Technology for repairing surfacing of piston rod of super large marine diesel engine

A technology for marine diesel engines and piston rods, which is applied in the field of surfacing welding, can solve the problems of increasing repair costs, high requirements on surface roughness and cleanliness of workpieces before plating, and achieves the effect of low repair costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

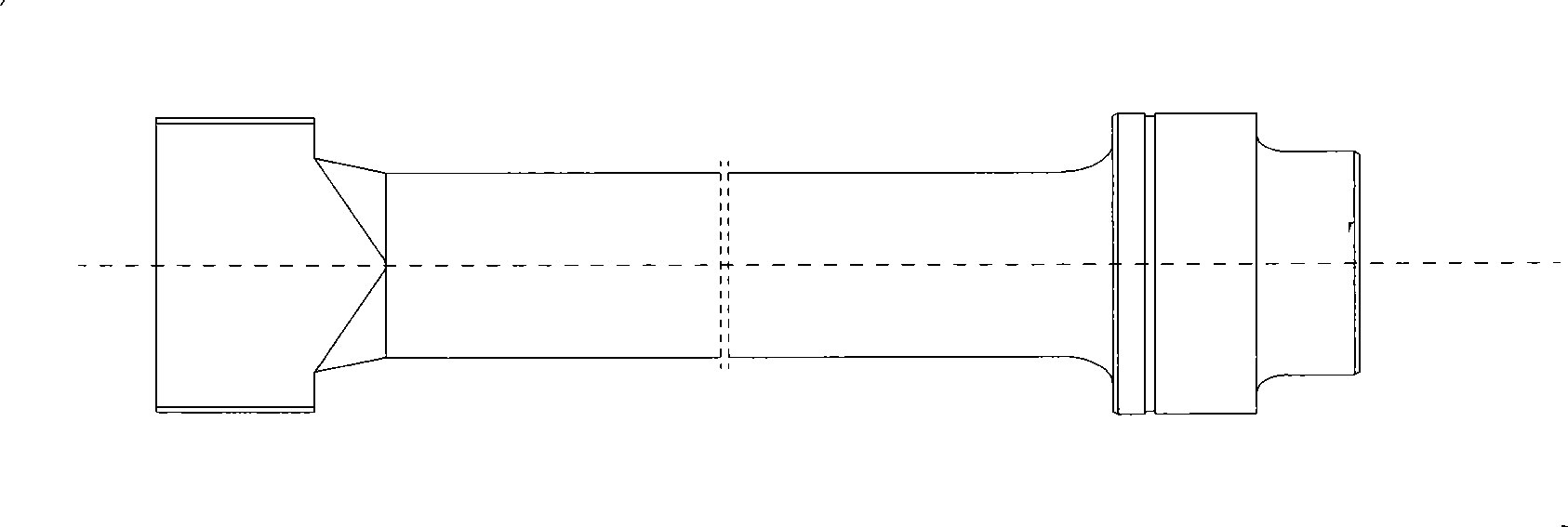

[0020] Taking the piston rod of RTA84T low-speed high-power diesel engine as an example, the surfacing welding process is described in detail.

[0021] The piston rod is made of 45# steel, and the piston rod is welded and repaired Φ320mm×3605mm;

[0022] 1. Flaw detection and straightening of the piston rod

[0023] Ultrasonic flaw detection on the surface and interior of the piston rod to determine the position and depth of surface defects for preparation for the next process; thermal straightening of the piston rod with an axial curvature greater than 2mm / m.

[0024] 2. Remove the surface defects of the piston rod

[0025] According to the flaw detection results, the surface of the piston rod is turned to remove the defect layer. The minimum removal depth is not less than 3mm and not more than 15mm on one side, and some deep cracks are manually ground.

[0026] 3. Flame heating

[0027] Since the material of the piston rod is 45# steel, the welding performance is poor, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com