Patents

Literature

1039 results about "Cutting glass" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

How to Cut Glass. Whether setting a window pane, creating a stained glass mosaic, or doing some other project, cutting glass is a handy skill that isn't difficult to pick up. With the right tools and a steady hand, anyone can start cutting...

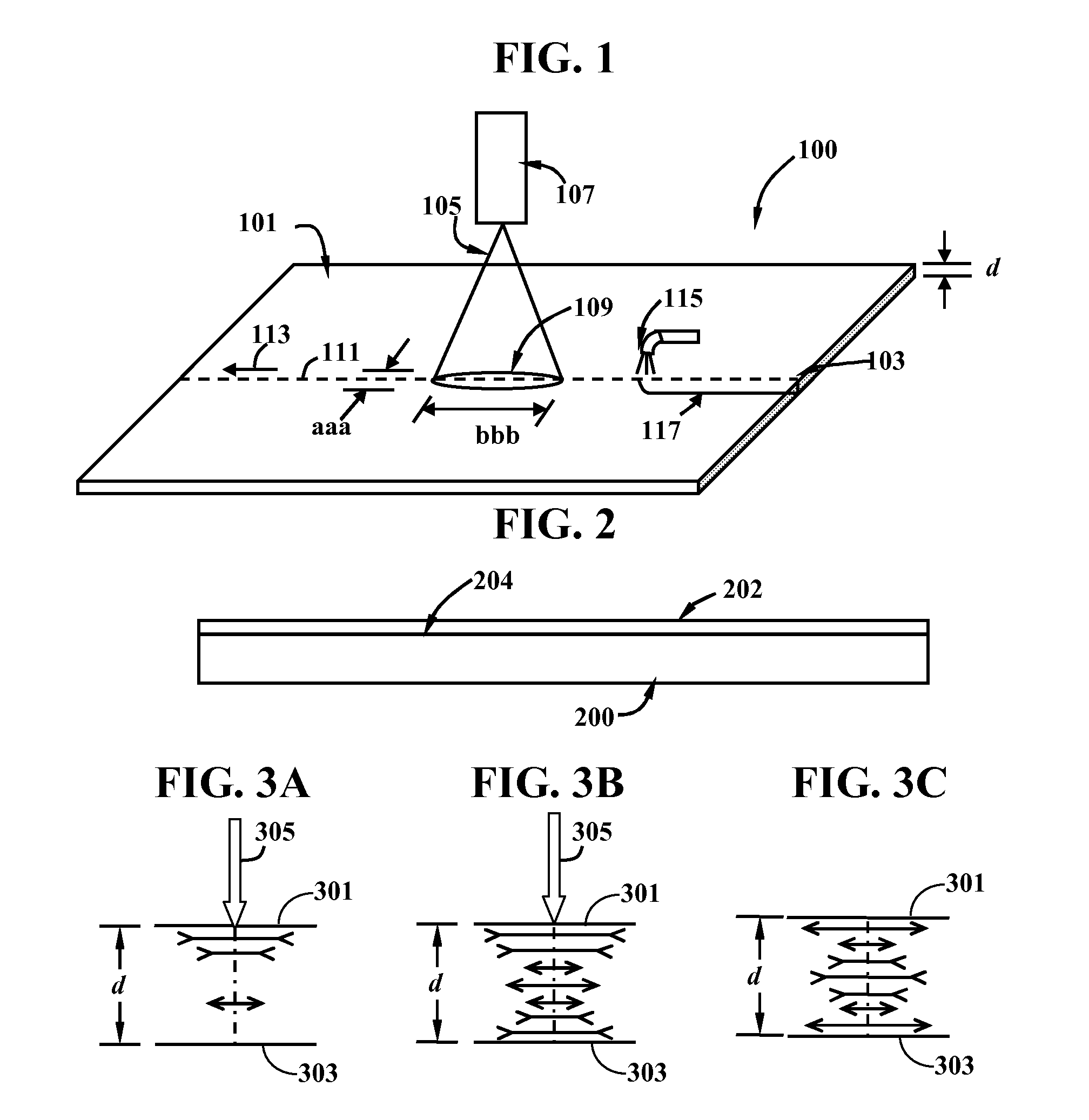

Methods for Laser Cutting Glass Substrates

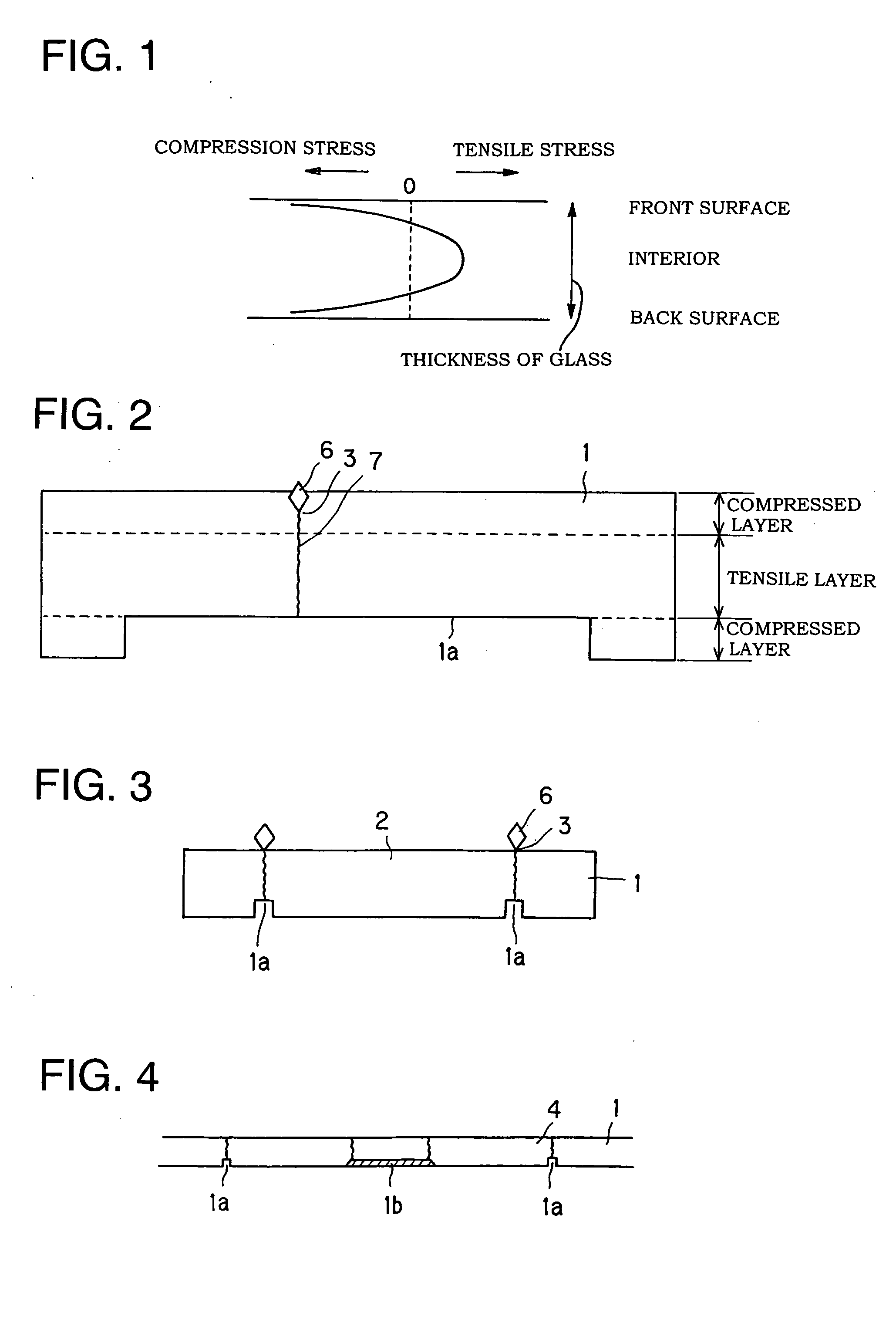

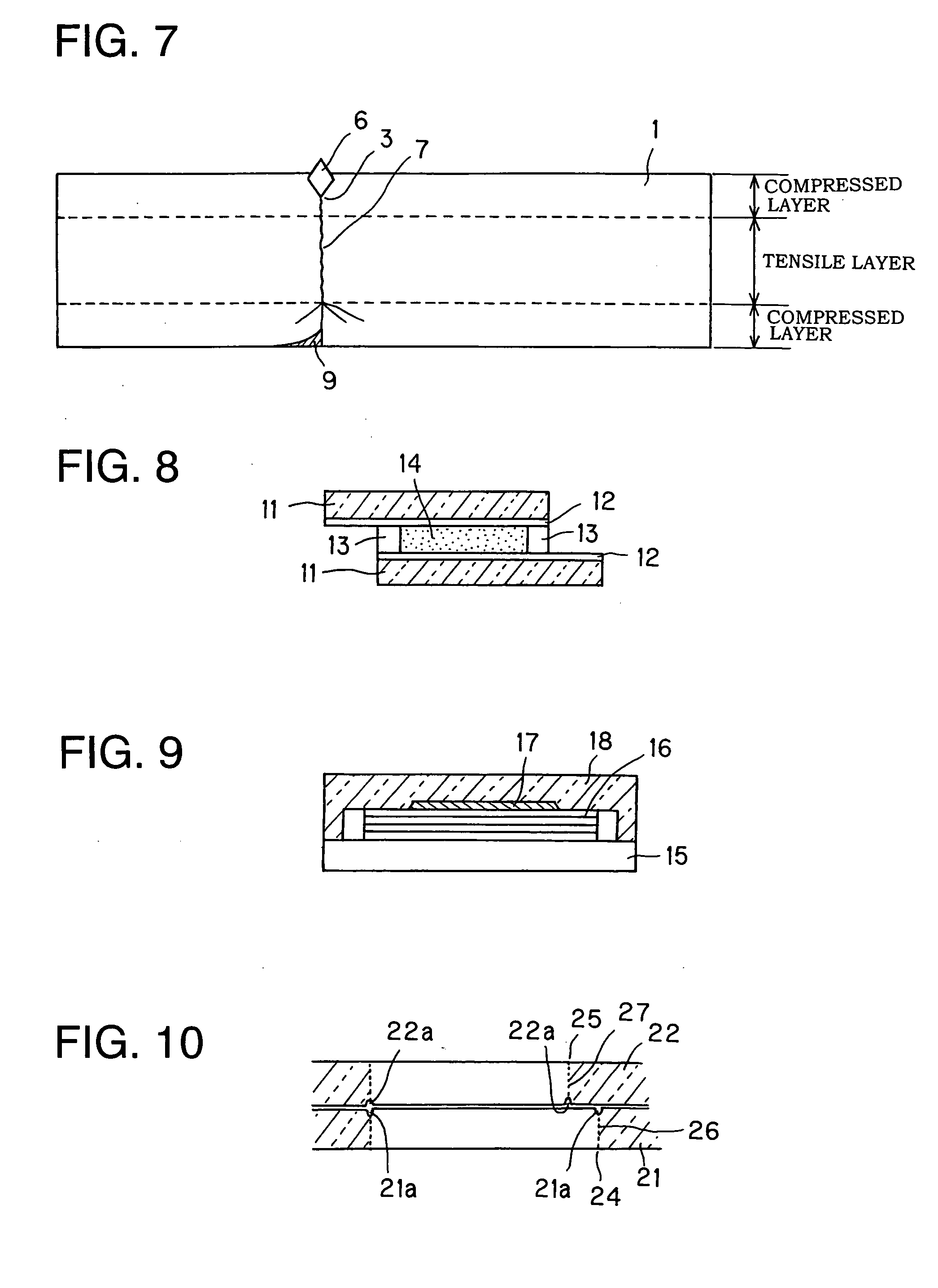

InactiveUS20110049765A1Glass severing apparatusWelding/soldering/cutting articlesCutting glassLaser cutting

A method for cutting a glass article from a strengthened glass substrate having a surface compression layer and a tensile layer includes forming an edge defect in the surface compression layer on a first edge of the strengthened glass substrate. The method further includes propagating a through vent through the surface compression and tensile layers at the edge defect. The through vent precedes a region of separation along a cut line between the glass article and the strengthened glass substrate.

Owner:CORNING INC

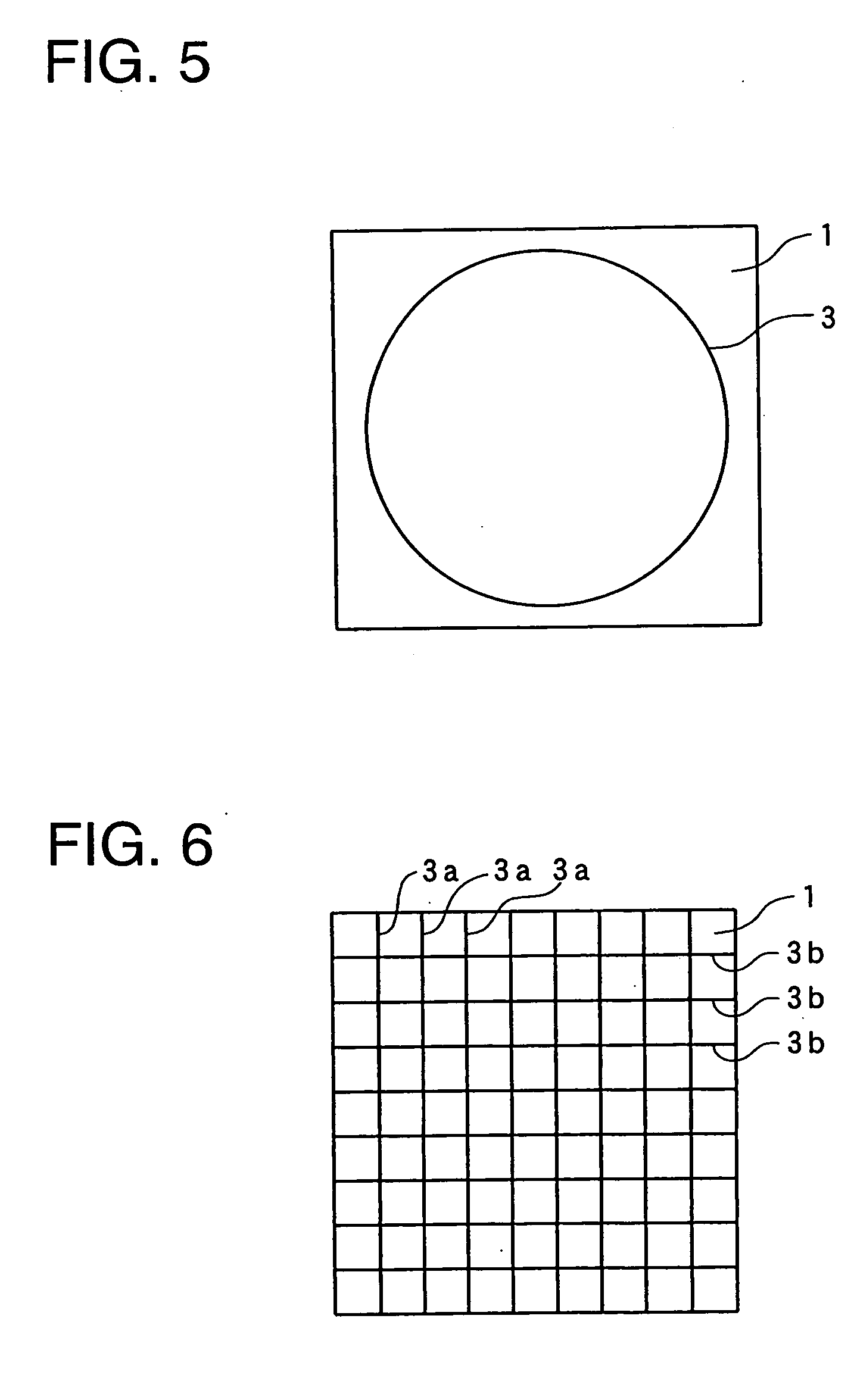

Method of separating strengthened glass

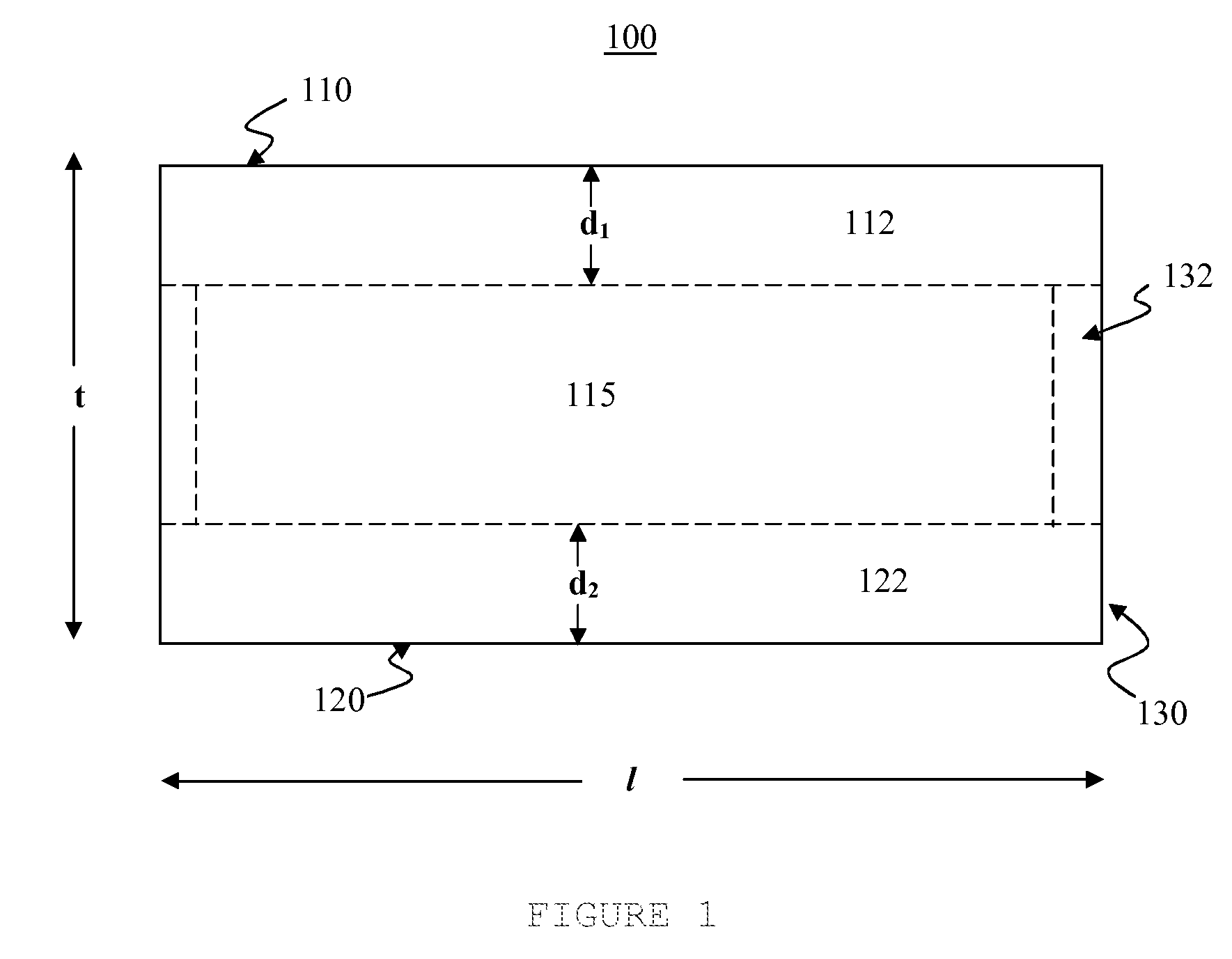

A method of cutting a glass sheet that has been thermally or chemically strengthened along a predetermined line, axis, or direction with high speed and with minimum damage on the cut edges. The strengthened glass sheet may be cut into at least two pieces, one of which having a predetermined shape or dimension. At least one damage line is formed within the strengthened glass sheet. The at least one damage line is formed outside the strengthened compressive stress surface layers and within the tensile stress layer of the strengthened glass sheet. The at least one damage line may be formed by laser treatment. A crack is initiated in the strengthened glass sheet and propagated along the at least one damage line to separate the strengthened glass sheet along the predetermined line, axis, or direction into at least two pieces.

Owner:CORNING INC

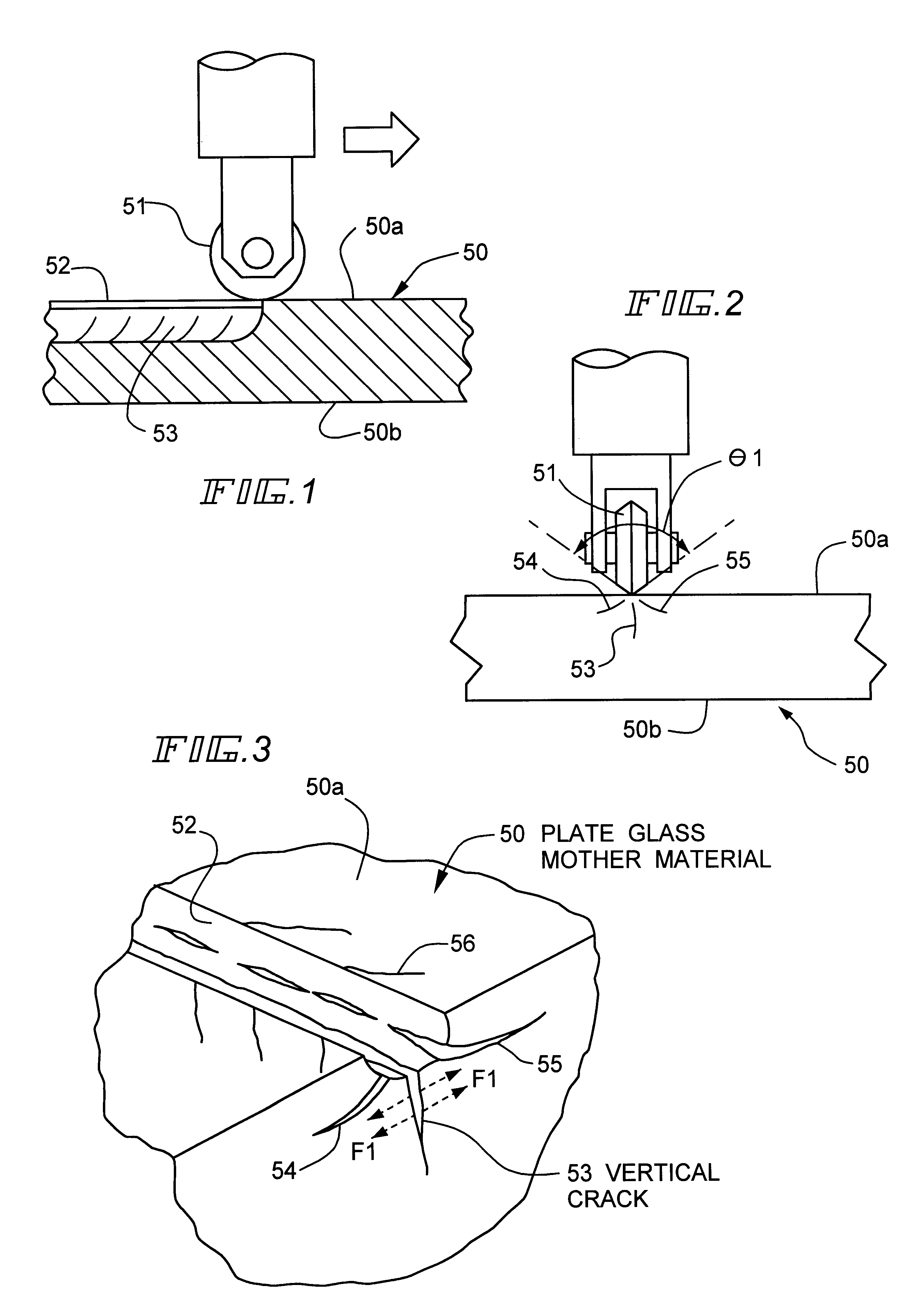

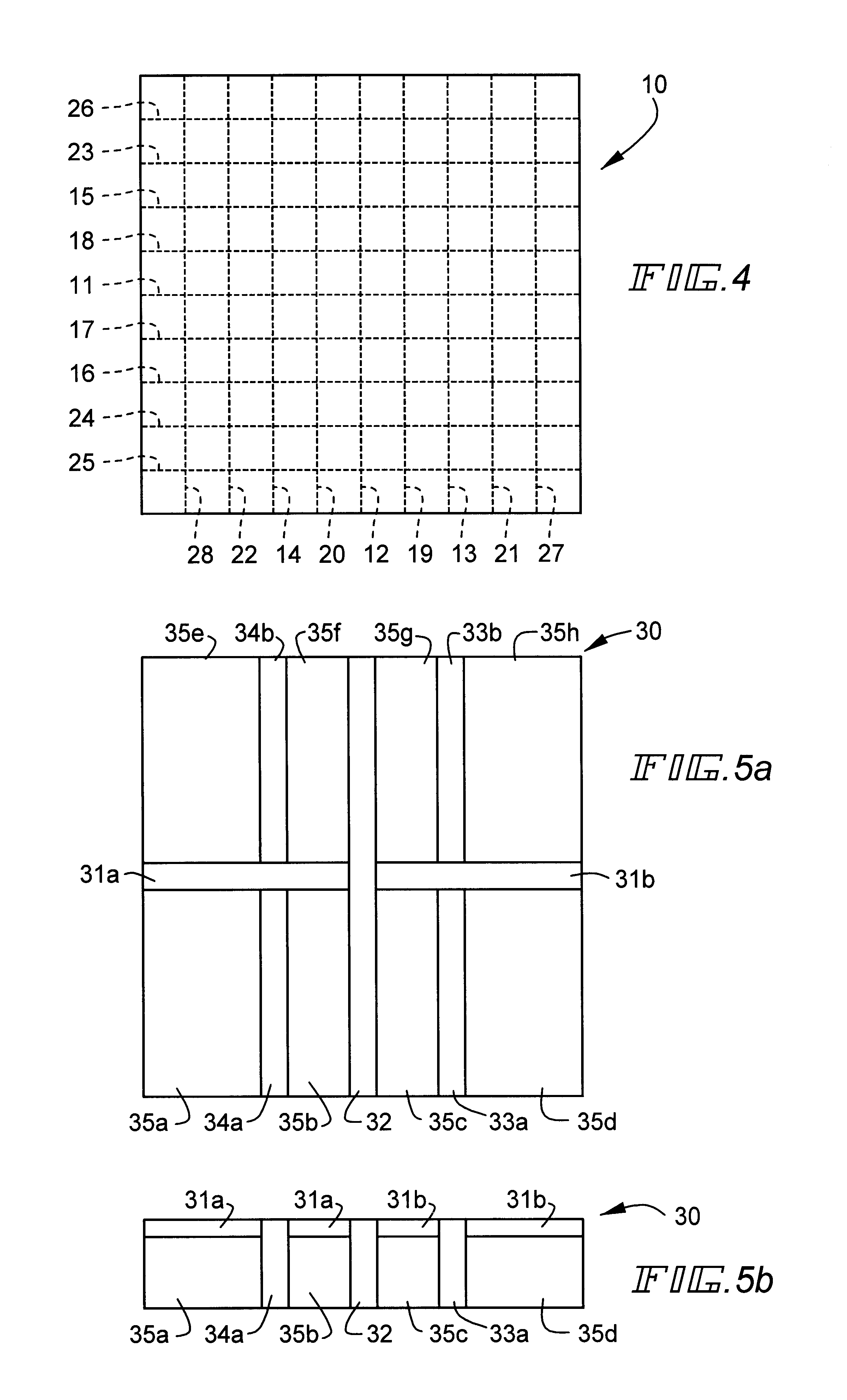

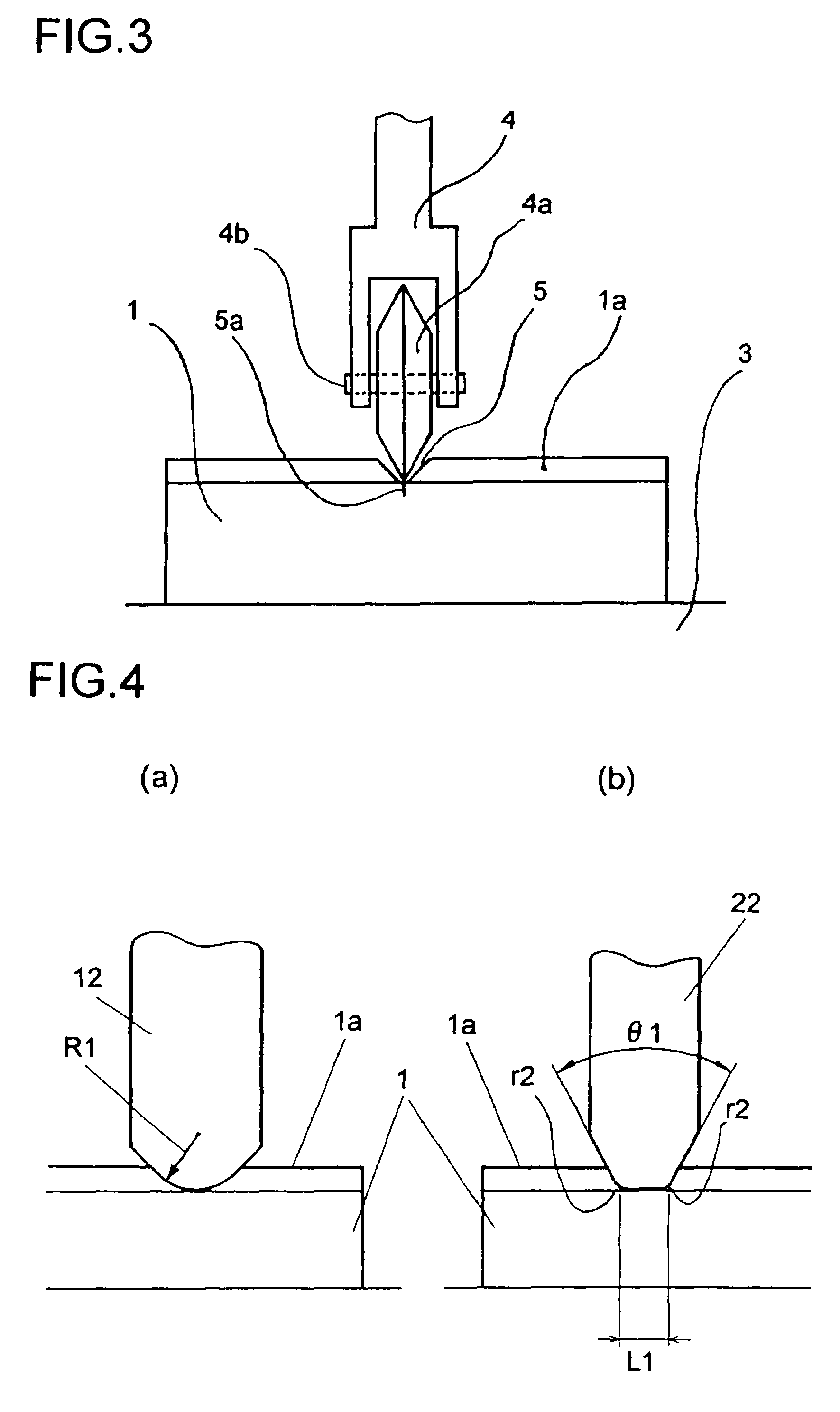

Cutting method for plate glass mother material

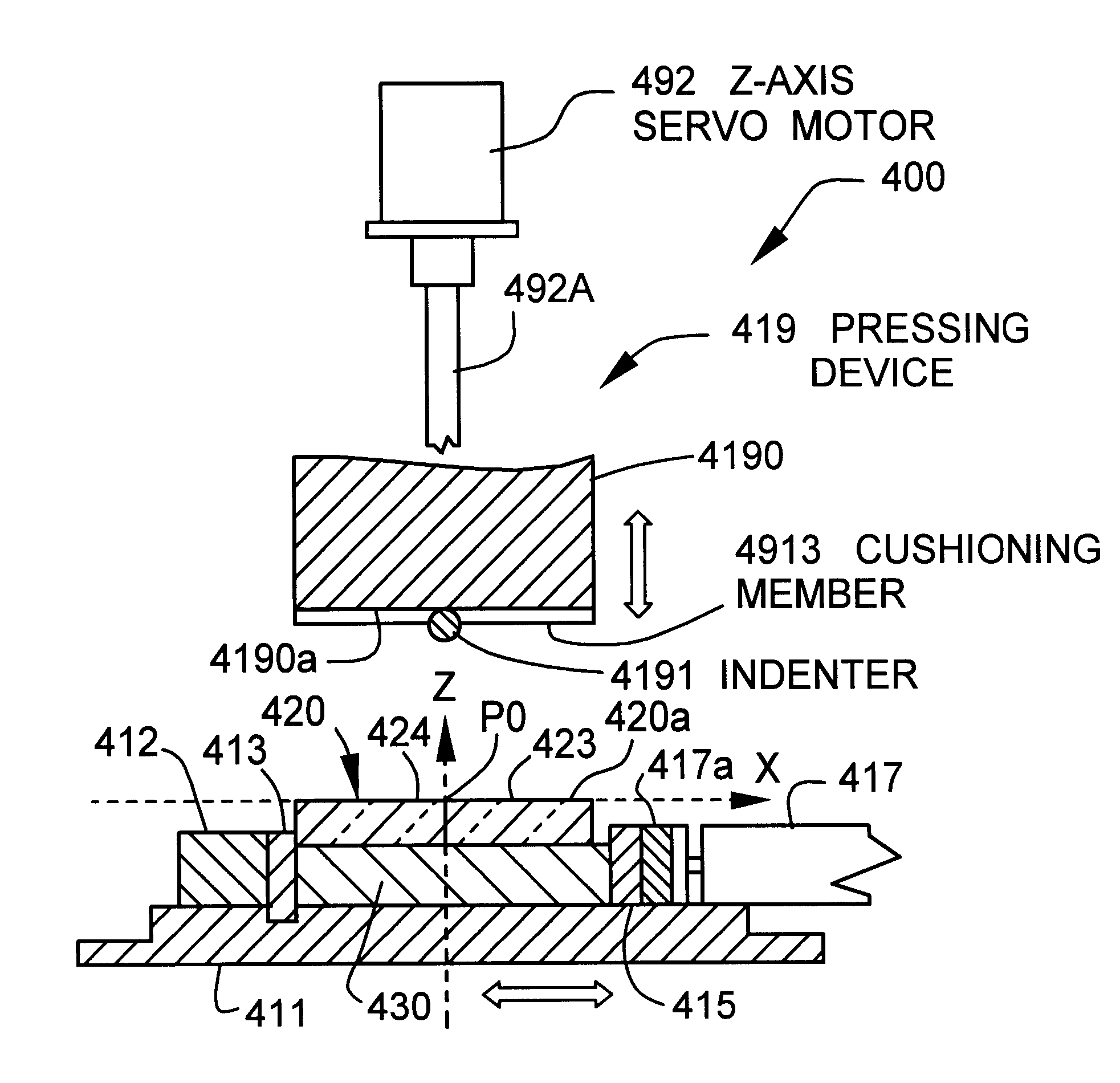

The present invention is directed to a method of cutting glass mother material involving preparing the plate glass mother material in which a plurality of grooves are scribed, disposing the plate glass mother material with the grooves turned inward; and pressing an outer surface of the plate glass mother material with a cushioning member having a thickness not to be protruded downward from a lowermost portion of an indenter, with the cushioning member being attached onto an under surface of an indenter base excluding the indenter, pressing a portion opposite to the groove on the outer surface with the indenter having a stretched shape, and cutting the plate glass mother material.

Owner:HOYA CORP

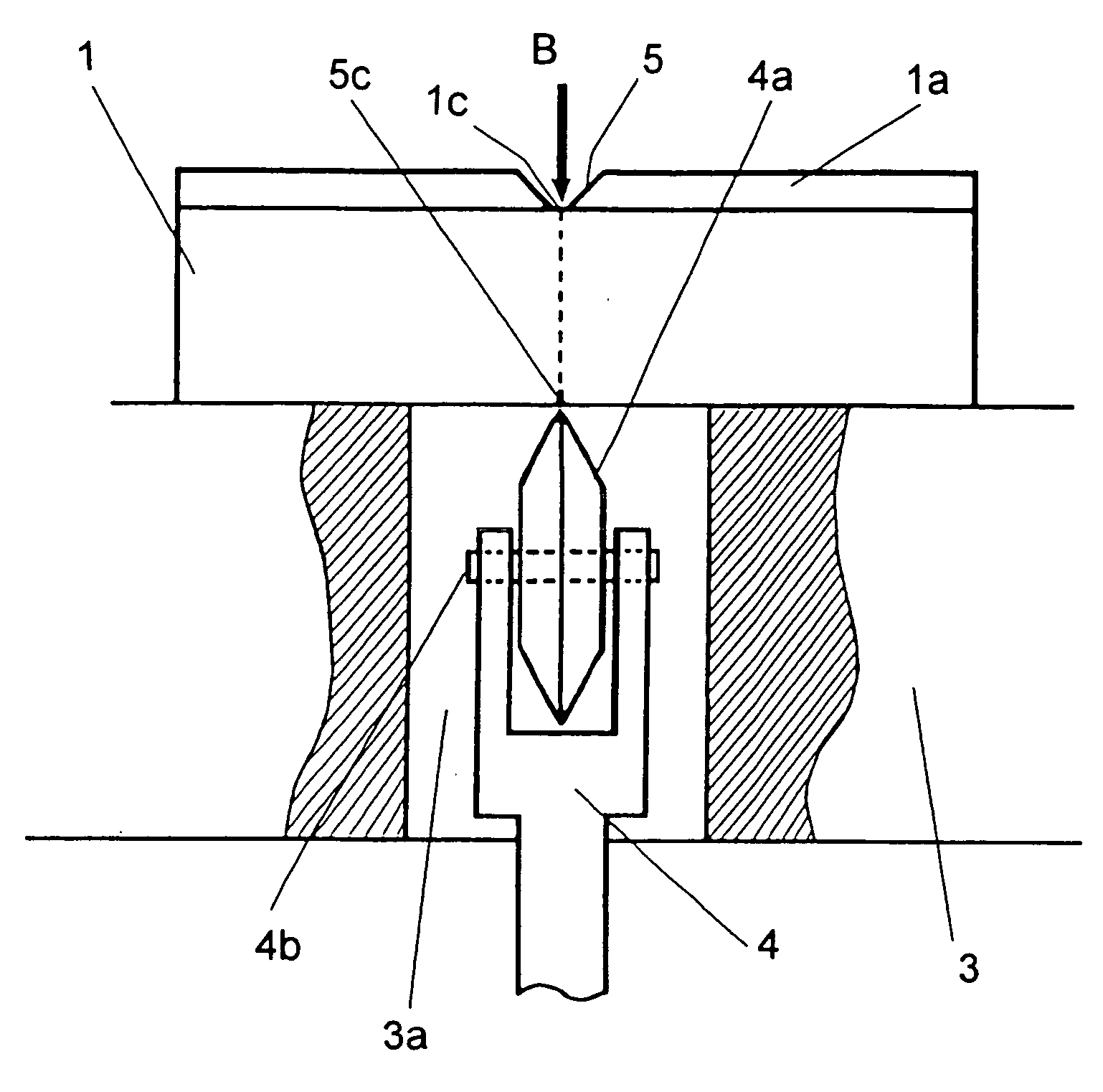

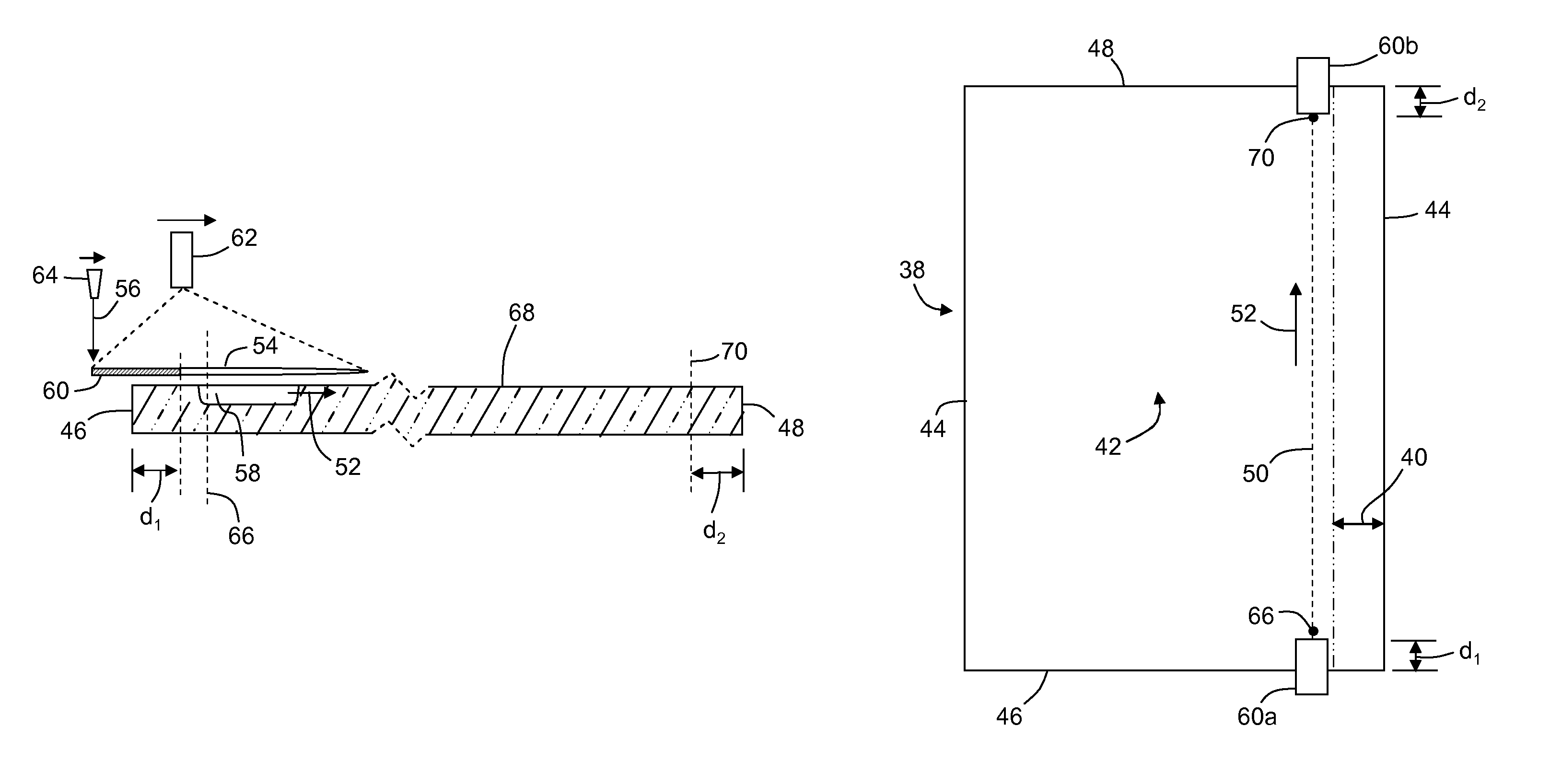

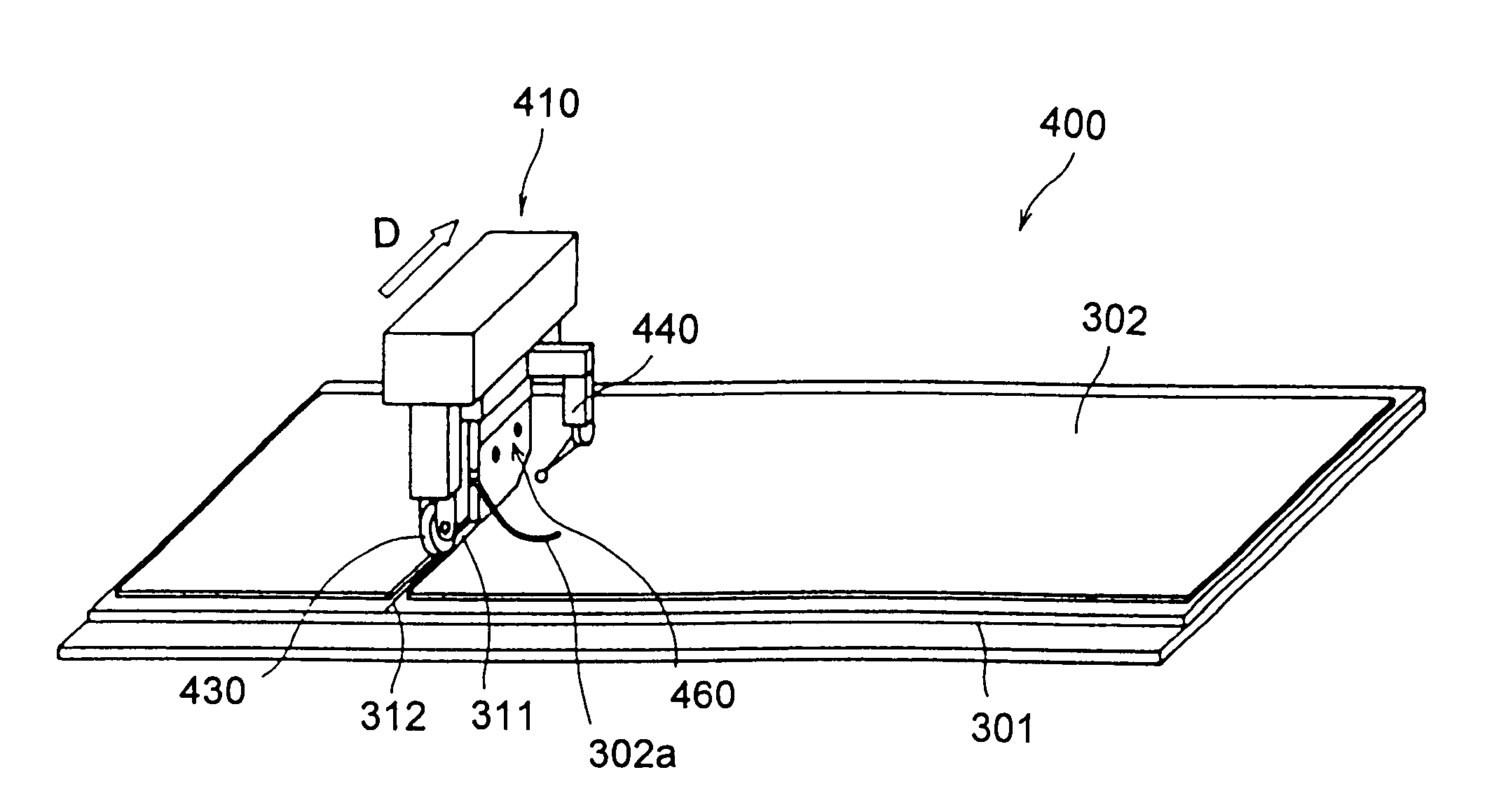

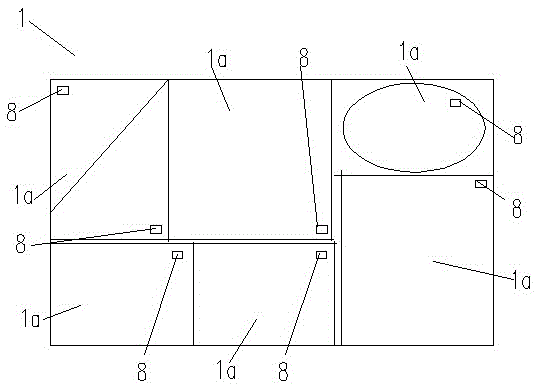

Method and device for parting glass substrate, liquid crystal panel, and liquid crystal panel manufacturing device

InactiveUS20050056127A1High mechanical strengthPrevent peelingLiquid crystal compositionsBox making operationsLiquid-crystal displayCutting glass

A method for cutting apart a glass substrate is provided whereby scribing of the glass substrate is possible without being affected by the presence or thickness of a deposited film formed thereon and without scratching the deposited film. To treat a glass substrate (1) having a deposited film (1a), such as a thin film or resin film, formed on one surface thereof, there are provided a shaving means (202), which is a blade that removes strip-shaped portions of the deposited film (1a) to expose strip-shaped regions on the glass substrate (1), and a wheel cutter (14a) that forms scribed lines along the strip-shaped regions exposed on the glass substrate (1). The glass substrate (1) is cut apart along the scribed lines.

Owner:SHARP KK +1

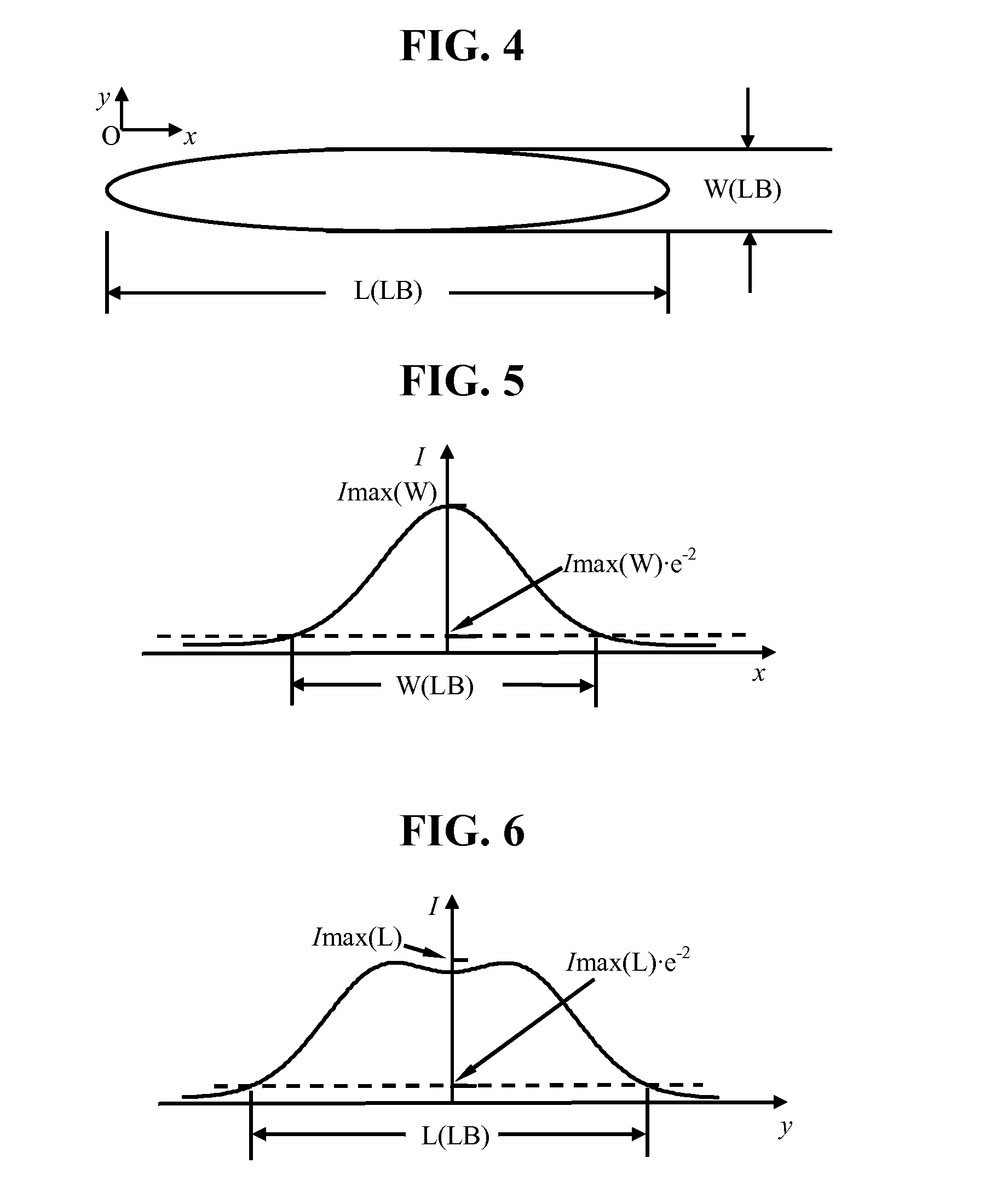

Laser cutting method

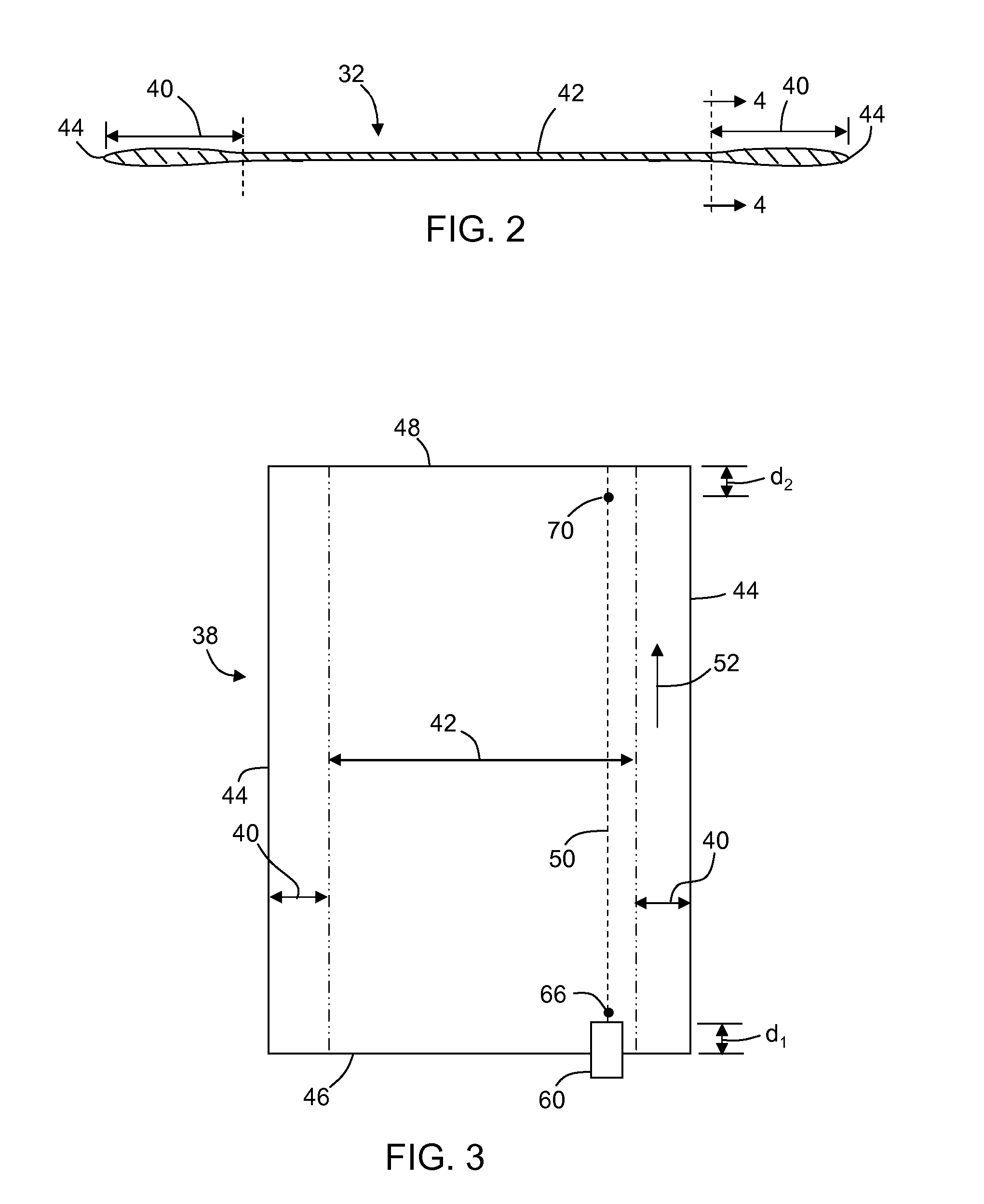

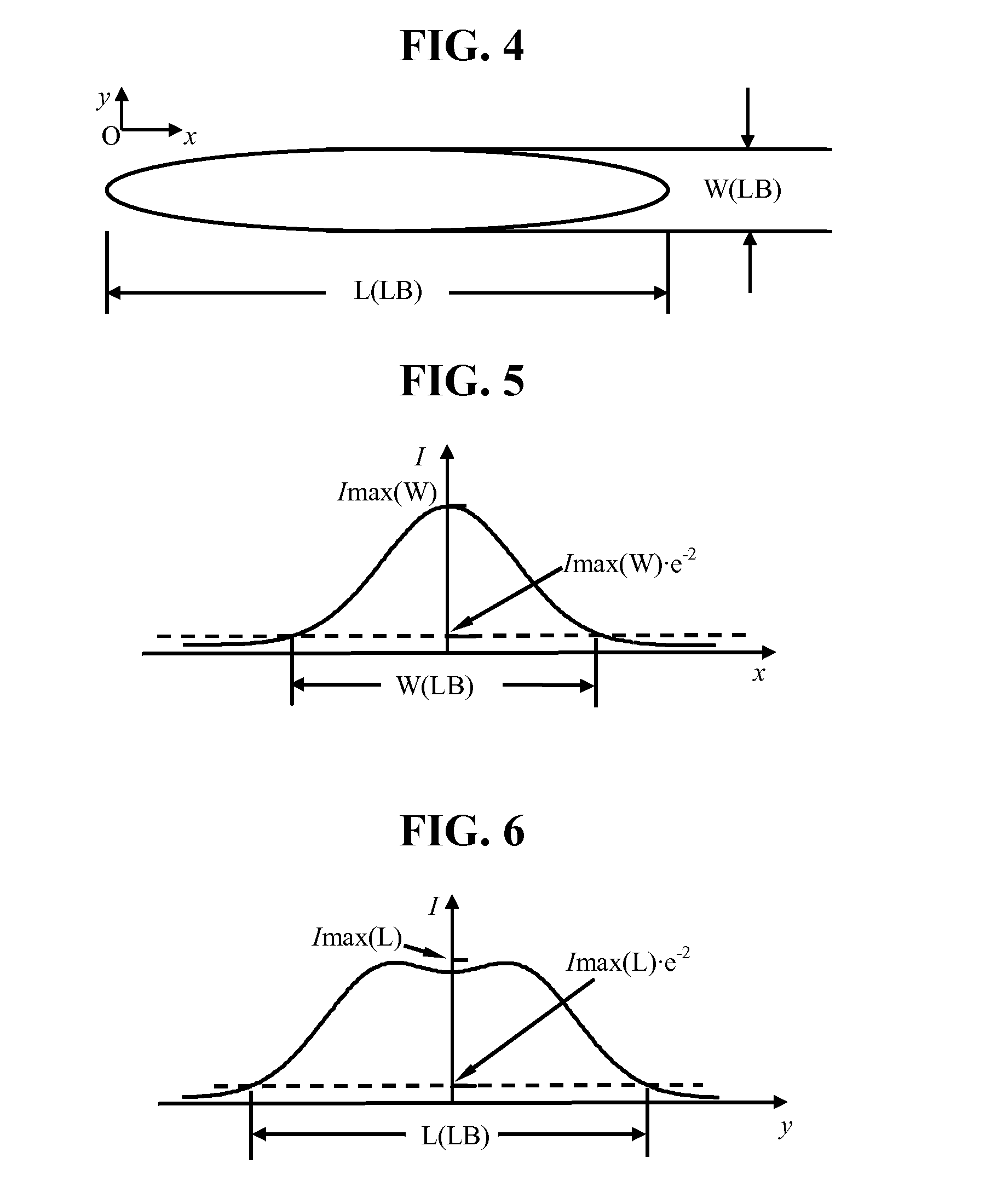

ActiveUS20120211923A1Reduce in quantityEasy to cutGlass reforming apparatusGlass severing apparatusShortest distanceCutting glass

A method for cutting a sheet of material having a thickness of at most 400 μm using an electromagnetic wave beam (EWB) such as a laser. The method comprises forming a surface initiation defect and irradiating the sheet along a predetermined path within a short distance from the initiation defect a scanning EWB, such that the sheet is heated and cooled to allow for the propagation of the initiation defect into the predetermined path, and further along the predetermined path to result in a separation of the sheet along the predetermined irradiation path. This method can be advantageously used to cut glass sheets having a thin thickness to result in high-quality edge substantially free of major defects carried over from the initiation defect.

Owner:CORNING INC

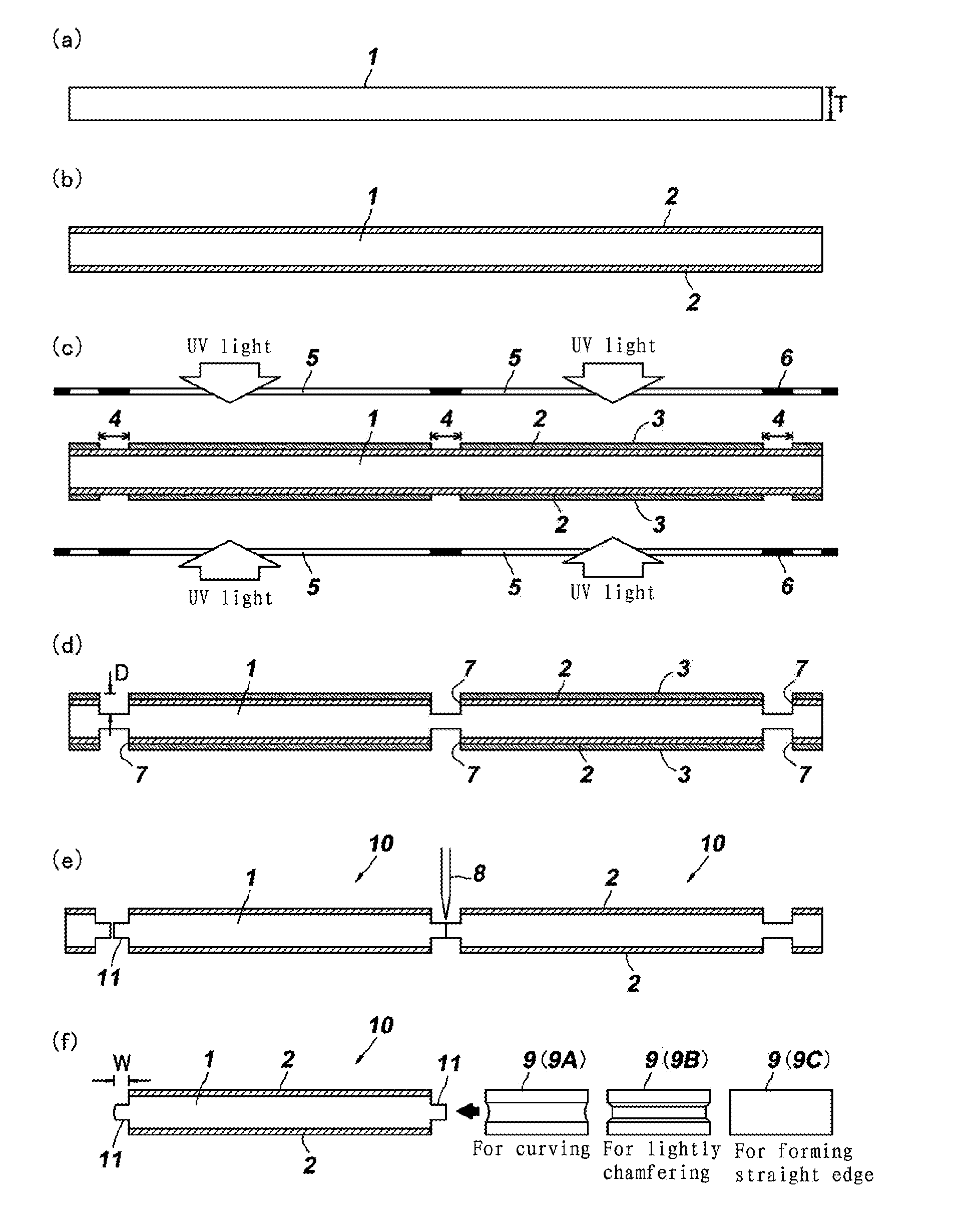

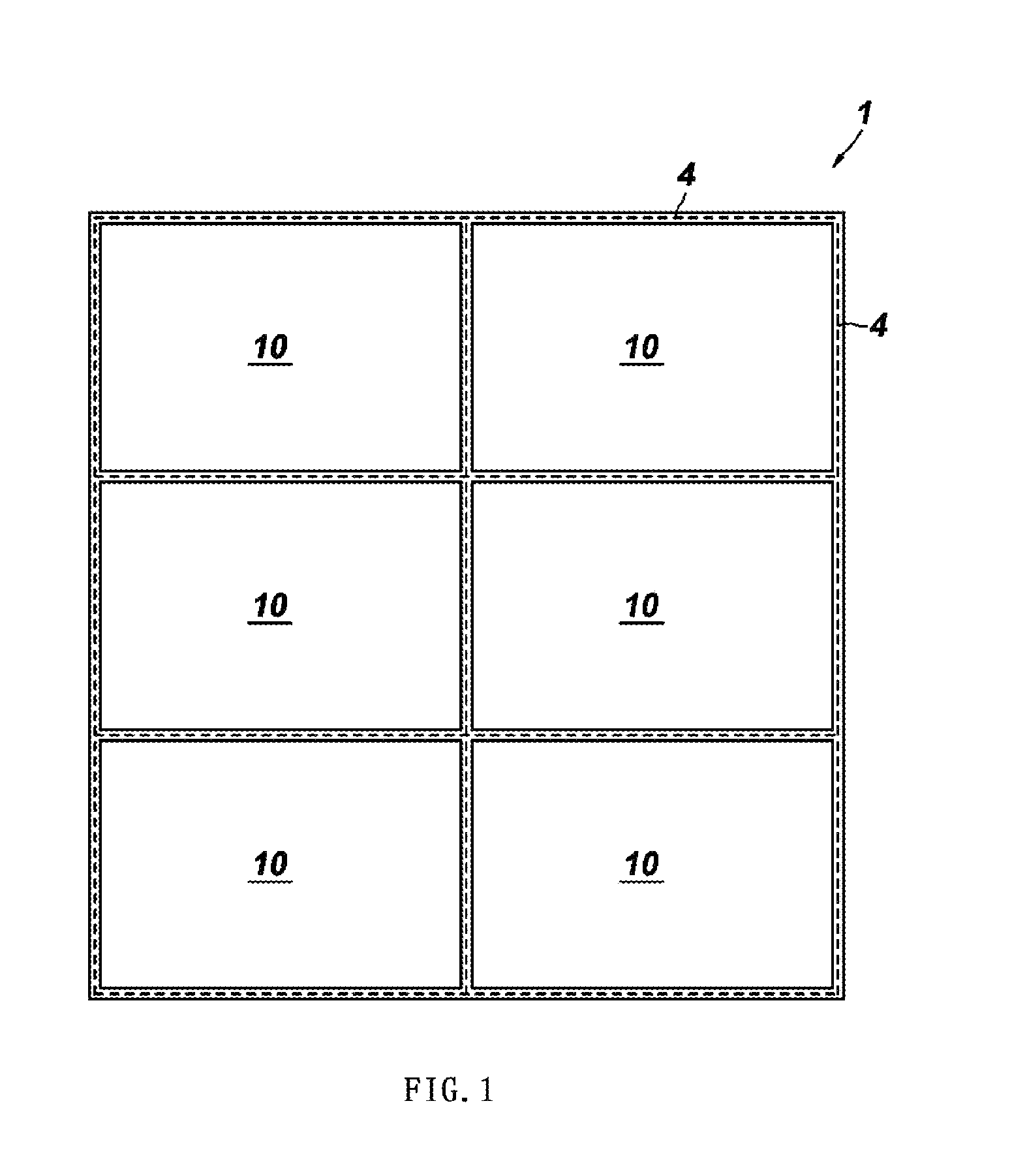

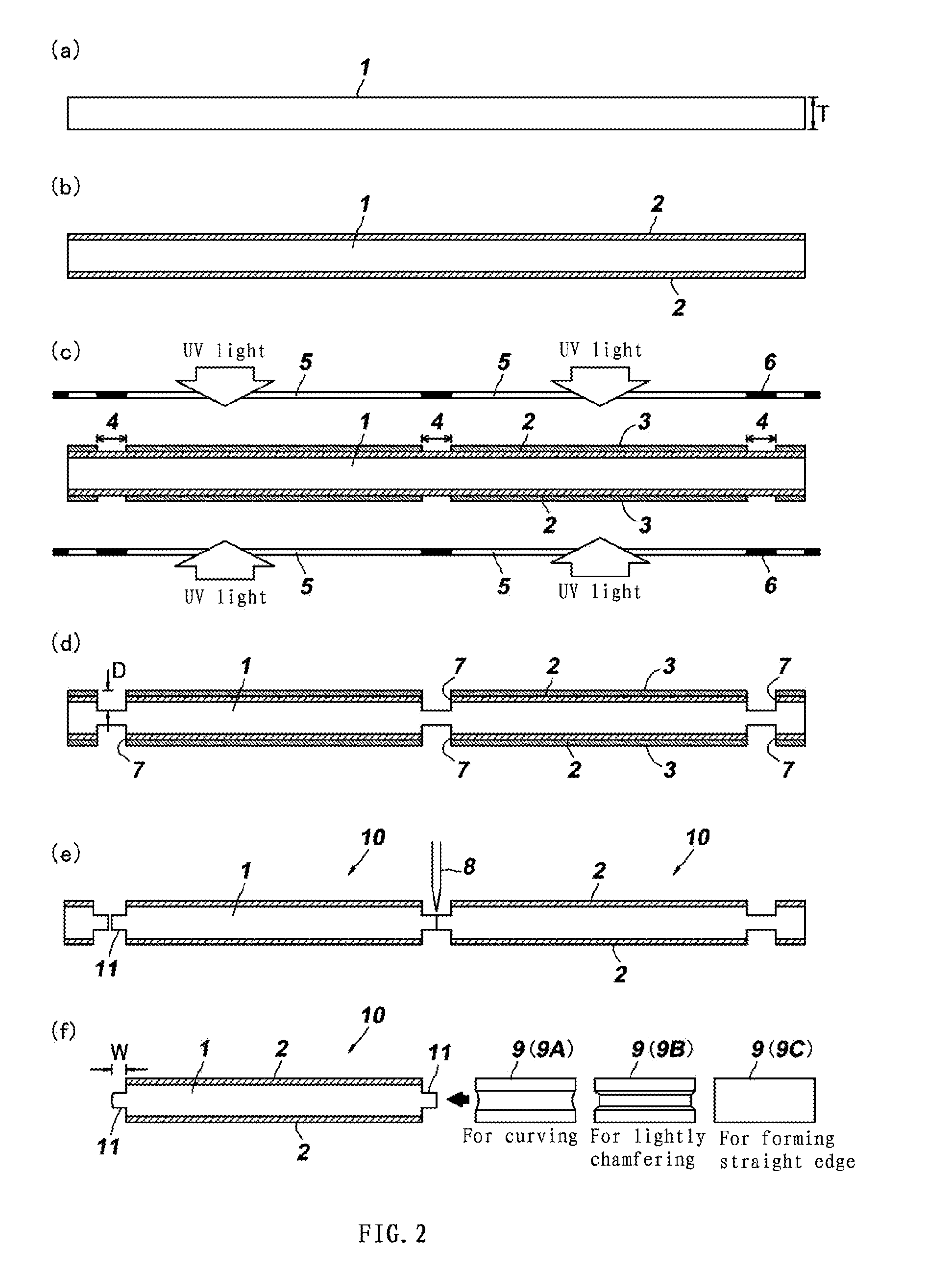

Process for producing glass/resin composite

InactiveUS20100192634A1High mechanical strengthReduce the possibilityLayered product treatmentLaminationCutting glassPolyresin

To provide a process for producing a glass / resin composite having a sufficient transportability, handling efficiency and processability, even though the thickness of the glass is very thin, without impairing excellent properties of glass.A process for producing a glass / resin composite, which comprises forming molten glass into a glass ribbon and forming a resin layer on at least one surface of the glass ribbon is provided. The resin layer is preferably formed by bonding to a glass ribbon, applying a heat melt resin or applying a curable resin. Further, a process for producing a glass / resin composite, wherein a cut glass substrate is bonded on a continuously supplied resin film is provided.

Owner:ASAHI GLASS CO LTD

Method for scoring a sheet of brittle material

InactiveUS8245540B2Increase pressureImprove scoreGlass reforming apparatusGlass severing apparatusCutting glassMaterials science

A method of cutting glass that prevents uncontrolled crack propagation when high background stress is present, either in the form of thermal residual stress, external mechanical stress or a combination thereof. The method includes masking an edge of the glass by blocking the beam using highly reflective or absorptive material located near the glass surface, or deposited on the surface in a form of a thin film (or highly reflective paint) to prevent uncontrolled crack initiation and propagation starting from the glass edge. The initiation of the laser scoring is located at a predetermined distance from the glass edge. Yet another aspect of the invention embodies stopping propagation of the vent at the exiting end of the score line.

Owner:CORNING INC

Laser cutting method

ActiveUS8584490B2Reduce in quantityEasy to produceGlass reforming apparatusGlass severing apparatusCutting glassEngineering

A method for cutting a sheet of material having a thickness of at most 400 μm using an electromagnetic wave beam (EWB) such as a laser. The method comprises forming a surface initiation defect and irradiating the sheet along a predetermined path within a short distance from the initiation defect a scanning EWB, such that the sheet is heated and cooled to allow for the propagation of the initiation defect into the predetermined path, and further along the predetermined path to result in a separation of the sheet along the predetermined irradiation path. This method can be advantageously used to cut glass sheets having a thin thickness to result in high-quality edge substantially free of major defects carried over from the initiation defect.

Owner:CORNING INC

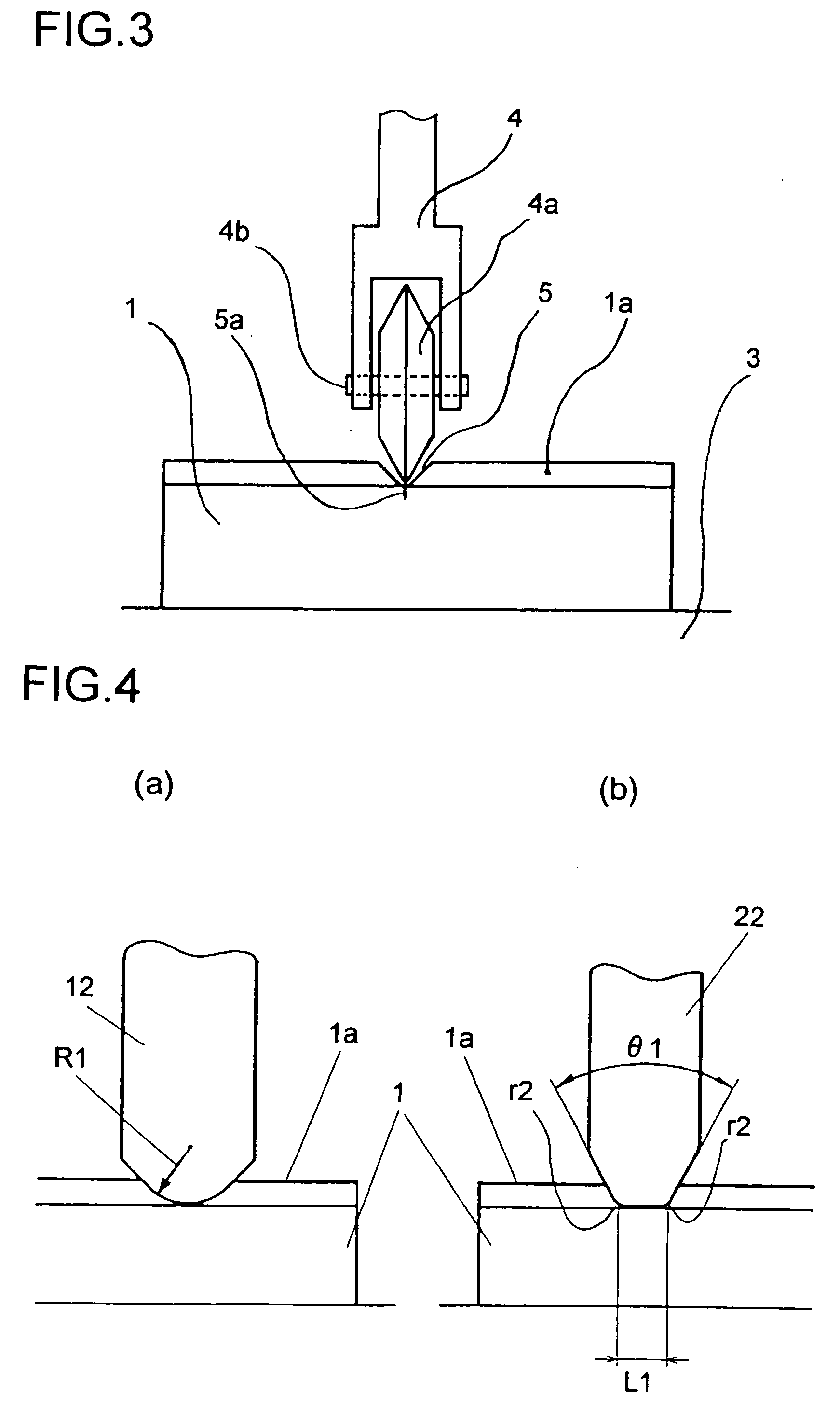

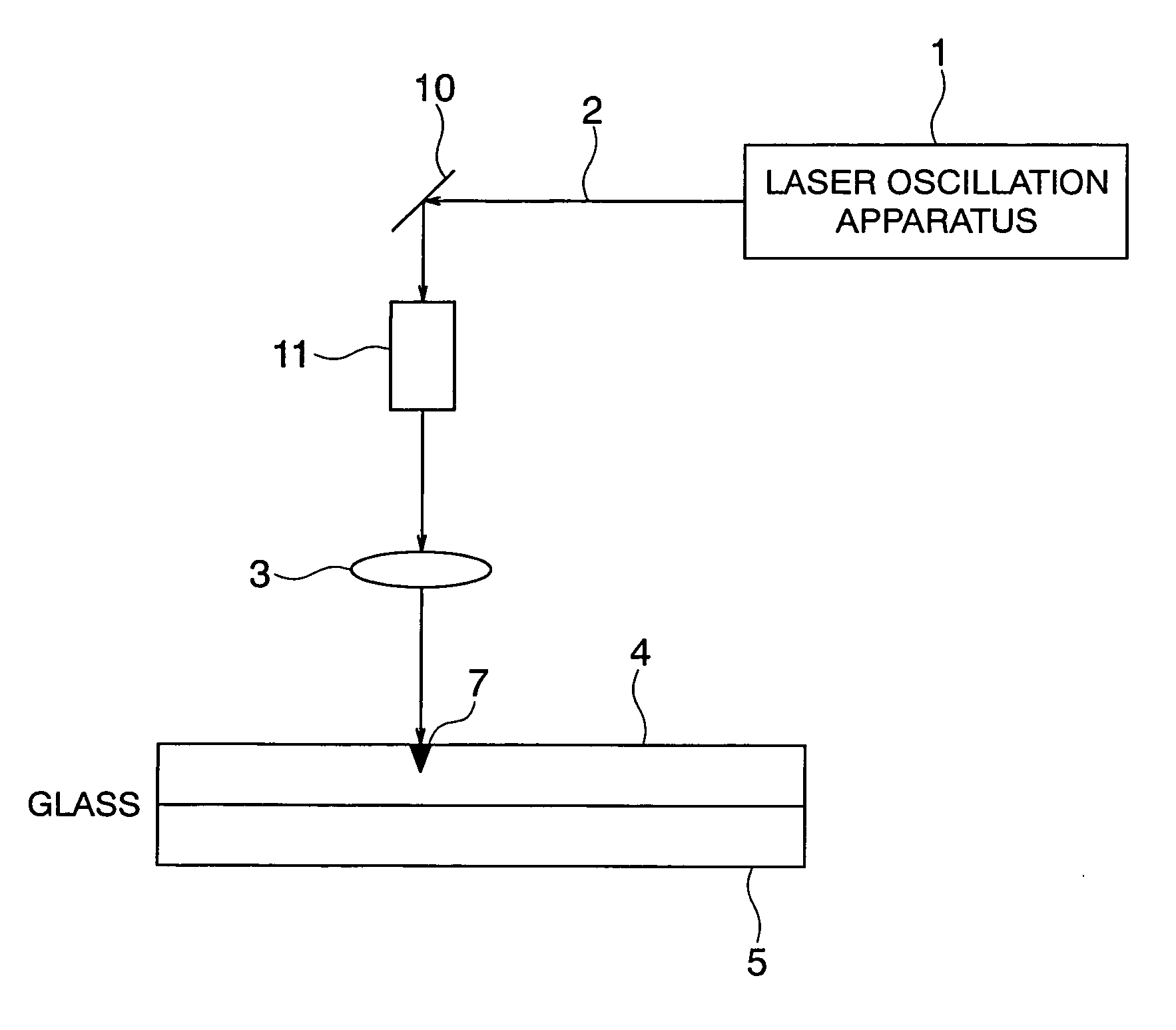

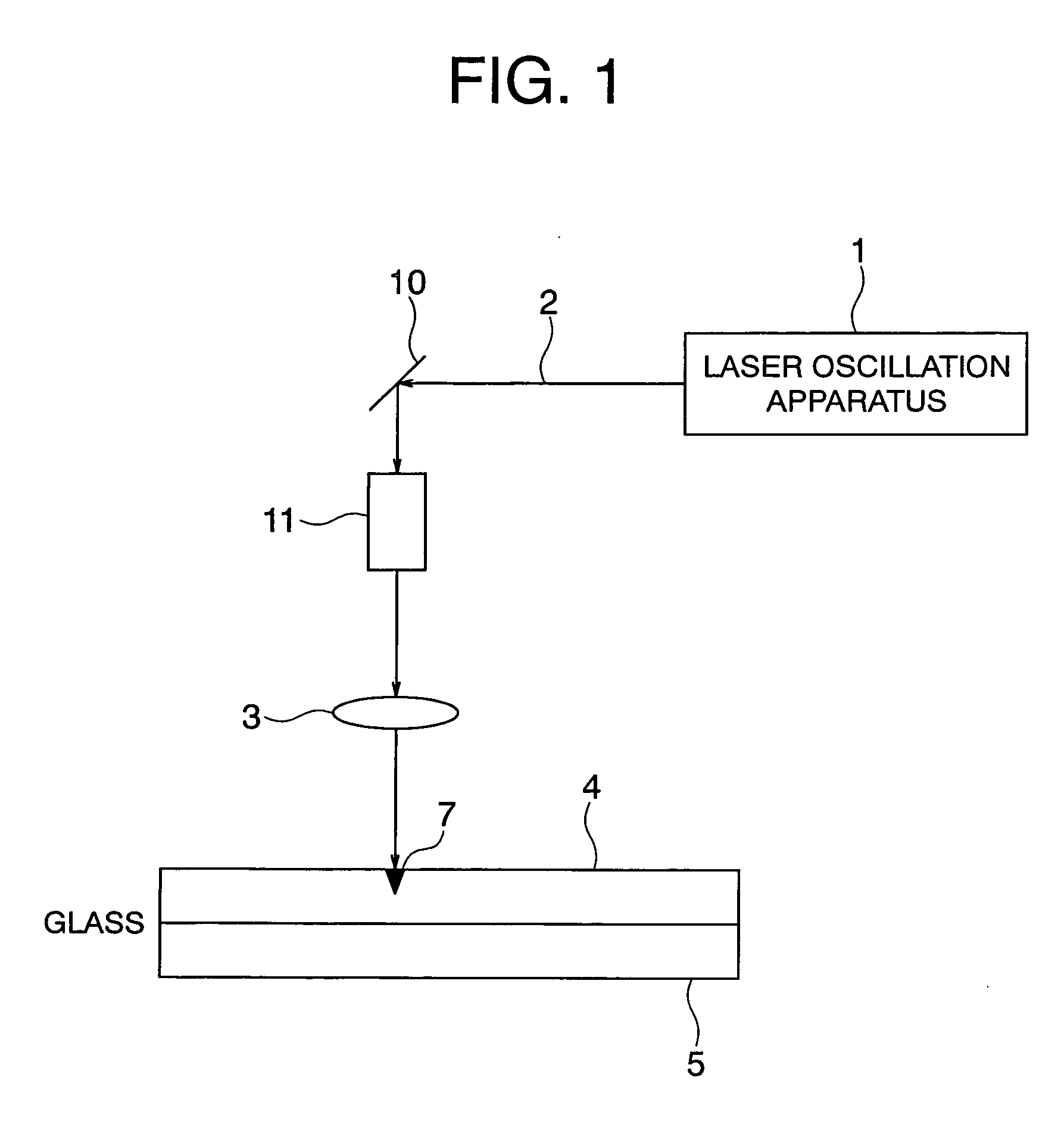

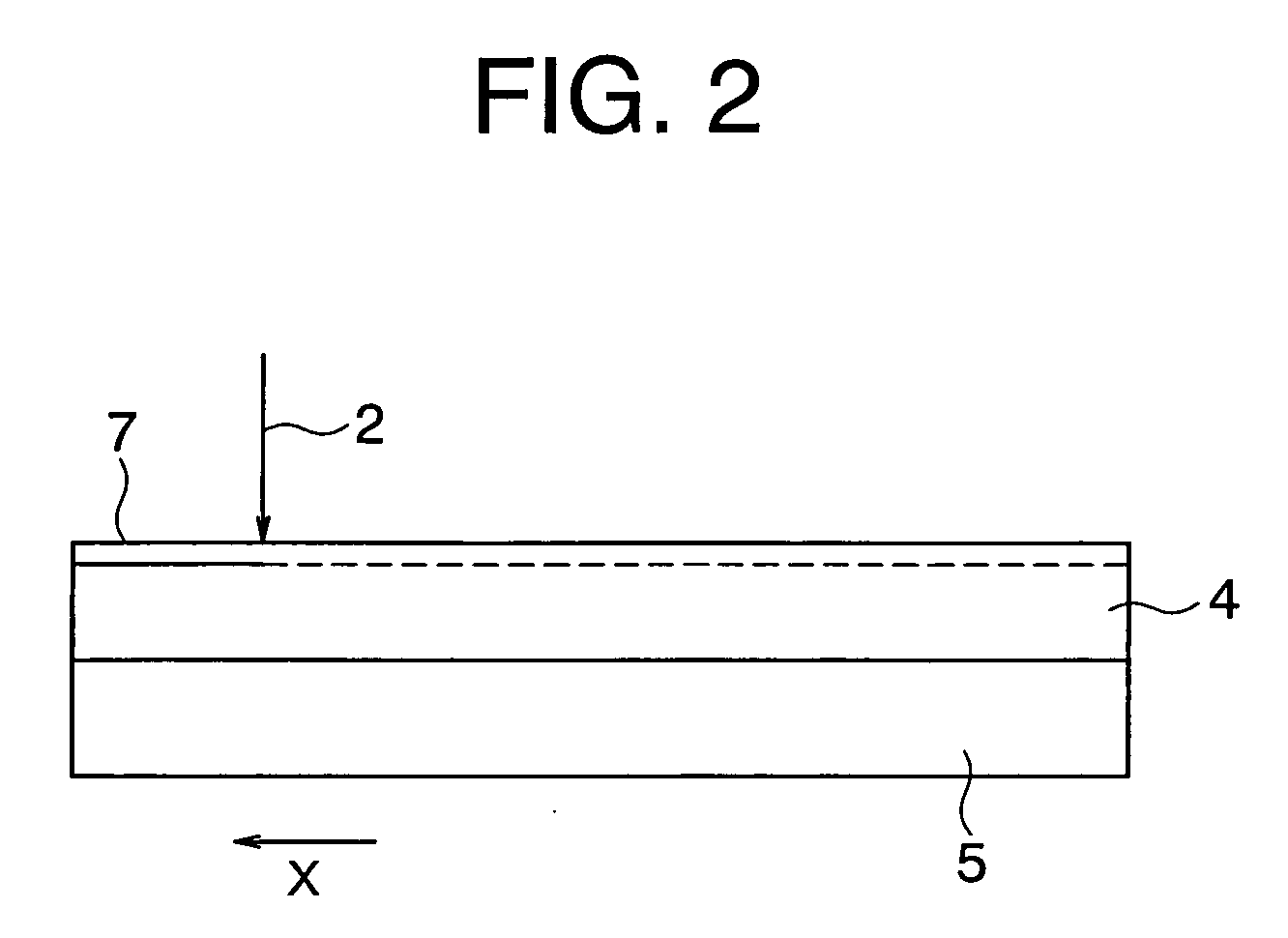

Glass cutting method and apparatus therefor

InactiveUS20070090100A1Formed rapidly and accuratelyPhoton energy is highFine working devicesGlass severing apparatusCutting glassUltraviolet

In the case of forming a scribe line by irradiating a laser in an ultraviolet range in one stroke, the glass bending strength after glass is cut is about 50 MPa or less, and the glass is likely to be subjected to crack damage during use as liquid crystal panel glass or the like. In a glass cutting method in which a portion to be cut of glass 4 is irradiated with a pulse laser 2 in one stroke of relative movement to form a scribe line 7, and then the glass is cut by applying a break force to the scribe line 7, a pulse laser of an ultraviolet range is used as the pulse laser 2, and the pulse laser 2 is irradiated while the pulse laser 2 is being relatively moved so that the total number of pulses at each irradiation portion is in a range of 2,667 to 8,000 pulses, whereby the scribe line 7 is formed to a depth of 1.8 to 6.3% of the thickness of the glass 4.

Owner:JAPAN STEEL WORKS LTD

Methods for laser cutting glass substrates

InactiveUS8932510B2Glass severing apparatusWelding/soldering/cutting articlesCutting glassLaser cutting

A method for cutting a glass article from a strengthened glass substrate having a surface compression layer and a tensile layer includes forming an edge defect in the surface compression layer on a first edge of the strengthened glass substrate. The method further includes propagating a through vent through the surface compression and tensile layers at the edge defect. The through vent precedes a region of separation along a cut line between the glass article and the strengthened glass substrate.

Owner:CORNING INC

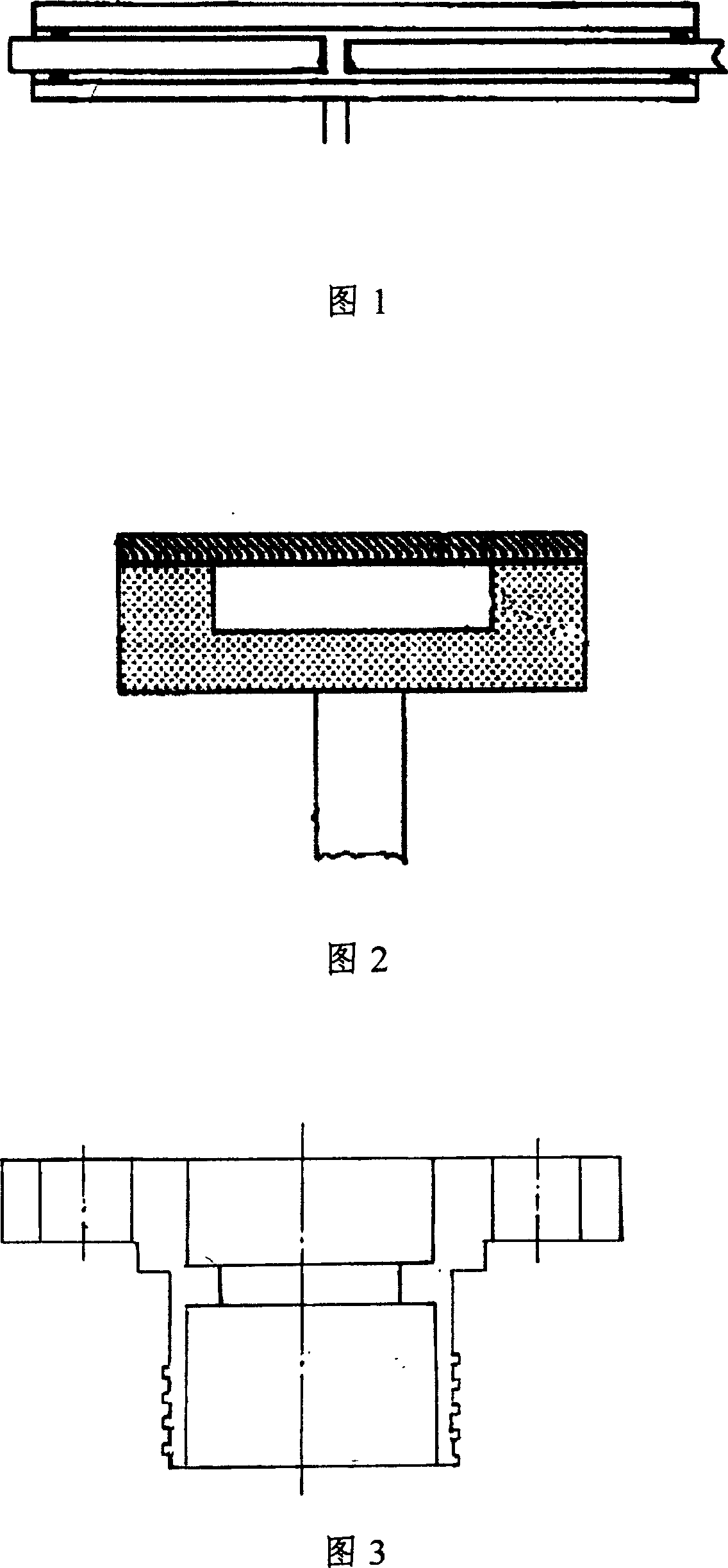

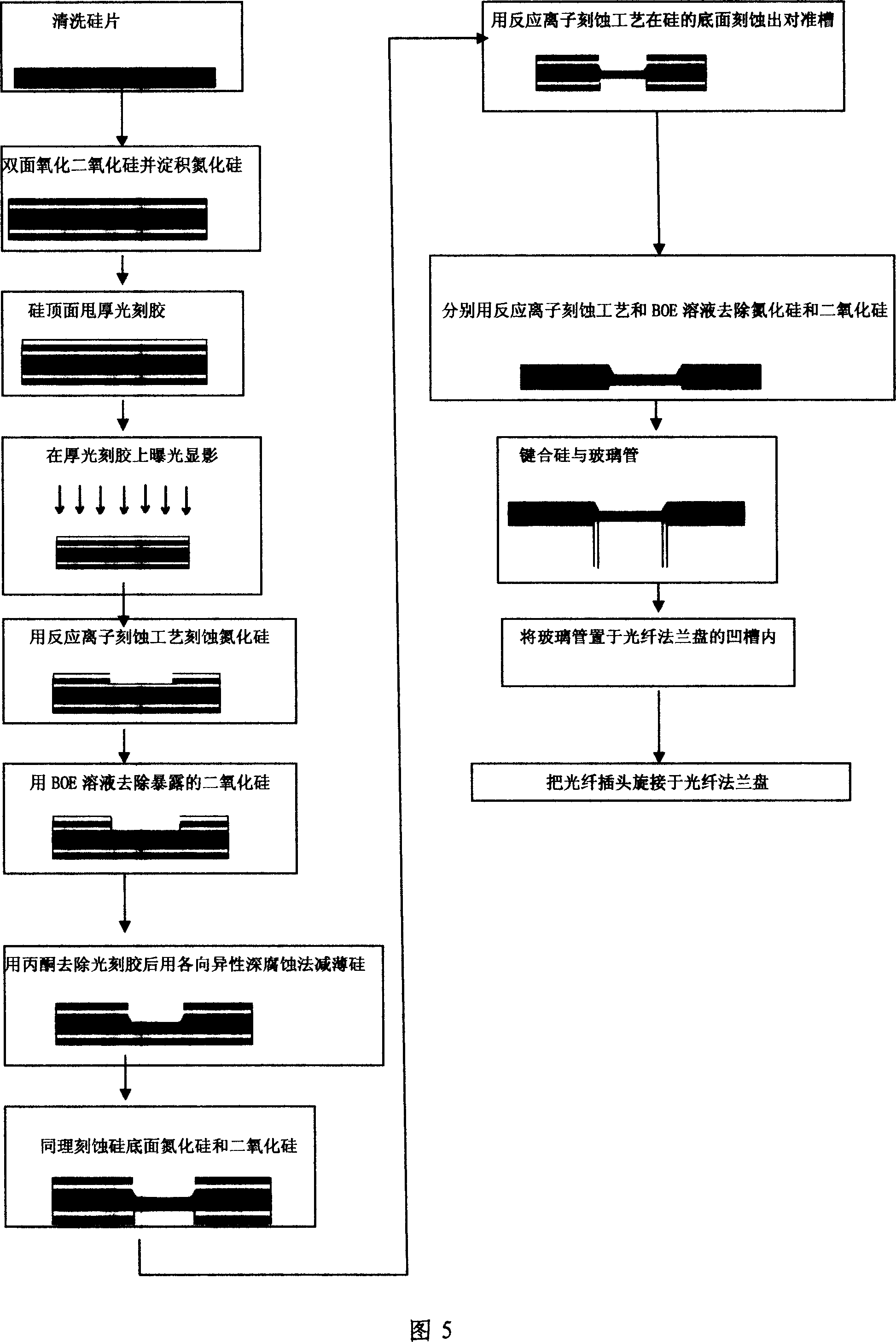

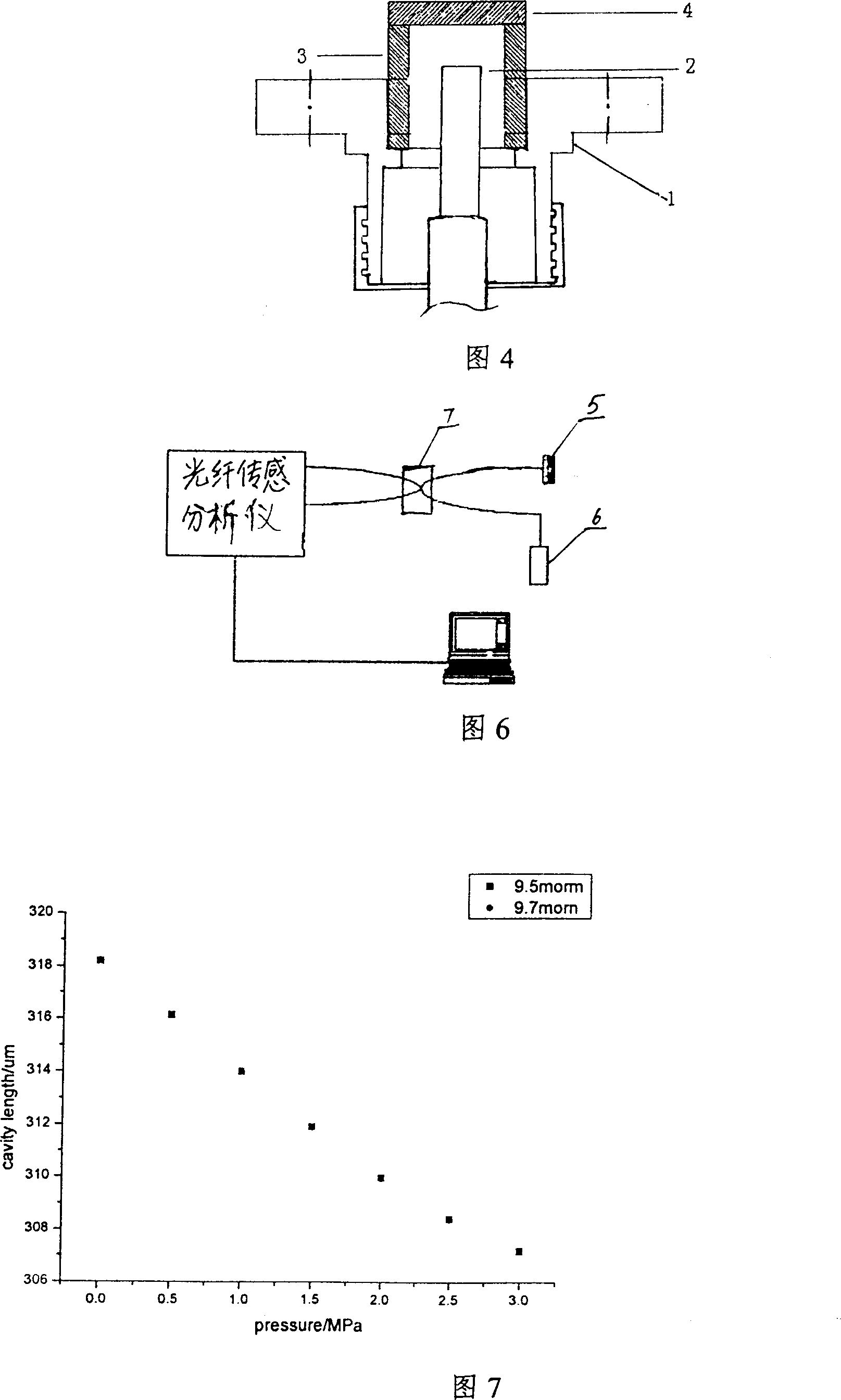

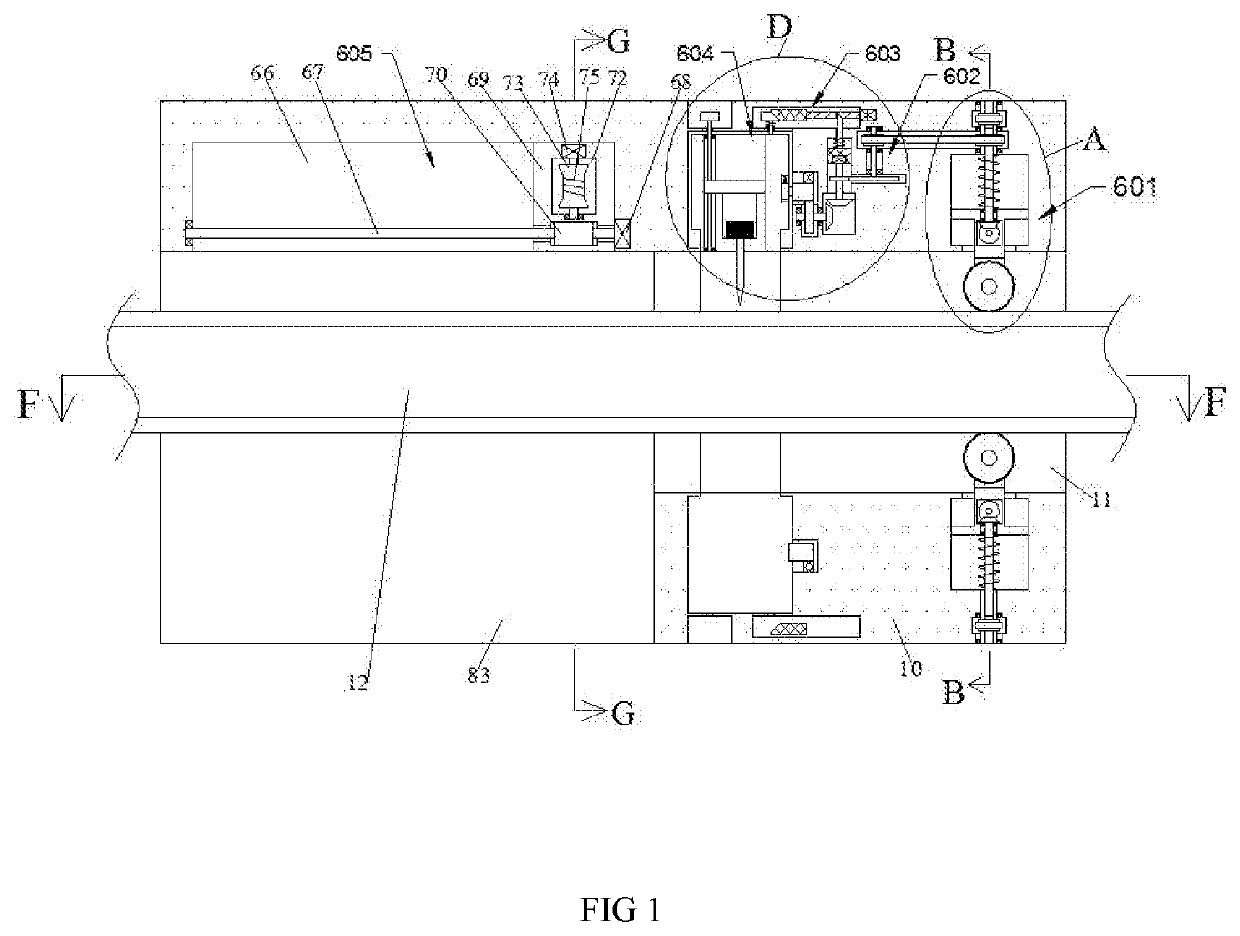

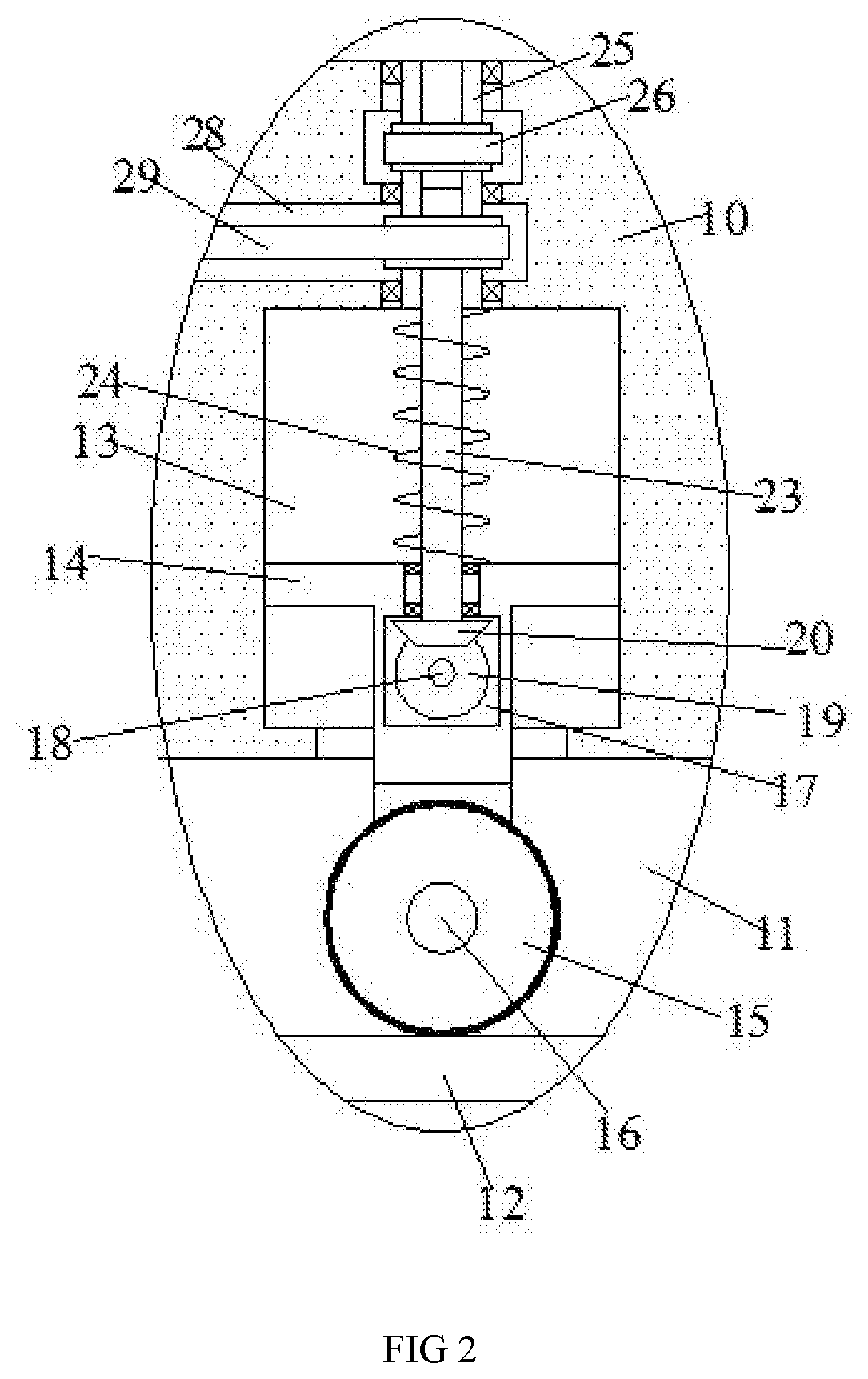

Fabry-Perotw fiber-optic pressure sensor and manufacture method therefor

InactiveCN101017116AAvoid influenceEasy to manufactureForce measurement by measuring optical property variationCoupling light guidesFiberCutting glass

This invention discloses one Fabry-Perot fiber pressure sensor, which comprises single silicon slice, glass round tube, fiber flange disc and fiber plug and is characterized by the following: the single silicon slice and glass round tube one end are connected through anode keys; other end of round tube is added to fiber flange disc tank; the fiber plug is connected to flange disc with ceramics needle and silicon slice form the chamber. This invention also discloses one method for it, which comprises the following steps: putting the cut glass tube and silicon slice onto key furnace; the glass tube outer wall is coasted with epoxy resin to flange concave tank; connecting the fiber plug into fiber flange disc to form the chamber.

Owner:NANJING NORMAL UNIVERSITY

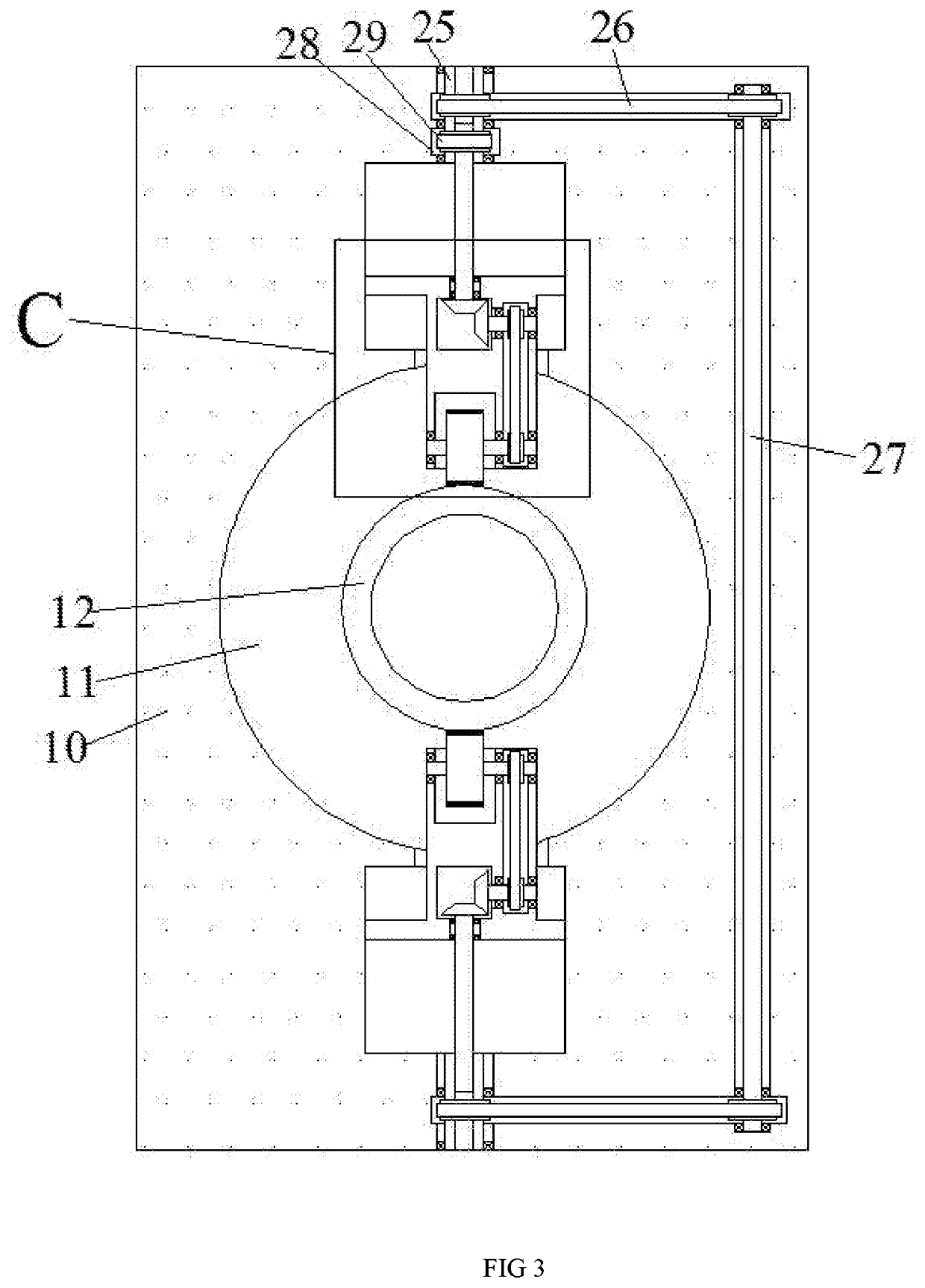

Protective glass cutting machine

InactiveUS20200079678A1Quick cutImprove stabilityGlass severing apparatusMetal working apparatusCutting glassProtective glasses

The invention discloses a protective glass cutting machine, including a cutting body, a cutting cavity is arranged in the cutting body, a conveying device is arranged in the cutting cavity, and the conveying device comprises a vertically symmetric conveying The rotating wheel, the opposite direction of the conveying wheel can drive the glass tube to move to the left for cutting. The invention rotates along the glass tube by the heated cutting knife, and the glass tube is quickly cut, and the glass tube is cut. The left and right sides are respectively provided with an output device and a conveying device to ensure the stability of the glass tube and improve the stability of the glass tube cutting. Secondly, when the glass tube is input to the left, the cutting knife and the glass tube are not abutted by the telescopic device.

Owner:YAO JIANHUA

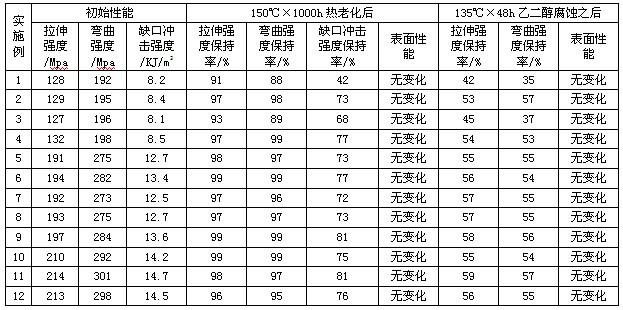

Hydrolysis-resistant alcoholysis-resistant nylon 66 composite material and preparation method thereof

The invention provides a hydrolysis-resistant alcoholysis-resistant nylon 66 composite material and a preparation method thereof. The hydrolysis-resistant alcoholysis-resistant nylon 66 composite material is characterized by comprising the following ingredients in parts by weight: 51.8 to 84.5 parts of nylon resin, 15 to 40 parts of short-cut glass fibers, 0.1 to 0.6 parts of nucleating agent, 0.1 to 0.6 parts of thermal stabilizer, 0.1 to 1.0 part of alcoholysis-resistant auxiliary agent, 0.1 to 5 parts of barrier material and 0.1 to 1.0 part of lubricant. The manufacturing method comprises the following steps that: the nylon 66 resin, antioxidant, hydrolysis-resistant agent, the barrier material, the nucleating agent and the lubricant, which are previously dried, are uniformly mixed at a high speed; and the mixture and the glass fiber are fed into a double-screw extruder to be extruded and pelleted. The hydrolysis-resistant alcoholysis-resistant nylon 66 composite material not only has good high temperature resistance and high thermal oxidation aging resistance, but also has excellent property for resisting the corrosion of glycol and solution thereof, and can completely satisfy the requirements on manufacturing components such as car heat radiator cooling water tanks, thermostats and charge air coolers.

Owner:SHANGHAI KINGFA SCI & TECH +1

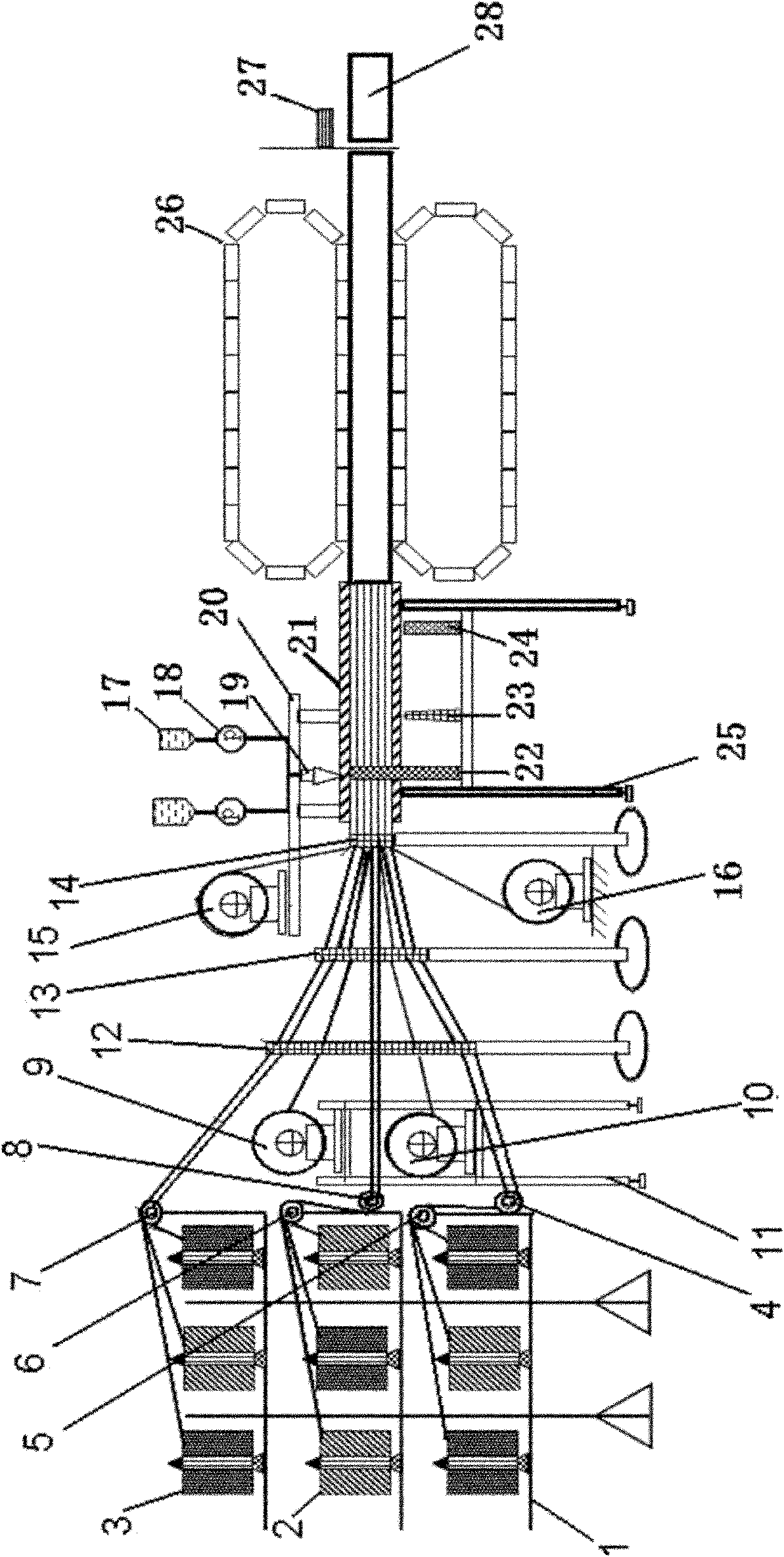

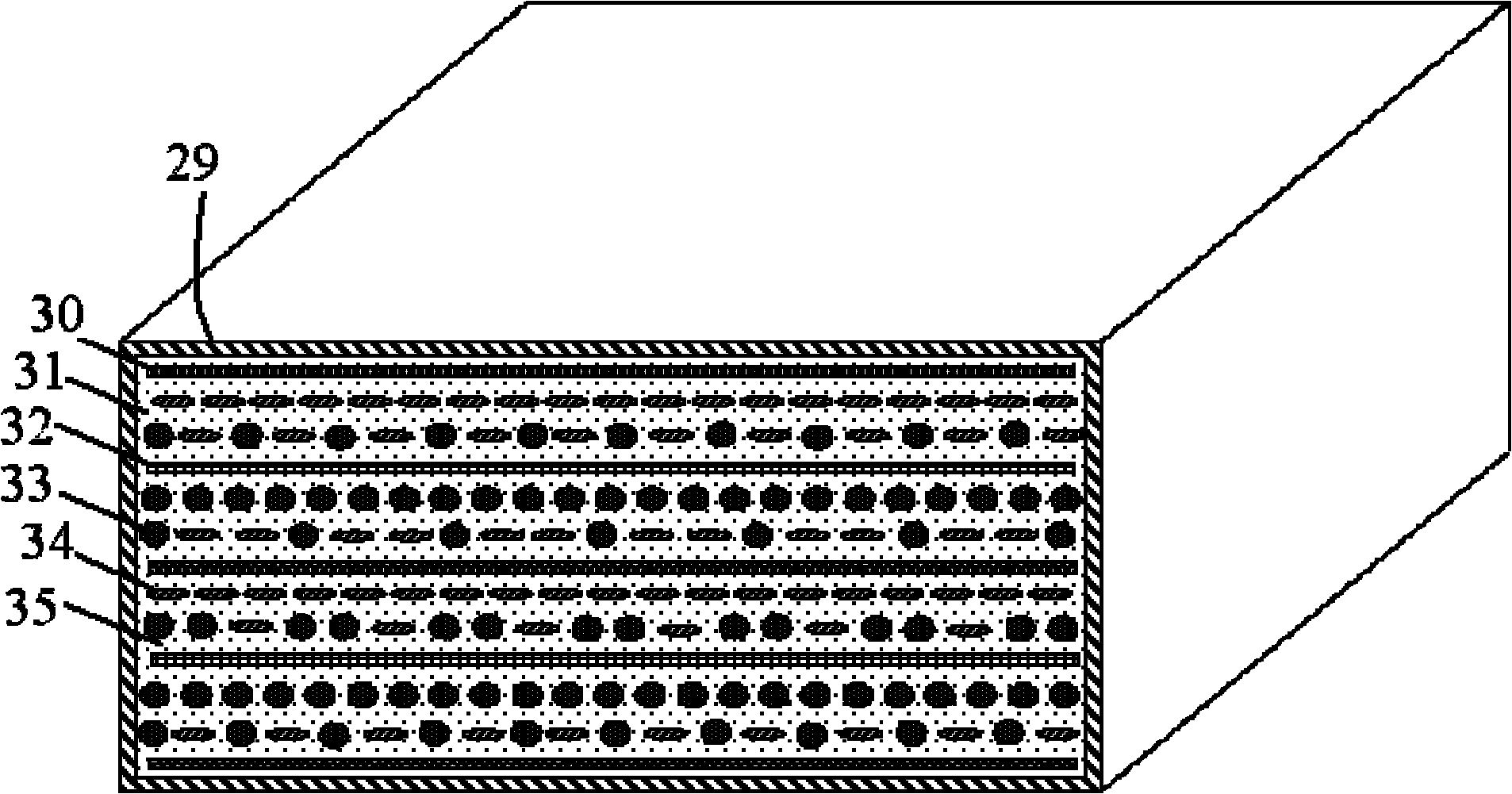

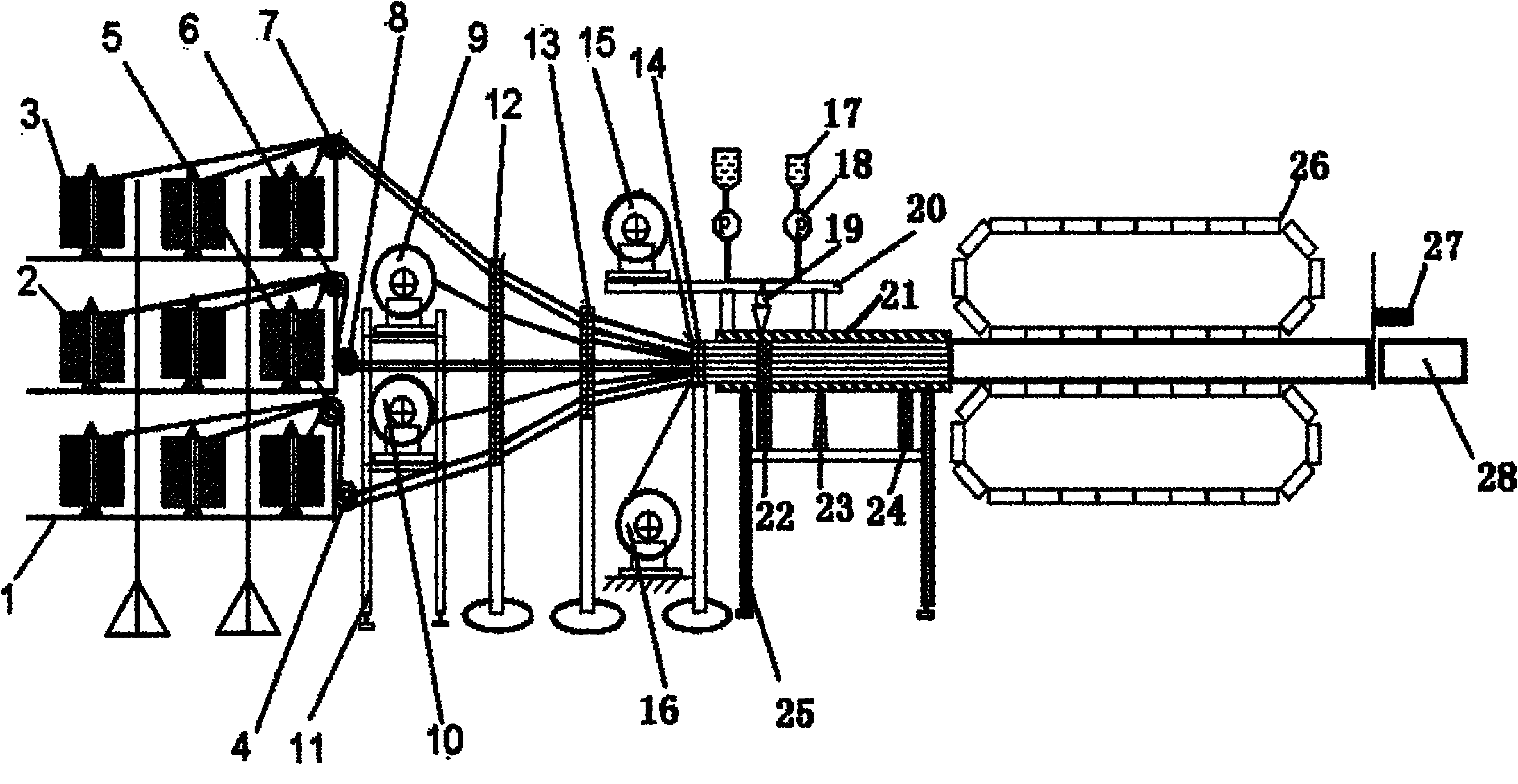

Combined fiber reinforced water-blown polyurethane hard foam composite board, production method and production equipment thereof

ActiveCN102059833AHigh strengthImprove rigiditySynthetic resin layered productsGlass/slag layered productsGlass fiberCarbon fibers

The invention provides a combined fiber reinforced water-blown polyurethane hard foam composite board, a production method and continuous production equipment thereof. In the combined fiber reinforced water-blown polyurethane hard foam composite board, one or mixtures of more of long glass fibers or long glass fibers and carbon fibers, glass fiber cloth, carbon fiber cloth or short-cut glass fibers are used as fiber reinforced bodies which are alternately distributed in a polyurethane foaming raw material matrix in a layered form. The combined fiber reinforced water-blown polyurethane hard foam composite board has the advantages of high strength, good rigidity and better size stability and high-temperature resistance. In the invention, the continuous production equipment is adopted, thereby the production efficiency and the product quality stability are improved.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

Method and device for parting glass substrate, liquid crystal panel, and liquid crystal panel manufacturing device

InactiveUS7553390B2Added fabricationLiquid crystal compositionsPaper-makingCrystallographyCutting glass

A method for cutting apart a glass substrate is provided whereby scribing of the glass substrate is possible without being affected by the presence or thickness of a deposited film formed thereon and without scratching the deposited film. To treat a glass substrate having a deposited film, such as a thin film or resin film, formed on one surface thereof, there are provided a shaving device, which is a blade that removes strip-shaped portions of the deposited film to expose strip-shaped regions on the glass substrate, and a wheel cutter that forms scribed lines along the strip-shaped regions exposed on the glass substrate. The glass substrate is cut apart along the scribed lines.

Owner:SHARP KK +1

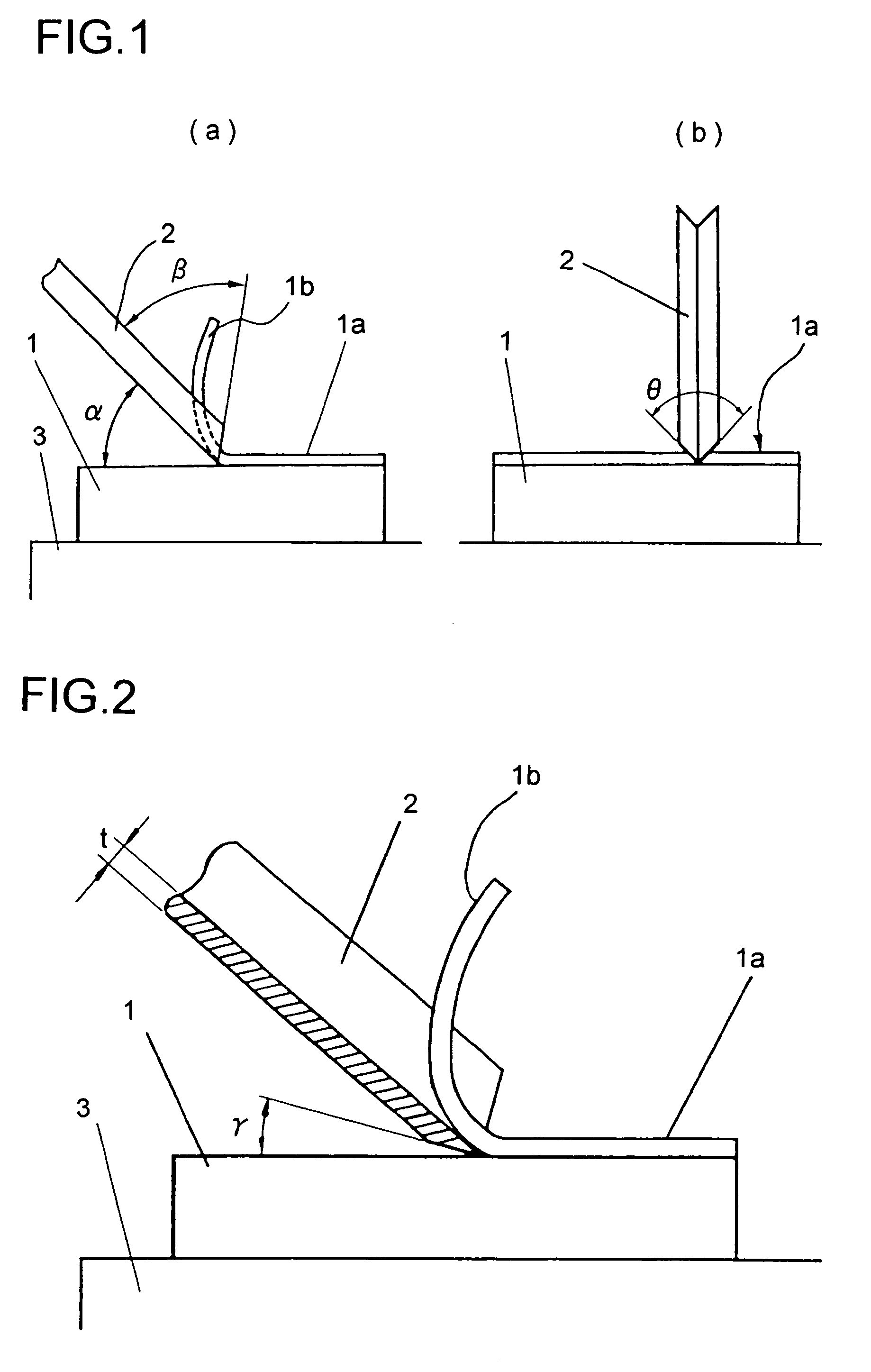

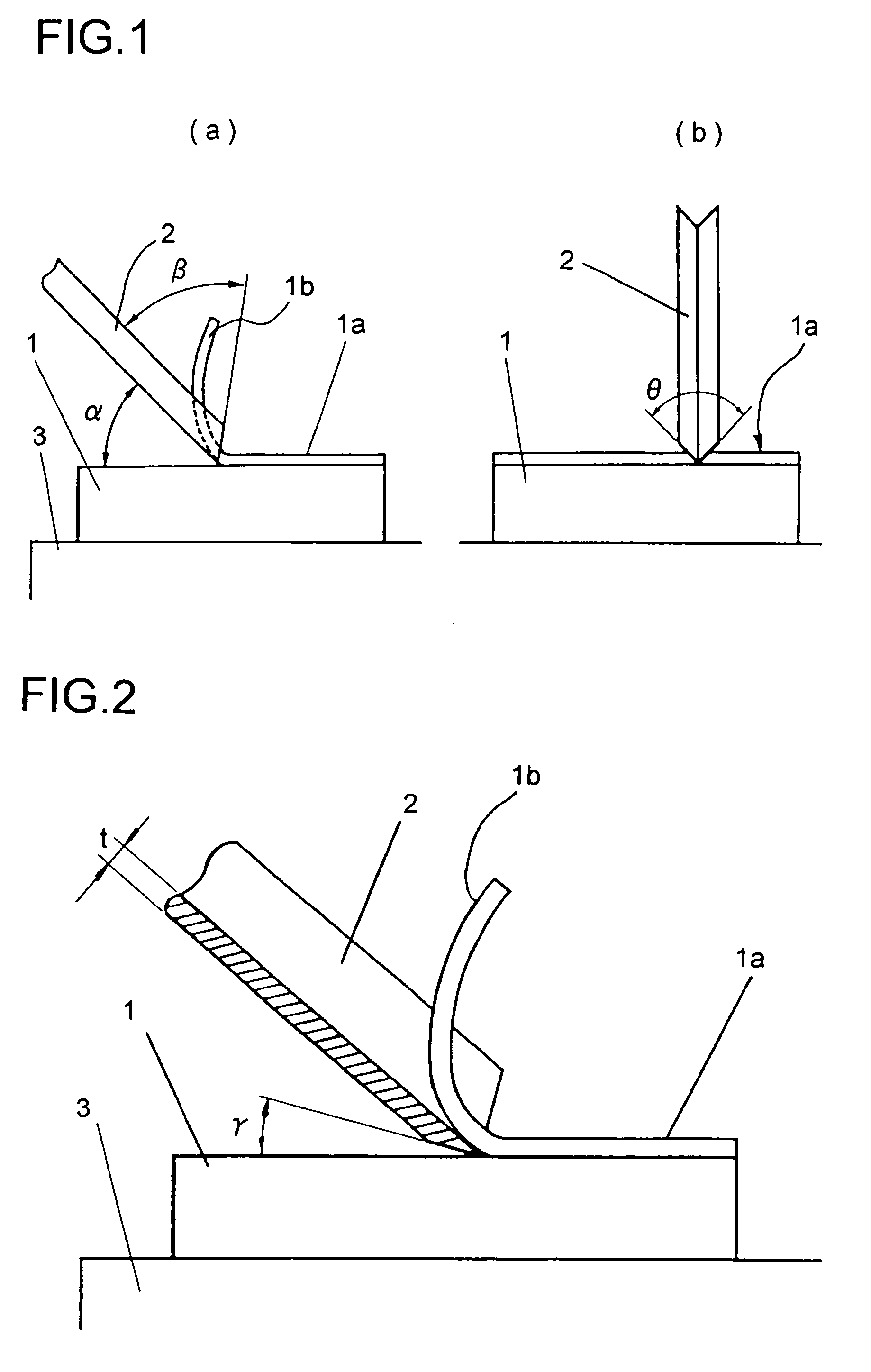

Method of cutting glass substrate material

InactiveUS20050258135A1High-quality and hard-to-chip cutting planeQuality improvementElectroluminescent light sourcesSolid-state devicesCutting glassEngineering

There is provided a method for cutting a glass substrate member capable of cutting the glass substrate member while forming a scribe line with a “scriber” and also obtaining a high-quality and hard-to-chip cutting plane. The cutting method for the glass substrate member according to the present invention comprises a removing step for removing a part or whole of a back surface portion of the glass substrate member; and a scribing step for forming a scribe line that produces a crack on a front surface of the glass substrate member. The crack extends to a back surface of the glass substrate member.

Owner:THK CO LTD +1

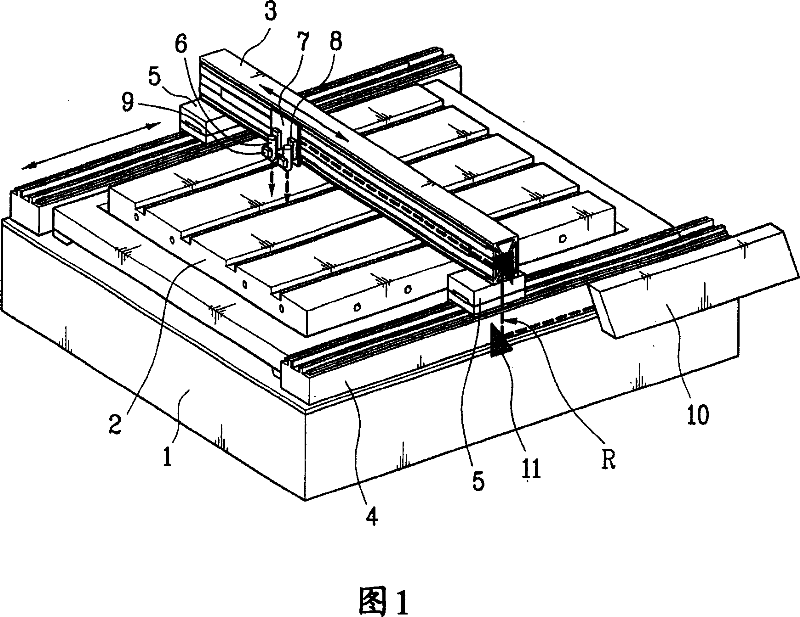

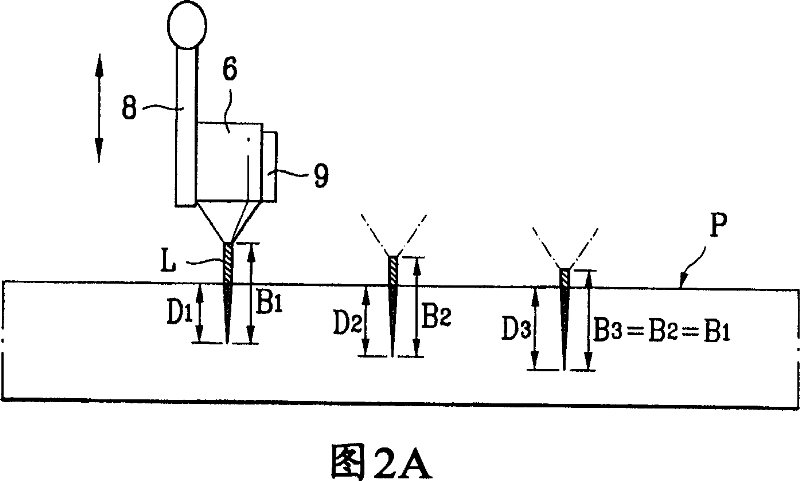

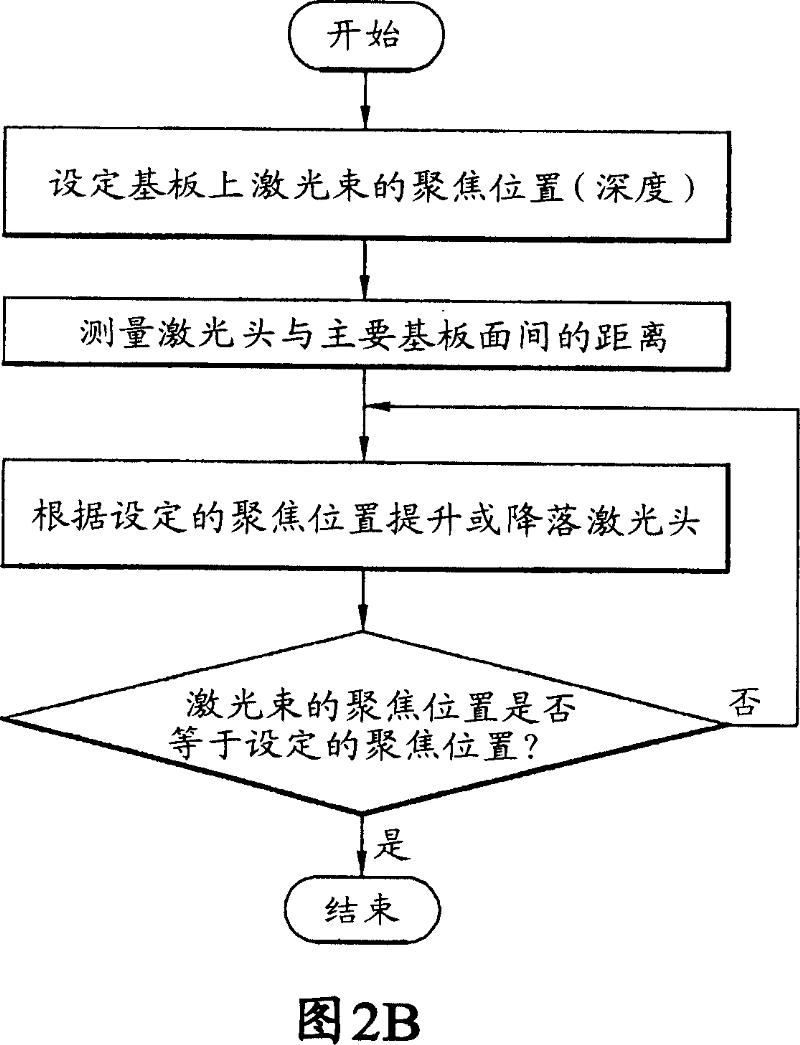

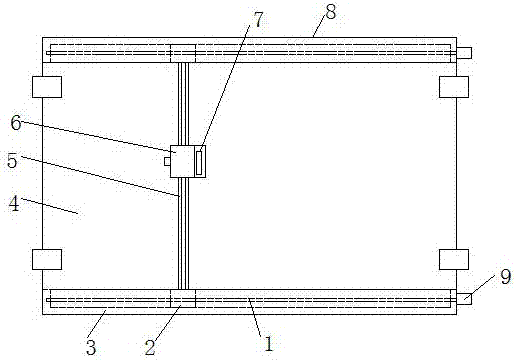

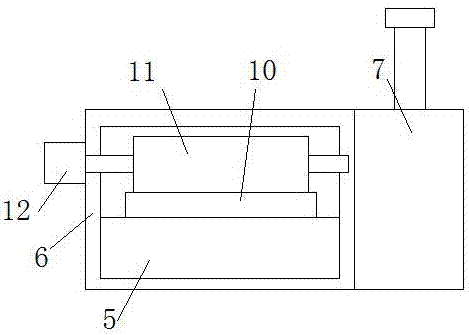

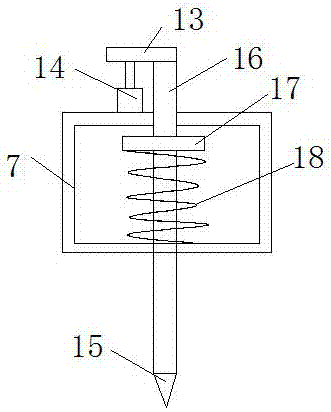

Device for cutting glass substrate and its method

ActiveCN101031383AControl the depth of cutPackaging toiletriesPackaging cosmeticsCutting glassUltraviolet

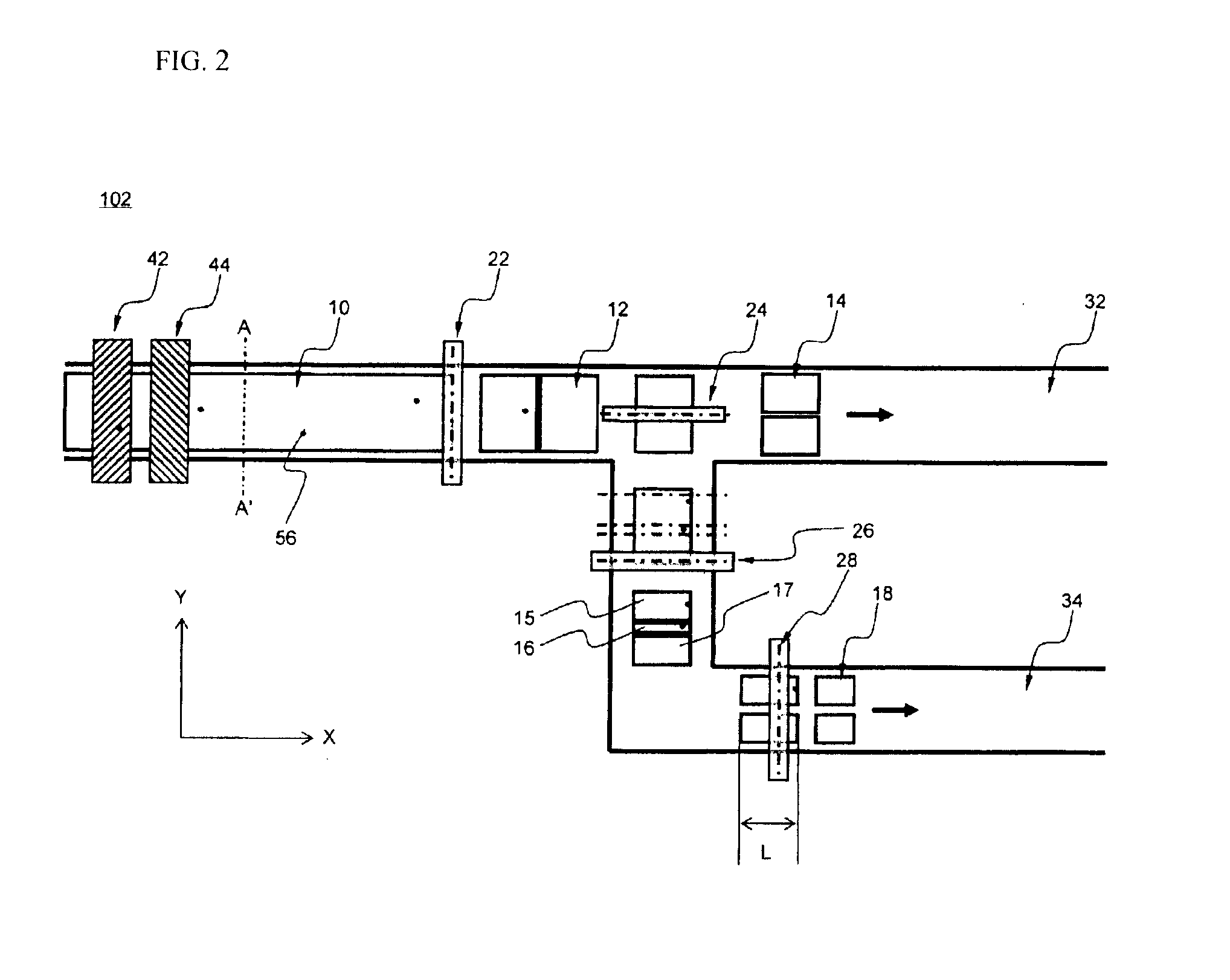

An apparatus for cutting a nonmetallic substrate (P) and method thereof are disclosed. The present invention is suitable for cutting upper and lower substrates (P) simultaneously or for cutting either an upper or lower substrate selectively in a manner of controlling a cutting depth by adjusting a focus position of a short wavelength laser beam in cutting various nonmetallic substrates (P) such as a glass substrate for fabricating a flat panel display such as TFT-LCD, PDP, OLED, etc. The present invention includes a laser beam generator (10) generating a UV short wavelength laser beam, a torch (6) applying the short wavelength laser beam to a specific location on the nonmetallic substrate to be cut, a focus moving means (8) for varying a focus location of the laser beam in a depth direction of the substrate, and a relative object moving means (3, 4) for allowing the substrate and the laser beam to make a relative movement to cut the substrate.

Owner:TOP ENG CO LTD

Glass cutting device

The invention discloses a glass cutting device. The includes a placement plate, fixed blocks are disposed on both sides at the top of the placement plate, one mutually closer side walls of the two fixed blocks are respectively equipped with a sliding chute, first motors are fixed on one end side walls of the fixed blocks through screws, output shafts of the first motors are connected to threaded rods, the threaded rods are rotatably connected in the sliding chutes and are in threaded connection with sliding blocks, the sliding blocks are slidably connected in the sliding chutes, the two sliding blocks are connected by a cross bar, a gear rack is disposed at the top of the cross bar, the cross bar is externally sleeved with a movable frame, a second motor is fixed on one side wall of the movable frame through a screw, an output shaft of the second motor is connected to a gear located inside the movable frame, and the gear is engaged with the gear rack. The glass cutting device provided by the invention can drive a cutting head to do up, down, left, right, front and back multidirectional movement so as to cut glass into arbitrary shape, and the cutting effect is good.

Owner:盐城市宁润玻璃制品有限公司

Strengthened glass, touch panel and method of manufacturing strengthened glass

InactiveUS20130155004A1Avoid it happening againAvoid damageGlass/slag layered productsGlass severing apparatusEdge surfaceCutting glass

A strengthened glass capable of shortening a process time for maintaining the strength to improve the production efficiency and forming an edge surface of the strengthened glass in any shape while preventing damage such as fracture due to micro-cracks or the like. Strengthening layers are formed on both surfaces of the glass plate, and protection films are formed in regions except for cutting portions. Recessed portions are formed by etching both surfaces of the glass plate at the cutting portions of the glass plate not covered by the protection films. Subsequently, the glass plate is cut along the recessed portions to form separated strengthened glass, and a stepped portion having a protruding cutting surface and including an interior side surface formed by etching a periphery of the glass plate and an exterior side surface formed by mechanical cutting is formed.

Owner:MICRO TECH CO LTD

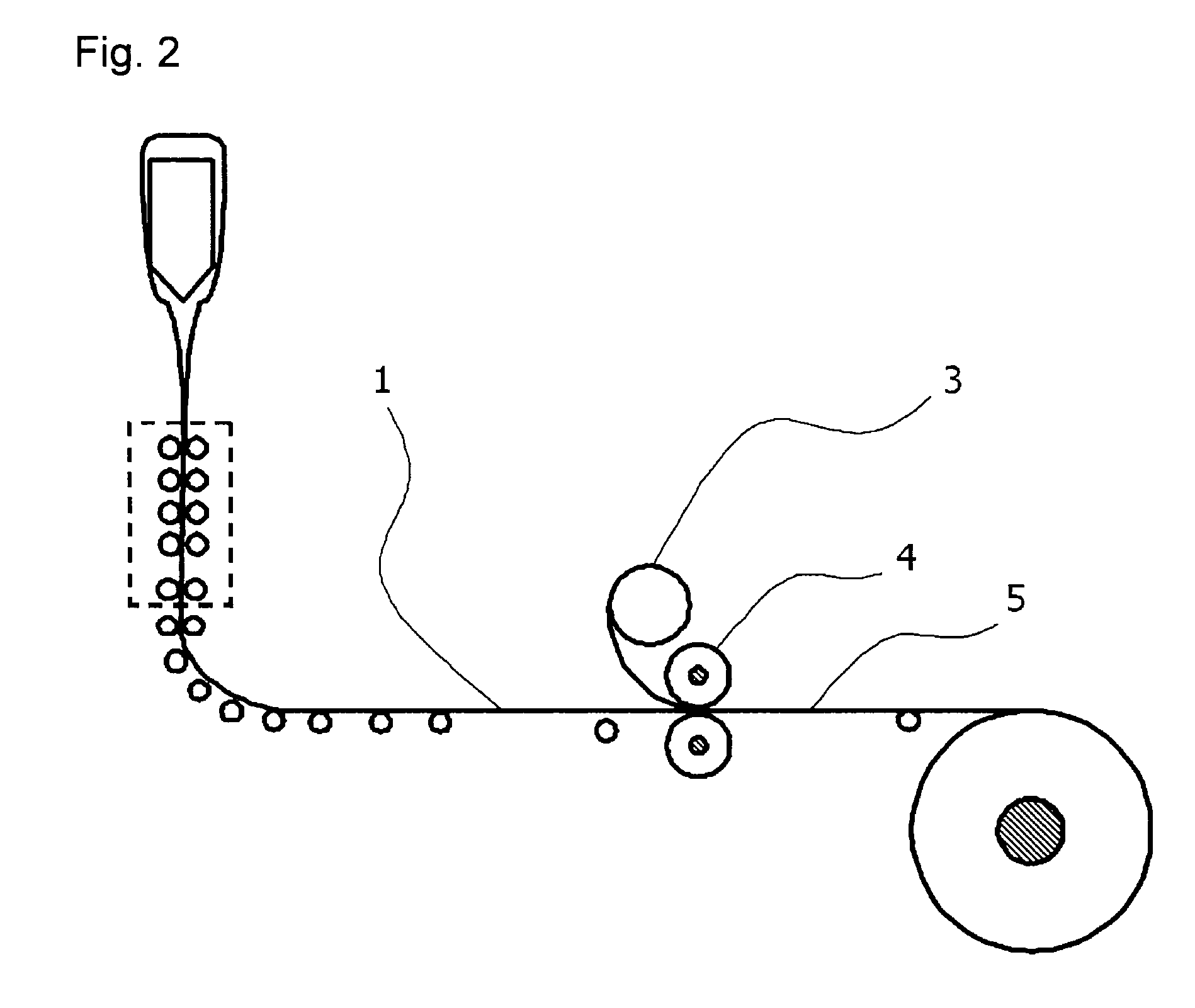

Method for scoring a sheet of brittle material

InactiveUS20100212361A1Increase pressureImprove scoreGlass reforming apparatusGlass severing apparatusCutting glassLight beam

A method of cutting glass that prevents uncontrolled crack propagation when high background stress is present, either in the form of thermal residual stress, external mechanical stress or a combination thereof. The method includes masking an edge of the glass by blocking the beam using highly reflective or absorptive material located near the glass surface, or deposited on the surface in a form of a thin film (or highly reflective paint) to prevent uncontrolled crack initiation and propagation starting from the glass edge. The initiation of the laser scoring is located at a predetermined distance from the glass edge. Yet another aspect of the invention embodies stopping propagation of the vent at the exiting end of the score line.

Owner:CORNING INC

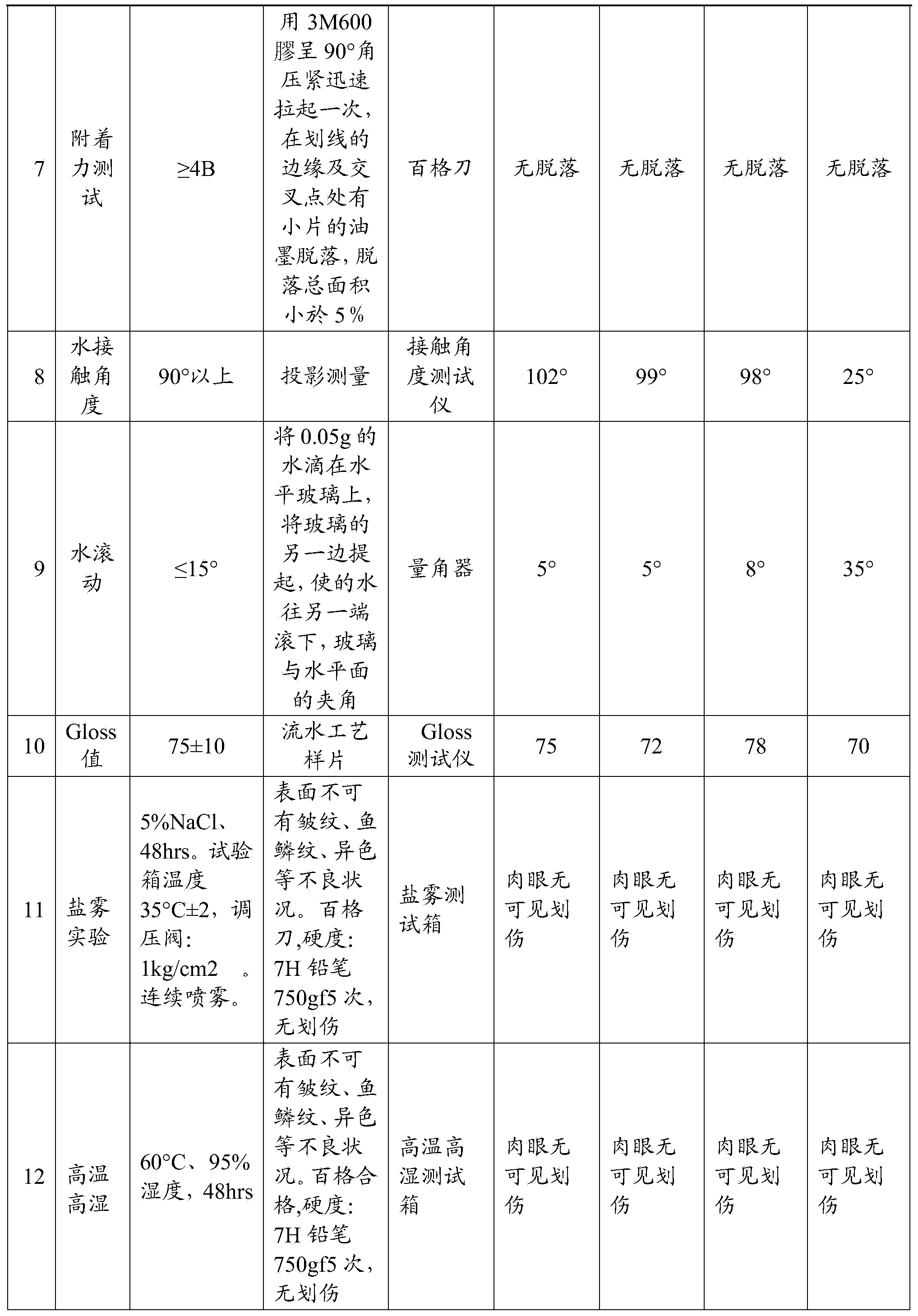

Antidazzle toughened glass and preparation method thereof

The invention discloses an antidazzle toughened glass and a preparation method thereof. The preparation method comprises the following steps: cutting glass, toughening, cleaning, spray-coating, baking, and cleaning. The method has the advantages of environmentally-friendly and pollution-free production technology and raw material, and no reduction of the thickness or the flatness of original sheet glass; and the antidazzle toughened glass prepared in the invention has antidazzle and anti-fingerprint functions, and has a light transmittance reaching above 89%.

Owner:GUANGZHOU SHIRUI ELECTRONICS

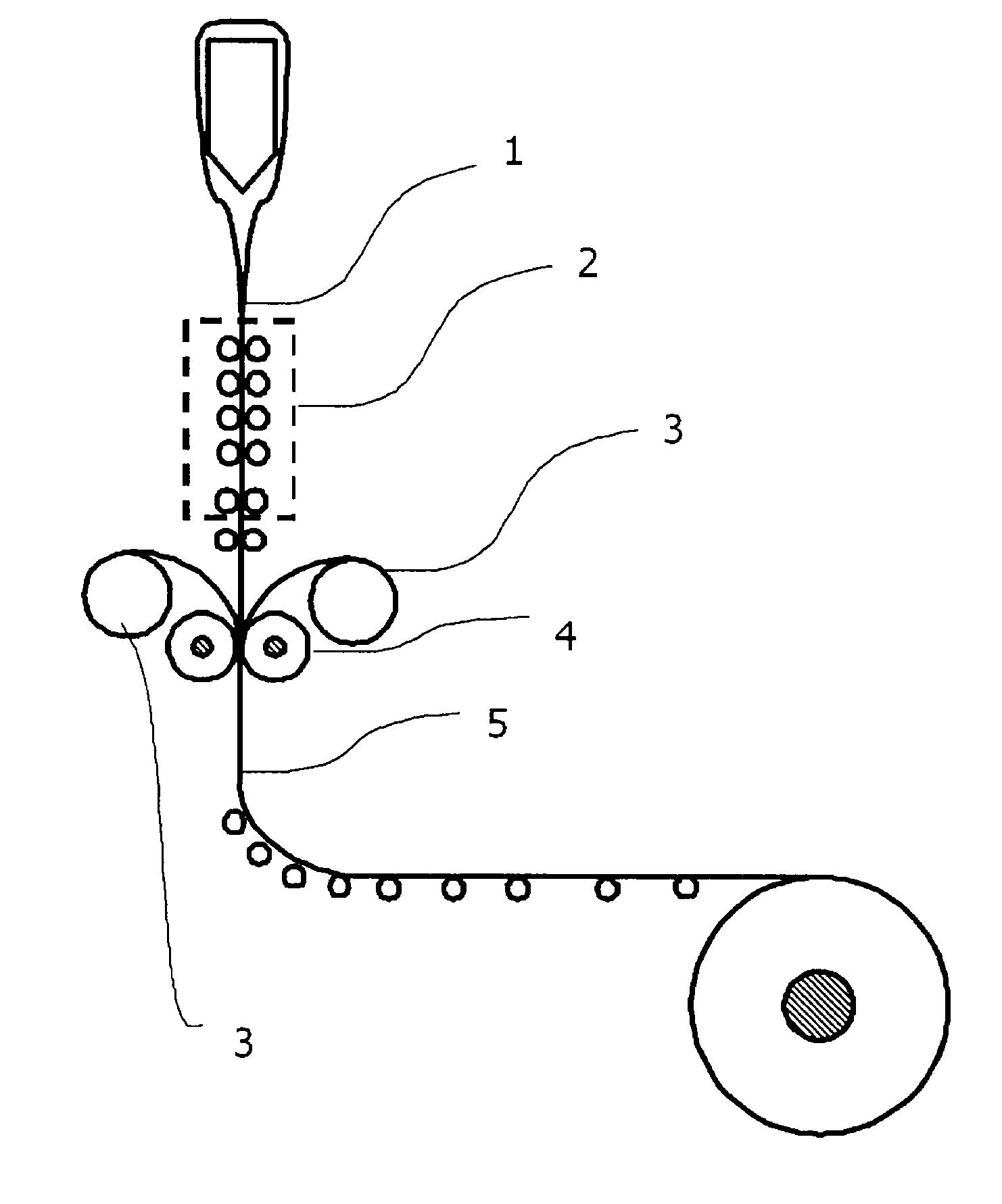

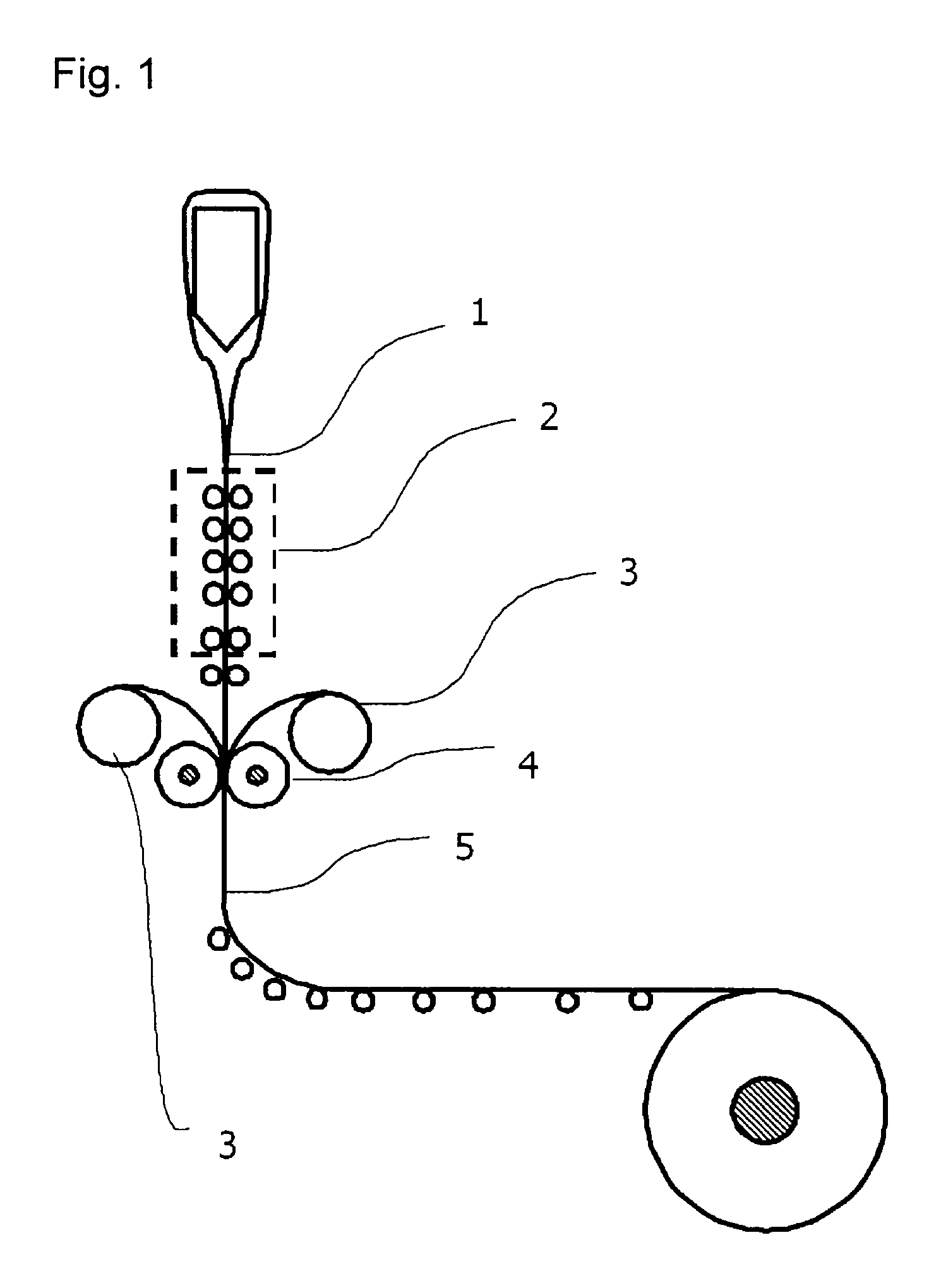

Process and apparatus for producing glass sheet

ActiveUS20100269542A1Sufficient in internal strainIncrease pressureGlass drawing apparatusGlass forming apparatusCutting glassRoom temperature

Provided is a process for producing a glass sheet including: a forming step of down-drawing a molten glass into a sheet-like glass ribbon, in which the molten glass is fed to a forming trough arranged in a forming furnace and the molten glass is caused to flow down from the forming trough through a conveyance passage extending vertically; an annealing step of removing an internal strain in the glass ribbon in an annealing furnace; a cooling step of cooling the glass ribbon to around room temperature; and a cutting step of cutting the glass ribbon in a given size, in which a pressure in an outside atmosphere of the forming furnace and / or the annealing furnace is elevated.

Owner:NIPPON ELECTRIC GLASS CO LTD

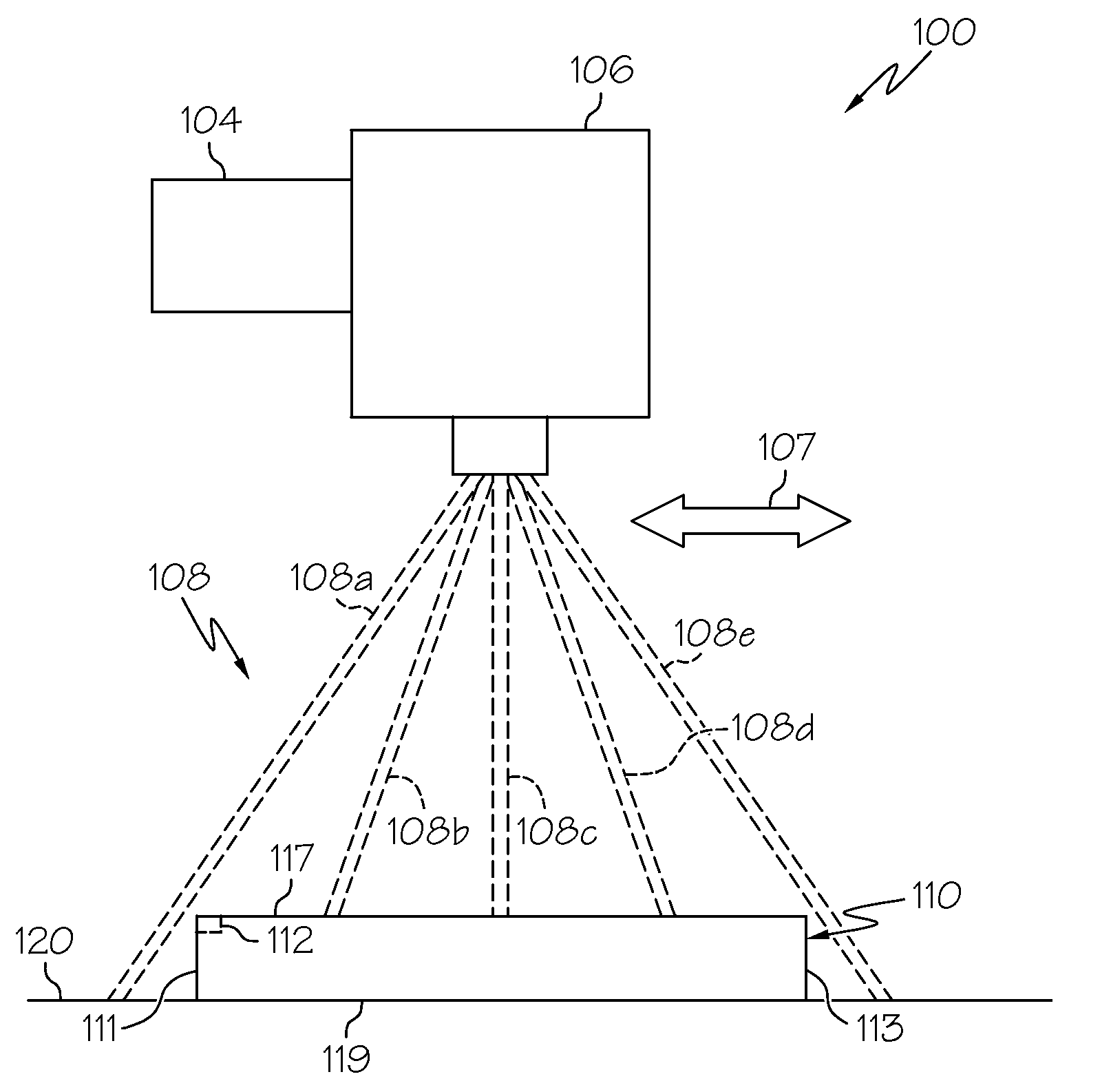

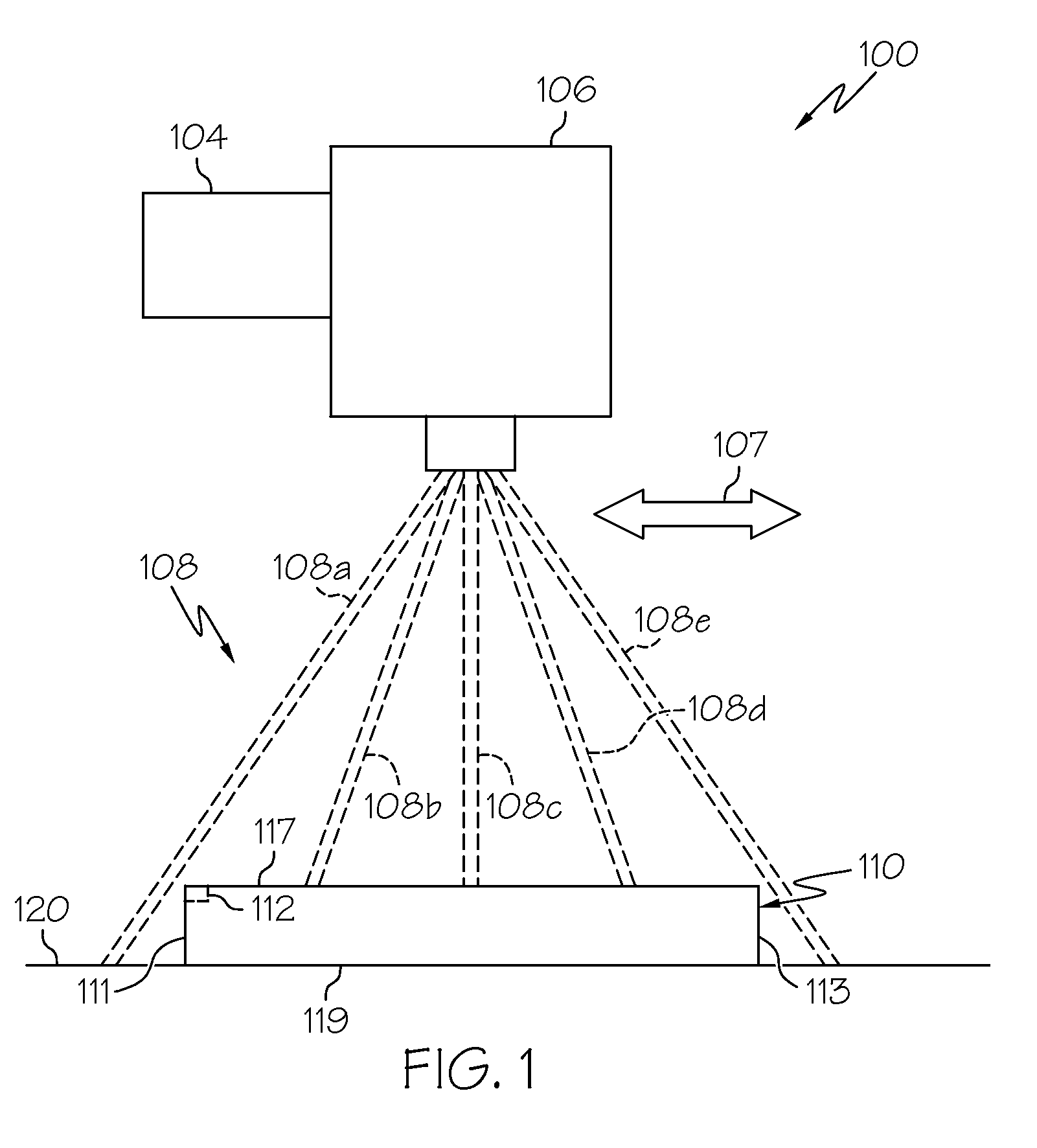

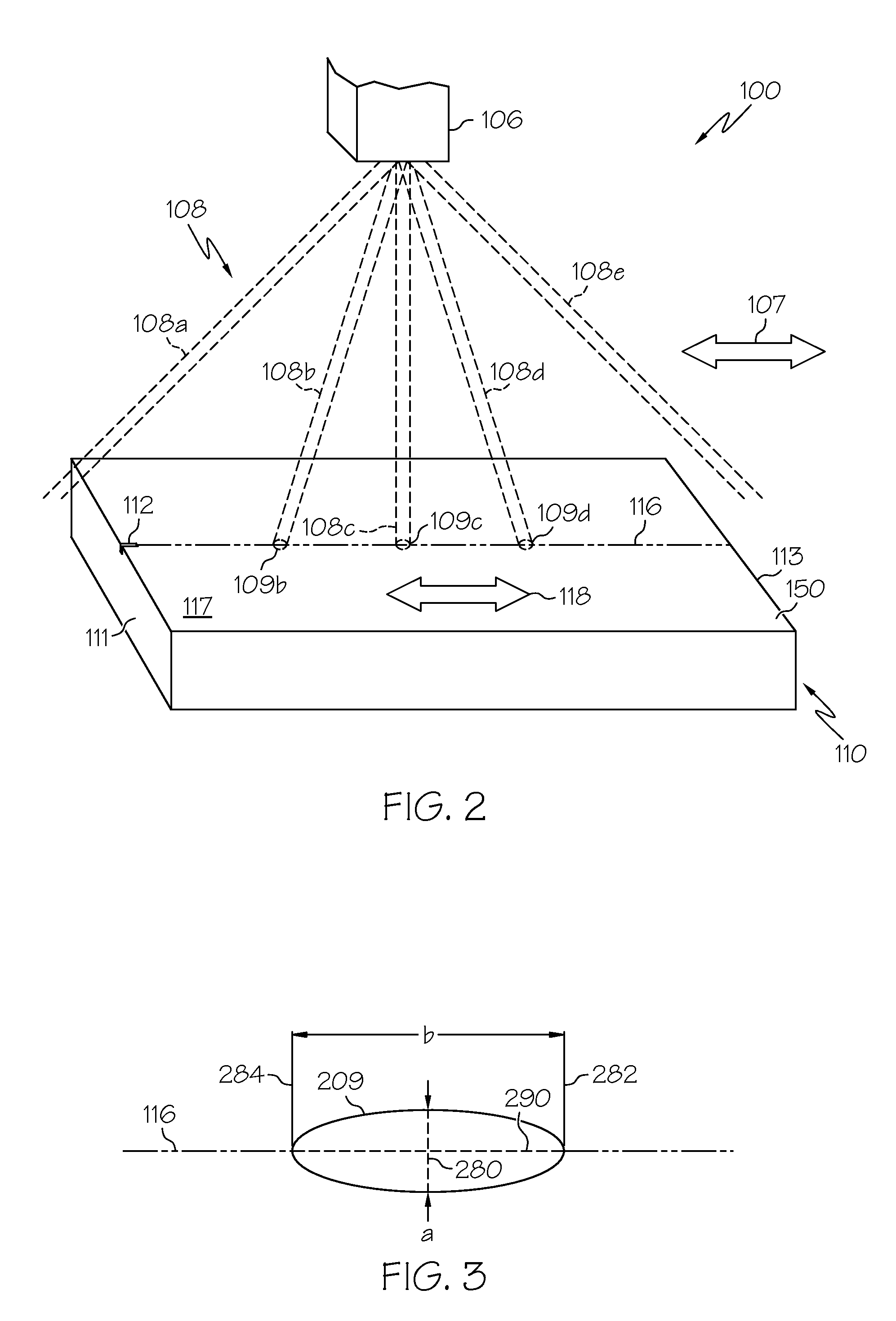

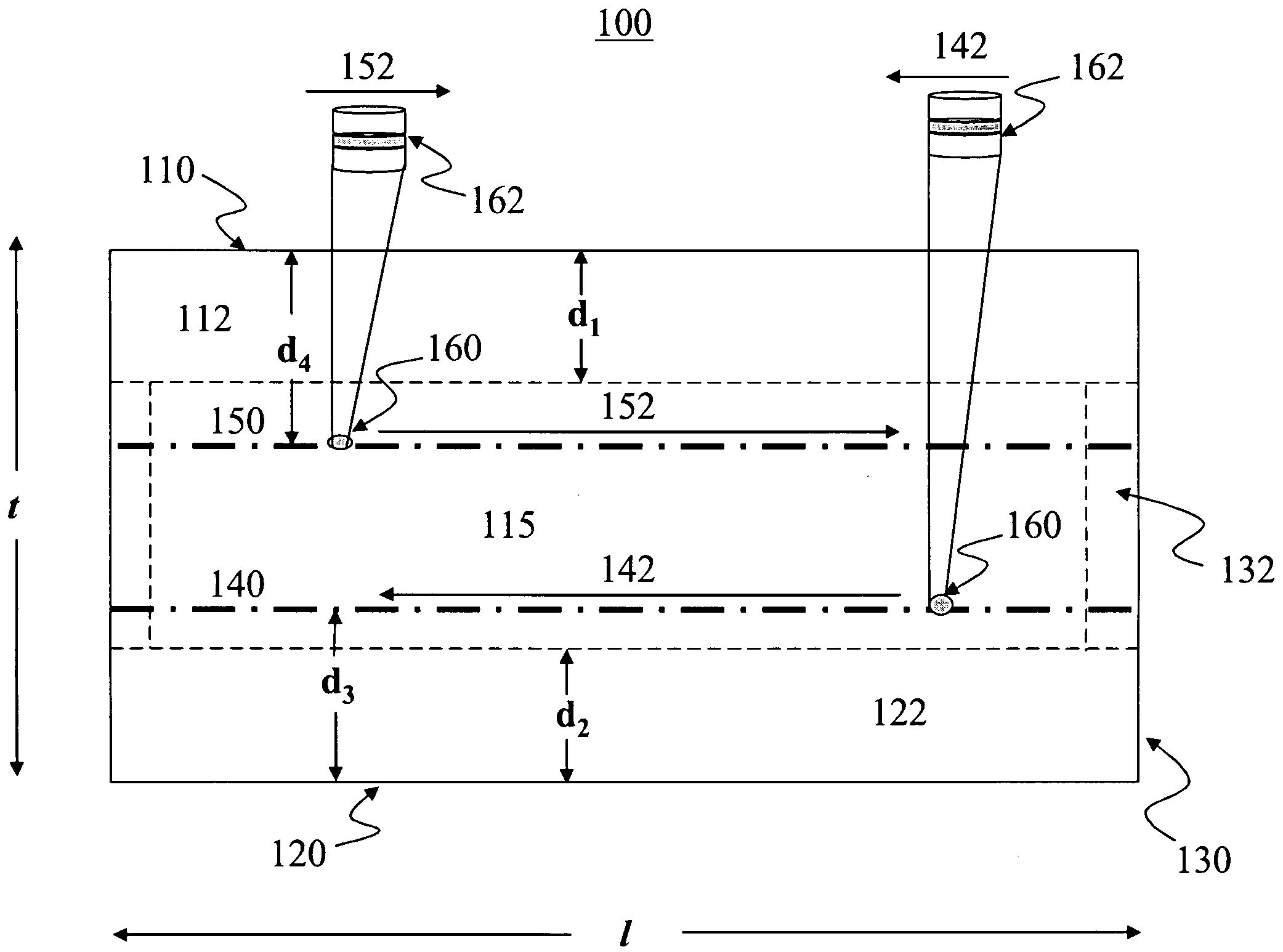

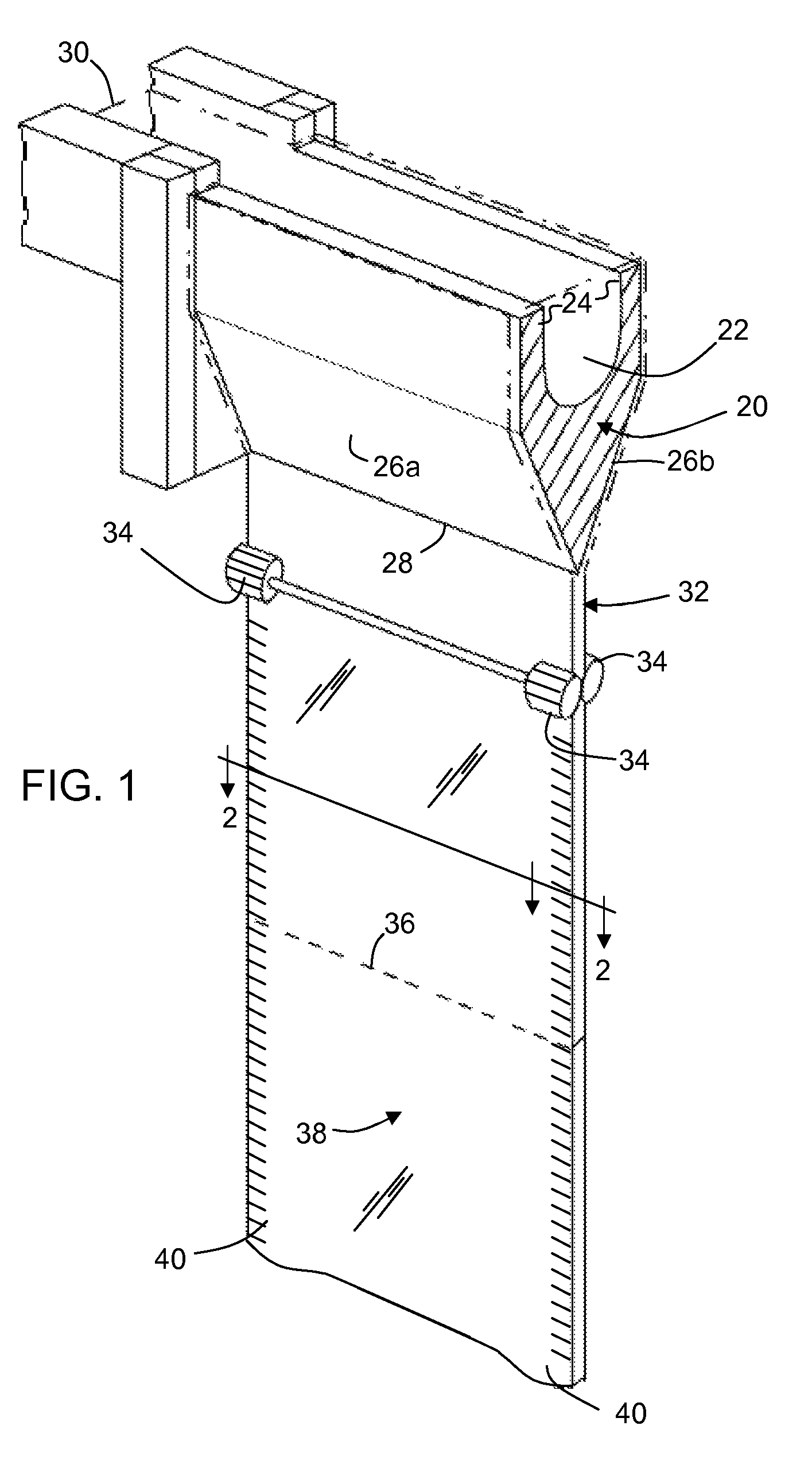

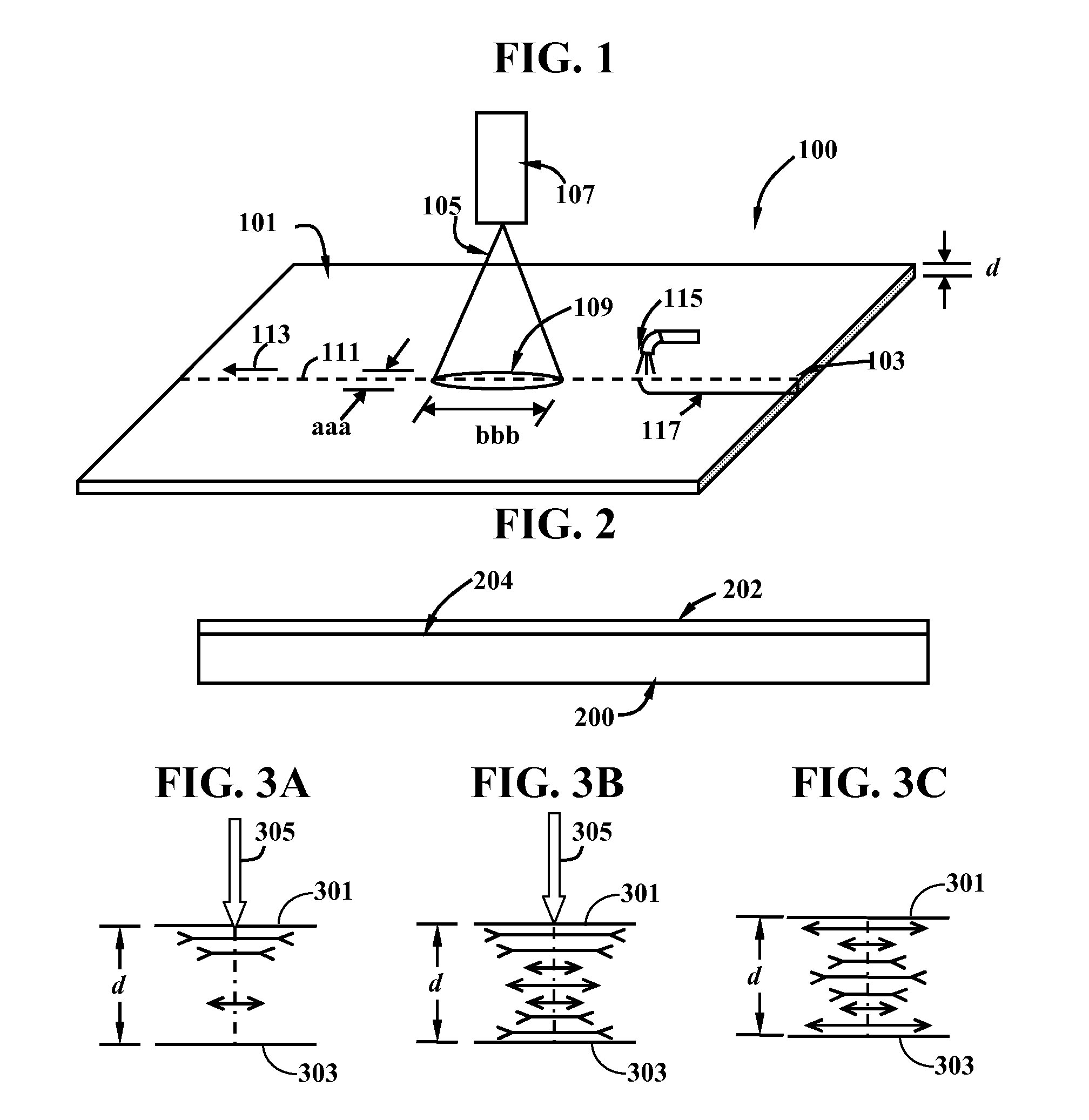

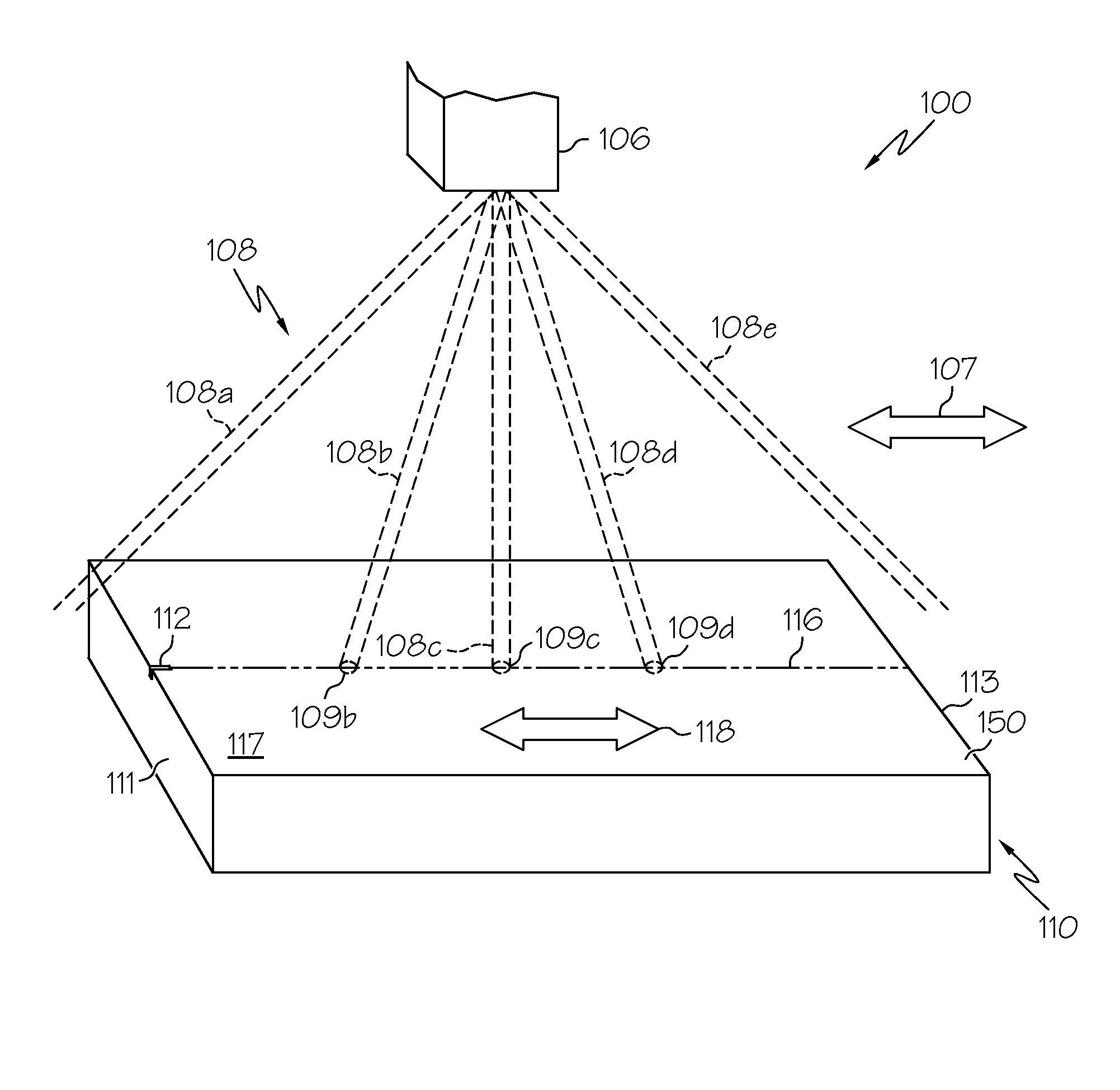

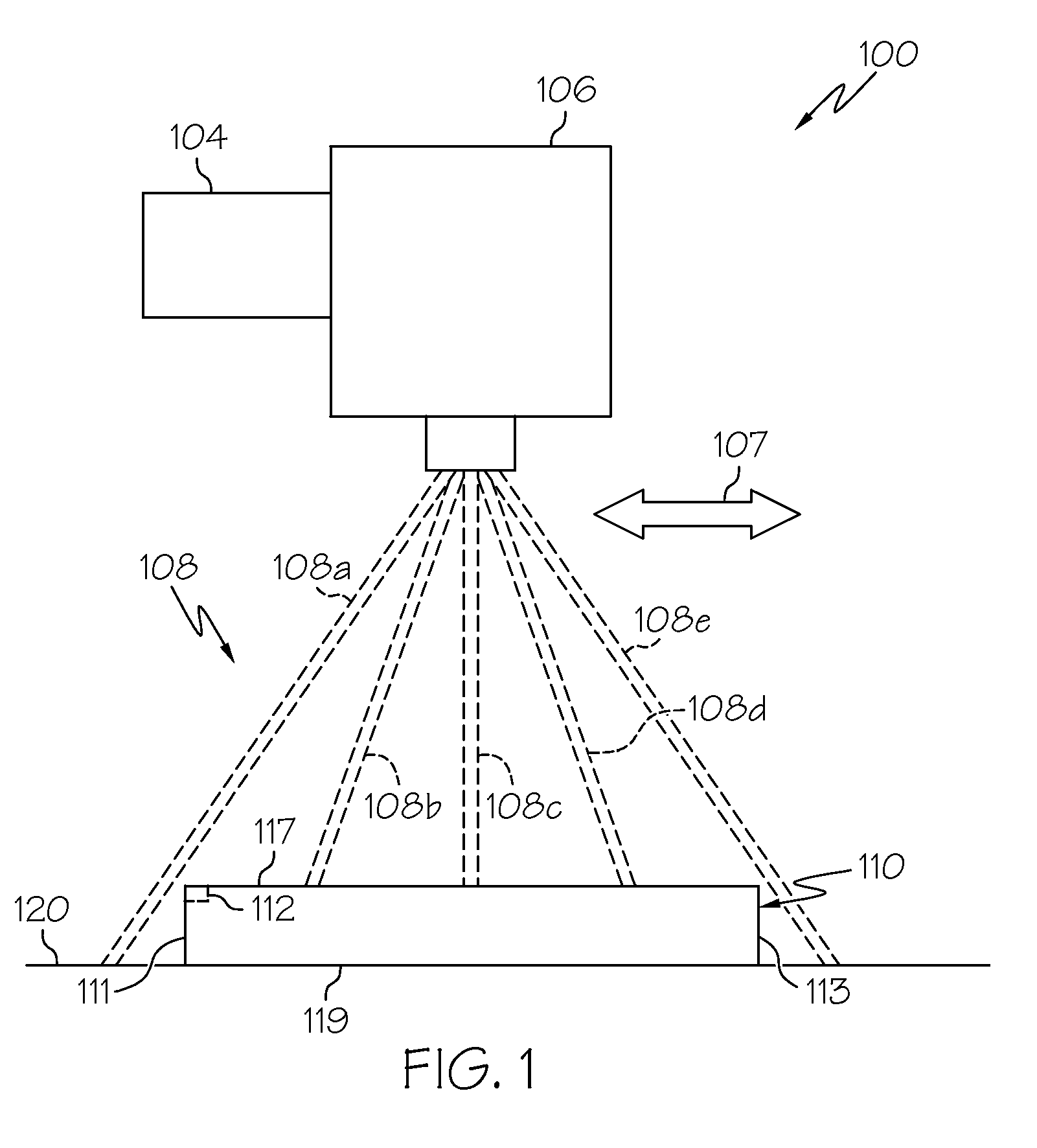

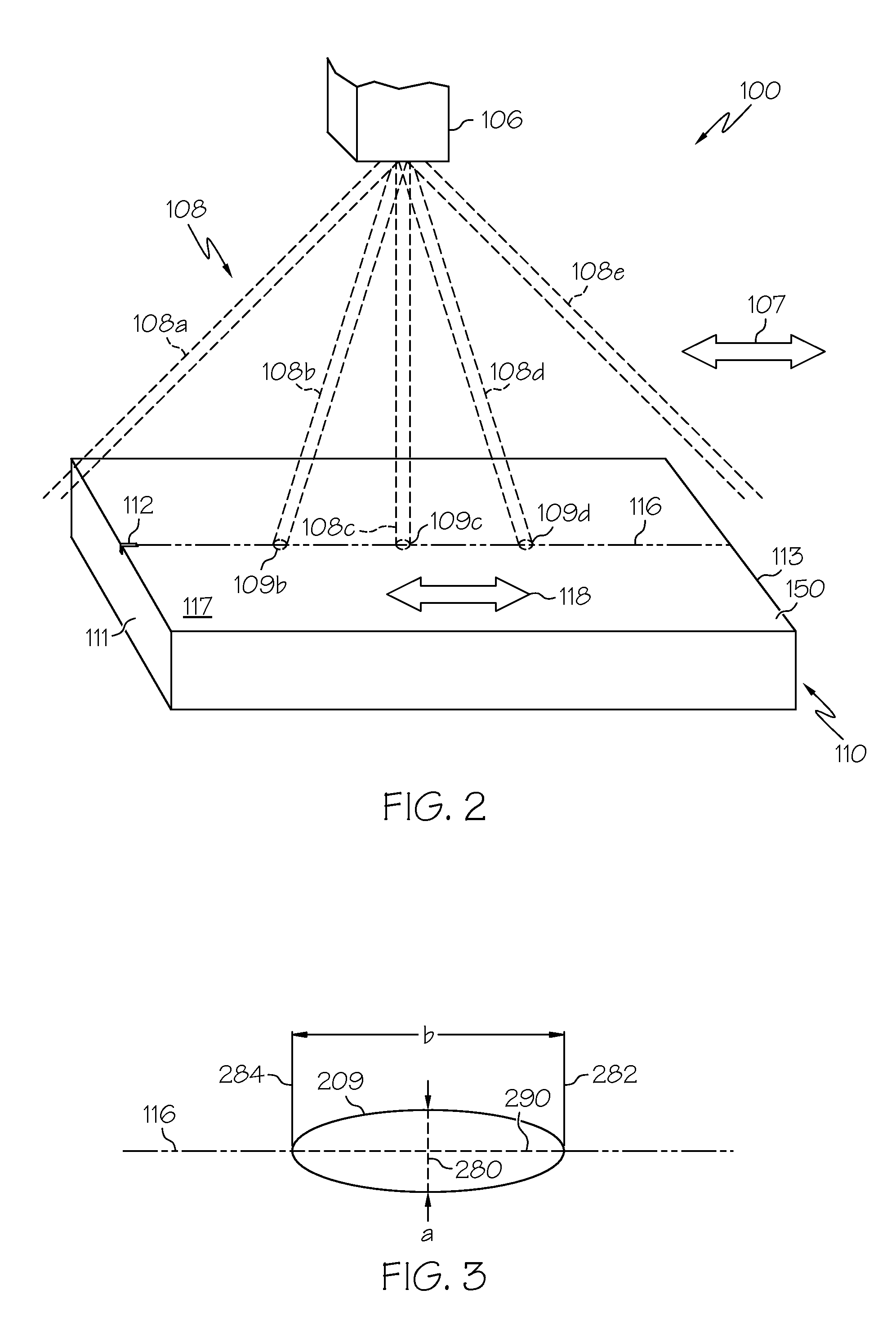

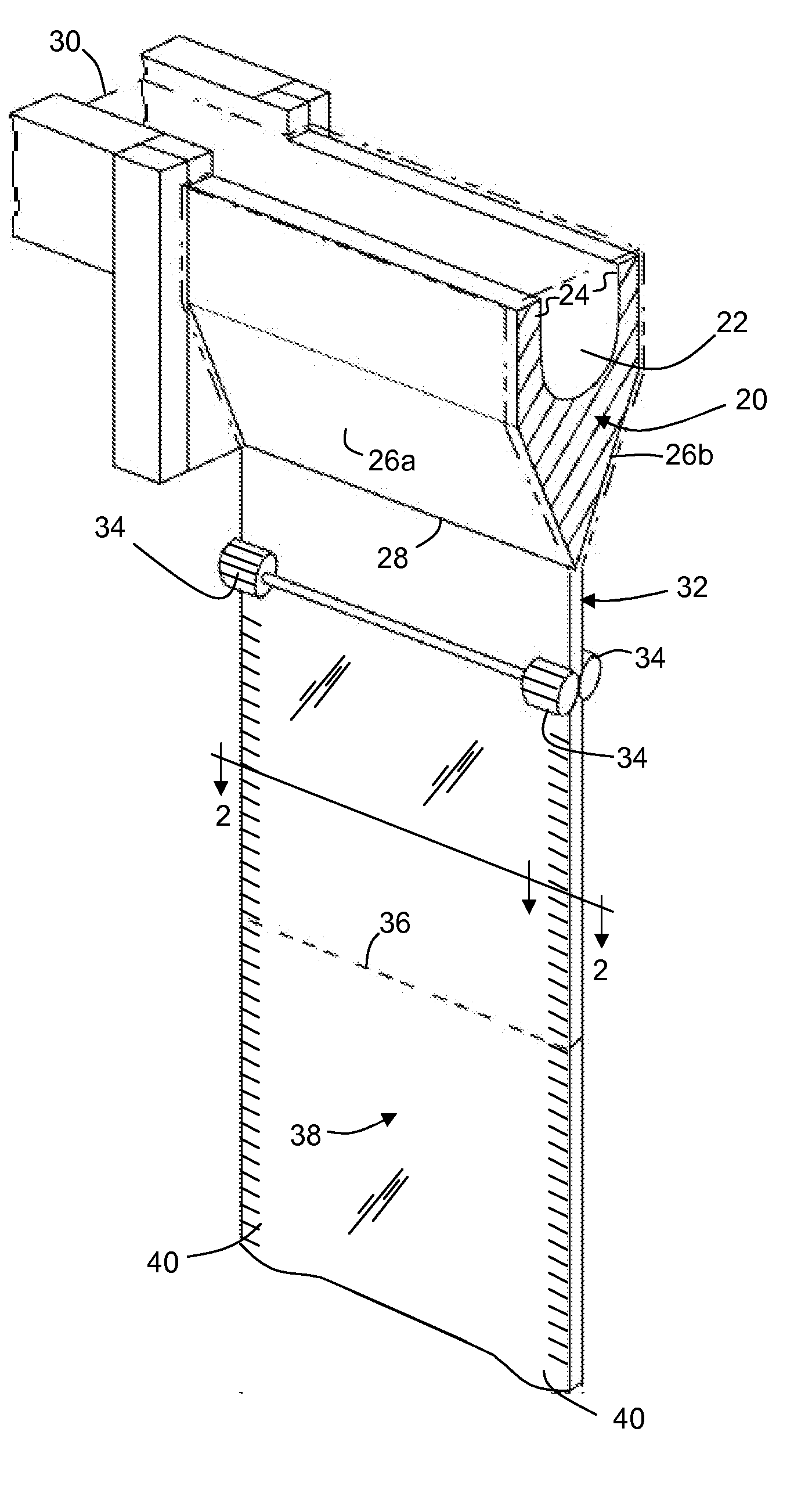

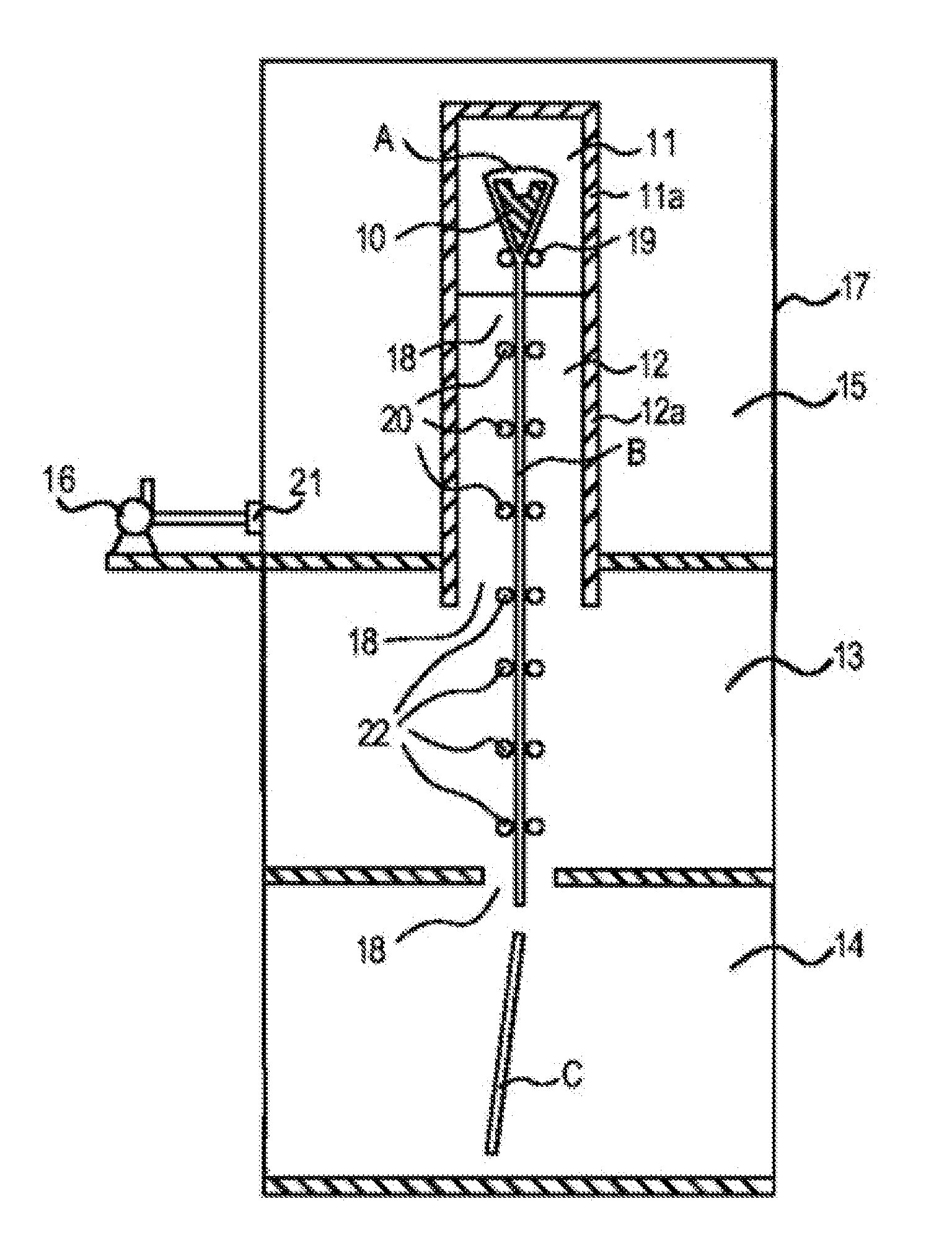

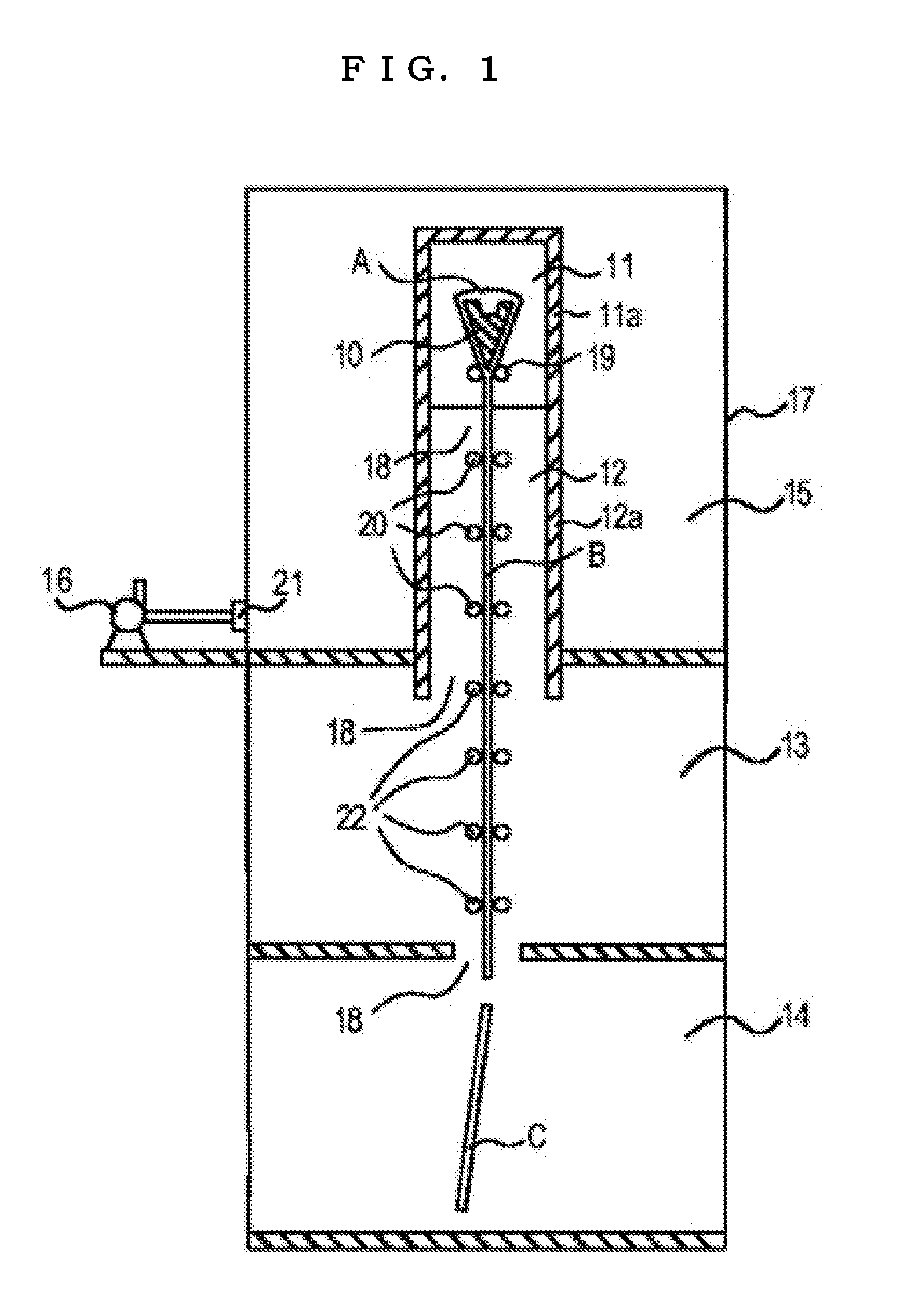

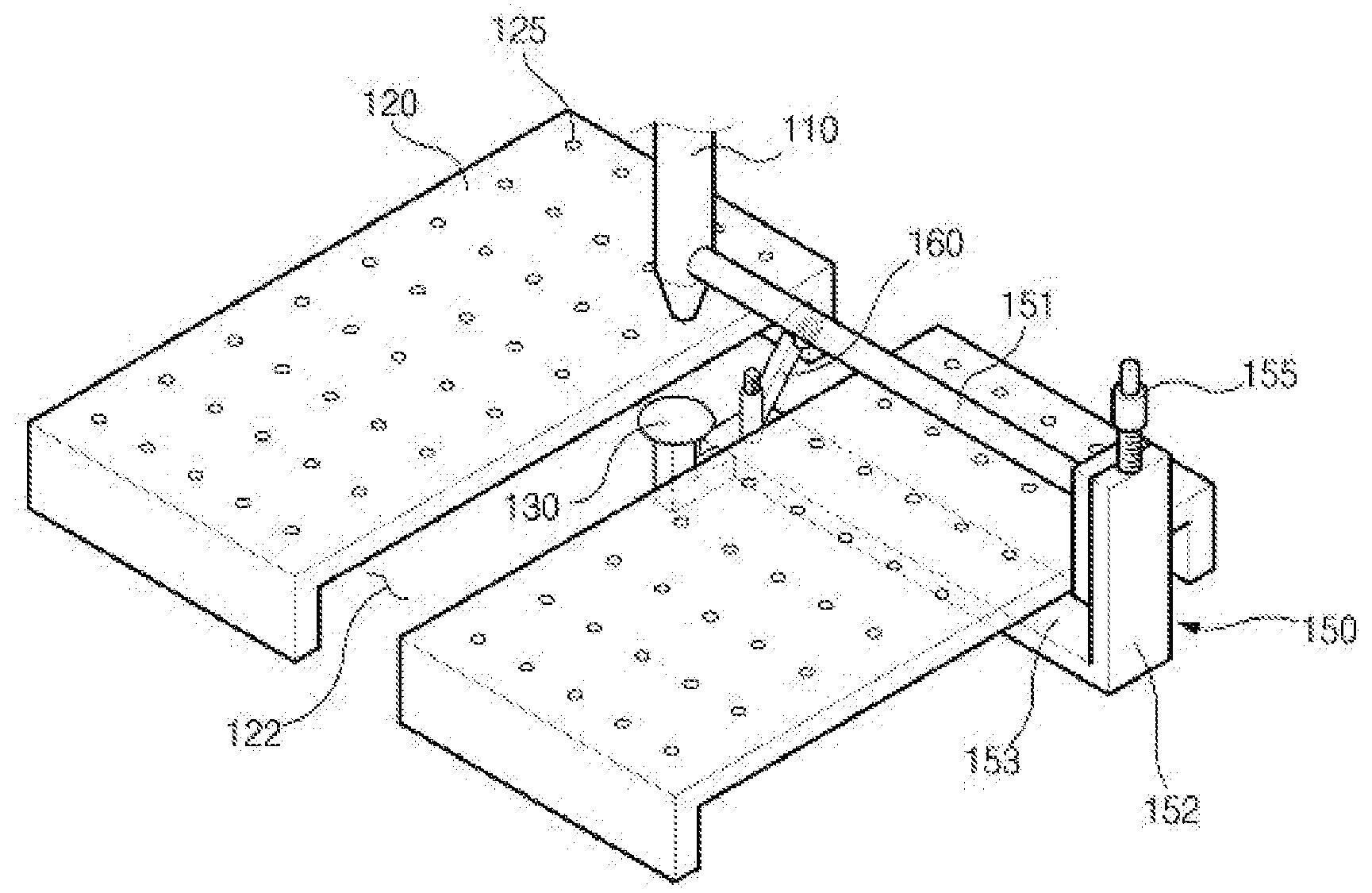

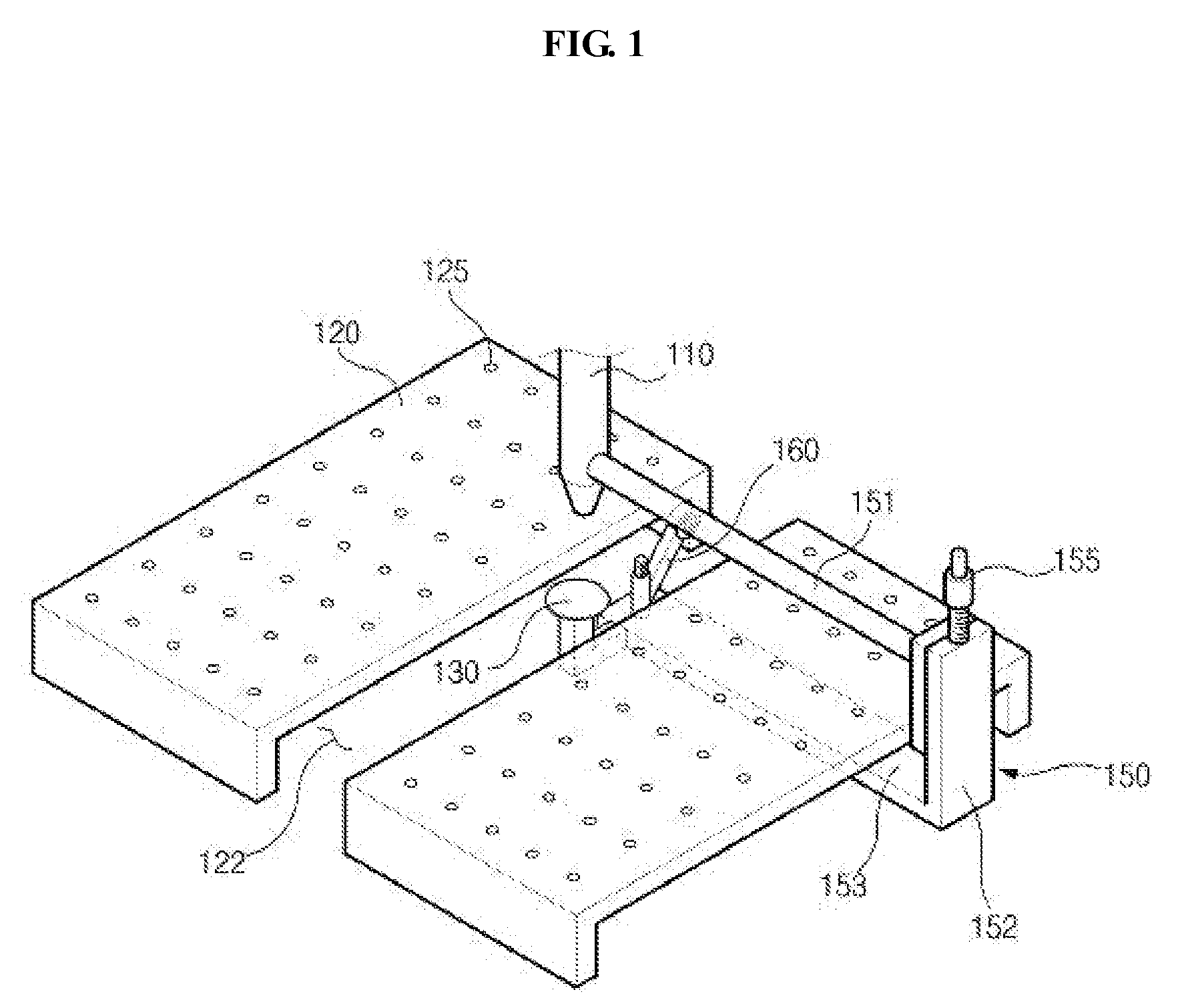

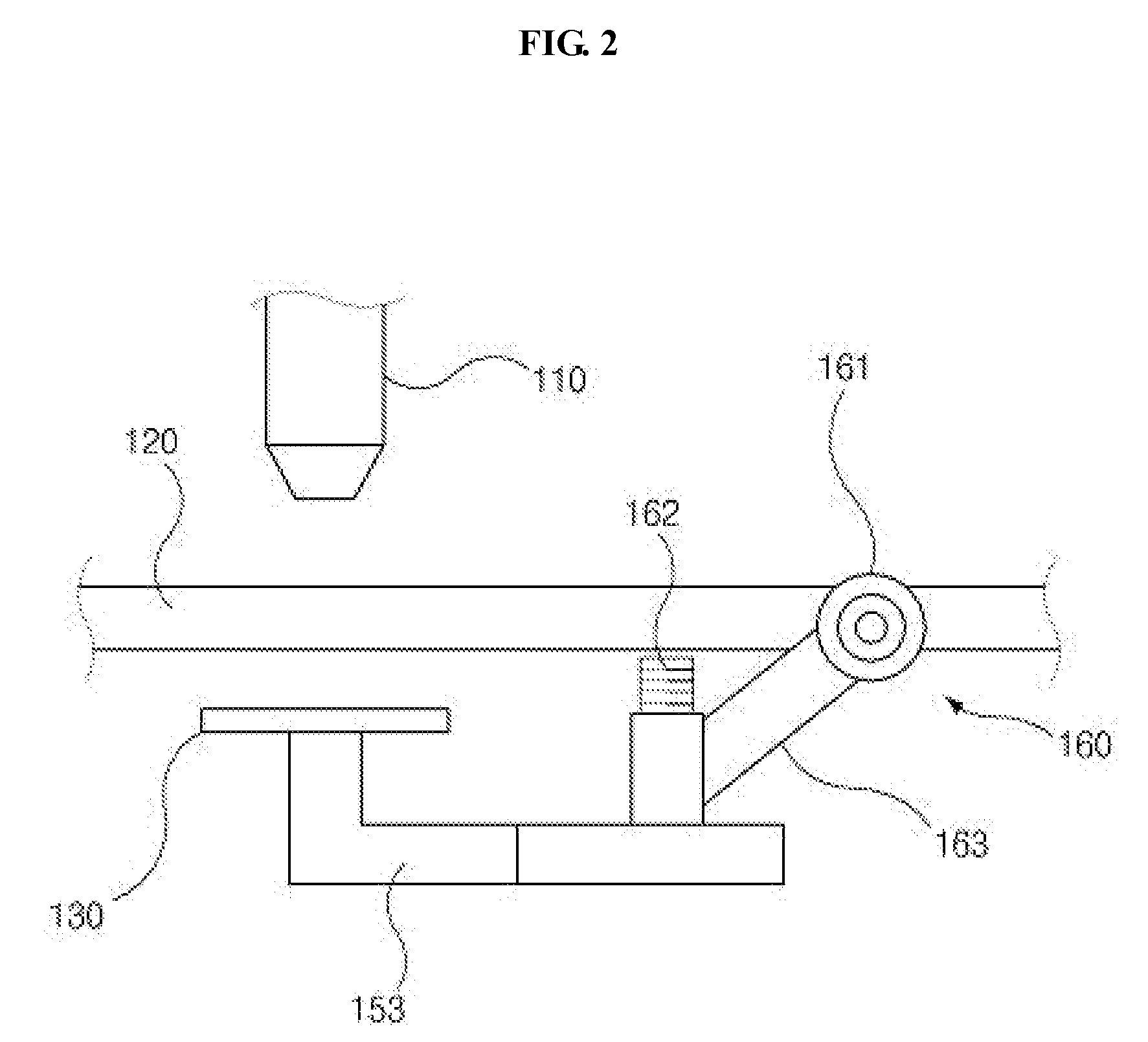

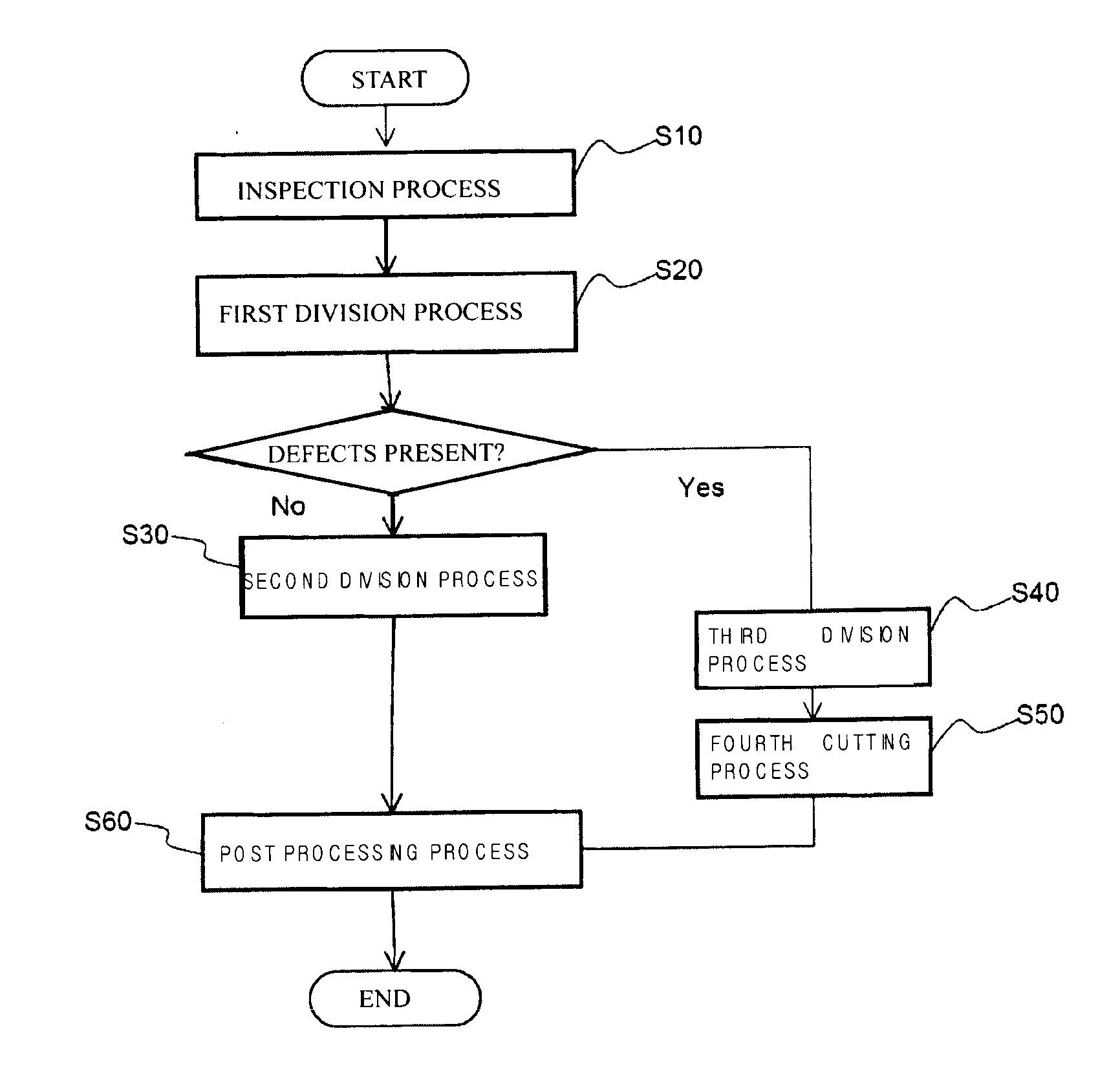

Glass Cutting Apparatus With Bending Member and Method Using Thereof

InactiveUS20090050661A1Easy to cutKeep energy smallConveyorsGlass severing apparatusCutting glassEngineering

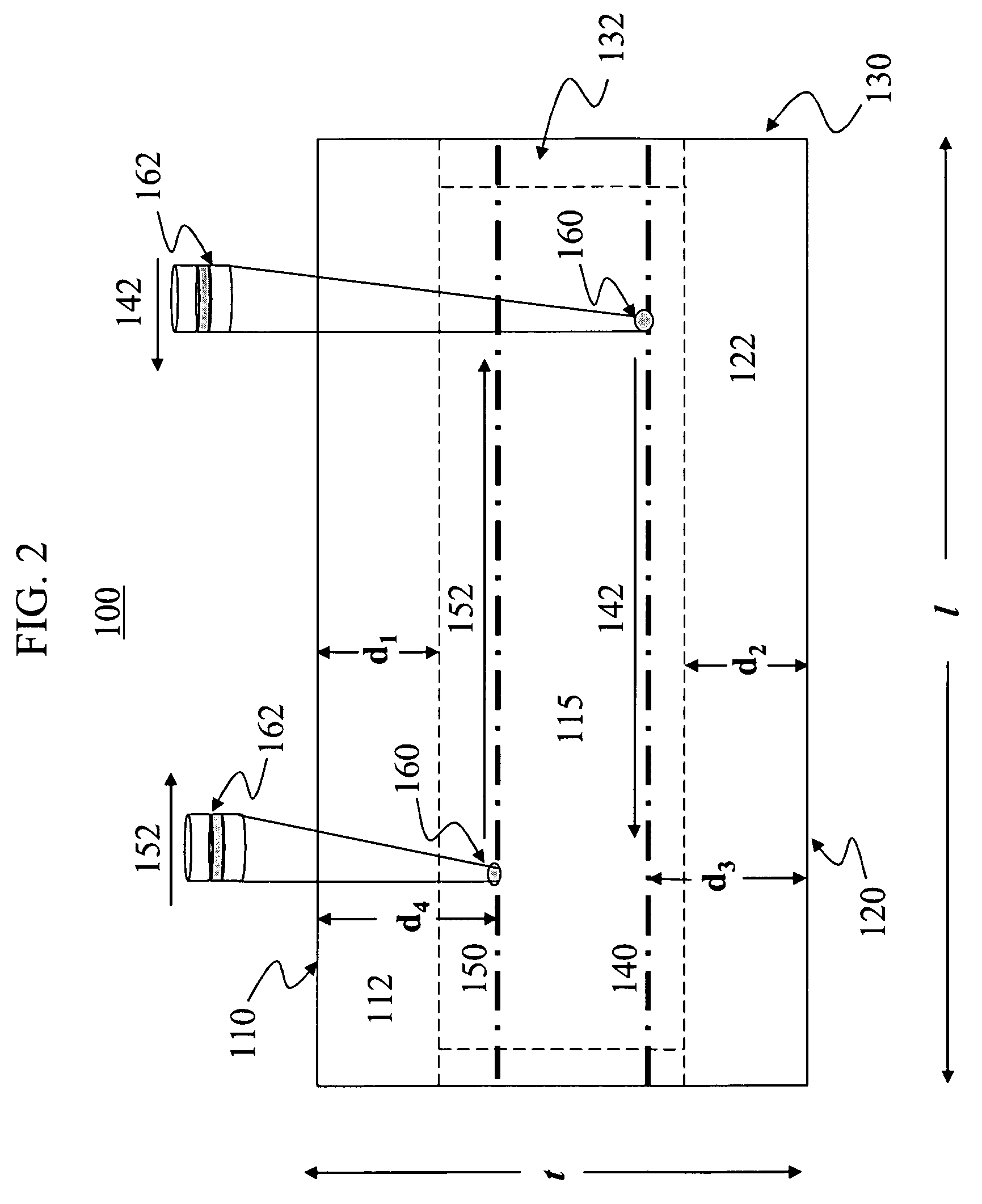

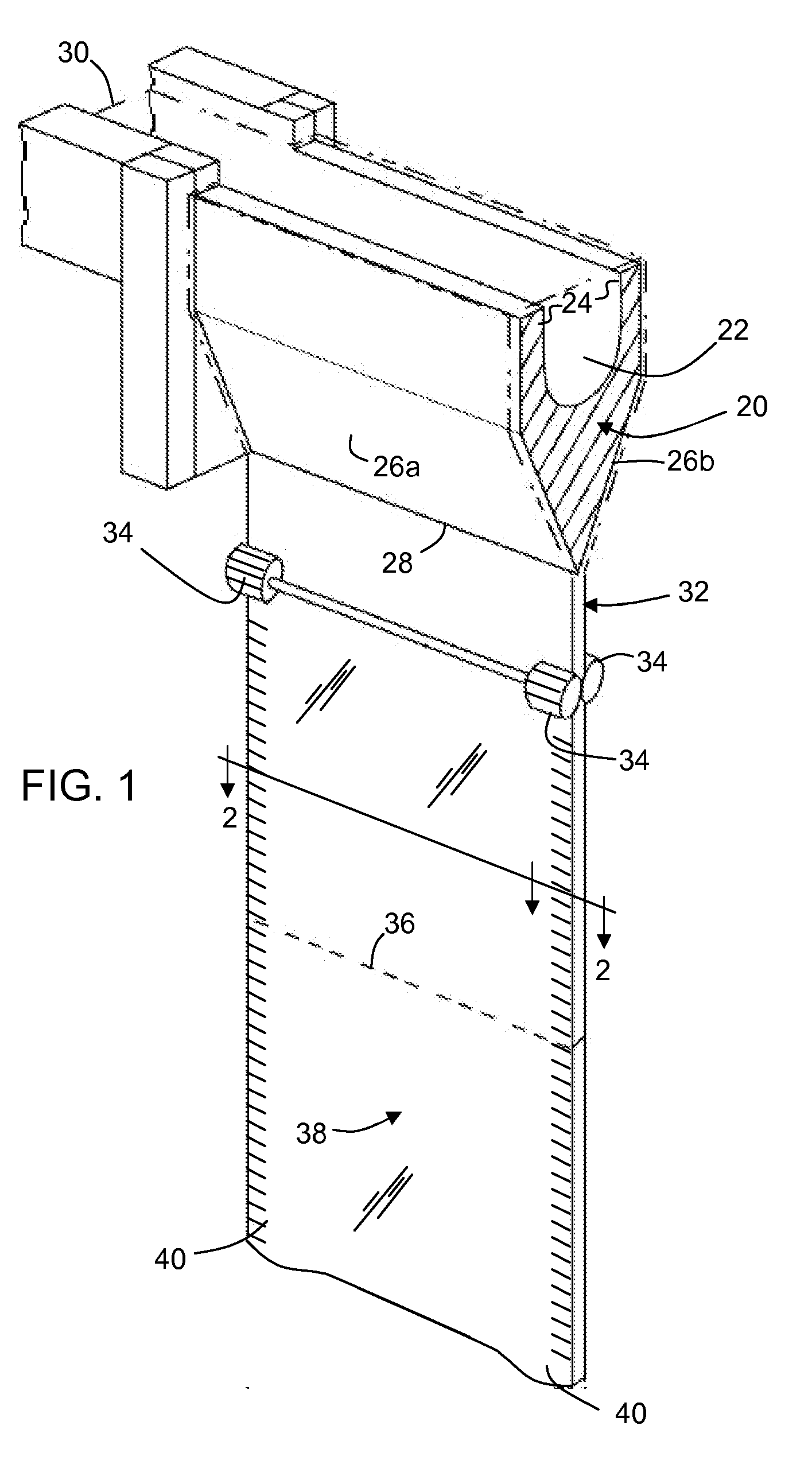

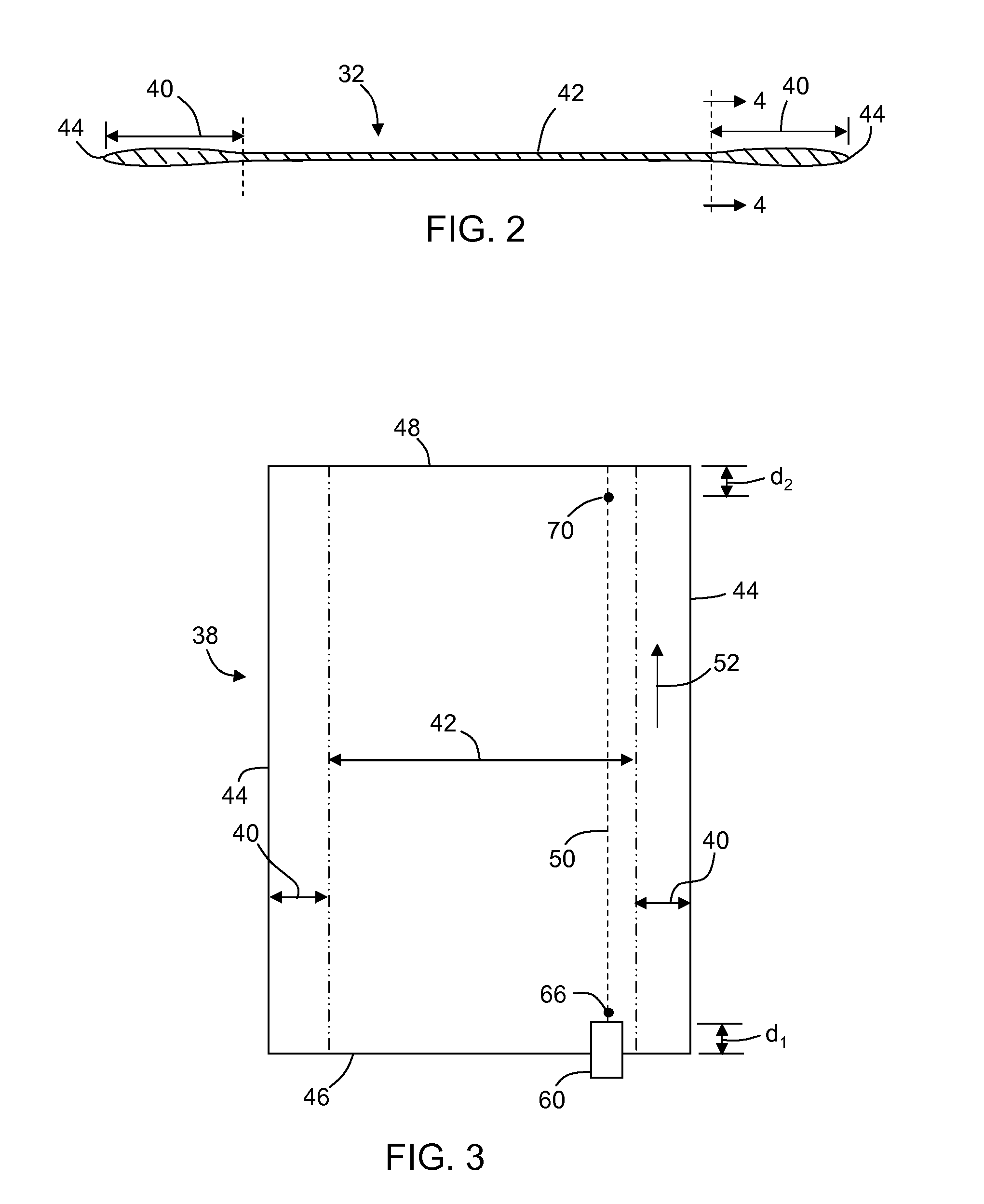

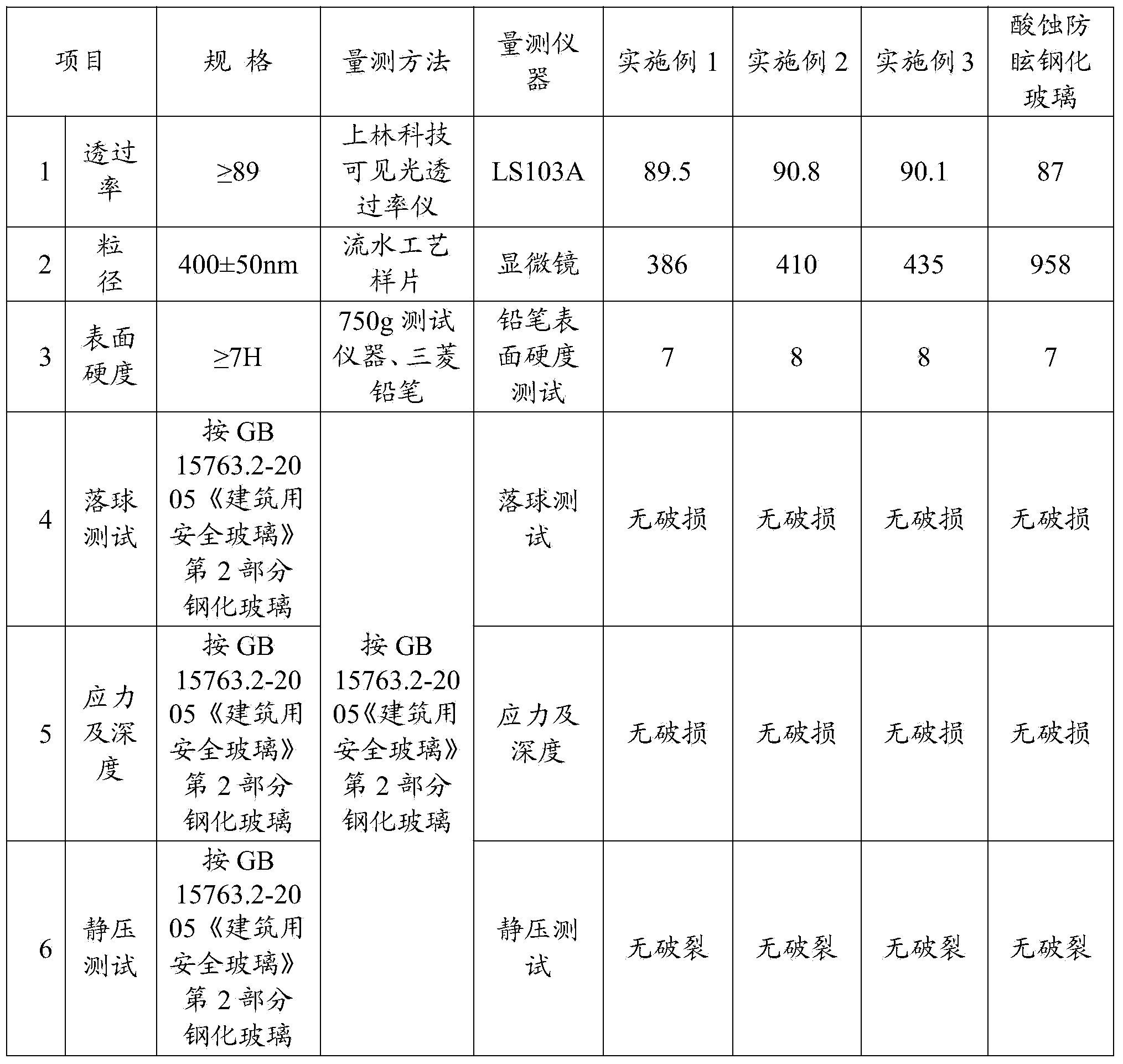

Disclosed herein is glass cutting apparatuses and methods of cutting glass using the glass cutting apparatuses. More particularly, disclosed is a glass cutting apparatus which cuts a glass sheet (140) by forming a crack in the glass sheet using a laser beam and by lifting the glass sheet using a bending unit (160), and a method of cutting glass using the glass cutting apparatus.

Owner:K ENG

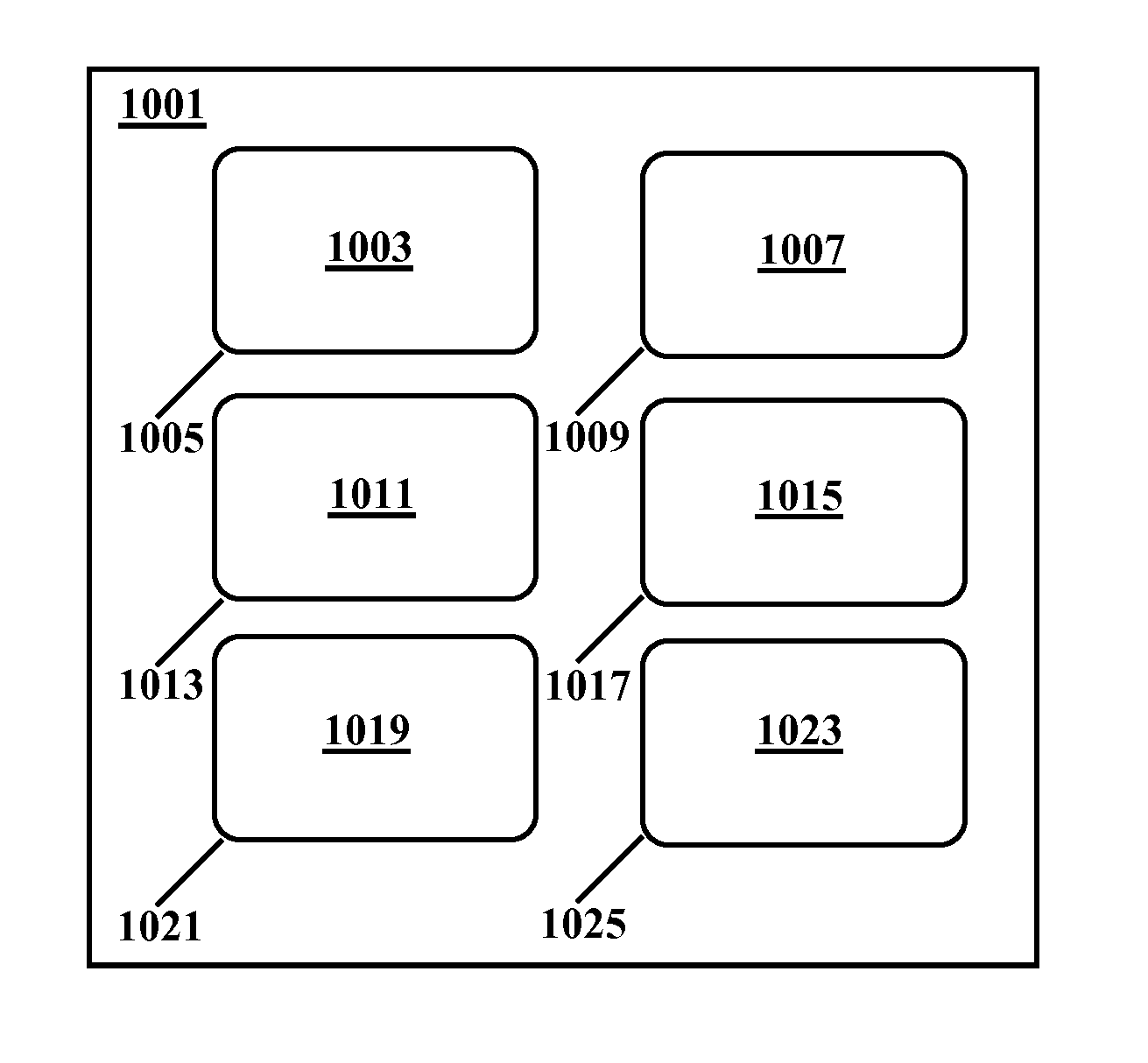

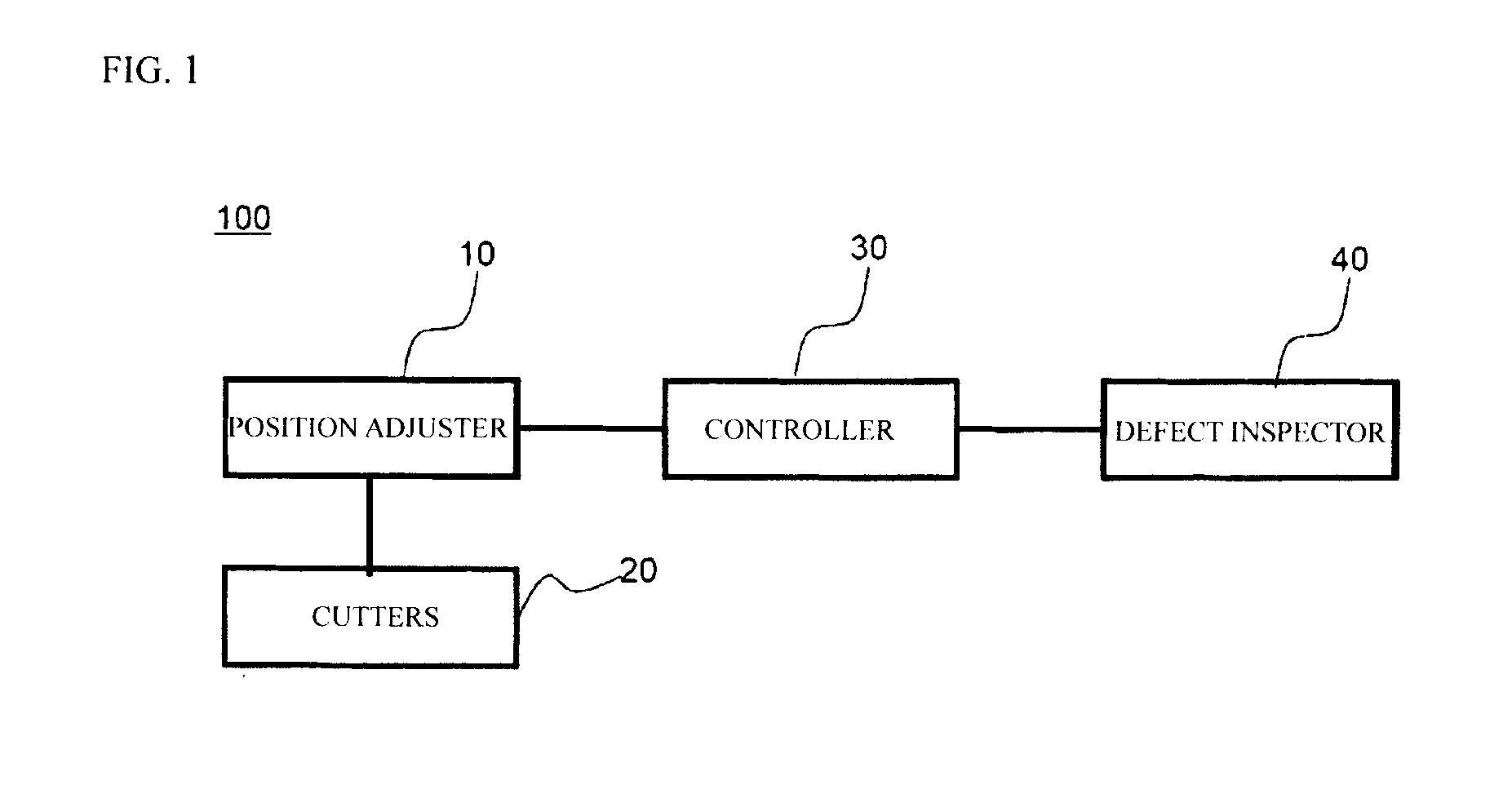

Device for cutting of glass sheet

ActiveUS20130078891A1Increase ratingsEasy to splitOptical surface grinding machinesComputer controlCutting glassGlass sheet

Disclosed herein is a device for cutting a glass sheet, continuously supplied after a melting and solidification process, into quadrangular glass substrates. The glass sheet cutting device includes two or more cutters for cutting a glass sheet into quadrangular glass substrates, a defect inspector for scanning the glass sheet to three-dimensionally check defect positions in a length direction, a width direction and a thickness direction of the glass sheet, a position adjuster for moving at least one of the cutters to a portion of the glass sheet at which few defects are distributed, and a controller for informing the position adjuster of positions of the cutters based on the scanned results received from the defect inspector.

Owner:LG CHEM LTD

Method for producing polyurethane plate for automobile ceiling

InactiveCN101628498AAvoid easy delaminationSimple production processSynthetic resin layered productsLaminationGlass fiberProduction line

The invention discloses a method for producing a polyurethane plate for an automobile ceiling, which comprises the following steps: flatly laying non-woven fabrics on a caterpillar belt of a compound machine; sequentially scattering short-cutting glass fibre and hot-melting adhesive powder on the non-woven fabrics; then melting and compounding at 160-250 DEG C at the pressure of 0.2-1MPa, cooling and rolling to obtain an adhesive glass fabric; sequentially decoiling, stacking and flatly laying the adhesive glass fabric and a bonding film on a working platform of a compound production line from bottom to top and placing a polyurethane rigid foam plate; sequentially scattering short-cutting glass fiber and hot-melting adhesive powder on the polyurethane rigid foam plate; flatly laying the hot-melting adhesive film and heating to 160-250 DEG C by a heating plate of the compound machine; carrying out hot-press compounding at the pressure of 0.2-1MPa and cooling to obtain a polyurethane multilayer composite plate. The invention has simple production process and stable product quality and solves the problem of easy delamination of the polyurethane plate produced by the prior one-step method.

Owner:浙江华江科技股份有限公司

Full-section pre-reinforcing construction method for tunnel free-machining anchor bar

InactiveCN101487393AGood deformation propertiesConstruction method safetyUnderground chambersTunnel liningGlass fiberFiber

The invention discloses a tunnel easy-cutting anchor-rod full-section pre-consolidation construction method, comprising the following steps: firstly, survey design before construction is carried out, pre-consolidation is carried out to a face core body to be excavated by adopting an easy-cutting anchor rod according to the sampling analysis and classification of rock-soil, meanwhile, a measuring instrument is installed to monitor the change thereof, and then full-section excavation is carried out. The construction method takes the problem of how to deal with the 'core body to be excavated' in front of the face as the key for controlling the integral stability of the tunnel, an easy-cutting glass fiber anchor rod which is pre-consolidated along tunnel vertical full-section is used for improving the equivalent stiffness of the 'core body to be excavated' and controlling the deformation of the 'core body to be excavated' so as to cause arching effect around the tunnel to function naturally, thus guaranteeing the full-section, safe and quick excavation and drivage of the tunnel. The construction method is safe and reliable, can realize tunnel full-section mechanized and modernized construction, and has good production efficiency, continuous and stable construction progress, and controllable project cost.

Owner:中铁西南科学研究院有限公司

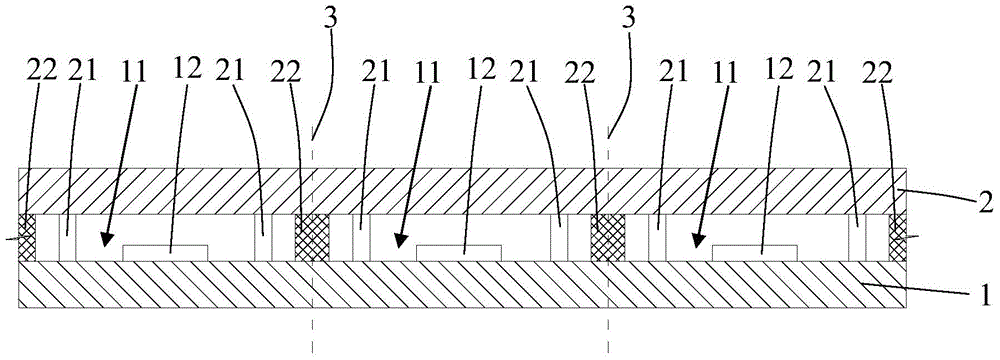

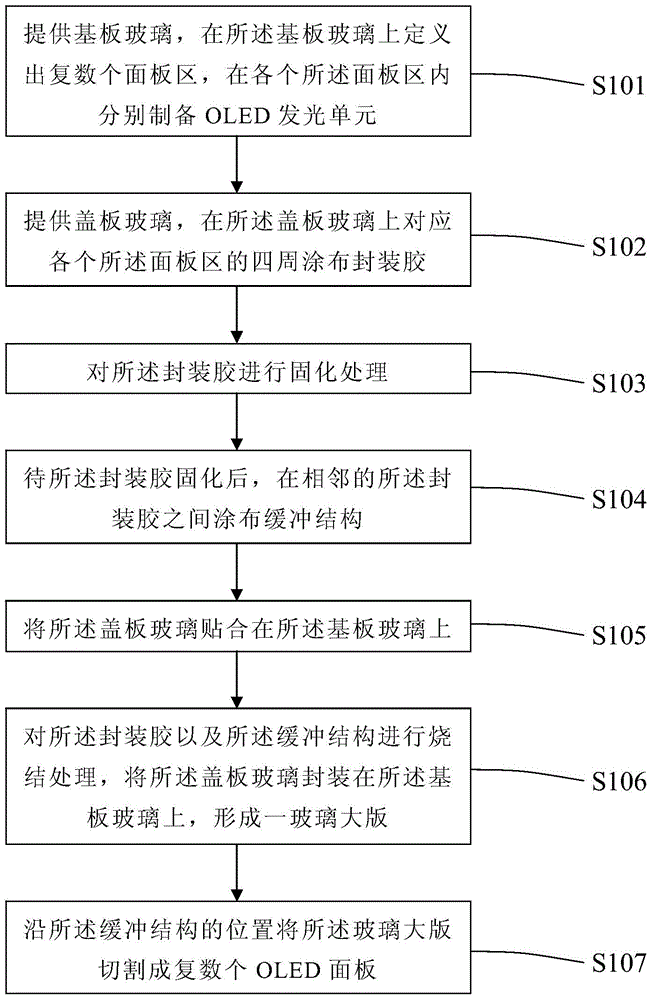

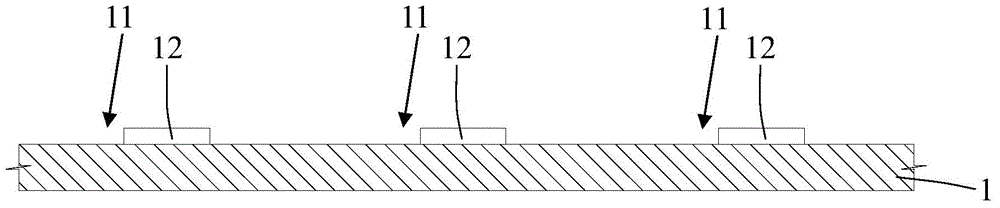

Packaging structure and preparation method of OLED (organic light emitting diode) panel

InactiveCN104485311AReduce shockImprove buffering effectSolid-state devicesSemiconductor/solid-state device manufacturingCutting glassEngineering

The invention discloses a packaging structure and a preparation method of an OLED (organic light emitting diode) panel. The preparation method comprises the following steps of providing substrate glass, defining a plurality of panel areas on the substrate glass, and respectively preparing an OLED light emitting unit in each panel area; providing cover plate glass, and coating packaging glue around the parts, corresponding to each panel area, of the cover plate glass; curing the packaging glue; after the packaging glue is cured, coating a buffer structure between the adjacent packaging glue; attaching the cover plate glass on the substrate glass; sintering the packaging glue and the buffer structure, and packaging the cover plate glass on the substrate glass to form a glass large template; cutting the glass large template into a plurality of OLED panels along the corresponding buffer structure. The preparation method has the advantage that by coating the buffer structure on the cover plate glass, when the glass is cut by a knife wheel, the shock caused by the glass cracks can be reduced by the buffer structures, the penetrating stress of the knife wheel and the stress of the glass cracks are absorbed, and the influence on the packaging glue by the cutting stress is reduced.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

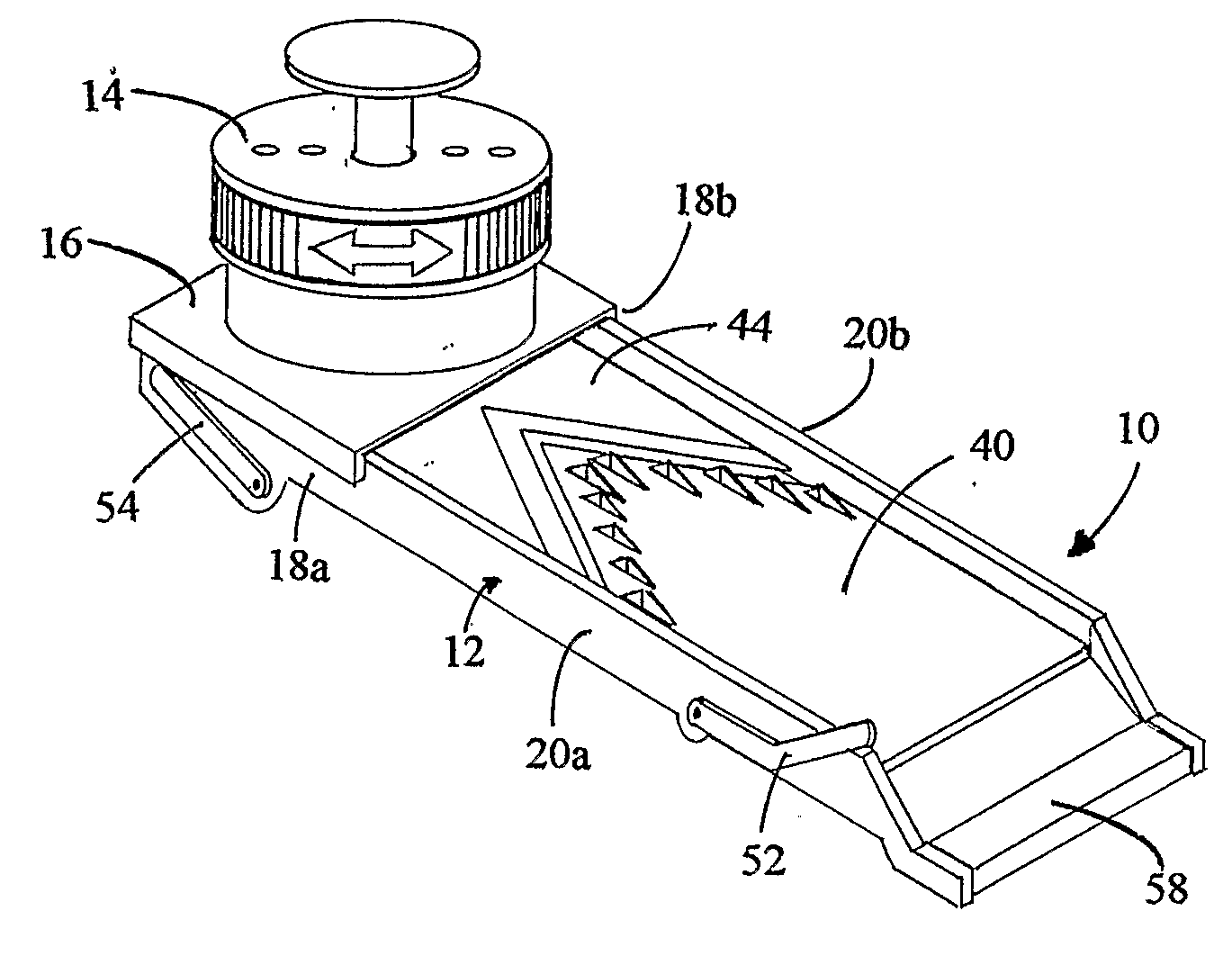

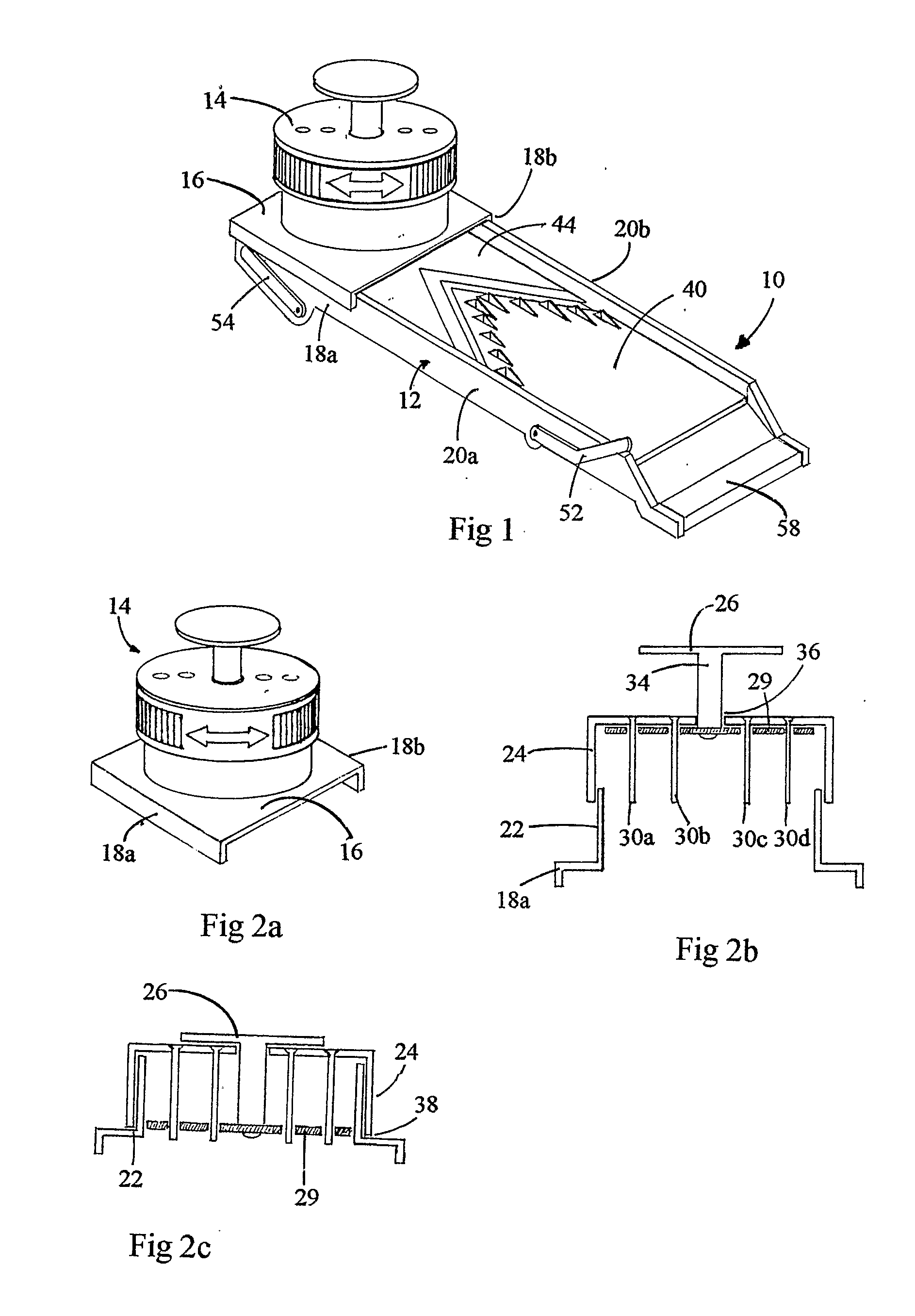

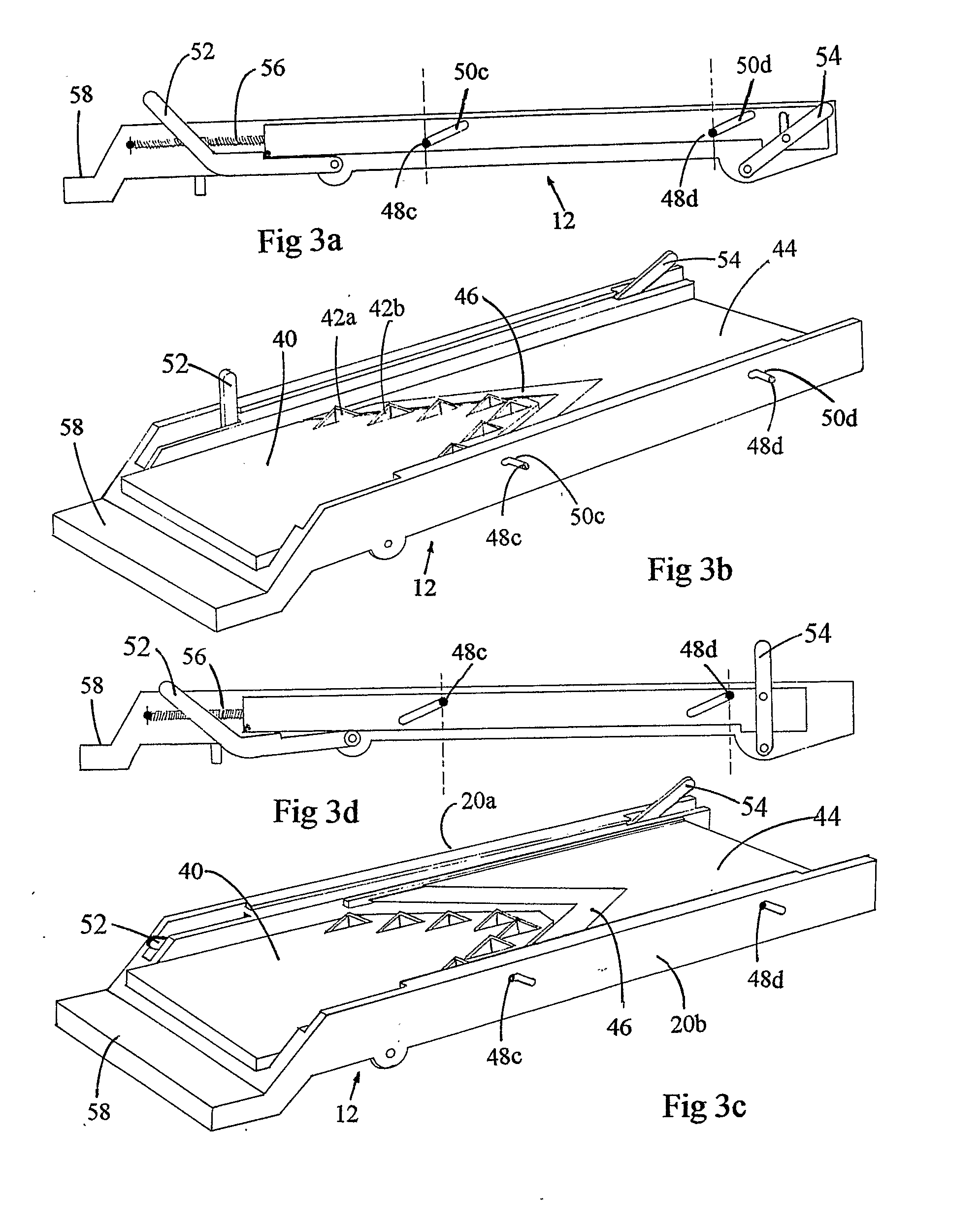

Food dicer

ActiveUS20090123623A1Reduce manufacturing costEasy to cleanFruit stoningSoldering apparatusDicerCutting glass

A dicing tool having: a foodstuff holder for holding a block of foodstuff and a cutting base; the cutting base having: a rectangular framework for sliding the foodstuff holder therealong; a first part having an triangular shaped front edge, equally spaced triangular cutting blades being arranged in a triangular arrangement that follows the profile of the triangularly shaped front edge; a handle; a second part having a second upper surface and a right front edge and a left front edge arranged in a deep V shape, with continuous blades attached to the right and left front edges; wherein the second upper surface is always parallel to the first surface and can be slidingly reciprocated between an upper position and a lower position where the horizontal blade is substantially on a level with the first surface and the base of the triangular cutting blades.

Owner:TWEG EDWARD

Glass cutting method and device

ActiveCN105541098AFacilitate flexible secondary processingIncrease productivityGlass severing apparatusGlass productionControl systemCutting glass

The present invention discloses a glass cutting method, a two-dimensional code is set on a glass substrate before glass cutting, two-dimensional code information is read before the glass cutting, and inputted into a control system, the control system interprets the two-dimensional code information and generates a cutting path according to interpretation information, and a cutting device cuts the glass substrate according to the cutting path. According to the method, different sizes and different shapes of glass to be cut can be optimized and arranged, the utilization rate of the glass substrate can be improved, the workload of manual input of parameters can be reduced, the relative position of the two-dimensional code on the cut glass is more precision, production efficiency of the glass subsequent processing can be improved, mixed production of different specifications of glass can be achieved, positional deviation increase, large glass size scattering difference and other defects caused by a plurality of times of repeated positioning can be avoided, and flexible secondary processing of the glass can be facilitated. The present invention also discloses the glass cutting device for cutting the glass substrate by use of the method.

Owner:LUOYANG LANDGLASS TECH CO LTD

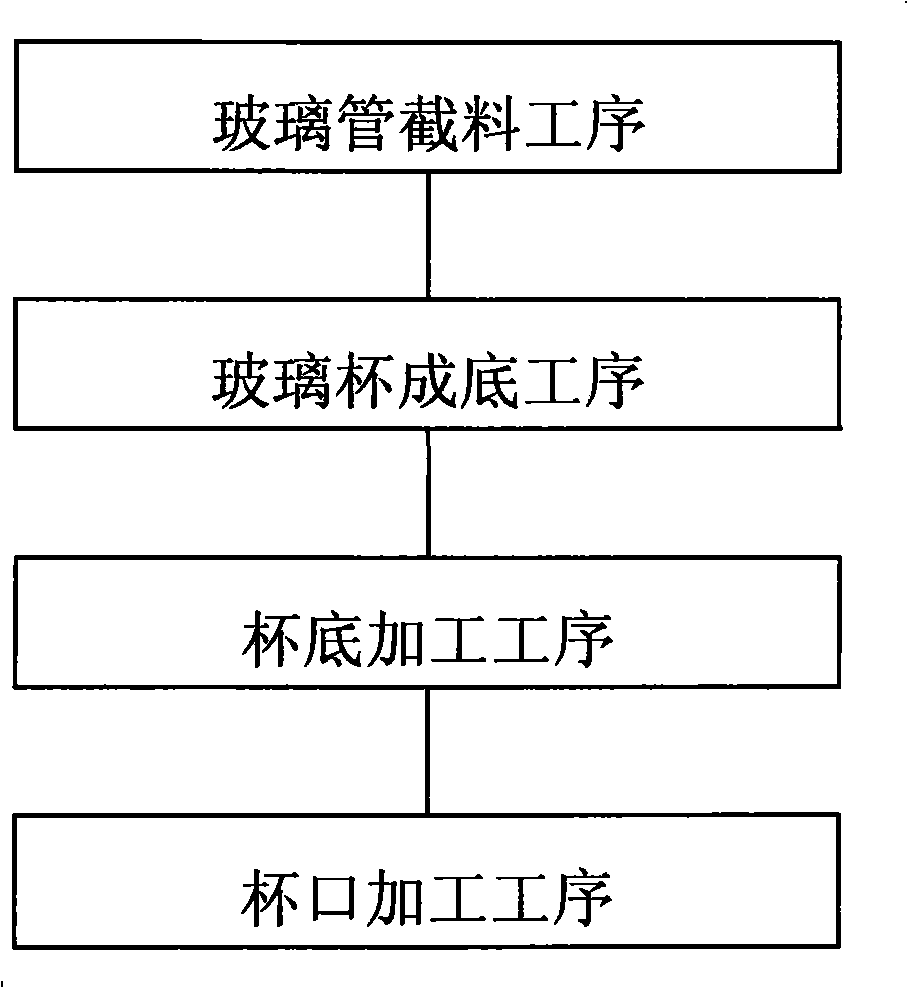

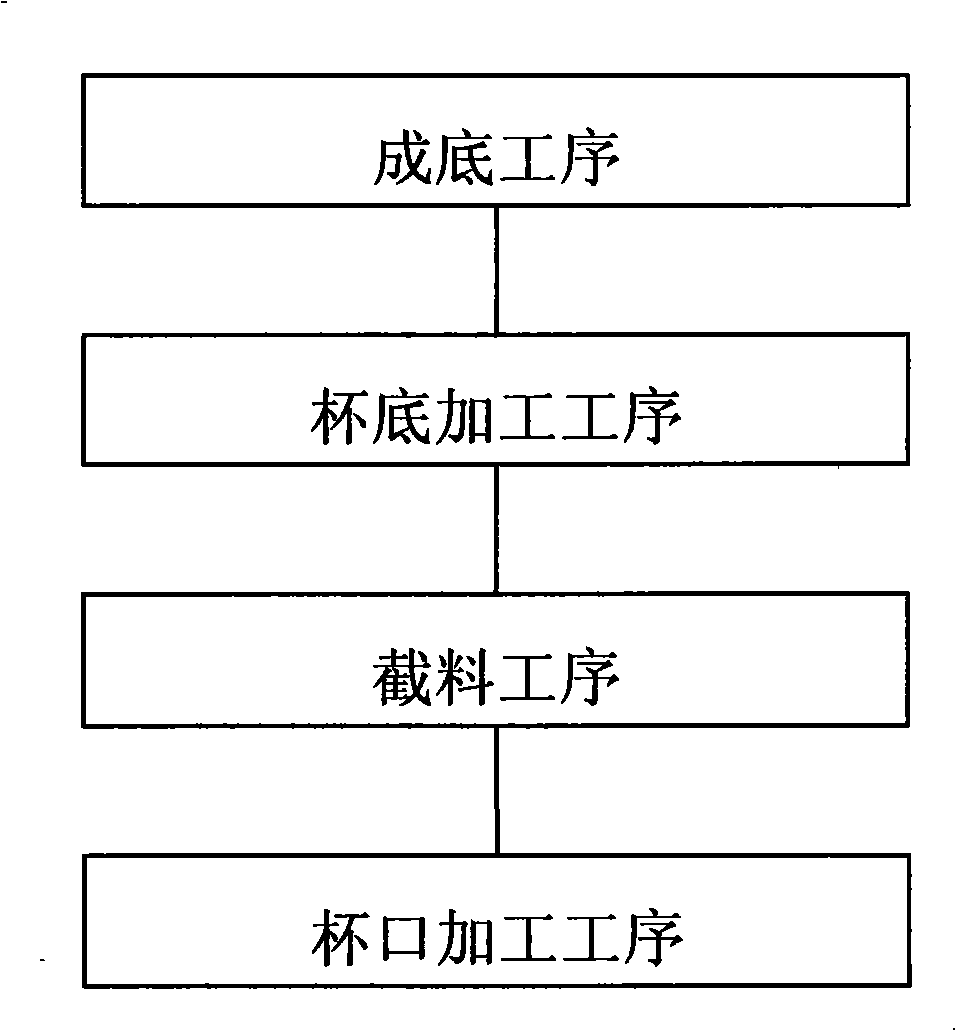

Method for preparing single layer glass by glass tube

InactiveCN101357820AGood light transparencyImprove yieldGlass reforming apparatusGlass productionCutting glassSoftening

The invention relates to a method for producing a single-layer glass cup by using a glass tube. The method comprises the following steps: A. material cutting process: the glass tube is cut into the glass tube material section with the height which is twice that of the finished glass cup; B. bottom forming process: the both ends of the cut glass tube material are clamped on a rotary device to locally heat the middle part of the tube material till the softening of the glass, a heat-resistant material blade with the thickness which is less than the width of a heating zone and does not have the affinity with the glass is used for cutting the middle part of the heating zone to form blanks of two cup bottoms; C. cup bottom processing process: the cup-shaped glass tube material is clamped on the rotary device, flames are used for heating the bottom part of the glass cup-shaped tube material along the transverse direction at the same time of rotation till the melting of the glass, and the cup bottoms are thickened to meet the design requirements. The method has simple production technology, greatly improved yield, good overall transparency of the cup and no need of polishing. The production efficiency is greatly improved, and the method can be used for large-scale production and family workshop operation. The equipment cost is greatly reduced, and the method can be used for the production by only using a special burning device, thereby eliminating the constraints of a kiln on the production scale and the place.

Owner:郝身峙

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com