Patents

Literature

2352results about How to "Improve firm performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

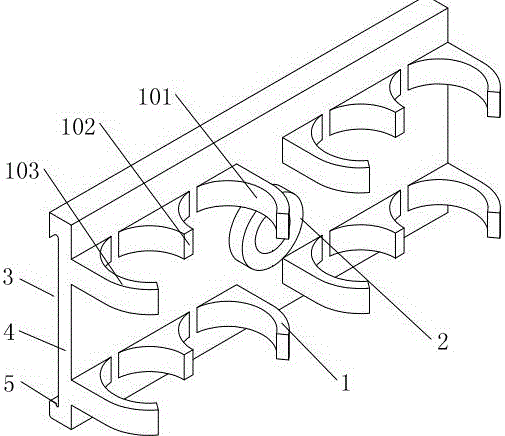

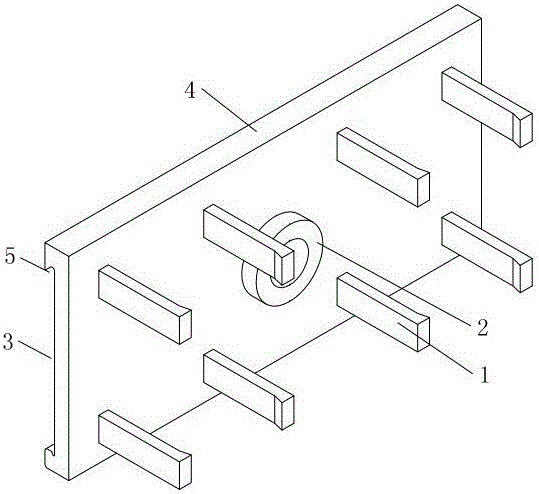

Novel inductor and manufacturing method thereof

InactiveCN103915236AImprove firm performanceReduction of post-processing proceduresVolume/mass flow measurementTransformers/inductances coils/windings/connectionsEngineeringInductor

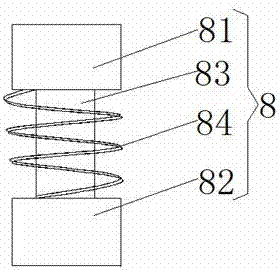

The invention discloses a novel inductor. The novel inductor is characterized by comprising an inset inner core, an electrode and an outer wrapping layer, the inset inner core comprises an enameled coil and a mandrel, and the inset inner core and the electrode are buried in the center of the outer wrapping layer. The novel inductor has the advantages that manufacturability and performance are improved.

Owner:深圳市科达嘉电子有限公司

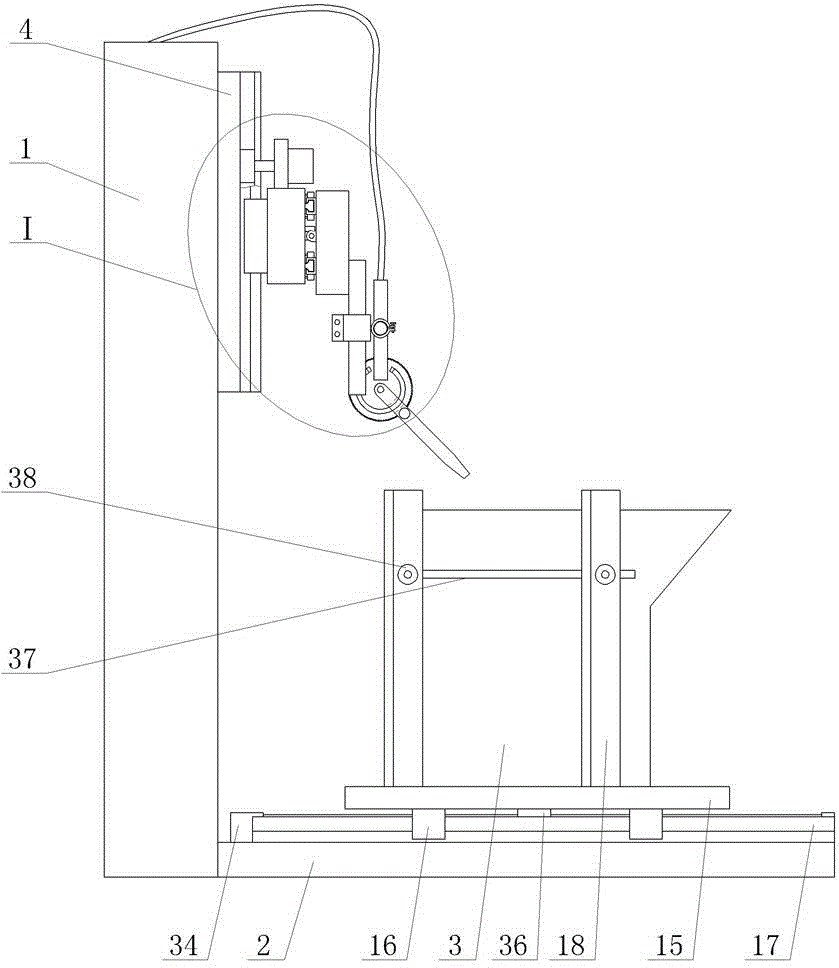

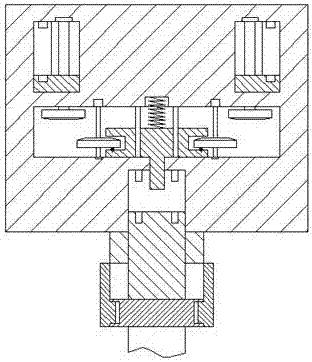

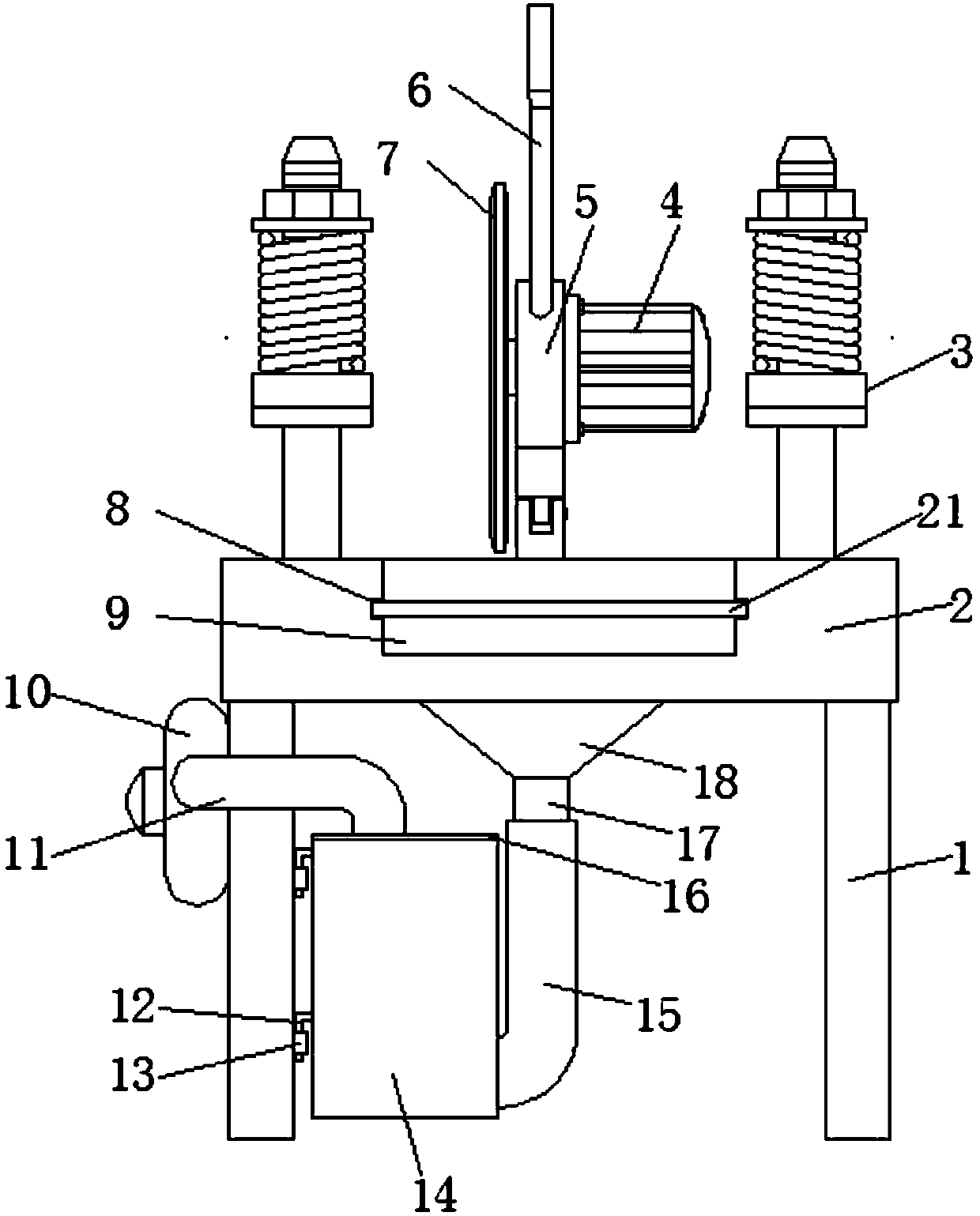

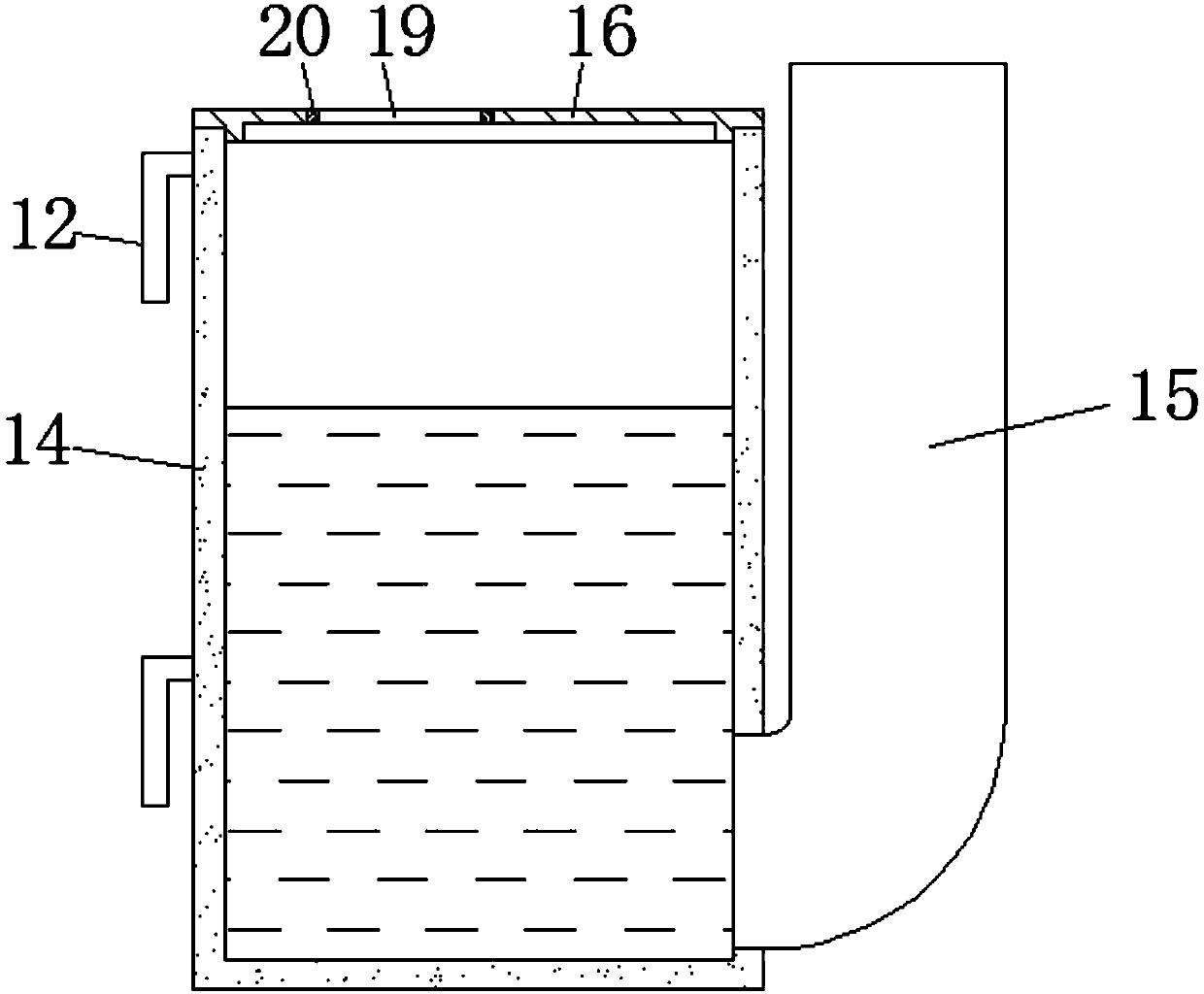

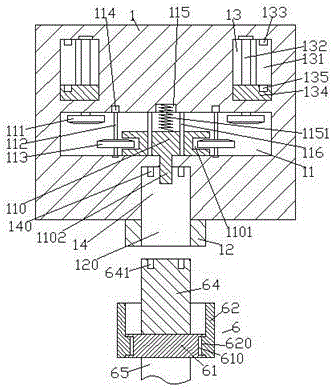

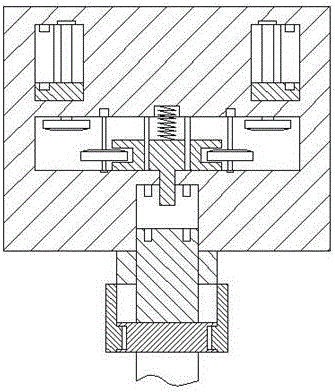

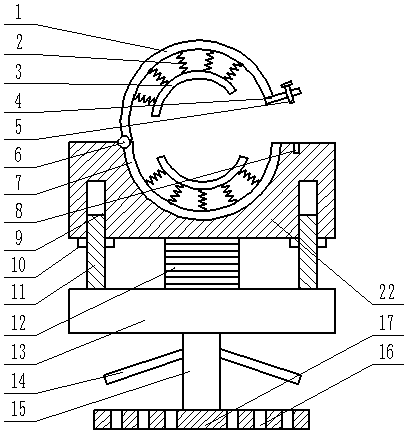

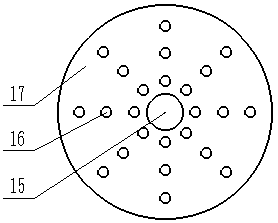

Automatic two-gun welding for heating stove

InactiveCN105436765AImprove firmnessImprove welding effectWelding/cutting auxillary devicesAuxillary welding devicesStart timeEngineering

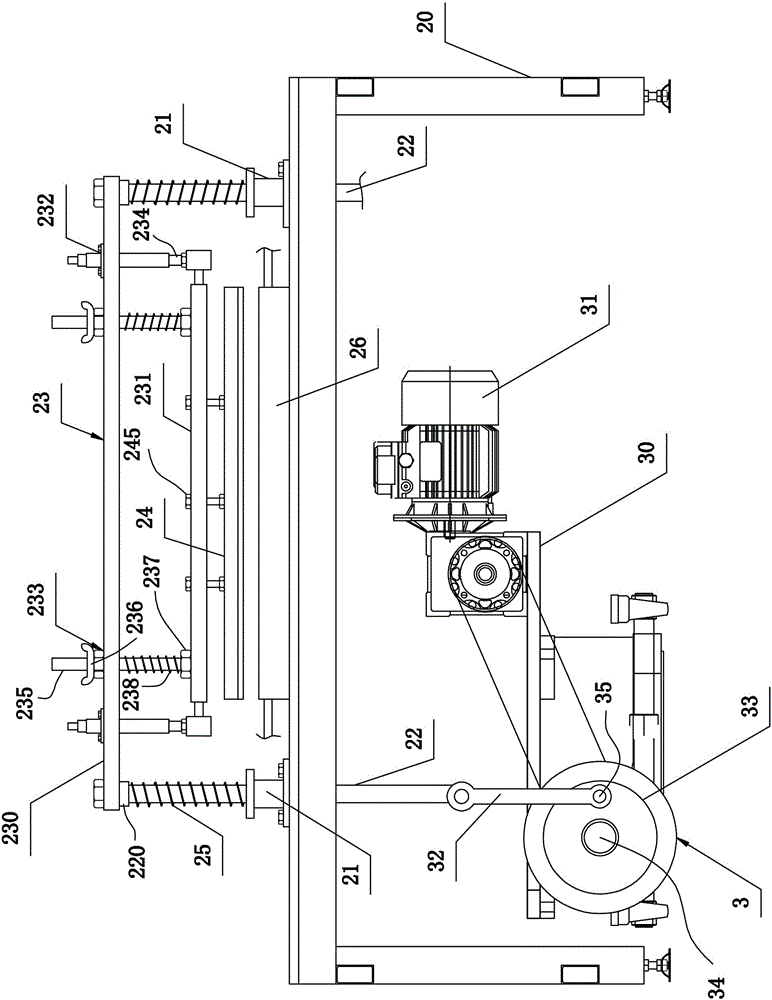

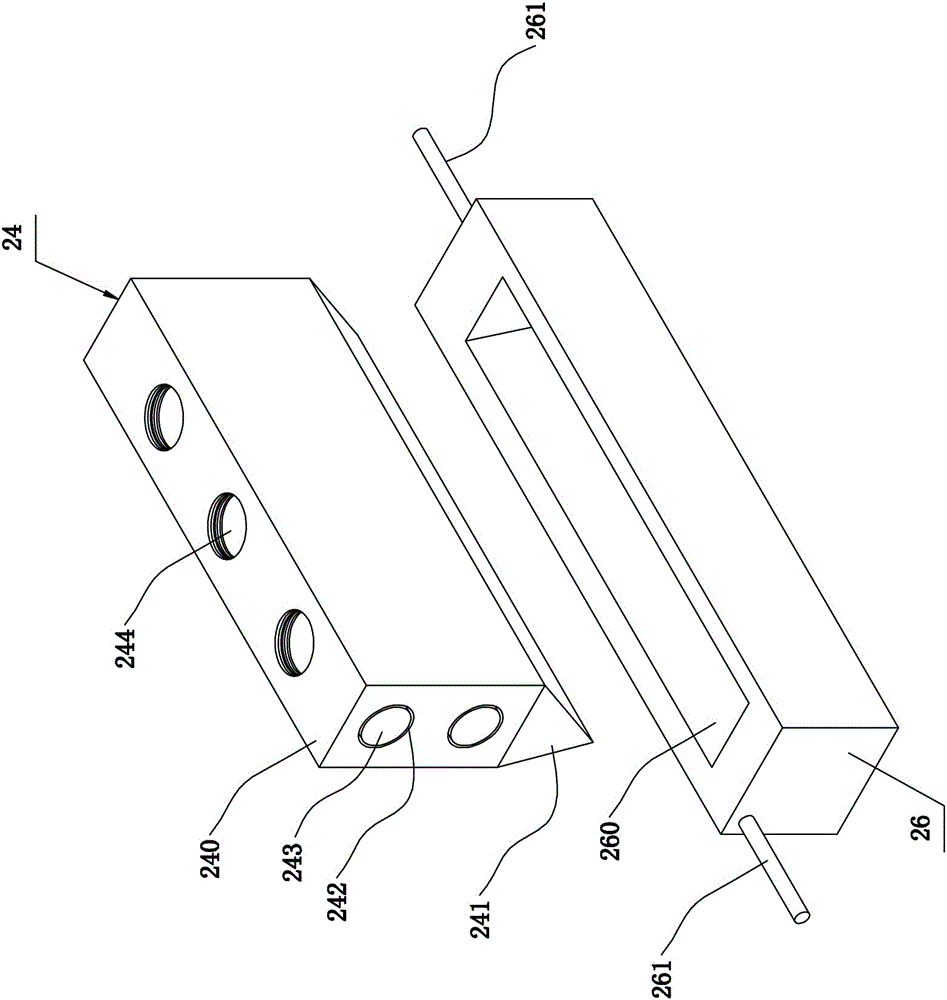

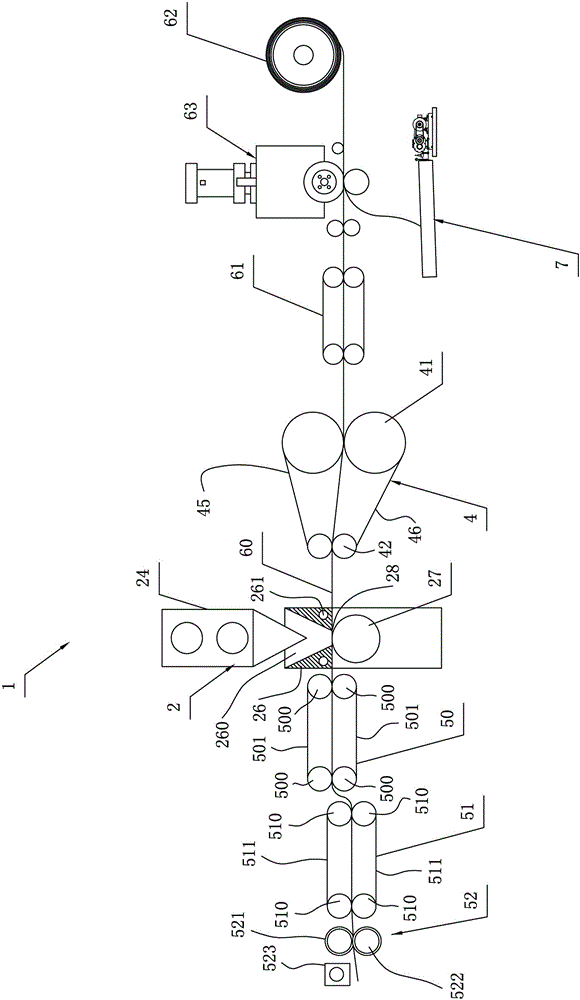

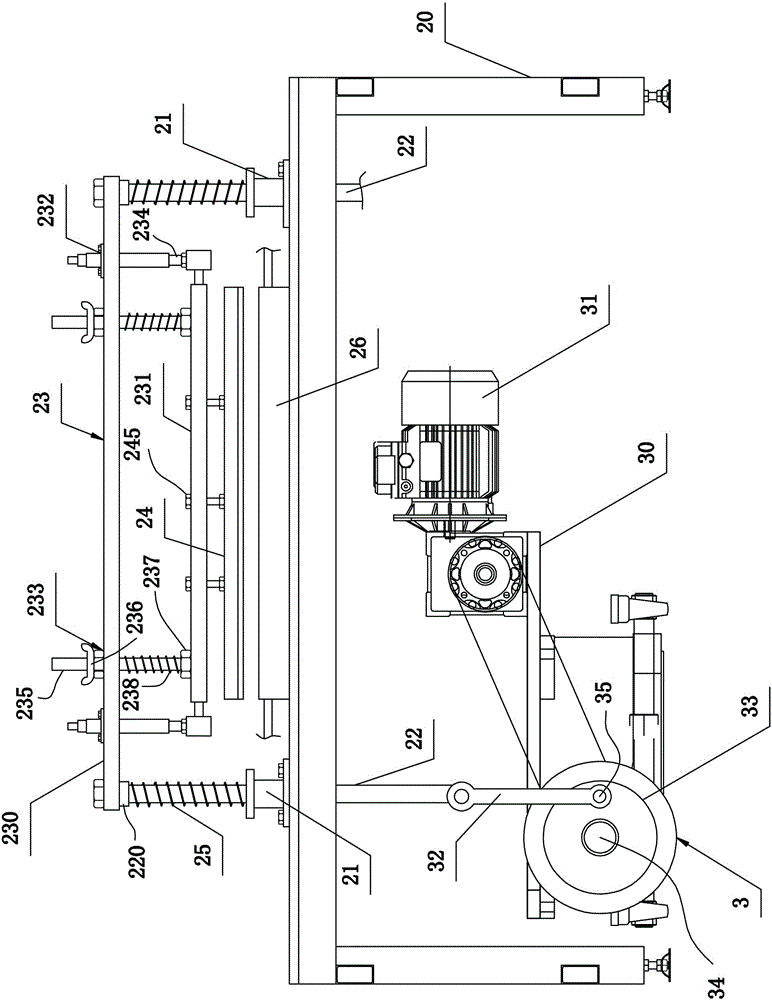

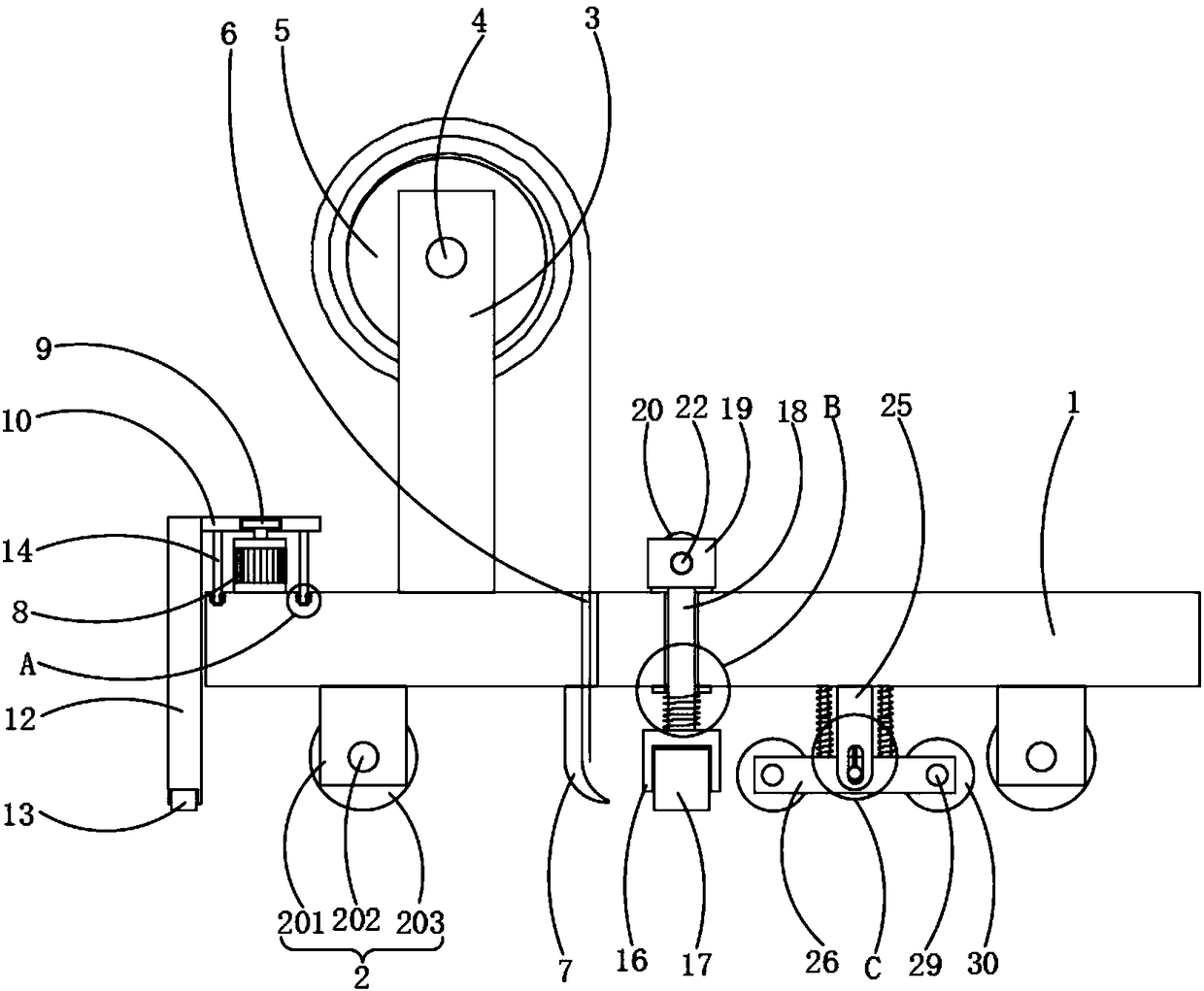

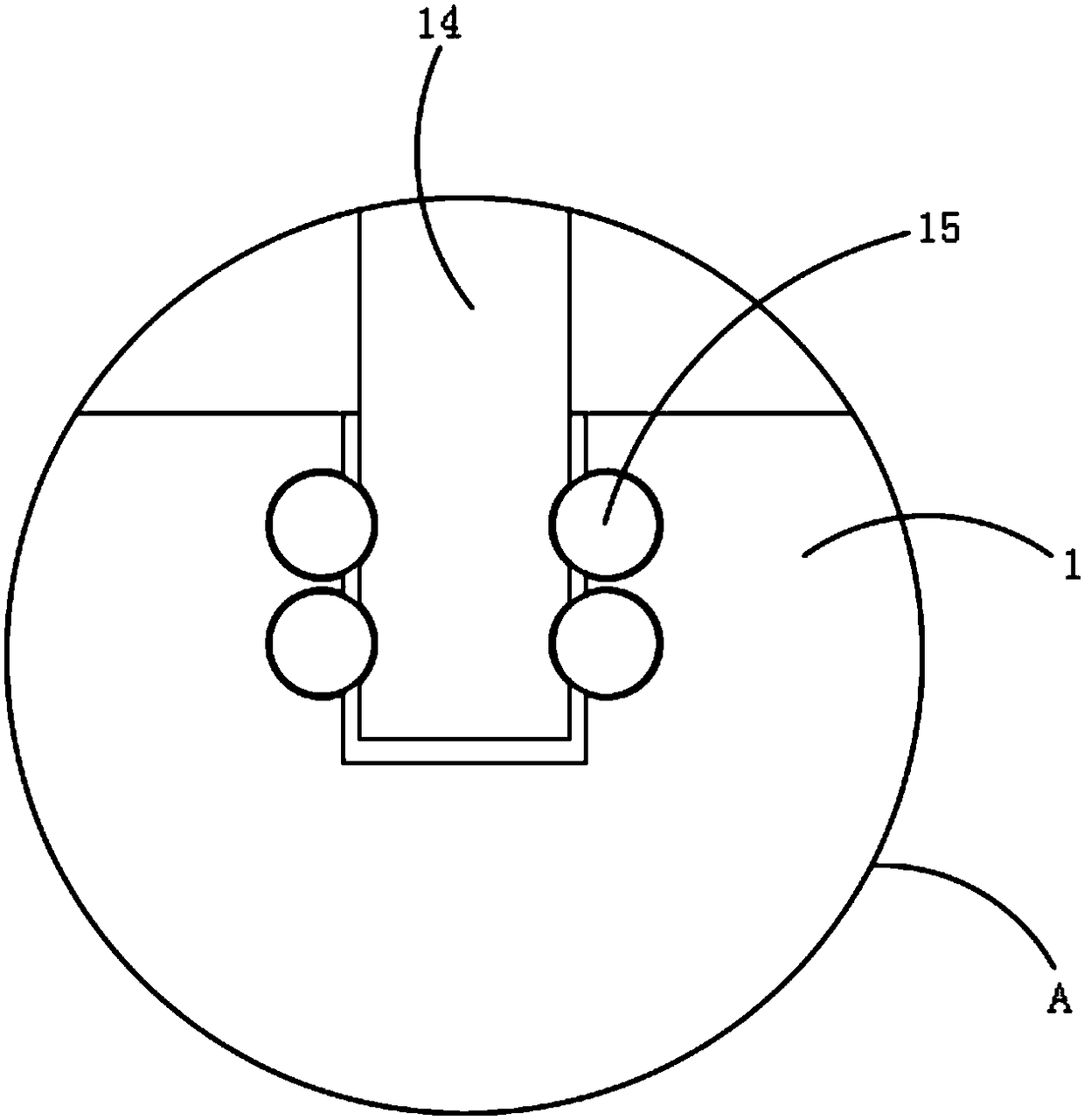

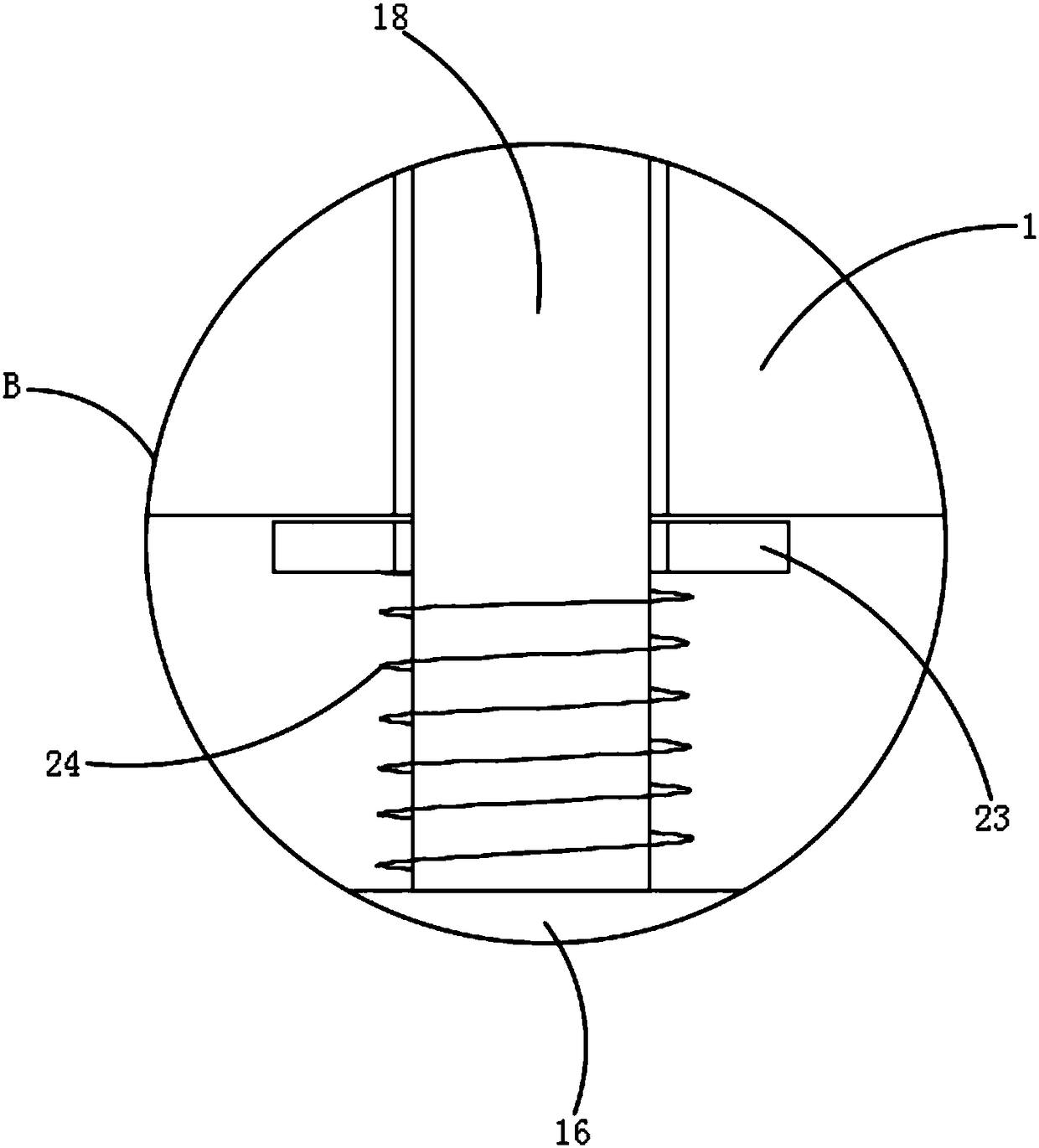

Disclosed is automatic two-gun welding for a heating stove. Automatic two-gun welding comprises a rack and a base. The base is connected with a bottom plate through a longitudinal moving mechanism. A welding platform is arranged on the bottom plate. A vertical plate is vertically installed on the rack. The vertical plate is connected with a transverse plate through a vertical moving mechanism. The transverse plate is connected with a sliding plate through a transverse moving mechanism. Two welding gun micro-adjusting mechanisms are arranged on the sliding plate. Circular fixed gears are vertically installed on the lower portions of the welding gun micro-adjusting mechanisms respectively. Welding guns are hinged to the middles of the fixed gears respectively. Automatic two-gun welding has the advantages that the welding guns are hinged to the circular fixed gears respectively, thereby being capable of rotating along the fixed gears through first motors and first gears respectively; the angles of the welding guns can be accurately controlled and welding angles can also be accurately adjusted by controlling the rotation speed and the starting time of the first motors, so that welding spots are prevented from shifting, and accordingly a gap, between a welded pipe mouth and a welded pipe shell, caused by a weld joint is avoided; the firmness and the welding effect are improved. In addition, according to automatic two-gun welding, simultaneous welding of two components can be achieved by arranging the two welding guns, so that the welding efficiency is improved.

Owner:李苗

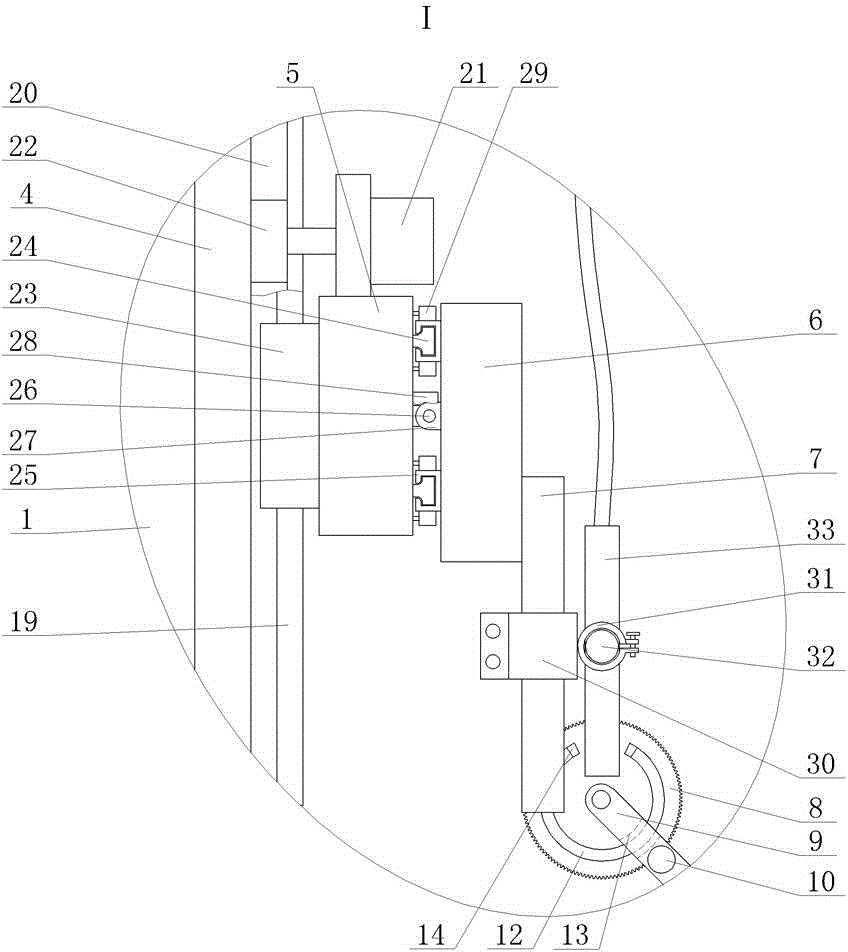

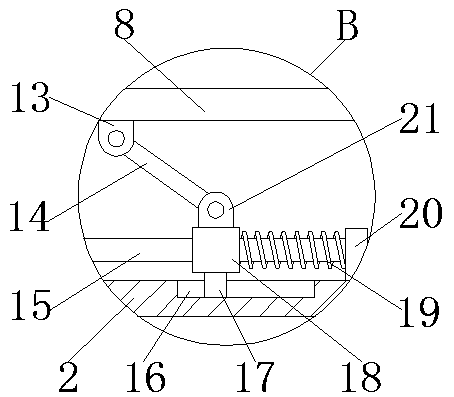

New energy automobile charging device

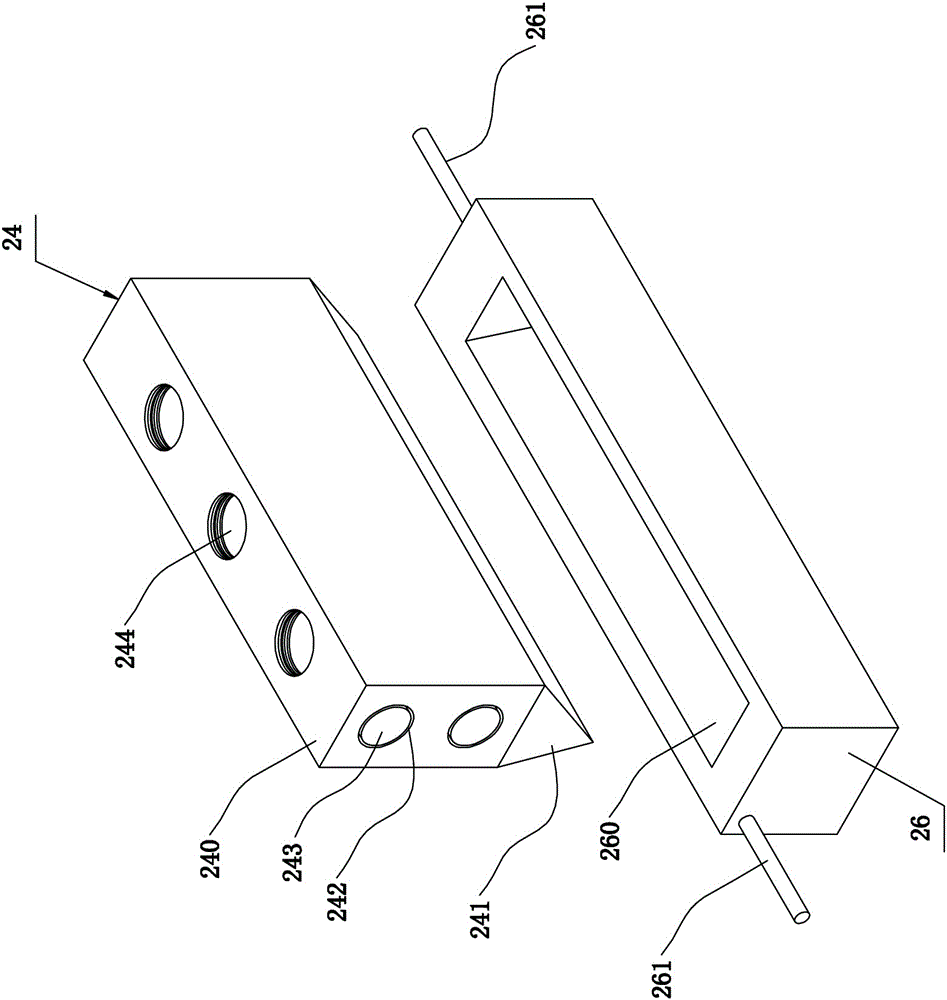

ActiveCN106945552AReduce stepsImprove work efficiencyEngagement/disengagement of coupling partsVehicle connectorsNew energyEngineering

The invention discloses a new energy automobile charging device. The new energy automobile charging device comprises a charging box, a supporting rod, a fixing base and a charging connector, wherein an outer thread connection part is arranged on the front end face of the charging box and internally provided with a through hole; an insertion-connection hole is formed in the position, on the rear side of the through hole, inside the charging box; a conductive insertion rod is arranged on the inner wall of the rear side of the insertion-connection hole; a first cavity is arranged in the position, behind the insertion-connection hole, in the charging box; a sinking tank is arranged on the inner wall of the rear side of the first cavity; a movable block is arranged at the position, on the front side of the sinking tank, in the first cavity; an ejecting spring is arranged between the end face of the rear side of the movable block and the sinking tank; guide rods are symmetrically arranged on the two sides of the ejecting spring and in the first cavity; the guide rods and the movable block are in sliding fit and connection; the front end side of the movable block is provided with an ejecting rod penetrating through the inner wall of the charging box and extending into the insertion-connection hole; grooves are formed in the end walls of the left and right sides of the movable block; spline rotary shafts are symmetrically arranged at the positions, on the outer side of the movable block, in the first cavity; and the rear side ends of the spline rotary shafts are in power connection with a motor. The new energy automobile charging device is simple in structure, firm in charging connection and high in safety.

Owner:PUJIANG KECHUANG IMPORT & EXPORT

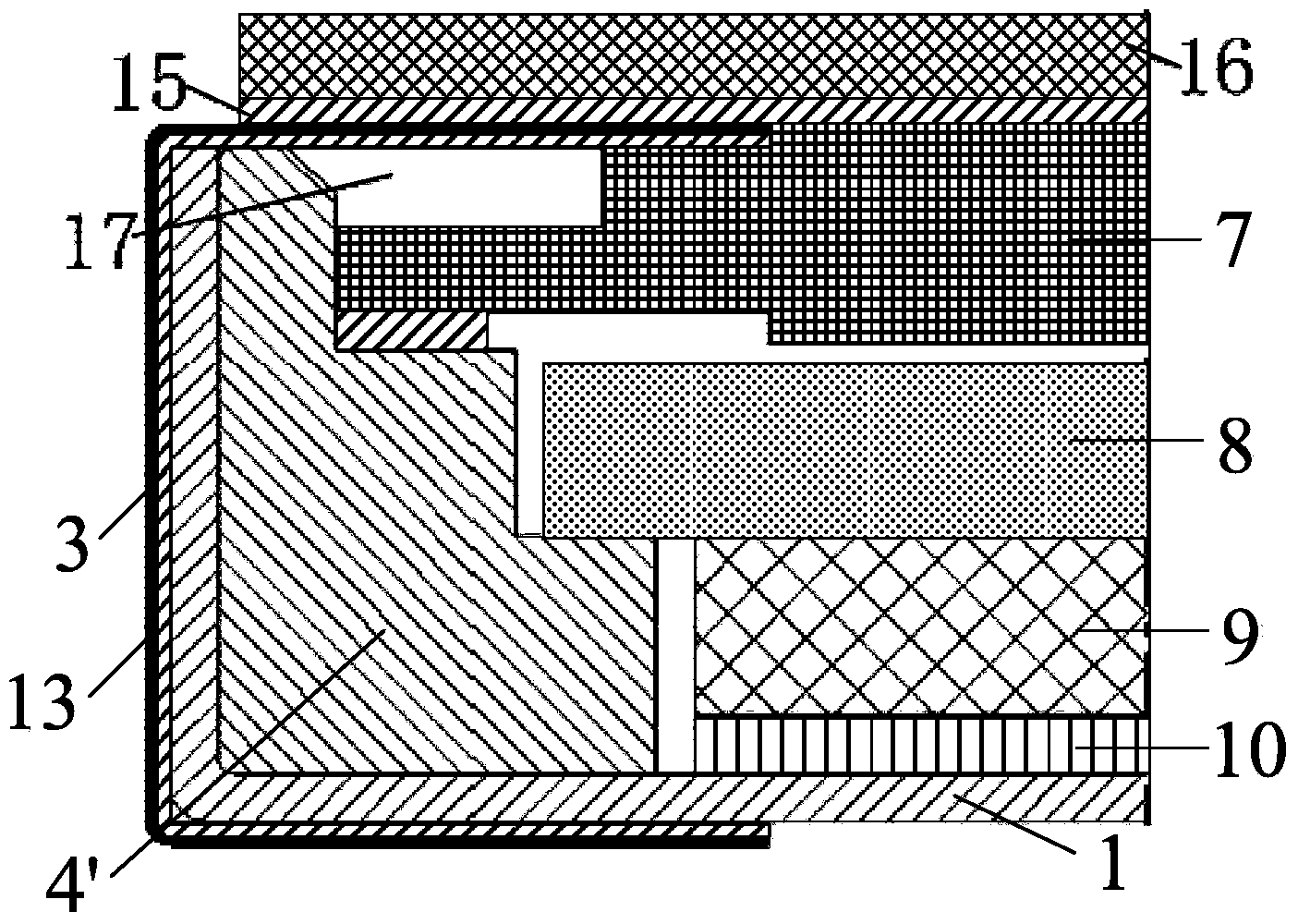

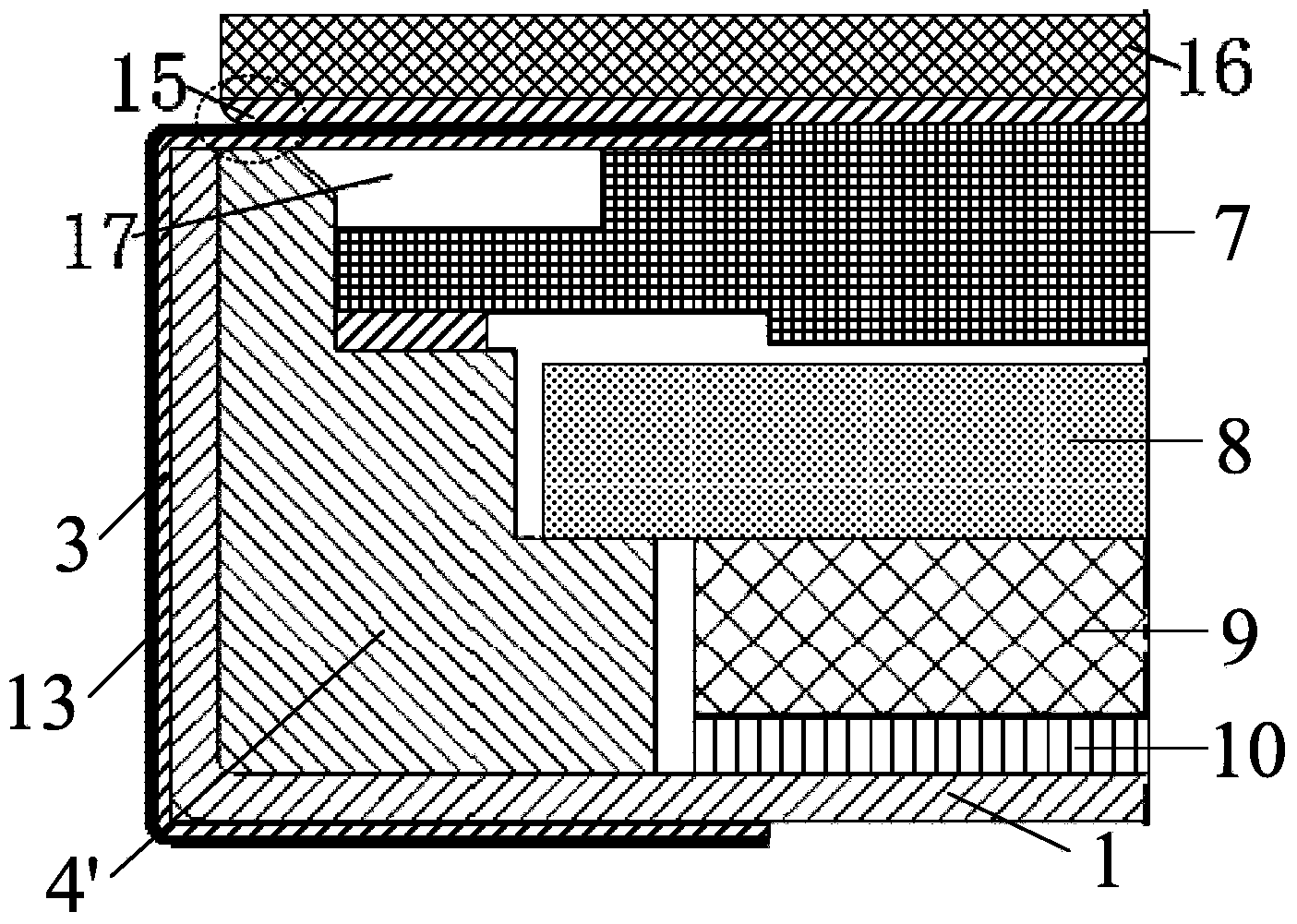

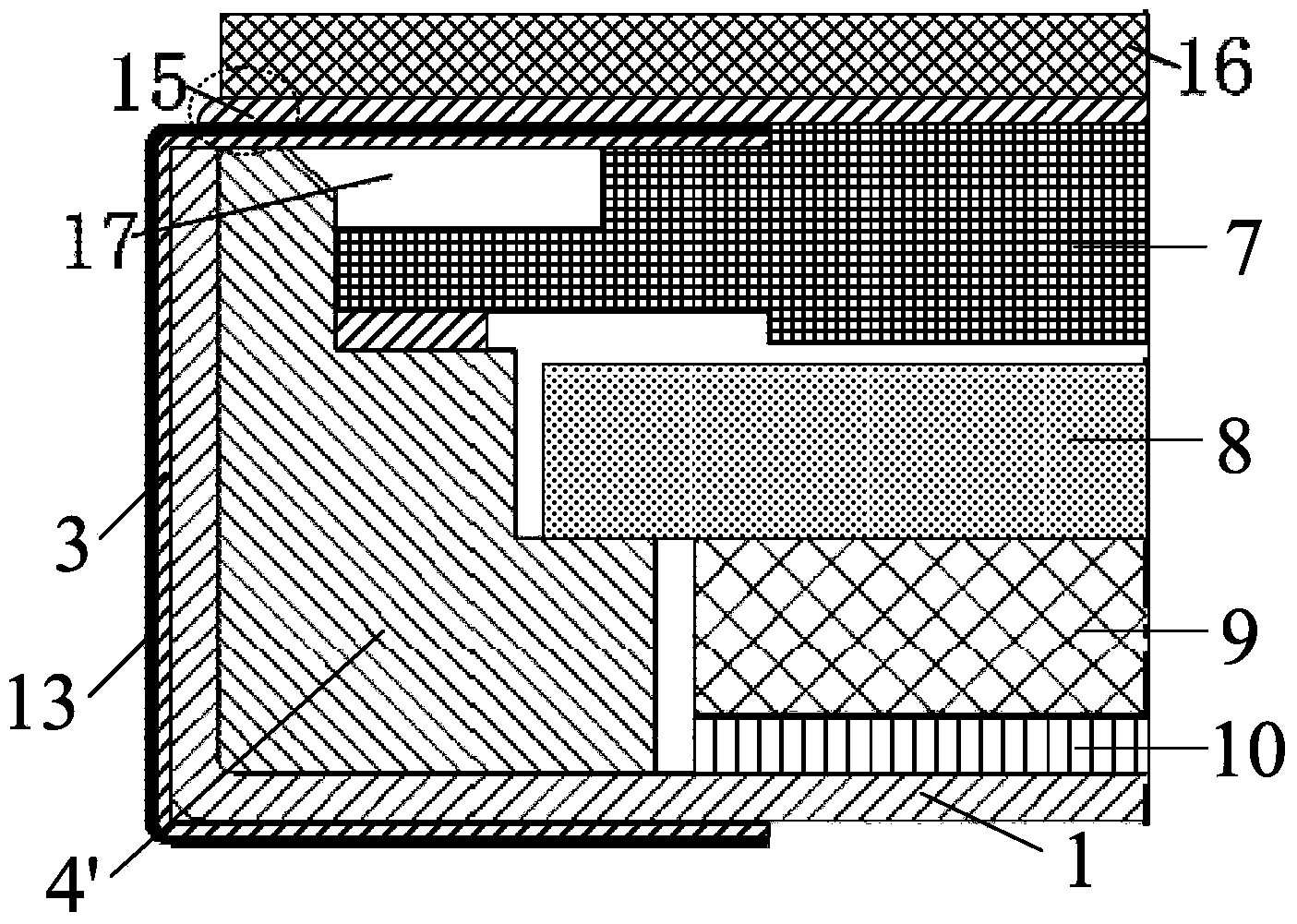

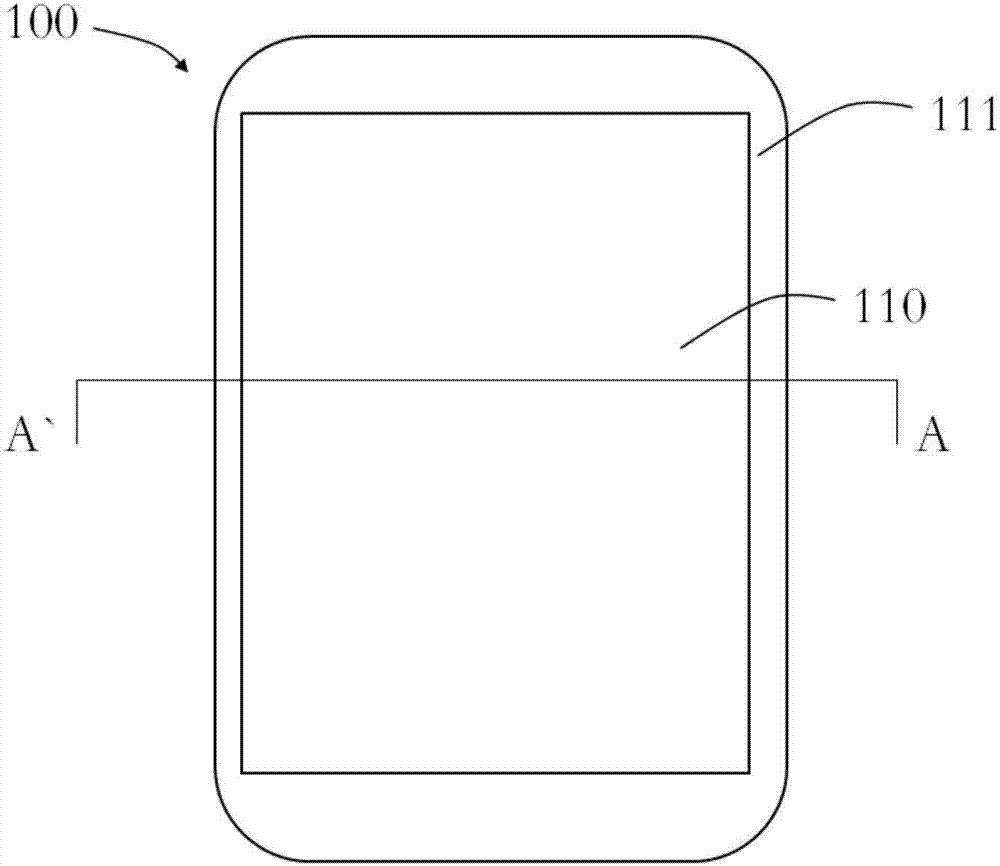

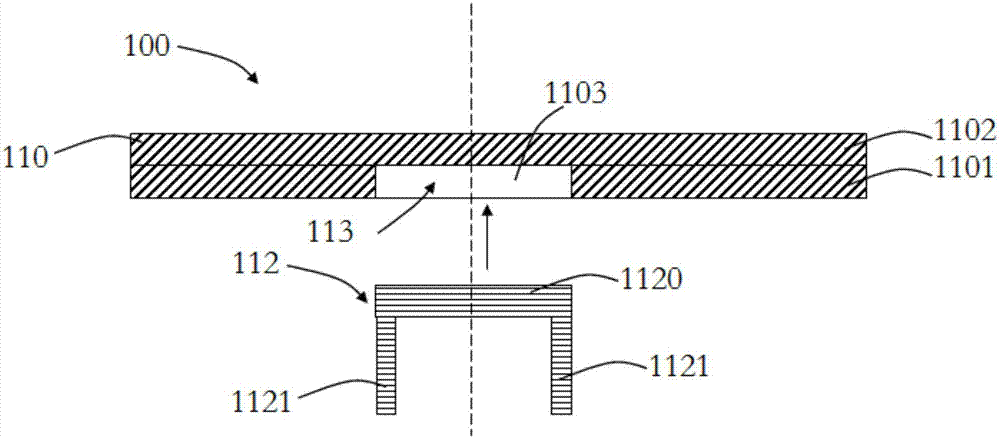

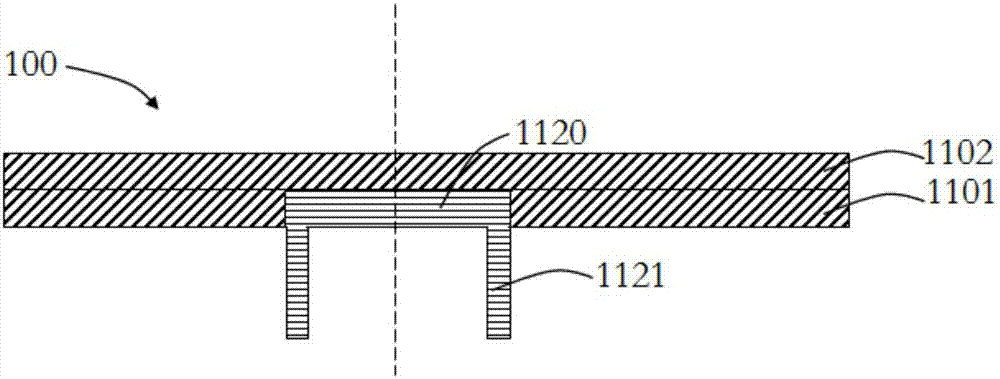

Backlight module and liquid crystal display device

InactiveCN104344292ASimple structureImprove firmnessLighting support devicesOptical light guidesTouch panelLiquid-crystal display

The invention relates to the technical field of display, and discloses a backlight module and a liquid crystal display device. The top of a plastic frame of the backlight module is provided with a cover integrally molded with the plastic frame and extending to the middle of the backlight module. When a liquid crystal display module is assembled, the cover is used for fixing a display panel. The cover and the plastic frame are integrally molded, so the structure of the backlight module is simplified; the cover has higher rigidity, so the firmness of the liquid crystal panel is improved. When the liquid crystal display device comprises an external hanging type function panel, the bonding effect of a touch panel and the backlight module is greatly improved by the higher rigidity of the cover, and the periphery of a product cannot generate whitening and light leakage problems under the action of pressure.

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

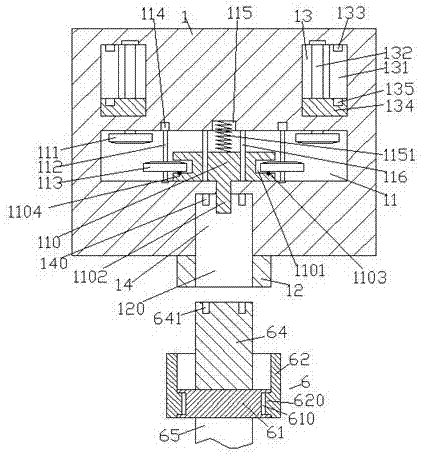

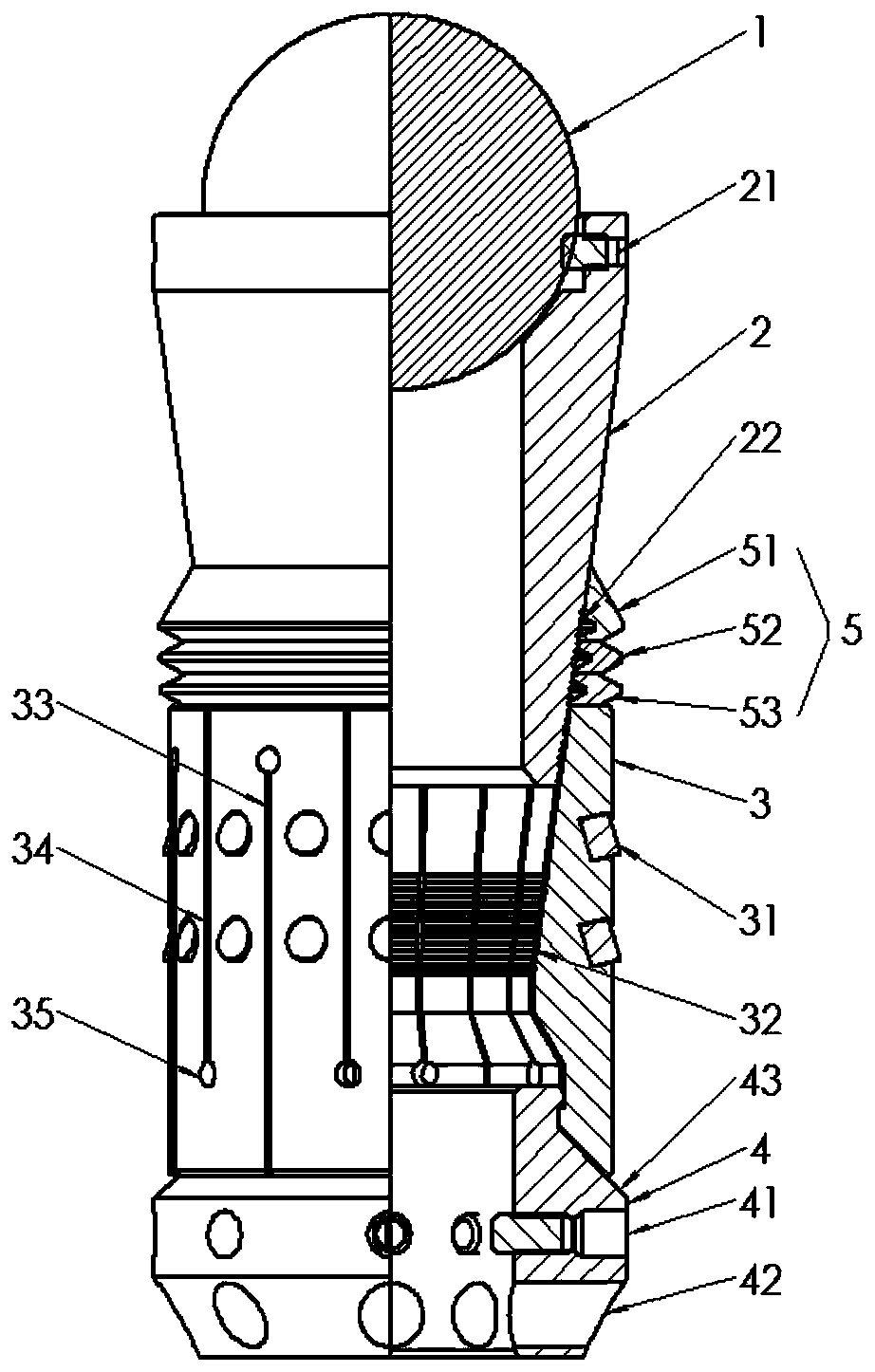

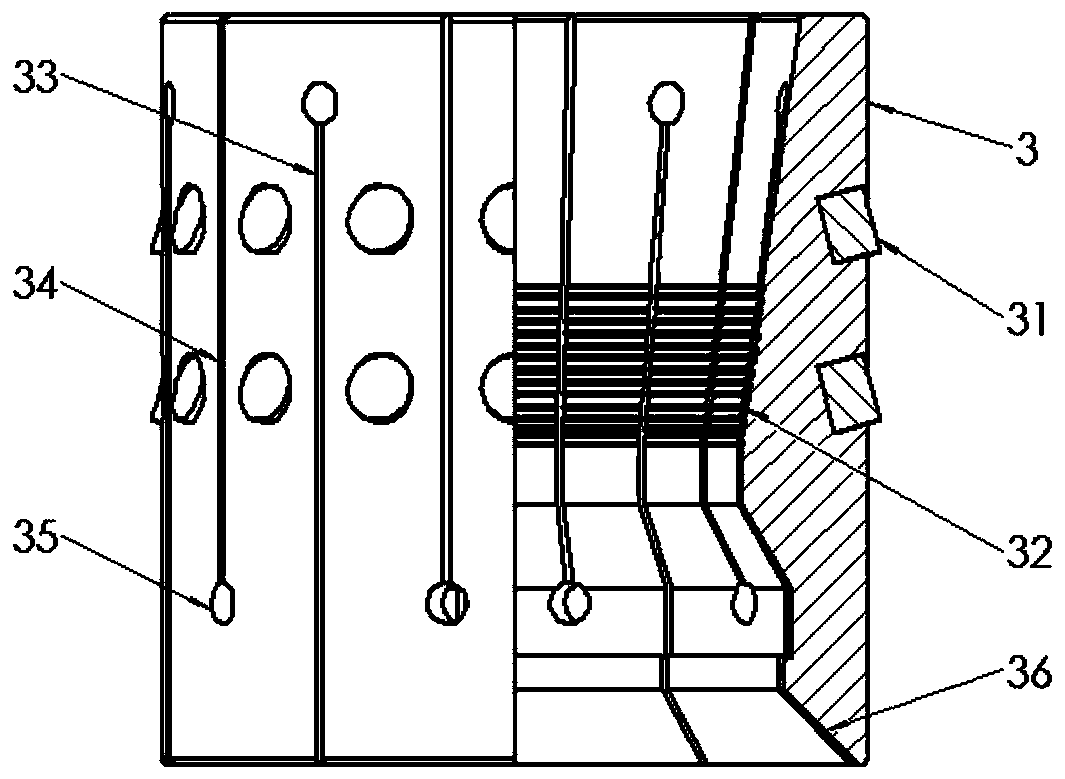

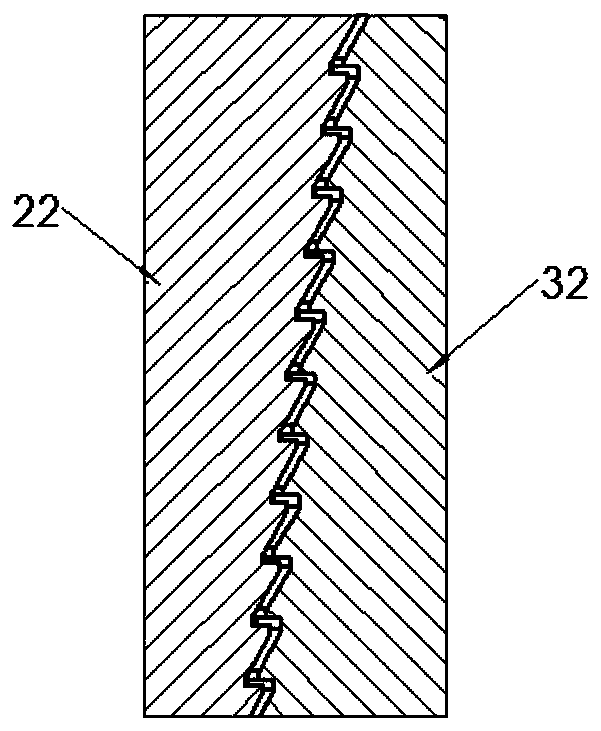

Hard sealing soluble bridge plug

PendingCN110792408AImprove the efficiency of fracturing operationsCompact structureSealing/packingEngineeringMechanical engineering

The invention relates to a hard sealing soluble bridge plug which comprises a body made of soluble metal. The body comprises a cone body, a slip and a guiding shoe which are connected from top to bottom; at least one metal sealing ring is arranged in a connecting position of the periphery of the cone body and the slip in a sleeving way; and the metal sealing ring is made of soluble metal. The hardsealing soluble bridge plug provided by the invention is applied to the field of fracturing yield increase operation of an oil gas well, so that the hard sealing soluble bridge plug can be more simply and conveniently stored, more stably sealed, and more firmly anchored; the setting success rate of the hard sealing soluble bridge plug is effectively improved; and the hard sealing soluble bridge plug better adapts to underground environment. In addition, the structure is simple and compact, and the processing and the manufacturing are easy, so that the cost of the soluble bridge plug is effectively reduced.

Owner:PETRO KING ENERGY TECH HUIZHOU CO LTD

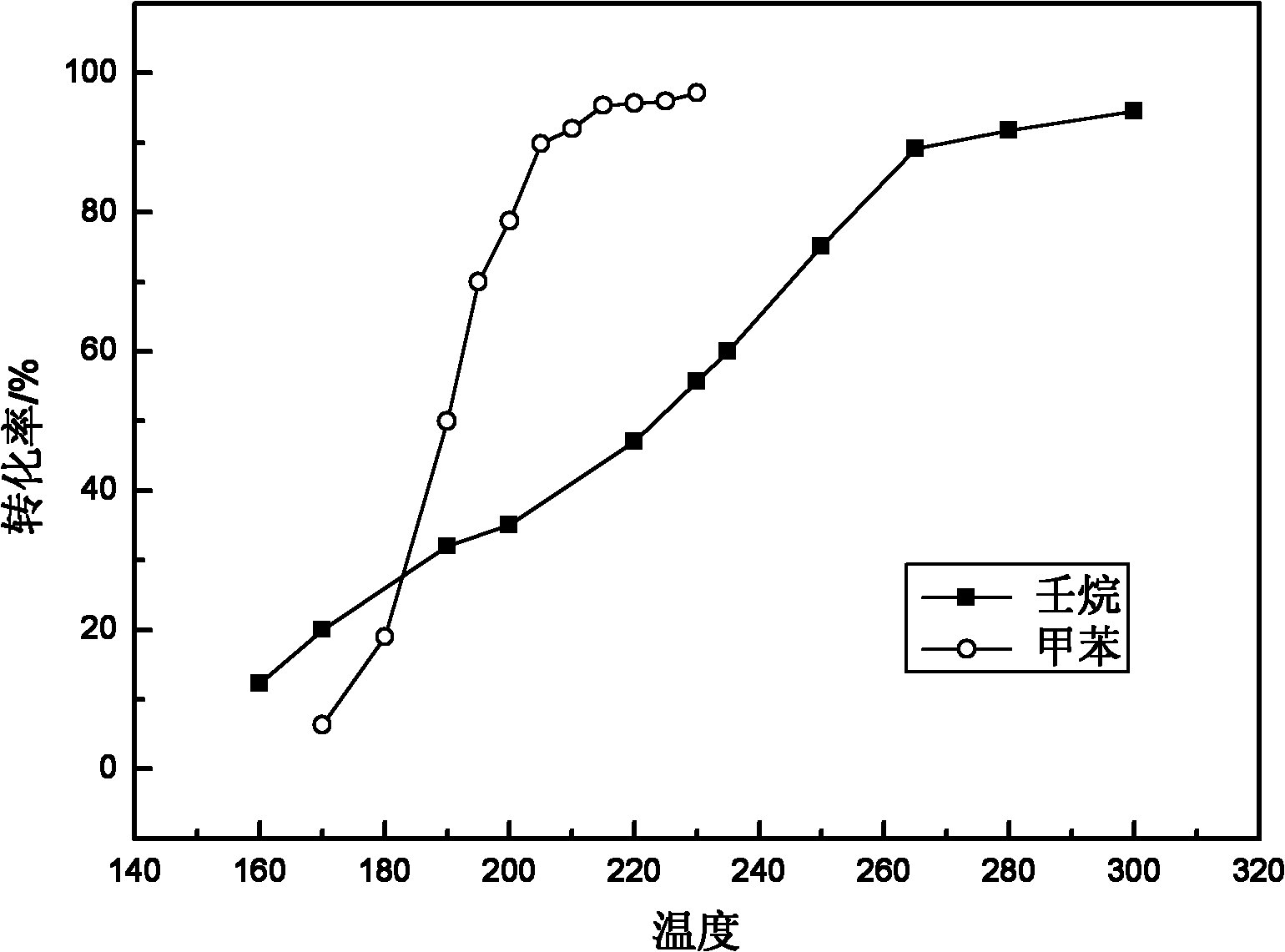

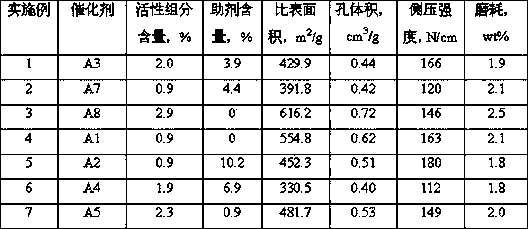

Composite catalyst used for catalytic combustion of organic waste gas as well as preparation method and application thereof

ActiveCN102240560ALow ignition temperatureReduce manufacturing costDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCouplingActive component

The invention discloses a composite catalyst used for catalytic combustion of organic waste gas as well as a preparation method and an application thereof, belonging to the technical field of catalysts. The composite catalyst is a Pt-Pd / Cu-Mn-Zn-Fe / transition layer / cordierite catalyst, macroporous high-sticky composite pseudo boehmite is taken as a second carrier, namely transition rubber, any two of La, Y, Ce and Zr are selected as assistants, non-precious metals such as Cu, Mn, Zn and Fe and precious metals Pd and Pt are taken as active components, wherein the second carrier and the assistants form the transition layer. The preparation method comprises the following steps of: carrying out acid treatment on the cordierite honeycomb ceramic surface and loading the transition layer, then loading the non-precious metal elements Cu, Mn, Zn and Fe by adopting an immersion method, and then sequentially loading the precious metals Pd and Pt by adopting a precipitation-thermal adsorption coupling method. By adopting the invention, sulphur poisoning of the catalyst can be prevented, the life of the catalyst can be prolonged, and the production cost of the catalyst can be reduced.

Owner:BEIJING UNIV OF CHEM TECH

Composite filter and manufacturing method thereof

InactiveCN101590345AGood acid and alkali resistanceImprove corrosion resistanceFiltration separationGlass fiberYarn

The invention discloses a manufacturing method of composite filter, comprising the steps: firstly, combining PTFE resin solution to glass fiber fabrics; sintering the glass fiber fabrics which are combined with the PTFE resin; coating one compact PTFE (polytetrafluoroethylene) protection layer on the surface of each yarn of the glass fiber filter cloth; and then, coating a PTFE film on the surface of the filter. The high temperature resistance, the corrosion resistance, the hydrolyzation resistance, the flexility, the wear resistance, the breaking resistance, and the like of the manufactured filter are greatly improved, the dust stripping property of the filter is good, and the dust of the filter is easy to clear. Compared with the prior art, the service life of the filters can be prolonged by over one time.

Owner:厦门美达斯环保工业有限公司

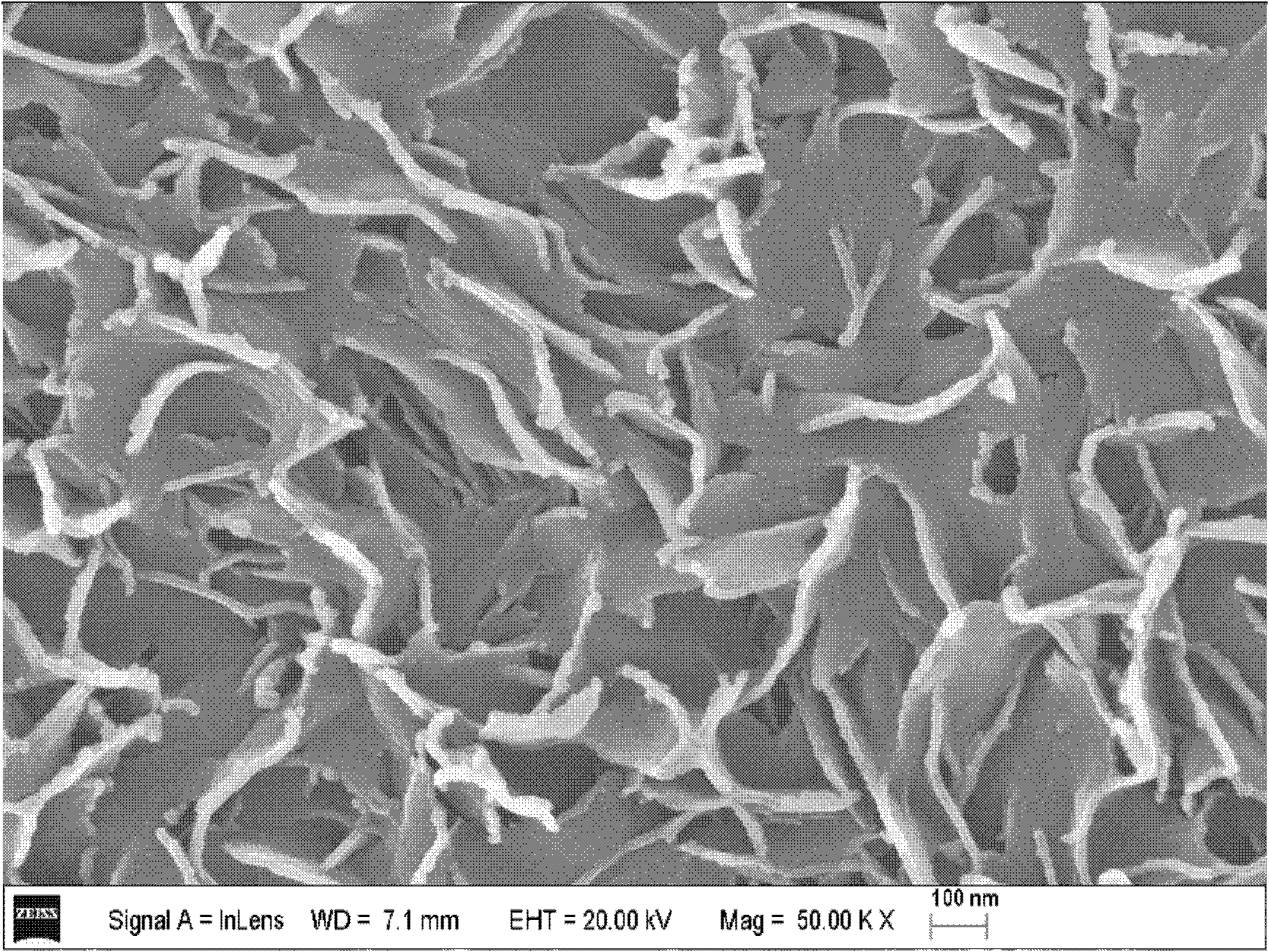

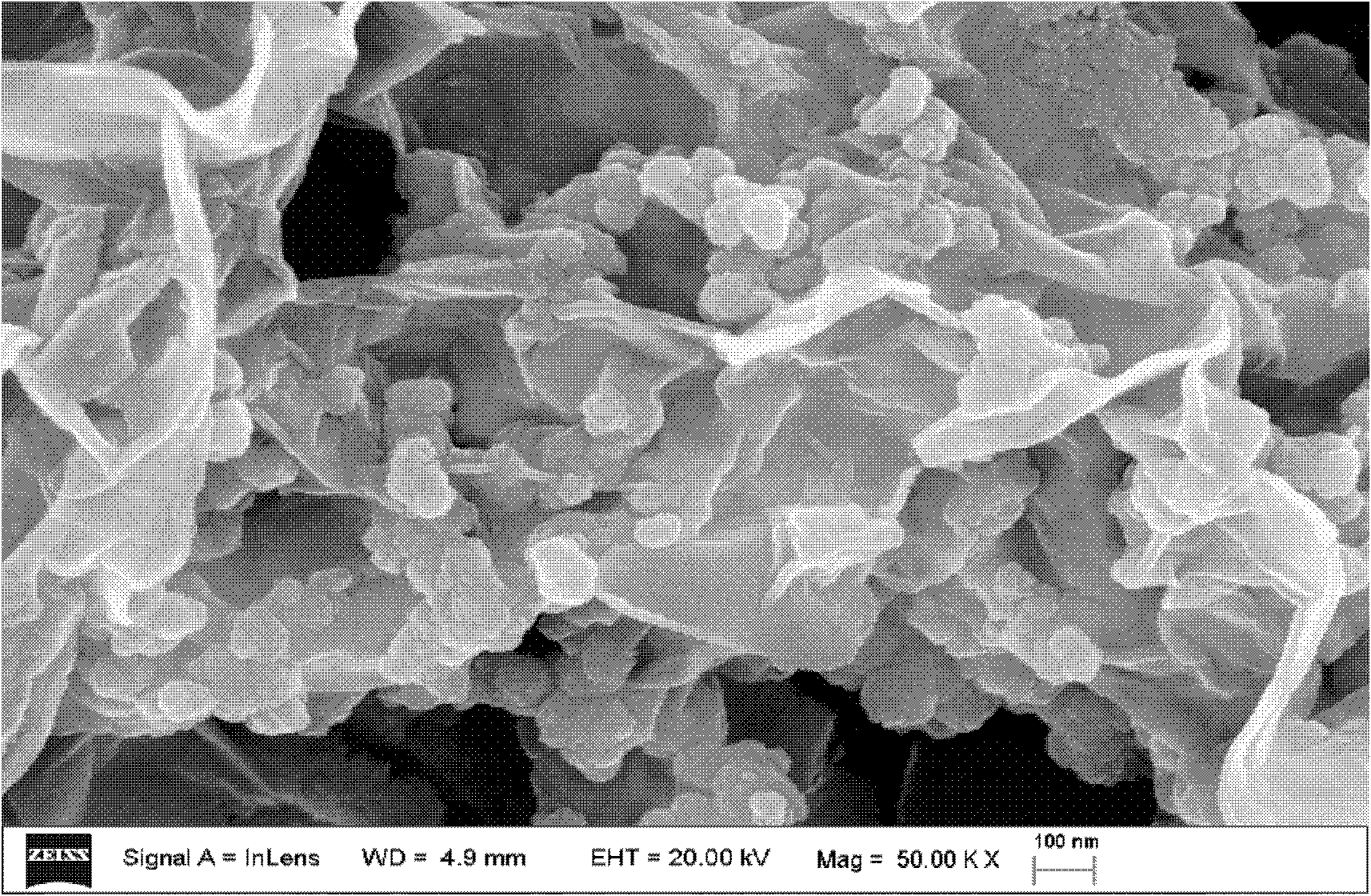

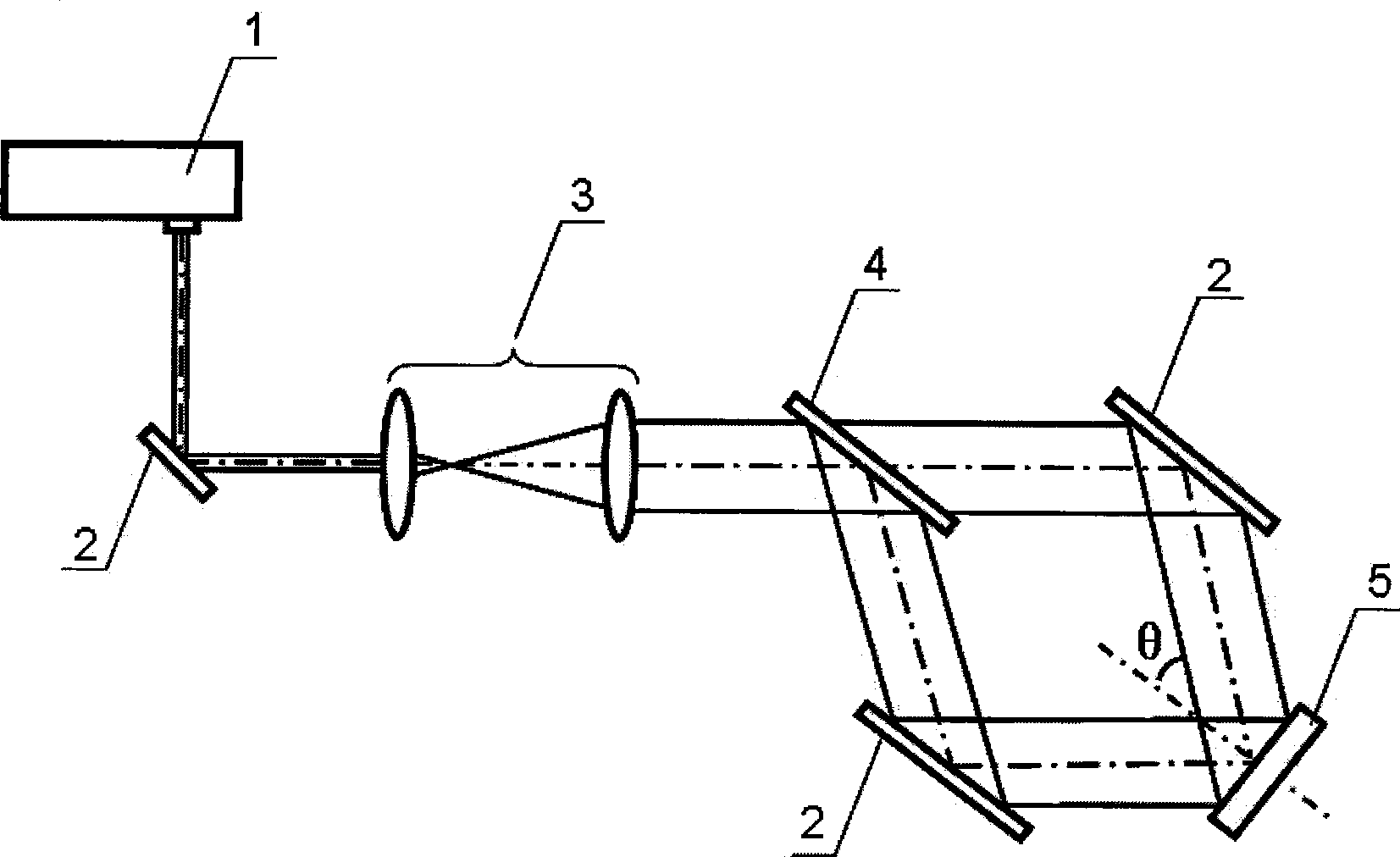

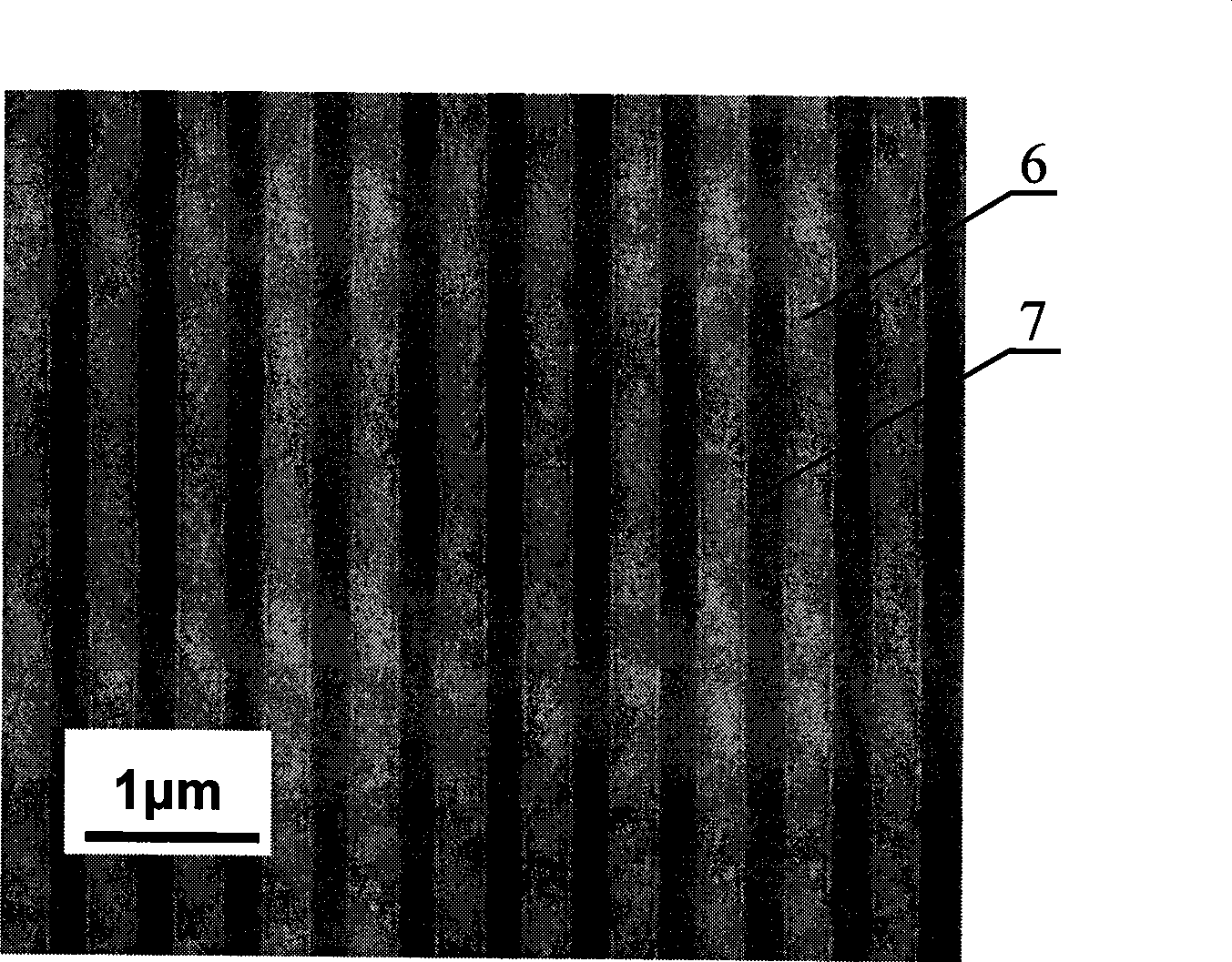

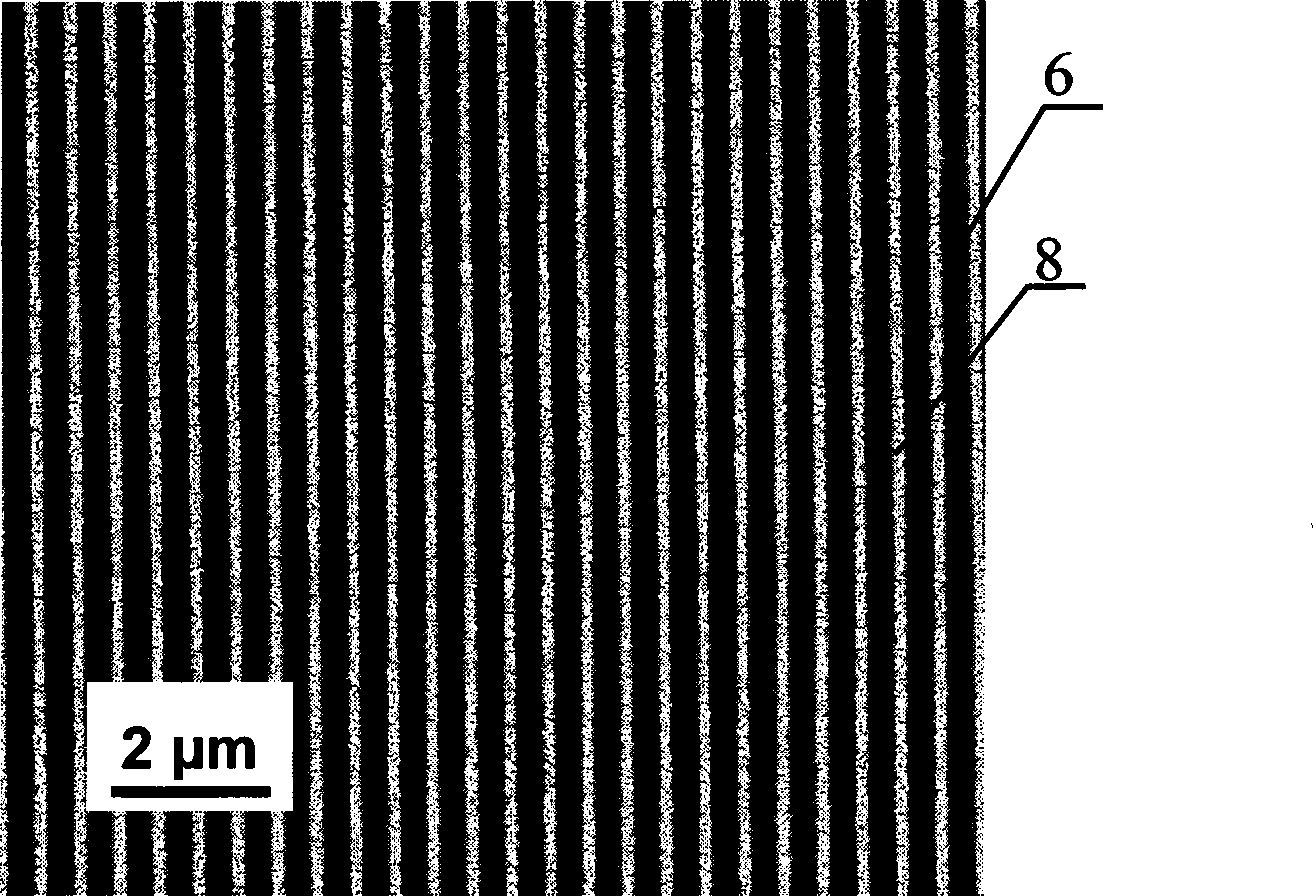

Solution method preparation for metal photon crystal

InactiveCN101487976ALow costGood repeatabilityPhotomechanical apparatusOptical light guidesResistGrating

The solution method for preparing metal photonic crystal belongs to the technical field of nano photoelectron materials and devices thereof. The existing method for preparing metal photonic crystal is faced with the problems such as high cost, low efficiency and small area of preparation, etc. In the invention, sequentially, optical resist is rotatably coated on a substrate; the interference photolithography is adopted to prepare one-dimensional or two-dimensional nano optical grating structures; metal nano particle sol is rotatably coated and goes through low temperature heat treatment, thus obtaining the metal photonic crystal. The invention has the advantages of low cost, high efficiency and preparation of the metal photonic crystal in a large acreage and the like.

Owner:BEIJING UNIV OF TECH

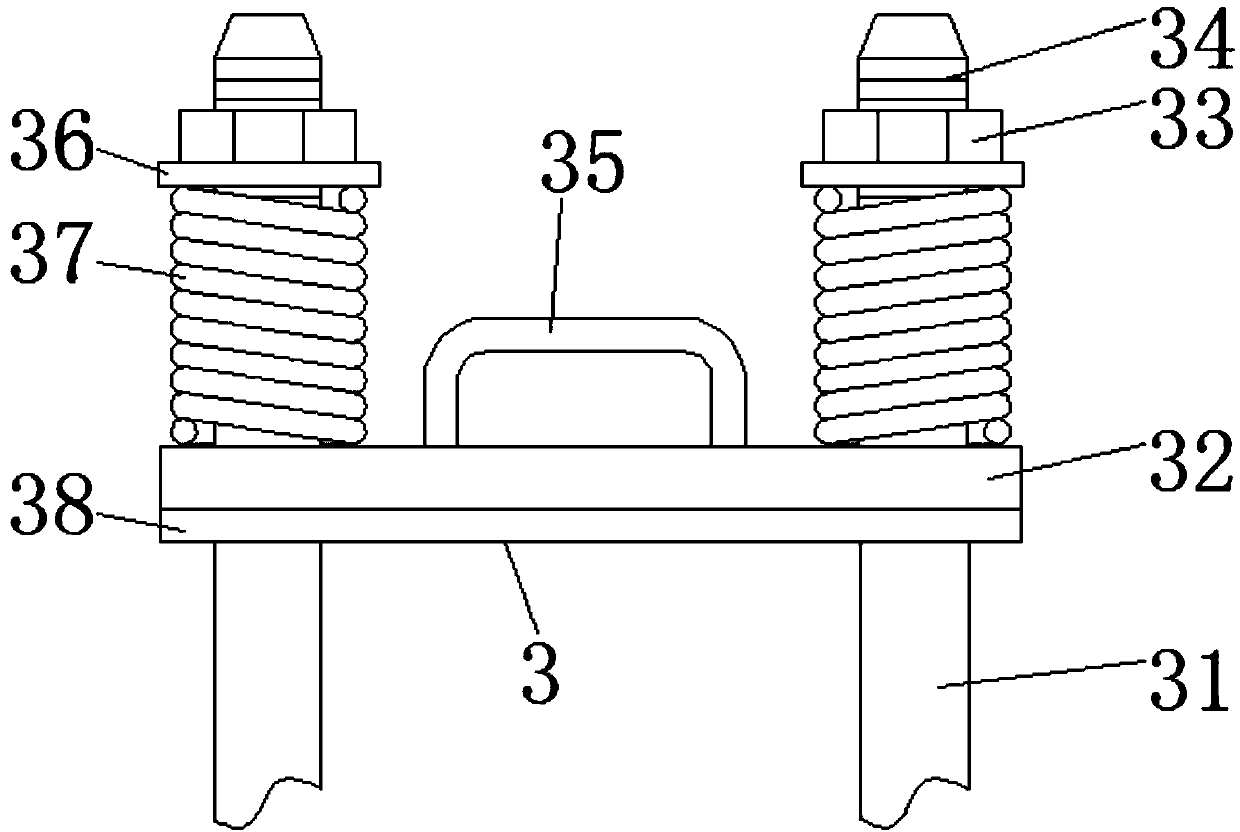

Intelligent cutting machine with locating and dust-collecting function

InactiveCN107081634AFunctionalAchieve the purpose of compressionShearing machinesMaintainance and safety accessoriesEngineeringRebar

The invention discloses an intelligent cutting machine with a locating and dust-collecting function. The intelligent cutting machine comprises a worktable, the four corners of the bottom surface of the worktable are all fixedly connected with supporting legs, the front part of the upper surface of the worktable is provided with a groove, the middles of the two sides of the inner wall of the groove are both provided with slide grooves, the slide grooves are internally slidably connected with frames, the inner sides of the frames are welded to a screening net, the front parts of the frames are welded to a handle, the upper surface of the worktable is in pin joint with a supporting plate, and the supporting plate is located at the rear portion of the groove. In the intelligent cutting machine with the locating and dust-collecting function, fixing devices are arranged at the two sides of the groove, when the intelligent cutting machine is in use, the handle can be drawn back, tubular products or reinforcing steel bars are placed on two stand columns at the same side of the groove, then the handle is loosened, under the effect of springs, a pressing plate is pressed on the upper surfaces of the tubular products or the reinforcing steel bars, and thus the purpose of pressing tightly the tubular products and the reinforcing steel bars is achieved, through deformation under compression of a rubber cushion, the bottom surface of the pressing plate can be more tightly attached to the reinforcing steel bars or the tubular products, and thus the firmness of stitching the reinforcing steel bars or the tubular products is improved.

Owner:金陈敏

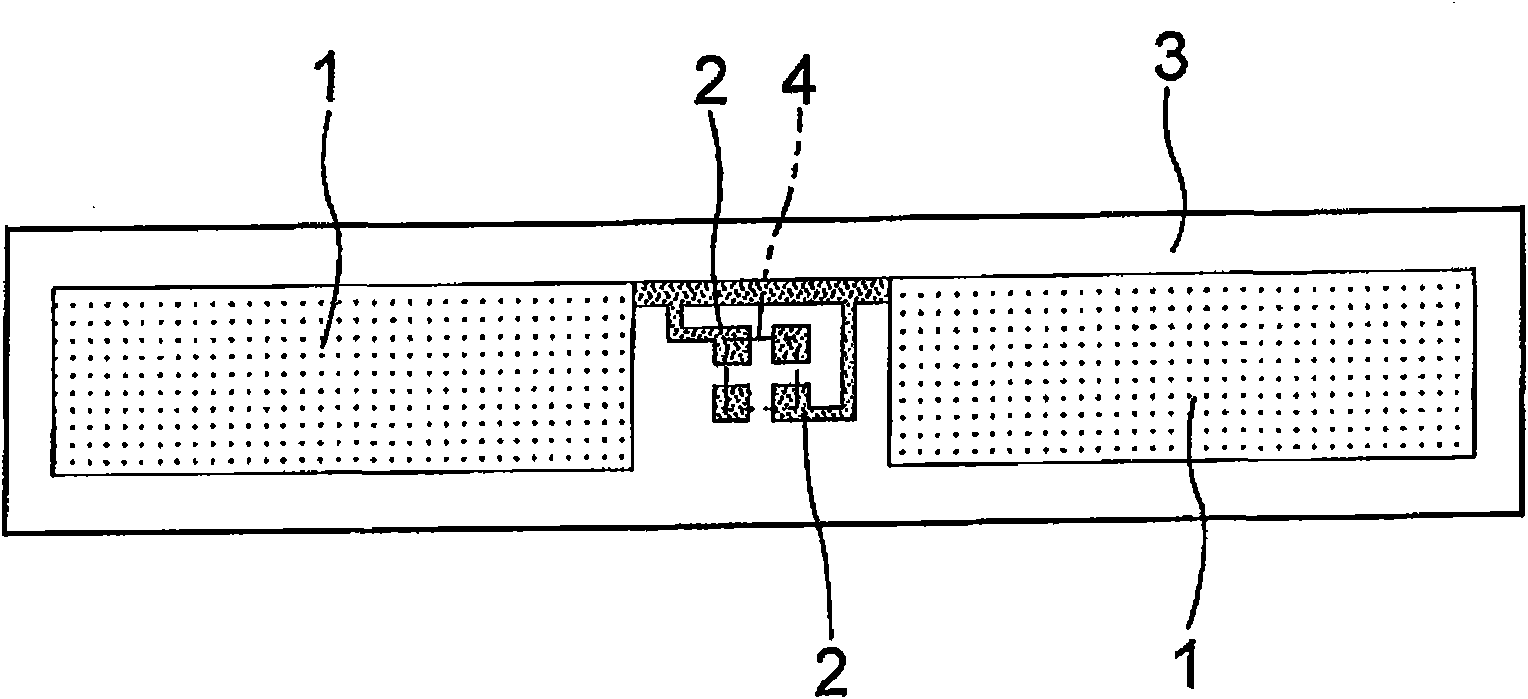

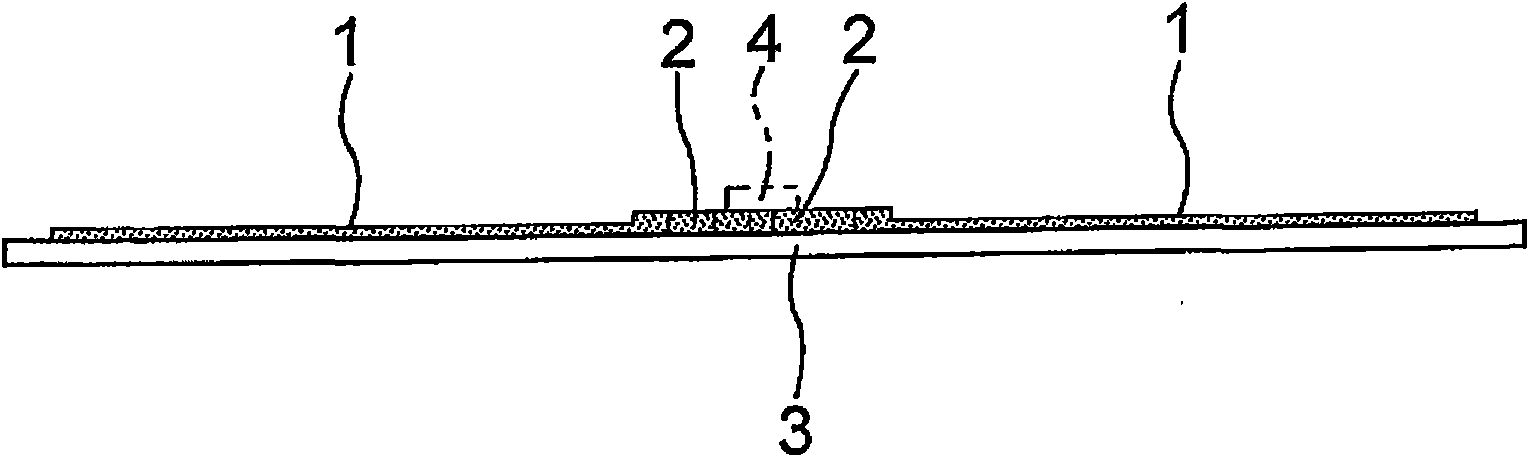

Antenna for ic tag and method of manufacturing the same

InactiveCN101888014AReduce manufacturing costLess quantityRadiating elements structural formsMetal/alloy conductorsAdhesiveEngineering

The invention provides an antenna for IC tag that has small membrane thickness than the prior products and can reach the necessary low resistance of the non-contact type storage medium, and method of manufacturing the antenna for IC tag at low cost efficiently. A film shape conductive film antenna with specified circuit pattern is formed on the surface of the substrate (3) by using the aqueous conductive ink containing silver particles, adhesive and water, the conductive film antenna includes an antenna part (1) for transmitting and receiving the electromagnetic wave, and an interconnecting piece (2) connected to the IC chip (4).

Owner:PROVIDENT

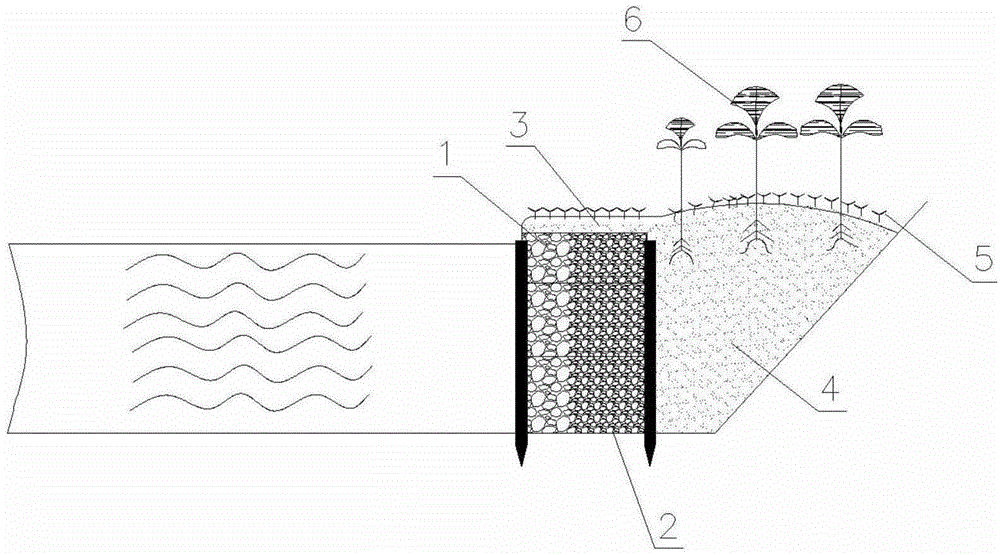

Taihu lake ecological dam revetment construction method

InactiveCN104404917AImprove ecological environment and water qualityImprove overall firmnessDamsDykesEcological environmentEngineering

The invention provides a Taihu lake ecological dam revetment construction method. Gabion net ecological gabions are adopted, are manually filled with stone blocks, and are ranged and accumulated in positions with a distance being 1 to 5m away from a lake bank, in addition, double-row anchoring pile anchoring is implemented for building an ecological dam, the surface of the ecological dam is 30 to 60cm higher than the water level, a position between the ecological dam and the original lake bank is directly filled with river sediment, local native grass tree plants for beautifying the environment are planted on the ecological dam and the filled river sediment zone for forming a landscape wall, the peripheral ecological environment and the water quality condition of a revetment can be improved, the ecological revetment with the landscape function is achieved, so that unique Taihu lake landscape can be formed. The Taihu lake ecological dam revetment manufactured by the method has various advantages of good ecological performance, water permeability, flexibility, impact resistance, wave resistance and the like.

Owner:JIANGSU LONG LEAPING ENG DESIGN

Display screen, display device and mobile terminal

ActiveCN107067971AImprove stabilityImprove firm performancePrintersProjectorsDisplay deviceEngineering

The invention provides a display screen. The display screen comprises a display portion, a non-display portion adjacent to the display portion, and an insertion piece. The display portion is provided with a positioning groove, and the opening of the positioning groove faces the side backing onto a user. The insert piece comprises an insertion portion and a supporting portion connected with the insertion portion, wherein the insertion portion is fixed in the positioning groove, the side, backing onto a user, of the insertion portion is used for fixing a camera, and the supporting portion is fixed to the side, close to the camera, of the insertion portion to be used for supporting the insertion portion. The invention further provides a display device. The display device comprises a camera, wherein the camera is fixed to the insertion portion and is located on the side, backing onto a user, of the display screen. The invention also provides a mobile terminal. The installation stability of the camera is improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Bag making machine hot-sealing and hot-pressing mechanism capable of working stably

The invention discloses a bag making machine hot-sealing and hot-pressing mechanism capable of working stably. The mechanism comprises a fixing frame body, two guide sleeves, pull rods, a cutter fixing frame and a hot-sealing cutter. The upper ends of the pull rods are fixedly connected to the two ends of the cutter fixing frame respectively and each provided with an upper end abutting portion. The side wall of the upper portion of each pull rod is sleeved with a compression spring. The upper end and the lower end of each compression spring are connected to the corresponding upper end abutting portion and the top of the corresponding sleeve respectively in an abutting mode. At least one pull rod penetrates through the corresponding guide sleeve and then is in transmission connection with an intermittent motion mechanism. According to the bag making machine hot-sealing and hot-pressing mechanism, it can be ensured that the hot-sealing and hot-pressing positions and motion strengths of the hot-sealing cutter for air bubble films or pearl wool films under the hot-sealing and hot-pressing cutter are consistent all the time, and the hot-sealing cutter will not shift even if hot-sealing and hot-pressing are frequently and constantly carried out; accordingly, the working efficiency of the bag making machine hot-sealing and hot-pressing mechanism is greatly improved, and the service life of the bag making machine hot-sealing and hot-pressing mechanism is greatly prolonged.

Owner:洪东坡

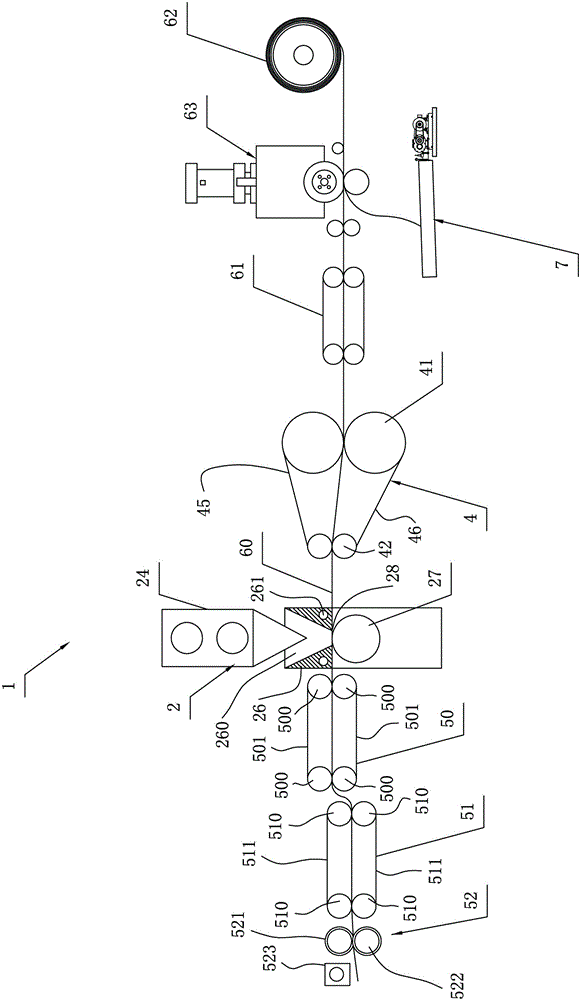

Bag machine with improved structure

ActiveCN104985864AThere will be no offsetSimple structureBox making operationsPaper-makingEngineeringMechanical engineering

A bag machine with an improved structure comprises a convey assembly, a feed assembly, and a hot-sealing hot-pressing mechanism; the hot-sealing hot-pressing mechanism comprises a fixed rack, two guide sleeves, pull rods, a cutter fixing rack and a hot-sealing cutter; tops of each pull rod are respectively fixed on two ends of the cutter fixing rack; each pull rod is provided with a top abut portion; an upper side wall of each pull rod is sleeved by a compression spring; at least one pull rod penetrates the corresponding guide sleeve and is in transmission connection with an intermittence motion mechanism, wherein the intermittence motion mechanism is used for controlling the cutter fixing rack to complete up-down mobile motions in cycle in a fixed time. The bag machine can ensure the hot-sealing cutter to carry out hot-sealing hot-pressing for right blow bubble films or pearl cotton films with consistent positions and motion forces in each time; even under frequent continuously hot-sealing hot-pressing, no hot-sealing cutter offset condition is generated, thus greatly improving work efficiency and life of the bag machine.

Owner:洪东坡

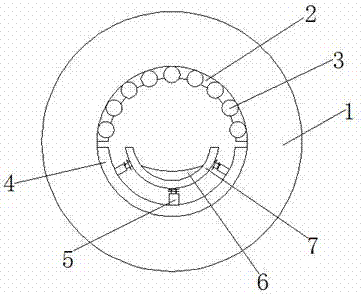

Rail robot with turning device

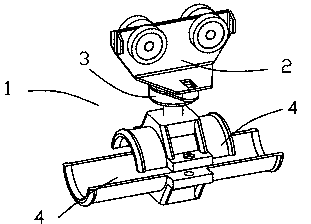

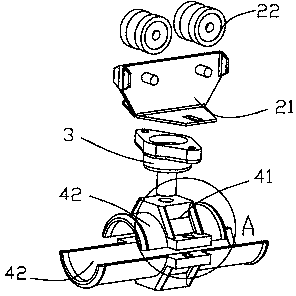

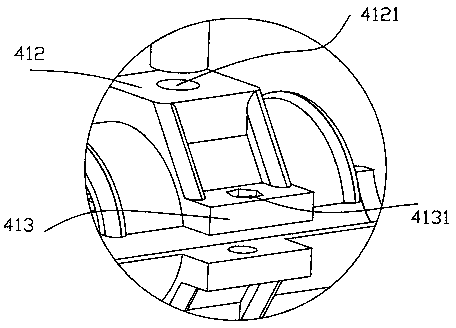

InactiveCN103963045AImprove stabilityImprove riding performanceManipulatorEngineeringMechanical engineering

The invention discloses a rail robot with a turning device. The rail robot comprises a guide part and a pair of guide tile clamps, wherein the guide part is detachably and fixedly connected with the guide tile clamps through a rotatable connecting part. According to the rail robot, by using the rotatable connecting part, when the rail robot passes through a right-angle curved road, the guide part and the rotatable connecting part automatically rotate, so that the stability and the smoothness of the rail robot are greatly improved; in addition, a guide device adopts the guide tile clamps, so that the clamping stress surface is enlarged and the clamping firmness is improved.

Owner:SHANGHAI HEHUA ELECTRONICS TECH

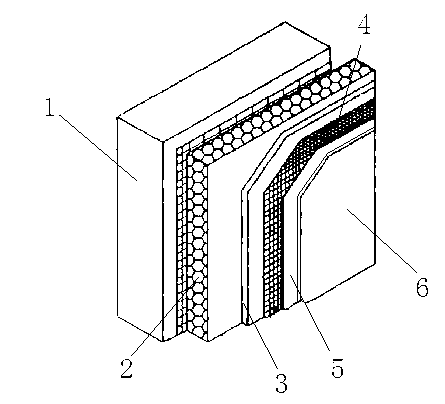

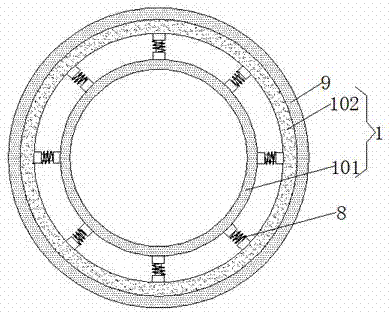

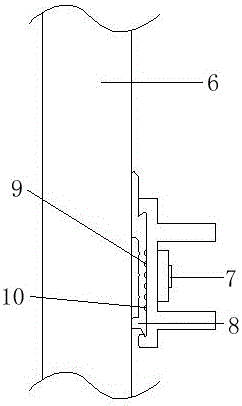

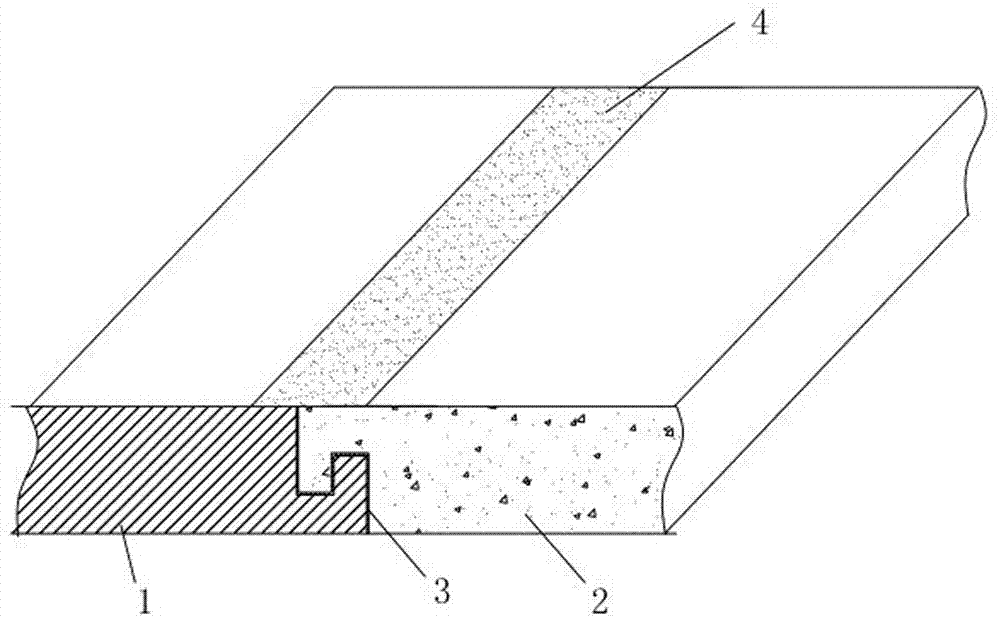

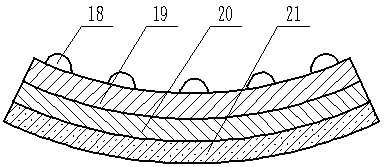

Thermal insulation wall body

InactiveCN103321319AImprove firm performanceImprove sound insulationWallsHeat proofingGlass fiberThermal insulation

The invention discloses a thermal insulation wall body. The thermal insulation wall body comprises a main wall body layer; the external side of the main wall body is sequentially provided with a thermal insulation board layer, a hot galvanizing steel wire mesh layer, an acoustic panel layer, a glass fiber grinding cloth layer and a decorative coating layer; the thermal insulation board layer and the main body wall layer are bounded together through the thermal insulation board adhesive; the thermal insulation board layer, the hot galvanizing steel wire mesh layer, the acoustic panel layer and the decorative coating layer are bounded through the fireproofing glue. The thermal insulation wall body has the advantages of improving firmness, increasing sound insulation effect, avoiding cracking and falling off, saving construction procedures, reducing production materials and having a good application prospect due to the fact that the hot galvanizing steel wire mesh layer, the acoustic panel layer and the glass fiber grinding cloth layer are added to the thermal insulation wall body.

Owner:ZHANGJIAGANG EVERNICE BUILDING MATERIALS

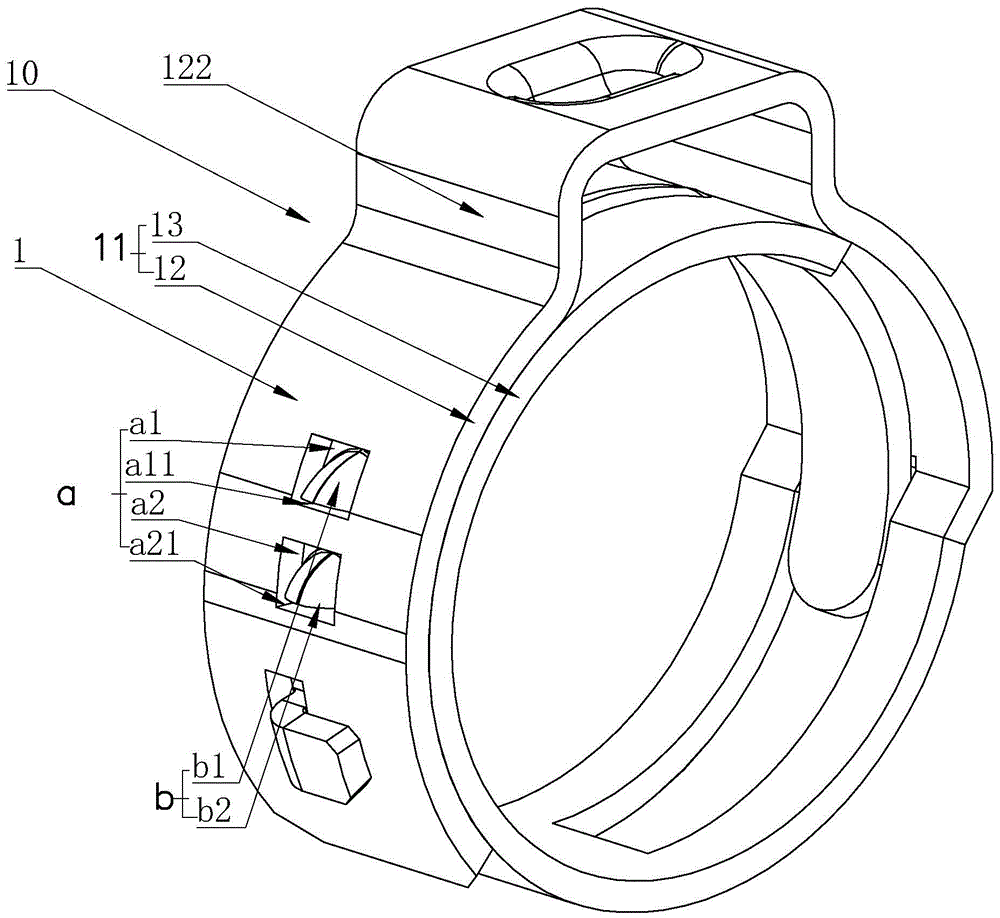

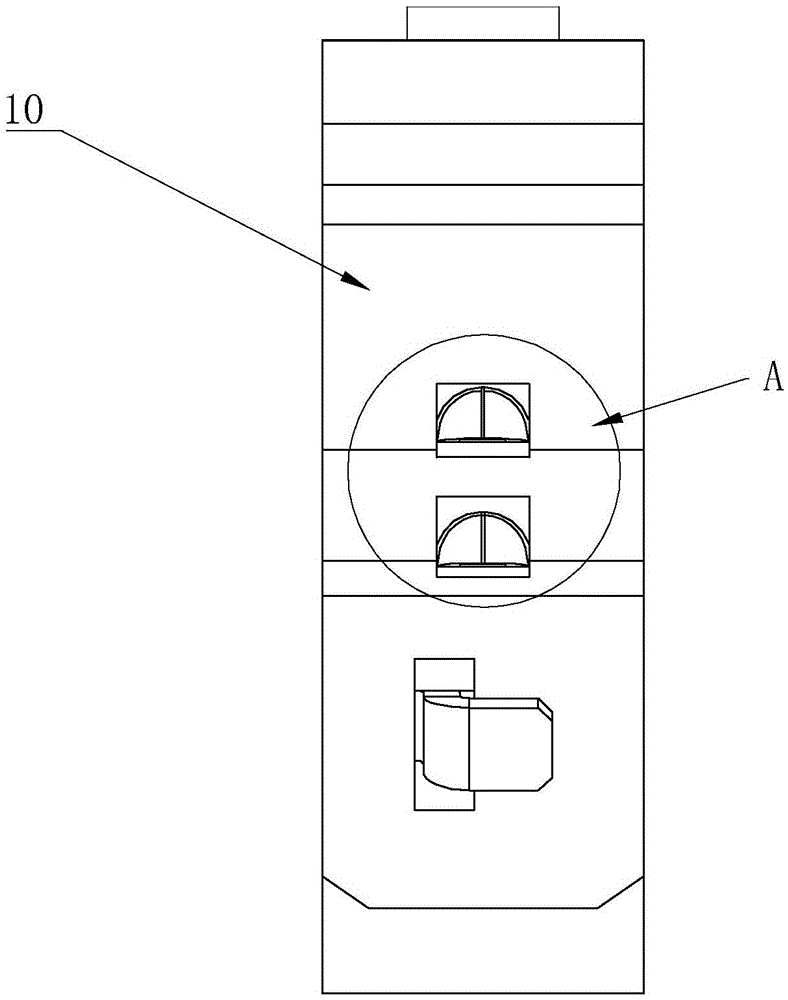

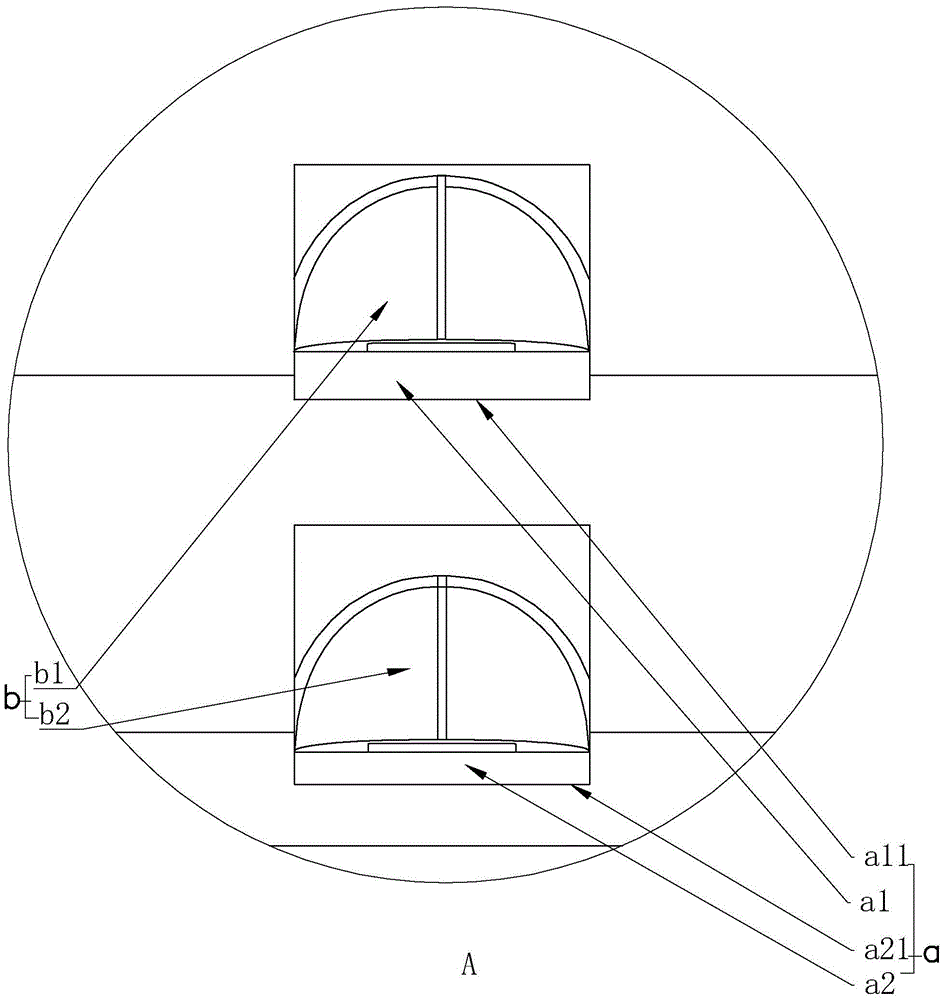

Hoop as well as manufacturing method and use method thereof

ActiveCN105587935APrevent looseningNot easy to loosePipe supportsHose connectionsPipe fittingEngineering

The invention discloses a hoop as well as a manufacturing method and a use method thereof. The hoop comprises a clamping belt, wherein the clamping belt is bent and formed into a hoop body with a sleeving area; the hoop body forms a superposed part; the superposed part comprises an outer-side belt body and an inner-side belt body; and the sleeving area is elliptical. The manufacturing method thereof comprises the following steps: producing a clamping belt at first, and then directly bending and forming the clamping belt into a hoop body with an elliptical sleeving area. The use method thereof comprises the following steps: directly bending and forming a clamping belt into a hoop body with a sleeving area; carrying out pre-forming treatment on the sleeving area and enabling the sleeving area to be elliptical; sleeving a pipe fitting with the hoop body, and enabling the hoop body to form abutting connection with the pipe fitting at a short shaft corresponding to the sleeving area; and further shrinking and clamping the hoop through a hoop clamping tool. The invention aims at providing a hoop; and the hoop has the advantages of being convenient to install, and capable of being effectively pre-fixed on the pipe fitting.

Owner:YUEQING DONGBO ELECTROMECHANICAL

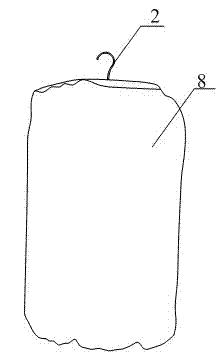

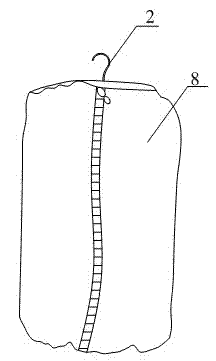

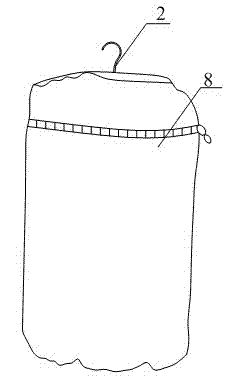

Portable clothes drying device

InactiveCN102926177ASave spaceFast fillOther drying apparatusTextiles and paperEngineeringClothes hanger

The invention discloses a portable clothes drying device, and solves the problems of large volume and inconvenience in carry of the clothes drying device in the prior art. The portable clothes drying device comprises a clothes drying device skeleton and a clothes drying cover (8) covering the outer side of the clothes drying device skeleton, and is characterized in that the clothes drying device skeleton comprises a supporting mechanism and a clothes hanger (1), wherein the top end of the supporting mechanism is provided with a hook (2), and the bottom end of the supporting mechanism is provided with a heating device (3); and the clothes hanger (1) is arranged at the upper end of the supporting mechanism, is movably connected with the upper end of the supporting mechanism and is umbrella-rib-shaped. The portable clothes drying device disclosed by the invention has the advantages that the structure is simple, the cost is low, the implementation is convenient, and the foldable design is adopted, so that the carry of people is facilitated. Therefore, the portable clothes drying device is suitable for being promoted and applied.

Owner:周斌

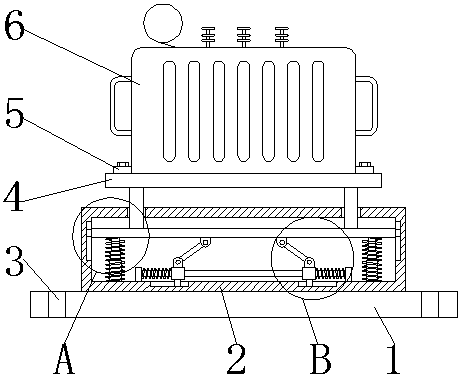

Power transformer fixing device

InactiveCN108831684AReduce wearExtended service lifeTransformers/reacts mounting/support/suspensionNon-rotating vibration suppressionTransformerEngineering

The invention discloses a power transformer fixing device. The power transformer fixing device comprises a mounting plate; a damping box is fixedly connected to the top of the mounting plate; telescopic rods are fixedly connected to the two sides of the bottom of the inner wall of the damping box; a supporting plate is fixedly connected to the tops of the telescopic rods; a first spring is arranged on the surface of each telescopic rod in a sleeved mode; and the bottom of the first spring is fixedly connected with the bottom of the inner wall of the damping box. By virtue of matched use of thedamping box, a fixed plate, a fixed piece, a transformer body, a supporting rod, the supporting plate, the first springs, the telescopic rods, a first fixed base, a connecting rod, a sliding rod, a sliding sleeve, second springs, fixed blocks and a second fixed base, the problem that an existing power transformer fixing device does not have a shock absorption function is solved; and the power transformer fixing device has the advantage of damping, so that the abrasion of the transformer is reduced, the service life of the transformer is prolonged, use of a user is facilitated, and the practicability of the power transformer fixing device is improved.

Owner:河南许智电力科技有限公司

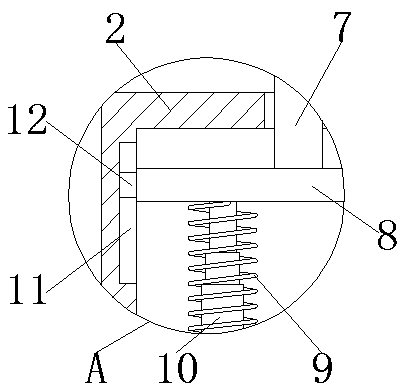

MPP electric power tube

The invention discloses an MPP electric power pipe, which comprises a pipe body, a positioning block is arranged on the top of the inner wall of the pipe body, balls are inlaid on the side of the positioning block away from the pipe body, and the bottom of the inner wall of the pipe body is fixedly connected with A ring block, and the top of the ring block is fixedly equipped with a telescopic rod, and the end of the telescopic rod away from the ring block is fixedly connected with a U-shaped bracket, the inside of the U-shaped bracket is provided with a buffer pad, and the pipe body includes an inner tube and outer tube. The MPP power pipe, through the improvement of the pipe body, improves the firmness of the pipe body itself, effectively protects the cable, and the setting of the buffer device not only achieves the protection effect of the pipe body when the cable is pulled, but also It also achieves the protective effect on the cable; the coordinated use of positioning blocks, balls, ring blocks, telescopic rods, U-shaped brackets and buffer pads further achieves the protective effect on the cable when pulling the cable, avoiding the Damage to cables.

Owner:RONGCHENG PIPE IND

Method for preparing antimicrobial modified polyvinyl alcohol-nonwoven compound microporous filtering film

InactiveCN101327408AImprove mechanical stabilityGood chemical stabilitySemi-permeable membranesChemical industryCross-link

The present invention belongs to the preparation technical field of the micro-filtering and ultra-filtering compound film, and relates to a method for preparing the antibiosis modified polyvinylalcohol-non-woven compound micro-hole filtering film, which is characterized in that the method comprises the following steps: casting film solution consisting of pyridine modified polyvinylalcohol, cross-linked agent and catalyst is prepared; the prepared casting film solution is performed the static deaeration and is filtered to remove the undissolved substance; under the sub-pressure effect, the filtered solution is coated on a post-treated melt-blown polypropylene non-woven cloth to be heat-treated, dried and washed to neutrality, and then to be undertaken the quaternize treatment; the film piece is immersed in the pure water for use. The method of the present invention has the advantages that the prepared compound film has favorable mechanical performance and chemical stability, and the surface of the film is neat and smooth. Particularly, the compound film has dual functions of hydrophile and antibiosis, and can reduce the absorption of the pollutant on the surface of the film, and can prevent the bacteria from breeding on the surface of the film, and maintaining the fluent property of the film holes, and has good micro-organism-pollution resistant property, and can be widely applied to the water treatment process in the fields such as the environment, the chemical industry, the food, the medical, etc.

Owner:DALIAN UNIV OF TECH

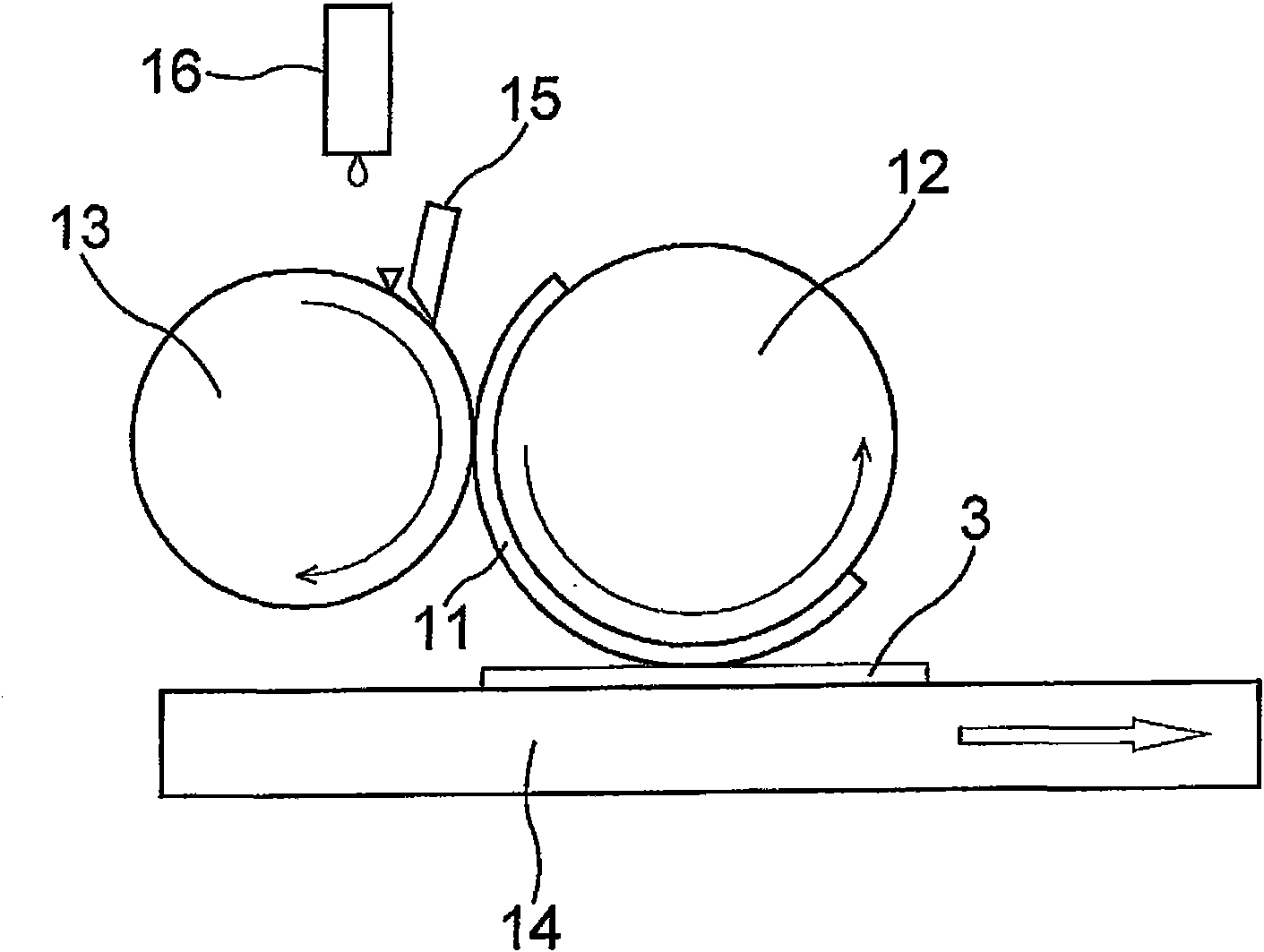

Petroleum asphalt coiled material laying equipment

ActiveCN108222384AEasy to attachImprove firm performanceRoof toolsRoads maintainencePetroleumAsphalt

The invention discloses petroleum asphalt coiled material laying equipment which comprises a mounting plate. Travel mechanisms are mounted at four corners of the lower side of the mounting plate, a cleaning mechanism is mounted on a side of the upper end of the mounting plate, a support frame is arranged on the upper side of the mounting plate, a feed roller is rotationally connected onto the support frame by a first rotary shaft, a discharge through opening is formed in the mounting plate, a guide plate which corresponds to the discharge through opening is arranged on the lower side of the mounting plate, a gas exhaust mechanism is mounted on the lower side of the mounting plate, the end, which is far away from the mounting plate, of the guide plate faces the gas exhaust mechanism, and aflattening mechanism is arranged on the side, which is far away from the guide plate, of the gas exhaust mechanism. The petroleum asphalt coiled material laying equipment has the advantages that the surfaces of laid locations can be cleaned by the cleaning mechanism, so that petroleum asphalt coiled materials can be conveniently attached to the laid locations, and the coiled material laying firmness can be improved; bubble between the coiled materials and the surfaces of the laid locations can be squeezed out by the gas exhaust mechanism, the petroleum asphalt coiled materials can be flattenedby the flattening mechanism, and accordingly the petroleum asphalt coiled material laying smoothness can be improved.

Owner:江苏东和循环科技有限公司

Air purification device

ActiveCN106785598AReduce stepsImprove work efficiencyLive contact access preventionAir purifiersElectrical connection

The invention discloses an air purification device which comprises an air purifier, a joint part connected with an electrical connection seat purifier by an electrical connection wire, and an electrical connection seat arranged on the front end face of a machine body. A control region is arranged at the center of the front end face of the purifier; an atomization opening is formed on the front end face of the purifier above the control region; an external screwing part is arranged on the front end face of the electrical connection seat; a through hole is formed in the external screwing part; an insertion slot is formed in the electrical connection seat at the rear side of the through hole; a second insertion needle is arranged on the inner wall of the rear side of the insertion slot; a first empty slot is formed in the electrical connection seat behind the insertion slot; a hole slot is formed on the inner wall of the rear side of the first empty slot; a pushing block is arranged in the first empty slot at the front side of the hole slot; a pushing spring plate is arranged between the end face of the rear side of the pushing block and the hole slot; guide feeding rods are correspondingly arranged in the first empty slot at both sides of the pushing spring plate; the guide feeding rods are movably matched and connected with the pushing block; a pressed-against rod which passes through an inner wall body of the electrical connection seat and extends into the insertion slot is arranged at the front end side of the pushing block; concave parts are formed in the left and right side end walls of the pushing block; a spline rotating shaft is correspondingly arranged in the first empty slot outside the pushing block; the rear side end of the spline rotating shaft is connected with a motor. The air purification device disclosed by the invention is simple in structure, convenient to operate, high in purification capacity and stable in power supply connection, and has an electric shock protection function; an electric shock accident is prevented; safety and stability of power supply are improved.

Owner:JIANGSU XIYI HIGH NEW DISTRICT TECH DEV CO LTD

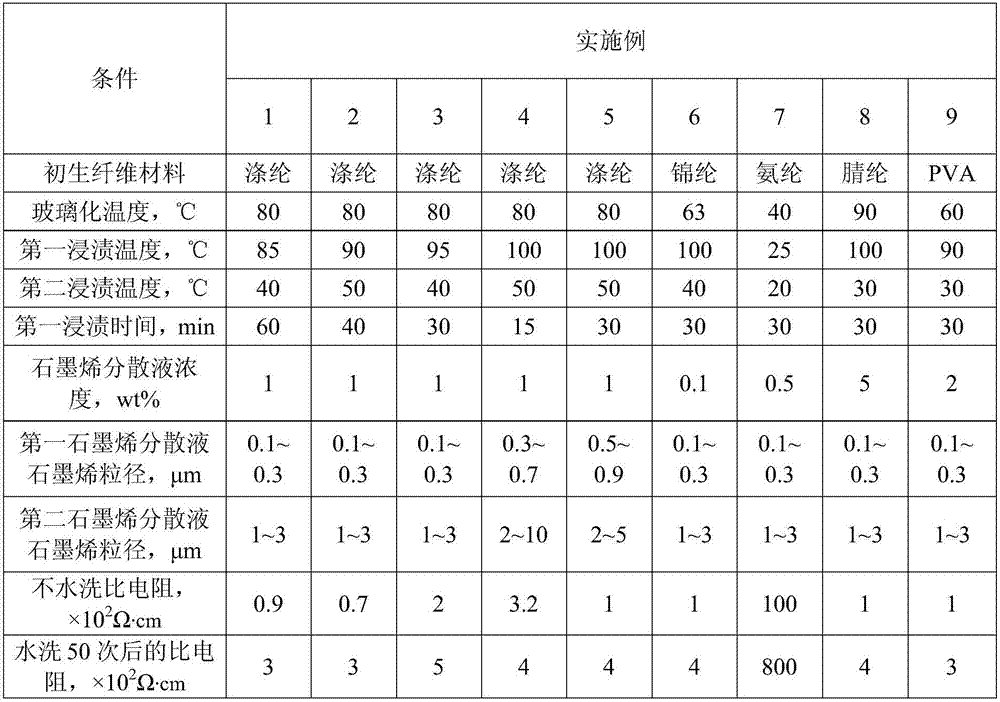

Composite fiber, preparation method and applications

The invention relates to a preparation method of composite fiber. The preparation method comprises the following steps: immersing nascent fiber in graphene substance dispersing solution and then cooling and drying to obtain composite fiber, wherein the range of immersing temperature is at high-elastic-state temperature of the nascent fiber material. By immersing nascent fiber into graphene substance dispersing solution at the high-elastic-state temperature, the compounding of the graphene substances inside and outside the fiber can be realized, and the evenness and firmness of the graphene substances in the fiber can be increased; the conductivity of the fiber can be enhanced by adding graphene and / or biomass graphene; the far infrared performance of the fiber can be further strengthened by adding graphene oxide and / and biomass graphene; and the graphene substances can be effectively added inside the fiber by adopting the preparation method, and the fiber is externally cladded with the graphene substances.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

Wire pipe or wire slot buckle and mounting method

ActiveCN106786235ARealize concealed installation workMake sure to adjust up and downElectrical apparatusKeelEngineering

The invention discloses a wire pipe or wire slot buckle and a mounting method. The wire pipe or wire slot buckle comprises a buckle panel, wherein the two side edges on the front surface of the buckle panel are turned inwardly to form turned edge buttons; a sliding groove is formed between two turned edge buttons and the front surface of the buckle panel; at least one row of wire pipe clamps are arranged on the back surface of the buckle panel; a screw thread through hole is formed in the center of the buckle panel; the sliding groove is connected with a wall surface transverse keel; the screw thread through hole is used for connecting a hoisting rod or a nut; and wire pipes or wire slots are fixed on the corresponding wire pipe clamps. According to the wire pipe or wire slot buckle disclosed by the invention, the mounting of the wire pipe or wire slot buckle is realized by the wall surface transverse keel on a wall body foundation layer; the buckle can slide left and right on the wall surface transverse keel to adjust the horizontal positions of the wire pipes or the wire slots, and the vertical positions of the wire pipes or the wire slots on the wire pipe clamps so as to realize position adjustment of a wire box; and the wire pipe or wire slot buckle is simple in structure, rapid, flexible and convenient to mount, and capable of realizing wire pipe hidden mounting operation.

Owner:ZHEJIANG YASHA DECORATION

Treatment process of corn bran

InactiveCN104647546AThe processing method is simpleImprove anti-corrosion performanceWood treatment detailsReed/straw treatmentSulfurBran

The invention relates to a treatment process of corn bran. The treatment process comprises the following steps: (1) washing, (2) preparing a treatment agent, (3) soaking, (4) suffocating, and (5) dyeing. The treatment process of the corn bran is simple, and corn bran is treated by virtue of the treatment agent, so that the anticorrosion property of the corn bran can be greatly improved, the anticorrosion time of the corn bran can reach more than 3 years; the corn bran can be dyed after being suffocated by utilizing sulfur, so that the fastness of the dyeing can be improved, the color fading problem in the application process can be avoided, and the attractiveness of a product can be improved.

Owner:阜南县金源柳木工艺品有限公司

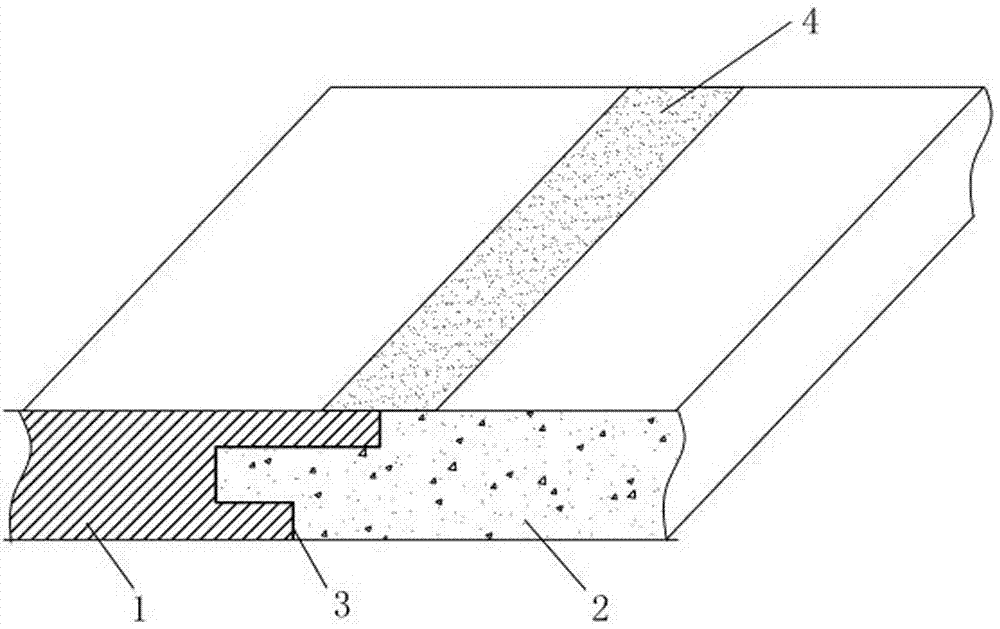

Overlapping structure of waterproof coil materials, and construction method

InactiveCN107313342AInhibition of Infiltration and PenetrationImprove bonding performanceUnderground chambersRoof covering using flexible materialsGraphene nanocompositesWater seepage

The invention discloses an overlapping structure and a construction method of a waterproof coiled material, and belongs to the technical field of waterproof layer construction. The overlapping structure includes two waterproof rolls whose ends are overlapped with each other, wherein one end of the waterproof roll is in an asymmetric concave shape, and the end of the other waterproof roll is in a corresponding convex shape. The overlapping parts of the waterproof membrane are connected by an adhesive layer, and a waterproof strengthening coating is also provided at the seam of the surface of the waterproof membrane. The construction method of the lap joint structure is as follows: clean up the lap joint ends of the two waterproof rolls and remove the protective film; evenly coat the contact surfaces of the two lap joint ends with adhesive epoxy resin / graphene nanocomposite material ;Tightly combine the two overlapping ends, press for 2~5 minutes, and then apply a strong waterproof coating on the seam of the upper surface of the waterproof membrane, and let it dry. The overlapping structure can greatly improve the firmness of the overlapping structure of the waterproof coiled material, avoid water seepage and leakage, and has a good application prospect.

Owner:安徽科徽联合认证有限公司

Catalyst for ozone catalytic oxidation reactions, and preparation method thereof

ActiveCN109908934AReduce contentIncrease profitCatalyst activation/preparationWater/sewage treatment by oxidationActivated carbonCatalytic oxidation

The invention discloses a catalyst for ozone catalytic oxidation reactions, and a preparation method thereof, wherein the catalyst comprises a composite carrier and an active metal component, a noblemetal is used the active metal component, and the composite carrier comprises active carbon and a basic carbonate. The preparation method comprises: mixing active carbon and a soluble organic salt solution, introducing a carbonate solution or an alkaline solution into the obtained material A to obtain a material B after uniformly mixing, carrying out solid-liquid separation on the obtained material B, drying, and calcining to obtain a material C; and mixing the material C and water, carrying out a reaction by introducing carbon dioxide gas, cooling, carrying out solid-liquid separation, dryingthe separated solid phase, calcining to obtain a composite carrier material, impregnating with an active metal and an optional auxiliary agent component, drying, and calcining to obtain the catalyst.According to the present invention, the catalyst has characteristics of simple preparation process, good stability and high COD removal ability, and can alleviate the problem of metal loss.

Owner:CHINA PETROLEUM & CHEM CORP +1

Shock-resistant pipeline mounting device

InactiveCN107676546AImprove impact resistanceImprove anti-corrosion performancePipe supportsNon-rotating vibration suppressionArchitectural engineeringScrew thread

The invention discloses an anti-seismic pipeline installation device, which comprises a base, a lifting seat is arranged above the base, through holes are opened on both sides of the bottom end of the lifting seat, a threaded rod is slidingly arranged in the through hole, and the threaded rod is threaded. A fixed ring is connected, and the upper end of the lifting seat is fixedly connected with a lower support half ring. The upper end of the lower support half ring is provided with an upper support half ring. The protection pad is fixedly connected with the upper support half-ring and the lower support half-ring respectively through a plurality of springs, and the end of the upper support half-ring away from the rotating shaft is fixedly connected with a connecting plate, and the connecting plate is threadedly connected with fastening bolts, and the lifting seat is provided with a The threaded hole has a simple structure and a reasonable design, which can greatly improve the anti-seismic ability of the pipeline, prevent the pipeline from breaking, and improve the safety of pipeline transportation.

Owner:曾国琼

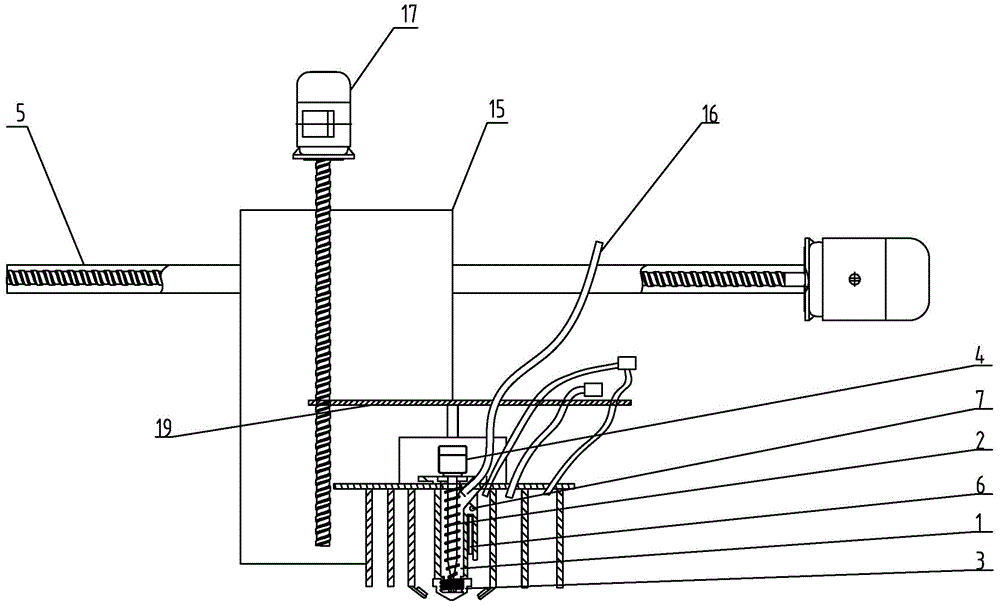

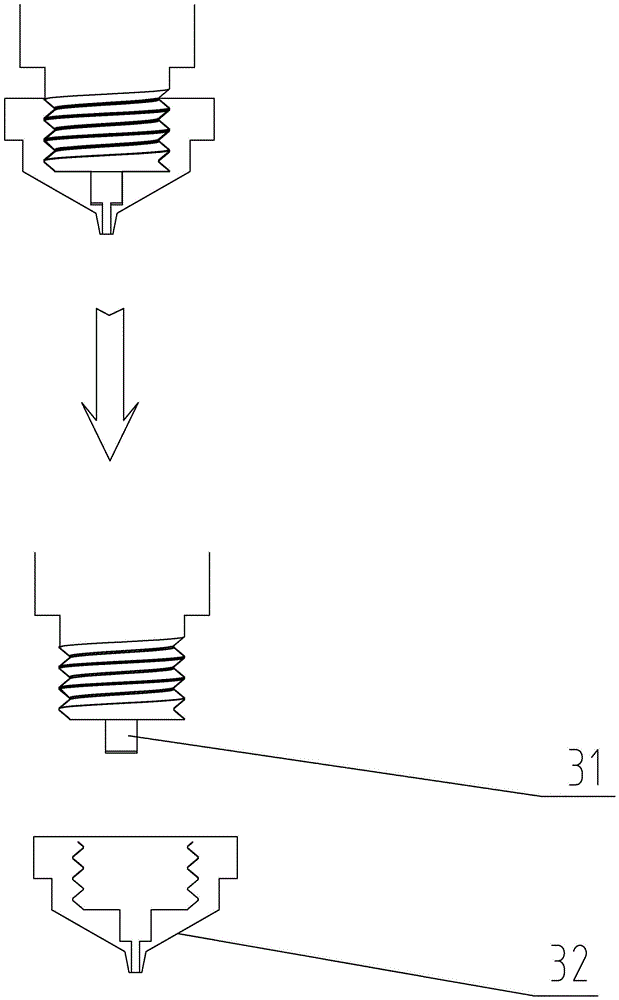

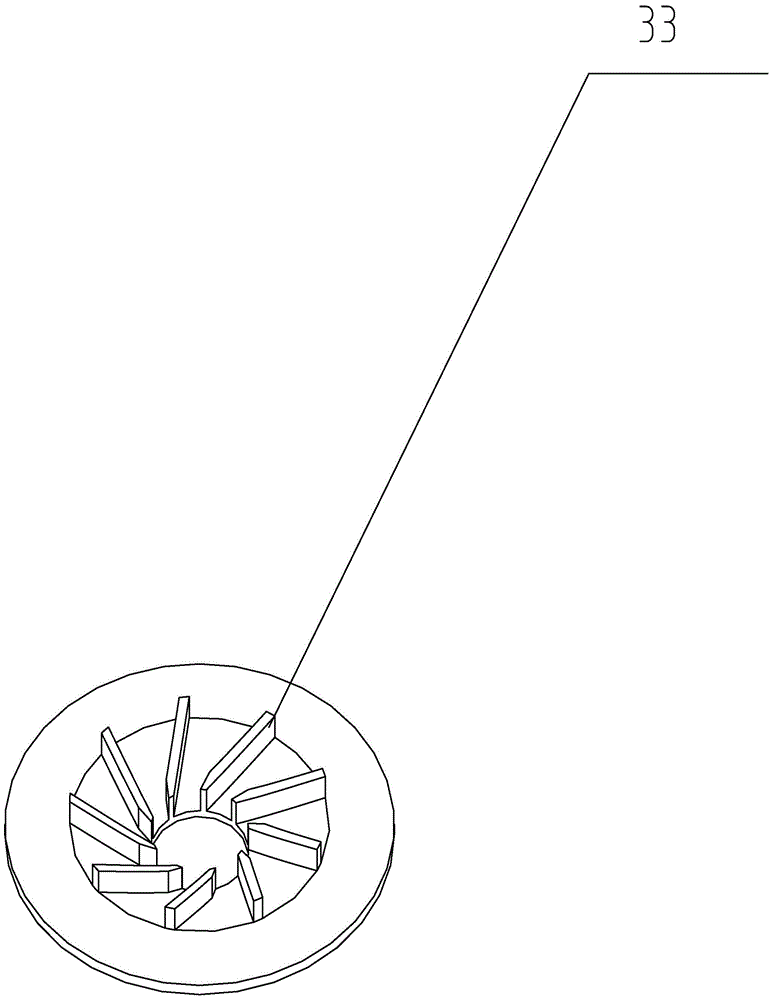

Multifunctional 3D printing head

The invention discloses a multifunctional 3D printing head, which is suitable for 3D printers in any hot melting additive stacking forms. The 3D printing head includes a hot melting chamber, an extrusion pump, a double sleeve spray nozzle, a hot air polishing and cold air shaping apparatus. During 3D printing by means of the multifunctional 3D printing head, a plurality of sub spray nozzles in different pore diameters can be selected conveniently. A raw material is hot-melted in the hot melting chamber, and then the hot-melted material is outputted by means of an extruding pump in an extruded manner. The double sleeve spray nozzle extrudes a paste-like melted wire which is then subjected to re-treatment through the hot air polishing and cold air shaping apparatus, wherein the extruded material is polished and extruded through spiral hot air, and meanwhile, the hot air is pumped back, and then the stacked material is cooled and shaped by means of cold air generated through semi-conductor refrigeration. Through the hot air for polishing and flatting and the cold air for cooling the material, printing precision is greatly increased, and the material after additive printing is flat and smooth and is free of deformation. A shaped product is more firm.

Owner:CHANGZHOU DONGKE ELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com