Patents

Literature

87results about How to "Low roughness requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

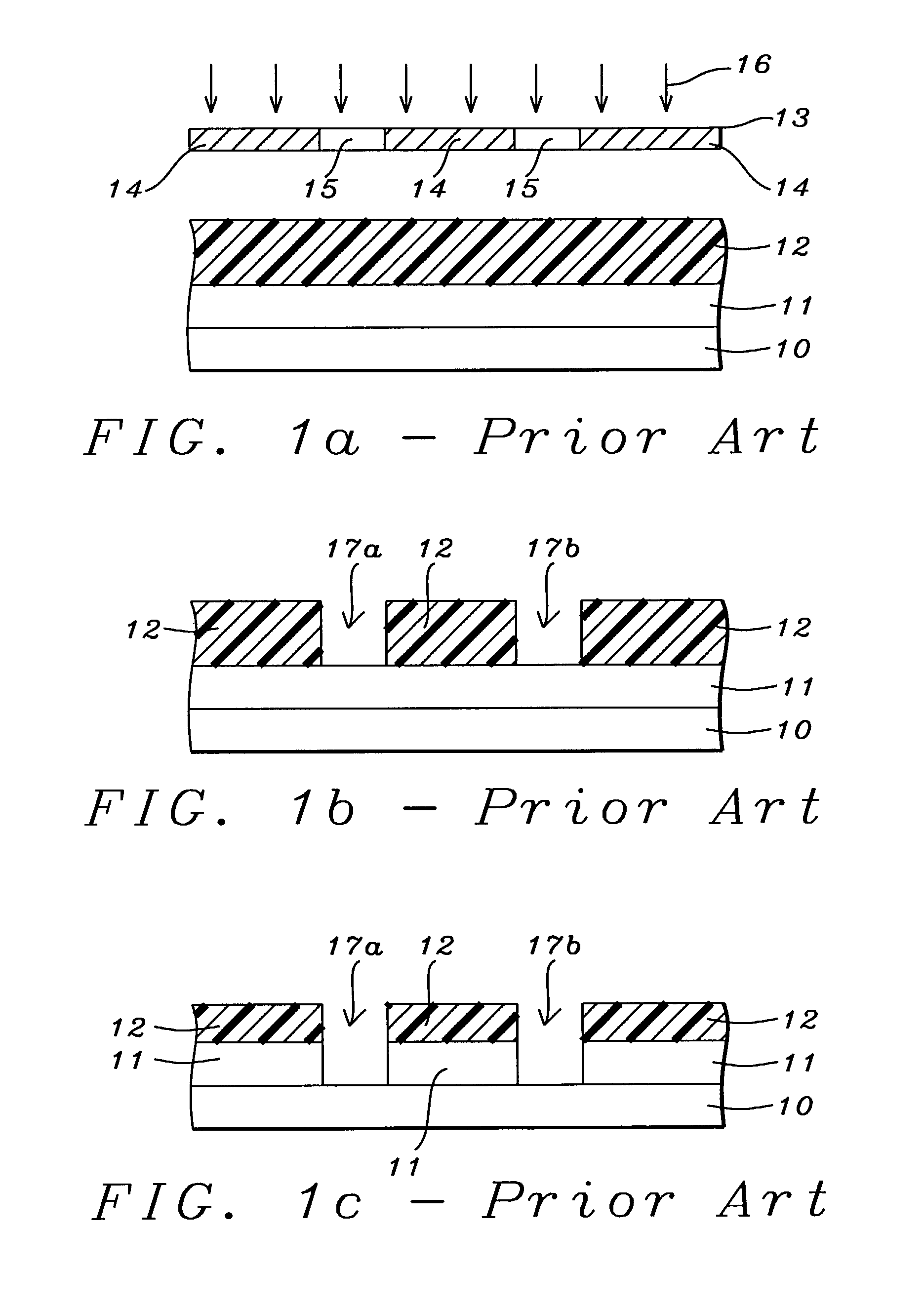

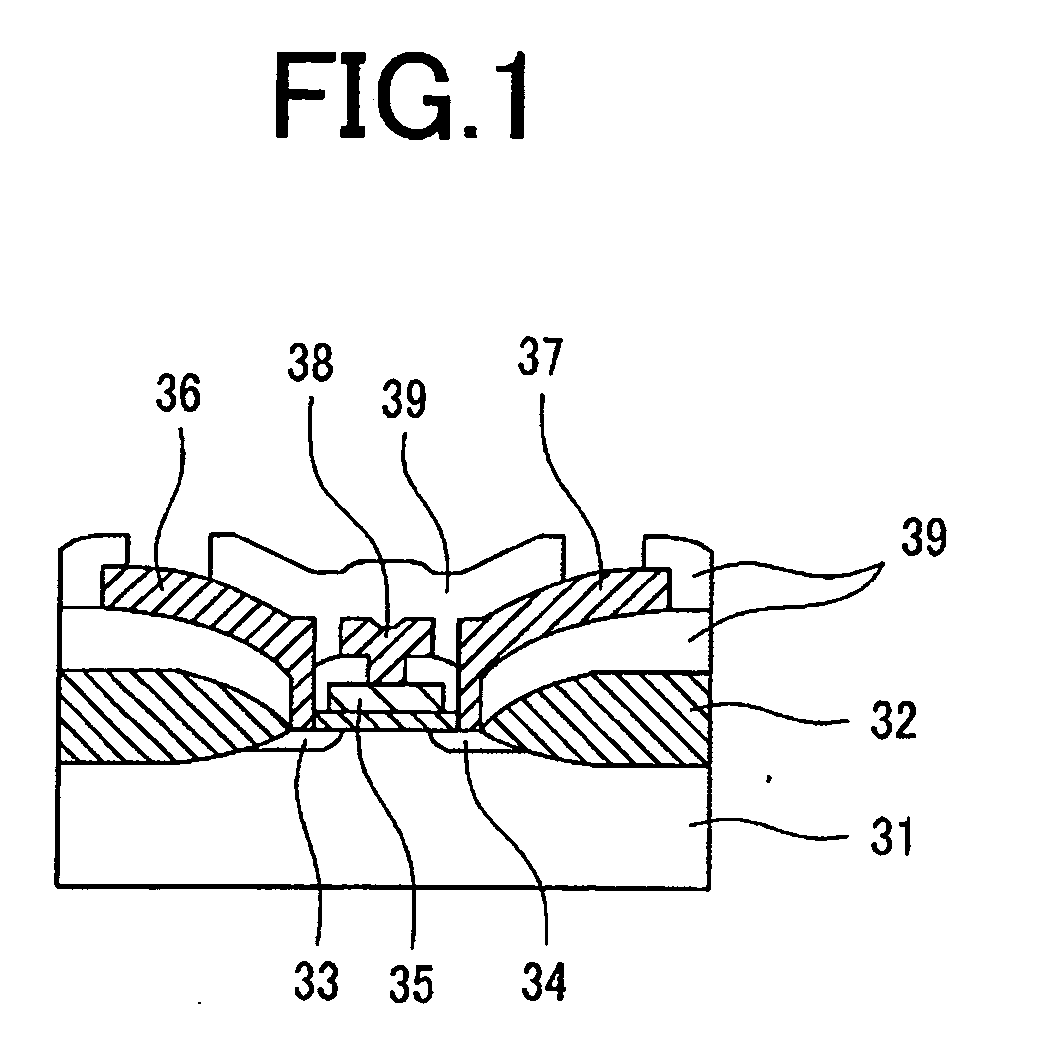

Manufacturing method of strained si substrate

InactiveUS20100003803A1Low densityLow roughness requirementsPolycrystalline material growthSolid-state devicesThreading dislocationsHydrogen

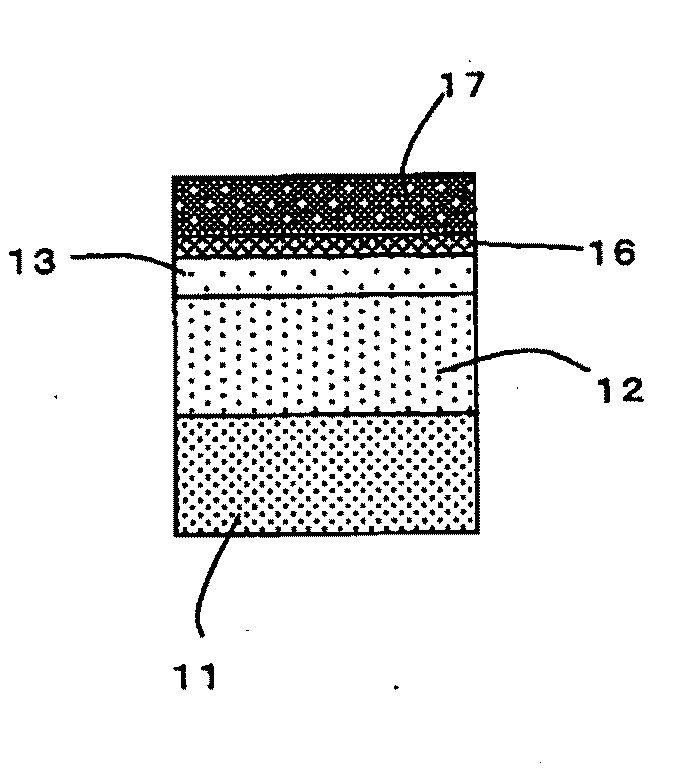

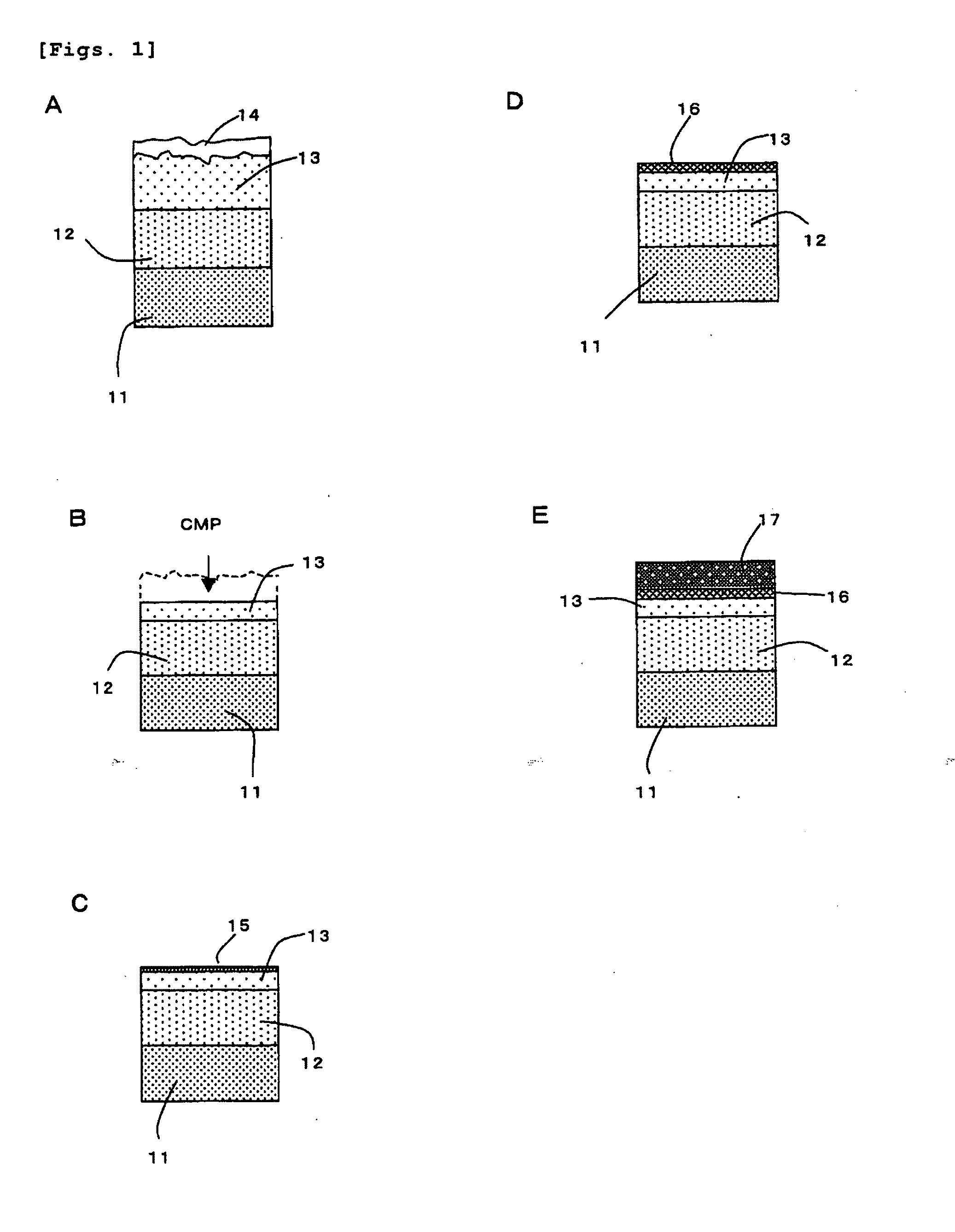

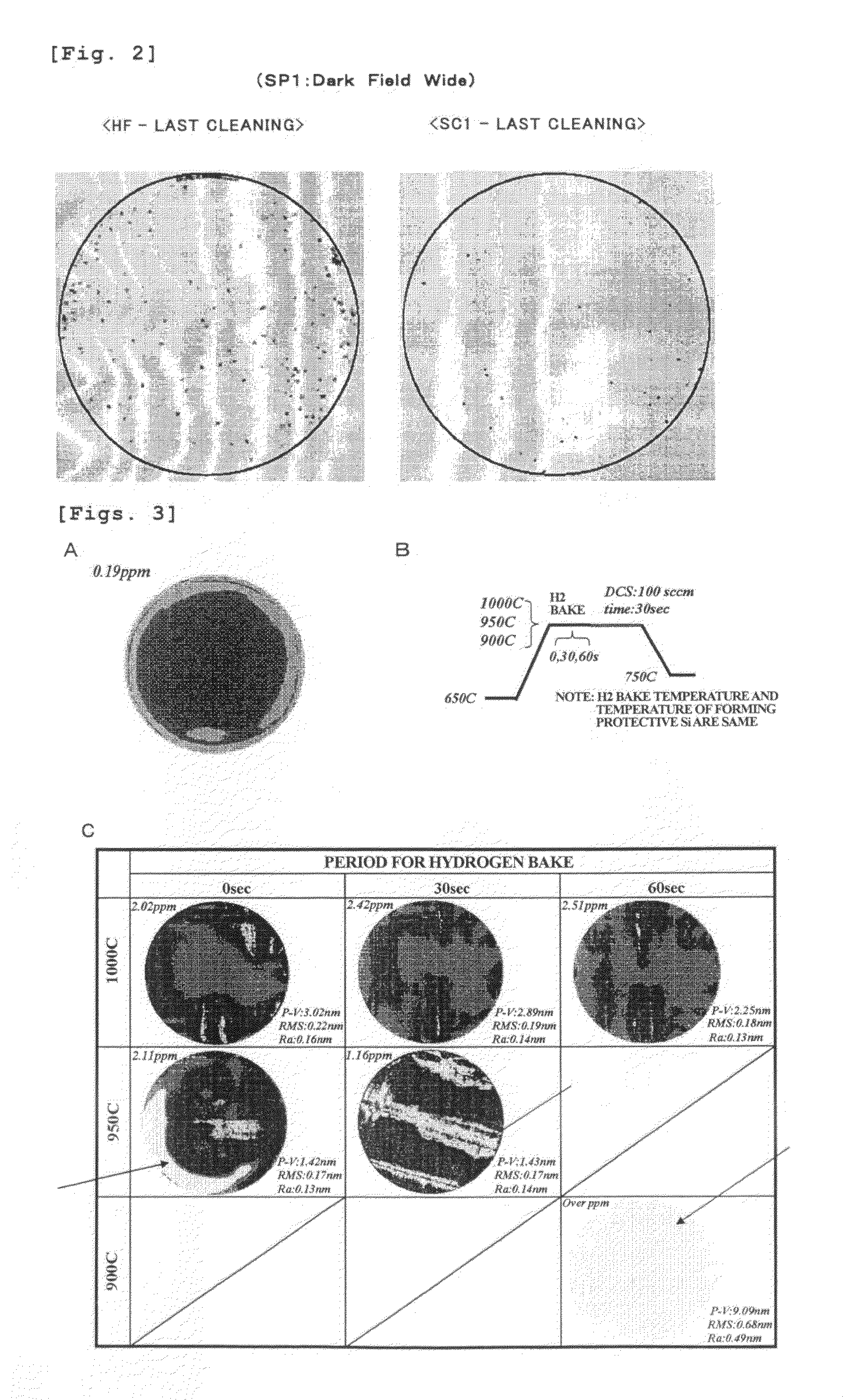

According to the present invention, there is provided a manufacturing method of a strained Si substrate including at least steps of: forming a lattice-relaxed SiGe layer on a silicon single crystal substrate; flattening a surface of the SiGe layer by CMP; and forming a strained Si layer on the surface of the flattened SiGe layer, wherein the method comprises steps of: subjecting the surface of the SiGe layer to SC1 cleaning, before forming the strained Si layer on the lattice-relaxed SiGe layer surface that is flattened; heat-treating the substrate having the SiGe layer after being subjected to SC1 cleaning in a hydrogen-containing atmosphere at 800° C. or higher; immediately forming a protective Si layer on the SiGe layer surface on the heat-treated substrate, without lowering the temperature below 800° C. after the heat treatment; and forming the strained Si layer on the surface of the protective Si layer at a temperature lower than the temperature of forming the protective Si layer. Thereby, a manufacturing method of a strained Si substrate having low surface roughness, threading dislocation density and low particle level can be provided.

Owner:SHIN-ETSU HANDOTAI CO LTD

Technology for repairing surfacing of piston rod of super large marine diesel engine

InactiveCN101444881ALow roughness requirementsLow cleanliness requirementsArc welding apparatusRoom temperatureEngineering

The invention discloses a technology for repairing surfacing of a piston rod of a super large marine diesel engine, and the technology can carry out the deep repair of the surface of the piston rod. The adopted surfacing process is as follows: flaw detection and straightening are carried out on the piston rod, turning machining is carried out on the surface of the piston rod to remove a defect layer, and individual deeper cracks are manually removed by grinding; fire whirl is used for heating the piston rod twice, the first heating is carried out till 200 DEG C-250 DEG C, the heating is stopped, the race rotation is carried out for 30 minutes, the second heating is further carried out after the temperature difference between the interior and the exterior is reduced, and a surfacing machine tool is rotated after reaching 250 DEG C-300 DEG C; submerged arc welding is used for rotating dual heads of the surfacing machine tool and a 2Cr13 flux-cored welding wire for carrying out the simultaneous surfacing, and asbestos cloth is used for wrapping and keeping the temperature during the welding process; the piston rod wrapped by the asbestos cloth for slow cooling after the surfacing achieves the size requirement, when the temperature is decreased to be lower than 100 DEG C, the piston rod wrapped by the asbestos cloth is vertically placed till the temperature is decreased to the room temperature, and then the temperature-keeping cloth is removed. The surface of the piston rod after the repair by employing the method has no weld defects, the piston rod fully meets the performance requirements, and the cost is only about one fifth of the cost for fabricating a new piston rod.

Owner:DALIAN XINZHONG GRP +1

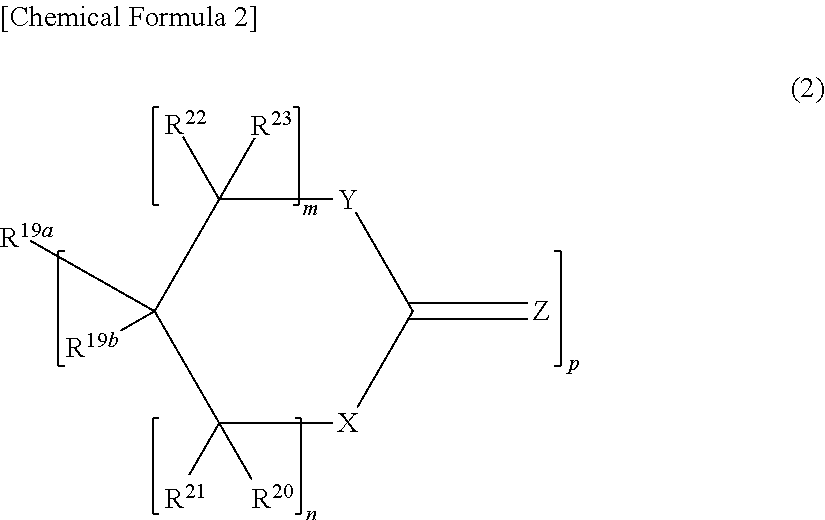

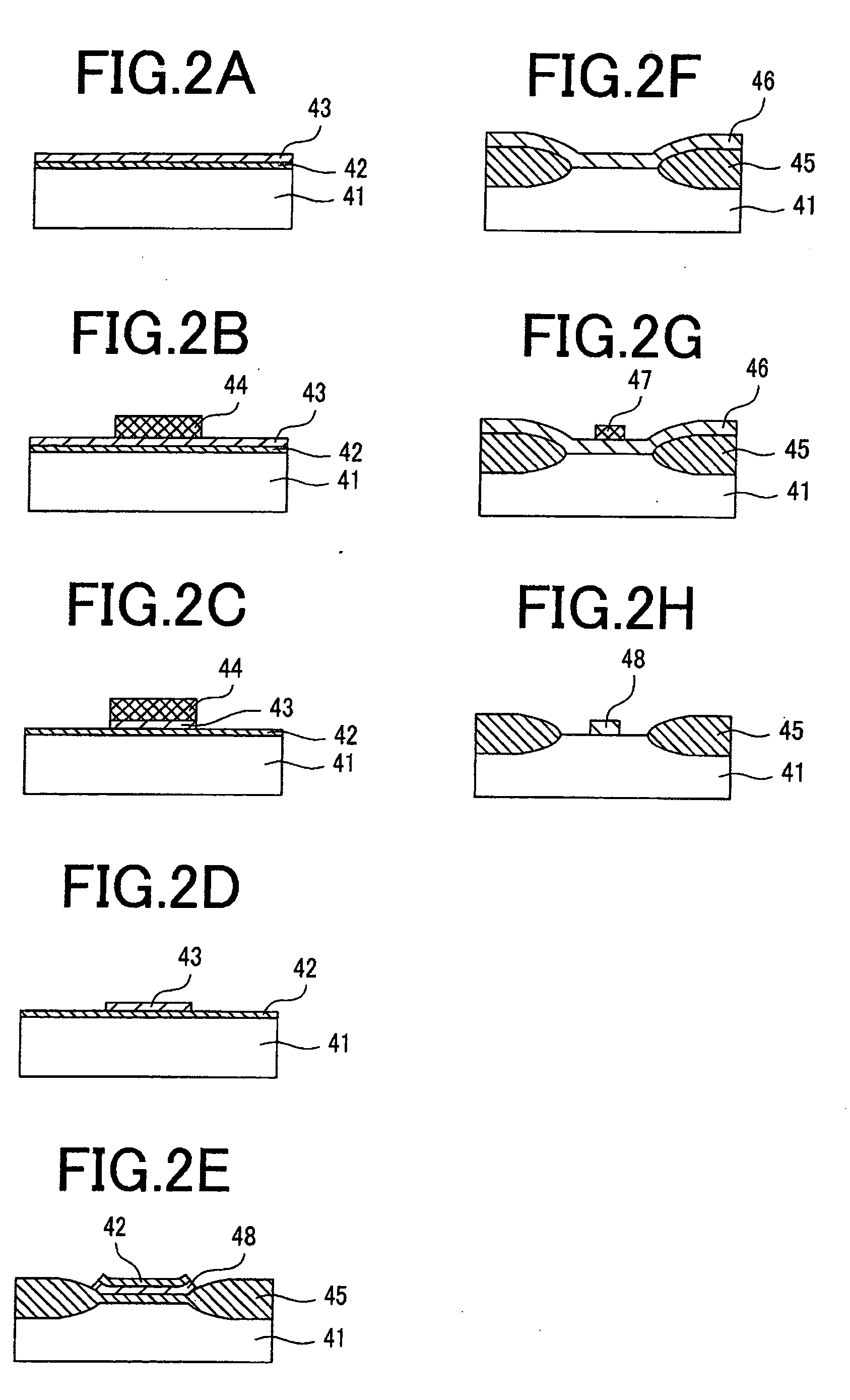

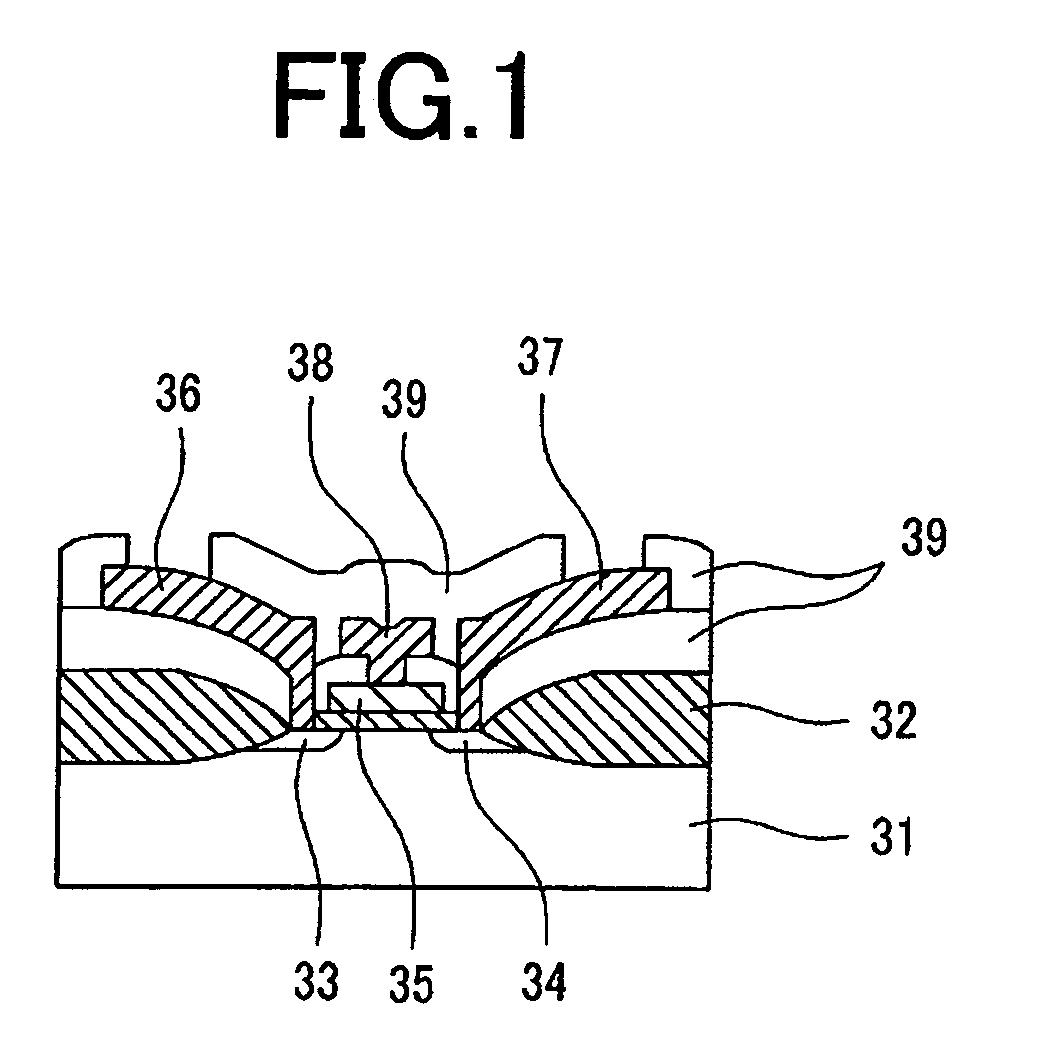

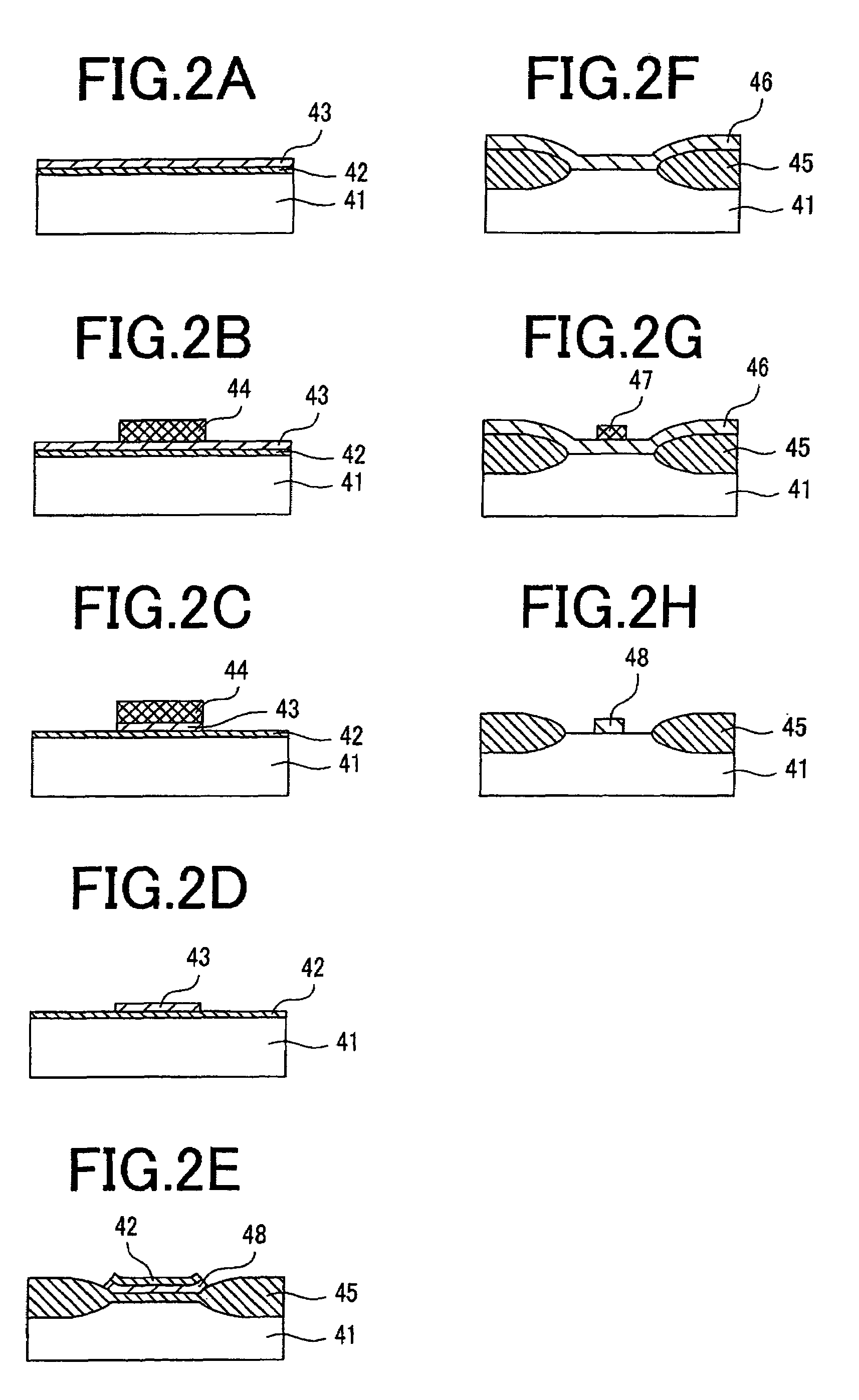

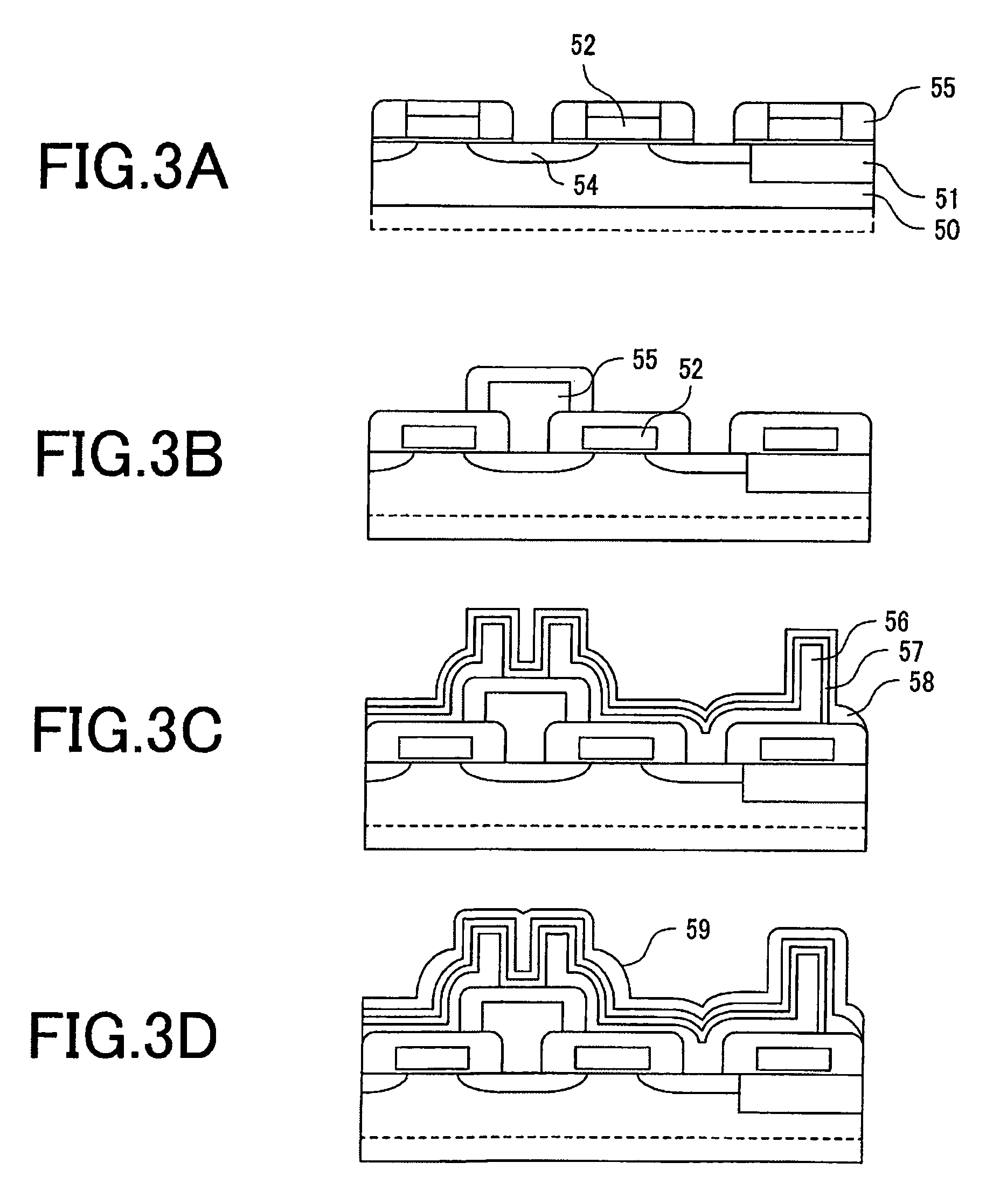

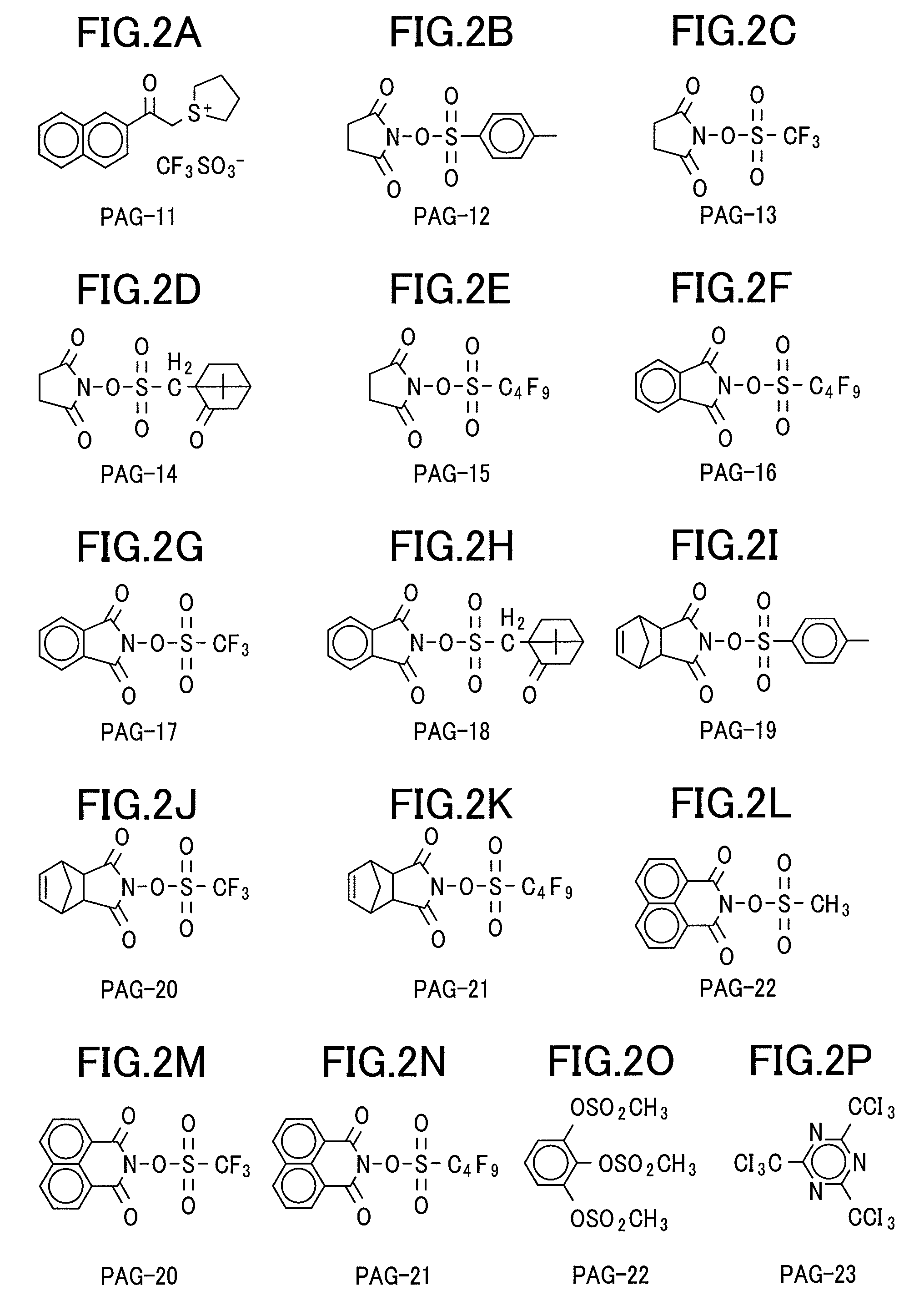

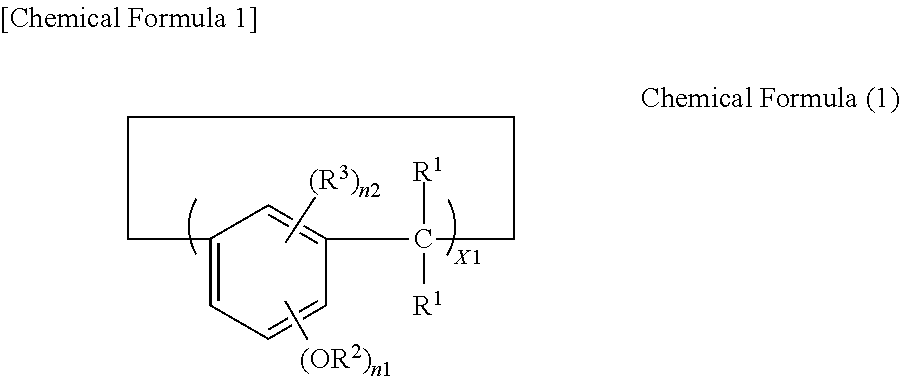

Process for production of fine structure

InactiveUS20110008577A1Pattern in good shapeLess and no defectLayered productsNanoinformaticsFine structurePolymer chemistry

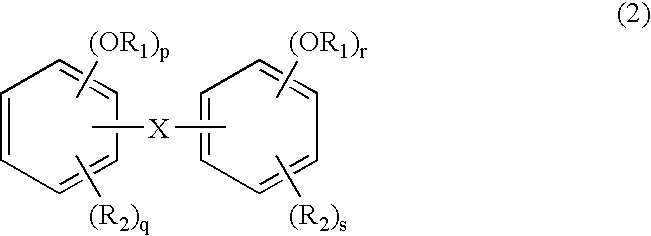

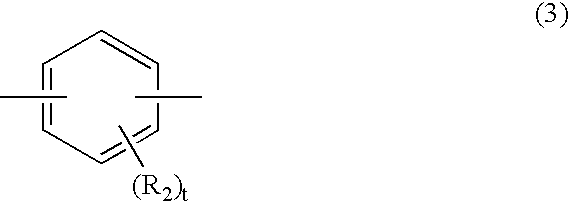

Disclosed is a process for the production of a fine structure through nanoimprinting a photocurable resin composition. The process includes the steps of (1) forming a photocurable resin composition for nanoimprint into a film on a support and transferring a pattern to the film by pressing the film with a nanostamper at a pressure of 5 to 100 MPa, in which the photocurable resin composition contains a curable compound component including at least one cationically polymerizable compound and / or at least one free-radically polymerizable compound; and (2) curing the patterned film to obtain the fine structure.

Owner:DAICEL CHEM IND LTD

Photosensitive resin composition, resist pattern forming method, substrate processing method, and device manufacturing method

InactiveUS20050221222A1Low line edge roughnessLow roughness requirementsPhotosensitive material processingSilver halide emulsionsChemistryResist

Owner:CANON KK

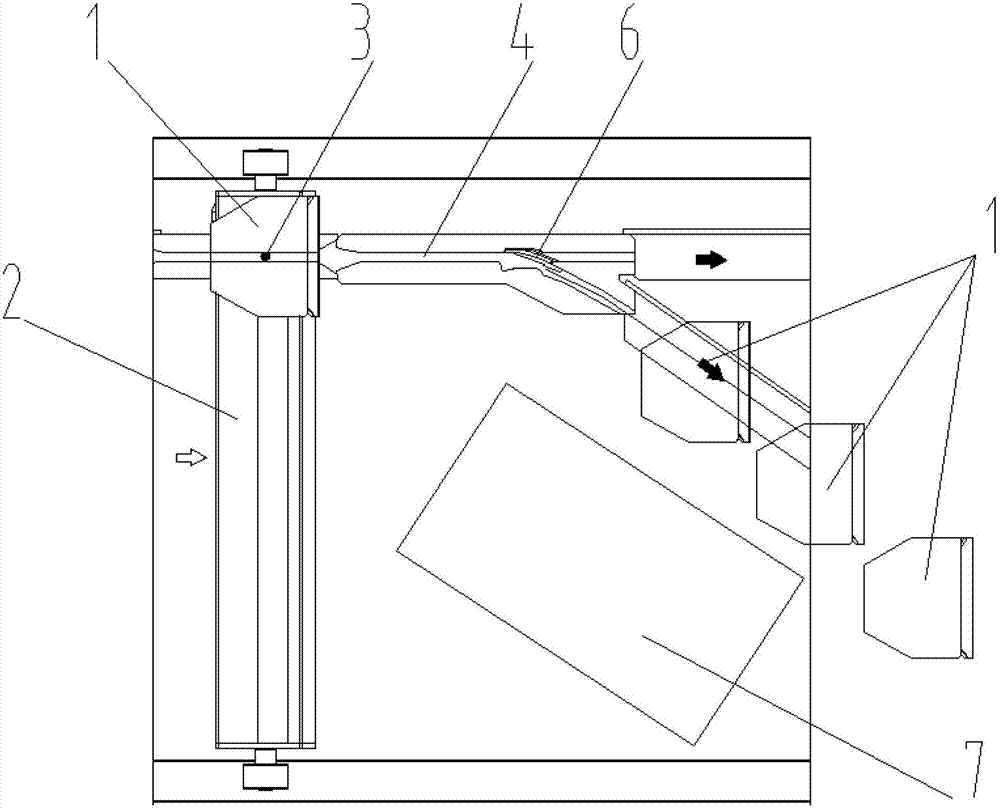

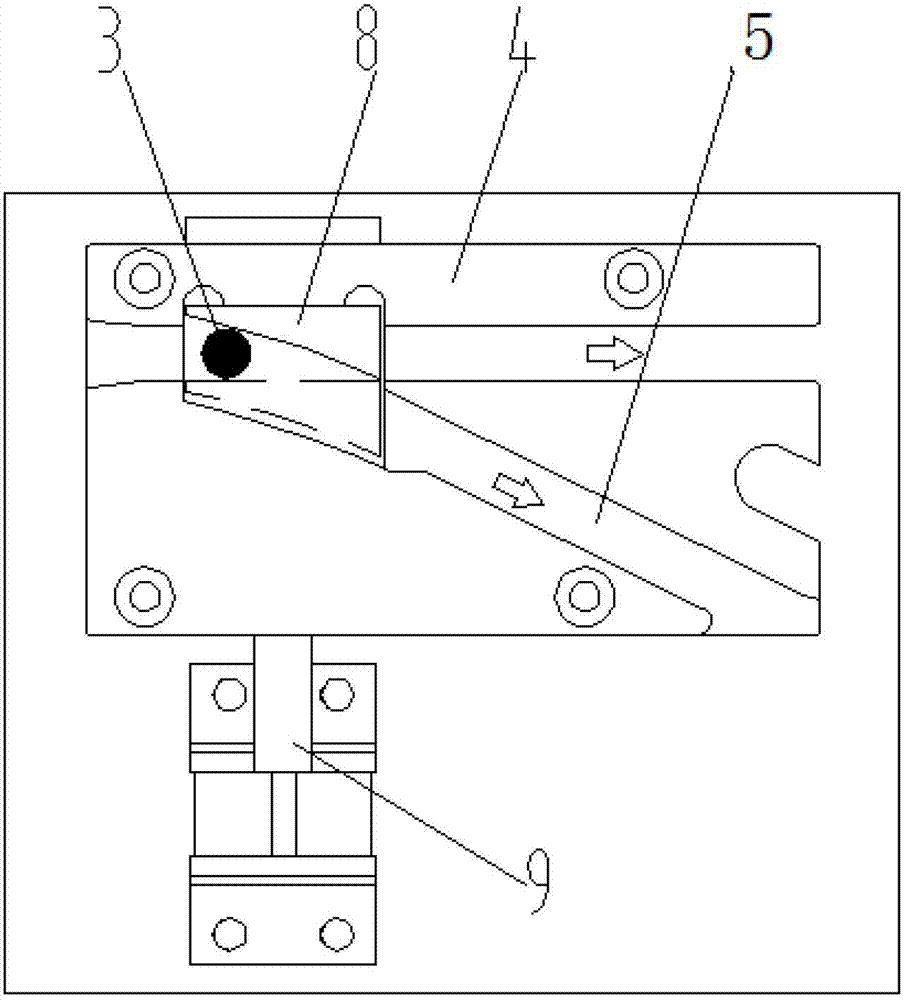

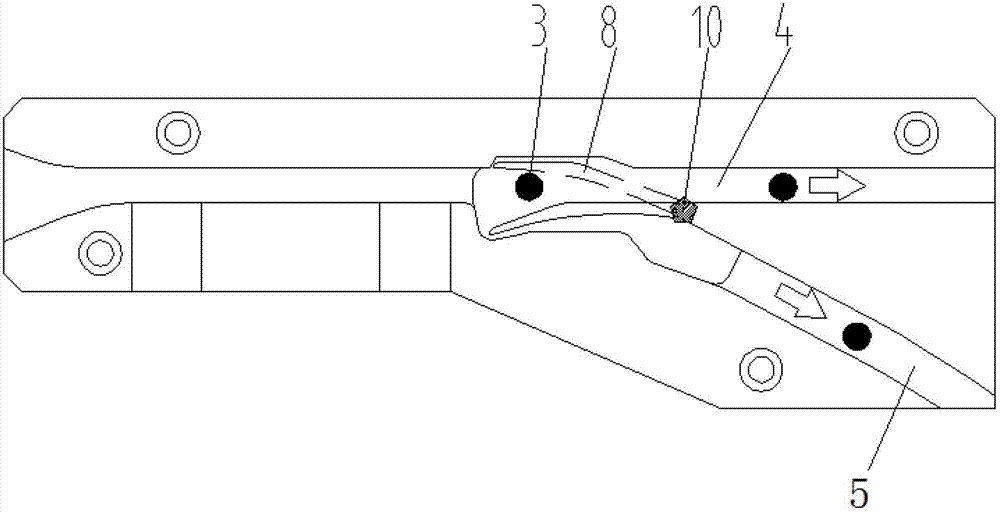

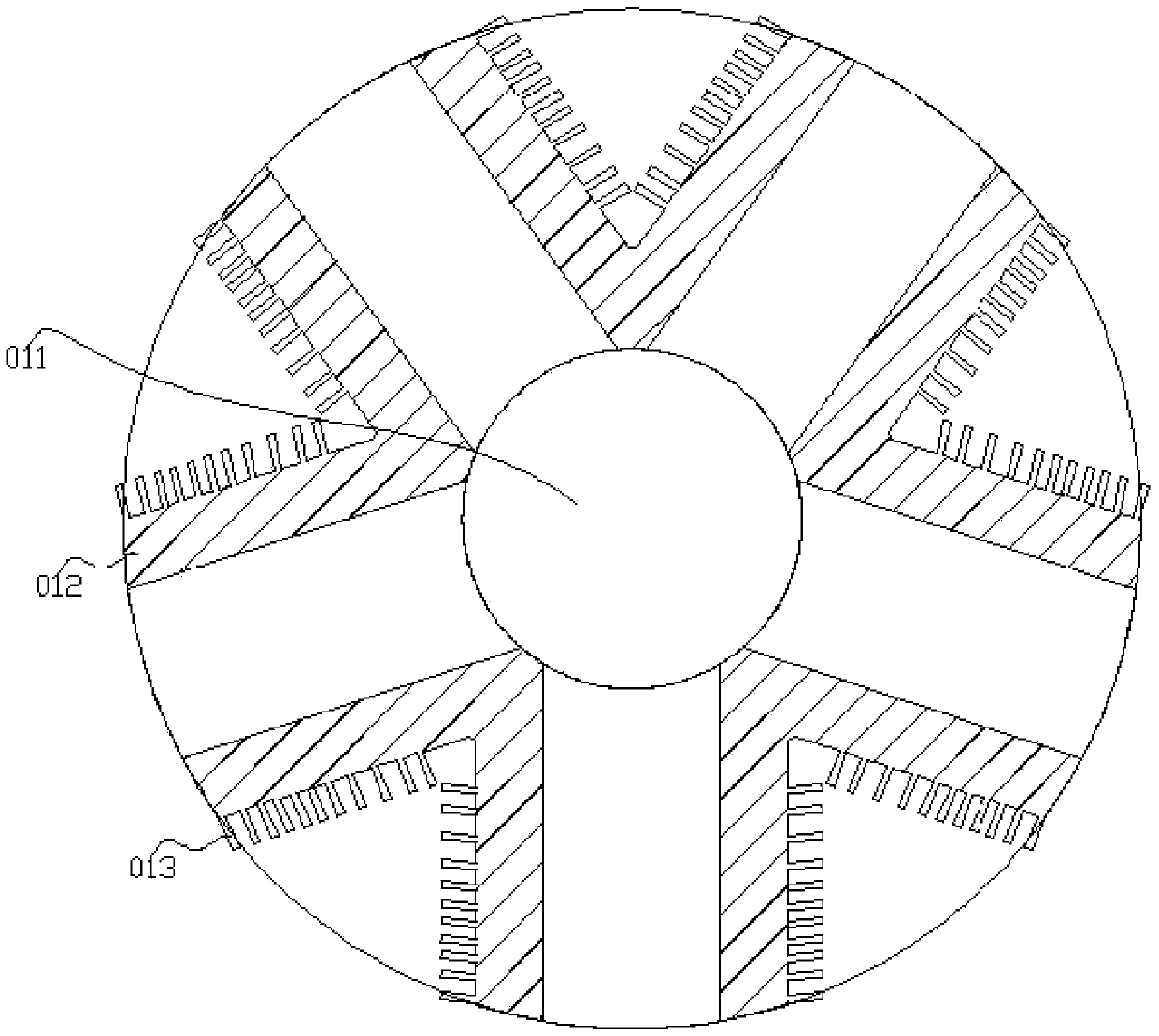

Electrically-driven high-speed turnout reversing device

ActiveCN102815529AIncrease operating frequencyLow roughness requirementsConveyor partsElectricityCross connection

The invention relates to a slider type sorting machine, particularly relates to an electrically-driven high-speed turnout reversing device for the slider type sorting machine, and belongs to the technical field of logistics equipment. The electrically-driven high-speed turnout reversing device is characterized in that one end of a strip shifting fork is fixed to a cross joint of two guide rails through a rotary shaft, the other end of the strip shifting fork can be electrically driven in arc movement along the rotary shaft to shift back and forth between two guide grooves, and an electromagnetic solenoid driving mode is adopted by a shifting fork driving device. By means of electrical driving, single-time shifting fork reversing action can be completed in 8ms which is much lower than air cylinder action time of 30ms. The strip shifting fork in arc movement along the rotary shaft instead of linear movement can greatly reduce operating amplitude, improve reversing efficiency and increase conveying speed; the requirement on roughness of the contact face of the shifting fork with a rail can be lowered, and safety reliability of equipment is greatly improved; and air source compression is not needed, and utilization cost and maintenance cost of the equipment can be reduced.

Owner:SHANGHAI DAMON LOGISTICS TECH

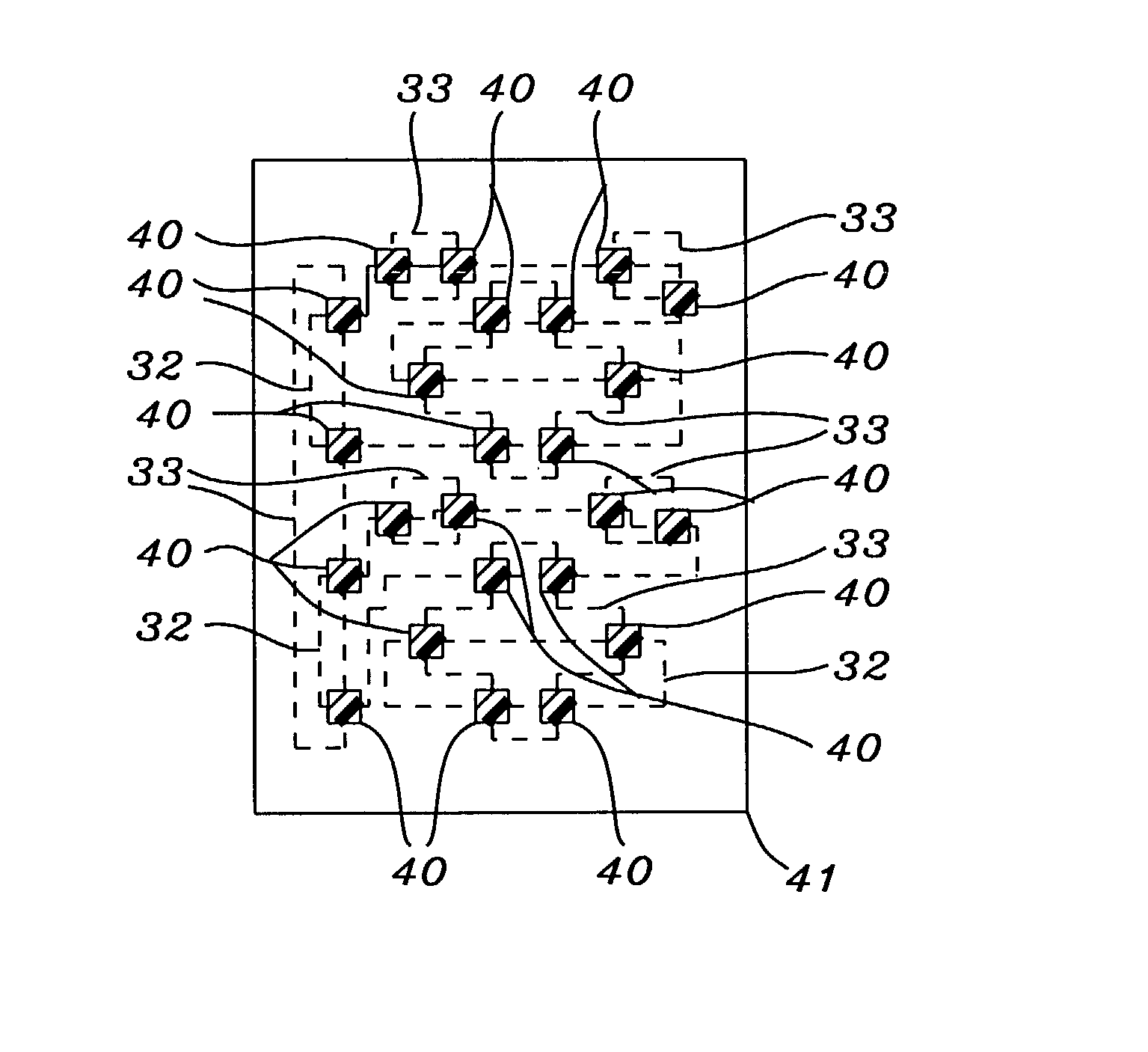

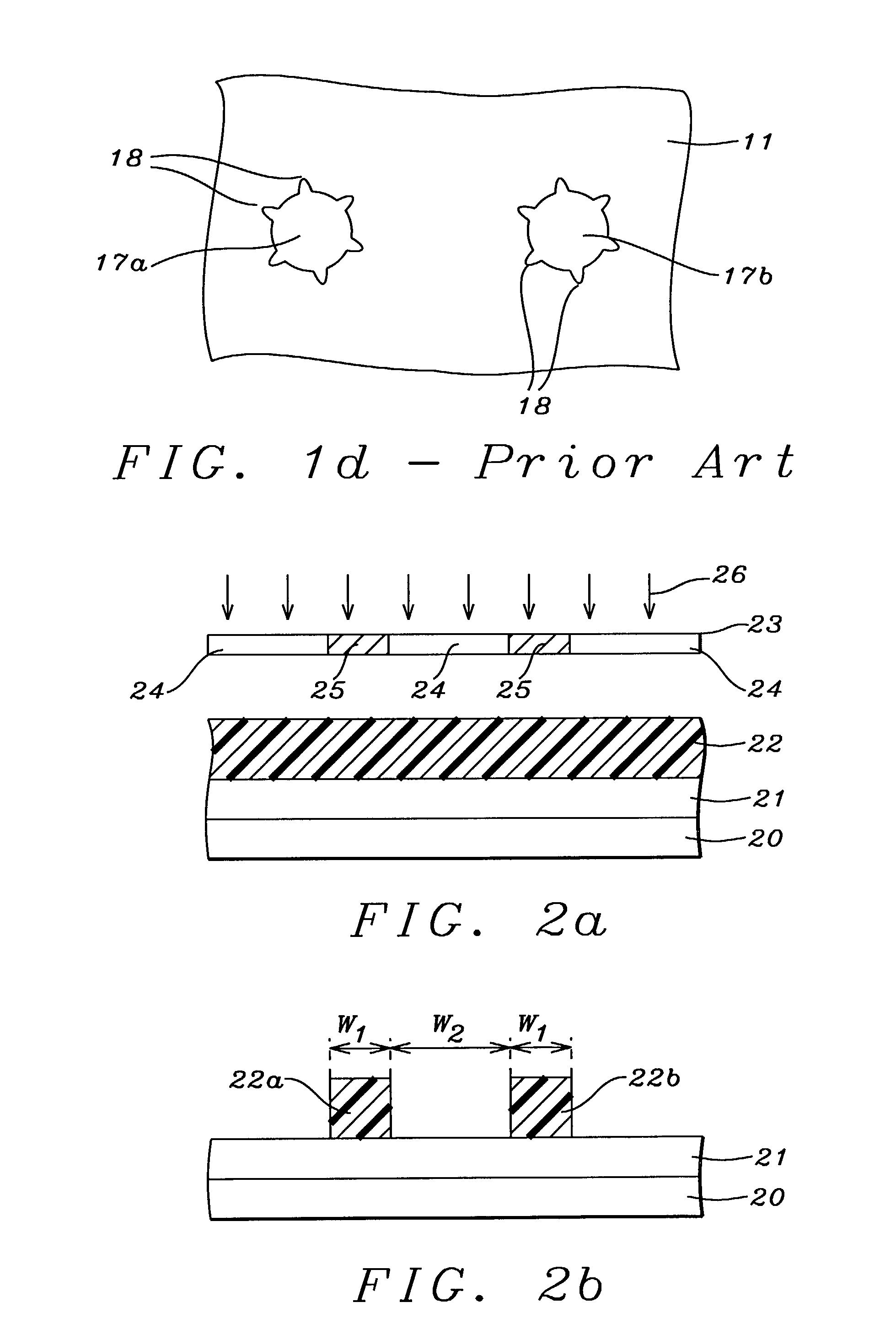

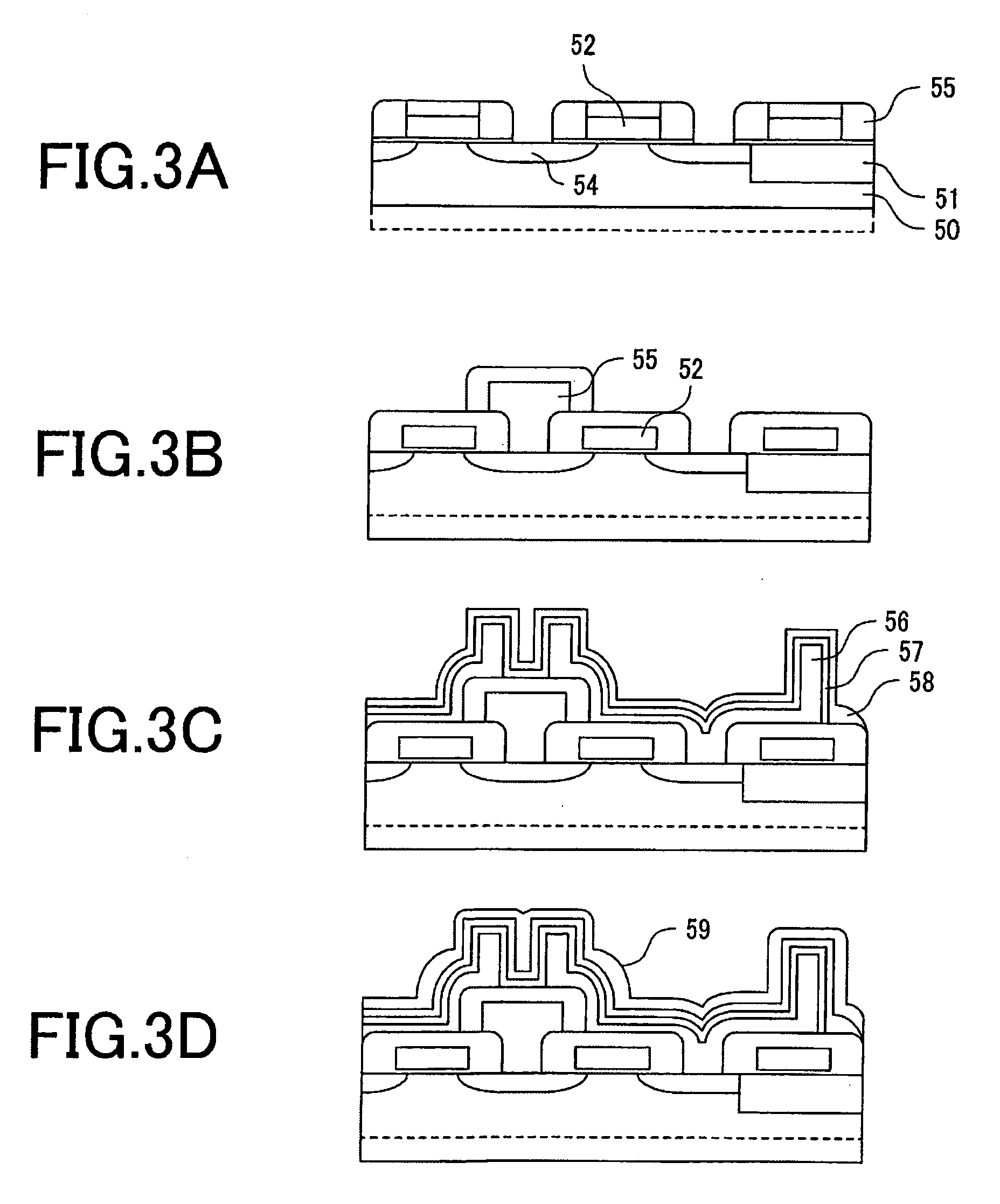

Complementary replacement of material

InactiveUS7399709B1Increase contrastMinimized roughnessDecorative surface effectsSolid-state devicesResistResolution enhancement technologies

An image reversal method is described that removes the etch resistance requirement from a resist. A high resolution resist pattern comprised of islands, lines, or trenches is formed with a large process window by exposing through one or more masks including phase edge masks and optionally with resolution enhancement techniques. A complementary material replacement (CMR) layer comprised of an organic polymer or material such as fluorosilicate glass which has a lower etch rate than the resist is coated over the resist pattern. CMR and resist layers are etched simultaneously to provide an image reversed pattern in the CMR layer which is etch transferred into a substrate. The method avoids edge roughness like bird's beak defects in the etched pattern and is useful for applications including forming contact holes in dielectric layers, forming polysilicon gates, and forming trenches in a damascene process. It is also valuable for direct write methods where an image reversal scheme is desired.

Owner:TAIWAN SEMICON MFG CO LTD

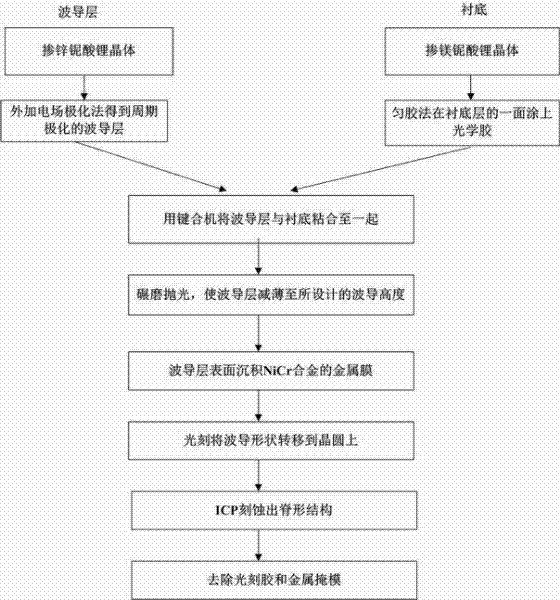

Preparation method of lithium niobate optical waveguide

InactiveCN102253451AStrong light field confinementImprove coupling efficiencyOptical waveguide light guideManufacturing technologyRefractive index

The invention provides a preparation method of a lithium niobate optical waveguide. The preparation method of the lithium niobate optical waveguide comprises the steps of: fabricating a periodical domain inversion structure on a doped lithium niobate crystal by adopting an applied electric field polarization method by selecting a zinc-doped or magnesium-doped lithium niobate crystal; bonding the periodical domain inversion structure as a waveguide layer with a lithium niobate substrate or a lithium tantalite substrate through optical cement the refractive index of which is lower than that of the waveguide layer; and etching to obtain a ridge waveguide structure by using an ICP (inductively coupled plasma) dry method to obtain the lithium niobate optical waveguide. The adhesive layer adopted by the invention has a reflective index more approaching that of air, therefore, in the waveguide, the optical field limiting function is stronger, the optical field is distributed symmetrically, and the coupling efficiency of single mode fibers is higher. By adopting adhesive bonding, the requirement on cleanness and roughness of the surface of a wafer is far lower than that of the surface of a directly bonded wafer, thus the preparation method is realized more easily in technology. The lithium niobate optical waveguide prepared by the method has more excellent performance in the aspects of improving the optical field limiting function, reducing the transmission loss of the waveguide, inhibiting the photorefractive effect, reducing the difficulty in manufacturing technology and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

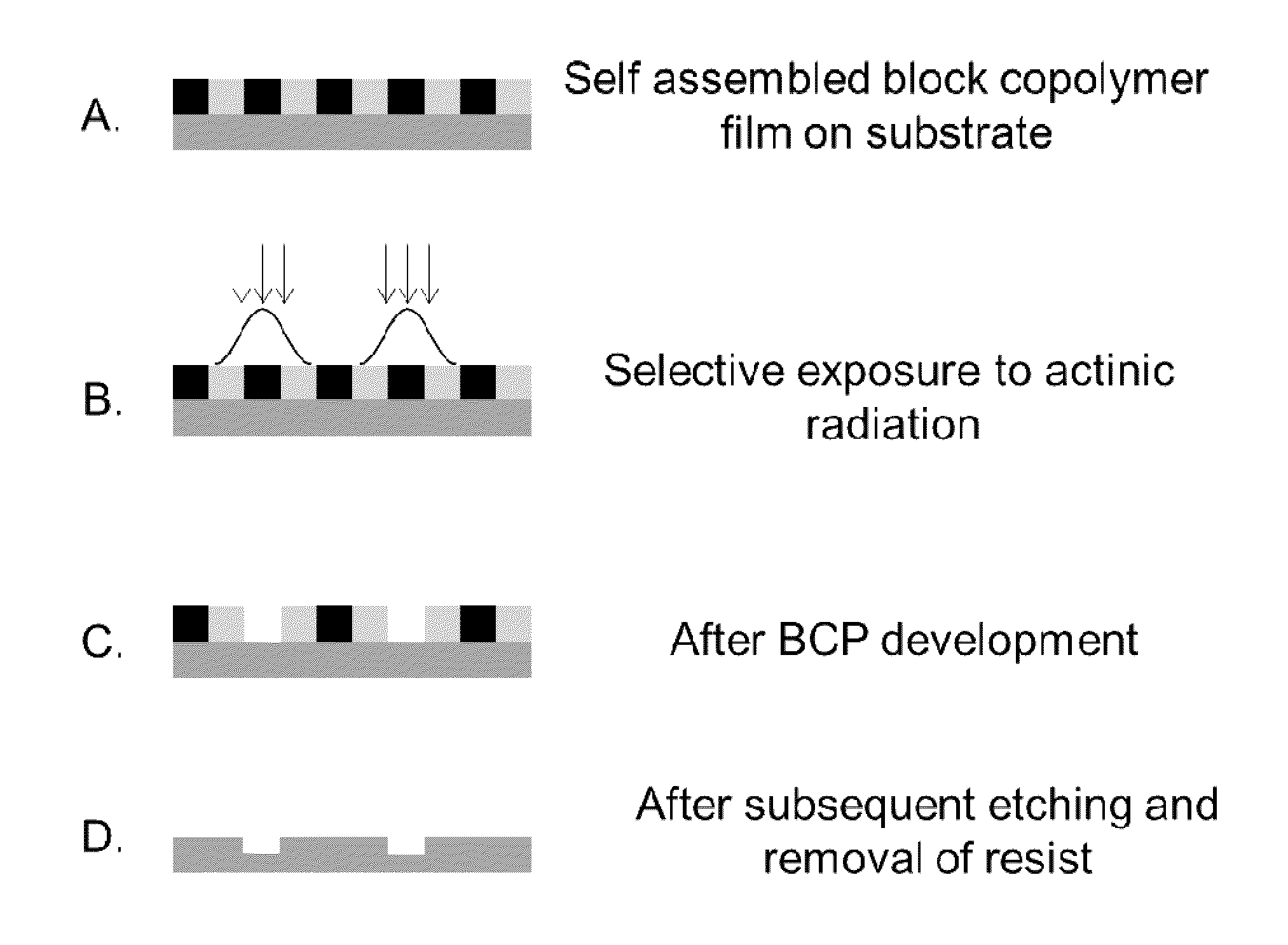

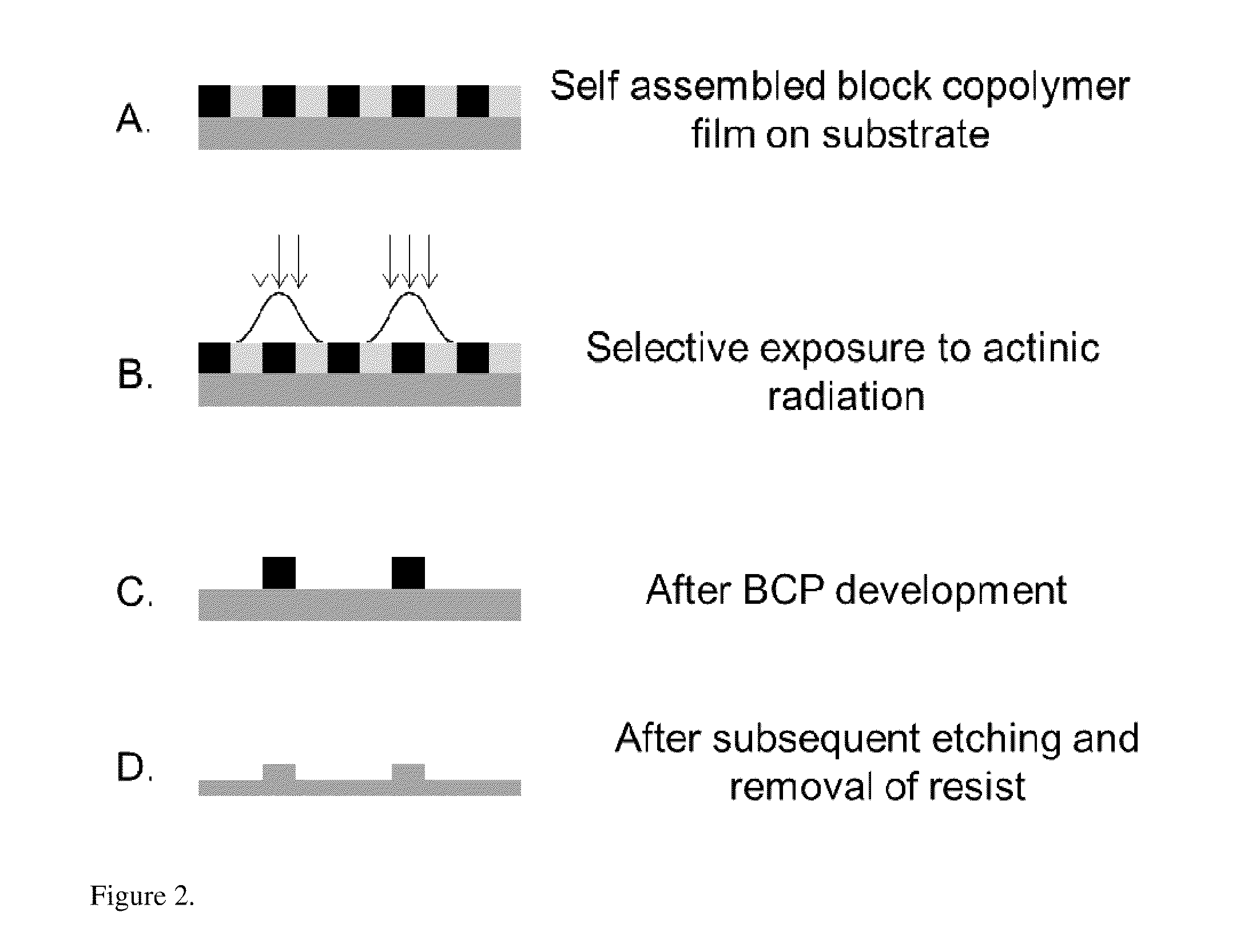

Block co-polymer photoresist

ActiveUS20130207238A1Increase etch resistanceLight increaseNanoinformaticsSolid-state devicesPhotoresistIntegrated circuit

An integrated circuit is made by depositing a pinning layer on a substrate. A block copolymer photoresist is formed on the pinning layer. The block copolymer has two blocks A and B that do not self-assemble under at least some annealing conditions. The exposed block copolymer photoresist is processed to cleave at least some block copolymer bonds in the exposed selected regions. The exposed pinning layer is processed to create a chemical epitaxial pattern to direct the local self assembly of the block copolymer.

Owner:PT SPE SUBCO LLC

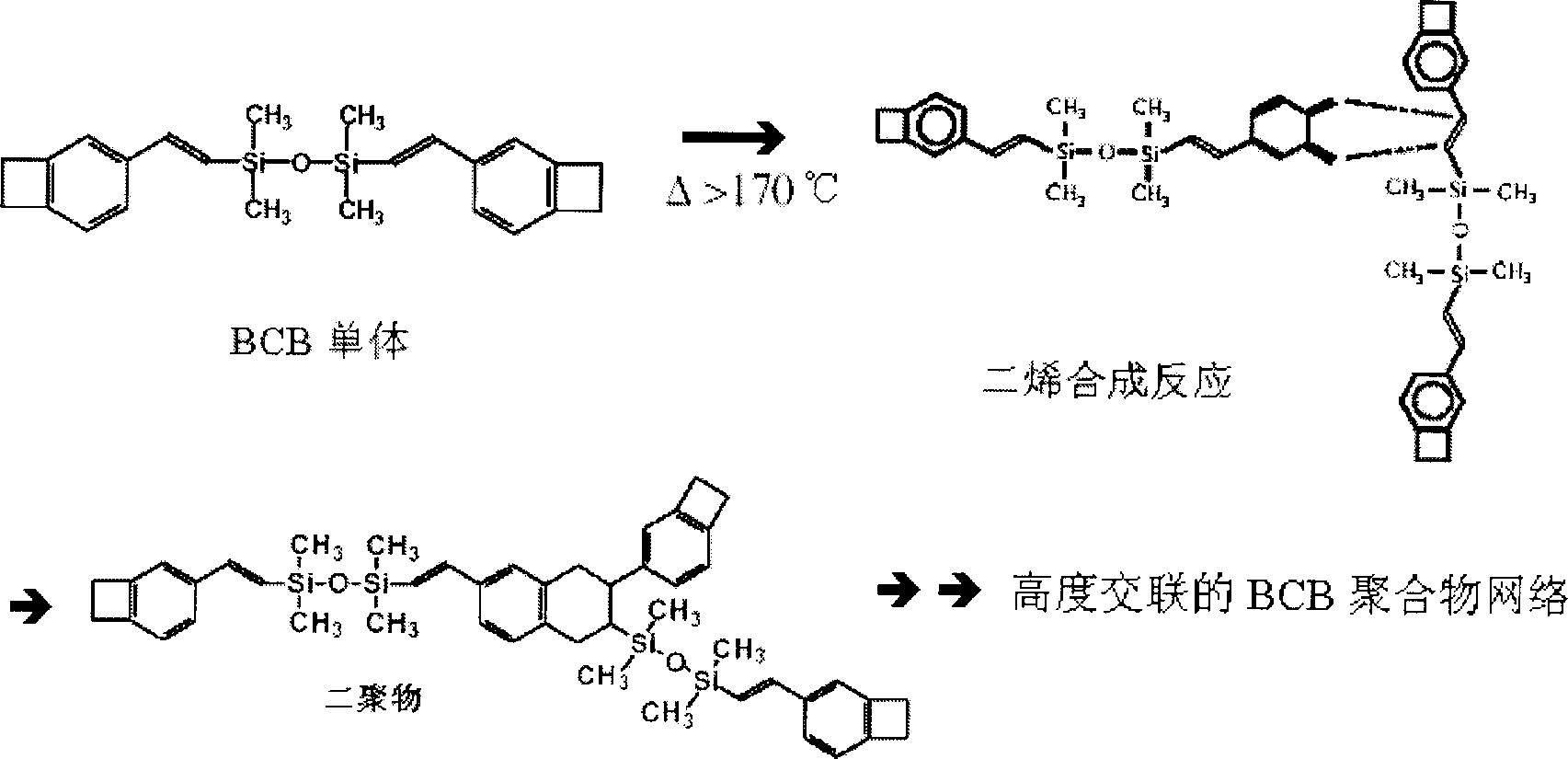

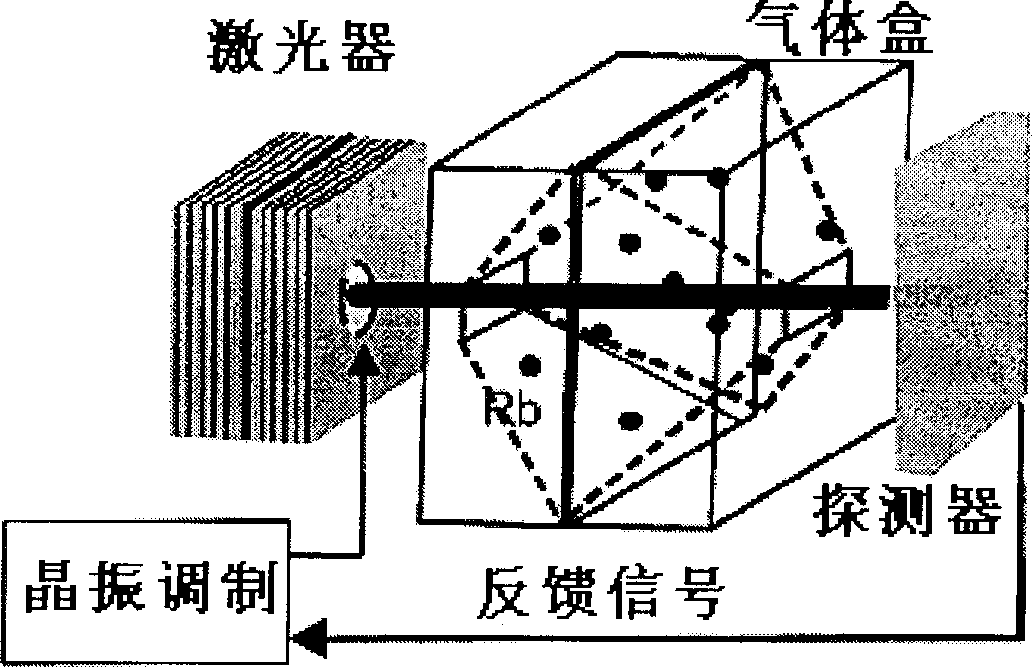

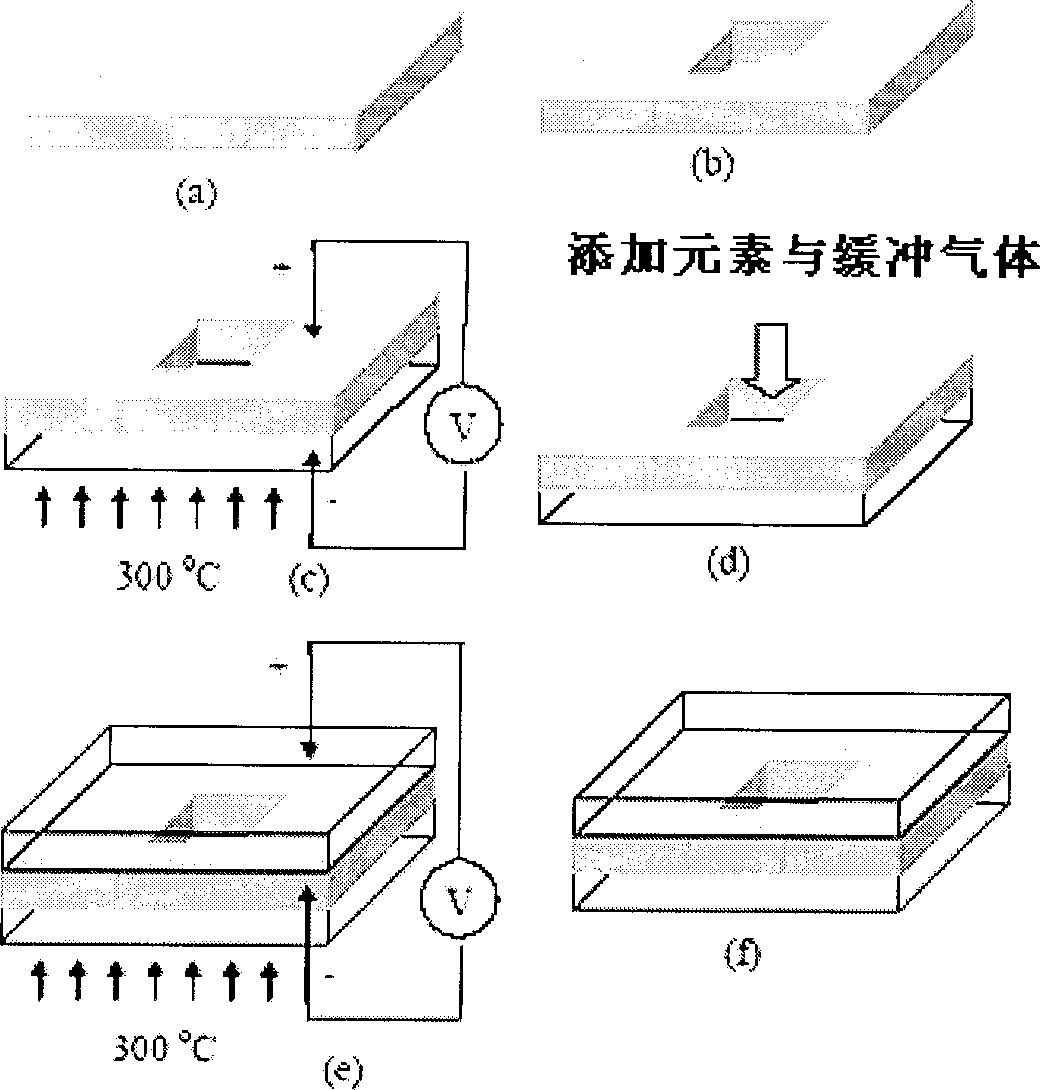

Process for preparing low-temperature wafer-level mini-sized gas container

InactiveCN1827522AMeet packaging requirementsAvoid lostNanostructure manufactureSemiconductor materialsAir tightness

The invention relates to a method for producing low-temperature circle sheet micro gas box, which is characterized in that: the benzocyclobutene is used to process material linkage with humid etching or dry etching technique of semi-conductor in 250Deg. C, to realize the circle sheet air-tightness sealing linkage of chip-level gas box. The invention comprises a atom gas box containing a chip-level atom clock gas box, a high-precision magnetic field sensor gas box, a atom feedback glimmer frequency stabilizer; a atom gas box containing a atom light filter, with glimmer Fabry-Perot chamber. The linked BCB glue is in 0.2ª–m thickness, the air-tightness of sealed He gas can reach 2.1-5.9X10-4Pa cm3 / s, and the linkage strength is higher than 4.65MPa, while the thermal cycle reliability can fully reach the packing standard of micro electric device.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Connecting method for TiAl-Ni dissimilar metal

ActiveCN105382406AWell formedHigh strengthWelding/soldering/cutting articlesNon-electric welding apparatusUltimate tensile strengthSuperplasticity

The invention discloses a connecting method for TiAl-Ni dissimilar metal. According to the method, a block amorphous alloy material serves as a middle layer during welding, and connection is achieved through the superplasticity of the amorphous alloy material in a supercooled liquid region. Then the amorphous layer is dispersed into a base material by improving the temperature, and therefore metallurgical bonding welding is achieved. The connecting method is particularly suitable for welding of plates. By means of the welding method, a TiAl-Ni dissimilar metal welding connector with high strength and good forming performance can be obtained. When GH4049 and Ti-48Al serve as the base material and Ni40Ti50Cu10 amorphous alloy powder serves as the middle layer, the highest tension strength can reach 480 MPa.

Owner:NANJING UNIV OF SCI & TECH

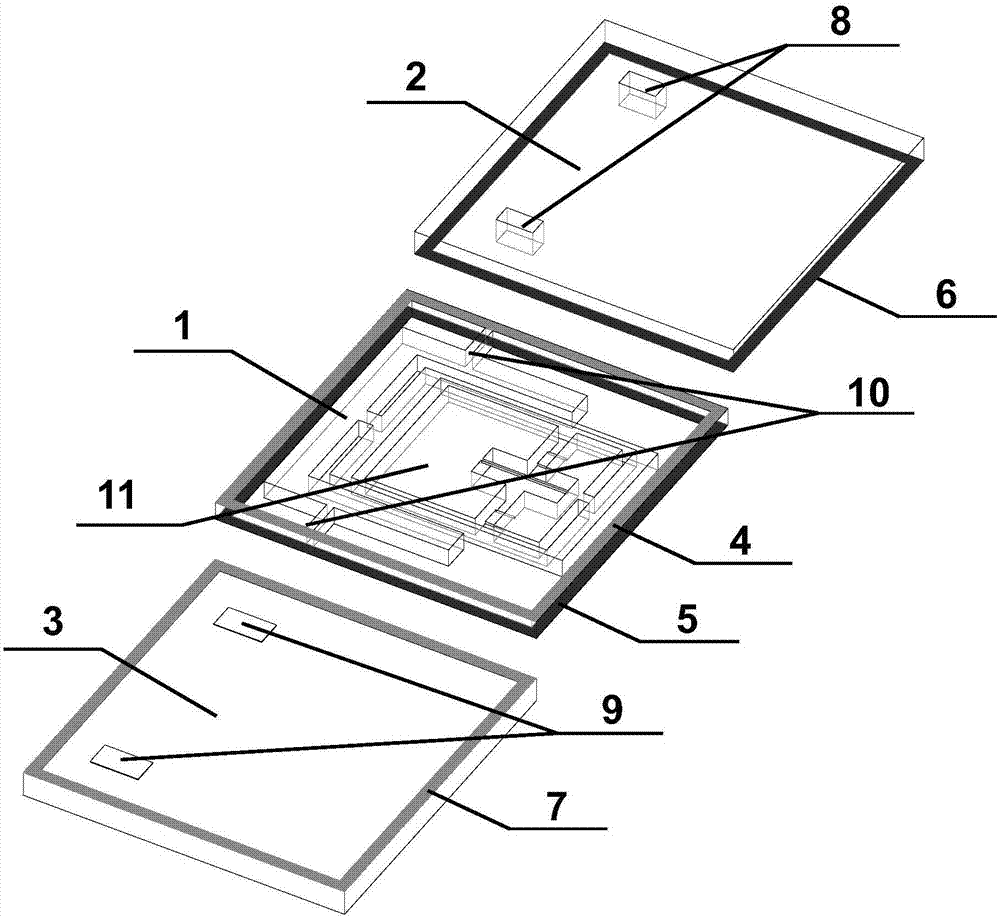

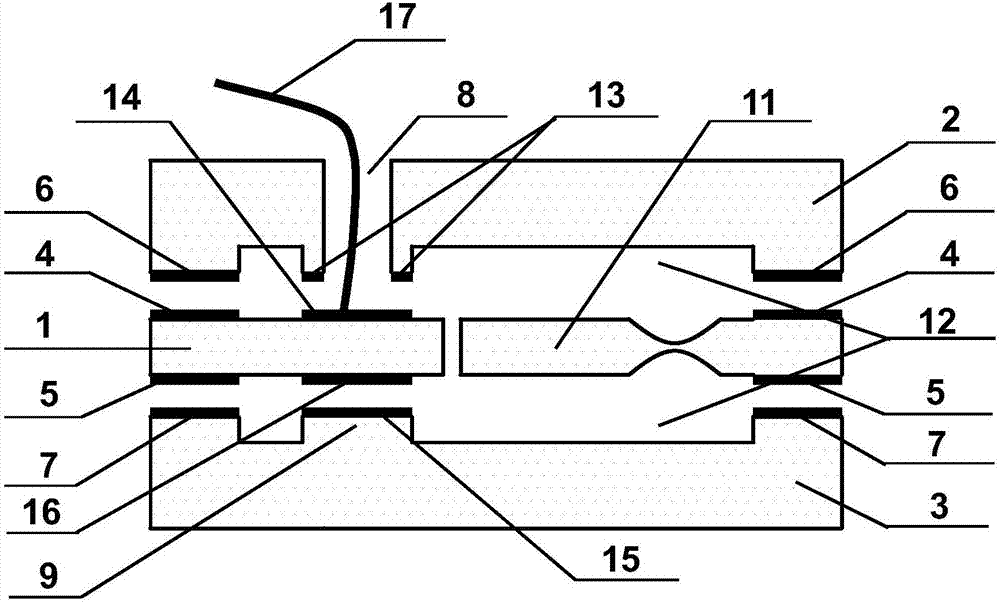

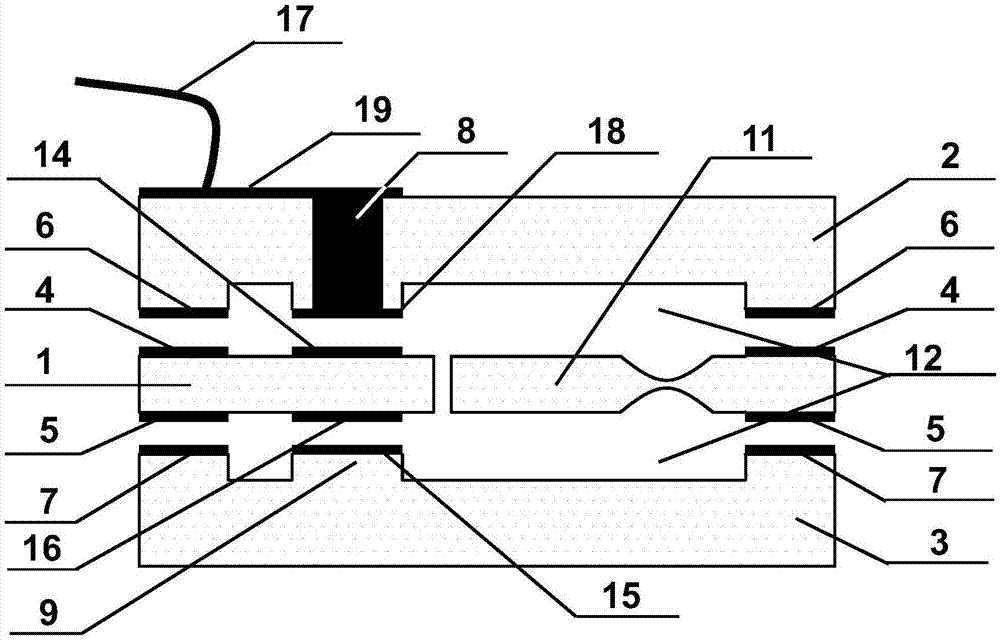

Quartz vibrating beam accelerometer sensitive chip based on gold-gold bonding

ActiveCN107478862ALow roughness requirementsLow cleanliness requirementsAcceleration measurementPhysicsQuartz

The invention relates to a quartz vibrating beam accelerometer sensitive chip based on gold-gold bonding and relates to the processing field of the quartz vibrating beam accelerometer sensitive chip. The sensitive chip comprises a sensitive unit layer, an upper protection unit layer and a lower protection unit layer, wherein the upper protection unit layer is arranged at an upper surface of the sensitive unit layer, the lower protection unit layer is arranged at the upper surface of the sensitive unit layer, the upper surface of the sensitive unit layer is equipped with a first sealing ring, a lower surface of the sensitive unit layer is fixedly equipped with a second sealing ring, a lower surface of the upper protection unit layer is fixedly equipped with a third sealing ring, an upper surface of the lower protection unit layer is fixedly equipped with a fourth sealing ring, one side of the upper protection unit layer is symmetrically provided with two square holes, and the upper surface of the lower protection unit layer is symmetrically provided with two bosses at the corresponding position. The sensitive chip is advantaged in that a problem of compatibility difficulty caused by airtight packaging and internal electrodes is effectively solved, excellent portability is realized, and the sensitive chip can be applied to the preparation process of MEMS devices taking quartz, silicon and glass materials as base materials.

Owner:BEIJING RES INST OF TELEMETRY +1

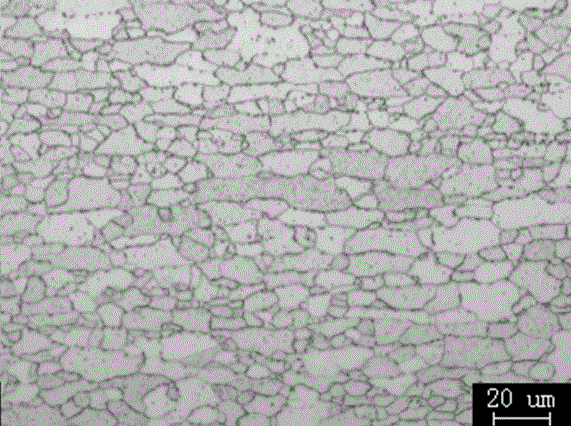

Low carbon cold-rolled steel sheet for LED lead frame and production method thereof

The invention relates to a low carbon cold-rolled steel sheet for a LED lead frame and a production method thereof, and mainly solves the technical problems that the low carbon cold-rolled steel sheet for the LED lead frame in prior art has nonuniform hardness, high surface roughness and bad aging-resistance. The production method comprises the following steps: smelting according to components, molten iron desulphurization, complex top-bottom blowing converter smelting, argon blowing from bottom of a ladle, protective casting with argon blowing in whole course, heating in a slab heating furnace, rough rolling, finish rolling, reeling for obtaining a hot-rolled steel coil, uncoiling, pickling, cold rolling, annealing in a vertical type continuous annealing furnace, flattening, and reeling for obtaining a finished product with a thickness of 0.4-0.5mm; the finishing temperature of the finish rolling is 860-900 DEG C, the reeling temperature of the hot rolling is 620-660 DEG C, the cold rolling reduction is 75-85%, the temperature scope of a soaking zone of the vertical type continuous annealing furnace for a band steel in hard rolled state after cold rolling is 710-730 DEG C, the soaking time for the band steel in the vertical type continuous annealing furnace is 105-120 s, and temper elongation is 1.0-1.4%. The low carbon cold-rolled steel sheet is mainly used for the LED lead frame.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Resist composition and pattern forming method using the same

ActiveUS20080081282A1High resolutionHigh sensitivityPhotosensitive materialsRadiation applicationsResistSolubility

A resist composition containing: a polymer having a group capable of decomposing under an action of an acid and having a weight average molecular weight of from 1,000 to 5,000, of which solubility in an alkali developer increases under an action of an acid; and a compound capable of generating a compound having a structure represented by the following formula (A-I) upon irradiation with actinic rays or radiation: Q1-X1—NH—X2-Q2 (A-I) wherein Q1 and Q2 each independently represents a monovalent organic group, provided that either one of Q1 and Q2 has a proton acceptor functional group, Q1 and Q2 may be combined with each other to form a ring and the ring formed may have a proton acceptor functional group; and X1 and X2 each independently represents —CO— or —SO2—.

Owner:FUJIFILM CORP

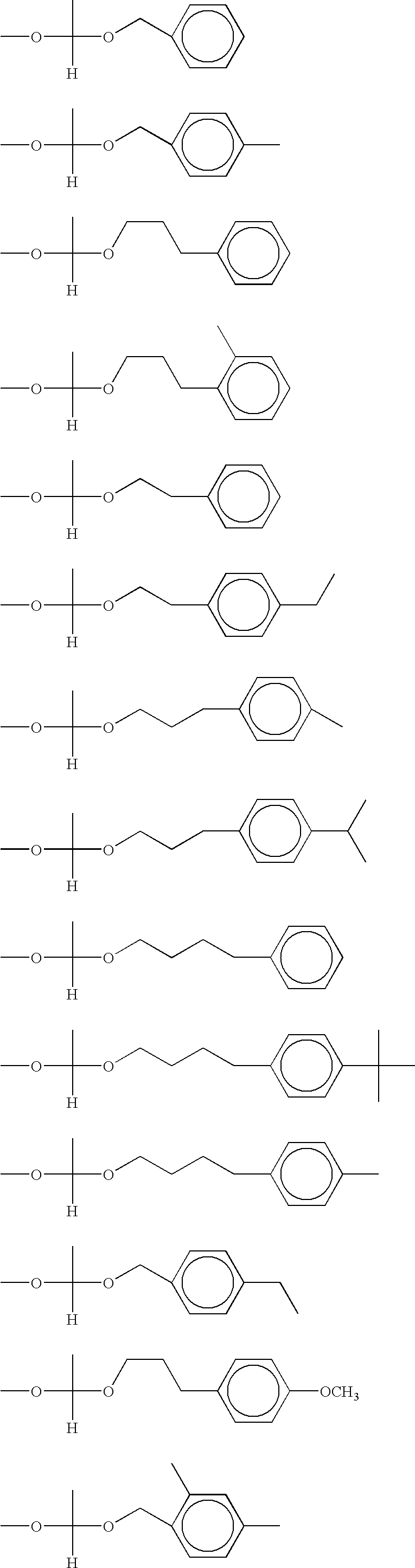

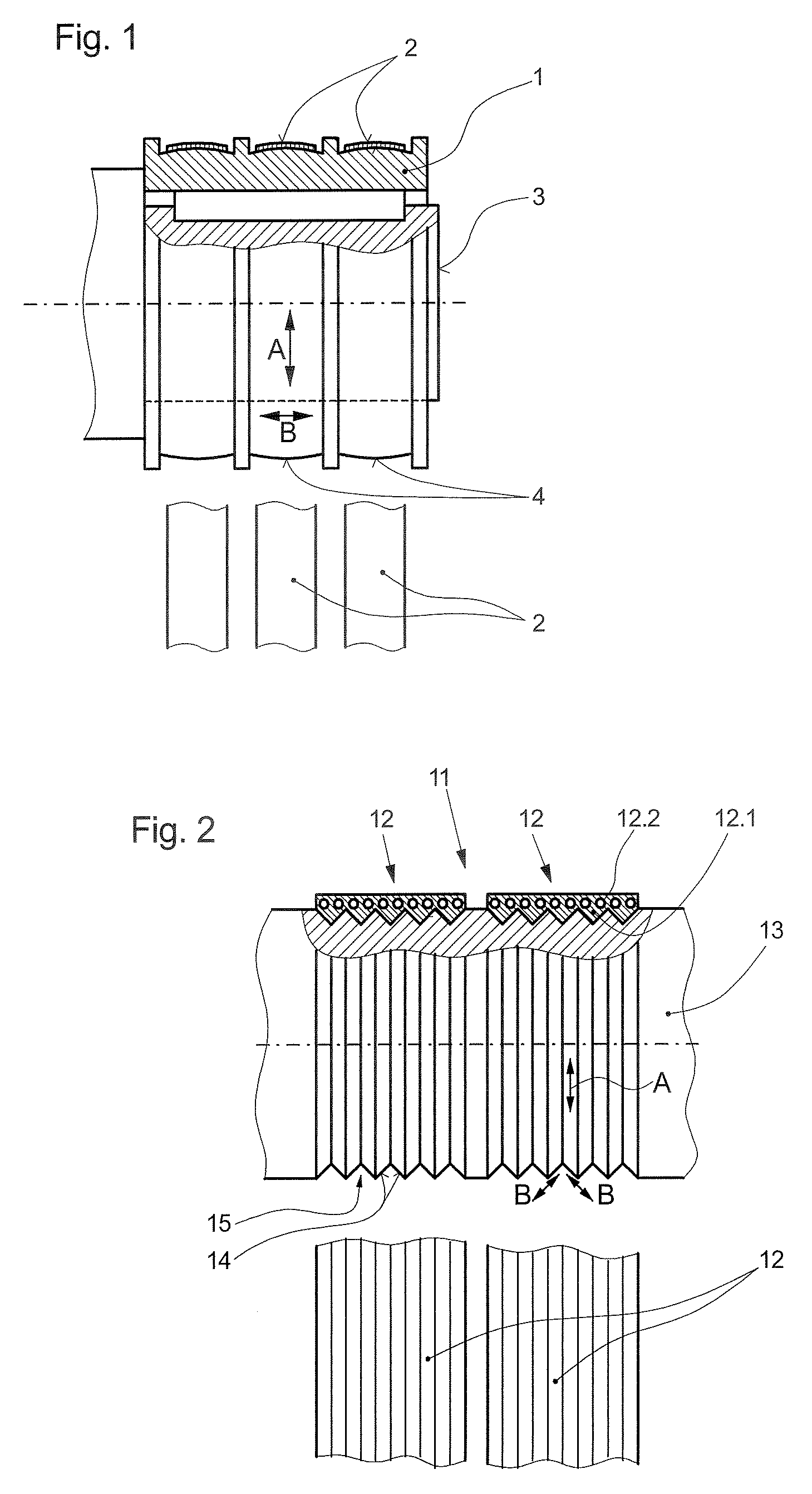

Elevator element for driving or reversing an elevator suspension means in an elevator system

ActiveUS8348019B2Reduce roughnessReduce manufacturing costMetal rolling stand detailsGearingElevator systemMicrometer

In an elevator element for driving or reversing an elevator suspension device in an elevator system, that interacts with an elevator suspension device, the arithmetic mean of the roughness value of the contact surface measured in the circumferential direction of the elevator element, and the mean roughness value of the contact surface measured in the axial direction of the elevator element, are different. The arithmetic mean roughness value of the contact surface measured in the circumferential direction of the elevator element is less than 1 micrometer.

Owner:INVENTIO AG

Process for treating a semiconductor wafer with a gaseous medium, and semiconductor wafer treated by this process

InactiveUS20060138539A1Avoid high concentrationsLow roughness requirementsSolid-state devicesSemiconductor/solid-state device manufacturingHydrogen fluorideWafering

A process for treating a semiconductor wafer with a gaseous medium containing hydrogen fluoride and at least one oxidizing agent which oxidizes the surface of the semiconductor wafer, involves flowing the gaseous medium onto the surface of the semiconductor wafer at a relative velocity in the range from 40 mm / s to 300 m / s. Semiconductor wafers and an SOI wafers prepared by the process have a low roughness and metal concentration in the absence of a subsequent polishing step.

Owner:SILTRONIC AG

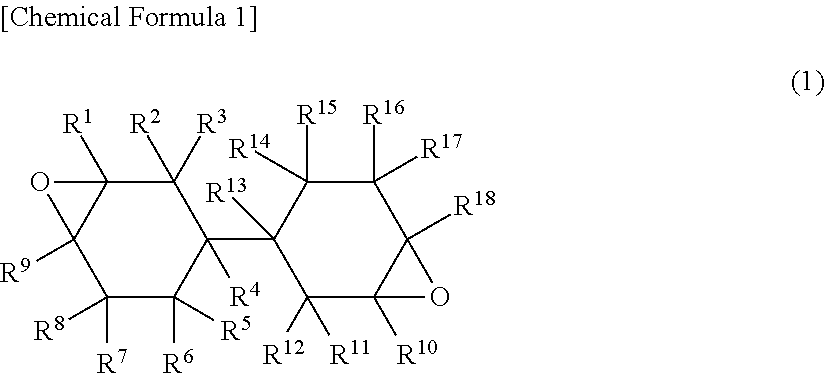

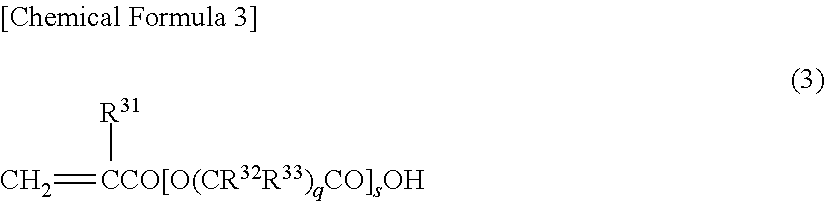

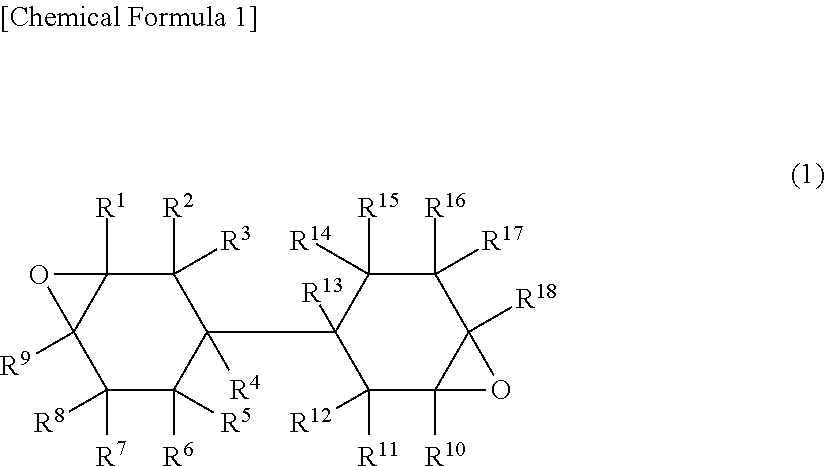

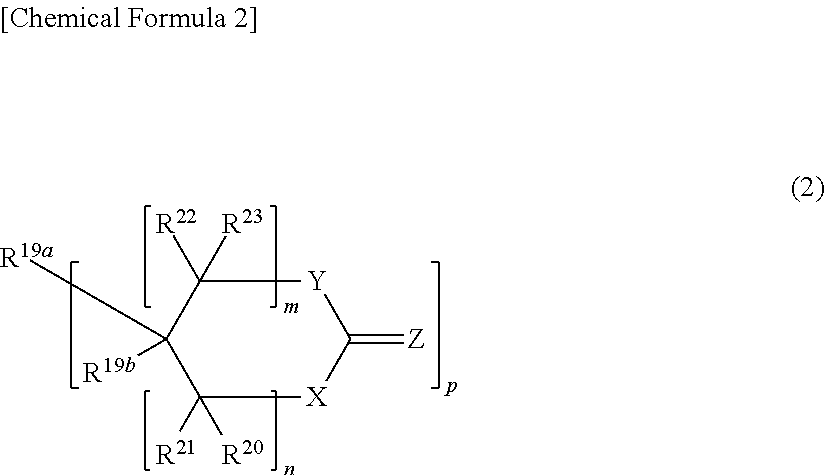

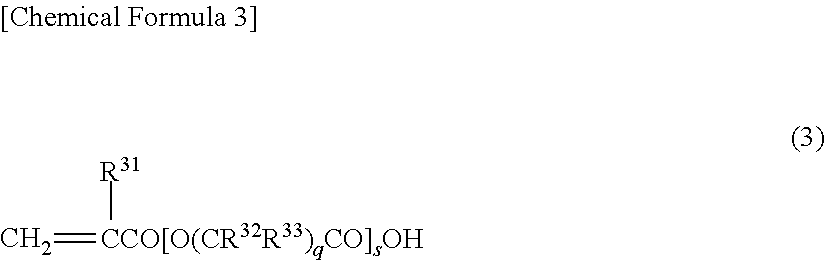

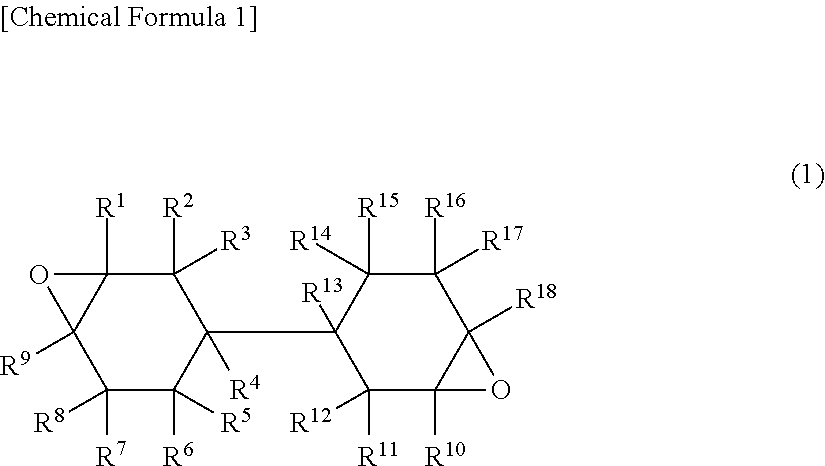

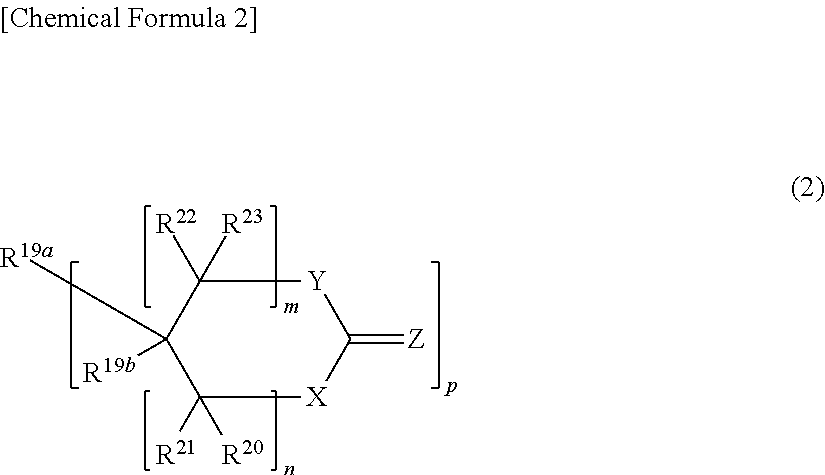

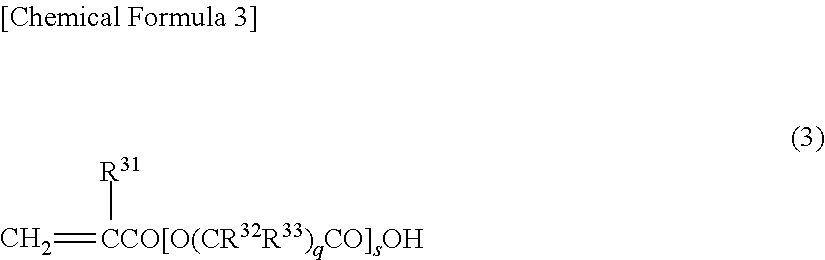

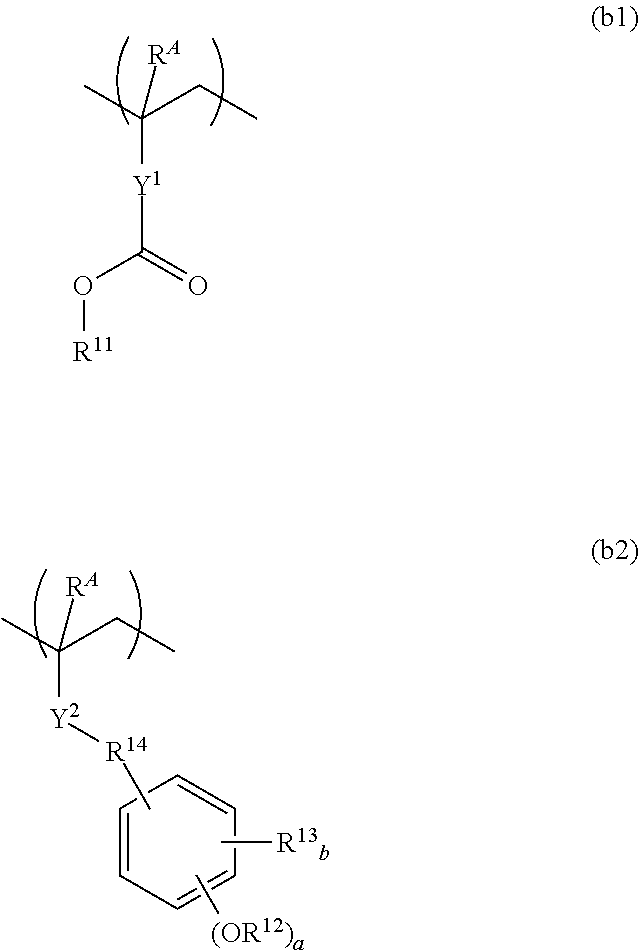

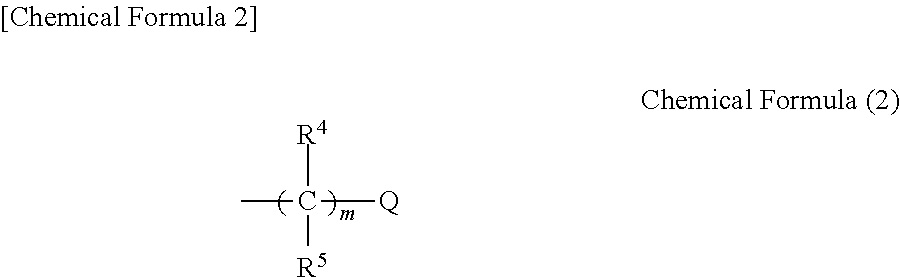

Curable resin composition for nanoimprint

InactiveUS8530539B2Satisfactory adhesionProcess economyOrganic chemistryLayered productsVinyl etherAliphatic hydrocarbon

Disclosed is a photocurable resin composition for nanoimprint, containing a curable monomer component with or without a binder resin. The composition further contains 0.001 to 5 parts by weight of a compound having a reactive functional group and a hydrophobic functional group in the same molecular skeleton, per 100 parts by weight of the total amount of the curable monomer component and binder resin. Preferably, the reactive functional group is at least one functional group selected from the group consisting of hydroxyl groups, epoxy groups, vinyl ether groups, oxetanyl groups, alkoxysilane groups, and free-radically polymerizable vinyl groups, and the hydrophobic functional group is at least one functional group selected from the group consisting of fluorine-containing groups, alkylsilane groups, alicyclic hydrocarbon groups, and aliphatic hydrocarbon groups having 4 or more carbon atoms.

Owner:DAICEL CHEM IND LTD

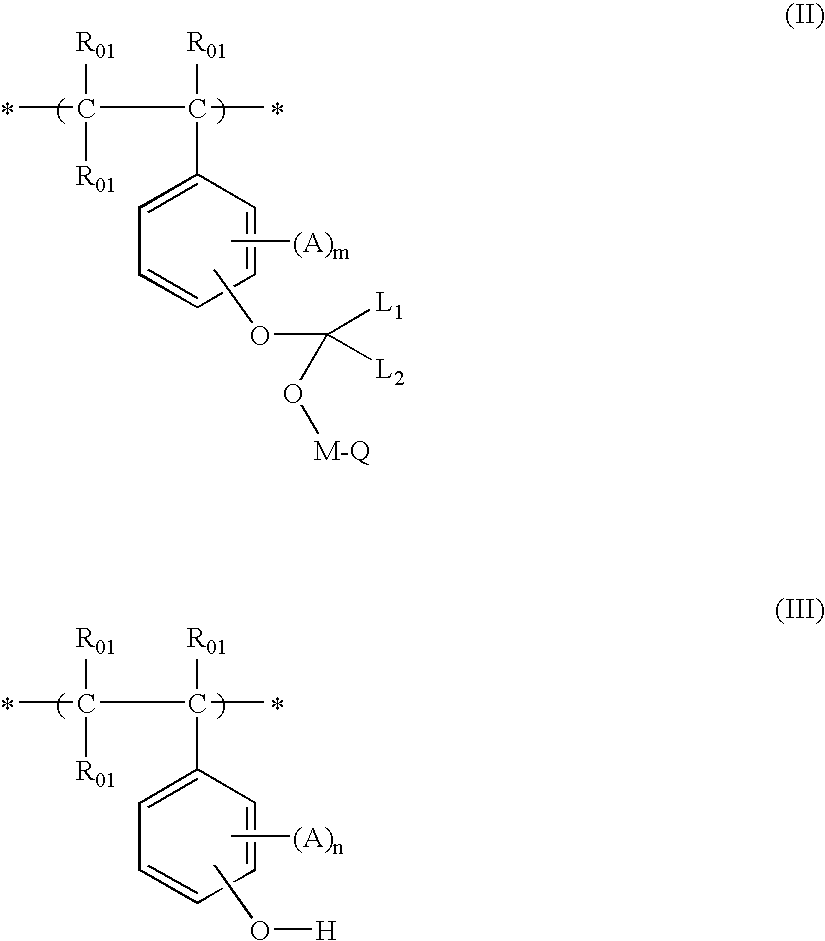

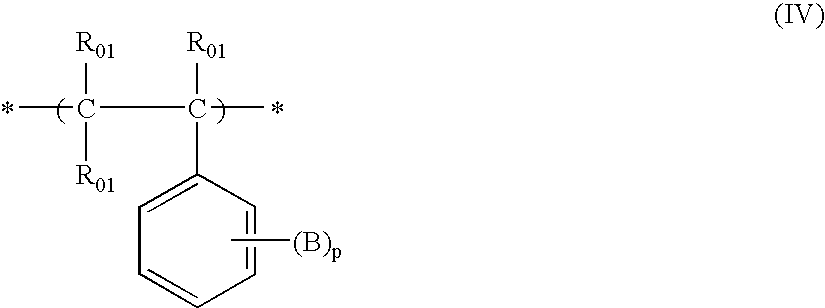

Curable resin composition for nanoimprint

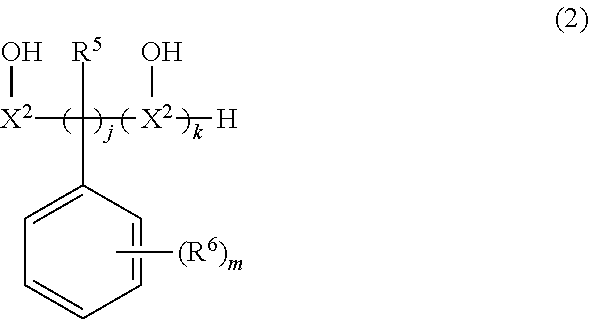

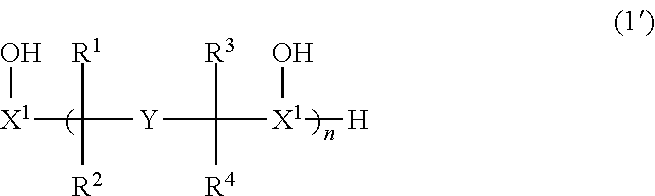

InactiveUS20120141738A1Good release effectPattern in good shapeOrganic chemistryLayered productsVinyl etherAlicyclic Hydrocarbons

Disclosed is a photocurable resin composition for nanoimprint, containing a curable monomer component with or without a binder resin. The composition further contains 0.001 to 5 parts by weight of a compound having a reactive functional group and a hydrophobic functional group in the same molecular skeleton, per 100 parts by weight of the total amount of the curable monomer component and binder resin. Preferably, the reactive functional group is at least one functional group selected from the group consisting of hydroxyl groups, epoxy groups, vinyl ether groups, oxetanyl groups, alkoxysilane groups, and free-radically polymerizable vinyl groups, and the hydrophobic functional group is at least one functional group selected from the group consisting of fluorine-containing groups, alkylsilane groups, alicyclic hydrocarbon groups, and aliphatic hydrocarbon groups having 4 or more carbon atoms.

Owner:DAICEL CHEM IND LTD

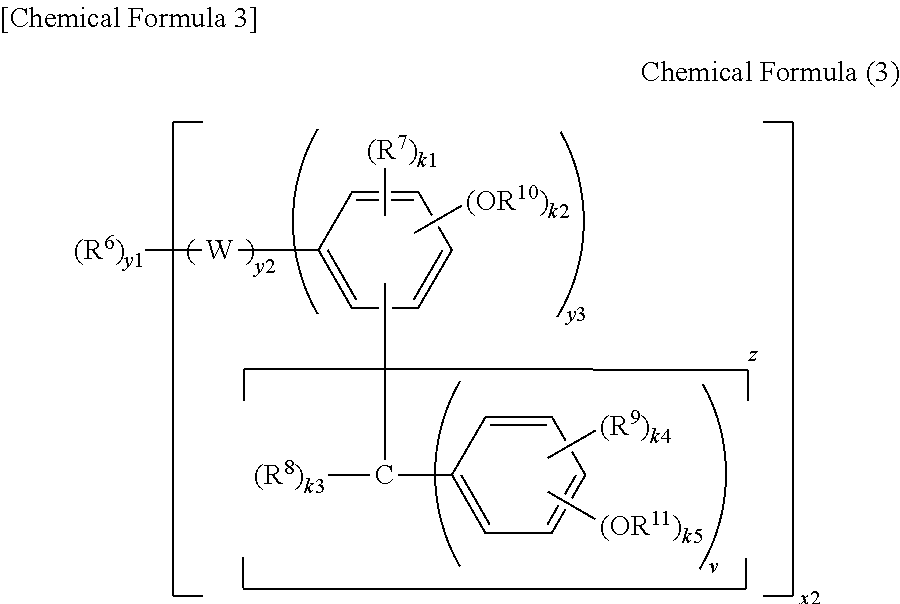

Resin composition for insulating layer for multi-layered printed board

ActiveUS20140102623A1Increase stickinessReduce roughnessSuperimposed coating processElastomeric polymer dielectricsPolymer scienceFirming agent

Epoxy resin compositions, which comprise (A) en epoxy resin having two or more epoxy groups in a molecule; (B) a phenol type curing agent where an average hydroxyl group content in a molecule (a mean value of (the total number of hydroxyl groups) / (the total number of benzene rings)), P, satisfies the equation 0<P<1; (C) a phenoxy resin; and (D) rubber particles, are suitable for use as an insulating layer of a multi-layered printed board in which, in spite of the fact that the roughness of a roughened surface after a roughening treatment is relatively small, an insulating layer having a good tight adhesion with a conductor layer formed by plating is able to be easily introduced into a multi-layered printed board.

Owner:AJINOMOTO CO INC

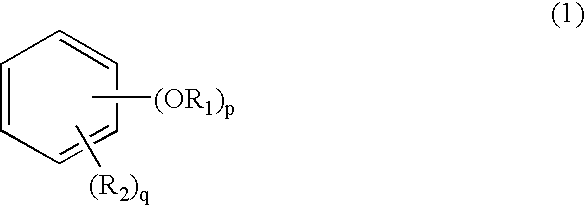

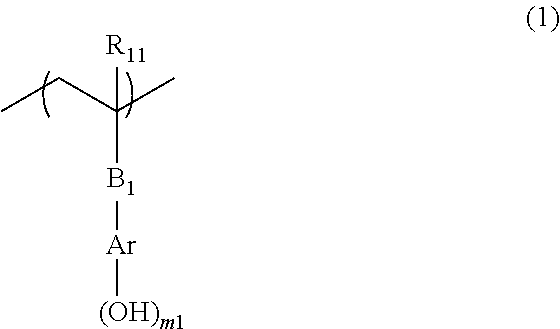

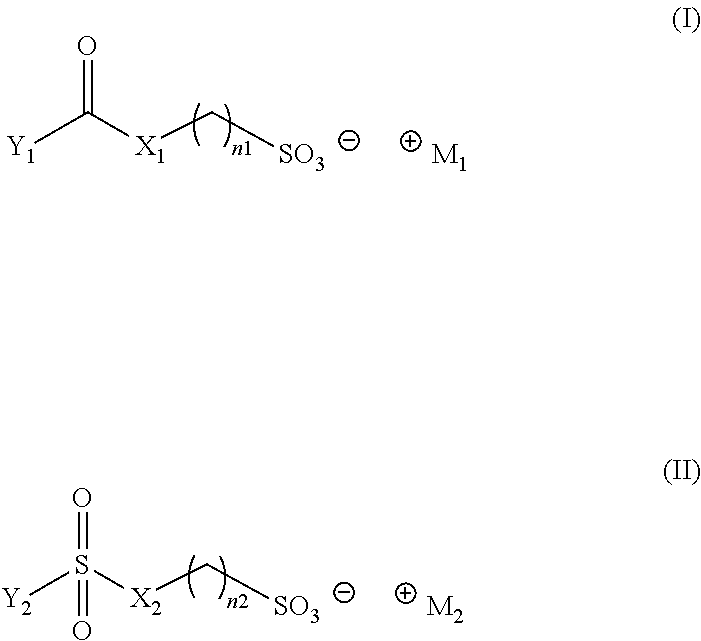

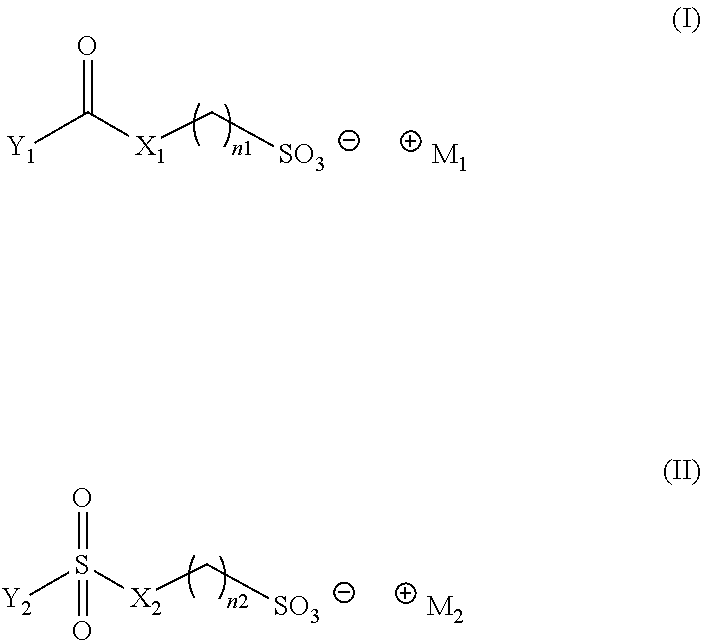

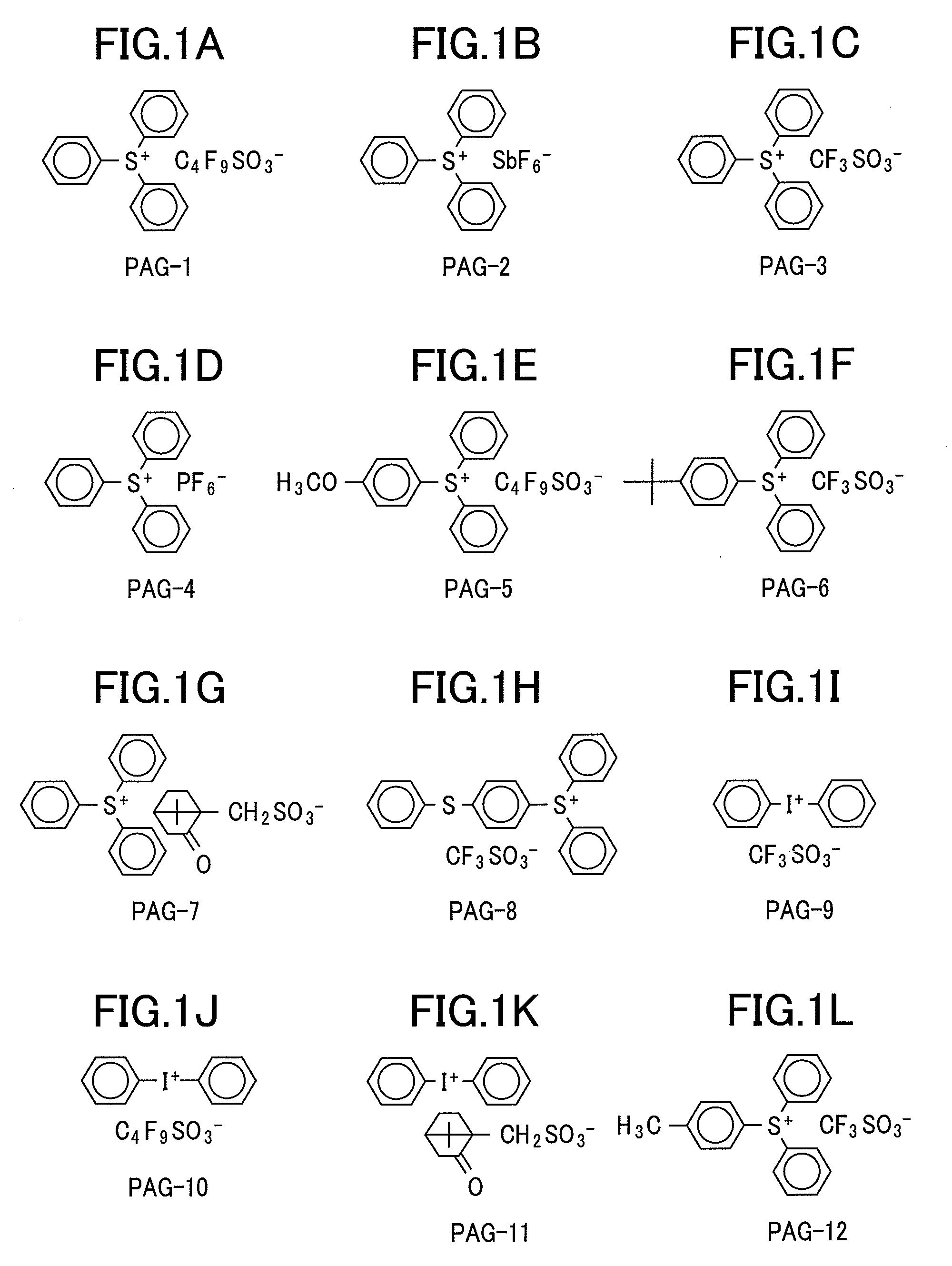

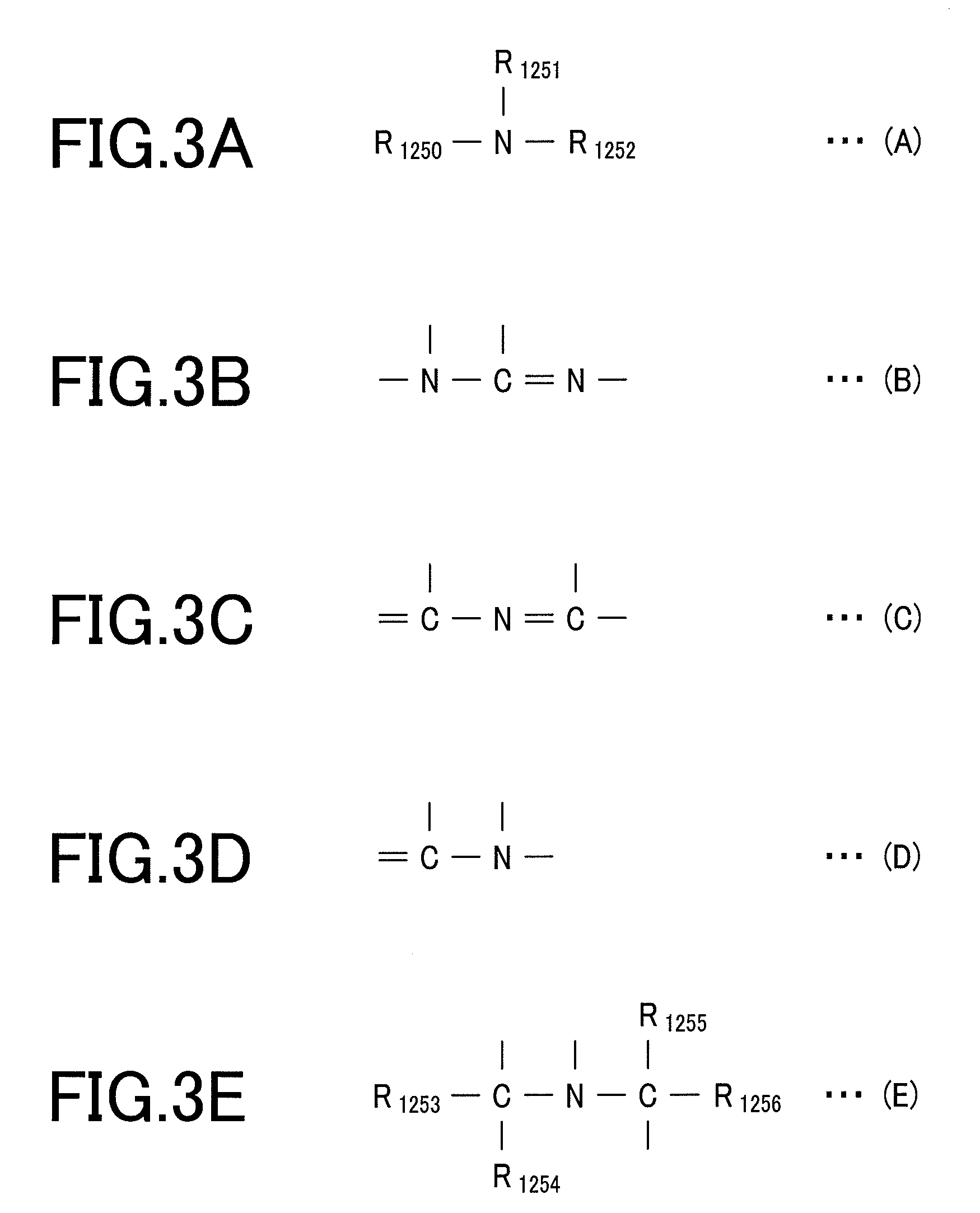

Compound, active light sensitive or radiation sensitive resin composition, resist film using same, resist-coated mask blank, photomask, pattern forming method, method for manufacturing electronic device, and electronic device

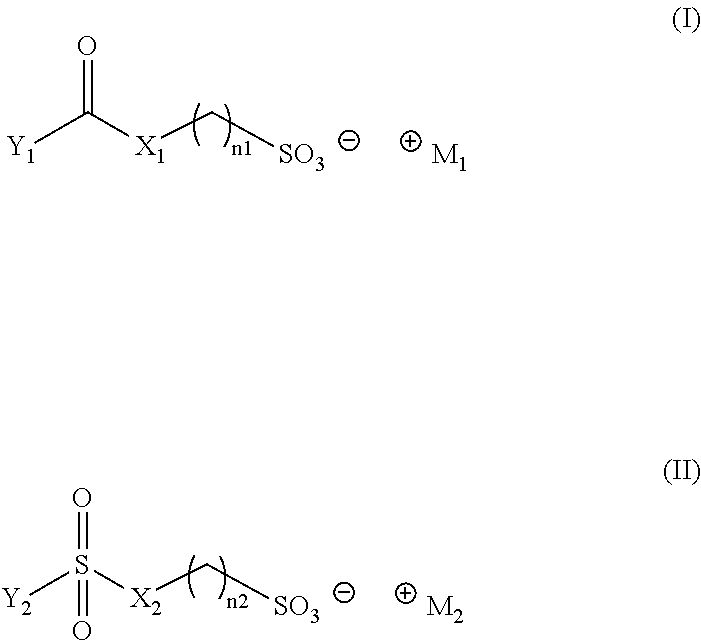

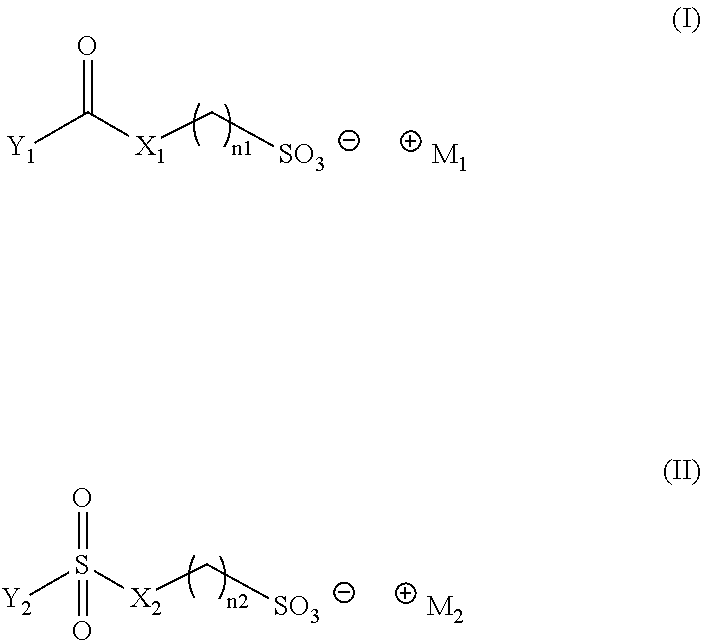

ActiveUS20160116840A1High resolutionPattern in good shapeOrganic compound preparationSemiconductor/solid-state device manufacturingOrganic groupOnium

Provided is an active light sensitive or radiation sensitive resin composition which contains a compound (A) represented by General Formula (I) or (II):in the formulae, each of Y1 and Y2 represents a monovalent organic group; each of M1+ and M2+ represents an organic onium ion; each of X1 and X2 represents a group that is represented by —S—, —NH—, or —NR1—; R1 represents a monovalent organic group; each of n1 and n2 represents an integer of 1 or more; and R1 and Y1 or Y2 may bond with each other to form a ring.

Owner:FUJIFILM CORP

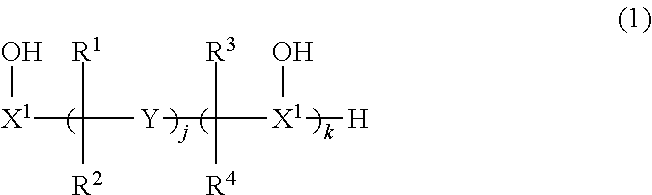

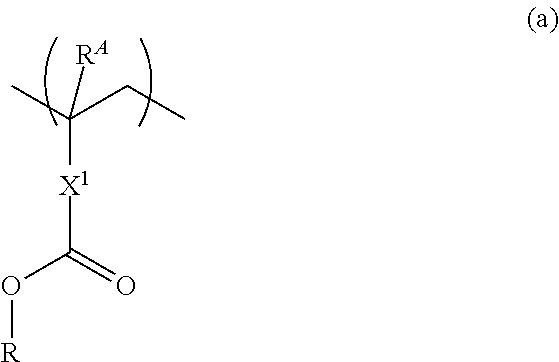

Positive resist composition and pattern forming process

ActiveUS20200192221A1High sensitivityHigh resolutionPhotosensitive material processingPolymer scienceMaterials science

A positive resist composition comprising a base polymer comprising recurring units having a nitrogen-containing tertiary ester structure exhibits a high sensitivity, high resolution, low edge roughness (LER, LWR) and small size variation, and forms a pattern of good profile after exposure and development.

Owner:SHIN ETSU CHEM IND CO LTD

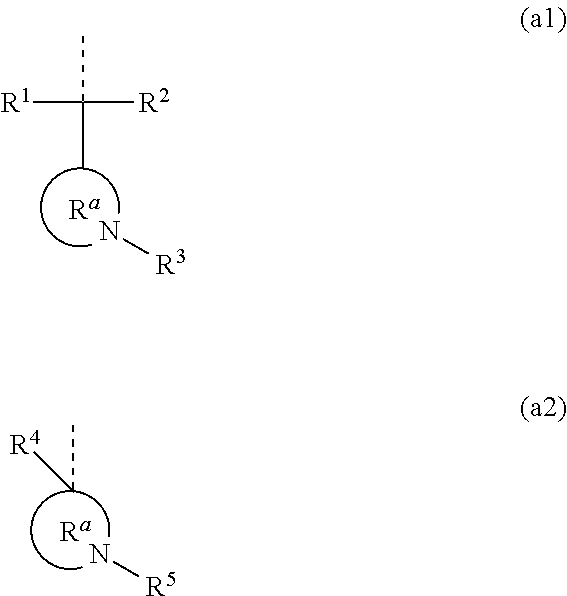

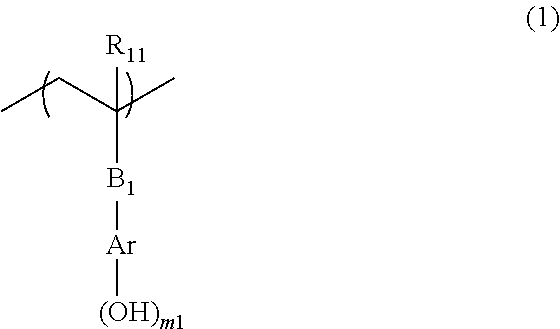

Materials for photoresist, negative-tone photoresist composition, method of forming resist pattern, and semiconductor device

ActiveUS20070128541A1Improve compatibilityReduce roughnessOrganic chemistryPhotosensitive materialsResistChemistry

With the tendency of reducing the size of semiconductor circuit patterns, edge roughness on a resist pattern is increased when pattern dimensions required are close to the size of the resist molecules. The present invention provides a technique for preventing degradation of the device performance and negative effects over the system performance caused by the phenomena. A photoresist compound is used, which is a molecule having functional groups that are chemically converted due to an action of an acid with reduced solubility in alkaline developer.

Owner:HITACHI LTD

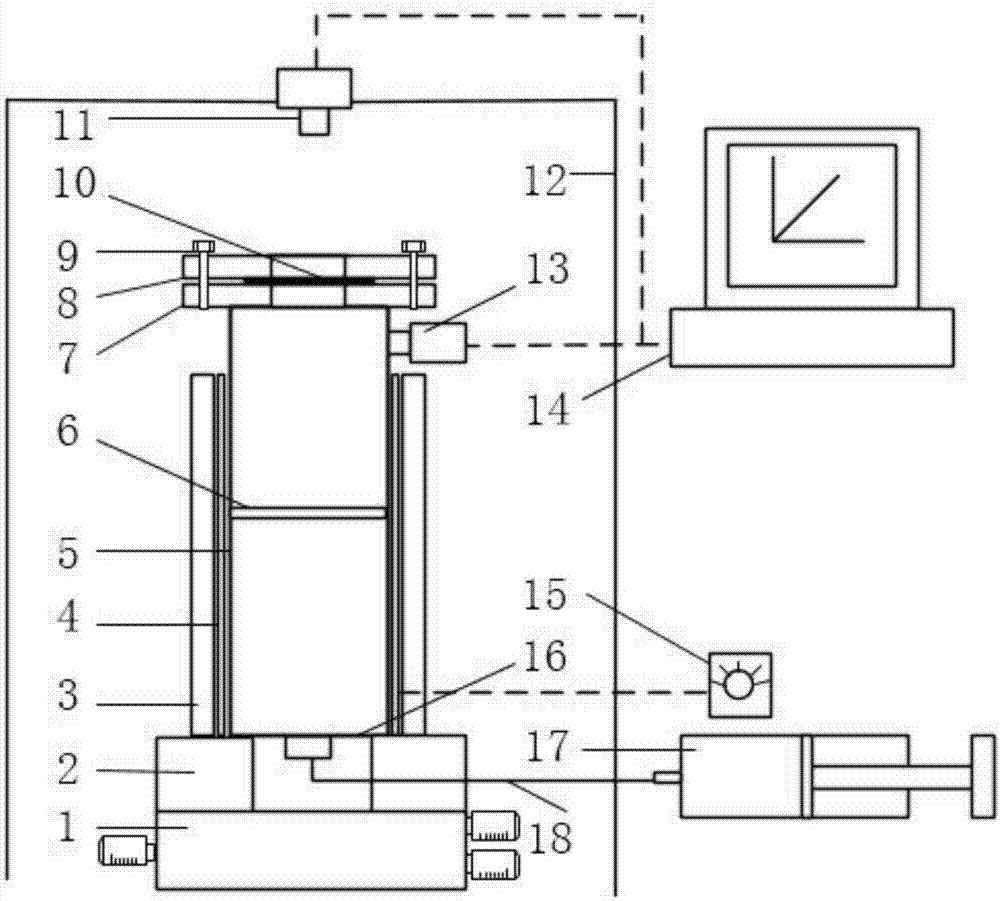

Temperature-controlled mechanical property test device for thin film

InactiveCN107462474ALarge temperature loading areaTemperature loading area and uniformMaterial strength using tensile/compressive forcesPiece tableInjector

The invention provides a temperature-controlled mechanical property test device for a thin film and belongs to the technical field of material property tests and optical measurement mechanics. The temperature-controlled mechanical property test device mainly comprises a temperature control part, a deflection measurement part, a pressure loading part, a test piece clamping structure and a data receiving and displaying part. During a test, an electric heating tape heats up gas in a pressure cavity to a certain temperature, and an injector is pushed to perform pressure loading; a flow equalizing plate in the pressure cavity ensures relatively uniform pressure exerted on the thin film; the increasingly rising pressure enables the thin film mounted on a test piece table to be subjected to bulging deformation; a laser displacement sensor above the test piece table is used for measuring central deflection of the deformed thin film in real time; and the data receiving and display part is used for receiving and displaying pressure and deflection data. In combination with a film-bulging theoretical model, such mechanical parameters as the elasticity modulus of the thin film at a certain temperature can be obtained according to such measured data as pressure and deflection.

Owner:NORTHEASTERN UNIV

Compound, active light sensitive or radiation sensitive resin composition, resist film using same, resist-coated mask blank, photomask, pattern forming method, method for manufacturing electronic device, and electronic device

ActiveUS9904167B2High resolutionPattern in good shapeSemiconductor/solid-state device manufacturingSteroidsOrganic groupOnium

Owner:FUJIFILM CORP

Materials for photoresist, negative-tone photoresist composition, method of forming resist pattern, and semiconductor device

ActiveUS7659047B2High sensitivityDefect occurrence rateOrganic chemistryPhotosensitive materialsDevice materialHemt circuits

With the tendency of reducing the size of semiconductor circuit patterns, edge roughness on a resist pattern is increased when pattern dimensions required are close to the size of the resist molecules. Provided is a technique for preventing degradation of the device performance and negative effects over the system performance caused by the phenomena. A photoresist compound is used, which is a molecule having functional groups that are chemically converted due to an action of an acid with reduced solubility in alkaline developer.

Owner:HITACHI LTD

Materials for photoresist, photoresist composition and method of forming resist pattern

InactiveUS20080081281A1Reduce the ratioImprove in-plane uniformityOrganic chemistryOrganic compound preparationResistSolubility

To overcome the problem that a device performance is degraded by the edge roughness of a photoresist pattern, a mixture of polynuclear phenol compounds having, in one molecule, 0 to 6 functional groups which are chemically converted due to actions of an acid with the solubility in an alkaline developer reduced is used as a material for photoresist. In the mixture, two or more triphenyl methane structures are bonded to portions other than the functional group in the nonconjugated state. Furthermore, the mixture comprises polynuclear compounds with the average number of functional groups of 2.5 or below and includes the polynuclear compounds not having any functional group per molecule by 15% or less in the term of weight ratio, and the polynuclear phenol compounds having 3 or more functional groups per molecule by 40% or less.

Owner:TOKYO OHKA KOGYO CO LTD +1

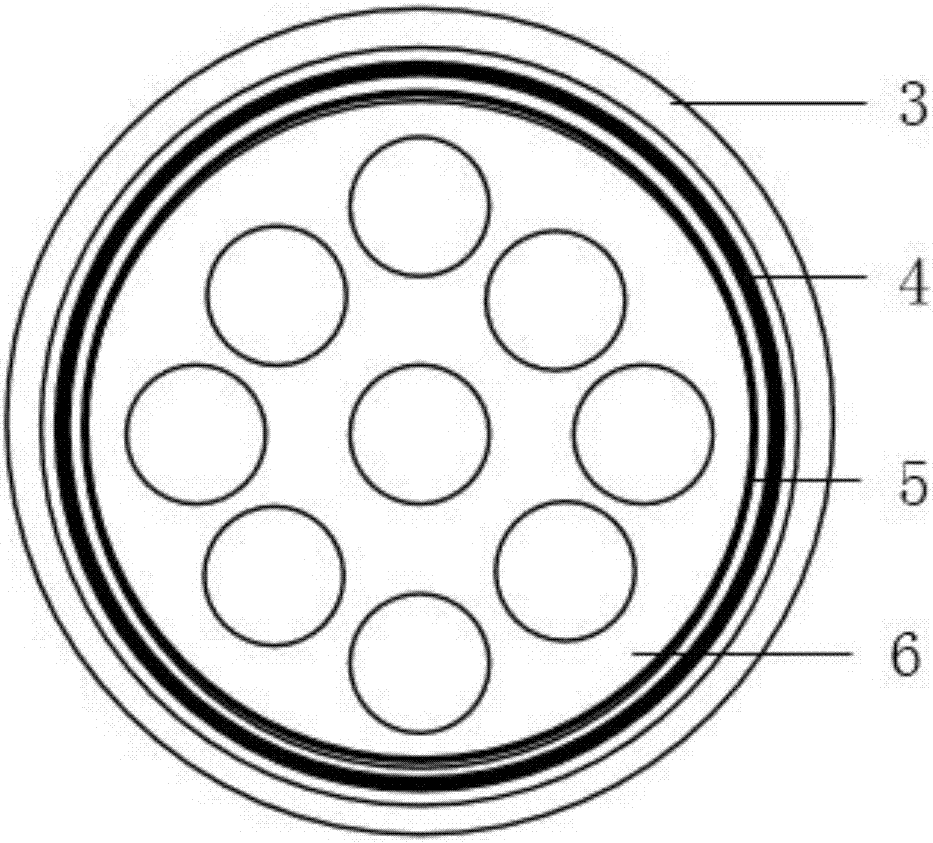

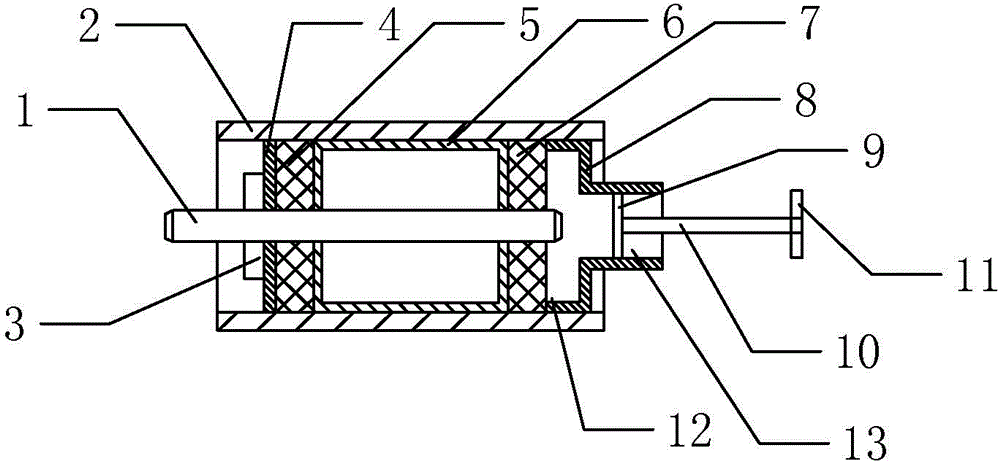

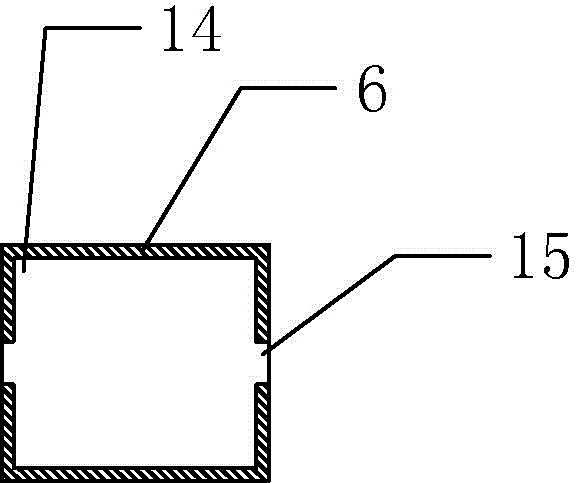

Pneumatic rubber expansion core shaft

ActiveCN104385187ASave materialImprove aerodynamicsWork holdersExpansion mandrelsPneumatic cylinderPneumatic valve

The invention discloses a pneumatic rubber expansion core shaft. The pneumatic rubber expansion core shaft comprises a core shaft and a top sleeve, wherein the core shaft is provided with a shaft shoulder; a first stepped hole is formed in the top sleeve, the first stepped hole comprises a large-diameter hole and two small-diameter holes which are equal in radius, and the two small-diameter holes are matched with the core shaft; a first rubber sleeve and a second rubber sleeve are respectively arranged in positions, which are positioned at two sides of the top sleeve, of the core shaft in a sleeving way, the first rubber sleeve is close to the shaft shoulder, the second rubber sleeve is far away from the shaft shoulder, a separating piece is arranged between the first rubber sleeve and the shaft shoulder, the outer side of the second rubber sleeve is also provided with a pneumatic cylinder, the pneumatic cylinder is also internally provided with a pneumatic valve, the pneumatic valve leans against the inner wall of the pneumatic cylinder, and the outer side of the pneumatic valve is provided with a pushing rod. According to the pneumatic rubber expansion core shaft disclosed by the invention, the technical defect that the supporting location on a pipe cannot be accurately carried out by using the pipe as the center or the requirement on the roughness of the inner wall of the pipe is higher at present is overcome, accurate location can be carried out by using the pipe as the center, and the requirement on the roughness of the inner wall of the pipe is not high.

Owner:CHONGQING RUIPU CABLE

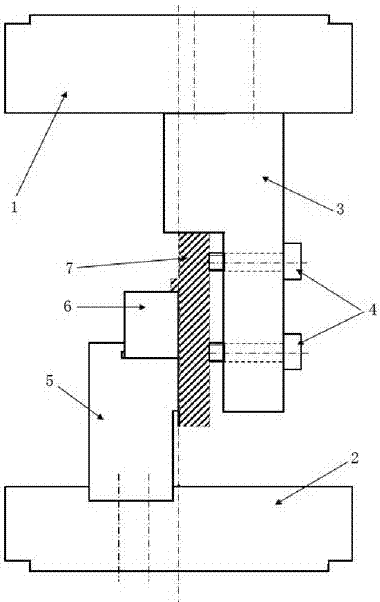

Device for composite steel plate shearing tests and using method thereof

PendingCN106918500ANo horizontal movementHigh hardnessMaterial strength using steady shearing forcesSteel platesEngineering

The invention provides a device for the composite steel plate shearing tests. The device is composed of three parts: an electronic universal tensile testing machine, a base of a shearing clamp, and a pressing device of the shearing clamp. The base of the shearing clamp comprises a blade, a blade seat, and a shearing base. The pressing device of the shearing clamp comprises a sample pressing device base, a sample backup plate, and a bolt for adjusting the sample gap. The device fully utilizes the auxiliary structure of a testing machine hydraulic clamp, the precise control of the test process is guaranteed, the electronic universal tensile testing machine does not need to be changed, the operation is simple and convenient, the design is reasonable, the cost is saved, and the device is user-friendly and convenient.

Owner:NANJING IRON & STEEL CO LTD

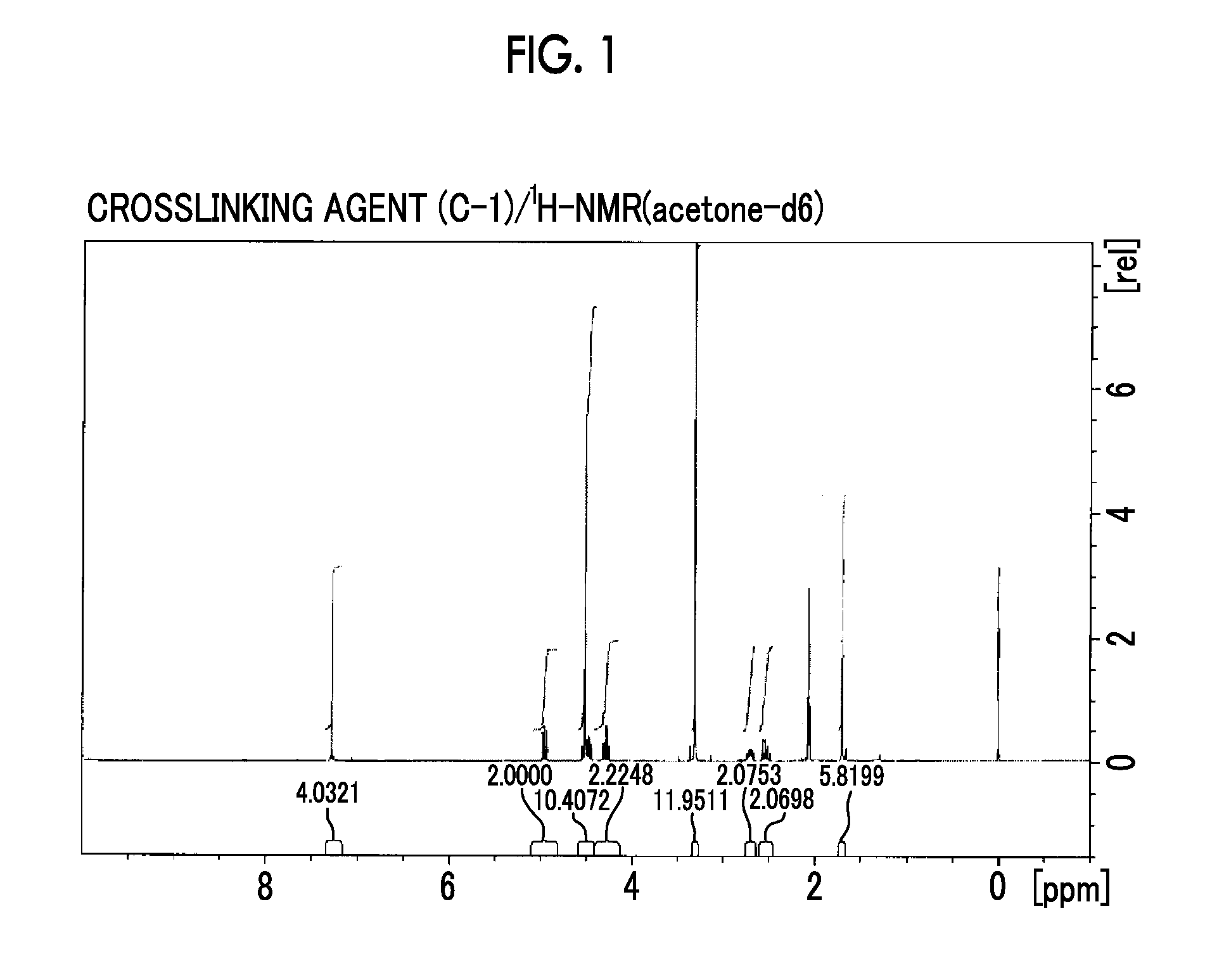

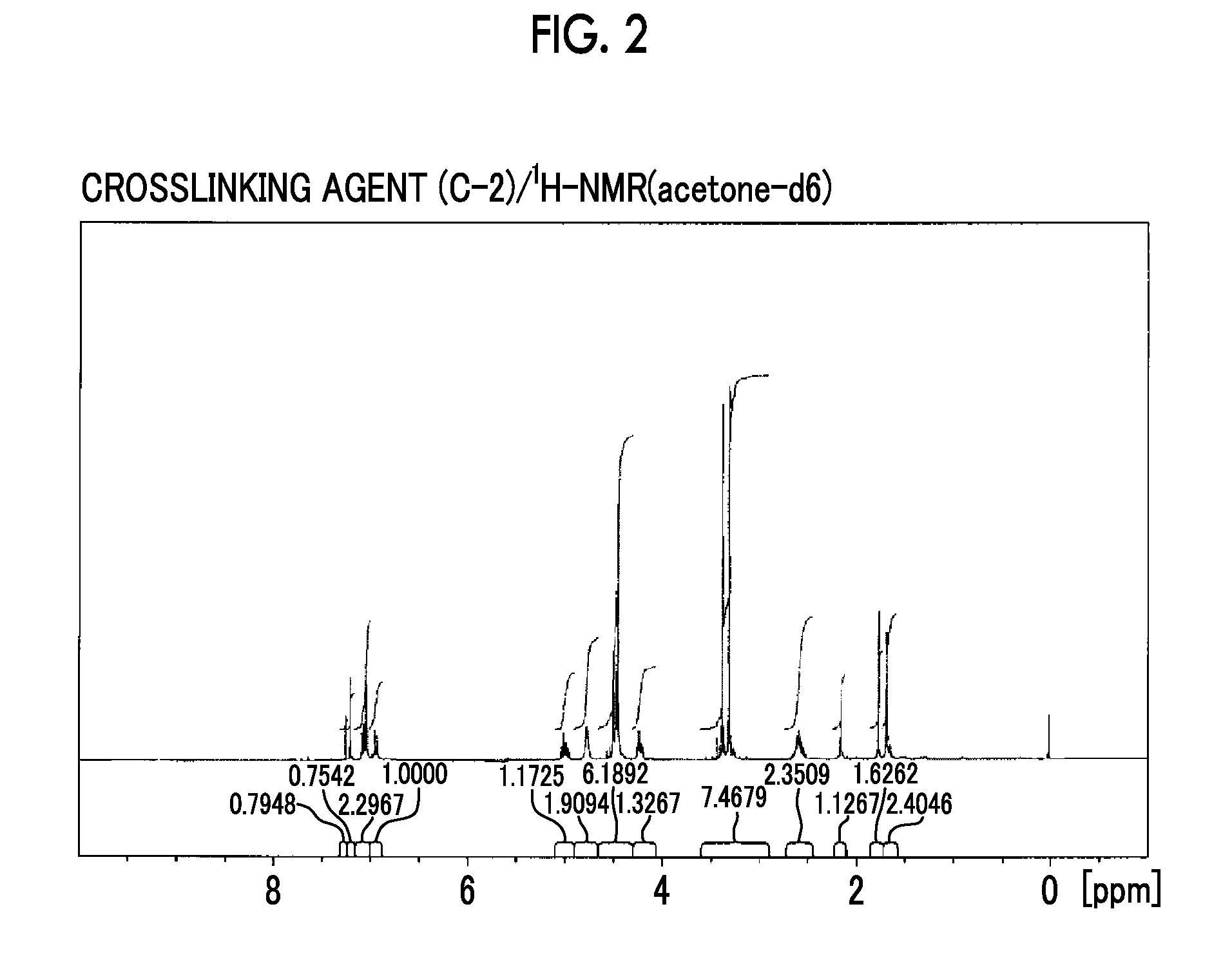

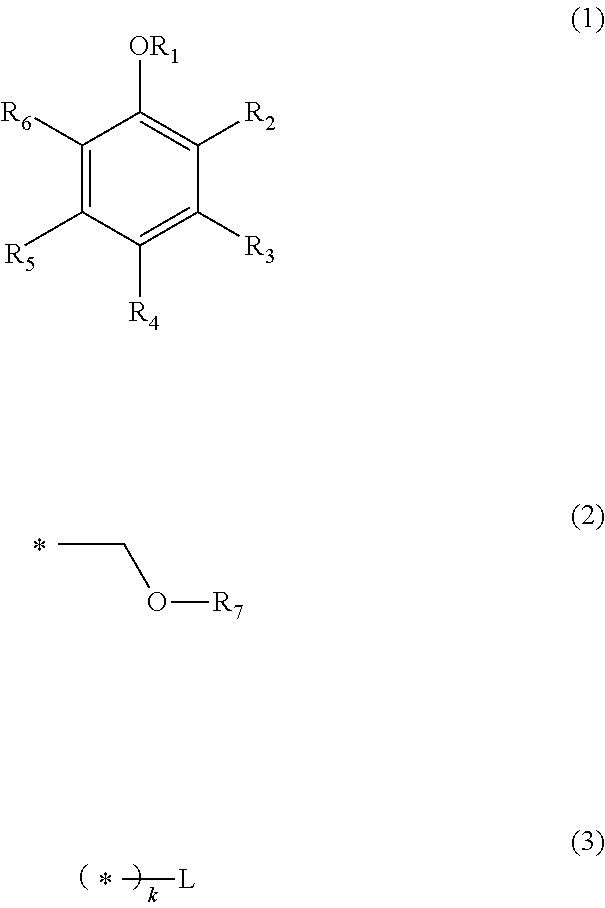

Actinic ray-sensitive or radiation-sensitive resin composition, actinic ray-sensitive or radiation-sensitive film, mask blank provided with actinic ray-sensitive or radiation-sensitive film, pattern forming method, method for manufacturing electronic device, electronic device, and compound

ActiveUS20160280675A1High resolutionLow line edge roughnessOrganic chemistryPhotomechanical exposure apparatusAlkaline waterActinic Rays

The actinic ray-sensitive or radiation-sensitive resin composition includes a crosslinking agent having a polarity converting group and an alkali-soluble resin, in which the polarity converting group is a group capable of decomposing by the action of an alkaline aqueous solution to generate a carboxylic acid or sulfonic acid on the side having a crosslinking group.

Owner:FUJIFILM CORP

Negative resist composition, method for producing relief pattern using the same, and electronic component using the same

ActiveUS20130017376A1High resolutionLow line edge roughnessElectric discharge tubesPhotosensitive materialsTotal solid contentOrtho position

An object of the present invention is to provide a negative resin composition which can produce a pattern with high sensitivity, high resolution and low line edge roughness in pattern formation by exposure to electron beams or EUV, a method for producing a relief pattern and an electronic component using the negative resist composition.Disclosed is a negative resist composition comprising a phenolic compound (A) which has: two or more phenolic hydroxyl groups per molecule; one or more substituents of one or more kinds selected from the group consisting of a hydroxymethyl group and an alkoxymethyl group per molecule in the ortho-position of any of the phenolic hydroxyl groups; and a molecular weight of 400 to 2,500, wherein the content of the phenolic compound (A) is 70% by weight or more of the total solid content of the negative resist composition.

Owner:DAI NIPPON PRINTING CO LTD

Five-cylinder electric magnetic engine

InactiveCN105375677ASimple and reliable control processQuality ratioMechanical energy handlingInterference fitEngineering

The invention discloses a five-cylinder electric magnetic engine, which comprises an engine body, support sleeves, connecting rods, an output shaft an a flywheel mechanism, wherein the engine body comprises a machine body and a machine cavity; the machine cavity is arranged in the machine body; the support sleeves are sleeved with the machine cavity in the machine body; permanent magnet groups are arranged between the machine body and the support sleeves; pistons are assembled in the support sleeves; a coil assembly winds one end of each piston and is fixed on each piston; the outer cylindrical surfaces of the support sleeves and the permanent magnet groups are in interference fit; the permanent magnet groups and an air cylinder body are in interference fit; the pistons and the inner cylindrical surfaces of the support sleeves are in interference fit; each piston is connected with one end of each connecting rod; the other end of each connecting rod is connected with the output shaft; the output shaft is located at the center of the machine body; the rotating center of the flywheel mechanism is connected with the output shaft; and off centers of the eccentric structure are distributed in a circumference array around the center. The five-cylinder electric magnetic engine is simple in structure, low in cost, simple and reliable in control principle, high in response speed, high in torque, environment-friendly and energy-saving; and consumption of the traditional fuel energy is reduced.

Owner:GUANGDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com