Lightweight galvanized steel springboard and processing process thereof

A technology of galvanized steel and springboard, which is applied in the direction of house structure support, ship parts, house structure support, etc., can solve the problems of disassembly, product shape inconsistency, steel springboard disassembly burden, waste of resources, etc., to reduce processing defects , Improve the overall bearing capacity and save the demand for steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0049] A light-gauge galvanized steel diving board is provided.

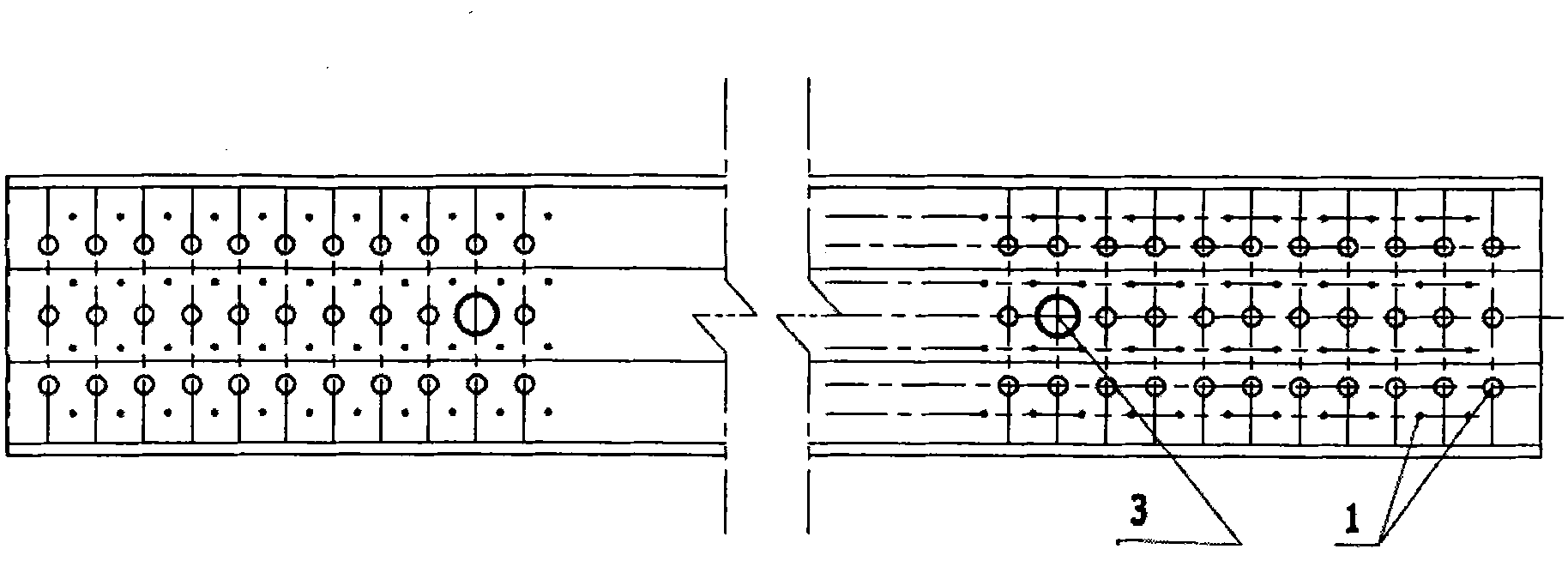

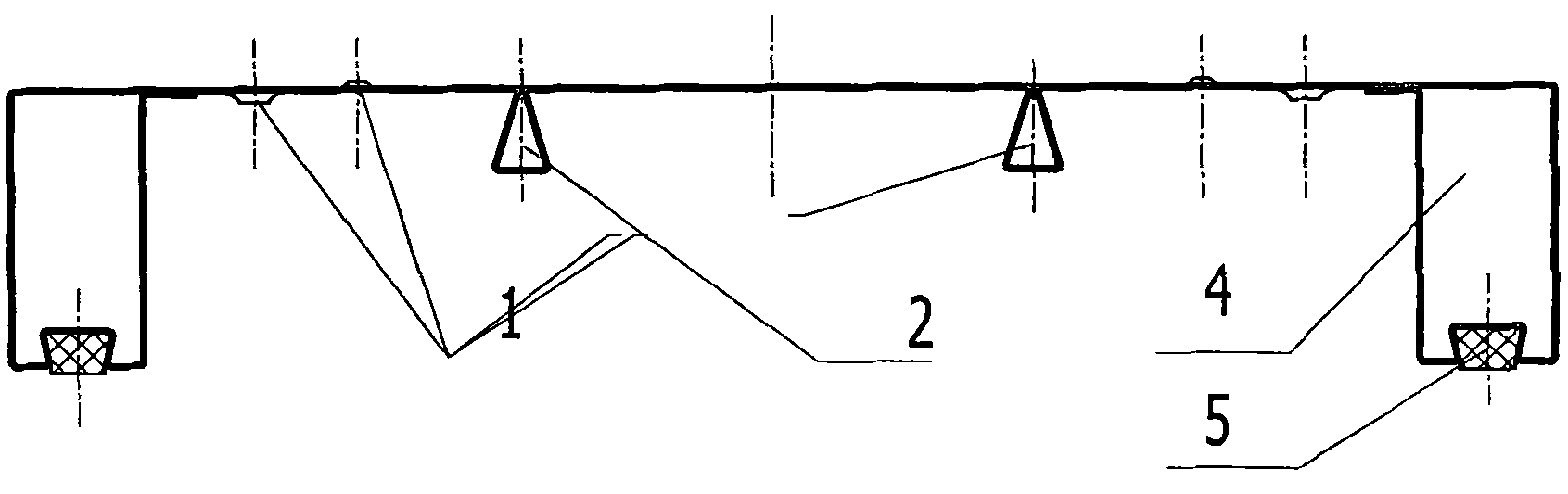

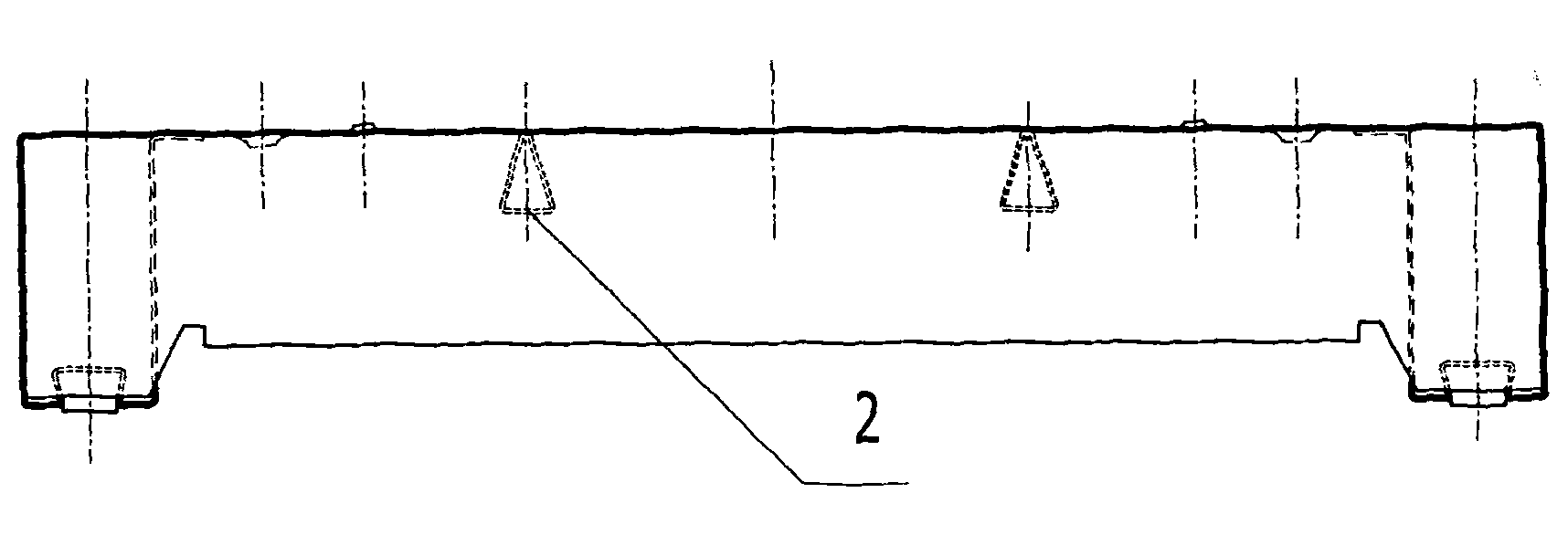

[0050] Such as figure 2 As shown, the cross-section of the light galvanized steel springboard is concave, the legs 4 on both sides are box-shaped, and grooves are arranged at the bottom of the feet; both ends of the light galvanized steel springboard are provided with end plates, and the shape of the end plates is as follows Figure 4 As shown; the bottom surface of the light galvanized steel springboard is welded with transverse ribs at intervals, and the transverse ribs are as follows Figure 5 Shown; the surface of the light galvanized steel springboard is provided with a cold extrusion punching hole 1.

[0051] A rubber block 5 is arranged in the groove of the foot; the groove of the foot can be Image 6 , 7 trapezoidal as shown, or Figure 8 So-style arch, also can be Figure 9 square shown.

[0052] Grooves matching the longitudinal ribs are arranged on the transverse ribs.

[0053] The surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com