Patents

Literature

44results about How to "Reduced chance of crushing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

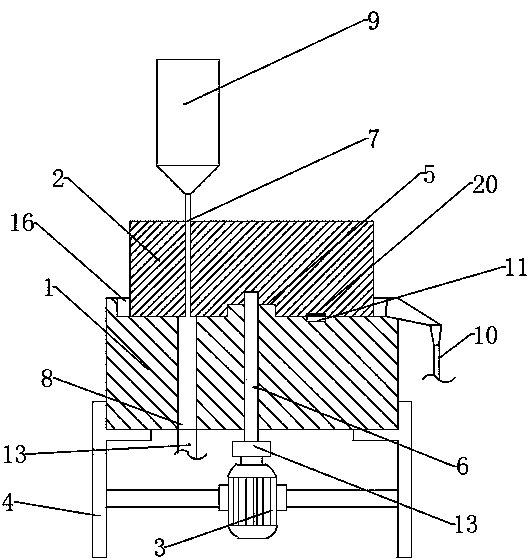

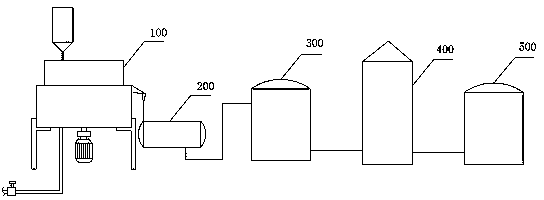

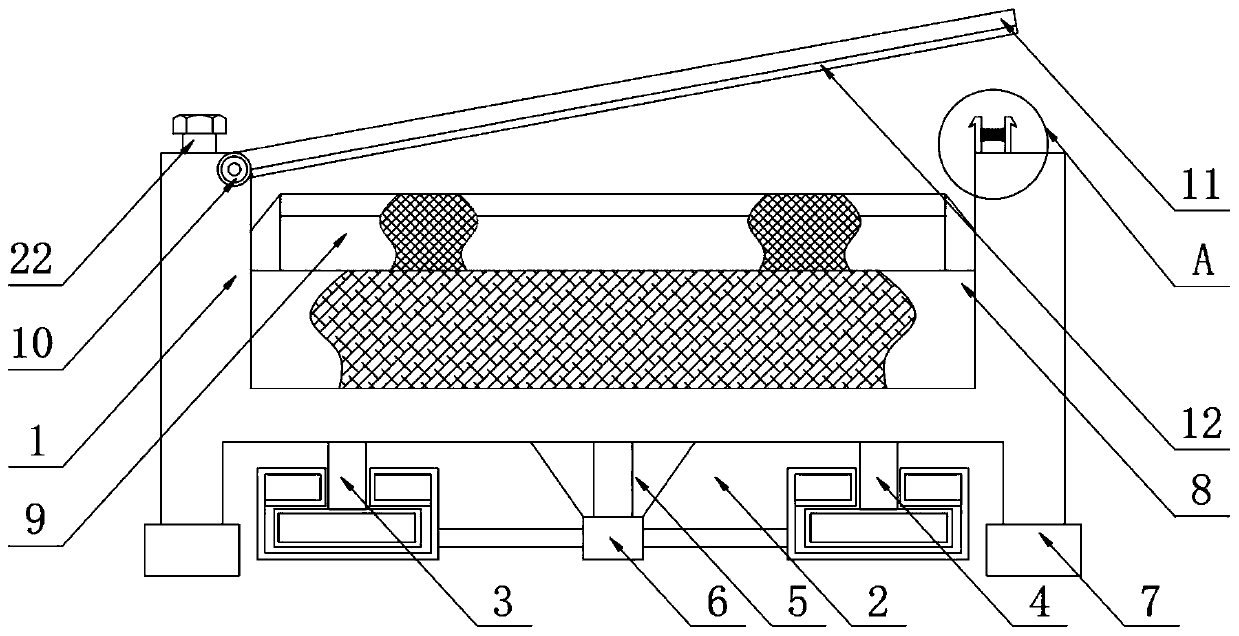

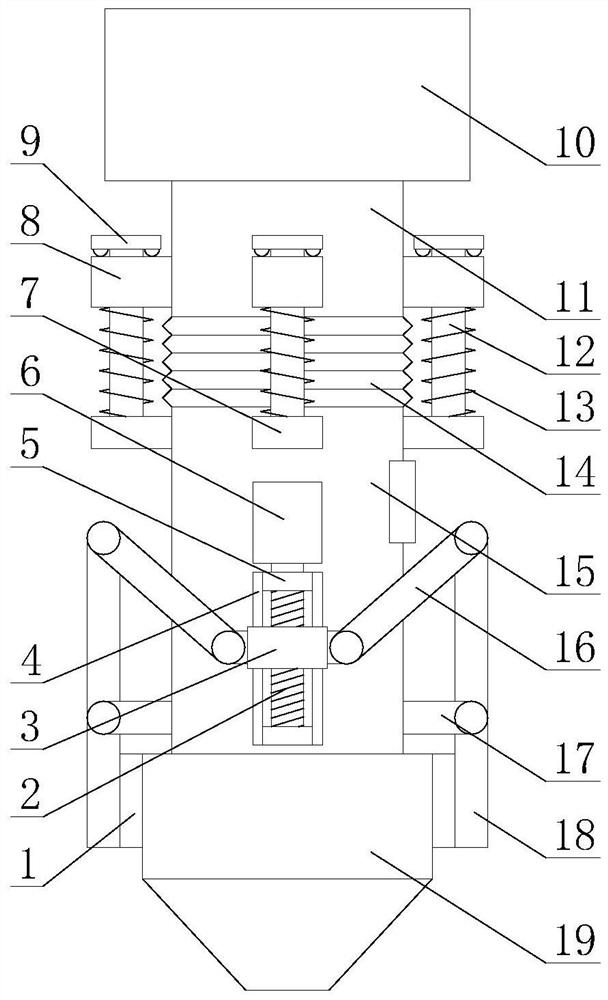

Graphene grinding and stripping device, graphene production system and production method

ActiveCN104401971AKeep the natural plane sizeReduce the chance of crushingCvd grapheneMechanical engineering

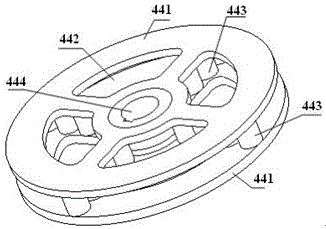

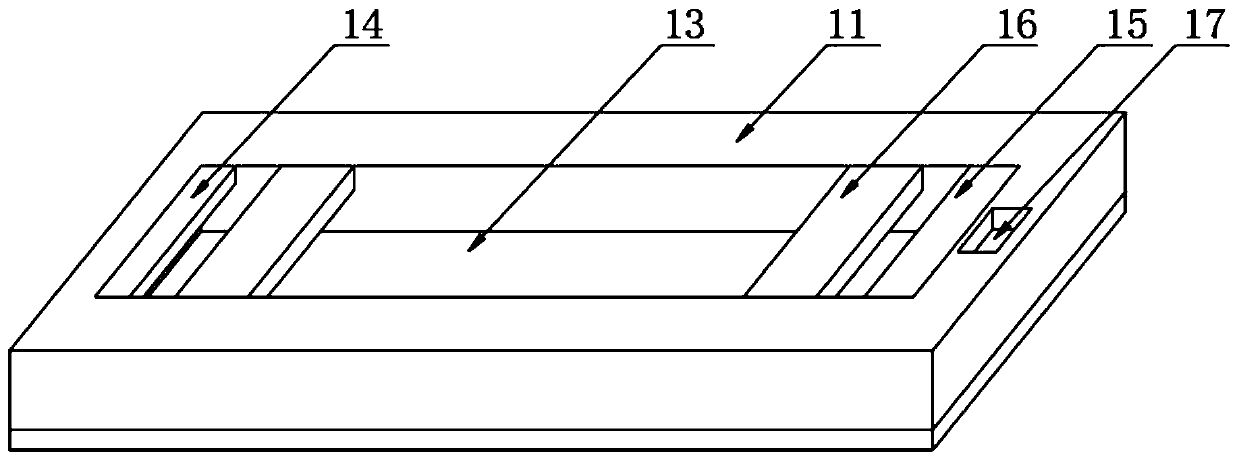

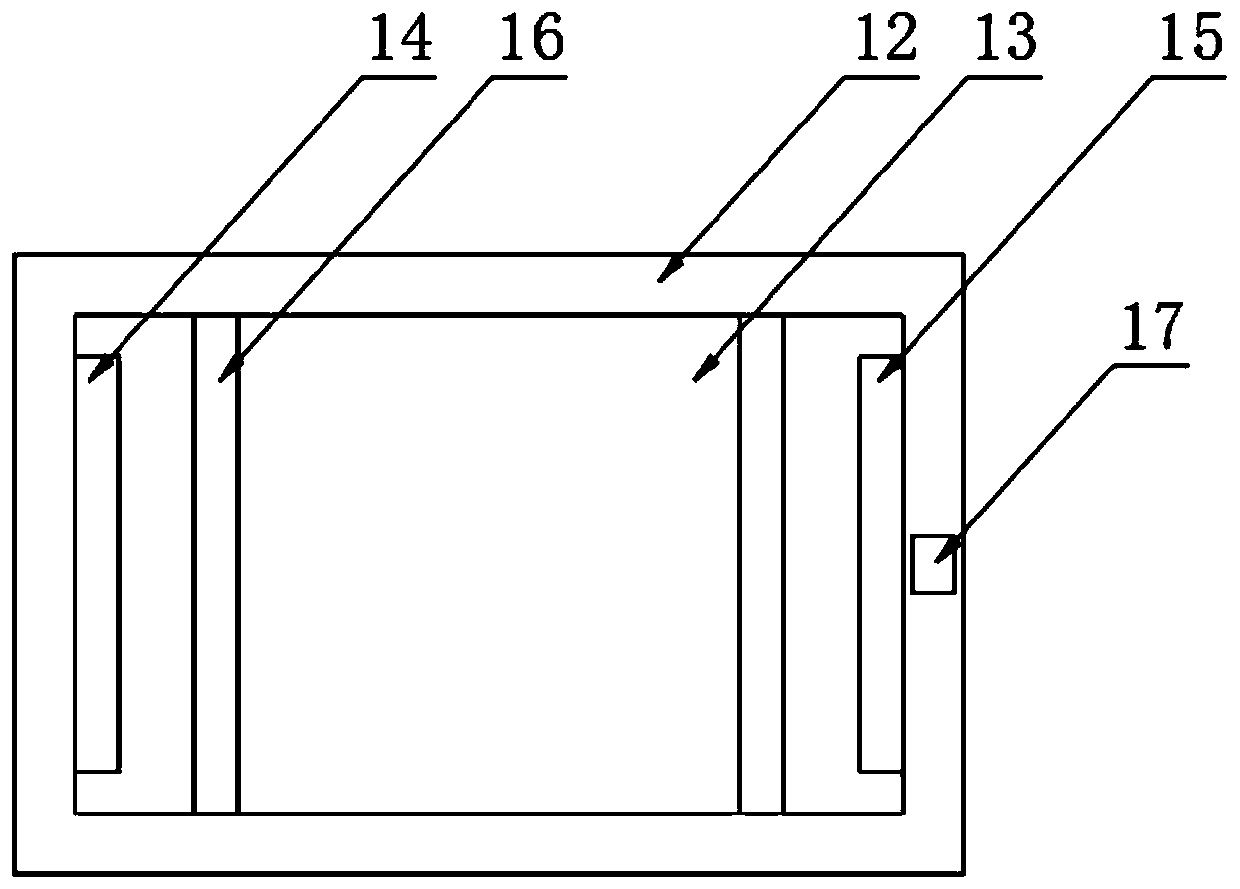

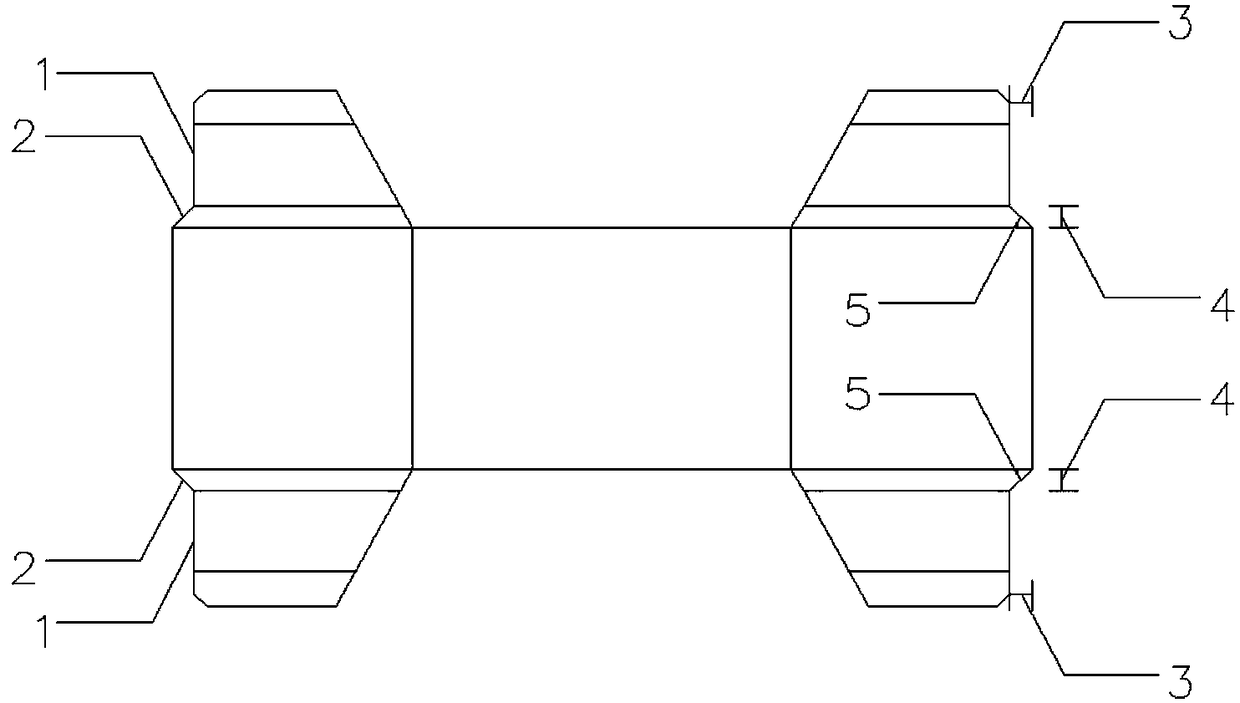

The invention discloses a graphene grinding and stripping device which comprises an upper grinding disc, a lower grinding disc, a driving mechanism for driving the upper grinding disc to rotate, and a material collection mechanism for collecting a product after grinding, wherein the upper grinding disc and the lower grinding disc are matched with each other; a horizontal contact surface is formed between the upper grinding disc and the lower grinding disc, the upper grinding disc is provided with an upper feed inlet, the lower grinding disc is provided with a lower feed inlet, the upper feed inlet and the lower feed inlet are both connected with the contact surface between the upper grinding disc and the lower grinding disc, and the lower end of the lower feed inlet is in sealed connection with one water inlet tube; moreover, the upper end face of the lower grinding disc is provided with a groove, and an annular region formed by rotary surrounding of the lower end of the upper feed inlet is surrounded in the groove. The graphene grinding and stripping device can realize large-size successful stripping of graphene. The invention also relates to a graphene production system containing the graphene grinding and stripping device and a graphene production method.

Owner:江苏碳谷二维世界科技有限公司

Non-mercury catalyst for production of vinyl chloride and preparation method thereof

InactiveCN102069000AAvoid pollutionEase of mass productionPhysical/chemical process catalystsPreparation by halogen halide additionBarium dichlorideCopper chloride

The invention discloses a non-mercury catalyst for the production of vinyl chloride and a preparation method thereof, belonging to the fields of chemical catalyst and the preparation thereof. The non-mercury catalyst of the invention uses cocoanut active charcoal as carrier and stannous chloride as main active substance, wherein the weight percentage of stannous chloride is 15%-30%; and at least one additive of barium chloride, zinc chloride and copper chloride is added and the total additive weight percentage is 0.5-2%. By using the non-mercury catalyst, the environmental pollution caused by the mercury-containing catalyst can be avoided; the large-scale production can be benefited, the conversion rate and selectivity of the catalyst can be increased, the yield of the product can be increased; by increasing the quality of the carrier, technical guarantee can be provided for the large-scale production device of vinyl chloride, the loss of the active matter can be slowed down, the service life of the catalyst can be prolonged; and the use efficiency of the catalyst can be increased by 500%.

Owner:YIBIN TIANYUAN GRP CO LTD

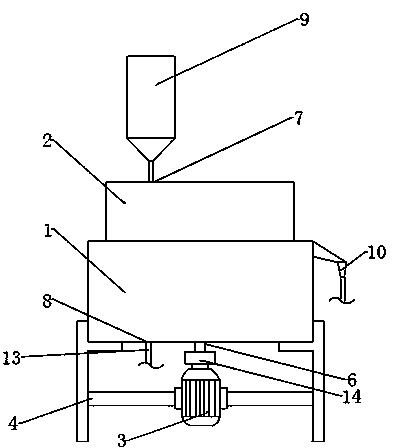

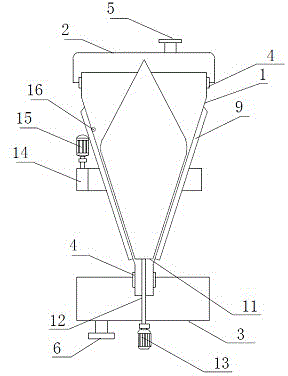

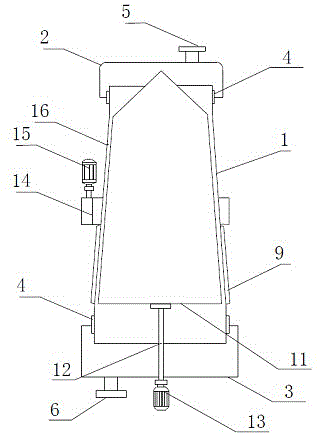

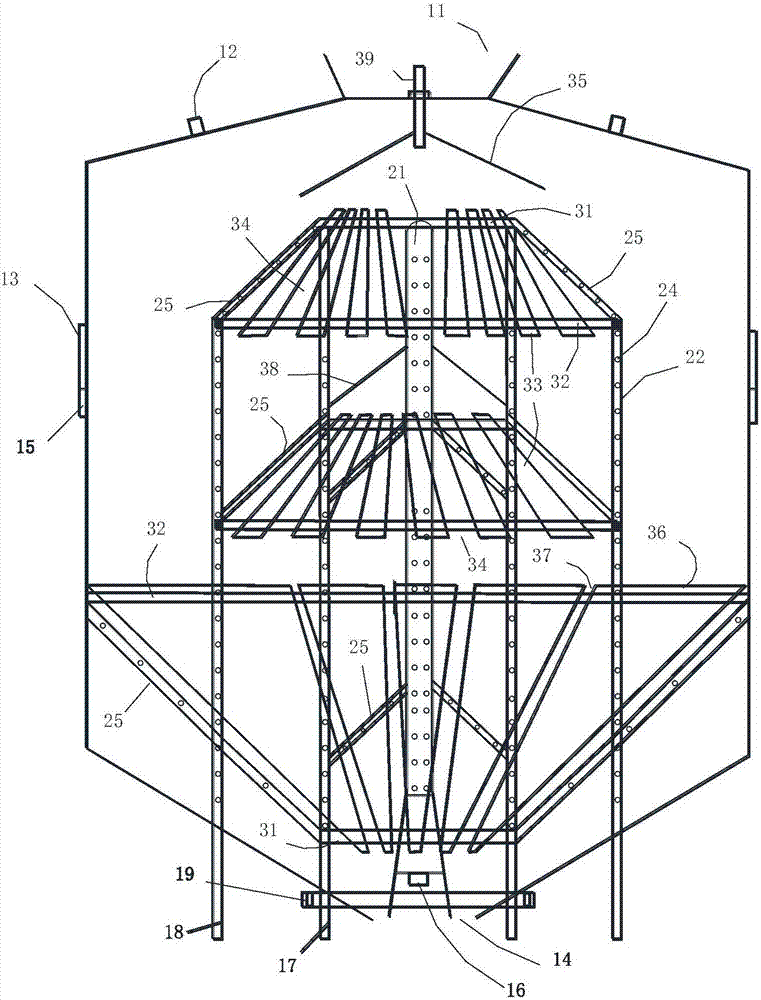

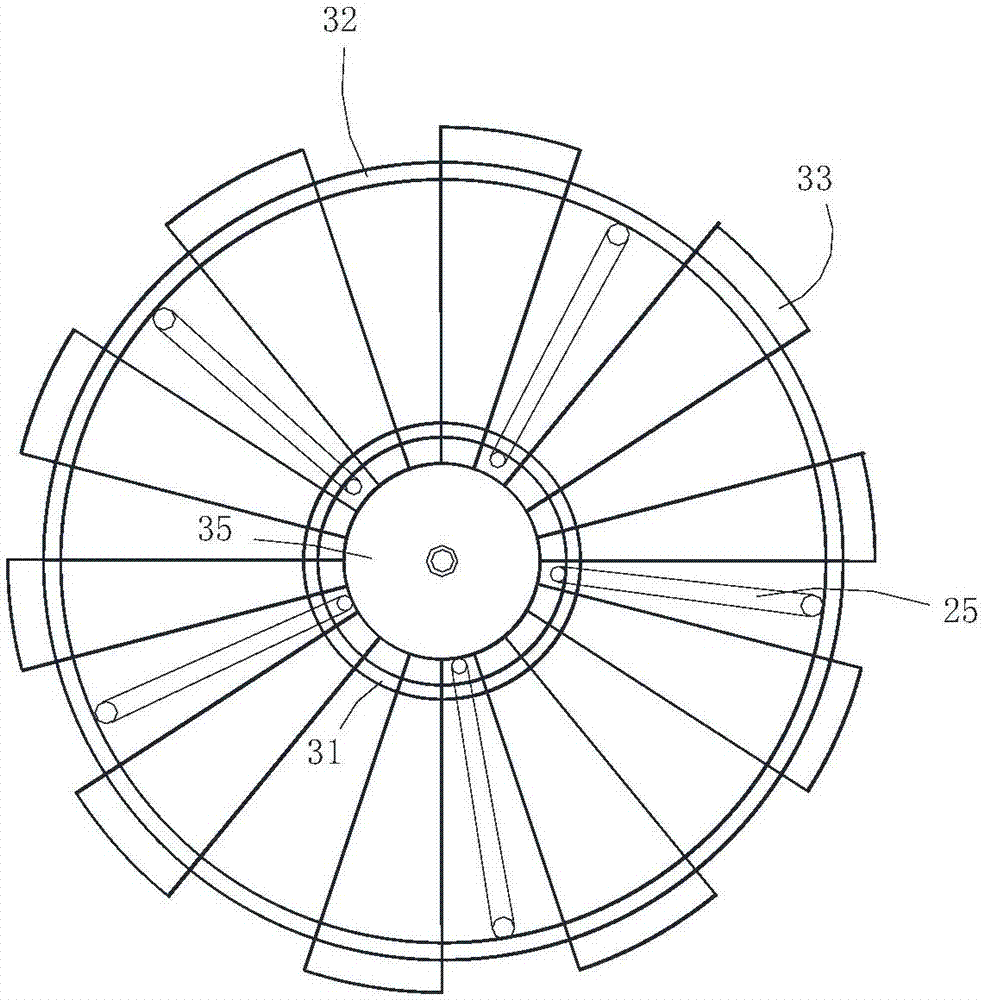

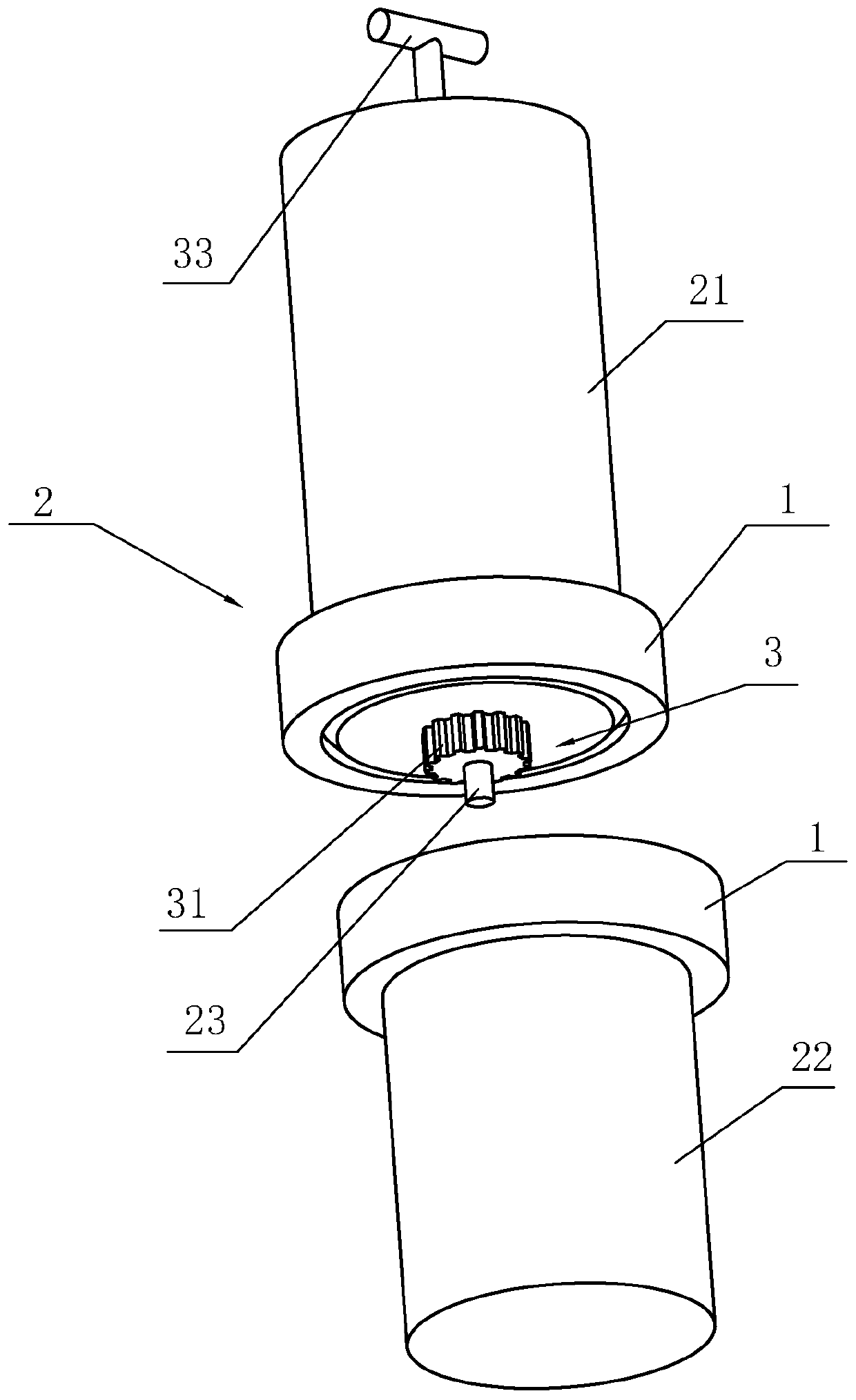

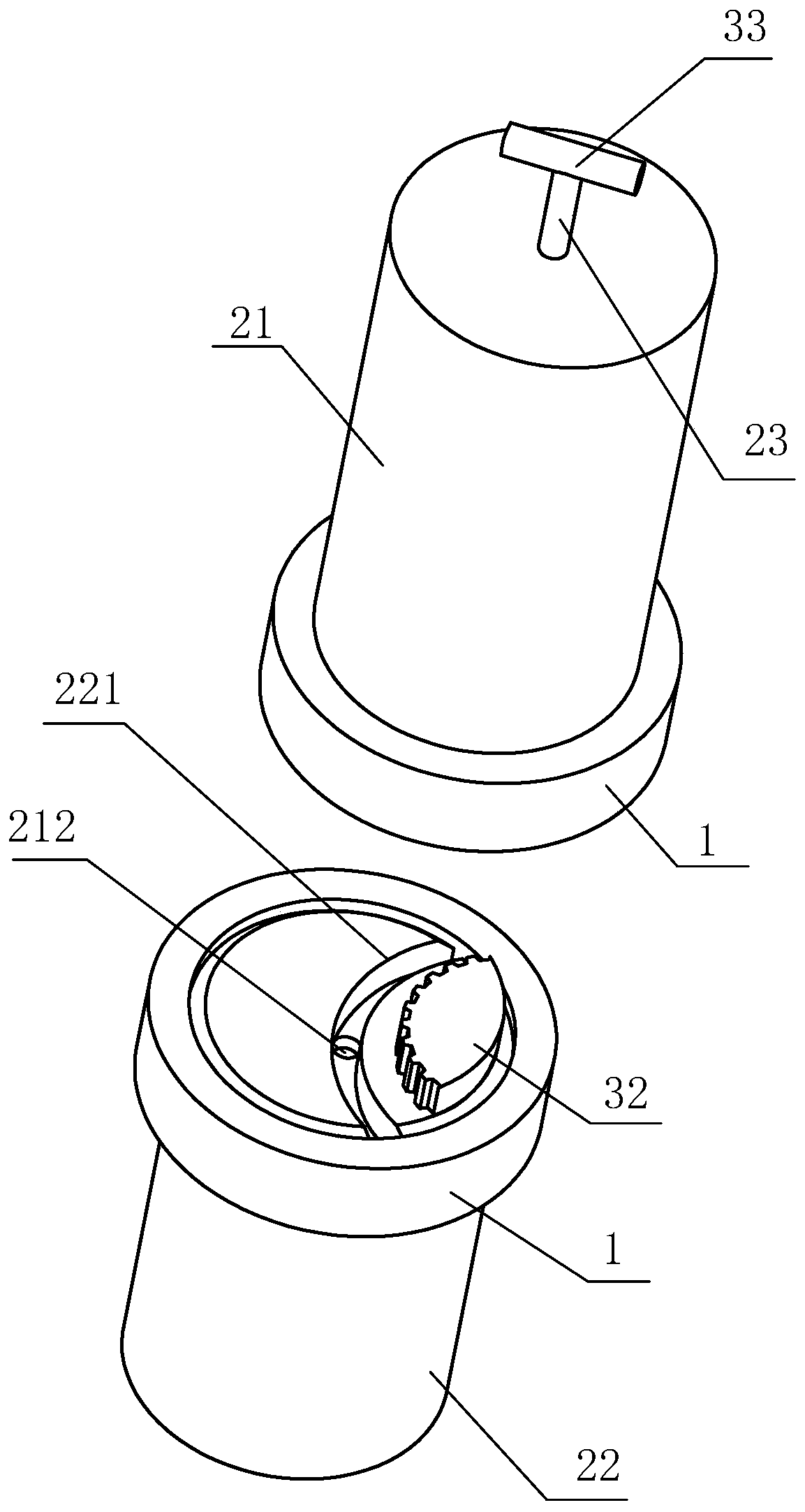

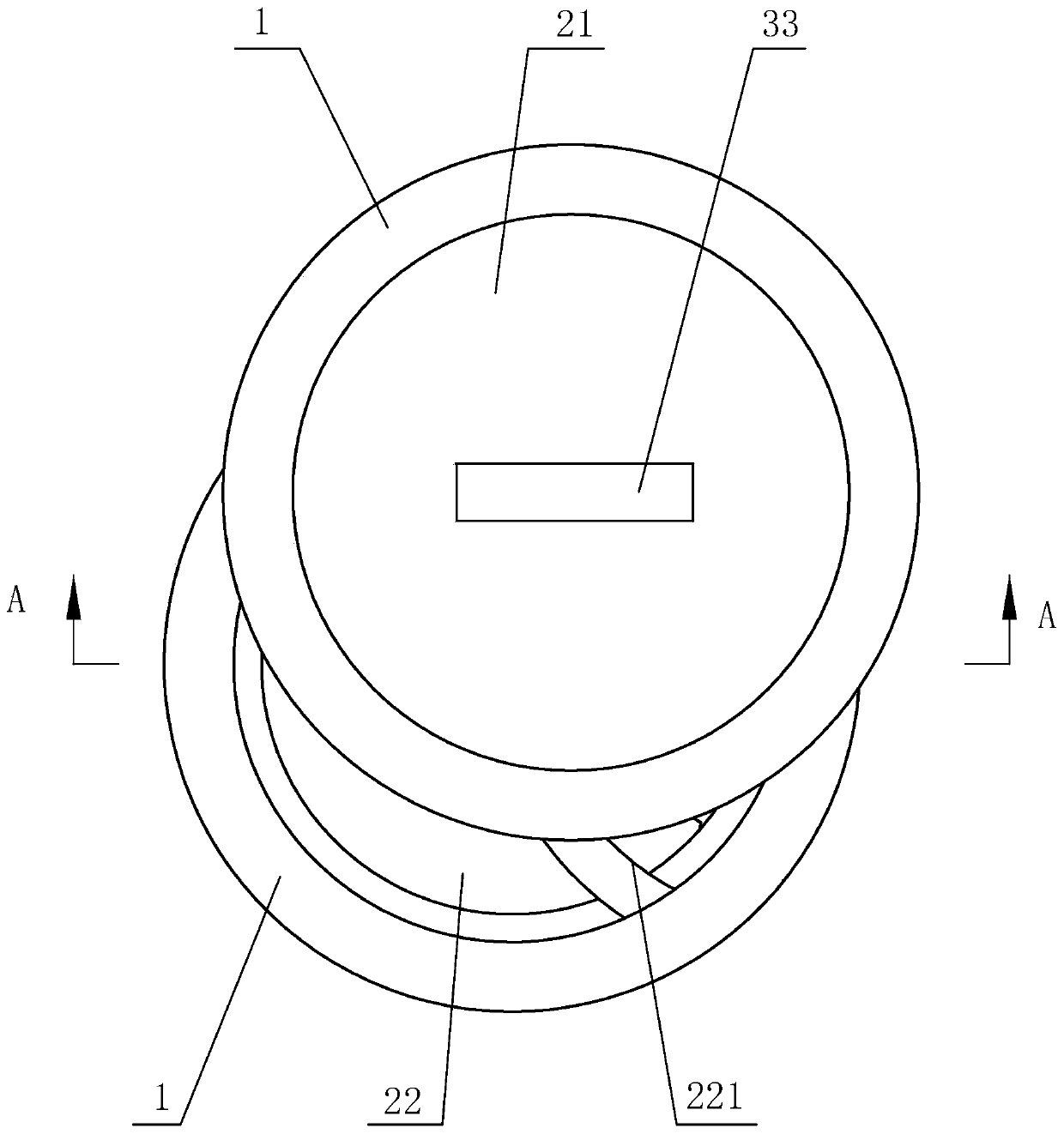

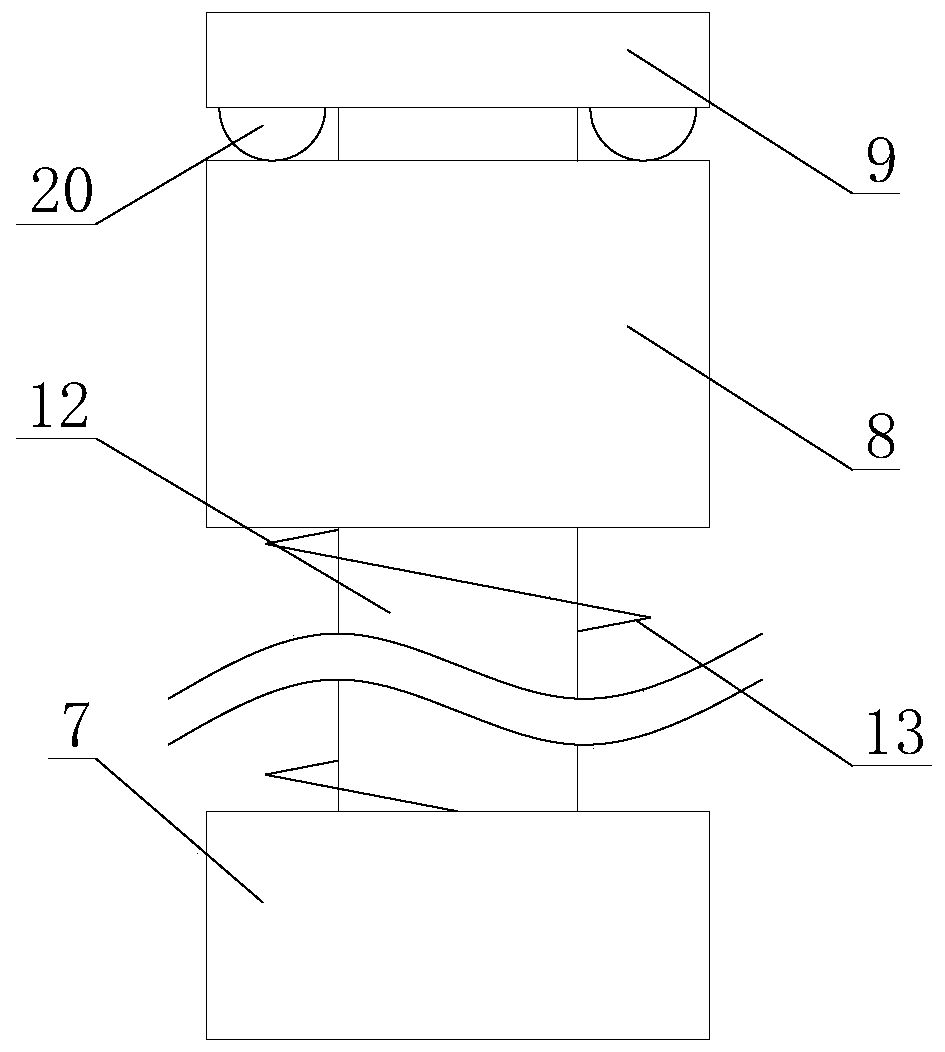

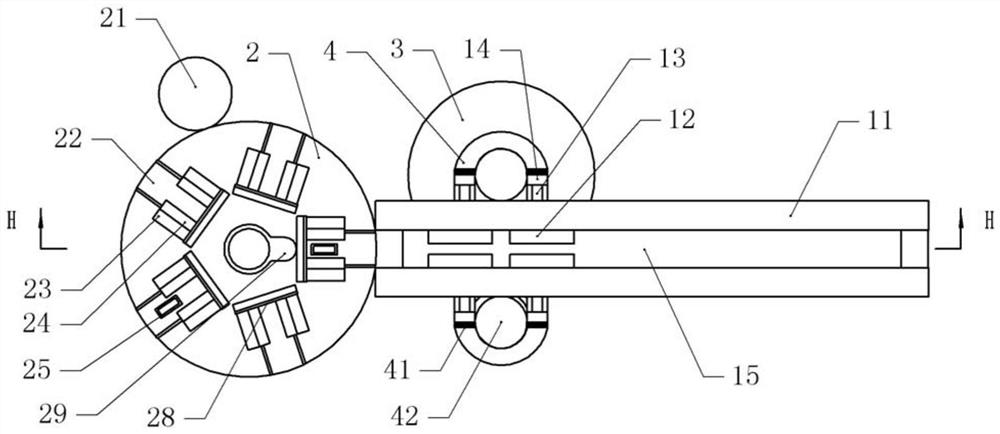

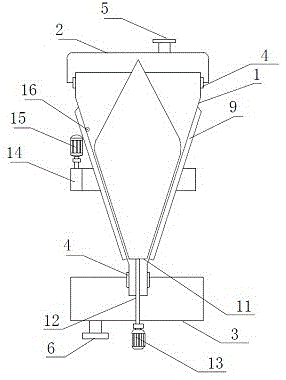

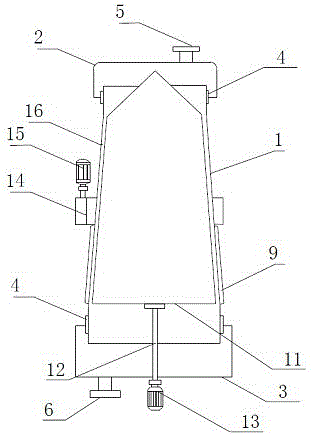

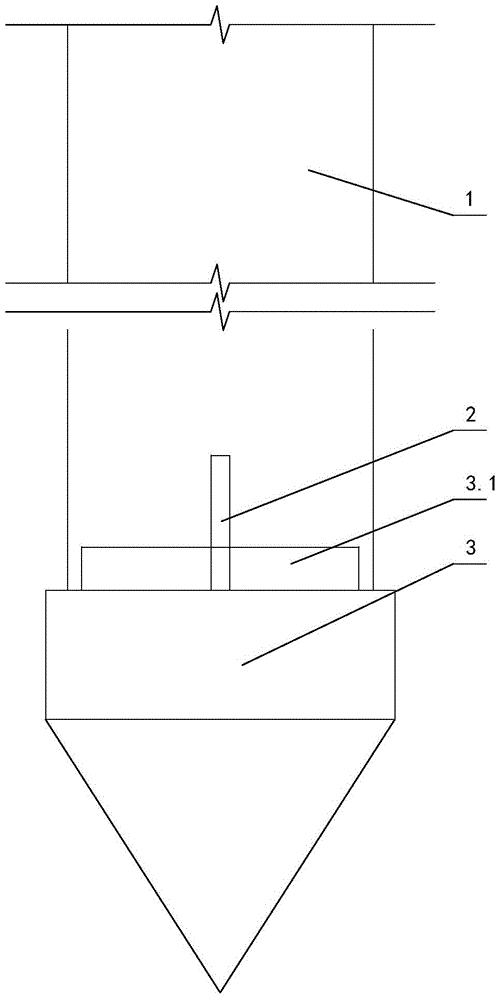

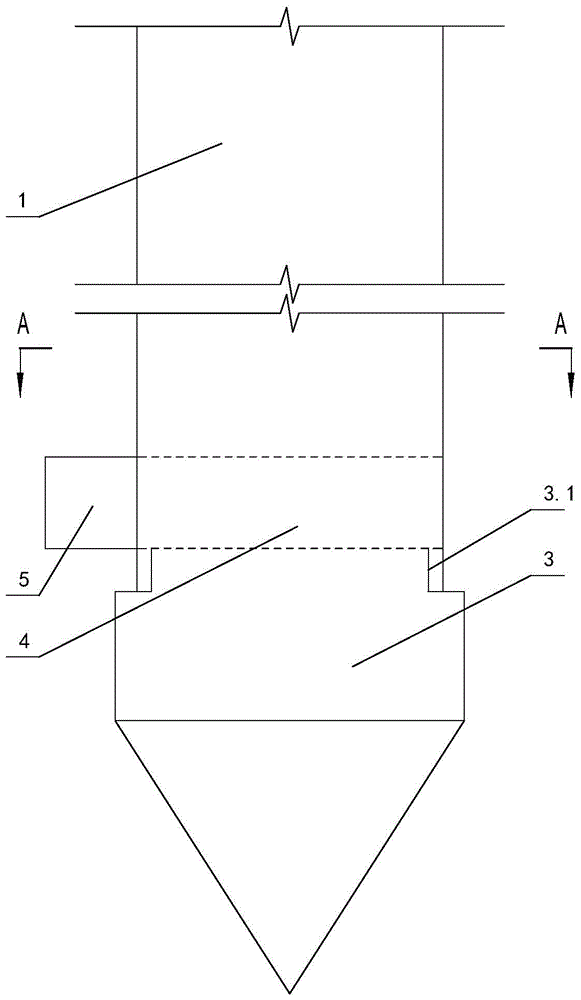

Rotary graphene stripping device, graphene production system and production method

The invention discloses a rotary graphene stripping device including a rotary cylinder body; a top cover is arranged above the rotary cylinder body, a bottom cover is arranged below the rotary cylinder body, the top of the top cover is provided with a feed inlet, the bottom of the bottom cover is provided with a discharge port, and the feed inlet is communicated with the interior of the rotary cylinder body; the outer side of the rotary cylinder body is provided with a first motor, and is used for driving the rotary cylinder body to horizontally rotate; the rotary cylinder body is also internally provided with an inner cylinder, and a second motor used for driving the inner cylinder to horizontally rotate in a direction opposite to the rotating direction of the rotary cylinder body is arranged below the rotary cylinder body; the upper part of the inner cylinder is shrunk in a certain angle, and a material storage space is left between the upper part of the inner cylinder and the upper part of the rotary cylinder body; the lower part of the inner cylinder and the lower part of the rotary cylinder body are in clearance fit to be used for grinding graphite sheets, and a clearance between the lower part of the inner cylinder and the lower part of the rotary cylinder body is successively decreased downward along the axial direction of the rotary cylinder body. The rotary graphene stripping device can achieve successful stripping of graphene. The invention also relates to a graphene production system containing the rotary graphene stripping device and a graphene production method.

Owner:江苏碳谷二维世界科技有限公司

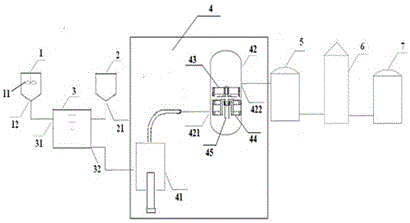

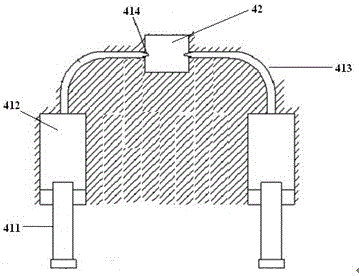

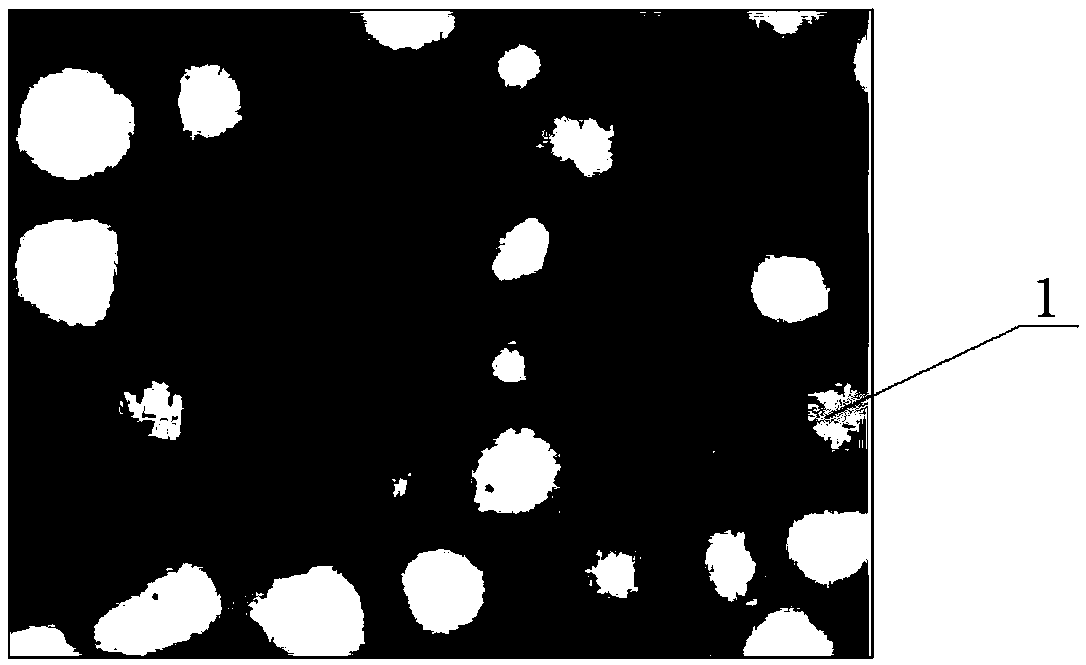

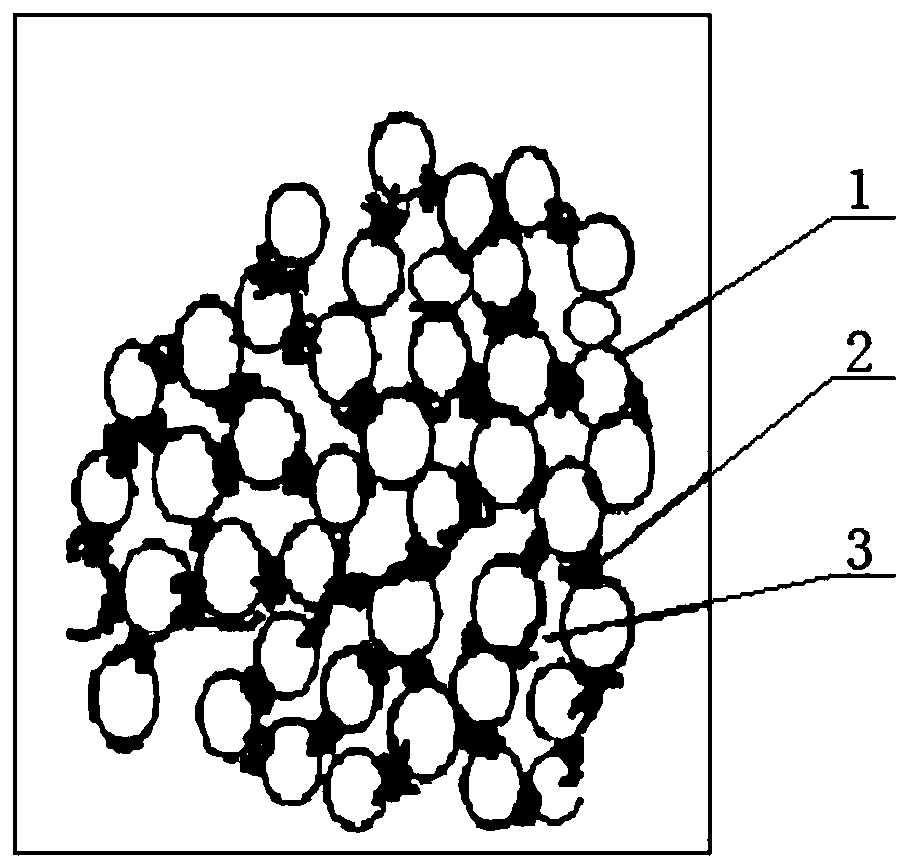

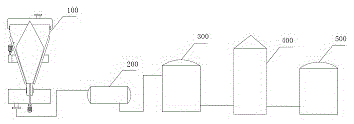

Device for continuously preparing graphene and method for producing graphene

The invention belongs to the technical field of graphene and particularly relates to a device for continuously preparing graphene and a method for producing graphene. The device comprises a raw material grinding tank, a grinding medium storage bin, a stirring tank, a continuous grinding mechanism, a material storage tank, a centrifugal filtering device and a drying device. A blade type stirring mill is arranged in the raw material grinding tank. The continuous grinding mechanism comprises a high-pressure pump, the grinding bin, a flow guide ring, a dispersion impeller and a transmission shaft. The flow guide ring is located in the middle of the grinding bin and fixedly connected with the transmission shaft, the dispersion impeller is located between the flow guide ring and the bottom of the grinding bin, and the transmission shaft passes through the center of the dispersion impeller. The probability that graphene is smashed is reduced through continuous stripping step by step, structural defects of graphene are reduced, and meanwhile the situation that structural defects are caused again to stripped graphene due to re-grinding is avoided. The invention further discloses the method for producing graphene by means of the device for continuously preparing graphene from the slurry.

Owner:淮安双洋新材料有限公司

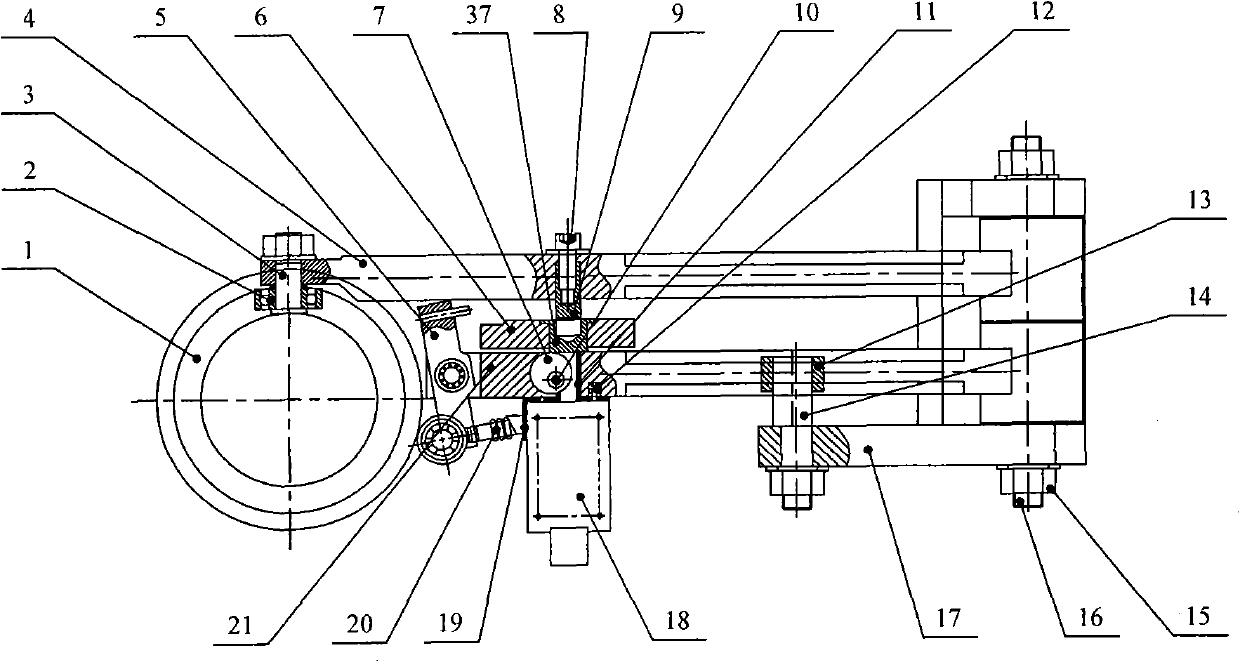

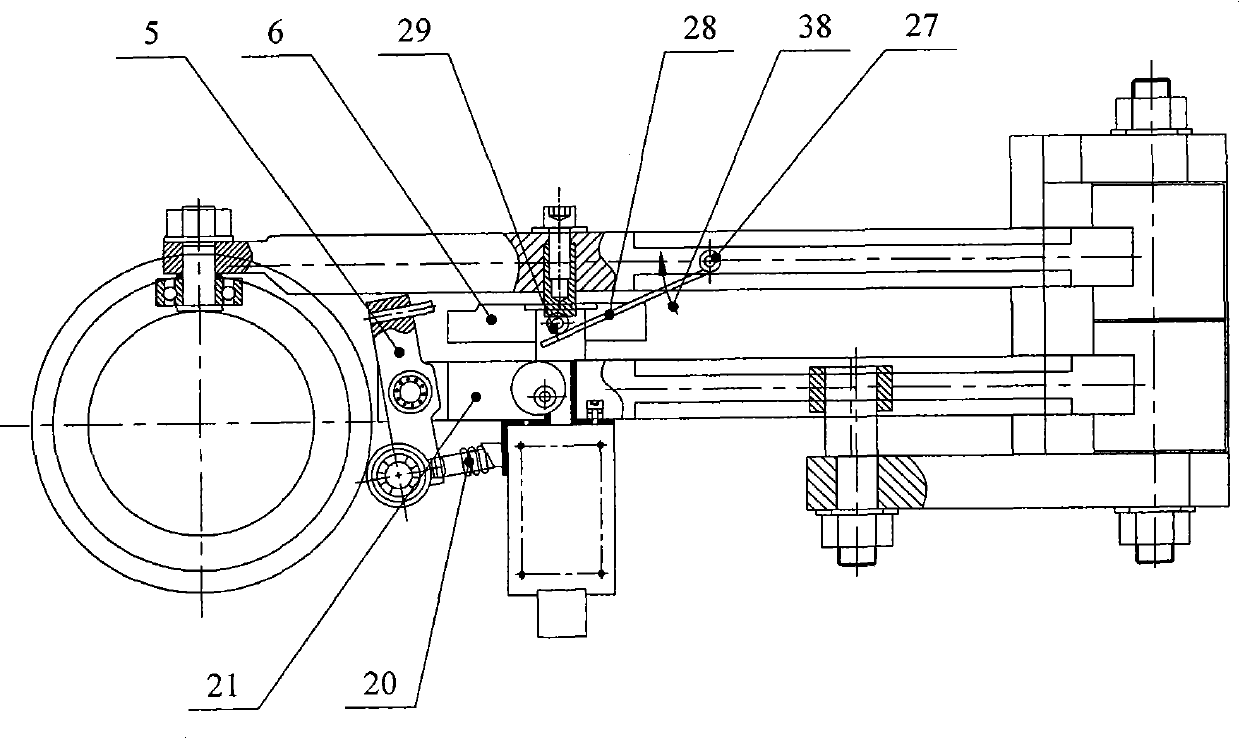

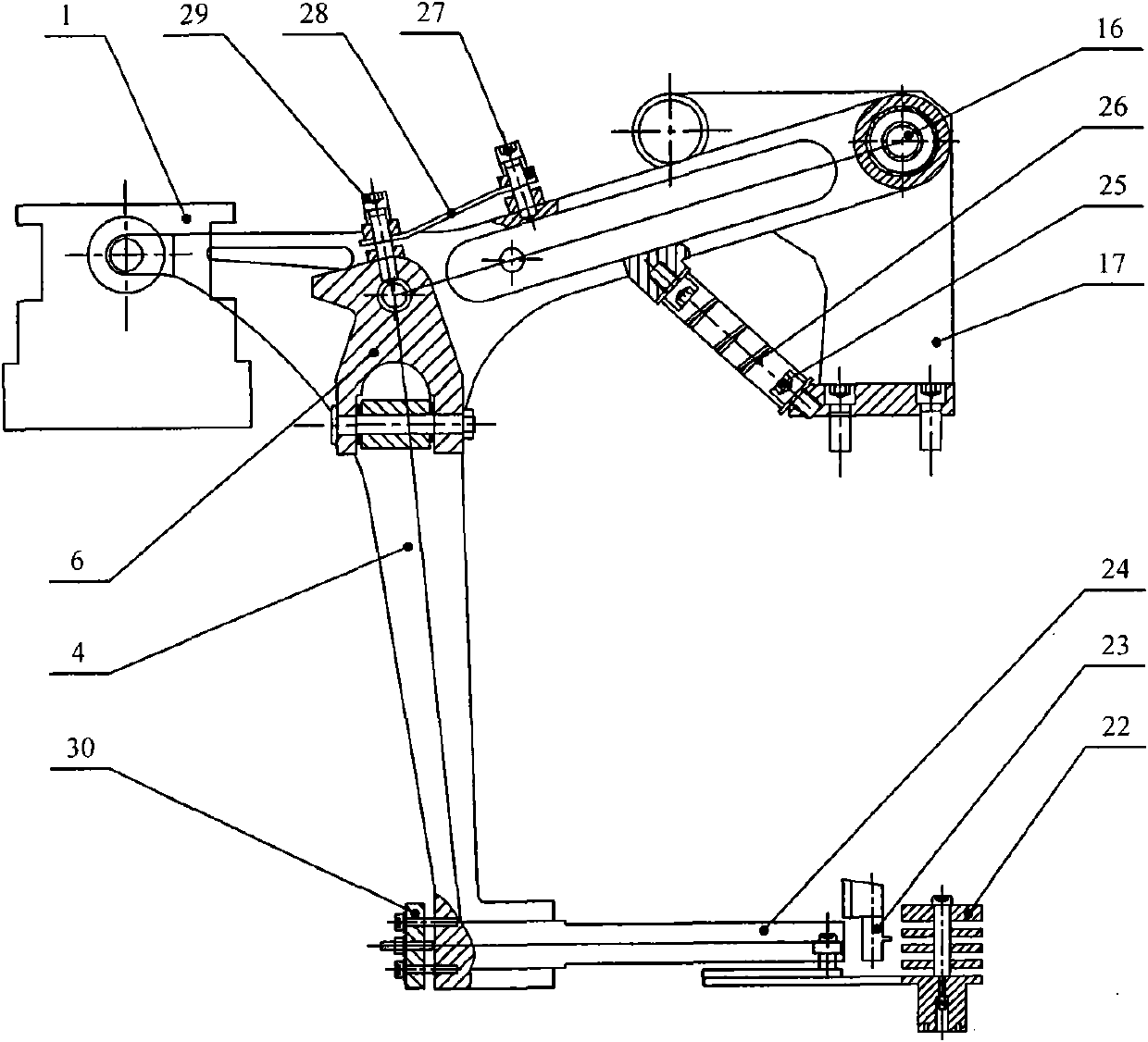

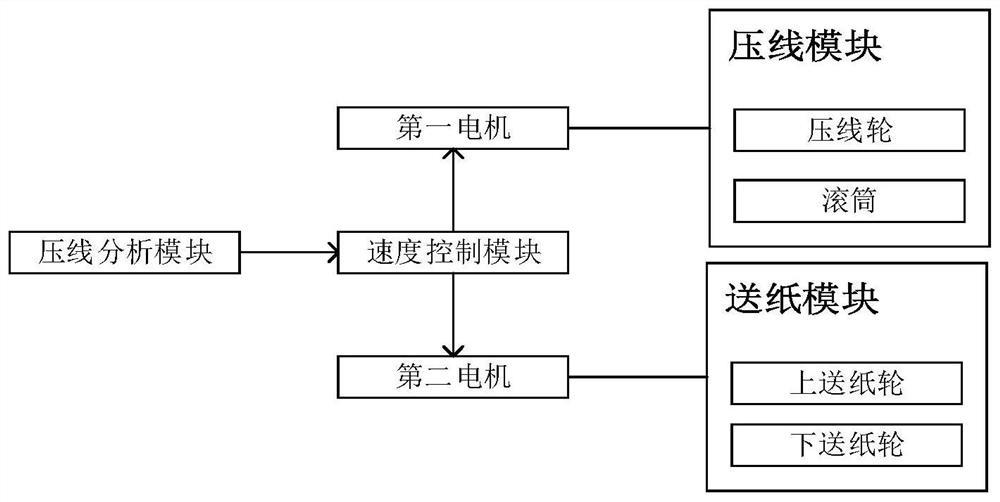

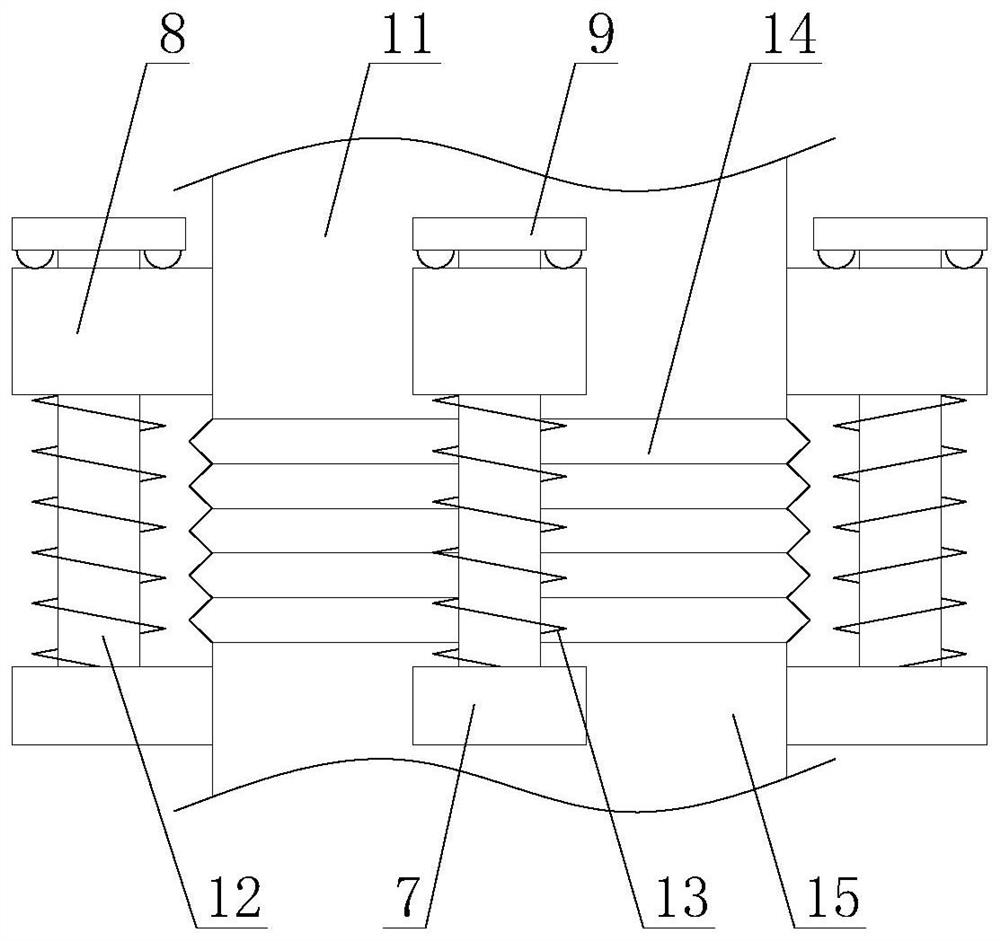

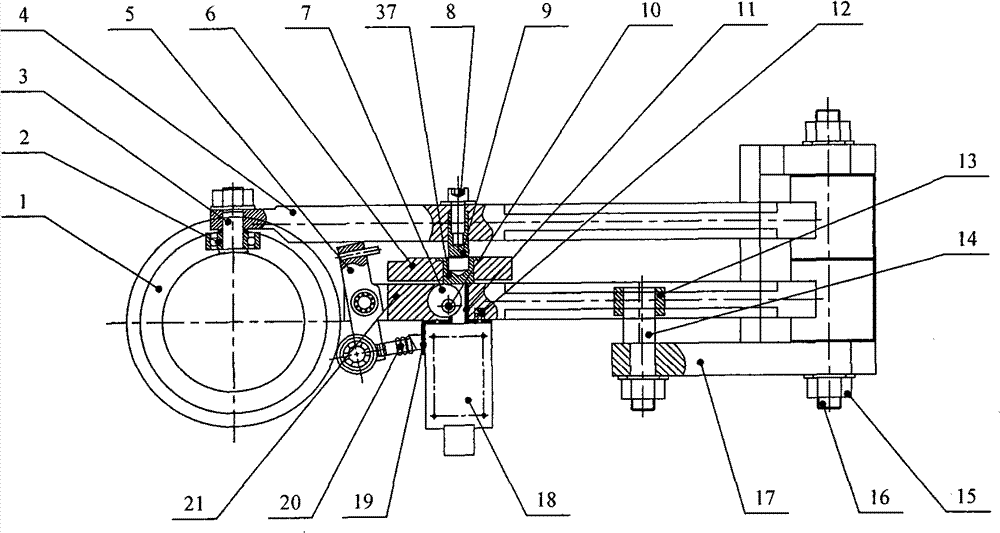

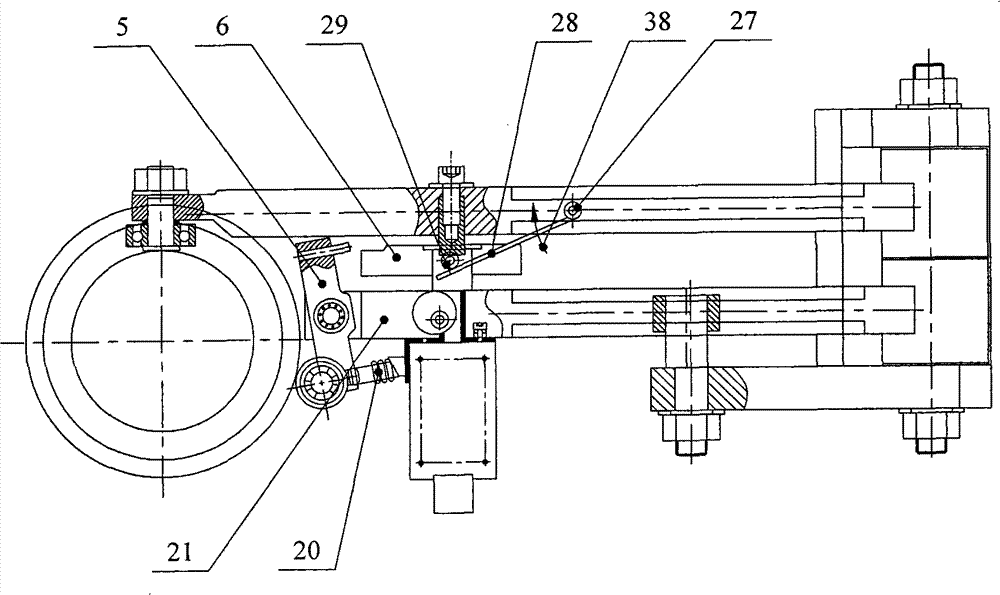

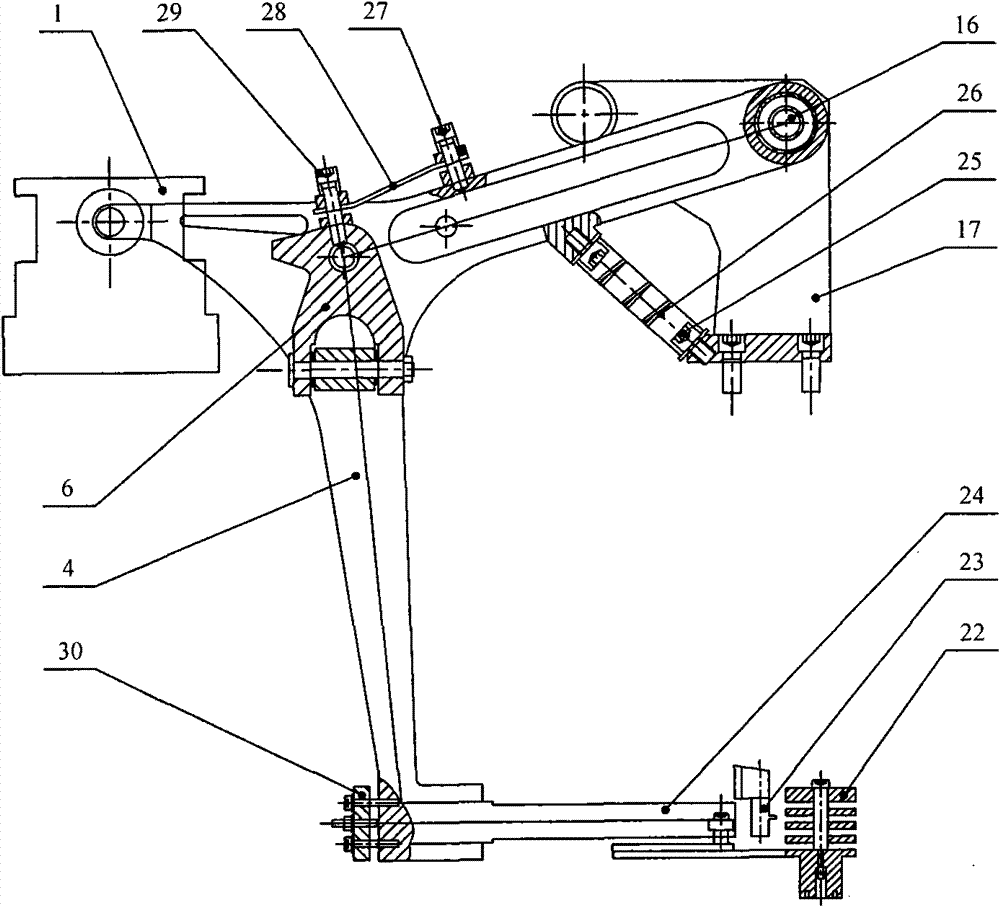

Multifunctional electric hydraulic straightening and mounting press apparatus

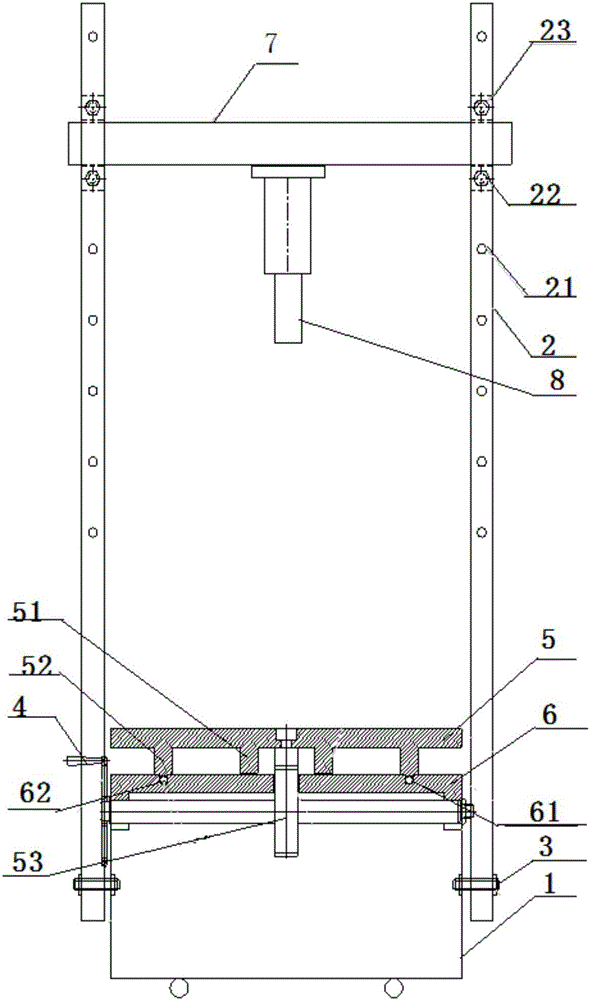

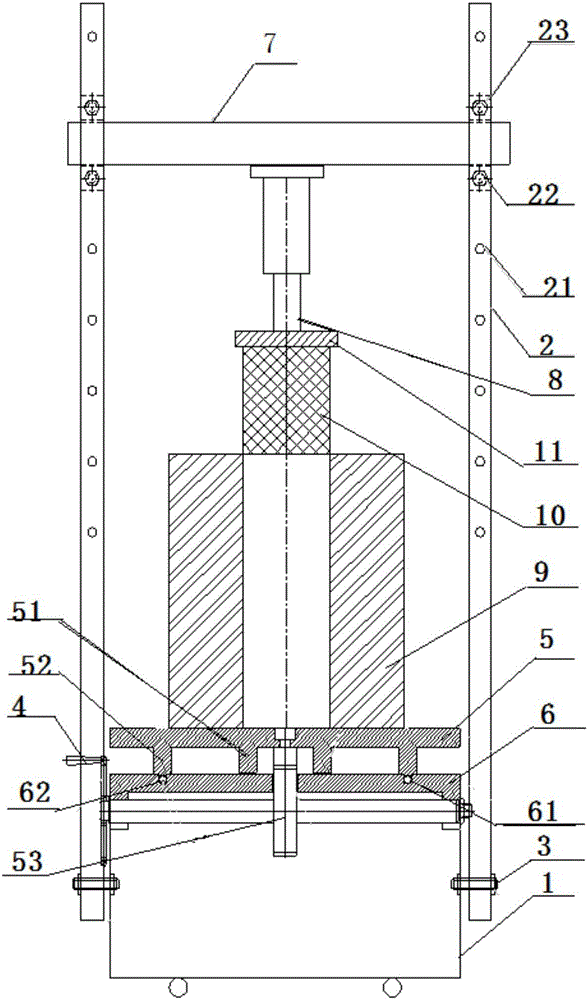

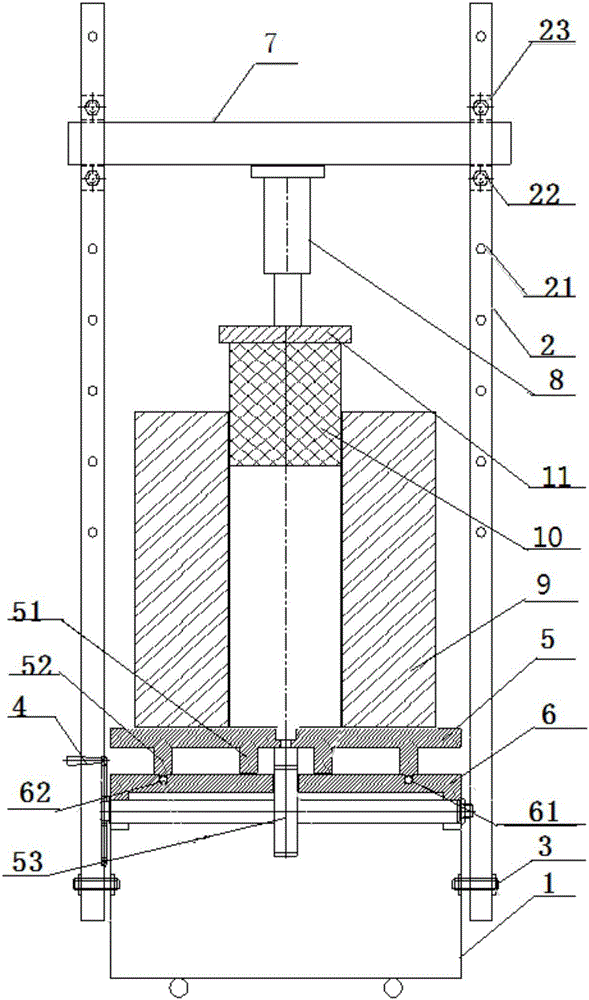

PendingCN106695669AImprove securityImprove reliabilityMetal-working hand toolsEngineeringPortal frame

The invention discloses a multifunctional electric hydraulic straightening and mounting press apparatus for pressing a nylon cover into a sleeve. The apparatus comprises a portal frame, a jack, a movable worktable, a bottom plate, a power mechanism and a base, wherein the portal frame comprises a horizontal top beam and a door-shaped frame; the bottom of the jack is fixed on a middle point of the horizontal top beam for providing a pressure to enable the nylon sleeve to move downward toward the sleeve; the movable worktable is located below the jack for bearing the sleeve; the bottom plate is arranged below the movable worktable for bearing the movable worktable; the power mechanism is connected to the bottom plate and the movable worktable for driving the movable worktable to move front and back relative to the bottom plate; the base is arranged below the bottom plate for bearing the bottom plate; the bottom end of the portal frame is fixed to the base and forms a rectangular space for accommodating the nylon cover and the sleeve with the base. According to the multifunctional electric hydraulic straightening and mounting press apparatus disclosed by the invention, the using reliability and the safety are improved; the probability of crushing the nylon cover is reduced to zero, so that the labor productivity is improved.

Owner:STATE GRID GANSU ELECTRIC POWER CORP +1

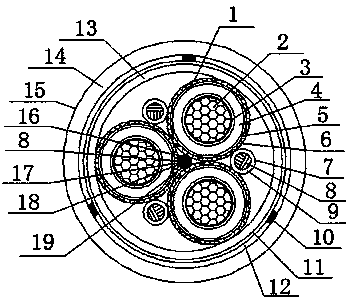

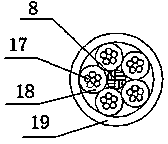

Noctilucence medium-voltage photoelectricity composite cable

InactiveCN104008805AImprove tensile propertiesImprove anti-rolling performanceInsulated cablesPower cablesVisibilityElectrical conductor

The invention discloses a noctilucence medium-voltage photoelectricity composite cable, and relates to the field of composite cable manufacturing. The noctilucence medium-voltage photoelectricity composite cable comprises a semi-conductive band wrapping layer, a monitoring layer, an inner protective layer, an outer sheath and three insulation power cable cores. The insulation power cable cores and an optical cable element are twisted to form a cable core. A tensile reinforcing part is arranged on the outer side between every two adjacent insulation power cable cores. The cable core is sequentially provided with the inner protective layer, the semi-conductive band wrapping layer, the monitoring layer and the outer sheath from interior to exterior. Monitoring cable core conductors are evenly arranged in the monitoring layer. The outer surface of the outer sheath is evenly coated with a layer of spiral noctilucence stripes. The noctilucence medium-voltage photoelectricity composite cable is simple in structural design, stable in performance, capable of being self-luminous or capable of reflecting light to improve the visibility at night, and capable of integrating the functions of electric energy transmission, signal control and video message transmission, and has the good tensile performance, the good wear-resisting performance, the good grinding-resisting performance and the like.

Owner:ANHUI LINGYU CABLE TECH

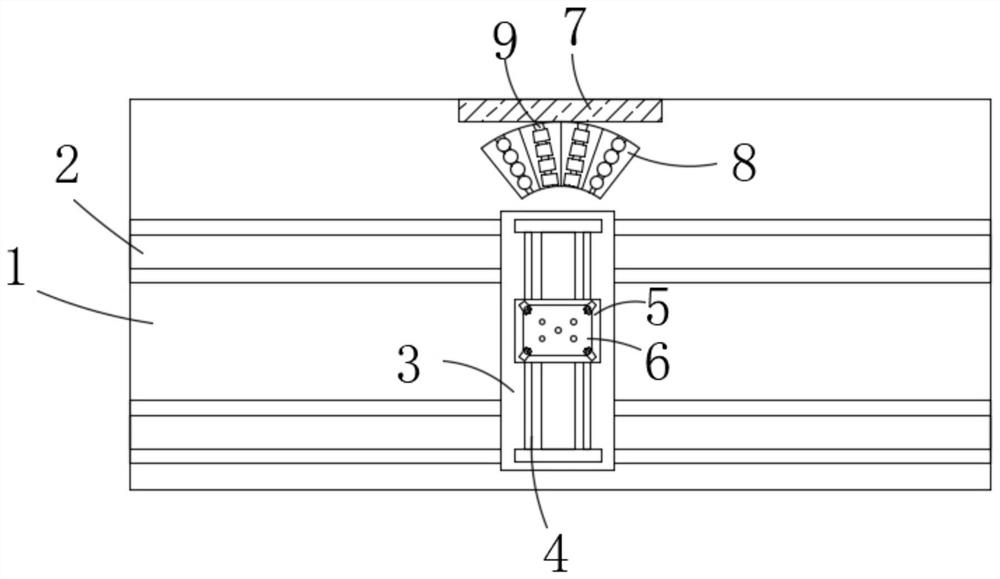

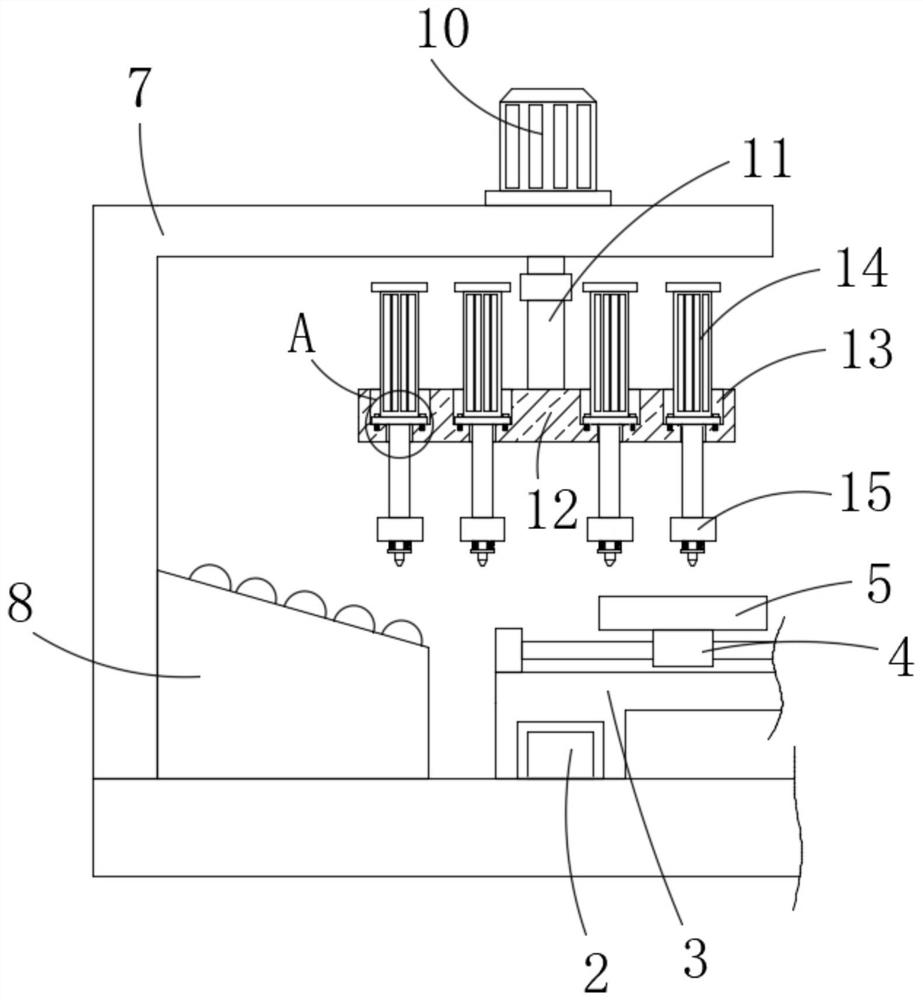

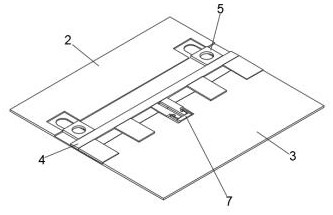

Flexible circuit board chip mounter

InactiveCN113056186AAvoid damageEasy to fixPrinted circuit assemblingVibration suppression adjustmentsFlexible circuitsSurface mounting

The invention discloses a flexible circuit board chip mounter which comprises a workbench, wherein a sliding rail is fixedly installed on the workbench, a sliding base is installed on the sliding rail in a sliding mode, an electric sliding table is fixedly installed on the sliding base, a carrier plate is fixedly installed on the sliding base of the electric sliding table, a groove is formed in the carrier plate, and a supporting column and a supporting block are arranged in the groove. According to the flexible circuit board chip mounter, the fixing effect of the circuit board is enhanced, the possibility of position deviation of the circuit board in the surface mounting process is reduced, the precision of the element in the surface mounting process is improved to a certain extent, the qualified rate of products is further improved, material suction and chip mounting can be continuously performed through five groups of air cylinders and suction nozzles, the chip mounting continuity is improved, the chip mounting speed is higher, the chip mounting working efficiency is improved to a certain extent, the pressure on a circuit board in the chip mounting process is reduced, the possibility that the circuit board is crushed is reduced, and the production cost is reduced to a certain extent.

Owner:胡煜

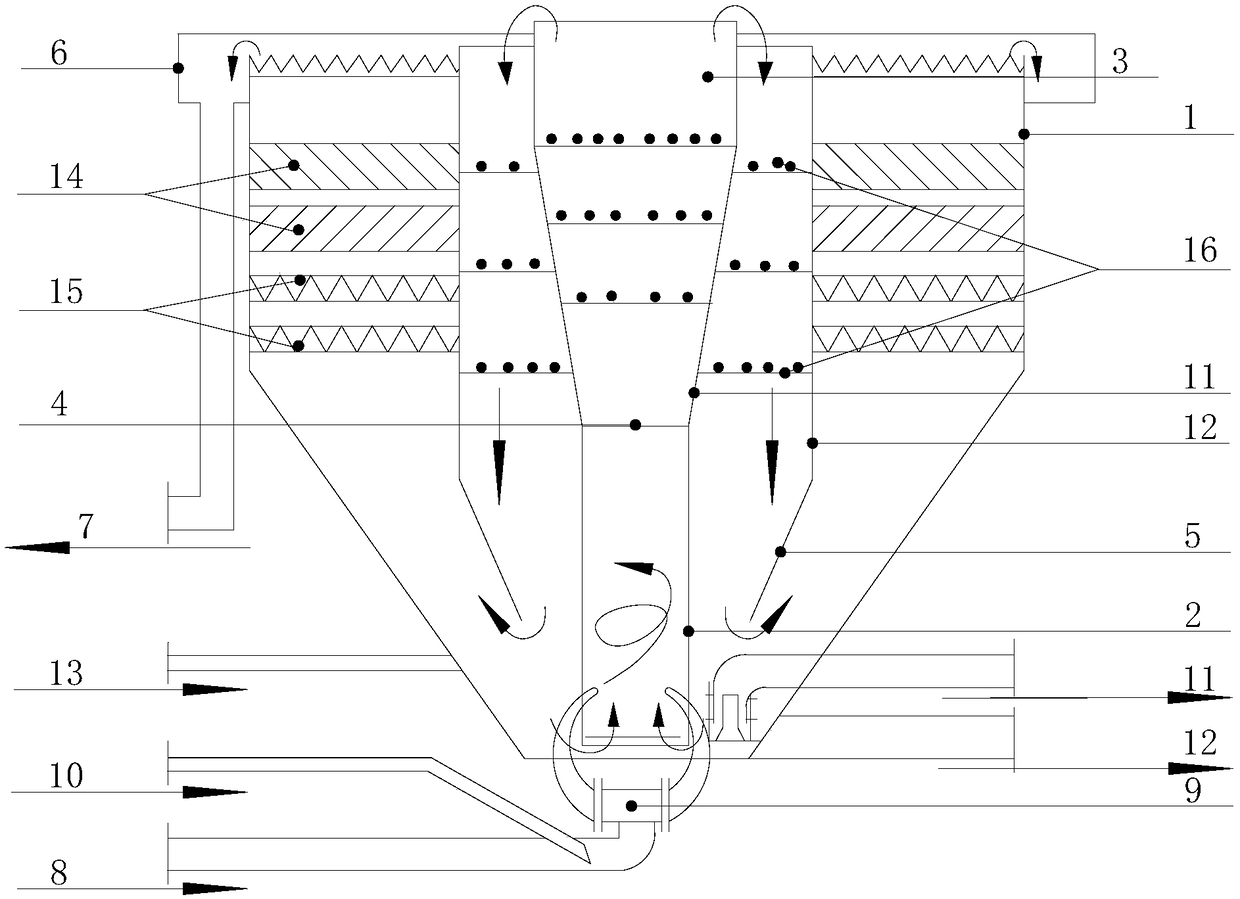

Vertical drying and screening tower

InactiveCN107152858AImprove protectionReduce crushGas current separationDrying gas arrangementsThermodynamicsEngineering

The invention discloses a vertical drying and screening tower. The vertical drying and screening tower comprises a tower body, a hot wind pipe, a screen plate and a distribution carriage plate; the hot wind pipe, the screen plate and the distribution carriage plate are arranged in the tower body; the distribution carriage plate is arranged above a grid section; the tower body is provided with a feed port and an exhaust port in the top, and is provided with a discharge port in the bottom; the hot wind pipe comprises a center hot wind pipe, longitudinal hot wind pipes and a hot wind inclined beam; the center hot wind pipe, the longitudinal hot wind pipes and the hot wind inclined beam are provided with hot wind holes; the grid section and the hot wind inclined beam are fixed between an inner ring beam and an outer ring beam; the hot wind inclined beam communicates with the longitudinal hot wind pipes and the center hot wind pipe; multiple longitudinal hot wind pipes are fixed on the inner sides or the outer sides of the inner and outer ring beams; two ends of the longitudinal hot wind pipes are closed; the bottoms of the longitudinal hot wind pipes outwards extend to support on the ground; and the bottoms of the longitudinal hot wind pipes on the inner ring outwards extend to support on the ground through a first hot wind box. The vertical drying and screening tower is uniform in ventilation, high in drying speed and low in cost.

Owner:郭大军

Placing device for computer CPU

InactiveCN110850926AImprove the quality of workEasy to fixDigital processing power distributionStructural engineeringMechanical engineering

The invention discloses a placement device for a computer CPU, in particular relates to the field of computer devices. The device comprises a device body, a straight groove is formed in the bottom endof the device body; a first base is fixedly mounted on the left side of the straight groove; a second base is fixedly connected to the right end of the straight groove, a connecting block is fixedlyconnected to the center of the bottom end of the straight groove, a supporting frame is fixedly installed on the bottom surface of the connecting block, a cushion block is bonded to the bottom end ofthe device body, a sponge plate is fixedly installed in the device body, and a fixing table is bonded to the top surface of the sponge plate. According to the invention, the rubber pad and the spongeplate are arranged; when the device is used for fixing the CPU of the computer; the clamping plate can be economically attached to the outer surface of the CPU of the computer; the situation that when a computer vibrates, the computer CPU collides with the clamping plate and moves is avoided, the fixing performance of the computer CPU is improved, and the problem that the computer CPU is scrappeddue to the fact that the computer CPU collides with the clamping plate seriously is avoided.

Owner:HUNAN UNIV OF SCI & ENG

Ceramic particle, and filtering element and preparation method thereof

ActiveCN110872188ALower firing temperatureHigh compressive strengthDispersed particle filtrationMembrane filtersKaolin clayTalc

The invention discloses a ceramic particle, and a filtering element and a preparation method thereof, wherein the ceramic particle is prepared by the following steps: mixing kaolin, talc, bauxite andspodumene, carrying out dry-method powder preparation, carrying out roll forming, and firing to obtain spherical particles. According to the invention, the spherical particles are uniform in particlesize, smooth in surface and high in compressive strength, and the prepared filtering element is uniform in pore size, low in filtering resistance and capable of improving the filtering performance.

Owner:SHANDONG RES & DESIGN ACADEMY OF IND CERAMICS

Rotor type expansion energy saver for carbon dioxide transcritical cycle

InactiveCN112344581AReduce the chance of deformationRelieve pressureCompression machinesThermodynamicsTranscritical cycle

The invention discloses a rotor type expansion energy saver for carbon dioxide transcritical cycle in the technical field of carbon dioxide transcritical cycle. The rotor type expansion energy saver comprises an expansion energy saver body, an expansion cylinder air inlet pipe and an electromagnetic valve, wherein the expansion cylinder air inlet pipe is fixedly arranged on the outer wall of the left side of the expansion energy saver body, the expansion cylinder air inlet pipe comprises an outer pipe fixedly connected with the outer wall of the left side of the expansion energy saver body, aninner pipe is arranged in an inner cavity of the outer pipe, the right end of the inner pipe communicates with the outer wall of the left side of the expansion energy saver body, and supporting devices are uniformly arranged between the outer wall of the inner pipe and the inner wall of the outer pipe. According to the rotor type expansion energy saver, a telescopic spring stretches out and drawsback, so that a moving rod and a moving plate move, a buffering effect is achieved, the pressure caused by supercritical high-pressure carbon dioxide fluid entering the inner pipe to the inner wall of the inner pipe is reduced, the inner pipe is protected, the probability that the inner pipe is deformed due to the extrusion of high-pressure gas is reduced, and the service life of the expansion cylinder air inlet pipe is prolonged.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

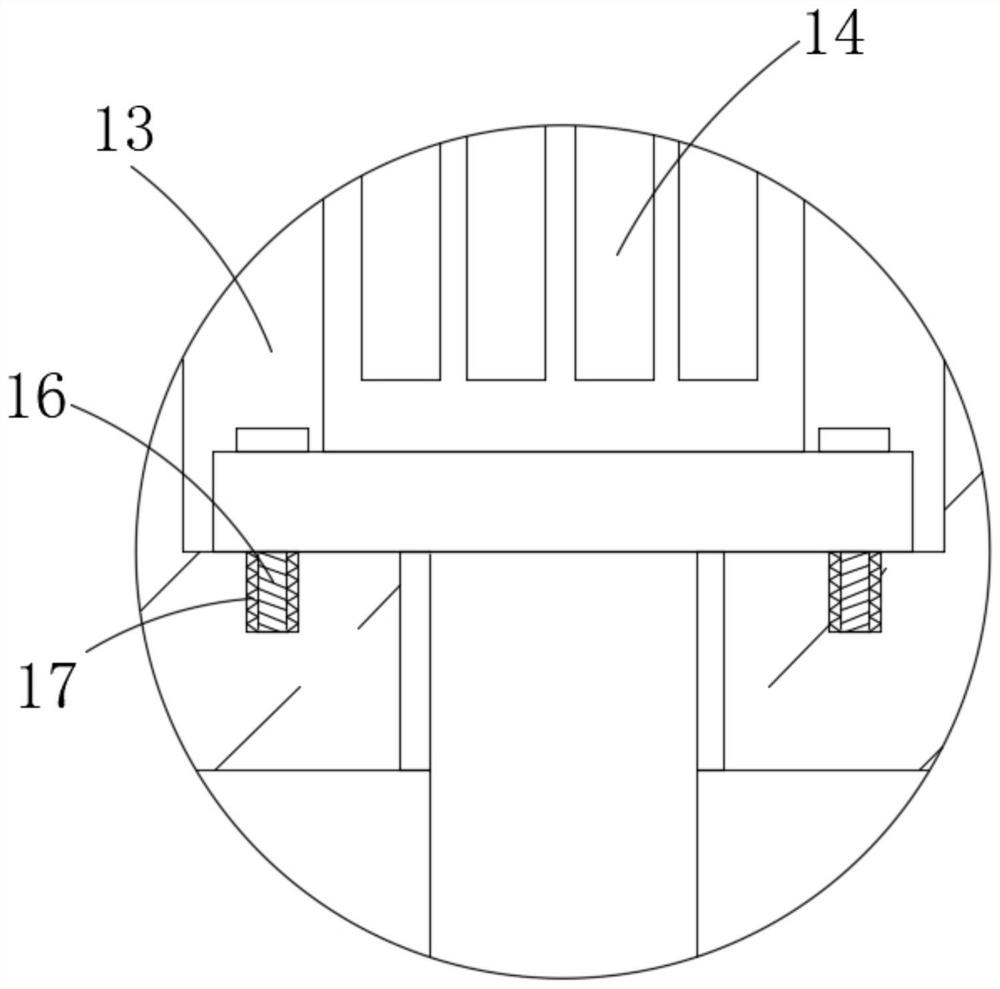

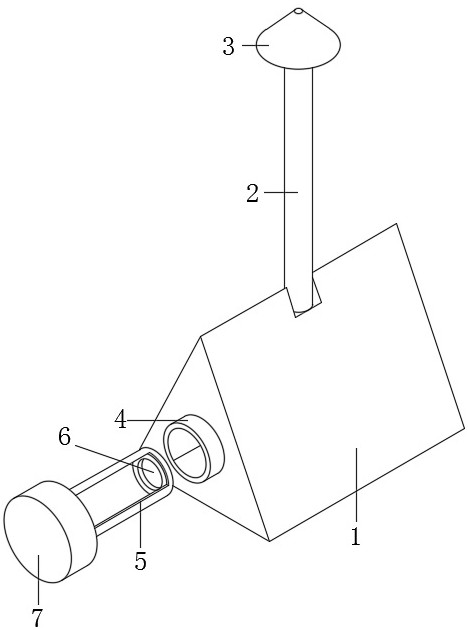

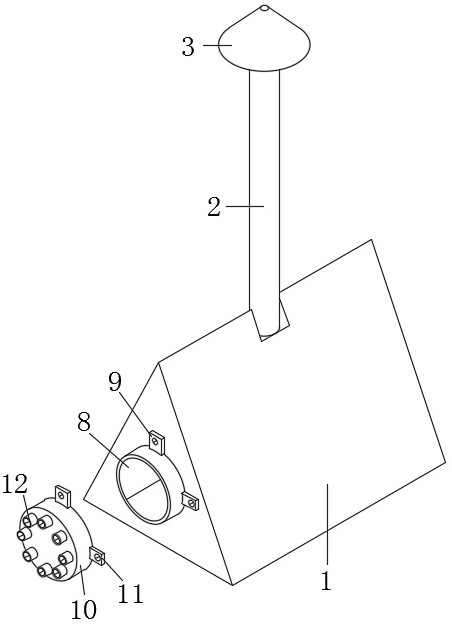

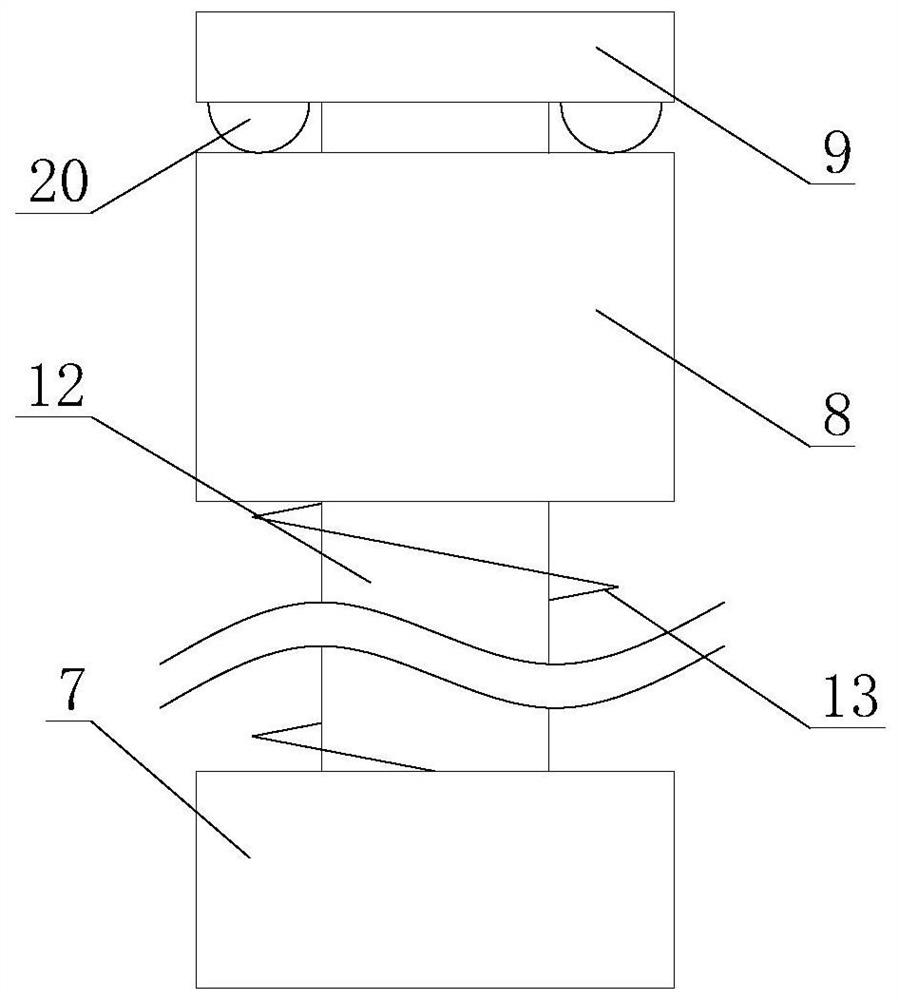

Permanent magnet ECR ion source permanent magnet ring mounting structure and processing method thereof

PendingCN110868788ASimplify the assembly processReduced chance of crushingPermanent magnetsIon beam tubesEngineeringNon magnetic

The invention relates to the field of permanent magnet type ECR ion sources, and particularly relates to a permanent magnet ECR ion source permanent magnet ring mounting structure and a processing method thereof. The structure comprises a movable bar material and a static bar material which are both made of non-magnetic materials and have the same inner diameter as a permanent magnet ring to be installed; a positioning rod coaxial with the movable bar material is arranged at one end of the movable bar material, an arc-shaped guide groove allowing the positioning rod to slide is formed in the end face of the static bar material and the guide groove passes through the axis of the static bar material so that the effects of simplifying the assembling process of the permanent magnet ring, saving time and labor and reducing the possibility that the magnetic ring is crushed are achieved.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Bottle reject mechanism of online visual inspection robot for visible foreign matters in bottled liquid

ActiveCN101767096AReliable separationReduce impactOptically investigating flaws/contaminationSortingForeign matterBall bearing

The invention discloses a bottle reject mechanism of an online visual inspection robot for visible foreign matters in bottled liquid, which is characterized in that the bottle reject mechanism comprises a rotatable cam, a swing link seat, a C-shaped long swing link, a C-shaped short swing link and a clutch mechanism, wherein the C-shaped long swing link and the C-shaped short swing link are both arranged on the swing link seat; the C-shaped long swing link is embedded in a groove of the rotatable cam through a deep groove ball bearing so as to lead the rotatable cam to drive the C-shaped longswing link to do periodic swinging along with the rotation of the rotatable cam; the free end of the C-shaped short swing link is provided with a push plate for rejecting a bottle body; and the clutch mechanism comprises a cylindrical pin arranged on the C-shaped long swing link, a frame-type electromagnet arranged on the C-shaped short swing link, a limit supporting block, a claw and a clutch plate. The bottle reject mechanism of the online visual inspection robot for the visible foreign matters in the bottled liquid can effectively realize the separation of accepted and unaccepted products by the visual inspection robot and dramatically reduces the possibility of extruded and blown bottles at the bottle outlet.

Owner:HUNAN UNIV

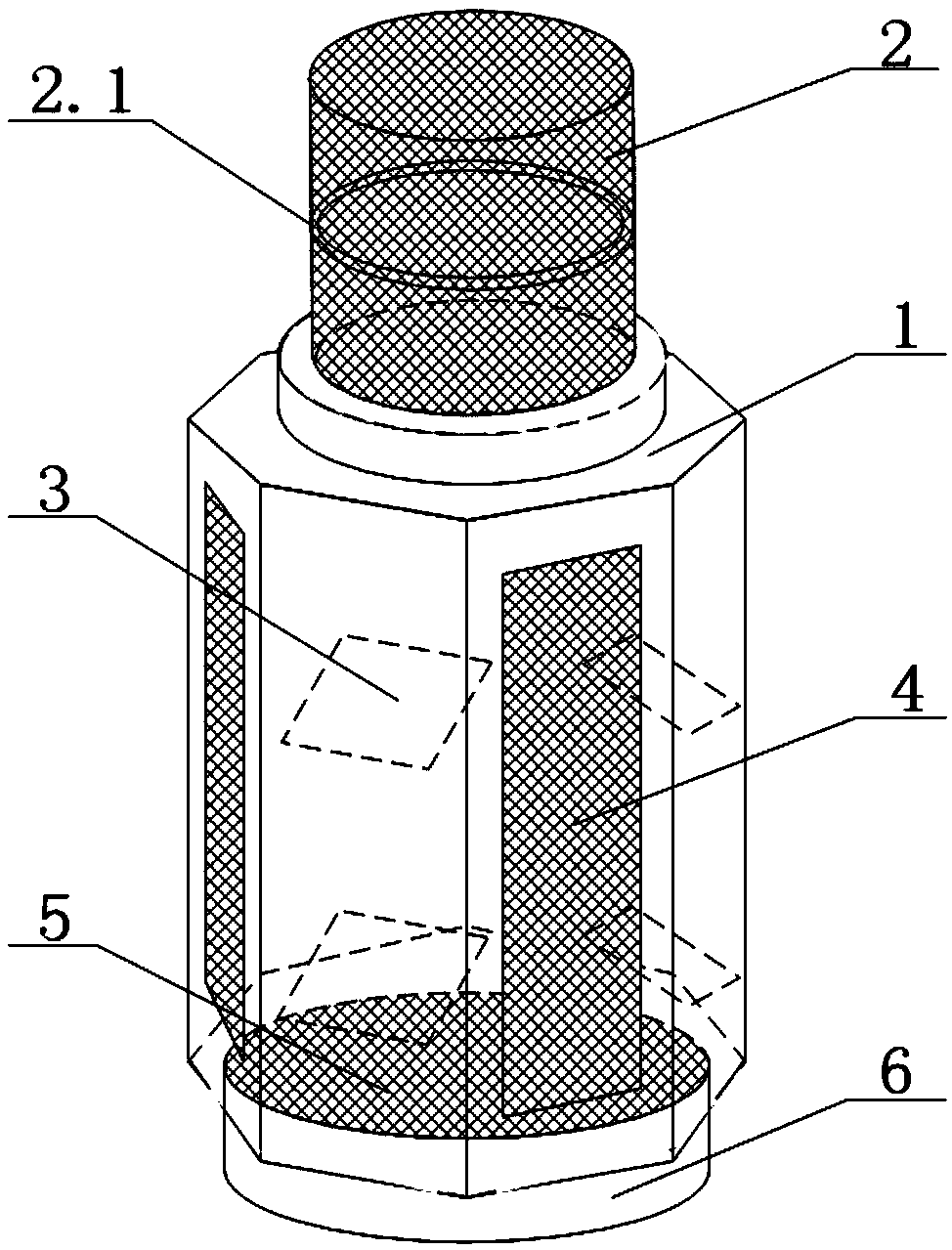

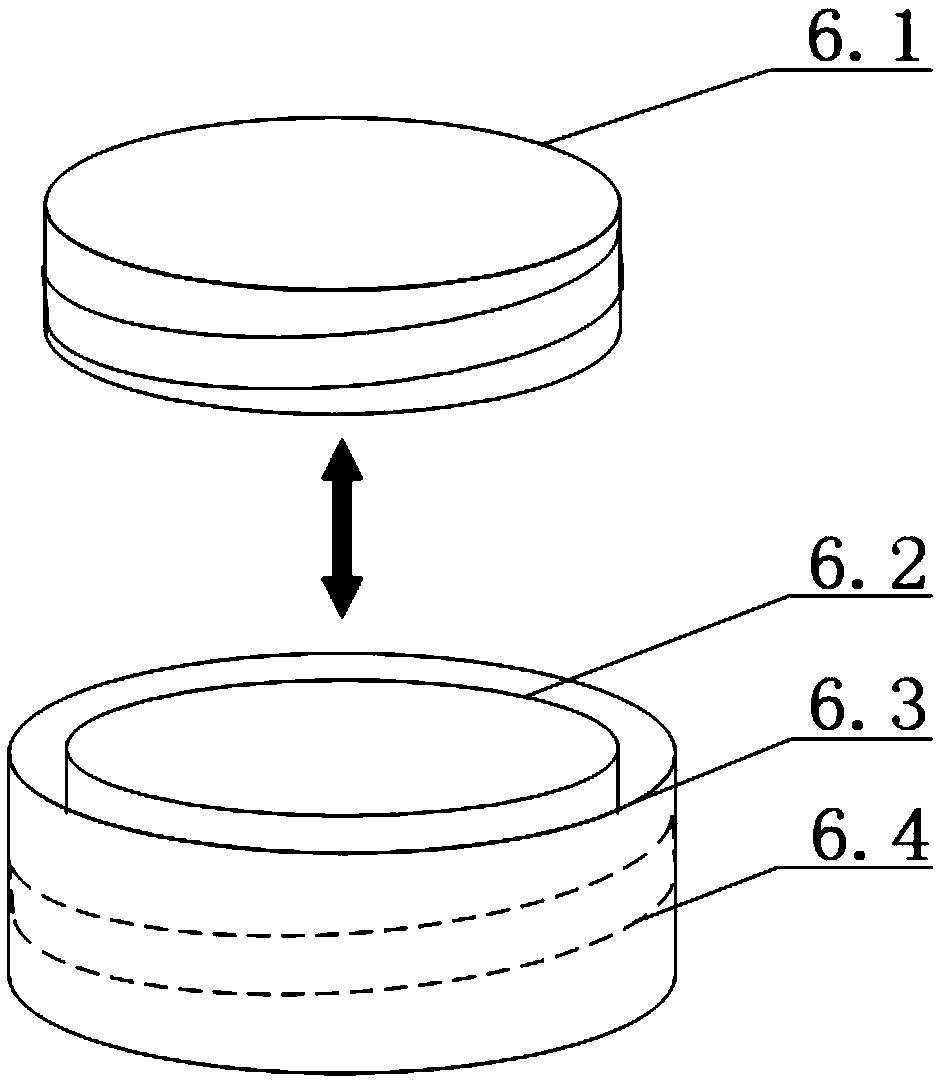

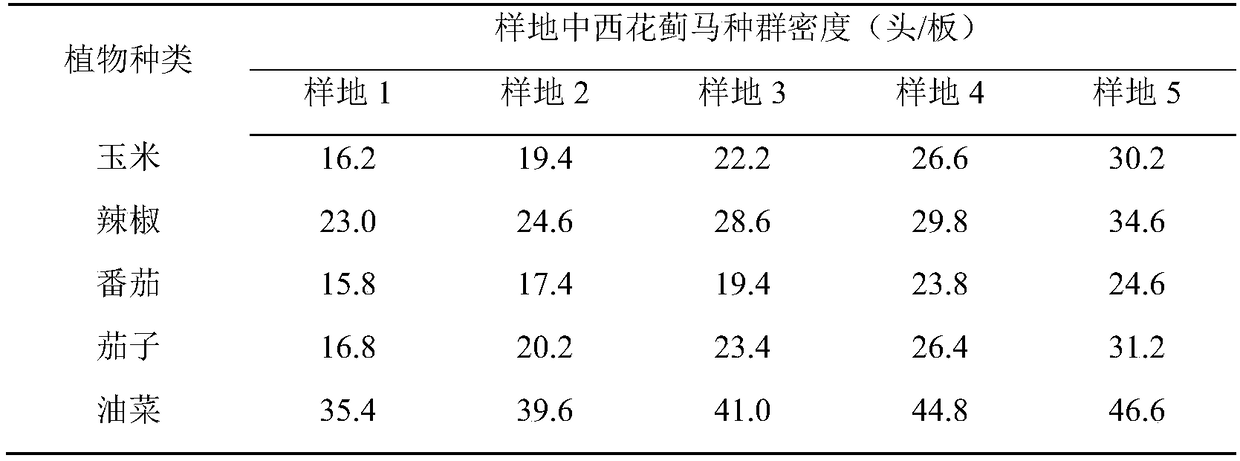

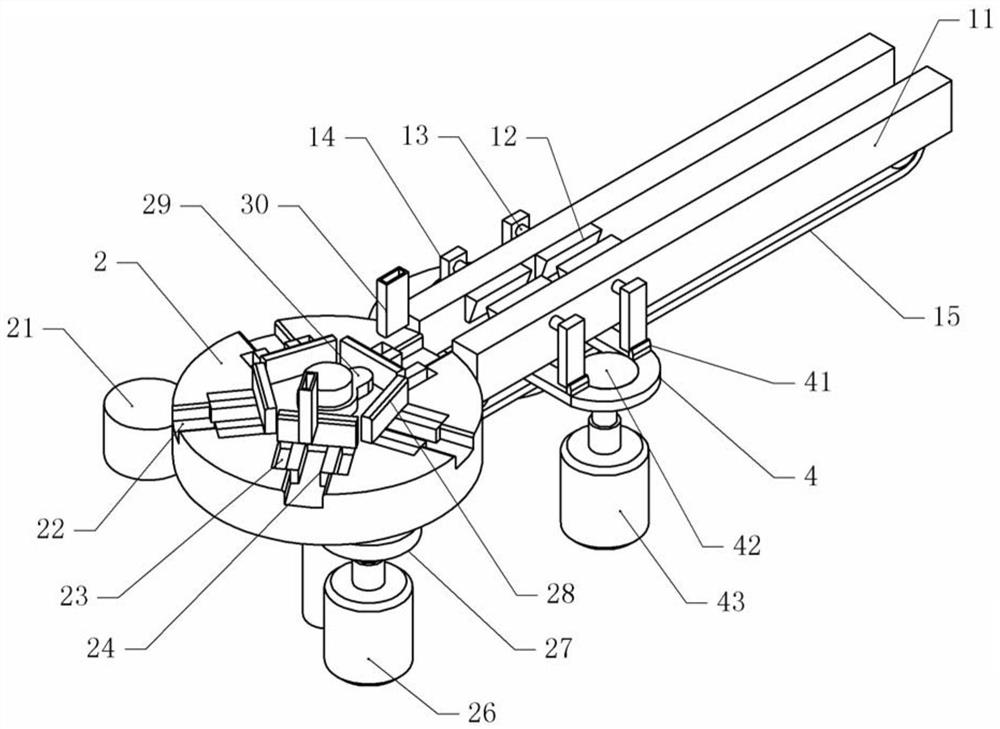

Multifunctional device and method applicable to integration of collection, feeding and long-distance transport of frankliniella occidentalis

PendingCN108887246ADiversified ways to collect western flower thripsReduce escape lossInsect catchers and killersAgainst vector-borne diseasesEngineeringPrism

The invention relates to a multifunctional device and method applicable to integration of collection, feeding and long-distance transport of frankliniella occidentalis. The device comprises a body, atop mesh cover, a bottom mesh plate and a base, the top mesh cover is fixedly connected to an opening of the upper bottom face of the body, the bottom mesh plate is fixedly connected to an opening ofthe lower bottom face of the body, and the base is connected with the opening of the lower bottom face. The body is a hollow prism, and every other lateral side of the prism is provided with a rectangular opening which is fixedly provided with a side wall mesh plate. The upper end of the top mesh cover is open, and the lower end of the top mesh cover is fixedly and hermetically connected with theopening of the upper bottom face. Problems of proneness to escaping, dying and the like of frankliniella occidentalis in a transport and feeding process are solved, and the death rate of frankliniellaoccidentalis is sharply decreased. In addition, a method for sucking frankliniella occidentalis in the device is provided, and suction efficiency is better improved.

Owner:YUNNAN AGRICULTURAL UNIVERSITY

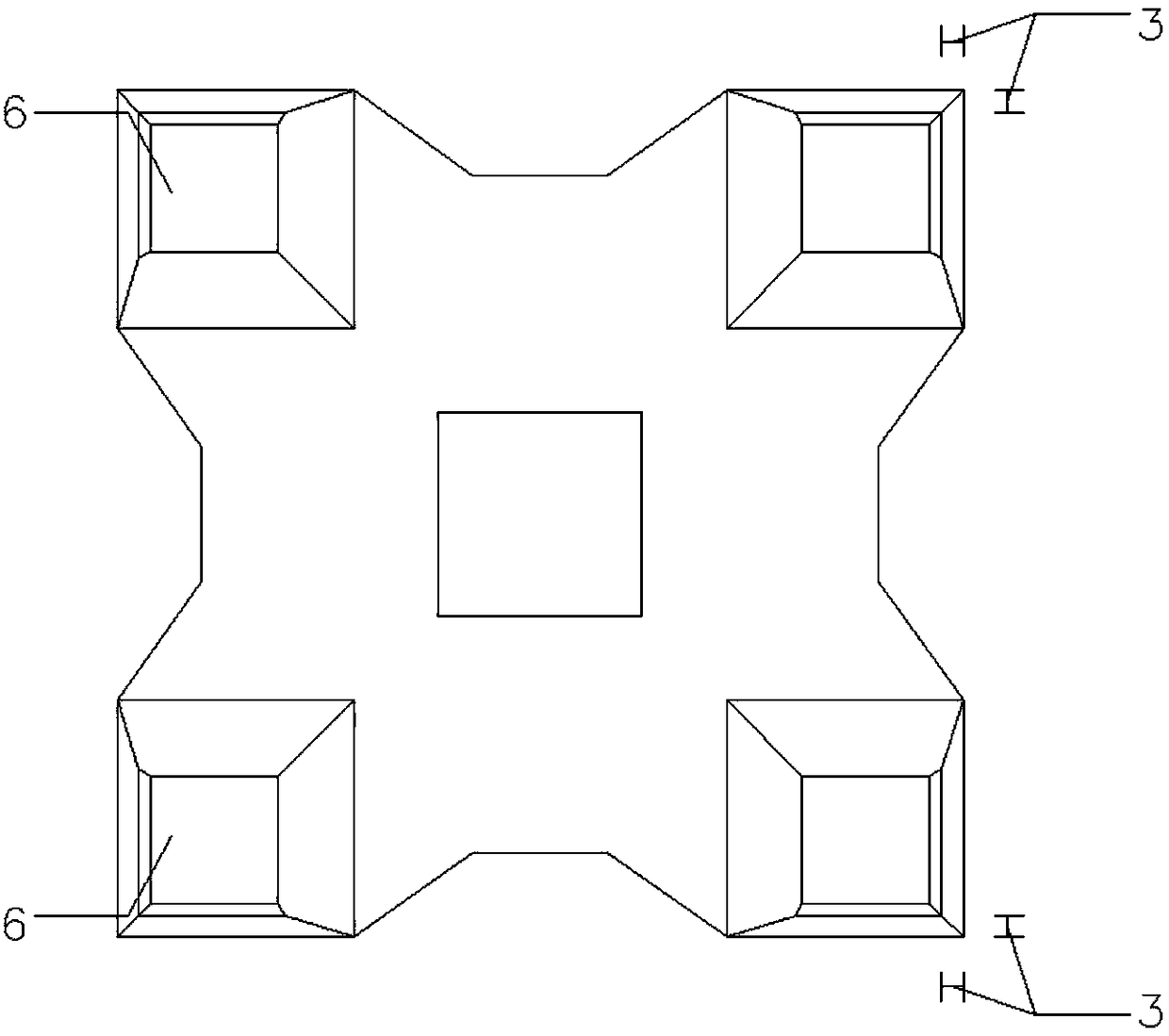

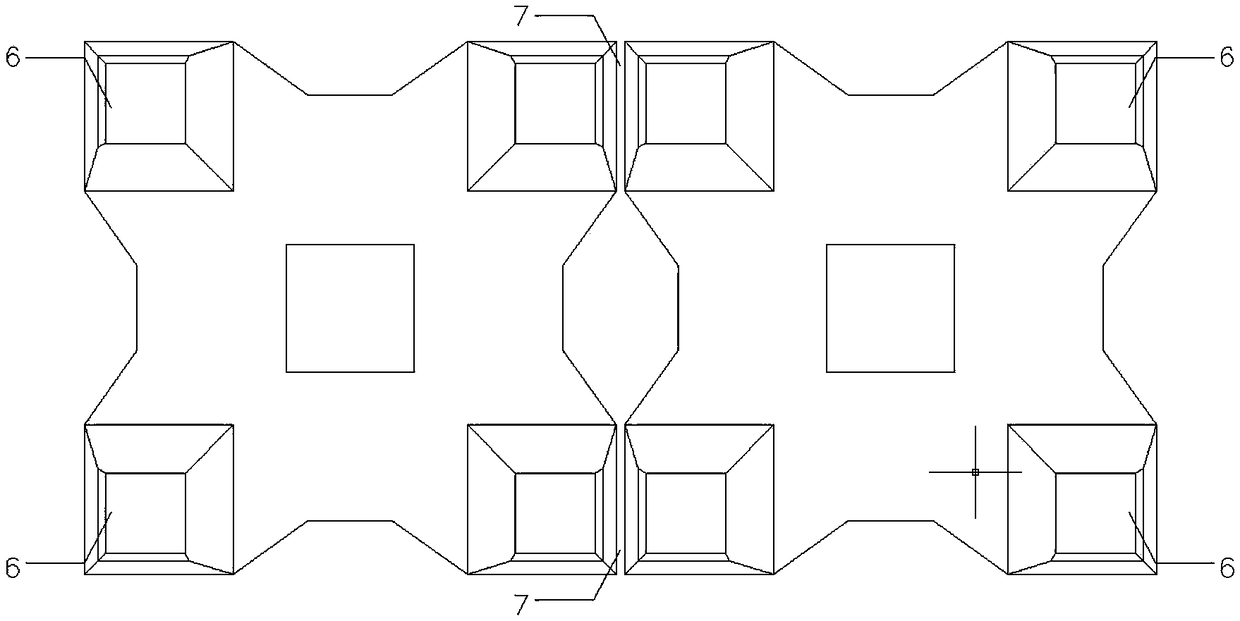

Four-foot hollow block with concaved outer side faces of convex feet and construction method of four-foot hollow block

PendingCN108221865ASolve the problem of easy crushingReduce the chance of crushingCoastlines protectionEngineeringMechanical engineering

Owner:杭州河口水利科技有限公司

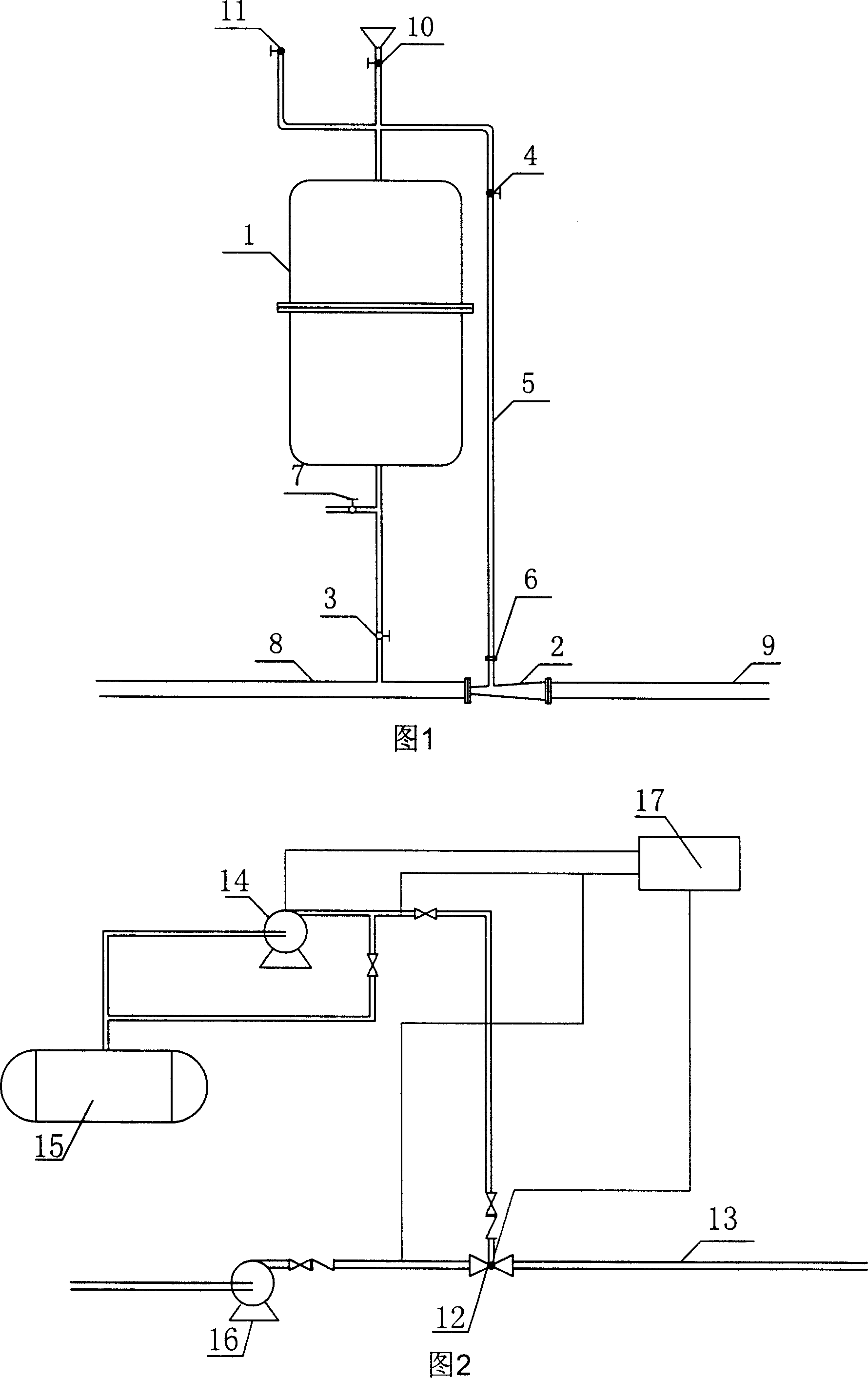

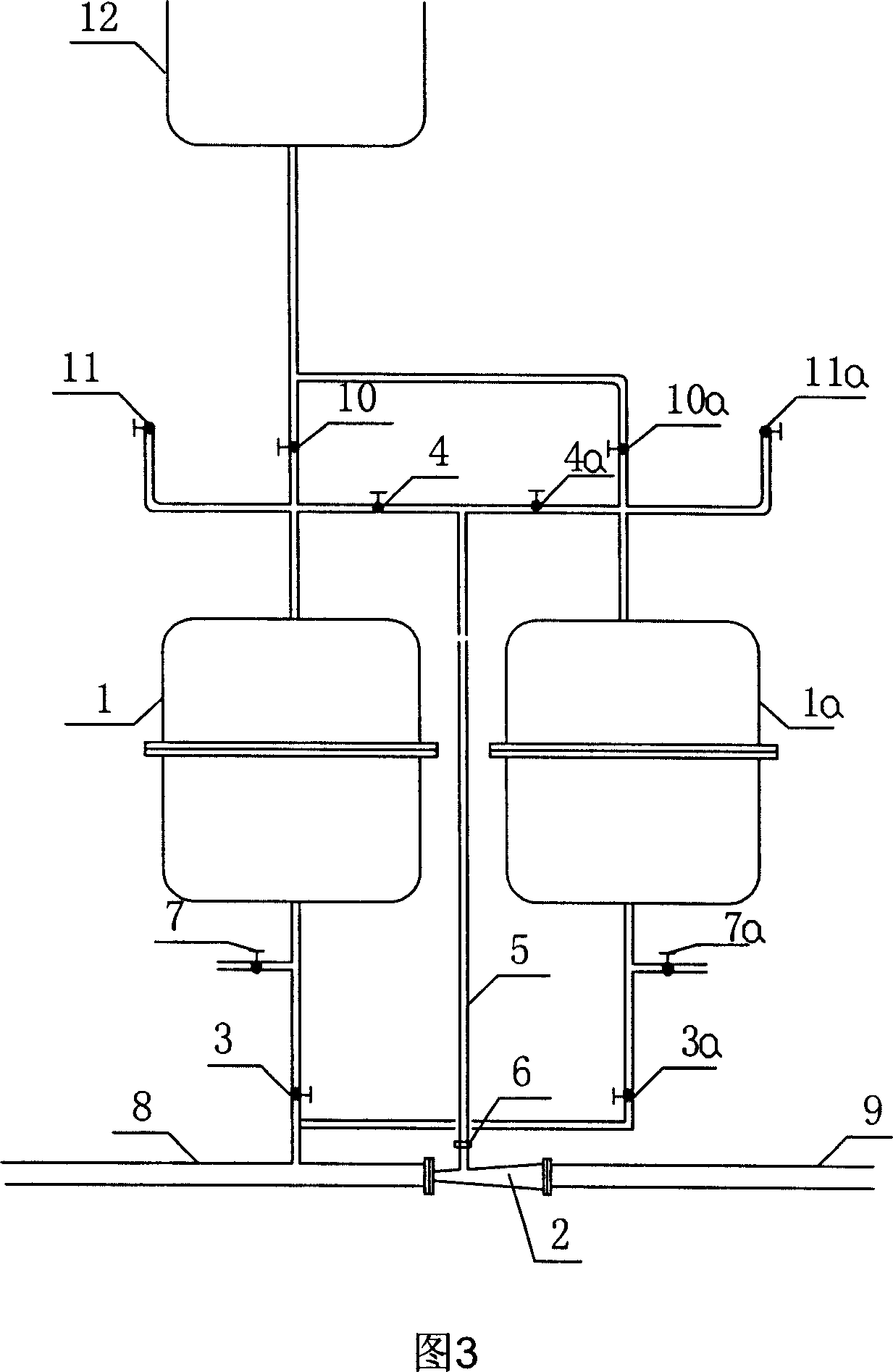

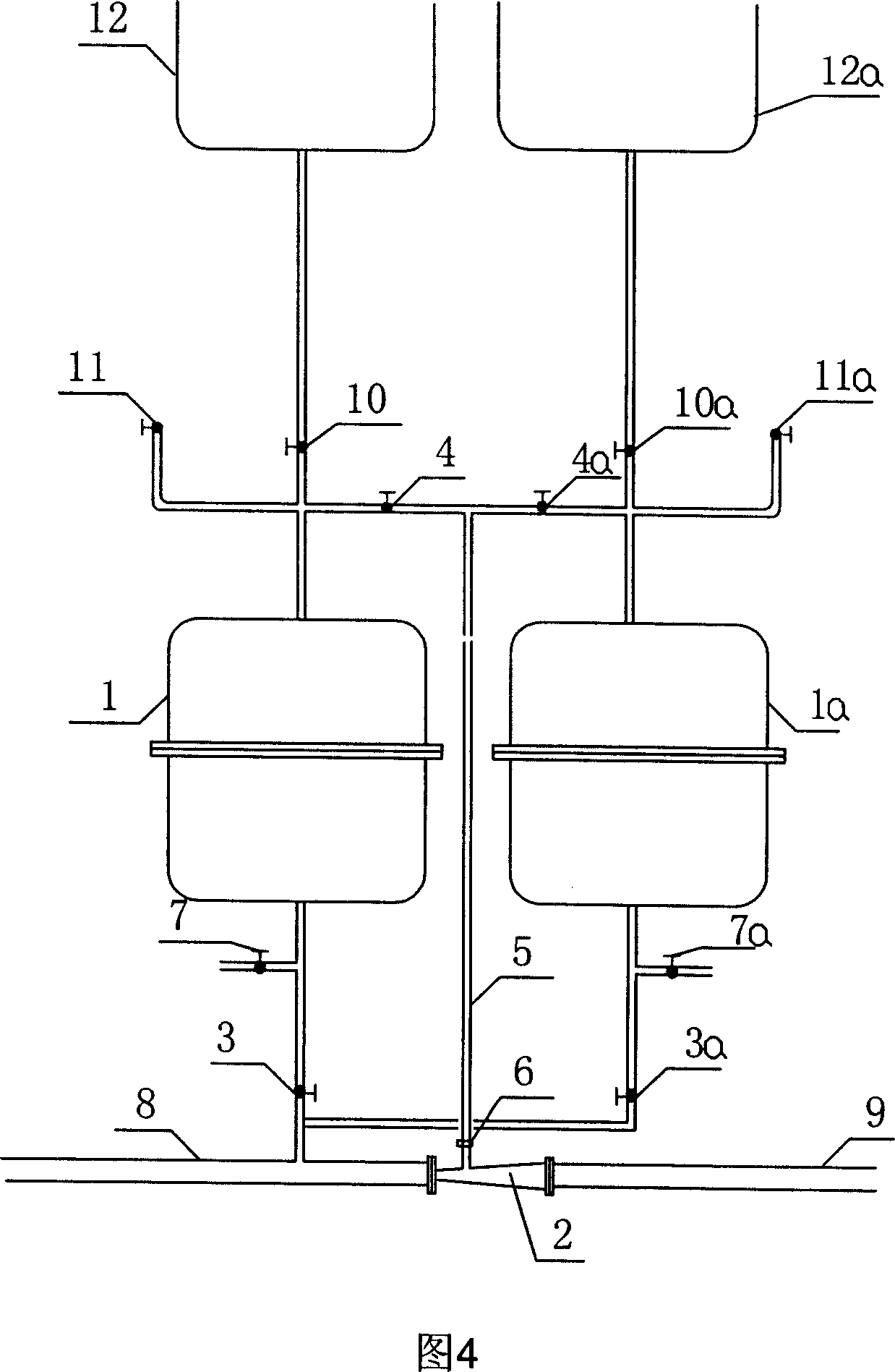

Alternation type foam storing and proportion mixer

InactiveCN101095974AReduced chance of crushingShort design and production cycleFire rescueEngineeringStandardization

The invention relates to an alternating foam storing and proportioning device for foam extinguishing system, comprising at least a foam storing container with normal pressure, at least two pressuring foaming tanks, at least a proportioning implement and control unit so on. The invention adopts at least a foam storing container to injecting foam to at least two pressuring foam tanks alternatively. Foam liquid in at least two pressuring foam tanks is outputted to the foam extinguishing system through at least a proportioning implement alternatively and continuously. The invention is provided with more accurate mixing foam liquid, simple device structure and uneasy break of rubber diaphragm. The key equipment, pressuring foam tank, in the invention can be produced in standardization. Its producing period is short and its cost is decreased greatly.

Owner:SURELAND IND FIRE SAFETY

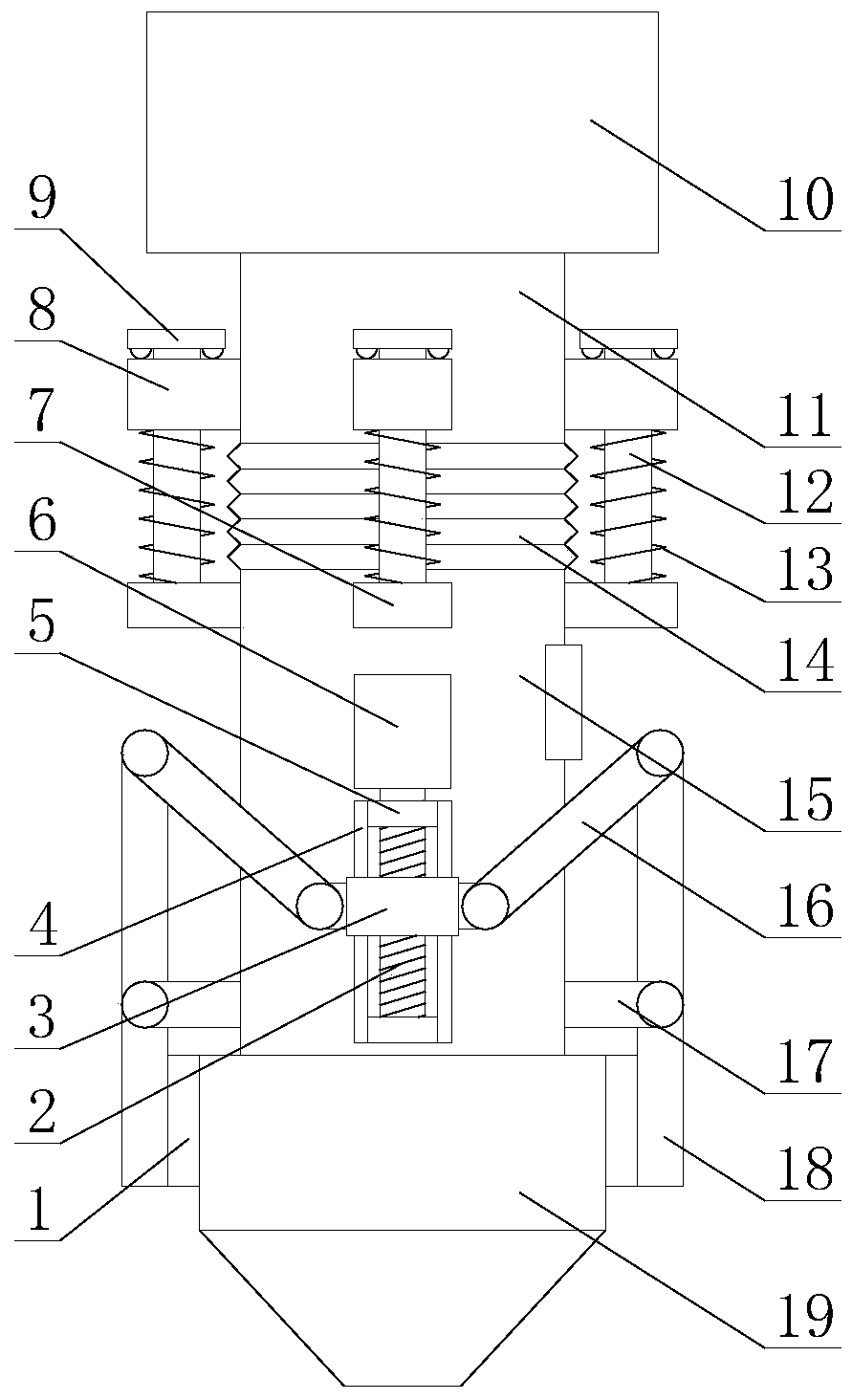

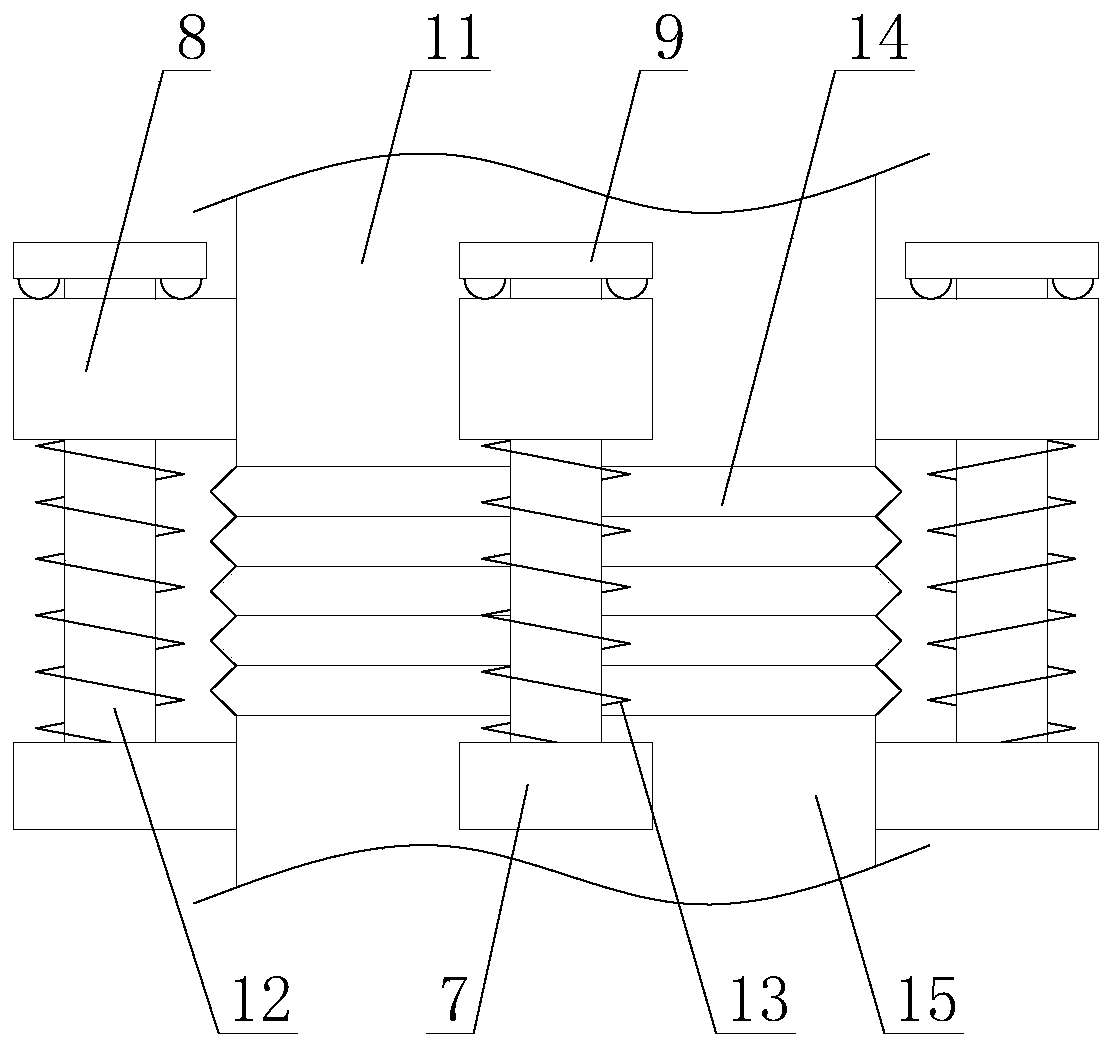

Chip pickup equipment with buffer and reinforcement functions

ActiveCN110098142ARelieve pressureReduced chance of crushingSemiconductor/solid-state device manufacturingConveyor partsEngineeringReinforcement - action

The invention relates to chip pickup equipment with buffer and reinforcement functions, which comprises a vacuum pump and a suction nozzle, and further comprises a buffer mechanism and a reinforcementmechanism, wherein the buffer mechanism includes a first suction pipe, a second suction pipe, a connecting hose and at least two buffer assemblies, each buffer assembly includes a second fixing block, a first fixing block, a connecting rod, a spring and a limit plate, the reinforcement mechanism includes a driving assembly and two fixing assemblies, each fixing assembly includes a first transmission rod, a second transmission rod and a supporting rod, and the driving assembly includes a motor, a lead screw, a driving block and two bearings. In the chip pickup equipment with the buffer and reinforcement functions, the pressure of the suction nuzzle on a chip is reduced under the buffer action of the buffer mechanism, so that the probability of being crushed of the chip is reduced, the practicability of the chip pickup equipment is improved, the probability of detachment of the suction nozzle is reduced under the reinforcement action of the reinforcement mechanism on the suction nozzle,and the practicability of the chip pickup equipment is further improved.

Owner:中义(杭州)医药科技有限公司

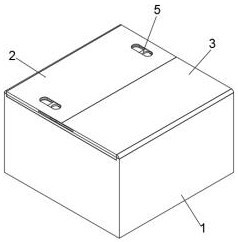

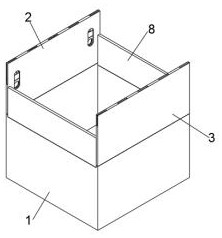

A buried cable branch box

ActiveCN110011265BImprove firm performanceReduced chance of crushingCable junctionsVentilation tubeStructural engineering

The invention discloses a buried cable branch box. The buried cable branch box comprises a branch box main body, a ventilation pipe is arranged at the center position of the top portion of the branchbox main body, the top portion of the ventilation pipe is provided with a canopy, the left side wall of the branch box main body is provided with a mounting port, a bearing groove is inserted at the inner cavity of the mounting port, the right side wall of the bearing groove is provided with a wire through port, and the left side of the bearing groove is provided with a sealing cover; the right side wall of the branch box main body is provided with a wiring port, a fixed seat is arranged at the side wall of the circumference of the wiring port, the right side of the wiring port is sleeved witha connection cover, the side wall of the circumference of the connection cover is provided with a connection seat, the right side wall of the connection cover is fixedly connected with a wiring duct,one end, extended to the inner cavity of the connection cover, of the wiring duct is sleeved with a plug cover, and a rubber sleeve of the inner cavity of the plug cover. The buried cable branch boxis reasonable in structure design, improves the firmness of the buried cable branch box and improves the sealing of the wiring position of the buried cable branch box so as to reduce the influence ofa humid environment on the working elements in the branch box main body.

Owner:南京润浩信息科技有限公司

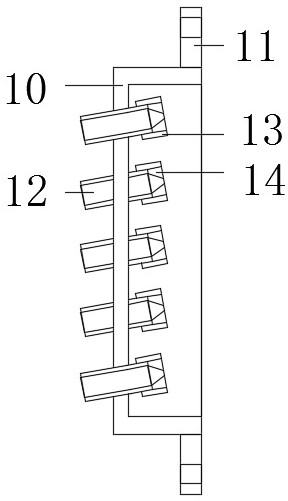

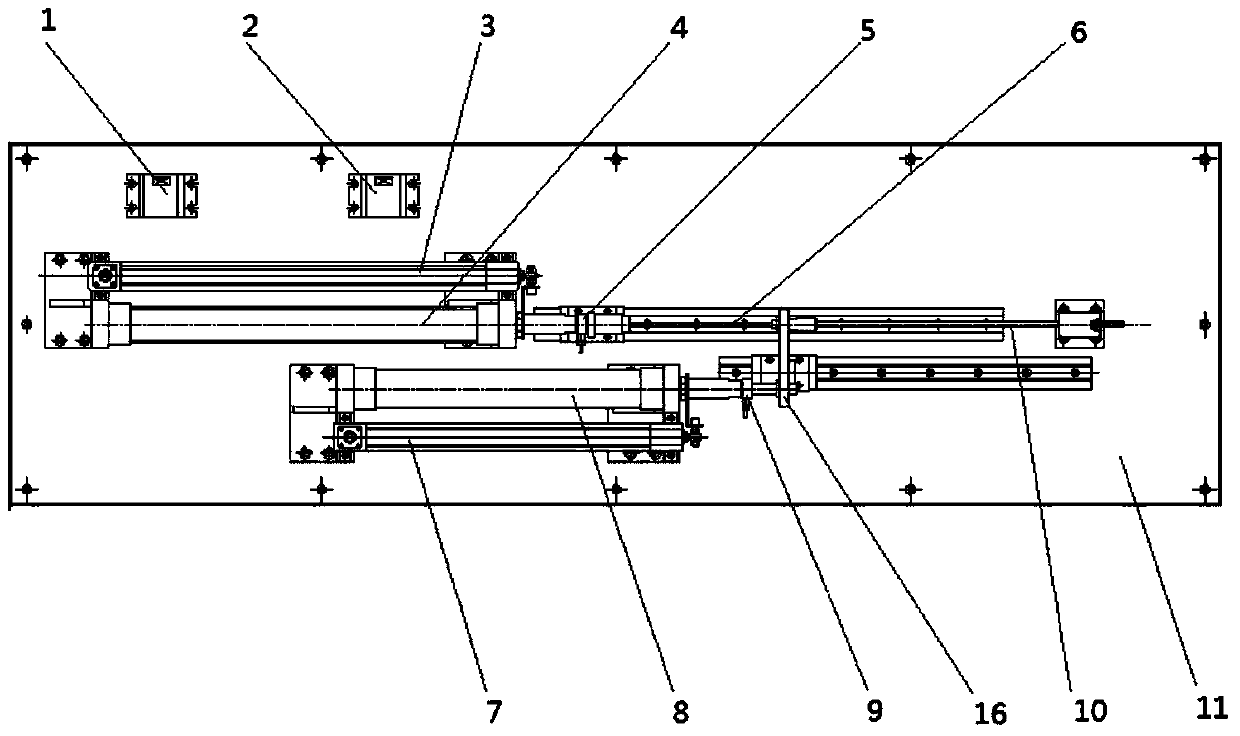

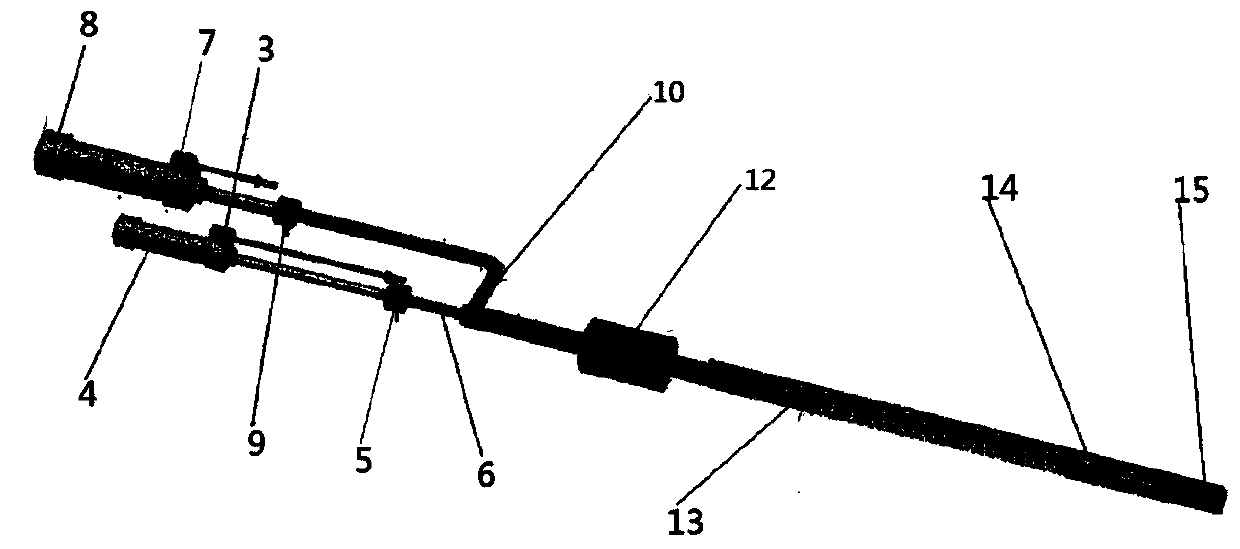

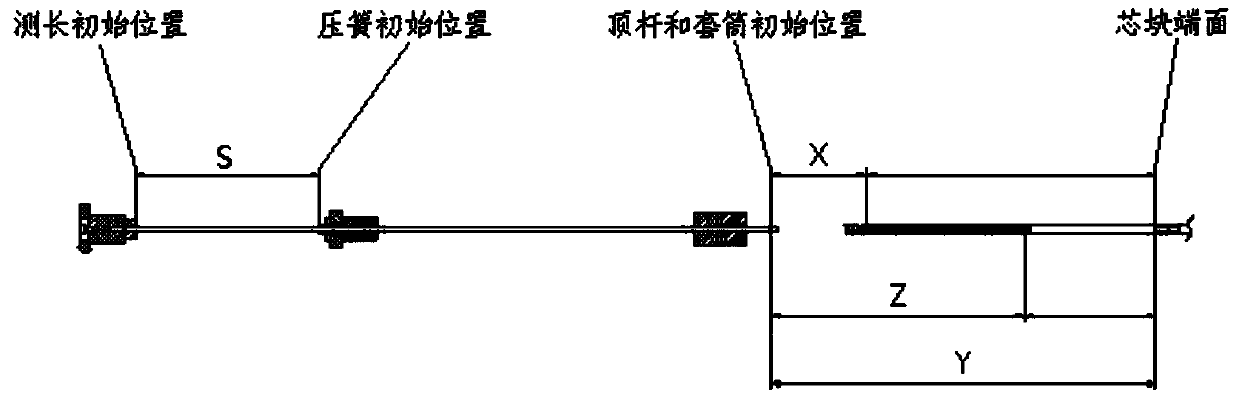

A fuel rod automatic compression spring device

ActiveCN106935300BImprove productivityReduce crushNuclear energy generationReactors manufactureProduction rateManufacturing technology

Owner:中国原子能工业有限公司

Continuous sealing machine transmission

ActiveCN112340126BEasy to put inLess work opening bagsWrapper twisting/gatheringPackaging protectionDrive shaftTransmission belt

The invention relates to the technical field of packaging bag sealing, and discloses a transmission device for a continuous sealing machine. The hollow clamping plate is connected with a negative pressure pump; the operating table is provided with a number of chutes that are evenly distributed along the circumference of the communication groove, and a driving member fixed on the frame is arranged under the operating table, and the output of the driving member is A drive plate is fixed on the shaft, and a drive shaft is fixed on the drive plate; a conveyor belt is arranged on one side of the operation table, guide frames located on both sides of the conveyor belt in the width direction are fixed on the frame, and a seal is fixed on the side of the guide frame close to the operation table mechanism; the sealing mechanism includes a first sealing assembly and a second sealing assembly, a first heater is installed on the first sealing assembly, a second heater is installed on the second sealing assembly, and the height of the first heater is lower than that of the second heater device. The present invention has a simple structure, and can continuously convey and seal the packaging bag.

Owner:CHONGQING QIGE FOOD CO LTD

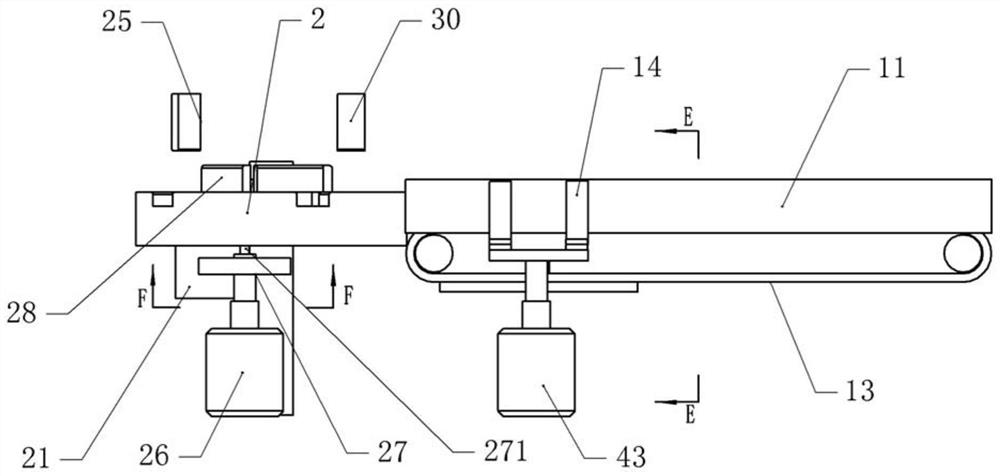

Paperboard line pressing control system and method thereof

PendingCN113733657AIncrease frictionReduce the possibility of crushingBox making operationsPaper-makingManufacturing engineeringControl system

The invention relates to the technical field of carton production and processing, in particular to a paperboard line pressing control system and a method thereof, and the paperboard line pressing control system comprises a speed control module, a paper feeding module and a line pressing module; the line pressing module comprises a first motor and a line pressing wheel, and an output shaft of the first motor is in transmission connection with the line pressing wheel; the paper feeding module comprises a second motor and a paper feeding wheel, and an output shaft of the second motor is in transmission connection with the paper feeding wheel; the speed control module is used for controlling the rotating speeds of the first motor and the second motor; therefore, the paper feeding wheel feeds paper at a constant speed, and the line pressing distance is adjusted by controlling the rotating speed of the line pressing wheel; and according to the paperboard line pressing control system and the method thereof, the line pressing distance is adjusted by controlling the rotating speed of the line pressing wheel, and therefore regulation and control over the interval between two lines are achieved during line pressing.

Owner:重庆安卡自动化工程有限公司

A chip pickup device with buffer and reinforcement functions

ActiveCN110098142BRelieve pressureReduced chance of crushingSemiconductor/solid-state device manufacturingConveyor partsElectric machineryStructural engineering

The invention relates to a chip pickup device with buffer and reinforcement functions, which includes a vacuum pump and a suction nozzle, and also includes a buffer mechanism and a reinforcement mechanism. The buffer mechanism includes a first suction pipe, a second suction pipe, a connecting hose and at least two buffer Assemblies, the buffer assembly includes a second fixed block, a first fixed block, a connecting rod, a spring and a limit plate, the reinforcement mechanism includes a drive assembly and two fixed assemblies, and the fixed assembly includes a first transmission rod, a second Two transmission rods and support rods, the drive assembly includes a motor, a screw rod, a drive block and two bearings. In the chip pickup device with buffer and reinforcement functions, under the buffer effect of the buffer mechanism, the impact of the suction nozzle on the chip is reduced. The pressure of the chip reduces the probability of the chip being crushed and improves the practicability of the chip pick-up equipment. Through the reinforcing effect of the reinforcement mechanism on the suction nozzle, the probability of the suction nozzle detaching is reduced, and the practicability of the chip pick-up equipment is further improved. sex.

Owner:中义(杭州)医药科技有限公司

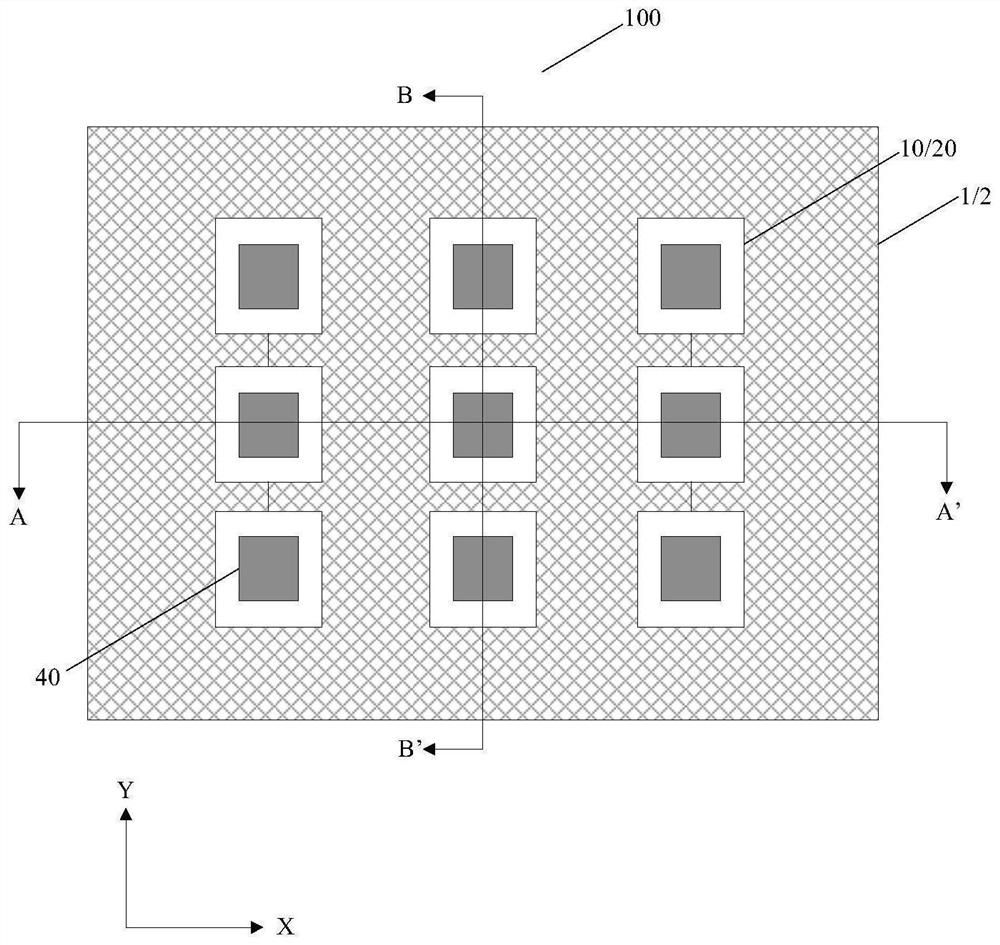

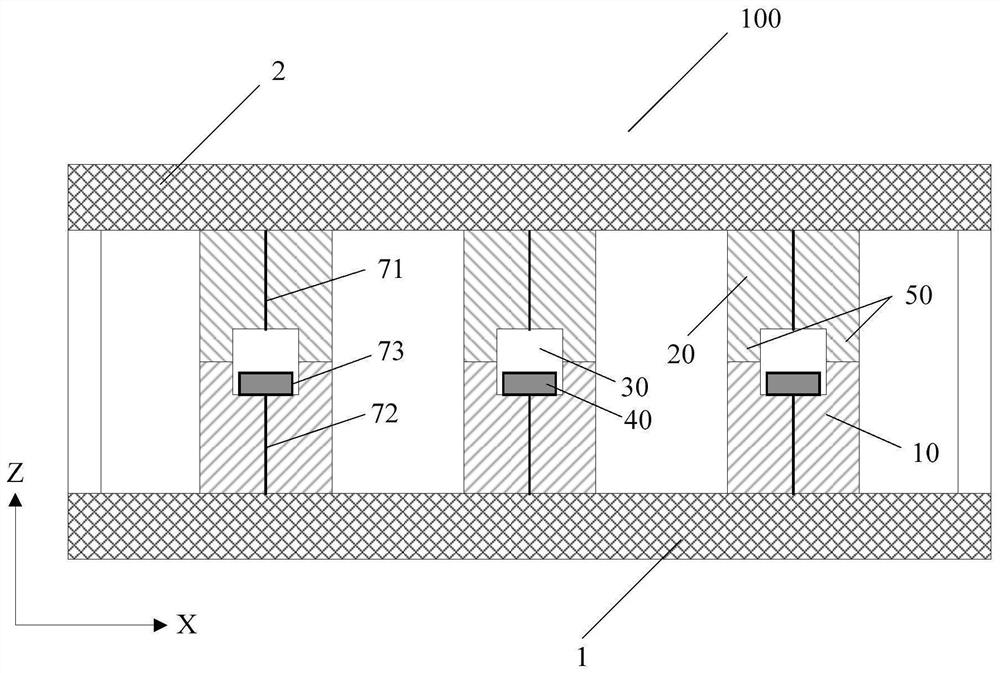

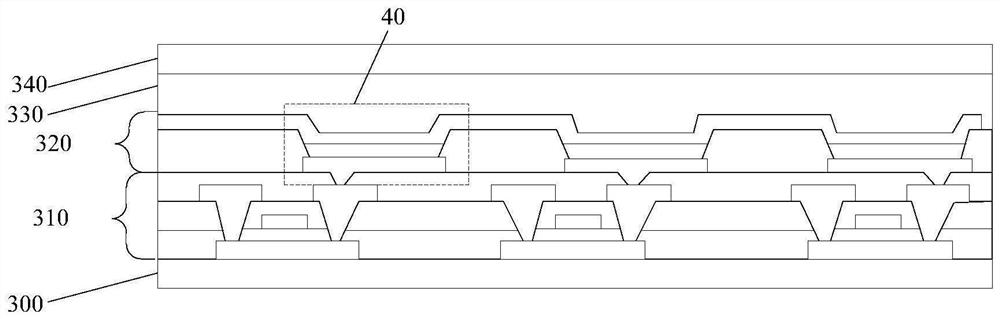

A display panel and display device

ActiveCN113410260BSqueeze freeReduced chance of crushingSolid-state devicesIdentification meansDisplay deviceMechanical engineering

The present application provides a display panel and a display device, comprising: a first stretchable substrate and a second stretchable substrate arranged oppositely; a plurality of first support columns are arranged on the first stretchable substrate, and the second stretchable substrate A plurality of second support columns are arranged on the extension base plate, the first support columns and the second support columns are in one-to-one correspondence, and there is a cavity between the first support columns and the second support columns in one-to-one correspondence; A light-emitting device is provided, and the length of the light-emitting device is smaller than that of the cavity. In the display panel provided by the embodiments of the present application, the first support column and the second support column in the area where the light emitting device is located are used to support the display panel when the display device is pressed, and the first support column and the second support column are formed between the first support column and the second support column. There is a cavity, and the size of the cavity is larger than the size of the light emitting device, which further ensures that the probability of the light emitting device being squeezed is reduced, thereby reducing the probability of damage to the light emitting device during the folding or stretching of the display panel.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

Collection method of live Antarctic krill samples

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

A rotary graphene peeling device, graphene production system and production method

The invention discloses a rotary graphene stripping device including a rotary cylinder body; a top cover is arranged above the rotary cylinder body, a bottom cover is arranged below the rotary cylinder body, the top of the top cover is provided with a feed inlet, the bottom of the bottom cover is provided with a discharge port, and the feed inlet is communicated with the interior of the rotary cylinder body; the outer side of the rotary cylinder body is provided with a first motor, and is used for driving the rotary cylinder body to horizontally rotate; the rotary cylinder body is also internally provided with an inner cylinder, and a second motor used for driving the inner cylinder to horizontally rotate in a direction opposite to the rotating direction of the rotary cylinder body is arranged below the rotary cylinder body; the upper part of the inner cylinder is shrunk in a certain angle, and a material storage space is left between the upper part of the inner cylinder and the upper part of the rotary cylinder body; the lower part of the inner cylinder and the lower part of the rotary cylinder body are in clearance fit to be used for grinding graphite sheets, and a clearance between the lower part of the inner cylinder and the lower part of the rotary cylinder body is successively decreased downward along the axial direction of the rotary cylinder body. The rotary graphene stripping device can achieve successful stripping of graphene. The invention also relates to a graphene production system containing the rotary graphene stripping device and a graphene production method.

Owner:江苏碳谷二维世界科技有限公司

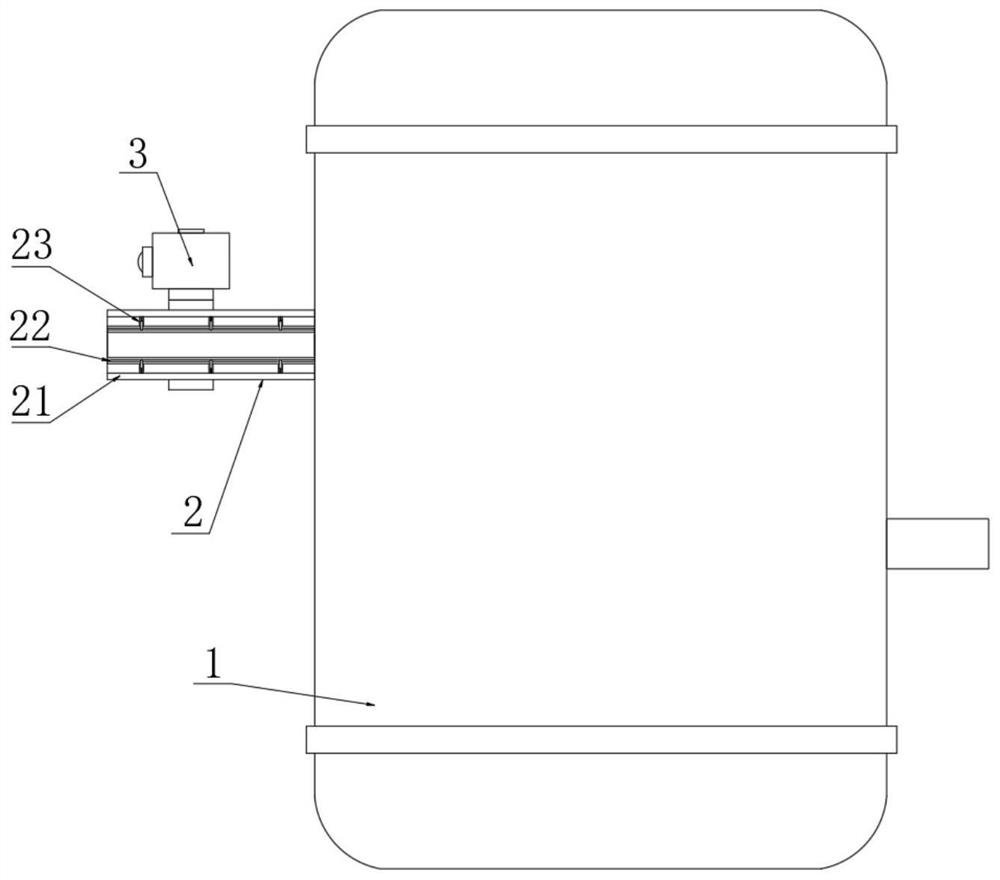

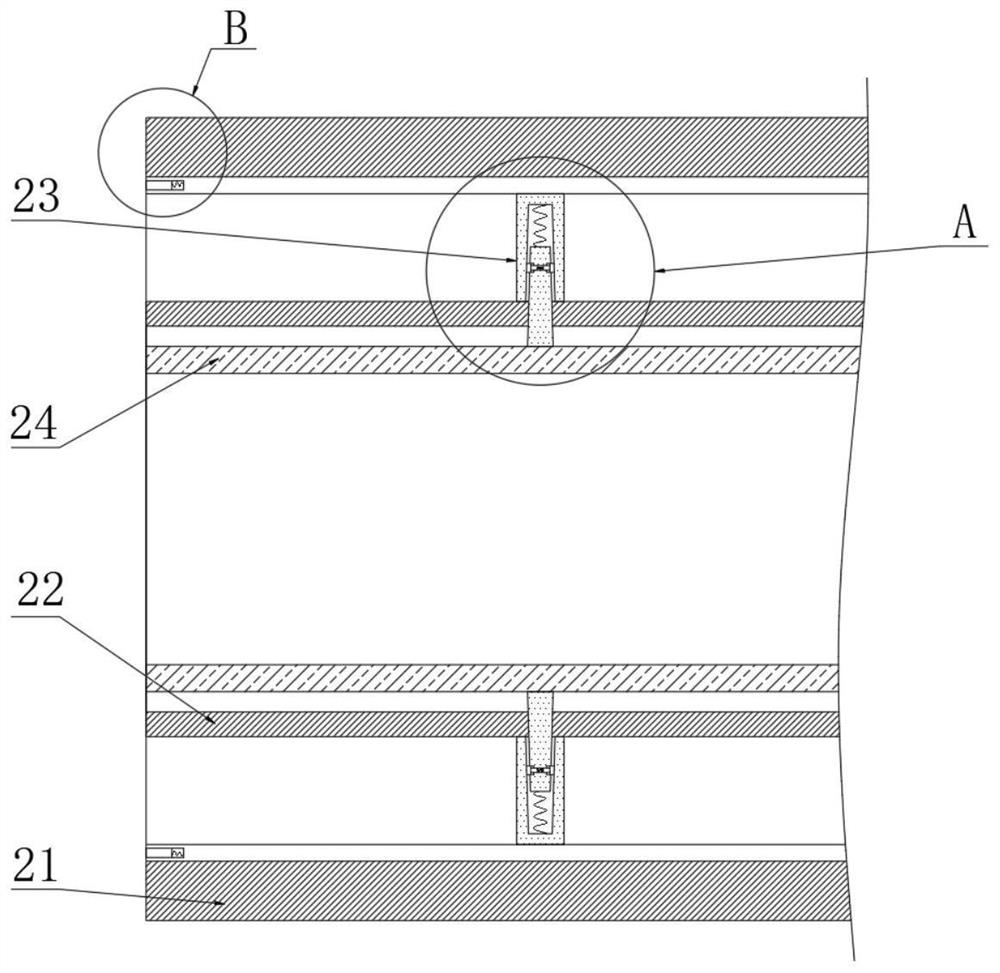

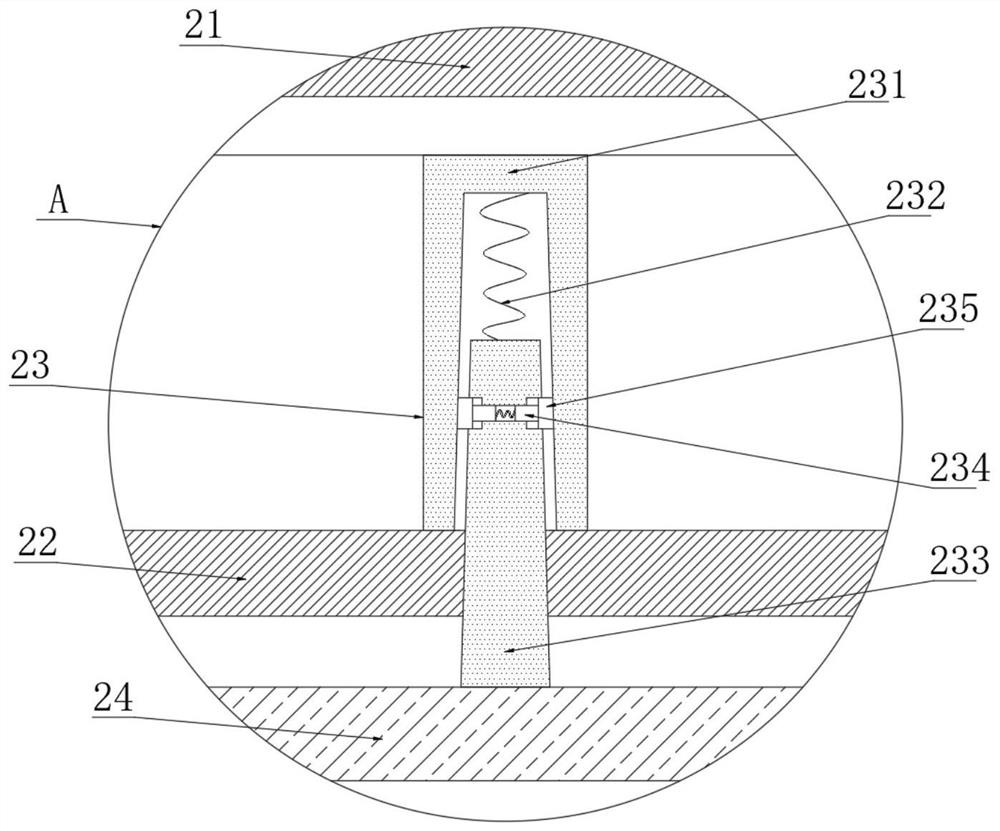

Magnetic resin water purification equipment

PendingCN109019750AReduce crackingReduced chance of crushingWater/sewage treatment by sorptionSpray nozzleEngineering

The invention discloses magnetic resin water purification equipment, which comprises a big tube body, wherein an exchange tube body is arranged under the big tube body; anfirstexchange tube body firstchamber is arranged above the exchange tube body; ansecond exchange tube body second chamber covers outside the first exchange tube body first chamber; a second chamber lower opening reverse skirt plate is arranged at the lower end of the second exchange tube secondbody chamber; the big tube body is divided into a separation region and a clean water region; a water collecting groove is arranged on the top of the big tube body; a water outlet pipe is arranged at the outer side of the big tube body; the water outlet pipe is communicated with the water collecting groove; a water inlet pipe is arranged at the bottom of the big tube body; the water inlet pipe is communicated with the exchange tube body through a cow head double-horn type spray nozzle assembly and the exchange tube body; a magnetic resin adding pipe is arranged on the water inlet pipe; a magnetic resin catching device is arranged under the big tube body; the bottom end of the big tube body is provided with an overhaul exhaust pipe; a magnetic resin unplugging device is arranged under the big tube body; the upper end of the exchange tube body first chamber is communicated with the lower end of the firstexchange tube bodyfirst chamber; the upper end of the first exchange tube body first chamber is communicated with the upper end of the second exchange tube bodysecond chamber. The magnetic resin water purification equipment disclosed by the invention has the advantages that the structure is simple;, the exchange effect is good;, the operation cost is lowandavoids the complex and inefficientstructuresexisting in the prior art.

Owner:江苏神洲环境工程有限公司

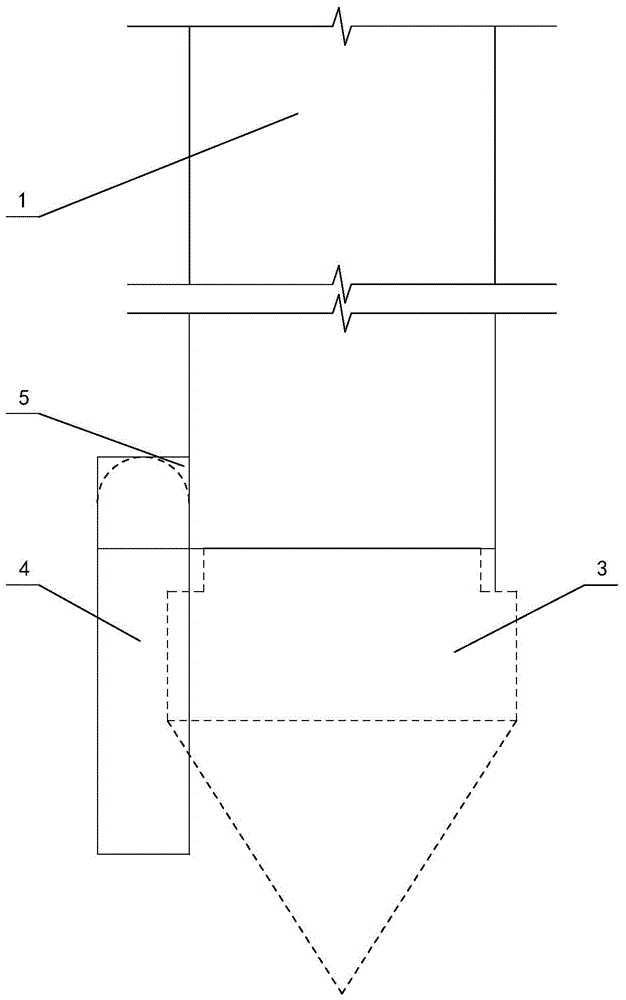

Piling anti-jamming sinking pipe of cast-in-situ pile and its construction technology

ActiveCN104790389BEnhance the rationality of the forceIncrease the bearing areaBulkheads/pilesReinforced concreteRebar

The invention discloses a pile-toe-blocking prevention immersed tube of a filling pile and a construction technology thereof. The pile-toe-blocking prevention immersed tube comprises an immersed tube body (1), a reinforced concrete pile toe (3) and a steel clamping strip (4). A radial through open groove (2) is formed in the bottom end of the immersed tube body (1), the steel clamping strip (4) is clamped into the open groove (2), the lower side face of the steel clamping strip (4) makes contact with the upper end face of the reinforcement concrete pile toe (3), and one end of the steel clamping strip (4) is connected with the immersed tube body (1) through a connecting assembly in the vertical direction in a rotating mode. The construction technology includes the steps of assembling the connecting assembly, welding the connecting assembly to the immersed tube body, pressing the pile and pulling out the tube. By the adoption of the structure and the construction technology, because the connecting assembly and the steel clamping strip are easy to assemble, and can be repeatedly used, on one hand, the construction cost can be greatly lowered, on the other hand, assembling and disassembling are convenient, construction requirements are greatly lowered, and then the construction efficiency is improved.

Owner:NINGBO HOUSING CONSTR GRP

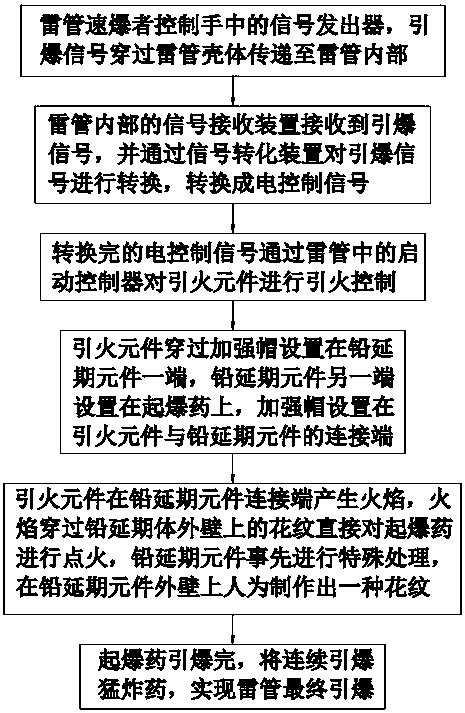

Method for fast detonation of detonator

The invention discloses a method for fast detonation of a detonator and relates to the technical field of detonation of detonators. A person for fast detonating the detonator controls a signal generator in a hand to detonate a signal to penetrate through a detonator casing to be transmitted to the inside of the detonator; a signal receiving device in the detonator receives the detonation signal, and a signal transformation device is used for transforming the detonation signal into an electric control signal; the electric control signal completing transformation performs fire-leading control ona fire-leading element through a start controller in the detonator; the fire-leading element penetrates through a reinforcing cap and is arranged at one end of a lead extension element, the other endof the lead extension element is arranged on initiating explosive, the reinforcing cap is arranged at the connecting end of the fire-leading element and the lead extension element. With the adoptionof the technical scheme, the method has the benefits as follows: the method is simple, convenient to operate, high in use value and easy to popularize, the probability of pressed explosion is reduced,the production efficiency is improved, the detonator can be detonated in super-short time, the detonation time is shortened, the detonation process is safe and accidents are reduced.

Owner:陈卫

An anti-extrusion storage device for PLA straw transportation

ActiveCN113697234BImproved anti-extrusion performanceReduce chance of crushingBio-packagingRigid containersProcess engineeringElectrical and Electronics engineering

The invention discloses an anti-extrusion storage device for transporting PLA straws, which belongs to the field of storage devices, and comprises a storage box main body. A No. 1 protective box cover and a No. 2 protective box cover are arranged on the storage box main body. The No. 1 protection box cover and a No. 2 protection box cover are left-right symmetrically arranged, and a strengthening device is installed inside the top of the No. 1 protection box cover. Swipe right. An anti-extrusion storage device for PLA straw transportation according to the present invention belongs to the field of storage devices. By setting a movable reinforcement device, the edges of the No. 1 protective box cover and the No. 2 protective box cover can be strengthened. The anti-extrusion performance of the edges of the No. 1 protective box cover and the No. 2 protective box cover is improved, thereby reducing the chance of the No. 1 protective box cover and the No. 2 protective box cover being pressed into the main body of the storage box during transportation. Ultimately reduces the chance of straws being squashed and reduces resource costs.

Owner:苏州环诺新材料科技有限公司

Bottle reject mechanism of online visual inspection robot for visible foreign matters in bottled liquid

ActiveCN101767096BReliable separationReduce impactOptically investigating flaws/contaminationSortingForeign matterBall bearing

The invention discloses a bottle reject mechanism of an online visual inspection robot for visible foreign matters in bottled liquid, which is characterized in that the bottle reject mechanism comprises a rotatable cam, a swing link seat, a C-shaped long swing link, a C-shaped short swing link and a clutch mechanism, wherein the C-shaped long swing link and the C-shaped short swing link are both arranged on the swing link seat; the C-shaped long swing link is embedded in a groove of the rotatable cam through a deep groove ball bearing so as to lead the rotatable cam to drive the C-shaped longswing link to do periodic swinging along with the rotation of the rotatable cam; the free end of the C-shaped short swing link is provided with a push plate for rejecting a bottle body; and the clutch mechanism comprises a cylindrical pin arranged on the C-shaped long swing link, a frame-type electromagnet arranged on the C-shaped short swing link, a limit supporting block, a claw and a clutch plate. The bottle reject mechanism of the online visual inspection robot for the visible foreign matters in the bottled liquid can effectively realize the separation of accepted and unaccepted products by the visual inspection robot and dramatically reduces the possibility of extruded and blown bottles at the bottle outlet.

Owner:HUNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com