Antistatic clothing

An antistatic and antibacterial layer technology, applied in the direction of clothing, clothing, protective clothing, etc., can solve the problems of affecting the pH balance, nausea, and the fabric is prone to static electricity, and achieve good antistatic effect, excellent strength and toughness, and improved antistatic performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

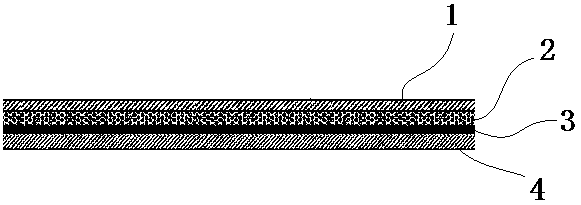

Image

Examples

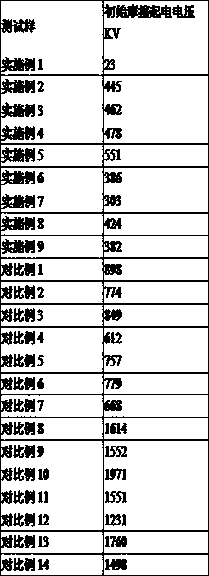

Embodiment 1

[0022] (1) Initially modify the polyester fabric by soaking it in the modification treatment solution, soak it for 10 h, and then dry it at 40 °C for 2 h to obtain the modified polyester fabric.

[0023] (2) Weigh 38 parts by weight of polyethylene terephthalate, 17 parts by weight of acetyl chitosan, and 9 parts by weight of guar gum in a beaker, add 80 parts by weight of hydrochloric acid absolute ethanol solution, stir magnetically for 2 hours, and put It is placed in 300W power, ultrasonic treatment under nitrogen atmosphere for 30 minutes, filtered with a vacuum pump, and the filtrate is taken for subsequent use;

[0024] (3) Take 50-90 parts by weight of the filtrate obtained in the above step (2), add 10-50 parts by weight of sepiolite / BaFe 12 o 19 / CrCl 3 Composite material, 20 parts by weight of deionized water, magnetically stirred for 2 hours to obtain an antistatic treatment solution, dipped the modified polyester fabric in the above treatment solution, bath rati...

Embodiment 2

[0029] Exactly the same as Example 1, the difference is: add 105 parts by weight of filtrate, 15 parts by weight of sepiolite / BaFe 12 o 19 / CrCl 3 composite material.

Embodiment 3

[0031] Exactly the same as Example 1, the difference is: add 100 parts by weight of filtrate, 20 parts by weight of sepiolite / BaFe 12 o 19 / CrCl 3 composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com