High-toughness resin optical filter and preparation method thereof

An optical filter, high toughness technology, applied in optical filters, nonlinear optics, optics, etc., can solve the problems of not meeting the requirements of use, easy to produce scratches, poor surface strength, etc., to achieve good strength and toughness, light transmission. Good quality and uniform particle distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

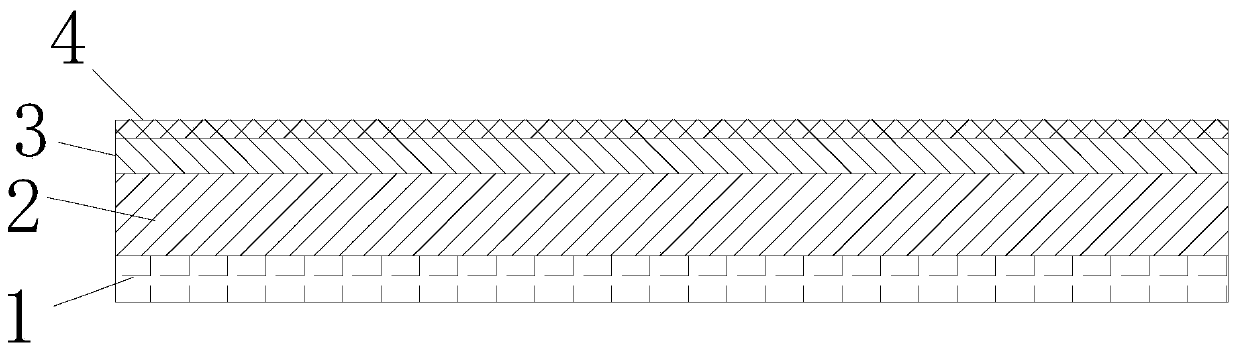

[0025] A high-toughness resin filter, comprising a substrate 2, a modified dispersion resin layer 3 is provided on the outside of the substrate 2, a repair coating 4 is coated on the outside of the modified dispersion resin layer 3, and a repair coating 4 is provided on the inside of the substrate 2. There is coating layer 1.

[0026] Wherein, the modified dispersion resin layer 3 includes 13 parts of methacrylate, 3 parts of methyl methacrylate, 4 parts of butyl methacrylate, 13 parts of benzyl methacrylate, 6 parts of phenethyl ester, propylene glycol methyl 5 parts of ether acetate, the modified dispersion resin layer 3 is mixed with an infrared adsorption layer, and the infrared adsorption layer is o-phthalimine nickel fuel, sulfide double tin nickel fuel and dichloromethane, and the mixing ratio 2.5:1.5:4, the repair coating 4 includes 5 parts of methyltriethoxysilane, 4 parts of ethyl orthosilicate, 4 parts of methanol, 5 parts of ethanol, 5 parts of 1,2-dipropanol and ...

Embodiment 2

[0036] A high-toughness resin filter, comprising a substrate 2, a modified dispersion resin layer 3 is provided on the outside of the substrate 2, a repair coating 4 is coated on the outside of the modified dispersion resin layer 3, and a repair coating 4 is provided on the inside of the substrate 2. There is coating layer 1.

[0037] Wherein, the modified dispersion resin layer 3 includes 12 parts of methacrylate, 1 part of methyl methacrylate, 2 parts of butyl methacrylate, 10 parts of benzyl methacrylate, 4 parts of phenethyl ester, propylene glycol methyl 3 parts of ether acetate, and the modified dispersion resin layer 3 is mixed with an infrared adsorption layer, and the infrared adsorption layer is phthalimine nickel fuel, sulfide double tin nickel fuel and dichloromethane, and the mixing ratio is 2:1:3, the repair coating 4 includes 3 parts of methyltriethoxysilane, 2 parts of ethyl orthosilicate, 2 parts of methanol, 3 parts of ethanol, 1 part of 1,2-dipropanol and 2...

Embodiment 3

[0047]A high-toughness resin filter, comprising a substrate 2, a modified dispersion resin layer 3 is provided on the outside of the substrate 2, a repair coating 4 is coated on the outside of the modified dispersion resin layer 3, and a repair coating 4 is provided on the inside of the substrate 2. There is coating layer 1.

[0048] Wherein, the modified dispersion resin layer 3 includes 16 parts of methacrylate, 4 parts of methyl methacrylate, 5 parts of butyl methacrylate, 15 parts of benzyl methacrylate, 8 parts of phenethyl ester, propylene glycol methyl 6 parts of ether acetate, the modified dispersion resin layer 3 is mixed with an infrared adsorption layer, and the infrared adsorption layer is phthalimine nickel fuel, disulfide-nickel fuel and dichloromethane, and the mixing ratio is 3:2:5, the repair coating 4 includes 6 parts of methyltriethoxysilane, 5 parts of ethyl orthosilicate, 5 parts of methanol, 6 parts of ethanol, 8 parts of 1,2-dipropanol and 9 parts of or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com