Patents

Literature

499results about How to "Reduce chipping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production method of semiconductor chip

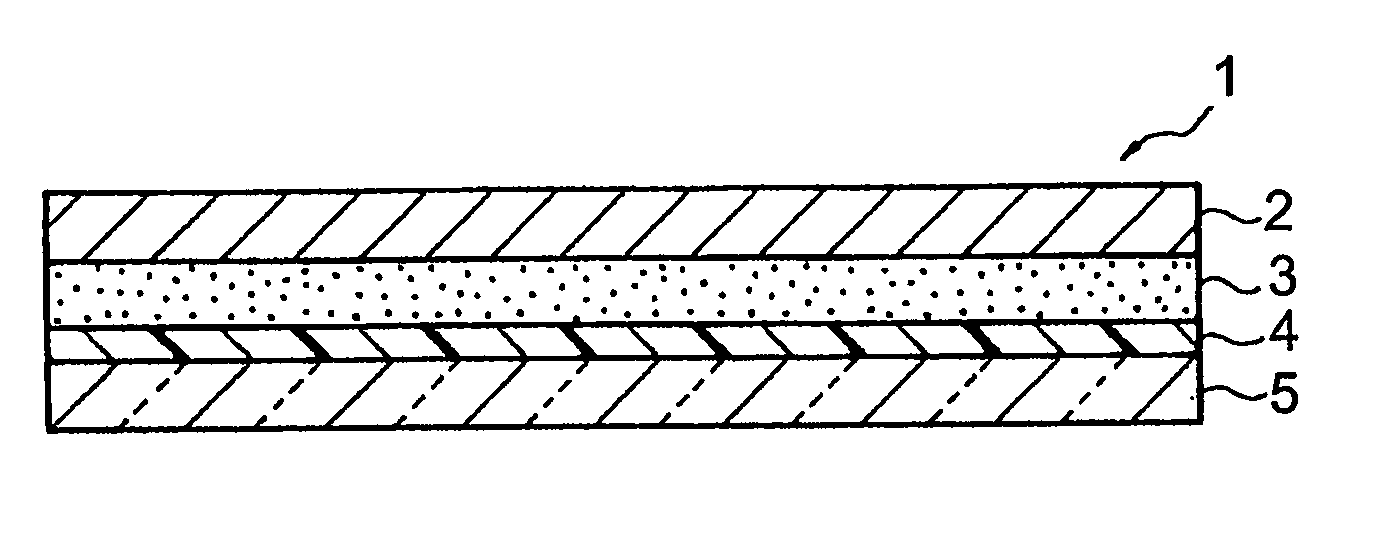

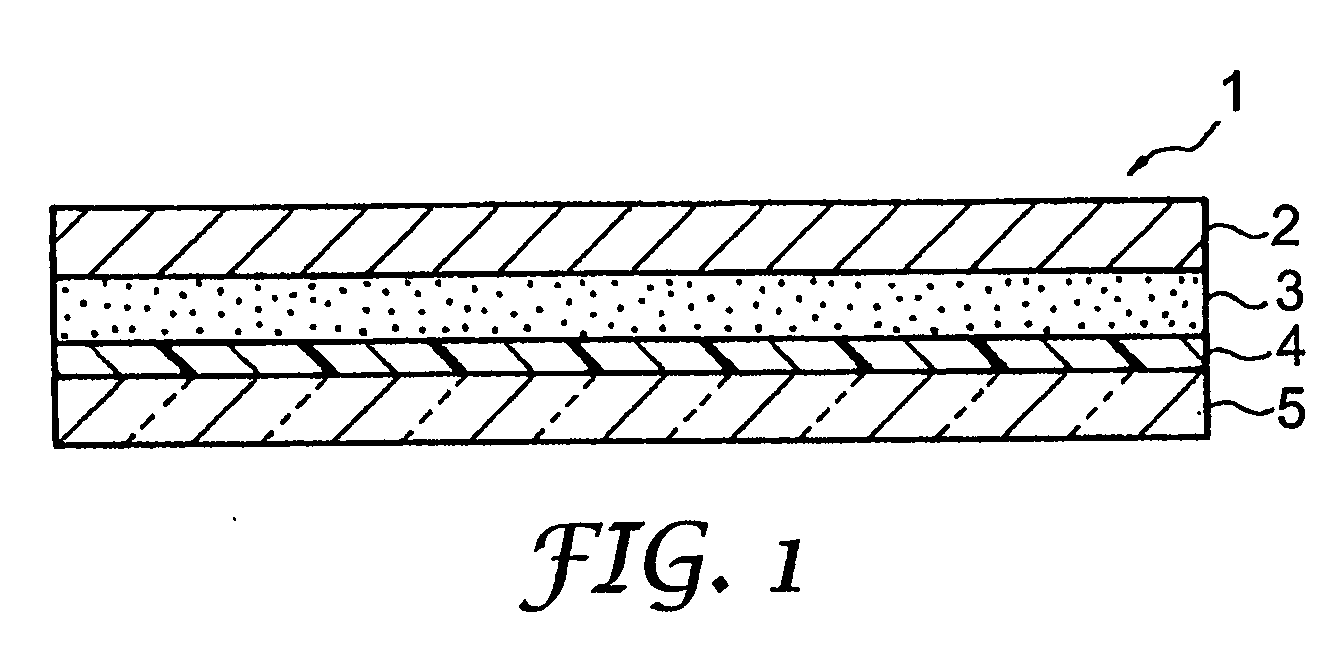

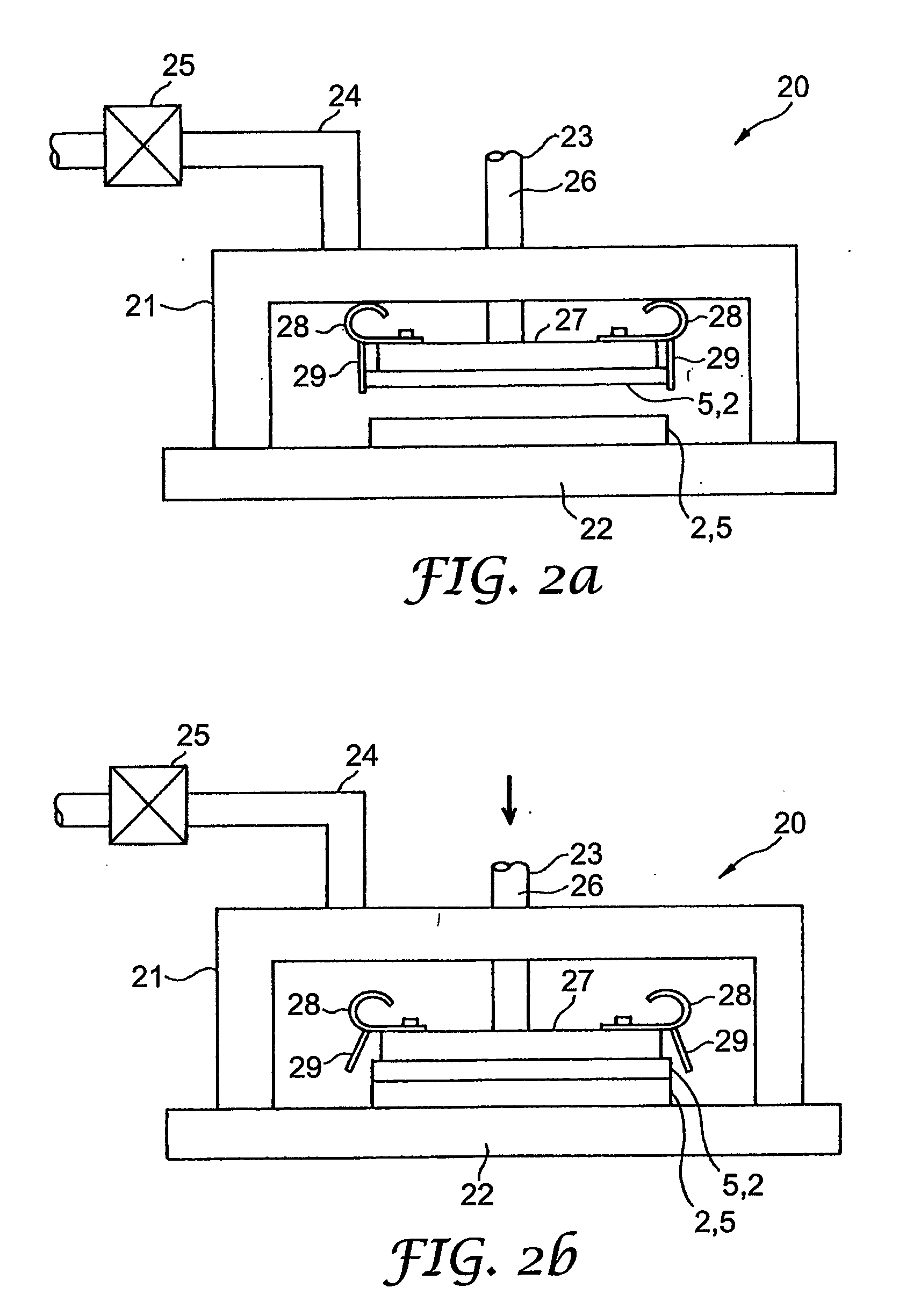

ActiveUS20070077685A1Reduce chippingChipping at the dicing can be reduced, minimized or even effectively preventedSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringAdhesive

Provided is a method for producing a semiconductor chip, comprising applying a photothermal conversion layer on a light-transmitting support, provided that upon irradiation of radiation energy, the photothermal conversion layer converts the radiation energy into heat and decomposes due to the heat; laminating the semiconductor wafer and the light-transmitting support through a photocurable adhesive by placing the circuit face and the photothermal conversion layer to face each other, thereby forming a laminated body having a non-circuit face on the outside; grinding the non-circuit face of the semiconductor wafer until the semi-conductor wafer reaches a desired thickness; dicing the ground semiconductor wafer from the non-circuit face side to cut it into a plurality of semiconductor chips; irradiating radiation energy from the light-transmitting support side to decompose the photothermal conversion layer, thereby causing separation into a semiconductor chips having the adhesive layer and a light-transmitting support; and optionally removing the adhesive layer from the semiconductor chips.

Owner:3M INNOVATIVE PROPERTIES CO

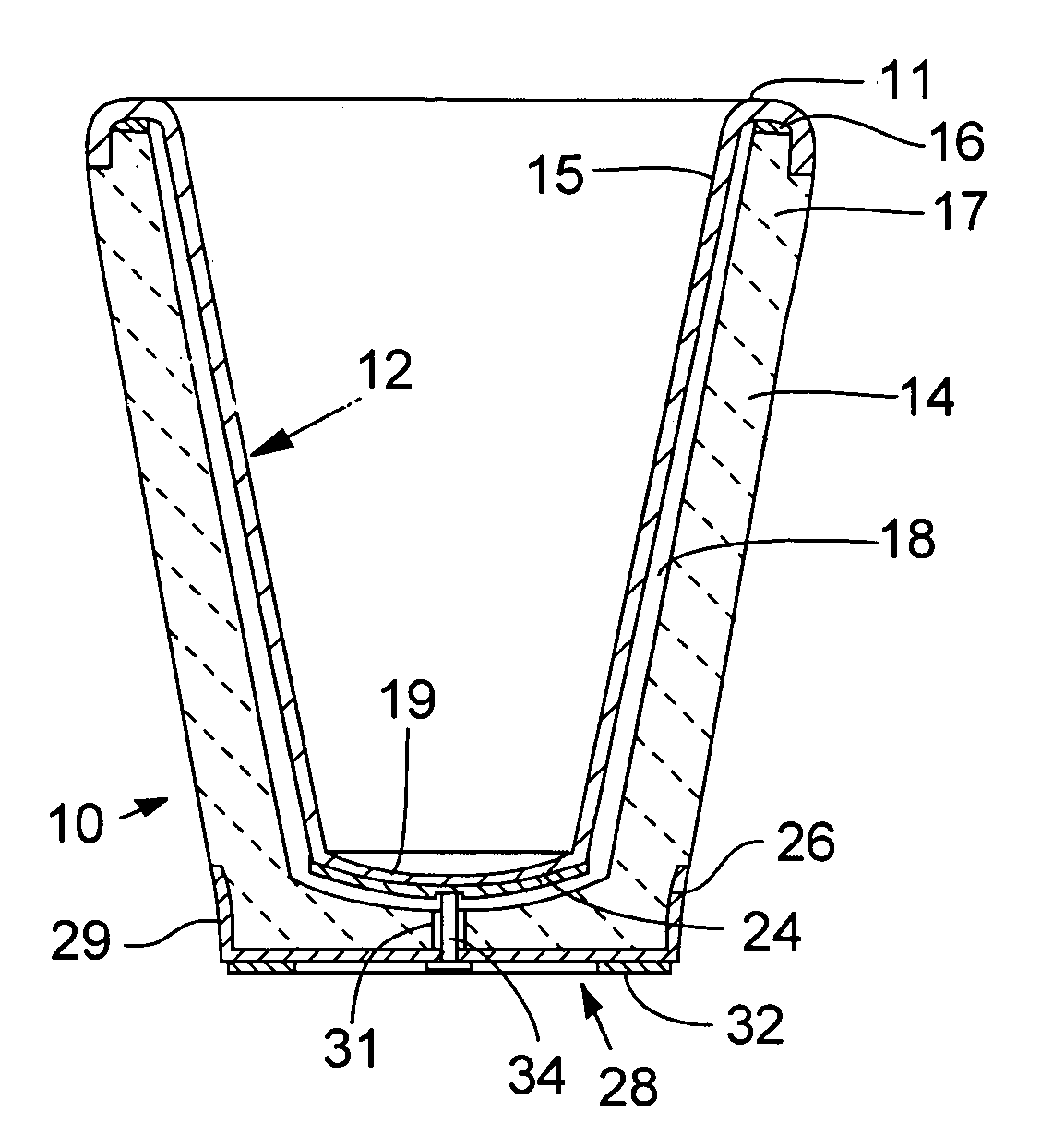

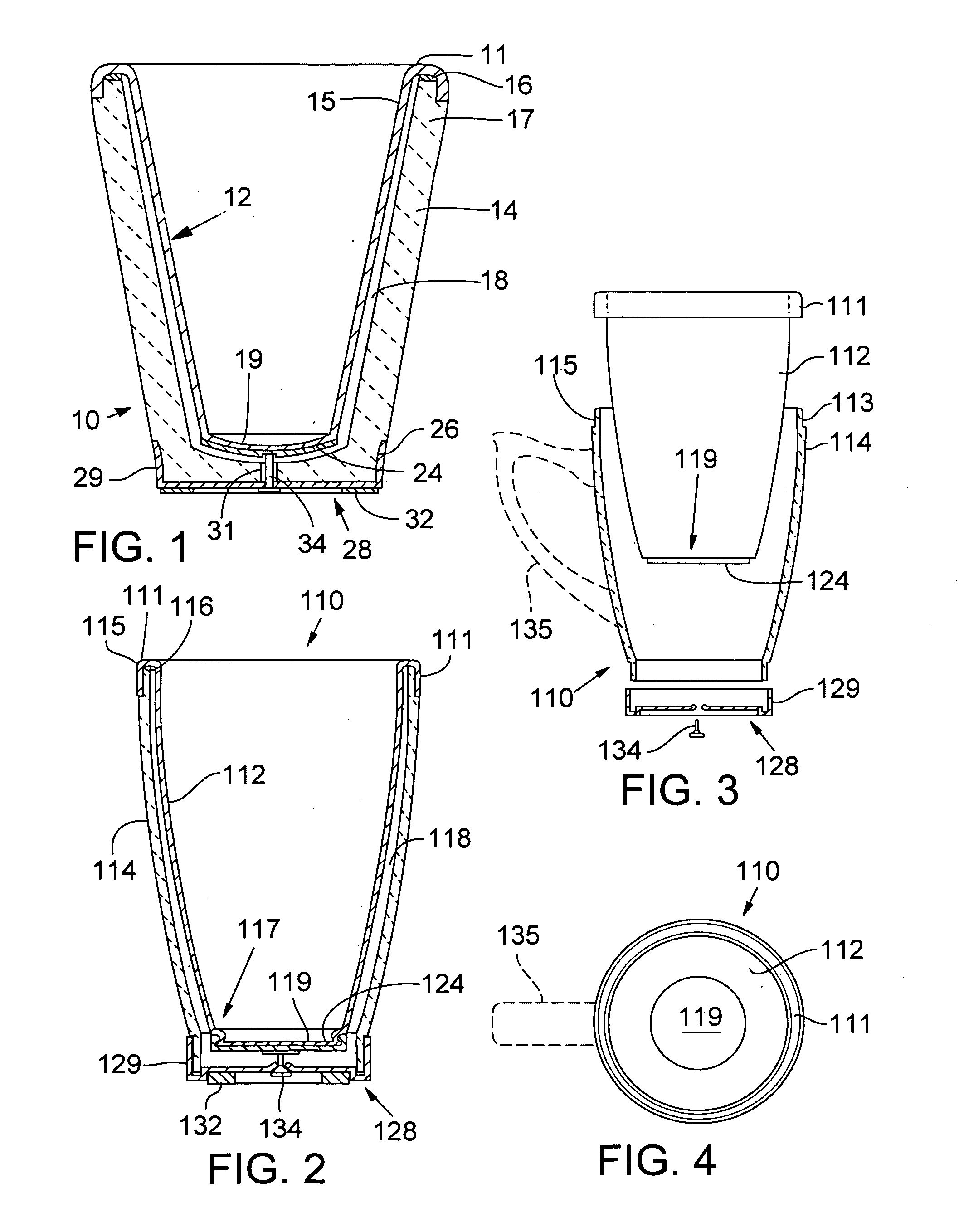

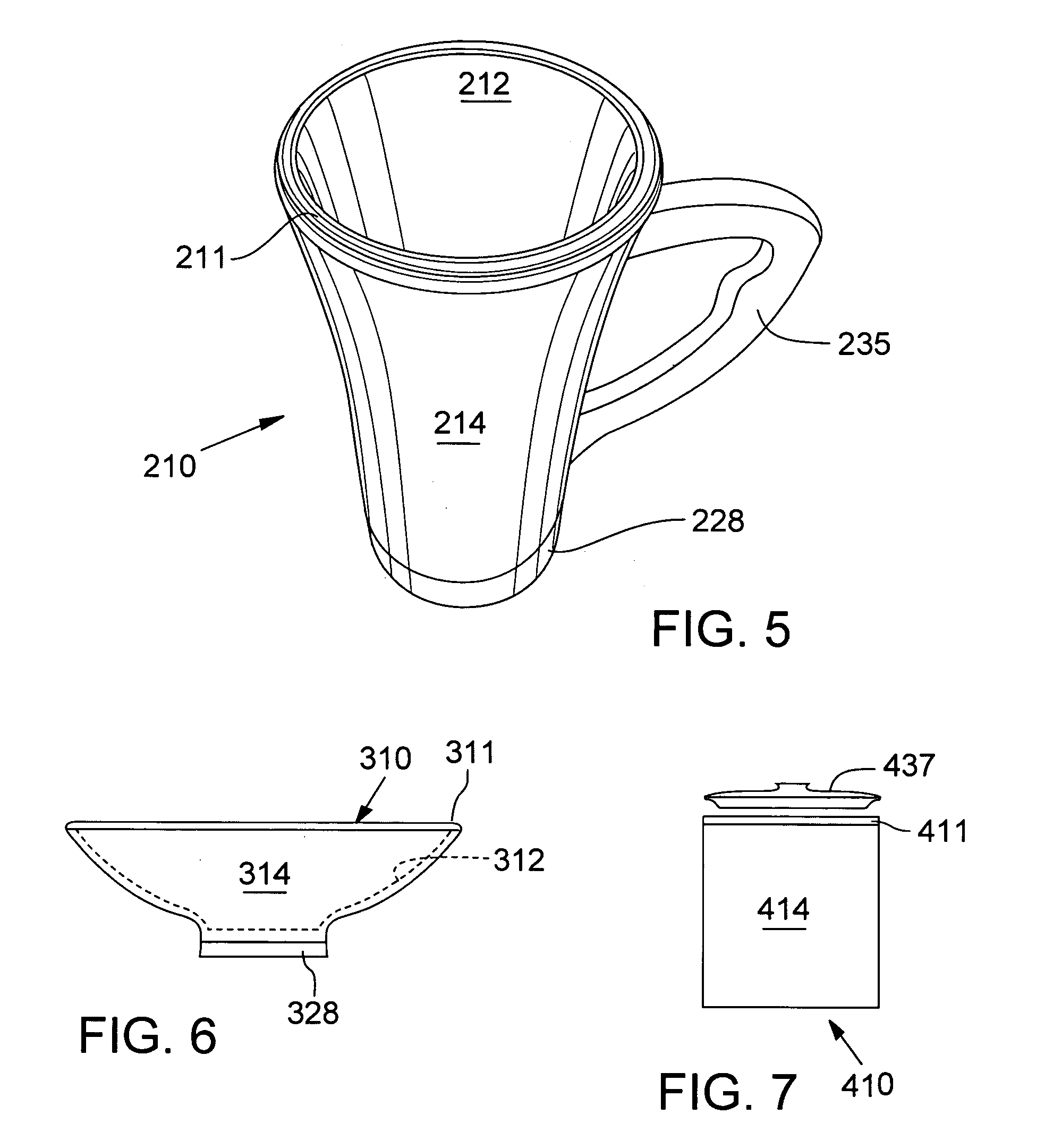

Ceramic metallic liquid holding vessel

InactiveUS7104413B2Reduce breakageReduce chippingDomestic cooling apparatusLighting and heating apparatusMetallic materialsAlloy

A vessel for holding liquid having an outer ceramic shell and an inner metallic lining. The metallic lining may extend over the top of the shell to provide protection from damage. A base member may be provided. The metallic material may be any food safe metal, including stainless steel and aluminum and alloys thereof. The ceramic may be any suitable ceramic including porcelain, earthenware and glass. Handle and non-handles vessels are disclosed as are resealable and non-resealable vessels. The metallic and ceramic materials may be separated by an insulative gap.

Owner:PACIFIC CORNETTA

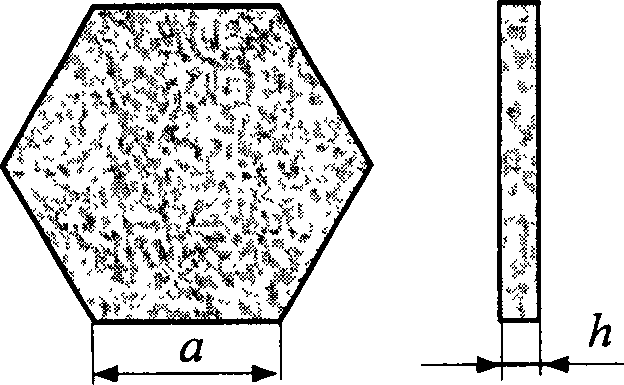

Composite bulletproof armour with steel honeycomb ceramic sandwich and manufacture thereof

In the invention, the composite bullet-proof armour plate consists of a metal panel, a honeycomb core board, a ceramic wafer core and a metal rear panel bonded with the metal brazing layer via the organic adhesive layer. The preparing method is that using the brozing and the line-cutting method are finished the honeycomb core board and the plain or curved ceramic wafer core, whose size must fit in that of the honeycomb hole of the honeycomb core board. The panel and the rear panel must be made of the bullet-proof steel plate through heat treating after cold rolling. The Ag72Cu metal brazing material and the epoxy resin group high strength structural sizing for connecting the interface are assembly welded.

Owner:UNIV OF SCI & TECH BEIJING

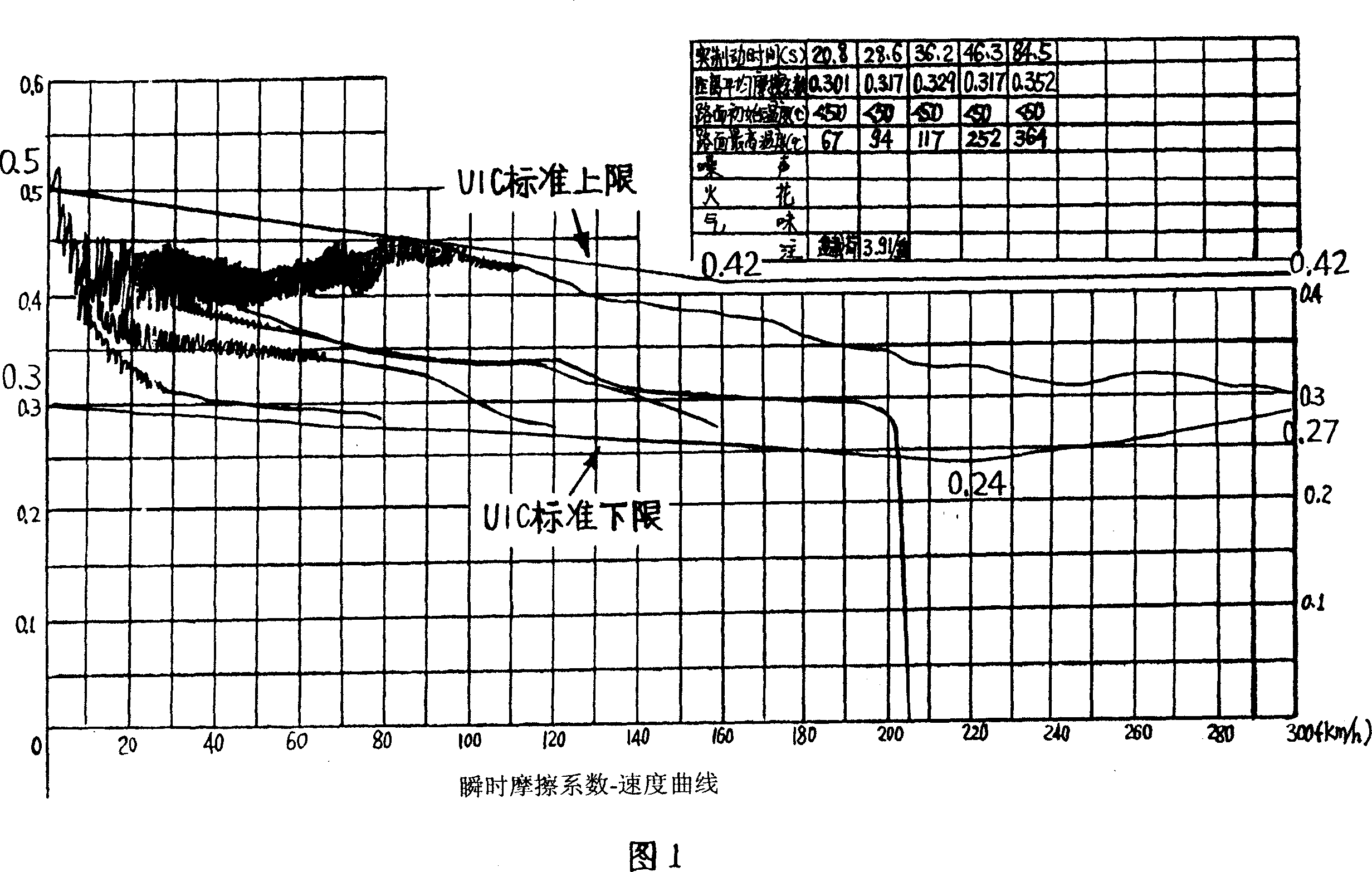

Copper base particle reinforced friction material

InactiveCN1995436AHigh degree of alloyingHigh strengthFriction liningManufacturing cost reductionGraphite

The invention discloses a reinforced friction material of copper-based particle in the friction material making domain, which comprises the following parts: 30-70% Cu, 4-11% Sn, 1-15% Al, 5-18% Fe, 2-15% Al2O3, 2-15% SiO2, 0-15% ferrochrome and 5-20% graphite.

Owner:大连远通制动制品有限公司

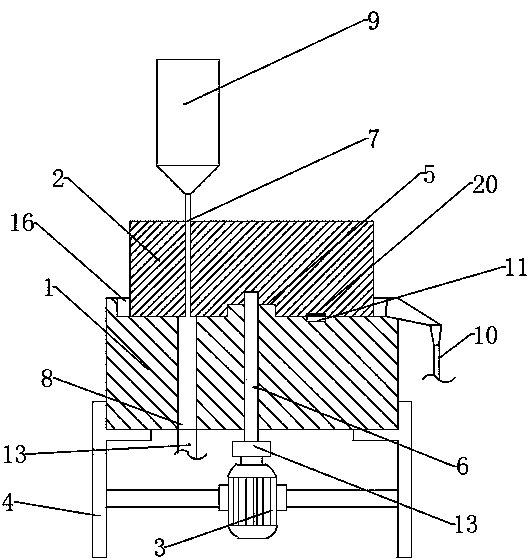

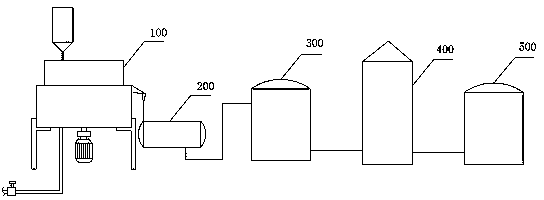

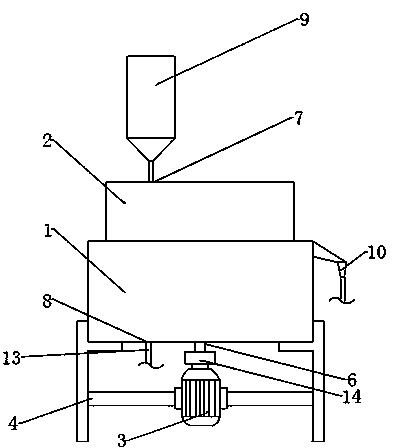

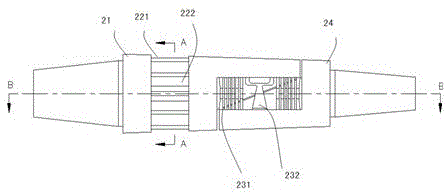

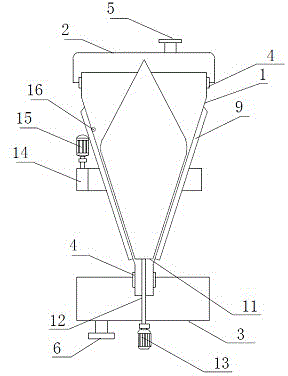

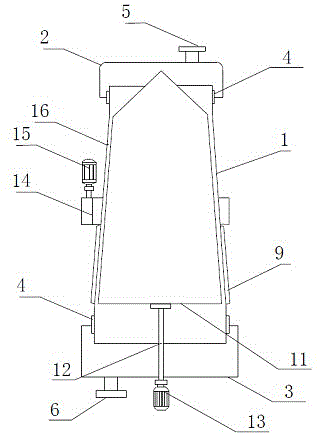

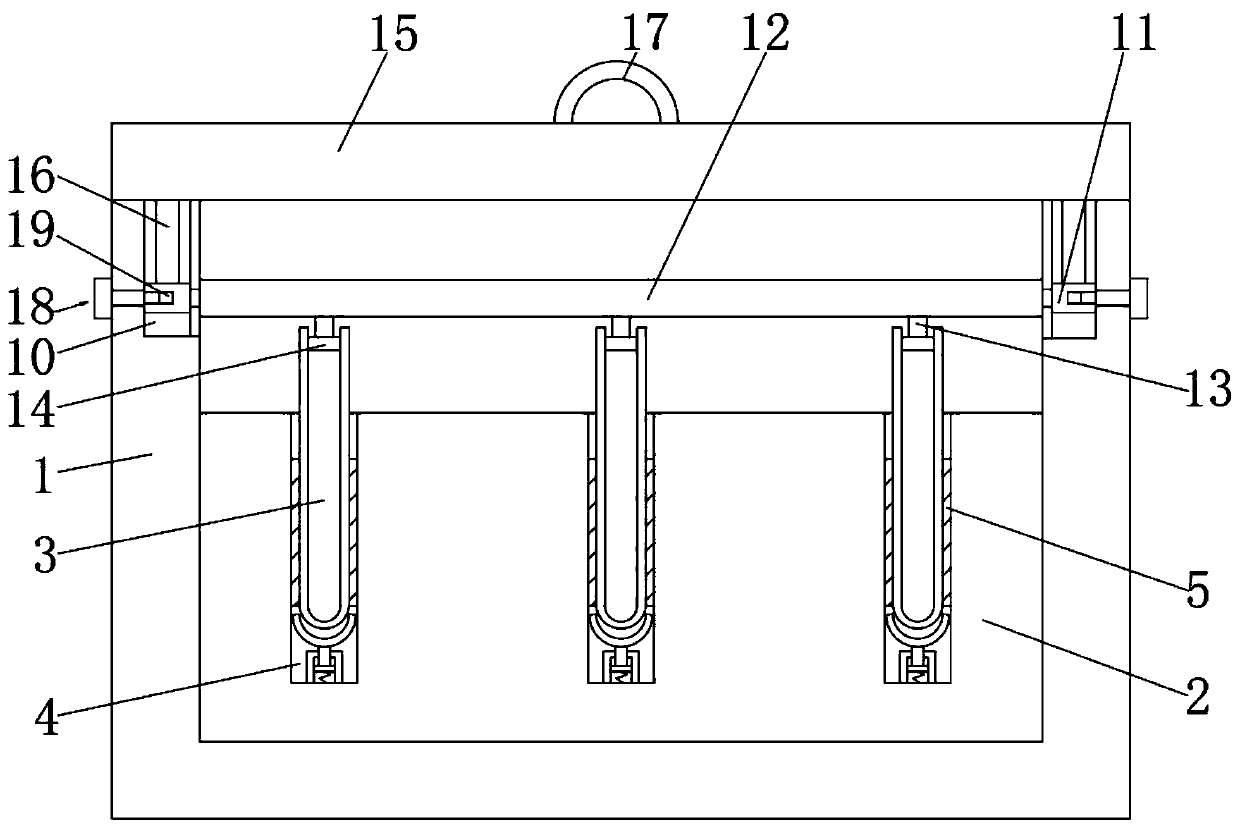

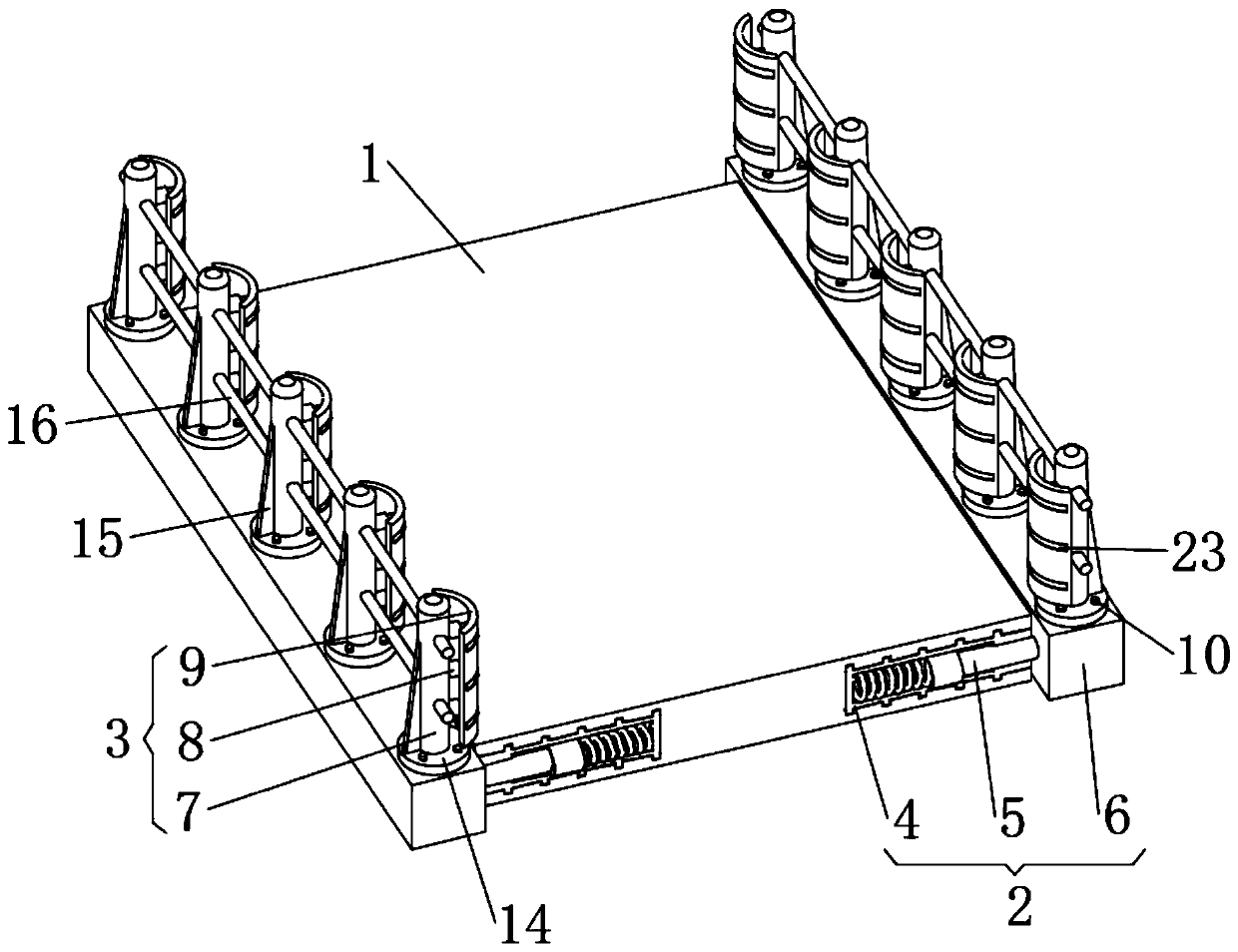

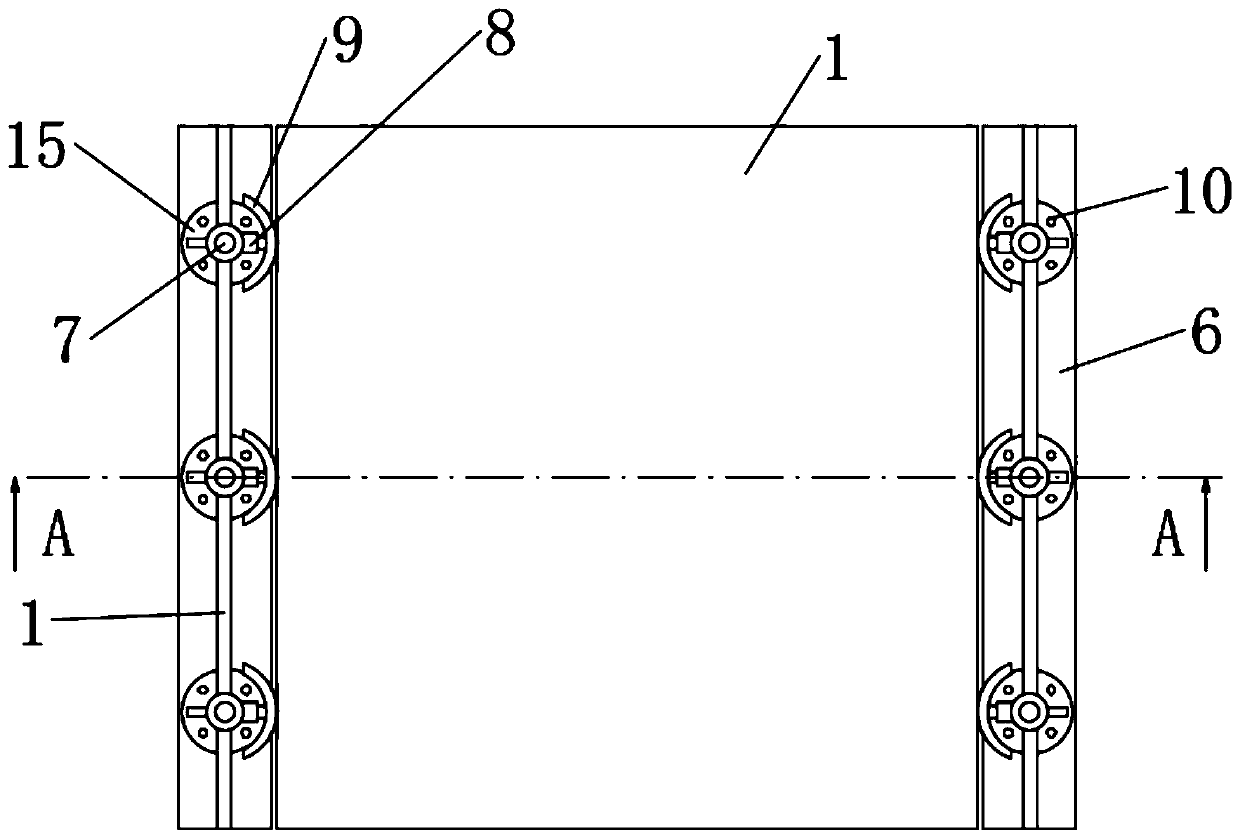

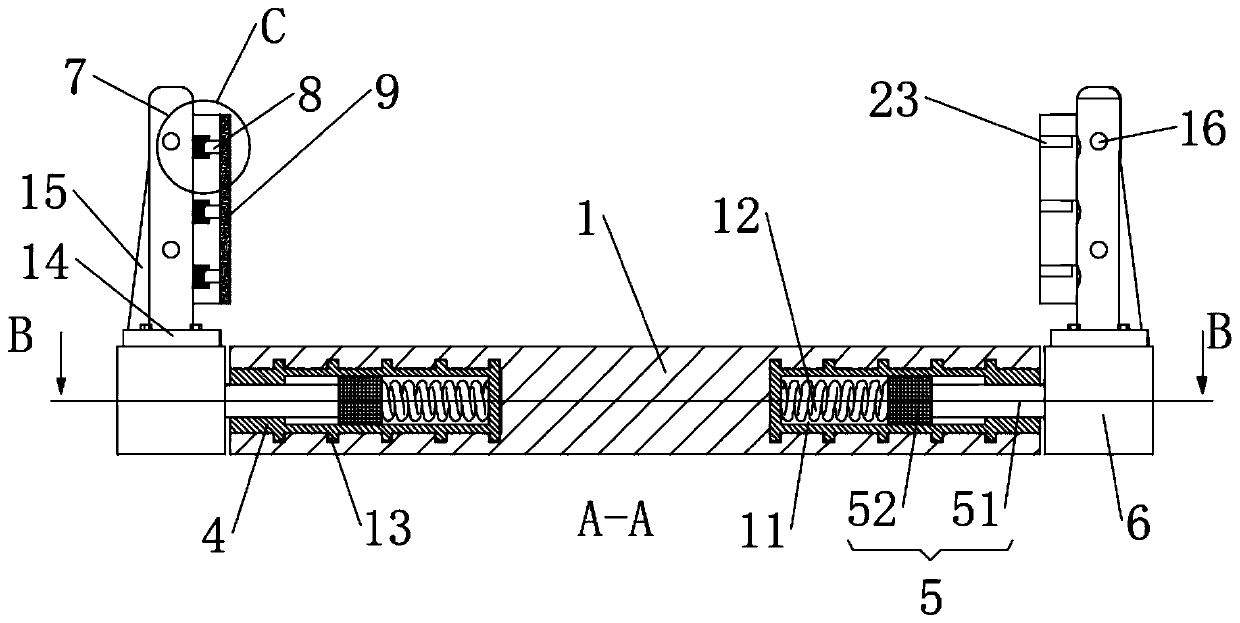

Graphene grinding and stripping device, graphene production system and production method

ActiveCN104401971AKeep the natural plane sizeReduce the chance of crushingCvd grapheneMechanical engineering

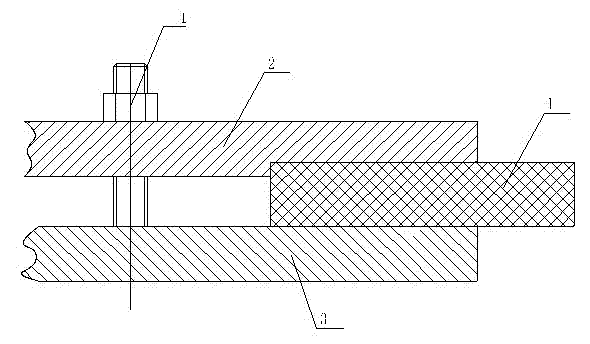

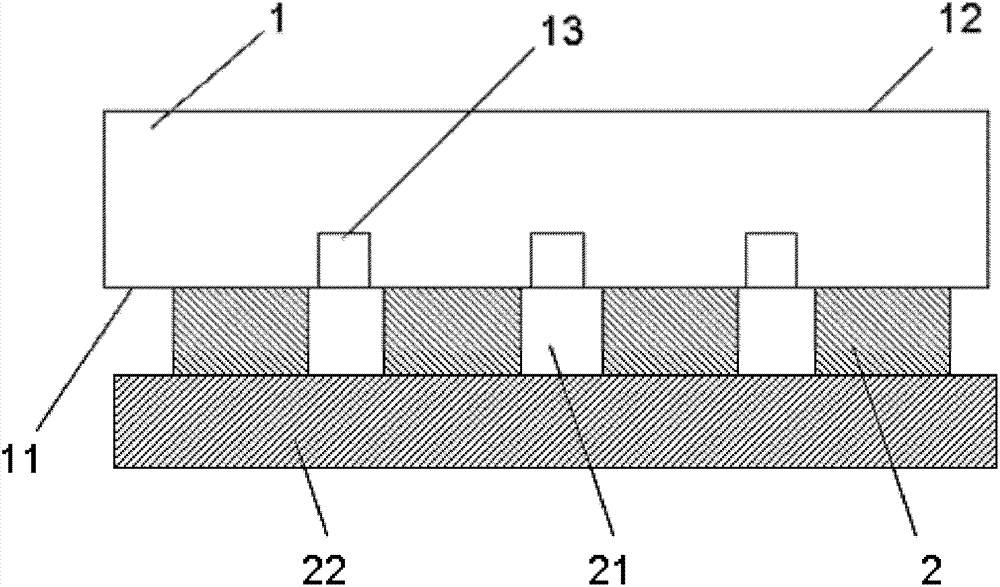

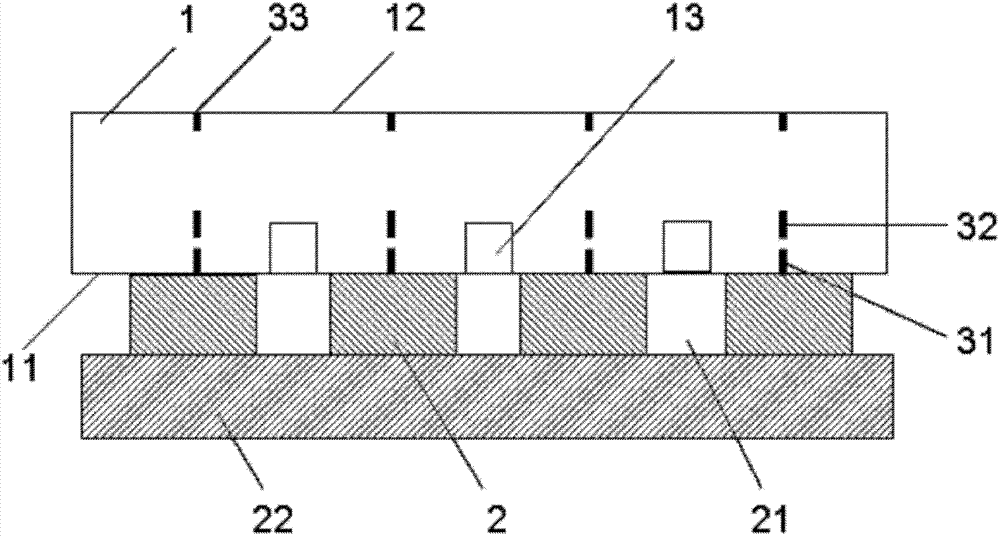

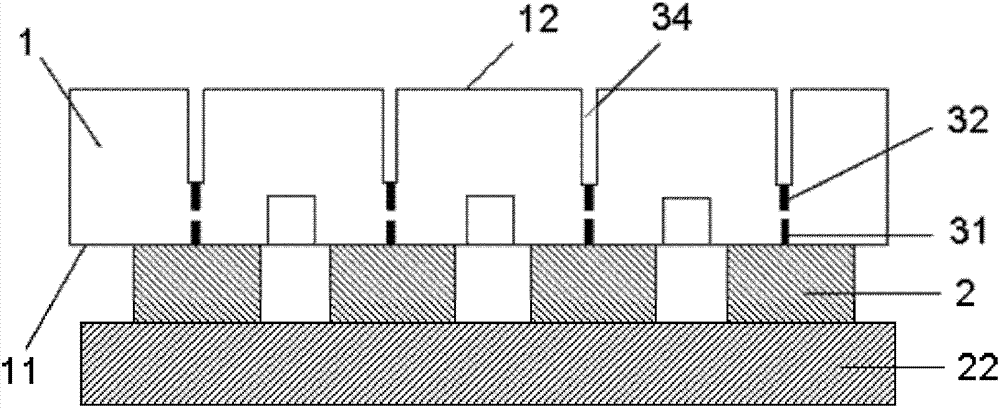

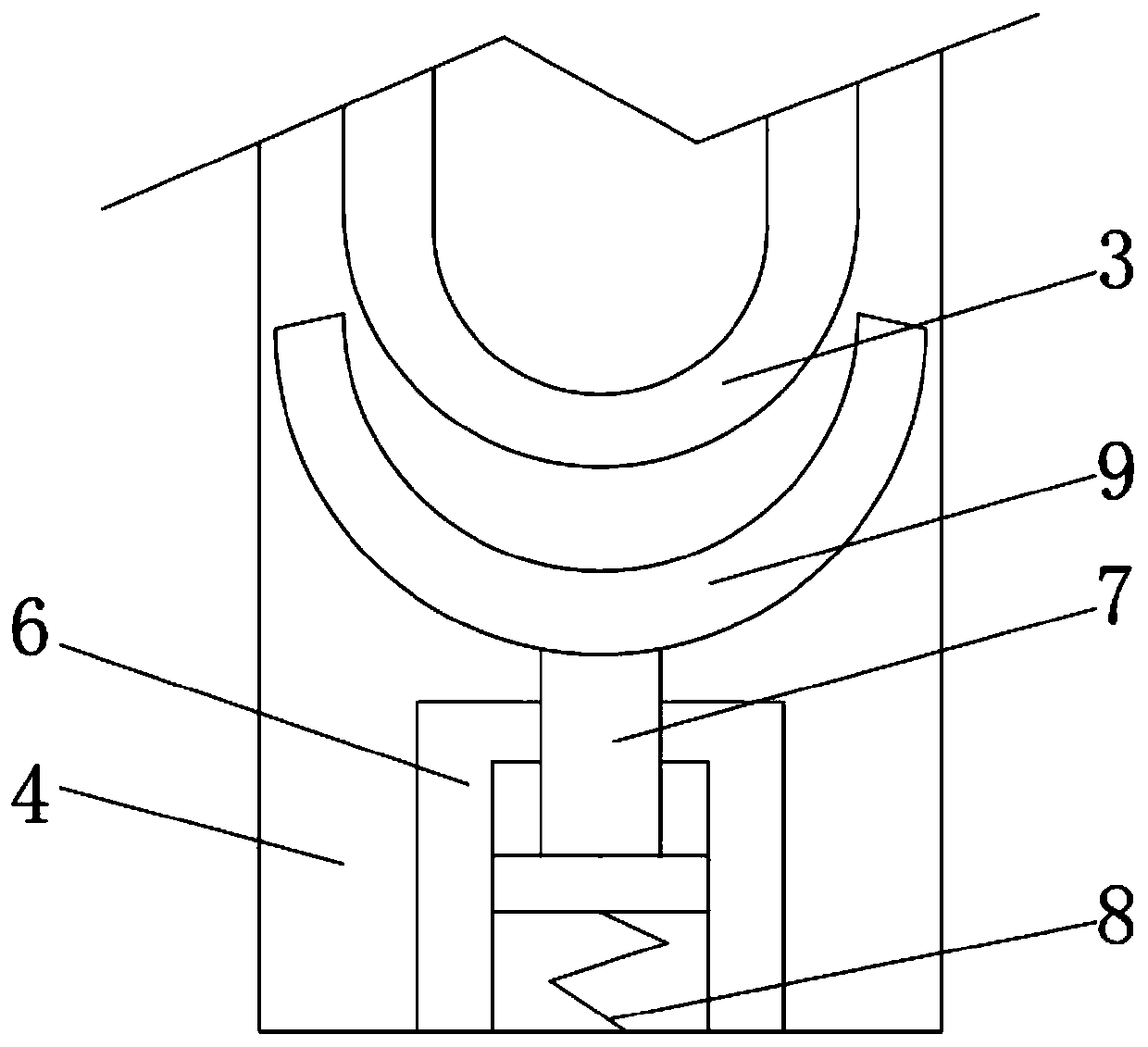

The invention discloses a graphene grinding and stripping device which comprises an upper grinding disc, a lower grinding disc, a driving mechanism for driving the upper grinding disc to rotate, and a material collection mechanism for collecting a product after grinding, wherein the upper grinding disc and the lower grinding disc are matched with each other; a horizontal contact surface is formed between the upper grinding disc and the lower grinding disc, the upper grinding disc is provided with an upper feed inlet, the lower grinding disc is provided with a lower feed inlet, the upper feed inlet and the lower feed inlet are both connected with the contact surface between the upper grinding disc and the lower grinding disc, and the lower end of the lower feed inlet is in sealed connection with one water inlet tube; moreover, the upper end face of the lower grinding disc is provided with a groove, and an annular region formed by rotary surrounding of the lower end of the upper feed inlet is surrounded in the groove. The graphene grinding and stripping device can realize large-size successful stripping of graphene. The invention also relates to a graphene production system containing the graphene grinding and stripping device and a graphene production method.

Owner:江苏碳谷二维世界科技有限公司

Method for preparing small expended and vitrified ball with reinforcing layer coated on surface

The invention relates to a method for preparing a small expended and vitrified ball with a reinforcing layer coated on the surface. By combining the advantages of the small expended and vitrified ball and a thermosetting polymer material, the small expended and vitrified ball with the reinforcing layer coated on the surface is prepared by forming an insoluble and infusible high molecular protective film on the surface of the small expended and vitrified ball through the crosslinking and solidification of thermosetting resin. The strength and the heat-preservation and heat-insulating performance of the small expended and vitrified ball with the reinforcing layer coated on the surface are improved, the problems that the small expended and vitrified ball is easy to crack in use and the like are reduced, and meanwhile, the water absorption rate of the small expended and vitrified ball is reduced greatly. The method has the advantages that the preparation process is simple, the small expended and vitrified ball is easy to control and the like. The small expended and vitrified ball with the reinforcing layer coated on the surface can be used as heat-preservation light mortar and a plaster material, a heat-preservation and heat-insulating layer in oil cans, liquefied gas storage tanks and industrial gas storage tanks and a raw material of a light high-grade refractory material.

Owner:WUHAN TEXTILE UNIV

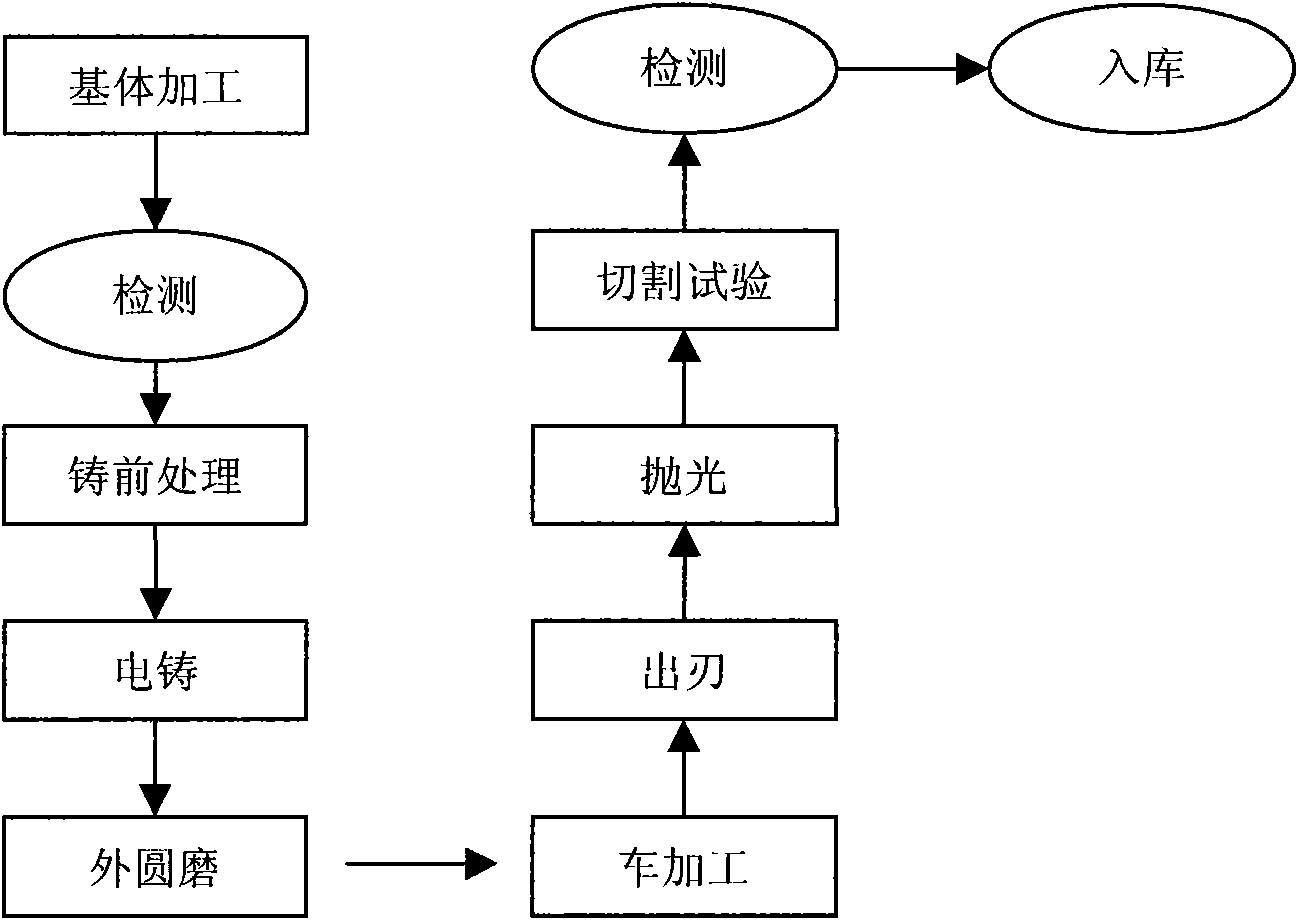

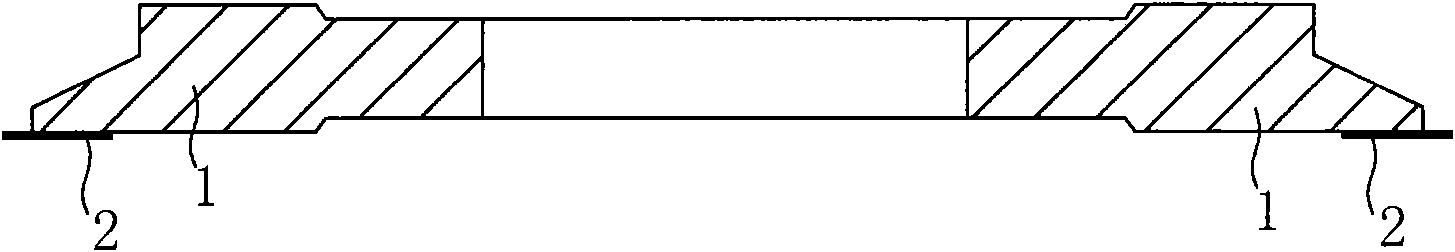

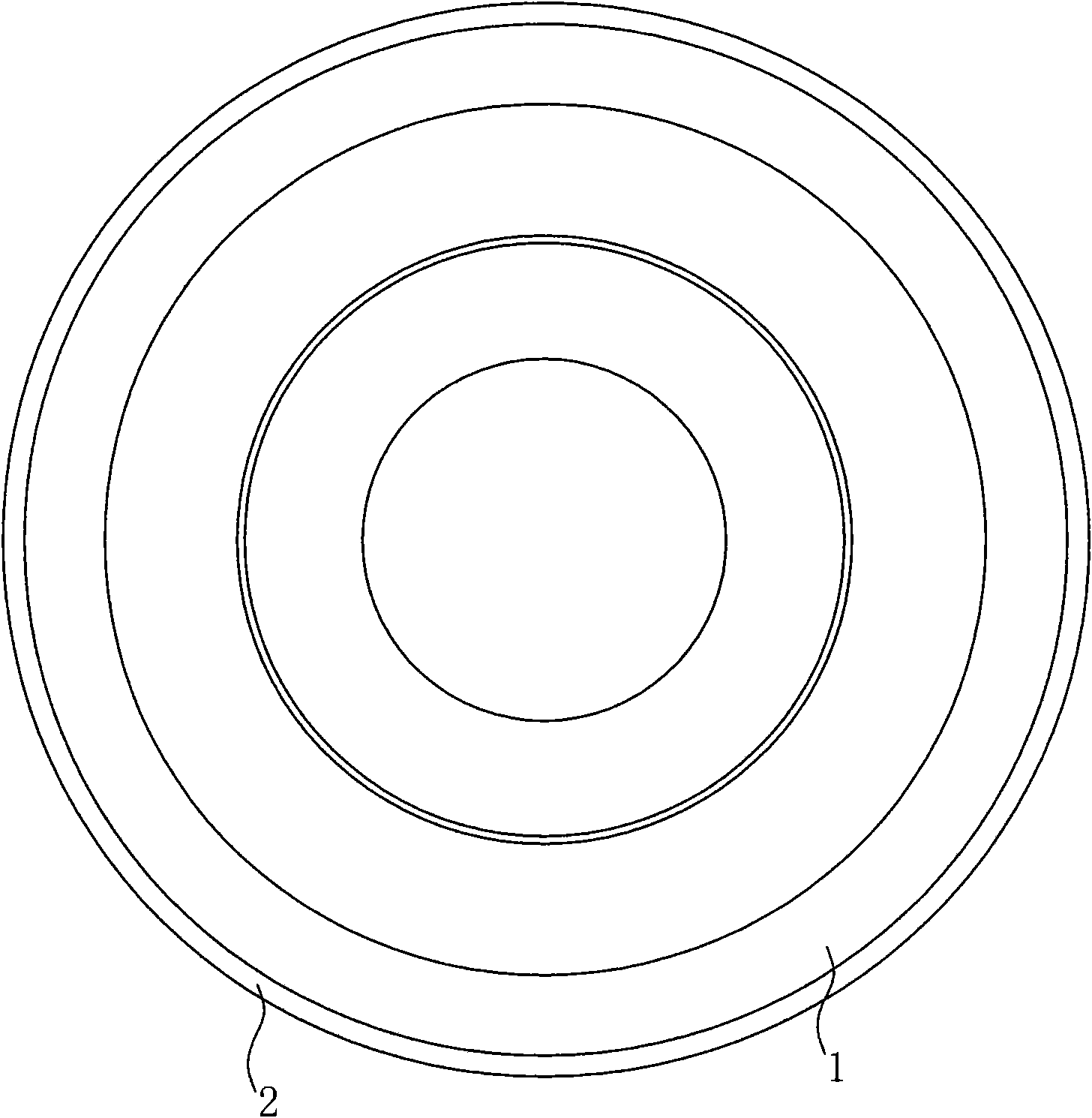

Diamond grinding wheel for cutting silicon crystal circle and preparation method thereof

ActiveCN101633158AHigh strengthImprove rigidityGrinding devicesGrinding machinesNumerical controlCobalt sulphate

The invention discloses a diamond grinding wheel for cutting a silicon crystal circle and a preparation method thereof. The method comprises the following steps: (1) preprocessing an aluminum alloy basal body; (2) configuring electroforming liquid: configuring the electroforming liquid according to the weight ratio of (38-43):(15-20):(43-57):(50-180):(4-8) of nickel sulphate, cobalt sulphate, deionized water, a diamond grinding material and a suspending agent; fully stirring evenly and obtaining the electroforming liquid; (3) carrying out insulation processing on the aluminum alloy basal body obtained in the step (1), putting the aluminum alloy basal body into the electroforming liquid, electroforming in an ultrasonic field, evenly precipitating the diamond grinding material in the electroforming liquid and metal on the basal body together and obtaining a grinding wheel blank body with a compound electroforming layer; and (4) taking out the grinding wheel blank body completing electroforming, and carrying out accurate processing on the grinding wheel blank body on a numerical control grinder and a numerical control lathe respectively according to the accuracy requirements of the required basal body and the required cutting edge. The diamond grinding wheel obtained by the invention meets the ultrathin and superfine technical conditions and also has favorable strength and rigidity.

Owner:赛尔科技(如东)有限公司

High-efficiency low-cost solar cell diffusion technology

InactiveCN103681976AReduce internal defectsImprove uniformityFinal product manufactureSemiconductor/solid-state device manufacturingNitrogenEngineering

The invention provides a high-efficiency low-cost solar cell diffusion technology, which is a multi-step variable temperature diffusion and annealing technology under the protection of small-flow nitrogen, and is characterized by adopting the following eight steps of diffusion processes under the protection of small-flow nitrogen: step 1, ultralow temperature boat entering process; step 2, constant temperature field process; step 3,variable temperature oxidation process; step 4, fixed temperature diffusion process; step 5, variable temperature diffusion process; step 6, knot pushing diffusion process; step 7, variable temperature annealing process; step 8, ultralow temperature boat exiting process. Compared with traditional constant temperature diffusion technology, the high-efficiency low-cost solar cell diffusion technology provided by the invention shortens diffusion technology time, reduces technology gas cost, improves uniformity and repeatability of diffusion sheet resistor.

Owner:百力达太阳能股份有限公司

Method for machining slotted holes on carbon fiber laminated boards

The invention discloses a method for machining slotted holes on carbon fiber laminated boards, which belongs to a machining method for nonmetallic materials, solves the problem that by the existing milling and drilling methods, carbon fiber laminated boards are easy to laminate, split and burn, and aims at improving the machining precision of carbon fiber composite products and reducing the surface roughness of carbon fiber composite products. The method disclosed by the invention comprises a clamping step, a machining step and a post-processing step, wherein the machining step is one or two of a milling machining step and a drilling machining step. According to the invention, in the machining process, a non-deformed clamping mode is used, and through selecting reasonable cutting tool materials, geometric parameters of cutting tools, and milling and drilling machining parameters, the appearance allowances in machining are reasonably arranged, thereby solving the quality problems of laminating, splitting and burning and the like existing in the process of opening or drilling carbon fiber thin-wall revolution bodies and carbon fiber laminated boards by using the traditional methods, so that the qualified rate of carbon fiber parts is increased from 50% to more than 99%.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

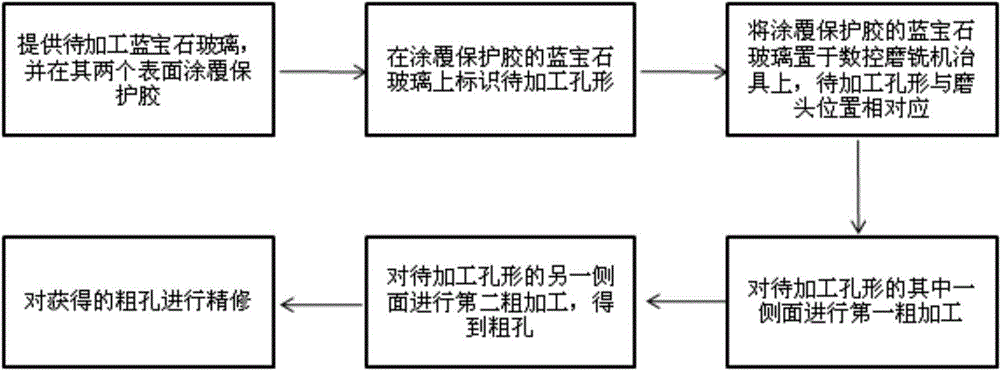

Machining method for drilling sapphire glass

InactiveCN104690615AReduce chippingReduce the chance of chippingRevolution surface grinding machinesEngineeringSapphire

The invention discloses a machining method for drilling sapphire glass. The machining method for drilling sapphire glass comprise the following steps of coating protection glue on the surface on to-be-machined sapphire glass, identifying a shape of a to-be-machined hole, respectively performing rough machining on bilateral sides of the hole, obtaining rough holes, finishing the tough holes to achieve drilling procedures. According to the machining method for drilling the sapphire glass, rough machining is performed on bilateral sides of the sapphire glass hole, the acting force cannot be concentrated on one lateral side, the machining acting force on the sapphire glass surface is scattered, the protection glue coats on the sapphire glass surface, the protection glue is dirty proof, rust preventing, acid and alkali resistant and scratch resistant and plays a role in buffering, hedging of the machining acting force and the sapphire glass stress is reduced, and accordingly possibilities of glass edge breakage or fragment are reduced, the yield can be improved to 99%, the use ratio of materials is greatly improved, and waste and material costs are reduced.

Owner:肖衍盛 +2

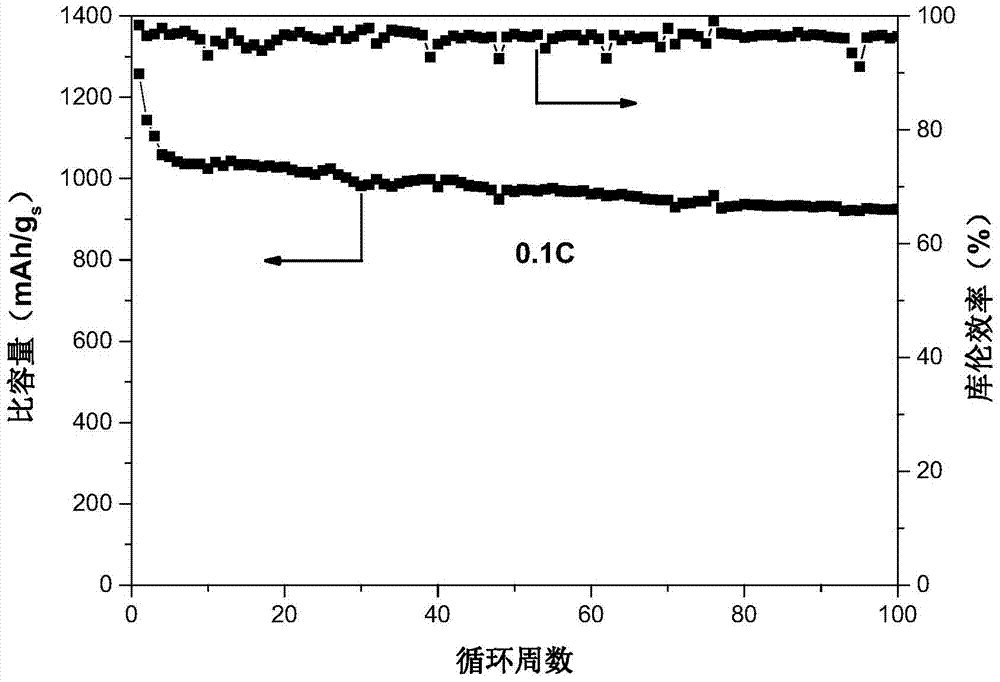

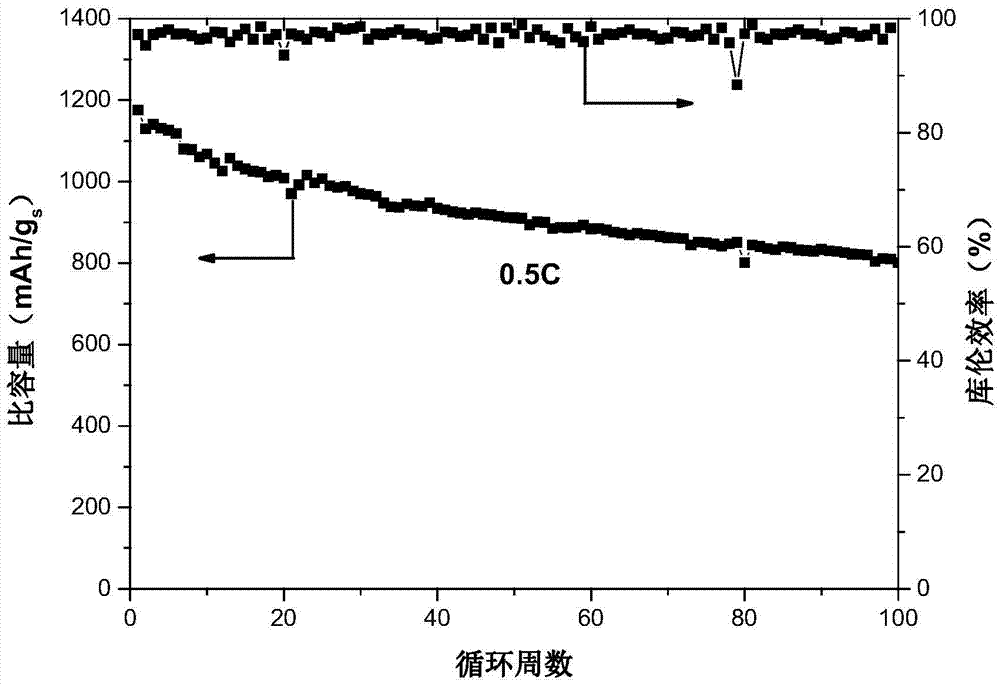

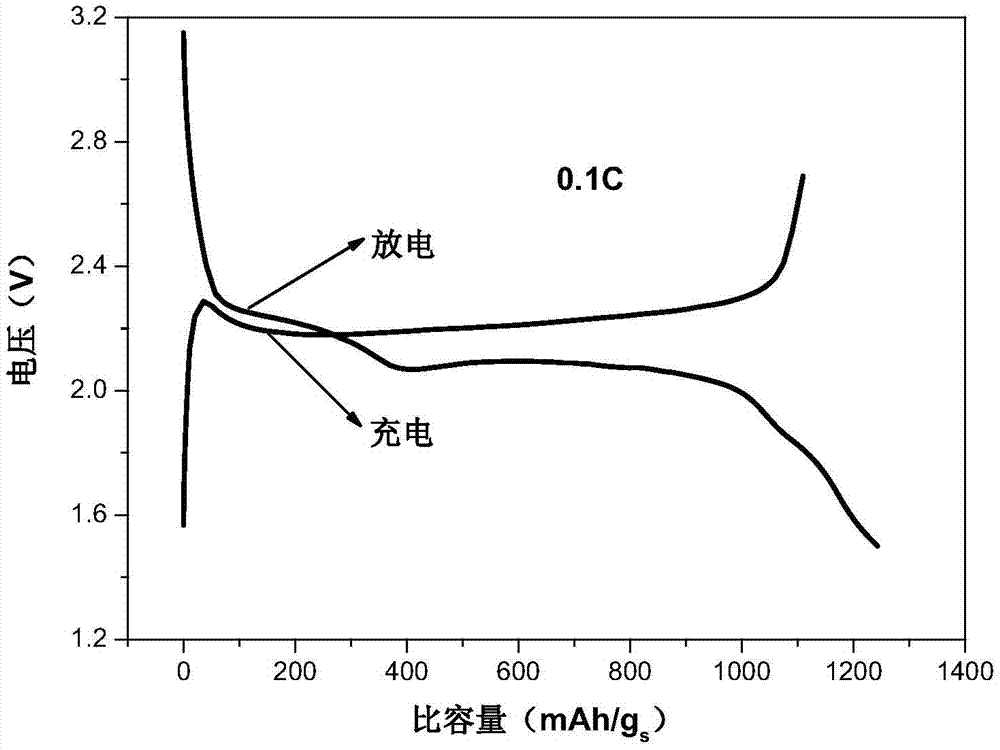

Nitrogen-rich eggshell type lithium sulfur battery anode material and preparation method and application thereof

InactiveCN105449209AImprove adsorption capacityThe first discharge specific capacity is highCell electrodesLi-accumulatorsChemical adsorptionMelamine formaldehyde resin

The invention discloses a lithium sulfur battery anode material and preparation method thereof, melamine formaldehyde resin rich in nitrogen is taken as a carbon source and nitrogen source, a nitrogen-rich hollow eggshell with the diameter of 100-300 nm is prepared with a nanometer SiO2 casting method, the interfacial adsorption of polysulfide is enhanced by the aid of the combined effect of physical adsorption and chemical adsorption, migration and shuttle effects of the polysulfide are effectively restrained, and charge and discharge stability of a lithium sulfur battery is enhanced. At the same time, an eggshell structure is formed after the hollow eggshell is filled with sulfur, and an interior gap exists between a sulfur inner core and a polymer shell so as to accommodate volume expansion in a sulfur atom lithiation process. The lithium sulfur battery anode material is applied to preparation of a lithium sulfur battery anode and the lithium sulfur battery. The lithium sulfur battery has excellent cycle performance and capacity retention ratio.

Owner:DALIAN UNIV OF TECH

Casting method of gear

The invention relates to a casting method. Ceramic anti-wearing grains are used for replacing fireproof materials, and a liquid coating formed by mixing the ceramic anti-wearing grain and a binding agent is coated on the surface of a module to prepare a section mould; a fired mould is smelted, and alloy liquid is injected; a casting piece is formed along with the cooling and the condensation of the injected alloy liquid; the ceramic anti-wearing grains are led to the surface of the casting piece to carry out heat treatment so as to increase one layer of a ceramic hardening layer on the surface of the casting piece and improve the surface hardness of the casting piece. With the adoption of the casting method, the casting piece is formed for one time, the surface is smooth and clean, and the size is accurate, so that the aim of less cutting or no cutting is achieved; and the surface is provided with the ceramic hardening layer, and the hardness is greatly improved, so that the casting method is particularly suitable for preparing an alloy casting piece such as a gear, which need higher surface hardness.

Owner:宁波吉威熔模铸造有限公司

Coating layer on blade base body

ActiveCN104085142AReduce crackingReduce internal stressLayered productsChemical vapor deposition coatingGas phaseChemical vapor deposition

The invention discloses a coating layer on a blade base body. The total thickness of the coating layer is 5-40 mu m. The coating layer at least comprises an aluminium oxide layer deposited by employing a chemical vapor deposition manner. The aluminium layer has the thickness of 1 mu m to 15 mu m, has extremely obvious fine-columnar crystal structure. Each crystal grain in the aluminium layer is arranged at a same direction and grows directionally uniformly. The columns of the columnar crystal have same width of 0.2 mu m to 4 mu m. On the one hand, the coating layer is capable of effectively reducing the internal stress of the coating, improving the toughness of the coating, preventing expansion of cracks and reducing tipping of a blade; and on the other hand, the coating layer is capable of improving the wear resistance of the blade. The coating layer of the cutting tool has excellent toughness and good wear resistance, and has excellent cutting performance in fields of cutting of materials such as steel, cast iron, stainless steel and the like.

Owner:XIAMEN GOLDEN EGRET SPECIAL ALLOY

Method for preparing tungsten-copper alloy based on loose-loading infiltration method

The invention discloses a method for preparing a tungsten-copper alloy based on a loose-loading infiltration method. The method comprises the following specific steps of: one, grain size selection of tungsten powder, copper powder and nickel powder; two, material mixing, namely calculating the masses of the tungsten and the copper according to the mass percentage of the tungsten-copper alloy to be prepared, weighing the tungsten powder, weighing the nickel powder which accounts for 0.05 to 0.15 percent of the total mass of the tungsten and the copper and weighing ethanol which accounts for 5 to 15 percent of the total mass of the tungsten and the copper according to the grain size selected in the step one, weighing pre-adding copper powder which is 5 percent of the total mass of the tungsten and the copper, and mechanically mixing the tungsten powder, the nickel powder, the ethanol and the pre-adding copper powder weighed in the step together; three, die-filling, namely filling the mixed powder into a graphite die, dropping gasoline into the die, and tamping the mixture to obtain a blank material; four, infiltration sintering, namely performing the infiltration sintering in a sintering furnace; and five, demoulding. The tungsten-copper alloy prepared by the method has sizes, shapes and components of any requirements, and is prepared without a steel die and a special pressing or forming device.

Owner:XIAN UNIV OF TECH

Cutting method for MEMS wafer

ActiveCN102897708ANo chippingReduce chippingDecorative surface effectsChemical vapor deposition coatingEngineeringIrradiation

The invention relates to a method for a MEMS wafer. The cutting method comprises the following steps of pasting a membrane on the front surface of the wafer to protect an MEMS structure; focusing a laser on the inner part of the wafer, irradiating to form a modified layer at a position from the front surface of the wafer to the inner part of the wafer; irradiating the laser to the back surface of the wafer at a position corresponding to that of the modified layer so as to form a mark groove on the back surface of the wafer; performing water jet cutting on the back surface of the wafer along the position of the mark groove but do not reach the bottom so as to form a water jet cutting groove from the back surface of the wafer to the inner part of the wafer, wherein one end far away from the back surface of the wafer of the water jet cutting groove is connected with the modified layer; and extending splits along the modified layer till to all the MEMS structures are separated completely from each other. The method for the MEMS wafer combines the advantages of laser irradiation and water jet cutting, and realizes the edge breakage-free and low-contamination cutting for the MEMS wafer.

Owner:MEMSIC SEMICON WUXI

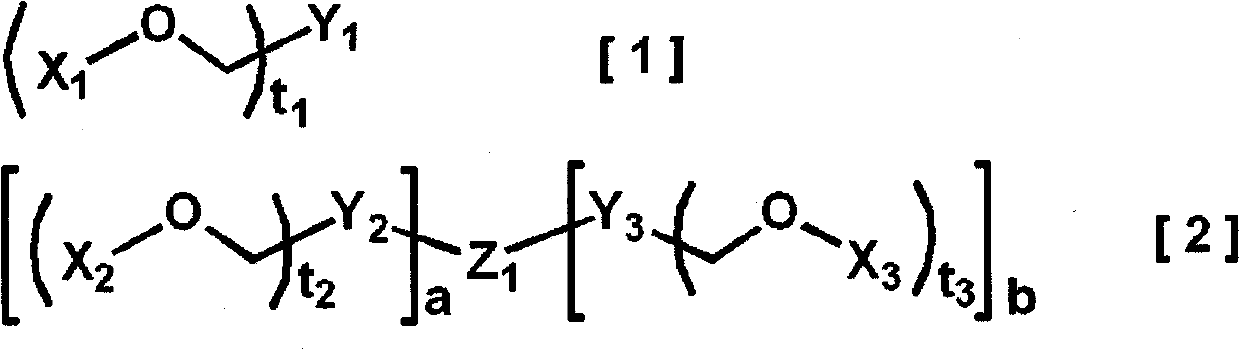

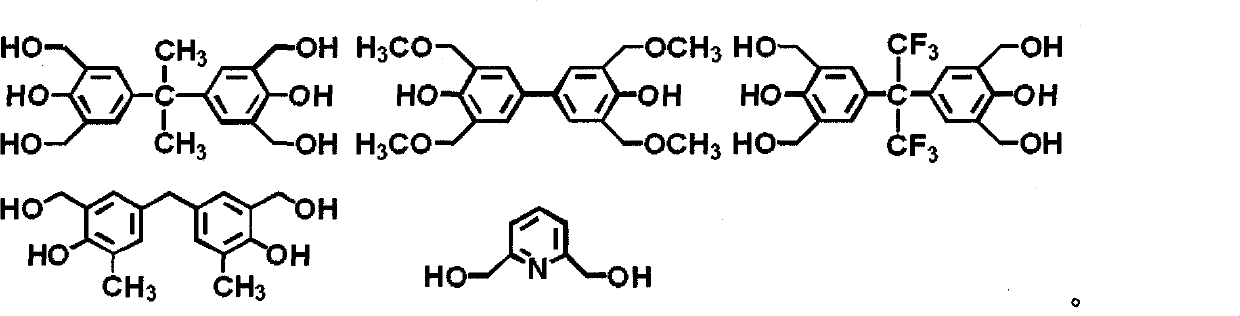

Liquid crystal aligning agent, liquid crystal alignment film, and liquid crystal display element

ActiveCN102317847AReduce chippingLow voltage retentionLiquid crystal compositionsNon-linear opticsCrystallographyHydrogen atom

Disclosed is a liquid crystal aligning agent which can provide a liquid crystal alignment film that is insusceptible to film chipping during a rubbing processing and exhibits only a small reduction in a voltage holding ratio even after the liquid crystal alignment film is exposed to a back light for a long period. Specifically disclosed is a liquid crystal aligning agent characterized by comprising a component (A) and a component (B), wherein the component (A) is a compound having such a structure that a group represented by formula [i] is bound to an aromatic ring and the component (B) is at least one polymeric compound selected from a group consisting of a polyimide and a polyimide precursor. In formula [i], X represents a hydrogen atom or an alkyl group having 1 to 3 carbon atoms.

Owner:NISSAN CHEM IND LTD

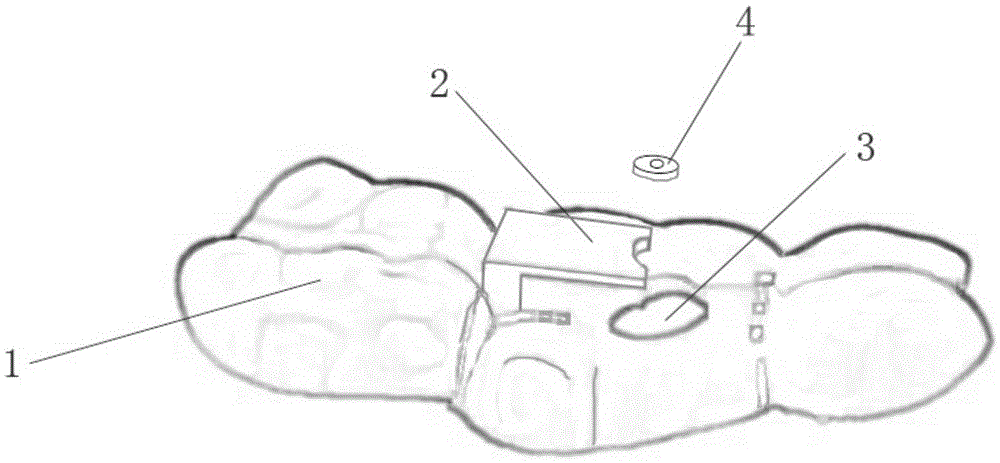

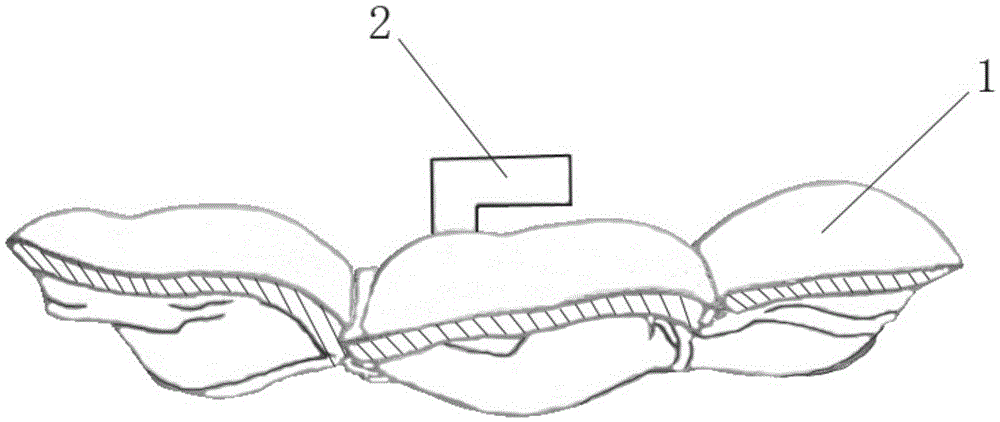

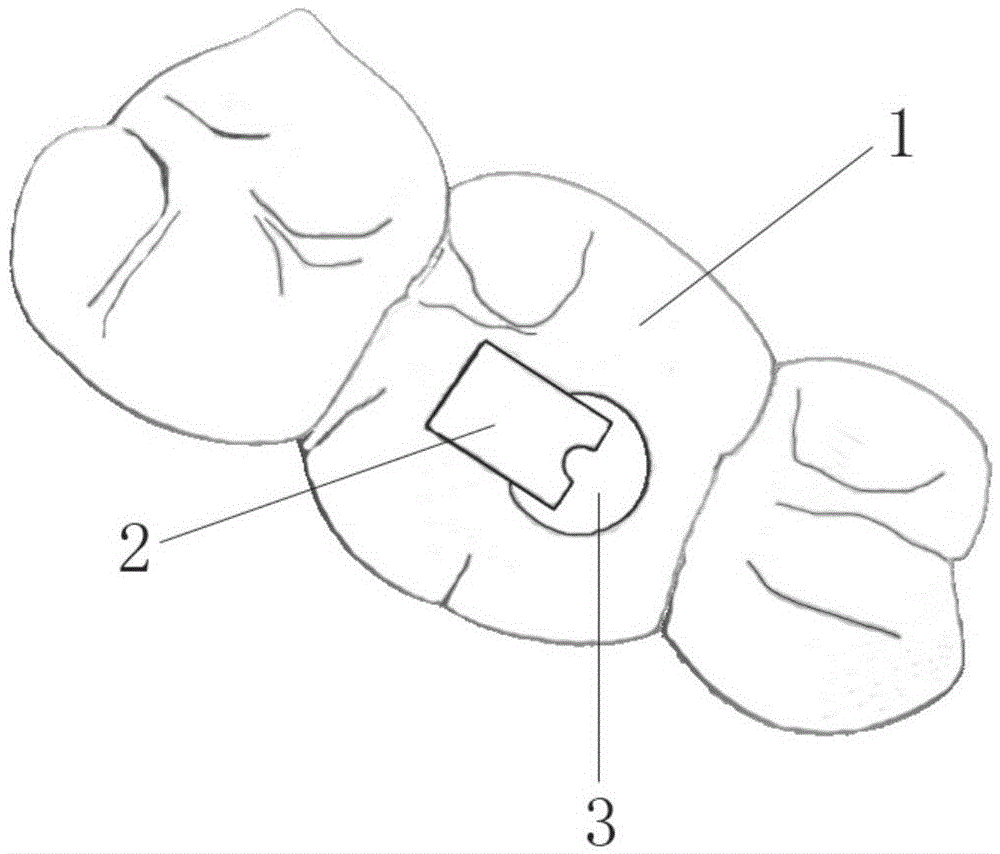

Navigation device for root canal treatment and making method thereof

ActiveCN105596091AProcess stabilityReduce adverse effectsTeeth fillingSurgical navigation systemsDental crownsTooth Fracture

The invention discloses a navigation device for root canal treatment. The navigation device is composed of plywood, a guide post and a working length marking plate, the plywood is a sleeve plate which is matched with the dental crown shape of an offending tooth or the offending tooth and a partial tooth or a whole tooth of an adjacent single tooth, and an exposure opening is formed in the portion corresponding to an offending tooth root canal; the cross section of the guide post is shaped like an inverted L, the guide post is connected with the plywood into a whole through the end of a vertical section, a notch is formed in the end of a horizontal section, the edge in the notch corresponds to an offending tooth root canal approach, and the distance between the lower surface of the horizontal section and the upper surface of the plywood is at least 1.5 mm; the working length marking plate is a disc with a hole formed in the middle and is movably fixed on a fissure drill or expansion or file, and matching and limiting of the working length marking plate and the upper surface of the notch of the guide post are achieved through the lower surface of working length marking plate. The invention further discloses a making method of the navigation device for root canal treatment. The navigation device has better compactness with a tooth body, accurate positioning can be achieved without relying on a doctor, tooth body tissue cutting is reduced, the probability of a tooth fracture of a patient is reduced, and it is guaranteed that root canal treatment is conducted smoothly.

Owner:SICHUAN UNIV

Health food for protecting liver and adjusting blood fat and method for preparing the same

InactiveCN1466990AHigh activityReduce cholesterolDigestive systemUnknown materialsCordycepsActive component

A health-care food for protecting liver and regulating blood fat is prepared through extracting active components from red sage root, peach kernel and gynostemma pentaphyllum in sub-boiling water, adding chitosan, flocculating setting, filter, mixing with fermented cordyceps powder, spray drying, adding starch and dextrin, mixing, granulating, drying, tabletting and coating.

Owner:SHANGHAI MODERN CHINESE TRADITIONAL MEDICINE TECH DEV

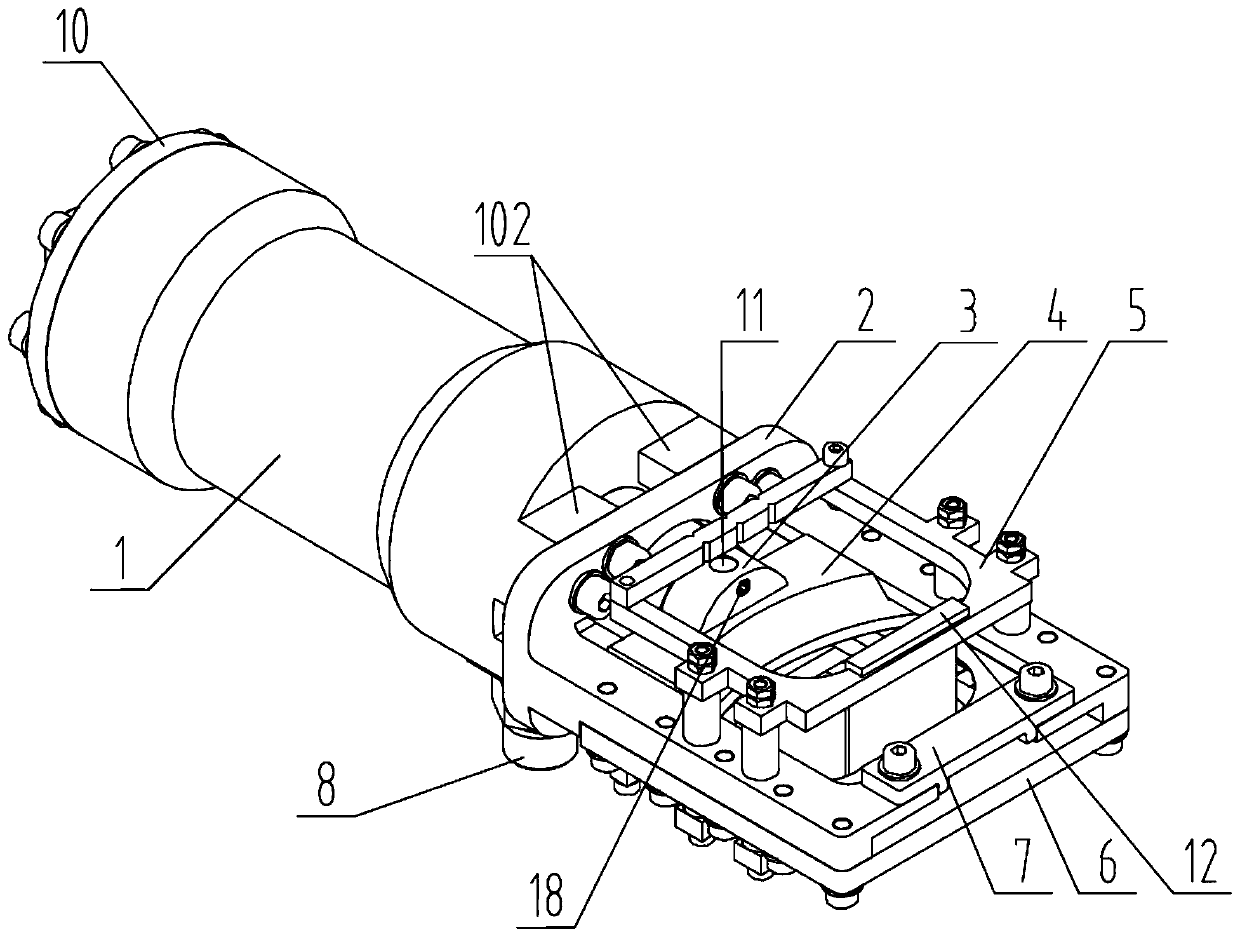

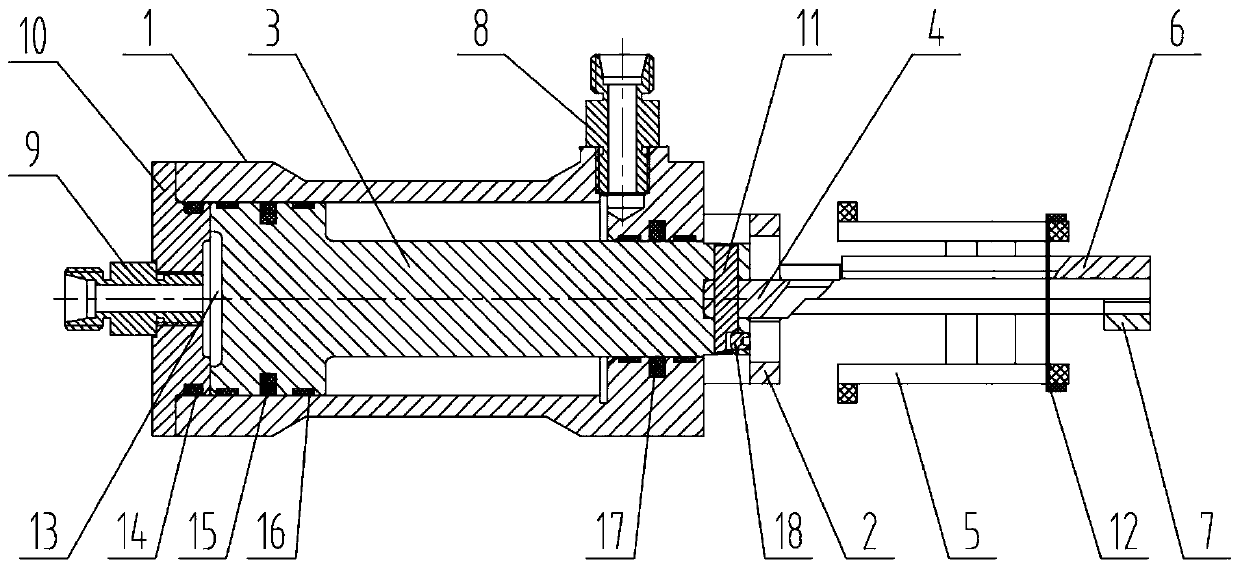

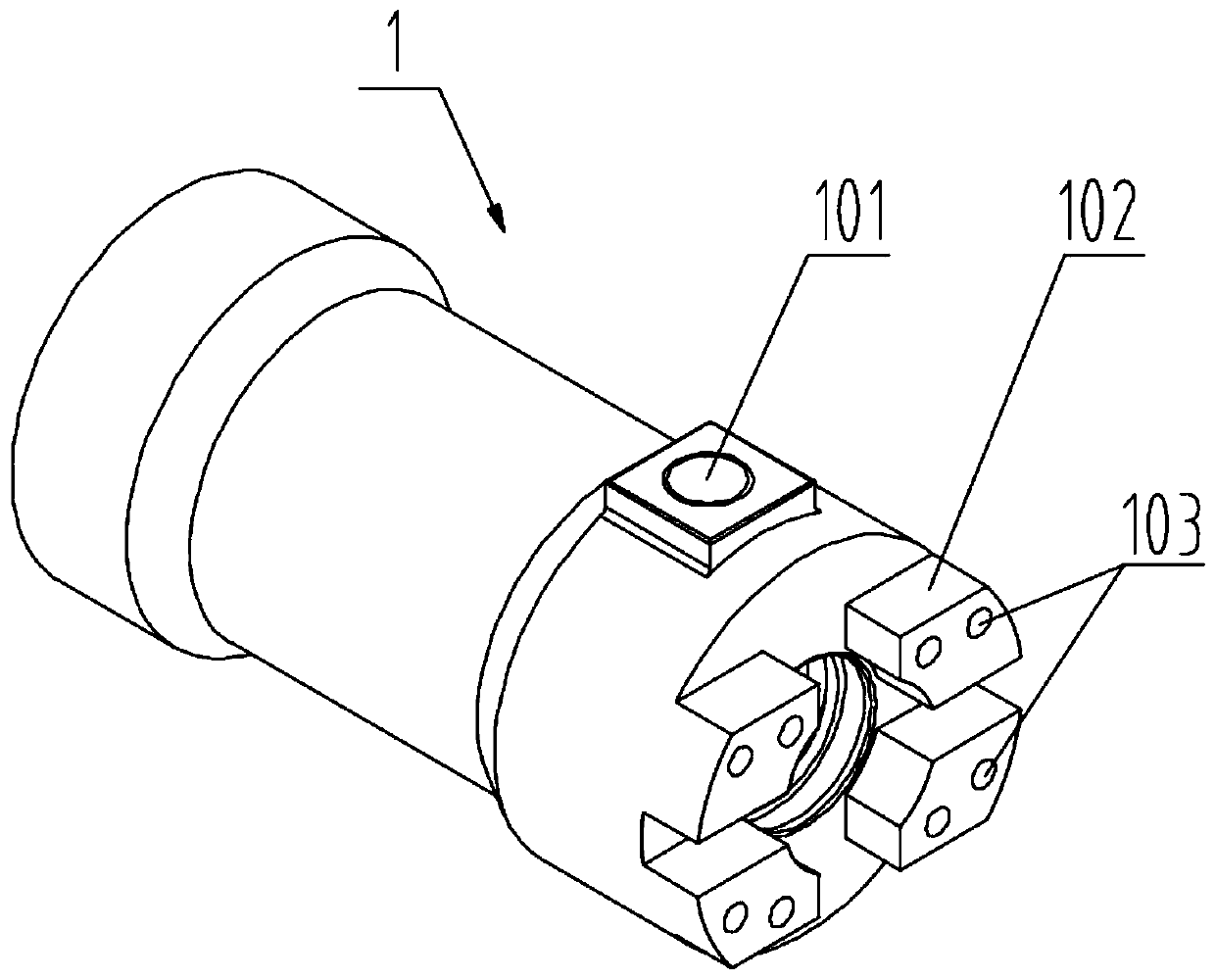

Small underwater cable cutting device

The invention relates to a small underwater cable cutting device which comprises an oil cylinder barrel, wherein a piston rod is mounted inside the oil cylinder barrel; a movable cutting knife is connected with one end part of the piston rod through a shaft pin and a set screw; a guiding frame is connected with one end of the oil cylinder barrel; after extending out of the guiding frame, the movable cutting knife is matched with a fixed cutting knife to cut off a cable; the fixed cutting knife is mounted on the bottom surface of the guiding frame; two limiting frames are correspondingly mounted on the upper surface of the guiding frame and the lower surface of the fixed cutting knife; one end of the upper limiting frame and that of the lower limiting frame are simultaneously connected witha vertically-mounted gasket; the movable cutting knife and the fixed cutting knife are positioned between the two limiting frame; and the gasket is positioned between the movable cutting knife and the fixed cutting knife. By the adoption of the small underwater cable cutting device provided by the invention, the technical problem that a conventional underwater cutting device is complex in structure, large in weight and occupied space, high in operating difficulty and low in autonomous operability can be solved; the space can be greatly saved; and the underwater cutting efficiency can be improved.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

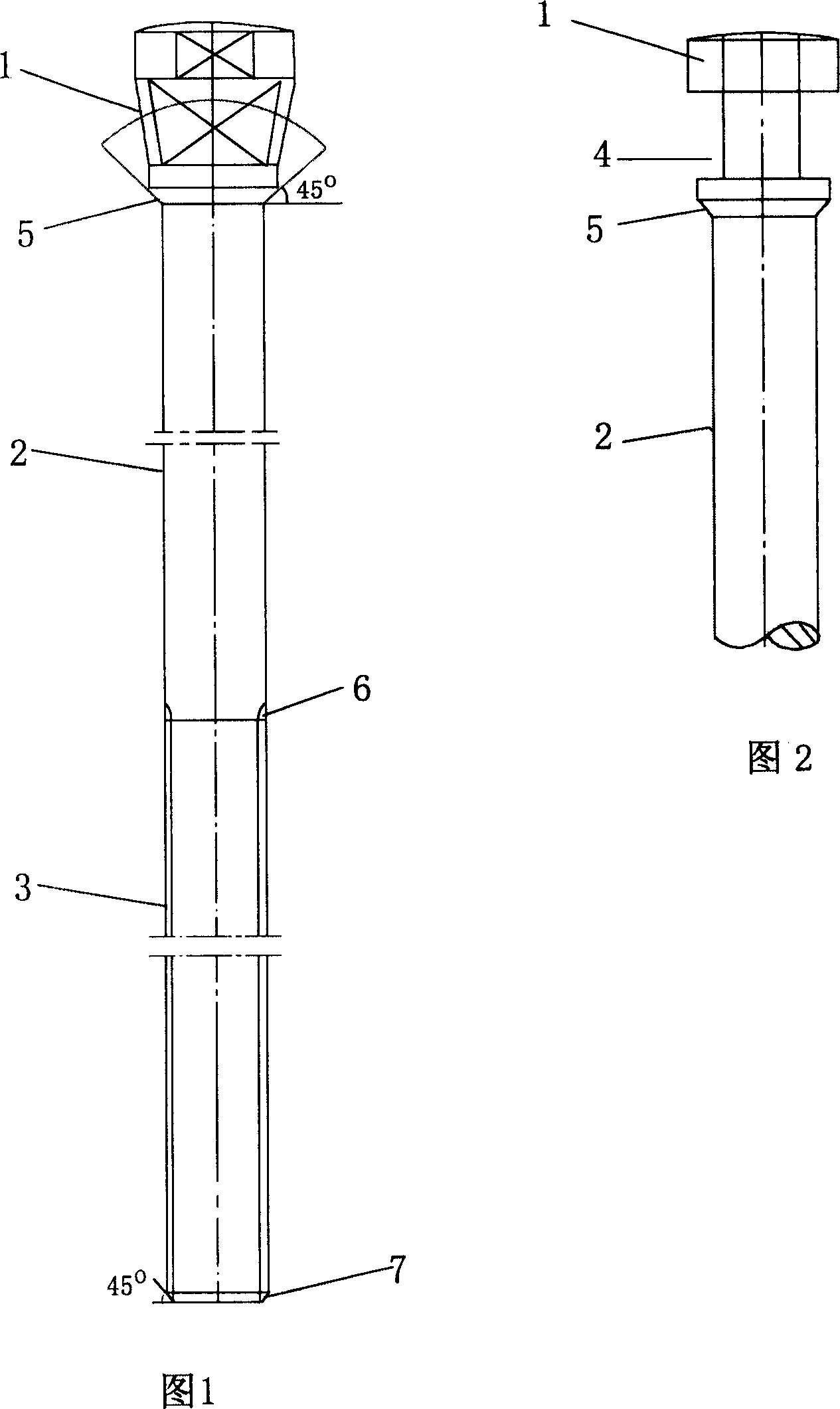

Valve rod forging and cold extruding formation process

The present invention relates to forging technology, and is especially valve rod forging and cold extruding formation process. The valve rod as the part of valve is one rod, and has one thicker end with slots as the head, the other end with thread and one middle part of smooth rod. The formation process includes the steps of cutting rod, end chamfering, slotting in the head, chamfering the sealing surface, chamfering the root of the thread part, cold extruding threads, rolling the smooth rod, etc. The production process has saving in material, high production efficiency and low cost.

Owner:朱志远

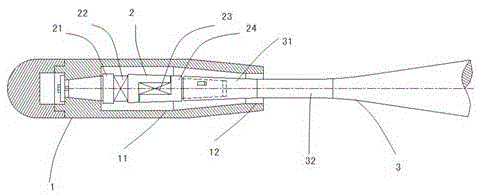

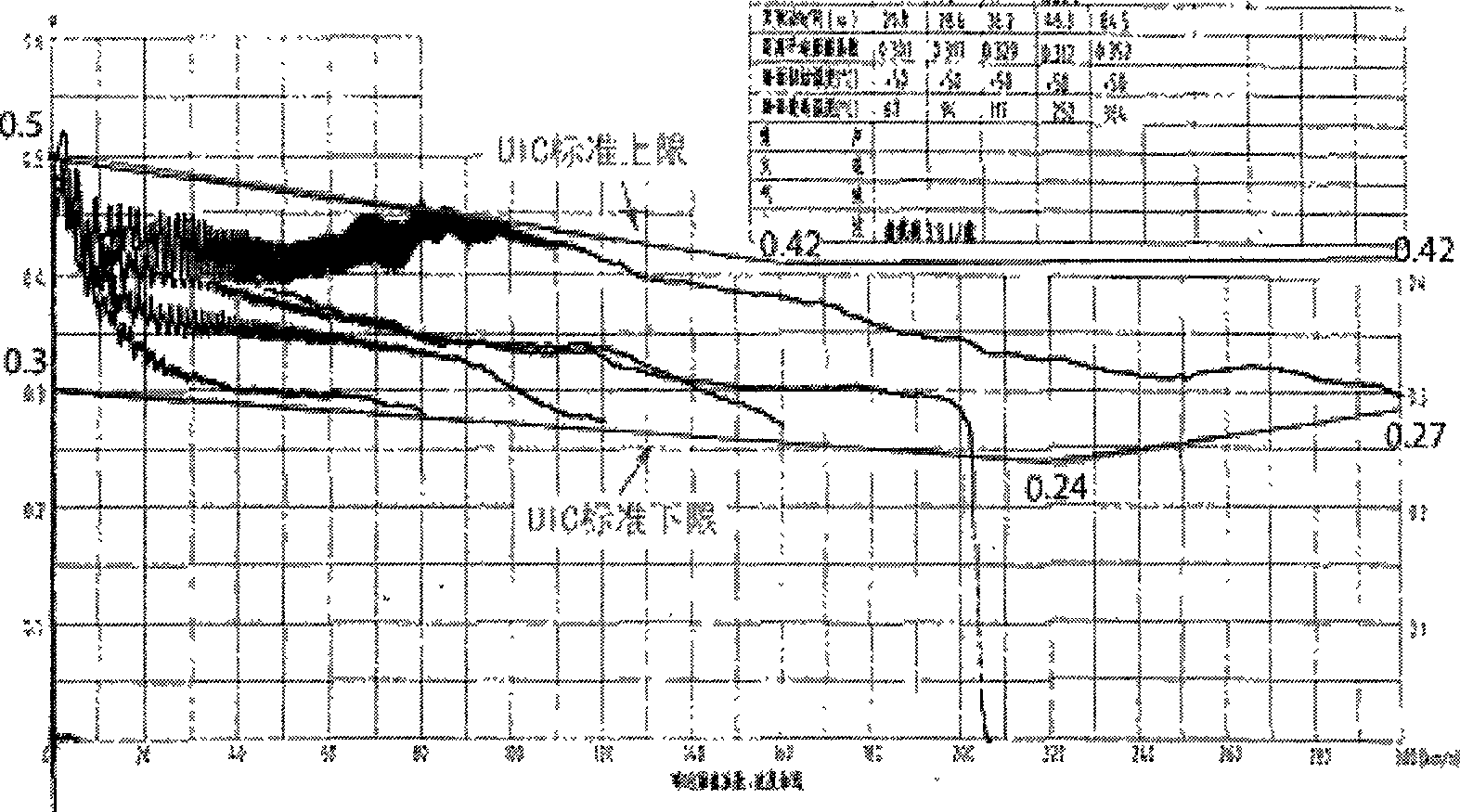

Small-deformation wind tunnel train balance

Provided is a small deformation wind tunnel train balance, comprising a rod-type balance and a support pole. Two ends of the rod-type balance have a conical structure. A balance element is arranged between the two ends of the rod-type balance. The balance element has a conical structure, which is provided thereon with a five-component element adjacent to the large-end part and a resistance element adjacent to the small-end part. The support pole comprises a conical front end and a straight segment. The rod-type balance and the conical front end of the support pole are matched via a conical surface and are tensioned via a wedge. The rod-type balance is arranged in an inner cavity of a tested model. The minimum diameter of the inner cavity of the tested model is greater than the maximum diameter of the rod-type balance. The invention breaks through the traditional equal-diameter balance support rod design method and the three-segment type rod-type balance structure, increases the diameter of the balance, shortens the balance length, realizes little deformation of the balance, improves the rigidity and the bearing ability of the balance, is applicable to balance development for wind tunnel experiments with large impact load or severe vibration, and achieves good practicability and popularization values.

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT

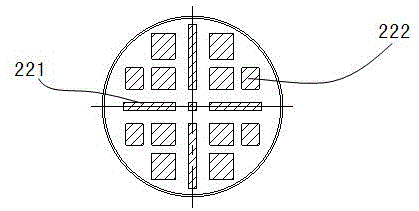

Rotary graphene stripping device, graphene production system and production method

The invention discloses a rotary graphene stripping device including a rotary cylinder body; a top cover is arranged above the rotary cylinder body, a bottom cover is arranged below the rotary cylinder body, the top of the top cover is provided with a feed inlet, the bottom of the bottom cover is provided with a discharge port, and the feed inlet is communicated with the interior of the rotary cylinder body; the outer side of the rotary cylinder body is provided with a first motor, and is used for driving the rotary cylinder body to horizontally rotate; the rotary cylinder body is also internally provided with an inner cylinder, and a second motor used for driving the inner cylinder to horizontally rotate in a direction opposite to the rotating direction of the rotary cylinder body is arranged below the rotary cylinder body; the upper part of the inner cylinder is shrunk in a certain angle, and a material storage space is left between the upper part of the inner cylinder and the upper part of the rotary cylinder body; the lower part of the inner cylinder and the lower part of the rotary cylinder body are in clearance fit to be used for grinding graphite sheets, and a clearance between the lower part of the inner cylinder and the lower part of the rotary cylinder body is successively decreased downward along the axial direction of the rotary cylinder body. The rotary graphene stripping device can achieve successful stripping of graphene. The invention also relates to a graphene production system containing the rotary graphene stripping device and a graphene production method.

Owner:江苏碳谷二维世界科技有限公司

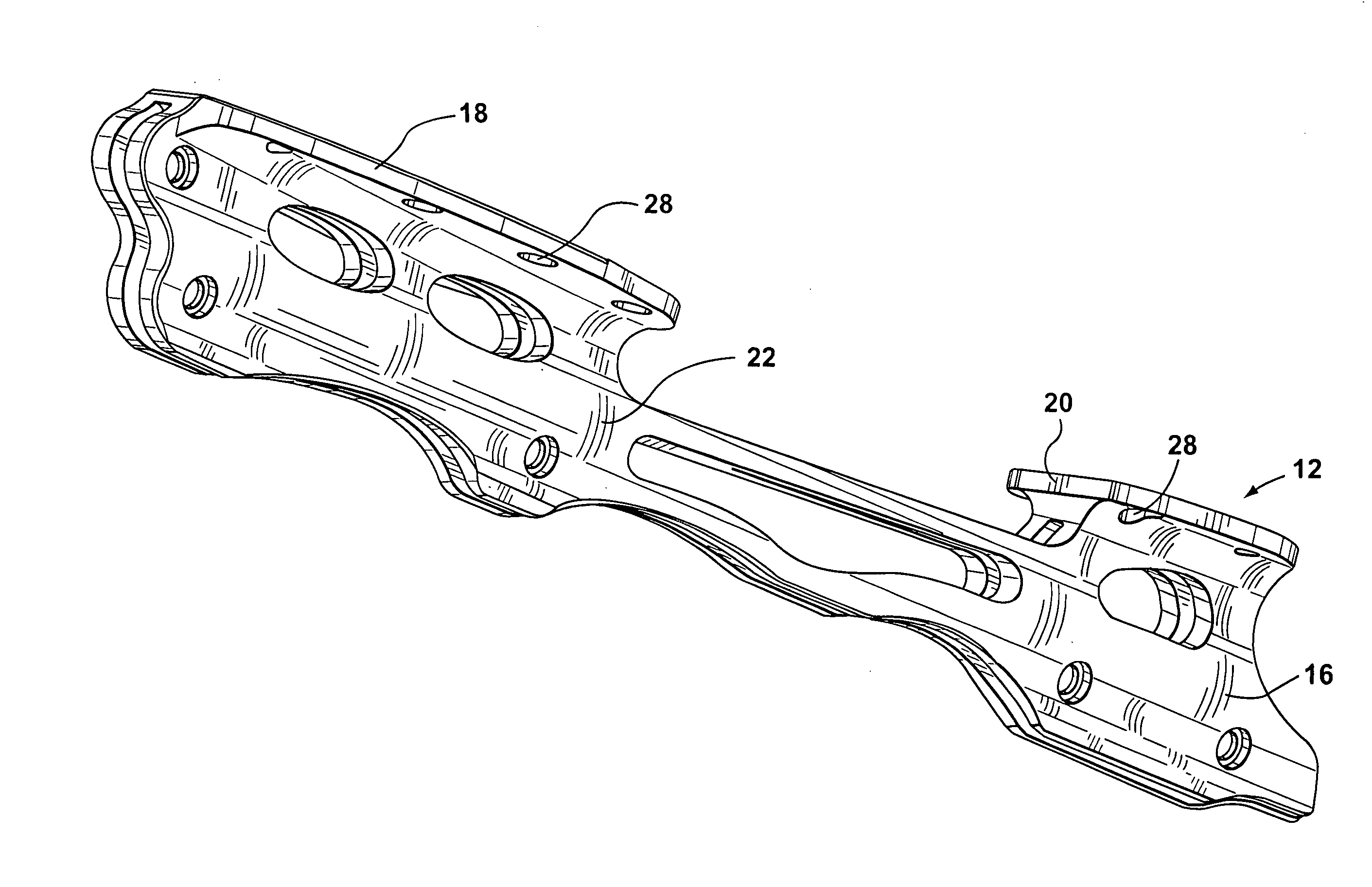

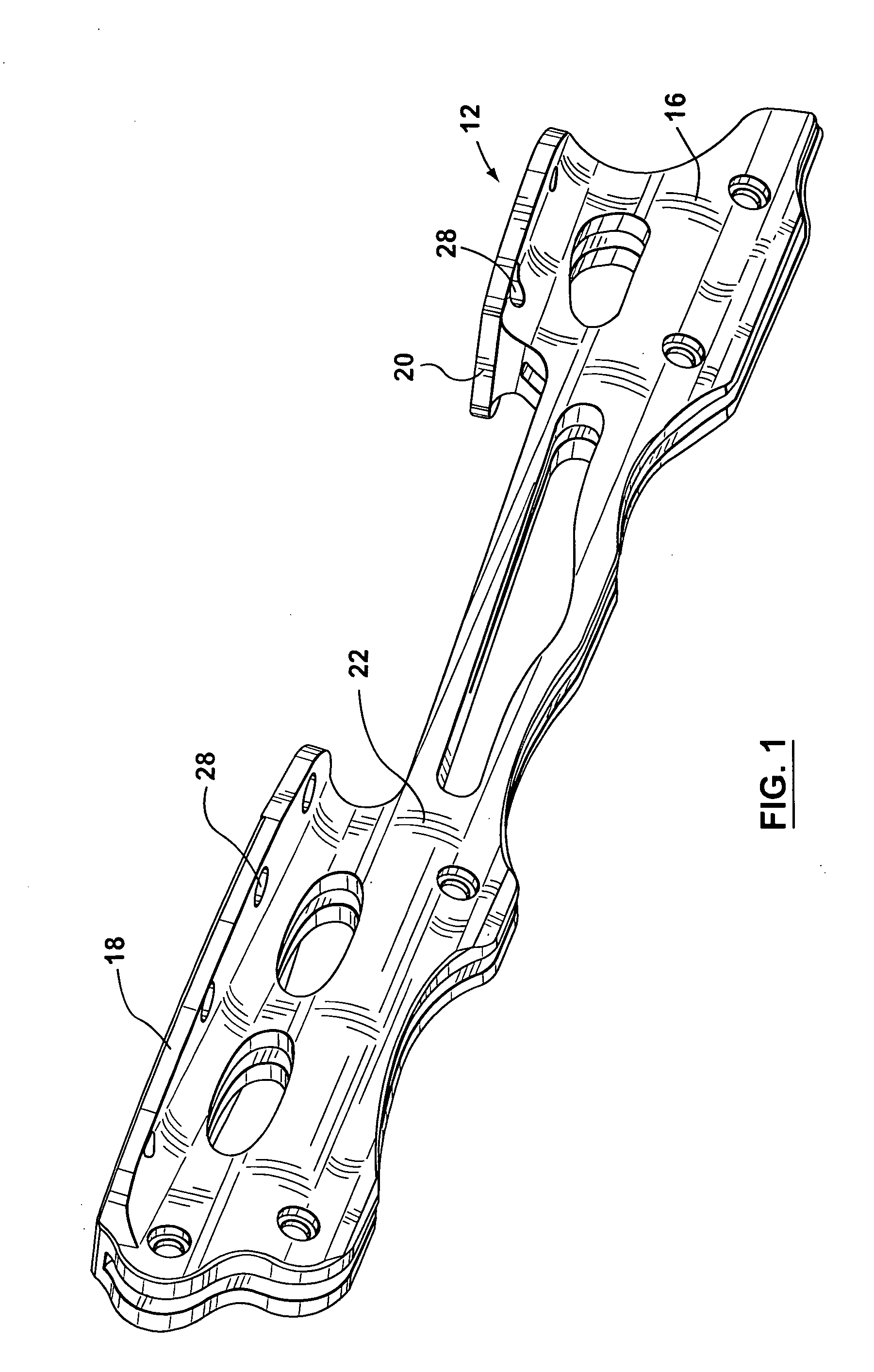

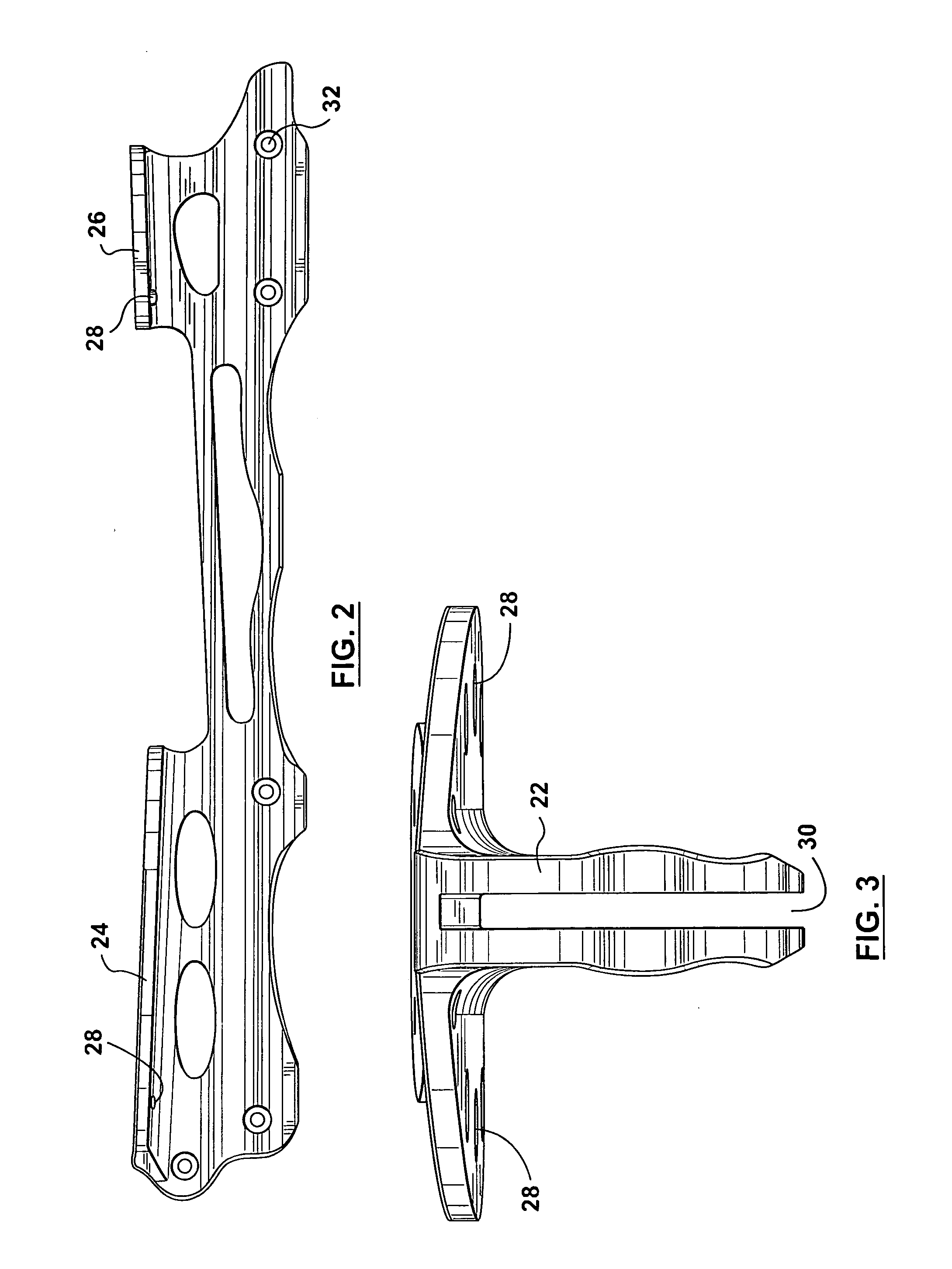

Extruded light-weight figure skate blade holder with two part blade

InactiveUS20060082081A1Reduce chippingReduces peeling issueSki bindingsSki-brakesCarbon steelAluminium

An extruded light-weight blade support with a blade for a figure skate including an extruded holding means having a first portion and a second portion and a blade removably mounted to the extruded holding means. The first and second portions may be mounted to the figure skate. The extruded holding means may be made from aluminium and the blade may be made from a light-weight alloy such as titanium or magnesium. A strip of carbon steel may be adhered to a bottom edge of the blade

Owner:TOURNAMENT SPORTS MARKETING

Copper base particle reinforced friction material

InactiveCN100467659CHigh degree of alloyingHigh strengthFriction liningManufacturing cost reductionGraphite

The invention discloses a reinforced friction material of copper-based particle in the friction material making domain, which comprises the following parts: 30-70% Cu, 4-11% Sn, 1-15% Al, 5-18% Fe, 2-15% Al2O3, 2-15% SiO2, 0-15% ferrochrome and 5-20% graphite.

Owner:大连远通制动制品有限公司

Virus detection kit

InactiveCN110077703APrevent leakageReduce chippingClosure with auxillary devicesSealingEngineeringVirus detection

The invention discloses a virus detection kit. The virus detection kit comprises a kit body, a storage plate is fixedly arranged at the lower end in the kit body, test tubes are slidably connected ina storage plate through reserved storage holes, rubber pads are placed in the storage holes, sleeves are fixed at the lower ends of the storage holes in a welded mode, sliding rods are slidably connected in the sleeves, springs are fixed at the lower ends of the sliding rods in a welded mode, bottom plates are fixed at the upper ends of the sliding rods in a welded mode, and the rubber pads are arranged at the upper ends of the bottom plates. According to the virus detection kit, through shock absorption of the rubber pads of the springs, the possibility of test tube cracking is effectively reduced and reagent is prevented from flowing out; and by directly connecting a sealing facility with a box cover, the used test tubes can be sealed while the box cover is closed, and no test tube can be missed.

Owner:HEFEI CAREER TECHNICAL COLLEGE

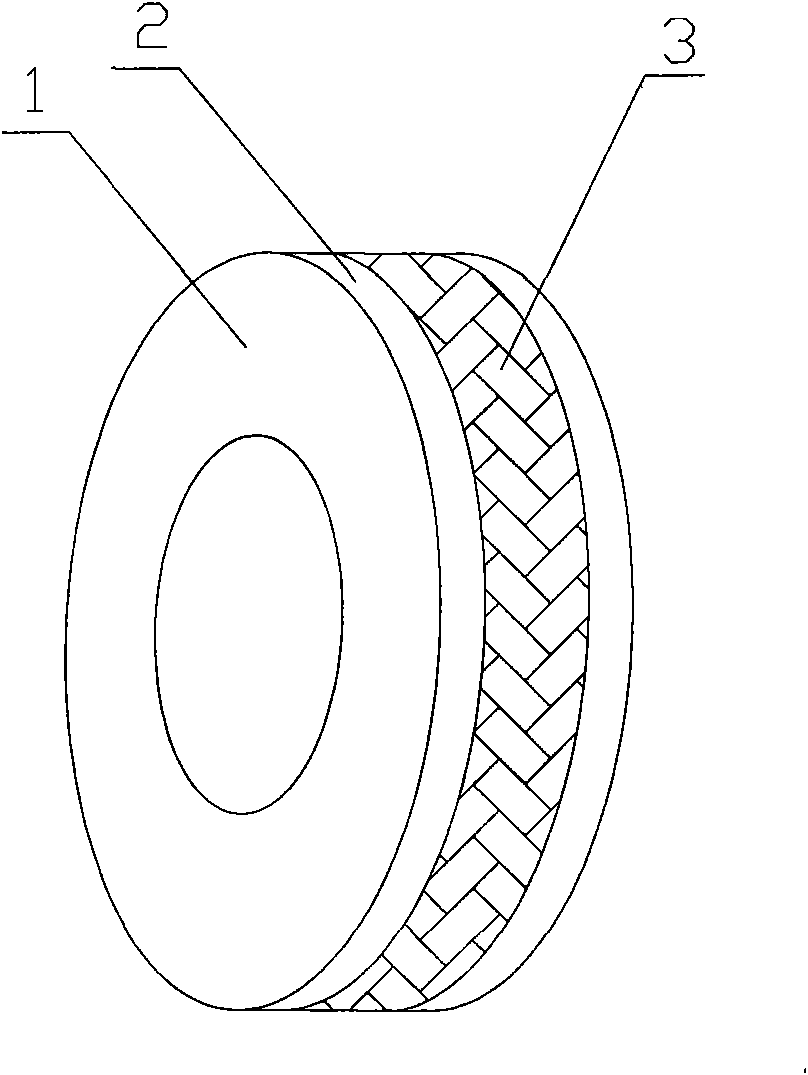

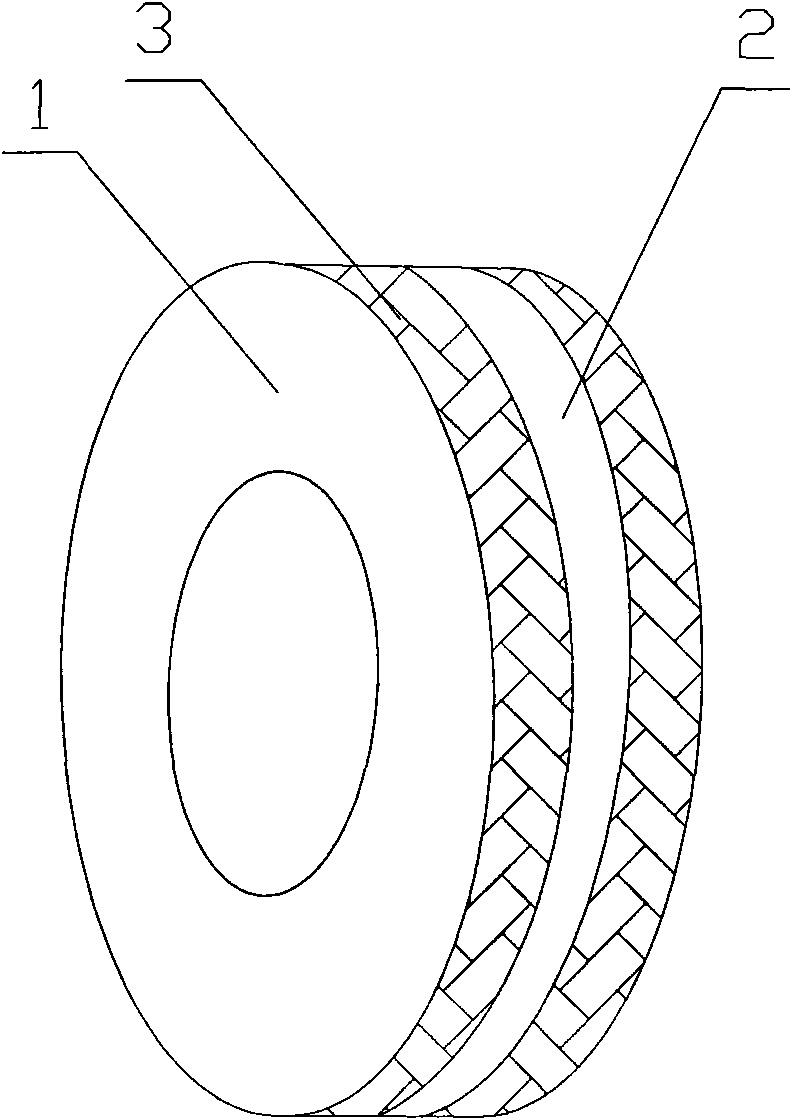

Method of retreading tyre

InactiveCN101549565AWithout breaking the balanceImprove handling comfortTyresMechanical engineeringTread

The invention relates to a method of retreading the old and useless full steel wire tyre by the meridian, comprising the steps as follow: milling the tyre surface, removing the vitiated tyre face and roughening the surface of the steel wire tyre by milling; gluing by coating the plasmagel on surface of the tyre; winding the new glued steel wire curtain cloth on the tread of tyre and adhering with the middle pad glue; adhering the matched type face glue on the tread of tyre, which wound by the glued steel wire curtain cloth, after the tyre face is adhered with glue; then sulphrizing in the tank that is sulphrizing the reinforced tread bracing layer into the sulphrizing tank. The invention will not damage the equilibrium of tyre, improve the controlling amenity, increase the anti-piercing and anti-explosion capability of the tread of tyre, prevent the skeleton of tyre from deforming and improve the retreading rate of tyre. The thickness of glue steel wire curtain cloth installed with the middle pad glue increase the cementation effect between tyre body and the tyre face, improve the anti-tearing capacity of tread block, decrease chunking and improve the bearing and buffer capacity of the tyre.

Owner:张乐平

Anti-collision device for highway bridge

ActiveCN109972508AAvoid damageReduce impact forceBridge structural detailsRoadway safety arrangementsPetroleum engineering

The invention discloses an anti-collision device for a highway bridge, and relates to the field of highway bridge equipment. The anti-collision device includes a road slab, main buffering mechanisms and auxiliary buffering mechanisms, wherein multiple groups of the main buffering mechanisms are symmetrically arranged on the two sides of the road slab, the main buffering mechanisms include main buffering sleeves, main buffering shafts and fence supporting bars, multiple groups of the auxiliary buffering mechanisms are arranged on the upper surfaces of the fence supporting bars in the longitudinal direction, and the auxiliary buffering mechanisms include fence supporting columns, buffering telescopic rods and protective plates. According to the anti-collision device, in protection, the fencesupporting columns inclined outwards by impacting, the fence supporting bars are moved outwards of the road slab under dragging of the fence supporting columns, the main buffering shafts connected with the fence supporting bars are drawn out of pulling shaft sliding cavities formed in the main buffering sleeves, main pulling springs connected between the main buffering shafts and the inner partsof the pulling shaft sliding cavities are stretched, the main pulling springs can effectively buffer the impact force generated in car impacting, and a car can be effectively held up.

Owner:河南中部建设工程有限公司

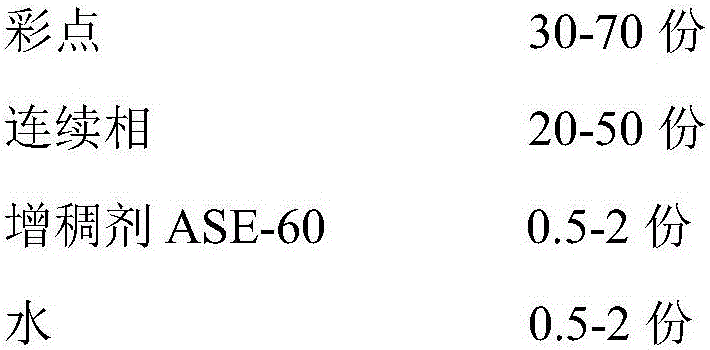

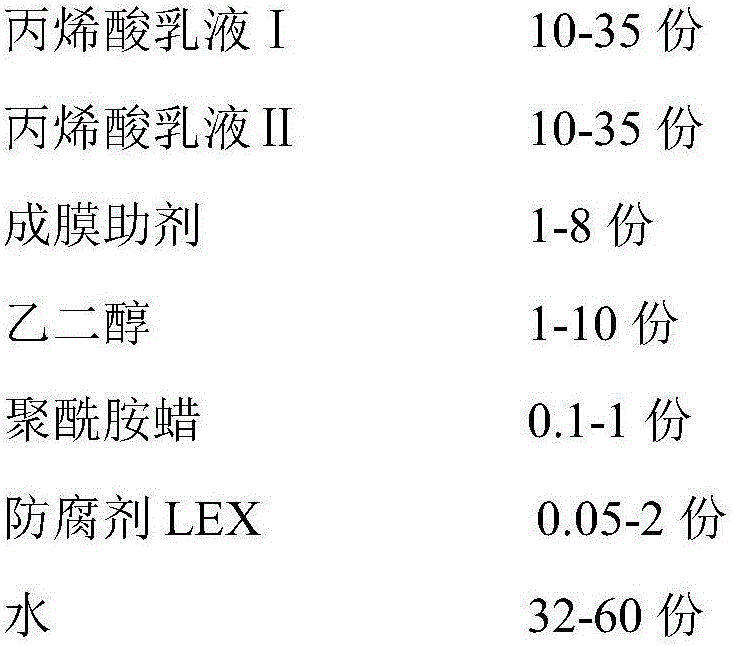

Finish-coat-free matte water-based colored paint and preparation method thereof

The invention relates to finish-coat-free matte water-based colored paint and a preparation method thereof and belongs to the field of building paint. According to the paint provided by the invention, styrene-acrylic emulsion, a phosphate type dispersant, cellulose, a colloidal solution and polyamide wax have a common effect so that color points are stable and the suspension property is high; COASOL and two types of silicone modified acrylic emulsion with obvious particle size difference, and the polyamide wax are used as continuous phases of multi-colored paint; compared with traditional finish-coat matte water-based multi-colored paint, matting powder does not need to be added into the multi-colored paint and matte finish-coat varnish does not need to be brushed, and the matting and vintage effects can also be realized; the finish-coat-free matte water-based colored paint has excellent water resistance, water white resistance and storage stability; the disadvantages of traditional finish-coat matte water-in-water multi-colored paint are successfully overcome; the finish-coat-free matte water-based colored paint is applicable to non-plane matte water-based water-in-water paint and finish-coat-free matte multi-colored paint and the like.

Owner:成都巴德富科技有限公司

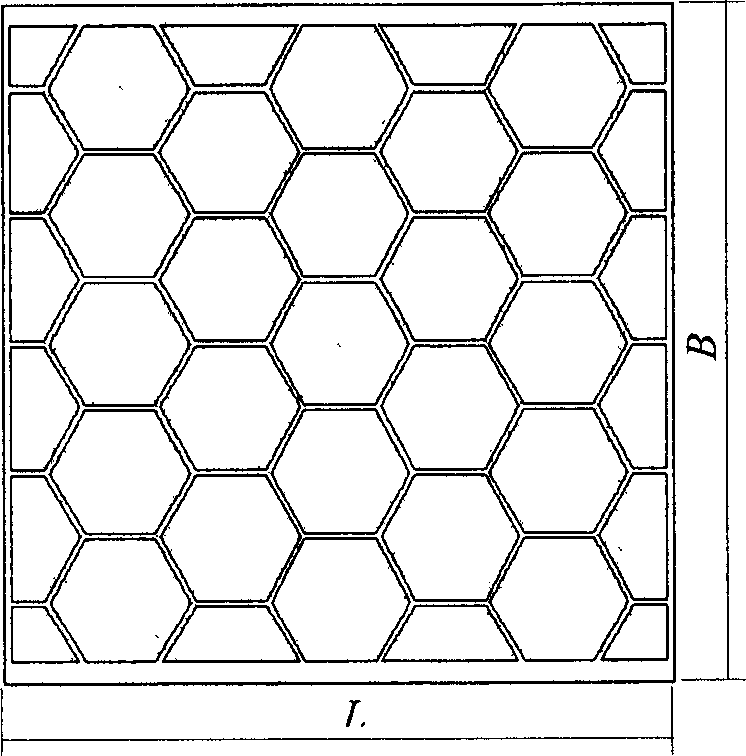

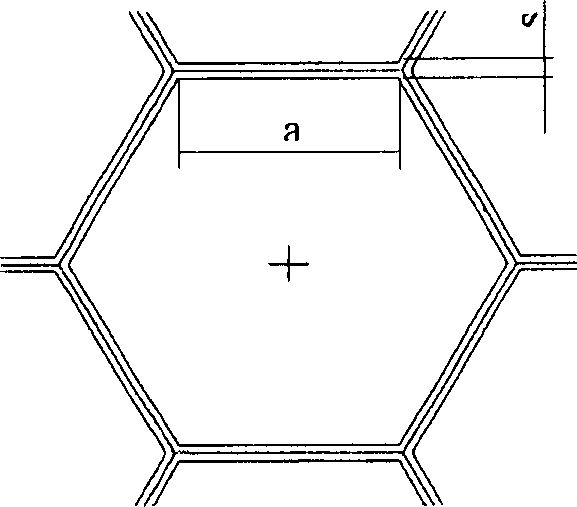

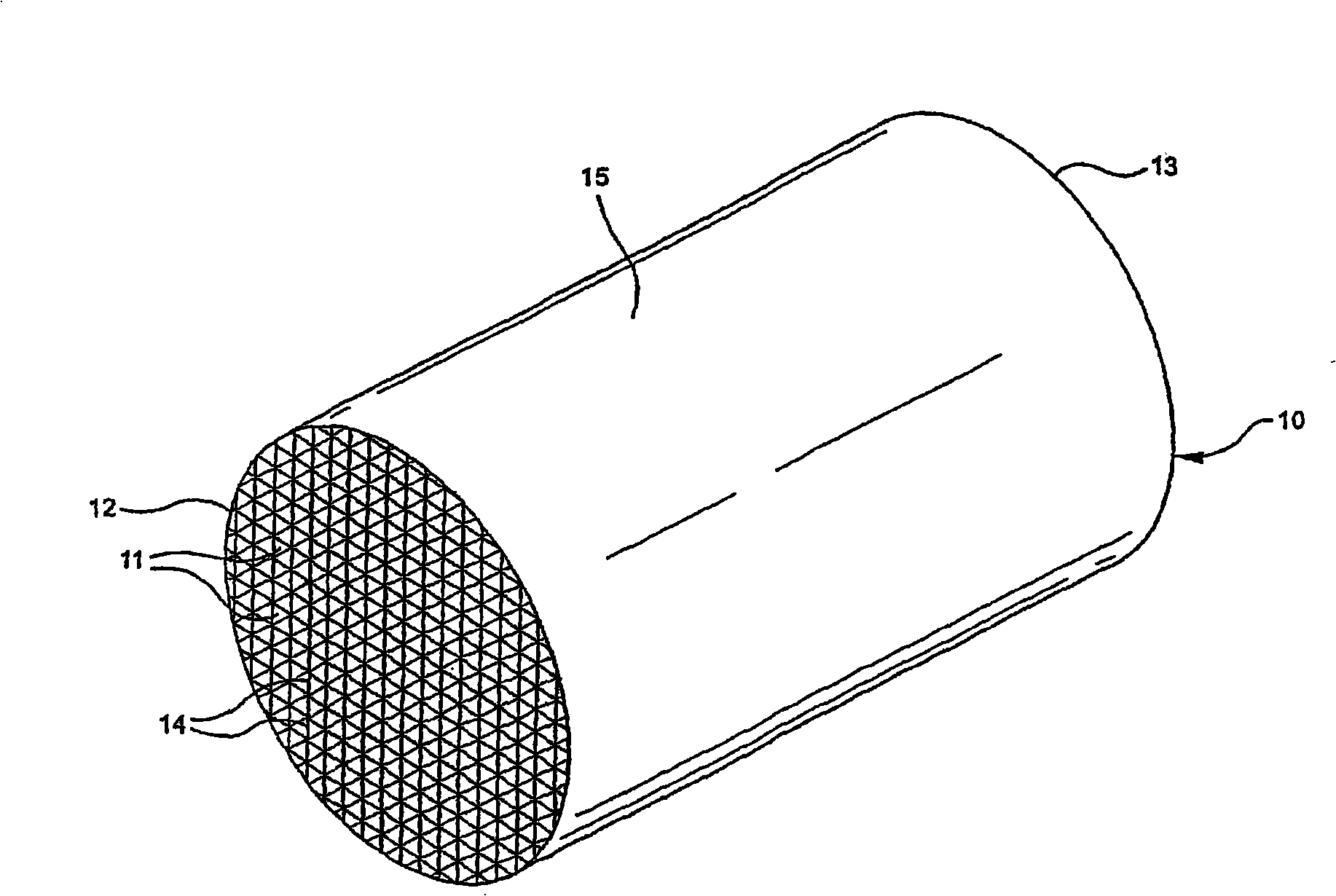

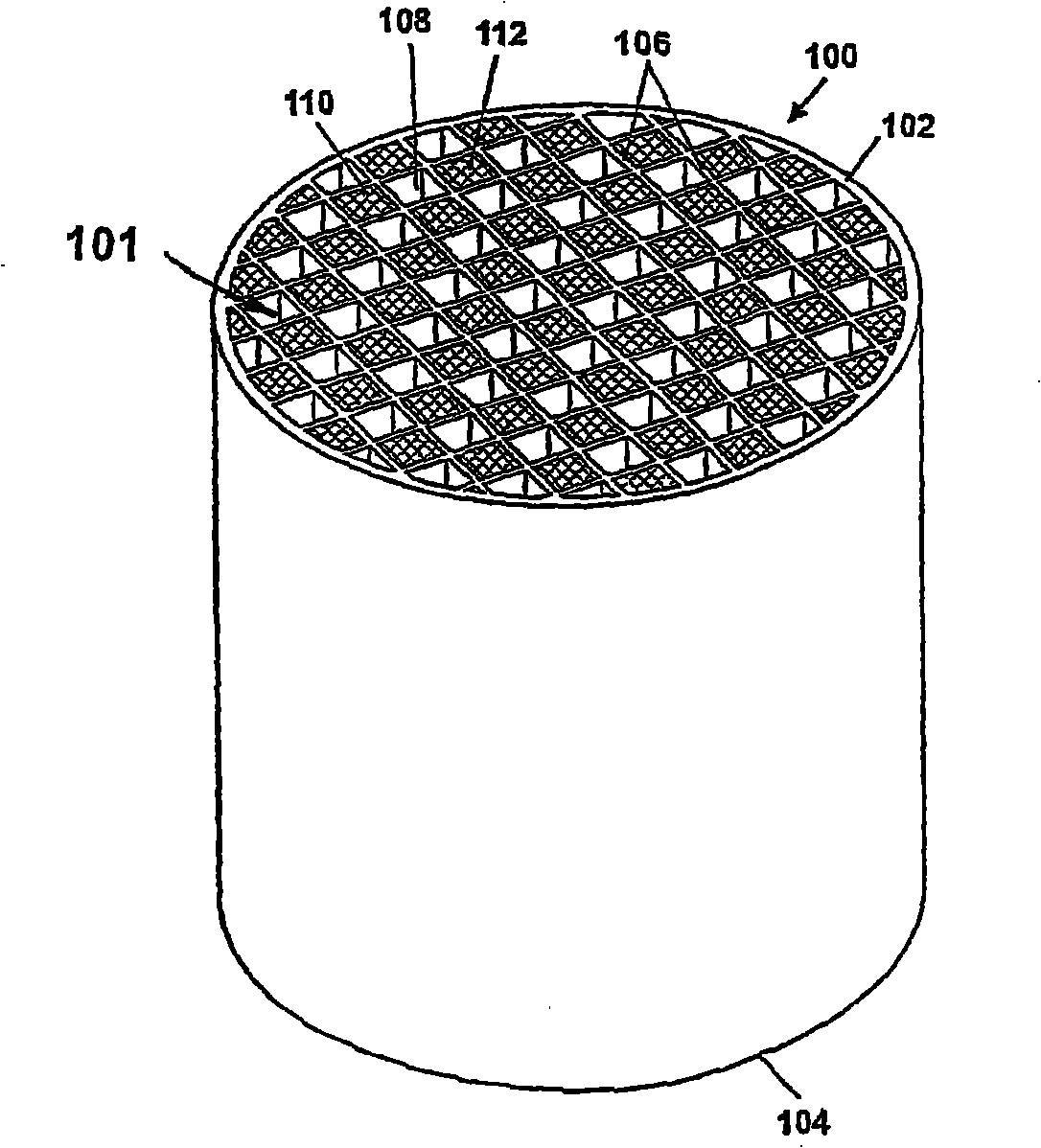

Controlled pore size distribution porous ceramic honeycomb filter, honeycomb green body, batch mixture and manufacturing method therefor

ActiveCN101316804ALong calcination cycle timeReduce chippingMembrane filtersFiltration separationPotato starchCordierite

A porous ceramic honeycomb filter manufactured from an oxide-based ceramic material having a pore size distribution with d1 7.0 microns. Preferably, the oxide-based material is cordierite or aluminum titanate. Alternatively, the filter contains a cordierite-containing ceramic body with a narrow pore size distribution with db 1.00, wherein db = (d90 - d10) / d50. Also disclosed is a batch mixture, method and honeycomb green body made from mixture of inorganic source materials selected from the group of magnesia sources, alumina sources, and silica sources, and a pore former having a narrow particle size distribution with dps 0.90, wherein dps = {(dp90-dp10) / dp50}. The pore former is preferably selected from a group consisting of canna starch, sago palm starch, green mung bean starch, and single-mode potato starch.

Owner:CORNING INC

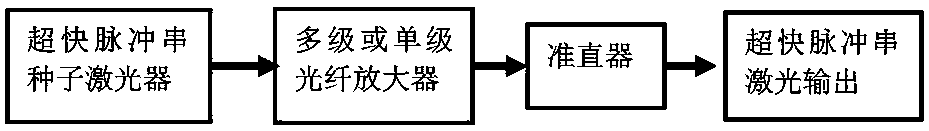

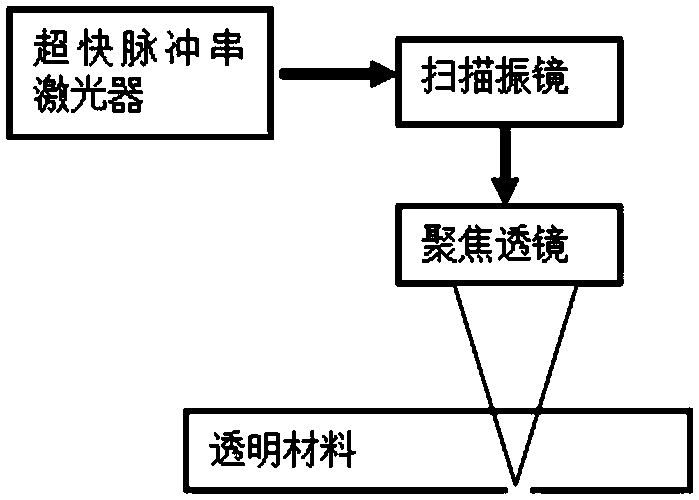

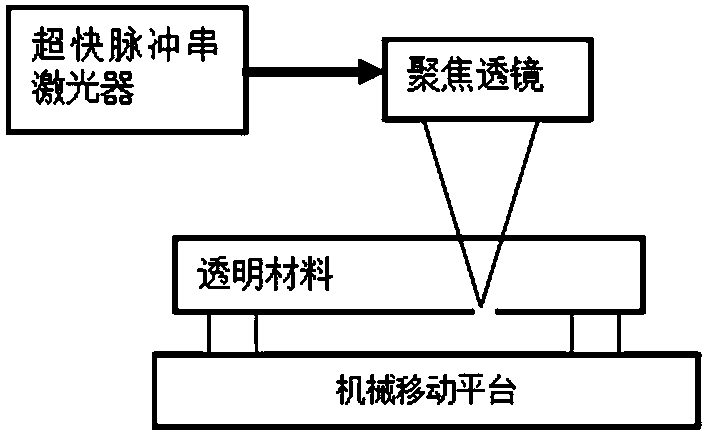

Ultrafast laser processing method and device of transparent material

PendingCN108788451AImprove removal efficiencyLaser output is stableLaser beam welding apparatusNanometreEtching

The invention discloses a processing method and device of a transparent material, and provides an optical fiber laser of which the wave length is 1020 nm to 1090 nm. The processing method is characterized in that laser beams output by a seed laser are subjected to energy amplification through an optical fiber amplifier, laser pulse trains are output, each pulse train comprises at least two laser pulses, pulse width is smaller than 200 ps, peak power of the pulses is larger than 100 kW, the time among the laser pulses in each pulse train is smaller than 90 ns, the interval among the pulse trains is larger than 240 ns, and the total pulse number in each second is larger than 50,000, wherein ultrafast laser beams output by the laser are subjected to energy amplification only through the optical fiber amplifier; and the laser is focused on a to-be-processed position of the transparent material, a focus position is moved, processing is carried out according to a set track, a focus point isgradually risen, and the transparent material is processed from bottom to up. According to the processing method, material removal efficiency can be greatly improved, a heating or etching follow-up procedure is not required, and bevel angles are avoided.

Owner:杭州银湖激光科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com