Grapefruit brandy and preparation method thereof

A technology of brandy and pomelo, which is applied in the field of wine making, can solve the problems of poor flavor and taste, and achieve the effect of increasing added value, improving anti-risk ability, and extending the industrial chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

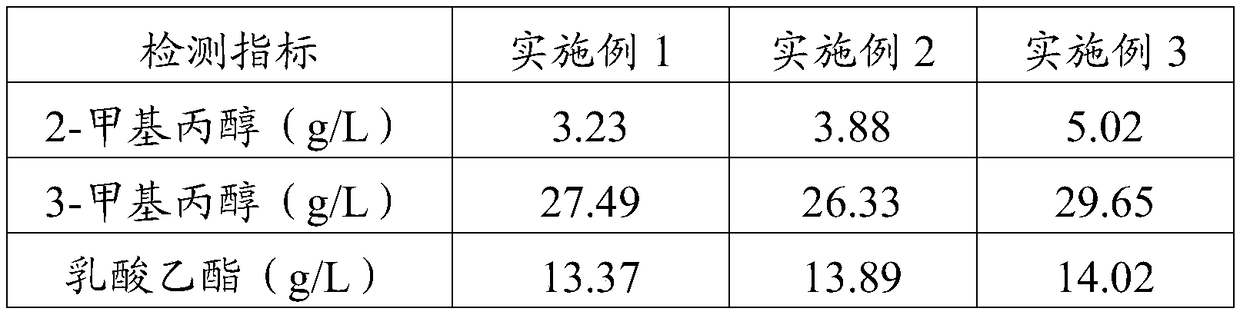

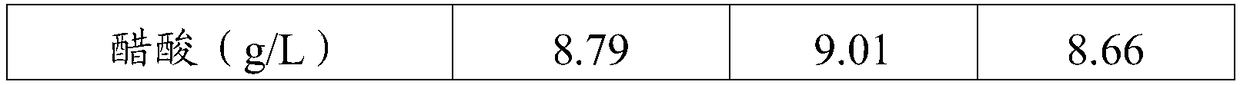

Examples

preparation example Construction

[0027] The present invention provides a kind of preparation method of pomelo brandy, comprises the following steps:

[0028] 1) The pomelo pulp is crushed and beaten, and the obtained pulp is heated to 105-115° C. to obtain the pulp of inactivated pectin;

[0029] 2) mixing the pulp of the inactivated pectin in the step 1), sugar and water to obtain the blended pulp;

[0030] The mass ratio of the pulp, sugar and water of the inactivated pectin is 10:0.9~1.1:9~11;

[0031] 3) mixing the blended pulp of the step 2) with yeast, and aerobically fermenting at 25-40° C. for 6-8 days to obtain the first fermentation product;

[0032] Stirring was carried out 1 to 3 times a day in the first 3 days of the fermentation;

[0033] 4) anaerobically fermenting the first fermentation product in step 3) at 20-25°C and an ambient humidity of 70%-85% for 28-32 days to obtain a second fermentation product;

[0034] 5) separating the solid-liquid of the second fermentation product in step 4),...

Embodiment 1

[0048] The pomelo pulp was crushed and beaten, and the obtained pulp was heated in steam at 105° C. for 3 minutes to obtain the pulp of inactivated pectin. Mix the pulp of the inactivated pectin, sugar and water (the mass ratio of the pulp of the inactivated pectin, sugar and water is 10:0.9:11), stir at a speed of 600r / min for 2min, and obtain the blended fruit. pulp. Mix the prepared fruit pulp with yeast and pomelo peel (the mass ratio of prepared fruit pulp, yeast and pomelo peel is 50:9:2, and the yeast is self-prepared yeast, the specific method is: mix raisins, water and white sugar by 1 : mixed at a mass ratio of 0.9:0.2, placed at 22°C for 5h under the condition of humidity above 85%, to obtain yeast.), fermented at 25°C for 8 days (the first 3 days of fermentation were carried out at a speed of 480r / min every day) 3 times of stirring, each stirring for 2min), to obtain the first fermentation product. The first fermentation product was anaerobically fermented for 32...

Embodiment 2

[0050] The pomelo pulp was crushed and beaten, and the obtained pulp was heated in steam at 115° C. for 2 minutes to obtain the pulp of inactivated pectin. Mix the pulp, sugar and water of the inactivated pectin (the mass ratio of the pulp, sugar and water of the inactivated pectin is 10:1.1:9), and stir for 1min at a speed of 480r / min to obtain the blended fruit. pulp. Mix the prepared fruit pulp with yeast and pomelo peel (the mass ratio of prepared fruit pulp, yeast and pomelo peel is 50:11:3, and the yeast is self-prepared yeast, the specific method is: mix raisins, water and white sugar by 1 : 1.1:0.1 mass ratio, placed at 28°C for 3.5h under the condition of humidity above 85%, to obtain yeast.), fermented at 40°C for 6 days (in the first 3 days of fermentation, with a rotating speed of 180r / min every day Carry out 2 stirrings, each stirring 1min), obtain the first fermentation product. The first fermentation product was anaerobically fermented for 28 days under the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com