Patents

Literature

242 results about "Diamond knife" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A diamond knife is a very sharp knife in which the edge is made from diamond, invented by Humberto Fernández-Morán in 1955. Diamond knives are used for medical and scientific applications where an extremely sharp and long-lasting edge is essential. The knives are very expensive to initially purchase, depending on the quality and size of the knife; in addition the knives must be professionally sharpened as the edge dulls.

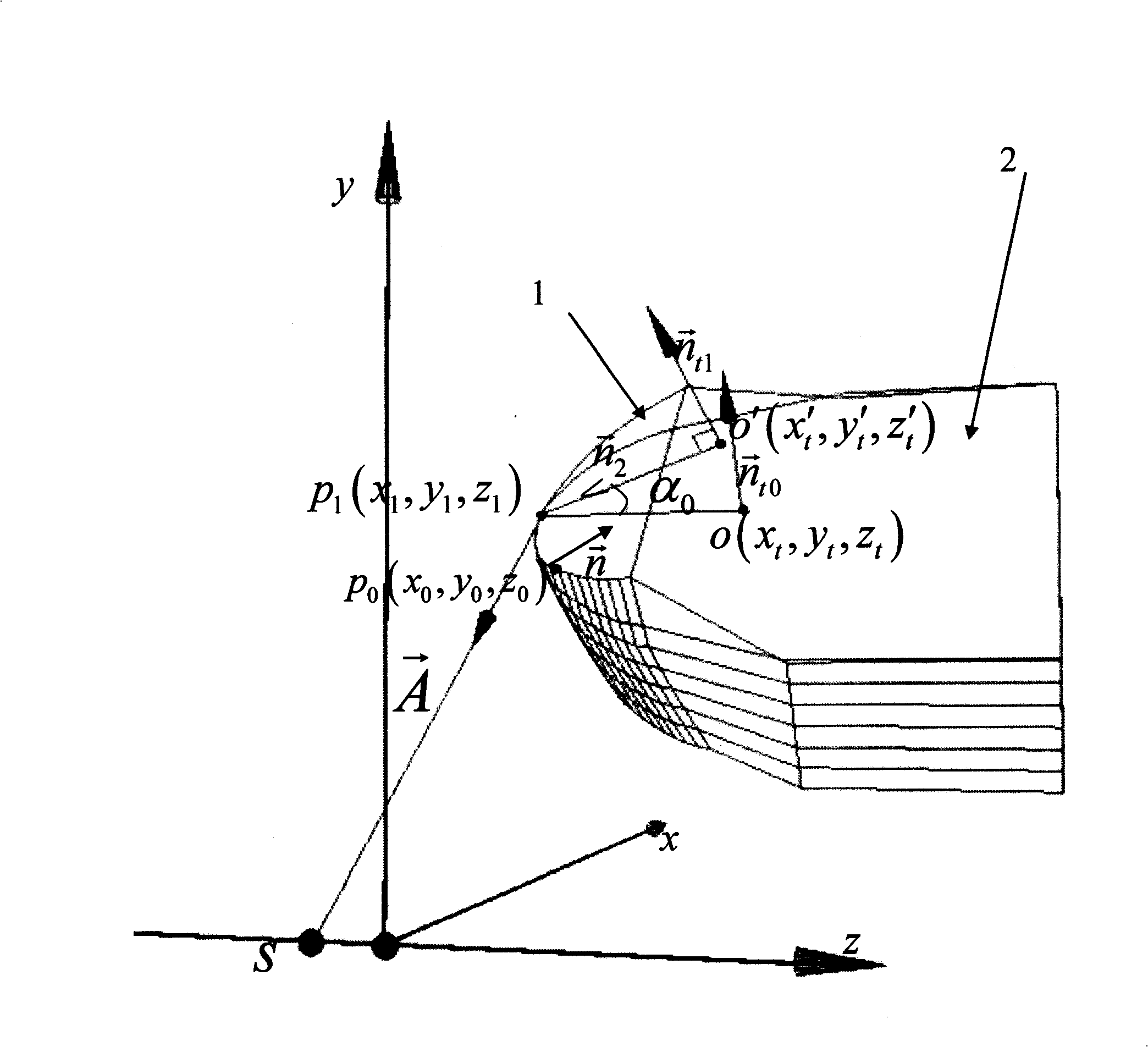

Ultra-precise turning method with diamond knife tool hook angle compensation

ActiveCN101246365AQuality improvementImprove practicalityNumerical controlManufacturing technologyPath generation

The invention belongs to ultra precise machining, complex parts fabrication technique field, relates to a ultra precise turning process with diamond knife tool anterior angle compensating for three axis diamond ultra precise machine tool. The method adapts above tool orthogonal rake compensating to search lathe coordinate of knife for many coordinate on the mould, and generates machining paths according to certain paths to realize the machining for surface model tool orthogonal rake compensating. In the paths generation method, the knife with anterior angle is compensated on the anterior angle to realize tool bit accurate control in case of machining brittleness material and ultra precise turning with high shape accuracy.

Owner:TIANJIN UNIV

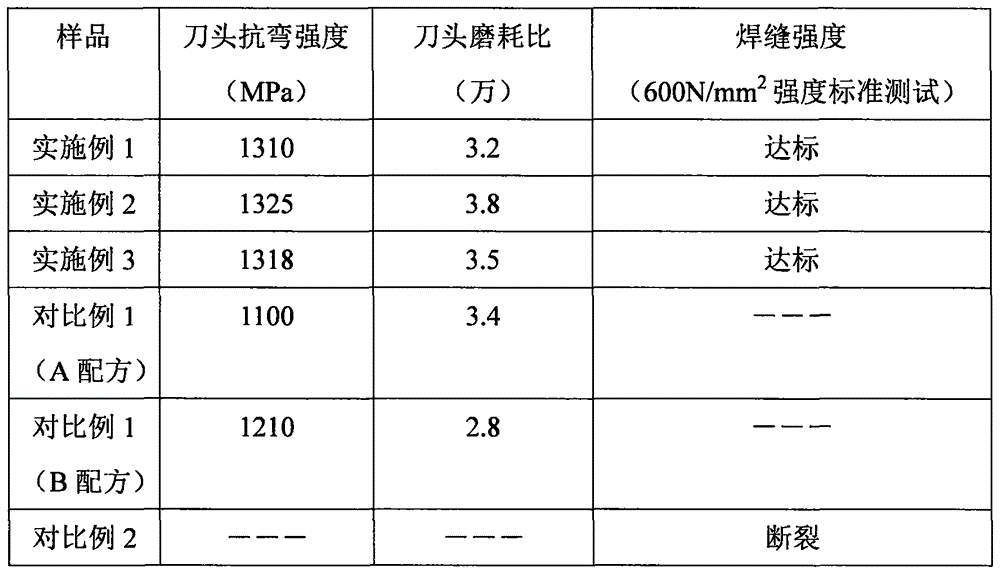

Metal cement diamond tool for preparing ultrathin saw blade diamond tool-bit

The invention relates to a metal binder for preparing an ultra-thin saw blade diamond knife head and the diamond knife head. The metal binder is prepared by 75-95wp of A, 3-20wp of B and 1-10wp of C; wherein, A is prepared by 50-80wp of Cu, 15-40wp of Fe and 1-20wp of Co; B is prepared by 70-95wp of Cu, 3-25wp of Sn and 0.2-6wp of P; and C is prepared by 88 percent of Al, 2 percent of CE and 10 percent of Ni according to atomic; the metal binder and 30 / 40mesh coarse particle excellent diamonds are mixed according to conventional concentration and sintered to form the ultra-thin saw blade diamond knife head which is matched with a 2.5mm ultra-thin substrate. The diamond knife head has good sharpness, stable cutting performance and high precision of cut boards and eliminates undesirable phenomena of angle board, step-shaped board, ax-shaped board, board with uneven thickness, and the like, thus fully meeting the requirements of the ultra-thin diamond knife head for matching the 2.5mm ultra-thin substrate.

Owner:泉州众志金刚石工具有限公司

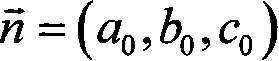

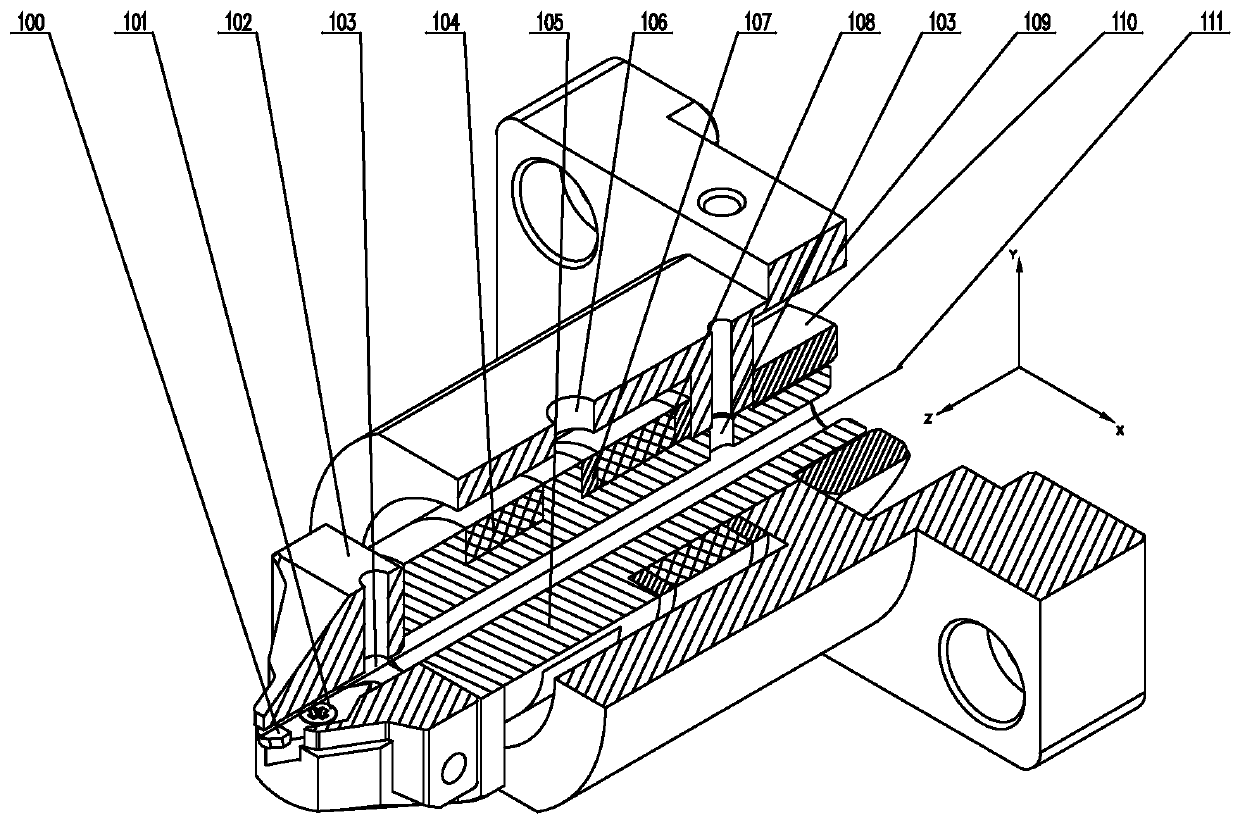

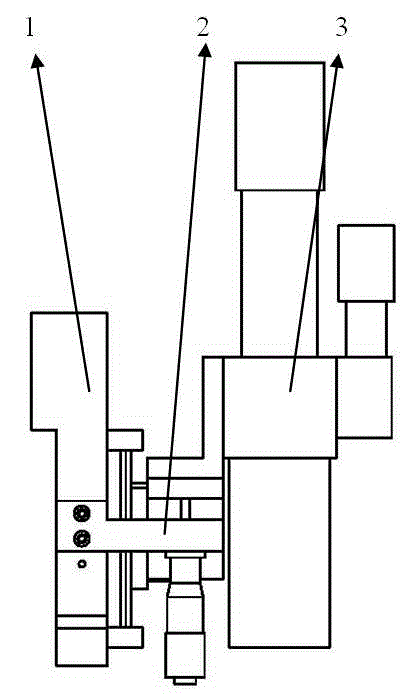

Tool holder device of adjustable type diamond knife tool

InactiveCN101474831AAchieve regulationLow costWorking accessoriesFine working devicesEngineeringDiamond knife

A cutter holder device of adjustable diamond cutter relates to a cutter holder device. The invention settles the problems of unsuitability for adjusting the angle of cutter in manufacturing, requirement for replacing different cutters, cost increase and low working efficiency in the cutter holder device of prior diamond cutter. The external edge of rotating guiding sleeve is symmetrically provided with two arc-shaped through holes. The rotating guiding sleeve is installed on the upper end of fine-adjusting feed screw shaft through guiding key. The inner sleeve of feed screw is sleeved at the middle part of fine-adjusting feed screw shaft and is connected with the fine-adjusting feed screw shaft through sleeve. A fine-adjusting spider handle is fixedly installed on the inner sleeve of feed screw. Two screws sequentially traverse an end cap and the arc-shaped through hole on the rotating guiding sleeve and are connected with circular cylinder. A swinging supporting axis is installed between the fine-adjusting feed screw shaft and the cutter holder. The fine-adjusting feed screw shaft is connected with the cutter holder through four rotating adjusting screws. The cutter holder device of the invention has the advantages of compact structure, convenient adjustment, high adjusting precision, and suitability for processing various precise and ultra-precise processing machine tools.

Owner:HARBIN INST OF TECH

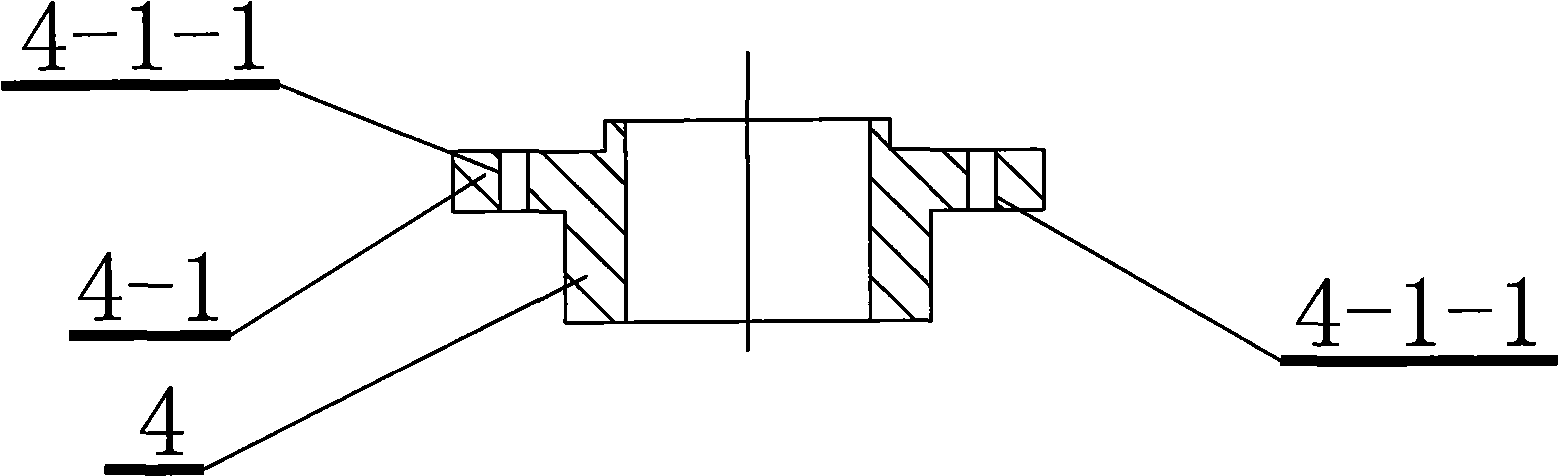

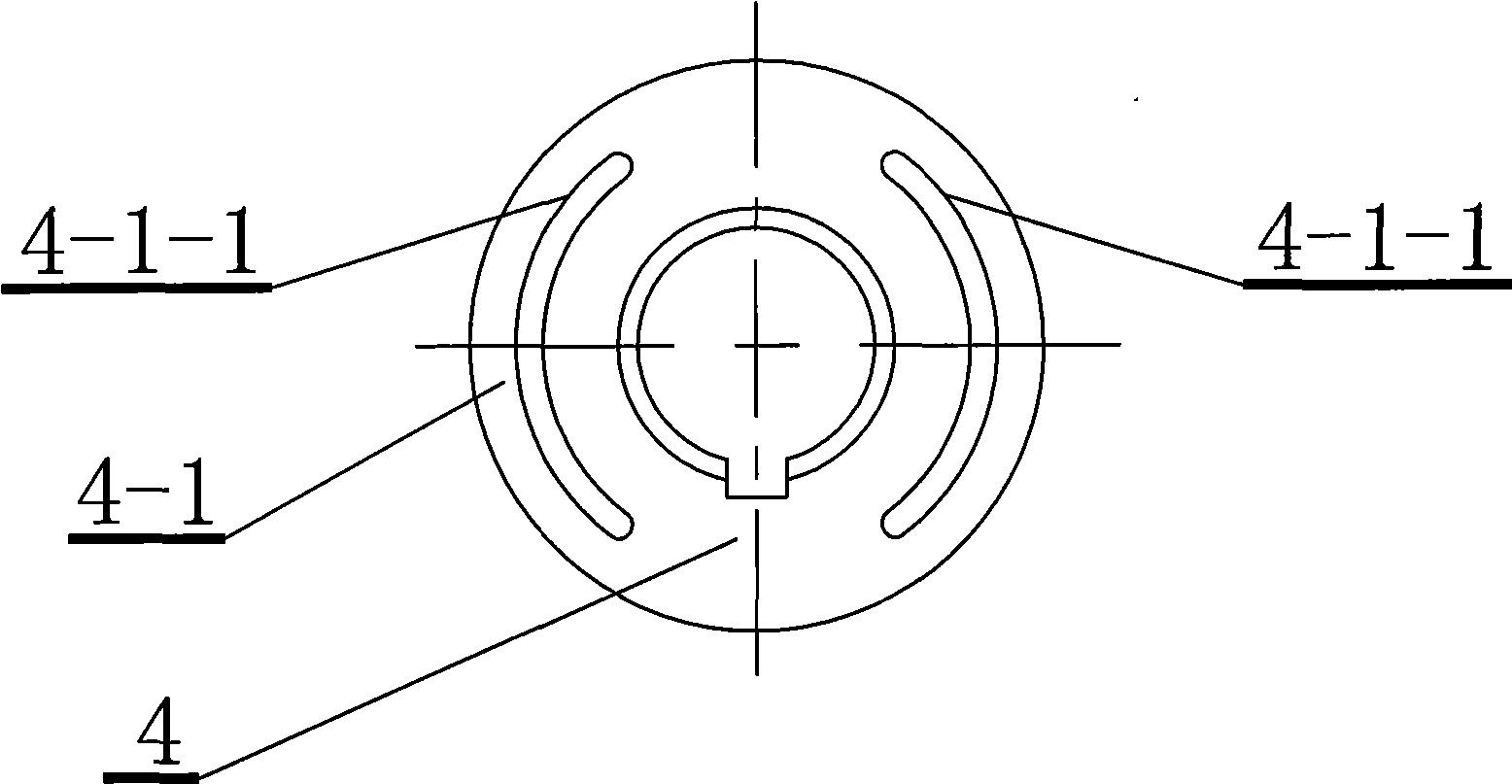

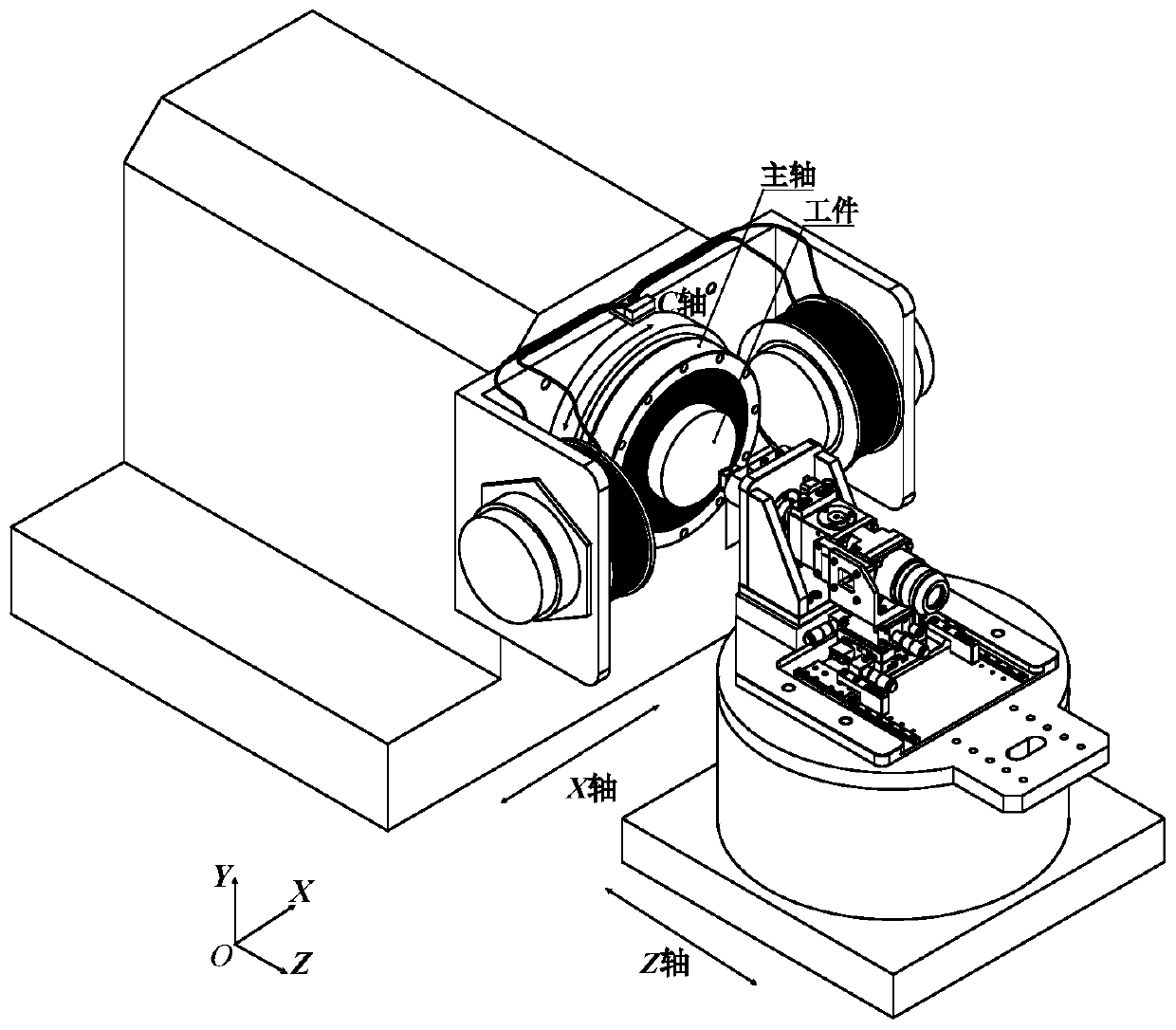

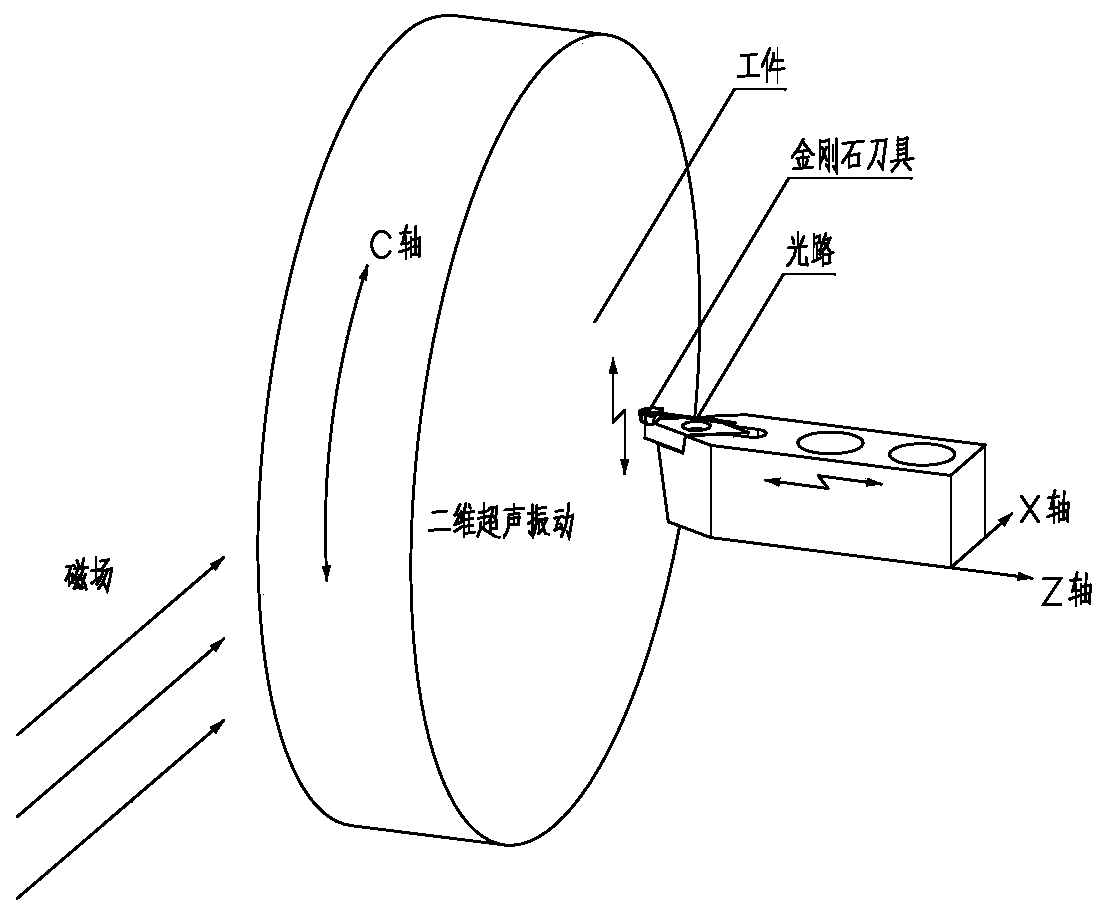

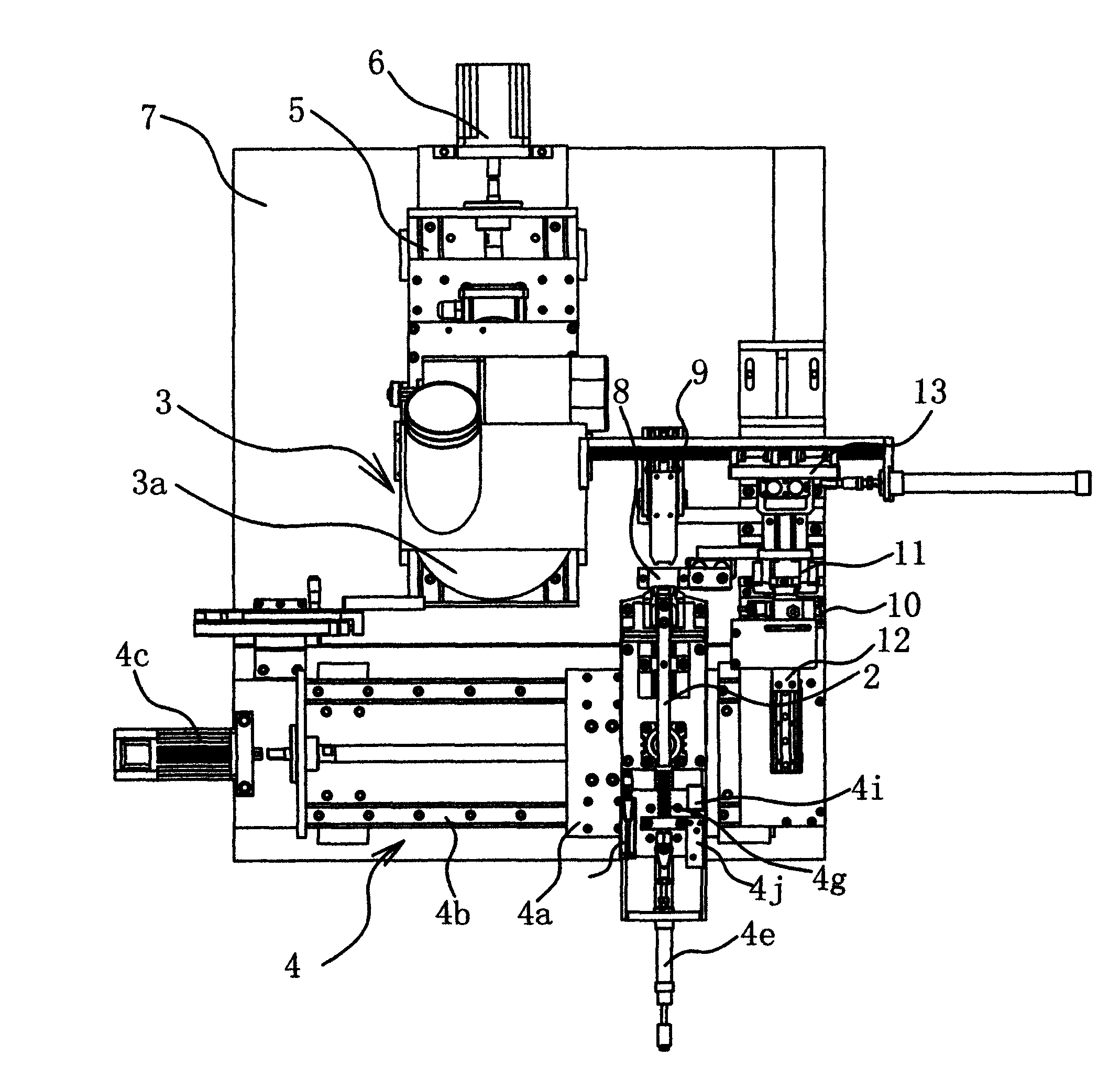

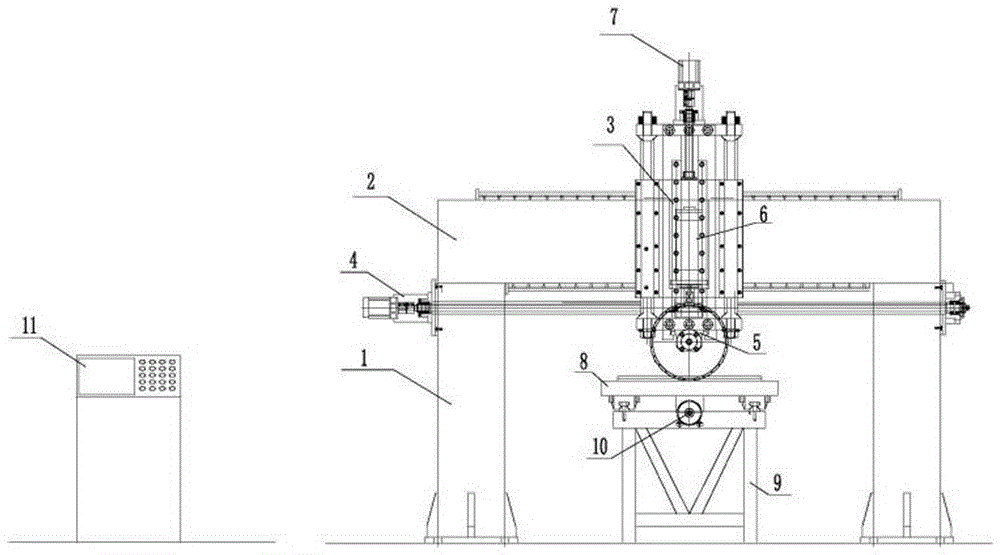

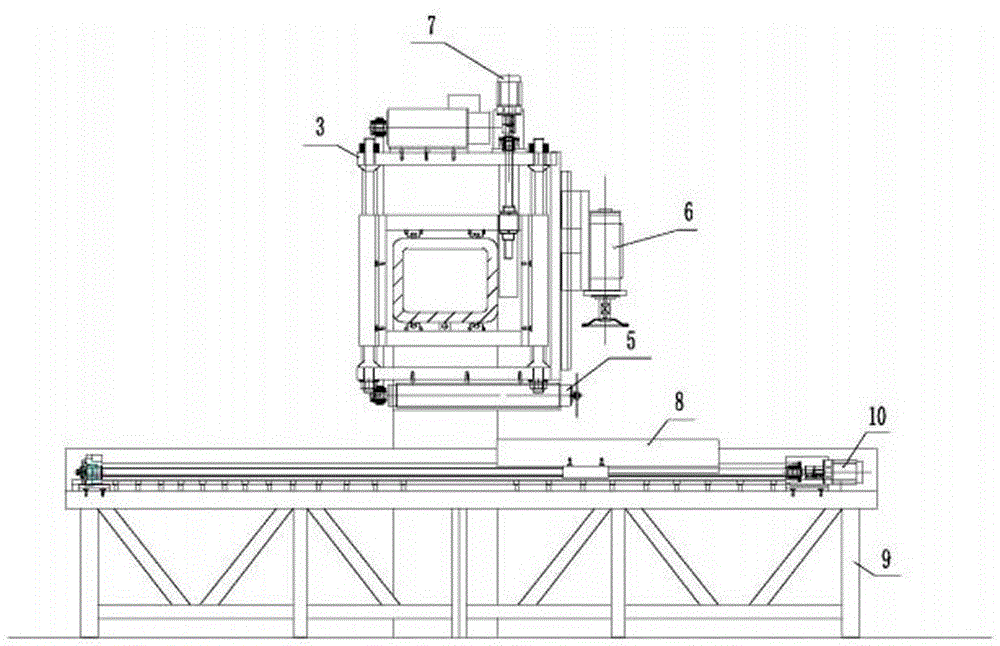

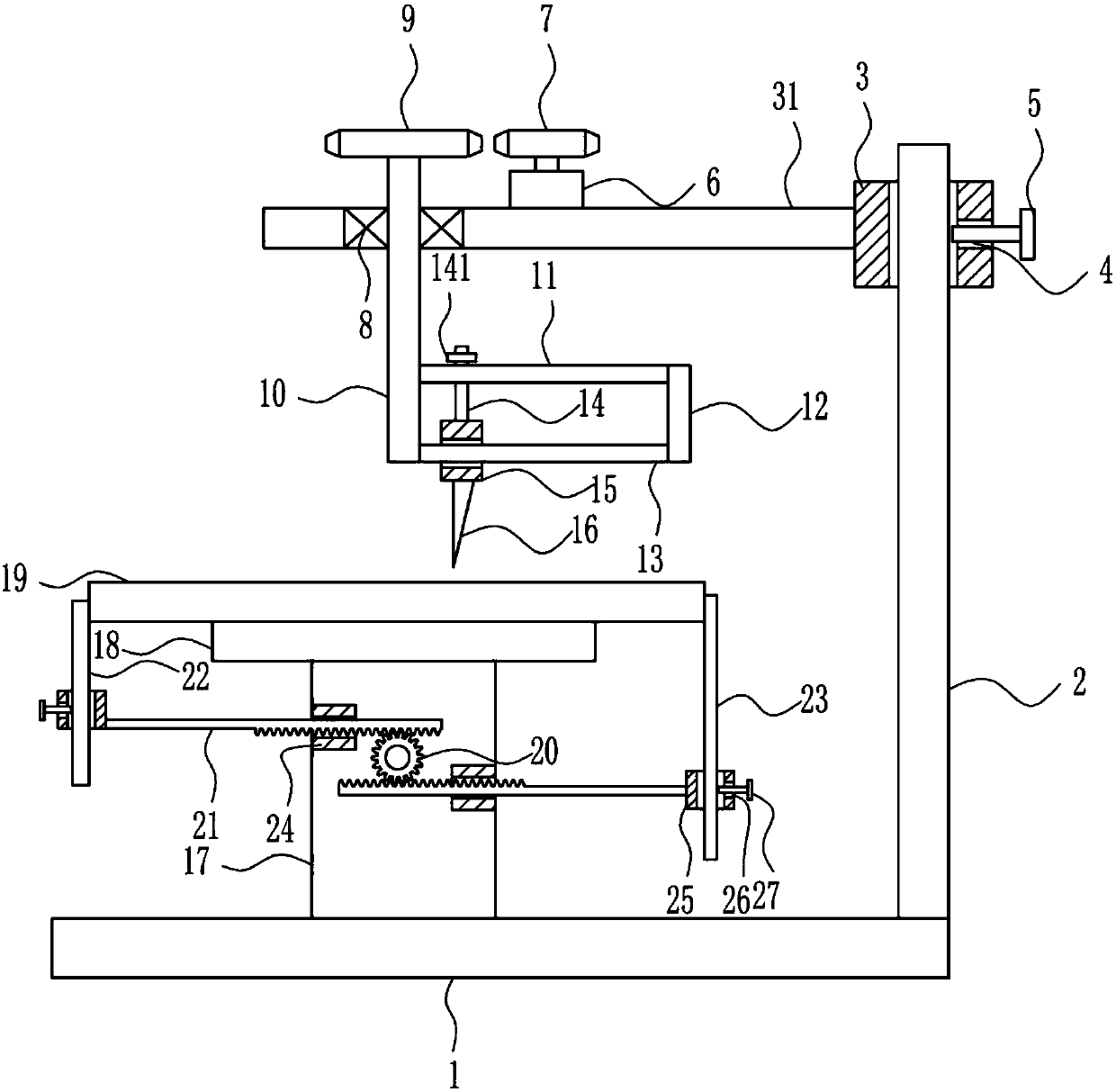

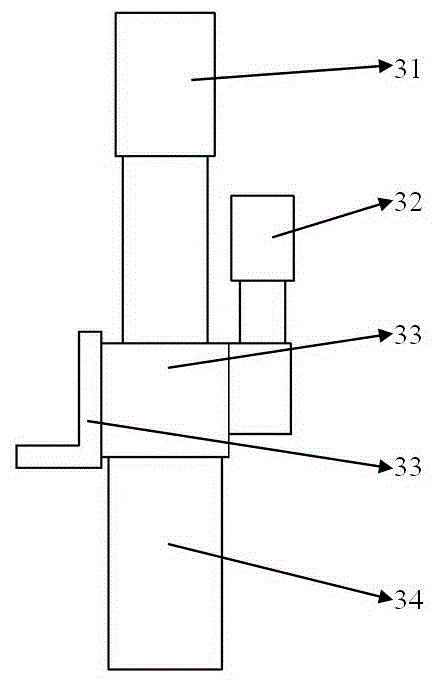

Multi-field-assisted diamond cutting equipment

ActiveCN111070433AIncreased depth of critical plastic-brittle transitionMinimize subsurface damageWorking accessoriesFine working devicesDiamond cuttingEngineering

The invention belongs to the technical field relevant to ultra-precision machining, and discloses multi-field-assisted diamond cutting equipment. The diamond cutting equipment comprises a laser auxiliary device, an ultrasonic vibration auxiliary device, a magnetic field auxiliary device and a machining auxiliary device, and the magnetic field auxiliary device and the ultrasonic vibration auxiliarydevice are arranged on the machining auxiliary device and oppositely arranged; the laser auxiliary device and the ultrasonic vibration auxiliary device are oppositely arranged; the machining auxiliary device is further used for bearing workpieces; in the machining process, the magnetic field auxiliary device generates a magnetic field, and the workpieces are located in the magnetic field; and thelaser auxiliary device emits a laser beam so as to conduct preheating softening or degrading on the workpieces, the ultrasonic vibration auxiliary device generates two-dimensional elliptic vibrationat a tool nose of a diamond cutting tool, and meanwhile the laser beam is focused on the tool nose of the diamond cutting tool. The machining efficiency and quality are improved, the life of the cutting tool is prolonged, and flexibility is good.

Owner:HUAZHONG UNIV OF SCI & TECH

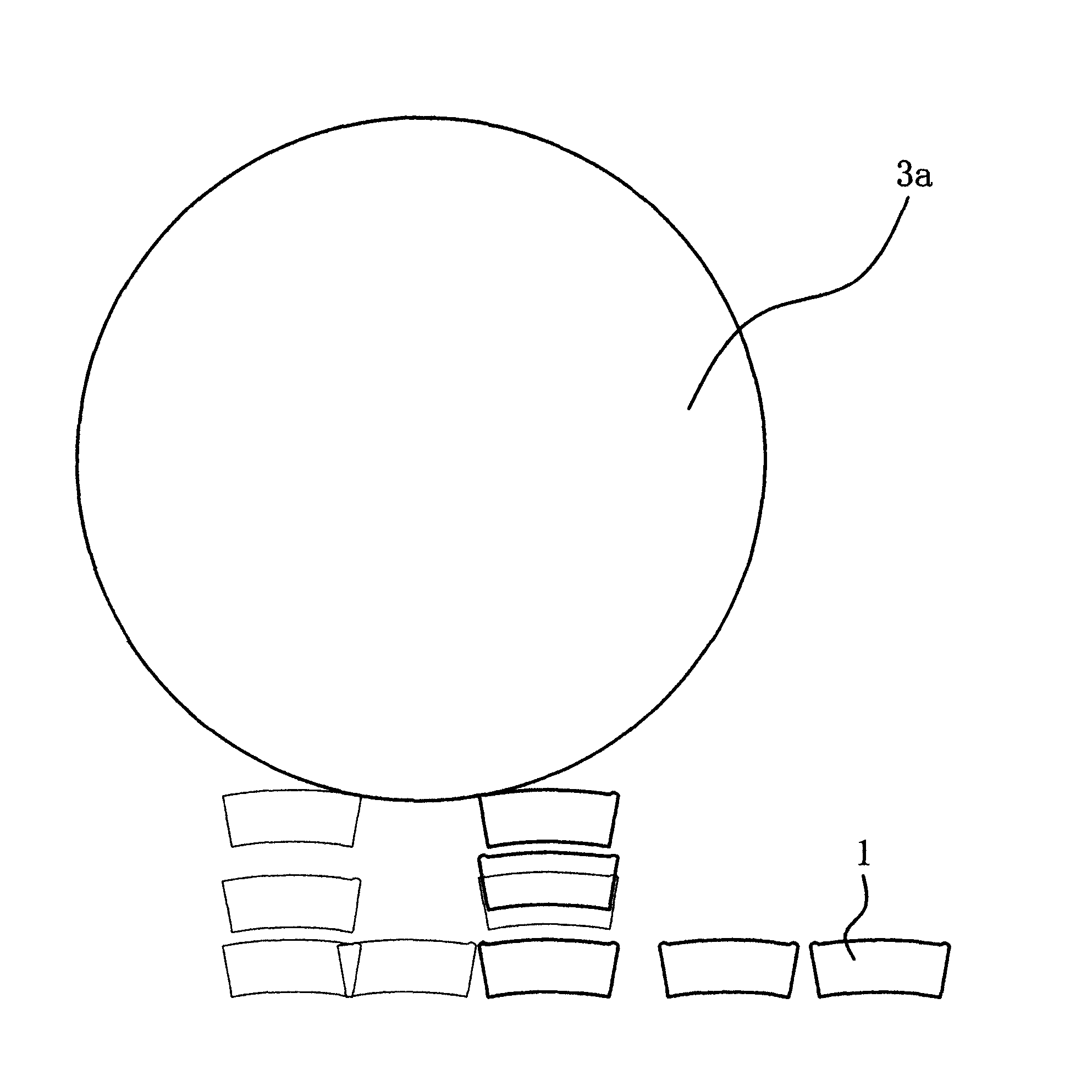

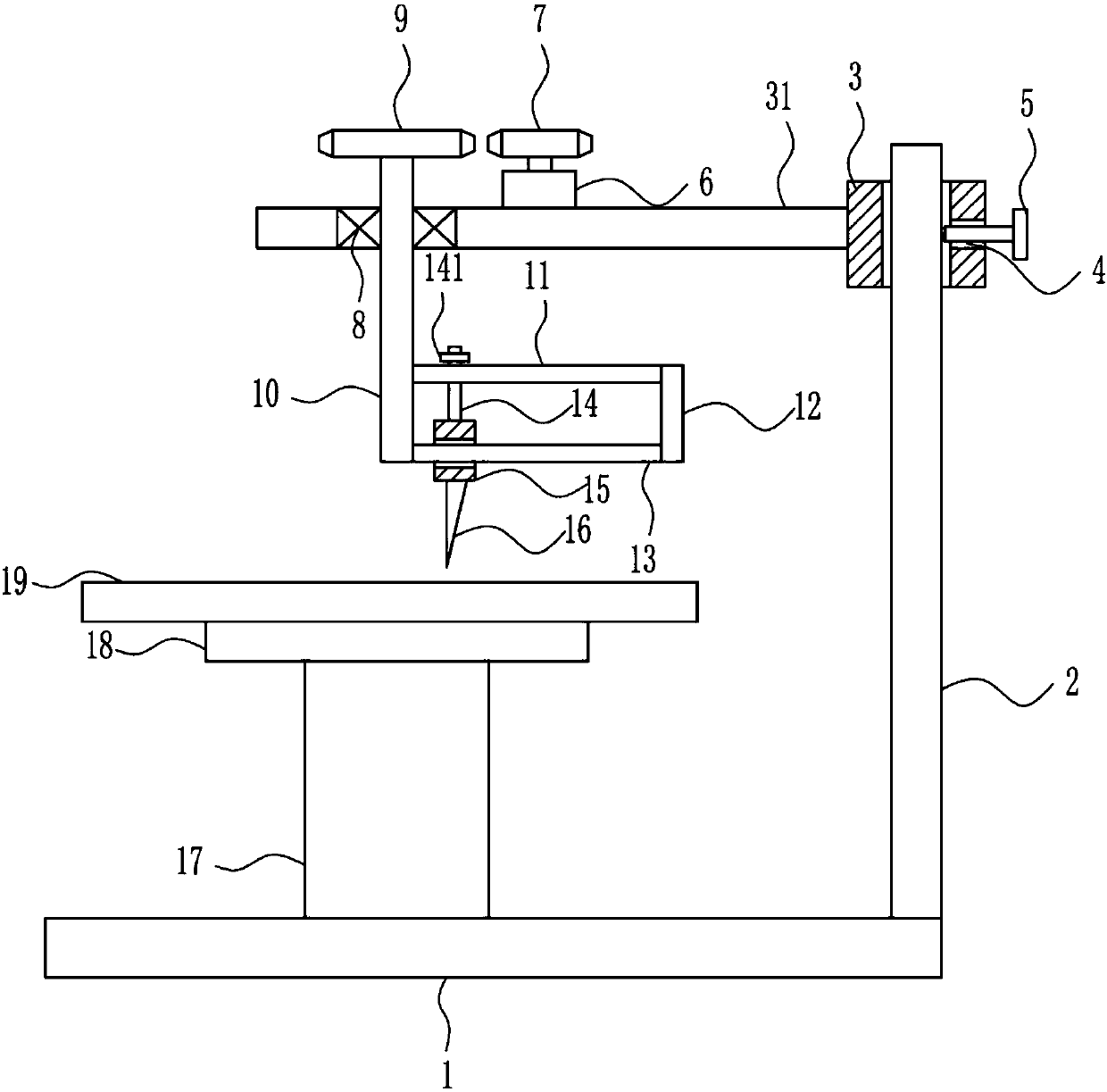

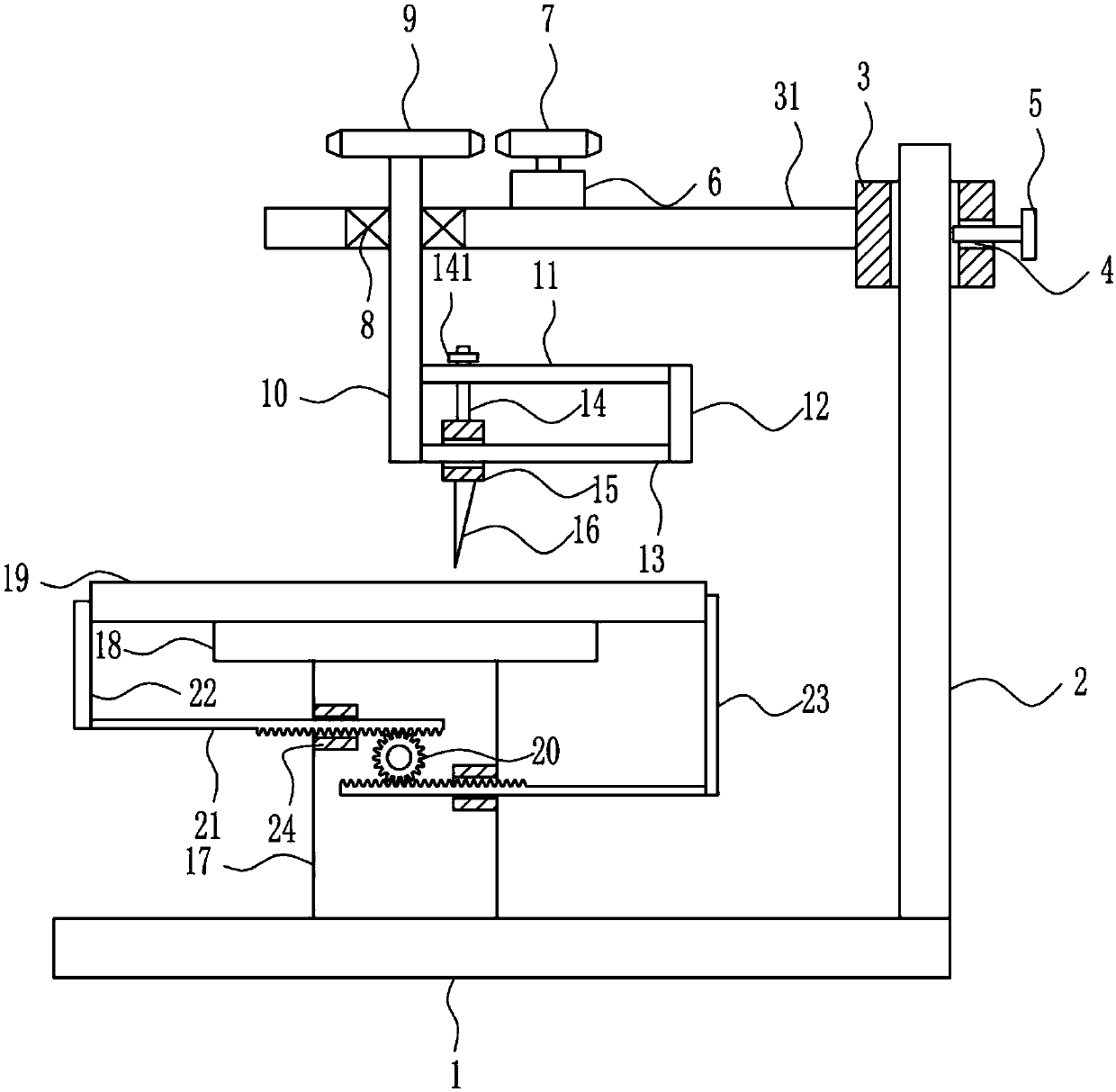

Diamond tool bit edge and corner grinding device

ActiveCN103317408ACompact layoutReasonable designEdge grinding machinesGrinding drivesGeneral purposeTool bit

The invention provides a diamond tool bit edge and corner grinding device, belongs to the technical field of machinery and solves the problem of low production efficiency due to the fact that presently, diamond tool bit edges and corners are grinded through the general-purpose machine tool. The diamond tool bit edge and corner grinding device comprises a machine frame and a clamp used for clamping a diamond tool bit and provided with an outward outer side surface. A grinding mechanism provided with a flat grinding wheel is arranged on the machine frame. A feeding mechanism capable of driving the clamp to move and leading the outer side surface of the diamond tool bit and the grinding surface of the flat grinding wheel to be tangent is further arranged on the machine frame, and the tangency point of the outer side surface of the diamond tool bit and the grinding surface of the flat grinding wheel is located on an edge and corner line. The diamond tool bit edge and corner grinding device has the advantages of being compact in arrangement, reasonable in design and simple in structure, being capable of grinding the edges and corners of the diamond tool bit flat and smoothly, having a high qualified rate, being capable of feeding and conveying materials automatically and accordingly being high in production efficiency.

Owner:ZHEJIANG BANNINGER FLUID CONTROL CO LTD

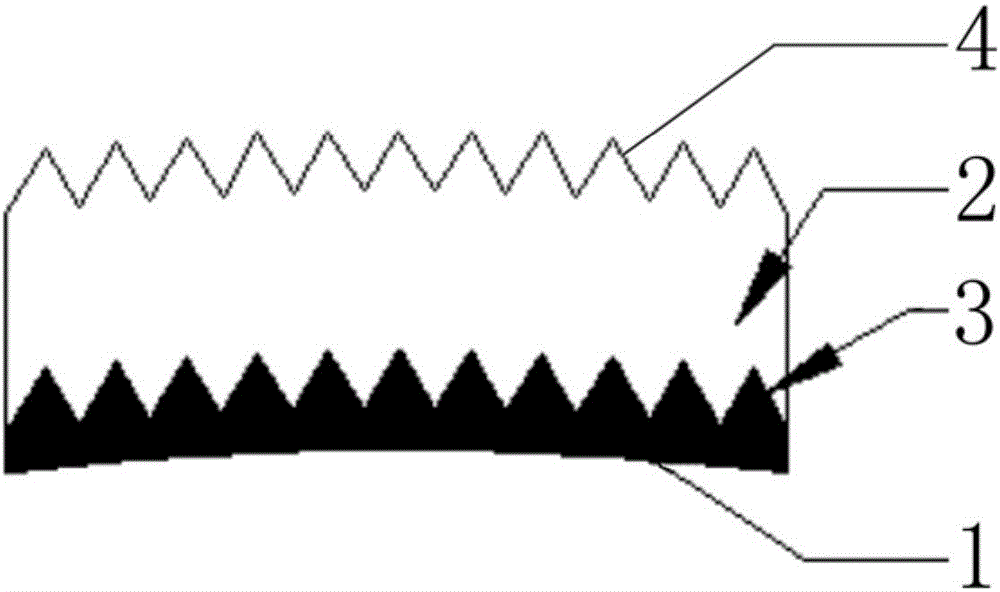

Anti-drop diamond brad and manufacturing process thereof

The invention discloses an anti-drop diamond brad, which comprises a cutter bit, a matrix and a base, and is characterized in that: the cutter bit is prepared from uniform powder prepared by mixing a soft matrix material and a superfine diamond in an irregular shape through hot-pressing sinter molding, wherein the soft matrix material consists of the following components in percentage by weight: 15 to 25 percent of copper, cobalt and iron alloy, 45 to 85 percent of bronze powder, 2 to 5 percent of tin powder, 5 to 10 percent of nickel powder, 2 to 5 percent of titanium powder, 2 to 6 percent of zinc powder and a proper amount of filler; the superfine diamond has the concentration of 12 to 25 percent; and a dovetail groove connecting mechanism is arranged on opposite surfaces of the cutterbit and the matrix. The diamond cutter bit is reasonable in components and proportion, the cutter bit has high bending strength and good self-sharpening property, and a holding force of diamond particles is improved; moreover, the dovetail groove connecting mechanism is arranged between the cutter bit and the matrix, so that the diamond cutter bit is firmly connected with the matrix, the phenomenon that the diamond cutter bit drops is avoided, potential safety hazards are eliminated, and the service life of the diamond brad is prolonged.

Owner:福建省泉州万龙石业有限公司

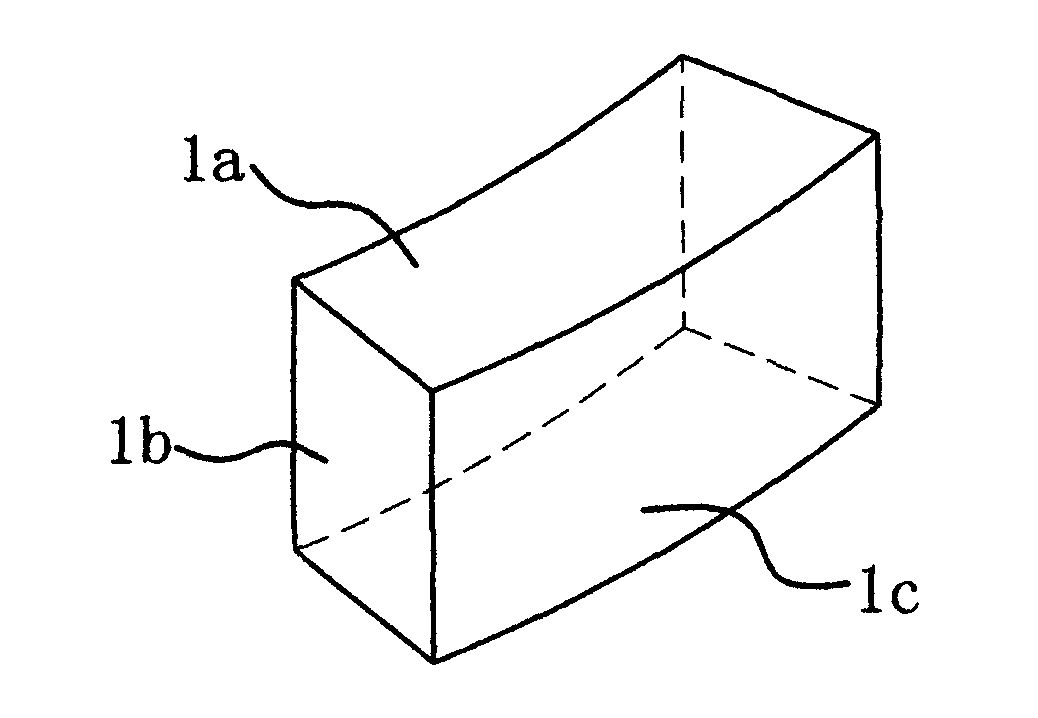

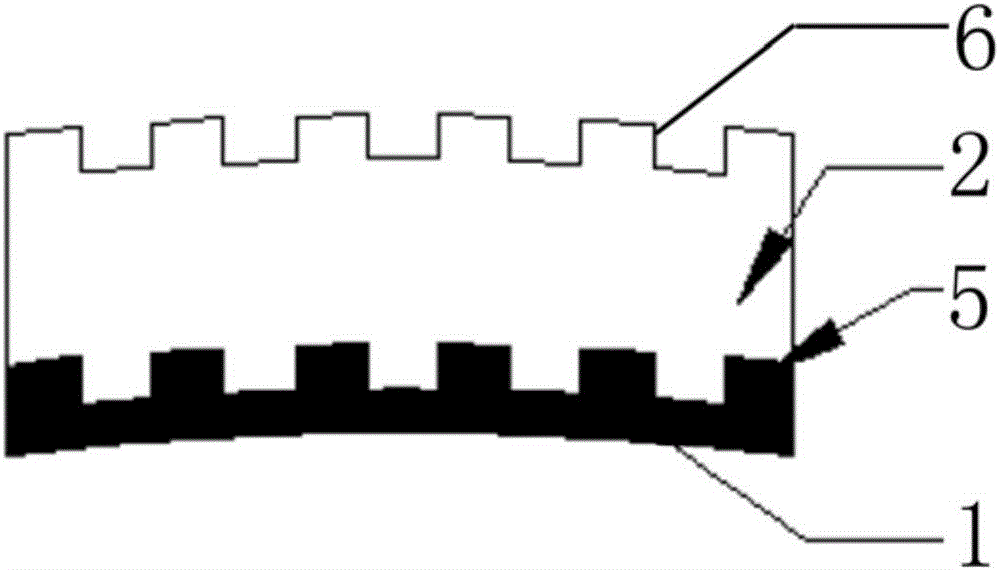

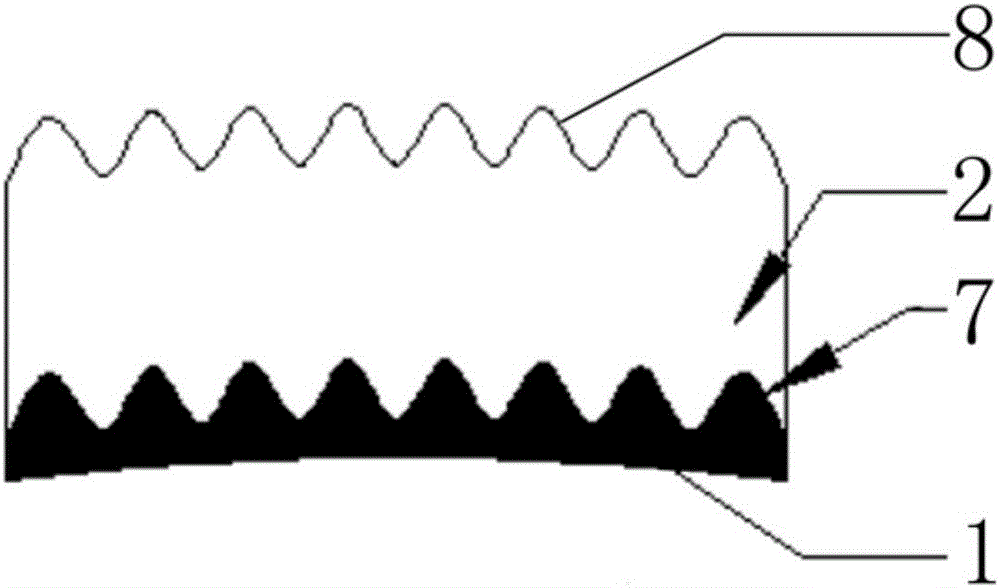

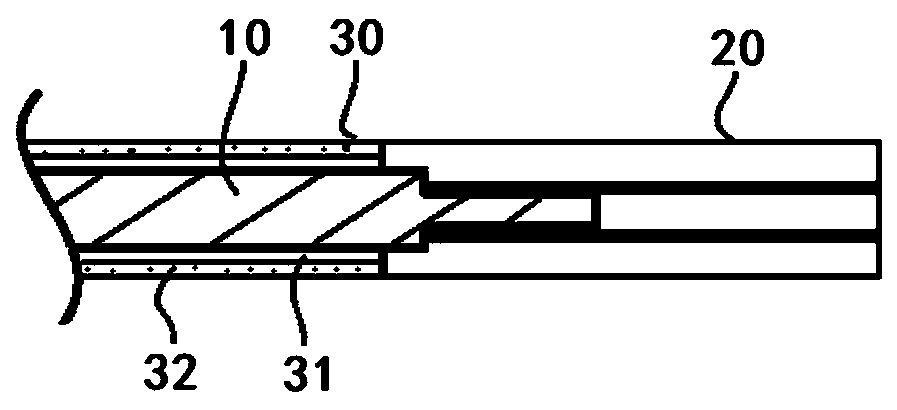

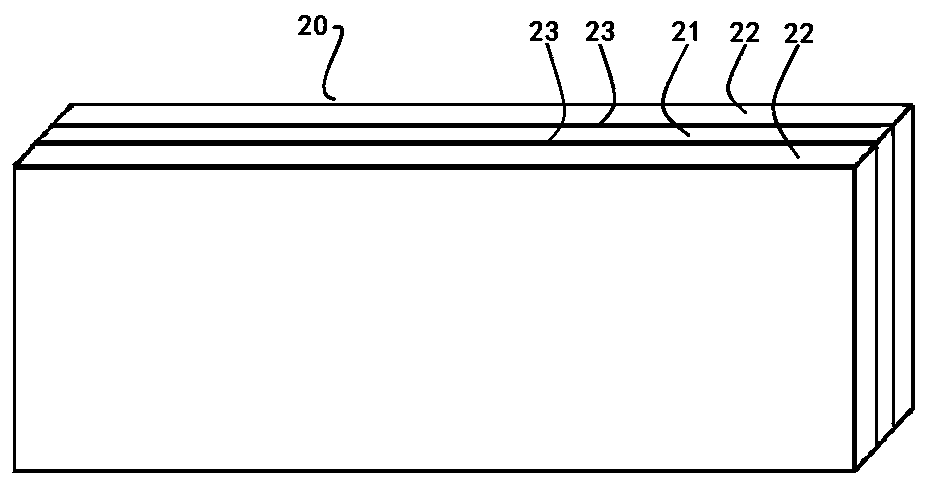

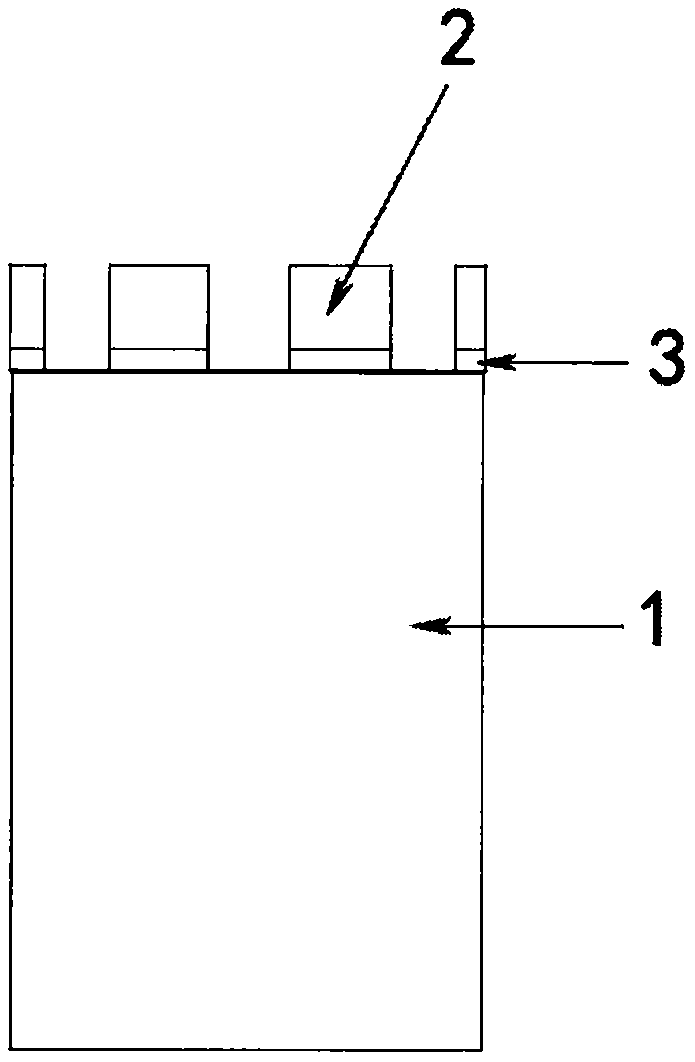

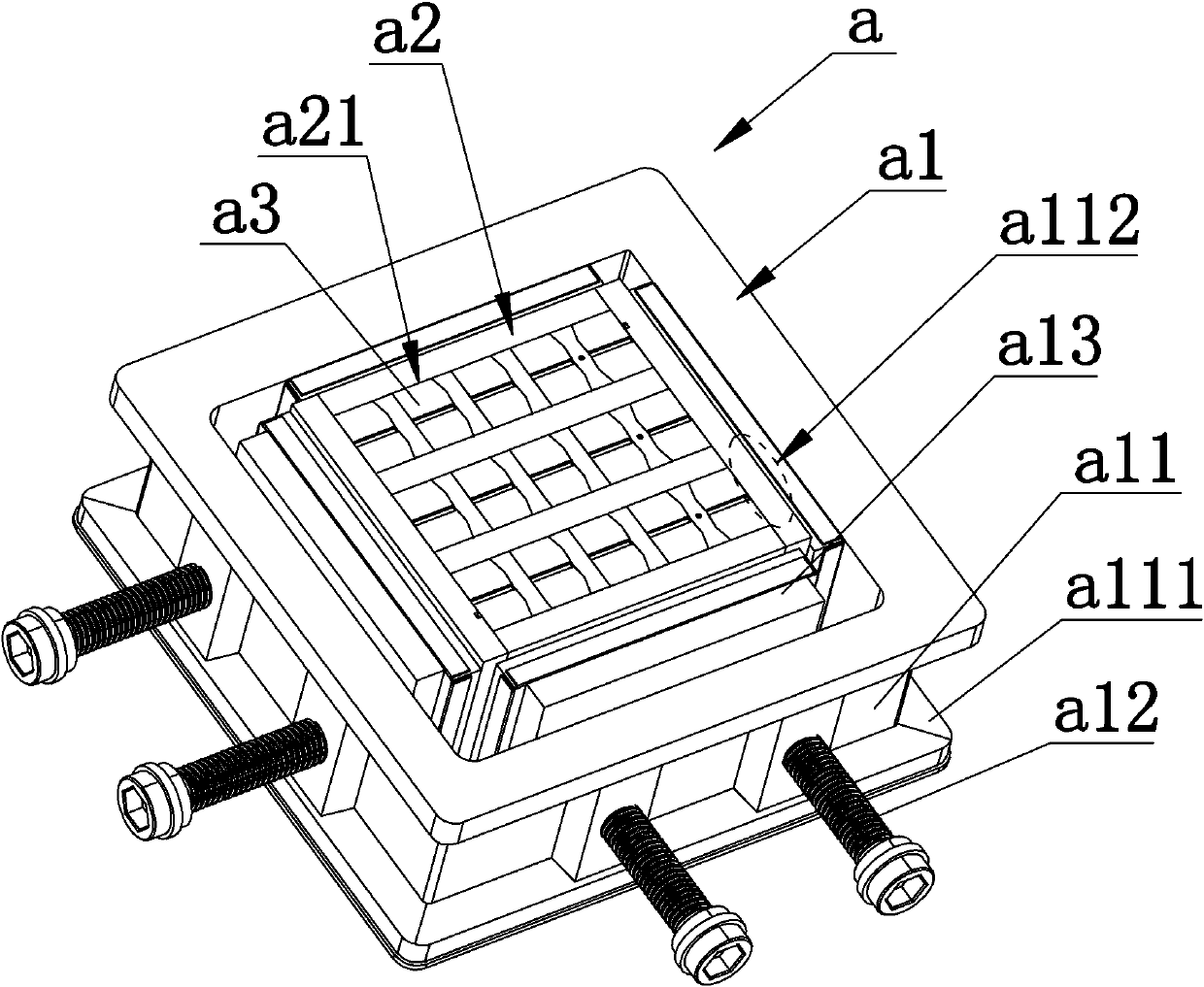

Diamond tool bit, preparation method of diamond tool bit, cold pressing mold for diamond tool bit, and diamond saw blade

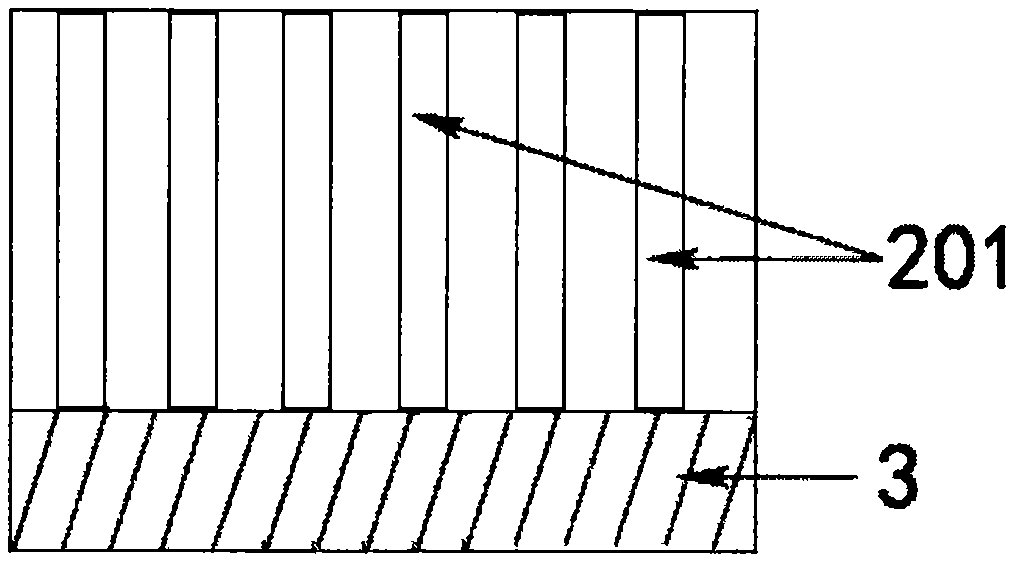

InactiveCN106272989AAvoid inclusionsIncrease binding areaStone-like material working toolsTool bitConvex structure

The invention discloses a diamond tool bit, a preparation method of the diamond tool bit, a cold pressing mold for a diamond tool bit, and a diamond saw blade. The diamond tool bit comprises a transition layer which does not contain diamonds and a working layer containing diamonds. A concave-convex structure is arranged at the joint of the transition layer and the working layer. According to the diamond tool bit, the transition layer which does not contain diamonds and the working layer containing diamonds are engaged mutually through the concave-convex structure, the bonding area of the transition layer and the working layer is increased, and the bonding strength between the transition layer and the working layer is high; and meanwhile, according to the diamond tool bit of the structure, the transition layer or the working layer can be independently formed at first during cold press molding, the situation that the transition layer and a substrate welding face include diamonds due to the fact that transition layer powder and working layer powder are simultaneously put into a mold cavity is avoided, and the effect that the transition layer does not contain diamonds is ensured, so that guarantees are provided for subsequent welding quality on the basis that the bonding strength of the transition layer and the working layer is also considered.

Owner:河南涵信金刚石工具有限公司

Micro-vibration auxiliary cutting device and method for brittle material

InactiveCN101544029ASimple structureLow costStone-like material working toolsDiamond knifeEngineering

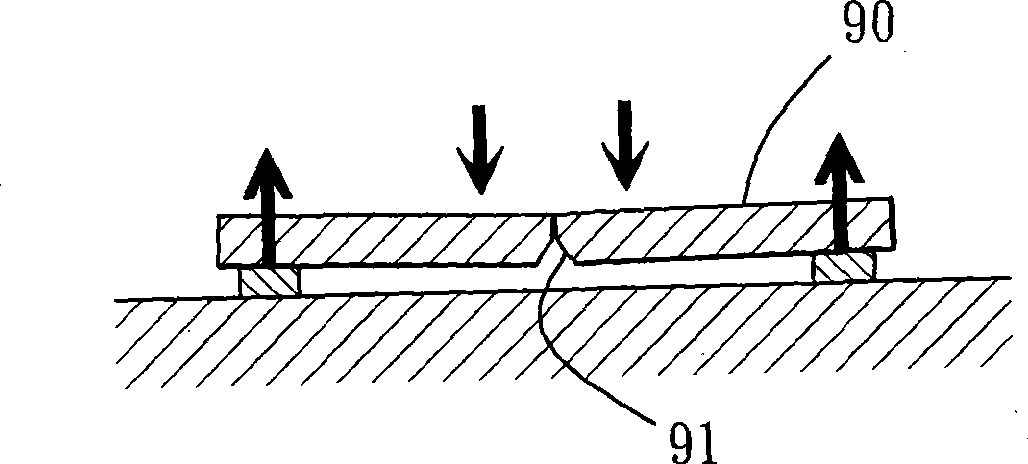

The invention relates to a micro-vibration auxiliary cutting device and a method for a brittle material. The method partially comprises the following steps: 1, a preparation step; 2, an initial cutting step; 3, a slot-following vibration step; and 4, a completion step. Therefore, an initial kurf with a first depth on a workpiece on a workpiece fixing part is obtained through the cutting of an initial cutting part; and a vibration contact part moves along the initial kurf and simultaneously produces a slight amount of vibration which is perpendicular to the initial kurf and has a preset frequency, so that the first depth of the initial kurf is deepened to a second depth and the workpiece is further ruptured. Therefore, the cutting device simultaneously has the advantages of being applicable to harder and thicker workpieces to be cut, adopting a minor tungsten carbide or diamond knife flywheel, having a simple structure and low cost, and the like.

Owner:CONTREL TECH CO LTD

Monocrystal diamond tool processing method and monocrystal diamond tool

The invention discloses a monocrystal diamond tool processing method and a monocrystal diamond tool. The monocrystal diamond tool processing method includes the following steps that firstly, a monocrystal diamond material is prepared; secondly, a hard alloy matrix end is processed so that positioning and welding of the monocrystal diamond material can be convenient; thirdly, the monocrystal diamond material is welded to the hard alloy matrix end, and the monocrystal diamond tool is formed; fourthly, according to the appearance and contour design requirement of the tool, a laser cutting method is adopted for processing the monocrystal diamond tool; and fifthly, a thermo-chemical polishing method is adopted for grinding a tool cutting edge of the monocrystal diamond tool. According to the monocrystal diamond tool processing method, the monocrystal diamond tool is processed through laser, and surface impacting groove marks caused by a machining method are avoided; the thermo-chemical polishing method is used for grinding the tool cutting edge of the monocrystal diamond tool, and the high-quality tool cutting edge can be obtained easily in a grinding manner; and during laser processing, the surface of the monocrystal diamond tool is coated with a coating, transmission and reflection of the laser are effectively prevented, and the processing efficiency and quality of the tool are improved.

Owner:深圳市力博刀具技术有限公司

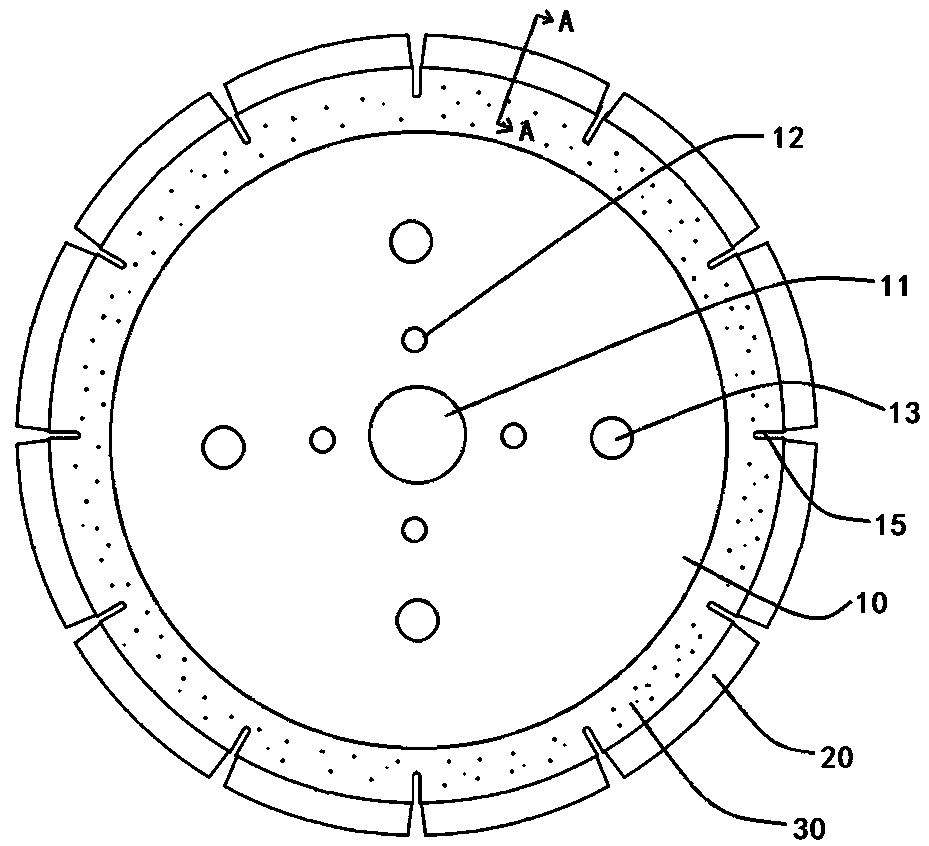

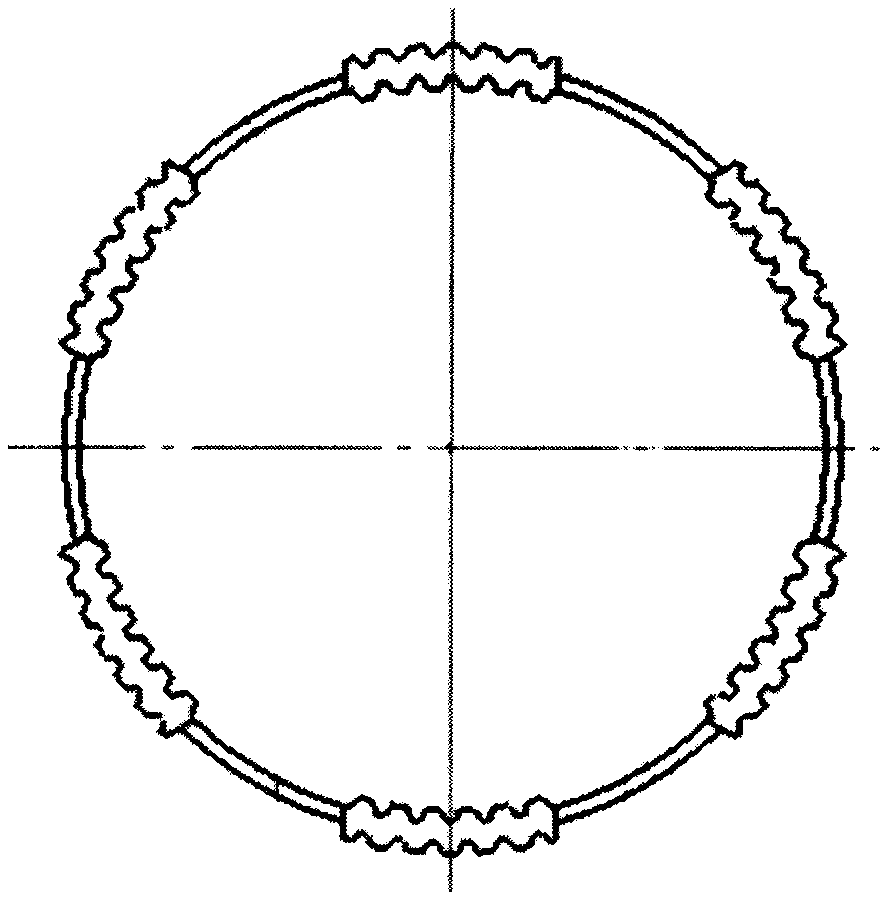

Diamond cutting circular saw blade

InactiveCN106272984AImprove crushing efficiencyImprove discharge efficiencyStone-like material working toolsDischarge efficiencyDiamond cutting

The invention discloses a diamond cutting circular saw blade. The diamond cutting circular saw blade comprises a base body, a diamond knife head and a central hole, wherein saw teeth which are uniformly distributed along the external circumference of the base body are fixed on the base body, the diamond knife head is welded on the saw teeth, the thickness of the diamond knife head is greater than that of the base body, a chip groove is formed in the bottom of a gap between every two saw teeth on the base body, and at least one debris baffle is fixed on each of lateral surfaces of two sides of the base body; abrasive layers are fixed on both the lateral surfaces of the two sides of the base body. The diamond cutting circular saw blade has the advantages that a cutting section is finely ground by the abrasive layers when the diamond knife head of the saw blade cuts materials to facilitate higher flatness of the cutting section while ensuring the cutting speed, thereby reducing production procedures and lowering the cost; the debris baffles crush residual materials generated while cutting again, and the crushed residual materials are discharged from the chip grooves to enhance the crushing and discharging efficiency of the residual materials to prevent the residual materials from being collided or wound on a transmission shaft of cutting equipment, so that the cutting equipment is easy to clean and is ensured to be normally operated.

Owner:江苏益林金刚石工具有限公司

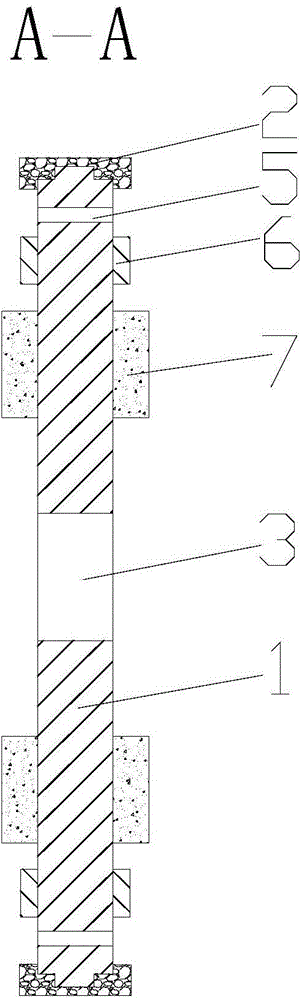

Preparation method of complex CVD (chemical vapor deposition) diamond cutter

ActiveCN102615490AAvoid moldingReduce manufacturing costChemical vapor deposition coatingDiamond knifeChemical vapor deposition

The invention relates to a preparation method of a complex CVD (chemical vapor deposition) diamond cutter. The preparation method is characterized by comprising seven steps, namely (1) preparation of a base material; (2) mold processing; (3) pretreatment of a mold cavity; (4) deposition; (5) mold stripping; (6) destressing; and (7) welding. According to the preparation method disclosed by the invention, a material which is easy to process is taken as a mold, and a CVD diamond thick film blade in a complex shape is deposited in the mold cavity, so that forming, grinding and polishing processing of a complex geometric surface of a cutting part of the diamond cutter can be avoided. According to the preparation method disclosed by the invention, the forming of the CVD diamond thick film blade with high precision and complex shape can be realized, and the complex CVD diamond cutter can be obtained by vacuum brazing. The method has the advantages of simplicity, easiness in realization and capability of greatly reducing the manufacturing cost of the complex diamond thick film cutter.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

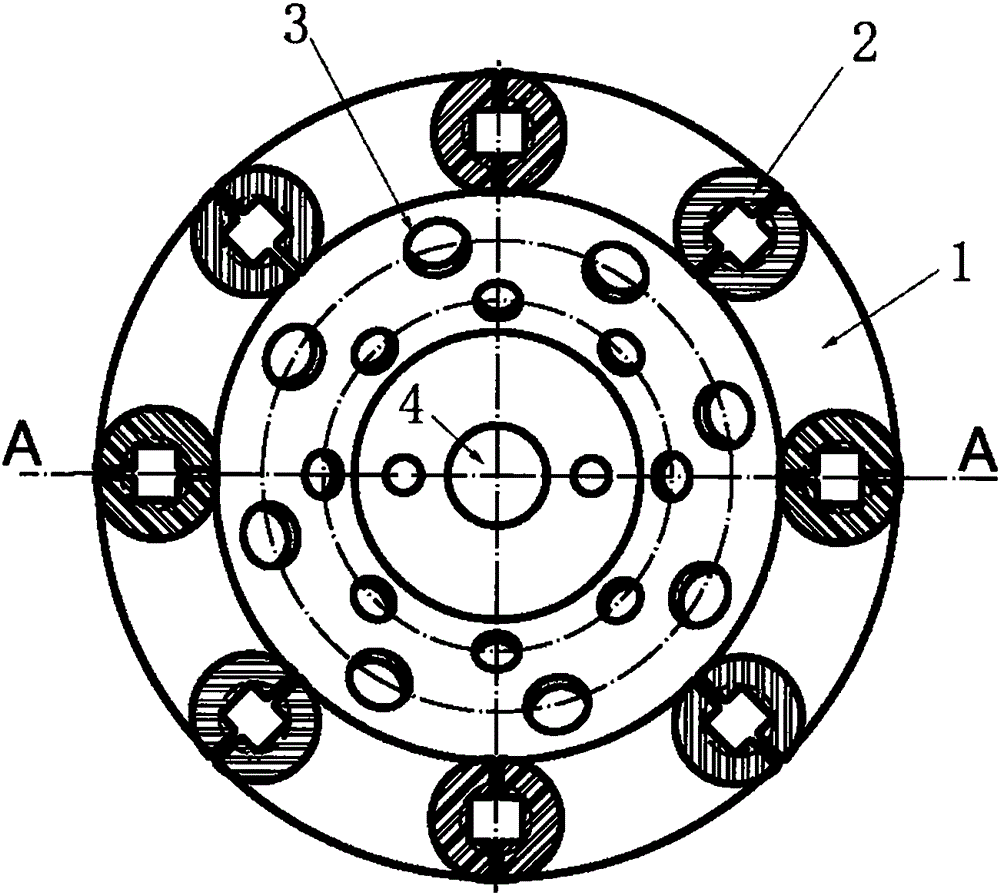

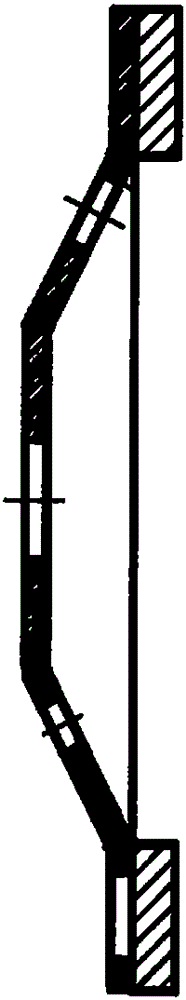

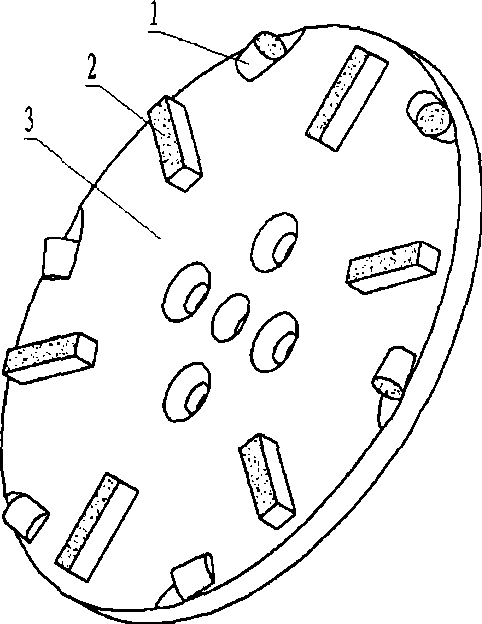

Dry-grinding diamond grinding wheel

ActiveCN105215866ATimely exclusionReduce the chance of collisionBonded abrasive wheelsGrinding devicesDiamond grindingBuilding material

The invention discloses a dry-grinding diamond grinding wheel and belongs to the technical field of grinding tools for building materials. The dry-grinding diamond grinding wheel comprises a grinding wheel base body and multiple diamond tool bits arranged on the grinding wheel base body; the grinding wheel base body is disk-shaped; the outer edge of the grinding wheel base body is an annular plane; the multiple diamond tool bits are uniformly distributed on the annular plane of the grinding wheel base body; each diamond tool bit adopts a round cake-shaped structure with a square through hole in the middle; annular heat dissipation holes are formed in the annular plane of the grinding wheel base body and correspond to the square through holes in the diamond tool bits in position. According to the invention, through special design of the cutter bits and the base body, the grinding wheel can remove scraps and dissipate heat more effectively, the problem of continuous working in the environment without cooling water is solved and work troubles of constructors under the environmental conditions of strict cooling conditions are eliminated.

Owner:JIANGSU FENGTAI TOOLS

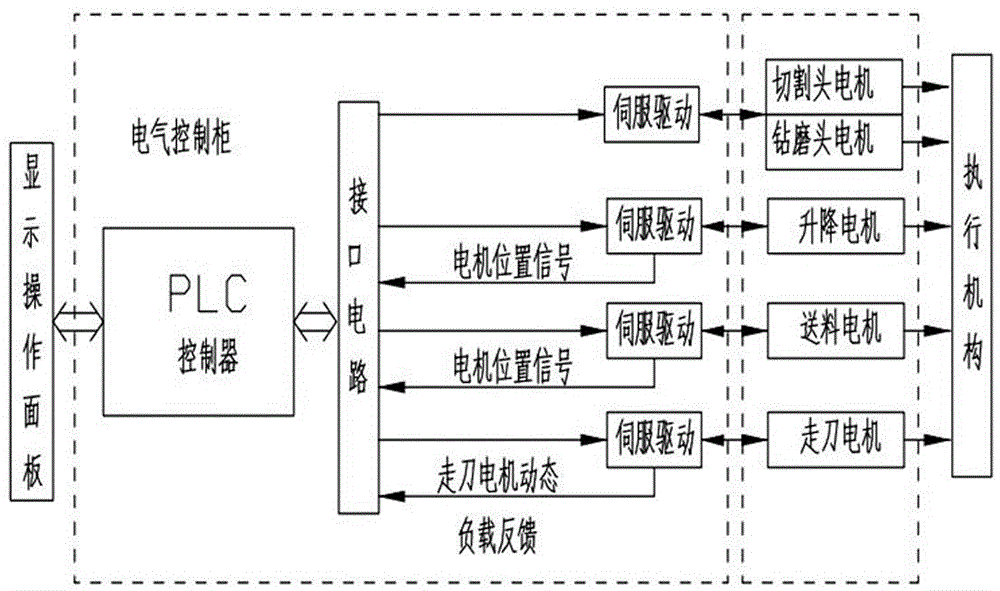

Test method for testing cutting performance of diamond saw blade

InactiveCN105954136ASolve instabilityRealize automatic measurementInvestigating abrasion/wear resistanceInvestigating machinabilityDiamond knifeMachine tool

The invention belongs to the technical field of diamond tool testing, and discloses a test method for testing the cutting performance of a diamond saw blade, which solves the problem in the prior art that existing test methods for testing the cutting performances of diamond cutters are not accurate and not uniform. The test method comprises the following steps of 1, obtaining a set load parameter value: controlling the feed quantity of a diamond saw blade, finding a load value K of the diamond saw blade when the feed quantity of the diamond saw blade on a cutting object is maximal, and setting M= 0.70K-0.85K, wherein M is the set load parameter value; 2, during the cutting process, controlling the cutting load value of the diamond saw blade to be 0.9M-1.1M by means of a servo system. According to the technical scheme of the invention, the unification of three cutting elements, namely a machine tool, an object and a feed thrust, is realized. Meanwhile, the cutting performance of a diamond cutter can be automatically and accurately tested. Therefore, a unified and standard testing standard is formed for the industry and the perfect development of the diamond tool industry is ensured.

Owner:CHENGDU HUIFENG NEW MATERIAL TECH CO LTD

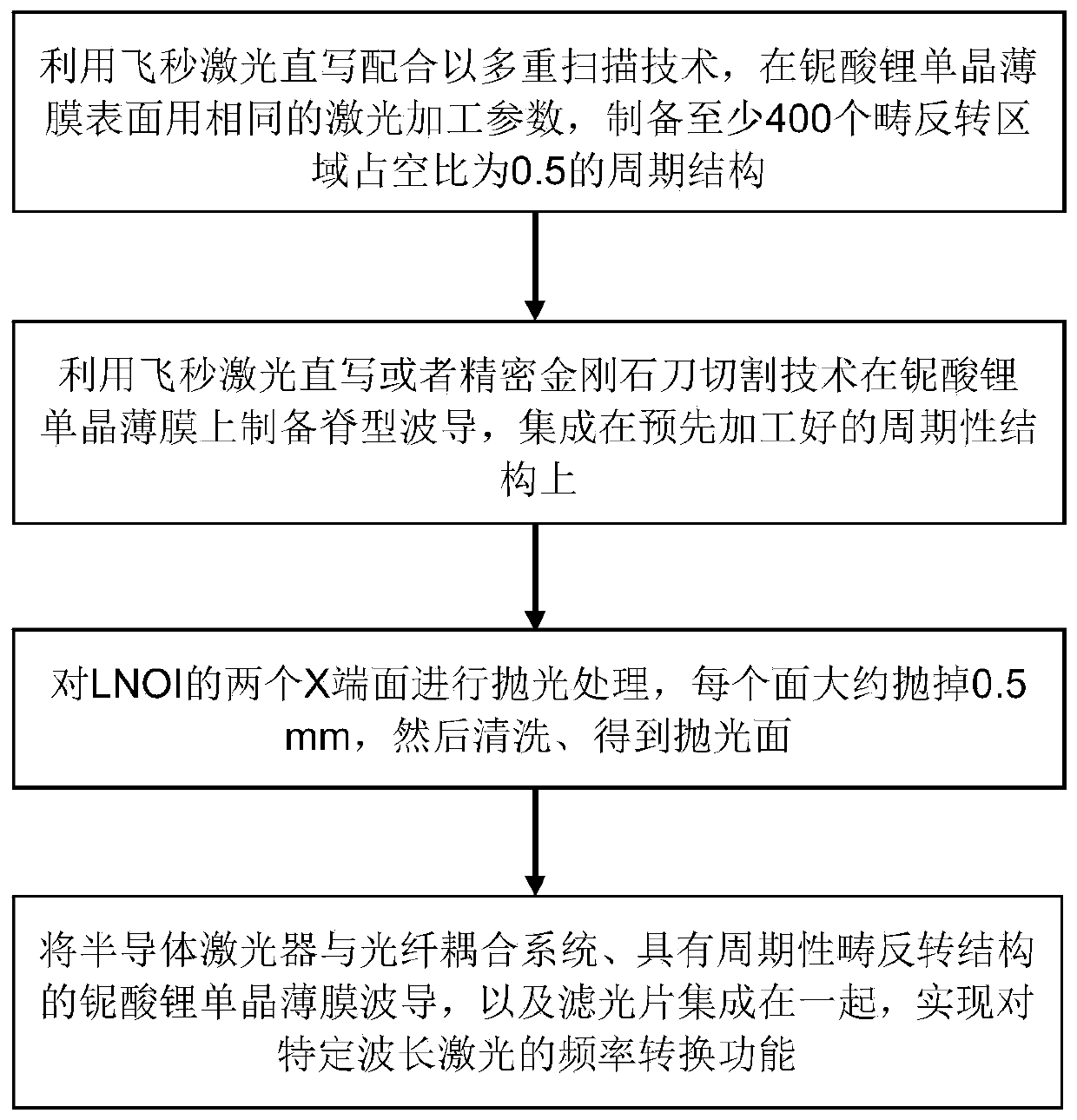

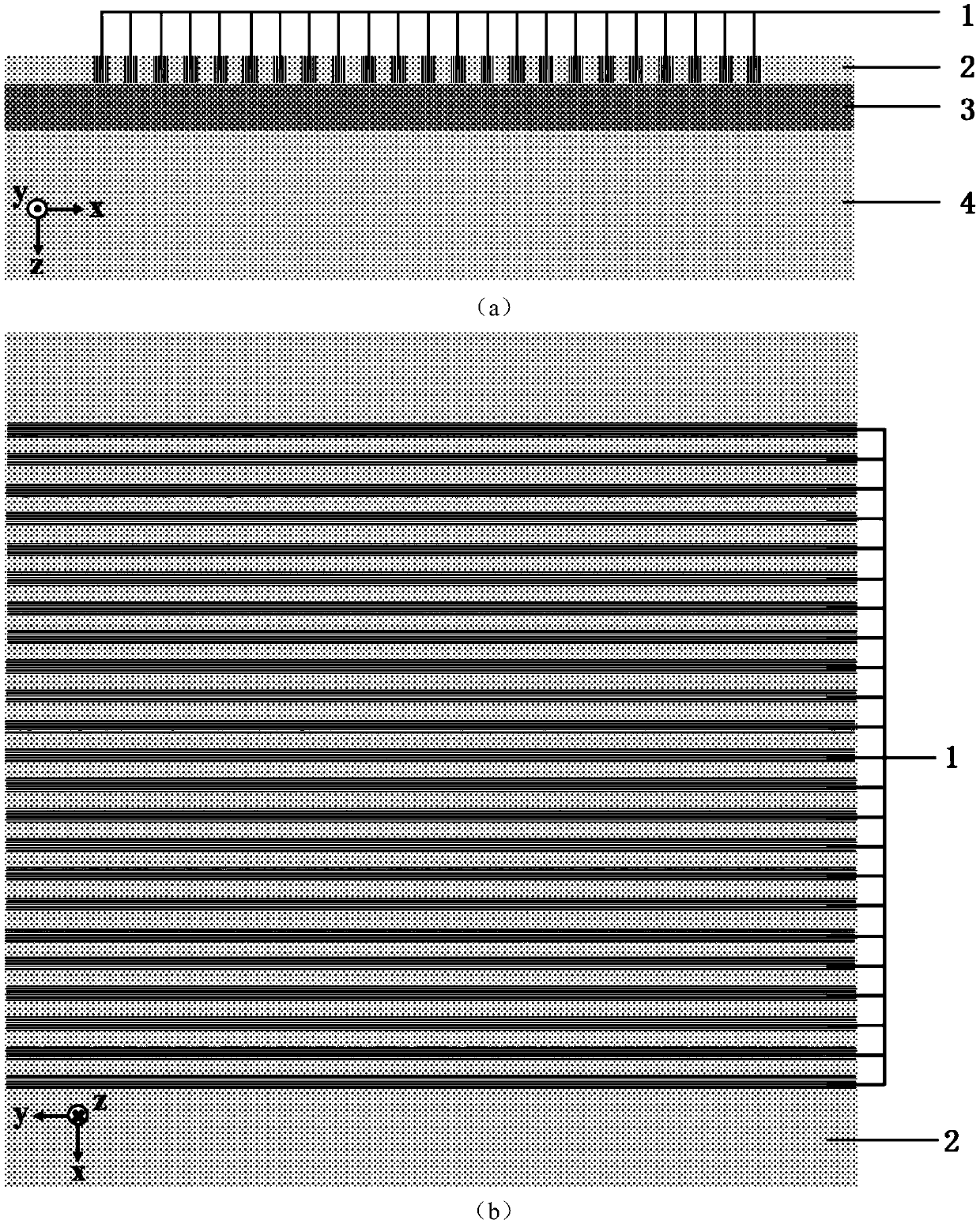

Frequency converter based on ridge-type lithium niobate monocrystal thin-film waveguide integrated periodic domain reversal structure, and preparation thereof

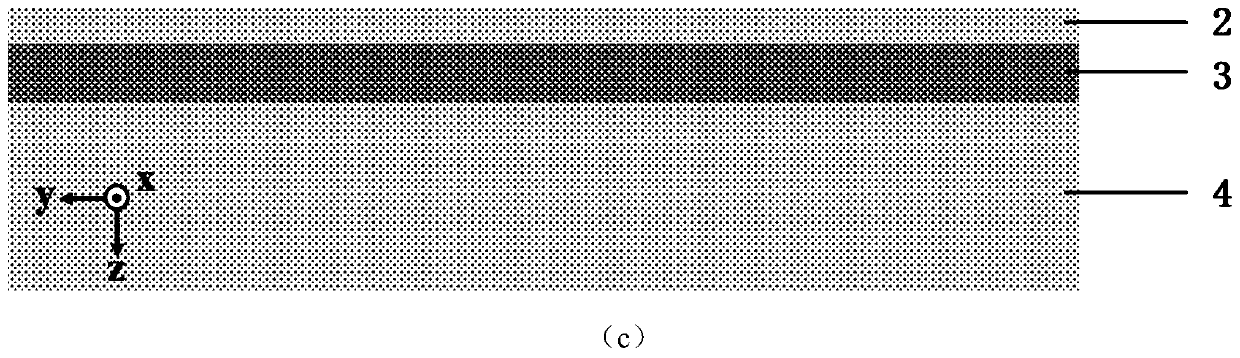

ActiveCN110568694AEfficient outputConvenient inductionNon-linear opticsLaser beam welding apparatusSingle crystalLithium niobate

The invention relates to a frequency converter based on a ridge-type lithium niobate monocrystal thin-film waveguide integrated periodic domain reversal structure, and preparation thereof. The preparation comprises the following steps: preparing a periodic structure with domain reversal region duty ratio as 0.5 on a lithium niobate monocrystal thin-film surface by using the same laser processing parameter; and then preparing ridge-type waveguide on the lithium niobate monocrystal thin-film by applying femtosecond laser direct writing or precise diamond knife-cutting technology, and integratingon a pre-processed periodic structure; and then performing polishing treatment on two X end surfaces of the LNOI, cleaning and obtaining polished surfaces; and then integrating a semiconductor laserand an optical fiber coupling system, the lithium niobate monocrystal thin-film waveguide with the periodic domain reversal structure and an optical filter, thereby realizing the frequency conversionfunction of the laser with specific wavelength. The frequency converter disclosed by the invention has the features of being high in conversion efficiency, good in beam quality and long in life; and the product is mainly applied to the optical fiber communication, the electronics device preparation, the information storage, the infrared detection and like fields.

Owner:SHANDONG UNIV

Machining method for diamond circular saw blade

The invention provides a diamond circular saw blade. The diamond circular saw blade is characterized in that the diamond circular saw blade comprises, by weight, 40-45% of metallic bonding agents, 30-32% of FC30 alloyed powder, 20-25% of copper and 6-8% of tin. A machining method for the diamond circular saw blade comprises the following steps of (1) working layer burdening, (2) pelleting, (3) cold pressing, (4) hot pressed sintering, (5) exposedness of a cutting edge, (6) paint spraying, and (7) detection and storage in a warehouse. According to the machining method for the diamond circular saw blade, a diamond bit tool and a steel base body are integrally formed through cold pressing, and welding is not required. Bonding force between part of the tool bit and the base body is strong, the phenomenon of tooth falling is not prone to occurring, a saw blade base body is assembled into a cold pressing forming steel mould, and forming is achieved through two-time feeding and one-time integral cold pressing. The phenomenon of piece burning is avoided, so that the saw blade cutting efficiency is stably and lastingly kept.

Owner:朱一飞

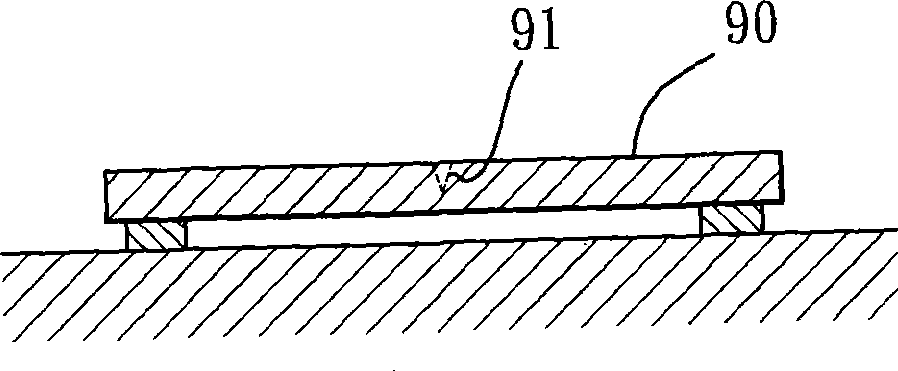

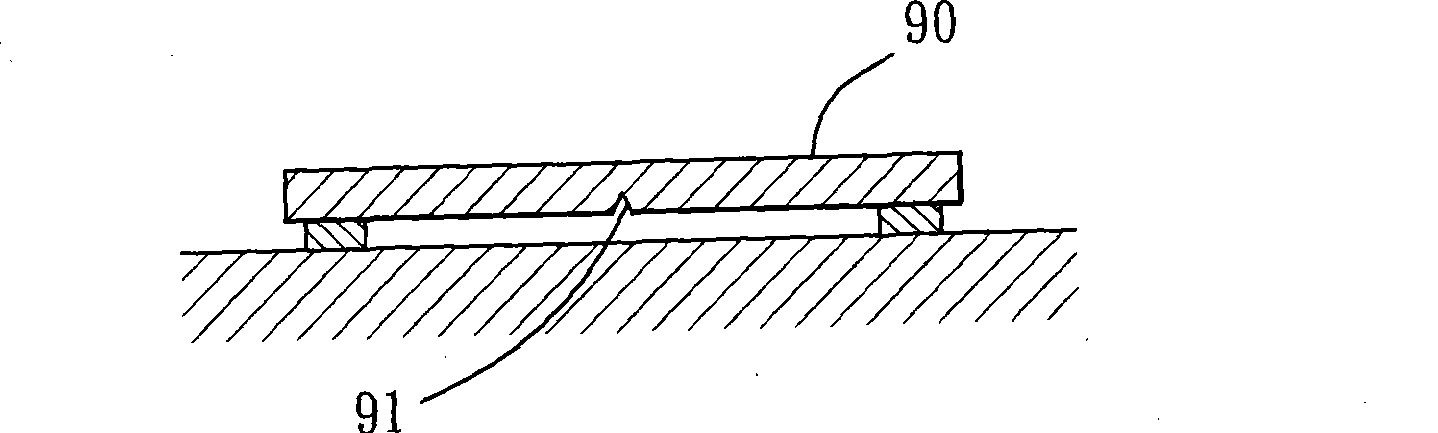

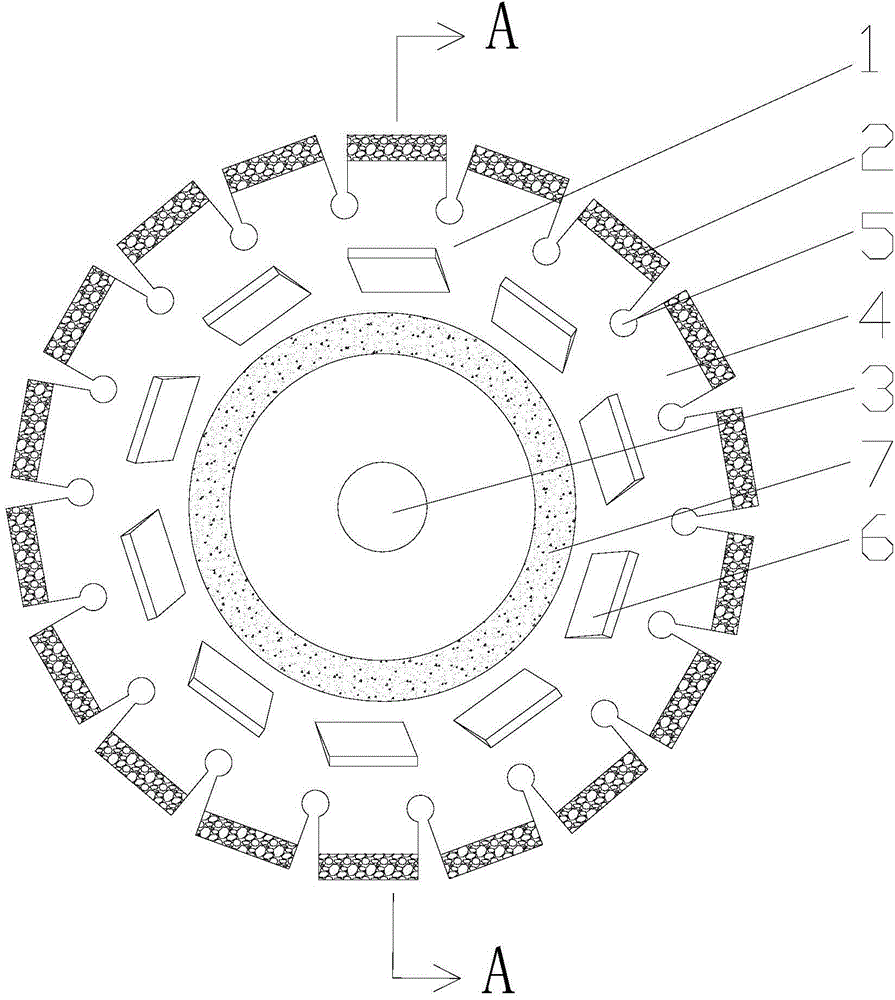

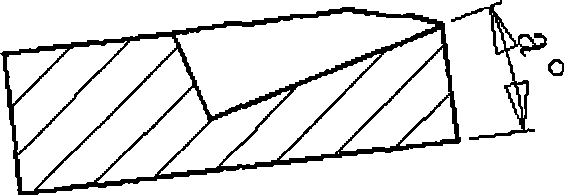

Superhard material cutting tool and preparation method thereof

ActiveCN101502926AGuaranteed smoothnessExclude smoothlySoldering apparatusOther manufacturing equipments/toolsSuperhard materialTool bit

The invention relates to a superhard material cutting tool and a preparation method thereof, which belongs to the technical field of superhard material. The superhard material cutting tool comprises a steel matrix and a cutting tool bit. The cutting tool bit consists of a polycrystalline diamond compact (1) and a diamond tool bit (2); 1 to 12 inclined cylindrical tanks used for welding the diamond compact are distributed on the outer circle surface of the steel matrix, and the center line of the inclined cylindrical tank forms a cutting angle with the cutting face; the diamond tool bit is welded on the surface of the steel matrix. The polycrystalline diamond compact is combined by PCD and cemented carbide matrix and is sintered from the mixture of diamond and the metal powder after being compacted; the structure thereof is in the shape of cylinder, ladder or squareness; the fringe area of the clad compact is the cutting blade. The superhard material cutting tool solves the materials hard to be processed in the cutting field, and ensures the surface of the machined part free of burr, nick, spray and chatter mark; the cutting and grinding combination not only improves the cutting speed, but also ensures the cutting quality.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD +1

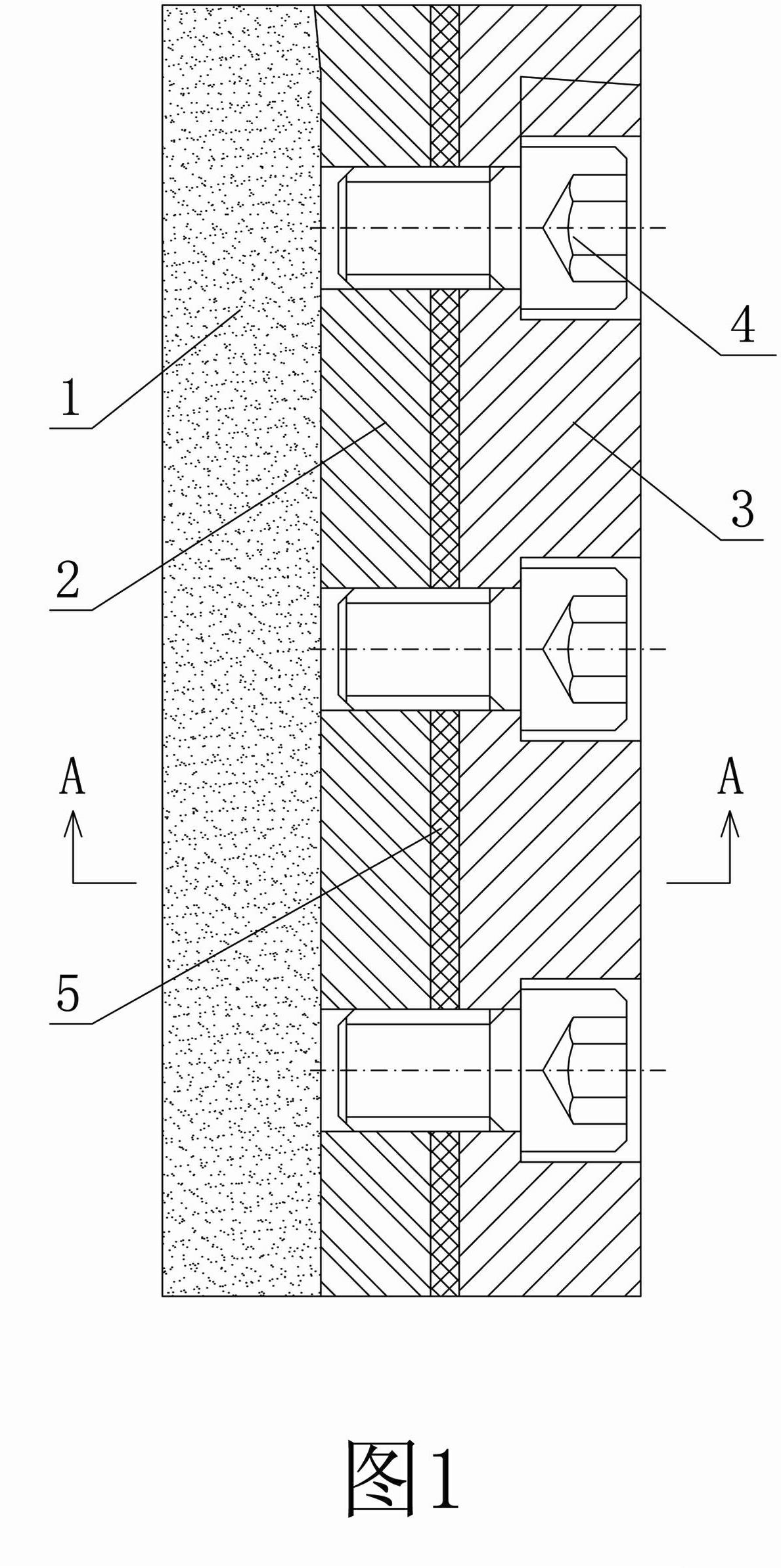

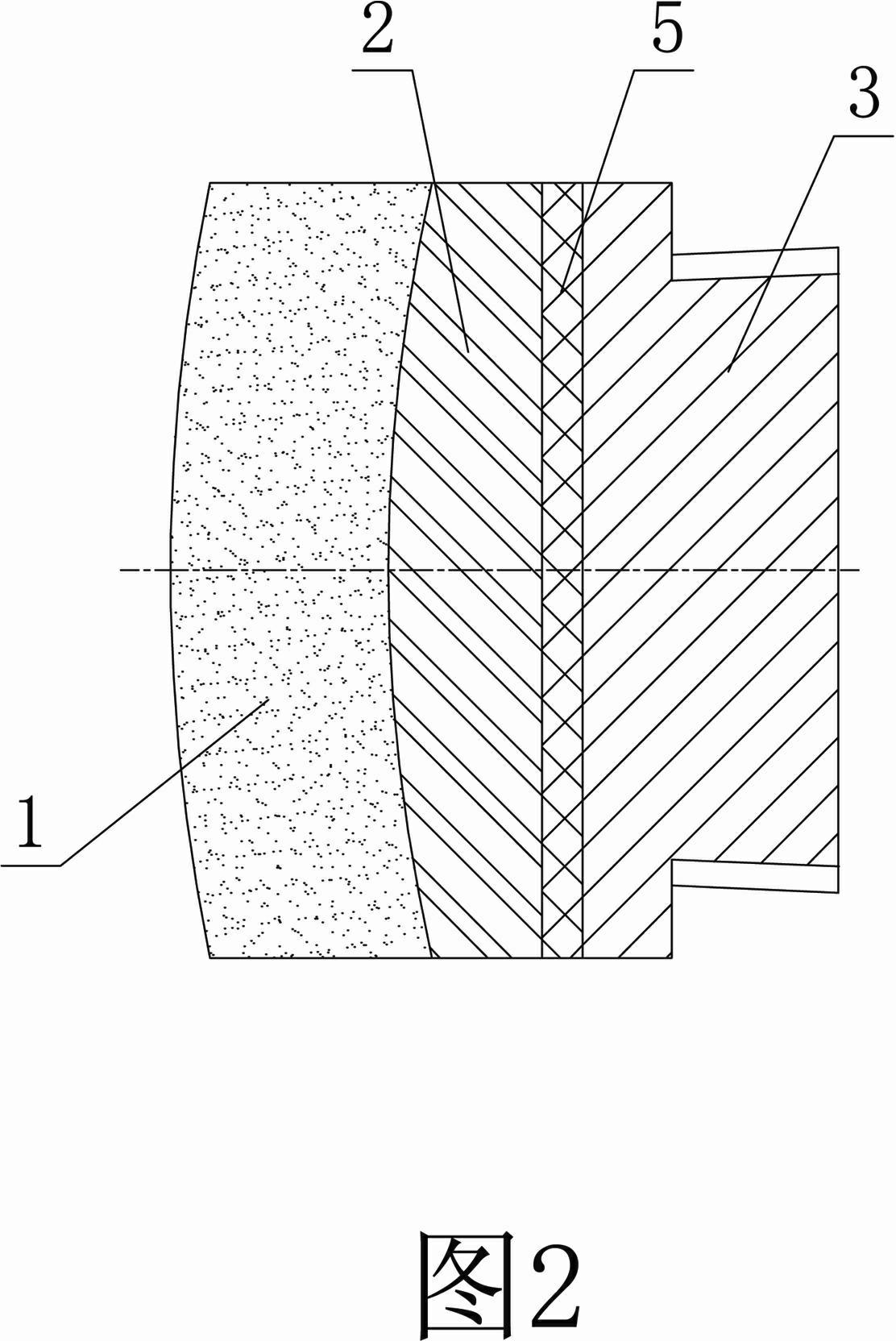

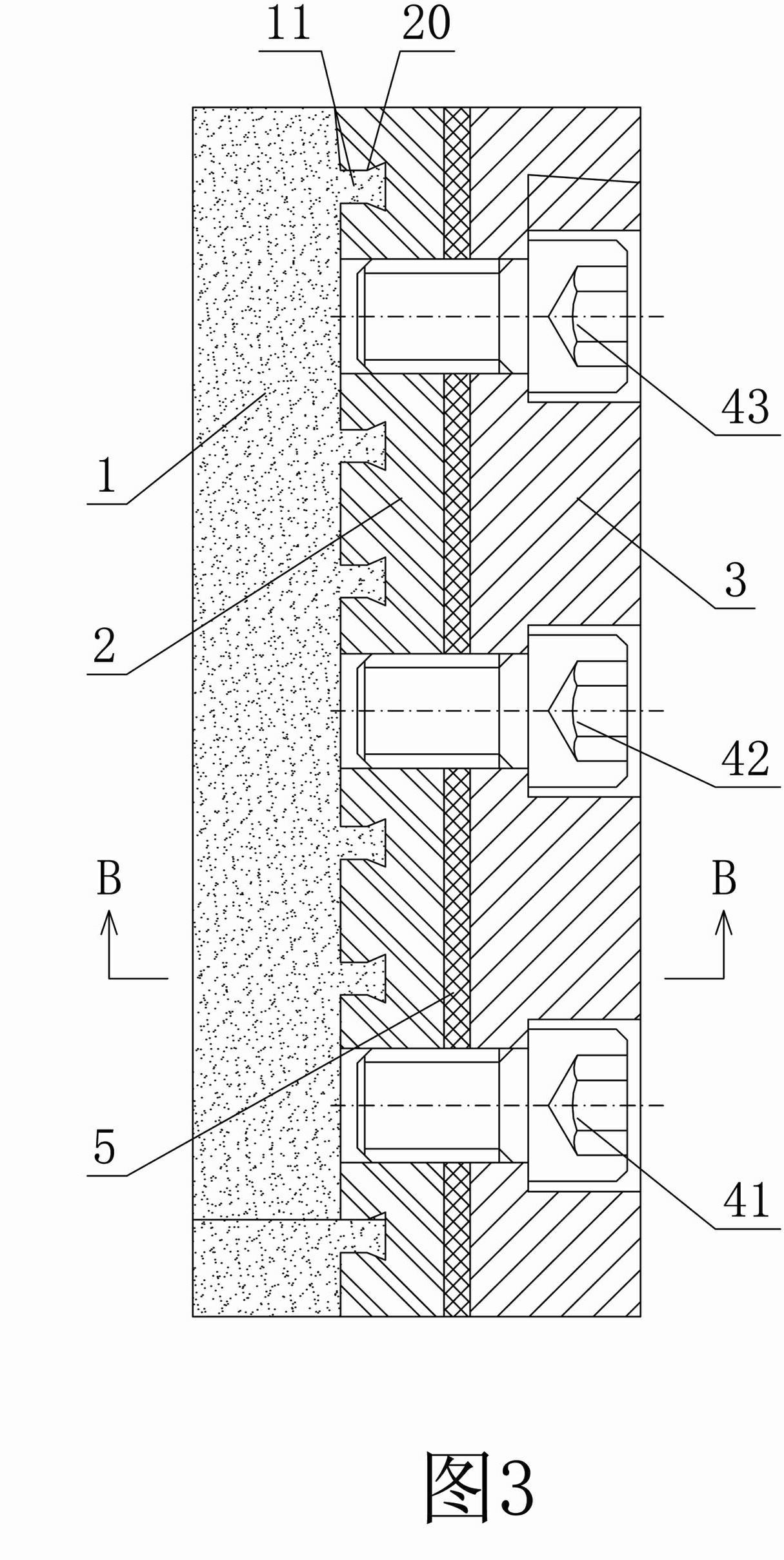

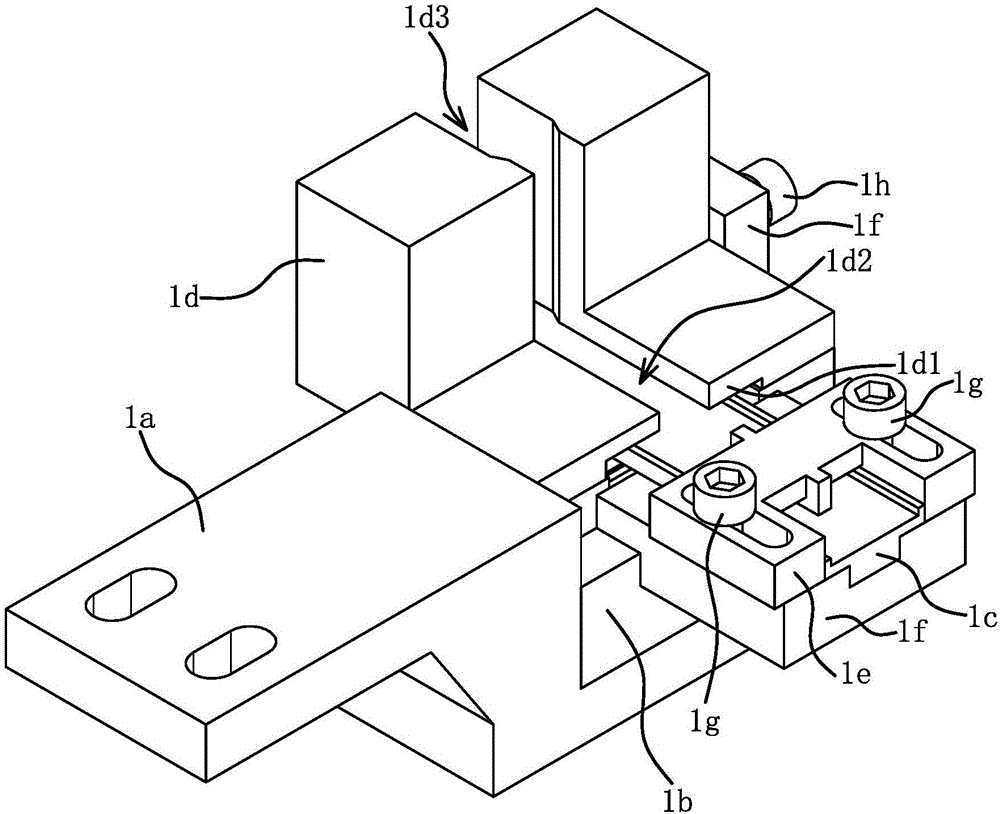

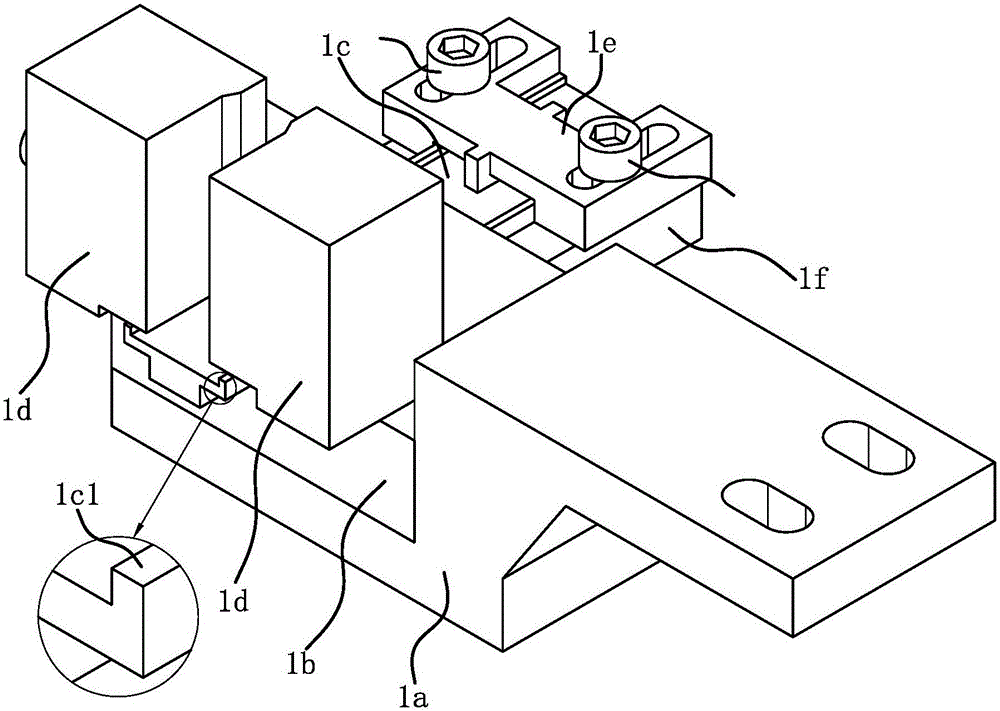

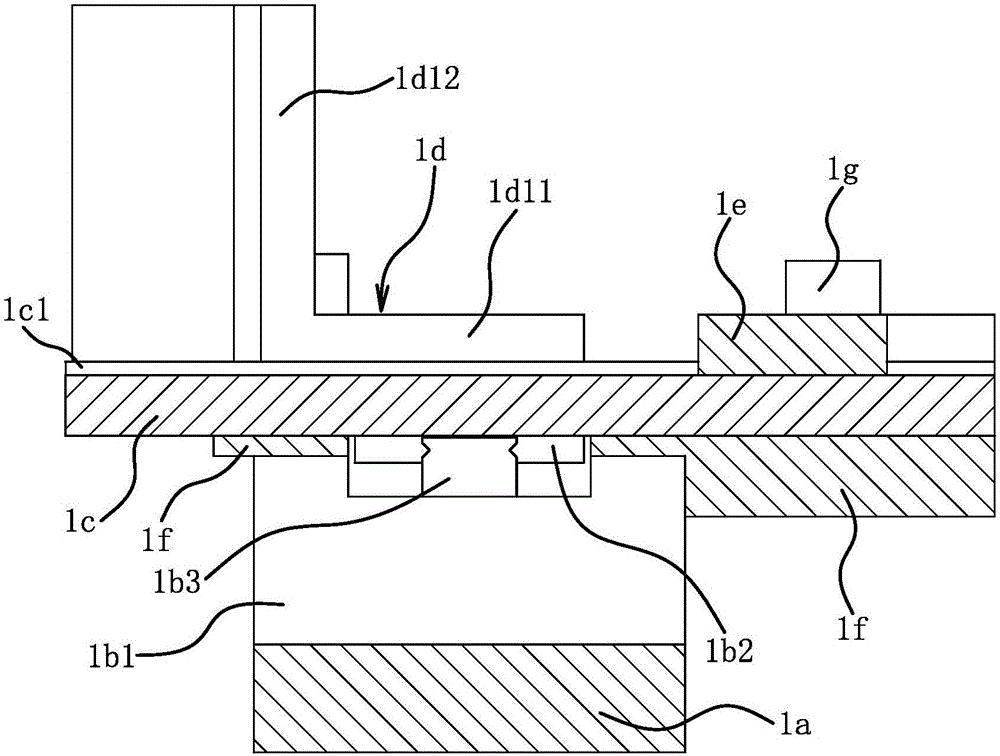

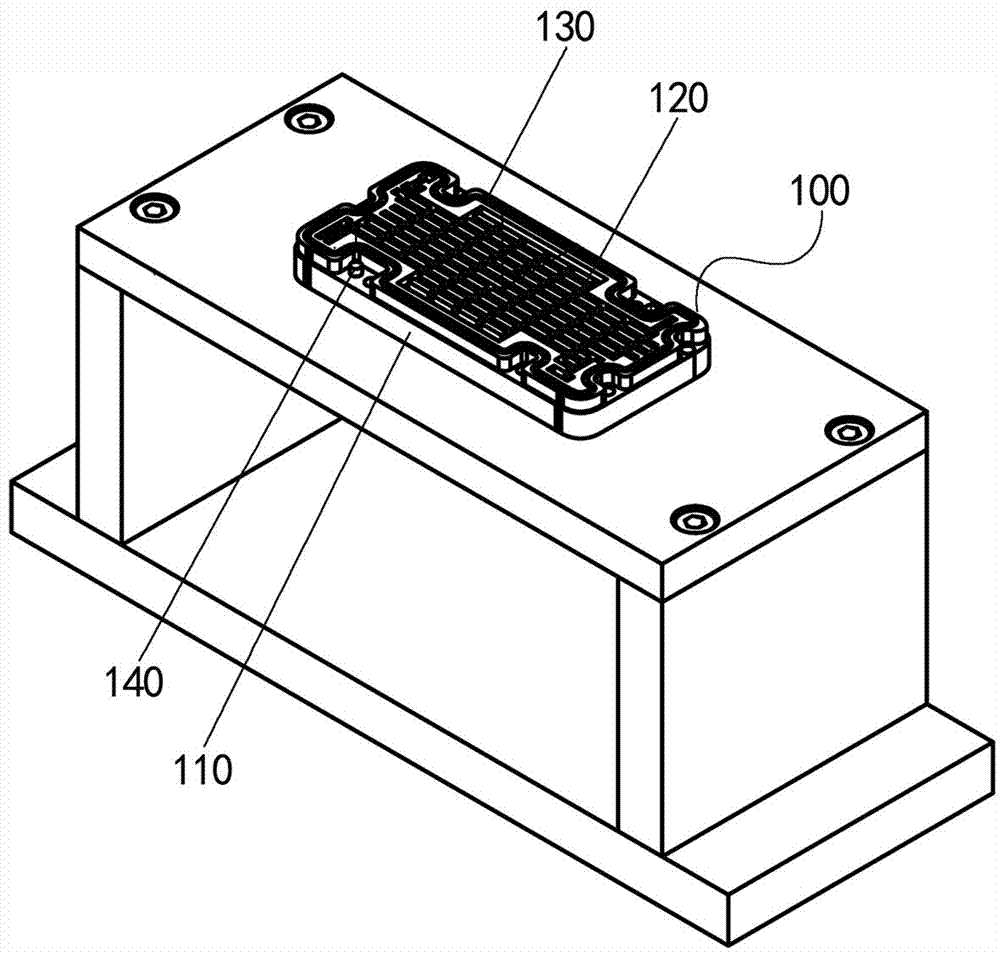

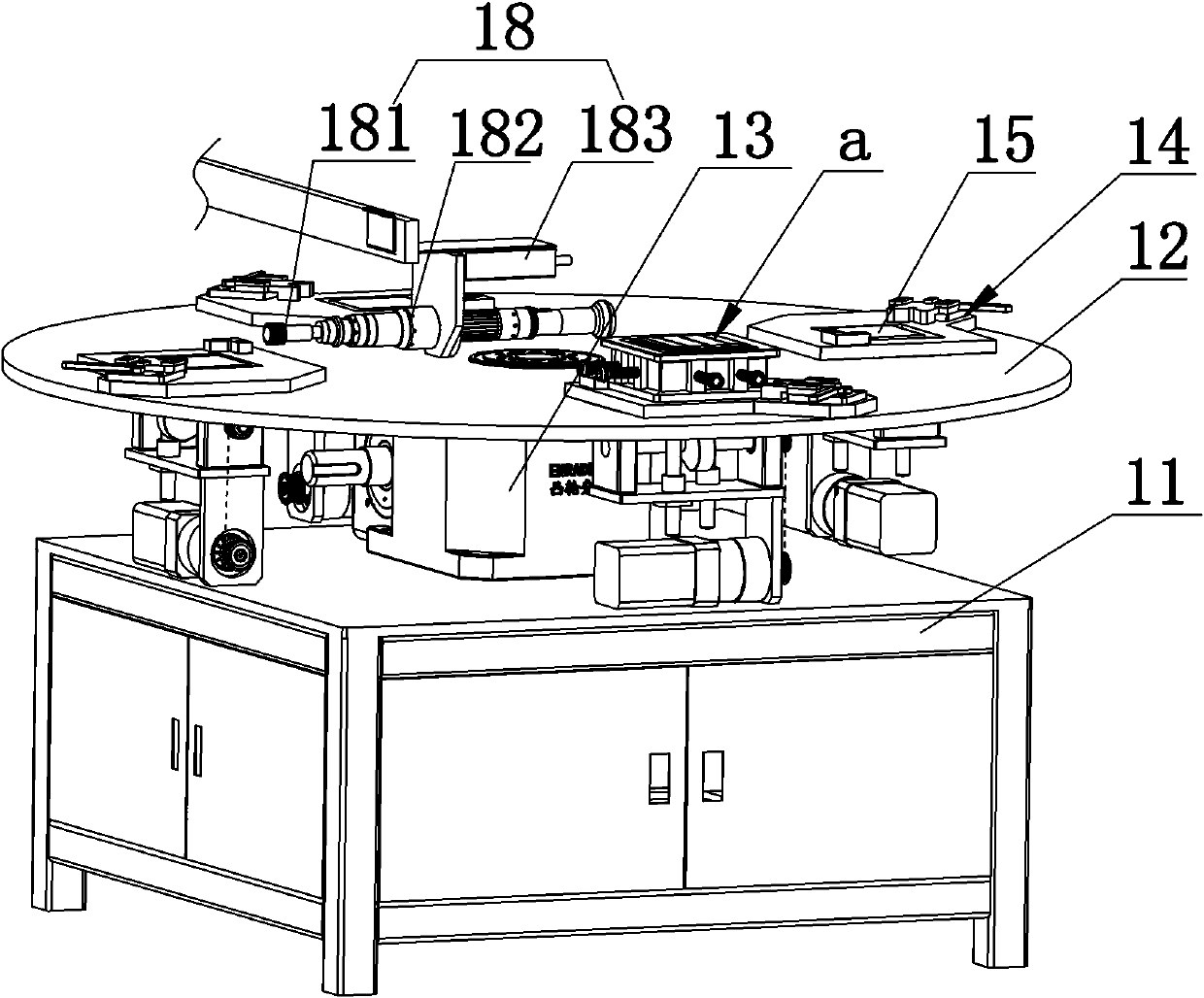

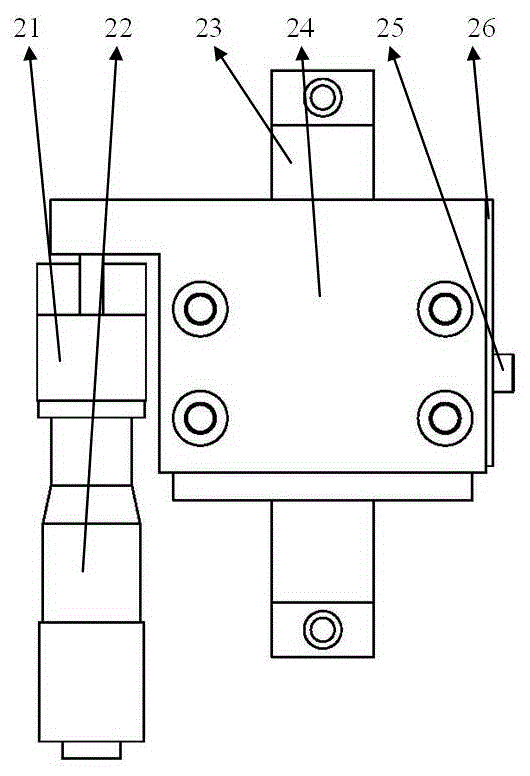

Diamond tool bit positioning seat and welding machine for diamond cutting tool

ActiveCN106180957AOmit the measurement and sorting processImprove general performanceOther manufacturing equipments/toolsMetal working apparatusTool bitDiamond cutting

The invention provides a diamond tool bit positioning seat and a welding machine for a diamond cutting tool and belongs to the technical field of operation. By the adoption of the diamond tool bit positioning seat and the welding machine for the diamond cutting tool, the problem that an existing tool bit positioning seat is poor in universality is solved. The diamond tool bit positioning seat comprises a base, a synchronous pneumatic clamp and a strip-shaped tool bit supporting plate. The synchronous pneumatic clamp is located under the tool bit supporting plate. The tool bit supporting plate is fixedly connected with the base. The synchronous pneumatic clamp is provided with a cylinder body and two sliding heads. The cylinder body is fixedly connected with the base. A chuck is fixedly connected to each sliding head. The tool bit supporting plate is located between the two chucks. Tool bit clamping lips located above the tool bit supporting plate are arranged on the opposite sides of the two chucks correspondingly. A tool bit end face abutting device is further arranged on the tool bit supporting plate. The positions of central planes of diamond tool bits clamped by the diamond tool bit positioning base are the same, namely after the diamond tool bits with different thicknesses are positioned through the diamond tool bit positioning base, and the positions, relative to the tool bit supporting plate, of the central planes of the diamond tool bits are the same.

Owner:项大清

Diamond saw blade

ActiveCN108748702AExtended service lifeImprove cutting stabilityStone-like material working toolsWear resistantAlloy

The invention relates to a diamond saw blade and belongs to the technical field of diamond tools. The diamond saw blade comprises a round metal matrix and a plurality of diamond tool bits arranged onthe outer end surface of the round metal matrix, wherein chip spaces are formed between adjacent diamond tool bits; an annular protecting coating is formed on the surface, close to the diamond tool bits, of the round metal matrix; the annular protecting coating is composed of a metal intermediate layer in contact with the round metal matrix and a hard alloy layer arranged on the metal intermediatelayer. The annular metal matrix of the diamond saw blade is provided with the annular wear-resistant protecting coating, so that erosion of cutting chip to the metal matrix is prevented effectively,and the heat dissipating property of the metal matrix is improved and vibration between the metal matrix and the diamond tool bits is reduced, and therefore, the service life of the diamond saw bladeis prolonged and the cutting stability of the diamond saw blade is improved favorably.

Owner:WEIHAI VOCATIONAL COLLEGE

Apparatus for circle cutting of glass curtain wall

The invention relates to processing equipment for glass curtain walls, especially to an apparatus for circle cutting of a glass curtain wall. The apparatus for circle cutting of the glass curtain wallin the invention realizes mechanical driving of a diamond knife for rotary cutting, so a perfect circle shape is cut and people are protected from hand injury since holding of the diamond knife withthe hand for cutting is not needed. The apparatus for circle cutting comprises a base plate, a first supporting rod, a first guide sleeve, an installation plate, a first screw, a motor, a first gear,a bearing pedestal, a second gear, a rotating shaft, a connecting rod, etc. The first supporting rod is connected with the right part of the upper side of the base plate. The apparatus allows the diamond knife to cut a perfect circle shape by mechanically driving the diamond knife to carry out rotary cutting and frees people from hand-holding of the diamond knife so as to protect people from handinjury during cutting with the diamond knife; and the motor drives diamond to carry out rotary cutting so as to cut a perfect circle.

Owner:嘉兴市新丰特种纤维有限公司

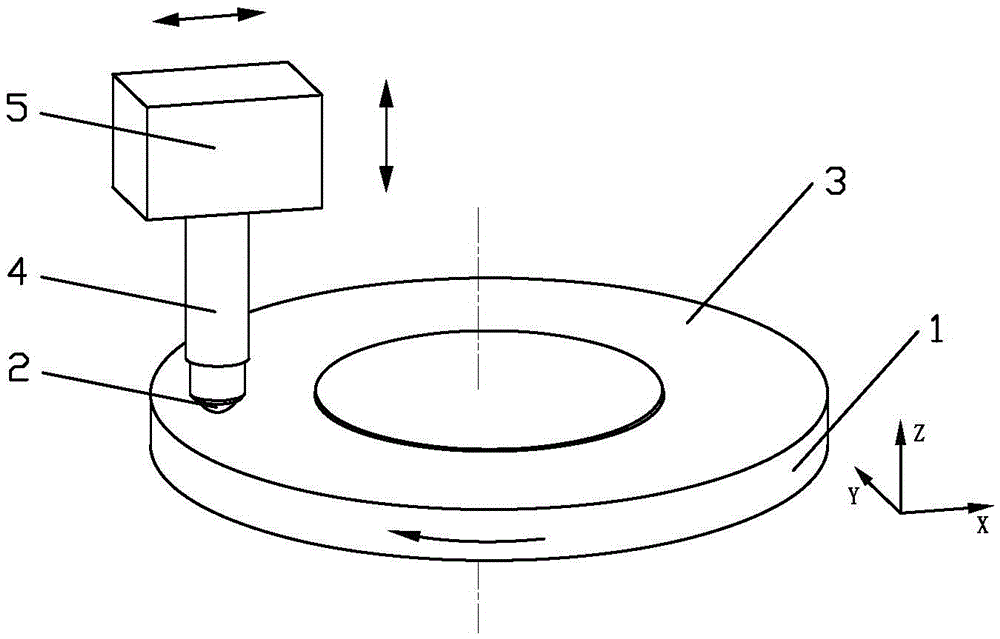

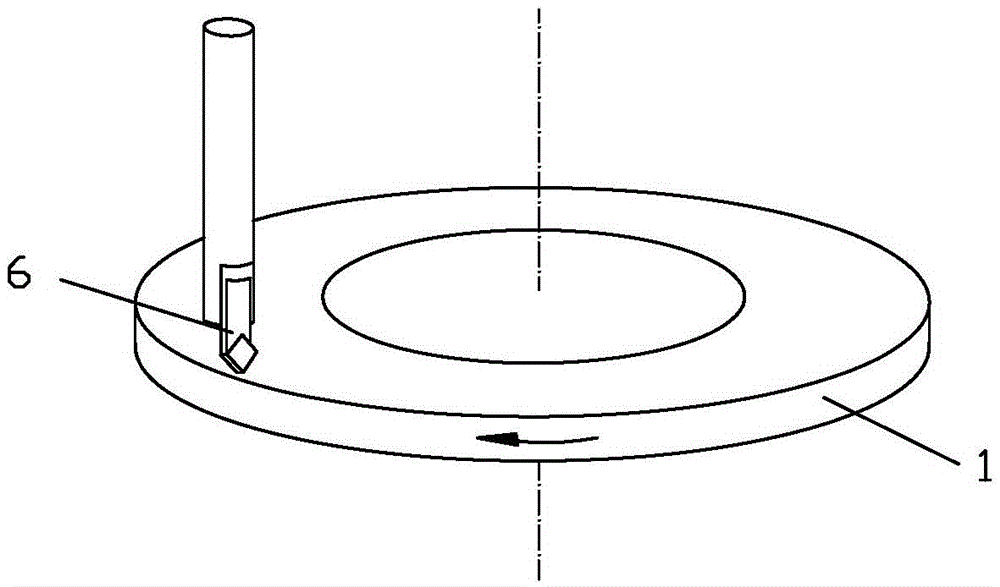

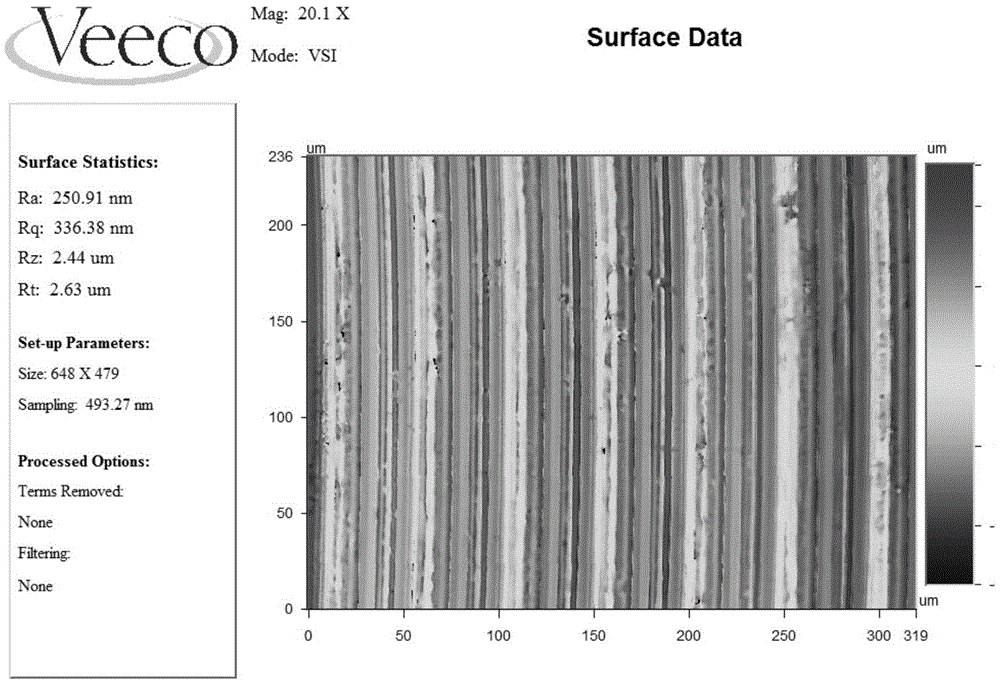

High-speed friction testing method of diamond knife pre-maintenance nonferrous metal friction pair

ActiveCN105628534AGuaranteed shape accuracyGuaranteed positioning accuracyPreparing sample for investigationUsing mechanical meansDynamic balanceNonferrous metal

The invention discloses a high-speed friction testing method of a diamond knife pre-maintenance nonferrous metal friction pair and belongs to the field of tribological testing and precise and ultra-precise machining. The high-speed friction testing method includes: fixing a nonferrous metal friction disc on an electric spindle, and performing online dynamic balancing on the friction disc; adopting a diamond knife to maintain the friction disc to reach requirements needed for testing end face jumping and coarseness; clamping a pair friction tool on a clamp connected with a force feedback device, conducting friction testing like ball-disc testing and pin-disc testing, enabling the friction disc to rotate at a specified rotating speed, enabling the pair friction tool to contact with the friction disc, maintaining pressure between the pair friction tool and the friction disc at a testing set value for testing until setting time is up, and collecting physical parameters like friction force and sound emitting signal in the process by a measuring system. By using the high-speed friction testing method, high-speed friction testing can be realized.

Owner:HUAQIAO UNIVERSITY

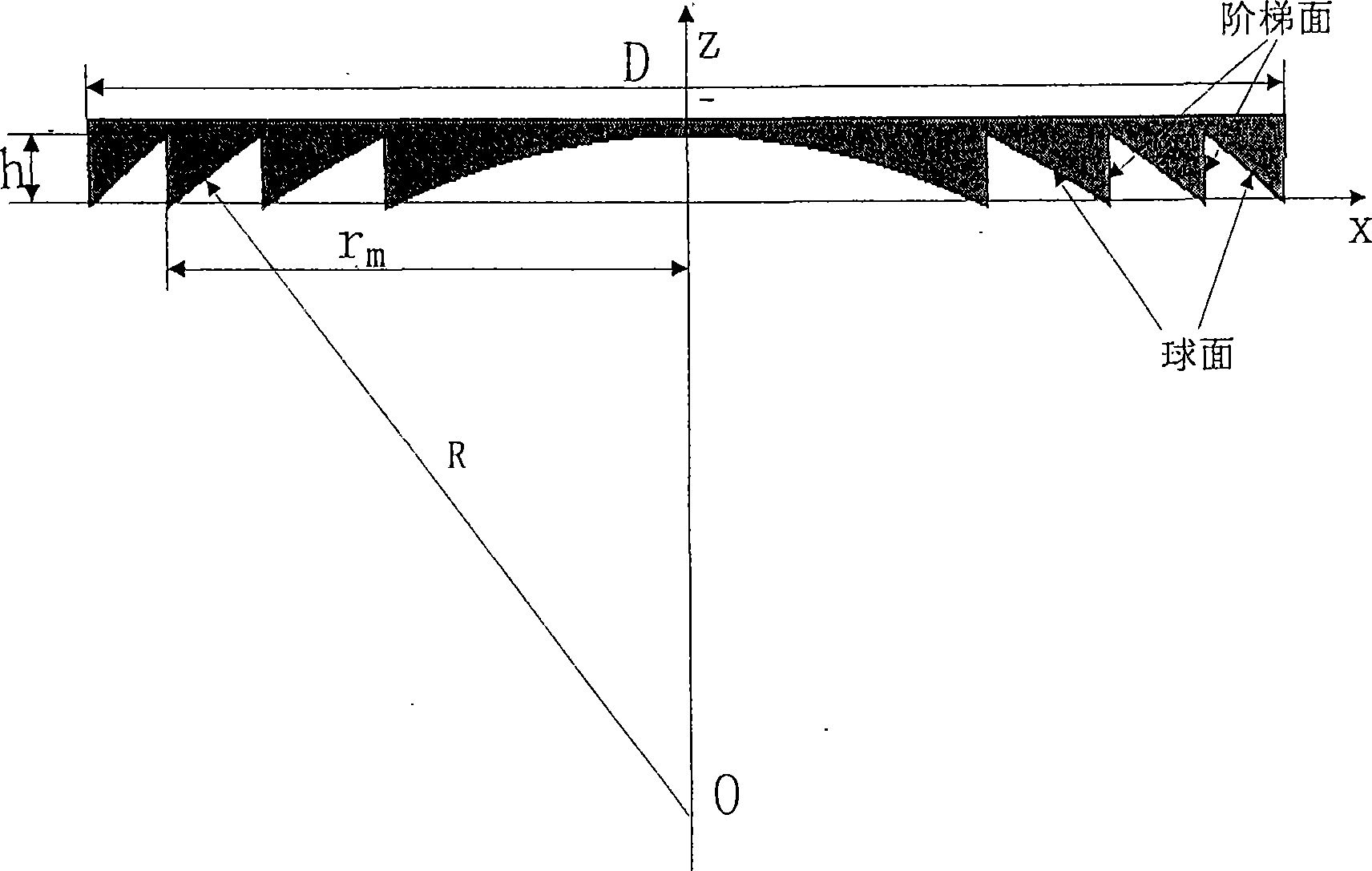

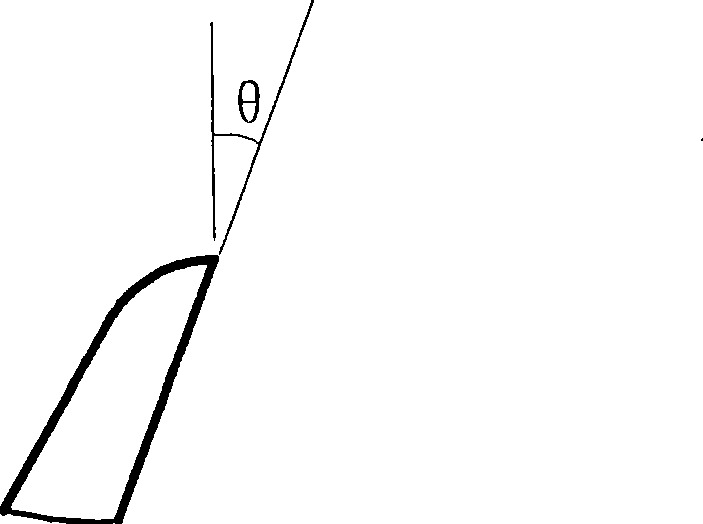

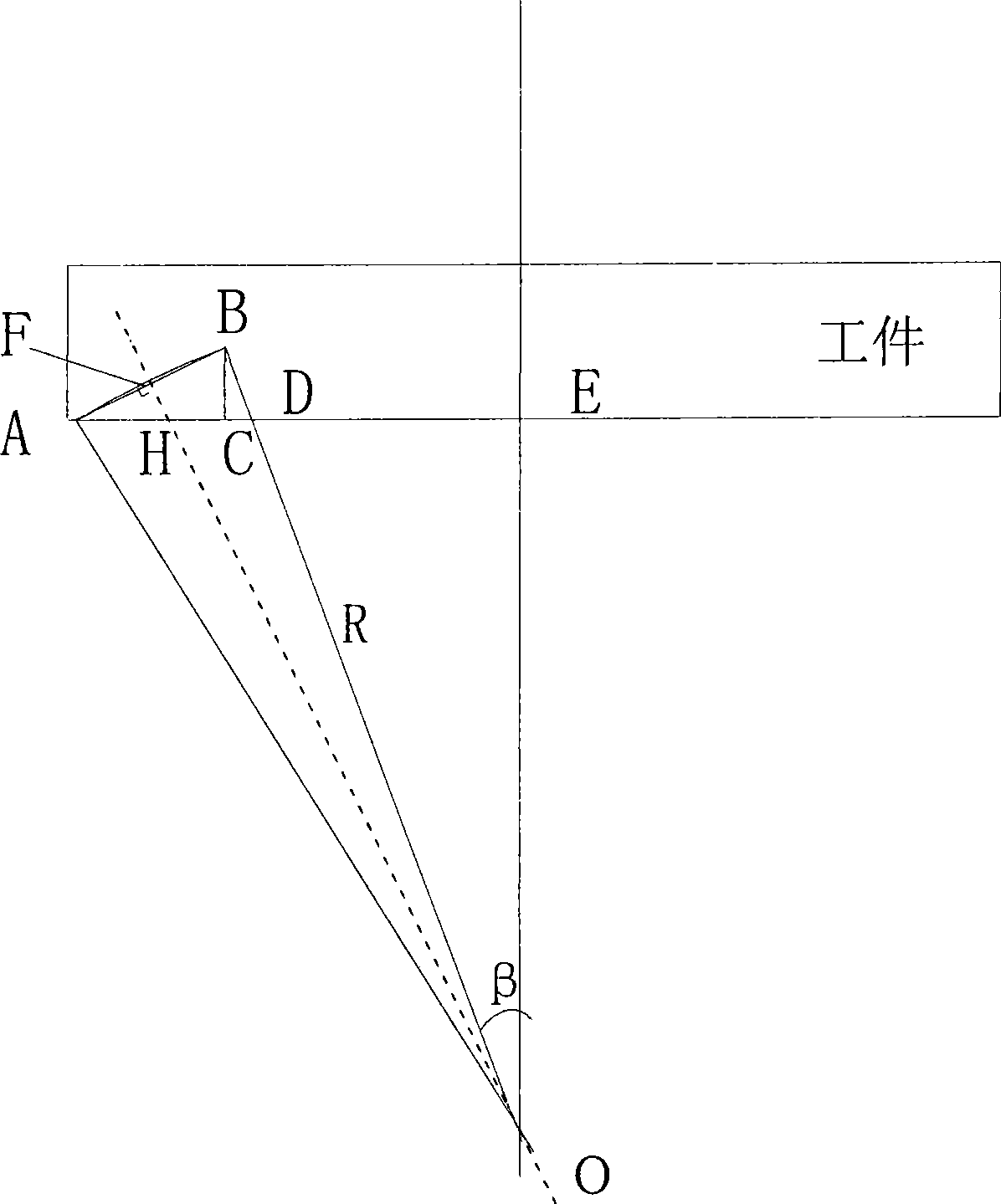

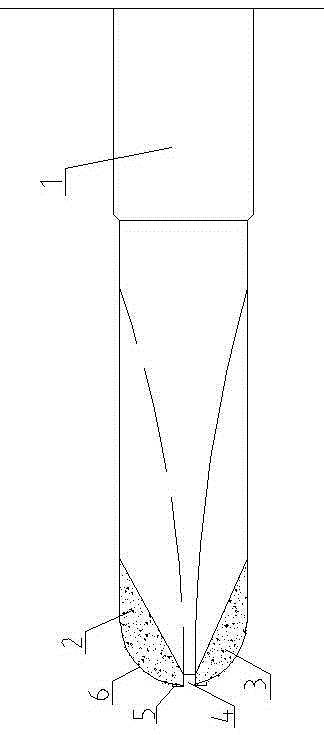

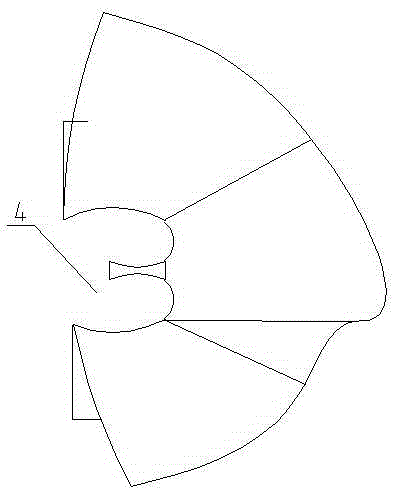

Design method for diamond knife tool for processing Fresnel lens

InactiveCN101367252AReduce lossesEliminate fundamental errorsStone-like material working toolsFresnel lensLight energy

The invention aims to provide a method for designing a diamond tool which is applied to diamond ultra-precision turning Fresnel lenses. When the diamond tool is designed, main parameter needing to be designed are a deflection angle theta, a tool nose angle phi, a tool nose arc radius Rl and a tool nose transition radius Rm. The principle of designing the deflection angle theta is to mainly ensure that interference can not occur when a step surface of an outermost zone is machined. The principle of designing the tool nose angle phi is to ensure that interference can not occur when a joint of a ball of the outermost zone and the step surface on the one hand, and to ensure the strength of a tool nose on the other hand. When the tool nose arc radius Rl and the tool nose transition radius Rm are designed, a main considered factor is that the tool nose arc radius can affect the diffraction efficiency of the Fresnel lenses. The designed diamond tool can realize the machining of the high-precision Fresnel lenses, eliminate principle errors in conventional machining and reduce the light energy loss of a Fresnel lens structure caused by the arc radius.

Owner:HARBIN INST OF TECH

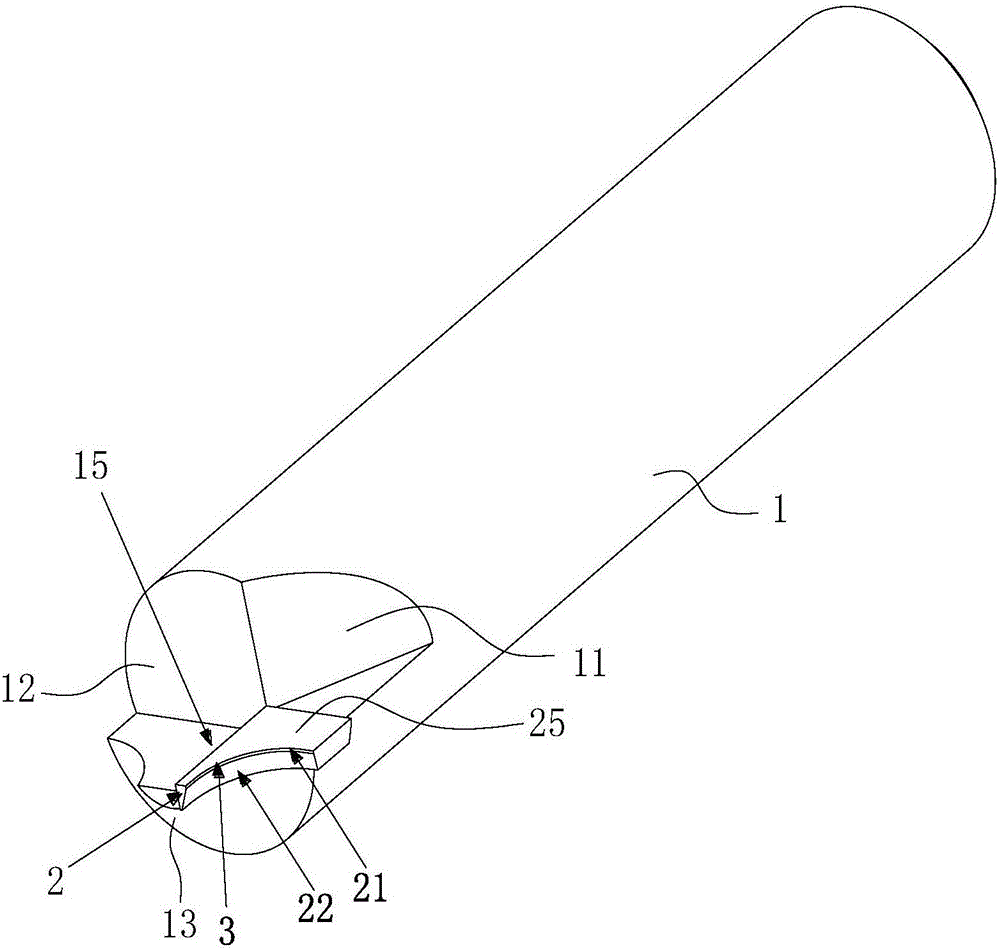

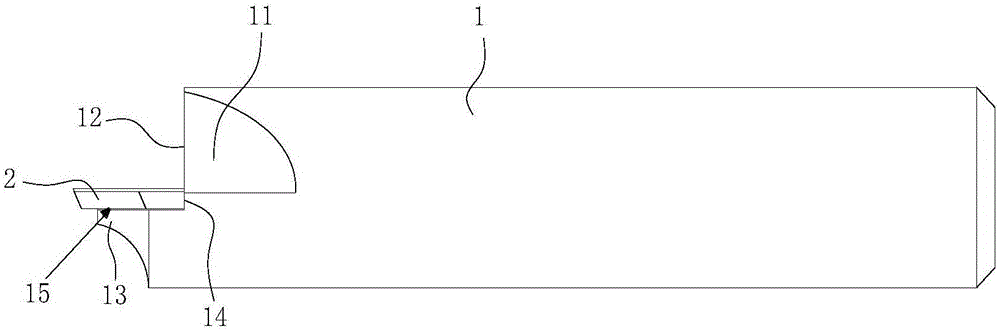

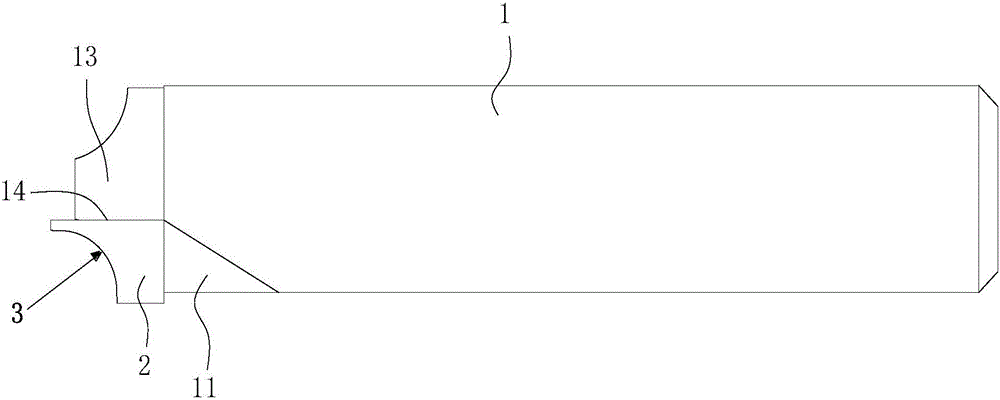

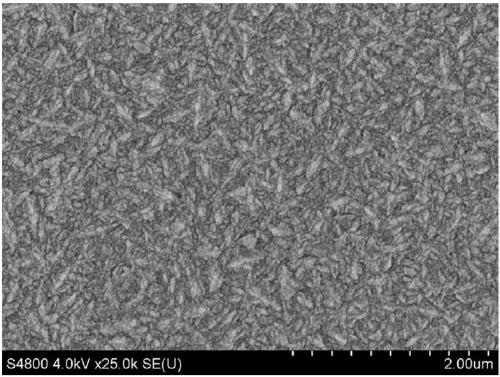

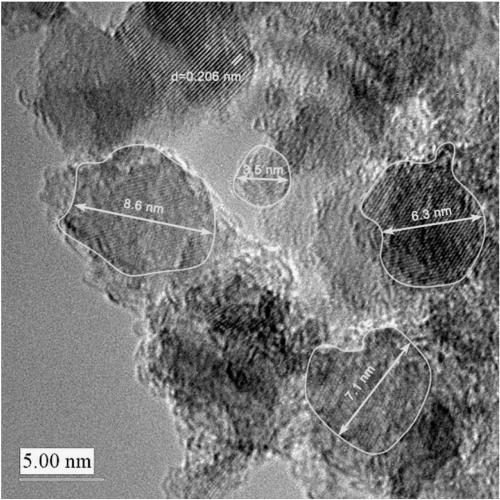

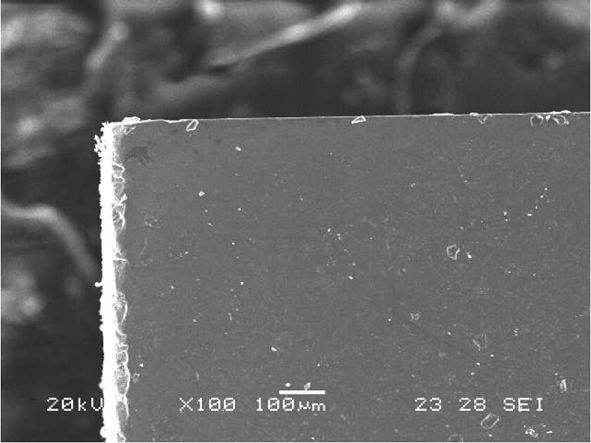

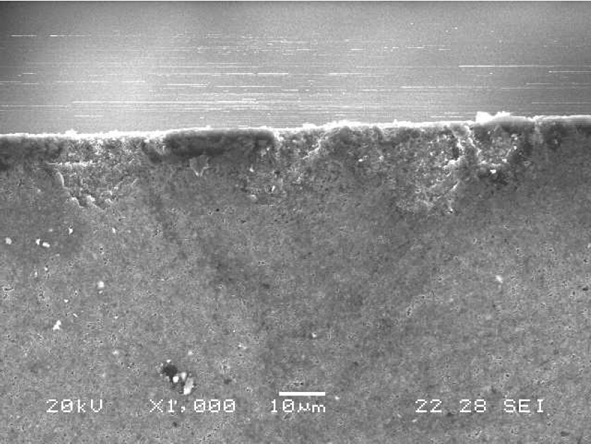

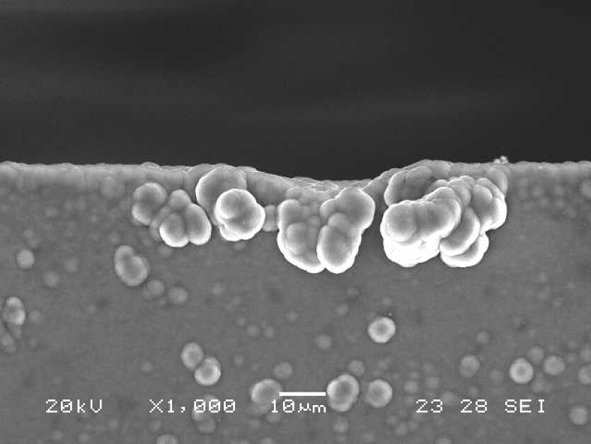

Superfine nanocrystalline diamond precision tool and manufacturing method thereof

InactiveCN110318032AHigh hardnessImprove toughnessTurning toolsChemical vapor deposition coatingGas phaseMicrometer

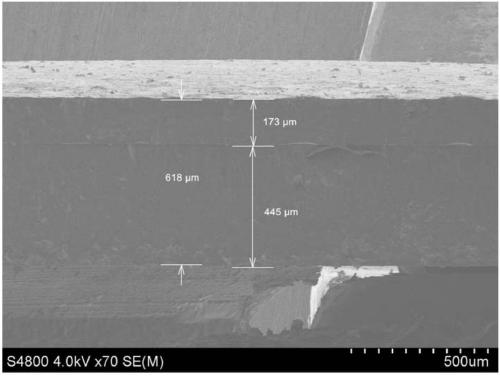

The invention discloses a superfine nanocrystalline diamond precision tool and a manufacturing method thereof. The tool comprises a tool handle and a diamond knife, wherein the diamond knife is prepared from a self-supporting superfine nanocrystalline diamond thick film, and the thickness of the thick film is 100-3,000 micrometers, wherein the sizes of diamond grains are larger than or equal to 1nanometer or smaller than or equal to 20 nanometers. By the adoption of a chemical vapor deposition method, superfine nanocrystalline diamond grows on a silicon substrate, then the silicon substrate is separated from the diamond, the self-supporting superfine nanocrystalline diamond thick film is obtained, the self-supporting superfine nanocrystalline diamond thick film is welded to a tool body through laser cutting, and after edge forming, coarse grinding and fine grinding are completed, the superfine nanocrystalline diamond precision tool is obtained.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

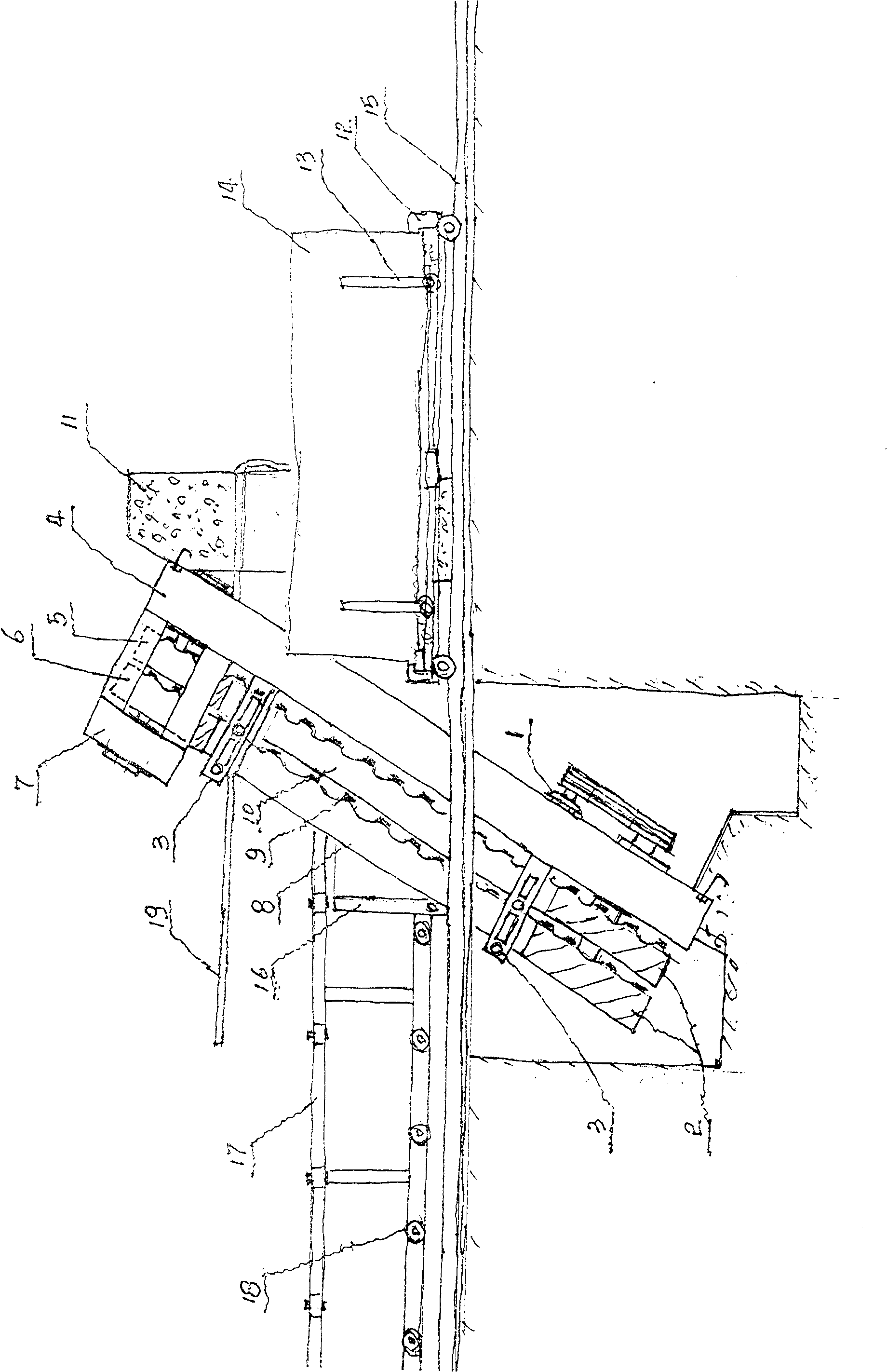

Incline type double-belt diamond saw machine

InactiveCN101357489AHigh yieldSmall thickness errorStone-like material working toolsNumerical controlFrequency conversion

The sloping-type double-strip diamond saw machine is aslope arranged on a column by a large frame with enough intensity. Two pairs of light flywheels with the diameter of 1600mm-1610mm are arranged on the large frame, and two driving flywheels are connected together at the lower end of the large frame and rotate under the driving of the driving motor. Two driven flywheels at the upper end of the large frame are respectively and correspondingly arranged on the slideways with different tensioners. The thickness of boards is made by anti-slip circles with different thickness. Two welding edge of the diamond knife head is strip steel in form of wave with the width of 200mm and the thickness of 1.4mm, the strip steel is welted into a circle and arranged on the two flywheels. The knife head is welted on the wave-shaped chimb by laser. When the host machine rotates, the knife head and the saw blades do high-speed rotation movement from top to down in the eight roller-type controllers. The cooling water pipe is located at the two sides of the top end of the saw blade and sprinkles water over the incision line of the saw blade. Under the driving of the frequency conversion motor, the flat vehicle filled with crude materials facilitates the crude materials to pass through the edge of the crude materials at different speeds and the demanded thickness under the control of the numerical control stowing tool. The working form that the saw blade B is at the front and the saw blade C is at the rear is formed gradually, and the two boards after being cut fall on the transportation bracket wheel which is horizontal to the bottom of the crude materials. When the flat vehicle returns to the stop point, the two boards on the bracket wheel are rotated by a plurality of bracket wheels simultaneously in the guard to the storage point, and the numerical control stowing tool carries out a second circulation to the thickness designed by pulsion of the crude materials.

Owner:陈双英

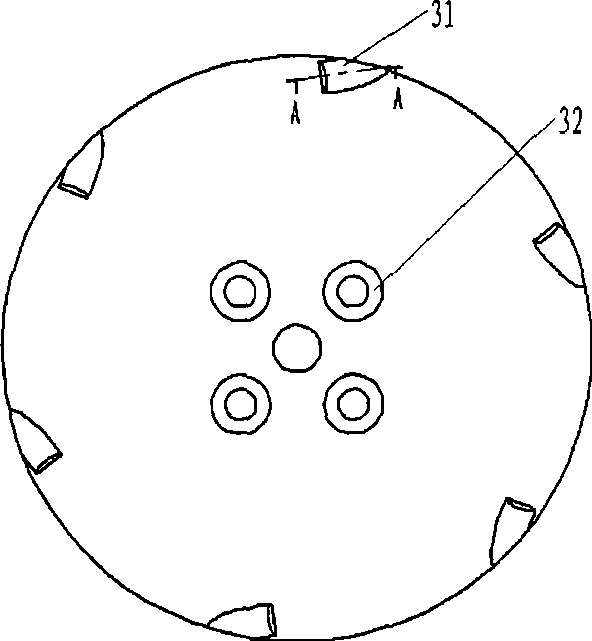

Diamond coring bit and a laser welding preparation process thereof

InactiveCN109736713AImprove coring efficiencyFast deliveryDrill bitsConstructionsTool bitSpecial design

The invention discloses a diamond coring bit and a laser welding preparation process thereof, and belongs to the technical field of diamond coring bits. The diamond coring bit is formed by connectinga metal base body and diamond tool bits, and the tool bits are evenly distributed on the end face of the metal base body. A transition layer is arranged between the metal base body and the diamond tool bit, a plurality of strip-shaped grooves are evenly formed in the side surface of the diamond tool bit, and the side surface of the wavy tooth structure is formed. And the metal base body and the tool bit are connected into a whole through a laser welding process. Through the special design of the shape of the tool bit, the high-speed coring drill bit can play a very good water cooling role during large-depth drilling, and meanwhile, the continuous wave tooth structure on the inner wall of the tool bit is more beneficial to timely discharging of smashed silt, so that very good cutting performance is kept. By optimizing the components of the tool bits and the transition layer and optimizing technological parameters such as laser power and welding speed, a welding seam with excellent performance is obtained.

Owner:江苏友美工具有限公司

Nano-diamond cutter and preparation method and application thereof

ActiveCN112025530AAvoid Corrosion ShockGuaranteed damagePolishing machinesChemical vapor deposition coatingMetallurgyDiamond knife

The invention discloses a preparation method and application of a nano-diamond cutter. Diamond is adopted as a raw material in the method, and the method includes a cutting and shaping procedure, a polishing procedure and a cutting edge machining procedure, and further particularly comprises a pretreatment procedure carried out before the cutting and shaping procedure and a surface modification procedure carried out after the cutting edge machining procedure. The pretreatment procedure is used for eliminating defects in the diamond as much as possible; the surface modification procedure is used for forming a protective layer on the surface of a cutting edge; in the polishing procedure, firstly, a diamond cutter base material is detected to recognize the crystal face of the diamond, then the crystal face (100) or the crystal face (110) of the diamond is selected to be subjected to subsequent polishing, and the polished crystal face serves as a front cutter face; and a protective cuttergrinding method or a laser directional cleavage method is adopted in the cutting edge machining procedure. The nano-diamond cutter prepared through the method can reach the cutting edge precision of 15 nm, and is suitable for being applied to the fields of turning, nano-probes, biological sectioning and the like.

Owner:SHANGHAI ZHENGSHI TECH CO LTD

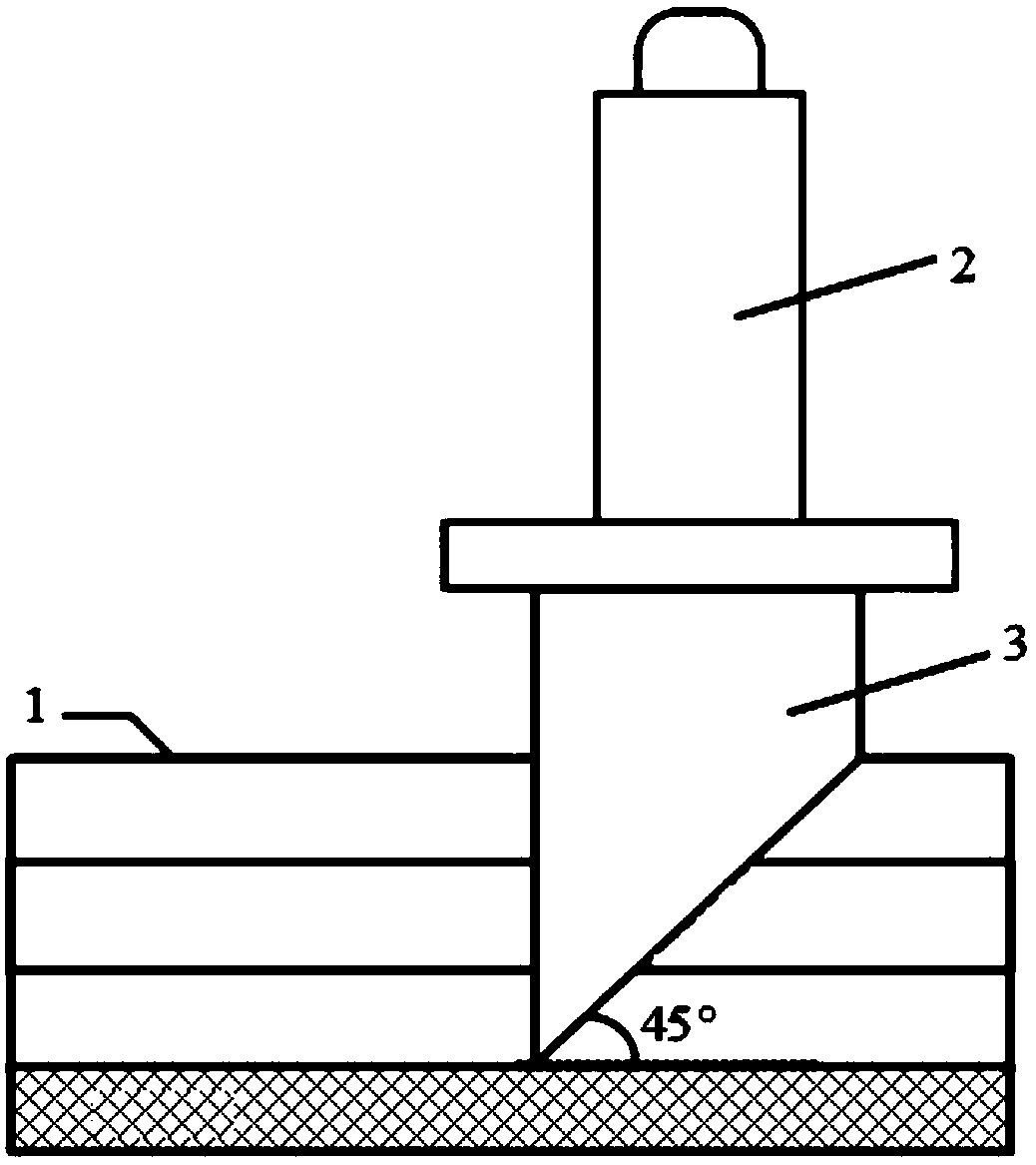

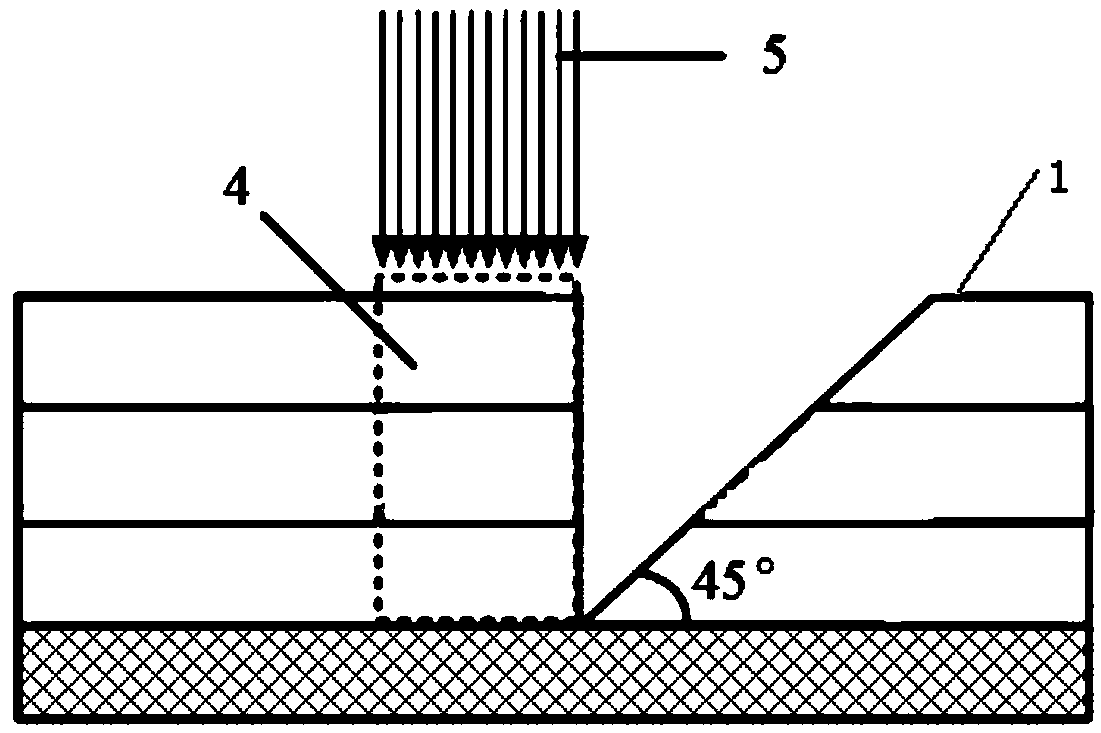

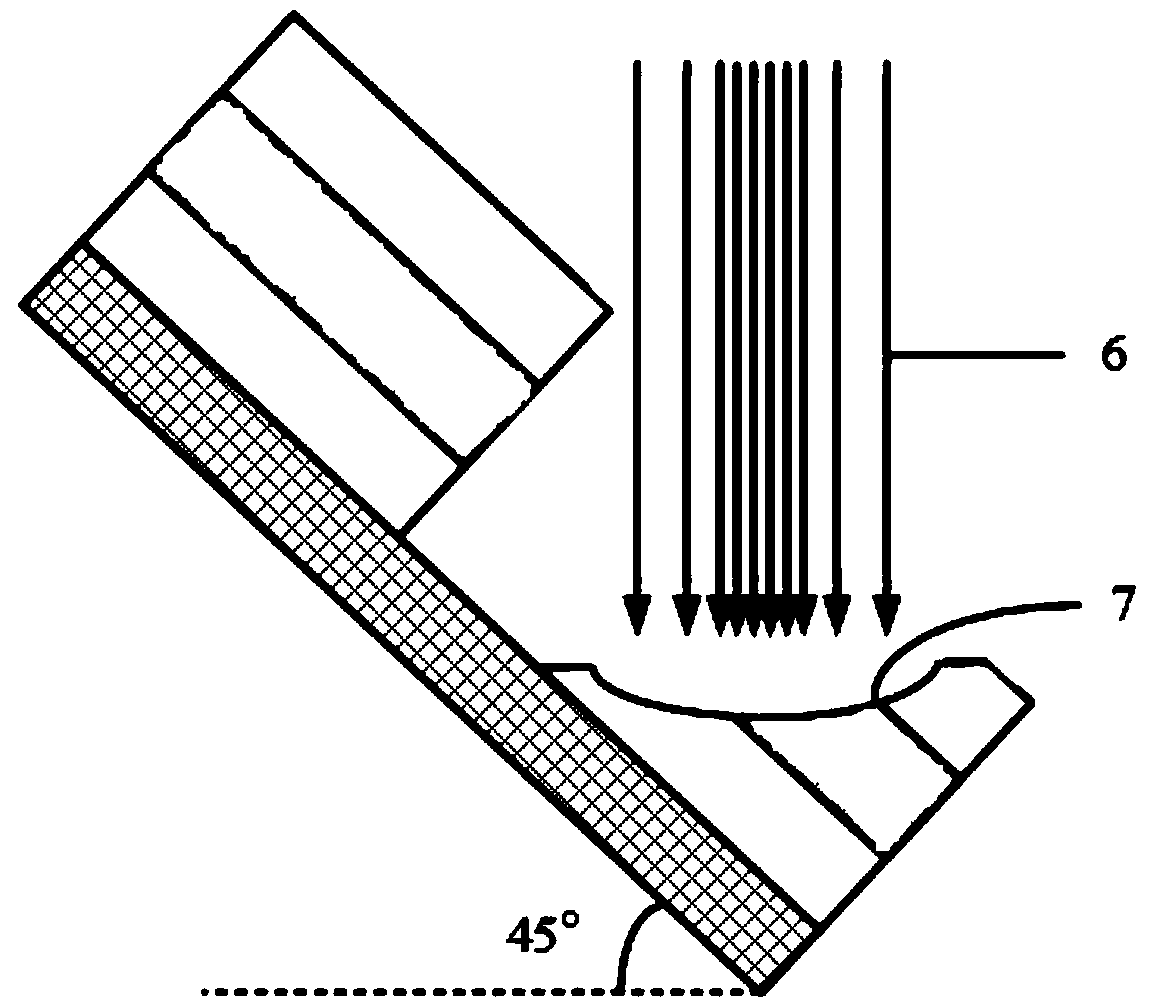

Method for preparing concave mirror on optical waveguide

ActiveCN108303767ASimple structureFlexible operationOptical waveguide light guideVertical planeDiamond knife

The invention discloses a method for preparing a concave mirror on an optical waveguide. The method includes following steps: step 1, cutting the optical waveguide to form a v-shaped groove by employing a v-shaped diamond knife, wherein one plane of the v-shaped groove is a 45-degree inclined plane, and the other plane is a vertical plane; step 2, etching a cube groove by employing one vertical plane, close to the v-shaped groove, of an excimer laser as one side, wherein the width of the cube groove is 2 / 3 or once of the depth of the v-shaped groove, and the depth of the cube groove and the depth of the v-shaped groove are the same; step 3, placing a plate in an inclined manner to enable the inclined plane of the v-shaped groove to be horizontal, and performing hot working on the inclinedplane of the v-shaped groove by employing a carbon dioxide laser to enable the inclined plane to be ablated to form a recessed surface; and step 4, plating a high-reflection film on the recessed surface to form the concave mirror. According to the method, based on the fact that the diamond knife fabricates the 45-degree inclined plane, hot working is further performed by the inclined plane by employing the carbon dioxide laser, a processing process has a thermal annealing effect due to the mechanism of hot working, and the reflective concave mirror with low roughness can be obtained.

Owner:苏州德睿电力科技有限公司

Finish-milling tool and method used for hub surface machining

InactiveCN105397164AAvoid bondingReduce processing costsMilling cuttersMilling equipment detailsMilling cutterDiamond knife

Owner:TAIAN QICHENG WHEEL MFG

Metal mirror processing device and process

ActiveCN107052866APlay the role of grindingAchieve mirror effectMilling cuttersMilling equipment detailsDiamond knifeMachine tool

The invention provides a metal mirror processing device and process. The metal mirror processing device comprises a machine tool body and a processing room arranged inside the machine tool body, and a metal mirror processing mechanism is arranged in the processing room. The metal mirror processing mechanism particularly comprises a vacuum fixture, a cutting device and a cutting fluid spraying device, wherein the vacuum fixture is used for fixing a metal workpiece; the cutting device is used for conducting mirror processing on the metal workpiece, arranged over the vacuum fixture, and connected with a main shaft of a machine tool; and the cutting fluid spraying device is used for cooling and lubricating the surface of the metal workpiece in the cutting process. According to the metal mirror processing device and the process, diamond knife grains arranged on a blade of the cutting device can be used for grinding the surface of the metal workpiece; through cooperation of stable adsorption of the vacuum fixture and the cooling and lubrication of the cutting fluid spraying device, a mirror effect of the metal workpiece can be achieved in one step through cutting processing, mirror processing procedures of the surface of the mental workpiece can be simplified, and the production efficiency can be improved.

Owner:沈阳机床(东莞)智能装备有限公司

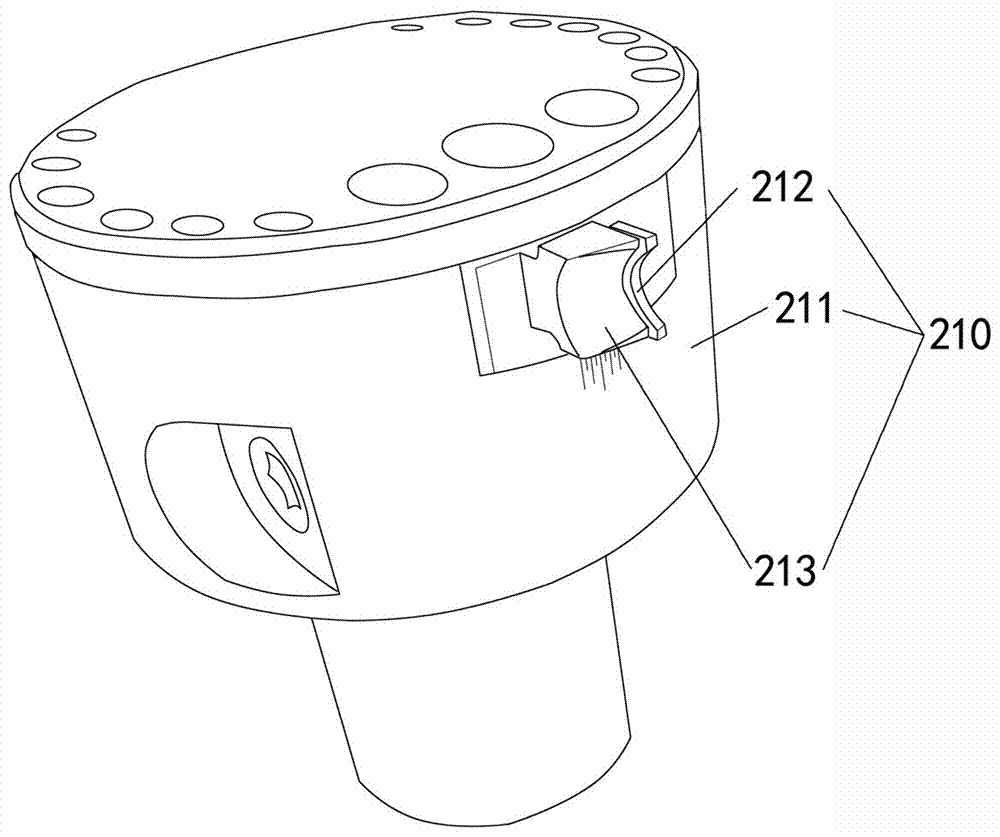

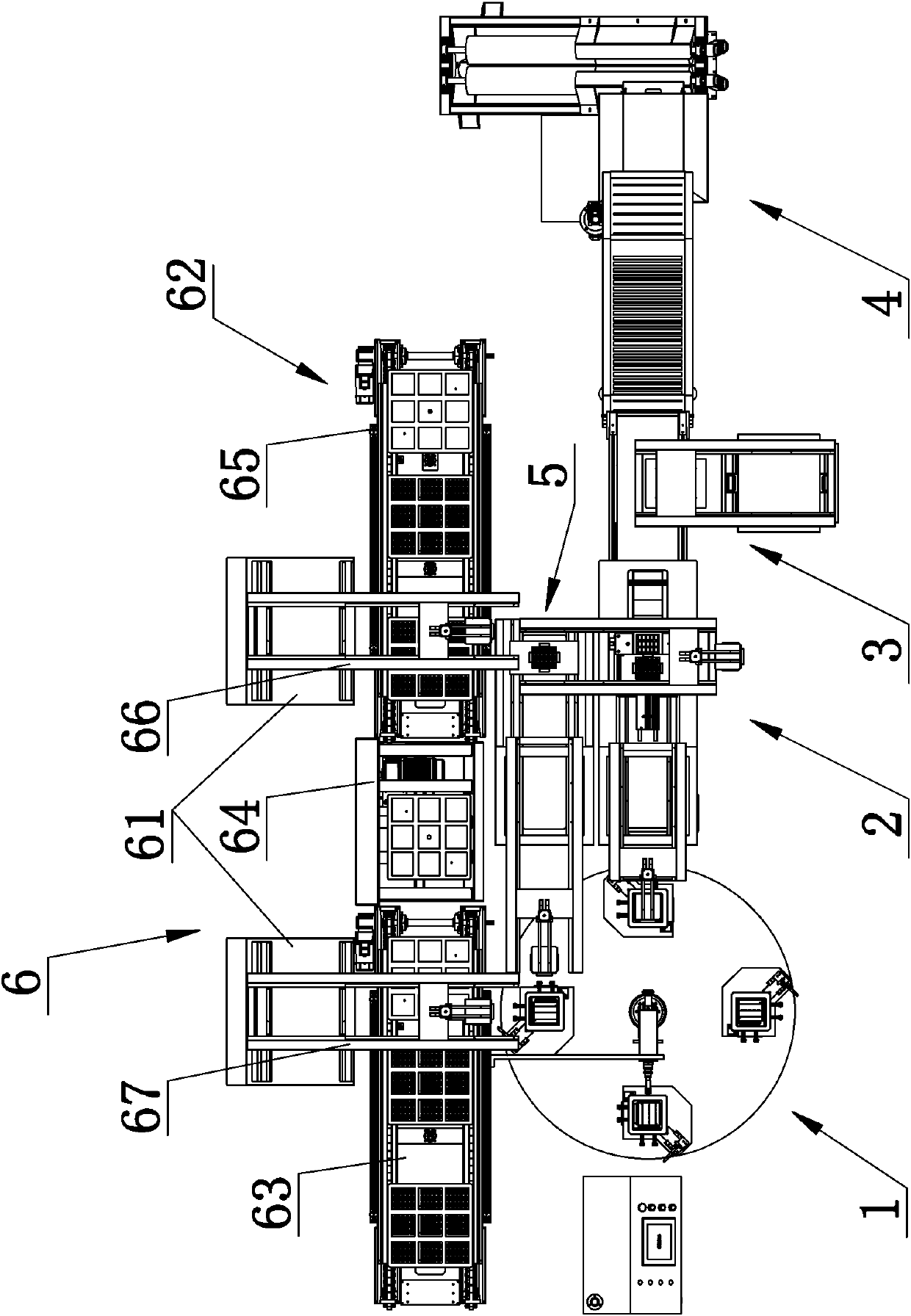

Automatic die dismantling and mounting method suitable for diamond knife head die

The invention discloses an automatic die dismantling and mounting method suitable for a diamond knife head die and relates to the field of mechanical automation. A production line mainly comprises anintermittent rotary table device, a die dismantling device, a screening device, a press cake sorting device, a die main body transferring device and a die main body changing device. According to the automatic die dismantling and mounting method, the intermittent rotary table device, the die dismantling device and the screening device are adopted to automatically dismantle a die frame, a die body,a pressing head and a cold green compact; and the die main body transferring device and / or the die main body changing device is utilized to re-mount the die body or the other die body into the die frame. The automatic die dismantling and mounting method can automatically dismantle the die, separate the cold green compact, and mount the die body to the die frame. The production line has the advantages of being compact in structure, continuous in action, and high in degree of automation.

Owner:福建省泉州万龙石业有限公司

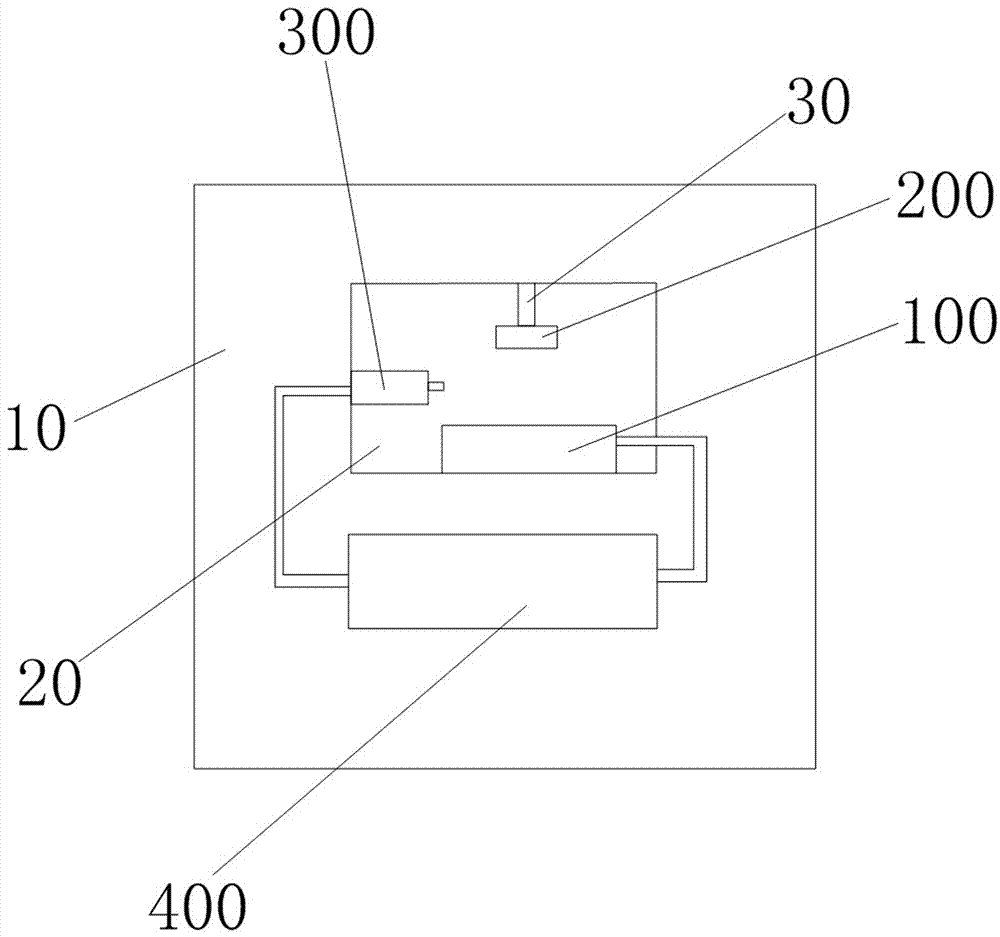

In-place detection and positioning device for diamond cutting tool

InactiveCN104647140AAchieve positioningImplement geometry parametersAutomatic control devicesPrecision positioning equipmentDiamond cuttingOptical mount

The invention provides an in-place detection and positioning device for a diamond cutting tool. The in-place detection and positioning device for the diamond cutting tool comprises an optical bracket, a fine adjustment and locking mechanism, an optical system and an industrial control computer, wherein the fine adjustment and locking mechanism is fixedly arranged on the optical bracket; the optical system is fixedly arranged on an adapter coupling plate of the fine adjustment and locking mechanism, and moves up and down along a sliding rail; the industrial control computer is connected with a CCD (Charge Coupled Device) sensor through a network cable, and is provided with upper computer software for receiving the image data of the CCD sensor and performing data processing. The device can be used for performing in-place detection and positioning on the diamond cutting tool, works independently to detect the diamond cutting tool off line, and is high in system resolution and positioning accuracy, simple in structure and convenient to operate.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com