Pneumatic rubber expansion core shaft

A technology of rubber expansion and mandrel, which is applied in the direction of expanding mandrel, workpiece clamping device, manufacturing tool, etc., can solve the problems of high requirements on the inner wall roughness of the pipe fittings, the support and positioning of the pipe fittings cannot be accurately positioned with the center of the pipe fittings, etc. Material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

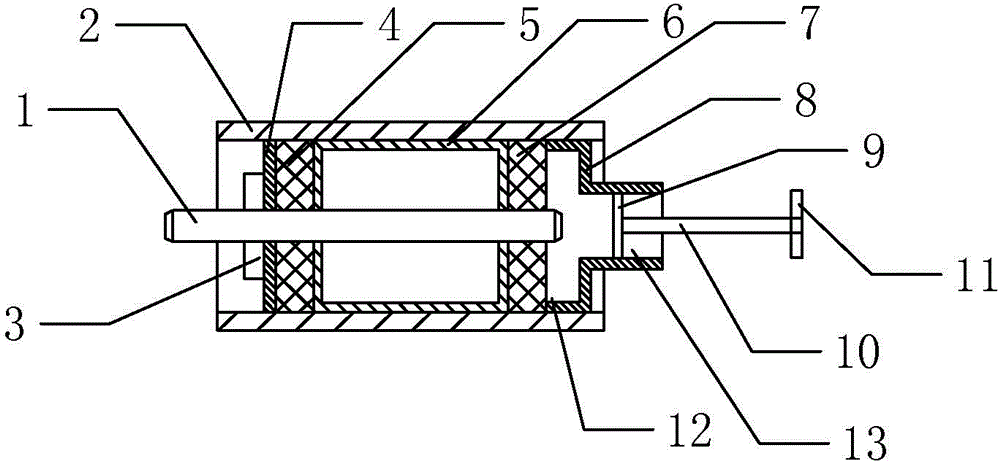

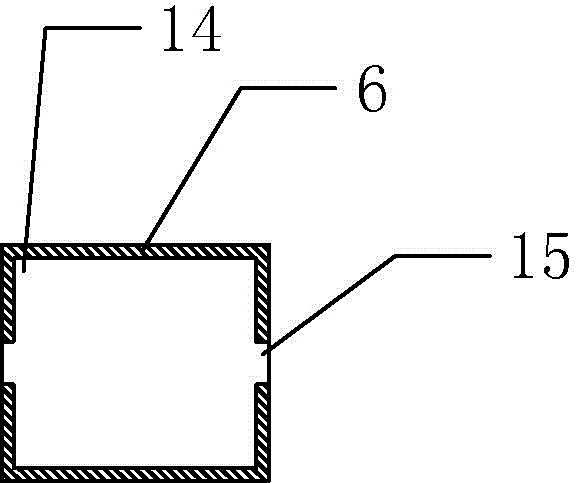

[0014] Among them: mandrel 1, pipe fitting 2, shaft shoulder 3, retainer 4, first rubber sleeve 5, top sleeve 6, second rubber sleeve 7, pneumatic cylinder 8, pneumatic valve 9, push rod 10, handle 11, large hole 12. Small hole 13, large diameter hole 14, small diameter hole 15.

[0015] Such as figure 1 As shown, the pneumatic rubber expansion mandrel 1 of the present invention includes a mandrel 1 and a top sleeve 6, and the mandrel 1 is provided with a shoulder 3; the top sleeve 6 is made of duralumin, and the outer diameter of the top sleeve 6 is less than The inner diameter of the pipe fitting 2, the top sleeve 6 is provided with a first stepped hole, the first stepped hole includes a large diameter hole 14 and two small diameter holes 15 with equal radii, the large diameter hole 14 is located between the two small diameter holes 15 between, such as figure 2 As shown, the top sleeve 6 is sleeved on the mandrel 1, and two small-diameter holes 15 are in clearance fit wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com