Hinge streamlined drilling production equipment

A production equipment and streamlined technology, used in drilling/drilling equipment, boring/drilling, metal processing equipment, etc., can solve problems such as poor control of drilling spacing, affecting processing quality, and poor stability. , to avoid debris splashing, reduce processing noise, and achieve the effect of good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

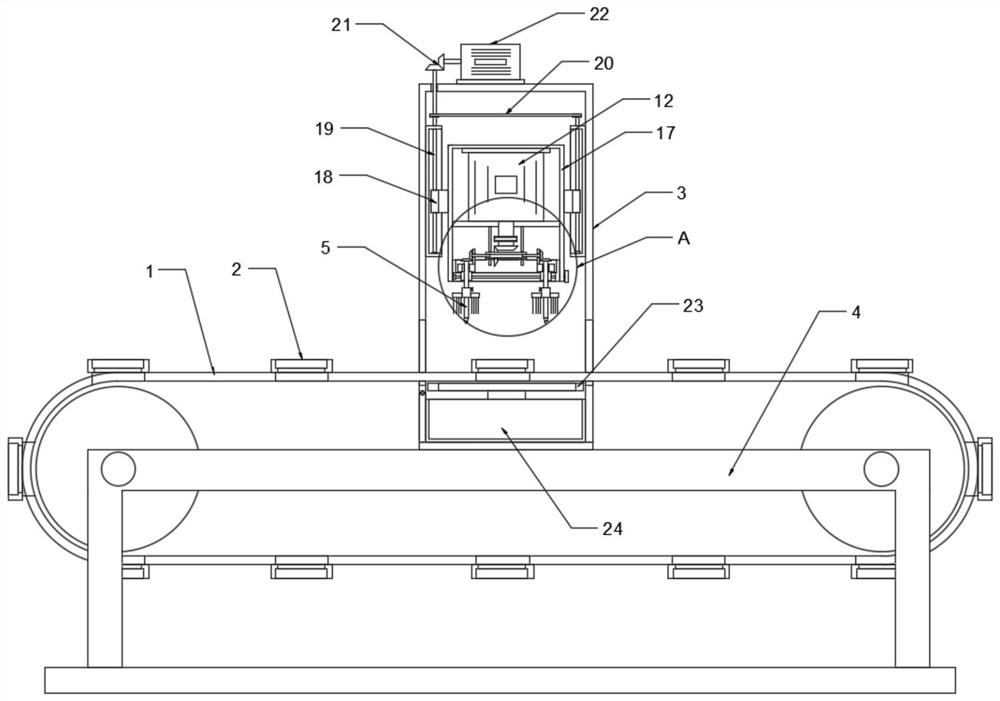

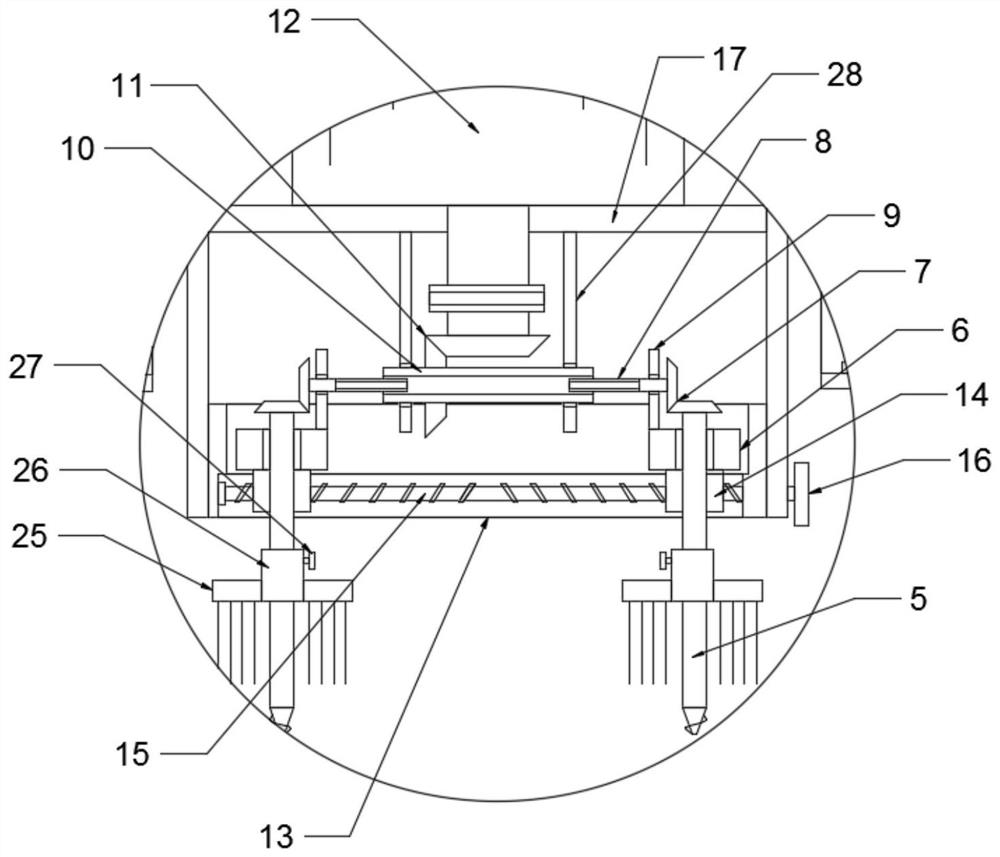

[0022] see Figure 1-6 , in an embodiment of the present invention, a hinge streamlined drilling production equipment includes a conveyor belt 1 and a drilling mechanism; the conveyor belt 1 is fixedly connected with carrying boxes 2 equidistantly distributed, and the carrying boxes 2 are hollow with an open upper end. The box body and the bottom of the carrying box are provided with a rectangular through-slot 201. Specifically, the drill pipe extends through the rectangular through-slot 201 when processing the hinge to ensure that the hinge is penetrated during processing. The through groove prevents the drill rod from damaging the conveyor belt, and at the same time, part of the debris generated by drilling falls into the bottom of the conveyor belt 1 for easy collection.

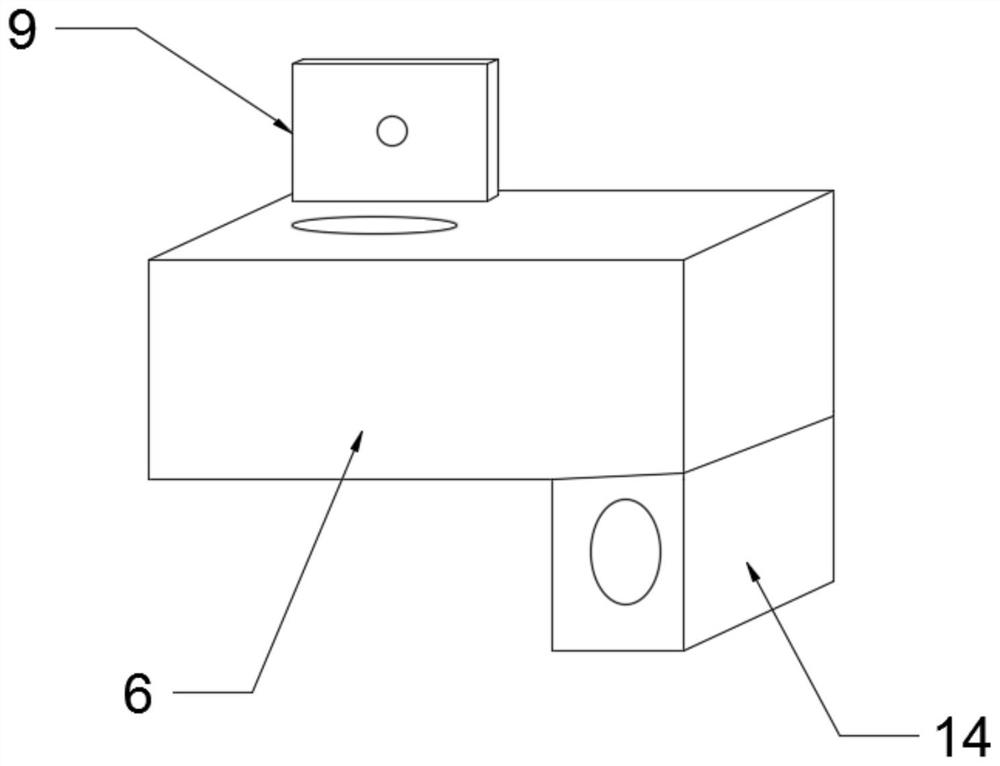

[0023] The drilling mechanism includes two groups of symmetrically arranged drill rods 5, the outer sides of the drill rods 5 are provided with a processing box 3, the conveyor belt 1 runs through the pro...

Embodiment 2

[0027] The difference between this embodiment and Embodiment 1 is: in order to facilitate the cleaning of debris; the bottom plate of the processing box 3 is fixedly connected with an abutment frame 23, the abutment frame 23 abuts with the conveyor belt 1, and the abutment frame 23 is provided with a The cooperating rectangular slot 201 on the carrier box 2 allows the debris to fall to the bottom of the abutment frame 23, and the bottom of the abutment frame 23 is provided with a slag box 24, which can be detachably nested and processed. Inside box 3.

[0028] In order to facilitate the cleaning of the debris remaining on the bearing box 2 during the processing of the drill pipe 5, a symmetrically arranged brush plate 25 is provided on the top of the drill pipe 5, and the brush plate 25 is fixedly connected with a sleeve 26, and the sleeve 26 is sleeved. On the upper part of the drill pipe 5, the sleeve 26 is fixedly connected with the drill pipe 5 through the locking bolt 27;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com