Patents

Literature

80results about How to "Solve the backlog" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rubbish classification operation and management system and method

ActiveCN105035600ASolve the backlogSolve wasteRefuse receptaclesResourcesVideo monitoringInformation processing

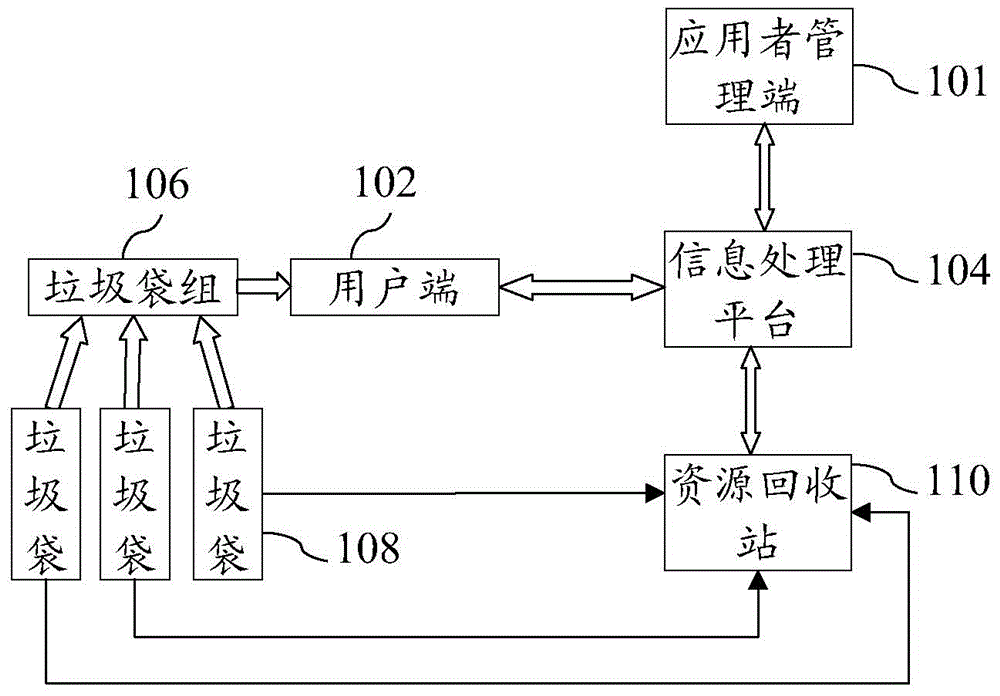

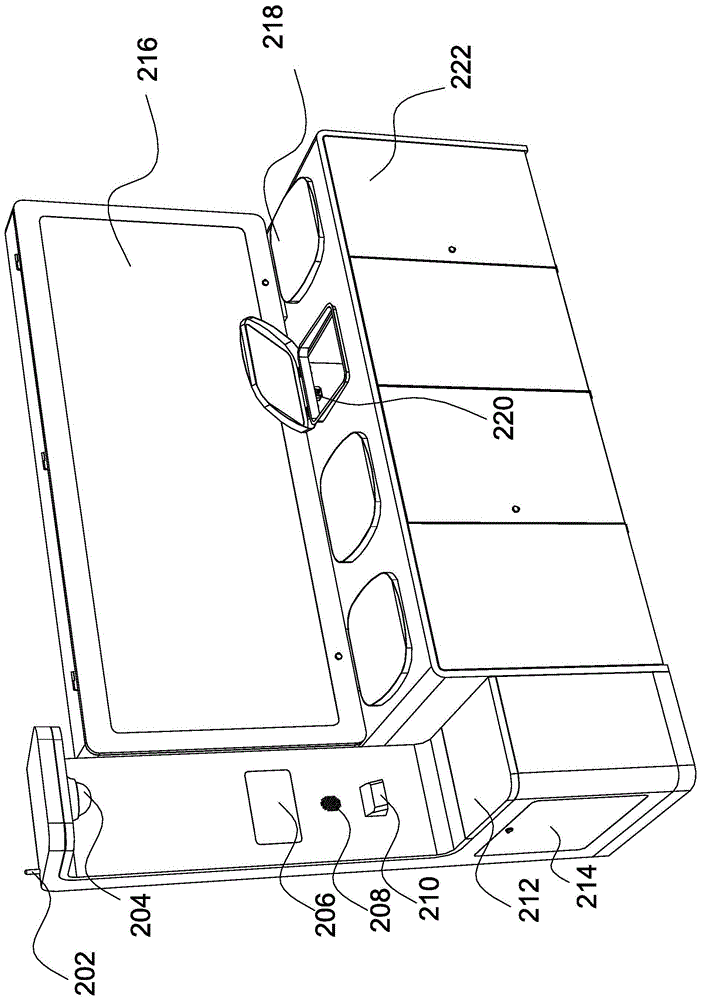

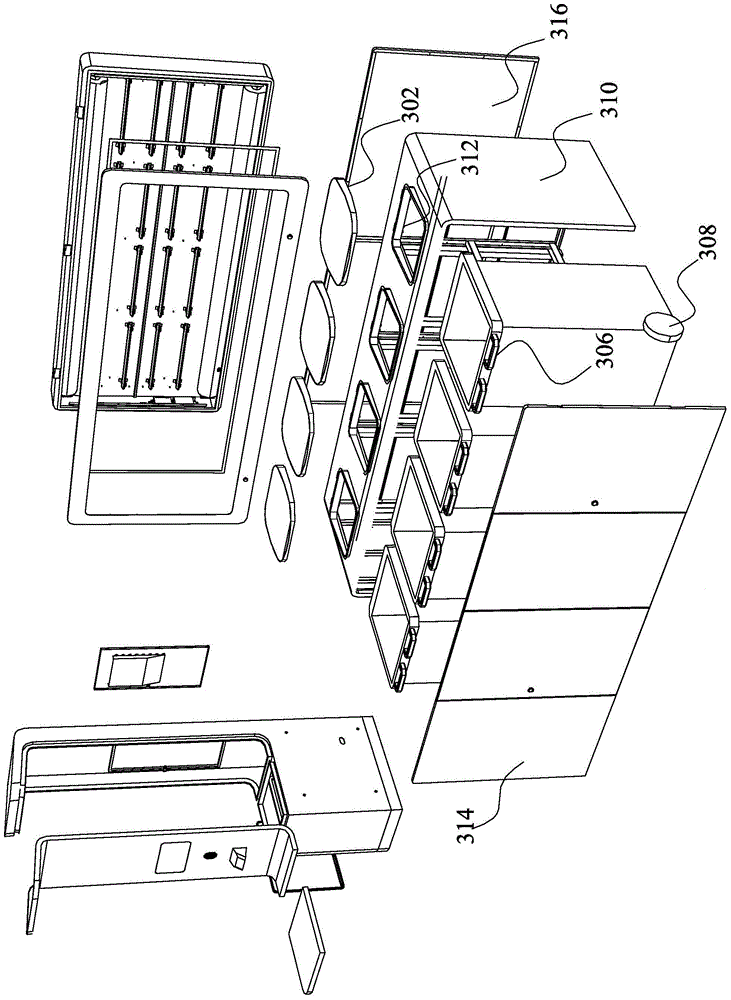

A rubbish classification operation and management system comprises a user terminal, an information processing platform, a user management terminal and a resource recovery station. The user terminal is used by a user, provided with a user account and used for scanning two-dimensional codes on a rubbish bag group of a plurality of rubbish bags, and therefore the serial number of the bar codes of each rubbish bag in the rubbish bag group can be associated with the user account. The resource recovery station comprises a bar code scanner, a voice module, a video module, a plurality of classification rubbish cans, a data transmission module and a control module. The bar code scanner is used for scanning the bar codes of the rubbish bags. The video module is used for performing video monitoring on the user. The voice module is used for performing voice guidance on the user and guiding the user to throw rubbish into the correct classification rubbish cans. The control module controls the data transmission module to send the information of the rubbish bags to the user management terminal through the information processing platform. The user management terminal is used for pushing rubbish throwing information and integral information to the user terminal.

Owner:SHENZHEN DECISION ENVIRONMENTAL ENG CO LTD

Garment customization production process automatic management system and management method

InactiveCN103870937AEasy to operateRealize streamlined productionResourcesProduction lineComputer module

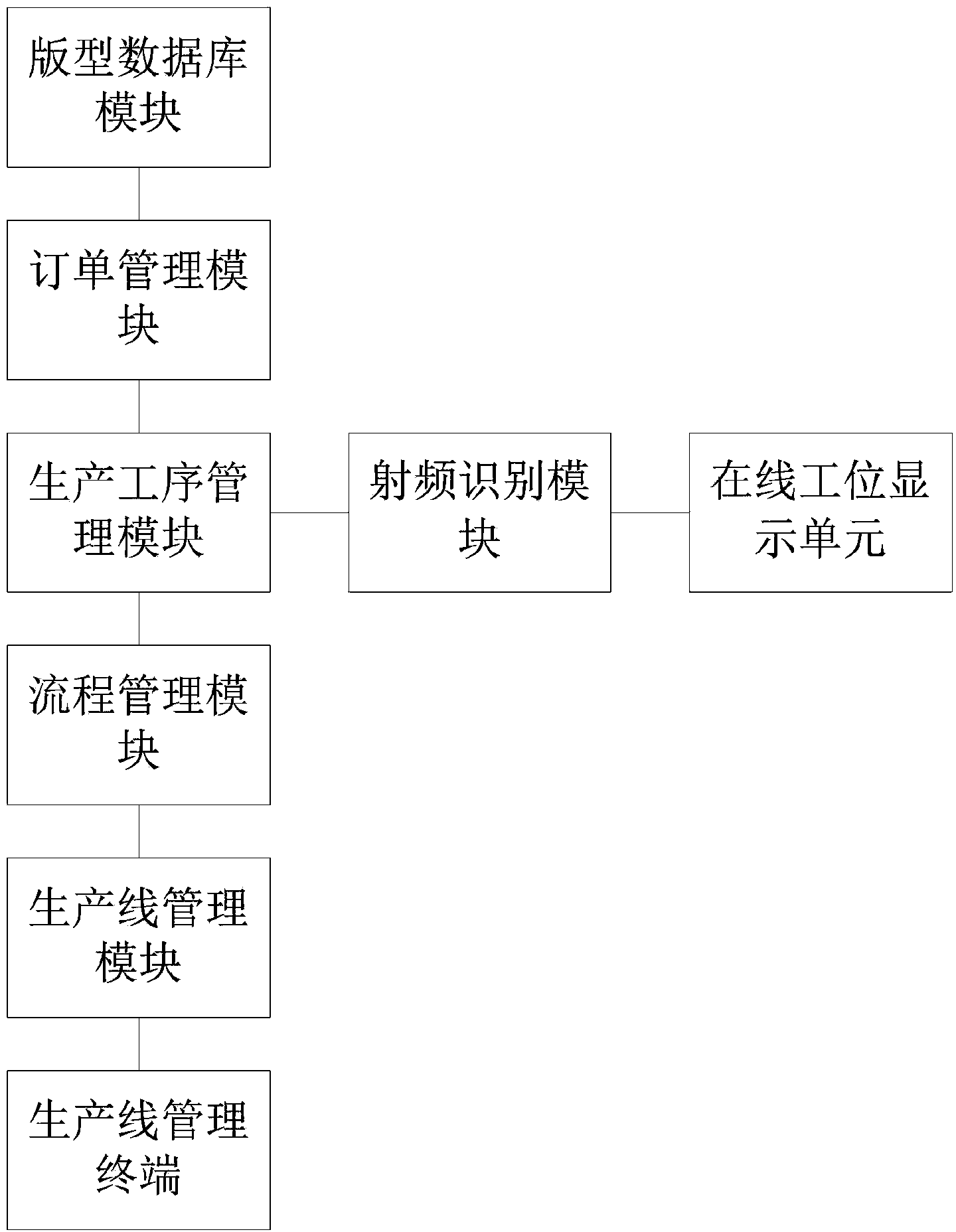

The invention relates to a garment customization production process automatic management system and management method. The management system comprises a model database module, an order management module, a production procedure management module, a process management module, a production line management module, a production line management terminal and a radio frequency recognition label and an online station display unit. According to the management method, functions of the system modules are taken into consideration comprehensively, and efficient streamline management of the production process can be achieved. The system divides production procedures and design elements in detail according to characteristics of garment customization, order information is analyzed into the design elements and converted into specific production procedures, the management system converts customization orders into the special production procedures, and production management and operations of operation workers are facilitated. Streamline production of personal customized garments can be achieved.

Owner:青岛酷特智能股份有限公司

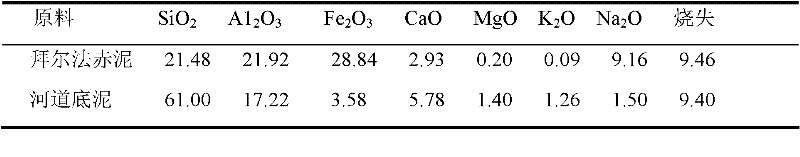

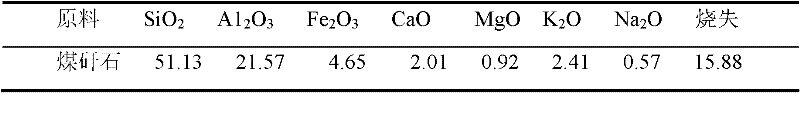

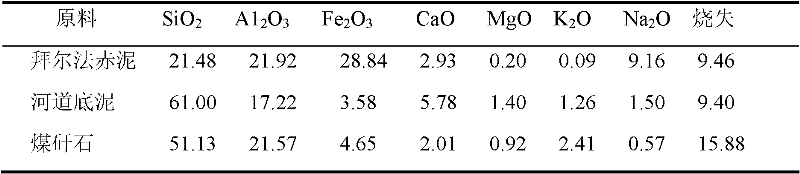

Preparation method of ceramsite filter material for water treatment

The invention provides a preparation method for a ceramsite filter material for water treatment. The method is characterized by comprising the following steps: (1) mixing Bayer red mud powder in aluminum manufacturers in Shangdong province, river sediment powder in Xiaofu River at the section of Huangtuya in Zibo city of Shangdong province, gangue powder and a pore forming agent according to a mass ratio of 40-50:40-50:0-5:5-10 to obtain a mixture; (2) putting the mixture into a pan granulator and adding water, the mass of which is 20 to 25% of the mixture, for granulation into spherical particles with phi being 3 to 10 mm; (3) sintering and cooling the spherical particles after drying so as to obtain the ceramsite filter material. According to the invention, Bayer red mud powder in aluminum manufacturers in Shangdong province and river sediment powder in Xiaofu River at the section of Huangtuya in Zibo city of Shangdong province are used as the main raw materials and added at an equal or substantially equal amount, and a small amount of the pore forming agent is blended for the preparation of the ceramsite filter material; therefore, low cost is realized, the problem of flood passage capability of rivers is overcome, and environment pollution and land occupation caused by accumulation of Bayer red mud are simultaneously eliminated.

Owner:SHANDONG UNIV OF TECH

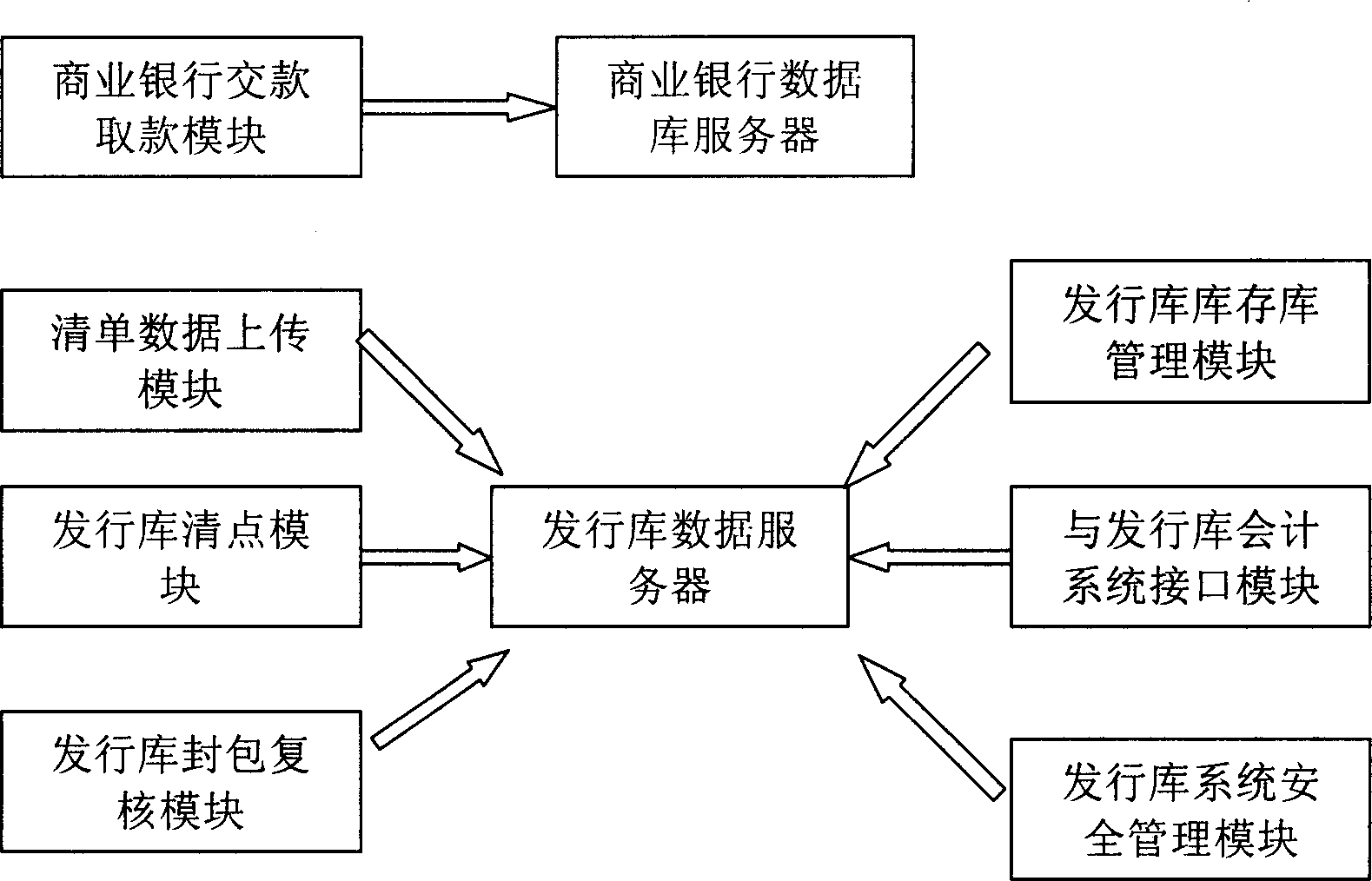

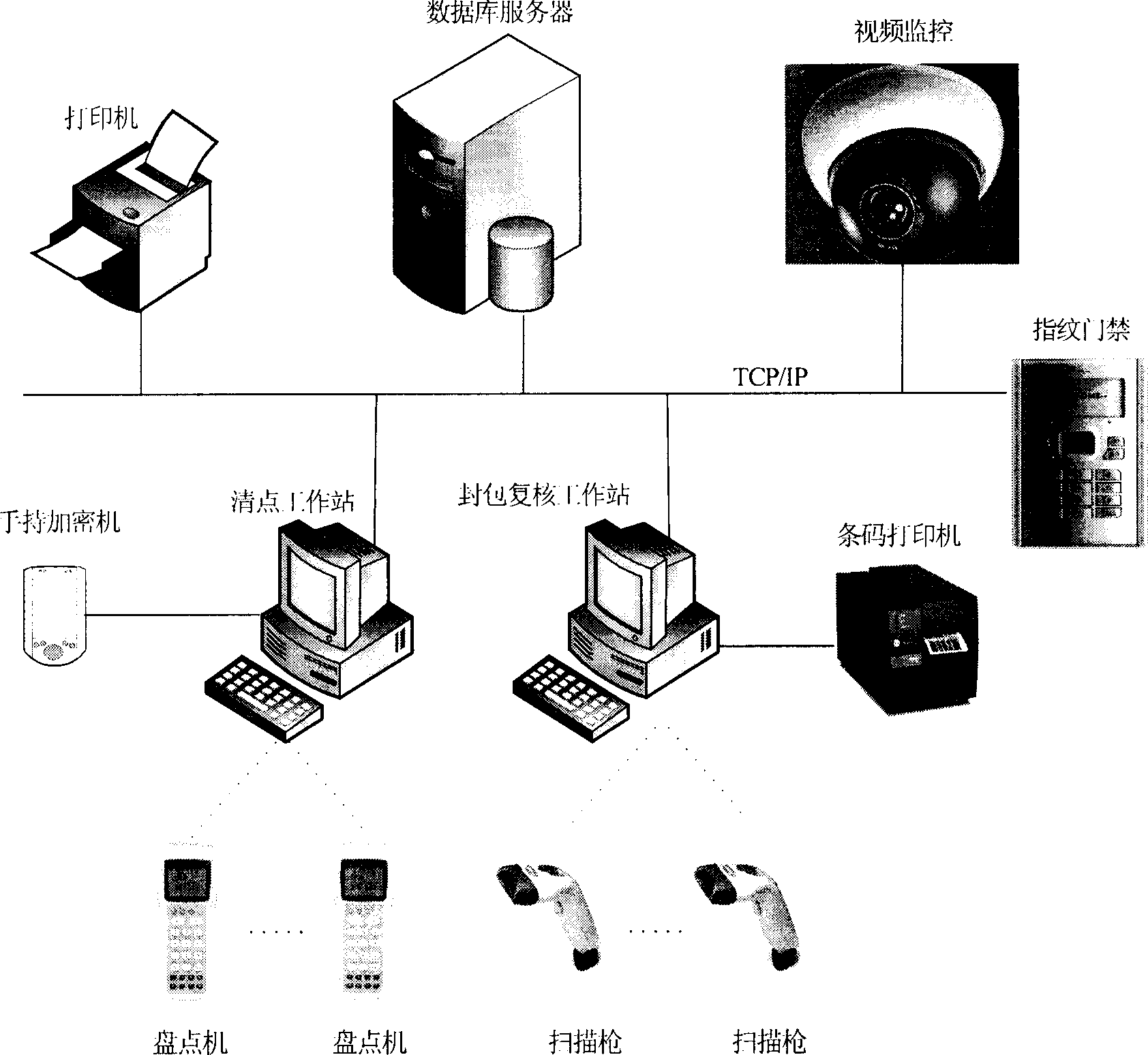

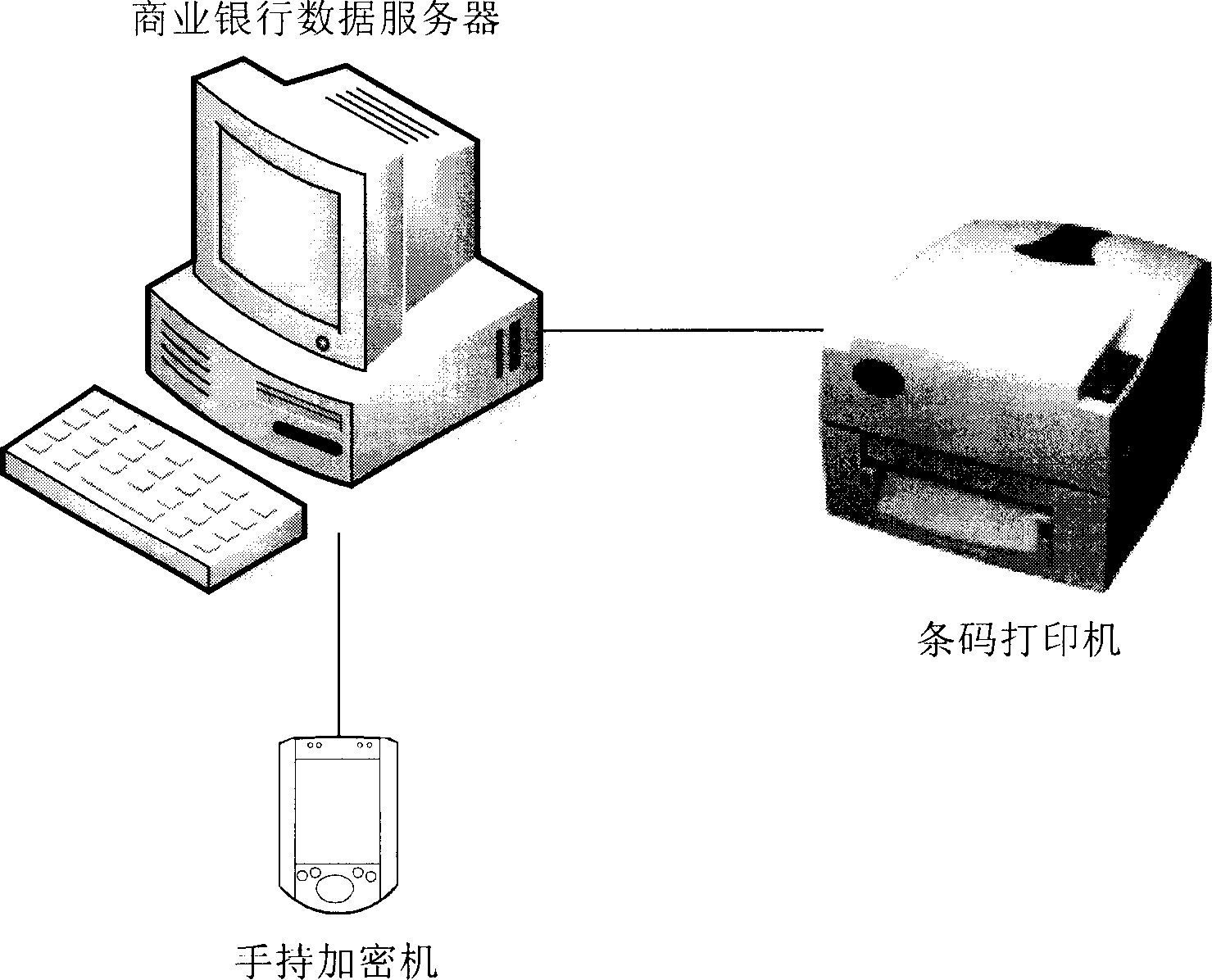

Coin warehouse-in and warehouse-out checking method and supporting system based on discriminating sign

ActiveCN1855154ASafe Electronic Operation MethodSafe deliveryComplete banking machinesData processing applicationsSupporting systemComputer science

The invention is a money inventory method for in and out of bank. Dispose the money for deposited into holds and bundles and set the first or second label on each of them. The commercial bank data server creates electron material list for imported money by each label, downloads into the encrypted storage equipment and carries to the data server of the emission bank by equipment or bank network, Changes the storage account information by automatically checking the amount and checking to the money according the said material list and the label. It can ameliorate the money inventory method for in and out of bank and checking process without depending on manpower checking the number, accounting and checking. It is a safe, convenience, shortcut and high efficiency electron method to deliver and distill money.

Owner:SHENZHEN POKA ELECTRONICS EQUIP

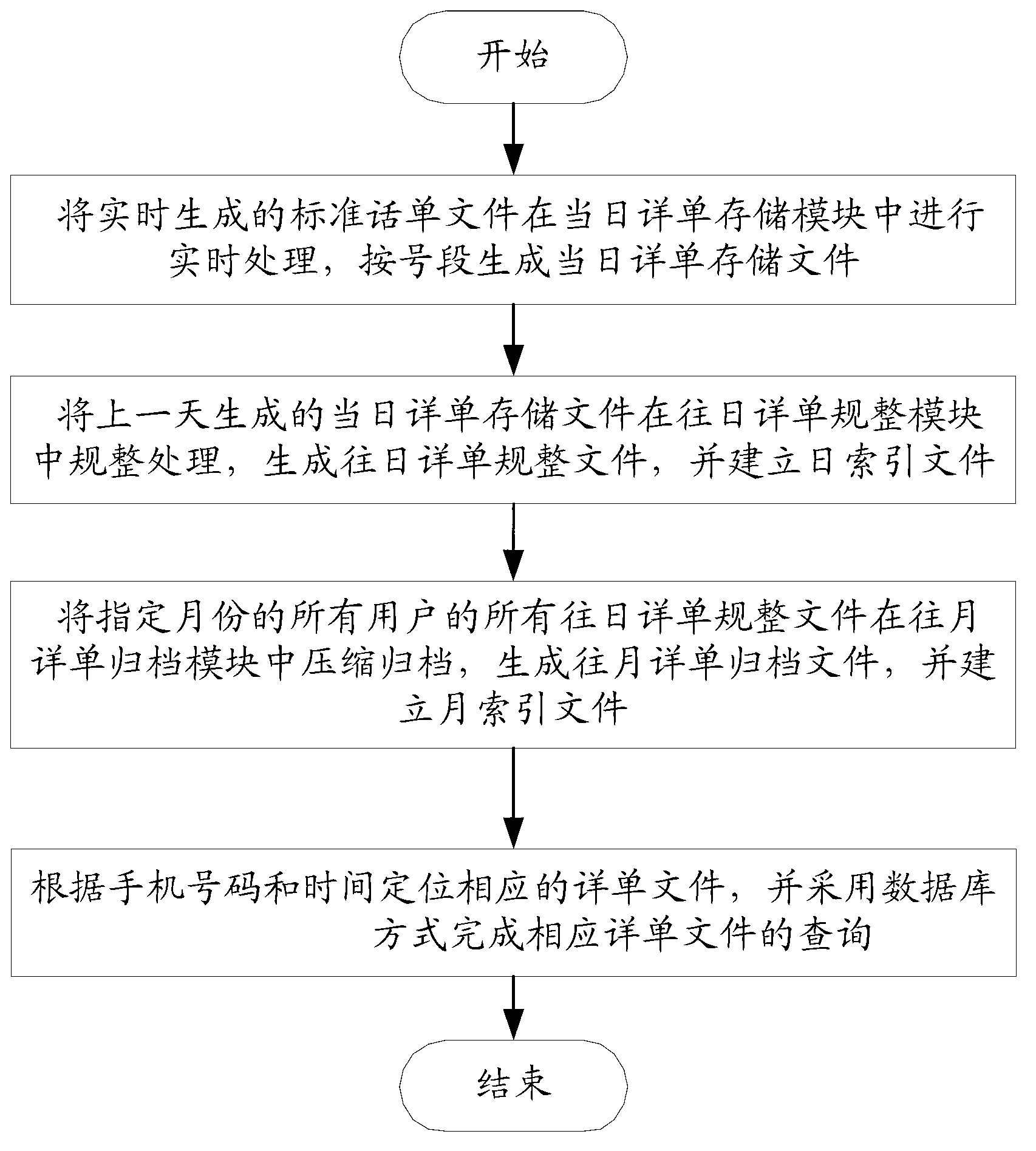

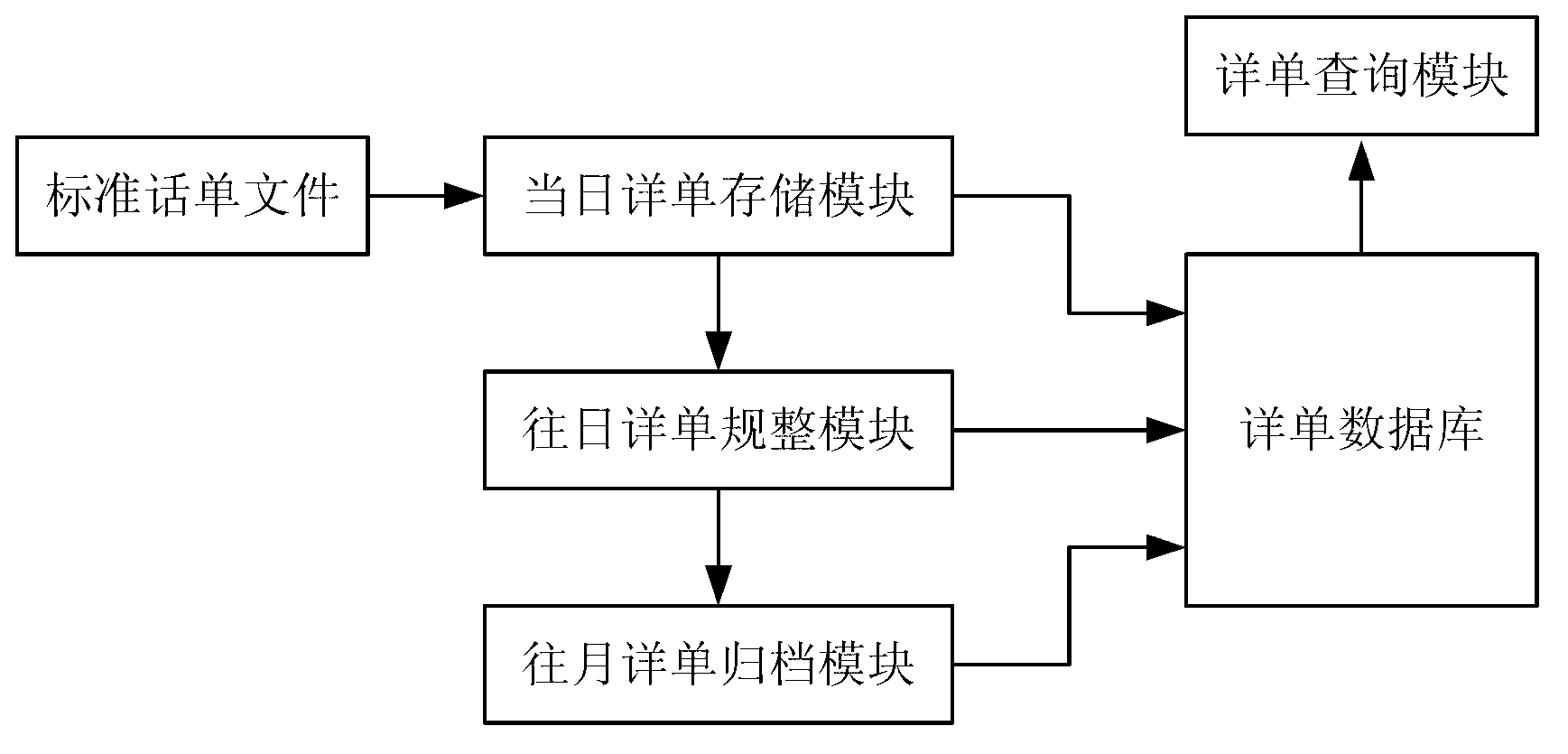

Method and system for realizing storage and query of communication detailed ticket

ActiveCN103020131AAccelerate the speed of detailed recordImprove query efficiencySpecial data processing applicationsOrganizational formArchive file

The invention relates to a method and a system for realizing storage and query of a communication detailed ticket. The method comprises the following steps: I, performing real-time processing on a real-time generated standard ticket file in a same day detailed ticket storage module to generate a same day detailed ticket storage file according to the number segment; II, performing regulation processing on the same day detailed ticket storage file generated in the former day in a former day detailed ticket regulation module to generate a former day detailed ticket regulation file and establish a day index file; III, compressing and filing all former day detailed ticket regulation files of all users in a designated month in a former month detailer ticket filing module to generate a former month detailed ticket filing file and establish a month index file; and IV, positioning corresponding detailed ticket files according to cell phone numbers and time to complete queries. The system and the method, provided by the invention, adopt different data organization forms for different detailed tickets and perform storage and queries in different ways, so as to reduce the cost and risk, and improve the efficiencies for storage and query of mass data.

Owner:北京思特奇信息技术股份有限公司

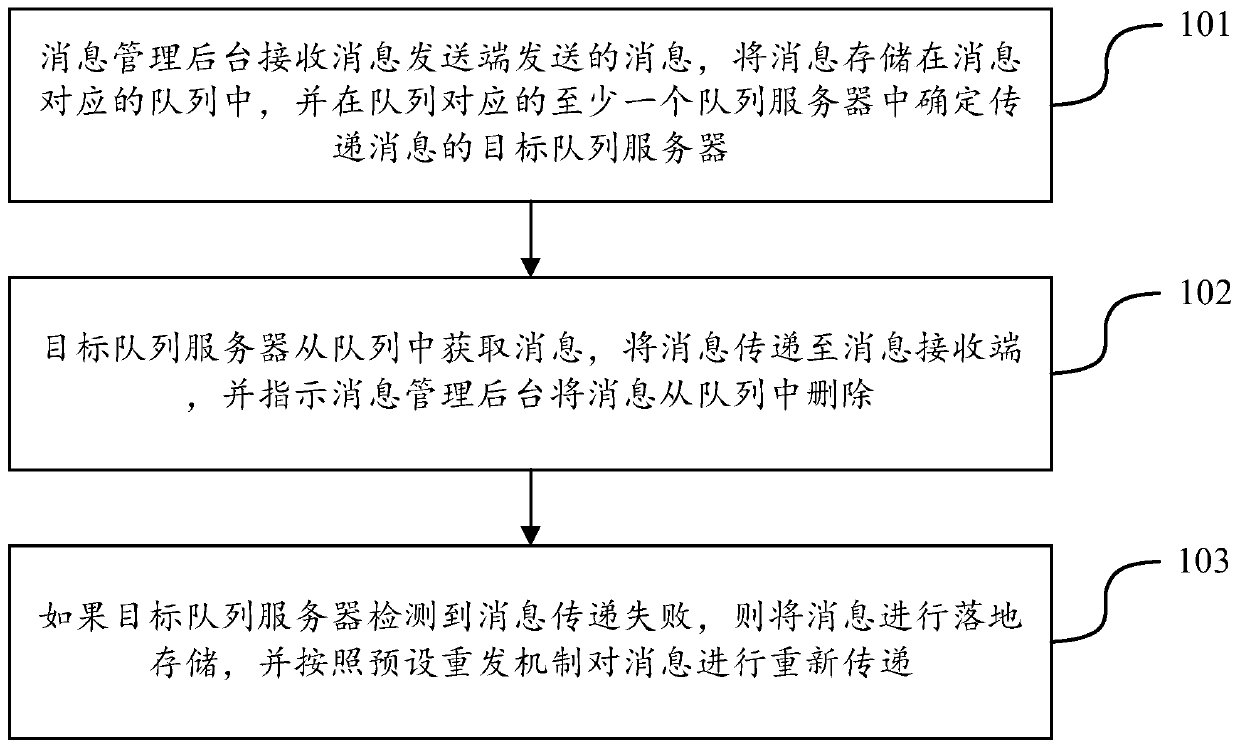

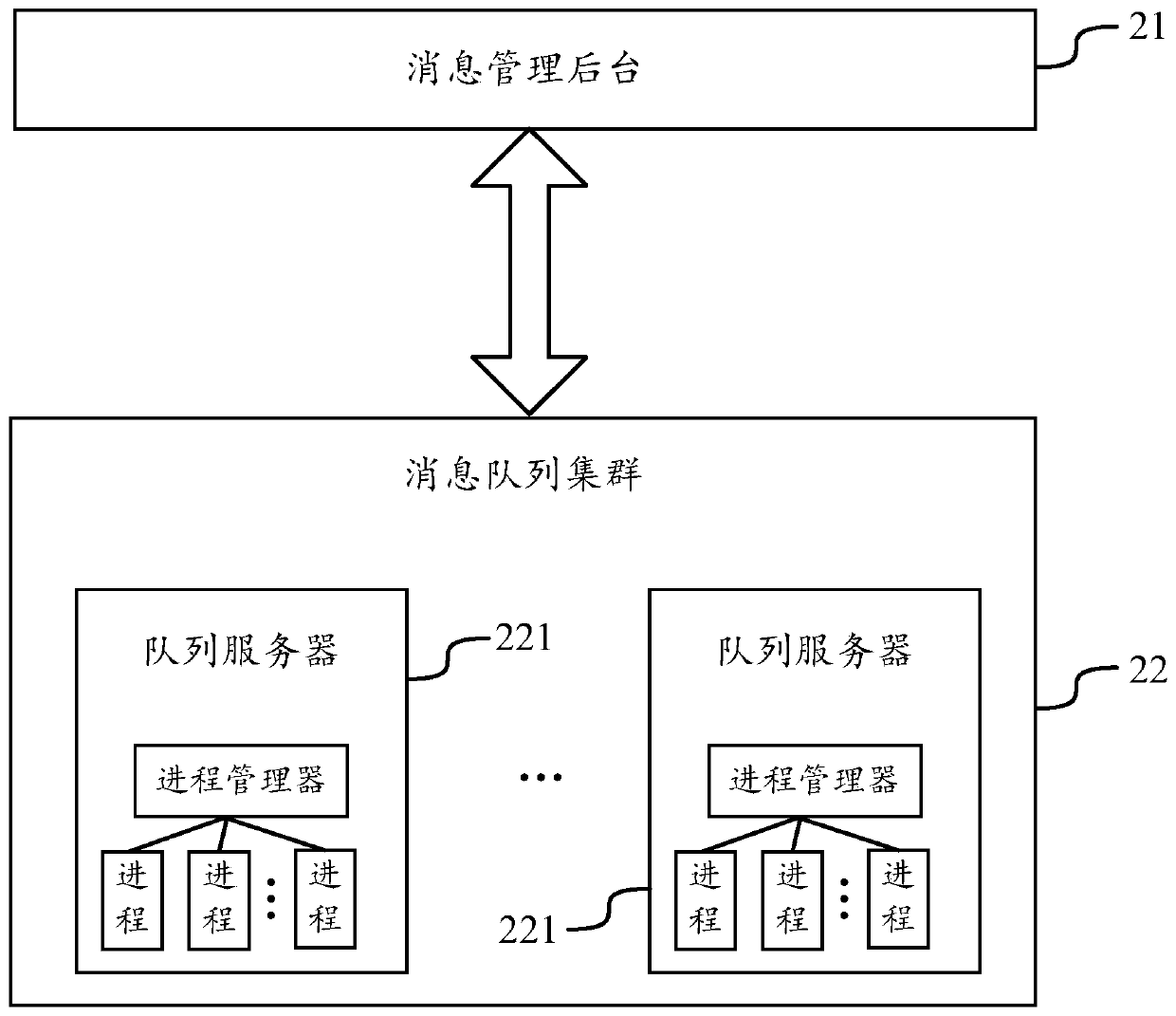

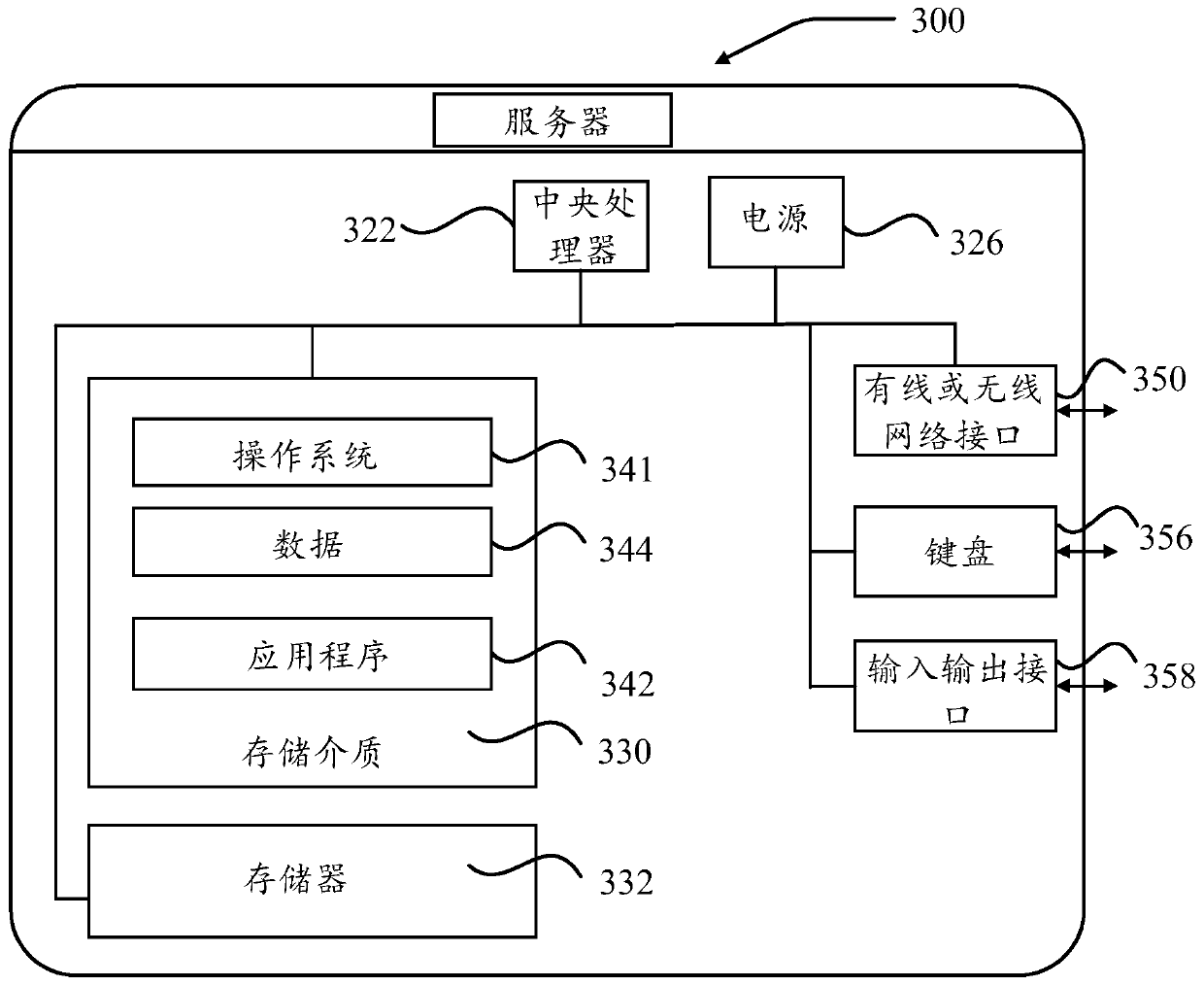

A message management method and system

ActiveCN109714409ASolve the backlogReduce loadError prevention/detection by using return channelData switching networksMessage passingManagement quality

The invention discloses a message management method and system, and belongs to the technical field of computers. The method comprises the following steps: a message management background receives a message sent by a message sending end, stores the message in a queue corresponding to the message, and determines a target queue server for transmitting the message in at least one queue server corresponding to the queue; The target queue server obtains the message from the queue, transmits the message to a message receiving end, and instructs the message management background to delete the messagefrom the queue; And if the target queue server detects that the message transmission fails, performing landing storage on the message, and re-transmitting the message according to a preset re-transmitting mechanism. By adopting the method, the problem of message backlog can be solved, and the message management quality is improved.

Owner:YOUGU SHANGHAI INFORMATION TECH CO LTD

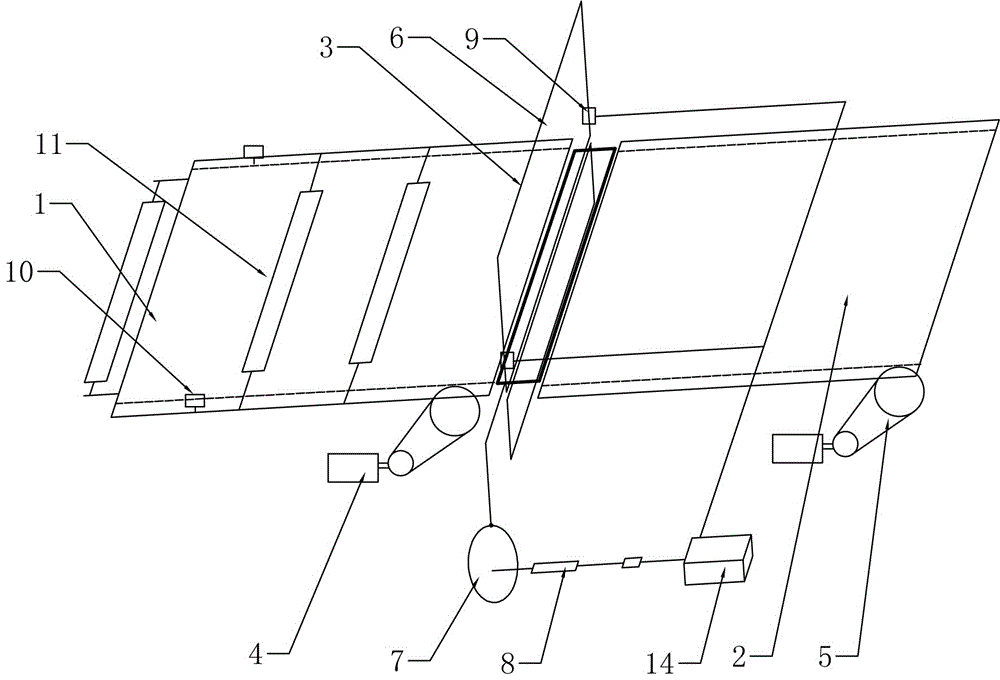

Automatic fixed-length cutting machine for rubber and cutting method

ActiveCN106584539ACutting length is accurateOvercoming adhesionsMetal working apparatusEngineeringRubber sheet

Provided is an automatic fixed-length cutting machine for rubber and a cutting method. The automatic fixed-length cutting machine mainly comprises a feeding conveyor belt, a discharging conveyor belt and a middle cutting mechanism. The feeding conveyor belt is driven by an independent feeding motor. The discharging conveyor belt is driven by an independent discharging motor. The cutting mechanism comprises a shearing blade. The shearing blade is driven by a cam and a rotary air cylinder. The feeding motor, the discharging motor and the rotary air cylinder are all controlled by a PLC to be started. According to the automatic fixed-length cutting machine for the rubber, by arranging the feeding conveyor belt, the discharging conveyor belt and the middle cutting mechanism, the PLC is used for control, and the technical problems that the cut length of rubber sheets is unstable, operation and adjustment are difficult in the continuous production process, and the yield of the rubber sheets is low are solved.

Owner:湖北华润科技有限公司

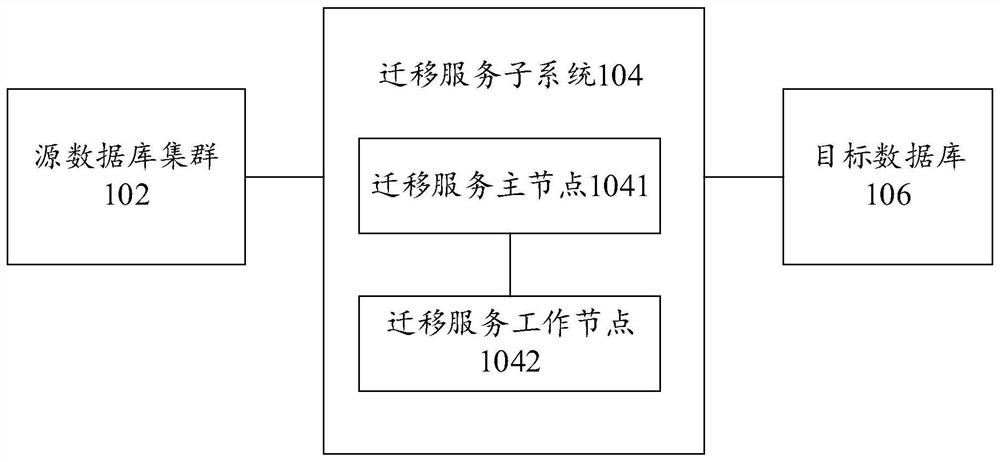

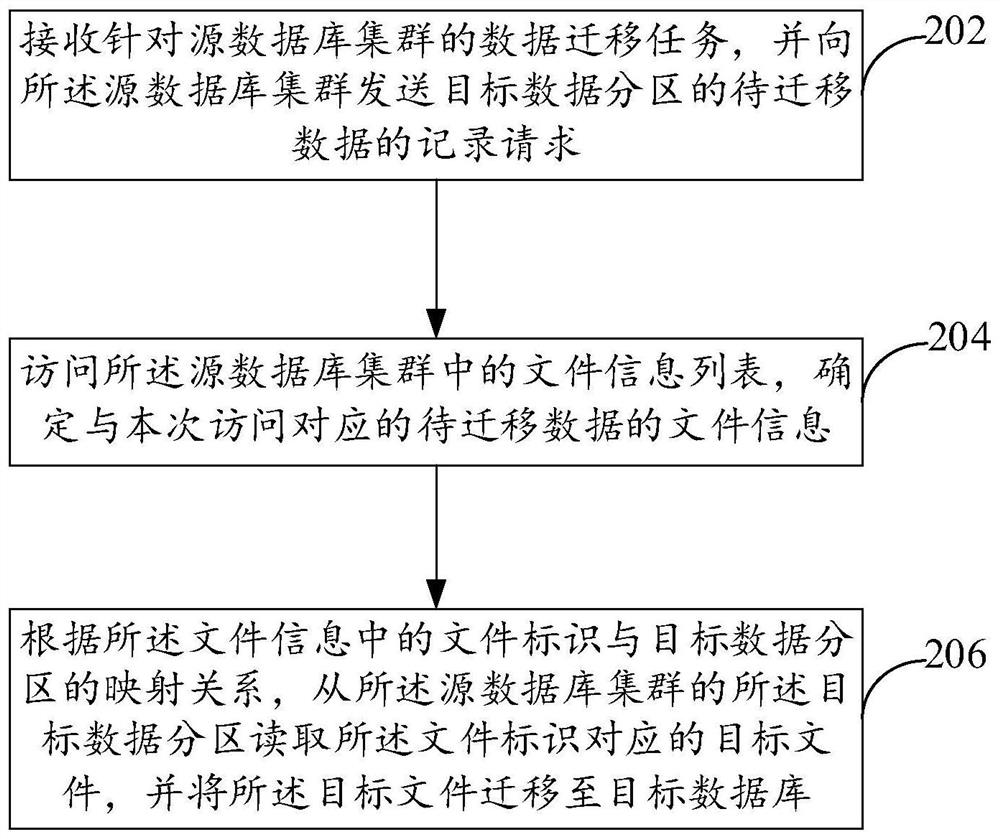

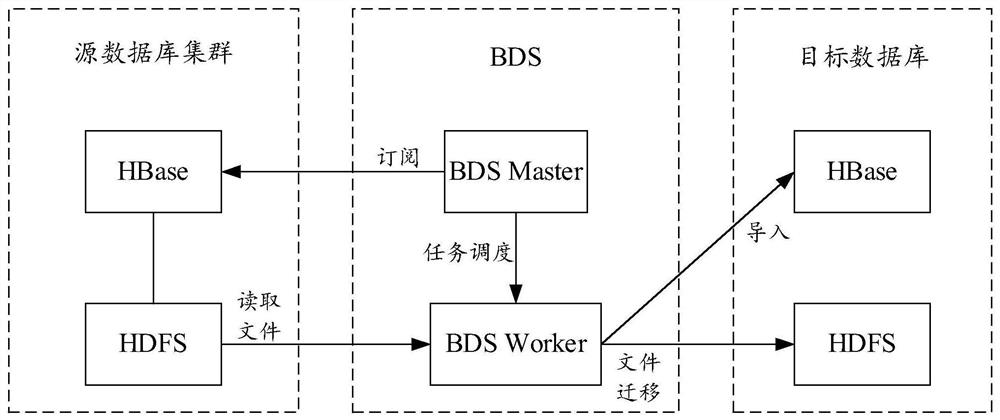

Data processing system, method and device

PendingCN113297166AImprove migration efficiencySolve the backlogDatabase management systemsSpecial data processing applicationsData processing systemDatabase clustering

The embodiment of the invention provides a data processing system, method and device. The data processing system comprises a source database cluster and a migration service subsystem. The migration service subsystem is configured to receive a data migration task and send a recording request of the to-be-migrated data of the target data partition to the source database cluster; the source database cluster is configured to create an initial file information list, monitor file generation information under the target data partition, and update the initial file information list based on the partition identifier of the target data partition and the file generation information to obtain a file information list; and the migration service subsystem is further configured to access the file information list, determine file information of the to-be-migrated data corresponding to the access, read a target file corresponding to a file identifier from a target data partition of the source database cluster according to a mapping relationship between the file identifier in the file information and the target data partition, and migrate the target file to the target database.

Owner:ALIBABA GRP HLDG LTD

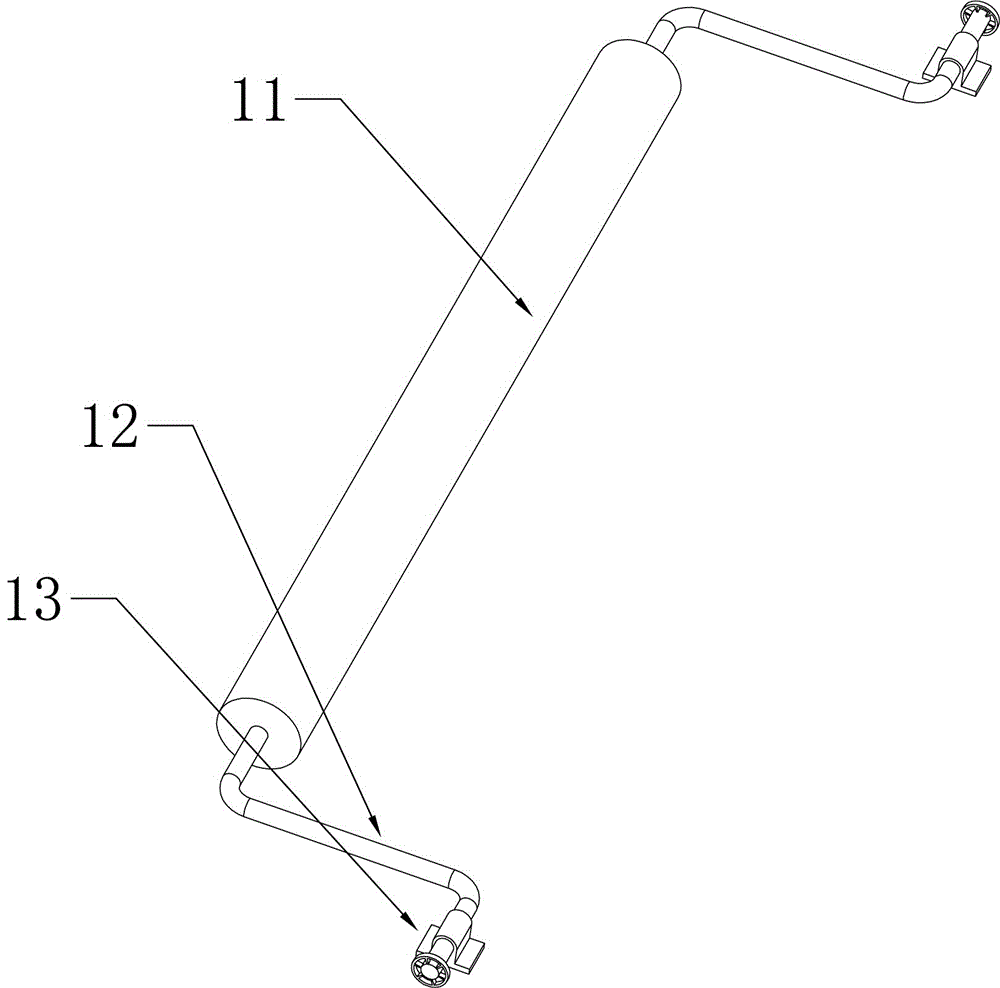

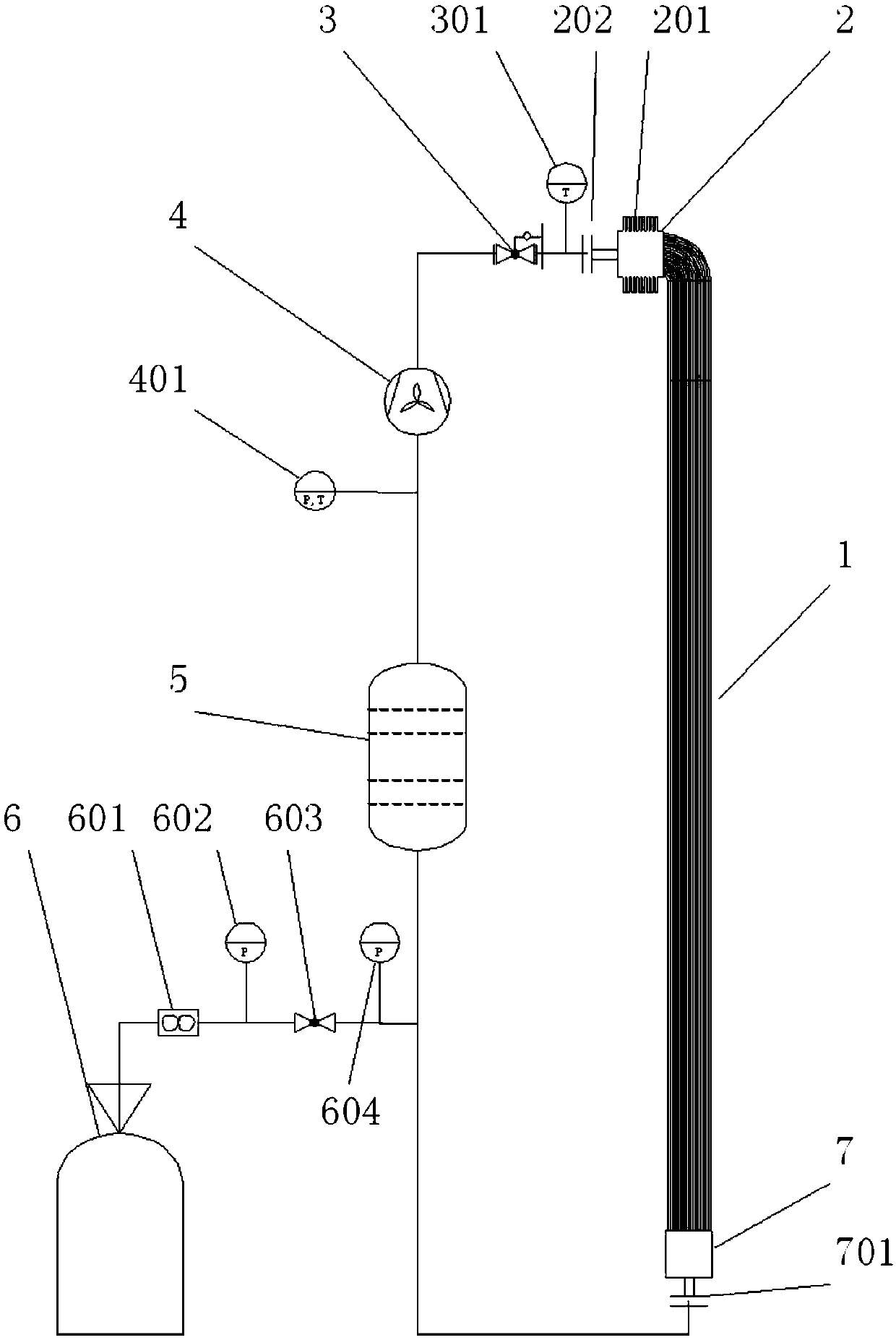

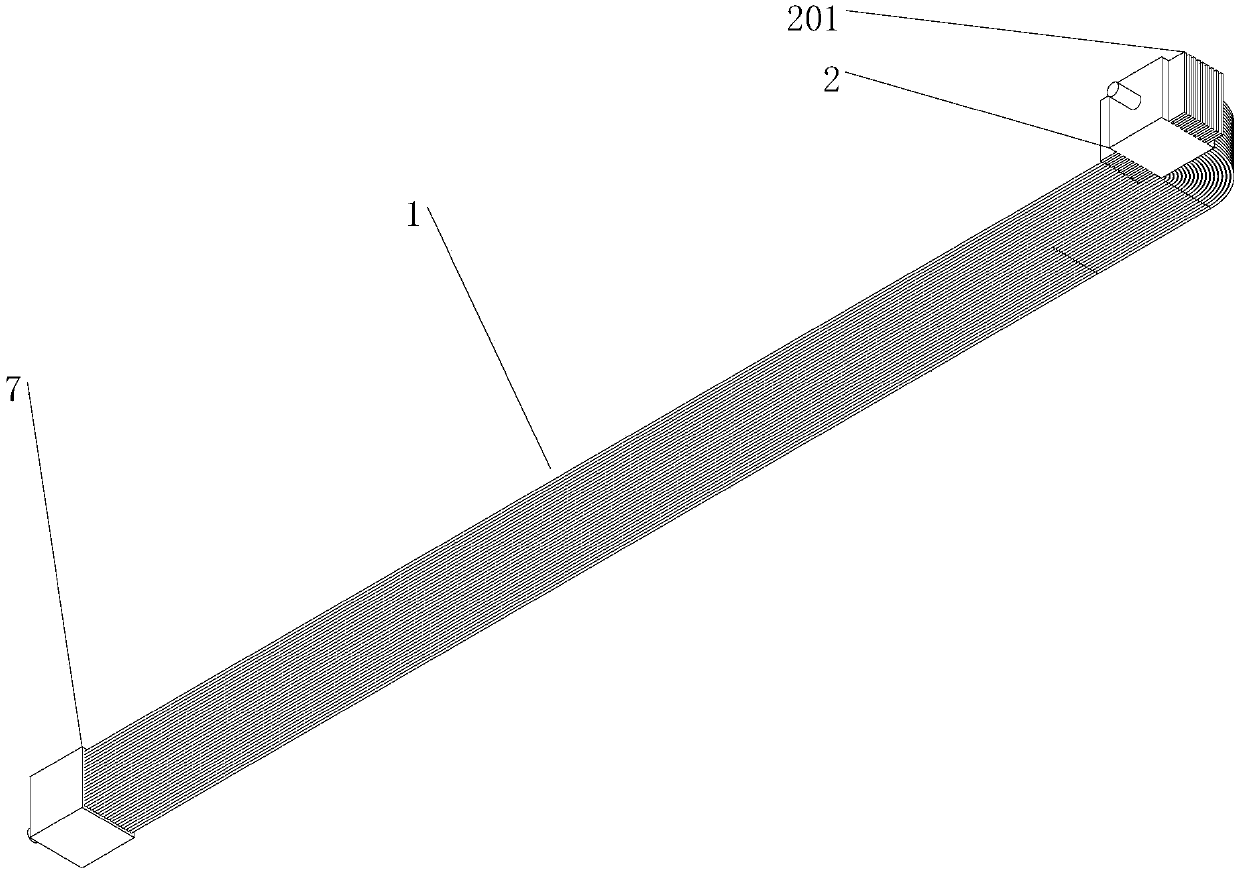

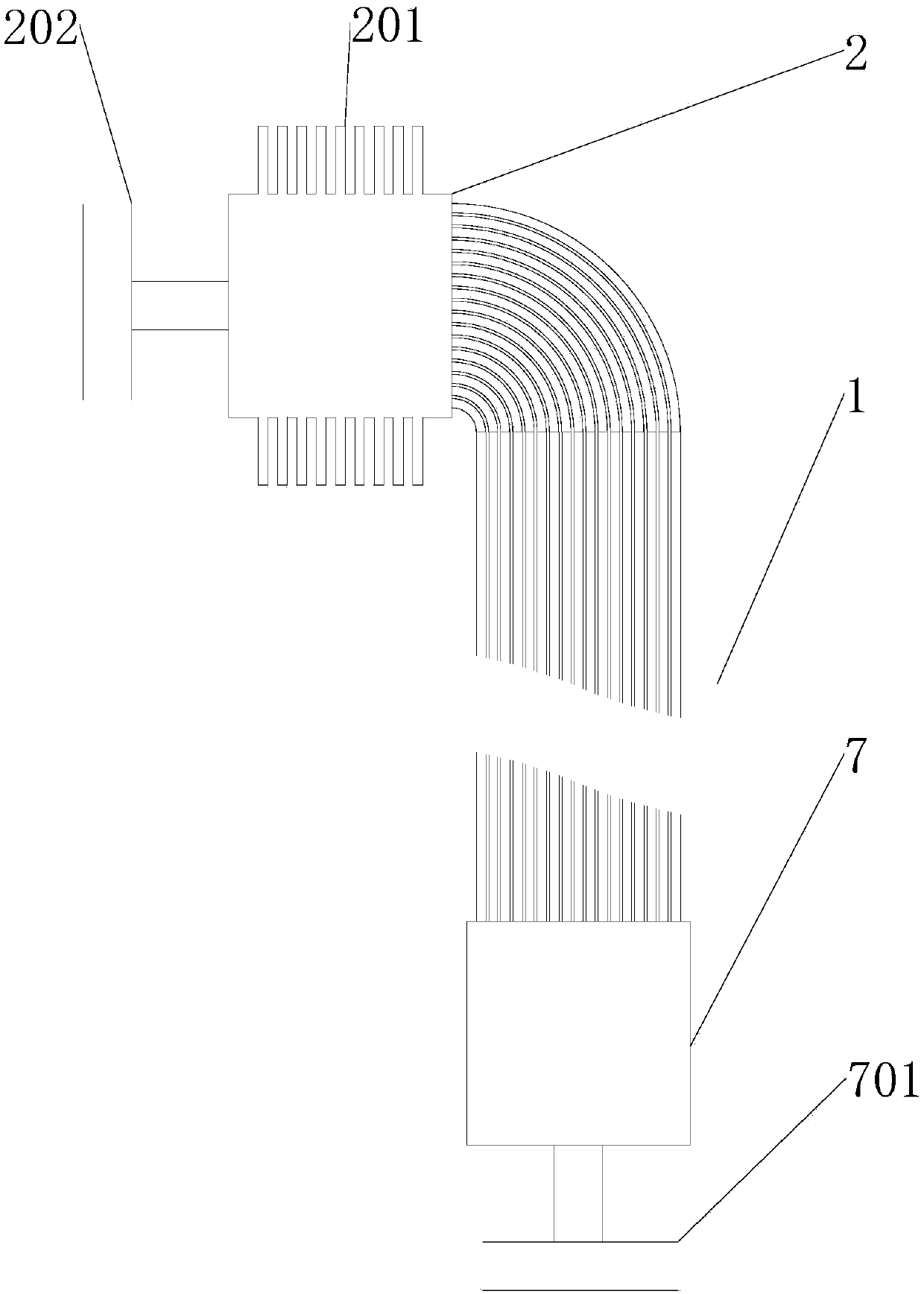

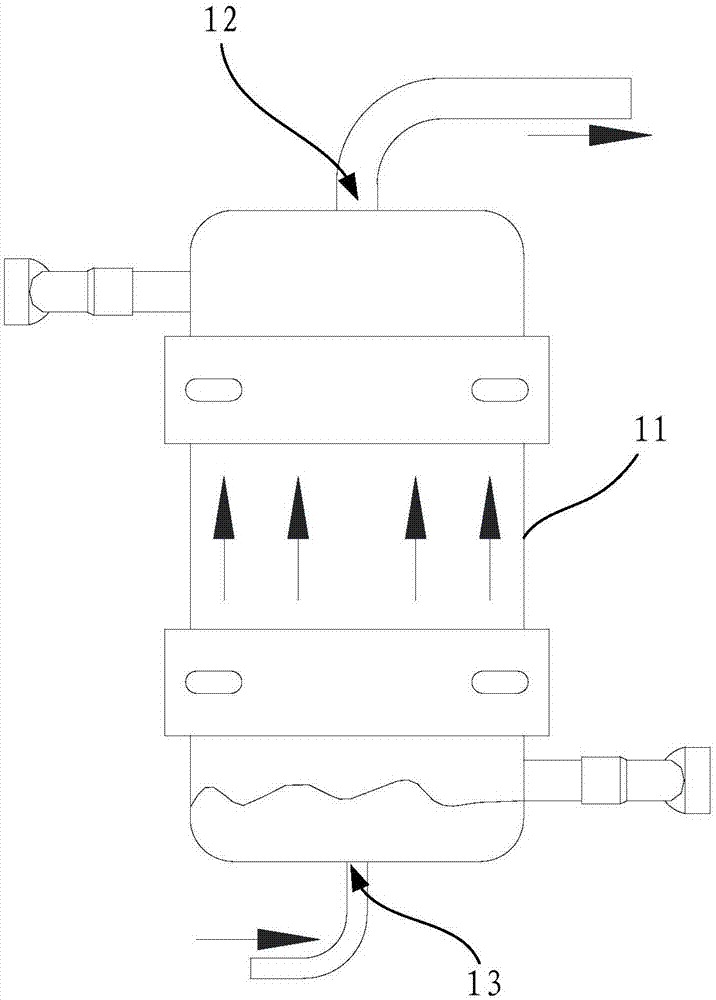

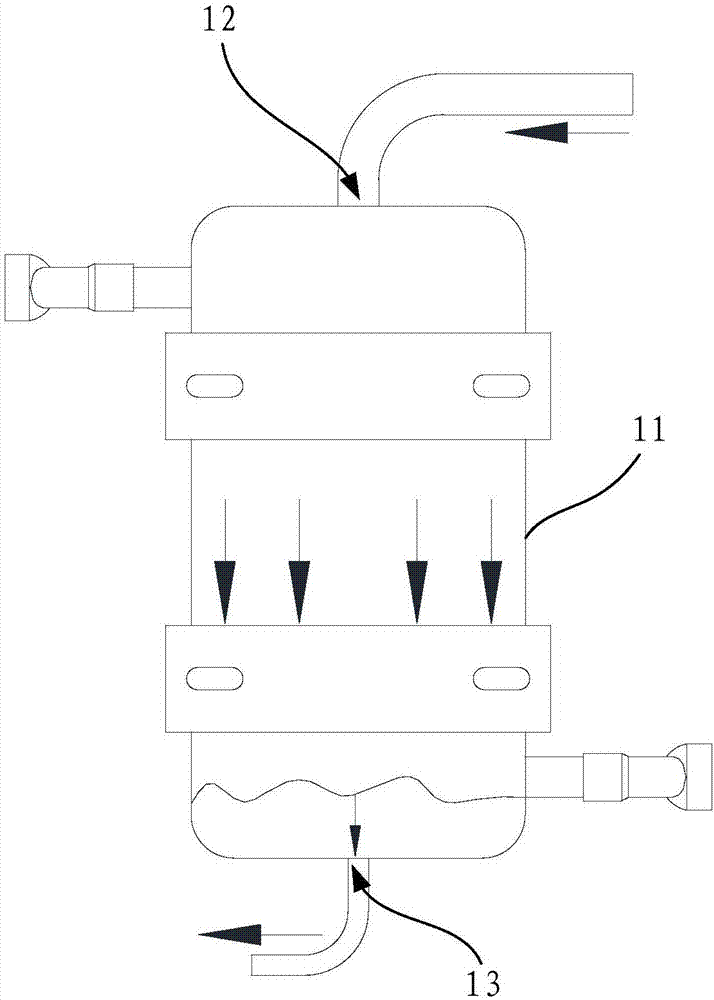

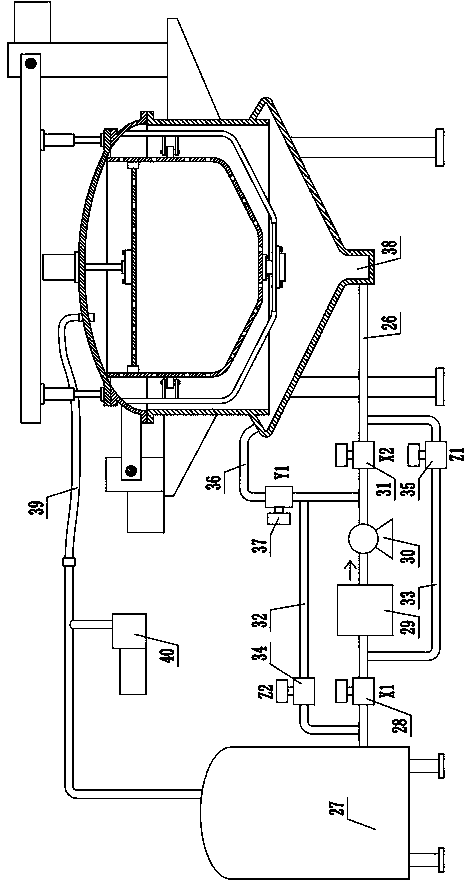

On-line removal device for pressurized water reactor fuel assembly fission gas

ActiveCN109545412ASolve the backlogImprove thermal conductivityNuclear energy generationReactor fuel elementsPressurized water reactorNeutron poison

The invention provides an on-line removal device for pressurized water reactor fuel assembly fission gas. The device consists of a fuel assembly, an upper buffer container, a flow regulating valve, acirculation pump, a fission gas adsorption apparatus, a helium gas supply apparatus and a lower buffer container. The upper part of the fuel assembly is connected to the upper buffer container, the upper buffer container is connected to the flow regulating valve, the flow regulating valve is connected to the circulation pump, the circulation pump is connected to the fission gas adsorption apparatus, the fission gas adsorption apparatus is connected to the lower buffer container, the helium gas supply apparatus is connected between the fission gas adsorption apparatus and the lower buffer container, and the lower buffer container is connected to the bottom of the fuel assembly. In the pressurized water reactor running process, the on-line removal device provided by the invention can achieveon-line removal of fission gas generated in the fuel assembly, improve the thermal conductivity in the enclosure gap, reduce the neutron poison in the reactor running process, and enhance the economical efficiency of the reactor.

Owner:SHANGHAI JIAO TONG UNIV

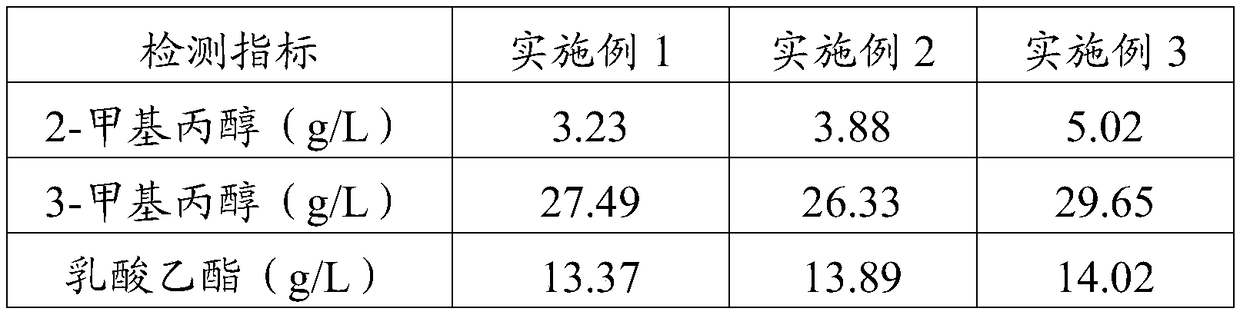

Grapefruit brandy and preparation method thereof

The invention provides grapefruit brandy and a preparation method thereof, and belongs to the technical field of wine brewing. The preparation method is characterized in that grapefruit is used as a raw material; before fermenting, fruit pulp is heated, so as to perform sterilizing on one hand and deactivate pectin on the other hand, so that prepared crude wine can meet a safety standard, namely the content of methanol is smaller than 0.12g / 100mL. By adopting the preparation method, most of beneficial components in the grapefruit can be reserved; the prepared grapefruit brandy is rich in aromatic component, naringin and limonin, and has the particular aroma of the grapefruit is contained; after the grapefruit brandy is drunk, a heavy fruit flavor and slight bitter taste are reserved in anoral cavity, and the bitter taste can be quickly dissipated.

Owner:江西省东篱柚业科技有限公司

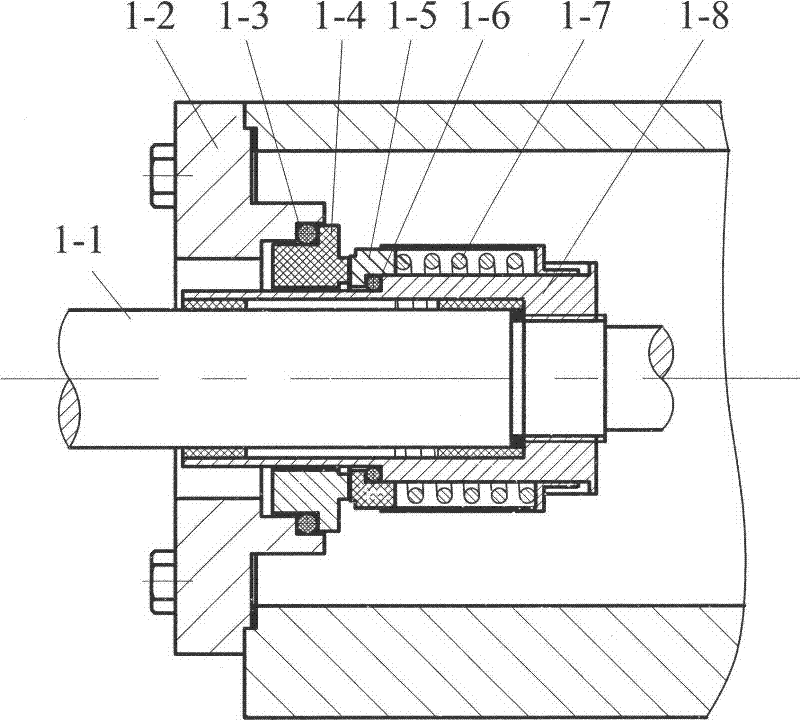

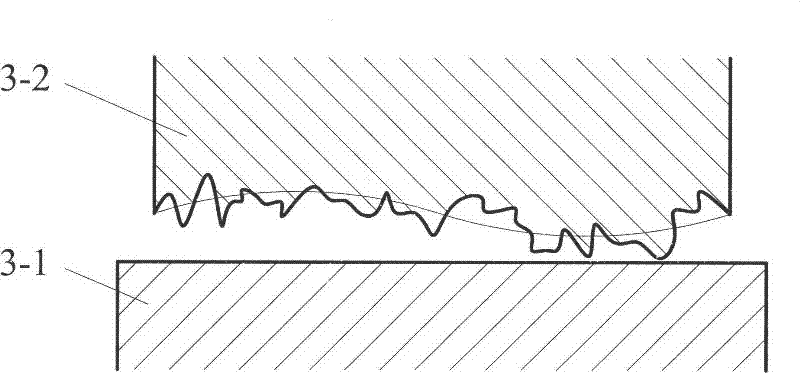

Prediction method of leakage rate of contact mechanical seal

ActiveCN102411669AGuarantee safety and reliabilityLow cost operationSpecial data processing applicationsEngineeringStress relaxation

The invention relates to a prediction technology of a leakage rate of an existing contact mechanical seal. By utilizing a seal interface topography evolvement rule in the wear process of a movable ring and a stationary ring, and a contact compression stress variation rule of primary and secondary seal interfaces due to the wear-down of the movable ring and the stationary ring and the stress relaxation of an O-shaped ring, the topography parameters of the seal interfaces and loads on the movable ring and the stationary ring seal interfaces, the O-shaped ring and the internal diameter and external diameter contact interfaces of the O-shaped ring are determined after the mechanical seal runs for a certain time, and the characteristic sizes of percolation channels between the movable ring and the stationary ring seal interfaces and the O-shaped ring and the internal diameter and external diameter contact interfaces of the O-shaped ring are obtained by a percolation theory, a contact mechanics theory and a fractal theory at the moment, the effect of surface tension and centrifugal force of the sealed medium is considered, and then the leakage state of the existing contact mechanical seal is predicated by a Navier-Stokes equation. The method is simple and practical, the accident problems caused by frequent replacement or expiration of the mechanical seal can be effectively solved, and the safety and reliability of equipment are improved.

Owner:NANJING FORESTRY UNIV

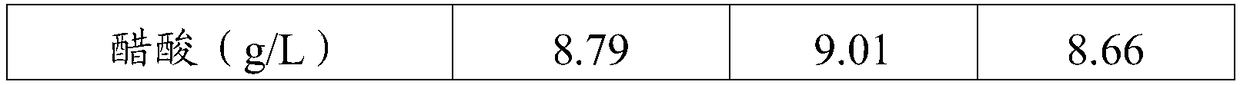

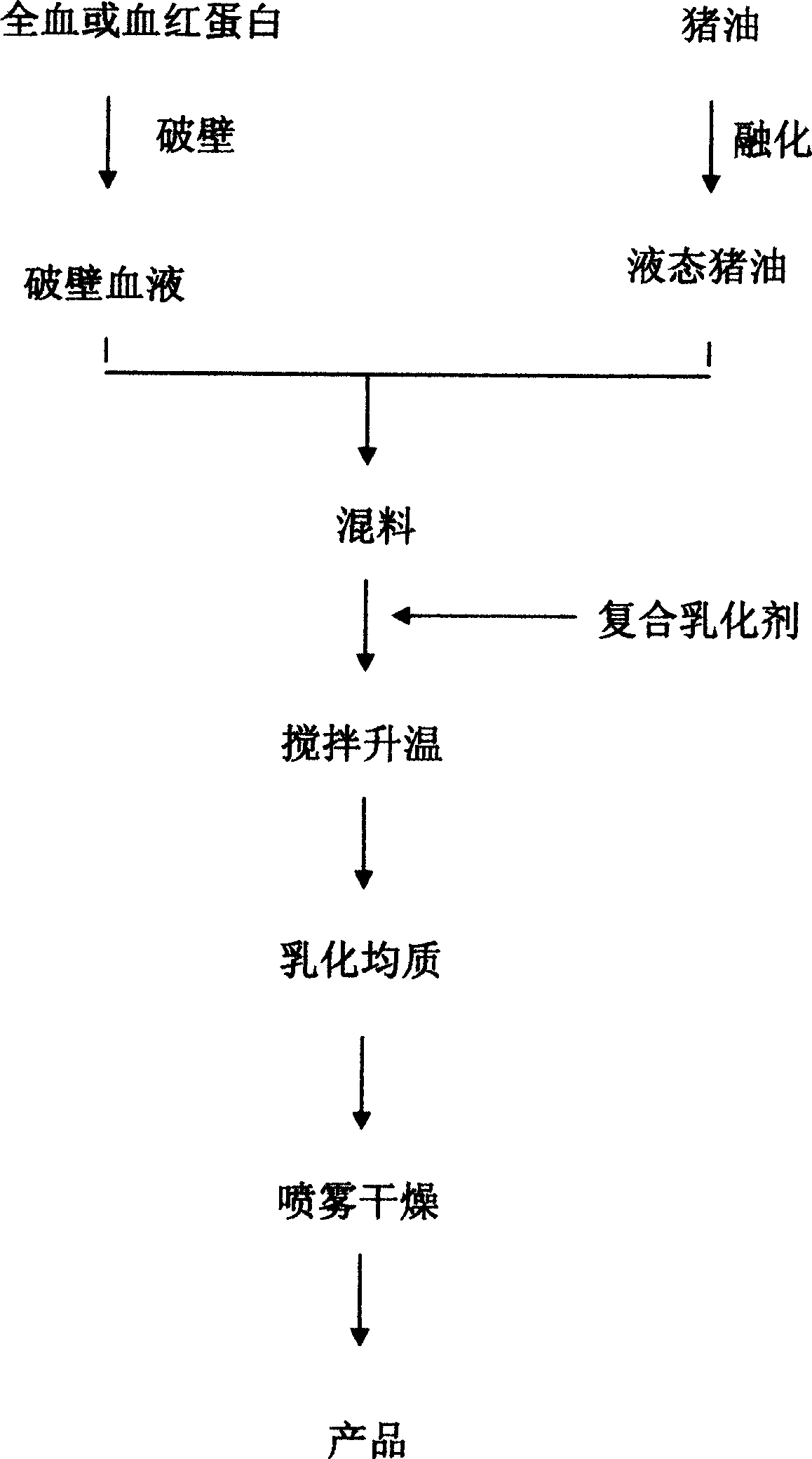

Method for producing powder blood fat

InactiveCN1561827ASolve the backlogHigh energyAnimal feeding stuffFood preparationFood additiveTrace element

A powdered blood fat as the additiv of feed is prepared from the blood of domestic animals and fowls, haematoglobin and oil through proportionally mixing, emulsifying for coating oil, and spray drying. It is rich in trace elements, protein and L-lysine.

Owner:辽源市麒鸣生物技术综合开发有限公司

Process for preparing chrome green by using K3 raffinate and sulfur method

InactiveCN107720824AEnvironmental protection is goodResolve disposal issuesChromium oxides/hydratesMuffle furnaceChemistry

The invention discloses a process for preparing chrome green by using K3 raffinate and a sulfur method. The process comprises two sections. The first section comprises the following steps: with neutral leaching yellow water or sodium chromate alkaline solution as a raw material in a workshop, adding liquid alkali in proportion to adjust alkalinity, carrying out heating to a certain temperature onan electric furnace, adding levigated sulfur paste, and carrying out curing for a period of time after completion of a pre-reaction; carrying out filtration and washing successively, wherein the content of Na2S2O3 in the last washing is ensured; and drying a filter cake, then calcining the dried filter cake in a muffle furnace to obtain crude chrome green, and subjecting the crude chrome green towashing and drying to obtain metallurgical-grade chrome green. The second section comprises the following steps: after complete reaction of chromium hydroxide, mixing a filtrate with primary washing water; adding the sodium chromate alkaline solution, carrying out heating and stirring, and then adding K3 raffinate at a certain temperature to adjust a pH value; carrying out curing for a certain period of time, carrying out filtering and measuring the content of Na2S2O3 in the obtained filtrate; then carrying out filtering, and leaching and roasting the obtained filter cake; and subjecting a semi-finished chrome green product to washing, drying and levigation so as to obtain the pigment-grade chrome green. The process provided by the invention solves problems in treatment of K3 raffinate, makes full use of the reducibility of Na2S2O3, and basically has no influence on the environment.

Owner:CHONGQING MINFENG CHEM

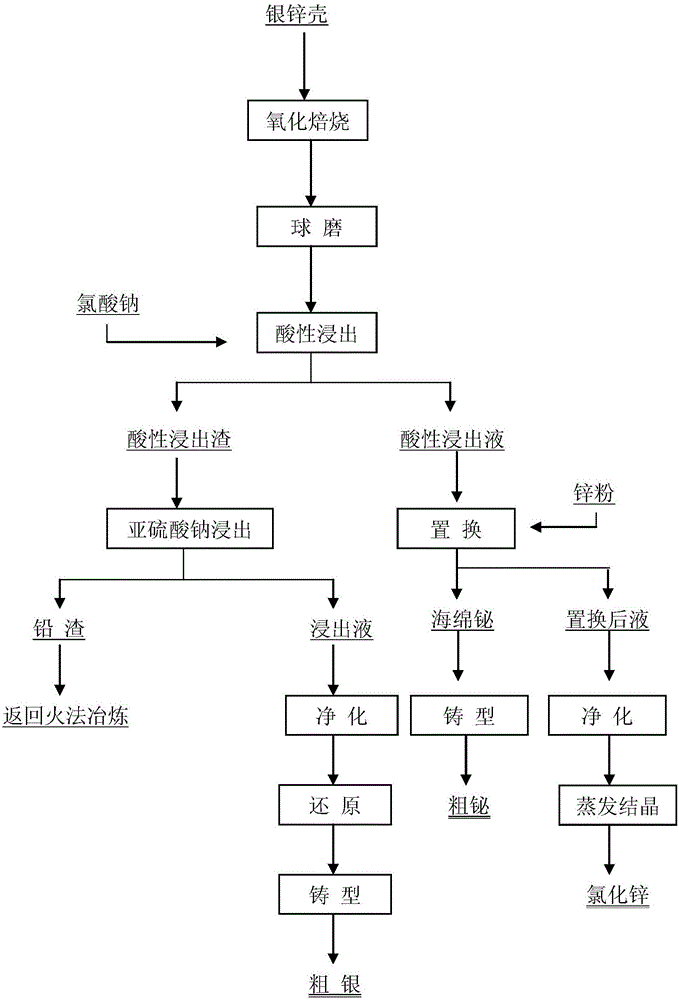

Silver-zinc crust wet process comprehensive recovery method

ActiveCN106011474ASolve the backlogSimple processProcess efficiency improvementRecovery methodSulfite salt

The invention discloses a silver-zinc crust wet process comprehensive recovery method which is characterized in that that silver-zinc crusts are subjected to thorough roasting and ball milling sieving; then through an acid leaching condition, an acid extract and acid leaching residues are obtained; after the acid leaching residues are leached by sodium sulfite, lead residues and an extract are obtained; the lead residues can return to a pyrogenic process smelting system, the extract is purified and then is reduced by formaldehyde, and crude silver is finally obtained after casting; the acid extract can be replaced by zinc powder and sponge bismuth is obtained; liquid after replacement is purified and then is subjected to evaporative crystallization, and zinc chloride is obtained; and direct recovery rates of silver, bismuth and zinc respectively reach above 95.7%, 94.1% and 88.9%. The silver-zinc crust wet process comprehensive recovery method is applicable to recovery of valuable metals, such as silver, bismuth and zinc, from the silver-zinc crusts rich in lead, silver, bismuth and zinc; the lead residues can return the pyrogenic process smelting system; the direct recovery rates are high; separation is thorough; and rapid recovery of valuable metals, especially silver, of the pyrogenic process smelting system is facilitated more.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

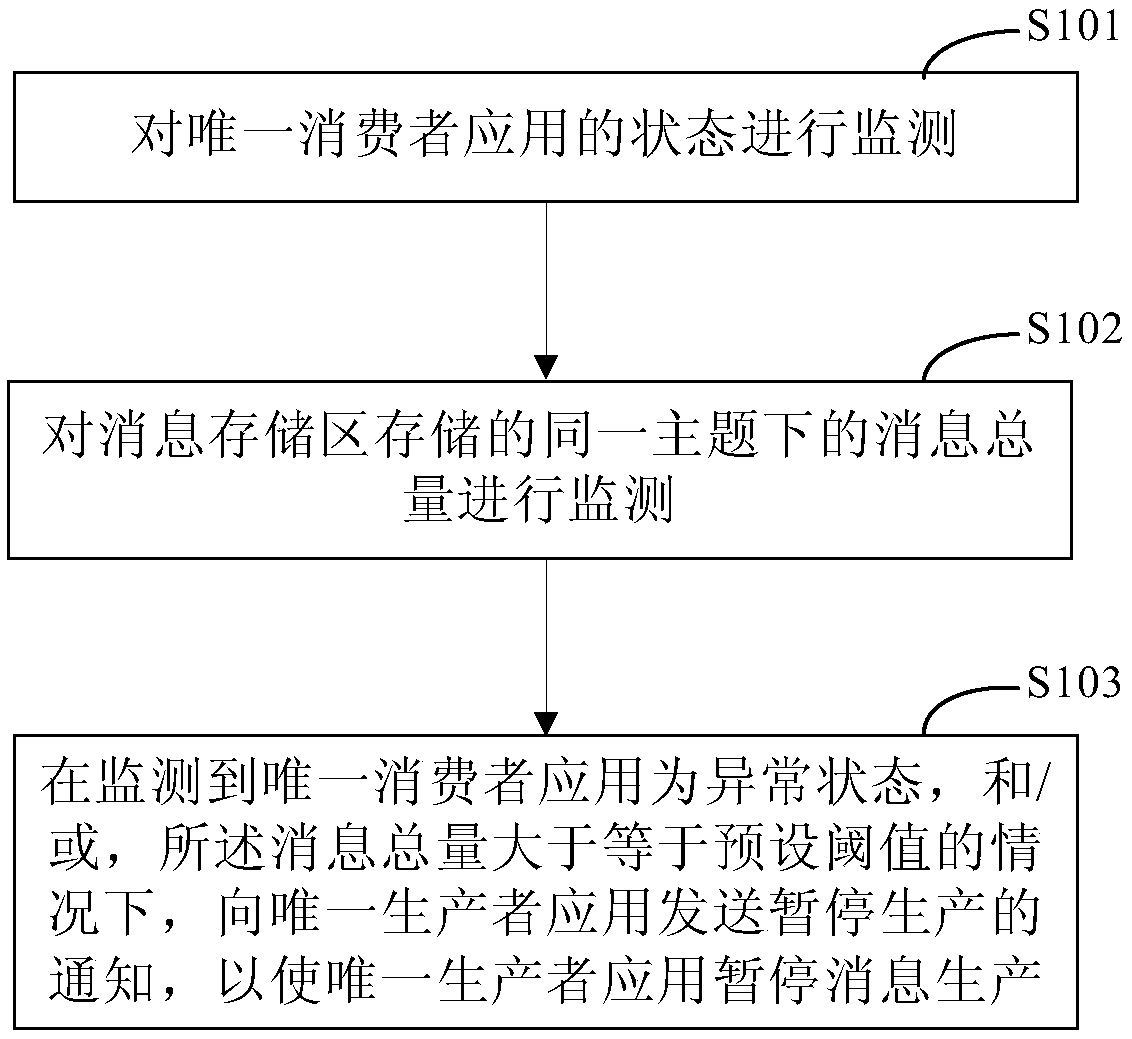

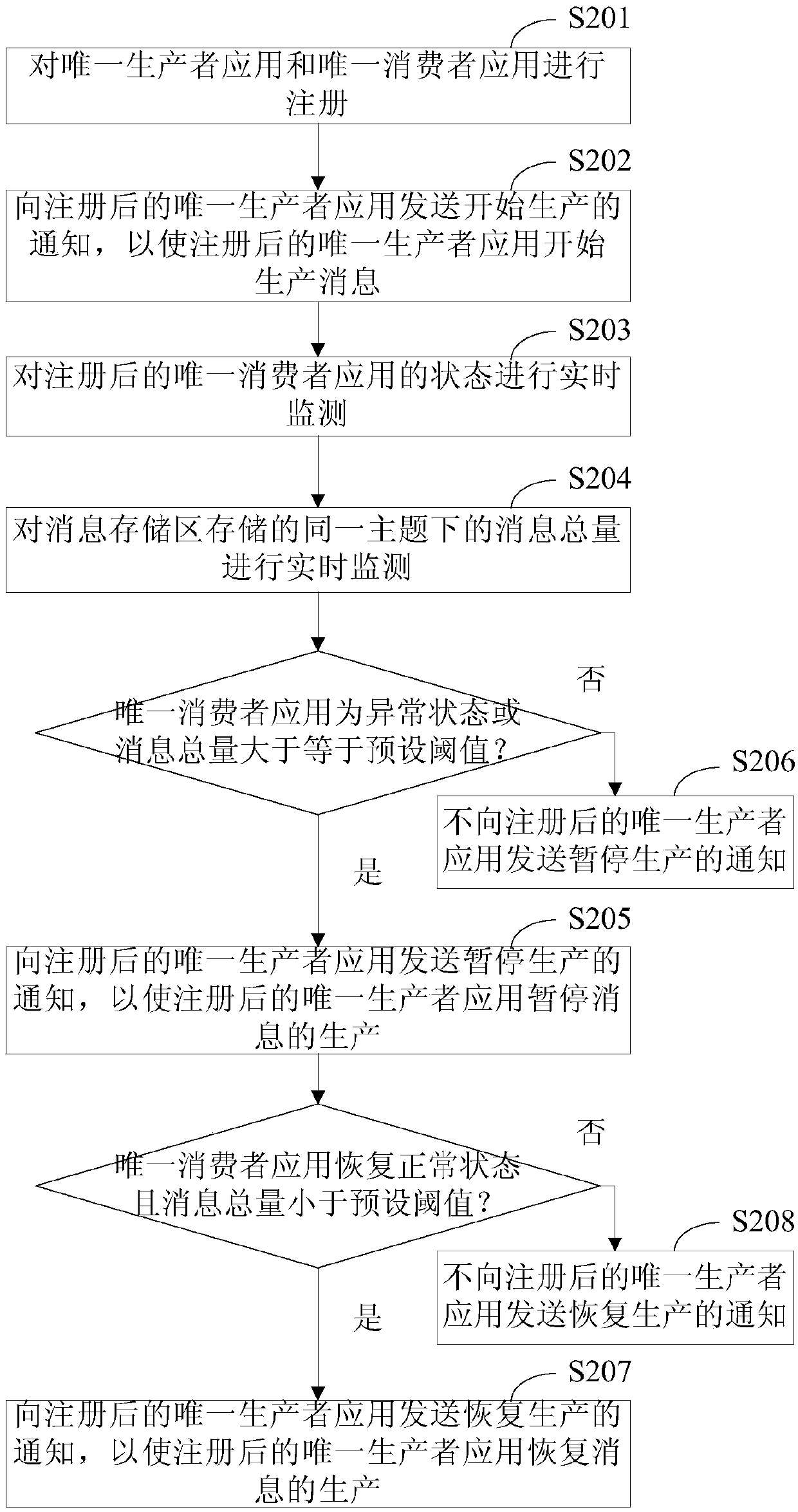

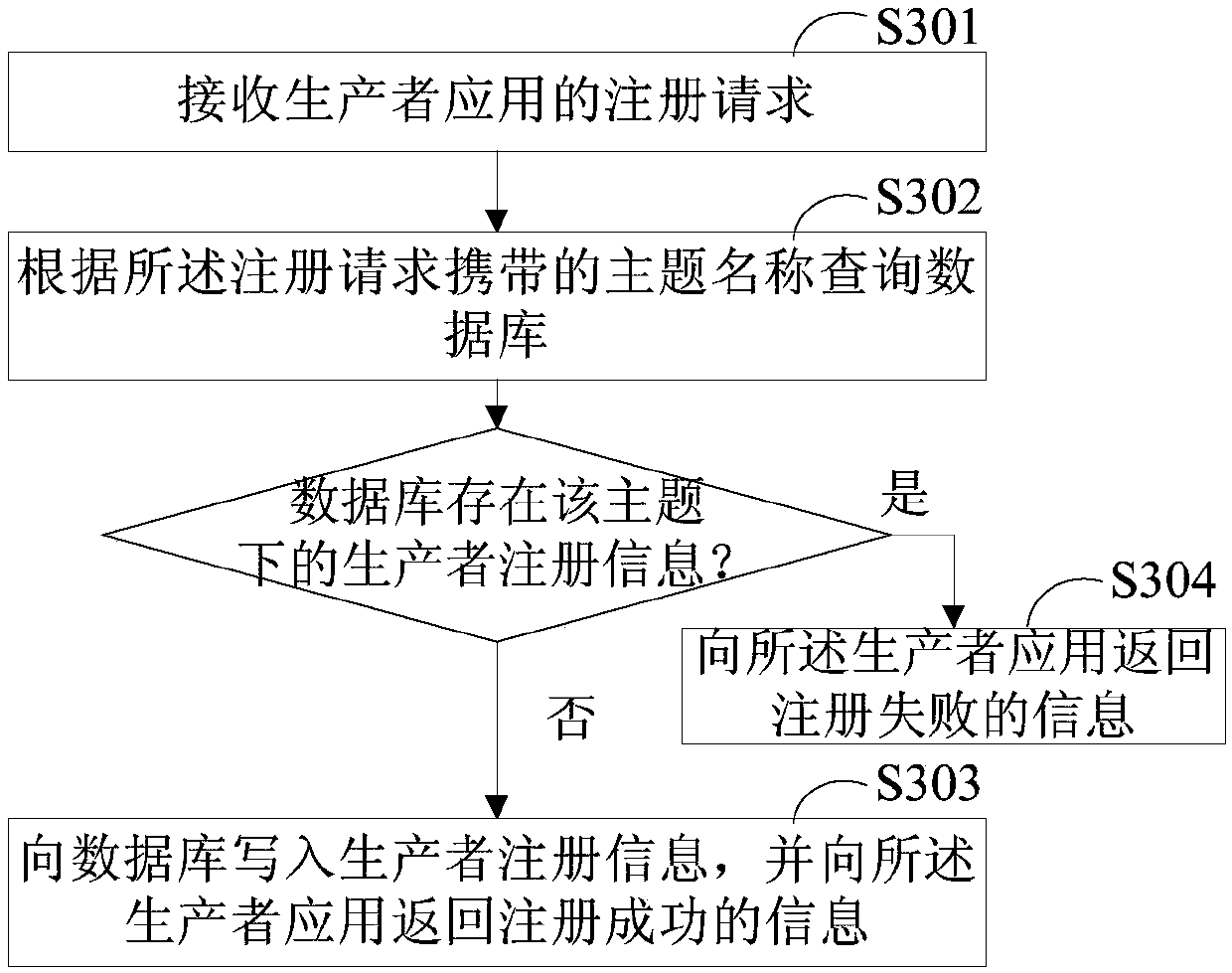

Message queue-based processing method and message queue

PendingCN110968430AImprove performanceSolve the backlogInterprogram communicationDatabase modelsMessage queueDistributed computing

The invention discloses a processing method based on a message queue and the message queue, and relates to the technical field of computers. The method comprises the steps that the state of a unique consumer application is monitored; monitoring the total amount of the messages under the same theme stored in the message storage area; when it is monitored that the unique consumer application is in an abnormal state and / or the total message amount is larger than or equal to a preset threshold value, a production pause notification is sent to a unique producer application, so that the unique producer application pauses production of a message; wherein the unique producer application and the unique consumer application belong to the same theme. By means of the method, the scene requirement fora one-to-one publishing-subscribing mode in actual life can be met, the problem that a large number of messages are overstocked on the production side or the consumption side can be effectively solved, and then the performance of unique producer application and the performance of unique consumer application can be improved.

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD +1

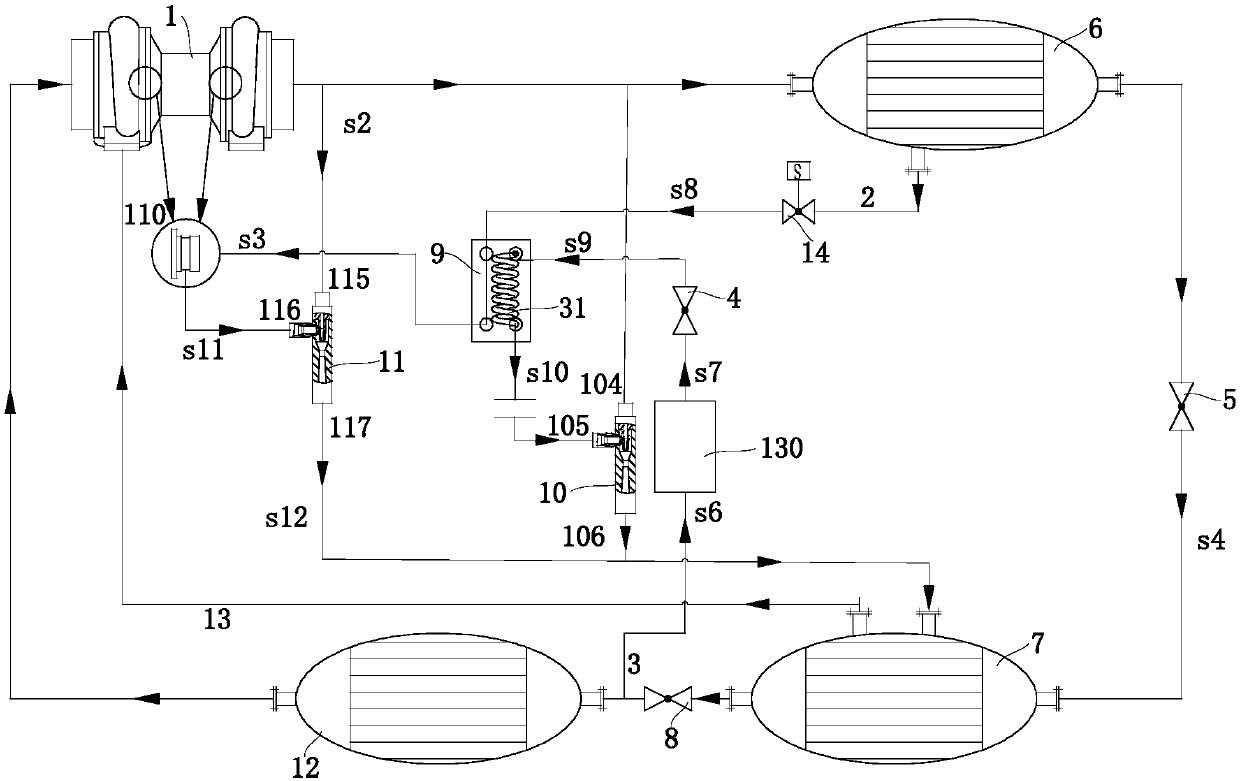

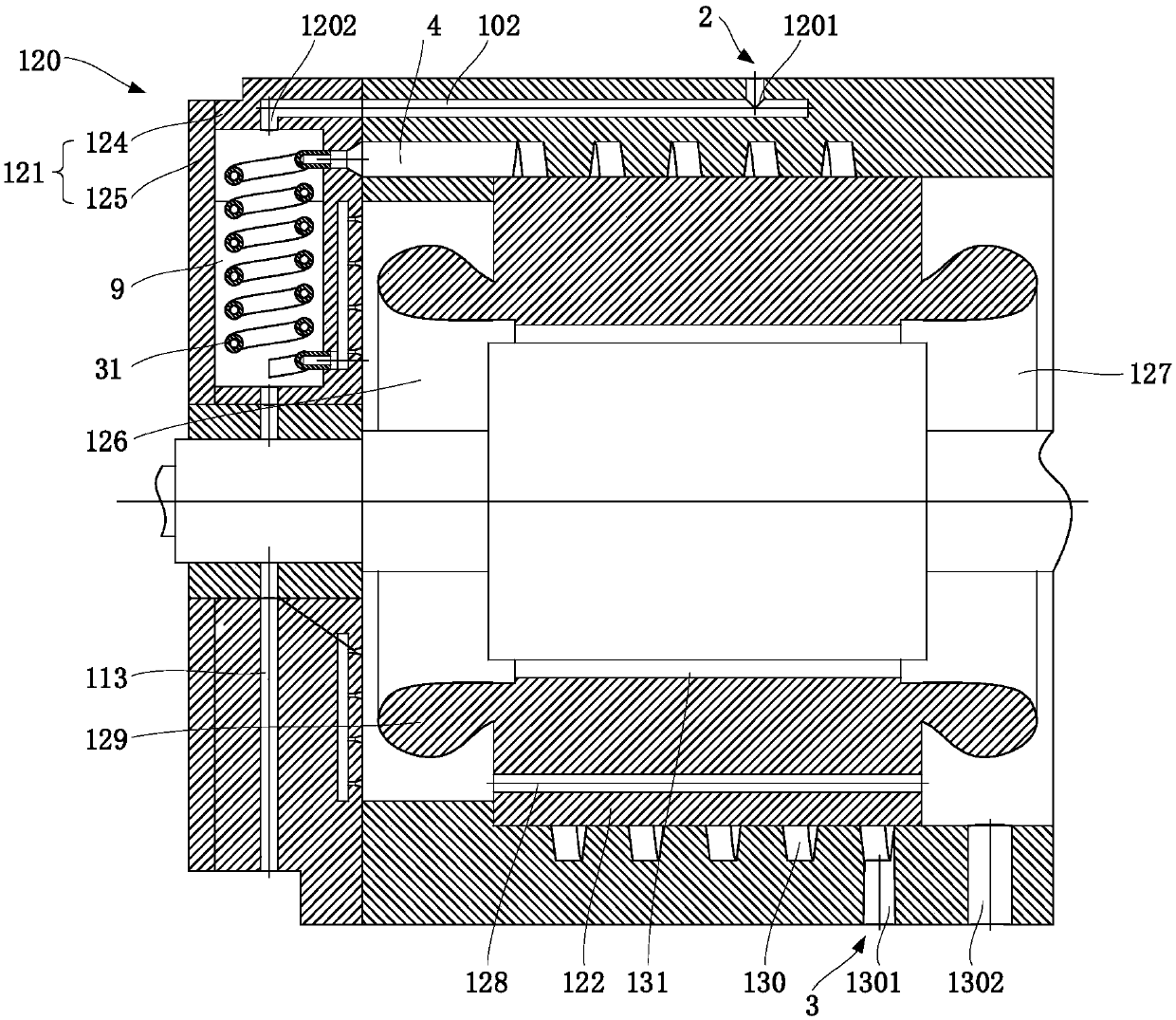

Refrigerant circulatory system with undercooling function

PendingCN111365908AAchieve supercoolingAchieve coolingCompressorMechanical apparatusElectric machineryEngineering

The invention discloses a refrigerant circulatory system with an undercooling function, and relates to the field of an air conditioner. The refrigerant circulatory system has the effect of optimizingcooling of an oilless bearing and includes a compressor, a drainage branch and a cooling branch. The compressor includes a bearing and an electromotor; the drainage branch is structured as a cooling bearing. Heat exchange between the cooling branch and the drainage branch is used to cool a refrigerant in the drainage branch; the cooling branch is further structured as a cooling electromotor. The technical scheme realizes undercooling of a bearing refrigerant so that the temperature of the refrigerant used to cool the bearing is lower; the cooling effect of the bearing is optimized; the problemof heat accumulation during work of the oilless bearing is solved; and meanwhile the cooling of the electromotor is realized.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

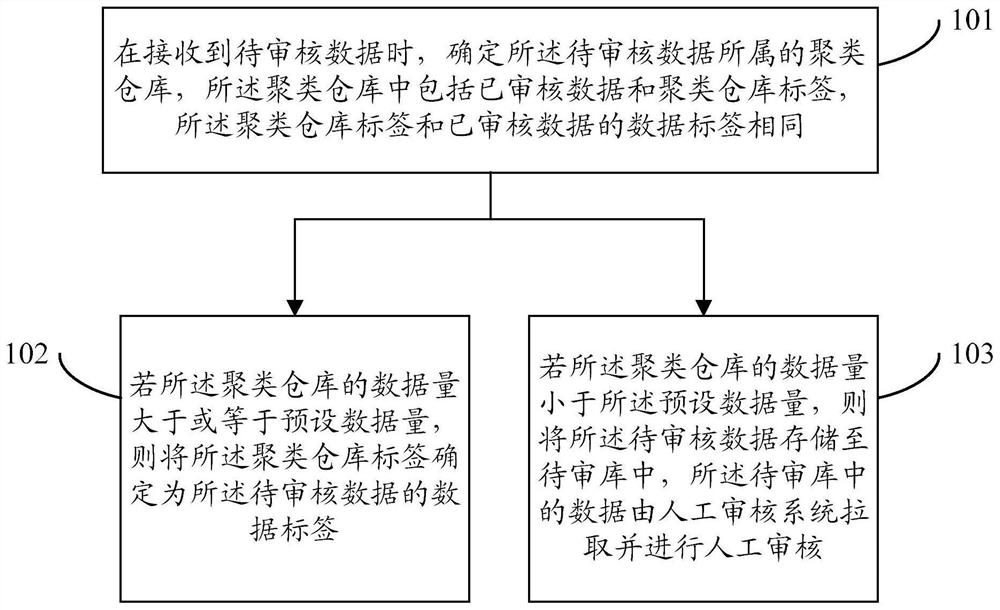

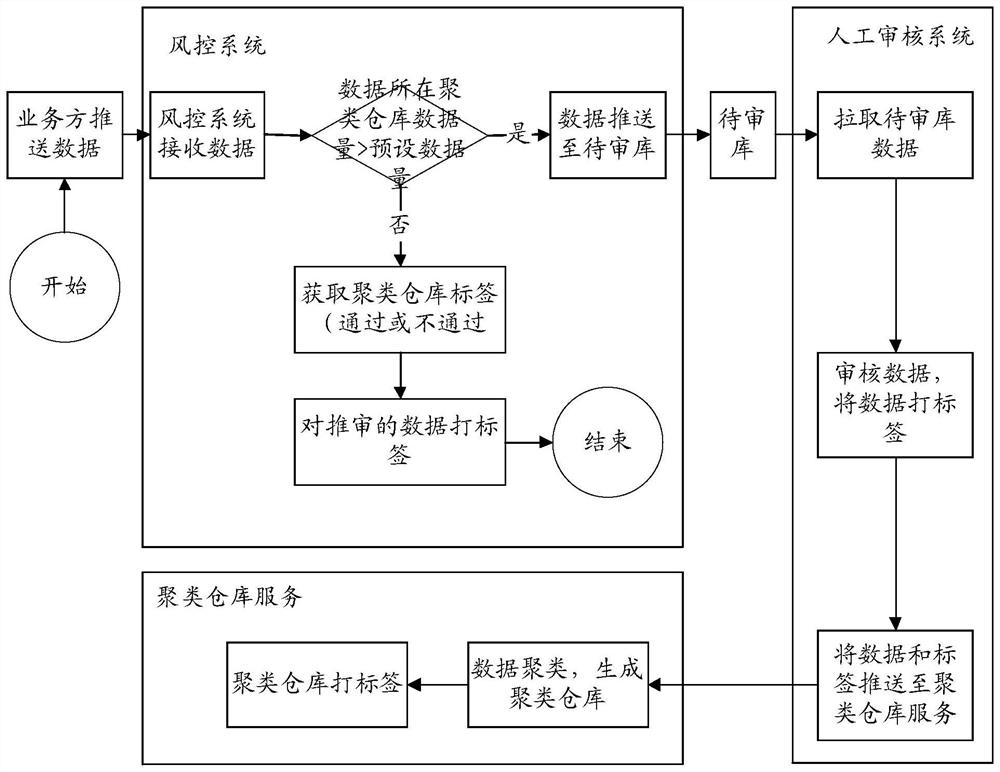

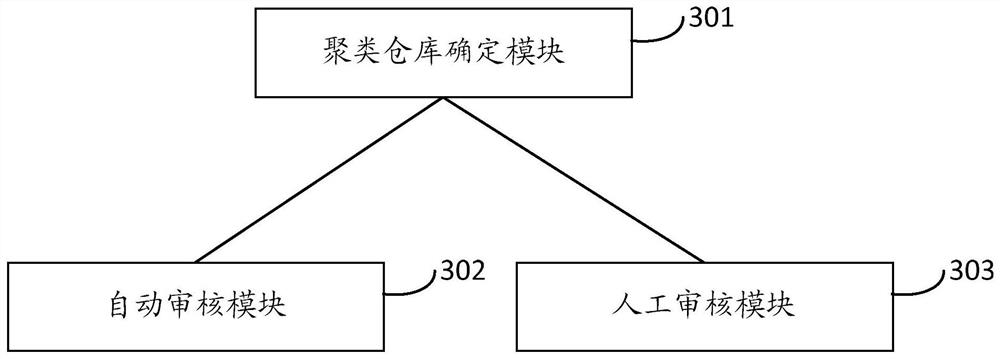

Data auditing method and device, electronic equipment and storage medium

ActiveCN113205130AAvoid reviewSolve the backlogCharacter and pattern recognitionEngineeringData mining

The invention provides a data auditing method and device, electronic equipment and a storage medium, and the method comprises the steps: when to-be-audited data is received, determining a clustering warehouse to which the to-be-audited data belongs, wherein the clustering warehouse comprises audited data and a clustering warehouse label, and the clustering warehouse label is the same as a data label of the audited data; if the data volume of the clustering warehouse is greater than or equal to the preset data volume, determining the clustering warehouse label as the data label of the to-be-audited data; if the data volume of the clustering warehouse is smaller than the preset data volume, storing the to-be-audited data in a to-be-audited library, and pulling and manually auditing the data in the to-be-audited library by a manual auditing system. The same or similar data does not need to be manually audited repeatedly, so the data is audited on the basis of a small amount of manual audited data, the audit efficiency is improved, and the problem of audited data overstock caused by manual audit is solved.

Owner:WUBA

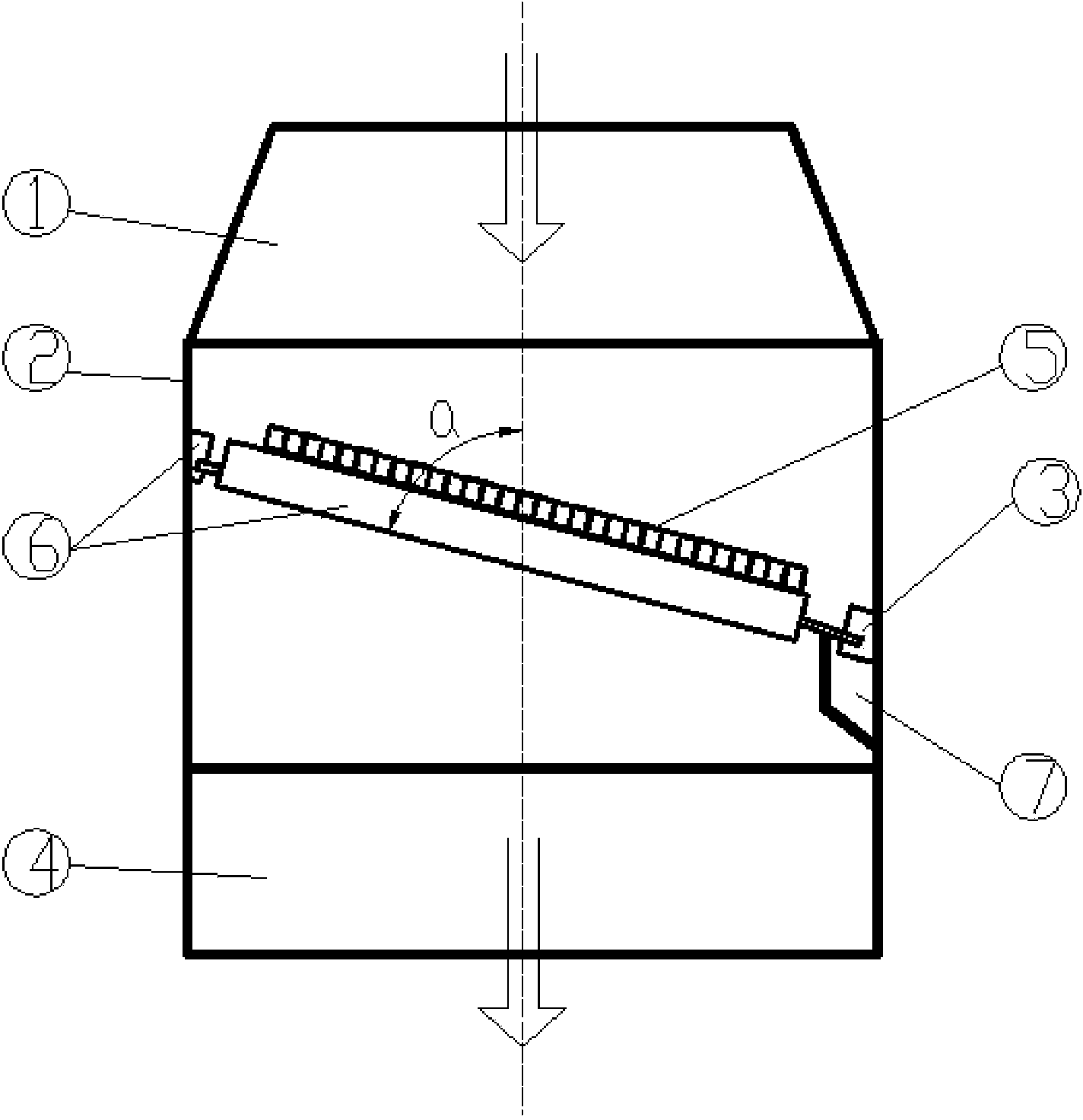

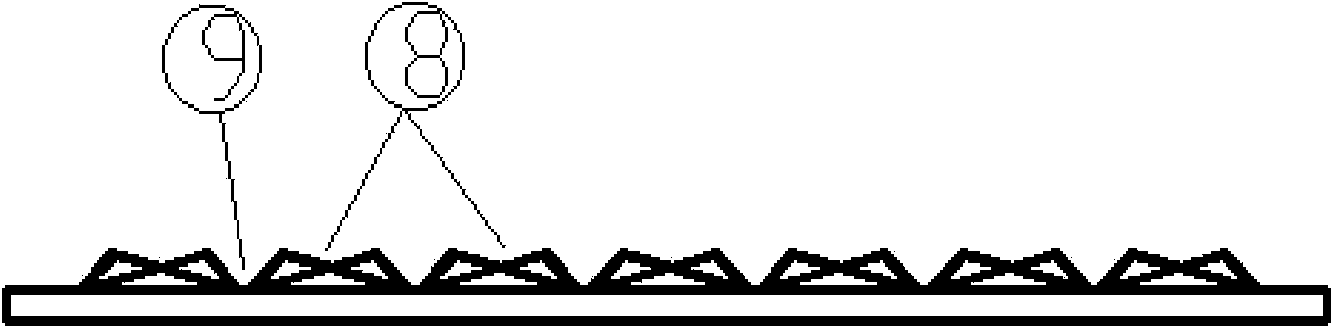

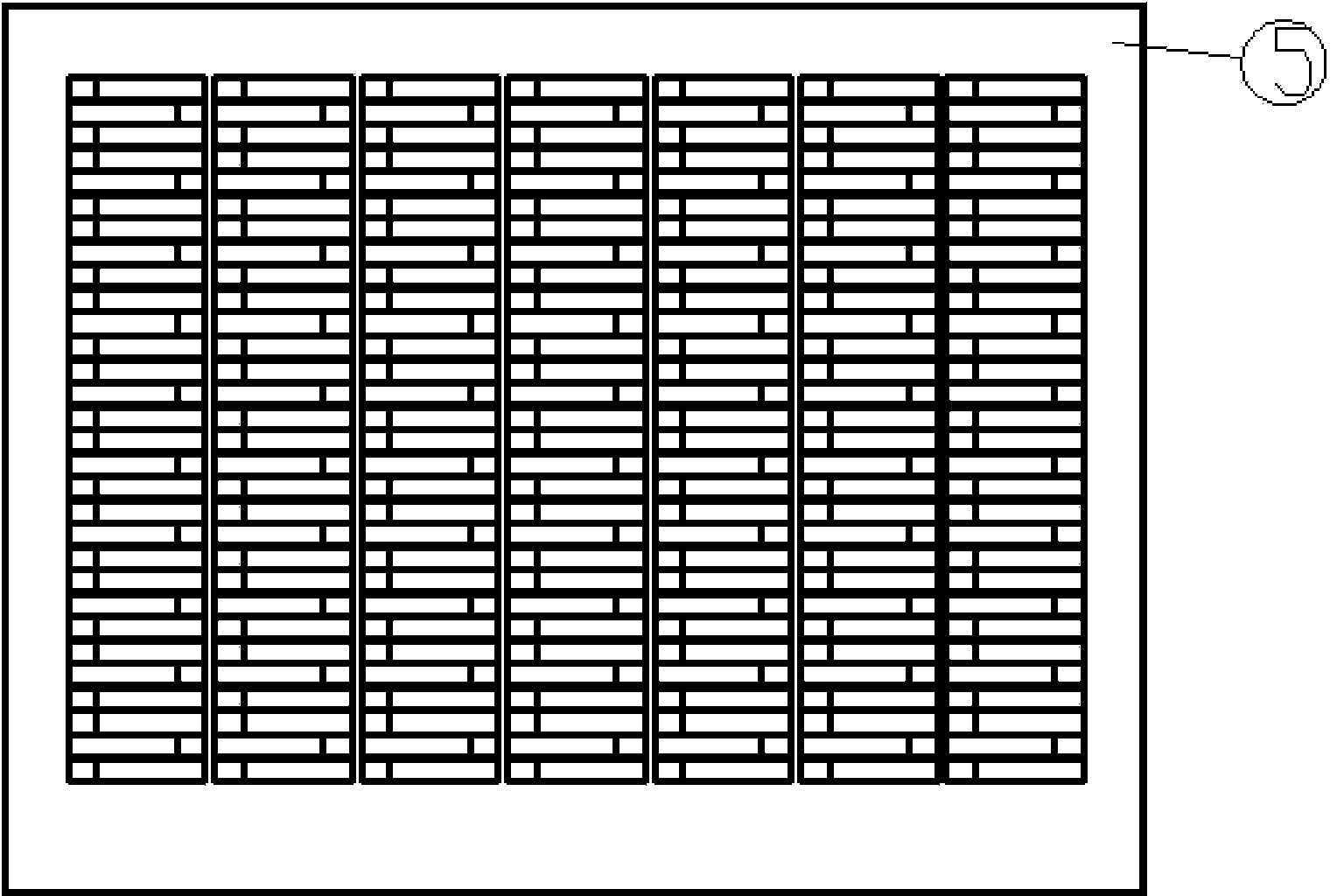

Air filter device of composite cooler of haulage motor

ActiveCN103934105ASolve the backlogSolve the cooling problemIC engine locomotivesGas turbine locomotivesFlueHeat sink

The invention discloses an air filter device of a composite cooler of a haulage motor. An air inlet of a shell is connected with an air outlet of a ventilator, an air outlet of the shell is connected with an air inlet of an oil-water cooler; a filter element is an electrostatic metal plate in a crossed and staggered grid plate structure, and is connected with a direct current supply and insulated with the shell; a dust collecting box is of a funnel structure with a door at one side, and is arranged at the downstream of the electrostatic metal plate. Tiny objects in airflow are adsorbed on the electrostatic metal plate by static electricity and are deposited in a funnel deposition box along a diversion trench under dual action of wind power and gravity of the tiny objects due to the included angle between the electrostatic metal plate and the axis of an air flue inside the shell and the crossed and staggered grid plate group structure, and thus the problems of dust retention and influence on heat dissipation of a cooling plate are effectively solved. At daily time, only the funnel-type dust collecting box with the door at the side needs to be cleaned, and under extreme conditions, the drawer-type electrostatic metal plate also can be easily taken down by opening the side door of the shell to clean. Thus, the cooling effect is greatly improved.

Owner:CRRC DALIAN CO LTD

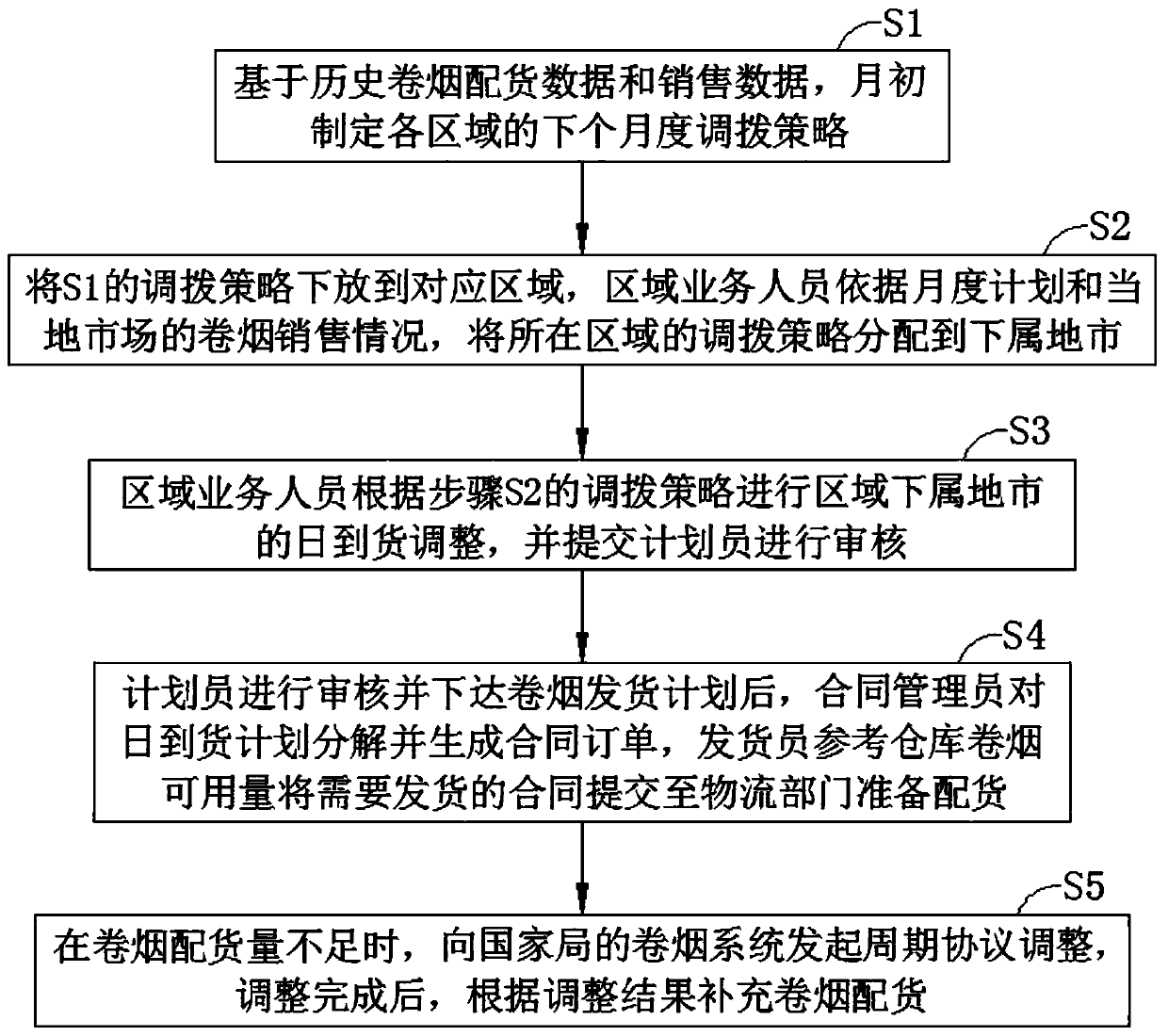

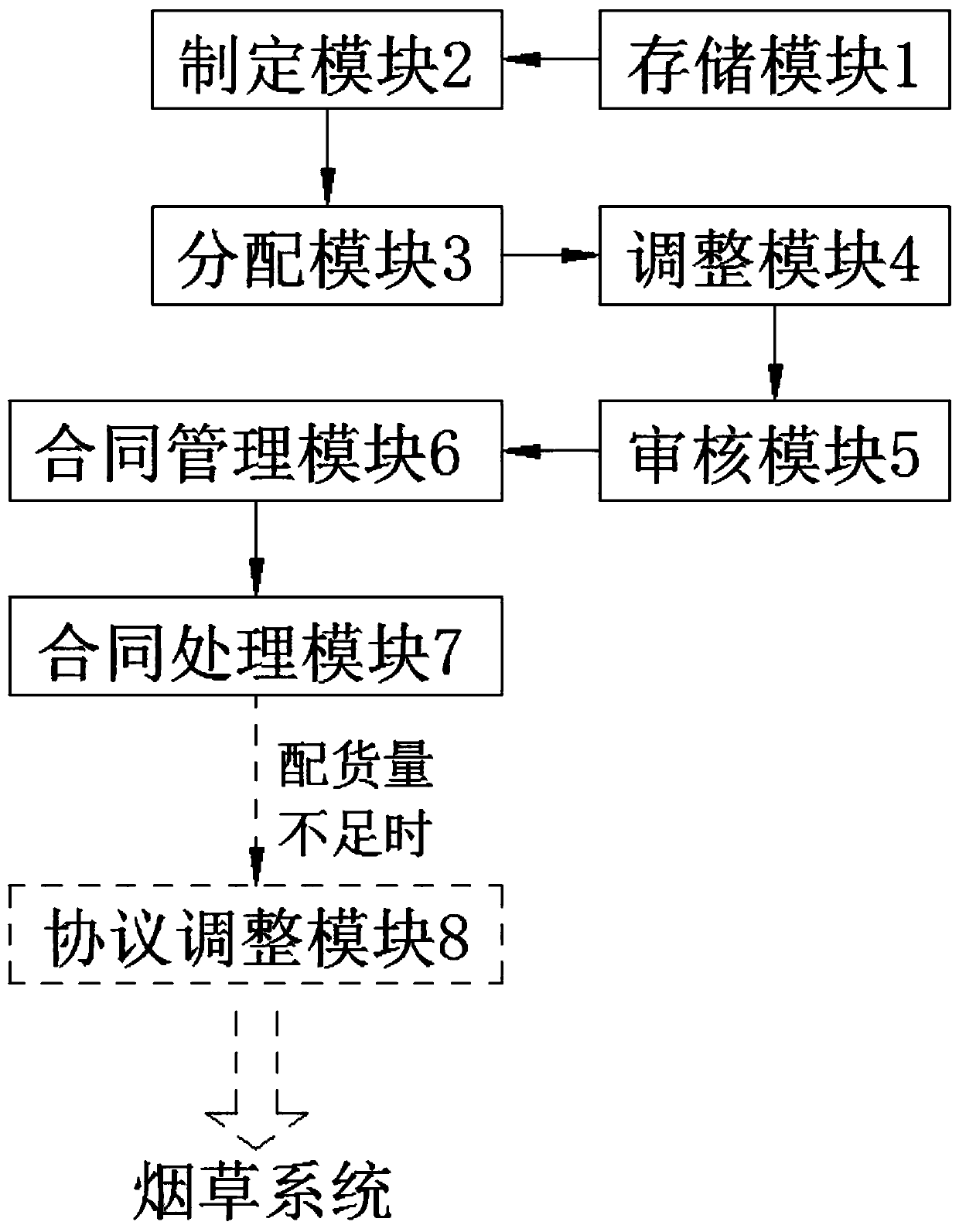

Cigarette distribution management method and system

PendingCN110490529ASolve the backlogInsufficient solversResourcesLogisticsProgram planningHysteresis

The invention discloses a cigarette distribution management method. The invention relates to the technical field of cigarette distribution. The management method is based on historical cigarette distribution data and sales data. The method comprises: firstly, formulating a next monthly allocation strategy of each region at the beginning of a month; allocating allocation strategies according to themonthly plan and the cigarette sales situation of the local market; and then carrying out daily arrival adjustment of subordinate cities of the region according to an allocation strategy, submittingthe cigarette delivery plan to a planner for auditing, issuing the cigarette delivery plan and generating a contract order after auditing is passed, performing cigarette distribution according to thecontract order, initiating periodic protocol adjustment to a cigarette system of the State Office once the planned distribution amount is insufficient in the distribution process, and supplementing cigarette distribution according to an adjustment result after adjustment is completed. The invention further discloses a cigarette distribution management system, the rest of the methods are combined,the cigarette distribution service can be promoted to better meet the market law, and the hysteresis problem of an existing cigarette distribution distribution strategy is jointly solved.

Owner:INSPUR QILU SOFTWARE IND

Processing method of low-value fish protein calcium peptide

InactiveCN107183729ANutritious and comprehensiveHigh purityPeptidesFermentationAntibiotic YAbsorption rate

The invention discloses a processing method of low-value fish protein calcium peptide. The processing technology uses low-value fish bones as raw materials, undergoes deodorization treatment, preparation of fish protein peptides, preparation of fish bone powder, extraction of soluble calcium in fish bone powder, Preparation steps of fish protein calcium peptide Fish protein calcium peptide was prepared. The beneficial effects are: the protein calcium peptide of the present invention is rich in nutrition and comprehensive, and the product has high purity, solves the problem of backlog of raw material fish and waste of resources in the production process of low-value fish, increases the added value of low-value fish products, and has great market development potential; the protein Calcium peptide is non-toxic, non-irritating, and has good solubility in the body. It not only has excellent compatibility with various nutrients including vitamins and antibiotics, and has a synergistic effect, but also the human body can absorb protein calcium peptide through the absorption route of protein peptide, and the absorption speed Fast, 2 to 3 times that of inorganic calcium, easy to be accepted by consumers; the processing technology of the present invention has low production cost, can be designed into fully automatic operation, and has high production efficiency.

Owner:舟山达康科技有限公司

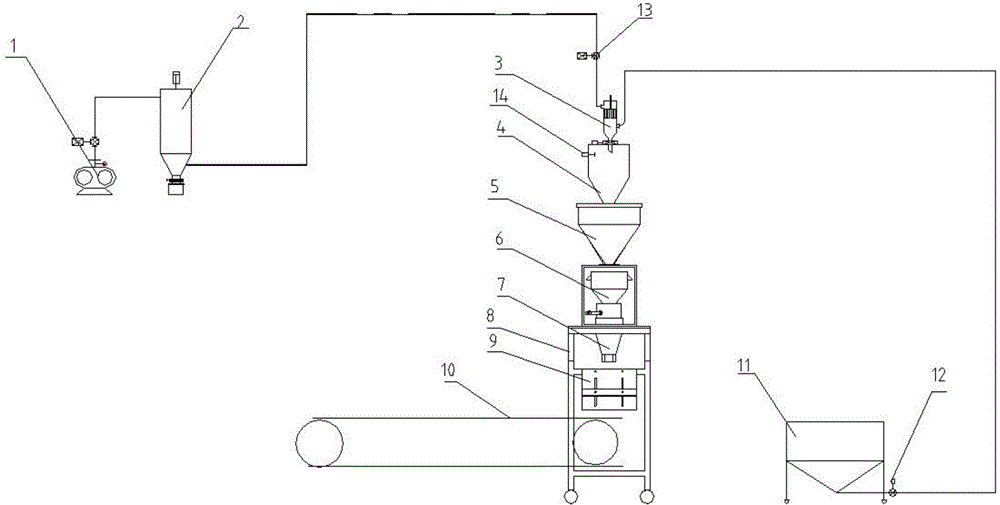

Automatic weighing and packaging system for hot melt colloidal particles

InactiveCN105270654ANo pollution in the processDoes not affect operationSolid materialEngineeringHot melt

The invention provides an automatic weighing and packaging system for hot melt colloidal particles. The automatic weighing and packaging system comprises a colloidal particle conveying unit. The colloidal particle conveying unit is connected to a filter through a colloidal particle conveying pipeline. The filter is connected to a vacuum batch feeder through a pipeline. The other side of the vacuum batch feeder is connected with a transition stock bin pipeline. The lower portion of the vacuum batch feeder is connected with a vacuum hopper. The lower portion of the vacuum hopper is connected with a metering bin. The lower portion of the metering bin is connected with a weighing module. The lower portion of the weighing module is connected with a bag sealing structure. The lower portion of the bag sealing structure is provided with a rotary bag distributing device. The lower portion of the rotary bag distributing device is provided with a conveying belt. The metering bin, the weighing module, the bag sealing structure and the rotary bag distributing device are fixed through a rack. The system is high in automation degree, free of environmental pollution and convenient to maintain; and in addition, operation of the packaging system is not affected when a main production system needs to be suddenly stopped.

Owner:江苏光辉粘合科技有限公司

High-efficiency catalyst used for preparing high ring 107 glue and preparation method thereof

ActiveCN102093561AReduce manufacturing costAppearance colorless and transparentSide productOrganosilicon

The invention relates to a high-efficiency catalyst used for preparing a high ring 107 glue and a preparation method thereof. The preparation method of the catalyst comprises the following steps of: adding a catalyst A and a catalyst B in a mole ratio of 0.25-1.1 according to weight ratio into a reaction bottle with a stirrer, a thermometer sleeve, a nitrogen inserted tube and a condensation pipe; and reacting the mixture in a nitrogen atmosphere with stirring to obtain the catalyst, wherein the catalyst component A is prepared by reacting octamethylcyclotetrasiloxane and potassium hydroxide,and the catalyst component B is prepared by reacting octamethylcyclotetrasiloxane and tetramethylammonium hydroxide. In the method, a polysiloxane high-boiling point ring is adopted; the polysiloxanehigh-boiling point ring belongs to by-products of high rings; the problem of accumulation of the by-products of an organic silicon monomer factory is solved; the production cost of the 107 glue is reduced; the profit space is expanded; and the core competition ability of an enterprise is enhanced. The catalyst has high stability; the storage period of the catalyst is more than 180 days; metamorphism phenomena, such as lamination, solidification and the like, are difficult to cause; and the high-efficiency catalyst has a plurality of low-boiling point cyclic utilization times.

Owner:JIANGXI BLUESTAR XINGHUO SILICONE CO LTD

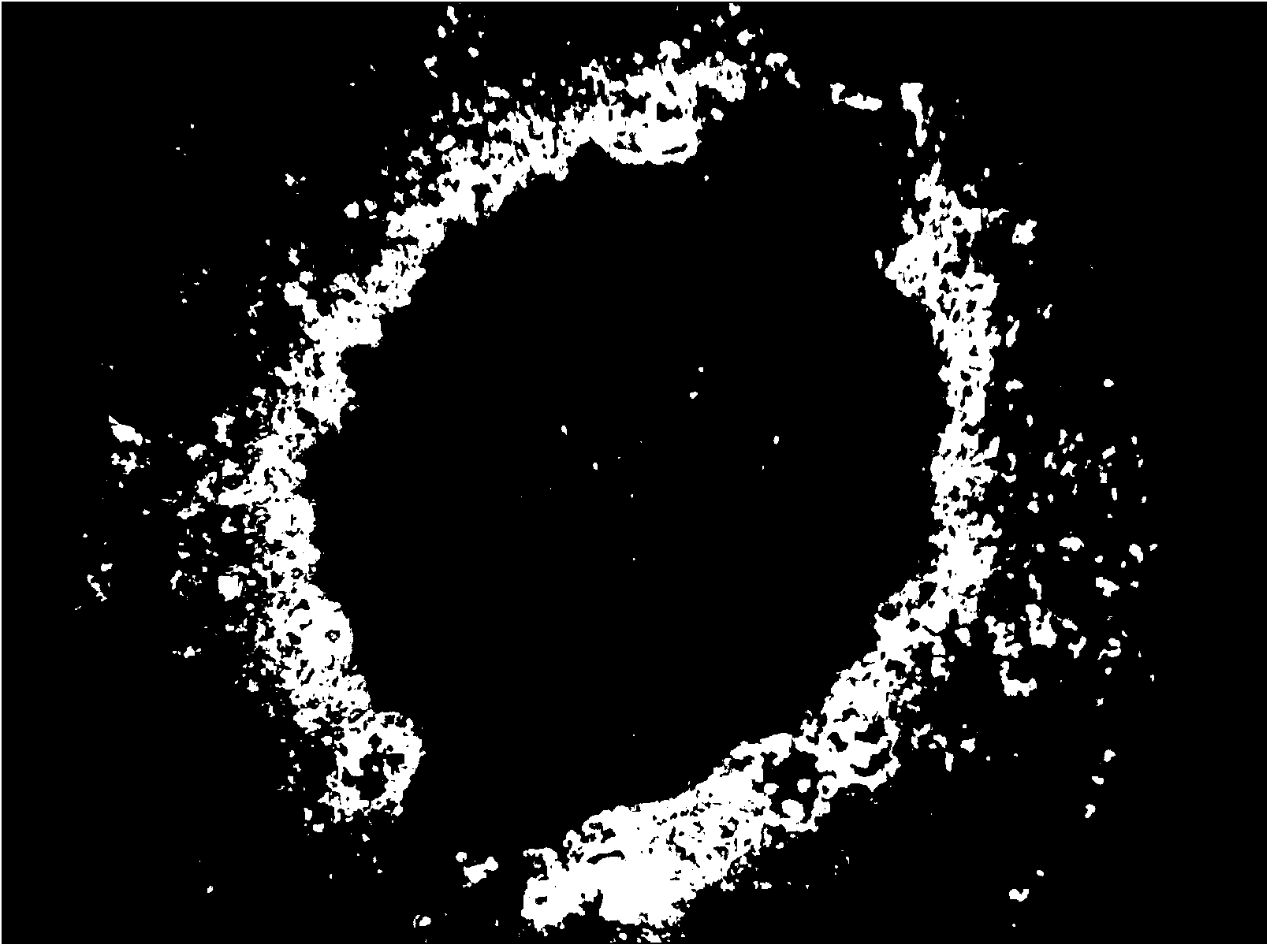

Method for fast indentifying linear defect of automobile panel

ActiveCN103954631AShort analysis timeEasy to popularizeAnalysis by electrical excitationOptically investigating flaws/contaminationNormal ironGreek letter sigma

The invention discloses a method for fast indentifying the linear defect of an automobile panel. The method comprises the following steps: 1) removing zinc layer on the surface of defective part of a defective sample to expose iron base by silicon carbide sandpaper; 2) analyzing the sample by analysis conditions set on a spark spectrometer, and exporting data after analyzing; and 3) according to the exported data, if the difference between the measured value of the element of the defective part and the measured value of a normal area is greater than 3 sigma, then indentifying that the defect belongs to inclusion defect, whereas the defect is scratch defect. The method disclosed by the invention can motivate the elements in the linear defect, can distinguish aluminum, calcium and other elements contained in the defect from the aluminum and the calcium in normal iron base by establishing a distinguishing rule, and can quickly identify the inclusion defect and the scratch defect of the linear defects of the automobile panel. The method has short sample analyzing time so as to solve problem of the backlog of the samples to be tested in a scene, and does not affect smoothly running production; and moreover, the method is accurate, intuitive, and is out of qualitative fuzzy problem.

Owner:武汉钢铁有限公司

Orange flesh dried orange peels and preparation method thereof

InactiveCN105918956ASolve the backlogSolve wasteClimate change adaptationFood ingredient functionsBiotechnologySugar

The present invention discloses orange flesh dried orange peels and a preparation method thereof. The orange flesh dried orange peels are mainly prepared from orange flesh, dried orange peels, minced ginger paste, sugar and longan meat. A large amount of the fresh orange flesh is utilized to effectively solve the problems of backlog and waste of the orange flesh and avoid the environment pollution and soil destroy of the discarded orange flesh. The preparation method changes the cold nature property of the orange flesh. The orange flesh dried orange peels are not cold and not dry, also have health-care functions of moistening lungs and stopping cough, and strengthening spleen and supplementing qi, and retain the original quality of the orange flesh. The preparation method of the orange flesh dried orange peels retains most of the nutrients in the fresh fruits, and the orange flesh dried orange peels are diverse in edible forms, can be matched with breads, biscuits and other food, and are delicate in smell, and sweet, sour and tasty.

Owner:何雪华

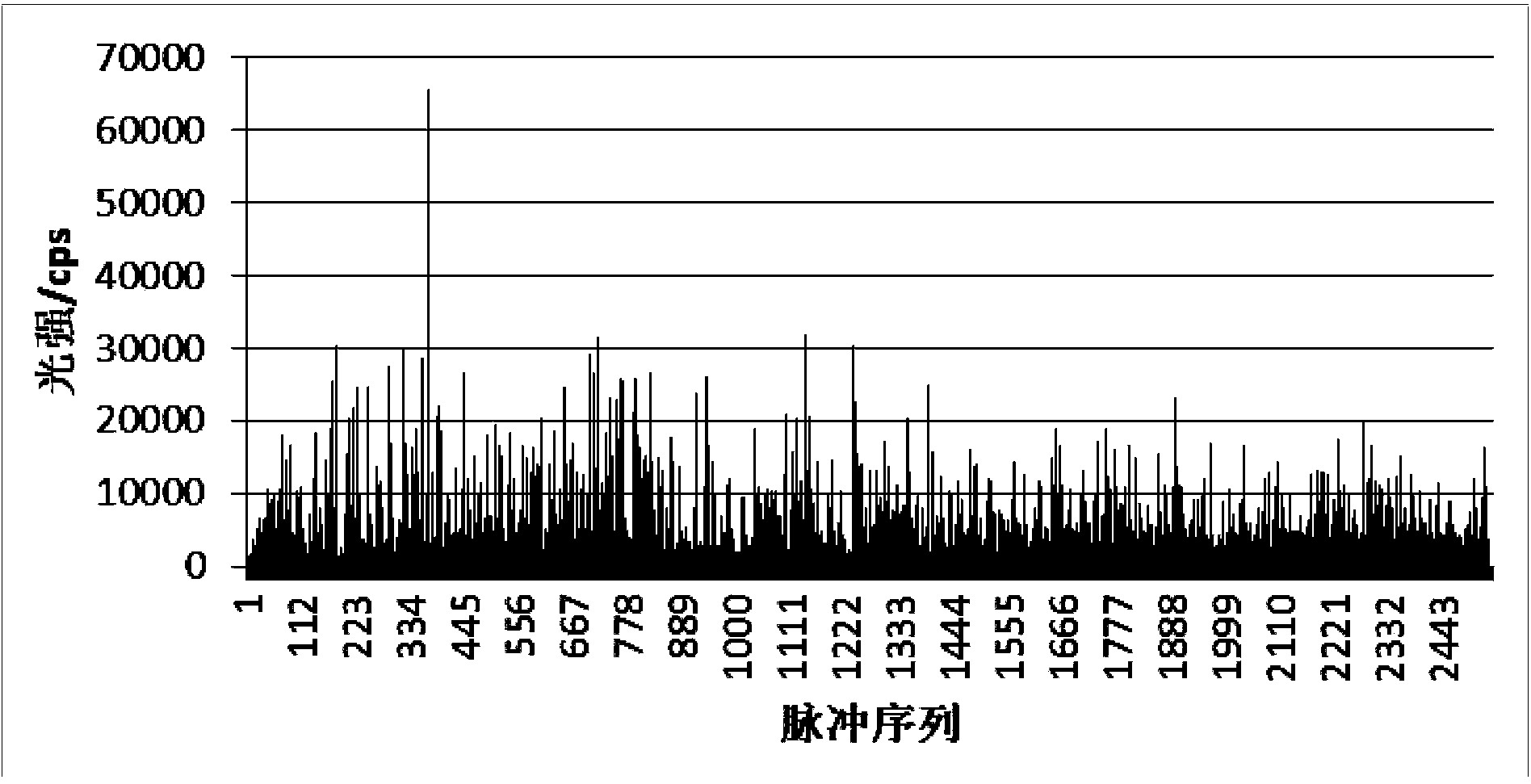

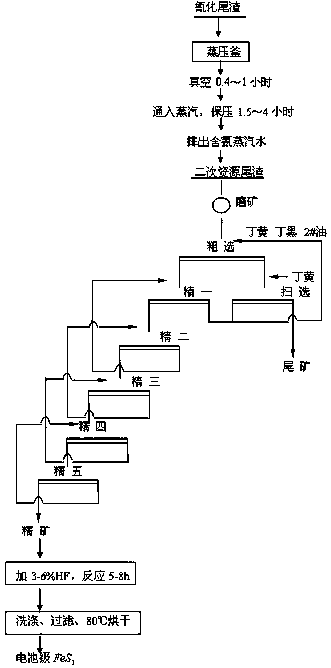

Technology for extracting ferrous sulfide from gold-bearing cyanide tailings

InactiveCN108043587AImprove qualityGood cyanide removal effectSolid waste disposalFlotationDibutyl dithiophosphateGold content

The invention relates to a technology for extracting ferrous sulfide from gold-bearing cyanide tailings. The technology comprises the steps that firstly, cyanide in the gold-bearing cyanide tailings is hydrolyzed by an autoclaving process, obtained secondary tailings are ground till a material in the secondary tailings, of which the fineness reaches 400 meshes, accounts for 95-98% of the secondarytailings; then, slurry blending is carried out to allow a liquid-solid mass ratio to be (3-4):1; and beneficiation reagents, namely, 60-120 g / t sodium n-butylxanthate and 15-35 g / t ammonium dibutyl dithiophosphate are added, a system pH value is adjusted to be between 6 and 9, and after one time of roughing, one time of scavenging and five times of cleaning are carried out, high-grade pyrites with the sulfur content being 52.87%, the gold content being 5.8 g / t, and the purity reaching 99.19% is obtained. With the adoption of the technology, the gold-bearing cyanide tailings in a smelting plant are recycled, secondary utilization of resources and the high value purpose are realized, and the amount of discharged pollutants is reduced substantially.

Owner:FUJIAN SHUANGQISHAN MINING +1

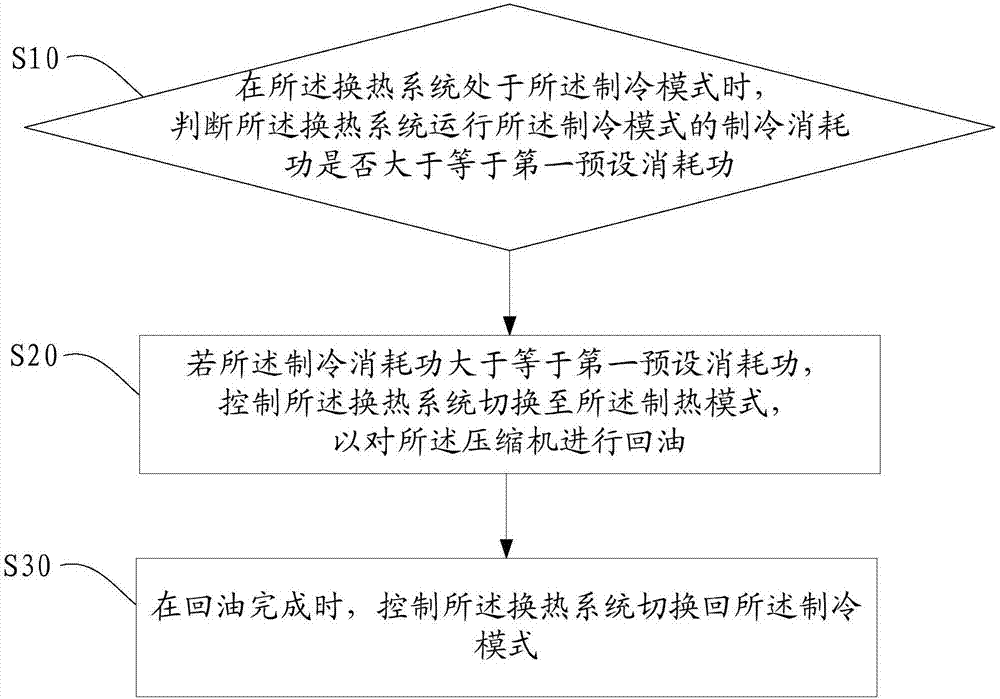

Heat exchange system and control method thereof

ActiveCN107490224ASolve the backlogImprove heat transfer efficiencyCompressorRefrigeration safety arrangementEngineeringRefrigeration

The invention discloses a heat exchange system and a control method thereof. The heat exchange system comprises a tank type heat exchanger and a compressor and is provided with a refrigeration mode and a heating mode. The control method of the heat exchange system comprises the steps that when the heat exchange system is in the refrigeration mode, whether the refrigeration consumed work of the heat exchange system in the refrigeration mode is greater than or equal to the first preset consumed work or not is judged; if the refrigeration consumed work is greater than or equal to the first preset consumed work, the heat exchange system is controlled to be switched to the heating mode so as to carry out oil return on the compressor; and when oil return is completed, the heat exchange system is controlled to be switched back to the refrigeration mode. According to the technical scheme of the heat exchange system and the control method thereof, the problem that lubricating oil of the compressor is accumulated in the tank type heat exchanger can be solved.

Owner:TCL AIR CONDITIONER ZHONGSHAN CO LTD

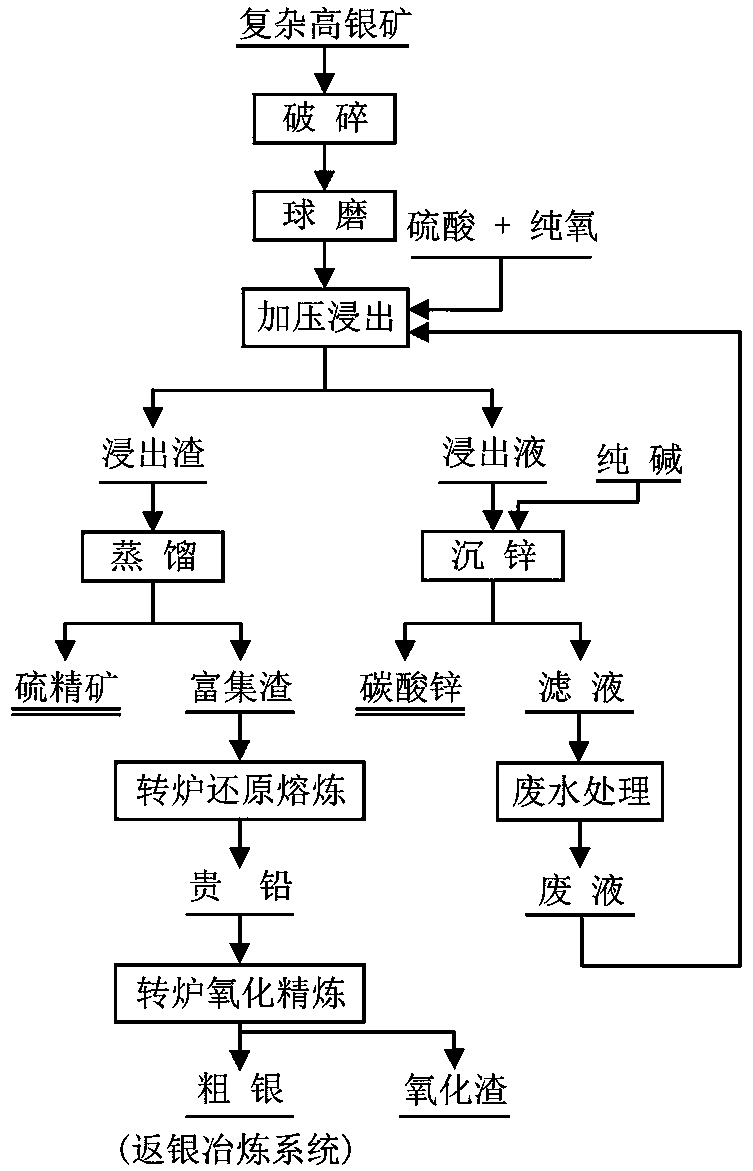

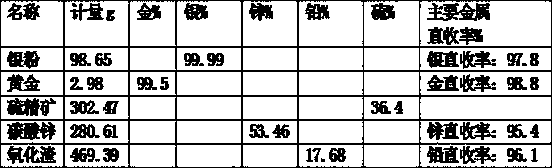

A method for comprehensive recovery of complex high-silver ore

ActiveCN108048651BSolve the backlogSimple processSulfur preparation/purificationProcess efficiency improvementDistillationSlag

The invention provides a complex high-silver mine comprehensive recycling method. The method includes the steps that the high-silver mine is subjected to oxygen-pressure acid leaching to enable zinc to enter a solution, gold, silver, lead and the like are enriched in a slag, the solution is deposited with sodium carbonate to form zinc carbonate which can be directly sold, the slag is subjected tolow temperature distillation to enable sulfur to be distilled out to be recycled, and the slag after being distillated is subjected to reduction smelting and oxidizing refining to recycle the gold andthe silver. The complex high-silver mine comprehensive recycling method is suitable for comprehensive recycling the gold, the silver, the zinc, the lead and the other valuable metal from the high-silver mine with high content of the gold, the zinc and the lead, and the direct recycling rate of the gold, the silver, the zinc and the lead are separately more than 98%, 97%, 95% and 96%. The direct recycling rate is high and the separation is complete, and precious metal in the smelting system, especially the rapid recycling of the gold and the silver is facilitated.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

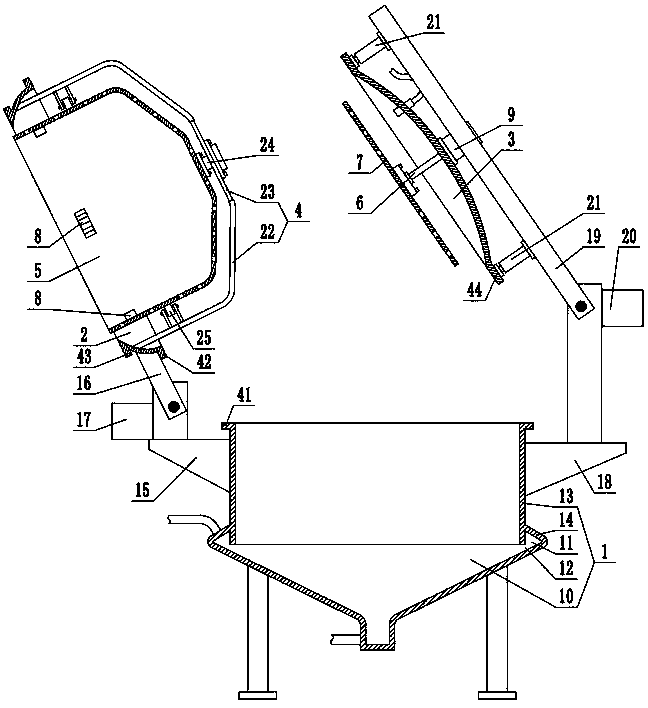

Upper driving type no-clean vacuum fryer

PendingCN111481076AGuaranteed cleanlinessSolve the retentionDeep fat fryersStructural engineeringMechanical engineering

The invention discloses an upper driving type no-clean vacuum fryer comprising a pot body, an annular pot cover pressed on the top of the pot body in a sealed mode, and a circular pot cover pressed onan opening of the annular pot cover in a sealed mode. A bracket extending into the pot body is connected to the inner wall of the annular pot cover, a frying basket with an opening in the top and located in the pot body is rotatably connected to the bracket, and a left driving mechanism capable of driving the annular pot cover to swing leftwards and upwards so as to swing the frying basket out ofthe outer side of the pot body is arranged on the outer side of the pot body; a pressing disc for driving the frying basket to rotate is mounted at the bottom of the circular pot cover; a right driving mechanism for driving the circular pot cover to lift up and down and swing towards the upper right side is arranged at the outer side part of the pot body. The vacuum fryer is simple in structure,the problems of residue retention and accumulation are solved, the residue discharging effect is improved, vacuum frying operation can be achieved, frying work and pan bottom self-cleaning work can beachieved at the same time, the cleanliness of oil in the frying process can be guaranteed, and the frying effect and the product quality are improved.

Owner:张培森

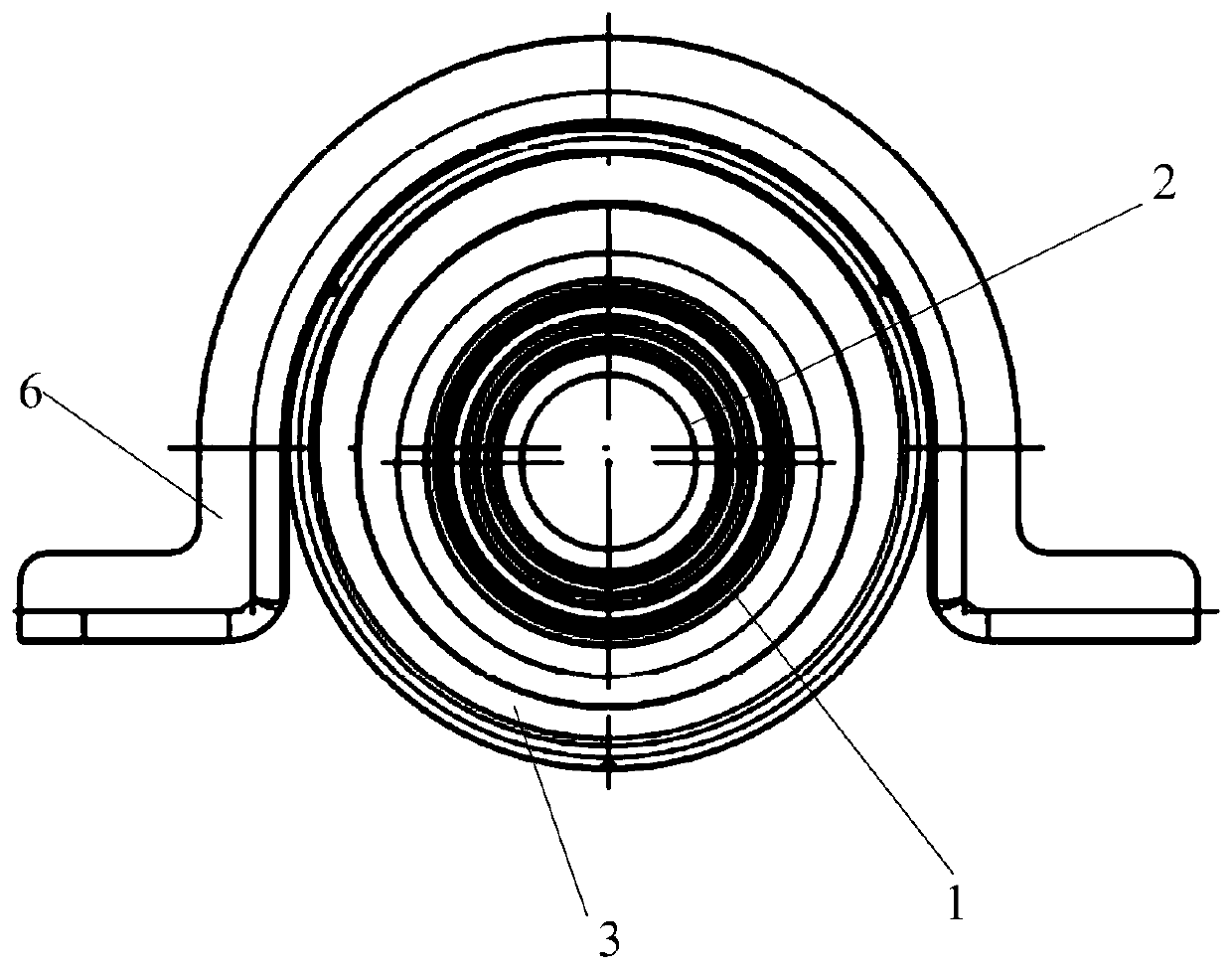

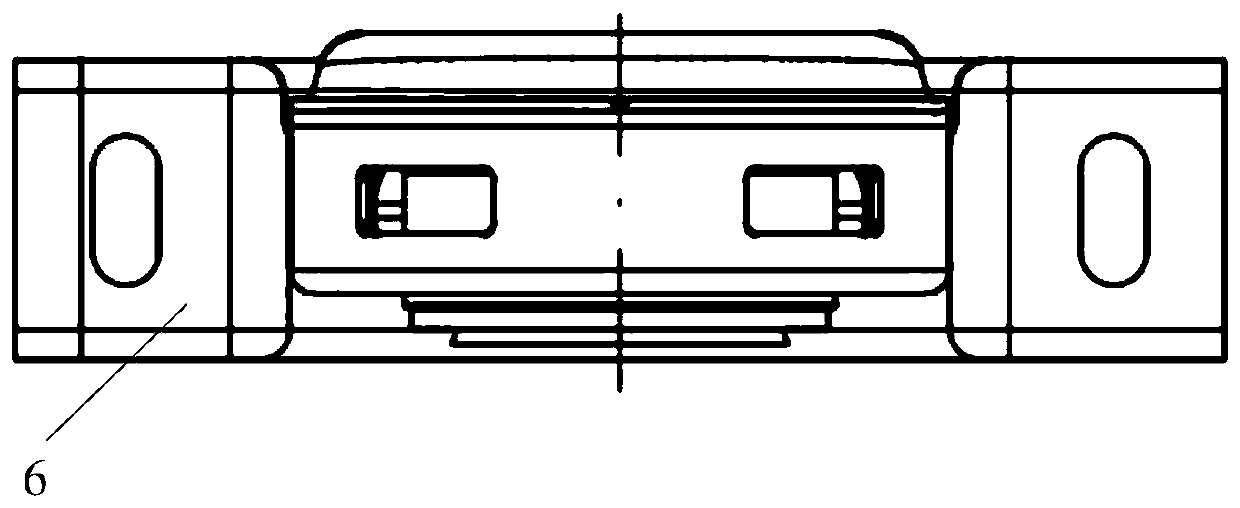

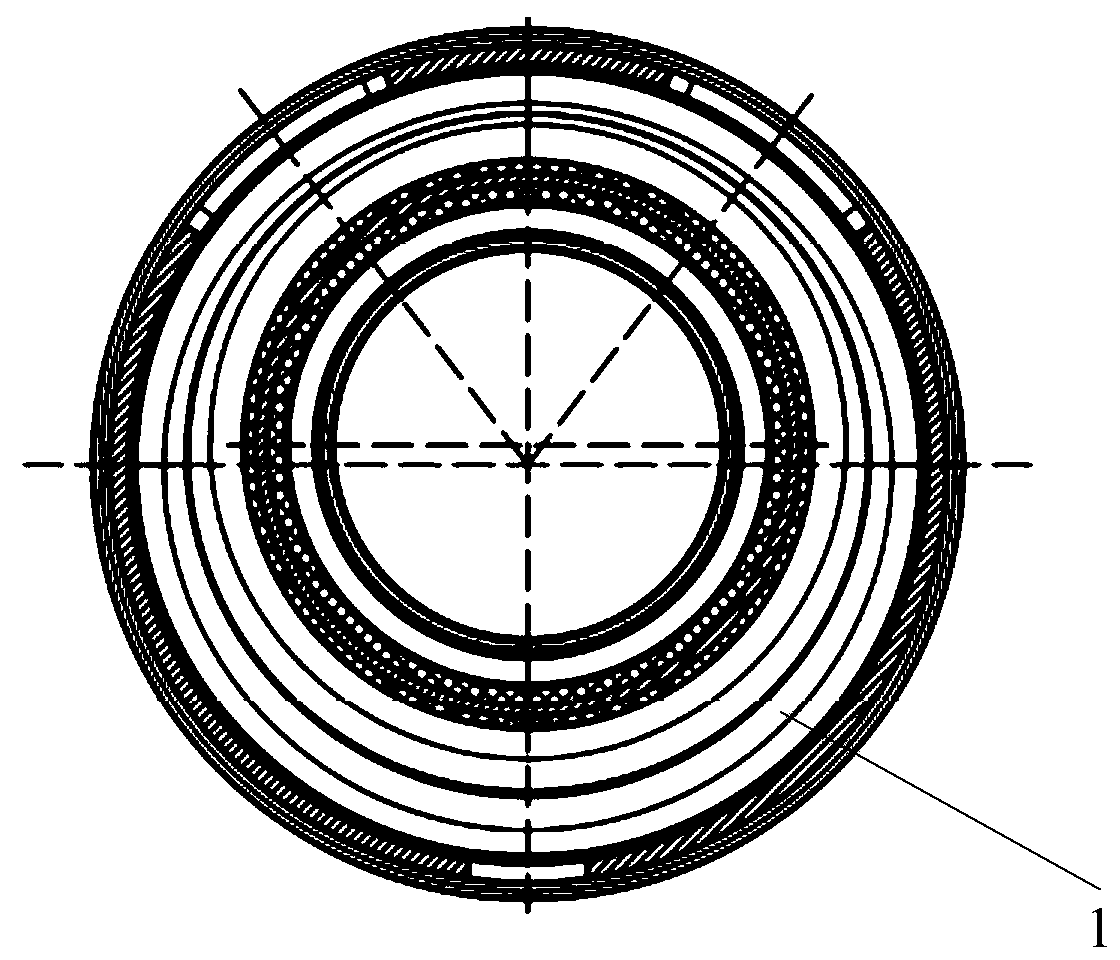

Novel transmission shaft support structure

PendingCN110242674ACompliant with NVH requirementsImprove pass rateEngine sealsRubber-like material springsDrive shaftEngineering

The invention provides a novel transmission shaft support structure. The novel transmissions shaft support structure comprises a rubber main spring, a rubber main spring inner metal piece, a rubber main spring outer metal piece and a standard bearing. The rubber main spring is mounted between the rubber main spring inner metal piece and the rubber main spring outer metal piece. The rubber main spring has a circular arc hollow inside. The rubber main spring inner metal piece is located at the inner ring of the rubber main spring, and the rubber main spring outer metal piece is located at the outer ring of the rubber main spring. The standard bearing is mounted on the rubber main spring. The novel transmission shaft support structure has the beneficial effects that product stiffness performance meets the whole vehicle NVH requirements; the reliability of the product is guaranteed, and the durability requirement of customers is met; the sealing performance of the product is improved, and the service life of the bearing is prolonged; the installation error of the yaw direction of a transmission shaft can be compensated for; by optimizing the structure of the inner metal piece, the qualification rate of the rubber main spring is increased; the problem of backlog of foreign liquids is solved; and the risk of falling off of parts of the product is reduced.

Owner:柳州日高汽车减振技术有限责任公司

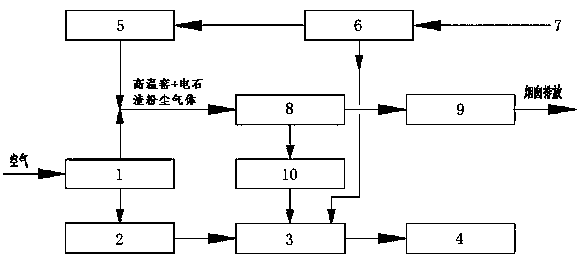

Safe and environment-friendly treatment system for carbide slag in cement production and storage and treatment process of safe and environment-friendly treatment system

ActiveCN108178534ASolve the backlogSolve the blockageSolid waste disposalTransportation and packagingSlagCarbide

The invention discloses a safe and environment-friendly treatment system for carbide slag in cement production and storage and a treatment process of the safe and environment-friendly treatment system. The problem of accumulation of acetylene gas in a carbide slag storage bin is solved through a replacement method; carbide slag dust-containing gas replaced from the carbide slag storage bin is heated by using high-temperature kiln exhaust gas produced by cement, so that after the dry carbide slag dust-containing gas is filtered through a bag dust remover, the carbide slag returns to the systemfor recycling; environmentally-friendly and standard-meeting gas is directly discharged; the problem that the carbide slag storage bin is extremely easy to explode due to the accumulation of the acetylene gas is effectively solved, and the problem of blockage of internal components of a pipeline, a valve and a dust remover in a dust removal system is also solved. The safe and environment-friendlytreatment system has the advantages of a small occupied space, small investment, high efficiency, safety, environmental friendliness, economical operation and the like.

Owner:CHINA CHENGDA ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com