Double-beam laser welding machine and welding method thereof

A laser welding machine, laser welding technology, applied in laser welding equipment, welding equipment, welding equipment and other directions, can solve the problems of low efficiency, high cost, large grinding amount, etc., to prevent welding defects, prevent oxidation, and ensure stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

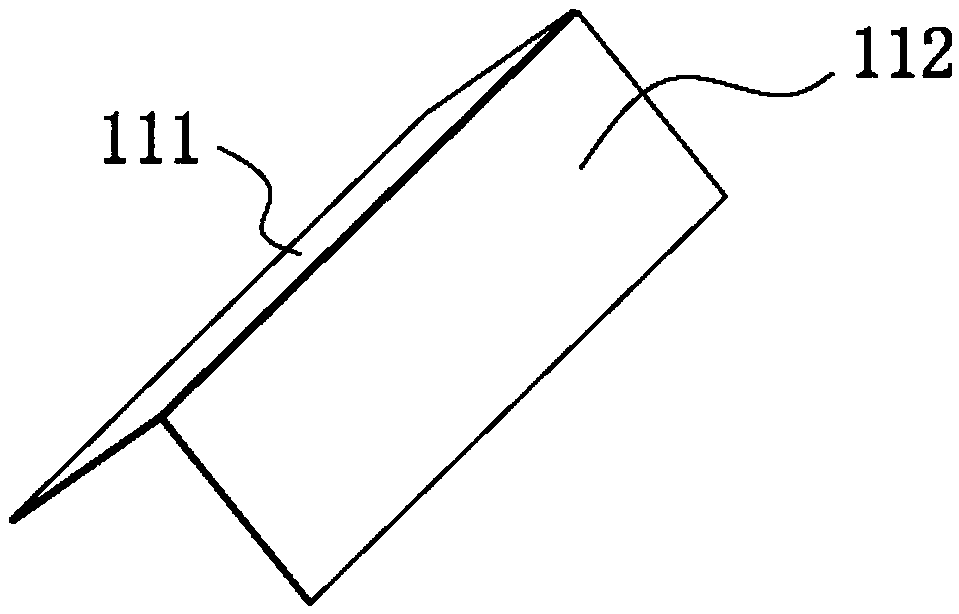

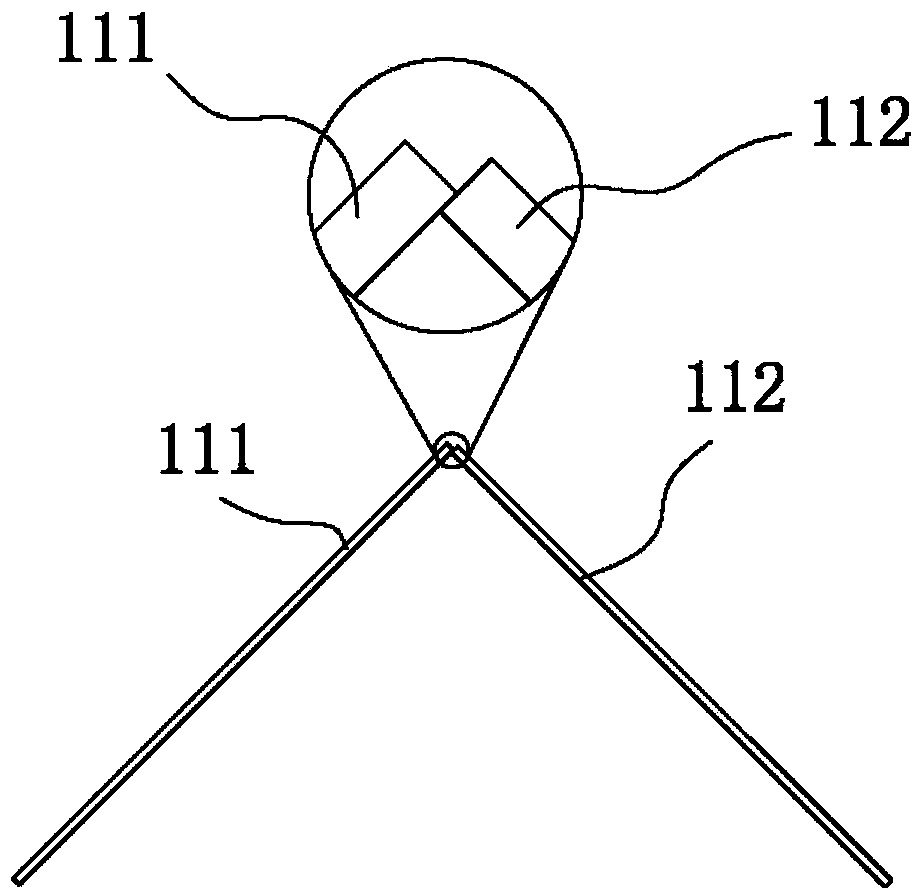

[0027] Refer to figure 1 As shown, the dual-beam laser welding machine of the present invention is used to fix and clamp the first thin plate (thickness 0.6 mm) 111 and the second thin plate (thickness 0.6 mm) 112 for laser edge welding.

[0028] The dual beam laser welding machine includes a fixture 120 for fixing the workpiece to be welded, a dual beam welding head 130 for welding the workpiece to be welded, and a multifunctional gas hood 140 located above the welding workpiece.

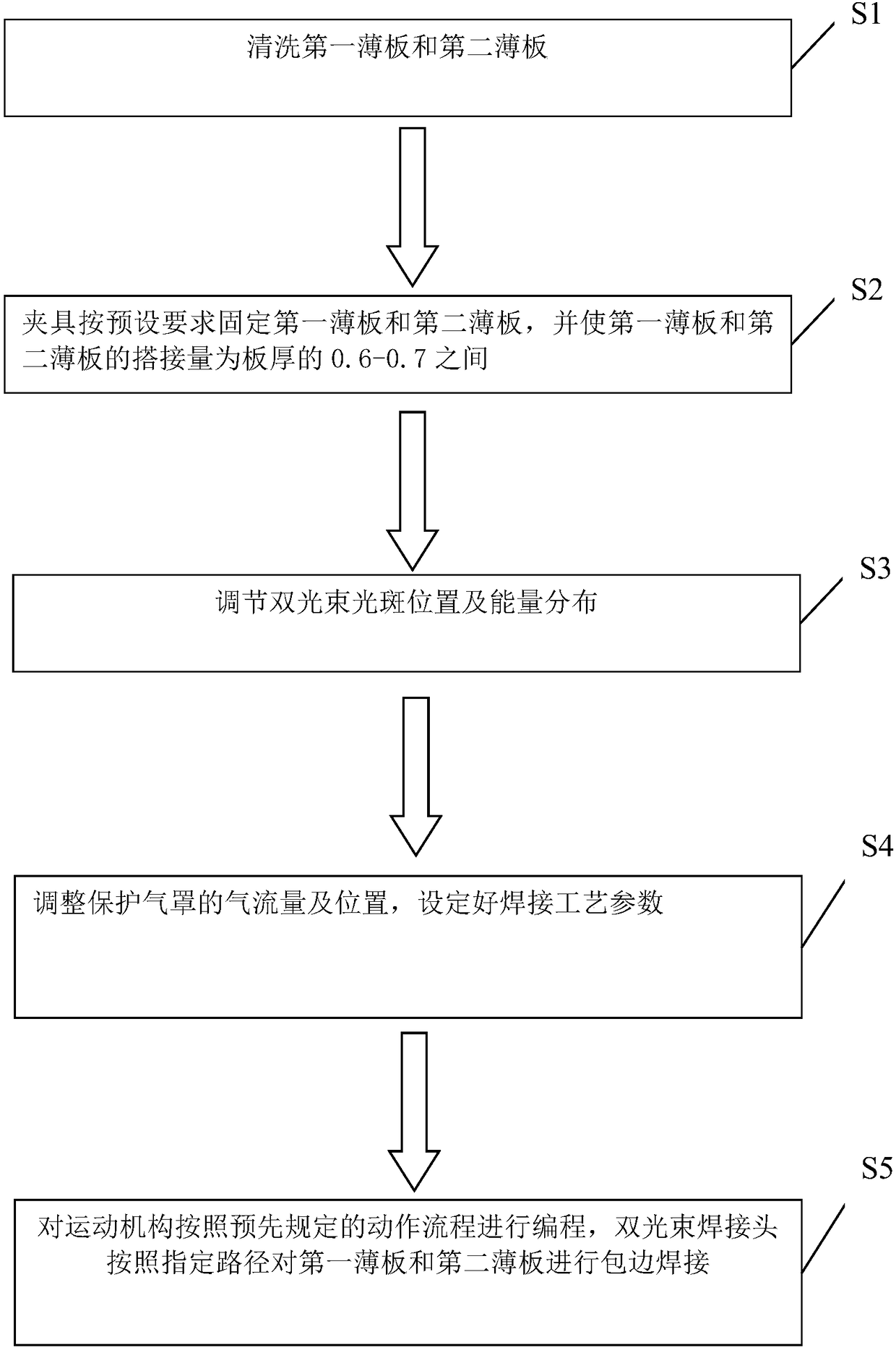

[0029] The double-beam laser welding method of the thin plate hemming weld in the preferred embodiment of the present invention includes steps S110 to S160.

[0030] The provided double-beam laser welding method of the thin plate edging weld is used to fix and clamp the thin plate (thickness 0.6mm) 111 and the thin plate (thickness 0.6mm) 112 and then perform laser edging welding. The thin plate package in the preferred embodiment of the present invention The double-beam laser welding method for side weld...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com