Impeller device and turbine flowmeter

An impeller and shaft technology, applied in the field of turbine flowmeters, can solve the problems of reduced sensitivity and accuracy of turbine flowmeters, and achieve the effects of improving sensitivity, reducing maintenance costs, and increasing the measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

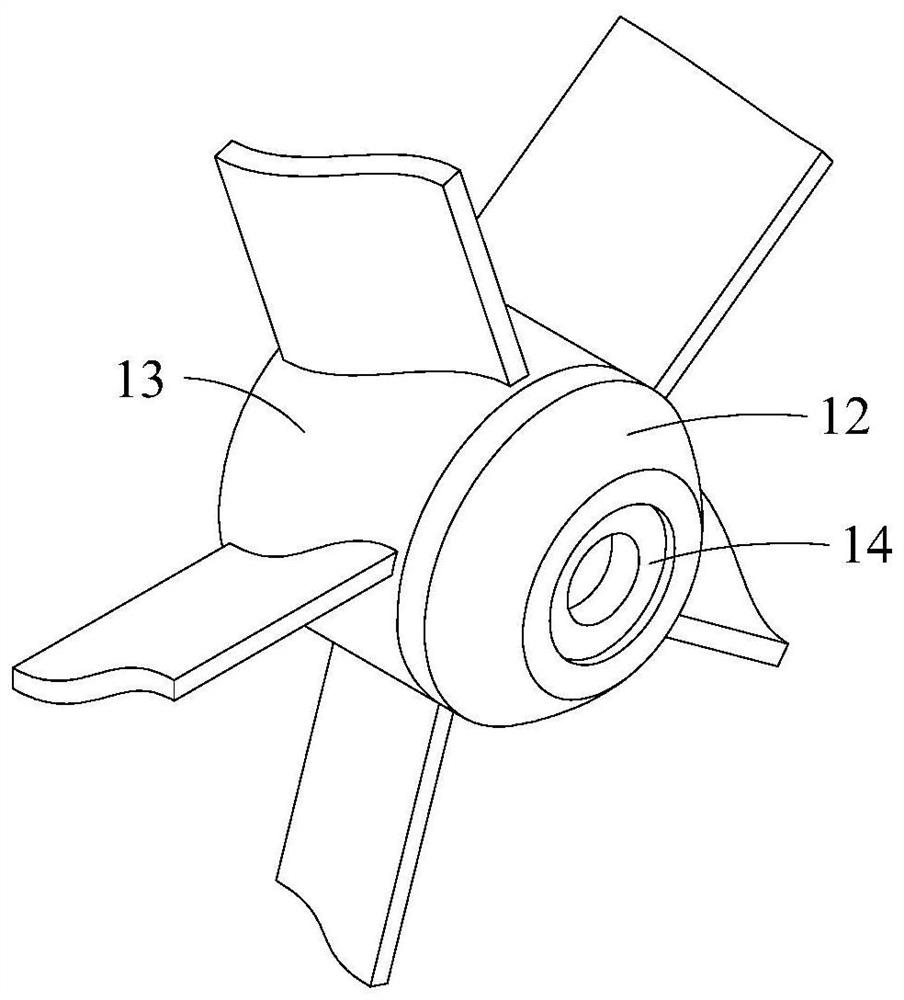

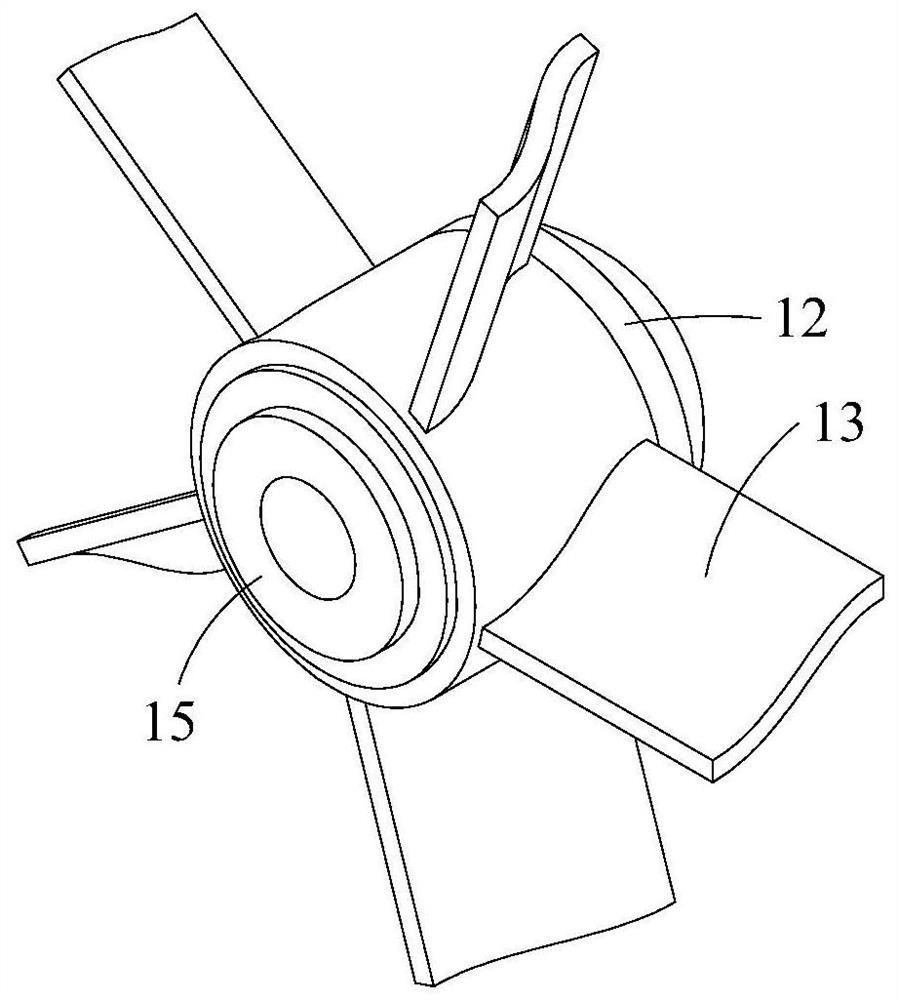

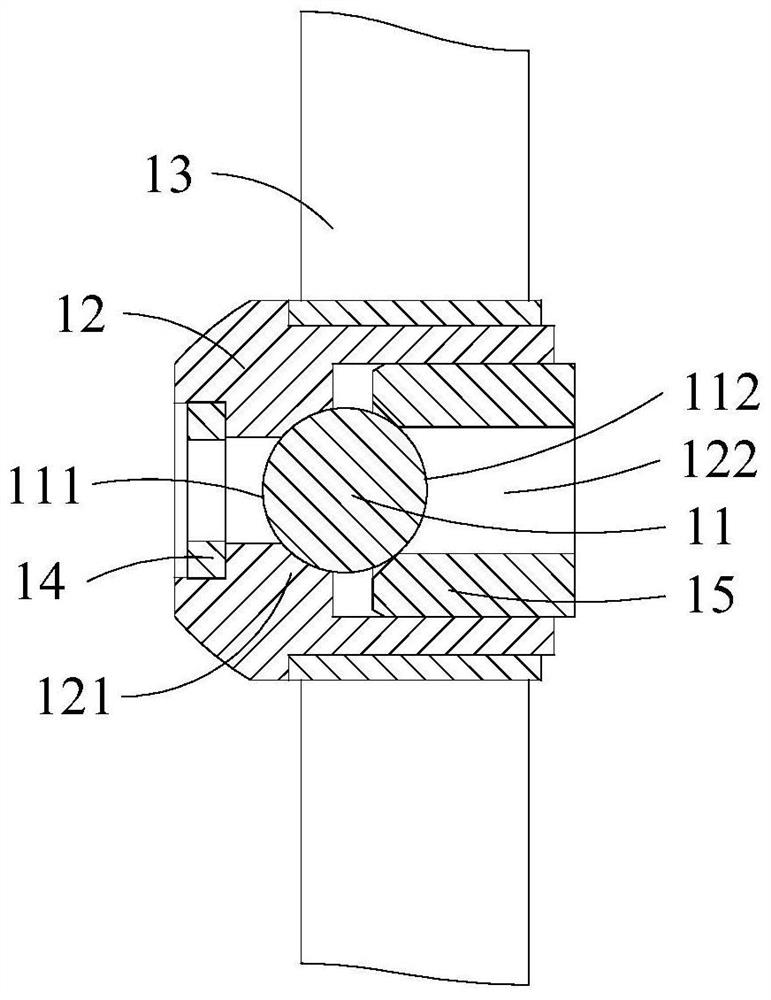

[0067] like Figure 1-4 As shown, an impeller device described in this embodiment includes an impeller assembly 1, a second rotating shaft 2 and a first rotating shaft 3, the impeller assembly 1 can rotate around the first rotating shaft 3, and the second rotating shaft 2 and the first rotating shaft 3 are coaxially arranged, the impeller assembly 1 is located between the second rotating shaft 2 and the first rotating shaft 3, the end of the second rotating shaft 2 and the end of the first rotating shaft 3 Both parts are capable of 1-point contact with the impeller assembly.

[0068] Specifically, the impeller assembly 1 includes a rotating sleeve 12 and an impeller structure 13 sleeved on the outside of the rotating sleeve 12. The rotating sleeve 12 and the impeller structure 13 are tightly fitted, that is, the rotating sleeve 12 and the The impeller structure 13 can rotate integrally. When dismounting or installing, a certain external force must be applied to make the two m...

Embodiment 2

[0087] like Figure 5-16 As shown, the present invention also discloses a turbine flowmeter, including a cylinder body 5 and the impeller device as described in Embodiment 1, the first rotating shaft 3 and the cylinder body 5 are connected through a first cage 6, The second rotating shaft 2 and the cylinder body 5 are connected through the second cage 4 , and the first cage 6 , the second cage 4 and the impeller assembly are all arranged in the cylinder body 5 .

[0088] The first cage 6 is specifically: the first cage 6 is provided with a first through hole 61 axially along the first rotating shaft 3 , and the first through hole 61 has a first threaded hole 612 and a first mounting hole 611 , the first mounting hole 611 is located on the side of the first threaded hole 612 close to the impeller assembly 1, the first mounting hole 611 is matched with the first rotating shaft 3, and the first cage 6 A first plug 62 for closing the end of the first through hole 61 is provided o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com