Patents

Literature

74results about How to "Reduce processing defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Semiconductor package

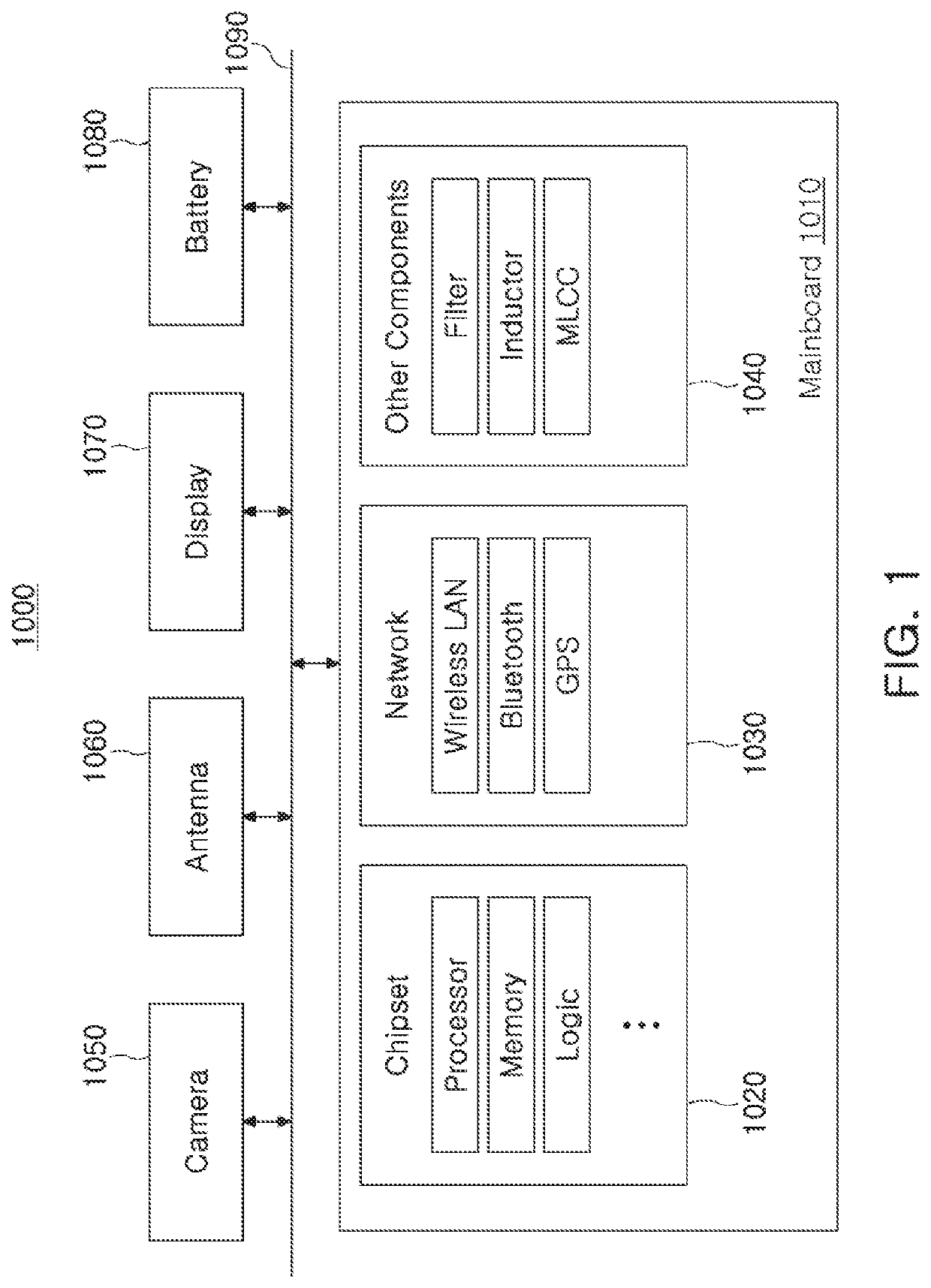

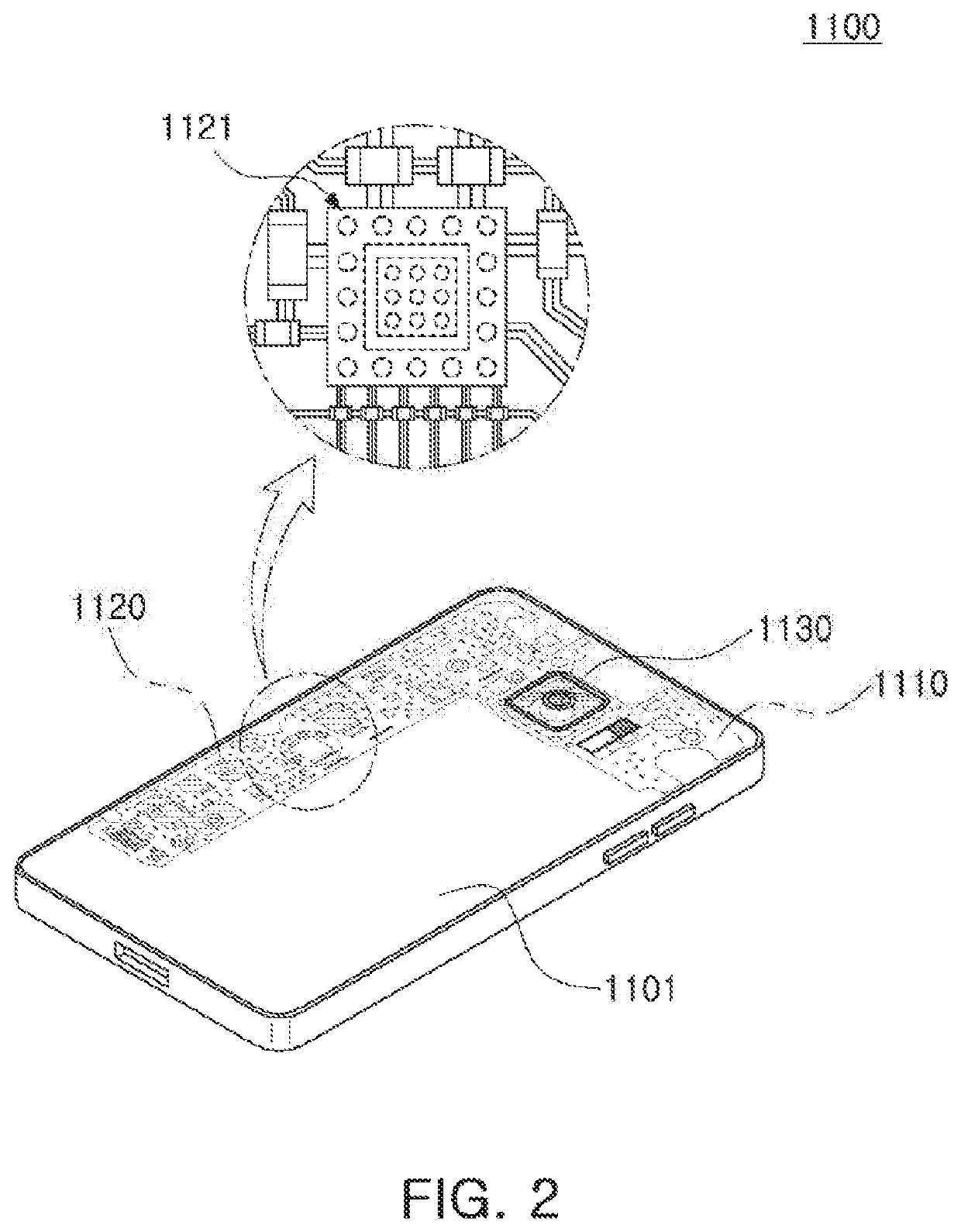

ActiveUS10727212B2Reduce areaFirmly connectedSemiconductor/solid-state device detailsSolid-state devicesInsulation layerSemiconductor package

Owner:SAMSUNG ELECTRONICS CO LTD

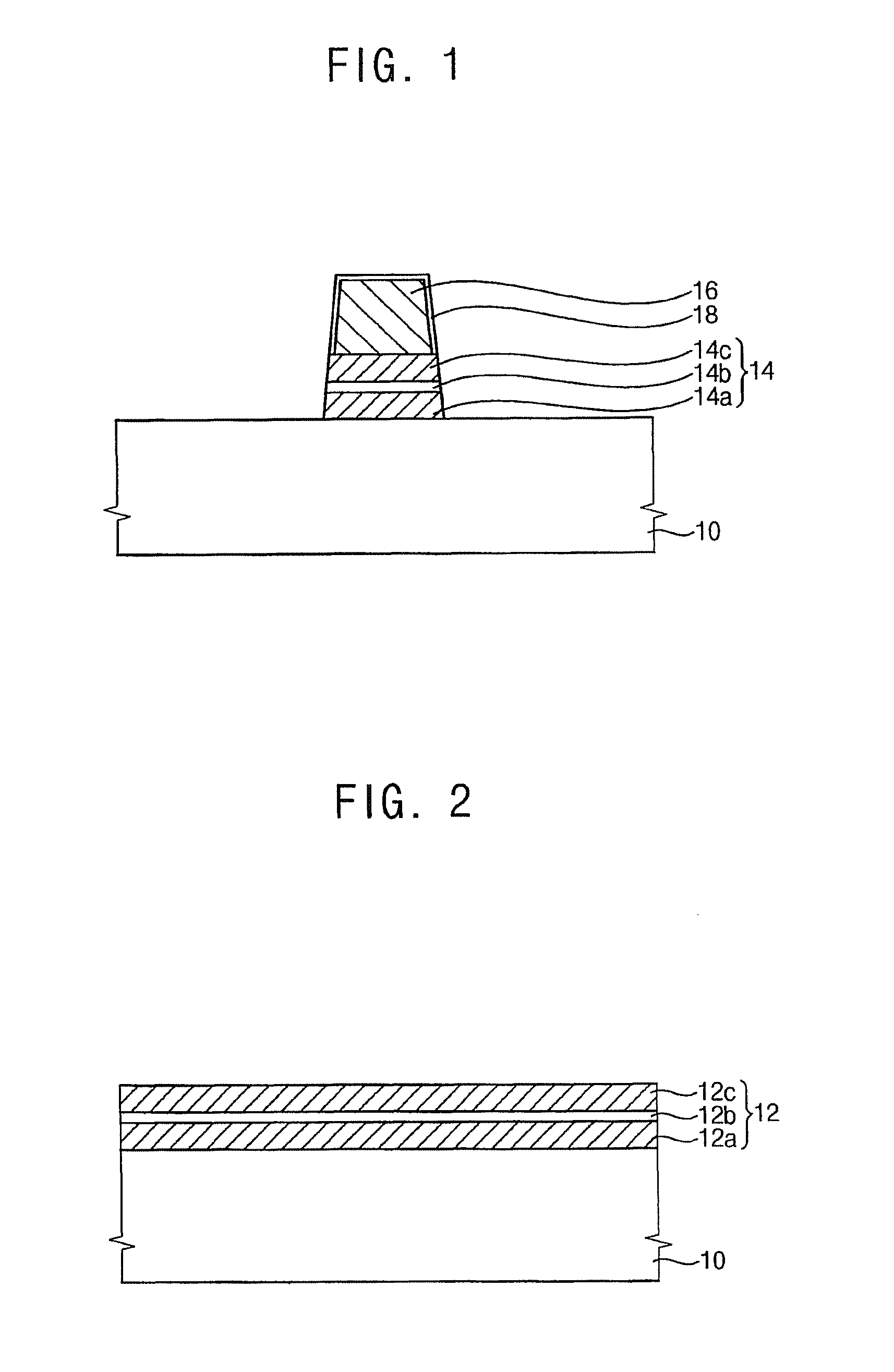

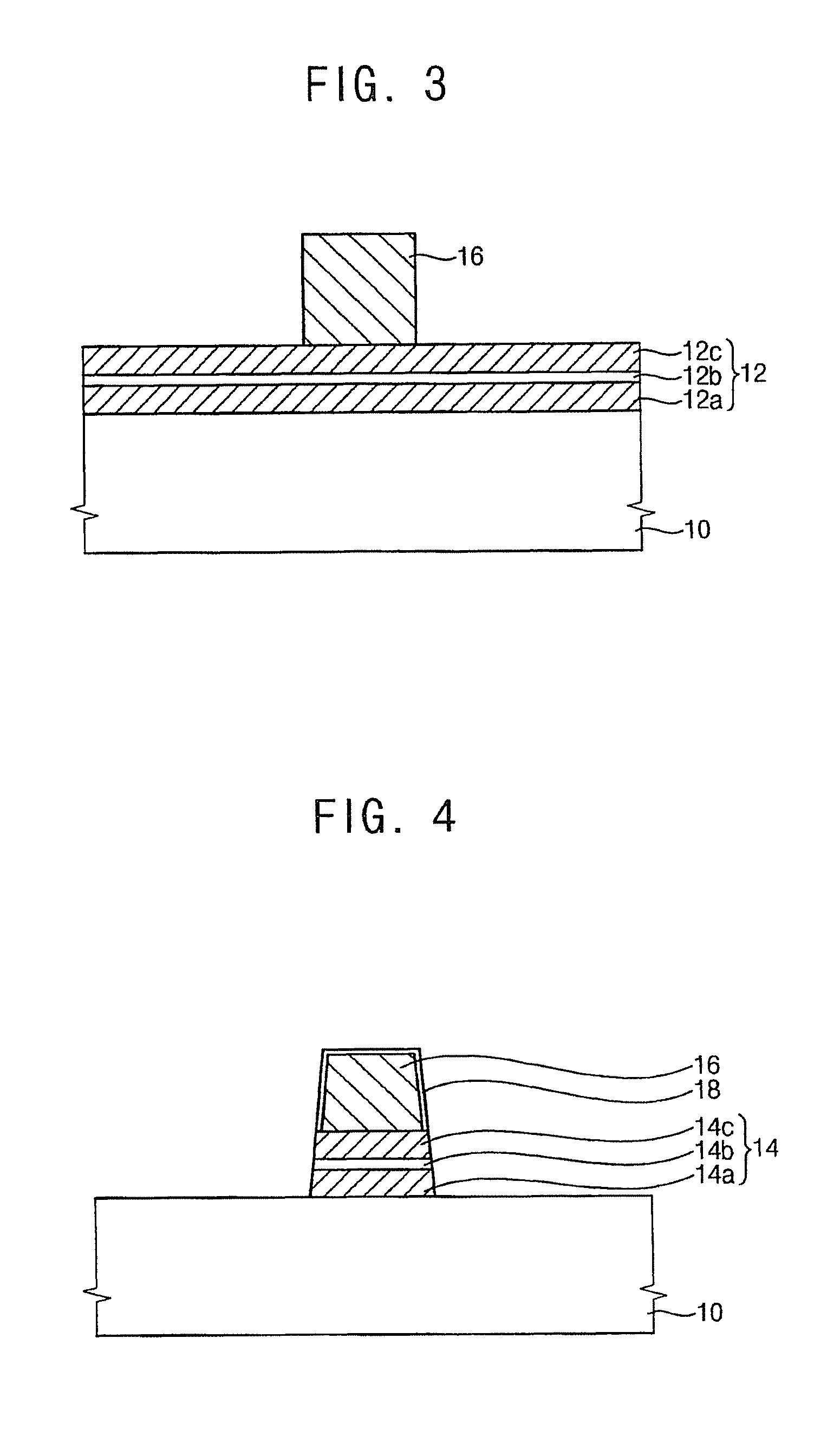

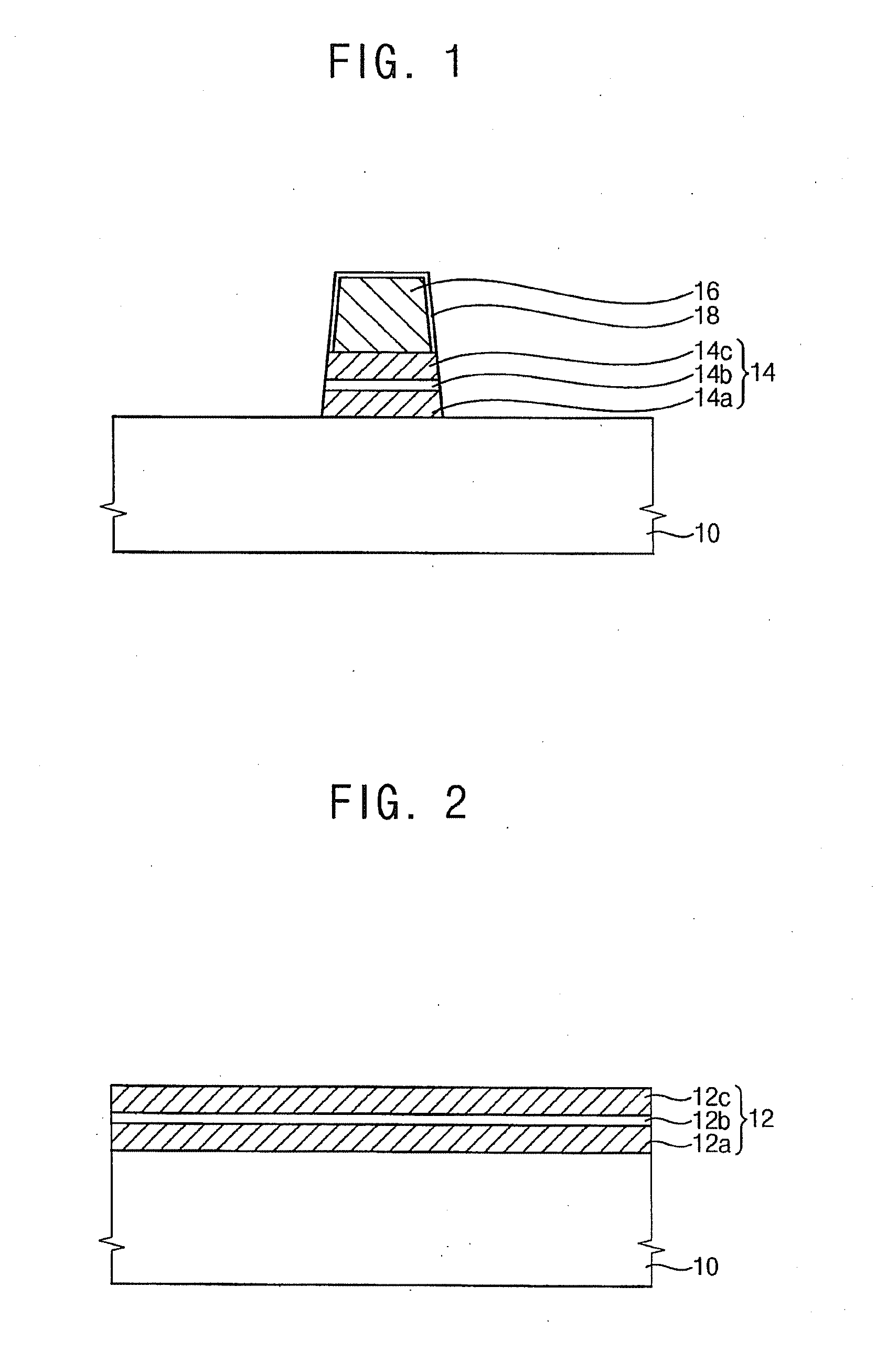

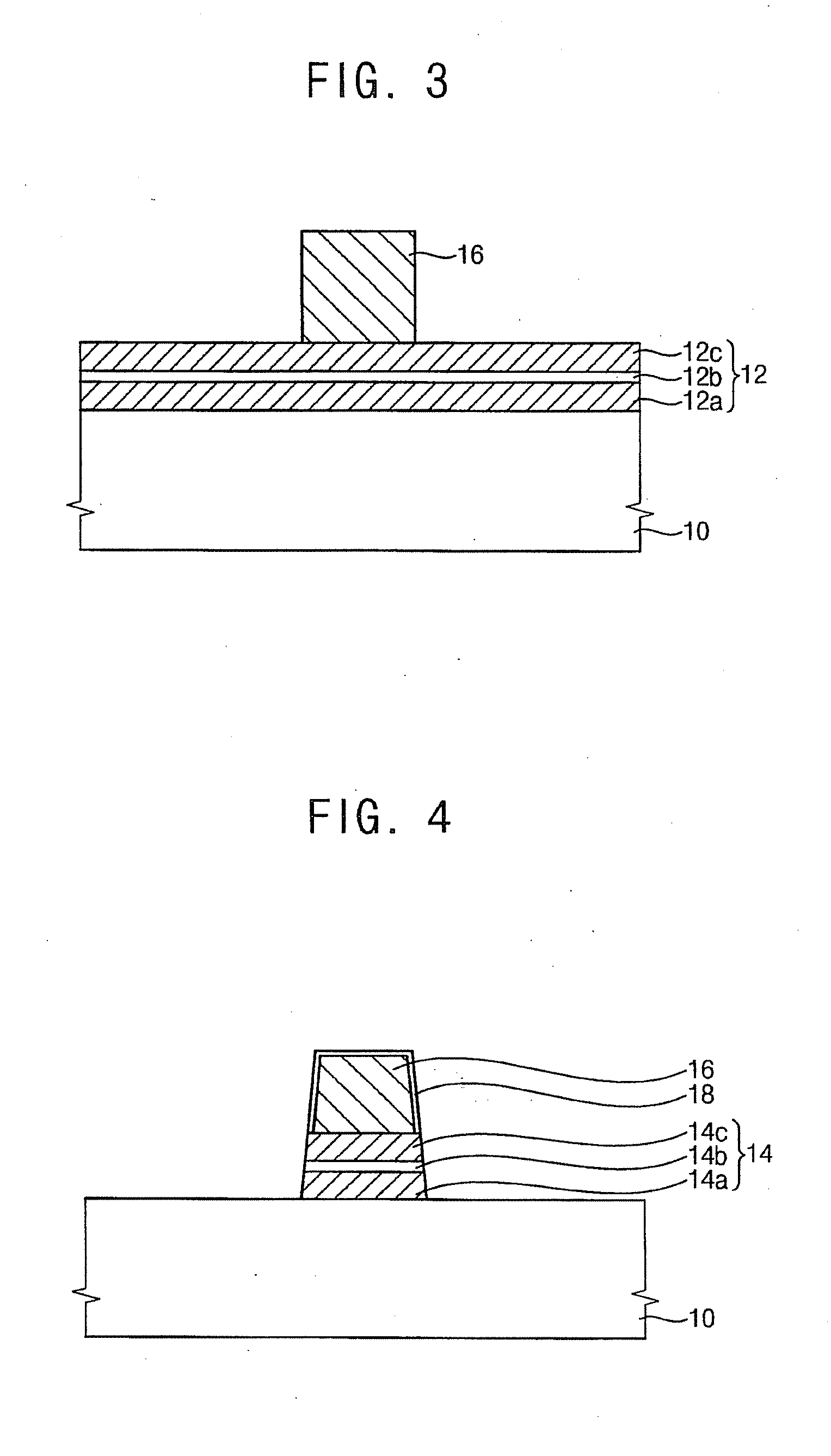

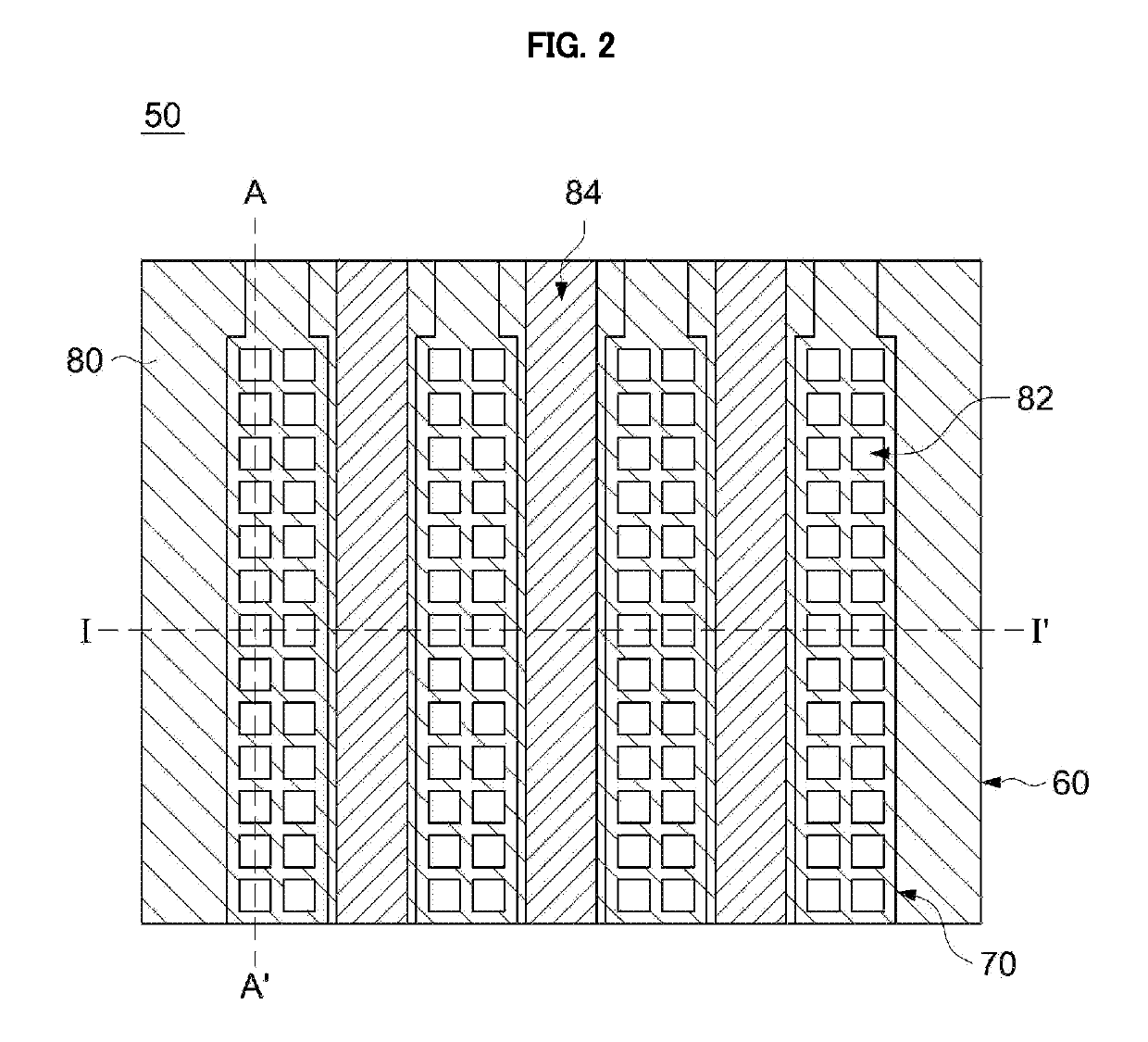

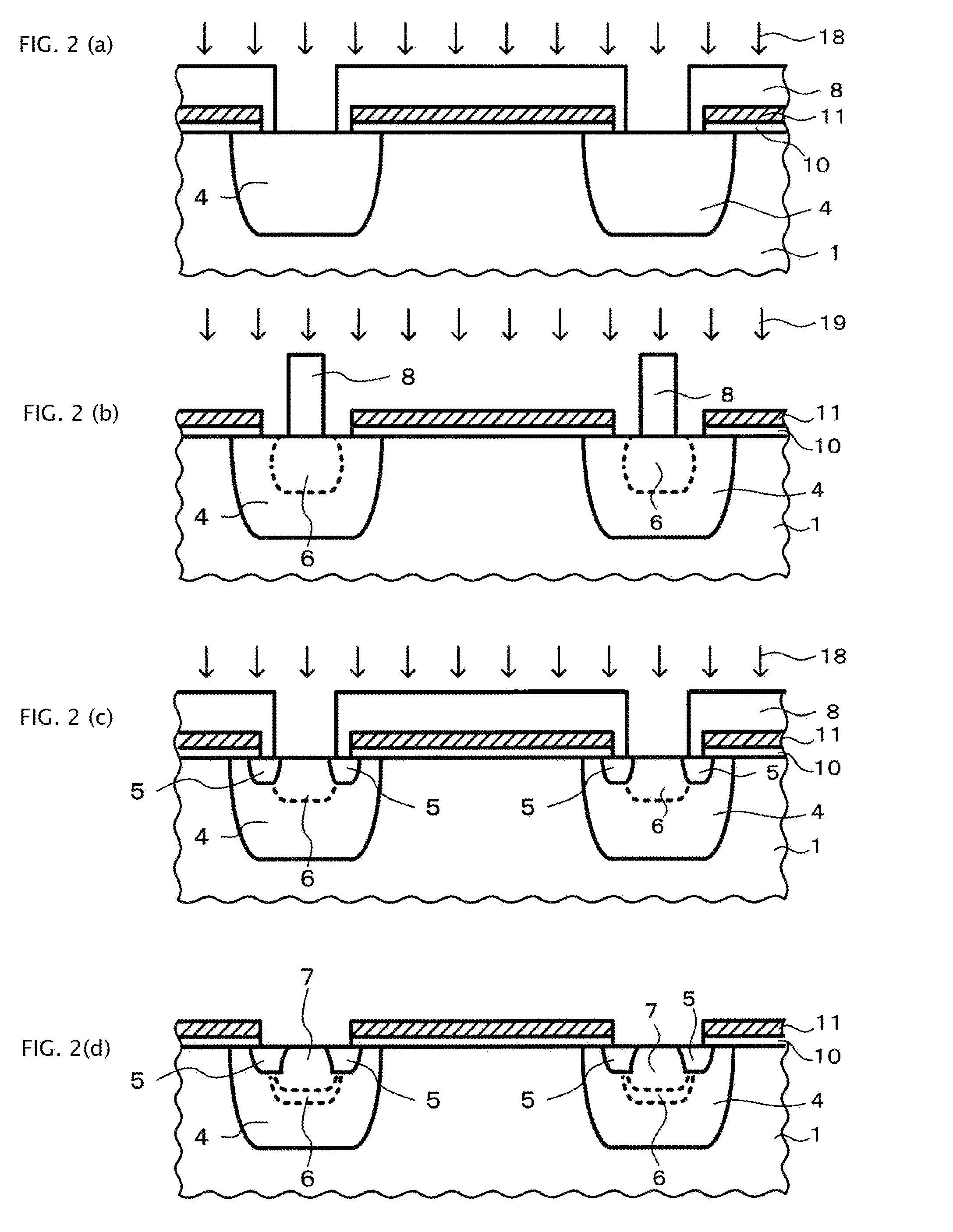

Methods of forming pattern structures

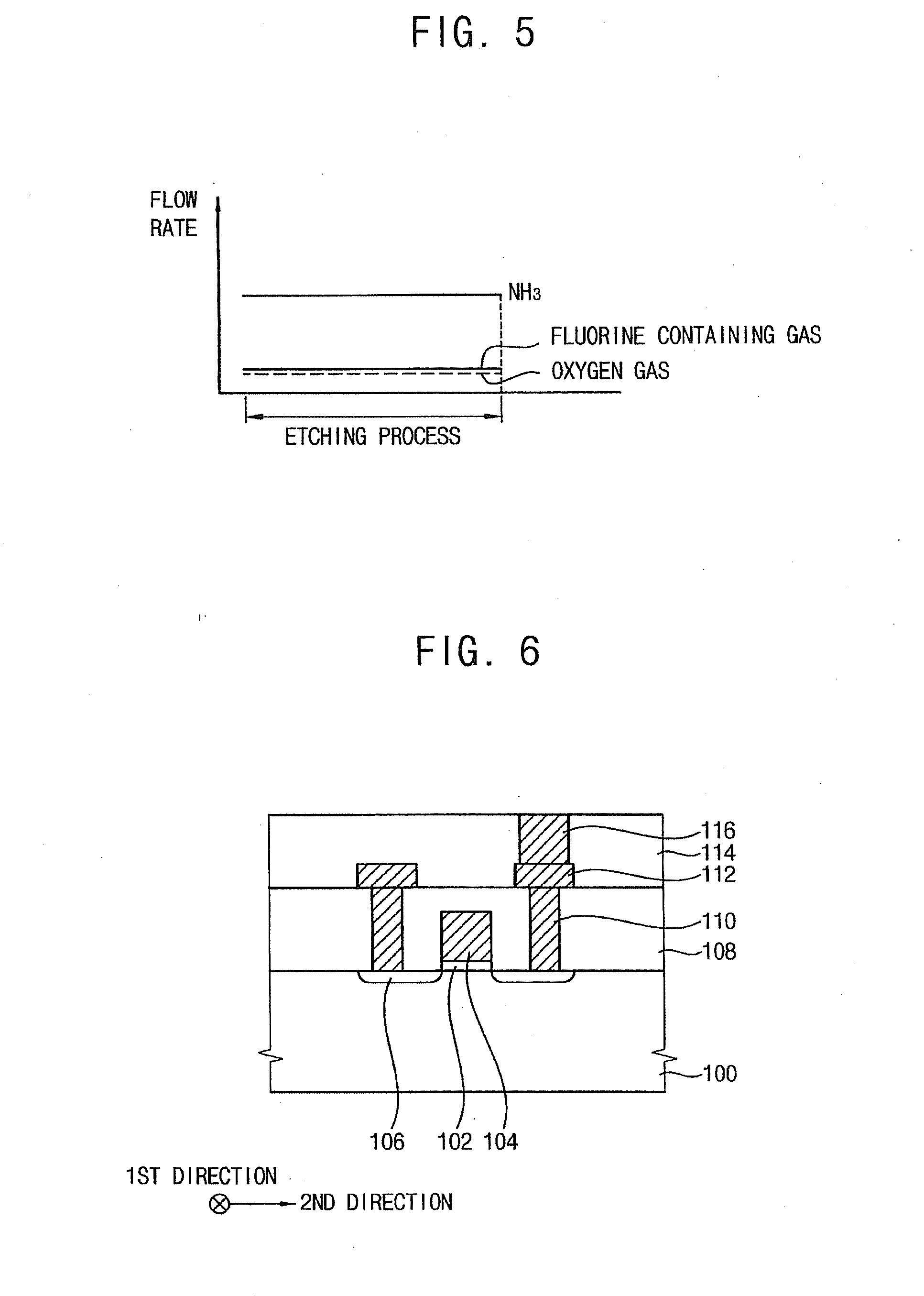

ActiveUS8334148B2Improve operating characteristicsReduce processing defectsSolid-state devicesSemiconductor/solid-state device manufacturingAmmoniaFluorine containing

An example embodiment relates to a method of forming a pattern structure, including forming an object layer on a substrate, and forming a hard mask on the object layer. A plasma reactive etching process is performed on the object layer using an etching gas including a fluorine containing gas and ammonia (NH3) gas together with oxygen gas to form a pattern. The oxygen gas is used for suppressing the removal of the hard mask during the etching process.

Owner:SAMSUNG ELECTRONICS CO LTD

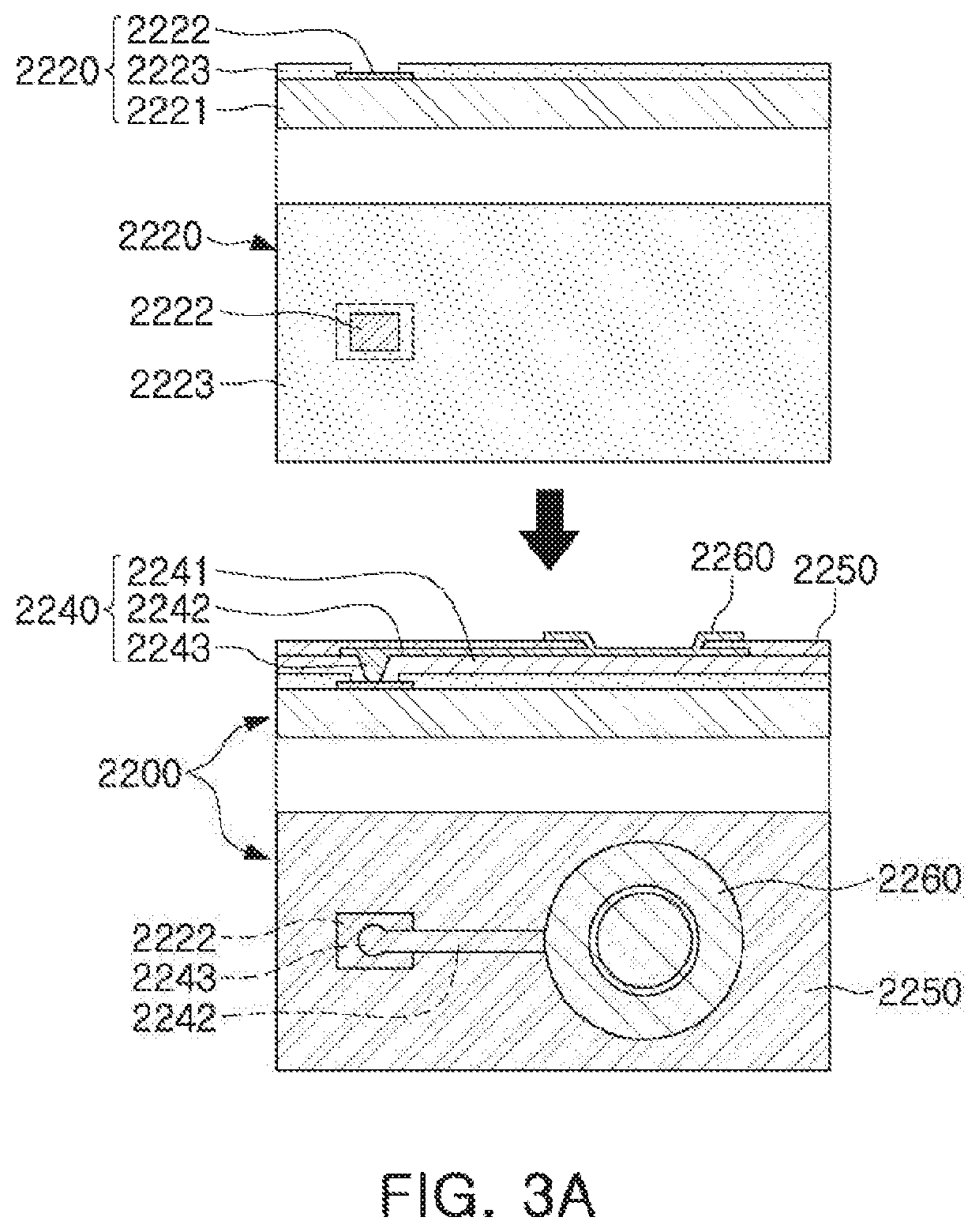

Methods of forming pattern structures

ActiveUS20110272380A1Suppress removalImprove operating characteristicsDecorative surface effectsSolid-state devicesAmmoniaFluorine containing

An example embodiment relates to a method of forming a pattern structure, including forming an object layer on a substrate, and forming a hard mask on the object layer. A plasma reactive etching process is performed on the object layer using an etching gas including a fluorine containing gas and ammonia (NH3) gas together with oxygen gas to form a pattern. The oxygen gas is used for suppressing the removal of the hard mask during the etching process.

Owner:SAMSUNG ELECTRONICS CO LTD

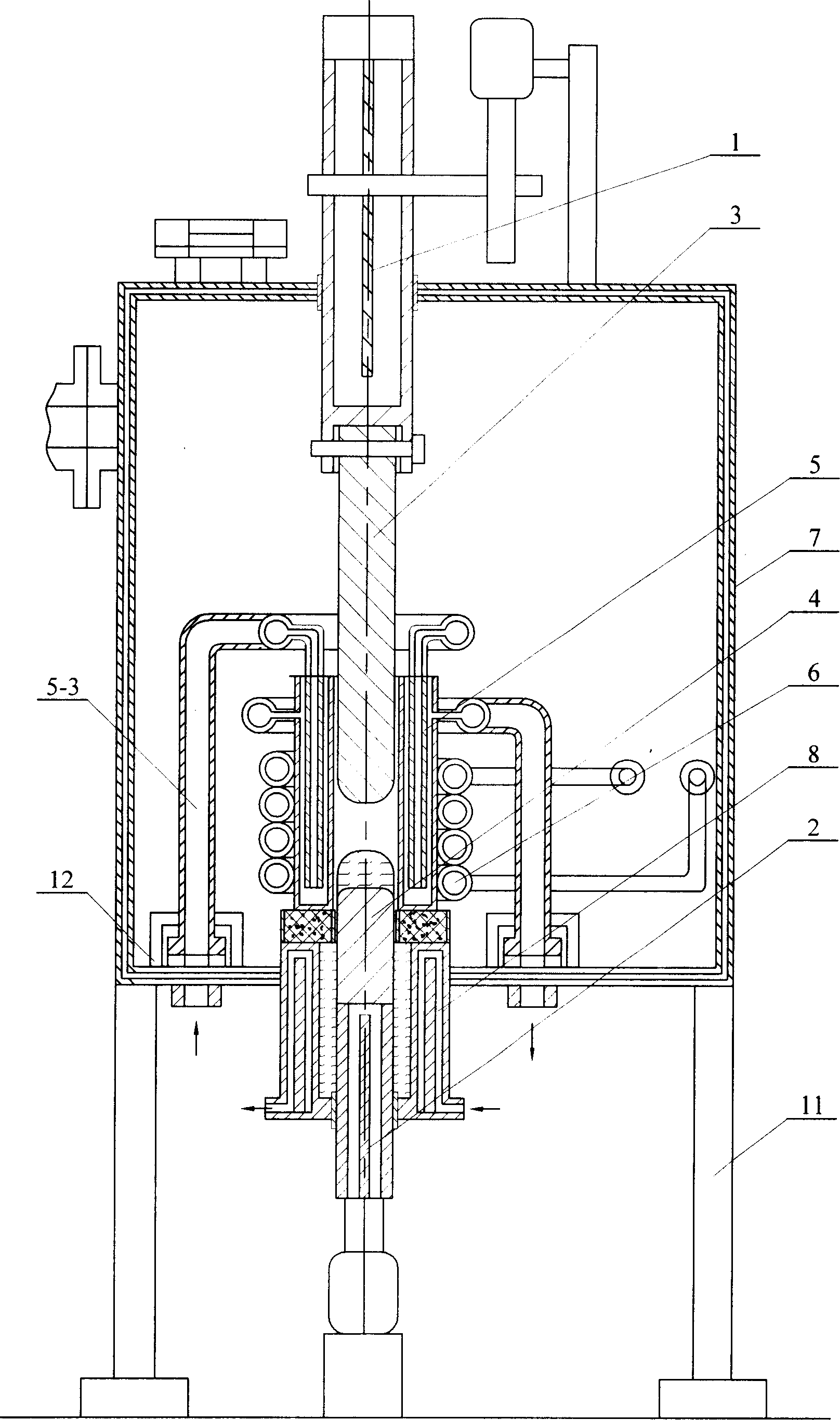

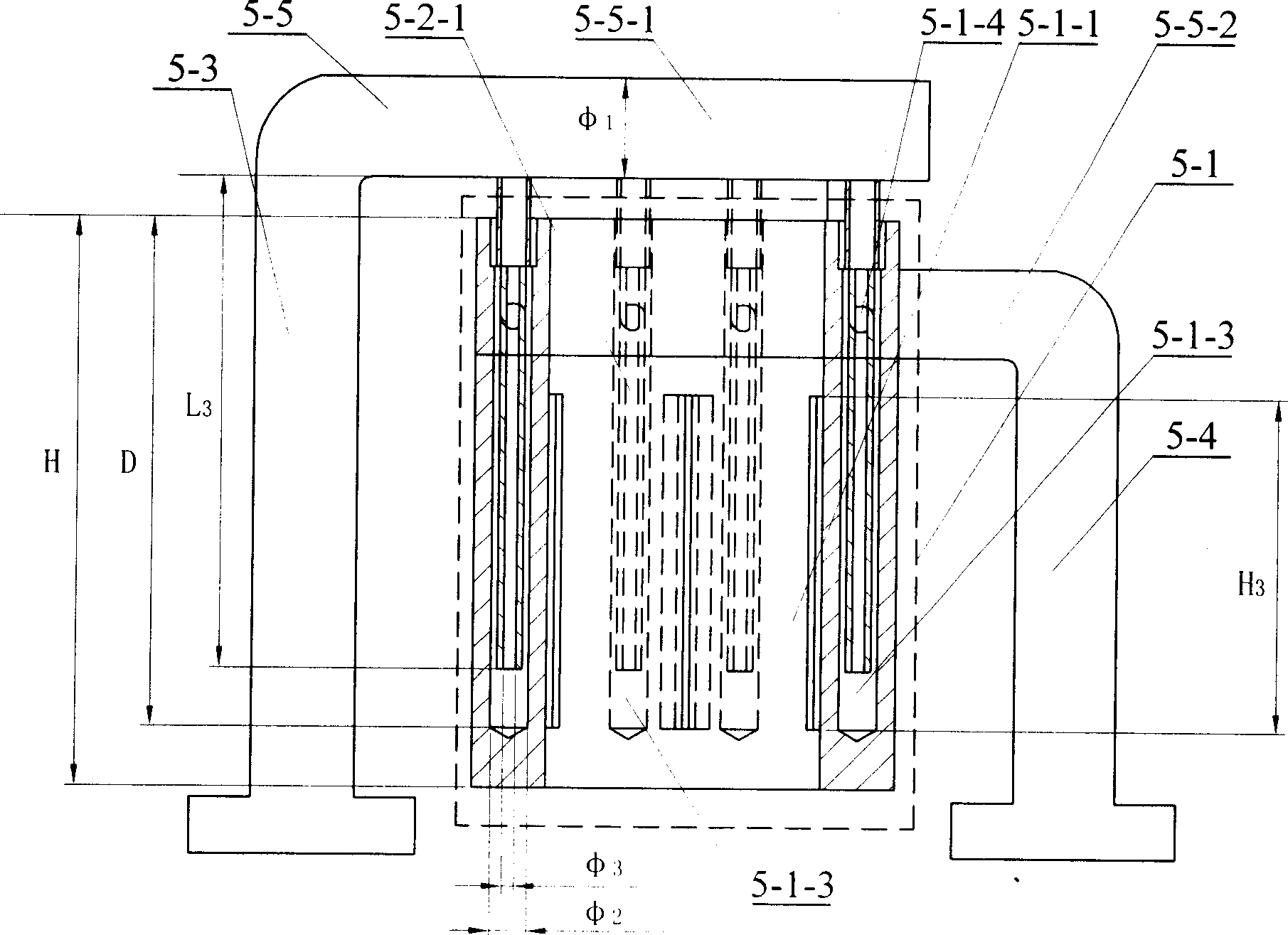

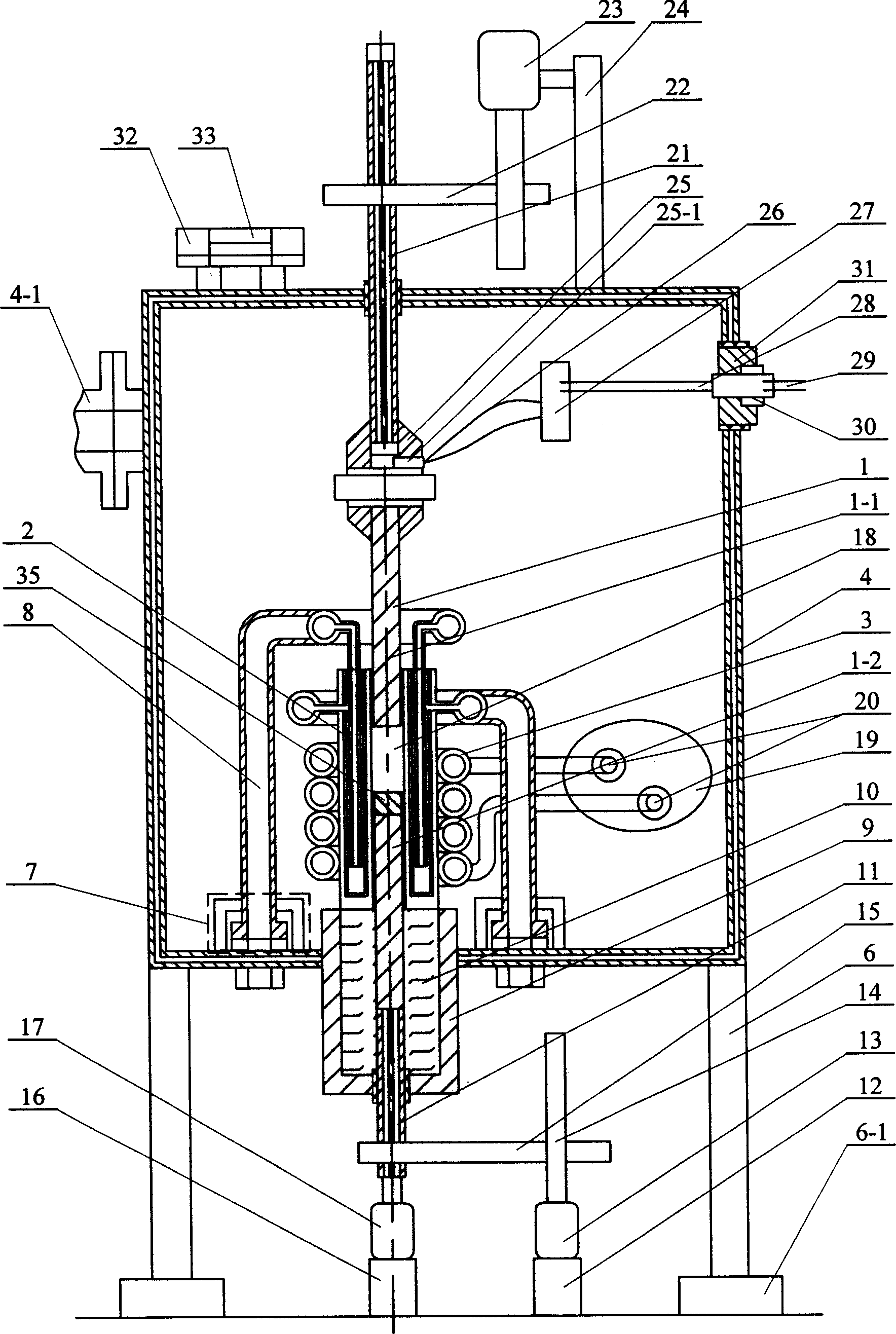

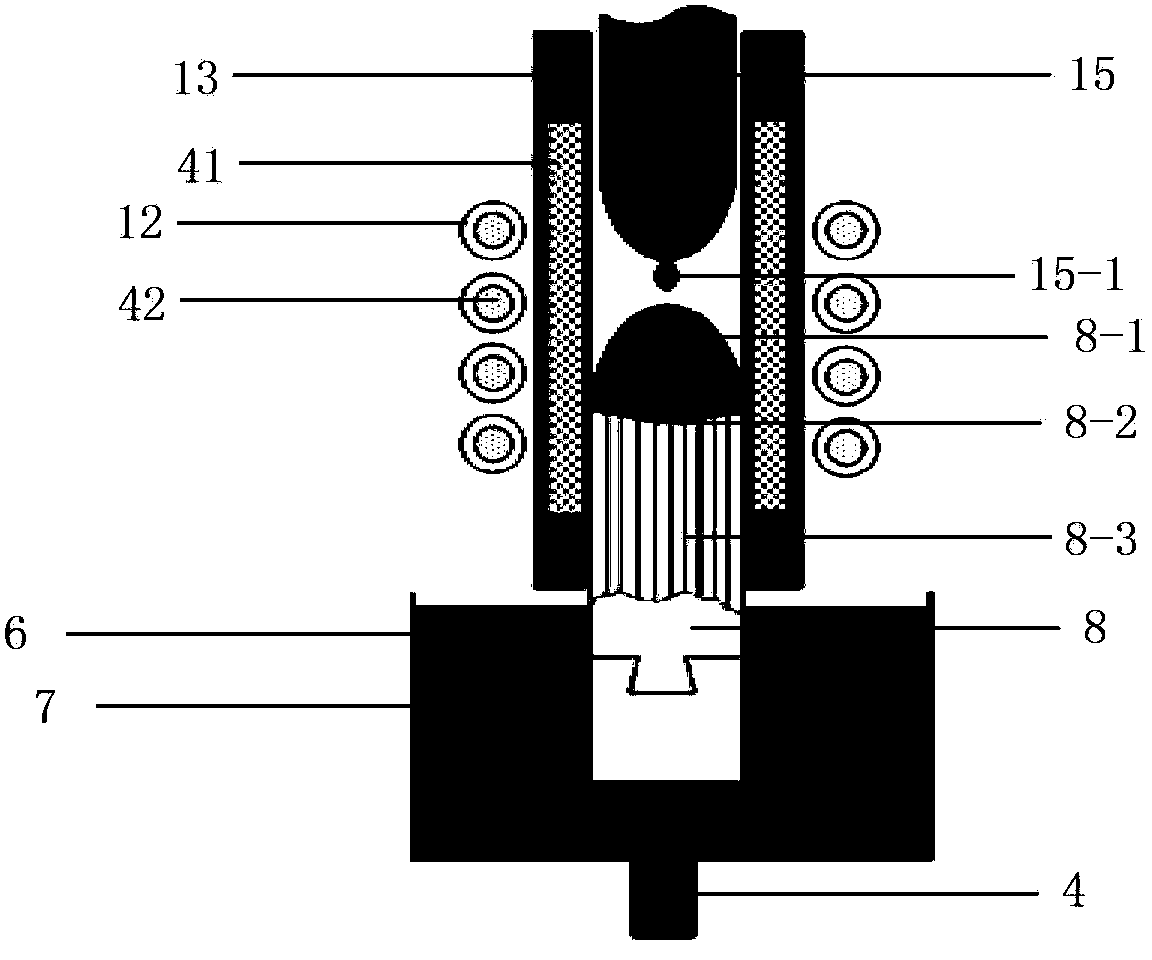

Directional freeze method for TiAl-based alloy plate

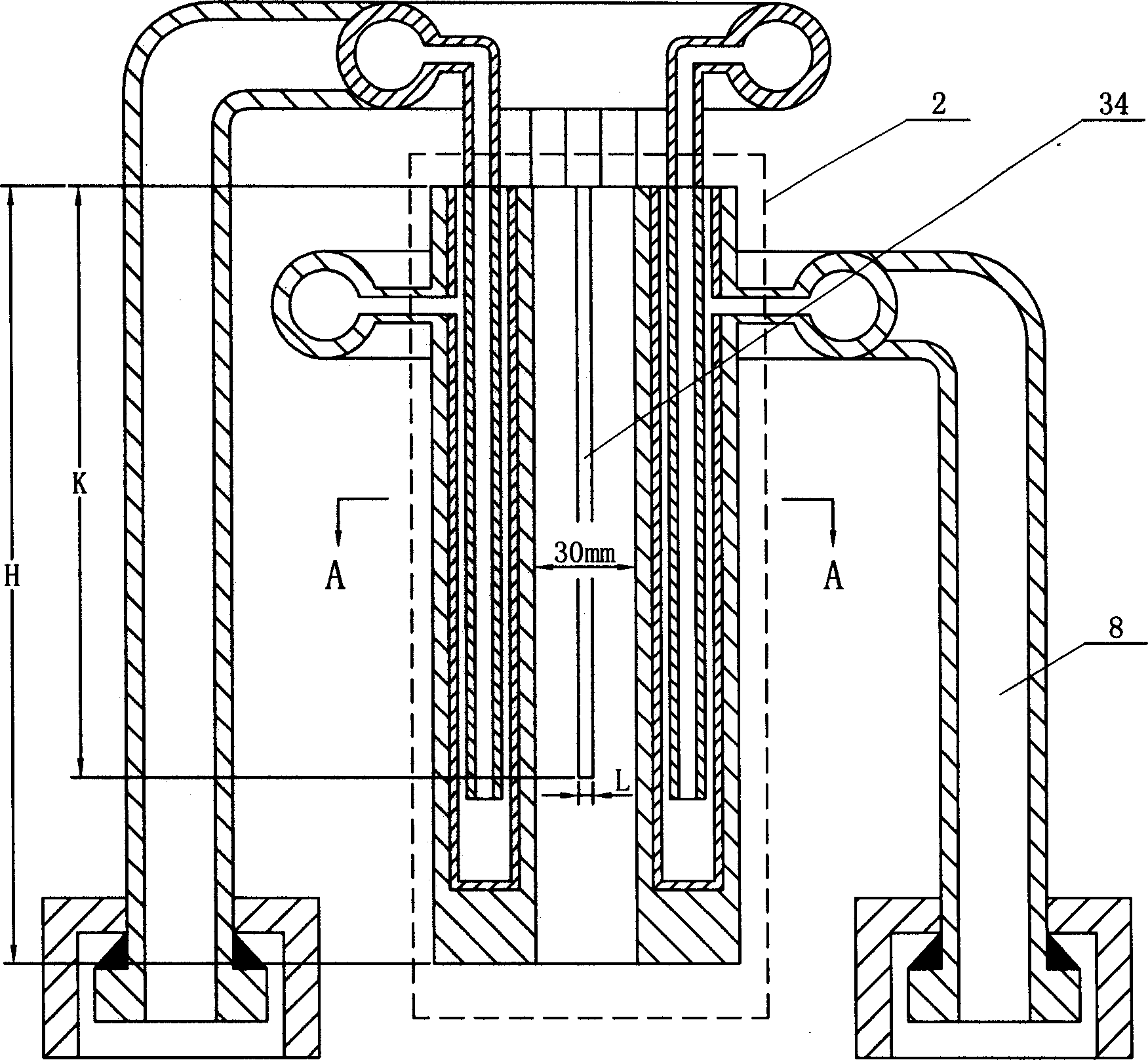

The continual casting directional solidification method for TiAl-base alloy plate comprises, putting TiAl alloy material bar 3 and dummy ingot 4 with rectangular intersection into the electromagnetic induction range of coil 6, galvanizing to coil 6 with single-phase alternating current with power of 75~100kW from electrical power for 20~25min; the alloy bar 3 and ingot 4 move downward with velocity of 0.01-0.05mm / min and get into the bottom crystallizer 8. This invention overcomes the limit to rectangular intersection blank and fits to press for high performance material in economy, science and national defense industry.

Owner:HARBIN INST OF TECH

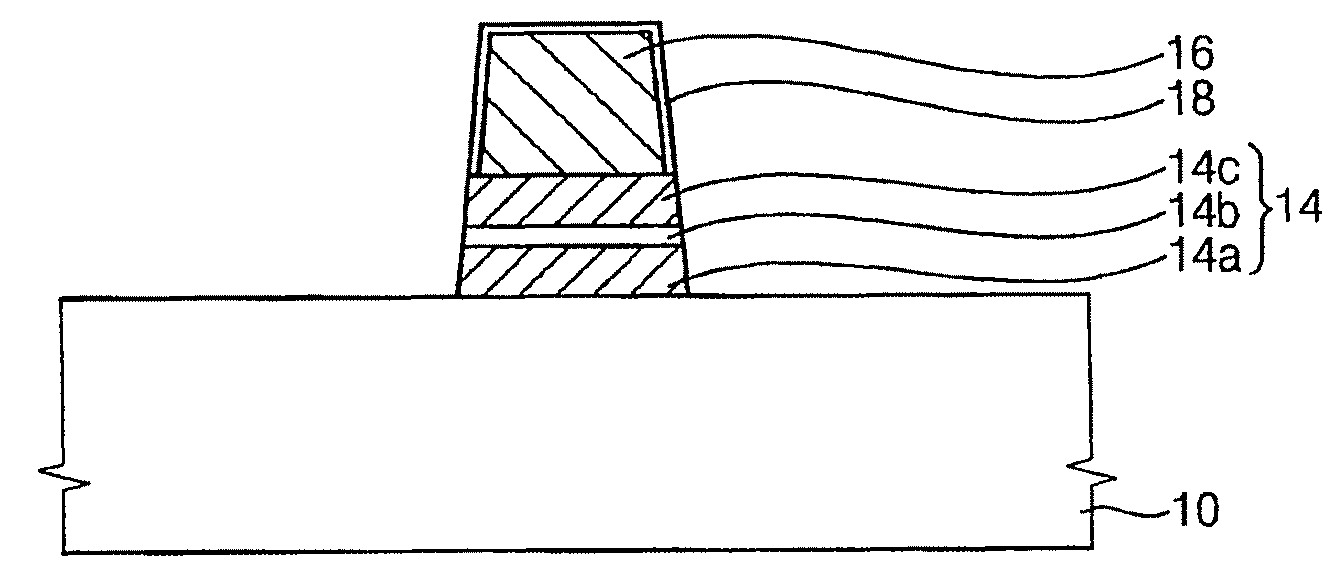

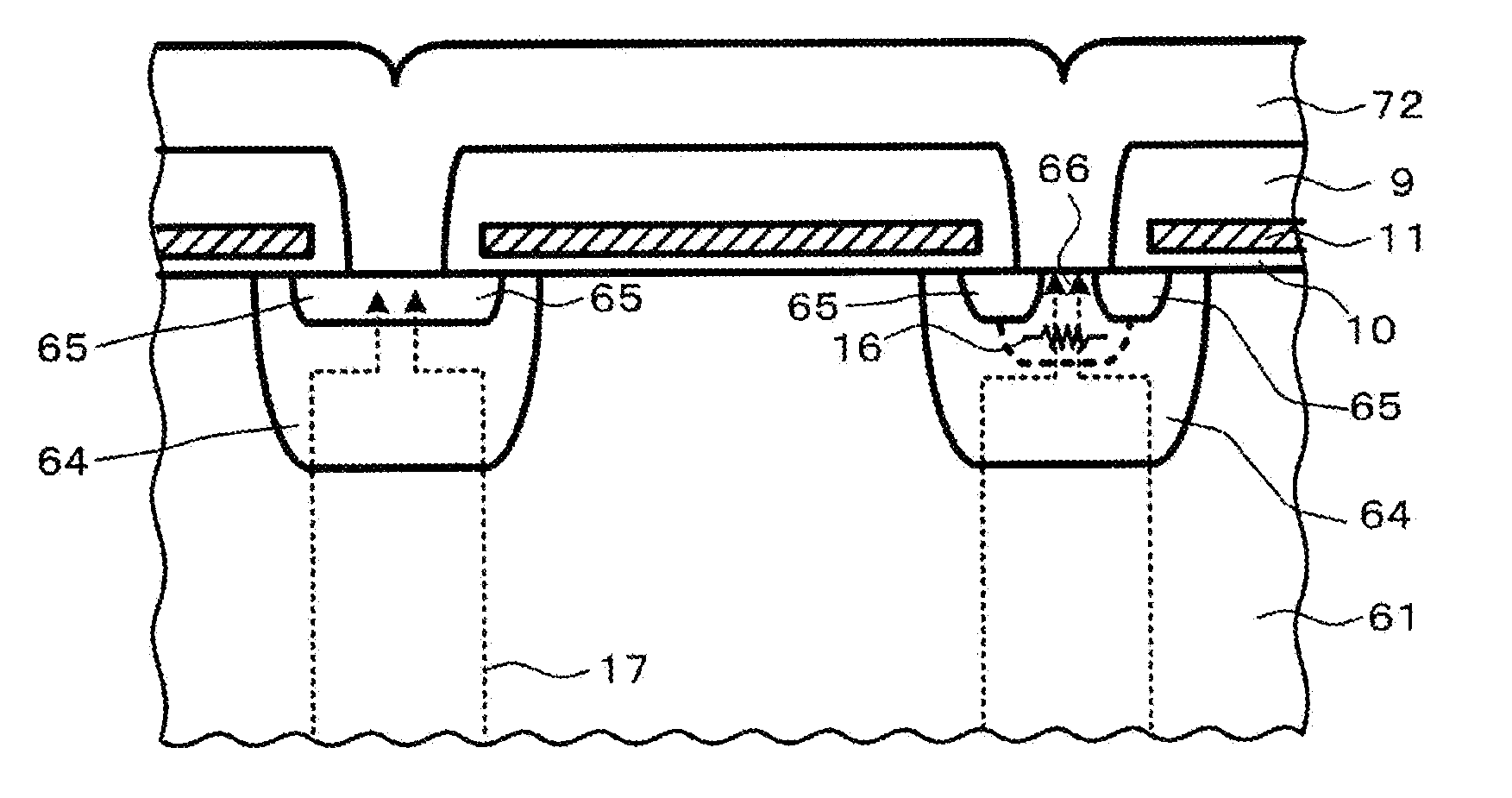

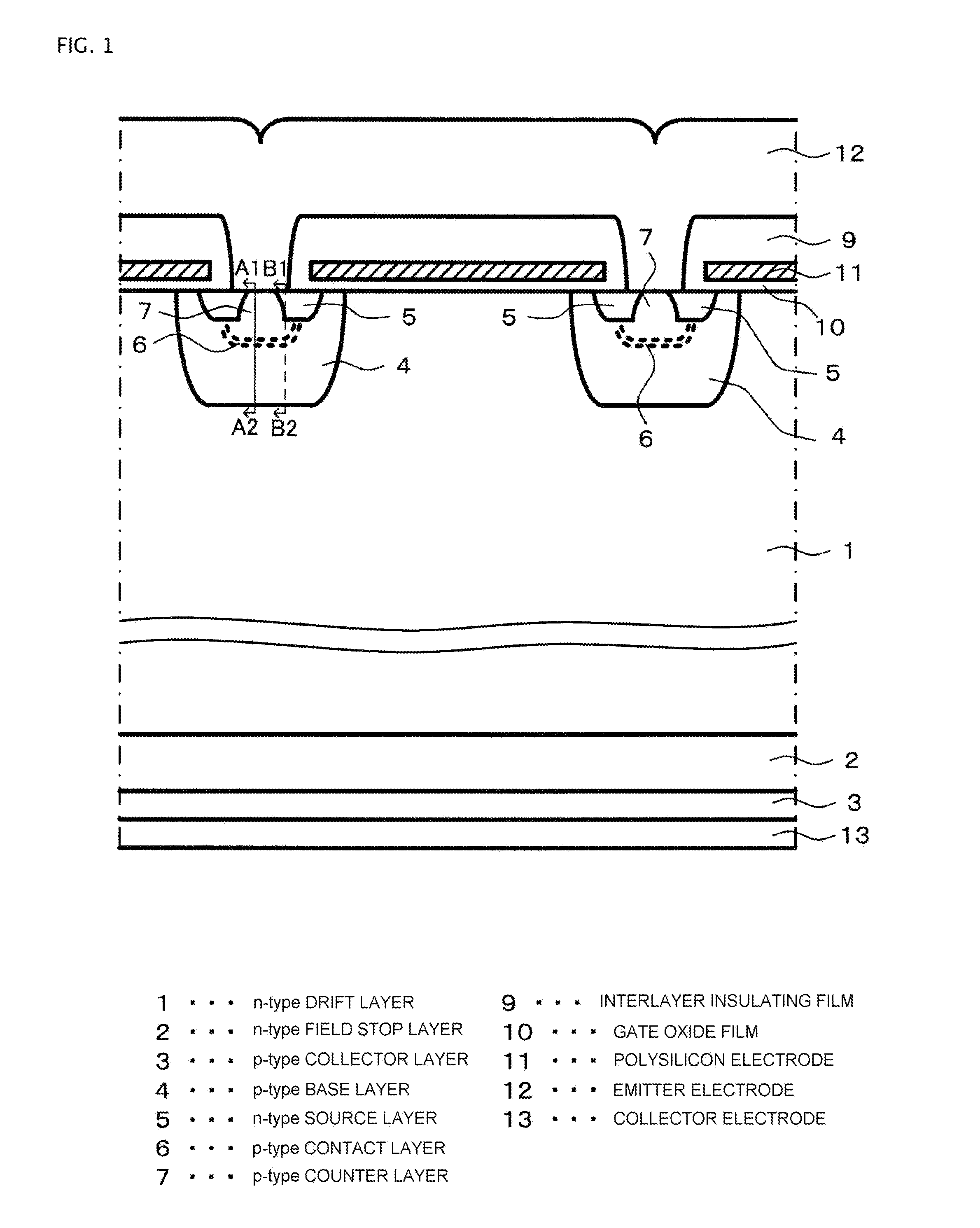

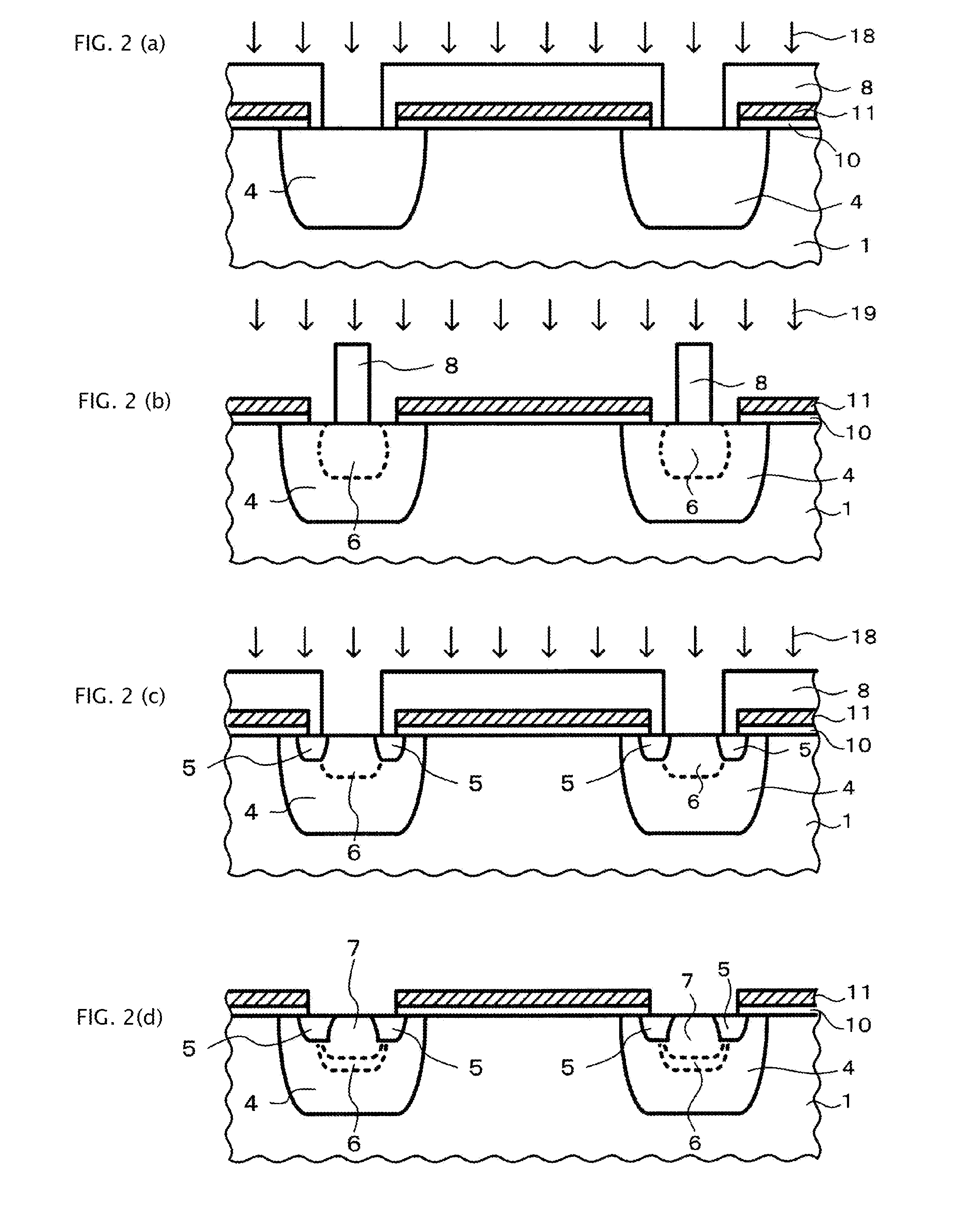

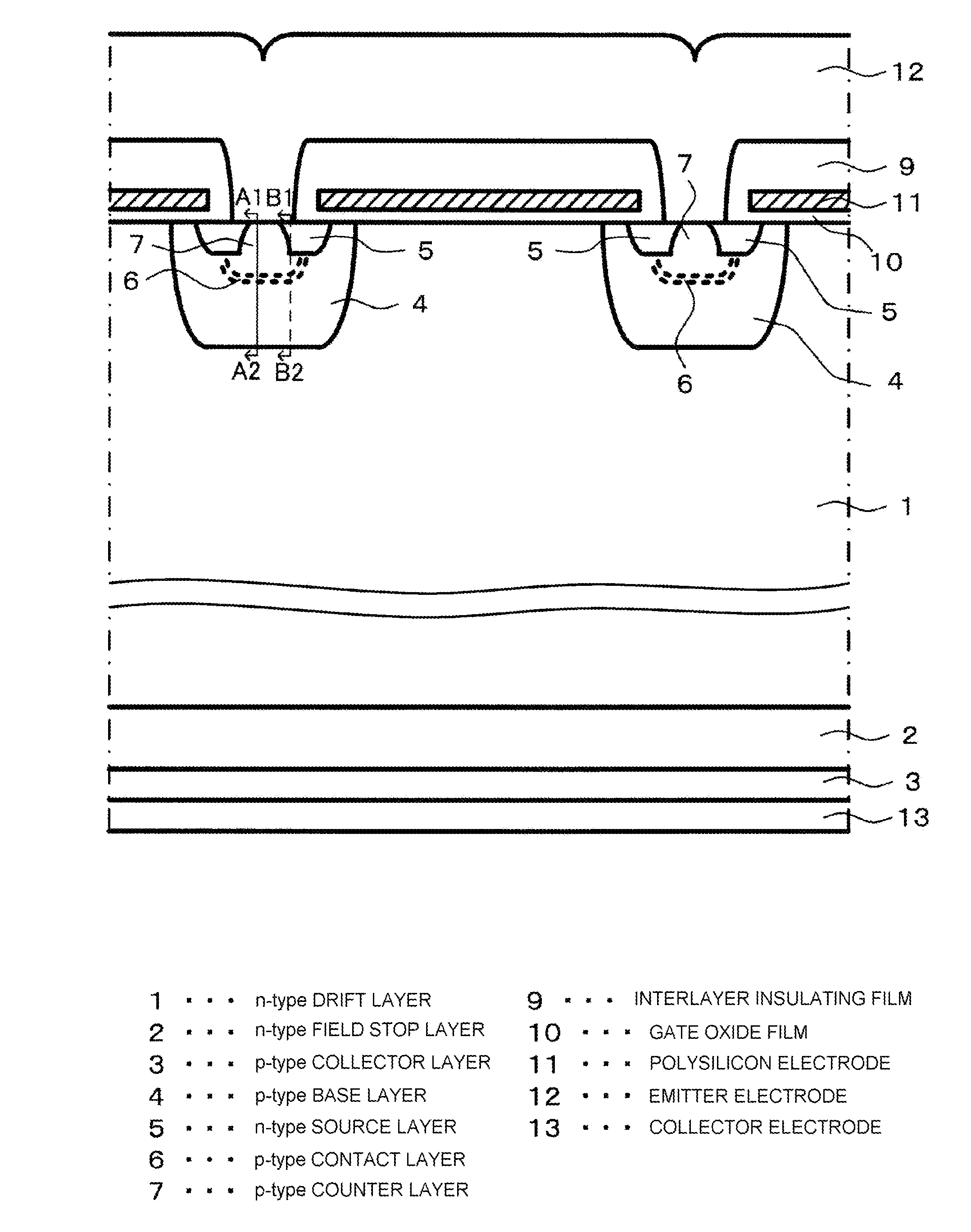

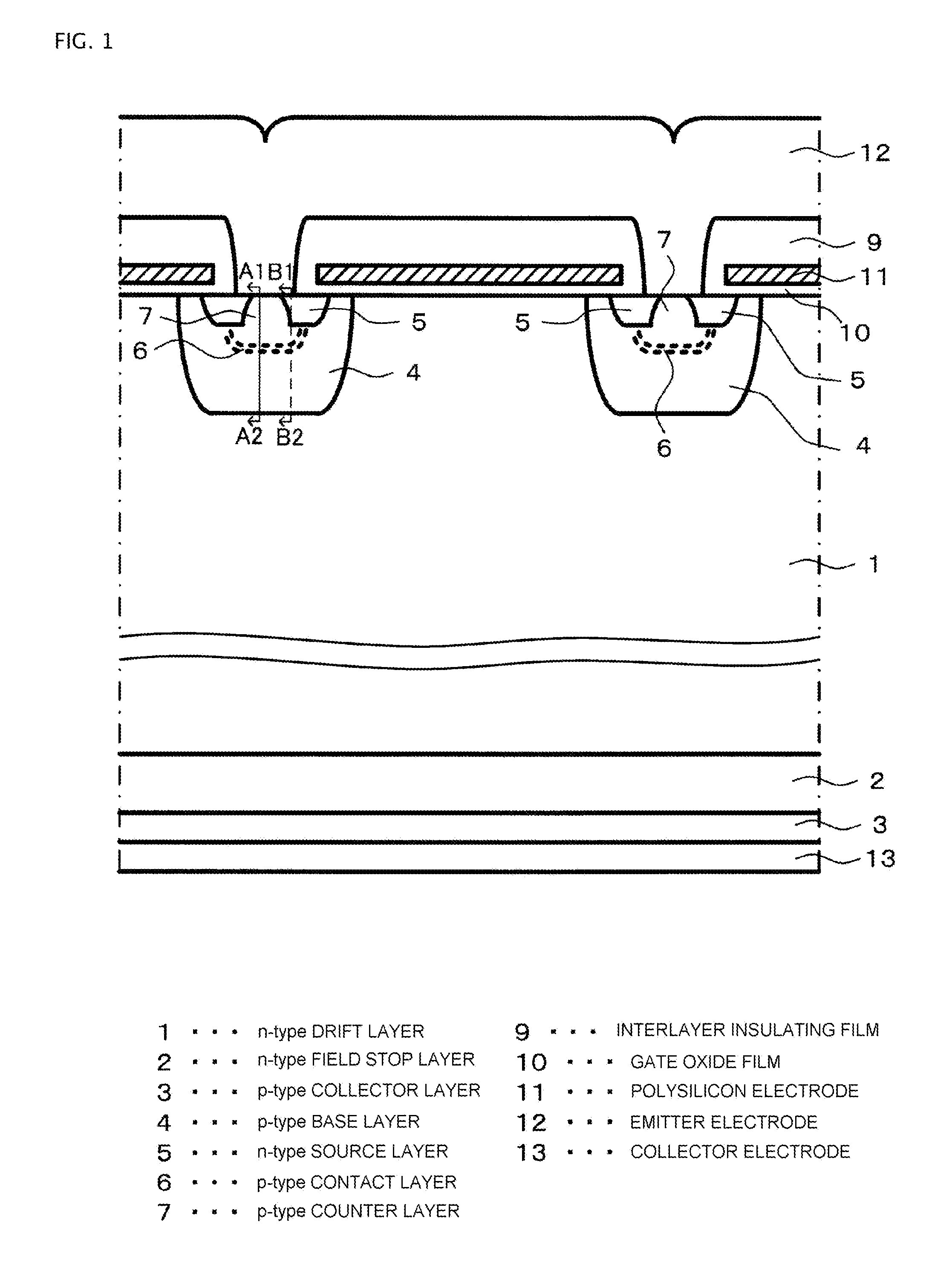

Semiconductor device and method of manufacturing the same

ActiveUS20130082301A1Reduce processing defectsDestruction of switchTransistorSolid-state devicesGate oxideSemiconductor

A p-type base layer is selectively formed on a surface of an n-type drift layer; an n-type source layer is selectively formed on a surface of the p-type base layer; and a p-type contact layer is formed to be in contact with the selectively-formed n-type source layer. A p-type counter layer is formed to be in contact with the n-type source layer, so as to overlap the p-type contact layer, so as to be separated from an interface where the p-type base layer and the gate oxide film are in contact with each other, and to be shallower than the p-type base layer. Accordingly, switching destruction caused by process defects in an insulated gate semiconductor device is reduced.

Owner:FUJI ELECTRIC CO LTD

Water cooling electromagnetic copper type directional solidification method of titanium base alloy

A water cooled electromagnetic directional solidifying method for Ti-based alloy features that the furnace containing crucible is vacuumized, and after the single-phase AC is applied to the coil for 4-16 min, the upper material rod and bottom material are moved downward to make the bottom material come in crystallier, resulting in uniform cooling speed and high mechanical performance of product.

Owner:HARBIN INST OF TECH

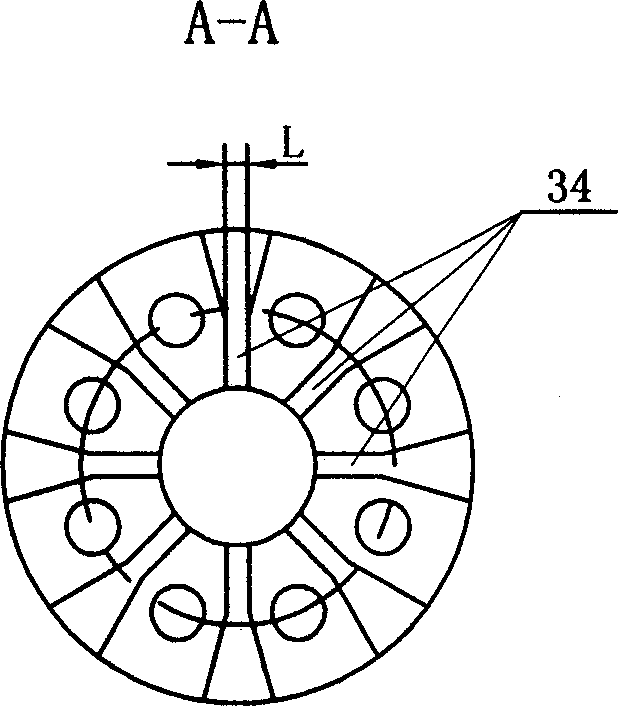

Martensite-granular bainite plastic die steel and manufacturing method thereof

The invention relates to martensite-granular bainite plastic die steel and a manufacturing method thereof, and belongs to the field of manufacturing of steel materials. The die steel consists of martensite and granular bainite, wherein the martensite accounts for 60 to 90 volume percent of the steel. The manufacturing method comprises the following steps of: performing hot processing, cooling to room temperature, heating a material to the temperature of between 800 and 920 DEG C again, preserving the heat, cooling to room temperature at a speed of 0.02 to 20 DEG C / second, and tempering at the temperature of between 100 and 600 DEG C to obtain the plastic die steel. The die steel has the advantages of high strength, elongation and impact toughness.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +1

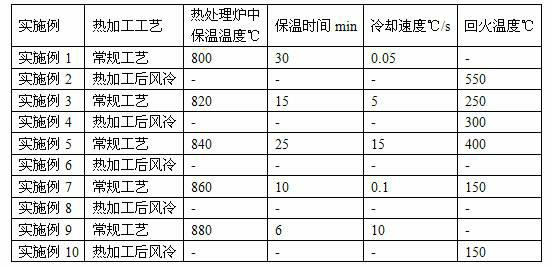

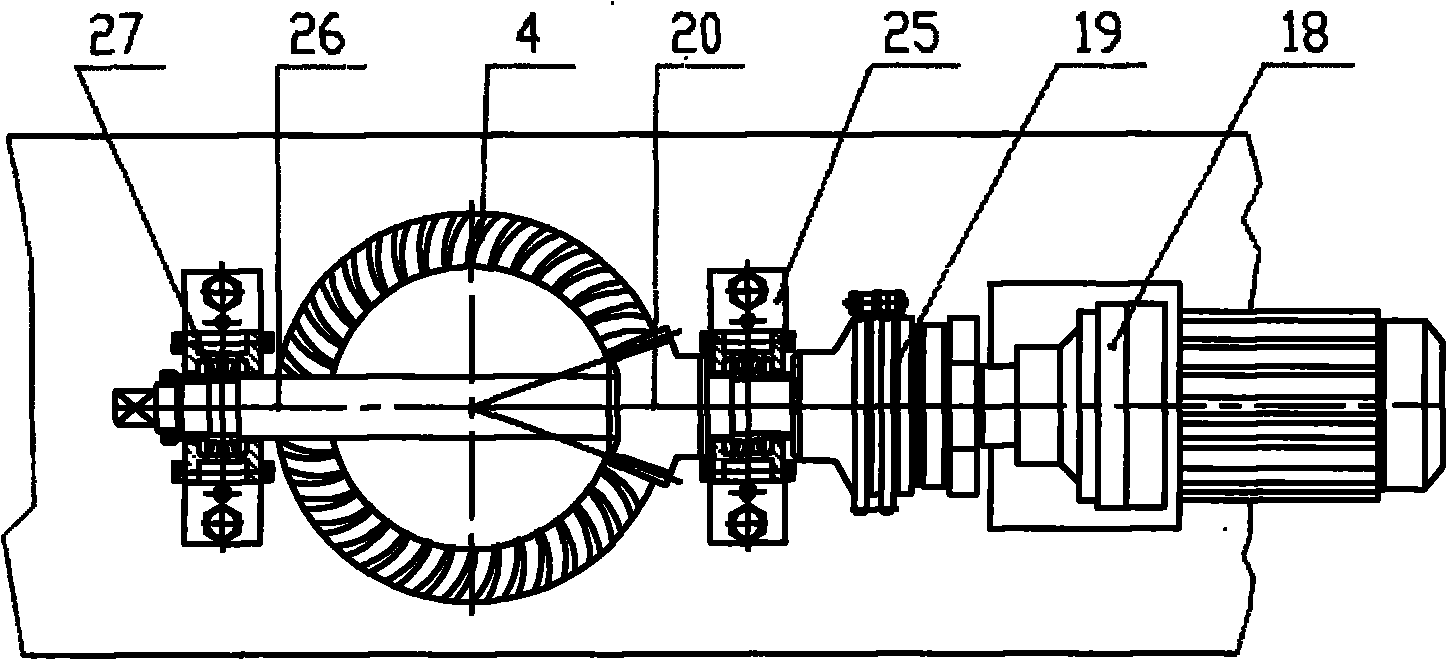

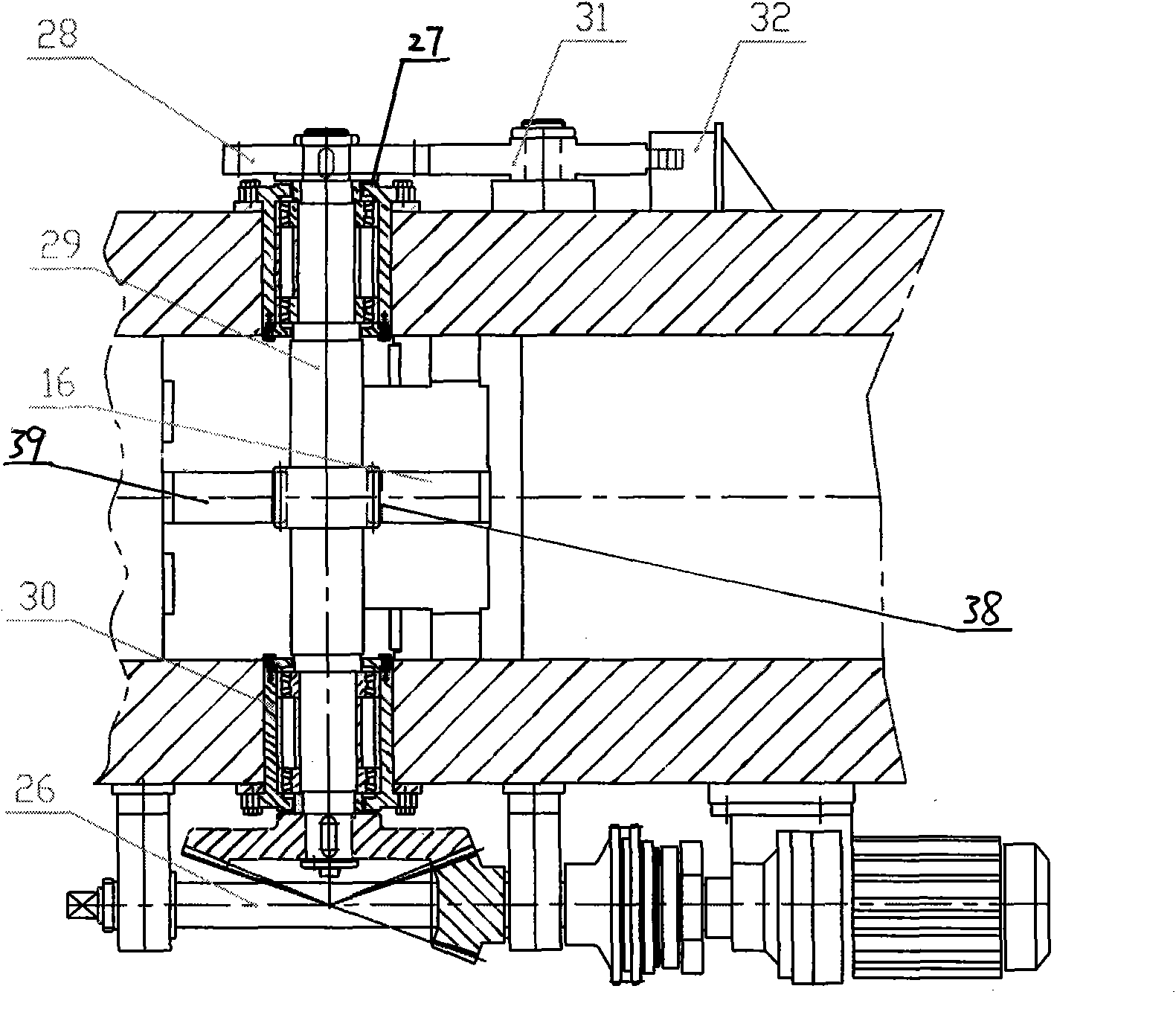

Electromagnetic braking translation-type rolling plate clamp

ActiveCN101927949AGuaranteed uptimeWith braking functionLoad-engaging elementsFriction gearingsSemi automaticEngineering

The invention discloses an electromagnetic braking translation-type rolling plate clamp comprising a hoisting device, a driving device, a braking device, a supporting cross beam, a left clamp arm, a right clamp arm, a clamp arm protection device and an electrical system, wherein the driving device comprises a three-in-one speed reducer, a torque limiter, a small spiral bevel gear, a big spiral bevel gear, a rack, a gear, an aligning roller bearing and a gear shaft; and the electromagnetic braking device comprises an electromagnet, a ratchet wheel and a pawl. When in brake, the other end of the pawl is supported on the root of the ratchet wheel; the middle of the pawl is hinged on the rear side wall of the supporting cross beam; a detection device comprises a position switch arranged on the cross beam and a centering switch and an edge detection switch which are arranged on the clamp arms. In the invention, the driving device has stable running; the electromagnetic braking is accurate and reliable; and a sliding plate is well protected and can be easily and accurately reset. The clamp has the advantages of compact structure, light dead weight, high safety factor, high strength, comprehensive protection measure and high working efficiency, can realize automatic and semi-automatic running and relieve the labor intensity of workers.

Owner:JULI SLING

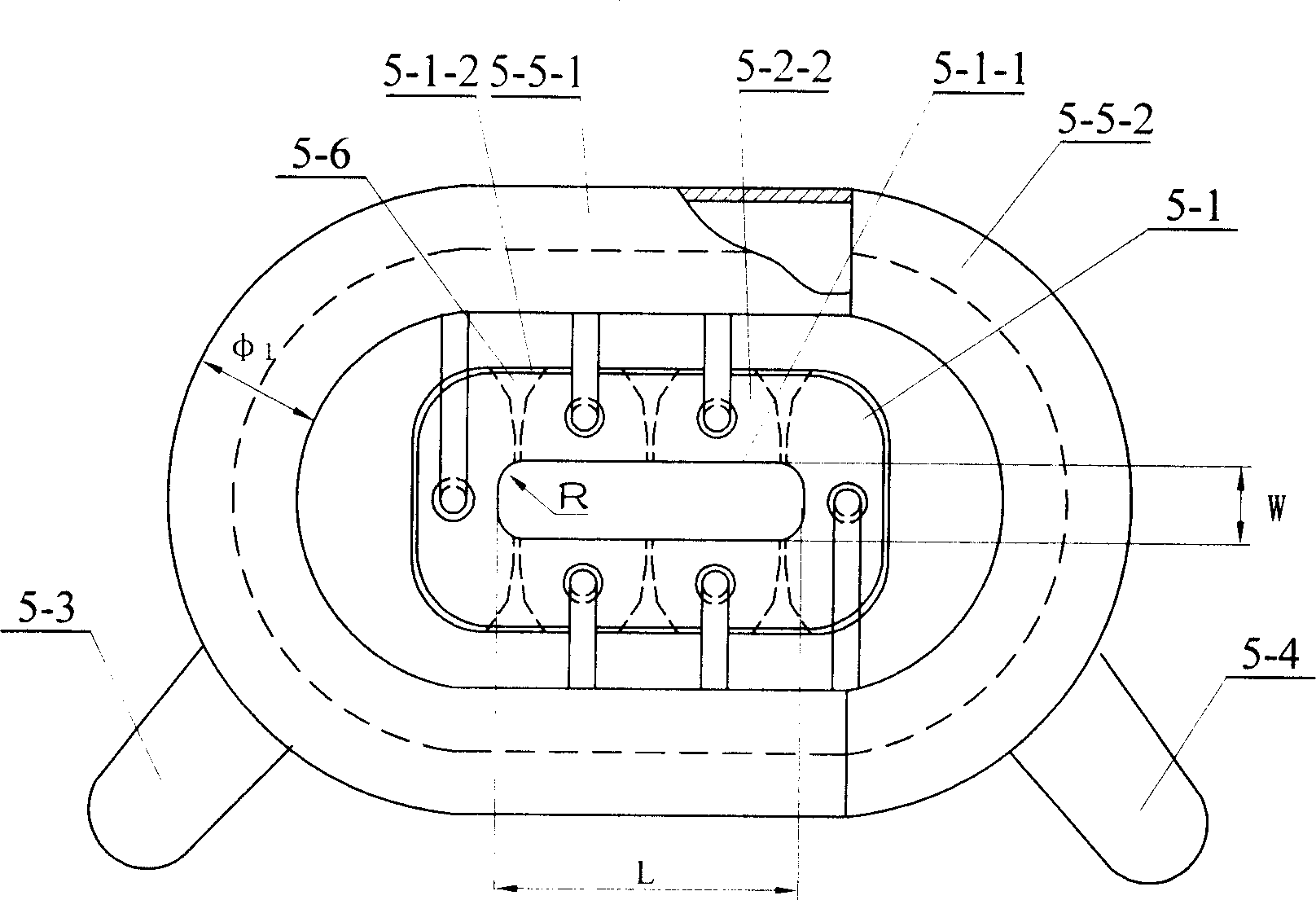

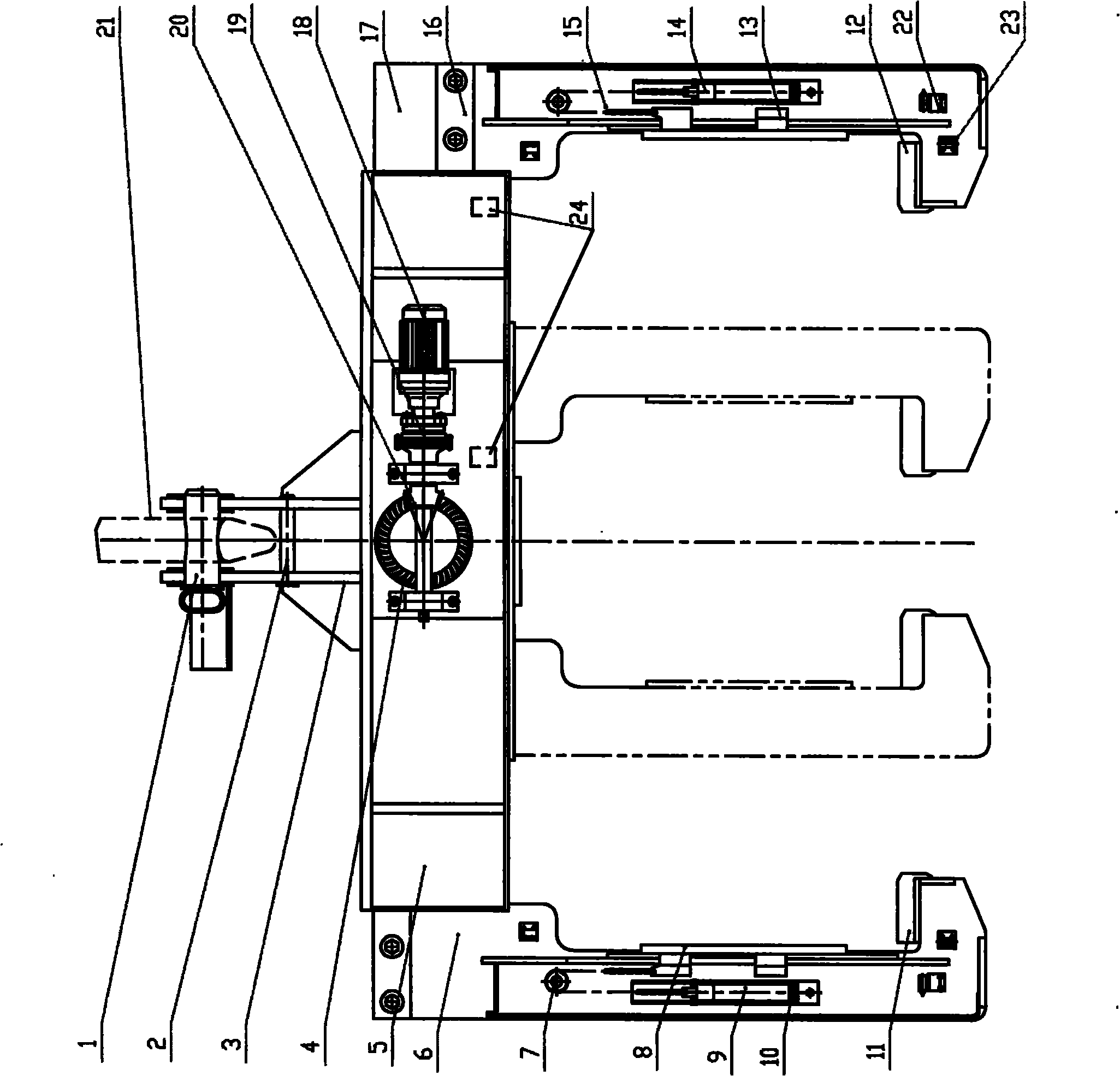

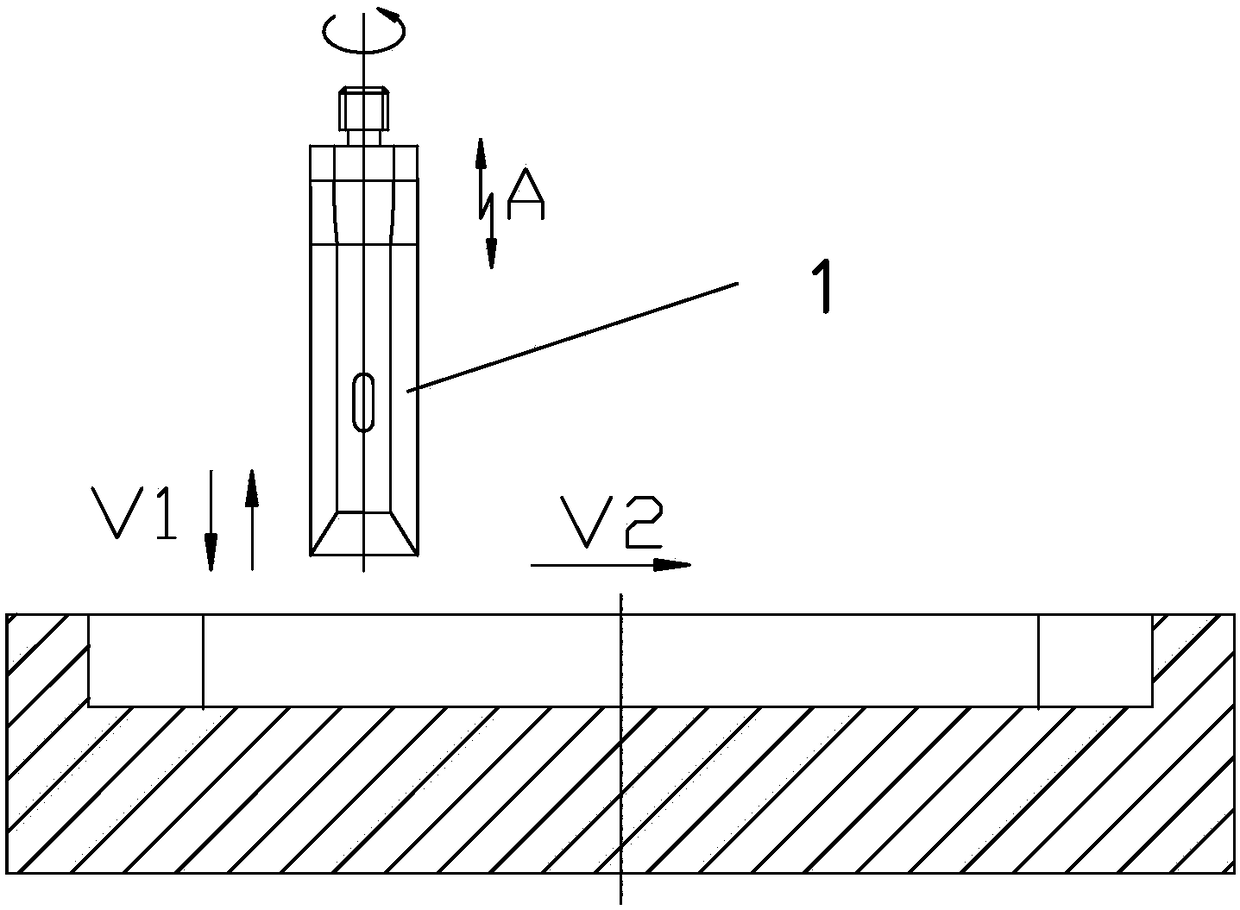

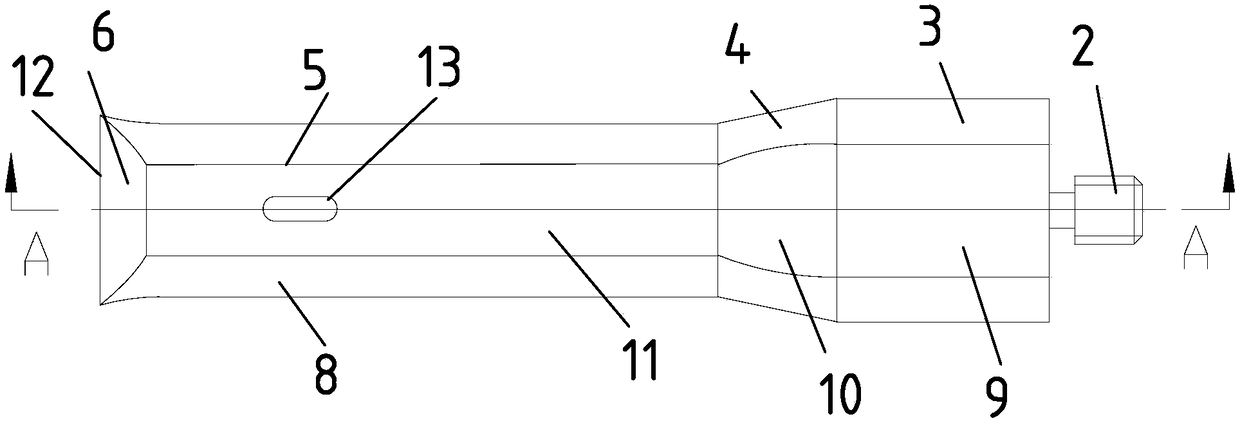

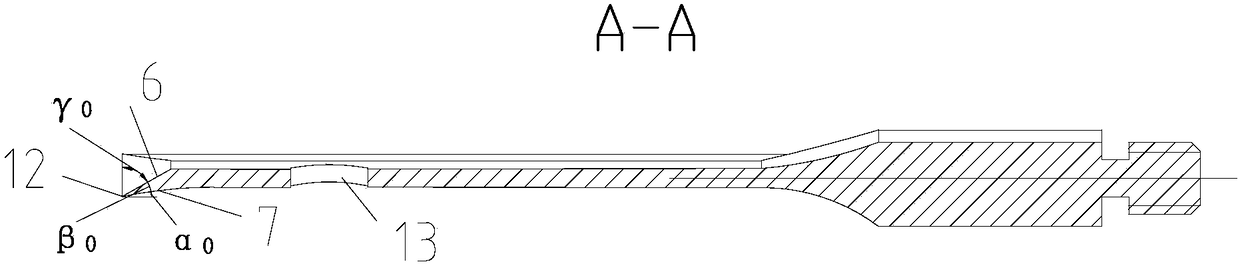

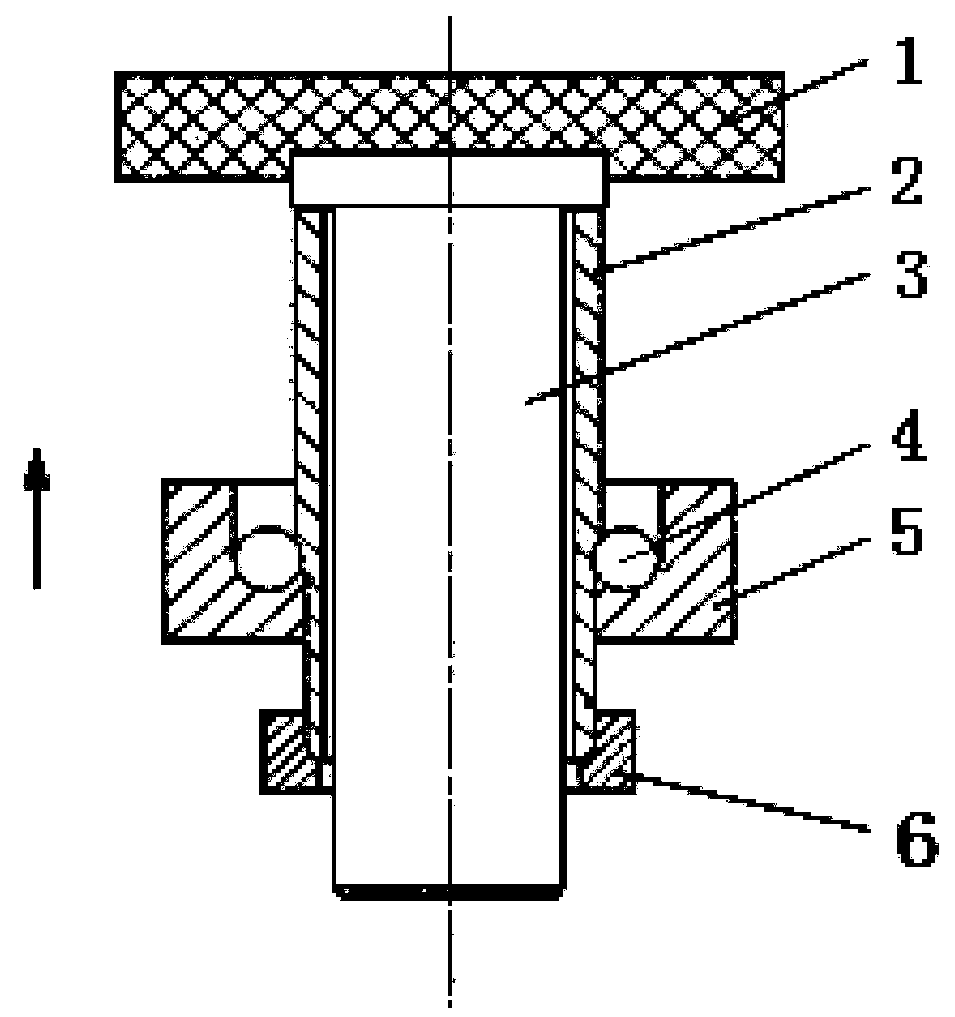

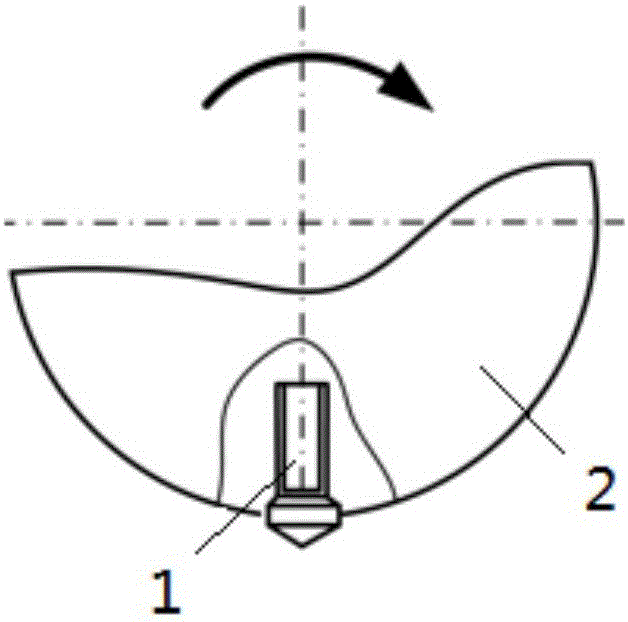

Ultrasonic inserting cutting tool for processing curve outline of honeycomb core

ActiveCN108356299AReduce processing defectsReduce wearPlaning/slotting toolsTurning toolsHoneycombUltrasonic vibration

The invention discloses an ultrasonic inserting cutting tool for processing a curve outline of a honeycomb core. The ultrasonic inserting cutting tool comprises a threaded section, a rigidity improving block, a trapezoid-like shaped platform transition block and a thin-sheet shaped open type tool body, wherein axes of the threaded section, the rigidity improving block, the trapezoid-like shaped platform transition block and the thin-sheet shaped open type tool body are positioned on an axis of the ultrasonic inserting cutting tool for processing the curve outline of the honeycomb core. According to the ultrasonic inserting cutting tool for processing the curve outline of the honeycomb core, the curve outline of the honeycomb core material is inserted and cut under ultrasonic vibration effect; the honeycomb core material can be smoothly cut through a circular arc shaped cutting bottom edge under the ultrasonic effect, thus the damage of the honeycomb core material in processing can be decreased, and the processing rigidity of the rest materials can be improved; in addition, the friction between the circular arc shaped cutting bottom edge and the processing surface of the honeycomb core is reduced by the ultrasonic effect, so that the processing defects of the curve outline of the honeycomb core can be reduced; the abrasion of the tool is reduced, and as a result, the service life of the tool is prolonged; and the curve outline of the honeycomb core is processed with high quality.

Owner:DALIAN UNIV OF TECH

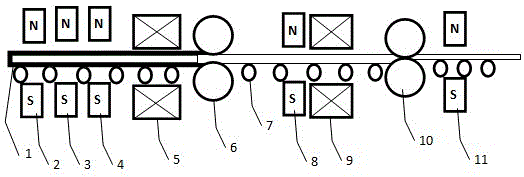

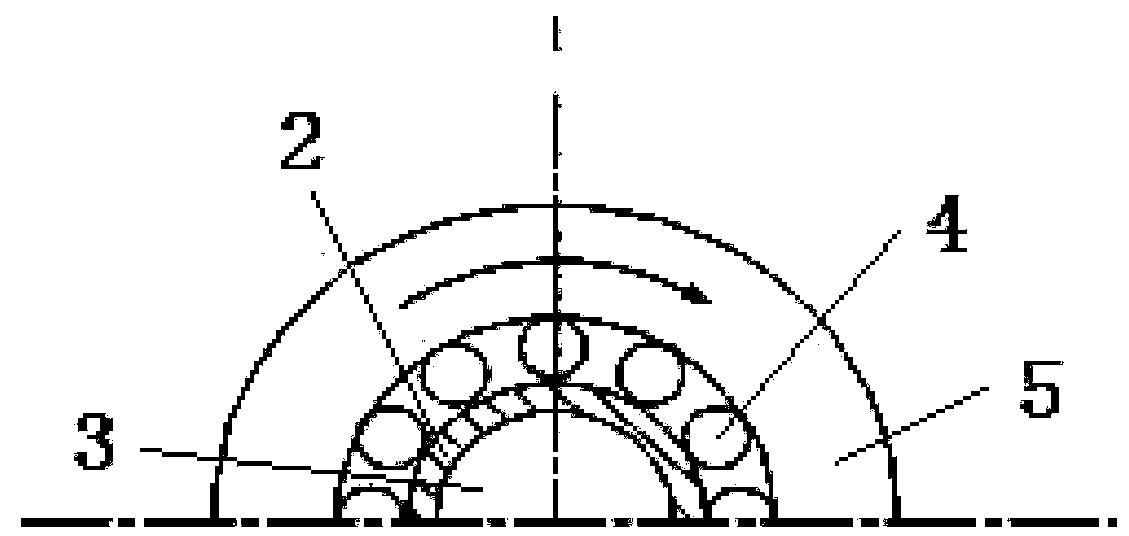

Method for rolling metal wire bars under magnetostatic field auxiliary effect

ActiveCN105032926AReduce deformation resistanceImprove plastic deformation abilityMetal rolling arrangementsUltimate tensile strengthMaterial Deformation

The invention mainly relates to the technical field of extrusion rolling and drawing of metal wire bars, in particular to a method for rolling metal wire bars under a magnetostatic field auxiliary effect. The method is characterized by comprising the following steps: a magnetostatic field is installed in the advancing direction of metal wire bar blanks; before the metal wire bar blanks are rolled, extruded and drawn, the metal wire bar blanks are suffered from a magnetic field effect in the process of passing through the magnetostatic field area; the longitudinal center line of the metal wire bar blanks is consistent with the advancing direction thereof; and the blanks are rolled, extruded and drawn by rollers after the treatment of the magnetostatic field auxiliary effect. For multiple times of rolling, extrusion and drawing, the magnetostatic field treatment is performed before each time of rolling. The method has the following advantages: the material deformation resistance is prominently reduced; the rolling defects are reduced; the finished product size precision is high; the material mechanical performance, in particular the strength and the toughness are improved; and the synchronous reinforcement of the material toughness is realized.

Owner:JIANGSU UNIV

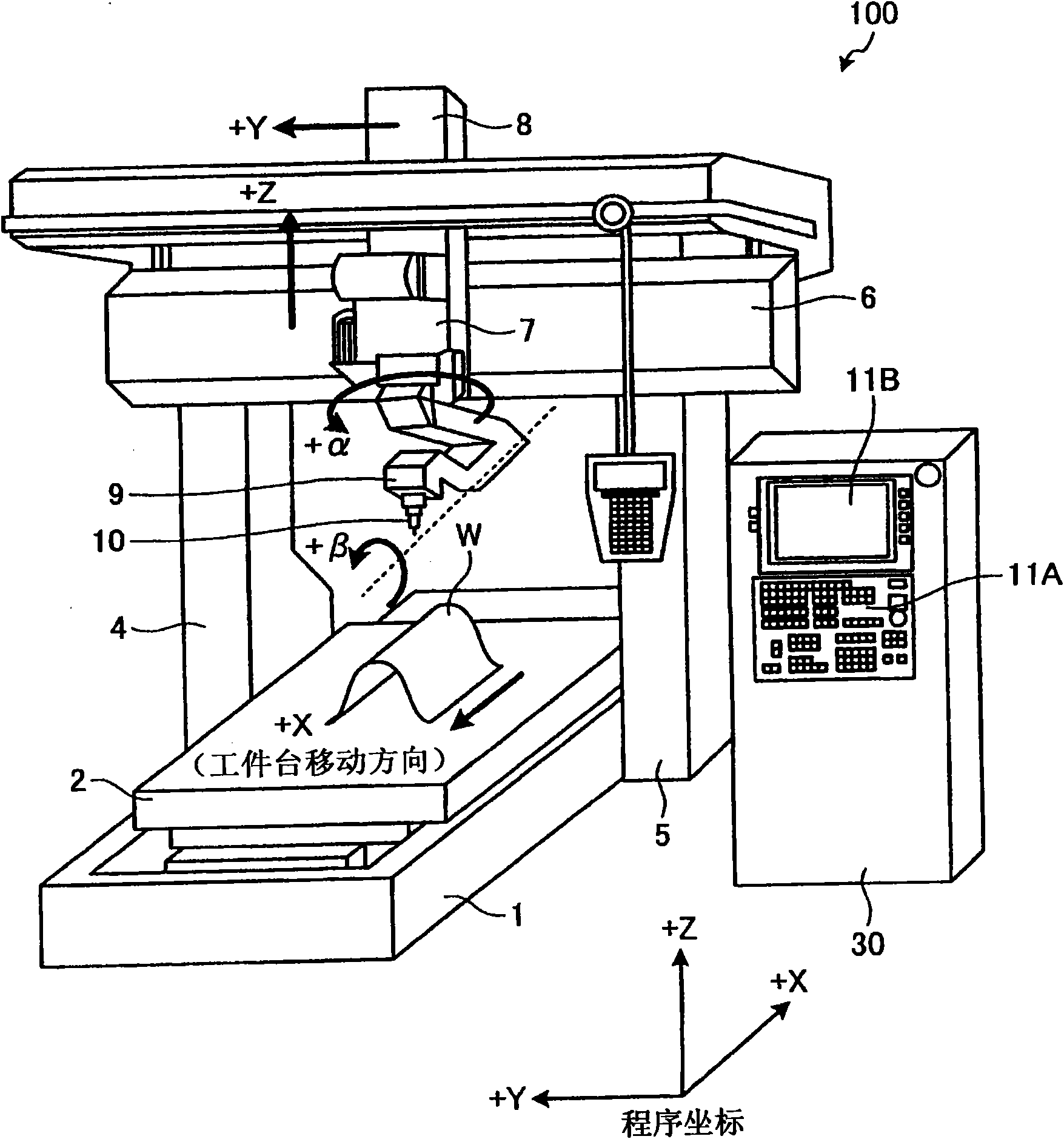

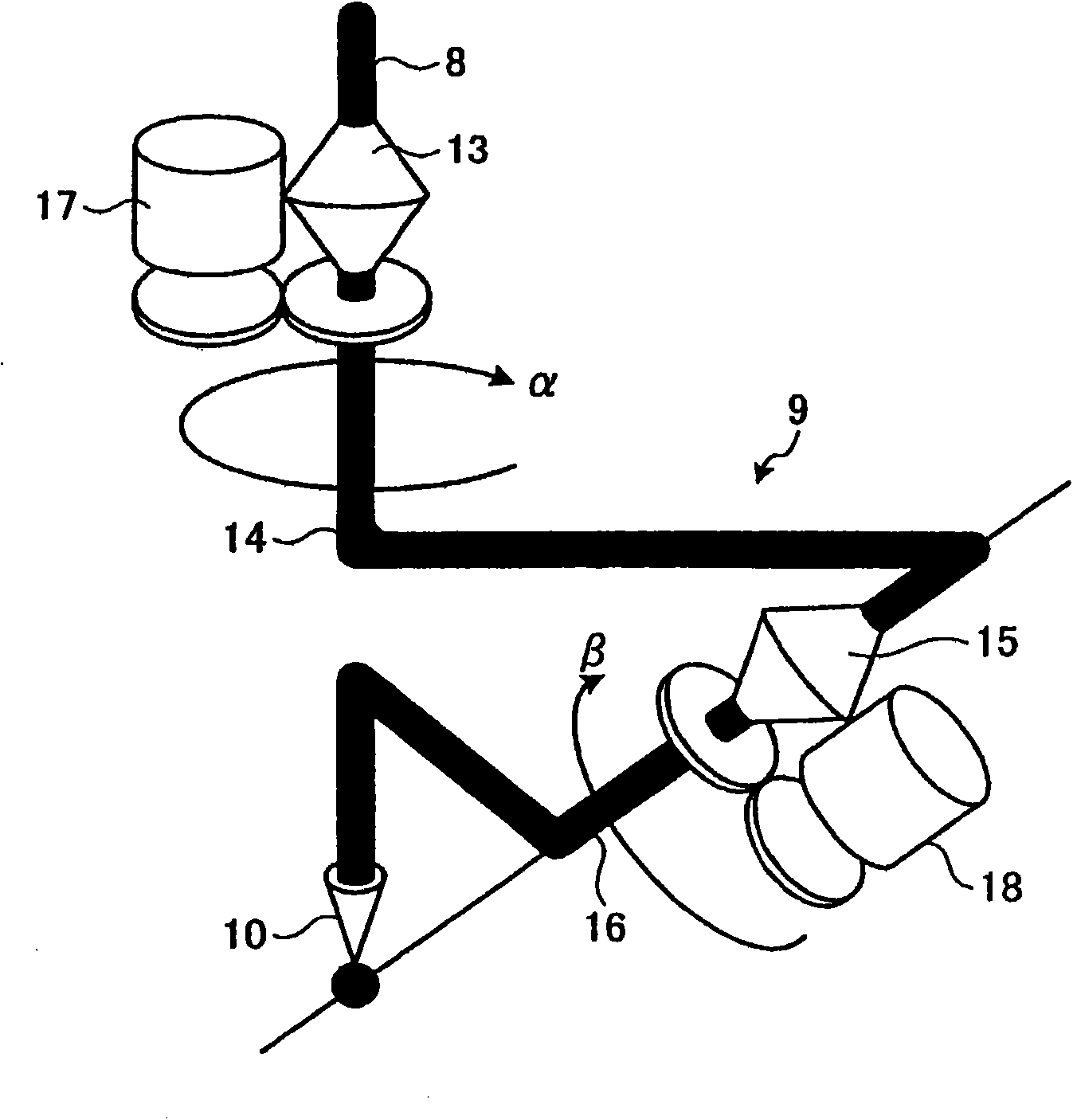

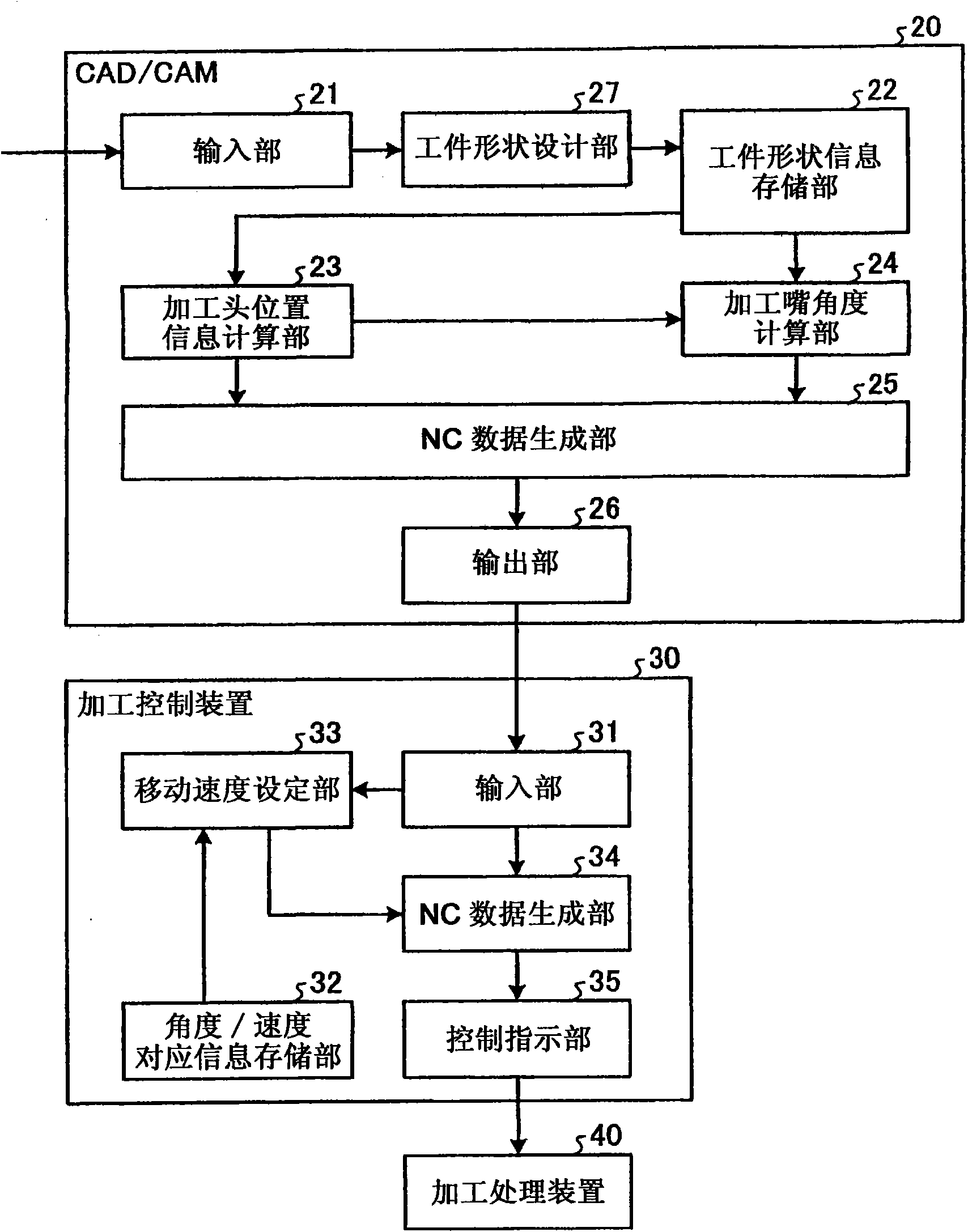

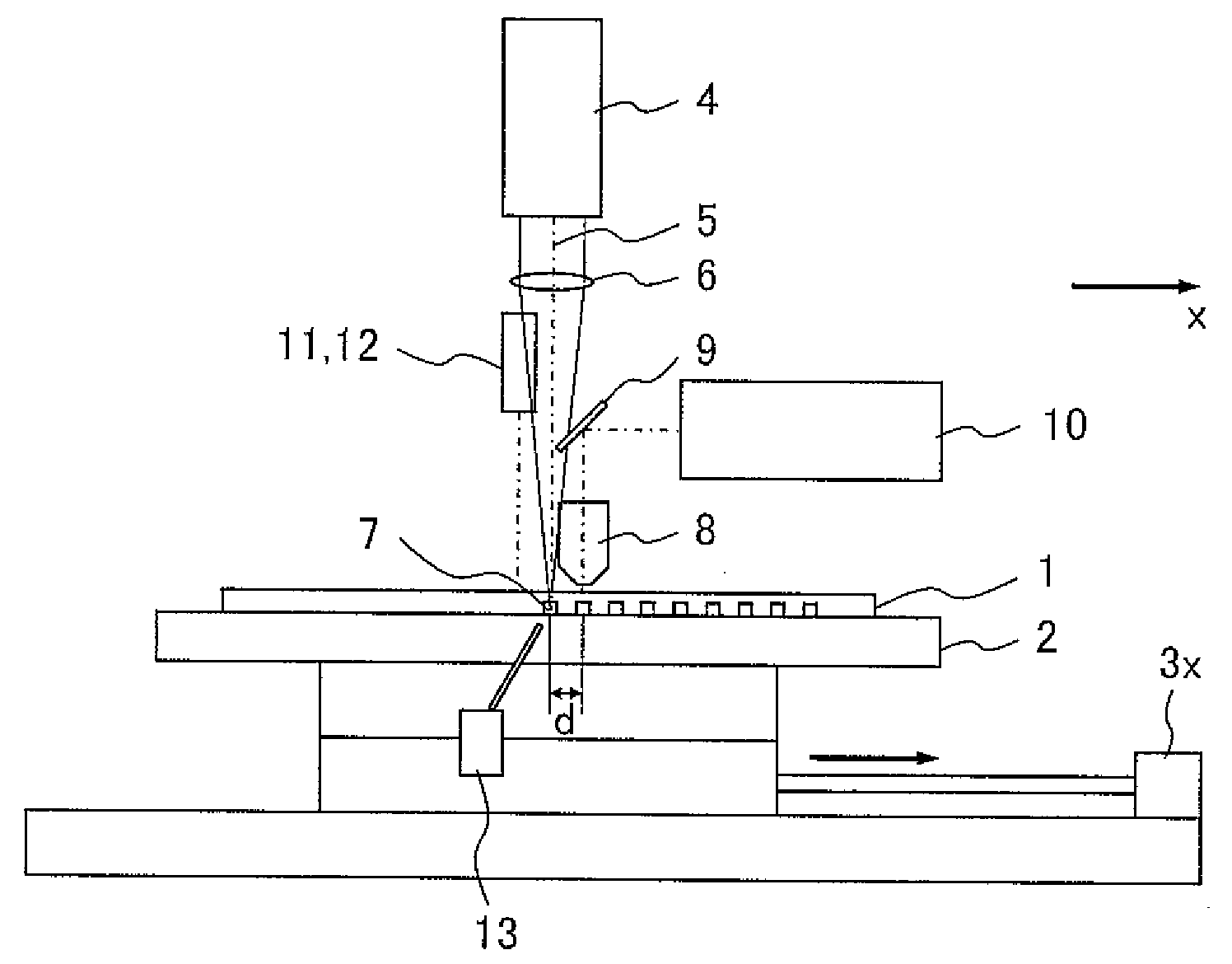

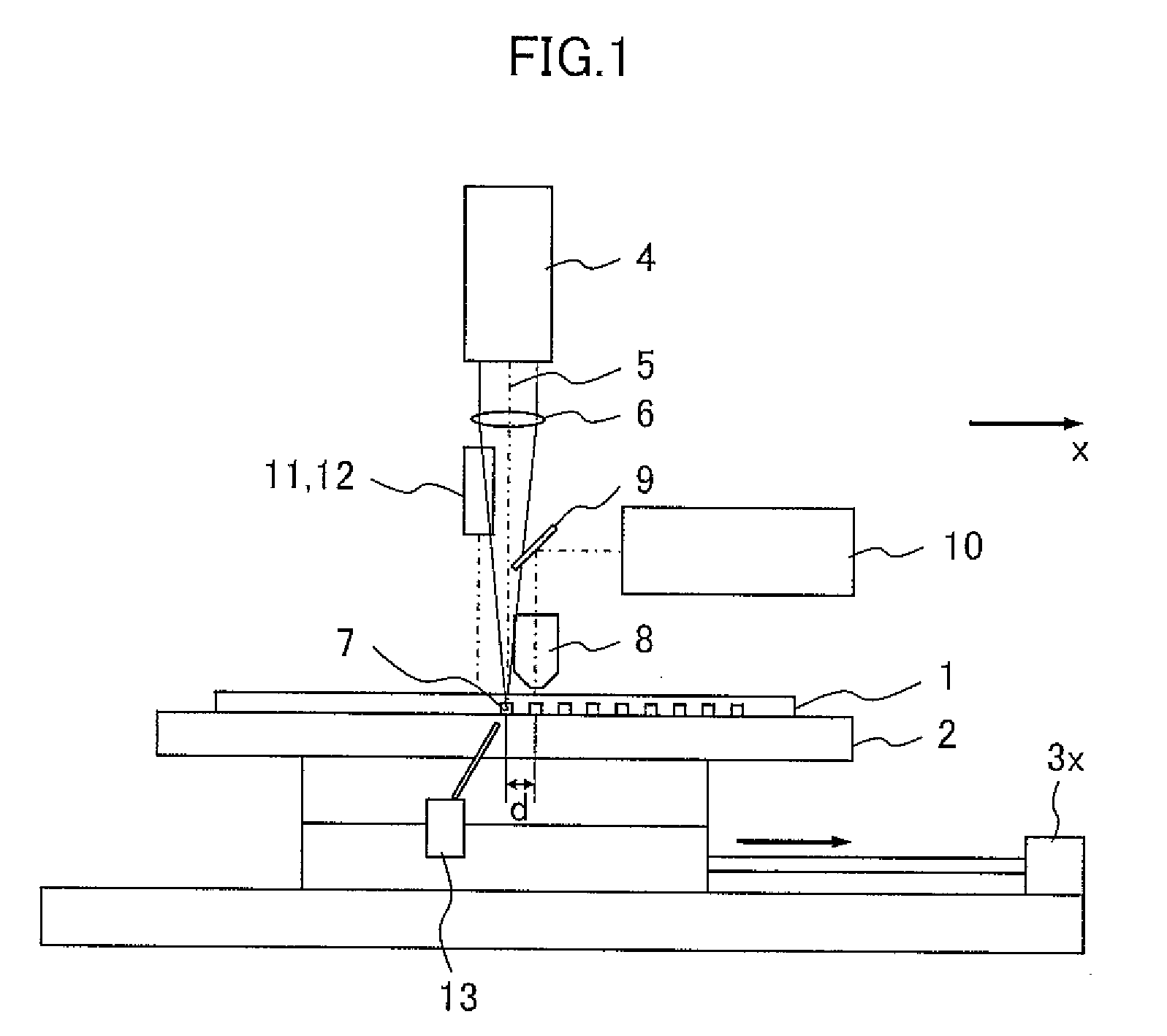

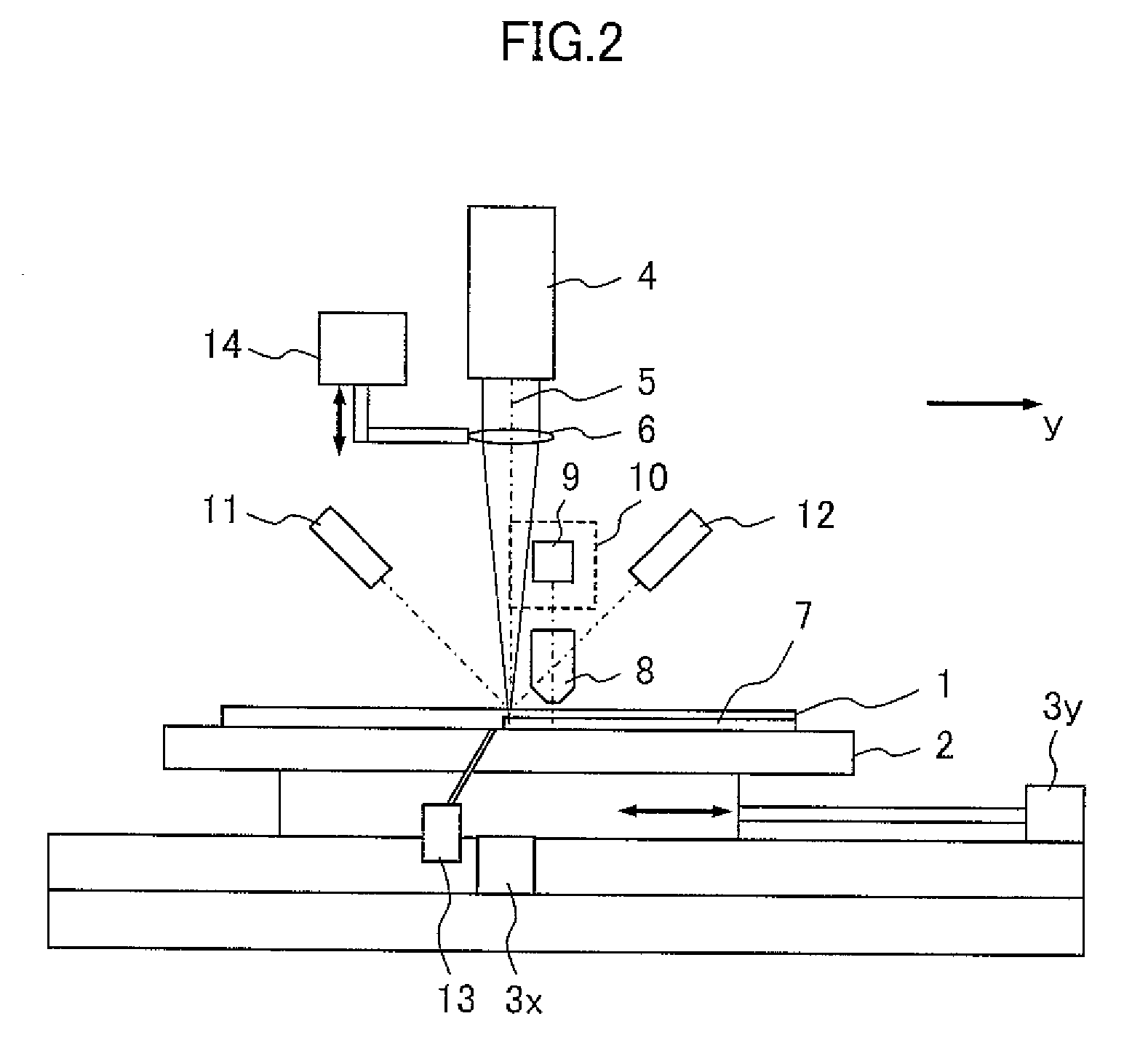

Processing-control device, laser processing device and laser processing system

ActiveCN102033511AReduce processing defectsComputer controlSimulator controlLaser processingMachining system

The invention provides a processing-control device, which can set appropriate moving speed of a processing head in a short time and reduce unqualified workpieces during process. The processing-control device which controls the three-dimensional laser processing of workpieces through laser irradiation comprises a moving speed setting part (33), which sets the moving speed of a processing head corresponding to the angle of a processing position for each processing position based on the angle formed between the surface of a processing position on a workpiece and the direction of the processing tip of a processing head; and a control indicating part (35), outputs control indication for a workpiece based on the moving speed set to control the three-dimensional laser process.

Owner:MITSUBISHI ELECTRIC CORP

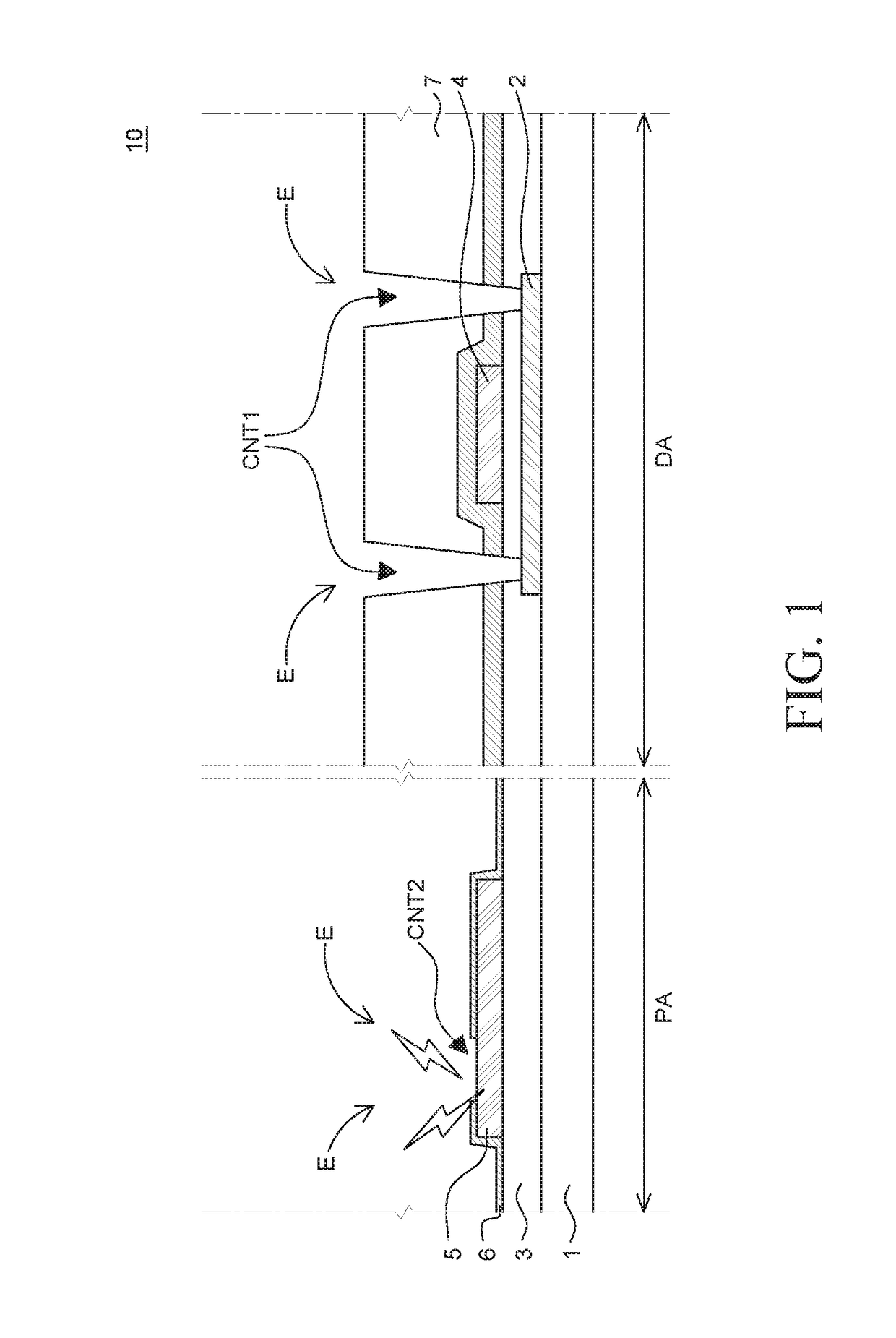

Electrode connection structure and electronic device including the same

ActiveUS20190129535A1AdhesionImprove product reliabilityInsulated cablesPower cablesEngineeringElectrode

An electrode connection structure includes a substrate layer, a plurality of pads on the substrate layer, and an insulation layer at least partially covering the substrate layer and the pads. The insulation layer includes a plurality of holes on the pads and at least one first groove line extending between the pads neighboring each other.

Owner:DONGWOO FINE CHEM CO LTD

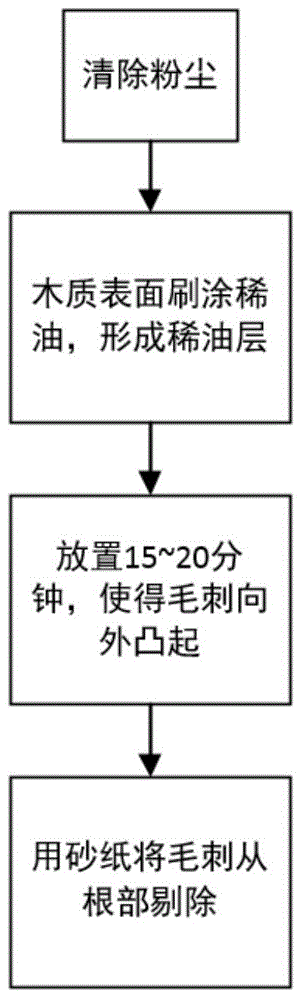

Wood burr thorough removing method

ActiveCN104400586AEasy to removeRemove completelyEdge grinding machinesWood working apparatusPulp and paper industrySandpaper

The invention discloses a wood burr thorough removing method. The wood burr thorough removing method comprises the following steps of 1) removing dust on the surfaces off wood; 2) brushing thin oil on wood surfaces or in holes or grooves by using a hairbrush to form a thin oil layer; 3) standing the wood for 15-20 minutes, wherein burrs on the wood surfaces or in the holes or grooves protrude outwards under the effect of the acting force of thin oil solidification, and a solidified thin oil layer is formed on the burns and the wood surfaces such that the burrs get far away from the wood surfaces, holes or grooves; 4) grinding the wood surfaces by using abrasive paper to remove the burrs from the roots of the wood surfaces. The wood burr thorough removing method has the advantages that since the thin oil is coated onto the wood to form the thin oil layer and the burrs of the wood are enabled to be outwards upright or warped to get far away from the surfaces of the wood during PU (polyurethane) resin solidification, then the burrs can be easily removed from the roots by using the abrasive paper and the effect of thoroughly removing the burrs is achieved.

Owner:DONGGUAN HOTLINE FURNITURE

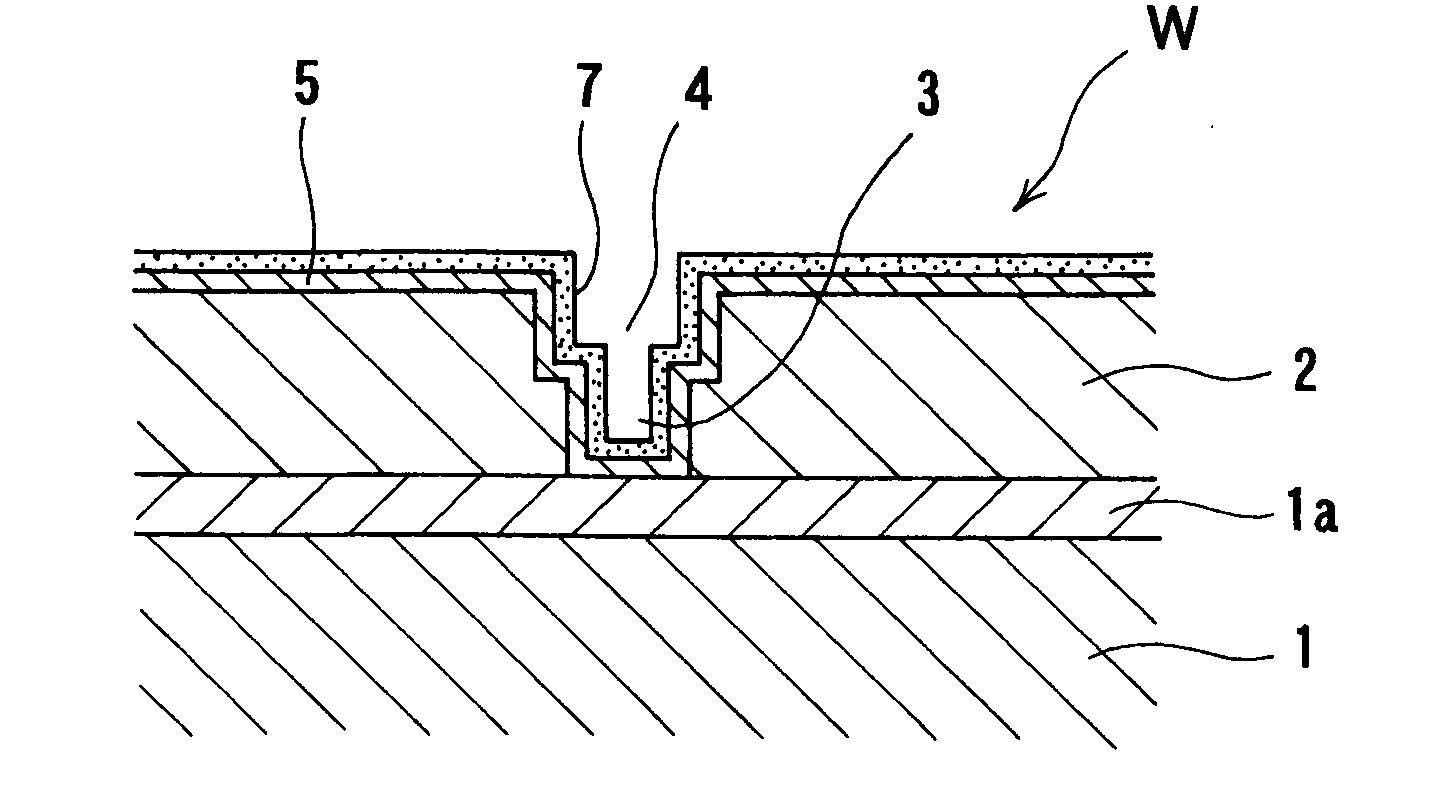

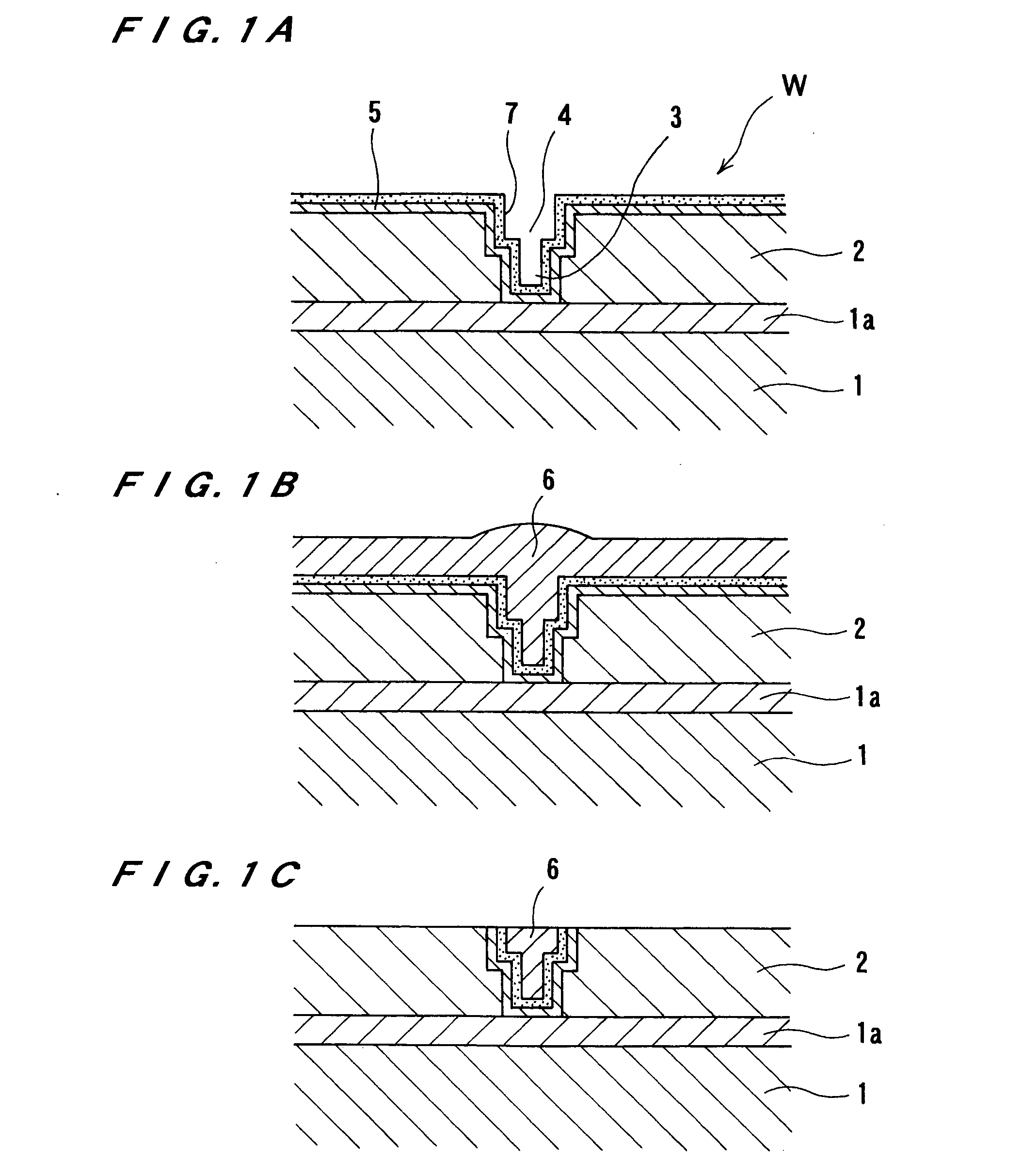

Laser processing apparatus

InactiveUS20100167431A1Reduce processing defectsShort TATLaser detailsSemiconductor/solid-state device testing/measurementOptoelectronicsRadiation

A laser processing apparatus which achieves both shorter TAT and reduction in processing defects. In the apparatus, a laser radiation section, an undulation measurement section for measuring undulation of a substrate or a film thickness measuring section for measuring the thickness of a thin film formed on the substrate, and an optical inspection section for optically inspecting grooves formed by laser-processing the thin film on the substrate are fixed so that their positional relationship is kept constant.

Owner:HITACHI HIGH-TECH CORP

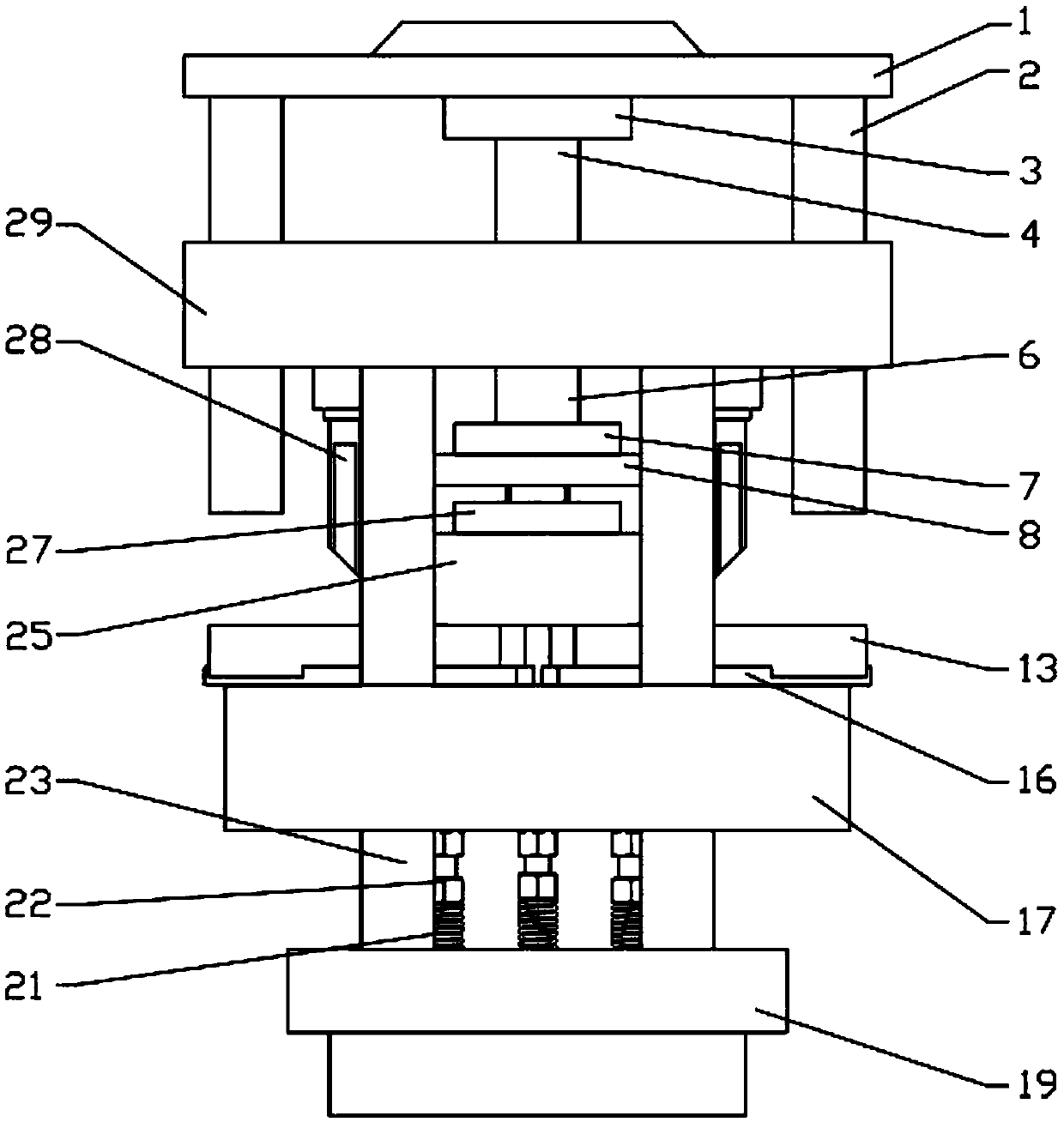

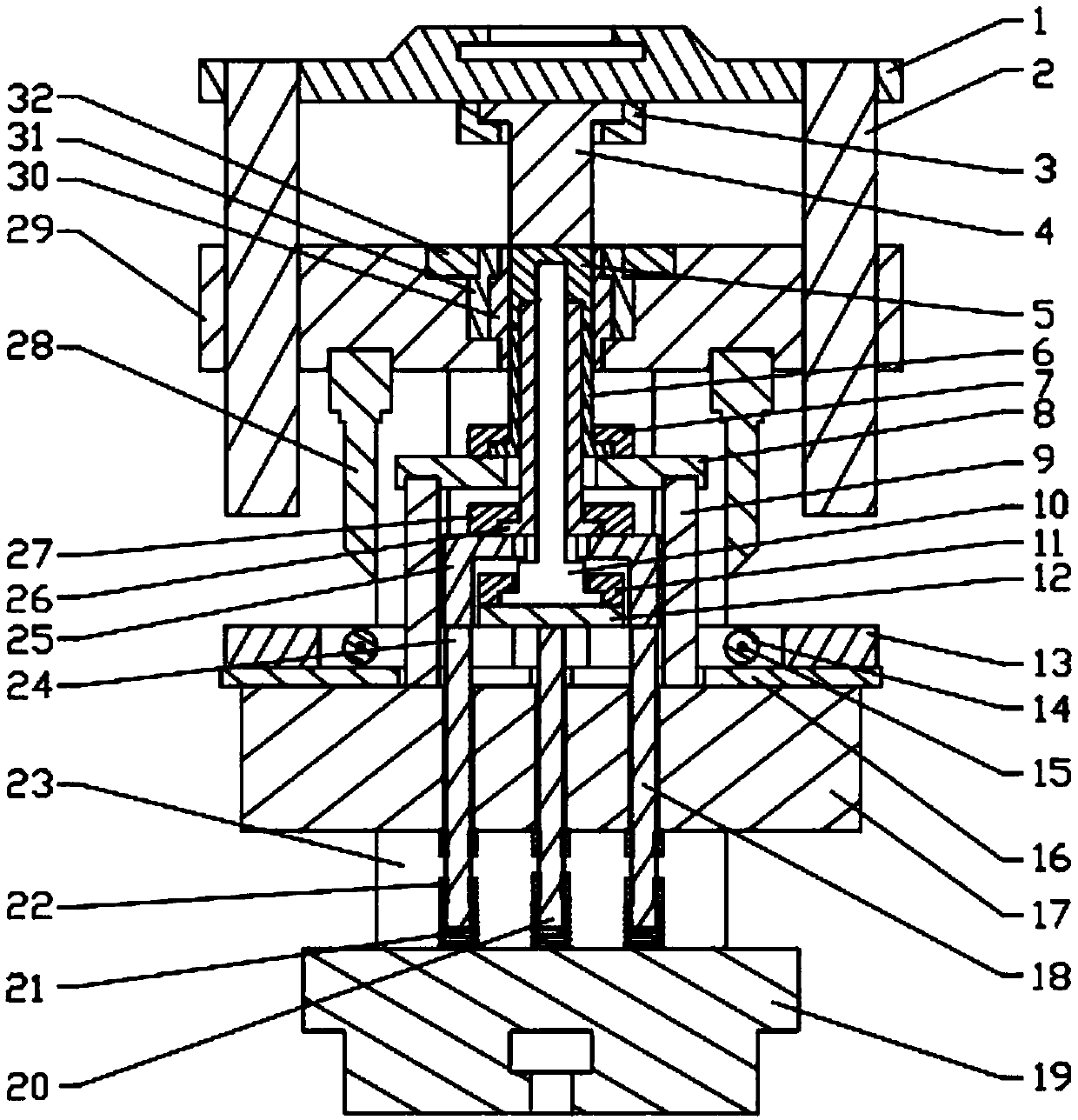

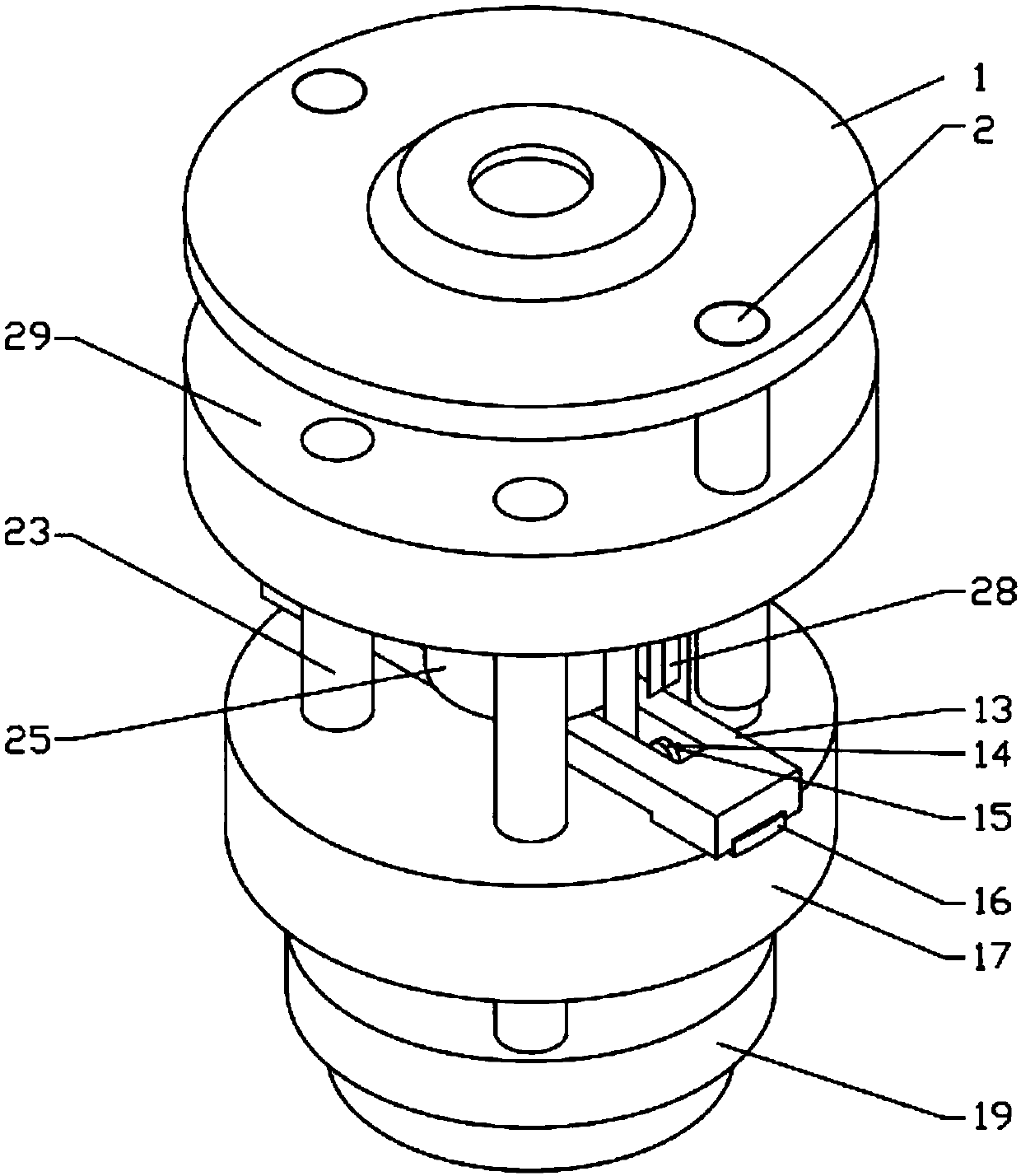

Die carrier for ceramimetallurgical automotive engine piston

The invention provides a die carrier for a ceramimetallurgical automotive engine piston. On the basis of a pull down type standard die carrier, the positions and structures of parts such as a first lower punch, a second lower punch and a third lower punch are reasonably distributed and designed; after a powder loading shoe loads piston powder into a female die cavity of the die carrier, compression molding of the automotive engine piston is completed by using the lifting action of a lifting rod, the locating action of a sliding block and a yoke-shaped plate and the pressure action of the upperand lower punches; then the whole die carrier is put into a high-temperature furnace and is heated till the temperature is below a powder liquid phase line, and the temperature is preserved for a period of time to complete manufacturing of a ceramimetallurgical blan of the piston; and finally, the automotive engine piston is manufactured and molded through machining of an air ring, an oil ring and the like. According to the die carrier, the automotive engine piston with high quality, high compactness and high intensity can be manufactured, and an aluminum-silicon engine piston with uniform ceramic particles or enhanced gradient can be manufactured more conveniently; and machining and the waste of materials are effectively reduced.

Owner:JILIN UNIV

Method and apparatus for drying semiconductor substrates using liquid carbon dioxide

InactiveUS20170092484A1Wider processing latitudeLower requirementDetergent mixture composition preparationDrying gas arrangementsLiquid stateEngineering

Method and apparatus for rinsing and drying a semiconductor substrate having a first rinse liquid such as water on the substrate in a substrate processing system. The method includes dispensing onto the substrate liquid carbon dioxide to displace any liquid present on the substrate and to dry the substrate. The apparatus includes a chamber for rinsing and drying the substrate.

Owner:TOKYO ELECTRON LTD

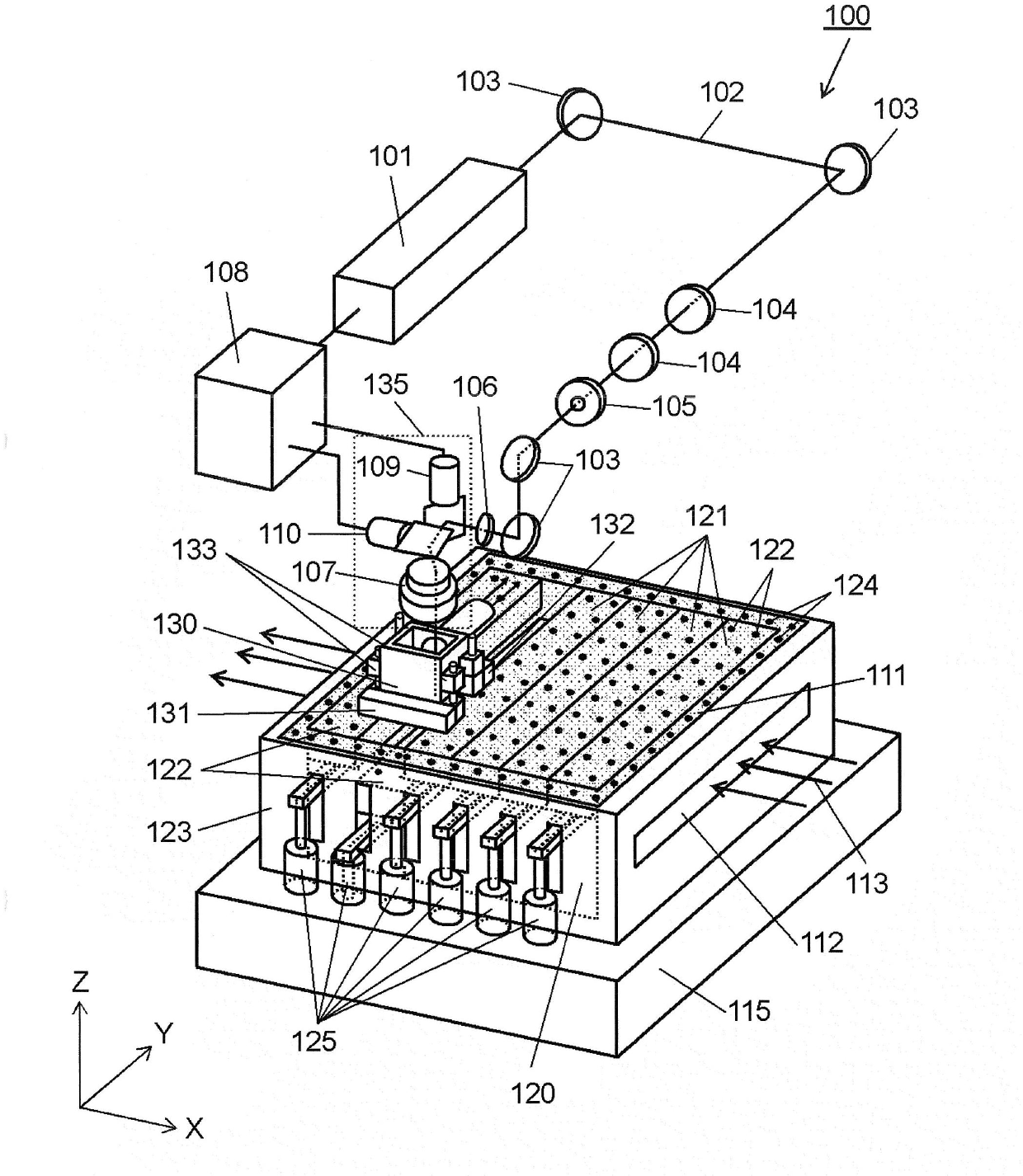

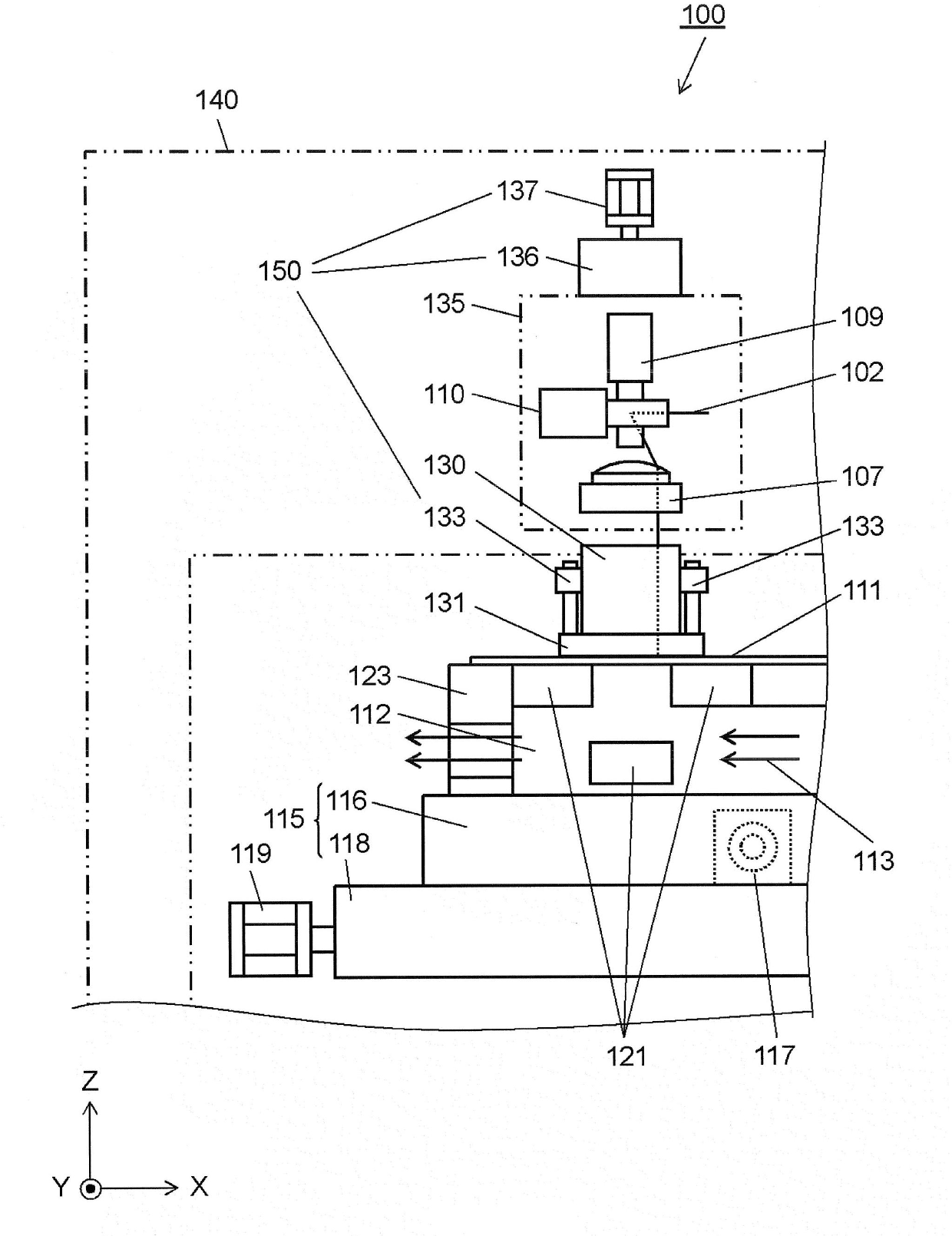

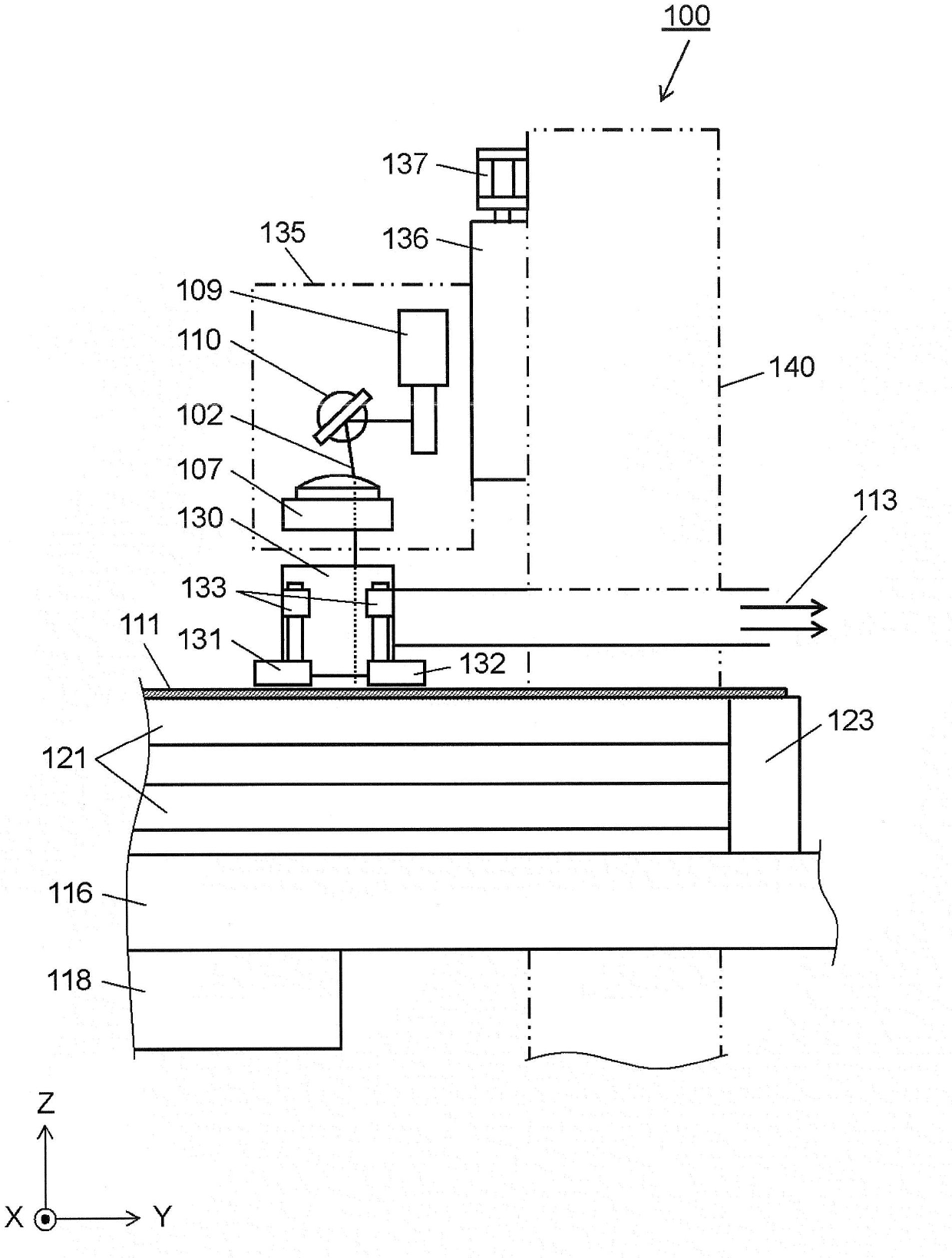

Laser processing device and laser processing method

ActiveCN102639282AReduce deflectionHigh precisionPositioning apparatusLaser beam welding apparatusLaser processingComputer science

This laser processing device (100) is provided with: a processing head section (135) which laser processes an item which is being processed; a mount section (120) which has a plurality of separated moveable mount sections (121) which rise and fall in the vertical direction, and which holds the item being processed; a processing table (115) which drives the mount section in the X and Y directions; an upper surface adhesion device (130) which is arranged above the item being processed and which adheres to the upper surface of the item being processed; and a drive unit (150) which drives the upper surface adhesion device so as to rise and fall in the vertical direction.

Owner:PANASONIC CORP

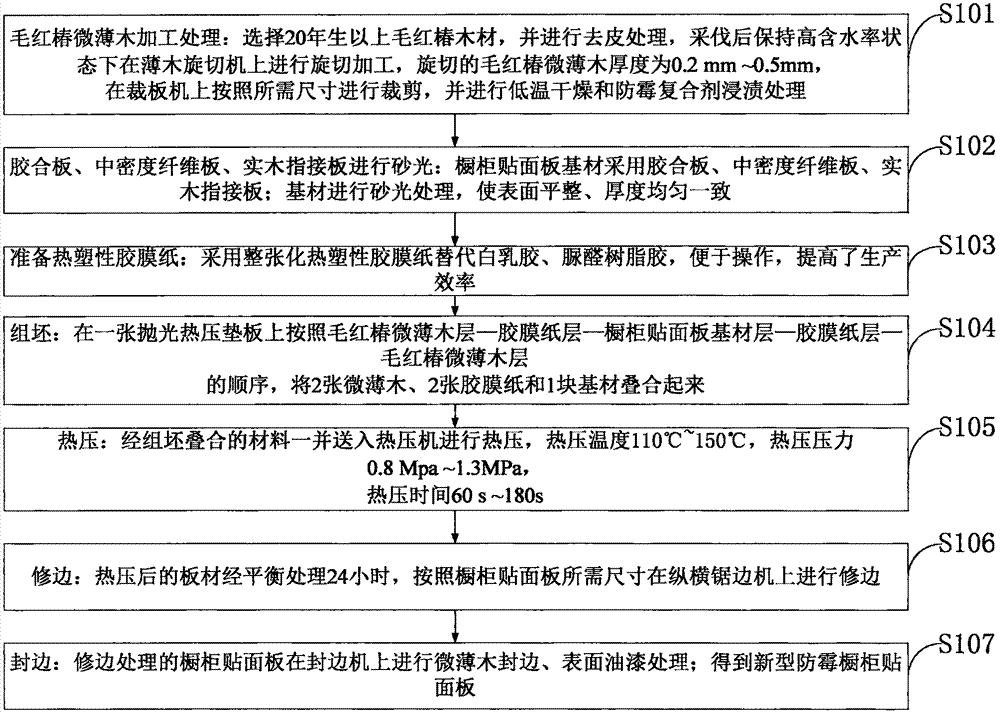

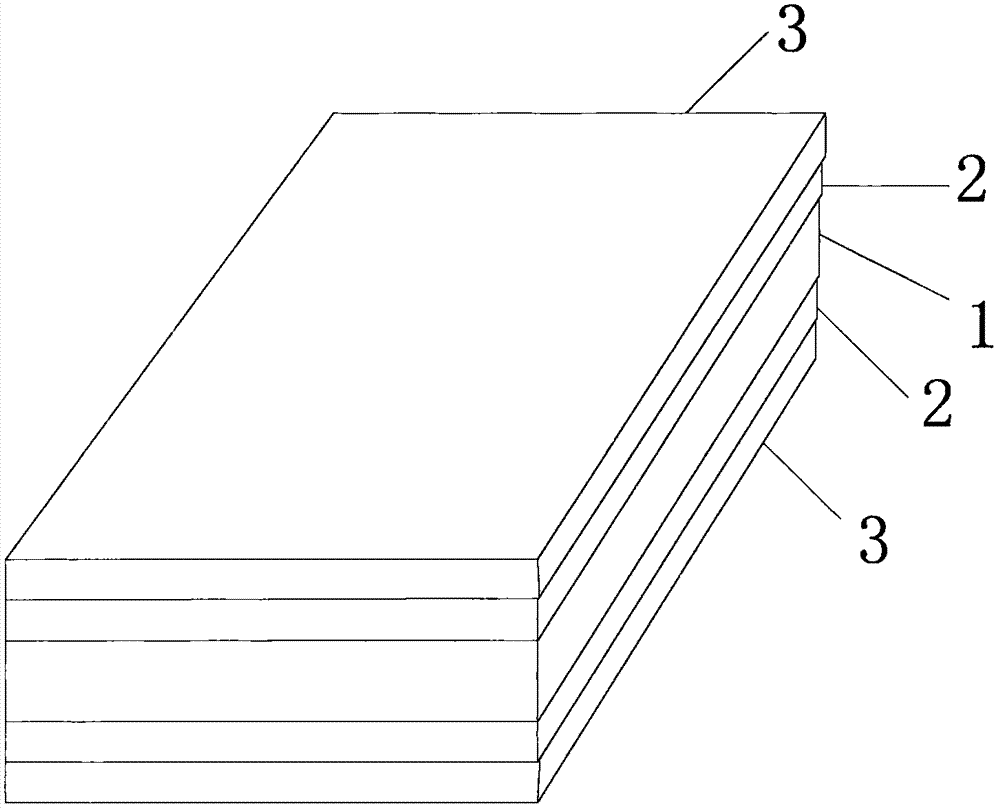

Novel mildew-proof laminated board of cabinet and manufacturing method of novel mildew-proof laminated board

PendingCN107127838ABeautiful surfaceReduce manufacturing costOther plywood/veneer working apparatusWood treatment detailsAdhesiveFinger joint

The invention belongs to the technical field of wood processing, and discloses a novel mildew-proof laminated board of a cabinet and a manufacturing method of the novel mildew-proof laminated board. Toona ciliata var. pubescens micro-veneer layers which are conducted mildew-proof treatment are glued on the upper surface and the lower surface of a base material layer of the laminated board of the cabinet of the novel laminated board of the mildew-proof cabinet; the base material layer of the laminated board of the cabinet comprises one of a plywood, a medium-density fiberboard and a solid-wood finger joint laminated board; the manufacturing method comprises the steps that processing treatment is conducted on toona ciliata var. pubescens micro-veneer, sanding of the plywood, the medium-density fiberboard and the solid-wood finger joint laminated board are conducted, a thermo-plasticity film adhesive is prepared, assembly, hot-pressing, trimming deflashing and edge banding are conducted, and the novel laminated board of the mildew-proof cabinet is acquired. According to the novel mildew-proof laminated board of the cabinet and the manufacturing method of the novel mildew-proof laminated board, by adopting materials of a new tree species to replace the micro-veneer produced by rear tree species, the production cost is reduced, the width of the micro-veneer can be cut out freely according to the specification of a product; and the manufacturing deficiency is effectively decreased, the production efficiency is improved, and the surface of a laminated product is attractive.

Owner:FUJIAN ACAD OF FORESTRY

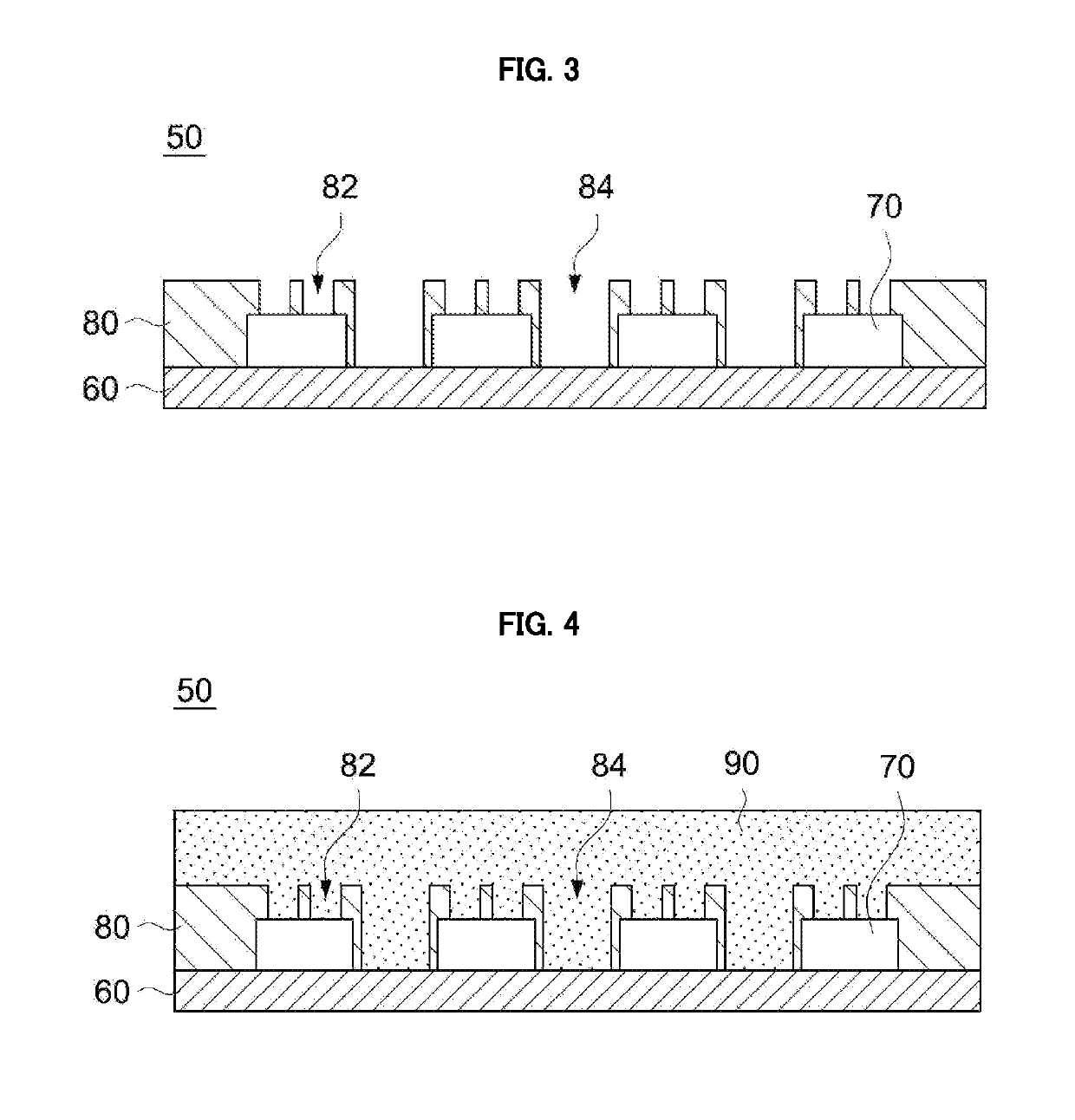

Semiconductor device including a counter layer, for power conversion and method of manufacturing the same

ActiveUS9082812B2Reduce processing defectsDestruction of switchTransistorSolid-state devicesPower semiconductor deviceGate oxide

A p-type base layer is selectively formed on a surface of an n-type drift layer; an n-type source layer is selectively formed on a surface of the p-type base layer; and a p-type contact layer is formed to be in contact with the selectively-formed n-type source layer. A p-type counter layer is formed to be in contact with the n-type source layer, so as to overlap the p-type contact layer, so as to be separated from an interface where the p-type base layer and the gate oxide film are in contact with each other, and to be shallower than the p-type base layer. Accordingly, switching destruction caused by process defects in an insulated gate semiconductor device is reduced.

Owner:FUJI ELECTRIC CO LTD

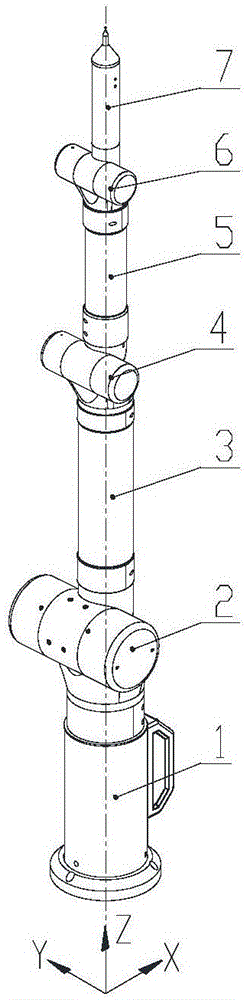

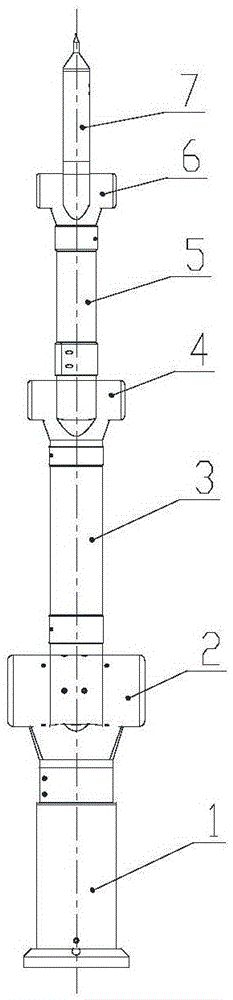

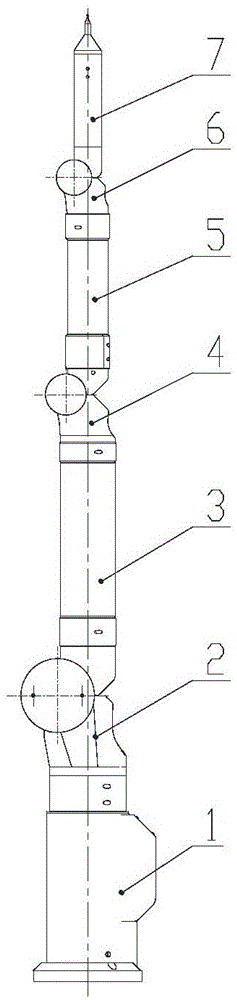

Mixed biasing type articulated arm measurement machine

ActiveCN105157647AHigh measurement accuracyExtended service lifeMeasurement devicesStructural rigidityKnuckle

The invention, which belongs to the field of the measurement machine of numerical control precision measurement equipment, especially relates to an articulated arm type measurement machine with an articulated arm structure. The measurement machine arranged symmetrically along a ZX plane comprises five steering knuckles capable of moving freely and independently and seven connecting arm segments. The five steering knuckles are in a dual-point support mode and support points of all knuckles except the knuckle 4 are arranged symmetrically along the ZX plane; and the knuckles 1 and 4 are infinite rotation knuckles. The measurement machine has comprehensive advantages of flexible operation, high structural rigidity, and light weight and the like.

Owner:CHINA PRECISION ENG INST FOR AIRCRAFT IND AVIC

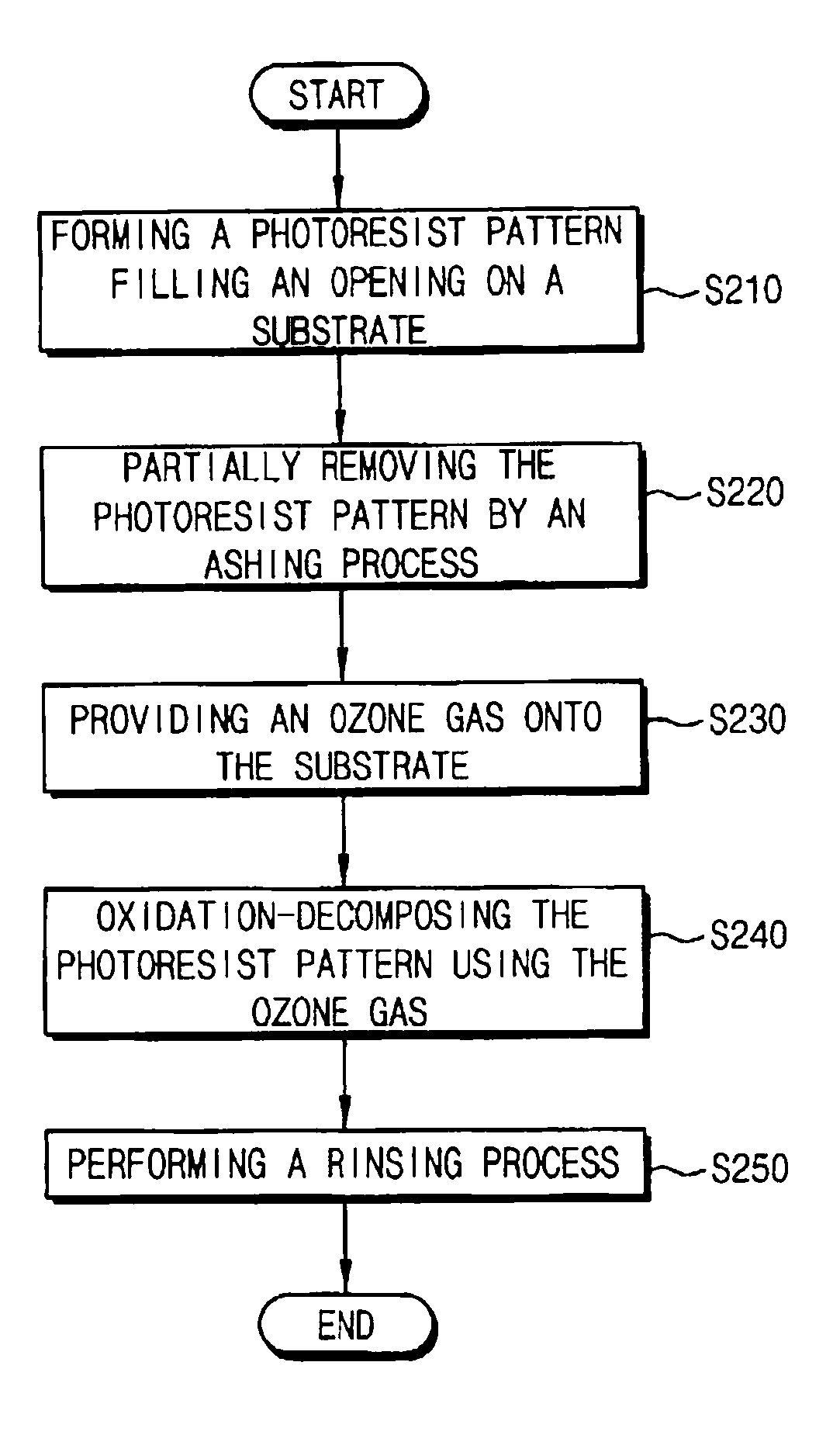

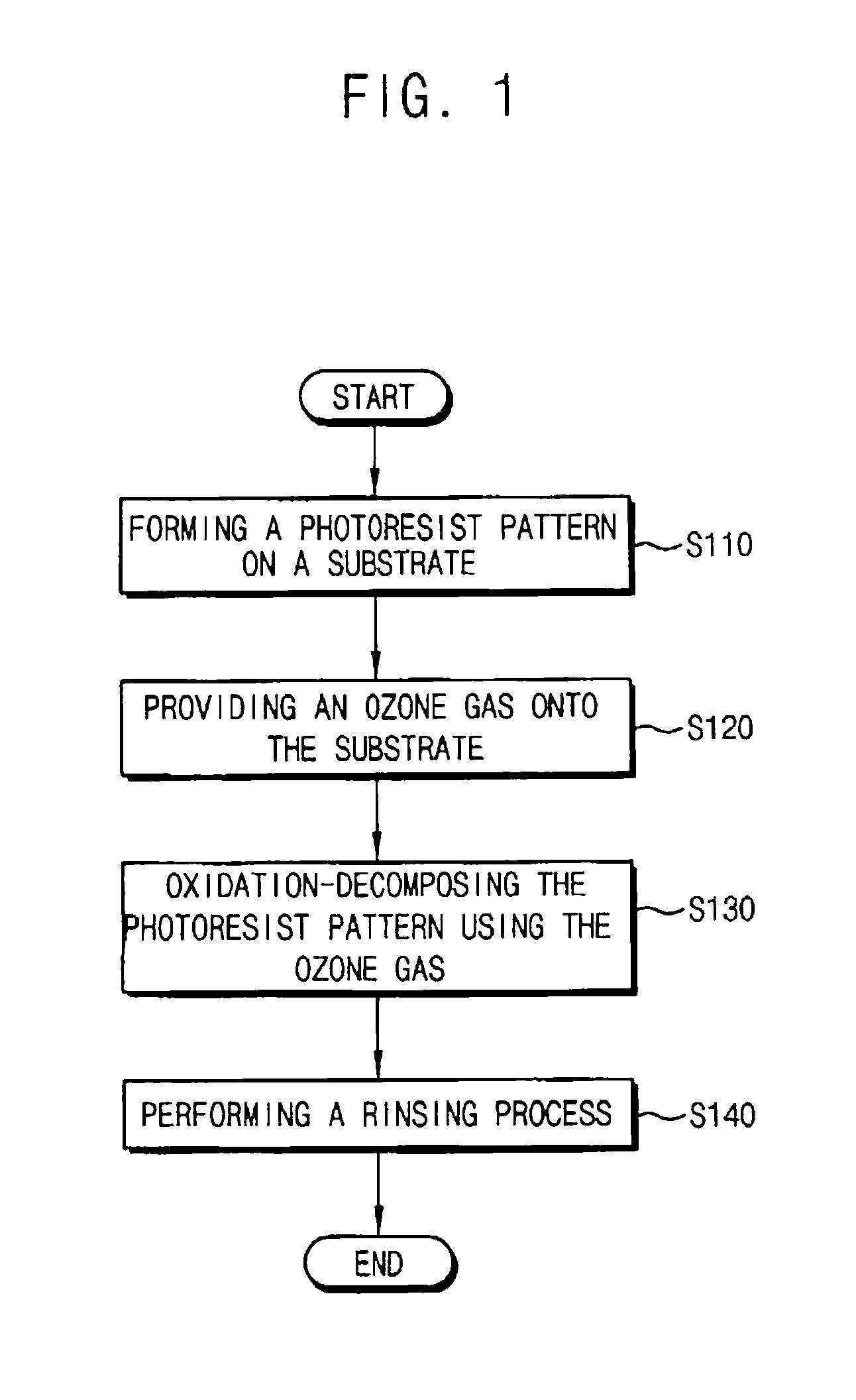

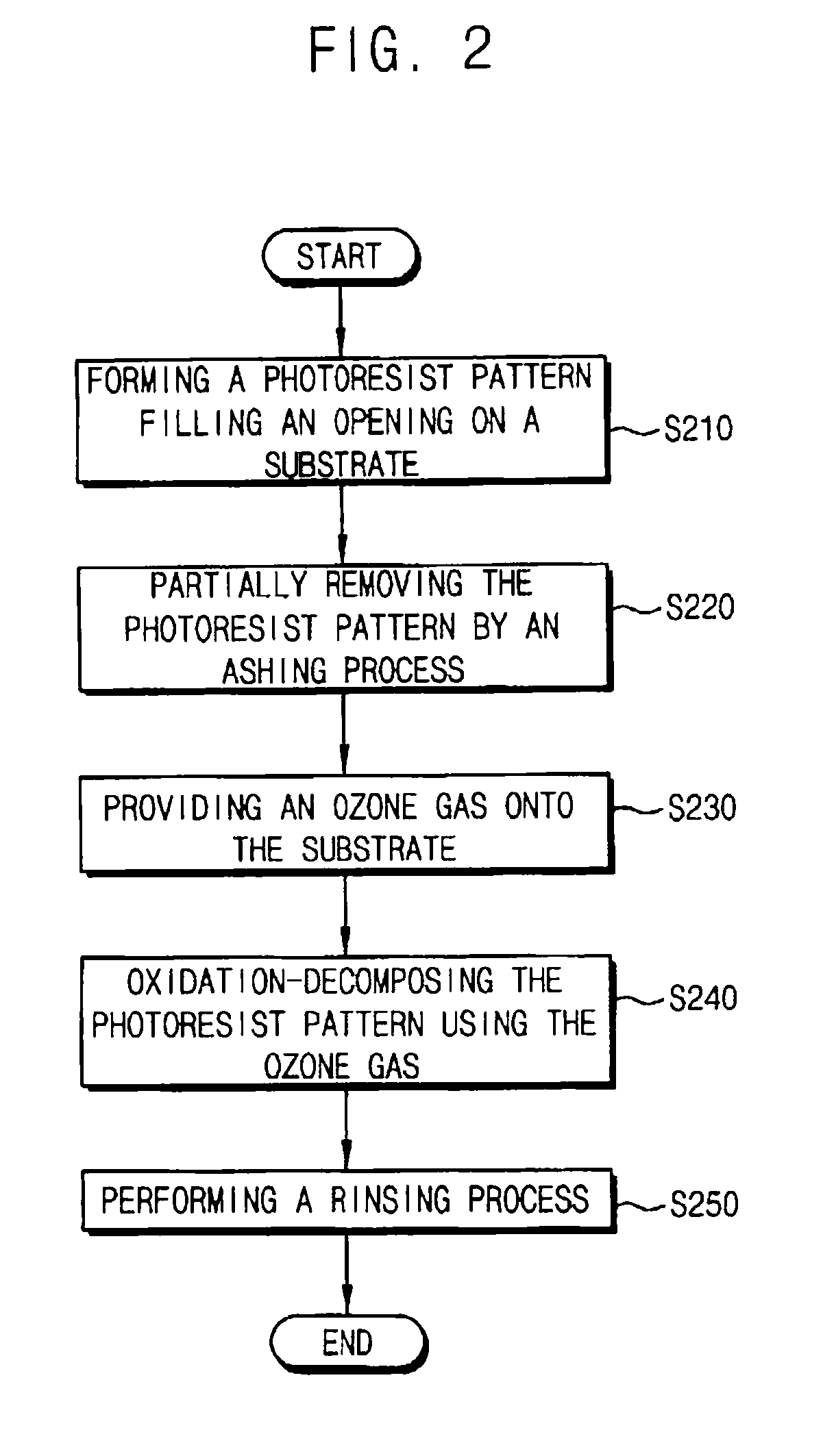

Method of removing a photoresist pattern and method of manufacturing a semiconductor device using the same

InactiveUS20060270241A1Reduce resistanceIncrease capacitancePhotomechanical apparatusSemiconductor/solid-state device manufacturingChemistryResist

Owner:SAMSUNG ELECTRONICS CO LTD

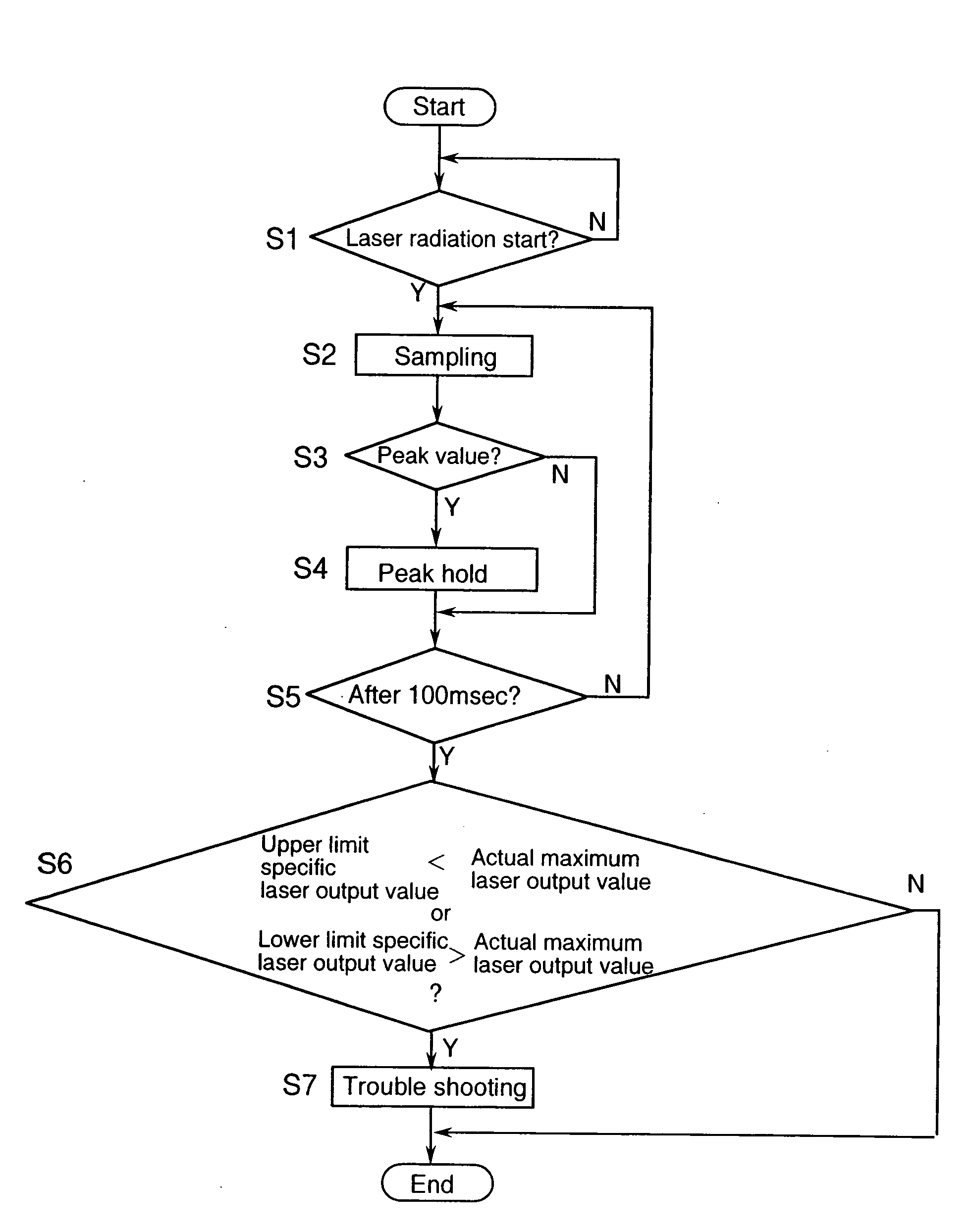

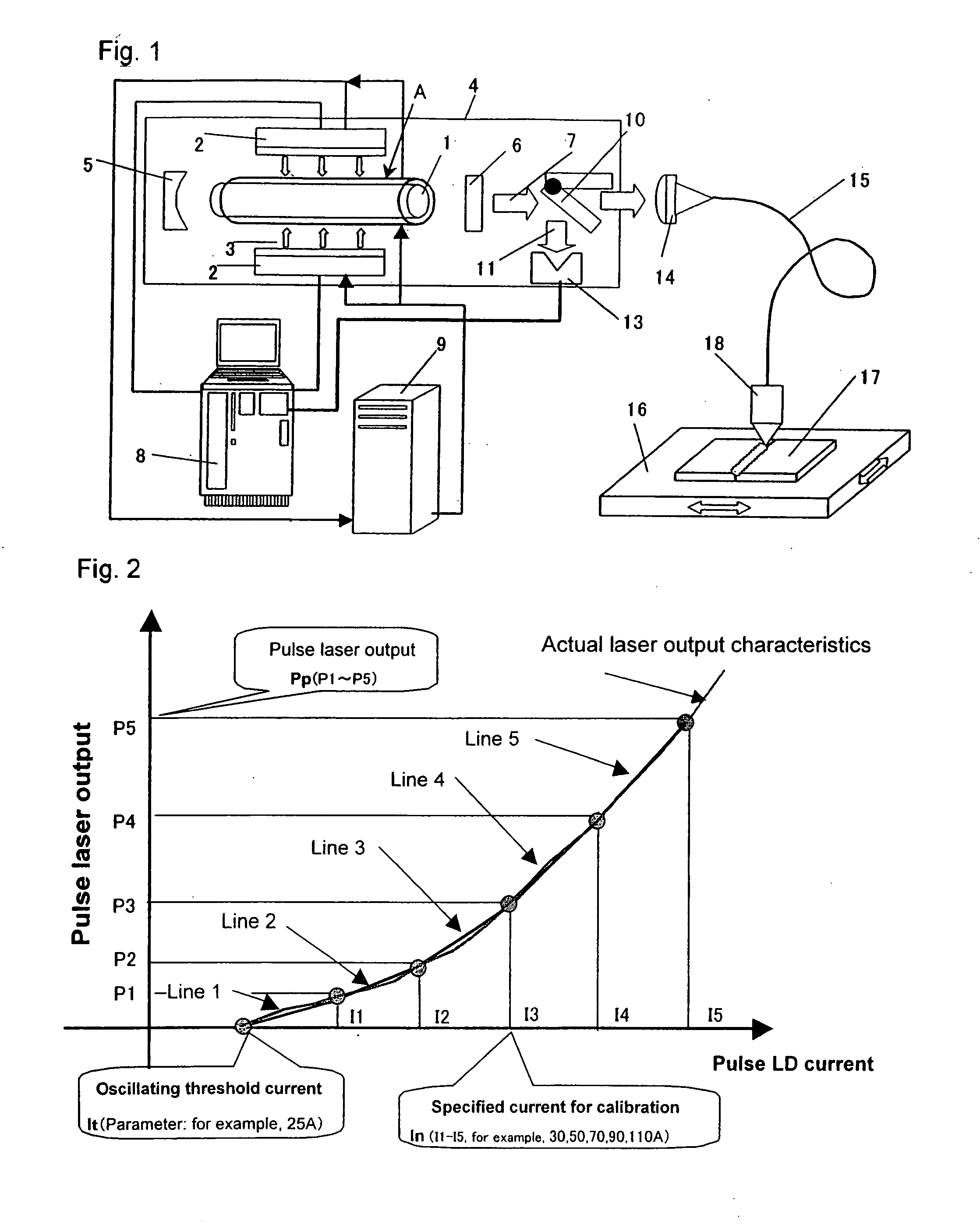

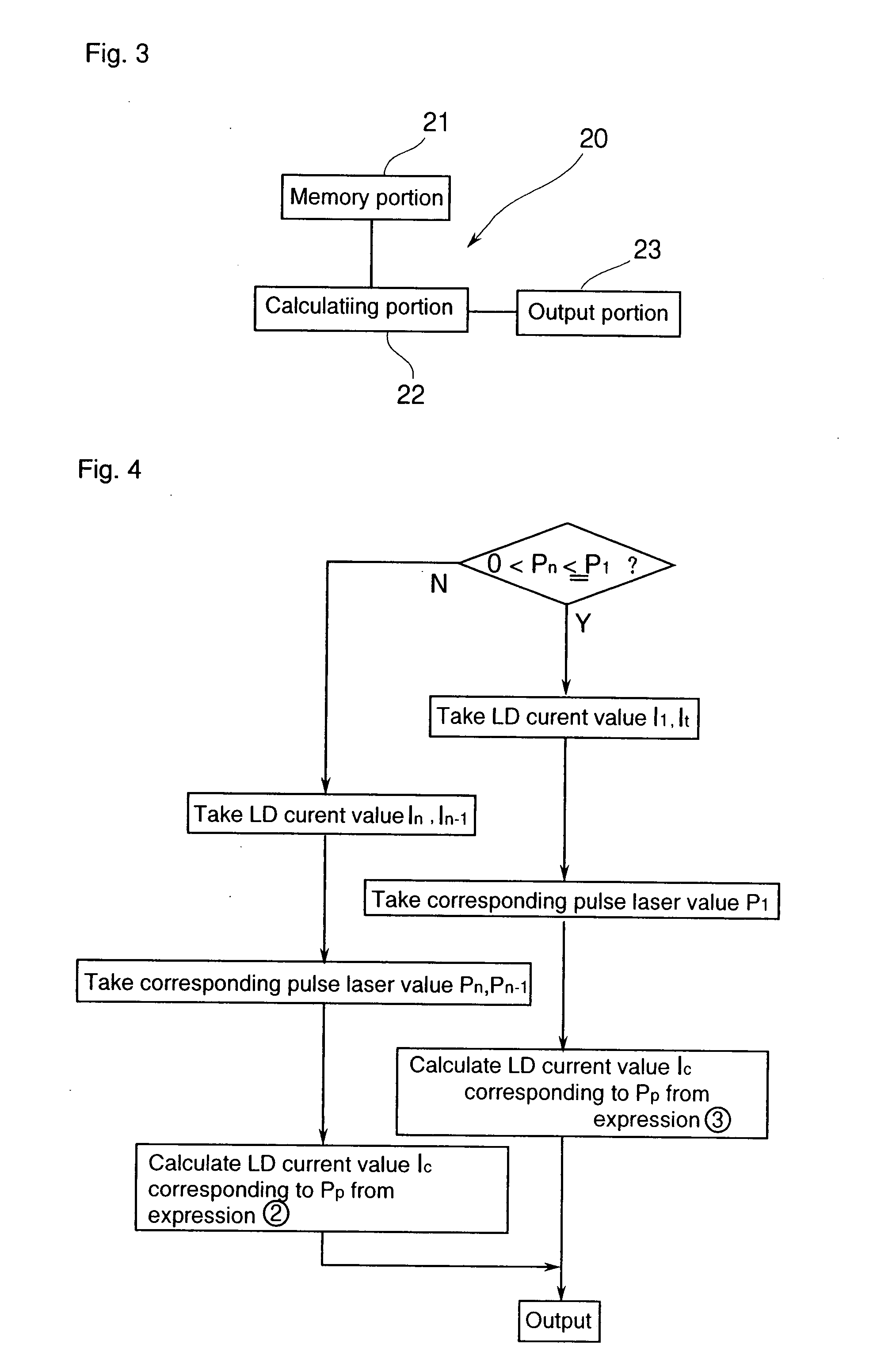

Pulse oscillating type solid laser unit and laser process unit

InactiveUS20080165814A1Stable valueHigh yieldLaser output parameters controlActive medium materialMeasuring instrumentLaser light

A pulse oscillating type solid laser unit that has a laser unit body whose exciting source is a laser diode that emits light in a principal energy absorbing spectrum of a solid laser activated media, and characterized by that prior to radiating laser light outside the laser unit body as a calibrating operation of a pulse laser output value, specified several varieties of rectangle pulse current values are conducted to a laser diode inside the pulse oscillating type solid laser unit so as to pulse-oscillate the laser unit body, a mean laser output value in each rectangle pulse current value is measured by the use of a laser output measuring instrument arranged inside the laser unit body so as to obtain a mean laser output value data, and in case that the laser output light is radiated outside the laser unit body, a pulse current value linear-predicted based on an obtained mean output value data is conducted to the laser diode so as to obtain a desired pulse laser output value.

Owner:KATAOKA

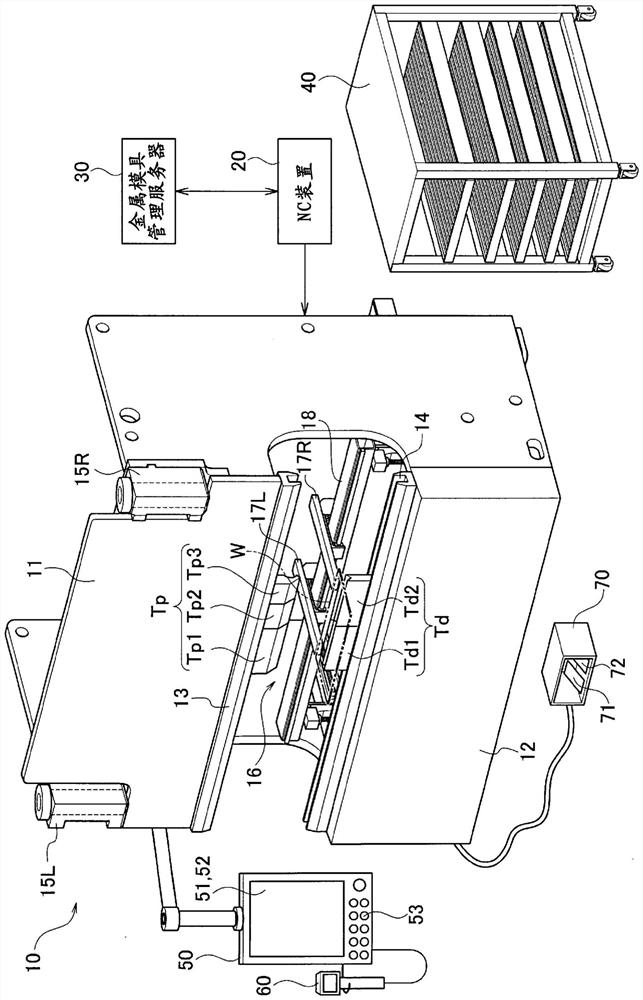

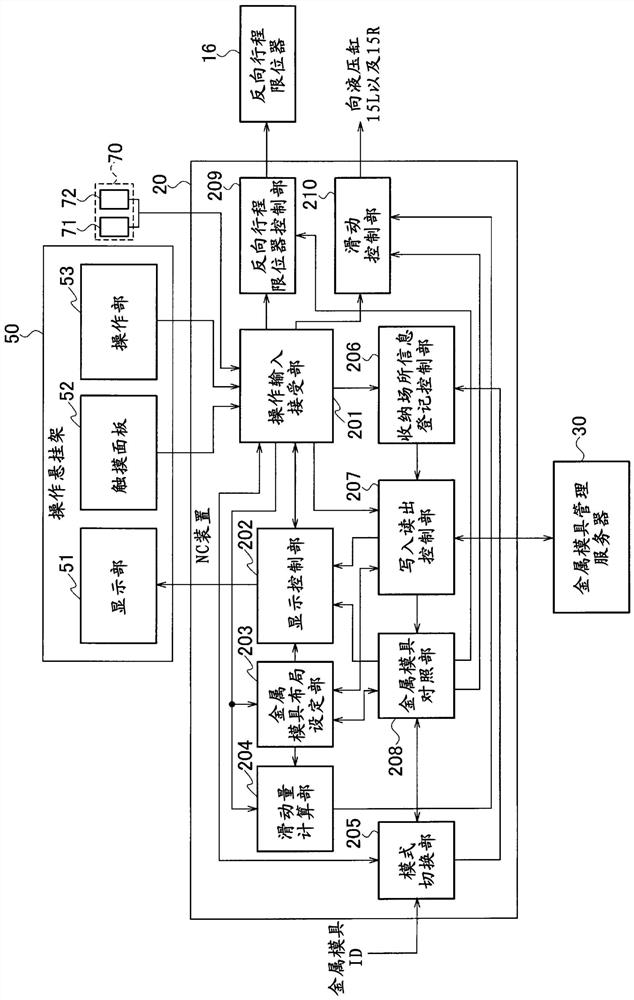

Press brake control device, press brake control method, die management method, and data structure for die management data

InactiveCN111683759AReduce breakageReduce processing defectsProgramme controlShaping toolsData displaySoftware engineering

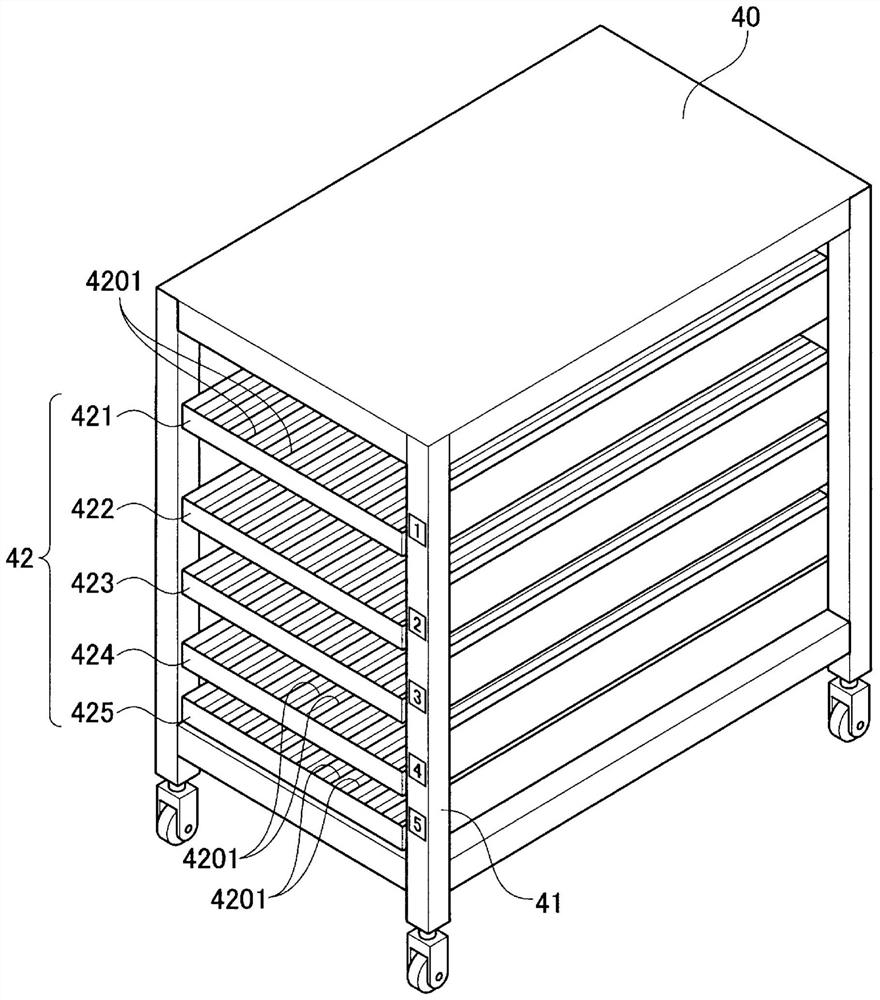

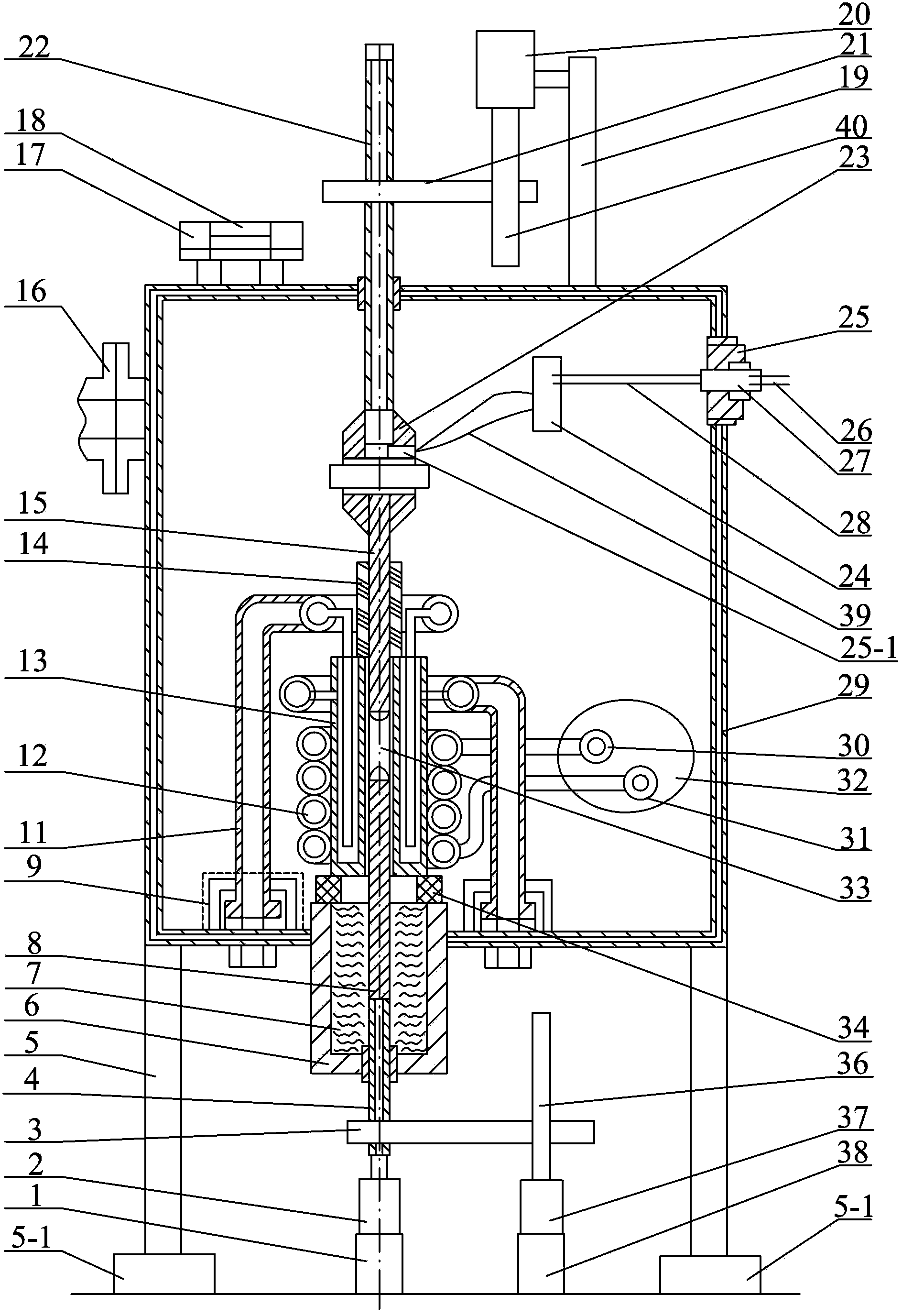

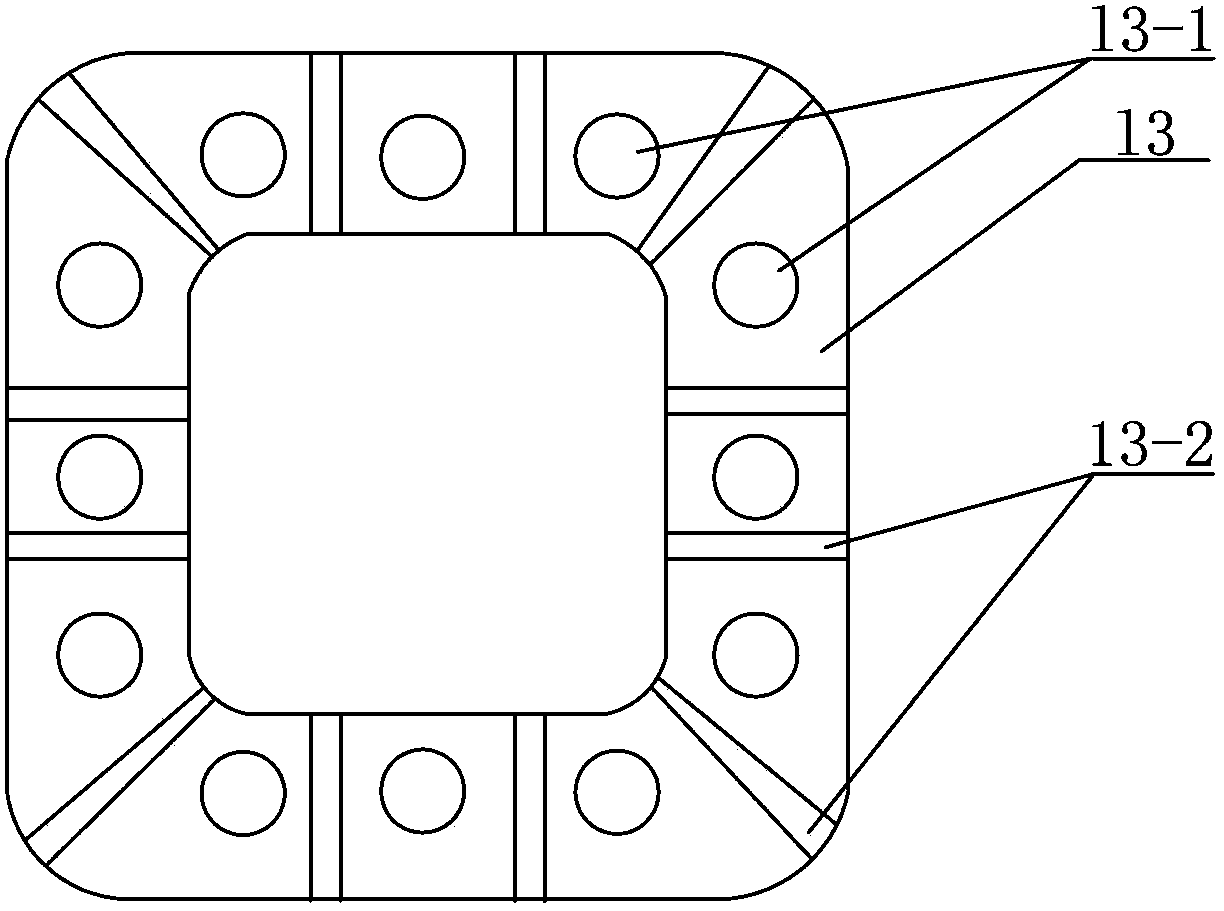

In the present invention, a die to be used for bending sheet metal is selected, and die layout data including a die ID, installation position information, and information of a storage location in diestorage for the selected die are created in advance. A display control unit (202) performs control so that information indicating the storage location of the die is displayed in a display unit (51). Adie collation unit (208) collates a die ID read by a reader when an operator takes a die out from die storage with a die ID of a die included in the die layout data. When the read die ID does not match the die ID of any die included in the die layout data, the display control unit (202) performs control so that a message indicating that the die taken out by the operator is a wrong die is displayed in the display unit (51).

Owner:株式会社天田集团

Water cooling copper crucible directional freezing method for superhigh-temperature Nb-Si alloy

InactiveCN102658362BImprove mechanical propertiesHigh directional solidification efficiencyPolycrystalline material growthFrom frozen solutionsCrucibleAlternating current

The invention relates to a water cooling copper crucible directional freezing method for a superhigh-temperature Nb-Si alloy, relates to a metal directional freezing method, in particular to a directional freezing method for the superhigh-temperature Nb-Si alloy, and aims at solving the problems of the existing directional freezing method that the metal is easy to be contaminated, the directional freezing efficiency is low, the structure form is not easy to adjust and the comprehensive mechanical property of the alloy is poor. The directional freezing method comprises the following main steps that 1. the interior of a furnace is provided with a loading rod and backing material, a water cooling copper crucible is arranged outside of the loading rod and the backing material, and an induction coil is arranged outside of the water cooling copper crucible; 2. the furnace is vaccumized firstly and then argon is introduced; 3. after the loading rod and the backing material are sent into the induction range of the induction coil, and single-phase alternating current is introduced to the induction coil so as to move the loading rod and the backing material downwards; and 4. when the material transmitting rod is moved downward and reaches the preset length, the material transmitting rod stops moving downward and the power applied to the induction coil is stopped. The method is applicable to preparing the superhigh-temperature Nb-Si alloy.

Owner:HARBIN INST OF TECH

Preparation method of high-quality large diameter extremely thin-walled seamless titanium tube

ActiveCN109396240AAvoid displacement deviationHigh dimensional accuracyShaping toolsSurface roughnessTitanium

The invention discloses a preparation method of a high-quality large diameter extremely thin-walled seamless titanium tube. The preparation method comprises the steps that a titanium tube is subjectedto multi-pass spinning by a vertical ball spinning machine to obtain the seamless titanium tube. The external diameter of the seamless titanium tube is 100mm-300mm, the ratio of wall thickness and the external diameter is not more than 0.001, the dimensional tolerance of the external diameter is + / -0.02mm, the tolerance of the wall thickness is + / -0.01mm, the straightness accuracy is less than 0.5mm / m, and the internal and external surface roughness of the seamless titanium tube Ra is less than 0.2[mu]m. According to the preparation method of the high-quality large diameter extremely thin-walled seamless titanium tube, by controlling the deviation of the external diameter of a core rod of the vertical ball spinning machine and the internal diameter of a spinning tube blank, and accordingto the thickness of the spinning tube blank, a ball bite angle is designed reasonably, then multi-pass spinning is carried out by controlling the thinning ratio and feed rate in the spinning process,dimensional accuracy and surface quality of the seamless titanium tube are improved, the seamless titanium tube with good surface quality, high dimensional accuracy and good plasticity is obtained, and the preparation method is suitable for the production of the various extremely thin-walled seamless titanium tubes with the cold spinning deformability.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

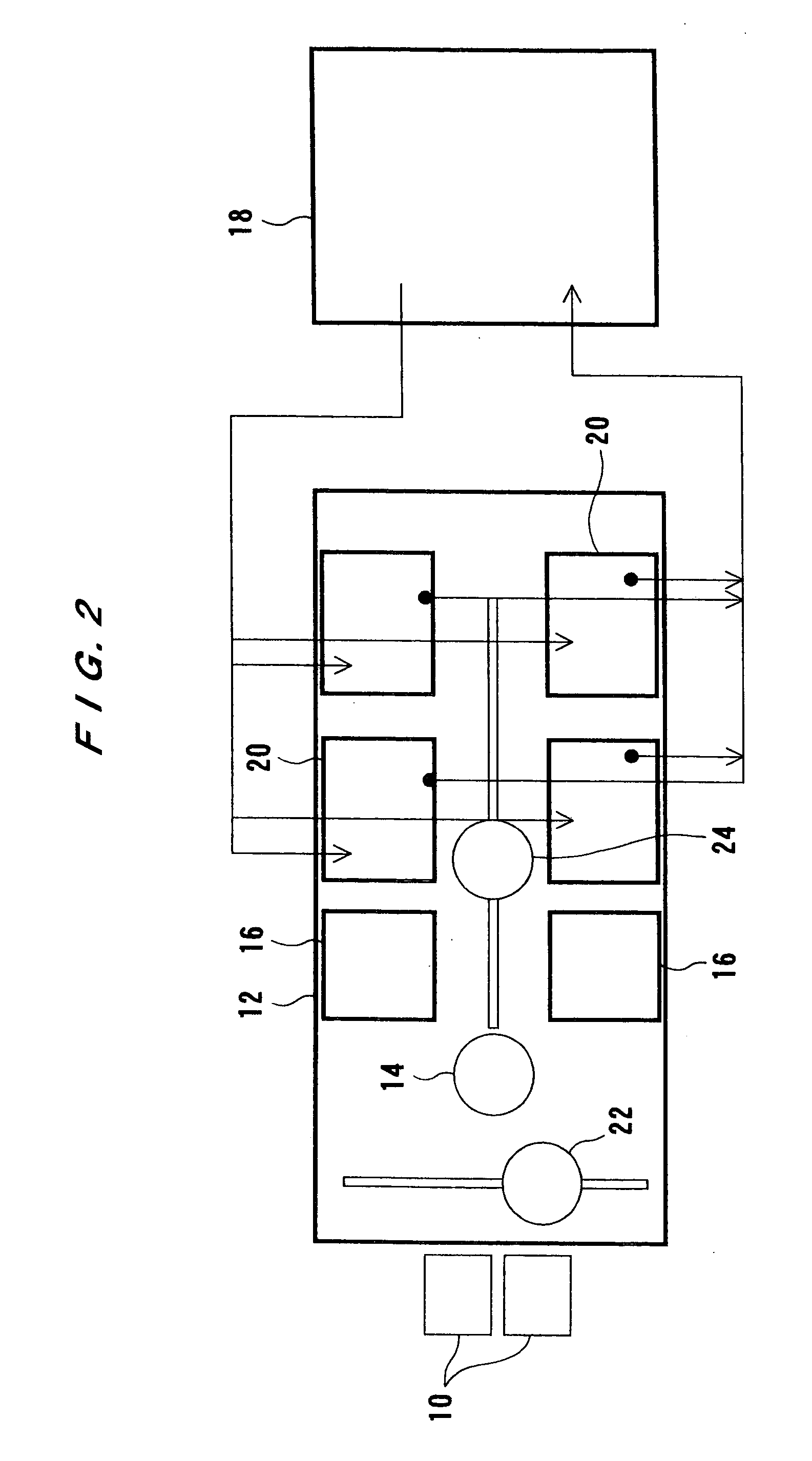

Substrate processing apparatus and substrate processing method

InactiveUS20050241955A1High yieldLow costCellsSemiconductor/solid-state device manufacturingEngineeringStatic electricity

A substrate processing apparatus and a substrate processing method can appropriately control the charge of a substrate depending on the type of wet processing, thereby reducing defective processing due to static electricity on the surface of the substrate. The substrate processing apparatus includes: a static electricity adjustment section for adjusting static electricity on a substrate; and a wet processing apparatus for carrying out wet processing of the static electricity-adjusted substrate. The static electricity adjustment section removes static electricity from the substrate or charges the substrate into a desired charged state, for example.

Owner:EBARA CORP +1

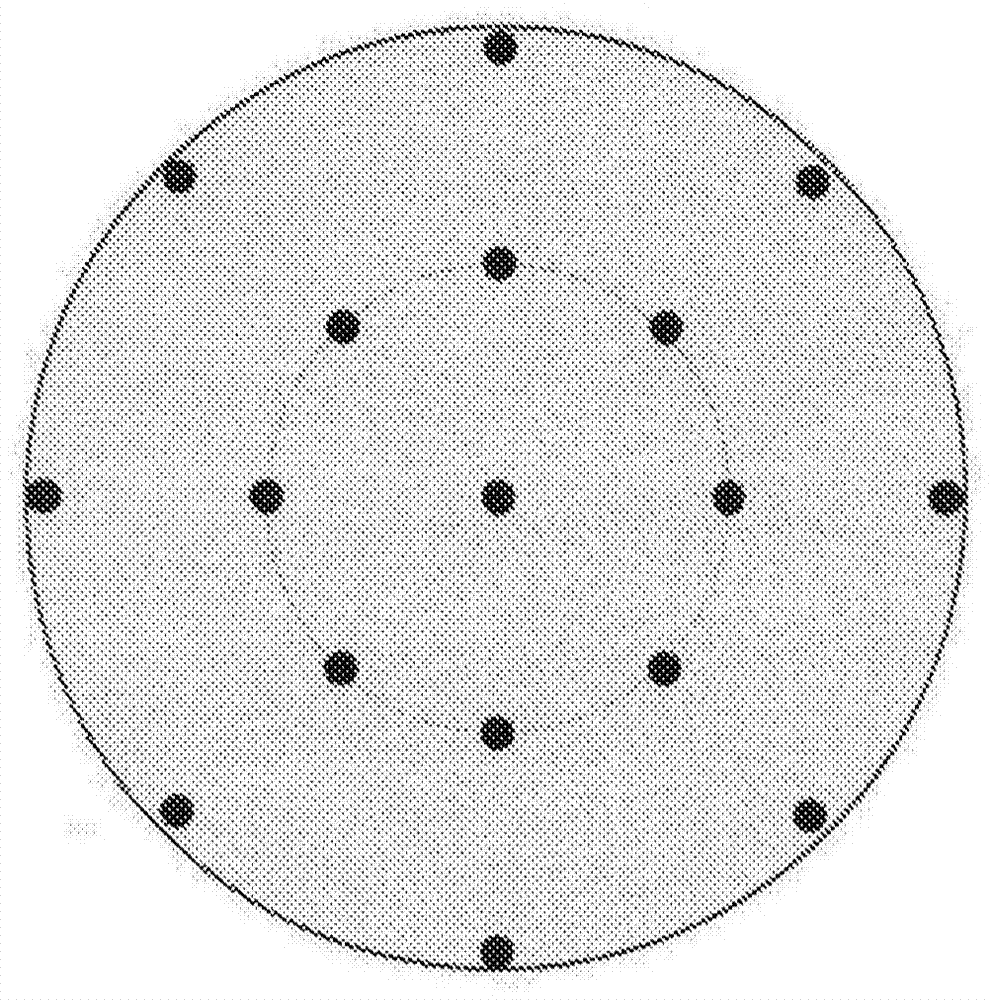

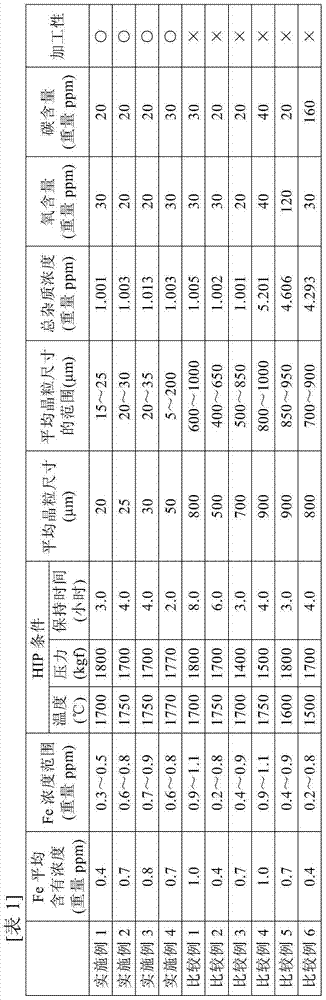

Tungsten sintered sputtering target and manufacturing method thereof

ActiveCN105102670BImprove yieldGrowth inhibitionElectric discharge tubesVacuum evaporation coatingAbnormal grain growthImpurity

Provided is a tungsten sintered compact sputtering target containing iron as an impurity in an amount of 0.8 wtppm or less, and remainder being tungsten and other unavoidable impurities, wherein a range of iron concentration in a target structure is within a range of ±0.1 wtppm of an average concentration. Additionally provided is a tungsten sintered compact sputtering target according to claim 1 or claim 2, wherein a relative density of the target is 99% or higher, an average crystal grain size is 50 µm or less, and a crystal grain size range is 5 to 200 µm. The present invention aims to inhibit abnormal grain growth in the tungsten target by reducing the amount of iron in the tungsten sintered compact sputtering target.

Owner:JX NIPPON MINING & METALS CORP

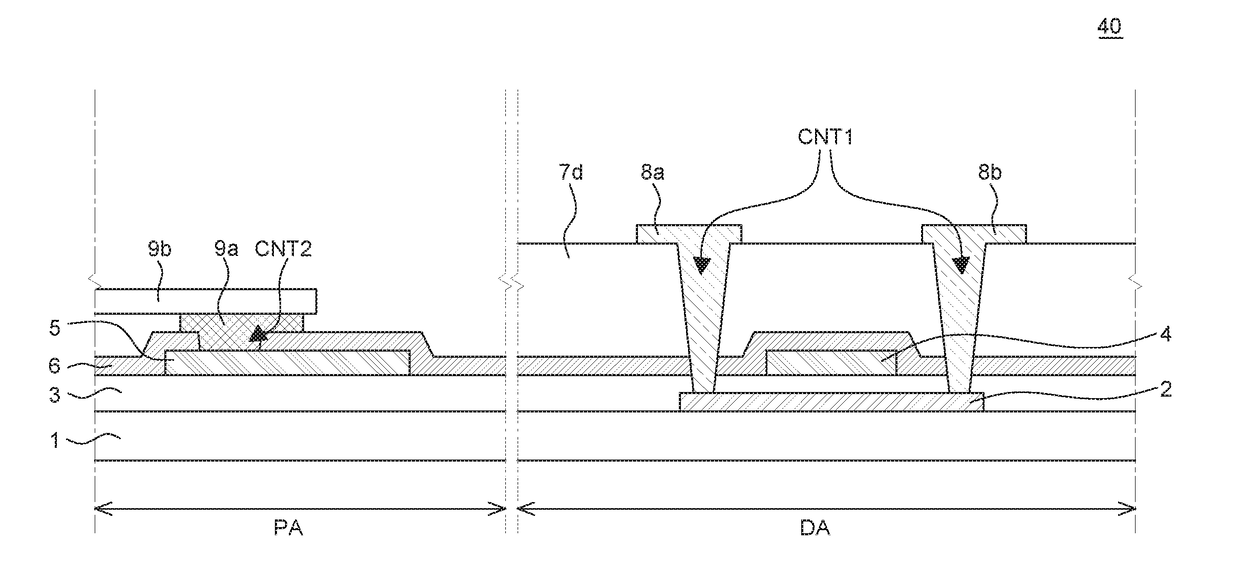

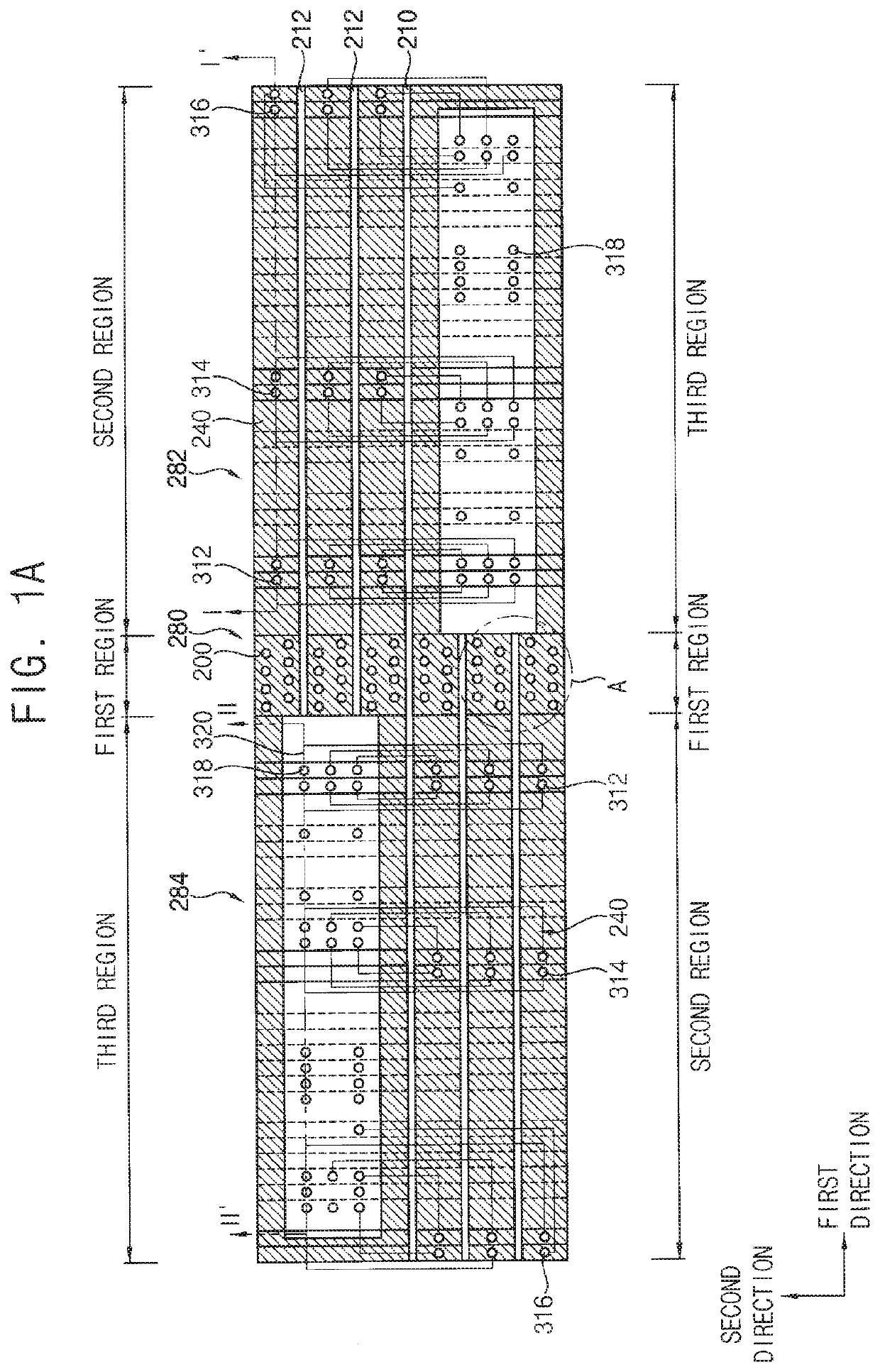

Display apparatus and method of manufacturing the same

ActiveUS20170092664A1Small thicknessReduce harmSolid-state devicesSemiconductor devicesMaximum diameterActive layer

A display apparatus is provided. The display apparatus includes a substrate having a display area and a pad area, an active layer in the display area of the substrate, a pad electrode in the pad area of the substrate, and a planarization layer on the active layer and the pad electrode with a contact hole for exposing a part of the active layer. A maximum diameter of the contact hole has a size considering an increase in maximum diameter of the contact hole while the planarization layer in the pad area is removed after the planarization layer is formed on the display area and the pad area. Accordingly, it is possible to minimize an increase in size of the contact hole in the display area while the planarization layer is removed, thereby reducing process defects, such as a gap error, of the display apparatus.

Owner:LG DISPLAY CO LTD

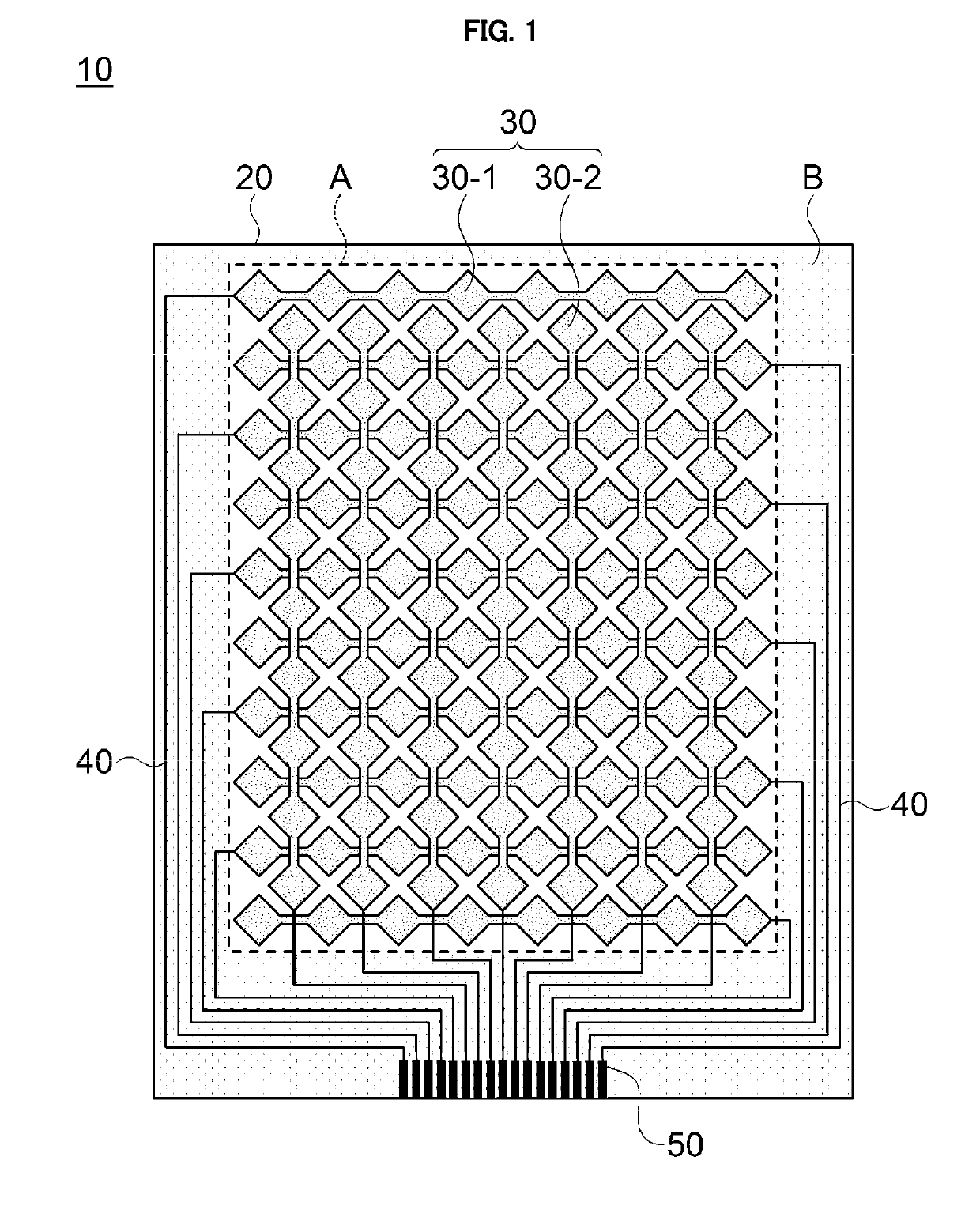

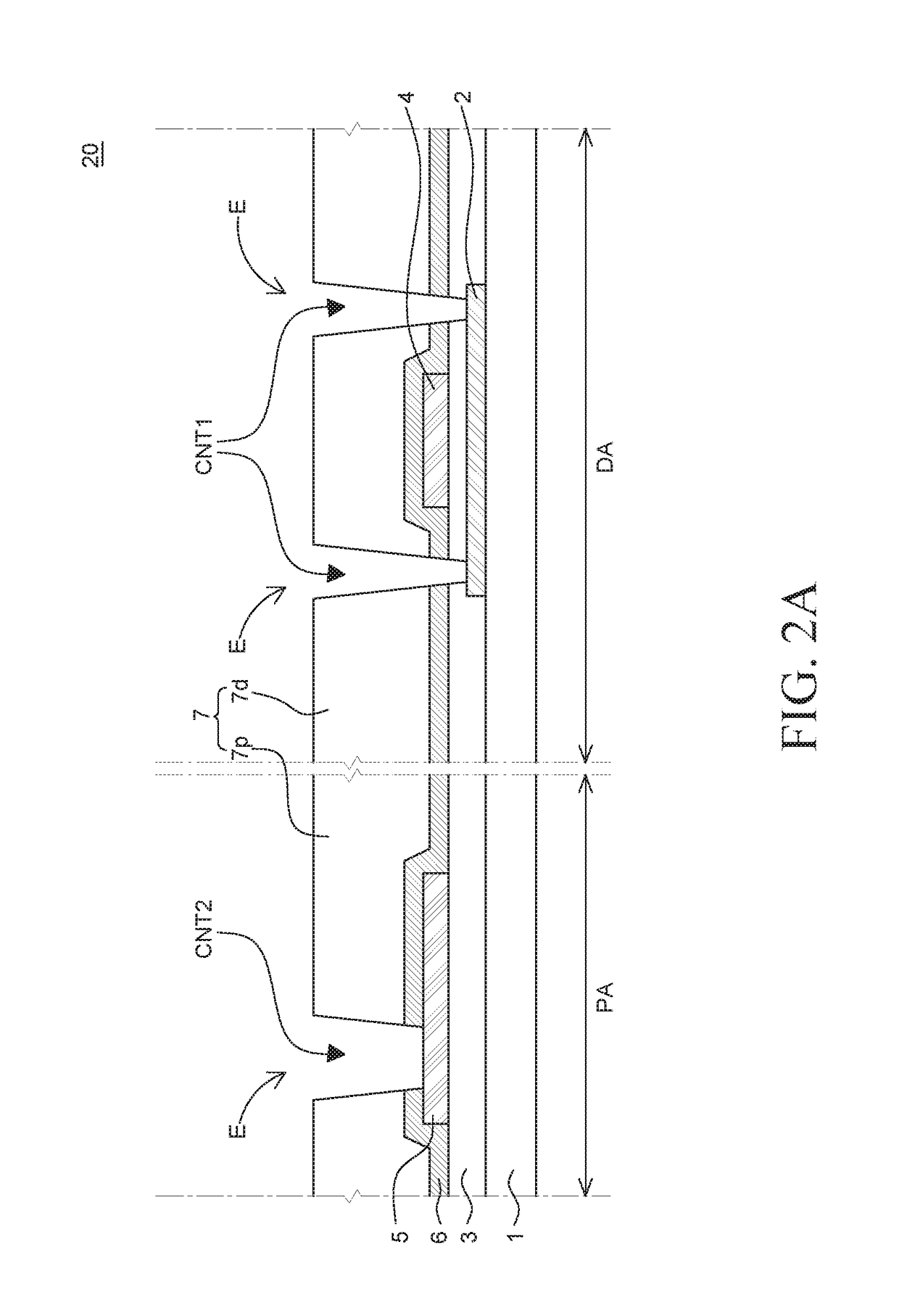

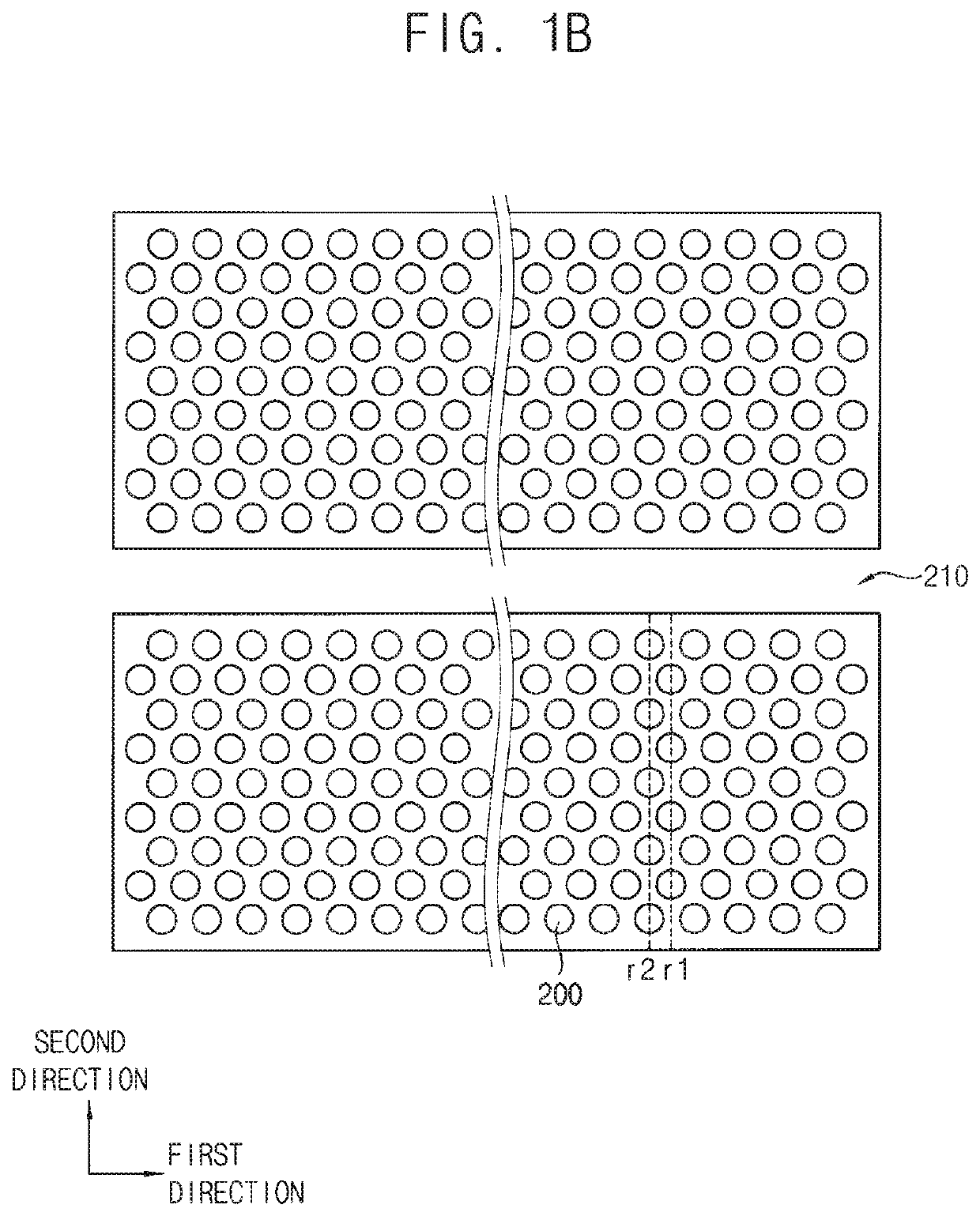

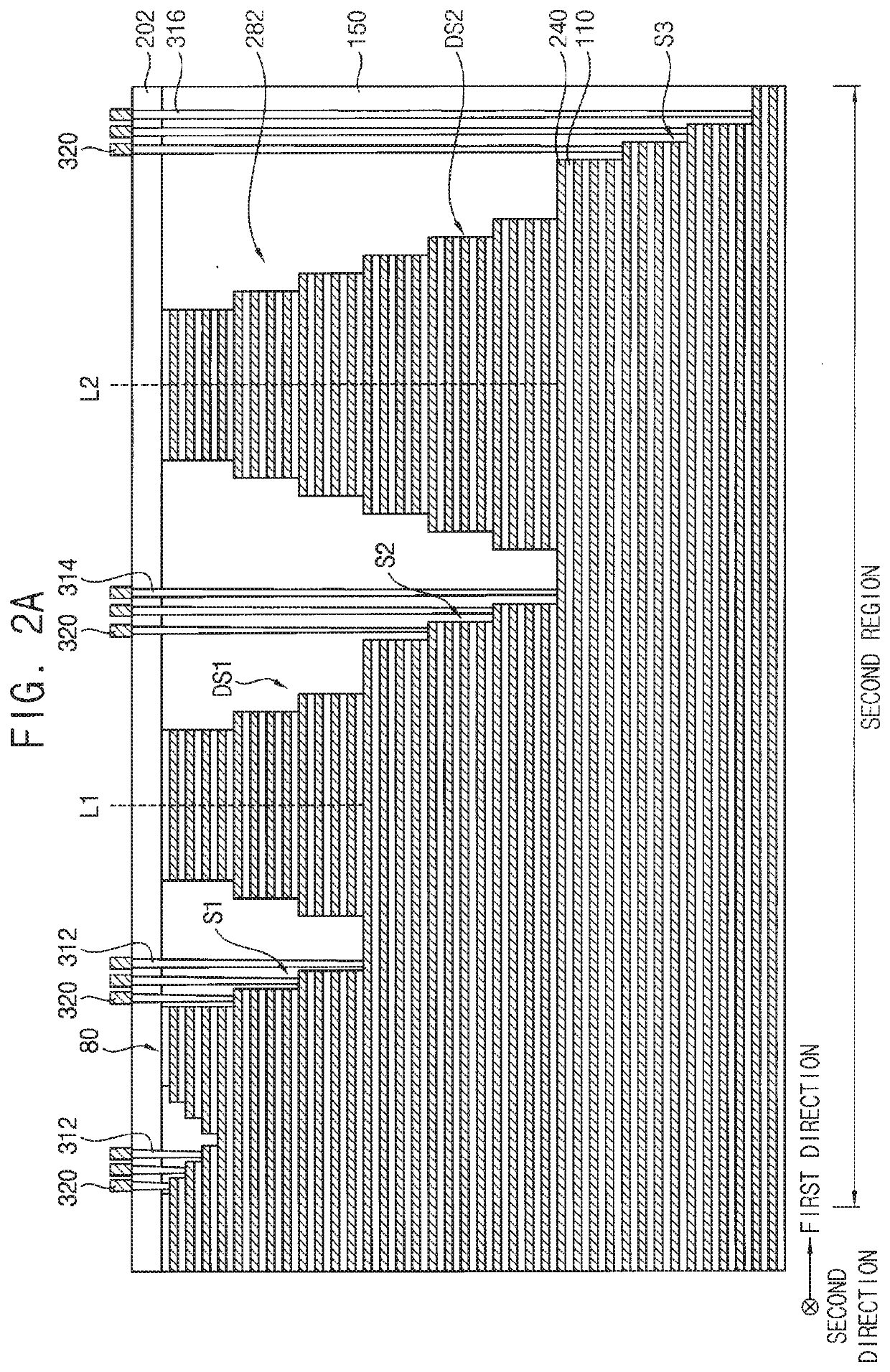

Vertical memory devices

ActiveUS20210272900A1Accurately formedUpper surfaceSemiconductor/solid-state device detailsSolid-state devicesElectrical and Electronics engineeringMechanical engineering

A vertical memory device includes a cell stacked structure, a wiring connection structure, and a first insulating interlayer. The cell stacked structure may include insulation layers and gate patterns repeatedly and alternately stacked on a first region of a substrate. The wiring connection structure may contact side walls of the cell stacked structure. The wiring connection structure may include a first staircase structure having one side of a stepped shape, a second staircase structure having one side of a stepped shape and disposed below the first staircase structure, and a first dummy staircase structure between the first and second staircase structures. The first and second staircase structures may be spaced apart from each other in the first direction, and both sides in the first direction of the first dummy staircase structure may have stepped shapes. The first insulating interlayer may be on the substrate to cover the wiring connection structure.

Owner:SAMSUNG ELECTRONICS CO LTD

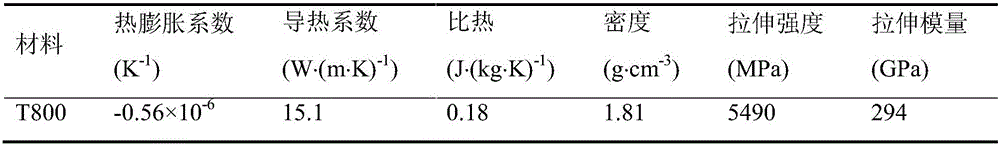

Test method for machining defect analysis of CFRP unidirectional laminates

ActiveCN105738239AAvoid processing quality accidentsReduce processing defectsInvestigating machinabilityCarbon fibersEngineering

The invention discloses a test method for machining defect analysis of CFRP unidirectional laminates. The test method is characterized by adopting multiple specimens made of carbon fiber prepreg cloth and having different fiber orientation angles to carry out an orthogonal fly cutting test, then carrying out photographic observation to material fractures of the cut specimens through a scanning electron microscope and obtaining image data, and thus providing an experimental data base for research of a CFRP cutting removal mechanism. According to the invention, material surface morphology change rules of CFRP in a cutting-off process are researched by using a single-point fly cutting method, cutting laws of carbon fibers under different fiber orientation angles are mainly concerned, a fracture formation mechanism of carbon fiber cutting is explained from two aspects of macroscopic and microscopic morphology, and based on the fracture formation mechanism, a formation mechanism of entrance and exit defects of the CFRP unidirectional laminates under different fiber directions is obtained, so that an experimental and theoretical basis is provided for reducing machining defects in a cutting process of CFRP materials to avoid component machining quality accidents caused by the machining defects.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com