Apparatus for circle cutting of glass curtain wall

A glass curtain wall, circular technology, used in glass manufacturing equipment, glass cutting devices, manufacturing tools, etc., can solve the problems of scratching people and inaccurate cutting, and achieve the effect of preventing scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

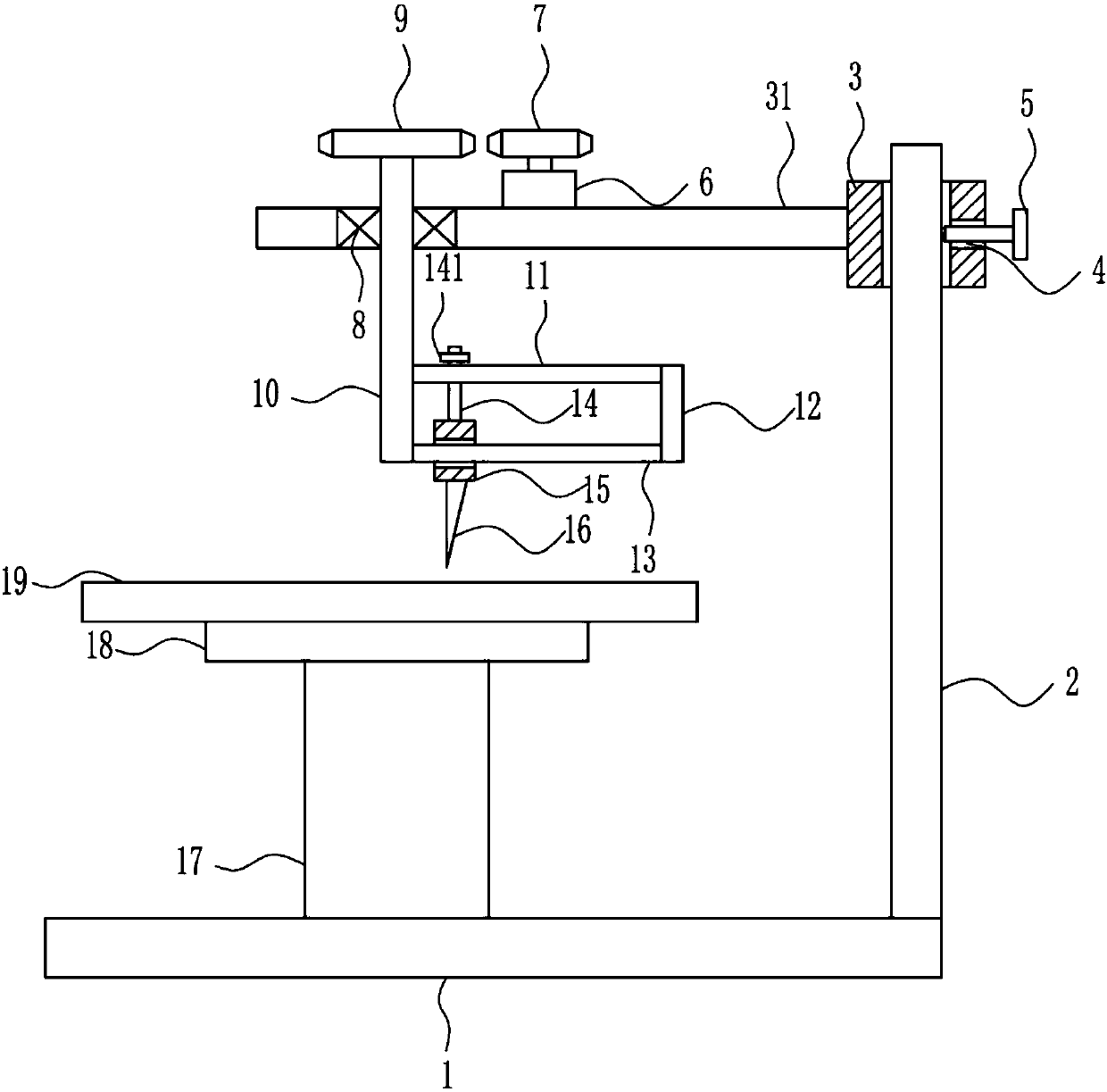

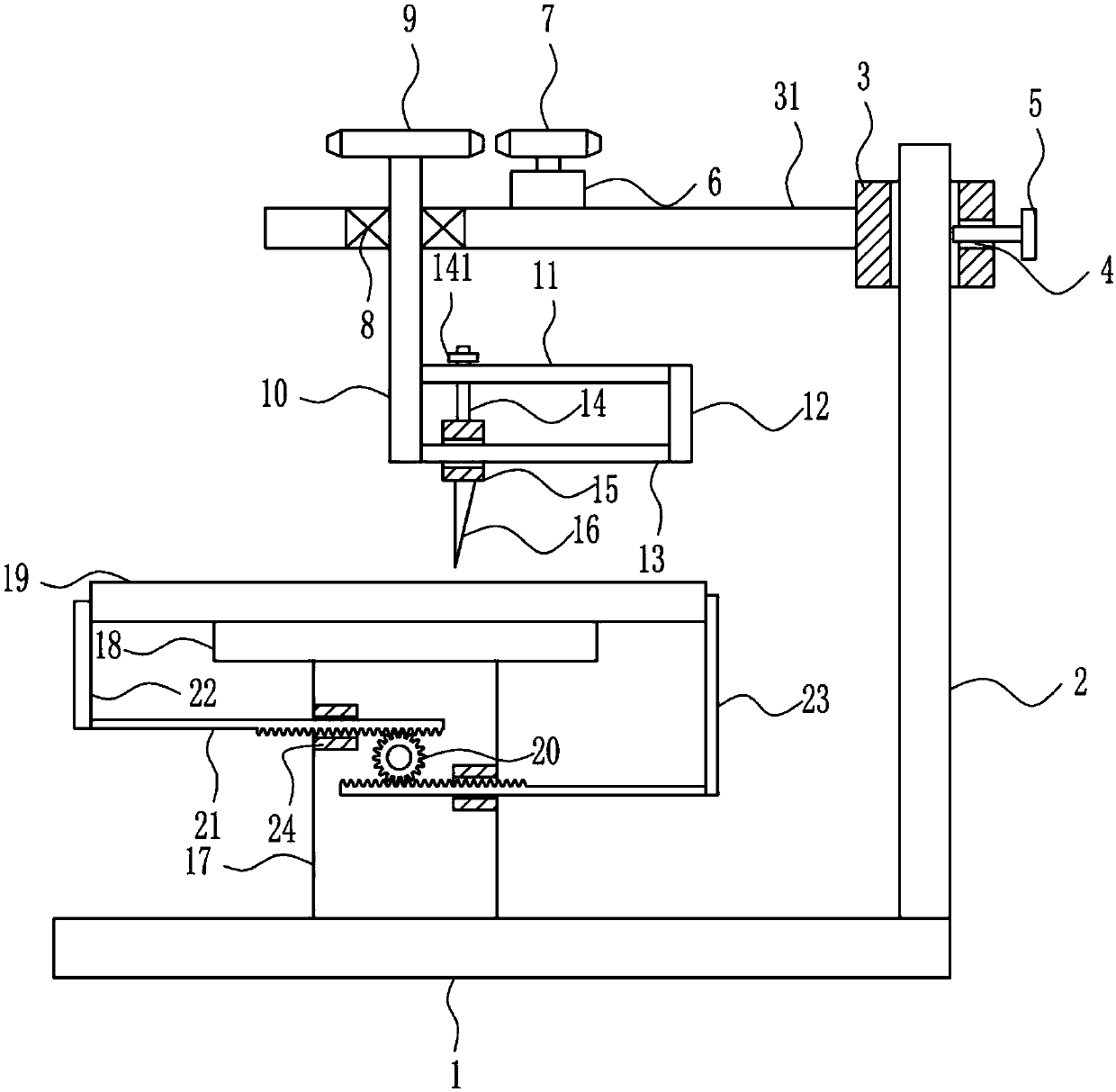

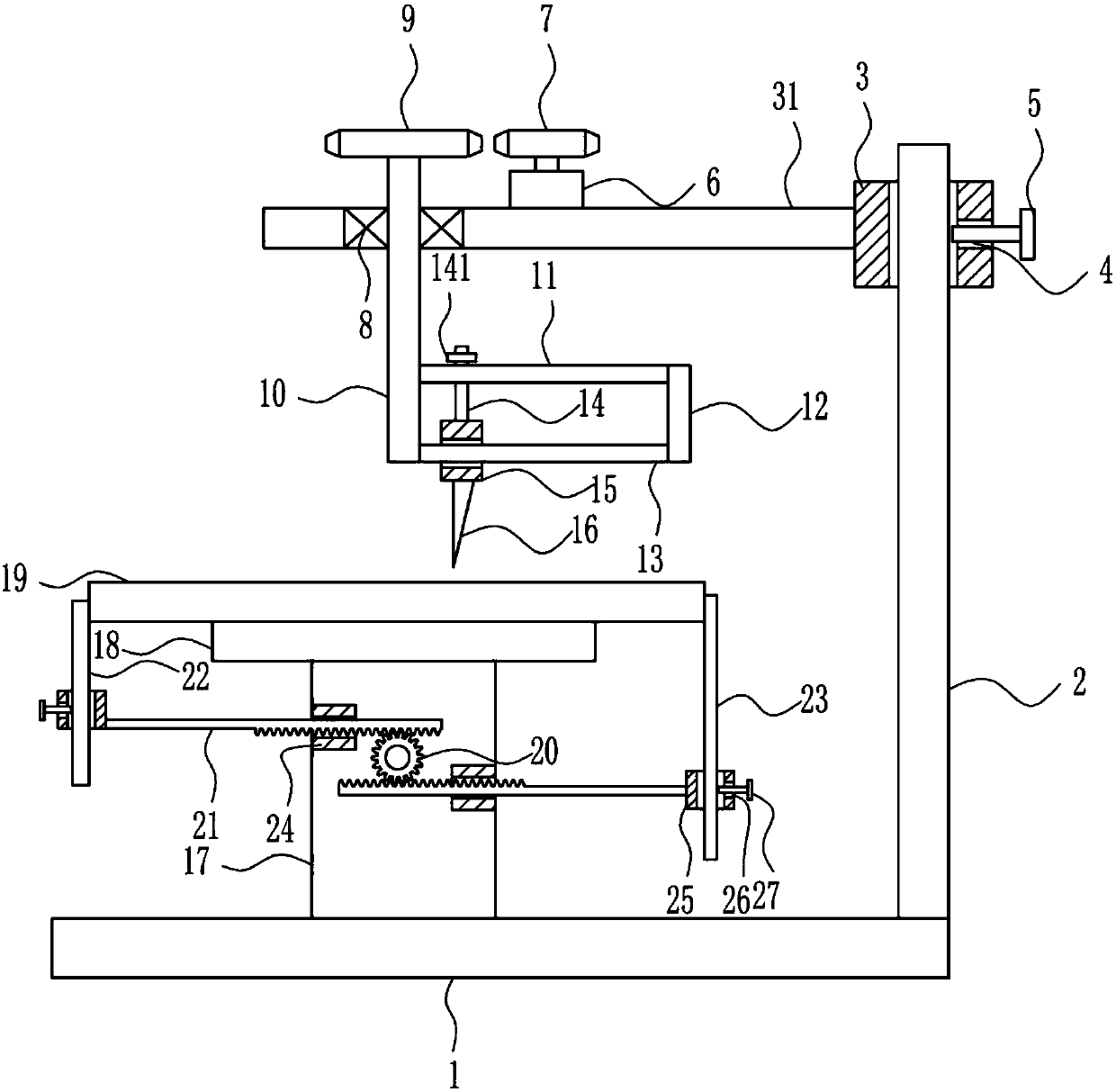

[0023] A device for circular cutting of glass curtain walls, such as Figure 1-3 As shown, it includes a base plate 1, a first support rod 2, a first guide sleeve 3, a mounting plate 31, a first screw rod 5, a motor 6, a first gear 7, a bearing seat 8, a second gear 9, a rotating shaft 10, a connecting Rod 11, connecting block 12, guide rod 13, second screw rod 14, nut 141, second guide sleeve 15, diamond knife 16, second support rod 17 and placement plate 18, the upper right side of bottom plate 1 is connected with the first support Rod 2, the upper side of the first support rod 2 is slidingly connected with the first guide sleeve 3, the middle part of the right wall of the first guide sleeve 3 has a first threaded hole 4, the first threaded hole 4 is screwed with the first screw rod 5, the first The screw rod 5 is matched with the first threaded hole 4, the left side of the first guide sleeve 3 is connected with a connecting rod 11, the upper left side of the connecting rod ...

Embodiment 2

[0025] A device for circular cutting of glass curtain walls, such as Figure 1-3As shown, it includes a base plate 1, a first support rod 2, a first guide sleeve 3, a mounting plate 31, a first screw rod 5, a motor 6, a first gear 7, a bearing seat 8, a second gear 9, a rotating shaft 10, a connecting Rod 11, connecting block 12, guide rod 13, second screw rod 14, nut 141, second guide sleeve 15, diamond knife 16, second support rod 17 and placement plate 18, the upper right side of bottom plate 1 is connected with the first support Rod 2, the upper side of the first support rod 2 is slidingly connected with the first guide sleeve 3, the middle part of the right wall of the first guide sleeve 3 has a first threaded hole 4, the first threaded hole 4 is screwed with the first screw rod 5, the first The screw rod 5 is matched with the first threaded hole 4, the left side of the first guide sleeve 3 is connected with a connecting rod 11, the upper left side of the connecting rod 1...

Embodiment 3

[0028] A device for circular cutting of glass curtain walls, such as Figure 1-3 As shown, it includes a base plate 1, a first support rod 2, a first guide sleeve 3, a mounting plate 31, a first screw rod 5, a motor 6, a first gear 7, a bearing seat 8, a second gear 9, a rotating shaft 10, a connecting Rod 11, connecting block 12, guide rod 13, second screw rod 14, nut 141, second guide sleeve 15, diamond knife 16, second support rod 17 and placement plate 18, the upper right side of bottom plate 1 is connected with the first support Rod 2, the upper side of the first support rod 2 is slidingly connected with the first guide sleeve 3, the middle part of the right wall of the first guide sleeve 3 has a first threaded hole 4, the first threaded hole 4 is screwed with the first screw rod 5, the first The screw rod 5 is matched with the first threaded hole 4, the left side of the first guide sleeve 3 is connected with a connecting rod 11, the upper left side of the connecting rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com