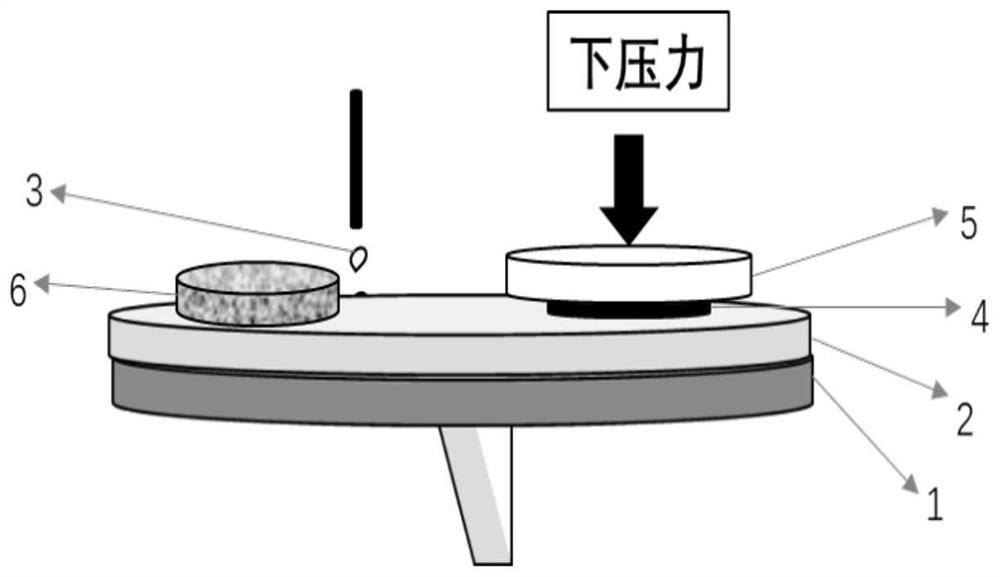

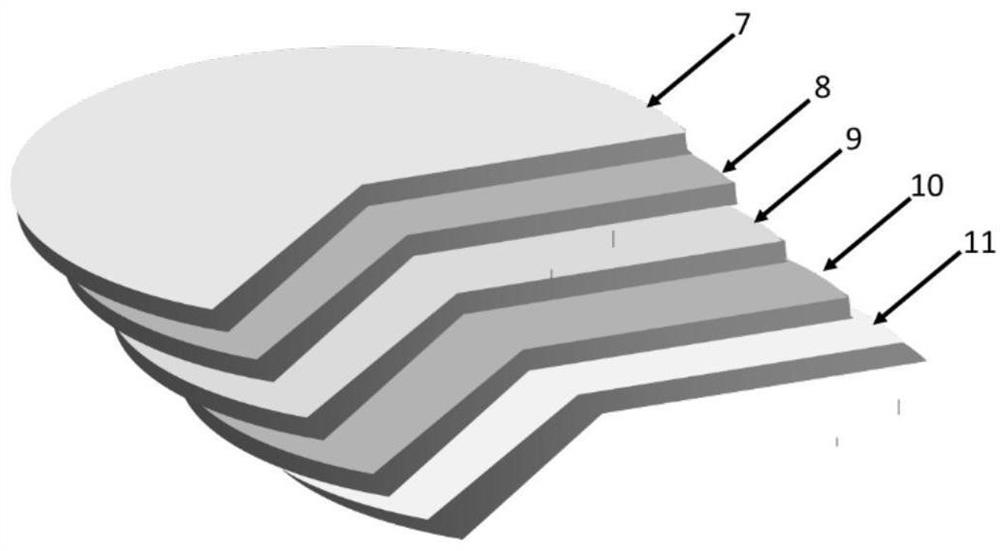

Multi-structure chemical mechanical polishing pad, and manufacturing method and application thereof

A technology of chemical machinery and structures, applied in chemical instruments and methods, manufacturing tools, grinding machine tools, etc., can solve the problem of low bonding strength, polishing disc bonding strength, easy delamination, separation, bonding surface delamination, etc. problems, achieve excellent adhesion, improved mechanical properties, and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

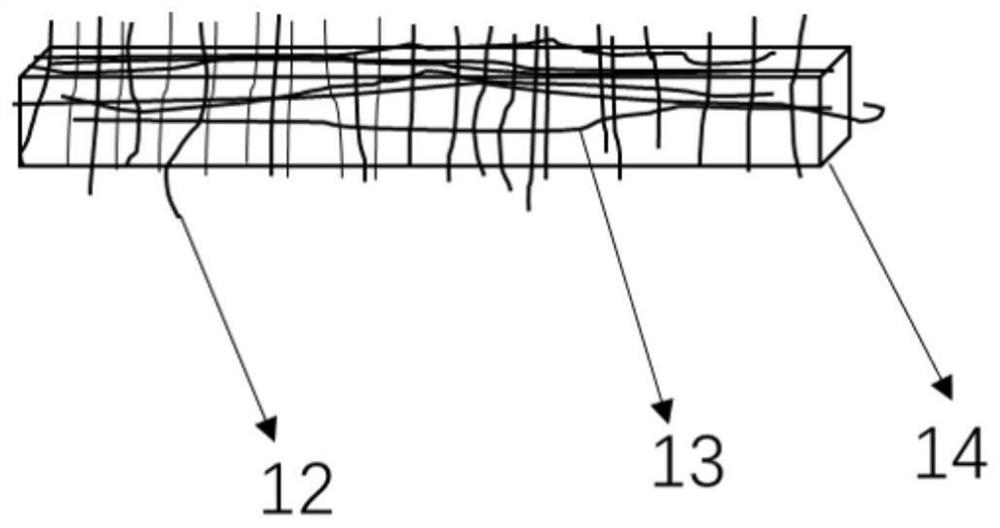

[0091] 1) Surface modification of secondary structures

[0092] Take 1kg of polyurethane surface treatment agent at 25°C Put it in a 4L bucket, add 1200g deionized water, adjust the solid content to 30±1.5%, and the corresponding viscosity is 5000mPa·S, use a stirrer to disperse and stir for 30min, then place it in a vacuum oven, vacuumize at room temperature for 30min to remove air bubbles, and place it in the coating Set the temperature of the trough to 25°C, set the coating speed of the coater to 300mm / min, and the coating thickness to 30μm, then spread the secondary structure SUBA IV on the coater table, adjust The coating head allows the surface treatment agent to be evenly coated on the surface of the secondary structure. After the coating is completed, the secondary structure coated with the polyurethane surface treatment agent is transferred to the drying tunnel, and the temperature of the drying tunnel is 100°C for drying. The drying time is 60 minutes. After drying...

Embodiment 2

[0096] Only change the coating thickness of the surface modification of the secondary structure in step 1) to 60 μm, and the other conditions / process steps are exactly the same as in Example 1.

Embodiment 3

[0098]Only change the coating thickness of the surface modification of the secondary structure in step 1) to 80 μm, and the other conditions / process steps are exactly the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com