Patents

Literature

2140results about "Volume/mass flow by dynamic fluid flow effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

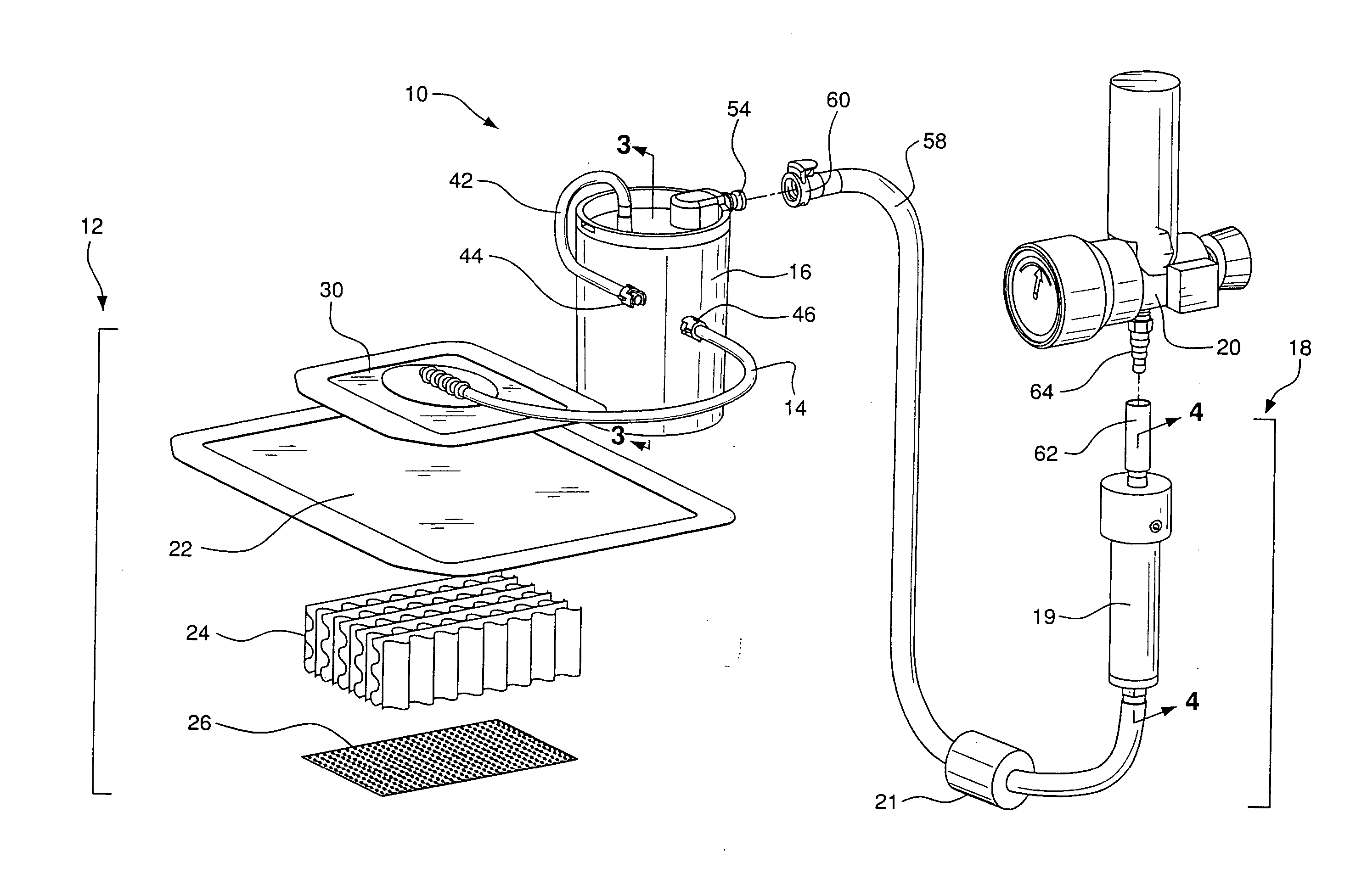

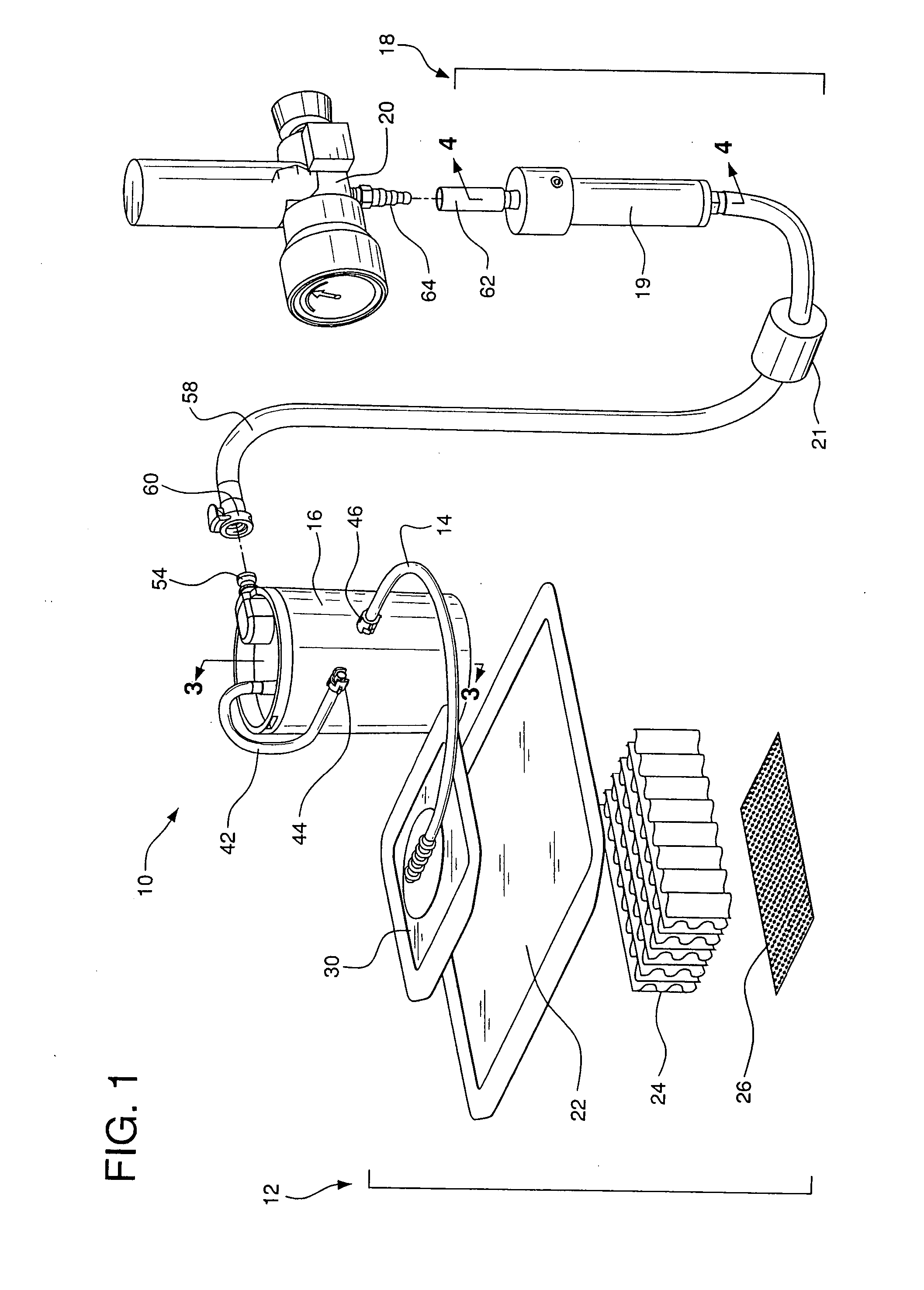

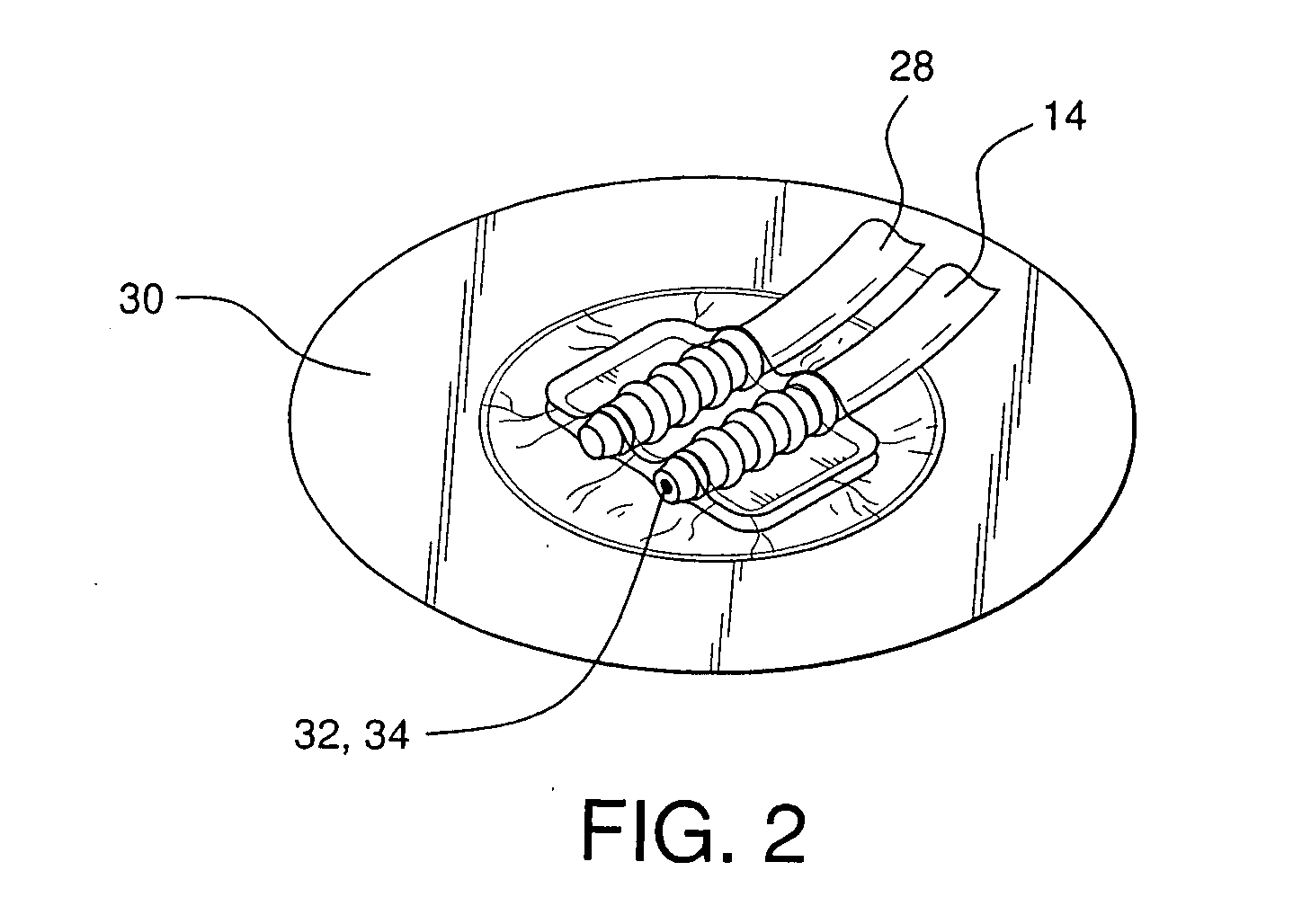

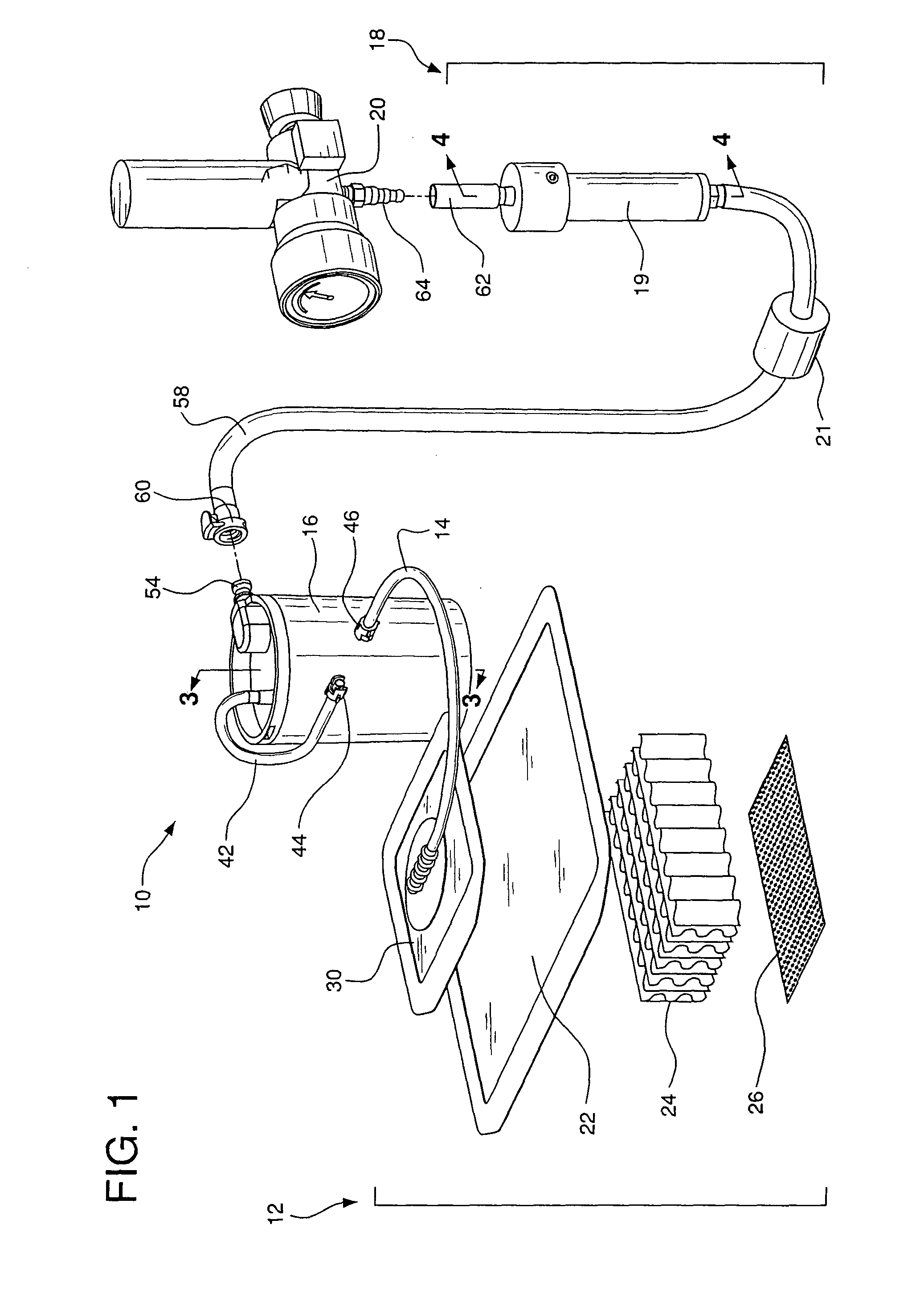

Pump system for negative pressure wound therapy

ActiveUS20070219532A1Reduce the possibilityTrend downWound drainsMedical devicesLevel sensorEngineering

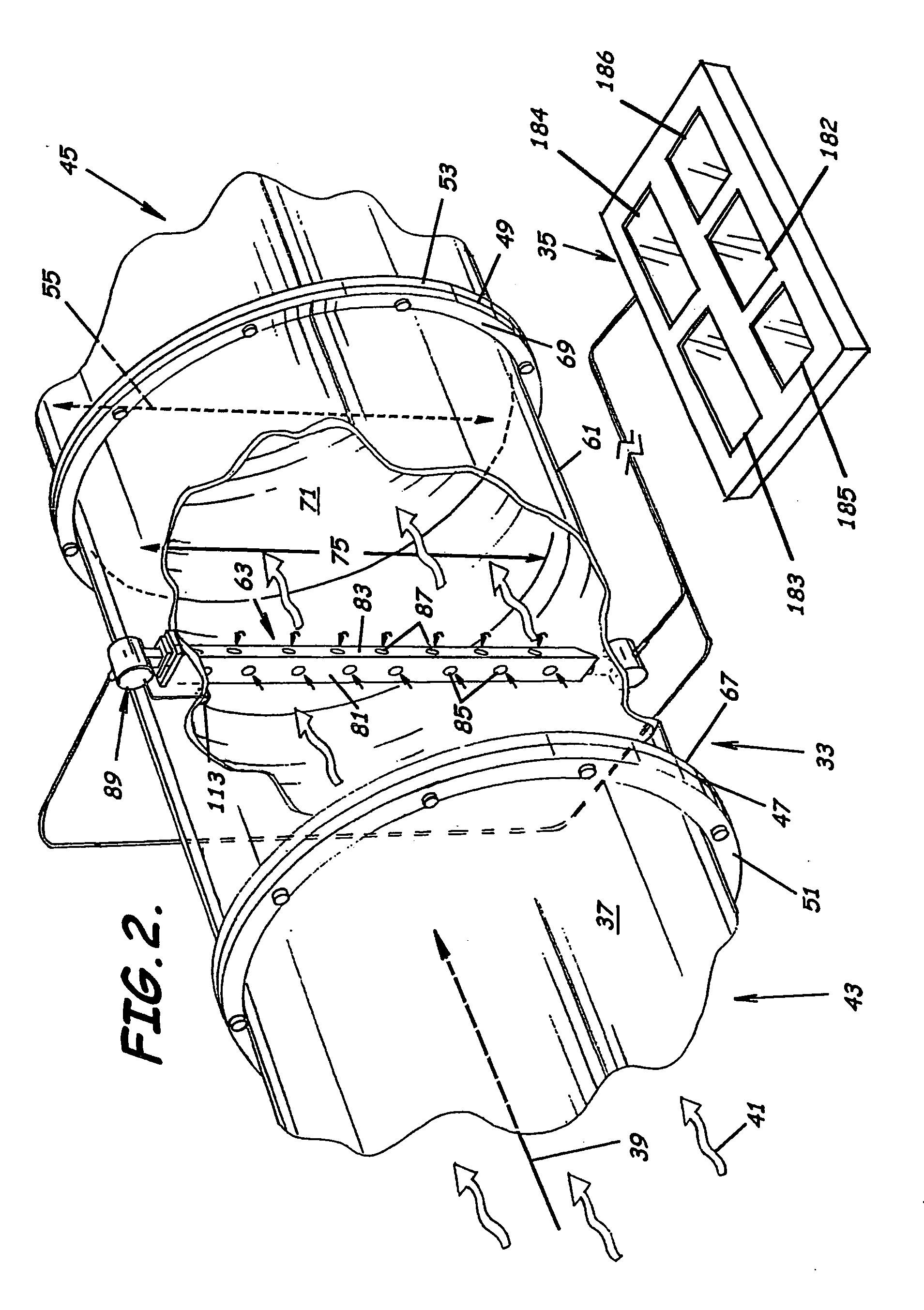

A pump system for applying negative pressure to a wound, including a flow monitor capable of detecting a deviation from a reference airflow rate provided by a controlled leak to determine whether the system is operating normally or abnormally, and a flow status annunciator to indicate a normal operating condition or whether an abnormal condition is a leak or an occluded line in the system. The pump system further includes a pressure controller for regulating operation of a pump to control pressure in the system at a range around a user-selected setpoint. The pump system may also include a waste collector and a level sensor for detecting when the collector is full.

Owner:PAUL HARTMANN AG

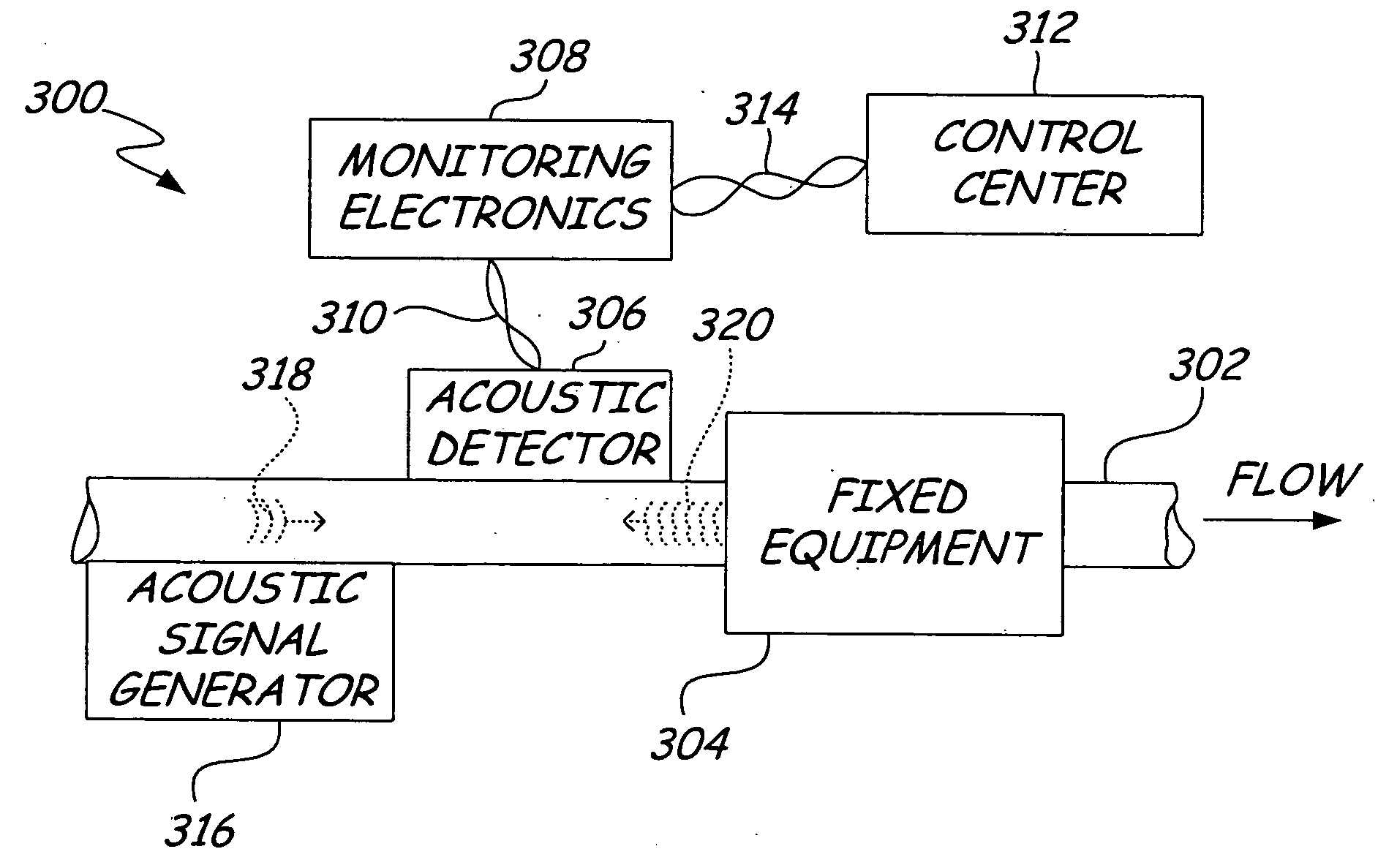

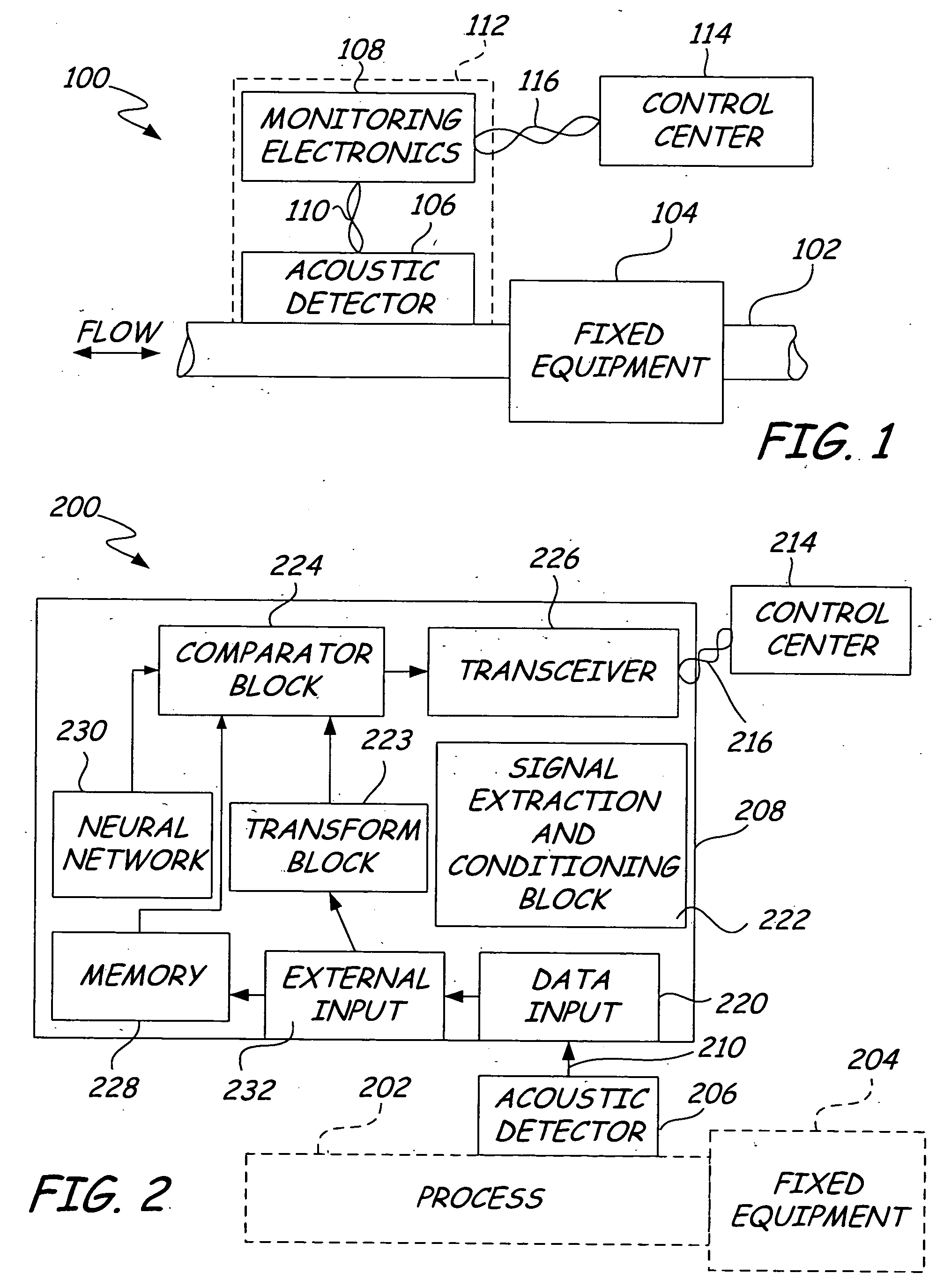

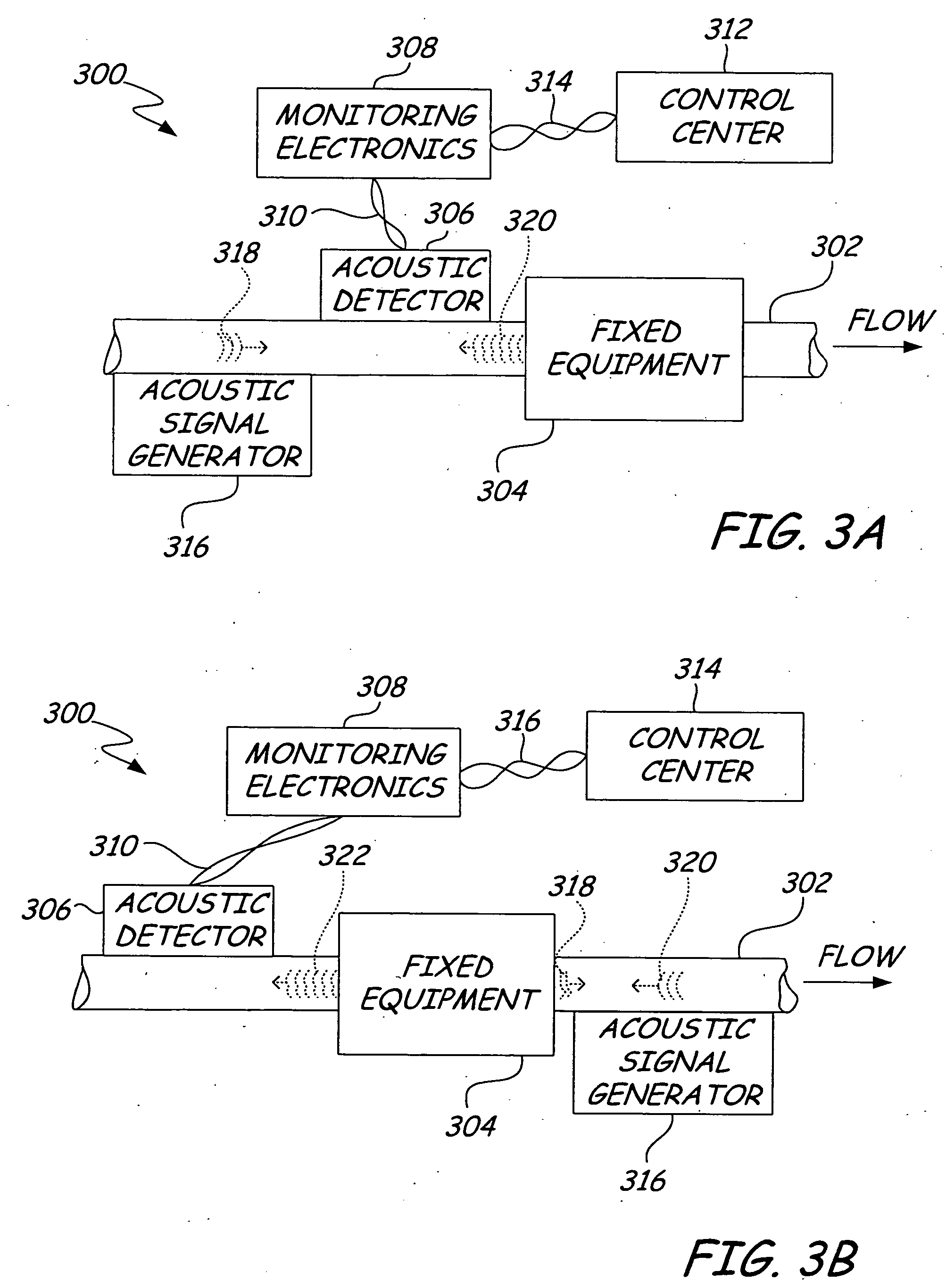

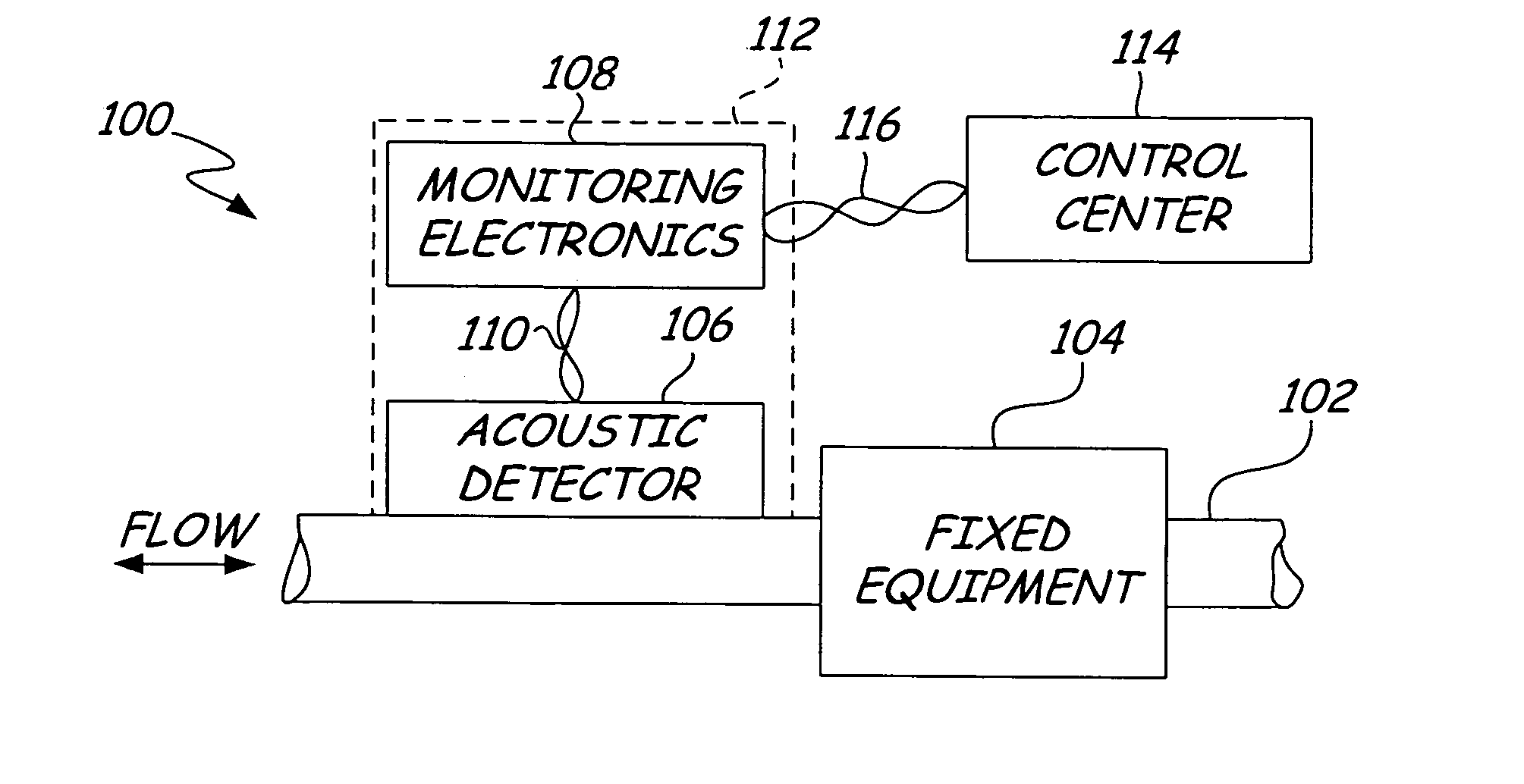

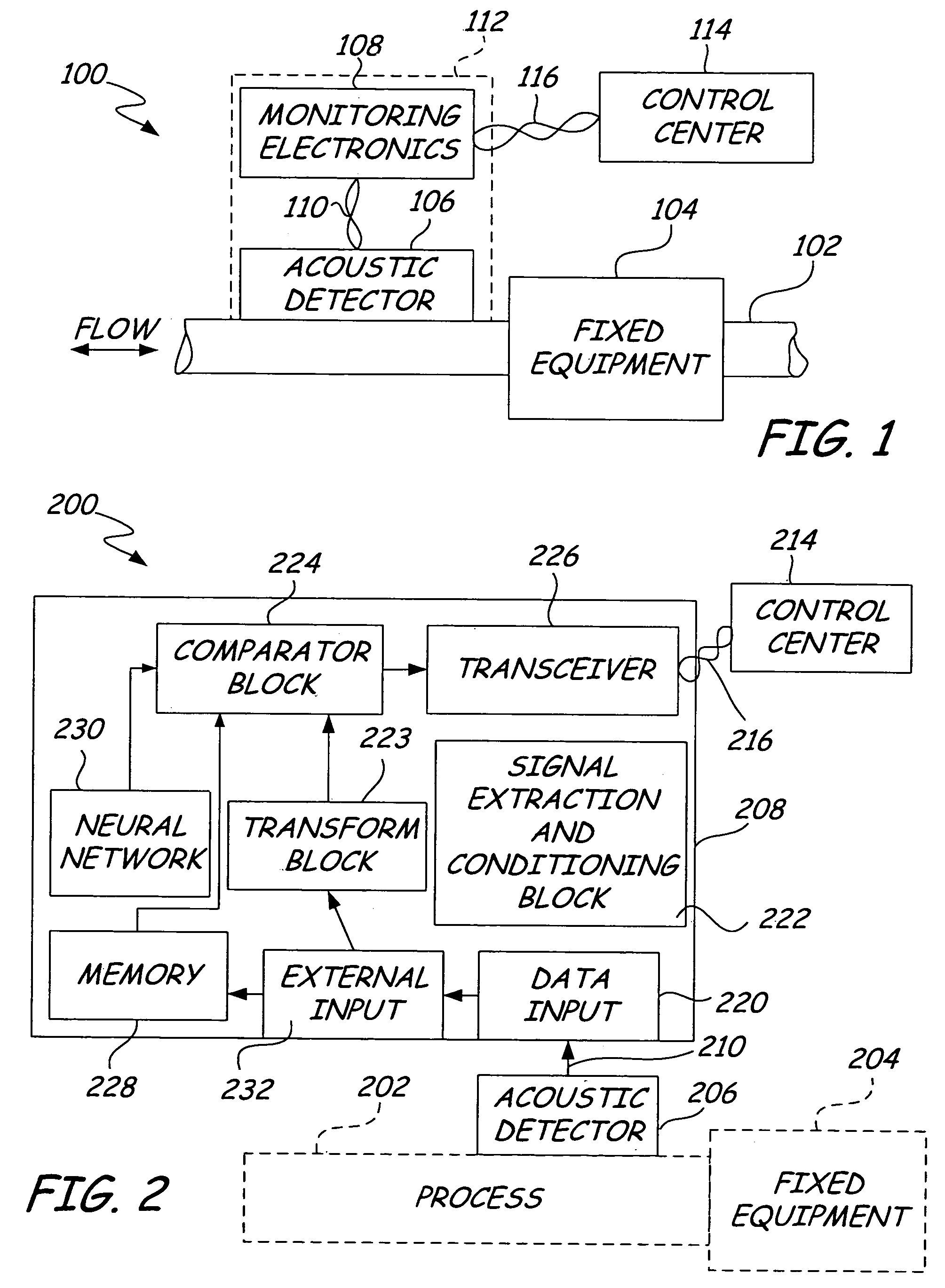

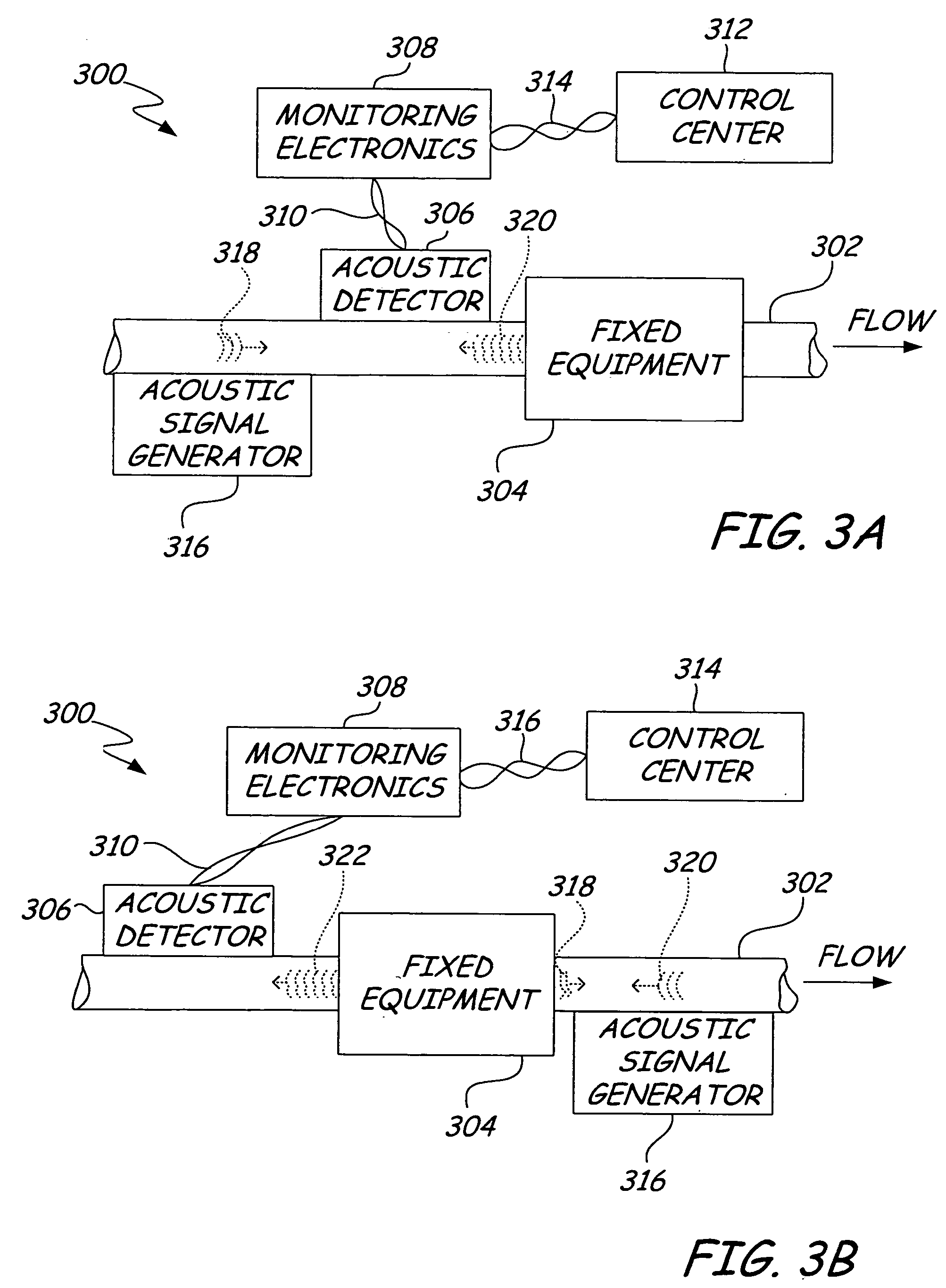

Process diagnostics

ActiveUS20050011278A1Improve abilitiesEasy to useVibration measurement in solidsAnalysing fluids using sonic/ultrasonic/infrasonic wavesTransducerEngineering

A diagnostic device for use in a industrial process includes monitoring electronics or diagnostic circuitry configured to diagnose or identify a condition or other occurrence in the industrial process. The system can be implemented in a process device such as a flowmeter, and in one example an acoustic flowmeter. A transducer can also be used and a frequency response, such as resonant frequency, can be observed.

Owner:ROSEMOUNT INC

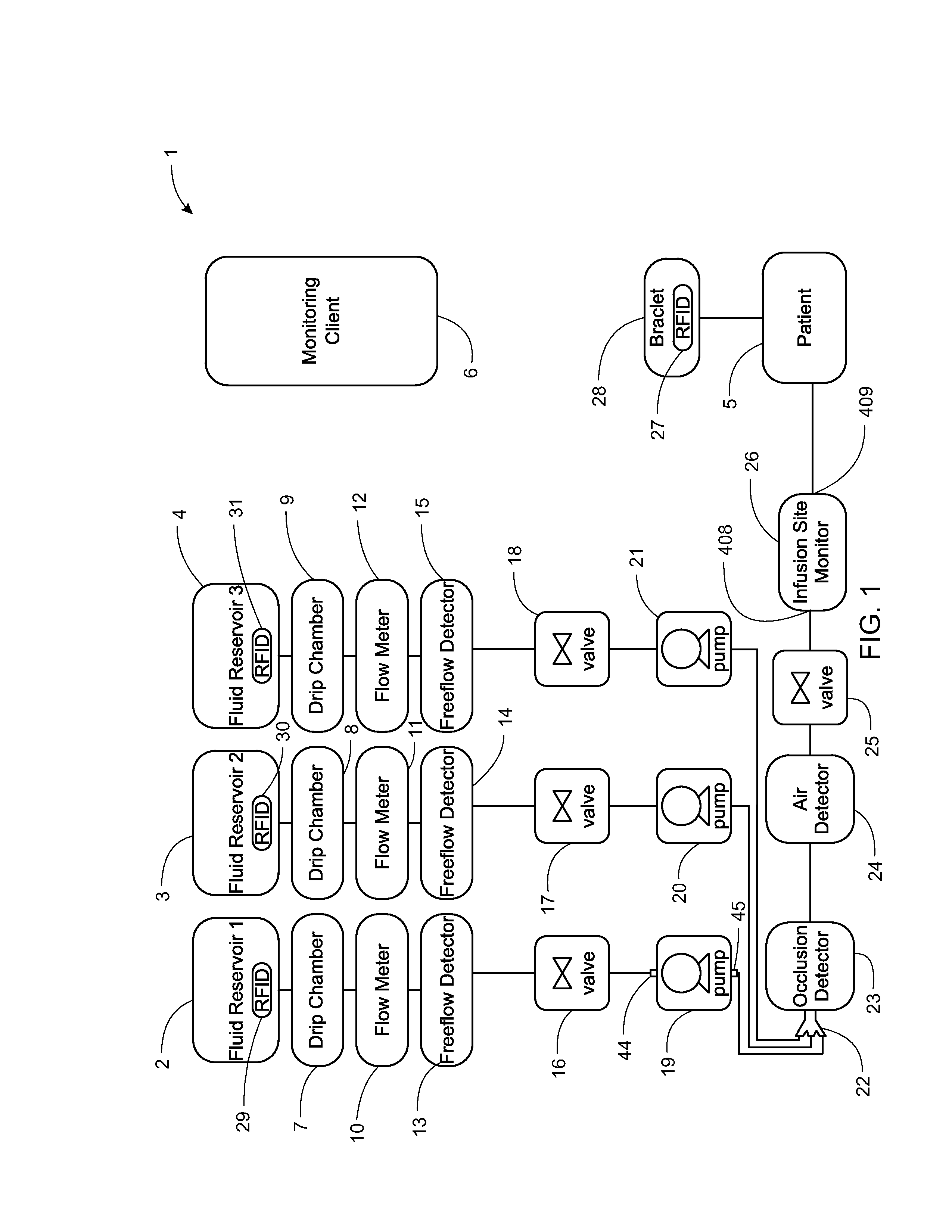

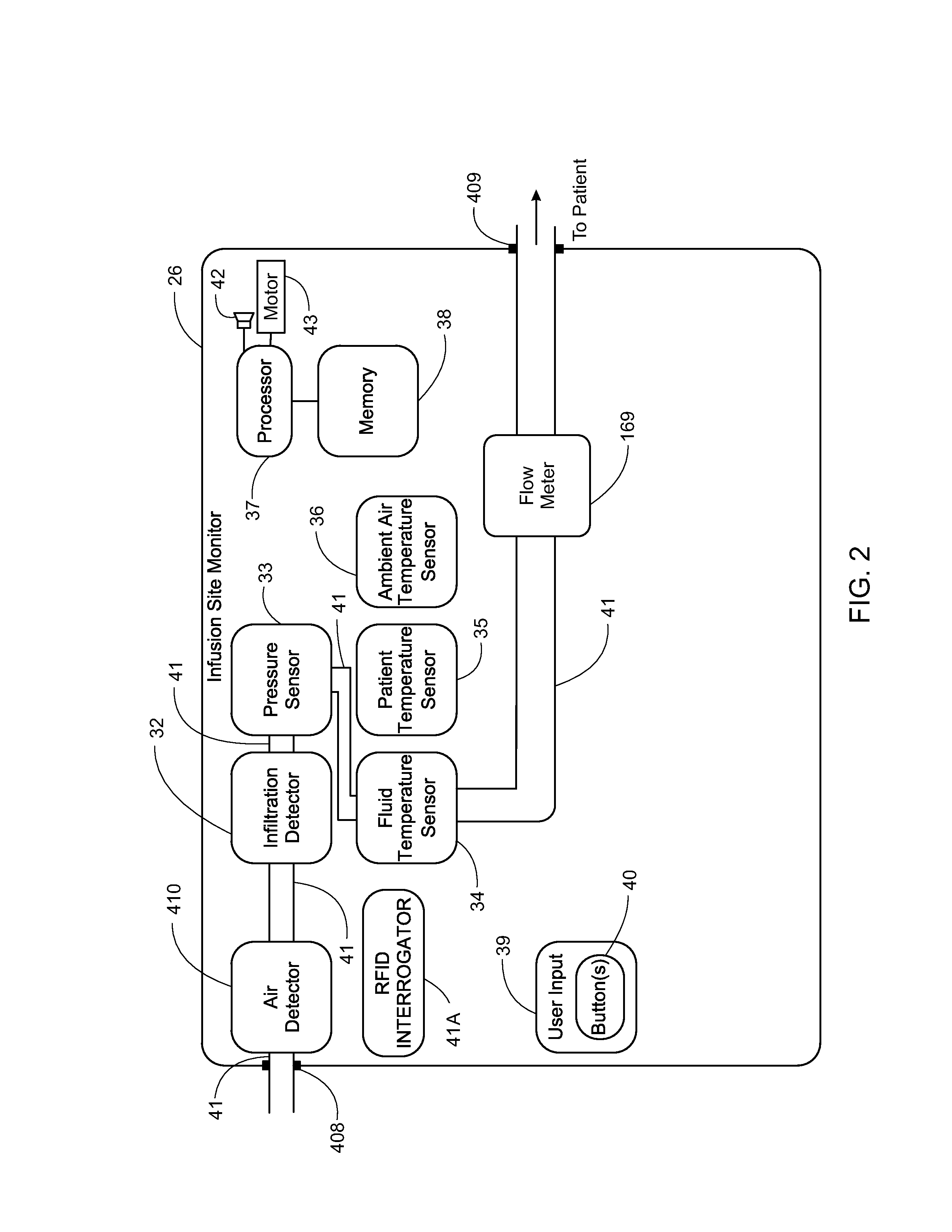

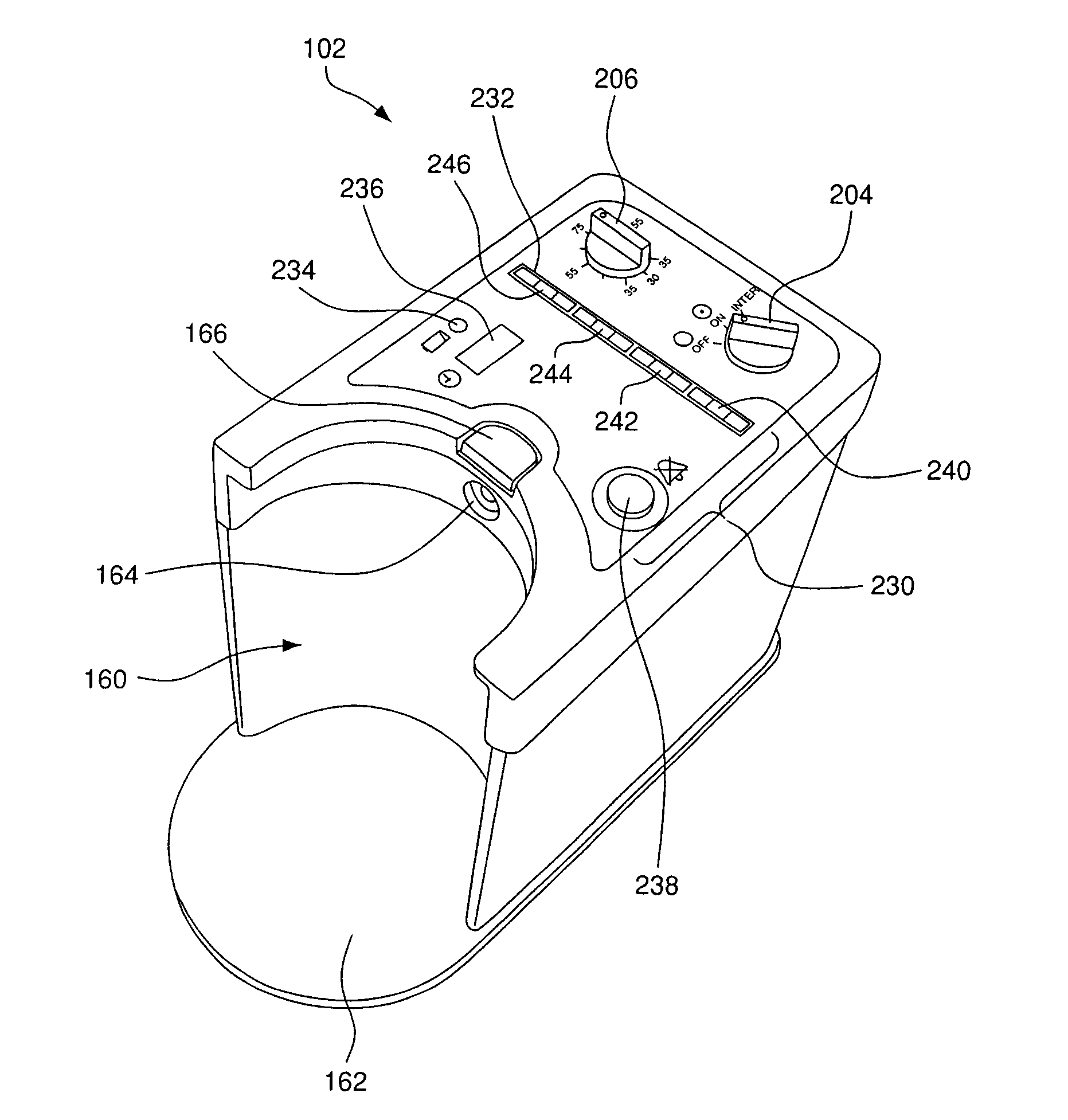

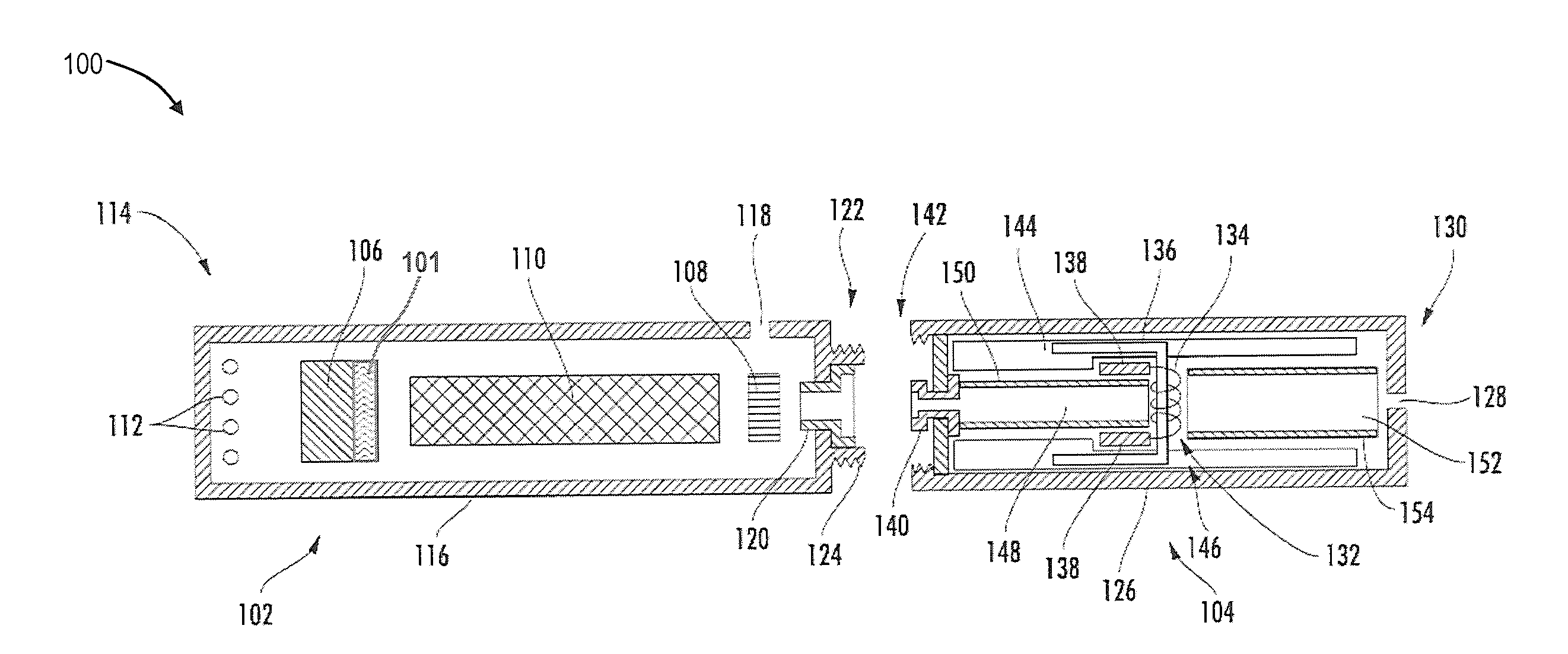

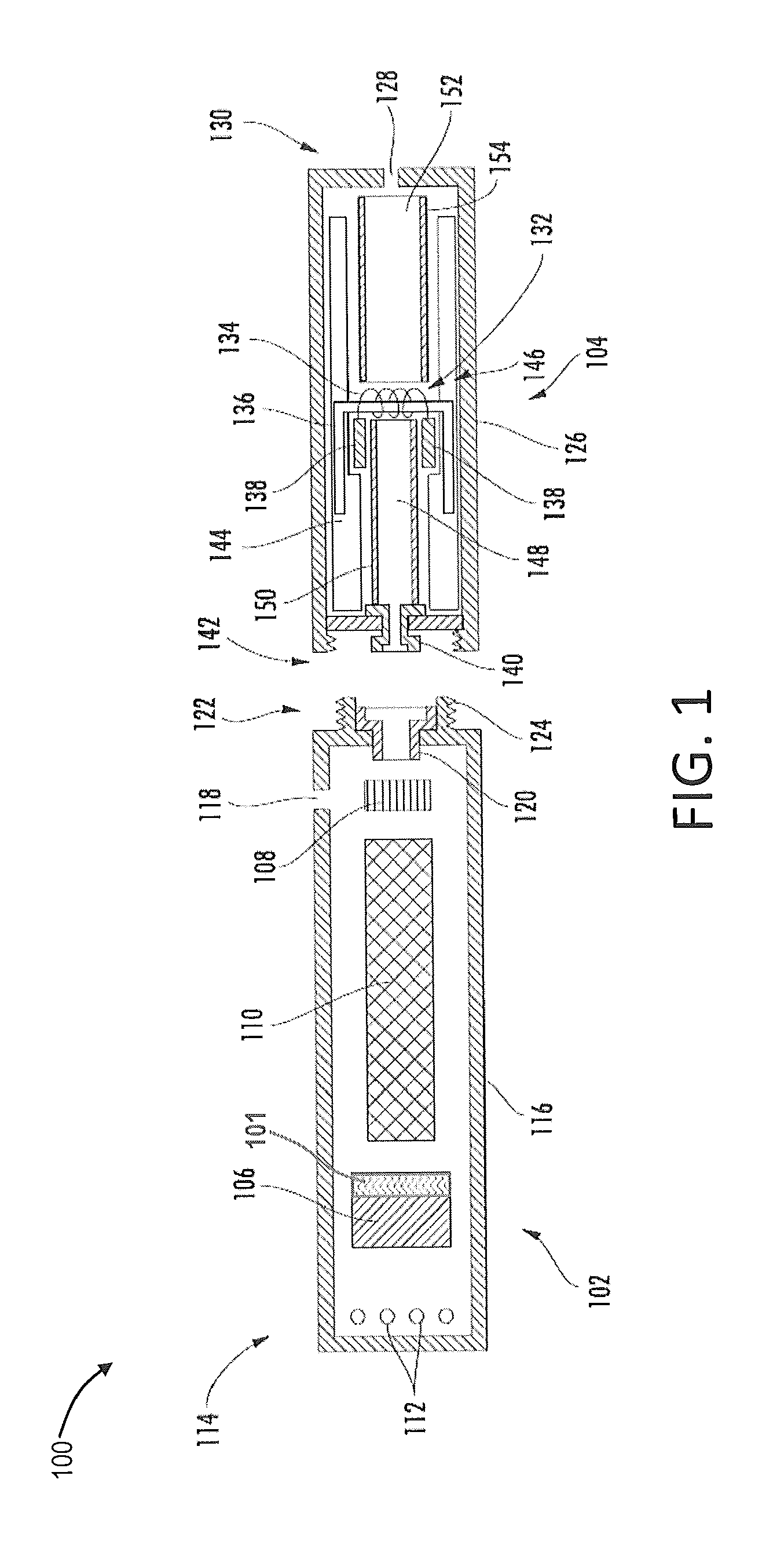

System, Method, and Apparatus for Infusing Fluid

ActiveUS20130177455A1Reduce peak torqueDrug and medicationsFlexible member pumpsPeristaltic pumpPinch valve

A peristaltic pump, and related system method are provided. The peristaltic pump includes a cam shaft, first and second pinch-valve cams, first and second pinch-valve cam followers, a plunger cam, a plunger-cam follower, a tube receiver, and a spring-biased plunger. The first and second pinch-valve cams are coupled to the cam shaft. The first and second pinch-valve cam followers each engage the first and second pinch-valve cams, respectively. The plunger cam is coupled to the cam shaft. The plunger-cam follower engages the plunger cam. The tube receiver is configured to receive a tube. The spring-biased plunger is coupled to the plunger-cam follower such that the expansion of the plunger cam along a radial angle intersecting the plunger-cam follower as the cam shaft rotates pushes the plunger cam follower towards the plunger and thereby disengages the spring-biased plunger from the tube. A spring coupled to the spring-biased plunger biases the spring-biased plunger to apply the crushing force to the tube.

Owner:DEKA PROD LLP

Pump system for negative pressure wound therapy

ActiveUS7857806B2Minimize the possibilityReduce the possibilityWound drainsMedical devicesControl systemLevel sensor

Owner:PAUL HARTMANN AG

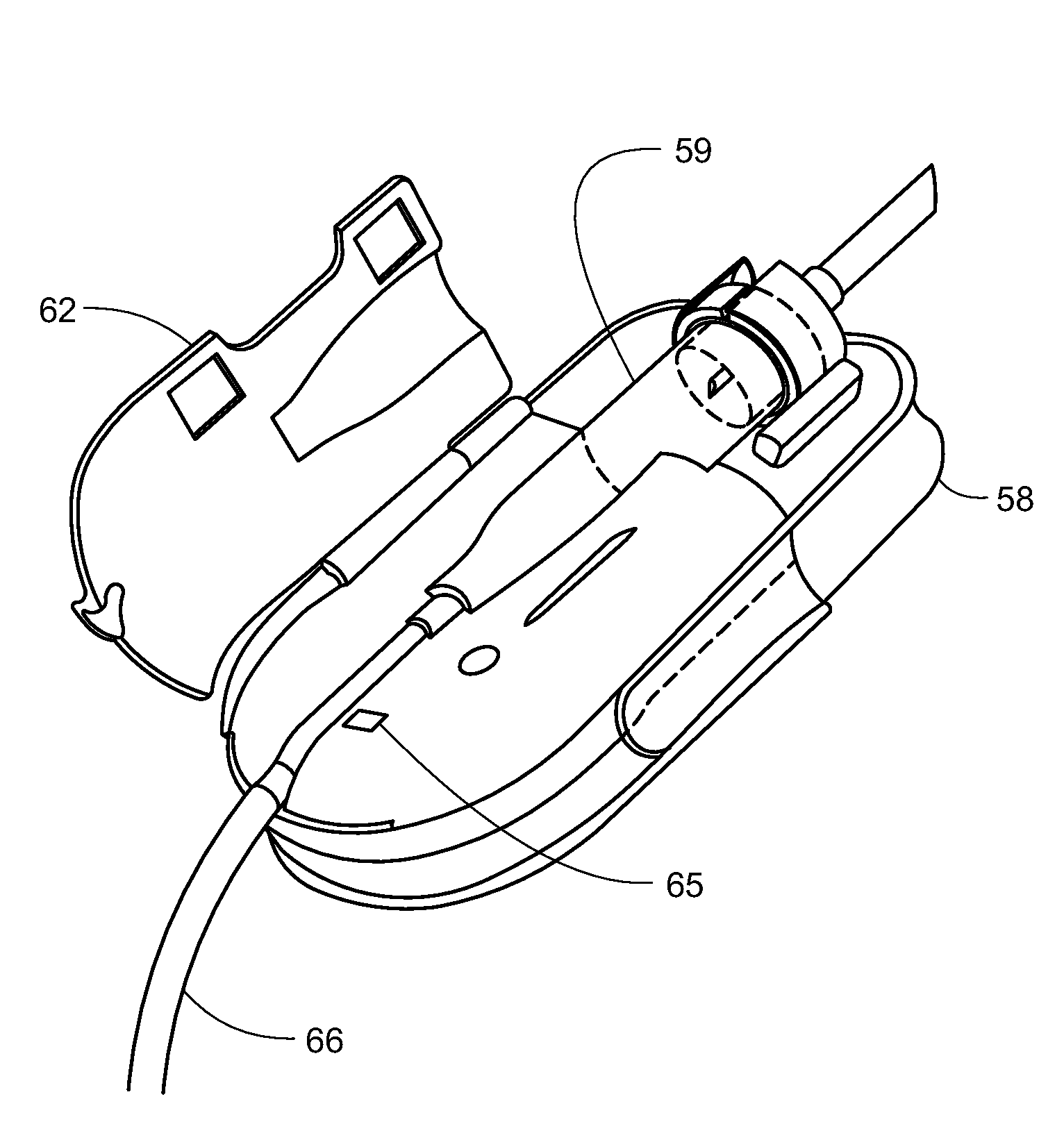

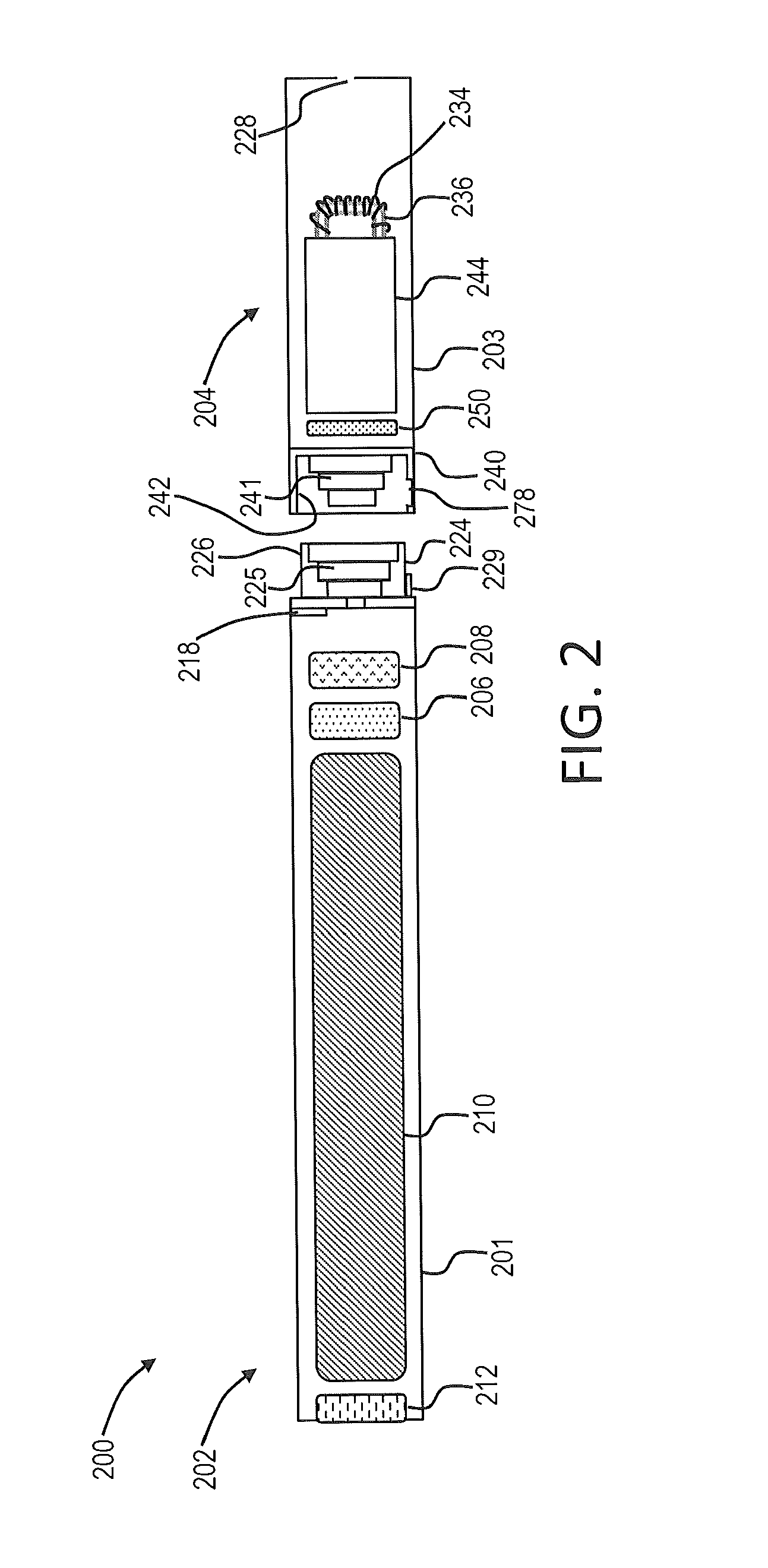

Sensor for an aerosol delivery device

ActiveUS20150282527A1Increase productionIncrease heatMedical devicesTobacco pipesSensory FeedbacksPower flow

The present disclosure relates to an aerosol delivery device including a variable output flow sensor. The variable output flow sensor particularly can be a flex / bend sensor wherein output from the sensor varies based upon changes in electrical current flow (e.g., resistance) along an extension of the sensor relative to flexing or bending of the extension resulting from airflow across the extension. The disclosure further provides methods for controlling operation of an aerosol delivery device through utilization of a variable output flow sensor. In particular, control of functional elements (e.g., a heating member, a fluid delivery member, and a sensory feedback member) can allow for real-time changes in the operation of the aerosol delivery device relative to airflow through the device.

Owner:RAI STRATEGIC HLDG INC

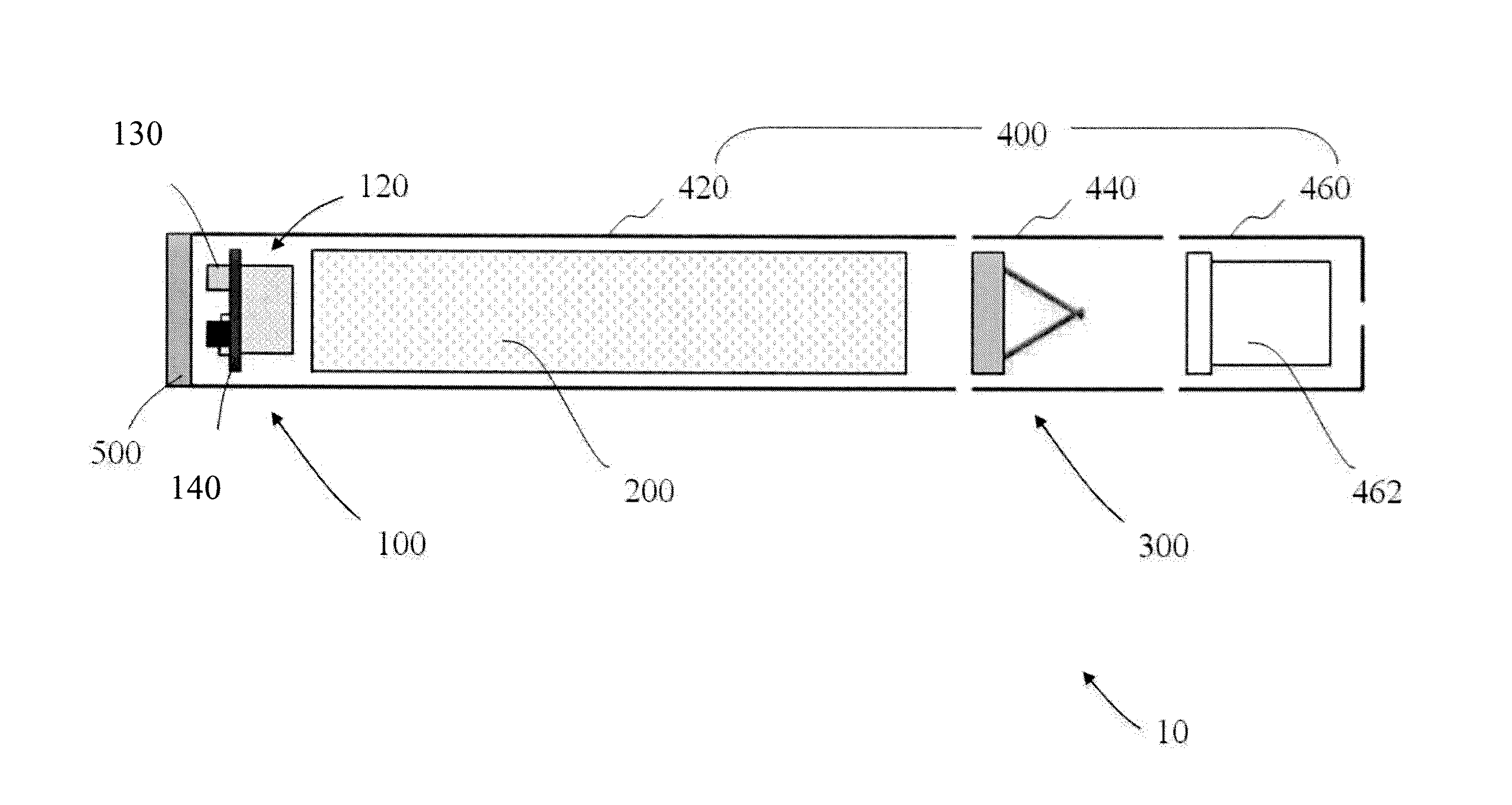

Electronic smoke

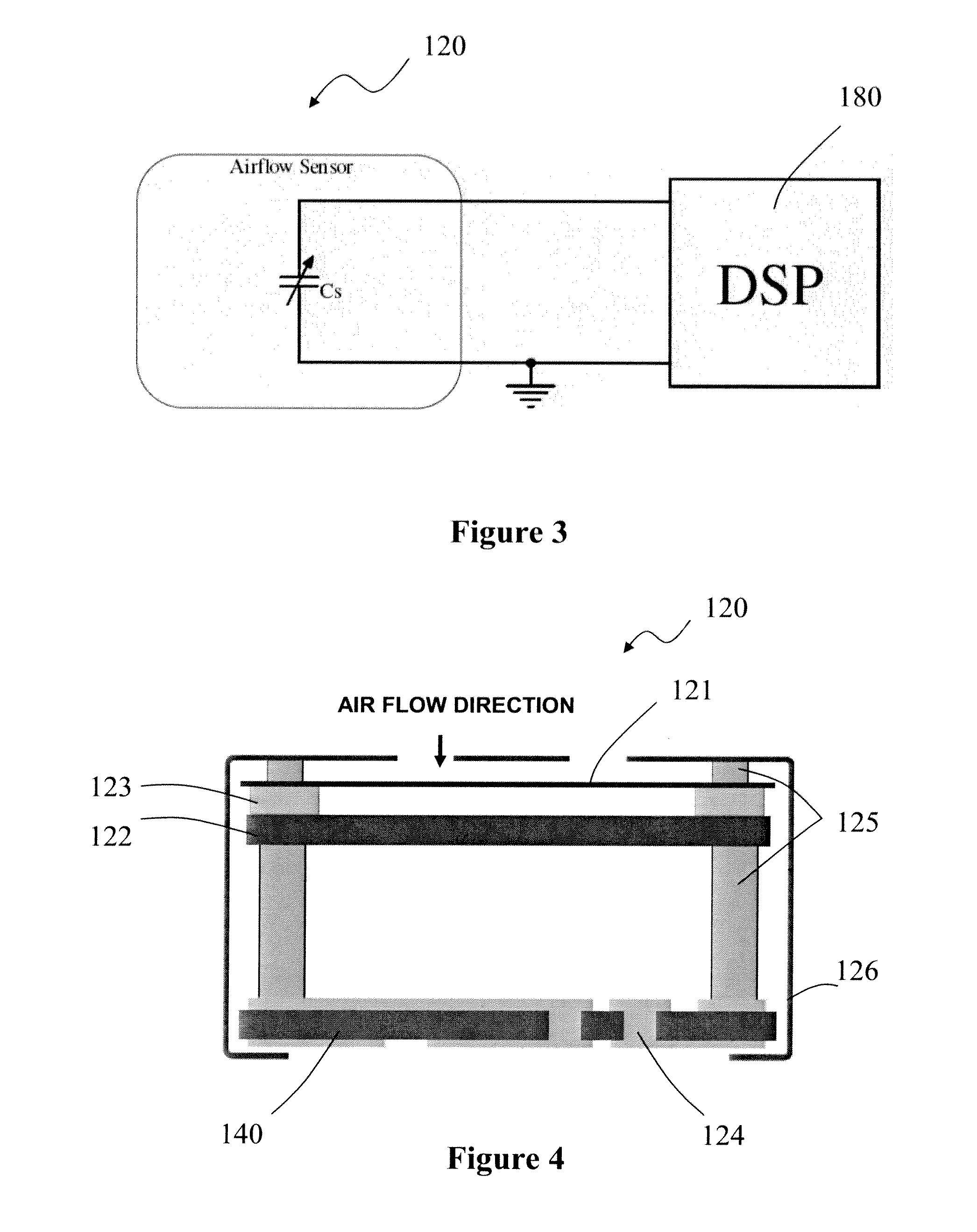

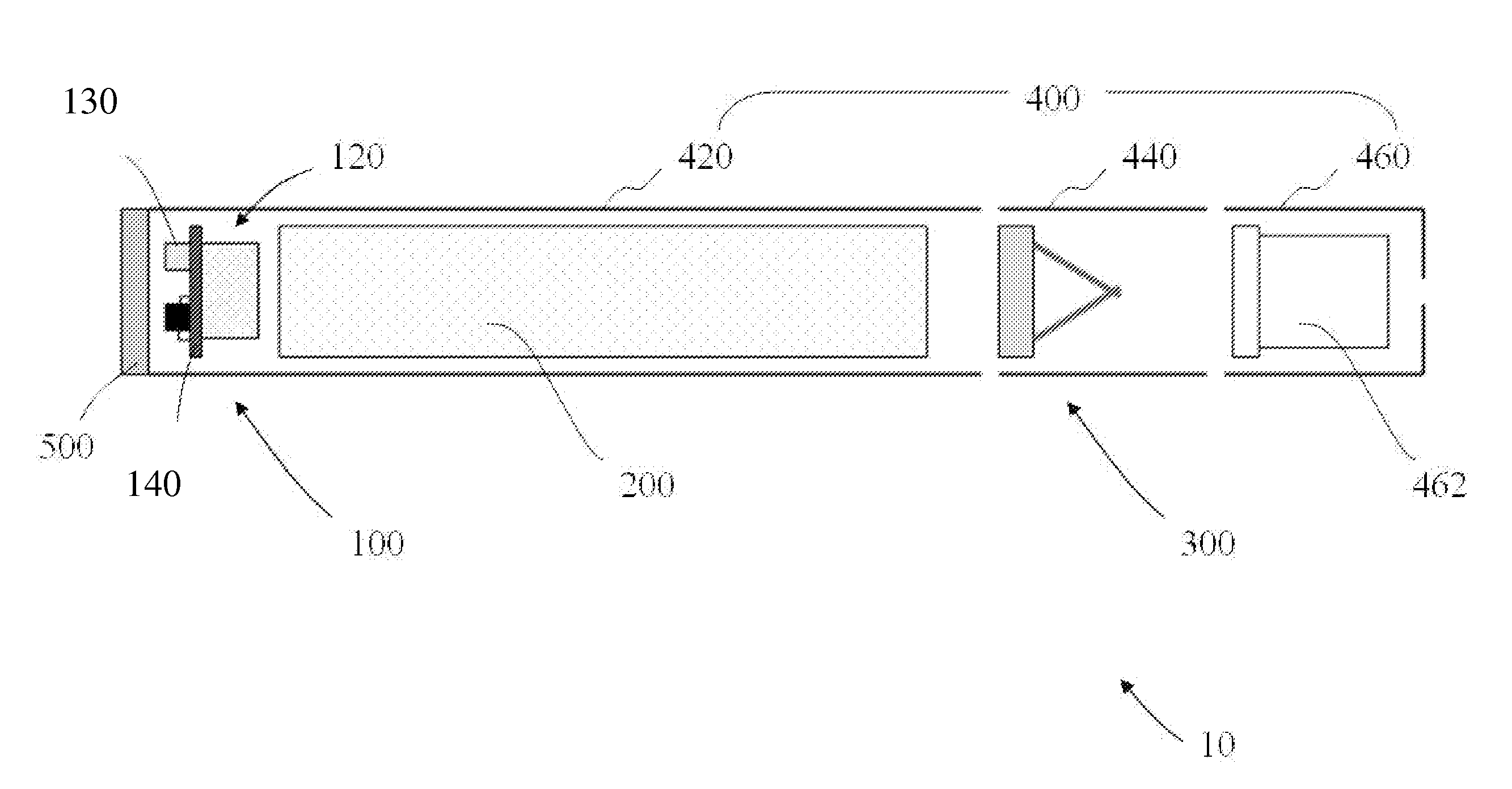

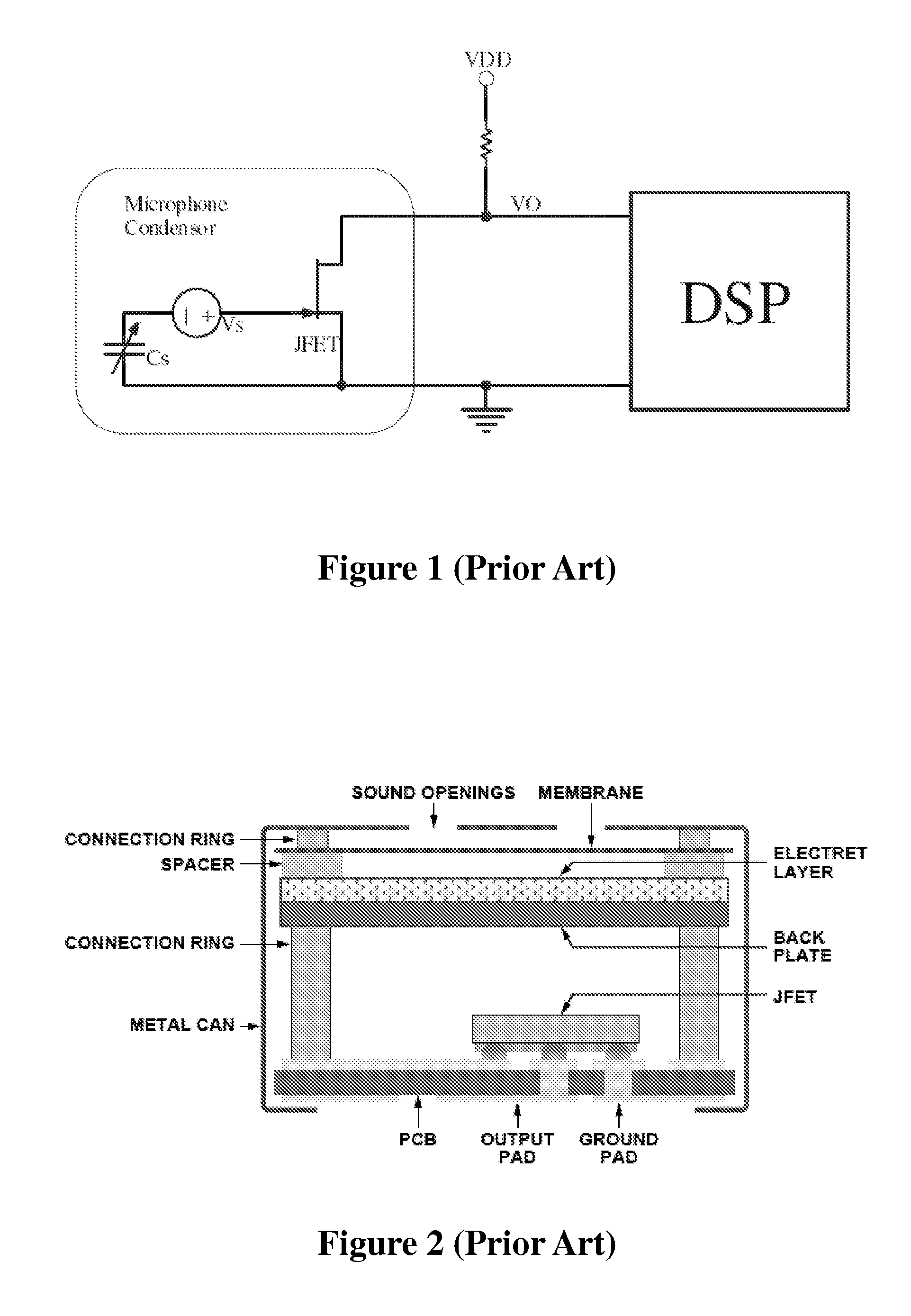

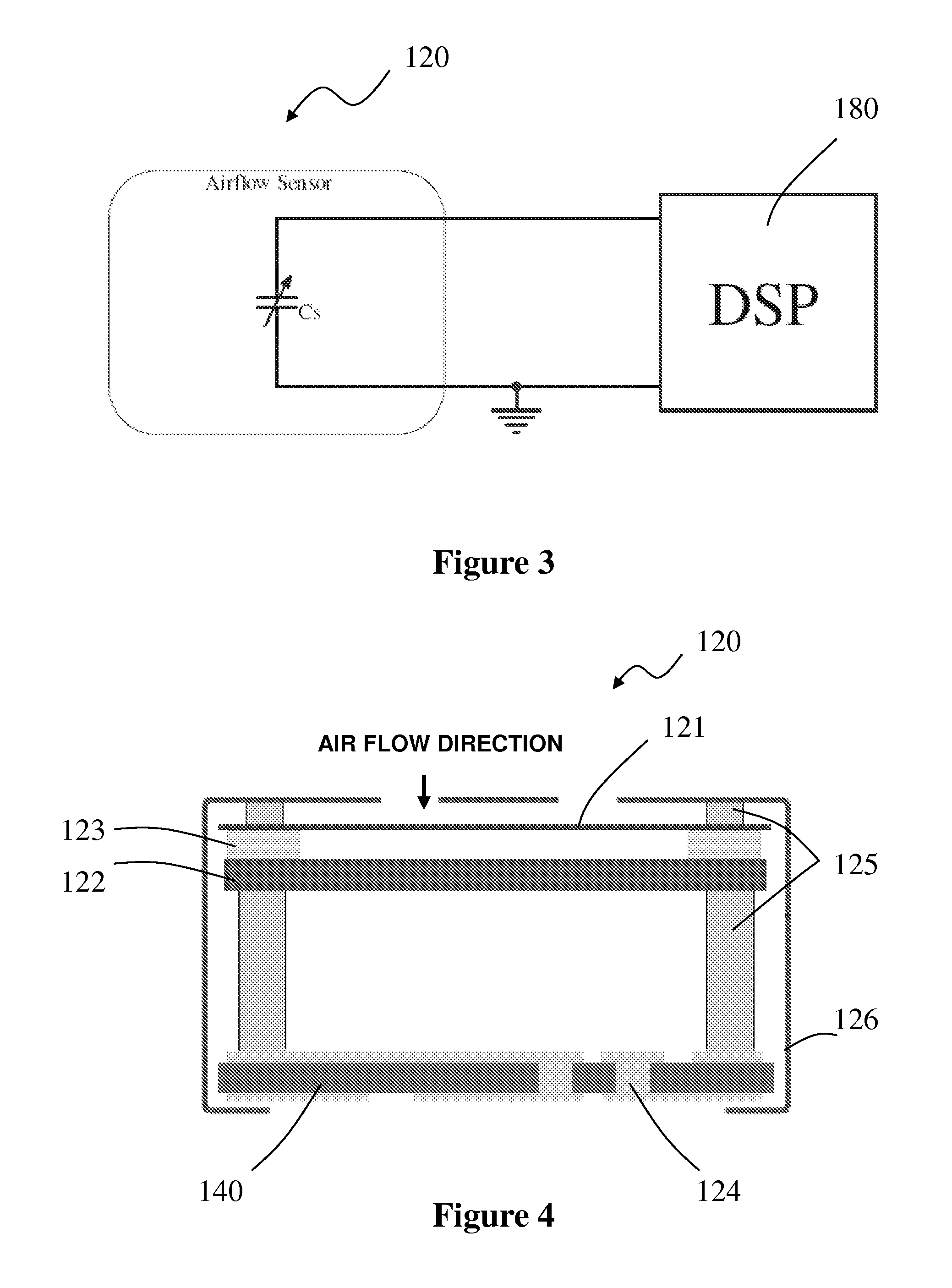

ActiveUS20120186594A1Reduce decreaseReduce riskTobacco pipesVolume/mass flow by electric/magnetic effectsElectronic cigaretteEngineering

An electronic smoke comprising an inhale detector and a smoke effect generating circuitry. The inhale detector comprises an air-flow sensor which is arranged to detect direction and rate of air flow through the smoke apparatus, and the smoke effect generating circuitry is arranged to operate the smoke effect generating circuitry to generate smoking effect when the air flow direction corresponds to inhaling through the apparatus and the air flow rate reaches at predetermined threshold. Such an electronic smoke alleviates the problem of inadvertent triggering due to environmental vibration or noise or children playing by blowing into the device.

Owner:AKRIA CLIENT SERVICES LLC

Electronic smoke

ActiveUS9072321B2Reduce decreaseReduce riskTobacco devicesIndication/recording movementElectronic cigaretteEngineering

An electronic smoke comprising an inhale detector and a smoke effect generating circuitry. The inhale detector comprises an air-flow sensor which is arranged to detect direction and rate of air flow through the smoke apparatus, and the smoke effect generating circuitry is arranged to operate the smoke effect generating circuitry to generate smoking effect when the air flow direction corresponds to inhaling through the apparatus and the air flow rate reaches at predetermined threshold. Such an electronic smoke alleviates the problem of inadvertent triggering due to environmental vibration or noise or children playing by blowing into the device.

Owner:AKRIA CLIENT SERVICES LLC

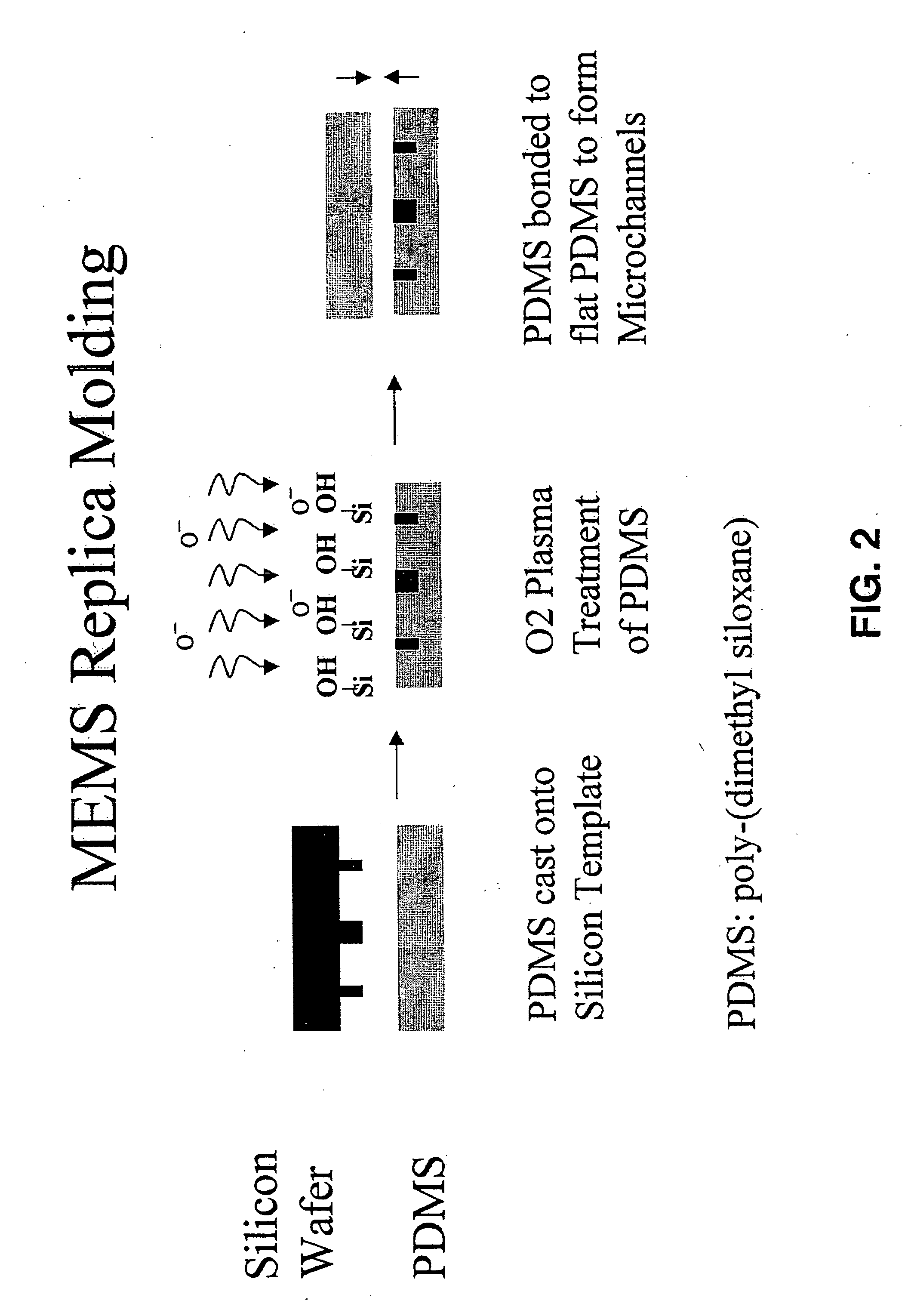

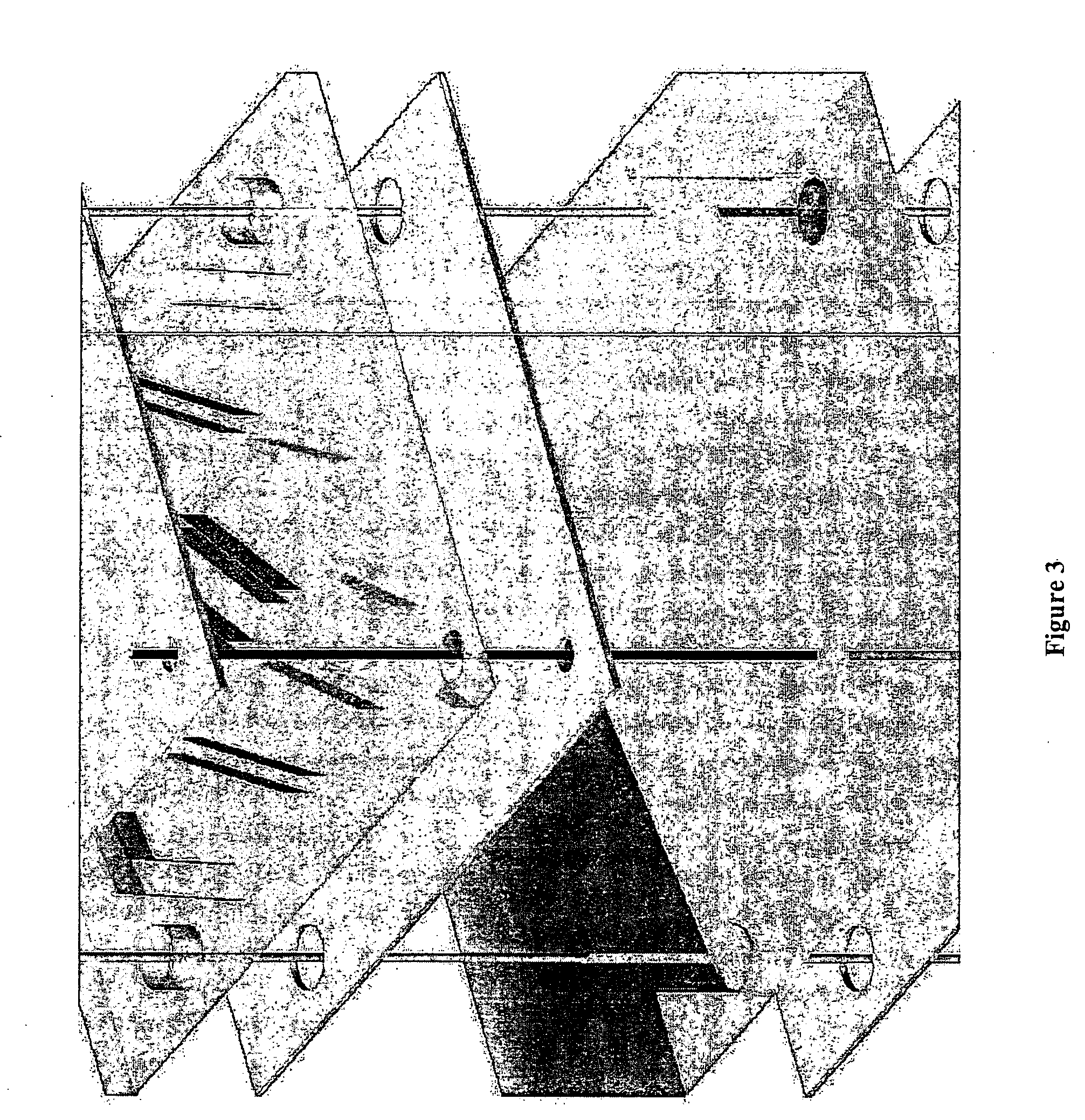

Three dimensional construct for the design and fabrication of physiological fluidic networks

ActiveUS20060136182A1Increase cell densityIncrease the number ofMedical simulationAdditive manufacturing apparatusEngineeringSmall vessel

Owner:MASSACHUSETTS INST OF TECH +2

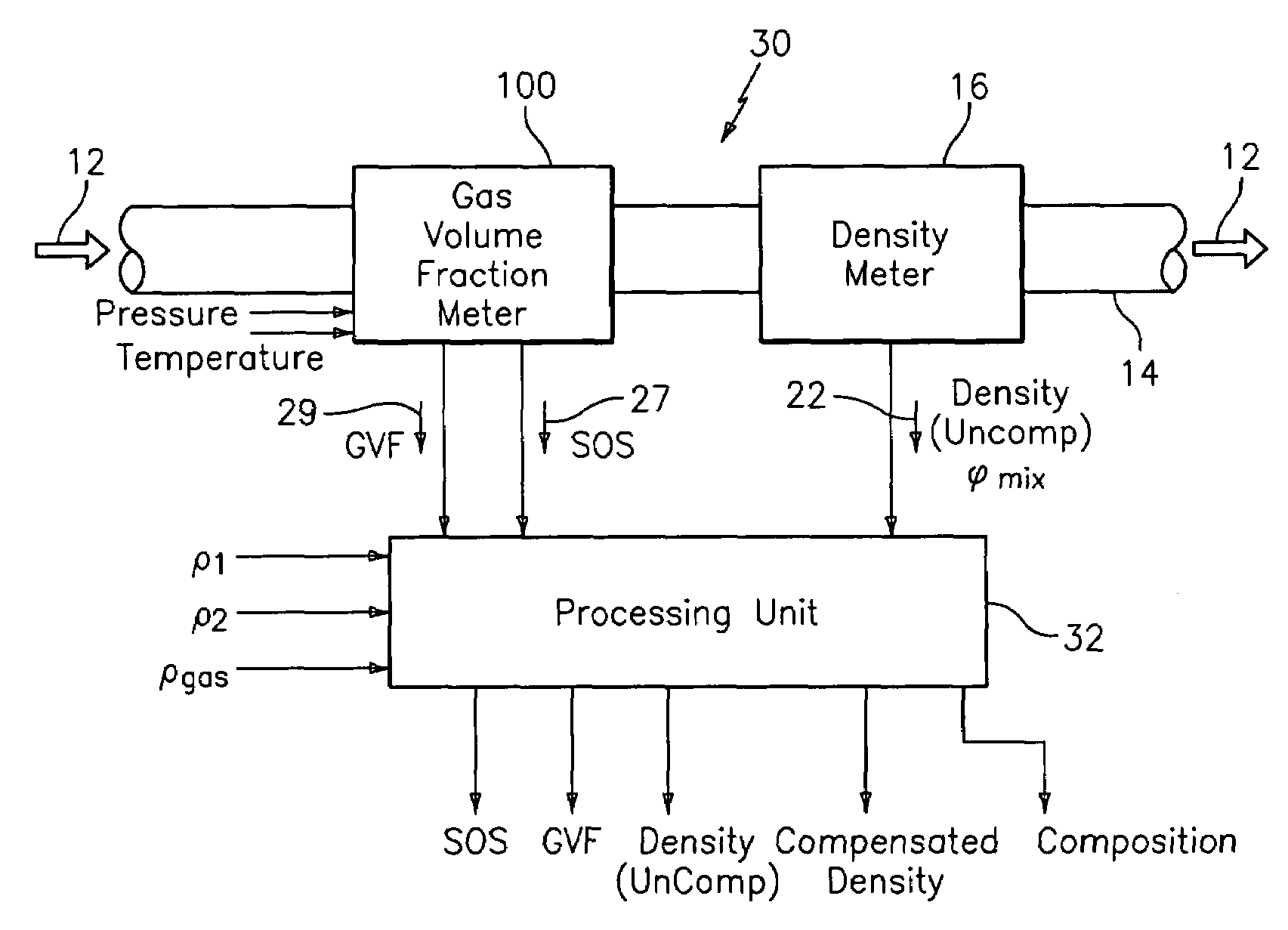

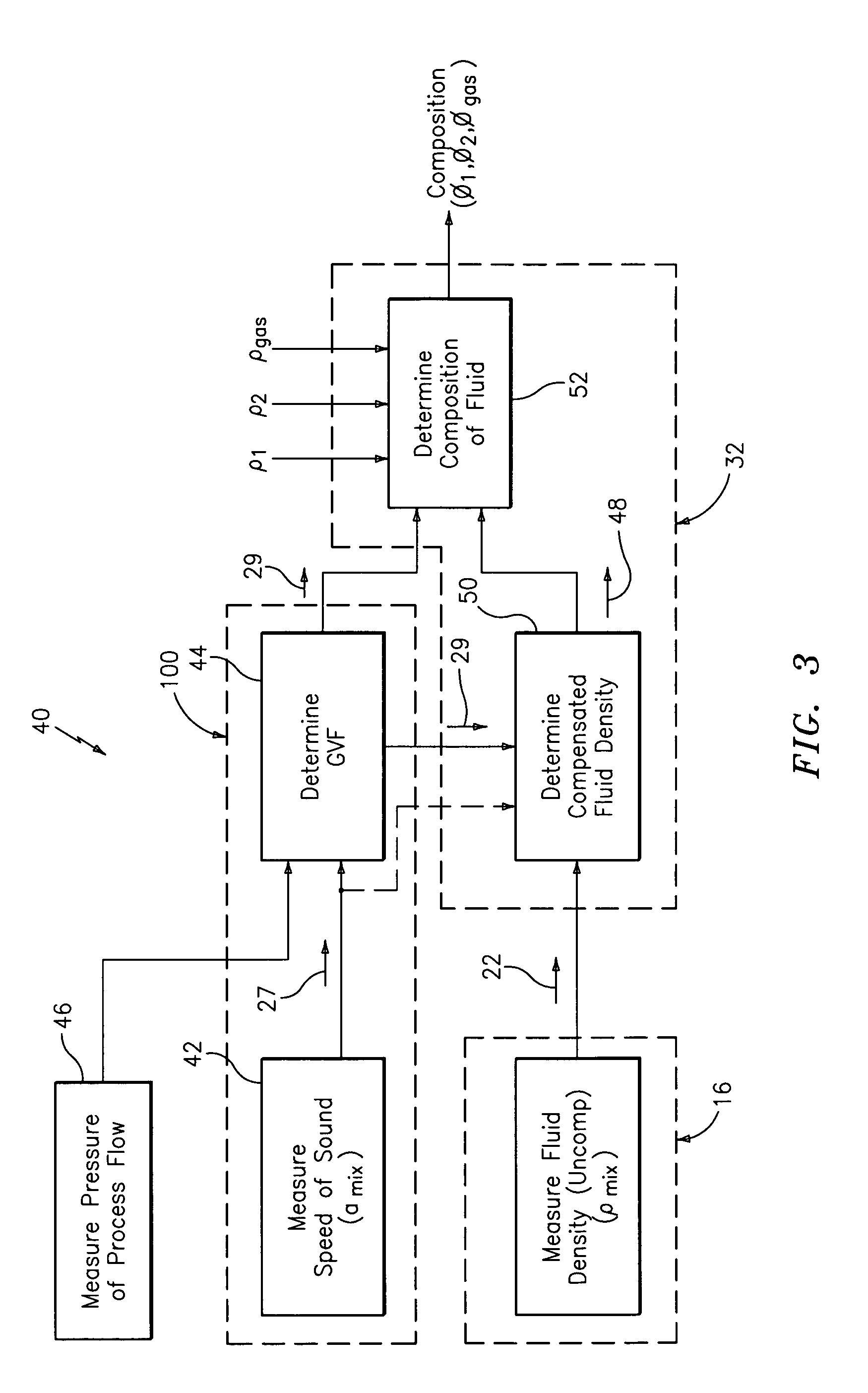

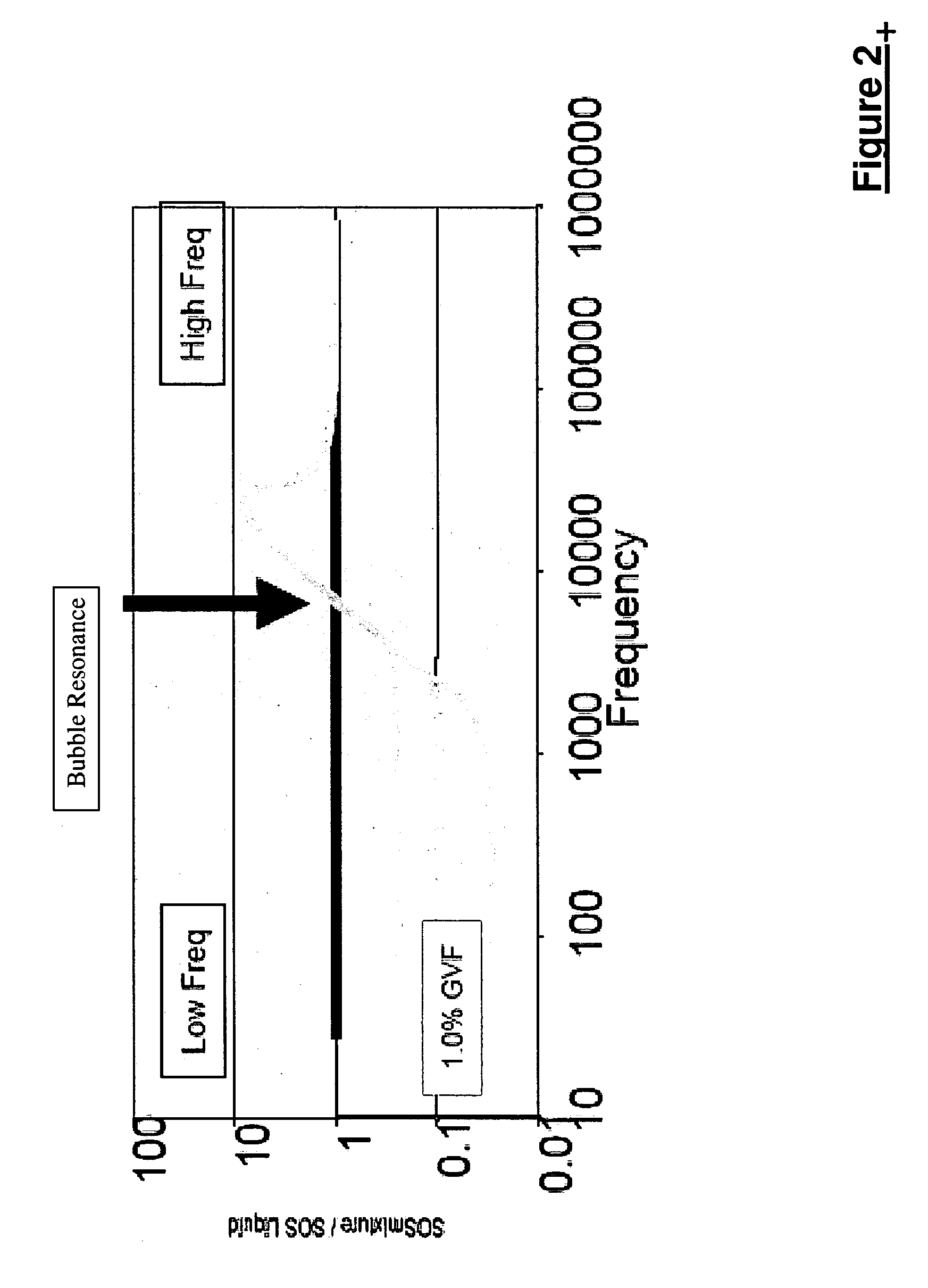

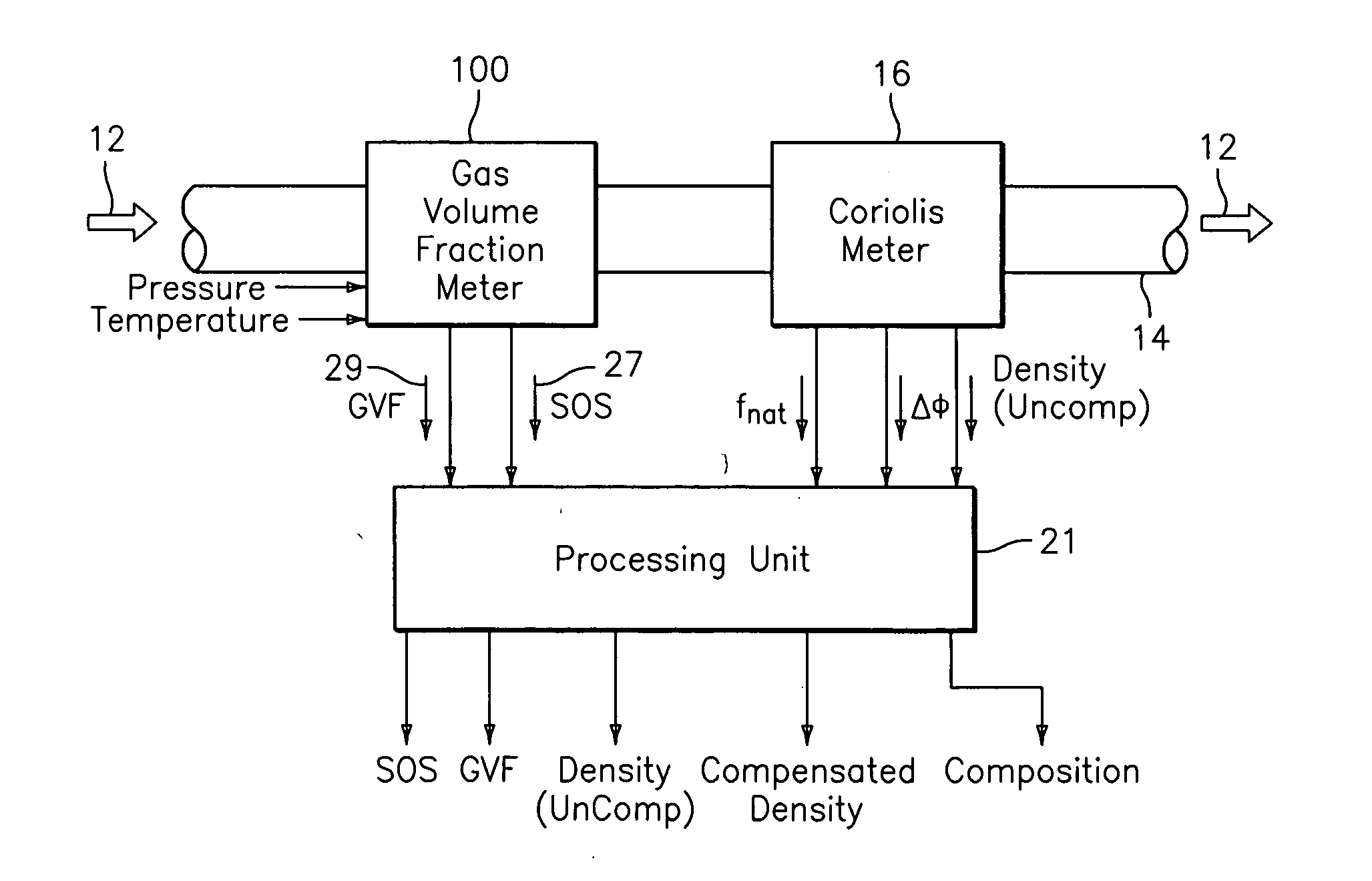

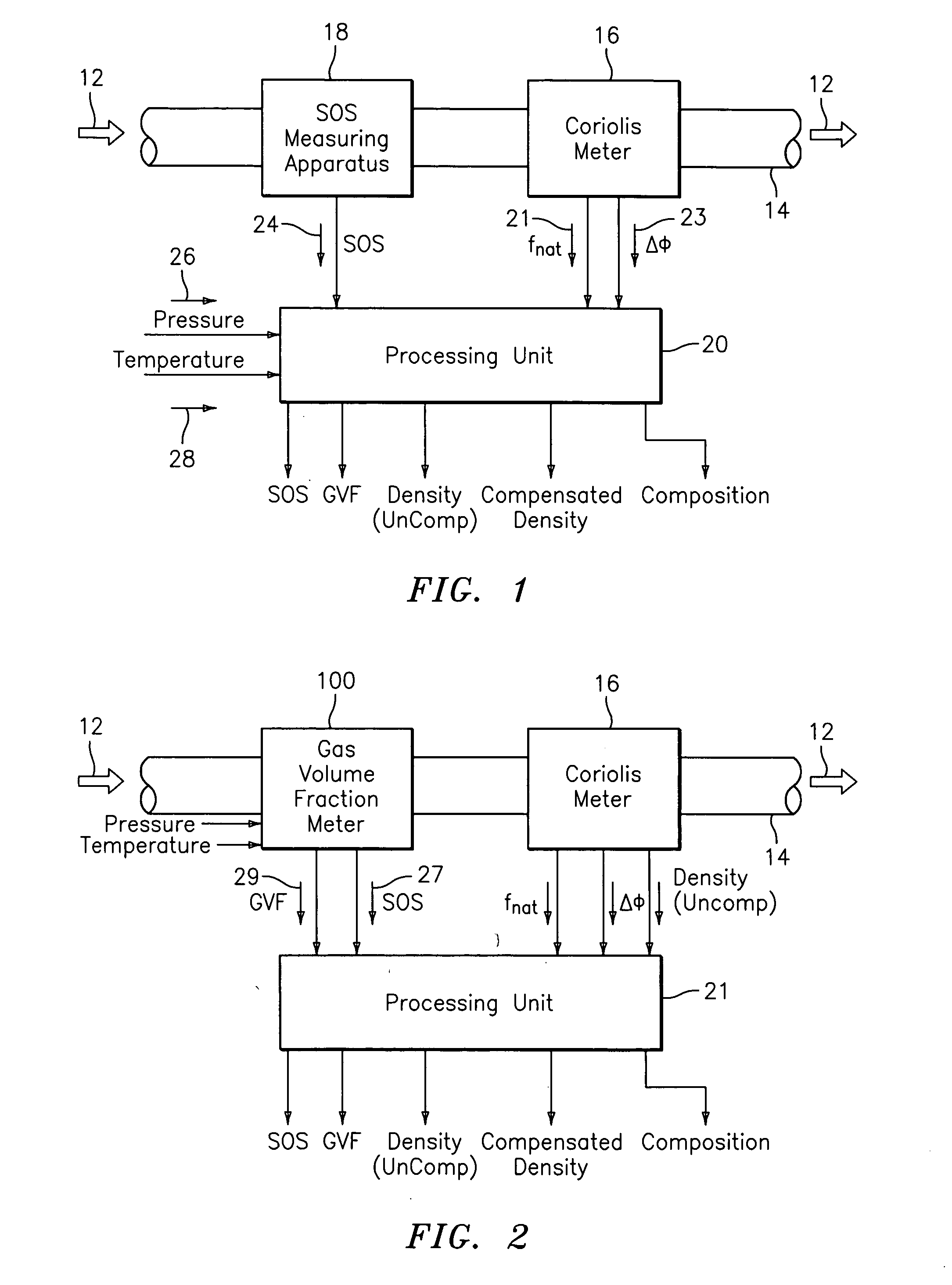

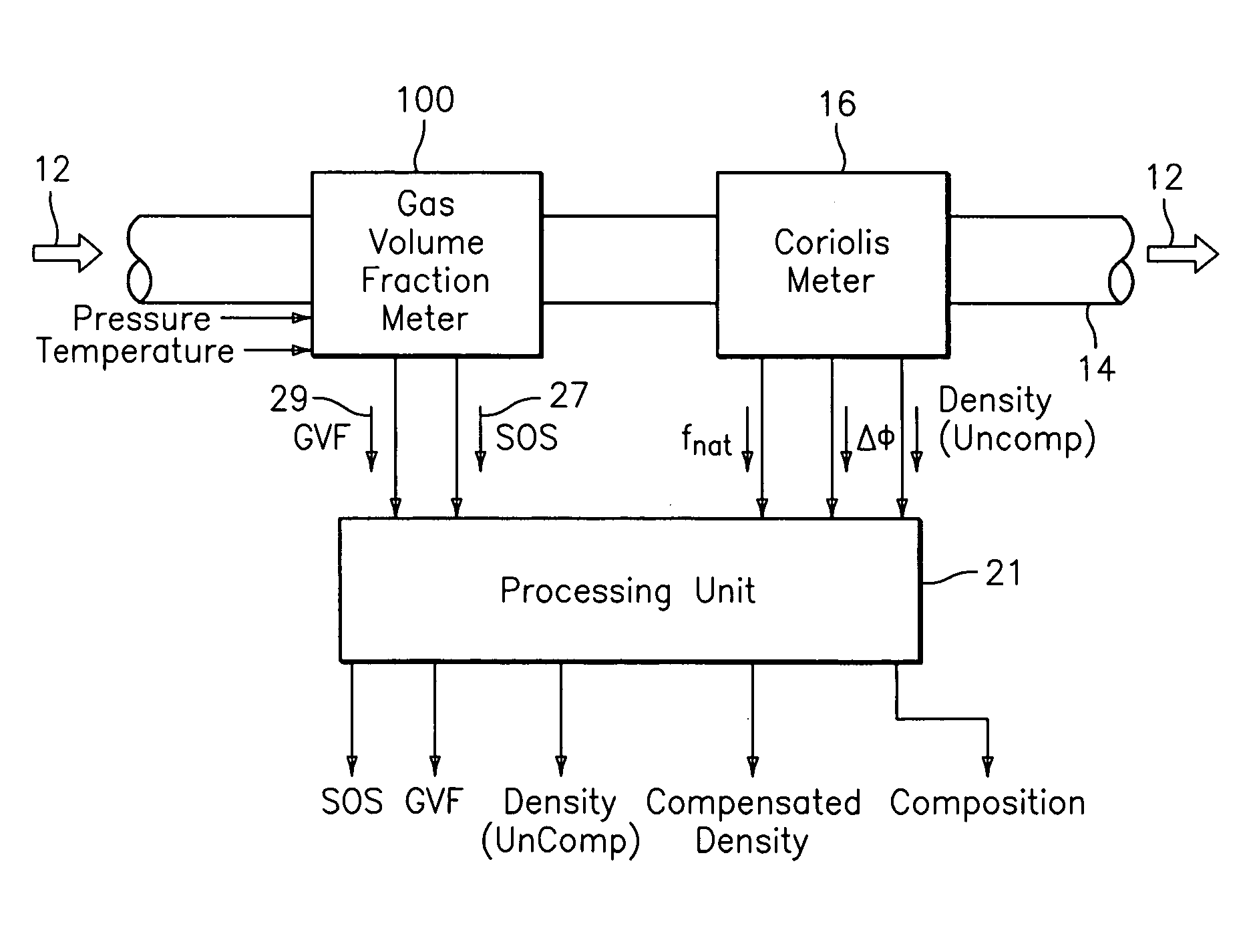

Apparatus and method for providing a density measurement augmented for entrained gas

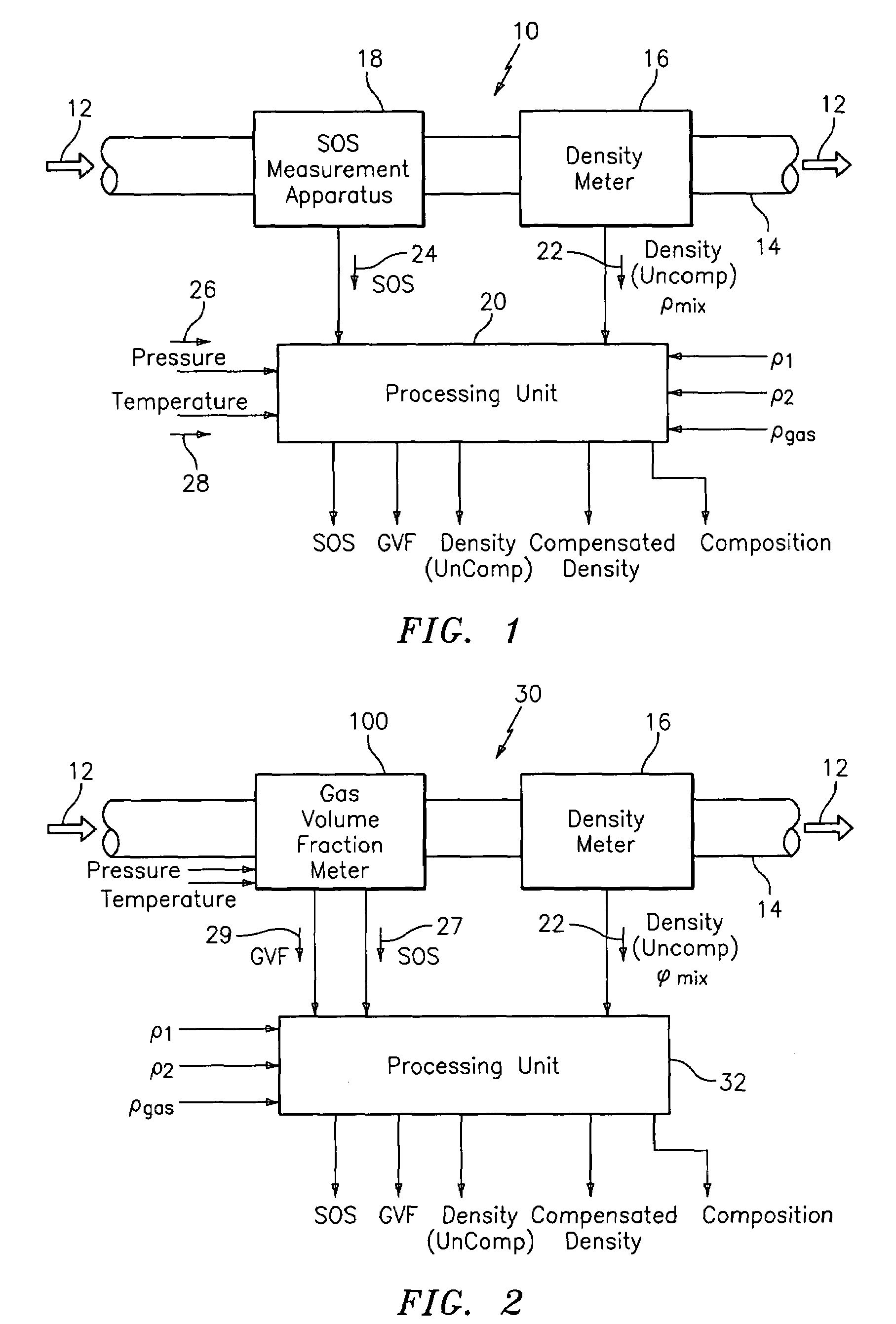

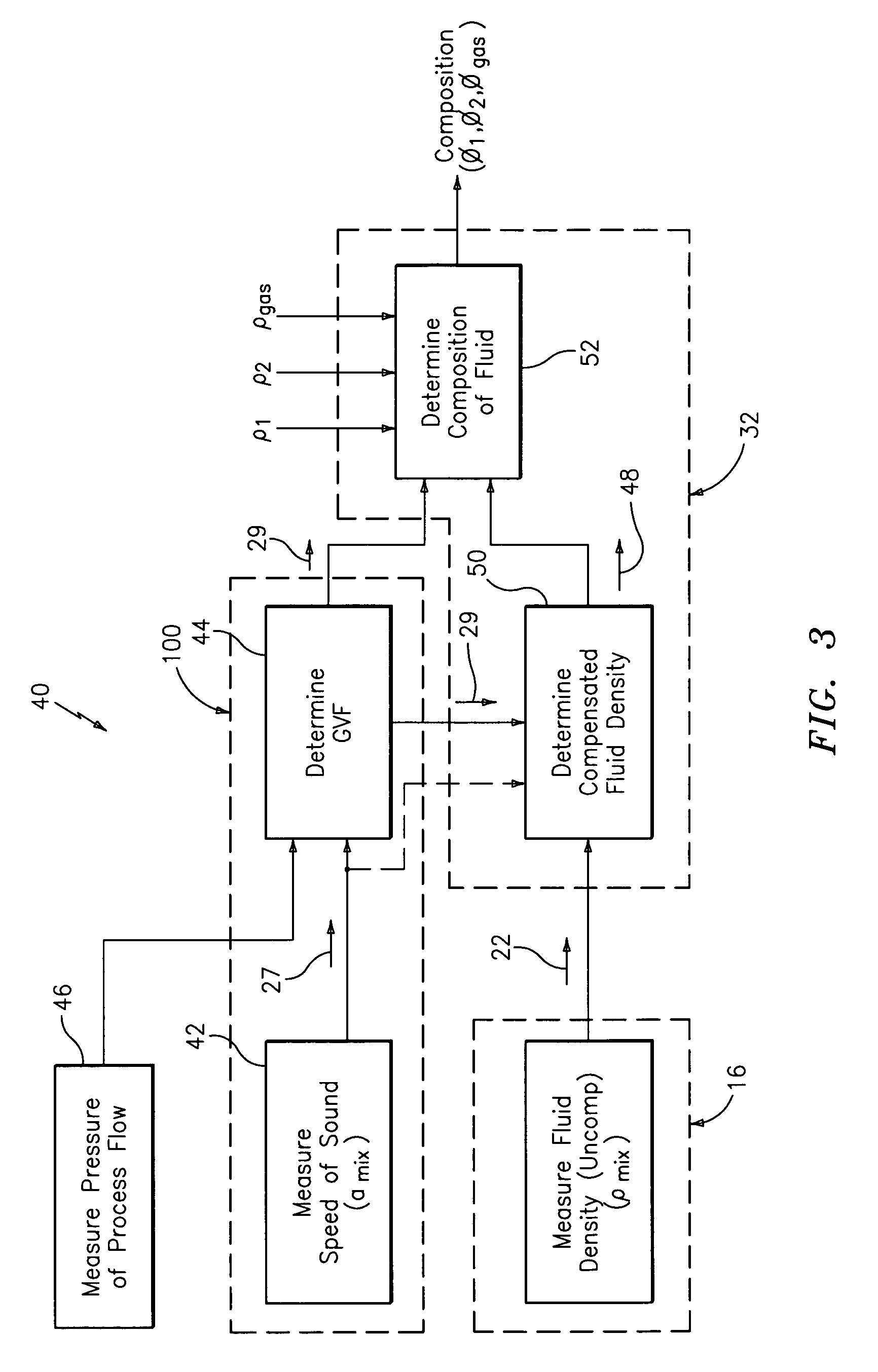

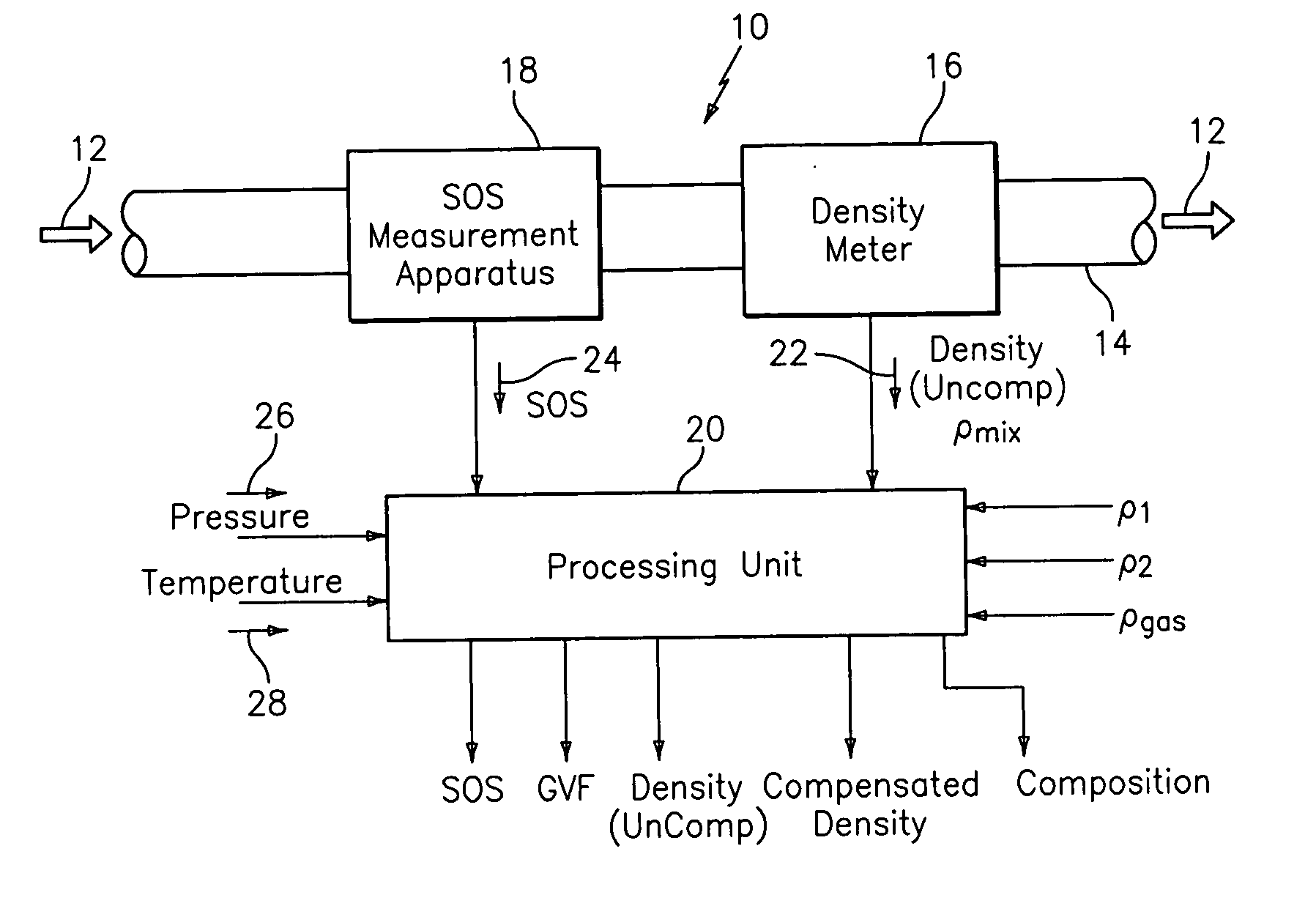

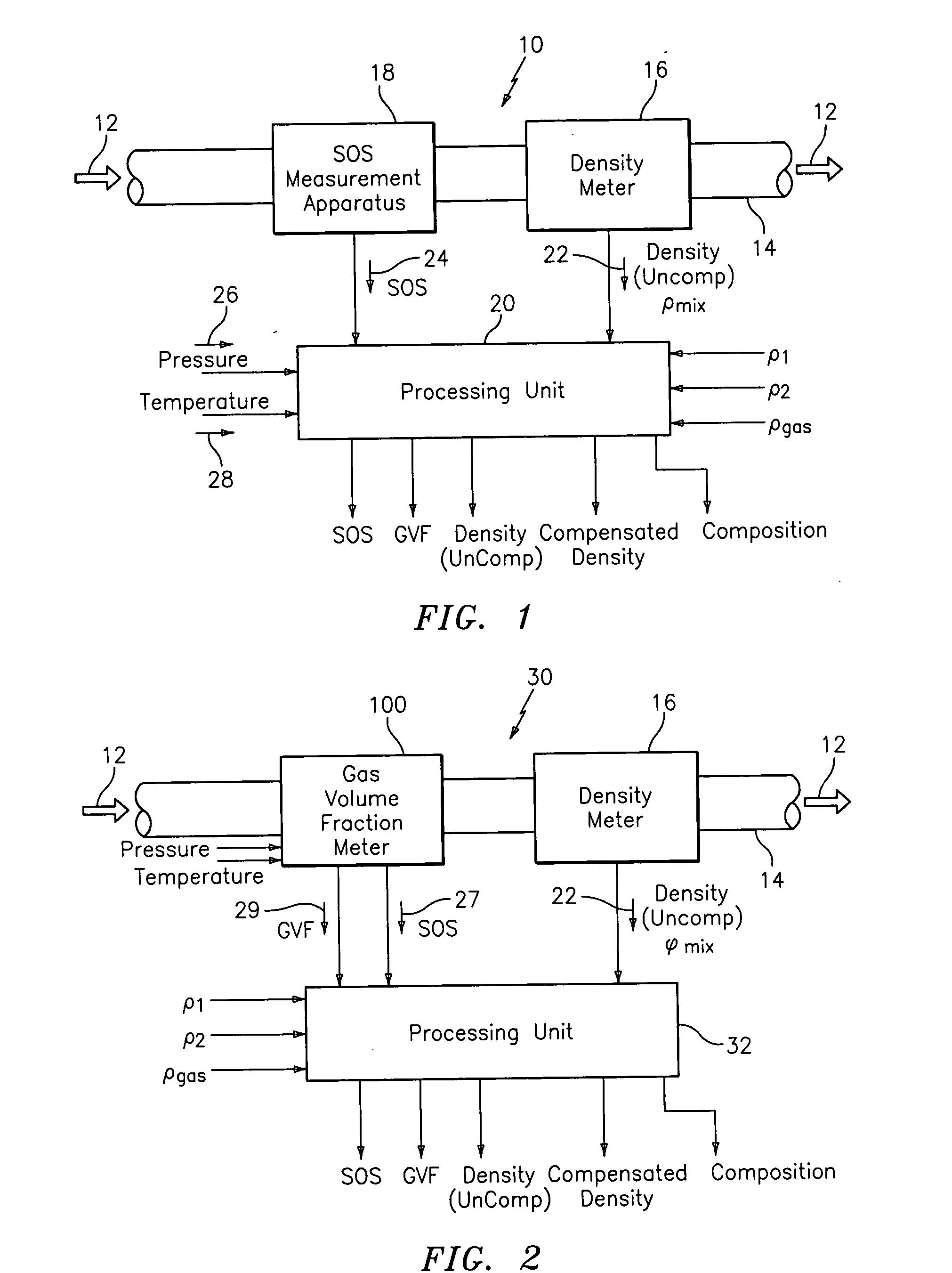

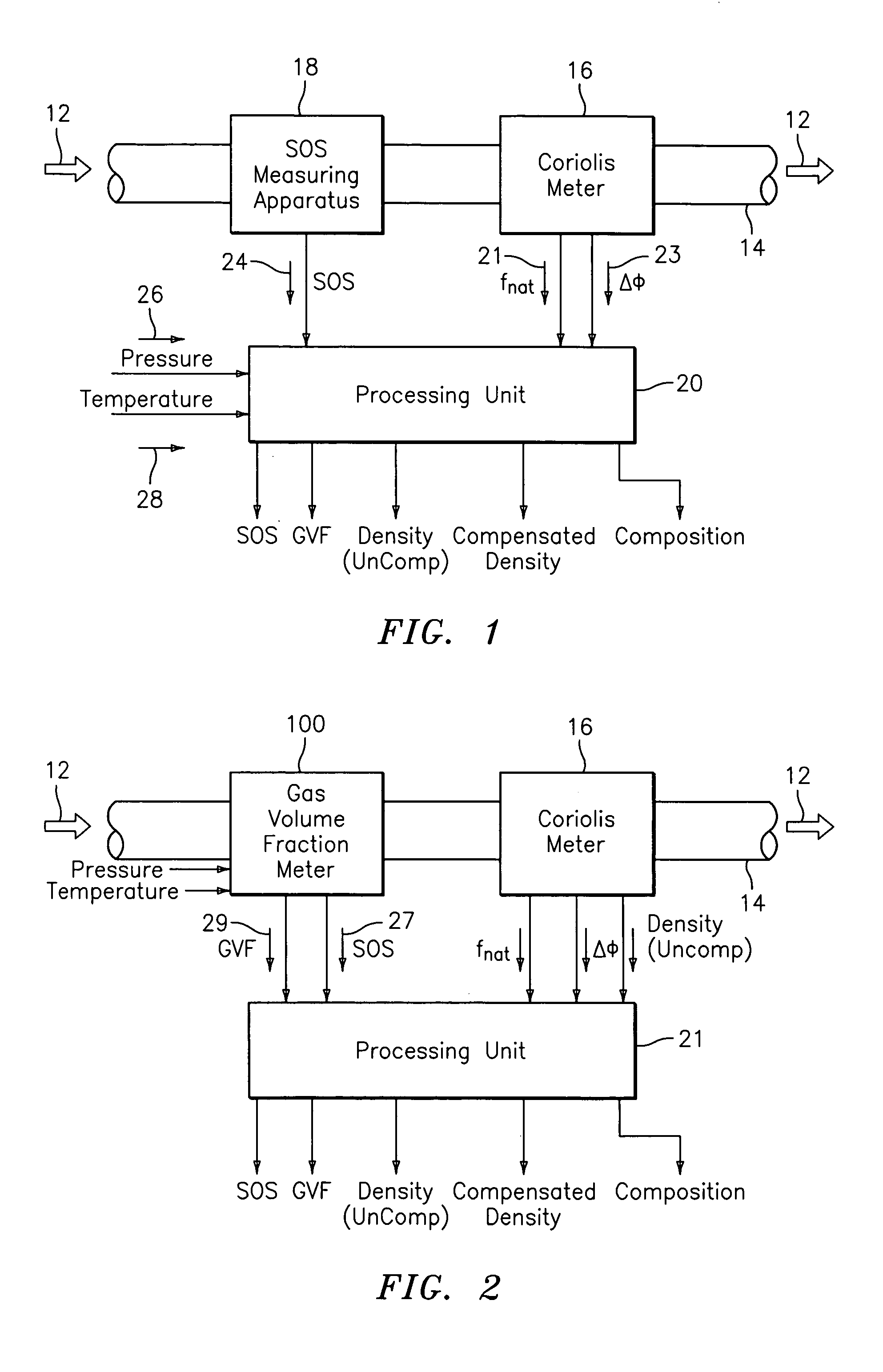

A flow measuring system combines a density measuring device and a device for measuring the speed of sound (SOS) propagating through the fluid flow and / or for determining the gas volume fraction (GVF) of the flow. The GVF meter measures acoustic pressures propagating through the fluids to measure the speed of sound αmix propagating through the fluid to calculate at least gas volume fraction of the fluid and / or SOS. In response to the measured density and gas volume fraction, a processing unit determines the density of non-gaseous component of an aerated fluid flow. For three phase fluid flows, the processing unit can determine the phase fraction of the non-gaseous components of the fluid flow. The gas volume fraction (GVF) meter may include a sensing device having a plurality of strain-based or pressure sensors spaced axially along the pipe for measuring the acoustic pressures propagating through the flow.

Owner:EXPRO METERS

Apparatus and method for providing a density measurement augmented for entrained gas

ActiveUS20050061060A1Improve accuracySpecific gravity using flow propertiesVolume/mass flow by dynamic fluid flow effectThree-phaseDischarge measurements

A flow measuring system combines a density measuring device and a device for measuring the speed of sound (SOS) propagating through the fluid flow and / or for determining the gas volume fraction (GVF) of the flow. The GVF meter measures acoustic pressures propagating through the fluids to measure the speed of sound αmix propagating through the fluid to calculate at least gas volume fraction of the fluid and / or SOS. In response to the measured density and gas volume fraction, a processing unit determines the density of non-gaseous component of an aerated fluid flow. For three phase fluid flows, the processing unit can determine the phase fraction of the non-gaseous components of the fluid flow. The gas volume fraction (GVF) meter may include a sensing device having a plurality of strain-based or pressure sensors spaced axially along the pipe for measuring the acoustic pressures propagating through the flow.

Owner:EXPRO METERS

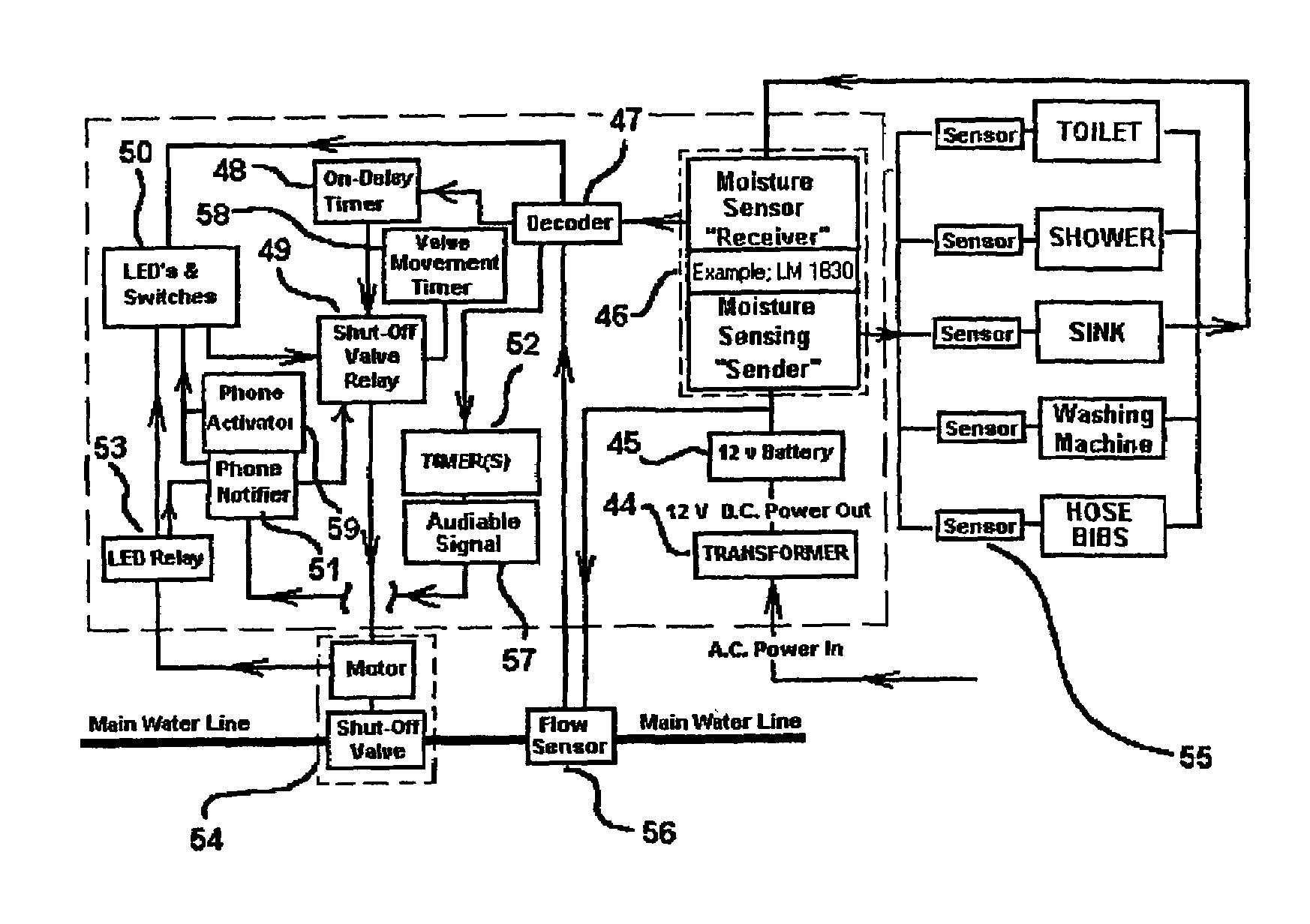

Liquid leak detector and automatic shutoff system

InactiveUS7032435B2Reduce leakageDetection of fluid at leakage pointMeasurement of fluid loss/gain rateCatheterGuide tube

Owner:HASSENFLUG BRIAN EDWARD

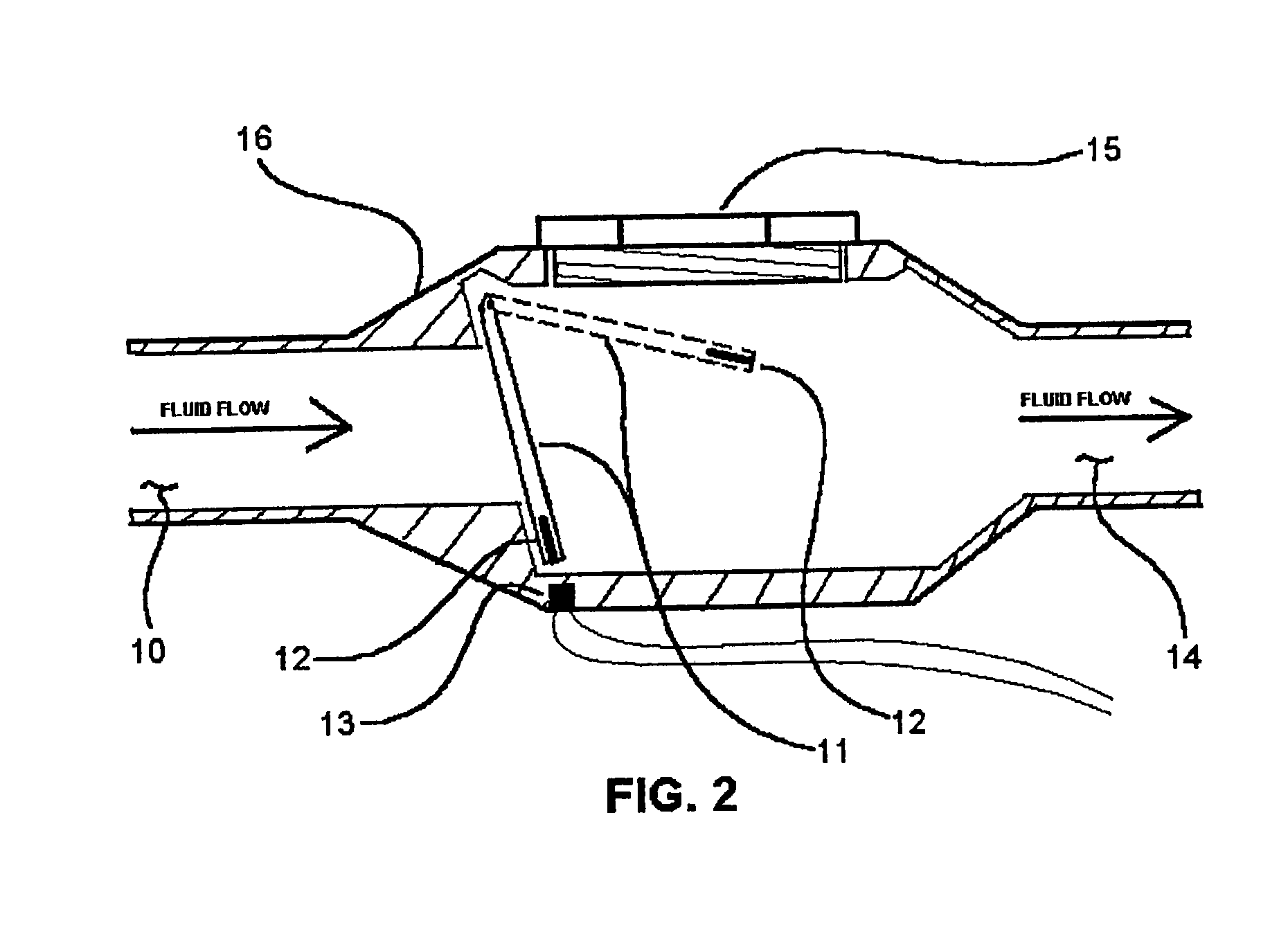

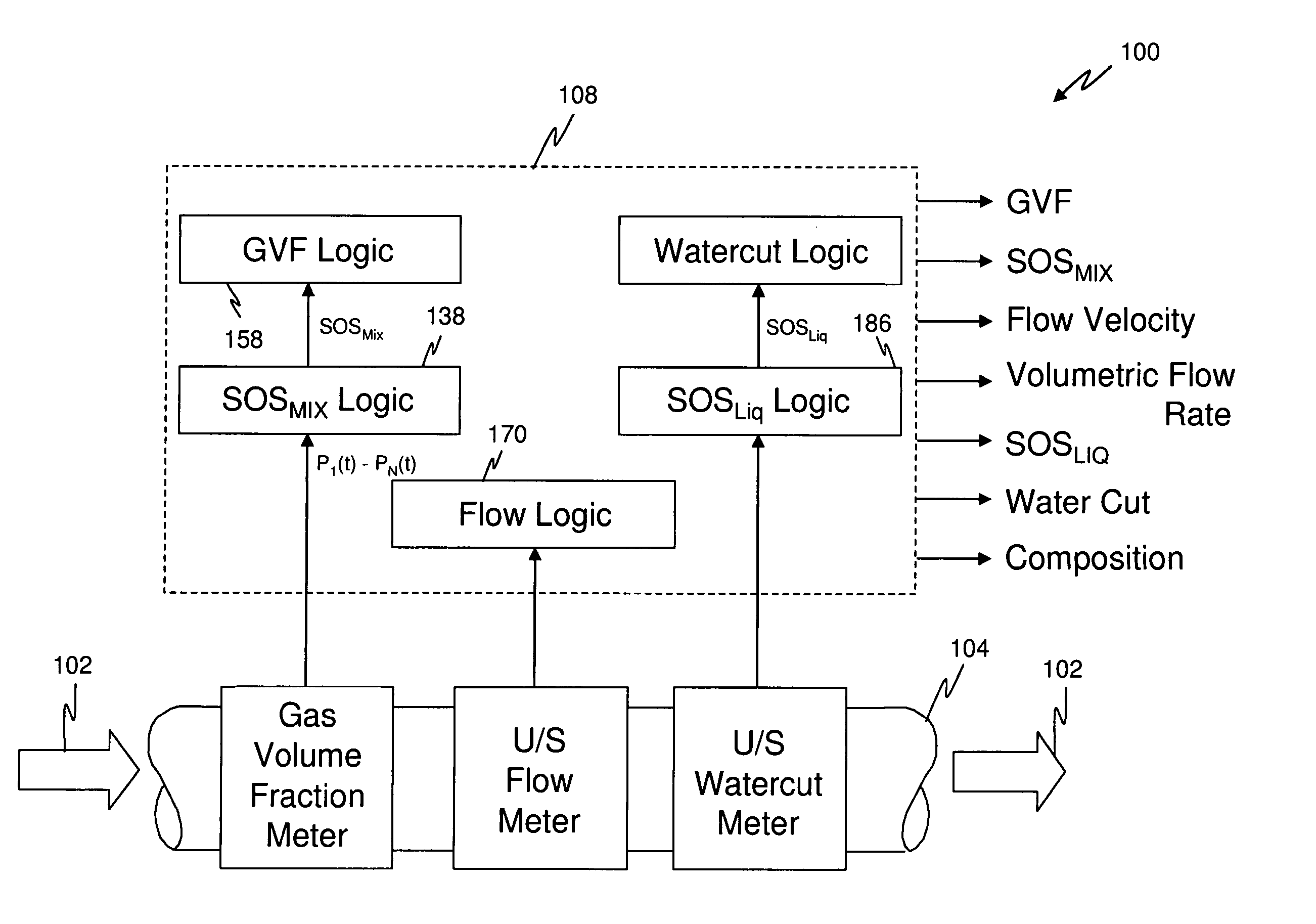

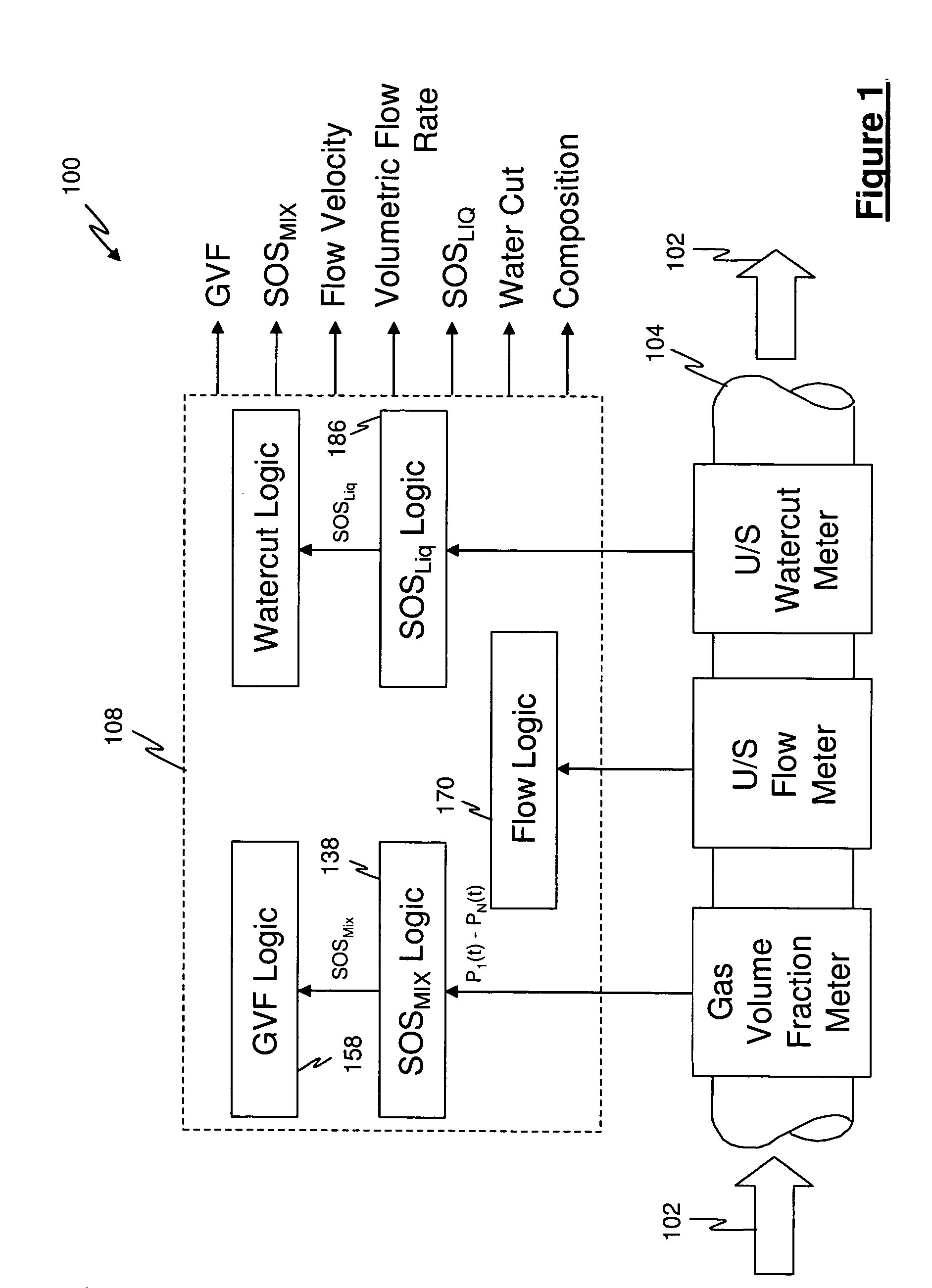

Apparatus and method for measuring a parameter of a multiphase flow

ActiveUS20070157737A1Volume meteringVolume/mass flow by dynamic fluid flow effectStream flowEngineering

An apparatus is provided that determines a characteristic of a multiphase fluid, such as an aerated oil and water fluid, flowing within a pipe. The apparatus includes a fluid flow meter, a water cut meter, and a density meter, wherein the density meter determines the density of the fluid flow to determine the gas volume (or void) fraction of the multiphase fluid flow. The output signal of each of the meters is provided to a multiphase flow model to provide a plurality of multiphase parameters, such as phase fraction, volumetric flow, mass flow of each of the phases of the multiphase mixture, optimized for various flow conditions. Each of the meters may be secured to the outer surface of the pipe using various means, such a clamping means.

Owner:EXPRO METERS

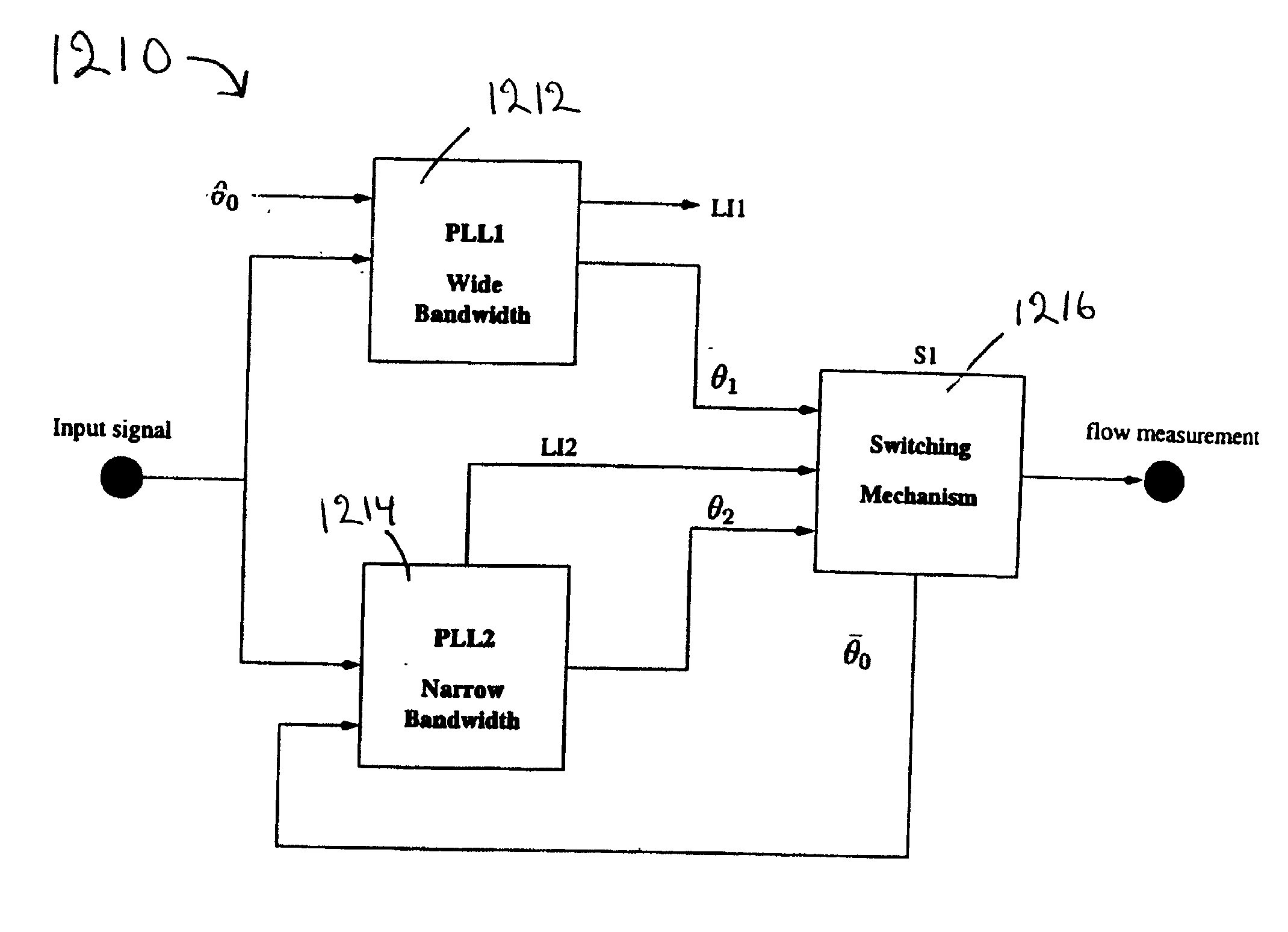

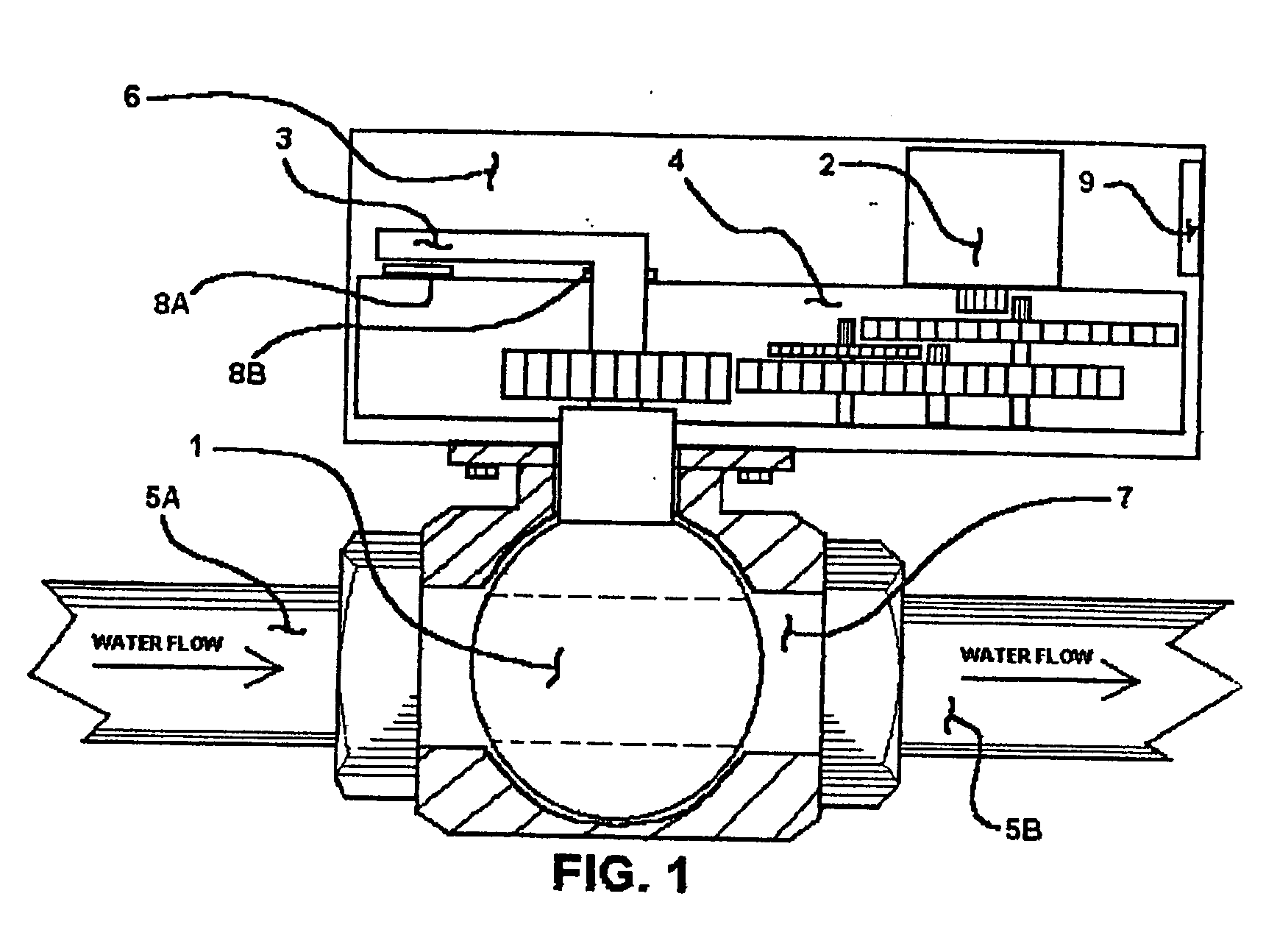

Vortex flowmeter

InactiveUS20020129661A1Improve accuracyIncrease speedElectrical measurementsVolume/mass flow by dynamic fluid flow effectEngineeringBand width

A process variable transmitter, implemented in a dual PLL structure, includes a first PLL having a first bandwidth producing a first output signal, and a second PLL having a second bandwidth narrower than the first bandwidth of the first PLL. The first and second PLLs are operable to lock into a frequency of an input signal and produce first and second output signals, respectively. The second PLL is operable to lock into the frequency of the input signal with greater accuracy and greater immunity to noise than the first PLL. A switch is operable to switch an output signal of the process variable transmitter between the first output signal and the second output signal.

Owner:SCHNEIDER ELECTRIC SYST USA INC

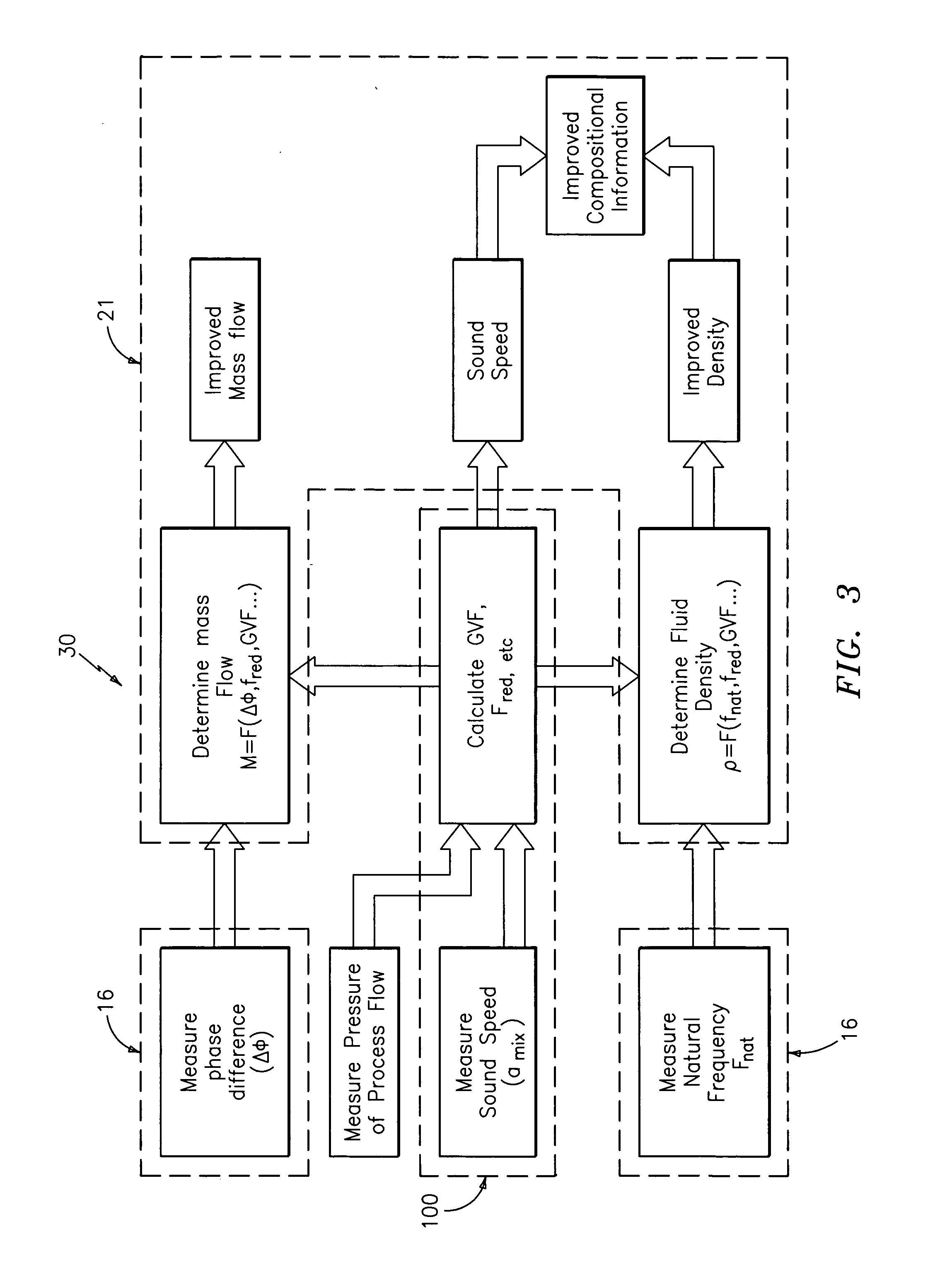

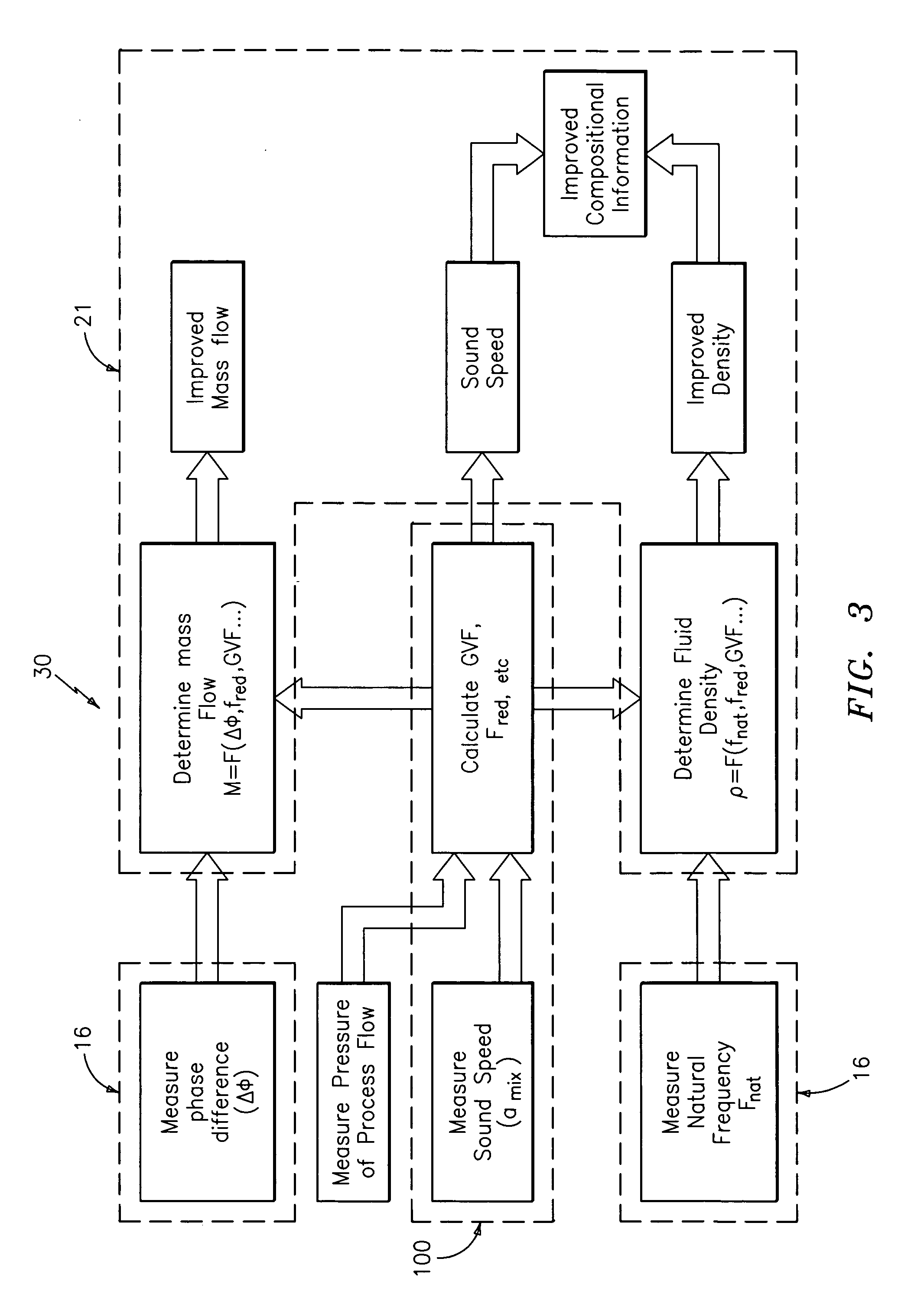

Apparatus and method for compensating a coriolis meter

ActiveUS20050044929A1High densityAdd additional massVolume/mass flow by dynamic fluid flow effectVolume meteringVolumetric Mass DensityDischarge measurements

A flow measuring system is provided that provides at least one of a compensated mass flow rate measurement and a compensated density measurement. The flow measuring system includes a gas volume fraction meter in combination with a coriolis meter. The GVF meter measures acoustic pressures propagating through the fluids to measure the speed of sound αmix propagating through the fluid to calculate at least gas volume fraction of the fluid and / or the reduced natural frequency. For determining an improved density for the coriolis meter, the calculated gas volume fraction and / or reduced frequency is provided to a processing unit. The improved density is determined using analytically derived or empirically derived density calibration models (or formulas derived therefore), which is a function of the measured natural frequency and at least one of the determined GVF, reduced frequency and speed of sound, or any combination thereof. The gas volume fraction (GVF) meter may include a sensing device having a plurality of strain-based or pressure sensors spaced axially along the pipe for measuring the acoustic pressures propagating through the flow.

Owner:EXPRO METERS

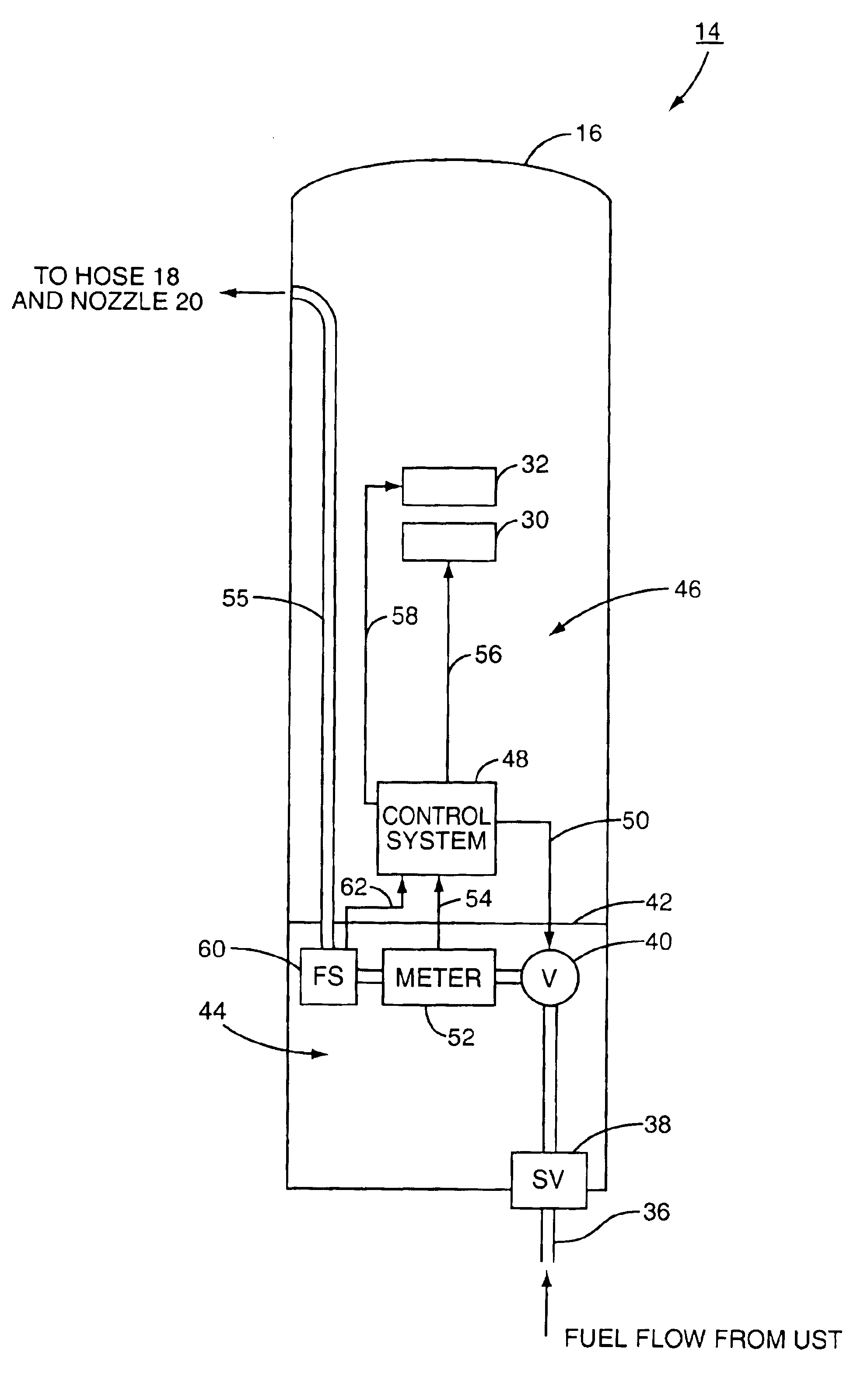

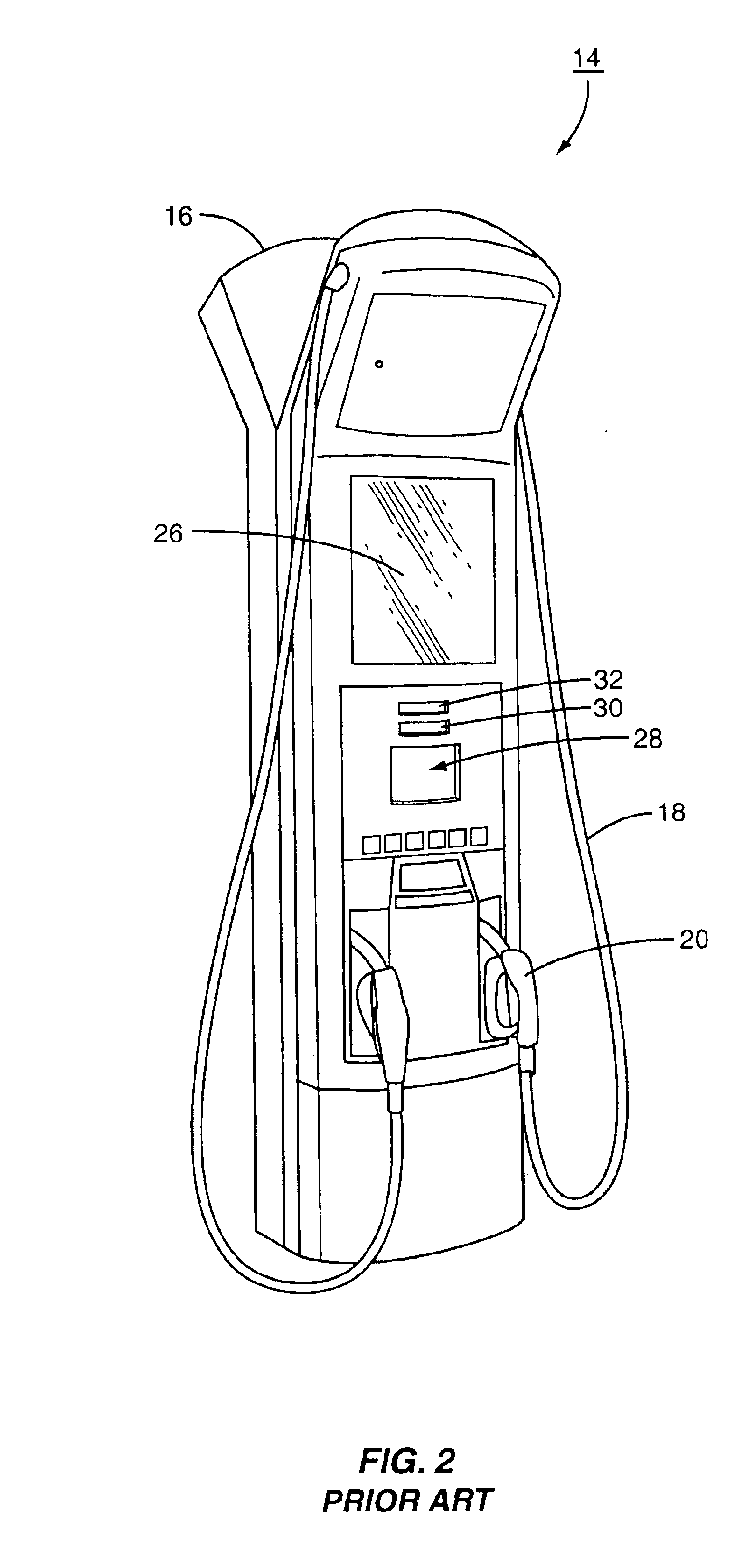

Fuel dispenser fuel flow meter device, system and method

ActiveUS6935191B2Accurate measurementImproper chargingValve arrangementsLiquid transferring devicesCombined useEngineering

A flow switch used on conjunction with a fuel flow meter in a fuel dispenser to determine when fuel flow rate signals form a fuel flow meter should be ignored in the calculation of flow rate and / or volume of fuel dispensed. An inferential fuel flow meter may be used as the fuel flow meter. The inferential fuel flow meter may be a turbine flow meter that comprises one or more turbine rotors that rotate in response to fuel flow flowing through the turbine flow meter. The turbine rotors may continue to generate pulses even when fuel is no longer flowing. A flow switch determines when fuel is actually flowing and fuel is not actually flowing. The flow switch is described as either a single poppet or dual poppet flow switch in examples described herein.

Owner:GILBARCO +1

Process diagnostics

ActiveUS7290450B2Improve abilitiesEasy to useVibration measurement in solidsAnalysing fluids using sonic/ultrasonic/infrasonic wavesTransducerEngineering

A diagnostic device for use in a industrial process includes monitoring electronics or diagnostic circuitry configured to diagnose or identify a condition or other occurrence in the industrial process. The system can be implemented in a process device such as a flowmeter, and in one example an acoustic flowmeter. A transducer can also be used and a frequency response, such as resonant frequency, can be observed.

Owner:ROSEMOUNT INC

Apparatus and method for compensating a coriolis meter

ActiveUS7152460B2High densityAdd additional massMaterial analysis using microwave meansVolume/mass flow by dynamic fluid flow effectDischarge measurementsVolumetric Mass Density

A flow measuring system is provided that provides at least one of a compensated mass flow rate measurement and a compensated density measurement. The flow measuring system includes a gas volume fraction meter in combination with a coriolis meter. The GVF meter measures acoustic pressures propagating through the fluids to measure the speed of sound αmix propagating through the fluid to calculate at least gas volume fraction of the fluid and / or the reduced natural frequency. For determining an improved density for the coriolis meter, the calculated gas volume fraction and / or reduced frequency is provided to a processing unit. The improved density is determined using analytically derived or empirically derived density calibration models (or formulas derived therefore), which is a function of the measured natural frequency and at least one of the determined GVF, reduced frequency and speed of sound, or any combination thereof. The gas volume fraction (GVF) meter may include a sensing device having a plurality of strain-based or pressure sensors spaced axially along the pipe for measuring the acoustic pressures propagating through the flow.

Owner:EXPRO METERS

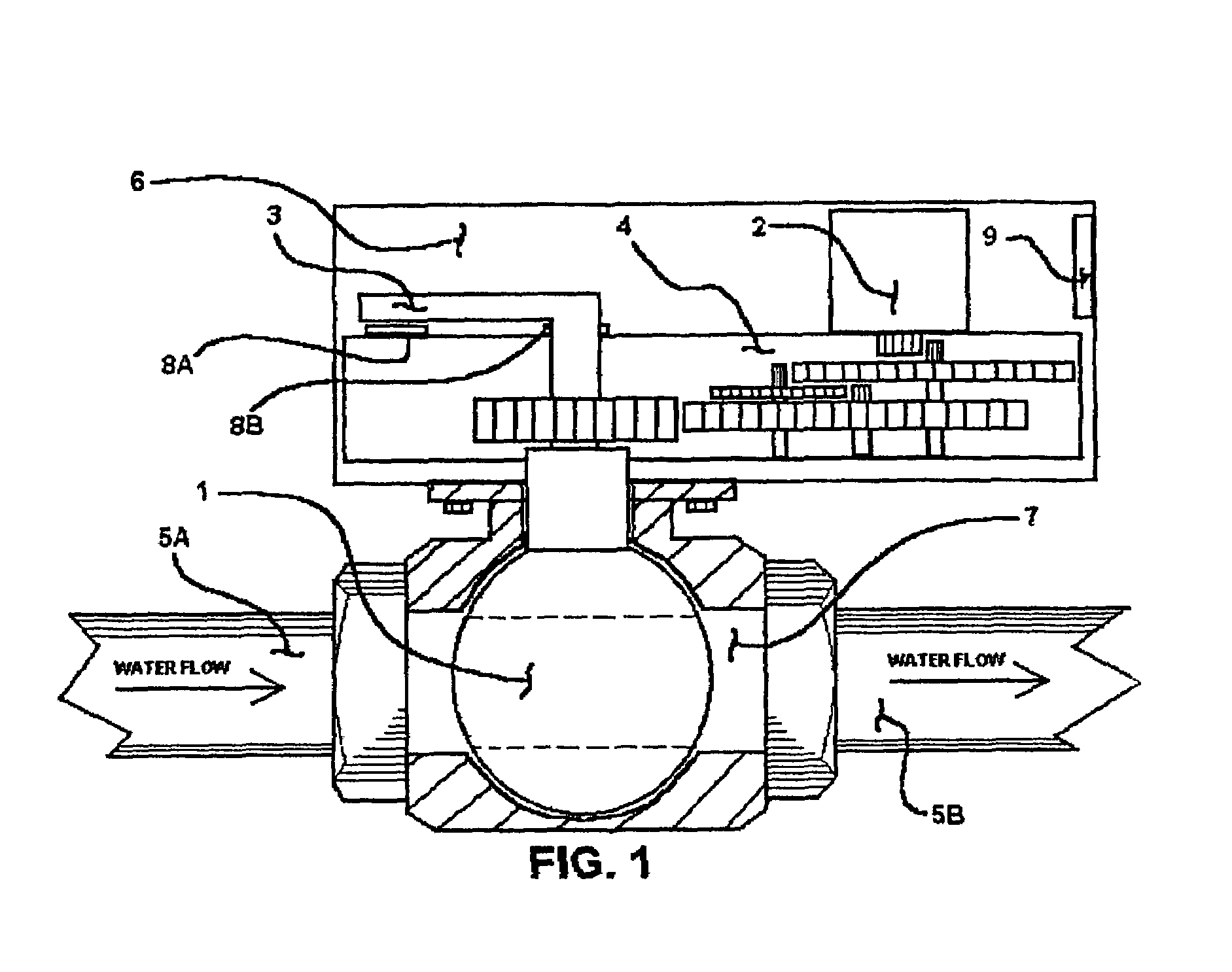

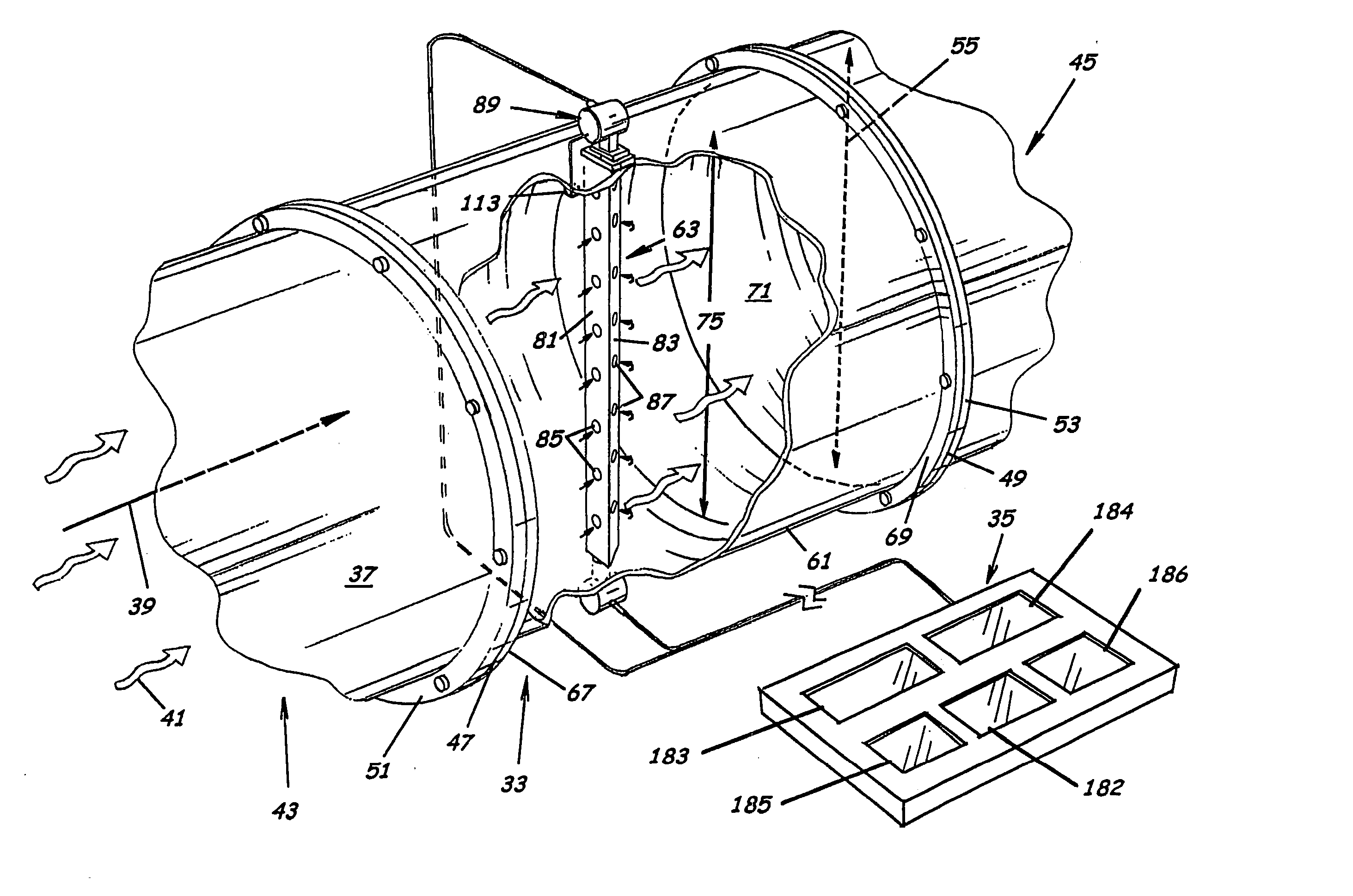

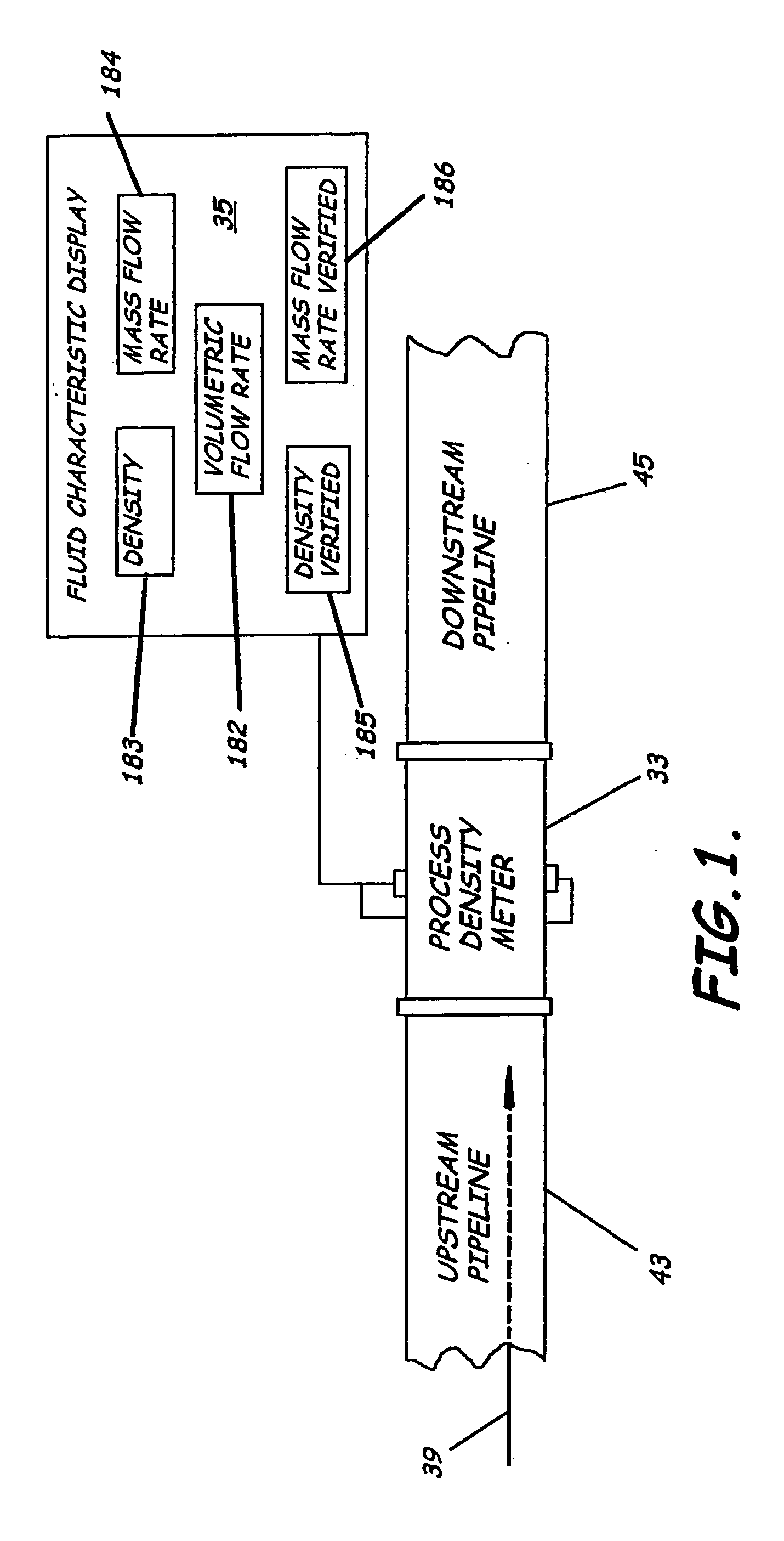

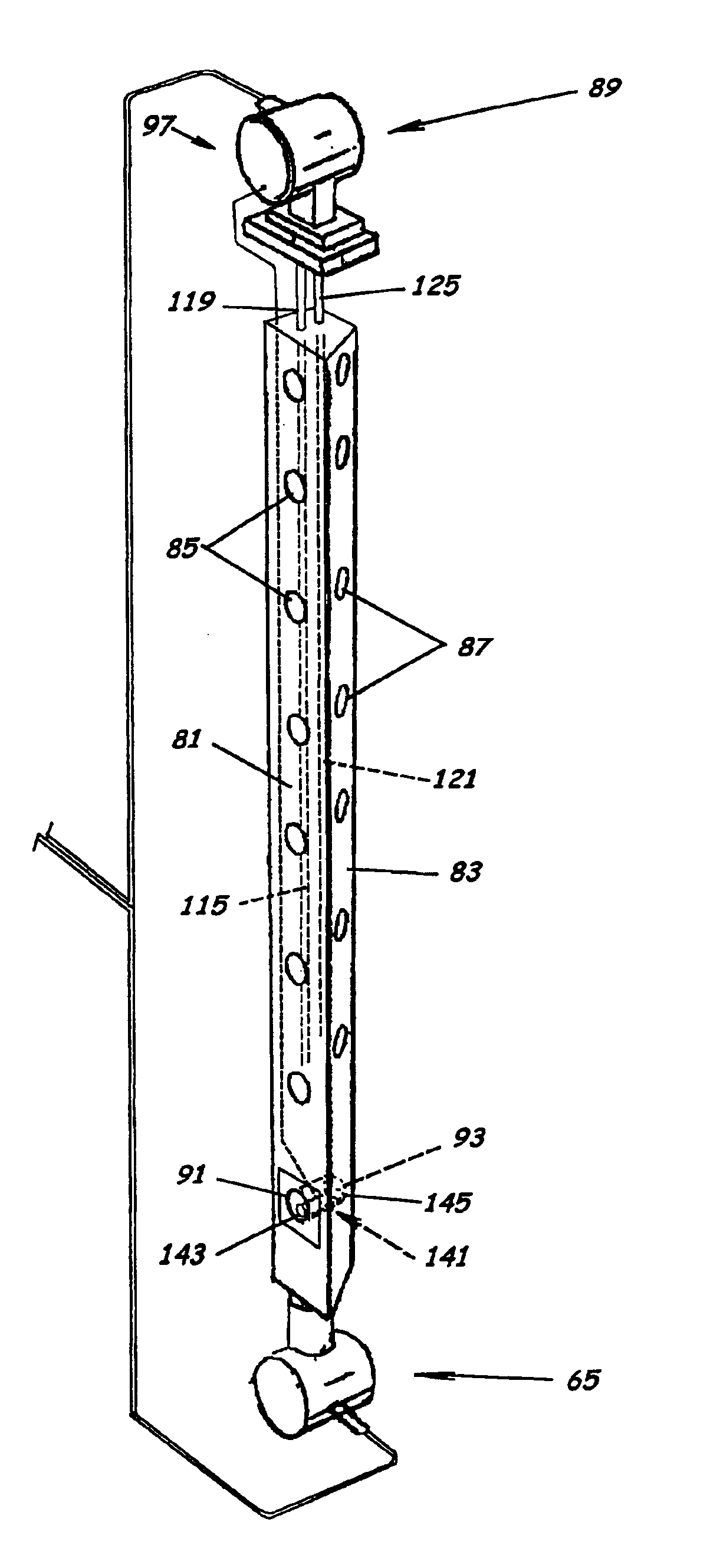

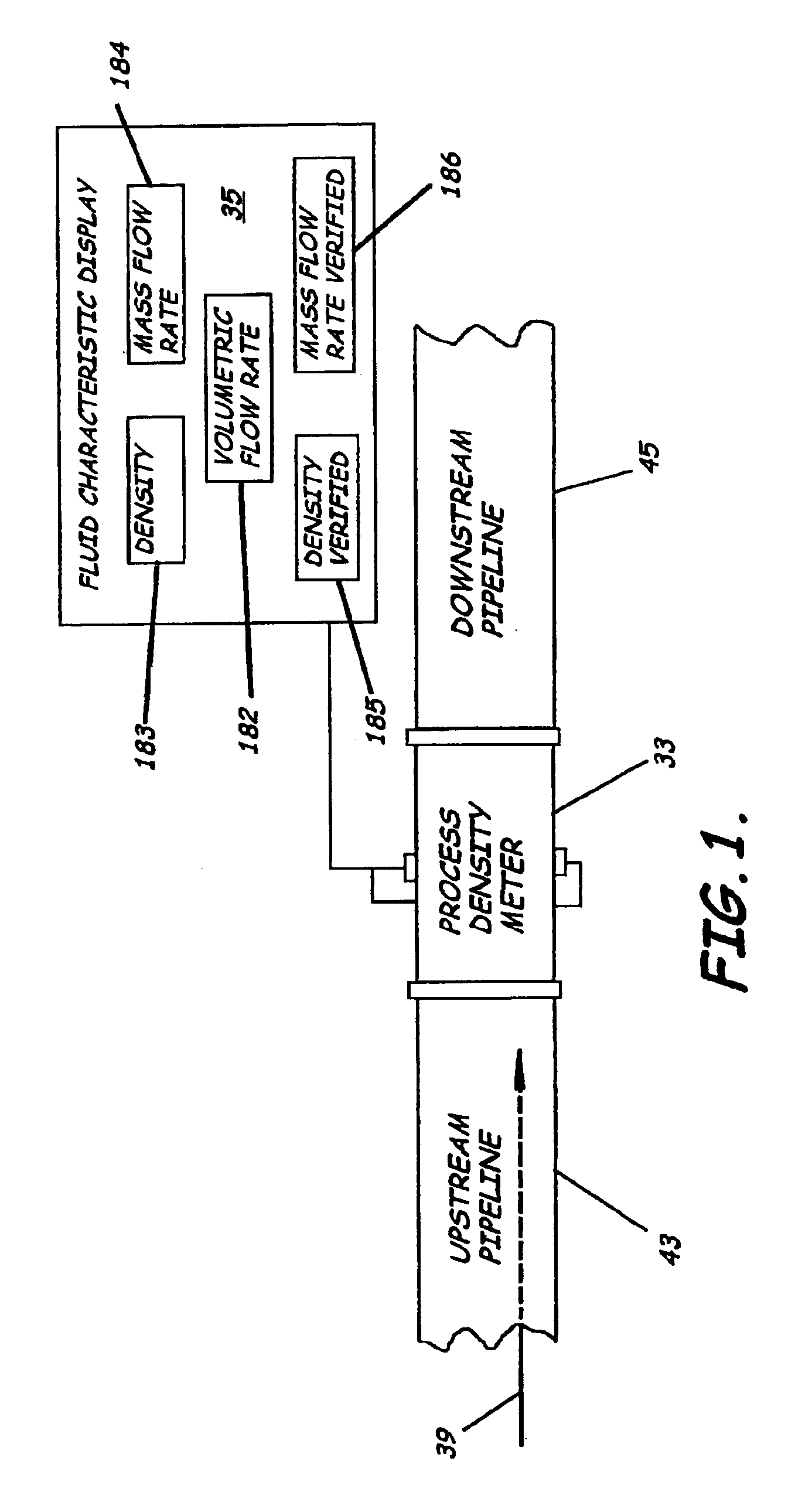

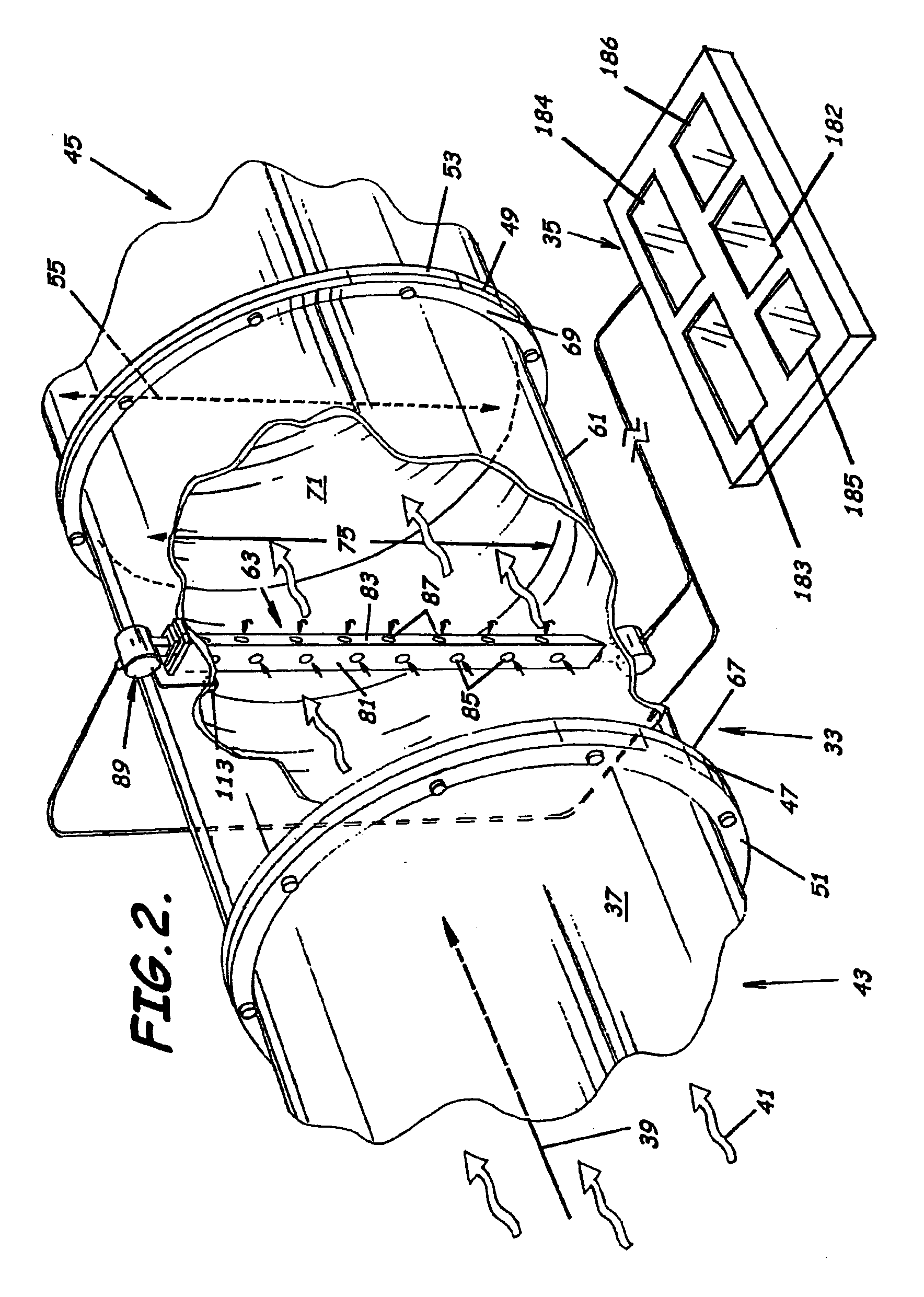

System to measure density, specific gravity, and flow rate of fluids, meter, and related methods

ActiveUS20050034535A1Little maintenanceMinimization needsVolume/mass flow by thermal effectsVolume/mass flow by dynamic fluid flow effectDifferential pressureDisplay device

A system to measure fluid flow characteristics in a pipeline, meter, and methods includes a pipeline having a passageway to transport flowing fluid therethrough, a process density meter including at least portions thereof positioned within the pipeline to provide flowing fluid characteristics including volumetric flow rate, fluid density, and mass flow rate of the flowing fluid, and a fluid characteristic display to display the fluid characteristics. The process density meter includes a vortex-shedding body positioned within the pipeline to form vortices and a vortex meter having a vortex frequency sensor to measure the frequency of the vortices and to determine the volumetric flow rate. The process density meter further includes a differential pressure meter positioned adjacent the vortex-shedding body to produce a differential pressure meter flow rate signal indicative of the density of fluid when flowing through the pipeline. The process density meter also includes a thermal flow meter positioned adjacent the vortex-shedding body to produce a mass flow rate signal indicative of the mass flow rate of fluid when flowing through the pipeline. The process density meter produces an output of a volumetric flow rate, a flowing fluid density, and a mass flow rate to be displayed by the fluid characteristic display.

Owner:SAUDI ARABIAN OIL CO

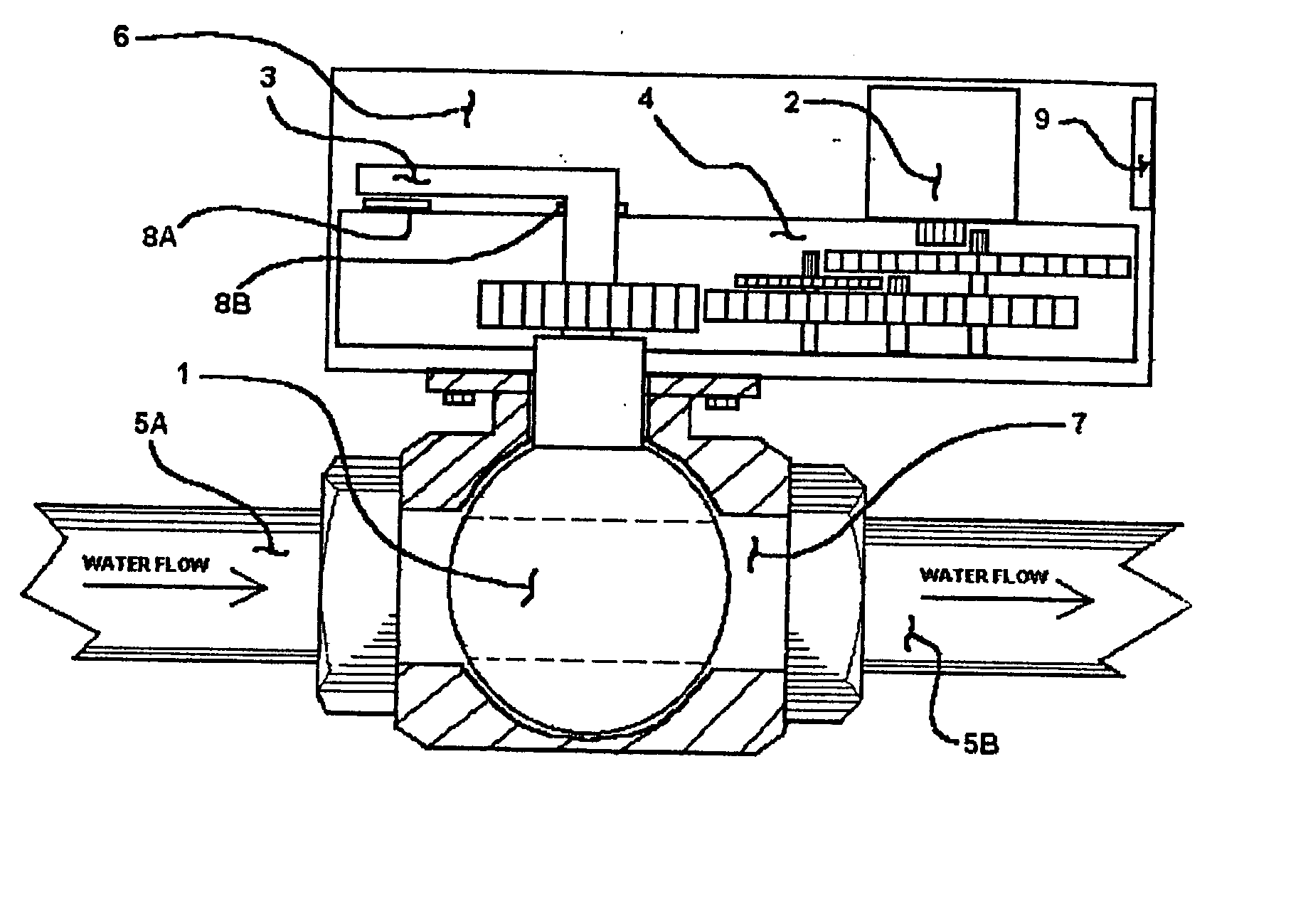

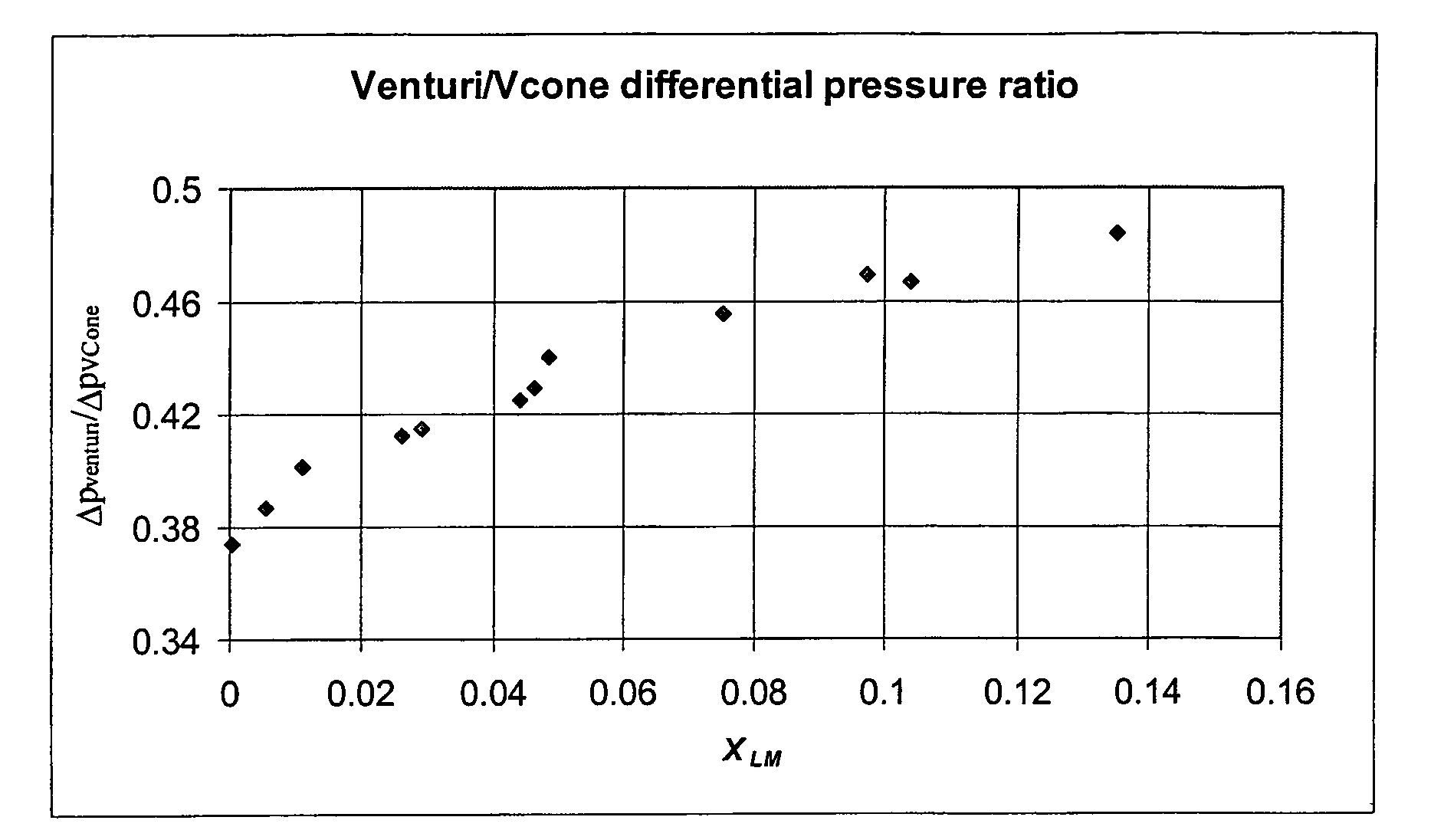

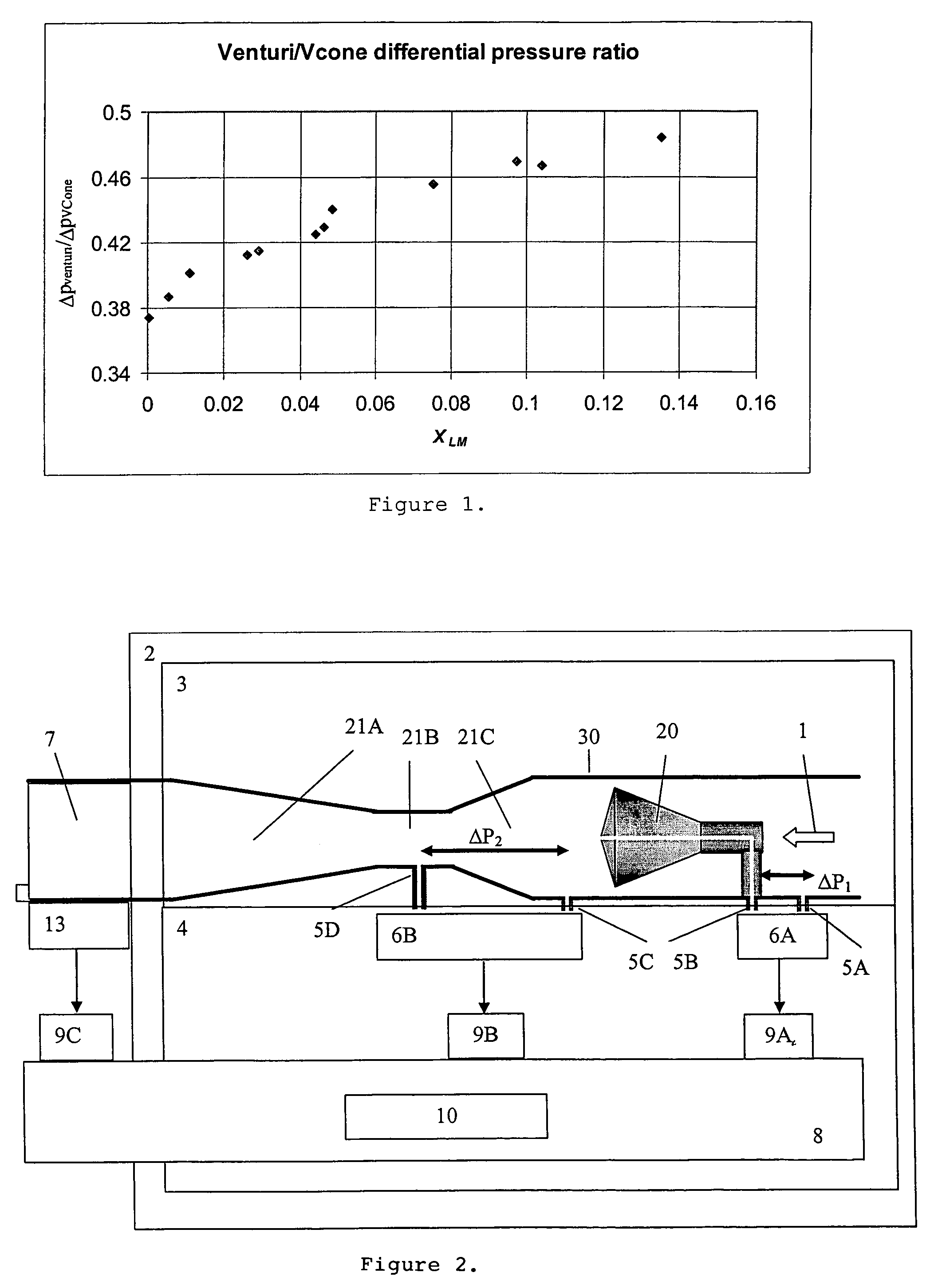

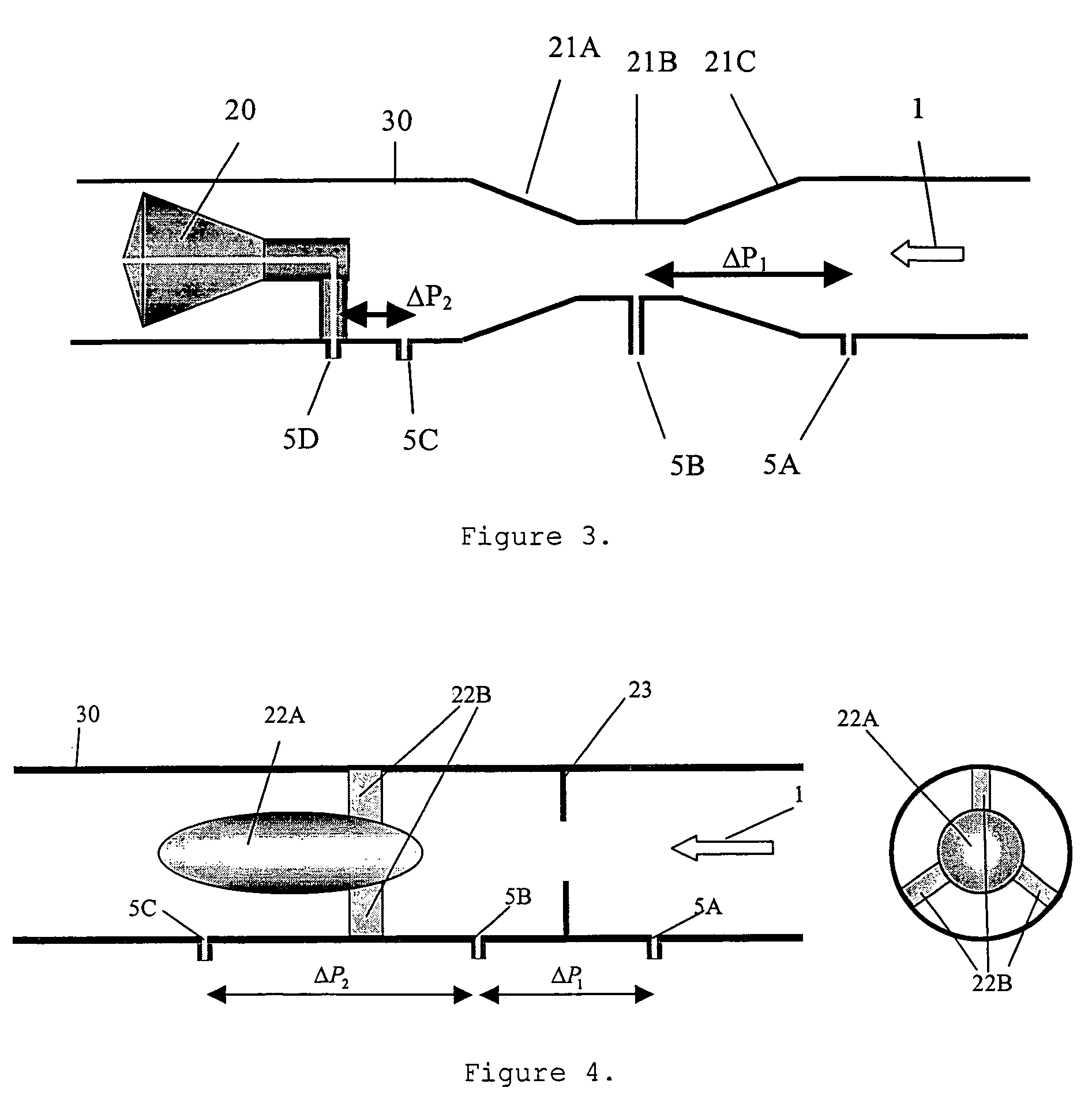

Flow meter

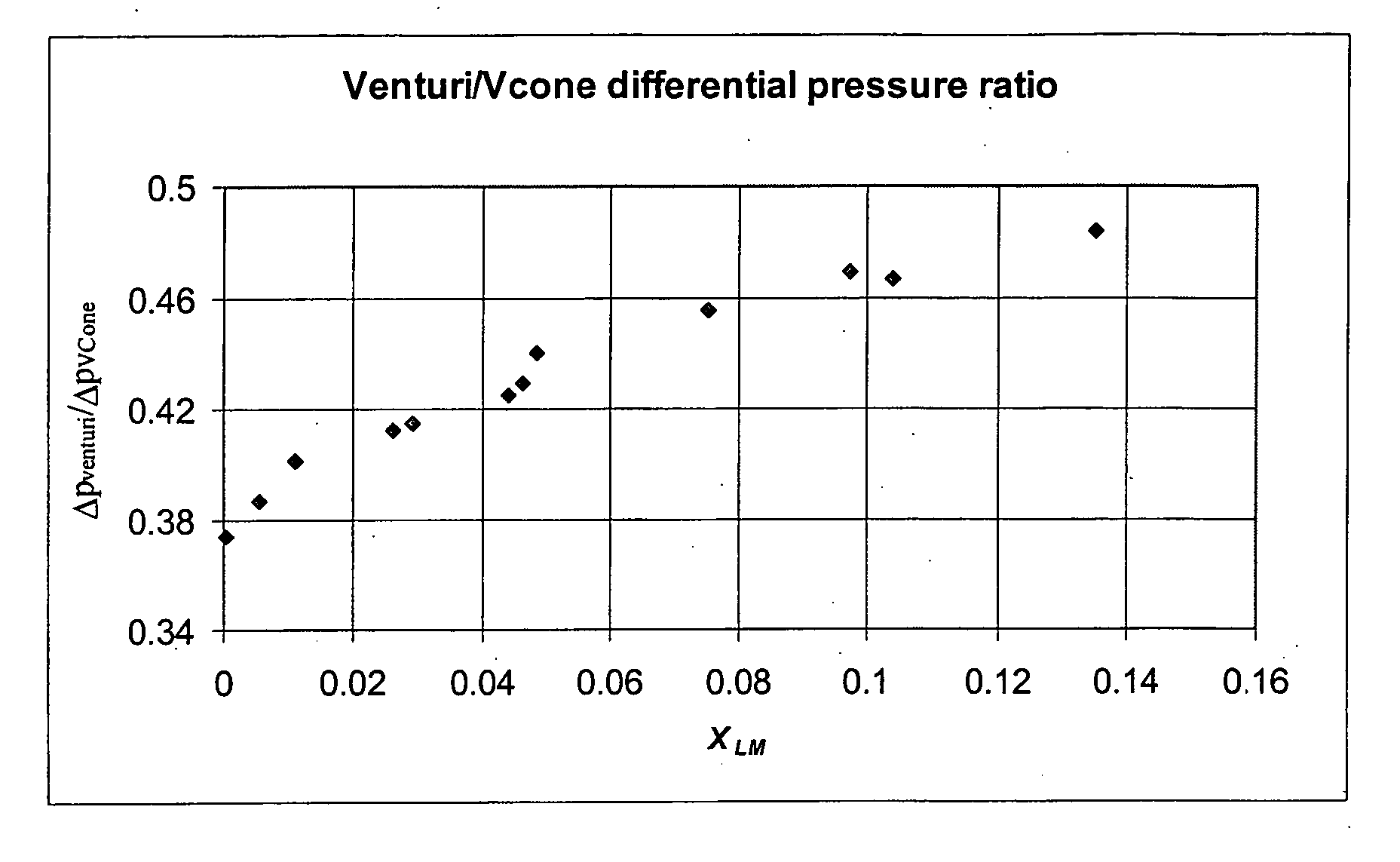

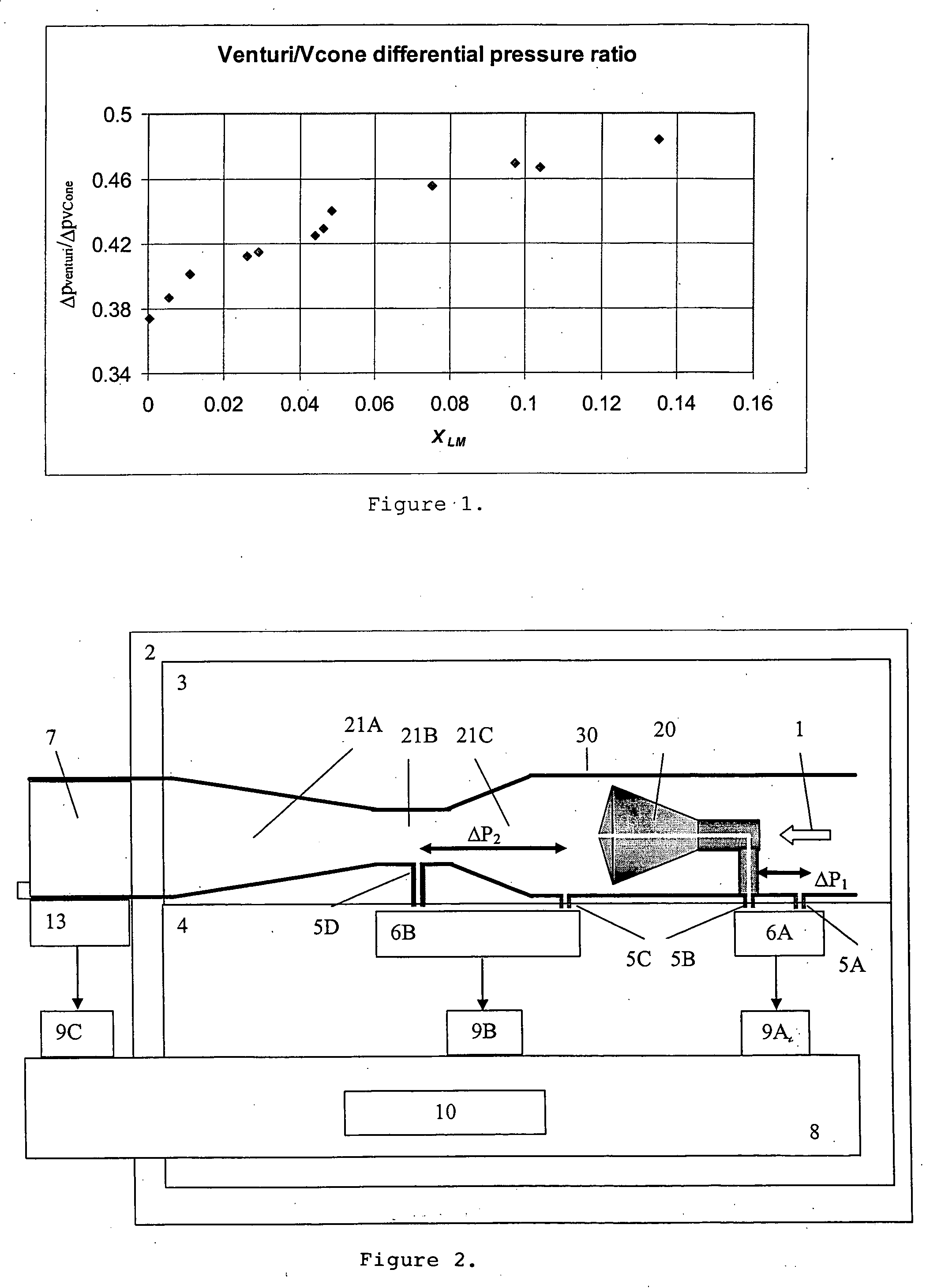

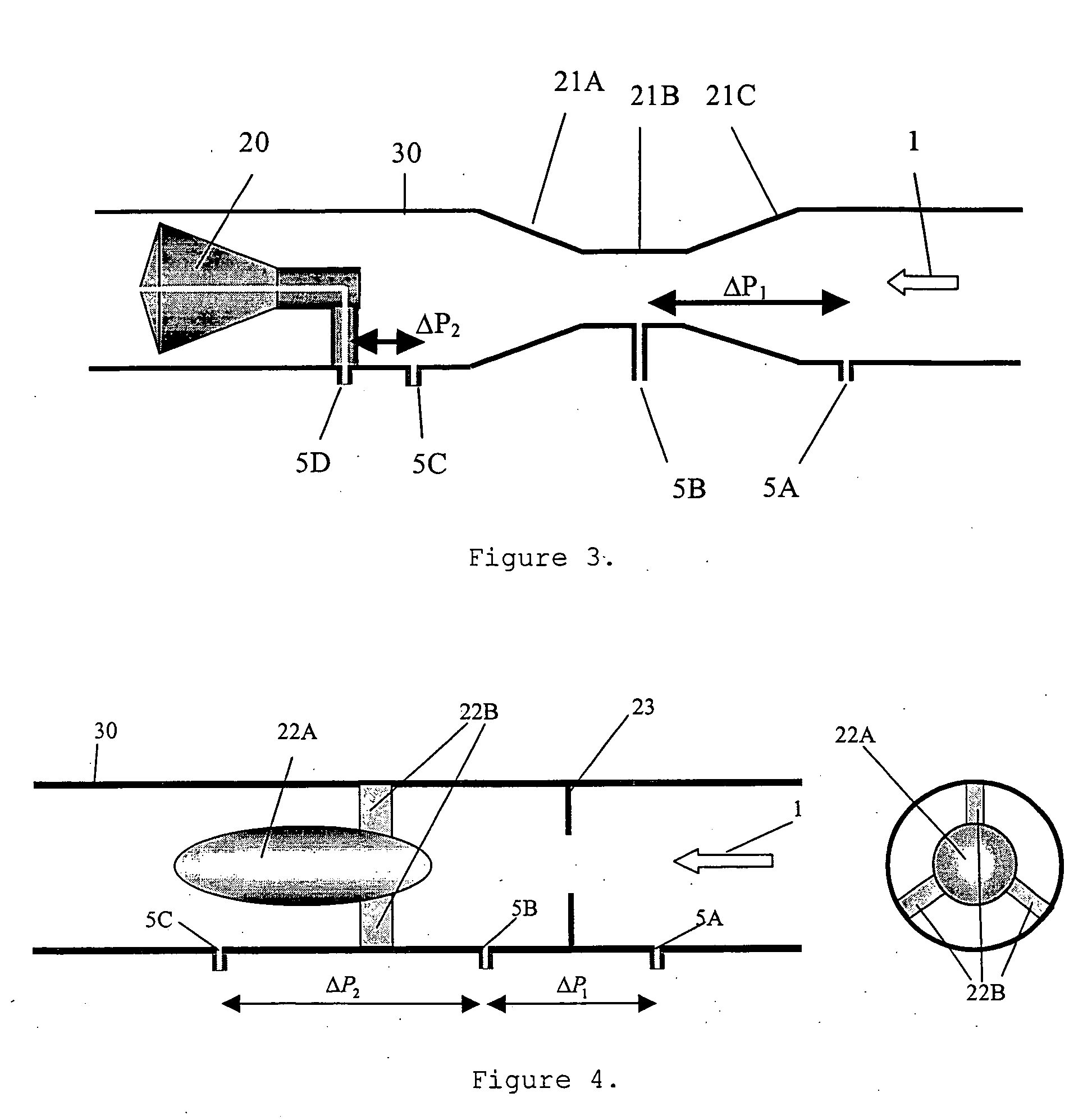

ActiveUS20050188771A1Specific gravity by measuring pressure differencesMaterial analysis by electric/magnetic meansLiquid stateDifferential pressure

A flow meter obtains the individual flow rates of gas, liquid hydrocarbons, and water in a predominantly gas-containing flowing fluid mixture. The flow meter comprises a water content meter (7) provides a signal representing a measure of the water content of said fluid. It also comprises a double differential pressure generating (3) and measuring (4) structure, denoted a DDP-unit (2), that provides two measurement signals (6A and 6B) representing two independent values of differential pressure (DP) in said fluid (1). In addition to the above, the meter also comprises a signal processing unit (8) having inputs (9A-C) for receiving the measurement signals and the water content signal, and a calculation module (10) which calculates values representing the volumetric flow rates of said gas, liquid hydrocarbons and water in said fluid.

Owner:ROXAR FLOW MEASUREMENT

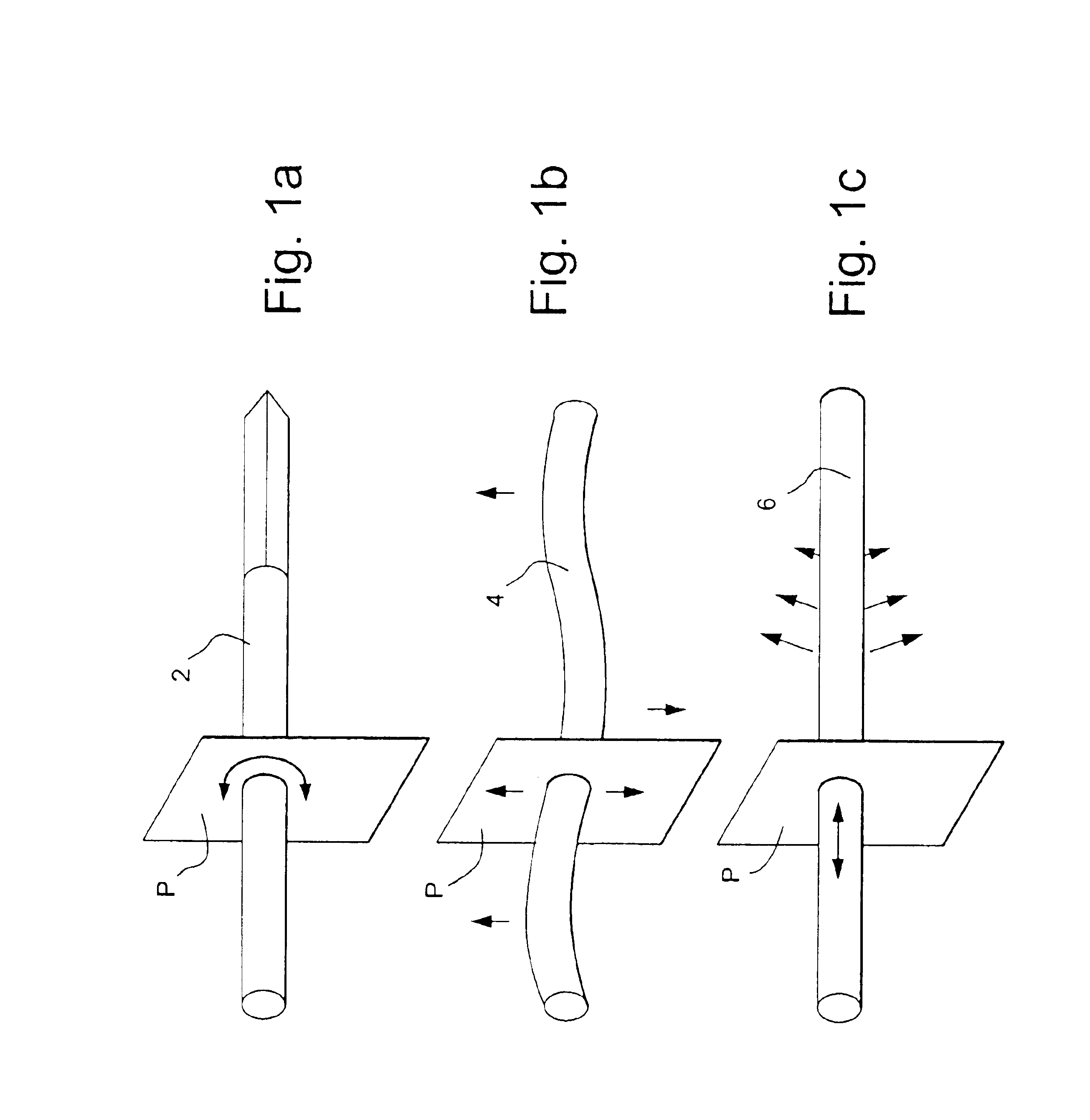

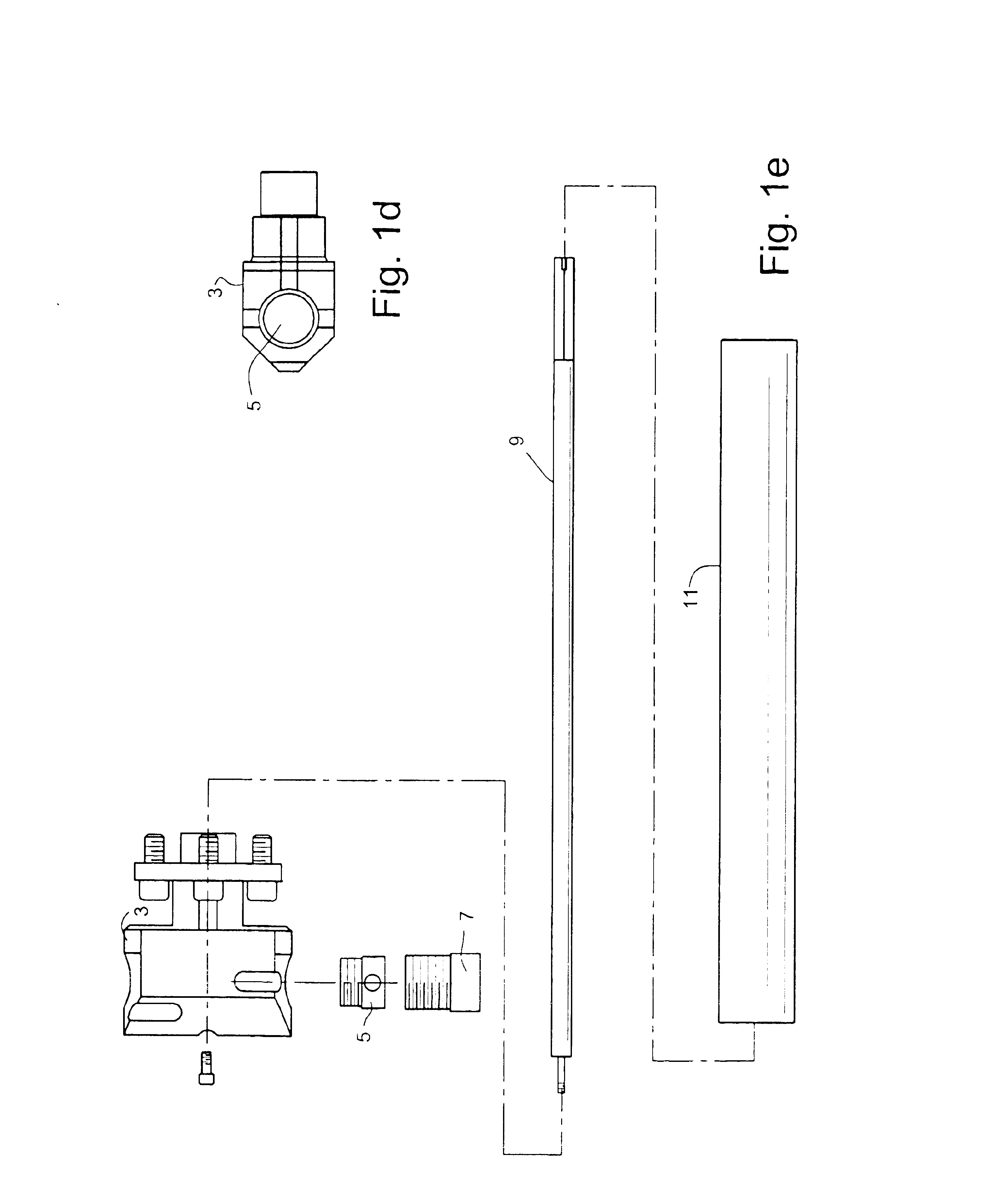

Bi-directional differential pressure flow sensor

InactiveUS6725731B2Volume variation compensation/correction apparatusFluid-pressure actuatorsDifferential pressureEngineering

Disclosed is a bi-directional differential pressure flow sensor that is configured to establish a direction and flow rate of a fluid flow. The flow sensor includes a flow restriction member, a differential pressure sensor, and processing electronics. The flow restriction member is configured to produce a pressure drop when placed inline with the fluid flow. The differential pressure sensor is embedded or integral with the flow restriction member and produces a differential pressure signal that is indicative of the pressure drop. The processing electronics produces a flow rate signal that is indicative of the direction and flow rate of the fluid flow as a function of the differential pressure signal.

Owner:ROSEMOUNT INC

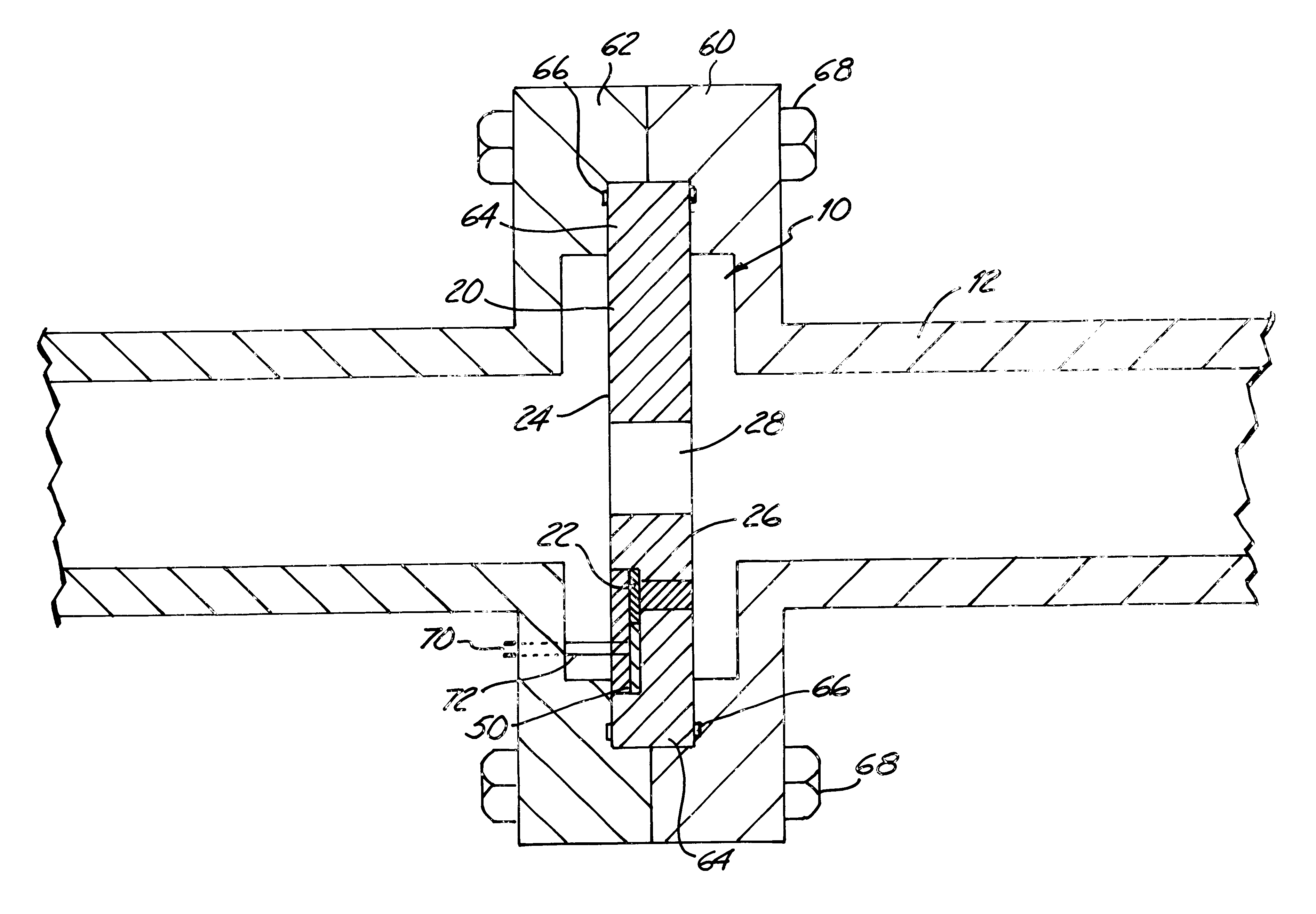

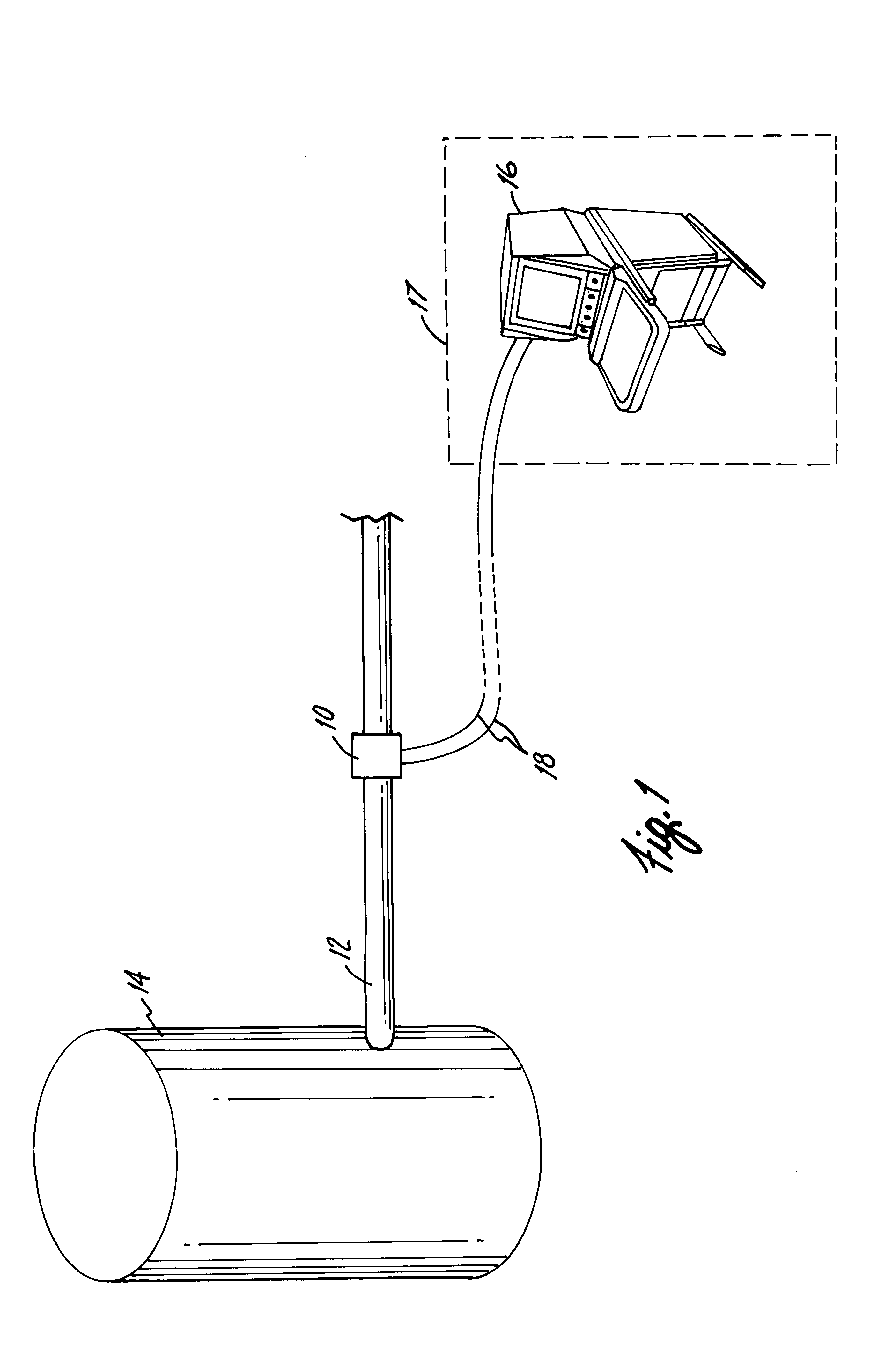

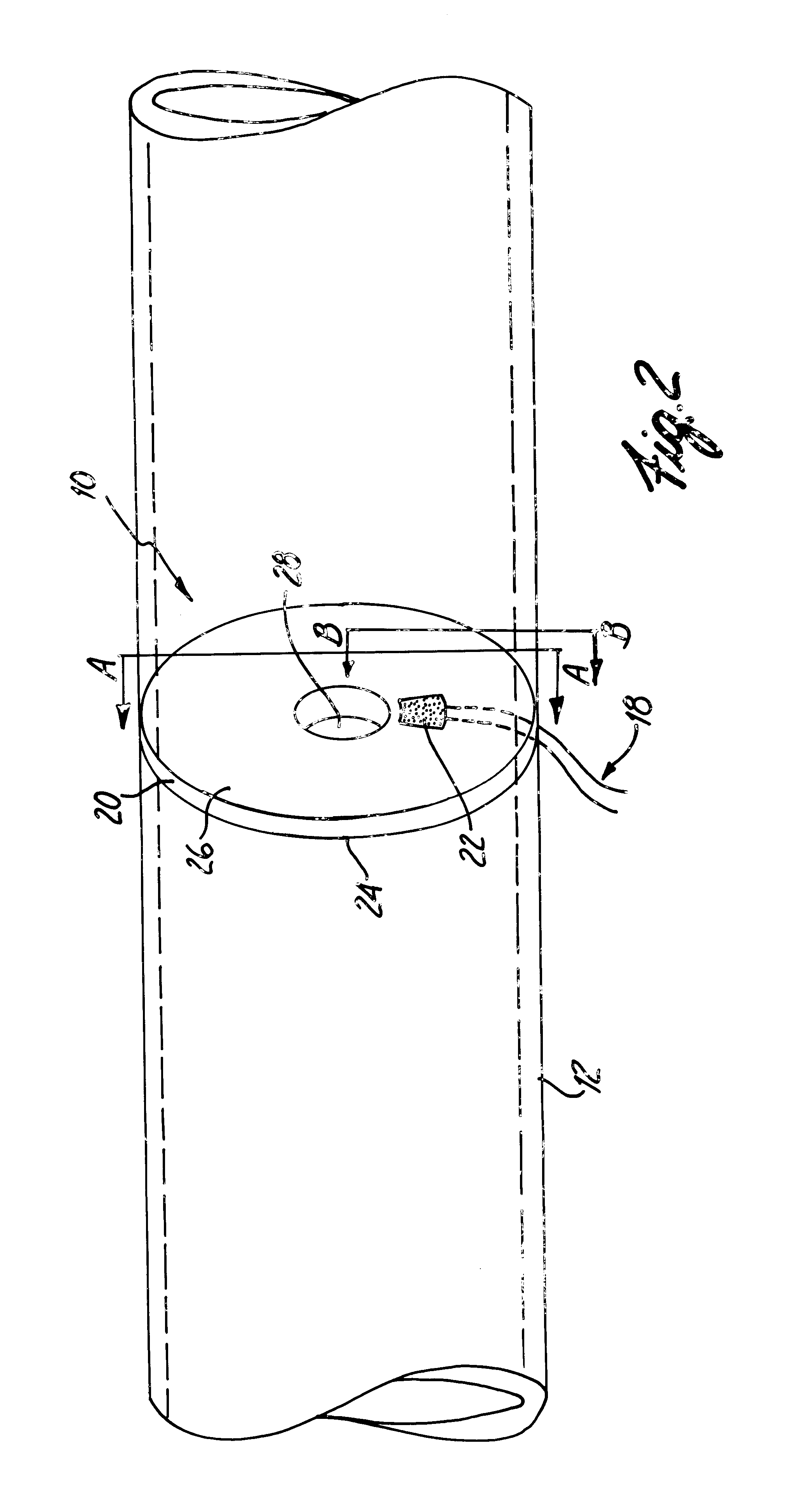

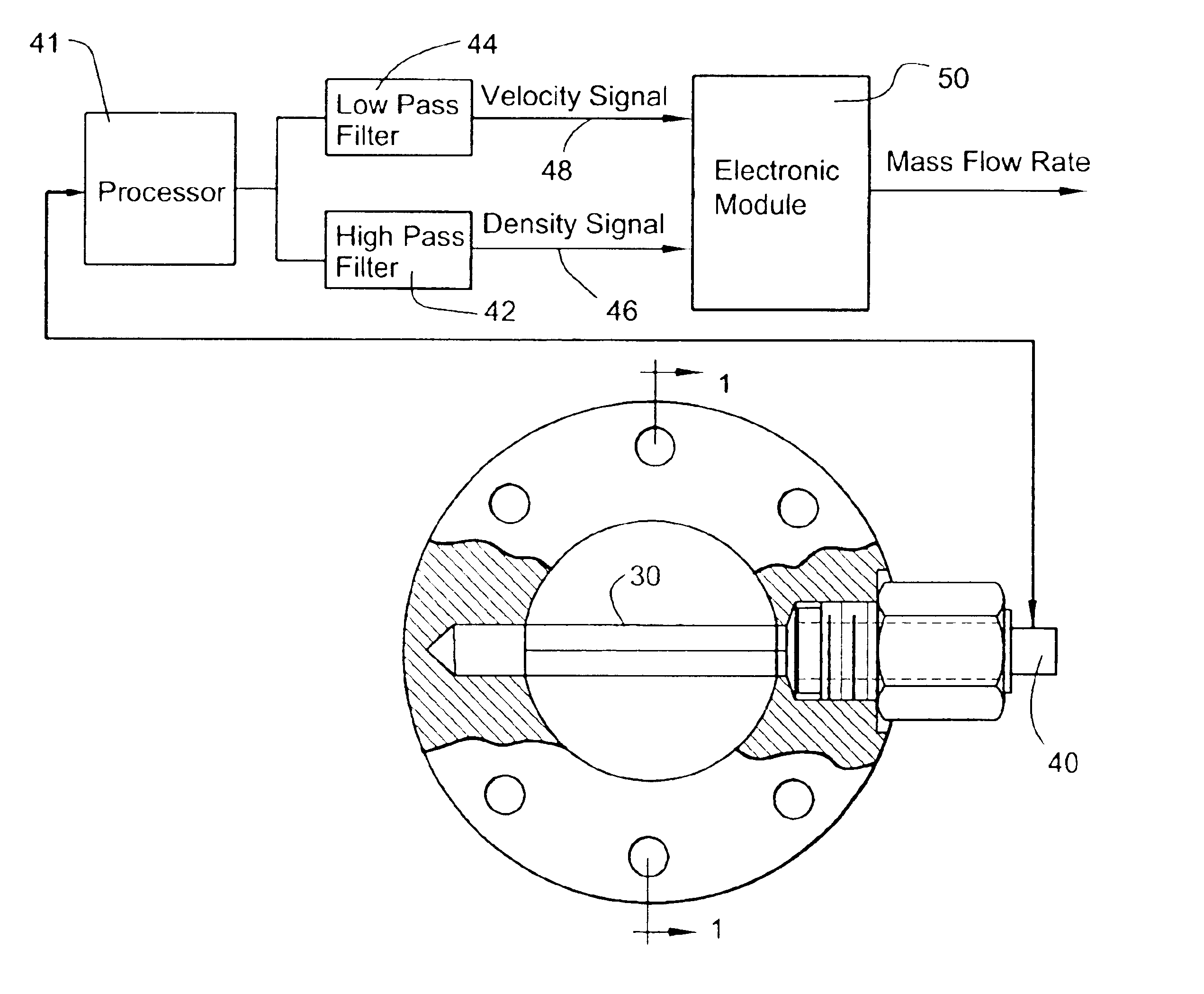

Mass flow sensor and methods of determining mass flow of a fluid

ActiveUS6912918B1Prevent leakageAvoid radiationVolume/mass flow by dynamic fluid flow effectSpecific gravity measurementSonificationUltrasonic beam

The mass flow rate sensor includes a waveguide disposed in a flow passage having a bluff body facing in an upstream direction. Waves are pulsed along the waveguide for interaction with the fluid. A receiver is coupled to the waveguide to detect a propagated wave and provides a first output signal proportional to the transit time of the propagated wave for determining fluid density. The receiver also provides a second output signal proportional to the shedding frequency of vortices from the waveguide to determine velocity. An electronics module calculates mass flow rate from the velocity times density times area of the flow passage and a constant. In other forms, the velocity is ascertained by transmitting an ultrasonic beam through the shedding vortices to determine vortex frequency which is proportional to velocity.

Owner:BAKER HUGHES INC

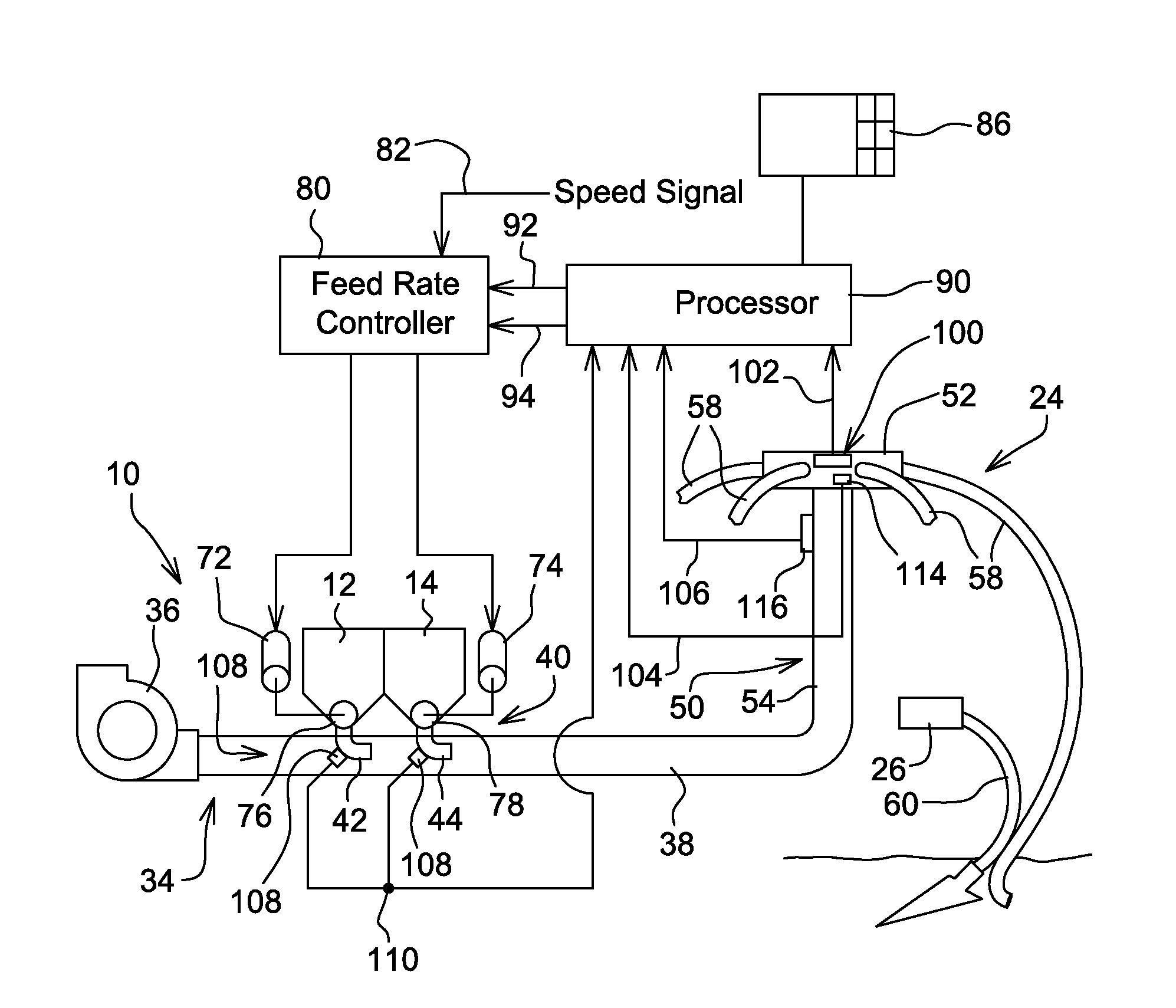

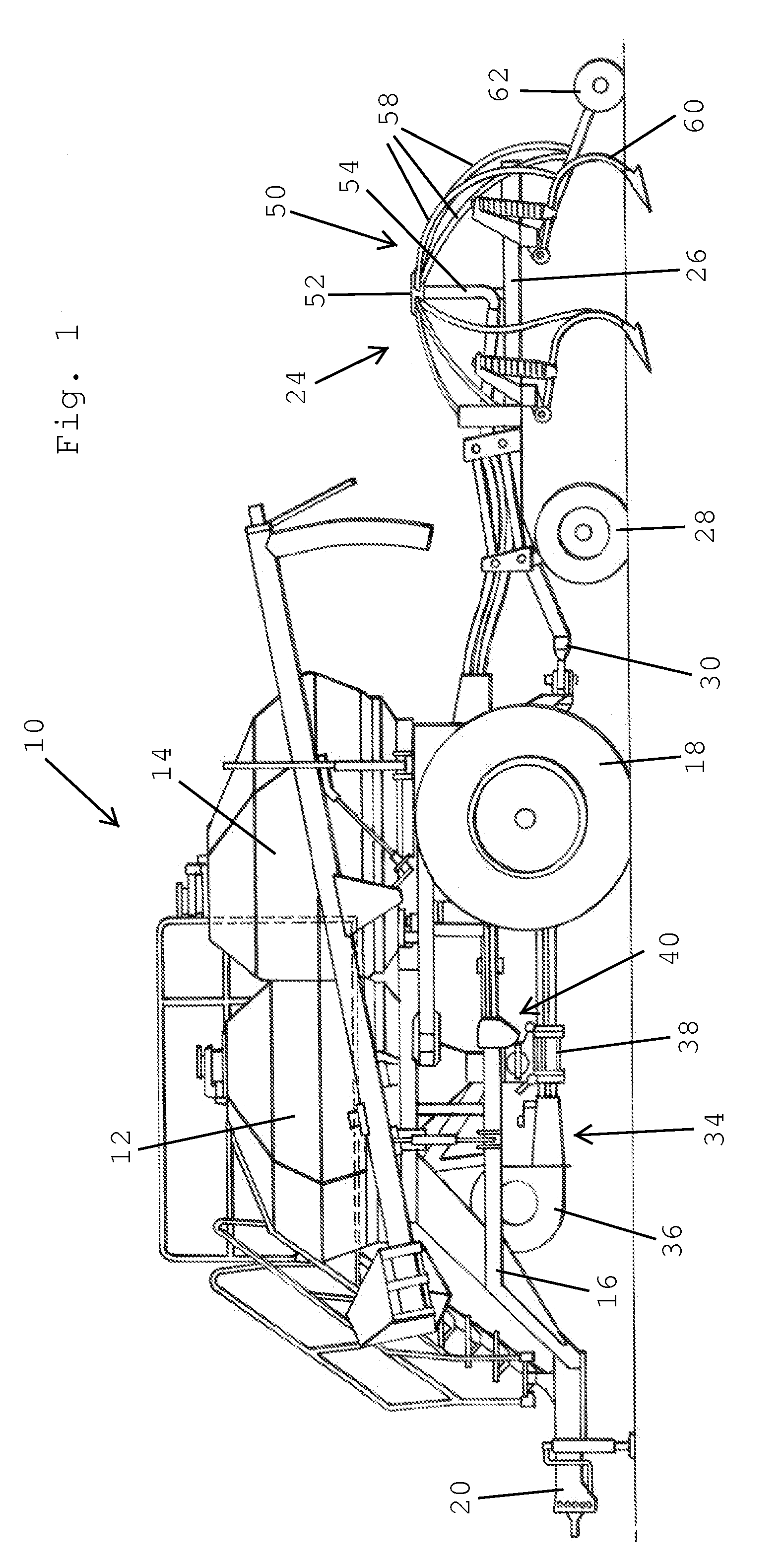

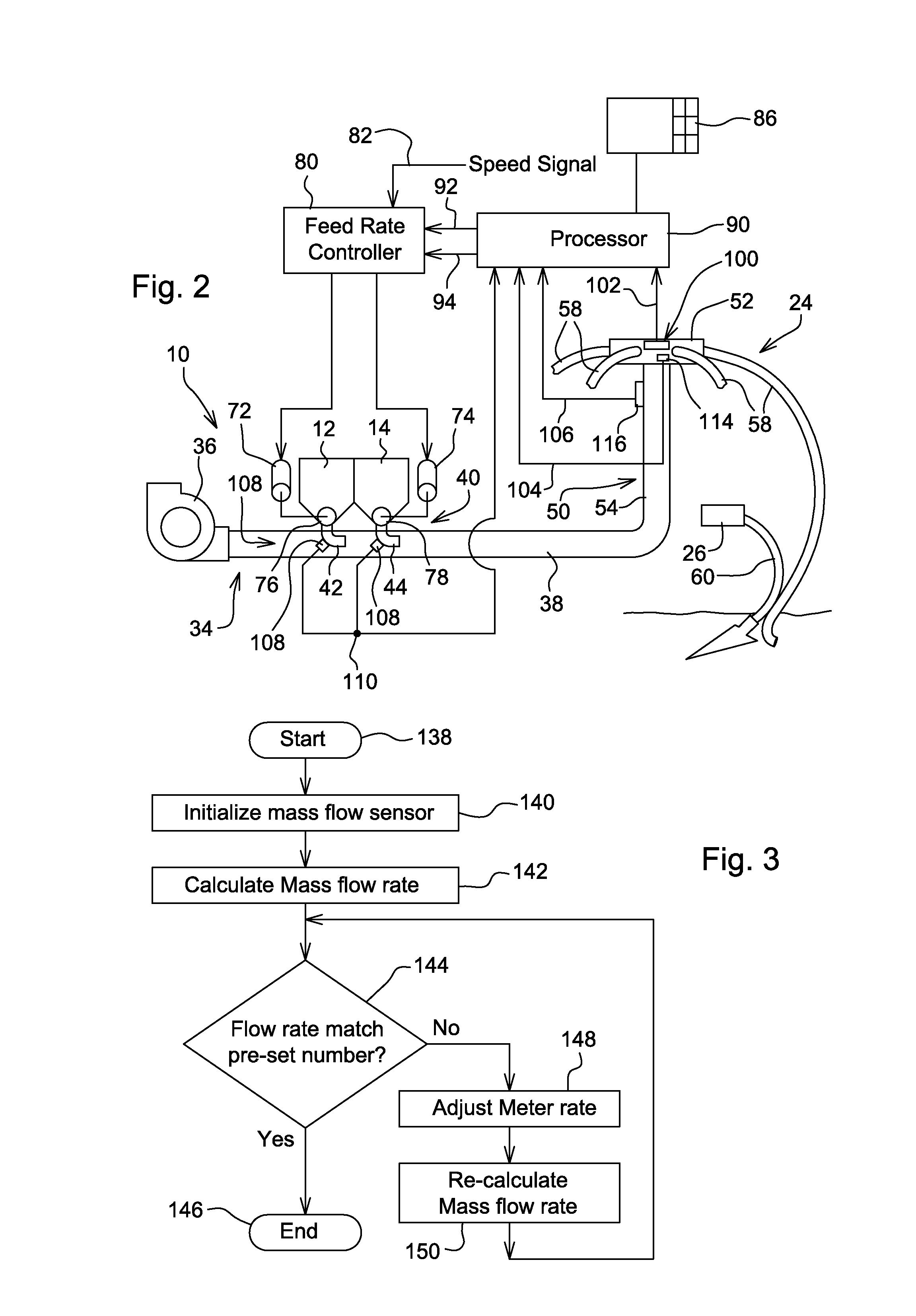

Particulate flow sensing for an agricultural implement

ActiveUS8504310B2Reduce delaysMore accurate seeding and fertilizing ratesFlow propertiesSowingAir velocityEngineering

Owner:DEERE & CO

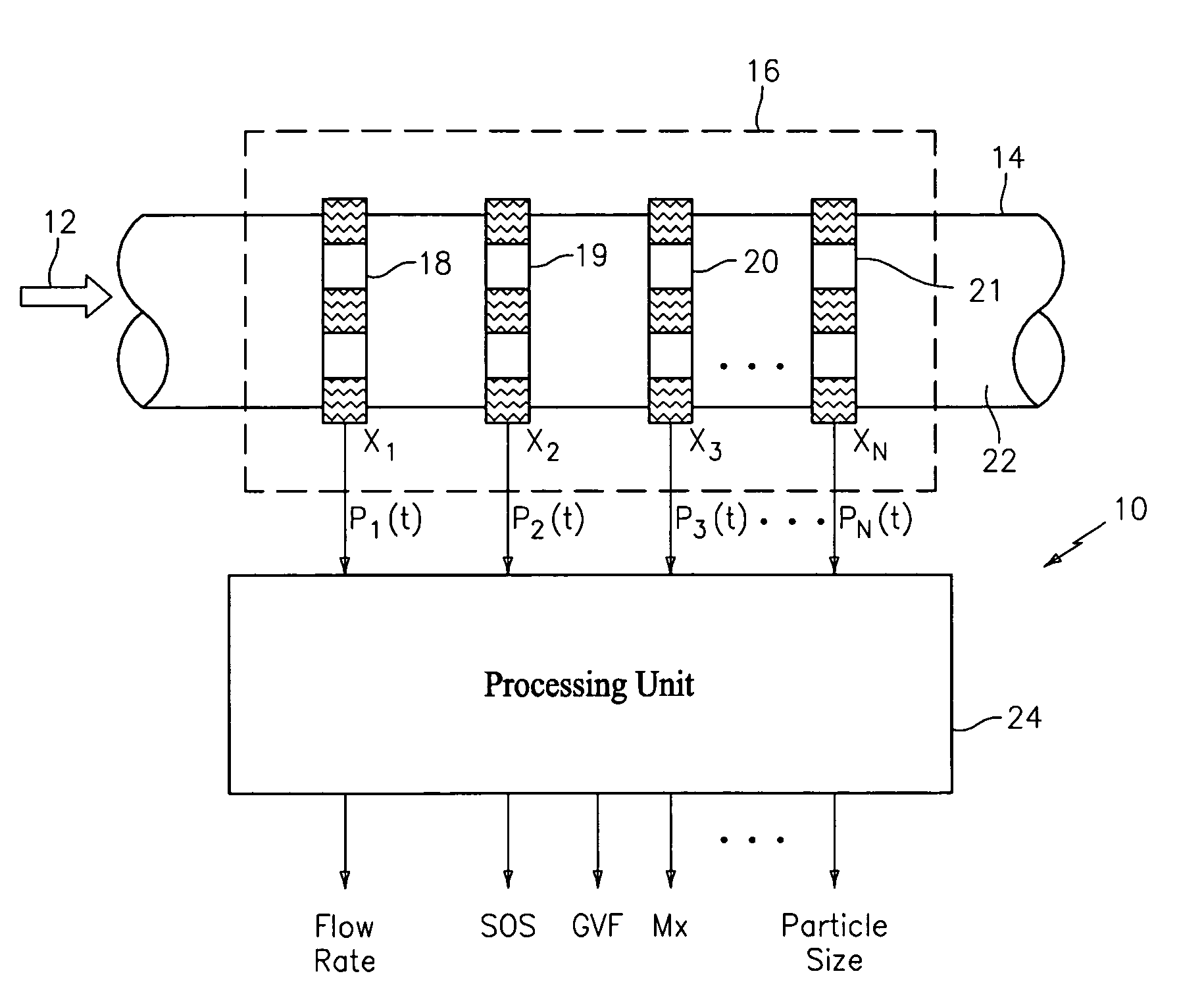

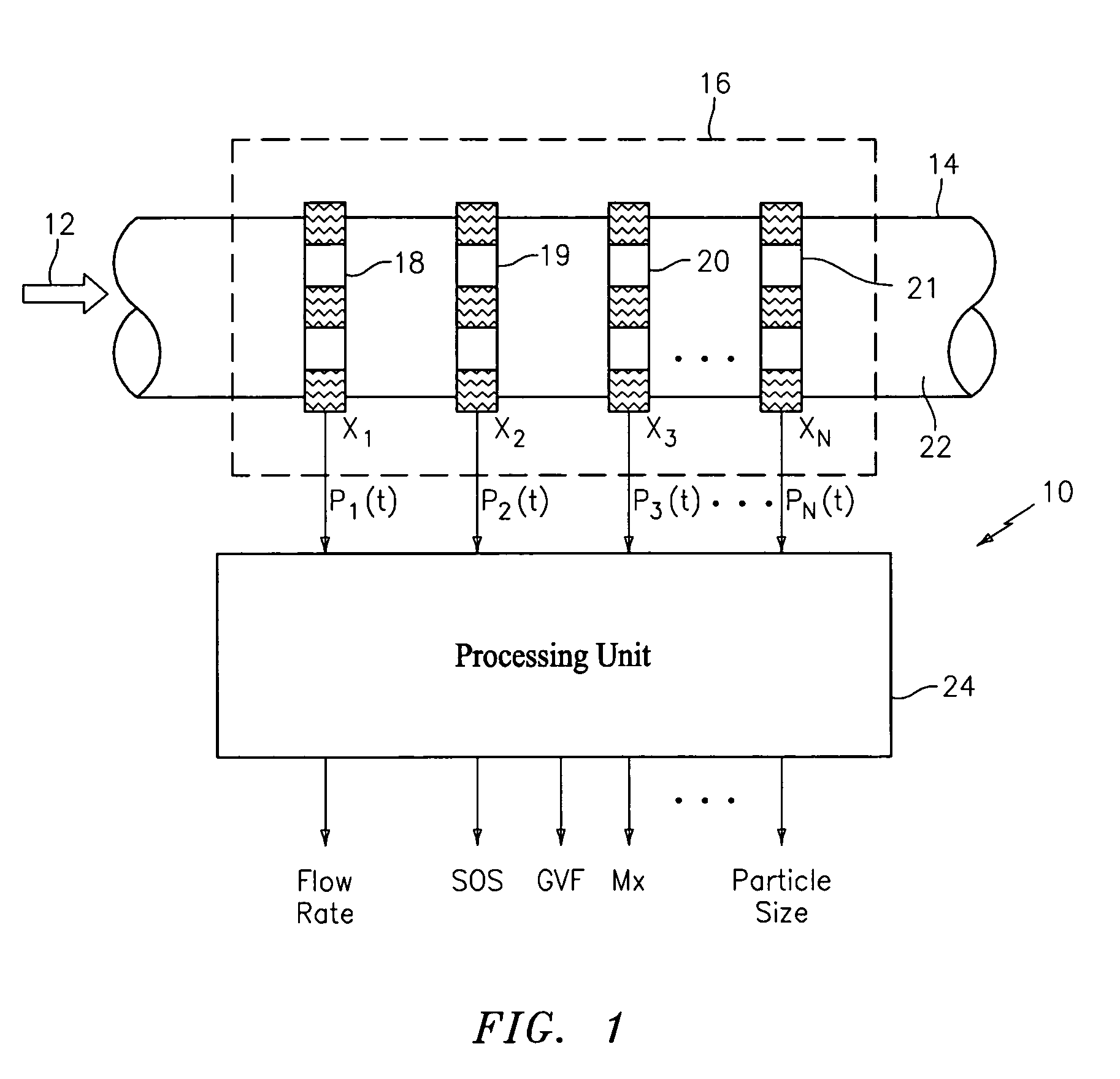

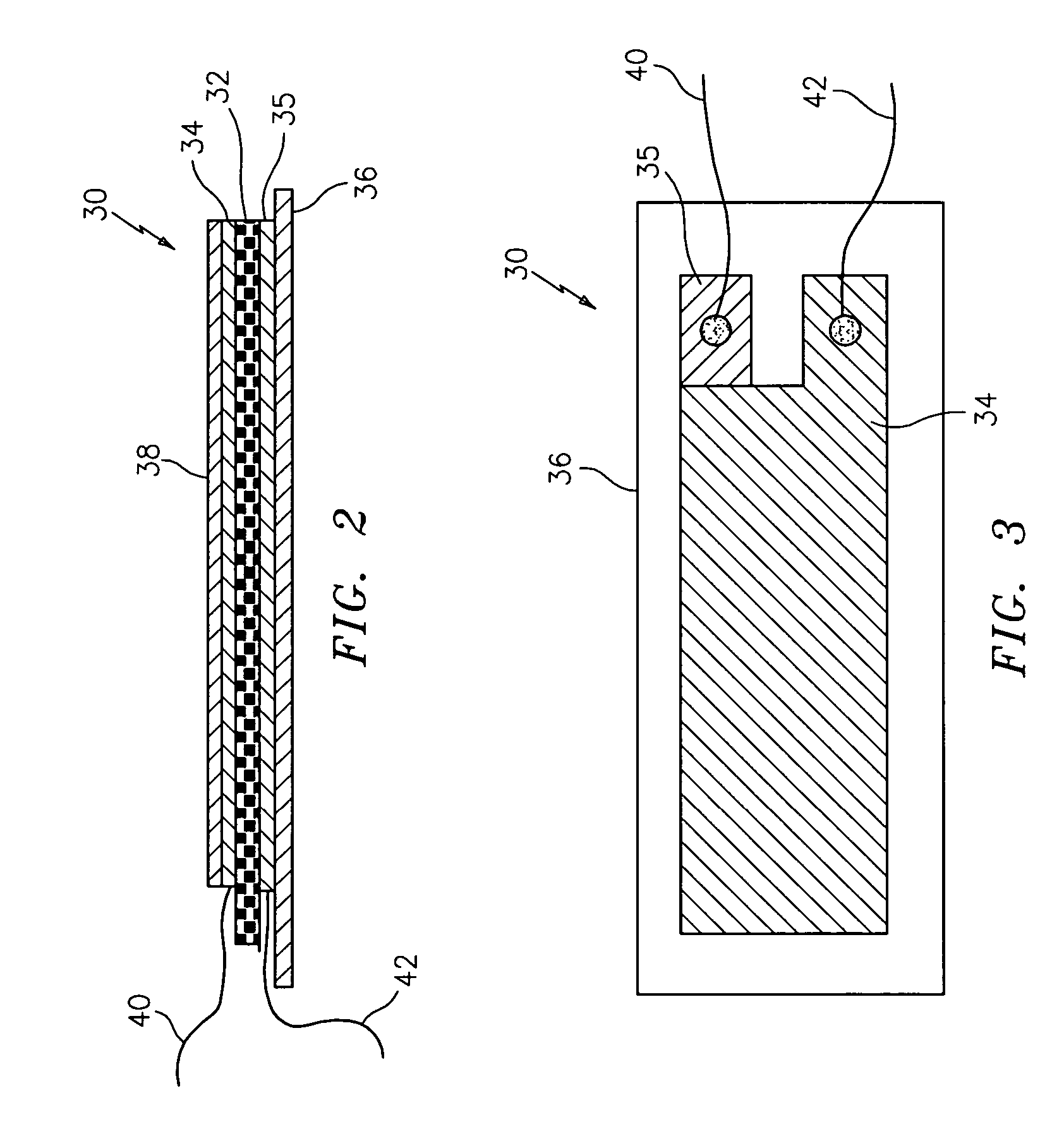

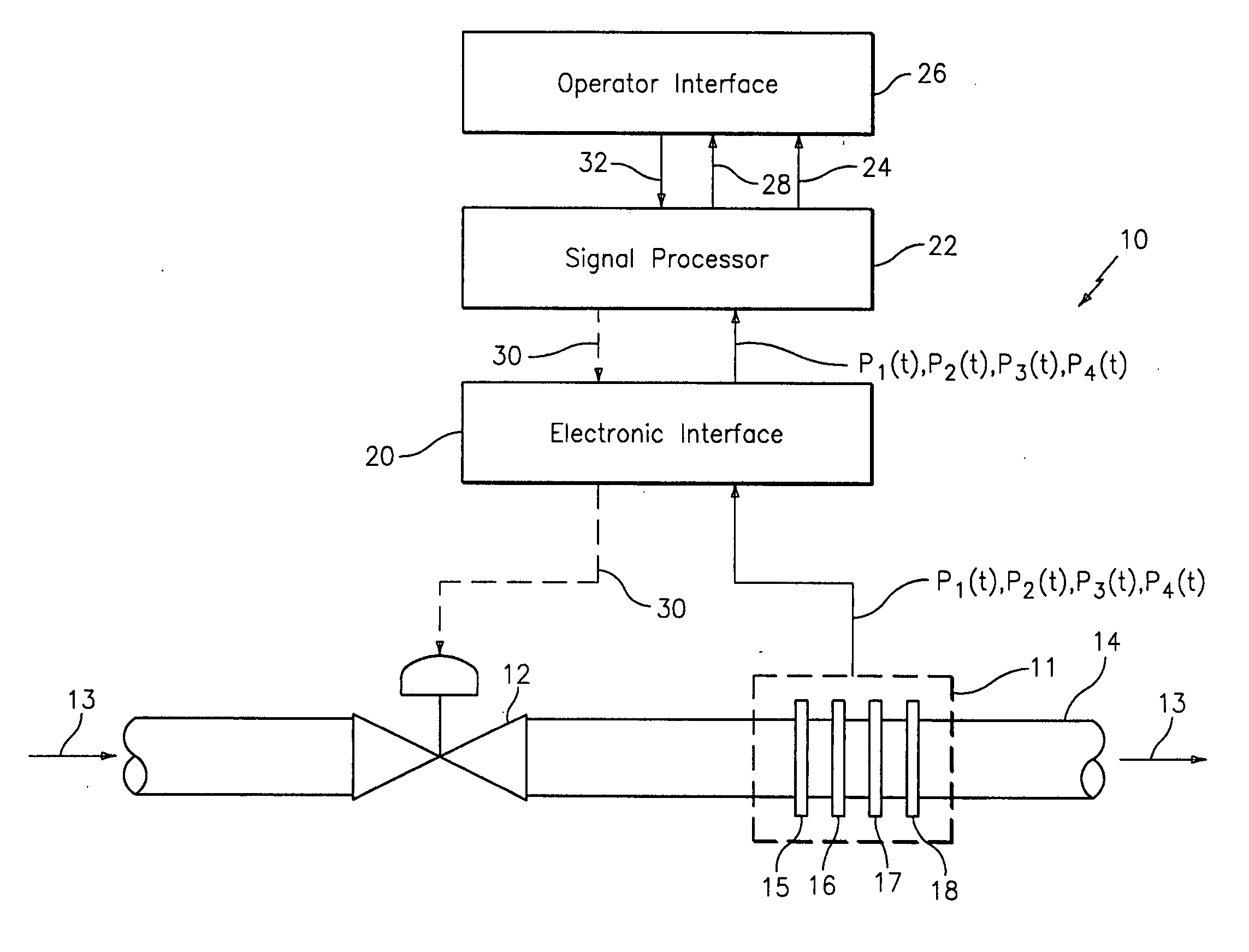

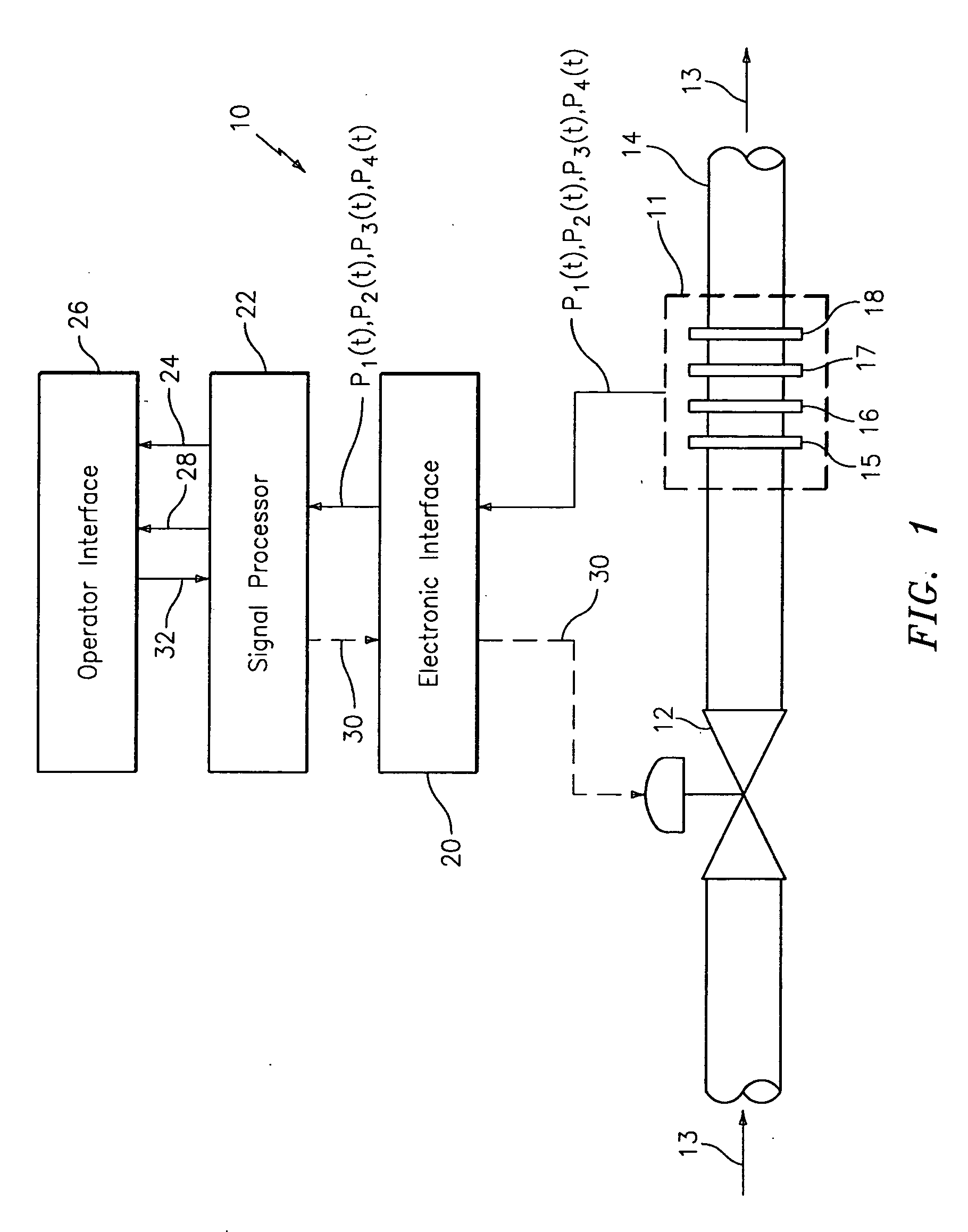

Apparatus and method for measuring unsteady pressures within a large diameter pipe

ActiveUS7058549B2Analysing fluids using sonic/ultrasonic/infrasonic wavesAmplifier modifications to reduce noise influencePressure senseEngineering

An apparatus 10 is provided that includes a spatial array of at least two unsteady pressure sensors 18–21 placed at predetermined axial locations x1–xN disposed axially along a pipe 14 for measuring at least one parameter of a fluid 12 flowing in the pipe 14. The pressure sensors 18–21 comprise a plurality of pressure sensing elements such as piezoelectric film sensors 23 for measuring unsteady pressures associated with acoustical pressures and / or vortical disturbances. The sensing elements are disposed circumferentially around the pipe and spaced a predetermined distance. The pressure signals P1(t)–PN(t) provided by the pressure sensors 18–21 are processed by a processing unit to provide an output signal indicative of a parameter of the fluid.

Owner:EXPRO METERS

System to measure density, specific gravity, and flow rate of fluids, meter, and related methods

ActiveUS6957586B2Little maintenanceMinimization needsVolume/mass flow by thermal effectsSpecific gravity using flow propertiesDifferential pressureDisplay device

A system to measure fluid flow characteristics in a pipeline, meter, and methods includes a pipeline having a passageway to transport flowing fluid therethrough, a process density meter including at least portions thereof positioned within the pipeline to provide flowing fluid characteristics including volumetric flow rate, fluid density, and mass flow rate of the flowing fluid, and a fluid characteristic display to display the fluid characteristics. The process density meter includes a vortex-shedding body positioned within the pipeline to form vortices and a vortex meter having a vortex frequency sensor to measure the frequency of the vortices and to determine the volumetric flow rate. The process density meter further includes a differential pressure meter positioned adjacent the vortex-shedding body to produce a differential pressure meter flow rate signal indicative of the density of fluid when flowing through the pipeline. The process density meter also includes a thermal flow meter positioned adjacent the vortex-shedding body to produce a mass flow rate signal indicative of the mass flow rate of fluid when flowing through the pipeline. The process density meter produces an output of a volumetric flow rate, a flowing fluid density, and a mass flow rate to be displayed by the fluid characteristic display.

Owner:SAUDI ARABIAN OIL CO

Conductive fluid leak detection system & automatic shut off valve

InactiveUS20030066340A1Minimize fluid leakageBlock fluid flowDetection of fluid at leakage pointIndication/recording movementLine tubingAlarm state

A flood control device and system which controls conductive fluid(s) in a conductive fluid supply line and or path, using the conductivity of said fluid(s). The conductive fluid system comprises; a conductive fluid supply line, in-line conductive fluid shut-off valve, in-line conductive fluid detector, conductive fluid sensor(s) (attached in or to conductive fluid dependent appliances), a D.C. powered central processing unit, and control panel. The conductive fluid flows through said conductive fluid line, said in-line conductive fluid shut-off valve, intern reaching said in-line conductive fluid detector which detects the flow of conductive fluid, thereby sending data to said central processing unit. When said central processing unit receives said data, said central processing unit delays for a predetermined amount of time (example 3 seconds) waiting to receive data from one or more of said conductive fluid sensor(s). If said central processing unit doesn't receive said data from said conductive fluid sensor(s) within said predetermined, said central processing unit will automatically send data to said in-line conductive fluid shut-off valve, to close, therefore terminating the forward flow of conductive fluid(s). System also includes audible signal(s) to signal an alarm condition, timing mode(s) for water conservation and monitoring in-line conductive fluid shut-off valve movements, a phone notifier for notifying user of said termination of conduct fluid due to a conductive fluid leak detection, and for (user-set) excessive water usage, means for communicating with said central processing unit by way of telephonic communication (to close or re-open said in-line conductive fluid shut-off valve), a battery back up system, and means of operating by way of manual means.

Owner:HASSENFLUG BRIAN EDWARD

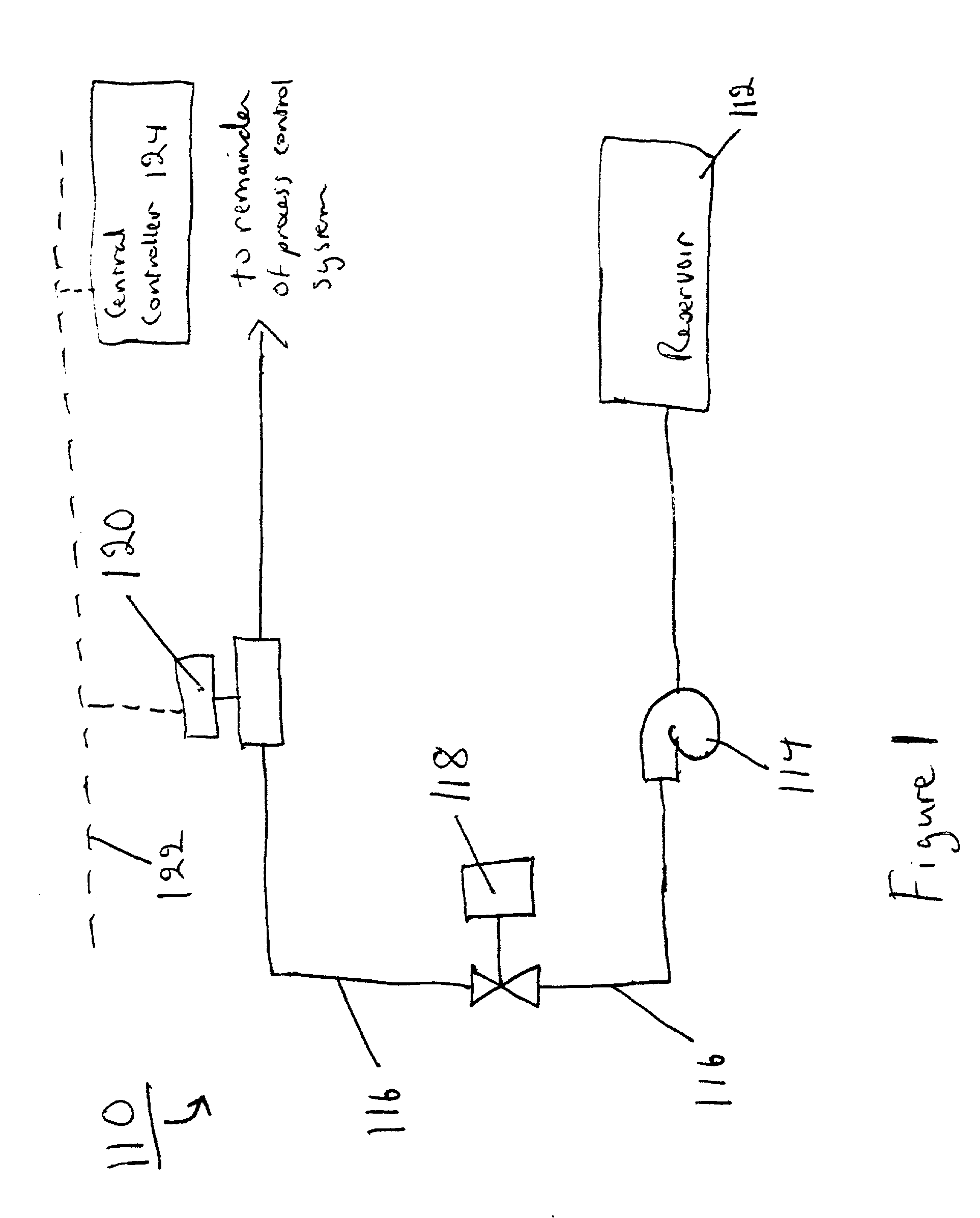

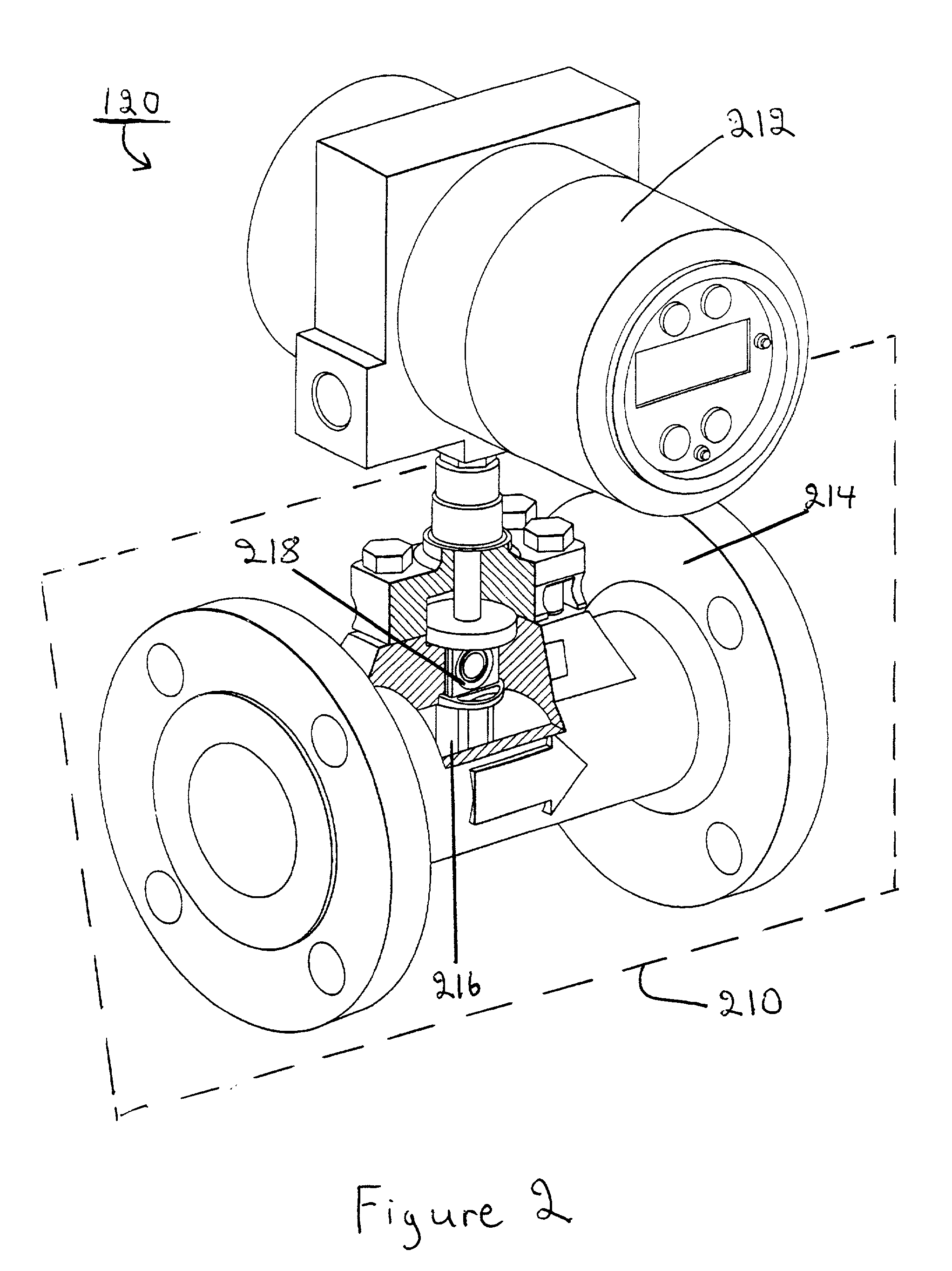

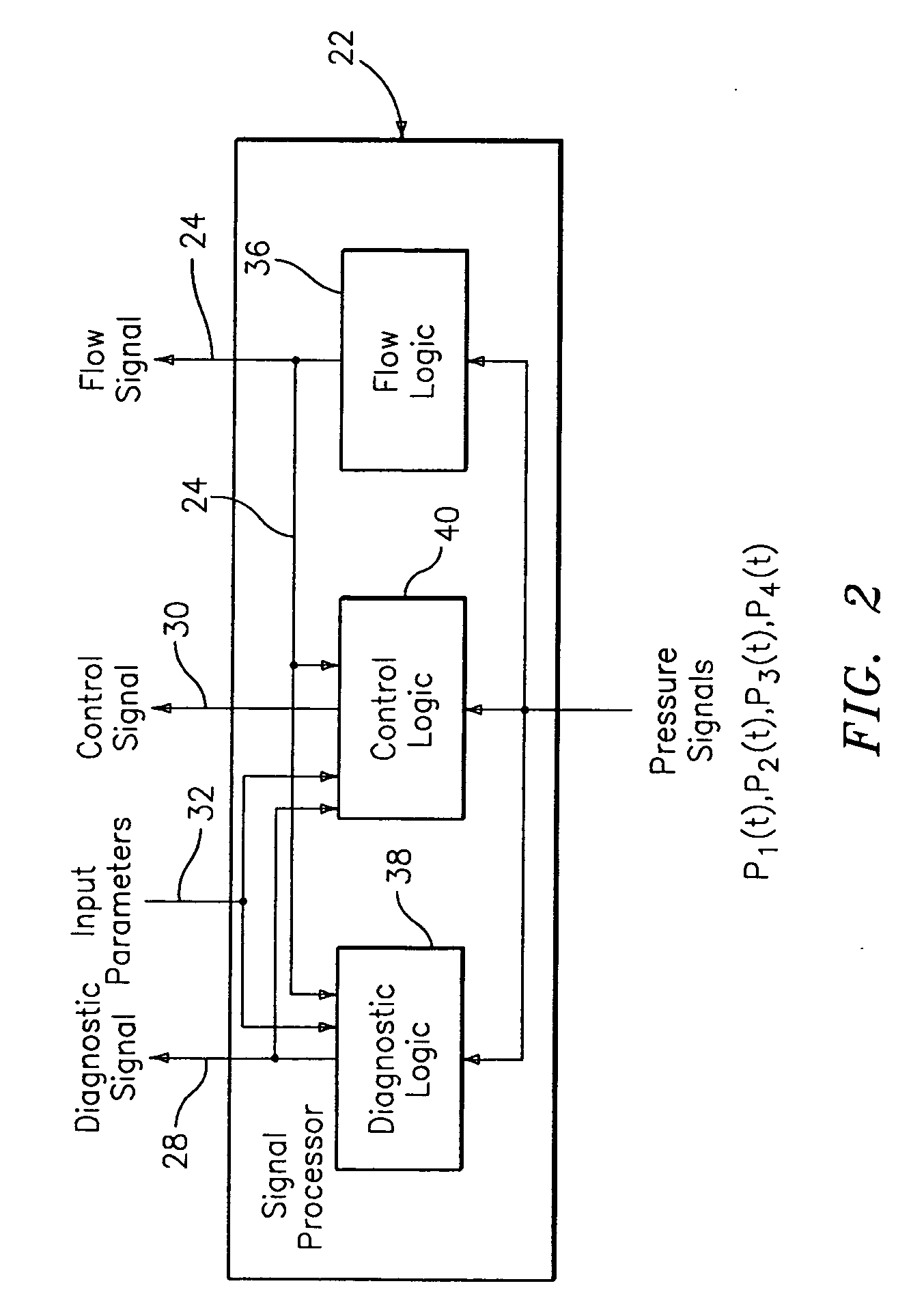

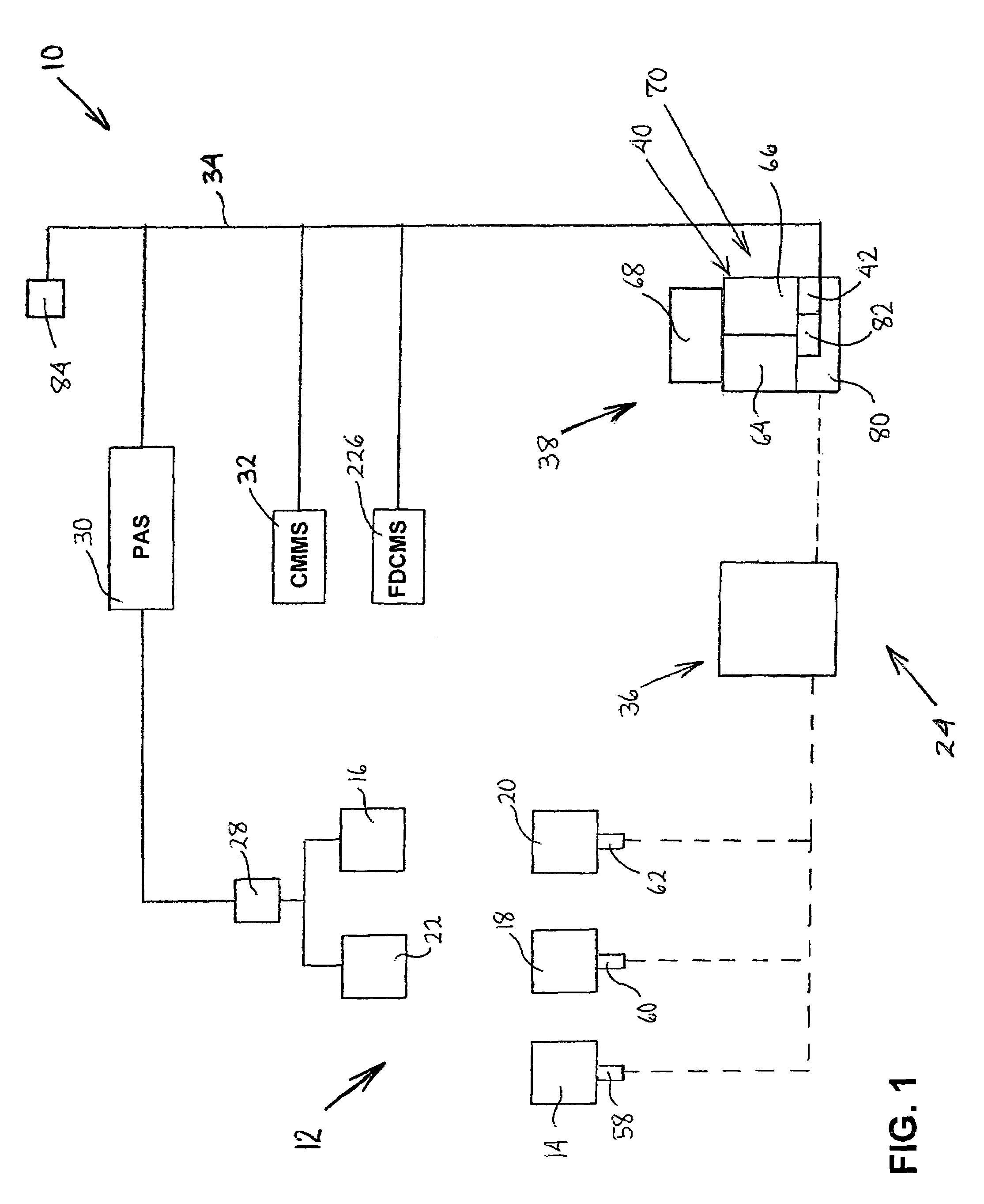

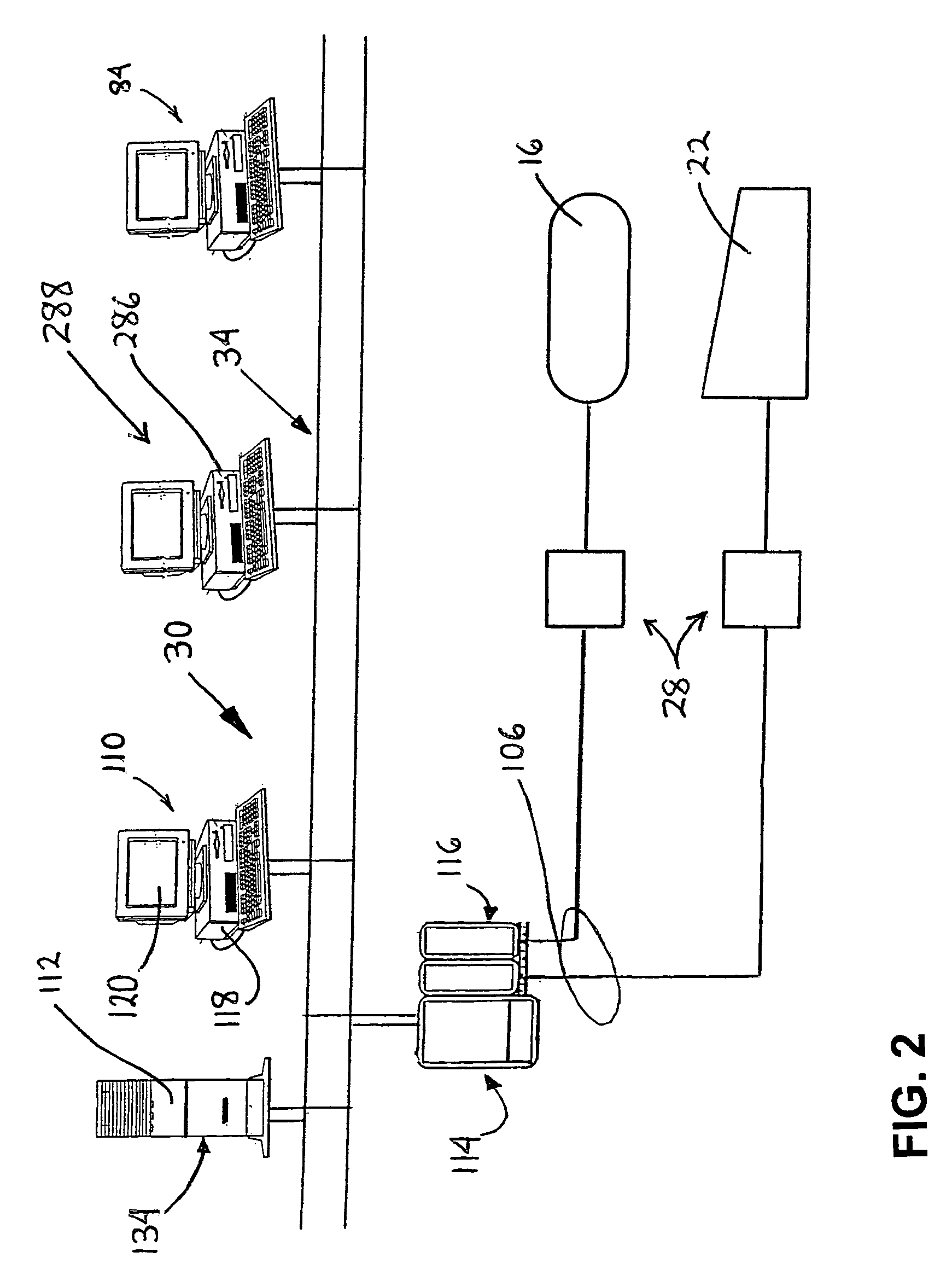

System and method for operating a flow process

ActiveUS20050005711A1Effective regulationTelemetry/telecontrol selection arrangementsTesting/calibration apparatusControl signalDistributed control system

A system for monitoring, diagnosing, and / or controlling a flow process uses one or more flow meters based on an array of pressure sensors. A signal processor outputs at least one of a flow signal, a diagnostic signal, and a control signal in response to the pressure signals from the pressure sensors. The flow signal indicates the at least one parameter of the fluid, the diagnostic signal indicates a diagnostic condition of a device in the flow process, and the control signal is effective in adjusting an operating parameter of at least one device in the flow process. The system may be arranged as a distributed control system (DCS) architecture for monitoring a plurality of flow meters based on array-processing installed at various locations throughout a flow process.

Owner:EXPRO METERS

Flow meter for measuring fluid mixtures

ActiveUS7293471B2Specific gravity by measuring pressure differencesMaterial analysis by electric/magnetic meansDifferential pressureLiquid hydrocarbons

Owner:ROXAR FLOW MEASUREMENT

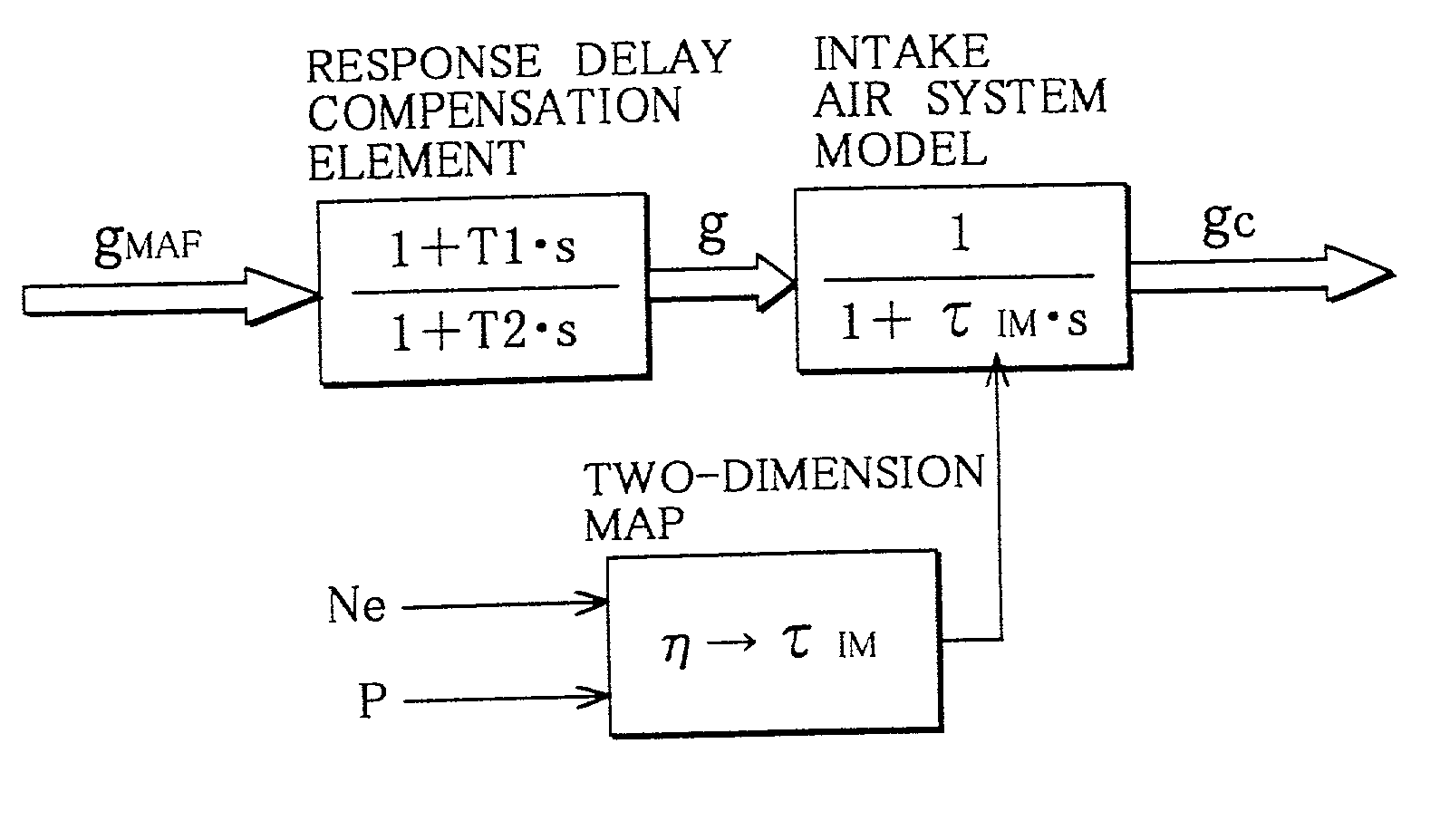

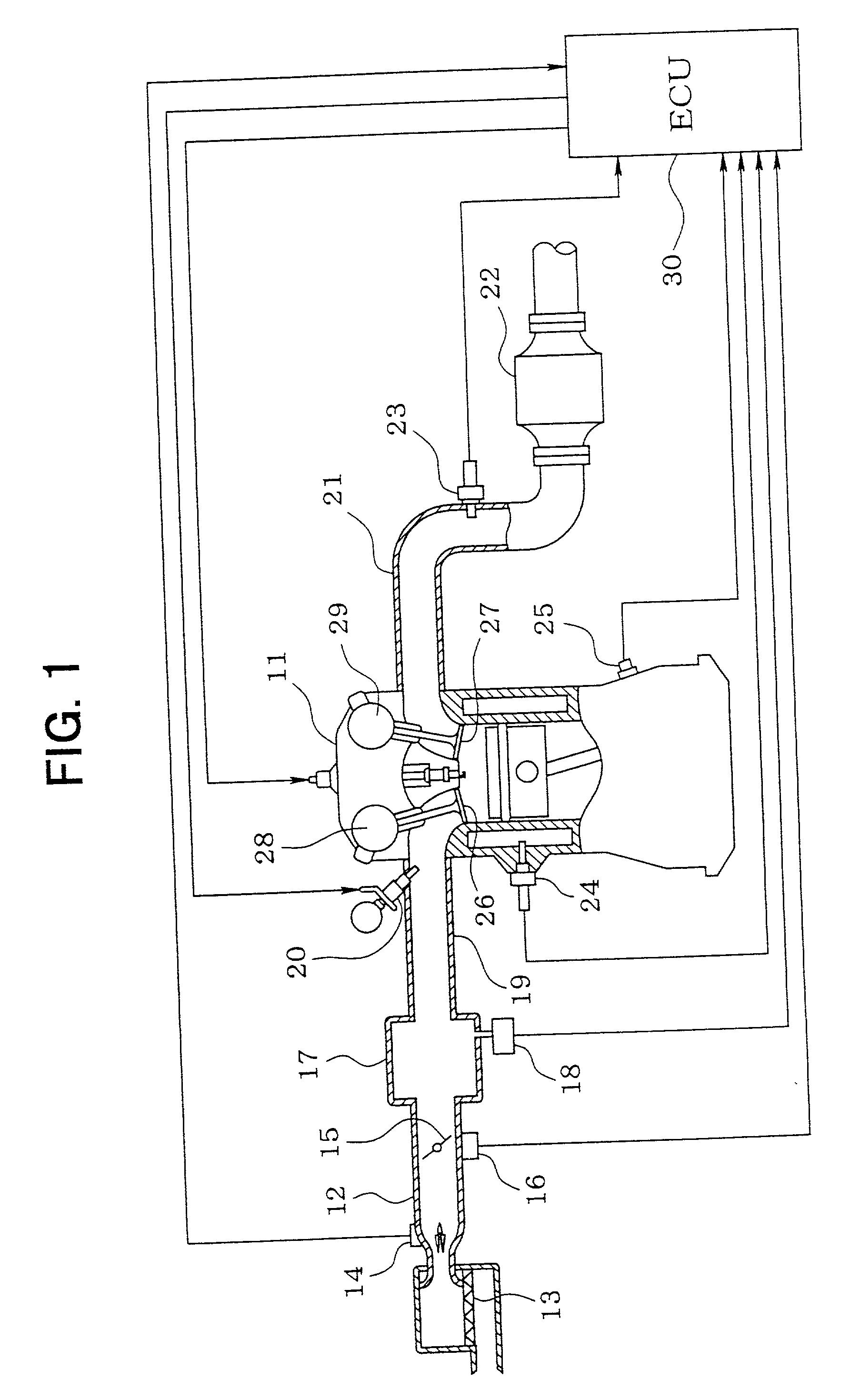

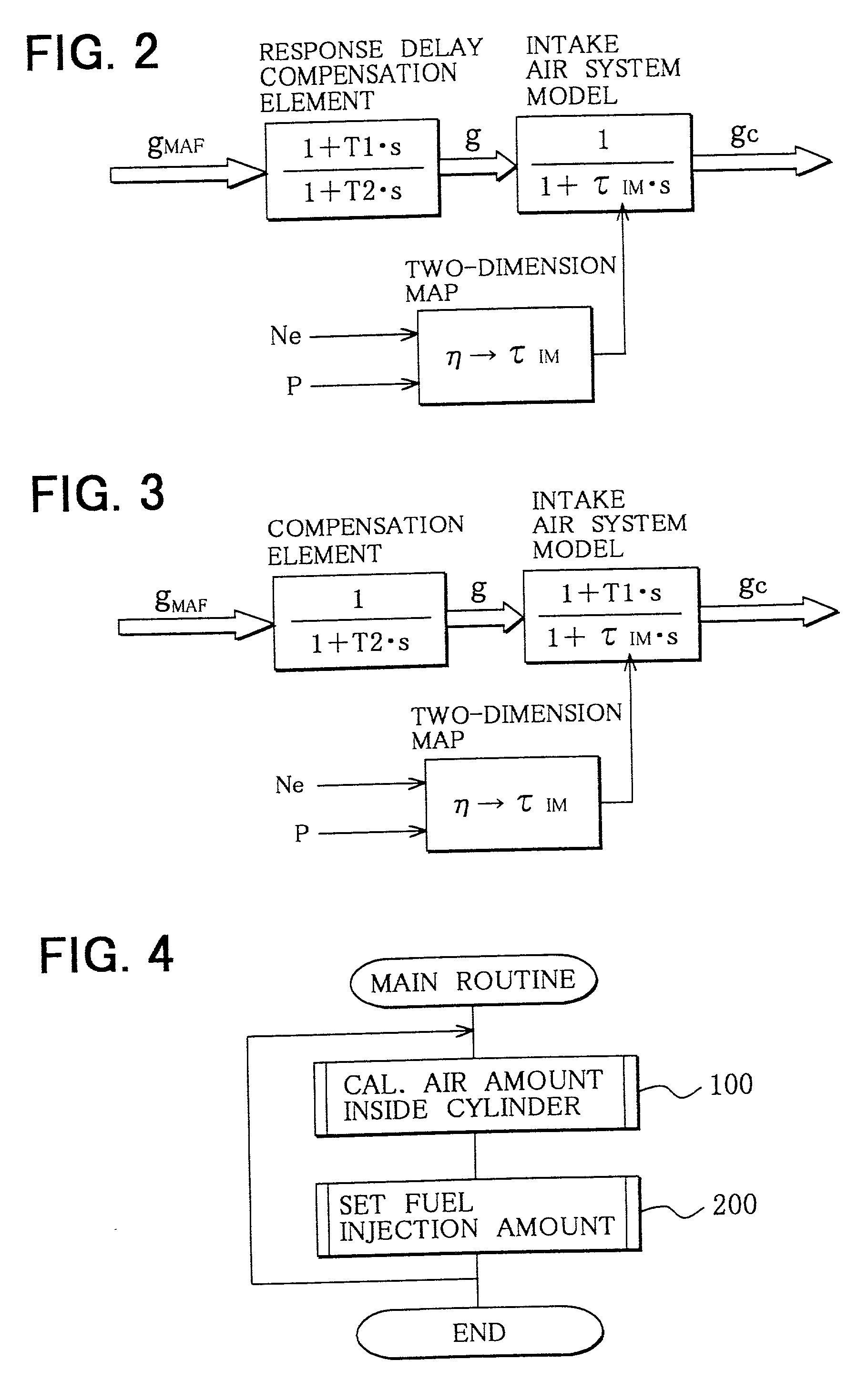

Air amount detector for internal combustion engine

InactiveUS20020107630A1Improve calculation accuracyAnalogue computers for vehiclesElectrical controlResponse delayPhase advance

A response delay compensation element for compensating a response delay of an output gMAF of an airflow meter by a phase advance compensation is provided so that an output g of the response delay compensation element is input to the intake air system model. A transfer function of the phase advance compensation is <paragraph lvl="0"><in-line-formula>g=(1+T1.s) / (1+T2s).gMAF< / in-line-formula>where T1 and T2 are time constant of the phase advance compensation, which is set based on at least one of the output gMAF of the airflow meter, engine speed, an intake air pressure, and a throttle angle. The model time constant τIM of the intake air system model is calculated by variables including volumetric efficiency and the engine speed. The volumetric efficiency is calculated by two-dimensional map having the engine speed and the intake air pressure as parameters thereof.

Owner:DENSO CORP

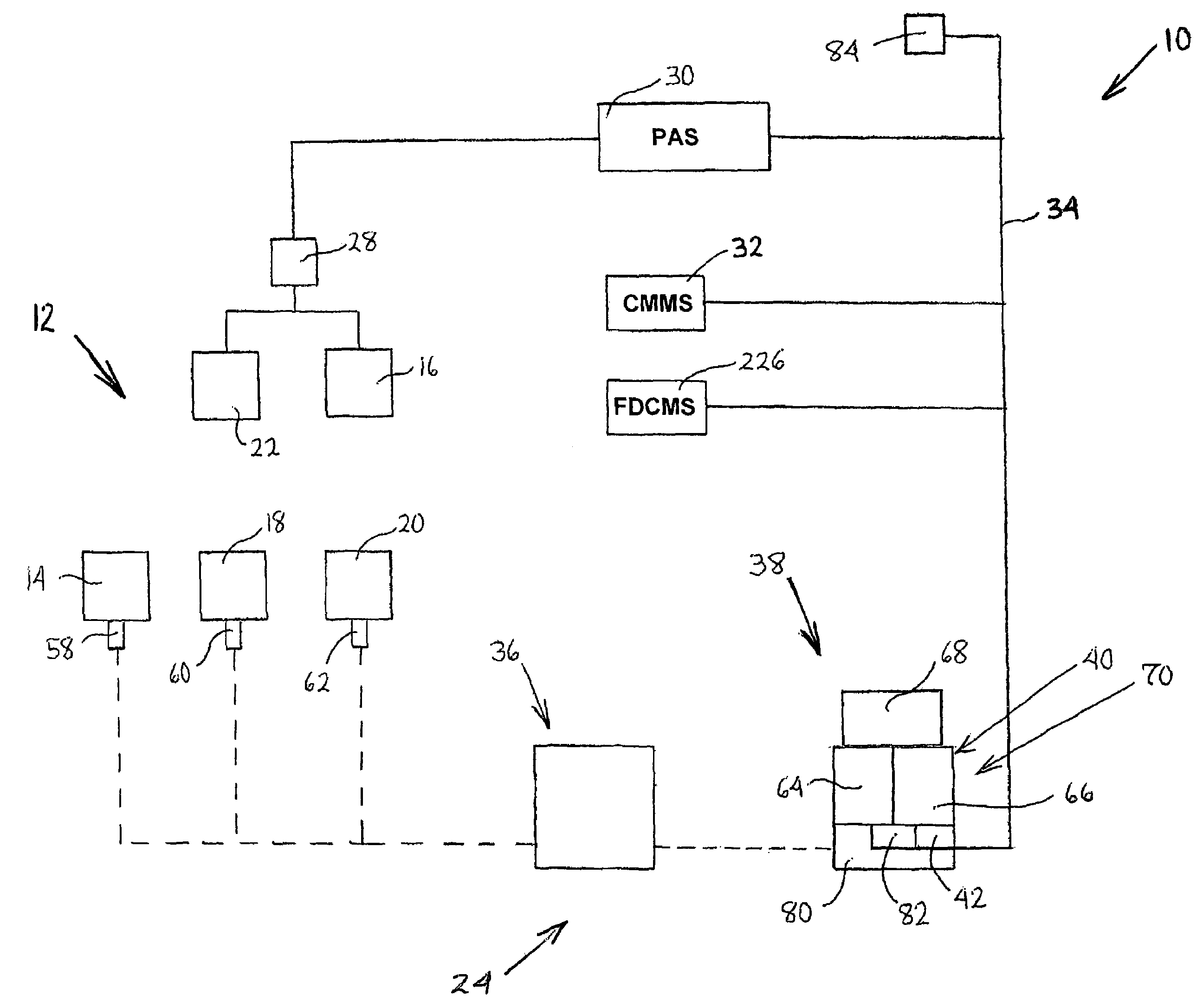

System and method for vibration monitoring

ActiveUS7283914B2Vibration measurement in solidsFlow propertiesComputerized maintenance management systemSoftware system

Owner:ABB (SCHWEIZ) AG

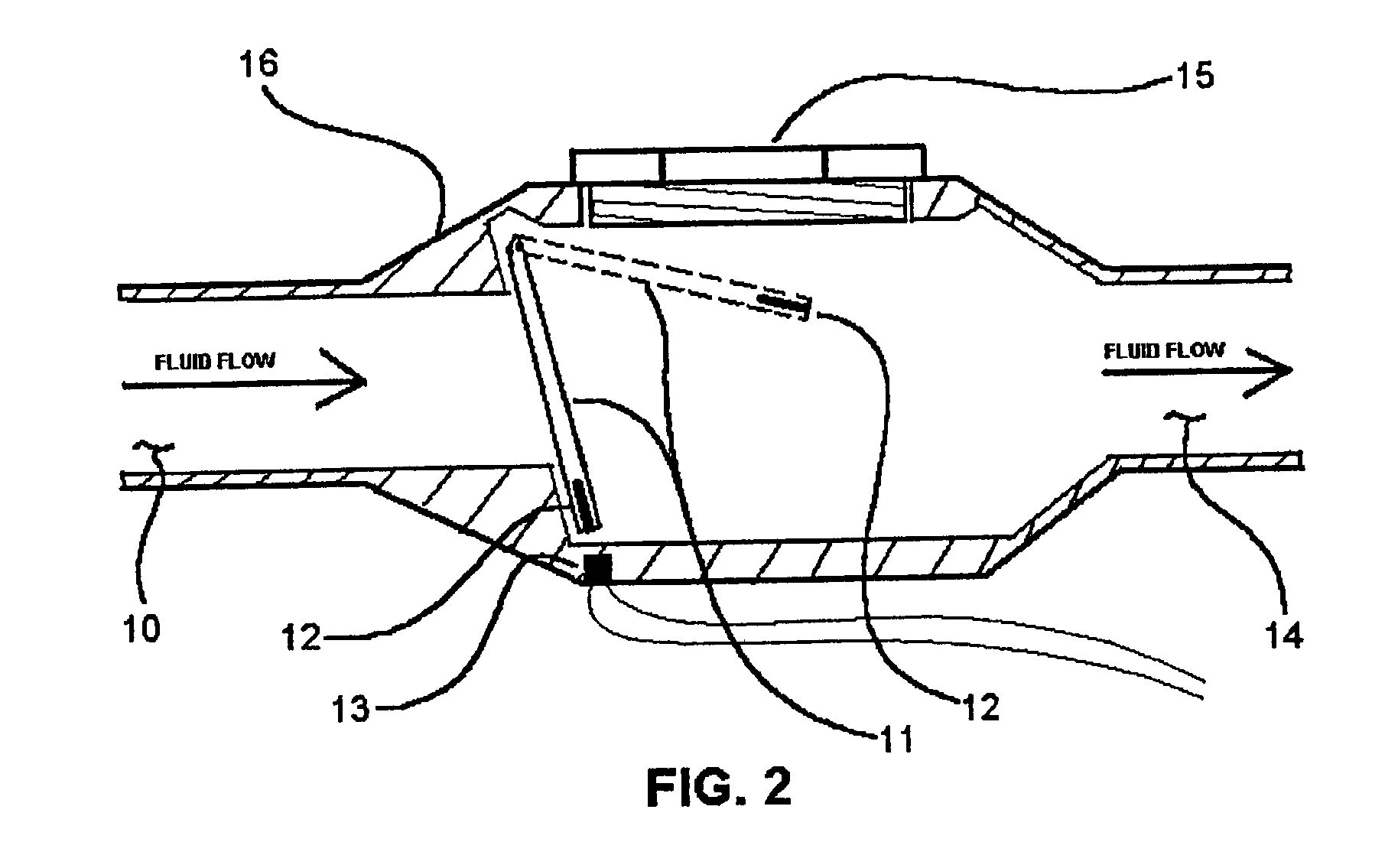

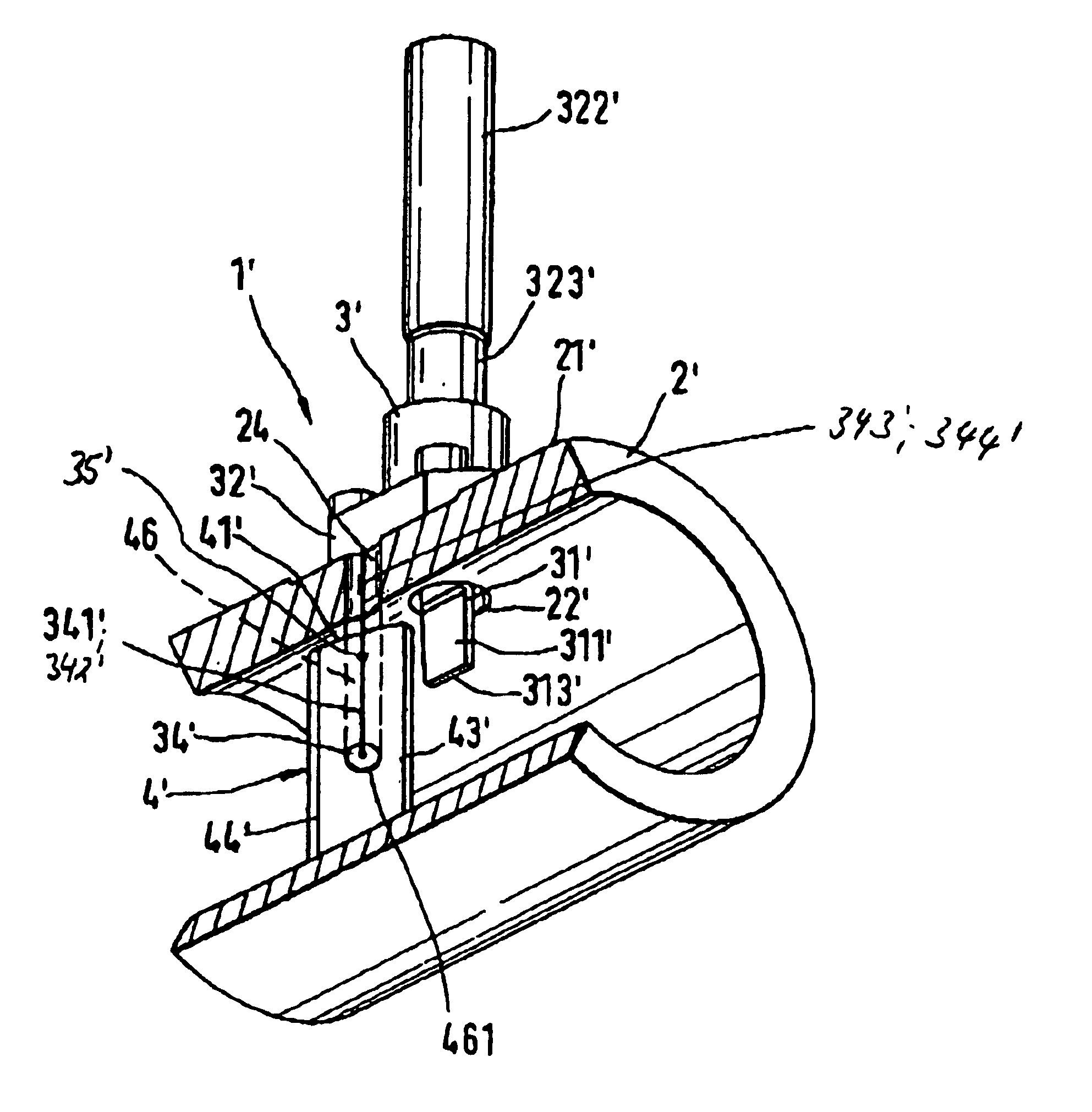

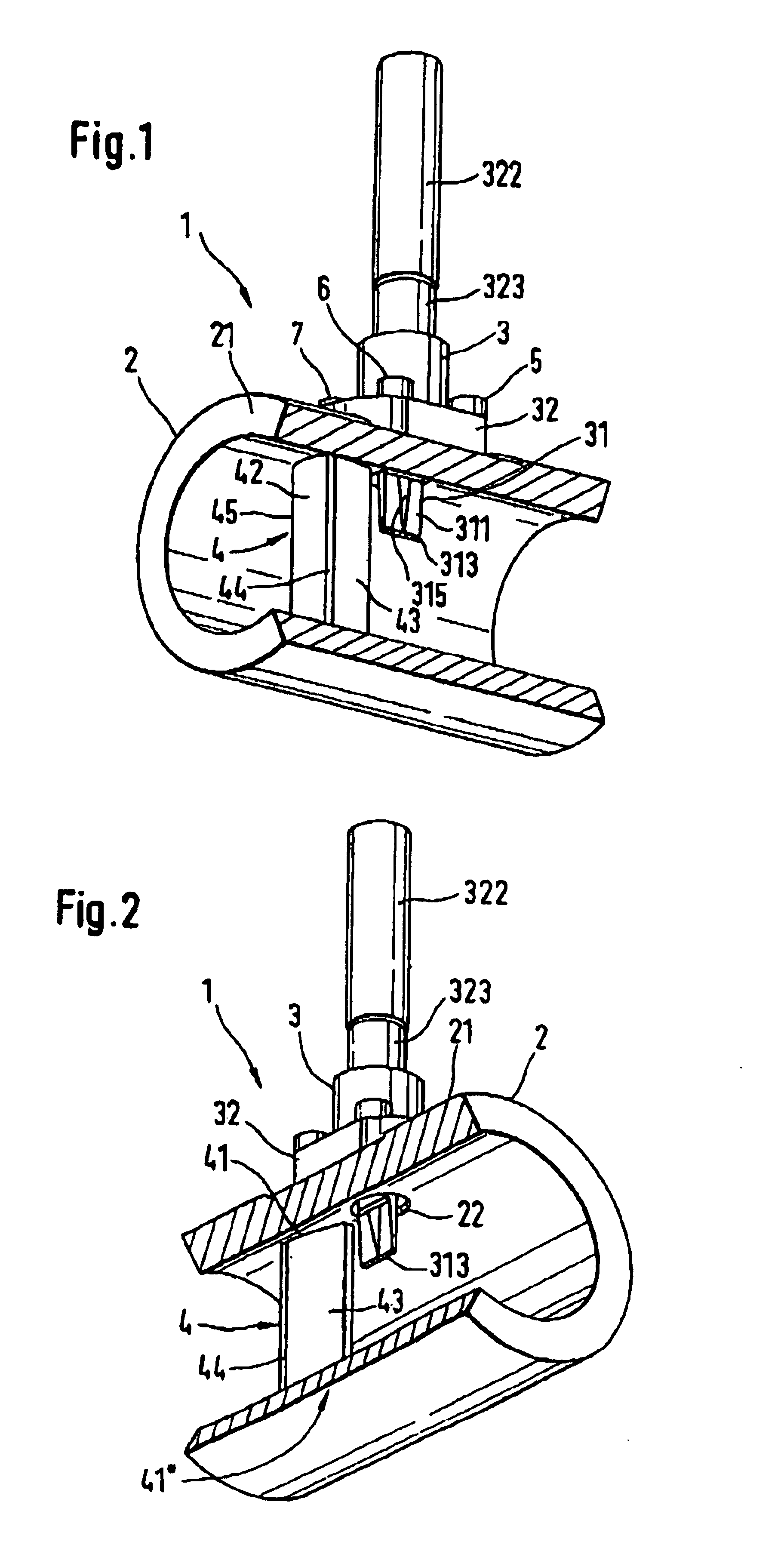

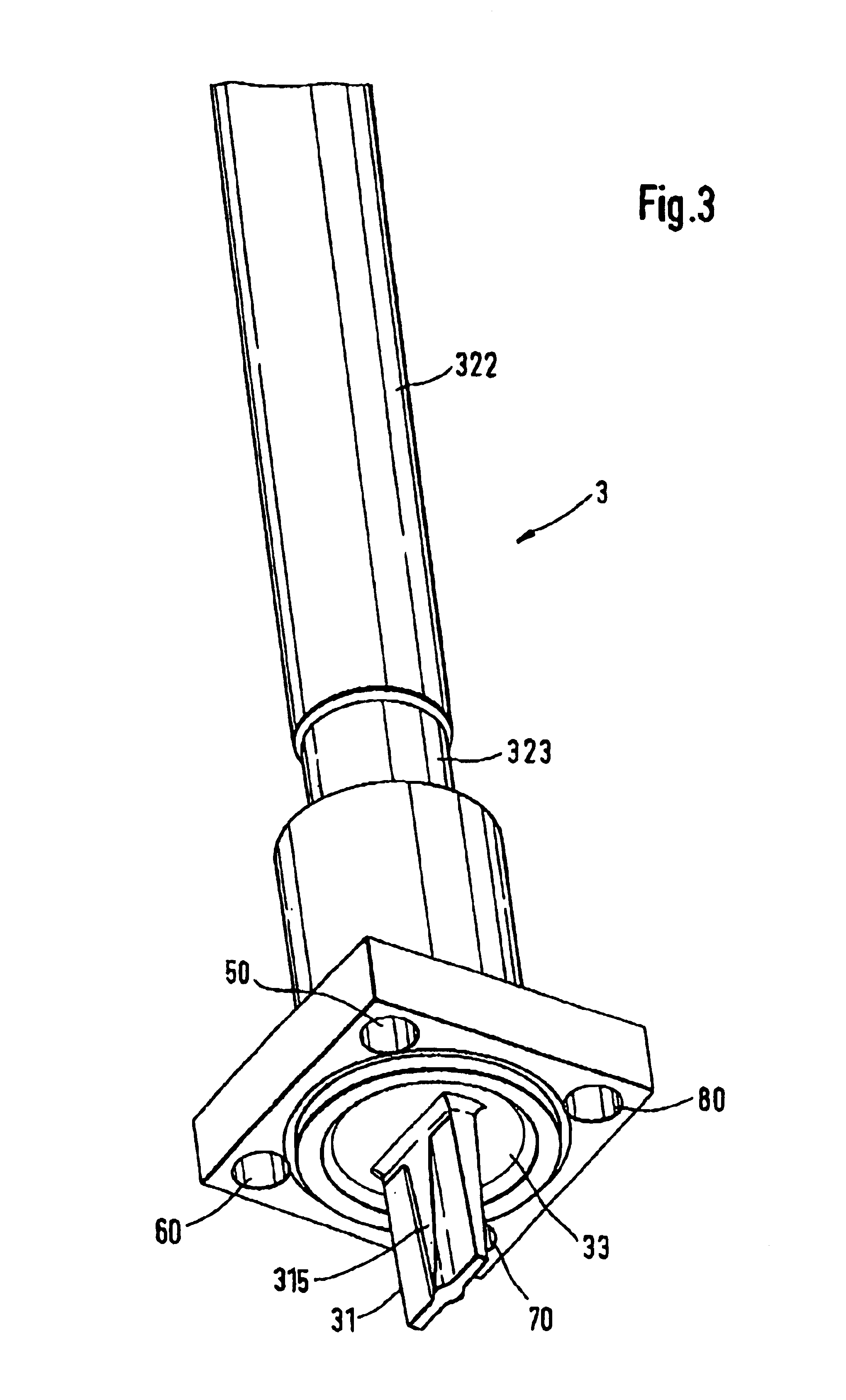

Vortex flow sensor for measuring fluid flow through a flow tube

InactiveUS6910387B2Improve thermal conductivityEasy to measureVolume/mass flow by dynamic fluid flow effectIndirect mass flowmetersTwo temperatureEngineering

The vortex flow sensor is designed to measure the mass flow rate, the volumetric flow rate, or the flow velocity of a fluid flowing in a flow tube having a tube wall, and has two temperature sensors arranged in such a way that the vortex flow sensor may also be used with fluids which would corrode the temperature sensors. A bluff body in the flow tube sheds vortices and thus causes pressure fluctuations. A vortex sensor device responsive thereto is fitted downstream of the bluff body in a hole provided in the wall of the flow tube. The vortex sensor device comprises a sensor vane extending into the fluid. The temperature sensors are disposed in a blind hole of the sensor vane. Alternatively, the temperature sensor may be disposed in blind hole of the bluff body.

Owner:ENDRESS HAUSER FLOWTEC AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com