Patents

Literature

71results about How to "No welding defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

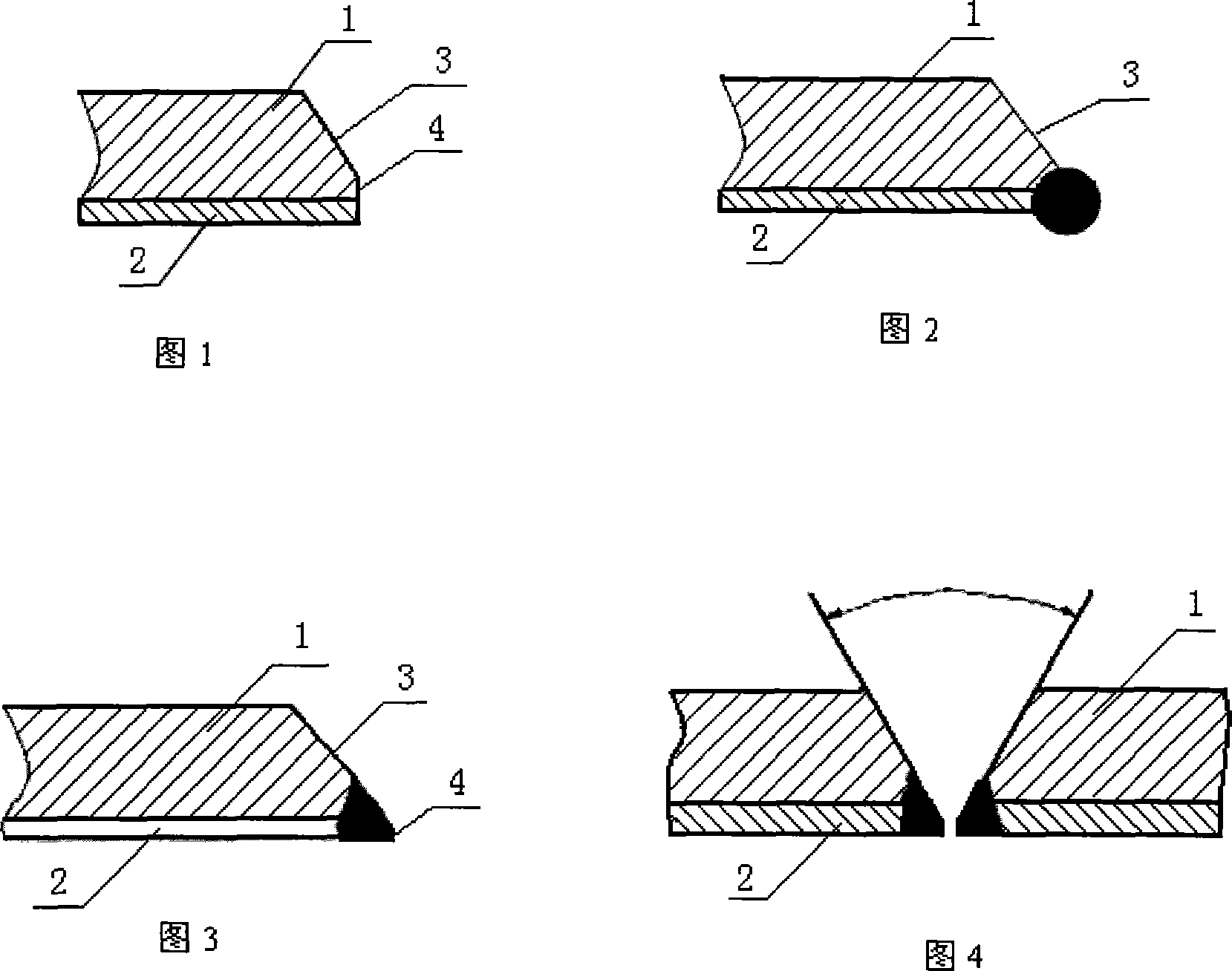

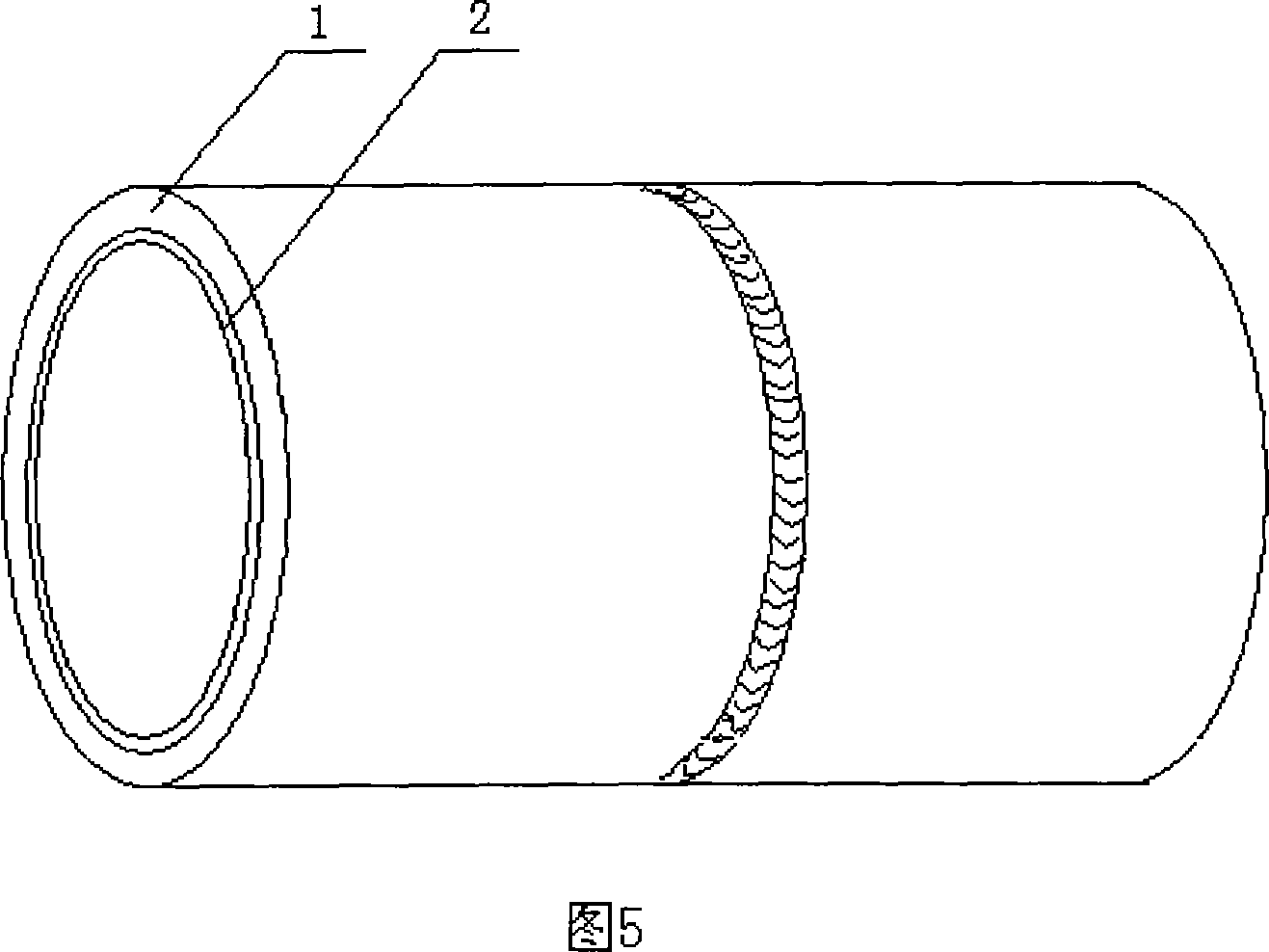

Thin-wall stainless steel double-layer and carbon steel base layer composite tube girth weld welding method

ActiveCN101100013AEliminate gapsIncrease the effective thicknessArc welding apparatusWelding/cutting media/materialsWeld seamMaterials science

The process of ring welding composite pipe comprising one thin stainless steel layer and one carbon steel base layer includes the following steps: 1. chamfering and eliminating oil stain; 2. bead welding and trimming chamfer; 3. pairing bimetal composite pipe chamfers; 4. argon shielded tungsten arc welding in the bottom; 5. welding the second layer to weld the base layers of two composite pipes; and 6. filling welding and finishing welding. During the welding process, stainless steel electrode and 309 or 309Mo welding material are adopted for reaching high strength and high toughness of the weld seam, and the chamfers have increased effective thickness of stainless steel layer for high welding quality and high corrosion resistance.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

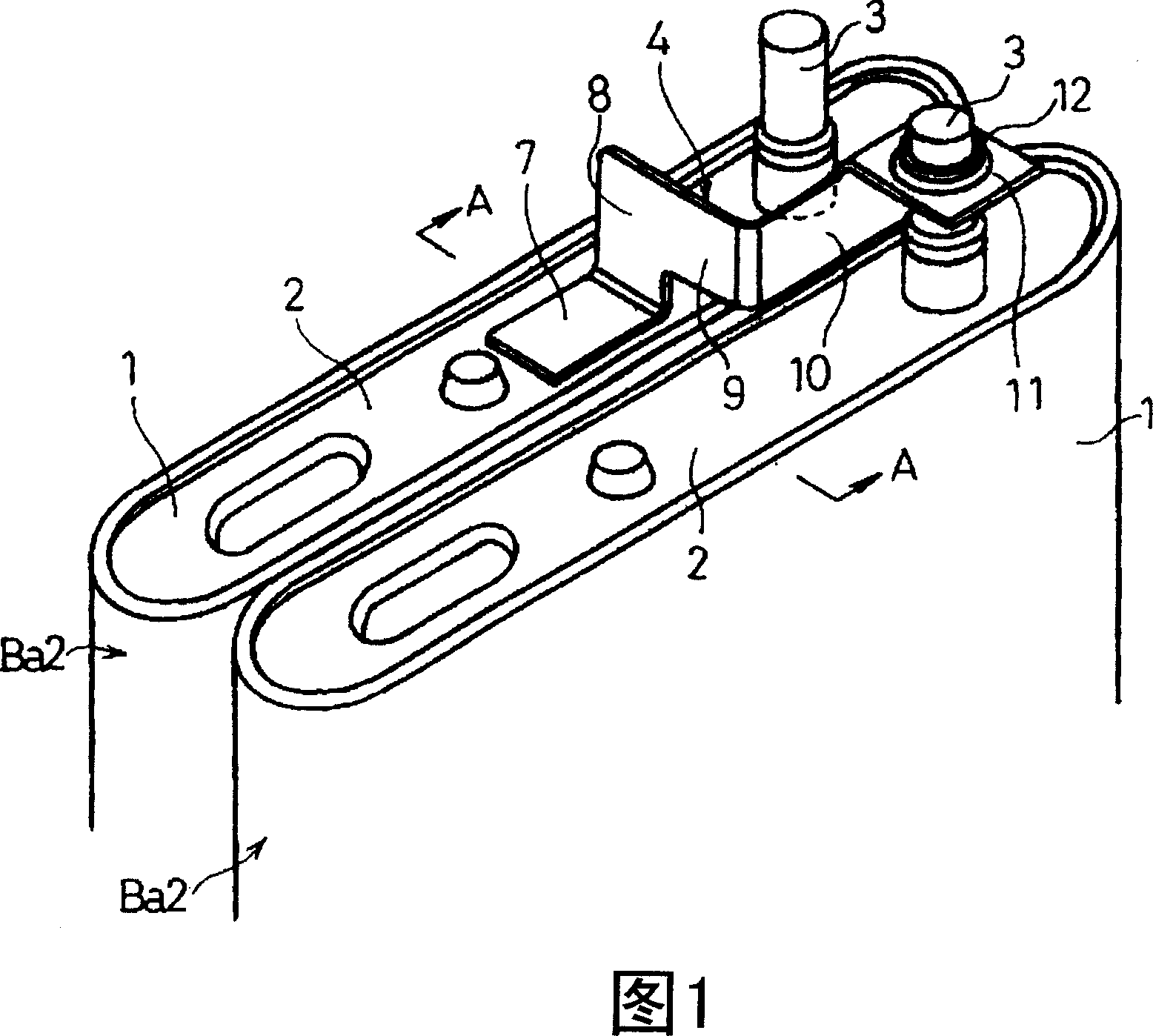

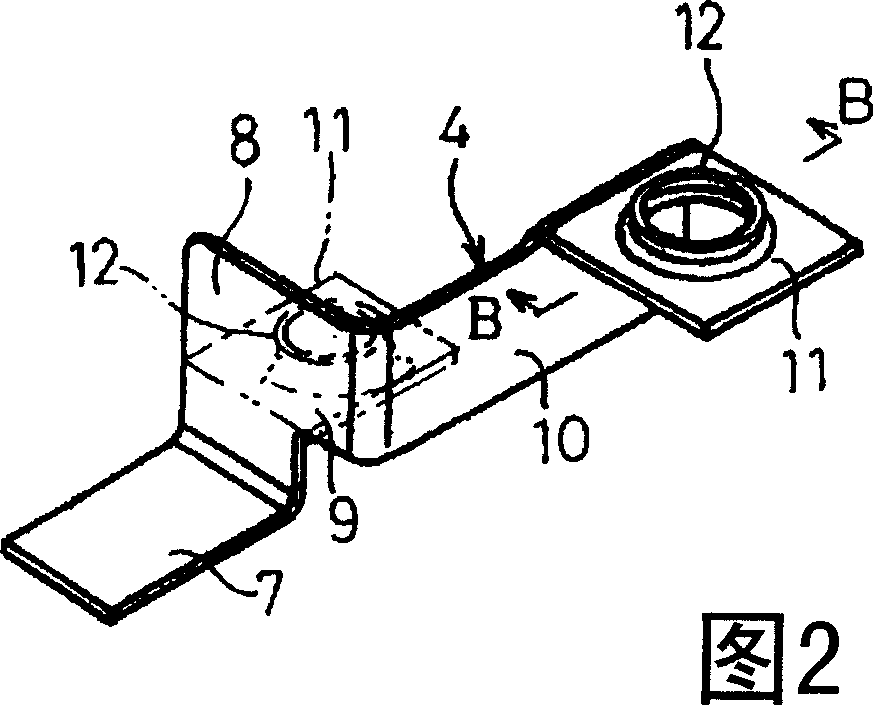

Battery pack

InactiveCN1976095ANo welding defectsEasy to operatePrimary cell to battery groupingSmall-sized cells cases/jacketsElectrical connectionBattery pack

A battery pack is made up of a plurality of flat prismatic batteries arranged face to face, each battery having one electrode terminal protruding from one end face in the height direction of the battery case and this end face or a side face of the battery serving as the other electrode terminal. The connector for electrically connecting adjacent prismatic batteries includes a flat part that is welded to one electrode terminal of one prismatic battery of the adjacent prismatic batteries, and a cylindrical part that is fitted onto and welded to the other electrode terminal of the other prismatic battery. The cylindrical part is formed in an attachment part that extends from the flat part through an upright part in the direction in which the batteries are aligned. The connector enables reliable electrical connection of the prismatic batteries despite possible variation in height of the electrode terminals.

Owner:PANASONIC CORP

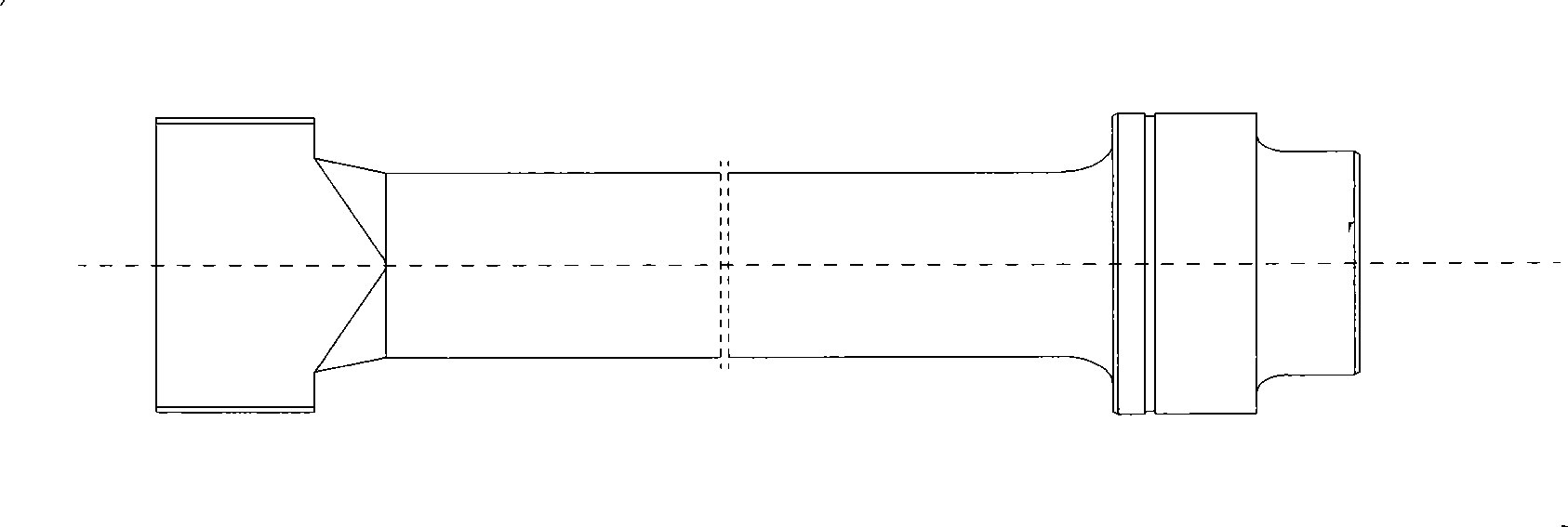

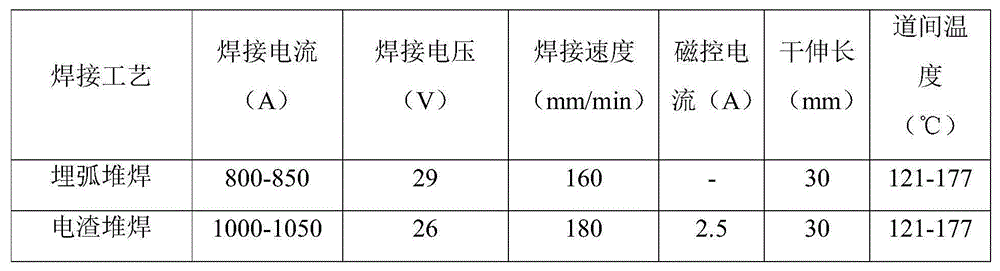

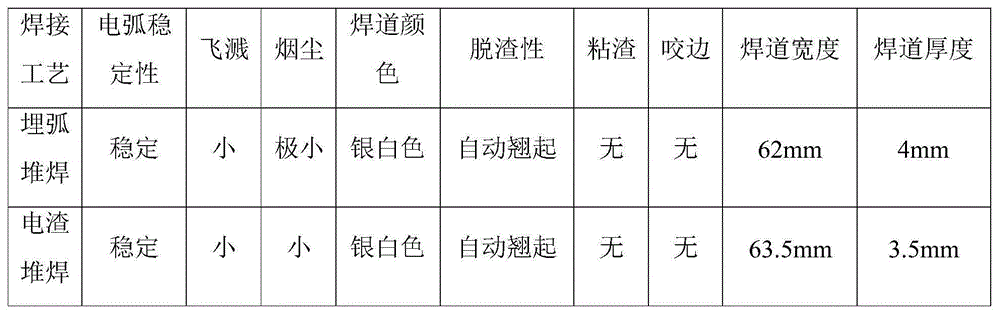

Technology for repairing surfacing of piston rod of super large marine diesel engine

InactiveCN101444881ALow roughness requirementsLow cleanliness requirementsArc welding apparatusRoom temperatureEngineering

The invention discloses a technology for repairing surfacing of a piston rod of a super large marine diesel engine, and the technology can carry out the deep repair of the surface of the piston rod. The adopted surfacing process is as follows: flaw detection and straightening are carried out on the piston rod, turning machining is carried out on the surface of the piston rod to remove a defect layer, and individual deeper cracks are manually removed by grinding; fire whirl is used for heating the piston rod twice, the first heating is carried out till 200 DEG C-250 DEG C, the heating is stopped, the race rotation is carried out for 30 minutes, the second heating is further carried out after the temperature difference between the interior and the exterior is reduced, and a surfacing machine tool is rotated after reaching 250 DEG C-300 DEG C; submerged arc welding is used for rotating dual heads of the surfacing machine tool and a 2Cr13 flux-cored welding wire for carrying out the simultaneous surfacing, and asbestos cloth is used for wrapping and keeping the temperature during the welding process; the piston rod wrapped by the asbestos cloth for slow cooling after the surfacing achieves the size requirement, when the temperature is decreased to be lower than 100 DEG C, the piston rod wrapped by the asbestos cloth is vertically placed till the temperature is decreased to the room temperature, and then the temperature-keeping cloth is removed. The surface of the piston rod after the repair by employing the method has no weld defects, the piston rod fully meets the performance requirements, and the cost is only about one fifth of the cost for fabricating a new piston rod.

Owner:DALIAN XINZHONG GRP +1

Method for welding thick aluminum alloy plate

ActiveCN102922098AReduce welding distortionEasy post-weld calibrationArc welding apparatusProduct gasWelding deformation

The invention discloses a method for welding a thick aluminum alloy plate. The method comprises a cleaning process, a preheating process and a welding process, wherein the cleaning process is carried out in a chemical cleaning way and comprises steps of: dipping a part to be welded in a 8-10% NaOH solution for more than 10 minutes, and then dipping in a 40-50% HNO3 solution for 30 seconds to 1 minute, wherein sensing heating equipment is adopted in the preheating process, and the preheating is carried out at 230 to 250 DEG C; joints in the welding process are in form of angle joint, and the non-melting electrode tungsten electrode gas shielded welding is carried out in the welding method, the welding parameter can be shown as that the current is 250 to 290A, the current polarity is performed by alternating current, Ar with purity not less than 99.99% is adopted as the protective gas, and the gas flow is at 7-13 liters per minute. Through the method, little welding deformation is generated, the correcting is easily carried out after welding, the product quality can be improved, the production efficiency can be increased, and the manufacturing cost can be greatly reduced.

Owner:BEIJING CED RAILWAY ELECTRIC TECH

Flux-cored wire and method for welding cold-rolled back-up roll by same

InactiveCN101722384AImprove wear resistanceImprove toughnessArc welding apparatusFurnace typesWork rollManganese

The invention discloses a flux-cored wire and a method for welding a cold-rolled back-up roll by the same, and relates to the welding technology. By using a steel strip as a sheath, the flux-cored wire comprises the following components in percentage by mass: 0.15 to 0.50 percent of carbon, 0.10 to 1.00 percent of silicon, 0.30 to 2.00 percent of manganese, 3.50 to 7.00 percent of chromium, 0.50 to 2.50 percent of molybdenum, 1.00 to 3.50 percent of tungsten, 0.20 to 1.00 percent of vanadium, 0.20 to 3.00 percent of nickel, 0 to 0.03 percent of sulfur, 0 to 0.03 percent of phosphorus, and the balance of iron. The flux-cored wire needs to maintain the surfacing interpass temperature of the cold-rolled back-up roll between 300 and 350 DEG C during constant temperature surfacing work. The flux-cored wire well solves the problem that the intensity of a surfacing material is not matched with the toughness after surfacing of the cold-rolled work roll, so that the hot-rolled back-up roll has high intensity and excellent toughness. Therefore, the service life of the cold-rolled back-up roll is improved.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

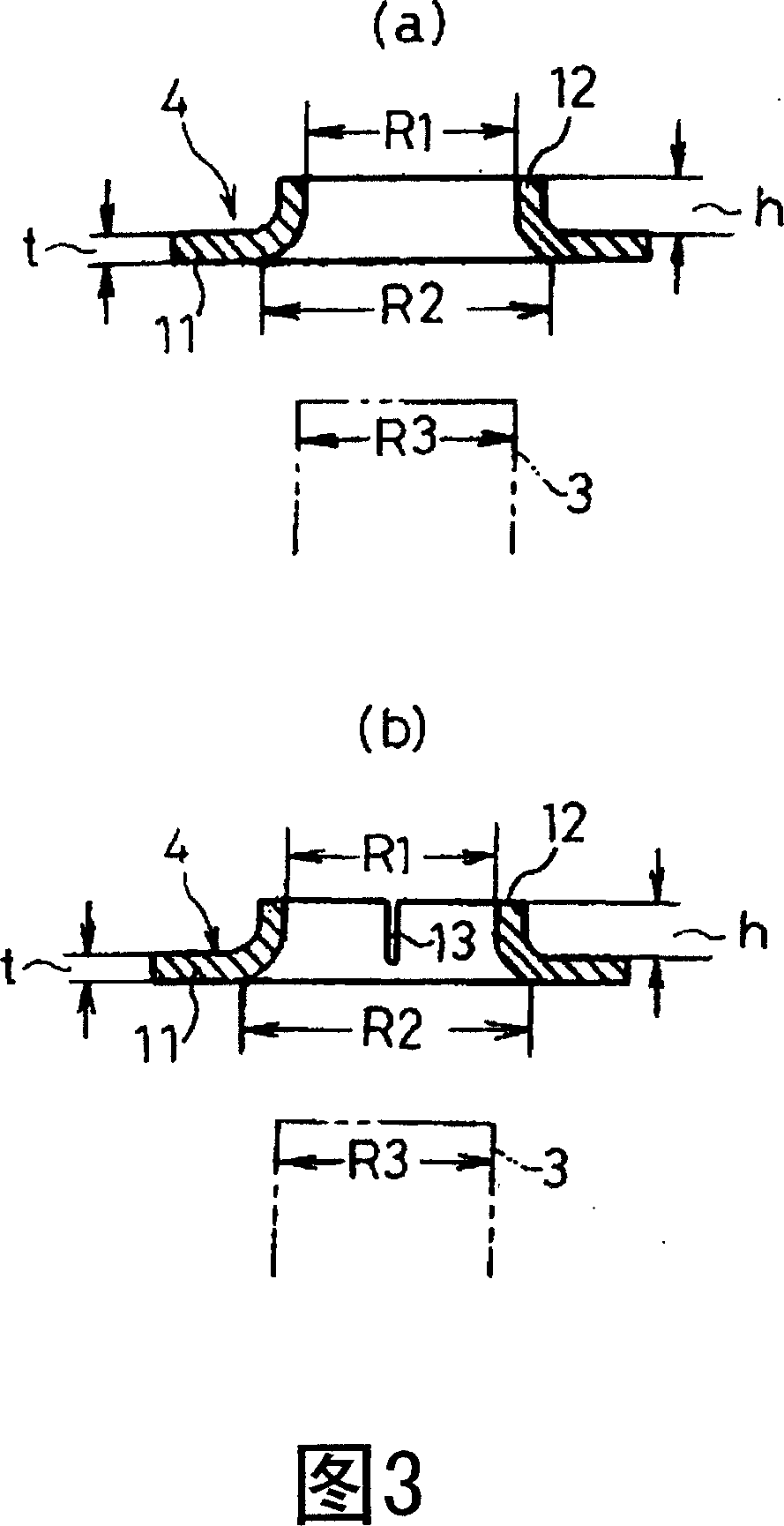

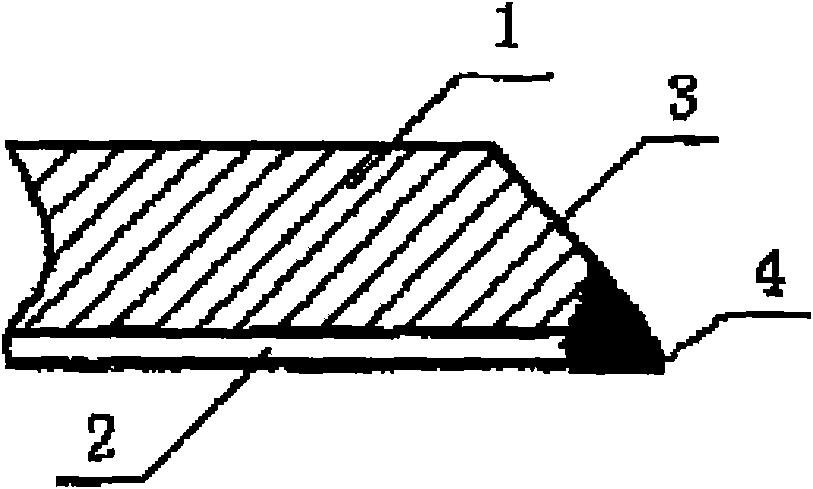

Method for welding circumferential weld between metal thin-wall clad layer and base layer of clad pipe

InactiveCN101927390AEliminate gapsIncrease the effective thicknessArc welding apparatusWelding/cutting media/materialsStainless steel electrodeUltimate tensile strength

The invention provides a method for welding circumferential weld between a metal thin-wall clad layer and a base layer of a clad pipe, which is used for welding circumferential weld of dual-metal clad steel pipes. The method is characterized by (A) groove processing: cleaning oil stains on the groove; (B) carrying out surfacing on the truncated edge, close to the clad layer, of the groove and coping the groove; (C) fitting up the groove of the dual-metal clad pipe; (D) root backing weld: adopting the gas tungsten arc welding method and carrying out welding along the groove of the dual-metal clad pipe under the state of argon-filled protection inside the pipe; (E) carrying out second layer welding on the root backing weld and welding the welding base layer of the dual-metal clad pipe; and (F) filled welding and cosmetic welding: wherein the welding materials are stainless steel electrodes. The method has the following effects: adopting 309 or 309Mo welding materials, thus ensuring the strength and good toughness of the weld; eliminating the gaps which probably exist between the clad layer and the base layer at the end of the groove; and increasing the effective thickness of the stainless steel layer at the groove root so that the quality of the welding joints are insensitive to misalignment, thus ensuring the corrosion resistance.

Owner:SHANGHAI HUGONG ELECTRIC WELDING MACHINE MFG

Repair weld composite leveller roll and its production process

InactiveCN1736627AHigh strengthImprove impact resistanceArc welding apparatusOther manufacturing equipments/toolsChemical compositionWorking life

It relates to a pile-up welding composite straightener roll and the preparation technique, belonging to the art of mechanical device, and it especially relates to a straighter roll for a plate hot straightening machine. The straightener roll uses alloy constructional steel 42CrMo wrought-steel as the base metal to prepare mandrel of roll body, and is built-up an operational layer of 5-15mm by thicken on the surface of the roll body, the chemical composition of the deposited material of the operational layer being: C:0.36-0.45%, Cr: 12.00-14.00%, Ni:2.00-2.50%, Mo: 2.00- 3.00%, W: 2.00- 3.00%, Ti: 0.85-1.25%, Si: <=1.50%, Mn: <= 2.00%, P<= 0.035%, and S: <=0.03%. In the technique it uses 1250 type automatic buried arc building-up device, applies bobbing building-up to build up the operation layer of roll body, and uses the 260 weld flux as the welding material. The straightener roll has a long work life and a high strength of roll body, and it can be repaired and reproduced a plural of times.

Owner:UNIV OF SCI & TECH BEIJING

Flux-cored wire and method for welding hot-rolled back-up roll by same

InactiveCN101722385AImprove wear resistanceImprove toughnessArc welding apparatusFurnace typesWork rollManganese

The invention discloses a flux-cored wire and a method for welding a hot-rolled back-up roll by the same, and relates to the welding technology. By using an iron-based steel strip as a sheath, the flux-cored wire comprises the following components in percentage by mass: 0.15 to 0.60 percent of carbon, 0.10 to 2.00 percent of silicon, 0.15 to 2.00 percent of manganese, 2.50 to 7.00 percent of chromium, 0.50 to 2.50 percent of molybdenum, 0.30 to 3.50 percent of tungsten, 0.20 to 1.00 percent of vanadium, 0.20 to 3.00 percent of nickel, 0 to 0.03 percent of sulfur, 0 to 0.03 percent of phosphorus, and the balance of iron. The flux-cored wire needs to keep the surfacing interpass temperature of the cold-rolled back-up roll between 300 and 350 DEG C during constant temperature surfacing work. The flux-cored wire well solves the problem that the intensity of a surfacing material is not matched with the toughness after surfacing of the cold-rolled work roll, so that the hot-rolled back-up roll has high intensity and excellent toughness. Therefore, the service life of the hot-rolled back-up roll is improved.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

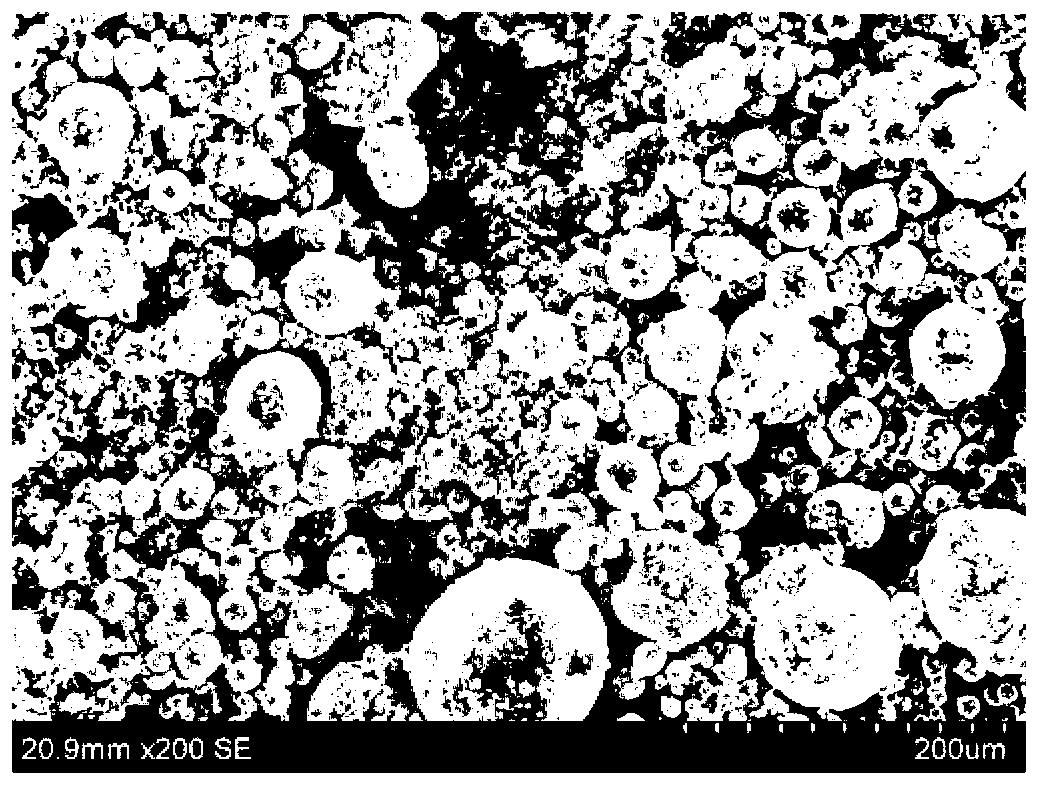

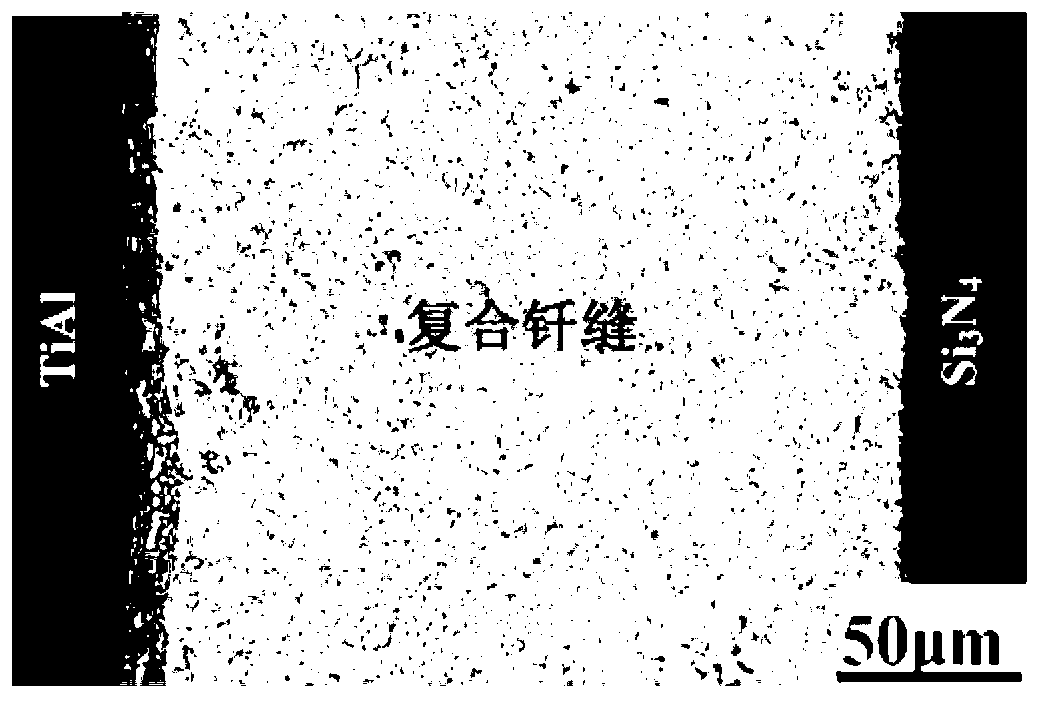

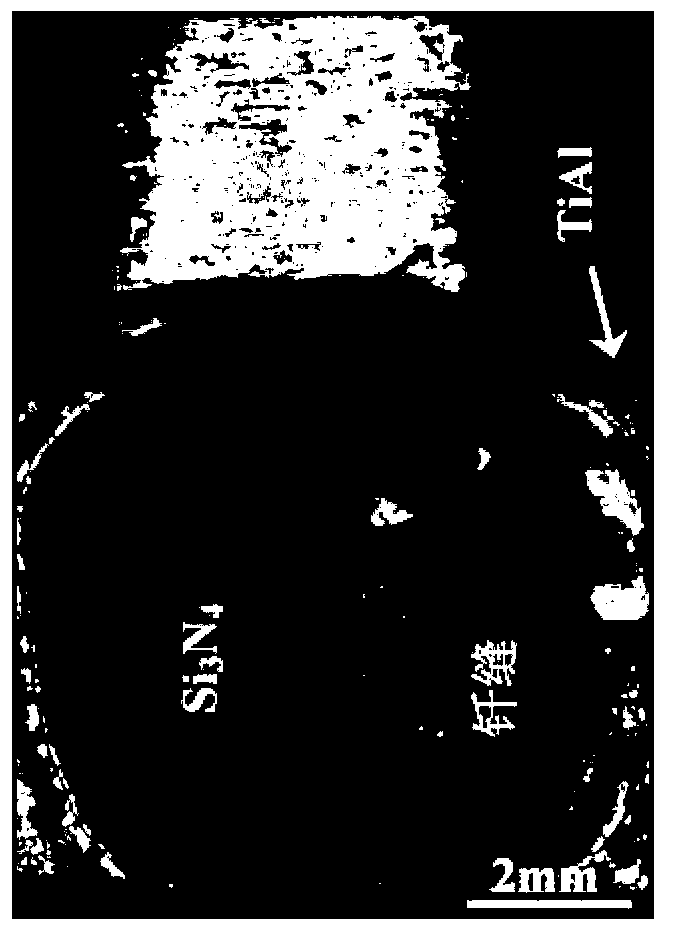

Nano particle reinforced Ag-base composite brazing filler metal and preparation method thereof

InactiveCN102699572AIncrease temperatureReduce residual stressWelding/cutting media/materialsGrain treatmentsNanoparticleRoom temperature

The invention provides a nano particle reinforced Ag-base composite brazing filler metal and a preparation method thereof and relates to a composite brazing filler metal and a preparation method thereof. The nano particle reinforced Ag-base composite brazing filler metal can be used for solving the technical problems that a joint obtained by a soldering ceramic and metal by utilizing a common Ag-base brazing filler metal is low in service temperature and poor in performance under a high temperature environment. The brazing filler metal provided by the invention is prepared from Ag powder, Cu powder, Ti powder and nano Si3N4 particles. The method comprises the following steps of 1, preparing materials; and 2, performing ball milling, so as to obtain the nano particle reinforced Ag-base composite brazing filler metal. The shearing strength of a joint obtained by soldering Si3N4 ceramic and TiAl alloy by utilizing the composite brazing filler metal provided by the invention at a high temperature of 400 DEG C is up to 156MPa, and is three times that of the joint obtained through soldering by utilizing a commercial AgCuTi brazing filler metal, and the shearing strength of the joint at room temperature is up to 115MPa.

Owner:HARBIN INST OF TECH

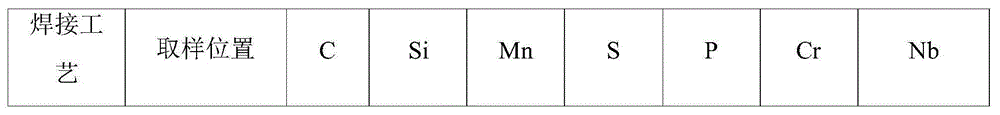

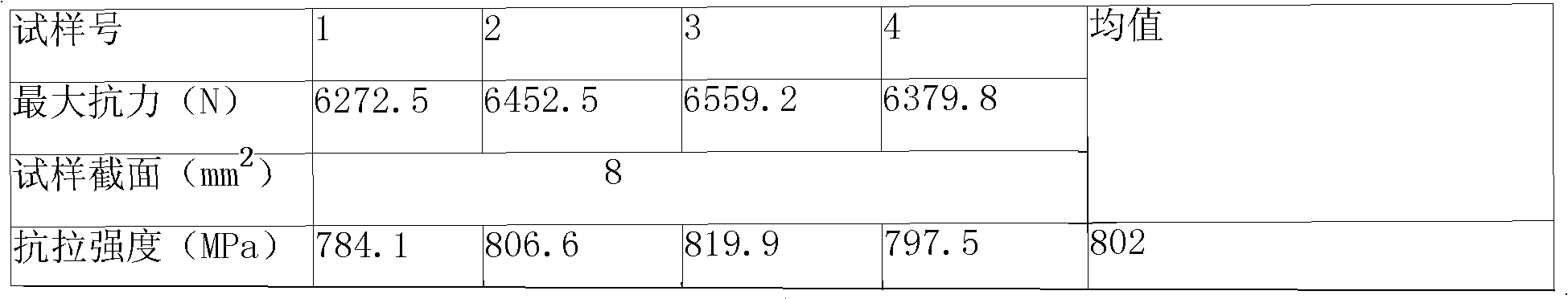

Mn and Nb added NiCrFe alloy surfacing solder strip for nuclear power and welding method

InactiveCN105215571AImprove deposition efficiencyLow dilution rateWelding/cutting media/materialsSoldering mediaCrack resistanceNuclear power

The invention provides a Mn and Nb added NiCrFe alloy surfacing solder strip for nuclear power and a welding method and belongs to NiCrFe nickel base alloy solder strips. The solder strip is composed of, by weight, less than 0.04% of C, less than 0.50% of Si, less than 5.0% of Mn, less than 0.015% of S, less than 0.020% of P, 28.0-31.5% of Cr, 7.0-12.0% of Fe, less than 2.5% of Nb, less than 0.30% of Cu, less than 0.50% of Al, less than 0.50% of Ti, and the balance nickel. The Mn and Nb added NiCrFe alloy surfacing solder strip for nuclear power can be applicable to a submerged arc overlay welding process and an electroslag surfacing process and can also be applicable to manufacturing of key components of a nuclear island of a nuclear power plant by being matched with corresponding soldering flux, the Mn element and the Nb element are added in the solder strip and improve the performance of resistance to high temperature plasticity-losing cracks of surfacing deposited metal, the surfacing deposited metal has high crystallization crack resistance and stress corrosion cracking resistance, the excellent corrosion resistance is achieved and integrated mechanical performance is good. By being matched with the soldering flux for surfacing, a weld pass is attractive in formation, corrugations are compact, deslagging is easy and welding defects are avoided.

Owner:HARBIN WELDING INST LTD +2

Application of laser weld in ultra-high tensile steel welding and welding method

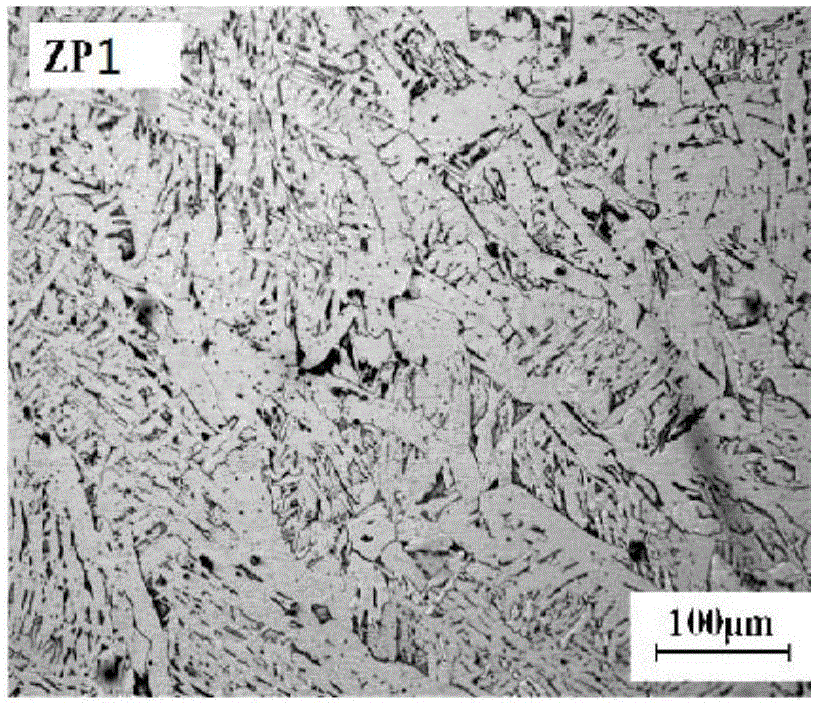

InactiveCN101284334ASimple security protectionImprove polarization performanceLaser beam welding apparatusEngineeringSand-paper

The invention discloses the application of laser welding on Unimach and a welding method thereof, which comprises the steps of cutting a Unimach welded sample cut by adopting a molybdenum wire; polishing the welding joint of the sample with metallographical sand paper before welding; removing rust and chips; cleaning with acetone; and adopting a CO2 laser for laser welding. Compared with prior art, the method adopts the laser for welding the Unimach without the need of gas shielding, and penetration welding with welding thickness of 1mm results in good welding effect. The welding joint is smooth and fine macroscopically, without cracks or holes generated. The microstructure analysis and the stretching fracture analysis show that the welding joint is free of welding defects, impurities and pores, and has good fusion, thus greatly improving the anti-cracking performance of the Unimach welding joint.

Owner:GUIZHOU UNIV

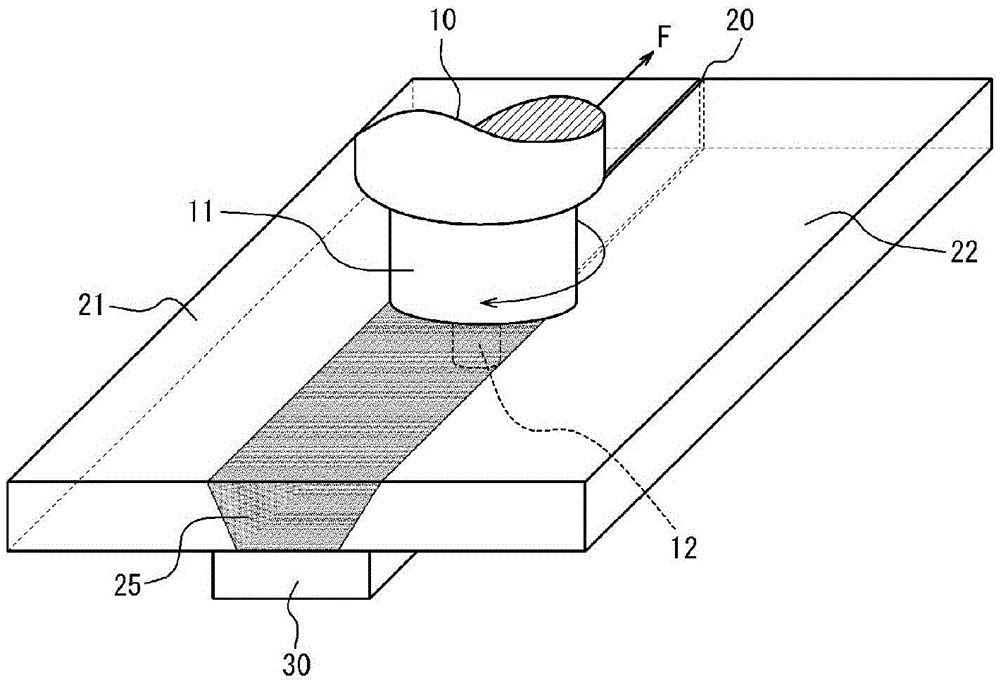

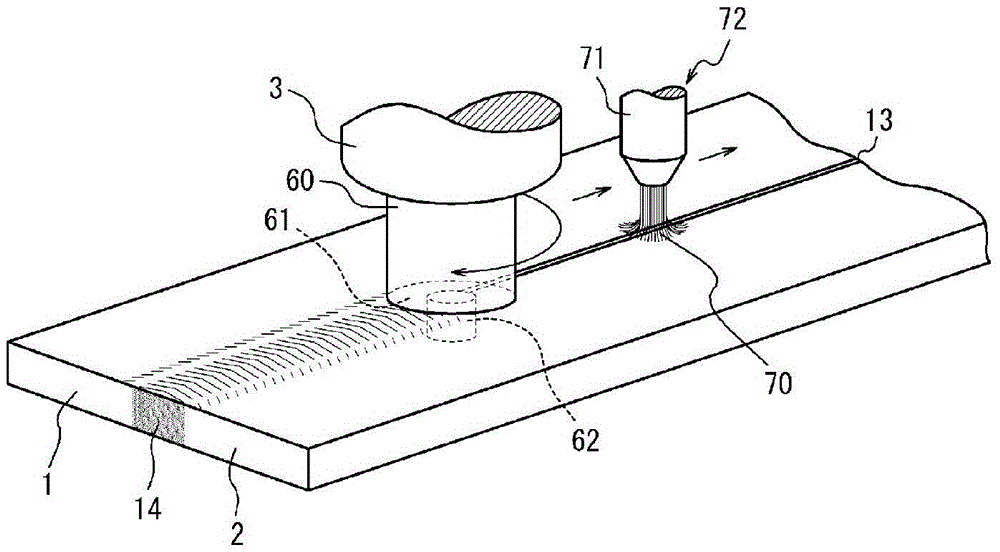

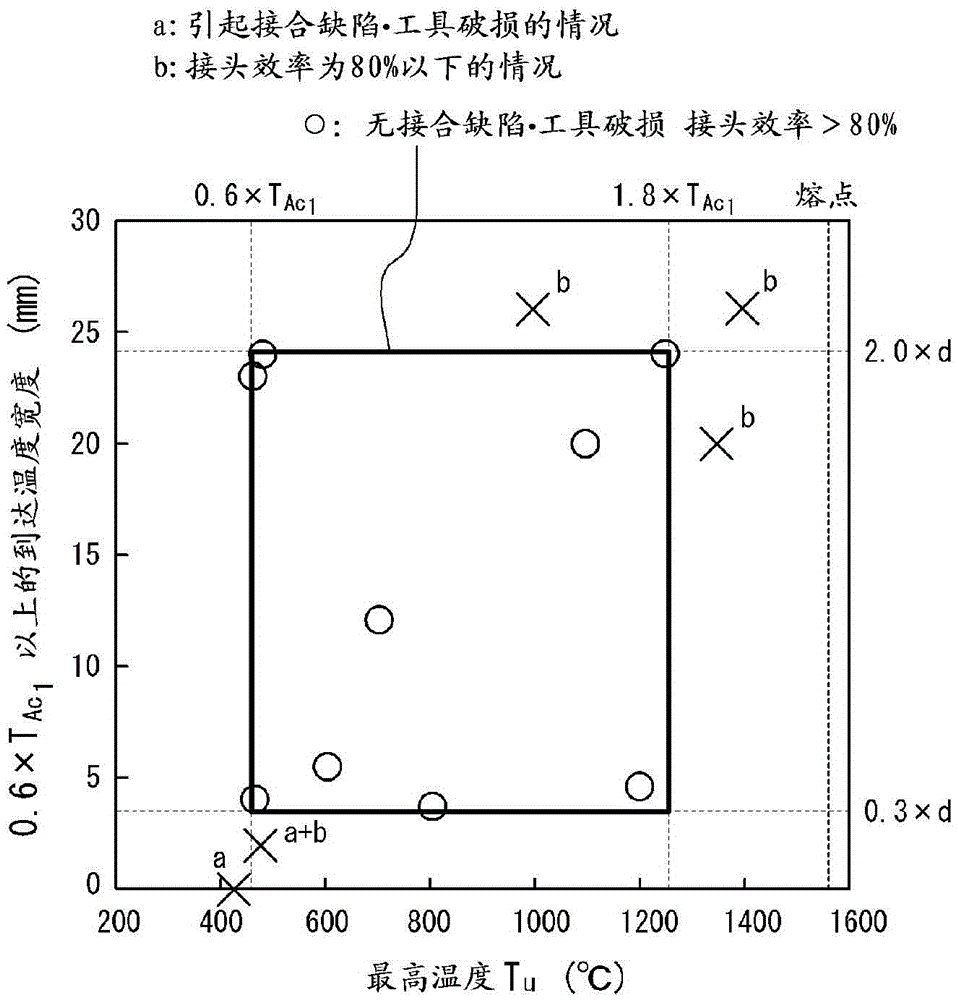

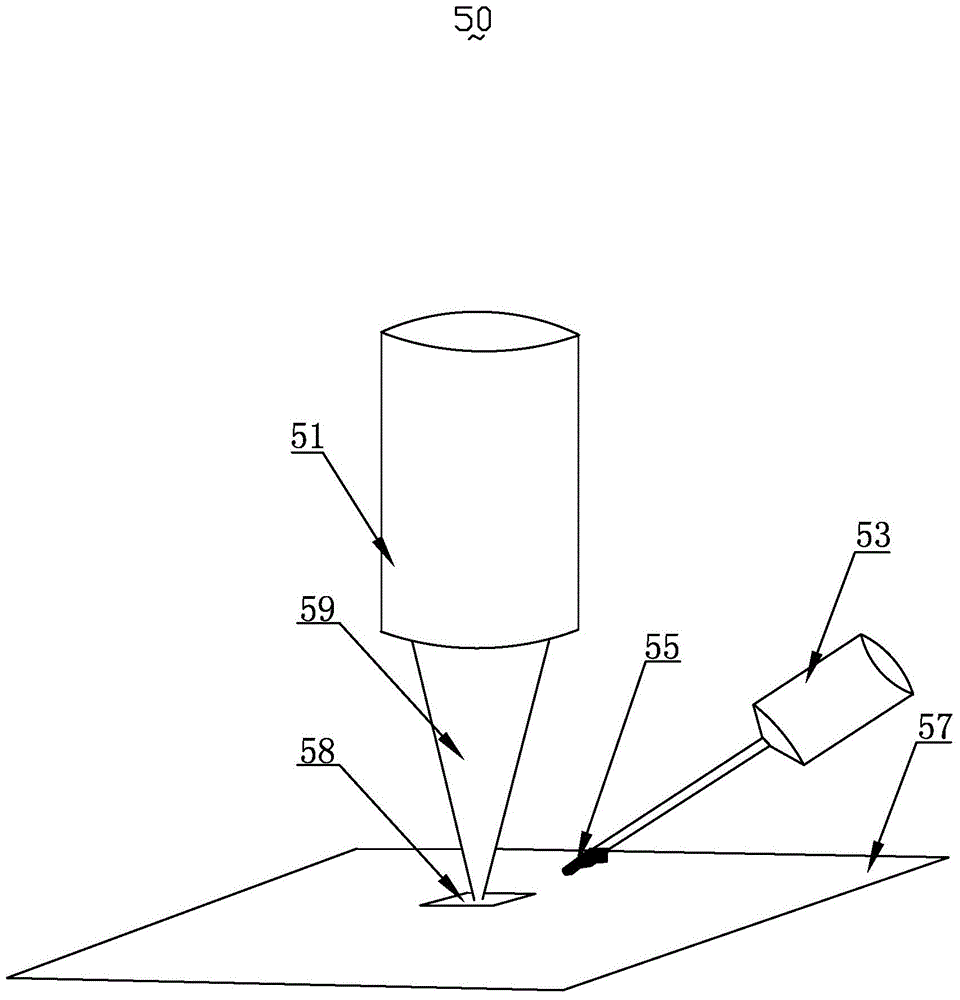

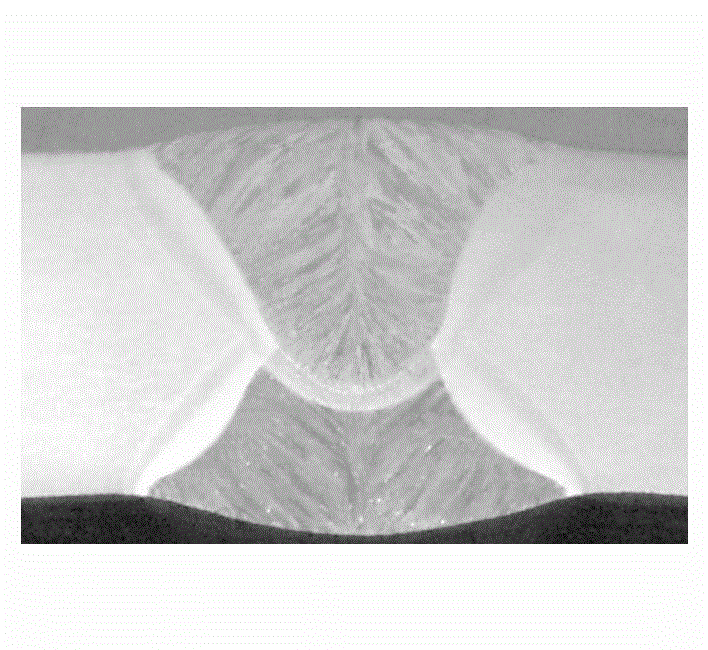

Friction stir welding method for steel sheets and method of manufacturing joint

ActiveCN105579183AQuick engagementNo welding defectsIncreasing energy efficiencyFurnace typesSheet steelEngineering

A friction stir welding method for joining steel sheets to one another, wherein a heating device (4) positioned to the front in the direction of travel of a rotating tool pre-heats a section to be joined prior to joining thereof by the rotating tool (10), and when doing so, the surface temperature distribution in the direction perpendicular to the direction of travel at the position at which the joining by the rotating tool (10) starts is set in a manner such that given that TAc1 serves as the Ac1 point of a steel sheet, then the maximum temperature (TU) is in the range of 0.6*TAc1<TU<1.8*TAc1, and given that L is the width of the heating region above temperature (TL)=0.6*TAc1, then the relationship 0.3*d<=L<=2.0*d is satisfied for the shoulder section diameter (d). As a result, it is possible to improve joint strength while operating at a high joining speed, without any risk of joining failures or joining-tool breakage, and without any risk of temper softening or embrittlement from curing in the heat-affected areas.

Owner:JFE STEEL CORP

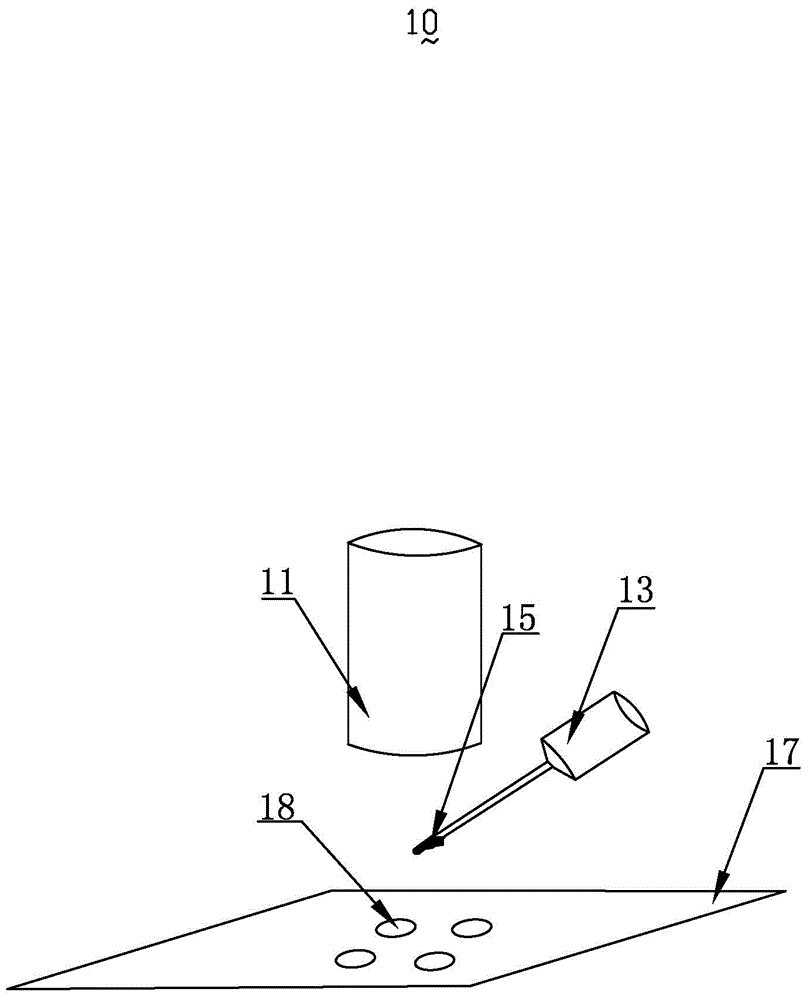

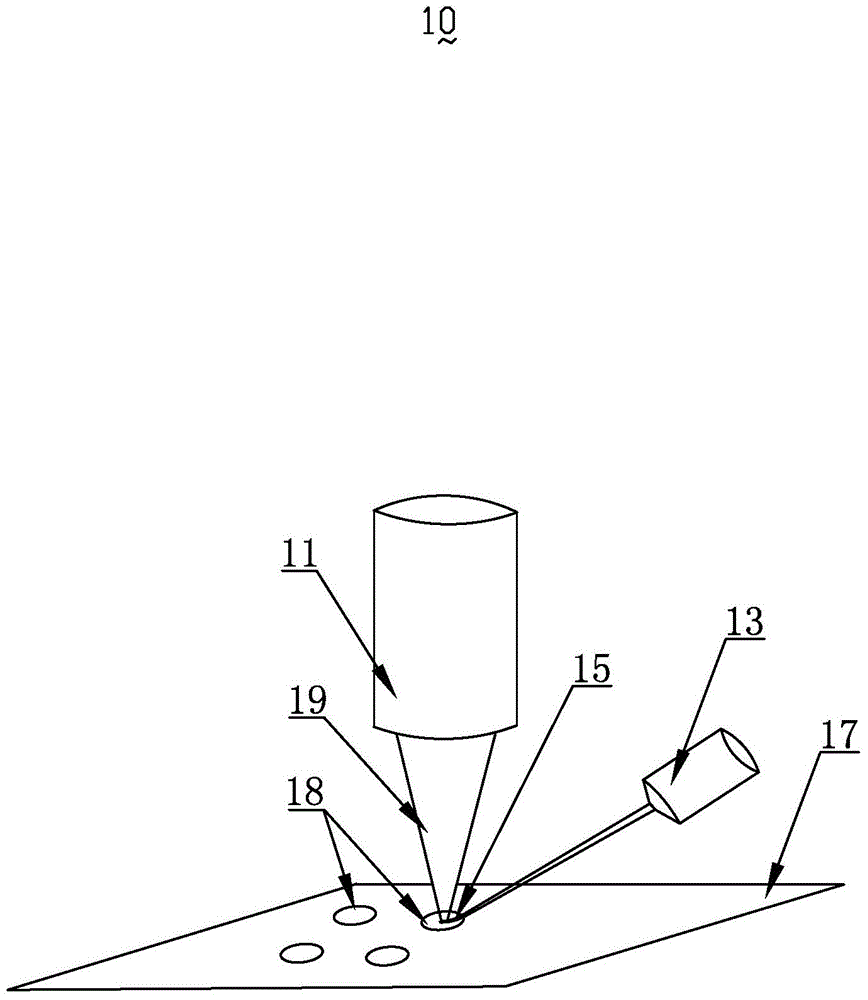

Laser welding method

InactiveCN104439587AImprove laser absorption rateHigh temperature toleranceSoldering apparatusLaser beam welding apparatusControl equipmentLaser

The invention provides a laser welding method. According to the method, a laser welding machine and a circuit board to be welded are provided, a plurality of bonding pads to be welded are arranged on the circuit board, the laser welding machine comprises a focusing head and a tin feeding head, the tin feeding head comprises a tin feeding end, the tin feeding end can feed a tin wire continuously, the tin feeding head is located between the focusing head and the bonding pads, before high-power light of the focusing head exits or while high-power light exits, a section of the tin wire is fed by the tin feeding head, and the tin wire, the focusing head and the bonding pads are located on the same straight line. According to the laser welding method, the welding speed is high, the welding precision is high, the requirement for control equipment is not high, the production cost is low, stability is improved greatly, and the laser welding method has high market value.

Owner:深圳云麟科技有限公司

Flux-cored wire for welding rotary cutter edge and method thereof

InactiveCN101406999AImprove wear resistanceImprove toughnessWelding/cutting media/materialsSoldering mediaEdge surfaceSteel belt

The invention provides a flux-cored wire for welding a circular shear edge. The flux-cored wire has a steel belt as an outer skin, wherein the flux core comprises the following components in weight percentage: 0.15 to 0.40 percent of C, 0.50 to 2.00 percent of Si, 0.30 to 2.00 percent of Mn, 4.00 to 7.00 percent of Cr, 0.50 to 2.50 percent of Mo, 1.00 to 3.50 percent of W, 0.20 to 1.00 percent of V, 0.20 to 1.00 percent of Ni, 0 to 0.03 percent of S, 0 to 0.03 percent of P and the balance being iron. When the flux-cored wire is used for the constant temperature surfacing welding, the interlayer temperature of circular shear edge surfacing welding is kept to be between 300 and 350 DEG C.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

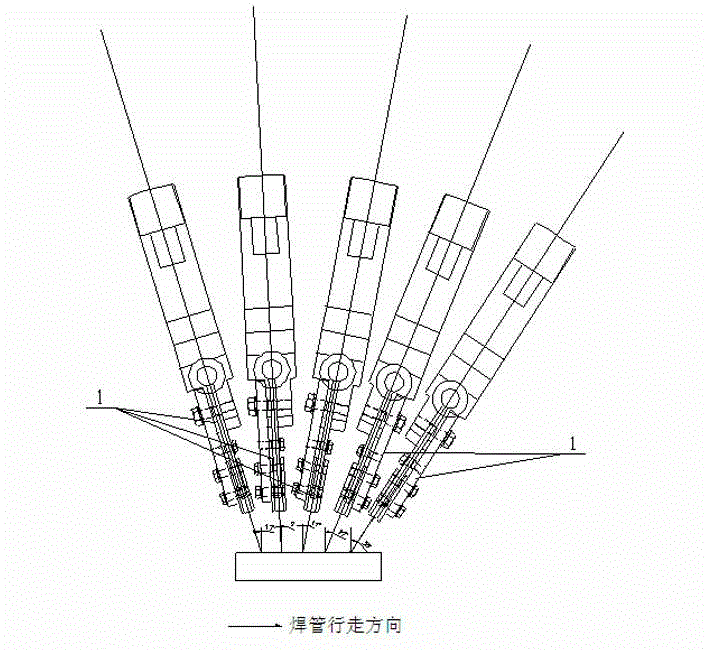

Automatic five-wire submerged arc welding method for thick-wall welded pipes

InactiveCN102744505AImprove productivitySmall heat affected zoneArc welding apparatusSteel tubeSubmerged arc welding

The invention discloses an automatic five-wire submerged arc welding method for thick-wall welded pipes. The automatic five-wire submerged arc welding method uses five welding wires. The welding inclination angles of the five welding wires along the travelling directions of the welded pipes are arranged from forward inclination to backward inclination sequentially. Therefore, the root of a welding pass of a weldment can be welded thoroughly, welding forming is achieved at one time, excess welding defects can be avoided, productivity is high, heat affected zone is small, and welding metal structure is uniform. The automatic five-wire submerged arc welding method for the thick-wall welded pipes can be widely applied to mass longitudinally submerged arc welding of steel pipes.

Owner:上海中油天宝巴圣钢管有限公司

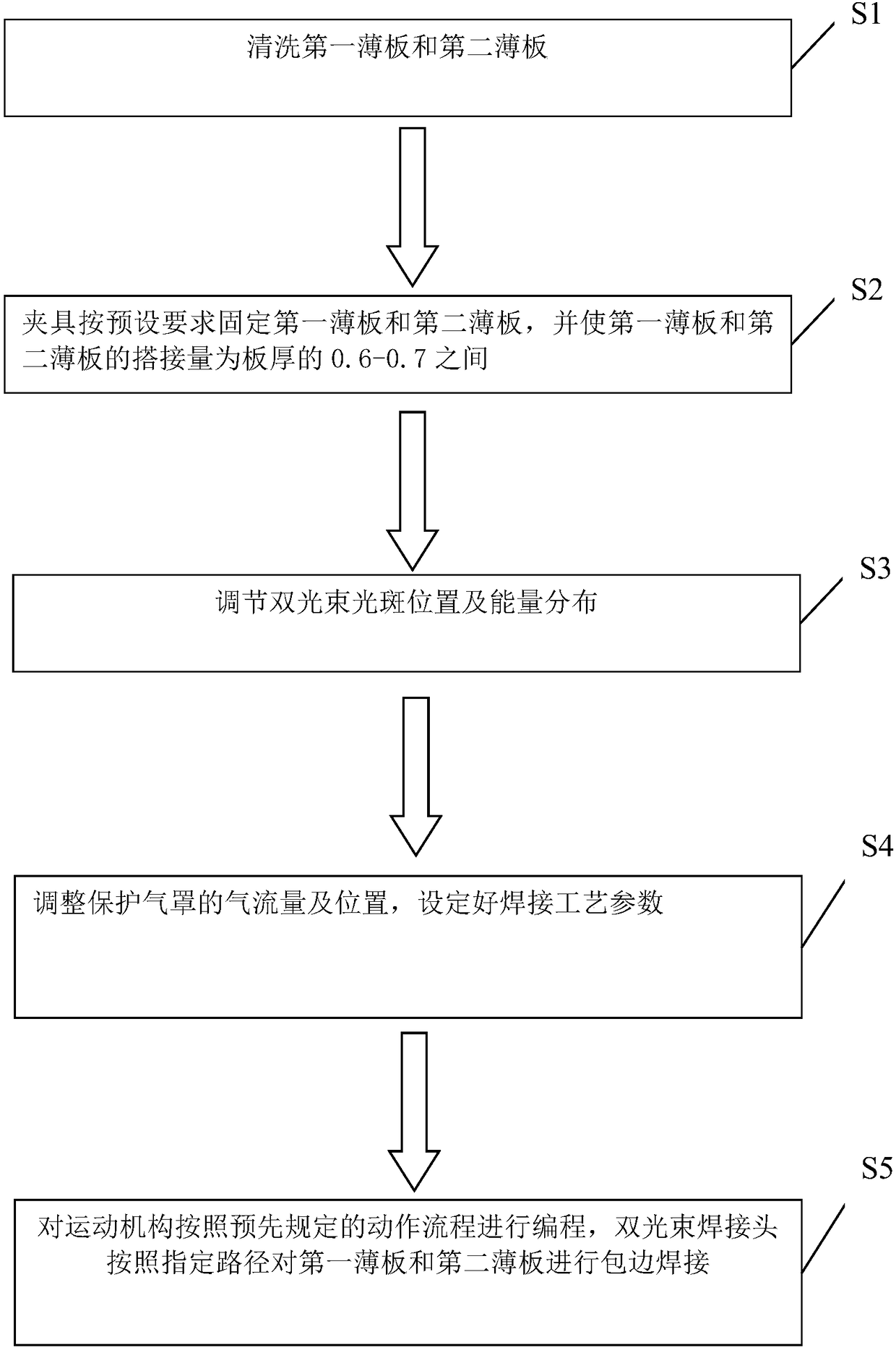

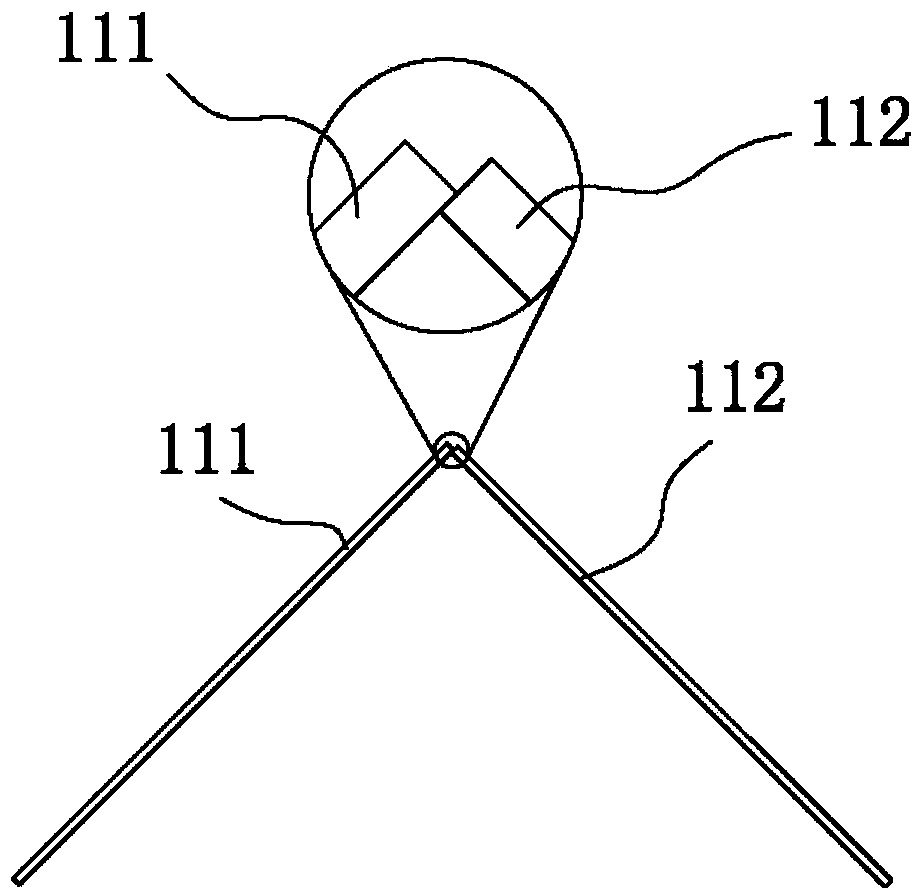

Double-beam laser welding machine and welding method thereof

ActiveCN108274121AAvoid Welding DefectsPrevent oxidationWelding/cutting auxillary devicesAuxillary welding devicesShielding gasLight beam

The invention provides a double-beam laser welding machine and a welding method thereof. The double-beam laser welding machine is used for carrying out binding welding on a first thin plate and a second thin plate. The double-beam laser welding machine comprises a fixture for the first thin plate and the second thin plate, a double-beam welding head which emits a first light spot and a second light spot, and a multifunctional gas hood which is located above the first thin plate and the second thin plate; and during welding, the first light spot and the second light spot are correspondingly distributed on the first thin plate and the second thin plate in parallel. Through selection on a laser light source and control on a double-beam light spot, the stability of a welding effect can be ensured effectively; through selection on the air supply mode of shielding gas and the gas, welding joint surface oxidization can be prevented effectively; through accurate control on technological parameters, the uniformity of weld penetration can be ensured; and by using the welding method, a thin plate binding welding joint can be a high-quality welding joint having the advantages of surface transition smoothness, no oxidization, and no welding defect.

Owner:HANS LASER TECH IND GRP CO LTD +1

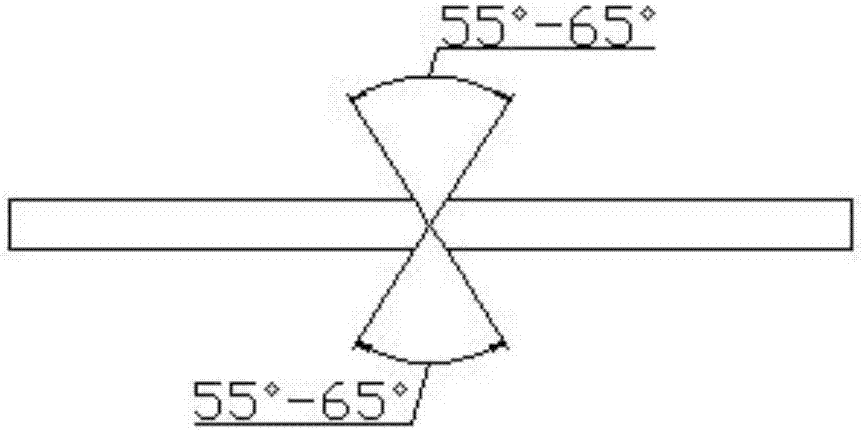

High-heat-input double-wire submerged-arc efficient welding method

InactiveCN108856992AAvoid welding throughEffective penetrationArc welding apparatusWelding/cutting media/materialsWeld seamSlow cooling

The invention discloses a high-heat-input double-wire submerged-arc efficient welding method. The high-heat-input double-wire submerged-arc efficient welding method includes technological steps of S1,adopting X-shaped grooves; S2, adopting special high-heat-input submerged-arc sintered welding flux and baking the special high-heat-input submerged-arc sintered welding flux; S3, carrying out preheating until the temperatures reach 100-150 DEG C and the interlayer temperatures reach 100-200 DEG C; S4, welding front surfaces under the condition of backing heat input lower than 80 KJ / cm and carrying out filling and cover surface welding under the condition of heat input of 80-120 KJ / cm; S5, directly thoroughly welding reverse surfaces by the aid of high currents without gouging under the condition of heat input of 100-150 KJ / cm; S6, carrying out post-weld slow cooling. The high-heat-input double-wire submerged-arc efficient welding method has the advantages that the high-heat-input double-wire submerged-arc efficient welding method with the high heat input of 80-150 KJ / cm is high in welding efficiency and little in welding deformation, weld seams are free of defects, and welded connectors are excellent in mechanical performance; particularly, the welded connectors are good in low-temperature impact toughness, and low-temperature impact energy of the welded connectors at the temperatures of -40 DEG C is higher than 100 J.

Owner:CHINA MERCHANTS HEAVY IND JIANGSU

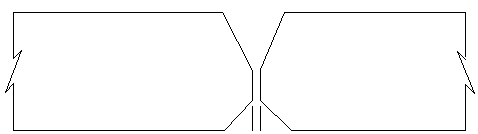

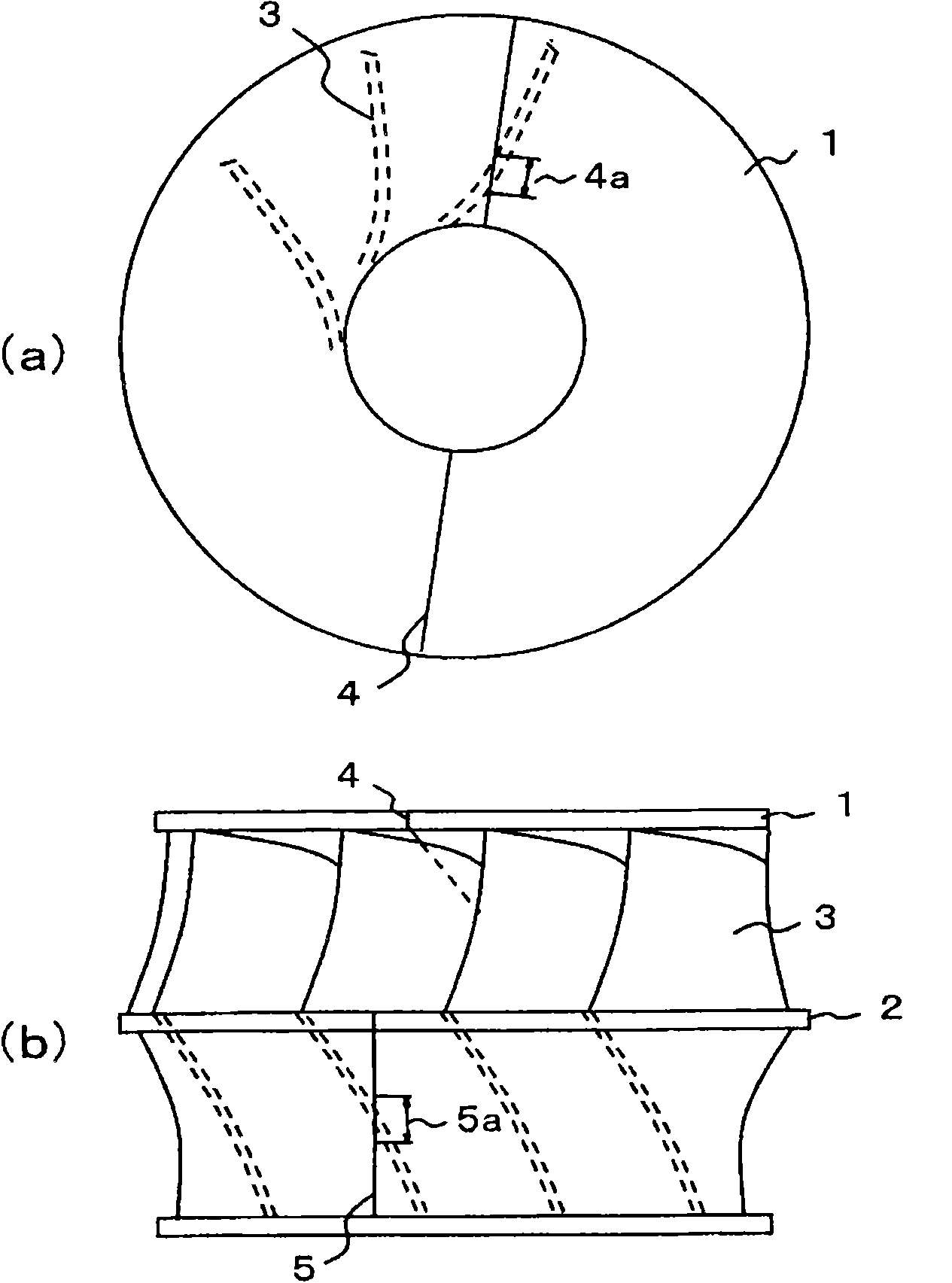

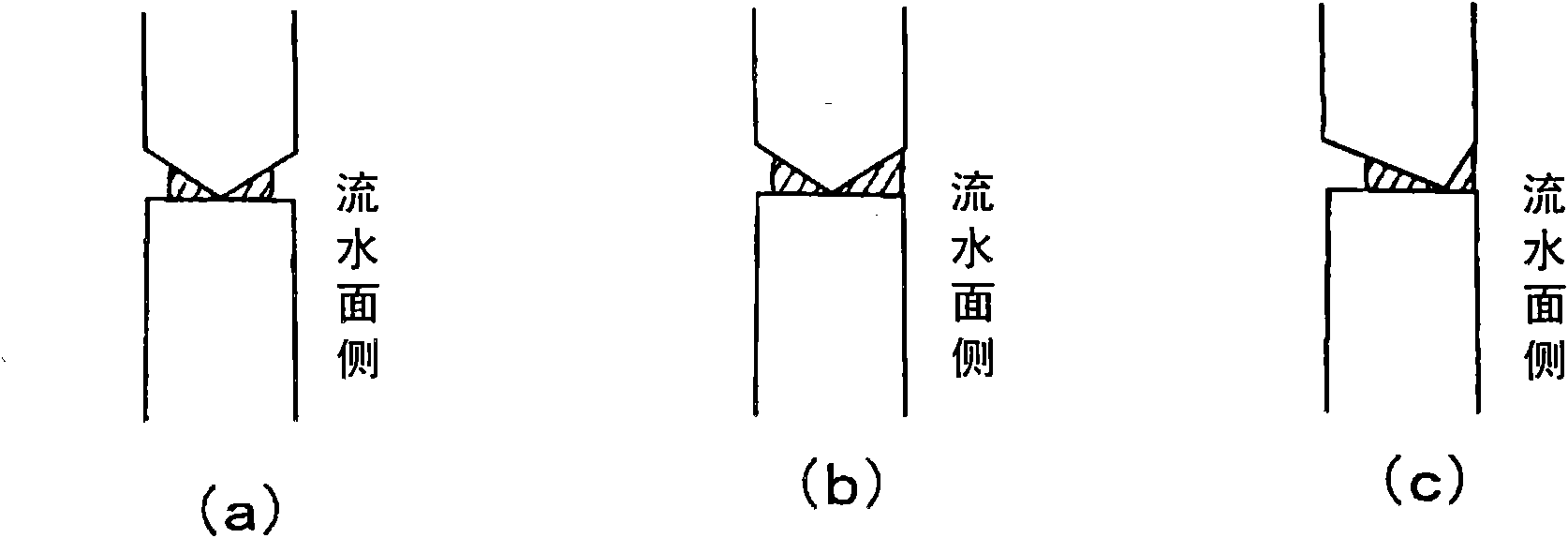

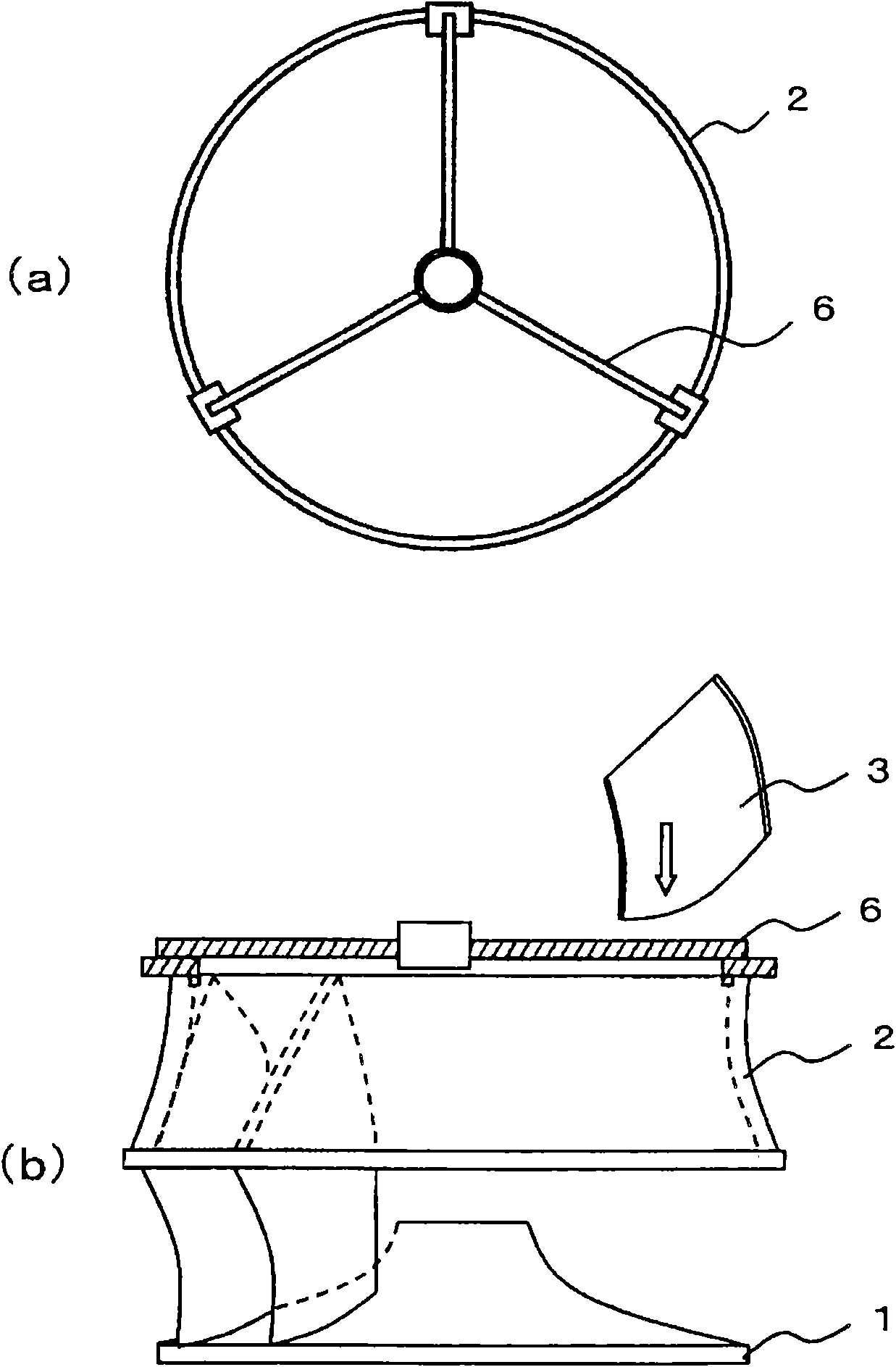

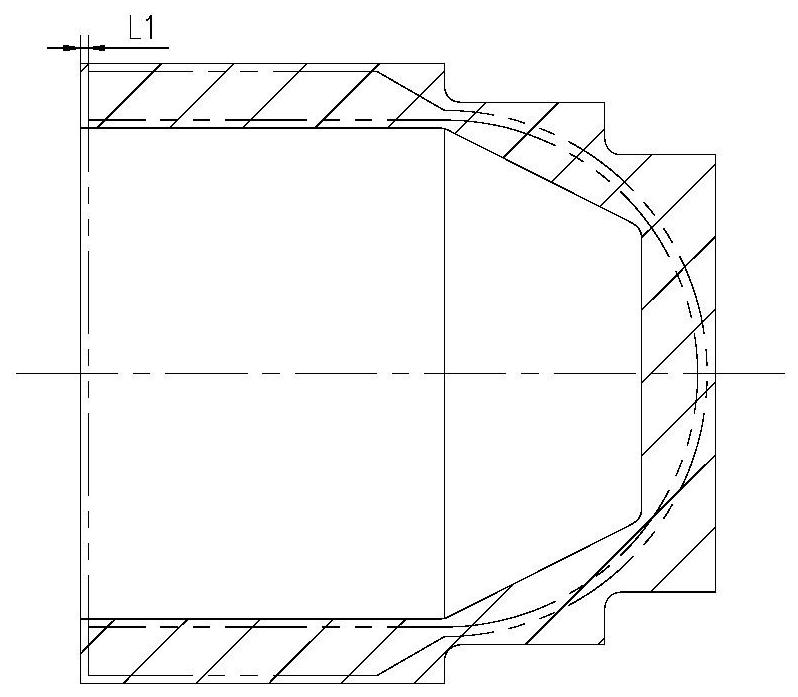

Assembling method of upper canopy or lower ring and assembling method of runner

ActiveCN101865068AAvoid deformationNo welding defectsEngine manufactureFinal product manufactureSplit linesEngineering

The present invention provides an assembling method of upper canopy or lower ring of Francis runner, which restrains welding deformation for preventing large-scale machining and welding defect while the upper canopy or lower ring that are divided into a plurality of members for integrally welding. Particularly, the assembling method of the lower ring (2) of a runner composed of the upper canopy (1), the lower ring (2) and blades (3) in a Francis hydraulic turbine or Francis pump-turbine comprises the following steps: a temporary welding step of performing welding with a welding quantity less than the welding quantity of full groove area of dividing line section and performing surfacing welding next to the crossed part of the blades (3) to a water surface; and a step of grinding and shaping the welding part at the periphery (5a) of the crossed part to the water surface. The upper canopy is assembled similarly.

Owner:KK TOSHIBA

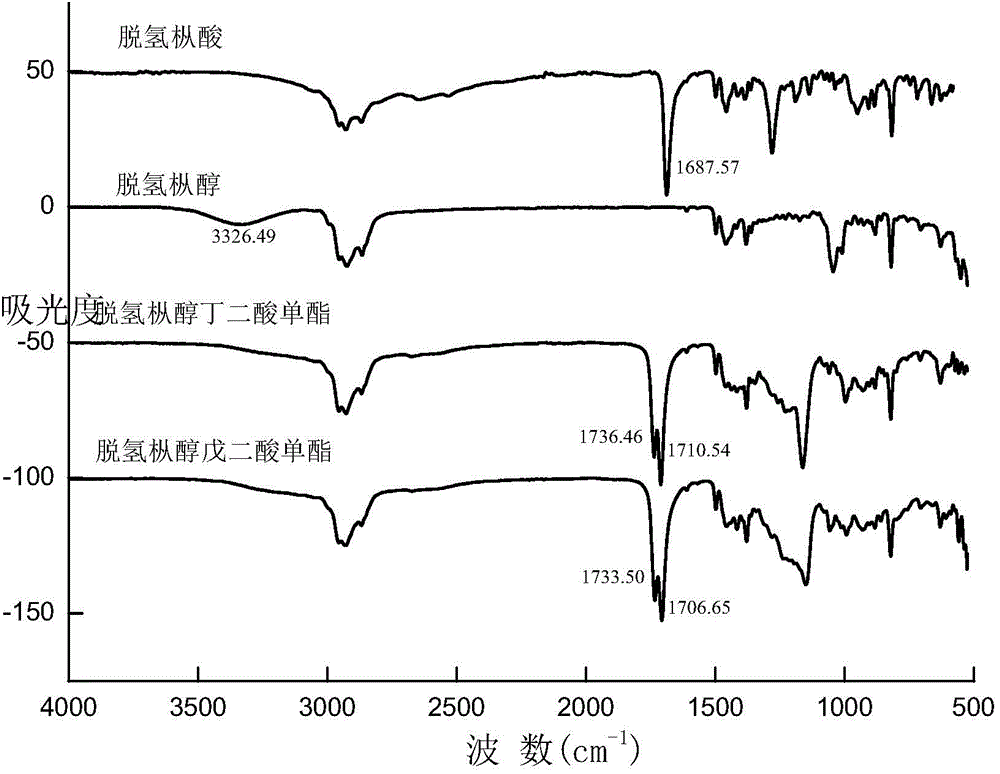

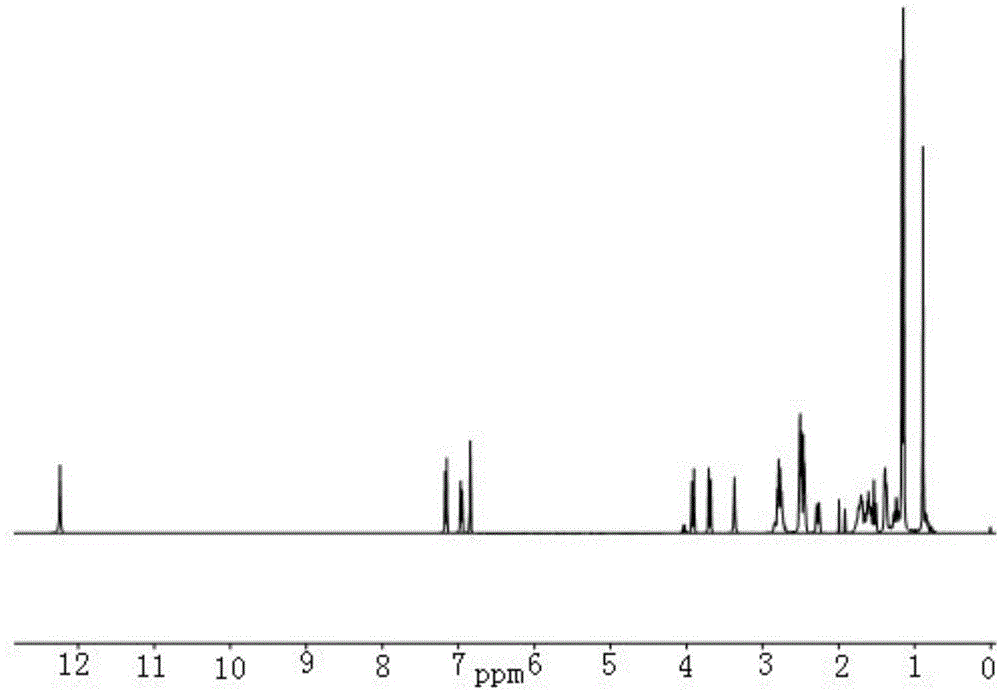

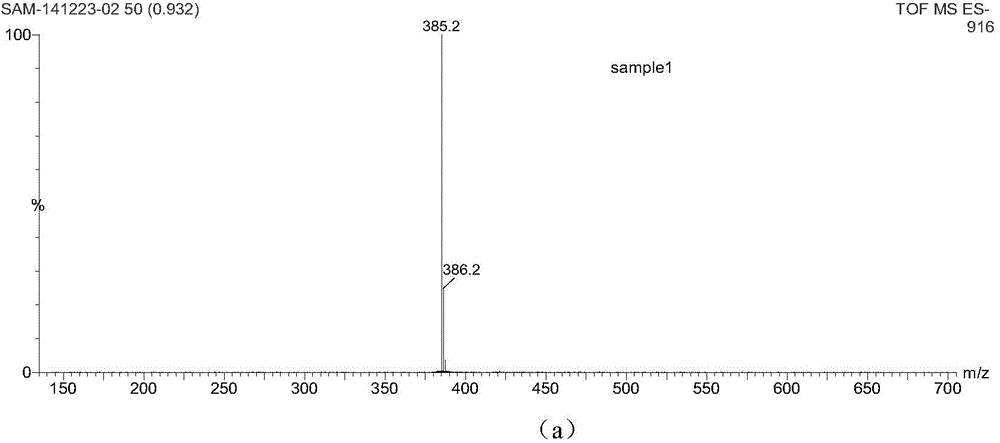

Rosin derivate for soldering flux and preparation method

ActiveCN104610053AImprove solubilityGood film formingOrganic compound preparationCarboxylic acid esters preparationSolubilityHalogen

The invention discloses a rosin derivate for soldering flux and a preparation method. The molecular structural formula of the rosin derivate for soldering flux sees the specification, wherein n is 3 or 4. The rosin derivate for soldering flux has a good solubleness with a solvent, and is free of crystallizing, high in film-forming property, outstanding in heat stability, high in performance for wetting lead-free solder, and high in soldering flux activity; when in use, a halogen activator is not needed to be added; the thermal stability is high, and degrading and carbonizing at high temperature can be avoided; the mobility and heat conductivity at high temperature are high; the formed welding points are regular and free of bubble, concave pits and other poor welding phenomena; in addition, the corrosion after welding is small; the preparation cost is low, and no pollution is generated.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

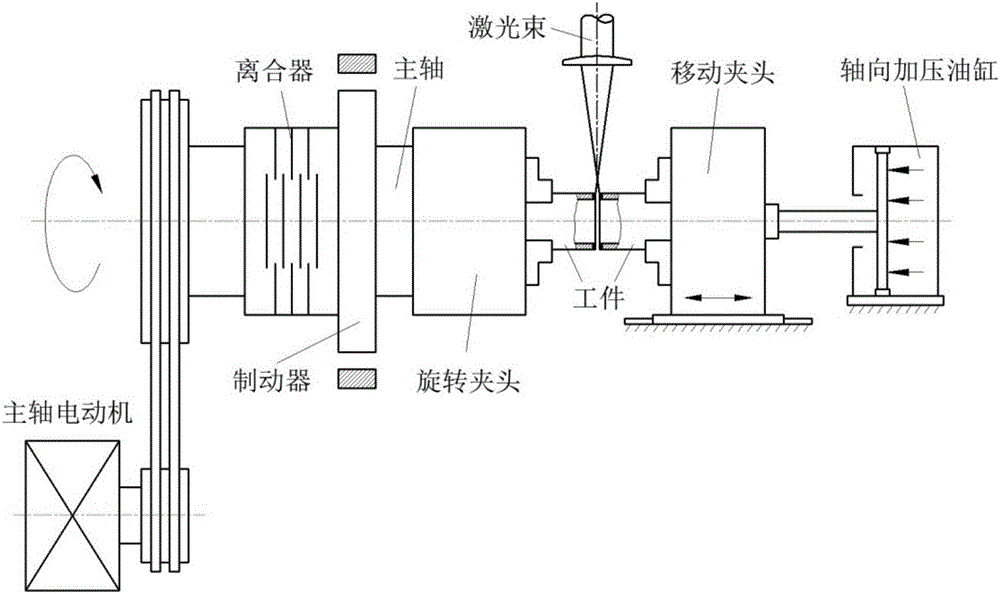

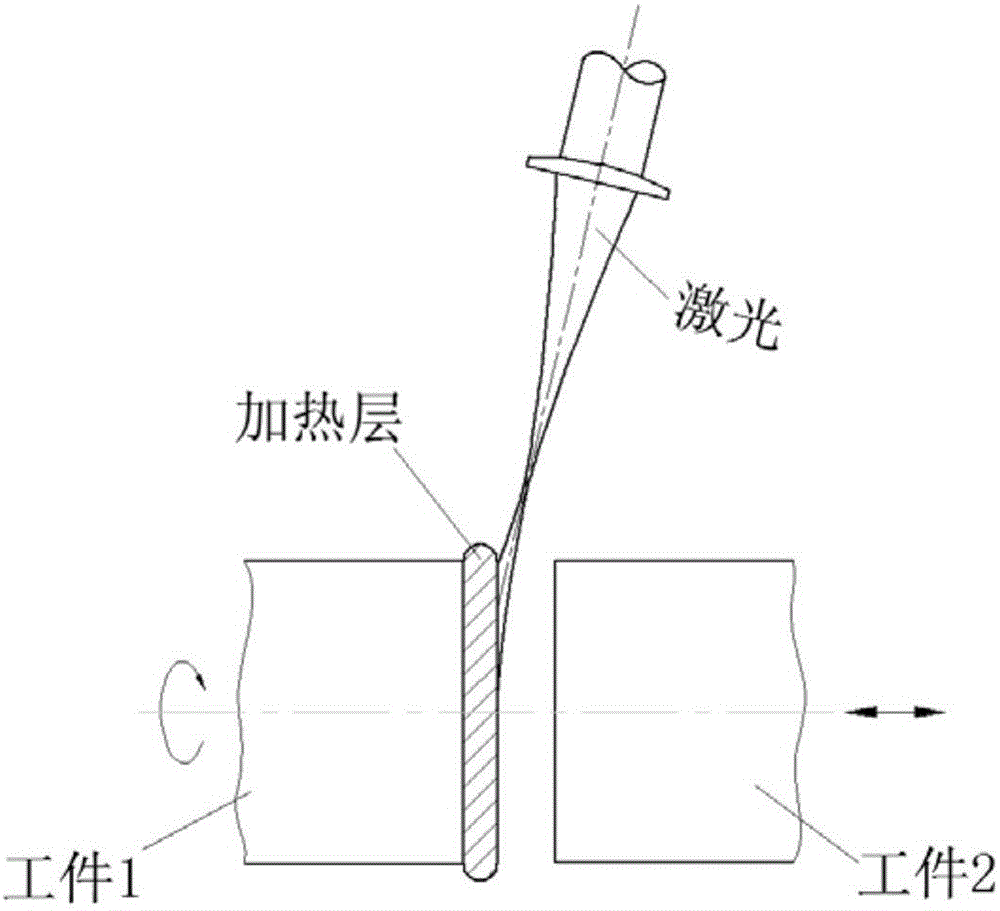

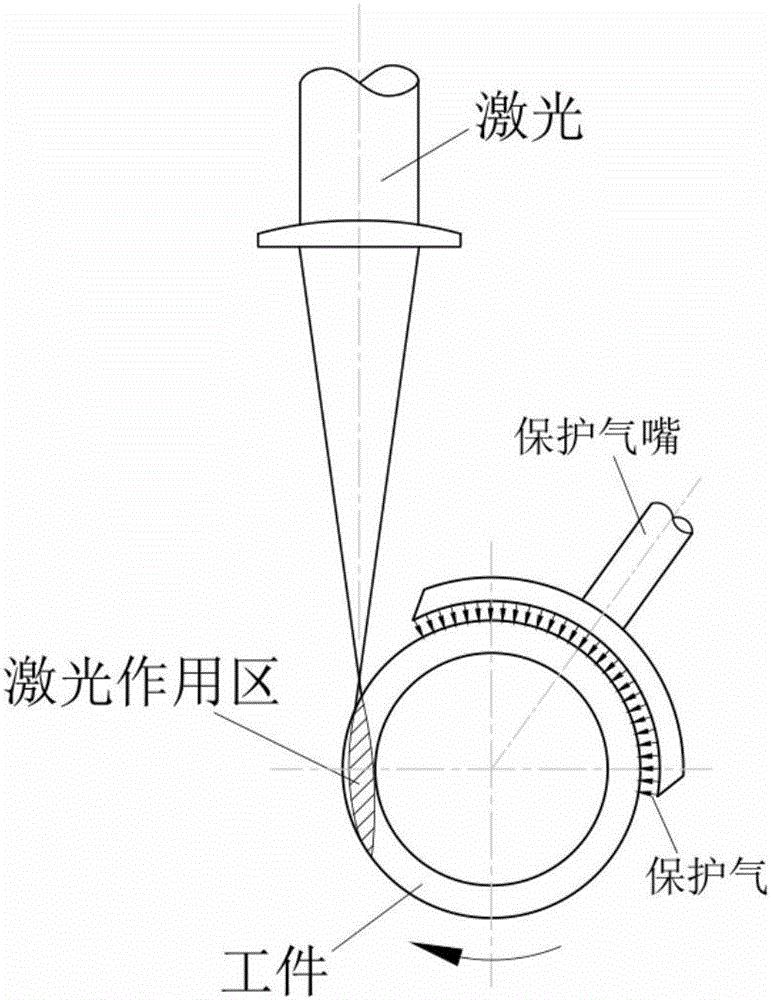

Friction welding heating method by using laser

ActiveCN106808095AReduce coefficient of frictionFast heat dissipationWelding apparatusLaser energy densityPlastic property

The invention relates to the field offriction welding, and provides a friction welding heating method by using laser. Particularly, before welding, end faces of work piecesare radiated by the laser, so as to make the surface layer in ahigh temperature or micro melting state, then friction and upsetting process are conducted swiftly, so as to extrude liquid metals and parts of thermoplastic metals, finally the connection is formed through diffusion and recrystallization. According to the method, the unique advantages of highdensity of laser energy, precise and controllable airspace and time domain, and the characteristics of good quality of friction welding joint and high production efficiency and the like are synthetically utilized. The method has the advantages that external input energy is used as a main energy source; the required pressure and torque of friction welding are greatly decreased; the requirementfora welding equipment is reduced; processing ranges of traditional friction welding are expanded: the heterogenetic materials with big difference in physical and chemical characteristics, workpieces with small stiffness, thin walls and minor diameters, and workpieces with low friction coefficient, with-surface layer, high temperature and strength are welded.

Owner:BEIJING UNIV OF TECH

Solid flux for automatic soldering of soldering tin and preparation method thereof

InactiveCN106271222AThe preparation method is simple and reasonableLow costWelding/cutting media/materialsSoldering mediaIonSolvent

The invention discloses a solid flux for automatic soldering of soldering tin, prepared from the following components by weight percent: 80-86% of deionized water, 4.5-10% of co-solvents, 4-7% of active agents, 0.4-1.2% of nonionic surfactants, 0.9-1.4% of film-forming agents and 0.2-0.4% of corrosion inhibitors. The active agents are prepared from the following components: 0.3-0.7% of 2-hydroxypropanoic acid, 0.7-1.3% of 1,2-ethane dicarboxylic acid, 0.4-0.8% of 1,3-acetone dicarboxylic acid, 0.6-1% of undecanedioic acid, 0.5-0.8% of malonic acid, 1-1.8% of polyethylene glycol PEG-200 and 0.5-1% of succinimide. Compared with the prior art, the solid flux is a water-based flux used for solving problems of no continuous soldering or pinholes of tin soldering of precision circuit boards, has the advantages of good soldering firmness, environmental protection performance and safety, high activity, excellent wettability, low corrosion and low cost, is simple and convenient to prepare, can be operated at room temperature, has low requirements for equipment and has a good application prospect.

Owner:THOUSAND ISLAND METAL FOIL

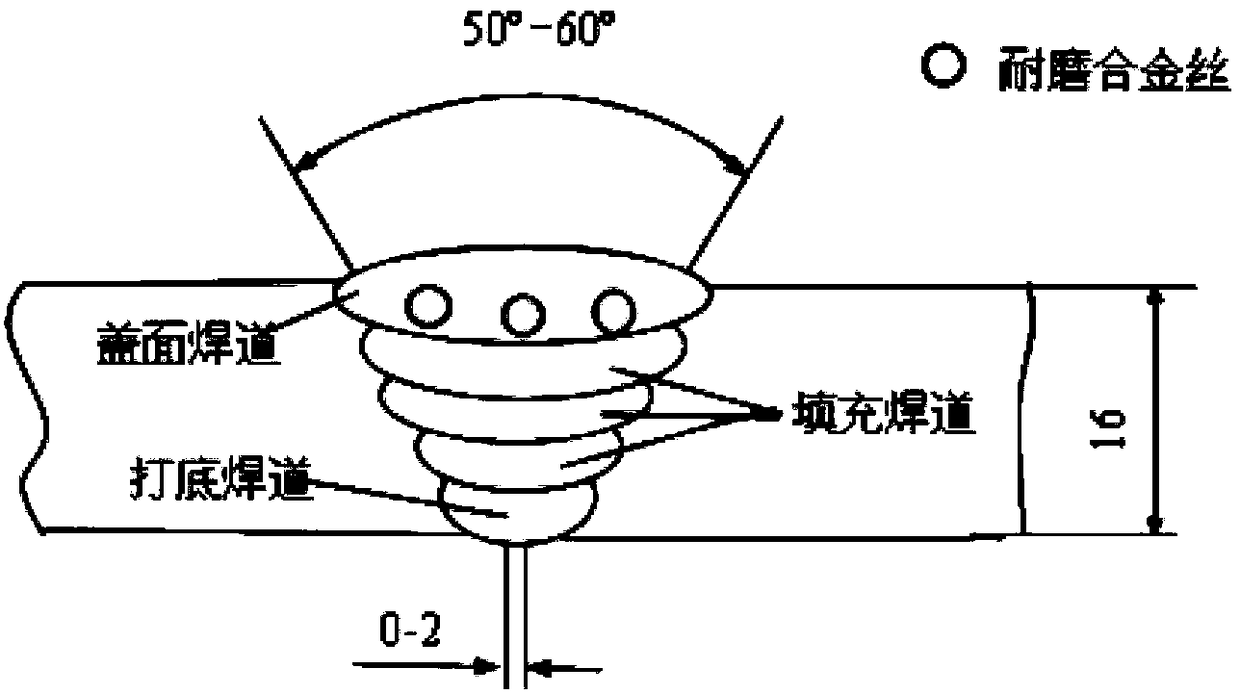

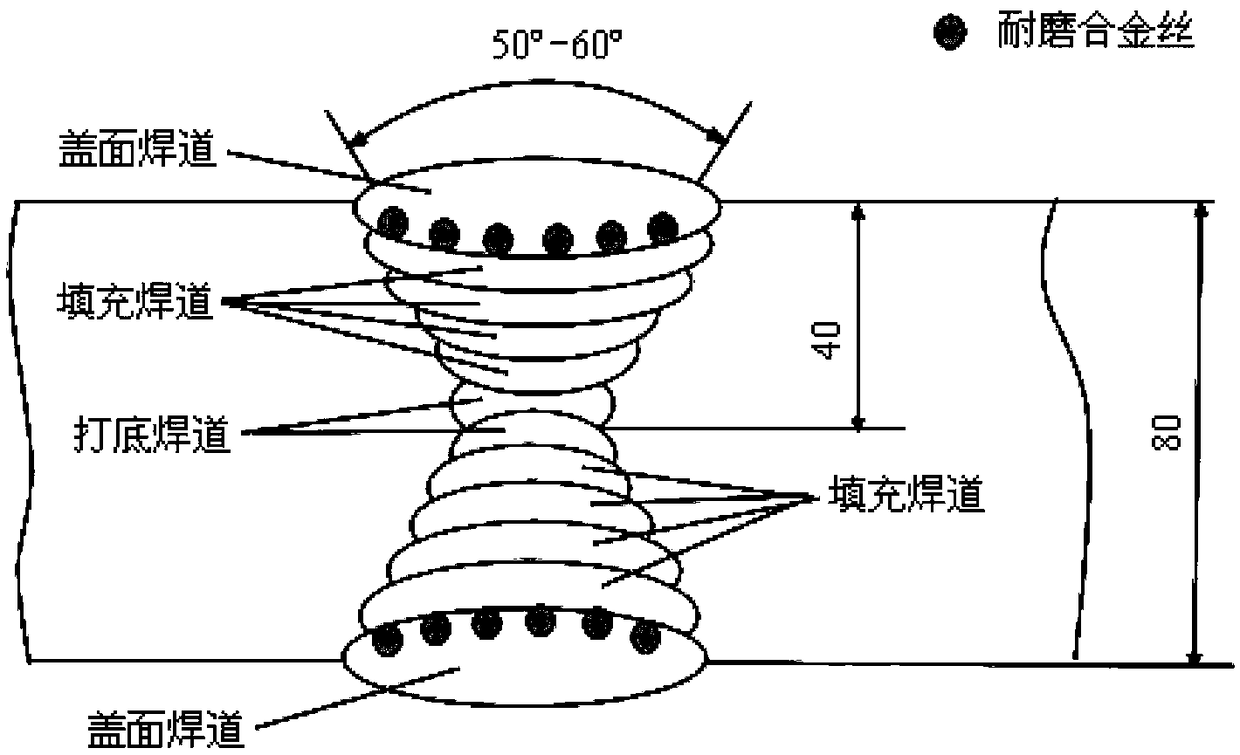

Welding method for increasing surface hardness of capping bead of wear resistant steel plate

ActiveCN109158739AImprove toughnessImprove mechanical propertiesArc welding apparatusWelding/cutting media/materialsWear resistantWeld seam

The invention discloses a welding method for increasing the surface hardness of a capping bead of a wear resistant steel plate. A high-strength wear resistant steel plate of which the hardness grade is HB360 to HB450 is adopted, the thickness of the high-strength wear resistant steel plate is 16 to 80 mm, a welding wire ER69-G of which the tensile strength Rm is greater than or equal to 690 MPa and argon-rich mixed gas shielded welding are adopted to perform backing welding and filling welding on the interior of a weld groove of a wear resistant steel member, when the capping bead is welded, awear resistant alloy wire is added into the groove, then the capping bead is welded, the fusion of a welded joint is good, and no welding defect exists in the welding seam junction of a capping layerand a packing layer. The welding wire does not need to be replaced in a welding process, only the wear resistant alloy wire is added when a welding seam of the capping layer is welded, and the manufacturing process is relatively simple. According to the process measure, the welded joint of the wear resistant steel member has good comprehensive mechanical properties, and the wear resistant alloy wire is added to the capping bead, so that the hardness of the capping bead reaches more than HRC35, the surface weld metal has high wear resistance, the wear resistant steel member is prevented from failing due to the wear of the welding seam, and the service life of the product is prolonged.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

Lead-free low-temperature solder and preparation method thereof

InactiveCN107877031AImprove liquidityImprove wettabilityWelding/cutting media/materialsSoldering mediaIndiumSlag

The invention belongs to the technical field of solder, and particularly relates to a lead-free low-temperature solder. The solder comprises, by mass, 0.001-58.0% of bismuth, 0.001-1.0% of silver, 0.001-2.0% antimony, 0.001-0.1% of indium, 0.001-0.15% of phosphorus, 0.001-0.08% of germanium, 0.001-0.015% of beryllium, 0.001-0.015% of cerium and the balance tin. Compared with the prior art, when welding is carried out at the temperature of 139DEG C to 200DEG C, little oxidation slag is generated, the surface of a tin furnace can be kept bright basically without oxidation at the temperature, thesolder can not be oxidized within 50 seconds at 200-260 DEG C, so that the welding efficiency is greatly improved, and the damage to electronic components of a PCBA board is reduced; the low-temperature solder is good in oxidation resistance; and in the welding process, compared with a common Sn-Ag-Cu system, the solder has fewer welding defects, the surfaces of welding spots are very light-bright, the welding spots are full, continuous welding does not occur, so that the welding quality is effectively improved, and the solder and the method are environment-friendly and safe.

Owner:THOUSAND ISLAND METAL FOIL

Welding process of longitudinal seam of blast furnace shell

InactiveCN107953043ASimple processImprove work efficiencyWorkpiece edge portionsWelding apparatusWeld seamCarbon dioxide

The invention discloses a welding process of the longitudinal seam of a blast furnace shell. The welding process has the advantages that the welding gun of carbon dioxide arc welding full-function equipment is clamped to an automatic welding machine, the matched welding process is provided, welding cracks on high-strength steel materials can be eliminated effectively, and accordingly the high-quality welding seam and the stable welding structure can be obtained; the requirements of high-strength steel in actual use are sufficiently satisfied; in addition, the welding process is simple to operate, low in cost and investment, capable of satisfying field actual requirements and high in work efficiency.

Owner:ANHUI MA STEEL EQUIP MAINTENANCE CO LTD

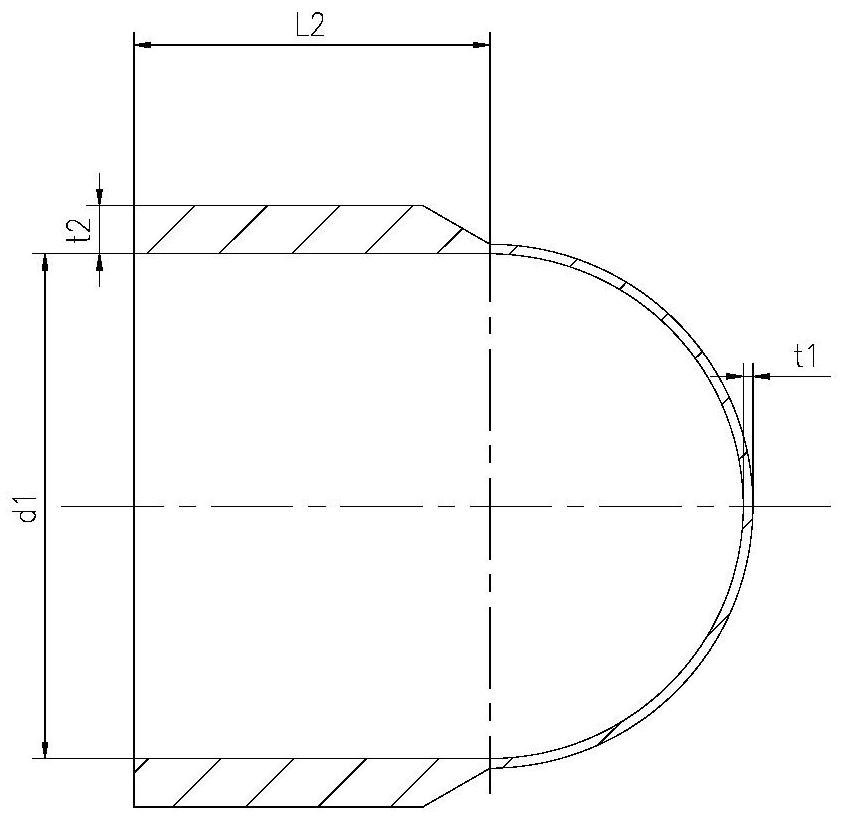

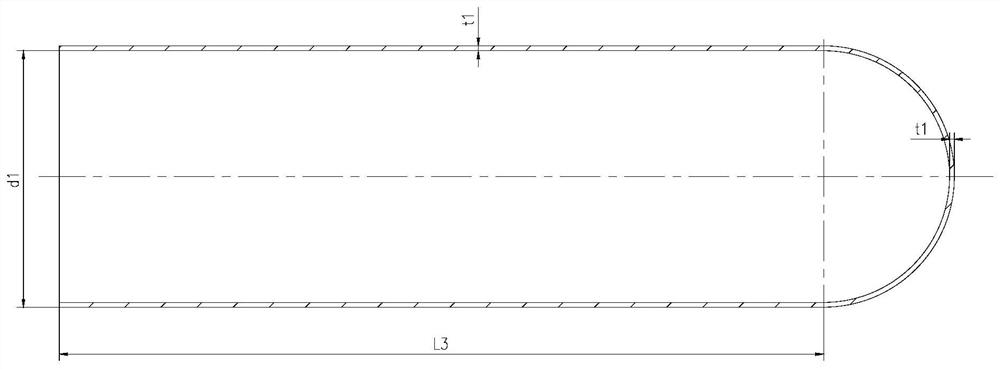

Forming and processing method of titanium alloy high-pressure seamless gas cylinder for ships

ActiveCN112246947AIncrease profitNo welding defectsMetal-working apparatusHollow articlesGas cylinderTitanium alloy

The invention discloses a forming and processing method of a titanium alloy high-pressure seamless gas cylinder for ships. The method comprises the following steps: forging a forging blank at the forging temperature of 800-960 DEG C; performing powerful spinning on the blank to machine a cylinder section at the heating temperature of 550-750 DEG C; performing powerful spinning to form the cylindersection; performing core-mold-free hot spinning to form a head end socket; and performing seamless gas cylinder solid solution, aging heat treatment and bottle opening machining. The product is goodin quality and has no welding defects and bottom end socket incomplete fusion defects of a traditional method; the product is high in reliability and fatigue resistance and long in service life; and the material utilization rate is high, and the manufacturing cost is low.

Owner:湖北三江航天江北机械工程有限公司

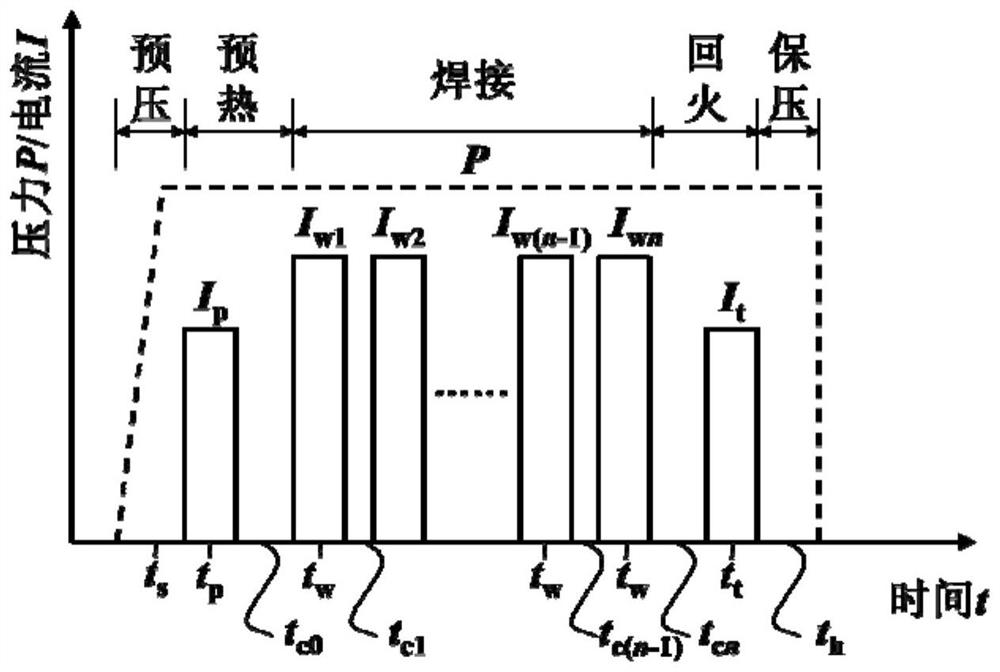

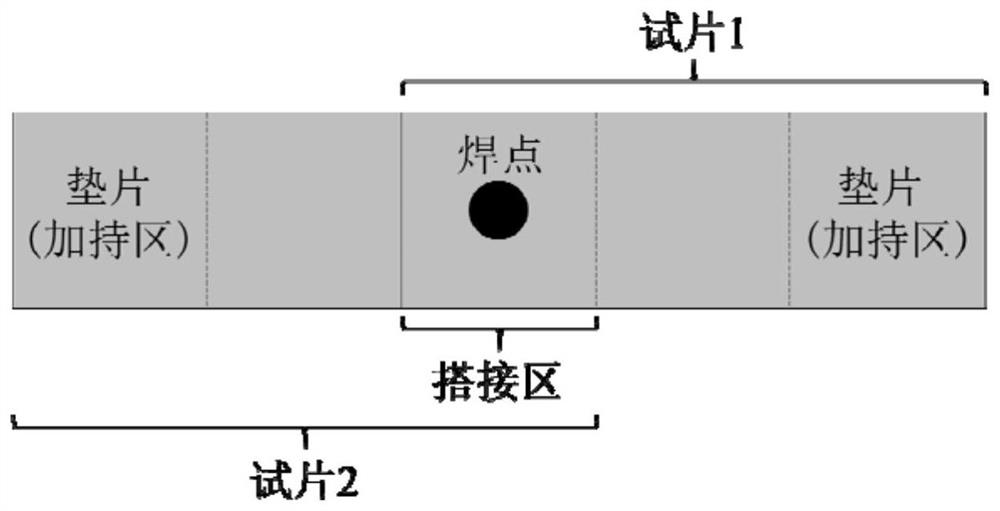

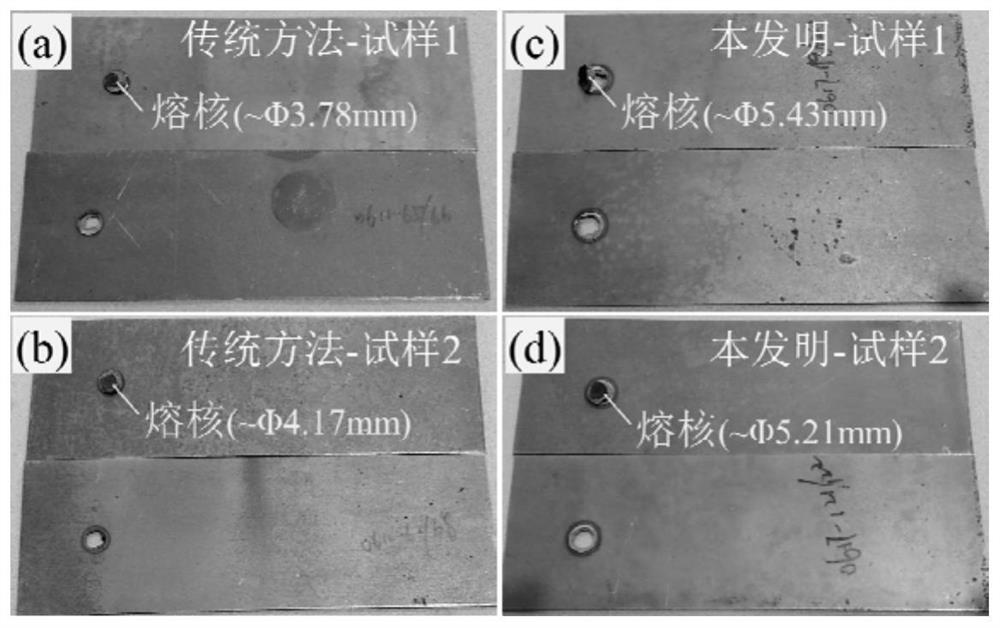

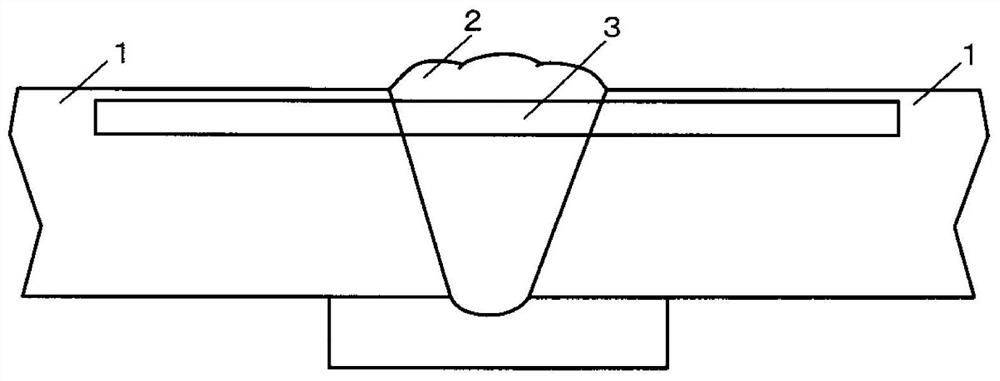

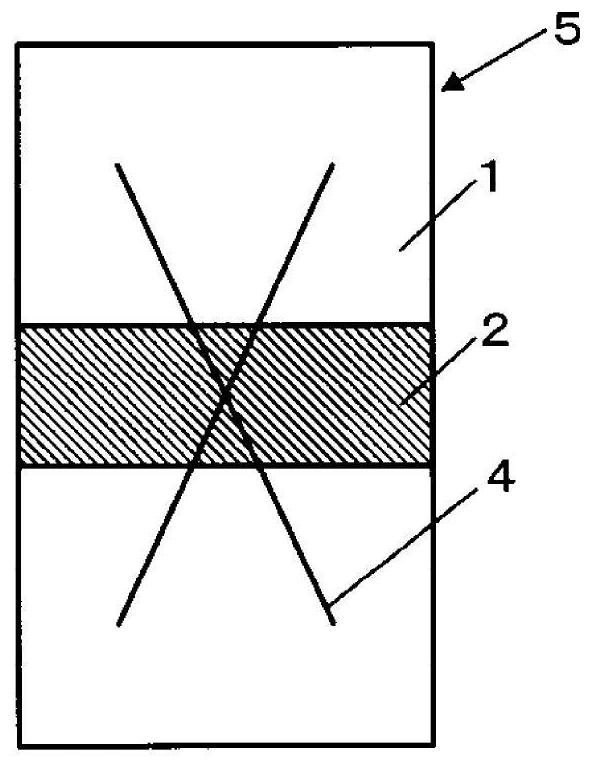

Resistance spot welding method matched for matching of steel plate containing super-strong thermal forming

PendingCN112846470AImprove joint performanceHigh tensile strengthResistance welding apparatusPhysicsSteel plates

The invention discloses a resistance spot welding method for matching of a steel plate containing super-strong thermal forming. The method comprises the following steps: 1) a correspondingly matched critical splash current I0 is found out on the basis of matching of super-strong thermal forming steel by adopting monopulse welding; 2) welding pulse parameters are determined according to the number j of matched steel plates to be welded, wherein j is an integer 2 or above; and 3) an intermediate frequency direct current spot welder is adopted to conduct welding according to the determined parameters and the time sequence of pre-pressing, preheating, welding, tempering and pressure maintaining. According to the resistance spot welding method, the welding nugget with the large enough diameter can be stably formed on the basis that obvious welding defects are not generated, a welding process window larger than 1.5 kA (an existing window generally does not exceed 0.5 kA, and a process window needed by actual production is larger than 1 kA) is obtained, and the joint strength is obviously improved (the tensile-shear strength is larger than 21 kN, and an existing process joint does not exceed 16 kN).

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI +1

Method for manufacturing flux-cored wire, flux-cored wire and method for manufacturing welded joint

ActiveCN111819029AGood weather resistanceImprove mechanical propertiesFurnace typesWelding/cutting media/materialsPhysicsSteel plates

This method for manufacturing flux-cored wire involves a step for filling flux into the inside of a steel plate while forming the steel plate into a cylindrical shape, a step for joining the two endsof the steel plate to obtain a steel pipe, and a step for rolling and annealing the steel pipe to obtain a flux-cored wire, wherein the chemical composition of the flux-cored wire is within prescribedranges, and the Sn content, the Sb content, the W content and the Mo content satisfy the relation Sn+Sb > Mo+W. The flux-cored wire according to another embodiment is manufactured by the aforementioned flux-cored wire manufacturing method. The method for manufacturing a welding joint according to another embodiment involves a step for welding using the flux-cored wire manufactured with the aforementioned flux-cored wire manufacturing method.

Owner:NIPPON STEEL CORP

Manufacturing method for bearing ball

InactiveCN107514425AExtended service lifeNo welding defectsBearing componentsFurnace typesPolishingCasting mold

The invention discloses a manufacturing method for a bearing ball. The manufacturing method specifically comprises the following steps that (1) blanking and upsetting of a billet are conducted; (2) edge removing is conducted, specifically, mould casting overspill is removed from the spherical billet obtained in the step (1), and thus a coarse ball is obtained; (3) heat treatment is conducted, specifically, the coarse ball is carburized and quenched; (4) grinding machining is conducted, specifically, a heated coarse ball billet is coarsely ground and accurately ground sequentially, thus a ground ball is obtained, and then the ground piece is subjected to annealing treatment, surface passivation treatment and lubricating treatment techniques sequentially; and (5) polishing is conducted, specifically, a polishing machine and a polishing agent are used for polishing treatment, and thus the bearing ball is obtained. Through the technique, the yield is high, the technique is simple, the bearing ball is manufactured, precise net shaping of a product is achieved, fracturing is avoided in the using process, and the service life of a bearing is prolonged.

Owner:WUXI NANLIGONG TECH DEV

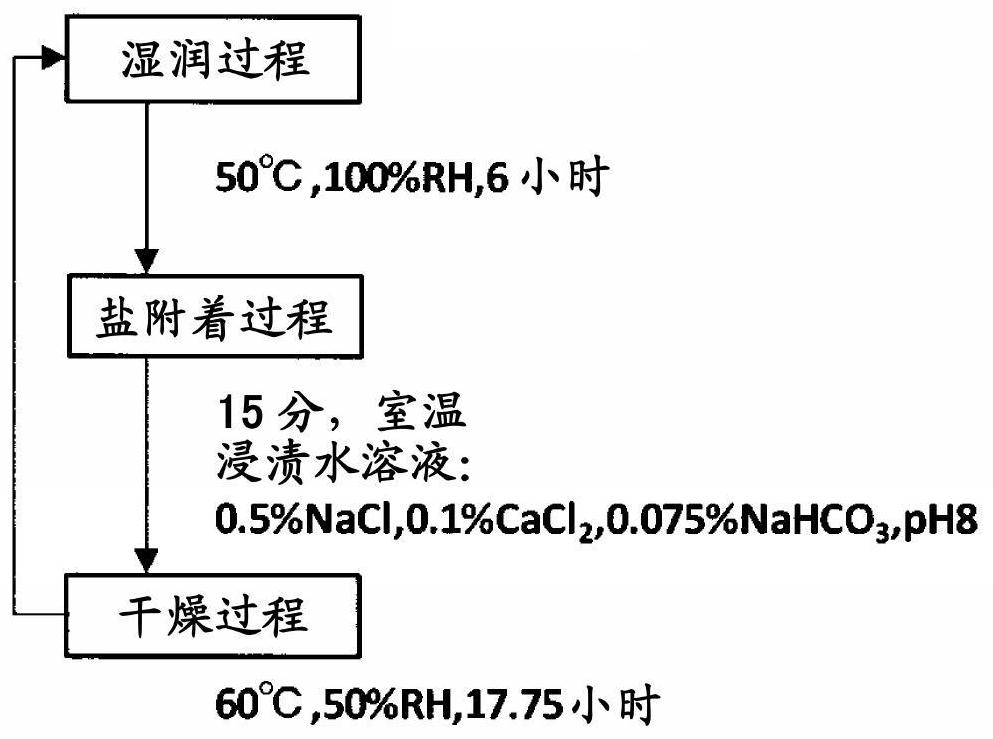

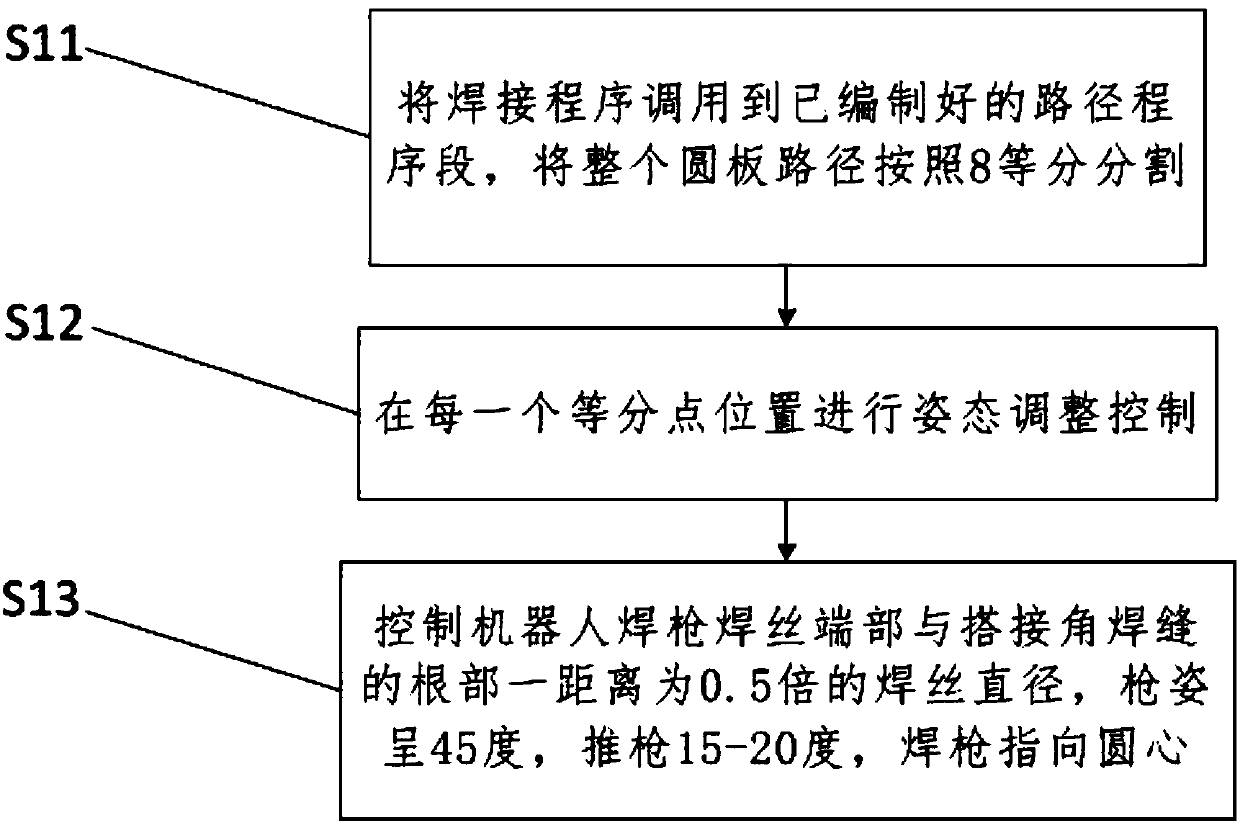

Automatic flat fillet welding method of heavy arc plate

The invention discloses an automatic flat fillet welding method of a heavy arc plate. The method comprises the steps of (1) path programming and (2) groove treatment and welding, wherein the path programming comprises the following steps: a whole circular plate path is divided into multiple equal parts; the gesture adjustment and control are performed in the position of each equal dividing point;the distance from the end part of a welding wire of a welding gun to the root part of a lap fillet weld is controlled to be 0.5 times of the diameter of the welding wire; the gesture of the gun is 45degrees; the gun is pushed by 15-20 degrees; and the welding gun is pointed to the circle center. The automatic flat fillet welding method of the heavy arc plate is low in investment, few in occupiedlands, liable to operate, good mass consistency, beautiful in shaping and free of welding defects and lap arc pits, saves both time and labors, needs no polishing and repair welding, has no recess andedge engagement phenomenon, is excellent in molding, has no defects of unwelding and cracking, totally meets the welding line quality requirements of bearing components, and greatly improves the working efficiency.

Owner:SHANGHAI ZPMC ELECTRIC +1

Low-hydrogen type iron-powder electrode and preparation method thereof

ActiveCN106425170AIncrease profitImprove welding efficiencyWelding/cutting media/materialsSoldering mediaHeat-affected zoneSlag

The invention belongs to the technical field of welding materials, and specifically relates to a low-hydrogen type iron-powder electrode and a preparation method thereof. The low-hydrogen type iron-powder electrode is characterized in that a coating is composed of the following components in parts by weight: 29 to 31 parts of marble, 13 to 15 parts of fluorite, 2 to 4 parts of ferrosilicon, 1.5 to 2.5 parts of titanium dioxide, 1.5 to 2.5 parts of wood meal, 14 to 16 parts of rutile, 4 to 6 parts of feldspar powder, 6 to 8 parts of quartz powder, 4 to 6 parts of mica powder, 12 to 14 parts of titanium powder, and 19 to 21 parts of iron powder. The low-hydrogen type iron-powder electrode has the best welding performance and processing property; a welding seam is nice in looking and does not have any obvious welding defect on the surface, and the welding seam is flat; the slag removing performance is high; obvious thick and big columnar crystals are generated at the weld joint structure and the welding seam, so that the welding requirement is met; a base material is combined well with the welding seam, and the structure transition is obvious; the heat affected area structure is close to the theory; the hardness of the low-hydrogen type iron-powder electrode is high; the utilization rate and the welding efficiency of the electrode can be improved.

Owner:PANZHIHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com