Patents

Literature

44results about How to "Reduce processing noise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

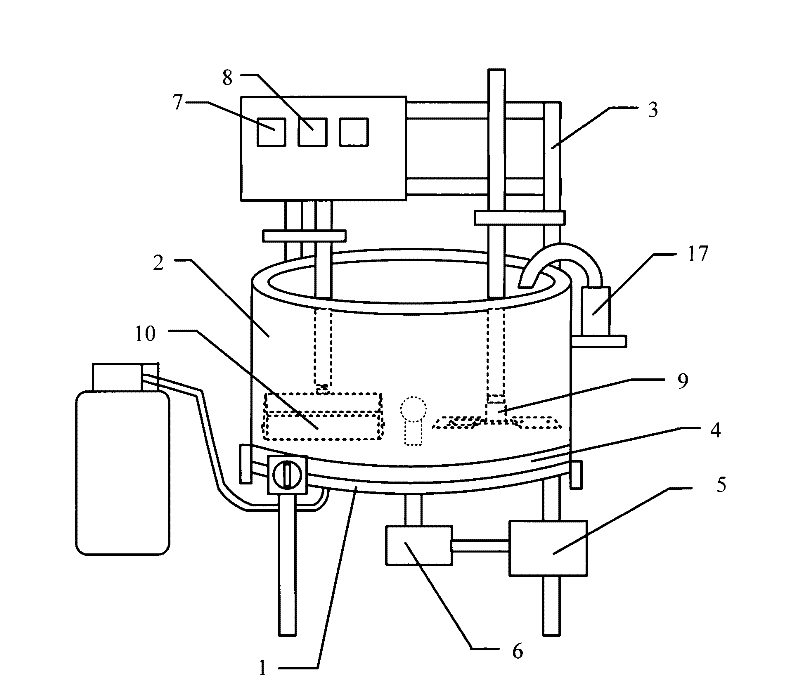

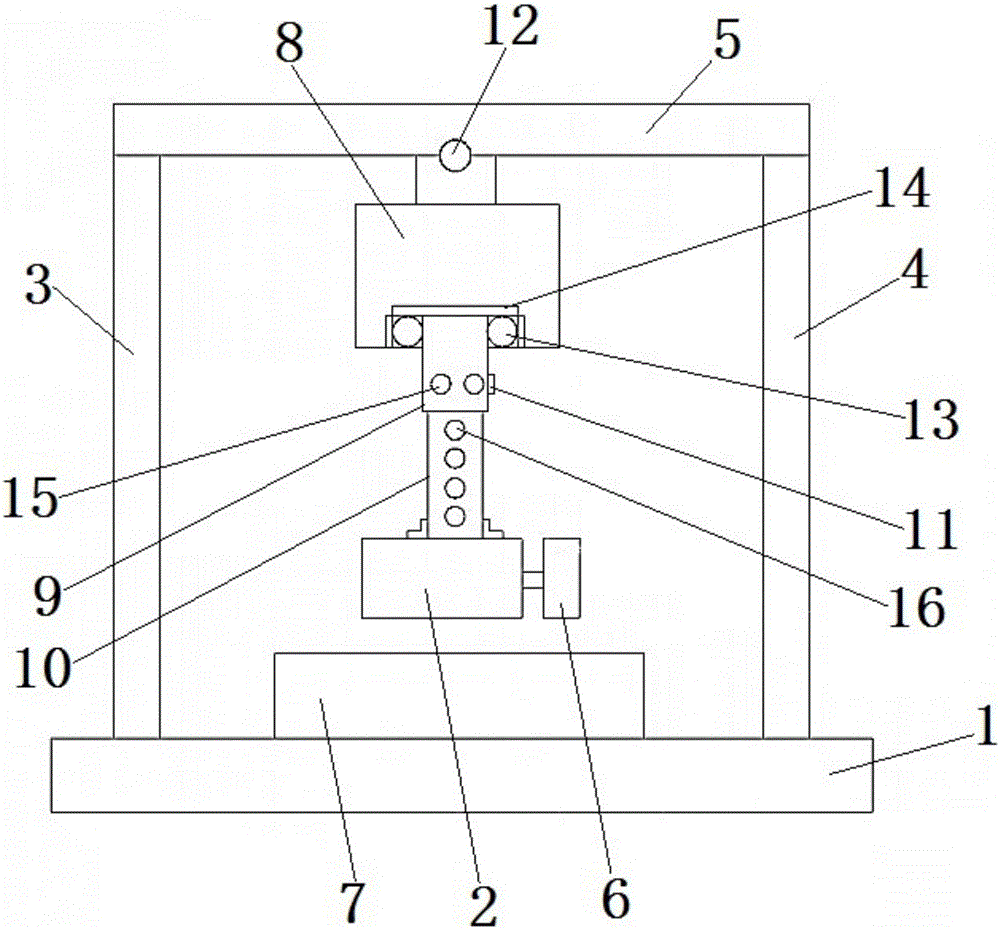

Equipment for processing Biluochun tea

InactiveCN101579022AReduce difficultyRealize automatic fryingPre-extraction tea treatmentReduction driveAgricultural engineering

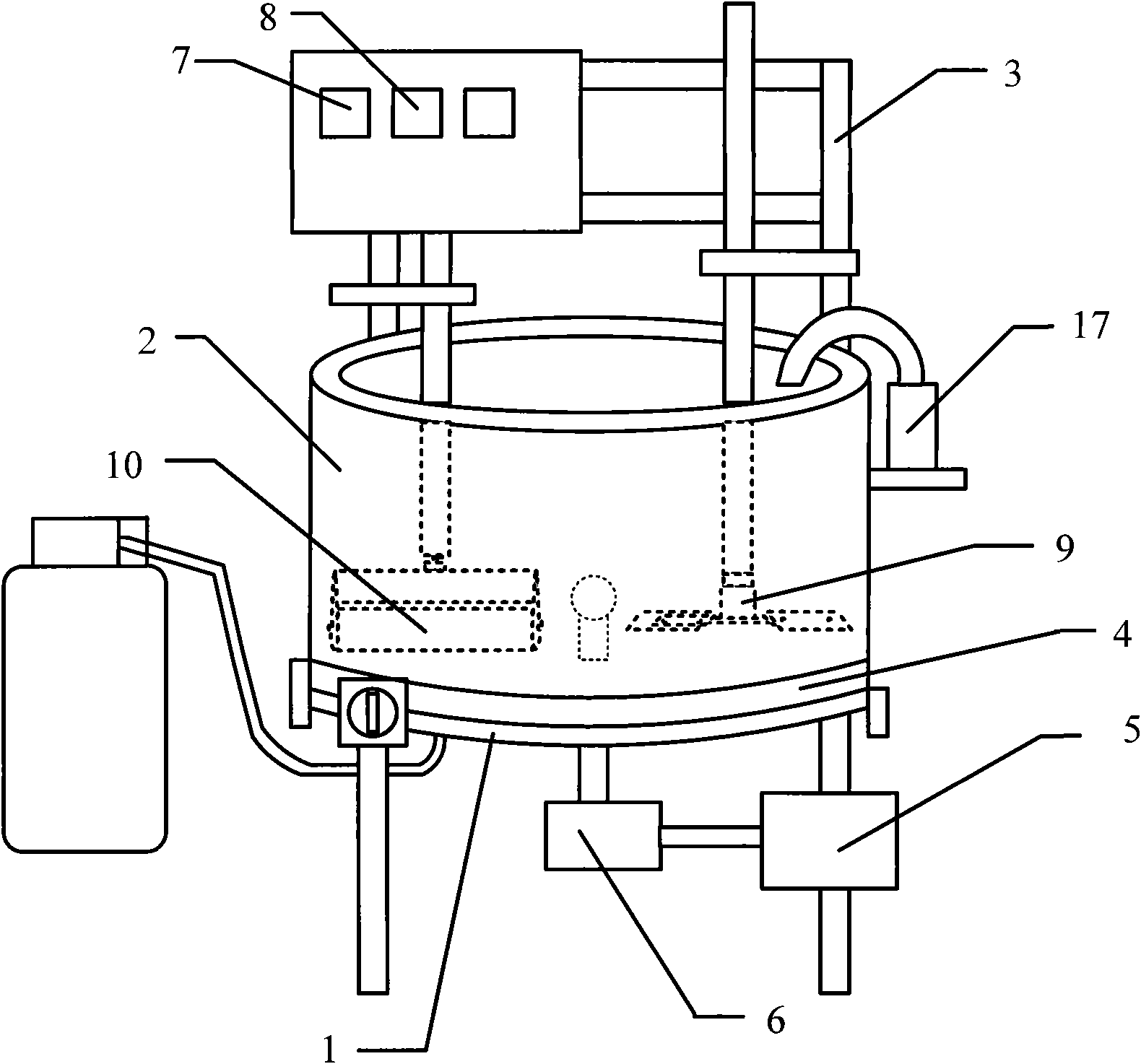

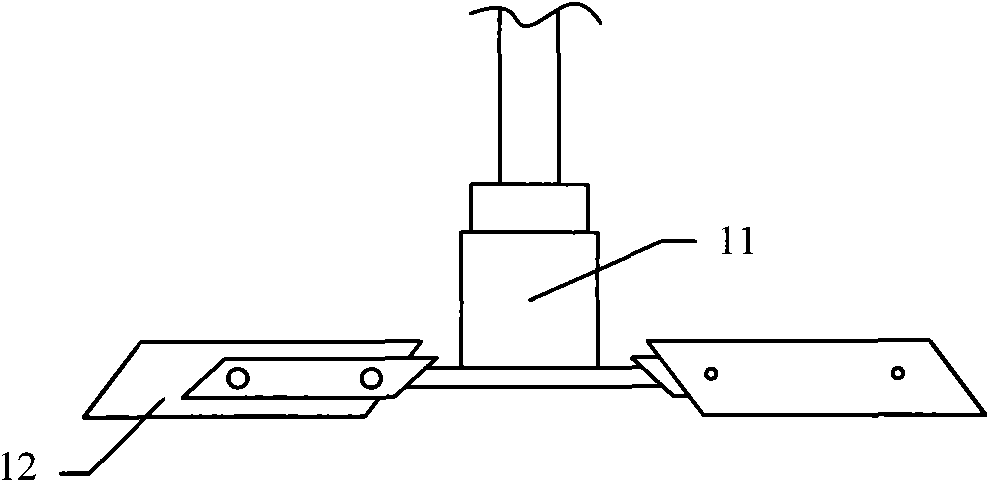

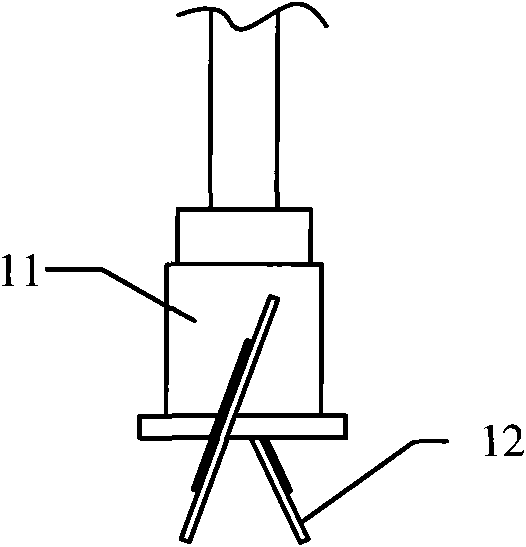

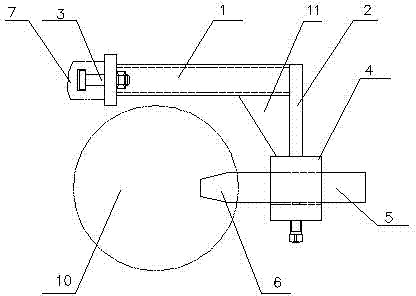

The invention relates to equipment for processing Biluochun tea, which comprises a tray, a tea frying pot, a bracket and a heating device. The tea frying pot is arranged inside the bracket; the heating device is connected between the tray and the tea frying pot; the equipment is characterized by also comprising a motor, a speed reducer, a rolling device and a comprehensive controlling device; the tea frying pot is placed on the tray; the heating device is connected between the tray and the tea frying pot; the tray is connected with the motor through the speed reducer; one end of the rolling device is connected with the bracket; the other end of the rolling device is put into the tea frying pot; the comprehensive controlling device is connected with the motor; and the rolling device comprises a rolling tea retainer and a rolling tea turner. After the equipment is adopted, the equipment can realize the automatic frying of the Biluochun tea, greatly reduce the difficulty of tea frying and is more convenient for developing large-scale production while saving manpower.

Owner:苏州创盛茶叶机械开发有限公司

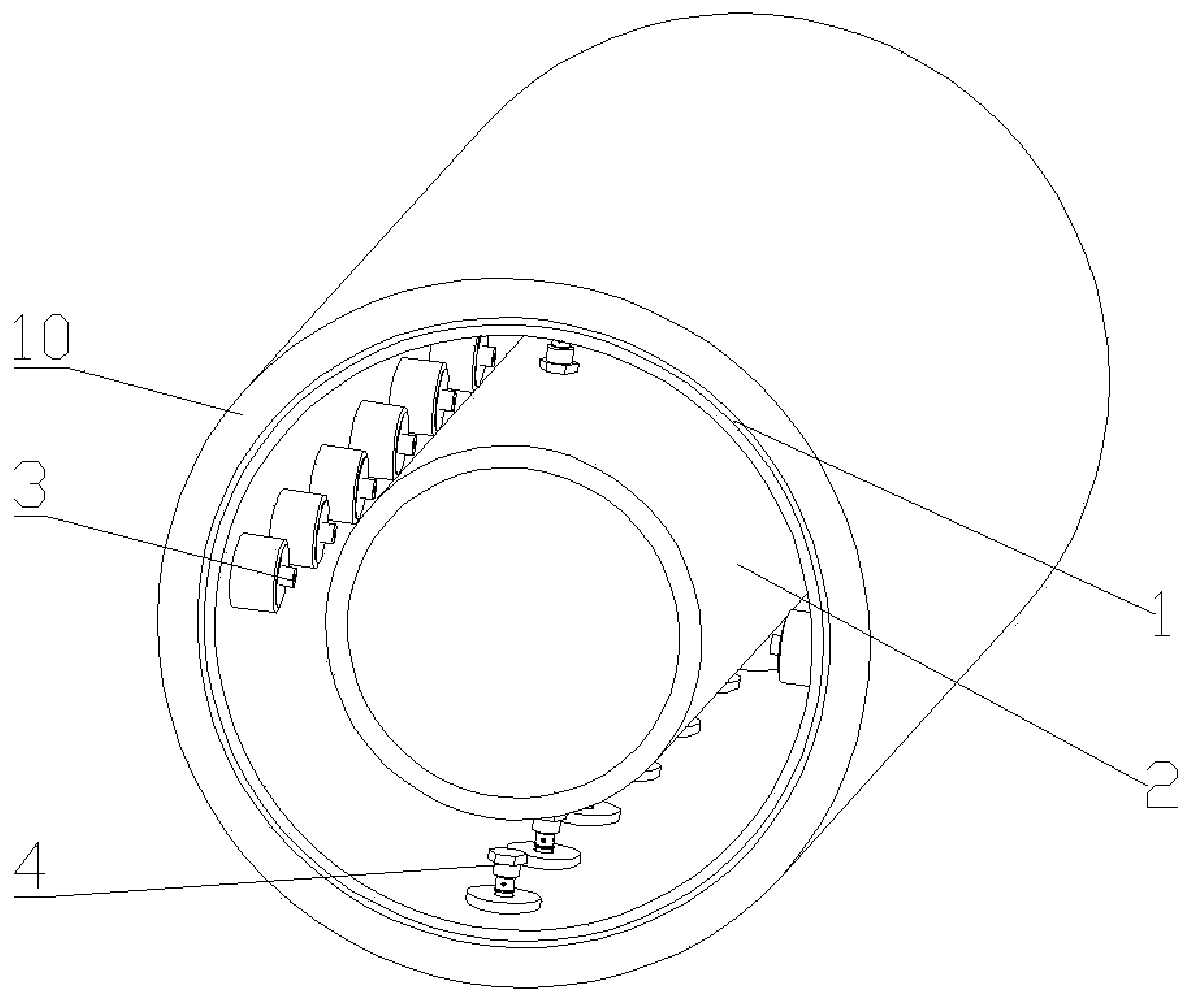

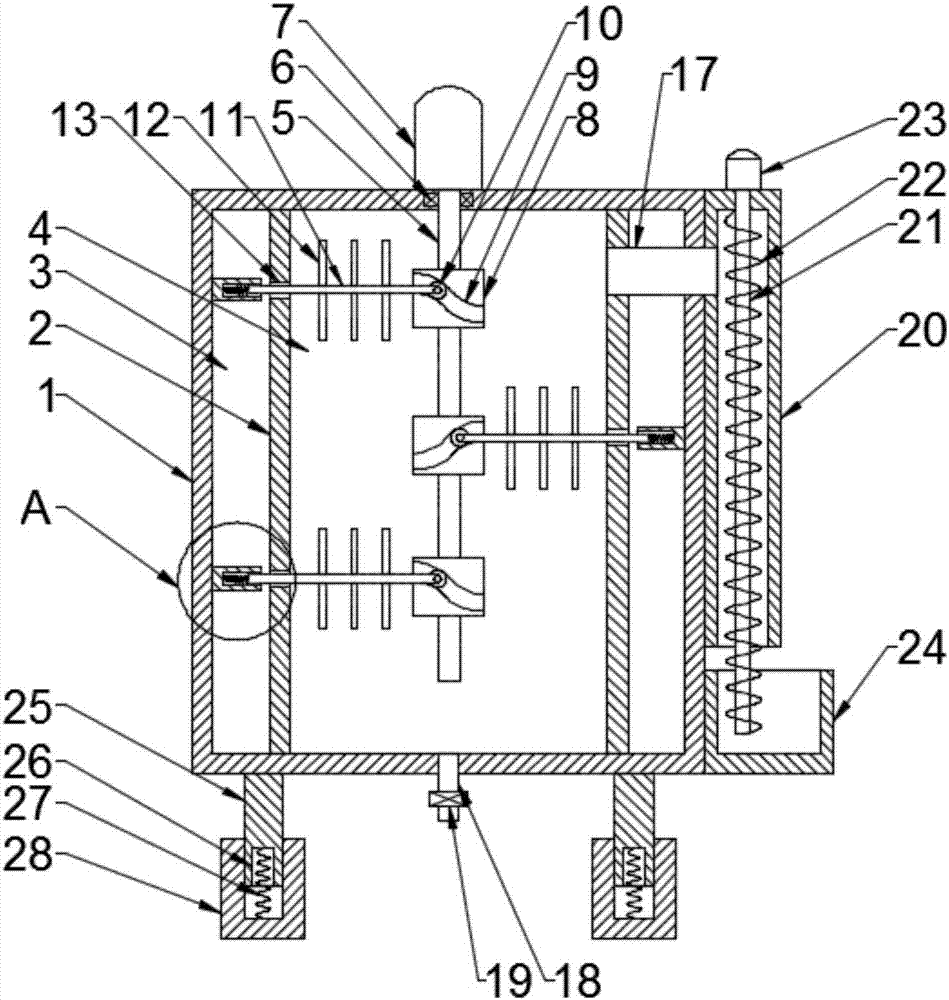

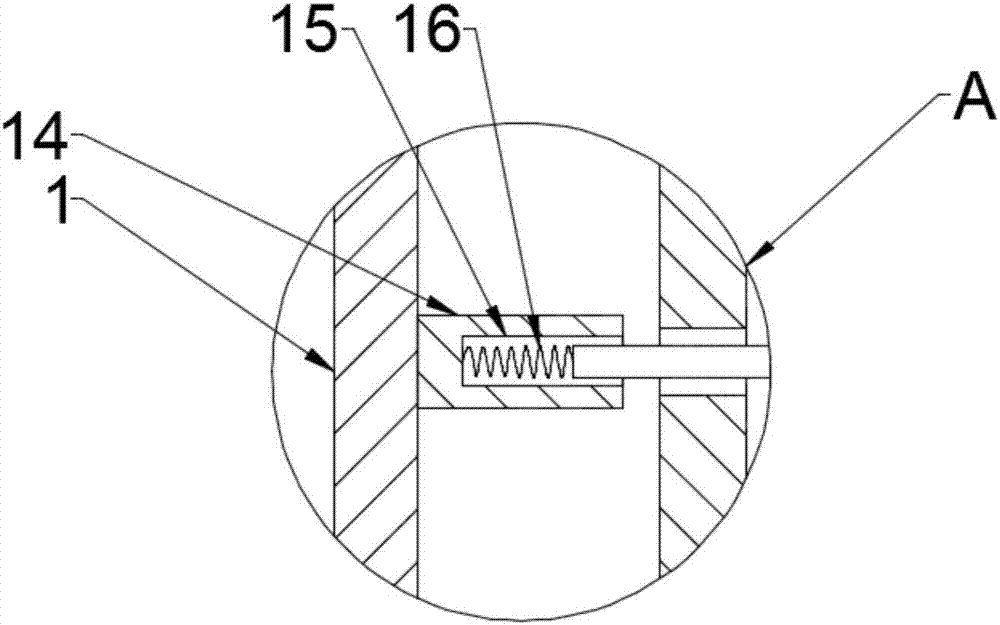

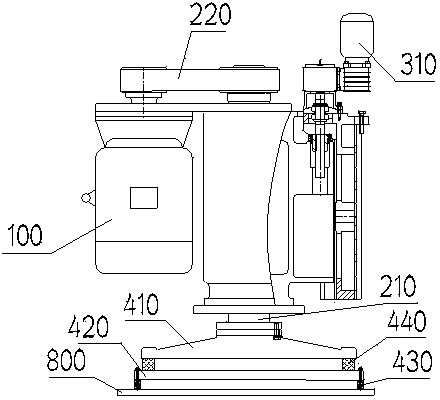

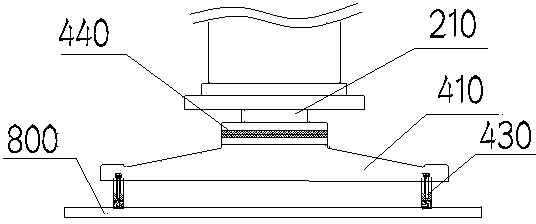

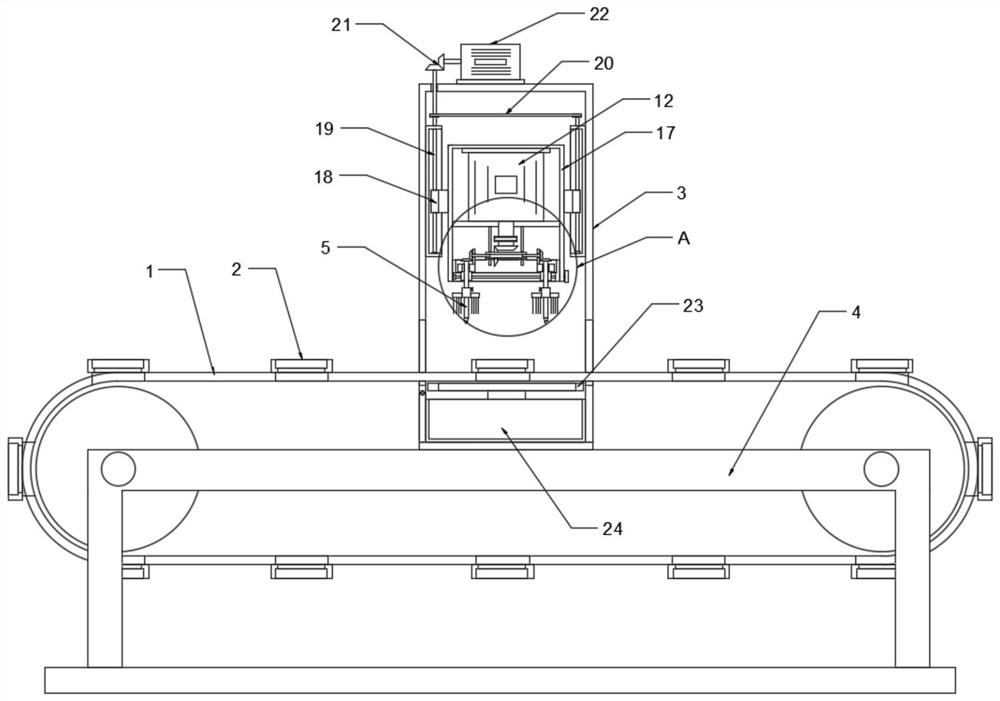

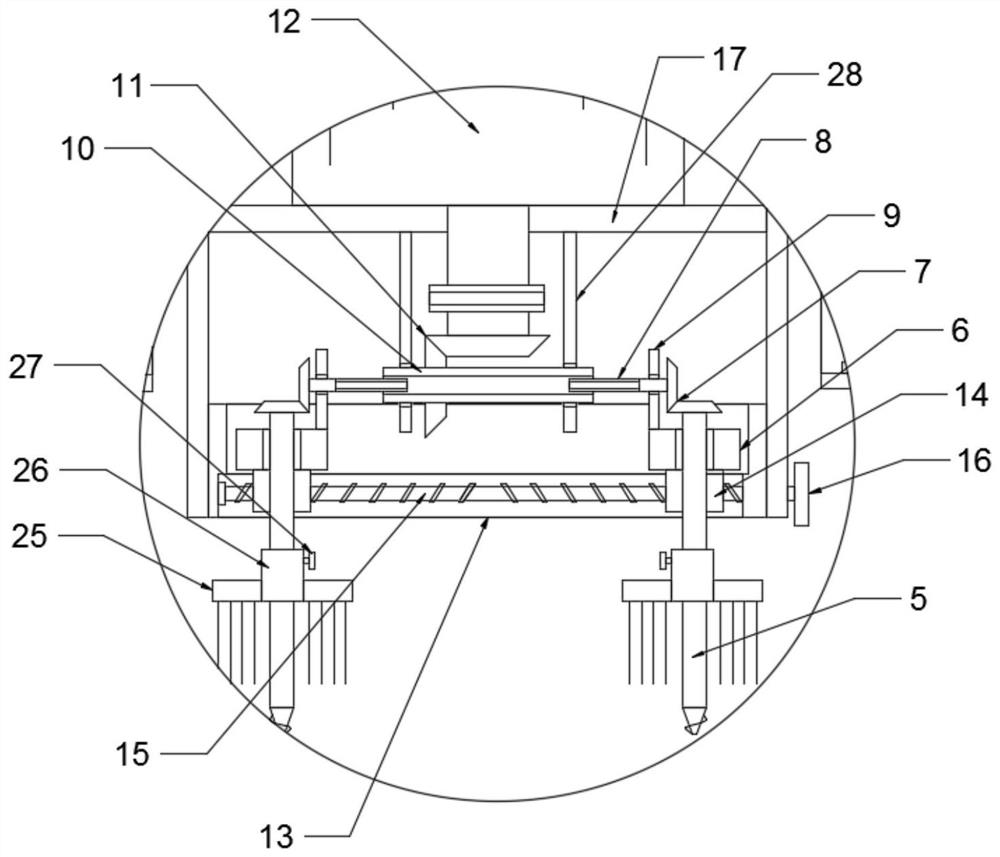

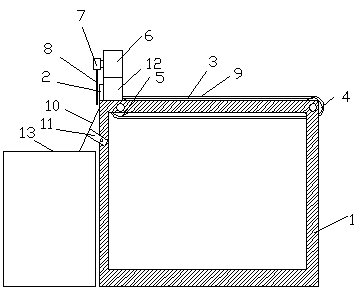

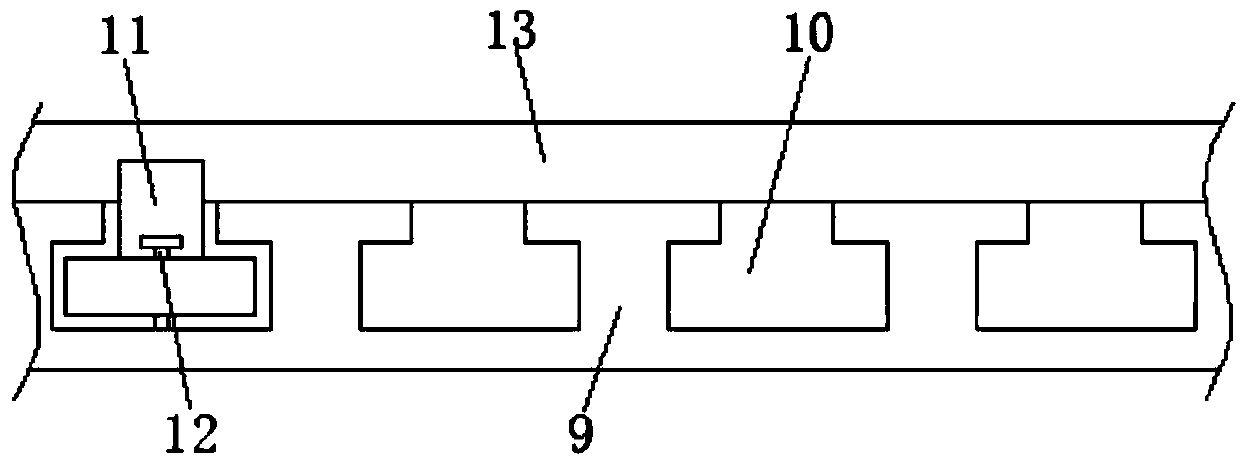

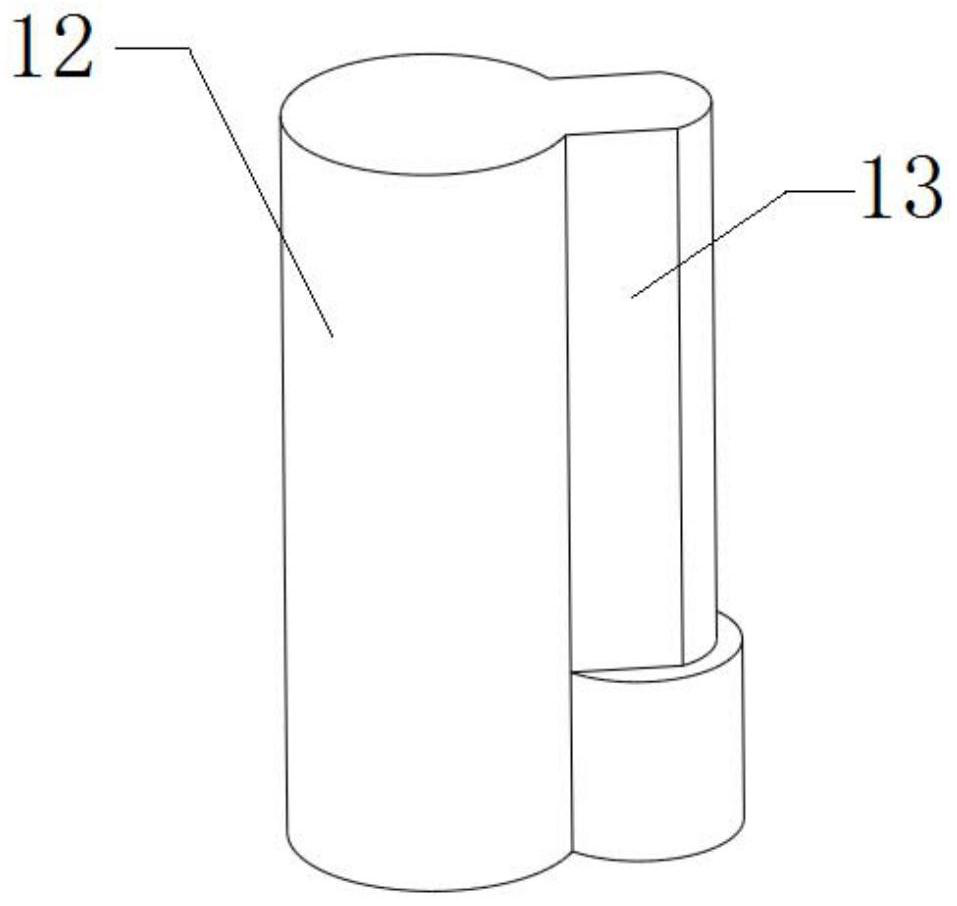

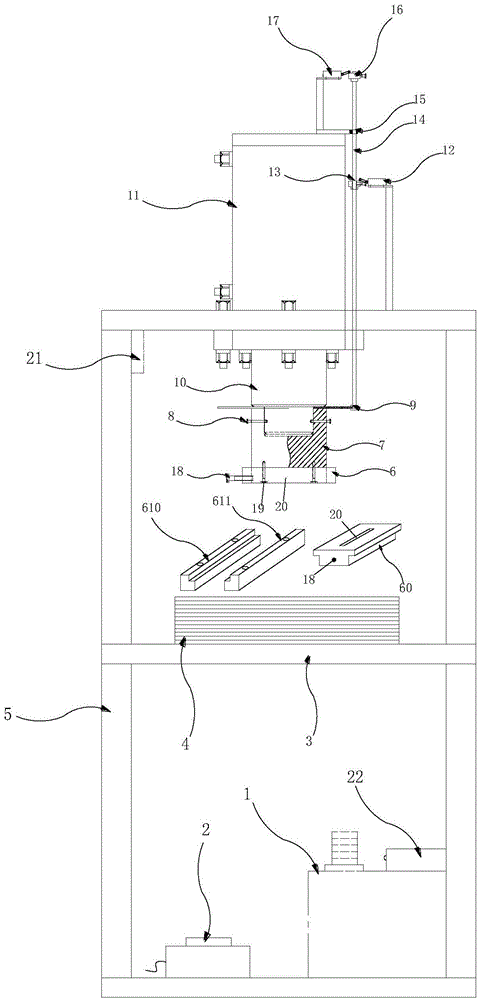

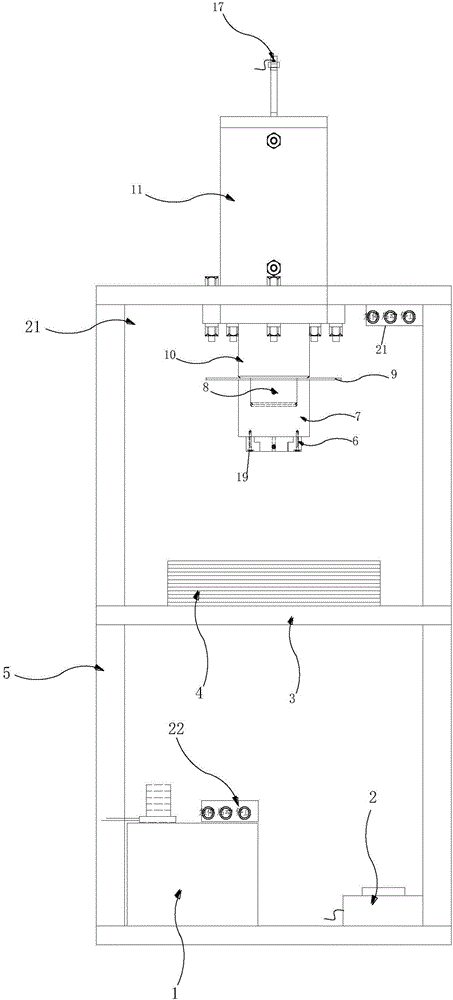

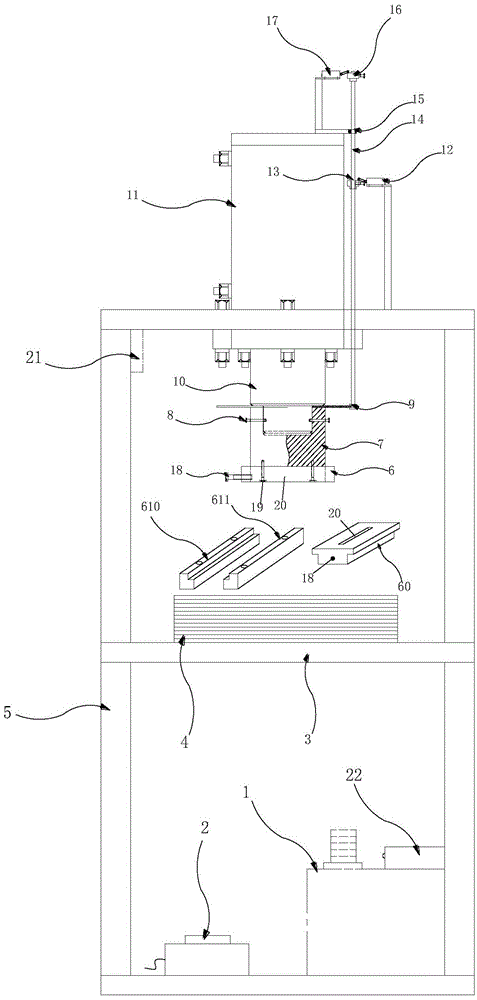

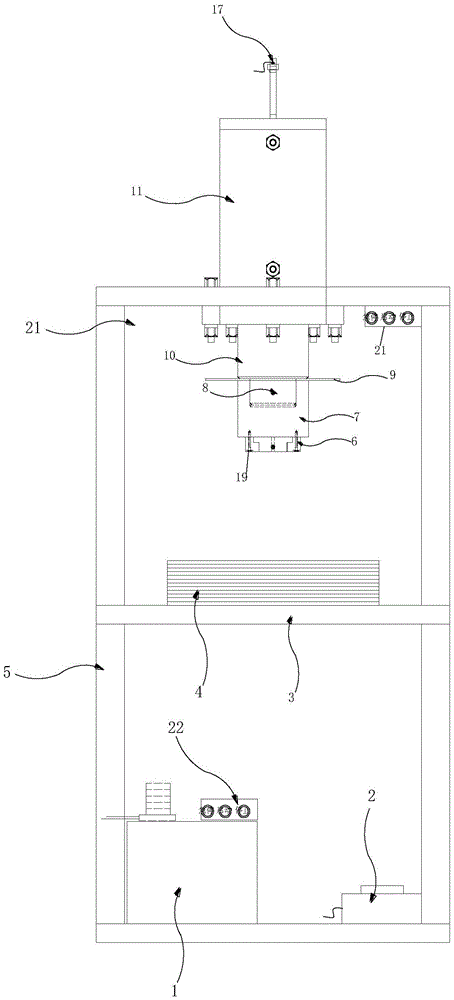

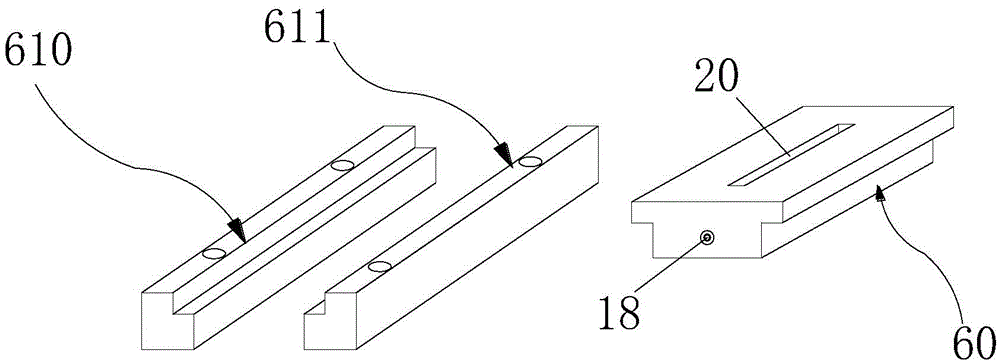

Auxiliary supporting device, system and method for thin-walled barrel piece machining

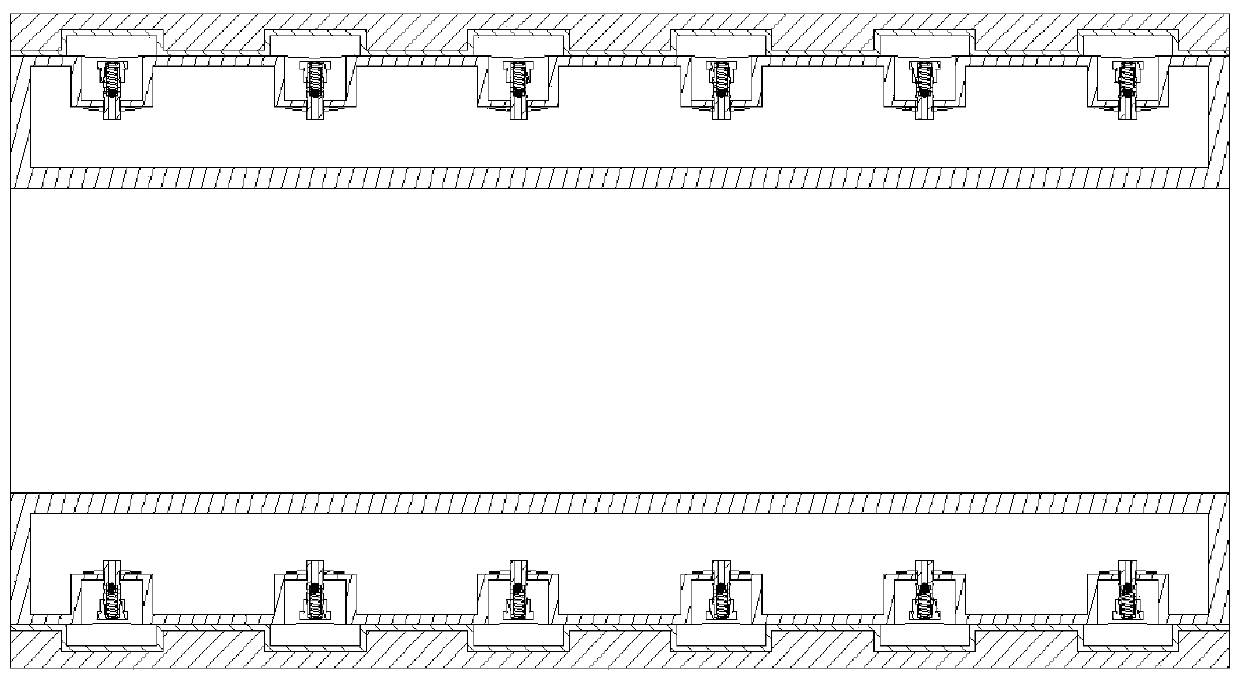

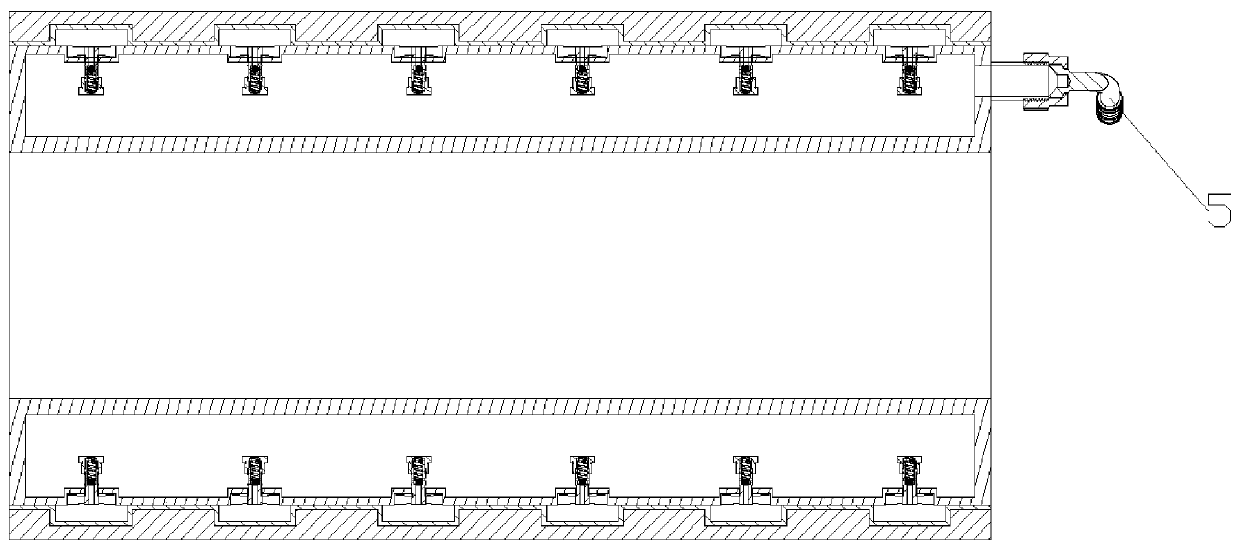

ActiveCN111230527APlay a supporting roleIncrease stiffnessWork clamping meansPositioning apparatusMachining deformationInlet valve

The invention discloses an auxiliary supporting device, system and method for thin-walled barrel piece machining. Machining deformation of a thin-walled barrel piece is reduced, vibration during machining is reduced, machining errors are decreased, and the machining precision is improved; and the problem that a common single-layer airbag is not suitable for supporting a thin-walled barrel piece ofwhich the surface is uneven is solved. The structure is simple, disassembling and assembling are convenient, and the auxiliary supporting device can be closely attached to the surface of the thin-walled barrel piece in a supporting mode. According to the technical scheme, an inner layer airbag and an outer layer airbag which are sleeved together are included, a plurality of air inlet valves and air outlet valves are installed between the inner layer airbag and the outer layer airbag, and under control of the air inlet valves, the inner layer airbag and the outer layer airbag expand in sequence so that the to-be-machined thin-walled barrel piece can be supported.

Owner:SHANDONG UNIV

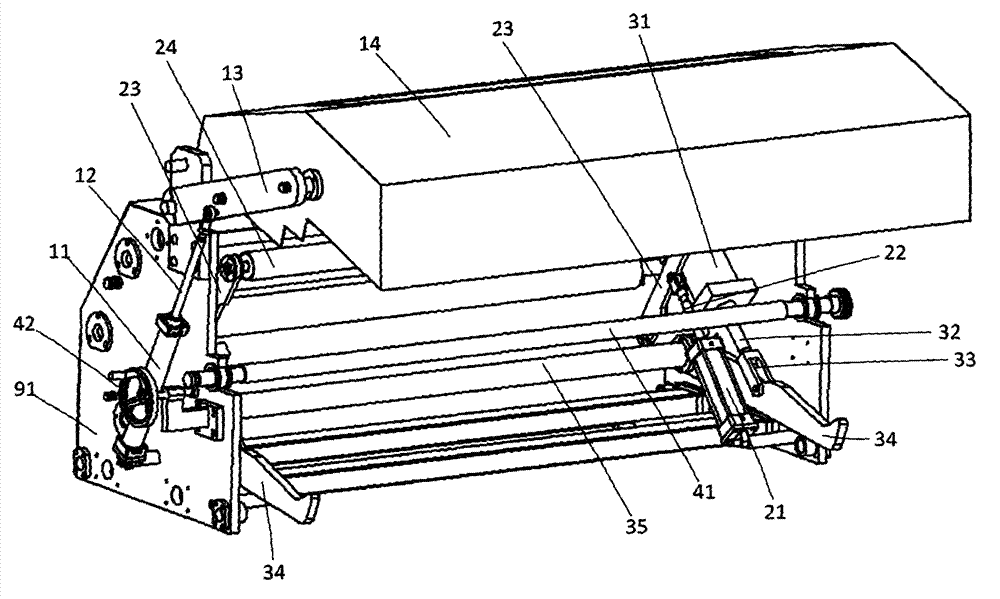

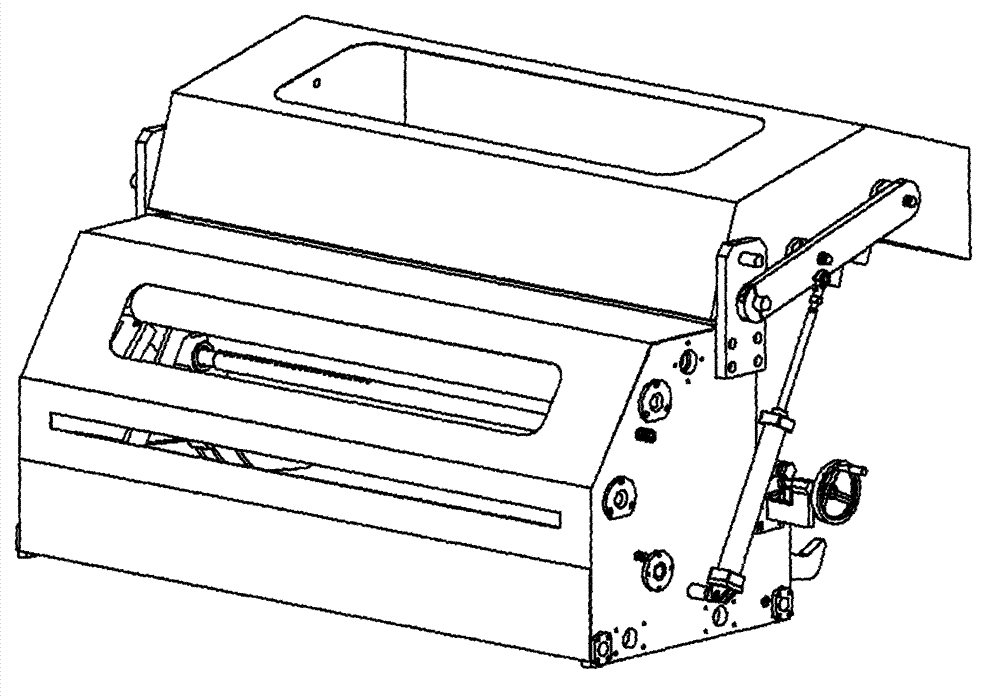

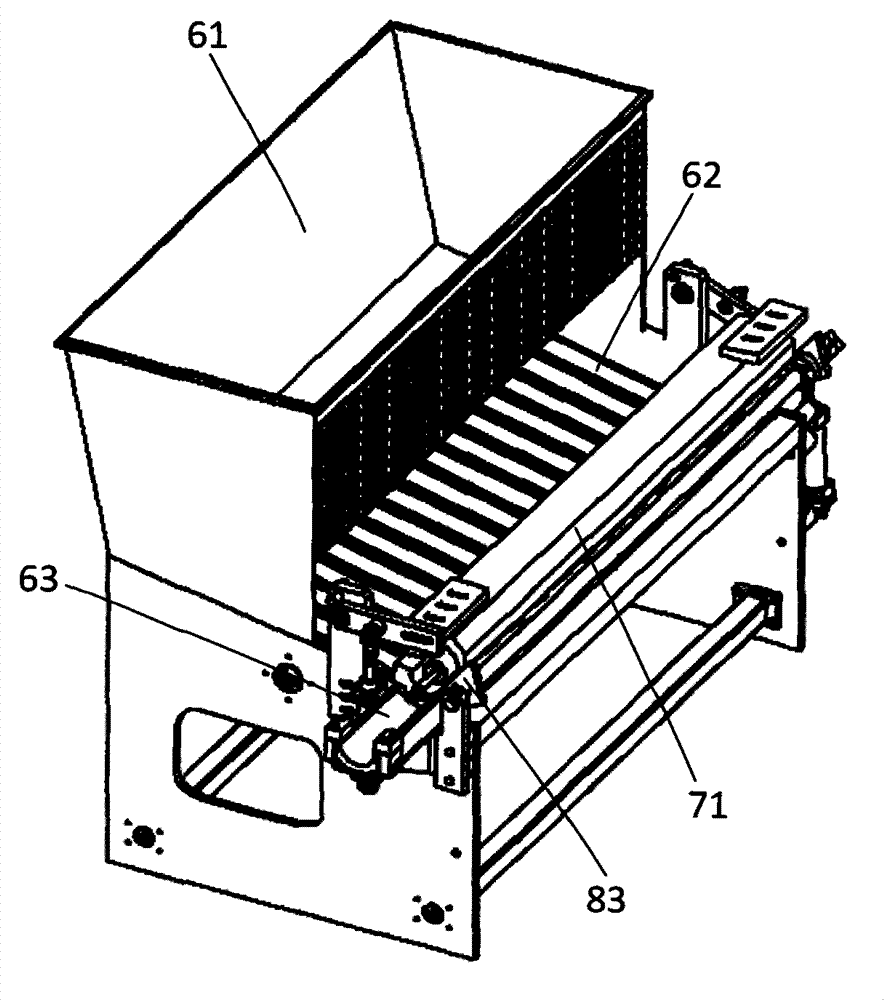

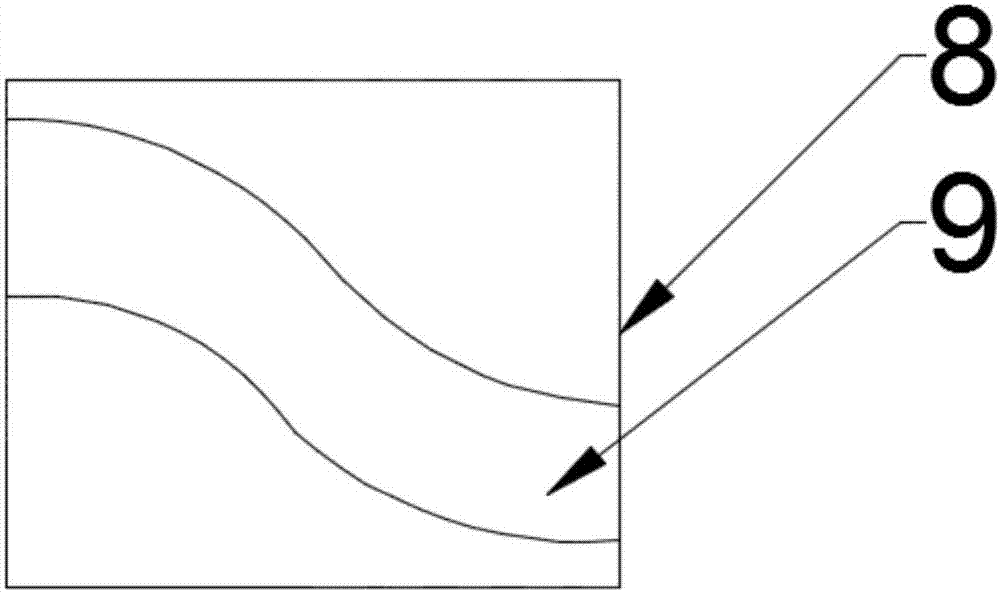

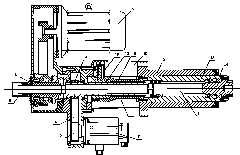

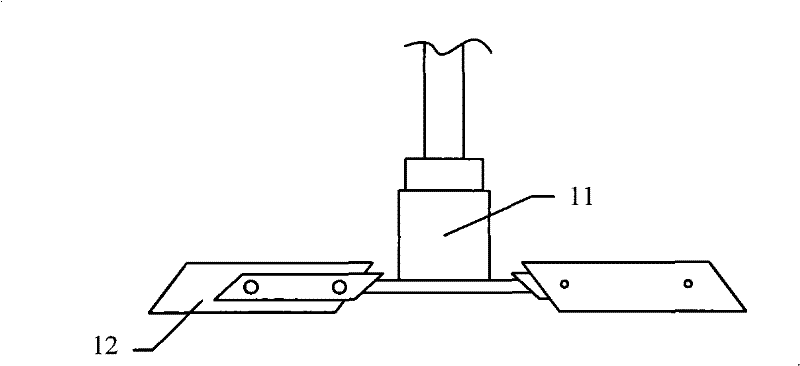

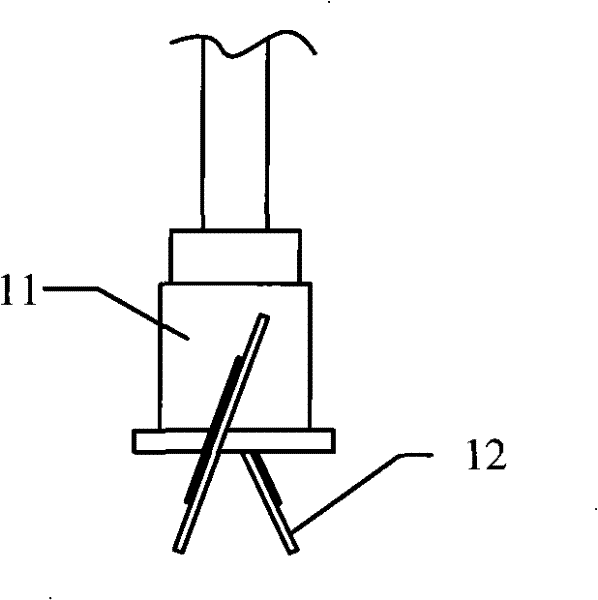

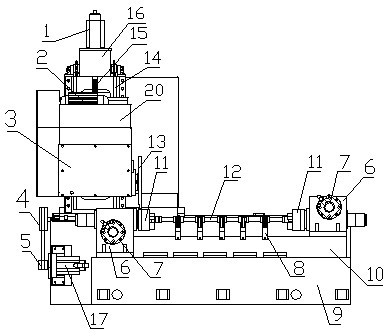

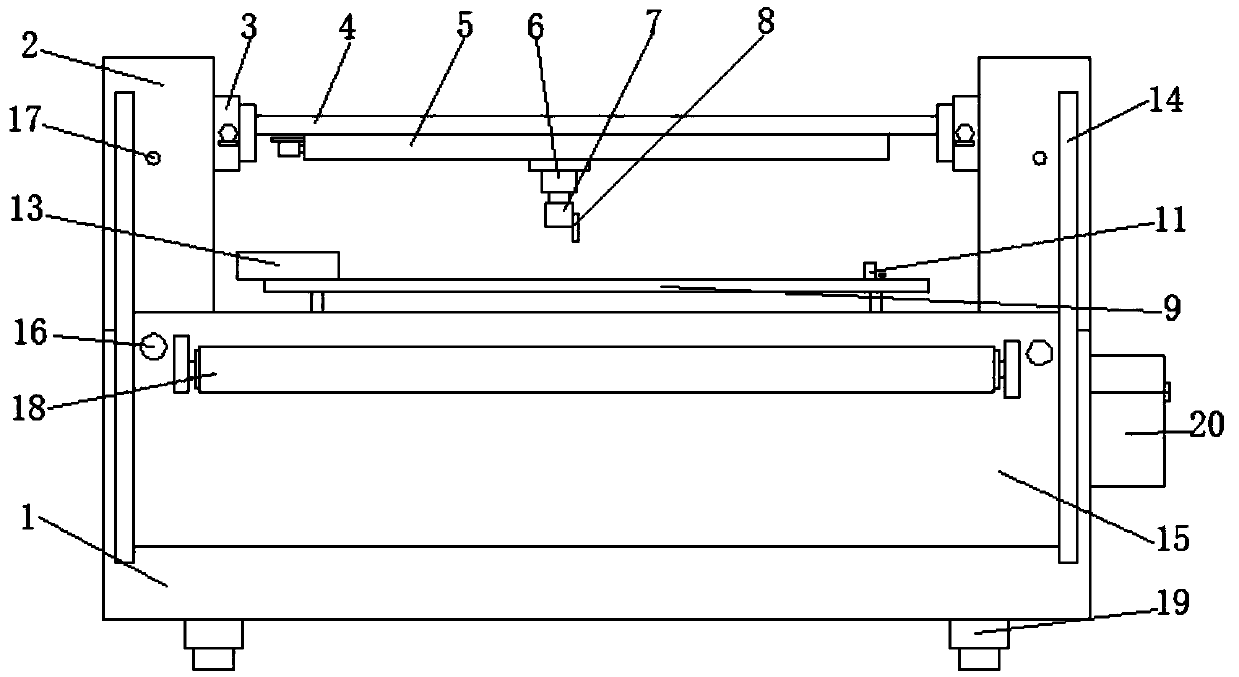

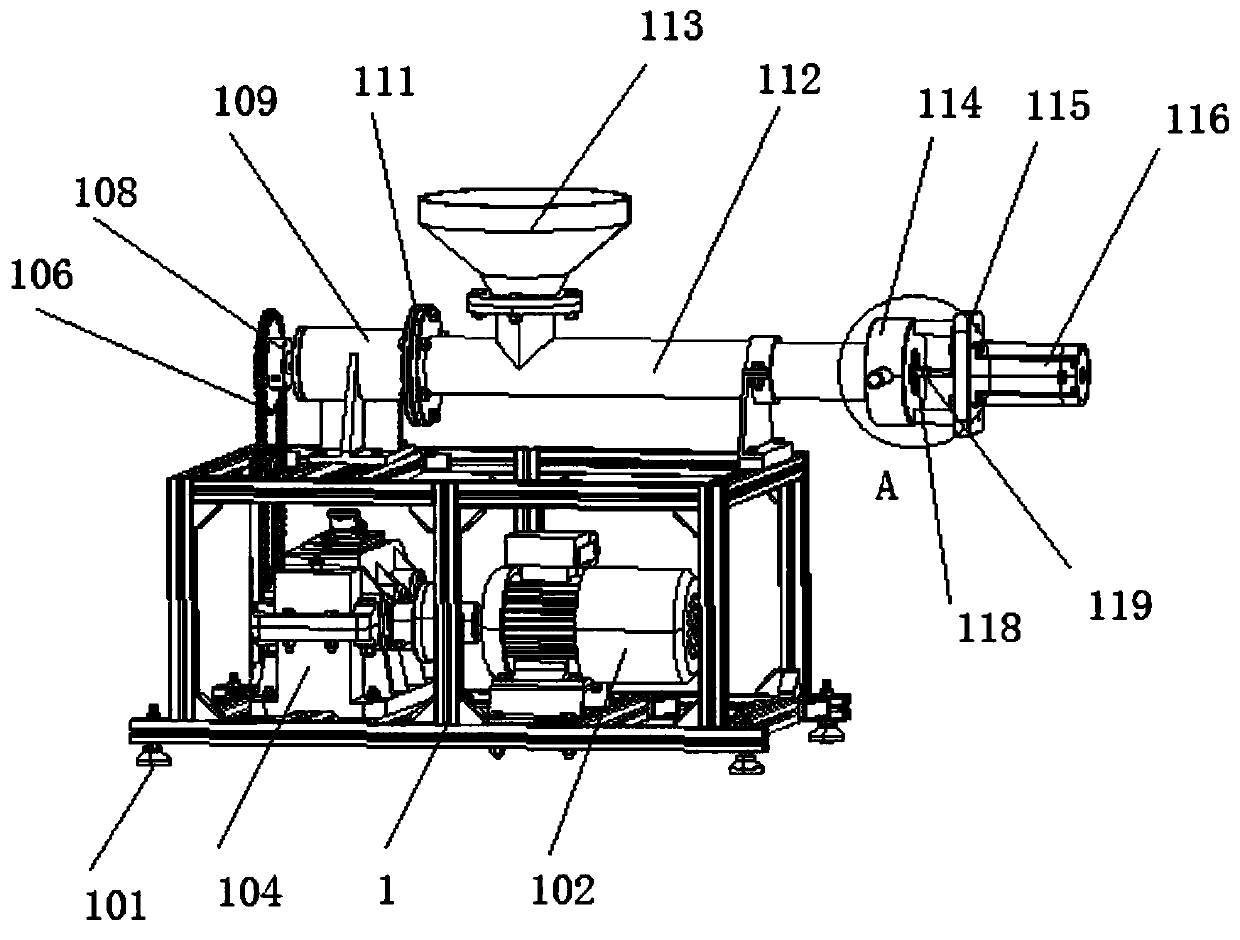

Slitting machine and feeding device thereof

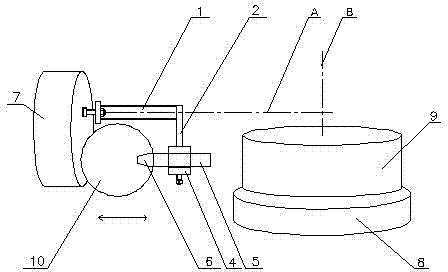

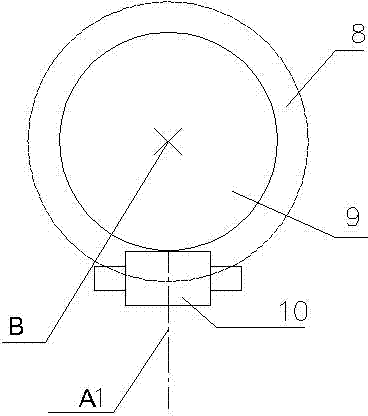

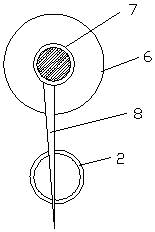

InactiveCN102862846ATo achieve the purpose of automatic feedingReduce processing noiseArticle deliveryWebs handlingMechanical engineeringPiston rod

The invention provides a feeding device of a slitting machine. The feeding device comprises a support plate arranged on two sides, a feeding shaft is arranged on a support plate upper frame, and an automatic feeding device is arranged below the feeding shaft. The automatic feeding device comprises a hook claw. One end of the hook claw is a free end, the other end of the hook claw is a fixed end hinged on a machine frame. The hook claw is hinged with a first connecting rod. One end of the first connecting rod is hinged with the hook claw, and the other end of the first connecting rod is connected with a first air cylinder. A first piston rod of the first air cylinder drives the first connecting rod to rotate, and the first connecting rod drives the hook claw to rotate. The feeding device can conduct feeding automatically or semi-automatically. When a whole roll of raw materials is arranged on the hook claw on the rear side of a reeling and unreeling mechanism of the slitting machine, the hook claw can rotate under the driving of the first air cylinder. The raw materials are sleeved on a feeding shaft, and a purpose of automatic feeding is achieved.

Owner:DONGGUAN XINDE MACHINERY TECH

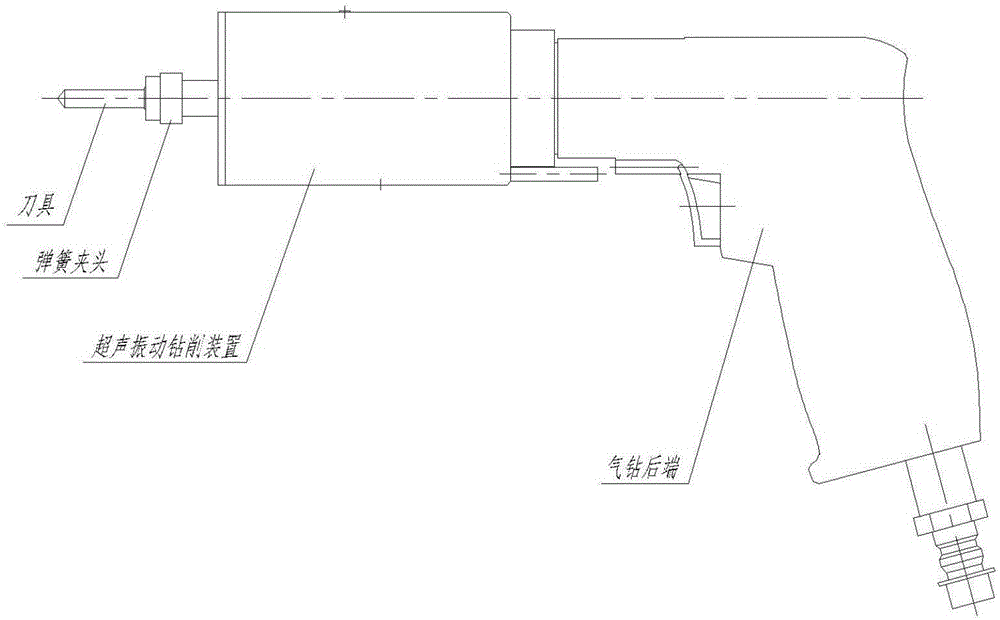

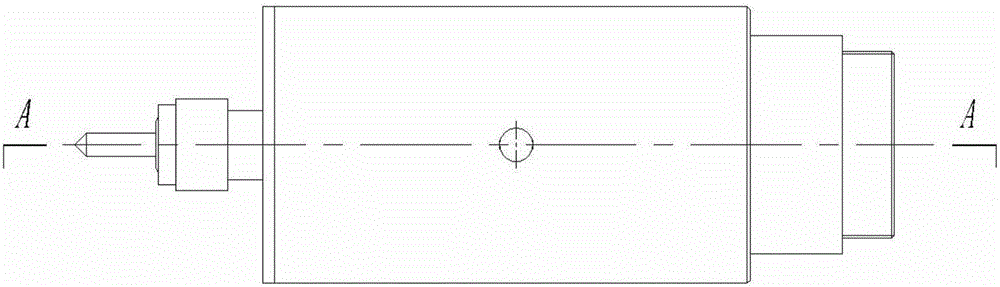

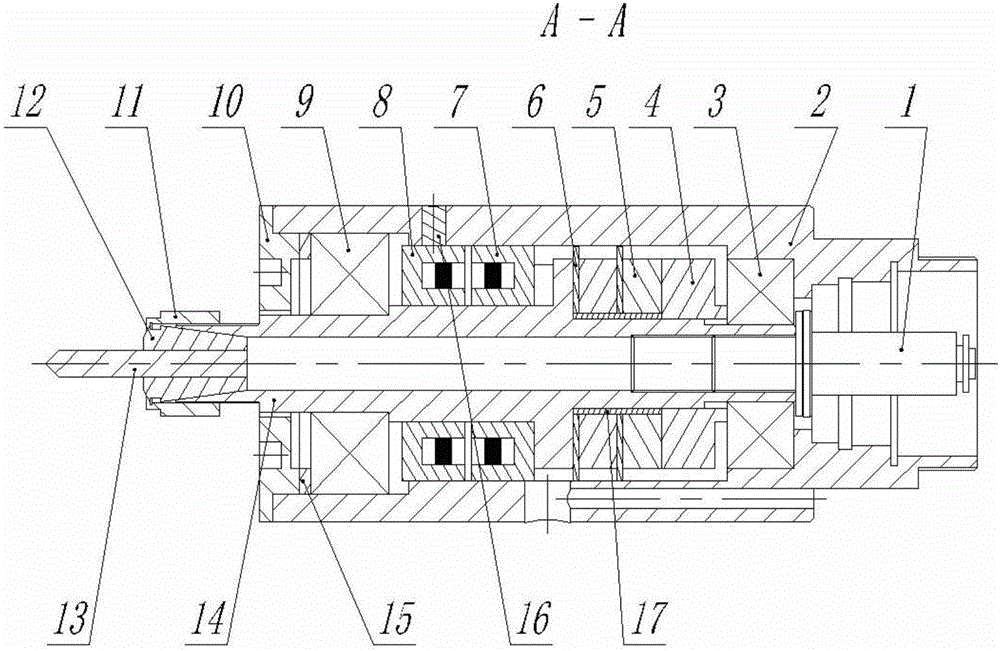

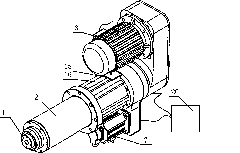

Ultrasonic vibration pneumatic drill based on rotary type wireless electric power transmission

InactiveCN106825679AKeep it workingImprove processing qualityCircuit arrangementsPortable drilling machinesElectric power transmissionSmall amplitude

The invention discloses an ultrasonic vibration pneumatic drill based on rotary type wireless electric power transmission. The ultrasonic vibration pneumatic drill comprises a rotary wireless electric power transmission assembly, an ultrasonic transduction assembly, an amplitude-change pole, a spring chuck assembly and a connecting assembly, wherein the rotary wireless electric power transmission assembly is used for realizing electric power transmission between two mechanisms rotating oppositely and comprises a wireless electric power transmission primary unit and a wireless electric power transmission secondary unit; the ultrasonic transduction assembly is used for converting ultrasonic-frequency electric signals into ultrasonic-frequency mechanical vibration; the ultrasonic vibration amplitude-change pole is used for amplifying small-amplitude mechanical vibration into large-amplitude mechanical vibration to meet requirements of ultrasonic vibration drilling machining; the spring chuck assembly is used for clamping tools; the connecting assembly is used for connecting ultrasonic vibration drilling parts with the rear end of the pneumatic drill so as to realize power transfer and electric power transmission. Ultrasonic vibration is applied to the traditional drilling machining process, and a combined machining mode of coupling of ultrasonic vibration and traditional drilling motion is formed, so that machining quality is effectively improved and machining efficiency is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Tool setting device and tool setting method for gear machining on large-sized press

InactiveCN103692030ASimple structureEasy to installAutomatic control devicesFeeding apparatusHobbingControl theory

The invention relates to a tool setting device and a tool setting method in machining. In order to overcome the defects generated by traditional gear machining, the invention provides the tool setting device used for gear machining on a large-sized press. The tool setting device is characterized by comprising a horizontal shaft and a vertical connecting yoke, wherein the left end of the horizontal shaft is provided with a stud fixed to a T-shaped groove in a facing head disk of a gear hobbing machine; the right end of the horizontal shaft is vertically welded to the vertical connecting yoke; the lower part of the connecting yoke is provided with a mounting sleeve with a mounting hole; a tool setting shaft parallel with the horizontal shaft is arranged in the mounting hole in the mounting sleeve; the end part of the tool setting shaft is provided with a tool setting head. The tool setting method comprises the following steps: fixing the left end of the horizontal shaft of the tool setting device and the T-shaped groove in the facing head disk of the gear hobbing machine, and adjusting the axial position of the gear hobbing machine to enable center cutter teeth or tooth sockets of the gear hobbing machine to be aligned with the tool setting head. According to the device and the method, the technical problems that tooth profiles of the left tooth surface and the right tooth surface of a to-be-processed gear on the large-sized press are asymmetric, and the precision of the tooth surfaces are hard to guarantee are fundamentally solved.

Owner:RONGCHENG METAL FORMING MACHINE GROUP

Concrete stirring device for construction site

InactiveCN107310032AImprove stirring efficiencyGuaranteed stirringMixing operation control apparatusCement mixing apparatusArchitectural engineeringMotor shaft

The invention discloses a concrete stirring device for a construction site, which comprises a case. The inner cavity of the case is symmetrically provided with baffles left and right, a plurality of through holes are arranged in the baffles, the baffles divide the inner cavity of the case into a stirring cavity and two clamping cavities, the inner wall on one side of each clamping cavity is provided with a plurality of pushing covers corresponding to the through holes, pushing holes are arranged in the pushing covers, a main stirring rod is arranged in the stirring cavity, the top end of the main stirring rod penetrates through the case and is fixedly connected to the motor shaft of a main motor, the main stirring rod is uniformly provided with a plurality of rollers, track grooves are arranged in the rollers, idler wheels are arranged in the track grooves, the idler wheels are fixedly connected to secondary stirring rods, the secondary stirring rods are uniformly provided with a plurality of stirring blades, and the bottom end of the case is uniformly provided with a plurality of support legs. The main motor of the concrete stirring device drives the main stirring rod to rotate and further drives the rollers to rotate, the rollers drive the secondary stirring rods to move and stir, such that the stirring blades stir materials irregularly, the stirring efficiency of the materials is improved, and sand, stones, and the like are enabled to be totally stirred.

Owner:童贤波

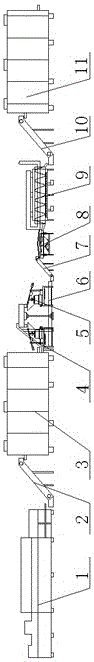

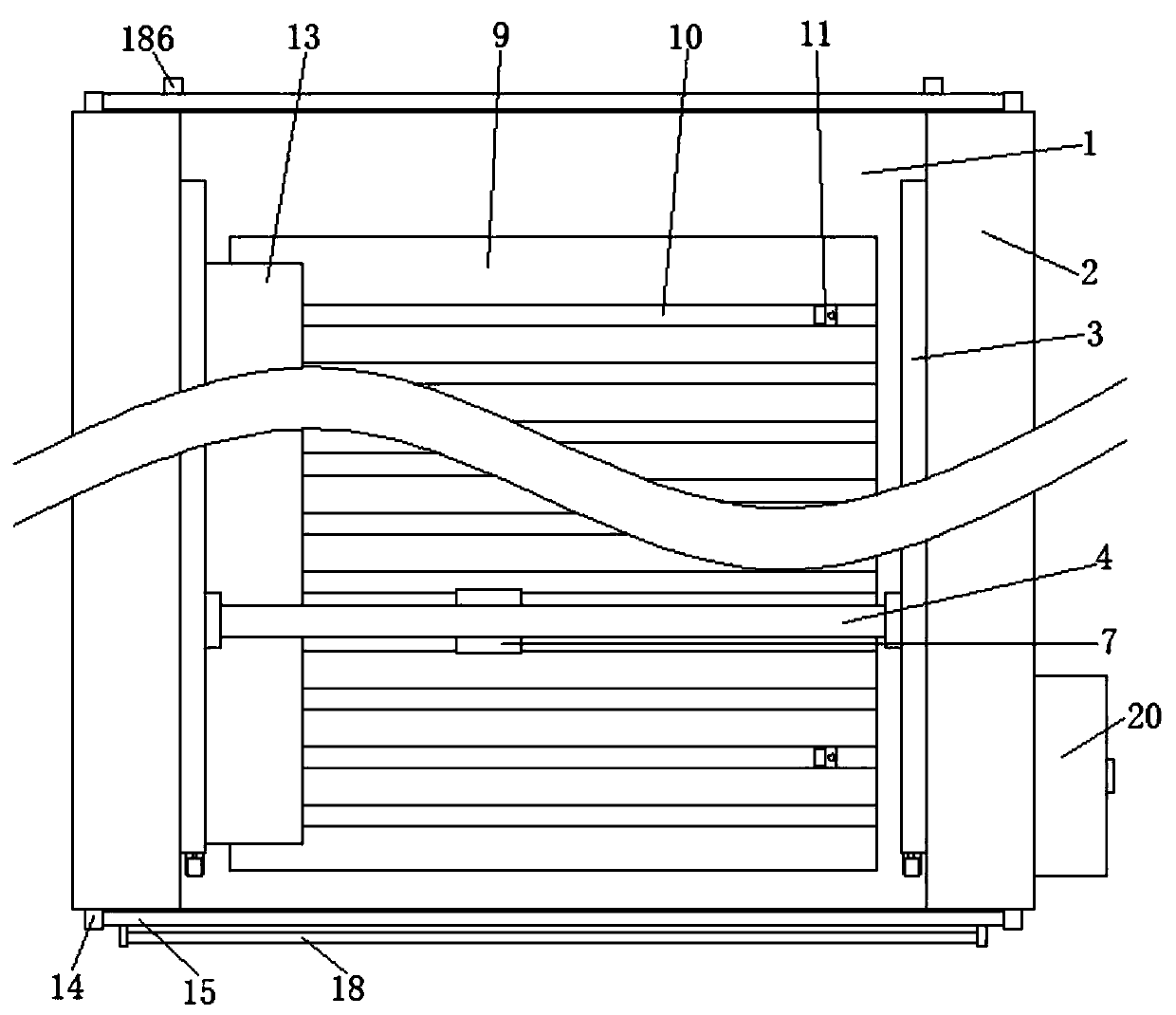

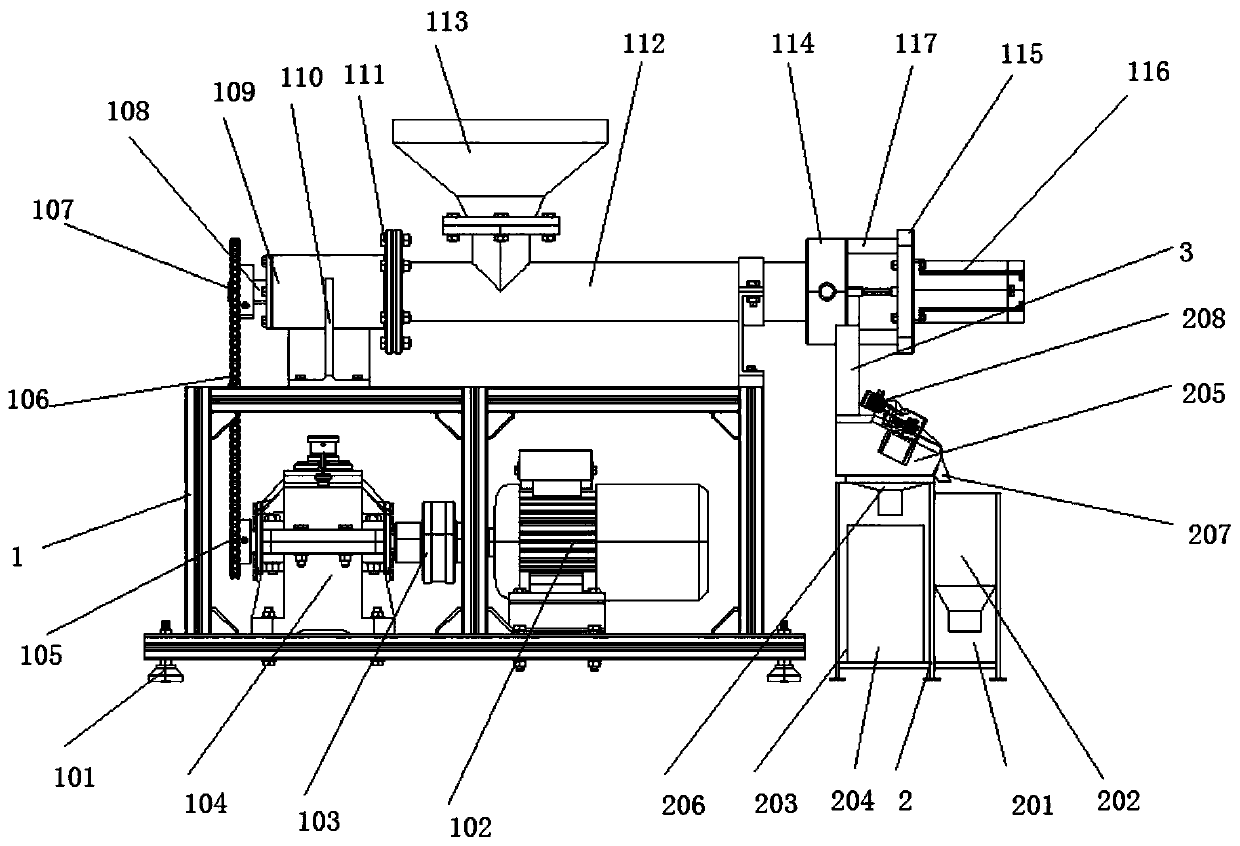

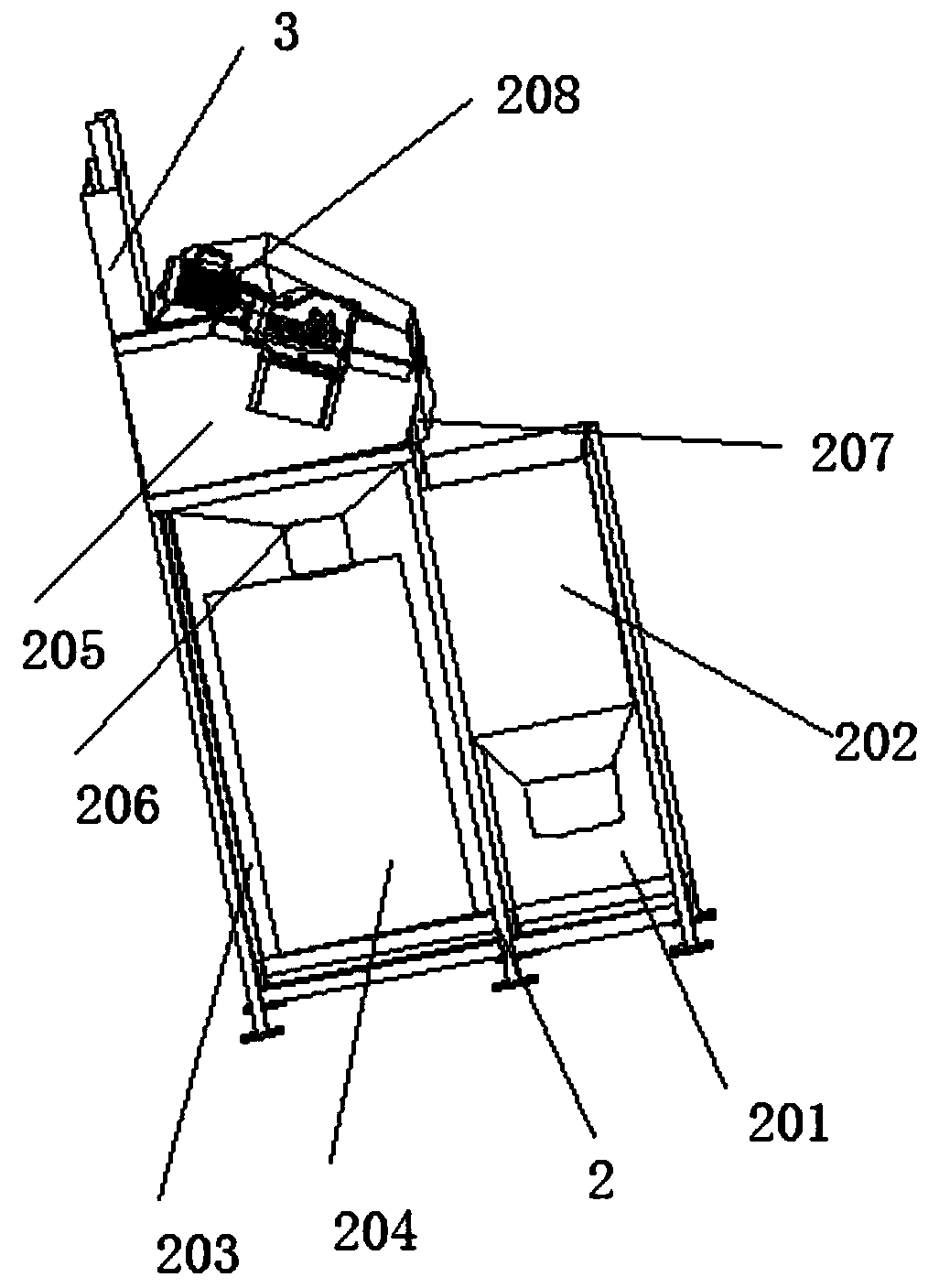

Automatic production line for green tea

ActiveCN105053294AAvoid residueIncreased kneading speedPre-extraction tea treatmentProduction linePulp and paper industry

The invention discloses an automatic production line for a green tea. The automatic production line comprises a fixation machine, wherein a fixation machine is connected with a baking machine through a first hoisting machine, and the baking machine is connected with a rolling machine set through a second hoisting machine; a conveying trough is formed under the rolling machine set, and is connected with a vibration conveyor through a third hoisting machine; the vibration conveyor is connected with a multi-functional machine, and the multi-functional machine is connected with a drying machine through a fourth hoisting machine. The automatic production line for the green tea, disclosed by the invention, has the advantages that tea leaves do not have residues when being rolled, the tea leaves cannot splash out, the processing noise is small, and the rolling efficiency is high; when the rolled tea leaves are deblocked, the tea leaves are not broken, and the shapes of the tea leaves are good; the multi-functional machine in the production line also has the advantages that the multi-functional machine can realize multiple functions, reduces the production equipment of the production line, and reduces the mounting cost of the production line.

Owner:黔南州梅渊商贸有限公司

Energy-gathered tile surface polishing machine

InactiveCN104002388AOvercoming profiling defectsDecrease stockStone-like material working toolsDiamond knifeEngineering

Owner:袁子科

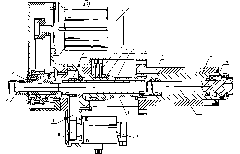

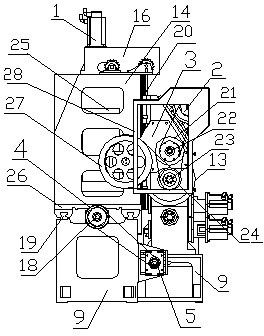

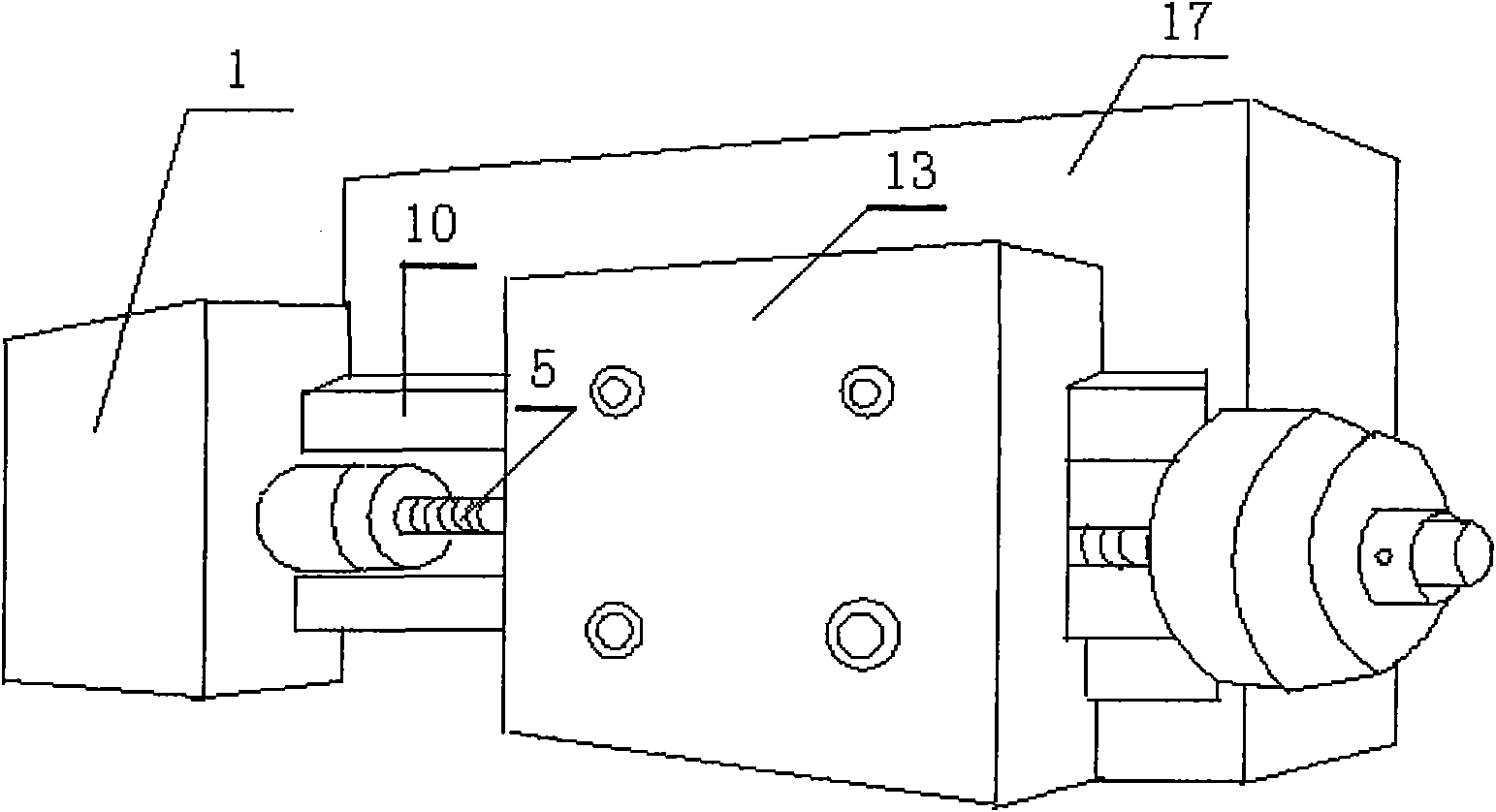

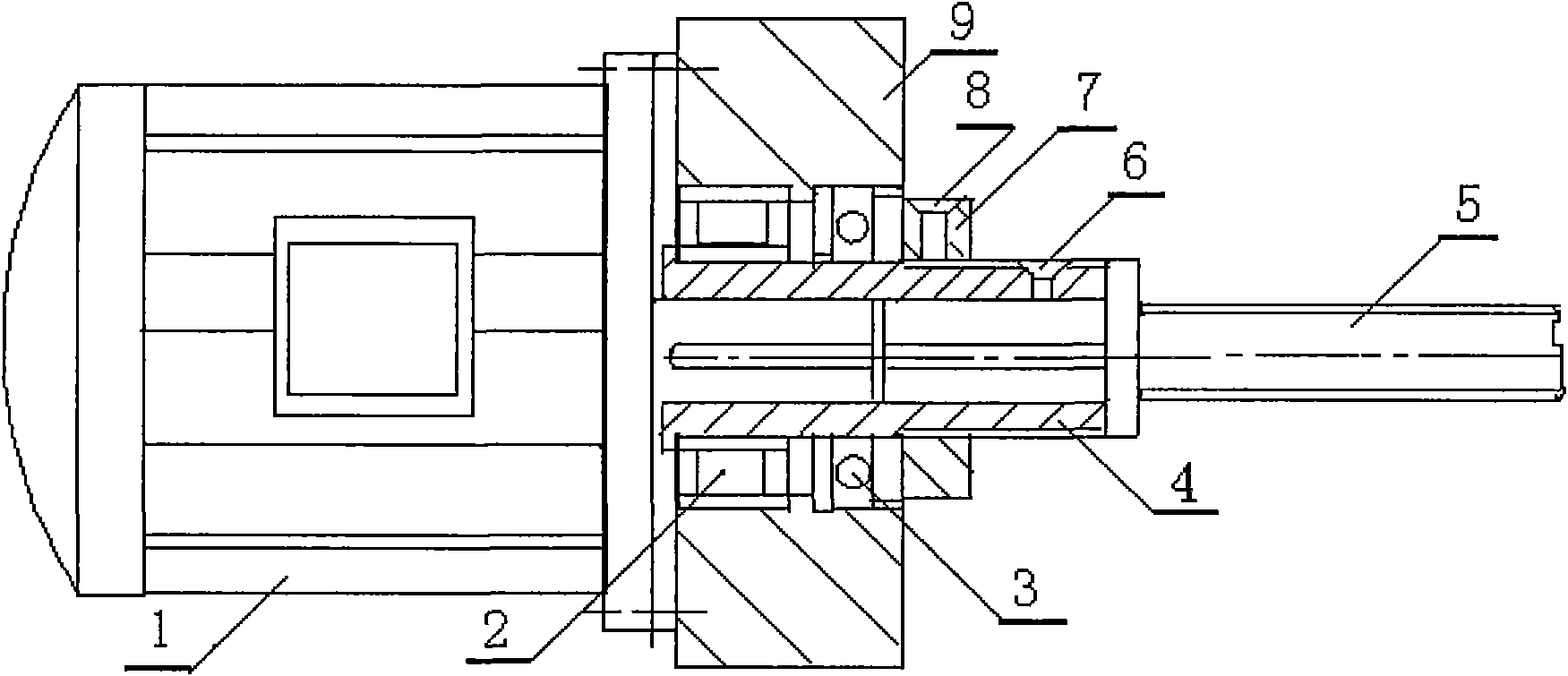

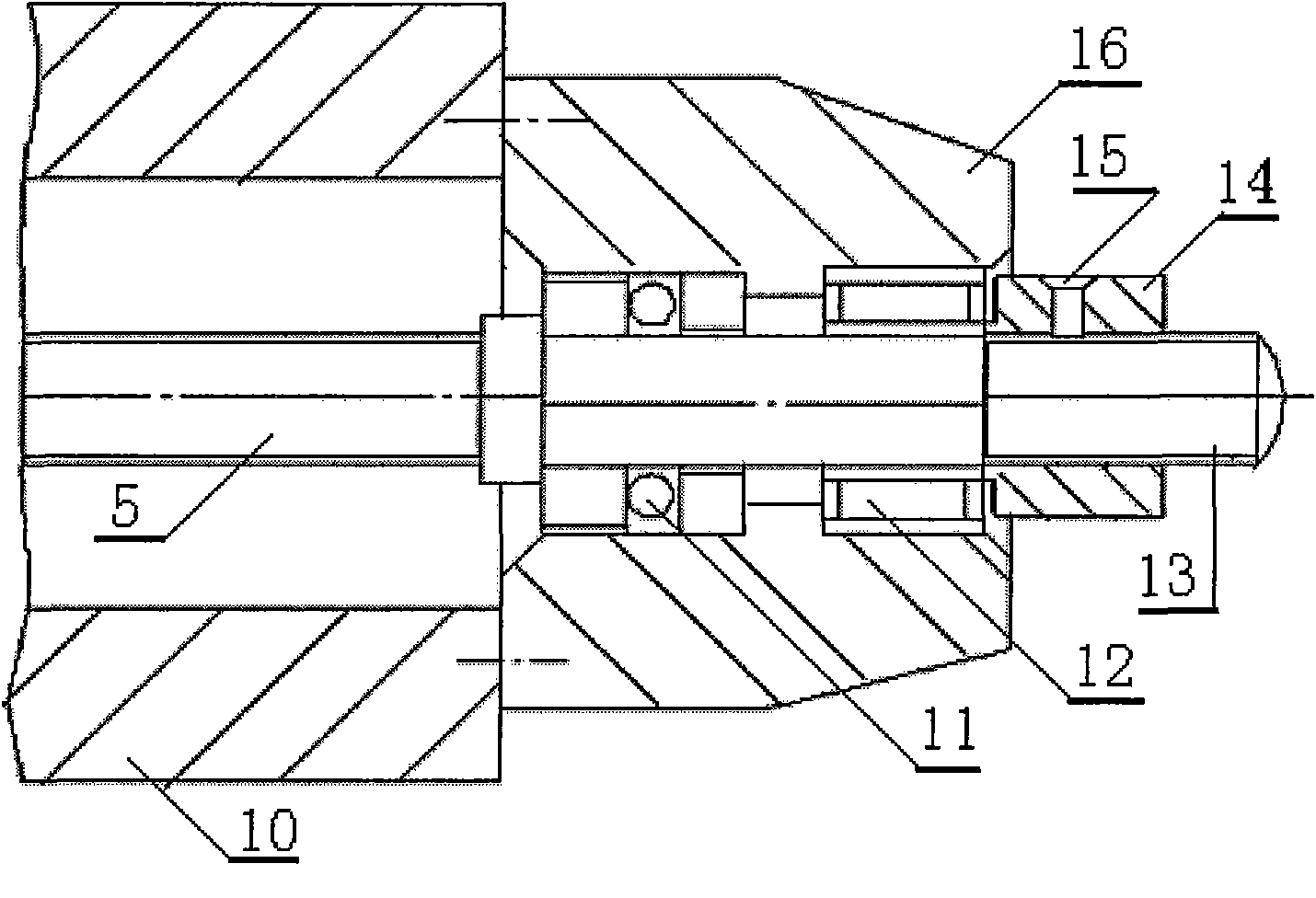

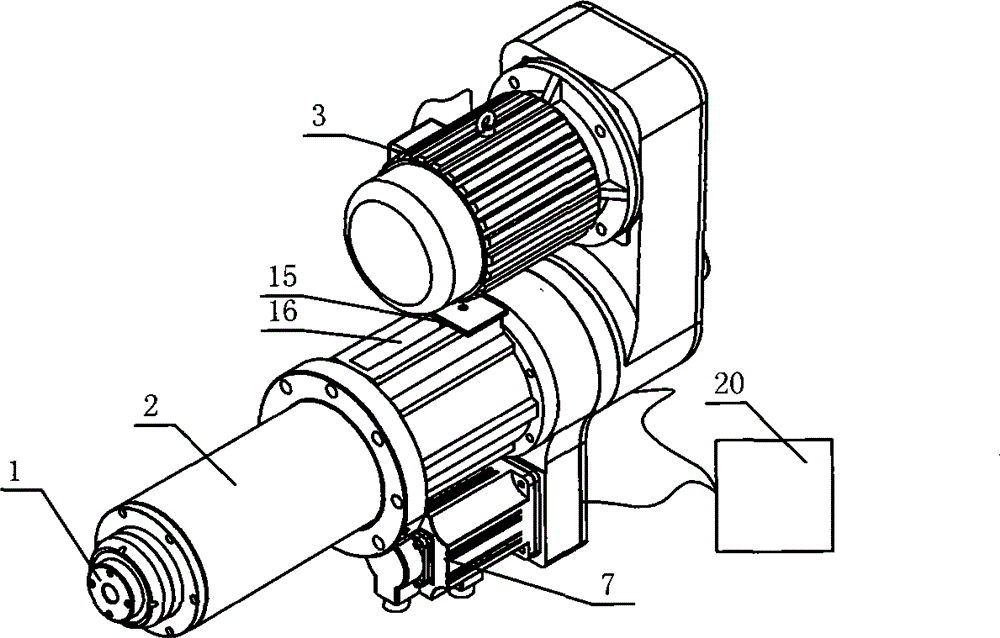

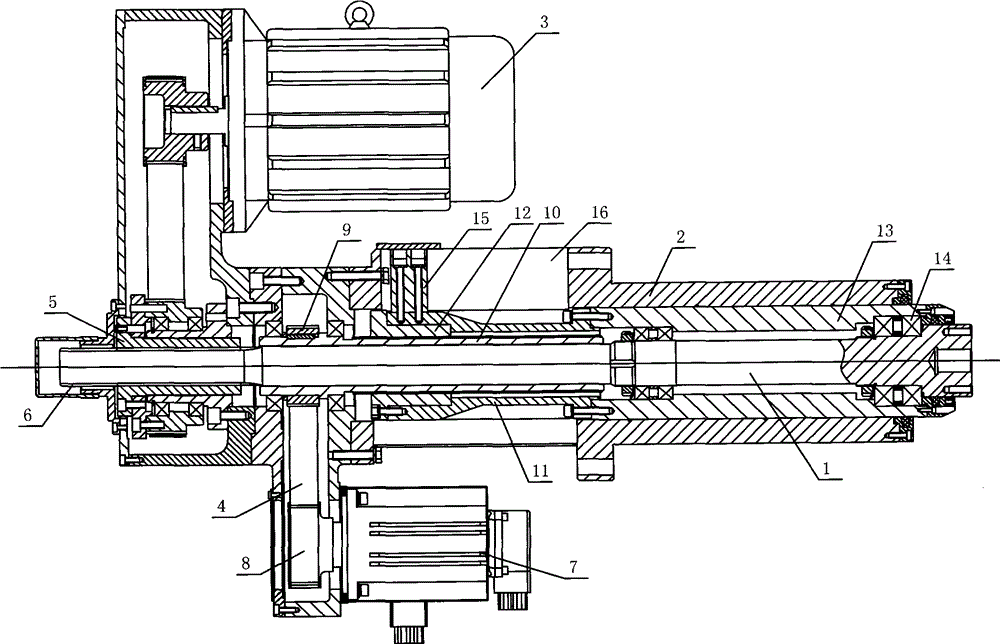

Power head for digital control hole drilling

InactiveCN101797692AImprove machining accuracyImprove processing accuracyOther manufacturing equipments/toolsElectric machineryMotor control

The invention discloses a power head for digital control hole drilling, which comprises a shell, a main shaft arranged on the shell, a main shaft drive system connected with the main shaft, a power tooth drive system and a digital controller, wherein the power tooth drive system is connected to the main shaft; the main shaft is connected with the main shaft drive system through an axial flexible connection mechanism; and the digital controller is connected with the main shaft drive system and the power tooth drive system through conducting wires respectively. The power head makes the main shaft realize axial feeding in the process of rotating by using the power tooth drive system to avoid abuses caused by the manual feeding or the feeding depending on a leading screw in the past. The overall structure of the power head is simple to operate and is convenient to mount and dismount, the processing noise is low, the replacement and the debugging are easy, and a servo motor controlled by the digital controller improves the processing precision and the processing accuracy; besides, the power head has a wide application range, and provides a good start for later total digitalization and automation.

Owner:南安市瑜鼎投资管理有限公司

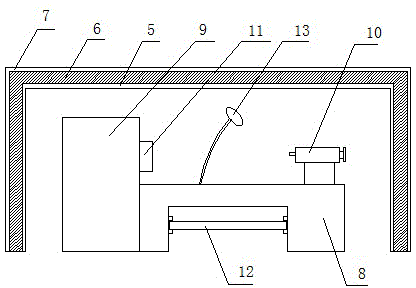

Silencing cover for lathe

InactiveCN104526452AReduce processing noiseSolve the noiseAuxillary equipmentMaintainance and safety accessoriesSurface layerEngineering

The invention provides a silencing cover for a lathe. The silencing cover is characterized in that a plurality of plates form a frame. The silencing cover comprises a top plate, a left plate, a right plate, a front plate and a rear plate. Each plate comprises an inner surface layer, a filling layer and an outer surface layer which are arranged sequentially and bonded, and a sound absorption plate is adopted on the inner surface layer and the outer surface layer respectively. The filling layer is made of absorbent cotton or absorbent felt. A single-opening door is arranged on the left plate, one side of the single-opening door is movably connected onto the left plate, the single-opening door is made of a hollow double-layer transparent plate made of acrylic, an observation window is arranged in the middle of the right plate, and the observation window is made of the hollow double-layer transparent plate made of the acrylic. Due to the fact that the silencing cover is arranged on the outside of the lathe body, the problem of noise during lathe machining in a workshop is solved, and dysphoria of the human body caused by the noise is reduced.

Owner:WUHU WANHUA PLASTIC PROD

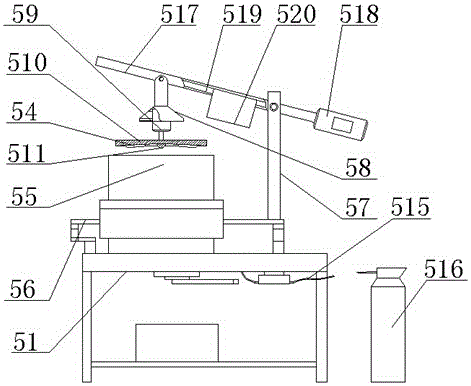

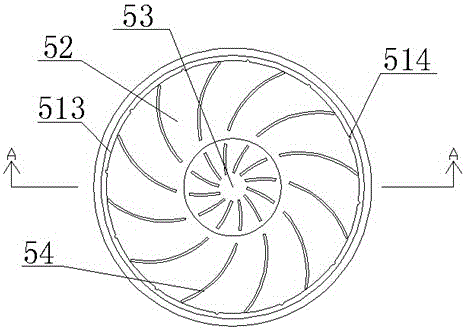

A kind of processing equipment of Biluochun tea

InactiveCN101579022BHighlight substantive featuresSignificant progressPre-extraction tea treatmentInsertion stentElectric machinery

The invention relates to a processing equipment for Biluochun tea leaves, which includes a tray, a tea frying pot, a support, and a heating device. The tea frying pot is placed in the support, and a heating device is connected between the tray and the tea frying pot. The processing equipment is characterized in that: It also includes a motor, a reducer, a kneading device, and a comprehensive control device. A frying tea pot is placed on the tray, and a heating device is connected between the tray and the frying tea pot. The tray is connected to the motor through a reducer. It is connected with the support, and the other end is put into the frying tea pot, the comprehensive control device is connected with the motor, and the kneading device includes a tea kneading device and a tea kneading device. After adopting the invention, the automatic frying of Biluochun tea leaves can be realized, the difficulty of tea frying is greatly reduced, and the deployment of large-scale production is more convenient while saving manpower.

Owner:苏州创盛茶叶机械开发有限公司

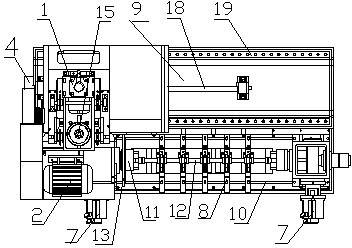

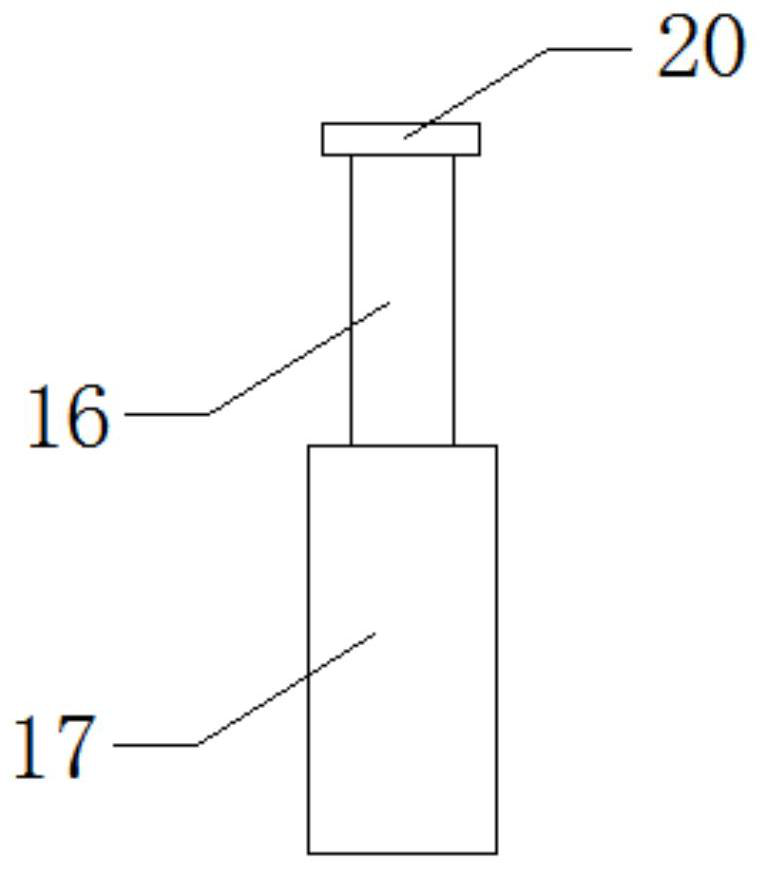

Fully CNC Camshaft Milling Machine

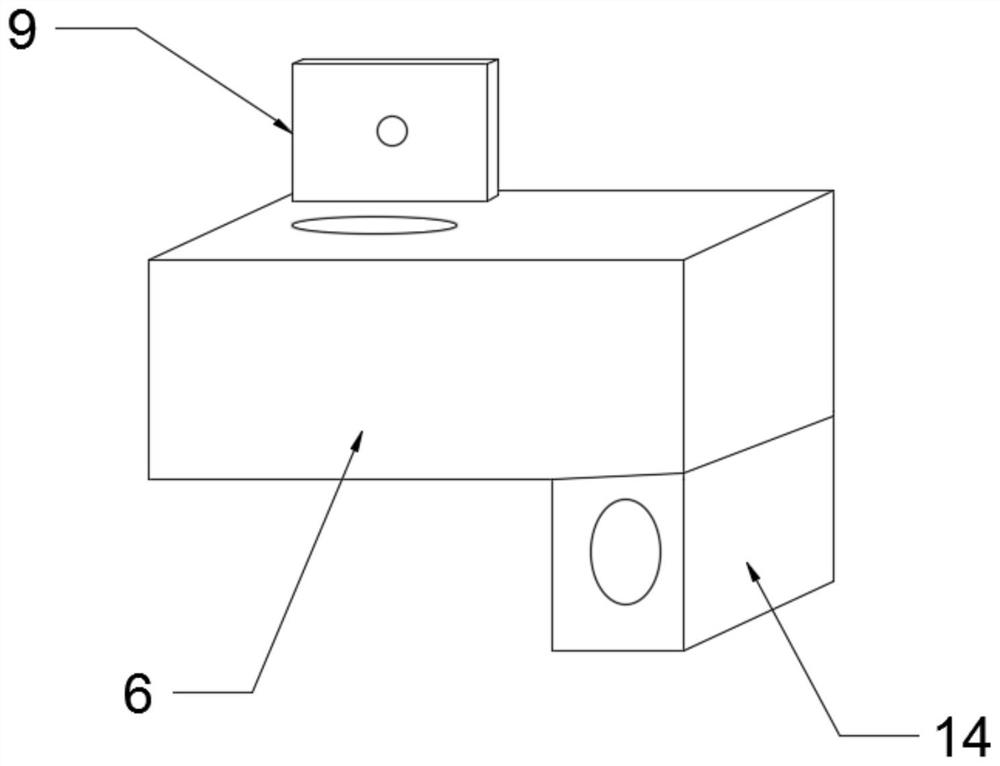

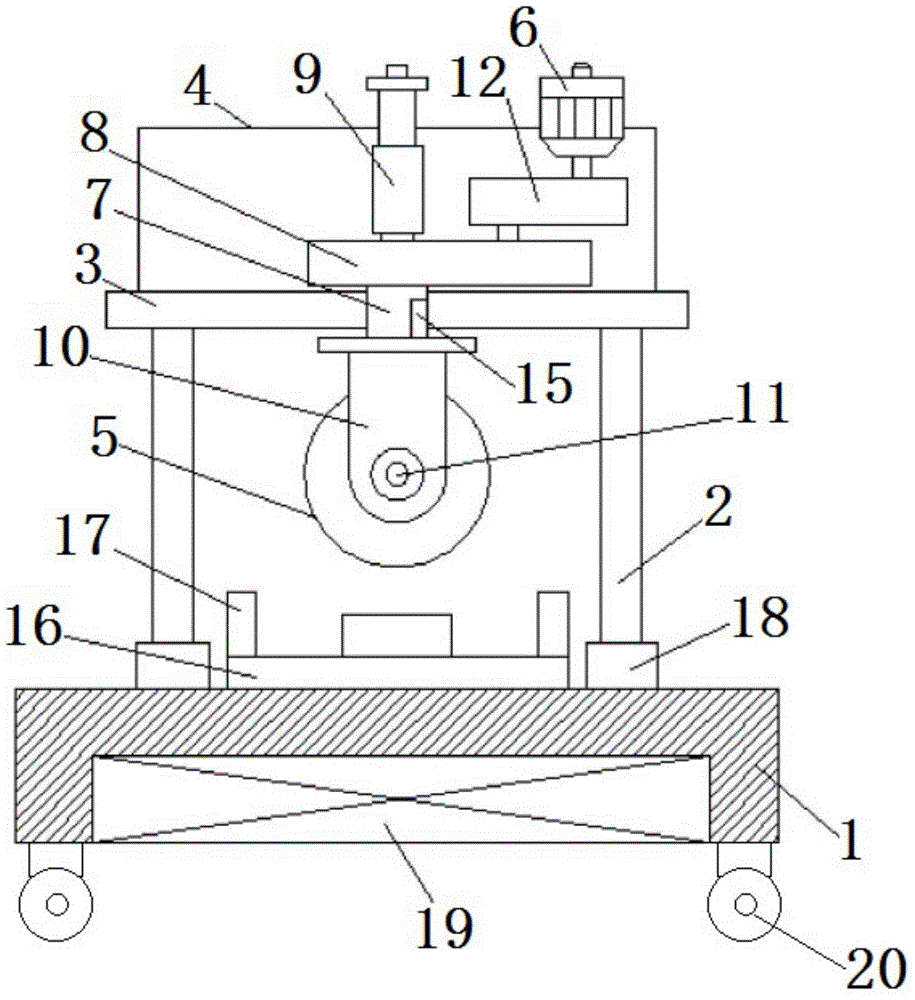

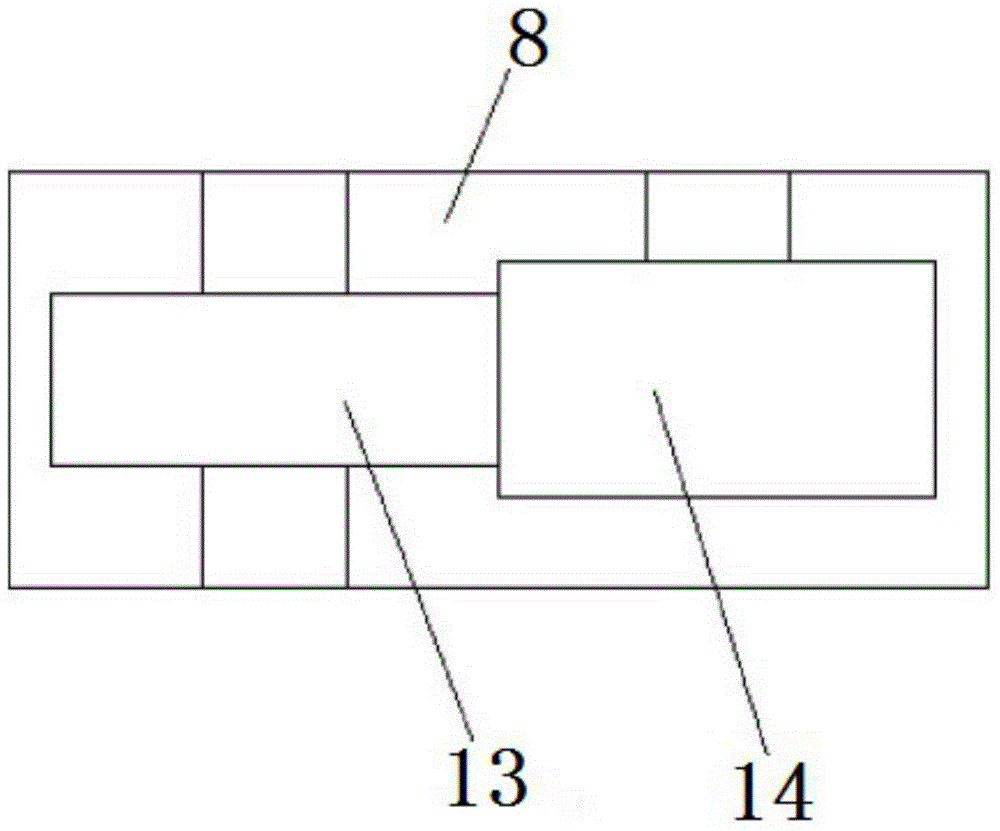

InactiveCN102274998AExtended service lifeUniform speedFeeding apparatusMilling equipment detailsDrive wheelMilling cutter

The invention discloses a full numerical control camshaft milling machine, which comprises a bed (9), a guide rail plate (10), a guide rail (19), a rotating power head (6), a milling power head (3) and a lifting power head (16), Rotary power heads are respectively arranged at both ends of the guide rail plate, hydraulic chucks (11) are arranged on the rotating power heads, and auxiliary supports (8) are arranged between the hydraulic chucks, and the milling power heads are arranged on the lifting platform, and the lifting platform (20) can move on the column (14). The milling power head includes the milling cutter spindle (23). The column can move left and right on the guide rail (19). An inertial balance wheel (27) or a milling cutter spindle is arranged on the milling cutter spindle. The main shaft is connected with the inertia balance wheel through the driven wheel (24) on the milling cutter main shaft. The milling cutter spindle of the present invention does not generate vibration, which not only reduces the processing noise, prolongs the service life of the milling cutter, but also improves the milling quality, reduces the reserved grinding amount, reduces the grinding workload, improves the processing efficiency, and reduces the Camshaft machining cost.

Owner:胡益萍 +2

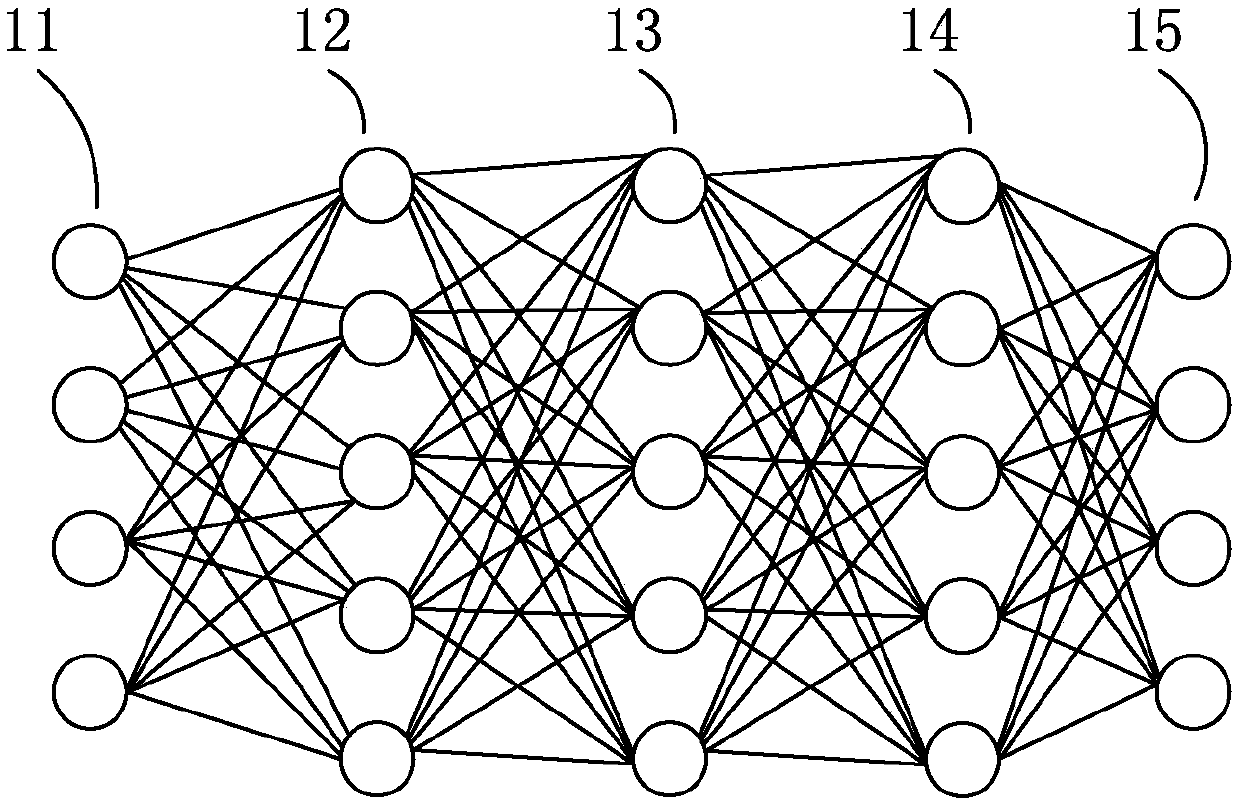

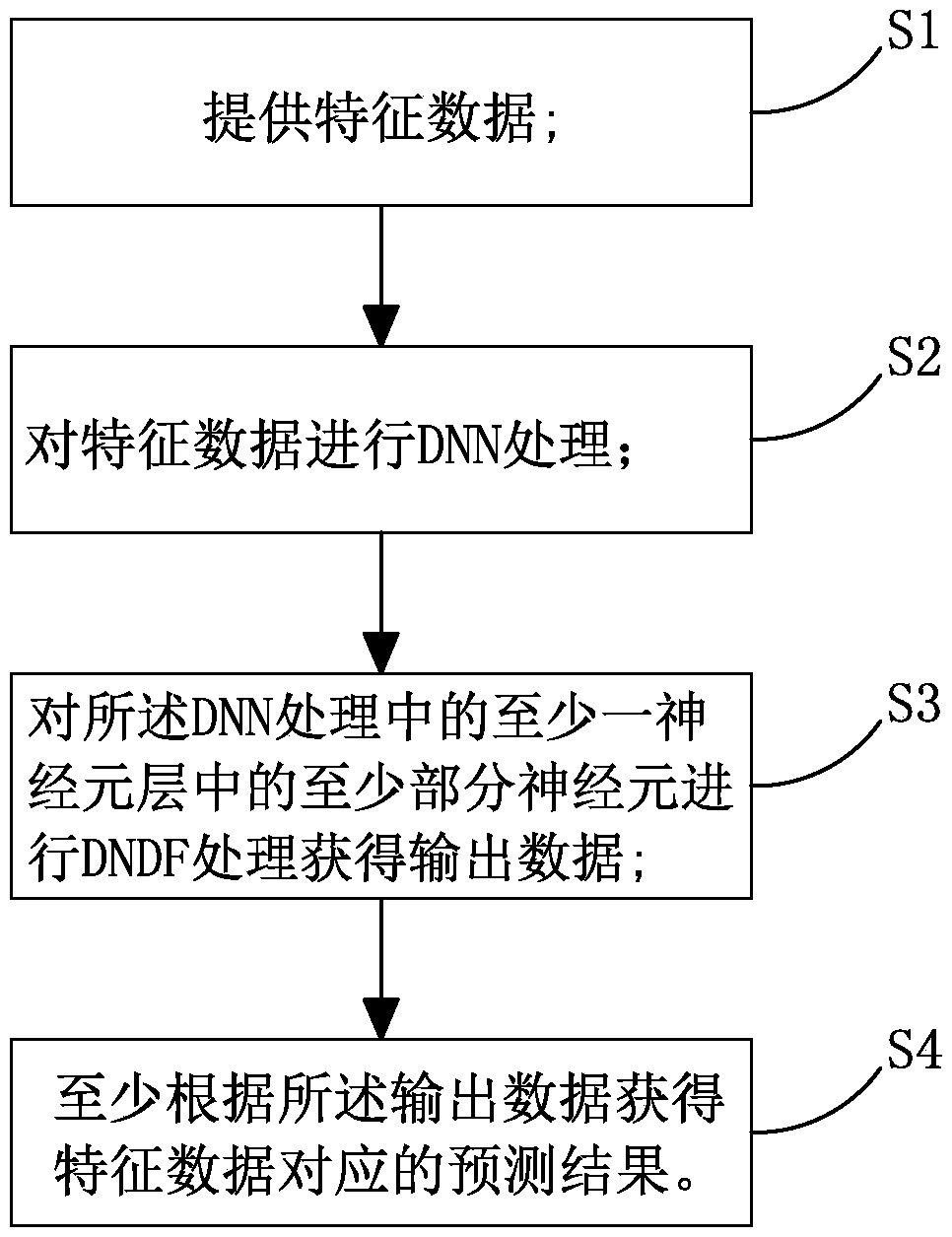

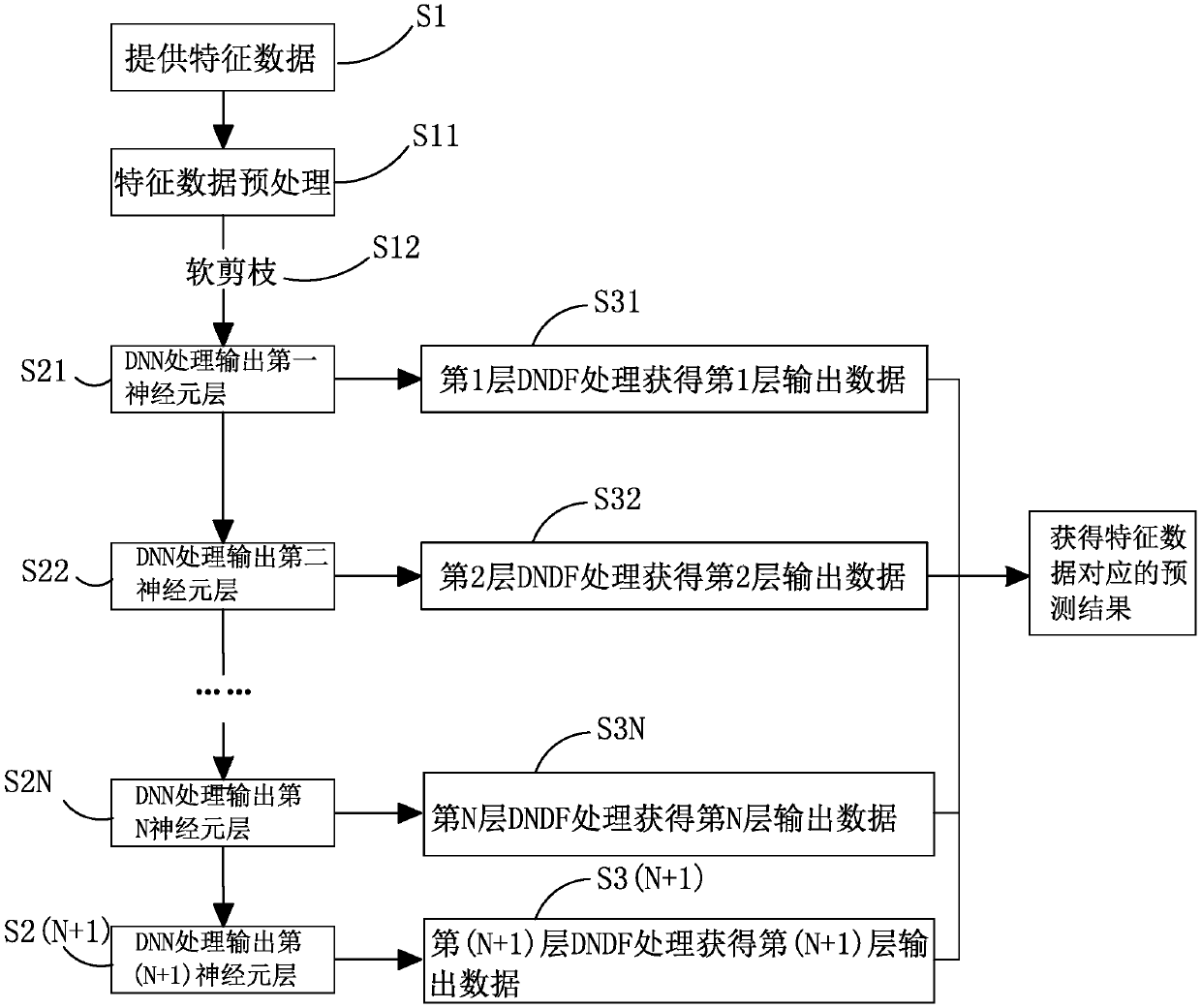

Model data processing method based on DNN, data processing model and electronic device

The invention provides a Model data processing method based on DNN. The method comprises the steps of providing feature data; Performing DNN processing on the feature data; Performing DNDF processingon at least part of neurons in at least one neuron layer in the DNN processing to obtain output data; And obtaining a prediction result corresponding to the feature data at least according to the output data. The invention further provides a data processing model based on the DNN. The data processing model comprises an input module; Wherein the input module is used for inputting feature data; A DNN processing module; Wherein the DNN module is used for performing DNN processing on feature data; The DNDF processing module is used for performing DNDF processing on at least part of neurons in at least one neuron layer in the DNN processing module to obtain output data; And a prediction module; And the prediction module is used for obtaining a prediction result corresponding to the feature dataat least according to the output data output by the DNDF processing module. The invention further provides an electronic device for executing the model data processing method. The model data processing method based on the DNN, the data processing model and the electronic device have the advantages that prediction precision is improved and the like.

Owner:青岛创新奇智科技集团股份有限公司

Hinge streamlined drilling production equipment

InactiveCN111872441APrevent debris from flyingReduce processing noiseCleaning using toolsFeeding apparatusElectric machineryDrive motor

The invention discloses hinge streamline drilling production equipment which comprises a conveying belt and a drilling mechanism. The drilling mechanism comprises two sets of symmetrically-arranged drill rods, the upper portions of the drill rods are provided with sliding blocks in a penetrating manner, and are rotationally connected with the sliding blocks through bearings, prism shafts are connected to the upper ends of the drill rods through first transmission gear sets in a meshed manner, and a rotary drum is connected with an output shaft of a driving motor through a second transmission gear set. By arranging a bearing box provided with a rectangular through groove and a machining box, streamlined production of hinges is achieved, meanwhile, chippings are prevented from splashing, andmachining noise is lowered; through the arrangement of a sliding block, a transverse moving block, a transverse lead screw, an adjusting wheel, the rotary drum and the prism shafts, manual adjustmentof the drilling distance is conveniently achieved, and good adaptability is achieved; and through arrangement of an abutting frame, a slag crushing box, a brush plate and a sleeve, chippings in the bearing box are centrifugally swept, and the chipping collecting effect is improved.

Owner:黄展雄

Stable and reliable bearing polishing machine

InactiveCN104959893ASimple structureEasy to useGrinding drivesGrinding machinesHydraulic cylinderGear wheel

The invention discloses a stable and reliable bearing polishing machine. The stable and reliable bearing polishing machine comprises a base, supporting columns, a sliding support, a hanging frame, a grinding wheel and a driving device. The supporting columns are arranged on the base. The sliding support is arranged on the supporting columns. The hanging frame is arranged on the sliding support. A rotating transmission mechanism is arranged on the sliding support. A transmission case and a hydraulic cylinder are arranged on the rotating transmission mechanism. A grinding wheel frame is arranged below the rotating transmission mechanism. The driving device is arranged on the hanging frame. A gearbox is connected to the output end of the driving device. The output end of the gearbox is connected with the transmission case. A driven gear matched with the hydraulic cylinder is arranged in the transmission case. A driving gear matched with the driven gear is arranged in the transmission case. A grinding cutter is composed of a grinding cutter base and a grinding disc, and a flange is arranged below the grinding cutter base in a connected mode. A connecting disc is arranged between the flange and the grinding disc. An elastic connecting device is arranged between the flange and the connecting disc.

Owner:ANHUI QIANSHAN BEARING MFG

Numeric control lathe

InactiveCN101920341AEasy to useExtend your lifeLarge fixed membersTurning machinesElectric machineryEngineering

The invention relates to a numeric control lathe which comprises a machine tool, a working platform and a driving motor of the working platform. The working platform is mounted on the guide rails of the machine tool; a screw rod is arranged in parallel between two guide rails at the bottom of the working platform; one end of the screw rod is fixed by a support saddle, and the other end of the screw rod is connected with the driving motor by an axial clearance adjusting device. The invention has simple structure, the axial clearance and the radial clearance of the screw rod are both limited in the play range of a bearing, the screw rod can work stably, the service performance and the service life of the screw rod are improved, and the processing noise of the lathe is reduced.

Owner:常州市科邦精密数控机械有限公司

Rice cake slicing machine

InactiveCN109333616AReduce processing noiseGood cutting precisionMetal working apparatusElectric machineryEngineering

The invention provides a rice cake slicing machine. The rice cake slicing machine comprises a machine frame, a conveying assembly and a cutting assembly, wherein the conveying assembly is arranged onthe machine frame, and the cutting assembly is arranged at the end of the machine frame. The rice cake slicing machine is characterized by further comprising a guide pipe, the conveying assembly comprises a conveying belt, a driving wheel and a plurality of driven wheels, wherein the two ends of the driving wheel and the two ends of the driven wheels are movably connected to the machine frame through bearings correspondingly, the conveying belt is wound around the driving wheel and the driven wheels, the driving wheel is driven by a conveying motor, the guide pipe is arranged at the end of theconveying belt, moreover, the guide pipe is arranged on the machine frame, the cutting assembly comprises a cutting motor, a shaft sleeve and one or more cutting knives, the cutting knives are arranged on the shaft sleeve, and the shaft sleeve is arranged on a rotating shaft of the cutting motor. According to the rice cake slicing machine, rotation of the cutting knives is driven through rotationof the cutting motor, so that slicing of a rice cake which is transmitted in the guide pipe is achieved; the rice cake slicing machine is small in processing noise, better in cutting precision, low in cost, reasonable in structural design and capable of being conveniently used for processing.

Owner:ANHUI JIAGUDOU FOOD CO LTD

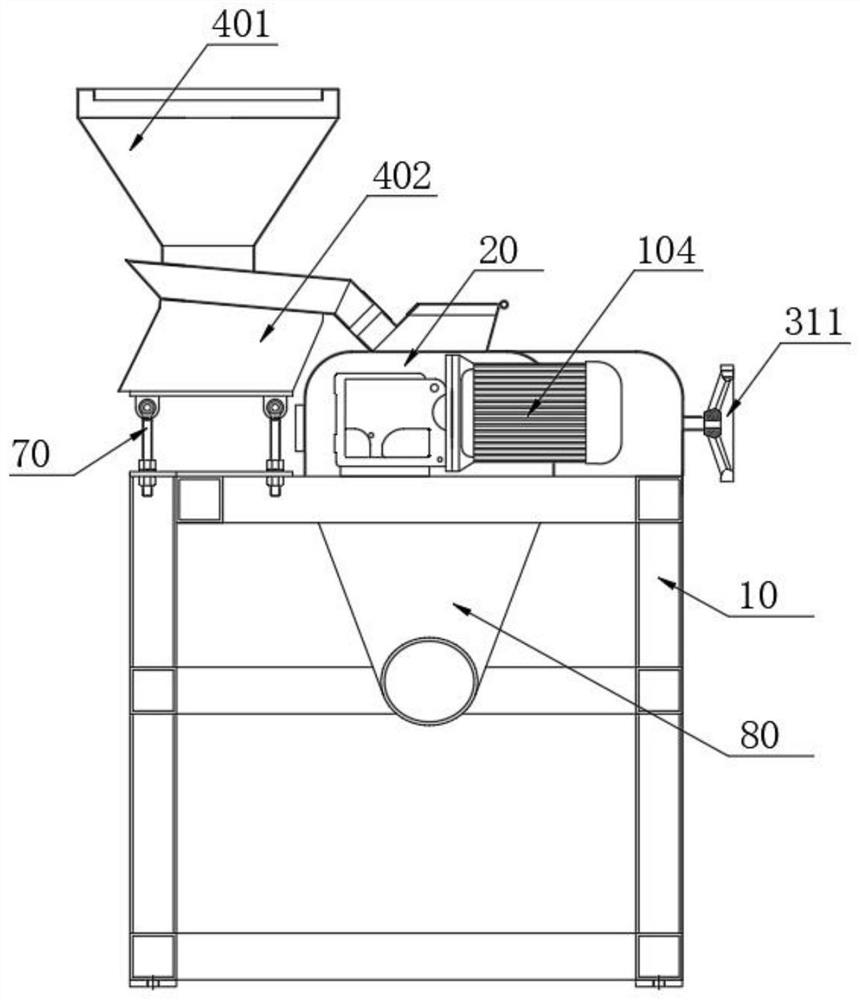

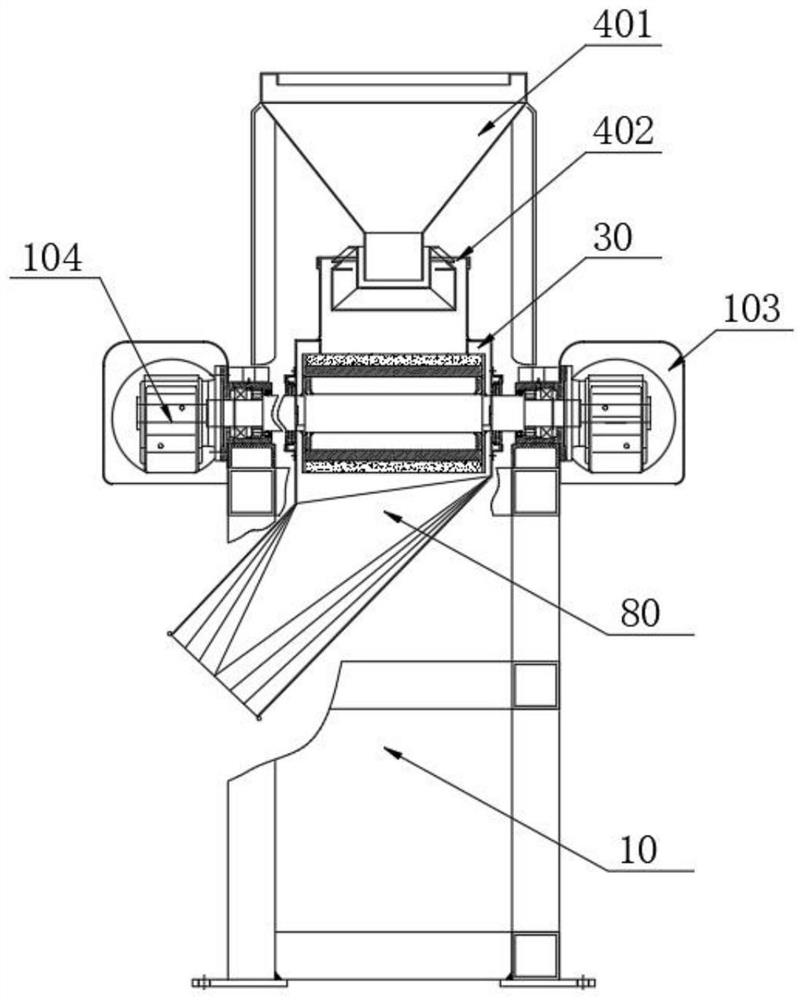

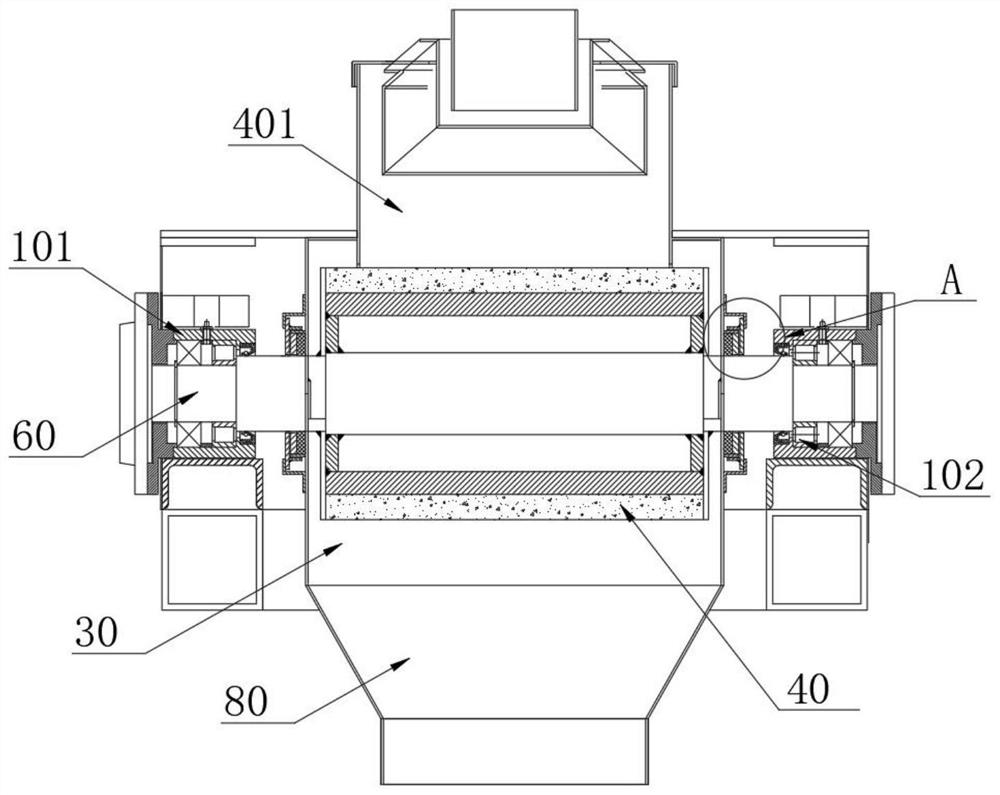

Efficient environment-friendly roll crusher and working method thereof

InactiveCN114130463AEasy to replaceEasy to removeDirt cleaningGrain treatmentsStructural engineeringReducer

The invention relates to the technical field of roll crushers, in particular to an efficient and environment-friendly roll crusher and a working method thereof.The efficient and environment-friendly roll crusher comprises a rack, a crushing box and a fixing box, and a sealing assembly and an adjusting assembly are arranged in the fixing box. Dust in the crushing box cannot overflow through the dustproof pad, so that the defects that a traditional double-roller crusher is large in dust amount and pollutes the environment are overcome; by arranging the adjusting assemblies on the two sides of the surface of the rotating shaft, the distance between the first crushing roller and the second crushing roller can be conveniently adjusted, and therefore finer crushing machining on materials is achieved; the hard tooth surface speed reducer is adopted, so that the mechanical efficiency can be further improved, and the machining noise is reduced; and the crushing box adopts a detachable structure of the upper box body and the lower box body, so that an operator can conveniently clean and daily maintain the interior of the crushing box.

Owner:WUXI XINYAN POWDER MASCH CO LTD

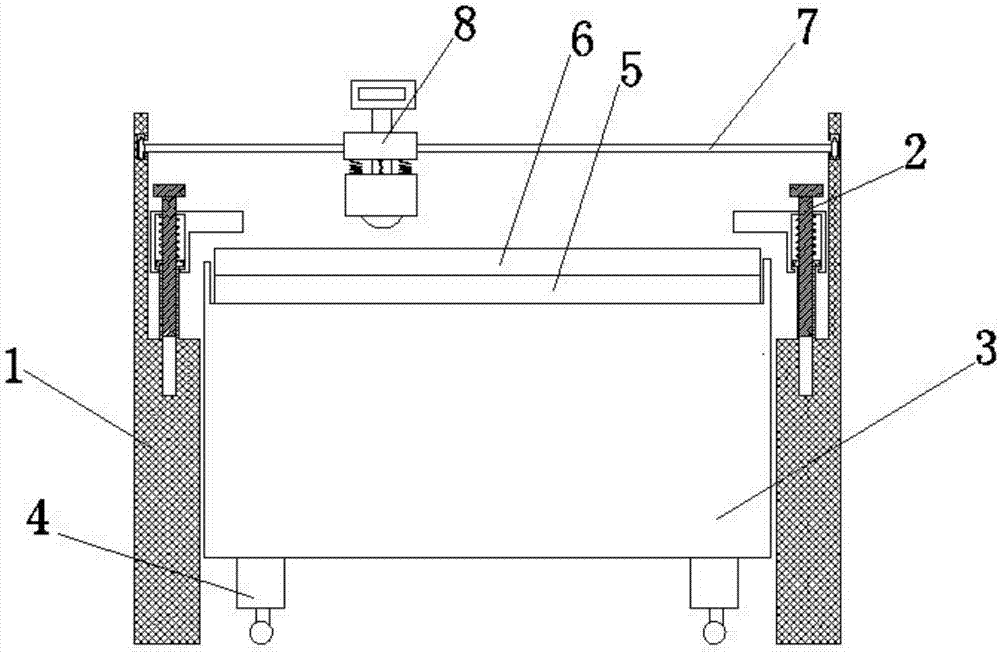

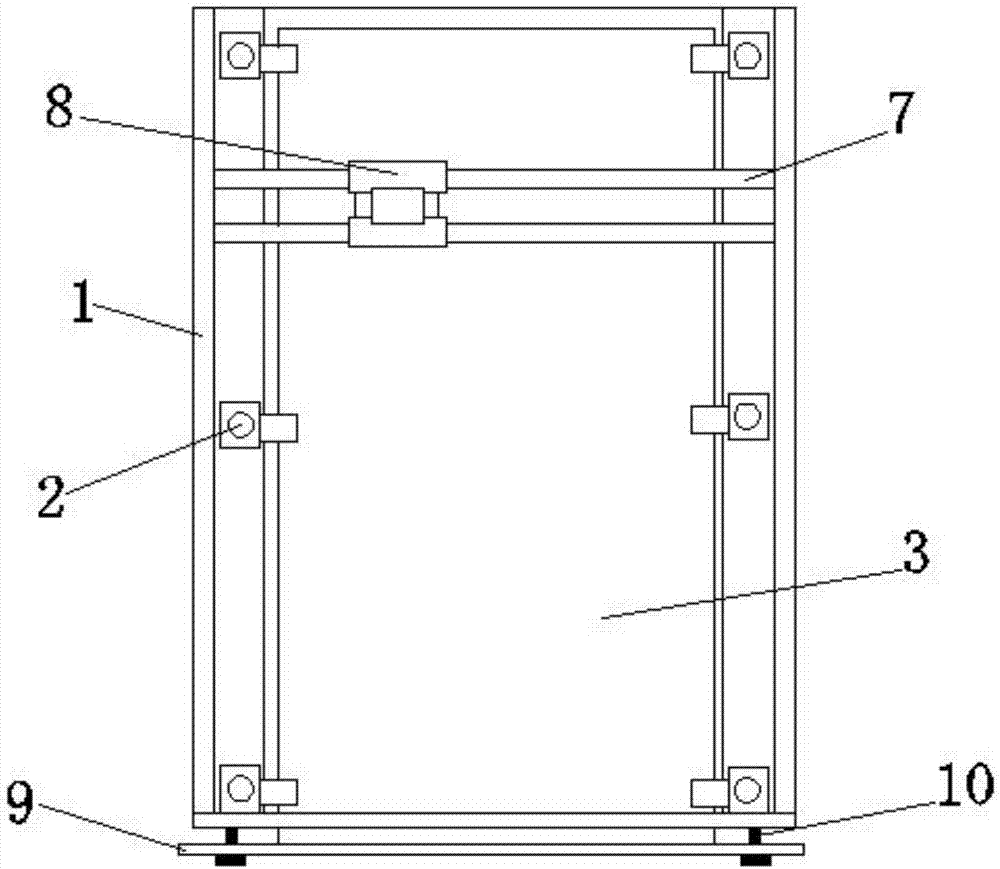

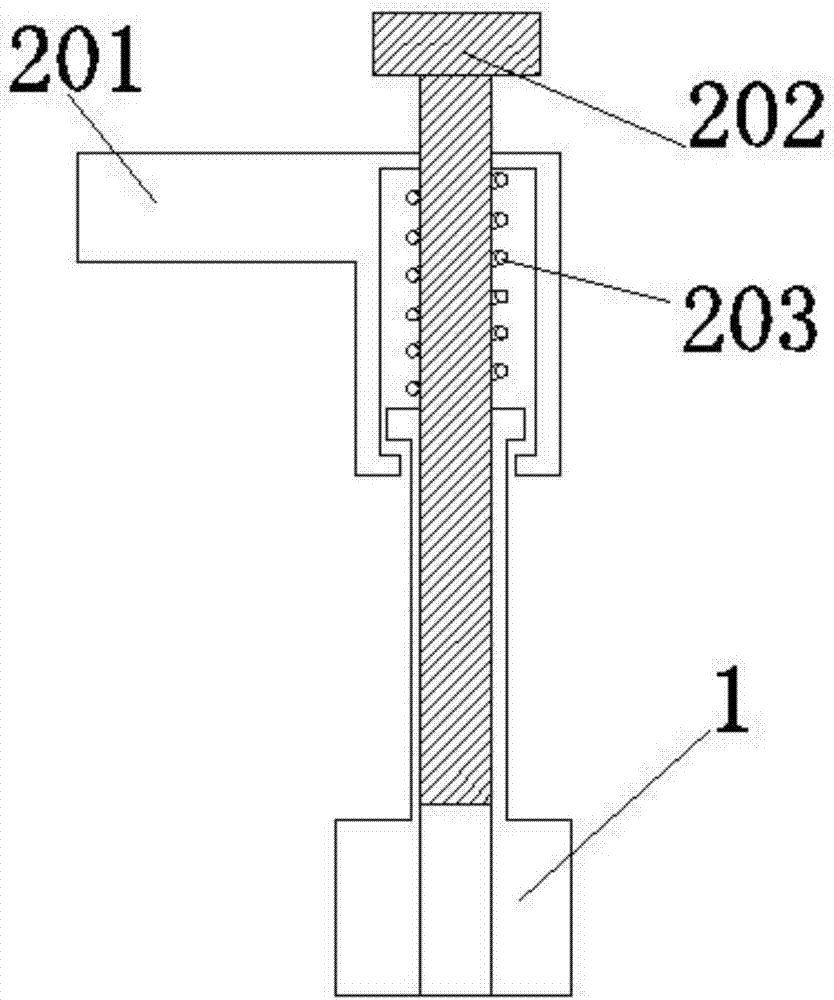

Timber carving machine

InactiveCN109591494APrevent splashReduce processing noiseModel makingEngravingSlide plateEngineering

The invention discloses a timber carving machine which comprises a base. Side plates are fixedly mounted on two sides of the top of the base, first linear guide rails are mounted on opposite inner sides of the two side plates, a cross bar is slidably connected between the two first linear guide rails, a second linear guide rail is fixedly mounted at the bottom of the cross bar, an electric telescopic rod is slidably connected to the bottom of the second linear guide rail, a carving machine head is mounted on the end part of the electric telescopic rod, a carving tool is mounted in the carvingmachine head, a support plate is mounted between the two side plates on the top of the base, a chute is formed in the support plate, a slide block is slidably connected in the chute, a locking bolt ismounted in the slide block, a stop dog is mounted on one side of the support plate, guide rails are mounted at two ends of the side plate, the guide rails stretch to the end part of the base, slide plates are slidably connected in the guide rails, plugs are mounted on the slide plates, insertion holes are formed in the side plates and the base, and soundproof assemblies are mounted on the outer sides of the side plates. The timber carving machine can be suitable for timbers of different sizes and fragments and noises generated by carving can be reduced.

Owner:YINGSHANG CHENJIA CRAFT FURNITURE

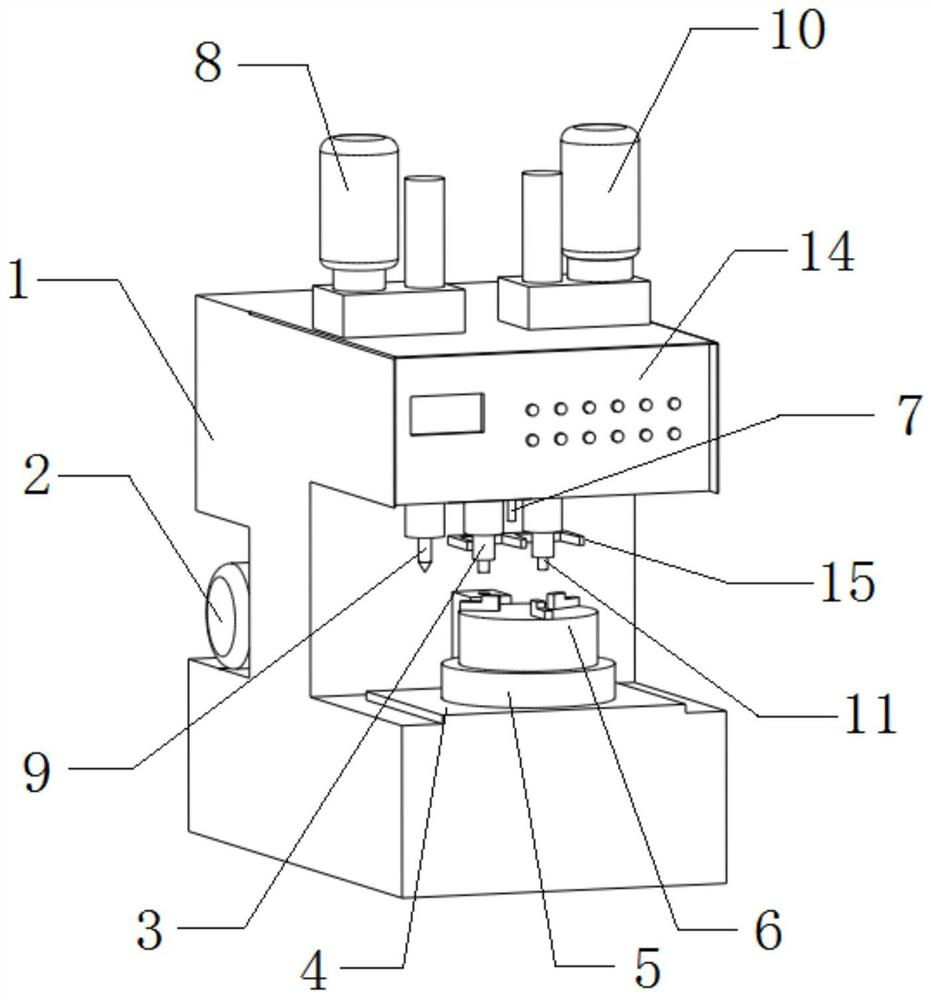

Drilling, punching and tapping all-in-one machine for square and round flange end plates

PendingCN112809383ALabor savingLow input costOther manufacturing equipments/toolsNumerical controlElectric machinery

The invention discloses a drilling, punching and tapping all-in-one machine for square and round flange end plates. The all-in-one machine comprises a numerical control punching machine, a punching knife fixing rod, a drilling assembly, a tapping assembly and a motion sensor, wherein a punching head, a numerical control index plate and a chuck are detachably arranged on the punching knife fixing rod, the drilling assembly comprises a drilling driving motor and a drill bit, the tapping assembly comprises a tapping driving motor and a screw tap, the punching head comprises a large hole punch and a rib passing hole punch which are integrally arranged, and the drill bit, the large hole punch, the rib passing hole punch and the screw tap are transversely arranged or arranged in an arc shape with the center of the numerical control dividing plate as the circle center. According to the machine, the four machining steps of drilling, large hole punching, rib passing hole punching and tapping are integrated, the four machining steps are completed through one machine, the labor force is relieved, the equipment input cost is lowered, and the machine has the advantages of high speed, high efficiency, high precision, low machining noise, low maintenance cost and fast die replacement and specification replacement and is suitable for popularization.

Owner:徐凯

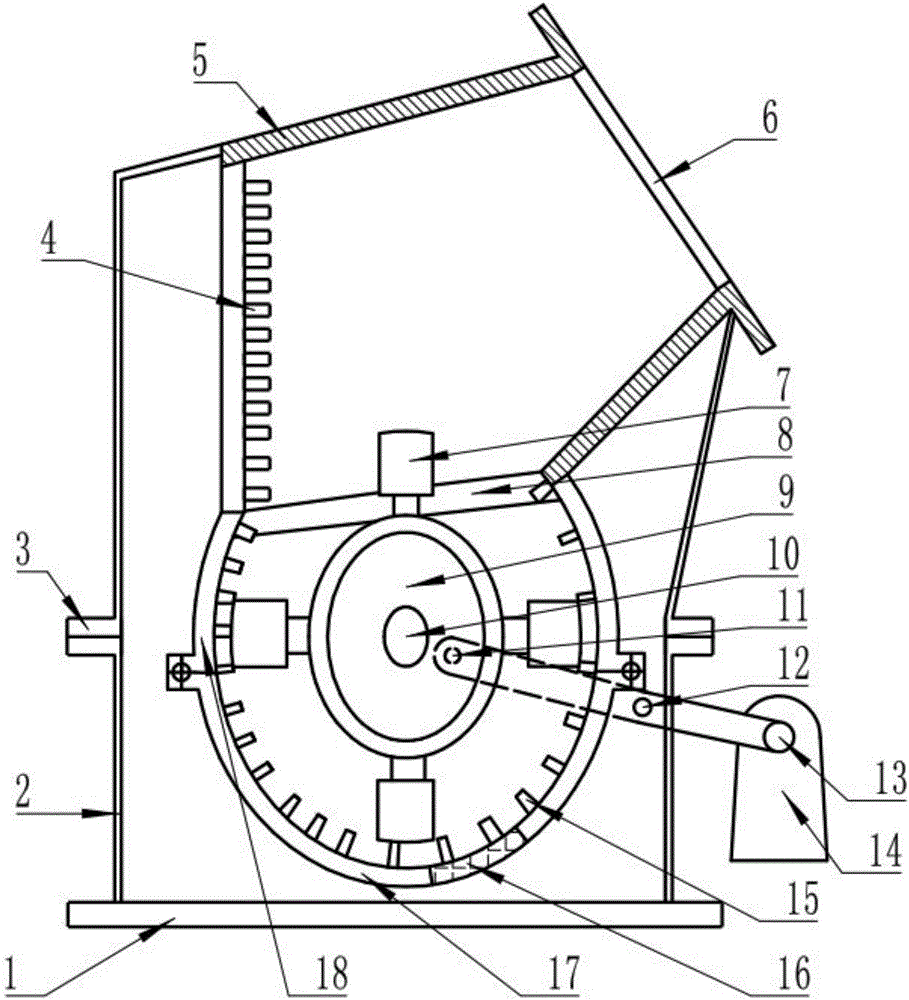

Pulverizer used for pulverizing coal gangue

InactiveCN106732945APrevent flying outPromote fragmentationGrain treatmentsEconomic benefitsEngineering

The invention discloses a pulverizer used for pulverizing coal gangue. The pulverizer is mainly composed of a base (1), a lower shell (2), an upper shell (3), upper baffles (4), material guiding channels (5), a material port baffle (6), a pulverizing hammer (7), a connecting transverse rod (8), a roller (9), a rotating shaft (10), a connecting rod (11), a fixing shaft (12), a pin (13), a balance weight hammer (14), lower baffles (15), a screen (16), a pulverizing bin lower cover (17) and a pulverizing bin upper cover (18). By means of the arrangement of the balance weight system, the stability of working can be improved; mechanical abrasion is reduced; the service life of the equipment is prolonged; the economic benefit is improved; the machining noise of the equipment can be reduced; and the structural stability of the equipment can be improved.

Owner:重庆市万盛区万兴建筑材料有限公司

Modified polymer plastic color masterbatch and preparation method thereof

InactiveCN110682466AImprove finished product qualityAvoid Standalone ScreeningCoatingsPolymer sciencePolystyrene

The invention discloses modified polymer plastic color masterbatch and a preparation method of the modified polymer plastic color masterbatch. The modified polymer plastic color masterbatch comprises,by weight, 60-80 parts of carrier resin, 15-20 parts of coloring agent, 3-5 parts of compatilizer, 10-15 parts of brominated polystyrene, 6-8 parts of ultraviolet absorber UV-P, 8-12 parts of light stabilizer, 3-5 parts of dispersing agent, 5-8 parts of environment-friendly plasticizer, 6-8 parts of antibacterial agent, 5-10 parts of wear-resisting agent and 100 parts of water. Polypropylene obtained after plasma treatment is adopted as the color masterbatch carrier, so that the surface adhesive force of the polypropylene can be effectively improved; and the compatilizer is added in the preparation process, the compatilizer system can improve the affinity between the color master and other materials and improve the interfacial compatibility between the color master and the materials, so that the product quality is improved, the coloring agent is more evenly mixed with the color masterbatch carrier under the action of the dispersing agent, and the coloring effect of the color masterbatch carrier is improved.

Owner:界首市楷讯塑胶科技有限公司

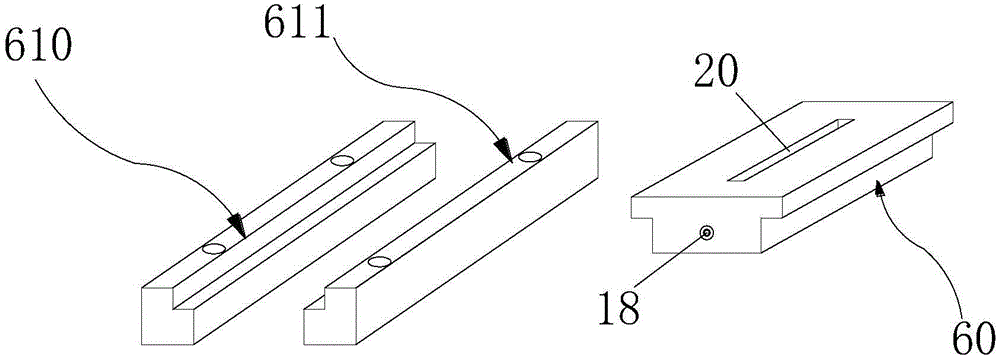

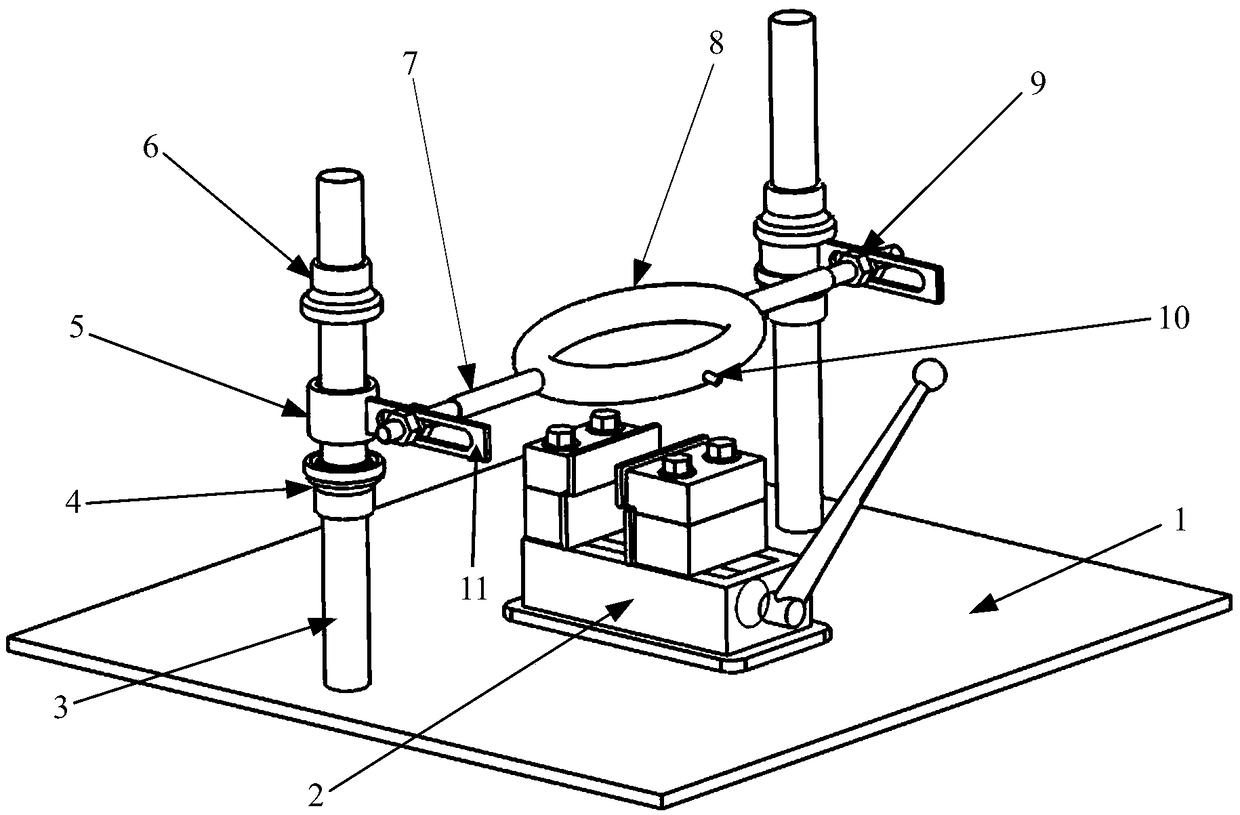

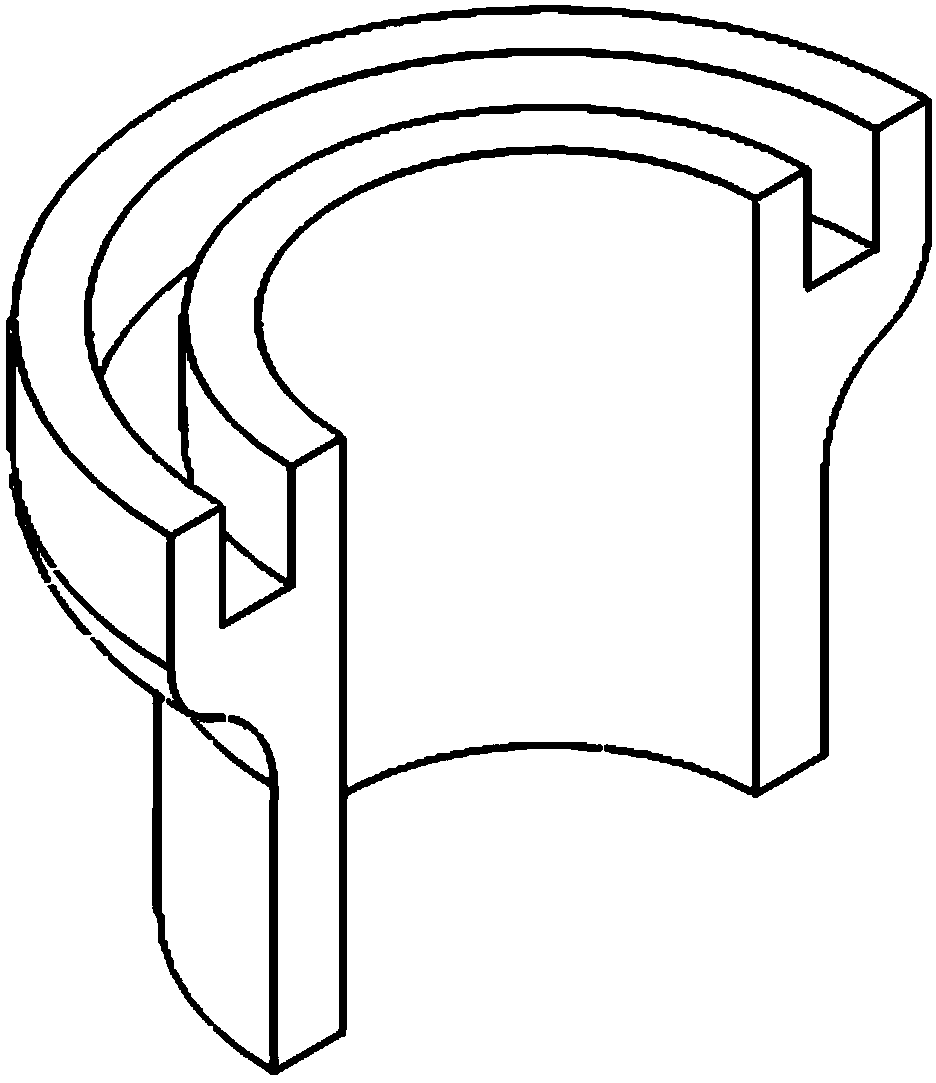

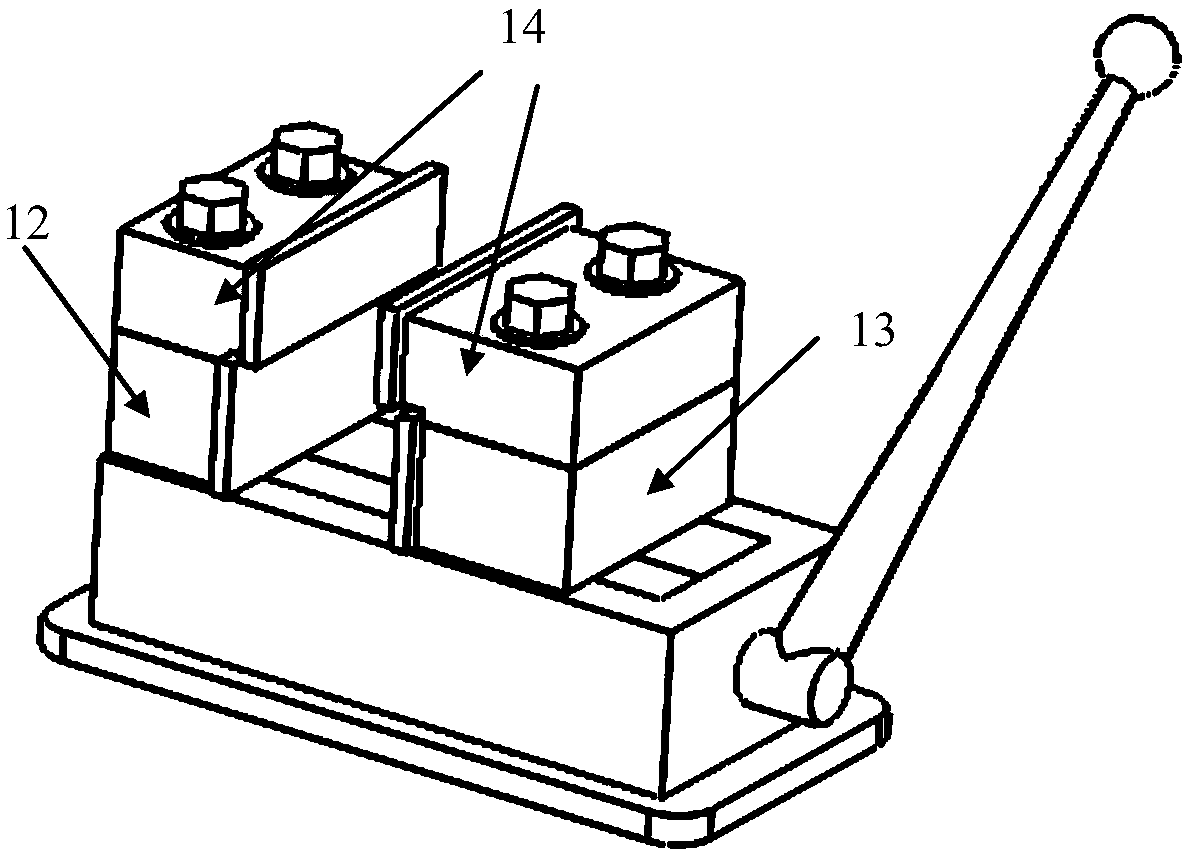

Steel seal processing device and steel seal box of steel seal processing device

The invention relates to a steel seal processing device adopting hydraulic pressure as driving power. The steel seal processing device comprises an operation assembly, a hydraulic power assembly, an electric control assembly, a work table, a support assembly and a position limiting assembly, wherein the hydraulic power assembly is connected with the operation assembly and provides hydraulic power, the electric control assembly controls the starting and the stopping of the hydraulic power assembly, the support assembly provides support effects, the operation assembly is a steel seal box, the steel seal box comprises a T-shaped channel steel seal module, a first L-shaped slide rail, a second L-shaped slide rail and character steel seal numbers arranged in the steel seal box, and the first L-shaped slide rail and the second L-shaped slide rail are symmetrically and fixedly arranged at the two sides of the T-shaped channel steel seal module through steel seal box locking screw bolts. The steel seal processing device has the technical effect that the hydraulic steel seal processing device with the advantages of low noise, high efficiency, safe operation stroke and capability of fast replacing different character steel seal numbers is provided.

Owner:SHANGHAI COSCO KAWASAKI HEAVY IND STEEL STRUCTURE

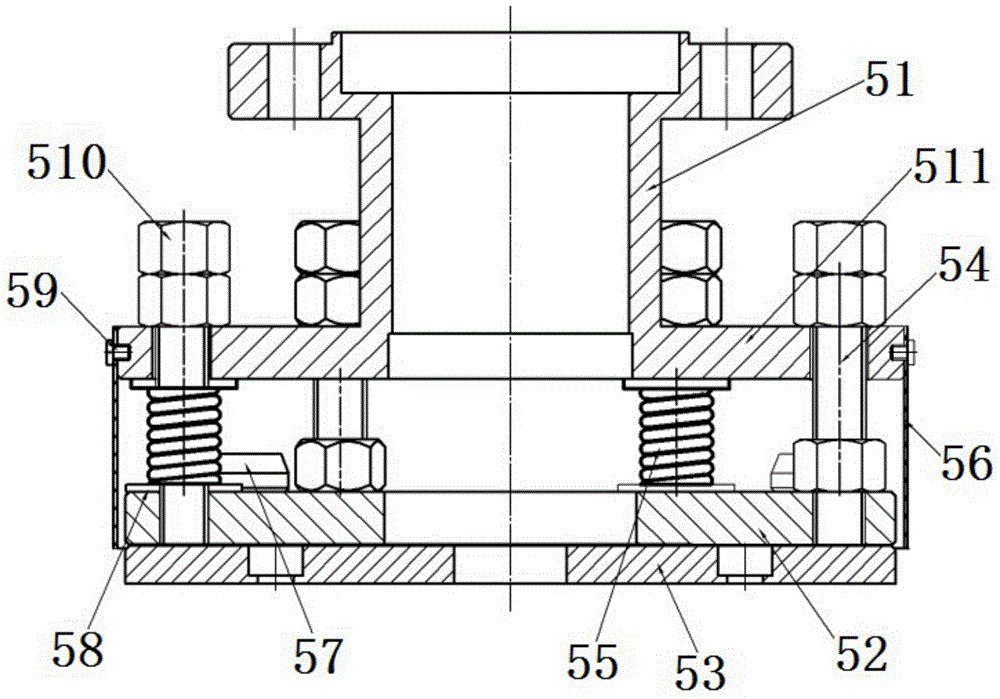

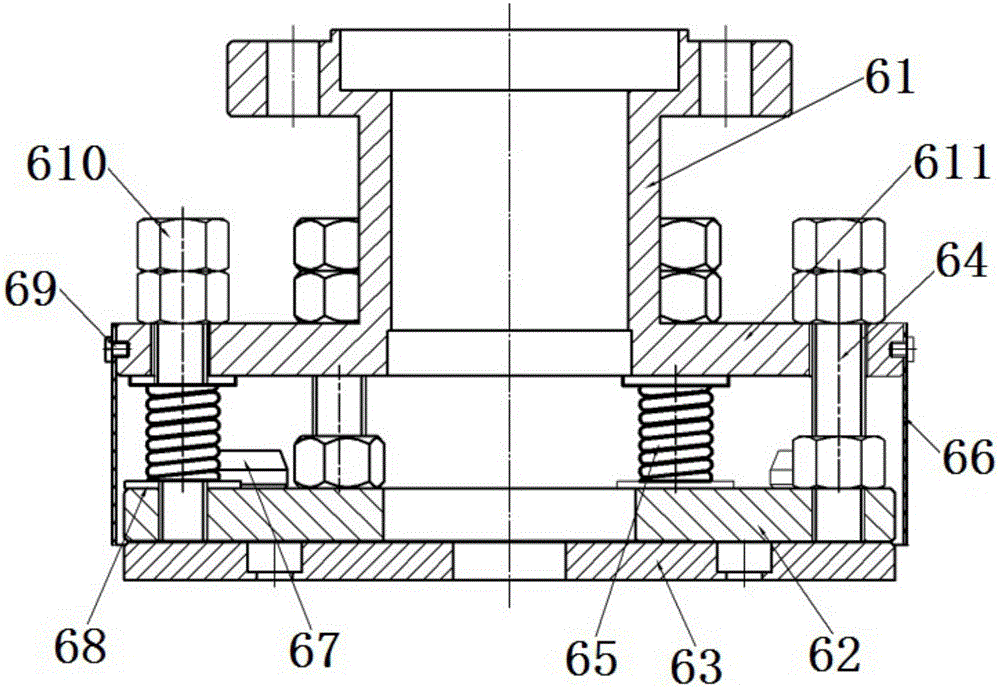

A flexible fixture and method for milling blades with large complex curved surfaces

ActiveCN106624907BSimple structureStable and reliableMilling equipment detailsPositioning apparatusMachining vibrationsEngineering

A flexible clamp and a method for use in milling blades having large complex curved surfaces, comprising: a lower portion clamping portion (2) which is arranged on a workbench (1), wherein a flexible clamping portion is cooperatively arranged at an upper side of the lower portion clamping portion (2); two ends of the flexible clamping portion are connected to a horizontal moving mechanism, and an end portion of the horizontal moving mechanism is connected to a vertical moving mechanism; the flexible clamping portion comprises an elastic clamping body which flexibly adheres to a side wall of a blade, the elastic clamping body flexibly clamping an upper portion side wall of the blade, while the lower portion clamping portion (2) clamps a bottom portion of the blade; during processing, the horizontal moving mechanism and the vertical moving mechanism drive the elastic clamping body to adjust the position at which the blade is clamped so as to preserve an area to be processed. The present invention solves the problem of processing vibration during the processing of a thin-walled part having a complex curved surface, and may also reduce processing distortion of thin-walled structures, such as a large-sized blades.

Owner:SHANDONG UNIV

Power head for digital control hole drilling

InactiveCN101797692BImprove machining accuracyImprove processing accuracyOther manufacturing equipments/toolsElectric machineMotor control

The invention discloses a power head for digital control hole drilling, which comprises a shell, a main shaft arranged on the shell, a main shaft drive system connected with the main shaft, a power tooth drive system and a digital controller, wherein the power tooth drive system is connected to the main shaft; the main shaft is connected with the main shaft drive system through an axial flexible connection mechanism; and the digital controller is connected with the main shaft drive system and the power tooth drive system through conducting wires respectively. The power head makes the main shaft realize axial feeding in the process of rotating by using the power tooth drive system to avoid abuses caused by the manual feeding or the feeding depending on a leading screw in the past. The overall structure of the power head is simple to operate and is convenient to mount and dismount, the processing noise is low, the replacement and the debugging are easy, and a servo motor controlled by the digital controller improves the processing precision and the processing accuracy; besides, the power head has a wide application range, and provides a good start for later total digitalization and automation.

Owner:南安市瑜鼎投资管理有限公司

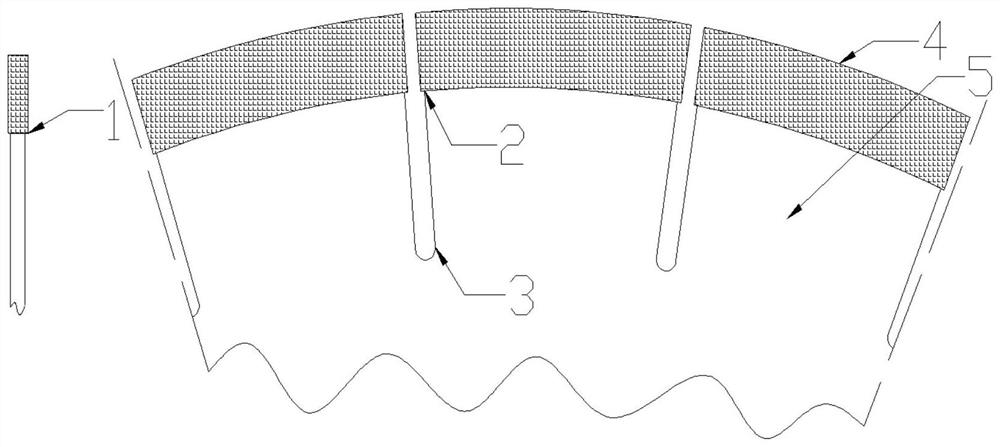

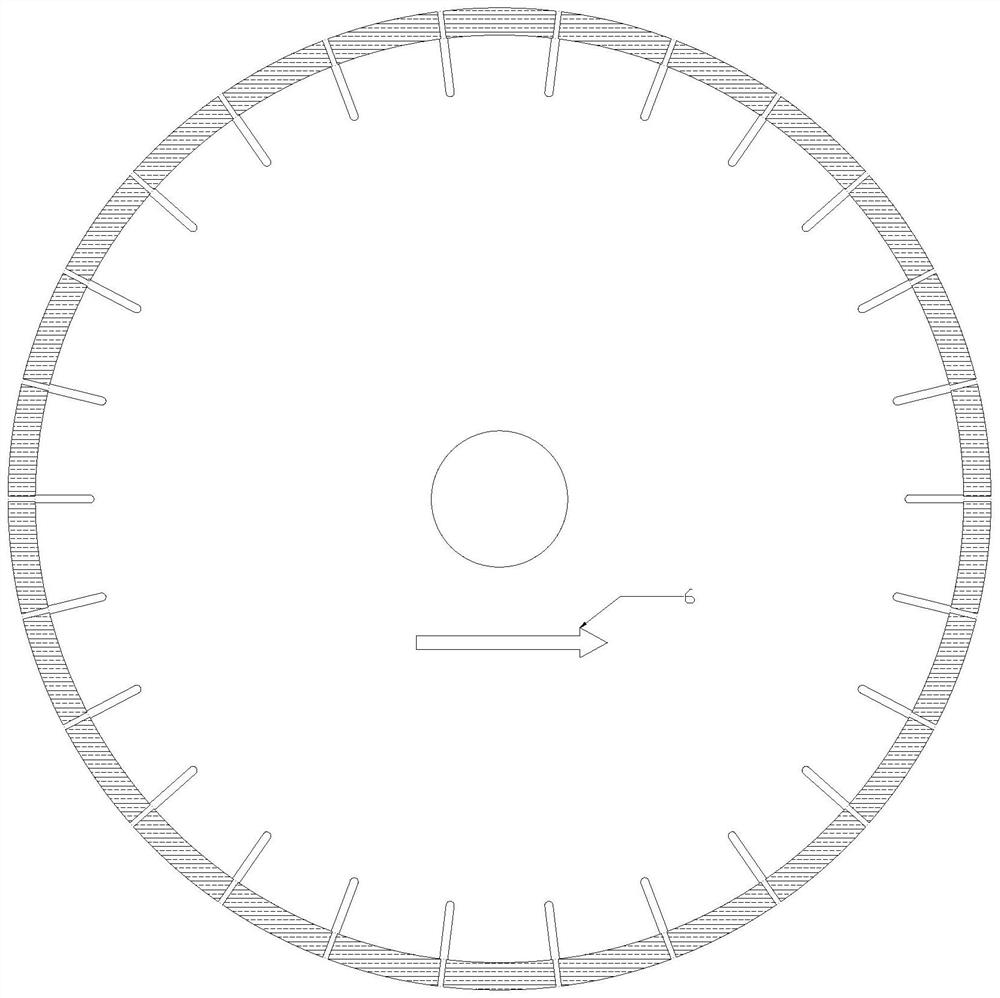

Diamond cutting blade special for fine cutting of marble by infrared bridge cutting machine and manufacturing method thereof

ActiveCN113070475AVibration and collision noise reductionEasy to processStone-like material working toolsDiamond cuttingEngineering

The invention discloses a diamond cutting blade special for fine cutting of marble by an infrared bridge cutting machine and a manufacturing method thereof. The cutting blade comprises a high-continuity fan-shaped segment and a matrix. The manufacturing method comprises a pre-alloyed powder formula, diamond grain size distribution and concentration, heating sintering process parameters and a welding process. A hot pressing sintering technology is used for manufacturing the fan-shaped segment with the customized size of the cutting blade, a high-frequency welding technology is adopted for welding the fan-shaped segment and the matrix, the welded cutting blade is polished, ground and edged and then used for cutting marble by the infrared bridge cutting machine, the cut marble is various in category, the universality is very excellent, edge breakage and bottom breakage are avoided during cutting, and the diamond cutting blade is small in noise, very good in cutting effect, long in cutting service life and high in plate outturn percentage, and is an edge tool for fine cutting of marble.

Owner:泉州华大超硬工具科技有限公司

Bearing polishing machine with high practicability

InactiveCN105033789AImprove practicalityAchieve lateral movementGrinding wheel securing apparatusRevolution surface grinding machinesBall bearingEngineering

A bearing polishing machine with high practicability comprises a base and a motor. A first supporting frame and a second supporting frame are arranged on the base. A transverse supporting frame is arranged at the top ends of the first supporting frame and the second supporting frame. An abrasive wheel is arranged at the output end of the motor. A placement table is arranged at the top end of the base. The bearing polishing machine with high practicability further comprises a connecting base, a first connecting rod, a second connecting rod and a fixing bolt. A slide way is arranged at the bottom end of the transverse supporting frame. A sliding wheel is arranged at the top end of the connecting base and is in transverse sliding fit with the slide way. A ball bearing and a limiting base are arranged in the connecting base. The abrasive wheel is composed of an abrasive wheel base and an abrasive disk. A flange plate is arranged at and connected with the lower portion of the abrasive wheel base. A connecting plate is arranged between the flange plate of the abrasive wheel base and the abrasive disk. An elastic connecting device is arranged between the flange plate of the abrasive wheel base and the connecting plate. The elastic connecting device is composed of three bolts, nuts of the bolts and compression springs, wherein the three bolts penetrate through connecting through holes in the flange plate, the compression springs are located between the flange plate of the abrasive wheel base and the connecting plate, and the bolts are sleeved with the compression springs. Washers are arranged at the two ends of each compression spring.

Owner:ANHUI QIANSHAN BEARING MFG

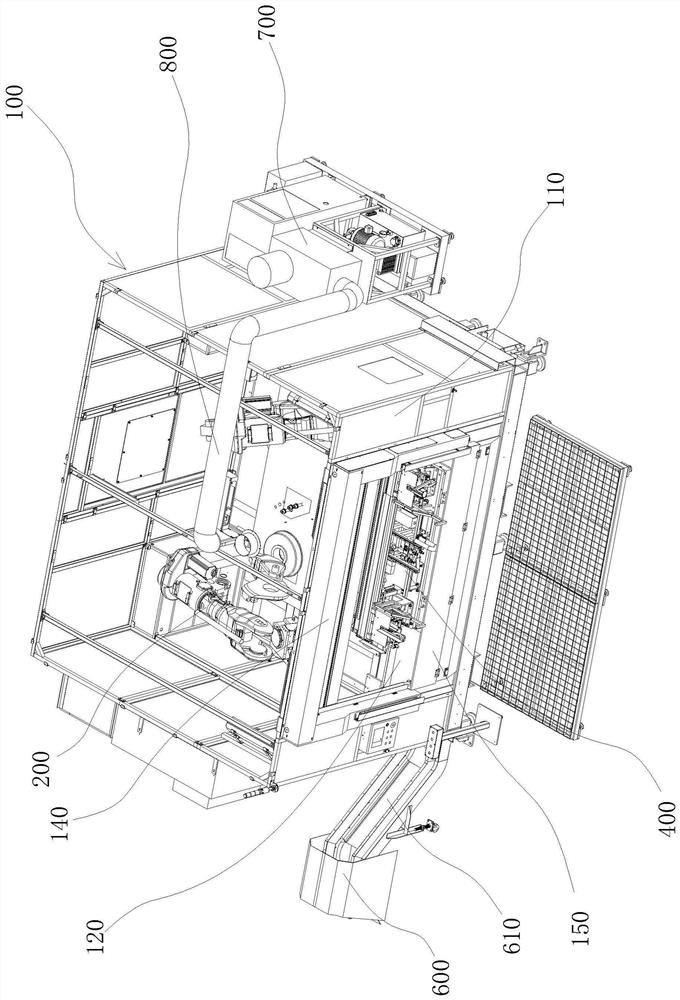

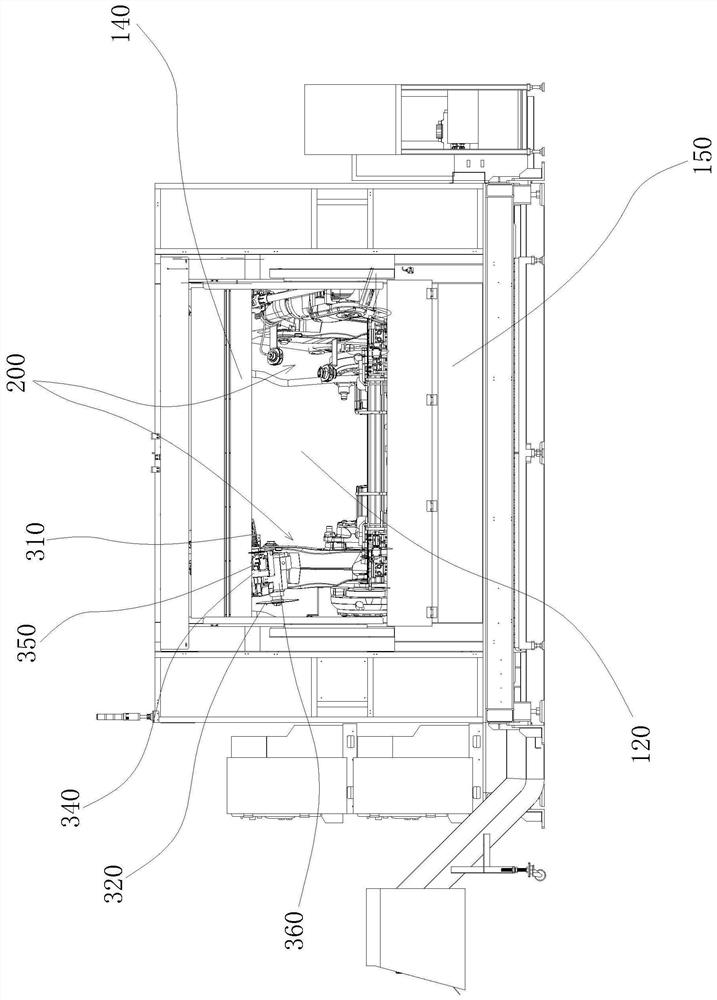

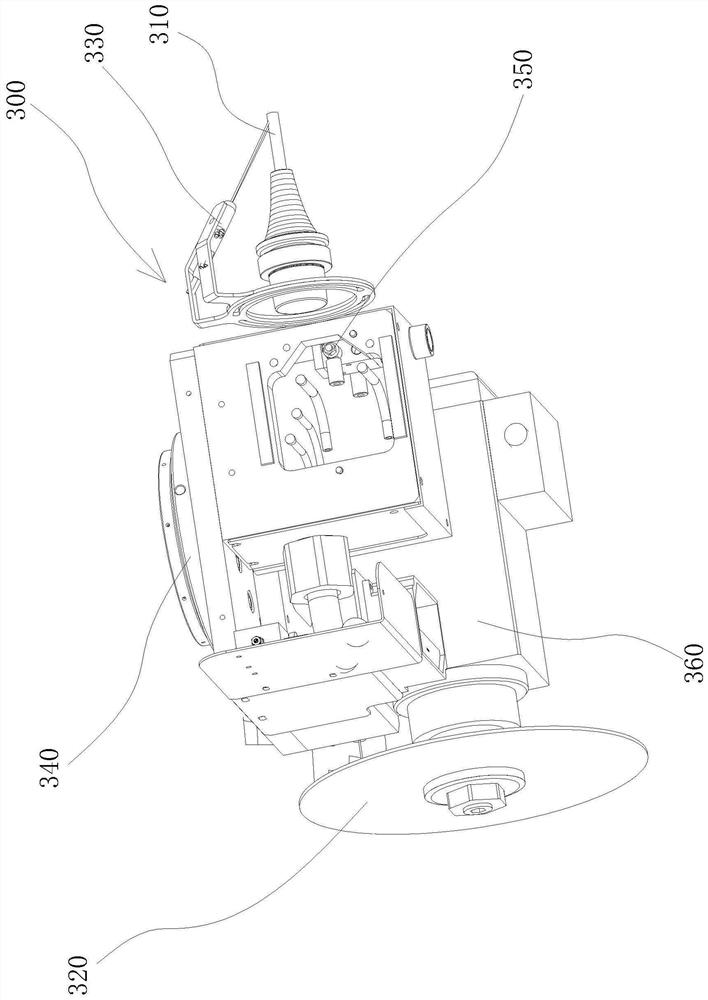

Robot sawing and milling system for automobile doorsill beam structural part

PendingCN113909900ASpecification typeOptimize layoutOther manufacturing equipments/toolsMetal working apparatusMilling cutterProcess engineering

The invention provides a robot sawing and milling system for an automobile doorsill beam structural member, and belongs to the technical field of automobile doorsill sawing and milling machining. The system comprises a machine table, a robot body is arranged on the machine table; a cutter assembly comprises a power head, a milling cutter, a saw blade and an oil mist nozzle, the power head and the oil mist nozzle are both connected with the robot body, and the milling cutter and the saw blade are both in linkage connection with the power head; the sawing and milling jig is installed on the machine table and used for fixing a workpiece; a chip removal machine is connected with the bottom of the machine table and used for discharging cutting waste chips; and an oil mist collecting device comprises an oil mist collector and an oil mist collecting pipe, one end of the oil mist collecting pipe is connected with the oil mist collector, and the other end of the oil mist collecting pipe is arranged on the top of the machine table. The system has the beneficial effects that automatic machining production is achieved through the robot, the overall layout is optimized, the occupied area is reduced, the types of tools are standardized, and therefore the machining efficiency is greatly improved, the machining noise is reduced, and aluminum scraps and oil mist can be collected.

Owner:NINGBO MINTH AUTOMOTIVE PARTS RES&DEV CO LTD

A steel stamp processing device and its steel stamp box

The invention relates to a steel seal processing device adopting hydraulic pressure as driving power. The steel seal processing device comprises an operation assembly, a hydraulic power assembly, an electric control assembly, a work table, a support assembly and a position limiting assembly, wherein the hydraulic power assembly is connected with the operation assembly and provides hydraulic power, the electric control assembly controls the starting and the stopping of the hydraulic power assembly, the support assembly provides support effects, the operation assembly is a steel seal box, the steel seal box comprises a T-shaped channel steel seal module, a first L-shaped slide rail, a second L-shaped slide rail and character steel seal numbers arranged in the steel seal box, and the first L-shaped slide rail and the second L-shaped slide rail are symmetrically and fixedly arranged at the two sides of the T-shaped channel steel seal module through steel seal box locking screw bolts. The steel seal processing device has the technical effect that the hydraulic steel seal processing device with the advantages of low noise, high efficiency, safe operation stroke and capability of fast replacing different character steel seal numbers is provided.

Owner:SHANGHAI COSCO KAWASAKI HEAVY IND STEEL STRUCTURE

Novel metalworking composite aluminum plate slotting hole cutting-off machine tool

InactiveCN108000211AReduce vibrationReduce processing noiseLarge fixed membersPositioning apparatusMachine toolPlastic foam

The invention discloses a novel metalworking composite aluminum plate slotting hole cutting-off machine tool. The tool comprises machine too legs, clamping devices, an aluminum plate containing trolley, universal wheels, a plastic foam layer, an aluminum plate, sliding rods, a handheld cutting machine, a vehicle tail fixing plate and fixing bolts; each clamping device comprises a clamping piece, alimiting bolt and a spring, and the handheld cutting machine comprises a cutting machine, a sliding block, a handle, a limiting iron chain and a limiting spring. According to the novel metalworking composite aluminum plate slotting hole cutting-off machine tool, the aluminum plate containing vehicle is adopted to convey an aluminum machine to be machined and the machined aluminum plate, through the clamping devices, the aluminum plate makes sufficient contact with the plastic foam layer, when the aluminum plate is machined, vibration of the aluminum plate can be reduced to a great degree, machining noise is reduced, a cutter blade is protected, the handheld cutting machine can slide to any position of the aluminum plate through the sliding block above the cutting machine, a spring connected with the handheld cutting machine mainly is used for saving labor of workers, and the machine tool is high in practicability and suitable for being universally popularized.

Owner:安徽福瑞尔铝业科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com