Patents

Literature

78results about How to "Realize streamlined production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Garment customization production process automatic management system and management method

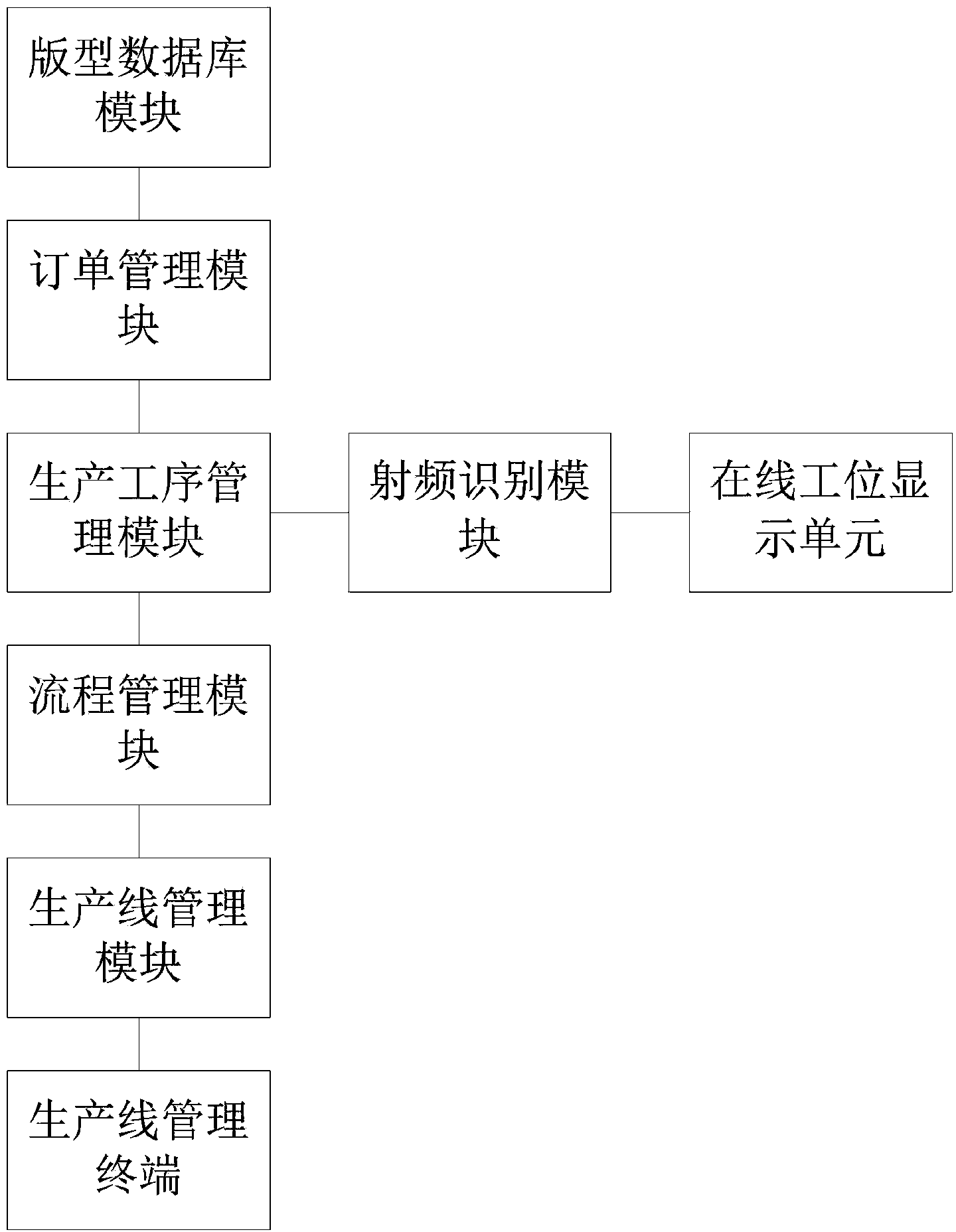

InactiveCN103870937AEasy to operateRealize streamlined productionResourcesProduction lineComputer module

The invention relates to a garment customization production process automatic management system and management method. The management system comprises a model database module, an order management module, a production procedure management module, a process management module, a production line management module, a production line management terminal and a radio frequency recognition label and an online station display unit. According to the management method, functions of the system modules are taken into consideration comprehensively, and efficient streamline management of the production process can be achieved. The system divides production procedures and design elements in detail according to characteristics of garment customization, order information is analyzed into the design elements and converted into specific production procedures, the management system converts customization orders into the special production procedures, and production management and operations of operation workers are facilitated. Streamline production of personal customized garments can be achieved.

Owner:青岛酷特智能股份有限公司

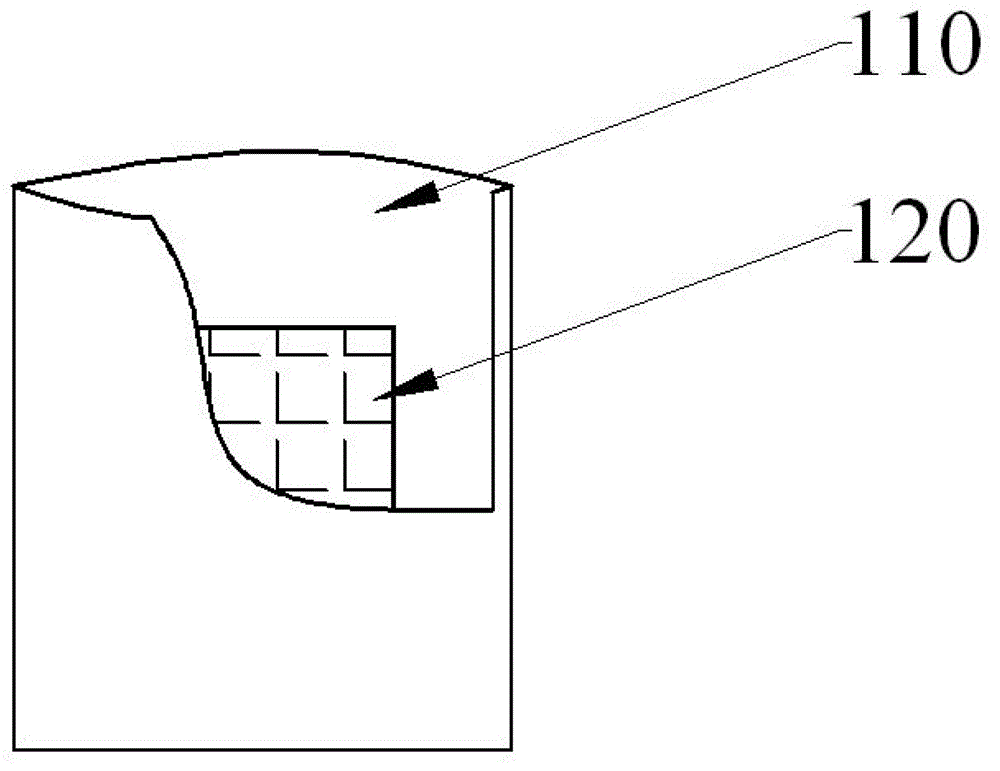

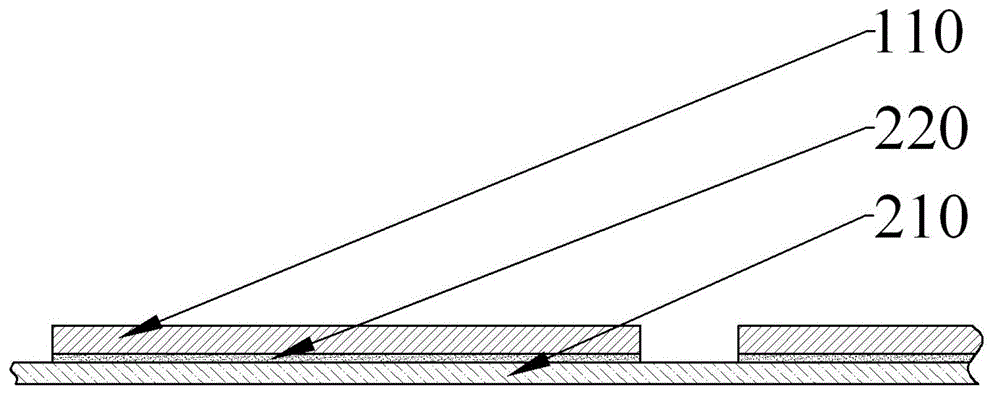

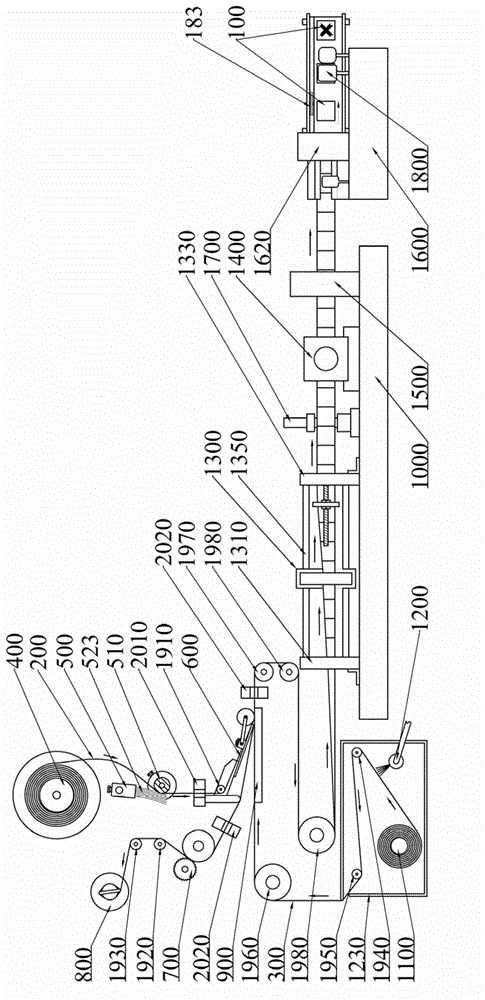

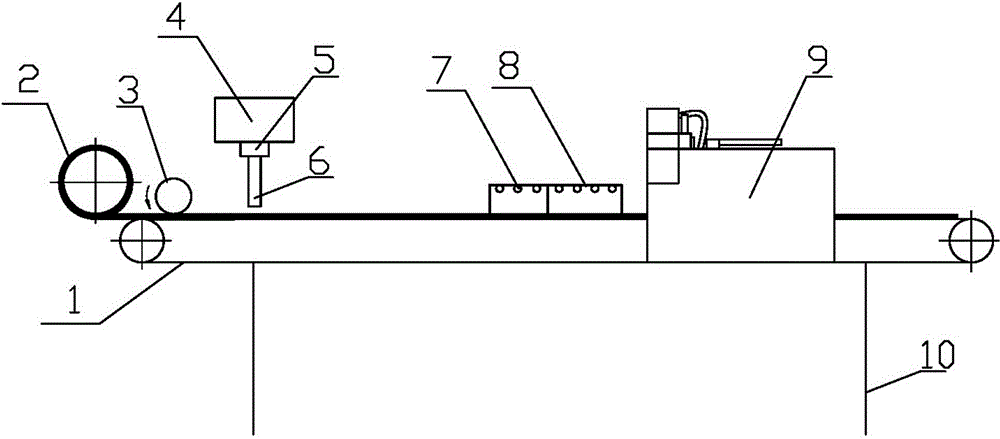

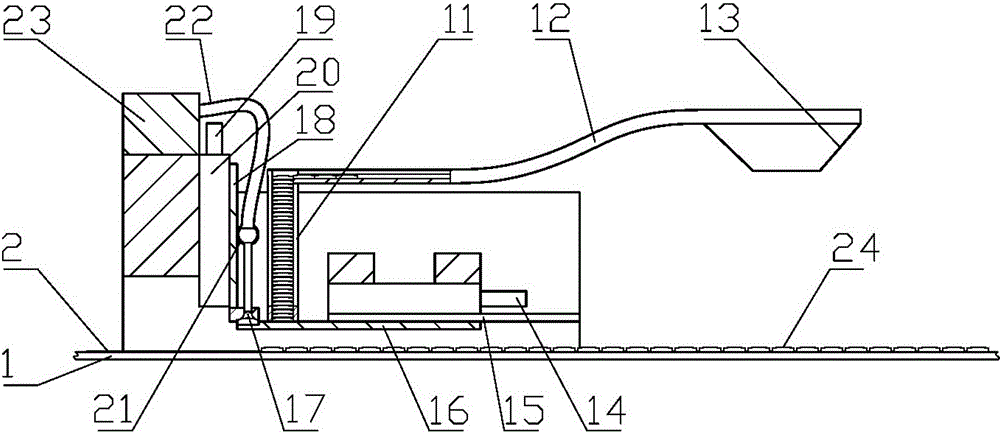

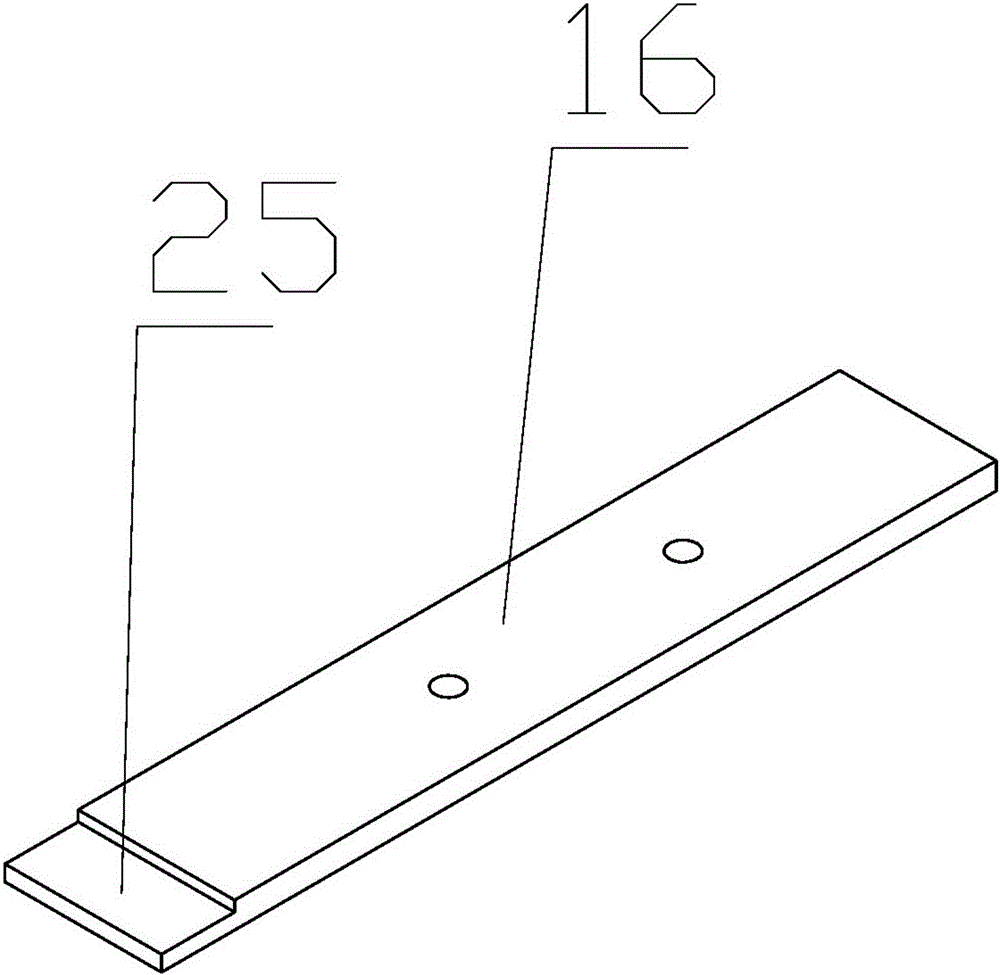

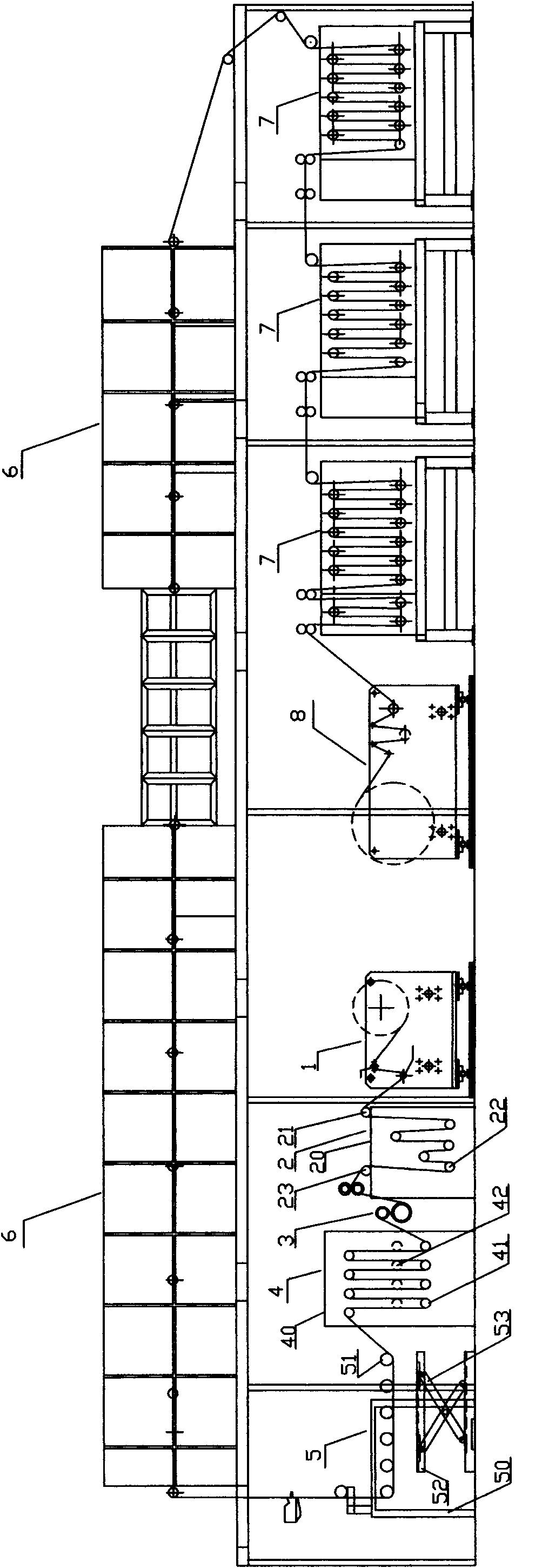

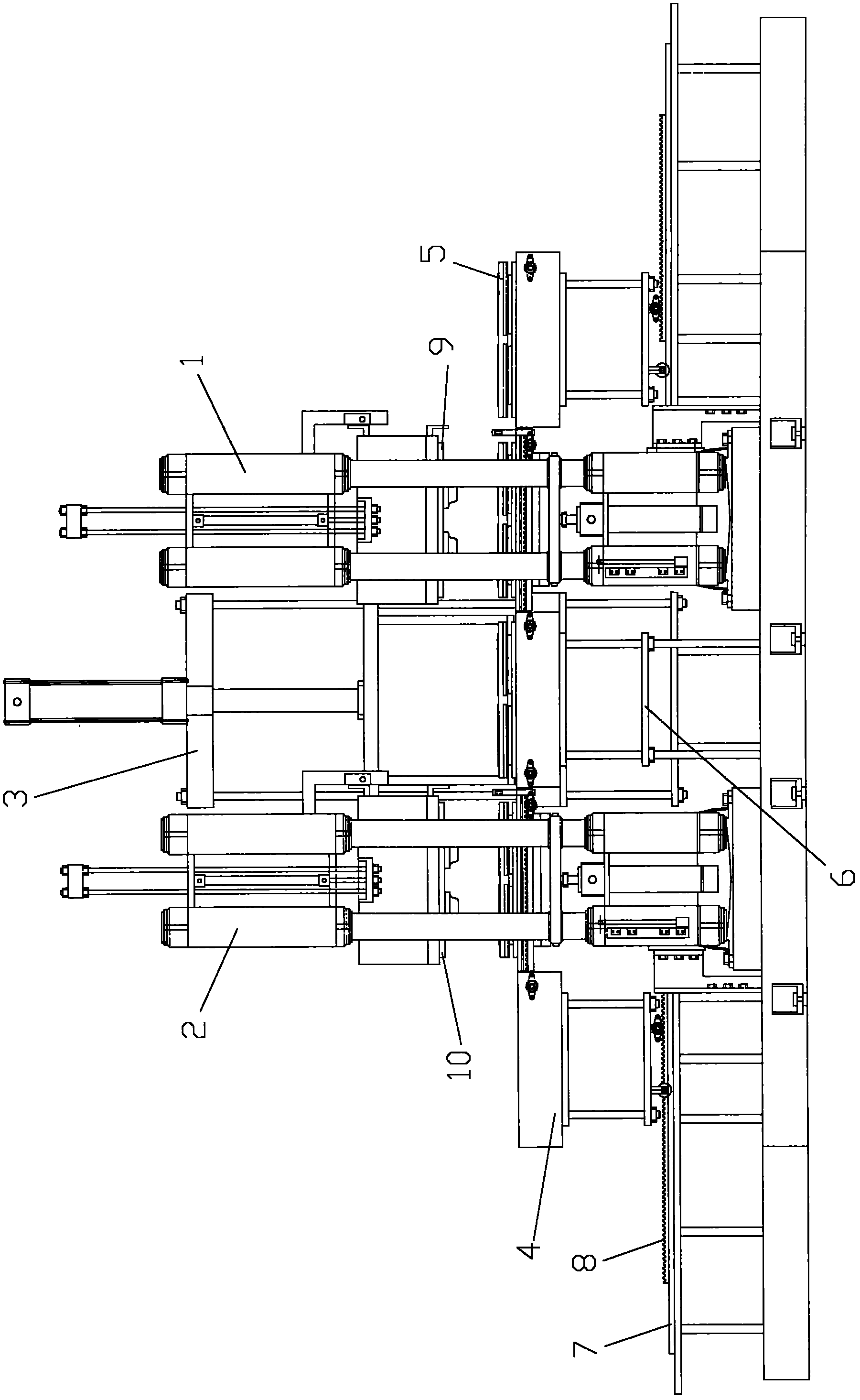

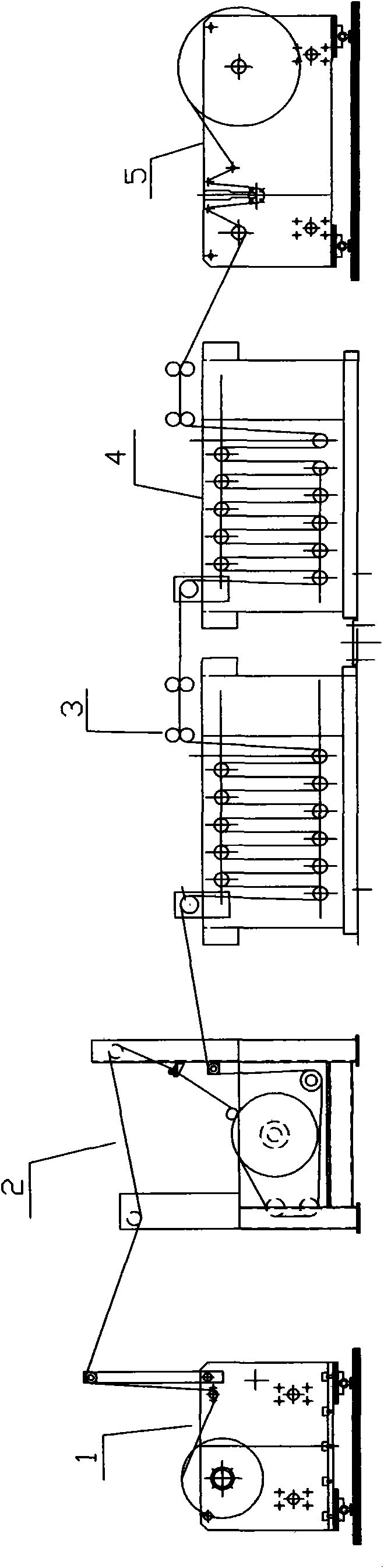

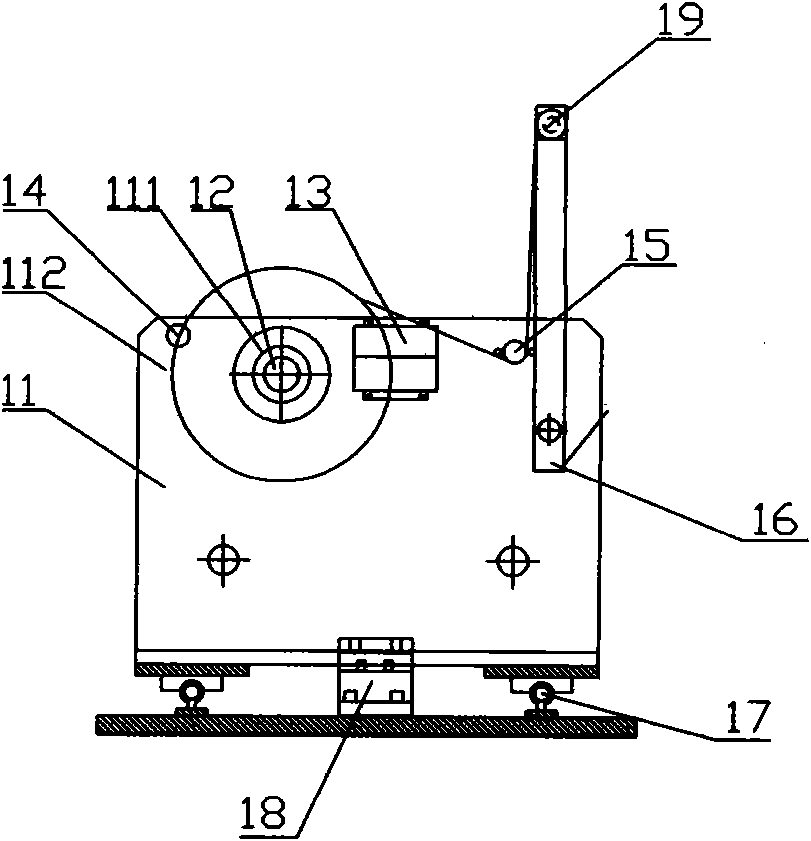

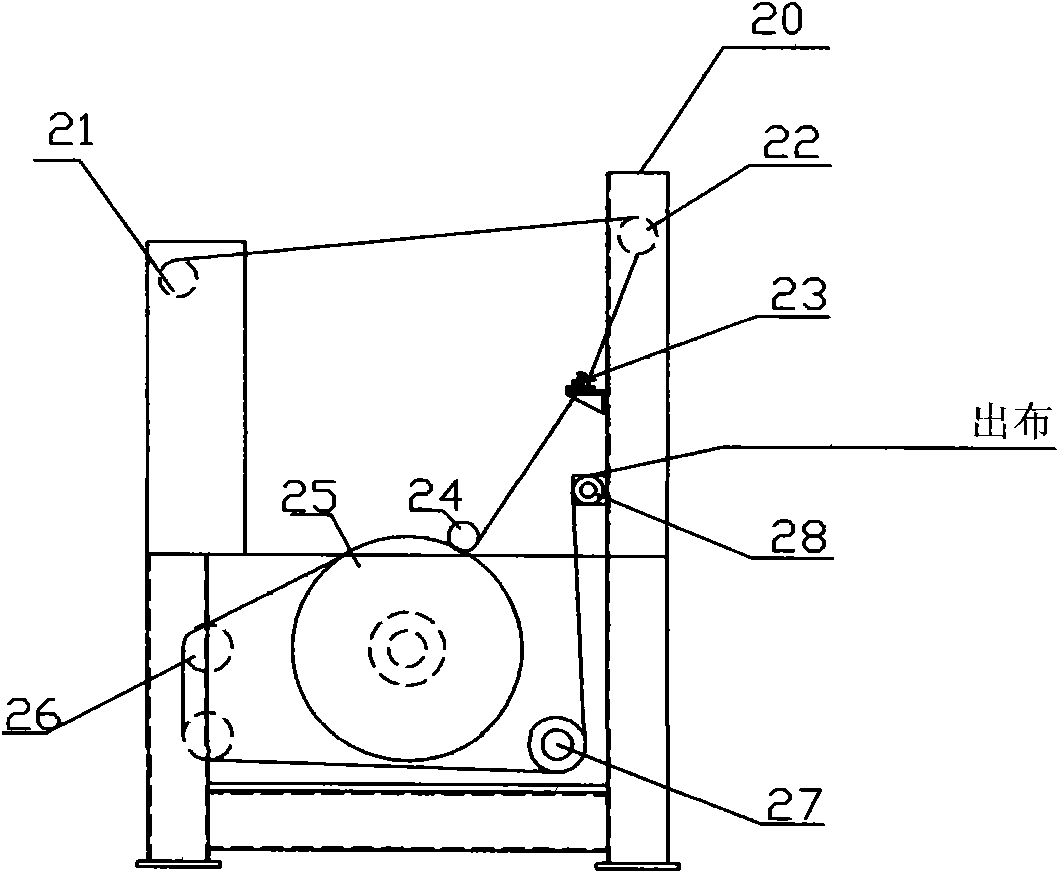

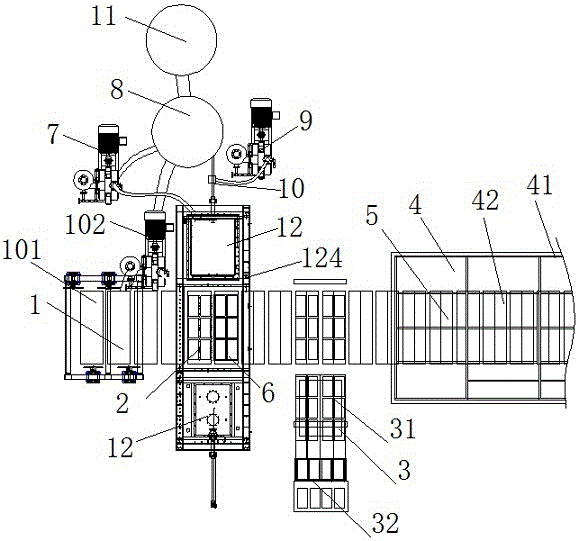

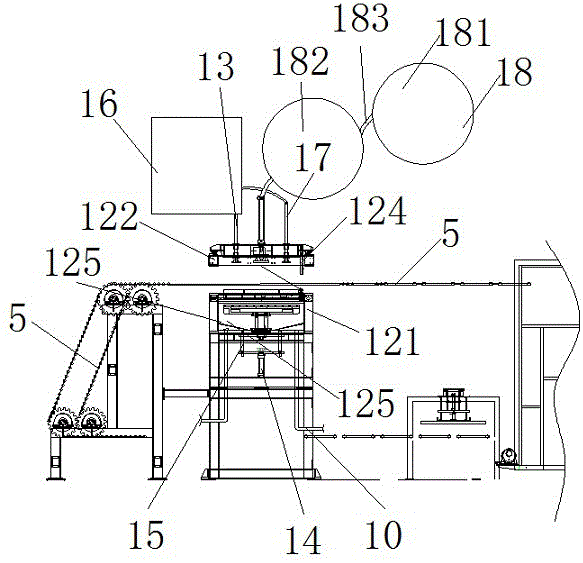

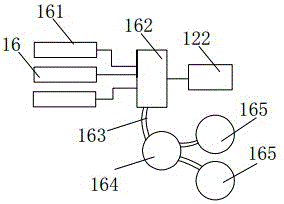

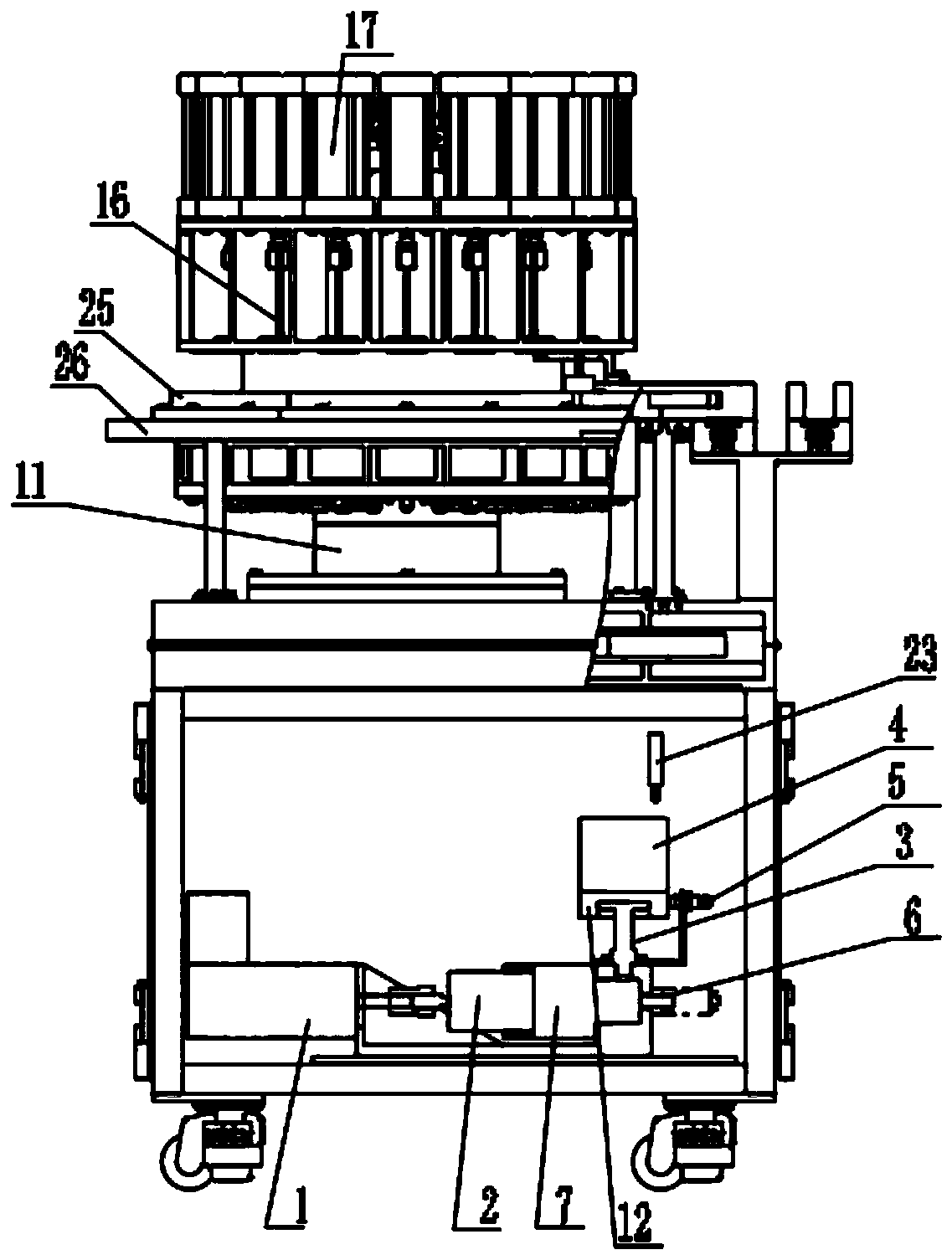

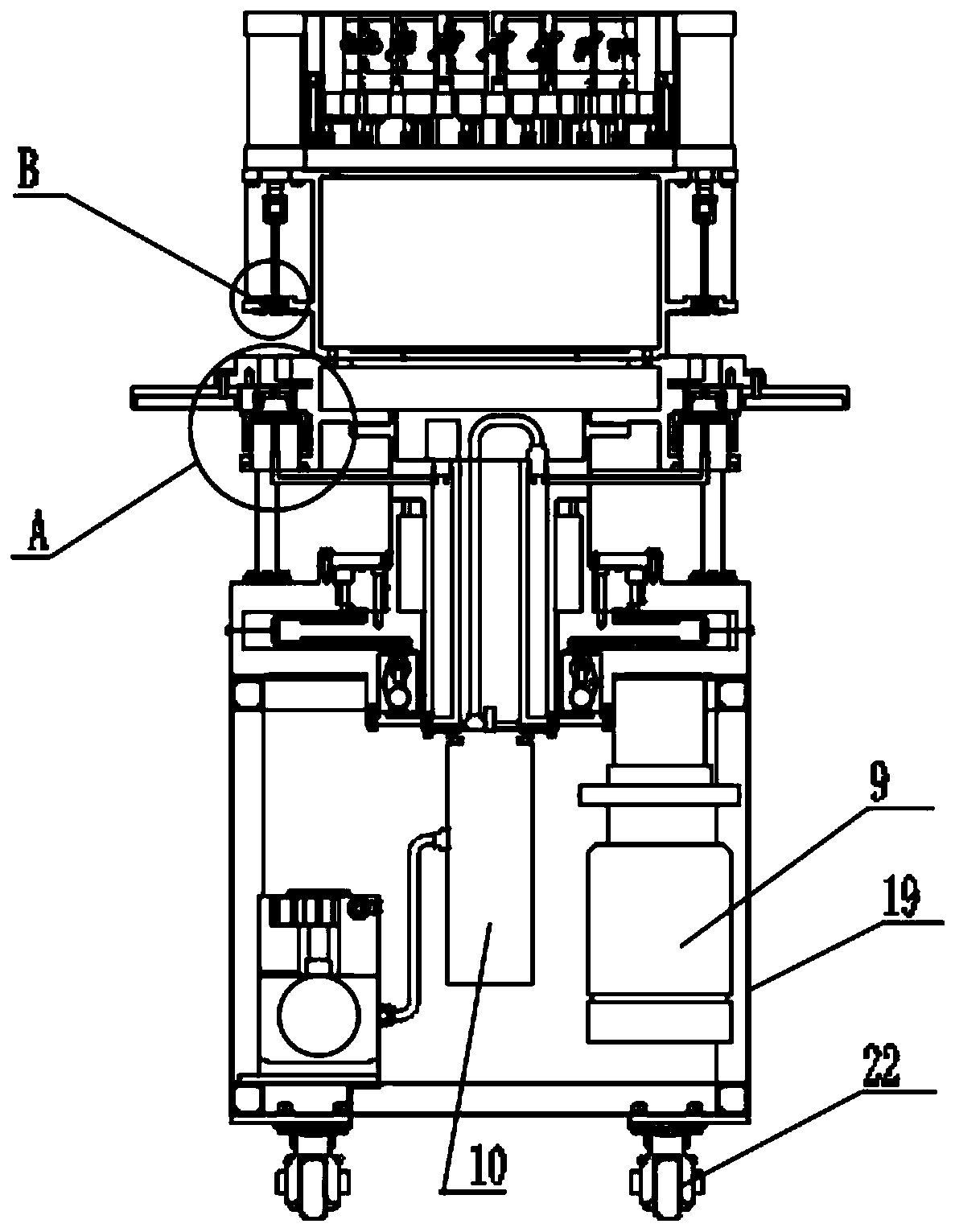

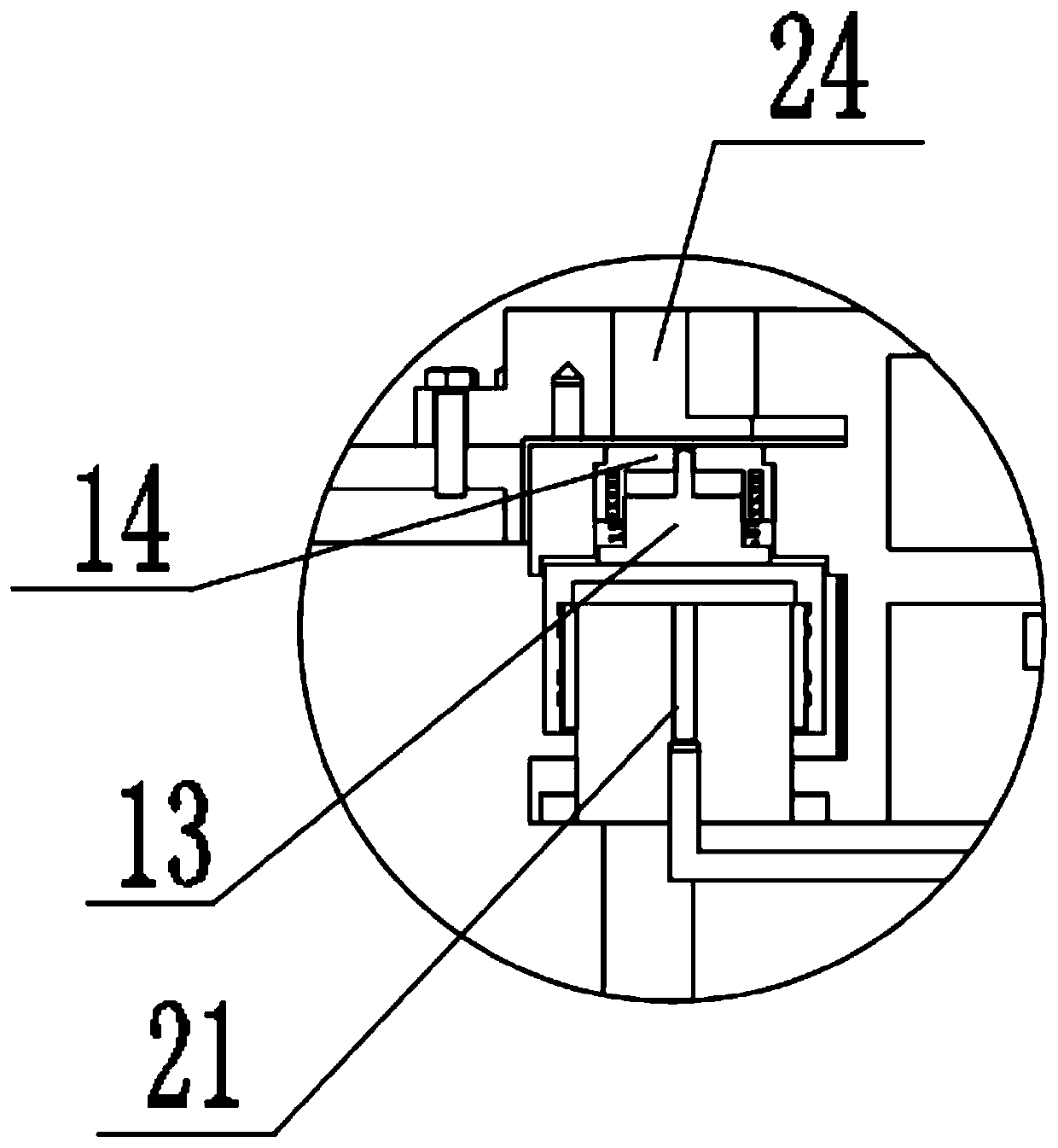

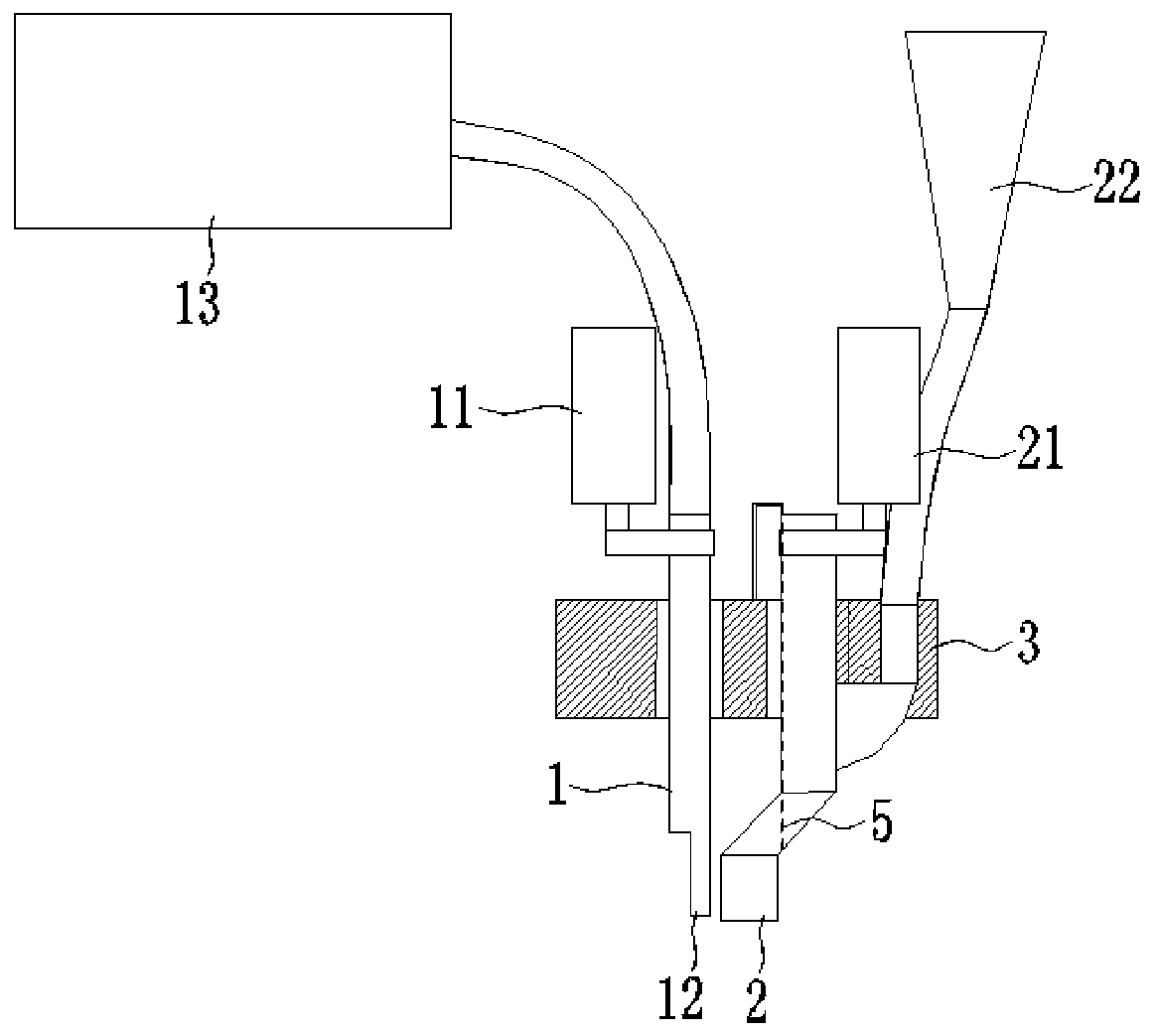

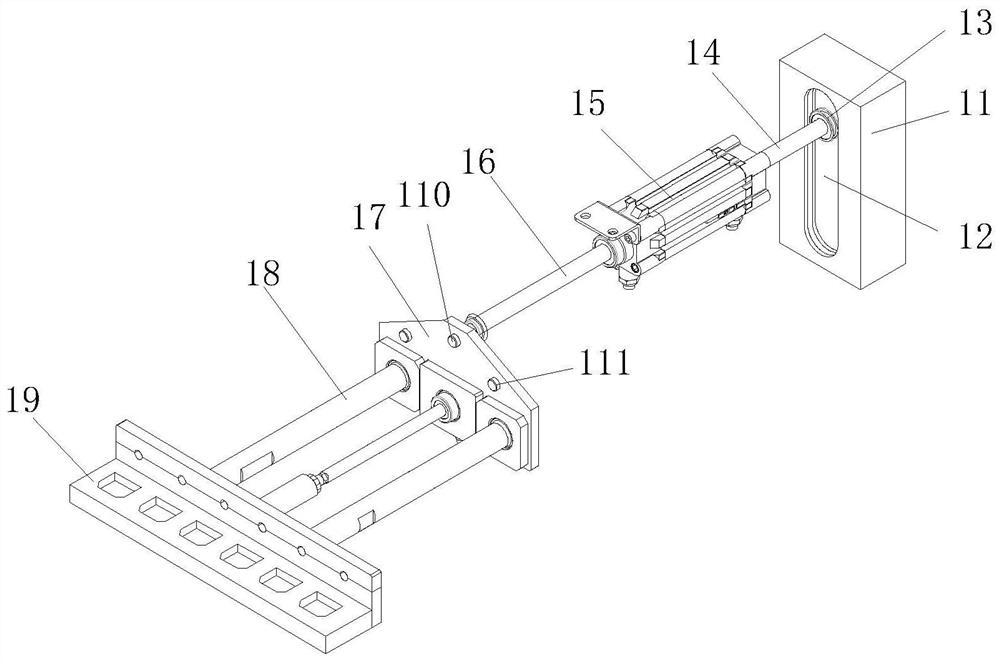

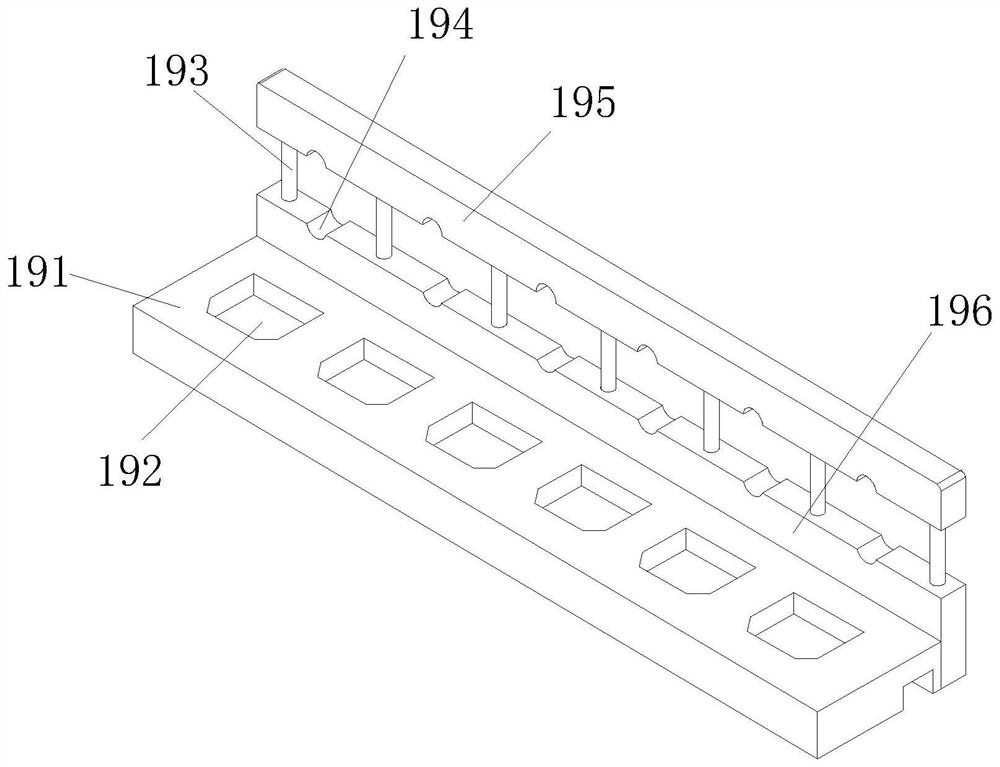

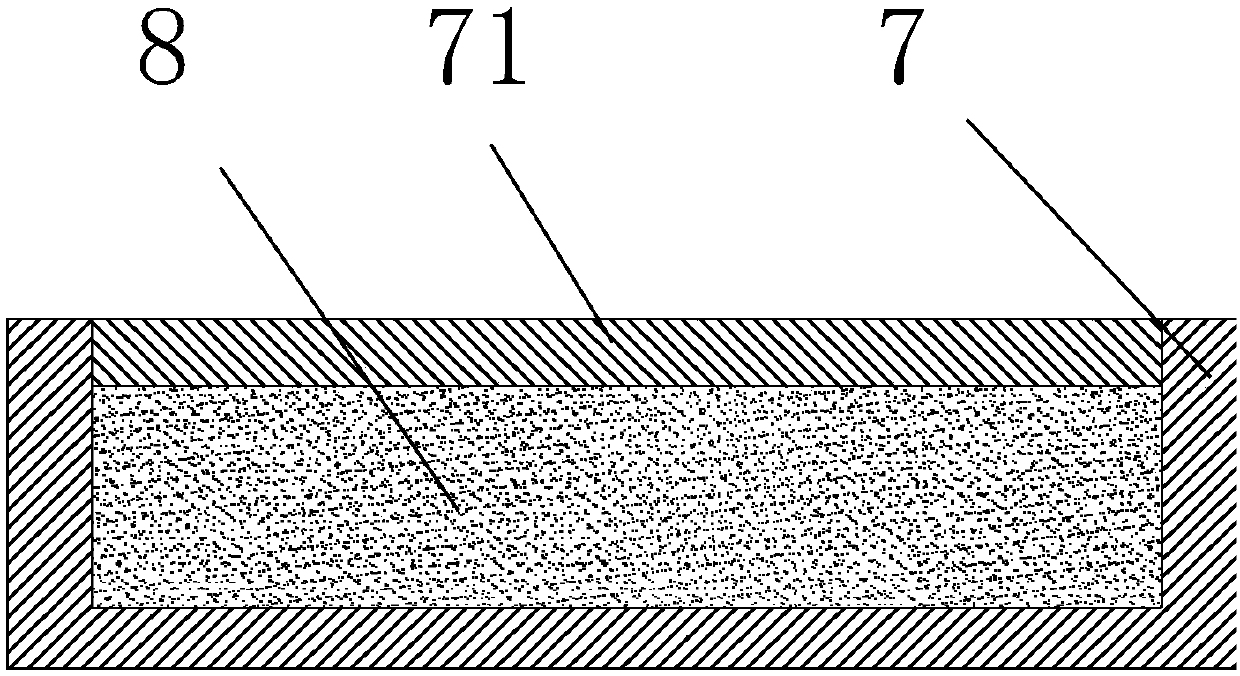

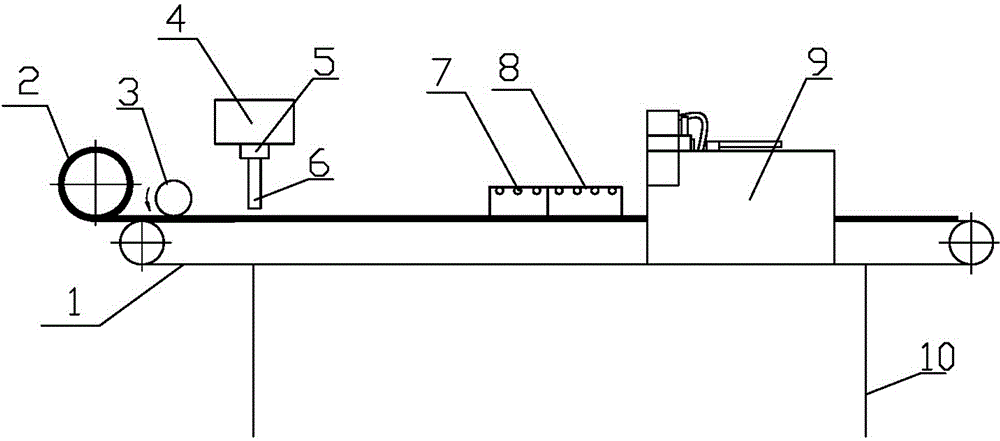

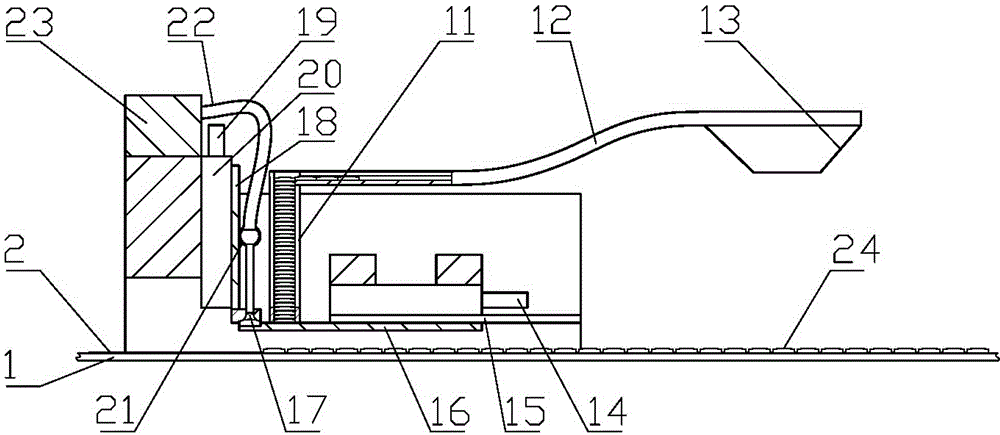

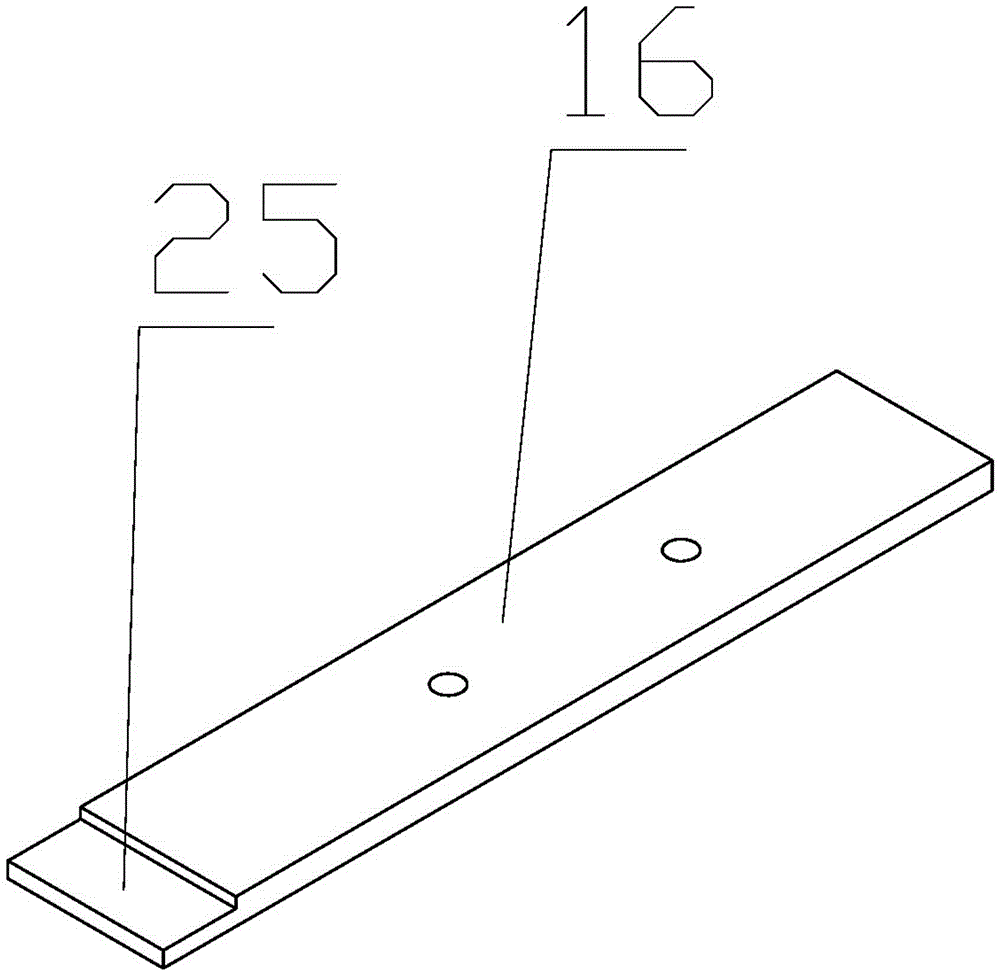

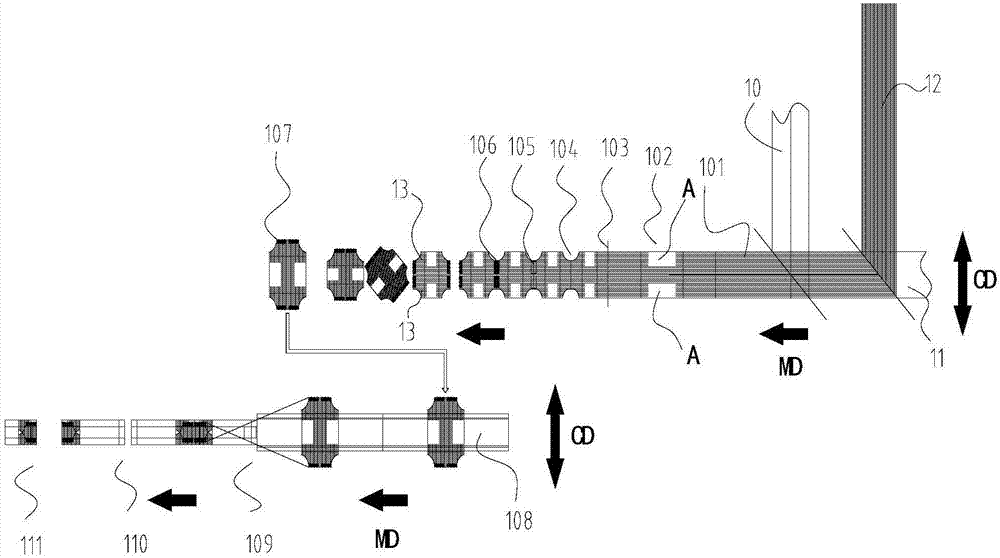

RFID (radio frequency identification device) label manufacturing equipment

ActiveCN102867208ARealize streamlined productionFast productionRecord carriers used with machinesPaper tapeMechanical equipment

The invention relates to the technical field of mechanical equipment, in particular to RFID (radio frequency identification device) label manufacturing equipment. The manufacturing equipment comprises a labeling system and a label bag forming system, wherein the labeling system comprises a paper tape unreeling wheel, a paper tape reeling wheel, a labeling roller, and a stripping plate and an embossing device which are used for restraining a release paper tape between the paper tape unreeling wheel and the paper tape reeling wheel sequentially; and the label bag forming system comprises a cloth tape unreeling wheel, a base plate, a folding mechanism, an ironing mechanism and a welding mechanism sequentially along a cloth tape delivery direction. The invention provides the RFID label manufacturing equipment, which realizes the flow production of RFID labels. The RFID label manufacturing equipment has the advantages of high production speed, good effects, simple structure, reliable operation, low cost, less faults and convenience for adjustment, greatly improves the production efficiency, can be used for producing the RFID electronic labels in different specifications and has extremely high practical value.

Owner:MAXIM SMART MFG CO LTD

Production method of bamboo sleep mat

ActiveCN105108867AReduce drillingReduce manual weavingPretreated surfacesWood working apparatusEnvironmental resistanceEngineering

The invention discloses a production method of a mahjong block-shaped bamboo sleep mat which is environmental-friendly in property, convenient to process and low in cost. The production method comprises the following steps of bamboo chip processing, base cloth preparing, hot glue applying, hot glue melting into a glue solution, bamboo chip sticking, and cutting, or the following steps of bamboo chip processing, base cloth preparing, polyurethane glue applying, bamboo chip sticking, cutting, and glue solution curing. Bamboo chips are stuck on base cloth, so that processes of drilling and manual weaving in bamboo chip processing are reduced, braided wires such as ox-tendon imitating wires are also omitted, the cost is reduced greatly, the thicknesses of the bamboo chips are also reduced, and the weight and the size of the bamboo sleep mat are reduced greatly to facilitate conveying, folding, carrying and storing of the bamboo sleep mat; and besides, hot glue or polyurethane glue is used for sticking the bamboo chips, so that the environment is protected, the cost is low, the flow-line production can be realized, and the production efficiency is improved greatly.

Owner:TAOJIANG BINGMENG HOUSEHOLD PROD

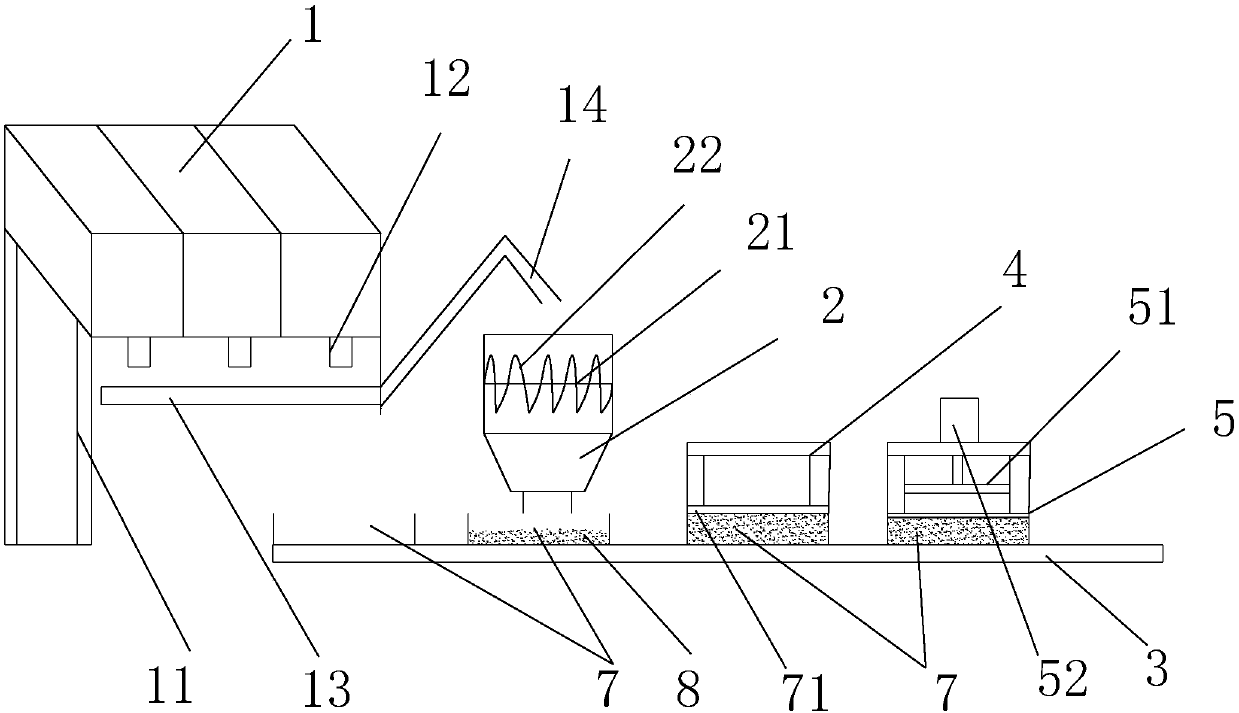

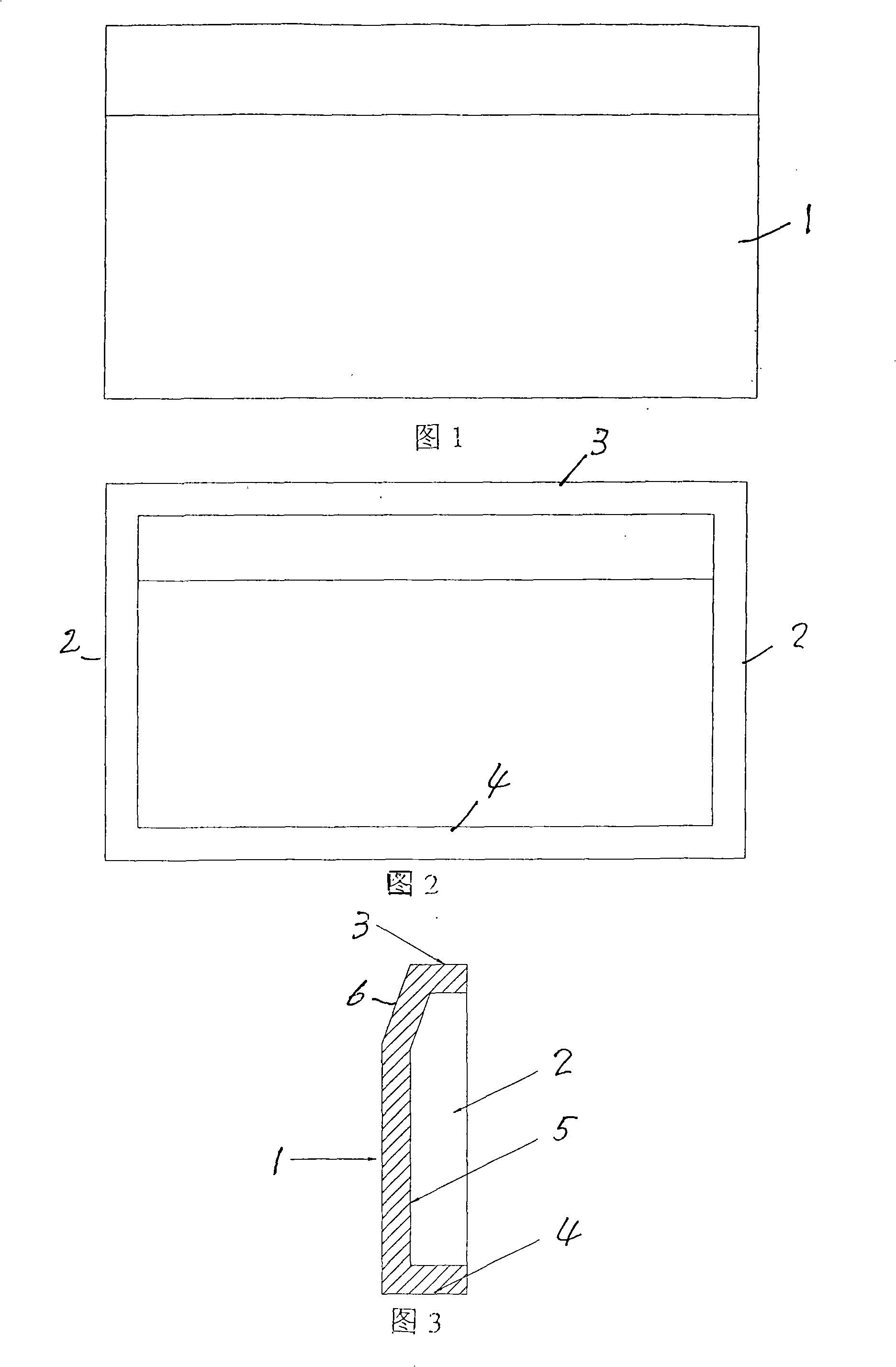

Composite membrane machine for manufacturing flat membrane

InactiveCN102002835ARealize streamlined productionReasonable structureSemi-permeable membranesLiquid/gas/vapor removalEngineeringComposite membrane

The invention discloses a device for manufacturing a flat membrane, in particular a composite membrane machine for manufacturing the flat membrane. The device is characterized by comprising an unfolding cloth charging unit, an immersion unit, a transport unit, a ventilating adjusting unit, a membrane manufacturing unit, a baking unit, a washing unit and a folding cloth discharging unit, wherein the unfolding cloth charging unit, the immersion unit, the transport unit, the ventilating adjusting unit, the membrane manufacturing unit, the baking unit, the washing unit and the folding cloth discharging unit are sequentially arranged in a streamline mode; and the transport unit is arranged on each function unit, and a plurality of groups of cloth guide rollers form a transport rail so that the base cloth can steadily run on the transport rail and is constantly processed by each function unit. The composite membrane machine for manufacturing the flat membrane is reasonable in structure and high in production efficiency, realizes streamline production of the non-woven flat membrane and is applicable to industrial promotion in a large scale.

Owner:ZHEJIANG SHENGSHI MECHANICS

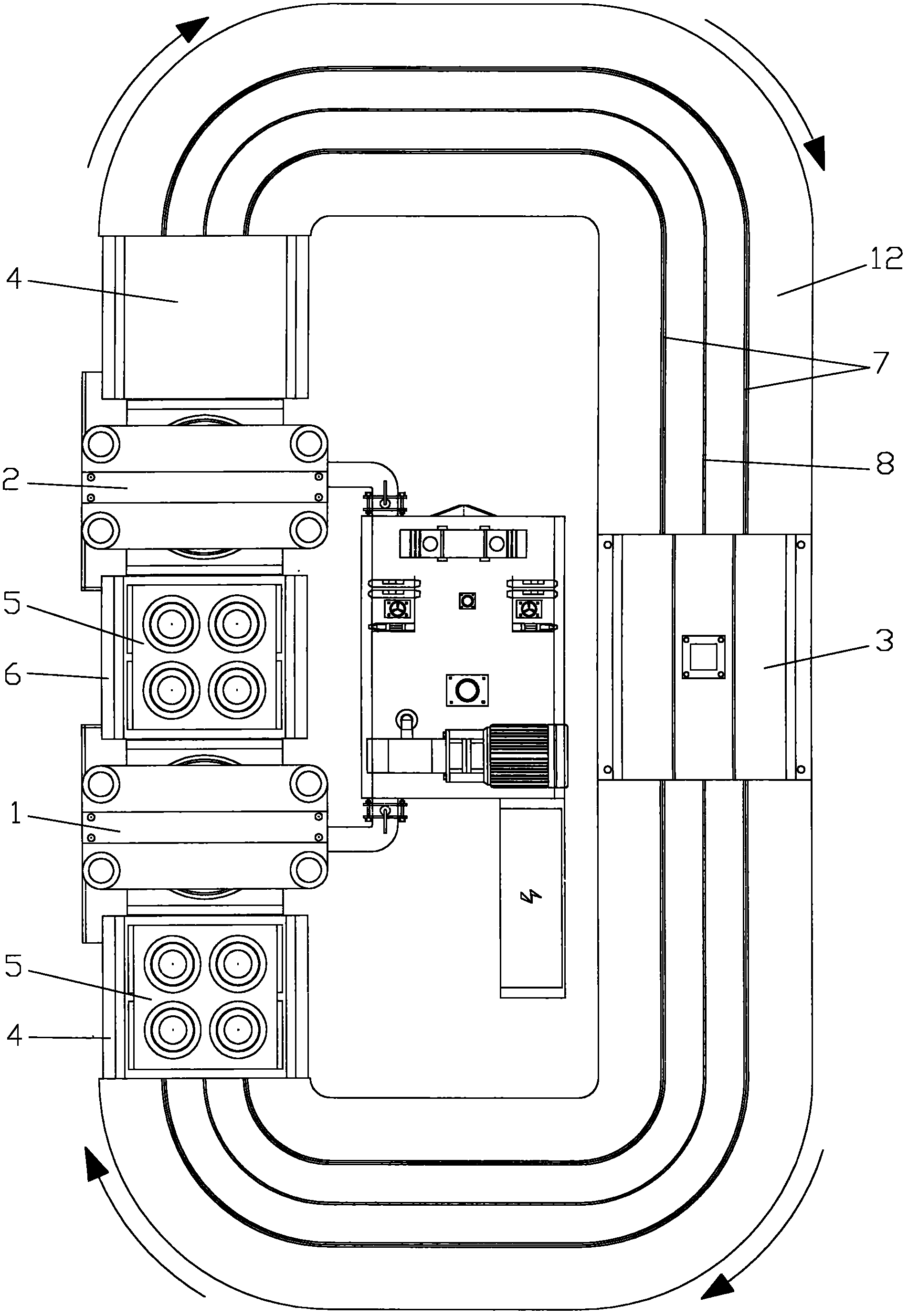

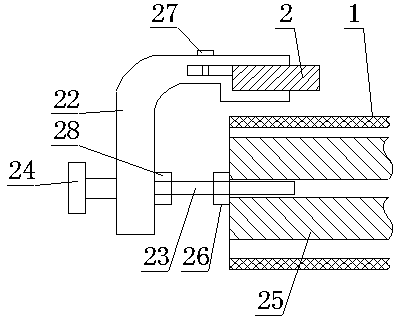

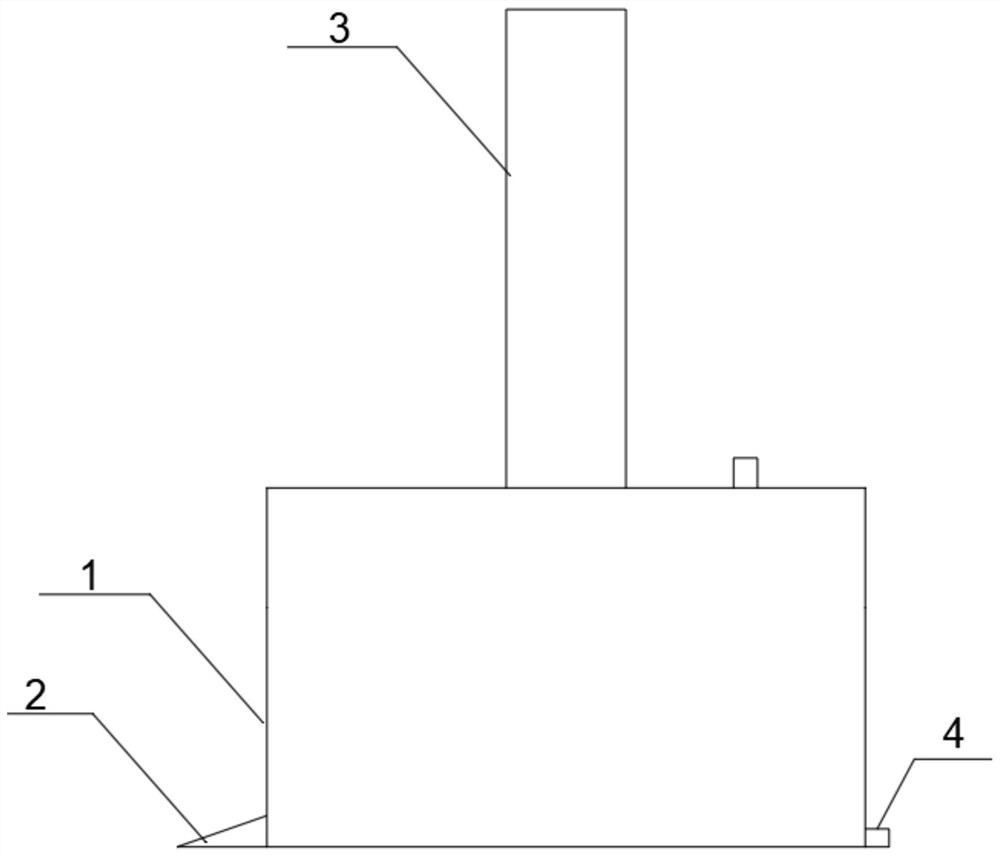

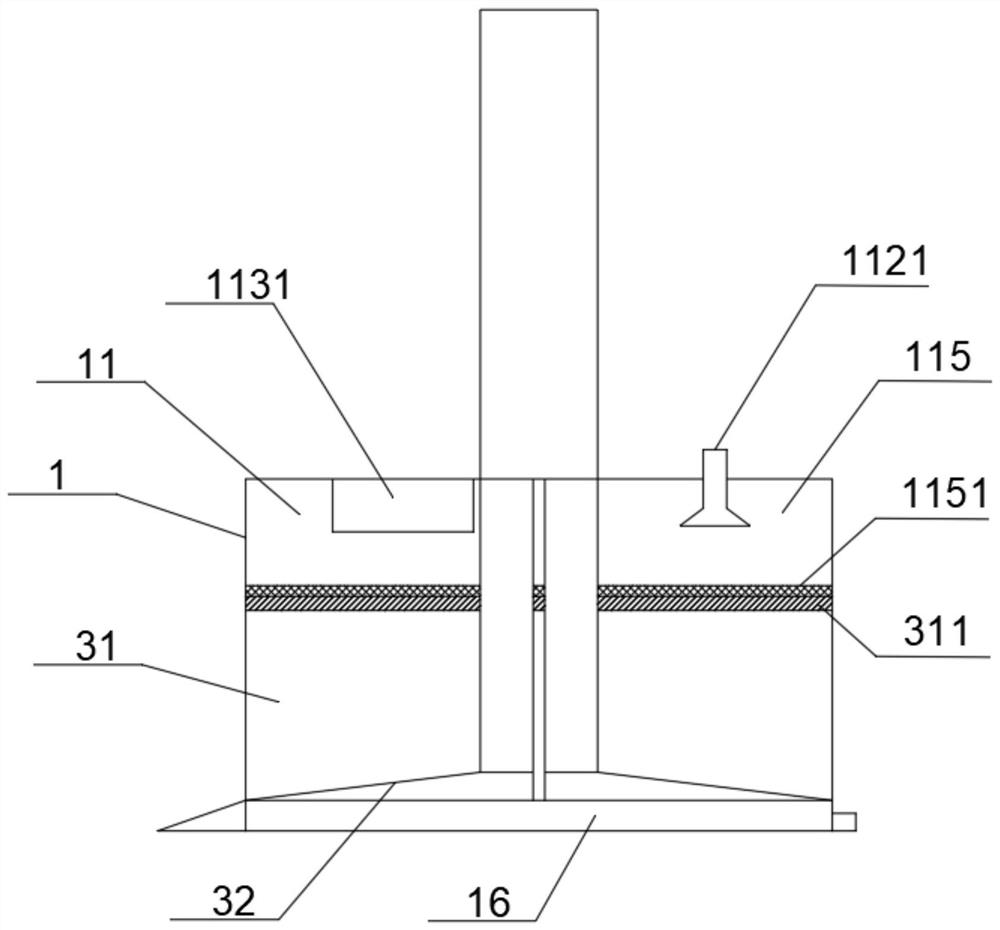

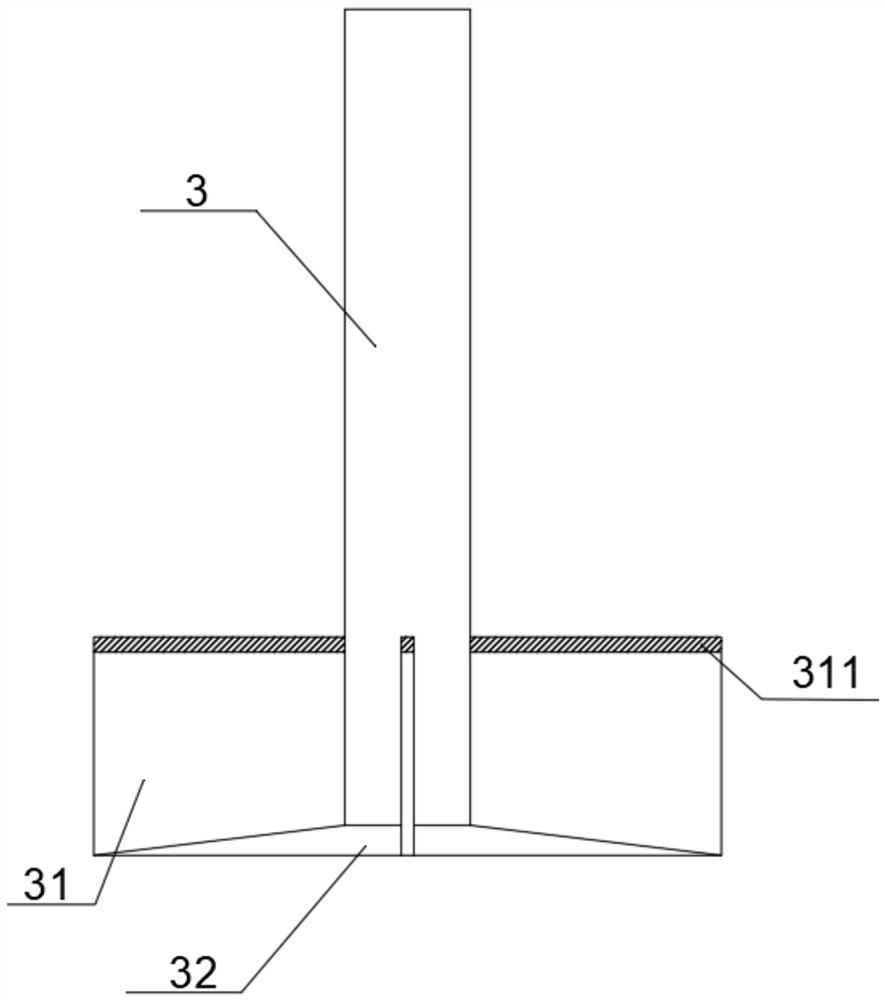

Rubber diaphragm circular vulcanizing device for brake chamber in automobiles

ActiveCN101987493ARealize streamlined productionImprove qualityDomestic articlesEngineeringMechanical engineering

The invention discloses a rubber diaphragm circular vulcanizing device for a brake chamber in automobiles. The device comprises first press, a second press, a demolding mechanism and a rubber diaphragm molding die, wherein the first press is used for performing primary vulcanizing treatment on the rubber diaphragm; the second press is used for performing secondary vulcanizing treatment on the rubber diaphragm; the demolding mechanism is used for separating a press ring and a lower die in the rubber diaphragm molding die; and a medium transmission mechanism is arranged between each press and the demolding mechanism, and a transition rail is arranged between the presses, so that a worktable closed moving loop from the first press to the second press to the demolding mechanism and to the first press is formed. In the device, the flow production of the rubber diaphragm can be realized by setting the two presses and the medium transmission mechanisms, the equipment utilization rate is improved, and the production operation is simplified, so the conventional single-person single-machine production mode can be changed into a mode that two persons operate four or more machines. Furthermore, primary vulcanizing treatment and secondary vulcanizing treatment on the rubber diaphragm are completed by the two presses respectively, and the setting and control of vulcanizing parameters are facilitated.

Owner:NINGGUO HAI TIAN LI IND DEV

Plate membrane coating machine

InactiveCN102011282ARealize streamlined productionReasonable structureSemi-permeable membranesLiquid/gas/vapor removal by scrapingBiochemical engineeringAssembly line

The invention discloses production equipment for plate membranes, in particular a plate membrane coating machine. The plate membrane coating machine is characterized by comprising an uncoiling feeding unit, a coating unit, a conveying unit, a washing unit and a coiling folding unit, wherein the uncoiling feeding unit, the coating unit, the washing unit and the coiling folding unit are arranged in turn according to an assembly line; and the conveying unit is arranged on the functional units and mainly comprises a conveying rail consisting of a plurality of groups of cloth guide rollers, so that base fabrics can be treated by each functional unit through the conveying rail uninterruptedly. The plate membrane coating machine is reasonable in structure and high in production efficiency, realizes streamlined production of non-woven plate membranes and is suitable for large-scale industrial popularization.

Owner:ZHEJIANG SHENGSHI MECHANICS

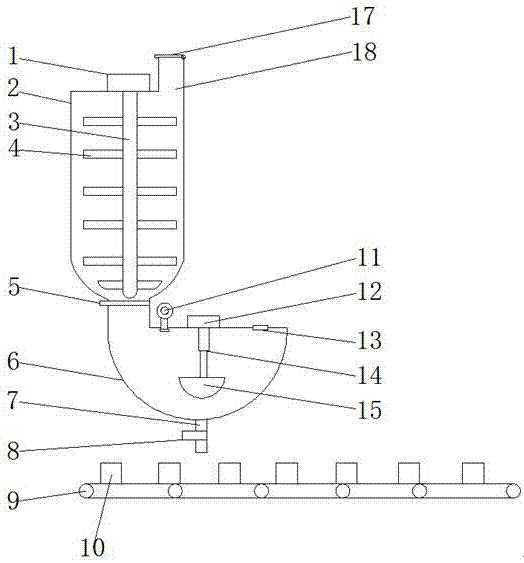

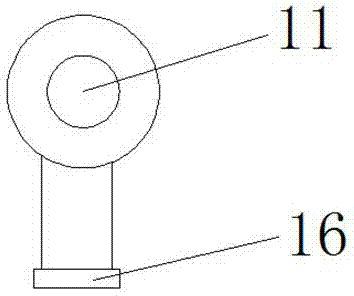

Traditional Chinese medicine powder preparing packaging machine

InactiveCN107161436APrevent floatingAvoid wastingSolid materialGrain treatmentsHydraulic cylinderMotor drive

The invention discloses a preparation and packaging machine for traditional Chinese medicine powder, which includes a No. 1 motor, a crushing cylinder, a connecting rod, a crushing blade, a plug plate, a grinder, a discharge pipe, a solenoid valve, a conveyor belt, a packaging tank, a hot air blower, and a No. 2 motor , nano-microporous composite material layer, hydraulic cylinder, grinding workpiece, blast hood, sealing cover and feeding pipe, the No. 1 motor drives the crushing blade on the connecting rod to rotate, and crushes the herbs inside the crushing cylinder, pull out the plug Plate, pour the herbal medicine inside the crushing cylinder into the grinder, the hot air will dry the medicine in the grinder first, and the water vapor will pass through the nano-microporous composite material layer and go to the outside of the grinder to ensure that the crushed medicine will be dried before grinding. Keep dry for easy grinding. The blast hood can expand the blowing surface of the hot air blower, and the No. 2 motor drives the hydraulic cylinder to rotate, and the grinding workpiece can be lifted up and down through the hydraulic cylinder, thereby realizing the effect of fine grinding.

Owner:王山友

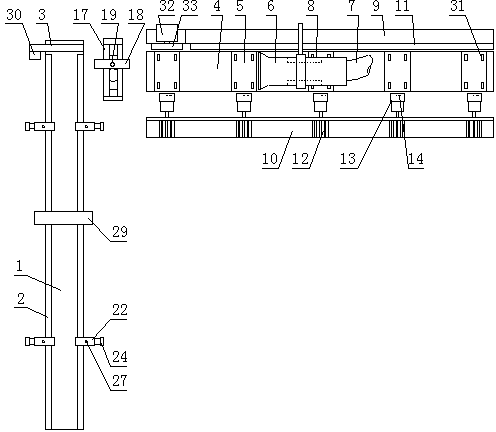

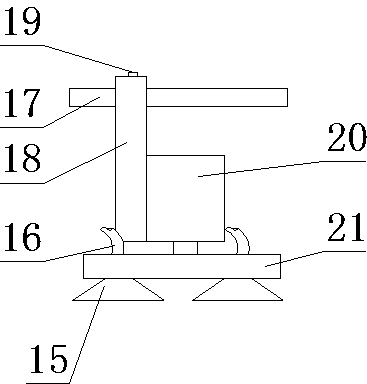

Bottle preprocessing unit of equipment for printing wine bottles with crooked mouths

InactiveCN103862844ASmooth and reliable conveying processAdjust alignmentScreen printersWine bottleEngineering

The invention discloses a bottle preprocessing unit of equipment for printing wine bottles with crooked mouths. The unit is characterized in that a bottle conveying device, a wine bottle preheating device and a bottle transfer device arranged between the bottle conveying device and the wine bottle preheating device are included; the bottle conveying device comprises a horizontal conveying belt, and the upper portion of the bottle outlet end of the conveying belt is provided with a wine bottle baffle; the preheating device comprises a horizontal preheating wine bottle installation table, a hot air duct is arranged above the preheating wine bottle installation table, and the two sides of the preheating wine bottle installation table are provided with preheating, clamping and transferring mechanisms; the bottle transfer device comprises a suction cup installation frame and two parallel suction cups arranged at the bottom of the suction cup installation frame side by side. By means of the bottle preprocessing unit, wine bottles are automatically distributed, adjusted and aligned, the function of preheating before printing is achieved, and the bottle preprocessing unit has the advantages of being high in automation degree, convenient to adjust, and smooth and reliable in wine bottle conveying and processing and the like.

Owner:CHONGQING ZHAOHUI GLASS CRYSTAL PROD

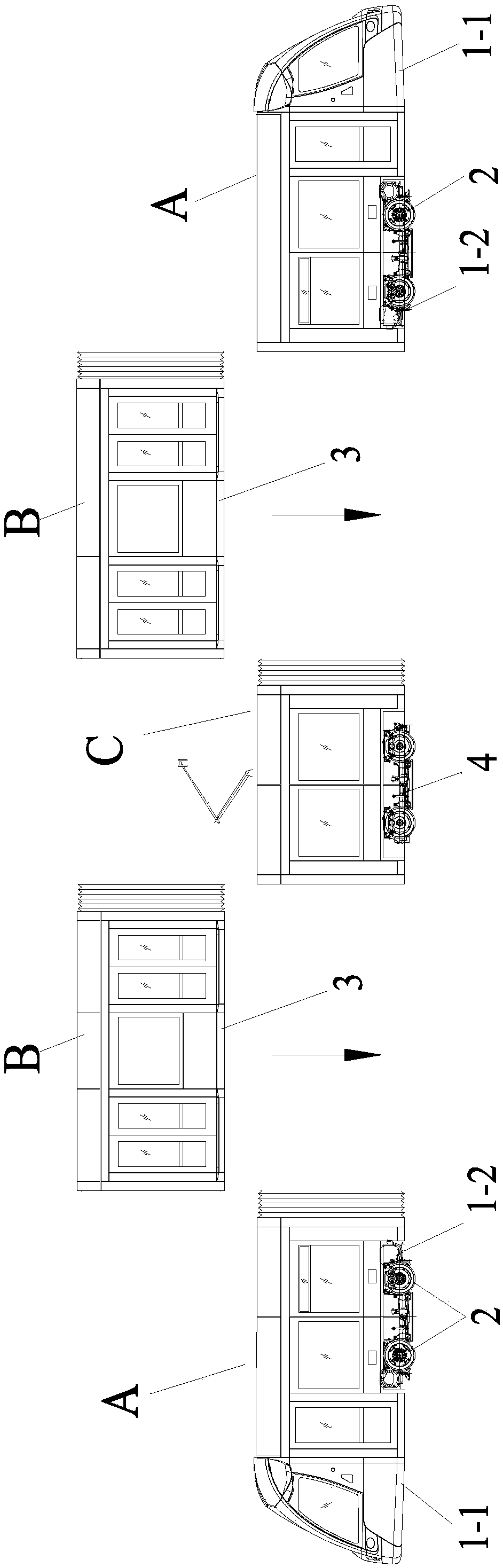

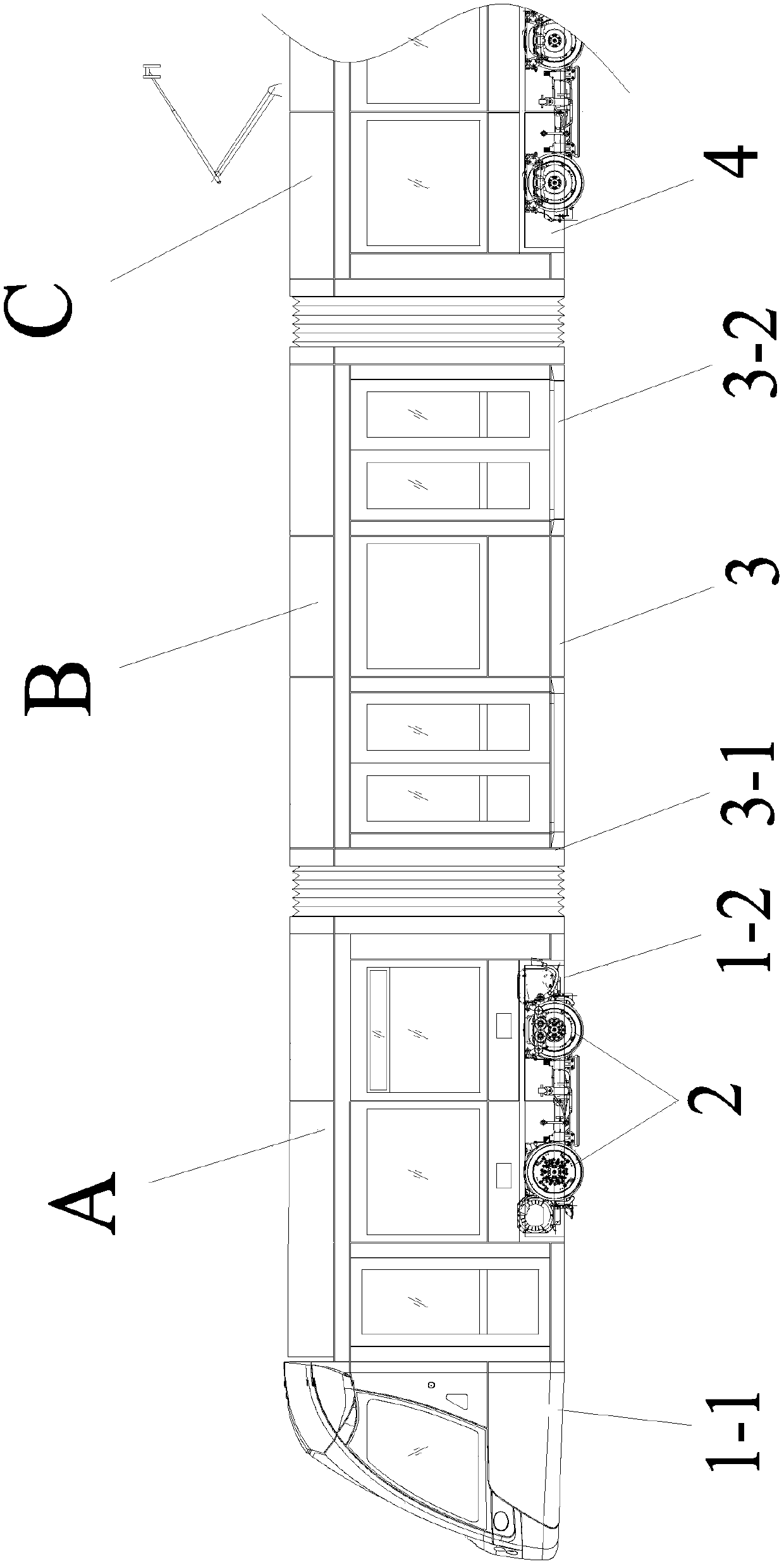

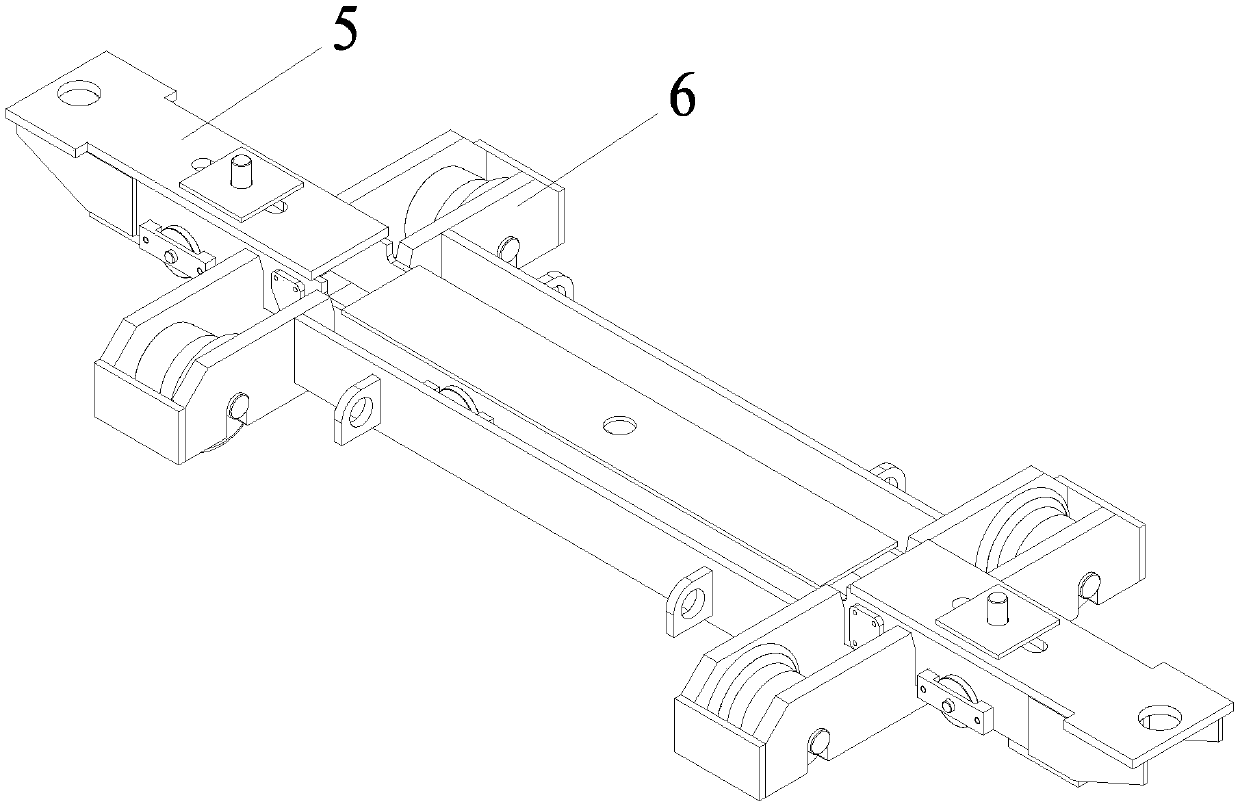

Combined type car lifting auxiliary tool and car descending method based on tool

ActiveCN107933597ASolve the problem of not being able to move backwards in a straight line along the trackEliminate docking attitude mismatch issuesBogie-underframe connectionsAutomotive engineeringContinuous production

The invention provides a combined type car lifting auxiliary tool and a car descending method based on the tool and belongs to the field of car descending coupling auxiliary devices of low-floor tramcars and car descending methods using the devices. The tool comprises a bottom frame auxiliary crossbeam used for a car lifting jack and a cab first-position end auxiliary lifting trolley. The cab first-position end auxiliary lifting trolley comprises two lifting trolley wheel set mechanisms and a steel channel crossbeam. Each lifting trolley wheel set mechanism comprises a rectangular wheel set installation frame and two transport rail wheels. By the adoption of the combined type car lifting auxiliary tool, the site for conducting the manufacturing procedure of compartments can be transferredat any time according to requirements, continuous production is achieved, and therefore production efficiency is improved. The bottom frame auxiliary crossbeam used for the car lifting jack can further be directly matched with an existing car lifting jack corbel, so that it is guaranteed that lifting and descending operation conducted on all the compartments is safe, efficient, smooth and reliable, the rework number of times is reduced, balance of a tramcar is guaranteed, the work rhythm is optimized, and occupation of crown block resources is reduced.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

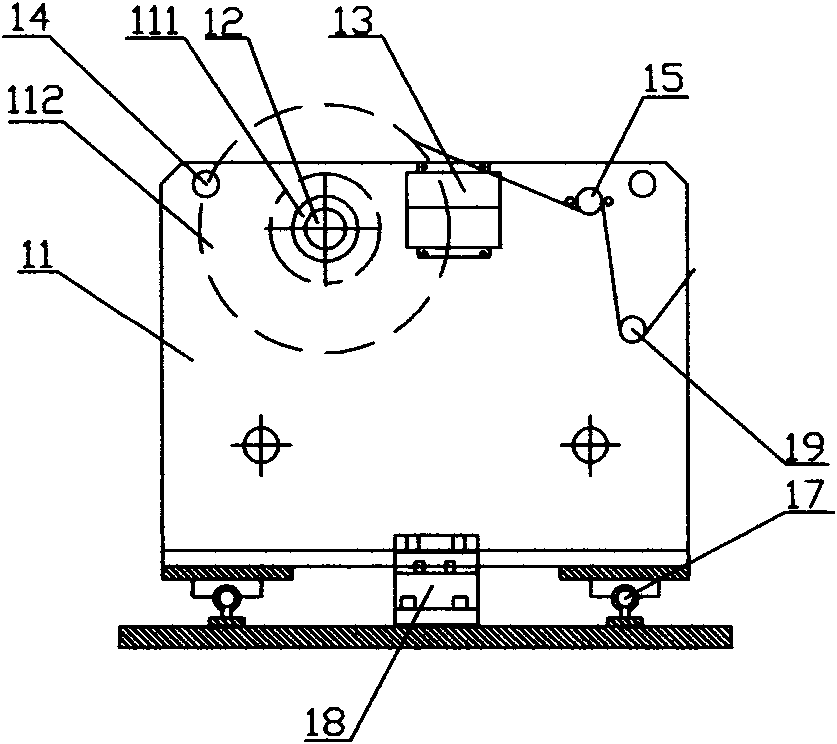

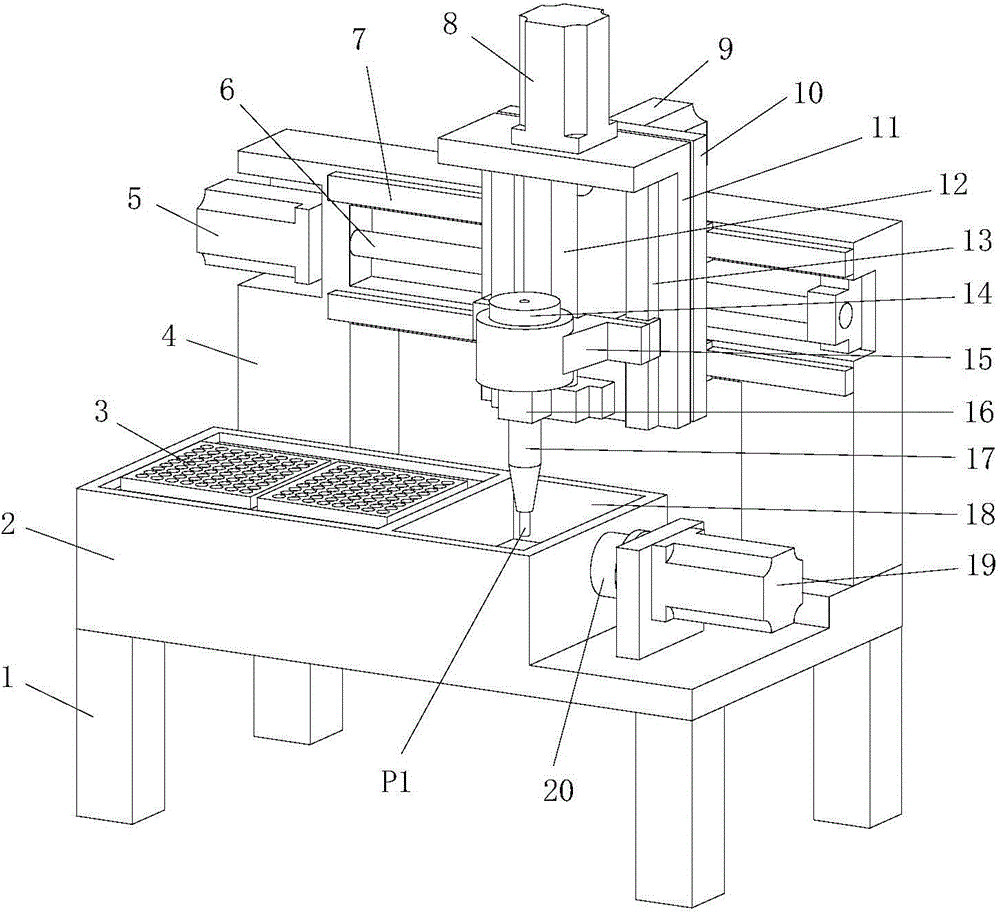

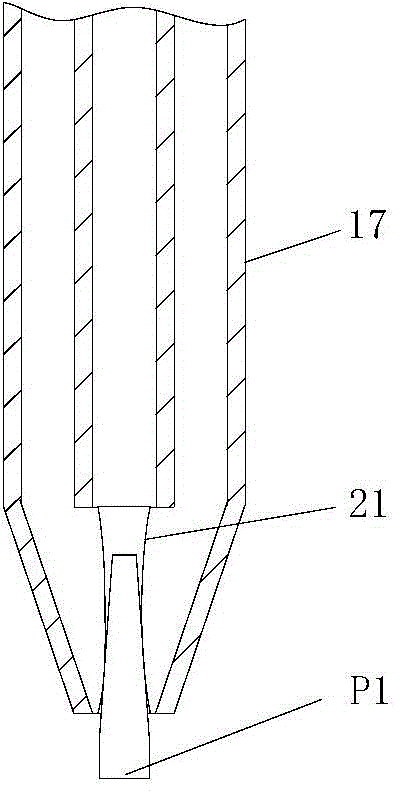

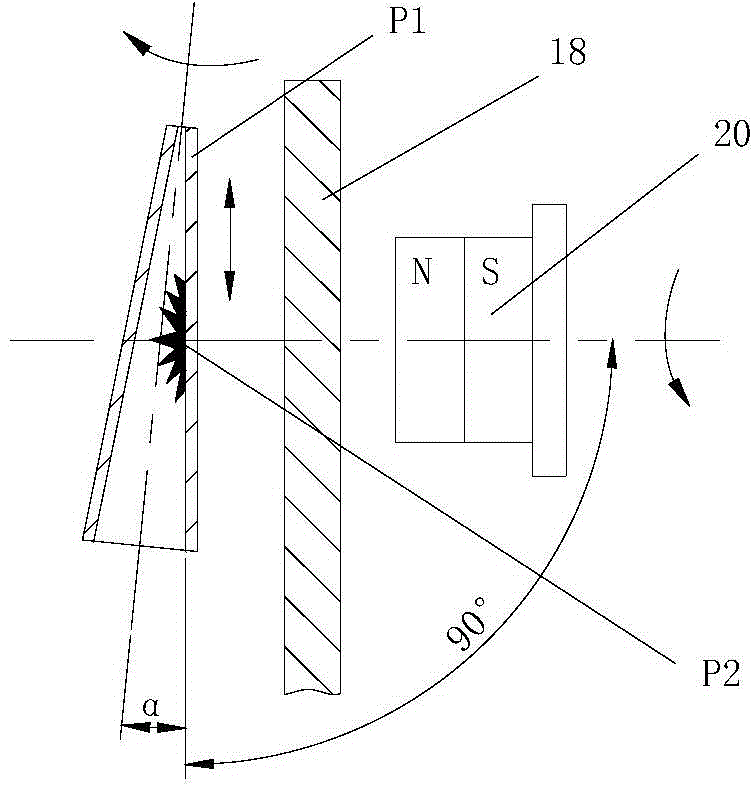

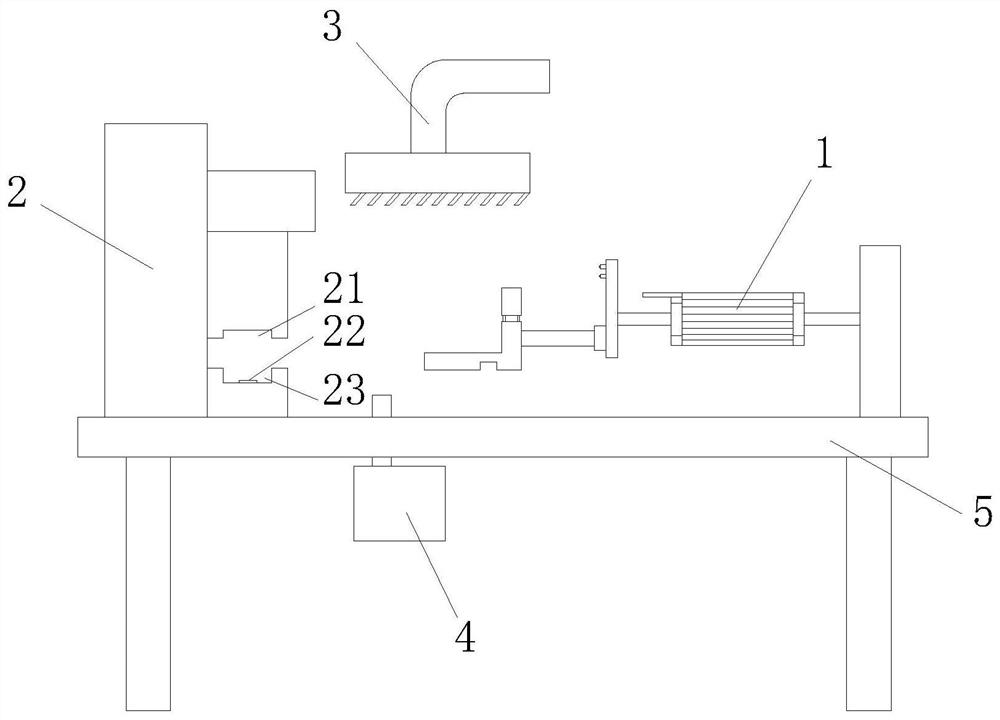

Minitype welding pin inner hole grinding device

ActiveCN104148993ASolving Polishing ProblemsImprove surface qualityGrinding work supportsUltrasonic sensorEngineering

The invention discloses a minitype welding pin inner hole grinding device and relates to inner hole grinding devices. The minitype welding pin inner hole grinding device is provided with a working table, a welding pin storage disc, a grinding groove, a stand column beam, an X-axis guide rail, an X-axis servo motor, an X-axis lead screw, an X-axis movable block, a Z-axis rotary motor, a Z-axis rotary block, a Z-axis guide rail, a Z-axis servo motor, a Z-axis lead screw, a spindle motor, a spindle, a welding pin clamping head, an ultrasonic transducer, a rotary motor and a magnet. By the adoption of the minitype welding pin inner hole grinding device, polishing of a minitype welding pin inner hole can be achieved, surface quality of the welding pin inner hole is improved remarkably, so that solder can be kept unblocked when a welding pin is used for welding and welding quality is guaranteed. Furthermore, the structure is simple, actual production can be conducted easily, and the welding pin clamping head is of a pneumatic type, small, convenient to use and capable of achieving clamping quickly. Meanwhile, streamline production enables machining time to be shortened greatly and work efficiency to be improved remarkably.

Owner:XIAMEN UNIV

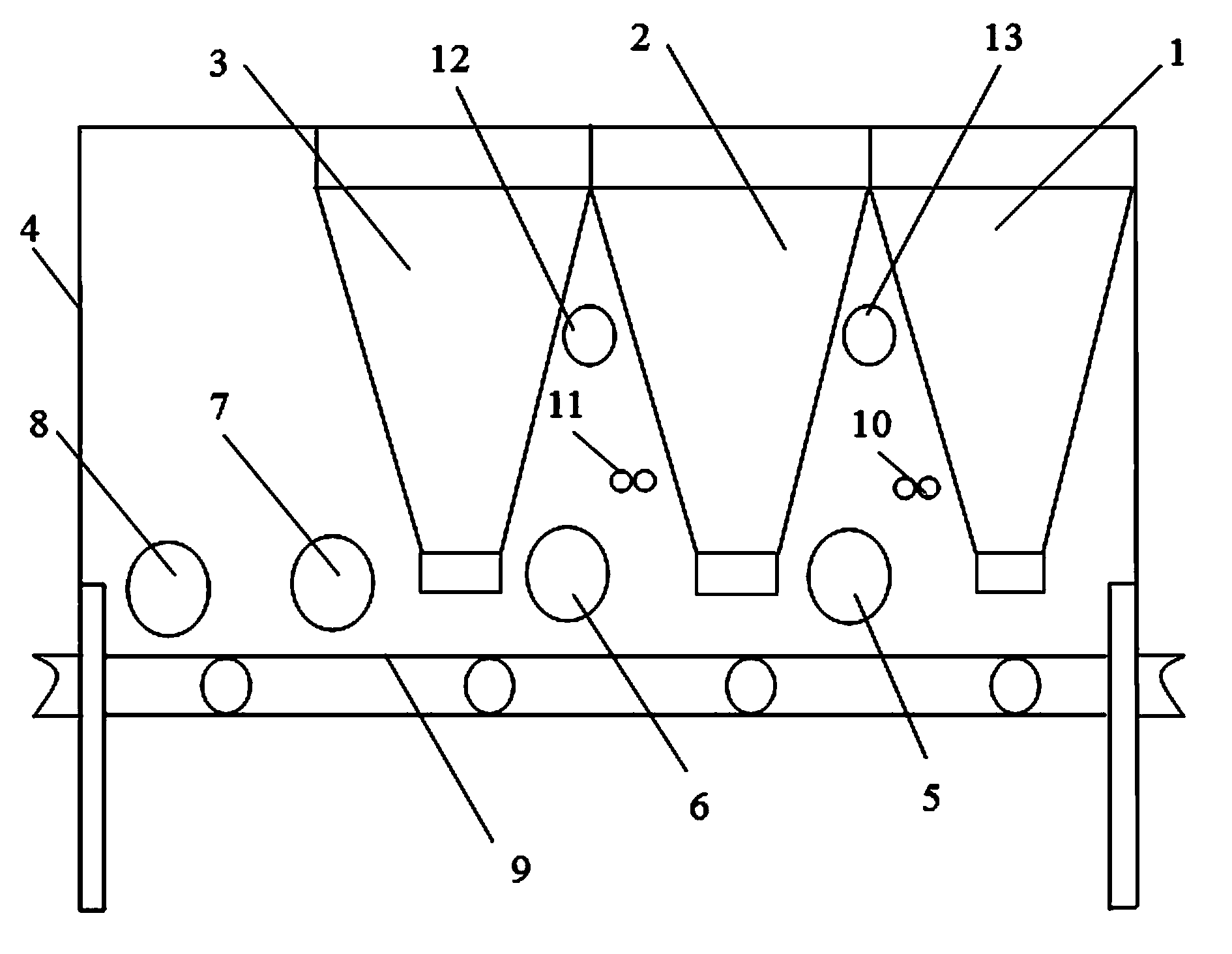

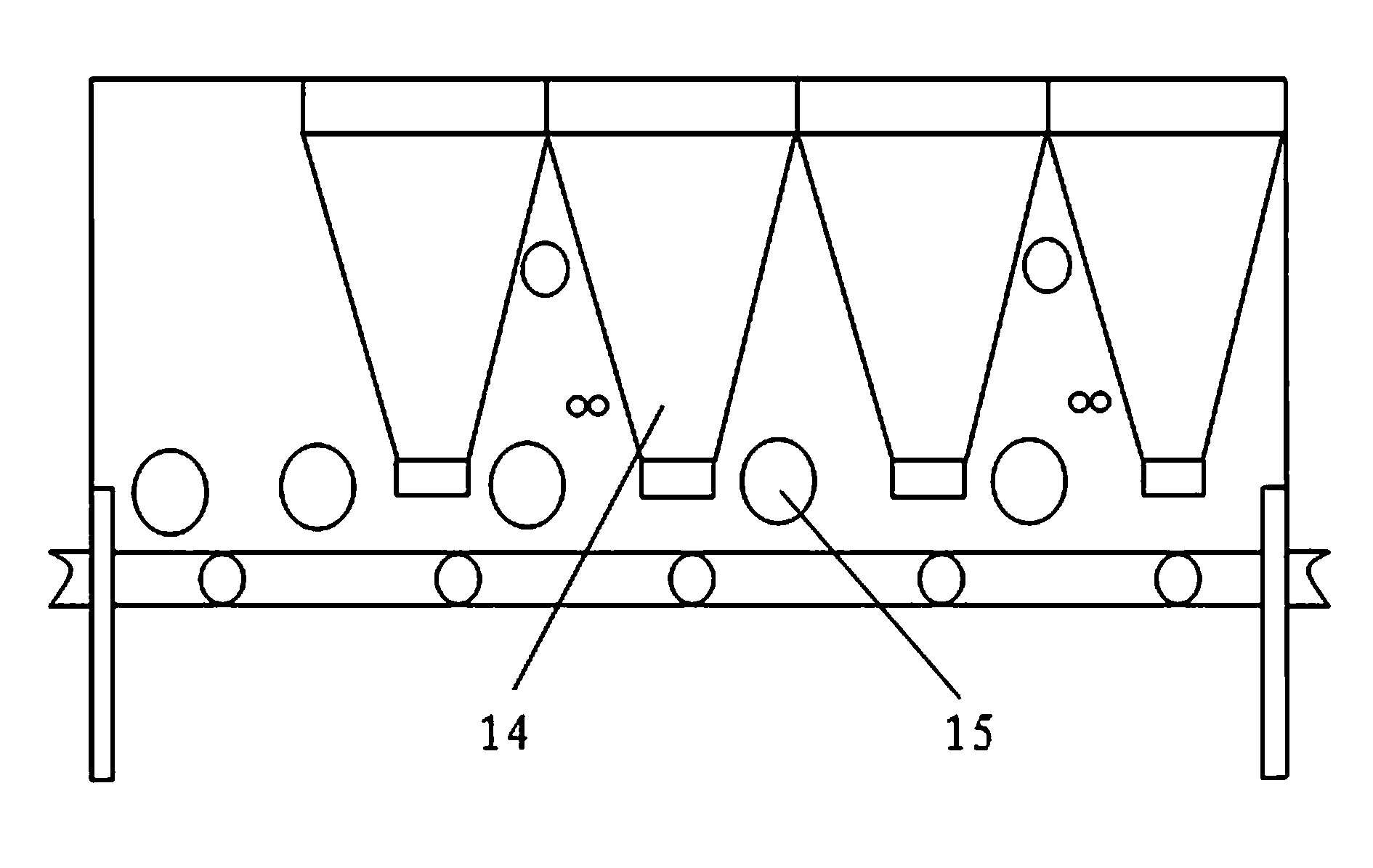

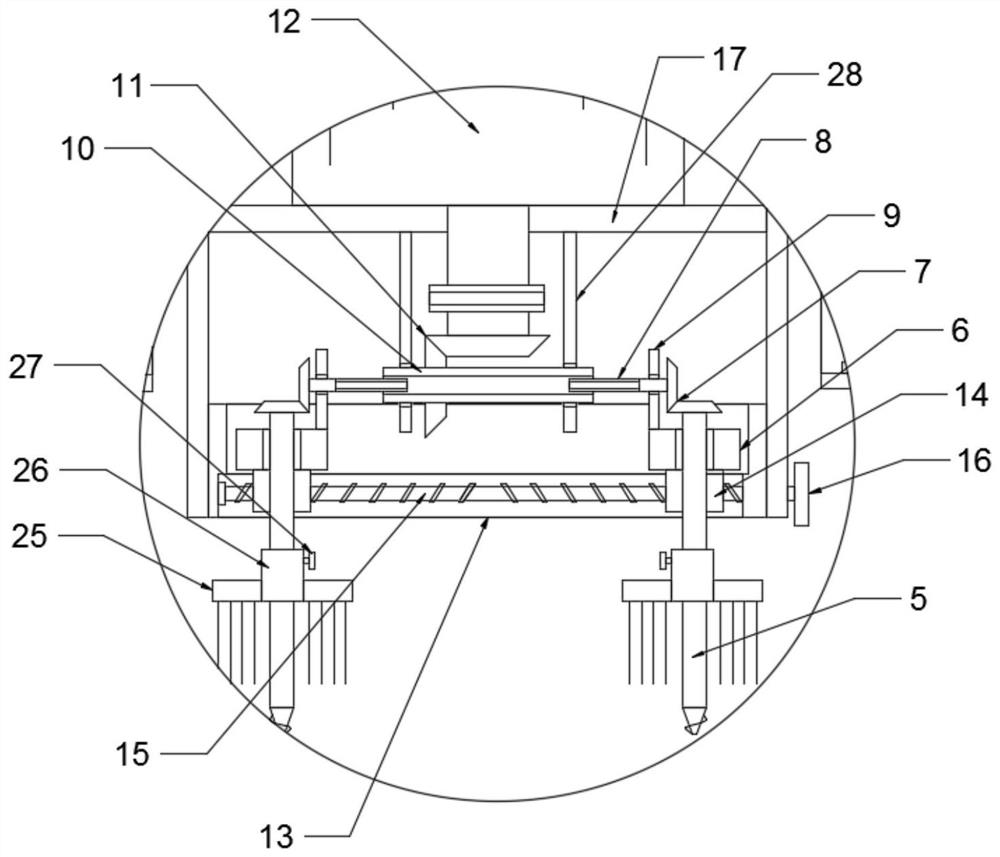

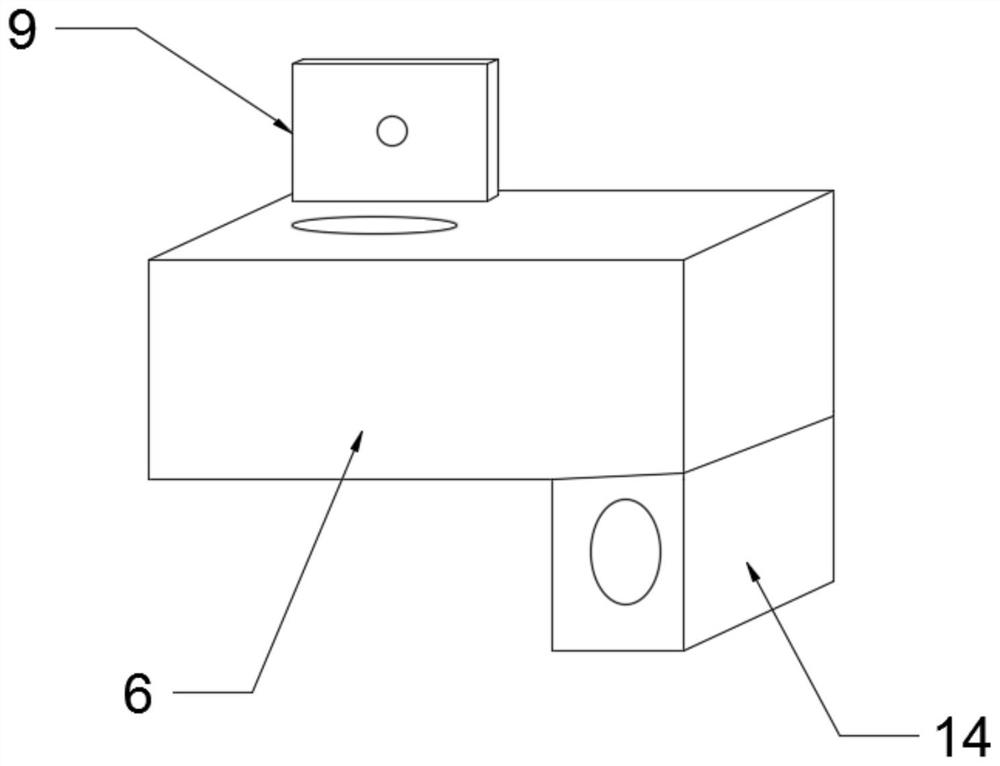

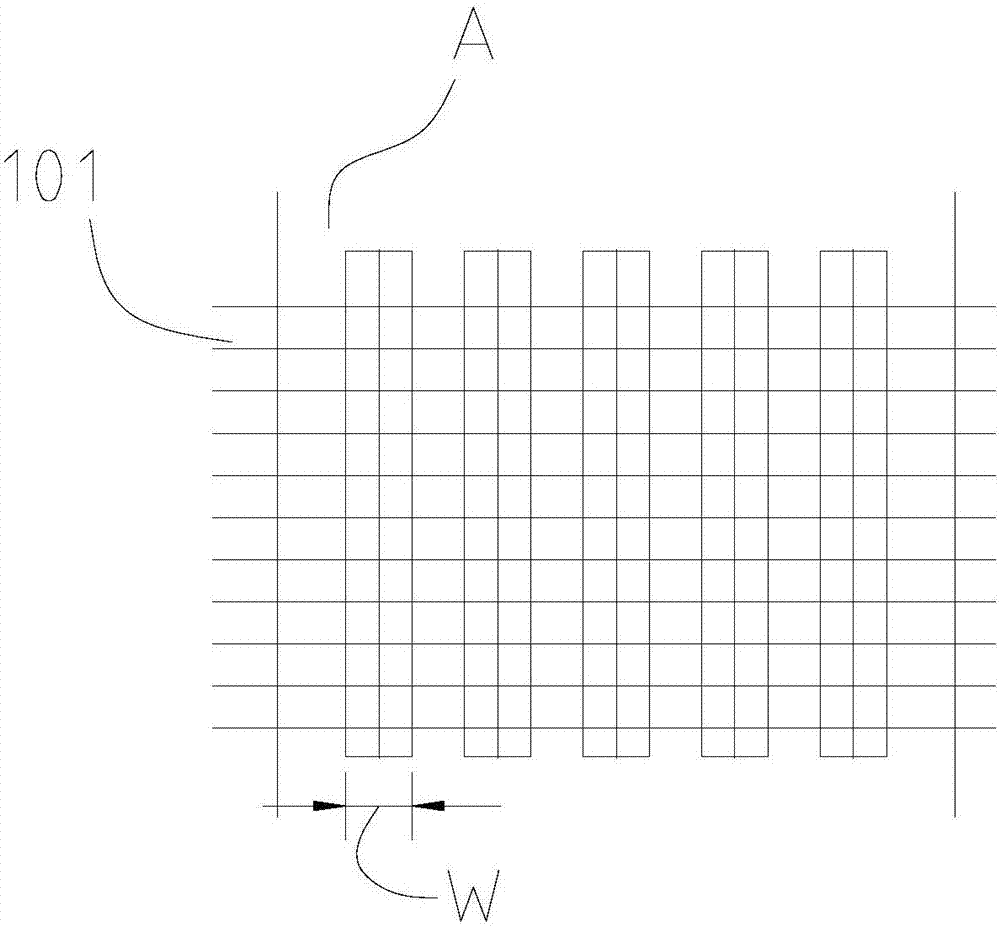

Plate putting machine for fireproof plate production line

InactiveCN104097250ARealize streamlined productionImprove product qualityPress rollersFeeding arrangmentsProduction lineEngineering

The invention relates to a plate putting machine for a fireproof plate production line. Hoppers and compression roller shafts are arranged above a material row conveyer belt, and the hoppers and shaft seats of the compression roller shafts are fixed to a frame. The plate putting machine is characterized in that a first hopper, a second hopper and a third hopper are sequentially arranged from front to back along the running direction of the material row conveyer belt; a first compression roller shaft is arranged between the first hopper and the second hopper; a second compression roller shaft is arranged between the second hopper and the third hopper; a third compression roller shaft is arranged on the rear side of the third hopper; the first compression roller shaft, the second compression roller shaft and the third compression roller shaft correspond to a first layer, a second layer and a third layer of a to-be-processed fireproof plate.

Owner:BEIJING WEIZHONG TECH DEV

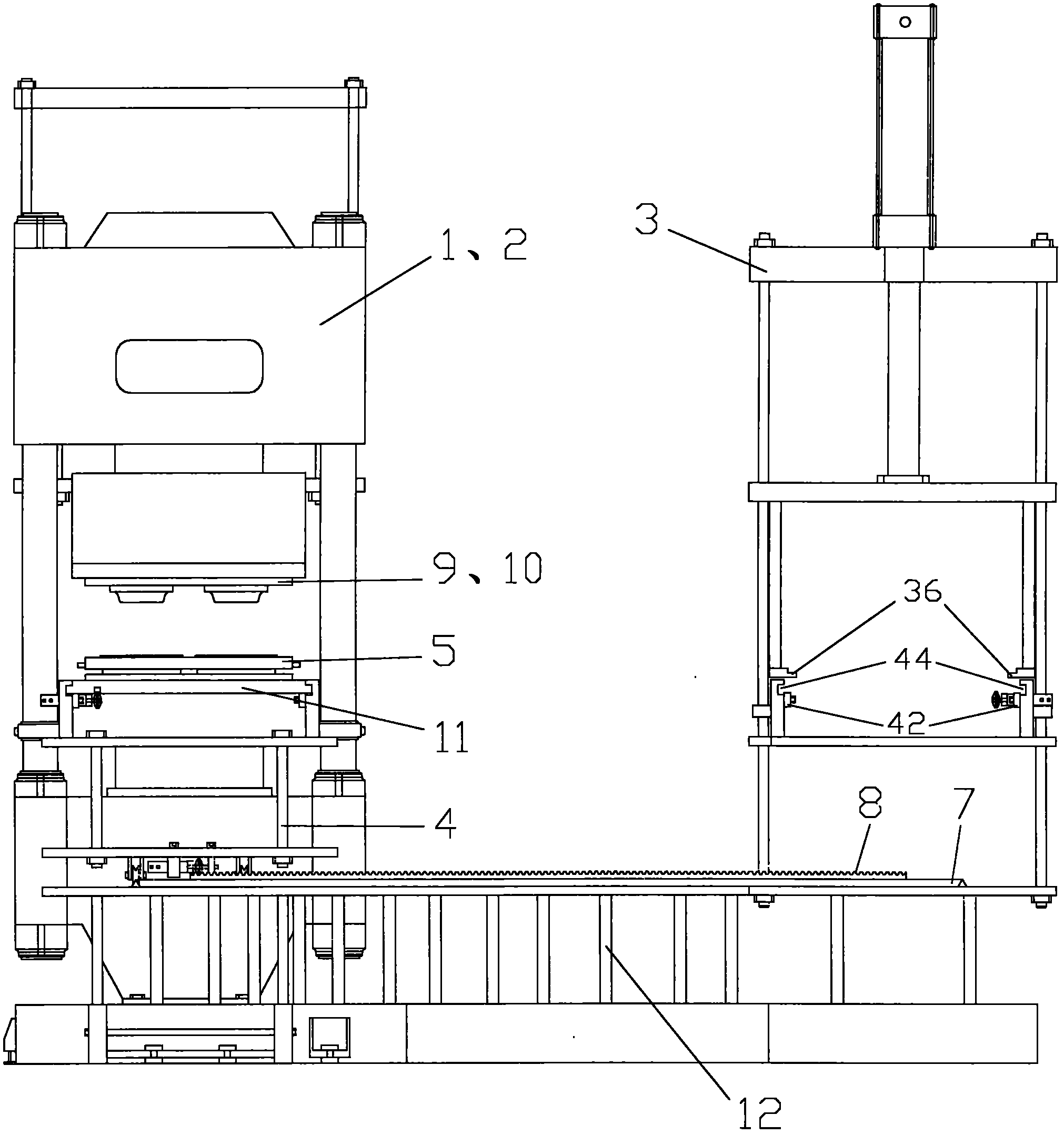

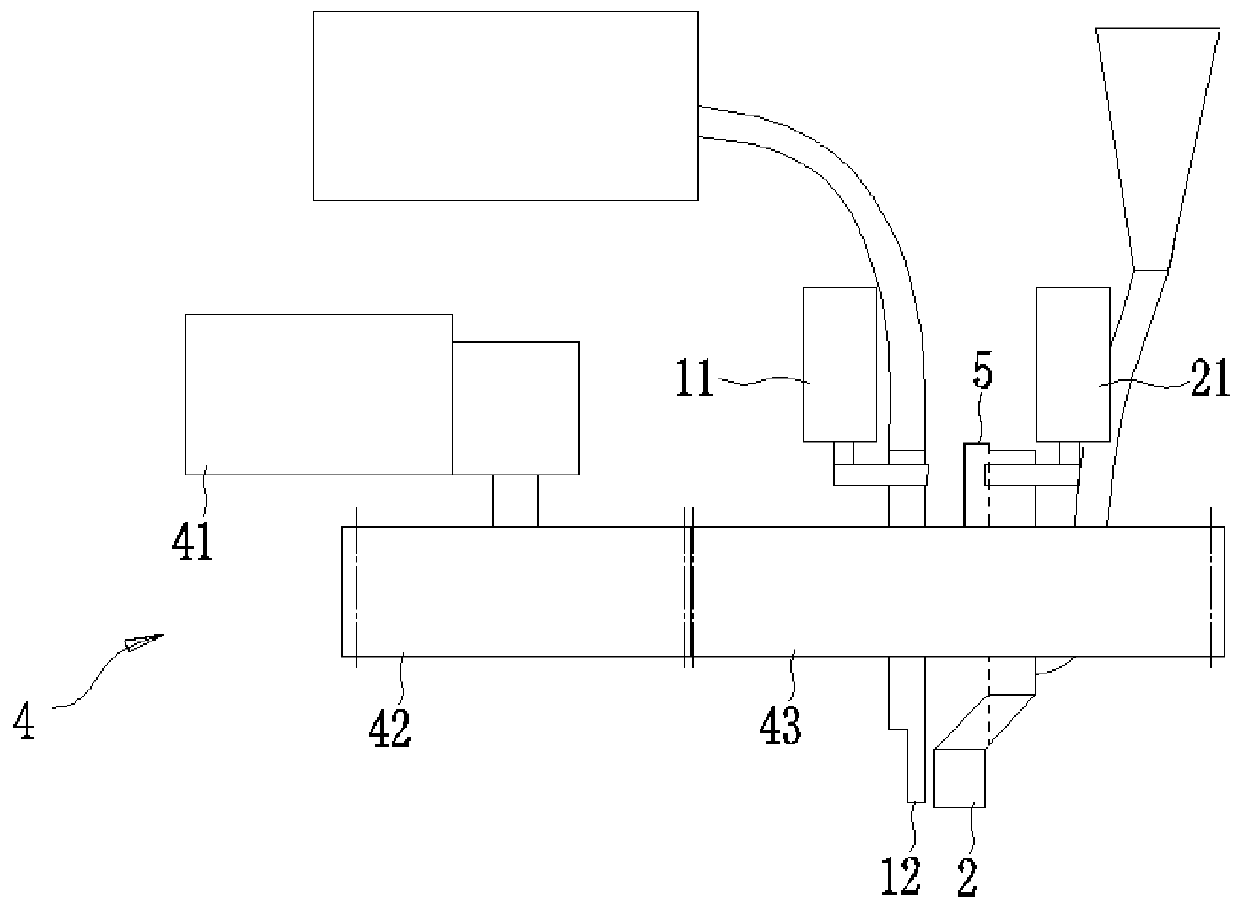

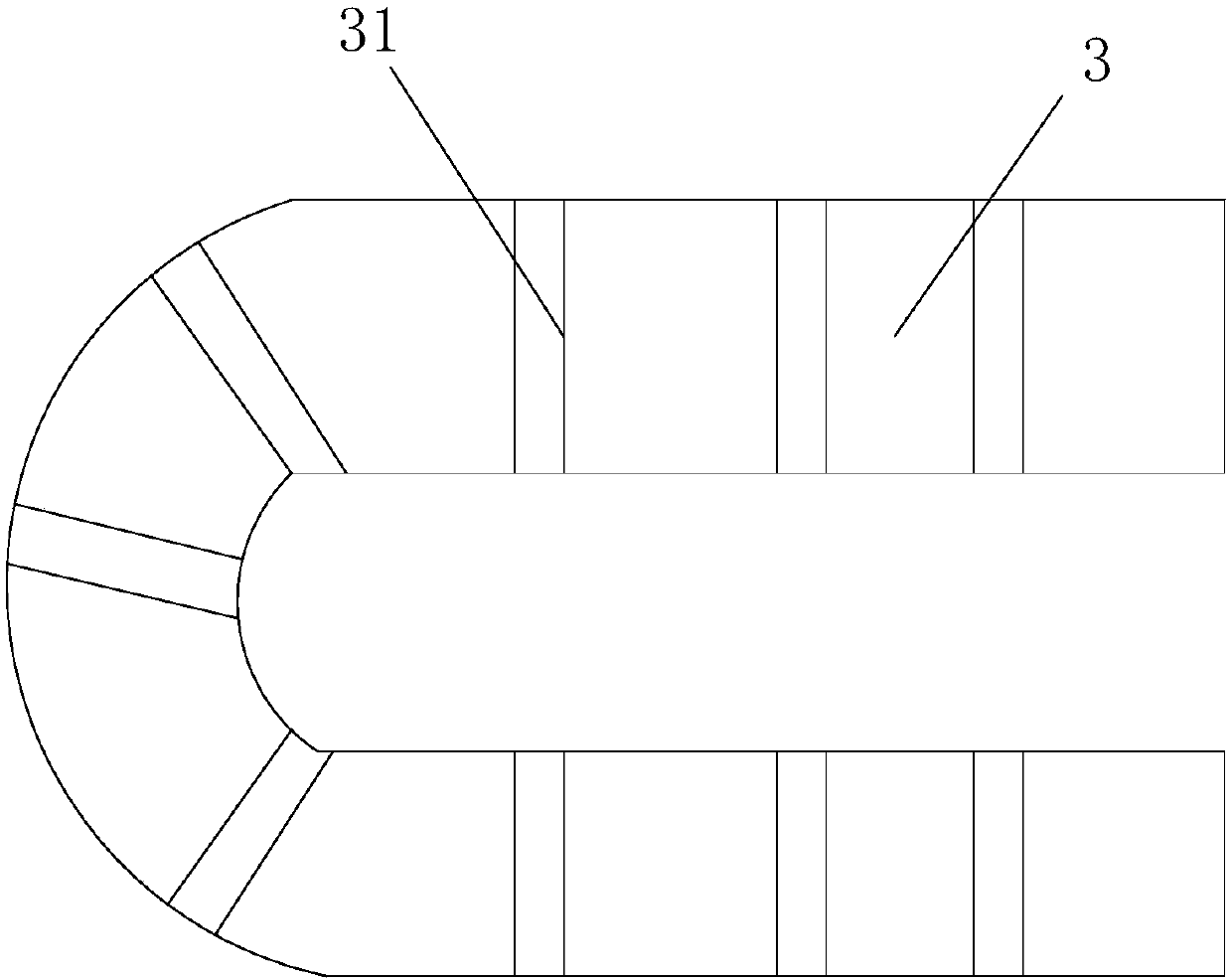

Rice seedling raising substrate mould pressing production line

PendingCN106718293AIncrease travel distanceSize specificationGrowth substratesCulture mediaProduction linePulp and paper industry

The invention discloses a rice seedling raising substrate mould pressing production line. The production line comprises a homogenating unit, a mould pressing forming machine, a dry piece collection and bundling unit and a drying unit which are sequentially connected through a transmission network chain. The homogenating unit comprises a homogenating machine and a slurry pipeline pump, and the slurry pipeline pump conveys slurry evenly stirred by the homogenating machine to a buffering tank; the mould pressing forming machine comprises two mould chambers arranged on the side faces of the transmission network chain; the mould chambers obtain suspension liquid from the buffering tank through a first pipeline pump and convey remaining buffering liquid into the buffering tank through a second pipeline pump; the dry piece collection and bundling unit comprises a network chain collection device and a bundling device, one end of the network chain collection device is connected with the output end of the drying unit, and the other end of the network chain collection device is connected with the input end of the bundling device; the drying unit comprises a drying box and heat-preserving plates on the side faces of the drying box. The production line is high in integrity and good in mould pressing effect, and is a mould plate and mould pressing integrated full-automatic production line.

Owner:JIANGSU HAIJIAN

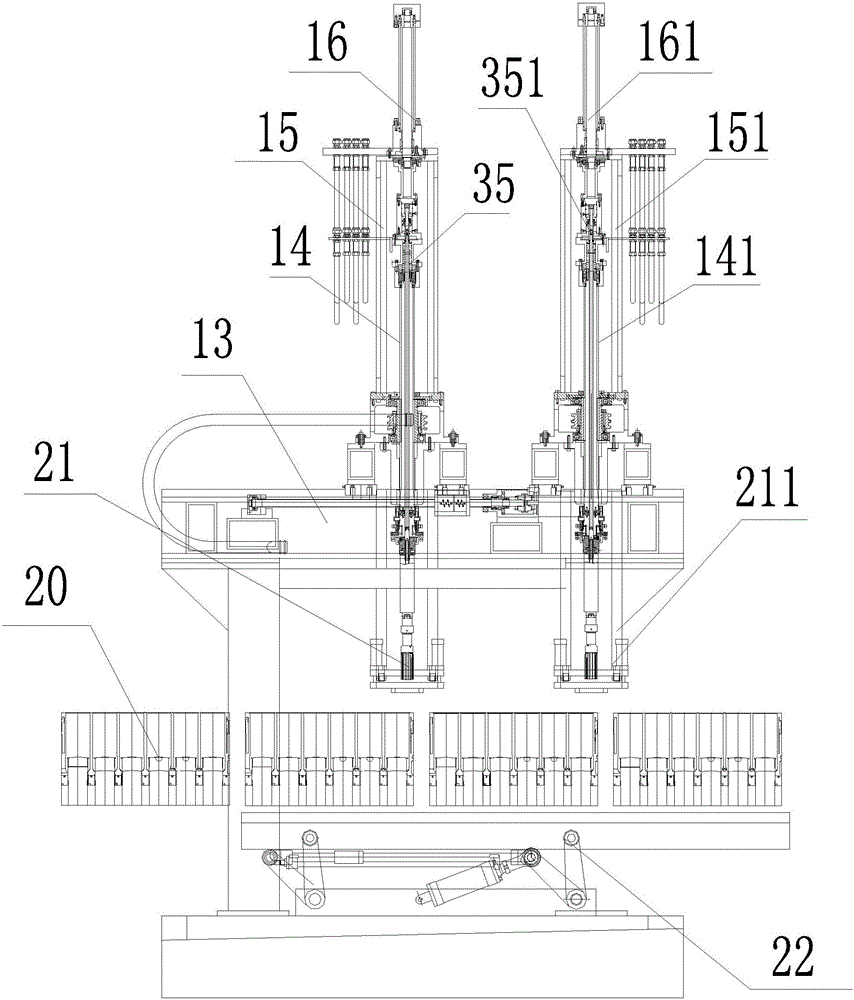

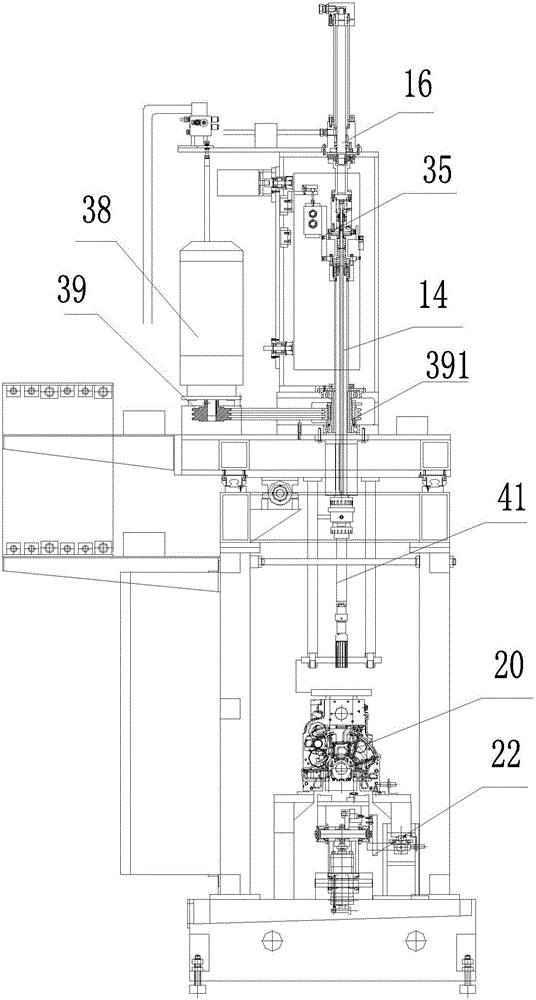

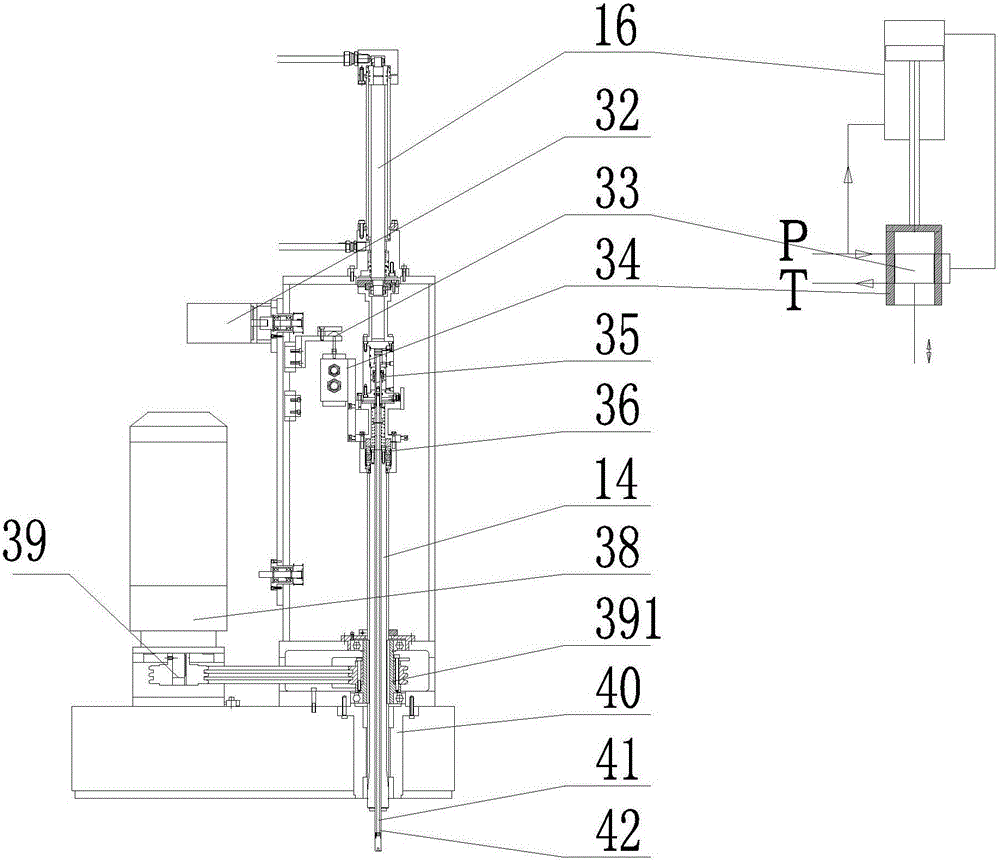

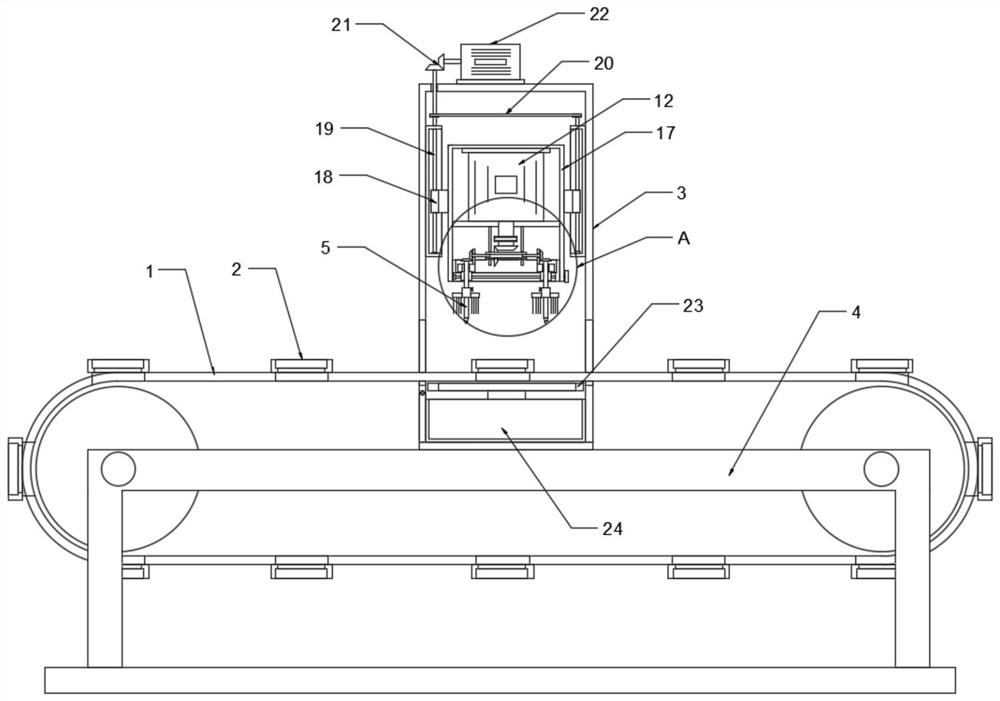

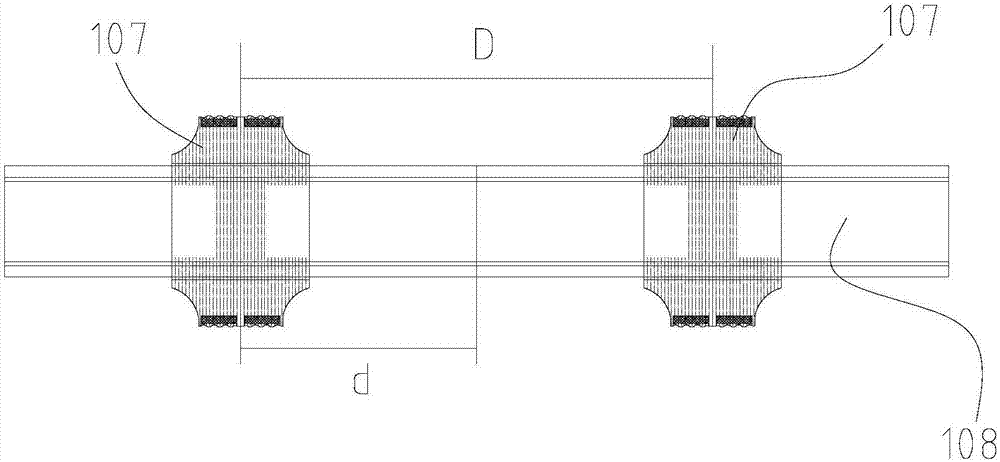

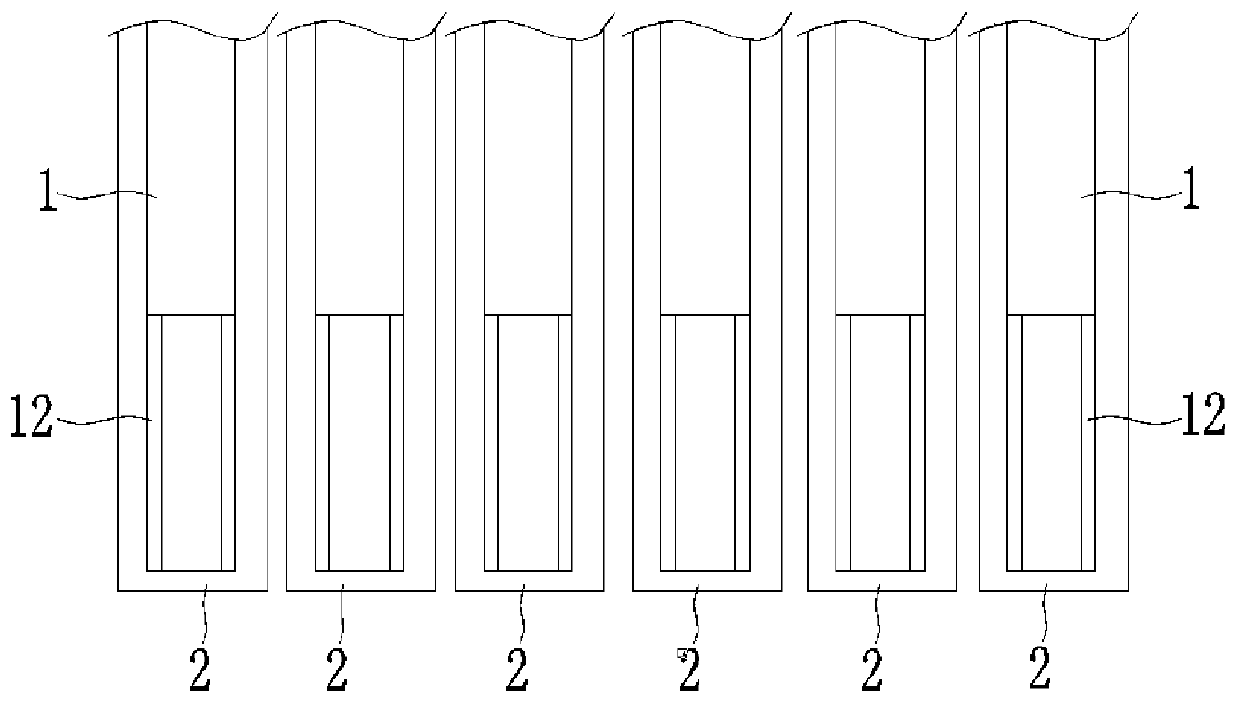

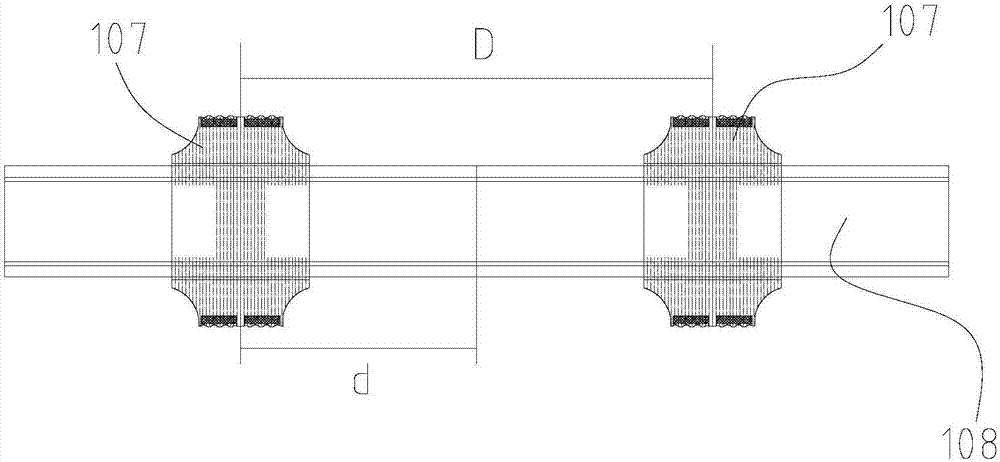

Dual-spindle type honing machine spindle reciprocating device

PendingCN107175575ARealize streamlined productionIncrease productivityGrinding carriagesGrinding drivesProduction lineReciprocating motion

The invention relates to a dual-spindle type honing machine spindle reciprocating device. The dual-spindle type honing machine spindle reciprocating device comprises main reciprocating oil cylinders which are arranged on a lathe bed, piston rods of the main reciprocating oil cylinders are connected with dual-feed oil cylinders correspondingly, piston rods of the dual-feed oil cylinders are connected with spindles correspondingly, and the spindles move up and down under driving of the main reciprocating oil cylinders; and a micro honing bar and a rough honing bar are connected on each spindle, a rough honing head is connected on each rough honing bar, and a micro honing bar is connected on each micro honing bar. According to the dual-spindle type honing machine spindle reciprocating device, the two spindles drive the honing bars and the honing heads to complete rough honing machining or micro honing machining on workpieces correspondingly, or complete one motion of rough honing and micro honing correspondingly according to time sequence; and the dual-spindle type honing machine spindle reciprocating device can be applied to a production line, and complete reaming and honing in order according to specified motions, pipelined production is achieved, and the production efficiency is enhanced.

Owner:NINGXIA YINCHUAN DAHE CNC MACHINE

Preparation technology of MC nylon active material

InactiveCN1718610ARealize industrial preparationRealize streamlined productionCarboxylic acid amide separation/purificationNylon materialEngineering

A process for preparing active nylon MC includes such steps as fusing the nylon monomer, loading in reactor, dewatering, adding catalyst, dewatering, examining specimen, loading in transfer container, proportionally loading in stirrer, adding cocatalyst and stirring.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES +4

Hinge streamlined drilling production equipment

InactiveCN111872441APrevent debris from flyingReduce processing noiseCleaning using toolsFeeding apparatusElectric machineryDrive motor

The invention discloses hinge streamline drilling production equipment which comprises a conveying belt and a drilling mechanism. The drilling mechanism comprises two sets of symmetrically-arranged drill rods, the upper portions of the drill rods are provided with sliding blocks in a penetrating manner, and are rotationally connected with the sliding blocks through bearings, prism shafts are connected to the upper ends of the drill rods through first transmission gear sets in a meshed manner, and a rotary drum is connected with an output shaft of a driving motor through a second transmission gear set. By arranging a bearing box provided with a rectangular through groove and a machining box, streamlined production of hinges is achieved, meanwhile, chippings are prevented from splashing, andmachining noise is lowered; through the arrangement of a sliding block, a transverse moving block, a transverse lead screw, an adjusting wheel, the rotary drum and the prism shafts, manual adjustmentof the drilling distance is conveniently achieved, and good adaptability is achieved; and through arrangement of an abutting frame, a slag crushing box, a brush plate and a sleeve, chippings in the bearing box are centrifugally swept, and the chipping collecting effect is improved.

Owner:黄展雄

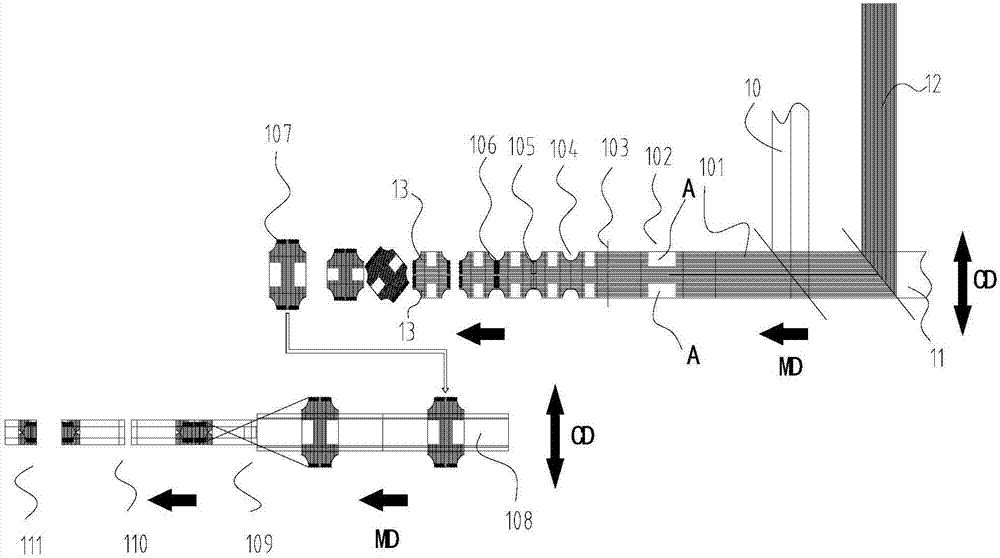

Elastic waistline sheet material processing method

ActiveCN106913420AImprove stabilityRealize streamlined productionAbsorbent padsBaby linensEngineeringStretch ratio

The invention discloses an elastic waistline sheet material processing method. The processing method comprises the following steps that first, strip-shaped elastic sheet material capable of retracting along a process direction is extended along the process direction and carried along the same direction; second, tension force of the elastic sheet material is released in the process direction until the tension force is zero or smaller than the tension force of the previous step; and third, the elastic sheet material is processed and cut according to a preset length. Stretching ratio of the elastic sheet material is segmentally controlled during the conveying process, and batch process of the elastic sheet material can be realized; product pace can be greatly improved and technology process can be shortened; besides, the cut elastic sheet material is rotated and amplified and configured to an absorbing main body, so poor switch-over of the elastic sheet material among different maintaining components can be avoided; production process stability can be improved; and the waistline sheet material has a compact structure and high production efficiency.

Owner:HUANGSHAN FUTIAN MACHINERY CO LTD

Enzymatic synthesis method of straight-chain dextrin

InactiveCN102533905ANarrow degree of polymerization distributionSimple processFermentationEnzymatic synthesisSucrose phosphorylase

The invention relates to an enzymatic synthesis method of straight-chain dextrin, belonging to the technical field of food. In the invention, cheap sucrose is used as a reaction substrate, and phosphate is used as a buffer solution; an expensive intermediate product glucose-1-phosphate is obtained by a sucrose phospholylase catalytic reaction; maltotetraose is added as a primer based on the reaction; and glucosyl is continuously added to maltotetraose through a glucanphosphorylase catalytic reaction so as to obtain the straight-chain dextrin. Through the method, the degree of polymerization of the straight-chain dextrin can reach 30; the enzymatic synthesis of straight-chain dextrin is adopted for the first time domestically; and foundation is provided for applying the straight-chain dextrin to the food industry.

Owner:JIANGNAN UNIV

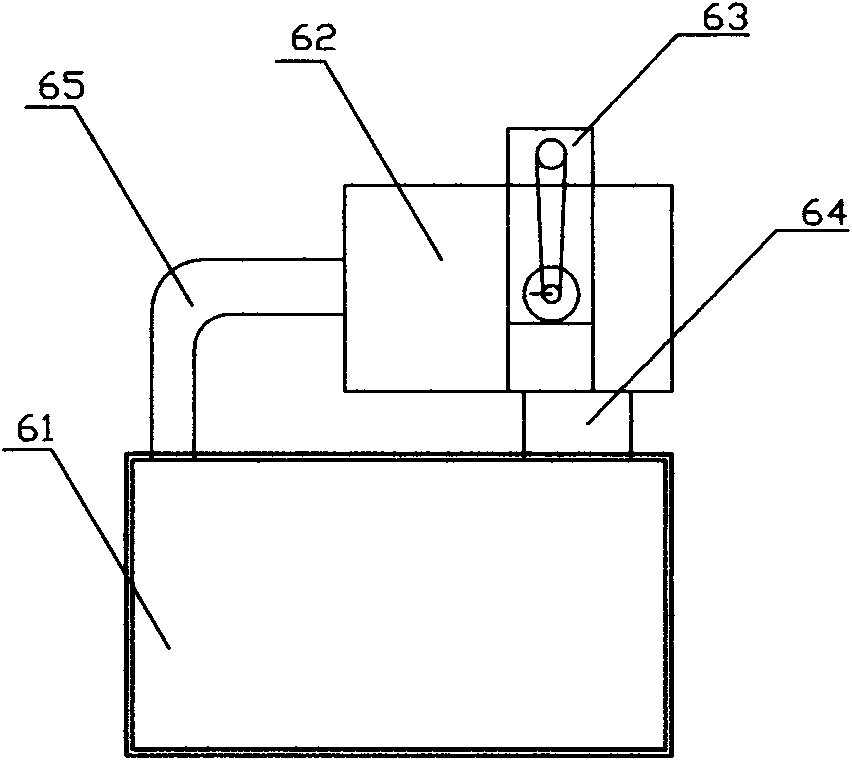

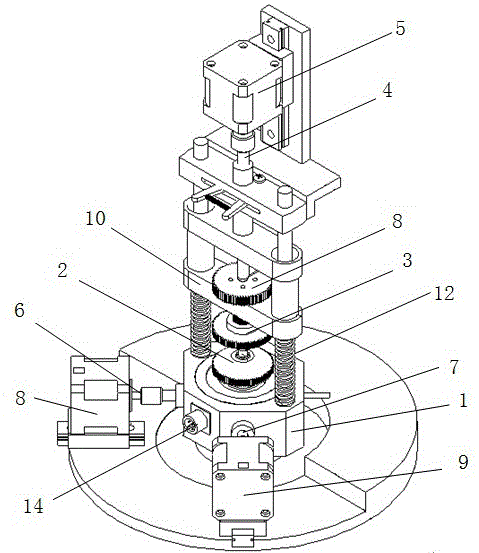

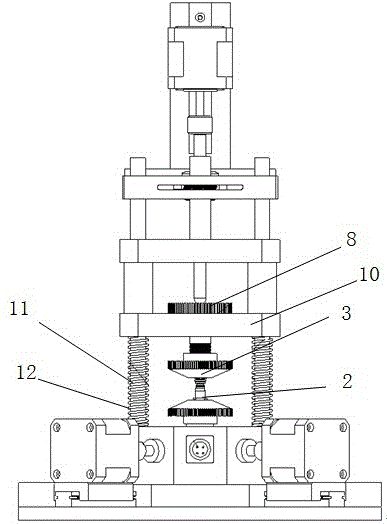

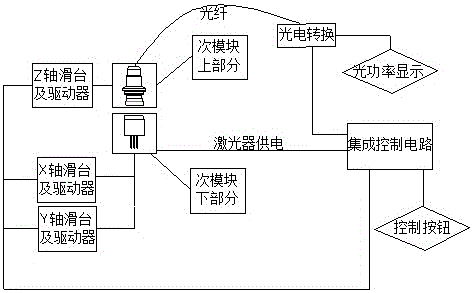

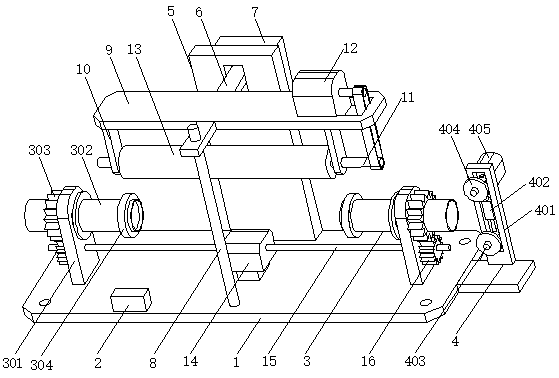

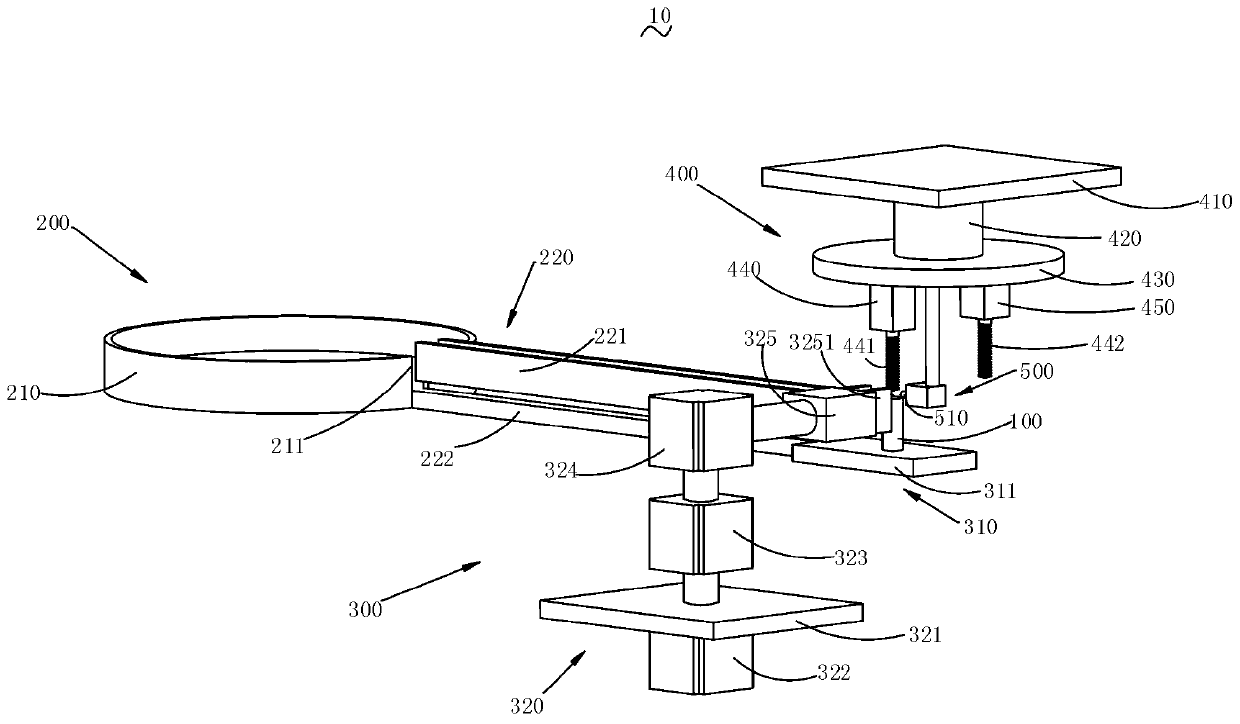

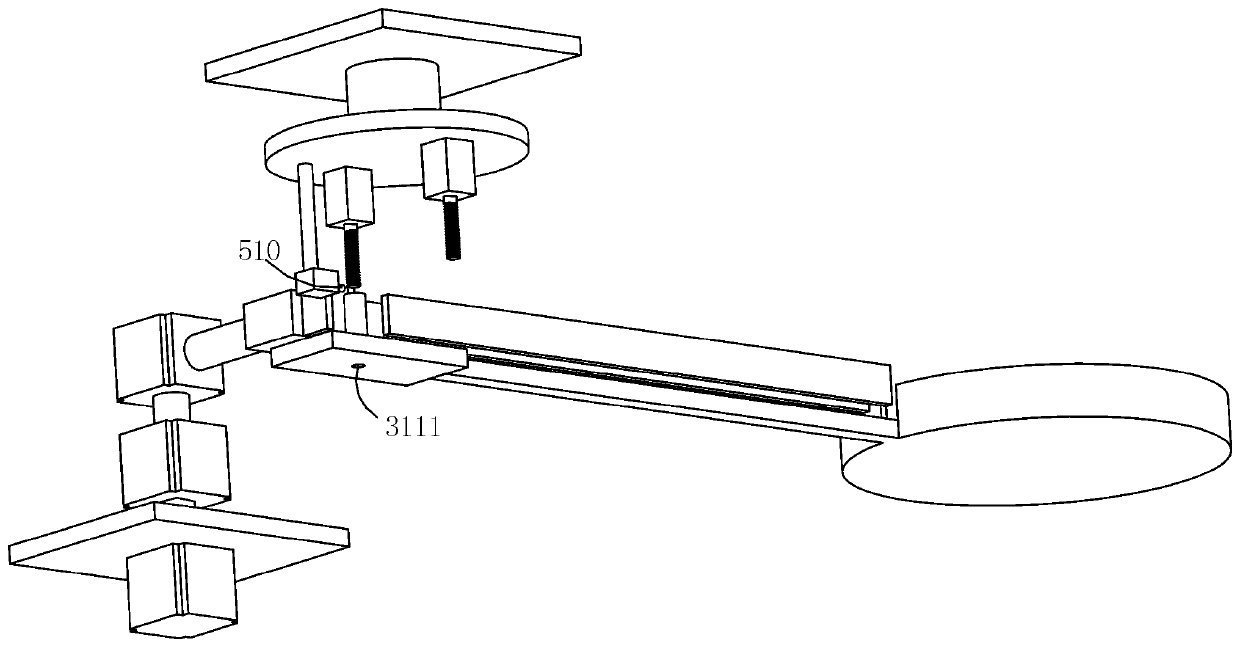

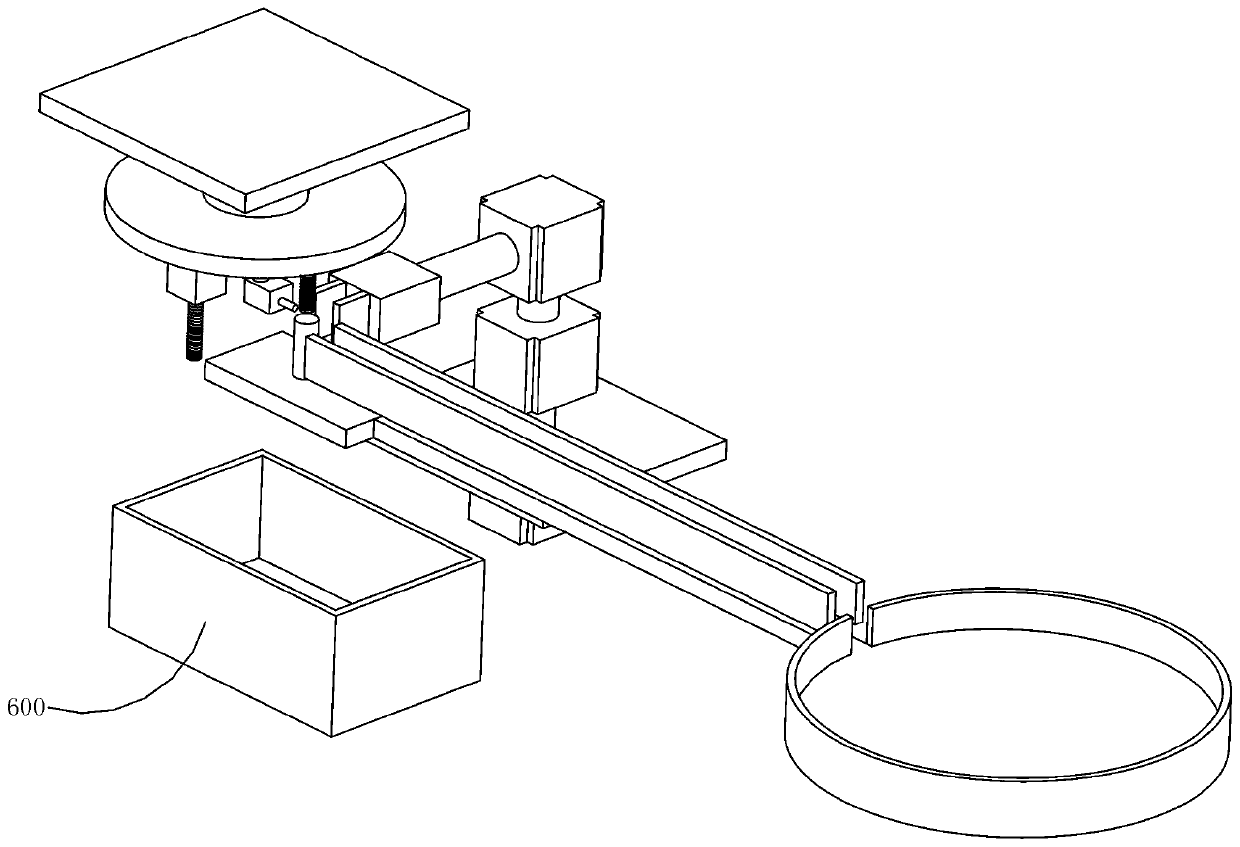

Device for automatically coupling optical communication sub-assemblies and method for eliminating delaying in coupling procedures

ActiveCN106772836AReduce human production costsReduce the influence of human factorsCoupling light guidesCouplingComputer module

The invention discloses a device for automatically coupling optical communication sub-assemblies and a method for eliminating delaying in coupling procedures. The device comprises a base, a lower fixture, an upper fixture, a Z shaft, a Z shaft driver, an X shaft, a Y shaft, an X shaft driver and a Y shaft driver. The lower fixture is carried on the base, the upper fixture corresponds to the lower fixture and is positioned above the lower fixture, the Z shaft is connected with the upper fixture, can move in the vertical direction and can be driven by the Z shaft driver to move, the X shaft is connected with the lower fixture and can transversely move, the Y shaft is connected with the lower fixture and can transversely move, the X shaft can be driven by the X shaft driver to move, and the Y shaft can be driven by the Y shaft driver to move; the lower portion of the lower fixture extends into the base, and the X shaft and the Y shaft are inserted into the base and are connected with the lower fixture; the movement directions of the X shaft are perpendicular to the movement directions of the Y shaft. The device and the method have the advantages that the traditional multi-operator manual coupling modes can be replaced owing to high-integration modes of equipment, and accordingly the production efficiency can be improved; optical power change can be automatically monitored in real time, accordingly, the product process monitoring capacity can be improved, products with great optical power change can be screened in real time, and the qualification rate of the products can be increased.

Owner:JIANGSU ALLRAY

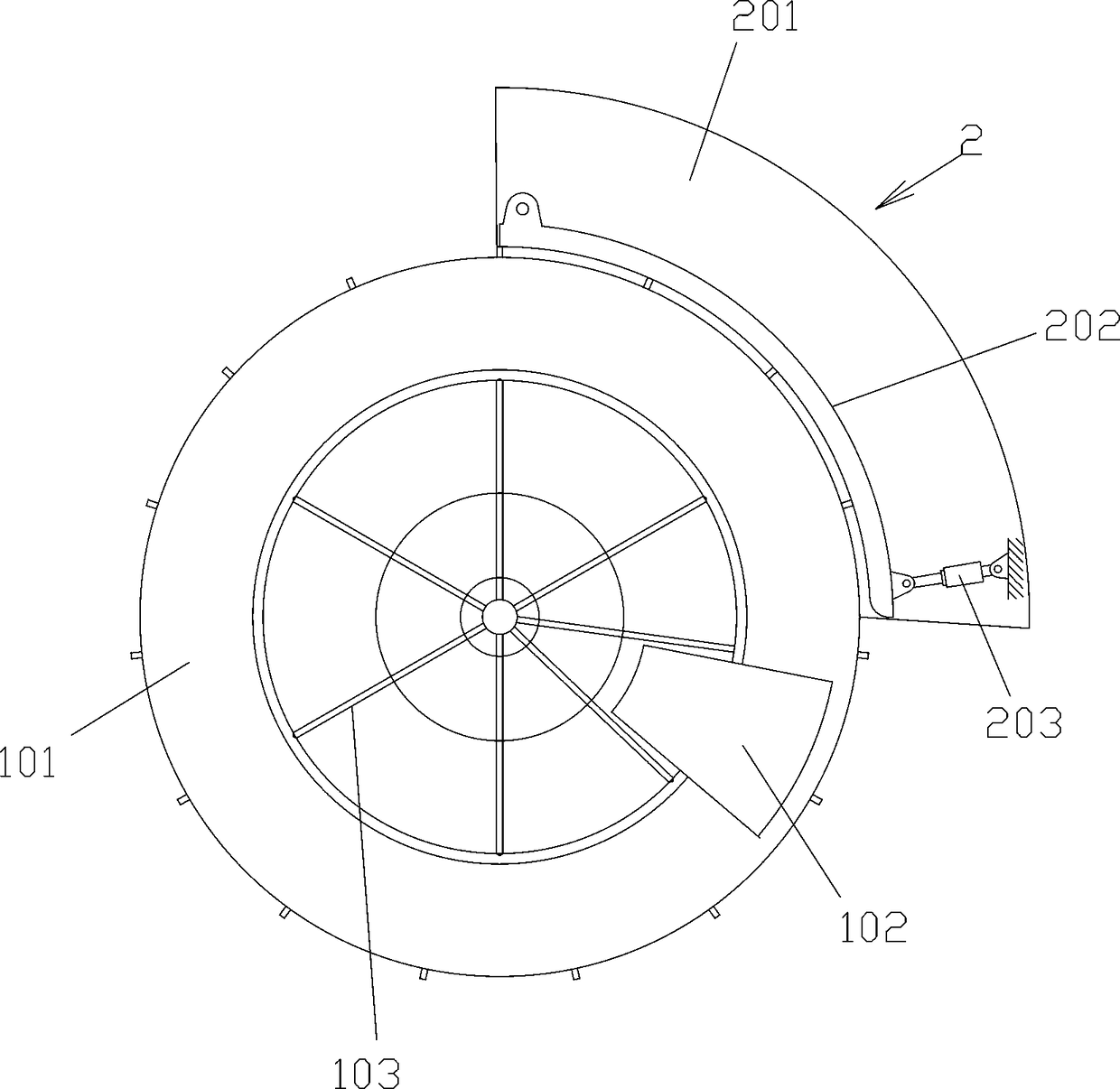

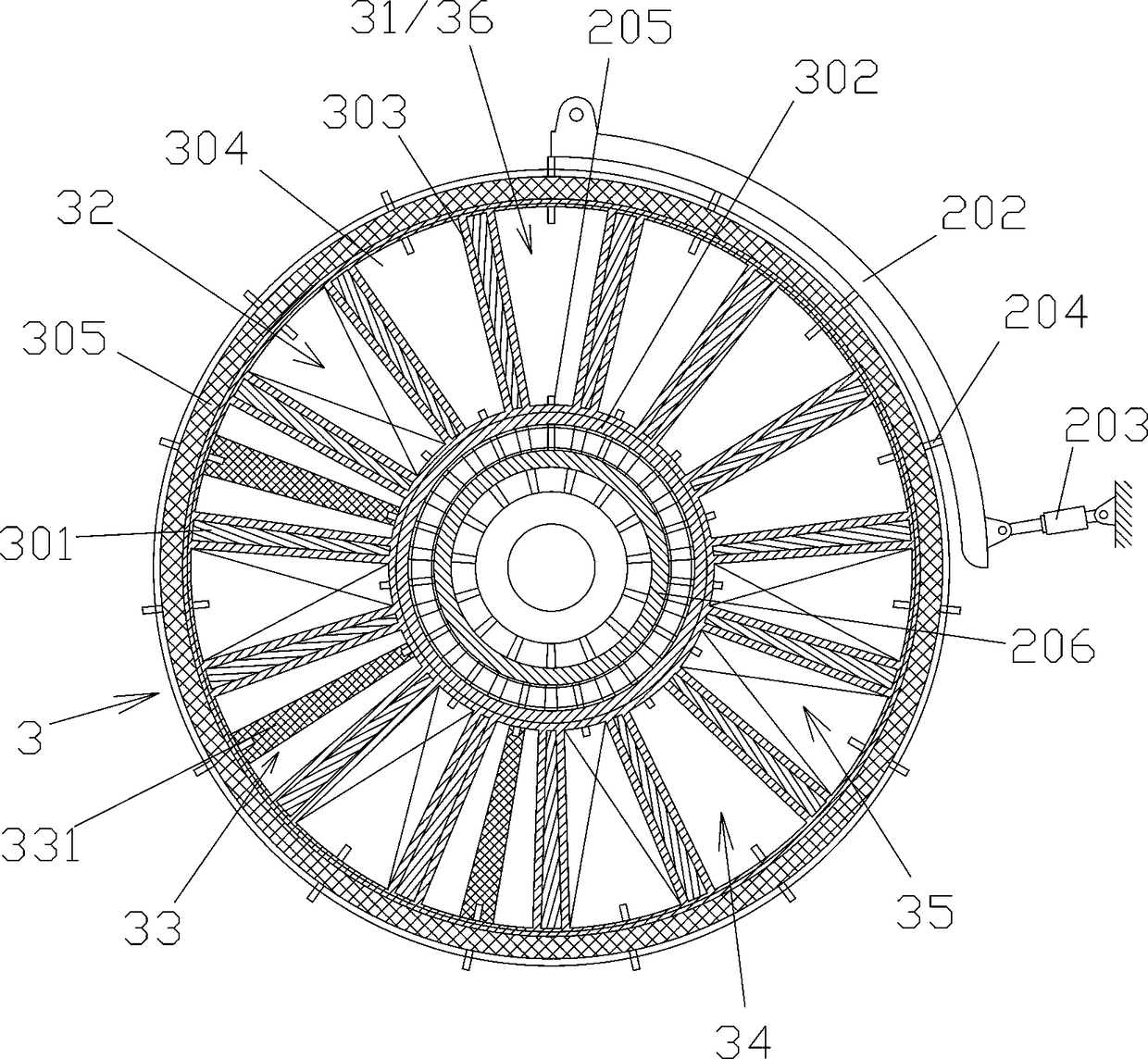

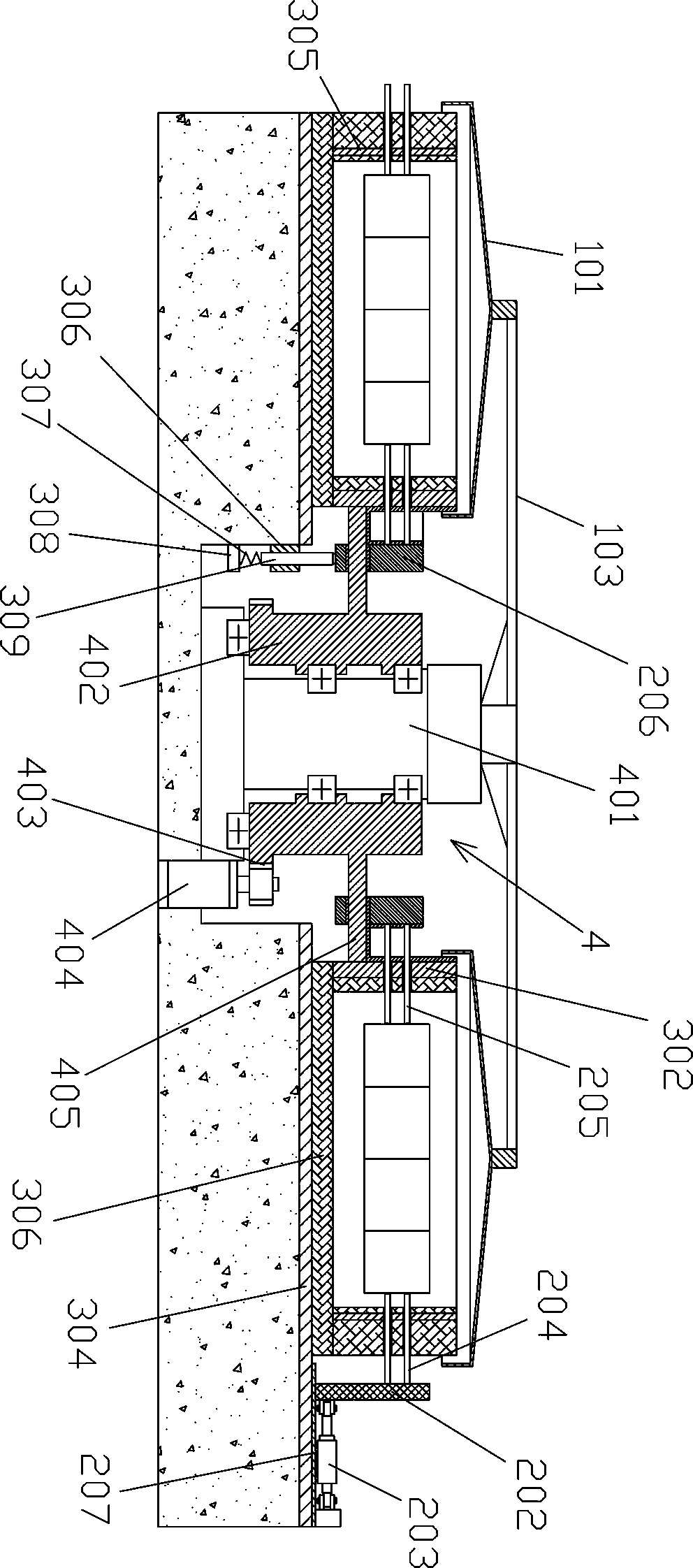

Disc single-shot detonator explosive pressing device and using method thereof

The invention discloses a disc single-shot detonator explosive pressing device and a using method thereof. The device comprises a central rotary table and a power assembly, wherein the central rotarytable is connected with the power assembly; a mold operation platform is arranged above the central rotary table; the mold operation platform comprises a rotating part and a fixed part; the rotating part is located in the center of the fixed part and connected with the center rotary table; a plurality of mold placing grooves are formed in the outer side of the rotating part, a mounting table is arranged above the mold operation platform, the mounting table is connected with the central rotary table, a plurality of pressing air cylinders are arranged on the mounting table, the pressing air cylinders correspond to the mold placing grooves one to one, the output ends of the pressing air cylinders are connected with pressing punching strips, and the pressing punching strips are located over the mold placing grooves. According to the invention, a single-shot detonator is used for pressing an explosive, so that the pressure required for pressing the explosive can be effectively reduced; eachsingle-shot mold corresponds to one pressing air cylinder, so that the grain in the mold is stressed more uniformly; and the device can be matched with other conveying mechanisms to realize streamlined production of the detonators, so that the production efficiency of the detonators is ensured.

Owner:YAHUA GROUP MIANYANG INDAL

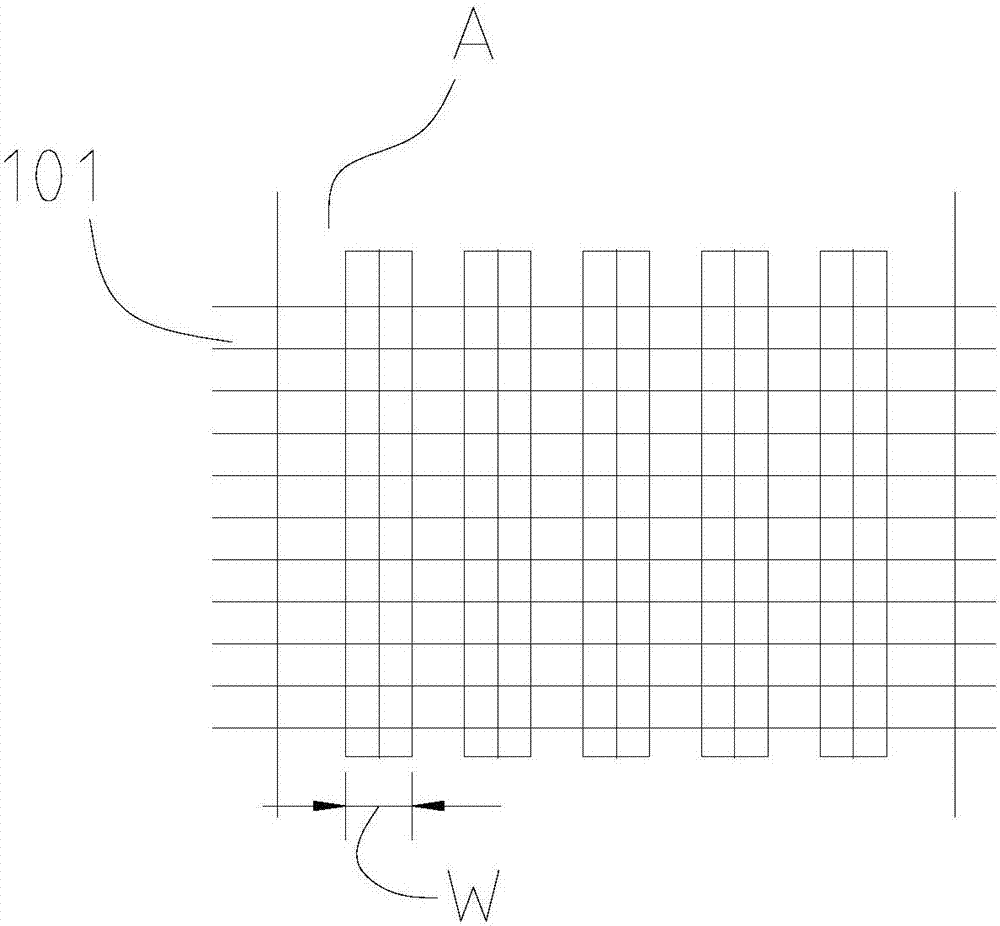

A method for distributing simulated ceramic tiles with internal texture and ceramic tiles

ActiveCN108068207BFlexible locationFlexible sizeFeeding arrangmentsAuxillary shaping apparatusAdobeConveyor belt

The invention discloses a cloth for imitating ceramic tiles with internal texture, which comprises the following steps: distributing basic powder on a conveyer belt to obtain a blank; The adobe of the tile forms the underlying texture; pressed to become the adobe. The invention also discloses a simulated ceramic tile with internal texture. The colored texture with a certain thickness is set on the adobe, and after the tiles are grooved, the bottom-through phenomenon can be avoided, the simulation degree of the tiles can be improved, and the construction speed can also be improved and the use effect can be enhanced. At the same time, the method of setting the texture on the blank by the way of partial material removal and filling makes the position, size and color setting of the tile texture more flexible and controllable. Using the conveyor belt can realize the continuous setting of the bottom texture of multiple blanks, and the conveyor belt transports the blanks to the press and presses them into adobes, realizing continuous and streamlined production and improving production efficiency.

Owner:FOSHAN DONGPENG CERAMIC +2

Plug and power line injection molding production line

ActiveCN111923324AHigh degree of automationIncrease productivityDomestic articlesProcess engineeringInjection molding machine

The invention discloses a plug and power line injection molding production line. The plug and power line injection molding production line comprises a placement table, the placement table is providedwith a mold inlet and outlet device, an injection molding machine is arranged on the side of the movable end of the mold inlet and outlet device, an air cooler is arranged above a position between themold inlet and outlet device and the injection molding machine, and an air heater is arranged below the position between the mold inlet and outlet device and the injection molding machine. Accordingto the plug and power line injection molding production line, through the mold inlet and outlet device, the overall automation degree of plug and power line injection molding is improved, the danger of manual placement injection molding is reduced, streamlined production of the plug and power line injection molding process is achieved, it is guaranteed that the process period is constant, the production efficiency is further improved, and the product quality is guaranteed.

Owner:浙江海宁和金电子科技有限公司

Turntable continuous graphite tube graphitization furnace and method for graphitizing a graphite tube

The invention discloses a turntable continuous graphite tube graphitization furnace and a method for graphitizing a graphite tube. The turntable continuous graphite tube graphitization furnace comprises a furnace body assembly, a drive mechanism, a conductive part and a cooling part; the furnace body assembly comprises a support ring plate, an inner ring wall plate and an outer ring wall plate; the conductive part comprises a first conductive component, a second conductive component, and a plurality of groups of conductive electrodes; the first conductive component comprises a conductive sleeve arranged between a shaft sleeve and the inner ring wall plate; a sleeve and a support block are arranged under the conductive sleeve; a conductive rod is arranged in the sleeve; a spring is arrangedbetween the conductive rod and the support block; the spring pushes the conductive rod to lean against the lower end surface of the conductive sleeve. The turntable continuous graphite tube graphitization furnace and the method for graphitizing a graphite tube disclosed by the invention are used for solving the problems that the existing graphitization furnace is large in power consumption, longin cooling time and unable for continuous production.

Owner:湖北红业建材科技开发有限公司

Embossing machine capable of adjusting pressing mark depth

The invention discloses an embossing machine capable of adjusting the pressing mark depth. A base is included, and a PLC is installed on the front side of the upper surface of the base; material transferring devices are oppositely arranged at the left and right ends of the upper surface of the base; a material feeder is installed on the upper surface of the portion, on the right side of the material transferring device on the right side, of the base; and an installing base is installed on the middle portion of the rear side of the upper surface of the base. The embossing machine capable of adjusting the pressing mark depth is simple in structure and stable in running; pipe materials are conveyed into the material transferring devices through the material feeder, adaption to the pipe materials in various lengths is achieved, and assembly line production is achieved; the engaging depth of an embossing roller and the pipe materials in a pipe sleeve is changed through a driving cylinder, the depth control over embossing of the outer wall of the pipe materials is achieved through the controllable engaging degree, embossing operation of different pipe materials can be achieved, and limitation by materials is avoided; and due to reverse rotating of the embossing roller and the pipe sleeve, embossing is performed on the outer wall of the pipe materials, it is guaranteed that embossingcan uniformly cover the outer side faces of the pipe materials, the uniformity and the attractiveness degree of the embossing process are guaranteed, operation is easy, and using is convenient.

Owner:JIANGSU YANGGUANG NOVAL FENCE SCI & TECH CO LTD

Formula and production technology used for preparing A grade non-combustible thermal insulation boards from cement polyphenyl particles

PendingCN110156391AImprove insulation effectImprove fire performanceThermal insulationCompressive strength

The invention relates to a formula and production technology used for preparing A grade non-combustible thermal insulation boards from cement polyphenyl particles. The production technology comprisesfollowing steps: a polyphenyl board particle board raw material is prepared at a preset ratio, and a stirring machine is used for stirring; after stirring, the raw material is introduced into a material cabin for another time of stirring, and the raw material is introduced into lower mould boxes; the mould boxes are conveyed on a guide rail, and are sealed with cover plates using a capping mechanism; the mould boxes are conveyed on the guide rail continuously, and the cover plates are pressed downward for a certain distance using a cover pressing mechanism for compaction of the raw material; after a certain period of time, the mould boxes are subjected box opening demoulding so as to obtain the cement polyphenyl particle boards. The cement polyphenyl particle boards prepared using the cement polyphenyl particle board production equipment and the technology possess excellent thermal insulation performance and flame resistance; and the compressive strength and the tensile strength are increased greatly.

Owner:北京华金盛科技有限公司

Production method of bamboo mat

ActiveCN105108867BReduce drillingReduce manual weavingPretreated surfacesWood working apparatusEnvironmental resistanceEngineering

The invention discloses a production method of a mahjong block-shaped bamboo sleep mat which is environmental-friendly in property, convenient to process and low in cost. The production method comprises the following steps of bamboo chip processing, base cloth preparing, hot glue applying, hot glue melting into a glue solution, bamboo chip sticking, and cutting, or the following steps of bamboo chip processing, base cloth preparing, polyurethane glue applying, bamboo chip sticking, cutting, and glue solution curing. Bamboo chips are stuck on base cloth, so that processes of drilling and manual weaving in bamboo chip processing are reduced, braided wires such as ox-tendon imitating wires are also omitted, the cost is reduced greatly, the thicknesses of the bamboo chips are also reduced, and the weight and the size of the bamboo sleep mat are reduced greatly to facilitate conveying, folding, carrying and storing of the bamboo sleep mat; and besides, hot glue or polyurethane glue is used for sticking the bamboo chips, so that the environment is protected, the cost is low, the flow-line production can be realized, and the production efficiency is improved greatly.

Owner:TAOJIANG BINGMENG HOUSEHOLD PROD

Magnetic material drilling and grinding device

PendingCN111468949ARealize automatic feeding processDrilling and grindingOther manufacturing equipments/toolsCircular discFixed frame

The invention discloses a magnetic material drilling and grinding device. The magnetic material drilling and grinding device comprises a magnetic core, a feeding mechanism, a positioning mechanism, adrilling and grinding mechanism and a cleaning mechanism, the feeding mechanism comprises a feeding disc and a feeding channel, the feeding disc and the feeding channel communicate, the positioning mechanism comprises a positioning frame and clamping mechanisms, the positioning frame is mounted on the tail end of the feeding channel, the positioning frame comprises a placing table, the placing table is used for placing the magnetic core, the bottom of the placing table is provided with a scrap leaking hole, the two clamping mechanisms are used for clamping the magnetic core, the drilling and grinding mechanism comprises a fixed frame, a hydraulic lifting rod, a rotating disc, a drilling device and a grinding device, the fixed frame is arranged above the positioning frame, the drilling device and the grinding device are oppositely mounted on the two ends of the symmetric axis of the rotating disc, the cleaning mechanism comprises a high-pressure gas spraying gun, a gun head of the high-pressure gas spraying gun right faces the placing table, according to the magnetic material drilling and grinding device, automatic loading, automatic drilling, automatic grinding and automatic scrapcleaning of the magnetic core can be achieved, assembly production is achieved, procedures are reduced, and production efficiency is improved.

Owner:惠州市磁源磁性材料有限公司

Slot shell type border stone

Owner:刘清秀

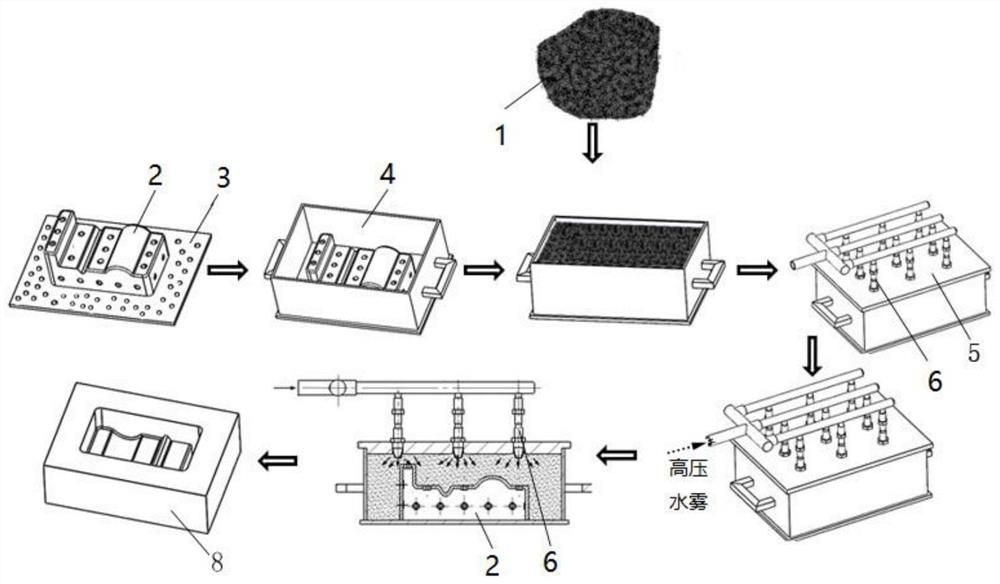

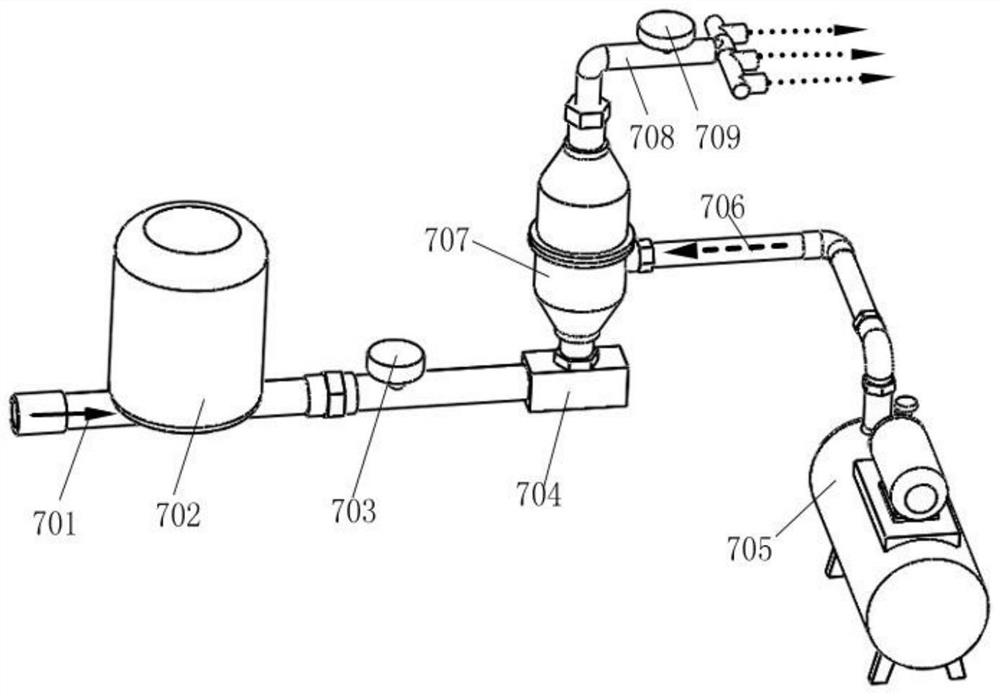

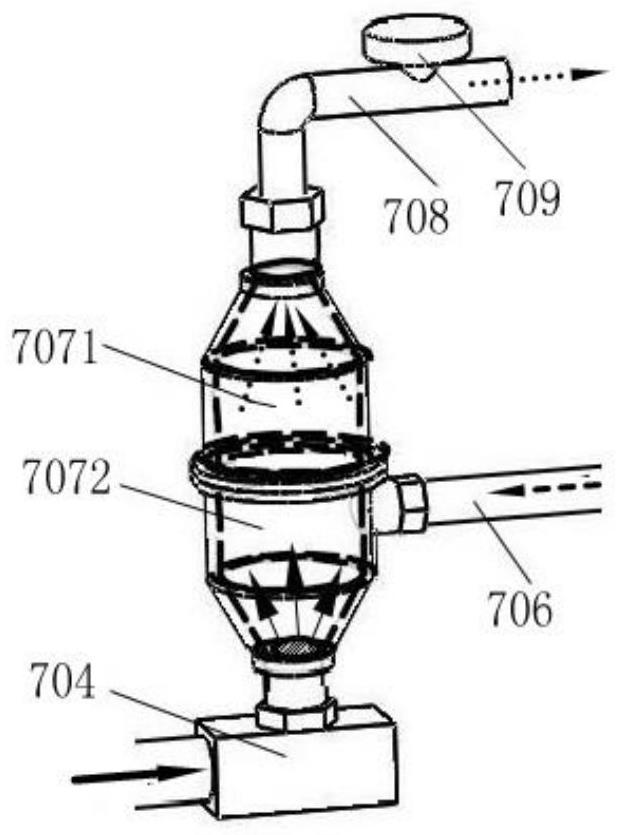

Manufacturing method of frozen casting mold

PendingCN114042861AIncrease productivityRealize streamlined productionFoundry mouldsMould handling/dressing devicesHazardous substanceProcess engineering

The invention relates to a manufacturing method of a frozen casting mold, which comprises the following steps of freezing crude sand to form low-temperature crude sand (1) with the temperature of 10 DEG C below zero to 30 DEG C below zero, fixing a mold (2) provided with a vent plug on a bottom plate (3) also provided with a vent plug, putting a sand box (4), injecting the low-temperature crude sand (1) into the sand box (4), moving a sand box upper cover (5) provided with a plurality of water mist nozzles (6) to the upper part of the sand box (4), spraying high-pressure water mist into the sand box (4) through a high-pressure water mist generator, enabling the high-pressure water mist to make contact with low-temperature crude sand in the sand box (4) to be condensed into ice, bonding molding sand together through the ice, and acquiring a frozen casting mold (8) after drawing. According to the manufacturing method of the frozen casting mold, streamlined production of sand mold casting with water as a binder can be achieved, the production efficiency is high, the production cost is low, the demanded quantity of molds in the production process is small, toxic and harmful substances cannot be generated, and waste sand obtained after pouring can be repeatedly used.

Owner:LUOYANG INST OF SCI & TECH

Preserved ginger production device

ActiveCN112568310ARealize streamlined productionGuaranteed uniformityConfectionerySweetmeatsEngineeringSUGAR/WATER

The invention provides a preserved ginger production device comprising a machine body and a rotating mechanism; the machine body is cylindrical, the rotating mechanism is arranged in the machine body,an inner cavity is formed in the machine body, and the rotating mechanism is located in the inner cavity; four inner cavity partition plates are arranged at the upper end of the inner cavity; the upper end of the inner cavity is equally divided into an upper structural area I, an upper structural area II, an upper structural area III and an upper structural area IV through the inner cavity partition plates; four rotating partition plates and a rotating disc are arranged at the lower end of the rotating mechanism; and the rotating partition plates are fixedly arranged at the lower end of a rotating shaft correspondingly, and the lower ends of the rotating partition plates are fixedly connected to the rotating disc; the rotating partition plates, the rotating disc and the side wall of the inner cavity are arranged. The inner cavity is divided into four working areas through the rotating mechanism, the inner cavity, the inner cavity partition plates and the rotating partition plates, lemonade pickling, sweet water pickling, drying and discharging are conducted respectively, streamlined production is achieved, and the production efficiency is improved.

Owner:九江鸿立食品有限公司

Elastic waistline sheet material processing method and manufacturing method for clothes products

ActiveCN106913419AConvenient Product PackagingIncrease productivityAbsorbent padsBaby linensManufacturing engineeringHead to head

The invention discloses an elastic waistline sheet material processing method. At a preset tension force or tension force free state, the method comprises steps of arc-cutting the elastic sheet material, composing a waist plaster, and cutting to a designated length. The invention further discloses a manufacturing method for clothes. The elastic waistline sheet material is configured to an absorbing main body via steering and size-enlarging at intervals to form a plurality of products with head-to-head and tail-to-tail in a process direction; at last, the elastic waistline sheet material after size enlargement in the third step is cut off along a center line of the elastic sheet material process direction and the required clothes product is achieved. The waistline sheet material processing method fills a blank of the full- waistline sheet material processing field, and is advantaged by high production efficiency and low cost; in the clothes product manufacturing method, a composing way of head-to-head and tail-to-end is first put forward, and enables products to be quickly packed, so production efficiency is improved and technology process is shortened; and space and time is saved.

Owner:HUANGSHAN FUTIAN MACHINERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com