Patents

Literature

48results about How to "Increase wine yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

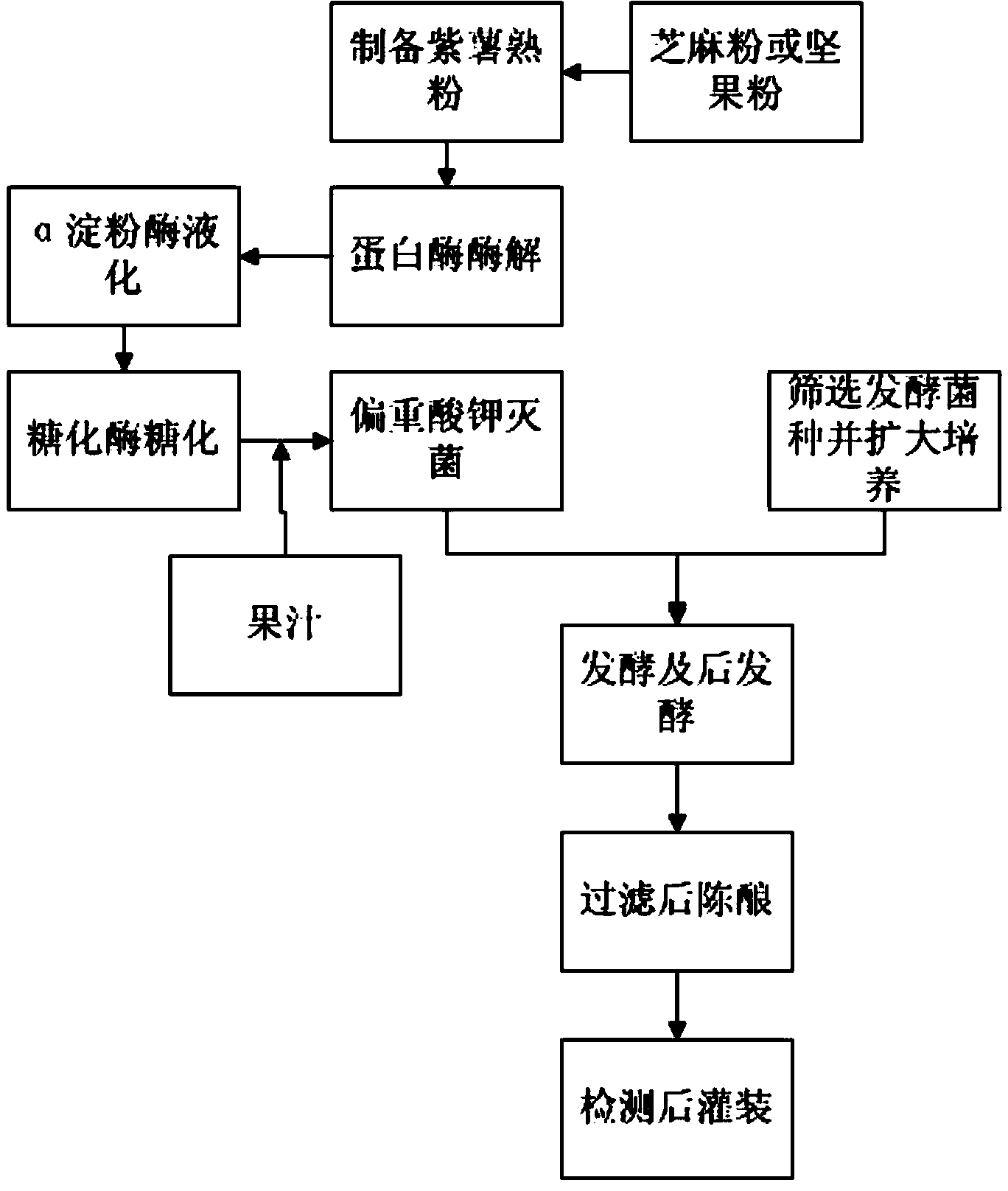

Purple sweet potato wine and preparation method thereof

ActiveCN104017689ASettle by seasonSolution conditionsAlcoholic beverage preparationMicroorganism based processesFruit juiceFermentation

The invention discloses a purple sweet potato wine and a preparation method thereof. The purple potato wine with a high anthocyanin content is prepared by preparing purple sweet potatoes into cooked powder, mixing the cooked powder with sesame powder or nut powder, subjecting the powder mixture to enzymolysis by enzymes, liquefying, saccharifying, adding fresh juice, and fermenting with monascus and screened yeast with a plurality of kinds of tolerance. The purple sweet potato wine is a fermented wine prepared by fermentation with a fruit wine process, and maintains original nutrition components of the purple sweet potatoes. The wine is noble in color and luster, mellow, excellent in quality, and rich in the bioactivator anthocyanin and selenium, and is an ideal healthcare drinking.

Owner:四川中世酒业有限公司

Method for producing ethanol by high-efficiency simultaneous saccharification and cofermentation

InactiveCN102251010AReduce pollutionNo pollution in the processBiofuelsMicroorganism based processesEthanol yieldHemicellulose

The invention discloses a method for producing ethanol by high-efficiency simultaneous saccharification and cofermentation, which comprises the following steps: pretreating; concentrating and detoxifying; preparing yeast seed solution; performing simultaneous saccharification and cofermentation; and distilling / rectifying. When the method provided by the invention is used, the inhibition action of a monosaccharide component formed by hydrolysis of cellulose on cellulose is relieved, the enzymolysis saccharification efficiency and fermentation yield are improved, the recovery rate of hemicelluloses in bagasse is about 60 percent, the cellulose recovery rate is about 86 percent, and the total ethanol yield of dry bagasse can reach about 20 percent.

Owner:GUANGZHOU YOURUI BIOSCI

Brewing method of tea plant flower yellow wine

InactiveCN101397530AIncrease wine yieldLow alcoholAlcoholic beverage preparationMicroorganism based processesBrownish red colorMoisture

The invention discloses a brewing method of yellow wine of tea flowers, relating to a brewing method of novel yellow wine of tea flowers. The method comprises the steps: a dimple is constructed; when the dimple is overflowing with sugar liquor, wine cube is replenished; 3 to 5 hours later, the leaching liquor of tea flowers prepared is put in the dimple; water with the weight of 1.0 to 2.0 times of rice is replenished; fully stirring is carried out, the temperature and the moisture are preserved; the mixture is stirred every 2 to 4 hours, the product temperature is reduced so as to lead the temperature in a tank to be consistent; after 20 to 30 days of tank dropping, the main fermentation is basically finished, the tank is irrigated to carry out post-fermenting and aging for 60 to 90 days and obtain fermented grains; and the yellow wine of tea flowers with the alcoholic strength of 11.0 to 15.0 is obtained by carrying out squeezing, defecating, wine boiling and storing. The brewing method adds no pigment, essence and additives, and leads the wine to be novel yellow wine which has brownish red color and luster, fruity taste, low alcoholic strength and richer nutrient components.

Owner:YANGZHOU UNIV

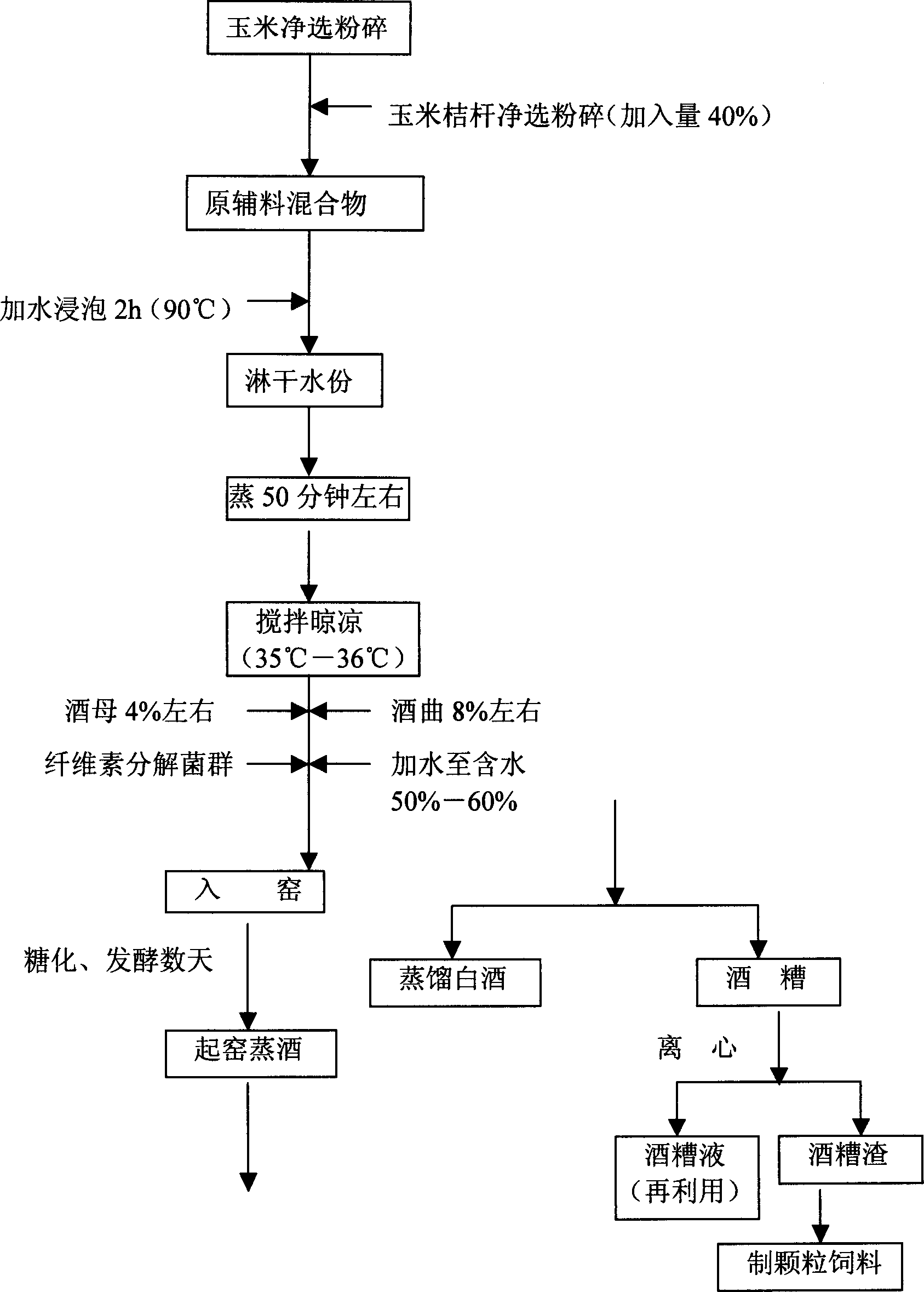

Method for preparing spirit or feeding stuff with corn stalk as auxiliary material

InactiveCN1840632AImprove qualityHigh in nutrientsFood processingAnimal feeding stuffAlcoholCellulase

The preparation method to corn straw supplementary material for alcohol or feed comprises: 1) mixing crushed corn or sorghum straw by weight ratio as 50-80:20-50, dipping in water for 1-5h at 70-90Deg; 2) trickling for initial and secondary steaming; 3) stirring, drying in the sun, adding barm and cellulase; 4) putting in vault for saccharifying and fermenting; 5) opening vault and steaming alcohol. The final alcohol has rich noutrition and low fat, and the feed has well quality fit to improve beef and pork.

Owner:魏汉莲

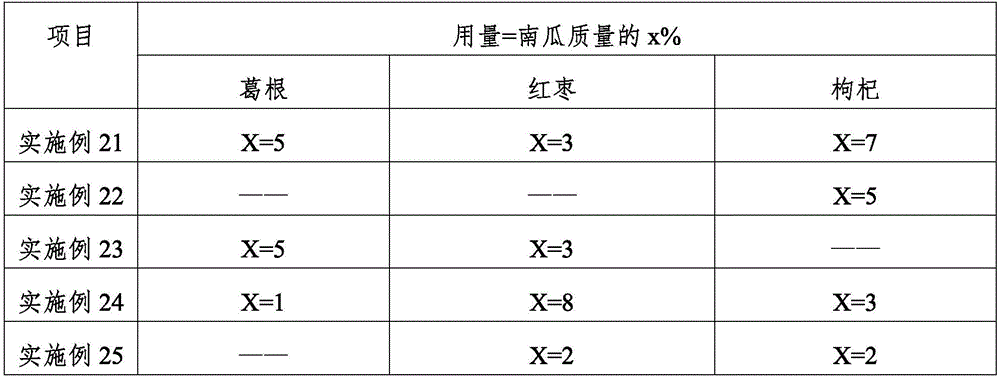

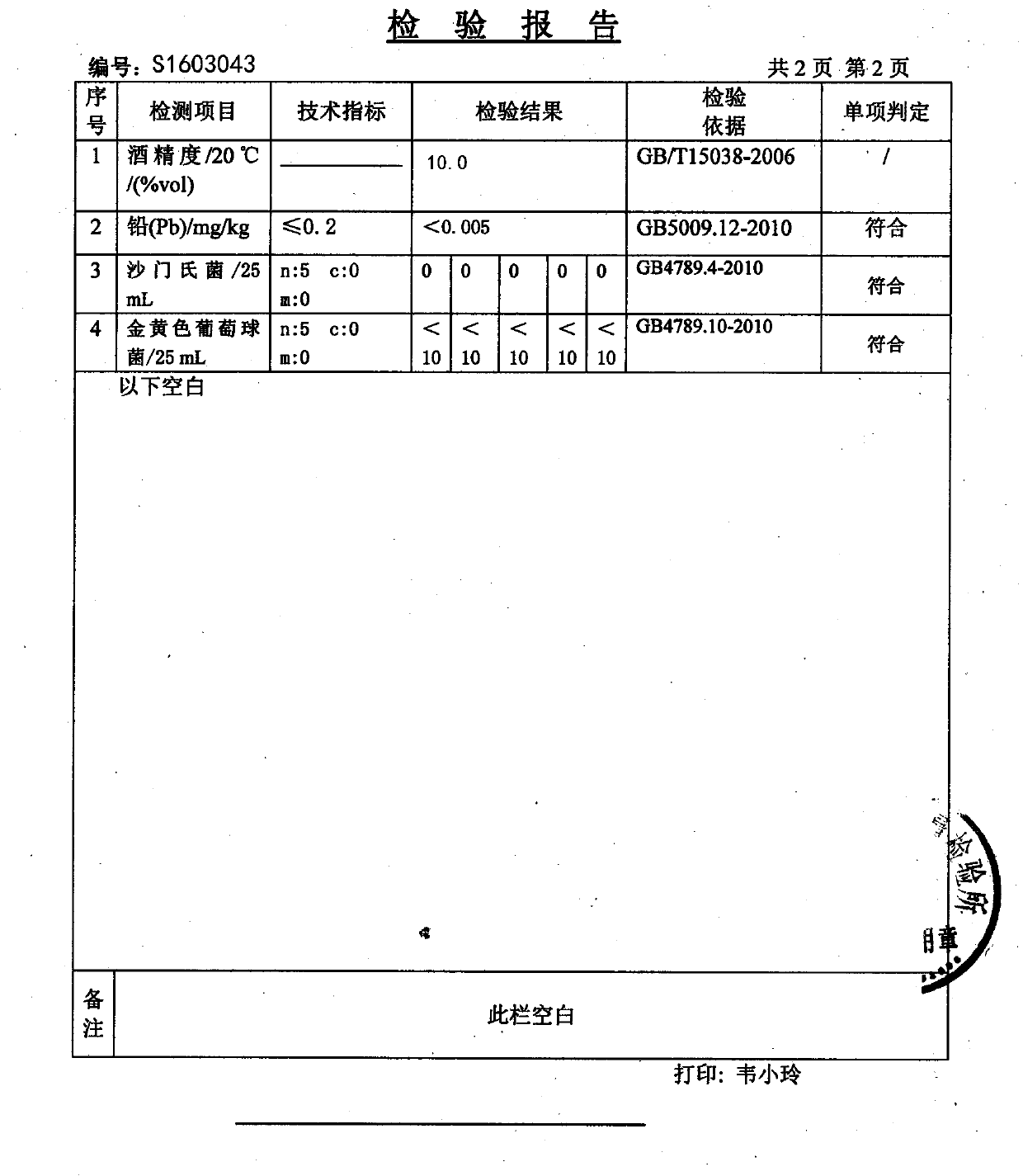

Grapefruit brandy and preparation method thereof

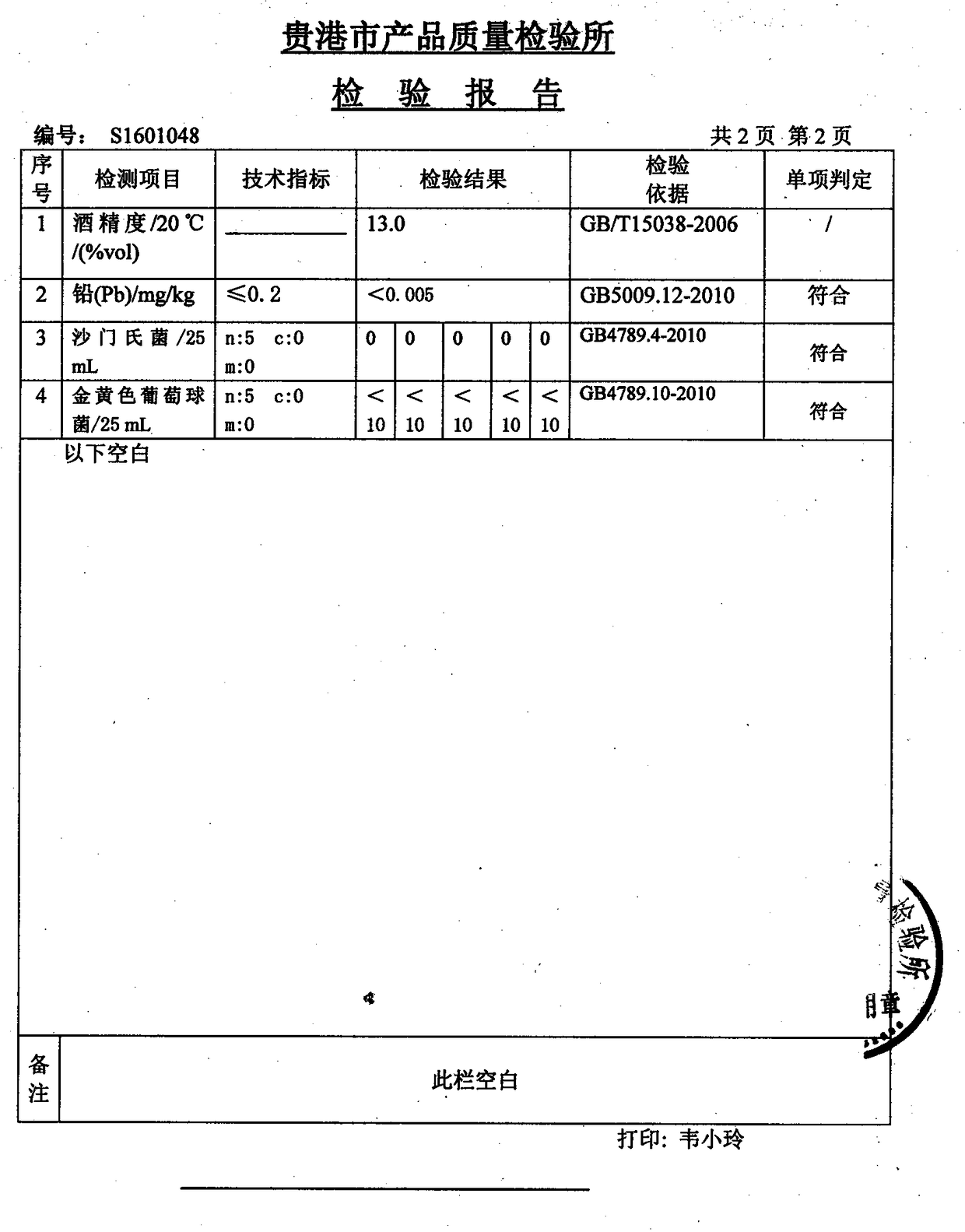

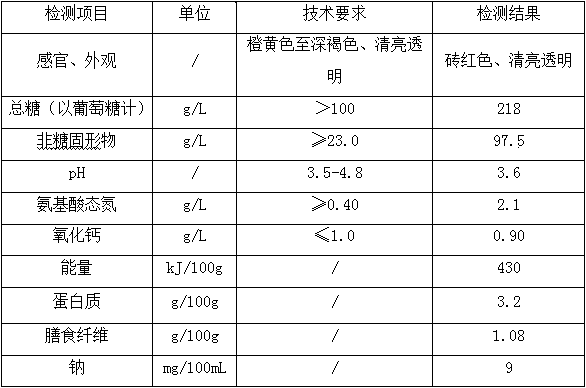

The invention provides grapefruit brandy and a preparation method thereof, and belongs to the technical field of wine brewing. The preparation method is characterized in that grapefruit is used as a raw material; before fermenting, fruit pulp is heated, so as to perform sterilizing on one hand and deactivate pectin on the other hand, so that prepared crude wine can meet a safety standard, namely the content of methanol is smaller than 0.12g / 100mL. By adopting the preparation method, most of beneficial components in the grapefruit can be reserved; the prepared grapefruit brandy is rich in aromatic component, naringin and limonin, and has the particular aroma of the grapefruit is contained; after the grapefruit brandy is drunk, a heavy fruit flavor and slight bitter taste are reserved in anoral cavity, and the bitter taste can be quickly dissipated.

Owner:江西省东篱柚业科技有限公司

Loquat wine and preparation method thereof

InactiveCN105273935AIncrease nutritionGreat tasteDigestive systemAlcoholic beverage preparationSucroseAlcohol

The invention relates to the field of production of loquat wine and provides loquat wine and a preparation method thereof. The loquat wine is mainly prepared from the following raw materials in parts by weight: 0.5-1 part of deodorizing alcohol or glutinous rice wine, 400-700 parts of loquat, 1-3 parts of clove, 5-10 parts of vanilla bean, 10-15 parts of lemon peel, 400-500 parts of cane sugar, 100-300 parts of honey, 50-150 parts of lucid ganoderma and 30-70 parts of cordyceps sinensis. The preparation method of the loquat wine mainly comprises the following steps: dissolving rock candy and honey with boiling water, then adding loquat, vanilla bean and lucid ganoderma, uniformly stirring to obtain loquat mixed solution, firstly soaking lemon peel with water in deodorizing alcohol or glutinous rice wine to obtain lemon mixed liquor, carrying out mixed fermentation on the loquat mixed solution and lemon mixed liquor, sealing and storing for 4-6 months, and straining off dregs, so as to obtain the loquat wine. The loquat wine provided by the invention is good in taste and full of nutrients, the preparation method of the loquat wine is simple in operation, and nutrients of loquat can be fully extracted out.

Owner:文燕鸿

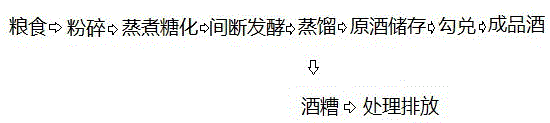

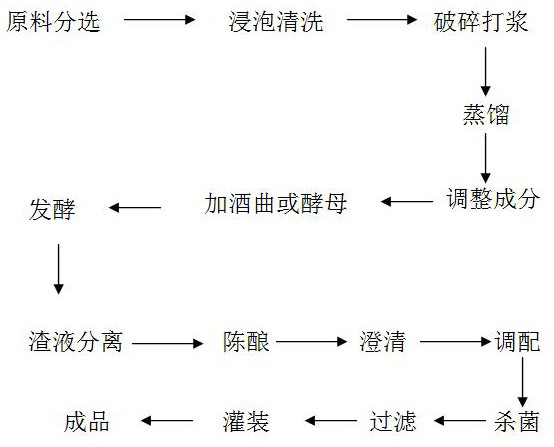

Liquid fermentation distilled liquor technique

InactiveCN105132244AIncrease wine yieldHigh product quality controllabilityAlcoholic beverage preparationDistillationEvaporation

The invention discloses a liquid fermentation distilled liquor technique. The liquid fermentation distilled liquor technique is characterized in that a mono-grain or various grains is / are taken as the raw materials, the grain raw material is crushed into a powder syrup, the powder syrup is heated and gelatinized to obtain a gelatinized mash, the gelatinized mash is processed under the action of maltogenic amylase to obtain a saccharified mash, saccharified mash is processed under the action of yeast to produce alcohol so as to obtain a fermented mash, or the gelatinized mash is added with distiller's yeast to be directly fermented to obtain a fermented mash, a distiller consisting of a distillation still, a distillation tower and a condenser is adopted to perform intermittent distillation to obtain a 60-94 percent (v) wine base, the wine base is placed in a wood barrel for storage, and blending, filtering and filling are performed to obtain a liquid fermentation distilled liquor. The liquid fermentation distilled liquor technique has the advantages of being high in liquor yield, low in labor intensity, controllable in production process, highly controllable product quality and the like, and fully conforms to the health concept requirements, discharged vinasse can directly serve as animal food or evaporated and dried to produce a DDGS high-protein feed, and the evaporation wastewater can be subjected to standard emission after simple anaerobic and aerobic treatment, so that the liquid fermentation distilled liquor technique conforms to the national environment-friendly industrial policy.

Owner:威海远航科技发展股份有限公司

Brewing process of mouldy bran strong-flavor Baijiu

The invention provides a brewing process of mouldy bran strong-flavor Baijiu. The brewing process relates to the field of Baijiu brewage, and comprises the following steps of smashing sticky rice, wheat, grain sorghum, peas and corns; mixing with hot water for a first time, and mixing with hot water for a second time; covering rice husks for moisturizing the material; steaming grains for gelatinizing, and cooling; adding a mixed distiller's yeast prepared from aspergillus candidus, a liquor-making yeast, a bacterium yeast and a medium-temperature starter for two times, and uniformly mixing; stacking, cellaring, and sealing with yellow mud; fermenting for 20 to 40d, distilling, carrying out ultrasonic treatment through ultrasonic wave, ageing and storing. The Baijiu brewed by applying the brewing process provided by the invention is fragrant and rich, soft and sweet, harmonious in aromas, sweet in initial taste, soft in drink, and long in tail remainder; the brewing process is simple, the production period is short, and the Baijiu can be produced in large scale.

Owner:ANHUI YUNJIU GRP

Production method of red-yeast glutinous rice wine

InactiveCN108060042ASimple production processReduce manufacturing costAlcoholic beverage preparationBiotechnologyYeast

The invention discloses a production method of red-yeast glutinous rice wine. The production method comprises the following production steps of (1), weighing and taking glutinous rice, cleanly washingby using clear water, and soaking for 1 to 3 hours by using clear water; (2), well streaming the glutinous rice, so as to obtain steamed glutinous rice; (3), cooling the well steamed glutinous rice to 35 to 38 DEG C; (4), taking sweet wine yeast, and melting by using warm boiled water at 38 DEG C or less for later use; (5), crosswise mixing red yeast with the cooled steamed glutinous rice together, wherein the weight ratio of the red yeast to the glutinous rice is (1 to 4) to 10; (6), pouring the well mixed red yeast and the steamed glutinous rice into a vat, sprinkling by using the melted sweet wine yeast, afterwards, sealing, fermenting for 12 to 24 hours, then adding rice wine brewed by a pure grain, putting the vat at a shady, cool and dry place, standing, sealing and fermenting for 60 to 200 days; (7), filtering fermented matters in the vat, taking liquid, passing inspection, bottling and sealing, so that a product can be obtained. The red-yeast glutinous rice wine is simple in production process and low in production cost, and has the functions of strengthening the spleen, eliminating stomach dryness, activating blood circulation to dissipate blood stasis, warming uterus fordispelling cold, maintaining beauty and keeping young.

Owner:曾海超

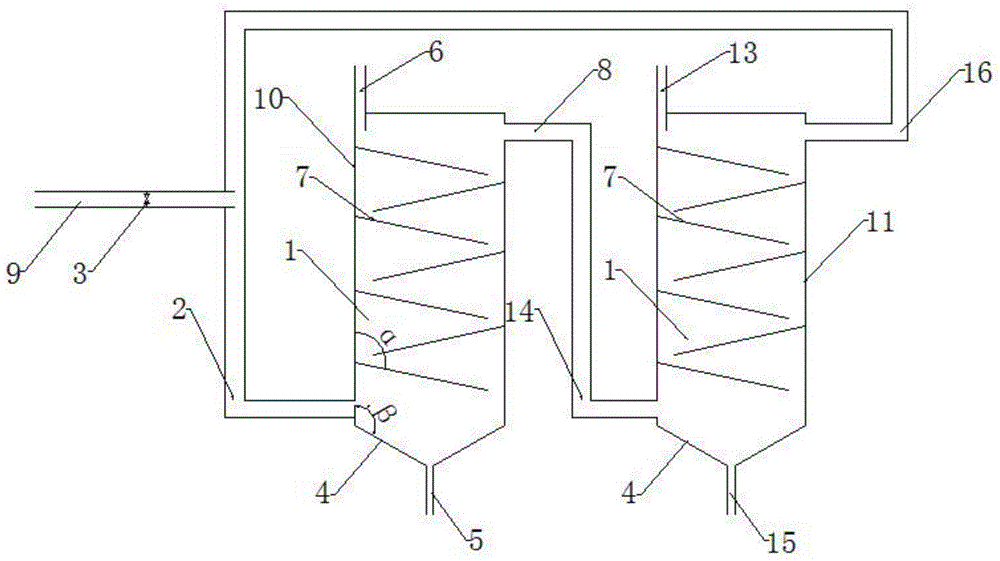

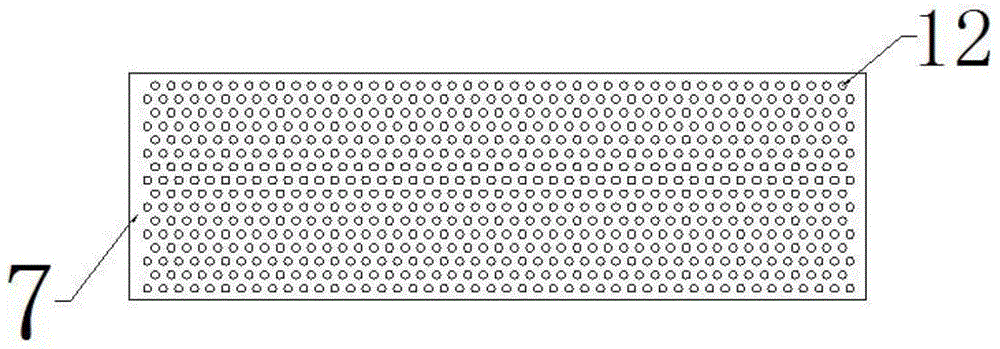

Vertical gas-solid direct heat exchange device and heat exchange method using excess heat of grains

ActiveCN104457319AEliminate the intermediate link of heat dissipationAchieve high utilizationDirect contact heat exchangersLaminated elementsEngineeringHot Temperature

The invention relates to a vertical gas-solid direct heat exchange device and a vertical gas-solid direct heat exchange method using excess heat of grains. The heat exchange device comprises two heat exchange cylinder bodies, wherein downward oblique heat exchange plates are arranged in the heat exchange cylinder bodies, and heat exchange holes are formed in the heat exchange plates; grain feed pipes are arranged at the upper parts of the heat exchange cylinder bodies, and bucket type grain collectors are arranged at the bottom parts of the heat exchange cylinder bodies; gas outlet pipes are arranged at the lower parts of the heat exchange cylinder bodies at the same sides of the grain feed pipes, and high-temperature grains enter grain cooling equipment of the heat exchange cylinder bodies; low-temperature grains enter grain preheating equipment of the heat exchange cylinder bodies, and a gas outlet of the cooling equipment is connected with a gas inlet of the preheating equipment. The gas-solid heat exchange is performed on the high-temperature grains by using the excess heat, and the heat exchange with air is performed by virtue of the gravity of the grains in the top-down flowing process, energy of hot grains at an outlet of a steaming bucket is recycled, and cold grains which do not enter the steaming bucket are preheated; the comprehensive utilization of energy is achieved. The energy source is saved, and the whole process flow is shortened.

Owner:TIANJIN UNIV

SOD active wine containing superoxide dismutase

ActiveCN111560304AIncrease wine yieldImprove antioxidant capacityMicroorganism based processesAlcoholic beverage preparationBiotechnologyDismutase

The invention discloses active wine containing superoxide dismutase, and belongs to the technical field of wine preparation. Stems and leaves of sorghum and daisy are used as raw materials, and the wine containing superoxide dismutase activity is prepared through optimization of Daqu varieties and optimization of wine production and aroma production process conditions. The wine containing superoxide dismutase activity prepared by the invention is good in quality and high in wine yield, and the wine is endowed with excellent oxidation resistance by adding daisy stem and leaf raw materials.

Owner:范维亮

Method for making papaya liquor

The invention discloses a method for making papaya liquor, and relates to the technical field of health-care liquor. According to the method, papayas, cereals and rice are fermented to obtain papaya fermented grains, cereal fermented grains and rice fermented grains respectively, and then three-stage distillation is carried out after the papaya fermented grains, the cereal fermented grains and the rice fermented grains are mixed; a method of respective fermentation of the papayas, the cereals and the rice is adopted, in the fermentation process, microorganisms in distiller's yeast take the papayas as raw materials, the papayas are saccharified and decomposed, nutritional components in the papayas are released fully, generated ester and acid substances are relatively large in quantity, the content of alcohol is relatively reduced, the prepared papaya liquor is high in yield, unique in flavor, mellow and sweet in taste, rich in aroma, pure and delicious.

Owner:陈圣明

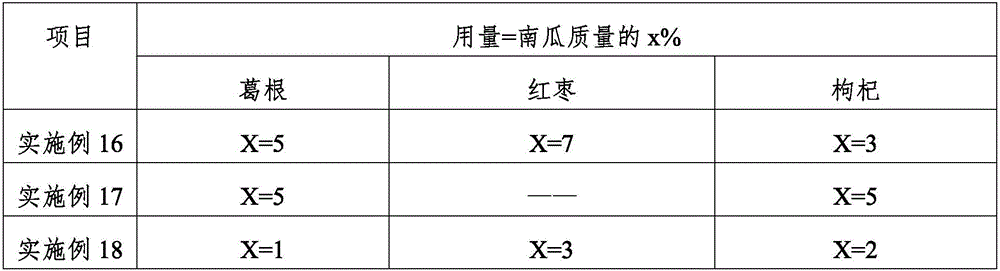

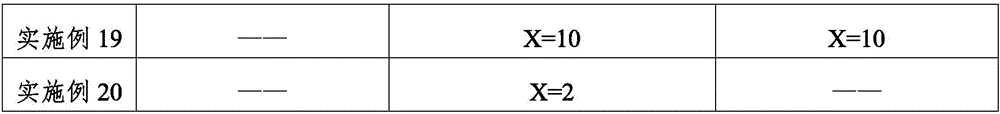

Processing method of pumpkin Baijiu

InactiveCN105754790AIncrease in soluble matterImprove total sugar contentMicroorganism based processesAlcoholic beverage preparationPumpkin seedHigh pressure

The invention relates to the technical field of processing of Baijiu, in particular to a processing method of pumpkin Baijiu. Pumpkins are heated to be well-done in a steam environment at the temperature of 80-100 DEG C firstly and then stirred into pumpkin paste, the pumpkin paste is cooled to the temperature of 50-55 DEG C, then a complex enzyme and an acidulant are added, the pH is adjusted to range from 4.0 to 5.0, the mixture is transferred to a constant-temperature environment at the temperature of 40-50 DEG C, inoculated with composite strains for fermentation and then transferred to an environment at the temperature of 15-30 DEG C, complex saccharomycetes are added for fermentation, water is added for stirring finally, then the mixture is sealed and placed for 1-2 months and subjected to high-pressure homogenization treatment, sterilization and bottling, and the finished product is obtained. Used raw materials are rich in source, few additives are consumed, the Baijiu production time is short, the Baijiu yield is high, and the prepared pumpkin Baijiu tastes pure, is good in palatability and rich in nutrition and has effects of strengthening bones and tendons, moistening the lung, tonifying qi, expelling parasites, removing toxins, realizing beautification and the like.

Owner:GUIZHOU MIAOLING MOUNTAINS ECOLOGICAL CROP DEV CO LTD

Preparation method of red yeast rice and glutinous rice wine with blood circulation activating and kidney tonifying effects

InactiveCN108048285ASimple production processReduce manufacturing costNervous disorderAlcoholic beverage preparationRed yeast riceRemove blood

The invention relates to a preparation method of red yeast rice and glutinous rice wine with blood circulation activating and kidney tonifying effects. The preparation method comprises the following steps of (1) respectively weighing black glutinous rice and white glutinous rice, cleaning by clean water, and soaking by clean water for 1 to 3h; (2) respectively steaming the black glutinous rice andthe white glutinous rice, so as to obtain steamed glutinous rice; (3) airing the steamed glutinous rice to the temperature of 35 to 38 DEG C; (4) weighing sweat distiller's yeast, and dissolving by warm boiled water for further use; (5) mixing and stirring the red yeast rice and the aired glutinous rice according to a weight ratio of (1 to 4):10; (6) pouring the mixed red yeast rice and steamed glutinous rice into a jar, spraying the dissolved sweat distiller's yeast, sealing and fermenting for 12 to 24h, adding pure grain-brewed rice wine, placing the jar in a shady dry area, standing, and sealing and fermenting for 60 to 200 days; (7) filtering fermenting matter in the jar, obtaining filtrate, and bottling and sealing after the filtrate is qualified in inspection, so as to obtain the product. The preparation method of the red yeast rice and glutinous rice wine has the advantages that the preparation technology is simple, the preparation cost is low, and the effects of activating blood circulation and removing blood stasis as well as tonifying spleen and invigorating Qi are realized.

Owner:曾海超

Preparation method for liquor or feed with corn straw as accessory material

InactiveCN105273908AImprove qualityHigh in nutrientsAlcoholic beverage preparationAnimal feeding stuffTemperature controlCentrifugation

The invention provides a preparation method for a liquor or feed with corn straw as accessory material. The preparation method comprises the following steps: 1) subjecting corn or sorghum to impurity removal and crushing, blending the crushed corn or sorghum with crushed corn straw, adding water and carrying out soaking for 1 to 5 h, with temperature controlled to be 80 to 90 DEG C; 2) carrying out draining, primary steaming and secondary steaming; 3) stirring the steamed raw materials, drying the steamed raw materials in the sun, adding distiller's yeast and barm, then adding water and adding cellulase; 4) putting the obtained mixture into vault for saccharifying and fermenting; 5) opening the vault and steaming liquor; 6) subjecting vinasse obtained after liquor steaming to centrifugation so as to produce vinasse slag; and 7) granulating the vinasse slag so as to obtain the feed.

Owner:高云

Liquor brewing method based on combination of solid fermentation and liquid fermentation

The invention discloses a liquor brewing method based on combination of solid fermentation and liquid fermentation, and belongs to the technical field of liquor brewing. The liquor brewing method combines the technical characteristics of solid state fermentation and liquid state fermentation. On the basis of solid state fermentation, fermented grains are taken out and mixed with sugar liquid witha certain concentration, the fermentation temperature is controlled, liquid state fermentation is performed, after the fermentation is completed, the liquor production is significantly increased, thecost is saved, and distillers' grains are reused.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Process and equipment for producing base liquor of white spirits by liquid-state fermentation of raw material

ActiveCN104388248AShorten the growth and reproduction timePrevent subsidenceMicroorganism based processesAlcoholic beverage preparationCooling coilEnzyme

The invention belongs to the technical field of white spirits brewing and discloses a process and equipment for producing base liquor of white spirits by liquid-state fermentation of raw material. The process comprises the following steps: activating saccharomyces cerevisiae through spread cultivation; adding the activated saccharomyces cerevisiae, rice milk and saccharifying enzyme into a fermenting tank together, wherein stirring and introduction of CO2 from the bottom of the fermenting tank are carried out at the same time during the addition process so that materials are mixed uniformly; by the end of the addition of the materials, further introducing CO2 for 5-15min; sealing the tank and fermenting for 4-6 days; after fermenting for 30-36h, introducing CO2 again from the bottom of the fermenting tank and stirring sedimentary rice milk by a mechanical stirring blade at a speed of 16-60r / min at the same time, wherein mash is obtained by the end of fermentation; and distilling the mash to obtain the base liquor. The equipment provided by the invention comprises a tank body and a stirrer, wherein a cooling coil pipe is arranged in the tank body, circular pipe ventilating equipment is arranged at the center of the bottom of the tank body, and a flow guide cylinder is arranged above the circular pipe ventilating equipment. The liquor yield and taste of liquor can be improved by the process and the equipment disclosed by the invention.

Owner:广东省九江酒厂有限公司

Technology for producing vinegar through brewing smoked jujubes

InactiveCN106047644AComposition scienceReasonable compositionDigestive systemVinegar preparationAcetic acidEnzymatic hydrolysis

The invention relates to the technical field of edible vinegar processing, and especially relates to a technology for producing vinegar through brewing smoked jujubes. The technology for producing vinegar through brewing smoked jujubes comprises the following steps: 1, preparing the following materials: dried smoked jujubes, radix bupleuri, Cordyceps militaris and Helianthus tuberosus; 2, mashing: adding water, mashing the materials and water, and separating jujube pits; 3, sterilizing: sterilizing the obtained slurry, and adjusting the pH value of the sterilized slurry; 4, carrying out enzymatic hydrolysis fermentation: adding pectase, carrying out steam heating, adding a composite yeast culture solution, and carrying out alcohol fermentation to obtain wash; 5, carrying out vinegar koji culture: taking wheat bran, adding water, steaming the wheat bran, cooling the steamed wheat bran, inoculating with a composite bacterium enzyme, and carrying out static culture; 6, blending: uniformly blending the statically cultured vinegar koji with the wash obtained in step 4, and preparing fermentation; 7, carrying out acetic acid fermentation: carrying out tank fermentation on the fermentation material prepared in step 6; 8, maturing and ageing; 9, sprinkling vinegar; and 10, sterilizing. The technology for producing vinegar through brewing smoked jujubes is scientific, and allows the jujube vinegar with good mouthfeel, nutrition, healthiness, drinking and eating combination effects to be obtained on the basis of completely reserving the nutritional components of the smoked jujubes.

Owner:济南卢氏农业科技有限公司

A kind of preparation method of distiller's yeast and distiller's yeast

ActiveCN104232401BQuality improvementIncrease wine yieldMicroorganism based processesAlcoholic beverage preparationYeastHordeum vulgare

The invention provides a distiller's yeast and a production method thereof. In the production method of the distiller's yeast, the distiller's yeast comprises the following raw materials in parts by weight: 3 parts of barley, 4 parts of wheat, 1.5 parts of soybean and 1.5 parts of peas; the adopted seed koji comprises the following raw materials by weight percent: 0.1% of aspergillus oryzae box seed koji, 0.1% of aspergillus flavus box seed koji, and 0.1% of aspergillus niger; the production method comprises the following steps: adding raw materials including barley, wheat, soybean and peas into aspergillus oryzae box seed koji, aspergillus flavus box seed koji, and aspergillus niger, evenly mixing, introducing a ventilating koji pond, adjusting the temperature to be 30-35DEG C, and standing and culturing for 6-8 hours; performing first koji turning after the koji is cultured for 12 hours in the pond, and keeping the normal temperature of 30-35DEG C; continuously culturing for 4-6 hours, and performing second koji turning; culturing for up to 24-28 hours; and drying to obtain the distiller's yeast. The distiller's yeast is prepared by adopting the production method. The distiller's yeast has stable quality, the defect existing during the process of producing the yeast from raw materials in the prior art can be avoided, and the production period can be shortened.

Owner:DANJIANGKOU QUZHIYUAN BIOTECH

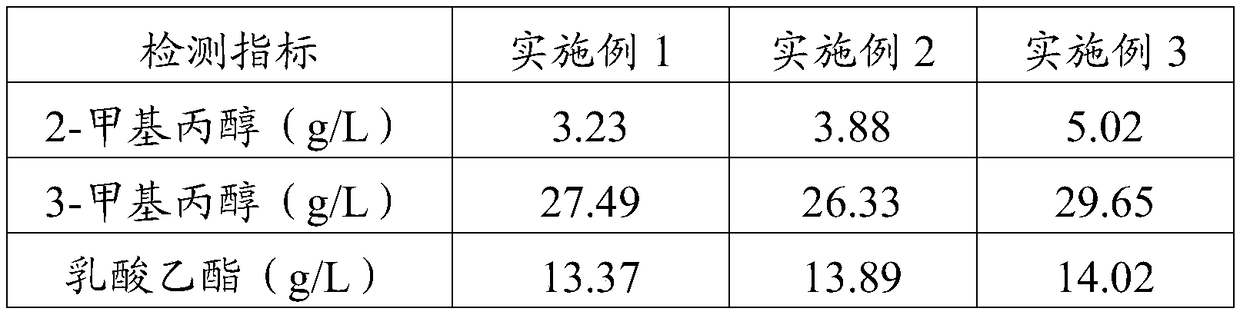

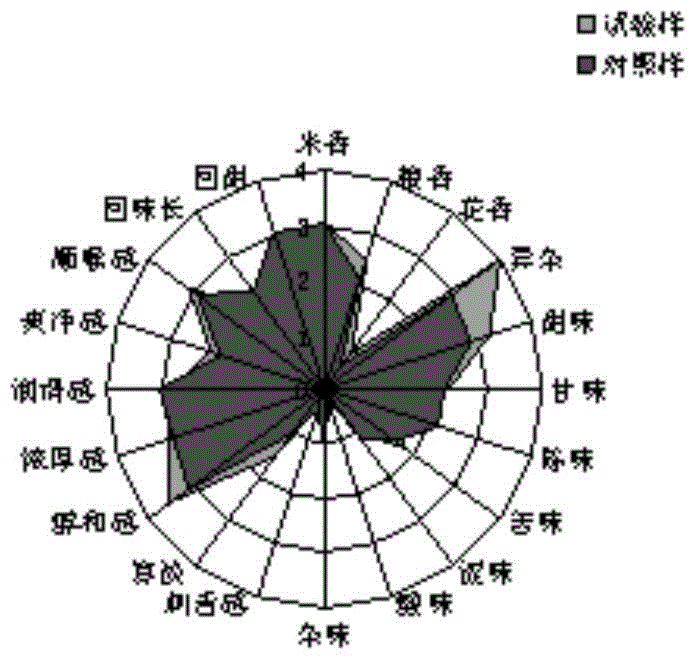

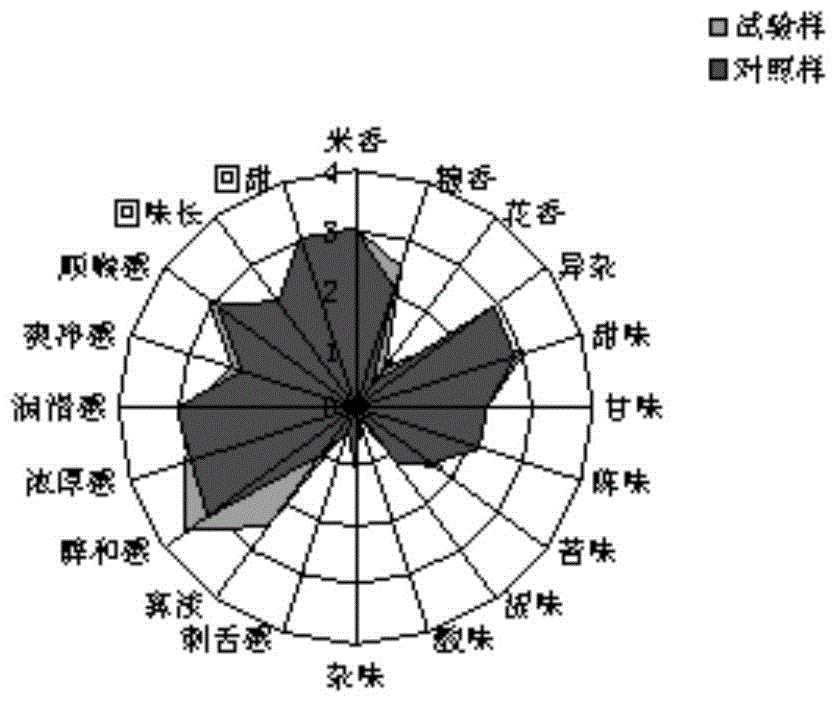

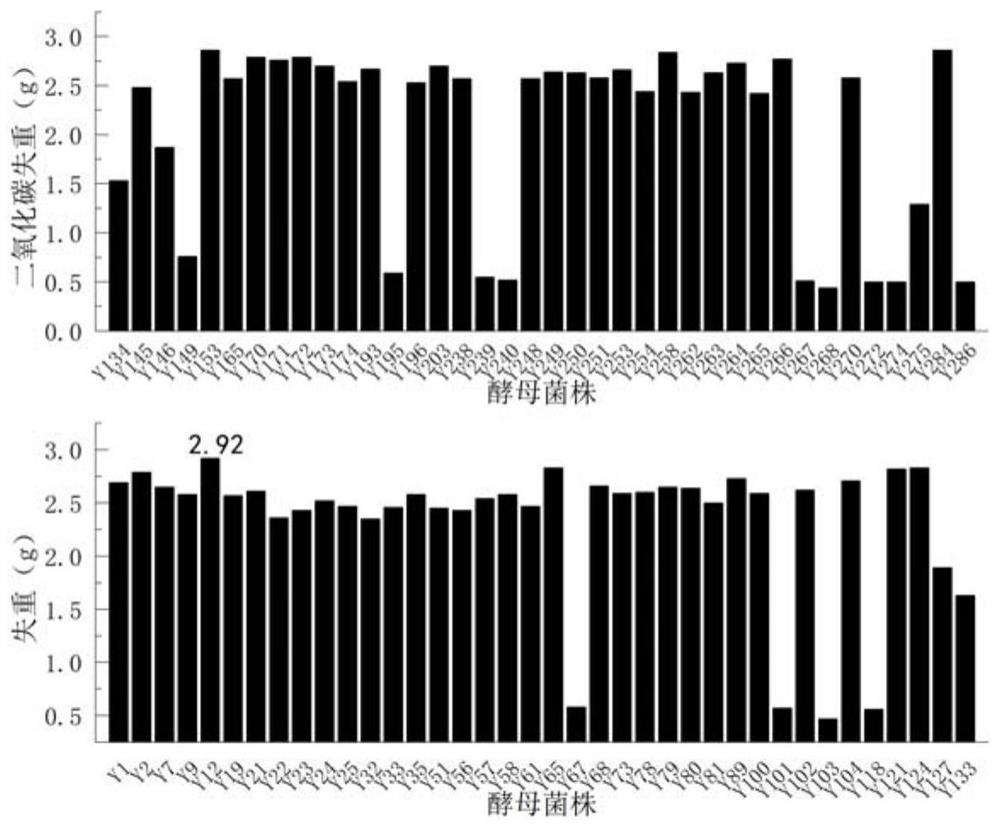

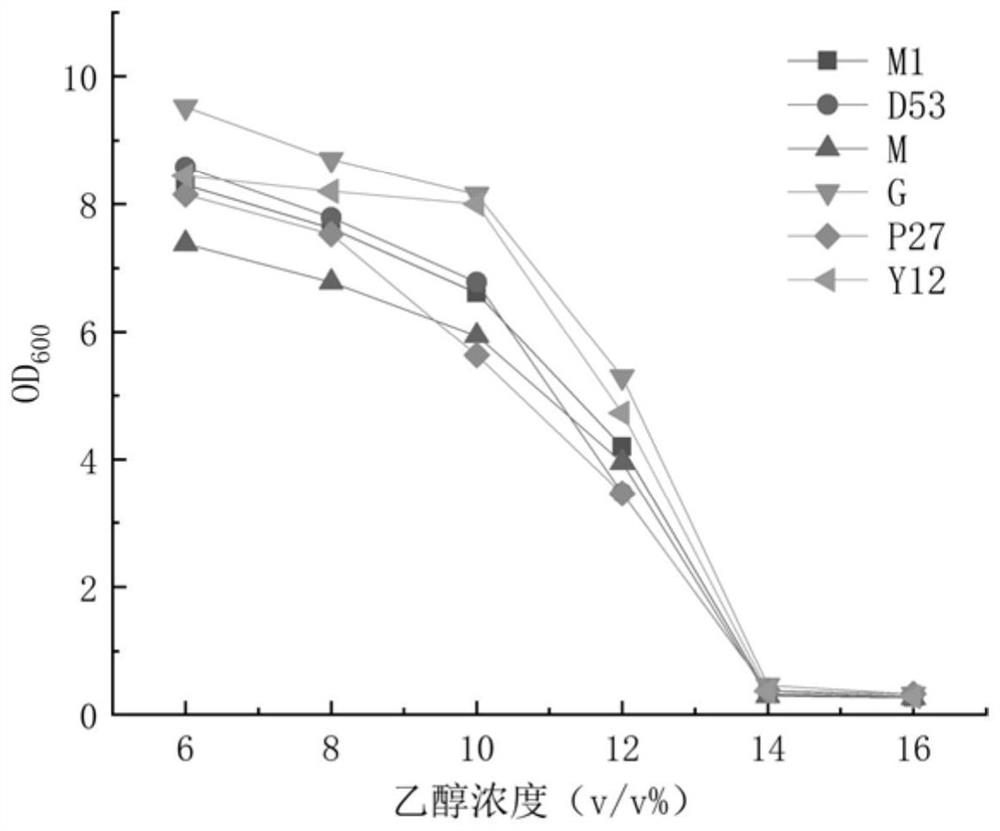

Saccharomyces cerevisiae Y12 and application of saccharomyces cerevisiae Y12 in brewing of pure macadawu raw wine

PendingCN113502234AImprove fermentation effectIncrease wine yieldFungiMicroorganism based processesBiotechnologyFusel alcohol

The invention discloses saccharomyces cerevisiae Y12 and application of the saccharomyces cerevisiae Y12 in brewing of pure macadawu raw wine. The saccharomyces cerevisiae Y12 is preserved in the China Center for Type Culture Collection on April 2, 2021, and the preservation number of the saccharomyces cerevisiae Y12 is CCTCC (China Center for Type Culture Collection) NO: M2021320. The Saccharomyces cerevisiae Y12 is separated from the distiller's yeast of Baijiu of Jiangbrand Co., Ltd., compared with commercial yeast, the Y12 shows the fermentation capacity which is not inferior to that of the commercial yeast, and the wine body has lower fusel oil and total ester content, especially the fusel oil content is 3.80 g / L which is about 42.2% and 11.2% lower than those of the commercial yeast with the highest fusel oil content and the commercial yeast with the lowest fusel oil content respectively. The saccharomyces cerevisiae is applied to brewing of pure macadamia raw wine, the fusel oil content is only 3.17 g / L, and the brewed pure macadamia raw wine is pure in fragrance and typical in style, has good commercial application potential and can be used for brewing the pure macadamia raw wine.

Owner:JING BRAND

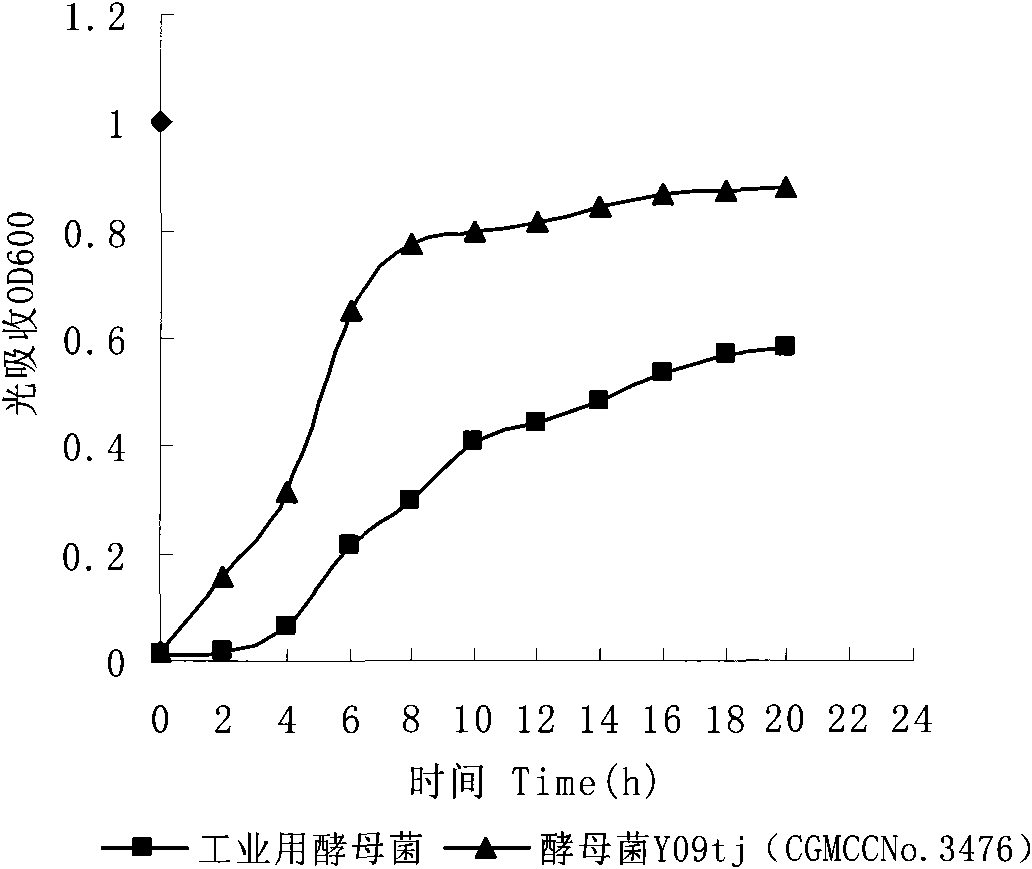

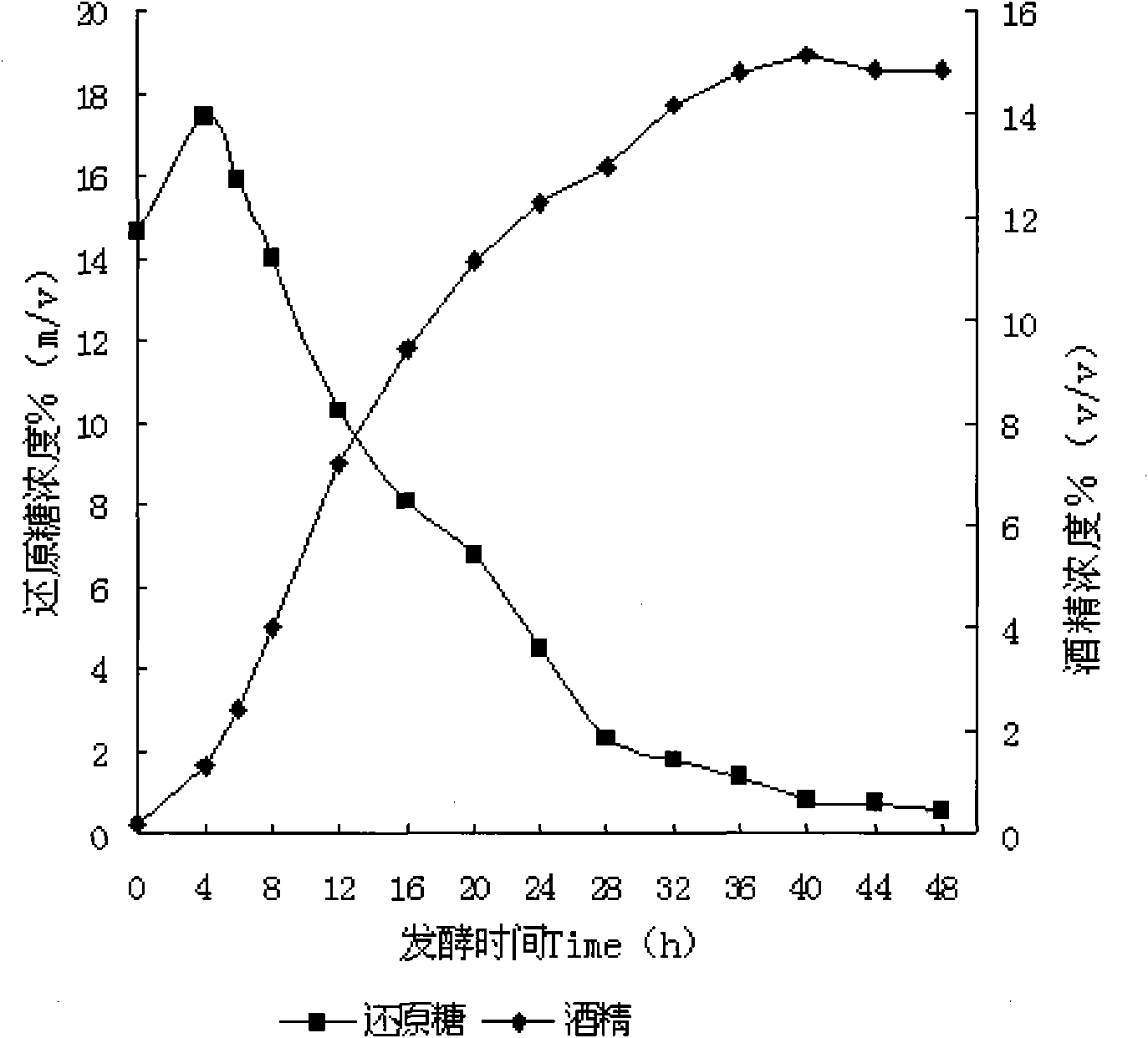

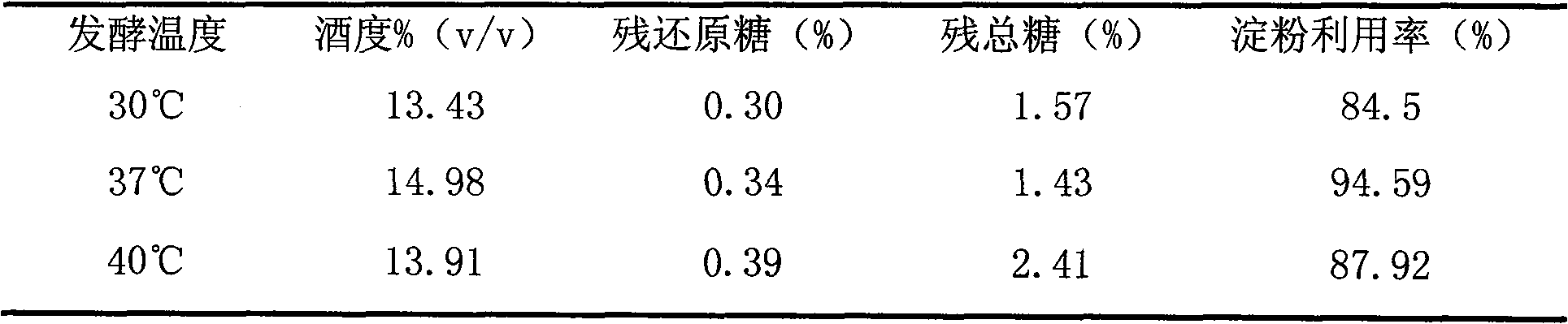

Brewing yeast strain, breeding method thereof, and application of the strain in alcohol production

InactiveCN101845404BWide growth temperature rangeGuaranteed normal fermentationFungiMutant preparationBiotechnologyAlcohol production

The invention discloses a brewing yeast strain, which has the classified name Saccharomyces cerevisiae Y09tj, and is preserved in Common Microorganism Center of China General Microbiological Culture Collection Center with the preservation number of CGMCC No.3476. The invention also provides a breeding method for the strain and a method for producing ethanol by quick high-temperature thick mash fermentation of starch. The strain is obtained by the following steps of: separating from common self-brewed sweet wine of peasant families; and performing ultraviolet mutagenesis for breeding. The brewing yeast strain CGMCC NO.3476 has the advantages of quick growth, strong fermentation capacity, high ethanol toxin resistance, and high-glucose concentration resistance of 62 percent (m / v) to the maximum. The average wine yield by the method is improved by 1.2 percent than that of other producing strains, and the wine yield can reach 16.0 percent (v / v); the fermentation period is short, and only 46 hours; the equipment utilization rate can be greatly improved; and the fermentation cost is greatly reduced.

Owner:GUANGXI ACAD OF SCI

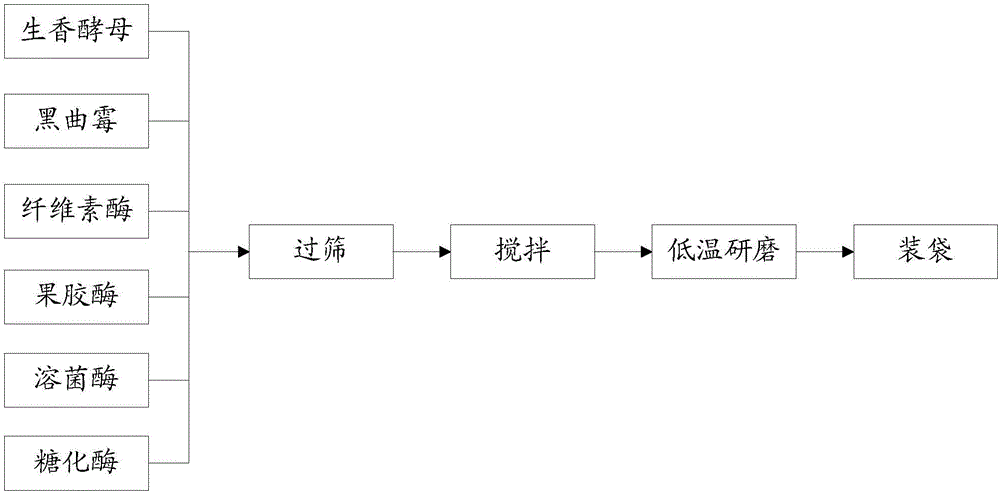

Aroma enhancement type saccharomyces cerevisiae for raw and cooked materials and preparation method thereof

PendingCN106701435AQuality improvementImprove conversion rateAlcoholic beverage preparationMicroorganism based processesCellulaseAspergillus niger

The invention discloses aroma enhancement type saccharomyces cerevisiae for raw and cooked materials. The aroma enhancement type saccharomyces cerevisiae is prepared from the following components in percentages by mass: 10 to 20 percent of aroma-producing yeast, 20 to 30 percent of aspergillus niger, 15 to 35 percent of cellulase, 15 to 25 percent of pectase, 1 to 10 percent of lysyme and 5 to 15 percent of saccharifying enzyme. The invention also discloses a preparation method of the aroma enhancement type saccharomyces cerevisiae for the raw and cooked materials. In the process of producing white spirit by utilizing the saccharomyces cerevisiae obtained by the preparation method, the lipid producing capacity is high; the conversion ratio of starch is higher than 80 percent; the enzymatic activity is higher than 43,000 / g; the obtained white spirit is pure in spirit odor, rich in pit flavor and long in aftertaste, is sweet, clear, refreshing and tasty, can be drunk without needing to be added with other additive, and is applicable to various spirit brewing processes and a vinasse discarding or vinasse recovery process.

Owner:成都醇中醇君明生物科技工程有限责任公司

A process and equipment for producing liquor-based liquor by liquid fermentation of raw material

ActiveCN104388248BShorten the growth and reproduction timePrevent subsidenceMicroorganism based processesAlcoholic beverage preparationLiquid stateCooling coil

The invention belongs to the technical field of white spirits brewing and discloses a process and equipment for producing base liquor of white spirits by liquid-state fermentation of raw material. The process comprises the following steps: activating saccharomyces cerevisiae through spread cultivation; adding the activated saccharomyces cerevisiae, rice milk and saccharifying enzyme into a fermenting tank together, wherein stirring and introduction of CO2 from the bottom of the fermenting tank are carried out at the same time during the addition process so that materials are mixed uniformly; by the end of the addition of the materials, further introducing CO2 for 5-15min; sealing the tank and fermenting for 4-6 days; after fermenting for 30-36h, introducing CO2 again from the bottom of the fermenting tank and stirring sedimentary rice milk by a mechanical stirring blade at a speed of 16-60r / min at the same time, wherein mash is obtained by the end of fermentation; and distilling the mash to obtain the base liquor. The equipment provided by the invention comprises a tank body and a stirrer, wherein a cooling coil pipe is arranged in the tank body, circular pipe ventilating equipment is arranged at the center of the bottom of the tank body, and a flow guide cylinder is arranged above the circular pipe ventilating equipment. The liquor yield and taste of liquor can be improved by the process and the equipment disclosed by the invention.

Owner:广东省九江酒厂有限公司

Production method of monascus glutinous rice wine containing dietary fibers

InactiveCN108070495ASimple production processReduce manufacturing costAlcoholic beverage preparationDietary fibreHorticulture

The invention discloses a production method of monascus glutinous rice wine containing dietary fibers. The production method includes the steps of weighing and obtaining sticky rice, using clean waterto clean the sticky rice, and soaking the sticky rice for 1-3 hours; steaming the sticky rice till the sticky rice is cooked well, extinguishing the fire and braising the sticky rice for 10-20 minutes to obtain glutinous rice; cooling the cooked glutinous rice till the temperature of the glutinous rice is 35-38 DEG C; blending monascus with the cooled glutinous rice; putting the glutinous rice blended with monascus into a vat, carrying out sealed fermentation for 12-24 hours, then adding rice wine brewed by pure grains into the vat, putting the vat still in a shady cool dry place for sealed fermentation for 60-200 days, and controlling the temperature at 28-35 DEG C, wherein the weight ratio of the added rice wine brewed by the pure grains to the glutinous rice is (2-3):(4-5); filtering fermented substances in the vat to obtain a filtrate, and bottling the filtrate after the filtrate successfully passes examination to obtain a finished product. The monascus glutinous rice wine is simple in production process, low in production cost, capable of maintaining original medicinal effects of monascus and abundant in dietary fiber.

Owner:曾海超

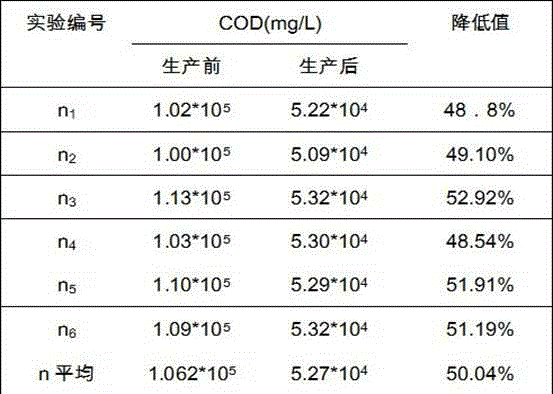

Method for producing alcohol by aid of yellow ginger hydrolysis waste water

InactiveCN105087658AIncrease productivitySimple processing methodFermentationChemical oxygen demandAlcohol

The invention relates to a method for producing alcohol by the aid of yellow ginger hydrolysis waste water. The method includes neutralizing the yellow ginger hydrolysis waste water by the aid of limestone so as to regulate a PH (potential of hydrogen) value of the waste water until the PH value reaches 2-3; regulating the PH value by the aid of alkali Ca(OH)<2> or NaOH until the PH value reaches 3.8-4.5; fermenting the yellow ginger hydrolysis waste water by the aid of yeast and distilling the yellow ginger hydrolysis waste water to obtain the alcohol. The method has the advantages that the yellow ginger hydrolysis waste water generated in hydrolysate producing procedures in yellow ginger processing enterprises is comprehensively utilized by the aid of the method for producing the alcohol by the aid of the yellow ginger hydrolysis waste water and is used as a raw material, accordingly, the high-purity alcohol can be produced, the COD (chemical oxygen demand) content of the yellow ginger hydrolysis waste water can be greatly reduced, the technological method is simple, and the alcohol produced from the waste water is high in yield.

Owner:BAIHE YONGHONG CHEM CO LTD

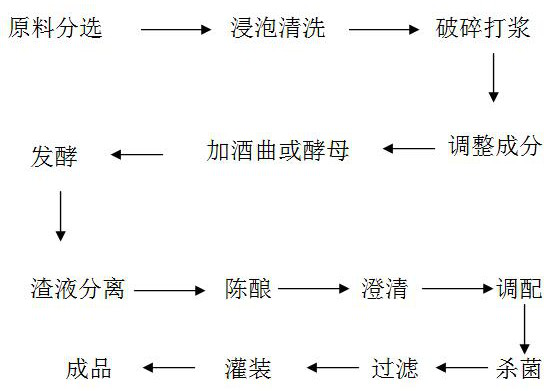

Citrus wine, brewing process of citrus brandy and citrus brandy

PendingCN114574308APromote rapid reproductionGuaranteed tasteAlcoholic beverage preparationBiotechnologyYield (wine)

The preparation method comprises the following steps: sorting raw materials of high-quality oranges, soaking and cleaning, peeling, denucleating, crushing and pulping, juicing, adjusting components, adding distiller's yeast or yeast, carrying out primary fermentation, carrying out secondary fermentation, carrying out residue-liquid separation, ageing, clarifying, blending, sterilizing, filtering and filling to obtain a finished product. According to the method, the wine yield and the savoury and mellow taste are effectively improved, the fragrance is refreshing, meanwhile, the health care effect is achieved, the wine yield is effectively improved through multiple times of fermentation, rapid propagation of thalli is facilitated, the influence of infectious microbes on the fermentation effect is reduced, and the taste of the citrus wine is guaranteed. The orange wine can treat stagnation and flatulence, can treat some flatulence symptoms, and can play a role in ventilating and regulating qi and playing a role in guiding qi downward; the orange wine can play a role in promoting blood circulation and stopping bleeding, and the orange wine contains vitamin P and has the effects of dredging collaterals and promoting blood circulation; the orange wine can regulate qi to alleviate pain, also has an analgesic effect, is a natural analgesic, can be drunk for improvement, and has a very remarkable effect.

Owner:湖南雅大智能科技有限公司

Yellow rice wine with coldness dispelling and stomach warming functions and preparation method of yellow rice wine

InactiveCN108424822AImprove starch gelatinizationIncrease wine yieldDigestive systemAlcoholic beverage preparationHorticultureRice flour

The invention discloses yellow rice wine with coldness dispelling and stomach warming functions and a preparation method of the yellow rice wine. The yellow rice wine is prepared from raw materials inparts by weight as follows: 40-60 parts of glutinous rice flour, 20-30 parts of wheat flour, 6-9 parts of oolong tea, 4-6 parts of magnolia denudate petals, 8-12 parts of rhizoma galangae, 4-6 partsof cortex cinnamomi, 3-5 parts of radix angelicae, 2-3 parts of rhizoma atractylodis, 3-5 parts of acid-soluble soybean protein, a proper amount of compound enzyme, a proper amount of a saccharifyingagent and a proper amount of dry yeast for yellow rice wine. Multiple natural raw materials with stomach warming, coldness dispelling, spleen tonifying and stomach nourishing functions are selected, aconventional yellow rice wine production process is improved, effective ingredients of raw materials can be sufficiently reserved, the nutritional and healthy value of the yellow rice wine is increased, and the finished yellow rice wine is clear, tastes soft, has unique flavor and tangy bouquet, remarkably keeps fragrance lasting and is high in stability.

Owner:安徽省禾裕黄酒有限公司

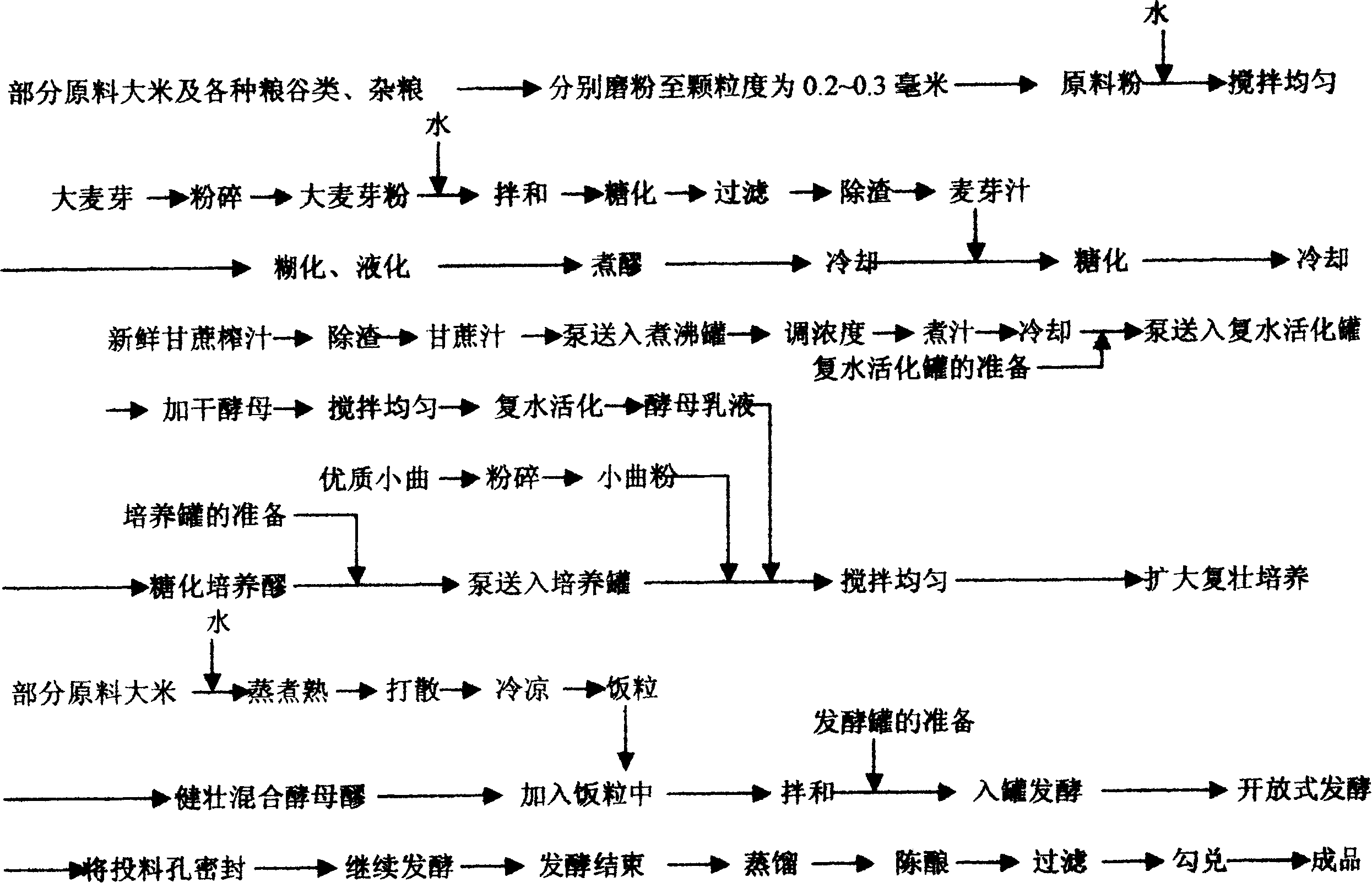

Method for making spirit with cereal grain as raw materials by using enzyme method fermentation multiple-yeast mixed-culturing technology

InactiveCN100371431CPromote reproductionPromote rejuvenationAlcoholic beverage preparationBiotechnologyYeast

The invention relates to a method for making spirit with cereal grain as raw materials by using enzyme method fermentation multiple-yeast mixed-culturing process, which comprises, activating dried yeast with sugarcane juice, disintegrating ditty and barley malt, watering for saccharifying to obtain malt extract, milling part of rice, grain, coarse cereal and mixing, charging water and liquifying enzyme for gelatinization, liquefying and charging malt extract and saccharifying enzyme, obtaining saccharified culture wine, mixing with disintegrated ditty and activated yeast emulsion, cooking the residual rice and fermenting 50-70 hours, semi-solid fermenting 12-14 days with sealing method, finally processing distillation, filtering and mixing.

Owner:黄艳文 +1

How to make papaya wine

InactiveCN106967563BReduce contentUnique flavorAlcoholic beverage preparationBiotechnologyChaptalization

Owner:陈圣明

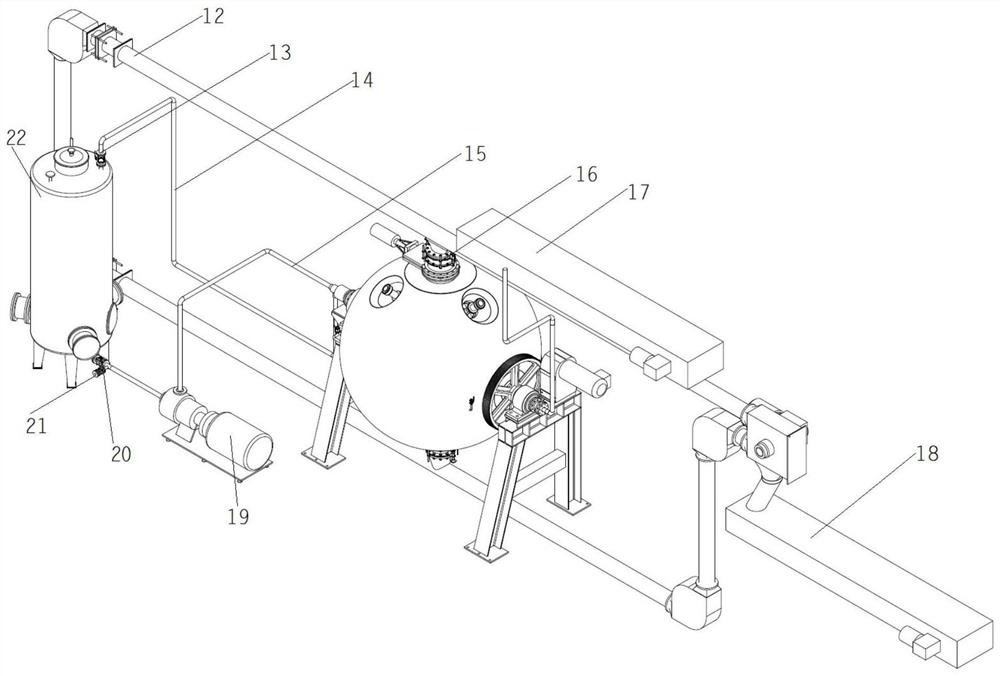

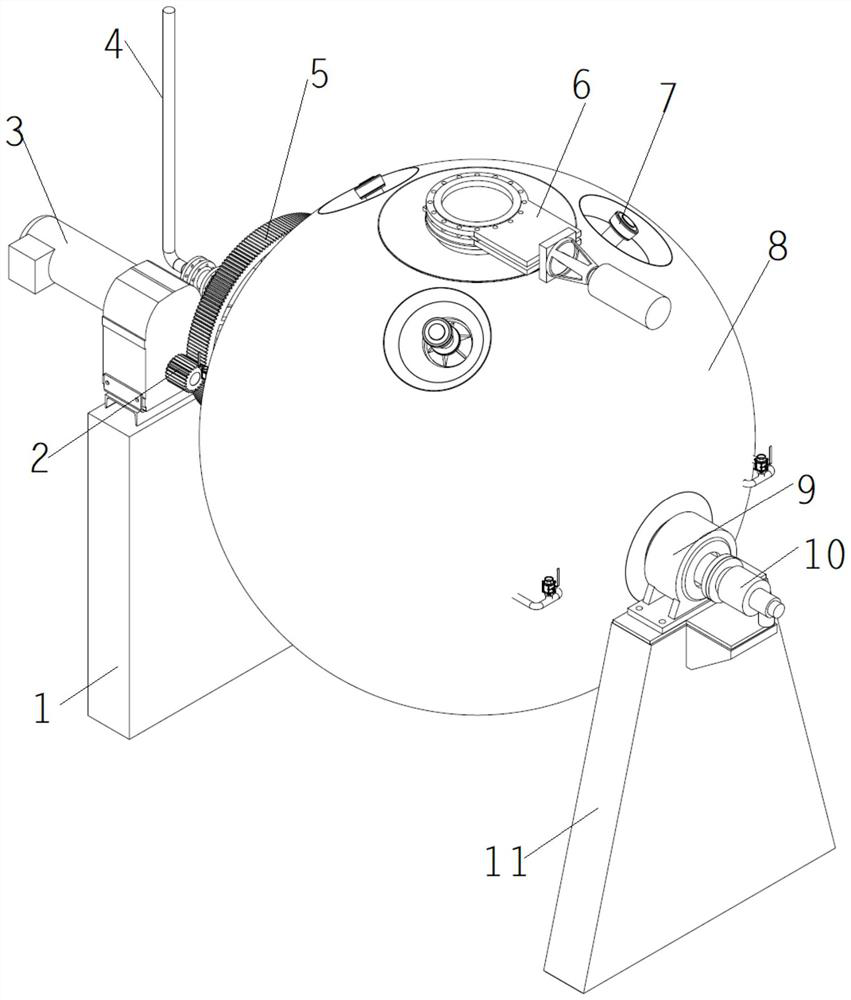

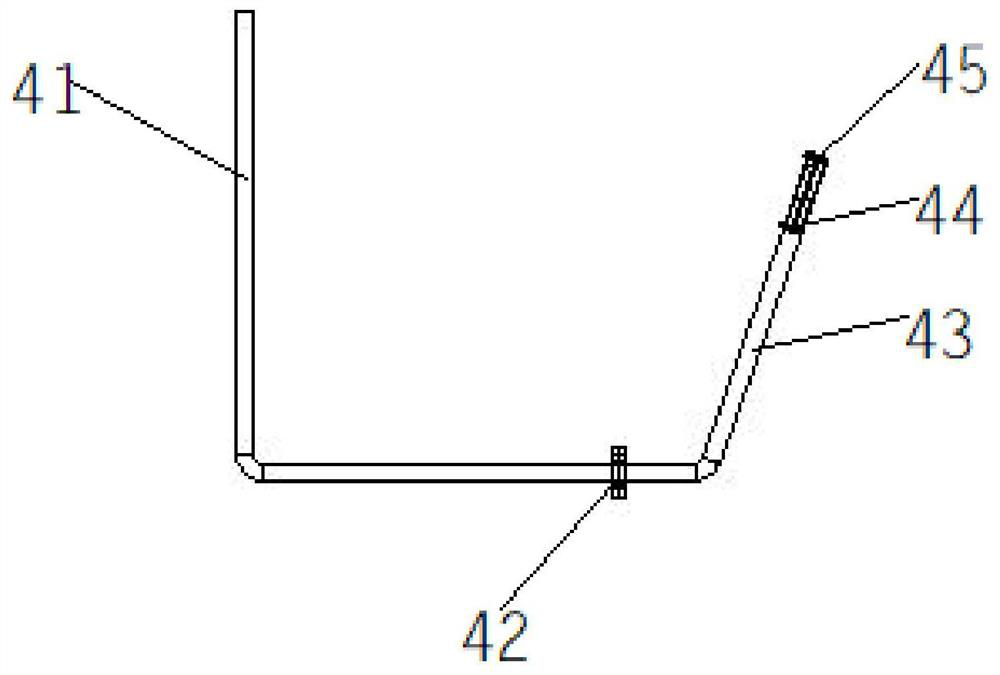

Yeast powder screening system

PendingCN114164069ARealize uninterrupted continuous productionImprove efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsMicroorganismYeast

The invention relates to the technical field of food processing, and provides a yeast powder screening system. Comprising a pipe chain conveyor, a closed belt feeding conveyor, a closed belt discharging conveyor, a hot water pump, a hot water tank and yeast powder heating equipment, the closed belt feeding conveyor is connected with the pipe chain conveyor, the pipe chain conveyor is connected with the yeast powder heating equipment and the closed belt discharging conveyor, and the hot water pump is connected with the yeast powder heating equipment; the yeast powder heating equipment is provided with a support, the support is provided with a driving device and a rotating structure, and the driving device drives the rotating structure to rotate on the support; a heating assembly is arranged on the rotating structure, and the heating assembly is used for heating the yeast powder which is uniformly stirred in the rotating structure to a certain temperature so as to screen out microorganisms and bacteria which are weak in vitality and poor in heat resistance in the yeast powder. The yeast powder screening device has the beneficial effects that yeast powder materials are automatically conveyed, output, heated and screened, uninterrupted continuous production can be achieved, and the yeast powder screening efficiency and quality are improved.

Owner:普瑞特机械制造股份有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com