Patents

Literature

283 results about "Chemo mechanical" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

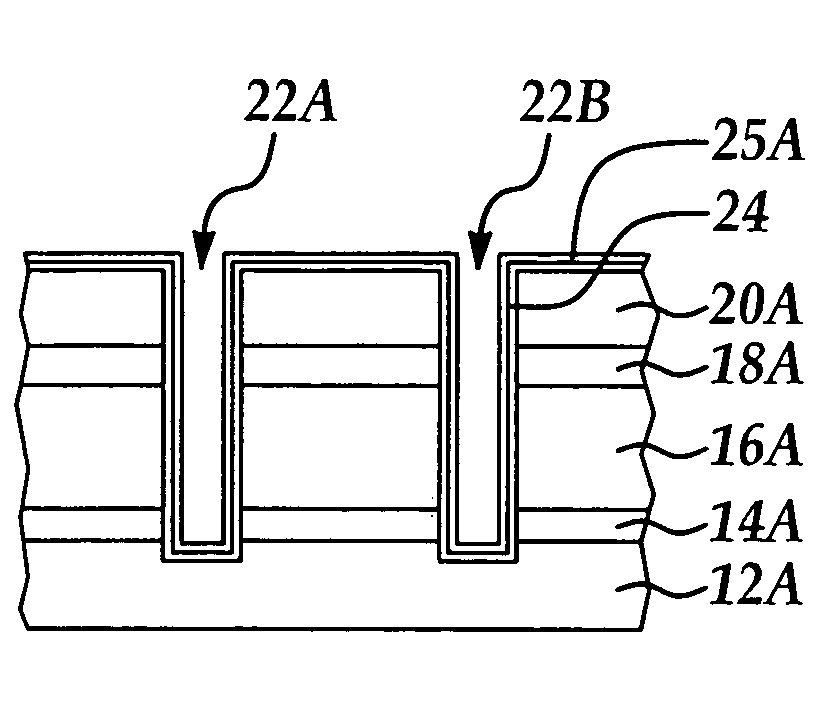

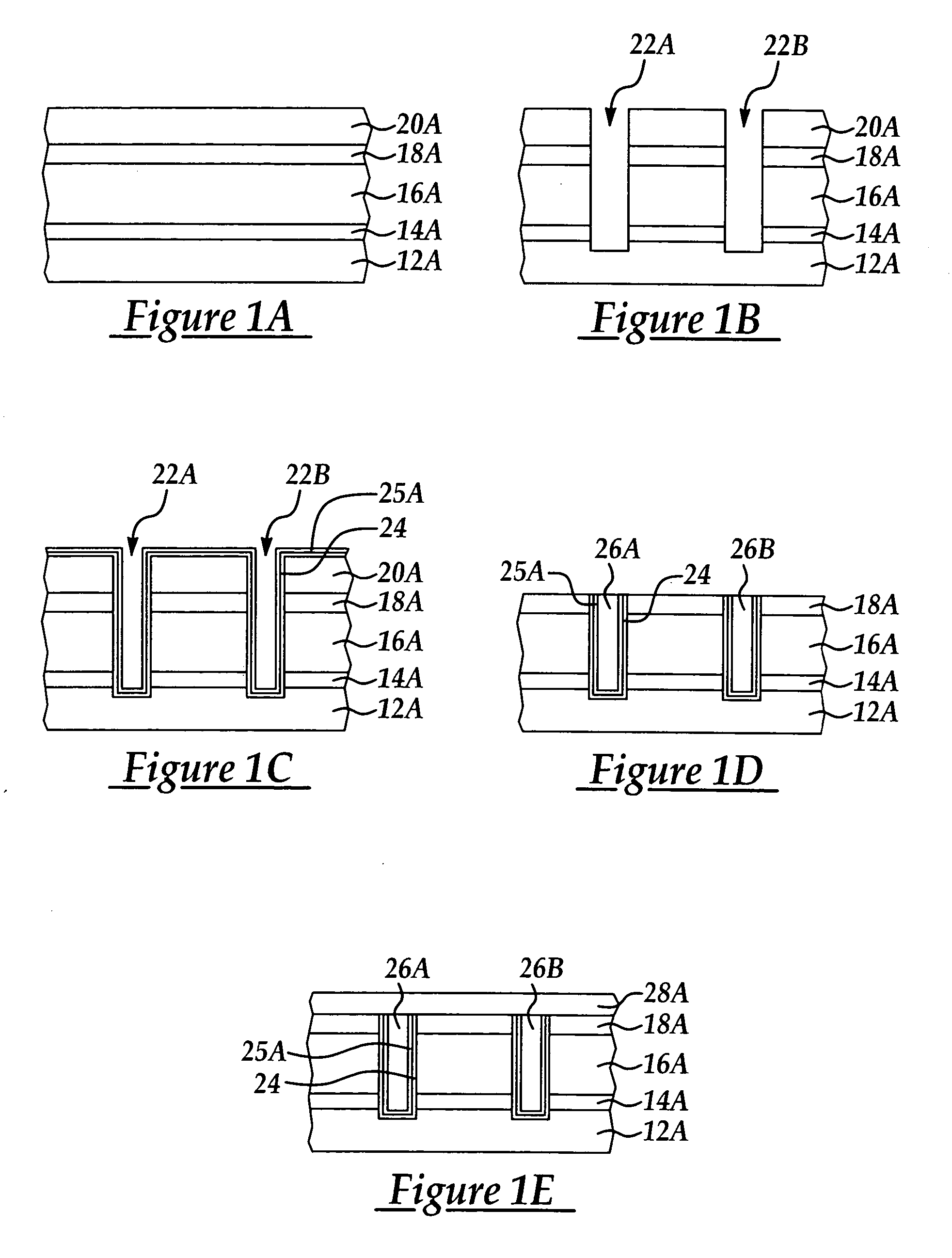

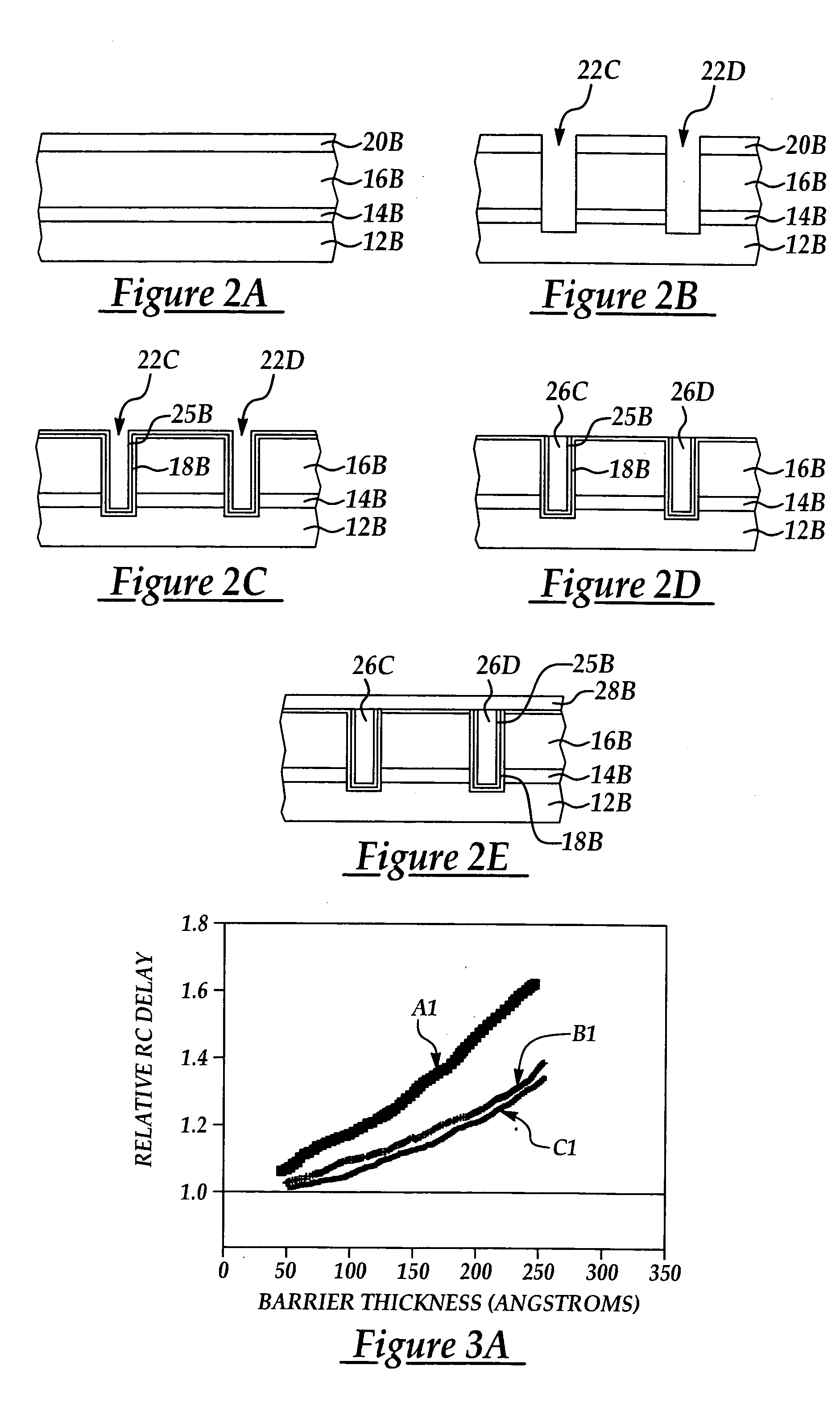

Copper damascene barrier and capping layer

InactiveUS20060024954A1Improve electrical performanceSemiconductor/solid-state device manufacturingAnti-reflective coatingEngineering

A method for forming a damascene with improved electrical properties and resulting structure thereof including providing at least one dielectric insulating layer overlying a first etch stop layer; forming an anti-reflectance coating (ARC) layer prior to a photolithographic patterning process; forming at least one opening extending through a thickness portion of the at least one dielectric insulating layer and first etch stop layer according to said photolithographic patterning and an etching process; blanket depositing a barrier layer including material selected from the group consisting of silicon carbide and silicon oxycarbide to line the at least one opening; blanket depositing a refractory metal liner over the barrier layer; blanket depositing at least one metal layer to fill the at least one opening; and, removing at least the at least one metal layer overlying the at least one opening level according to a chemical mechanical polish (CMP) process.

Owner:WU ZHEN CHENG +3

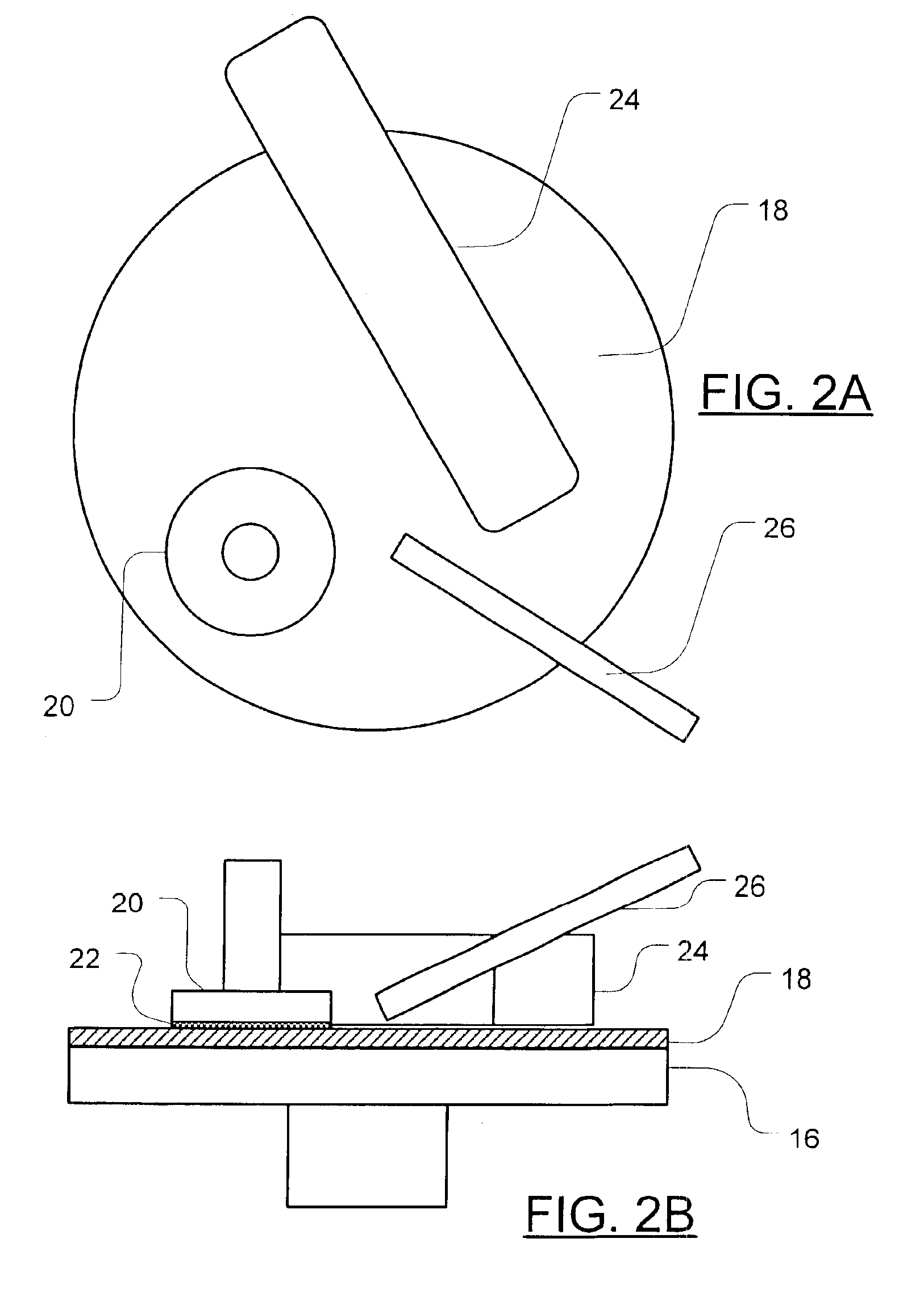

Method and apparatus for removing a reversibly mounted device wafer from a carrier substrate

ActiveUS20110308739A1Solid-state devicesSemiconductor/solid-state device manufacturingWaferingEngineering

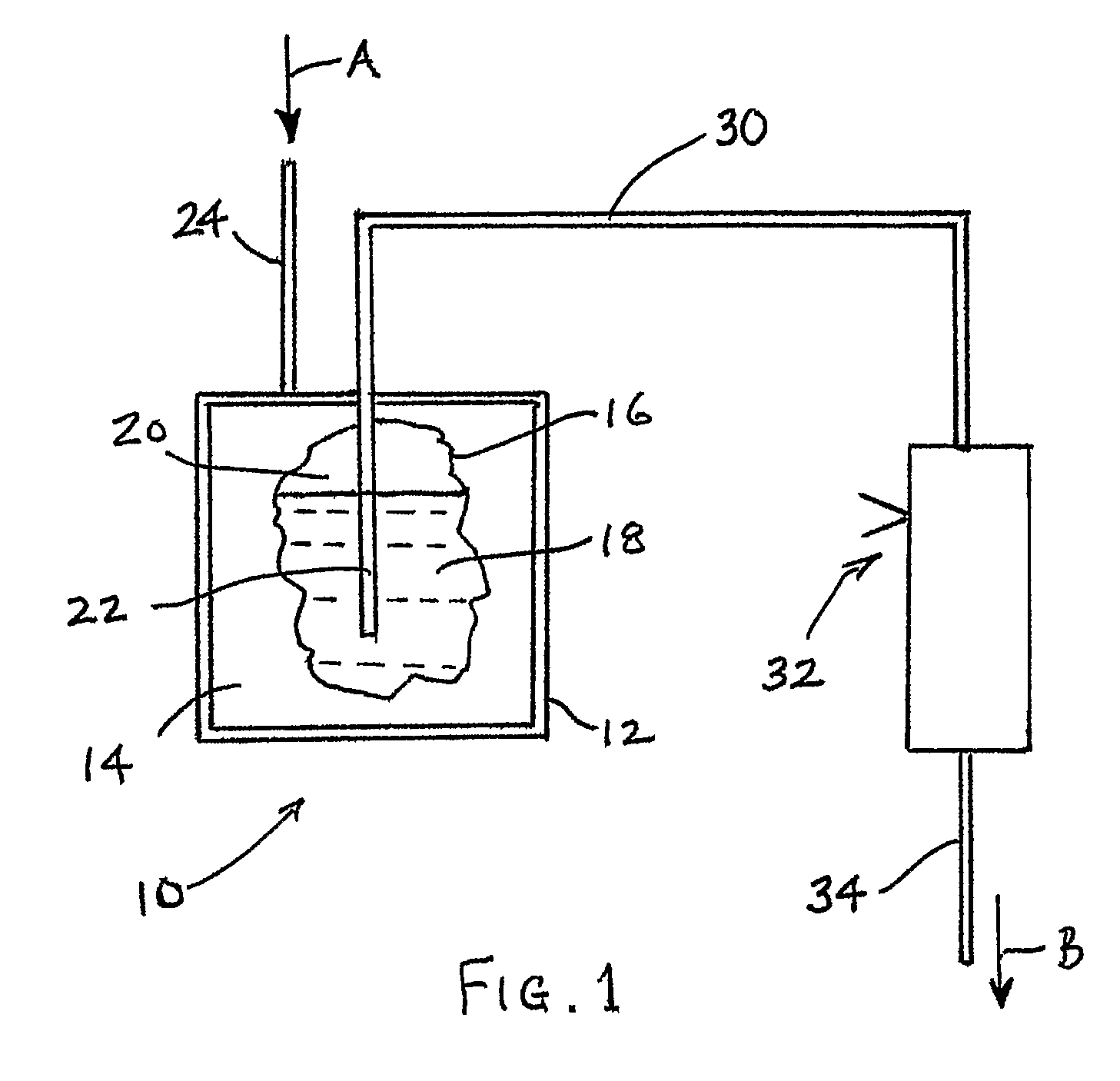

New demounting methods and apparatuses for separating temporarily, permanently, or semi-permanently bonded substrates and articles formed from those methods and apparatuses are provided. The methods comprise demounting a device wafer from a carrier wafer or substrate that have only been strongly bonded at their outer perimeters. The edge bonds are chemically, mechanically, acoustically, or thermally softened, dissolved, or disrupted to allow the wafers to be easily separated with very low forces and at or near room temperature at the appropriate stage in the fabrication process. A clamp for facilitating separation of the bonded substrates is also provided.

Owner:BREWER SCI

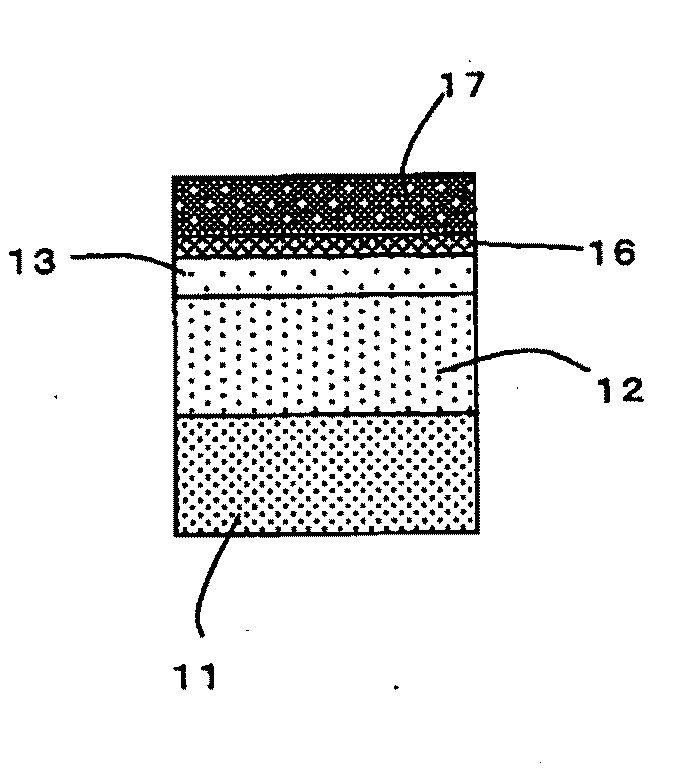

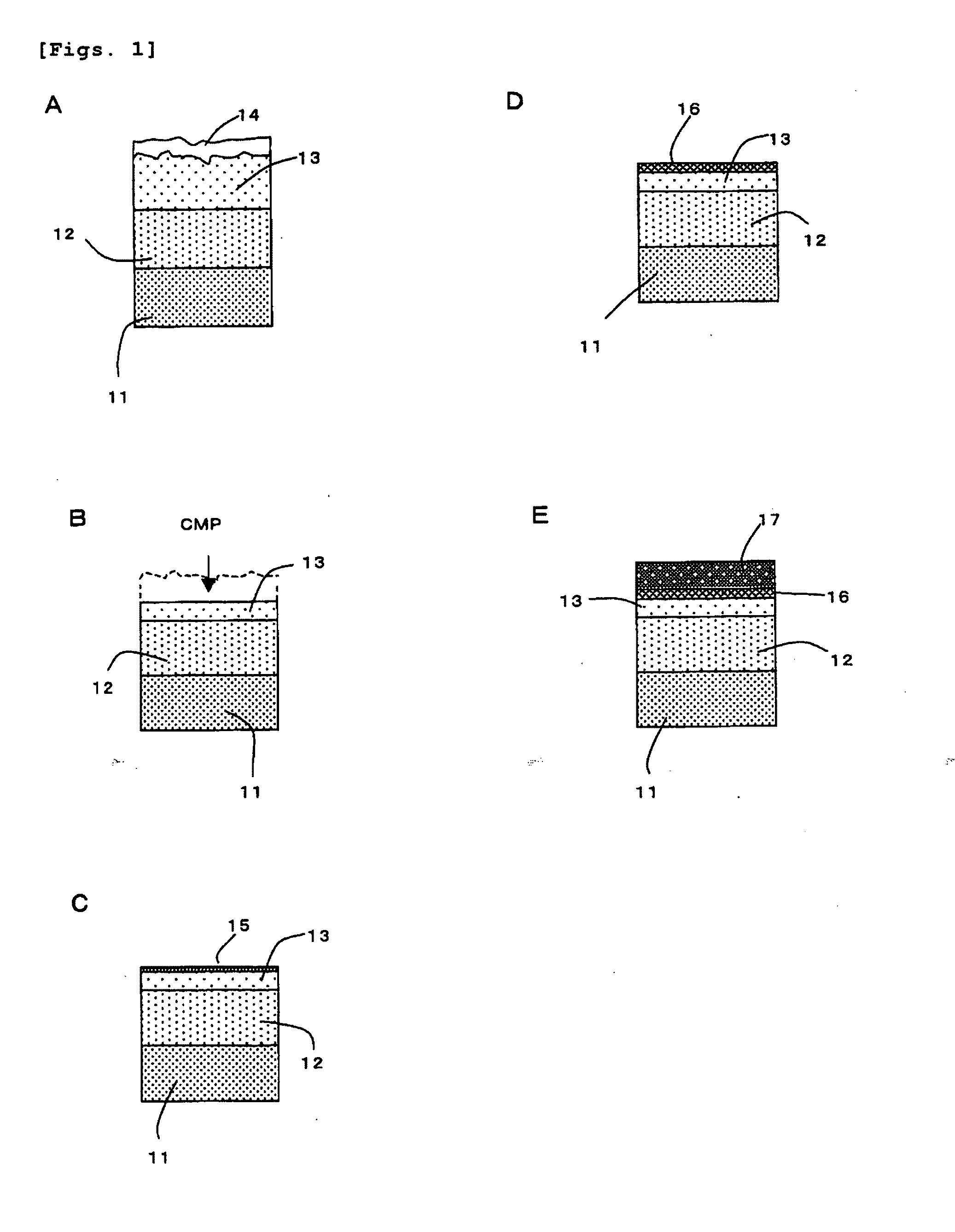

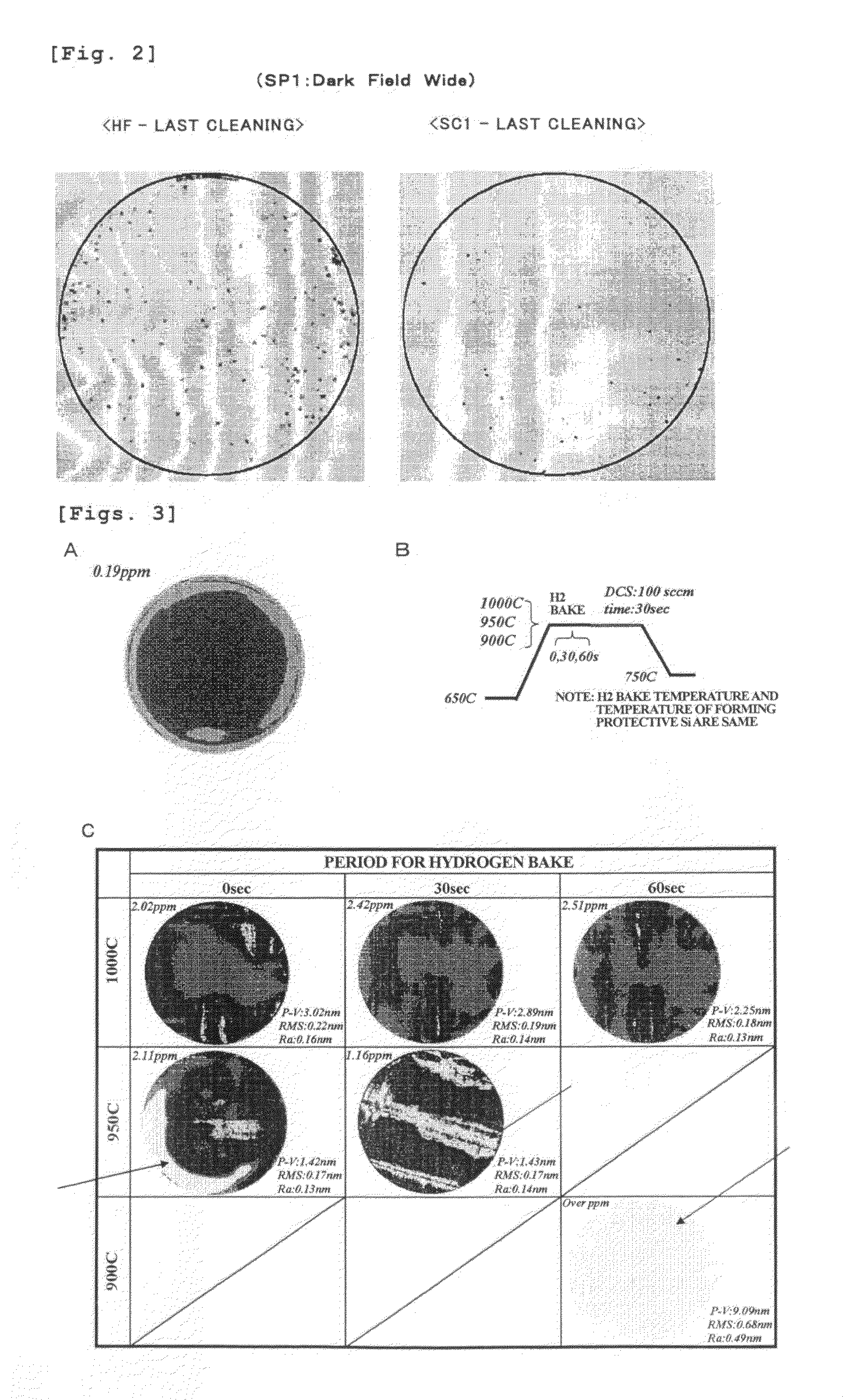

Manufacturing method of strained si substrate

InactiveUS20100003803A1Low densityLow roughness requirementsPolycrystalline material growthSolid-state devicesThreading dislocationsHydrogen

According to the present invention, there is provided a manufacturing method of a strained Si substrate including at least steps of: forming a lattice-relaxed SiGe layer on a silicon single crystal substrate; flattening a surface of the SiGe layer by CMP; and forming a strained Si layer on the surface of the flattened SiGe layer, wherein the method comprises steps of: subjecting the surface of the SiGe layer to SC1 cleaning, before forming the strained Si layer on the lattice-relaxed SiGe layer surface that is flattened; heat-treating the substrate having the SiGe layer after being subjected to SC1 cleaning in a hydrogen-containing atmosphere at 800° C. or higher; immediately forming a protective Si layer on the SiGe layer surface on the heat-treated substrate, without lowering the temperature below 800° C. after the heat treatment; and forming the strained Si layer on the surface of the protective Si layer at a temperature lower than the temperature of forming the protective Si layer. Thereby, a manufacturing method of a strained Si substrate having low surface roughness, threading dislocation density and low particle level can be provided.

Owner:SHIN-ETSU HANDOTAI CO LTD

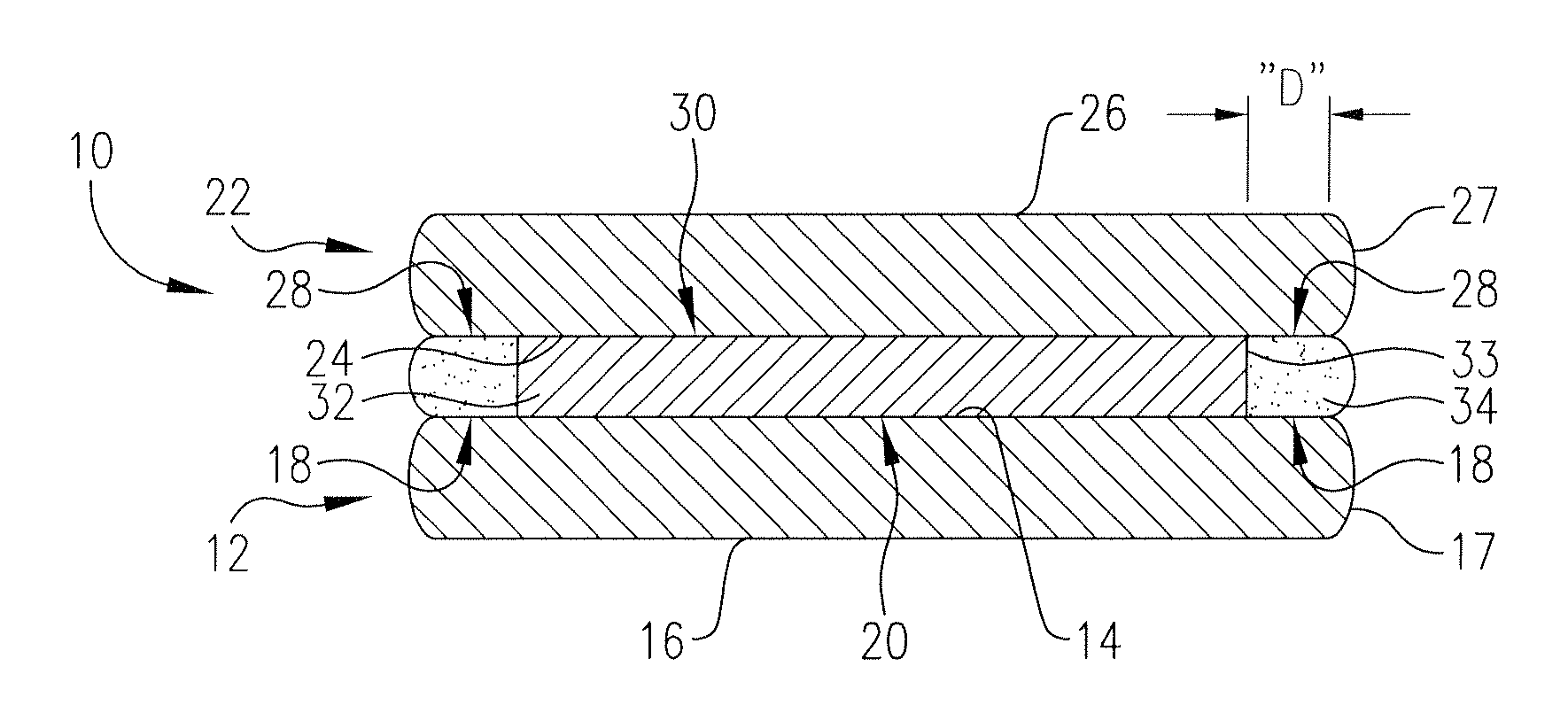

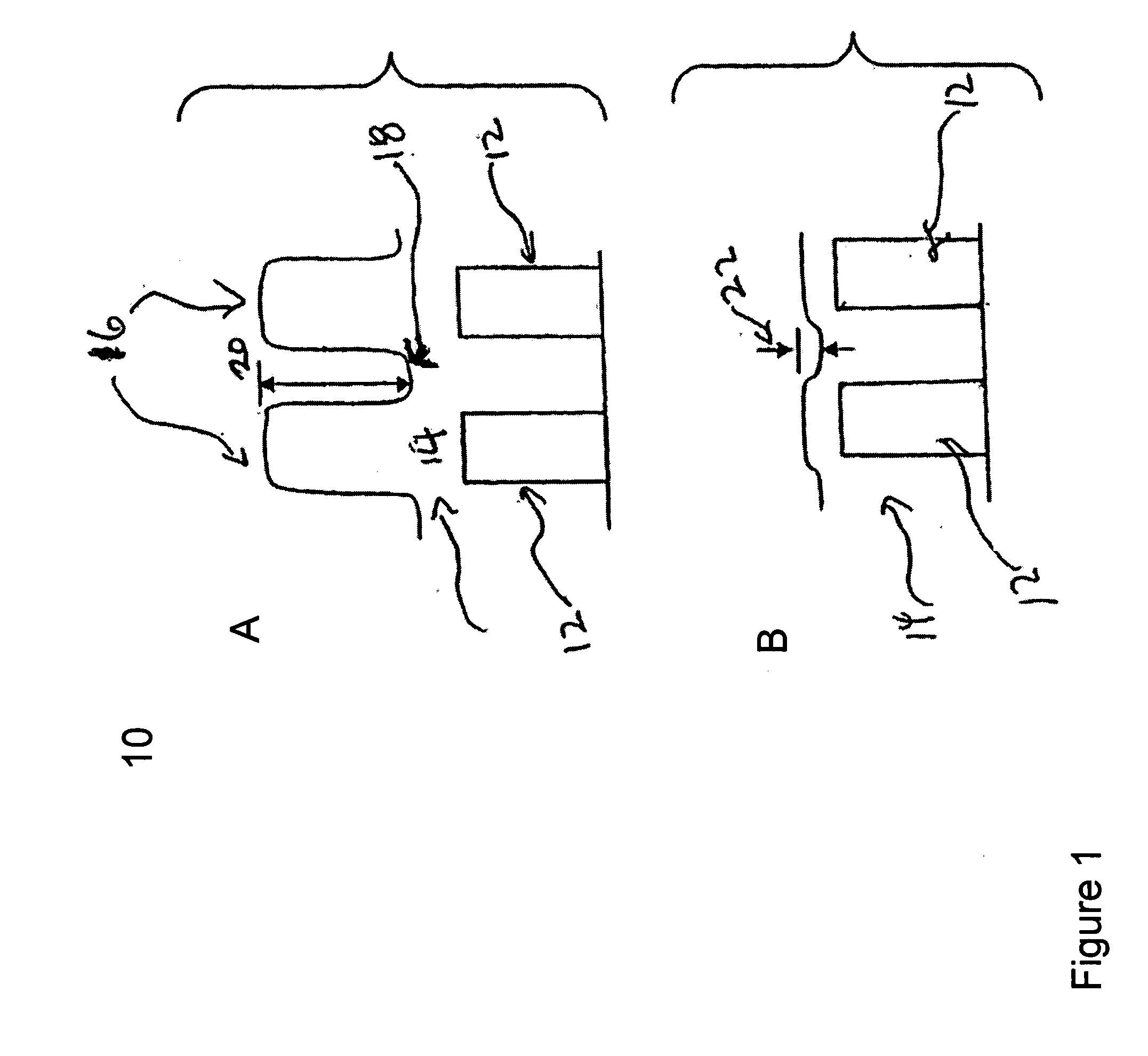

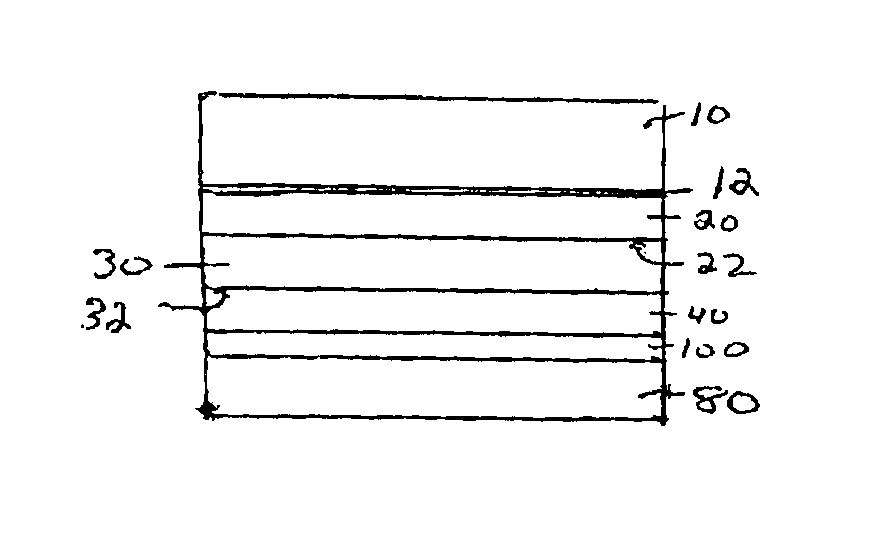

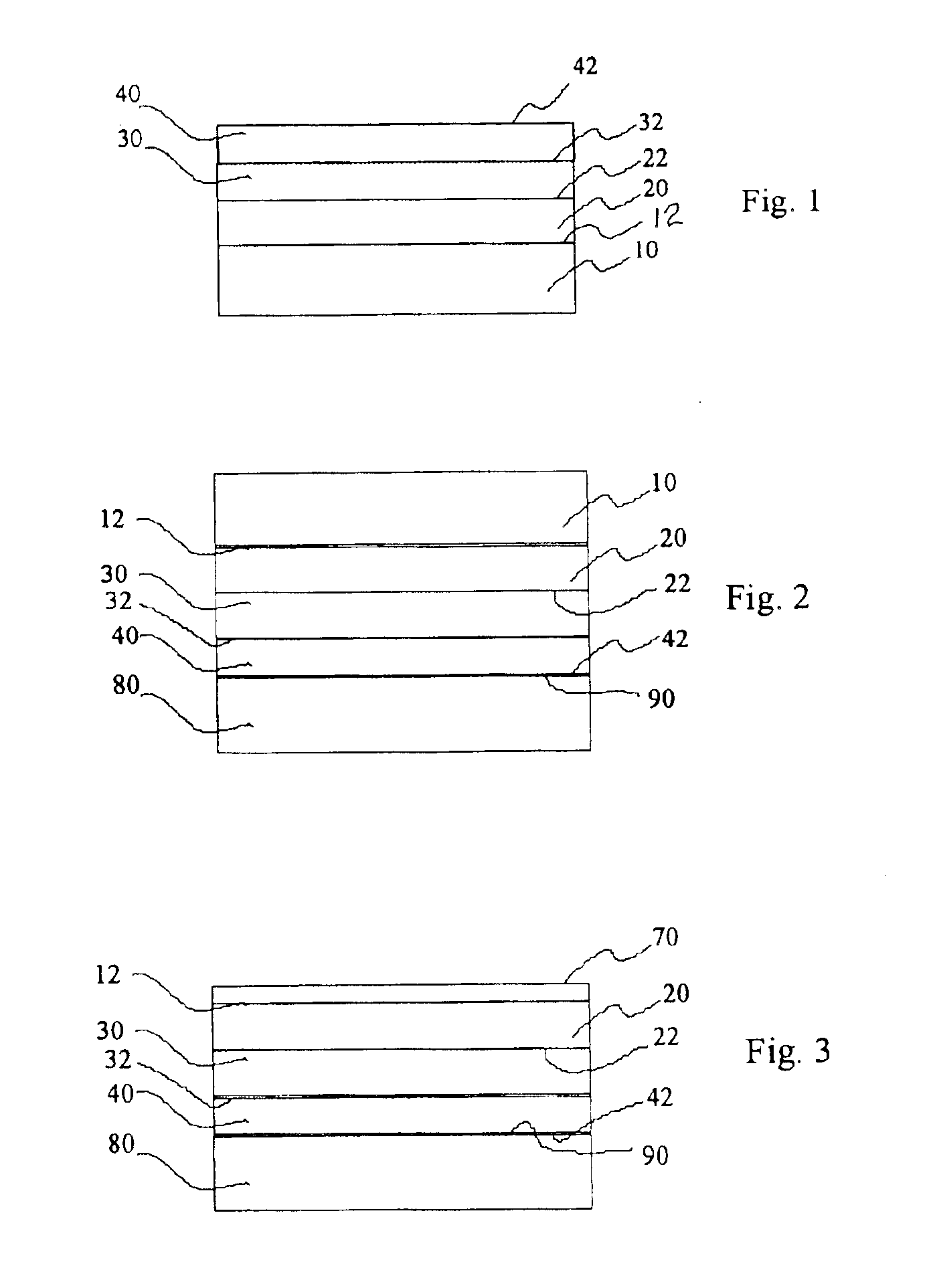

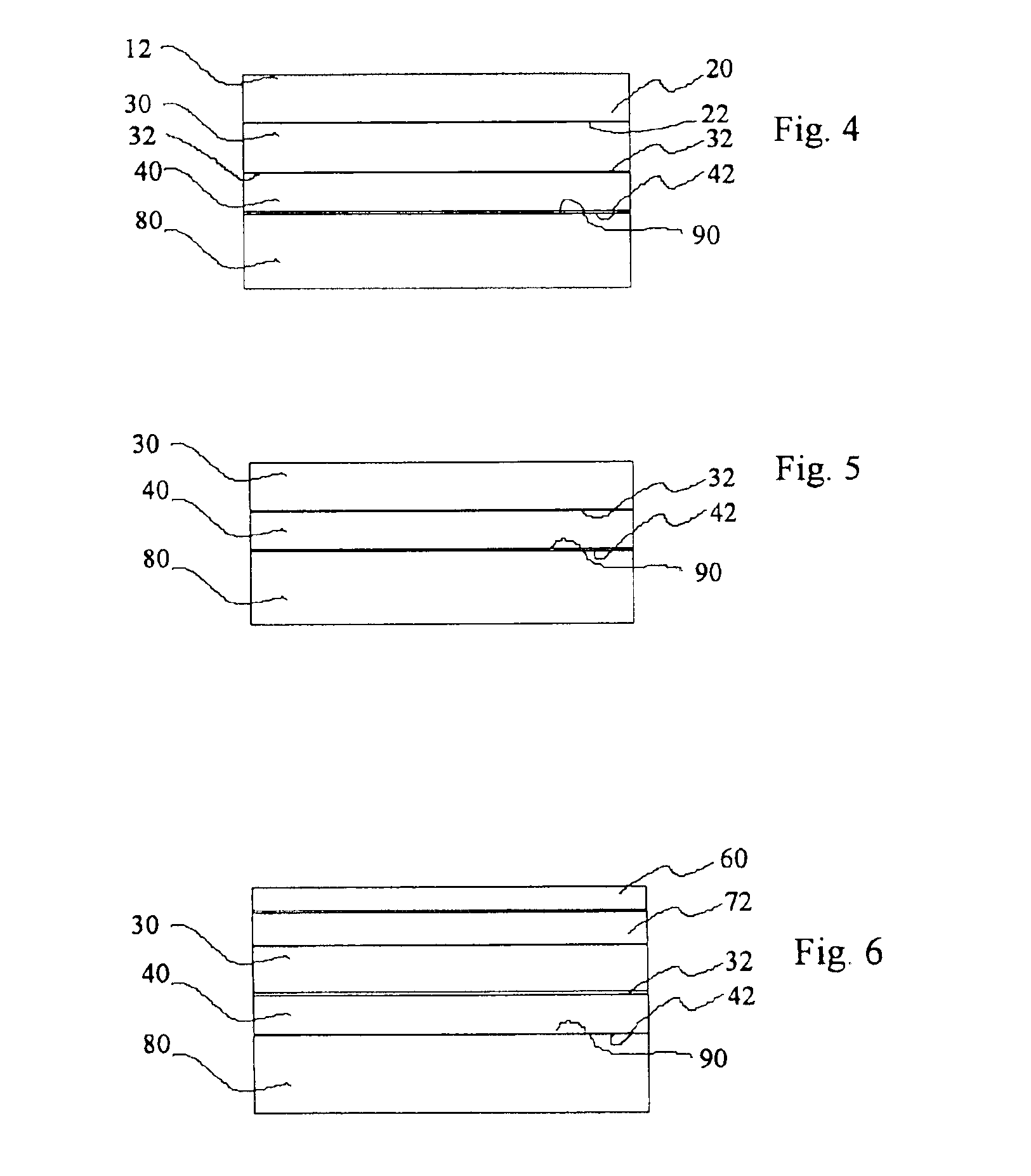

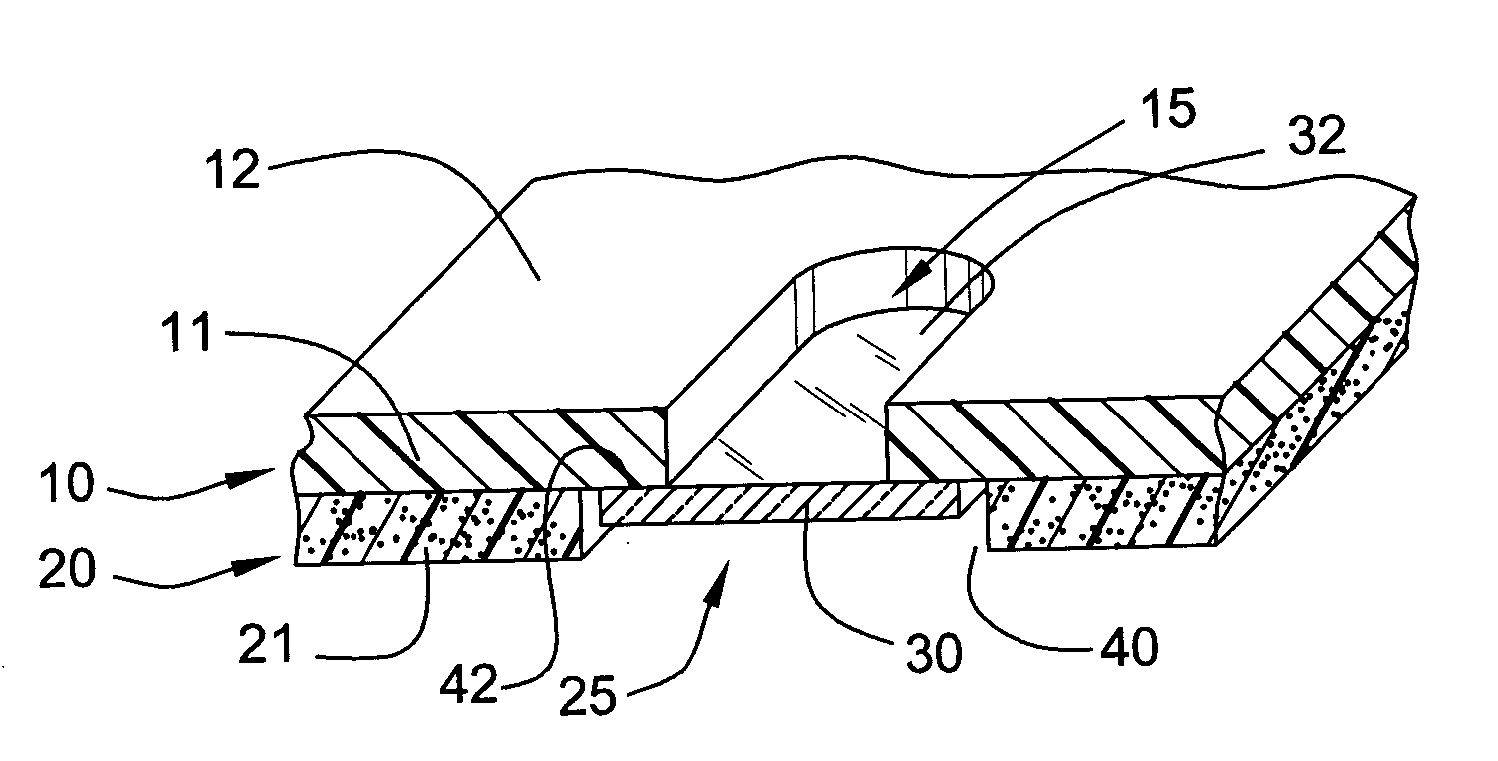

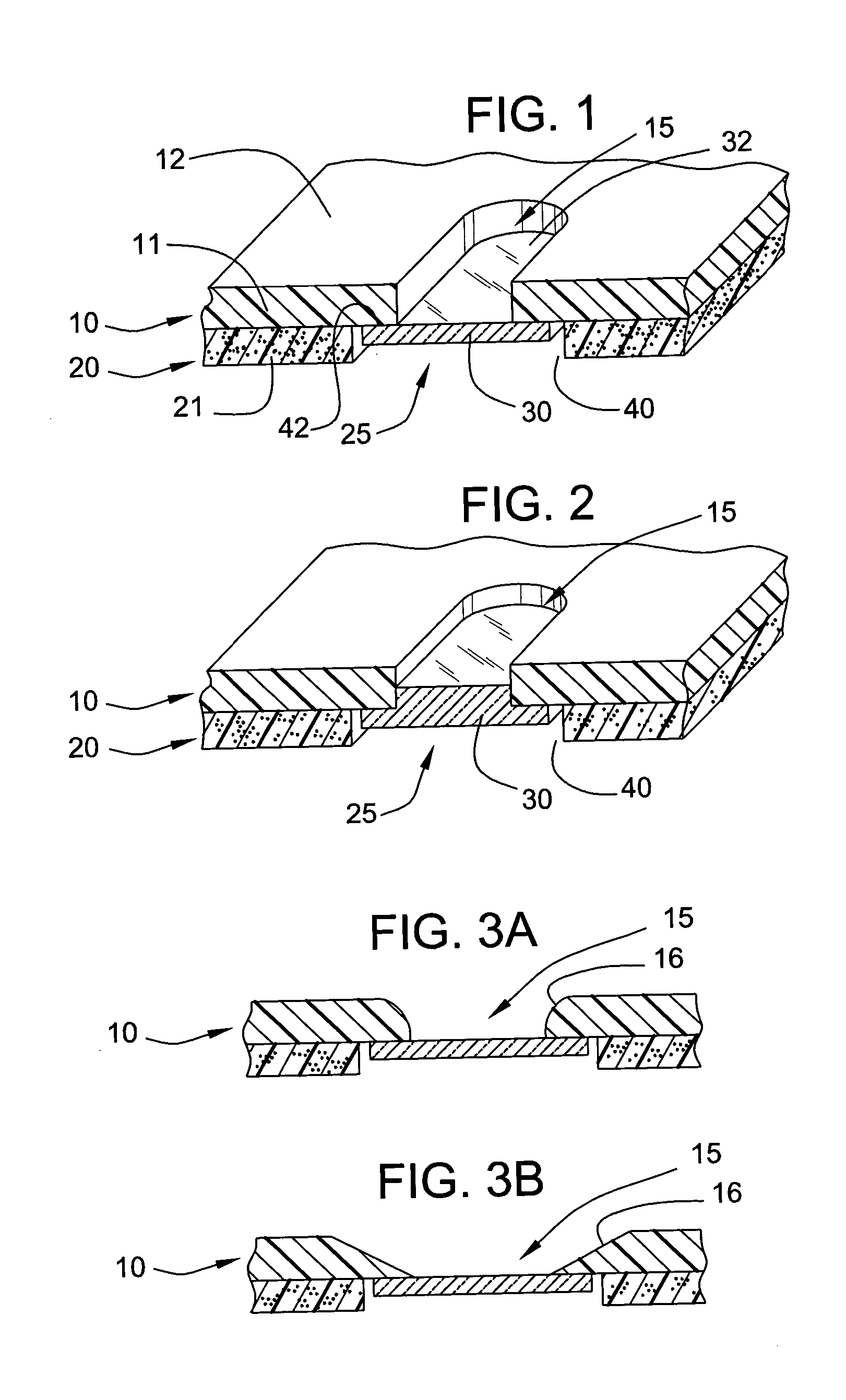

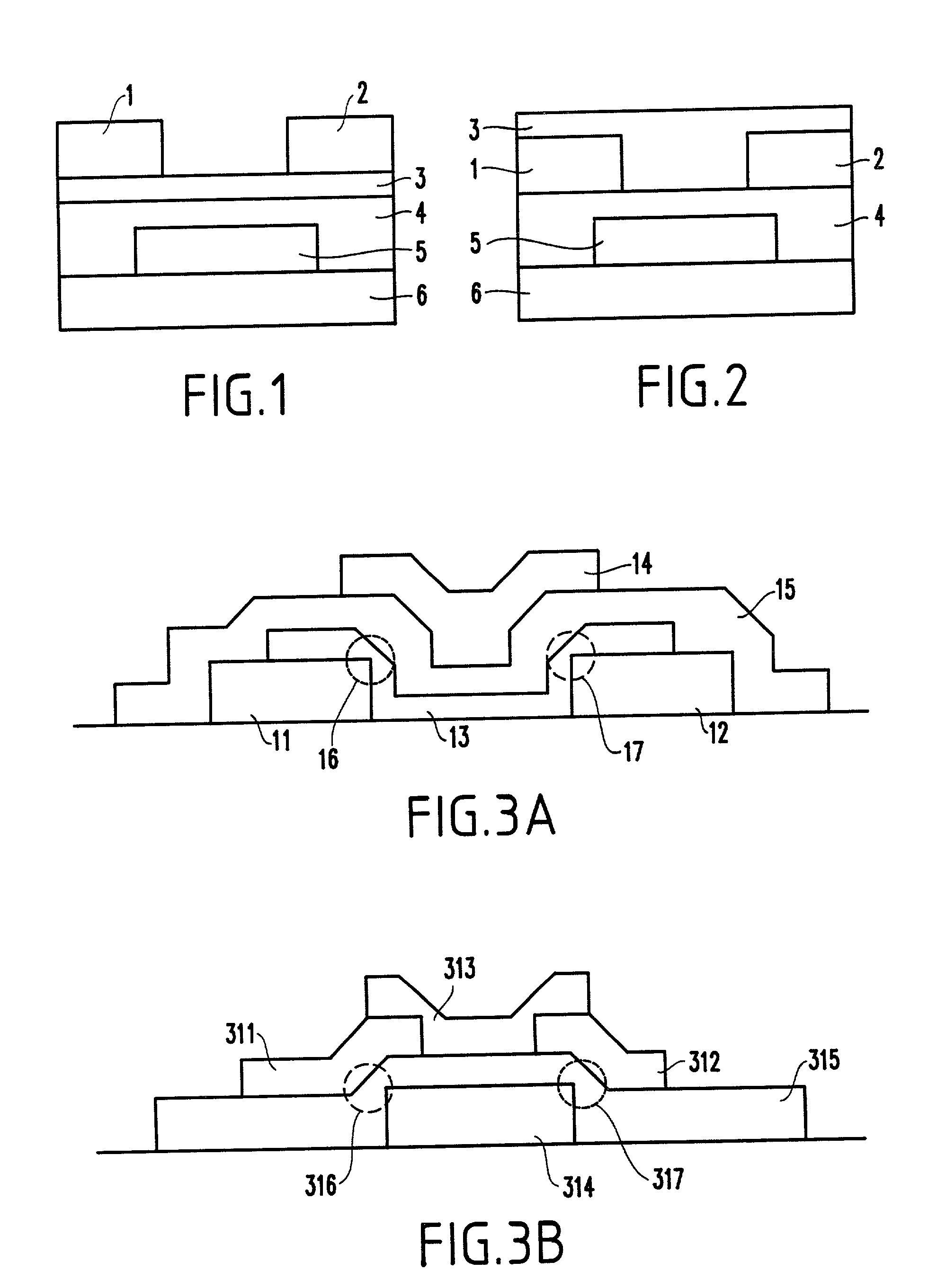

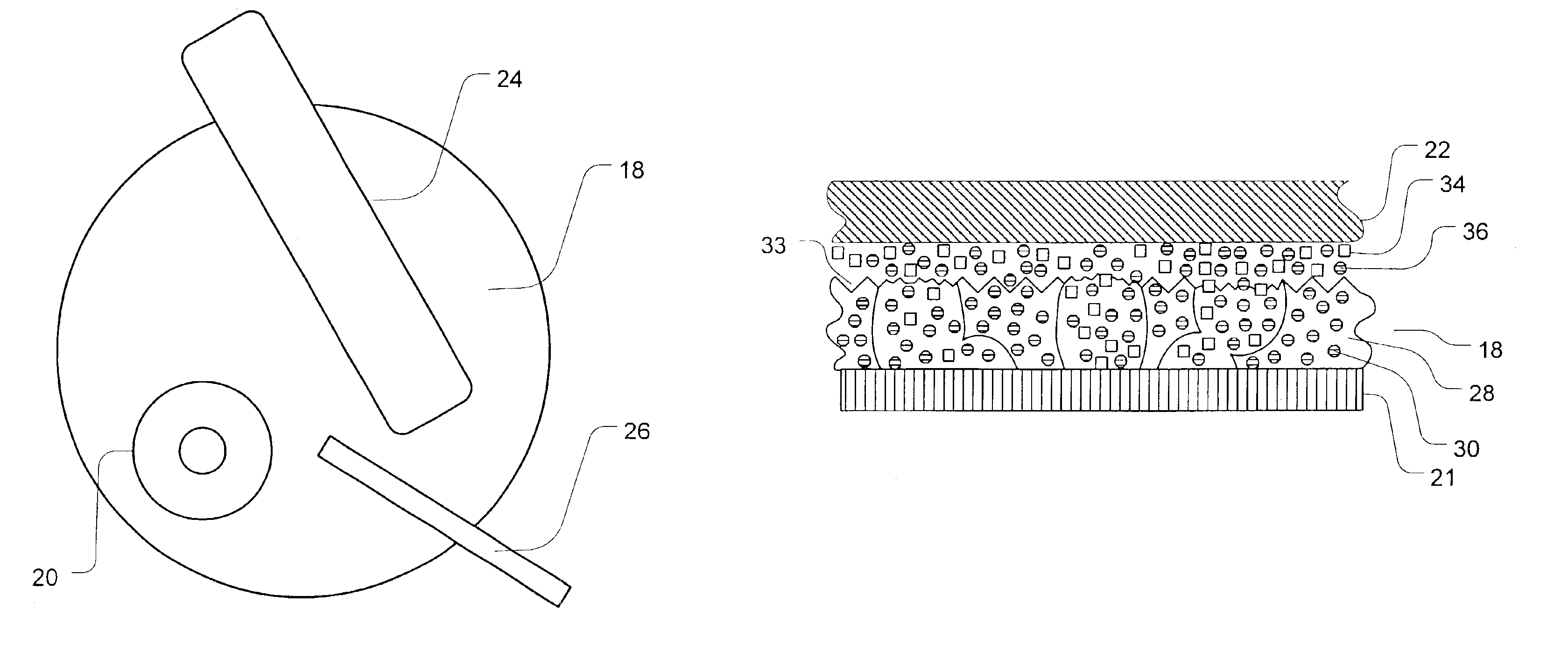

Customized polishing pads for CMP and methods of fabrication and use thereof

ActiveUS20060276109A1Easy to controlImpact on polishing propertyAdditive manufacturing apparatusLapping machinesPorositySurface engineering

The present application relates to polishing pads for chemical mechanical planarization (CMP) of substrates, and methods of fabrication and use thereof. The pads described in this invention are customized to polishing specifications where specifications include (but not limited to) to the material being polished, chip design and architecture, chip density and pattern density, equipment platform and type of slurry used. These pads can be designed with a specialized polymeric nano-structure with a long or short range order which allows for molecular level tuning achieving superior themo-mechanical characteristics. More particularly, the pads can be designed and fabricated so that there is both uniform and nonuniform spatial distribution of chemical and physical properties within the pads. In addition, these pads can be designed to tune the coefficient of friction by surface engineering, through the addition of solid lubricants, and creating low shear integral pads having multiple layers of polymeric material which form an interface parallel to the polishing surface. The pads can also have controlled porosity, embedded abrasive, novel grooves on the polishing surface, for slurry transport, which are produced in situ, and a transparent region for endpoint detection.

Owner:CMC MATERIALS INC

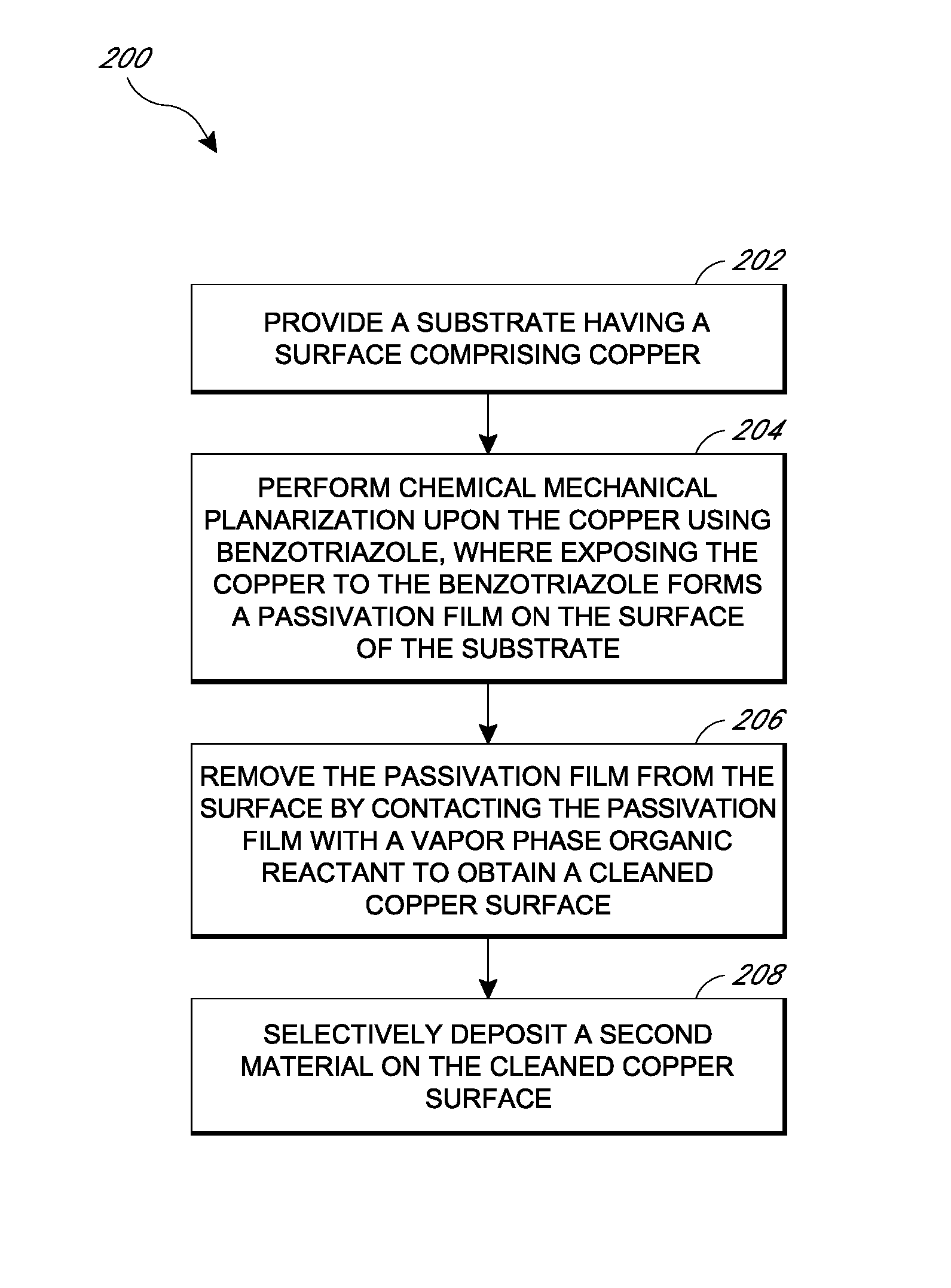

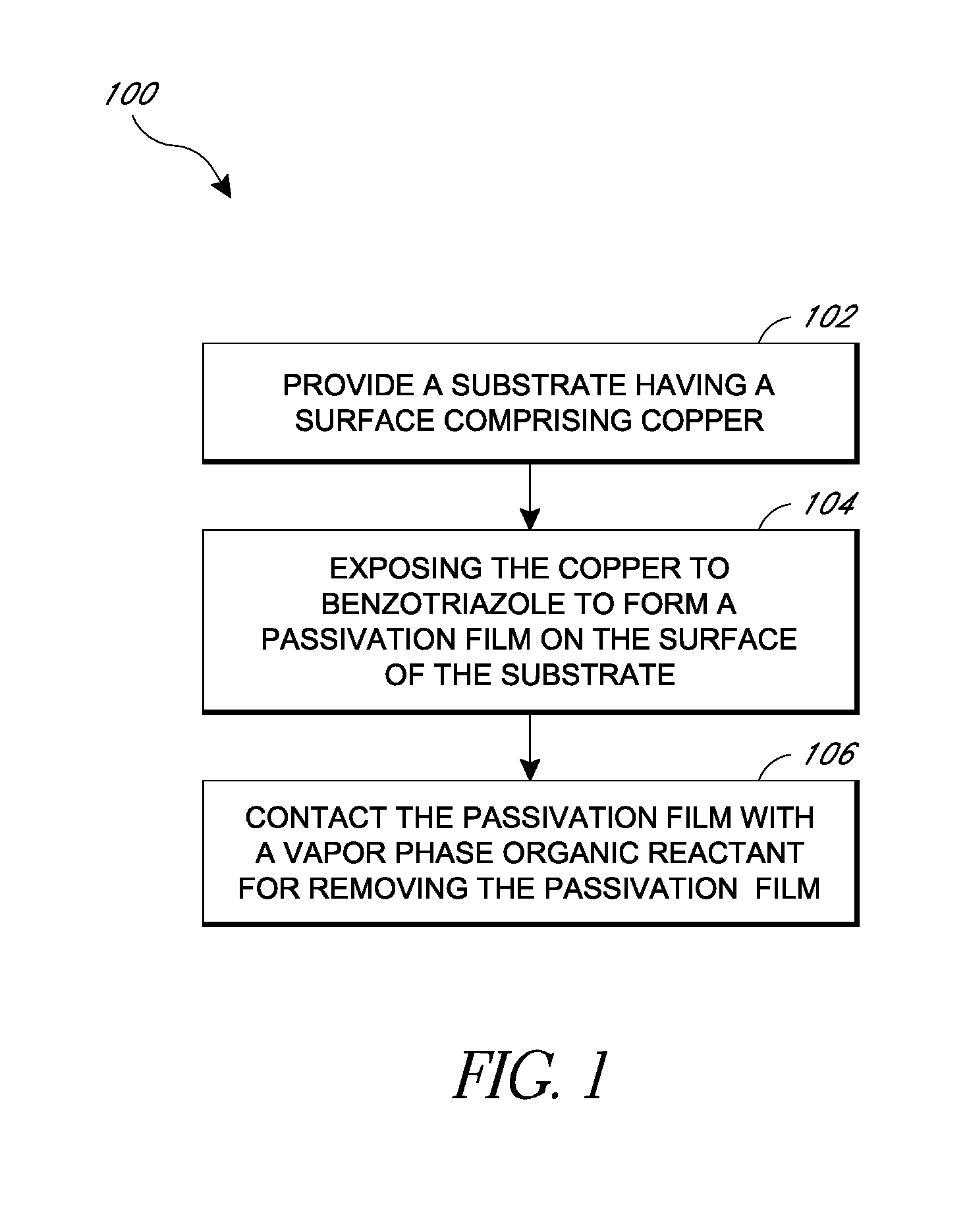

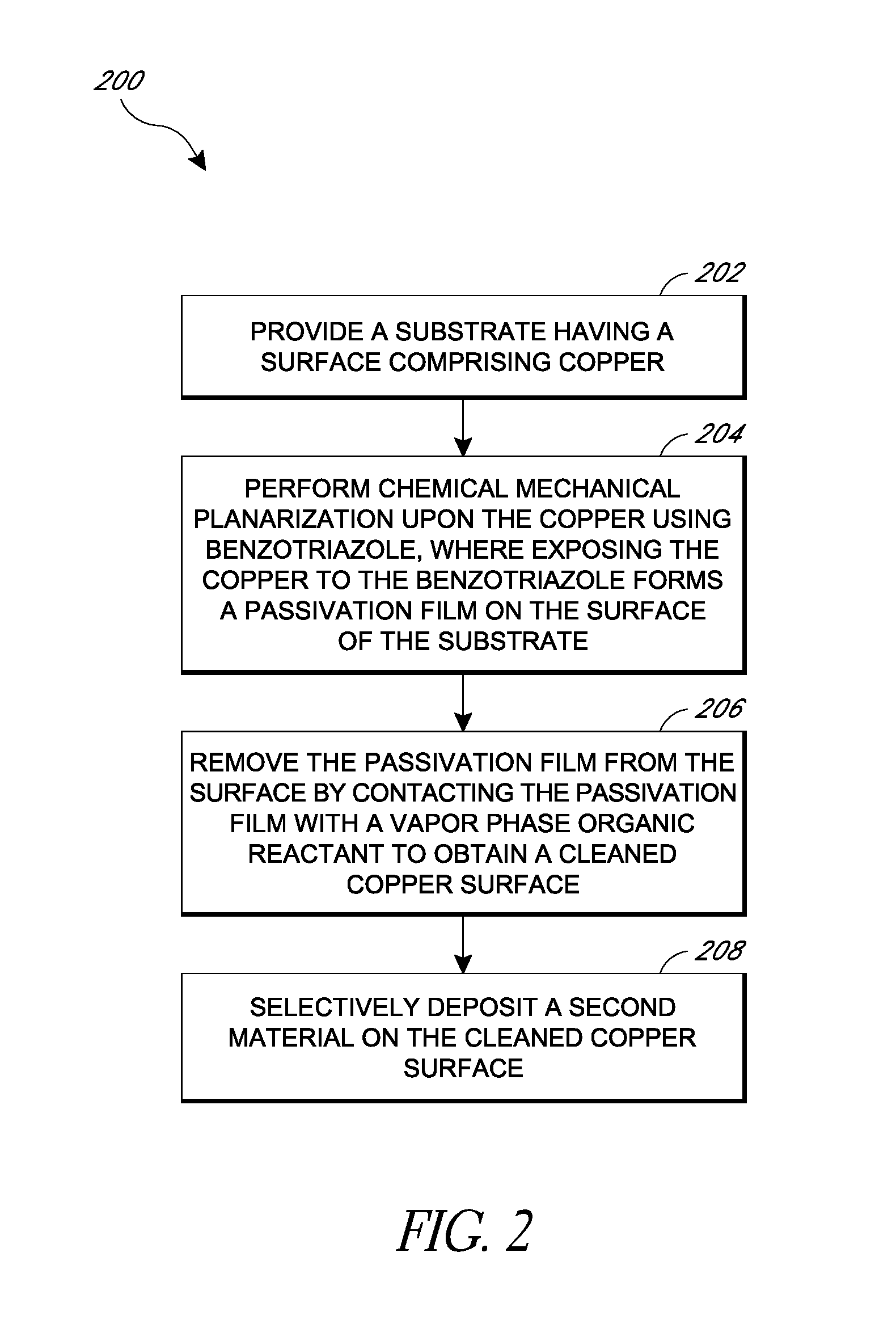

Removal of surface passivation

Methods for removing a passivation film from a copper surface can include exposing the passivation film to a vapor phase organic reactant, for example at a temperature of 100° C. to 400° C. In some embodiments, the passivation film may have been formed by exposure of the copper surface to benzotriazole, such as can occur during a chemical mechanical planarization process. The methods can be performed as part of a process for integrated circuit fabrication. A second material can be selectively deposited on the cleaned copper surface relative to another surface of the substrate.

Owner:ASM IP HLDG BV

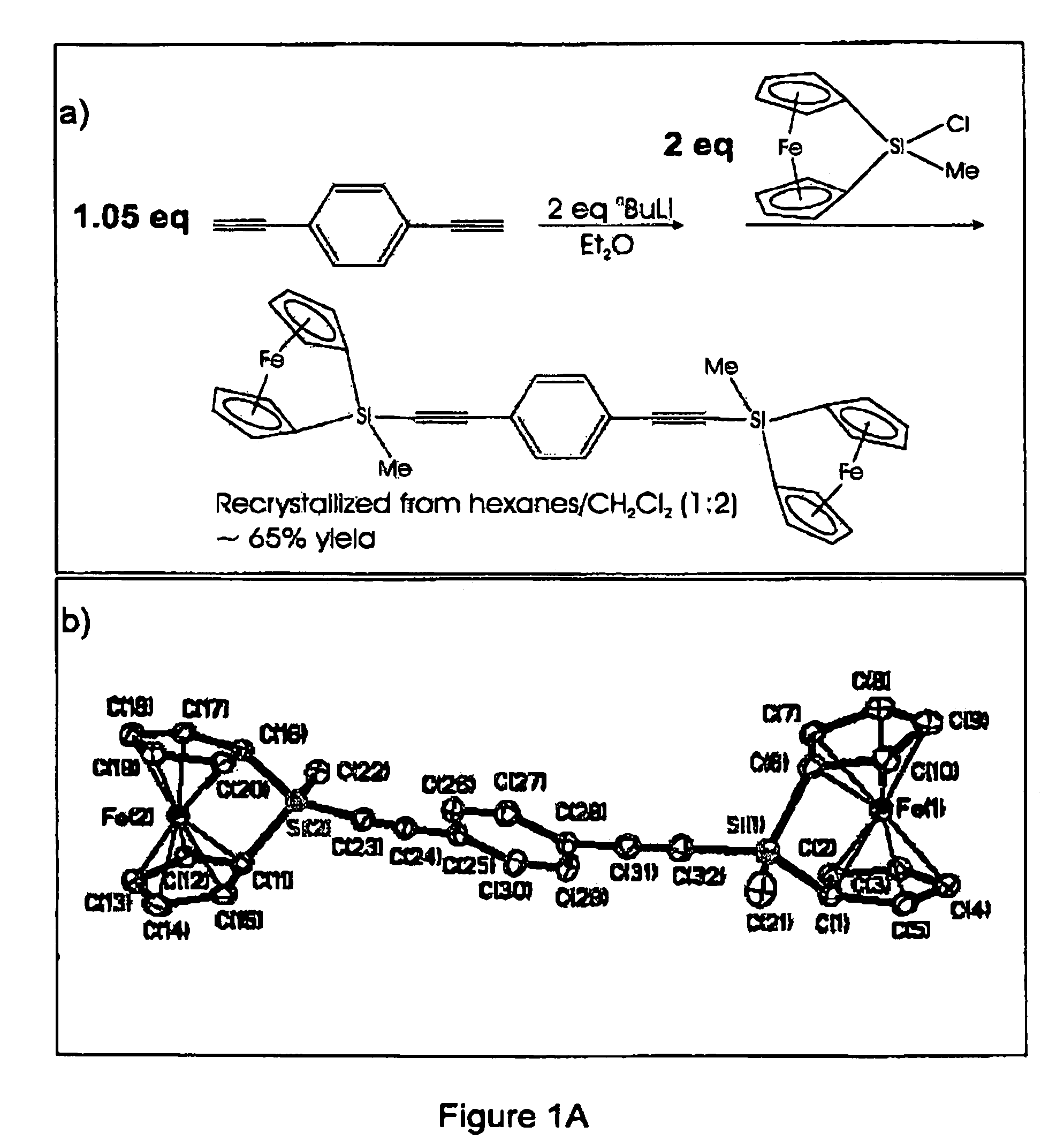

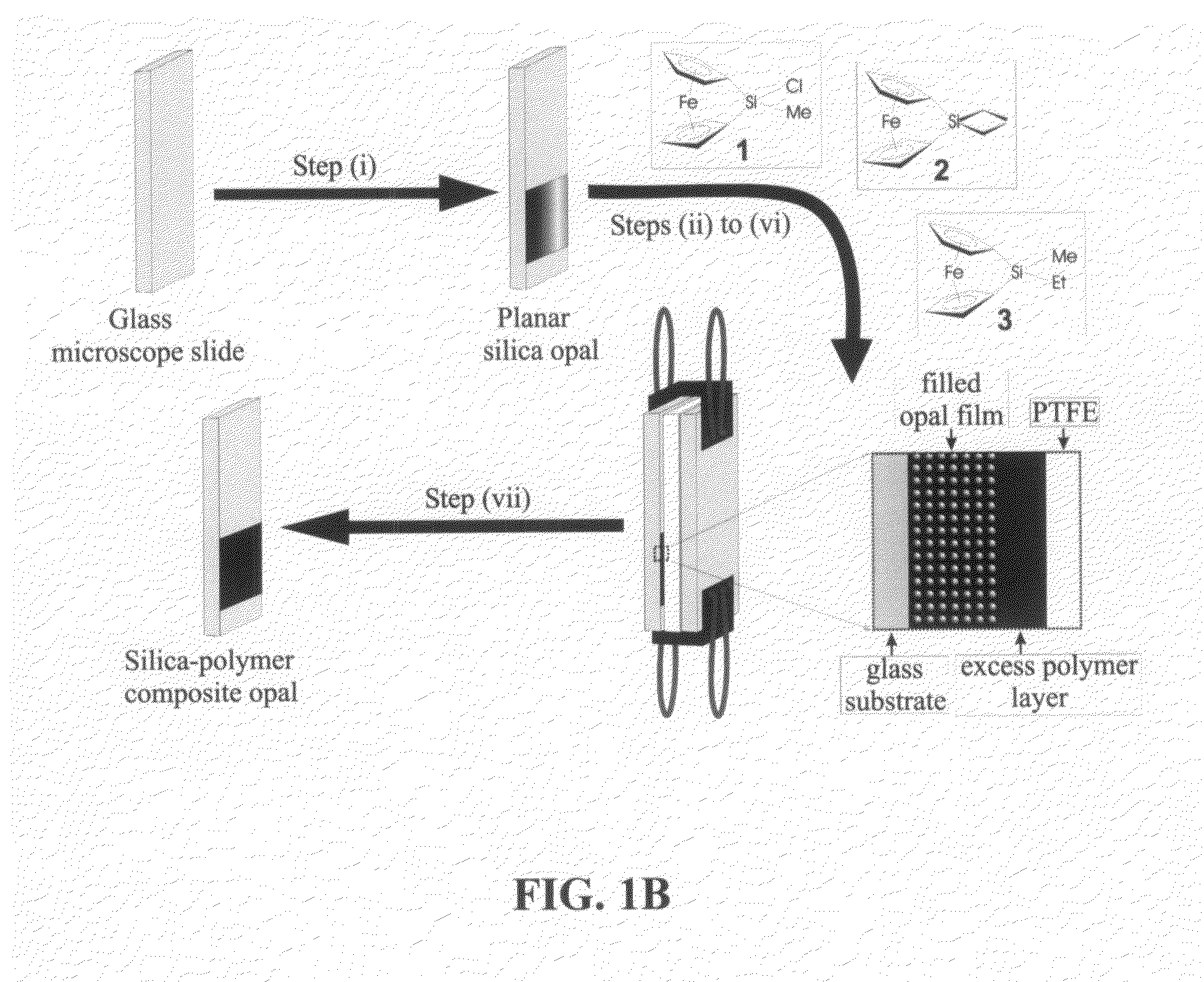

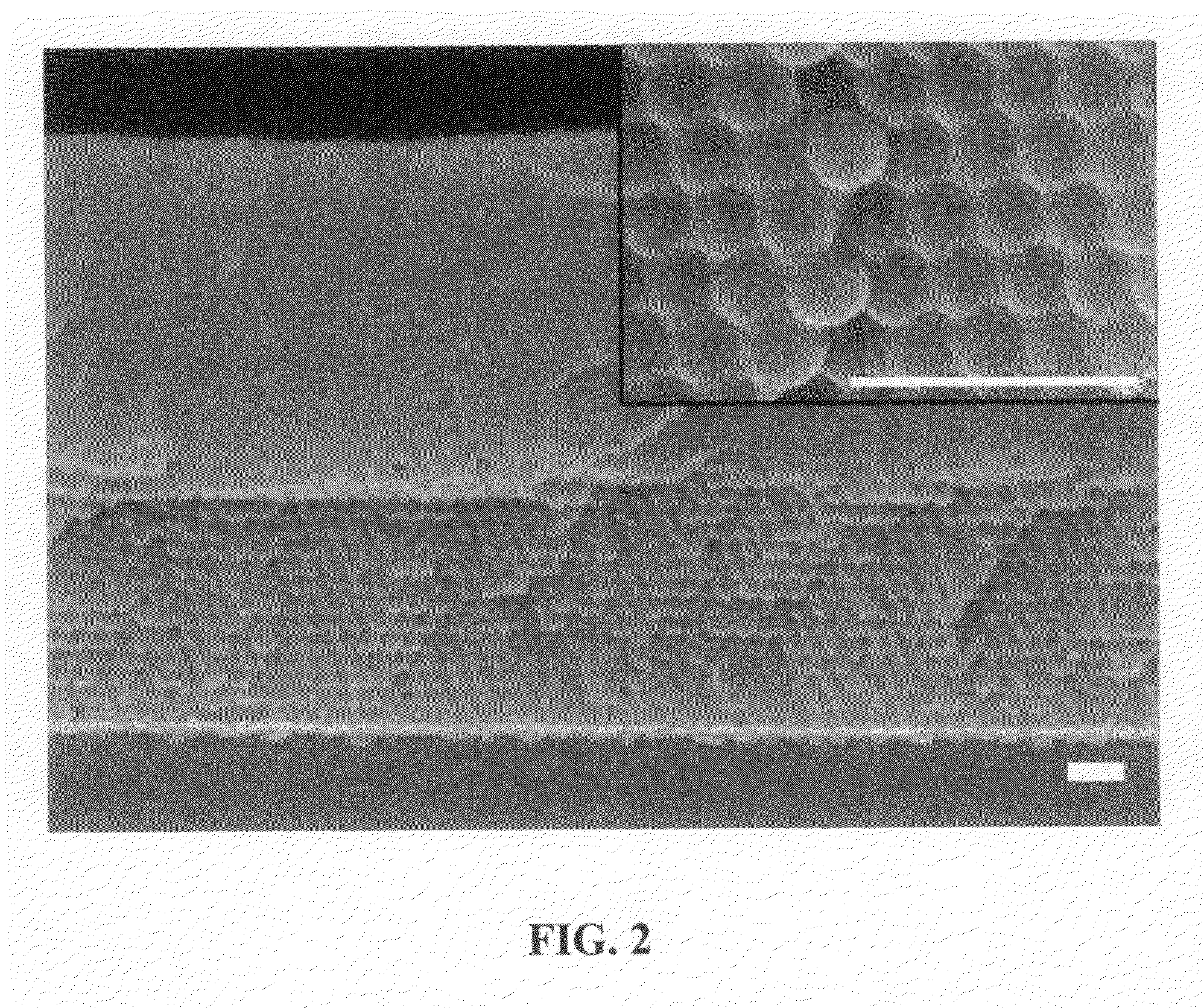

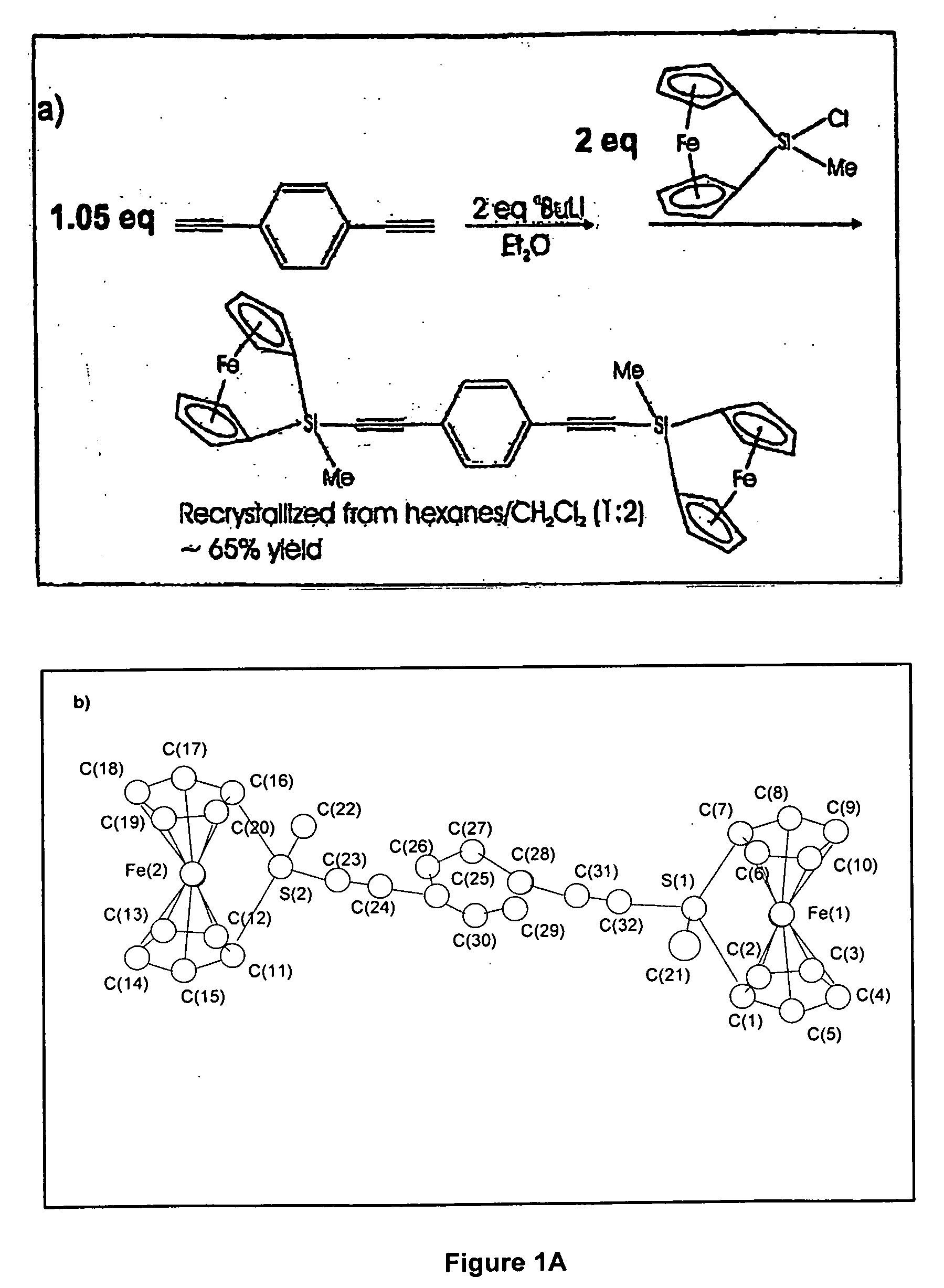

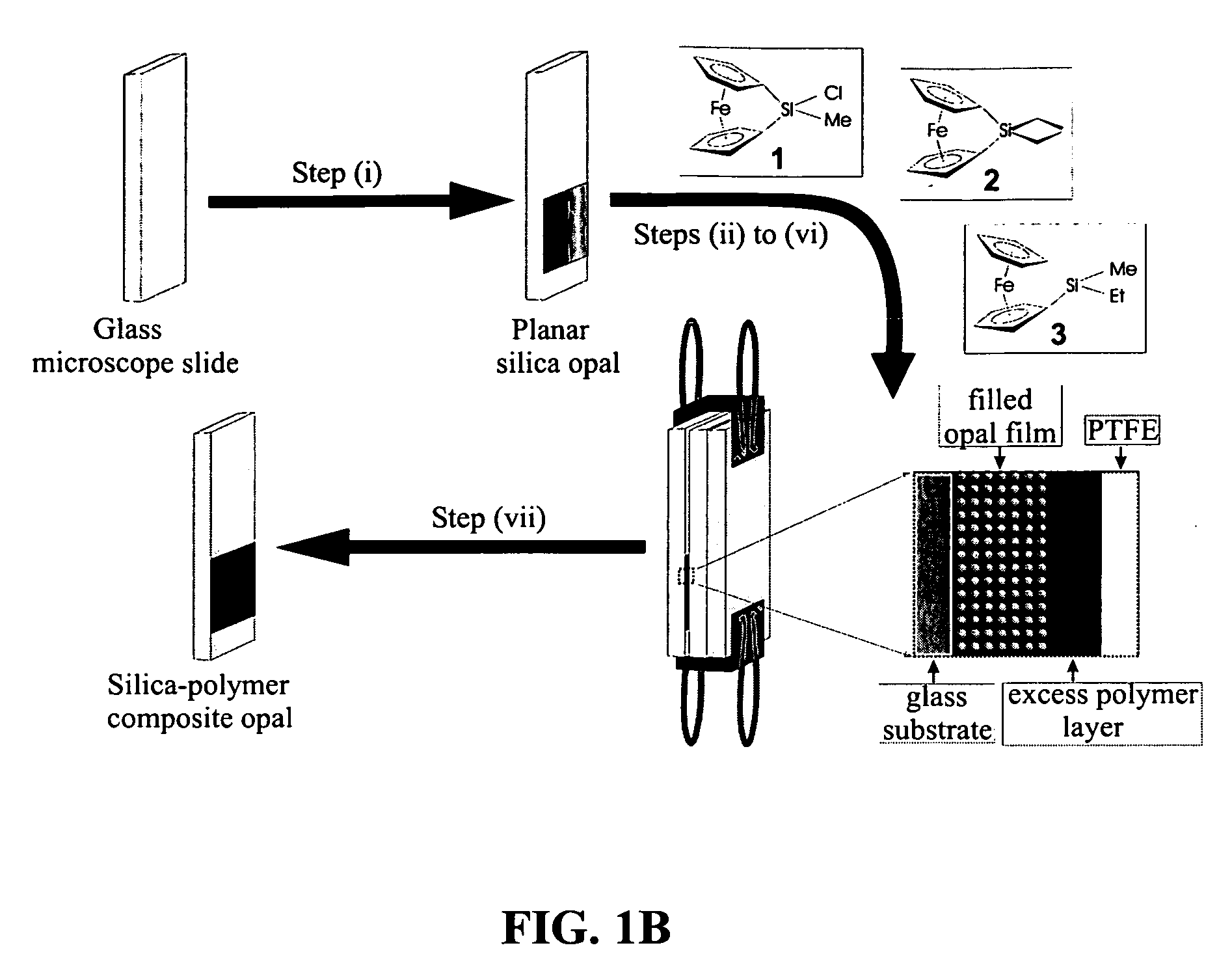

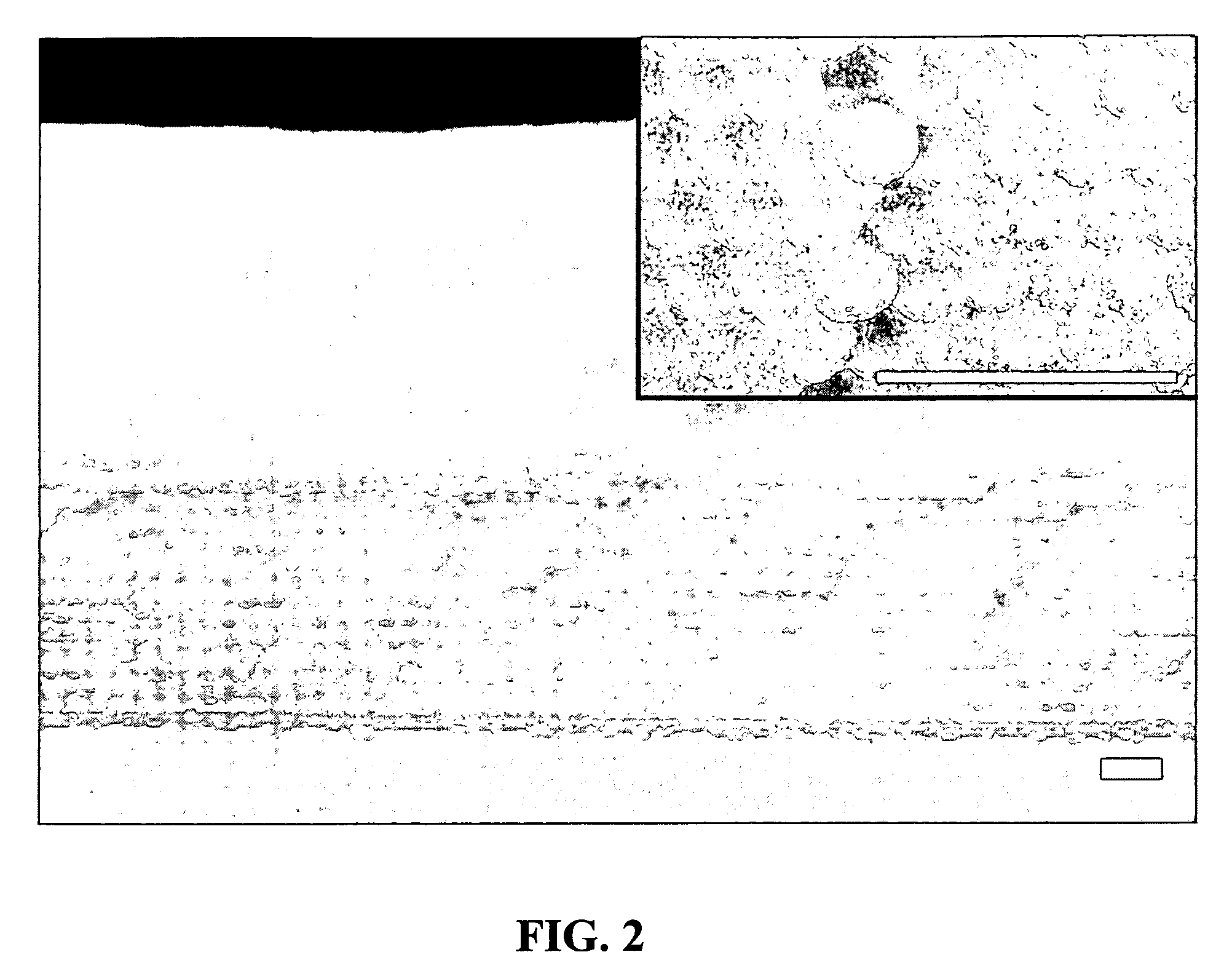

Widely wavelength tuneable polychrome colloidal photonic crystal device

The present invention discloses a widely wavelength tunable polychrome colloidal photonic crystal device whose optical Bragg diffraction stop bands and higher energy bands wavelength, width and intensity can be tuned in a continuous and fine, rapid and reversible, reproducible and predictable fashion and over a broad spectral range by a controlled expansion or contraction of the colloidal photonic lattice dimension, effected by a predetermined change in the electronic configuration of the composite material. In its preferred embodiment, the material is a composite in the form of a film or a patterned film or shape of any dimension or array of shapes of any dimension comprised of an organized array of microspheres in a matrix of a cross-linked metallopolymer network with a continuously variable redox state of charge and fluid content. The chemo-mechanical and electro-mechanical optical response of the colloidal photonic crystal-metallopolymer gel is exceptionally fast and reversible, attaining its fully swollen state from the dry shrunken state and vice versa on a sub-second time-scale. These composite materials can be inverted by removal of the constituent microspheres from the aforementioned colloidal photonic crystal metallopolymer-gel network to create a macroporous metallopolymer-gel network inverse colloidal photonic crystal film or patterned film or shape of any dimension optical Bragg diffraction stop bands and higher energy bands wavelength, width and intensity can be redox tuned in a continuous and fine, rapid and reversible, reproducible and predictable fashion and over a broad spectral range by a controlled expansion or contraction of the colloidal photonic lattice dimensions.

Owner:THE GOVERNINIG COUNCIL OF THE UNIV OF TORANTO

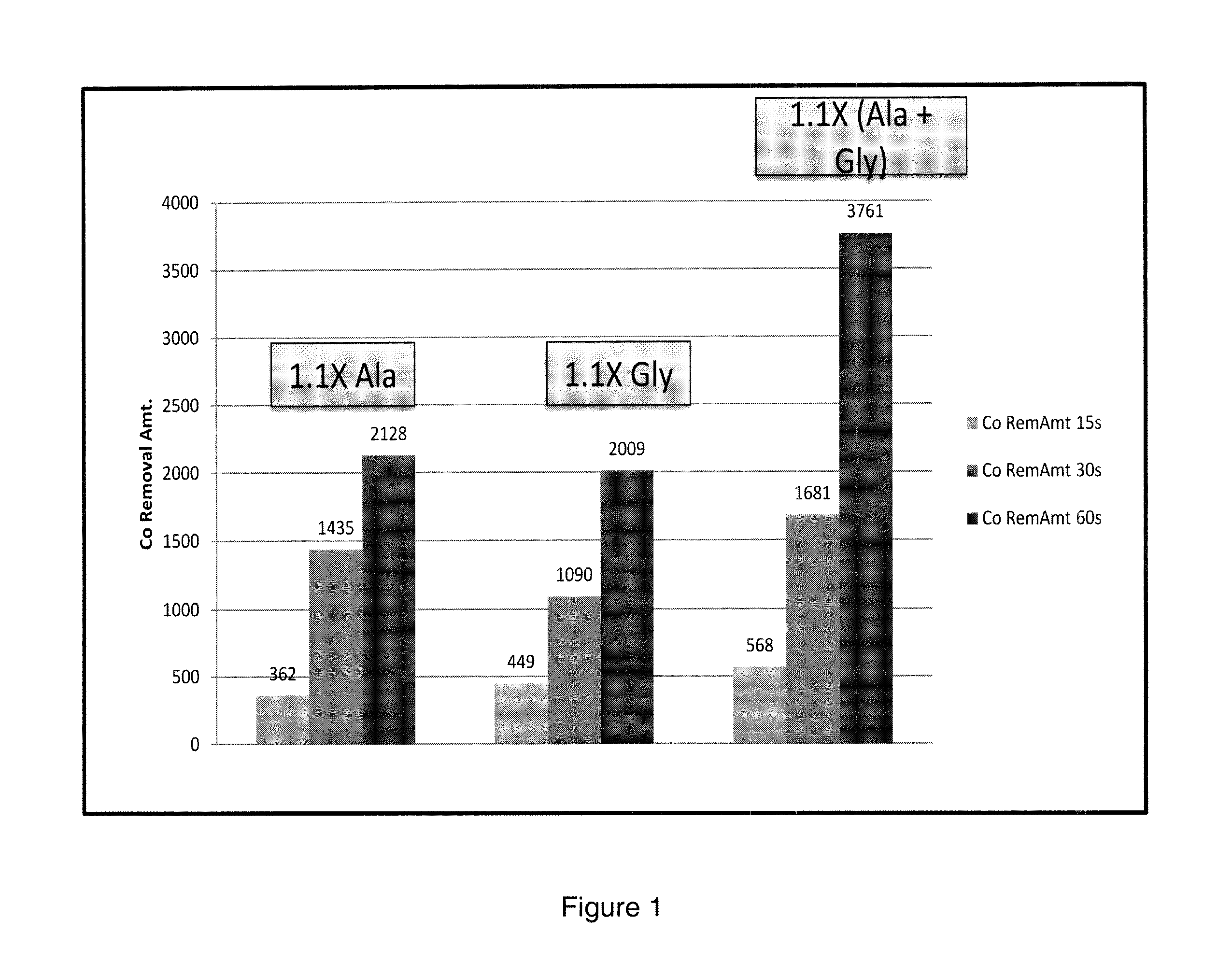

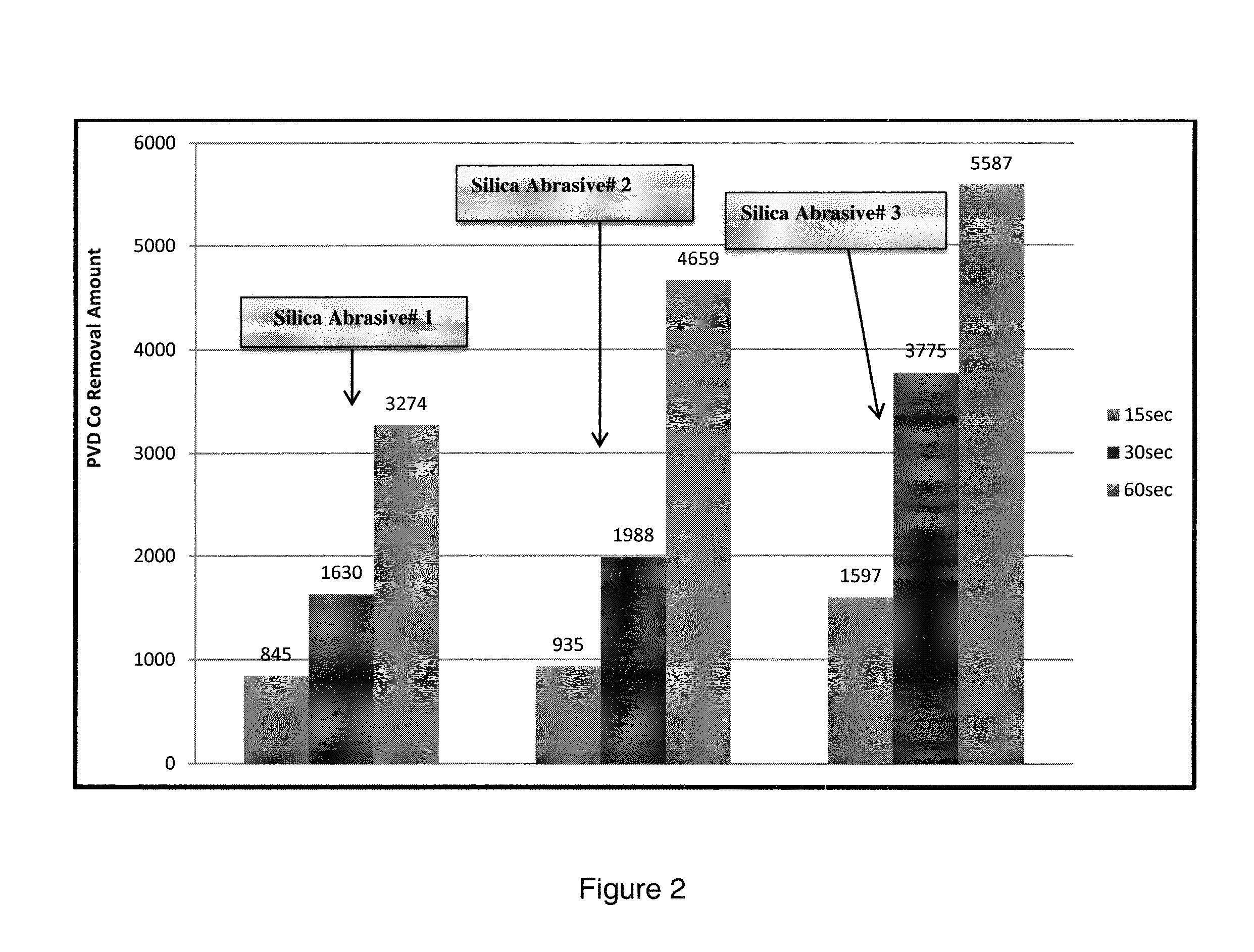

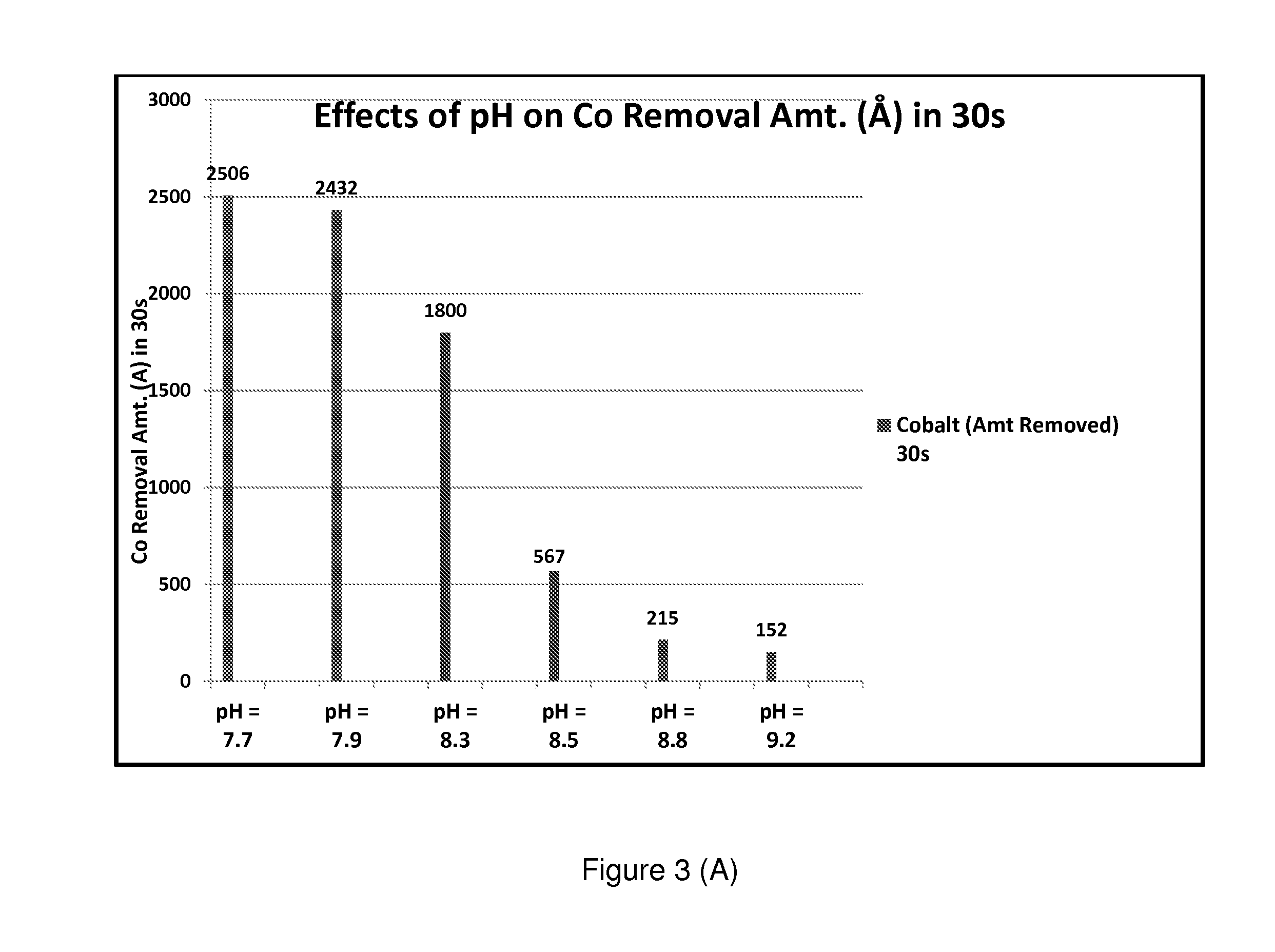

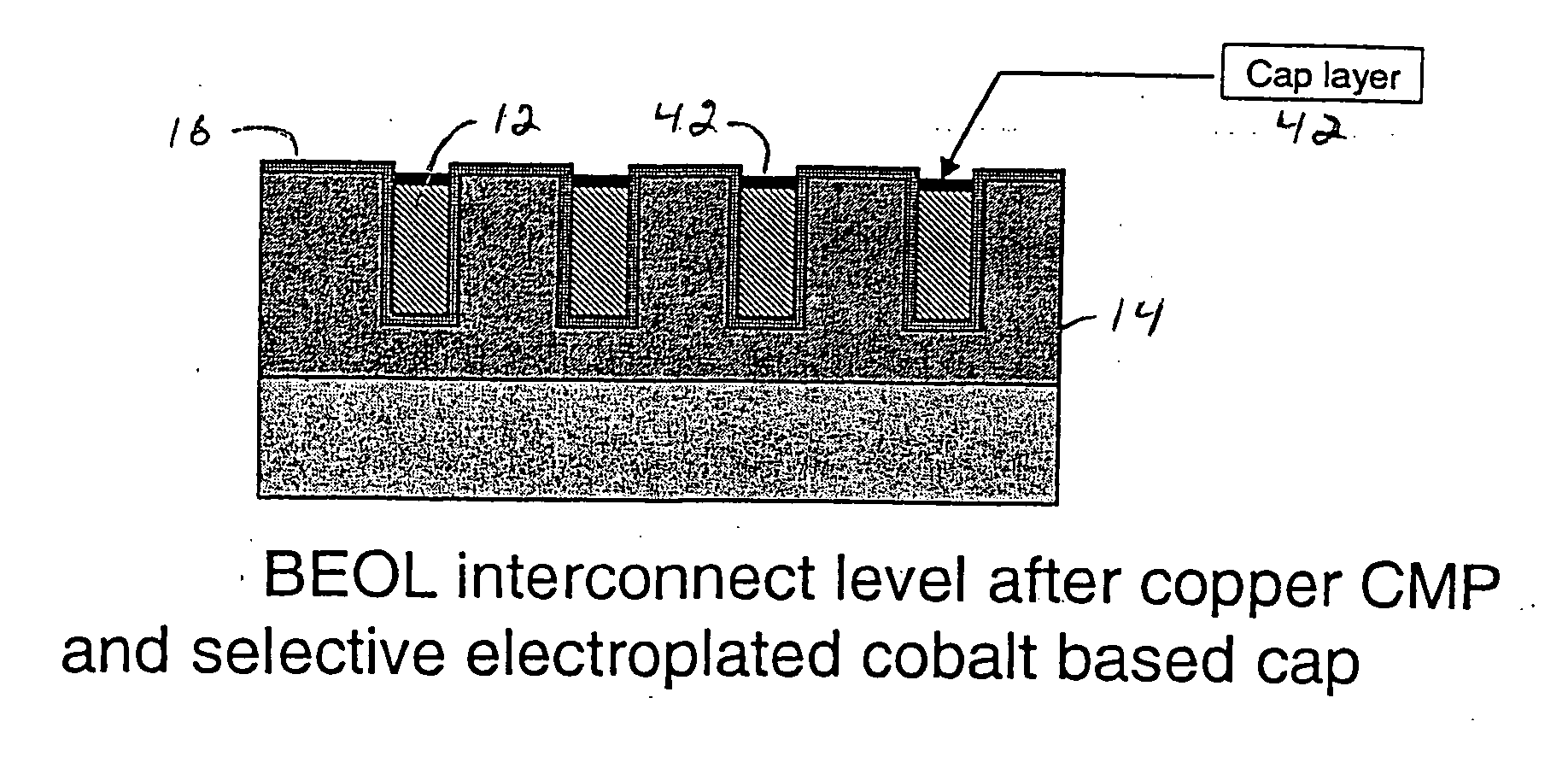

Chemical Mechanical Polishing (CMP) of Colbalt-Containing Substrate

ActiveUS20160027657A1High removal rateHigh and tunable Co film removal rateSemiconductor/solid-state device manufacturingSurface treatment compositionsCobaltHigh selectivity

Chemical mechanical polishing (CMP) compositions, methods and systems for polish cobalt or cobalt-containing substrates are provided. Dual, or at least two chelators were used in the CMP polishing compositions as complexing agents for achieving the unique synergetic effects to afford high, tunable Co removal rates and with low static etch rates on Co film surface for the efficient Co corrosion protection during CMP process. The cobalt chemical mechanical polishing compositions also provide very high selectivity of Co film vs. other barrier layers, such as Ta, TaN, Ti, and TiN, and dielectric film, such as TEOS, SiNx, low-k, and ultra low-k films.

Owner:VERSUM MATERIALS US LLC

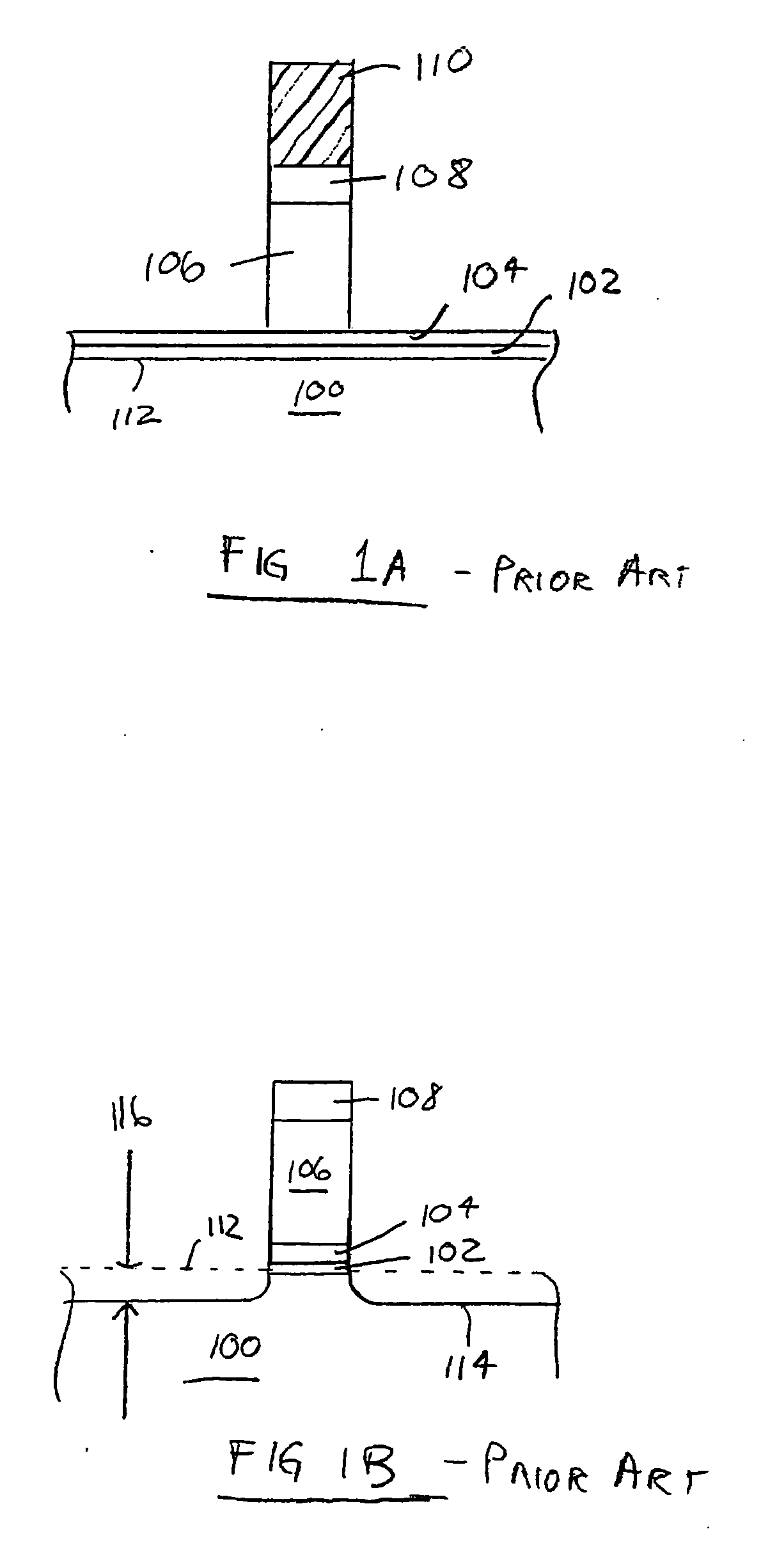

Layer transfer of low defect SiGe using an etch-back process

InactiveUS6890835B1Reduce defectsQuality improvementTransistorPolycrystalline material growthThermal treatmentSemiconductor

A method for forming strained Si or SiGe on relaxed SiGe on insulator (SGOI) or a SiGe on Si heterostructure is described incorporating growing epitaxial Si1-yGey layers on a semiconductor substrate, smoothing surfaces by Chemo-Mechanical Polishing, bonding two substrates together via thermal treatments and transferring the SiGe layer from one substrate to the other via highly seletive etching using SiGe itself as the etch-stop. The transferred SiGe layer may have its upper surface smoothed by CMP for epitaxial deposition of relaxed Si1-yGey, and strained Si1-yGey depending upon composition, strained Si, strained SiC, strained Ge, strained GeC, and strained Si1-yGeyC or a heavily doped layer to make electrical contacts of the SiGe / Si heterojunction diodes.

Owner:GLOBALFOUNDRIES INC

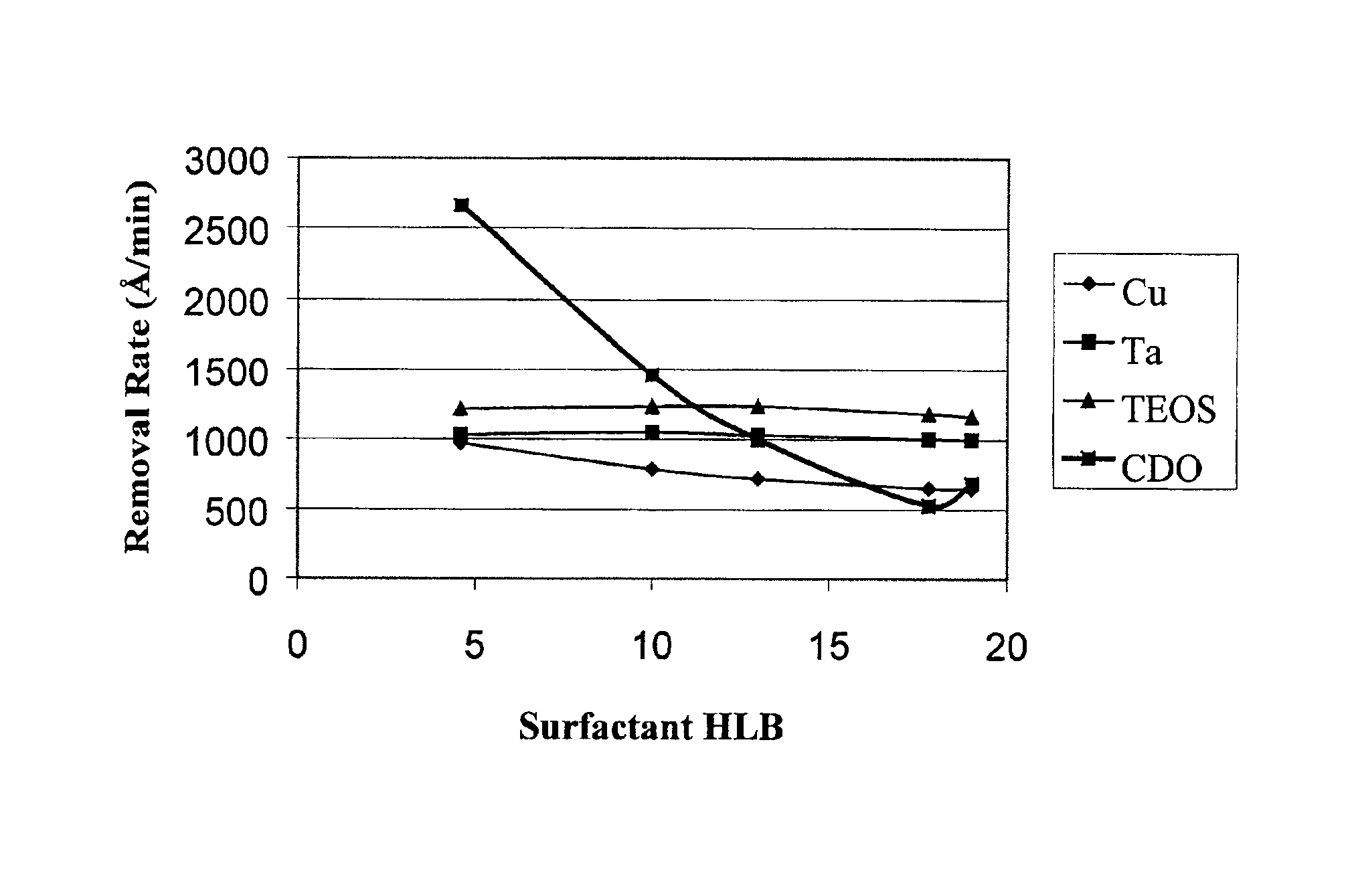

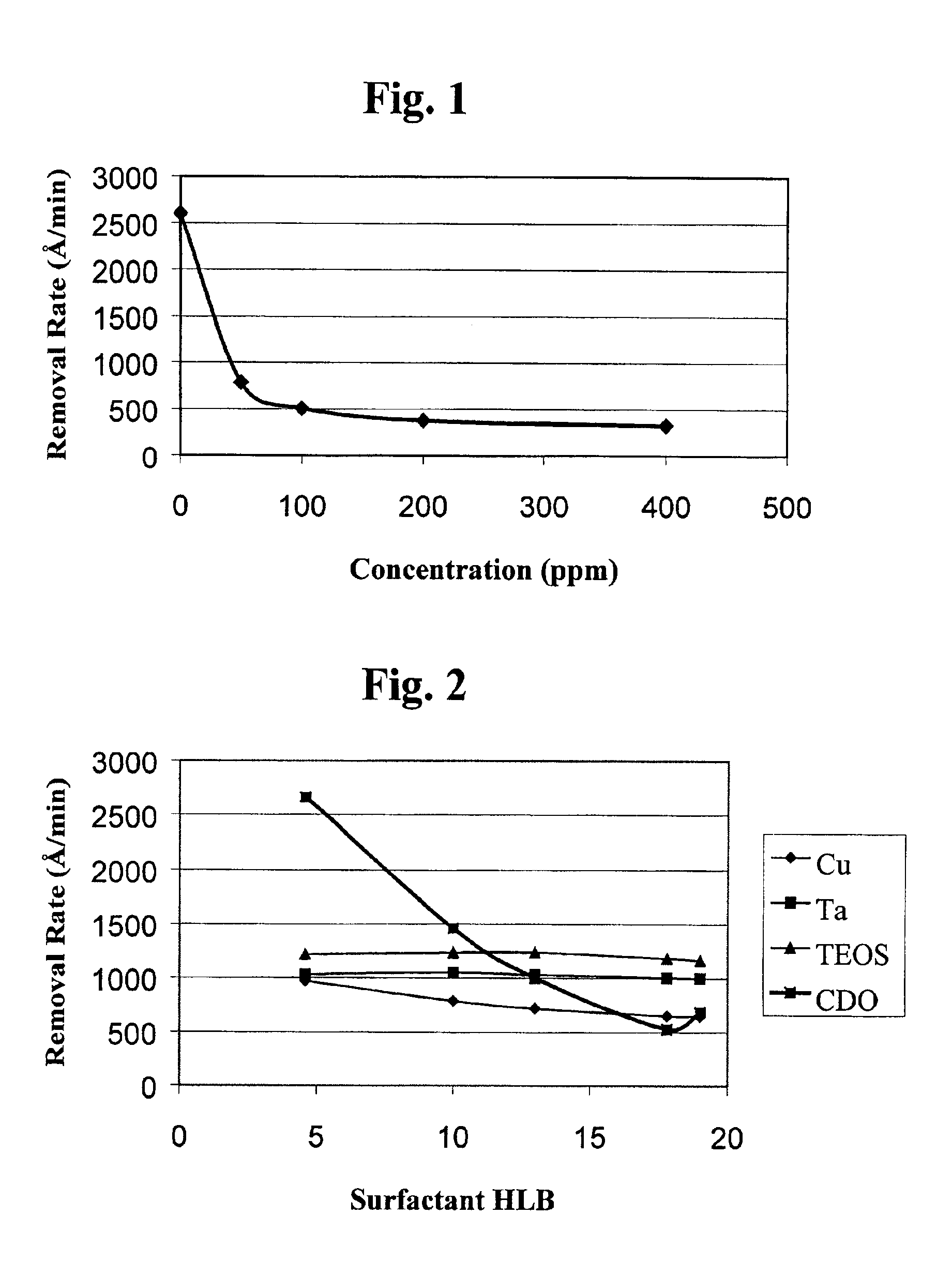

CMP compositions for low-k dielectric materials

InactiveUS6974777B2Non-ionic surface-active compoundsOther chemical processesLow-k dielectricNonionic surfactant

The invention provides a method of polishing a substrate containing a low-k dielectric layer comprising (i) contacting the substrate with a chemical-mechanical polishing system comprising (a) an abrasive, a polishing pad, or a combination thereof, (b) an amphiphilic nonionic surfactant, and (c) a liquid carrier, and (ii) abrading at least a portion of the substrate to polish the substrate.

Owner:CMC MATERIALS INC

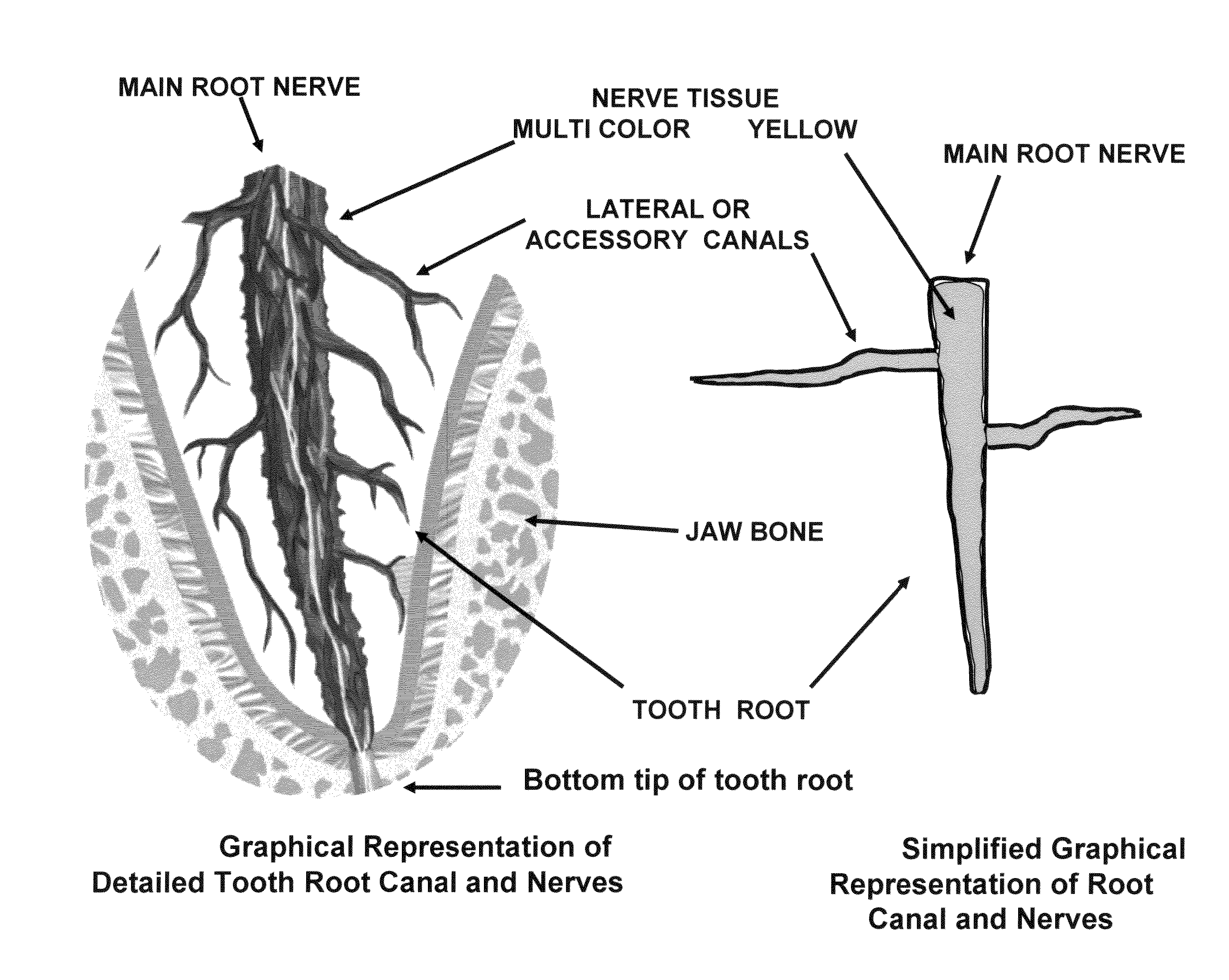

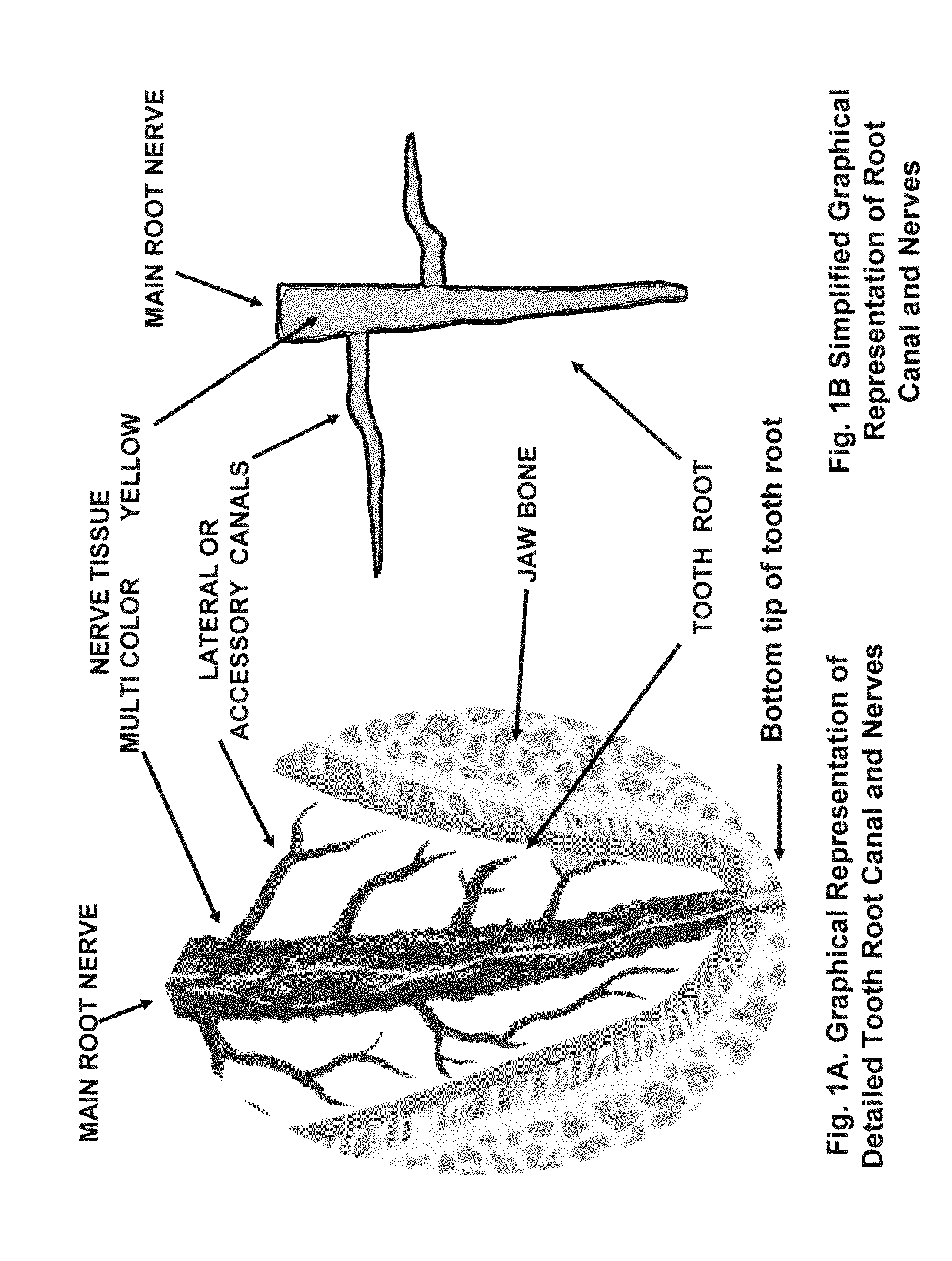

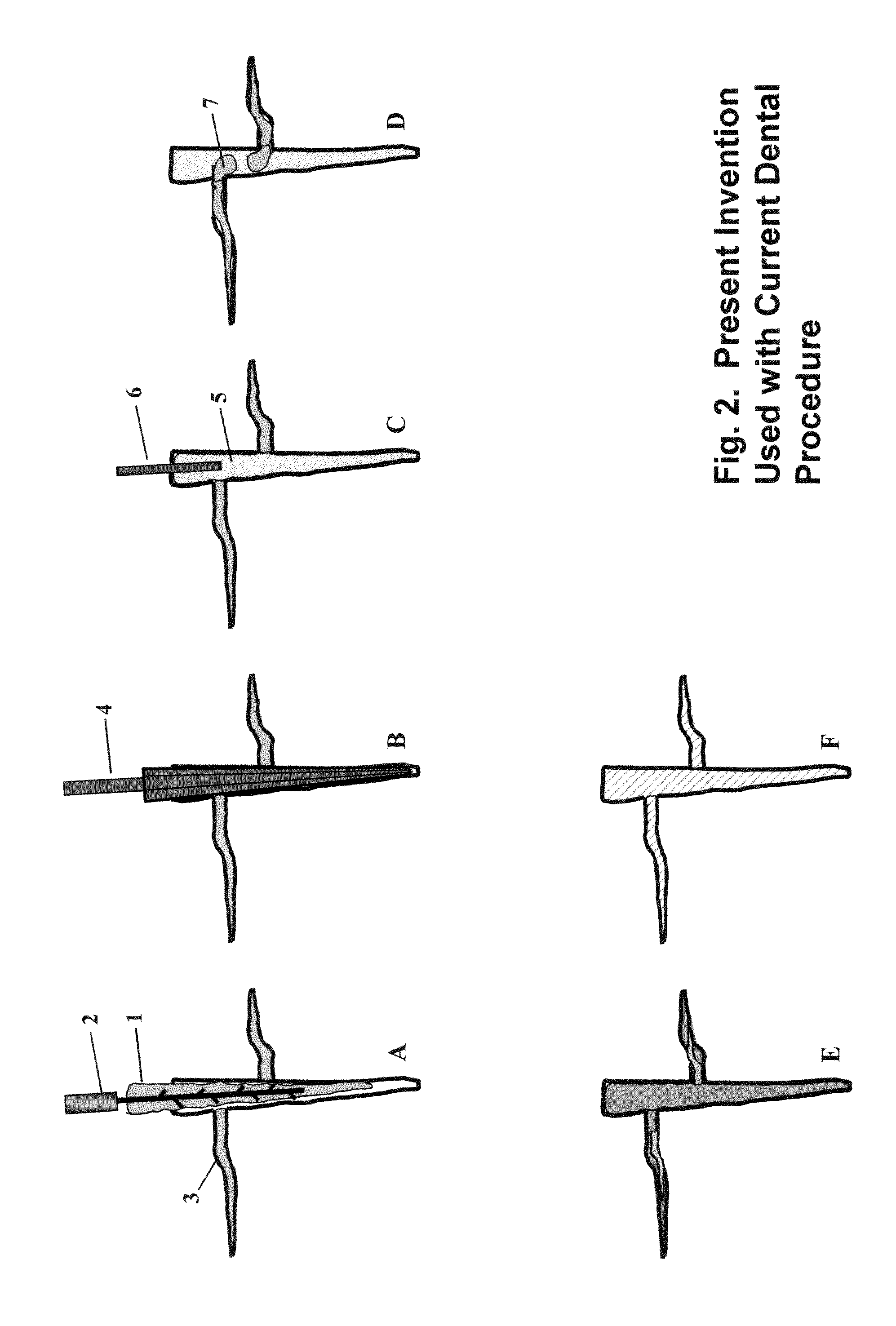

Energetically activated biomedical nanotheurapeutics integrating dental and medical treatments and procedures

A method that includes the following effects: the ability to expand, porositize, clean, decontaminate, debride, break-down and / or destroys, or aids and accentuates the dissolution or extraction of biological structures, nerves and tissues. The methodology uses nano-technology and / or other chemistries may or may not be excited by energy sources to expand and porositize the tissue, which enhances the penetration and effectiveness and acceleration of subsequent chemical, mechanical, and / or procedural steps in the protocol or process. Furthermore, the method includes the ability to associate with and / or initiate in the reconstructive growth and healing process associated with healthy tissue after surgery and / or the ability to destroy diseased or necrotic tissues or cells. The method also includes the ability to begin, construct or stage the activation of cells and / or tissues, including the area of transplantation and use in stem or primordial cell accentuation, their attachment and / or stimulation for growth and differentiation.

Owner:PIPSTEK LLC

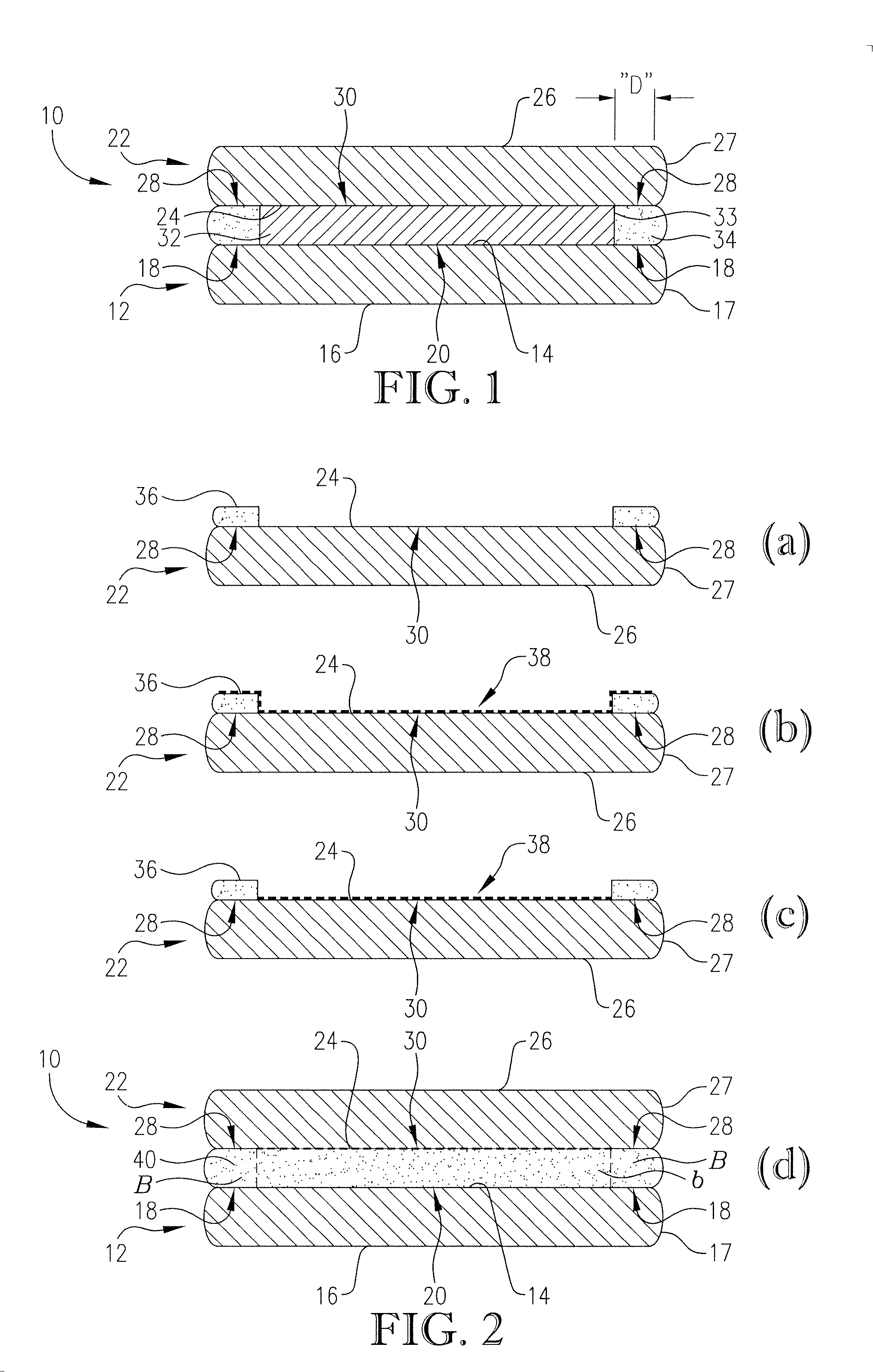

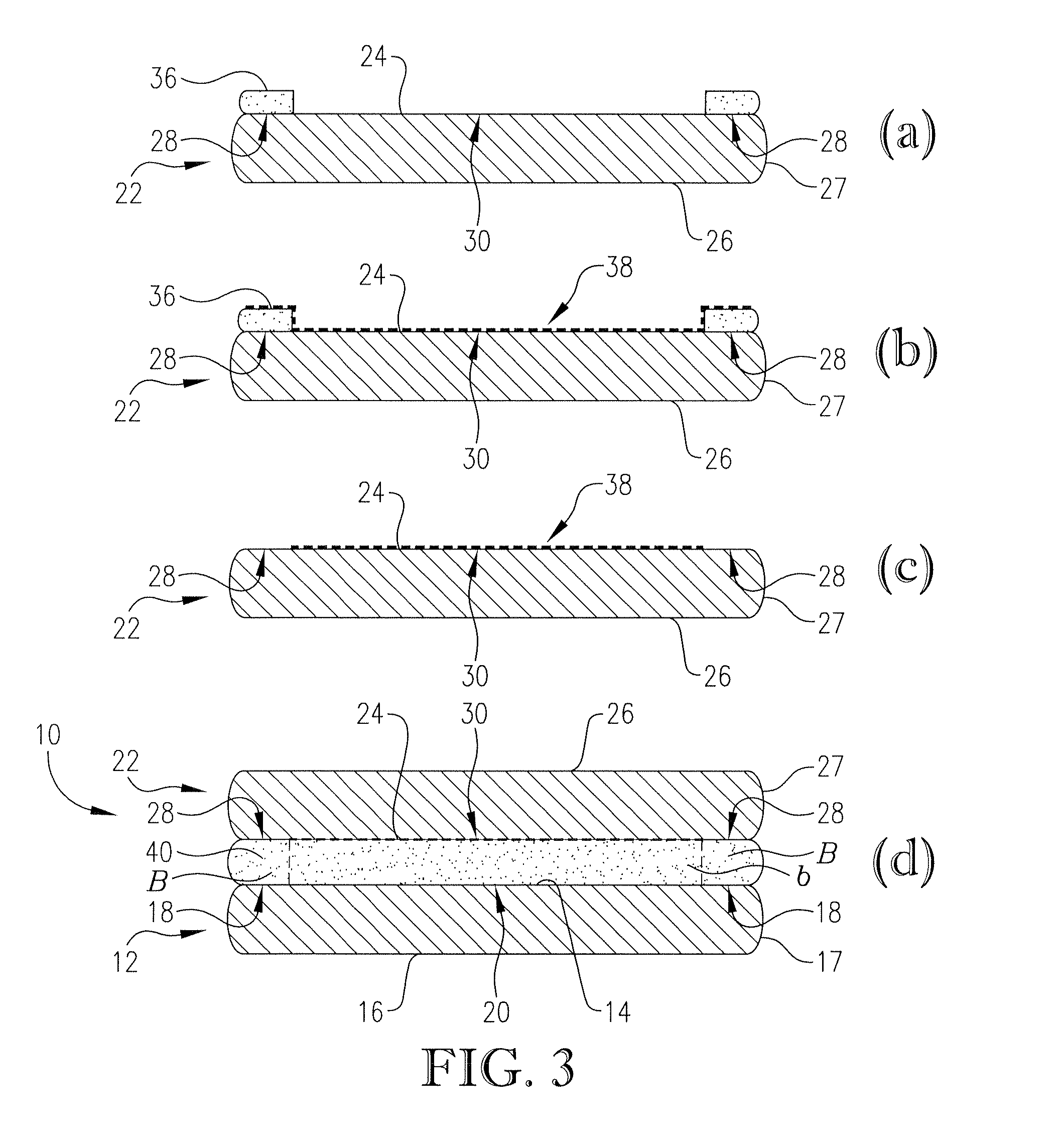

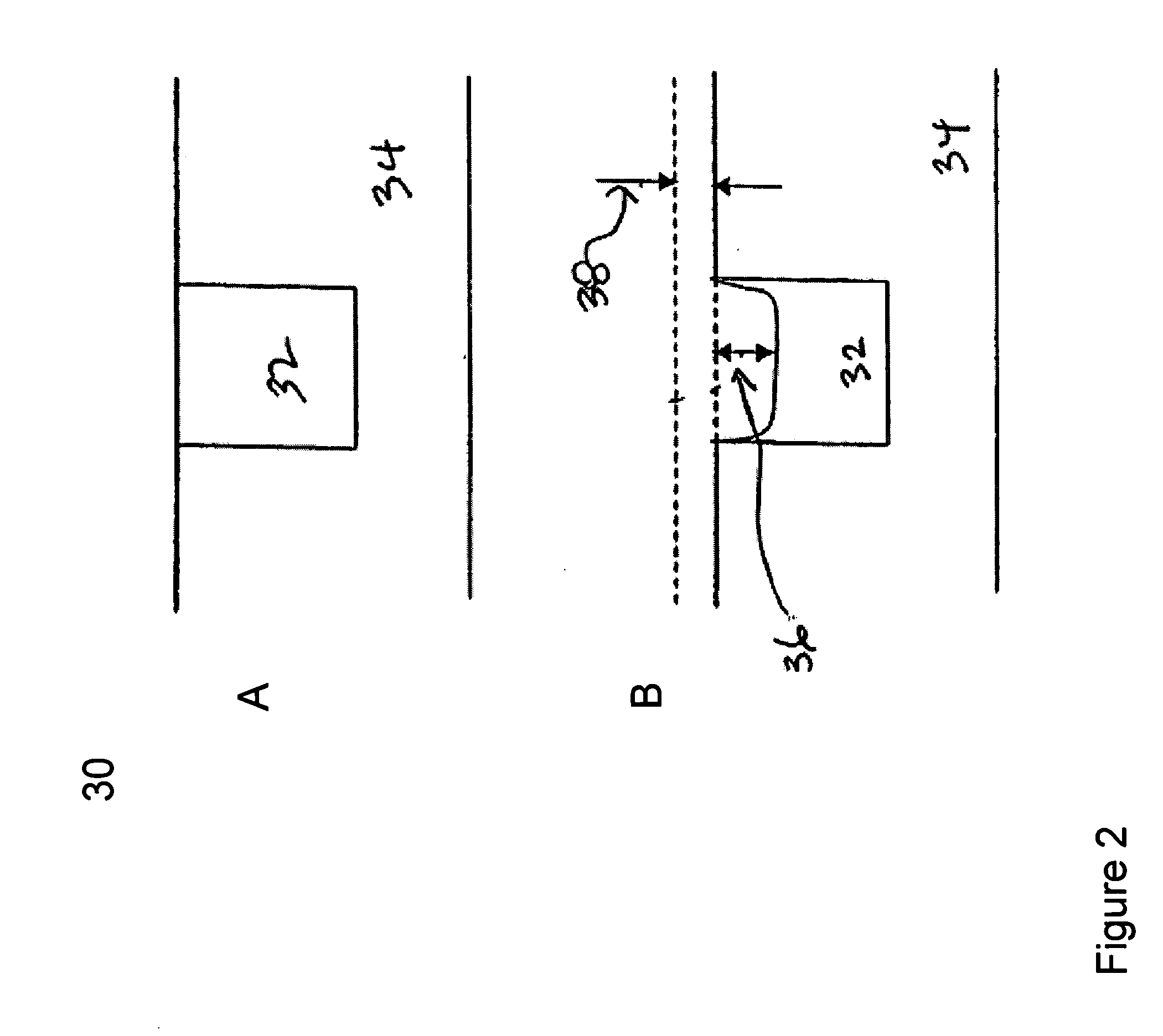

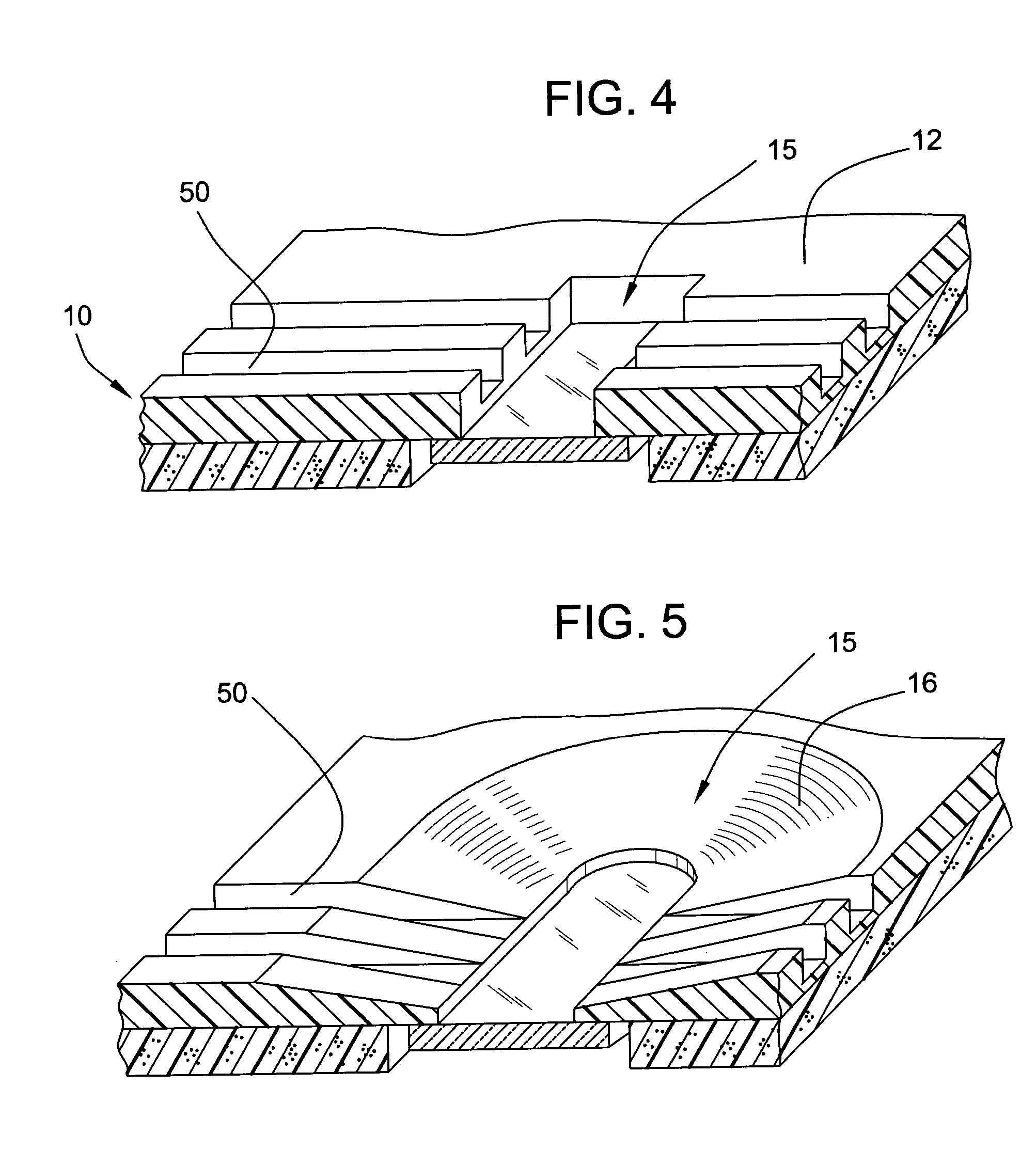

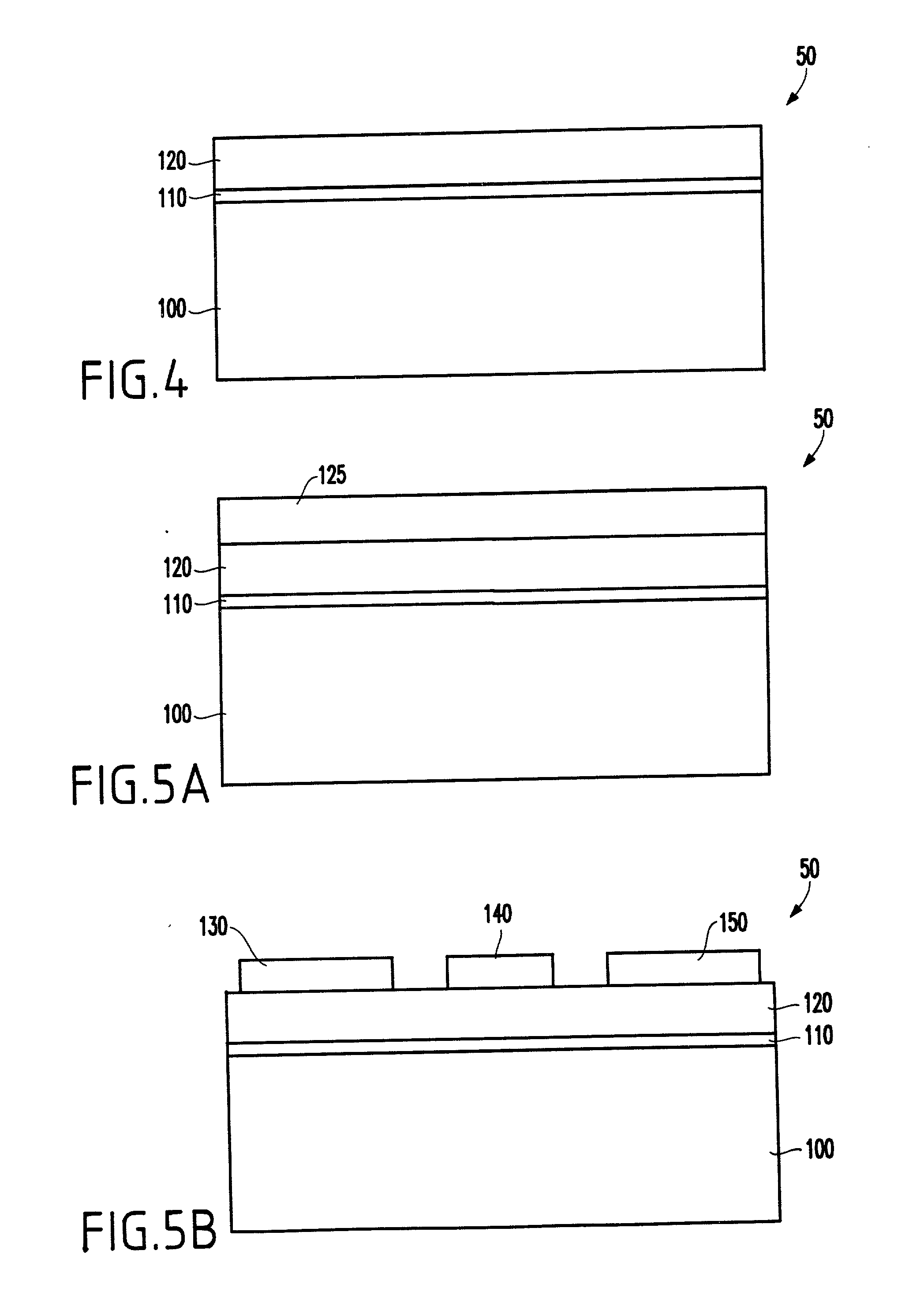

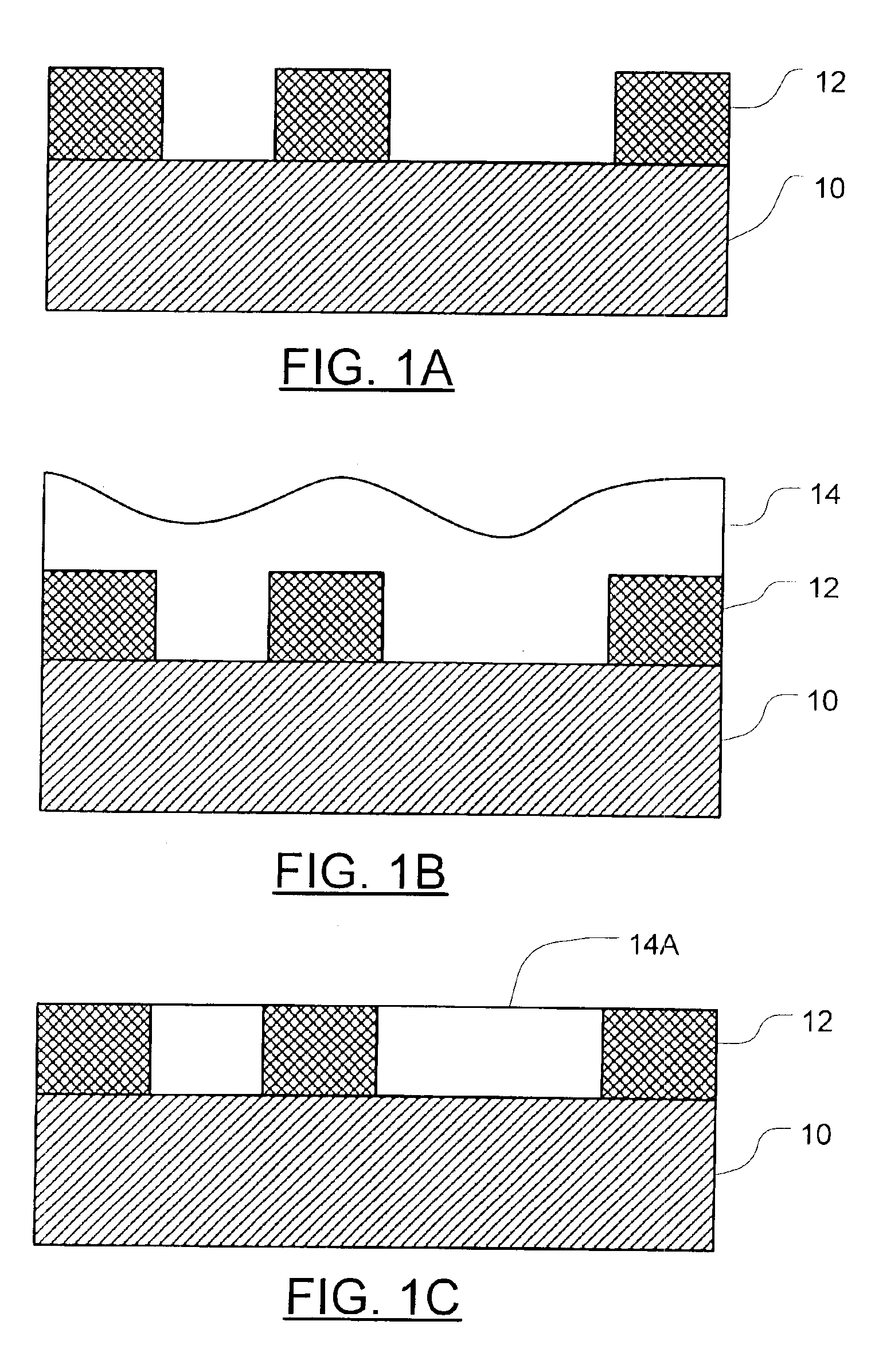

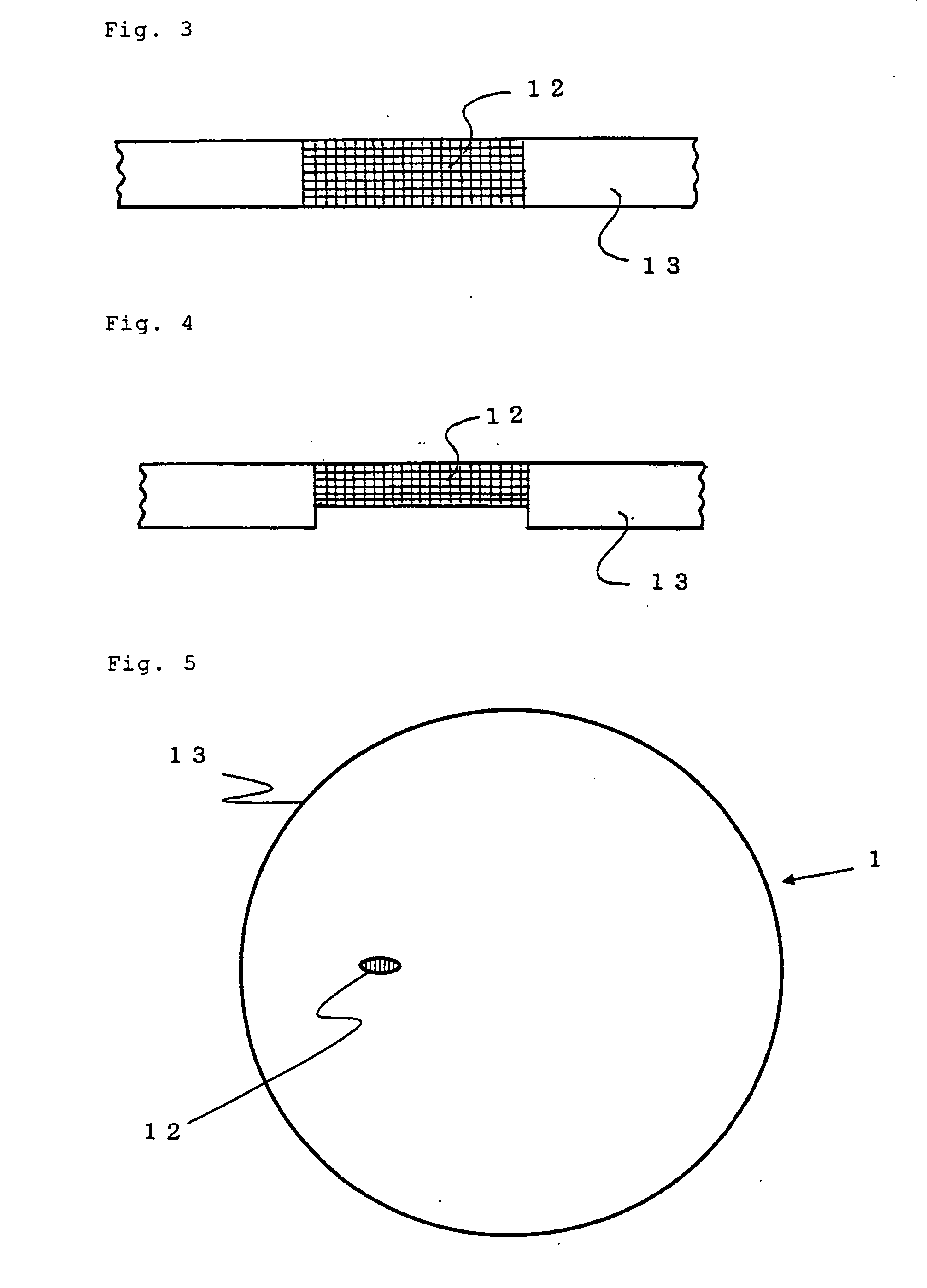

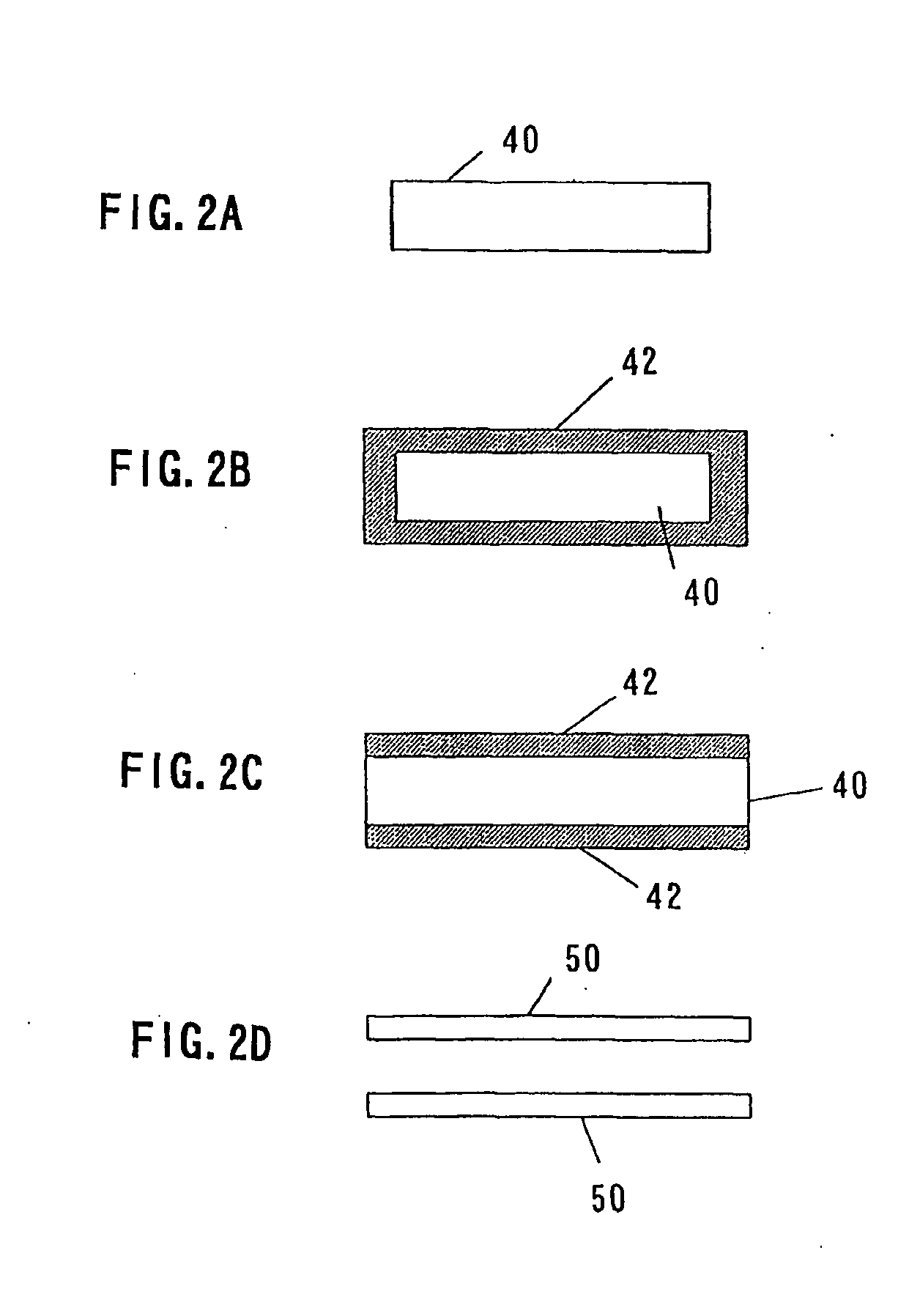

Polishing pad with recessed window

ActiveUS20050060943A1Semiconductor/solid-state device manufacturingFlexible-parts wheelsCompound (substance)Engineering

The invention provides a polishing pad for chemical-mechanical polishing comprising (a) a first polishing layer comprising a polishing surface and a first aperture having a first length and first width, (b) a second layer comprising a body and a second aperture having a second length and second width, wherein the second layer is substantially coextensive with the first polishing layer and at least one of the first length and first width is smaller than the second length and second width, and (c) a substantially transparent window portion, wherein the transparent window portion is disposed within the second aperture of the second layer so as to be aligned with the first aperture of the first polishing layer and the transparent window portion is separated from the body of the second layer by a gap. The invention further provides a chemical-mechanical polishing apparatus and method of polishing a workpiece.

Owner:CMC MATERIALS INC

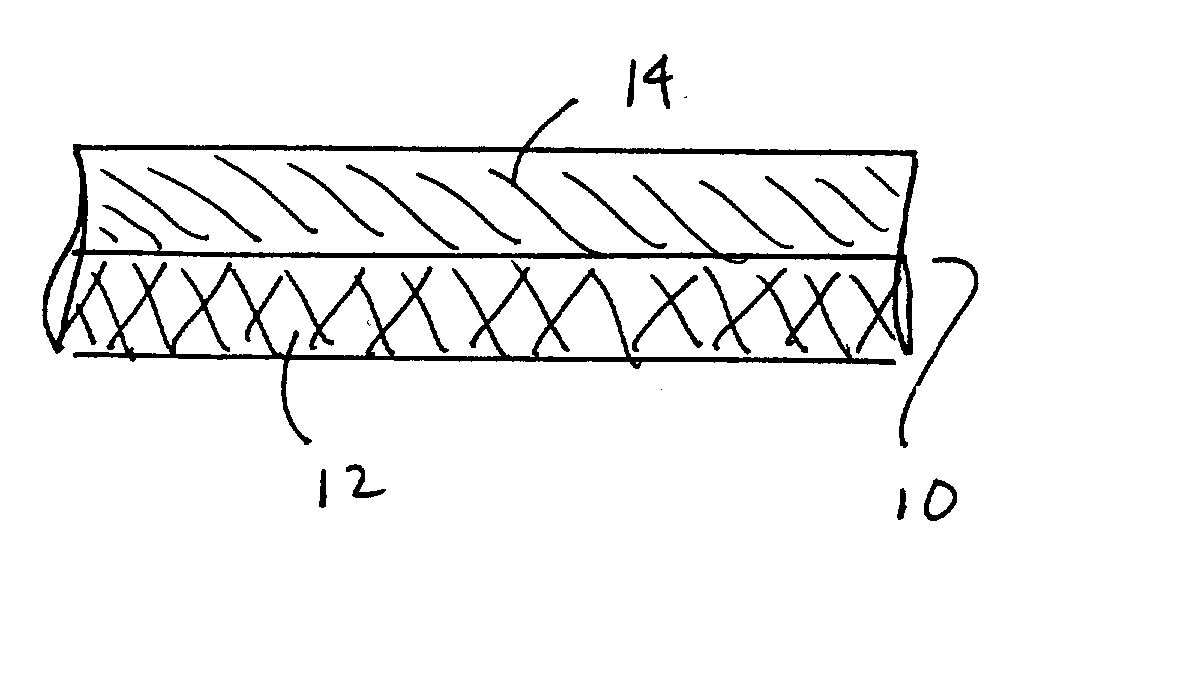

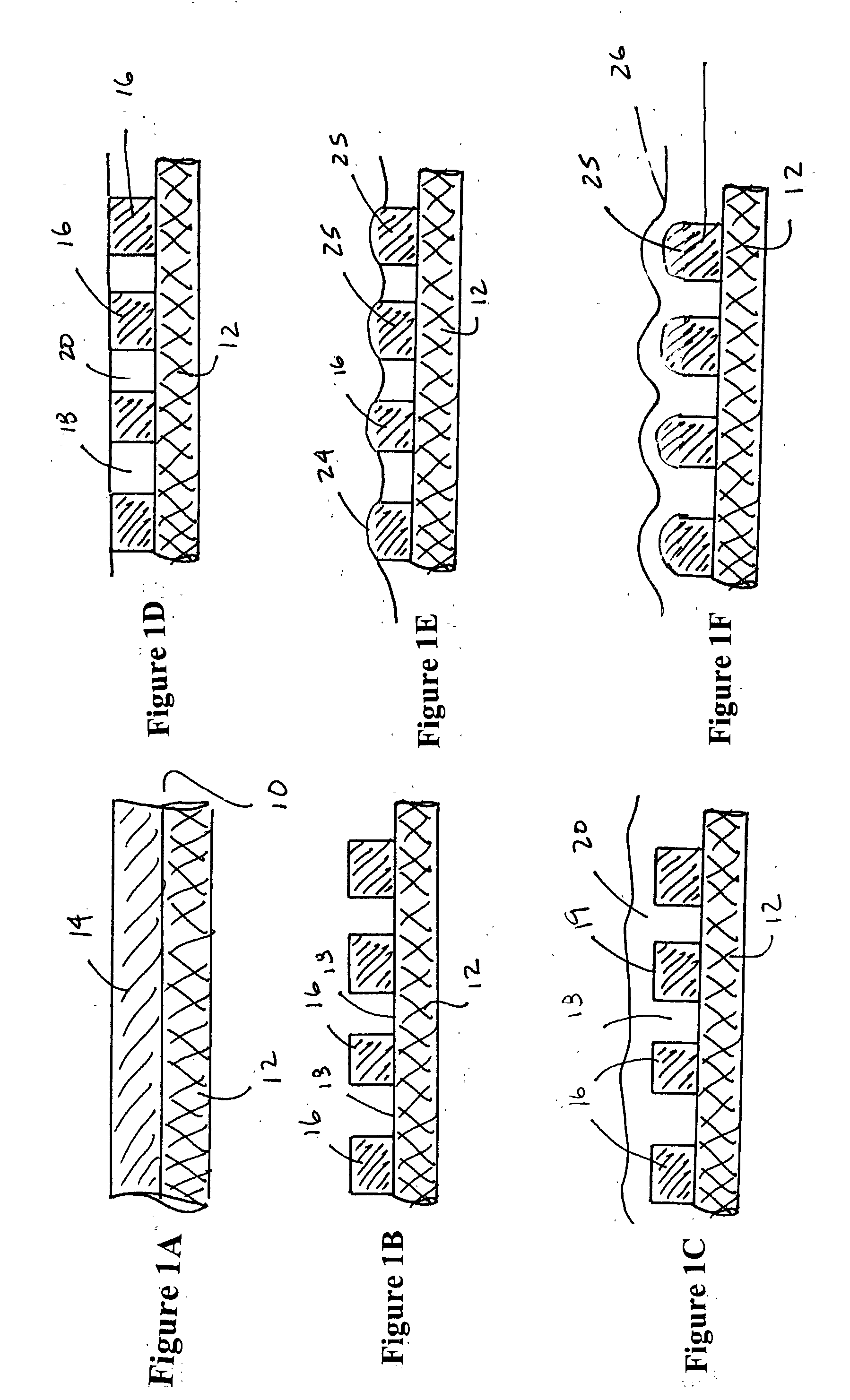

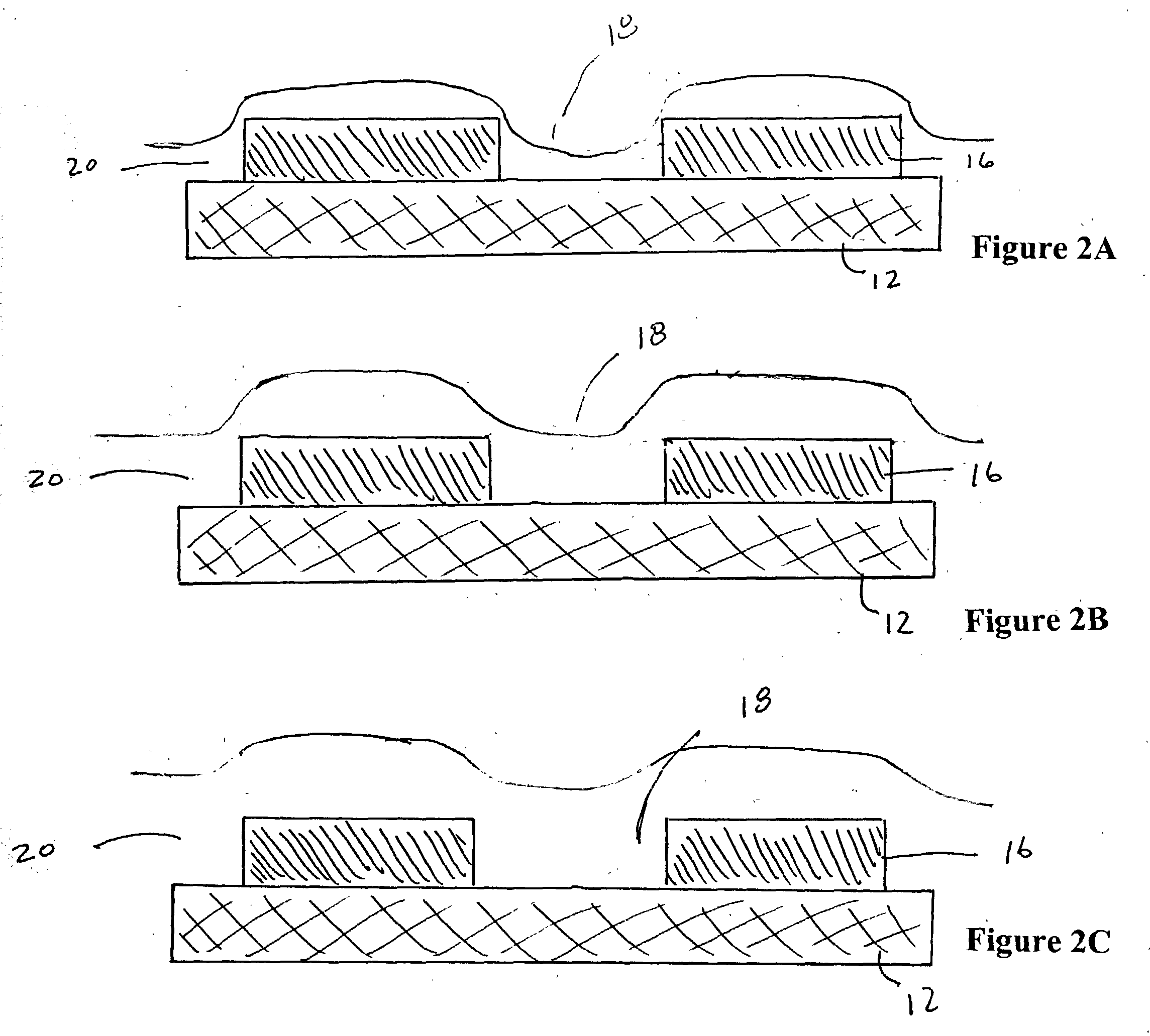

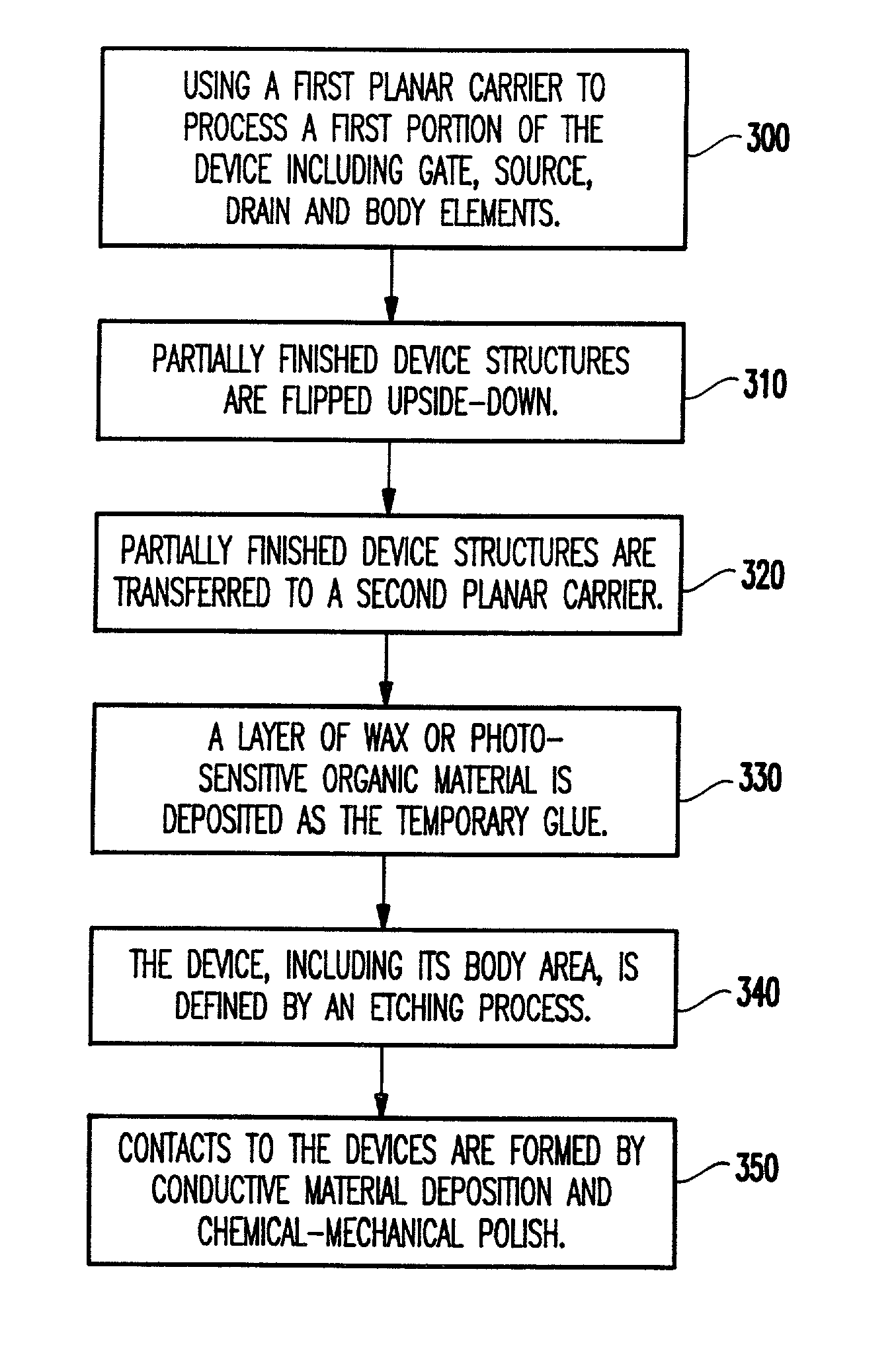

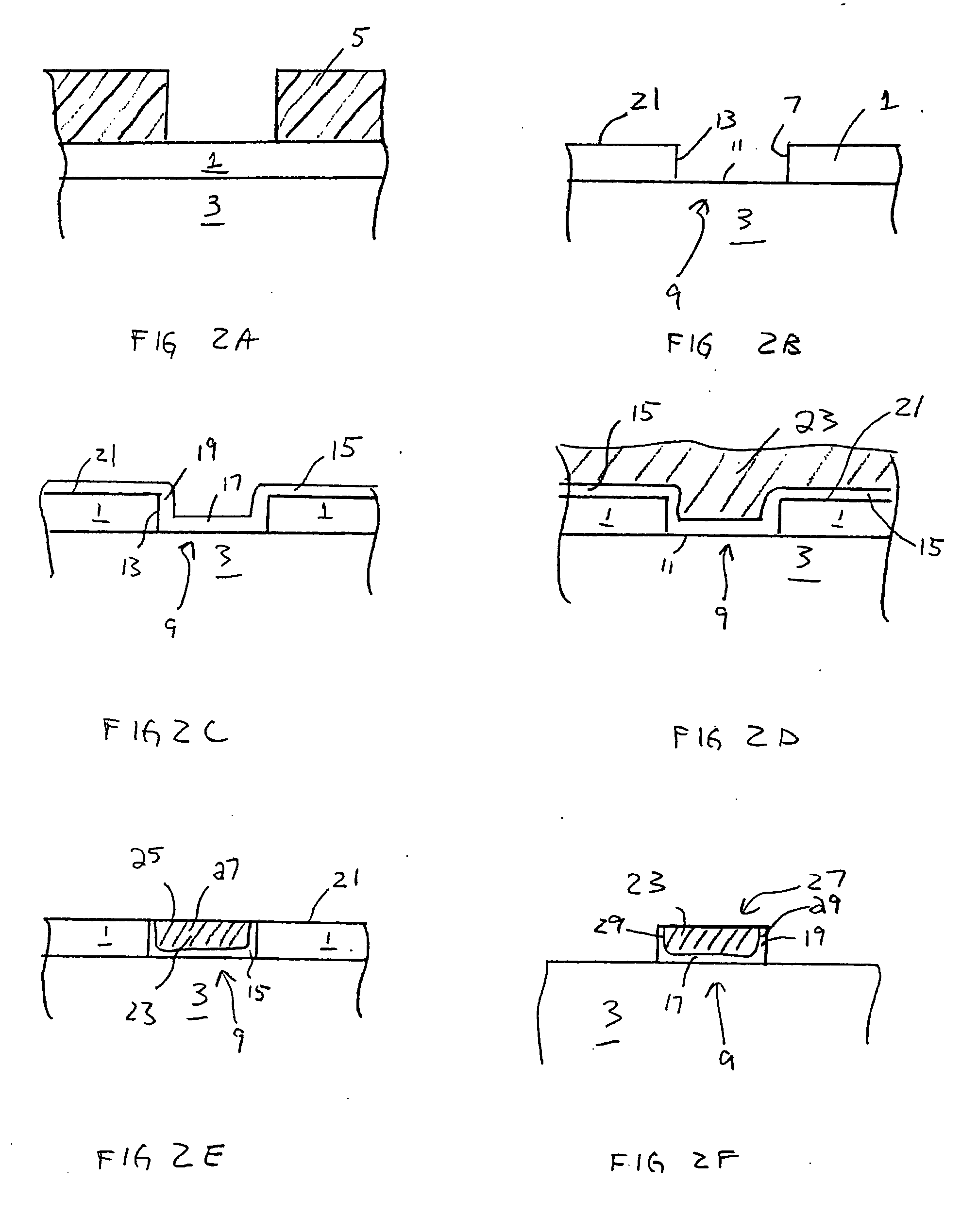

Method of forming a planar polymer transistor using substrate bonding techniques

A structure and method of forming a fully planarized polymer thin-film transistor by using a first planar carrier to process a first portion of the device including gate, source, drain and body elements. Preferably, the thin-film transistor is made with all organic materials. The gate dielectric can be a high-k polymer to boost the device performance. Then, the partially-finished device structures are flipped upside-down and transferred to a second planar carrier. A layer of wax or photo-sensitive organic material is then applied, and can be used as the temporary glue. The device, including its body area, is then defined by an etching process. Contacts to the devices are formed by conductive material deposition and chemical-mechanical polish.

Owner:IBM CORP

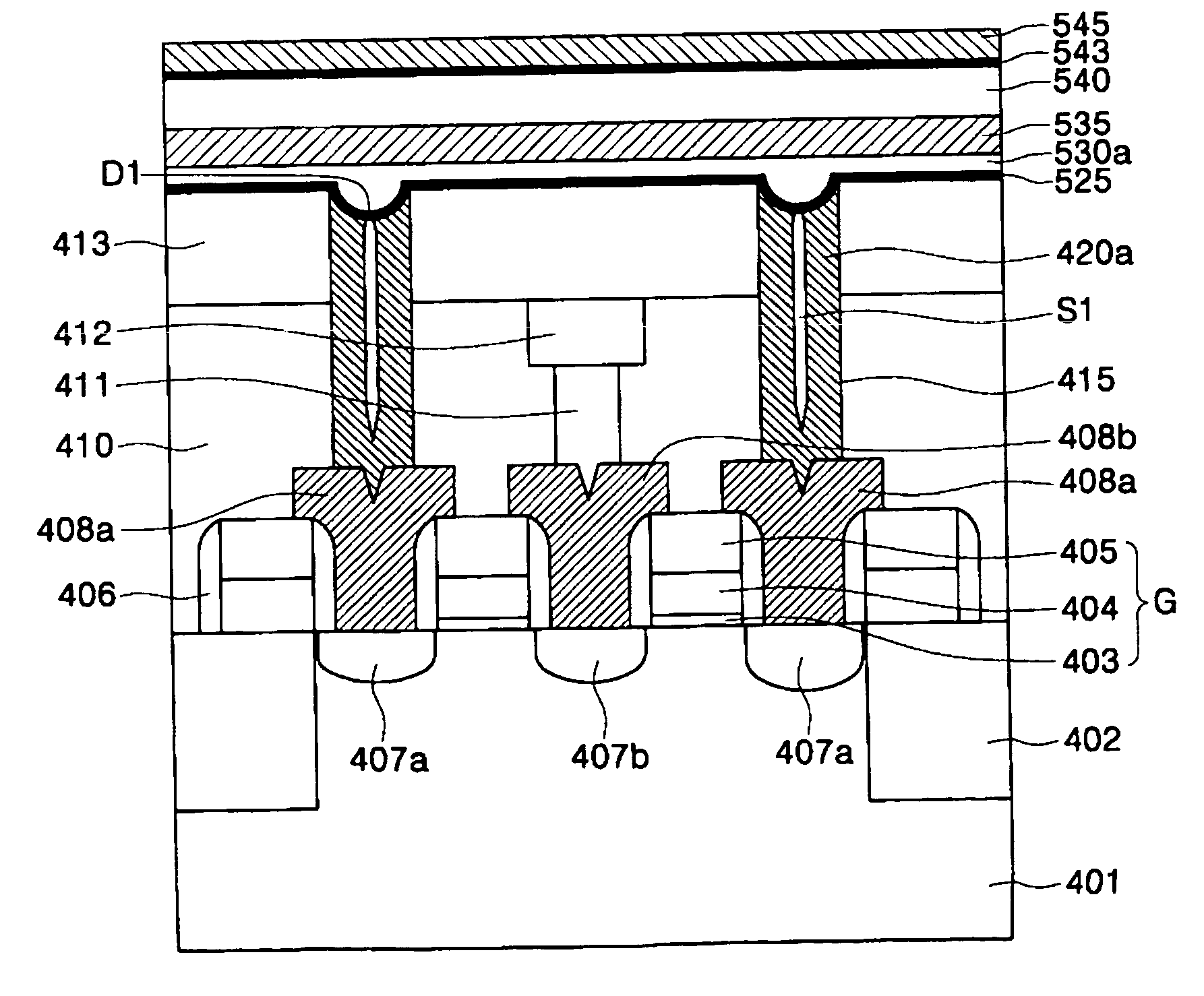

Transistor with high dielectric constant gate and method for forming the same

InactiveUS20060063322A1Semiconductor/solid-state device manufacturingSemiconductor devicesDielectricGate dielectric

A semiconductor device provides a gate structure that includes a conductive portion and a high-k dielectric material formed beneath and along sides of the conductive material. An additional gate dielectric material such as a gate oxide may be used in addition to the high-k dielectric material. The method for forming the structure includes forming an opening in an organic material, forming the high-k dielectric material and a conductive material within the opening and over the organic material then using chemical mechanical polishing to remove the high-k dielectric material and conductive material from regions outside the gate region.

Owner:TAIWAN SEMICON MFG CO LTD

Materials and methods for chemical-mechanical planarization

InactiveUS6910951B2Low costImprove throughputGrinding drivesBelt grinding machinesDevice materialMaterial removal

Provided are materials and methods for the chemical mechanical planarization of material layers such as oxide or metal formed on semiconductor substrates during the manufacture of semiconductor devices using a fixed abrasive planarization pad having an open cell foam structure from which free abrasive particles are produced by conditioning and combined with a carrier liquid to form an in situ slurry on the polishing surface of the planarization pad that, in combination with relative motion between the semiconductor substrate and the planarization pad, tends to remove the material layer from the surface of the semiconductor substrate. Depending on the composition of the material layer, the rate of material removal from the semiconductor substrate may be controlled by manipulating the pH or the oxidizer content of the carrier liquid.

Owner:DOW GLOBAL TECH LLC

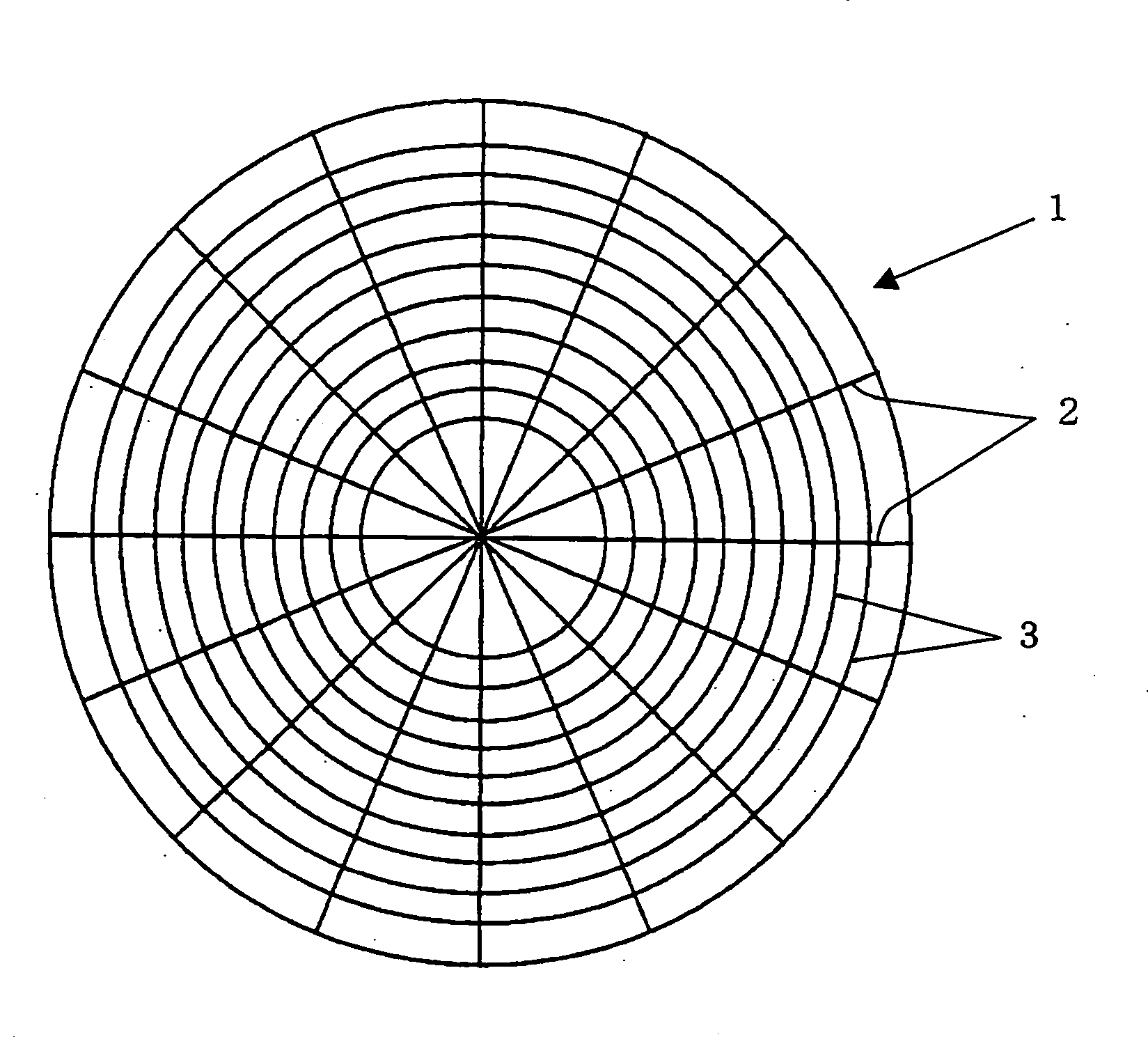

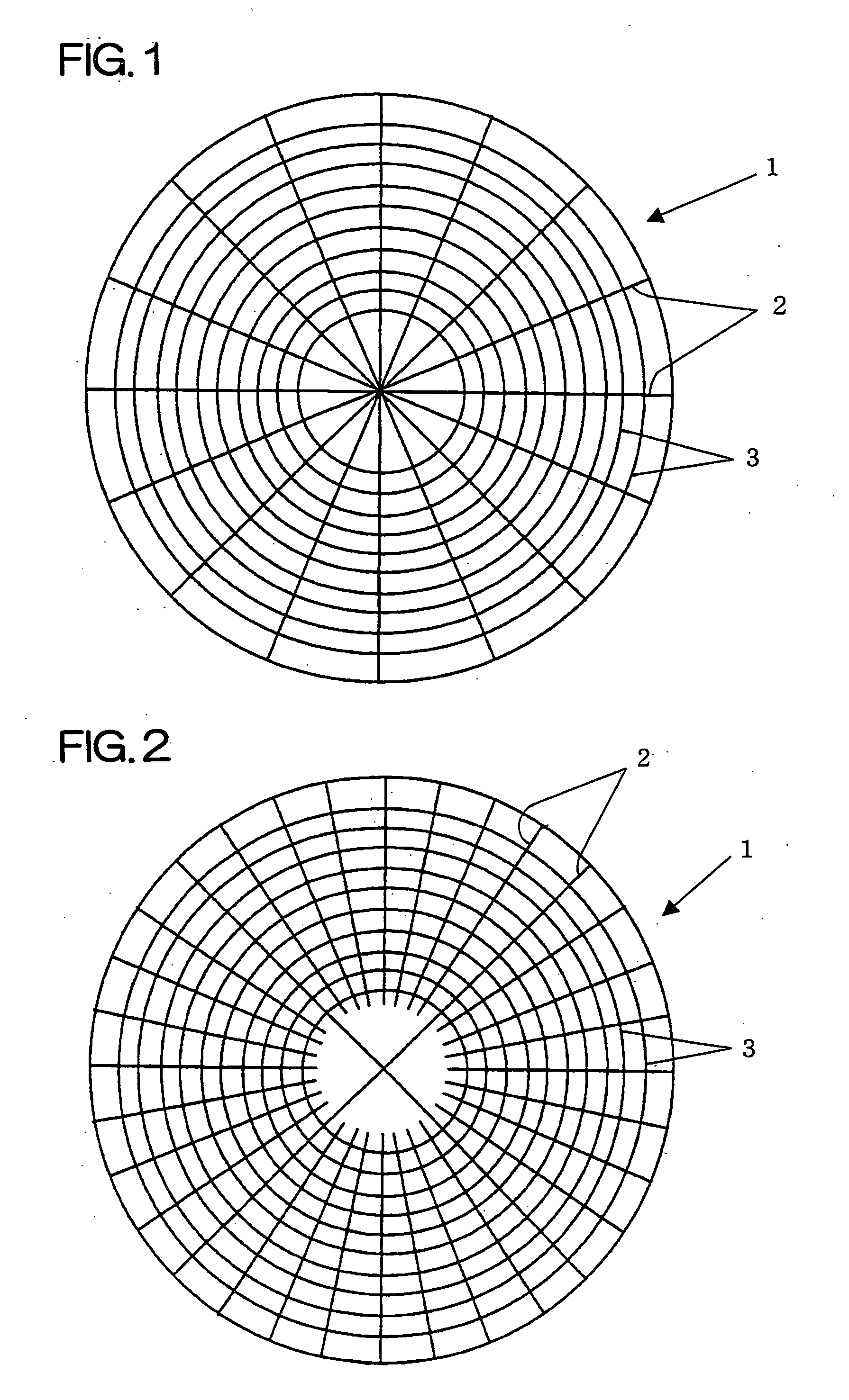

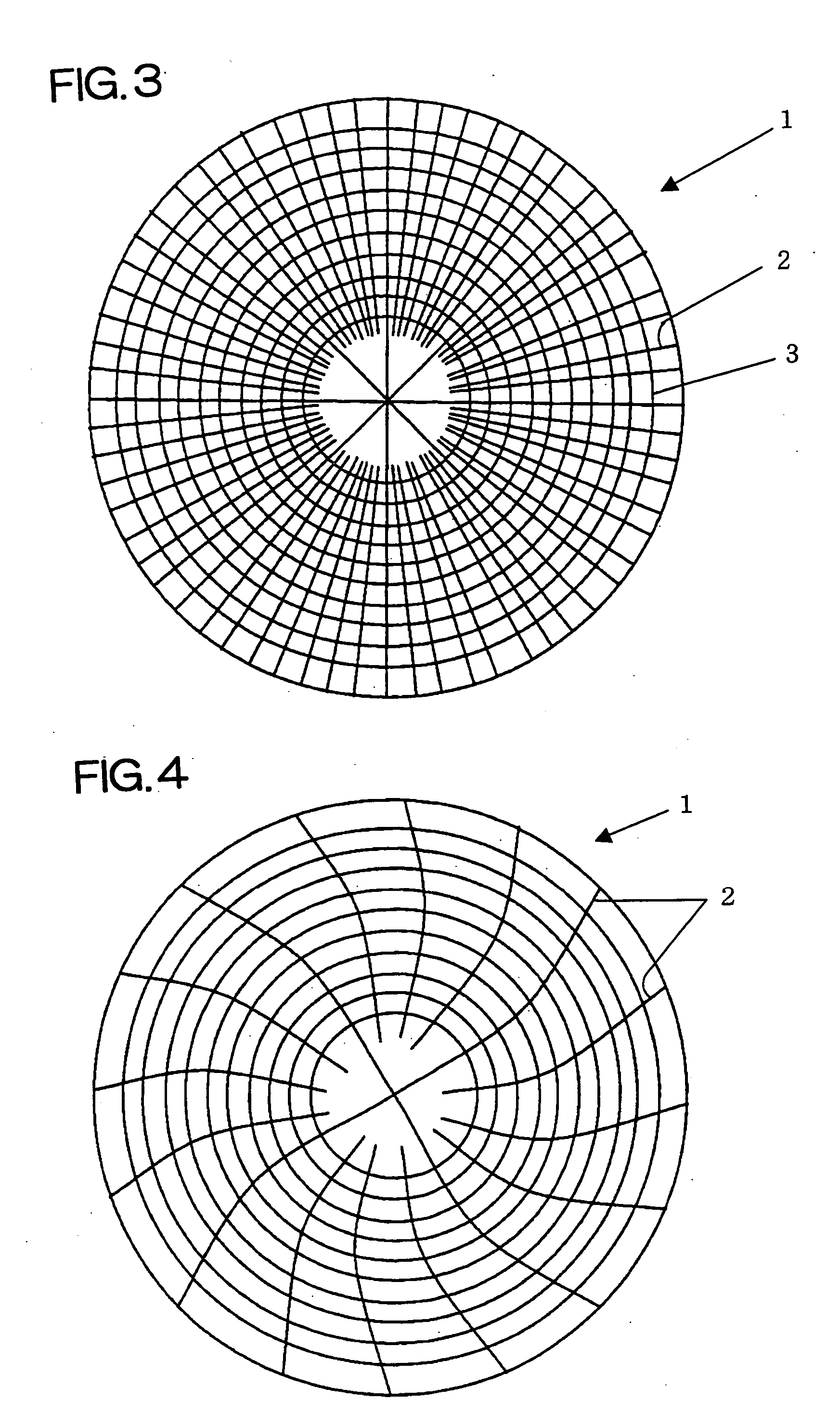

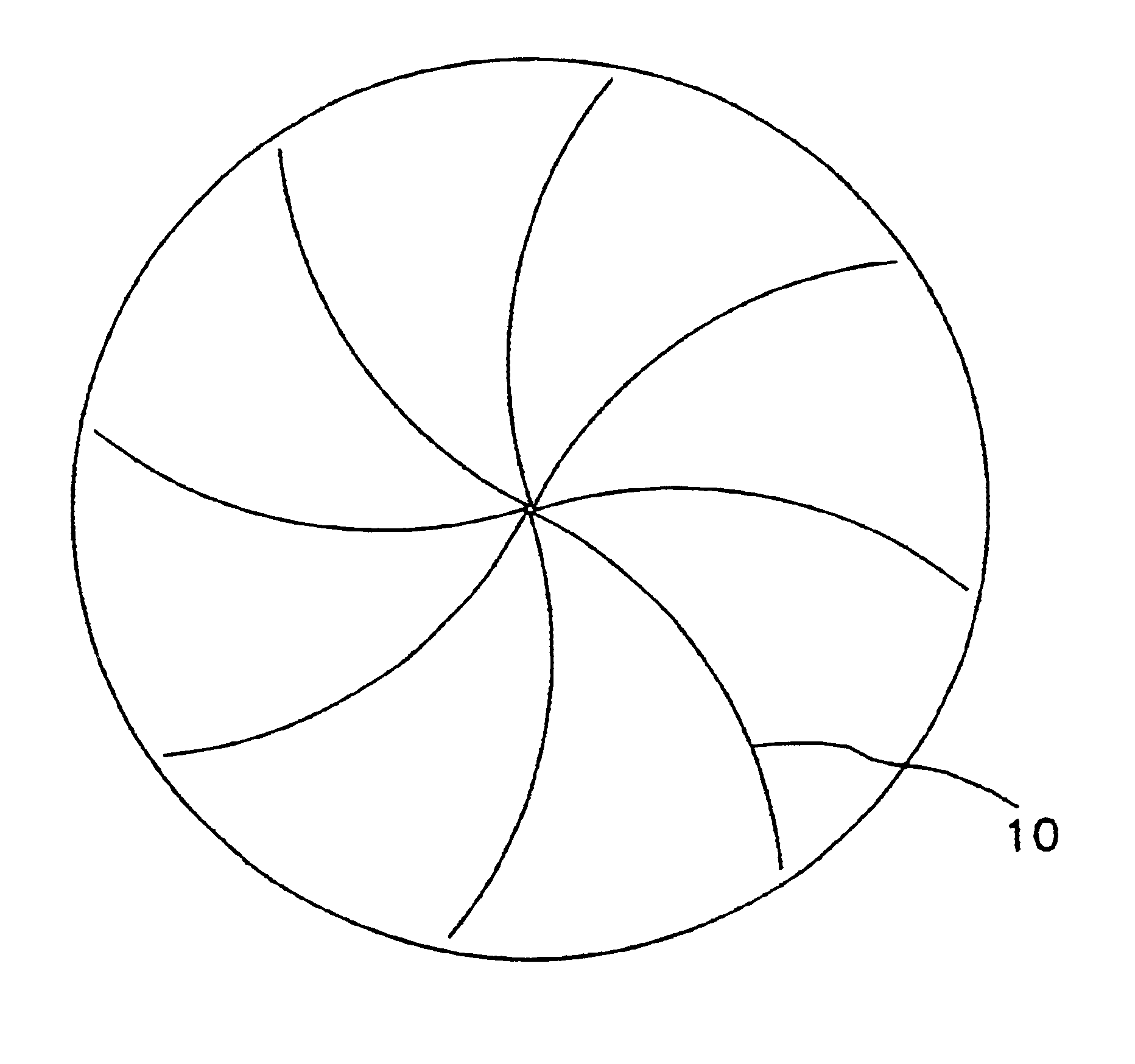

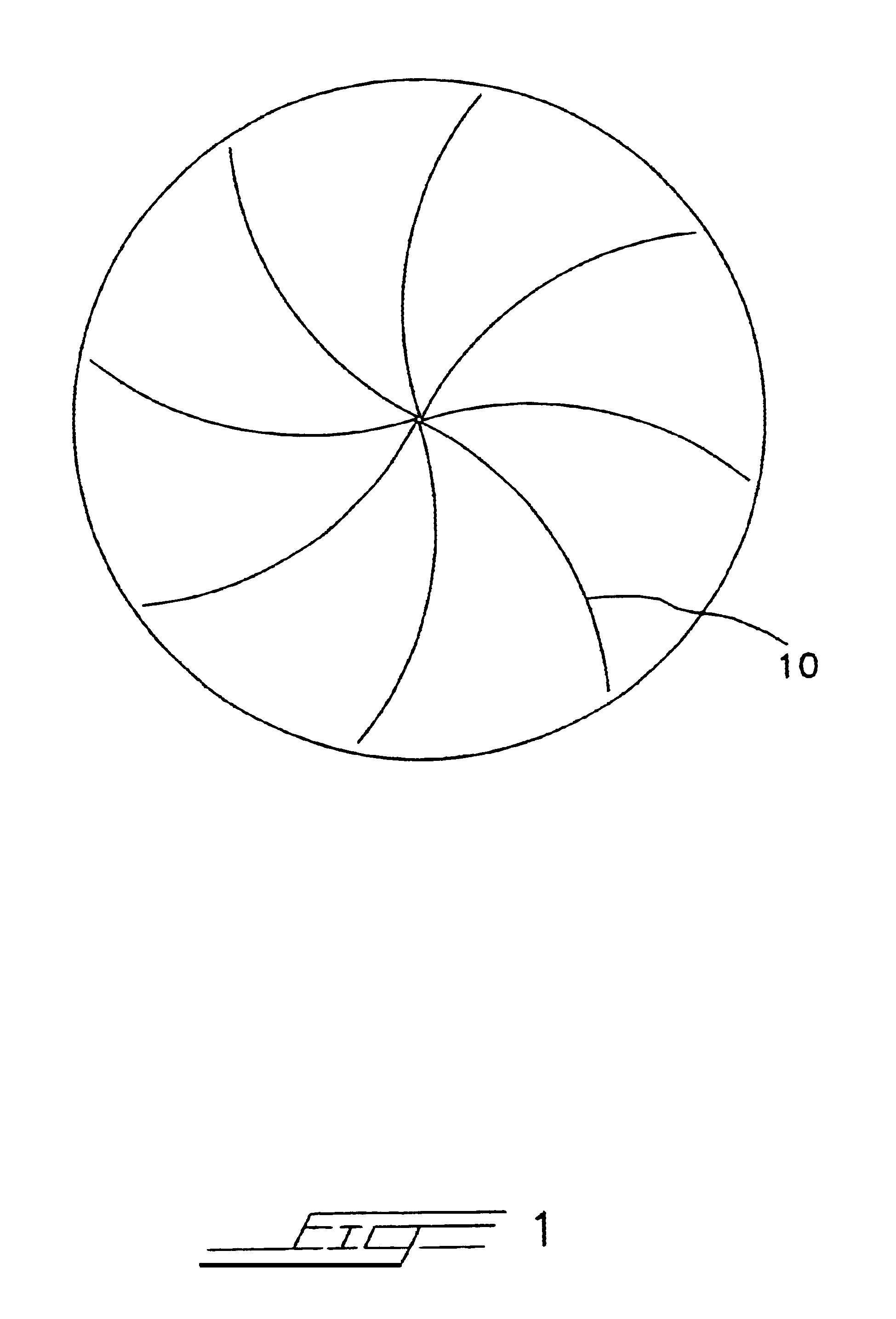

Chemical mechanical polishing pad and chemical mechanical polishing method

InactiveUS20050260929A1InhibitionIncrease ratingsSemiconductor/solid-state device manufacturingLapping machinesCompound (substance)Engineering

A chemical mechanical polishing pad having a polishing surface, a non-polishing surface opposite to the polishing surface and a side surface for defining these surfaces, the polishing surface having (i) a first group of grooves which intersect a single virtual straight line extending from the center toward the peripheral portion of the polishing surface and do not cross one another, or a single first spiral groove which expands gradually from the center portion toward the peripheral portion of the polishing surface, and (ii) a second group of grooves which extend from the center portion toward the peripheral portion of the polishing surface, intersect the first group of grooves or the first spiral groove and do not cross one another. Since this chemical mechanical polishing pad fully suppresses the occurrence of a scratch on the polished surface and has an excellent polishing rate, it is advantageously used in a chemical mechanical polishing method.

Owner:JSR CORPORATIOON

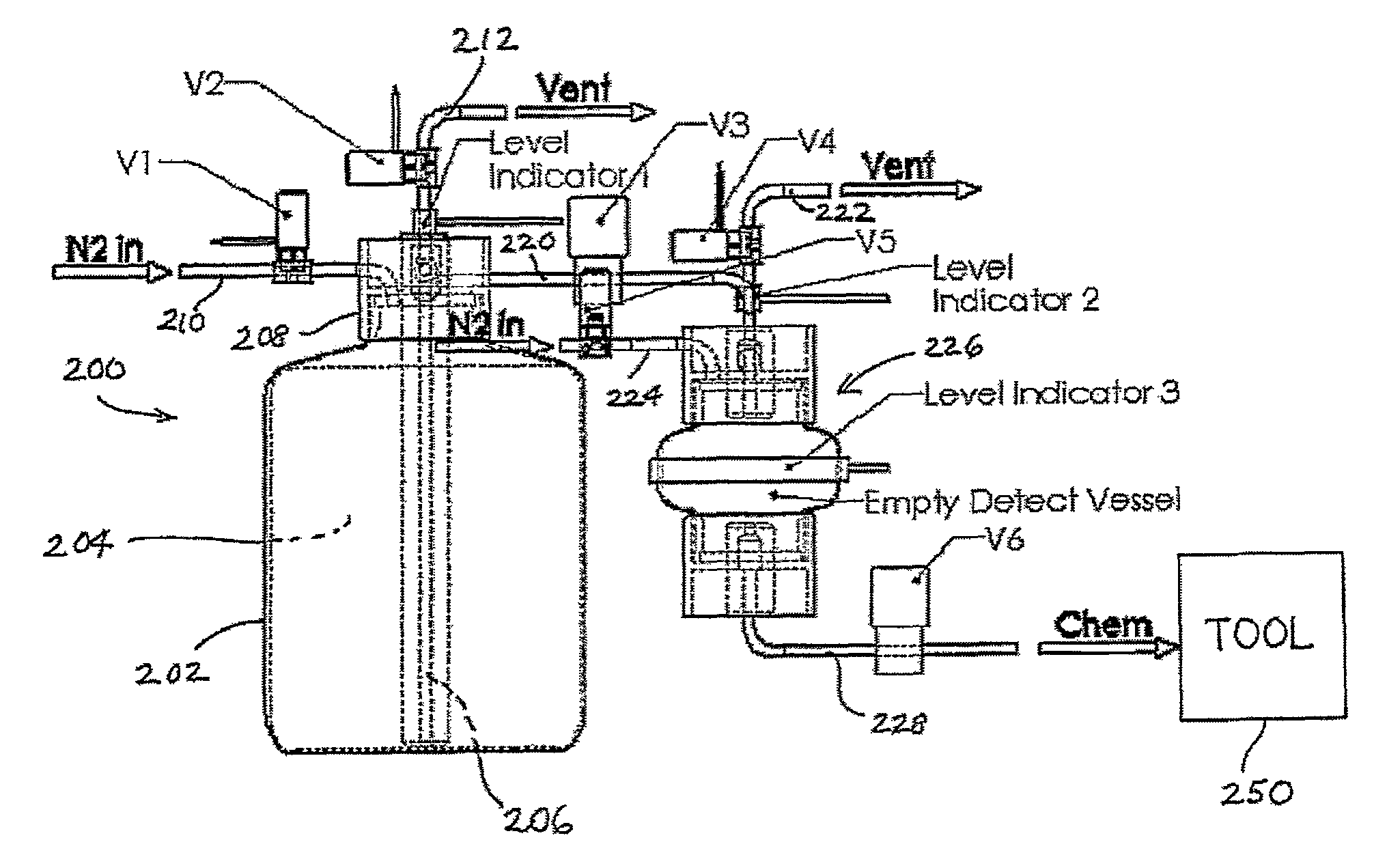

Liner-based liquid storage and dispensing systems with empty detection capability

Fluid supply systems for storage and dispensing of chemical reagents and compositions, e.g., high purity liquid reagents and chemical mechanical polishing compositions used to manufacture microelectronic device products, having capability for detection of an empty or near-empty condition when the contained liquid is at or approaching depletion during dispensing operation. Fluid delivery systems employing empty detect arrangements are described, including pressure transducer monitoring of dispensed material intermediate the supply package and a servo-hydraulic dispense pump, or monitoring of dispenser chamber replenishment times in a dispenser being replenished on a cyclic schedule to flow material from the dispenser to a downstream tool utilizing the dispensed material.

Owner:ADVANCED TECH MATERIALS INC

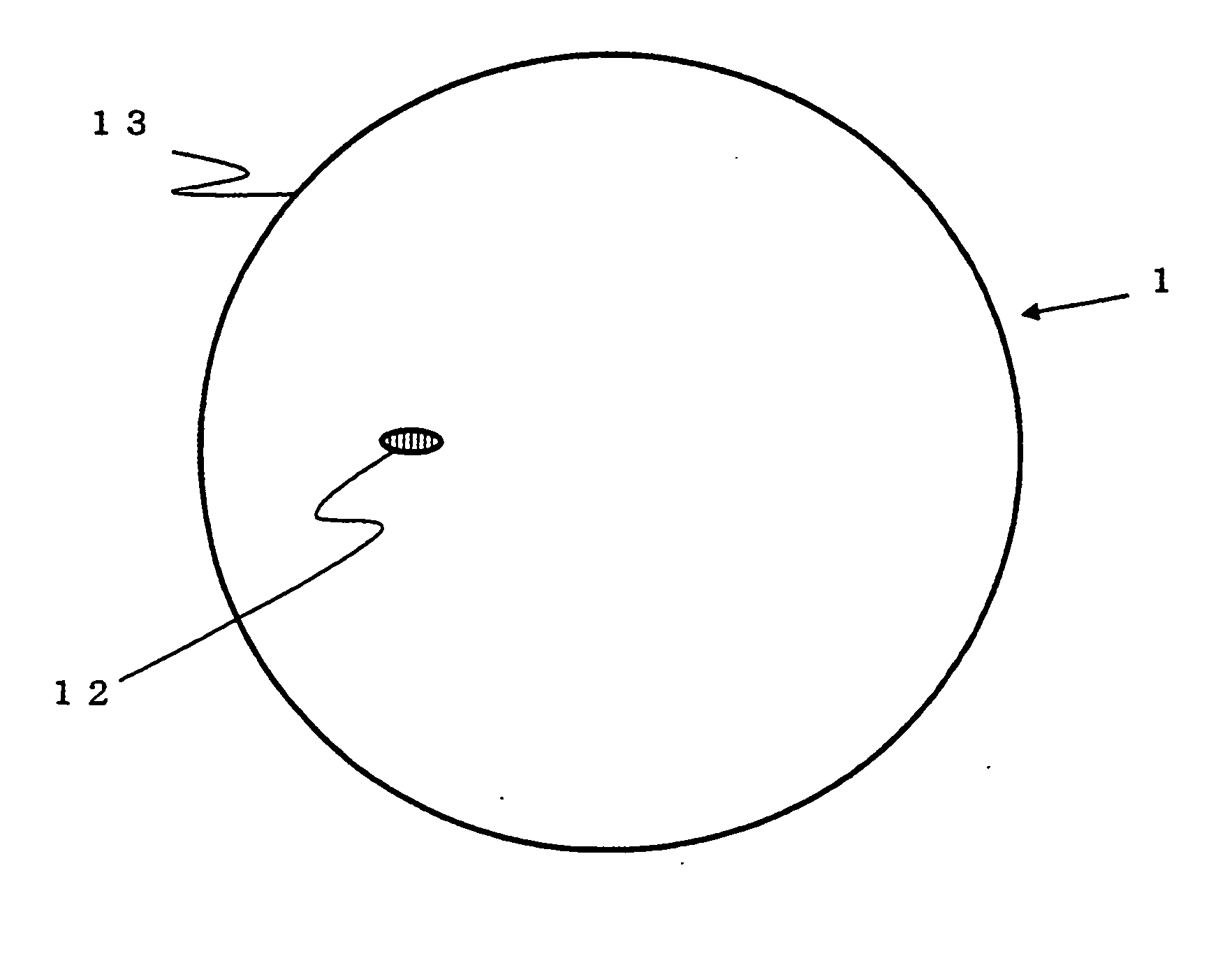

Chemical mechanical polishing pad, manufacturing process thereof and chemical mechanical polishing method for semiconductor wafers

InactiveUS20050245171A1Improve polishing efficiencySemiconductor/solid-state device manufacturingLapping machinesLongest DiameterCompound (substance)

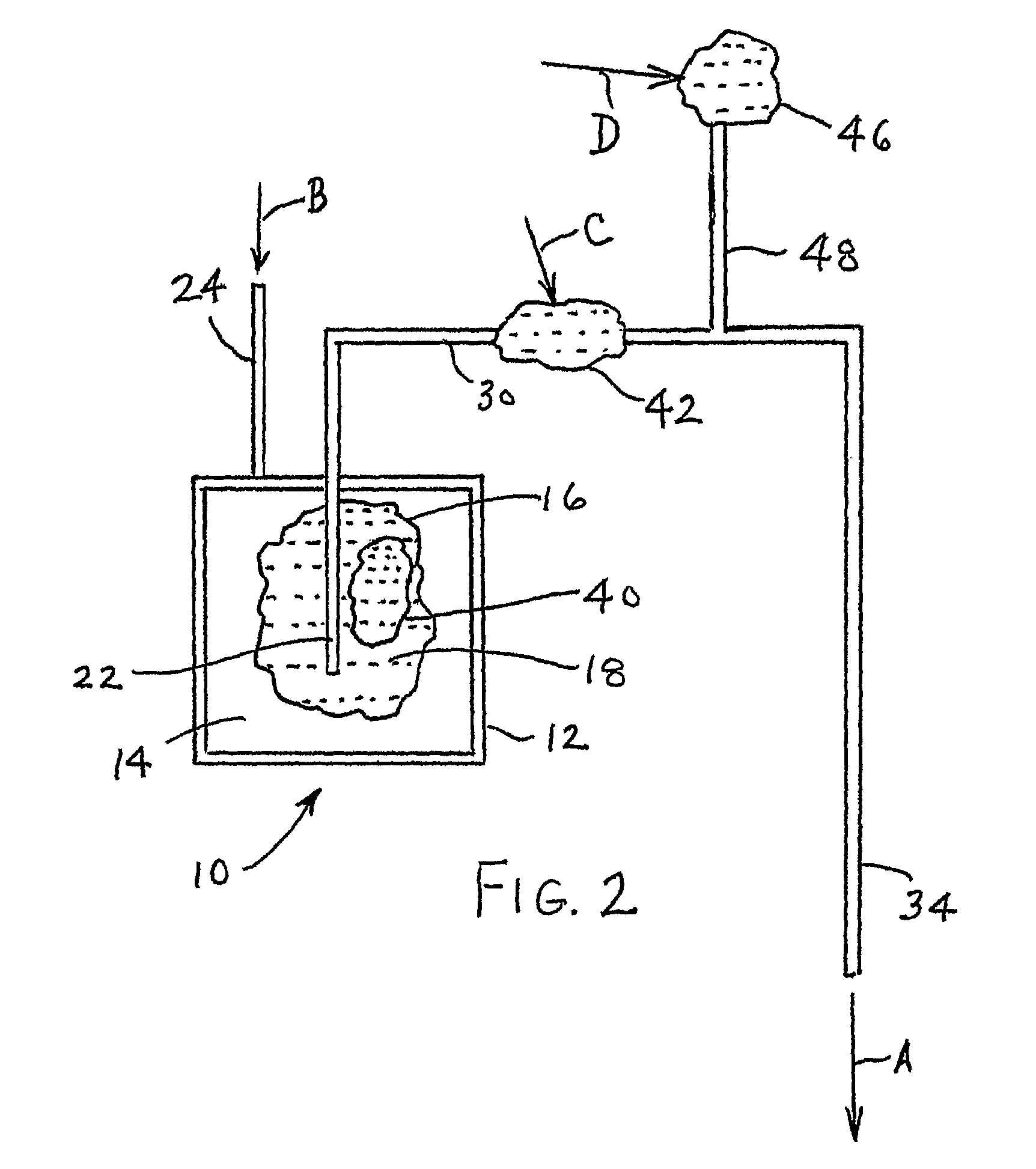

There is provided a chemical mechanical polishing pad containing a polishing substrate having a polishing surface and a light-transmitting member fused to the polishing substrate. The sectional form of the light-transmitting member when it is cut with a plane parallel to the polishing surface is elliptic with a value obtained by dividing its long diameter by its short diameter of more than 1. The pad is capable of transmitting end-point detection light without reducing its polishing efficiency in polishing a semiconductor wafer.

Owner:JSR CORPORATIOON

Polishing pad for use in chemical-mechanical planarization of semiconductor wafers and method of making same

InactiveUS6852020B2Prolong lifeSolution to short lifeOther chemical processesAbrasion apparatusFiberSlurry transport

A polishing pad for use in chemical mechanical polishing of substrates that being made of a porous structure comprising a matrix consisting of fibers, such as cotton linter cellulose bound with a thermoset resin, such as phenolic resin. The polishing pad surface has voids in which polishing slurry flows during chemical mechanical polishing of substrates, and in which debris formed during the chemical-mechanical polishing of substrates is temporarily stored for subsequent rinsing away. The polishing surface of the pad is ground to form asperities that aid in slurry transport and polishing, as well as opening the porous structure of the pad. The porous pad contains nanometer-sized filler-particles that reinforce the structure, imparting an increased resistance to wear as compared to prior-art pads. Also disclosed is a method of making the polishing pad.

Owner:RAYBESTOS POWERTRAIN

Composition and associated methods for chemical mechanical planarization having high selectivity for metal removal

A composition and associated methods for chemical mechanical planarization (or other polishing) are described. The composition may comprise an abrasive and a dispersed hybrid organic / inorganic particle. The composition may further comprise an alkyne compound. Two different methods for chemical mechanical planarization are disclosed. In one method (Method A), the CMP slurry composition employed in the method comprises comprise an abrasive and a dispersed hybrid organic / inorganic particle. In another method (Method B), the CMP slurry composition employed in the method comprises comprise an abrasive and an alkyne compound. The composition may further comprise an oxidizing agent in which case the composition is particularly useful in conjunction with the associated methods (A and B) for metal CMP applications (e.g., tungsten CMP).

Owner:VERSUM MATERIALS US LLC

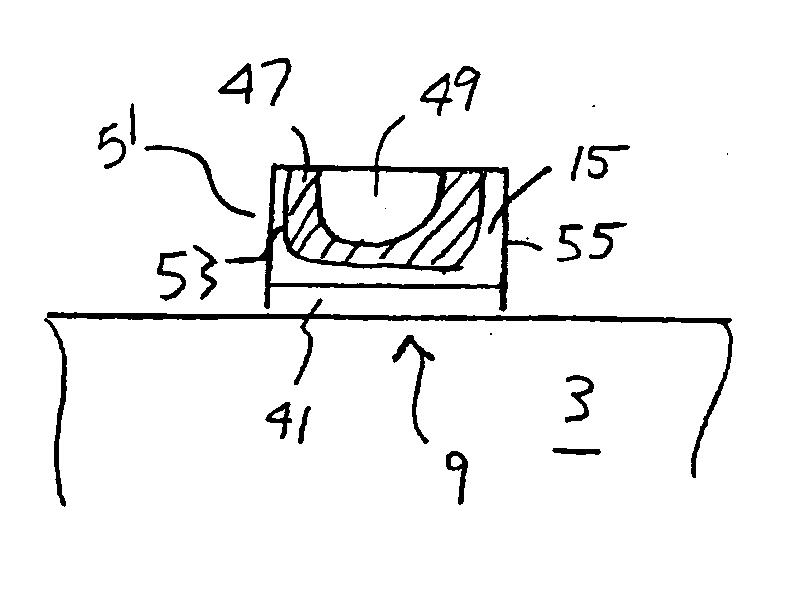

CMP pad with composite transparent window

InactiveUS6960120B2High light transmittancePolishing machinesRevolution surface grinding machinesPolymer resinTransmittance

The invention is directed to chemical-mechanical polishing pads comprising a transparent window. In one embodiment, the transparent window comprises an inorganic material and an organic material, wherein the inorganic material comprises about 20 wt. % or more of the transparent window. In another embodiment, the transparent window comprises an inorganic material and an organic material, wherein the inorganic material is dispersed throughout the organic material and has a dimension of about 5 to 1000 nm, and wherein the transparent window has a total light transmittance of about 30% or more at at least one wavelength in the range of about 200 to 10,000 nm. In yet another embodiment, the transparent window comprises an inorganic / organic hybrid sol-gel material. In an additional embodiment, the transparent window comprises a polymer resin and a clarifying material, wherein the transparent window has a total light transmittance that is substantially higher than a window comprising only the polymeric resin.

Owner:CMC MATERIALS INC

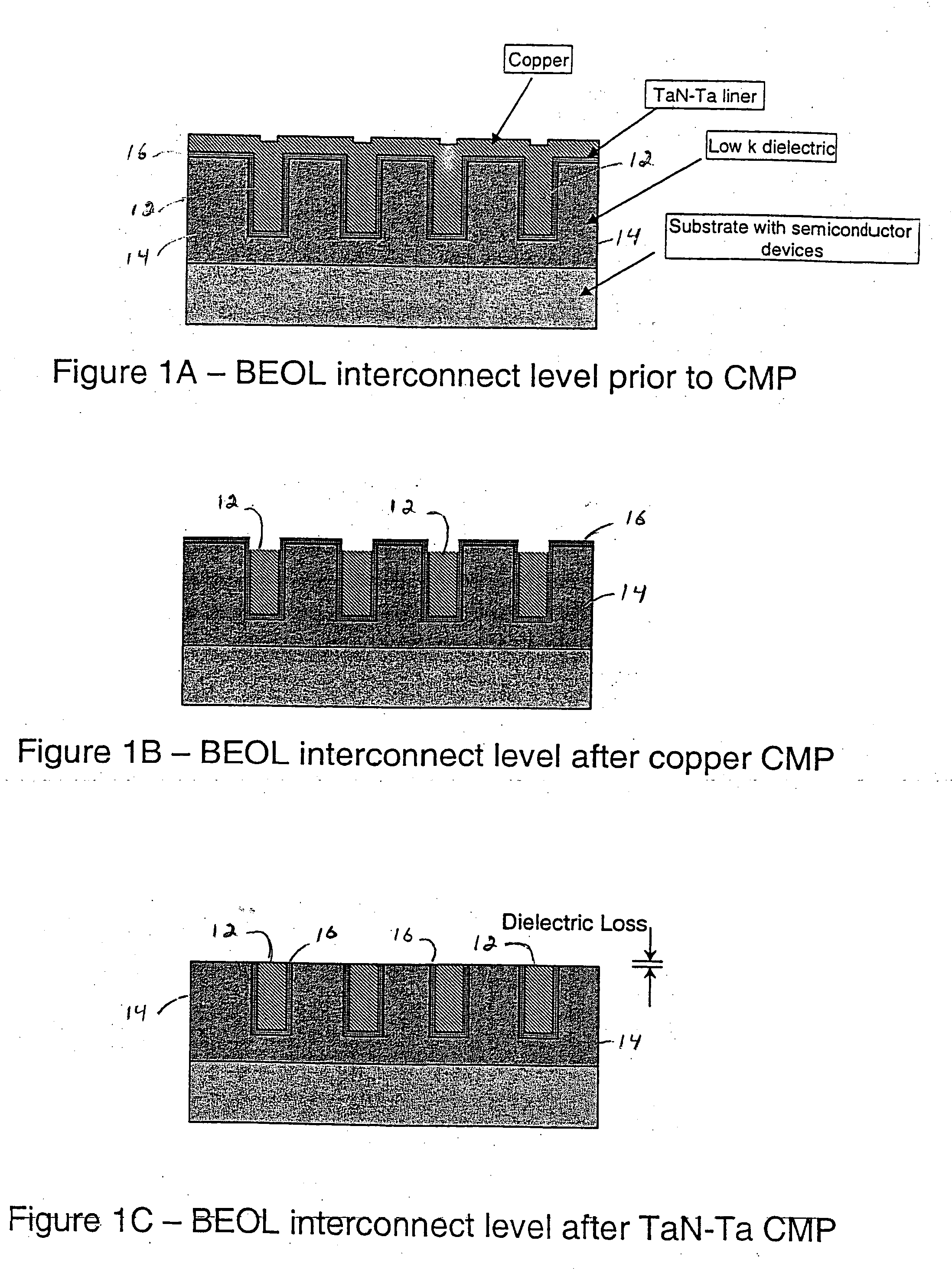

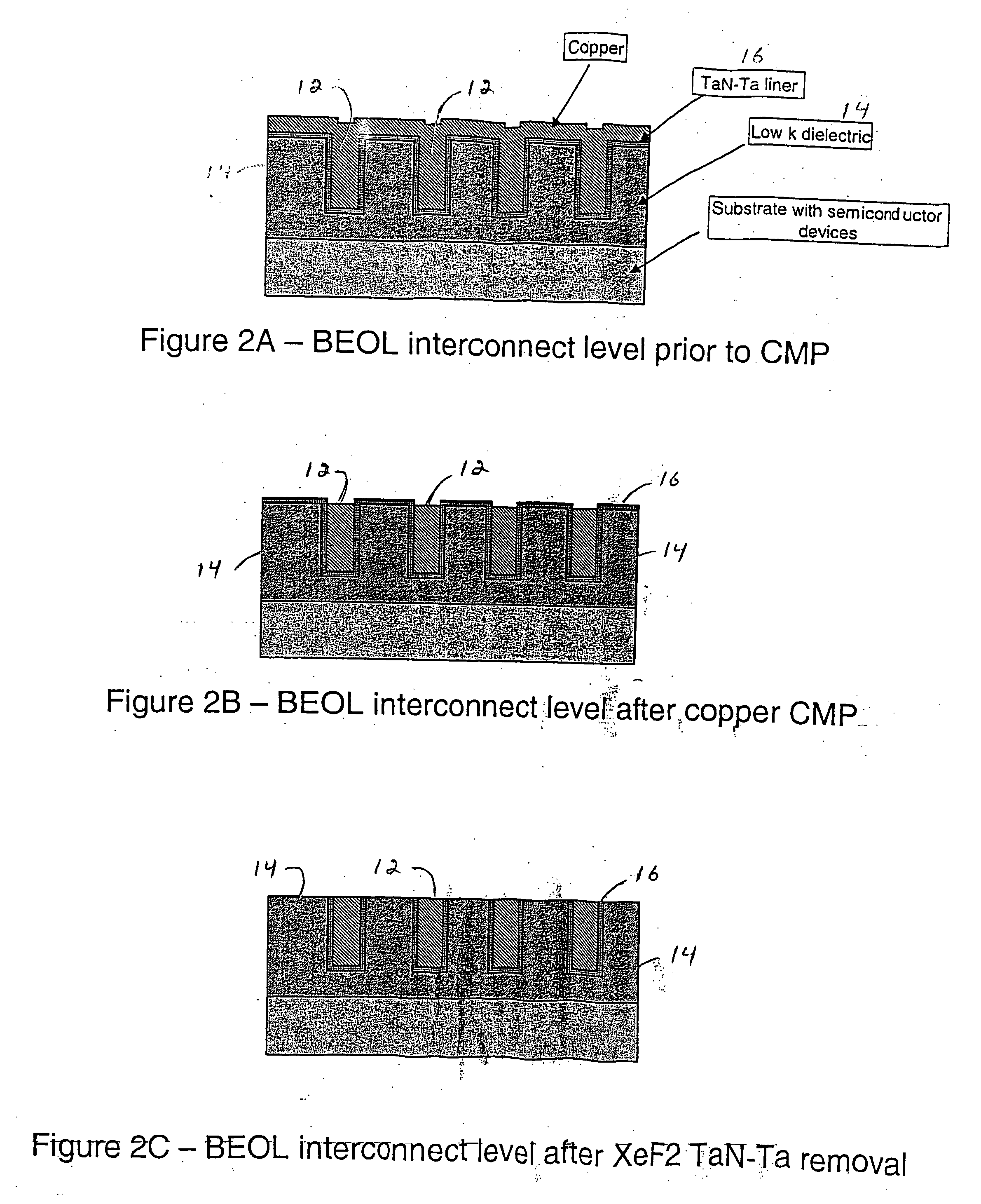

Ta-TaN selective removal process for integrated device fabrication

ActiveUS20060189134A1Minimizes mechanical stressImprove planaritySemiconductor/solid-state device detailsSolid-state devicesEngineeringIntegrated devices

Disclosed are a method and a system for processing a semiconductor structure of the type including a substrate, a dielectric layer, and a TaN—Ta liner on the dielectric layer. The method comprises the step of using XeF2 to remove at least a portion of the TaN—Ta liner completely to the dielectric layer. In the preferred embodiments, the present invention uses XeF2 selective gas phase etching as alternatives to Ta—TaN Chemical Mechanical Polishing (CMP) as a basic “liner removal process” and as a “selective cap plating base removal process.” In this first use, XeF2 is used to remove the metal liner, TaN—Ta, after copper CMP. In the second use, the XeF2 etch is used to selectively remove a plating base (TaN—Ta) that was used to form a metal cap layer over the copper conductor.

Owner:TAIWAN SEMICON MFG CO LTD

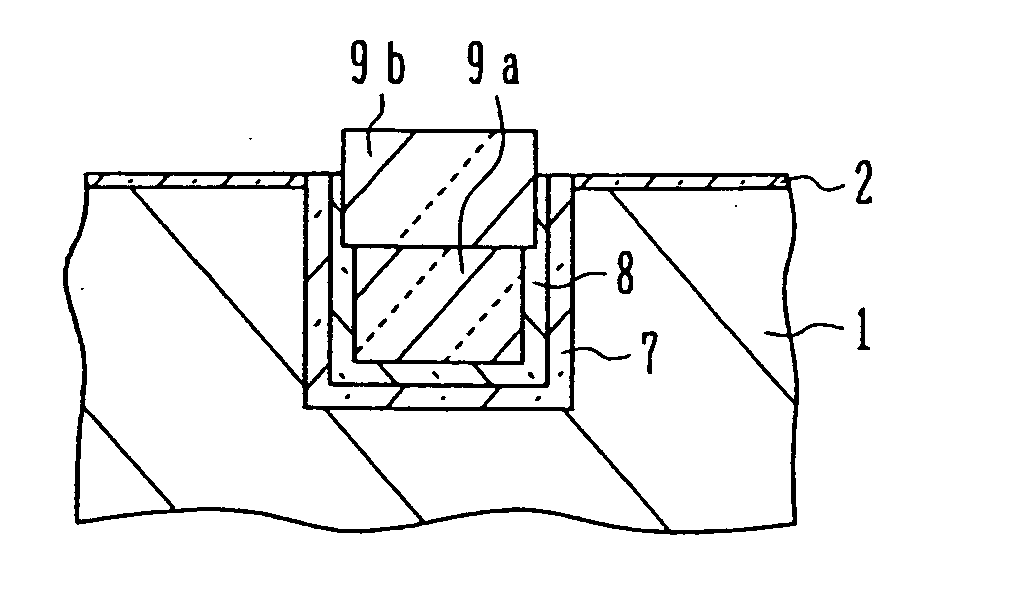

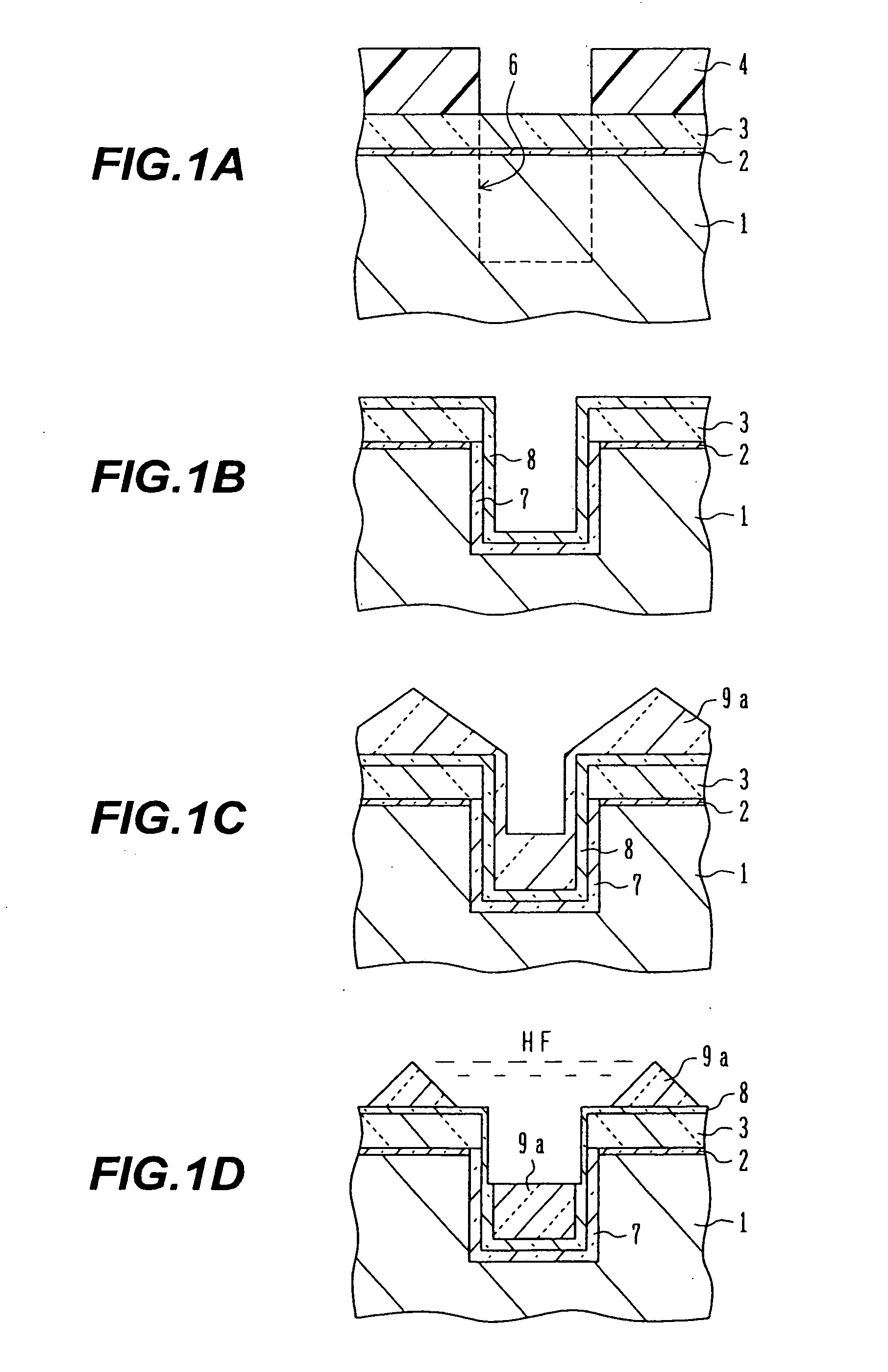

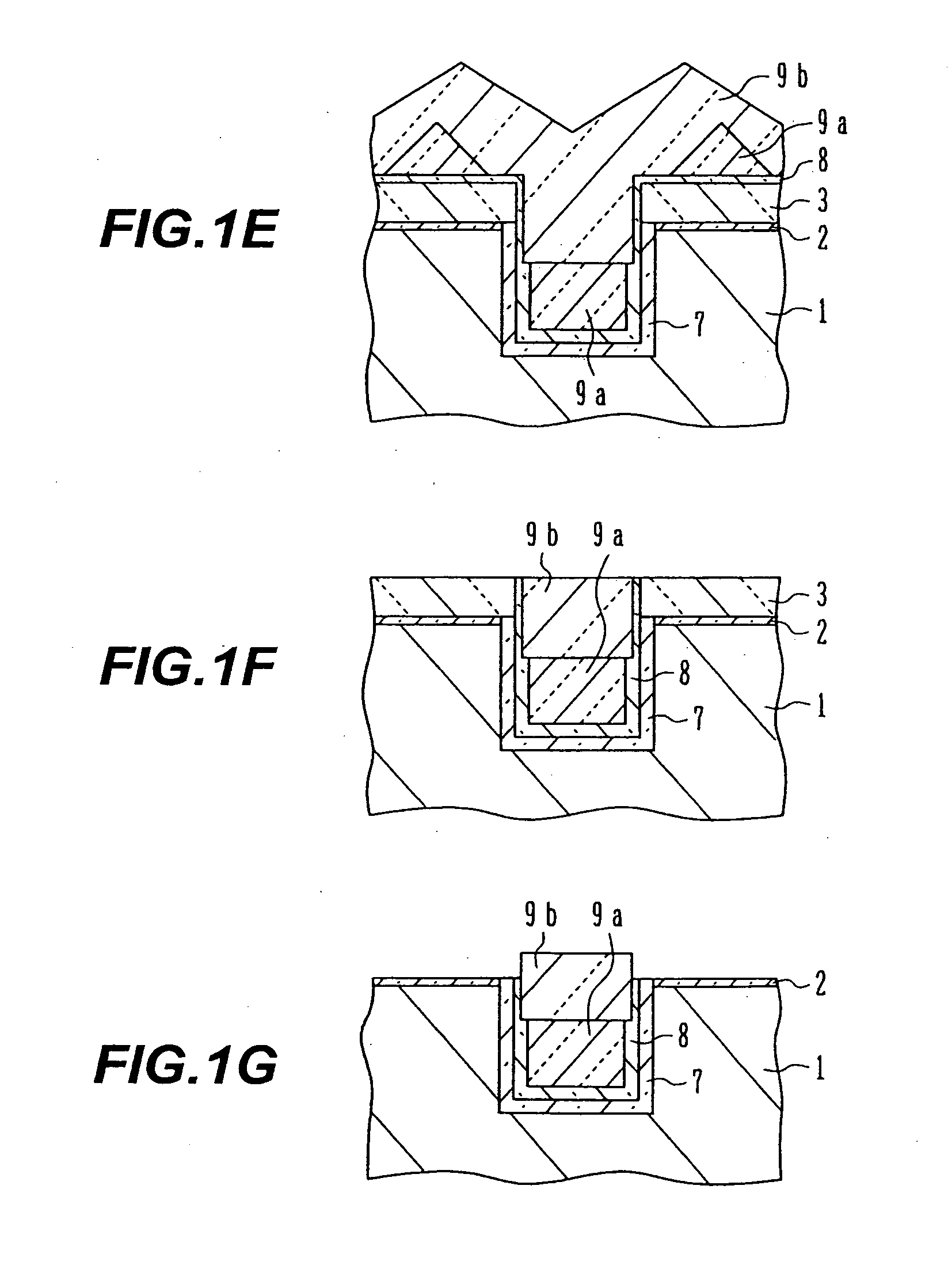

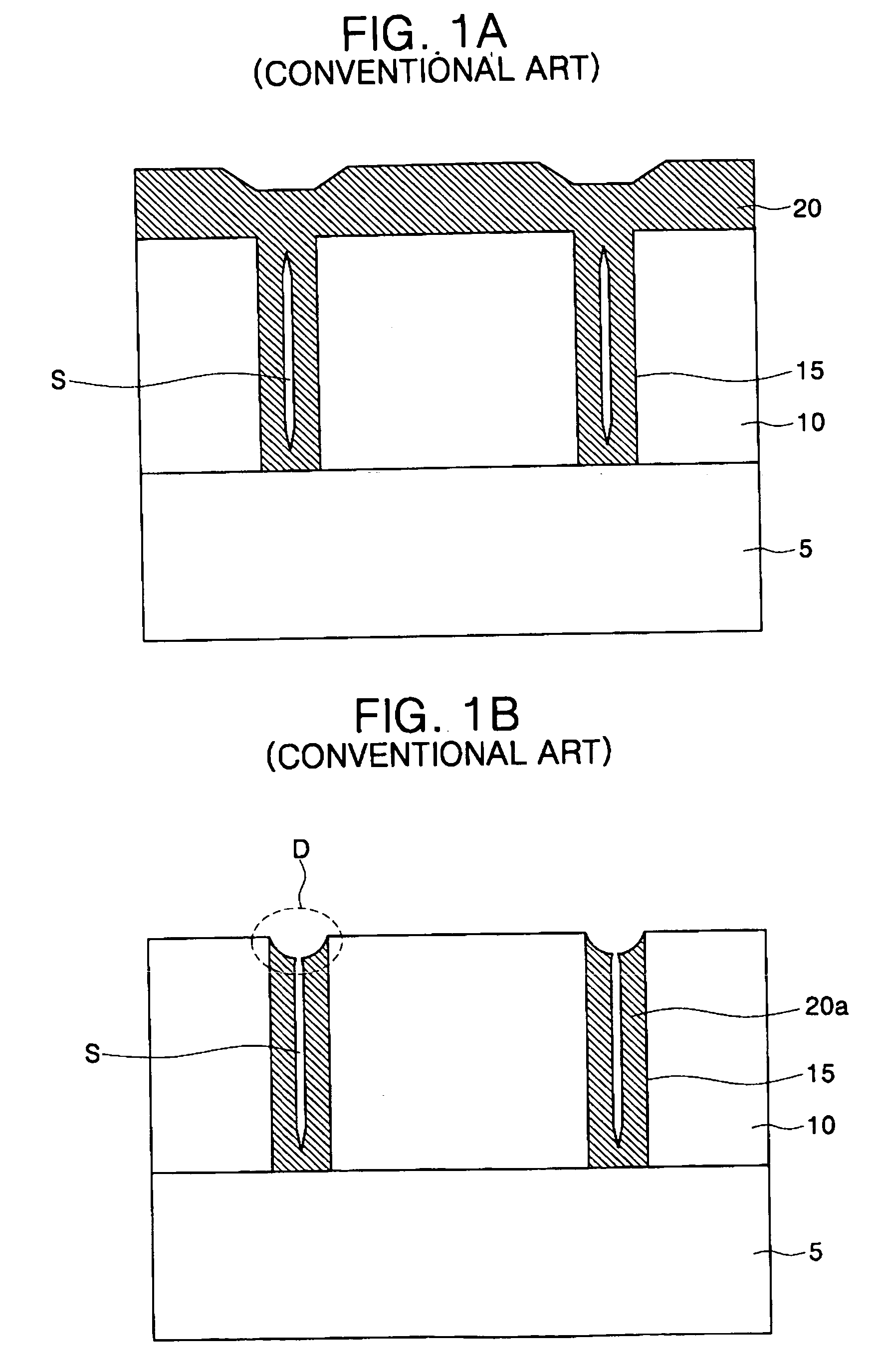

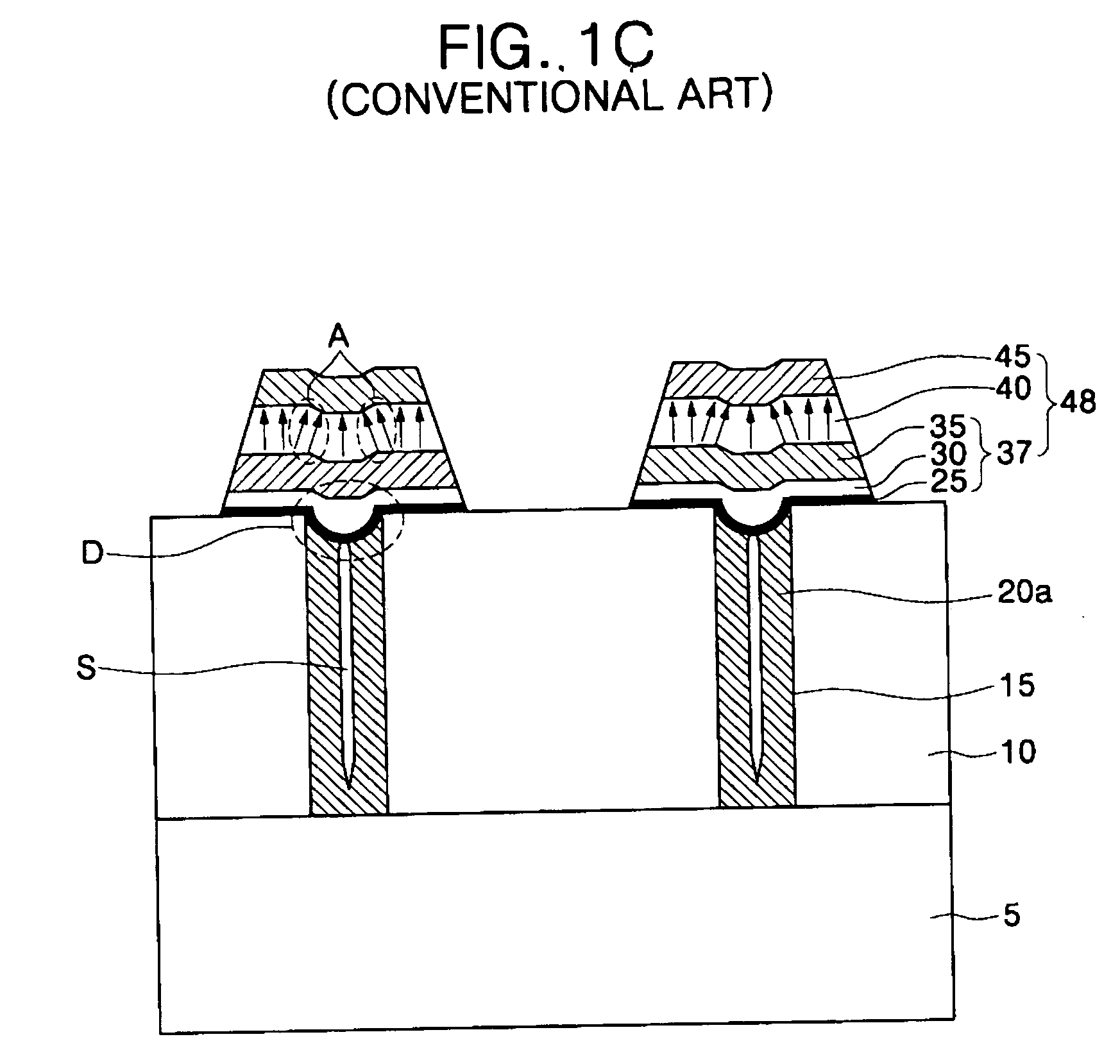

Semiconductor device with shallow trench isolation and its manufacture method

InactiveUS20060255426A1Improve transistor characteristicsIncrease currentSolid-state devicesSemiconductor/solid-state device manufacturingHydrofluoric acidHigh density

A semiconductor device manufacturing method includes the steps of: (a) forming a stopper layer for chemical mechanical polishing on a surface of a semiconductor substrate; (b) forming an element isolation trench in the stopper layer and the semiconductor substrate; (c) depositing a nitride film covering an inner surface of the trench; (d) depositing a first oxide film through high density plasma CVD, the first oxide film burying at least a lower portion of the trench deposited with the nitride film; (e) washing out the first oxide film on a side wall of the trench by dilute hydrofluoric acid; (f) depositing a second oxide film by high density plasma CVD, the second oxide film burying the trench after the washing-out; and (g) removing the oxide films on the stopper layer by chemical mechanical polishing.

Owner:FUJITSU SEMICON LTD

Method And Apparatus For Detecting The Endpoint Of A Chemical-Mechanical Polishing Operation

InactiveUS20070105247A1Used to determineSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsAnti-reflective coatingMetal interconnect

A structure in a semiconductor device useful in determining an endpoint in a chemical-mechanical polishing process is provided. The structure comprises a dielectric layer, an anti-reflective coating, and a metal layer. The dielectric layer has an opening extending therein. The anti-reflective coating extends over at least a portion of the first dielectric layer. The metal layer extends over at least a portion of the anti-reflective coating and within the opening. Thus, during the CMP process, the metal layer is removed, exposing the anti-reflective coating but leaving the metal layer in the opening to form a metal interconnect.

Owner:ADVANCED MICRO DEVICES INC

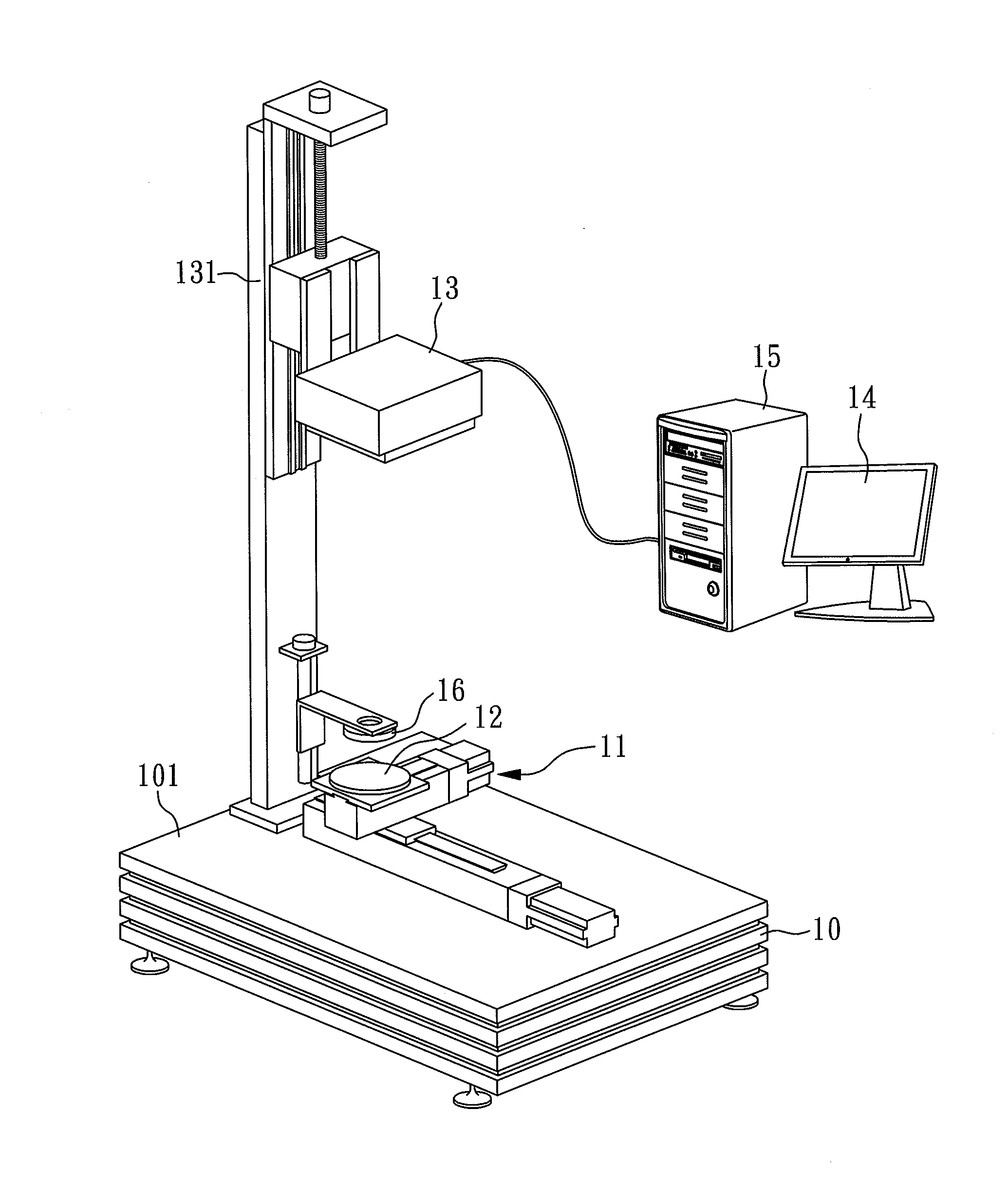

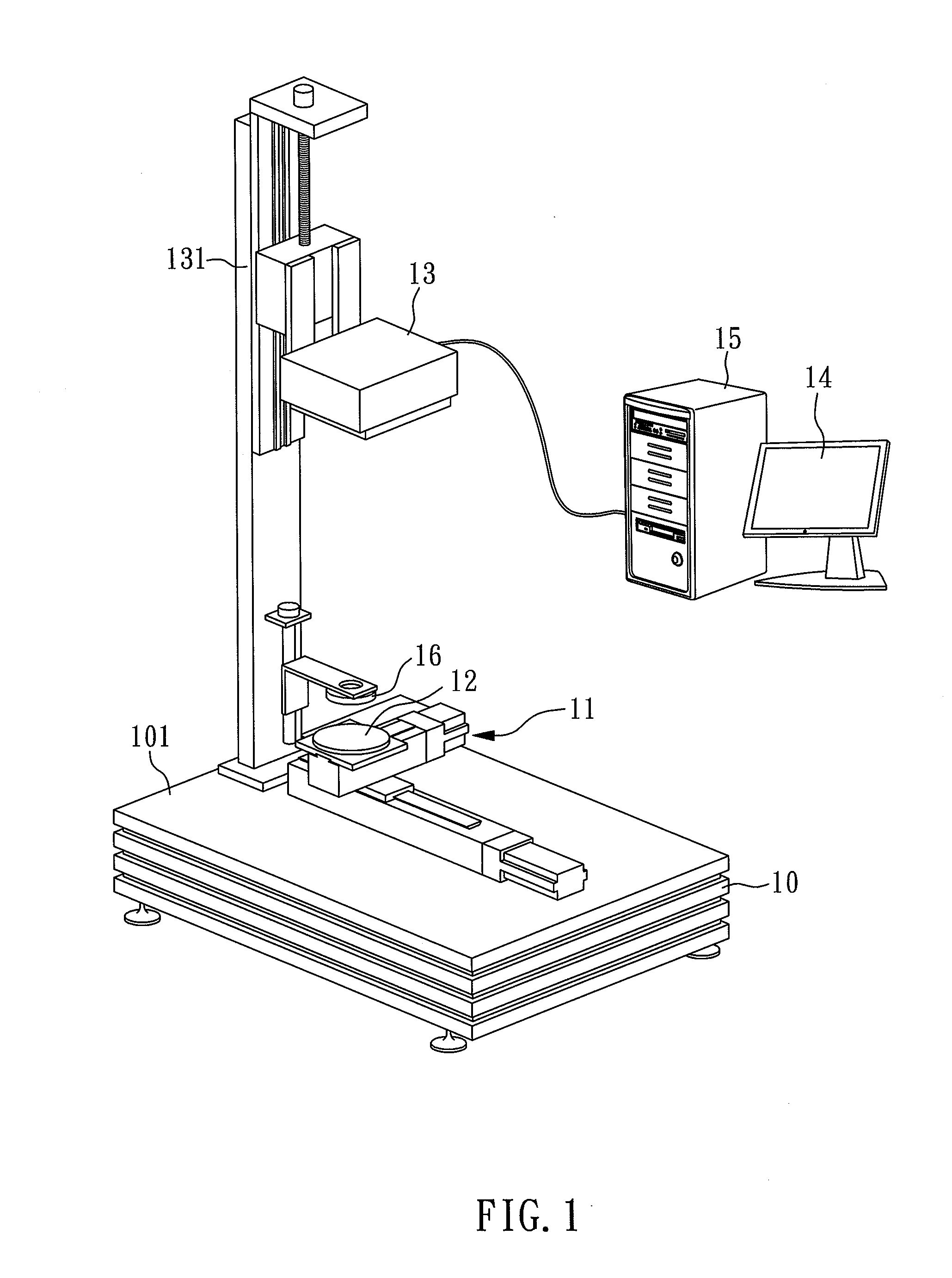

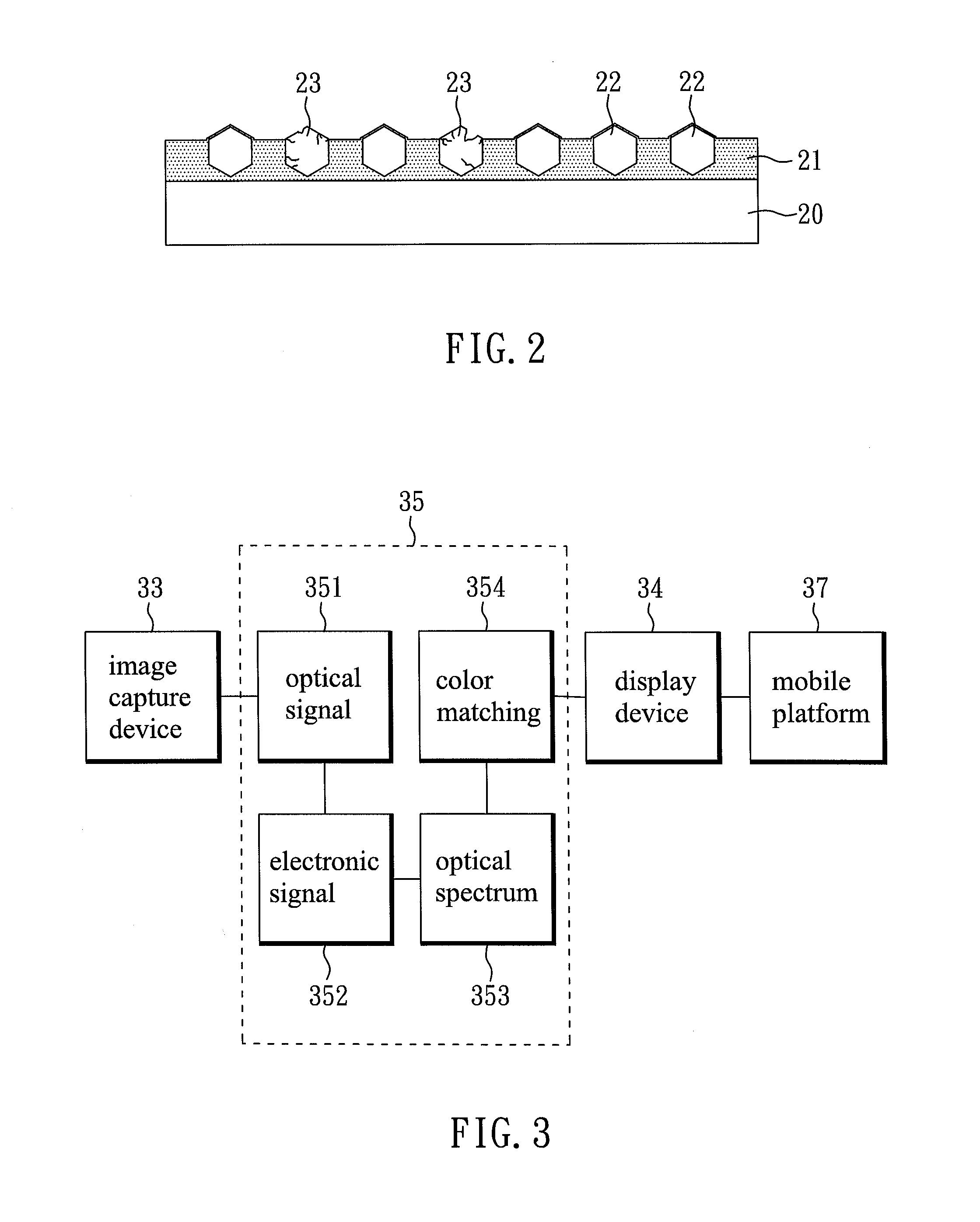

Detection apparatus and method of chemical mechanical polishing conditioner

InactiveUS20140335761A1Avoid breakingWasting energyGrinding feed controlAbrasive surface conditioning devicesDevice formDisplay device

The present invention relates to a detection apparatus of chemical mechanical polishing conditioner, comprising: a working platform with a working plane; a placement base disposed on the working plane of the working platform, for carrying a chemical mechanical polishing conditioner; an image capture device forming one or a plurality of captured images on different regions of the chemical mechanical polishing conditioner; a display device; an image recognition module, wherein the captured images are performed a color matching by the image recognition module to determine one or a plurality of risk diamonds on the chemical mechanical polishing conditioner, and the coordinate location of the risk diamonds are outputted into the display device; and a mobile platform for moving the risk diamonds to specified locations. A detection method of the above mentioned detection apparatus is also disclosed.

Owner:KINIK

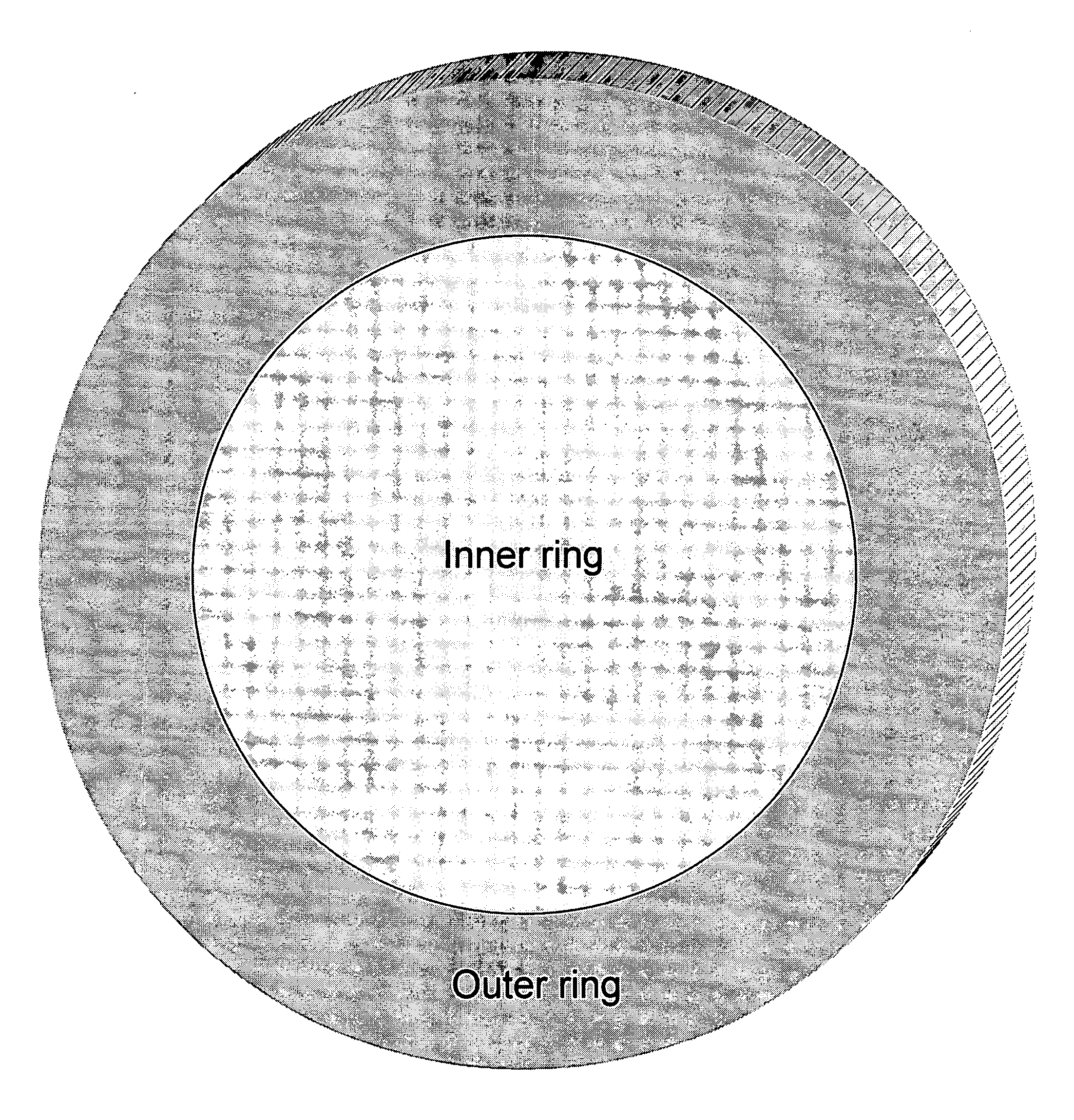

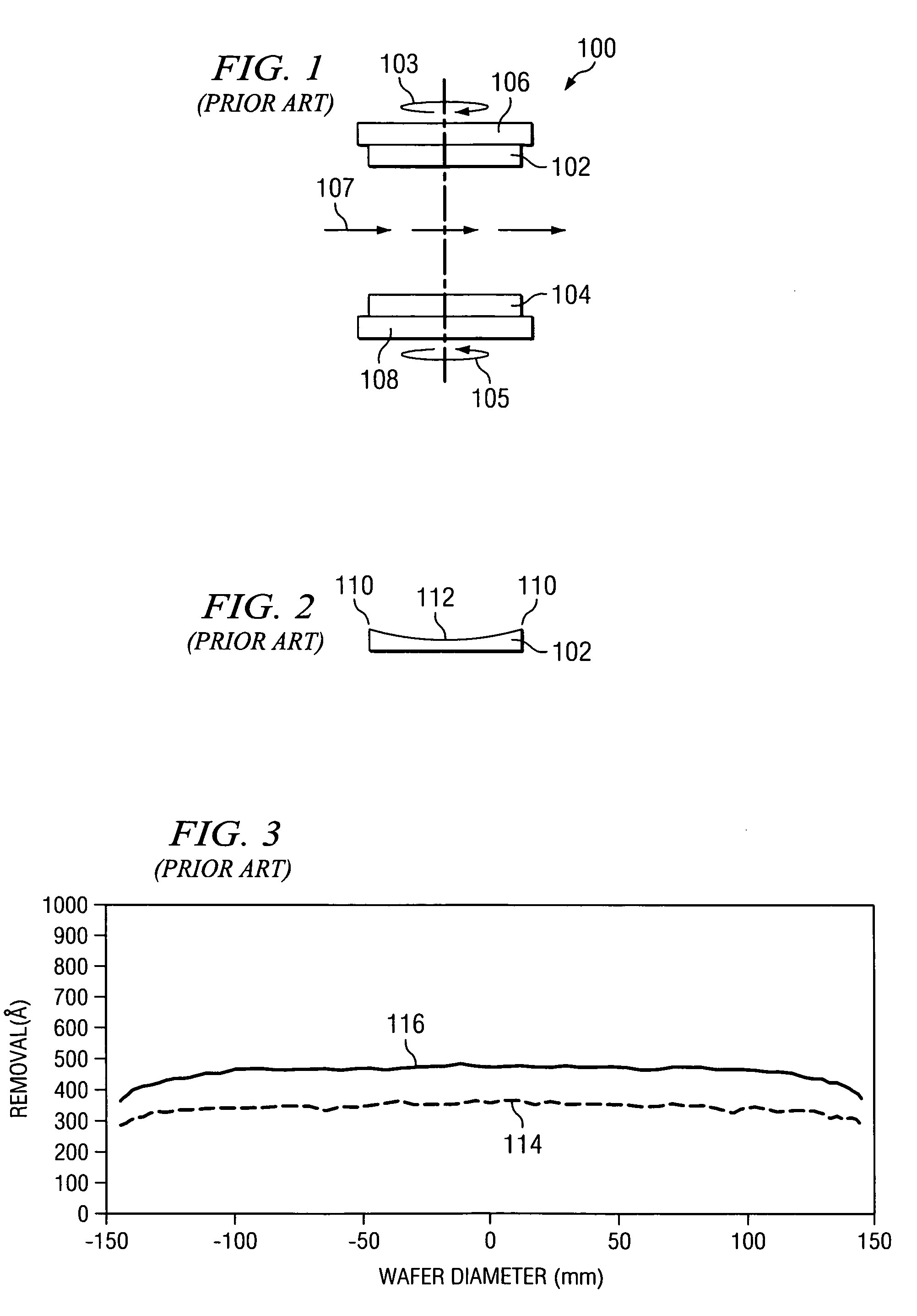

Chemical mechanical polish with multi-zone abrasive-containing matrix

InactiveUS20060079159A1Improved CMP profilePolishing machinesRevolution surface grinding machinesMaterial removalCompound (substance)

Chemical mechanical polish (CMP) devices, CMP systems, methods of CMP, and methods of manufacturing CMP devices. A CMP device comprises a plurality of zones, with each zone having a matrix of fixed abrasive features disposed therein. The abrasive-containing matrix within each zone has material removal properties that differ from the material removal properties of the abrasive-containing matrixes of the other zones. The material removal property differences of the abrasive-containing matrixes of the zones may achieved by using different abrasive materials, densities, heights, or shapes, or combinations thereof, of the fixed abrasive features within the zones, or by using physical or chemical conditioning. When the novel CMP device is used to planarize a semiconductor wafer, a substantially planar surface with an improved CMP profile results.

Owner:IBM CORP +1

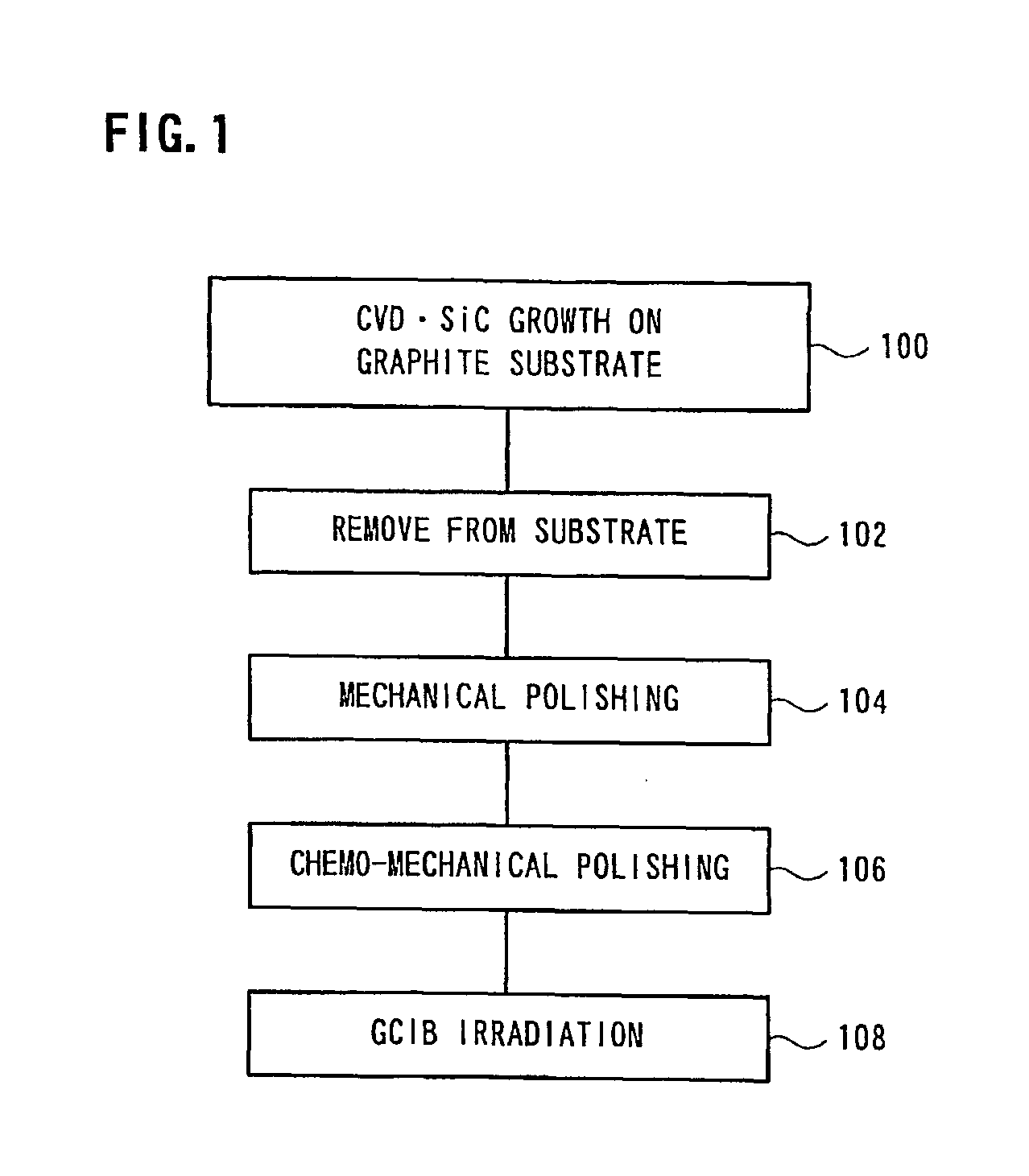

Production method of sic monitor wafer

InactiveUS20050042800A1Inhibit etch rateLow costPolycrystalline material growthAfter-treatment detailsWaferingGas cluster ion beam

The present invention has its object to obtain an SiC monitor wafer which can flatten the surface until particle detection is possible. SiC of a crystal system 3C is deposited on a substrate by a CVD (Chemical Vapor Deposition) method, and the SiC is detached from a substrate. After the SiC surface is flattened by using mechanical polishing alone or in combination with CMP (Chemo Mechanical Polishing), GCIB (Gas Cluster Ion Beam) is irradiated to the surface until the surface roughness becomes Ra=0.5 nm or less and the impurity density of the wafer surface becomes 1*1011 atoms / cm2 or less to produce the SiC monitor wafer.

Owner:MITSUI E&S MACHINERY CO LTD

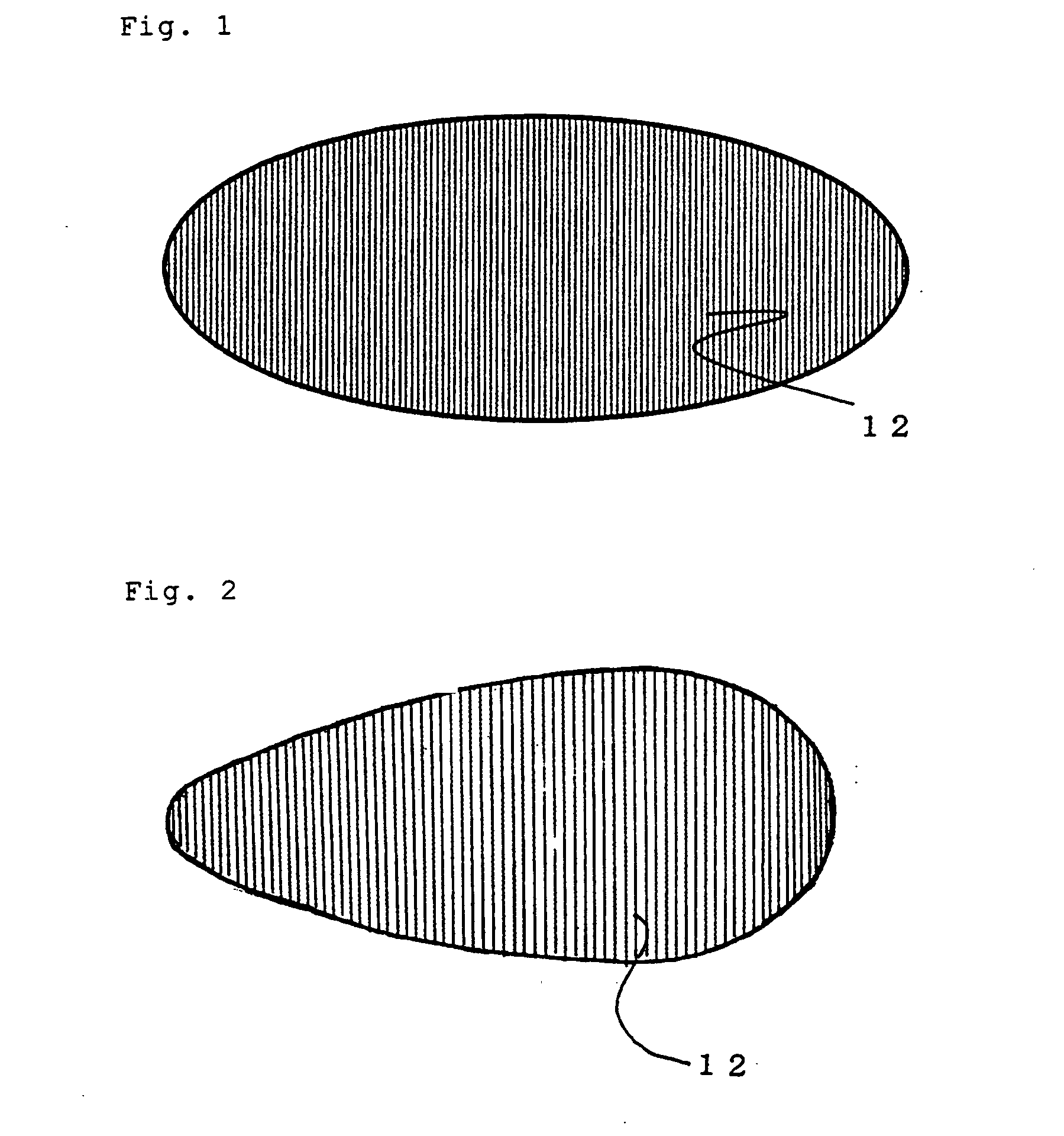

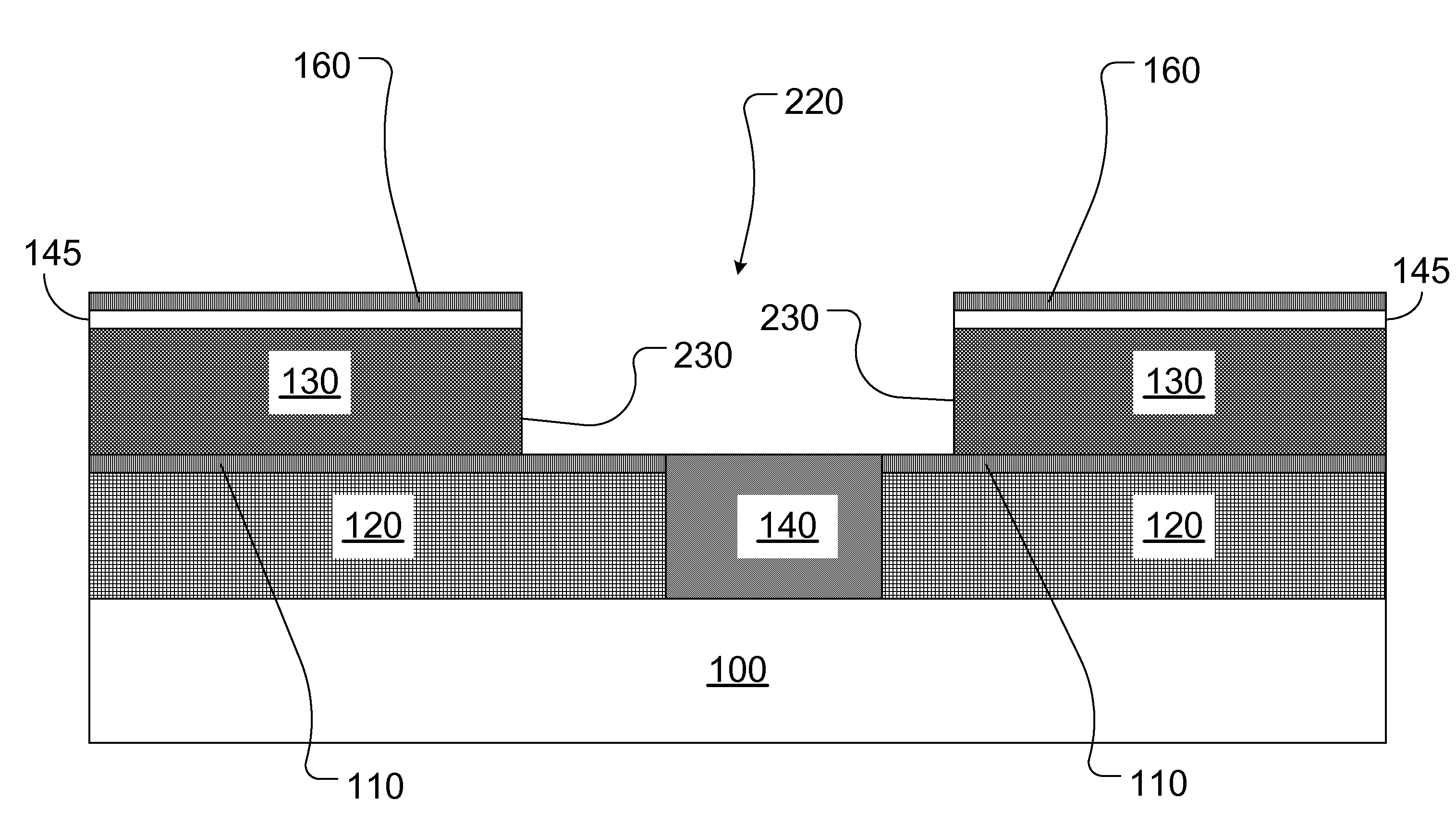

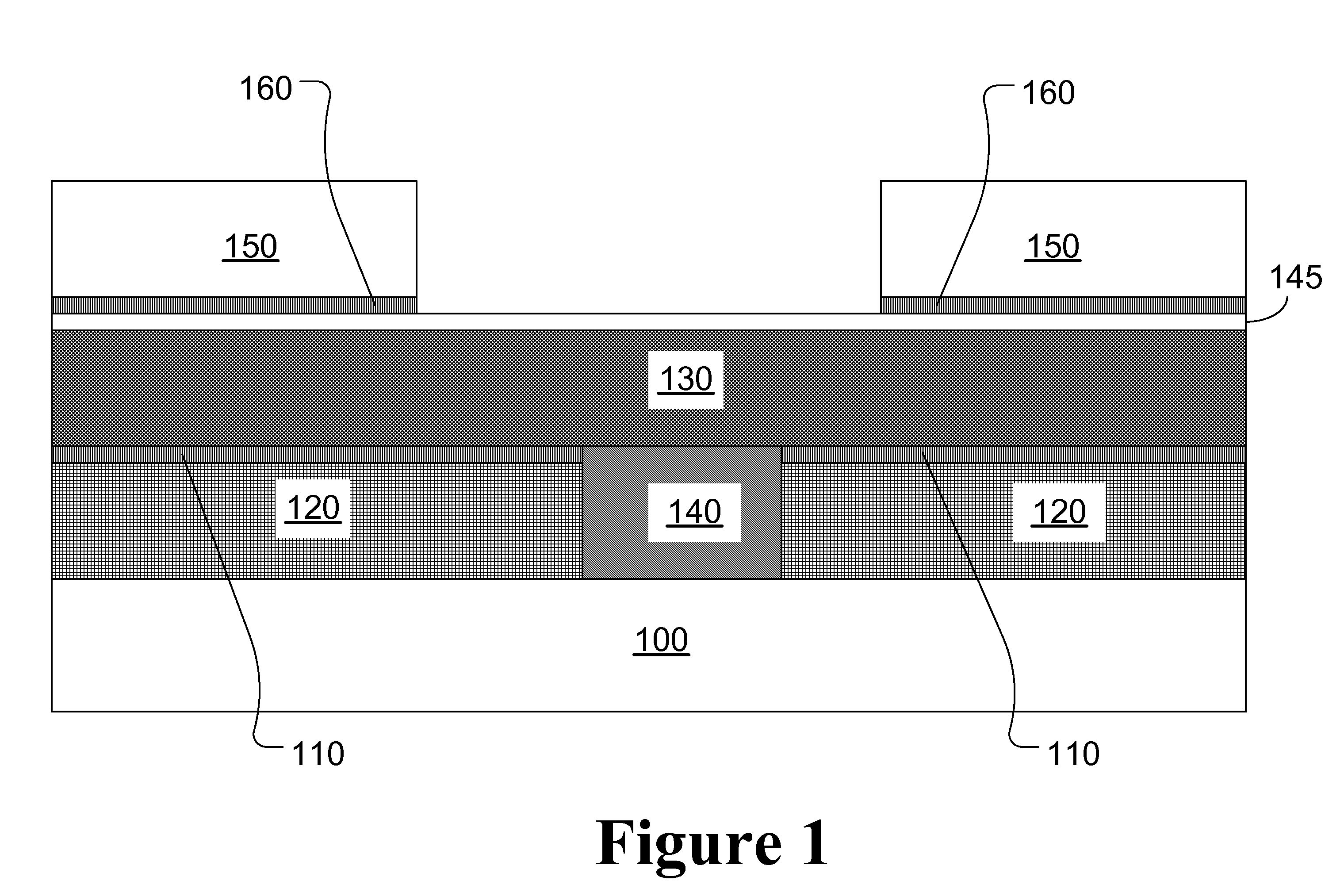

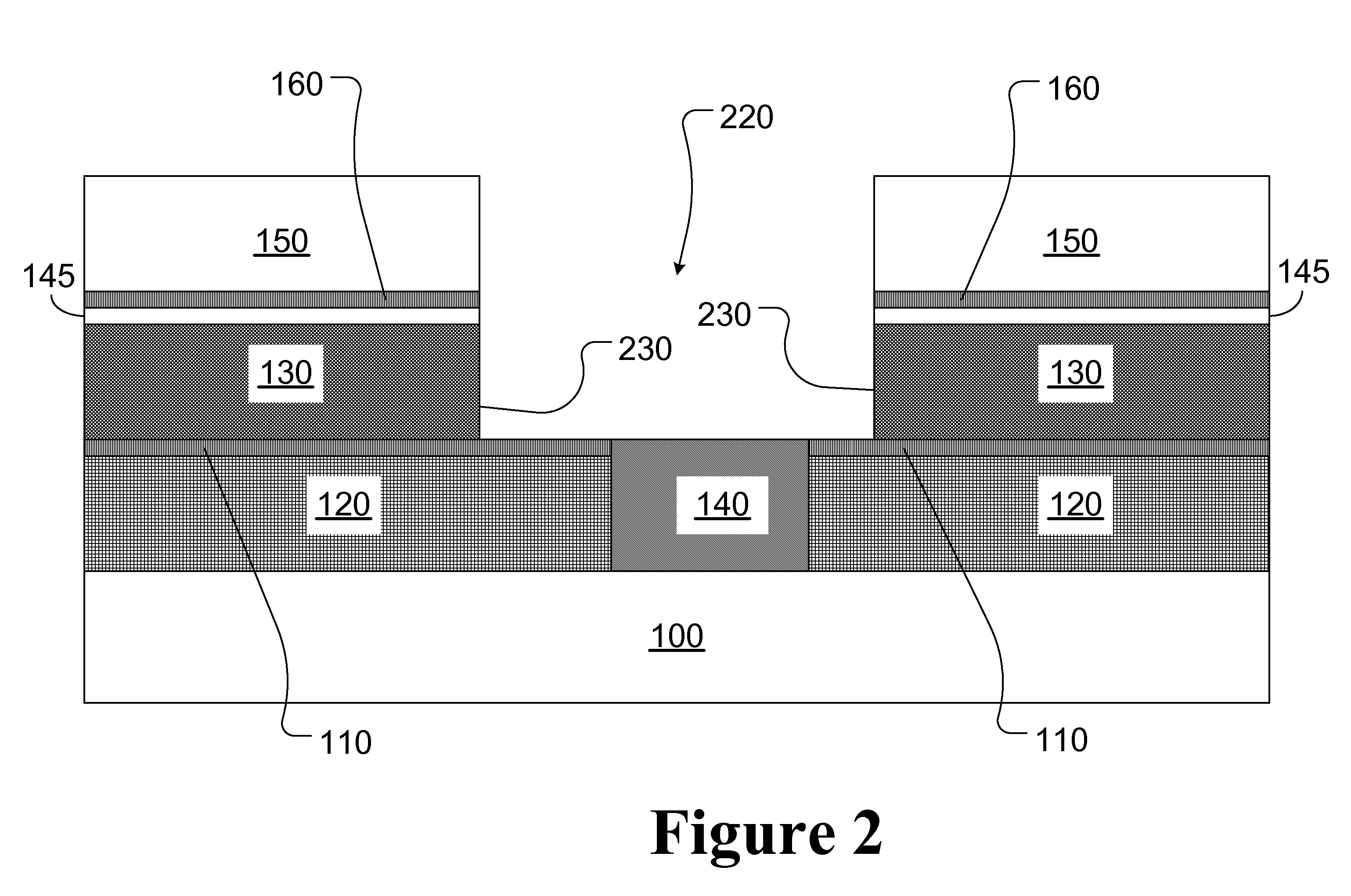

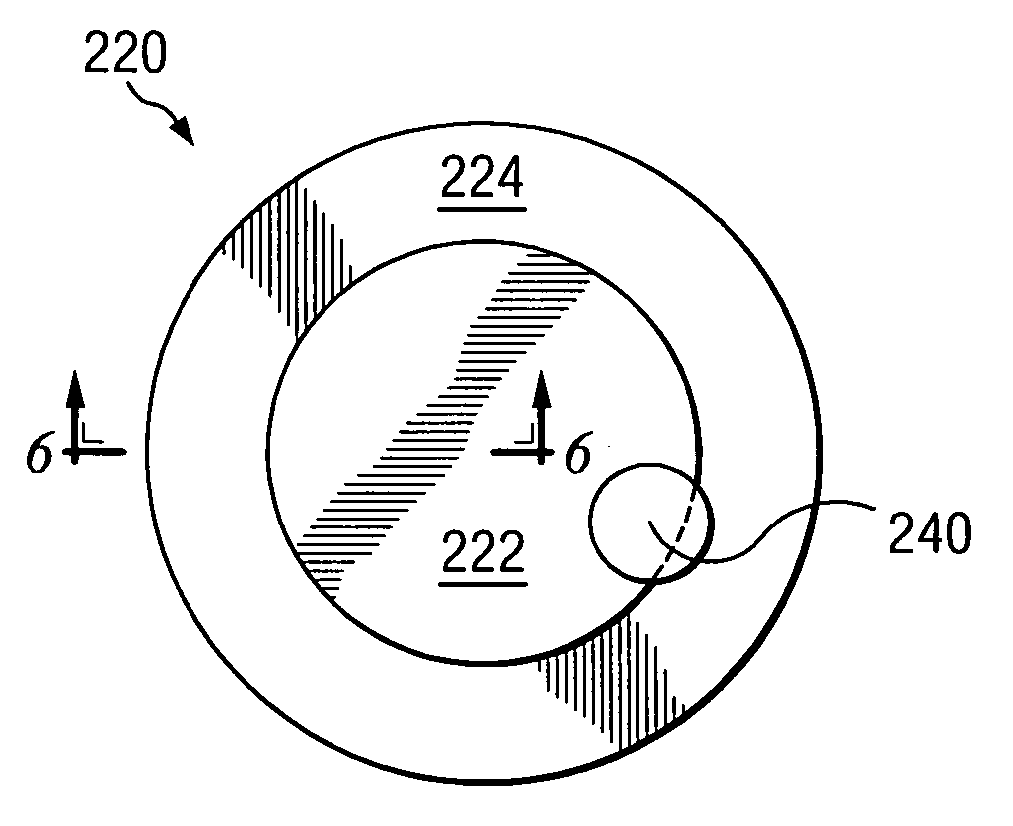

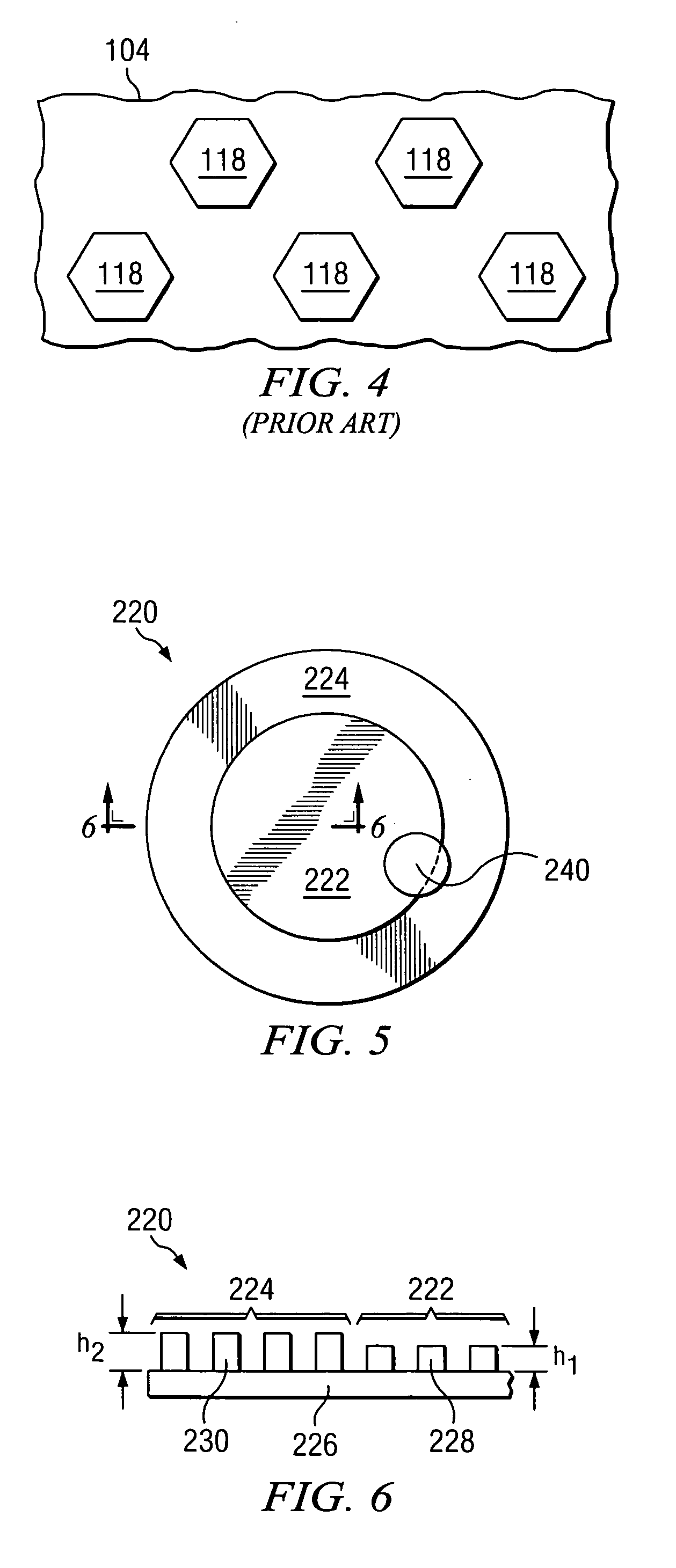

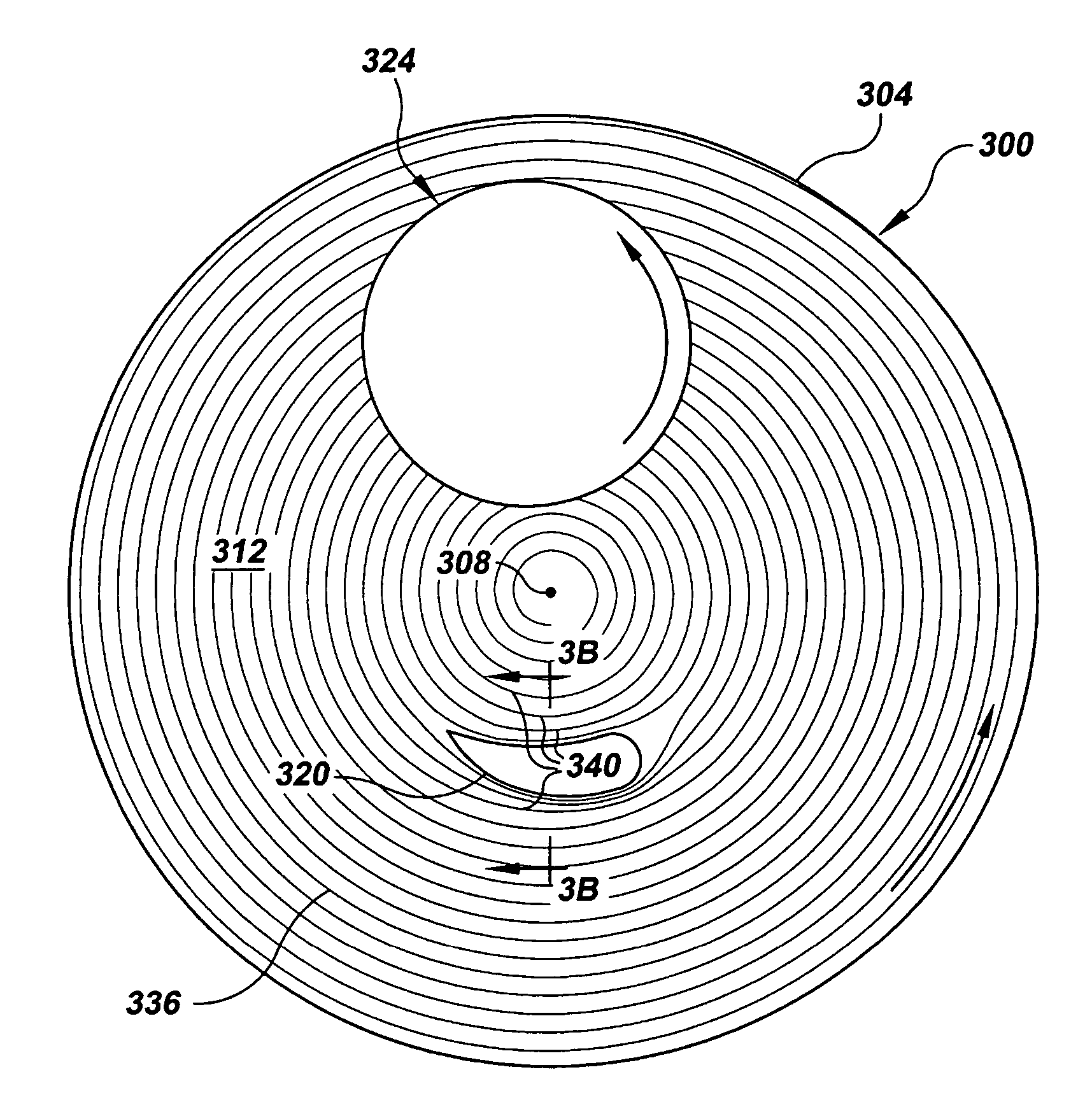

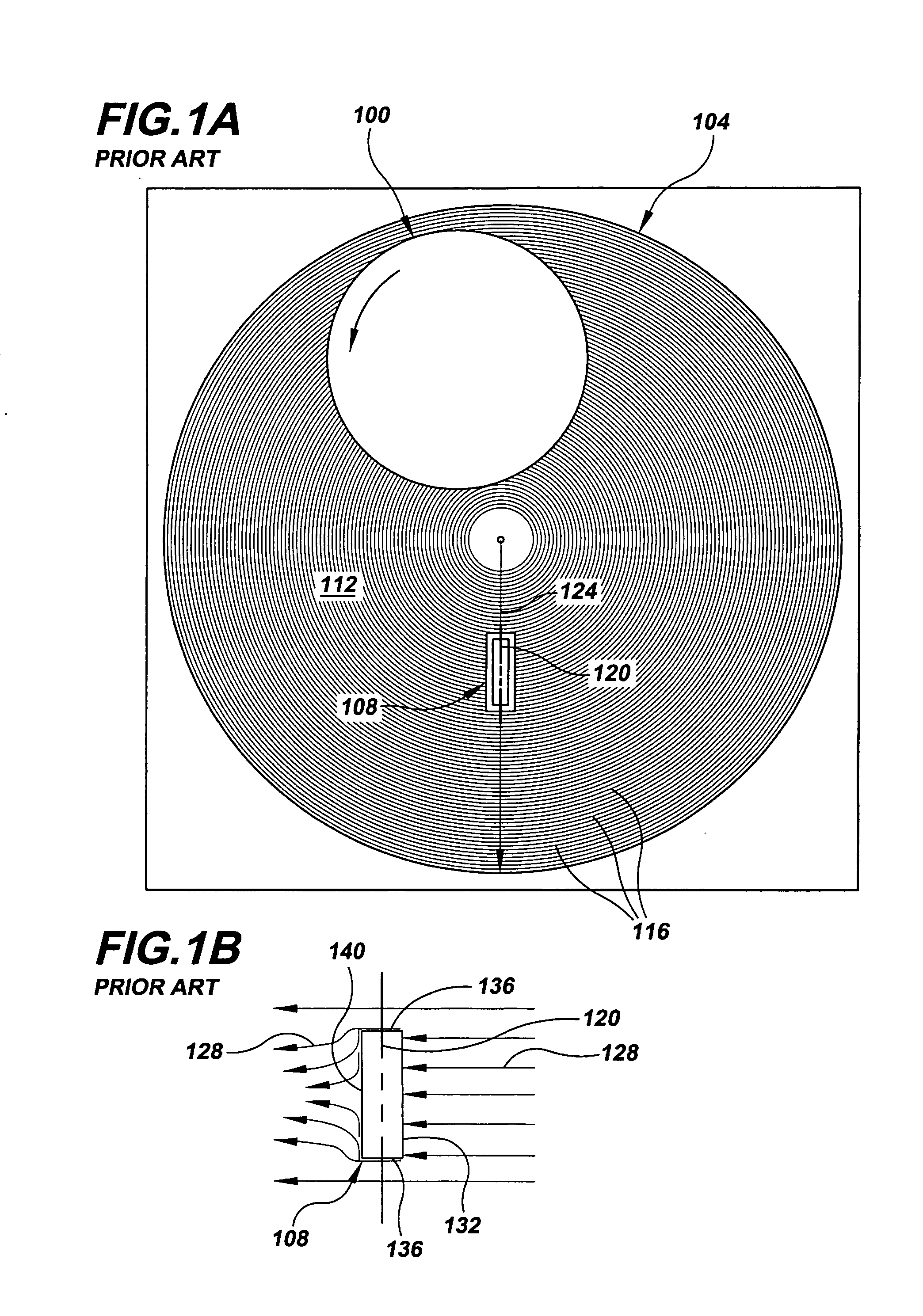

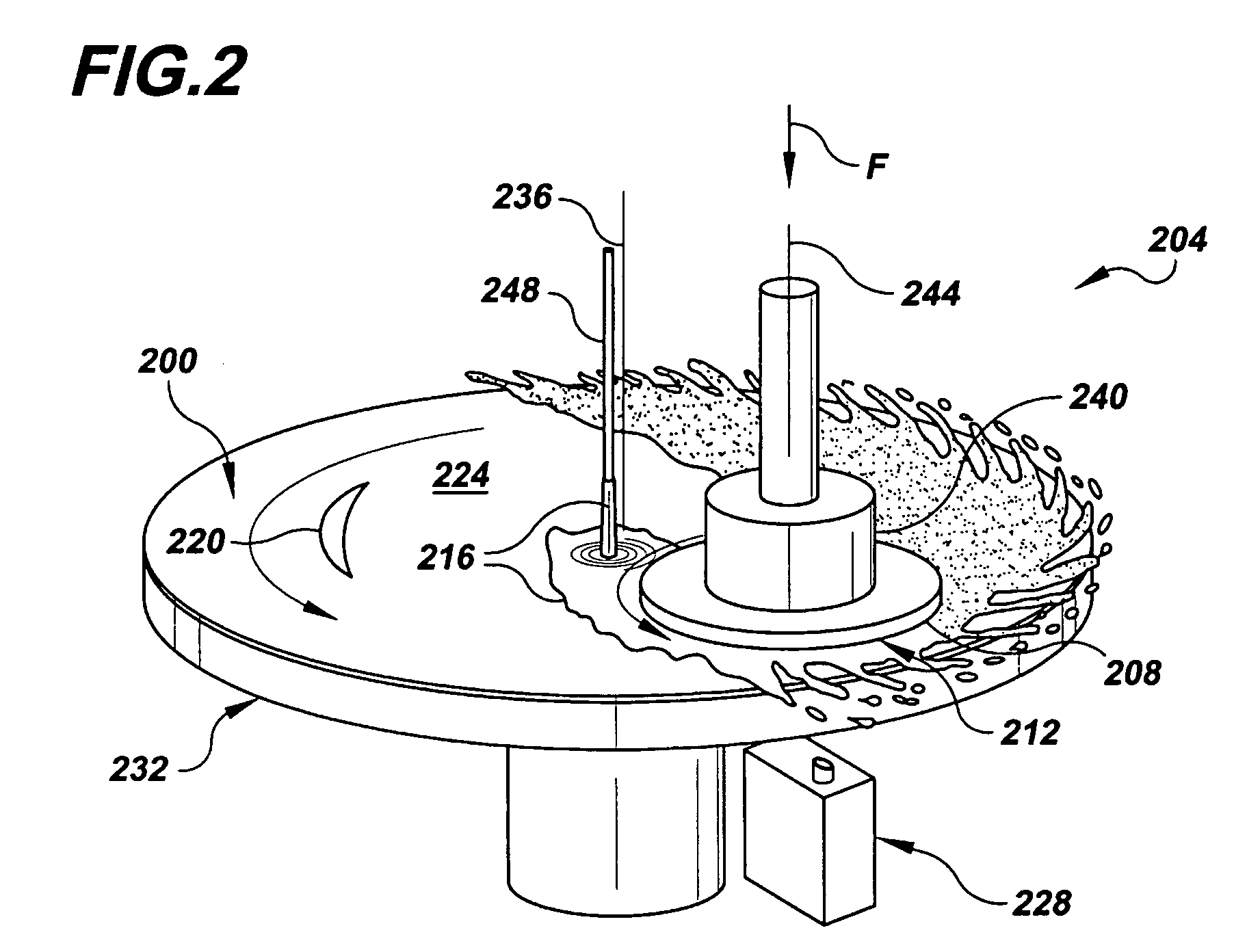

CMP pad having a streamlined windowpane

A chemical mechanical polishing pad (200, 300, 400, 500, 600) that includes a translucent windowpane (220, 320, 404, 516, 524, 604) that allows optical measurements to be made using light energy reflected from the surface of a wafer (212, 324, 608) or other object being polished. The windowpane includes a trailing end (350, 416, 632) and a leading end (348, 412, 628) each having a streamlined shape so as to reduce the disturbance to the flow of a polishing medium (216) around the windowpane. The polishing pad may further include grooves (336, 428, 520, 640) that are diverted around the windowpane so as to provide a continuous path for the polishing medium in the region of the windowpane.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

Widely wavelength tuneable polychrome colloidal photonic crystal device

The present invention discloses a widely wavelength tunable polychrome colloidal photonic crystal device whose optical Bragg diffraction stop bands and higher energy bands wavelength, width and intensity can be tuned in a continuous and fine, rapid and reversible, reproducible and predictable fashion and over a broad spectral range by a controlled expansion or contraction of the colloidal photonic lattice dimension, effected by a predetermined change in the electronic configuration of the composite material. In its preferred embodiment, the material is a composite in the form of a film or a patterned film or shape of any dimension or array of shapes of any dimension comprised of an organized array of microspheres in a matrix of a cross-linked metallopolymer network with a continuously variable redox state of charge and fluid content. The chemo-mechanical and electro-mechanical optical response of the colloidal photonic crystal-metallopolymer gel is exceptionally fast and reversible, attaining its fully swollen state from the dry shrunken state and vice versa on a sub-second time-scale. These composite materials can be inverted by removal of the constituent microspheres from the aforementioned colloidal photonic crystal metallopolymer-gel network to create a macroporous metallopolymer-gel network inverse colloidal photonic crystal film or patterned film or shape of any dimension optical Bragg diffraction stop bands and higher energy bands wavelength, width and intensity can be redox tuned in a continuous and fine, rapid and reversible, reproducible and predictable fashion and over a broad spectral range by a controlled expansion or contraction of the colloidal photonic lattice dimensions.

Owner:THE GOVERNING COUNCIL OF THE UNIV OF TORONTO

Methods of fabricating ferroelectric capacitors utilizing a partial chemical mechanical polishing process

InactiveUS20060183250A1Reduce complexityQuality improvementSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringFerroelectric capacitor

The invention provides methods for fabricating ferroelectric capacitors and ferroelectric memory devices incorporating such capacitors. The methods according to the invention each include a partial chemical mechanical polishing process by which a planarized surface may be formed on a material layer formed between a buried contact plug and a ferroelectric layer. In particular, the methods according to the invention compensate for recessed or dishing regions formed in the surface of the buried contact plug to suppress or eliminate the propagation of profile of the recessed or dishing regions through intermediate layers to the ferroelectric layer, thereby improving the ferroelectric performance.

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com