Patents

Literature

65results about How to "Achieve the purpose of compression" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

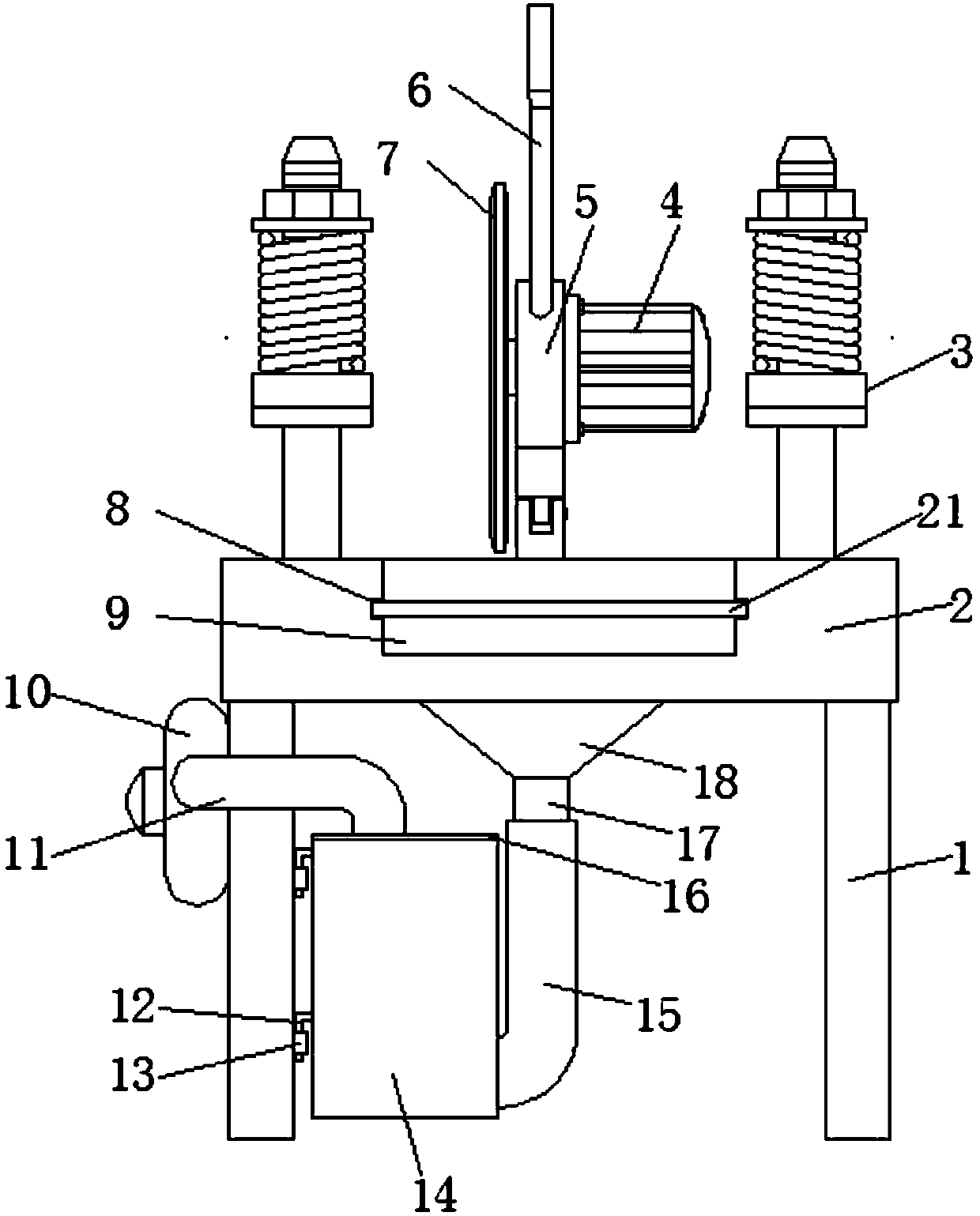

Intelligent cutting machine with locating and dust-collecting function

InactiveCN107081634AFunctionalAchieve the purpose of compressionShearing machinesMaintainance and safety accessoriesEngineeringRebar

The invention discloses an intelligent cutting machine with a locating and dust-collecting function. The intelligent cutting machine comprises a worktable, the four corners of the bottom surface of the worktable are all fixedly connected with supporting legs, the front part of the upper surface of the worktable is provided with a groove, the middles of the two sides of the inner wall of the groove are both provided with slide grooves, the slide grooves are internally slidably connected with frames, the inner sides of the frames are welded to a screening net, the front parts of the frames are welded to a handle, the upper surface of the worktable is in pin joint with a supporting plate, and the supporting plate is located at the rear portion of the groove. In the intelligent cutting machine with the locating and dust-collecting function, fixing devices are arranged at the two sides of the groove, when the intelligent cutting machine is in use, the handle can be drawn back, tubular products or reinforcing steel bars are placed on two stand columns at the same side of the groove, then the handle is loosened, under the effect of springs, a pressing plate is pressed on the upper surfaces of the tubular products or the reinforcing steel bars, and thus the purpose of pressing tightly the tubular products and the reinforcing steel bars is achieved, through deformation under compression of a rubber cushion, the bottom surface of the pressing plate can be more tightly attached to the reinforcing steel bars or the tubular products, and thus the firmness of stitching the reinforcing steel bars or the tubular products is improved.

Owner:金陈敏

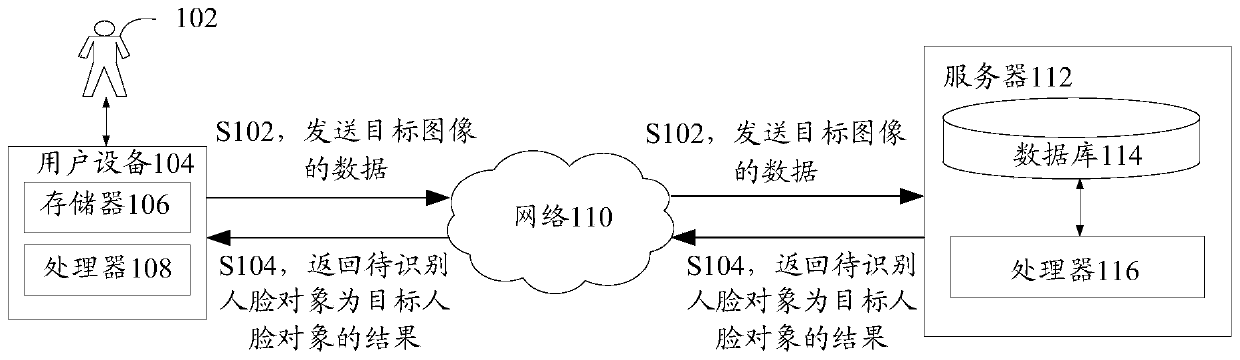

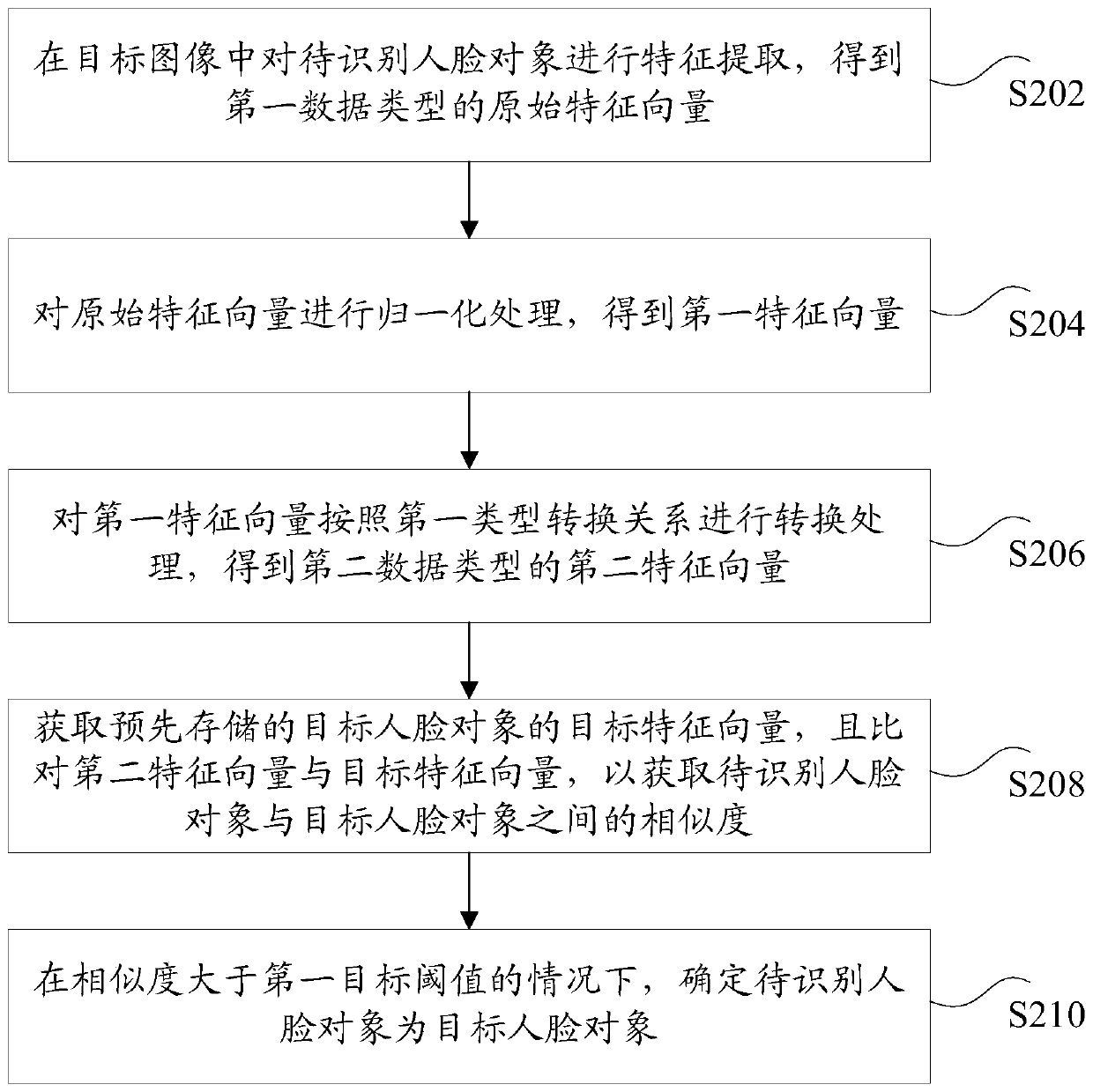

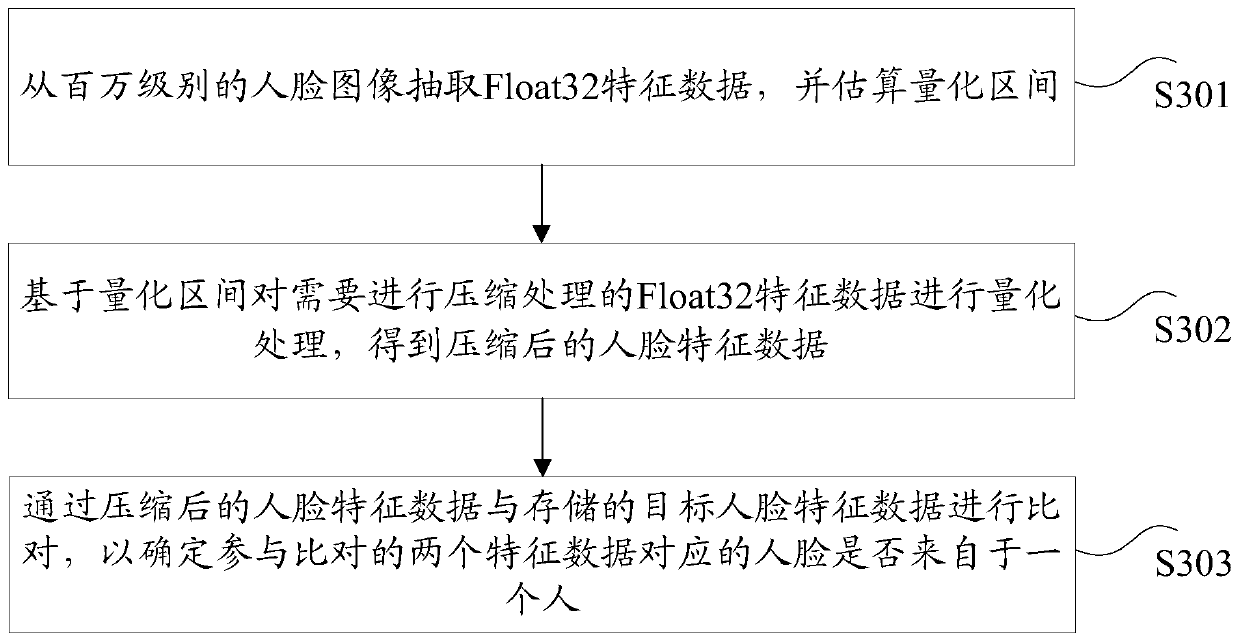

Face feature processing method and device, and storage medium

ActiveCN110147710AReduce storage pressureRelieve pressureImage enhancementImage analysisFeature vectorFeature extraction

The invention discloses a face feature processing method and device, and a storage medium. The face feature processing method comprises the following steps: carrying out feature extraction on a to-be-identified face object in a target image to obtain an original feature vector of a first data type; performing normalization processing on the original feature vector to obtain a first feature vector;performing conversion processing on the first feature vector according to a first type conversion relation to obtain a second feature vector of a second data type, the storage space occupied by the second feature vector being smaller than the storage space occupied by the original feature vector; obtaining a pre-stored target feature vector of the target face object, and comparing the second feature vector with the target feature vector to obtain the similarity between the to-be-identified face object and the target face object; and under the condition that the similarity is greater than a first target threshold, determining the to-be-identified face object as a target face object. According to the invention, the technical problem of high cost for processing the face features in the priorart is solved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

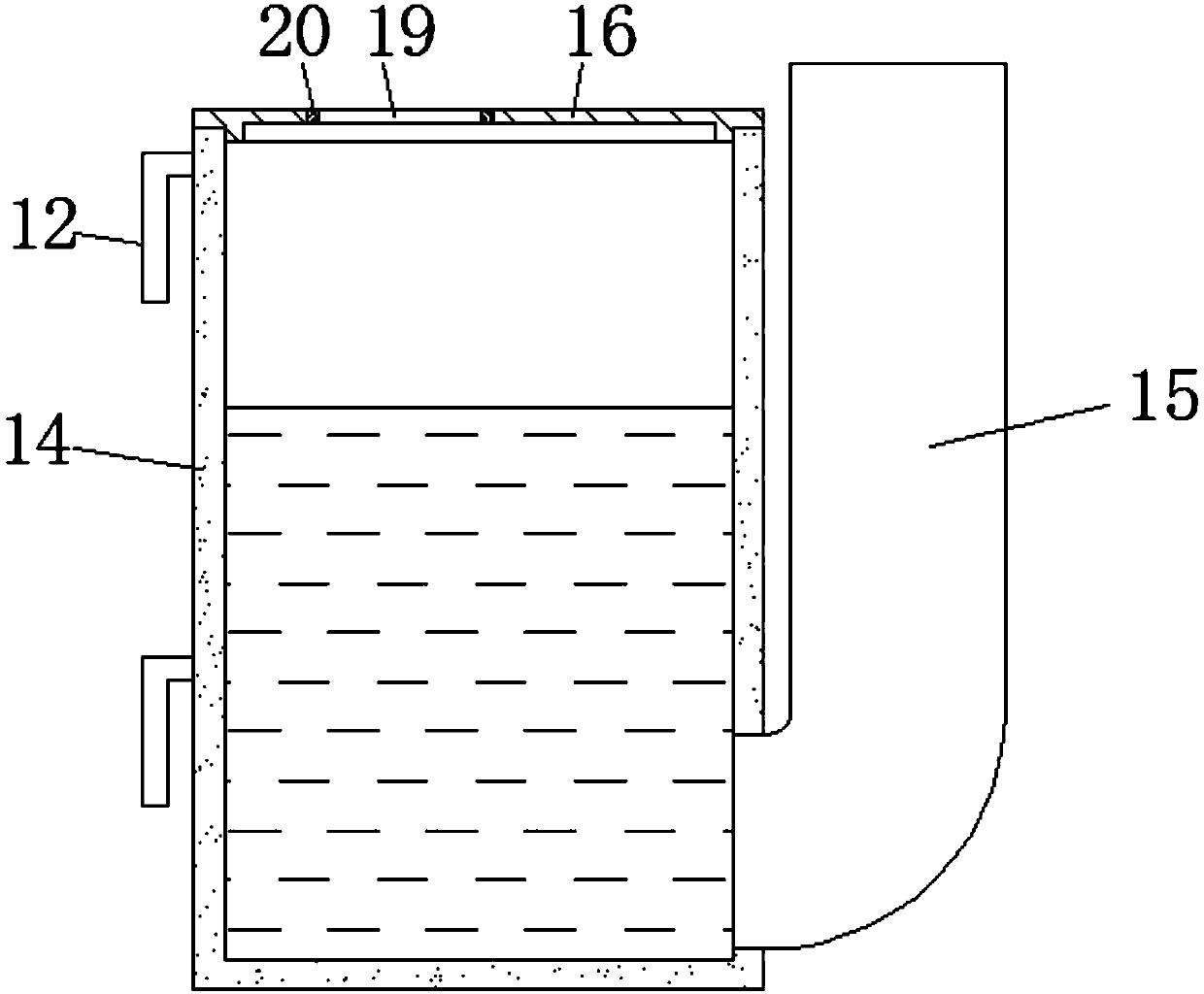

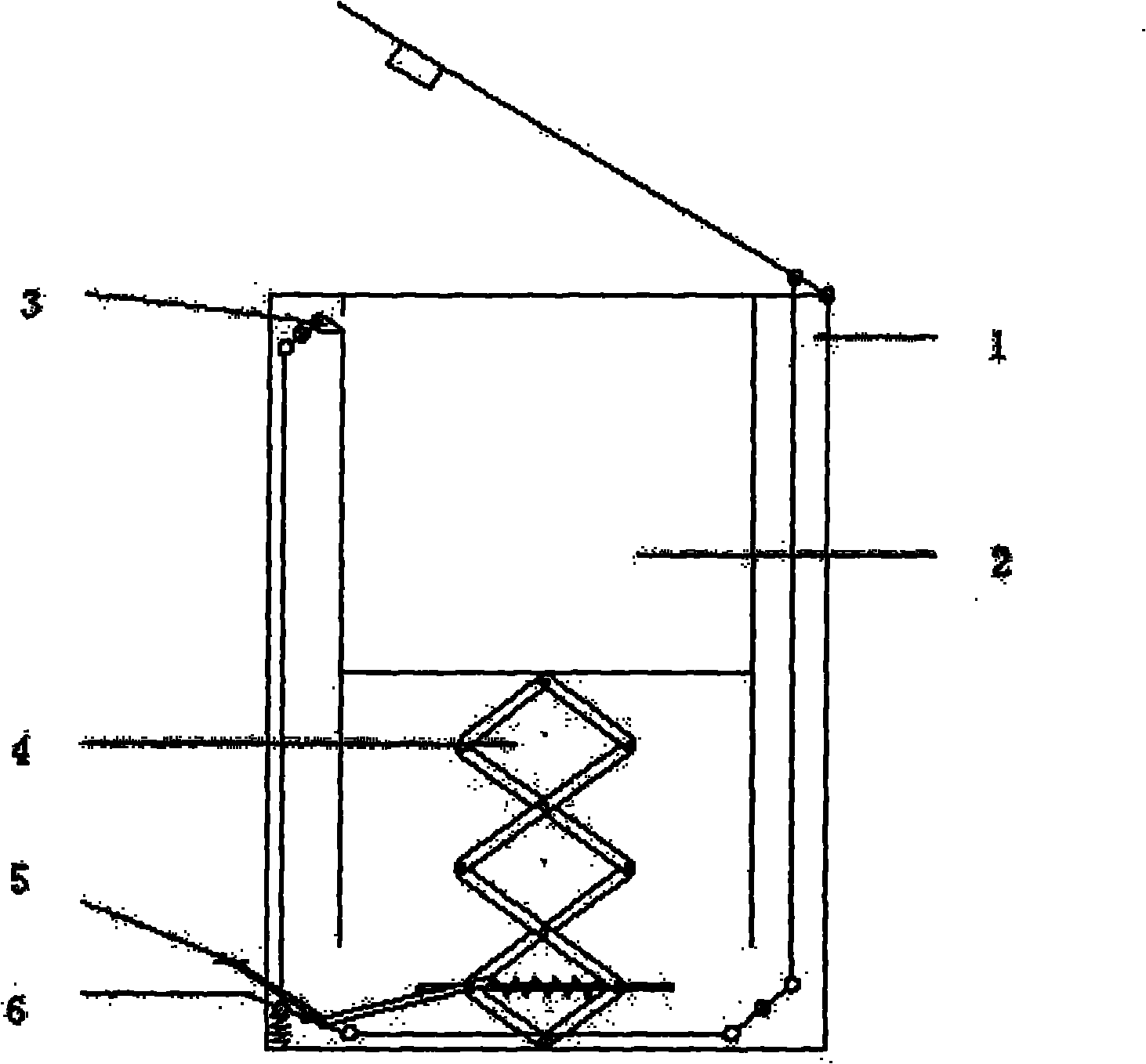

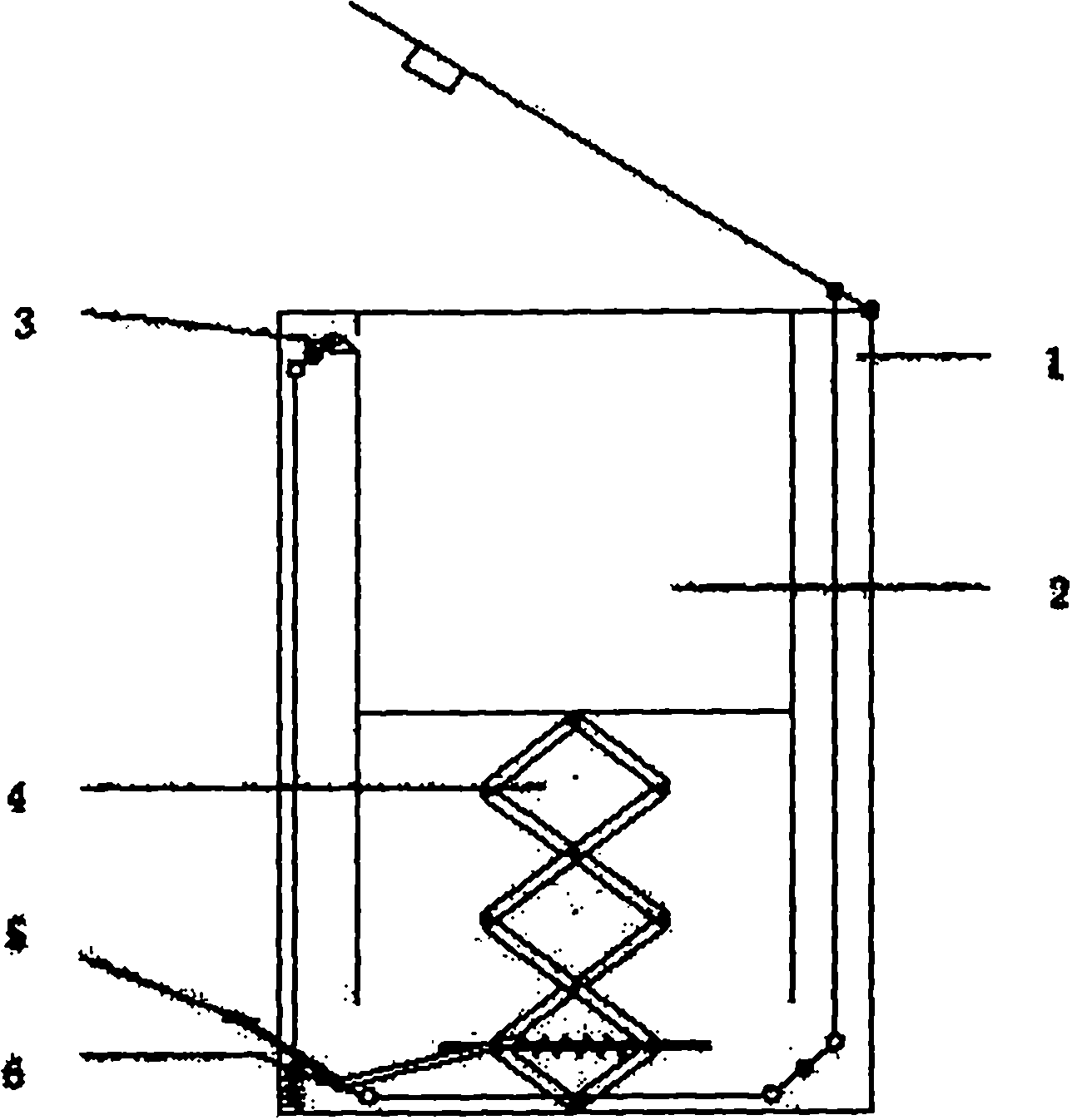

Garbage can capable of compressing garbage

InactiveCN102060156ACapable of compressingAchieve the purpose of compressionRefuse receptaclesControl systemEngineering

The invention discloses a garbage can capable of compressing garbage. The garbage can comprises an outer case, a buckle, an outer case cover, an inner case, an inner case bottom, a lift device, pedals and a lever device, wherein the inner case is sleeved inside the outer case; the inner case bottom is connected with the outer case bottom through the lift device; the lift device is connected to one control pedal on the outer case through a transmission lever; and the buckle on the upper end of the inner case and the outer case cover are connected to the other control pedal on the outer case through the transmission lever. Besides functions of the traditional garbage can, the garbage can also has the function of compressing garbage. When the garbage is compressed, the inner case bottom moves upwards under the control of a control system, and presses the garbage together with the case cover, so that the aim of compressing the garbage is realized. Lifting of the lift device in the case, tightening and loosening of the buckle and opening of the case cover are realized by the pedals through levers. The garbage can capable of compressing garbage provides great convenience for daily life of people.

Owner:曾耿辉

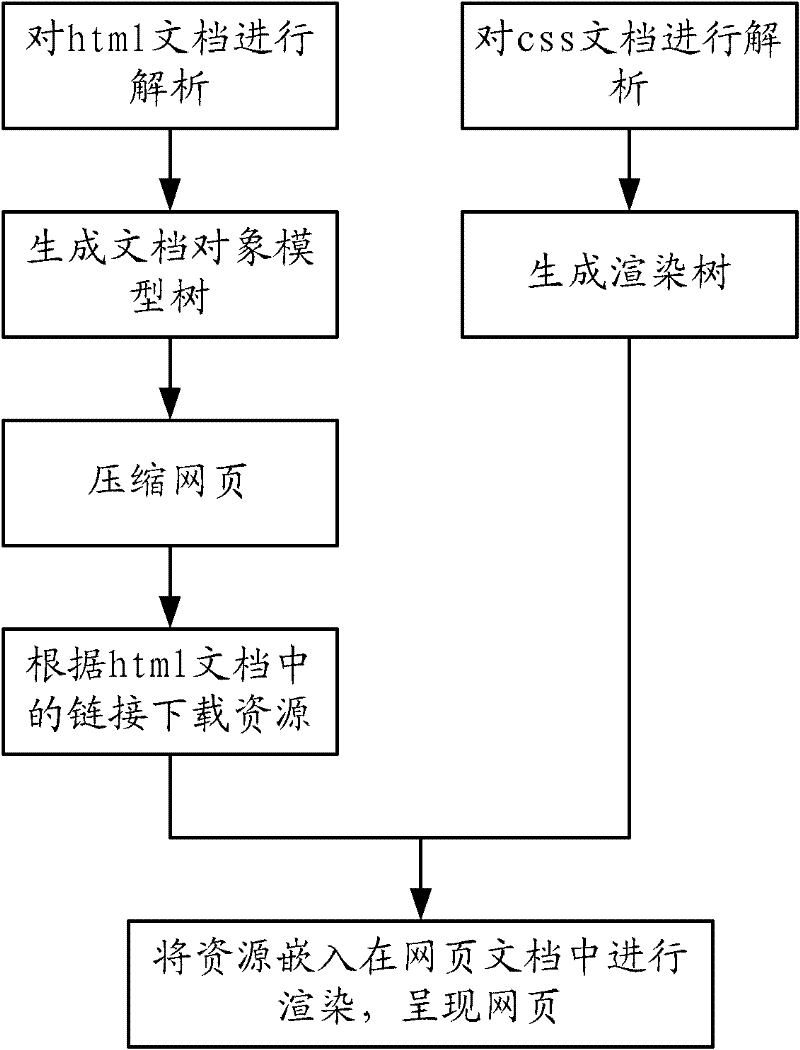

Webpage compression method applied to mobile terminal

ActiveCN102541863AAchieve the purpose of compressionImprove browsing experienceSpecial data processing applicationsDocument preparationCompression method

The invention discloses a webpage compression method applied to a mobile terminal. The webpage compression method comprises the following steps of: firstly respectively analyzing an html document and a css document, generating a document object model tree and a render tree, downloading the required resource according to a link in the html file, and finally embedding resource into a webpage file to be rendered and presenting a webpage; and compressing the webpage after a document object model tree is generated, and downloading the required resource according to the link in the html document after the webpage is compressed. The invention relates to the field of mobile communication, the webpage compression method applied to the mobile terminal is applicable to various internet-connected mobile terminals, and a webpage browsing speed of a mobile terminal browser can be effectively improved.

Owner:JLQ TECH CO LTD

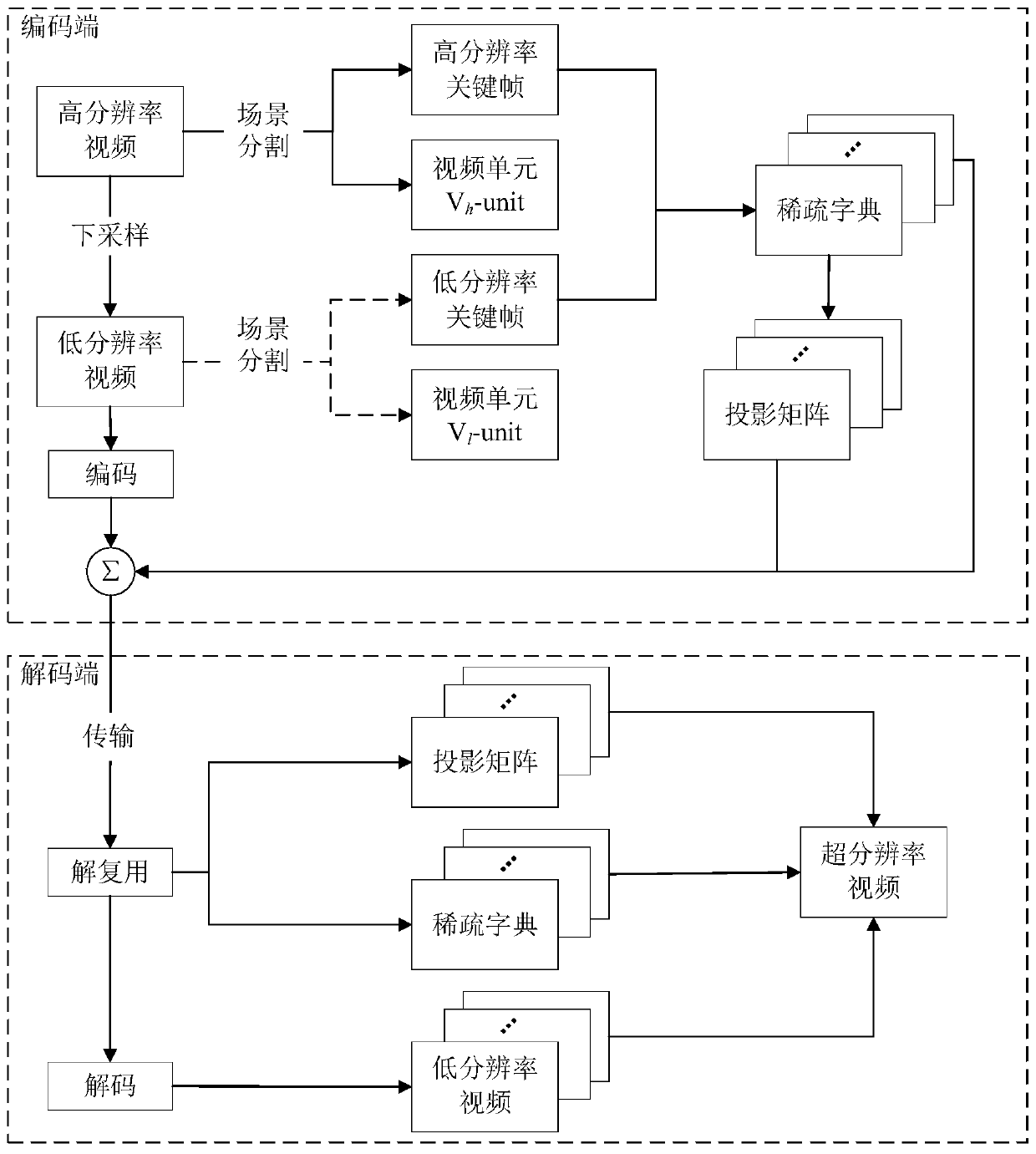

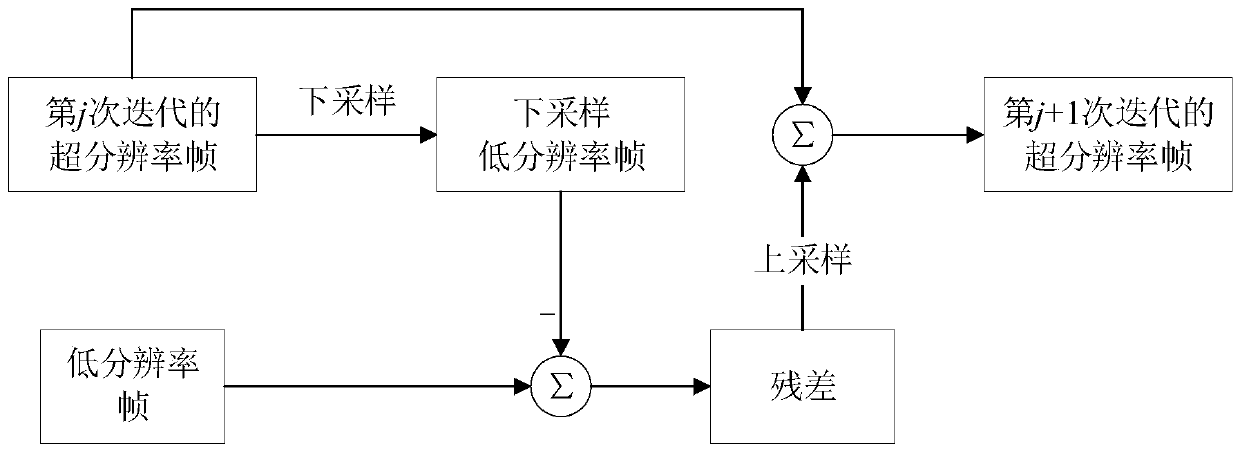

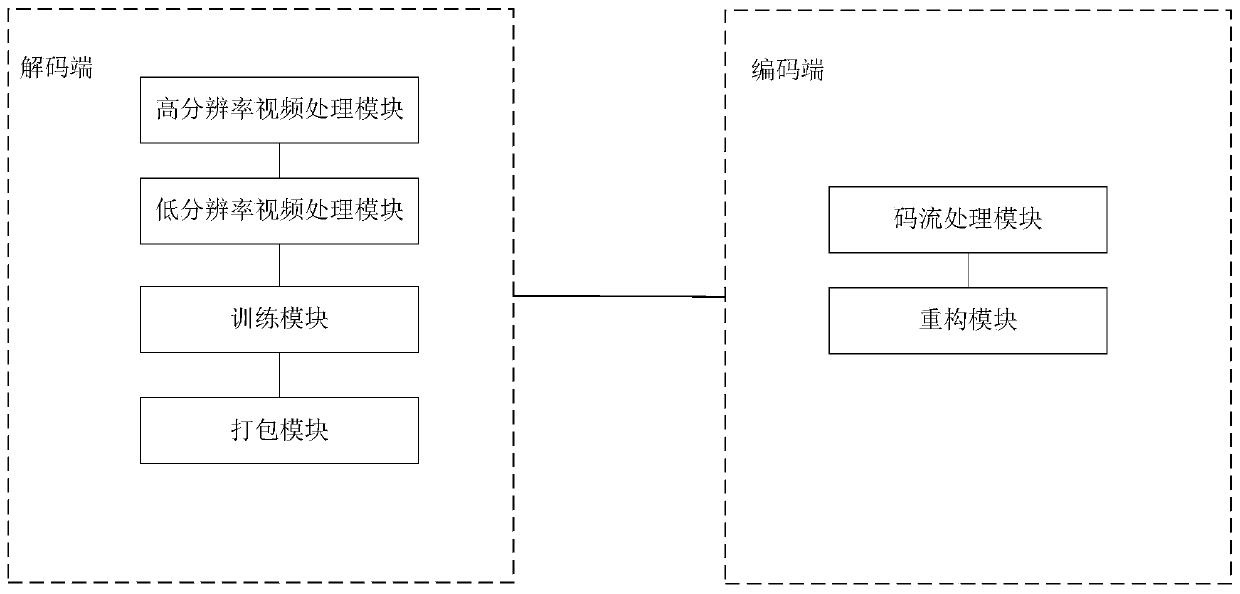

Video compression method and system based on super-resolution

InactiveCN110062232AAchieve the purpose of compressionReduce bandwidth requirementsDigital video signal modificationHat matrixImage resolution

The invention discloses a video compression method and system based on super-resolution. the segment-by-segment training of a mapping relation is carried out after a down-sampling video is segmented in a coding stage, and a sparse dictionary, a projection matrix and a video are transmitted together; in the decoding stage, the unique mapping matrix of each video segment is utilized to restore the low-resolution video to the original size through super-resolution, so that the requirements for bandwidth and storage are reduced, and the requirement for watching the high-resolution video is met. Onthe basis of the existing video compression coding standard, the coding code rate is greatly reduced by using the super-resolution technology through the internal information of the video, and meanwhile, the subjective quality of the decoded video is ensured as much as possible.

Owner:HANGZHOU DIANZI UNIV

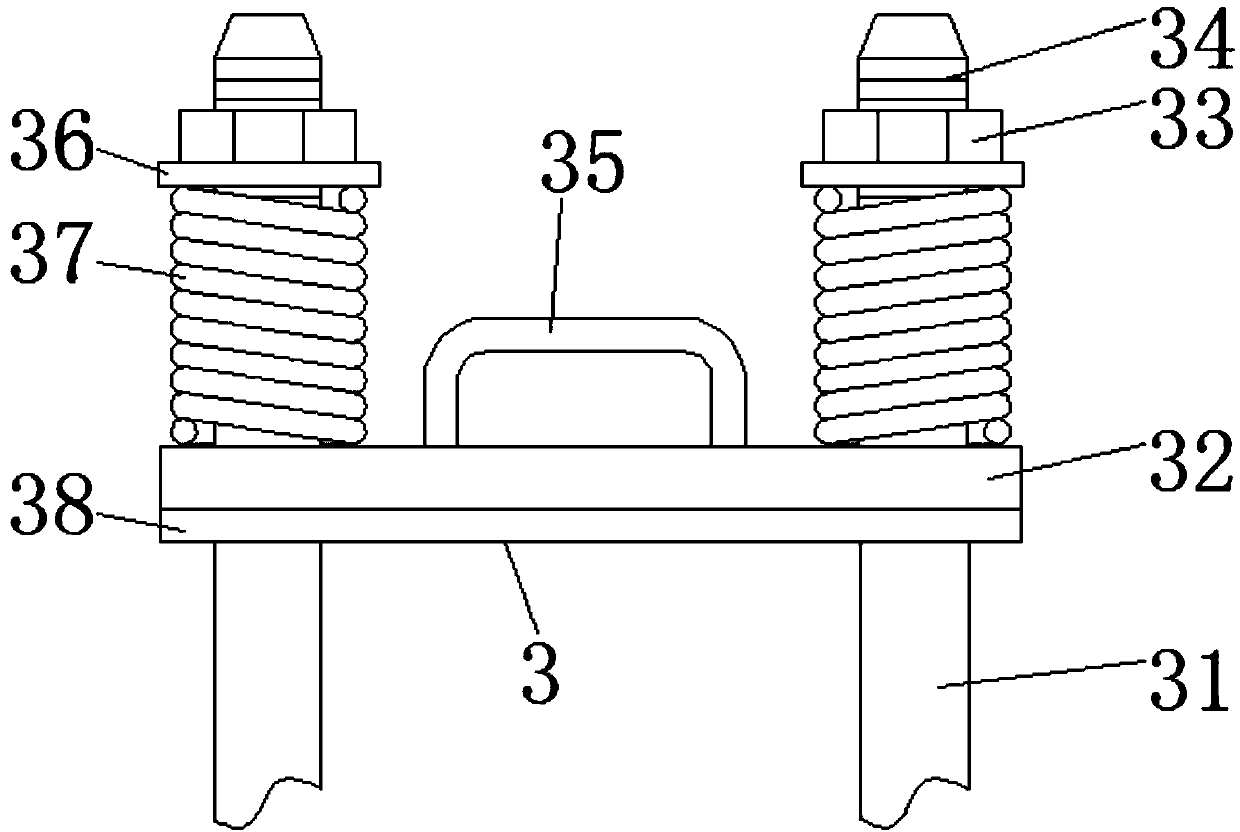

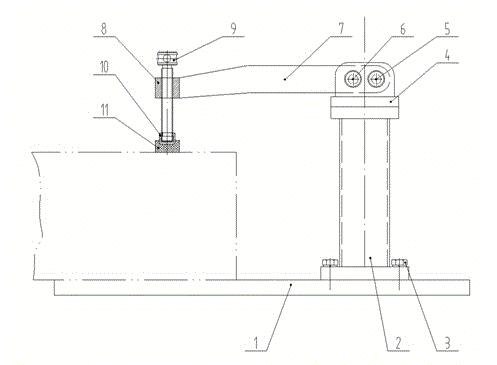

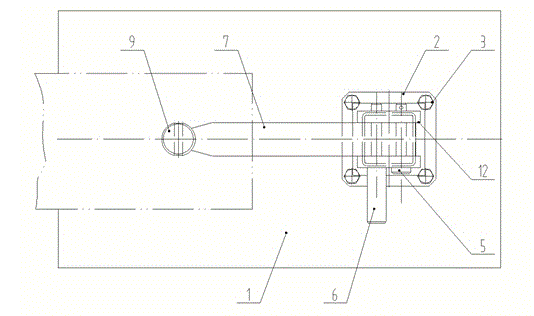

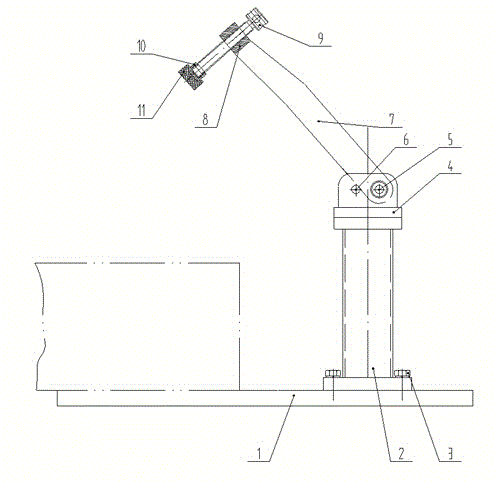

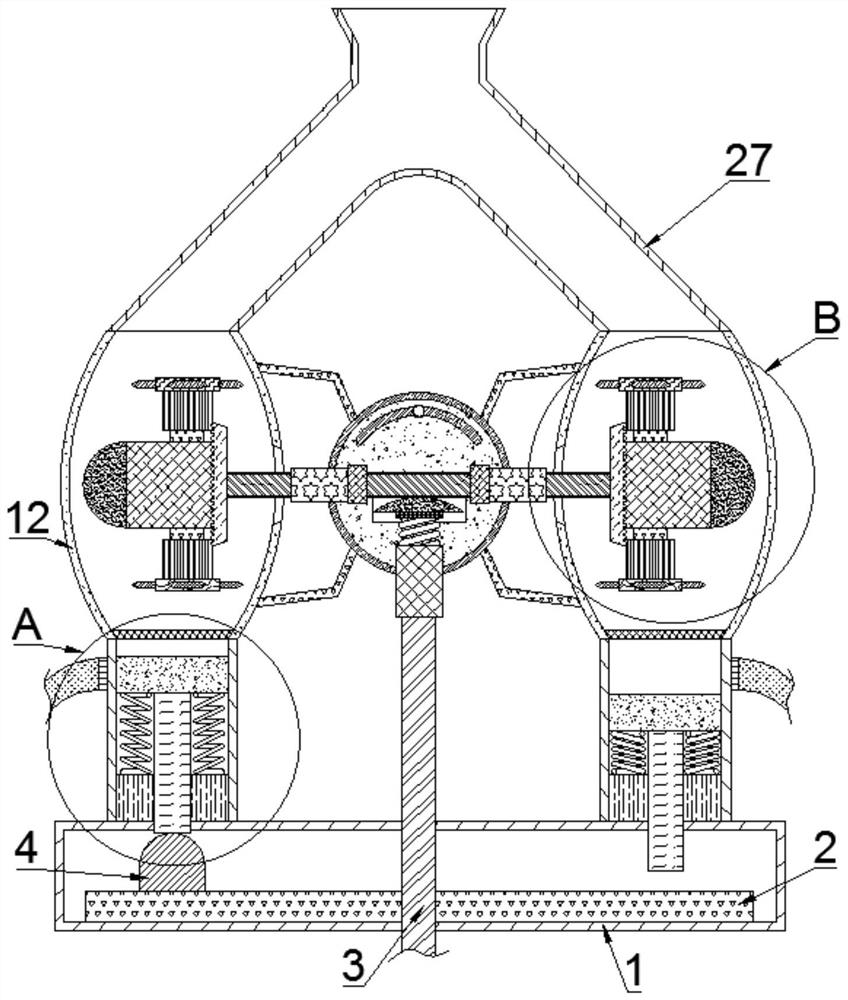

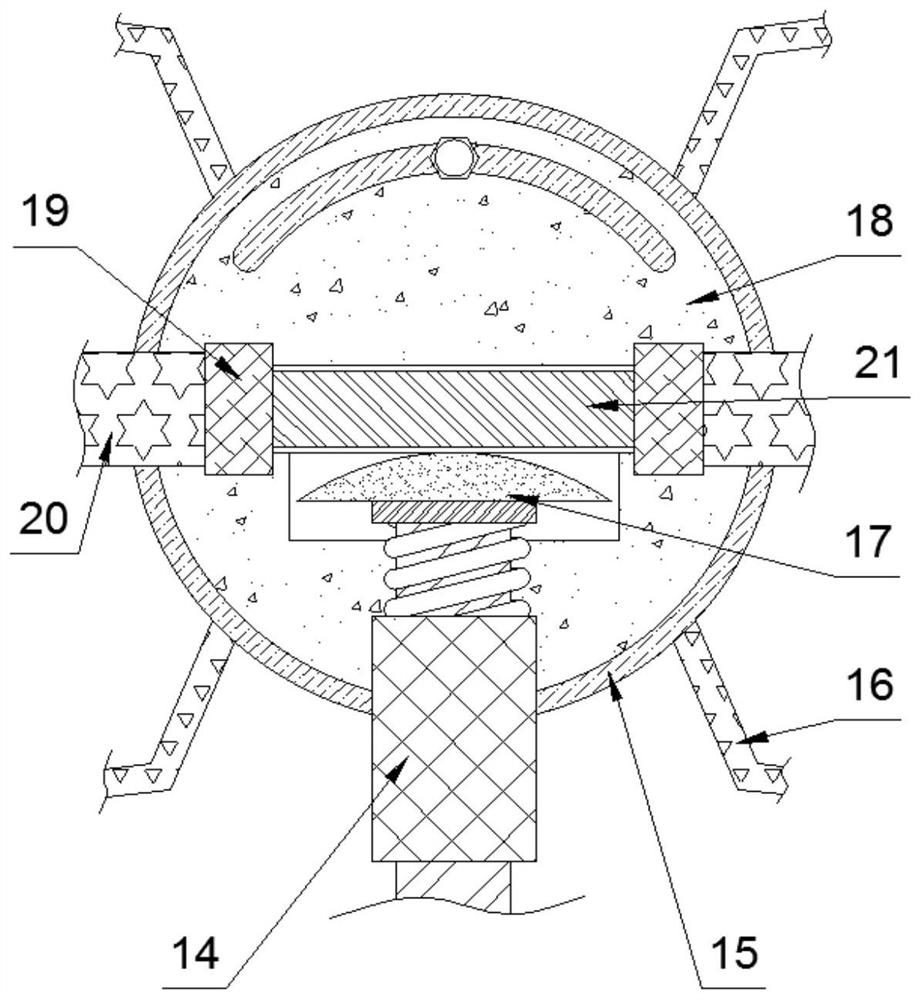

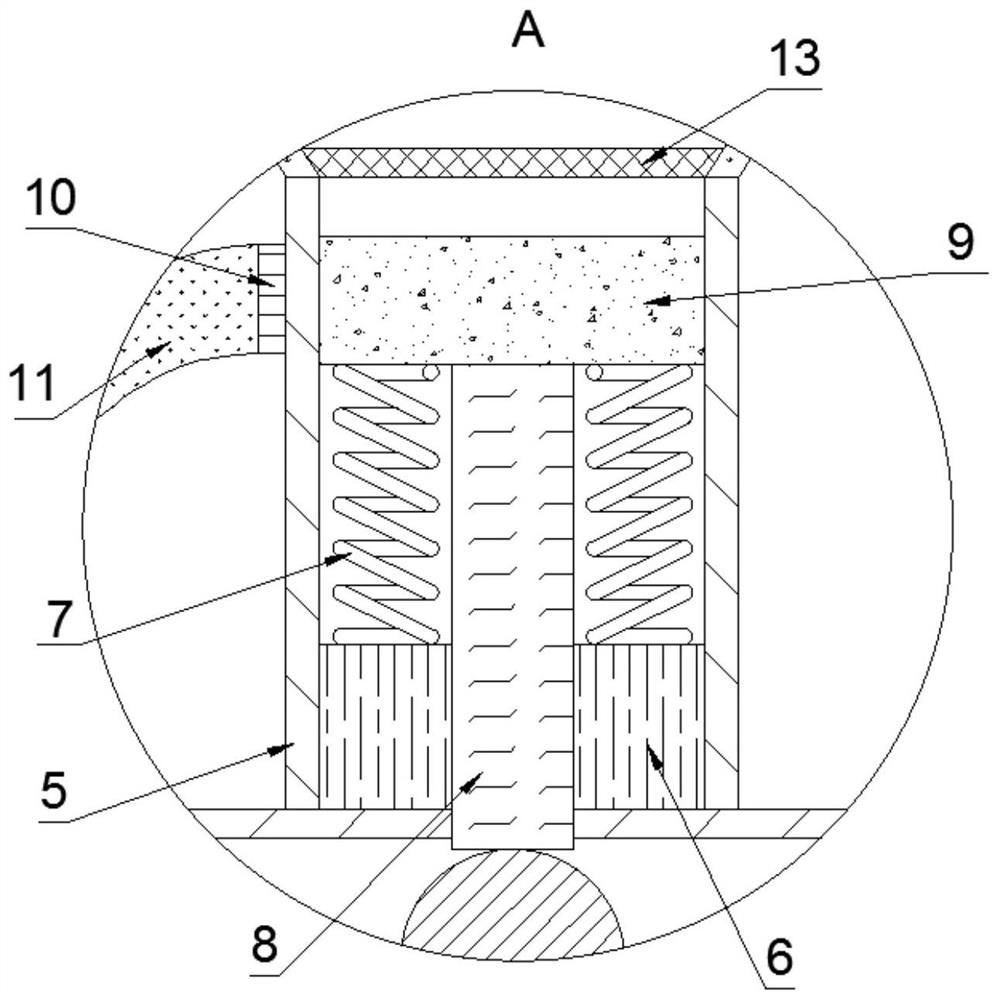

Plug pin turnover type compressing device

InactiveCN106312860ASimple structureAchieve the purpose of compressionWork holdersPositioning apparatusEngineeringMechanical engineering

Owner:陆应根

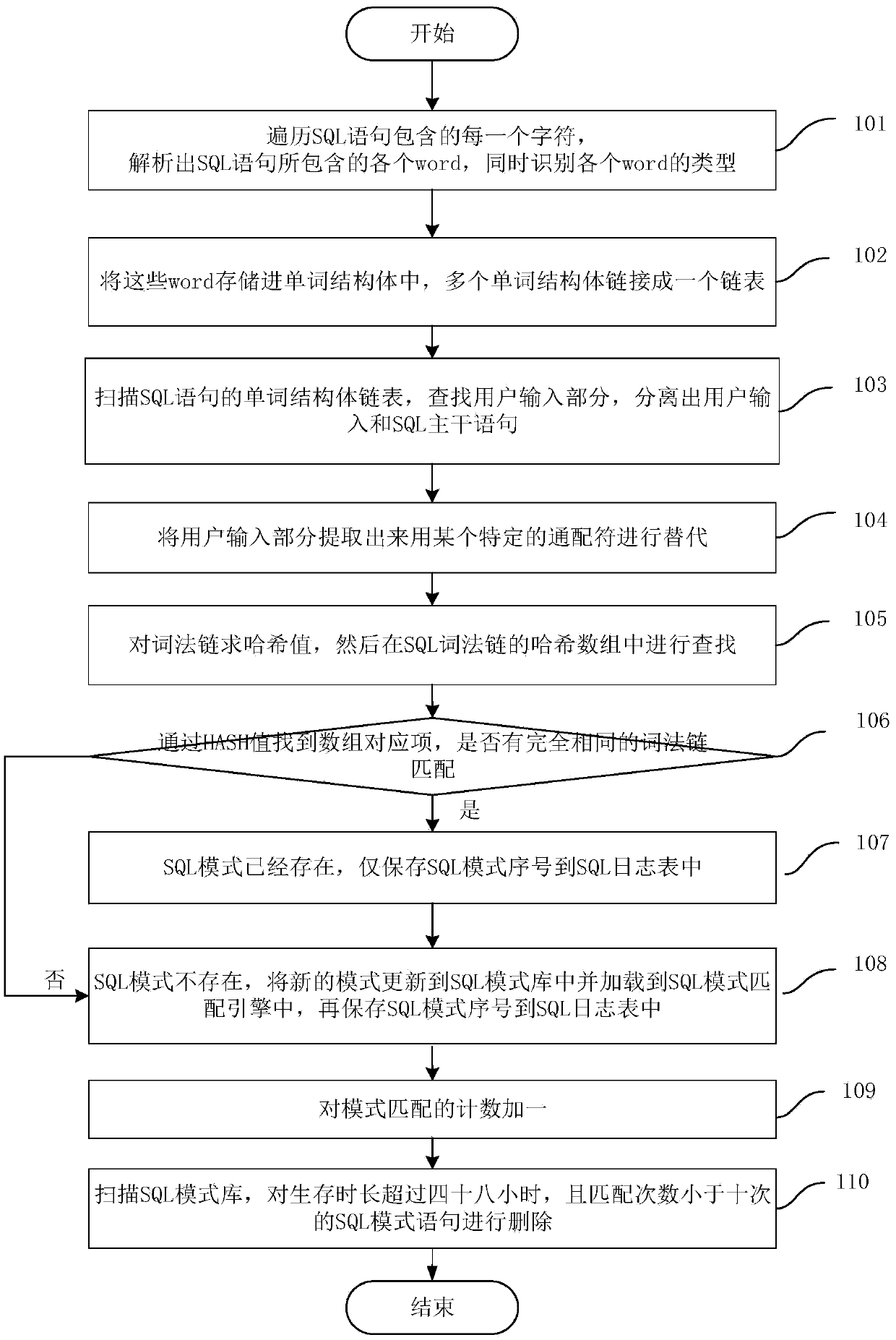

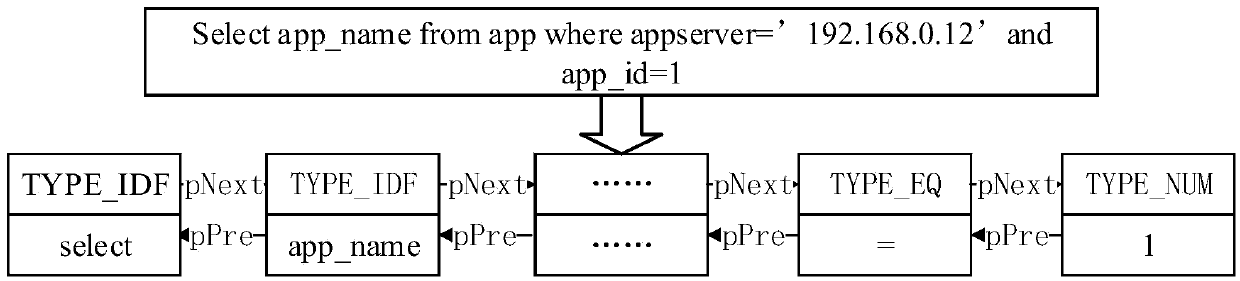

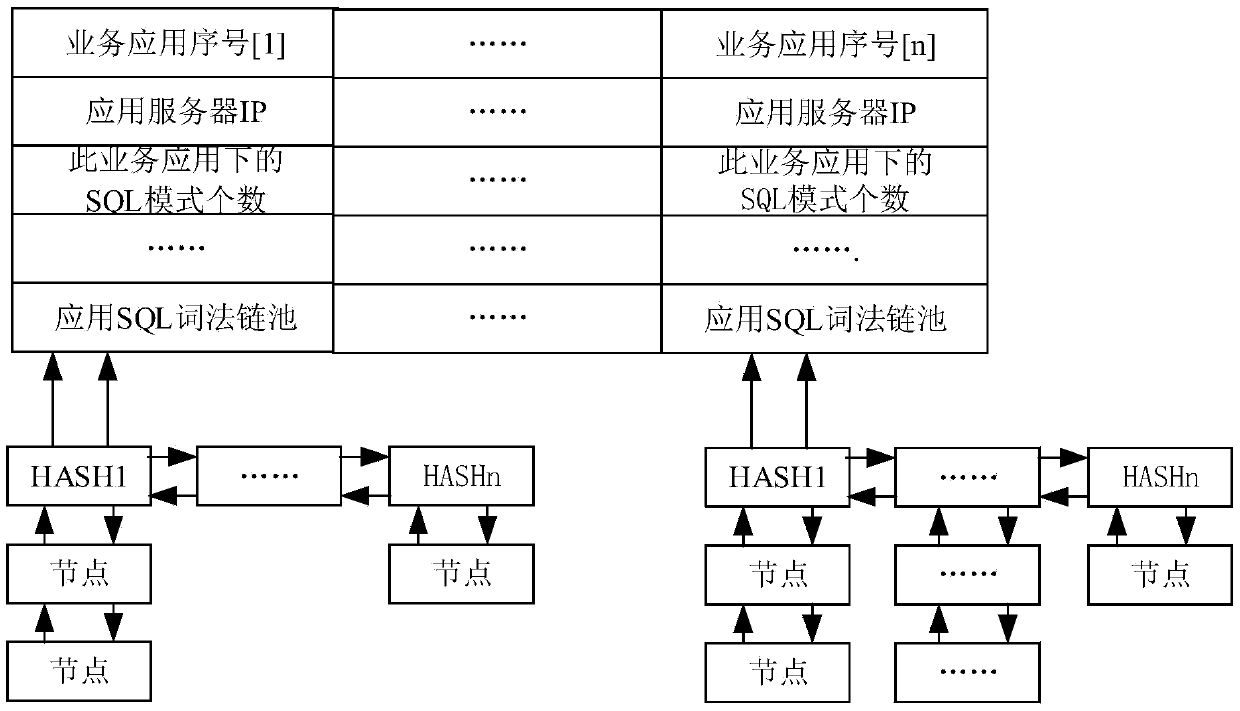

Method for compressing SQL access log of power business system

ActiveCN105373607AAchieve the purpose of compressionImprove matching speedSpecial data processing applicationsPart of speechPattern matching

The invention provides a method for compressing an SQL access log of a power business system. The method comprises the following steps: (1) decomposing an SQL statement of storing a period of continuous buffer zone into a word structure chain table of parts of speech and contents; (2) replacing a user input part in the word chain table, and creating an SQL pattern statement; and (3) adding a new SQL pattern statement to an SQL pattern library and building an SQL pattern matching engine. According to the method provided by the invention, the SQL access log of the power business system can be effectively compressed, so that extraction of useful information is facilitated; the utilization rate of resources is improved; and loss of internal information of original data is avoided.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

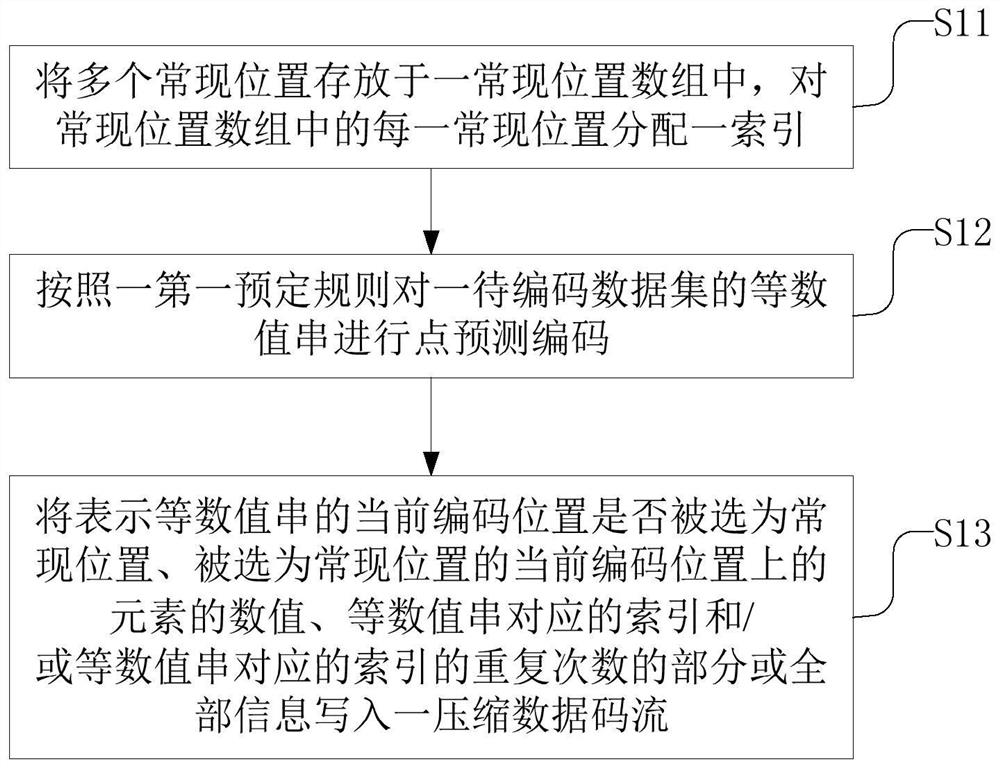

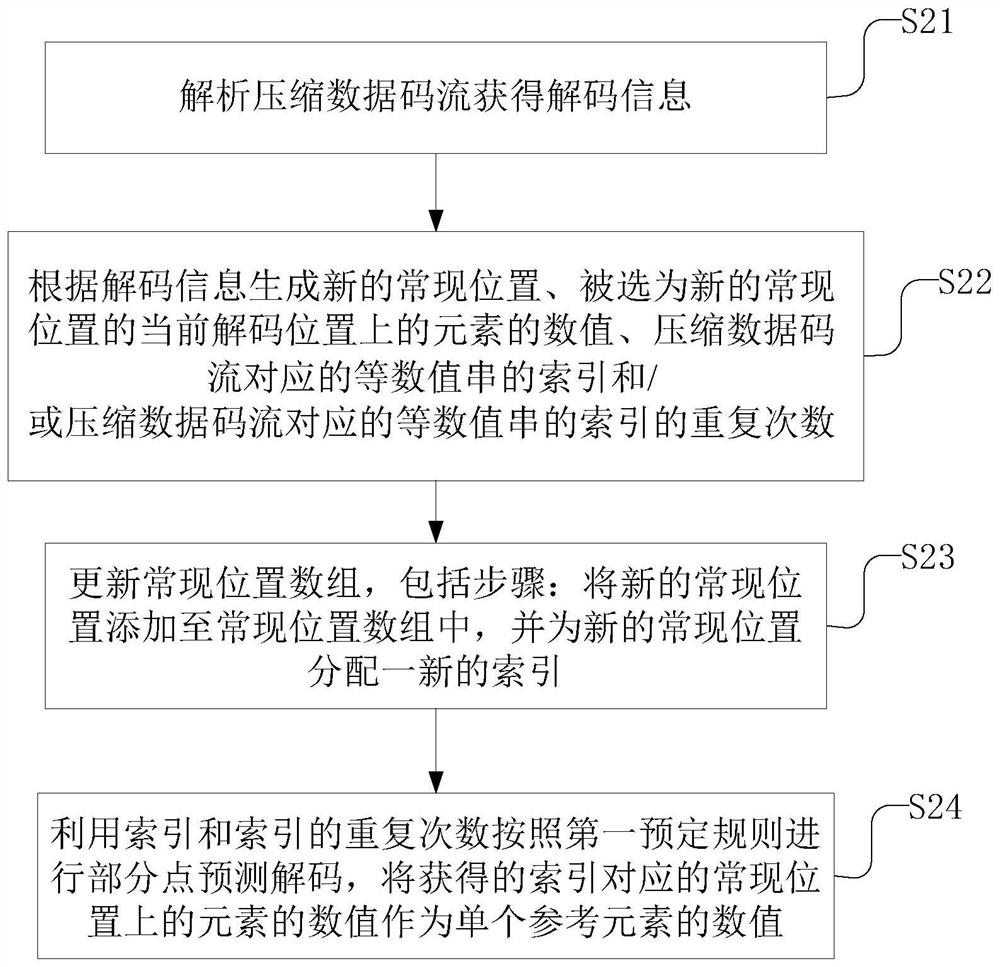

Data encoding method and decoding method using point prediction and normally-occurring position array

The invention provides a data encoding method and decoding method using point prediction and a normally-occurring position array, and the encoding method comprises the steps: S11, a plurality of normally-occurring positions being stored in the normally-occurring position array, and distributing an index to each normally-occurring position in the normally-occurring position array; S12, performing point prediction coding on the equal value string of a to-be-coded data set according to a first predetermined rule; and S13, writing part or all of information representing whether the current codingposition of the equal numerical string is selected as a normal position, the numerical value of the element at the current coding position selected as the normal position, the index corresponding to the equal numerical string and / or the repetition frequency of the index corresponding to the equal numerical string into a compressed data code stream. According to the data encoding method and decoding method using the point prediction and the normally-occurring position array, the numerical value of each element in an equal numerical value string does not need to be recorded one by one, and the purpose of data compression is achieved, and a small number of bits can be used for representation.

Owner:TONGJI UNIV

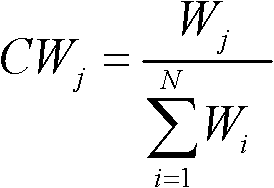

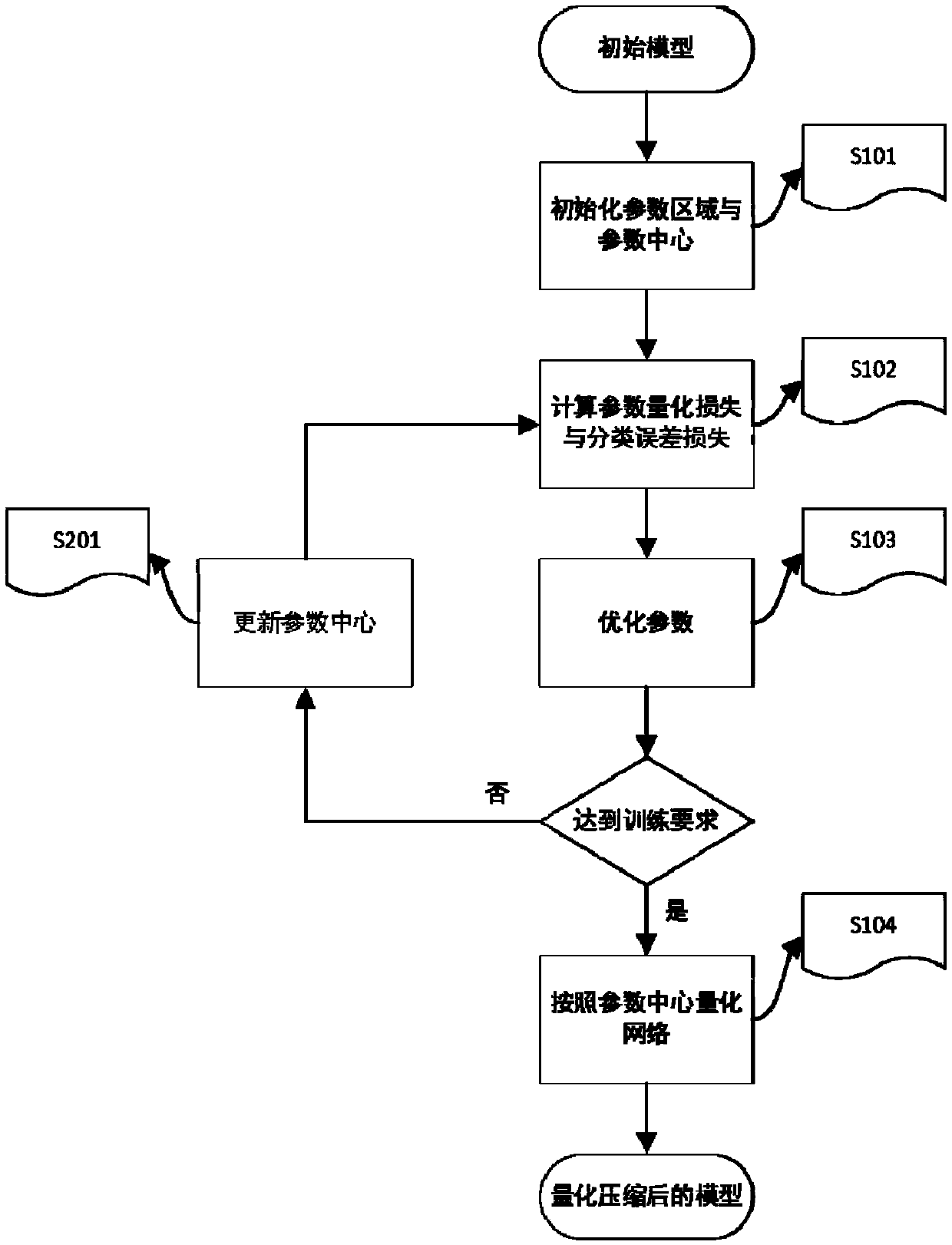

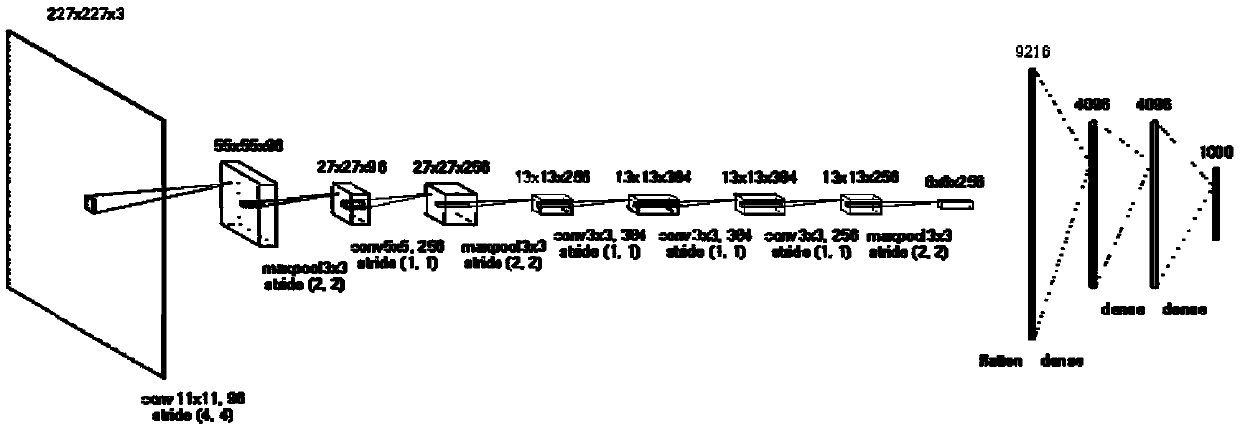

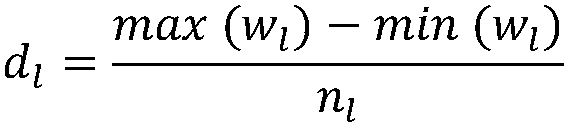

Neural network quantification method based on parameter norms

PendingCN108805257AReduce the burden onImprove accuracyBiological neural network modelsQuantification methodsNetwork model

The invention provides a neural network quantification method based on parameter norms. The method comprises the steps that for a given pre-trained neural network parameter model, a quantification center is divided by performing statistical analysis on values of parameters of needed quantification layers; according to the selected quantification center, quantification loss of the parameters of each corresponding quantification layer is calculated; the quantification loss and classification error loss of the neural network training parameter model are added to serve as total loss, back propagation optimization is performed, and meanwhile the quantification center is updated during optimization; and after training is over, quantification operation is performed on the corresponding layers according to the quantification center, and a compression model after quantification is obtained. Through the method, a weight center can be divided, and the neural network model is quantified by exerting simple quantification loss and using an optimizer the same as that in a traditional method, so that the compression model of the original model is obtained, and the network storage volume and operation complexity are reduced.

Owner:PEKING UNIV

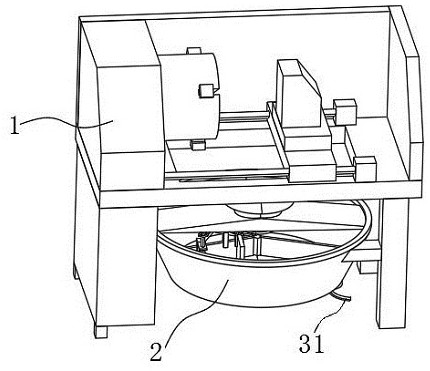

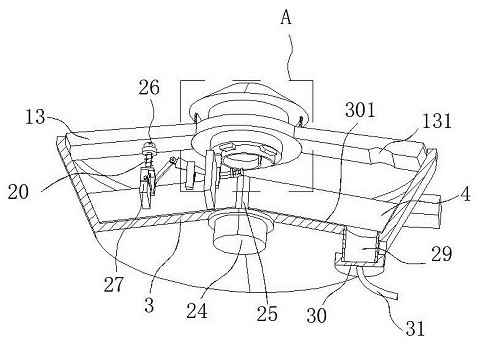

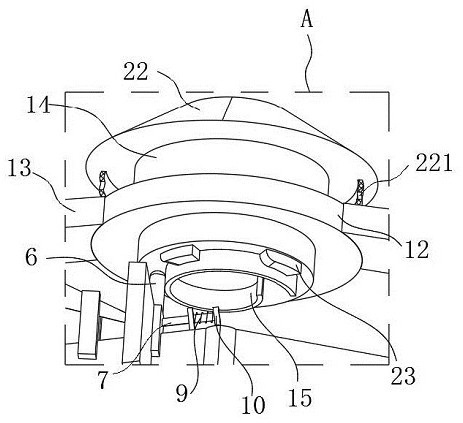

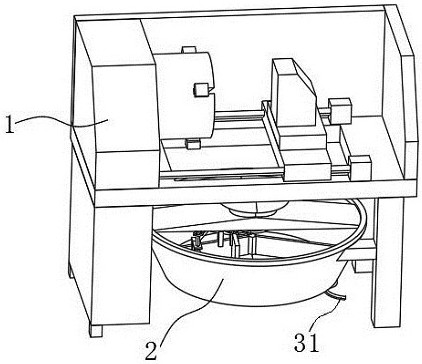

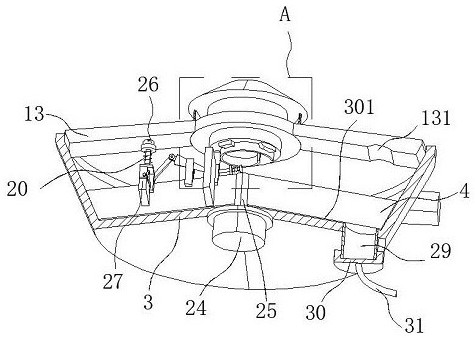

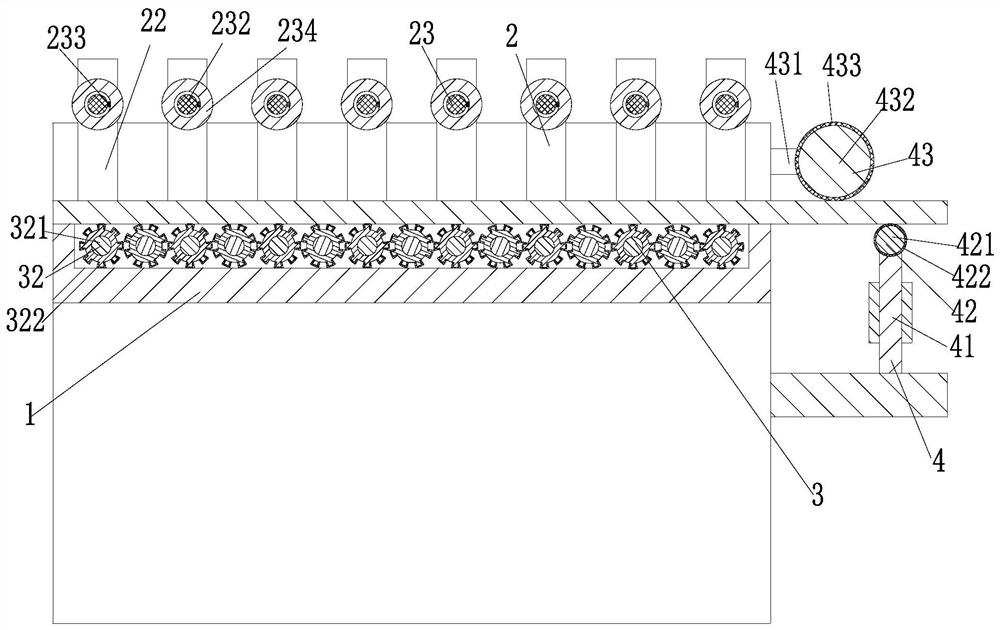

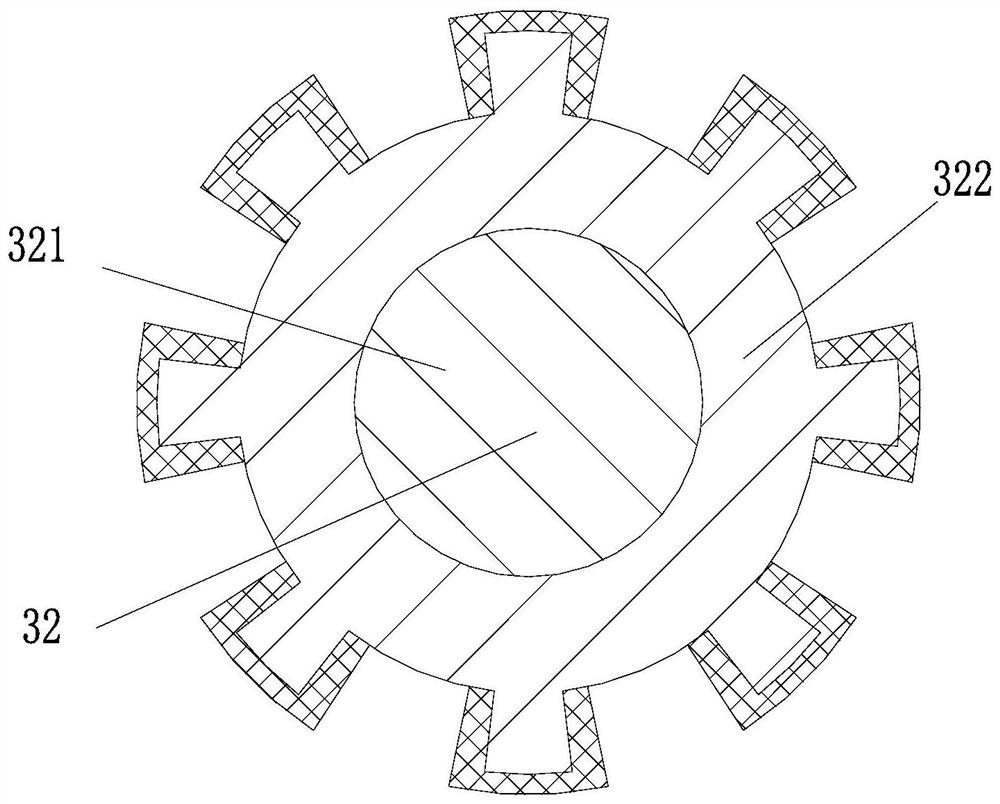

Numerical control machine tool capable of automatically cleaning waste chips away

ActiveCN113319644AConvenient for centralized processingFast cleaningMaintainance and safety accessoriesNumerical controlElectric machinery

The invention discloses a numerical control machine tool capable of automatically cleaning waste chips away. The numerical control machine tool comprises a machine tool workbench and a circular-truncated-cone-shaped collecting frame installed at the bottom of the machine tool workbench. According to the numerical control machine tool, rotating plates are driven by a motor to rotate, the cutting chips can be gathered towards one side of each rotating plate, a round rod is pressed to be attached to the outer side face of a spiral plate through a first spring, and the round rod moves along the outer side face of the spiral plate and enables the first spring to be continuously compressed along with rotation of the rotating plates; and meanwhile a supporting rod pushes a first sliding base to slide downwards along the rotating plates, and in the descending process, a scraping plate downwards pushes and gathers the cutting chips on a lower bottom plate of the collecting frame along the inclined plane. When the round rod arrives at the outermost end of the spiral plate, namely the round rod is suspended, the round rod is recovered to the starting point end of the spiral plate under the springback effect of the first spring, and collection can continue. The rotating plates rotate and collect the cutting chips as the scraping plate can downwards gather the cutting chips, the cutting chips are gathered together, centralized treatment of the cutting chips is facilitated, the cleaning speed is increased, and the working efficiency is improved.

Owner:南通福根机械制造有限公司

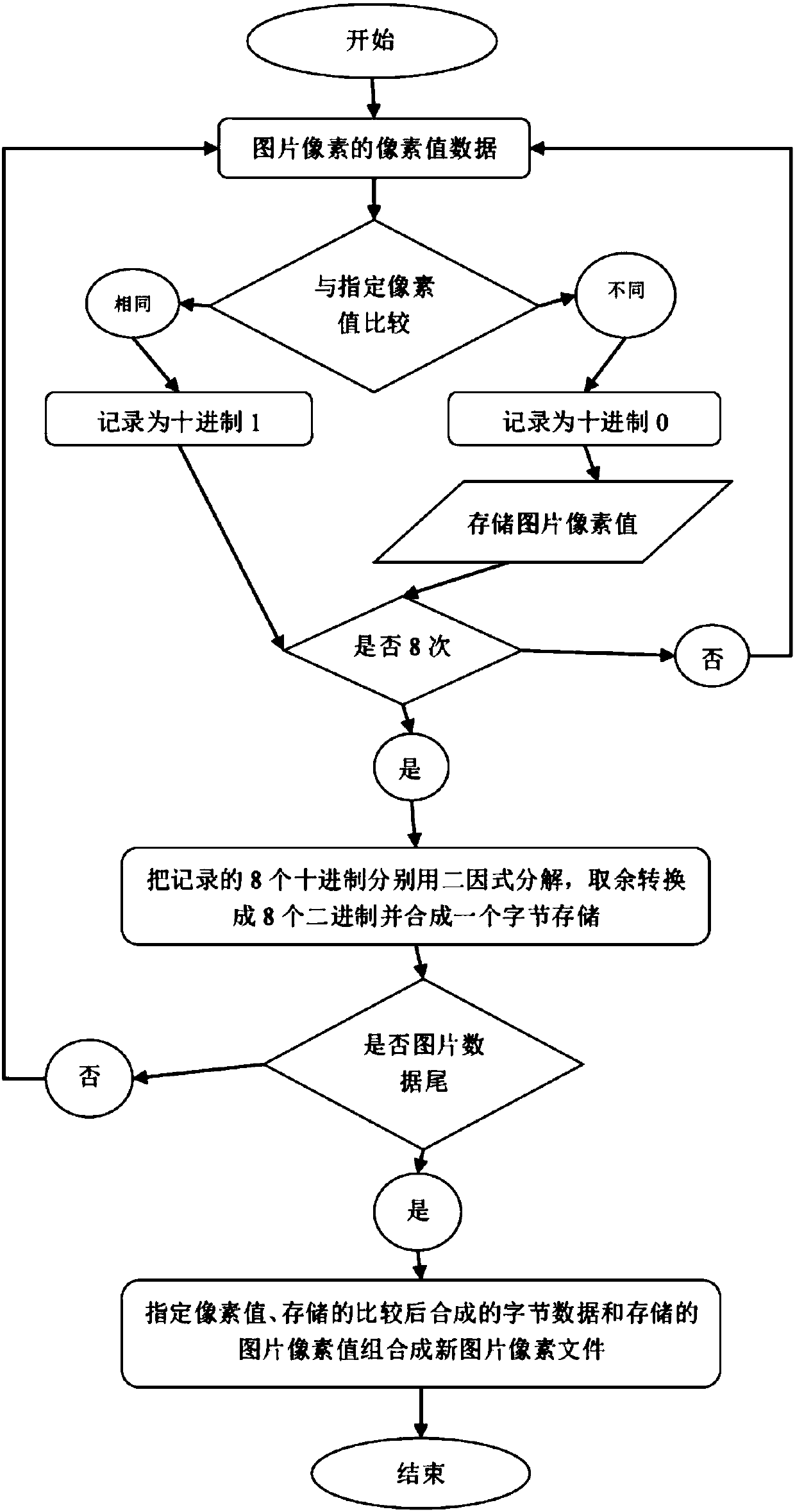

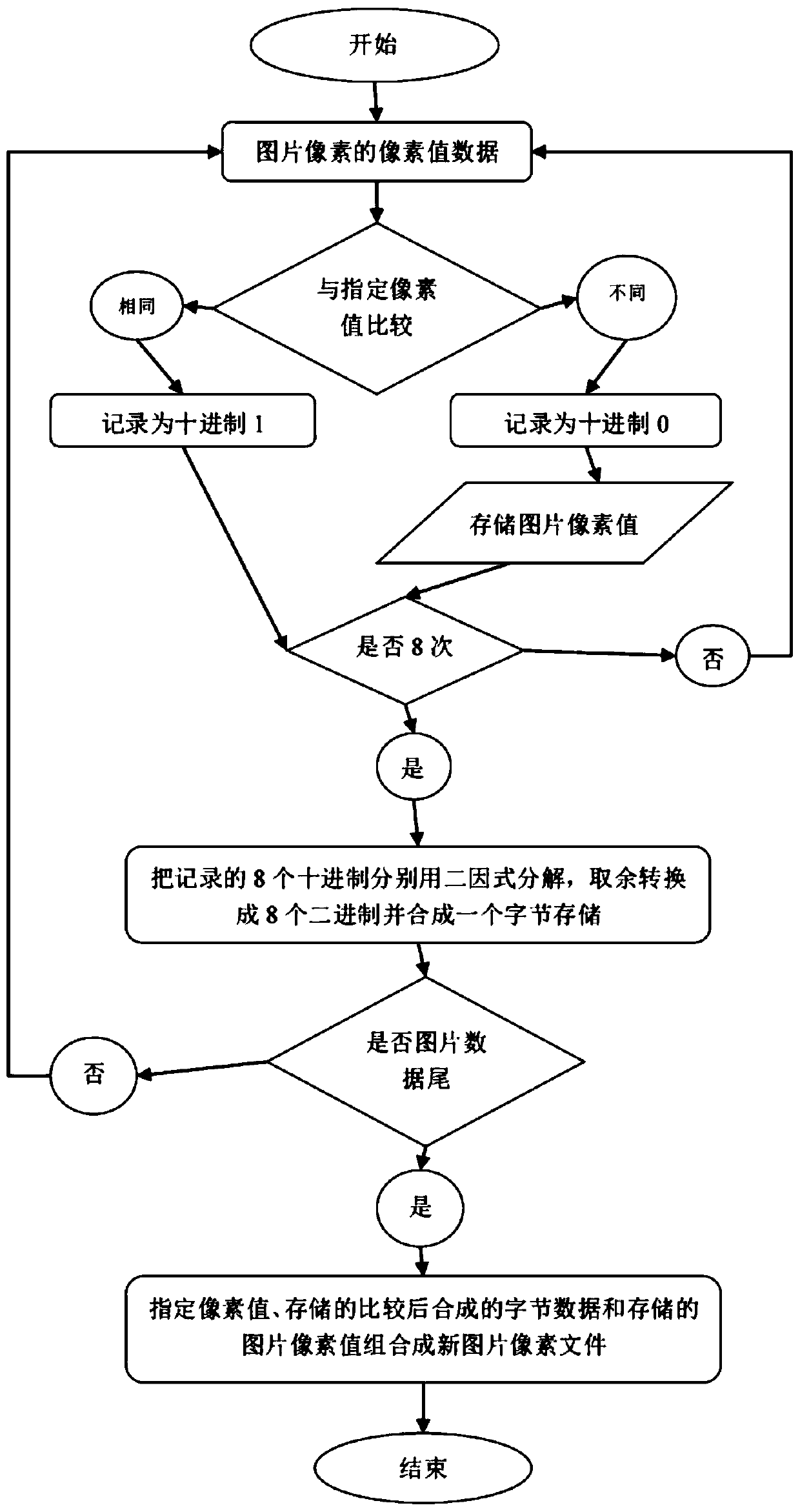

Lossless compression coding method for pure trichromatic picture data

ActiveCN107801031AIncrease the compression ratioOvercoming low compression ratioDigital video signal modificationPattern recognitionData file

The invention relates to a lossless compression coding method for pure trichromatic picture data. The method comprises the following steps: comparing pixel value data of each pixel in a picture to becompressed with a specified pixel value, if the pixel value data of each pixel are equal to the specified pixel value, then recording as decimal 1, otherwise recording as decimal 0 and recording the value of the pixel; and sequentially comparing the decimal 1 with the decimal 0 for many times and combining the decimal 1 and the decimal 0 into one byte through an algorithm and recording the byte, circularly comparing until the pixel data are picture data file tails to be compressed, and finally generating a compressed new picture data file including the specified pixel value, all synthesized byte data and all stored pixel values. The invention provides a picture data lossless compression method for the lossless compression coding method for the pure trichromatic picture data, which can overcome the problems of low picture compression rate, insufficient compression effect and lossy compression in the prior art; and even scattered discontinuously repeated pixels can be recorded by using fewer bytes, so that the picture data compression rate is improved, and the picture data are kept complete and lossless.

Owner:广州物启科技有限公司

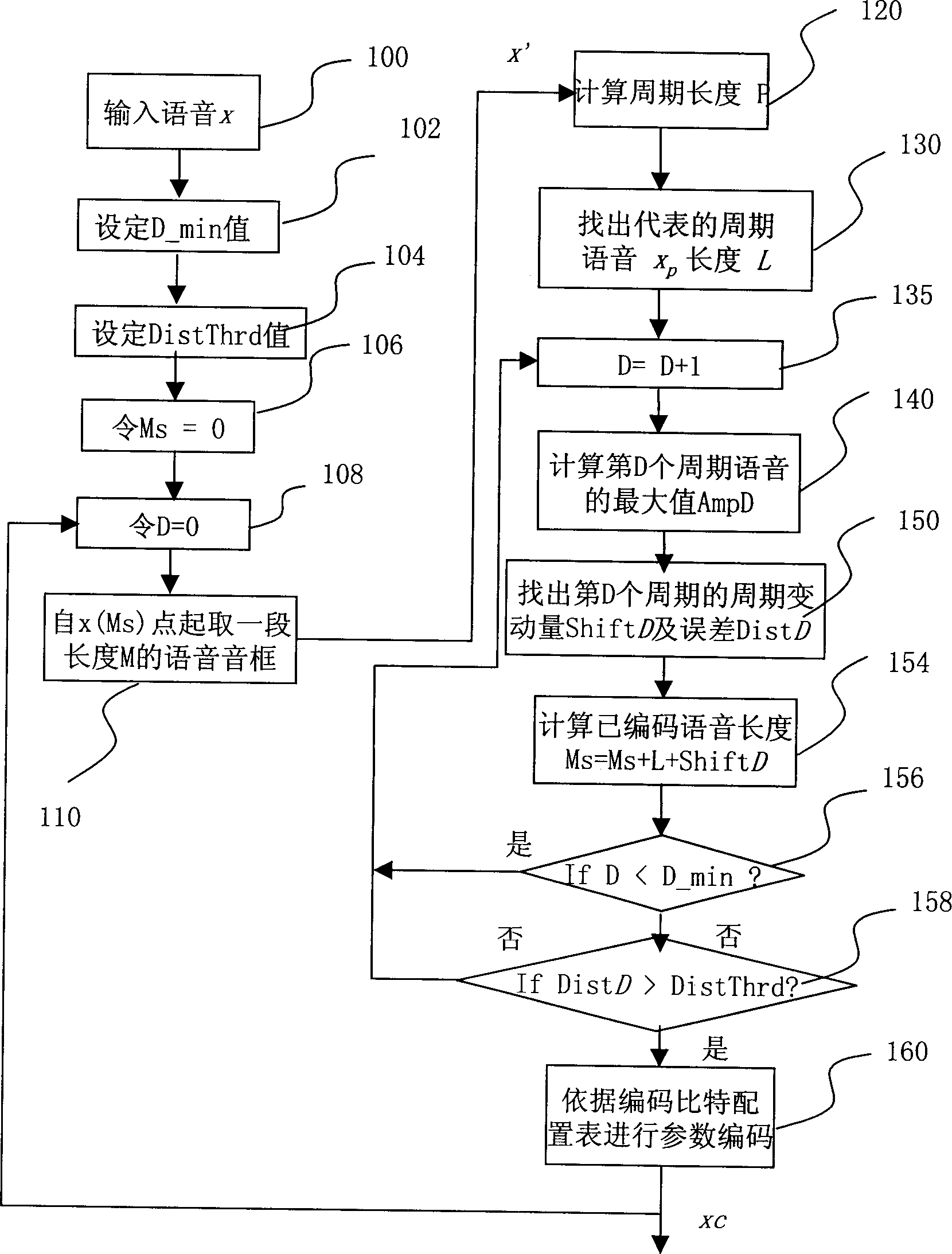

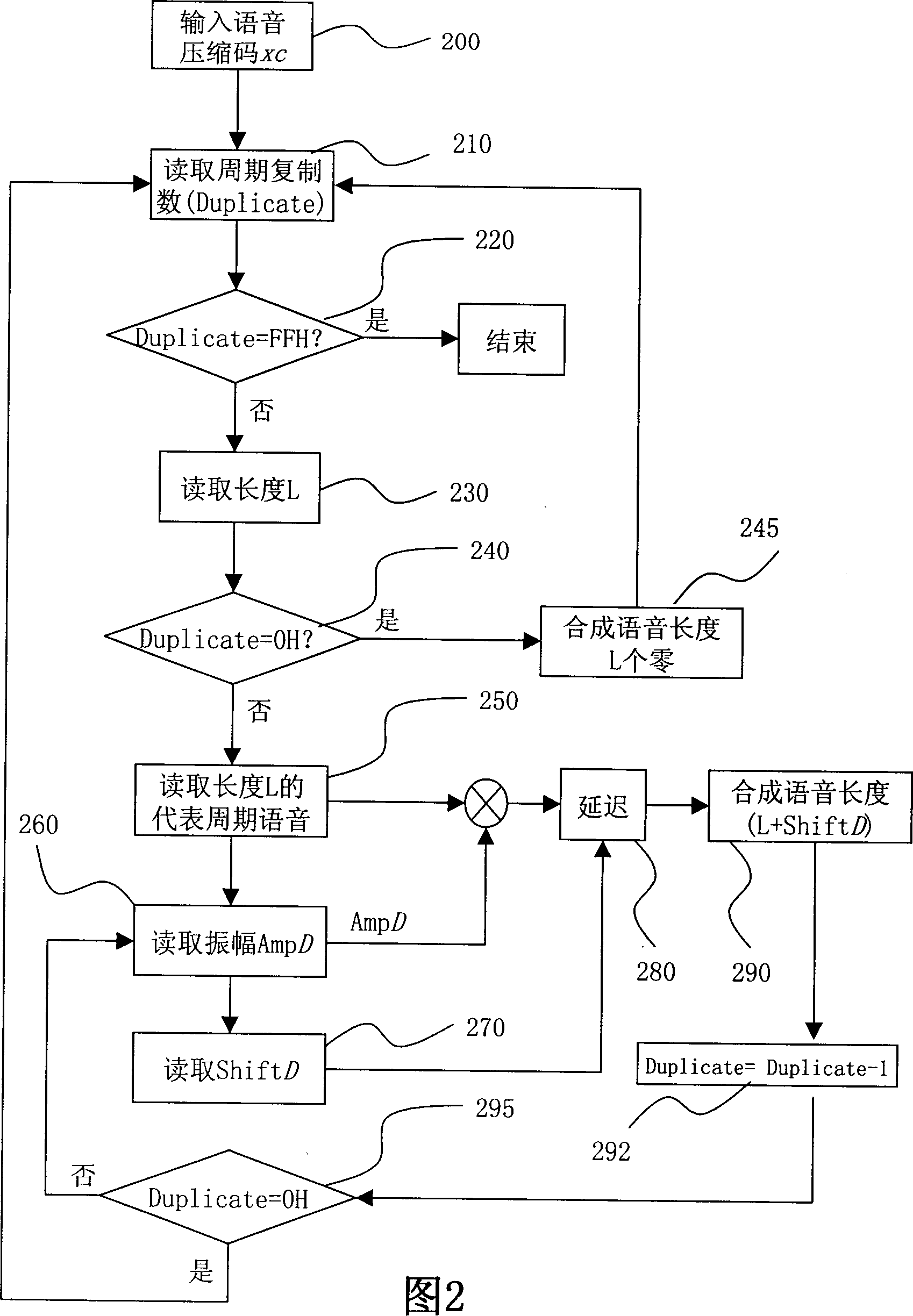

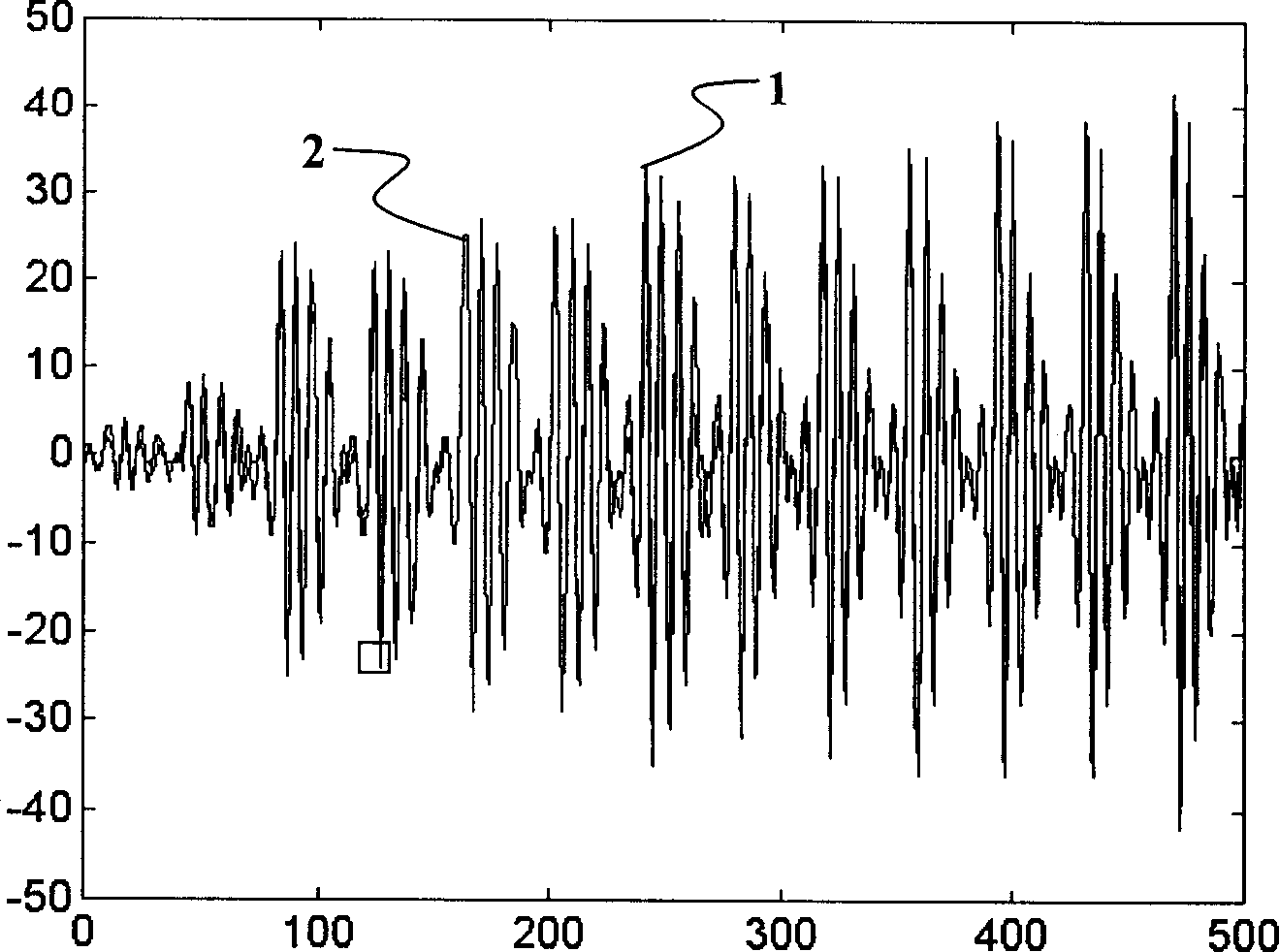

Voice compressing method for quasi-periodical waveform

InactiveCN1404033AAchieve the purpose of compressionSpeech synthesisDigital converterSpeech synthesis

In the voice compression of quasi-periodical waveform, one representative period is taken and the other periods are generated via duplication, and only the change in amplitude and miniature period change are recorded to reach the aim of compression. The deression may be performed in a Z80 microprocessor and the playback may be performed with only simple DAC and no DSP and speech synthesizer. The present invention is suitable for application in not-expensive true voice product.

Owner:INVENTEC BESTA CO LTD

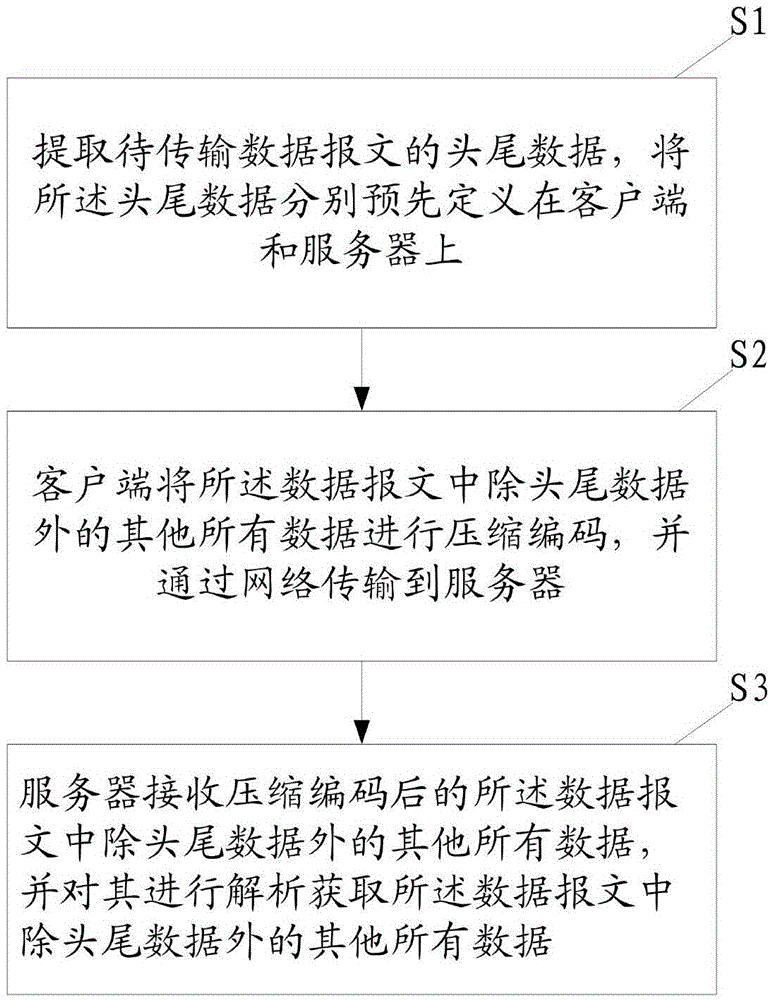

Data compression transmission method and system

ActiveCN105635182AAchieve the purpose of compressionReduce data volumeSubstation equipmentTransmissionData compressionComputer hardware

The invention discloses a data compression transmission method and system. The method comprises: extracting header and trailer data of a data message to be transmitted, and separately predefining the header and trailer data onto a client and a server; compressing and coding all other data in the data message except the header and trailer data and transmitting the compressed and coded data to the server via a network by the client; and receiving all the other compressed and coded data in the data message except the header and trailer data and analyzing all the other compressed and coded data to acquire all other data in the data message except the header and trailer data by the server. By adopting the method and the system, the data volume of network data transmission is reduced.

Owner:依柯力信息科技(上海)股份有限公司

A CNC machine tool for automatically cleaning waste

ActiveCN113319644BConvenient for centralized processingFast cleaningMaintainance and safety accessoriesNumerical controlElectric machinery

The invention discloses a numerically controlled machine tool for automatically cleaning waste chips, which includes a machine tool workbench and a circular table-shaped collecting frame installed at the bottom of the machine tool workbench. The invention drives a rotating plate to rotate through a motor, so that the cutting chips gather toward the side of the rotating plate. The spring one makes the round rod press against the outer surface of the spiral plate, and with the rotation of the rotating plate, the round rod moves along the outer surface of the spiral plate and makes the spring one continue to be compressed, and at the same time, the support rod pushes the sliding seat one Slide down along the rotating plate. During the descent, the scraper pushes and gathers the cutting chips on the lower bottom plate of the collection frame along the inclined plane; At the same time, under the rebound action of spring 1, the round rod returns to the starting point around the spiral plate, and can continue to collect. When the rotating plate rotates and collects, the scraper makes the cutting chips gather downward, and the cutting chips are gathered together, which is convenient for centralized processing. Cutting chips, speed up cleaning and improve work efficiency.

Owner:南通福根机械制造有限公司

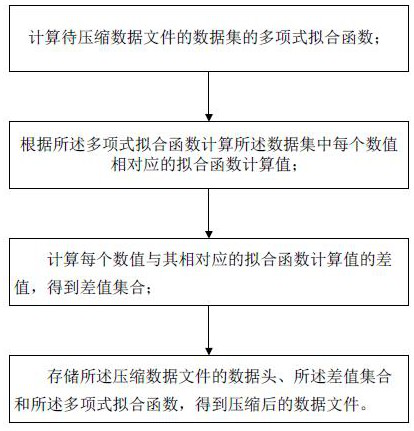

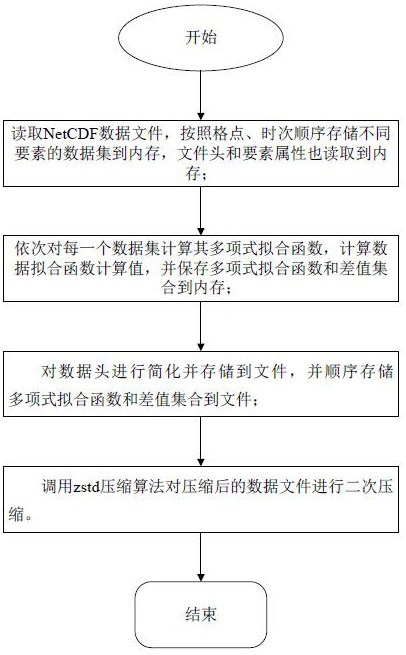

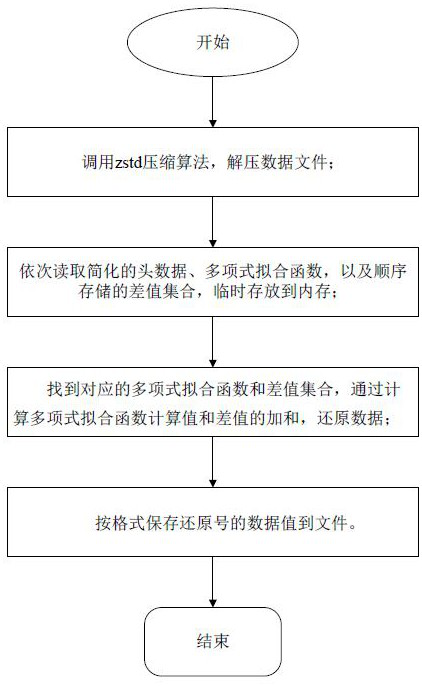

Data compression method and system, and equipment

InactiveCN113258934AAchieve the purpose of compressionNo loss of accuracyCode conversionData compressionData set

The embodiment of the invention discloses a data compression method. The method comprises the following steps: calculating a polynomial fitting function of a data set of a data file to be compressed; calculating a fitting function calculated value corresponding to each numerical value in the data set according to the polynomial fitting function; calculating a difference value between each numerical value and a corresponding fitting function calculated value to obtain a difference value set; and storing the data head of a compressed data file, the difference value set and the polynomial fitting function to obtain a compressed data file. The invention also discloses a data compression system and equipment. The data compression method and system have the beneficial effects that the data precision is not reduced, the compression ratio and the compression efficiency of the data can be improved, the data storage overhead is reduced, the bandwidth requirement during network transmission is reduced, and the data transmission under the condition of poor network conditions is facilitated.

Owner:BEIJING HIGHLANDER DIGITAL TECH

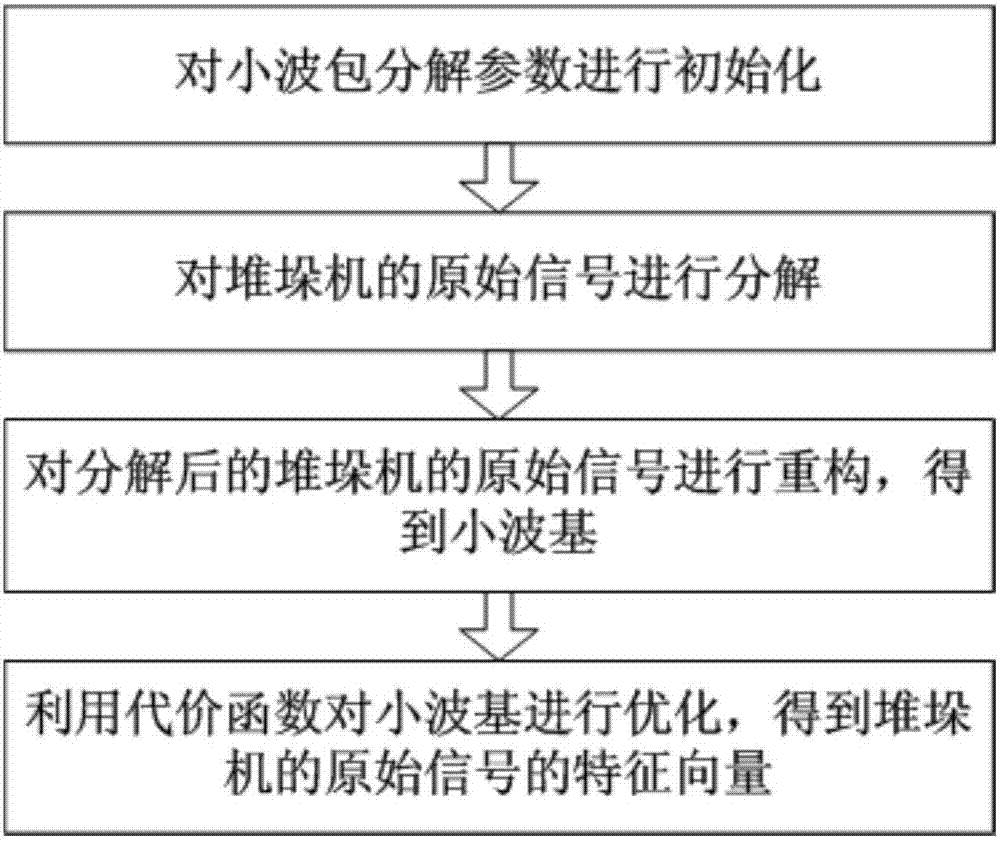

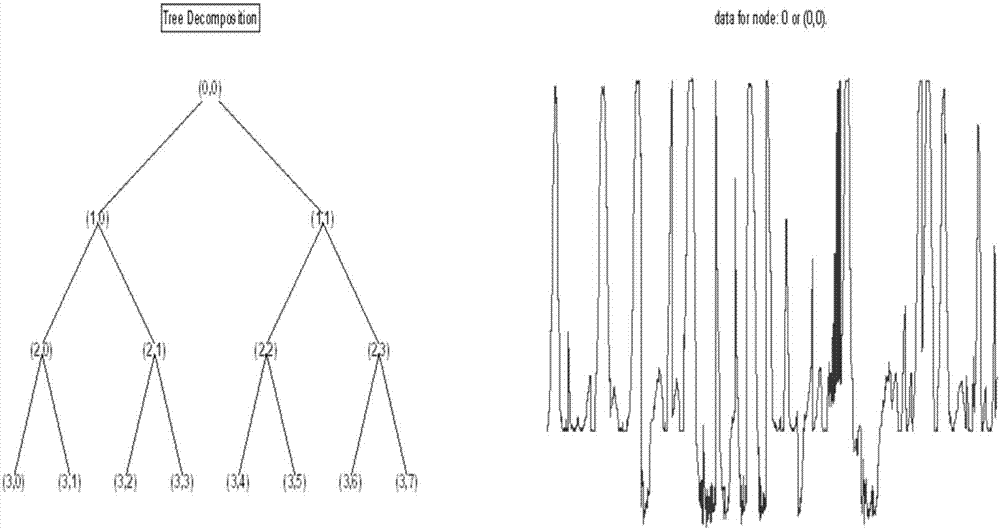

Method for extracting characteristic data of stacker based on wavelet packet analysis

InactiveCN107368801AAchieve the purpose of compressionReasonable decompositionCharacter and pattern recognitionComplex mathematical operationsData ingestionFeature vector

The present invention discloses a method for extracting characteristic data of a stacker based on wavelet packet analysis. According to the method disclosed by the present invention, a wavelet packet decomposition parameter is initialized, an appropriate scaling function is selected, and a wavelet library is generated through the scaling function, so that the optimal decomposition effect is achieved, and the signal is decomposed reasonably; an appropriate cost function is selected so as to seek the optimal wavelet base, and the cost function satisfies the monotonicity and additivity; through the functions, the purpose that the original signal is compressed is achieved, and the size of the data is reduced; eigenvectors containing complete information of the original signal is obtained, and the working state signal for the stacker is processed and expanded; and the eigenvectors of the original signal of the stacker are extracted in the process, so that the purpose of data compression is achieved and good application prospect is ensured.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO ELECTRIC POWER RES INST +2

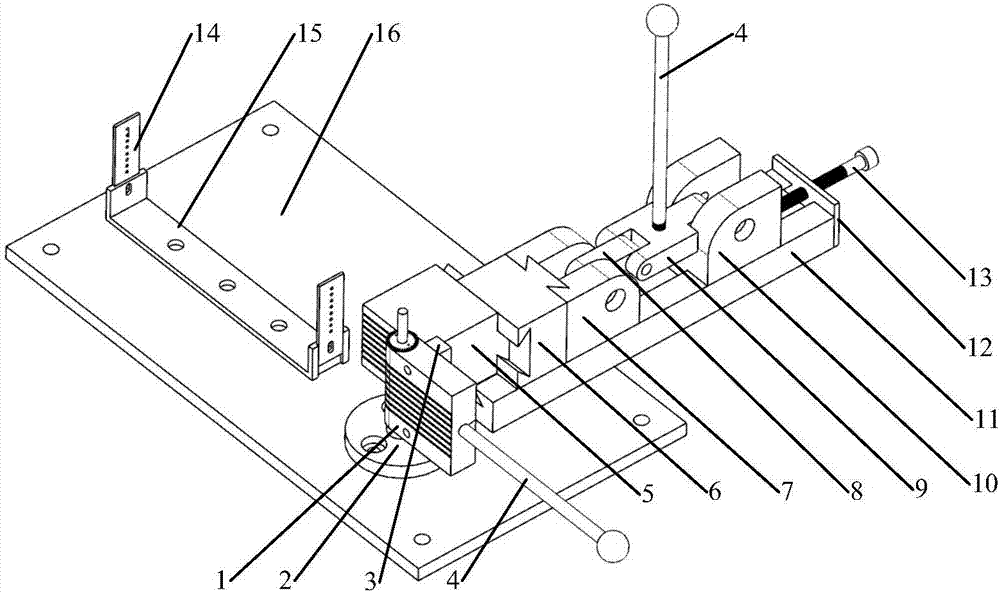

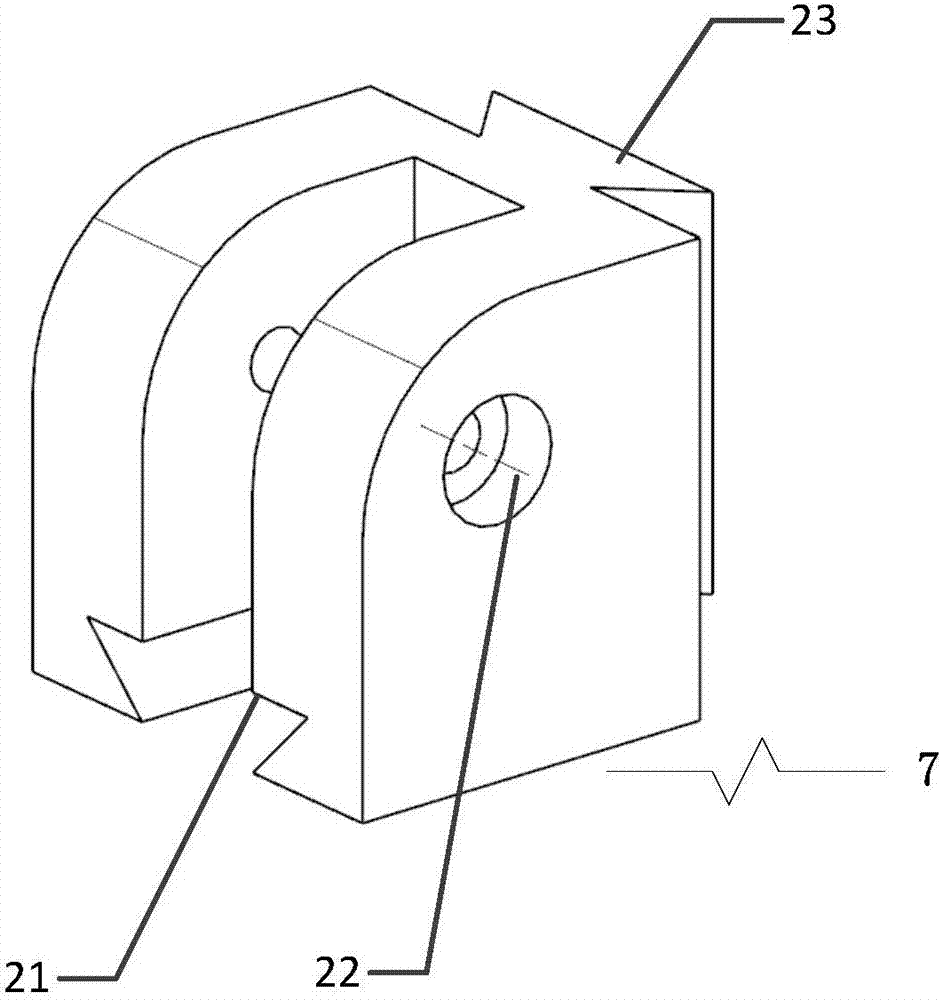

Adjustable die frame for heat exchanger micro-diameter thin-wall pipe bending die

ActiveCN107186083AImprove forming qualityGuaranteed matching accuracyShaping toolsEngineeringMachining

The invention provides an adjustable die frame for a heat exchanger micro-diameter thin-wall pipe bending die. The adjustable die frame comprises a compressing part, a fixed connecting part and a guide part. The guide part is fixed to a workbench. Displacement of the compressing part in a certain direction is restrained on the guide part. The guide part is connected with the workbench through threads. All the parts of the adjustable die frame are simple in working principle, machining is convenient, replaceability is high, and the adjusting range is large. The locating error can be reduced during use, and forming quality is improved.

Owner:BEIHANG UNIV

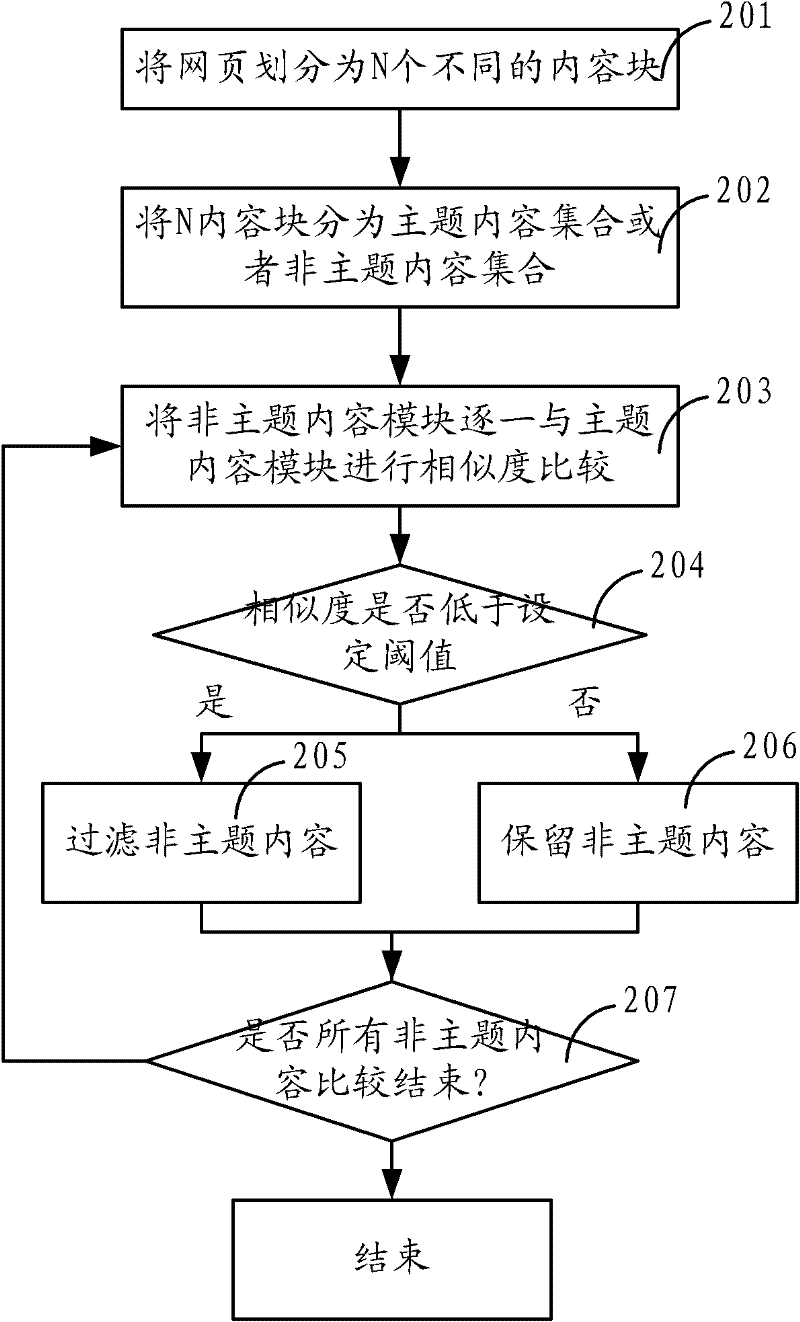

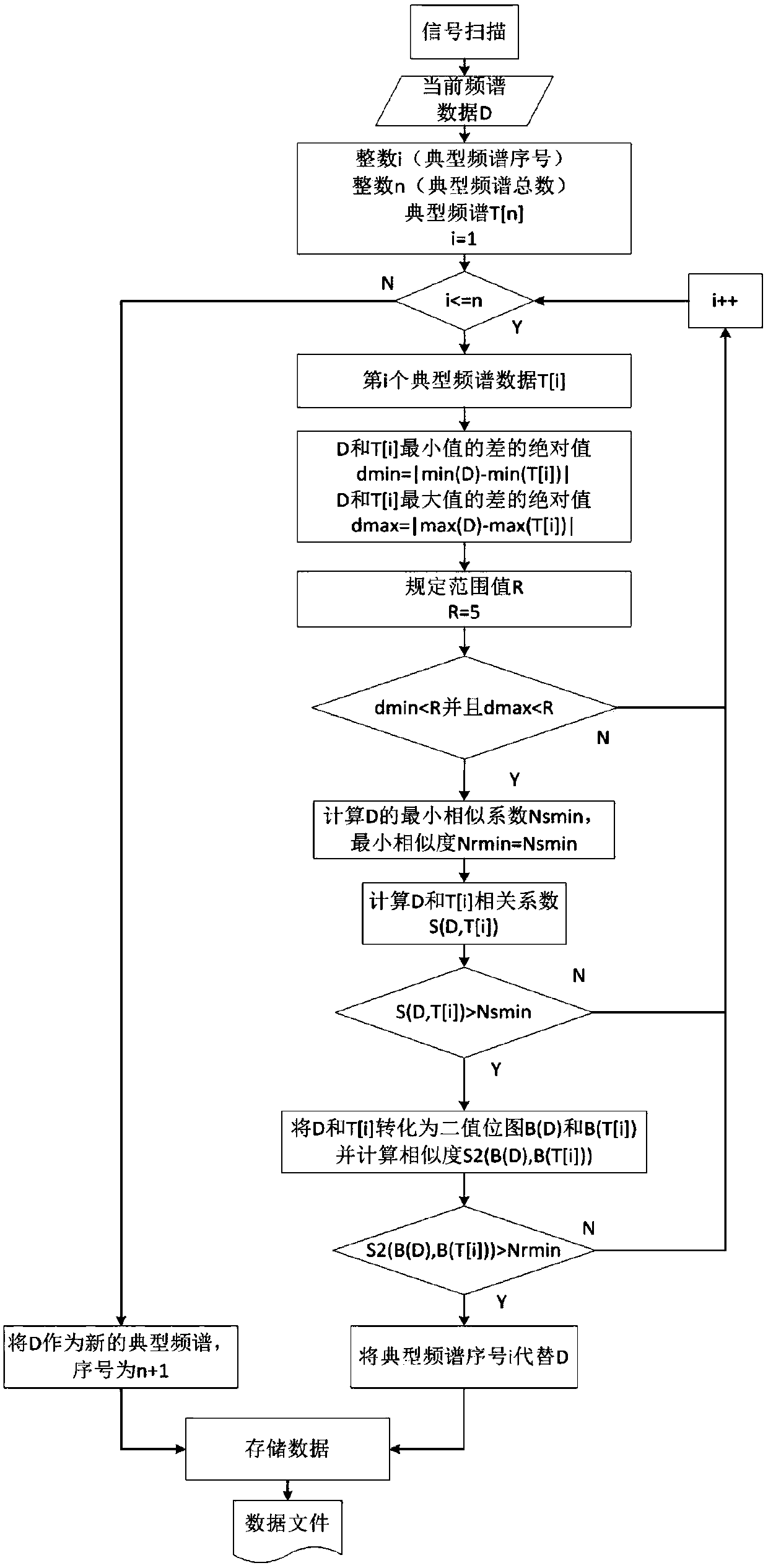

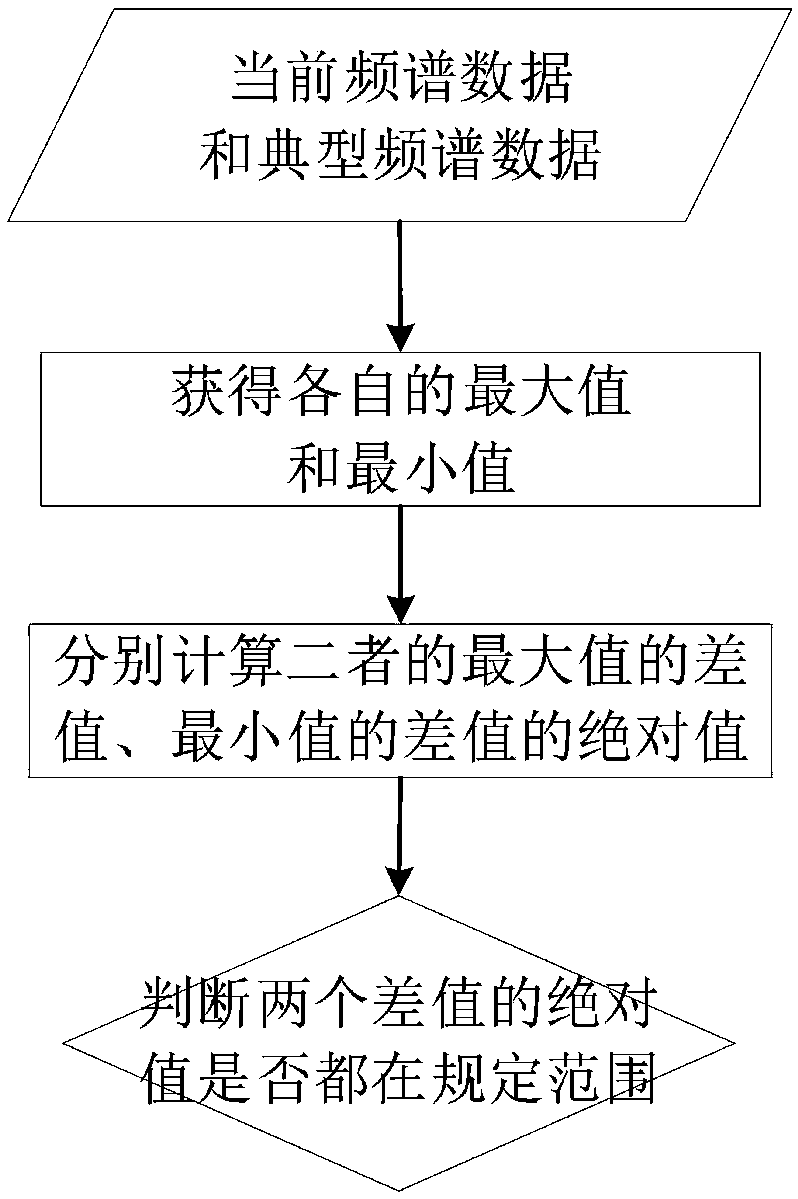

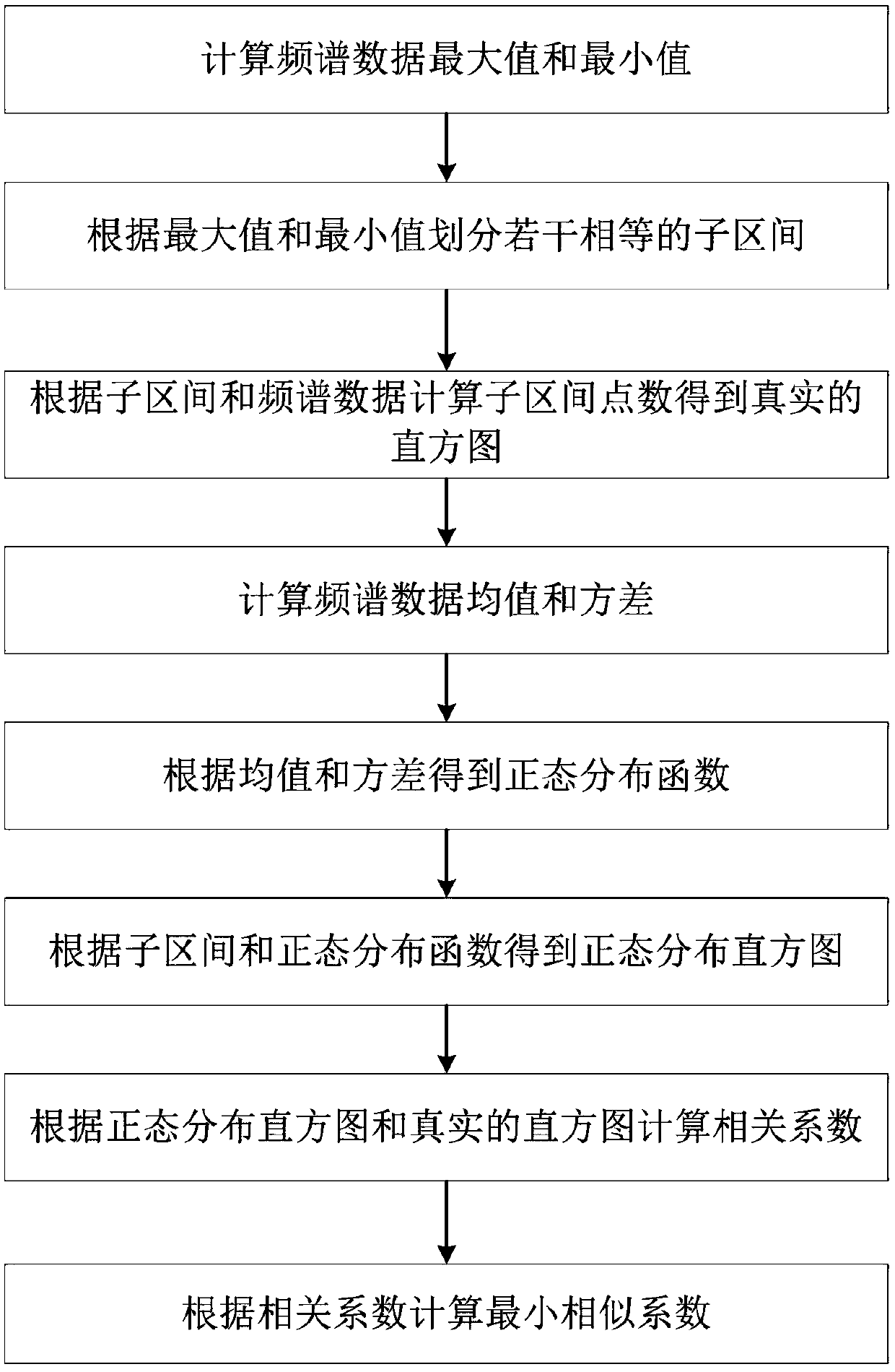

An adaptive real-time spectrum data compression method and system

ActiveCN108990108AReduce time and space consumptionReduce loadNetwork traffic/resource managementTransmissionSelf adaptiveData compression

The invention discloses an adaptive real-time spectrum data compression method and a system thereof. The compression method comprises the following steps: similarity between a current spectrum and a typical spectrum is calculated, and whether the current spectrum is similar to the typical spectrum is judged; if the current spectrum is similar to one of the typical spectra, the serial number of thetypical spectrum is used to store instead of the current spectrum; if the current spectrum is not similar to all the typical spectrum, the current spectrum is treated as a new typical spectrum, and asequence number is given to store the current spectrum and the corresponding sequence number. The method and the system of the invention can greatly reduce the storage amount, reduce the requirementon storage space, adapt to the requirement of real-time spectrum data storage, and reduce the cost of network transmission by substituting the serial number of a typical spectrum for the original dataof the spectrum for storage through similarity calculation.

Owner:XIHUA UNIV

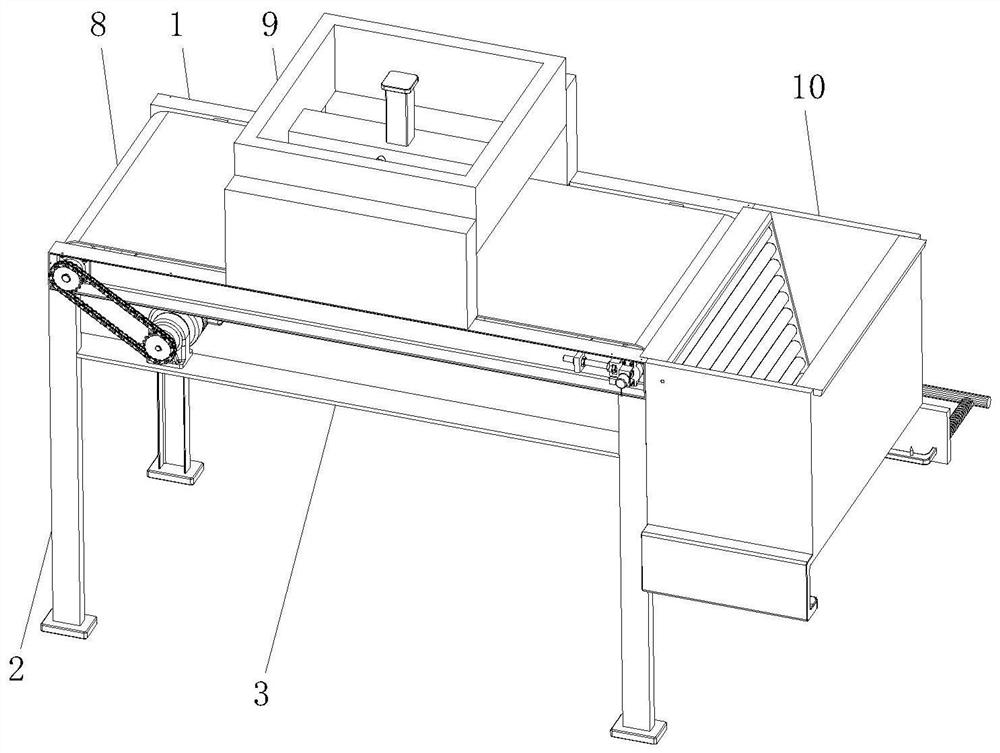

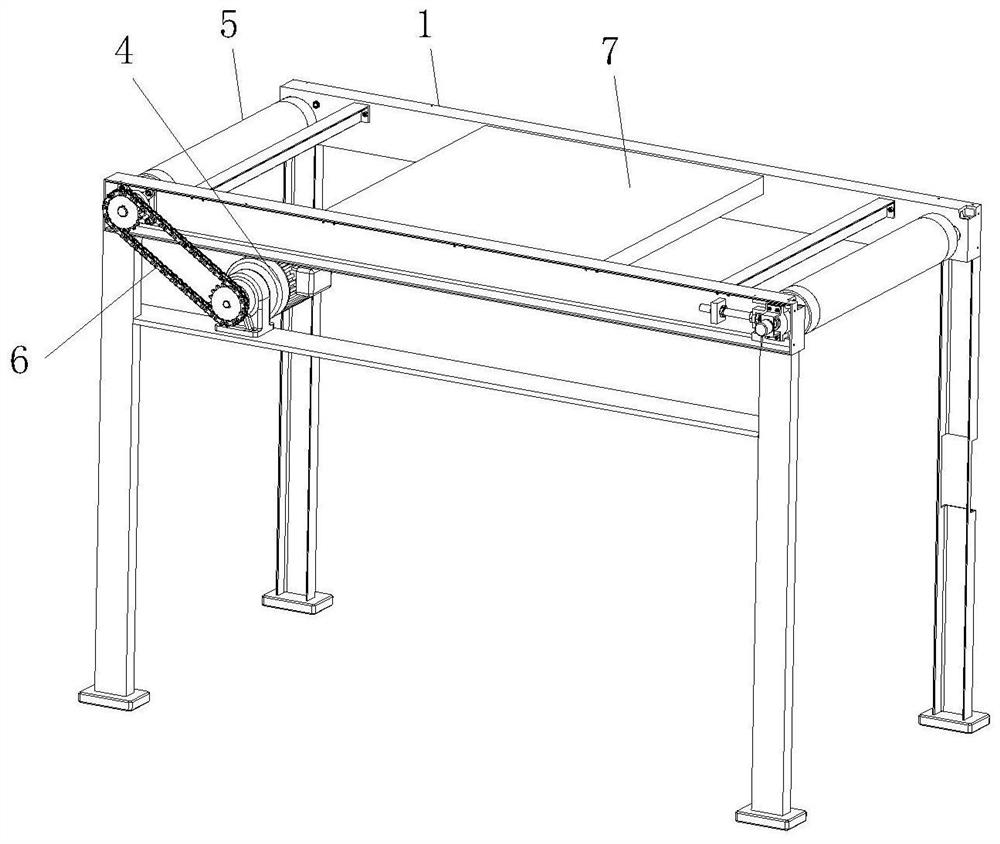

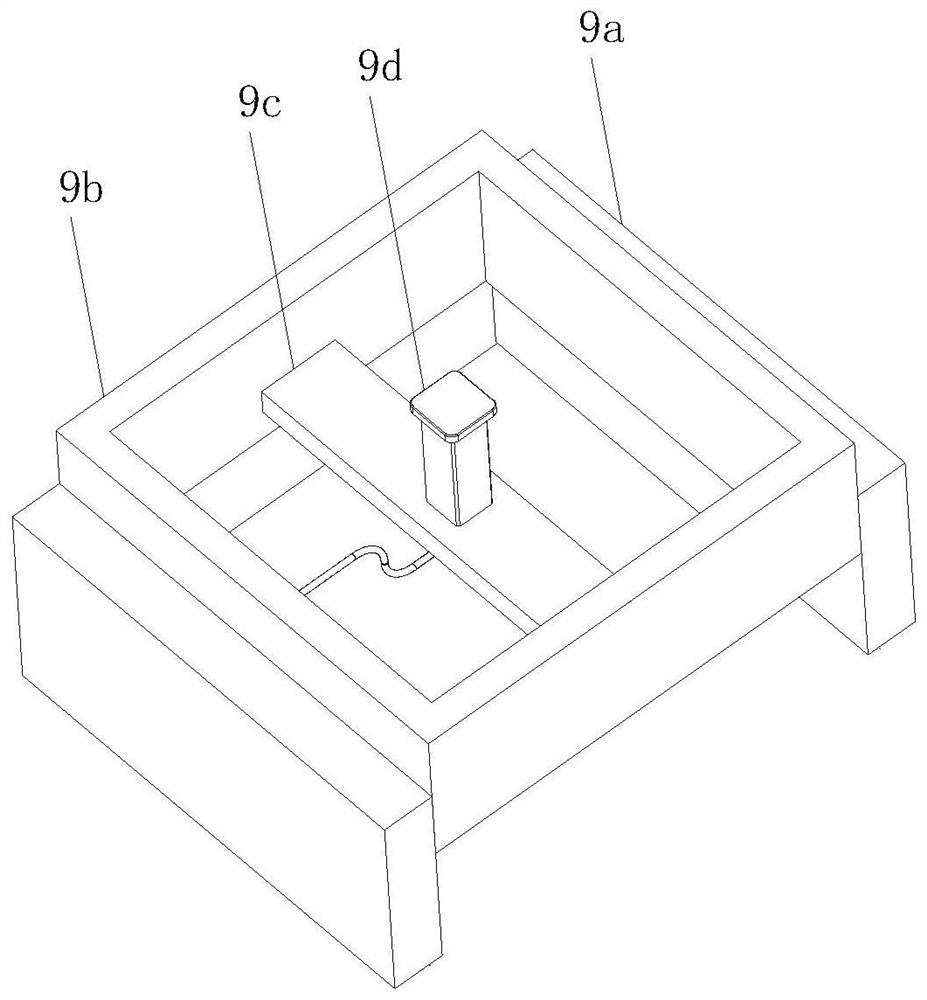

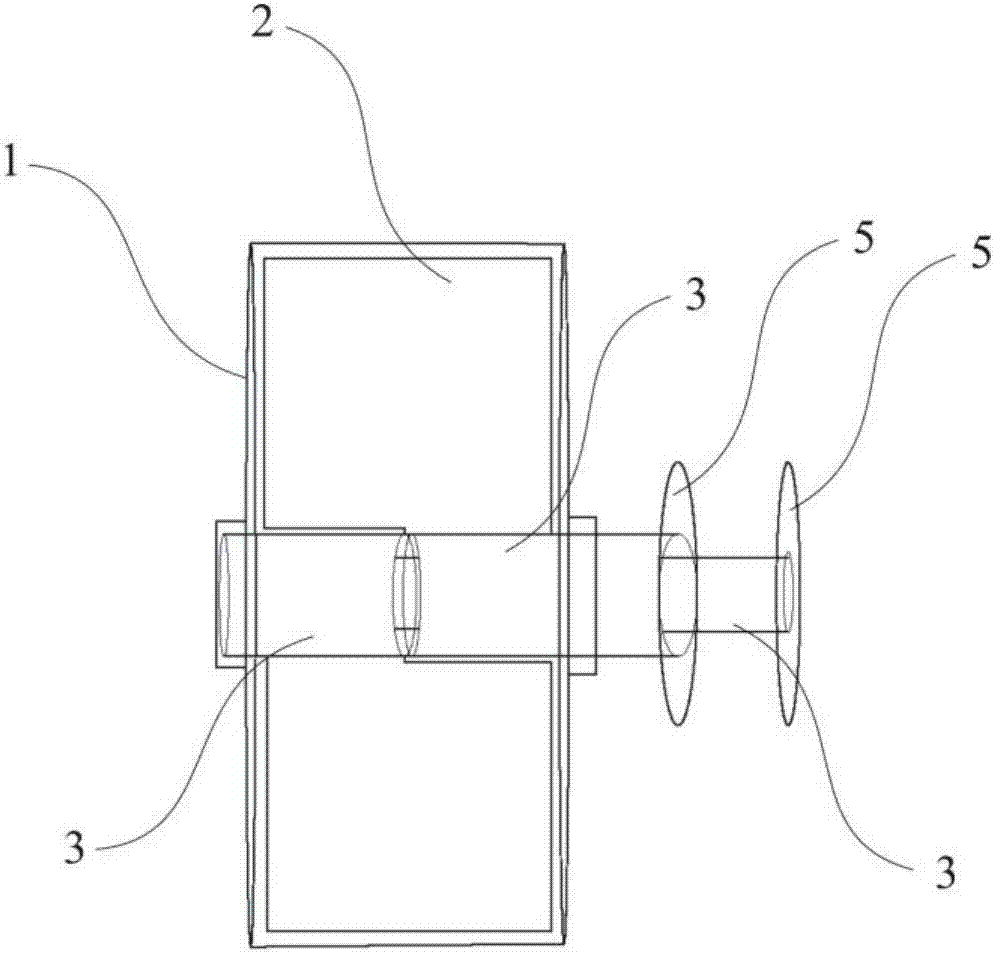

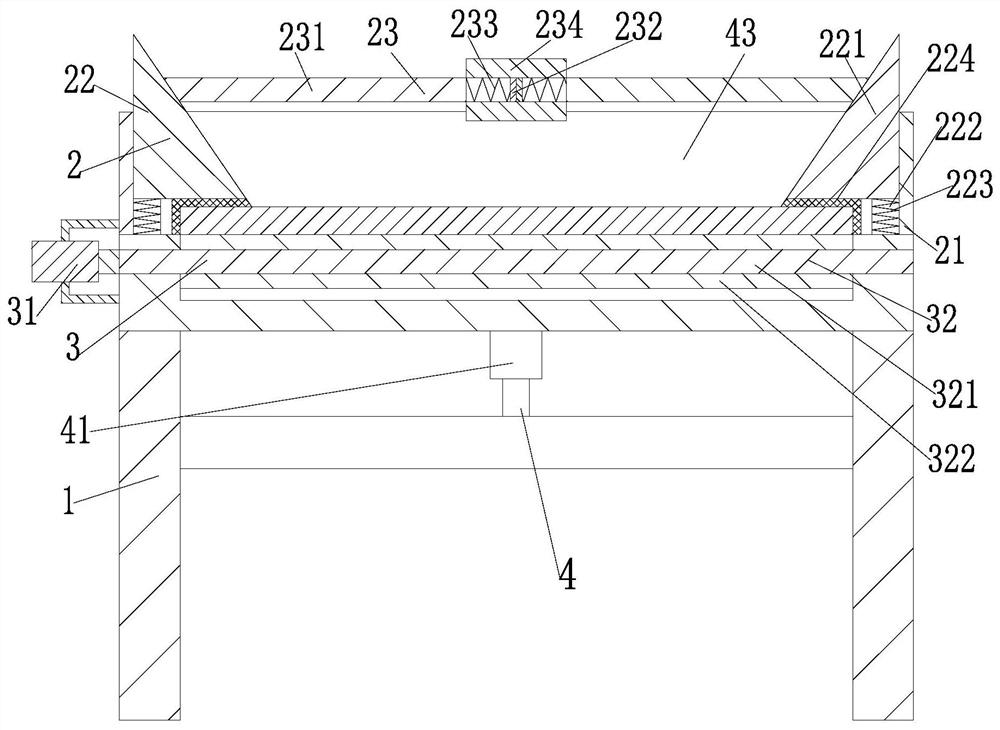

Textile compressor capable of packaging

InactiveCN112340153AAchieve the purpose of compressionImprove compression efficiencyPackagingElectric machineryDrive motor

The invention relates to the technical field of textile compressors, in particular to a textile compressor capable of packaging. The textile compressor comprises a base conveying body, wherein supporting legs are arranged at the lower end of the conveying body; a mounting plate is fixedly arranged at the inner sides of the supporting legs; a driving motor is fixedly arranged at the upper end of the mounting plate; a rotary drum is arranged at the inner side of the conveying body; a transmission mechanism is arranged between the driving motor and the rotary drum; a supporting plate is fixedly arranged at the side, close to the rotary drum, of the inner side of the conveying body; a conveyor belt is arranged at the outer side of the rotary drum and the outer side of the supporting plate; a compression mechanism is arranged over the portion, close to the supporting plate, of the upper end of the conveying body; a discharging frame is arranged at one end of the conveying body; a material guiding mechanism is arranged in the discharging frame; and a supporting framework is arranged at the lower end of the discharging frame. According to the textile compressor capable of packaging, the textile compression efficiency can be improved, a packing bag does not need to be opened manually in the textile packaging process, and the textile compressor is practical.

Owner:诸暨市惠联精密机械制造有限公司

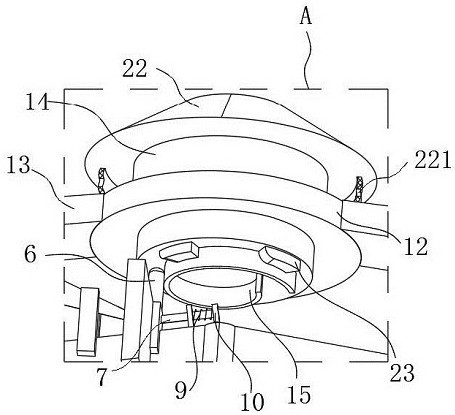

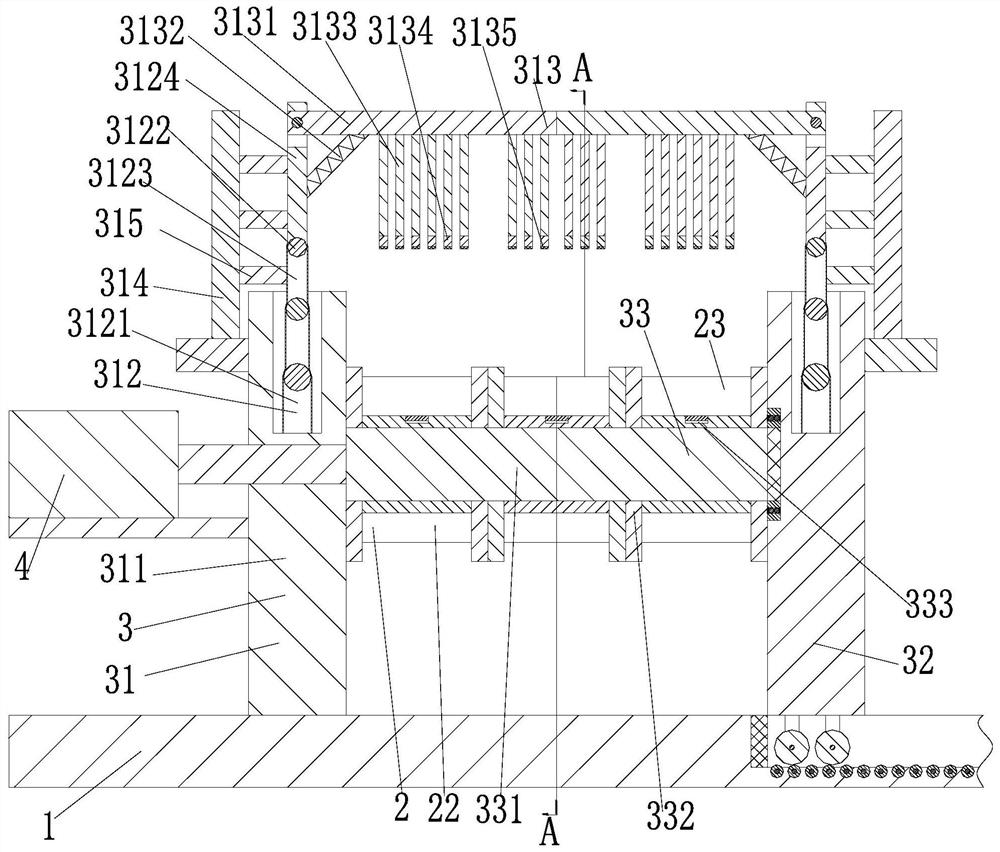

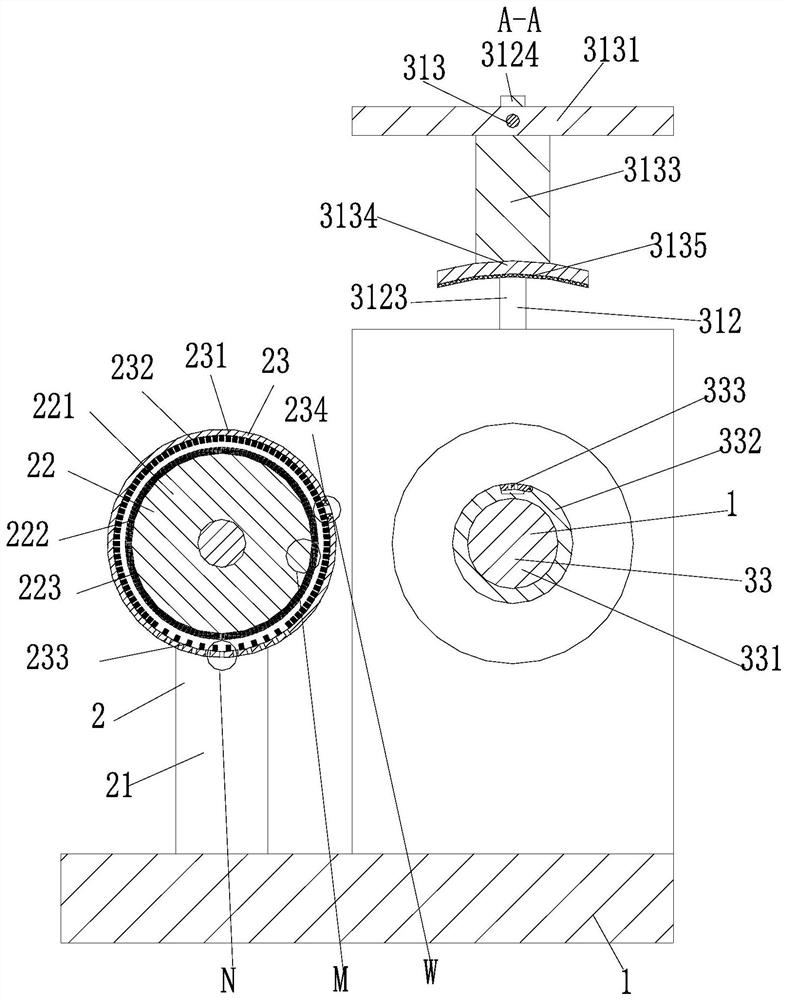

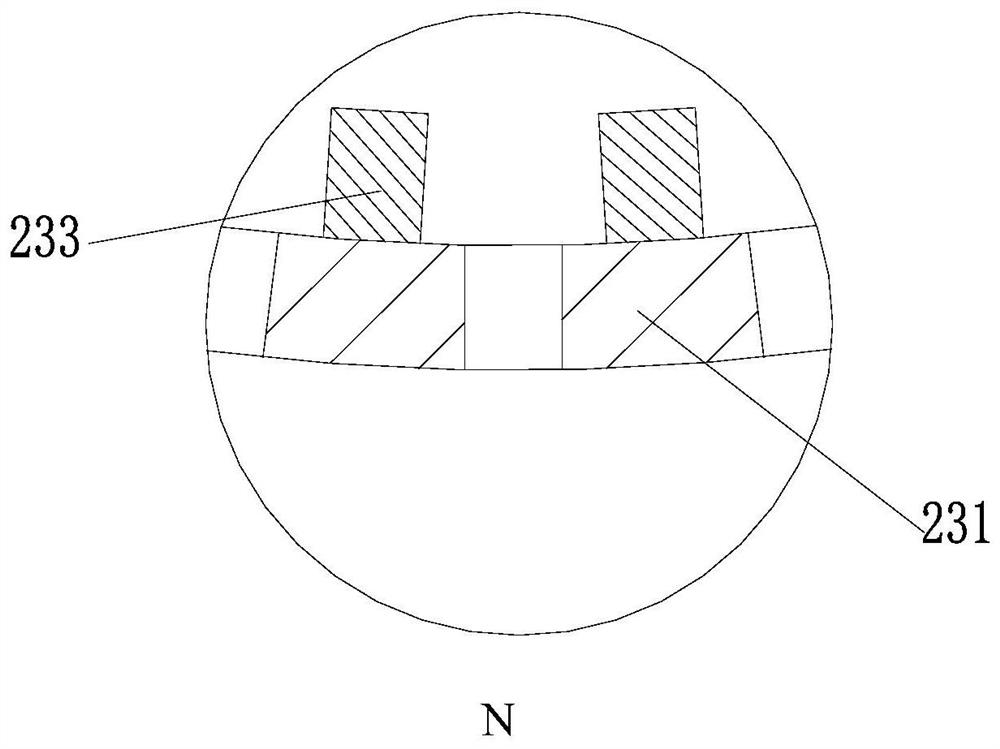

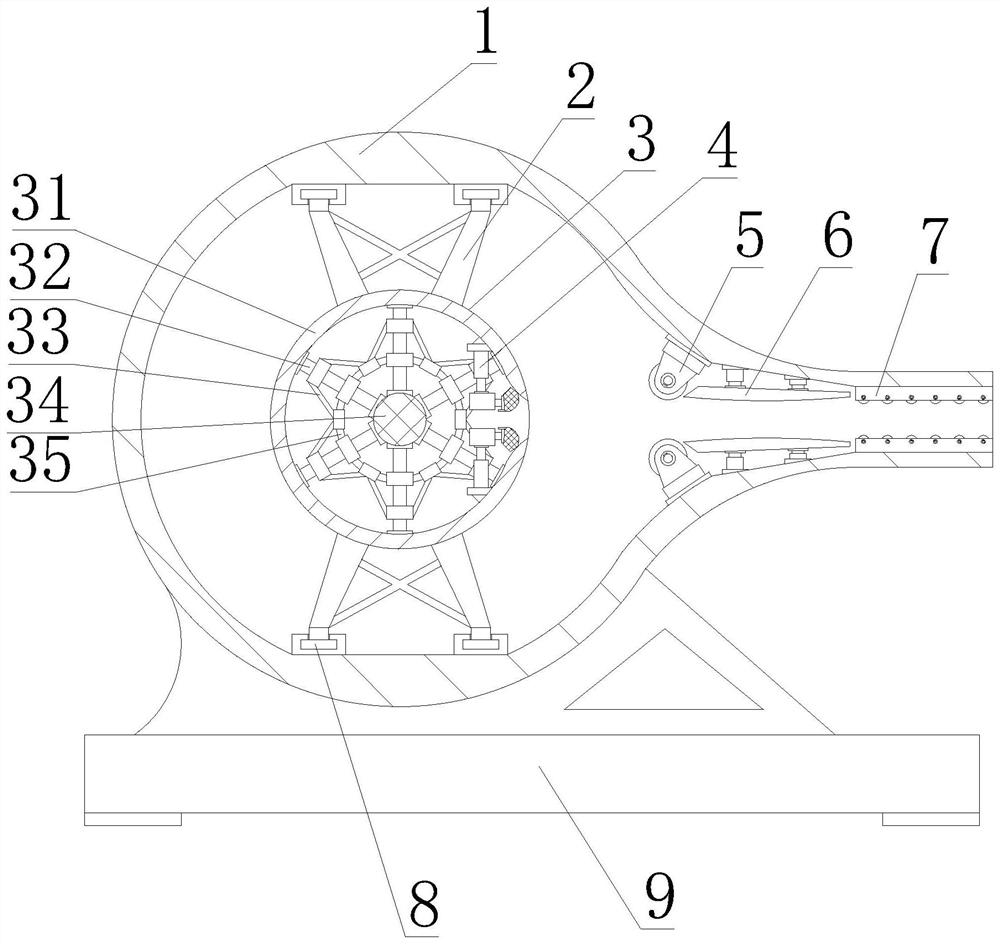

Wheel moving type rotor compressor

ActiveCN107178501AAvoid Burnout SituationsHigh Compression DisplacementRotary/oscillating piston combinations for elastic fluidsRotary/oscillating piston pump componentsMotor driveEngineering

The invention discloses a wheel moving type rotor compressor, and belongs to refrigerant compressors. A compression cavity is cylindrical, an air inlet and an air outlet are formed in end covers at the two ends of the compression cavity, two wheel moving blades are arranged in the compression cavity, and are staggered in position, the radial outer edge of the two wheel moving blades is in tight contact with the inner side of the compression cavity, and the axial outer edges of the two wheel moving blades are in tight contact with the end in the compression cavity; a transmission motor drives the two wheel moving blades to intermittently rotate in the compression cavity, the two wheel moving blades serve as a fixed piece which stays still and a movable piece rotatably compressing gas in turn, and repeated circulation is carried out, so that the compression aim is achieved; the two wheel moving blades carry out compression in turn, and therefore the compressor has the higher compression displacement, the compression ratio is high, the wheel moving blades in the compression cavity are driven by an external transmission motor, too high work temperature can be avoided, and the application field of an air energy heat pump can be effectively widened.

Owner:四川熙缘科技有限公司

A fast winding device for the production and preparation of rubber strips

ActiveCN110790054BPrevent loosening and falling offAvoid bending deformationCleaning using toolsWebs handlingElectric machineEngineering

The invention relates to a rapid rewinding device for the production and preparation of rubber strips, which includes a workbench, a cleaning device, a rewinding device and a motor. A cleaning device is fixedly installed at the front end of the workbench, and a rewinding device is installed at the rear end of the workbench. The left end of the device is equipped with a motor through a motor base. This invention uses the gap between the cleaning inner wheel and the cleaning outer jacket to clean the rubber strip so that the surface of the rubber strip is cleaned. The cleaned rubber strip is in contact with the winding roller. The rubber strip squeezes the compression plate, and the cylindrical column and the lead ball move upward until the lower end of the cylindrical column clamps the lead ball. The density of the lead ball is larger to achieve the purpose of compressing the rubber strip by gravity. The support rod and the support The plates cooperate with each other to orient the telescopic rod to prevent the telescopic rod from being skewed due to excessive force on the compression plate, thereby preventing the rubber strip from loosening and falling off during the rewinding process.

Owner:ANHUI LIXIN RUBBER TECH CO LTD

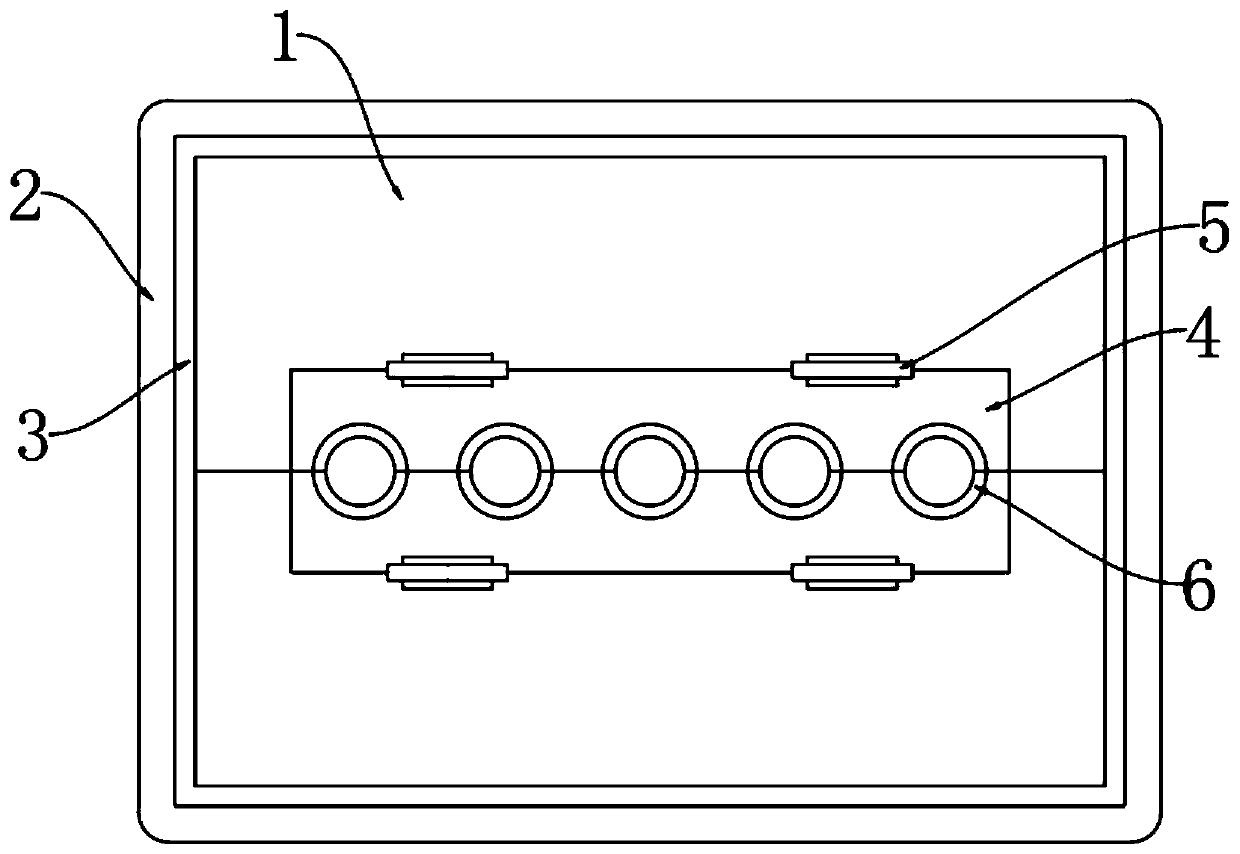

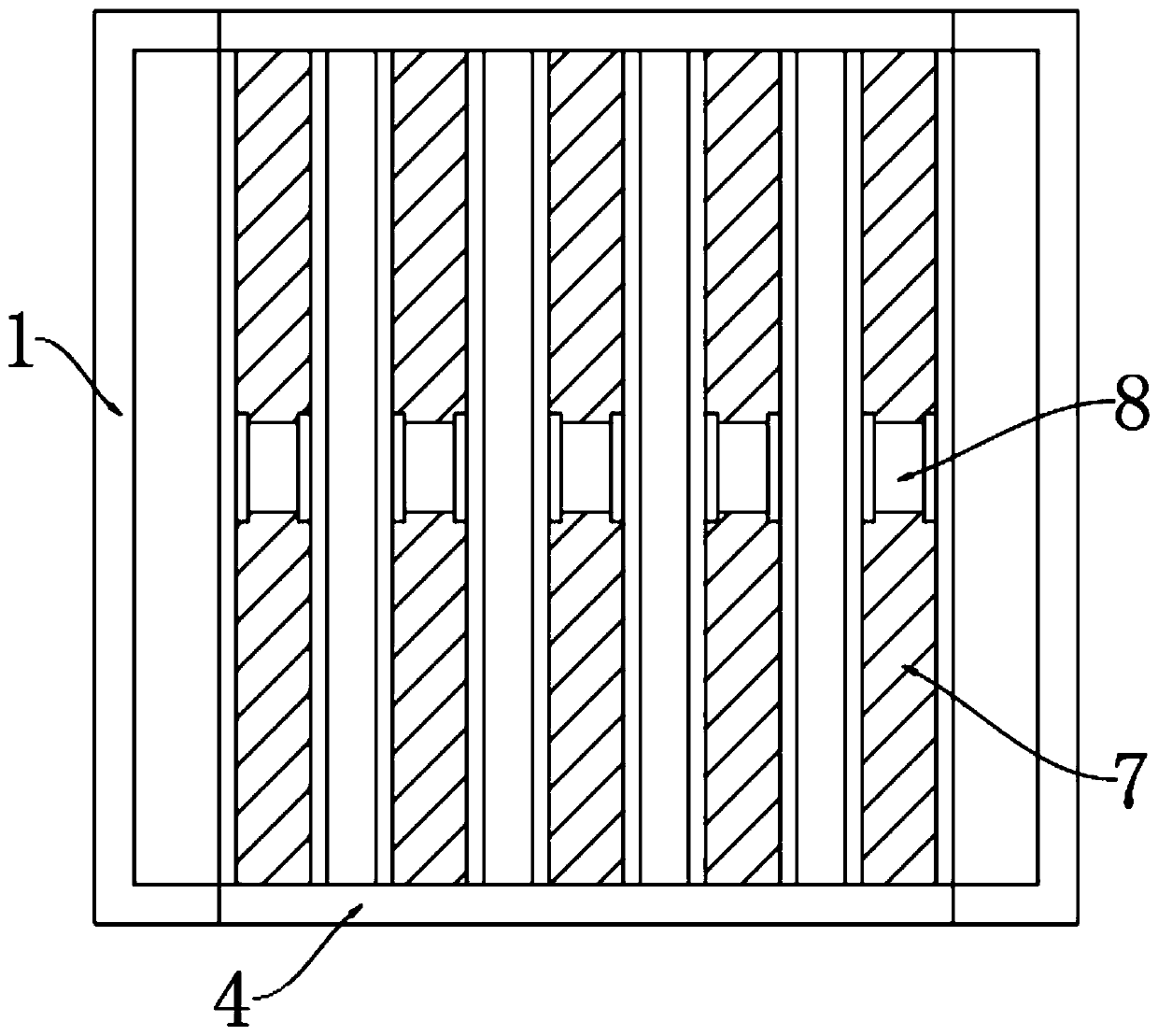

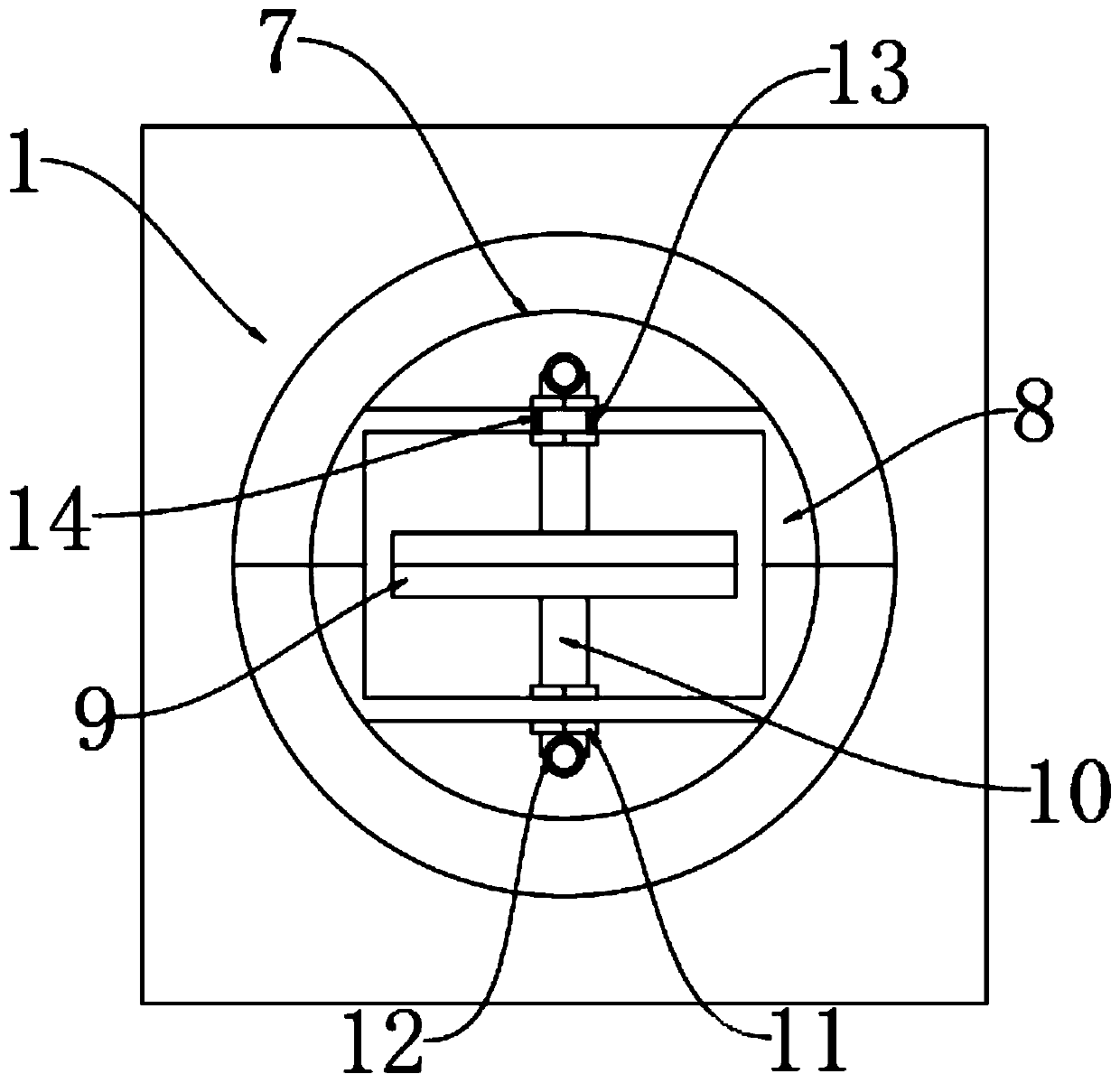

Ethernet cable connection clamping groove

InactiveCN110932027AOvercome loosenessOvercome sheddingEngagement/disengagement of coupling partsAdhesive beltStructural engineering

The invention discloses an Ethernet cable connecting clamping groove, relates to the technical field of Ethernet cables, and aims to solve the problems that two network cables connected with each other are easily influenced by external factors in the using process of the existing Ethernet cable, so that loosening and falling off are caused. The number of the network cable clamping plates is two. The two network cable clamping plates are bundled and connected through an adhesive tape; outer sheaths are arranged on the outer walls of the two network cable clamping plates; the two network cable clamping plates are symmetrically distributed relative to the horizontal line of the outer sheath; sealing plates are arranged on the front end surface and the rear end surface of the network cable clamping plate; the sealing plate is rotatably connected with the network cable clamping plate through a hinge, five cable inlet holes are formed in the sealing plate, five line channels are formed in the network cable clamping plate, the five line channels are communicated with the five cable inlet holes respectively, and a fastening mechanism is arranged in the center of each line channel.

Owner:SUZHOU AINAGE INFORMATION TECH CO LTD

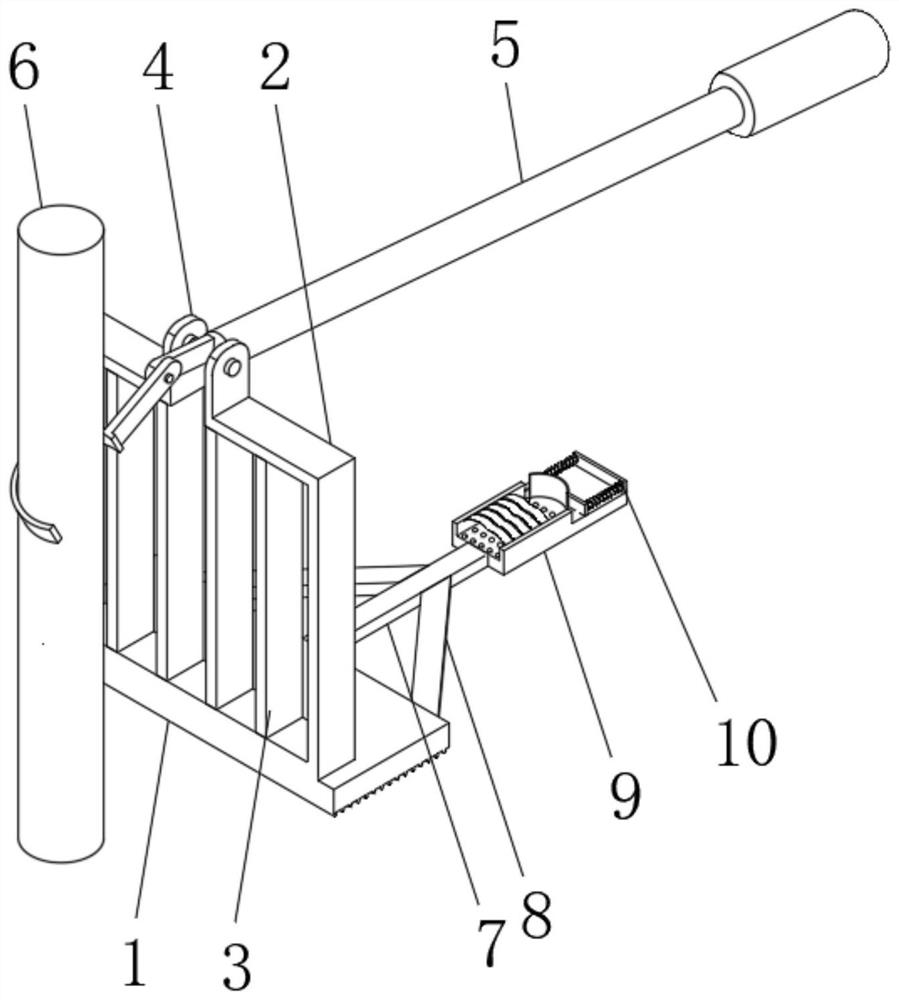

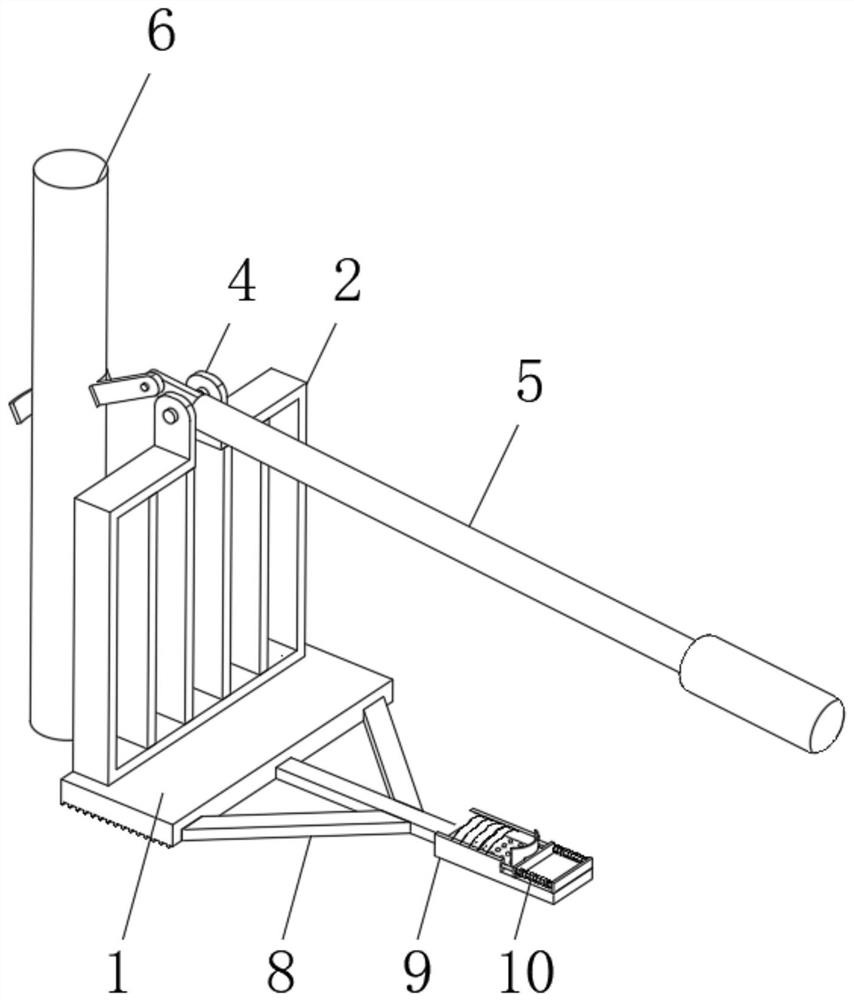

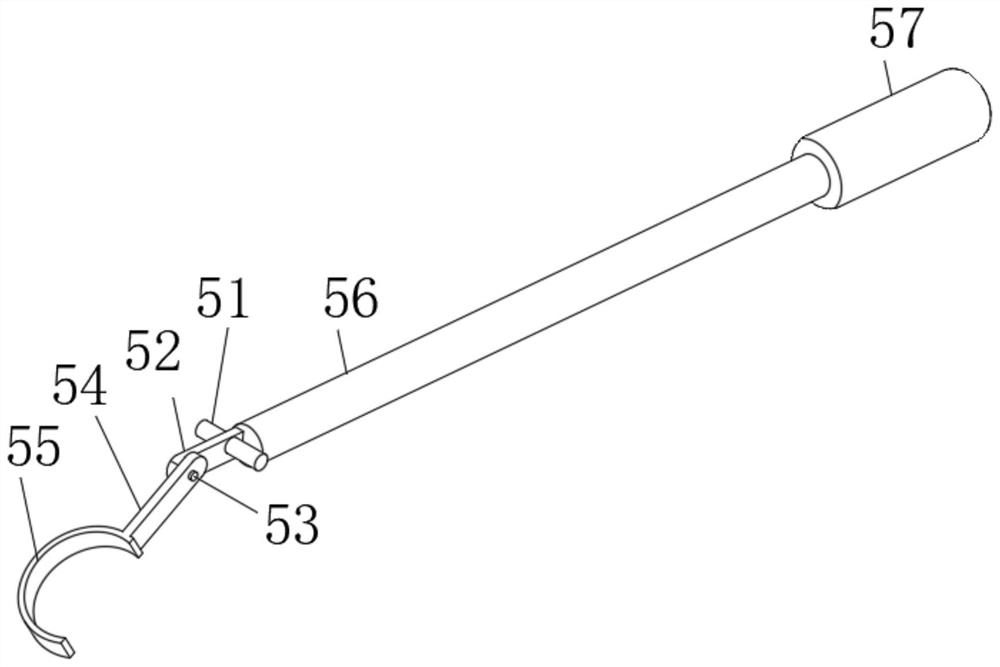

Manual forestry waste fence pulling-up device

ActiveCN111962969AAchieve the purpose of compressionPrevent slippingFencingForest industryStructural engineering

The invention relates to the technical field of forestry, in particular to a manual forestry waste fence pulling-up device, including a base, wherein a fixing frame is arranged on the outer surface ofthe upper end of the base. A rotating shaft frame is arranged on the outer surface of the upper end of the fixing frame; a pull-up mechanism is arranged on the surface of the inner side of the rotating shaft frame; the pull-up mechanism comprises a first rotating shaft, a lever, a second rotating shaft, a movable rod, limiting rings, an extension rod and a rubber sleeve; fence rods are arranged on the inner sides of the limiting rings; a connecting rod is arranged on the outer surface of the rear end of the base; a placing mechanism is arranged on the outer surface of the rear end of the connecting rod; the placing mechanism comprises a placing plate, a side plate, a protective bulge and a limiting belt; and an anti-falling mechanism is arranged on the outer surface of the upper end of the placing mechanism. According to the manual forestry waste fence pulling-up device, the device can be more stable in the working process, a foot sole used for stabilizing the device can be preventedfrom slipping, and waste fence rods can be easily pulled up according to the lever principle.

Owner:杨成利 +2

A Lossless Compression Coding Method for Pure Three Primary Color Picture Data

ActiveCN107801031BCompression reachesAchieve the purpose of compressionDigital video signal modificationPattern recognitionData file

Owner:广州物启科技有限公司

Automatic garbage waste crushing and compressing equipment

PendingCN113877928AIncrease speedTo achieve the purpose of fine cutting and grindingConstruction waste recoverySolid waste disposalSlagRefuse Disposals

The invention relates to the field of garbage treatment, and discloses automatic garbage waste crushing and compressing equipment. The edge of the upper end of a rotating disc is fixedly connected with a convex block, the two sides of the top of a bottom frame are fixedly connected with slag storage cylinders, the lower ends of the two sides inside the slag storage cylinders are fixedly connected with supporting seats, the upper ends of the supporting seats are fixedly connected with springs, pressing plates are fixedly connected to the upper ends of the springs, vertical rods are fixedly connected to the lower ends of the pressing plates, slag outlets are fixedly connected to the upper ends of one sides, away from power shafts, of the slag storage cylinders, and conveying pipes are fixedly connected to the other sides of the slag outlets. Waste garbage cut into disintegrating slag in a cutting cavity falls into the slag storage cylinders through filter screens and falls at the upper ends of the pressing plates, when the power shafts rotate to drive the rotating disc to rotate, when the convex block moves to the lower sides of the vertical rods, the vertical rods can be jacked upwards, so that the pressing plates move upwards, waste slag inside the slag storage cylinders is pressed, the waste slag is compressed, and the compressed waste slag is discharged through the slag outlet and flow into a storage position through the conveying pipes, so that the purpose of compressing the waste slag is achieved.

Owner:张菊

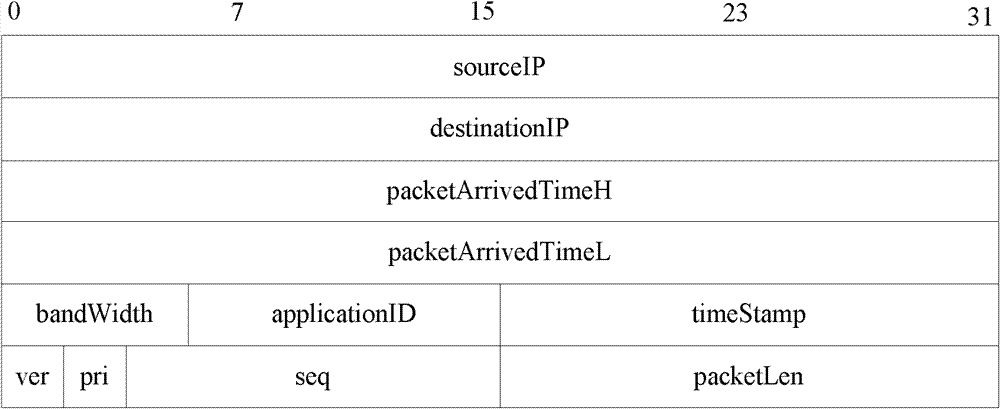

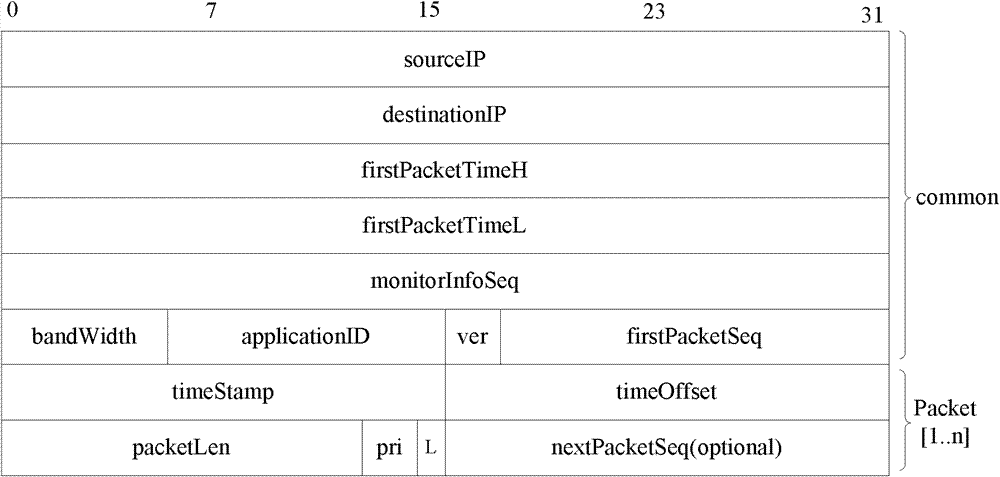

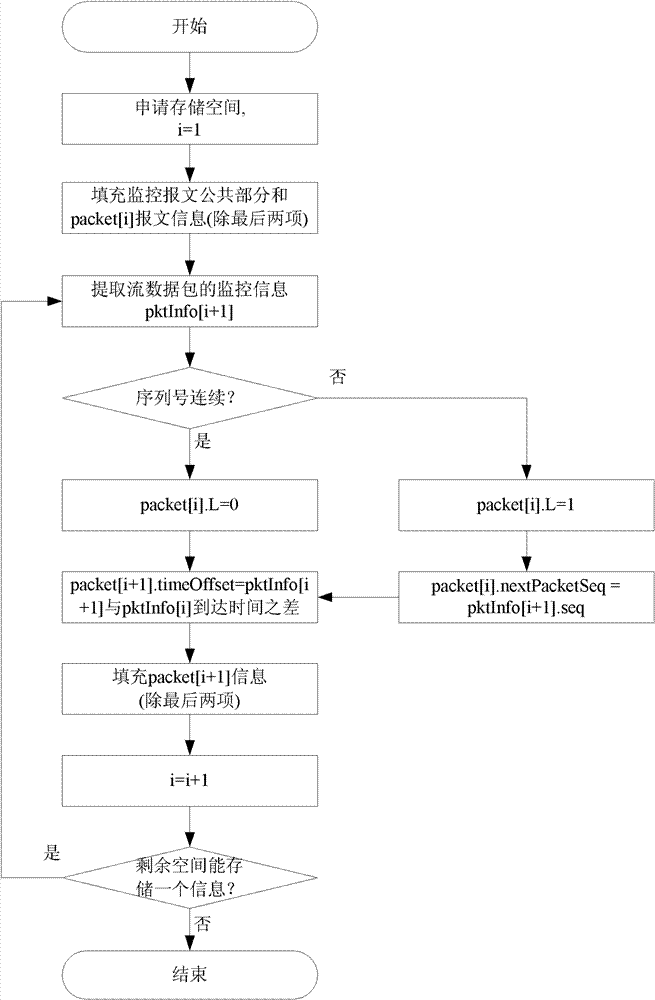

Monitor information compressing method orientating streaming media transmitting quality

The invention discloses a monitor information compressing method orientating streaming media transmitting quality. Monitor information monitored by the steaming media transmitting quality is set to be a public part and a change part so as to compress the monitor information of continuously received streaming media messages, especially, parameters of message sequence numbers, message arrival time and the like in the monitor information are subject to efficient lossless compression by using the information of the public part in the method. According to the method, the transmitting efficiency of the monitor information monitored by the streaming media transmitting quality is improved by 3-4 times, thus the network resources occupied by the monitor information during the transmission are greatly reduced.

Owner:NAT UNIV OF DEFENSE TECH

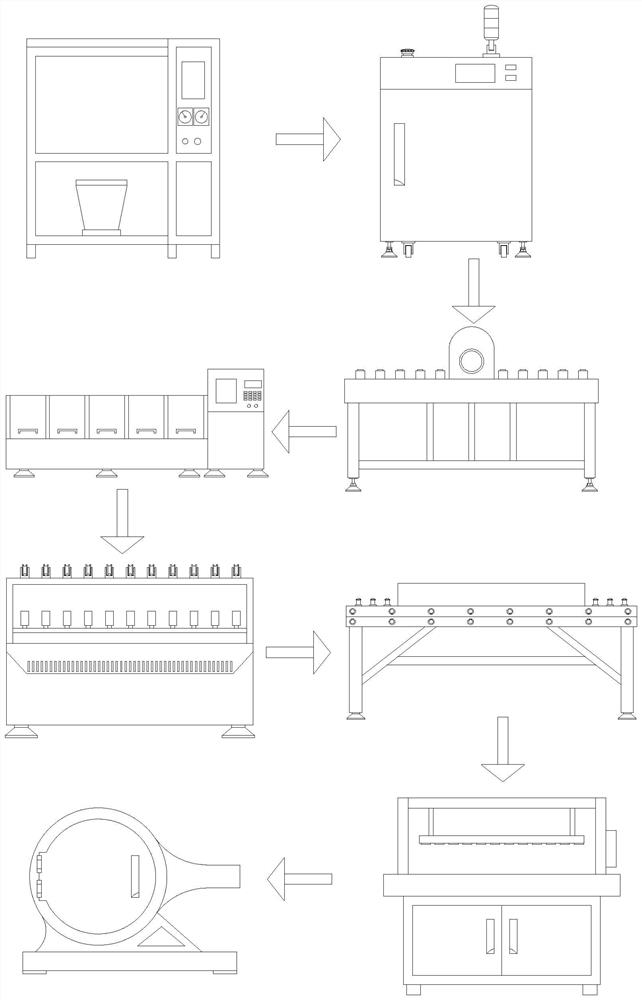

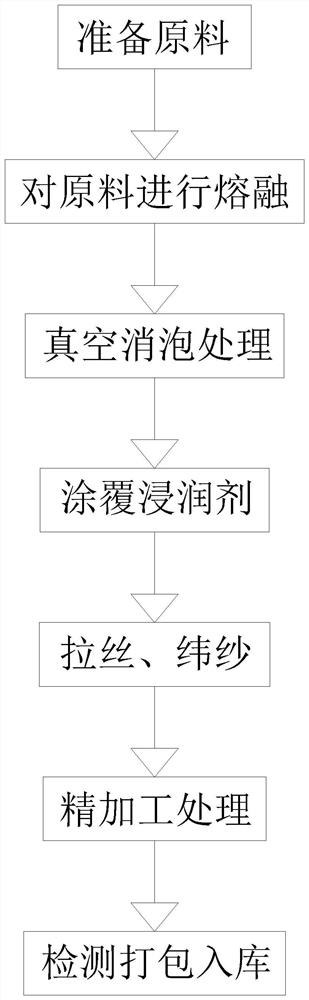

Production and preparation method of acid and alkali resistant electronic cloth

ActiveCN114808234AAvoid pass ratePrevent the yield from being affected by air bubbles generated in the molten raw materialSpinning solution filteringBinding material applicationMachiningGas bubble

The invention discloses a production and preparation method of acid and alkali resistant electronic cloth, and relates to the technical field of electronic cloth production.The production and preparation method of the acid and alkali resistant electronic cloth comprises the following steps that firstly, raw materials are prepared; 2, melting the raw materials; step 3, vacuum defoaming treatment; step 4, coating an impregnating compound; step 5, wiredrawing and weft yarns; sixthly, finish machining treatment is conducted; and 7, detecting, packaging and warehousing. The step 2 comprises the step of putting the prepared raw materials into melting equipment. Through the action of the vacuum defoaming equipment, air in the inner bin of the vacuum defoaming equipment in which the molten raw materials are placed is pumped out, bubbles in the molten raw materials are conveniently removed, the removal efficiency of the bubbles in the molten raw materials is improved through the action of the defoaming reagent, and the removal efficiency of the bubbles in the molten raw materials is improved. Therefore, the purpose of removing the bubbles in the molten raw materials is achieved, and the situation that the qualified rate of the acid and alkali resistant electronic cloth after production is affected by the bubbles generated in the molten raw materials is prevented.

Owner:TONGCHENG GLASS FIBER OF ANHUI DANFENG GROUP

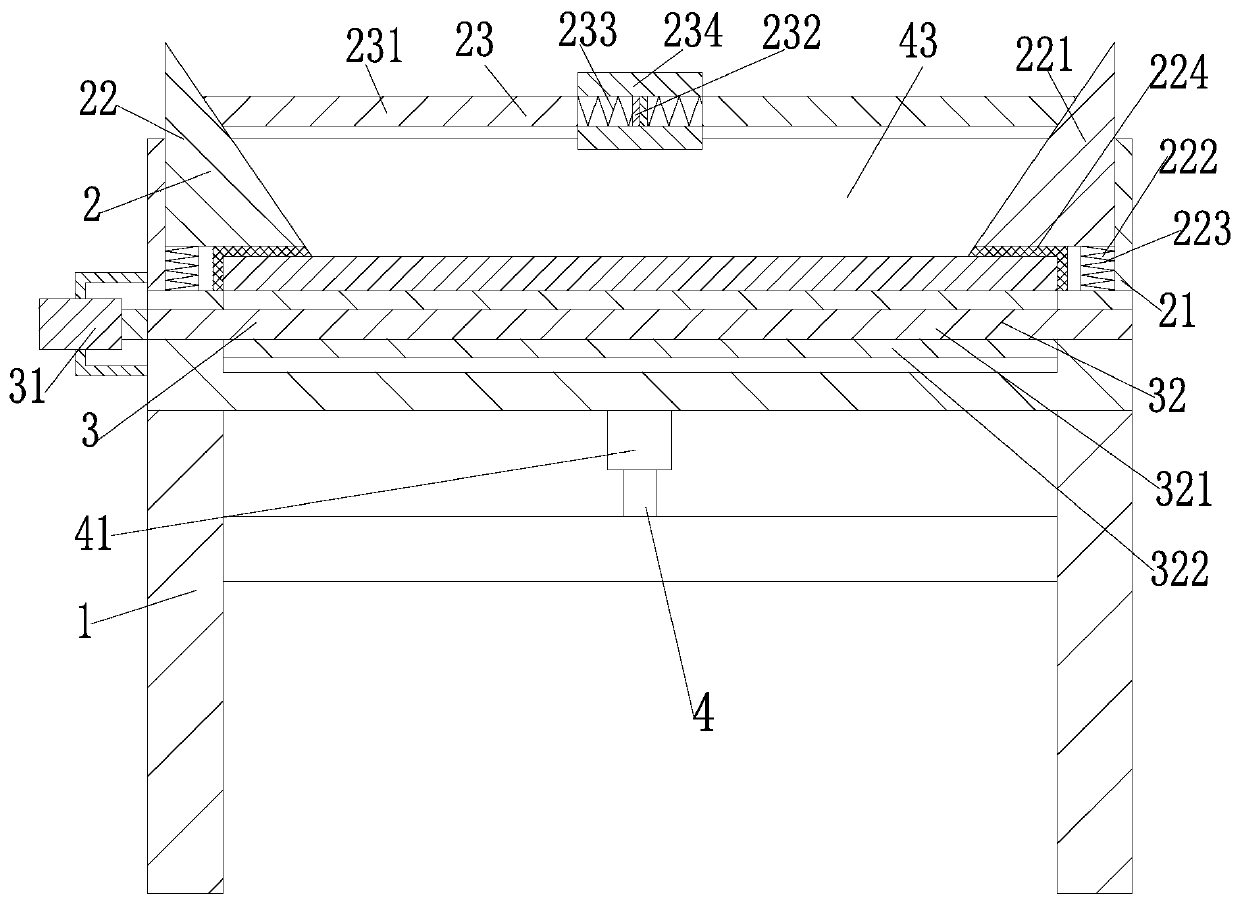

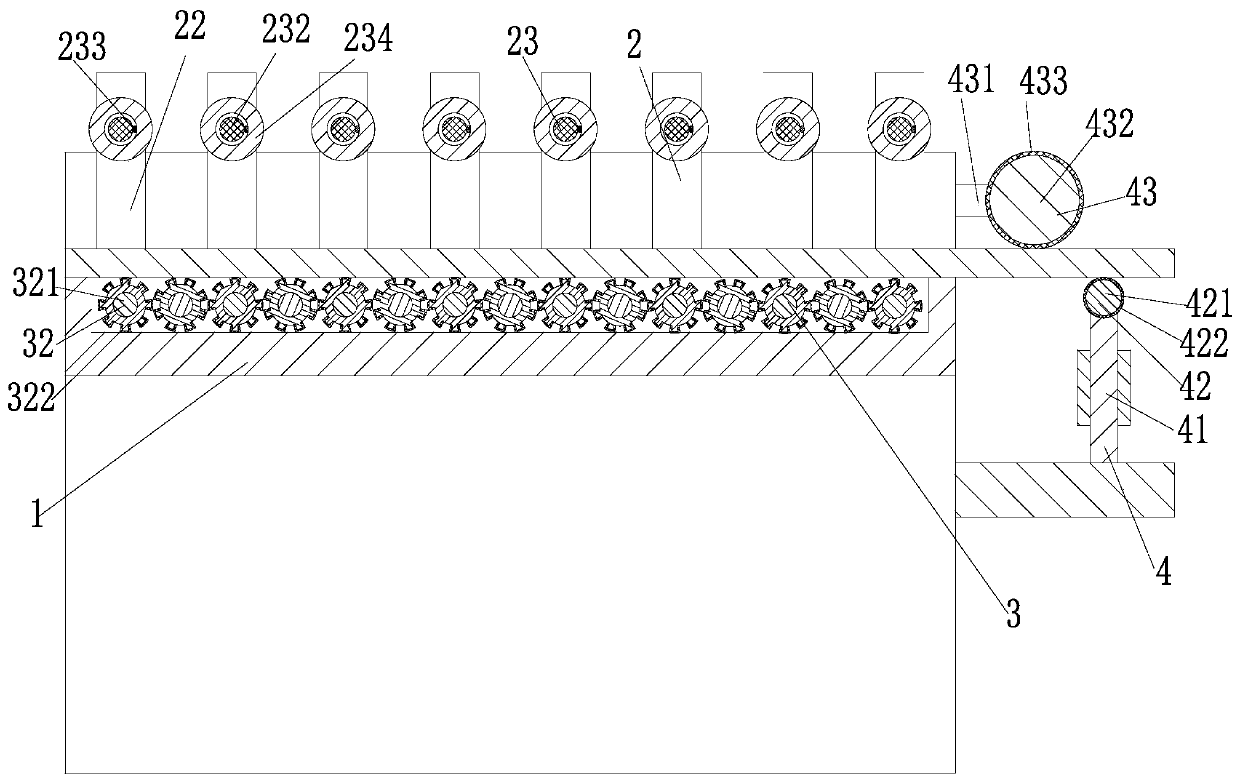

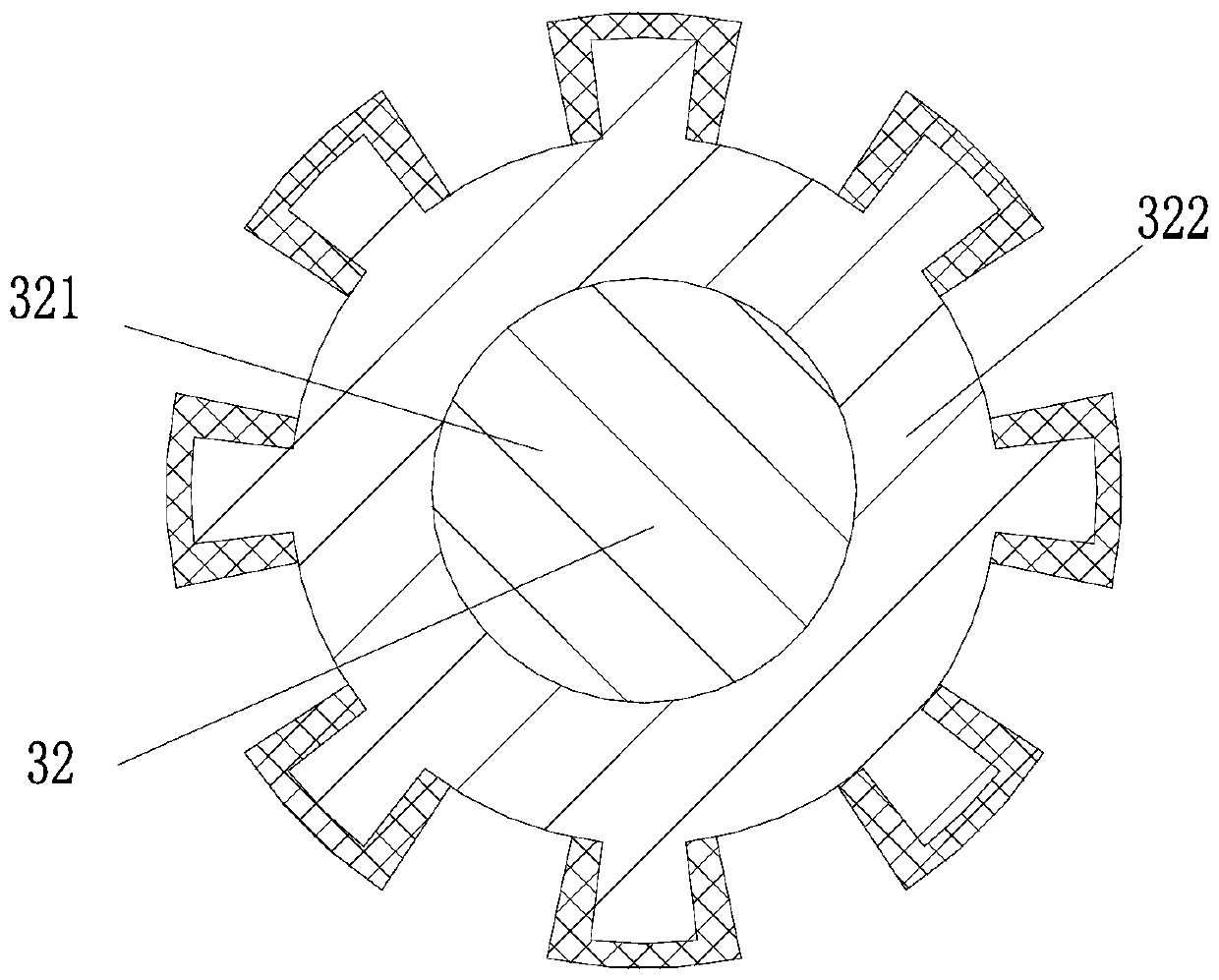

A kind of galvanized steel plate bending processing equipment and steel plate processing method

ActiveCN110756625BAvoid driftingAvoid damageMetal-working feeding devicesPositioning devicesRubber ringCylinder head

The invention relates to a galvanized steel plate bending processing equipment and a steel plate processing method, including a workbench, a pressing device, a transmission device and a bending device, characterized in that: the upper end of the workbench is equipped with a pressing device on the left and right sides, There is a rectangular groove in the middle of the workbench, and the rectangular groove is connected with the transmission device in a sliding fit manner. The front end of the workbench is equipped with a bending device, including, the present invention drives the steel plate to move forward through the transmission device, and through the pressing device Press the steel plate tightly to prevent the steel plate from shifting due to excessive force during the bending process. The steel plate is bent through the bending device. The small rubber ring on the surface of the cylinder head and the cylinder frame and the large The rubber ring prevents the galvanized layer on the surface of the steel plate from being damaged due to excessive impact force when the small cylindrical block is pressed against the surface of the steel plate.

Owner:WENXING ELECTRICAL TECH CO LTD

Galvanized steel plate bending processing equipment and steel plate processing method

ActiveCN110756625AAvoid driftingAvoid damageMetal-working feeding devicesPositioning devicesRubber ringEngineering

The invention relates to galvanized steel plate bending processing equipment and a steel plate processing method. The galvanized steel plate bending processing equipment comprises a workbench, pressing devices, a transmission device and a bending device, the galvanized steel plate bending processing equipment is characterized in that the left and right sides of the upper end of the workbench are provided with pressing devices, a rectangular groove is formed in the middle of the workbench, the rectangular groove is connected with the transmission device in a sliding fit mode, and the front endof the workbench is provided with the bending device. According the galvanized steel plate bending processing equipment, the transmission device drives the steel plate to move forwards, the steel plate is pressed by the pressing device to prevent the steel plate from shifting due to excessive stress in the bending process; the steel plate is bent by the bending device, the small rubber ring and the large rubber ring on the surface of the cylindrical head and the cylindrical frame prevent the galvanized layer on the surface of the steel plate from being damaged due to excessive impact force when the small cylindrical block presses the surface of the steel plate.

Owner:WENXING ELECTRICAL TECH CO LTD

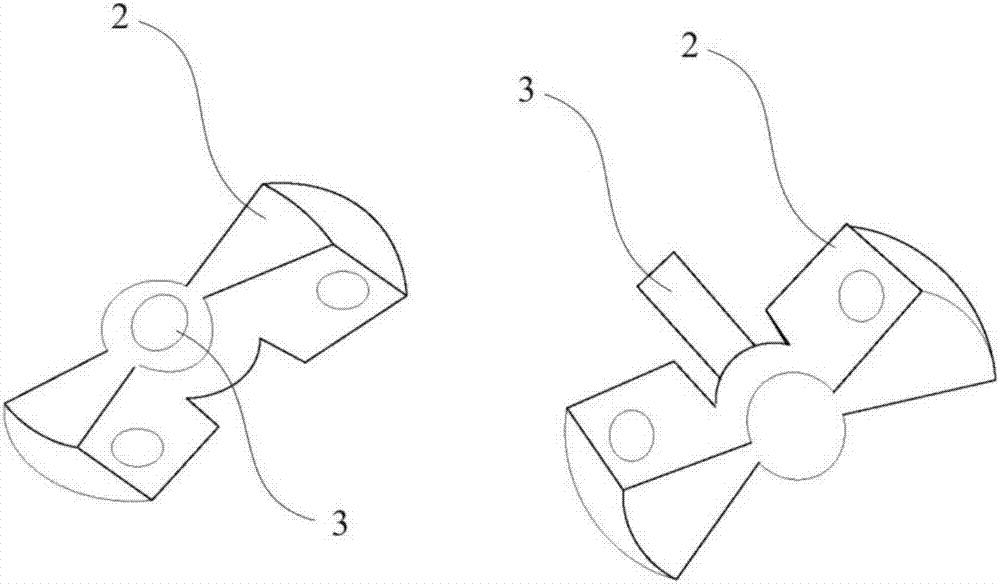

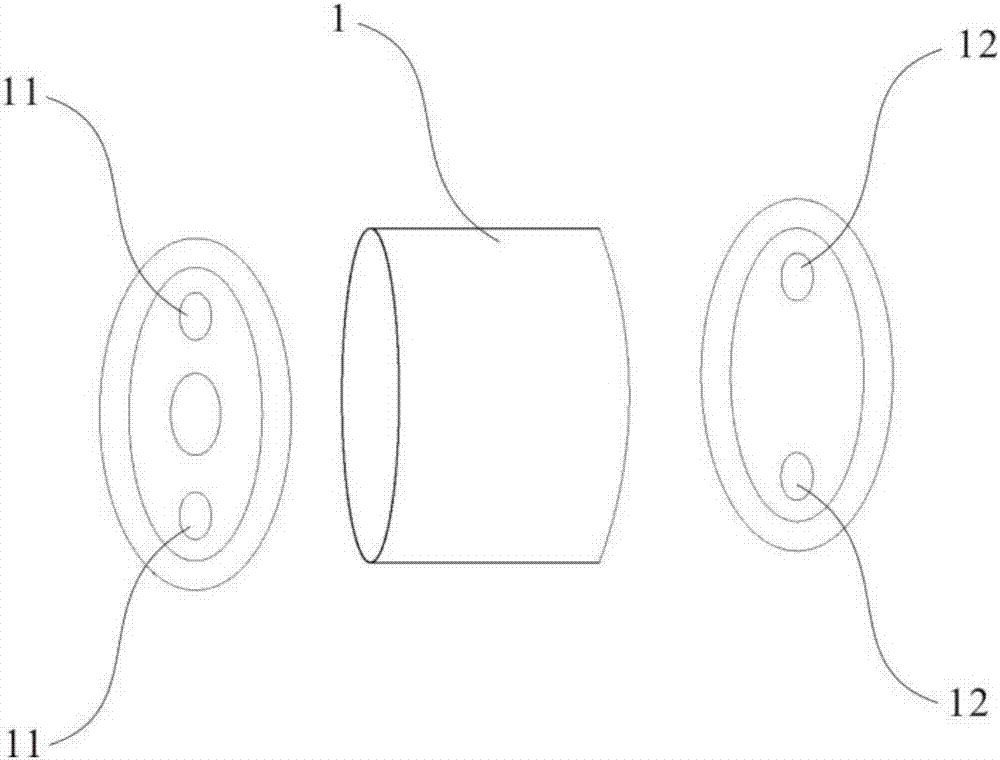

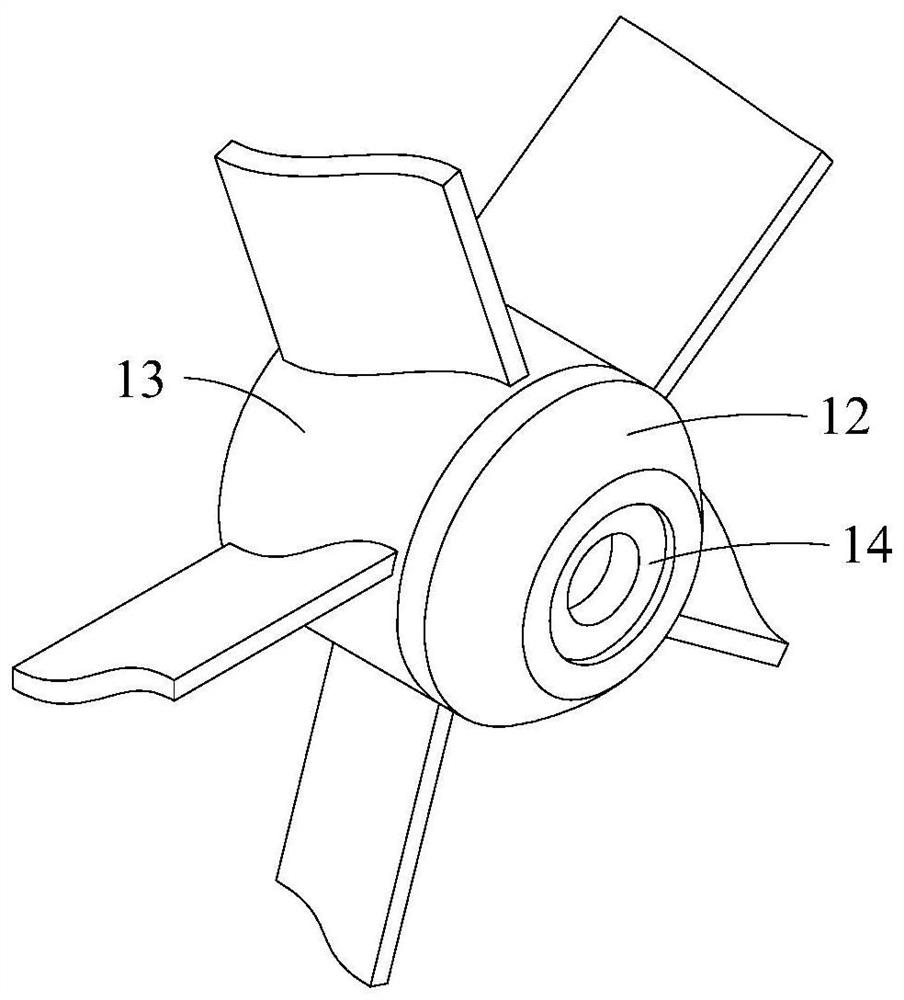

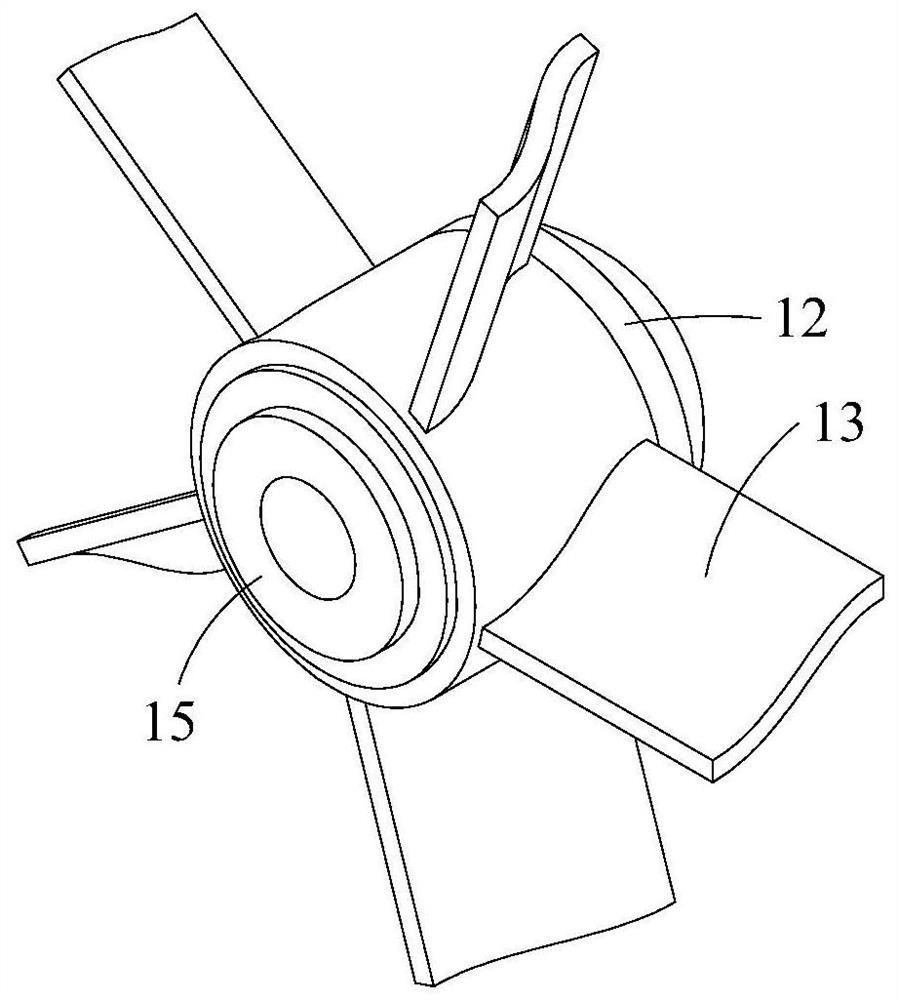

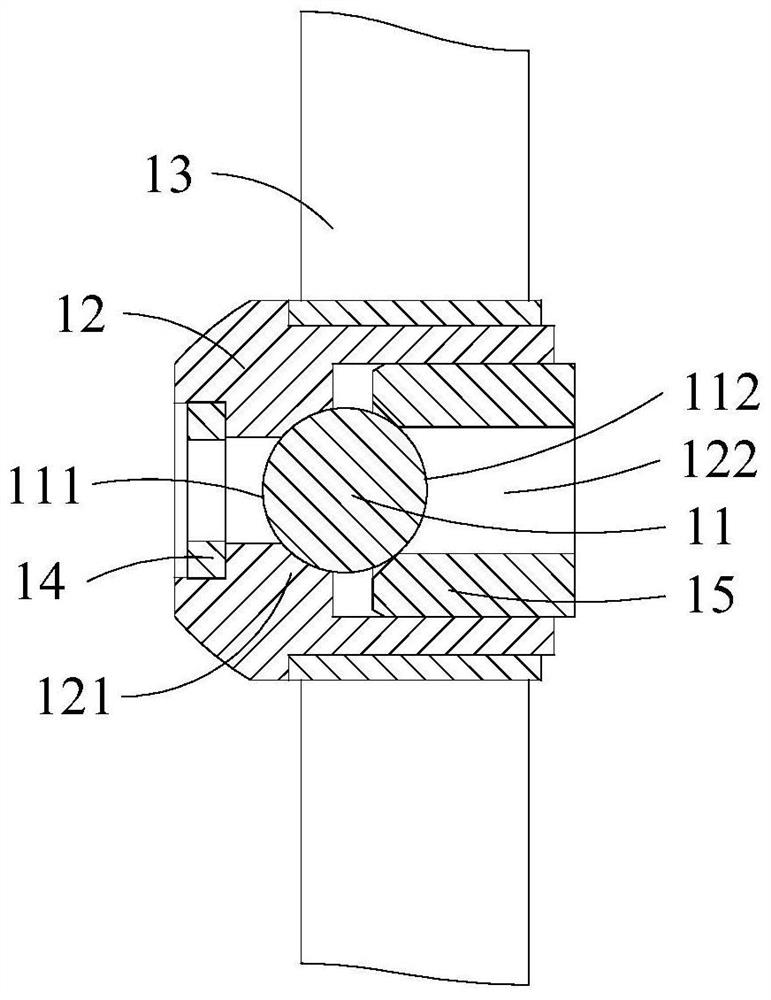

Impeller device and turbine flowmeter

PendingCN111721369AExpand the scope of measurementHigh metering sensitivityVolume meteringVolume/mass flow by dynamic fluid flow effectImpellerFrictional resistance

The invention relates to a turbine flowmeter, particularly to an impeller device and a turbine flowmeter. The impeller device comprises an impeller assembly and a first rotating shaft, wherein the impeller assembly can rotate around the first rotating shaft, and the end of the first rotating shaft abuts against the impeller assembly and makes point contact with the impeller assembly. According tothe impeller device, when the impeller assembly rotates, the frictional resistance of the impeller device is smaller than that of an existing turbine flow meter, so that the metering sensitivity of the impeller device is high, and the minimum value capable of being metered is small so as to widen the metering range of the turbine flow meter.

Owner:隆昌市力佳商贸有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com