Method for preparing low alloy high wear resistant cast steel plate

A high wear-resistant, low-alloy technology, applied in the field of wear-resistant cast steel manufacturing, can solve the problems of high production cost, complicated process, difficult to control, etc., and achieve the effect of good strength and toughness, simplified process, and simple composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

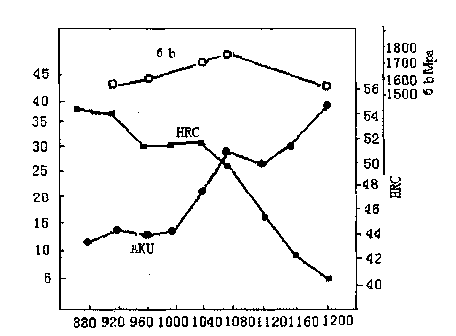

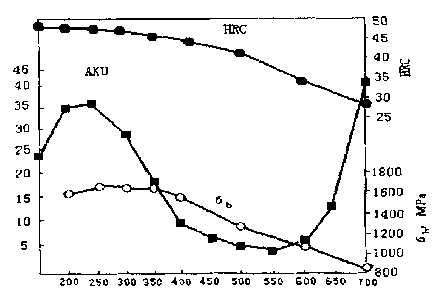

Image

Examples

Embodiment 1

[0051] 1) Use scrap steel, ferrosilicon, ferromanganese, ferrosilicon, ferromolybdenum, ferrochrome, ferrotitanium, ferrovanadium, ferroniobium, and rare earth silicon as raw materials for smelting, and make ingredients according to the following components: C: 0.25 wt.%;

[0052] Si: 0.9 wt.%;

[0053] Mn: 0.3 wt.%;

[0054] Cr: 0.7 wt.%;

[0055] Mo: 0.15 wt.%;

[0056] Ti: 0.05 wt.%;

[0057] Nb: 0.01 wt.%;

[0058] V: 0.05 wt.%;

[0059] RE: 0.01 wt.%;

[0060] P, S≤0.01 wt.%

[0061] The rest is Fe and unavoidable impurities;

[0062] 2) Using medium frequency induction furnace for smelting, first heat and melt ordinary steel scrap and ferrochrome, and conduct pre-furnace analysis;

[0063] 3) Add ferromanganese, ferrosilicon, and ferromolybdenum in turn, wait until all are melted, then add ferrochrome and then further melt, deoxidize with aluminum wire, then pour molten steel into it and place ferrotitanium, ferrosilicon, ferroniobium, and rare earth at the same ...

Embodiment 2

[0071] 1) Use steel scrap, ferrosilicon, ferromanganese, ferrosilicon, ferromolybdenum, ferrochrome, ferrotitanium, ferrovanadium, ferroniobium, and rare earth silicon as raw materials for smelting, and make ingredients according to the following components: C: 0.3 wt.%;

[0072] Si: 1.2 wt.%;

[0073] Mn: 1.0 wt.%;

[0074] Cr: 0.85 wt.%;

[0075] Mo: 0.2 wt.%;

[0076] Ti: 0.25 wt.%;

[0077] Nb: 0.03 wt.%;

[0078] V: 0.15 wt.%;

[0079] RE: 0.06 wt.%;

[0080] P, S≤0.02 wt.%

[0081] The rest is Fe and unavoidable impurities;

[0082] 2) Using medium frequency induction furnace for smelting, first heat and melt ordinary steel scrap and ferrochrome, and conduct pre-furnace analysis;

[0083] 3) Add ferromanganese, ferrosilicon, and ferromolybdenum in turn, wait until all are melted, then add ferrochrome and then further melt, deoxidize with aluminum wire, then pour molten steel into it and place ferrotitanium, ferrosilicon, ferroniobium, and rare earth at the same t...

Embodiment 3

[0091] 1) Use scrap steel, ferrosilicon, ferromanganese, ferrosilicon, ferromolybdenum, ferrochrome, ferrotitanium, ferrovanadium, ferroniobium, and rare earth silicon as raw materials for smelting, and make ingredients according to the following components: C: 0.35 wt.%;

[0092] Si: 1.6 wt.%;

[0093] Mn: 1.8 wt.%;

[0094] Cr: 1.0 wt.%;

[0095] Mo: 0.3 wt.%;

[0096] Ti: 0.35 wt.%;

[0097] Nb: 0.05 wt.%;

[0098] V: 0.25 wt.%;

[0099] RE: 0.1 wt.%;

[0100] P, S≤0.03 wt.%

[0101] The rest is Fe and unavoidable impurities;

[0102] 2) Using medium frequency induction furnace for smelting, first heat and melt ordinary steel scrap and ferrochrome, and conduct pre-furnace analysis;

[0103] 3) Add ferromanganese, ferrosilicon, and ferromolybdenum in turn, wait until all are melted, then add ferrochrome and then further melt, deoxidize with aluminum wire, then pour molten steel into it and place ferrotitanium, ferrosilicon, ferroniobium, and rare earth at the same time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Impact toughness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com