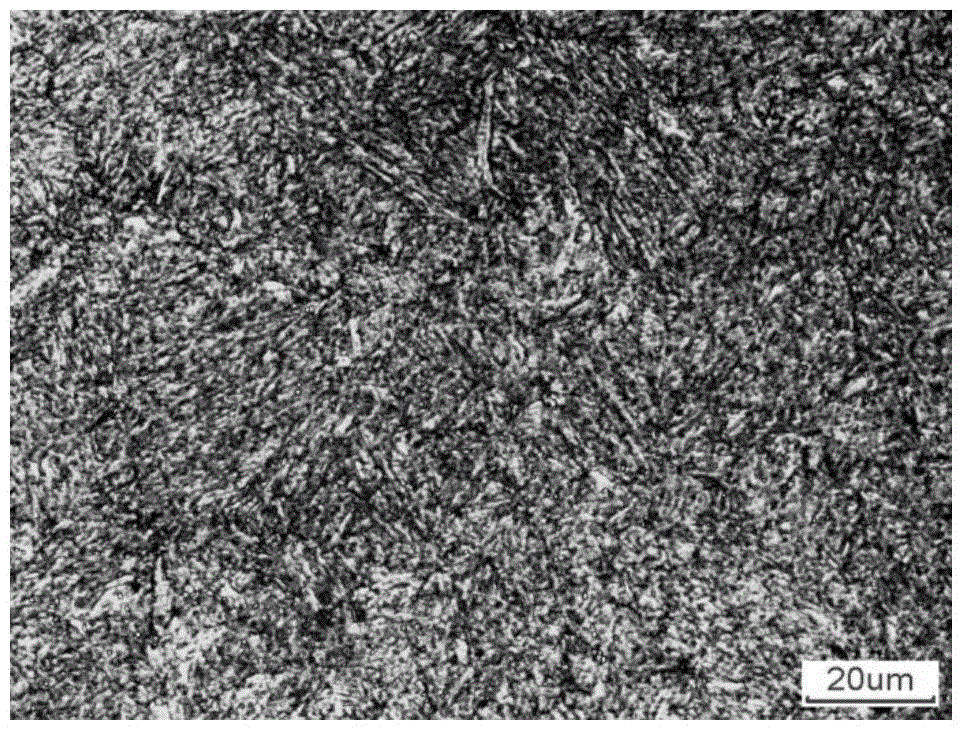

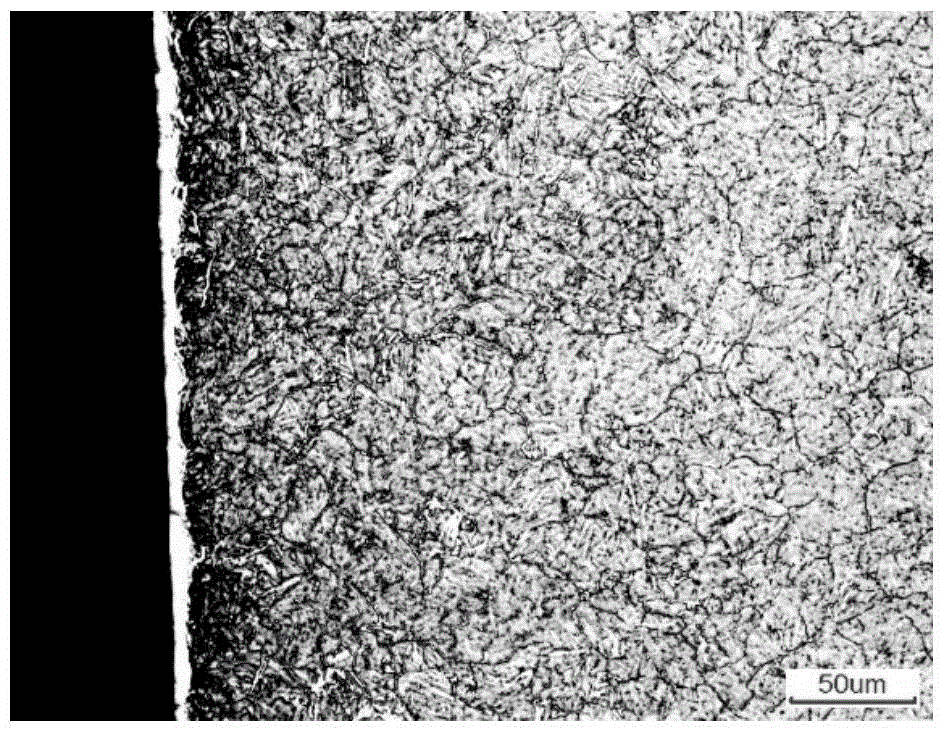

Silicon carbide based reinforced composite ceramic and preparation

The invention discloses a reinforced silicon carbide-based composite ceramic and a preparation method thereof. The composite ceramic is characterized by comprising the following components based on weight percentages: 30%-40% of silicon carbide powder, 5%-17% of boron carbide powder, 9%-12% of nano carbon black and 40%-50% of silicon metal. The method comprises the following steps: firstly, ball milling and wet mixing are performed on the silicon carbide powder, the carbon black and the boron carbide powder to obtain mixed powder, and a bonding agent PVB is added for granulation, die pressing is performed for forming; then the formed green compact is dried and put in an air furnace for binder removal; and finally, the obtained green compact is put into a graphite crucible with silicon powder, and siliconizing and sintering are completed after 1-3h heat preservation at 1450-1550 DEG C under a vacuum environment, thus obtaining a sintering body. The boron carbide particle reinforced reaction sintered silicon carbide composite ceramic prepared by the method can be widely used as a structural material under high-temperature atmosphere and corrosive atmosphere, a frictional wear material and the like; and as the composite ceramic has better obdurability and hardness, the ceramic can be used as a substitute material of the traditional reaction sintered silicon carbide.

Owner:珠海亿特立新材料有限公司

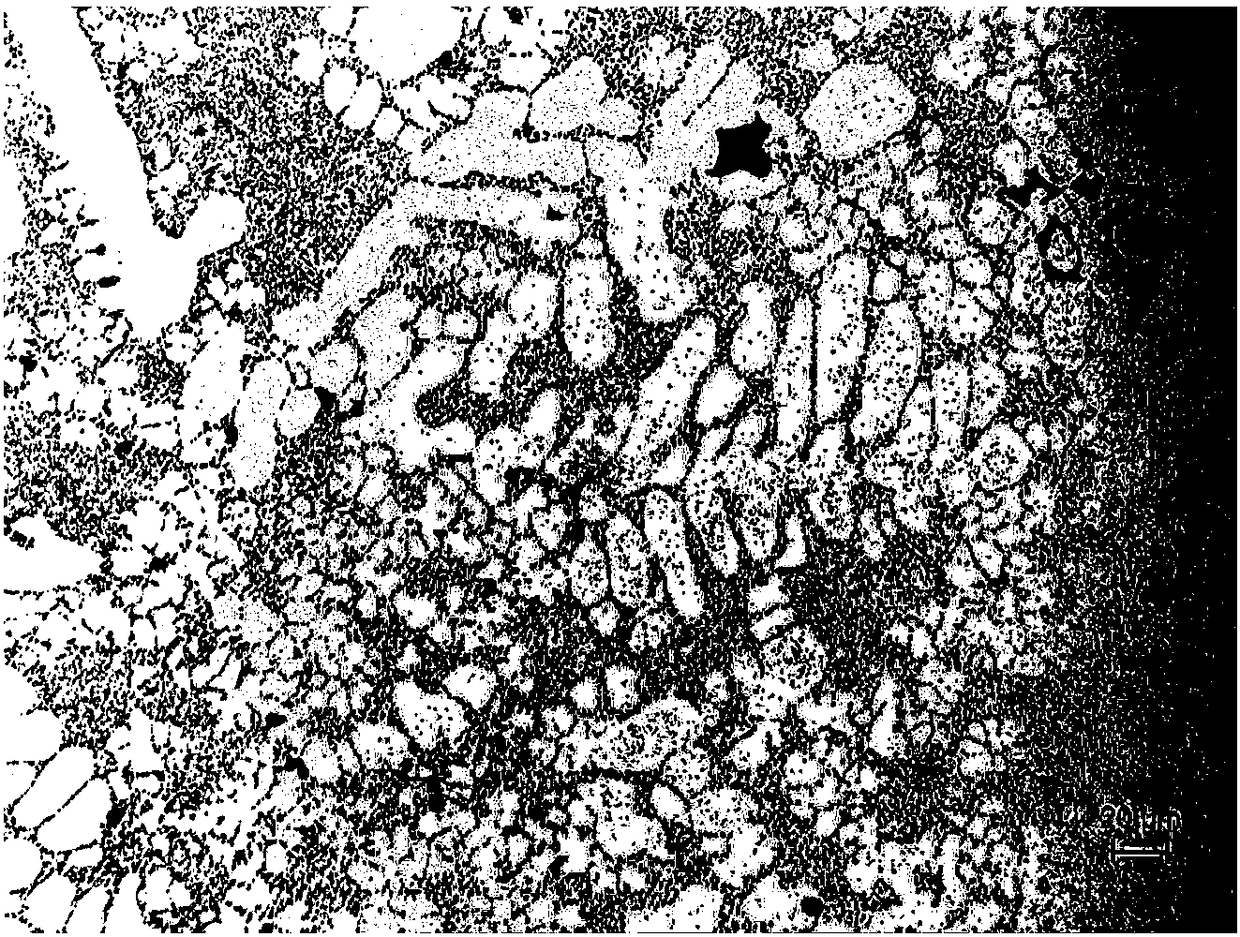

Hot stamping die steel and production method thereof

InactiveCN104928586AImprove the quality of heat treatmentImprove strength and toughnessSolid state diffusion coatingHot stampingHardness

The invention provides hot stamping die steel and a production method thereof. The hot stamping die steel is composed of, by weight, 0.45-0.50% of C, 0.1-0.3% of Si, 0.1-0.3% of Mn, 2.0-2.3% of Cr, 2.3-2.5% of Mo, 0.8-1.0% of V, smaller than or equal to 0.03% of P, smaller than or equal to 0.03% of S and the balance Fe and other inevitable impurities and meets the relational expressions that Mo / Cr=1-1.25 and V / Cr=0.35-0.43. By means of the electroslag remelting process, the ultrafine thermal treatment process, the vacuum thermal treatment process and the plasma nitriding surface treatment process, the produced and obtained hot stamping die steel is low in cost and high in comprehensive performance; the hot stamping die steel has a thermal conductivity coefficient of 34.3 W / m.k, quenching and tempering hardness of 50-53 HRC, ballistic work of 180-210 J, surface hardness of 850-1040 HV0.3 and diffusion thickness of 230-300 microns, and a white bright layer is ceaseless after nitriding.

Owner:BAOSHAN IRON & STEEL CO LTD

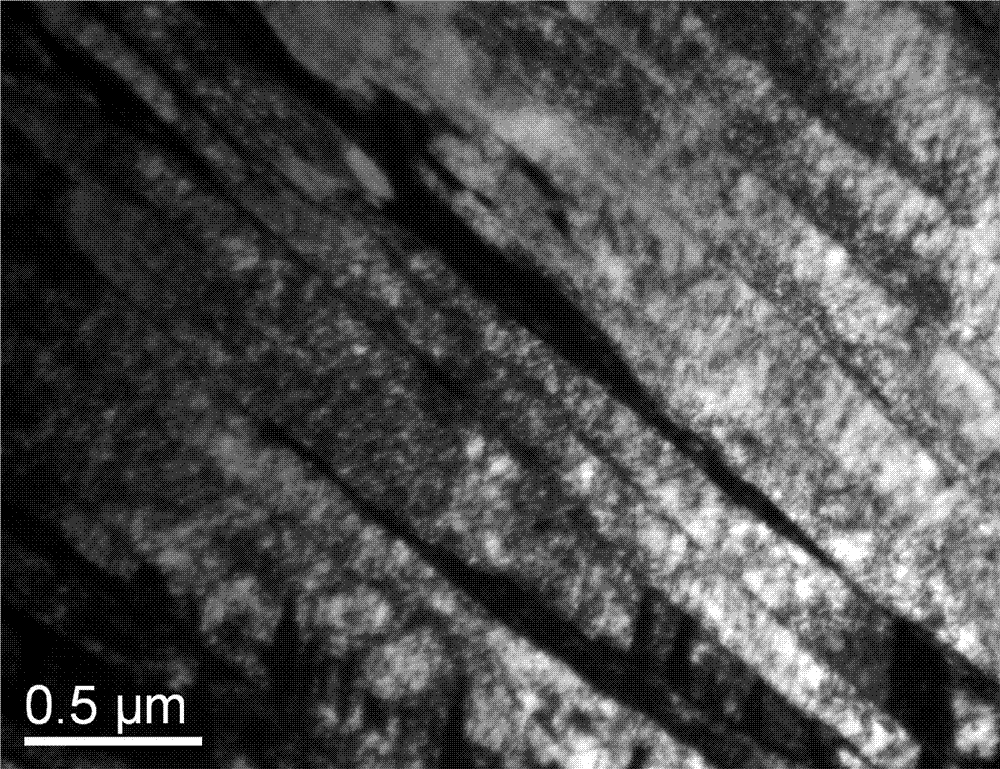

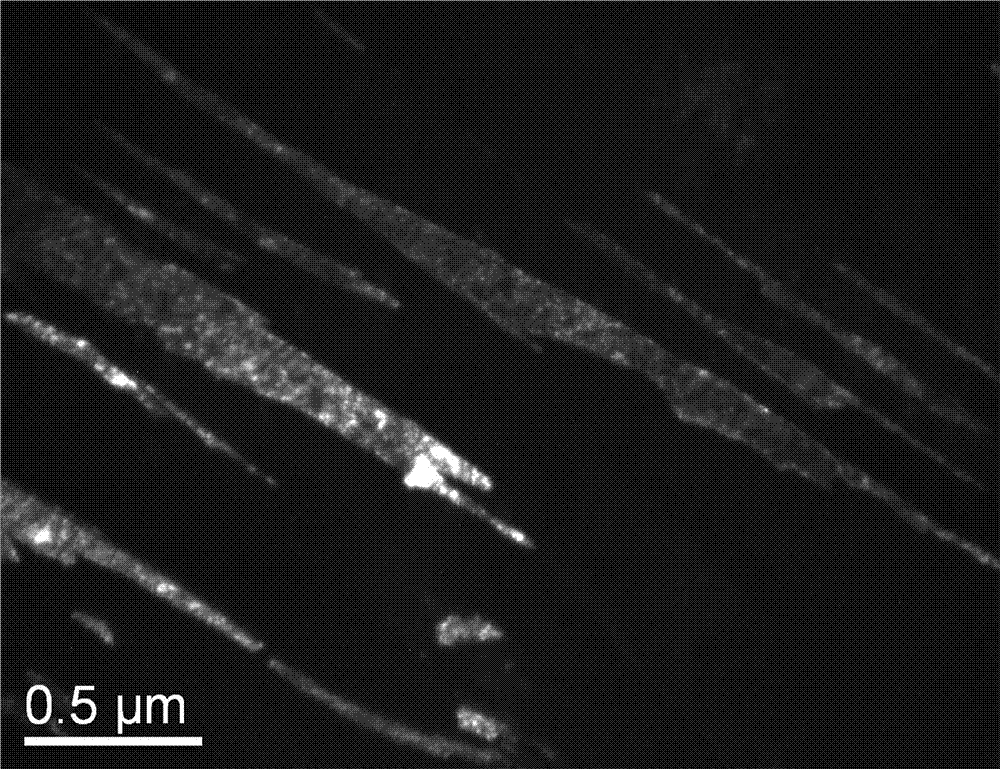

Method for preparing hybrid composite material of carbon fibers/carbon nanotubes/bismaleimide resin

InactiveCN101787128AIncreased interlaminar shear strengthImprove interface strengthFiberCarbon fibers

The invention belongs to the technical field of nano materials, and in particular relates to a method for preparing a hybrid composite material of carbon fibers / carbon nanotubes / bismaleimide resin. The method comprises the following steps: after carboxylating, acylating and chlorinating the surfaces of purified carbon nanotubes and dried carbon fibers, introducing diamine or polyamine with a feature structure thereon, wherein a large amount of the diamine or the polyamine are jointed on the surfaces of the carbon nanotubes and the carbon fibers; performing an addition reaction on the carbon nanotubes jointed with the amidogen and the bismaleimide resin to obtain a carbon nanotubes-containing bismaleimide resin linear block polymer serving as a substrate; and compositing the substrate and the carbon fibers in a certain mode to form a multi-dimensional hybrid composite material structure linked by covalent bonds finally. The method has the advantages of strengthening and toughening bismaleimide by using the strength and the toughness of the carbon nanotubes, improving the bonding strength between the bismaleimide and the carbon fiber substrate surface, improving overall performance of the multi-dimensional hybrid composite material of the carbon fibers / the carbon nanotubes / the bismaleimide resin, and widening the application of the carbon fibers, the carbon nanotubes and the bismaleimide resin.

Owner:TONGJI UNIV

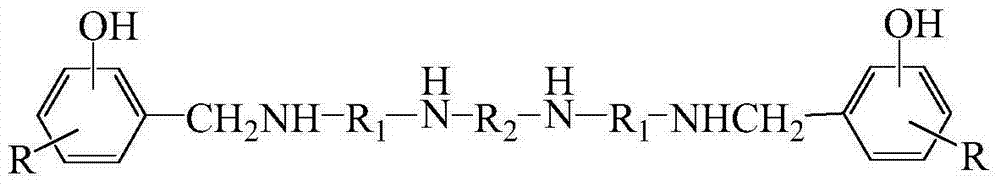

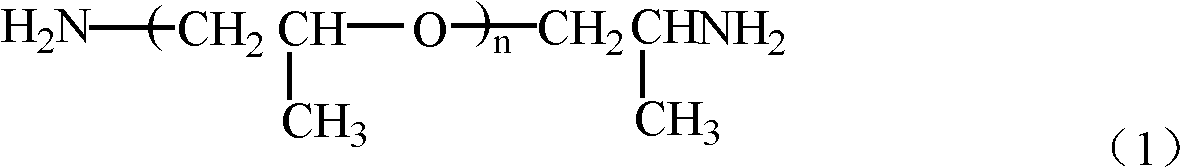

Nonionic self-emulsifying water-based epoxy curing agent with Gemini surfactant structure and preparation method thereof

InactiveCN104262589AThe synthesis process is simpleThe synthesis process is simple and controllableOrganic compound preparationAmino-hyroxy compound preparationWater basedEpoxy

The invention discloses a nonionic self-emulsifying water-based epoxy curing agent with Gemini surfactant structure, of which the molecular general formula is disclosed in the specification. The preparation method comprises the following steps: 1) adding alkyl phenol, polyamine and formalin in a solvent to carry out Mannich reaction, and removing the solvent and byproduct after the reaction finishes, thereby obtaining Mannich amine containing primary amine group; and 2) sufficiently reacting the Mannich amine containing primary amine group with diglycidyl ether, cooling after the reaction finishes, adding water, and sufficiently dispersing to obtain an emulsion, thereby obtaining the product. The synthesis technique is simple and pollution-free; the synthesized curing agent does not need to perform salification reaction to implement self-emulsifying action by using organic acid; the epoxy curing agent has the advantages in the Gemini surfactant and has the characteristics of excellent wettability, excellent emulsibility, excellent stability and the like; and the epoxy curing agent can directly emulsify and cure the liquid epoxy resin, and can also cure an epoxy resin dispersion solution.

Owner:GUANGZHOU SUPER CHEM COATING CO LTDGUANGZHOU SUPER CHEM COATING CO LTD

Aluminum alloy material suitable for vacuum low-speed die-casting method

The invention relates to an aluminum alloy material suitable for a vacuum low-speed die-casting method. The aluminum alloy material comprises the following components of, by weight, 4.5-12.5% of silicon (Si), 0.2-2.5% of copper (Cu), 0.15-0.55% magnesium (Mg), less than 0.8% of iron (Fe), less than 0.5 % of manganese (Mn), less than 0.3% of chromium (Cr), and 0.05-0.2% of titanium (Ti); and the aluminum alloy material comprises, by weight, iron, manganese and chromium satisfying the formula that the sum of Fe, 2Mn and 3Cr is greater than 0.5% and smaller than 1.2%, no more than 0.2% of zirconium, no more than 0.15% of vanadium, no more than 0. 15 % of niobium, no more than 0.10 % of one or more of strontium, sodium and antimony, other elements with the weight of each element being less than 0.04% and the total weight being less than 0.12%, and the balance aluminum.

Owner:山东弗泽瑞金属科技有限公司 +1

High low-temperature impact toughness thick steel plates for hydrogen-contacting equipment and production method thereof

ActiveCN102605297AImprove strength and toughnessMeet manufacturing requirementsFurnace typesHeat treatment furnacesHydrogenWater flow

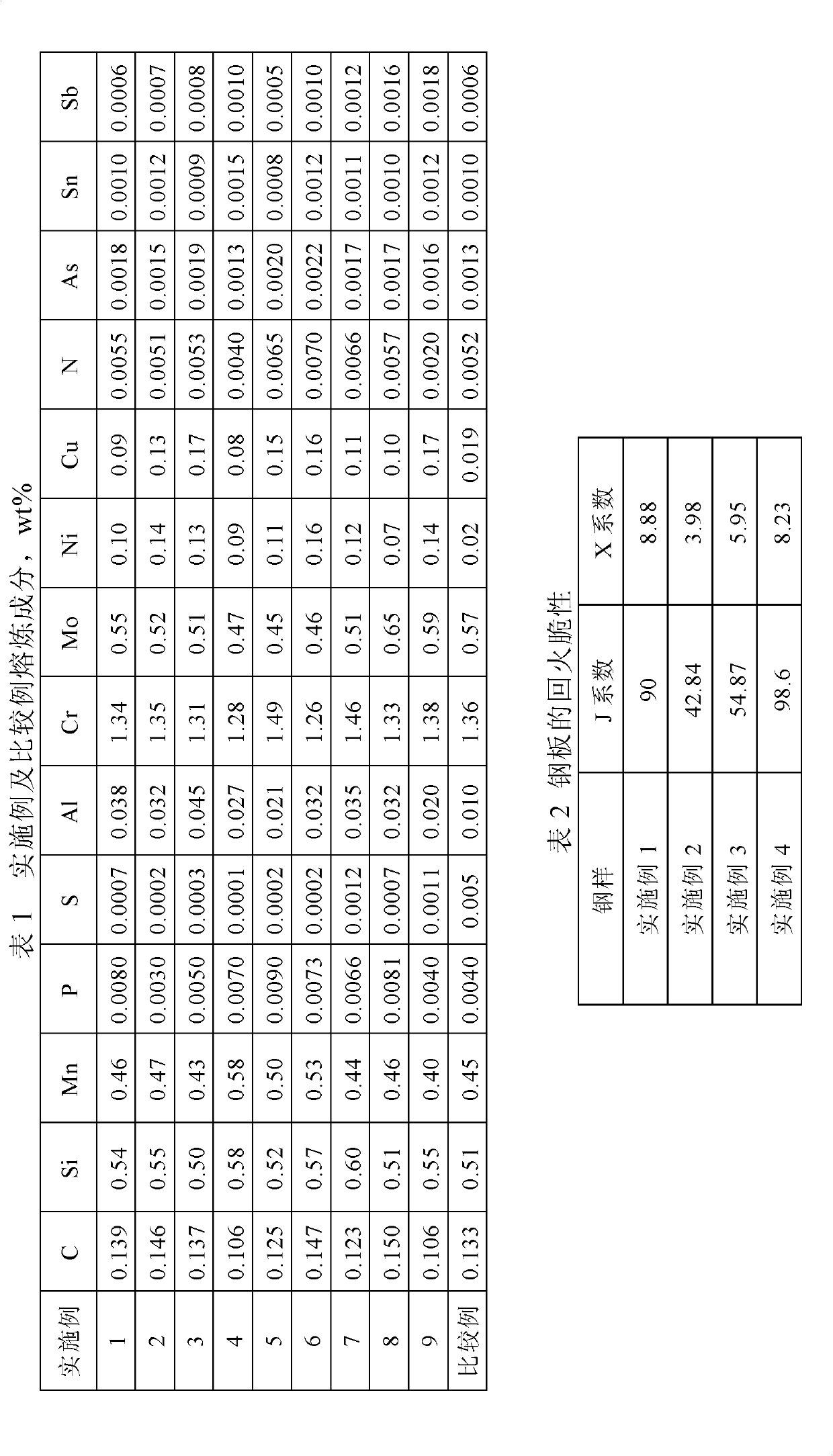

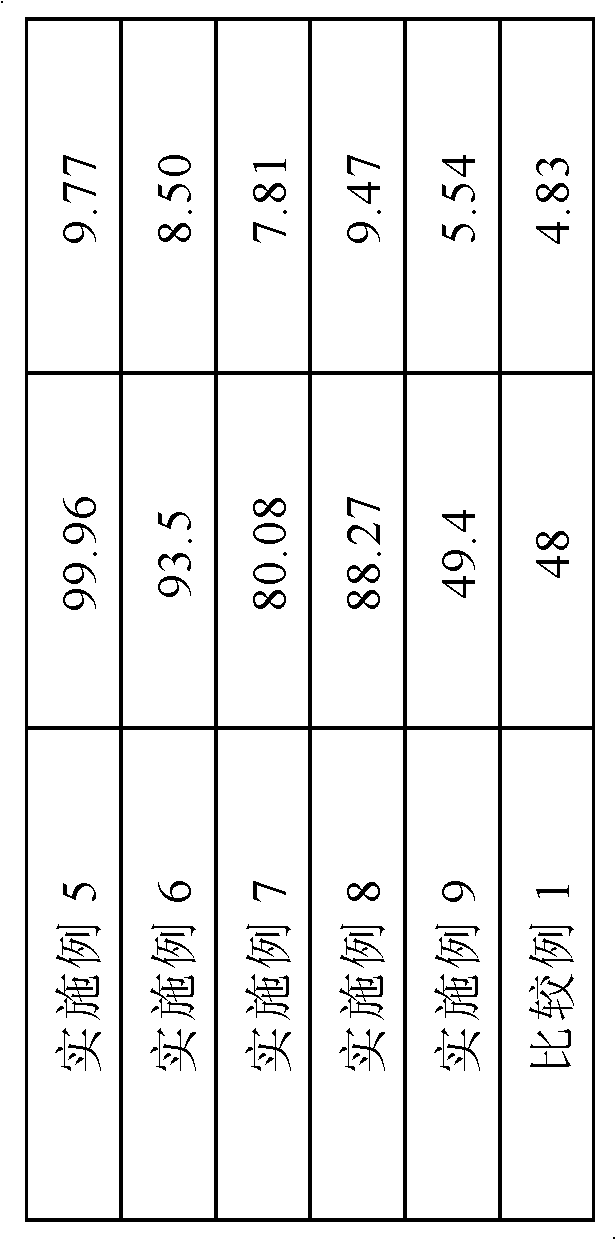

Disclosed are high low-temperature impact toughness thick steel plates for hydrogen-contacting equipment and a production method thereof. The production method includes the steps: firstly, smelting and casting; secondly, heating plate blanks at 1070-1210 DEG C and rolling the plate blanks according to a compression ratio of 2.7-6.4; thirdly, normalizing within an austenitization temperature range; fourthly, accelerated cooling with water for 4-15 minutes; and fifthly, tempering at 700-750 DEG C; and sixthly cooling, wherein the steel plates comprise, in weight percentage, 0.10-0.15% of C, 0.50-0.60% of Si, 0.40-0.60% of Mn, not more than 0.010% of P, not more than 0.003% of S, 1.25-1.50% of Cr, 0.45-0.65% of Mo, 0.08-0.18% of Cu, 0.07-0.17% of Ni, 0.020-0.045% of Al, not more than 0.003% of Sn, not more than 0.003% of Sb, not more than 0.003% of As, 0.0020-0.0070% of N, the balance of Fe and unavoidable impurities, low-pressure section water flow of a pressure quenching machine is 18-38m<3> / min, top-to-bottom water volume ratio of each steel plate is 1:1.0-1.3, and the surface temperature of the steel palate at an outlet of the pressure quenching machine is not more than 120 DEG C.

Owner:BAOSHAN IRON & STEEL CO LTD

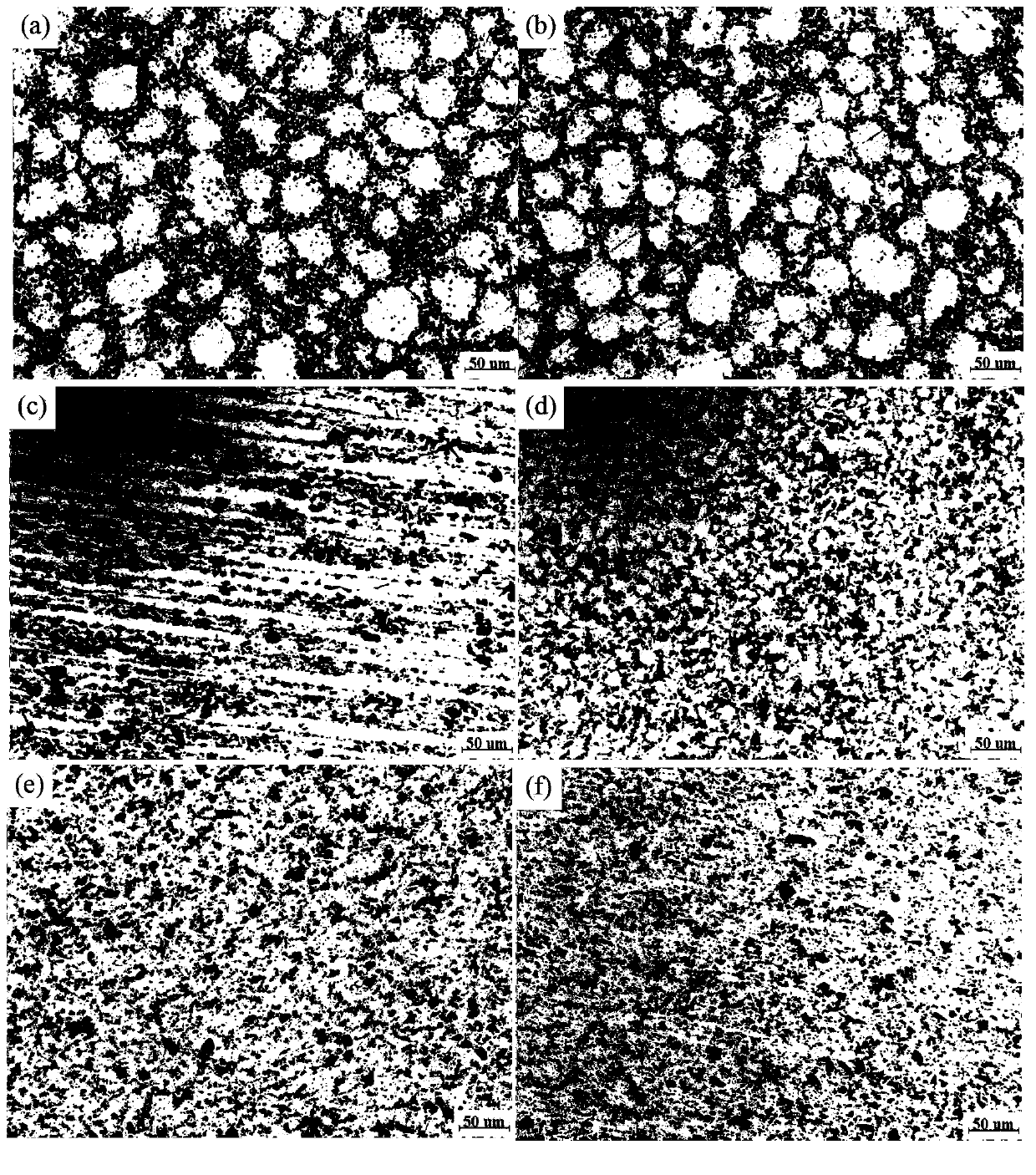

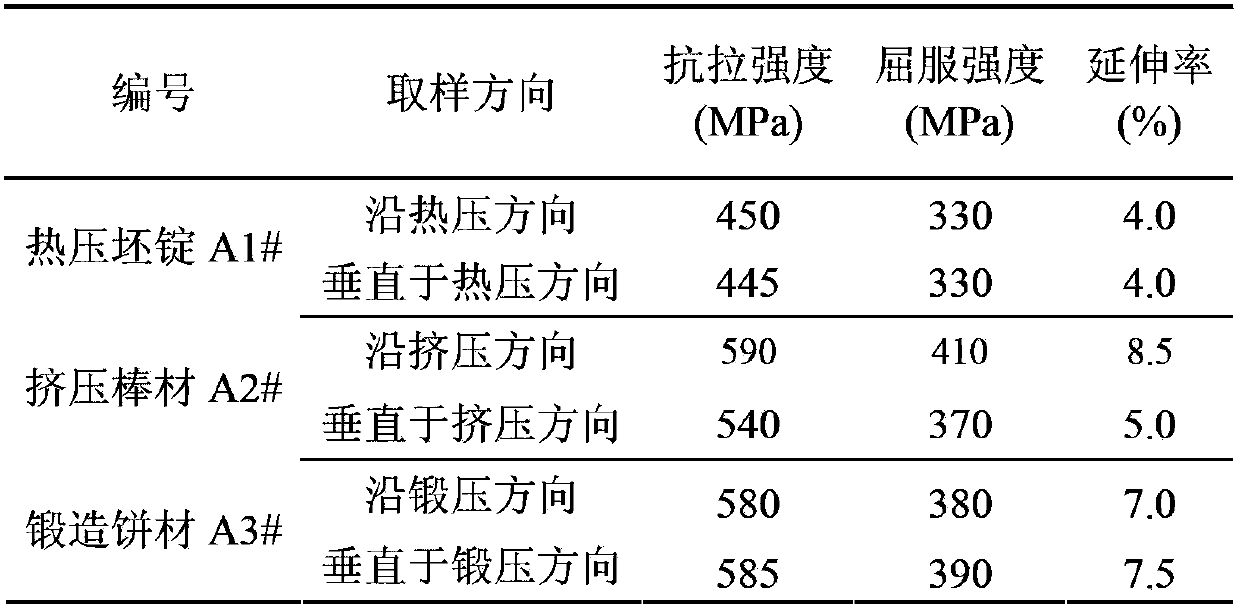

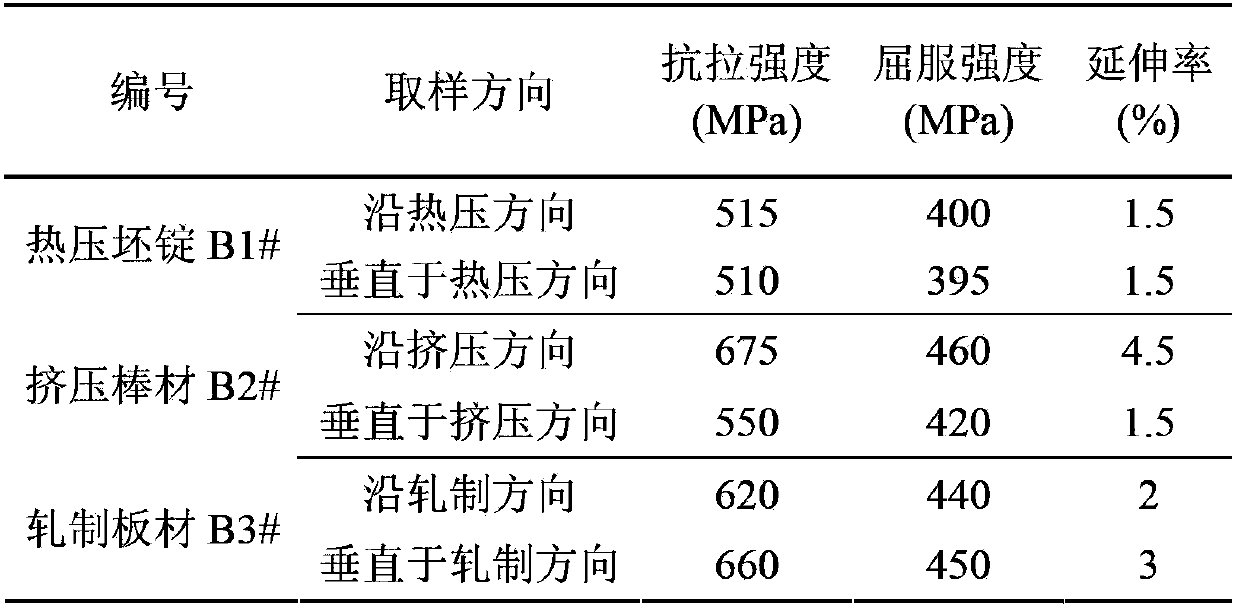

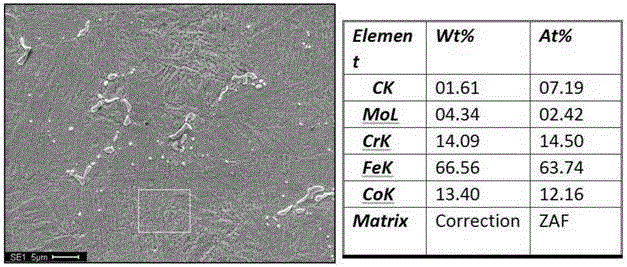

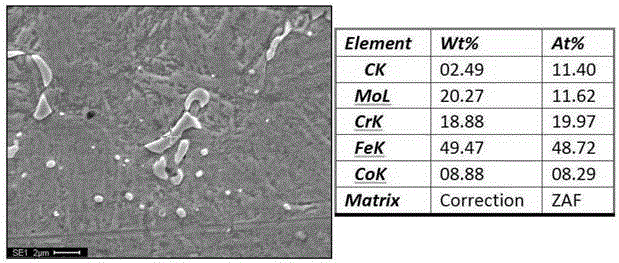

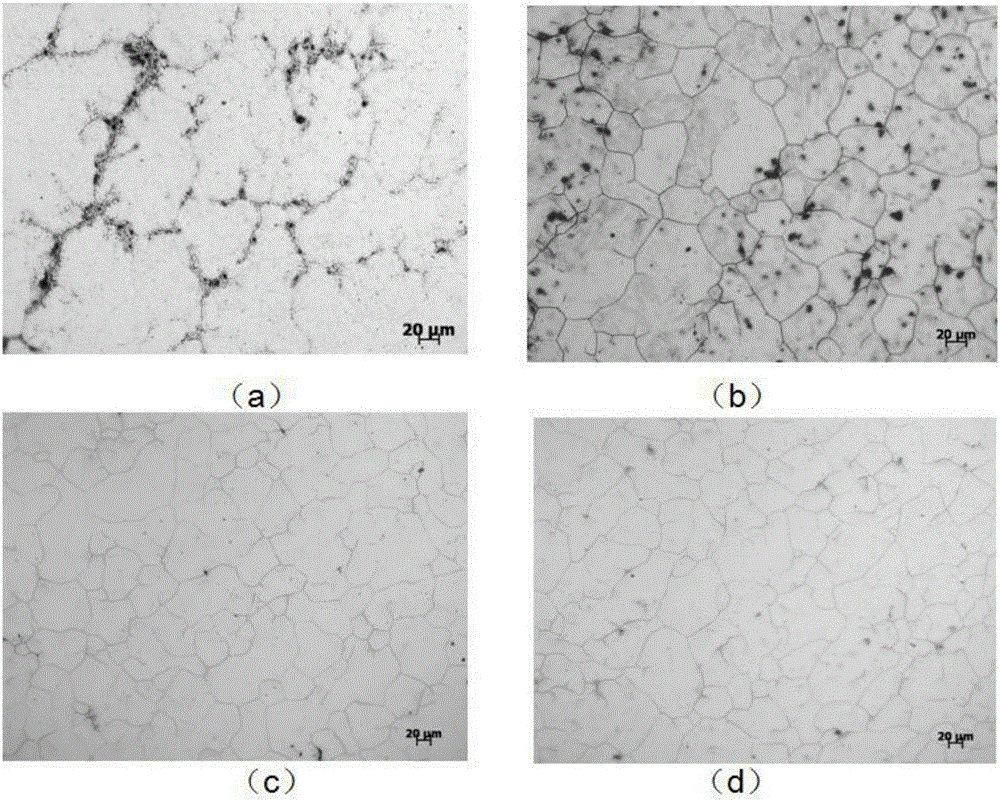

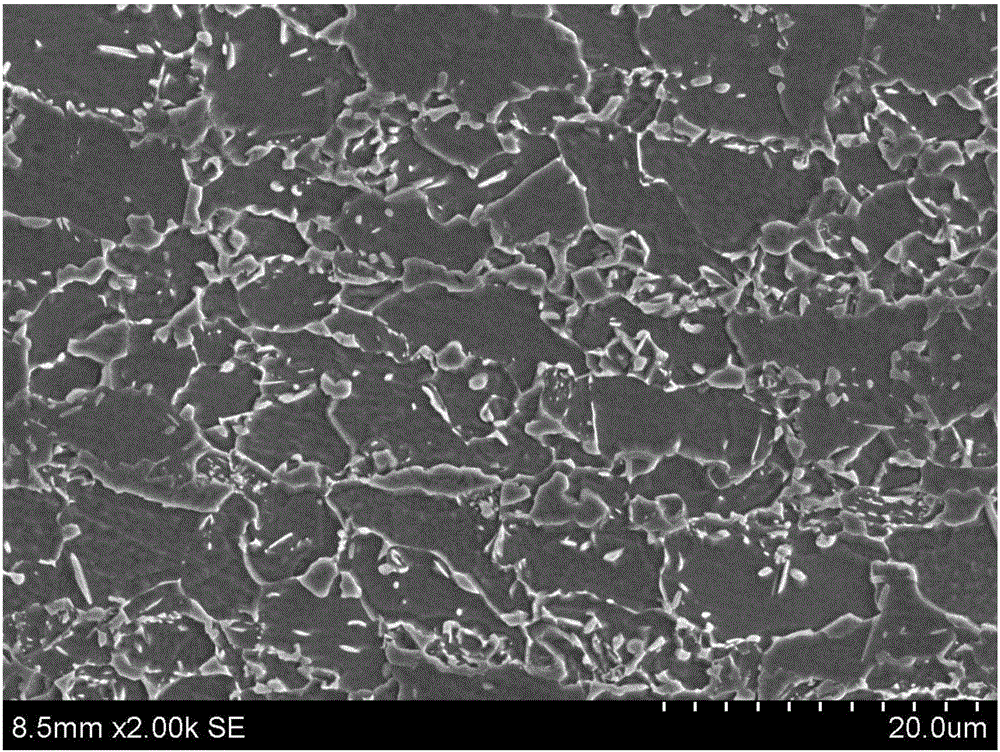

Isotropical high-strength high-toughness particle reinforced aluminium-based composite material and preparation method thereof

InactiveCN103866165AGuaranteed isotropyGuarantees the isotropy of the composite materialGranularityHigh intensity

The invention relates to isotropical high-strength high-toughness particle reinforced aluminium-based composite material and a preparation method thereof. In the composite material, the granularity of reinforced particles is 1-25 mu m, the volume percentage is 5%-30%, the reinforced particles are dispersed and distributed in a substrate in the aspect of space, and the reinforced particles and the substrate form high-strength interface combination. The preparation method comprises adding the reinforced particles and aluminium alloy powder into a material mixing barrel for mechanical mixing, so as to obtain a composite material, then performing vacuum hot pressing on the composite material to form preform bodies, and successively performing extrusion, forging and rolling on the preform bodies for deformation. The prepared composite material can be used as bearing members with complex stress in the aerospace field. The product is characterized in that the material has excellent properties such as isotropical property, high strength, high toughness and the like, and is stable in quality, low in cost, easy for large-scale industrial production, and the like.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Method for manufacturing X100 pipeline steel submerged arc straight weld pipe

ActiveCN101205597AIncrease productivityImprove molding qualityArc welding apparatusWelding/cutting media/materialsSteel tubeSteel plates

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

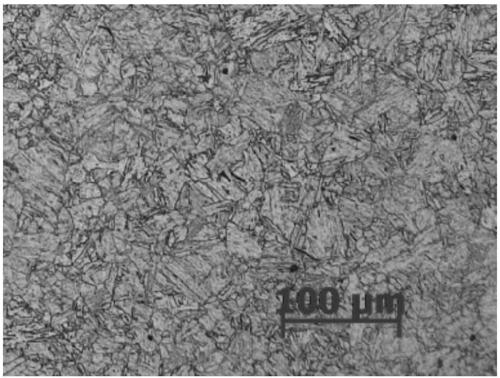

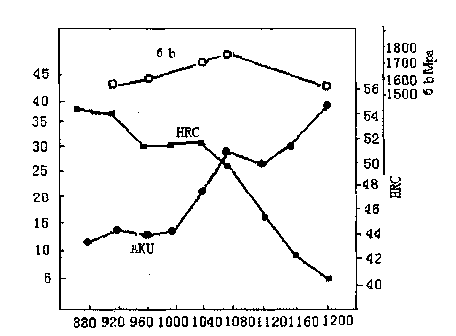

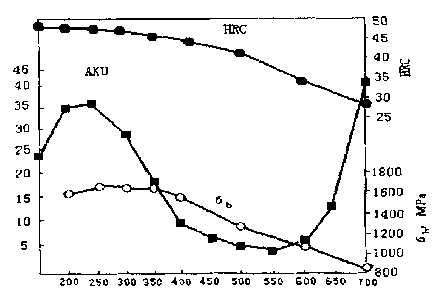

Heat treatment method for maraging stainless steel

The invention aims at providing a heat treatment method for maraging stainless steel. The heat treatment method is characterized by comprising the following steps of performing solution treatment on the maraging stainless steel at the temperature of 1100 to 1250DEG C for 40 to 90 minutes, and performing water cooling; then performing cryogenic treatment; and finally, performing ageing treatment for two times at the temperature of 500 to 580DEG C, insulating for 1 to 2 hours each time, and performing air cooling to room temperature. For an alloy treated by adopting the method, the tensile strength reaches 1900Mpa, the impact toughness reaches ak60J / cm<2>, the hardness is HRC50, and the strength and the toughness are well matched.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Super-high-strength martensite aging stainless steel resistant to seawater corrosion

ActiveCN107653421AGuaranteed toughnessGuaranteed corrosion resistanceChemical compositionHigh intensity

The invention belongs to the field of high-strength stainless steel and provides martensite aging stainless steel which is high in toughness and good in corrosion resistance. The strength of the martensite aging stainless steel reaches 2000 MPa or above. The specific chemical constituents of the martensite aging stainless steel comprise, by weight percentage, less than or equal to 0.03% of C, 13.0-14.0% of Cr, 5.5-7.0% of Ni, 5.5-7.5% of Co, 3.0-5.0% of Mo, 1.9-2.5% of Ti, less than or equal to 0.1% of Si, less than or equal to 0.1% of Mn, less than or equal to 0.01% of P, less than or equal to 0.01% of S and the balance Fe. The stainless steel has the excellent seawater corrosion resistance; the pitting potential Epit is greater than or equal to 0.15 V, and high tough fit is achieved; sigma b is greater than or equal to 2000 MPa, sigma 0.2 is greater than or equal to 1700 MPa, delta is greater than or equal to 8%, and psi is greater than or equal to 40%; the martensite aging stainlesssteel is applicable to manufacturing of high-strength and high-toughness structural components used in a chloridion-containing rigorous corrosion environment such as seawater; the content of preciousmetal Co in the steel is low; material production cost is effectively lowered; and wide application prospect is achieved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

Preparation method of glass fiber/carbon nanotube/epoxy resin multi-dimensional hybrid composite material

InactiveCN102276795AIncreased interlaminar shear strengthImprove interface strengthResin matrixCarbon nanotube

The invention relates to a preparation method of a glass fiber / carbon nanotube / epoxy resin multi-dimensional hybrid composite material. The preparation method provided by the invention comprises the following steps of: treating glass fiber with a silane coupling agent; carrying out surface carboxylation and chlorination on carbon nanotubes, then introducing diamine or polyamine to the carbon nanotubes, and modifying the carbon nanotubes connected with an amino group by a polybasic anhydride compound to prepare the carbon nanotubes carrying an anhydride group; dispersing the treated carbon nanotubes in an epoxy resin matrix by ultrasonic oscillation and high-speed stirring, and curing with an organic anhydride curing agent; and compounding the obtained carbon-nanotube-containing epoxy resin polymer used as a matrix with the coupling-agent-treated glass fiber to form a multi-dimensional hybrid composite material structure linked through covalent bonds. The preparation method provided by the invention has the advantages that: the composite material is convenient to prepare, the dispersion of the carbon nanotubes in epoxy resin is improved, and the strength and toughness of the carbon nanotubes are utilized to toughen epoxy resin and to improve the bonding strength with the base surface of the glass fiber, thereby enhancing the overall performance of the glass fiber / carbon nanotube / epoxy resin multi-dimensional hybrid composite material and broadening the applications of the glass fiber, carbon nanotubes and epoxy resin.

Owner:TONGJI UNIV

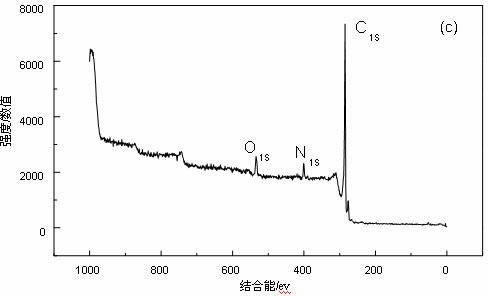

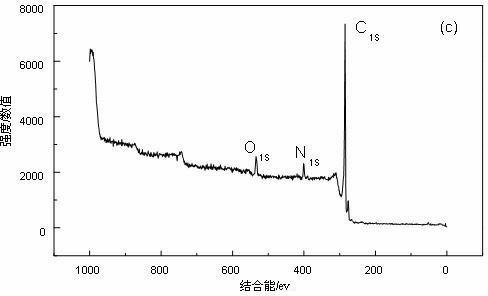

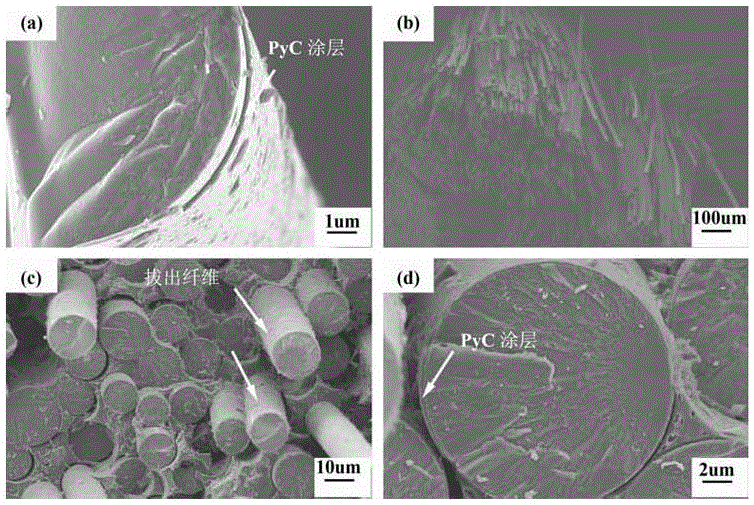

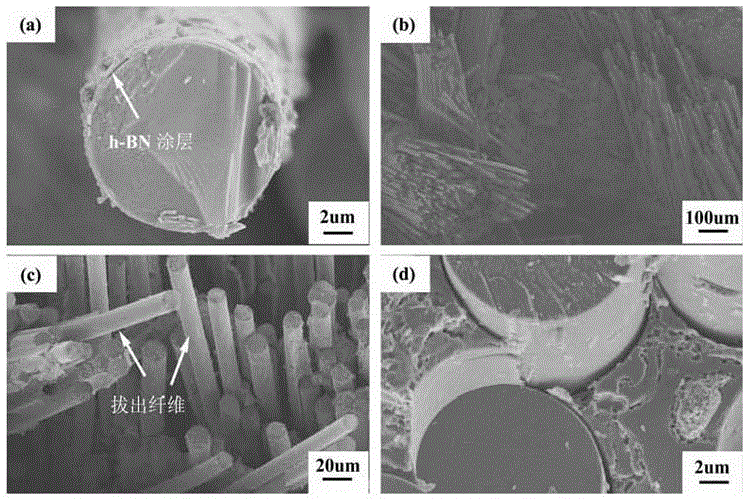

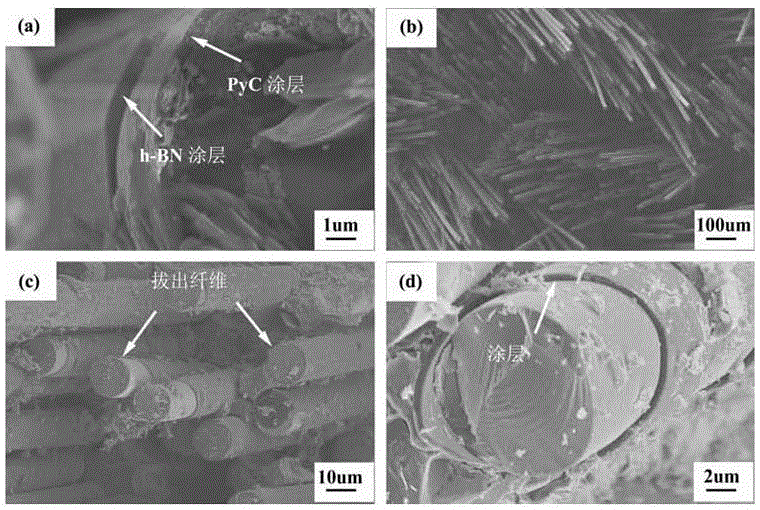

Interface modification method of SiCf/SiC composite material

ActiveCN105152671AImprove bending strengthImprove fracture toughnessSic fiberUltimate tensile strength

Owner:NAT UNIV OF DEFENSE TECH

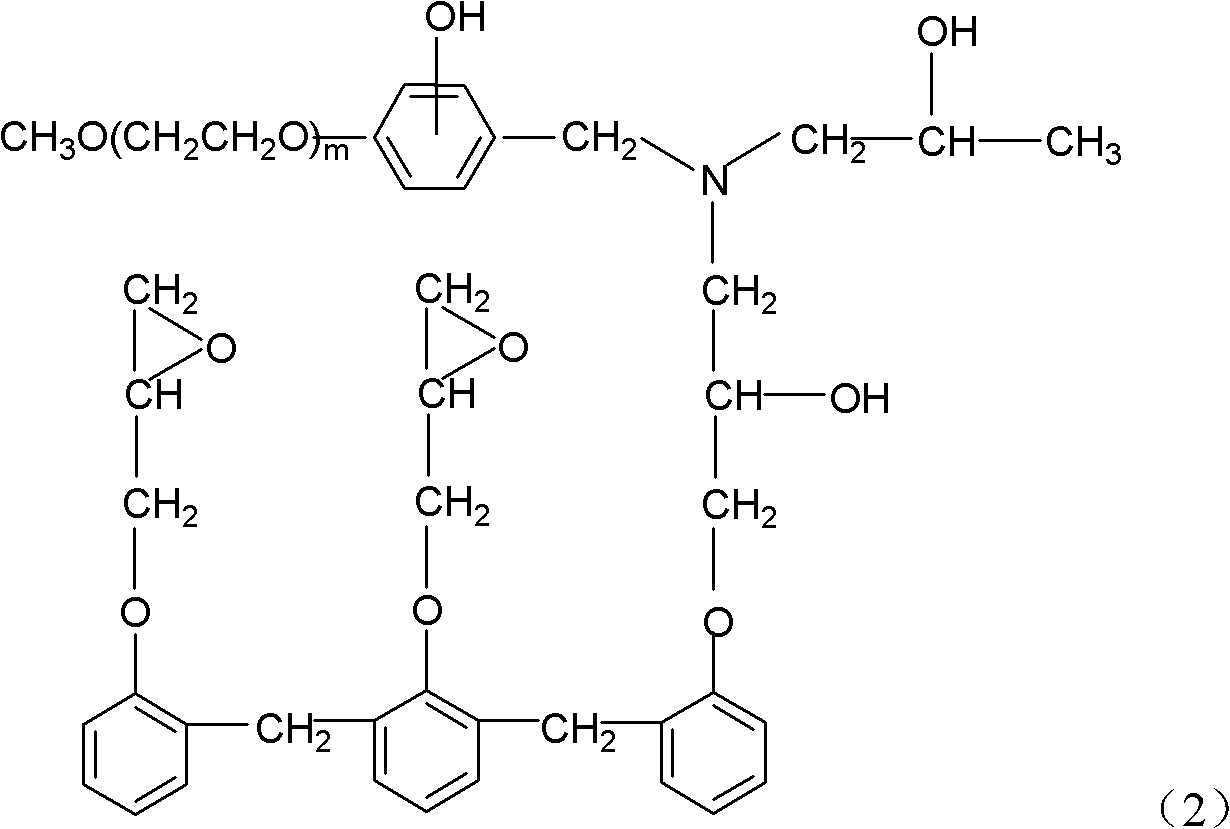

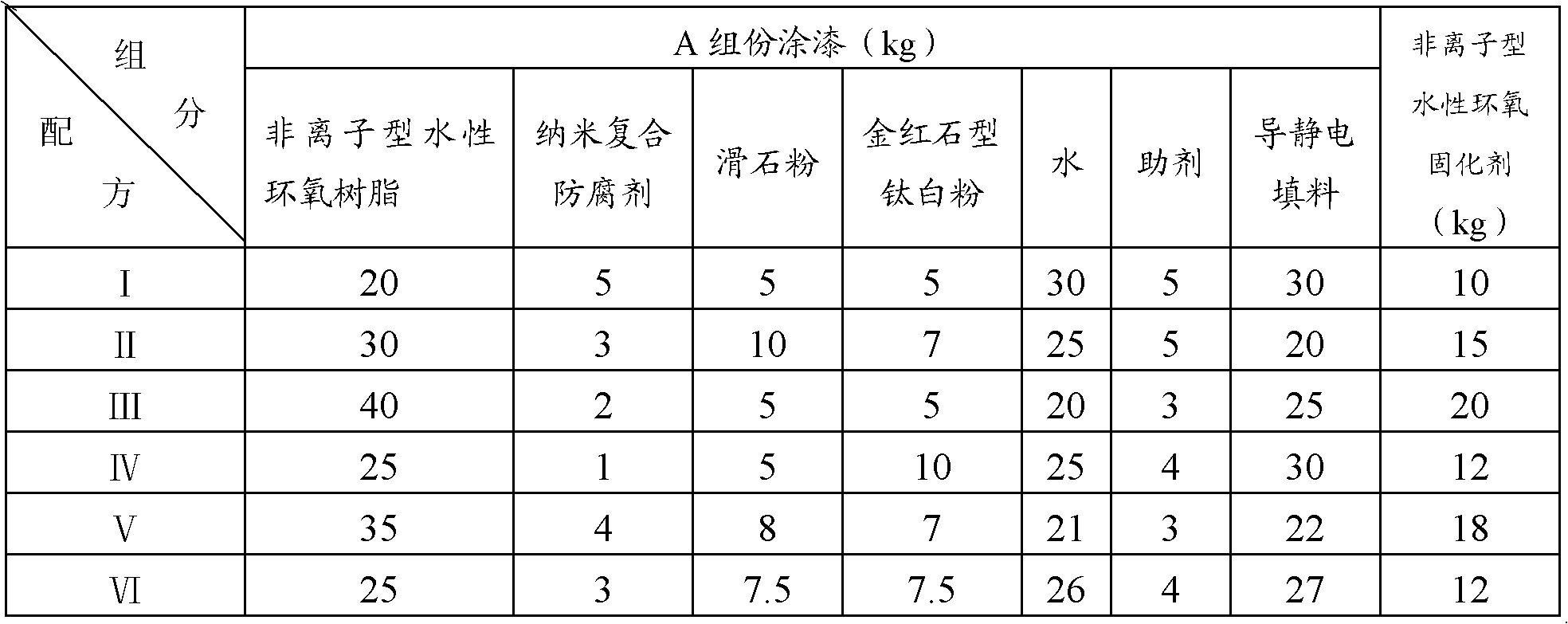

Environment-friendly water-based static electricity conductive corrosion-resistant coating and preparation method thereof

InactiveCN102627903AAdd lessImprove adhesionAnti-corrosive paintsEpoxy resin coatingsWater basedEpoxy

The invention discloses an environment-friendly water-based static electricity conductive corrosion-resistant coating. The environment-friendly water-based static electricity conductive corrosion-resistant coating is prepared from the raw materials in percentage by weight: component A and nonionic water-based epoxy curing agent in the ratio of 100:(10-20), wherein the component A is prepared from raw materials in percentage by weight: 20-40 percent of nonionic water-based epoxy resin, 20-30 percent of static electricity conductive material, 5-10 percent of rutile type titanium dioxide, 5-10 percent of talcum powder, 3-5 percent of additive, 1-5 percent of nanocomposite preservative and 20-30 percent of water. The invention also discloses a preparation method for the environment-friendly water-based static electricity conductive corrosion-resistant coating. The environment-friendly water-based static electricity conductive corrosion-resistant coating has the characteristics of environment friendliness, light weight, color light, stable static electricity conductive performance, excellent preservative performance, mechanical property, chemical stability and the like. The environment-friendly water-based static electricity conductive corrosion-resistant coating can be widely applied to the fields of electronics, petroleum, ordnance industries and the like, is especially suitable for building inner walls having requirement on electrostatic protection, such as hospitals and electronicelectrical workshops and can provide an economic and environment-friendly scheme for solving the electrostatic protection in the indoor buildings.

Owner:KING STRONG MATERIAL ENG LTD +1

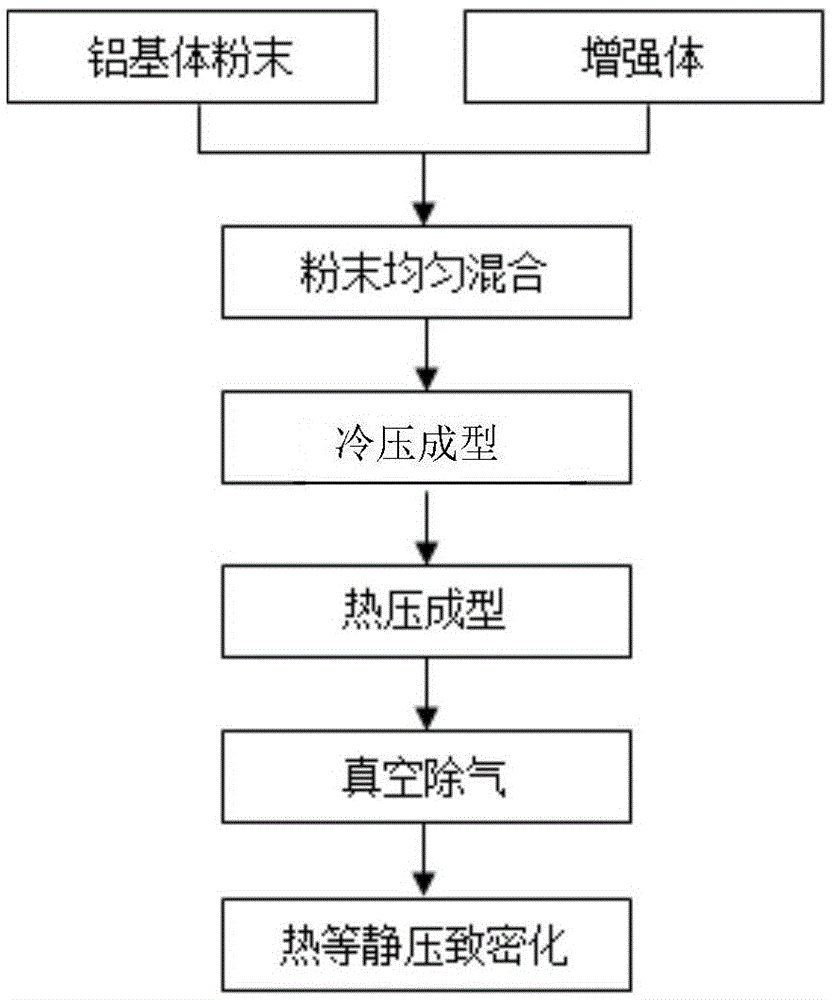

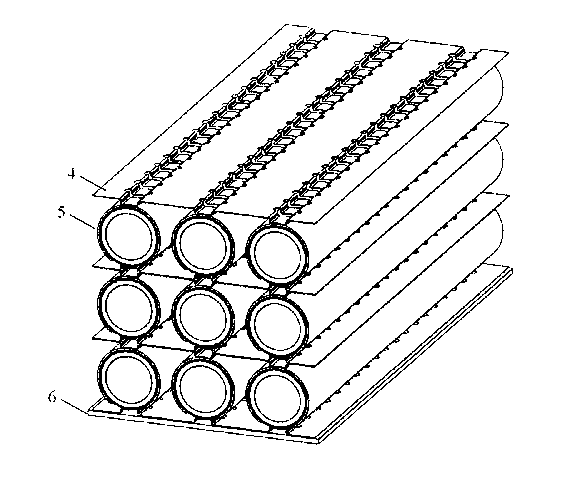

Manufacturing method of laminated aluminum matrix composite for electronic packaging

ActiveCN105483454AWill not oxidizePrecise content controlElectronic packagingCeramic matrix composite

The invention relates to a manufacturing method of a laminated aluminum matrix composite for electronic packaging. The method includes the steps that reinforcement powder and aluminum matrix powder are evenly mixed according to different proportions, obtained composite powder with different reinforcement contents is sequentially packaged to cylindrical steel dies to be subjected to cold press molding, and cold press billets are subjected to hot press molding in the inert gas atmosphere, so that the density of the billets is increased, the hot press billets are degassed in a high-temperature vacuum manner and then subjected to hot isostatic pressing densification, and the completely-dense billets are manufactured. The manufacturing method is simple and low in cost, the quality is stable, and the composite has the characteristics of being high in strength and tenacity and good in welding performance and can be applied to the electronic packaging field.

Owner:有研金属复材技术有限公司

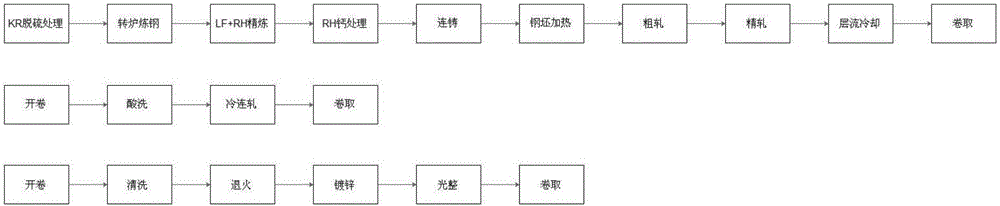

Zinc-plated double-phase steel and production method thereof

The invention belongs to the technical field of cold rolled steel and discloses zinc-plated double-phase steel and a production method of the zinc-plated double-phase steel. The zinc-plated double-phase steel comprises, by weight percentage, 0.085%-0.115% of C, 0.15%-0.24% of Si, 1.45%-1.55% of Mn, not larger than 0.015% of P, not larger than 0.005% of S, 0.025%-0.065% of Alt, 0.14%-0.24% of Cr, 0.24%-0.29% of Mo, not larger than 0.006% of N and the balance Fe and other inevitable impurities. The production method includes the steps of KR desulfuration, converter steelmaking, LF+RH refining treatment, RH calcium treatment, continuous steel casing, billet heating, rough rolling, finish rolling, laminar cooling and winding; unwinding, acid pickling, cold continuous rolling and winding; and unwinding, cleaning, annealing, zinc plating, finishing and winding. Through composition design and process control, the zinc-plated double-phase steel is suitable for annealing production lines having the rapid cooling segment or not.

Owner:SHOUGANG CORPORATION

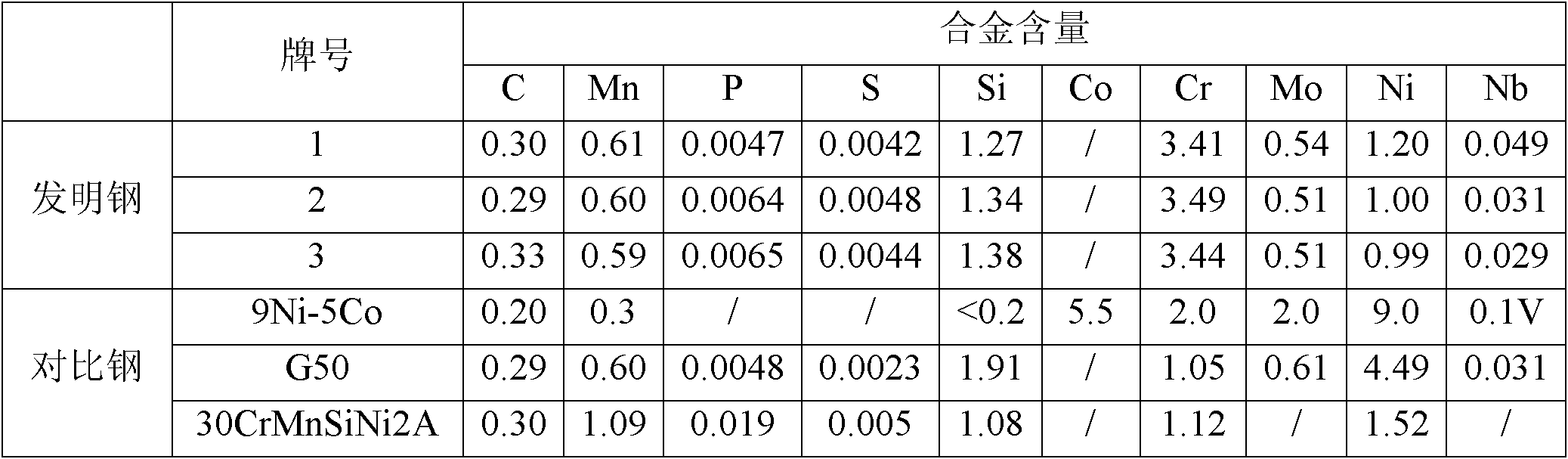

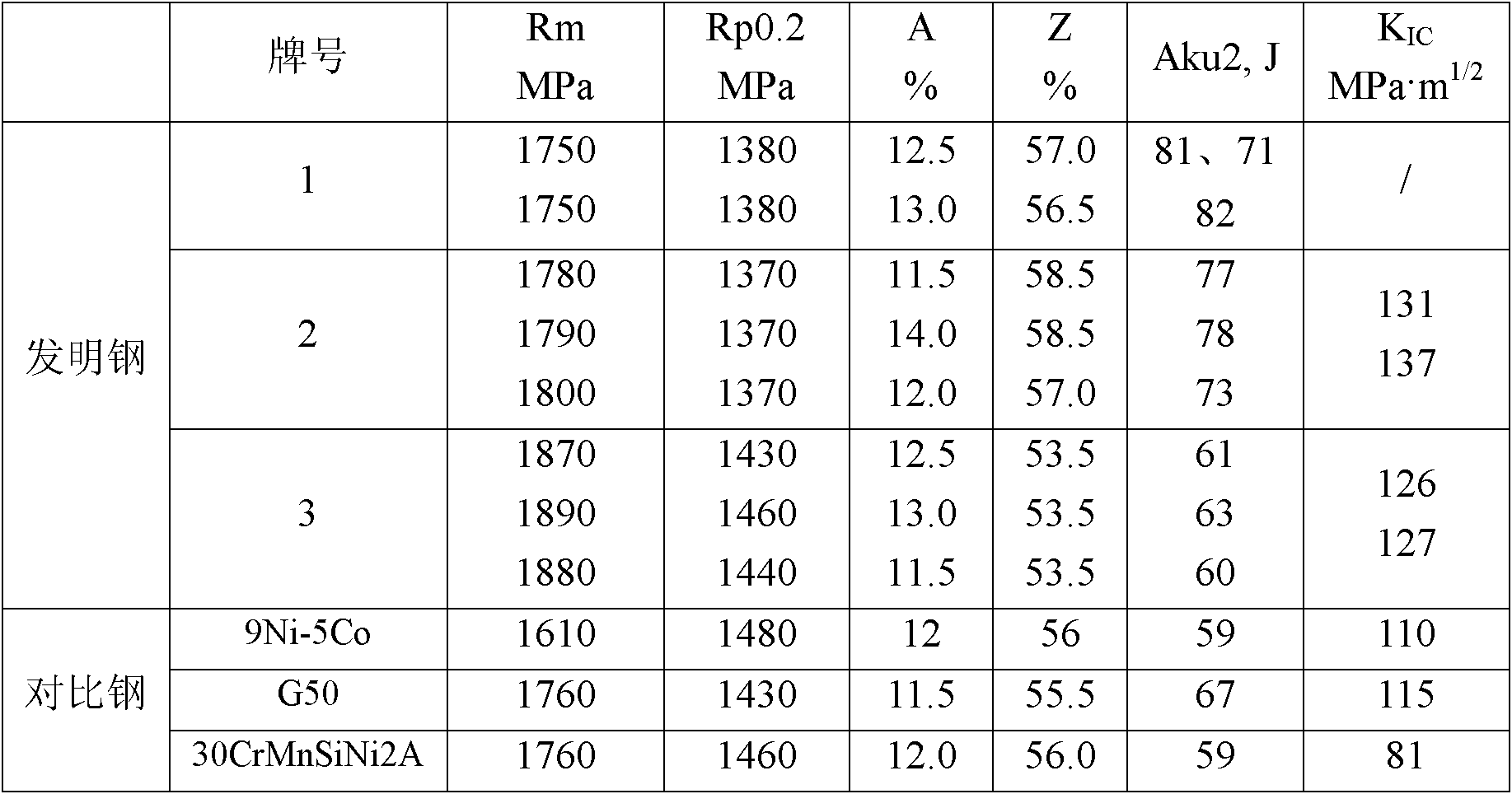

Steel with high toughness and ultrahigh strength

The invention discloses steel with high toughness and ultrahigh strength, and belongs to the technical field of alloy steels. The steel comprises the following chemical components in percentage by mass: 0.20 to 0.35 percent of C, 0.5 to 2.0 percent of Mn, 1.25 to 2.25 percent of Si, 2.0 to 5.0 percent of Cr, 0.5 to 2.5 percent of Ni, 0.3 to 0.8 percent of Mo, 0.01 to 0.10 percent of Nb, 0.05 to 0.3 percent of V, less than or equal to 0.005 percent of S, less than or equal to 0.01 percent of P, and the balance of Fe. Compared with the conventional steel with ultrahigh strength, the steel has the advantages of ultrahigh strength, high fracture toughness, high hardening property and low cost.

Owner:CENT IRON & STEEL RES INST

Method for preparing carbon nanofiber and carbon nanotube modified carbon fiber/epoxy resin multi-dimensional hybrid composite

InactiveCN101979436AImprove the shortcomings of insufficient interlaminar shear strength, etc.CurableFiberCarbon fibers

The invention belongs to the technical field of nano materials and particularly relates to a method for preparing a carbon nanofiber and carbon nanotube modified carbon fiber / epoxy resin multi-dimensional hybrid composite. The method comprises the following steps of: performing surface carboxylation and acylation treatment on carbon nanotubes, carbon nanofibers and carbob fibers; introducing diamine or polyamine to the obtained product; modifying amino carbon nanofibers and carbon nanotubes with an aromatic polyanhydride compound to prepare the carbon fibers, the carbon nanofibers and the carbon nanotubes carrying anhydride radicals; and ultrasonically oscillating the carbon nanofibers, the carbon nanotubes and the epoxy resin with the anhydride and stirring the mixed materials at a high speed to make the carbon nanofibers and the carbon nanotubes uniformly dispersed in the epoxy resin matrix and make the carbon nanofibers and the carbon nanotubes grafted with the anhydride and the epoxy resin fully undergo a chemical crosslinking reaction so as to obtain an epoxy resin linear block polymer, and combining the epoxy resin linear block polymer serving as a matrix and the carbon fibers to form multi-dimensional hybrid composite structures connected by covalent bonds. In the invention, by using the carbon nanotubes, the carbon nanofibers and the strength and toughness toughened epoxy resin, the bonding strength of carbon fiber interfaces is improved, so that the integral performance of the carbon fiber / epoxy resin multi-dimensional hybrid composite is improved, and the application range of the carbon fibers and the epoxy resin is widened.

Owner:TONGJI UNIV

Preparation method of carbon fiber/carbon nano tube/epoxy resin multi-dimensional hybrid composite

InactiveCN101811661AIncreased interlaminar shear strengthImprove interface strengthNanostructure manufactureFiberCarbon fibers

The invention belongs to the technical field of nano materials, and in particular relates to a preparation method of a carbon fiber / carbon nano tube / epoxy resin multi-dimensional hybrid composite. The invention comprises the following steps: carrying out surface carboxylation and chloride acetylation on carbon nano tubes and carbon fibers, introducing diamine or polyamine, and modifying the amino-grafted carbon nano tubes with small-molecule aromatic polyanhydride compounds to prepare carbon nano tubes carrying with anhydride groups; carrying out ultrasonic oscillation, stirring at a high speed to dispersing the carbon nano tubes in an epoxy resin matrix, and curing with organic anhydride curing agent to obtain an epoxy resin polymer containing carbon nano tubes; and using the epoxy resinpolymer containing the carbon nano tubes as the matrix for being compounded with the carbon fibers to form the covalently-bonded multi-dimensional hybrid composite structure. The invention has the advantage of convenient preparation; the carbon nano tubes are endued with activity for participating in the reaction, and the anhydride groups on the carbon nano tubes and the epoxy groups in the epoxyresin generate chemical crosslink, thereby promoting the dispersion of the carbon nano tubes in the epoxy resin; and the epoxy resin is toughened by using the strength and the toughness of the carbonnano tubes to enhance the bonding strength with the carbon fiber substrate, thus improving the overall performance of the carbon fiber / carbon nano tube / epoxy resin multi-dimensional hybrid composite,and widening the application of the carbon fibers, the carbon nano tubes and the epoxy resin.

Owner:TONGJI UNIV

Carbide-free bainitic steel, toothed plate adopting steel and preparation method thereof

InactiveCN103397273AImprove anti-wear performanceExtend your lifeFoundry mouldsFoundry coresCarbideMachining process

The invention discloses carbide-free bainitic steel and a rod-toothed crusher toothed plate prepared from the carbide-free bainitic steel. The bainitic steel comprises the following chemical components in percentage by weight: 0.3 to 0.4 percent of C, 1.0 to 2.0 percent of Si, 1.5 to 2.5 percent of Mn, 0.8 to 1.4 percent of Cr, 0.1 to 0.6 percent of Mo, 0.8 to 1.6 percent of Ni, 0.004 to 0.008 percent of B, 0.2 to 0.5 percent of Ti, less than or equal to 0.015 percent of P, less than or equal to 0.015 percent of S, and the balance of Fe and accompanying impurities. The carbide-free bainitic steel is prepared into the rod-toothed crusher toothed plate through a specific processing technology; the toothed plate has good strong-toughness coordination, which reaches the working performance index of the rod-toothed crusher toothed plate; and the abrasion resistance of the rod-toothed crusher toothed plate is greatly improved, the service life of the rod-toothed crusher toothed plate is greatly prolonged, and the cost is reduced.

Owner:MIANYANG JINDING ELECTROMECHANICAL TECH

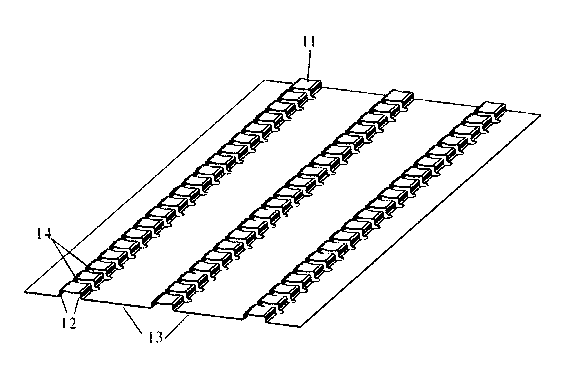

Current collection component of anode supporting tube type solid oxide fuel cell and application thereof

ActiveCN102760896AEasy to assembleHigh strength and toughnessFinal product manufactureSolid electrolyte fuel cellsFuel cellsSpinel

The invention discloses a current collection component of an anode supporting tube type solid oxide fuel cell and an application thereof. The current collection component comprises a plate-like alloy base material and a protective coating coated to the surface of the base material surface and capable of inhibiting high temperature oxidation of alloy. Materials used to form the protective coating on the surface of the alloy base material comprise at least two oxide components: 40%-90% of composite oxide and 10%-60% of single oxide in molar percentage, wherein the composite oxide comprises one or more than two of oxides with perovskite structure, spinel structure, fluorite structure or wurtzite structure, and at least one composite oxide has the conductivity greater than 1 S / cm at 500-900 DEG C. A hole or groove throughout the plate body is arranged on the plate-like alloy base material, and one or more than two bulges or grooves are arranged in the axial direction on the surface of the alloy base material parallel to a tube type cell unit, and the shape of the bulges or grooves is matched with an external electrode or a ceramic connector on the tube type cell unit. The current collection component provided by the invention can simultaneously play the actions of supporting and connecting the fuel cell unit and collecting and conducting current, and has the advantages of high temperature oxidation resistance, good conductivity, high strength and toughness, easiness in cell stack assembly, etc. The invention also discloses a method for making the current collection component.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

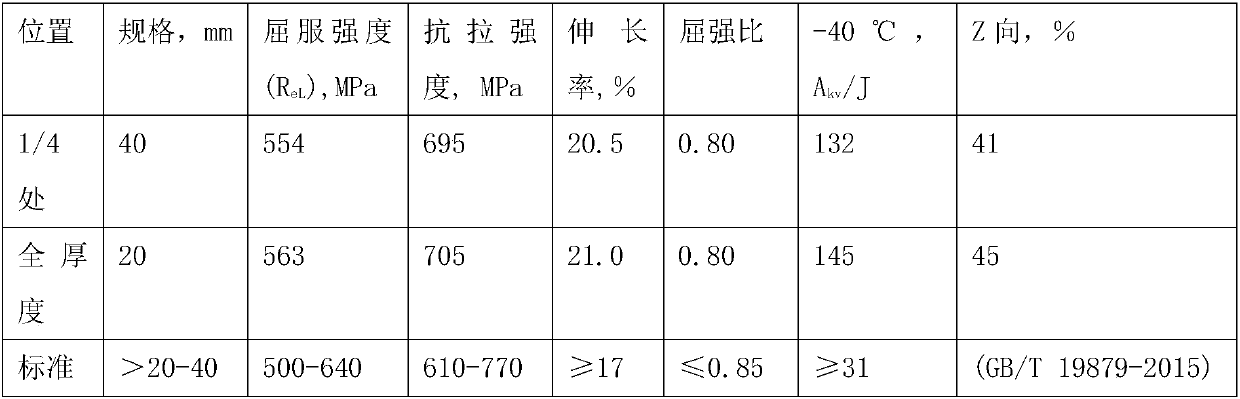

High-strength steel plate for Q500GJE quenched and tempered building structure and manufacturing method of high-strength steel plate

ActiveCN110184525AGood brittle transition temperatureLower brittle transition temperatureImpact energyBainite

The invention relates to a high-strength steel plate for a Q500GJE quenched and tempered building structure. The high-strength steel plate comprises the following chemical components: less than or equal to 0.14% of C, 0.20%-0.50% of Si, 1.10%-1.60% of Mn, less than or equal to 0.015% of P, less than or equal to 0.005% of S, less than or equal to 0.20% of Cr, less than or equal to 0.30% of Mo, lessthan or equal to 0.90% of Ni+Mo, less than or equal to 0.30% of Cu, 0.02%-0.04% of Al, less than or equal to 0.20% of V+Nb+Ti, less than or equal to 0.006% of N, and the balance of Fe and inevitableimpurity elements, wherein the carbon equivalent is less than or equal to 0.52%. The yield strength is 545-585 MPa, the tensile strength is 670-715 MPa, and the elongation is larger than or equal to 18.5%. A high-strength steel product for a building, with the yielding-to-tensile ratio less than or equal to 0.84, and the V-type impact energy higher than or equal to 110 J at -40 DEG C, is of a ferrite+pearlite+bainite structure, and the grain size is 8.5 levels or above. The comprehensive performance can completely meet GB / T 19879-2015 and the clients' requirements of steel plates for high-risebuildings.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Steel for marine riser flange of marine deepwater drilling and manufacturing method of marine riser flange

InactiveCN102191442AImprove strength and toughnessMeet the technical requirements of low-carbon high-strength toughnessDrilling rodsDrilling casingsElectric arc furnaceDeepwater drilling

The invention discloses steel for a marine riser flange of marine deepwater drilling. The steel comprises the following components in percentage by weight: 0.13 to 0.21 percent of C, 1.65 to 1.95 percent of Mn, 0.25 to 0.35 percent of Mo, 0.03 to 0.09 percent of Nb, 0.02 to 0.08 percent of V, less than or equal to 0.015 percent of Ti, 0.5 to 0.9 percent of Ni, 0.07 to 0.2 percent of Cu, less than or equal to 0.15 percent of Cr, less than or equal to 0.22 percent of Si, less than or equal to 0.01 percent of S, less than or equal to 0.02 percent of P and the balance of Fe. The invention also discloses a manufacturing method of the marine riser flange of marine deepwater drilling. The method comprises the following steps of: preparing the materials according to the content of the components, and smelting the materials in an arc furnace to obtain molten steel, and heating the molten steel with arc in vacuum and stirring the molten steel by blowing argon to degas the molten steel; casting a steel ingot, blowing an inert gas through a blowing sliding water gap, balancing the components and the temperature and purifying the molten steel; forging the obtained steel ingot and annealing the steel ingot after forging; machining and polishing the steel ingot; and performing die forging on the steel ingot to obtain the finished product of the marine riser flange. By the manufacturing method, each mechanical property of the steel and the marine riser flange meets the requirements on API related steel for marine riser flange by setting the best component proportion and a heat treatment process.

Owner:BAOJI PETROLEUM MASCH CO LTD

Method for preparing low alloy high wear resistant cast steel plate

The present invention relates to a method for preparing a low alloy high wear resistant cast steel plate. The cast steel plate includes the following components: 0.25-0.35 wt% of C, 0.9-1.6 wt% of Si, 0.3-1.8 wt % of Mn, 0.7-1.0 wt% of Cr, 0.15-0.3 wt% of Mo, 0.05-0.35 wt% of Ti, 0.01-0.05 wt% of Nb, 0.05-0.25 wt% of V, 0.01-0.1 wt% of RE, no more than 0.03 wt% of P and S, and the balance Fe. The components are melted and molded, and then a processed ingot is placed therein for heating. When the temperature reaches 1050-1070 DEG C, the heat preservation lasts. After the completion of heat preservation, the ingot is placed into a 240-245 DEG C salt bath furnace for heat preservation. The ingot is finally cooled by the air. The casting and heat treatment process of the present invention is relatively simple, easily controlled, and low in cost, and the produced material has good strength and toughness.

Owner:HAIAN COUNTY SHENLING ELECTRICAL APPLIANCE MFG

High strength spring steel with excellent anti-fatigue property

The invention belongs to the steel alloy domain and is mainly fit for the high strength spring steel with excellent ability of resisting the tire wreck and the resisting draw intension keeping above 1800MPa. The element component (weight percent) of the steel: C 0.35-0.55%, Mn 0.40-0.70%, Si 1.70-2.50%, Cr 0.70-1.10%, V 0.05-0.20%, RE 0.005-0.10%, Ca 0.005-0.10%, Ca 0.0005_0.020%, P<0.020%, S<0.015%, O<0.015%, the remaining quantity is Fe and unavoidable impurity. The steel also contains the B 0.0005_0.0030%, Ti 0.01-0.10% or the Ni 0.01-1.50%. Compared to the existing technology, the invention has many merits such as the high resisting drag intension, the excellent resisting tire ability and the low cost.

Owner:CENT IRON & STEEL RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com