Patents

Literature

36results about How to "Avoid easy delamination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

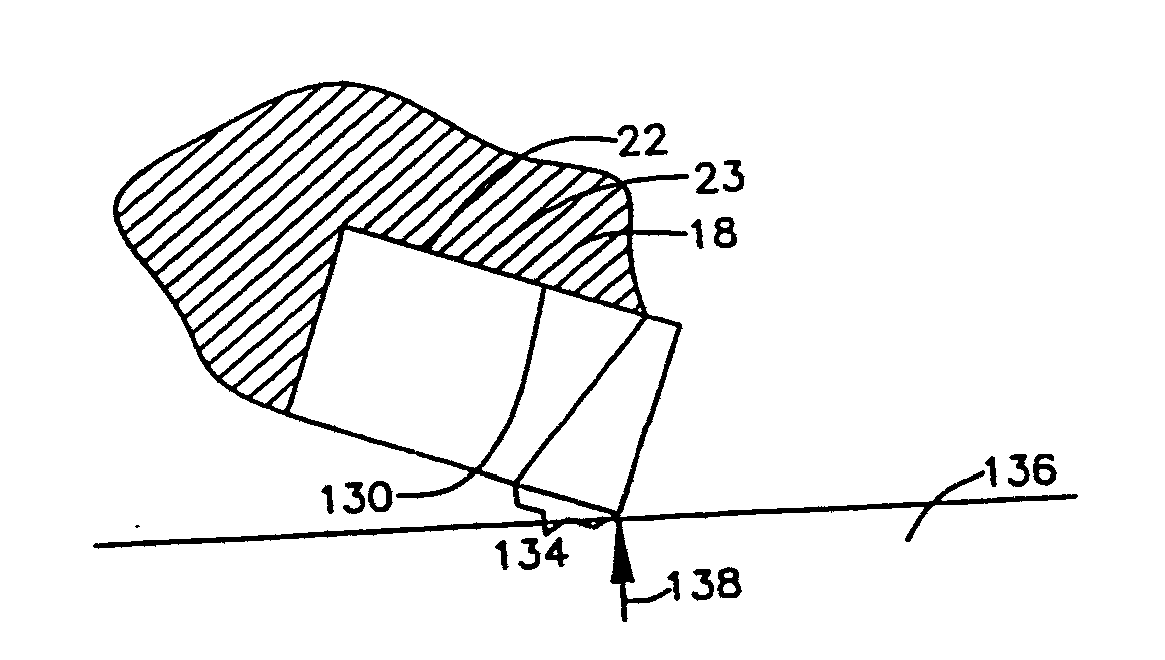

Cutting element

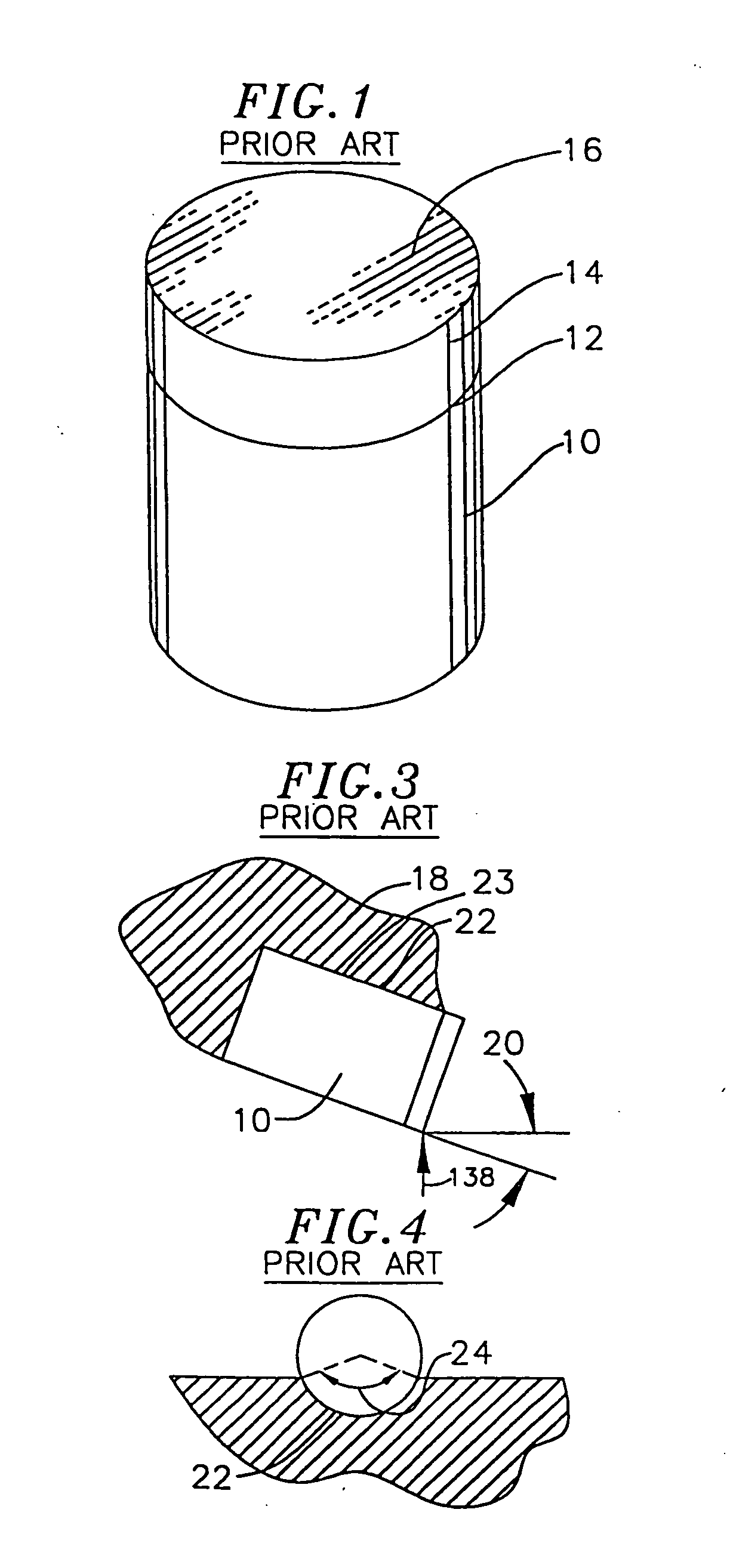

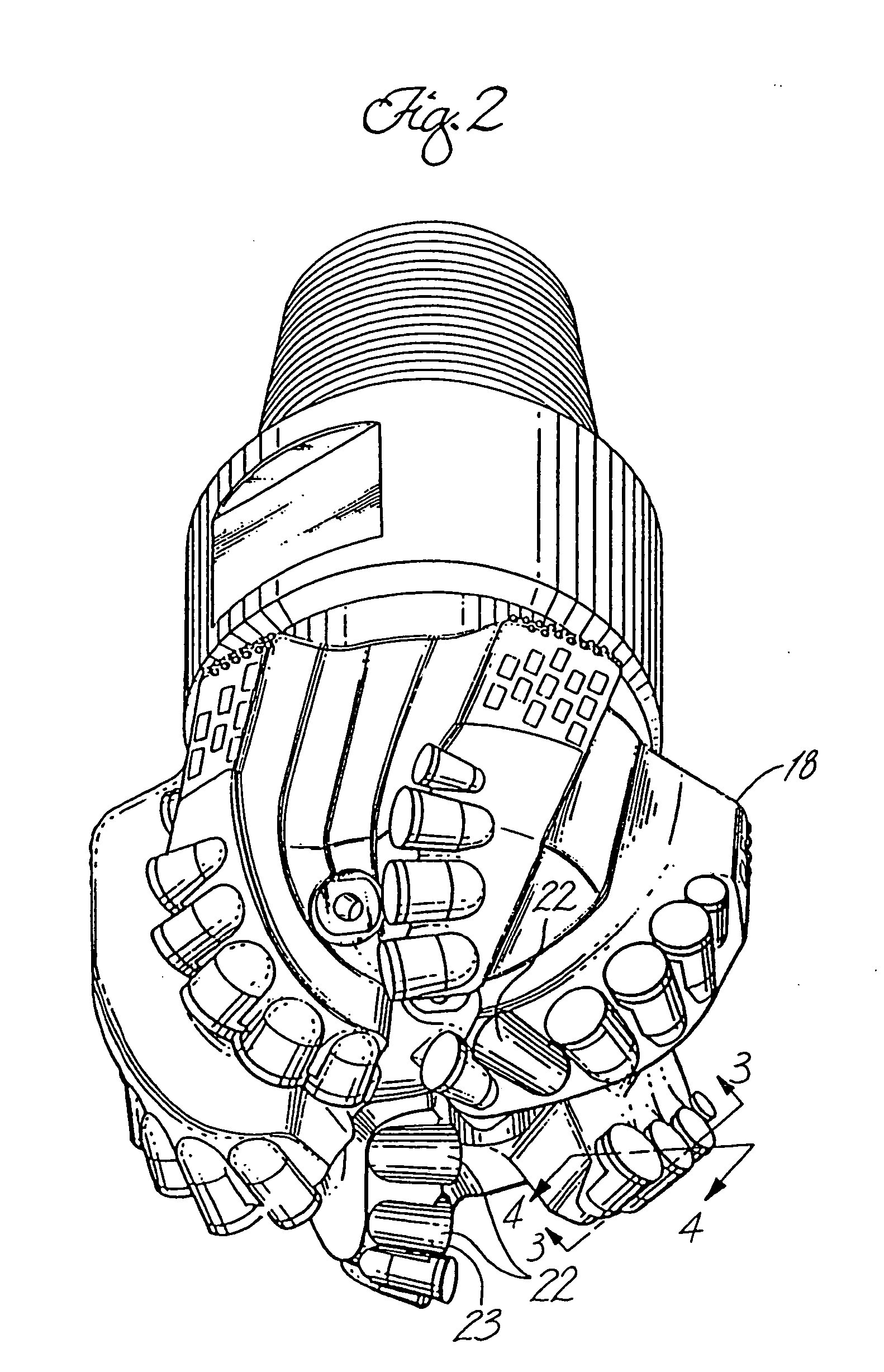

InactiveUS6991049B2Increasing thicknessImprove wear resistance and fatigue strengthDrill bitsConstructionsBiomedical engineeringSuperhard material

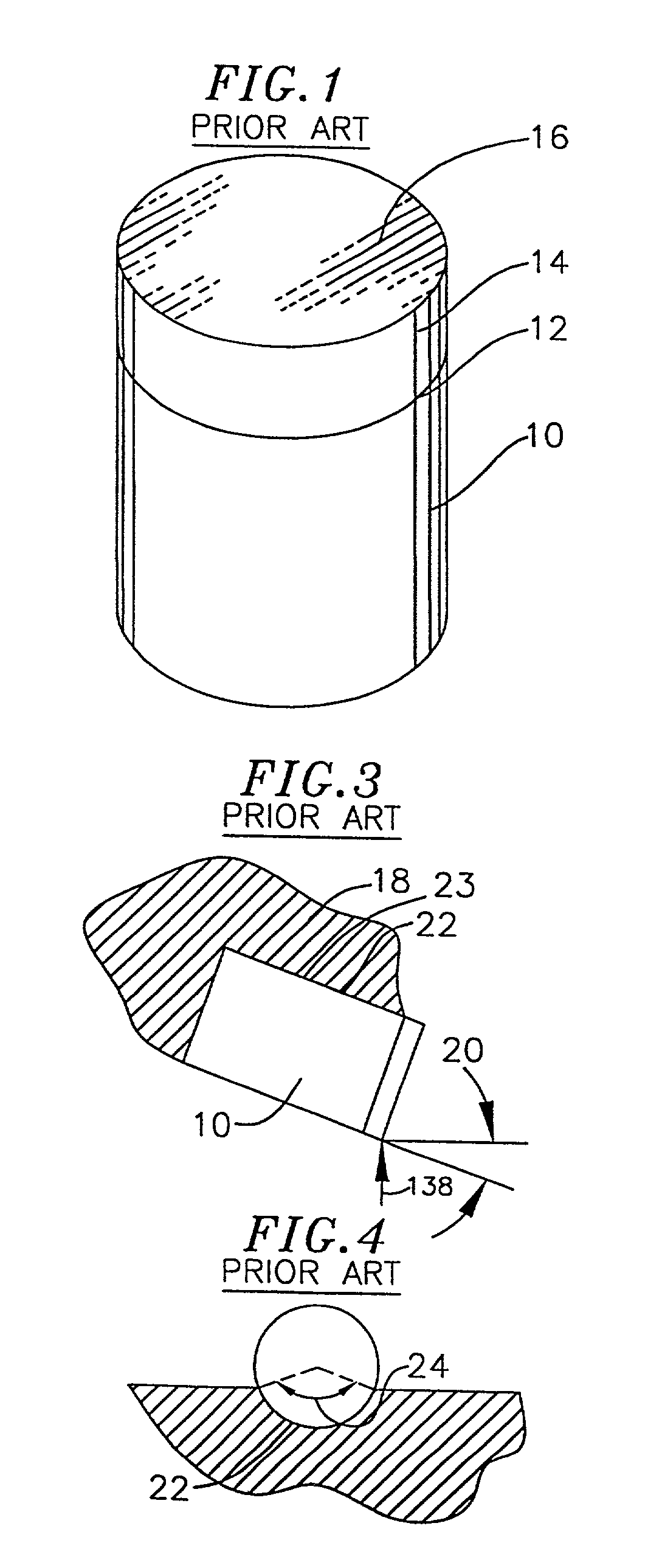

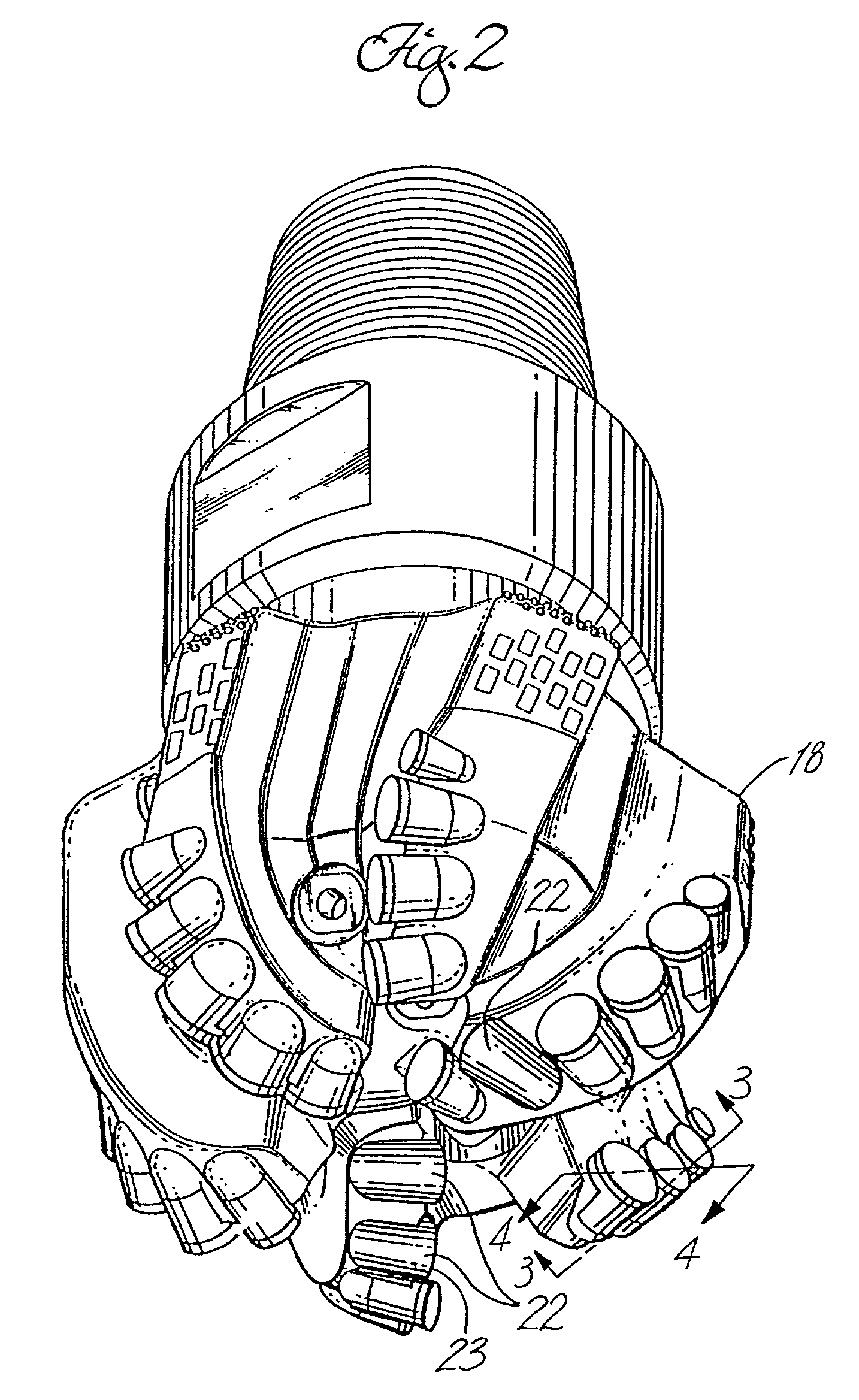

The present invention provides a cutting element having a cylindrical body having a canted end face on which is formed an ultra hard material layer and a method of forming the same. One or a plurality of transition layers may be provided between the ultra hard material layer and the cutting element body.

Owner:SMITH INT INC

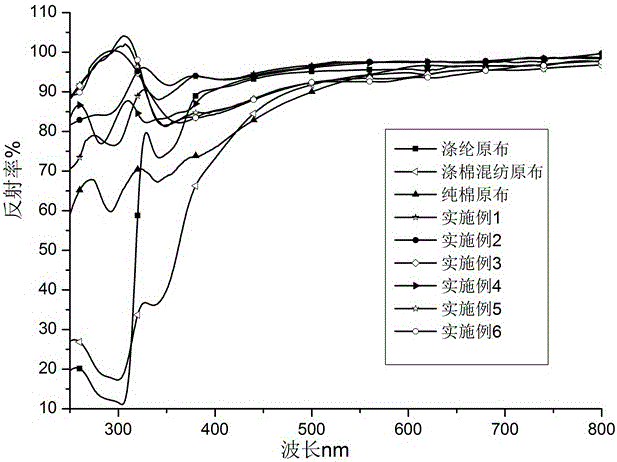

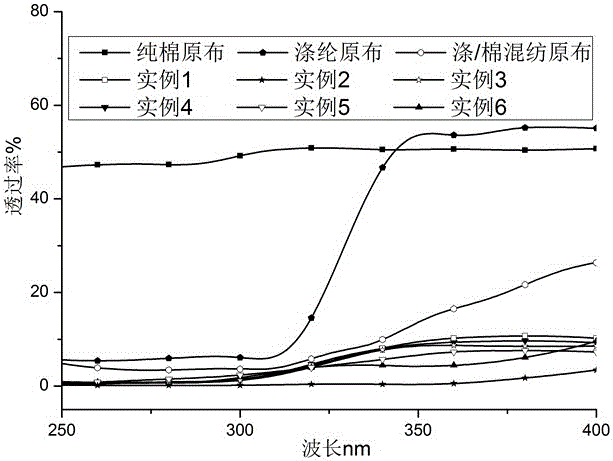

White printing paste, preparation method and application of white printing paste

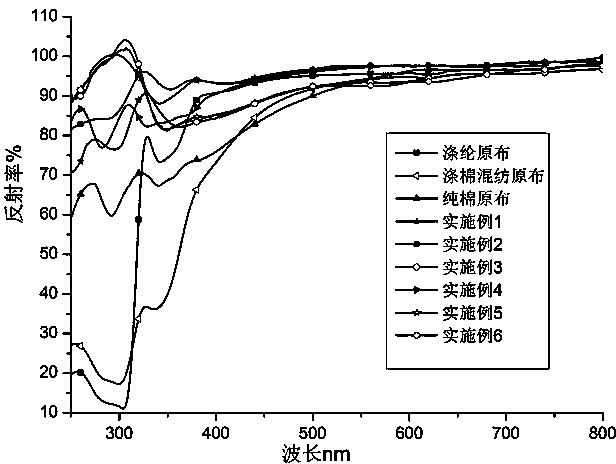

The invention discloses white printing paste, a preparation method and application of white printing paste. The white printing paste comprises the following components in parts by weight: 1 to 20 parts of white pigment, 2 to 5 parts of a thickening agent, 5 to 30 parts of an adhesive, 0.1 to 2 parts of a dispersing agent, and 43 to 91.9 parts of deionized water. The preparation method comprises the following steps: adding the dispersing agent and white pigment to deionized water under normal temperature; oscillating to uniformly disperse the pigment; then adding the thickening agent and the adhesive; agitating to obtain white printing paste; uniformly printing the white printing paste to a base fabric through a screen printing machine; preliminarily drying and then drying again; and then performing standard water washing to obtain snow pretending protective fabrics. According to the white printing paste and the preparation method, the printing technique is simple, the process is short; and the printed fabrics have snow pretending and ultrasonic proofing effects, and are also outstanding in wearability.

Owner:ZHEJIANG SCI-TECH UNIV +1

High-thermal-conductivity graphite-high silicon aluminium-based composite material and preparation process for same

The invention relates to a high-thermal-conductivity graphite-high silicon aluminium-based composite material and a preparation process for the same. The composite material is composed of, in volume fraction, 10-70% of graphite, 5-30% of silicon, and the balance of aluminium or aluminium alloy. The preparation process comprises the following steps of: (1) uniformly mixing graphite powder and silicon powder to obtain mixed powder; (2) placing the mixed powder in a heat treatment furnace, and performing vacuum hot-pressing sintering to form a precast block; (3) placing the sintered precast block in a die and preheating, and heating aluminium or aluminium alloy in a crucible until aluminium or aluminium alloy is melted; (4) pouring an aluminium melt or aluminium alloy melt in the die; (5) applying an axial pressure by a hydraulic machine, and enabling the aluminium melt or aluminium alloy melt to infiltrate in pores in the precast block; and (6) cooling and releasing the die, and taking out the composite material. Compared with the prior art, the composite material obtained by the preparation process disclosed by the invention is low in density and cost, and has the characteristics of low expansibility, high thermal conductivity and the like simultaneously.

Owner:SHANGHAI JIAO TONG UNIV

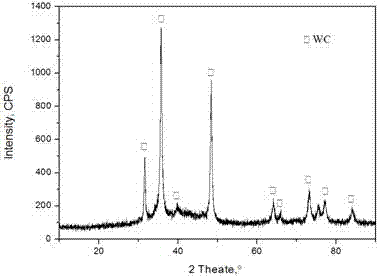

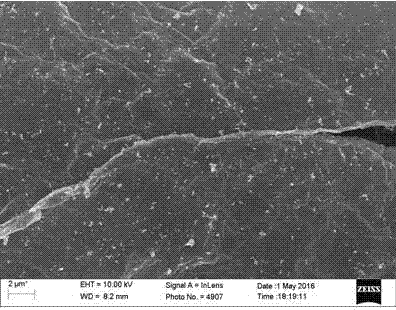

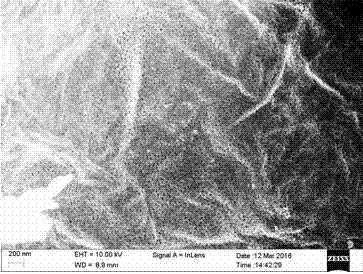

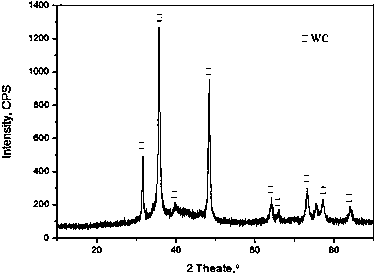

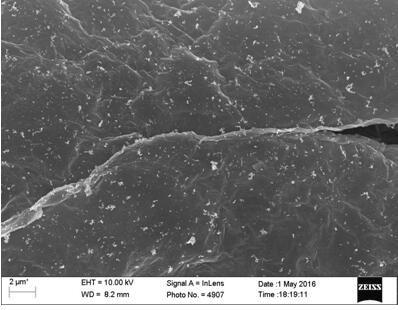

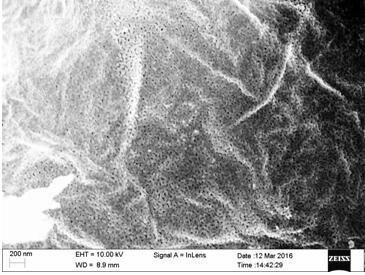

Modified-graphene-containing tungsten carbide spraying powder used for preparing self-lubricating abrasion-resistant coating

ActiveCN107350470AWeight increasePrevent oxidative denaturationMolten spray coatingTransportation and packagingThermal sprayingAlcohol

The invention provides modified-graphene-containing tungsten carbide spraying powder used for preparing a self-lubricating abrasion-resistant coating. A method comprises the following steps that (1) a certain amount of a modified graphene / nano tungsten carbide composite is weighed and mixed with a certain amount of absolute ethyl alcohol, and a mixed solution of a graphene / nano tungsten carbide composite is obtained after ultrasonic dispersion; (2) a certain amount of tungsten carbide / cobalt spraying powder is weighed and added into the mixed solution of the graphene nano tungsten carbide composite; (3) modified graphene composited tungsten carbide / cobalt spraying powder is obtained through a vacuum freeze drying method; and (4) the modified graphene composited tungsten carbide / cobalt self-lubricating abrasion-resistant coating is prepared on the surface of a part subjected to cleaning and sand blasting through a thermal spraying process. According to the modified-graphene-containing tungsten carbide spraying powder, the layered single-layer carbon structure characteristics of graphene are reserved, the proportion of the graphene is increased through grown nano carbide particles, and in addition, losses of the graphene caused by ball milling or other powder mixing processes can be avoided through the freeze drying method.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

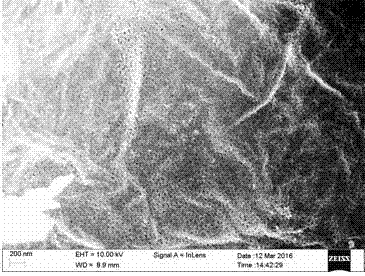

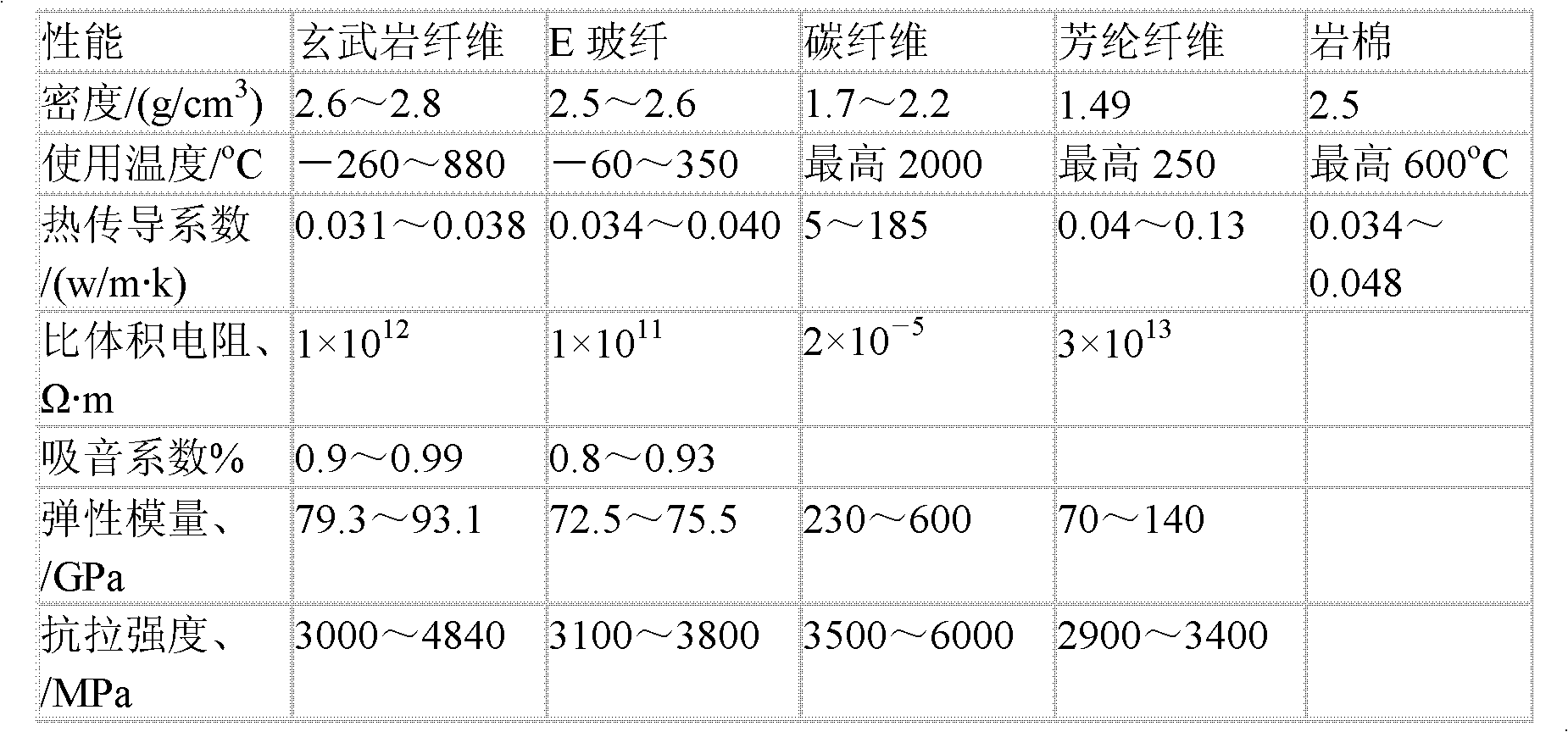

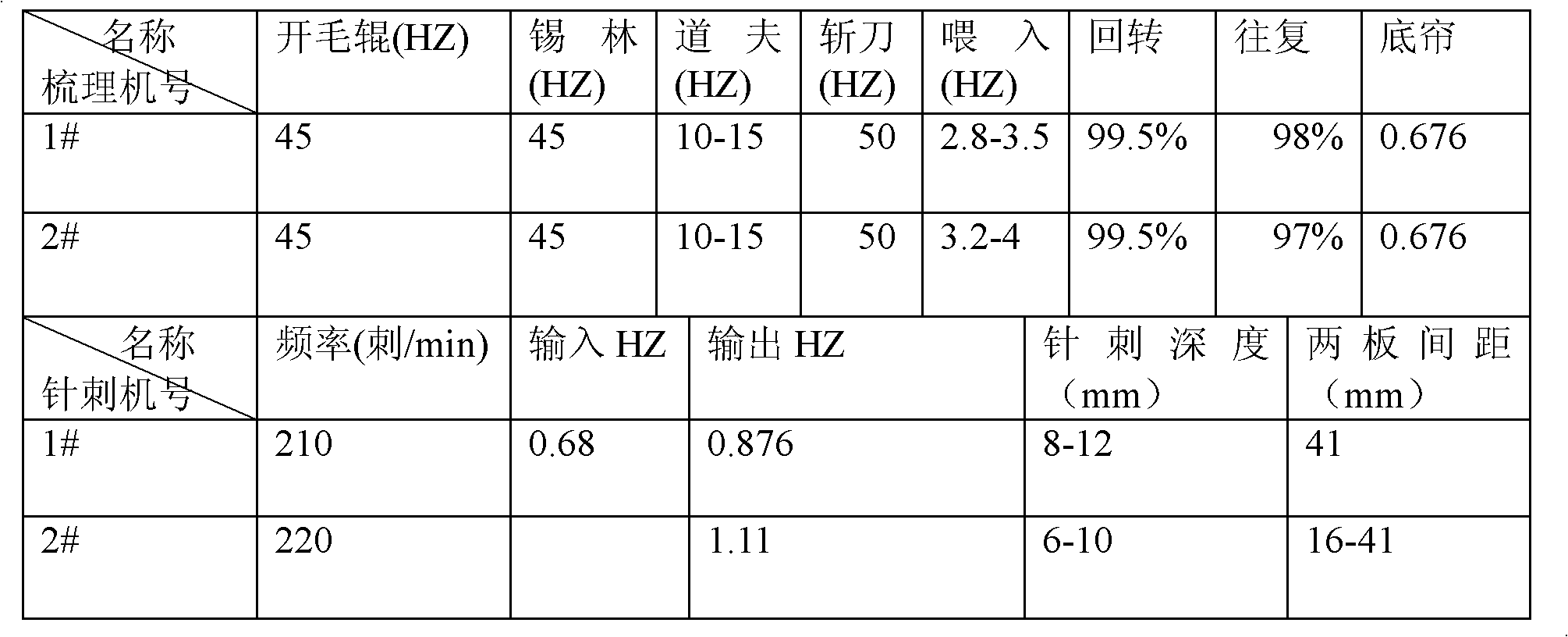

Basalt needling thermal insulation material and manufacturing process thereof

InactiveCN102505344AAvoid damageSolve the problem of no pulling force when the net is outNon-woven fabricsBreaking strengthYarn

The invention relates to a basalt needling thermal insulation material and a manufacturing process thereof, belonging to the technical field of thermal insulation materials. The basalt needling thermal insulation material is prepared from basalt chopped yarns with the lengths of 5-7 cm and 8-12 cm through the processes of mixing, opening, carding, lapping and needling, wherein the basalt chopped yarn with the length of 5-7 cm is 70-80% of the total weight of the material, and the basalt chopped yarn with the length of 8-12 cm is 20-30% of the total weight of the material. The novel basalt needling thermal insulation material provided by the invention is wider in temperature application range and higher in breaking strength.

Owner:SHANDONG XINLI ENVIRONMENTAL PROTECTION MATERIAL

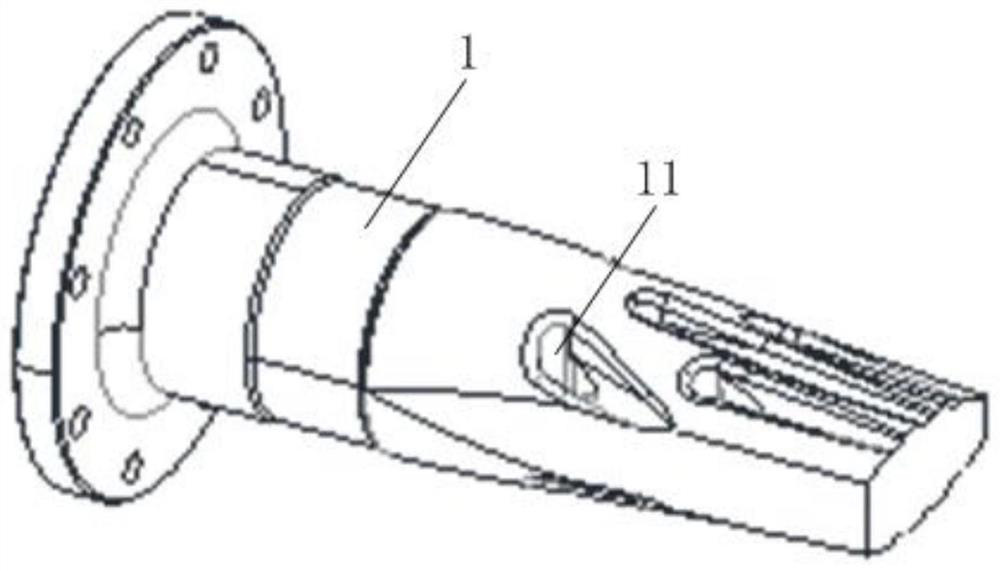

Method for forming cutting elements

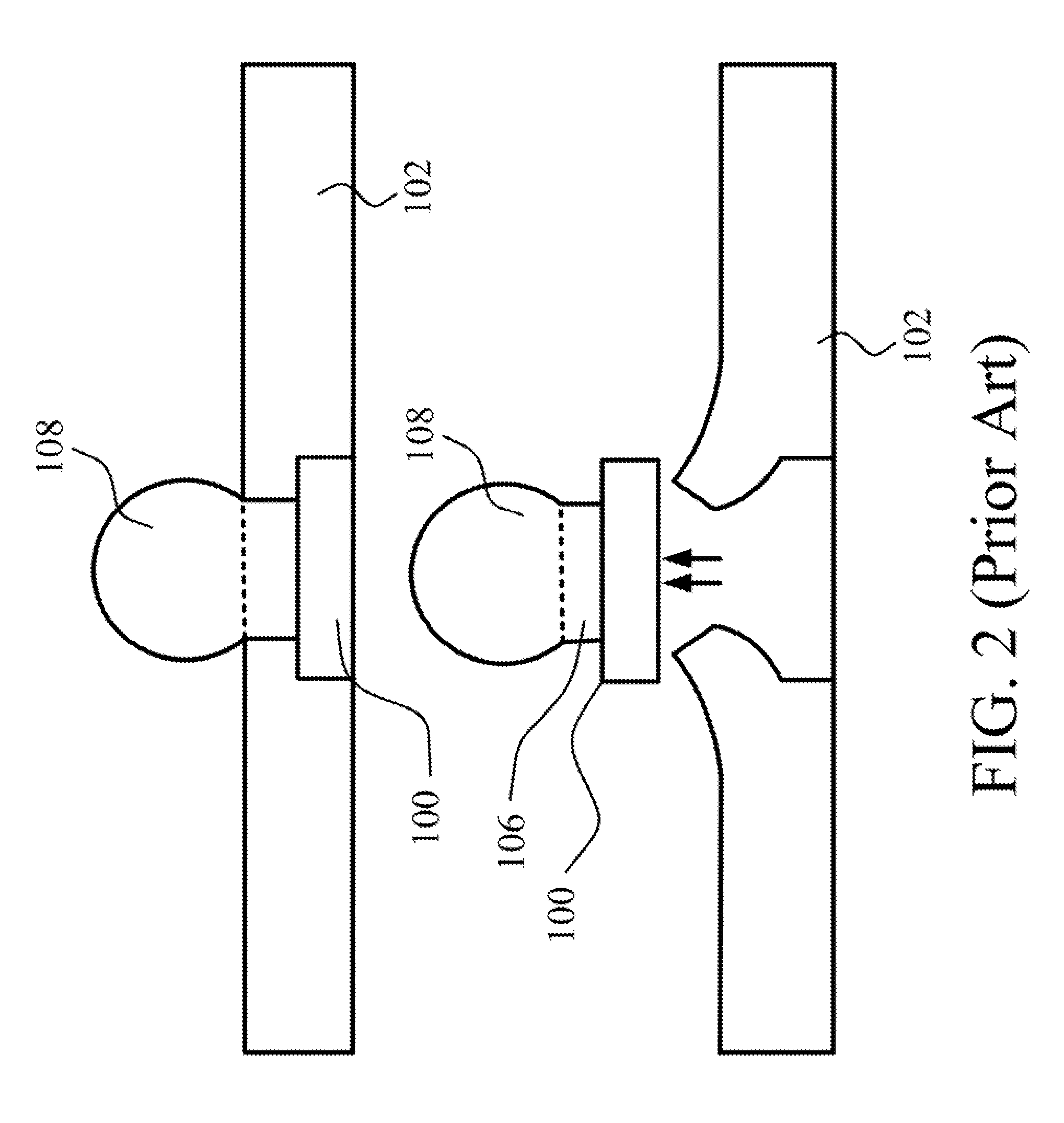

InactiveUS20060054363A1Increasing the thicknessAvoid easy delaminationDrill bitsConstructionsSuperhard materialEngineering

The present invention provides a cutting element having a cylindrical body having a canted end face on which is formed an ultra hard material layer and a method of forming the same. One or a plurality of transition layers may be provided between the ultra hard material layer and the cutting element body.

Owner:SMITH INT INC

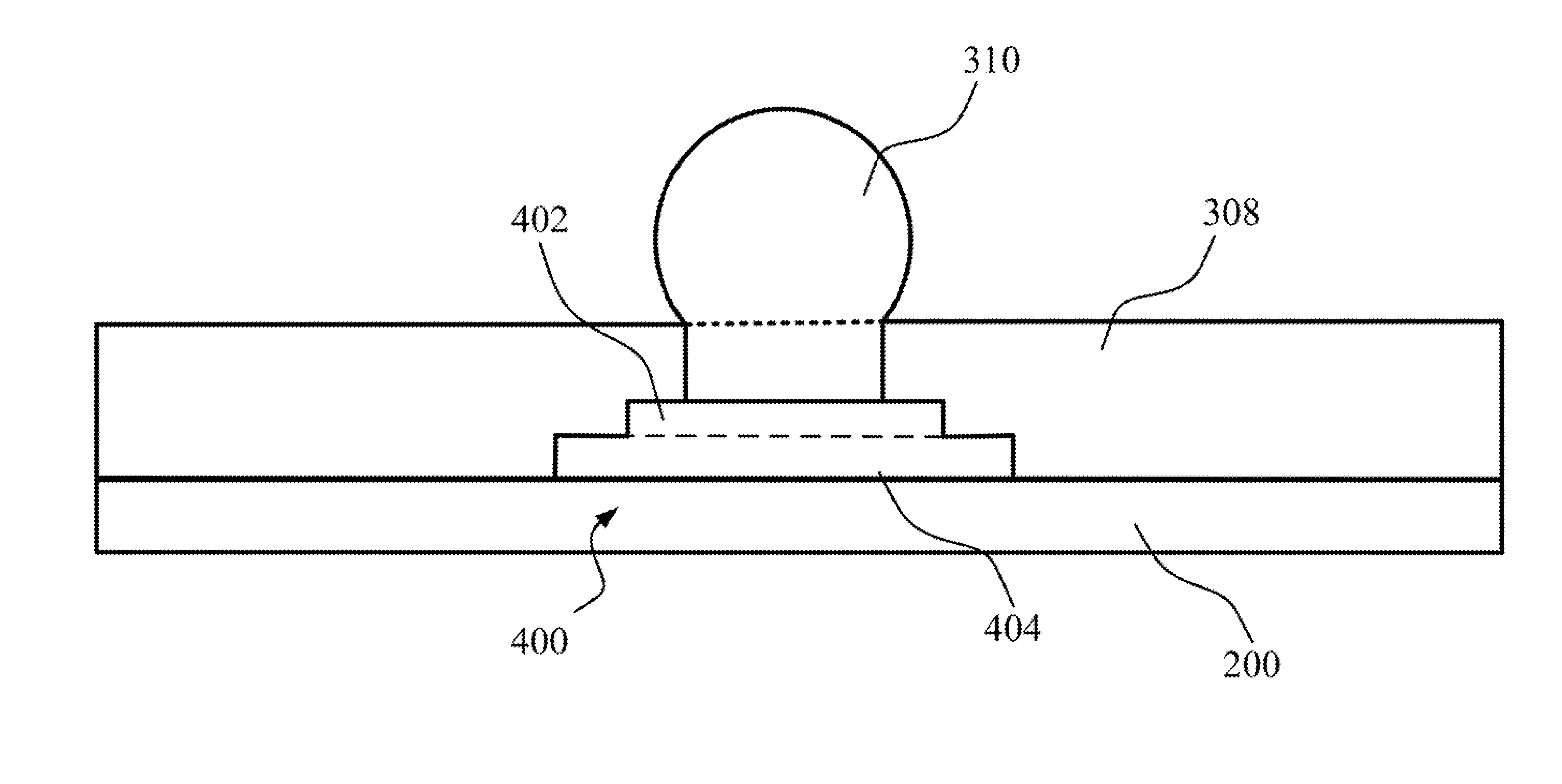

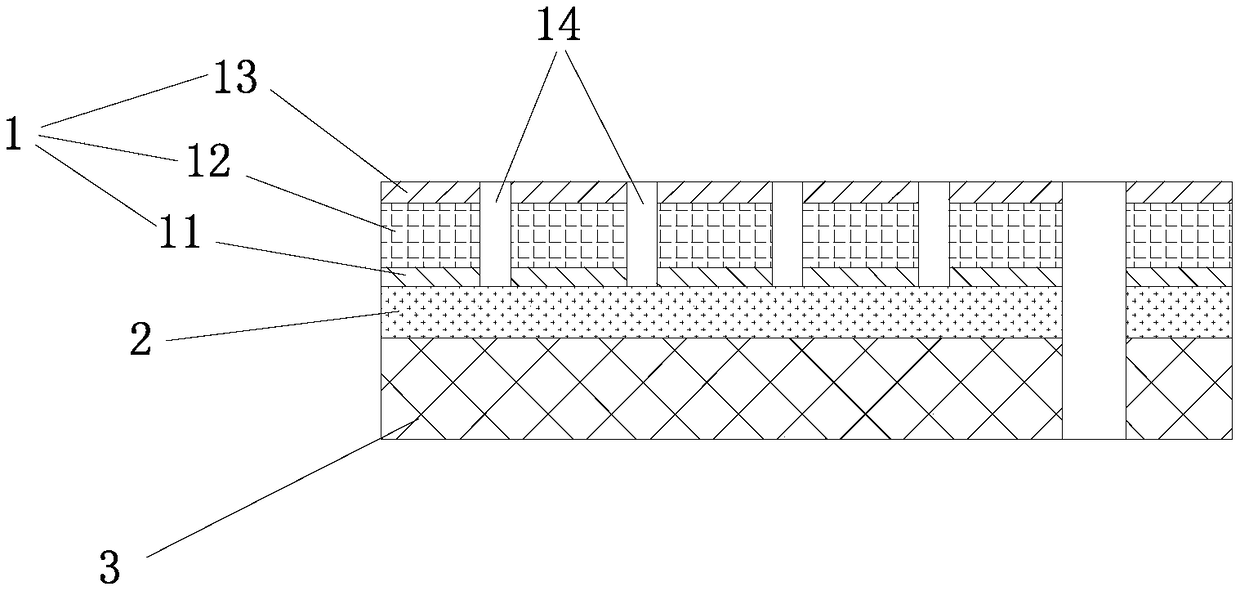

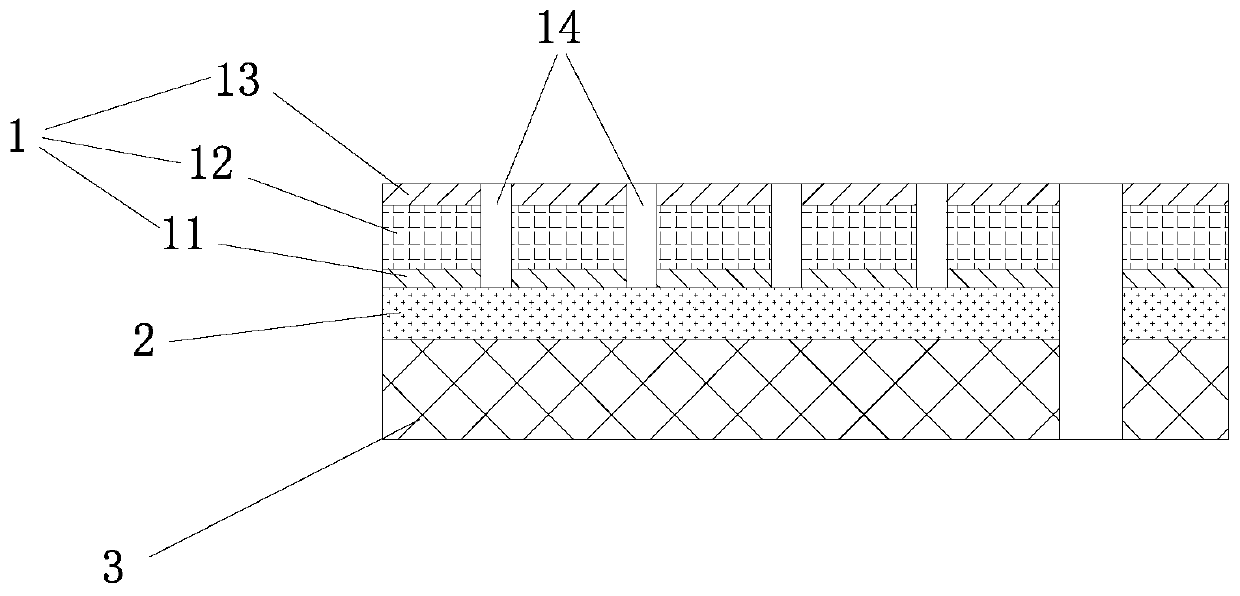

Metal structure of flexible multi-layer substrate and manufacturing method thereof

ActiveUS20110088929A1Avoid easy delaminationAvoid easy separationSemiconductor/solid-state device detailsSolid-state devicesOptoelectronicsMetal

Disclosed is a metal structure of a multi-layer substrate, comprising a first metal layer and a dielectric layer. The first metal layer has an embedded base and a main body positioned on the embedded base. The base area of the embedded base is larger than the base area of the main body. After the dielectric layer covers the main body and the embedded base, the dielectric layer is opened at the specific position of the first metal layer for connecting the first metal layer with a second metal layer above the dielectric layer. When the metal structure is employed as a pad or a metal line of the flexible multi-layer substrate according to the present invention, the metal structure cannot easily be delaminated or separated from the contacted dielectric layer. Therefore, a higher reliability for the flexible multi-layer substrate can be achieved.

Owner:PRINCO CORP

Twice-mallard-reaction-type chicken-flavor material, as well as formulation and preparation method thereof

InactiveCN107549764AThe formula is rich and easy to obtainLow costFood scienceYolkMonosodium glutamate

The invention relates to a twice-mallard-reaction-type chicken-flavor material, as well as a formulation and a preparation method thereof, and belongs to the field of foods. The formula of the twice-mallard-reaction-type chicken-flavor material comprises L-cysteine, vitamin B1, DL-methionine, glucose, chicken oil, phosphoric acid, chicken meal, yolk meal, onions, gingers, peppers, a yeast extract,edible salt, monosodium glutamate, sugar, disodium 5'-ribonucleotide, denatured starch, and xanthan gum. The formula is rich in ingredients; and the ingredients are easy to obtain, and relatively lowin costs. And the ingredients have relatively good effects under the proportion of the formula. The preparation method of the twice-mallard-reaction-type chicken-flavor material comprises the following steps of mixing main raw materials with a reaction base for the first mallard reaction according to the formula; carrying out first mallard reaction so as to obtain a primary flavoring material; mixing auxiliary materials with the primary flavoring material, and carrying out homogenization so as to obtain the twice-mallard-reaction-type chicken-flavor material. The preparation method is simple,rapid, safe, and healthy; moreover, the processes can be easily controlled so that inter-batch differences of products can be effectively reduced. The twice-mallard-reaction-type chicken-flavor material prepared by the preparation method is small in heat-sensitive substance loss, high in flavor substance content, and strong in sense of hierarchy and fidelity.

Owner:四川丁点儿食品开发股份有限公司

Preparation method for graphene modified thermal spraying powder of heat-indicating thermal barrier coating

InactiveCN107400843AWeight increasePrevent oxidative denaturationMolten spray coatingTransportation and packagingNano compositesThermal spraying

The invention provides a preparation method for modified-graphene-containing tungsten carbide spraying powder of a self-lubricating and wear-resisting coating. The preparation method comprises steps as follows: 1), a certain quantity of modified graphite / tungsten carbide nano-composites are weighed and mixed with a certain amount of absolute ethyl alcohol, and after ultrasonic dispersion, a mixed solution of a graphite / tungsten carbide nano-composite is obtained; 2), a certain amount of tungsten carbide / cobalt spraying powder is weighed and added to the mixed solution of the graphite / tungsten carbide nano-composite; 3), tungsten carbide / cobalt spraying powder composited with modified graphene is obtained with a vacuum freeze drying method; 4), a tungsten carbide / cobalt self-lubricating and wear-resisting coating composited with modified graphene is prepared with a thermal spraying technology on the surface of a part after cleaning and sand blasting. According to the preparation method, characteristics of a laminated single-layer carbonaceous structure of graphene are reserved, a ratio of graphene is further increased by growing carbide nano-particles, and besides, with the adoption of the freeze drying method, loss of graphene due to ball milling or other powder mixing technologies can be avoided.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Double-layer one-side copper-based circuit board making process

ActiveCN108617095AIncrease the pressure cushioning forceAvoid oil lossNon-metallic protective coating applicationSolder maskInternal layer

The invention discloses a double-layer one-side copper-based circuit board making process comprising the following steps: baking a FR4 board, obtaining an internal layer line on the FR4 board, and silkprinting a solder mask on the internal layer line; stacking a plurality of slots and / or vias on a copper base, and placing a high temperature glue film or release film below slot / via on the copper base; laminating the FR4 board, a bonding sheet and the copper base at a high temperature; drilling blind holes on the FR4 board, electroplating copper on the FR4 board and etching same, thus obtainingan external layer line. The high temperature glue film or release film are placed on hollow positions before lamination, thus increasing lamination buffer force, and effectively preventing the soldermask from dropping oil under ununiform lamination of the board; the process can prevent the circuit board from layering and foaming via the board baking and pad high temperature lamination; a dry filmof 45-55 um is selected so as to fully cover the blind holes, thus preventing blind hole broken caused by developing and etching, and preventing the copper layer from being broken.

Owner:ZHUHAI KINGROAD ELECTRONICS

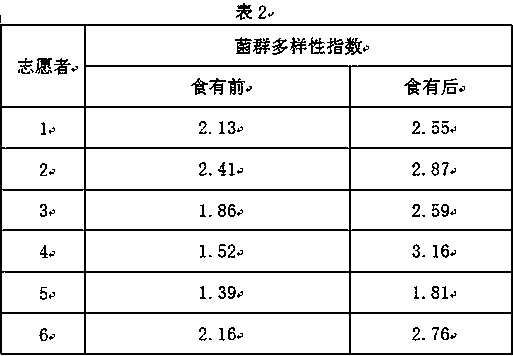

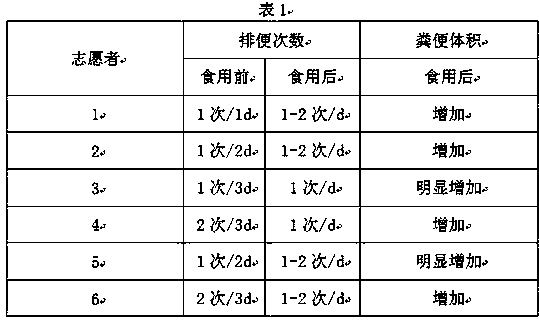

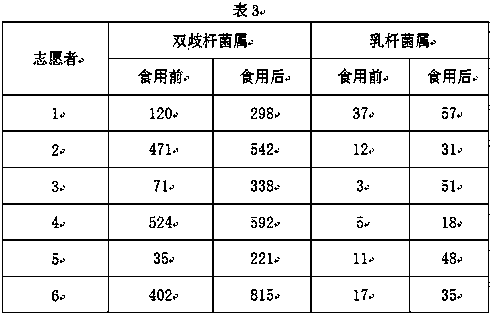

Flaxseed liquid preparation for relaxing bowels and proliferating probiotics and preparation method thereof

InactiveCN110179086AGood for healthImprove the ecological environmentFood mechanical treatmentFood ingredient functionsVitamin CIntestinal peristalsis

The invention discloses a flaxseed liquid preparation for relaxing bowels and proliferating probiotics. The flaxseed liquid preparation is prepared from the following raw materials: flaxseed hull andkernel mixed granules, vitamin C, prebiotics, and pure water. The invention further discloses a preparation method of the flaxseed hull and kernel mixed granules and a preparation method of the liquid preparation. The liquid preparation is good in mouthfeel and less liable to stratify, loss of nutritional components is avoided, the growth and reproduction of the prebiotics are promoted, intestinal peristalsis is promoted, and the preparation is easily absorbed by a human body.

Owner:浙江中科中创健康科技有限公司

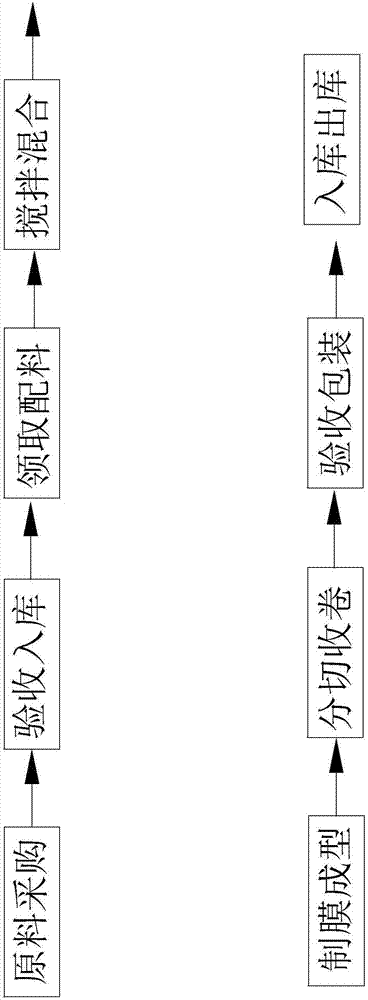

Base membrane of medical dental towel and preparation method thereof

ActiveCN106928526AAvoid easy delaminationImprove composite qualityFlat articlesCoatingsAdditive ingredientToilet paper

The invention provides a base membrane of a medical dental towel and a preparation method thereof. The base membrane of the medical dental towel comprises the following components in percentage by mass: 40-50% of PE particles 7042, 15-25% of PE particles 1C7A, 6-14% of PE particles 2020H, 15-25% of PE particles 8008, 4-7% of an additive 265 and 2-5% of an additive 78CB. The preparation method of the base membrane of the medical dental towel comprises the following steps: A) purchasing the raw materials; B) inspecting prior to stocking; C) getting ingredients; D) stirring and mixing; E) preparing the membrane and forming the same; F) slitting and rolling; G) inspecting and packaging; and H) putting in storage and removing from storage. The process difficulty is reduced when the base membrane and toilet paper are compounded, no glue needs to be used, and released layers are avoided in follow-up use, so that the quality of the finished product is improved.

Owner:浙江麦普拉科技股份有限公司

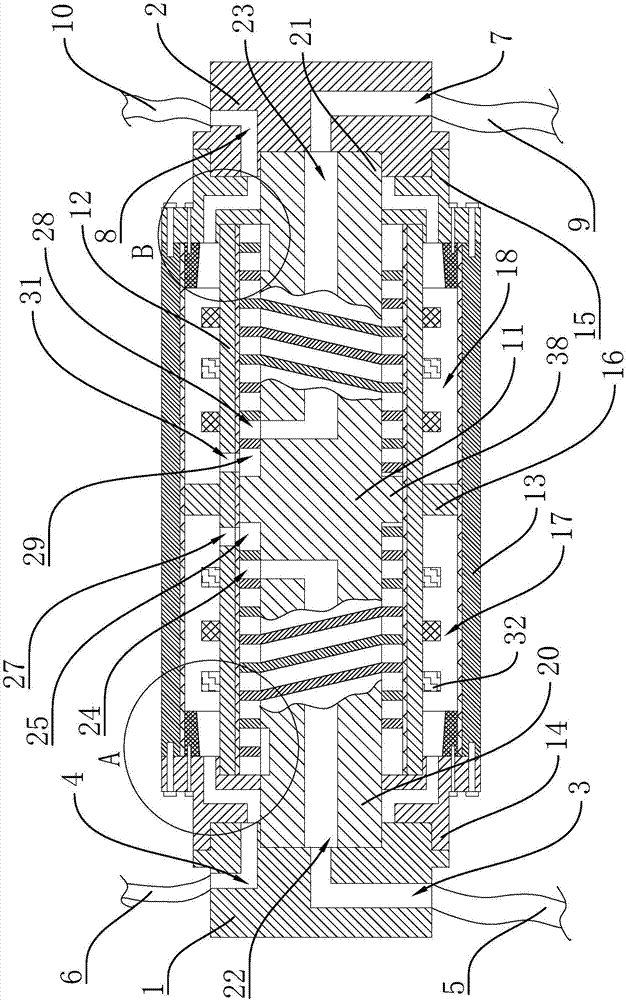

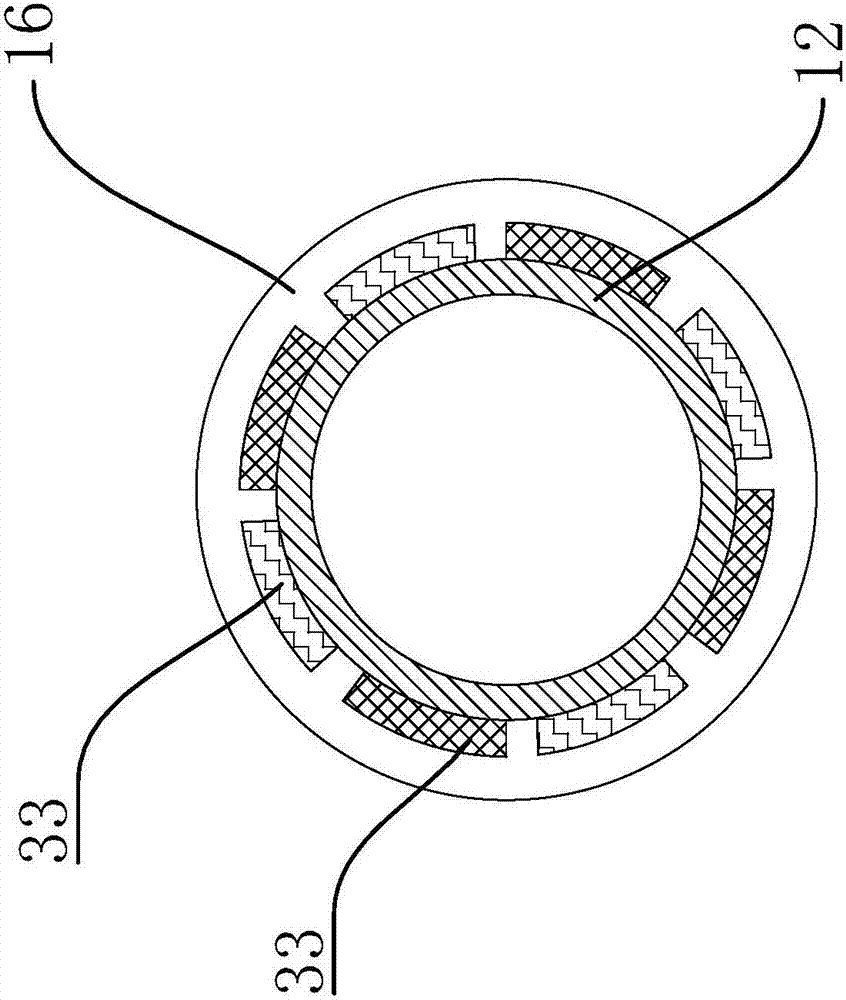

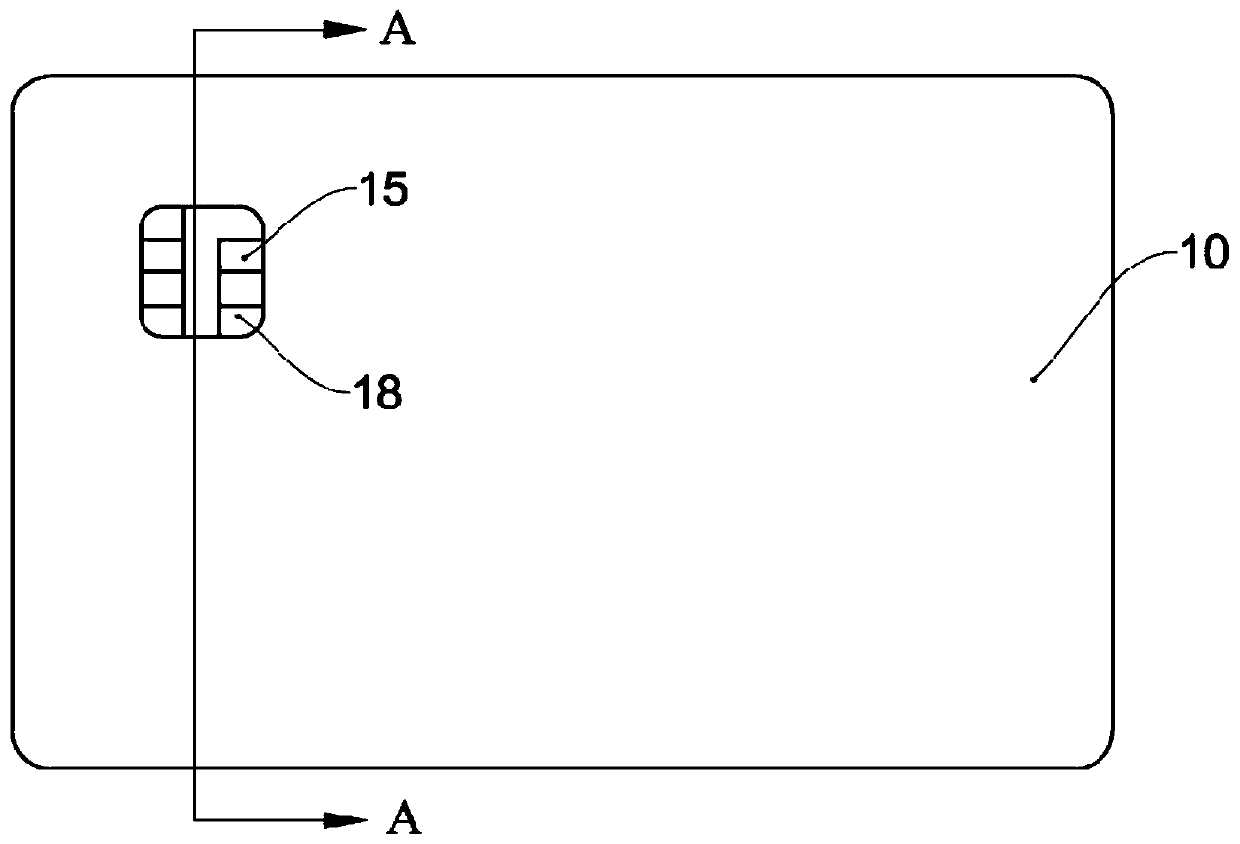

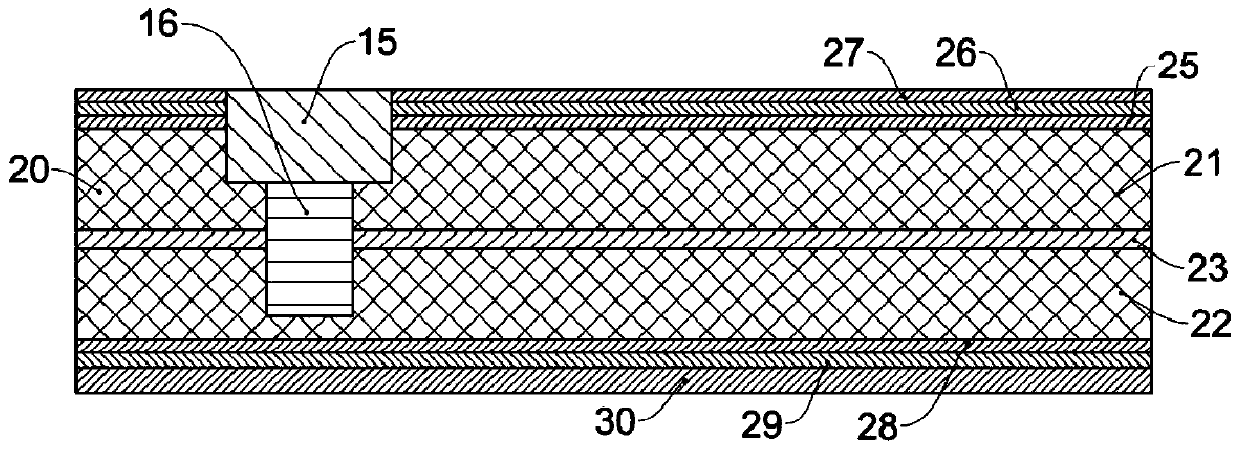

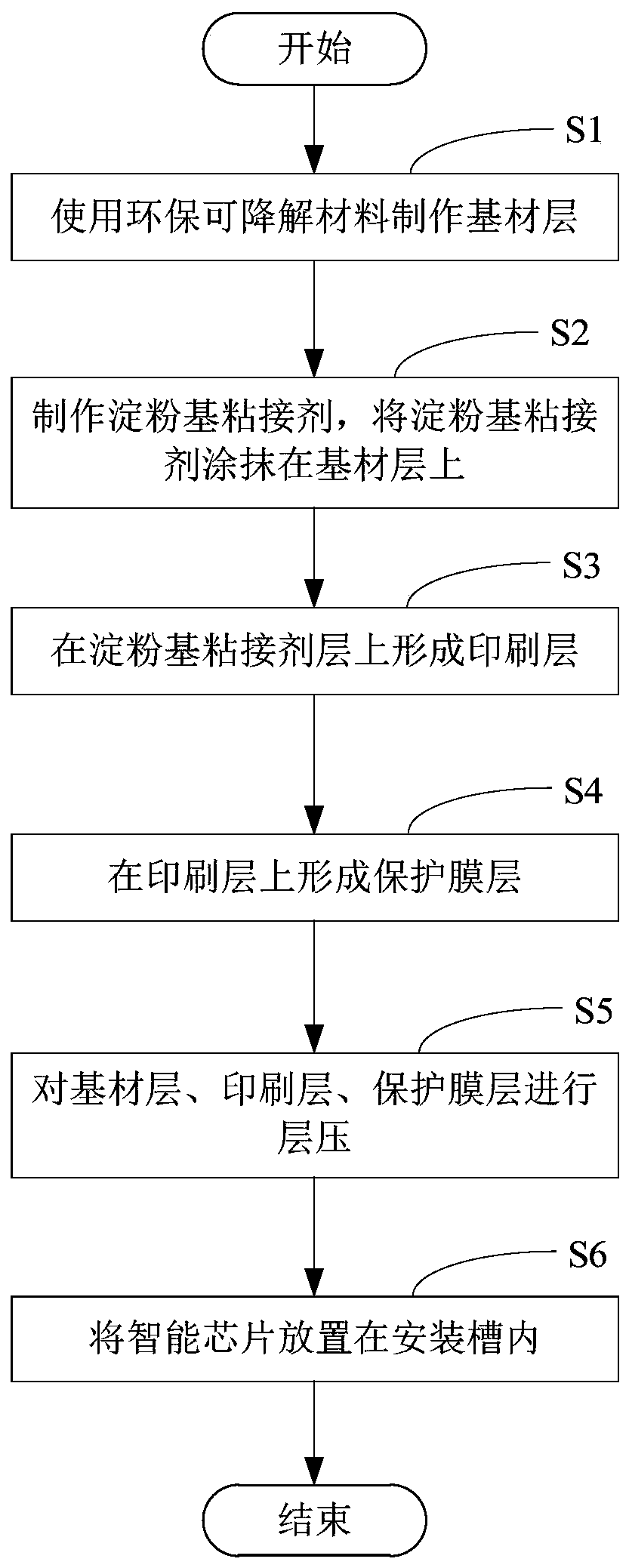

Environment-friendly degradable intelligent card and manufacturing method thereof

PendingCN110909851ABiodegradableNon-toxic and harmlessRecord carriers used with machinesAdhesivePrinting ink

The invention provides an environment-friendly degradable intelligent card and a manufacturing method thereof. The intelligent card comprises a base material layer, an intelligent chip is embedded inthe base material layer, a printing layer is formed on one surface of the base material layer, and the base material layer is made of a degradable material; the base material layer comprises two or more base material sub-layers, and every two adjacent base material sub-layers are bonded through a preset adhesive; and / or the printing layer is adhered to the surface of the base material layer through a preset adhesive. The method comprises the steps that a degradable material is used for manufacturing a base material layer, and a mounting groove is formed in the base material layer; one surfaceof the base material layer is coated with a preset adhesive, ink is printed on the surface coated with the preset adhesive to form a printing layer, and after the base material layer and the printinglayer are laminated, the intelligent chip is installed in the installation groove. The card base of the intelligent card is made of the environment-friendly degradable material, the intelligent card can be naturally degraded after being scrapped, and pollution to the environment is avoided.

Owner:GOLDPAC GRP LTD

A kind of white printing paste and its preparation method and application

The invention discloses a white printing paste, its preparation method and application. The white printing slurry is 1-20 parts of white pigment by weight, 2-5 parts of thickener, 5-30 parts of binder, 0.1-2 parts of dispersant and 43-91.9 parts of deionized water; Add dispersant and white pigment to deionized water, shake to disperse the pigment evenly; then add thickener and binder and stir to make white printing paste; then pass the white printing paste through the screen printing machine to print evenly The base fabric is prebaked and then baked, and the snow camouflage protective fabric is prepared through standard water washing. The printing process of the invention is simple and the process is short, and the printed fabric not only has the functions of snow camouflage and ultraviolet protection, but also has good wearing performance.

Owner:ZHEJIANG SCI-TECH UNIV +1

Preparation method of chemically modified asphalt

The invention discloses a preparation method of chemically modified asphalt. The method comprises the steps of: adding matrix asphalt into a reactor; adding an initiator 0.05-1wt% of the matrix asphalt; heating to 80-160 DEG C; adding naphthalene vinyl compounds and conjugated olefinic compounds; maintaining the pressure at 0.1-0.4 MPa; reacting for 4-6h; degassing; and filtrating to obtain the modified asphalt. The method for modifying asphalt can endow the produced asphalt with good usage performance, and can effectively improve liquidity at high temperature and flexural performance at low temperature, so as to meet the requirements of highway, bridge and housing on asphalt.

Owner:JURONG NINGWU SCI & TECH DEV

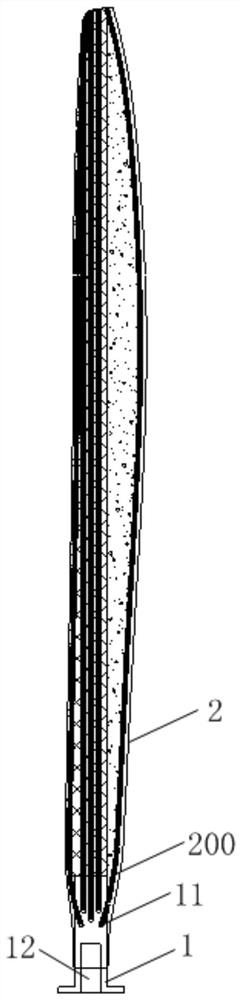

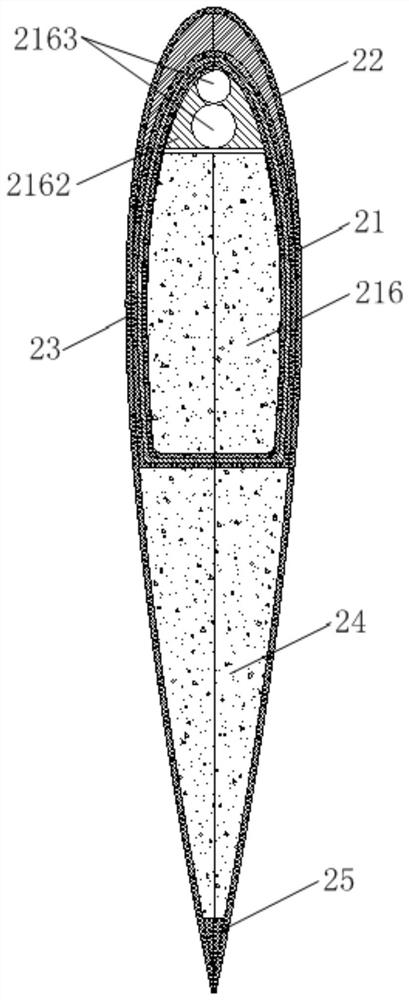

Super-thick polycrystalline diamond composite material, preparing method and application of super-thick polycrystalline diamond composite material

ActiveCN111283205AImprove stabilityExtended service lifeTurbinesOther manufacturing equipments/toolsPolycrystalline diamondAlloy

The invention discloses a super-thick polycrystalline diamond composite material. A polycrystalline diamond layer and a hard alloy matrix are included. The hard alloy matrix is a cobalt containing matrix. The diameter of the polycrystalline diamond composite material is larger than or equal to 30 mm, and the thickness of the polycrystalline diamond layer is larger than or equal to 3 mm. Accordingto a composite material preparing method, the hard alloy matrix and at least one polycrystalline diamond micro powder layer are stacked, when the hard alloy matrix and one polycrystalline diamond micro powder layer are stacked, one face of the polycrystalline diamond micro powder layer makes contact with the hard alloy matrix, and the other face makes contact with a cobalt source layer; when the hard alloy matrix and at least two polycrystalline diamond micro powder layers are stacked, a cobalt source layer is laid between the polycrystalline diamond micro powder layers; and a high-temperatureand high-pressure sintering method is adopted to prepare and obtain a super-thick polycrystalline diamond composite layer. By adoption of the provided technology, the super-thick polycrystalline diamond composite material with abrasion resistance, impact resistance and other performance meeting the requirements can be obtained, and the material can be directly used for cutting, preparing and machining of a tool.

Owner:成都比拓超硬材料有限公司

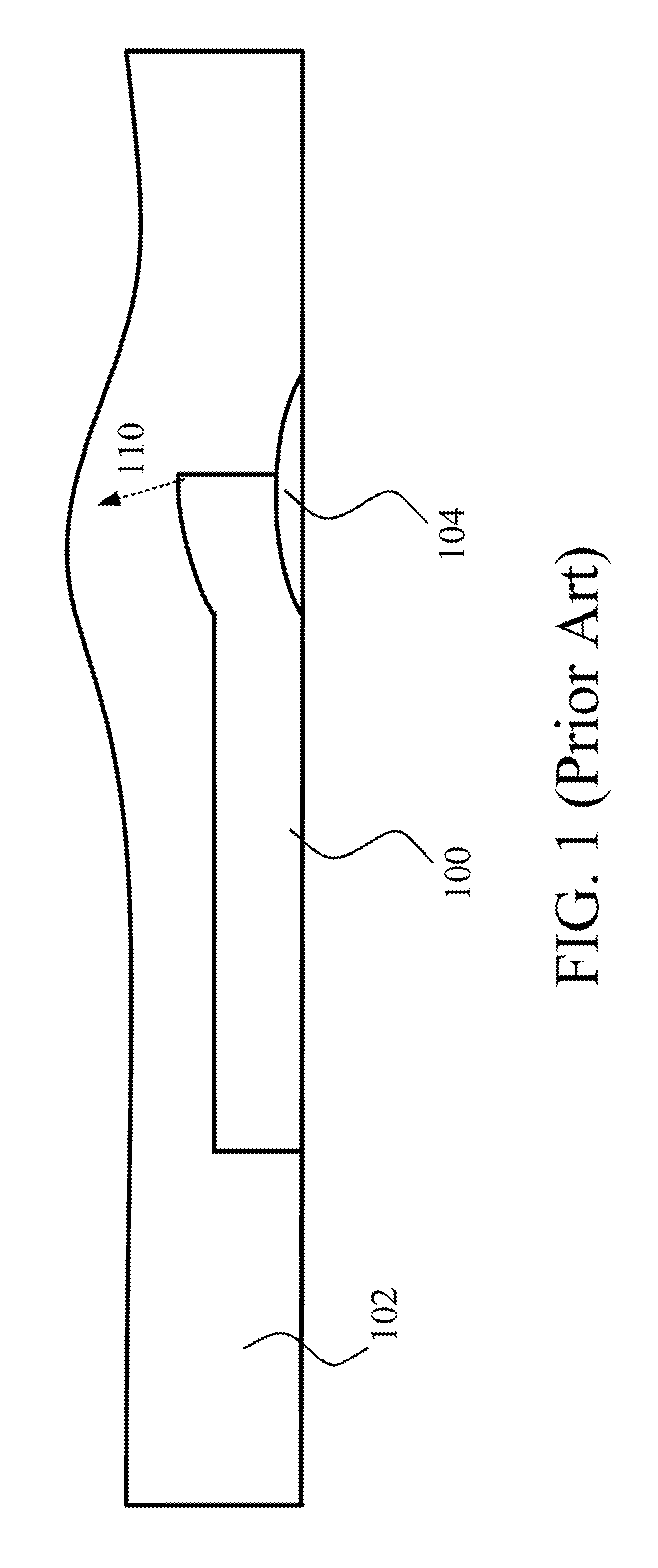

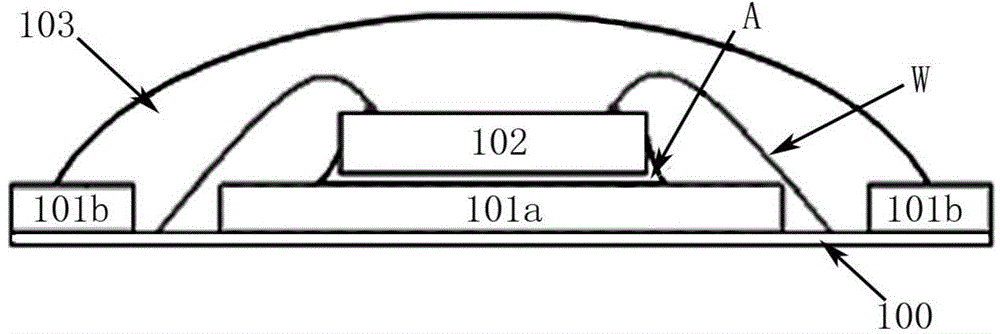

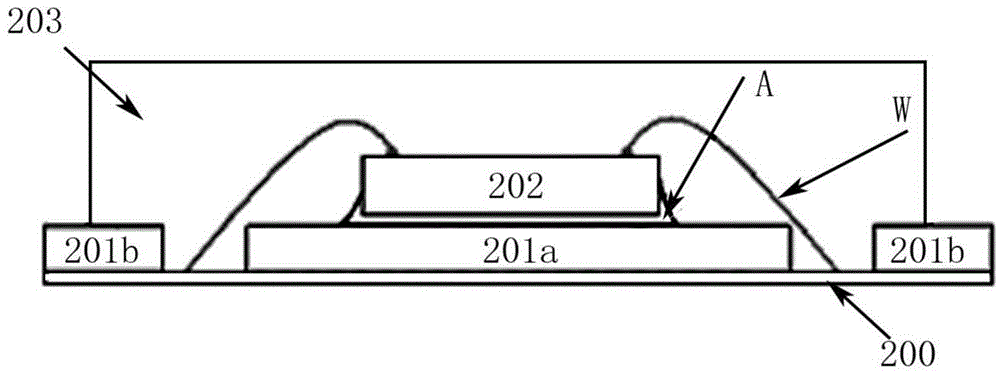

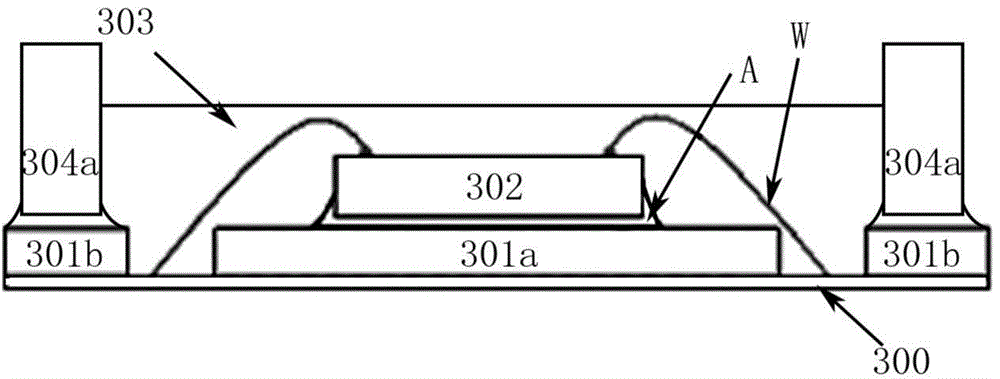

Package and method of manufacturing package

InactiveCN104916593AAvoid easy delaminationEasy to control sizeSemiconductor/solid-state device detailsSolid-state devicesElectrical and Electronics engineering

The invention provides a package and a method of manufacturing the package. The package includes a substrate, a first combining component, a second combining component, a chip, a blocking component and an encapsulation component; the substrate has a first surface and a second surface which backs on to the first surface; a plurality of pads are arranged in the substrate; the first combining component and the second combining component are arranged on the substrate; the second combining component is located around the first combining component; the chip is arranged on the first combining component and is electrically connected with the plurality of pads through leads; the blocking component is arranged on the second combining component; the encapsulation component is arranged at the inner side of the blocking component so as to encapsulate the chip, the first combining component and the leads.

Owner:SAMSUNG SEMICON CHINA RES & DEV +1

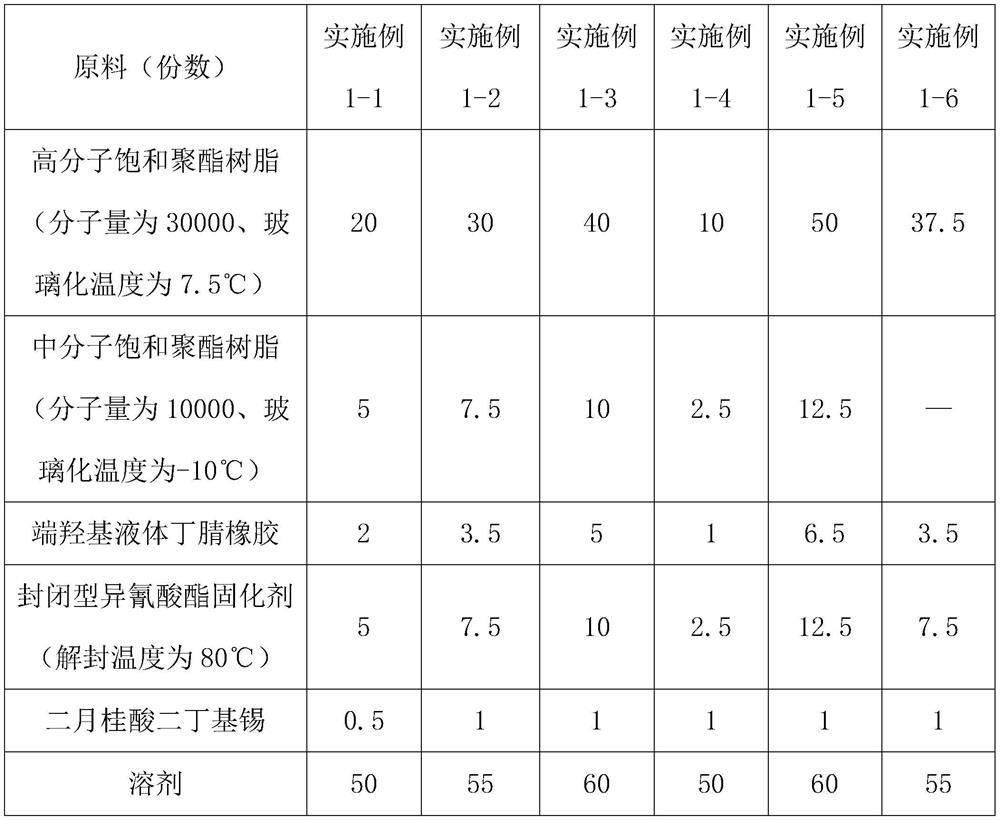

A kind of steel plate coating glue that can be laminated at low temperature and its preparation method and hot melt adhesive film

ActiveCN110467889BImprove heat resistanceAvoid easy delaminationFilm/foil adhesivesRubber derivative adhesivesPolymer sciencePtru catalyst

The invention discloses a low-temperature laminated steel plate coating glue, which comprises the following raw material components in terms of mass parts: 20-40 parts of high-molecular saturated polyester resin, 5-10 parts of medium-molecular saturated polyester resin, 2-5 parts of hydroxyl-terminated liquid nitrile rubber, 5-10 parts of blocked isocyanate curing agent, 0.5-1 part of catalyst and 50-60 parts of solvent, which can be laminated at a low temperature of 160 ° C and have good resistance Heat, to overcome the deficiencies in the prior art. The present invention further proposes a preparation method of the above-mentioned steel plate coating adhesive, which can effectively reduce the loss of heat resistance of the hot melt adhesive in the preparation process, and also proposes a hot melt adhesive film using the above steel plate coating adhesive, which can effectively Avoid delamination of hot melt adhesive film and steel plate.

Owner:广东莱尔新材料科技股份有限公司

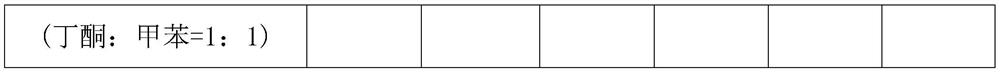

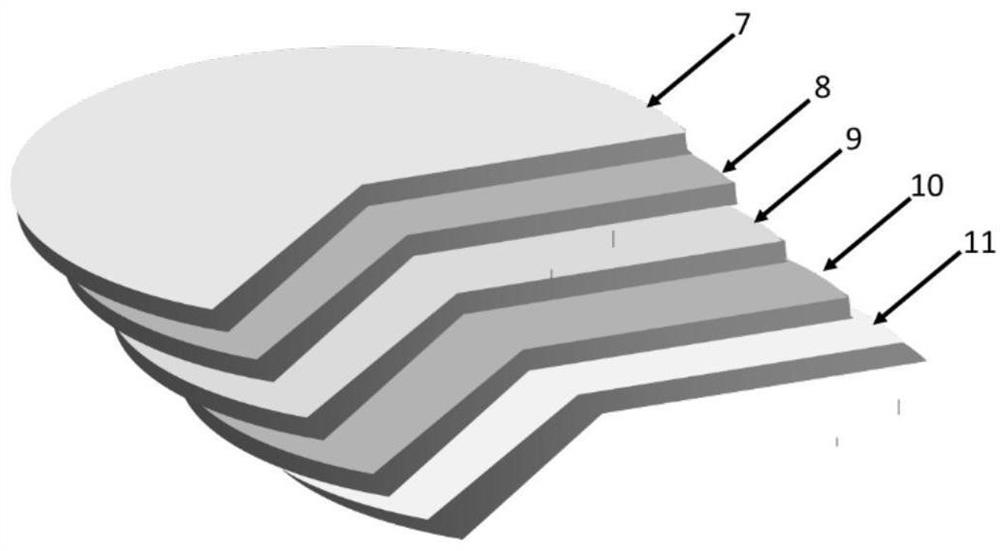

A method of manufacturing a circuit board with stepped grooves

ActiveCN104519665BSimple processAvoid easy delaminationPrinted circuit aspectsPrinted circuit manufactureEngineeringDelamination

Owner:SHENNAN CIRCUITS

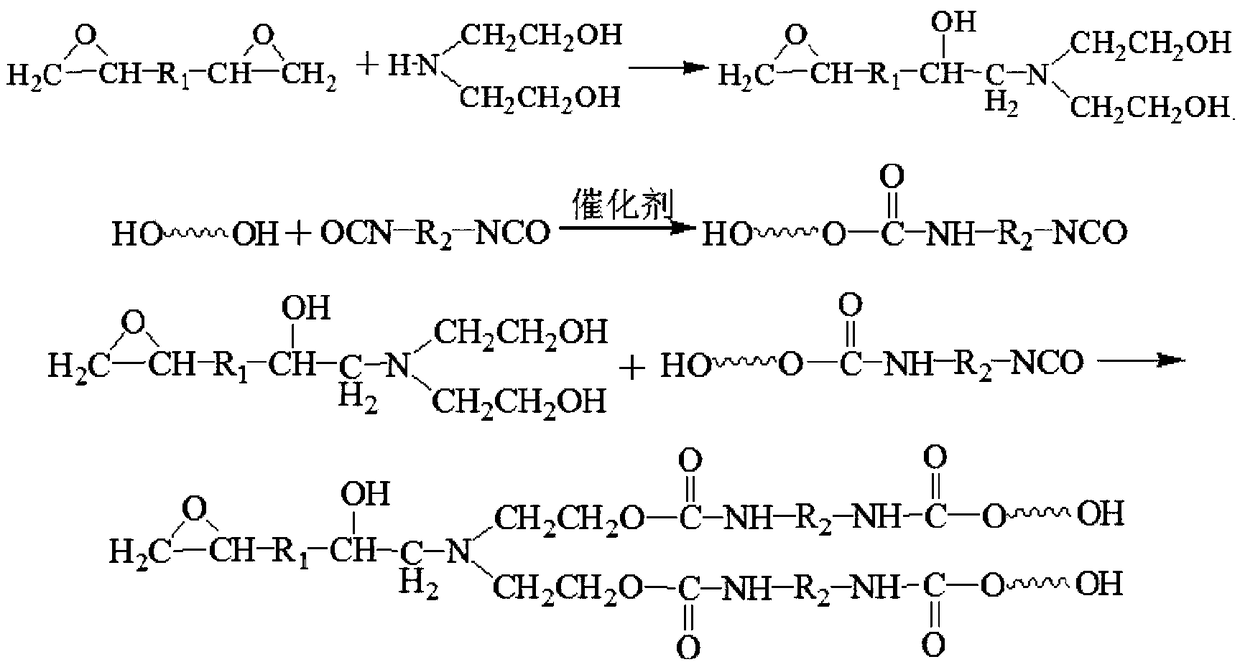

A kind of asphalt emulsifier and preparation method thereof

ActiveCN106496498BImprove surface activityPrevent bitumen from settlingBuilding insulationsPrepolymerIsocyanate

The invention relates to a multifunctional asphalt emulsifier and a preparation method thereof. The preparation method comprises the following specific steps: dissolving bisphenol A with an organic solvent at 40-60 DEG C, slowly dropwise adding diethanolamine, heating to 70-90 DEG C after dropwise addition and reacting for 2-4 h to obtain diethanolamine-modified bisphenol A epoxy resin; adding diisocyanate into polyethylene glycol and a catalyst, reacting at 40-60 DEG C under nitrogen protection for 2-4 h to obtain a polyurethane prepolymer; slowly dropwise adding the above diethanolamine-modified bisphenol A epoxy resin into the polyurethane prepolymer, reacting at 50-70 DEG C for 1-2 h, heating to 70-90 DEG C and reacting for 1-2 h so as to obtain the multifunctional asphalt emulsifier. In comparison with the prior art, the multifunctional asphalt emulsifier is an emulsifier and a modifier. By introducing waterborne epoxy into emulsified asphalt while emulsification, the phenomenon of layering which is easily caused by the step of emulsification before modification is avoided.

Owner:SHANXI PROVINCIAL RES INST OF COMM

Rotary spray paint multi-layer device

The invention belongs to the field of spray head configuration or installation, and particularly discloses a rotary multilayer paint spraying device. The rotary multilayer paint spraying device comprises an air pump, a fixed base, a top-sealed rotary drum and a sealed outer shell. A rotating shaft is connected to the fixed base through threads, the rotating shaft is rotationally connected to the two side walls of the outer shell, and the rotating shaft is provided with a fixture, a power gear and blades. The blades are located in the outer shell. An air inlet pipe is arranged on the outer shell, and an air outlet hole is formed in the outer shell. A gear ring and a spray gun are arranged on the inner wall of the rotary drum. A planetary gear is rotationally connected to the fixed base and located between a power gear and the gear ring, and the planetary gear, the power gear and the gear ring are mutually cooperated. An exhaust hole is formed in the center of the bottom of the rotary drum, one end of the air inlet pipe is connected to the output end of the air pump, the input end of the air pump is connected with the exhaust hole, and the tooth width of the power gear is larger than the tooth width of the planetary gear. The mist paint in the rotary drum is discharged out of the rotary drum through the air pump, and the situation that when entering the rotary drum, a worker inhales the mist paint, and the health of the worker is jeopardized is avoided.

Owner:徐州市旺缘家具有限公司

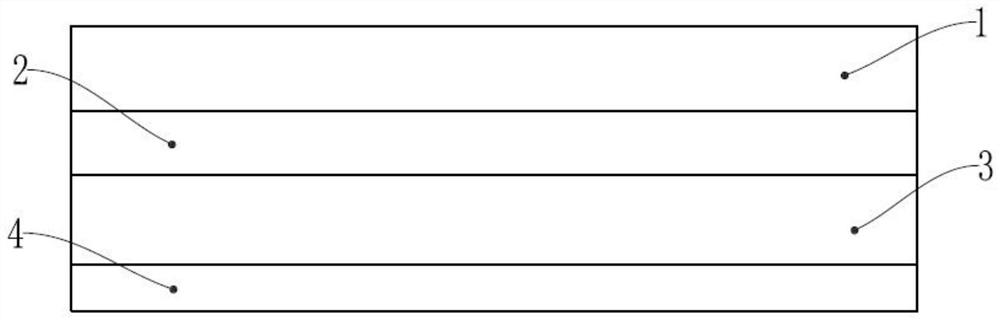

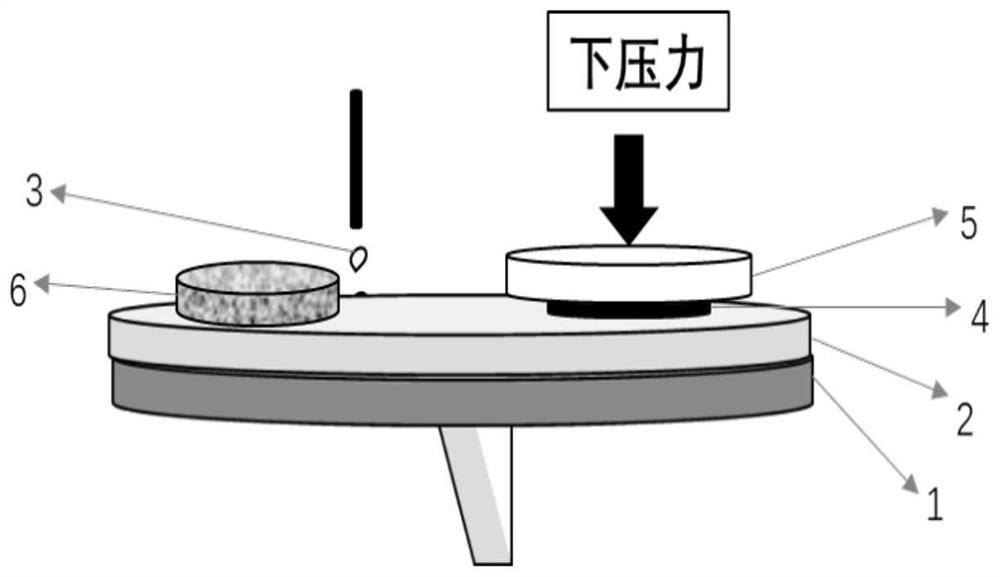

Multi-structure chemical mechanical polishing pad, and manufacturing method and application thereof

ActiveCN112757153AImprove mechanical propertiesGood spreadabilityLaminationLapping machinesPolishingUltimate tensile strength

The invention discloses a multi-structure chemical mechanical polishing pad and a manufacturing method and application thereof. The multi-structure chemical mechanical polishing pad comprises a main structure body, a surface-modified secondary structure body, a protective structure body, an upper connecting body which is used for bonding the main structure body and the surface-modified secondary structure body, and a lower connecting body which bonds the surface-modified secondary structure body and the protective structure body together. The surface-modified secondary structural body has excellent mechanical properties such as elongation at break and tensile strength, the thickness of the surface-modified secondary structural body is more uniform, and the bonding peel strength of the surface-modified secondary structural body and the connecting bodies is more excellent, so that the chemical mechanical polishing pad made of the surface-modified secondary structural body has better combination performance.

Owner:万华化学集团电子材料有限公司

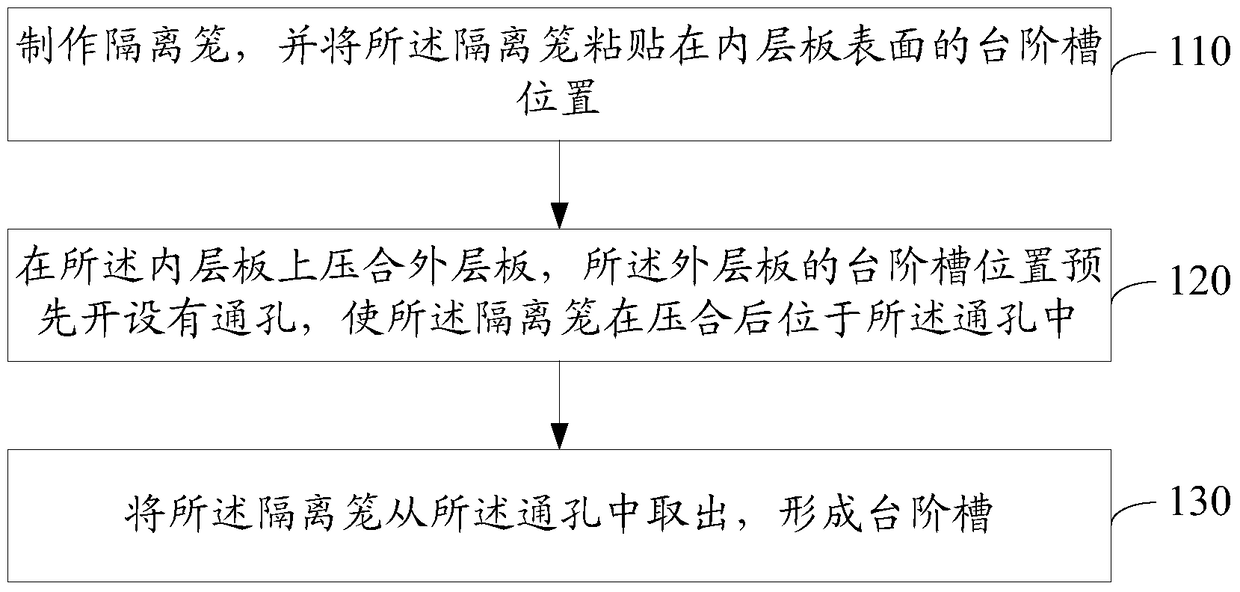

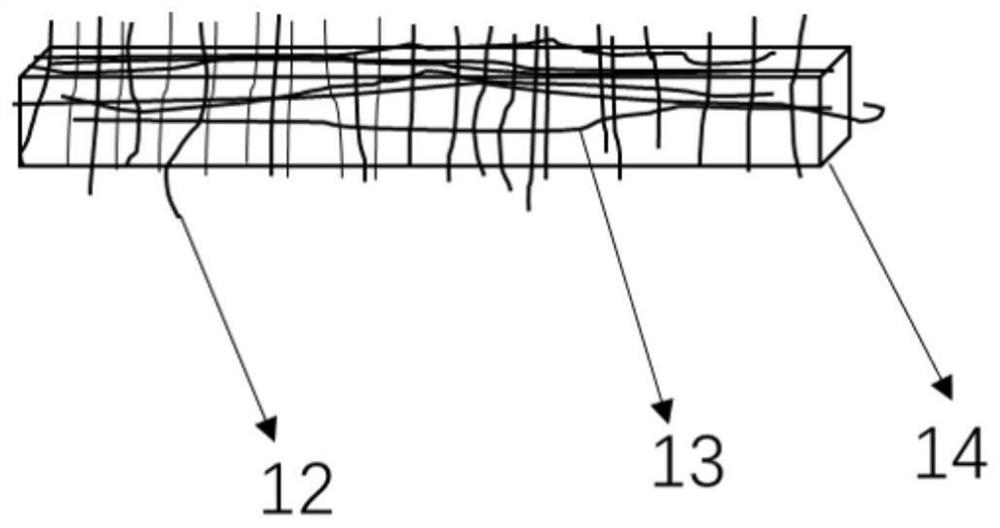

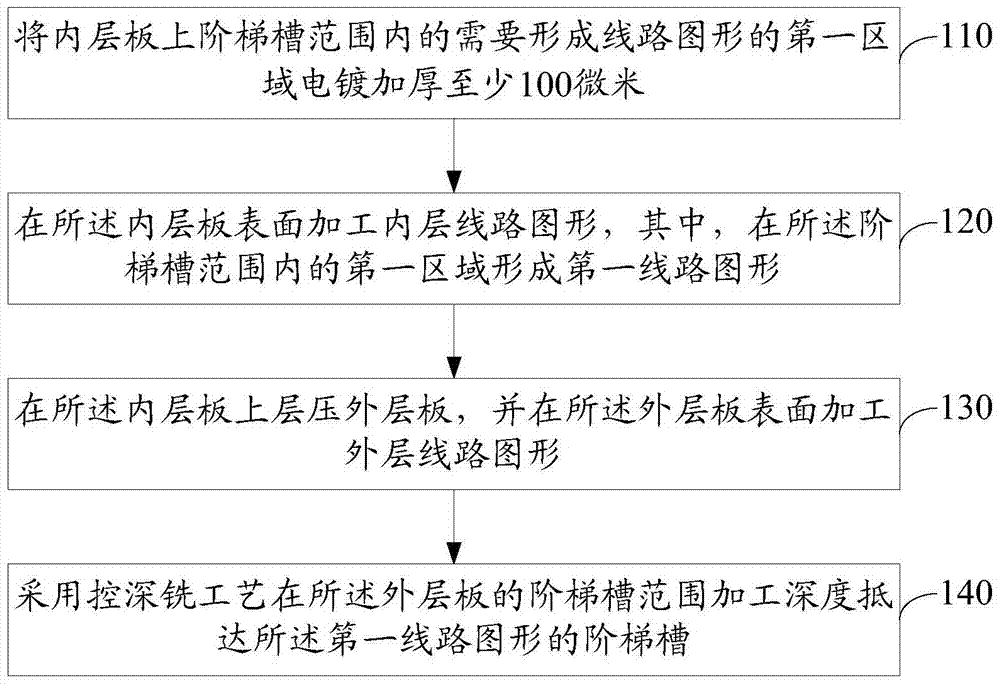

A method of manufacturing a stepped circuit board

ActiveCN104582273BAvoid easy delaminationPrinted circuit aspectsPrinted circuit manufactureMicrometerPrinted circuit board

The invention discloses a manufacturing method of a step-type circuit board. The manufacturing method comprises the following steps: a first area where a circuit pattern needs to be formed in a step-slot range on an inner-layer board is electrically plated and thickened by at least 100 micrometers; an inner-layer line pattern is machined on the surface of the inner-layer board, wherein a first line pattern is formed in the first area in the step-slot range; an outer-layer board is arranged on an upper layer of the inner-layer board, and an outer-layer line pattern is machined in a surface of the outer-layer board; a step slot with the bottom reaching the first line pattern is machined in step-slot range of the outer-layer board in a depth milling control process. Due to the fact that gaskets do not need to be used in the technical scheme, the problems that the gaskets cannot be removed easily and are left can be avoided, and the problem that layering is likely to occur due to the gaskets can be also avoided; additionally, when multiple step slots need to the machined, all that is needed is to laminate the inner-layer board and the outer-layer board to reach a needed number of layers once and then machine the step slots in the outer-layer board in the depth milling control process, and the problem that layering is likely to occur due to multiple times of lamination can be avoided.

Owner:SHENNAN CIRCUITS

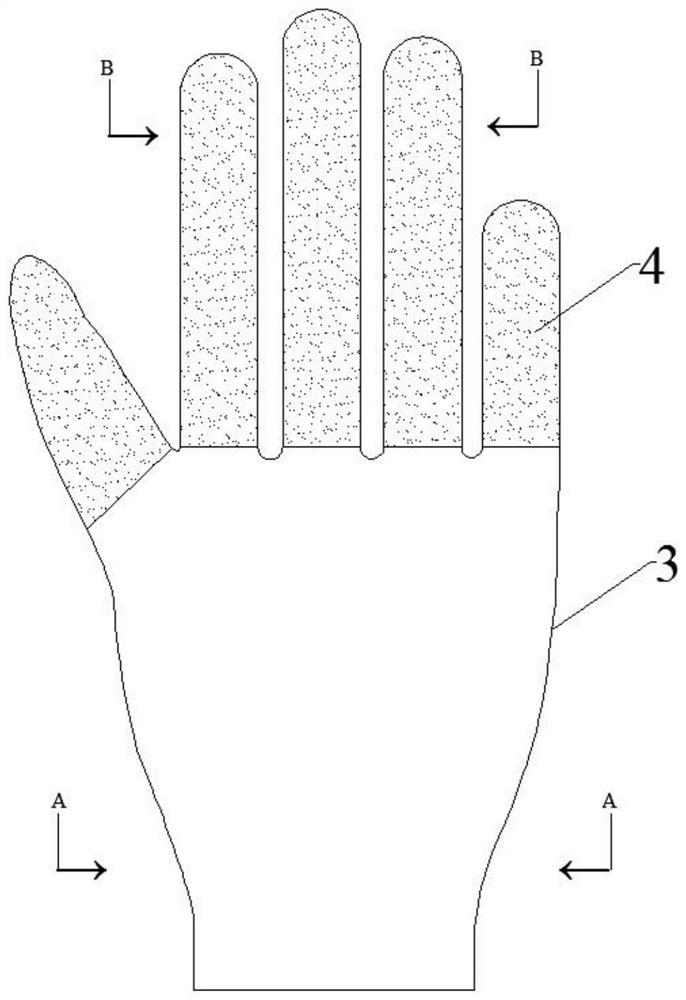

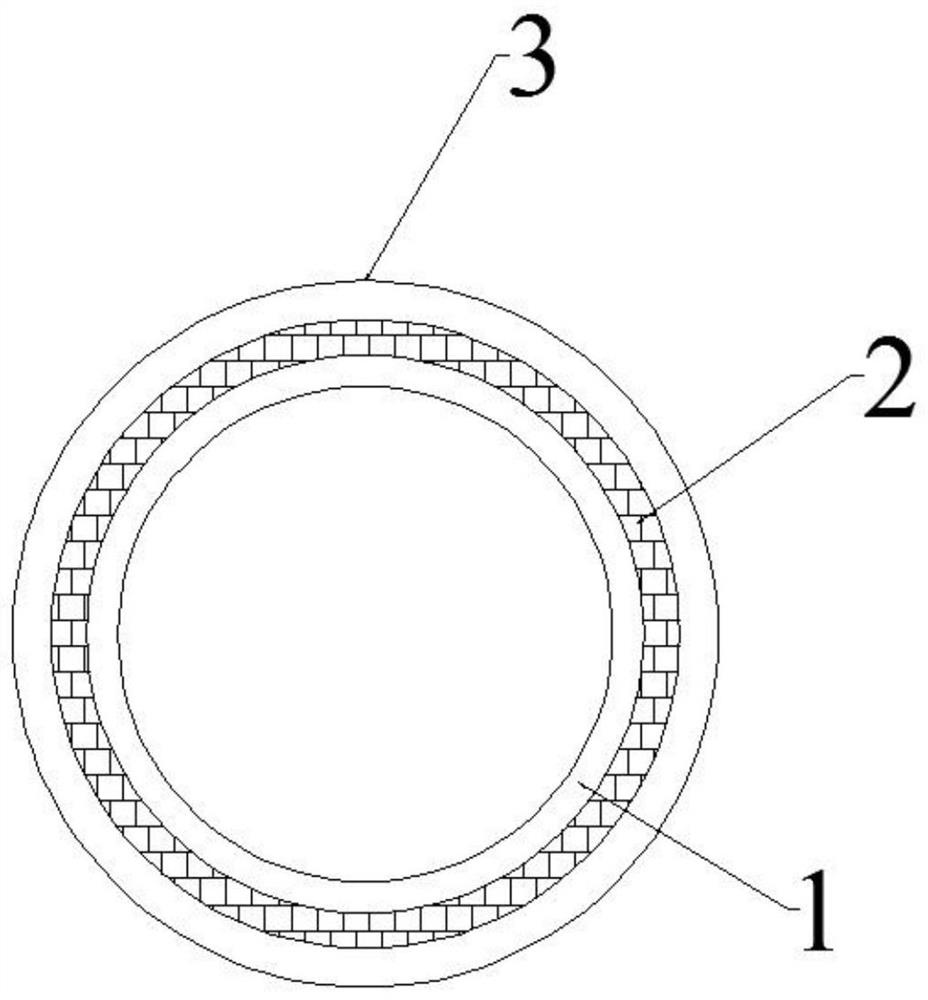

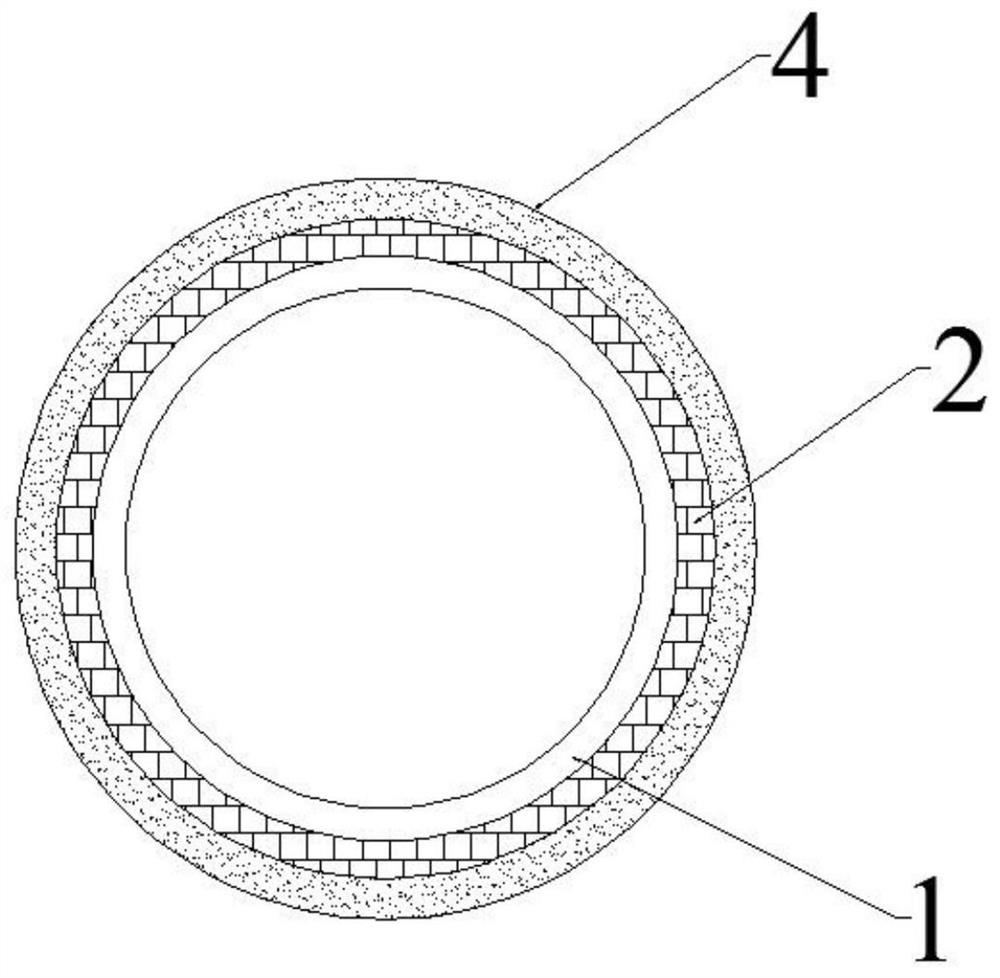

Anti-static PVC (polyvinyl chloride) glove as well as preparation method and application thereof

PendingCN113619213AImprove conductivityDoes not affect softnessSynthetic resin layered productsGlovesFiberPolymer science

The invention relates to the technical field of PVC gloves, in particular to an anti-static PVC glove and a preparation method and application thereof. The glove structurally comprises a glove inner layer, a glove middle layer, a glove outer layer and a finger sleeve layer, the glove inner layer and the glove outer layer are both made of polyvinyl chloride (PVC) materials, and the glove middle layer is made of carbon fibers. The glove middle layer is connected to the outer surface of the glove inner layer in a wrapping mode, the glove outer layer is connected to the outer surface of the glove middle layer in a wrapping mode, but finger parts of the glove outer layer are not wrapped by the glove outer layer, the finger sleeve layer is connected to the finger parts of the glove middle layer in a wrapping mode, and the finger sleeve layer is formed by mixing flexible silica gel and conductive fibers. According to the anti-static glove, a novel structure with the inner layer being the PVC base body, the middle layer being the carbon fiber braided fabric and the outer layer being the discharge wear-resistant layer formed by the PVC, the flexible silica gel and the conductive fibers is adopted, the anti-static effect can be achieved, better wear resistance is achieved, and the durability of the glove is enhanced.

Owner:山东奥博医用器械股份有限公司

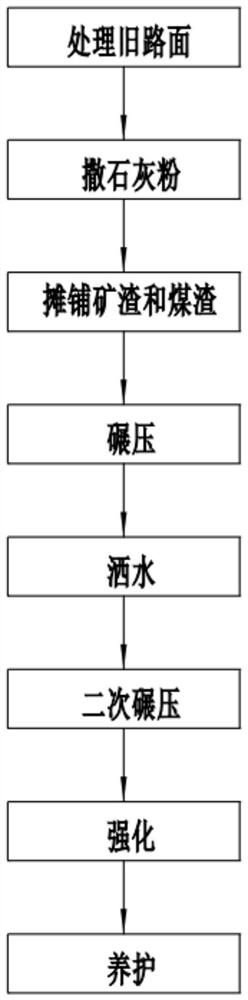

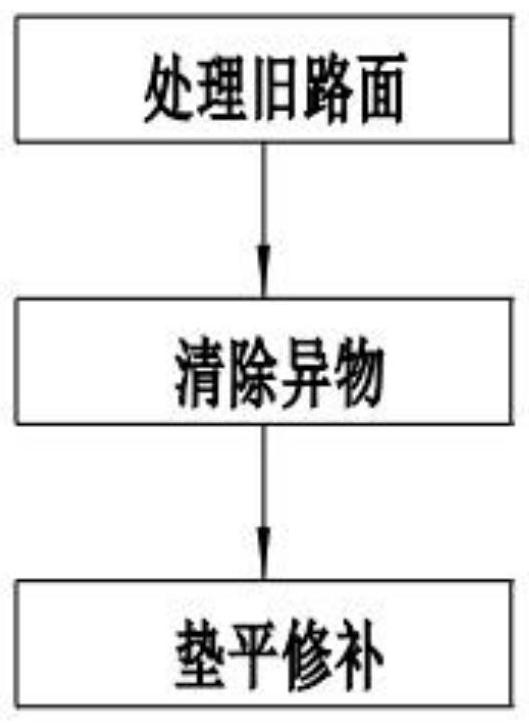

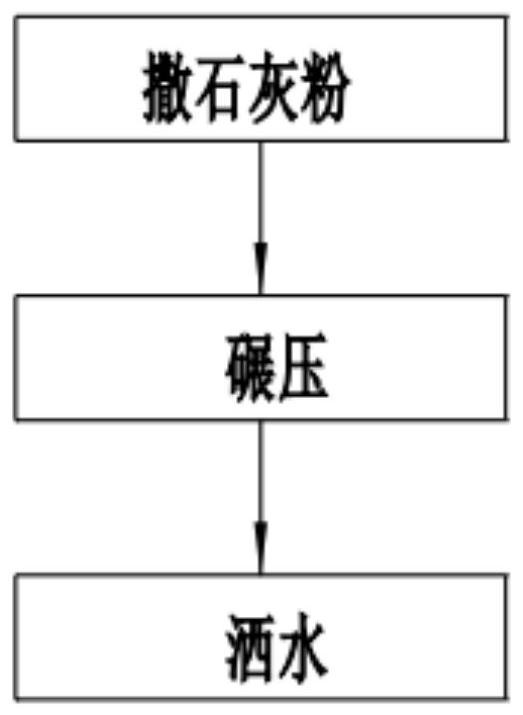

Pavement paving filling type large-particle-size cement stabilized macadam base material and method

InactiveCN114180917AImprove deformation resistanceStrong bending and tensile strengthSolid waste managementForeign matterFiberglass mesh

The invention relates to the technical field of road materials, in particular to a filling type large-particle-size cement stabilized macadam base material for pavement paving and a method. The filling type large-particle-size cement stabilized macadam base material is prepared from the following materials in parts by weight: 10-20 parts of cement; 10-20 parts of medium sand; 10-20 parts of fine sand; 60-80 parts of stones; 40-50 parts of slag; 20-30 parts of coal cinder; 20-30 parts of lime powder; and 10-20 parts of a glass fiber mesh. A preparation method of the filling type large-particle-size cement stabilized macadam base material for pavement paving comprises the following steps that S1, an old pavement is treated, foreign matter on the old pavement is cleared away, a road roller is adopted for rolling and flattening, and then watering and airing are conducted; s2, lime powder is spread, specifically, lime powder is spread on the old pavement treated in the S1, a road roller is adopted for rolling and flattening, and then water spraying treatment and air drying are conducted. The multiple layers of glass fiber nets are embedded in the concrete base layer during construction, so that the deformation resistance of the base layer is high, the bending and tensile strength is high, the cracking phenomenon of the pavement base layer can be effectively prevented, and the service life of a road is prolonged.

Owner:滁州市公路管理服务中心

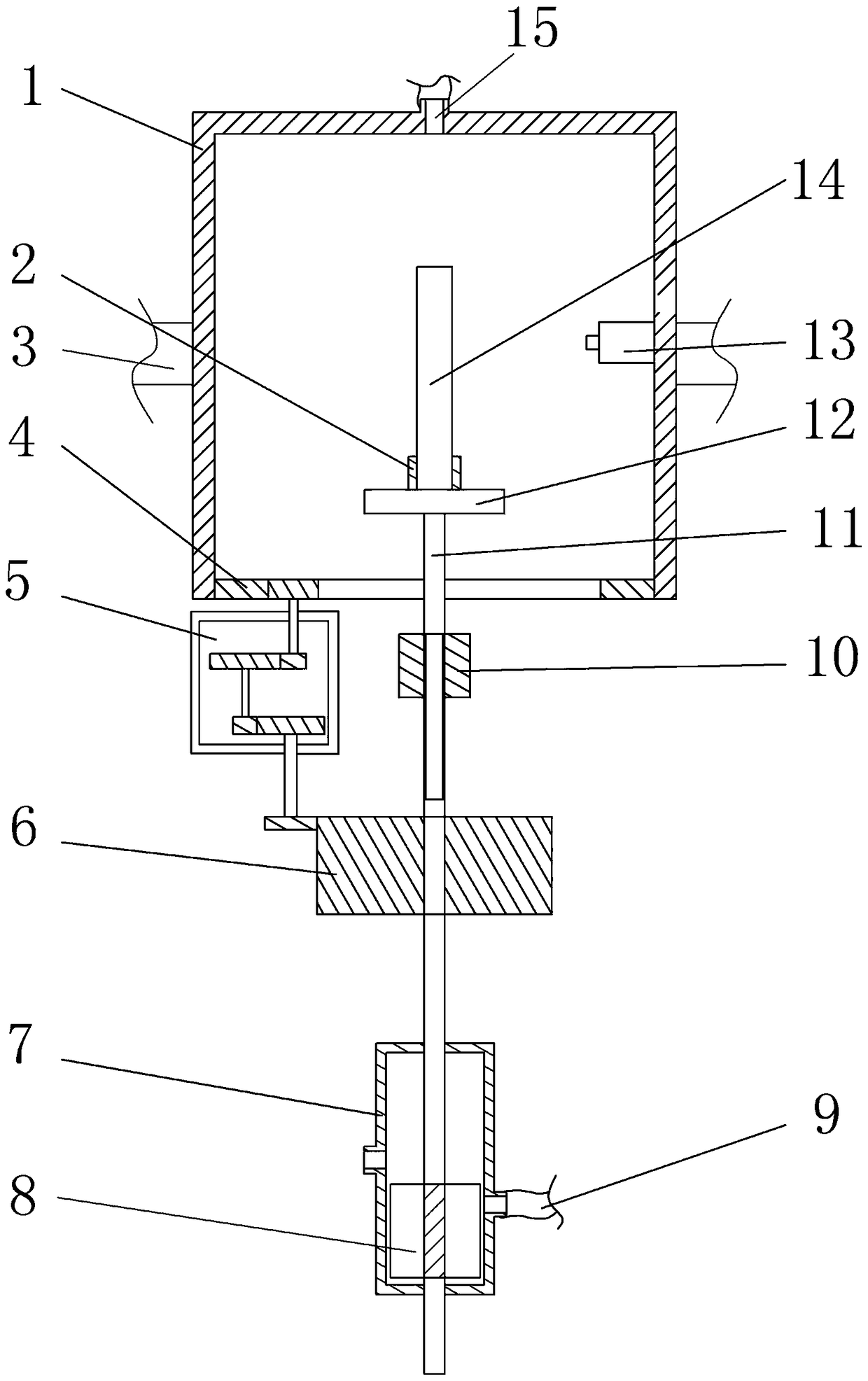

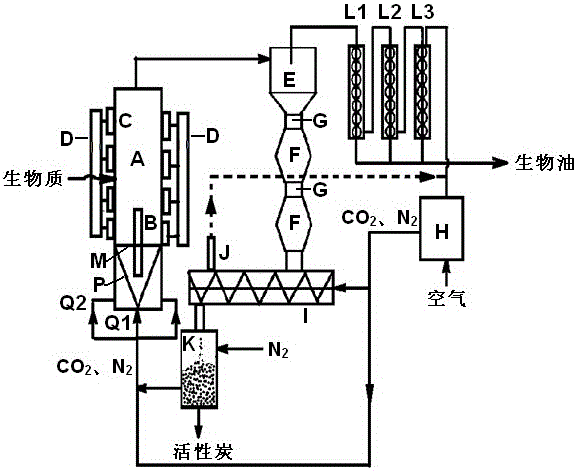

A system for preparing bio-oil and activated carbon by microwave pyrolysis

ActiveCN104560074BReduce cokingOvercome the shortcomings of jet instabilityCarbon compoundsDirect heating destructive distillationNitrogen generatorActivated carbon

The invention discloses a system for preparing bio-oil and activated carbon by microwave pyrolysis. The system comprises a microwave pyrolysis reactor, a cyclone separator, a condenser, a coke storage bin, a microwave activation reactor, a gas burner, an activated carbon cooling tower and a nitrogen generator, wherein the microwave pyrolysis reactor is connected with the cyclone separator through a pipeline; a gas outlet in the top of the cyclone separator is connected with the condenser; the bottom of the cyclone separator is connected with the coke storage bin; the bottom of the coke storage bin is connected with a material inlet of the microwave activation reactor; a material outlet of the microwave activation reactor is connected with a feed opening of the activated carbon cooling tower through a pipeline; a gas outlet of the microwave activation reactor is connected with a feed pipeline of the gas burner through a pipeline; a gas outlet of the condenser is connected with the gas burner through a pipeline; a gas outlet pipeline of the gas burner is divided into two paths, wherein one path is connected with the microwave activation reactor, and the other path is connected with a fluidizing gas and spouting gas pipeline of the microwave pyrolysis reactor; a gas inlet of the activated carbon cooling tower is connected with a nitrogen pipeline; a gas outlet of the activated carbon cooling tower is merged into the fluidizing gas and spouting gas pipeline through a pipeline; a material outlet is formed in the bottom of the activated carbon cooling tower. The system is high in biomass pyrolysis rate, can obtain high-yield bio-oil and high-quality activated carbon products, and has a favorable application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Tungsten carbide spray powder containing modified graphene for preparing self-lubricating wear-resistant coating

ActiveCN107350470BWeight increasePrevent oxidative denaturationMaterial nanotechnologyMolten spray coatingFreeze-dryingCarbide

The invention provides a modified graphene-containing tungsten carbide spray powder for preparing a self-lubricating wear-resistant coating, which comprises the following steps: 1) weighing a certain amount of modified graphene / nano-tungsten carbide composite material. Mix with a certain amount of absolute ethanol, and obtain a mixed solution of graphene / nano-tungsten carbide composite material after ultrasonic dispersion. 2) Weigh a certain amount of tungsten carbide / cobalt spray powder and add it into the mixed solution of graphene nano-tungsten carbide composite material. 3) The tungsten carbide / cobalt spray powder compounded with modified graphene was obtained by vacuum freeze-drying. 4) A tungsten carbide / cobalt self-lubricating wear-resistant coating compounded with modified graphene was prepared on the surface of the cleaned and sandblasted parts by thermal spraying process. The invention not only retains the layered single-layer carbonaceous structural characteristics of graphene, but also increases the specific gravity of graphene by the grown nano-carbide particles. In addition, the freeze-drying method can avoid the loss of graphene caused by ball milling or other powder mixing processes. .

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

A manufacturing process of a double-layer single-side copper-based circuit board

ActiveCN108617095BAvoid easy delaminationAvoid Bubble ProblemsNon-metallic protective coating applicationSolder maskRelease liner

The invention discloses a double-layer one-side copper-based circuit board making process comprising the following steps: baking a FR4 board, obtaining an internal layer line on the FR4 board, and silkprinting a solder mask on the internal layer line; stacking a plurality of slots and / or vias on a copper base, and placing a high temperature glue film or release film below slot / via on the copper base; laminating the FR4 board, a bonding sheet and the copper base at a high temperature; drilling blind holes on the FR4 board, electroplating copper on the FR4 board and etching same, thus obtainingan external layer line. The high temperature glue film or release film are placed on hollow positions before lamination, thus increasing lamination buffer force, and effectively preventing the soldermask from dropping oil under ununiform lamination of the board; the process can prevent the circuit board from layering and foaming via the board baking and pad high temperature lamination; a dry filmof 45-55 um is selected so as to fully cover the blind holes, thus preventing blind hole broken caused by developing and etching, and preventing the copper layer from being broken.

Owner:ZHUHAI KINGROAD ELECTRONICS

High-thermal-conductivity graphite-high silicon aluminium-based composite material and preparation process for same

The invention relates to a high-thermal-conductivity graphite-high silicon aluminium-based composite material and a preparation process for the same. The composite material is composed of, in volume fraction, 10-70% of graphite, 5-30% of silicon, and the balance of aluminium or aluminium alloy. The preparation process comprises the following steps of: (1) uniformly mixing graphite powder and silicon powder to obtain mixed powder; (2) placing the mixed powder in a heat treatment furnace, and performing vacuum hot-pressing sintering to form a precast block; (3) placing the sintered precast block in a die and preheating, and heating aluminium or aluminium alloy in a crucible until aluminium or aluminium alloy is melted; (4) pouring an aluminium melt or aluminium alloy melt in the die; (5) applying an axial pressure by a hydraulic machine, and enabling the aluminium melt or aluminium alloy melt to infiltrate in pores in the precast block; and (6) cooling and releasing the die, and taking out the composite material. Compared with the prior art, the composite material obtained by the preparation process disclosed by the invention is low in density and cost, and has the characteristics of low expansibility, high thermal conductivity and the like simultaneously.

Owner:SHANGHAI JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com