Press brake control device, press brake control method, die management method, and data structure for die management data

A technology of metal molds and control devices, applied in the direction of program control, manufacturing tools, comprehensive factory control, etc., to achieve the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Hereinafter, a bending machine control device, a bending machine control method, a mold management method, and a data structure of mold management data according to an embodiment will be described with reference to the drawings.

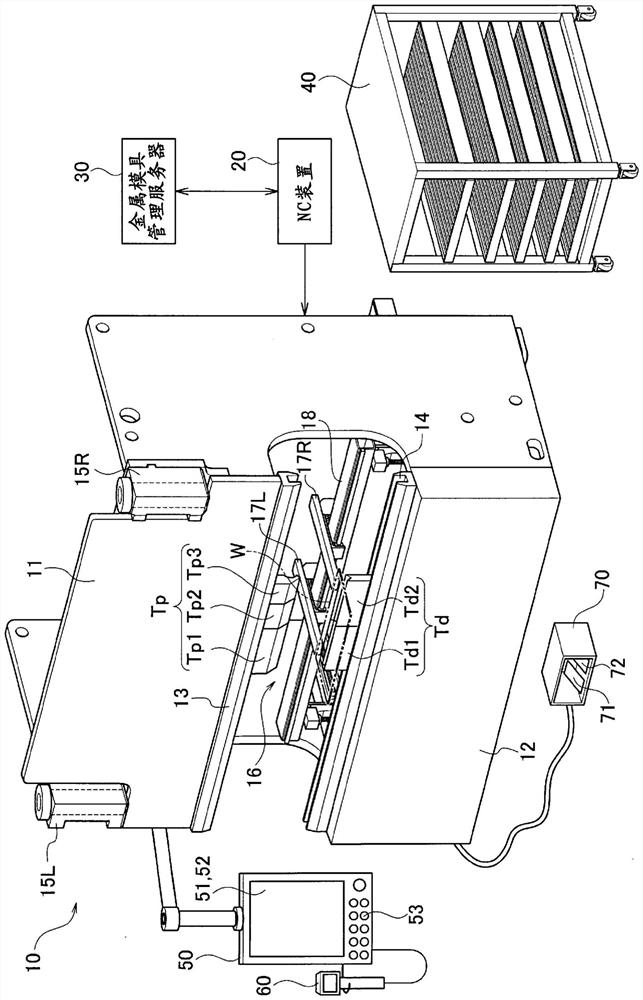

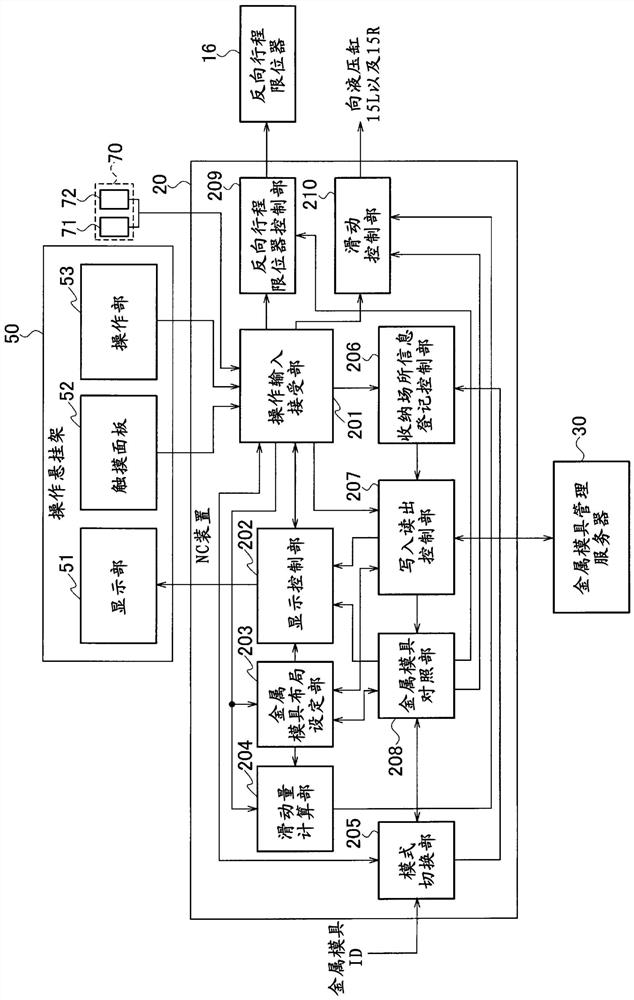

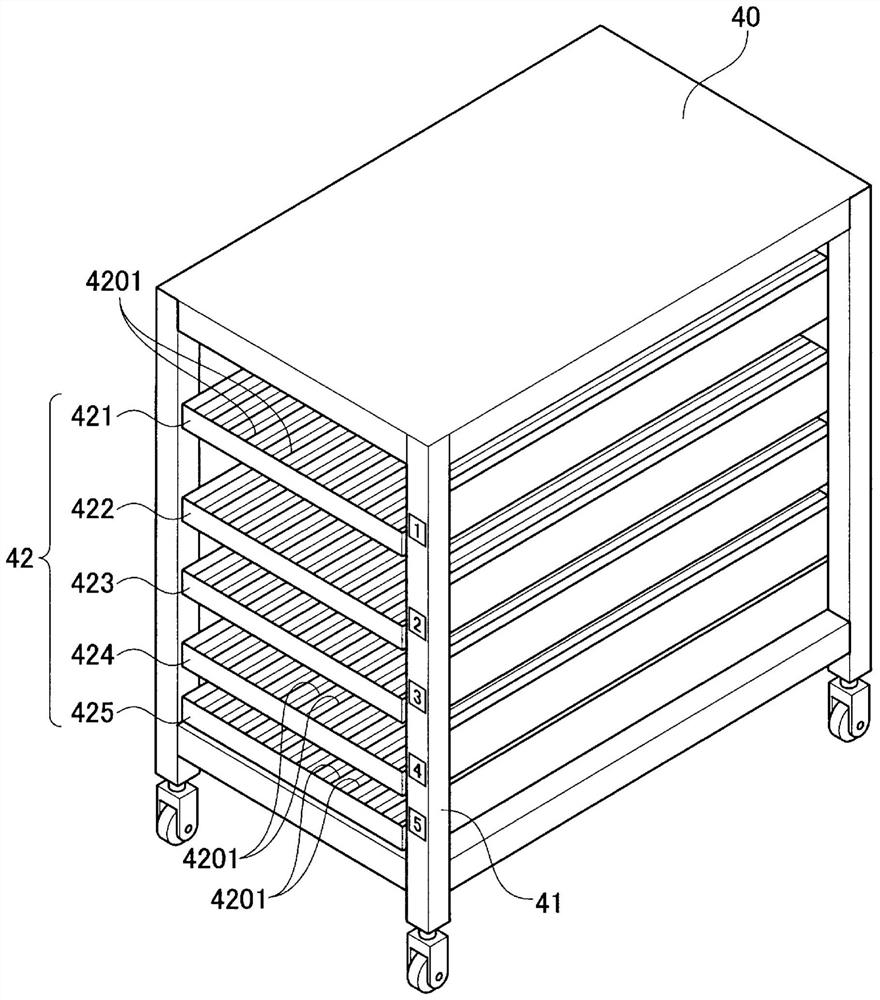

[0038] Such as figure 1 As shown, an NC device 20 functioning as a bending machine control device is connected to the bending machine 10 . A mold management server 30 is connected to the NC device 20 . The mold management server 30 may be installed in a place separate from the NC device 20 via a network. A die storage 40 is disposed near the press brake 10 . There may be a plurality of mold storages 40 .

[0039] The plate bender 10 includes an upper plate 11 and a lower plate 12 . An upper die holder 13 is attached to the upper plate 11 , and a lower die holder 14 is attached to the lower plate 12 . The upper plate 11 is configured to move up and down by hydraulic cylinders 15L and 15R provided on the left and right.

[0040] Three punc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com