Heat treatment method for maraging stainless steel

A heat treatment method and aging treatment technology, applied in the field of heat treatment of maraging stainless steel, can solve problems such as insufficient strength and toughness coordination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] Sample preparation:

[0035] Select high-purity electrolytic Fe, electrolytic Ni, high-purity Mo, Co and other raw materials, and use an ultra-high vacuum induction furnace to melt a 25kg steel ingot. The composition of the sample steel is shown in Table 1. The steel ingot is forged at 1100°C±10°C, the final forging temperature is 900°C±10°C, and it is forged into a Φ40mm bar. The forging is annealed within 24 hours after forging, and annealed at 860°C±10°C for 2-3 hours. Furnace cold and ready to use.

[0036] Table 1 Example stainless steel chemical composition (mass percentage %)

[0037]

Embodiment 1

[0039] Take sample 1 stainless steel for solution treatment, solution heat treatment temperature is 1000 ° C, 1050 ° C, 1100 ° C, 1150 ° C for 60 minutes, water cooling; cryogenic treatment (mixed solution of liquid nitrogen + alcohol -78 ° C); and then in different Temperature (520°C, 540°C, 560°C, 580°C) aging heat treatment twice, each time for 2h, air cooling to room temperature. The specific process parameters are shown in Table 2. The heat treatment furnaces for solid solution and aging treatment are both 8KW muffle furnaces.

[0040] Solution treatment:

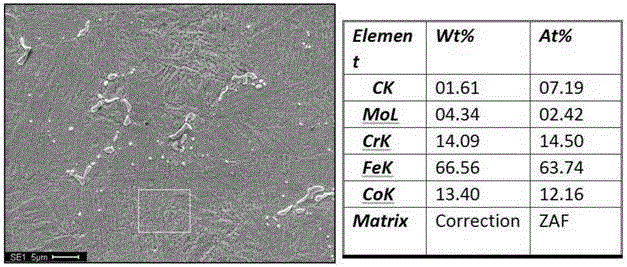

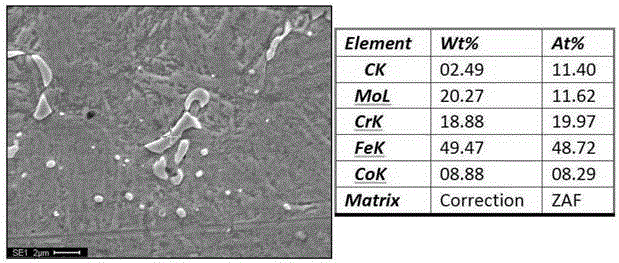

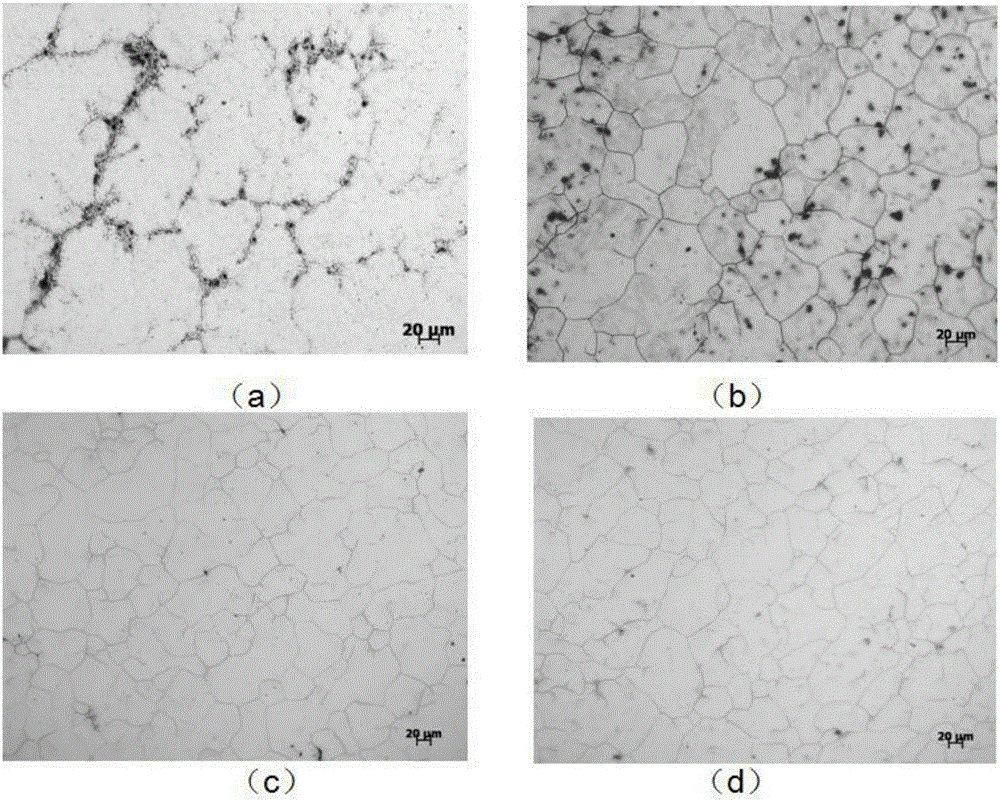

[0041] figure 1 Shown is the grain structure state of sample 1 after solid solution treatment + cryogenic treatment, which is represented by figure 1It can be seen that the grains after solid solution treatment at different temperatures are all equiaxed, and the grain sizes treated at different temperatures are measured, such as figure 2 As shown, with the increase of the solid solution temperature, the grain size ...

Embodiment 2-9

[0050] Samples 2-9 were taken to undergo solid solution + aging treatment under different conditions, and the process parameters are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Impact toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com