Patents

Literature

776 results about "Discharge measurements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Discharge is the volume of water moving down a stream or river per unit of time, commonly expressed in cubic feet per second or gallons per day. In general, river discharge is computed by multiplying the area of water in a channel cross section by the average velocity of the water in that cross section:

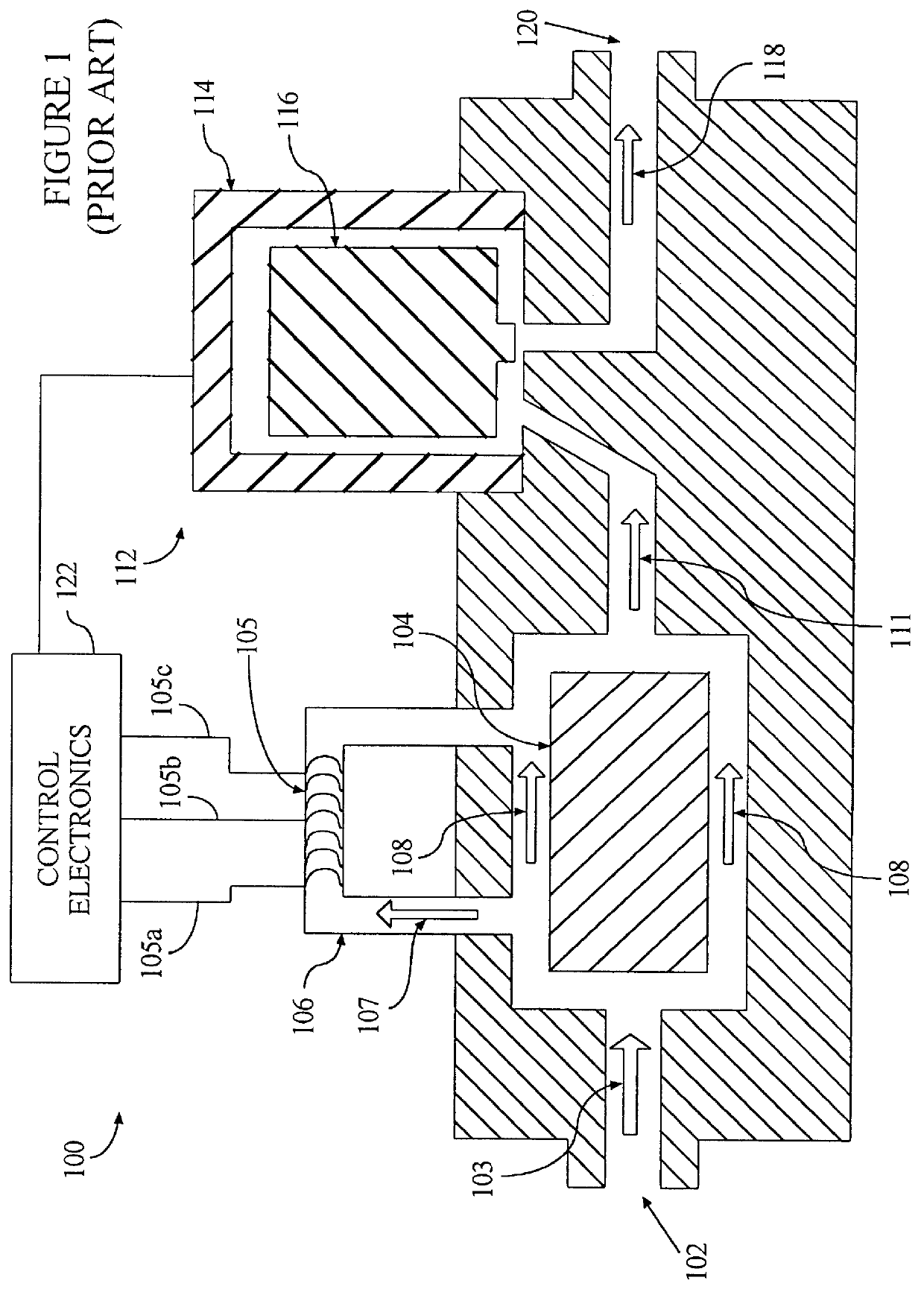

Method for wide range gas flow system with real time flow measurement and correction

InactiveUS6119710AAccurate measurementAccurate flowOperating means/releasing devices for valvesVolume/mass flow by thermal effectsDifferential pressureInlet valve

A gas delivery system accurately measures and optionally regulates mass flow rate in real time. A fluid conduit connects an inlet valve, calibration volume, flow restrictor, and outlet valve in series. Pressure and temperature sensors are coupled to the calibration volume. One or more pressure sensors may be attached across the flow restrictor. Alternatively, an absolute pressure sensor may be attached upstream of the flow restrictor. One embodiment of differential pressure sensors comprises a floating reference differential pressure sensor, including a first transducer attached to the fluid conduit upstream of the flow restrictor and a second transducer attached to the conduit downstream of the flow restrictor. In this embodiment, each transducer receives a reference pressure from a reference source, and optionally, after the calibration volume is charged, the floating reference differential pressure transducers are calibrated. When gas flow is initiated, differential and / or absolute pressure measurements are repeatedly taken, and a measured mass flow rate calculated thereon. Gas flow is adjusted until the measured mass flow rate reaches a target mass flow. Using the temperature / pressure sensors at the calibration volume, repeated calculations of actual flow rate are made to uncover any discrepancy between actual and measured mass flow rates. Whenever a discrepancy is found, the manner of calculating measured mass flow is conditioned to account for the discrepancy; thus, the measured mass flow rate more accurately represents the actual mass flow rate thereby providing an actual mass flow rate more accurately achieving the target mass flow rate.

Owner:CYBER INSTR TECH LLC AN ARIZONA LIMITED LIABILITY +1

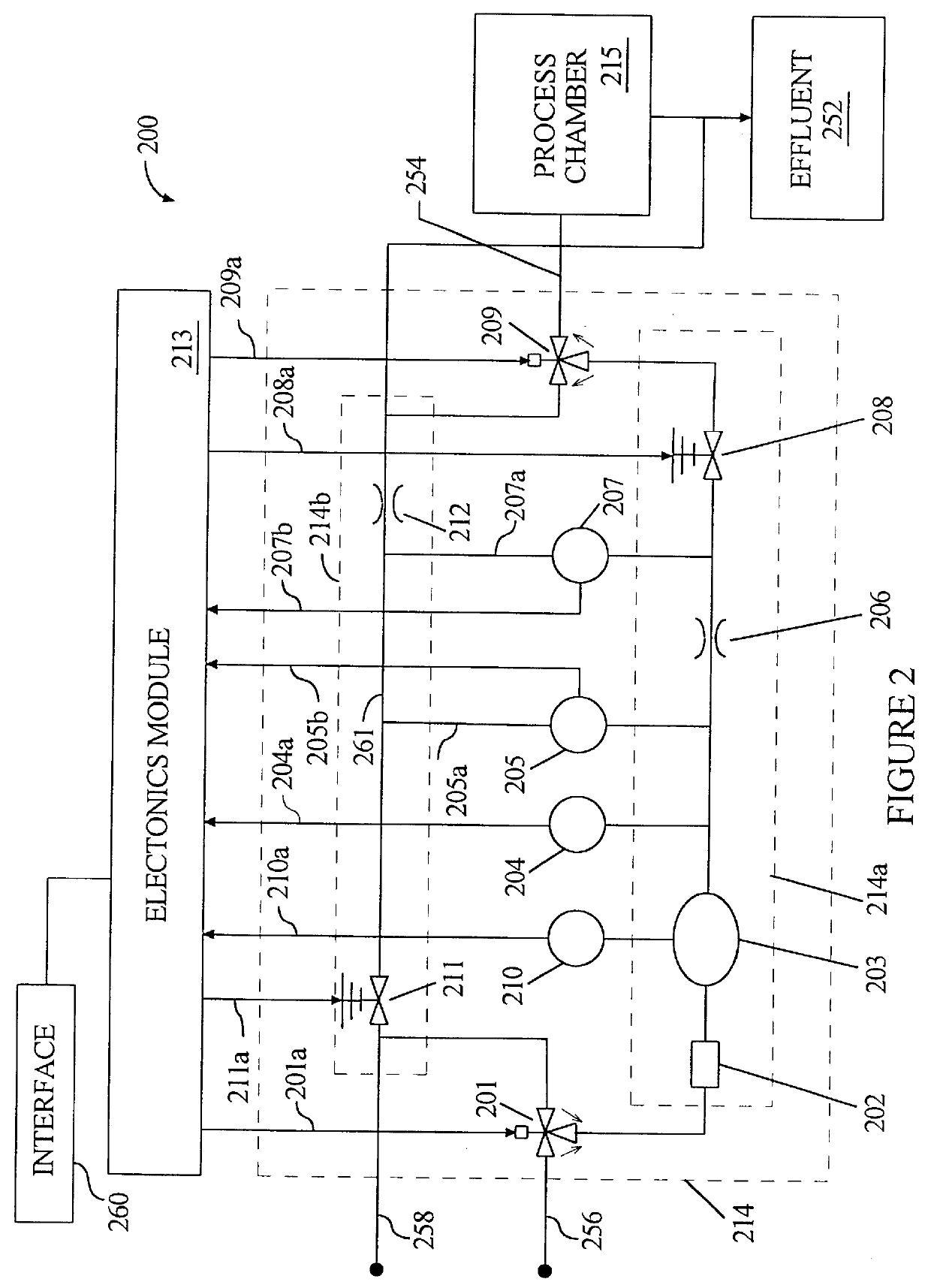

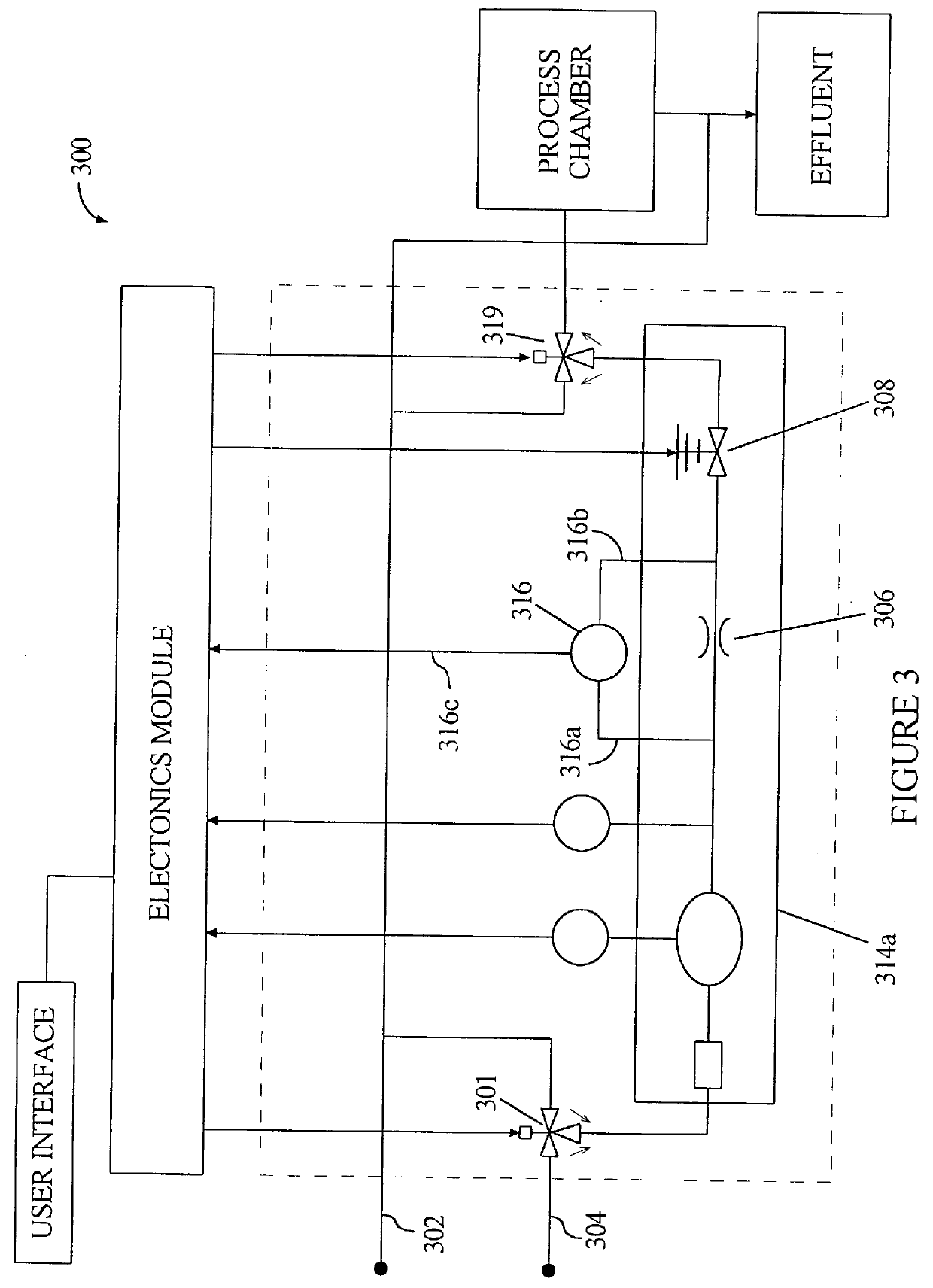

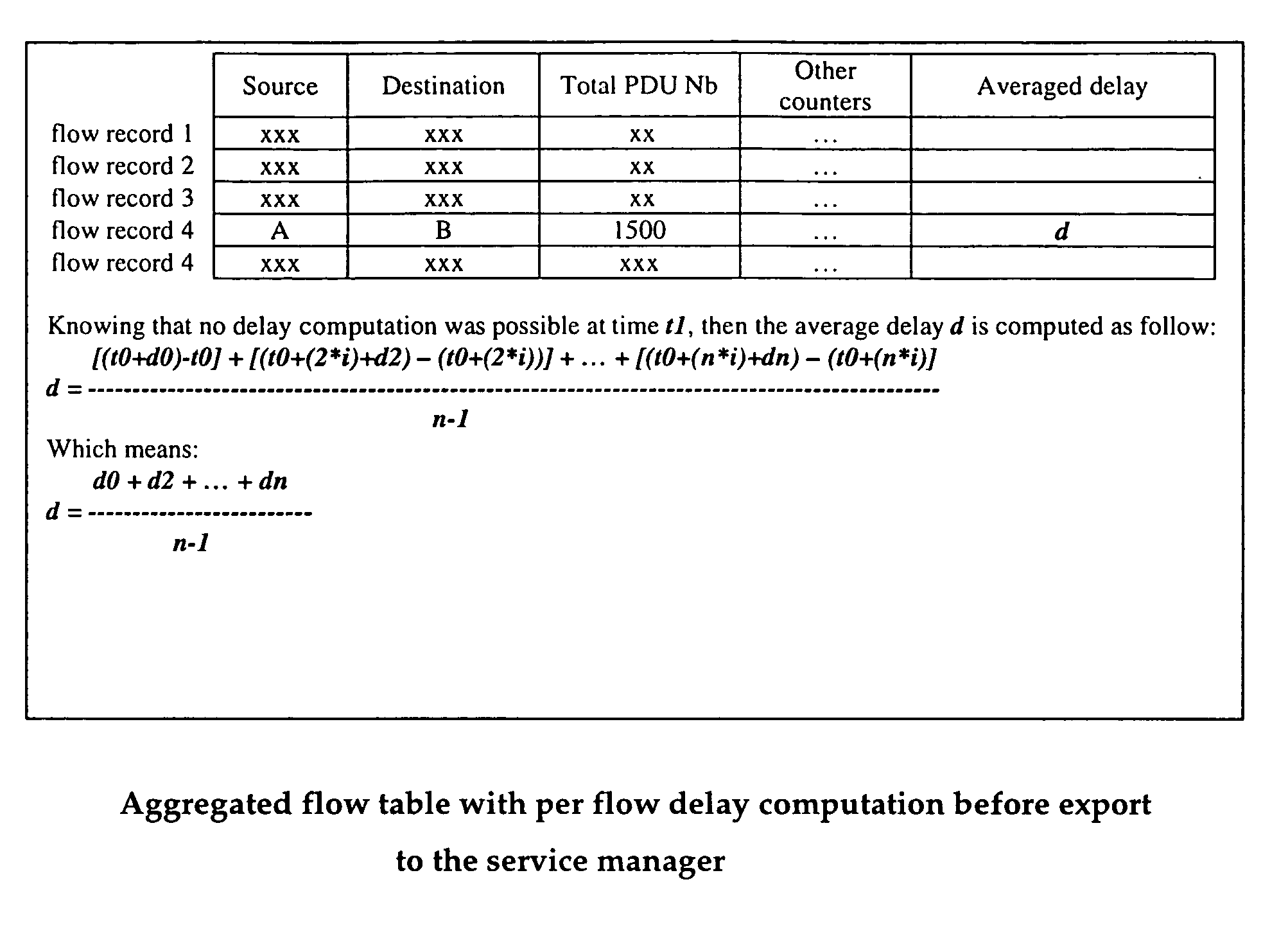

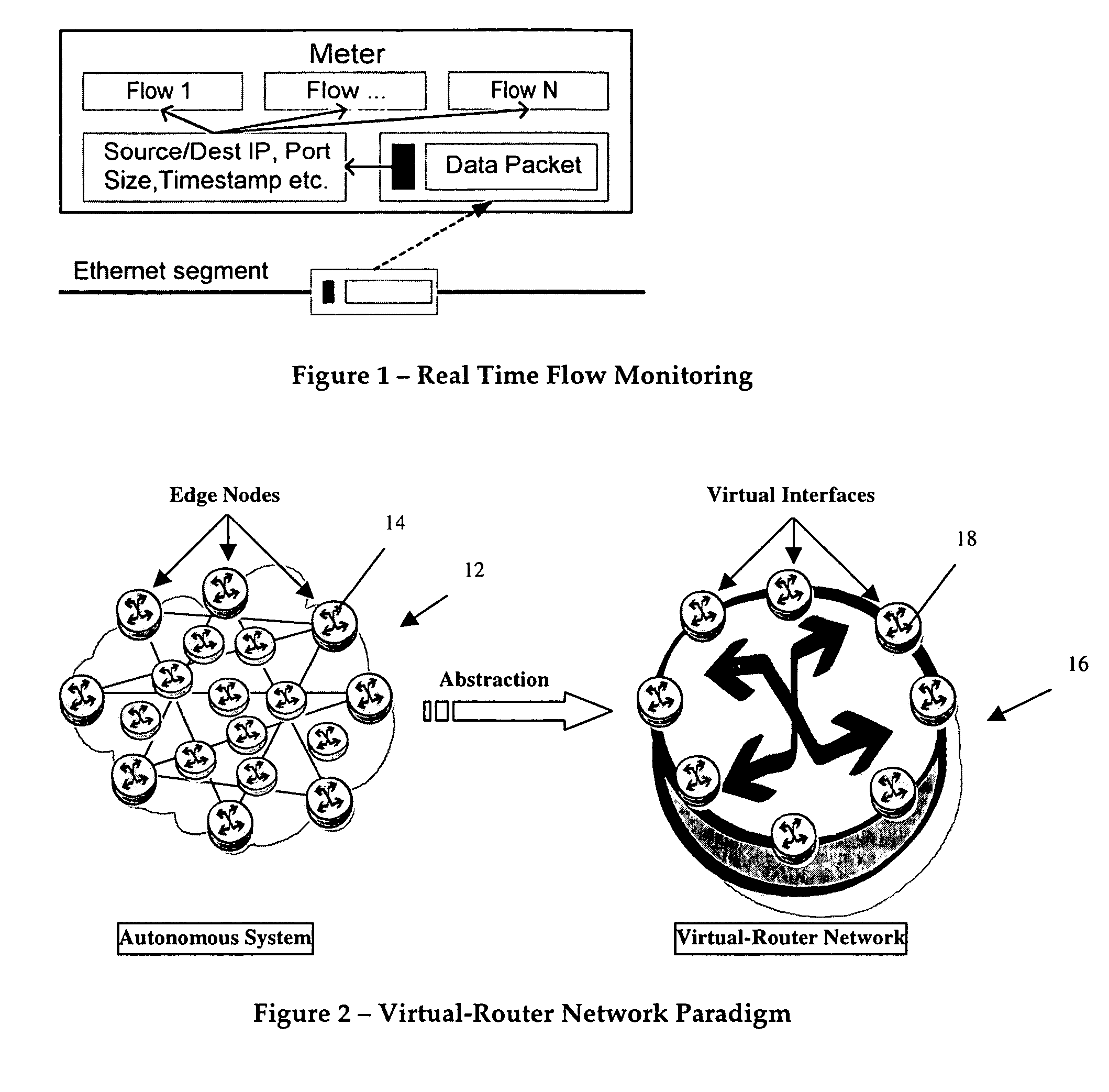

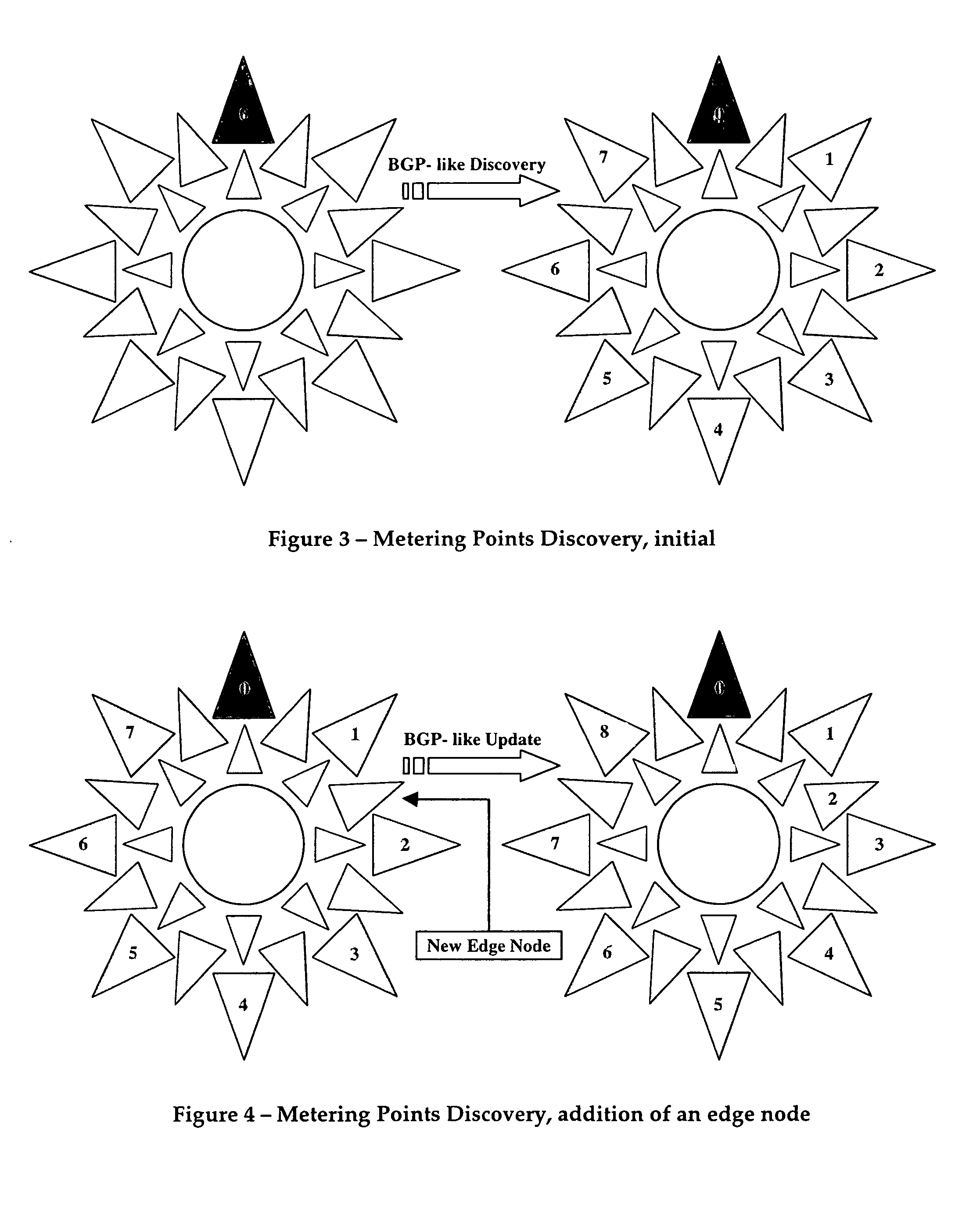

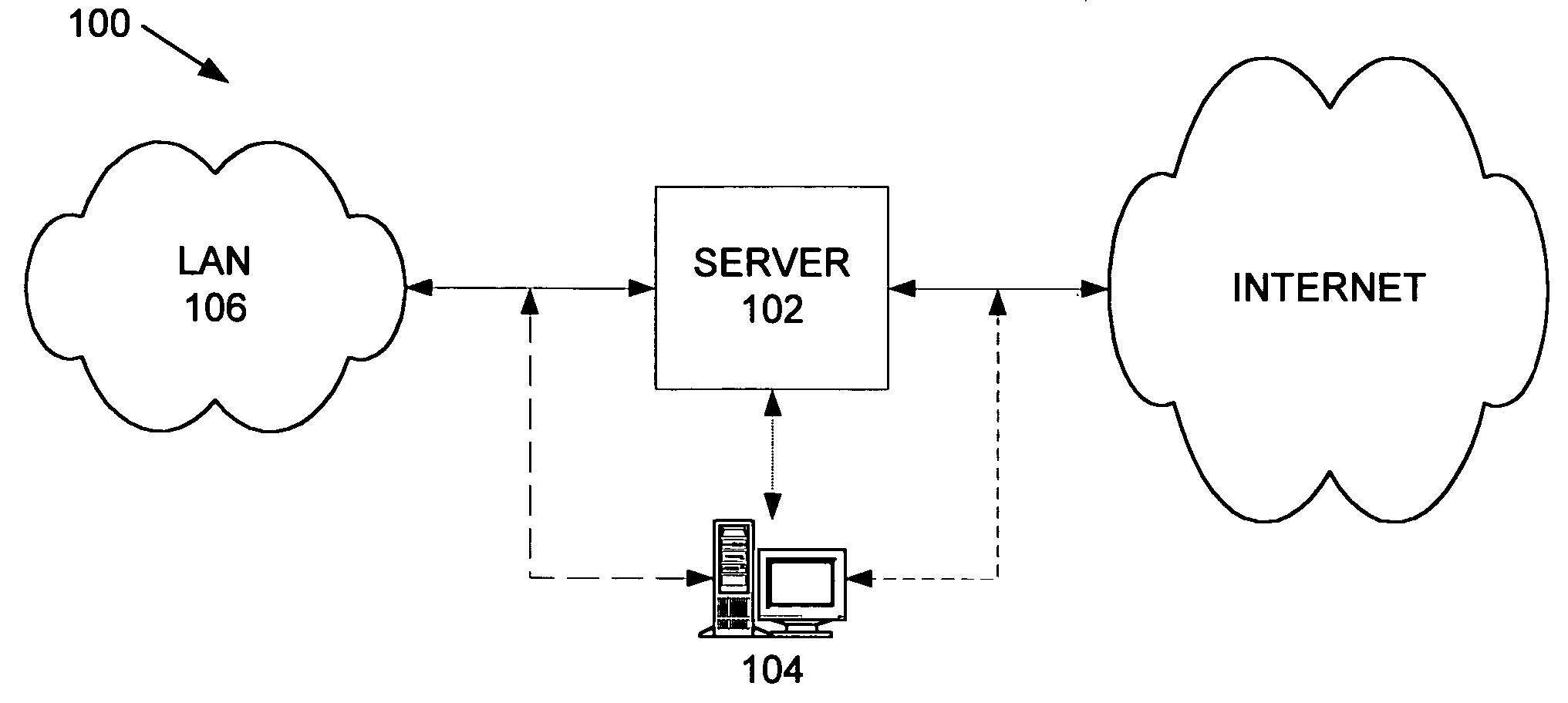

Distributed architecture for real-time flow measurement at the network domain level

ActiveUS8095640B2Energy efficient ICTDigital computer detailsCommunications systemRelevant information

A virtual router network (VRN) for performing real-time flow measurements (RTFM) is provided. The VRN effectively reduces the number of traffic metering points required thereby simplifying the aggregation and exportation of flow records to a collector. The collector may be service manager in a network management system. The metering points, in a preferred embodiment, are at virtual interfaces (VI) which are edge nodes in VRN. One of the virtual interfaces is selected as a master virtual interface and act as a collector and distributor of flow related information. In one aspect of the invention the VRN is used to provide, non-invasively, per-flow delay monitoring in a communication system.

Owner:ALCATEL LUCENT SAS

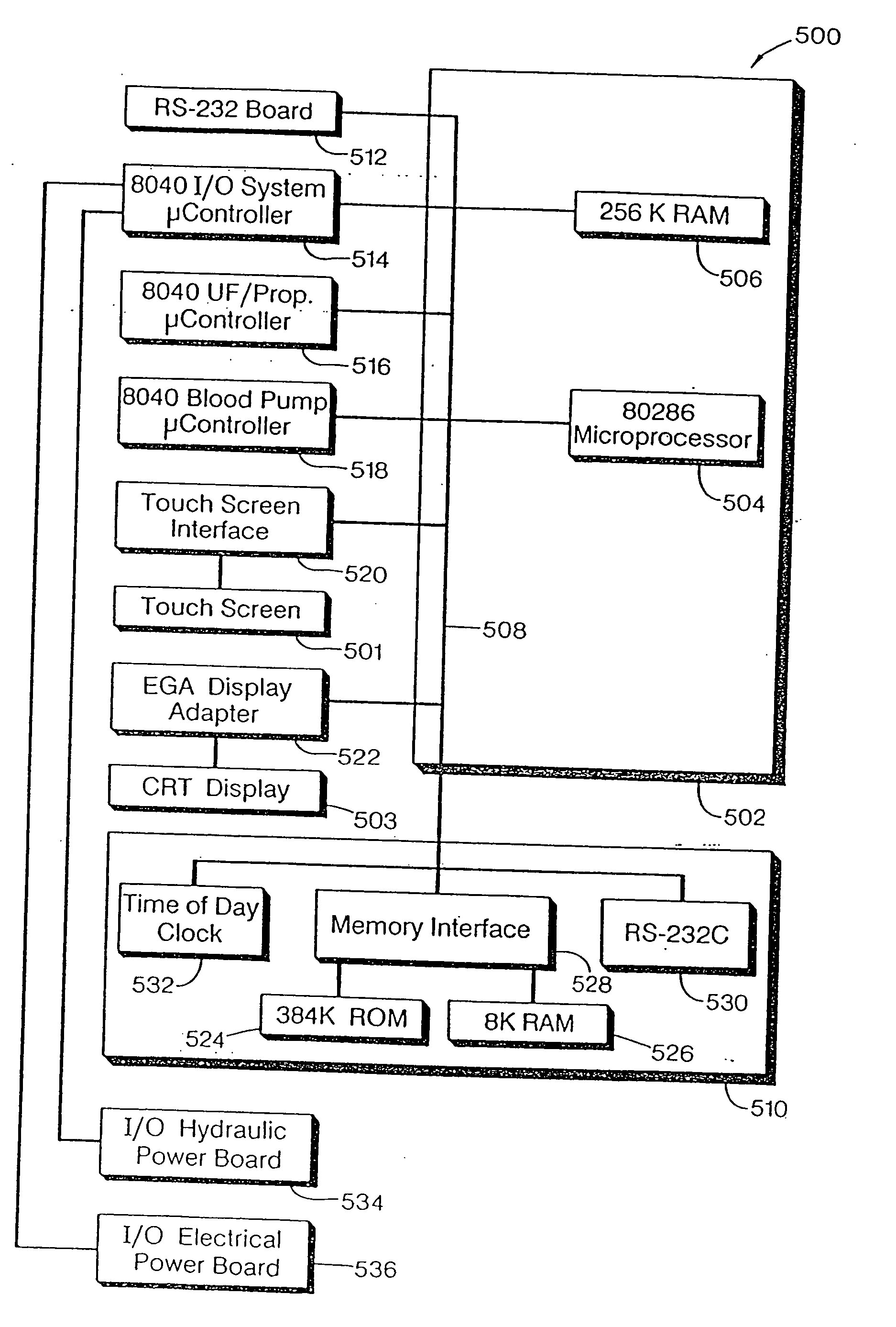

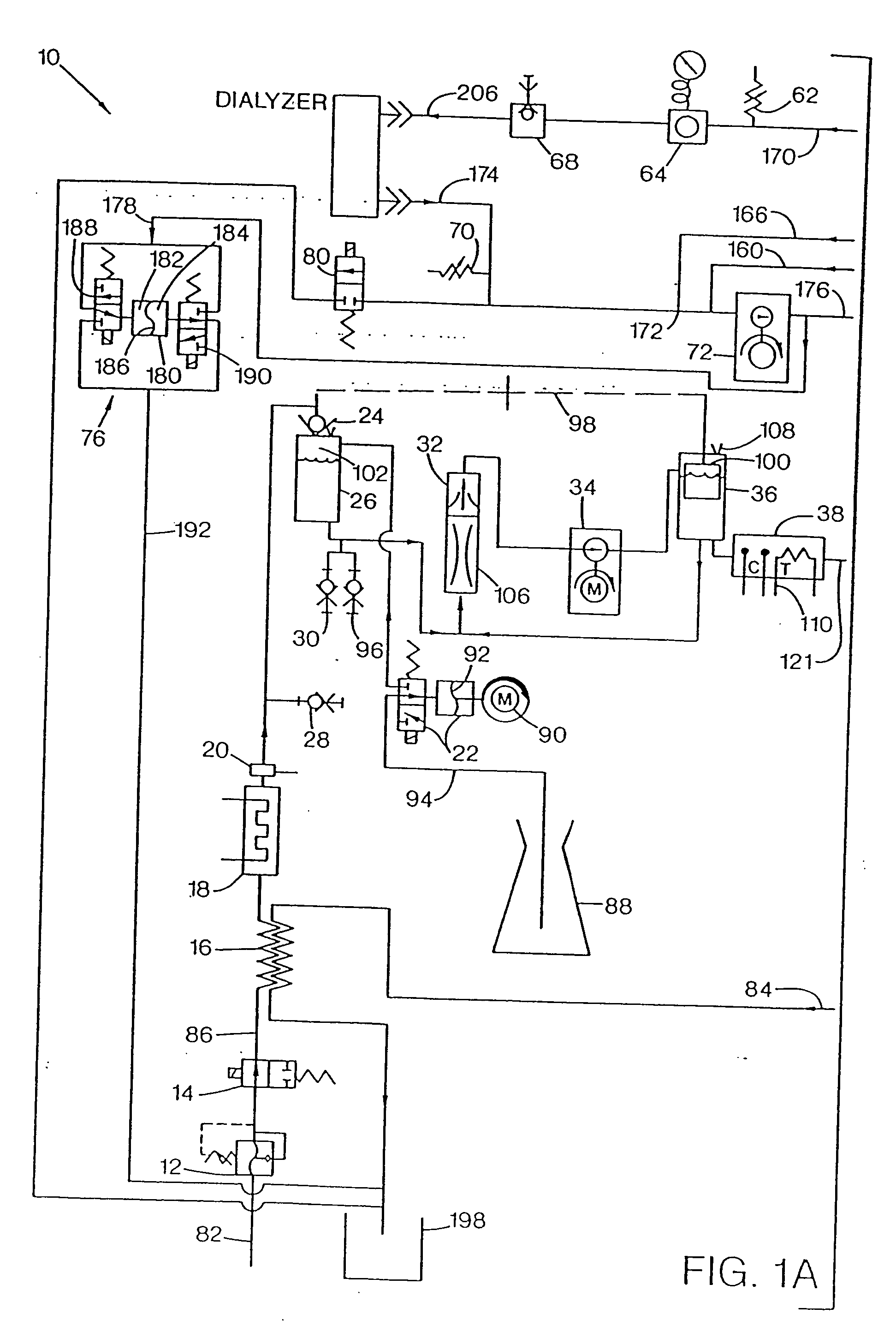

Method and apparatus for kidney dialysis

InactiveUS20050242034A1Mechanical/radiation/invasive therapiesOther blood circulation devicesUltrafiltrationDischarge measurements

Owner:BAXTER INT INC

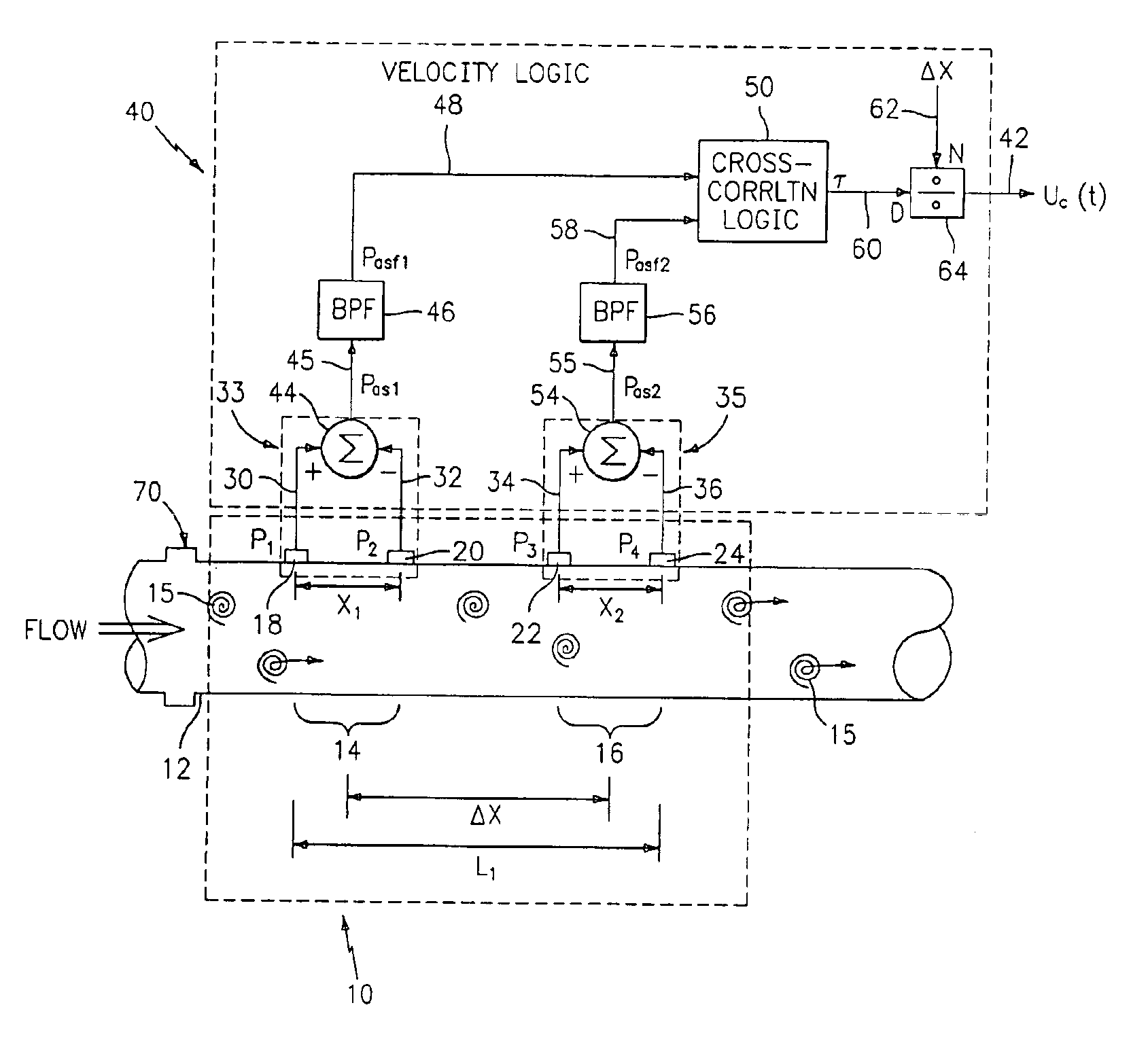

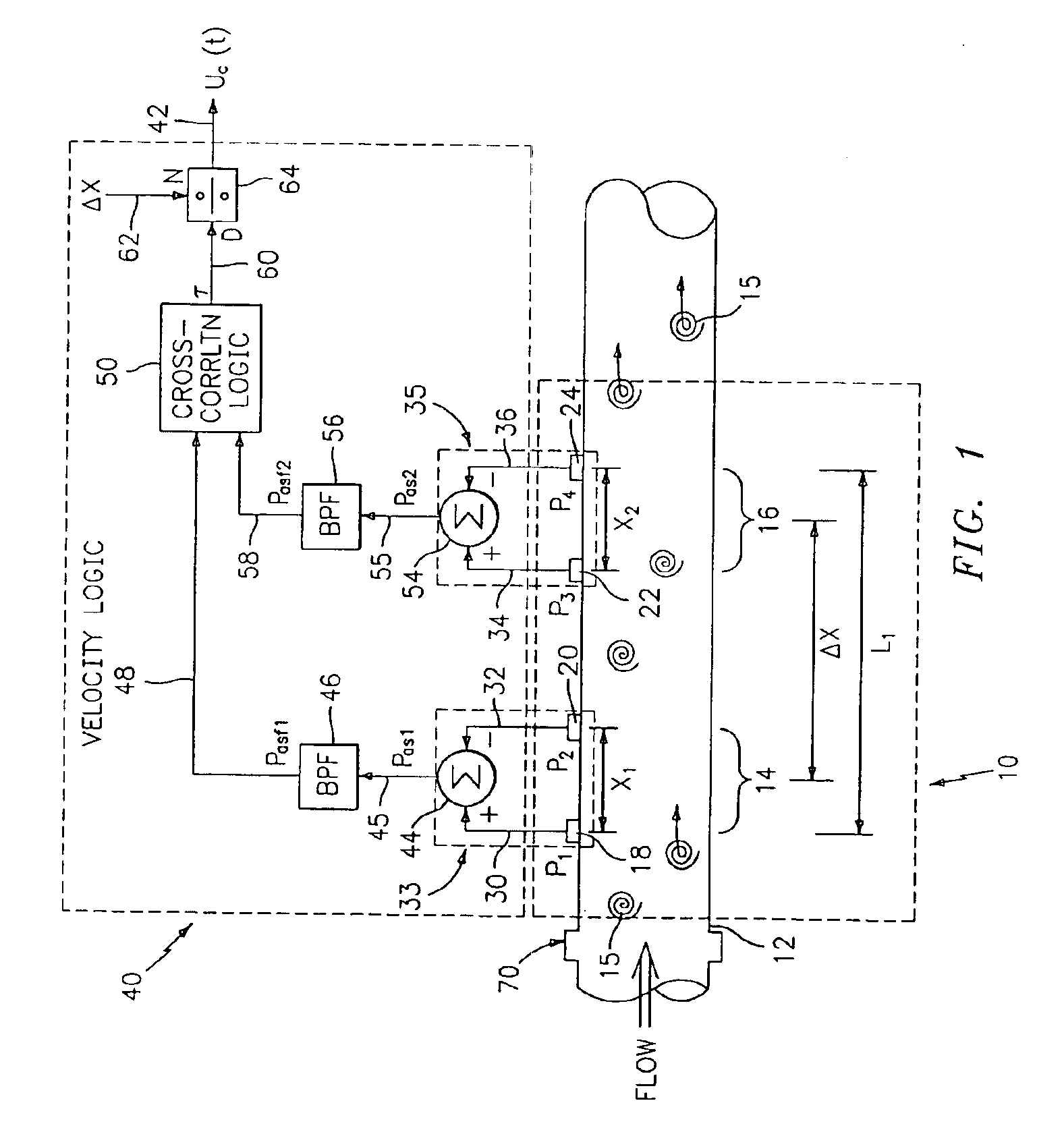

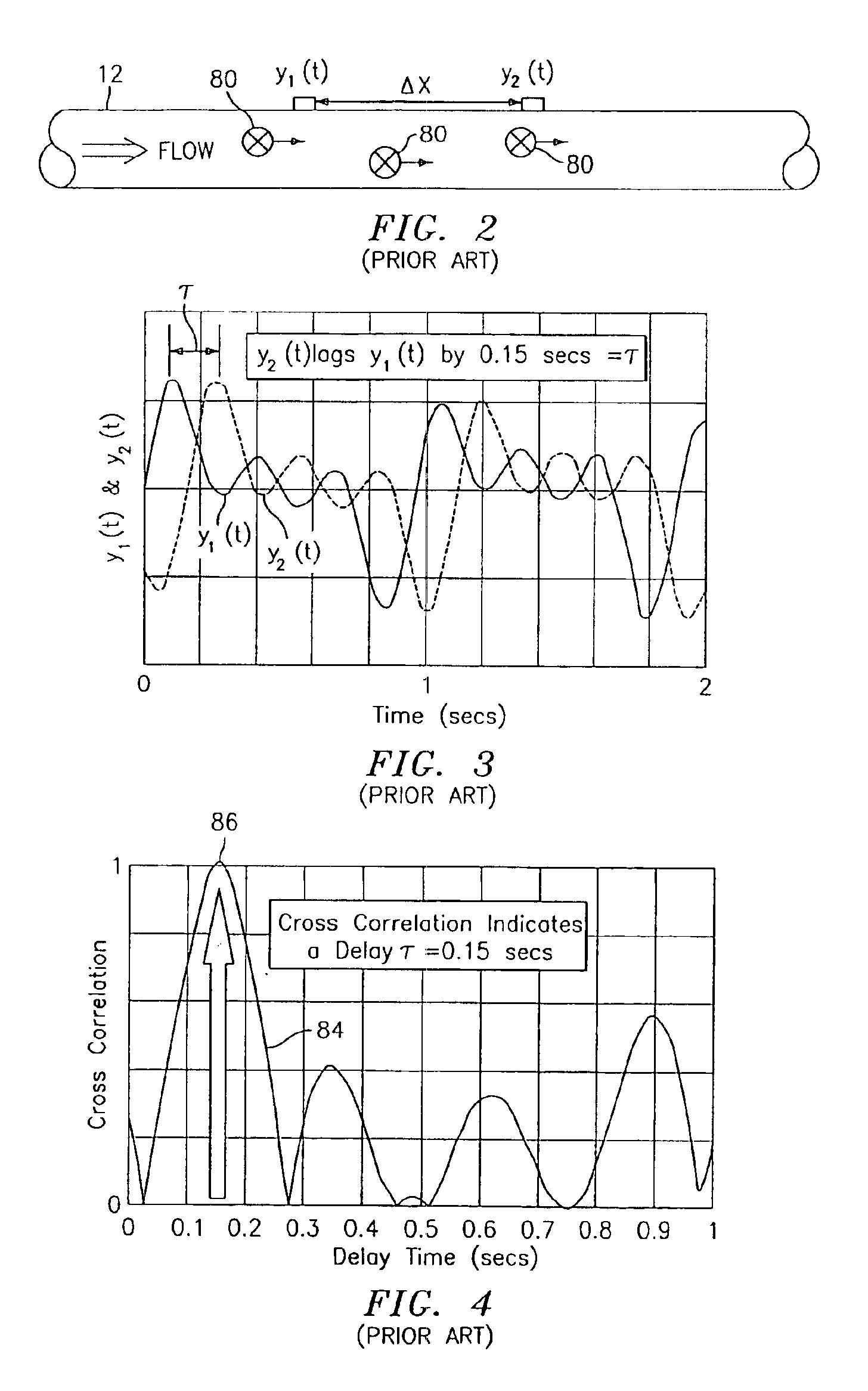

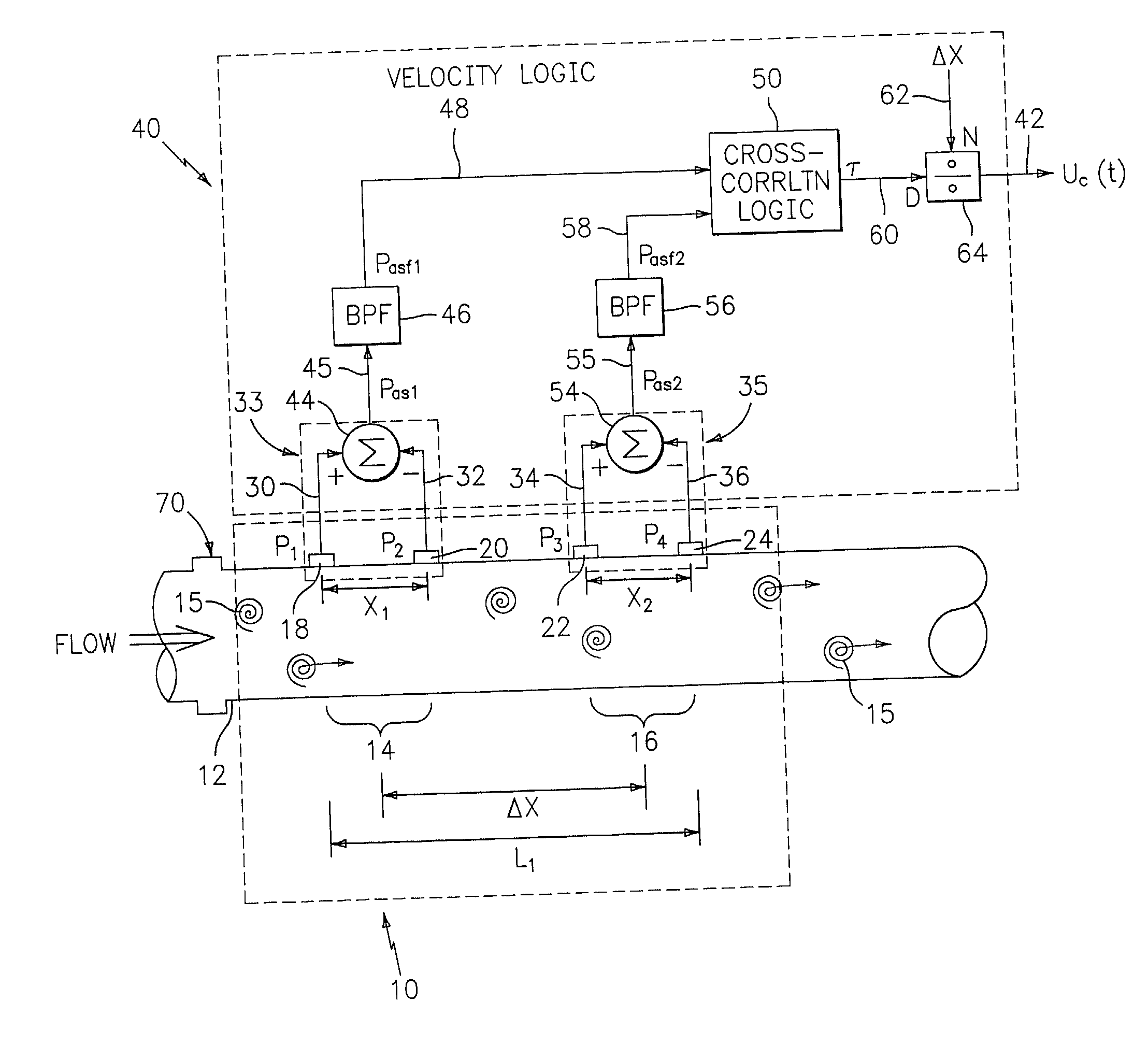

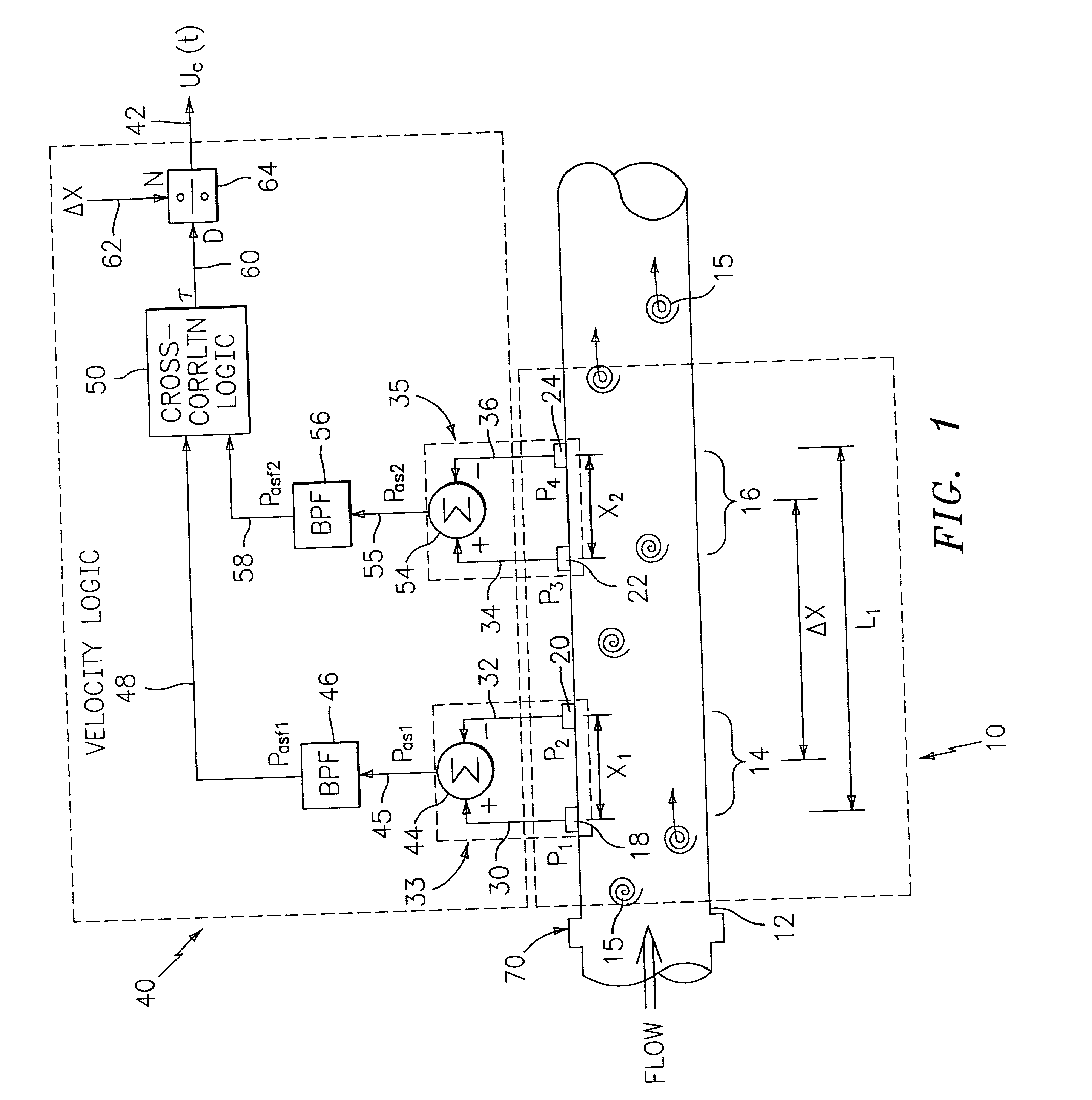

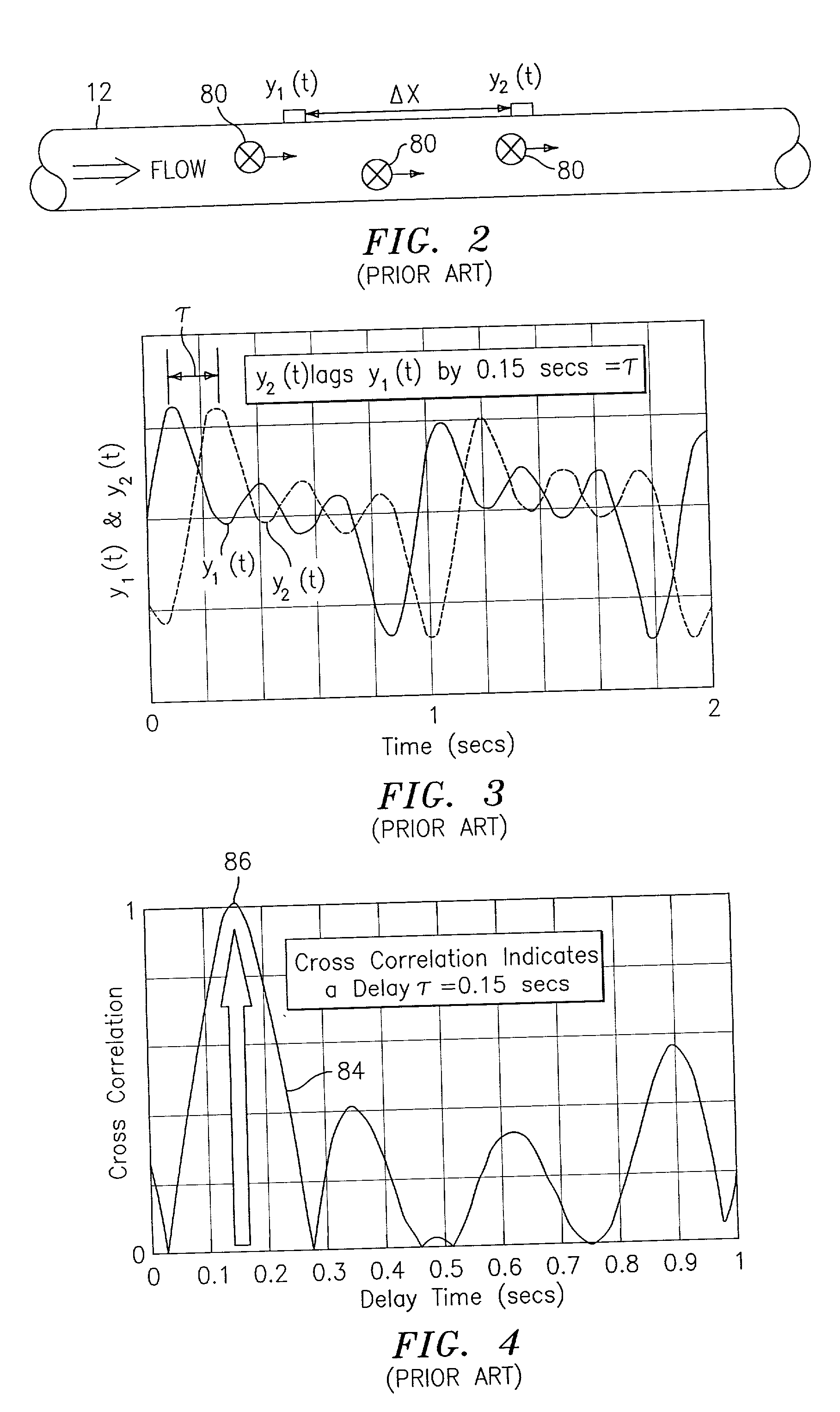

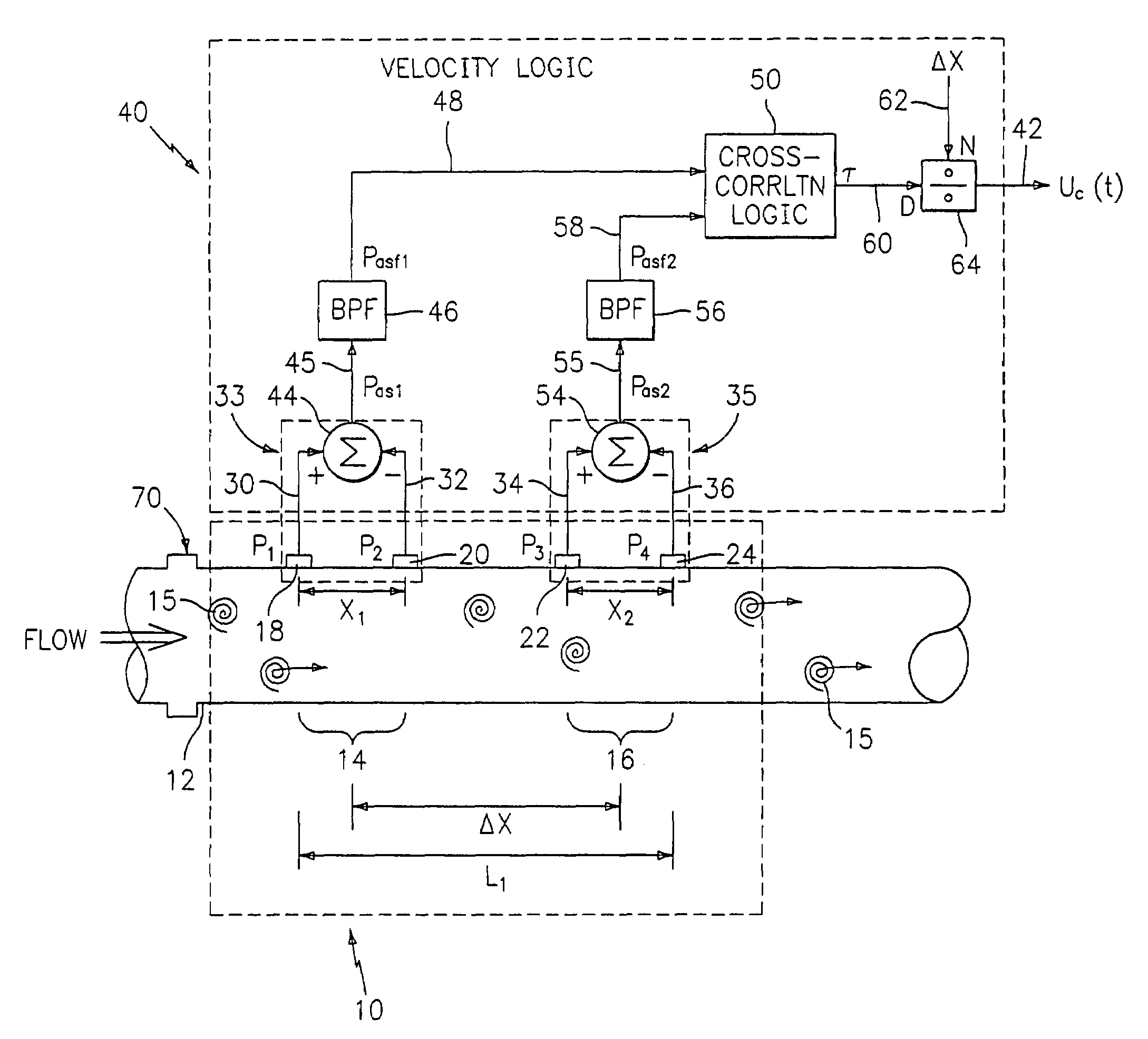

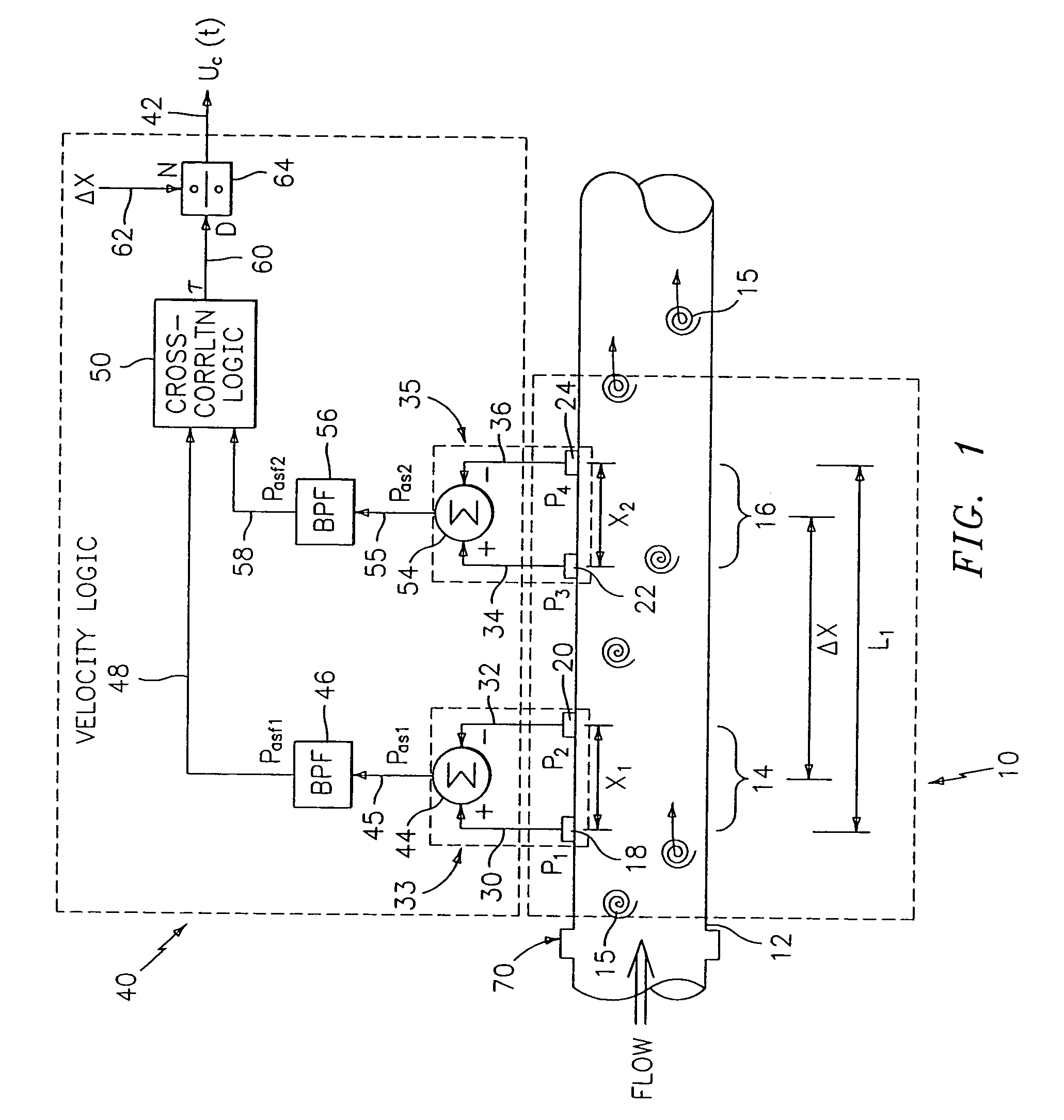

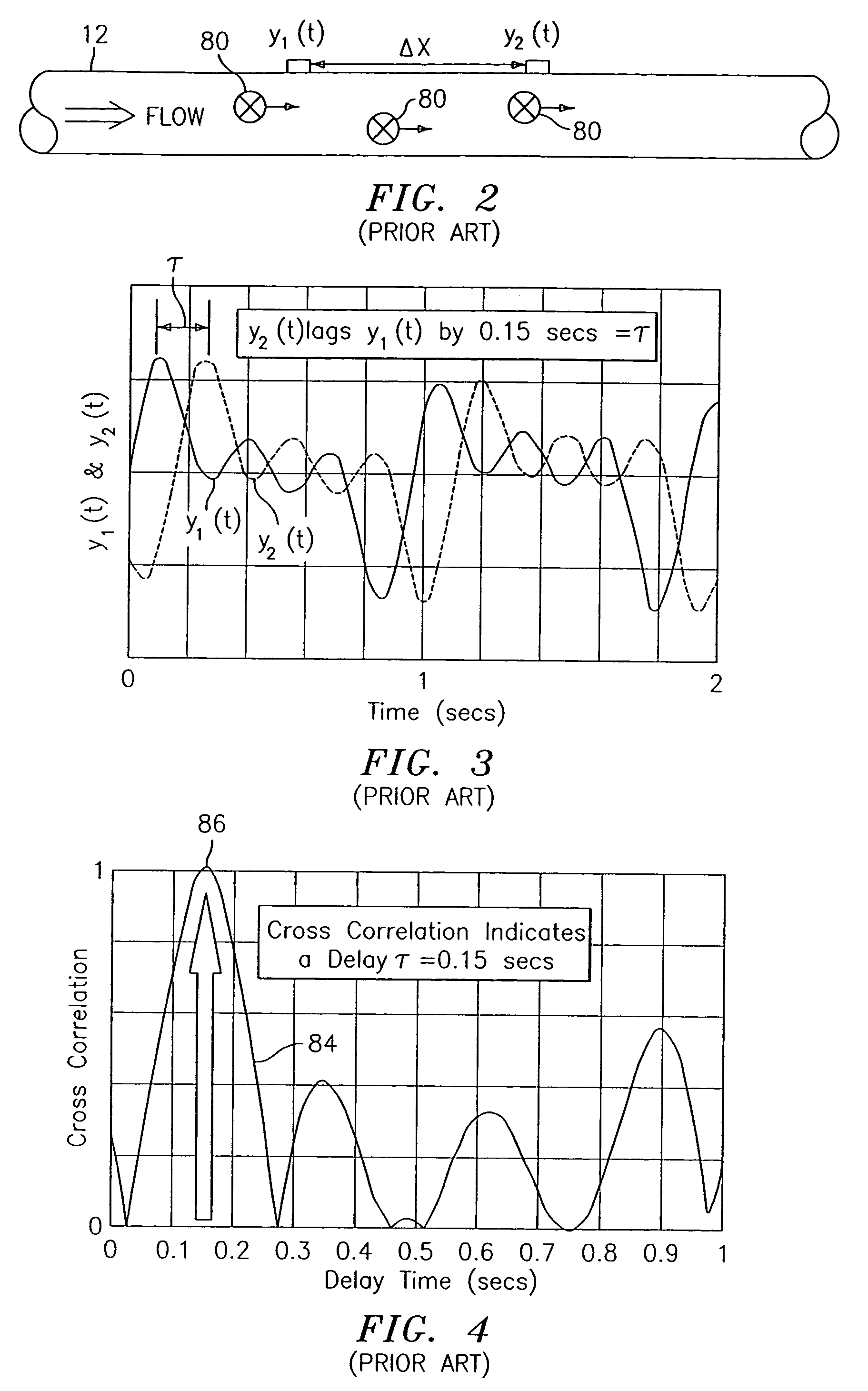

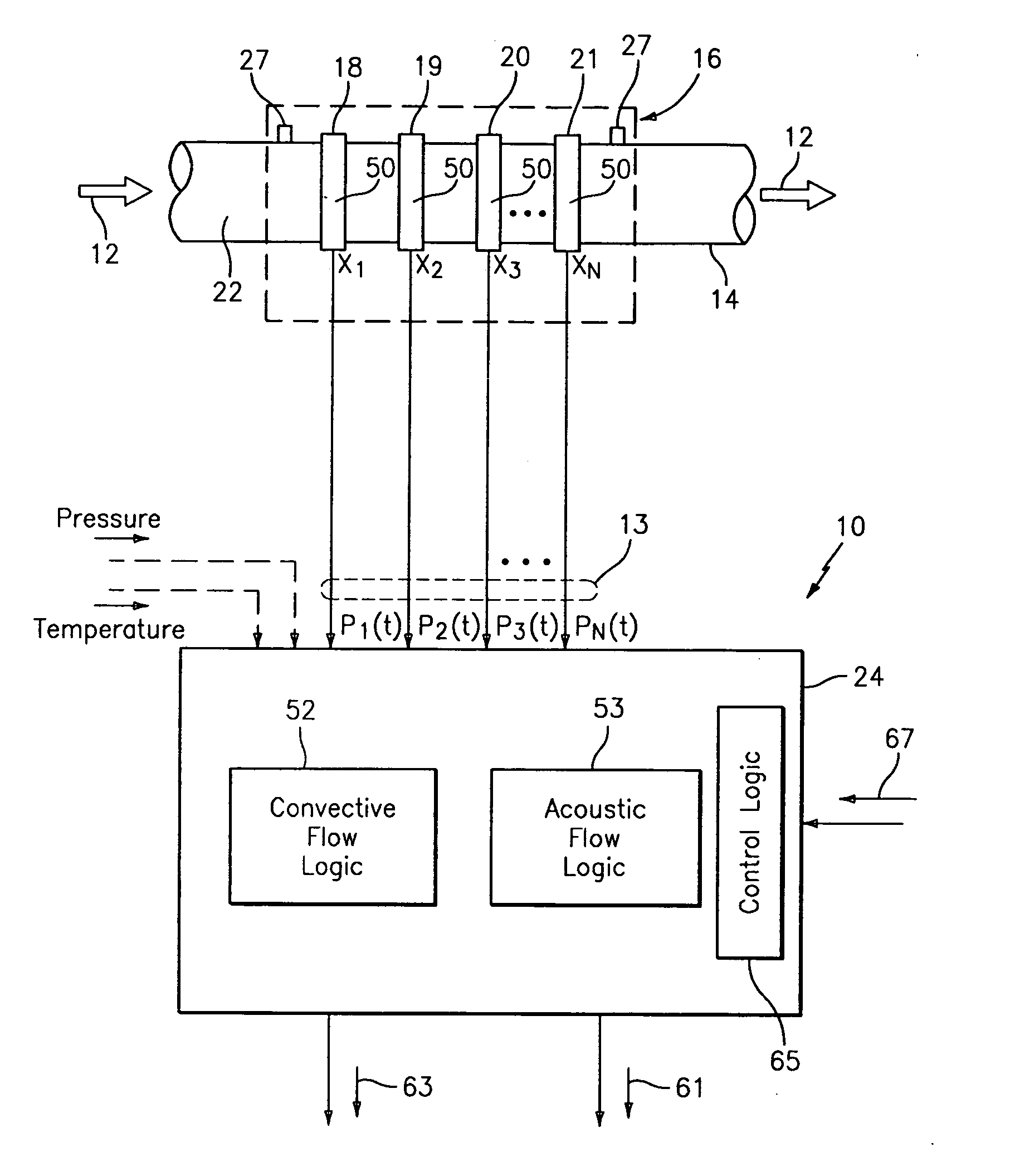

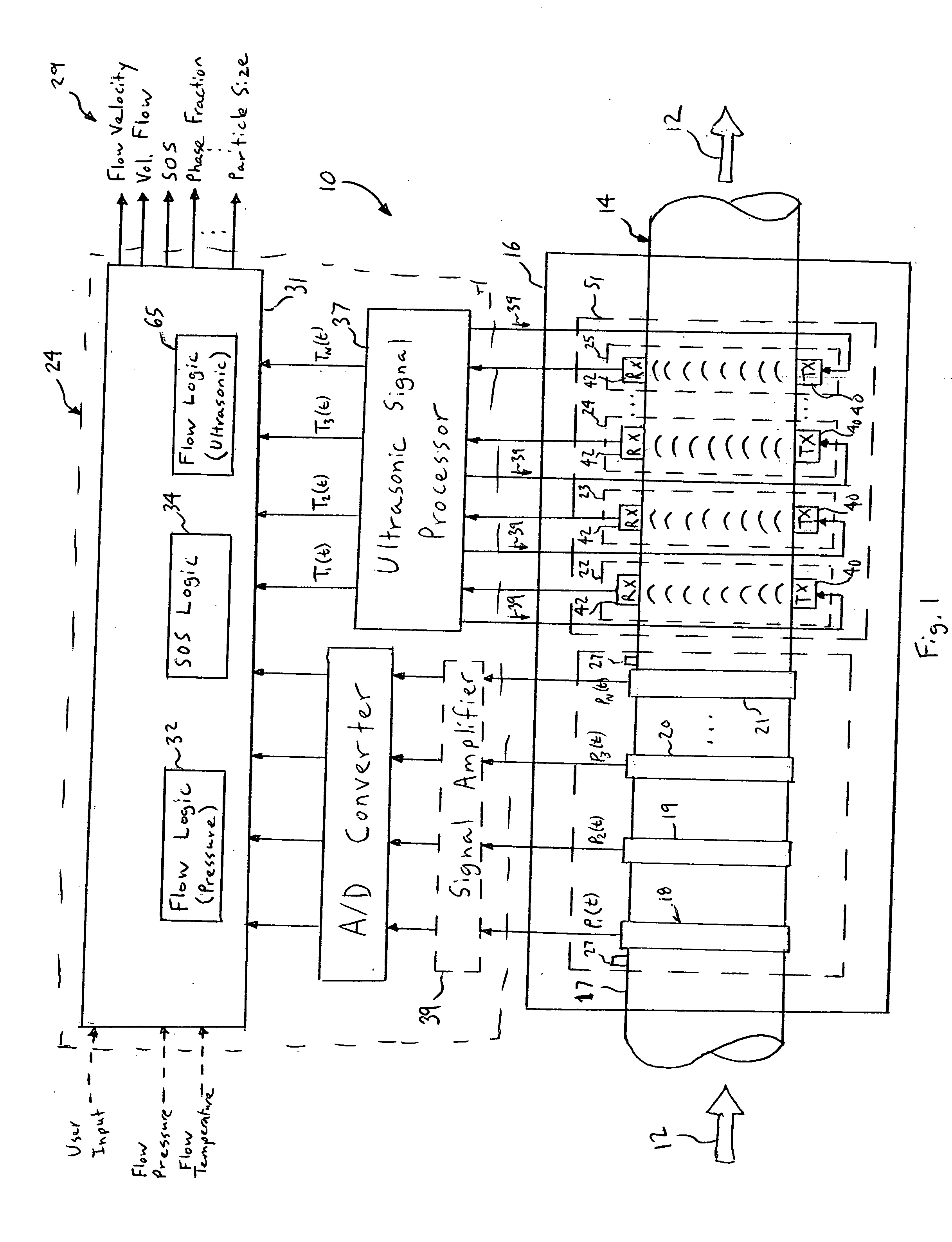

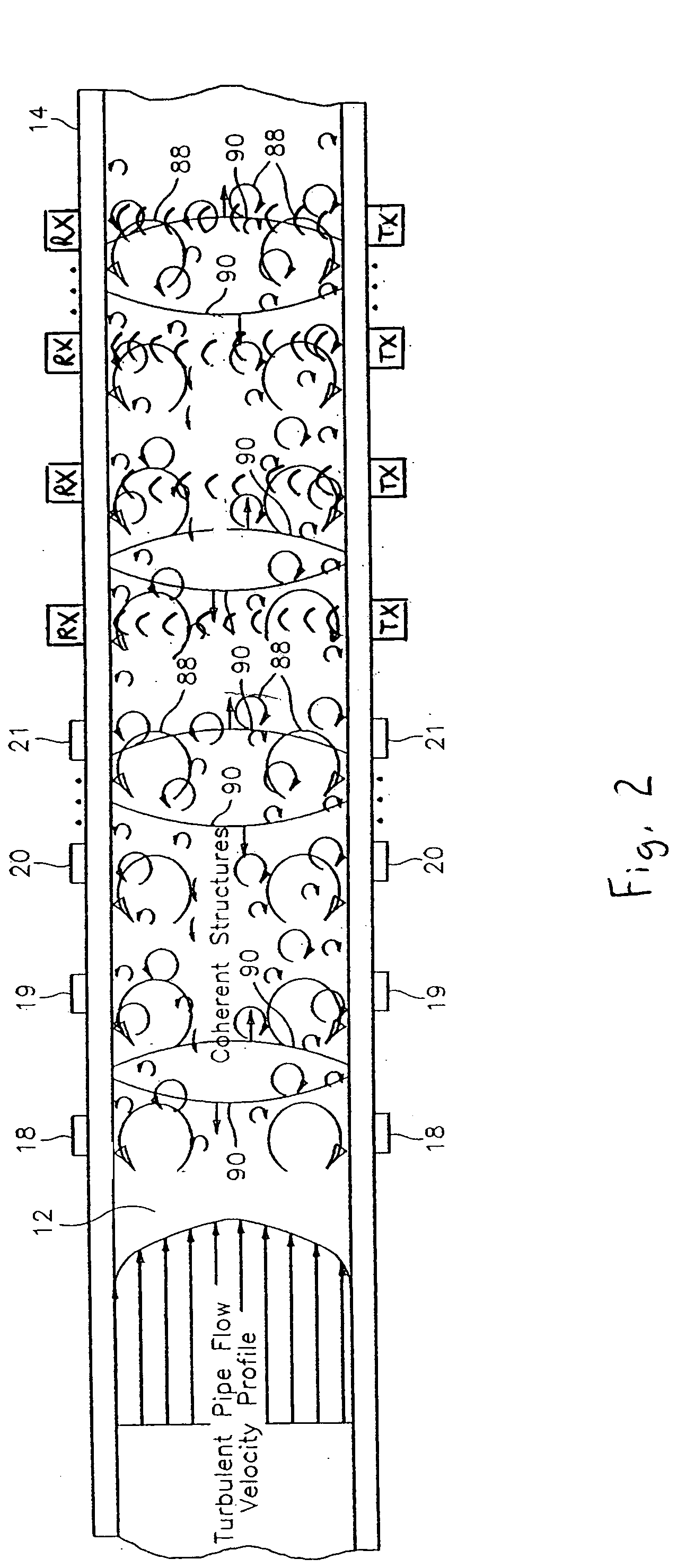

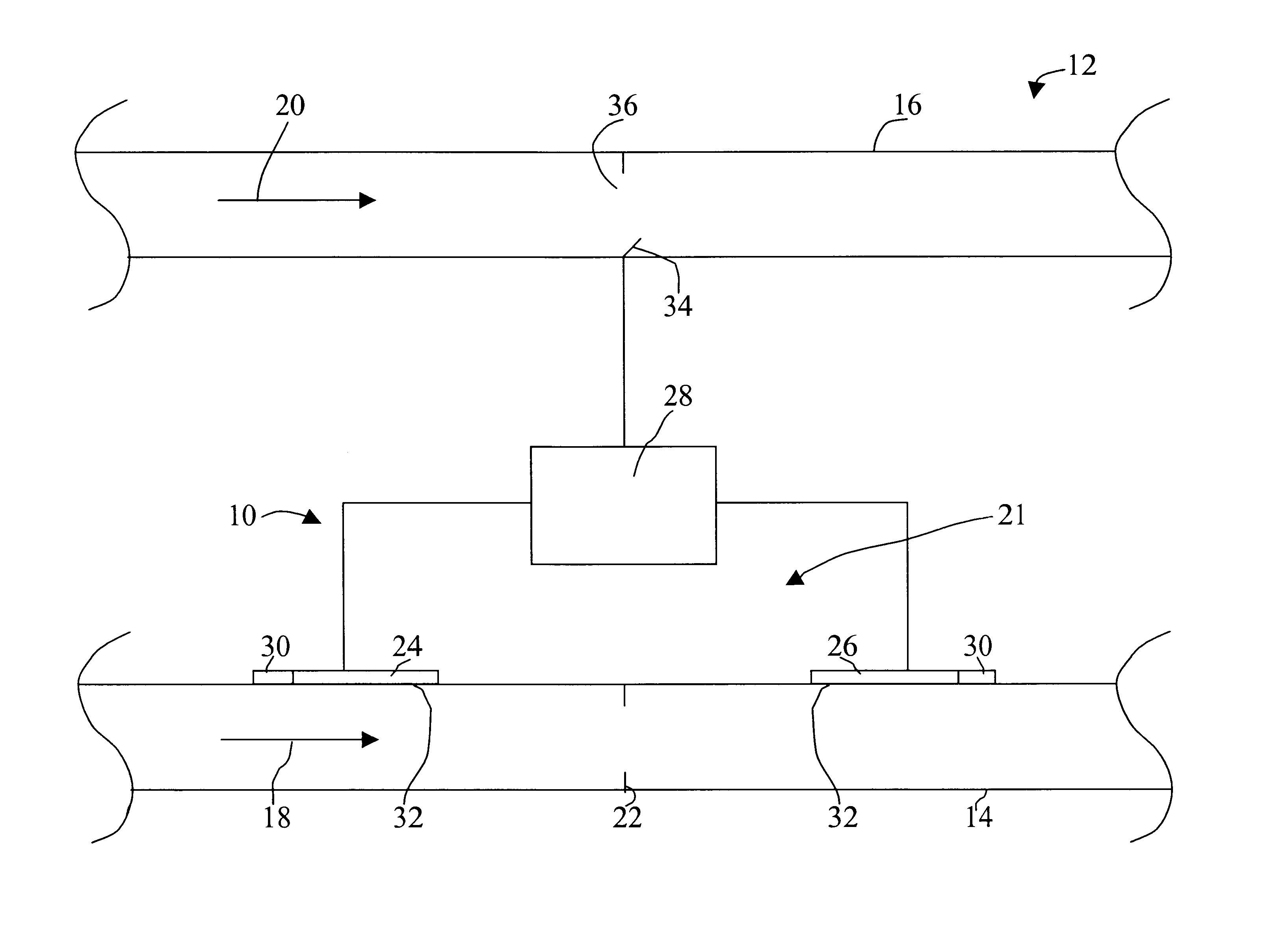

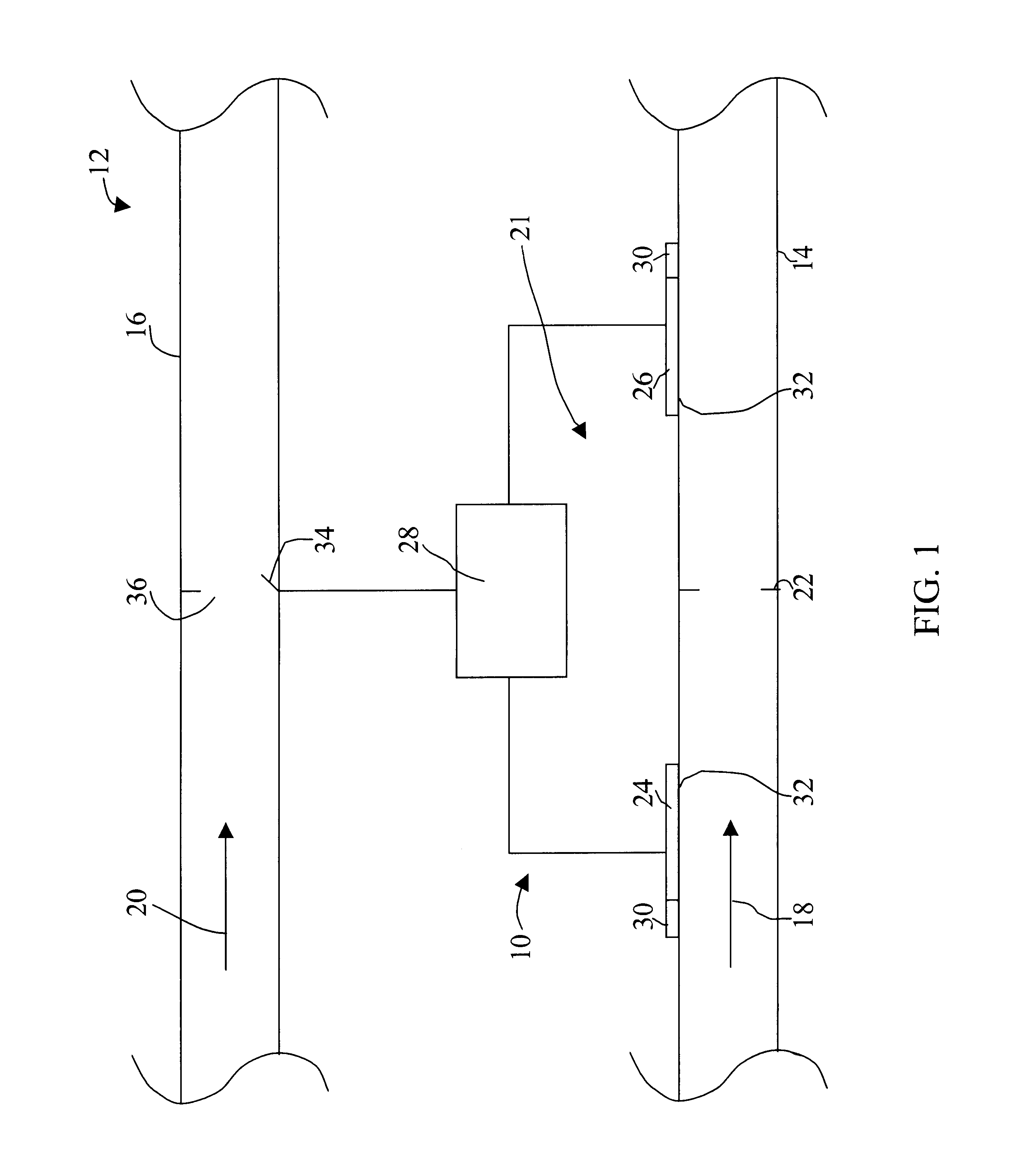

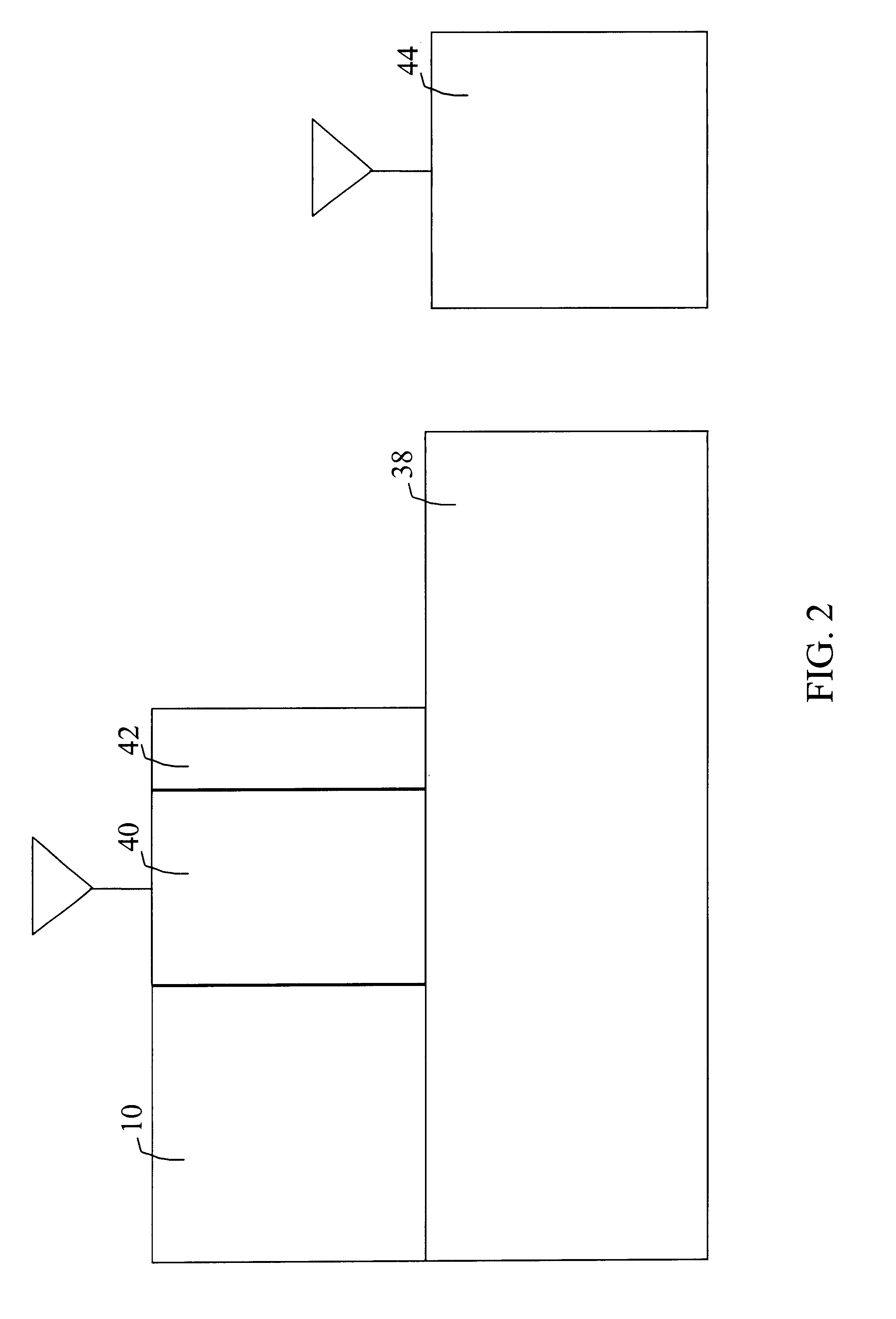

Flow rate measurement for industrial sensing applications using unsteady pressures

Flow rate measurement system includes two measurement regions 14,16 located an average axial distance ΔX apart along the pipe 12, the first measurement region 14 having two unsteady pressure sensors 18,20, located a distance X1 apart, and the second measurement region 16, having two other unsteady pressure sensors 22,24, located a distance X2 apart, each capable of measuring the unsteady pressure in the pipe 12. Signals from each pair of pressure sensors 18,20 and 22,24 are differenced by summers 44,54, respectively, to form spatial wavelength filters 33,35, respectively. Each spatial filter 33,35 filters out acoustic pressure disturbances Pacoustic and other long wavelength pressure disturbances in the pipe 12 and passes short-wavelength low-frequency vortical pressure disturbances Pvortical associated with the vortical flow field 15. The spatial filters 33,35 provide signals Pas1,Pas2 to band pass filters 46,56 that filter out high frequency signals. The Pvortical -dominated filtered signals Pasf1,Pasf2 from the two regions 14,16 are cross-correlated by Cross-Correlation Logic 50 to determine a time delay τ between the two sensing locations 14,16 which is divided into the distance ΔX to obtain a convection velocity Uc(t) that is related to an average flow rate of the fluid (i.e., one or more liquids and / or gases) flowing in the pipe 12. The invention may also be configured to detect the velocity of any desired inhomogeneous pressure field in the flow. The invention may also be combined with an instrument, an opto-electronic converter and a controller in an industrial process control system.

Owner:EXPRO METERS

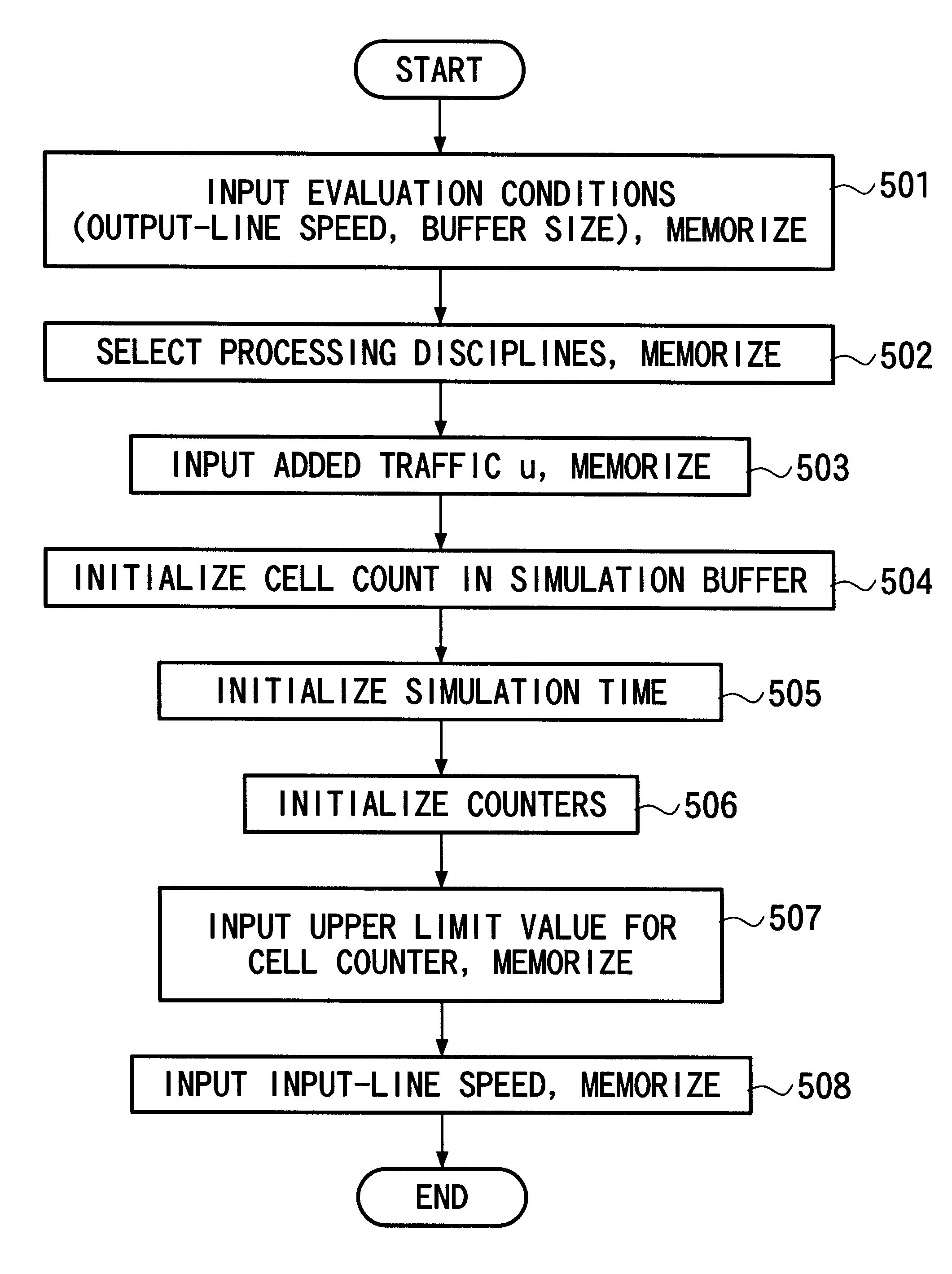

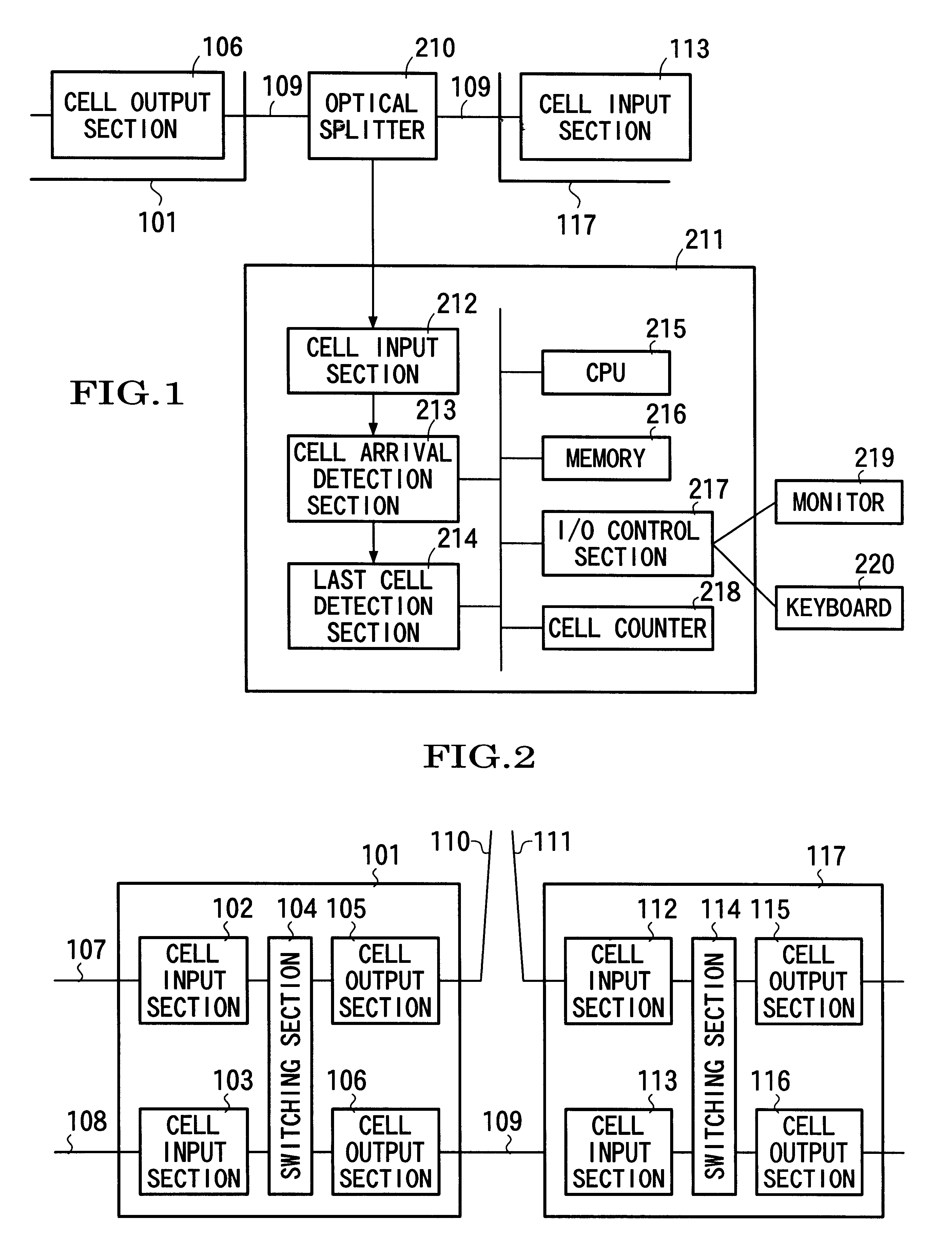

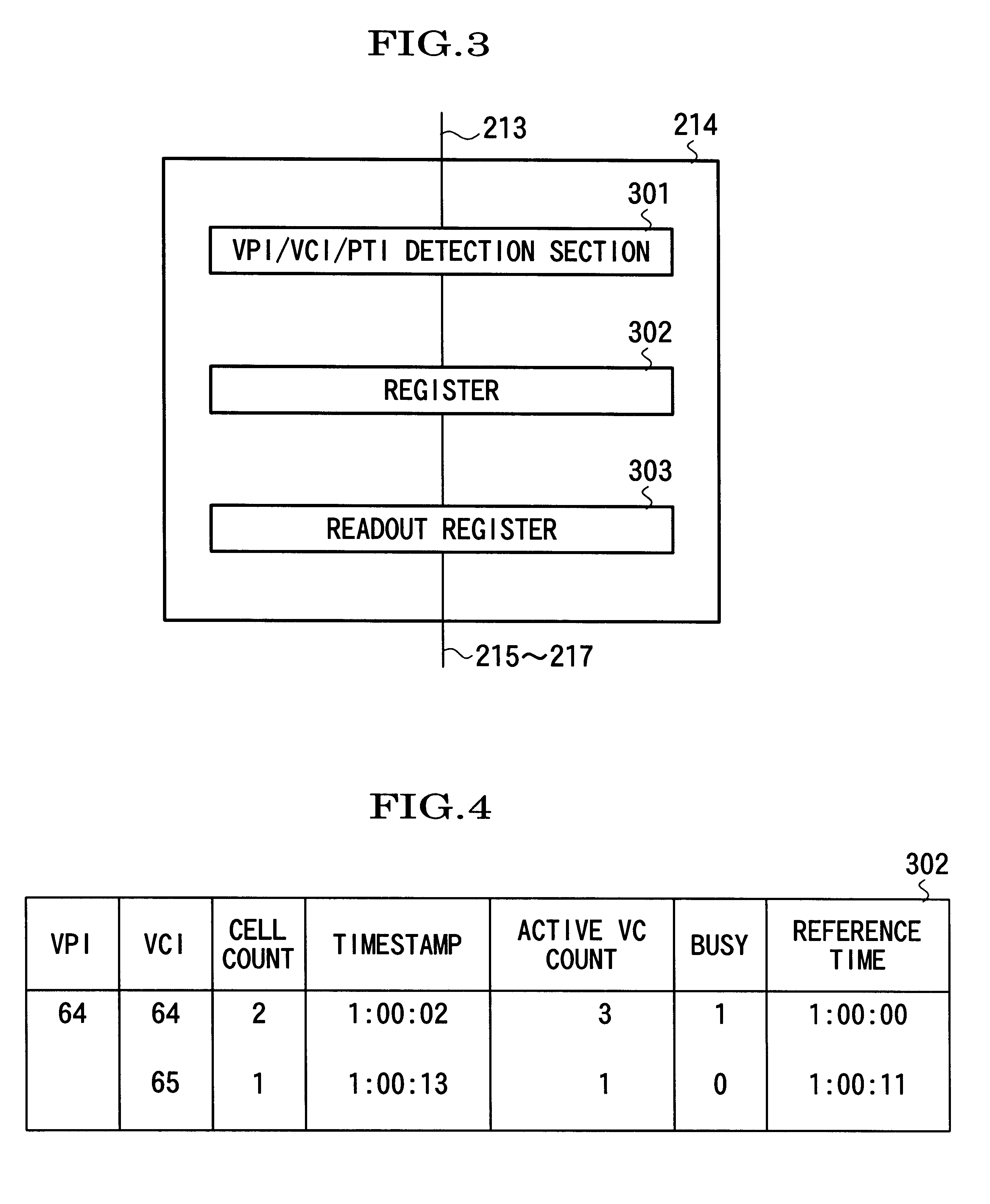

Apparatus for quality of service evaluation and traffic measurement

The present invention concerns an apparatus for evaluating the quality of service in a network. The QoS evaluation apparatus includes an arrival detection section to provide a timestamp to a specific processing unit included in a packet that arrives at an attention point in the network and is branched off by duplicating from a switching system. An estimation section estimates the arrival times of the plurality of processing units arriving at the attention point, and a simulation section simulates arrival times corresponding to the estimated arrival times at the attention point, produced by the arrival time estimation section, according to a pre-determined logic equation.

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

Flow rate measurement for industrial sensing applications using unsteady pressures

Flow rate measurement system includes two measurement regions 14,16 located an average axial distance .DELTA.X apart along the pipe 12, the first measurement region 14 having two unsteady pressure sensors 18,20, located a distance X.sub.1 apart, and the second measurement region 16, having two other unsteady pressure sensors 22,24, located a distance X.sub.2 apart, each capable of measuring the unsteady pressure in the pipe 12. Signals from each pair of pressure sensors 18,20 and 22,24 are differenced by summers 44,54, respectively, to form spatial wavelength filters 33,35, respectively. Each spatial filter 33,35 filters out acoustic pressure disturbances P.sub.acoustic and other long wavelength pressure disturbances in the pipe 12 and passes short-wavelength low-frequency vortical pressure disturbances P.sub.vortical associated with the vortical flow field 15. The spatial filters 33,35 provide signals P.sub.as1,P.sub.as2 to band pass filters 46,56 that filter out high frequency signals. The P.sub.vortical -dominated filtered signals P.sub.asf1,P.sub.asf2 from the two regions 14,16 are cross-correlated by Cross-Correlation Logic 50 to determine a time delay .tau. between the two sensing locations 14,16 which is divided into the distance .DELTA.X to obtain a convection velocity U.sub.c(t) that is related to an average flow rate of the fluid (i.e., one or more liquids and / or gases) flowing in the pipe 12. The invention may also be configured to detect the velocity of any desired inhomogeneous pressure field in the flow. The invention may also be combined with an instrument, an opto-electronic converter and a controller in an industrial process control system.

Owner:EXPRO METERS

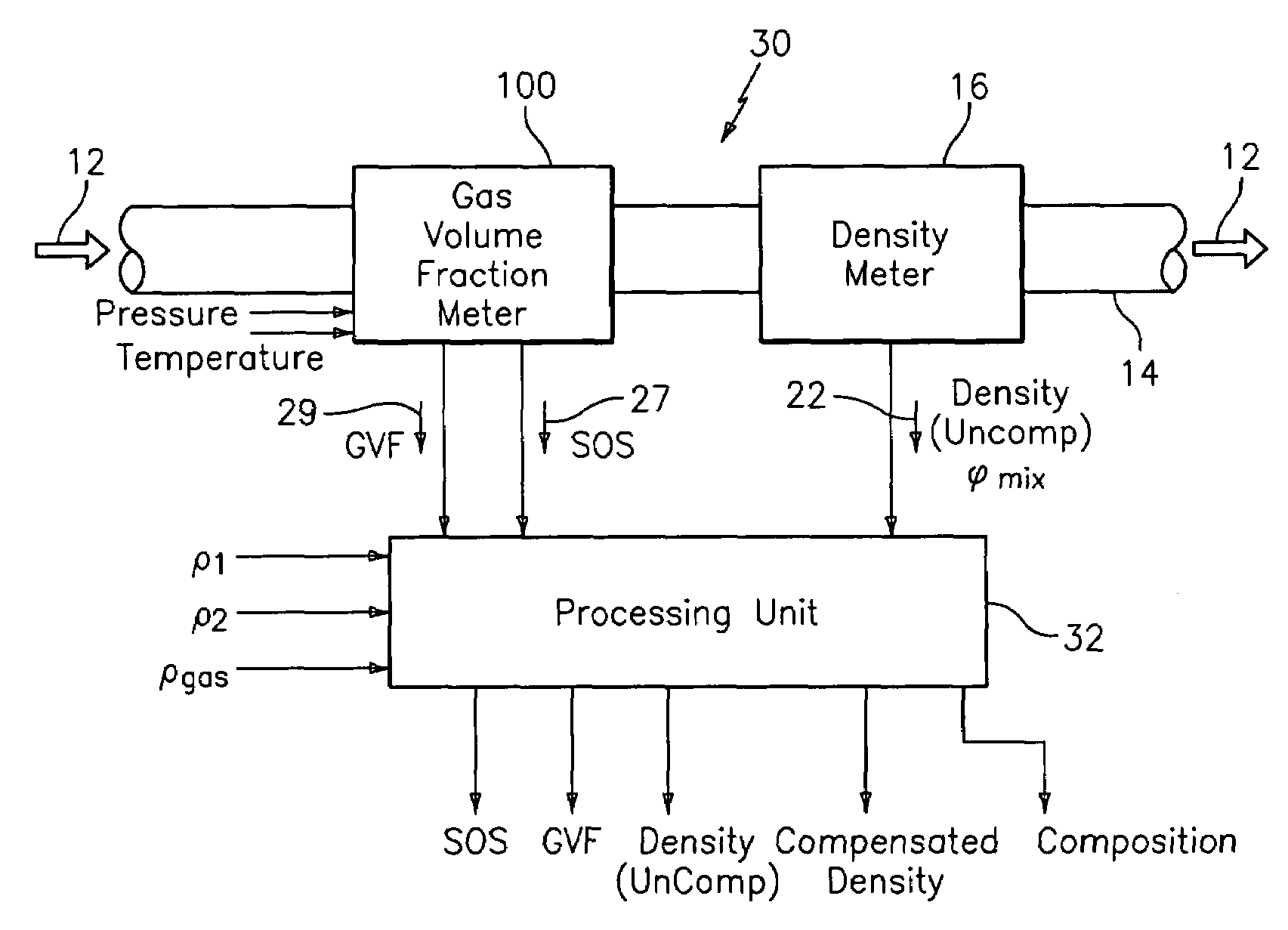

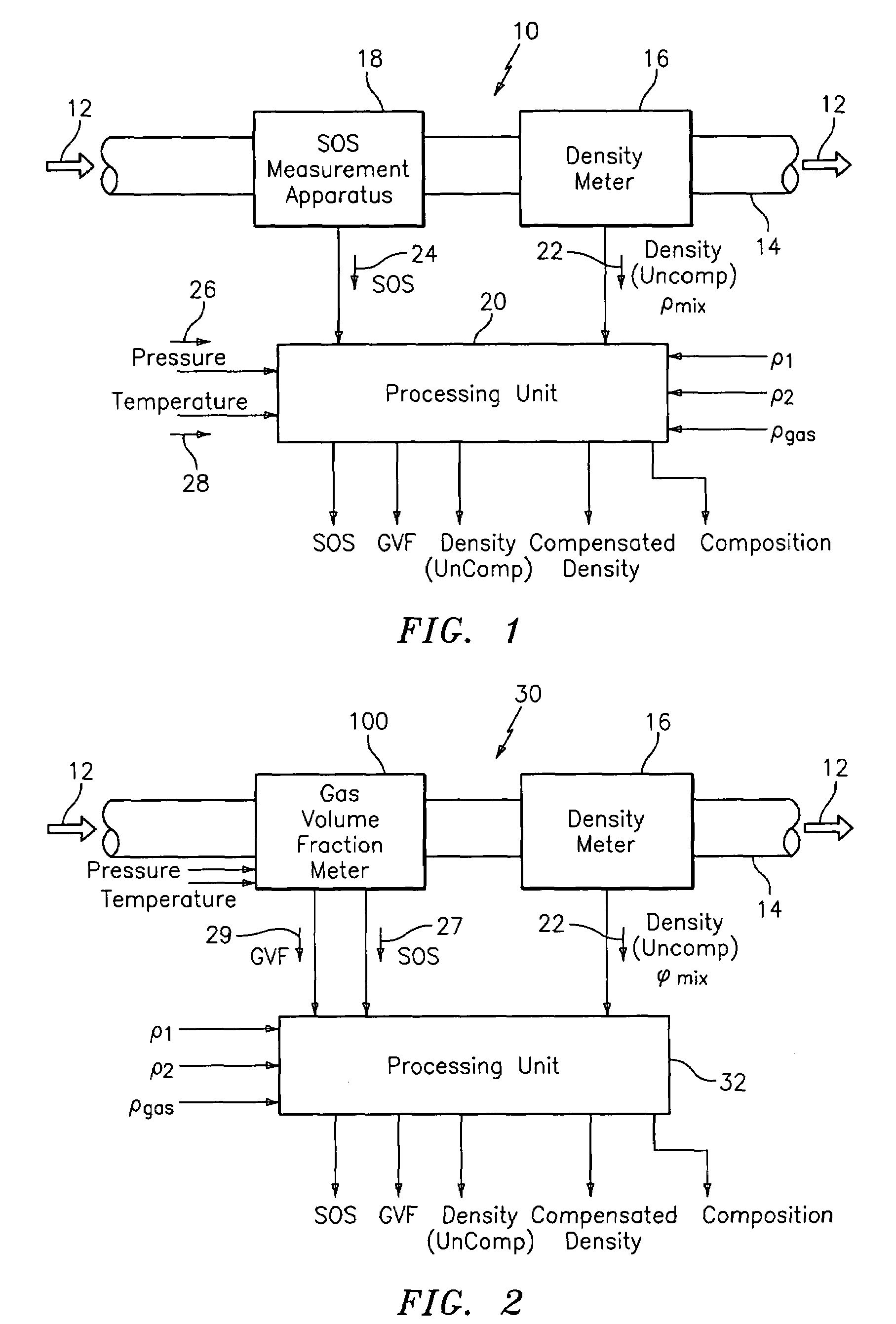

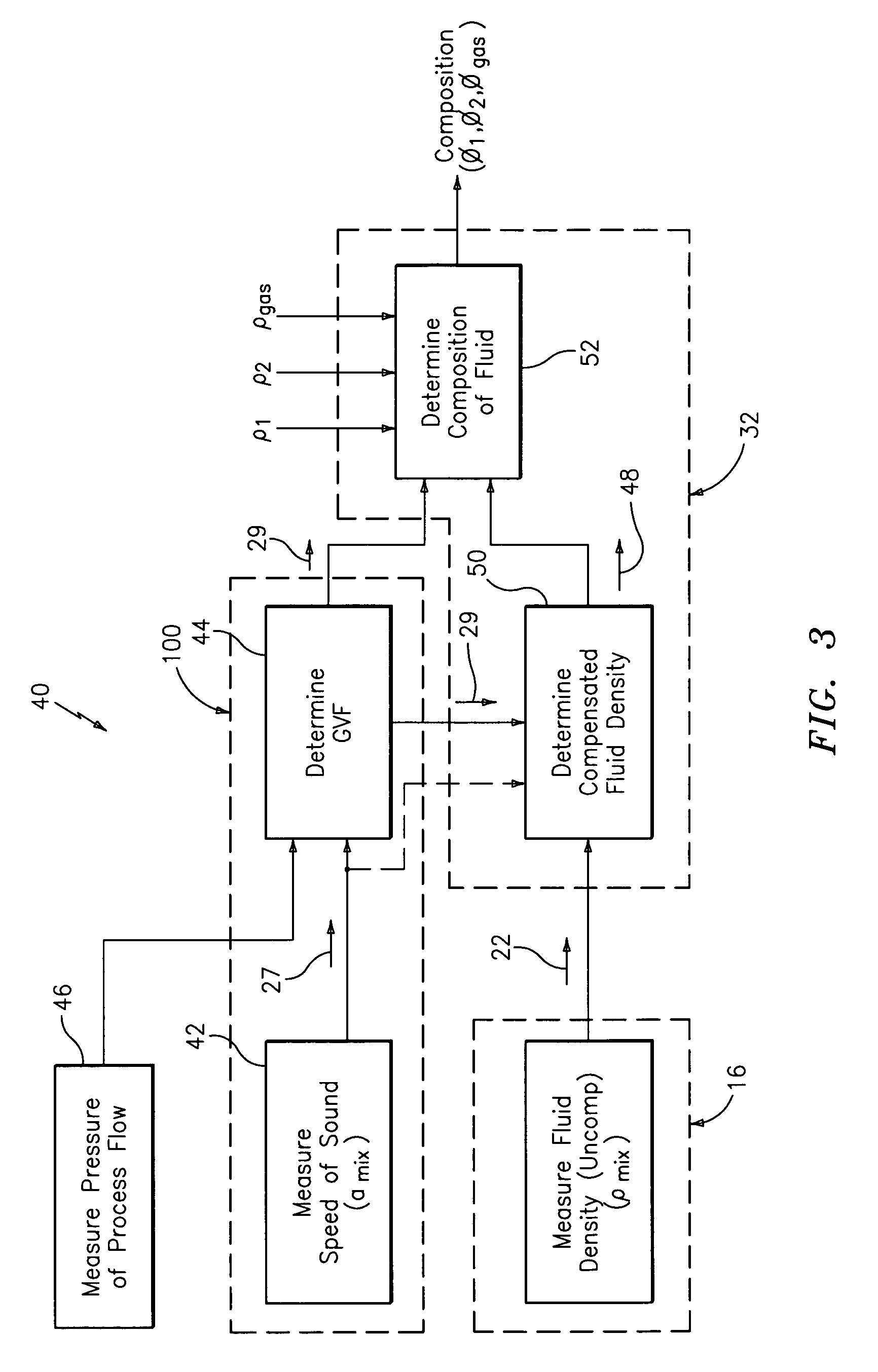

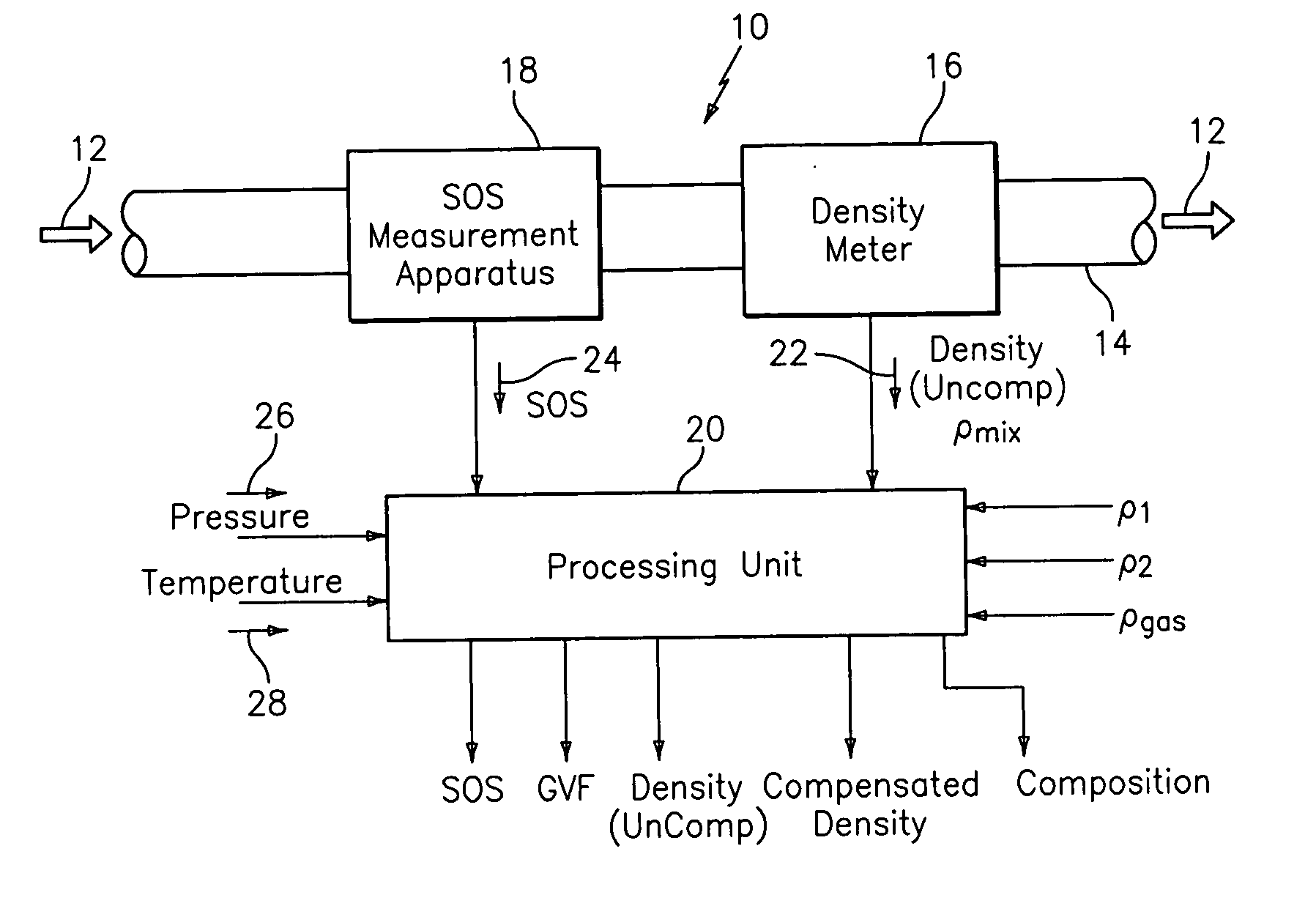

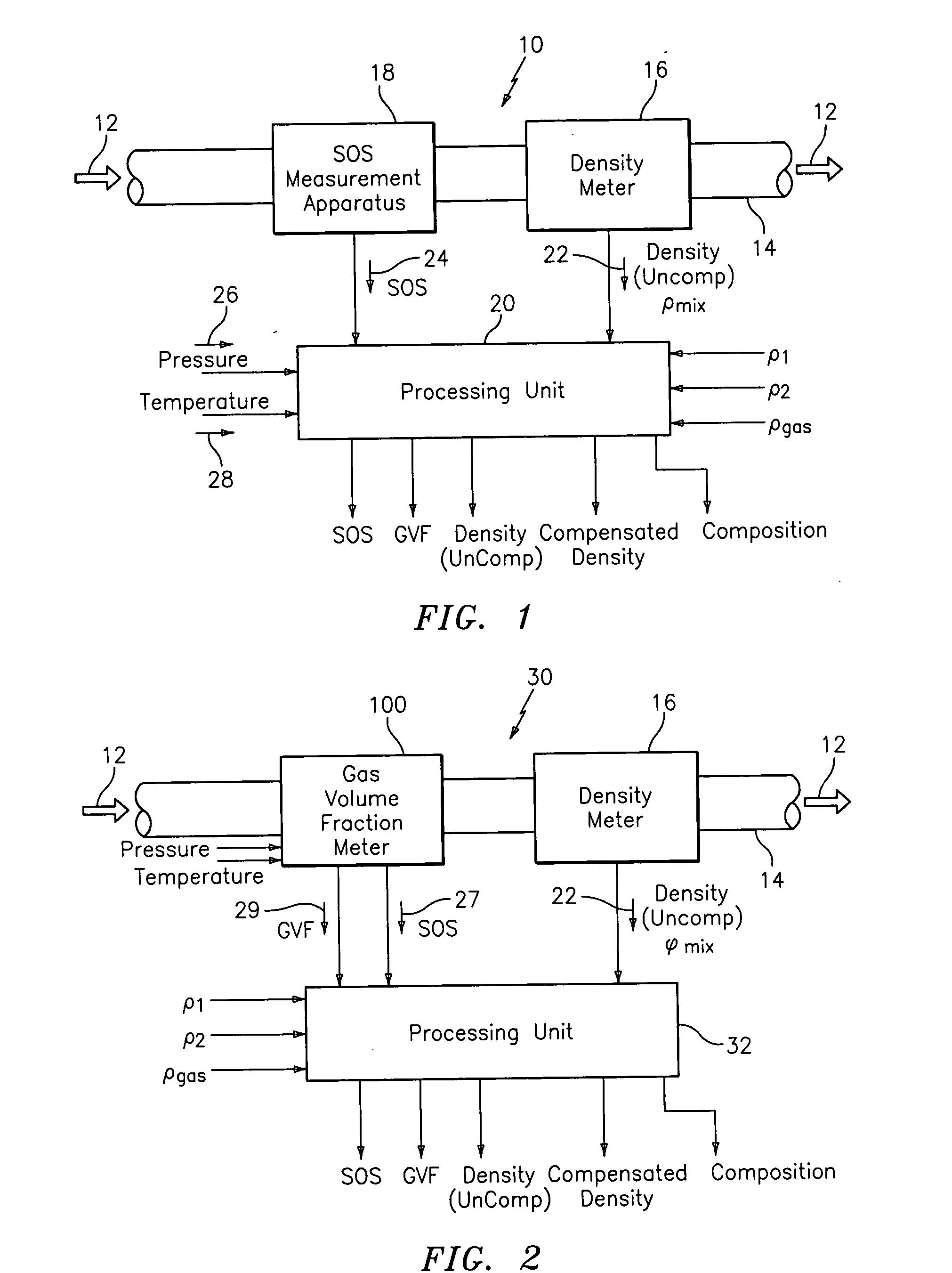

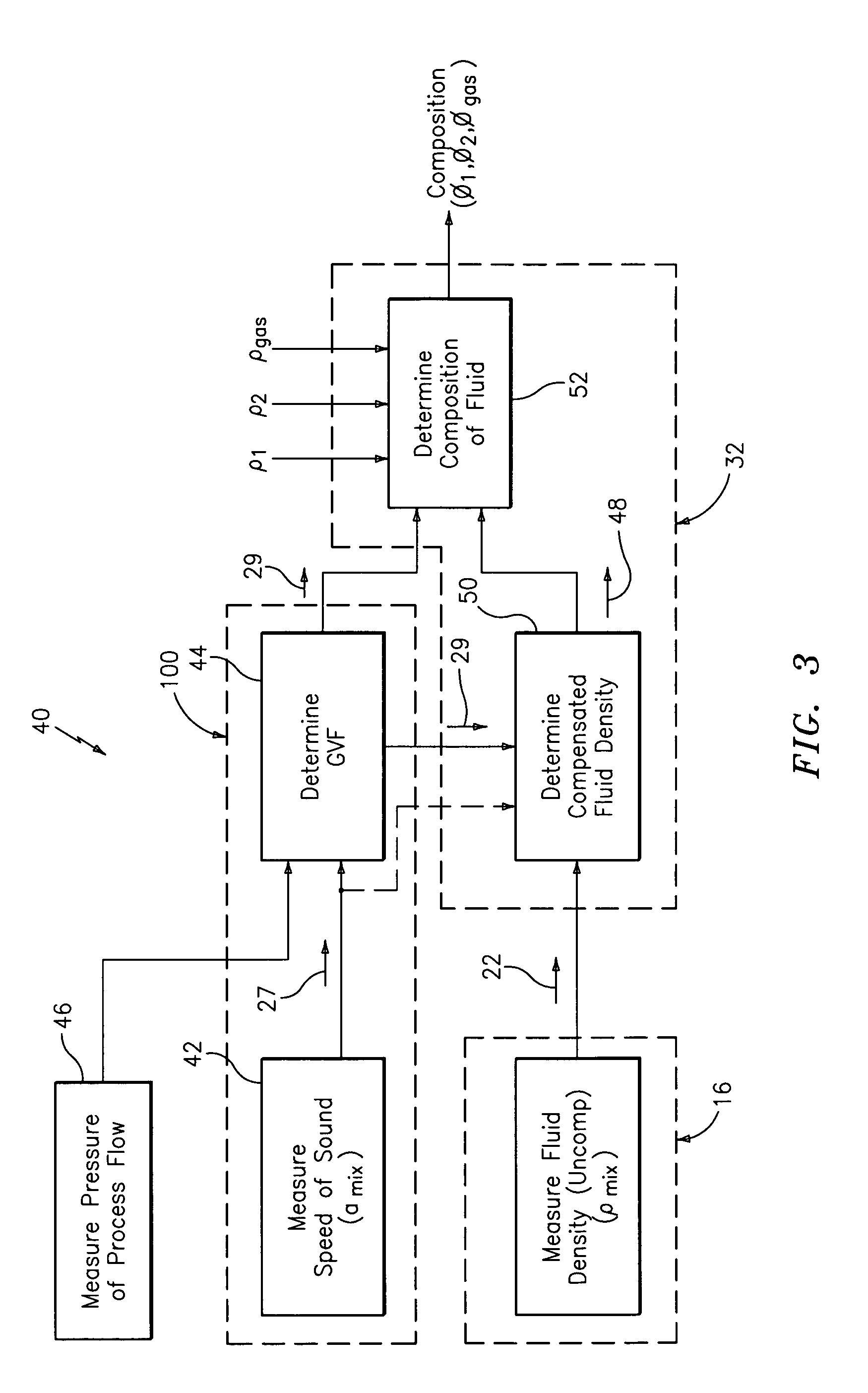

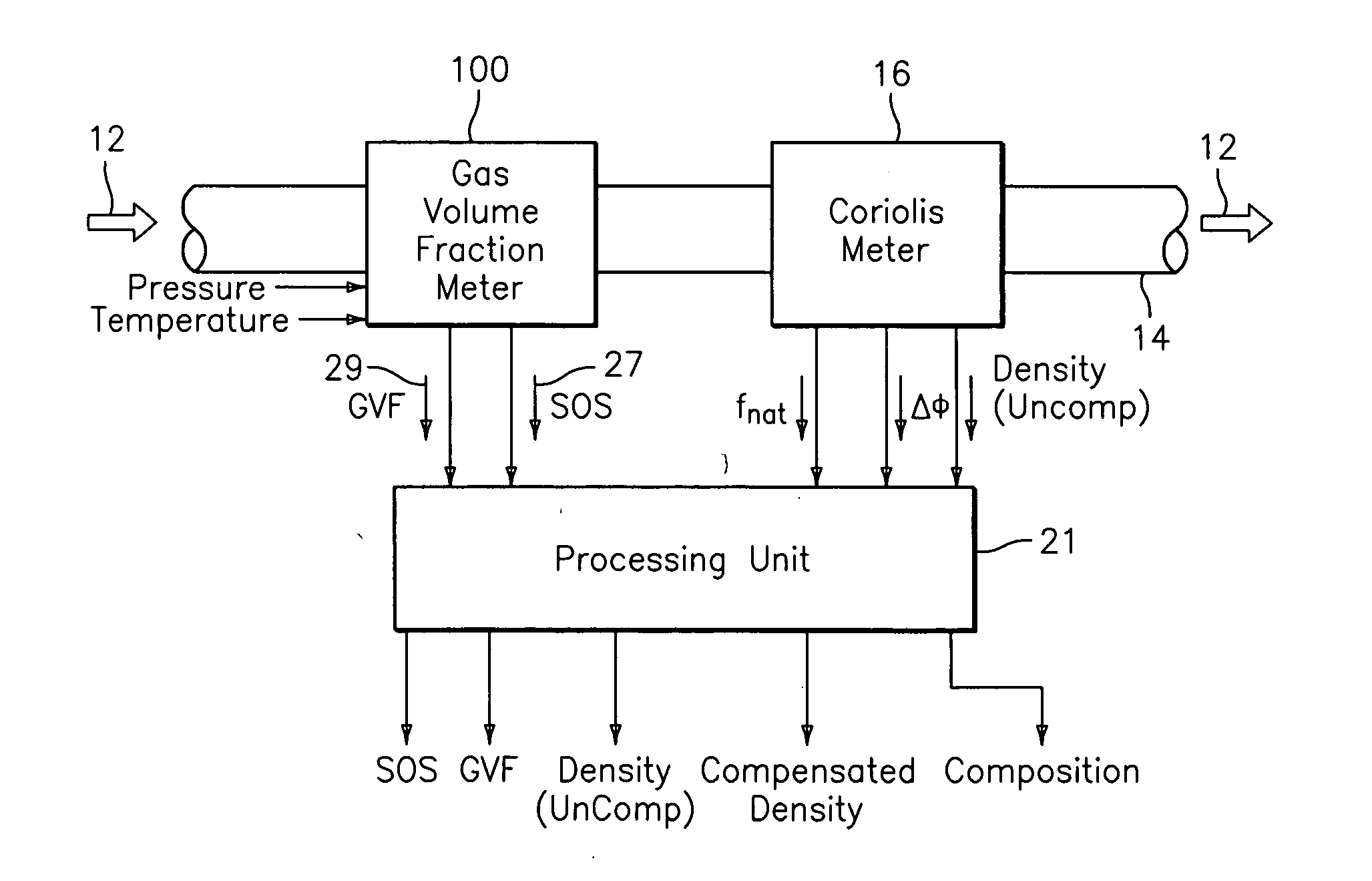

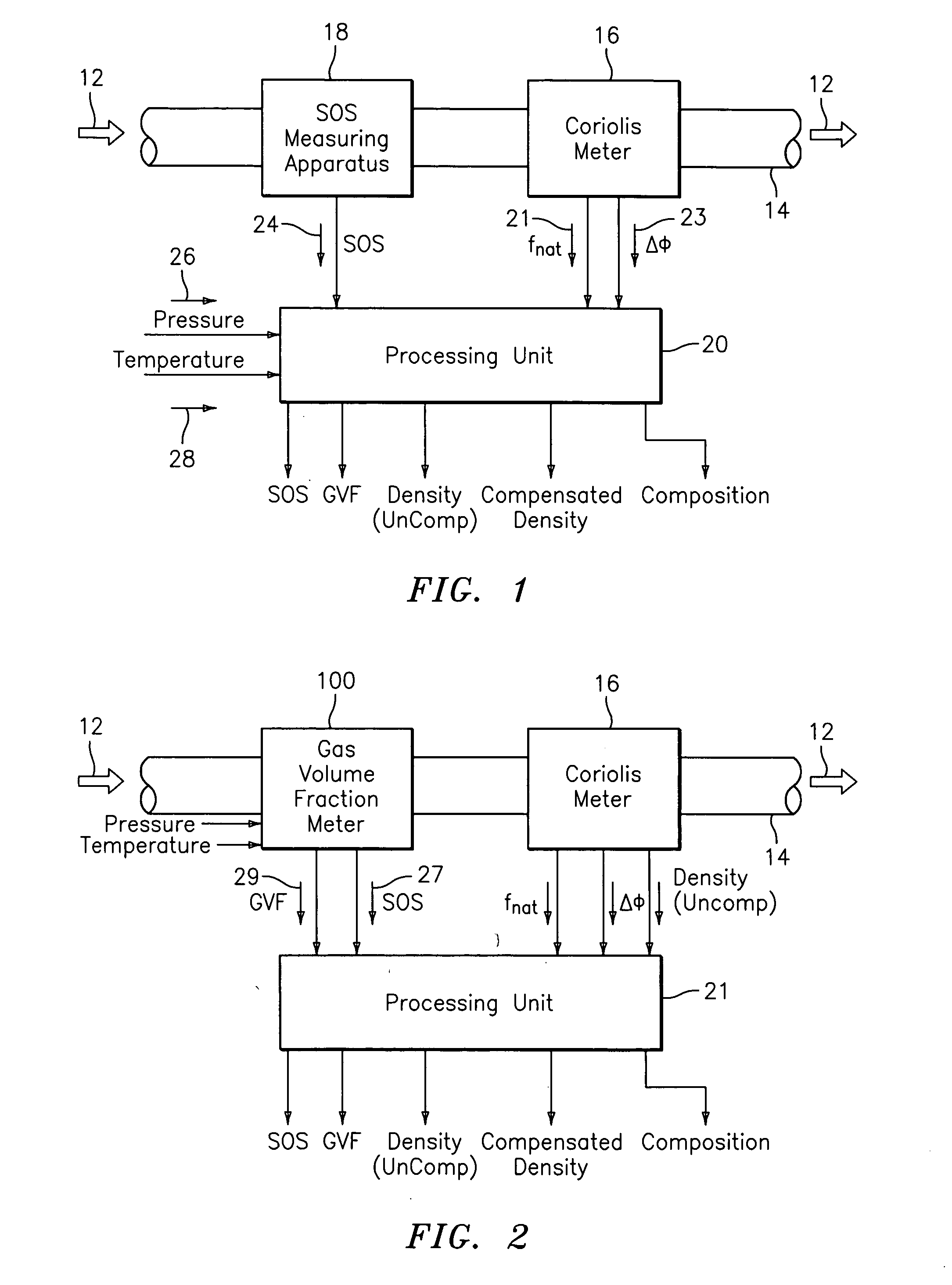

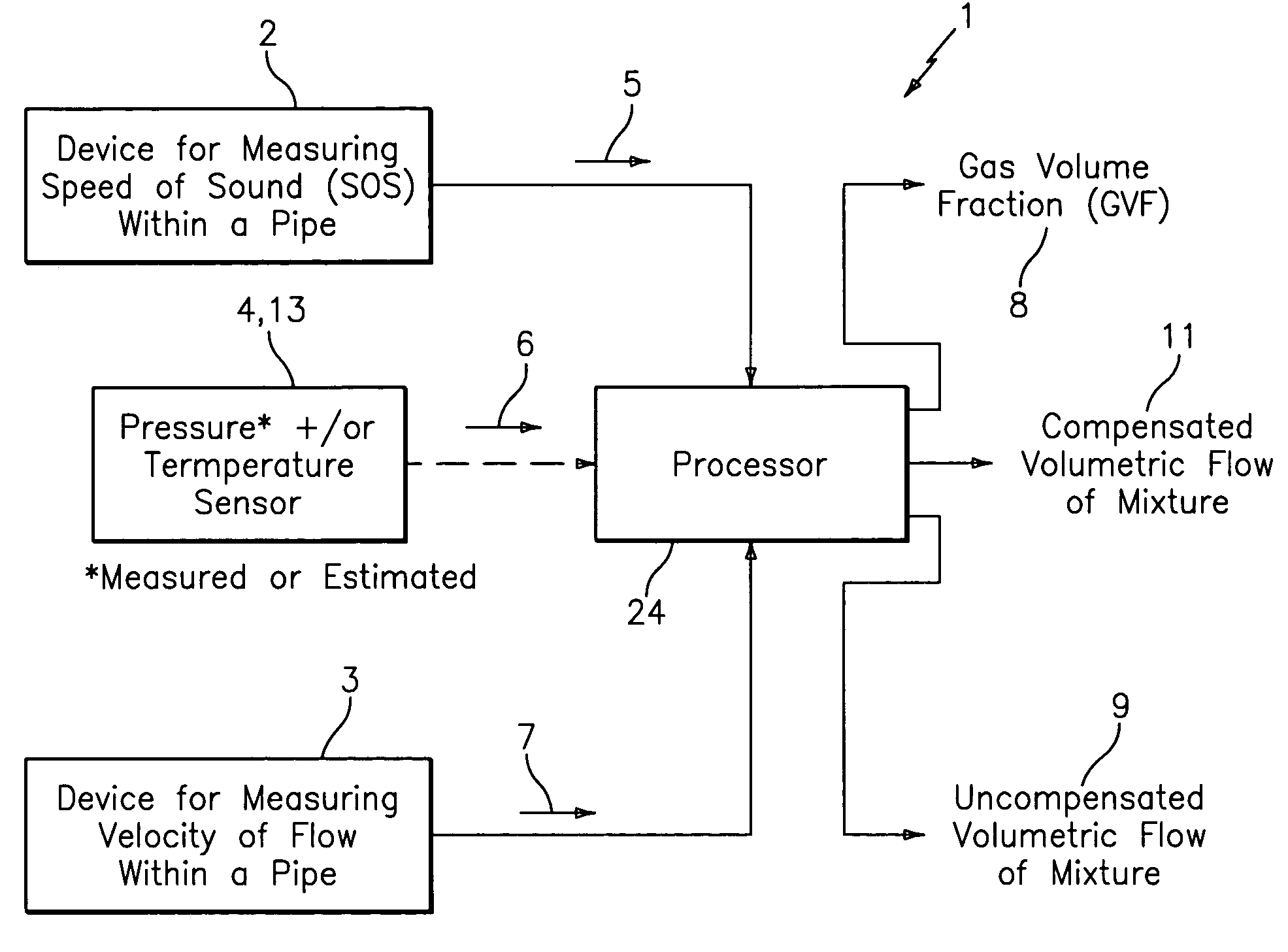

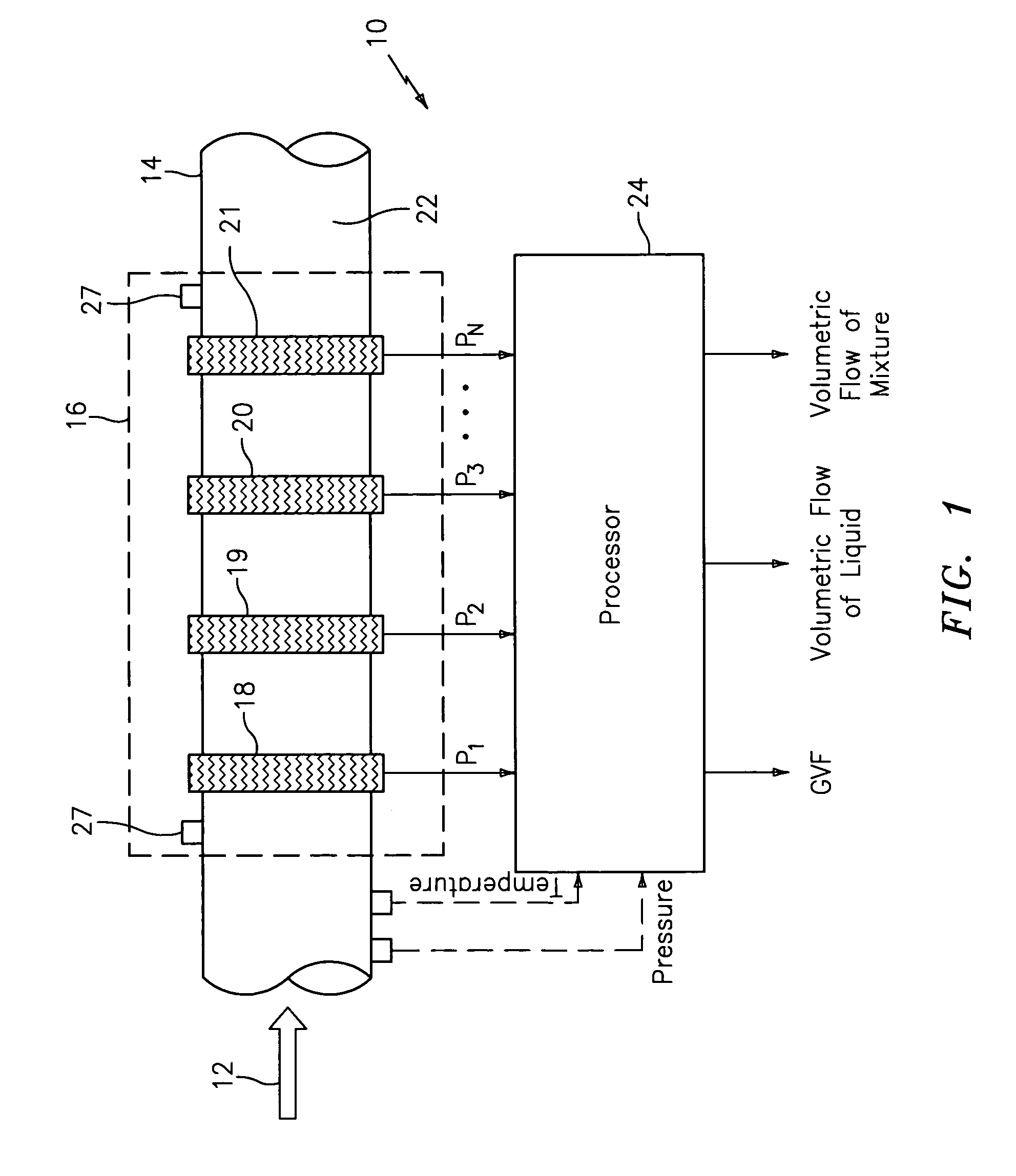

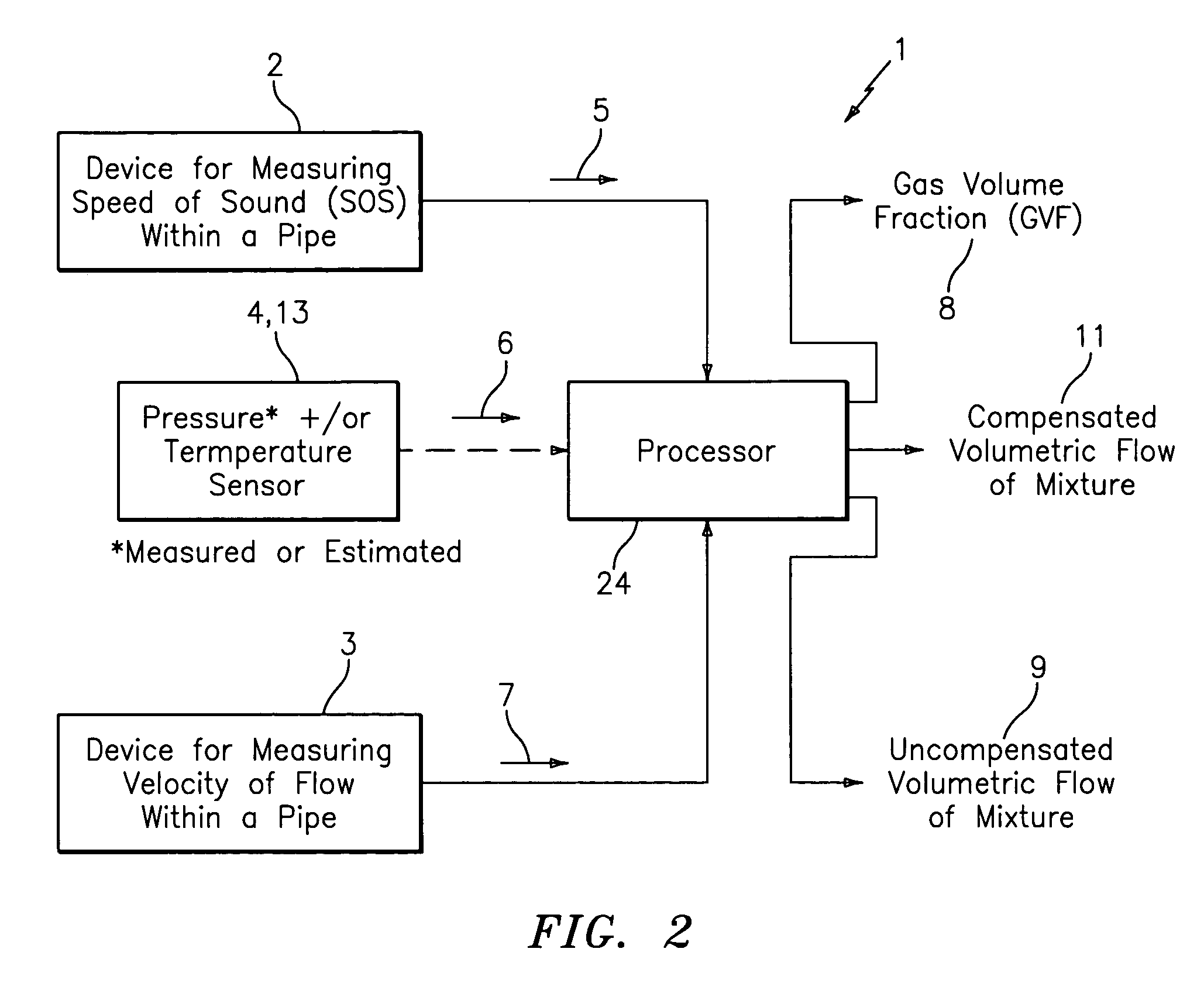

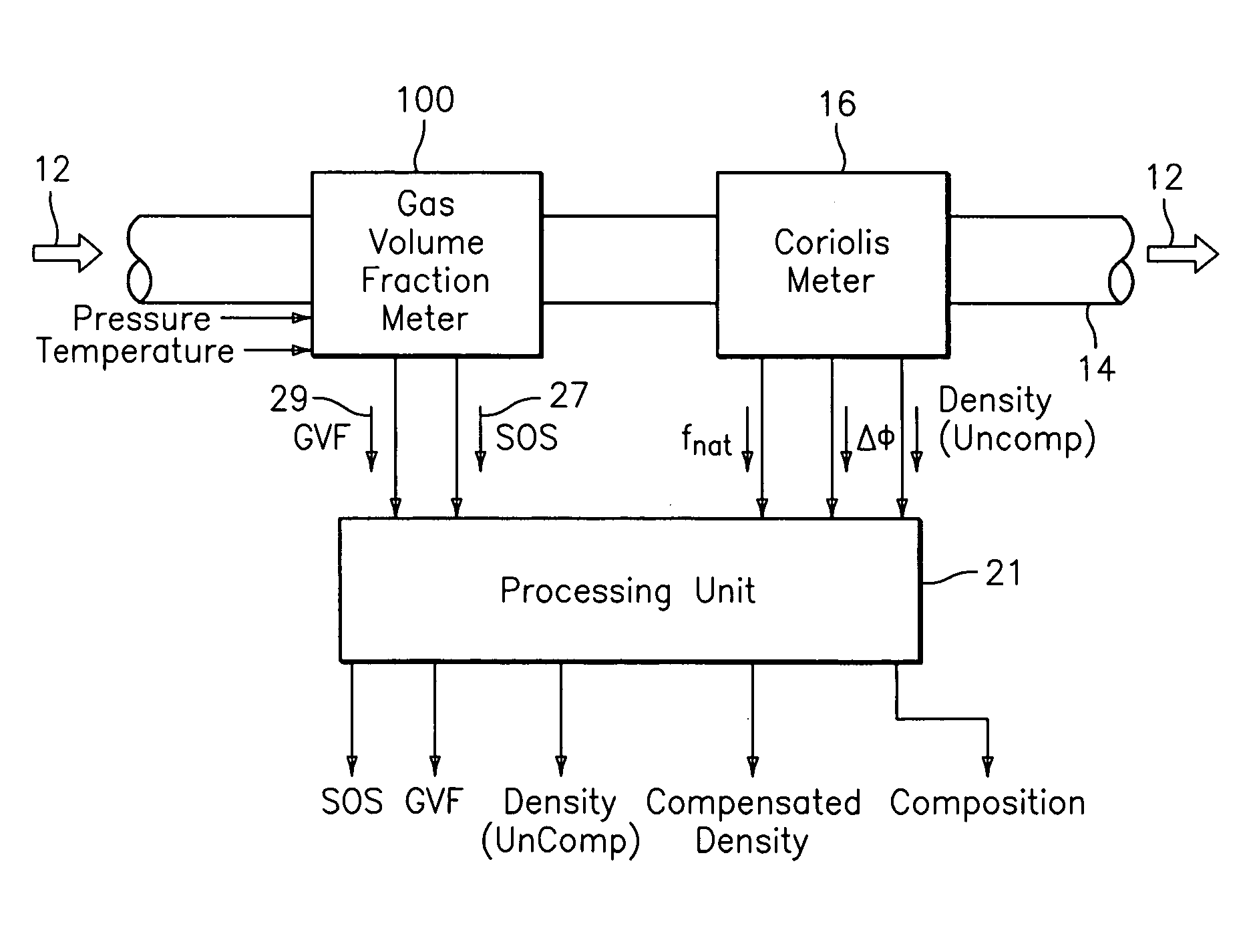

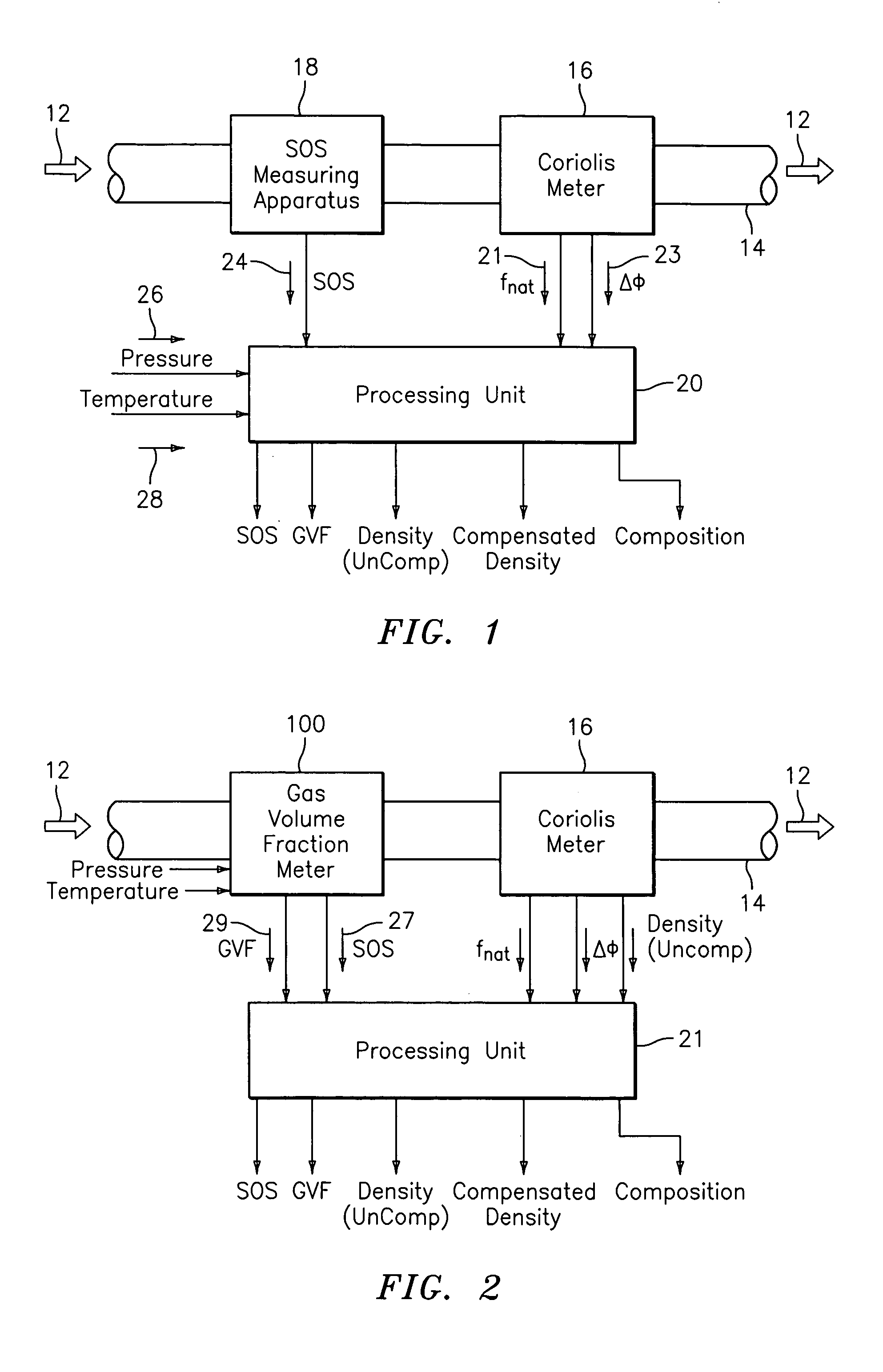

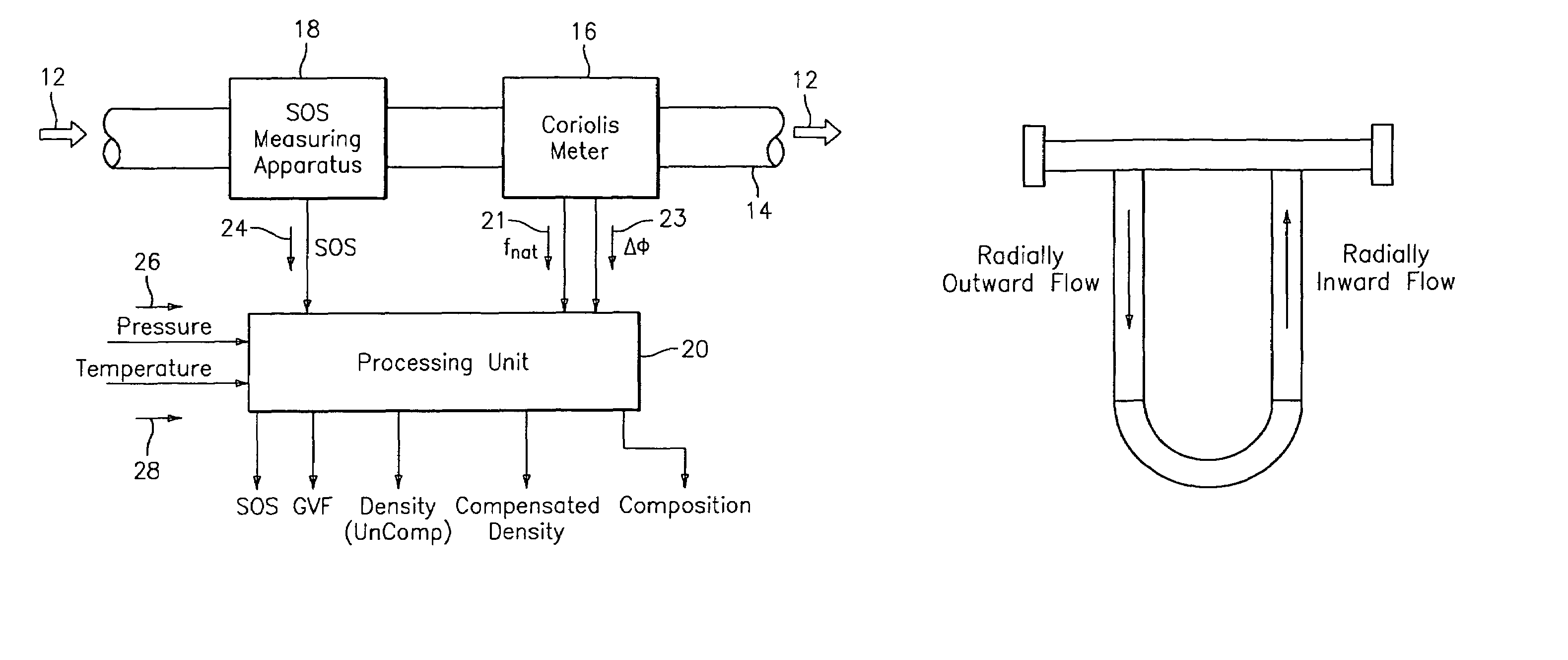

Apparatus and method for providing a density measurement augmented for entrained gas

A flow measuring system combines a density measuring device and a device for measuring the speed of sound (SOS) propagating through the fluid flow and / or for determining the gas volume fraction (GVF) of the flow. The GVF meter measures acoustic pressures propagating through the fluids to measure the speed of sound αmix propagating through the fluid to calculate at least gas volume fraction of the fluid and / or SOS. In response to the measured density and gas volume fraction, a processing unit determines the density of non-gaseous component of an aerated fluid flow. For three phase fluid flows, the processing unit can determine the phase fraction of the non-gaseous components of the fluid flow. The gas volume fraction (GVF) meter may include a sensing device having a plurality of strain-based or pressure sensors spaced axially along the pipe for measuring the acoustic pressures propagating through the flow.

Owner:EXPRO METERS

Apparatus and method for providing a density measurement augmented for entrained gas

ActiveUS20050061060A1Improve accuracySpecific gravity using flow propertiesVolume/mass flow by dynamic fluid flow effectThree-phaseDischarge measurements

A flow measuring system combines a density measuring device and a device for measuring the speed of sound (SOS) propagating through the fluid flow and / or for determining the gas volume fraction (GVF) of the flow. The GVF meter measures acoustic pressures propagating through the fluids to measure the speed of sound αmix propagating through the fluid to calculate at least gas volume fraction of the fluid and / or SOS. In response to the measured density and gas volume fraction, a processing unit determines the density of non-gaseous component of an aerated fluid flow. For three phase fluid flows, the processing unit can determine the phase fraction of the non-gaseous components of the fluid flow. The gas volume fraction (GVF) meter may include a sensing device having a plurality of strain-based or pressure sensors spaced axially along the pipe for measuring the acoustic pressures propagating through the flow.

Owner:EXPRO METERS

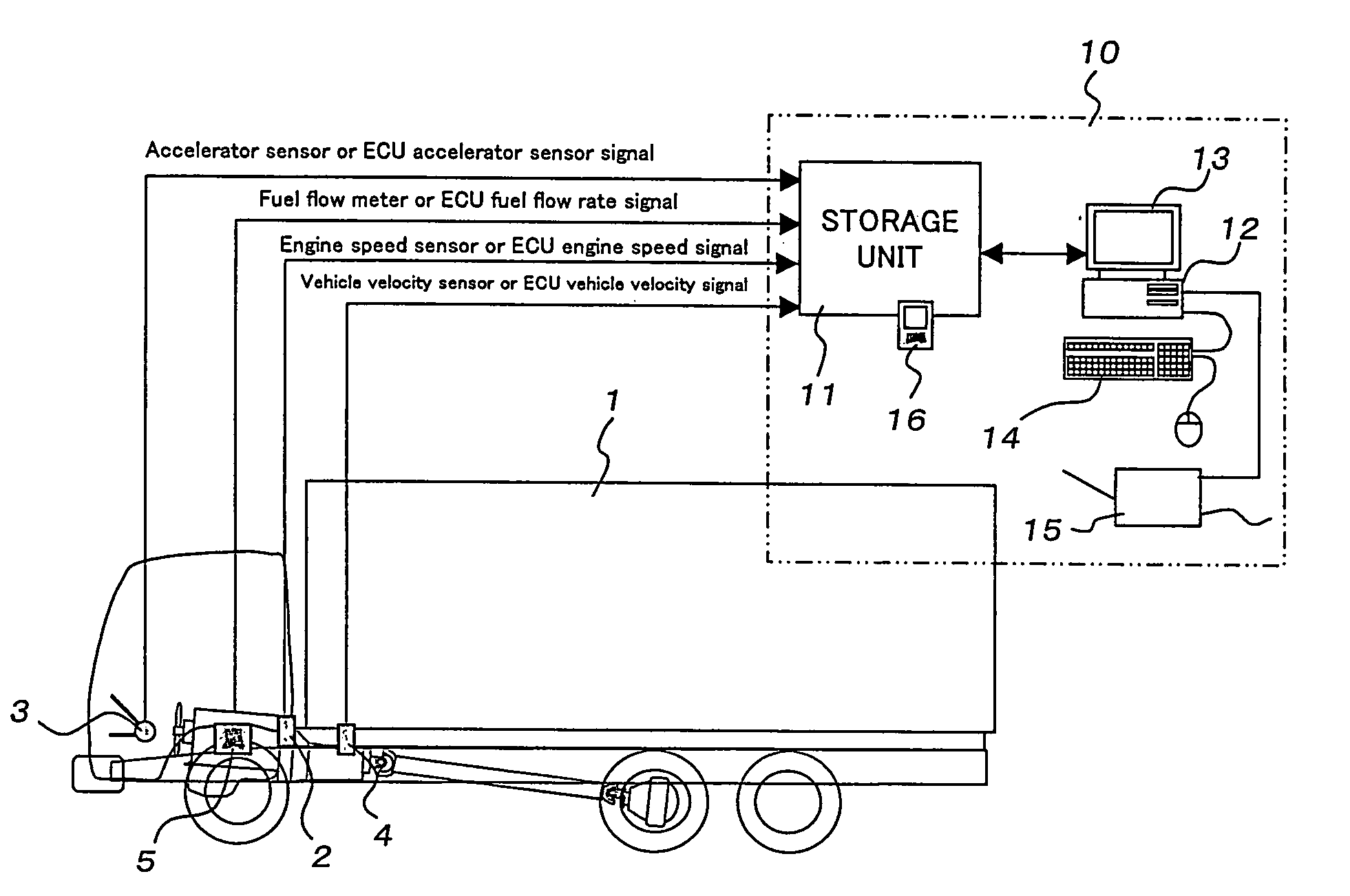

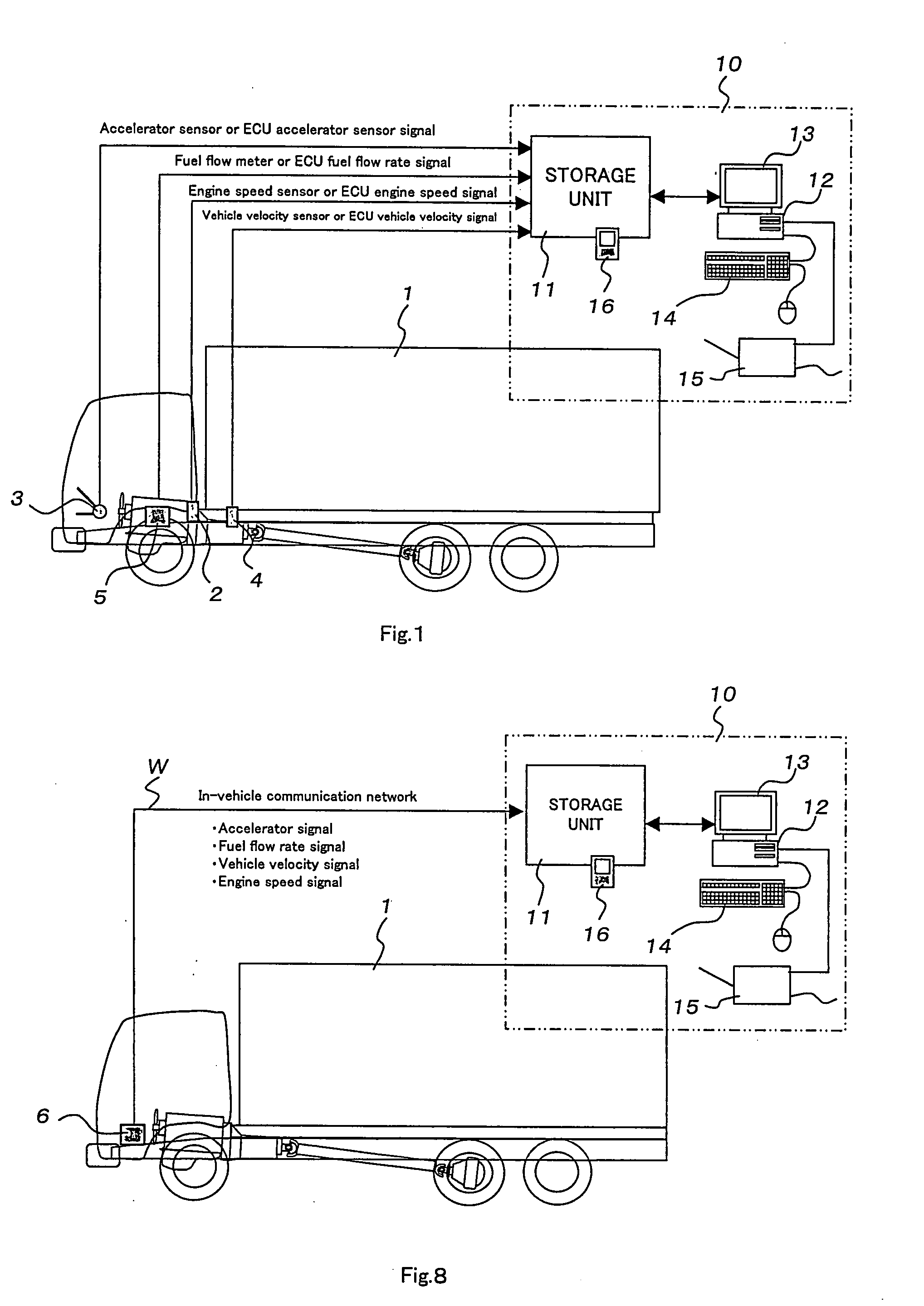

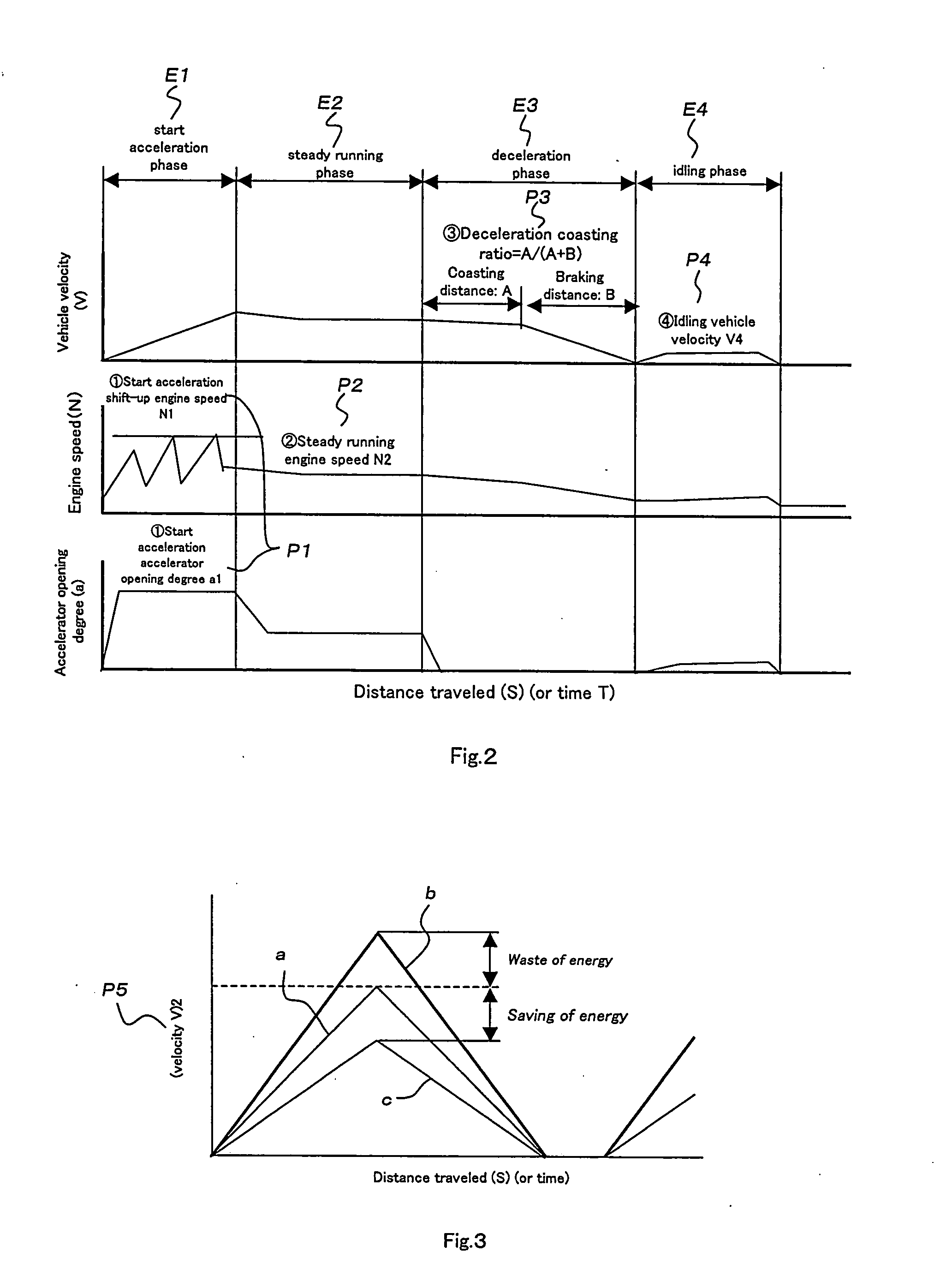

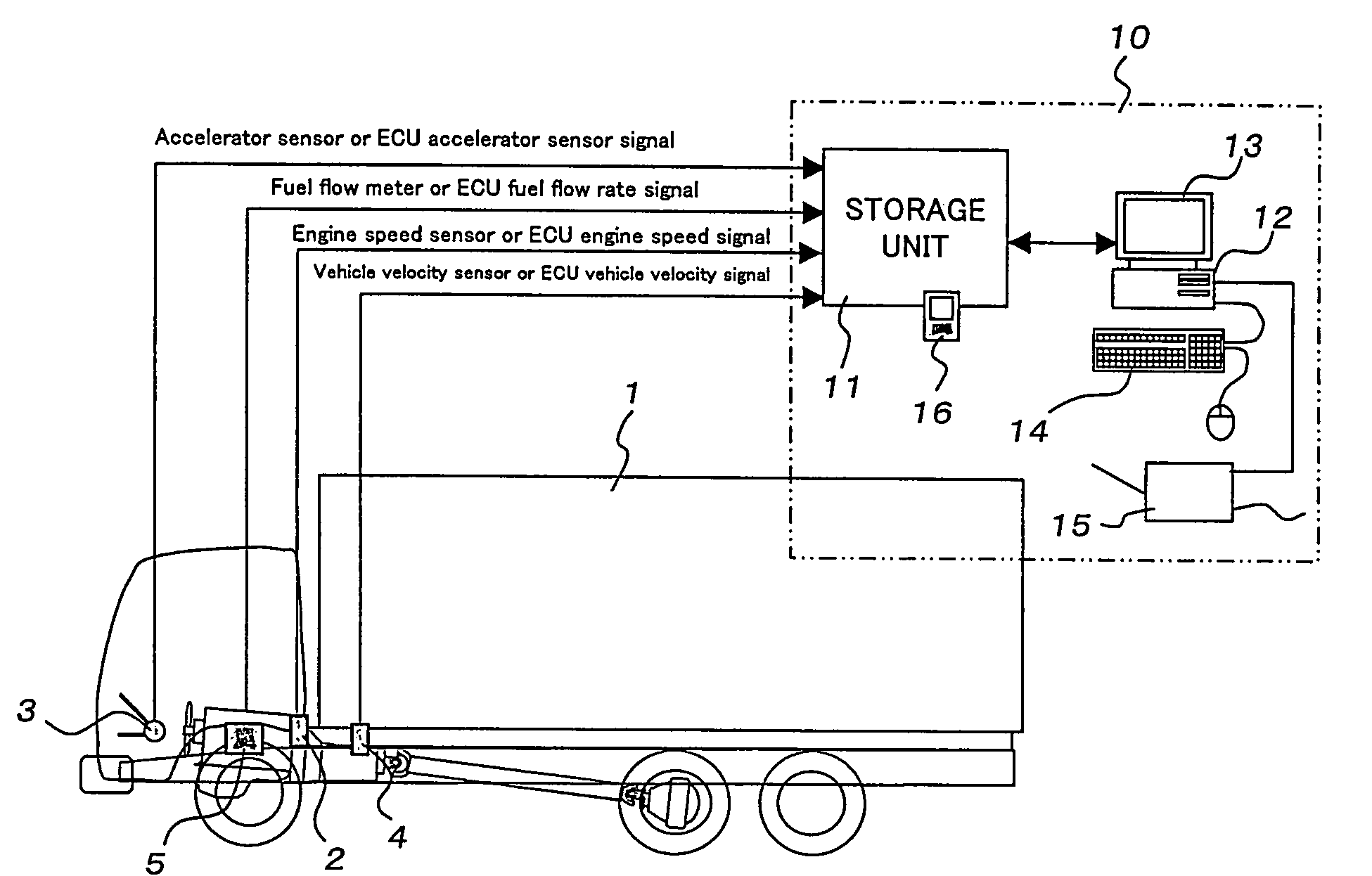

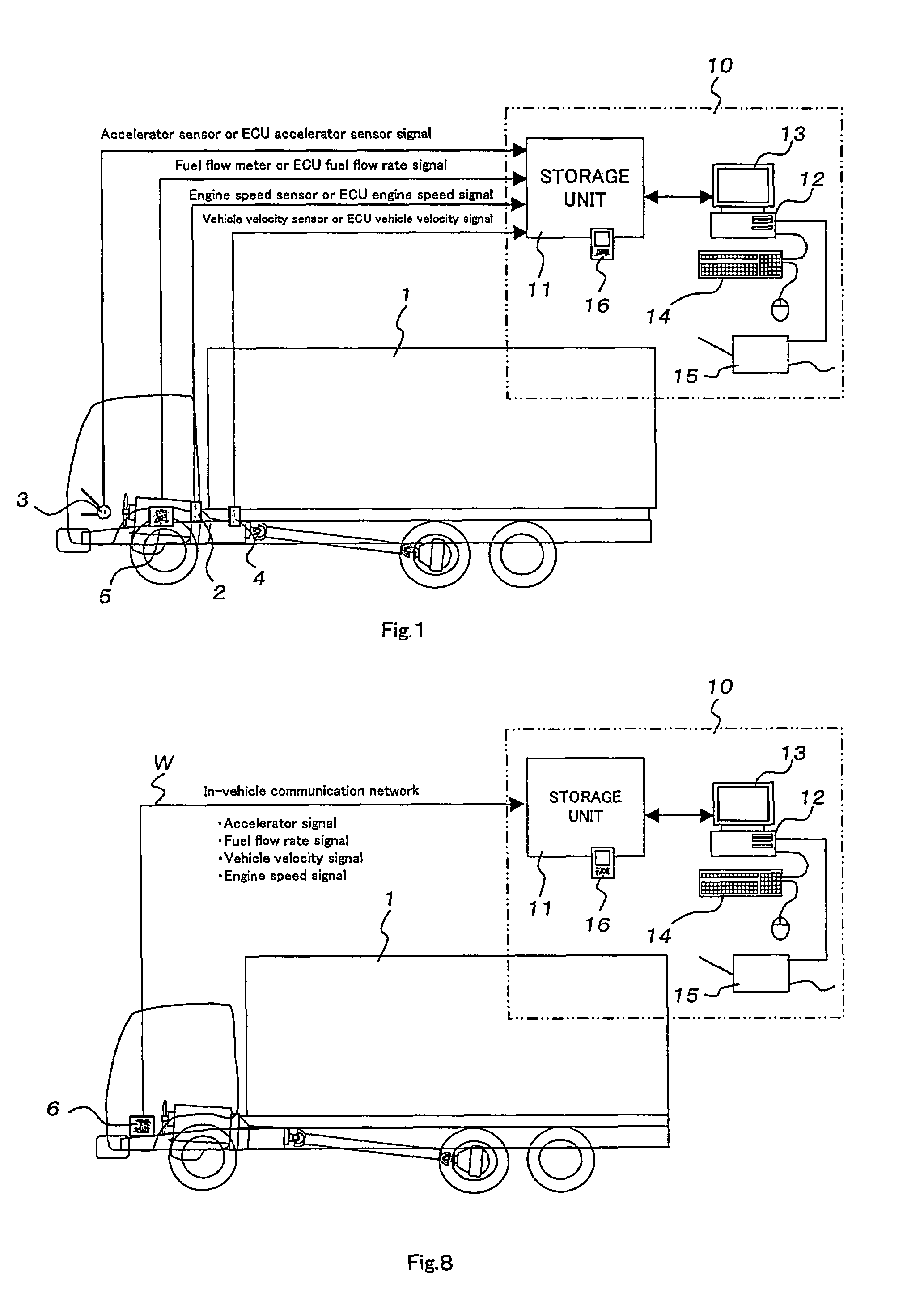

Fuel Consumption Evaluation System

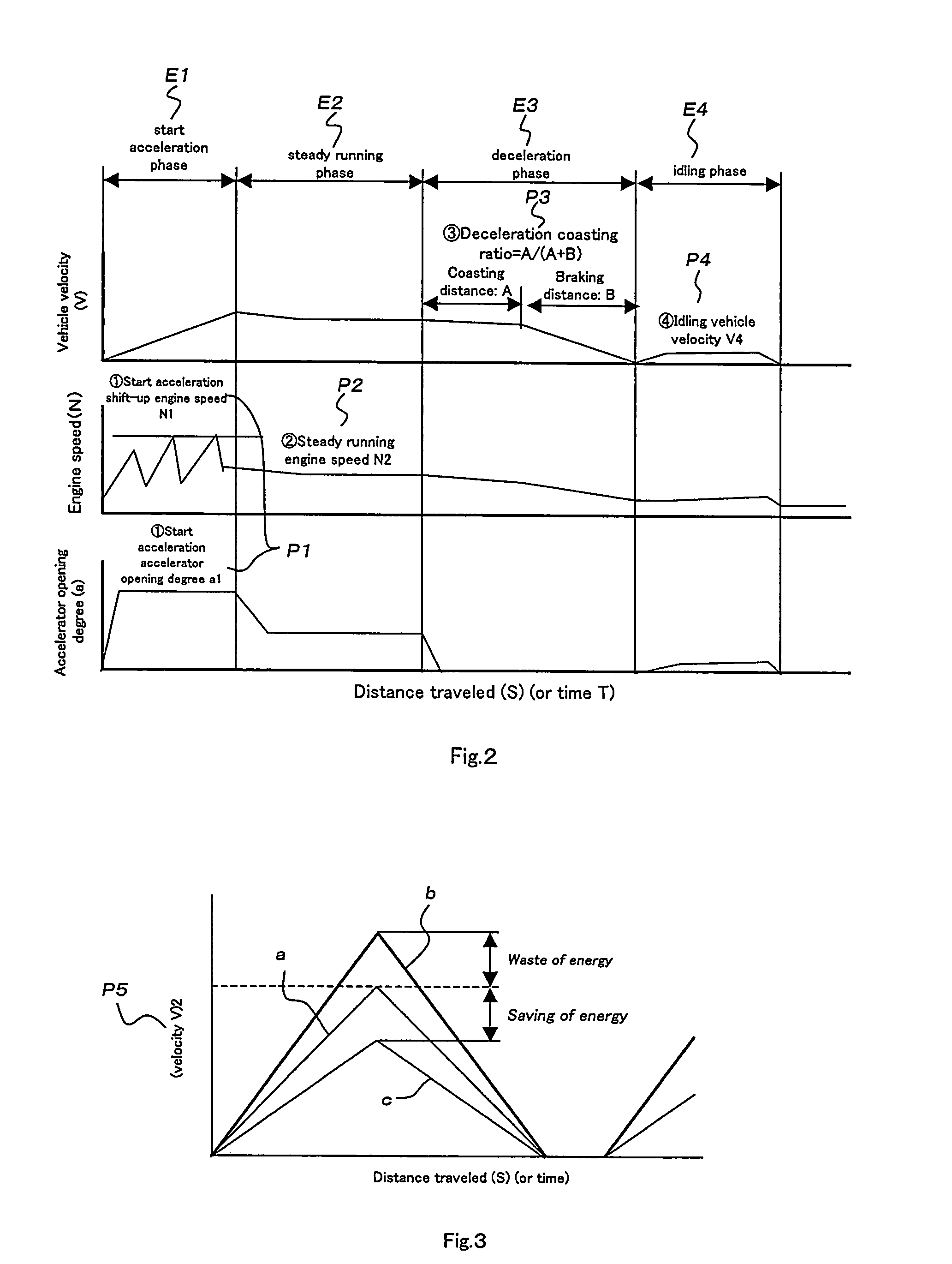

ActiveUS20070256481A1Improve accuracyAnalogue computers for vehiclesAnalogue computers for trafficDriver/operatorIn vehicle

The present invention is intended to provide a fuel consumption evaluation system which obtains quantitative data to determine whether actual driving has consumed fuel more efficiently or less efficiently than average driving and gives the driver and / or manager concrete advice for fuel-efficient driving based on the obtained data, and also provide a fuel consumption evaluation system which decides, based on obtained fuel efficiency data, whether driving is more fuel-efficient than average driving and sets a target and gives the driver and / or manager concrete advice for fuel-efficient driving based on the obtained data in consideration of change in vehicle total mass without any influence of slopes and traffic flows and particularly encourages and instructs, in real time, the driver to do fuel-efficient driving. The system comprises: engine speed measuring means (2) which measures engine speed of a truck (1); accelerator opening degree measuring means (3) which measures an accelerator opening degree (α); vehicle velocity measuring means (4) which measures vehicle velocity (V); fuel flow rate measuring means (5) which measures a fuel flow rate (Fw); and control means (10) which evaluates fuel consumption of the truck from measured engine speed (N), accelerator opening degree (α), vehicle velocity (V) and fuel flow rate (Fw). The control means, which has storage means (11), divides a run from start to stop into plural phases (start acceleration phase E1, steady running phase E2, deceleration phase E3, idling phase E4), sets fuel consumption-related parameters (“start acceleration shift-up engine speed N1 and start acceleration accelerator opening degree α1” P1, “steady running engine speed N2” P2, “deceleration coasting ratio” P3 and “idling velocity V4” P4) for each of the plural phases (E1-E4, determines fuel consumption (Q) for each of the plural phases (E1-E4) based on correlation (correlation line F in FIG. 5) between the parameters (P1, P2, P4) and fuel consumption (fuel consumption per unit distance traveled q), and makes an evaluation based on the determined fuel consumption (Q).

Owner:VOLVO LASTVAGNAR AB

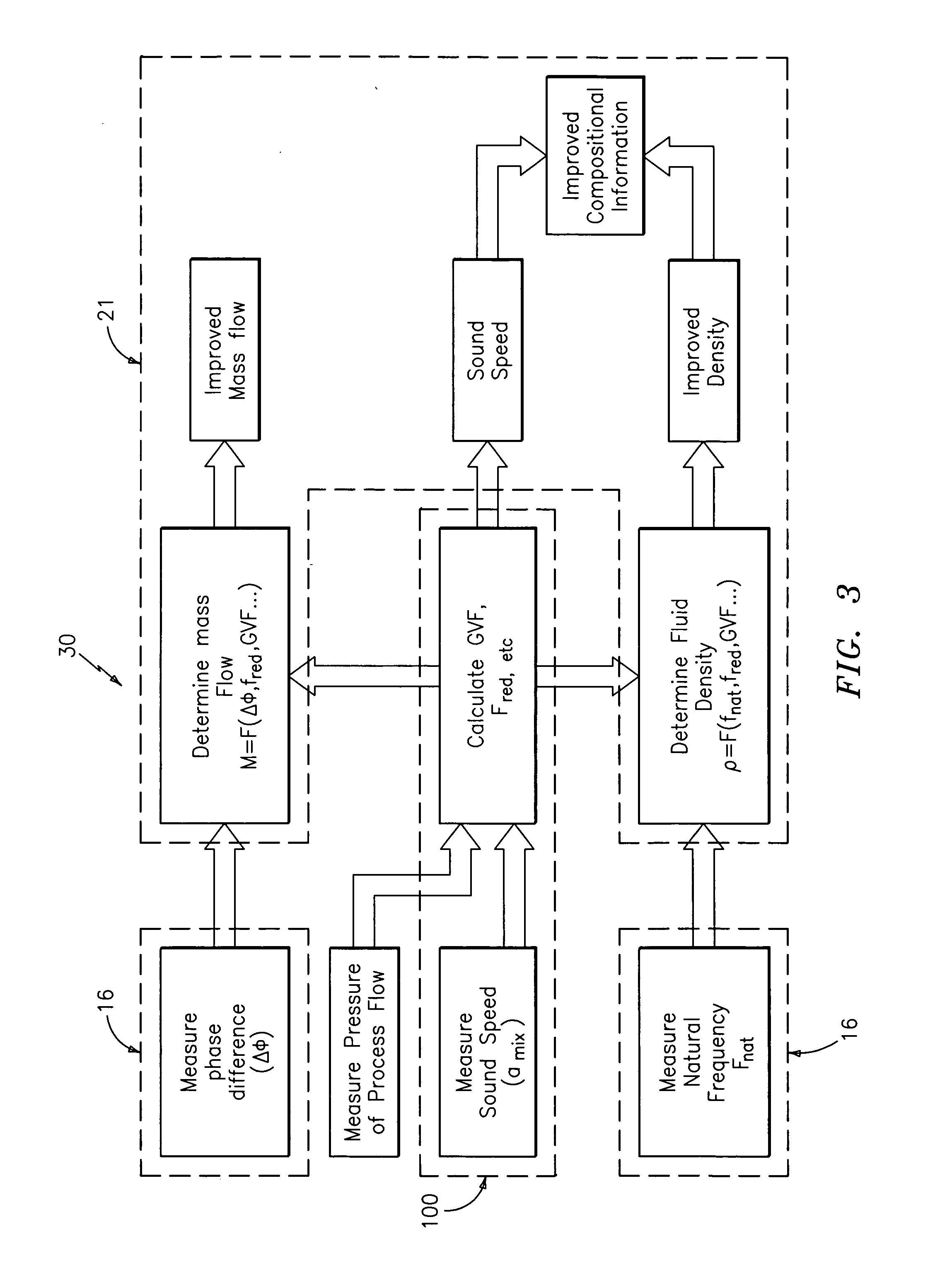

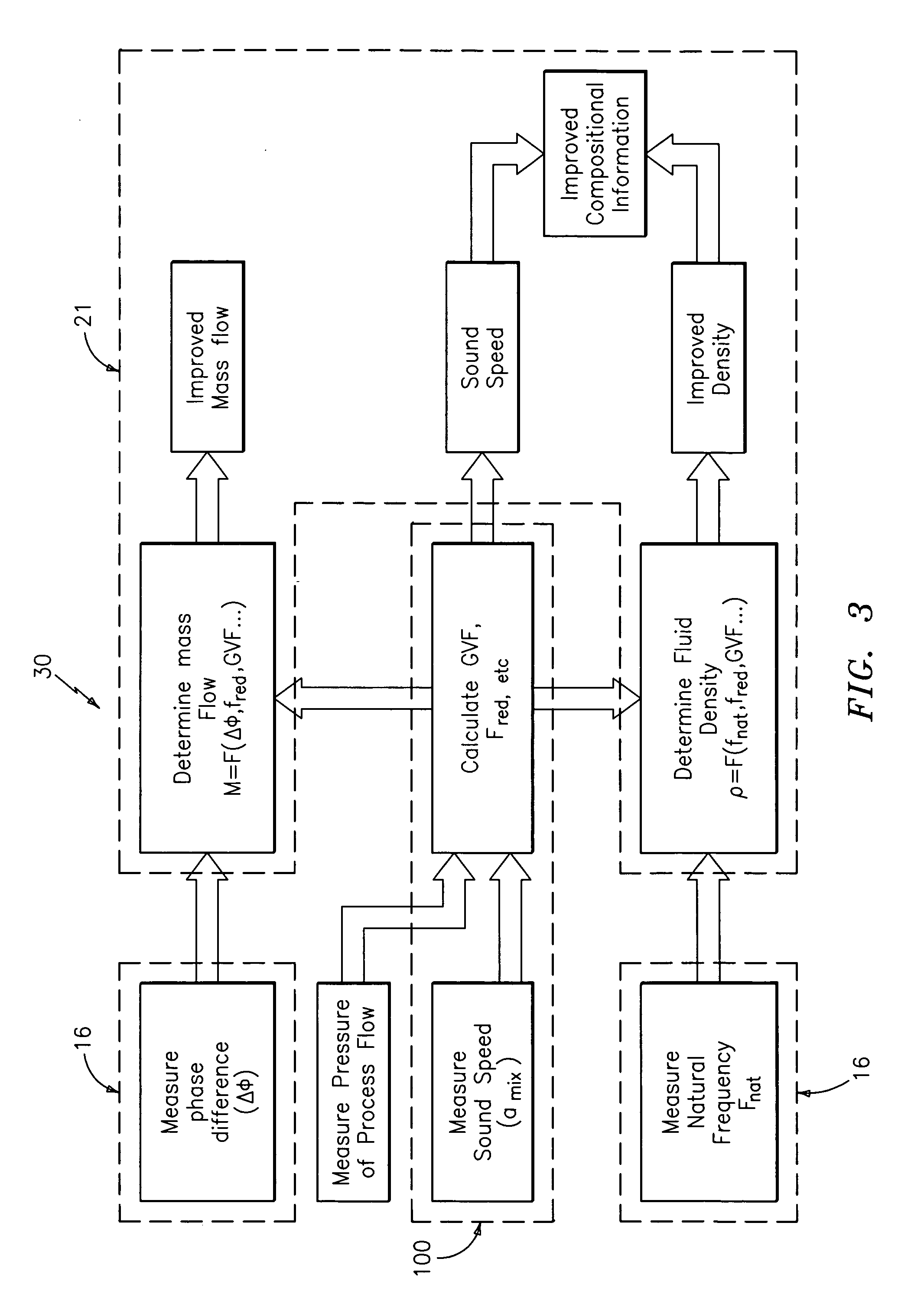

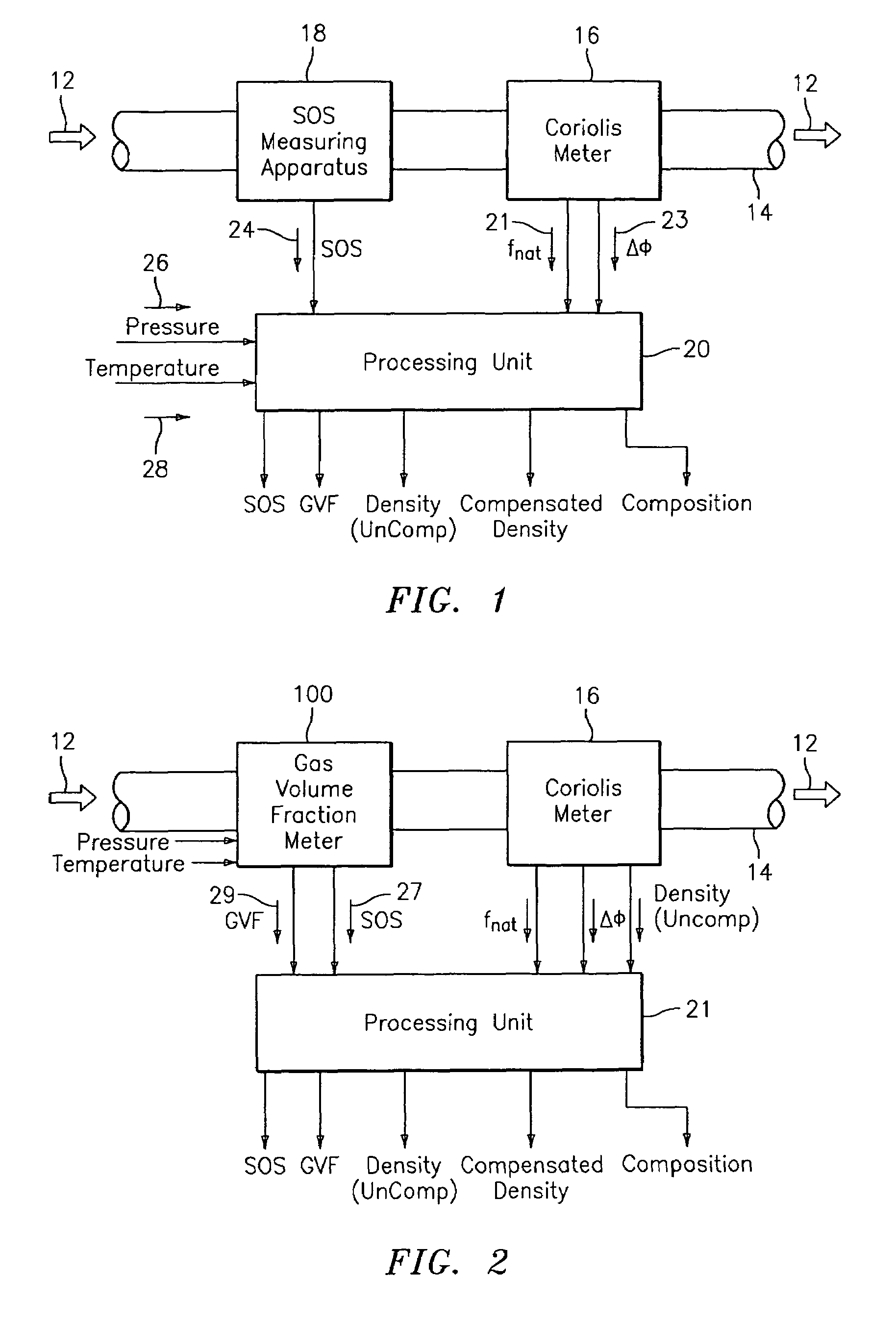

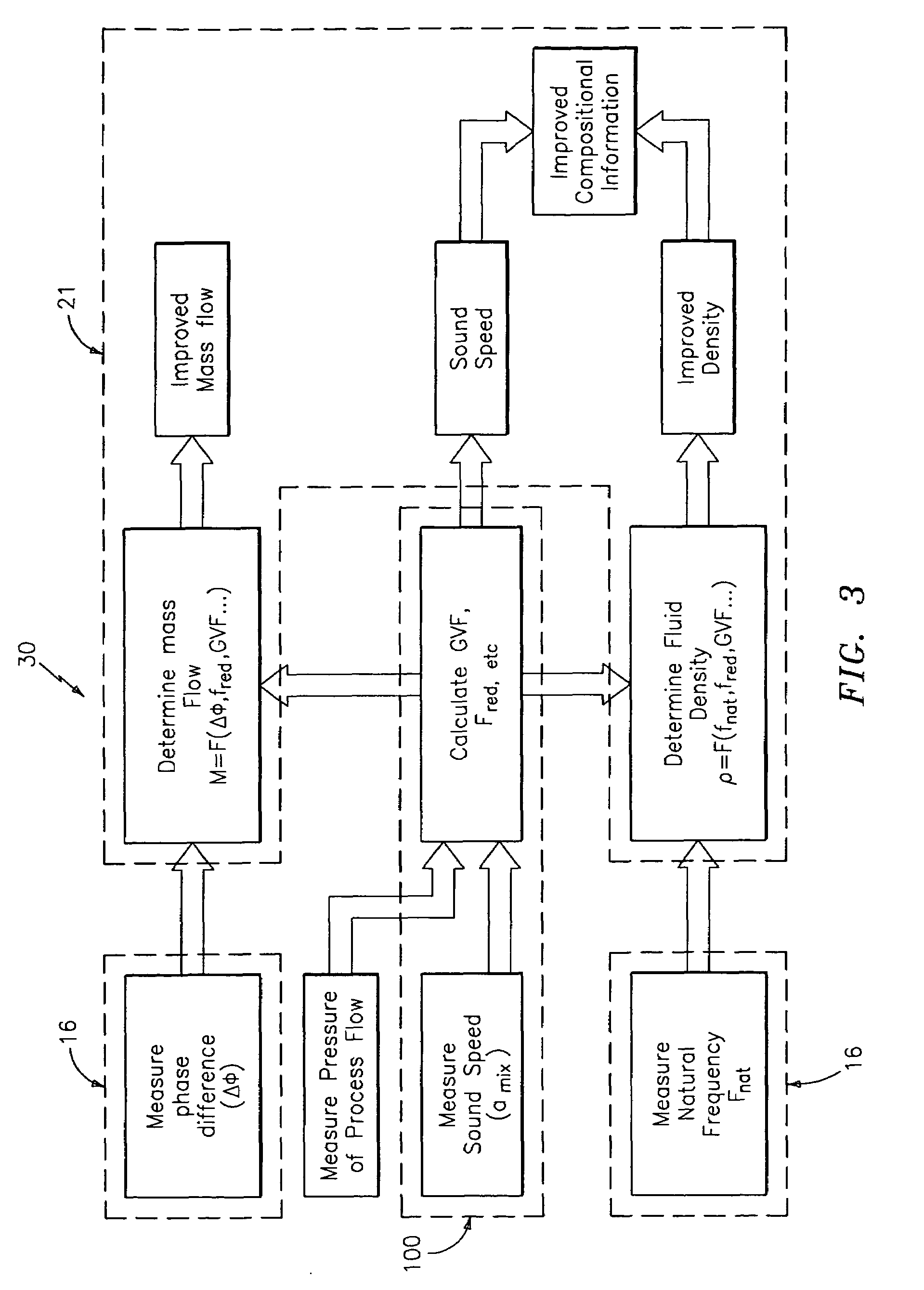

Apparatus and method for compensating a coriolis meter

ActiveUS20050044929A1High densityAdd additional massVolume/mass flow by dynamic fluid flow effectVolume meteringVolumetric Mass DensityDischarge measurements

A flow measuring system is provided that provides at least one of a compensated mass flow rate measurement and a compensated density measurement. The flow measuring system includes a gas volume fraction meter in combination with a coriolis meter. The GVF meter measures acoustic pressures propagating through the fluids to measure the speed of sound αmix propagating through the fluid to calculate at least gas volume fraction of the fluid and / or the reduced natural frequency. For determining an improved density for the coriolis meter, the calculated gas volume fraction and / or reduced frequency is provided to a processing unit. The improved density is determined using analytically derived or empirically derived density calibration models (or formulas derived therefore), which is a function of the measured natural frequency and at least one of the determined GVF, reduced frequency and speed of sound, or any combination thereof. The gas volume fraction (GVF) meter may include a sensing device having a plurality of strain-based or pressure sensors spaced axially along the pipe for measuring the acoustic pressures propagating through the flow.

Owner:EXPRO METERS

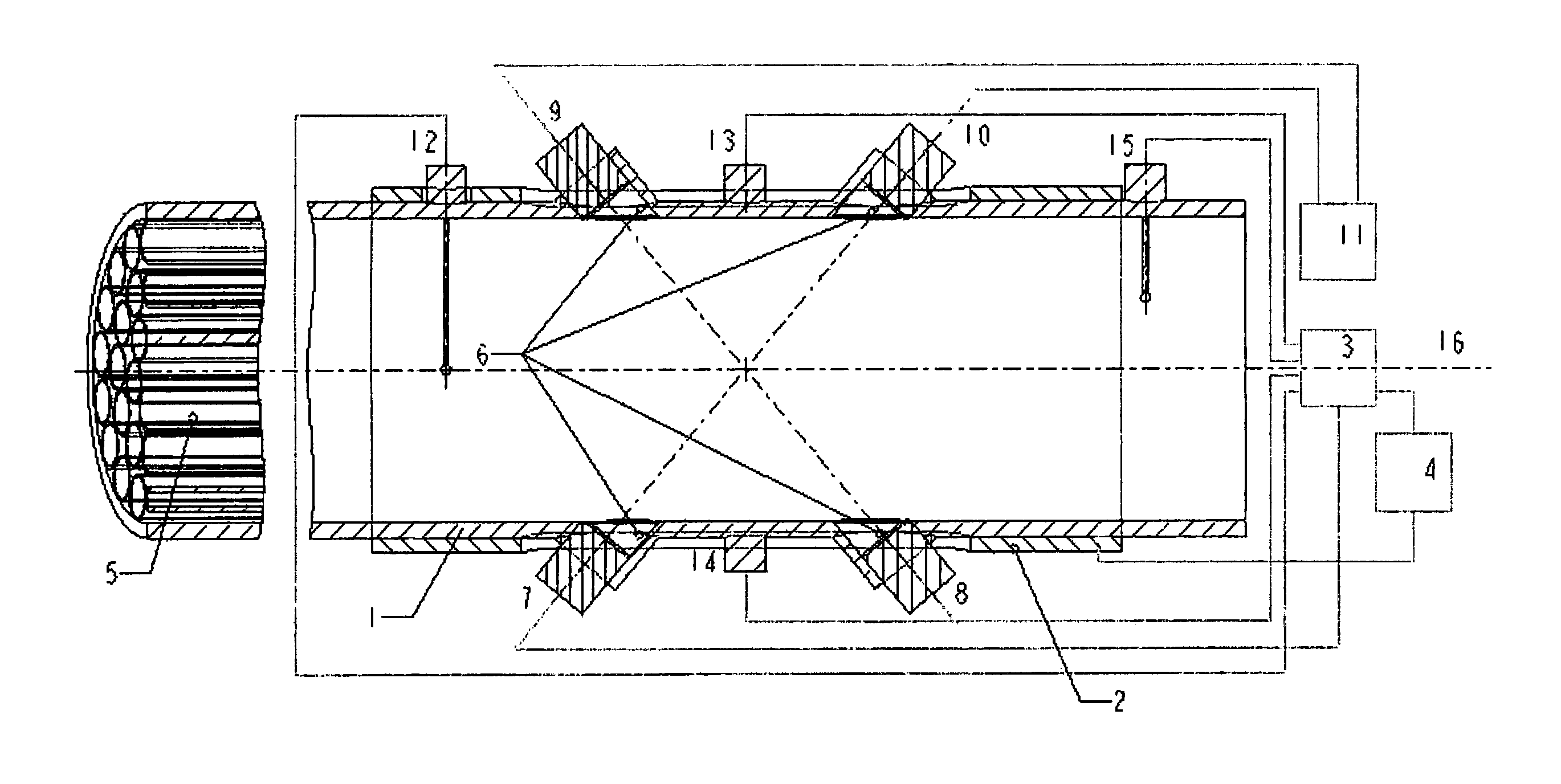

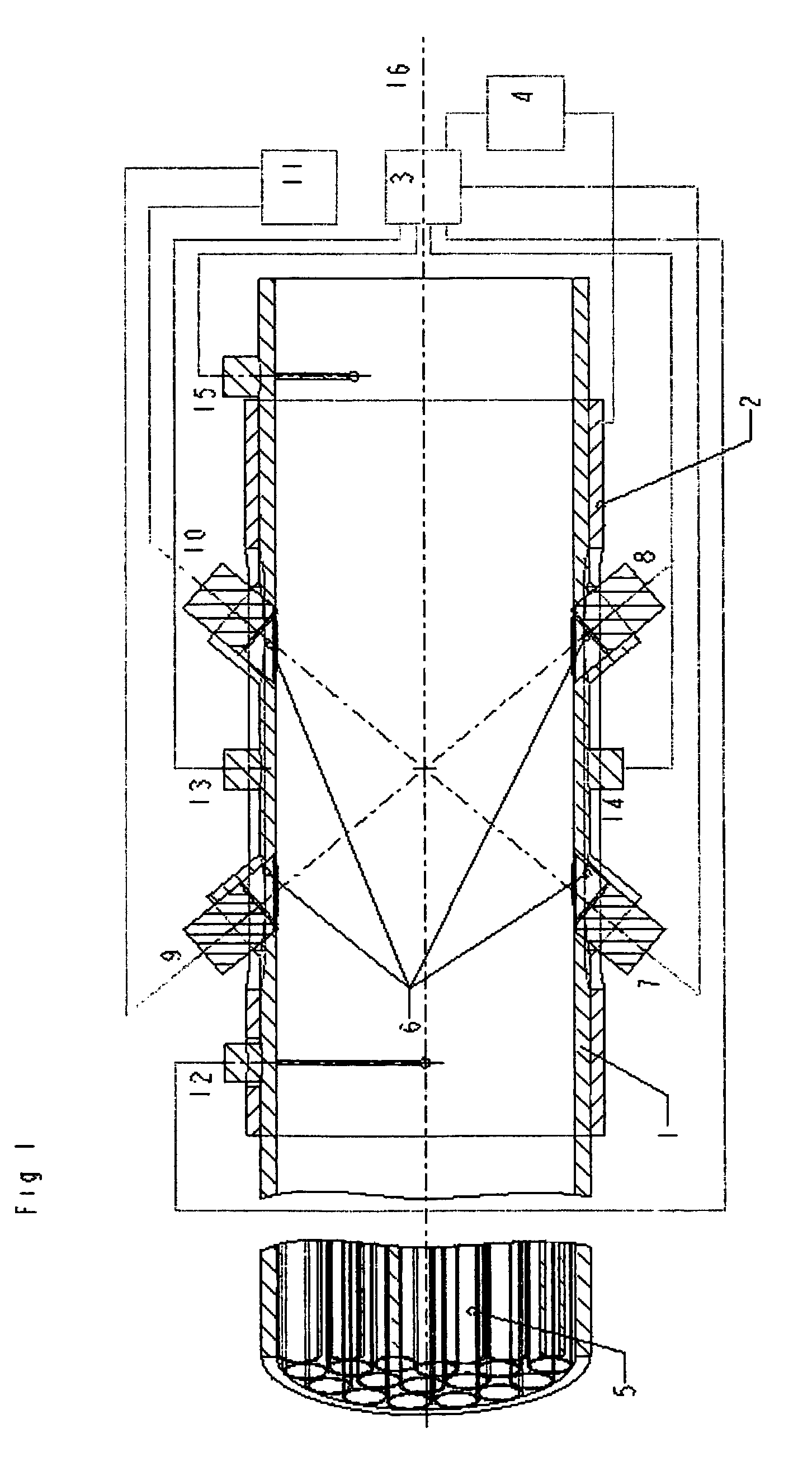

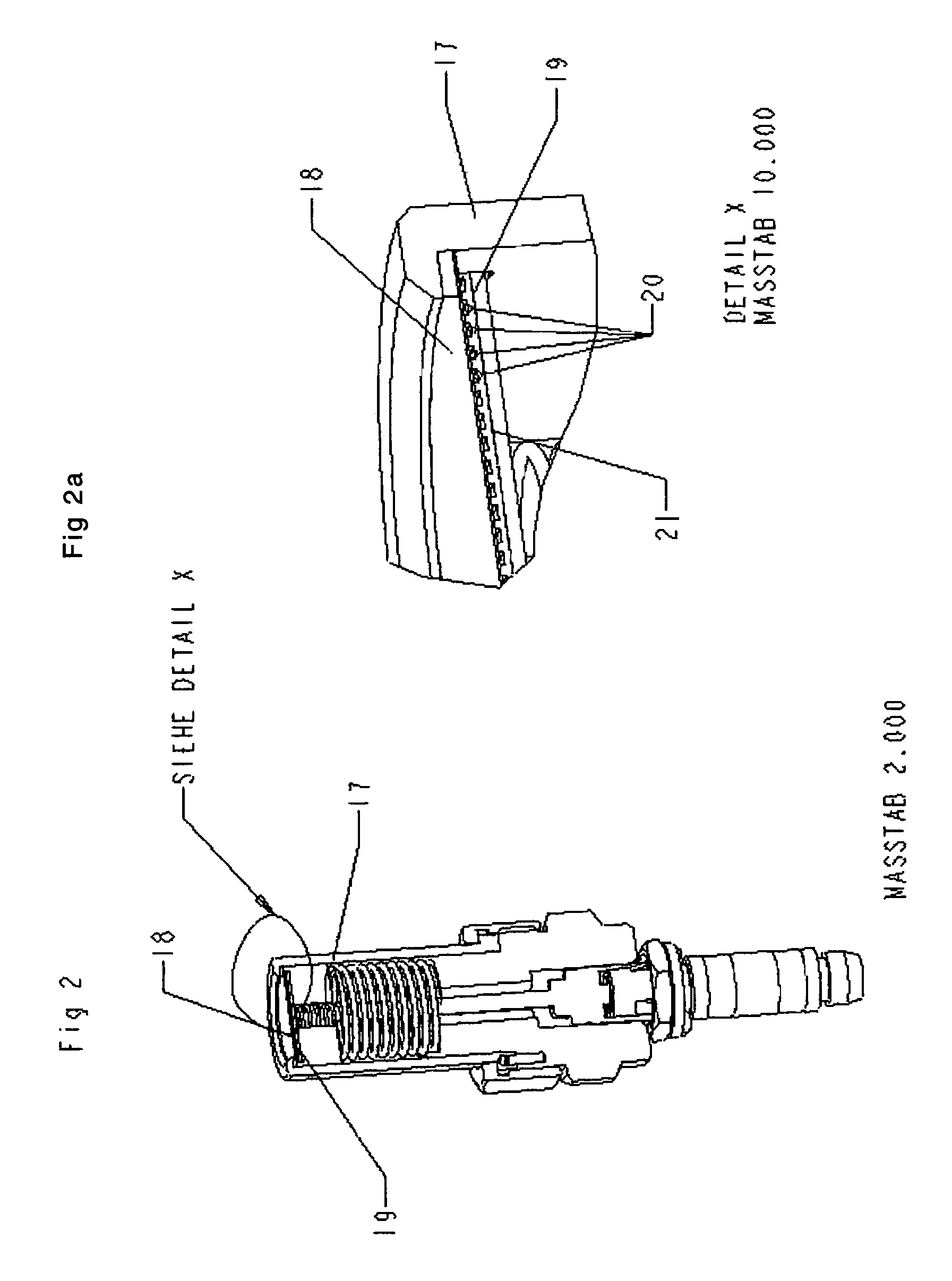

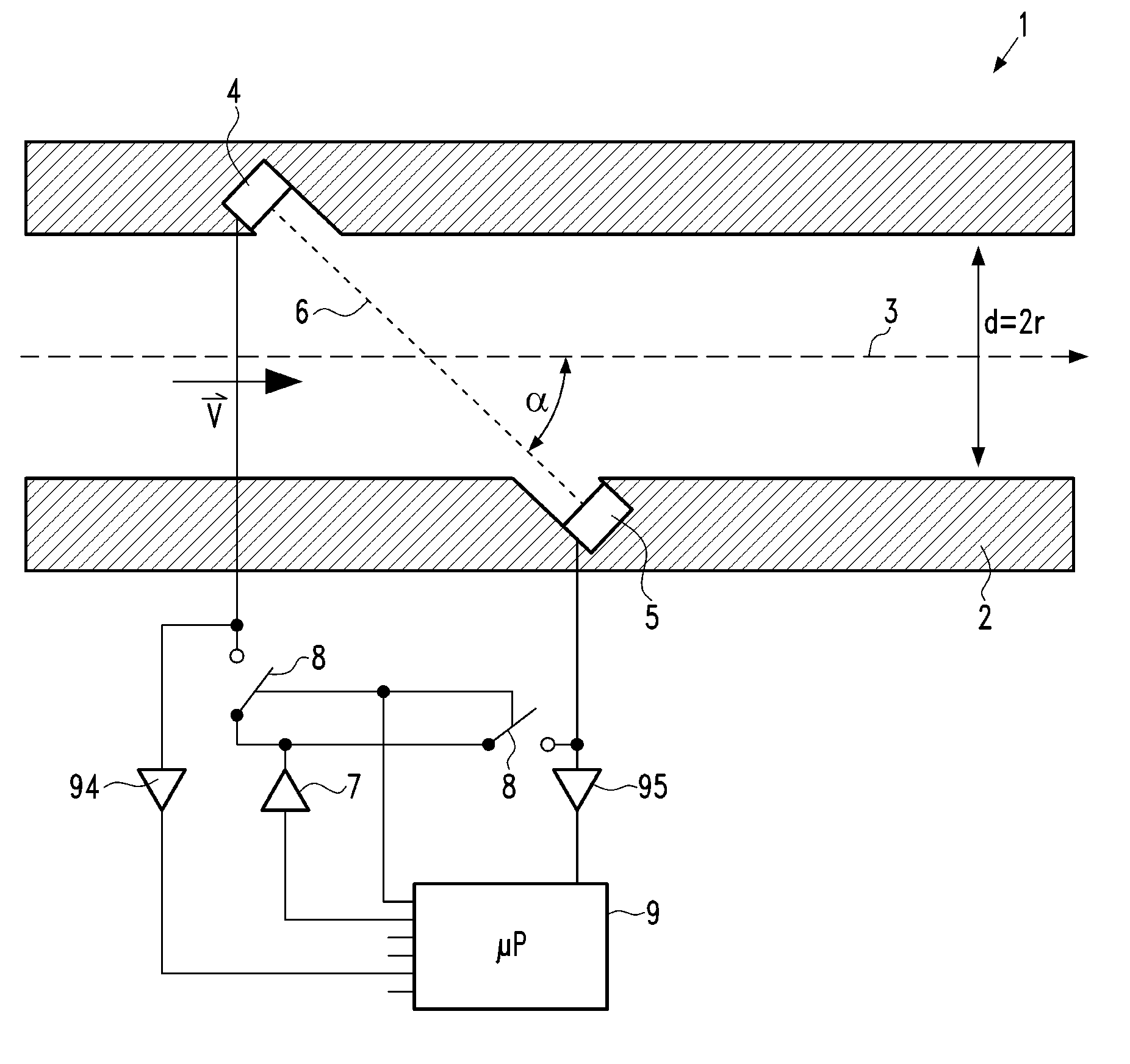

Ultrasonic gas flowmeter as well as device to measure exhaust flows of internal combustion engines and method to determine flow of gases

ActiveUS7093502B2Level gas temperature profileMinimize impactVolume/mass flow measurementVolume variation compensation/correction apparatusUltrasonic sensorDischarge measurements

An ultrasonic gas flowmeter includes a measuring pipe with flowing gas, transmitting and receiving sound transducers, transmission and reception electronics, and evaluation electronics. The sound transducers (7, 8, 9, 10) are designed as capacitive electro-acoustic ultrasonic transducers to construct a flowmeter with improved capacity, especially in view of temperature stability and the reduction and consideration of a temperature profile. Devices (5, 6) are provided to level the gas temperature profile and to minimize the influence of the temperature profile on the flow measurement. A more accurate and dependable detection of the volume flow or the mass flow of gases is to be achieved, especially in highly dynamic flows, for the method of determining the flow of gases whereby the mean flow velocity is determined and the flowing gas quantity is determined with highly synchronized resolution from the two transit times of two acoustic signals. In addition, an assessed value is computed (35) for the flow after the determination of the transit times and the assessed value is corrected at least by means of a characteristic temperature of the gas and the temperature of the wall of the measuring pipe (36).

Owner:AVL LIST GMBH

Apparatus and method for providing a flow measurement compensated for entrained gas

ActiveUS7165464B2Material analysis using sonic/ultrasonic/infrasonic wavesMaterial analysis using microwave meansSensor arrayAir entrainment

A apparatus 10,110 is provided that measures the speed of sound and / or vortical disturbances propagating in a fluid or mixture having entrained gas / air to determine the gas volume fraction of the flow 12 propagating through a pipes and compensating or correcting the volumetric flow measurement for entrained air. The GVF meter includes and array of sensor disposed axially along the length of the pipe. The GVF measures the speed of sound propagating through the pipe and fluid to determine the gas volume fraction of the mixture using array processing. The GVF meter can be used with an electromagnetic meter and a consistency meter to compensate for volumetric flow rate and consistency measurement respective, to correct for errors due to entrained gas / air.

Owner:EXPRO METERS

Flow rate measurement for industrial sensing applications using unsteady pressures

Flow rate measurement system includes two measurement regions 14,16 located an average axial distance ΔX apart along the pipe 12, the first measurement region 14 having two unsteady pressure sensors 18,20, located a distance X1 apart, and the second measurement region 16, having two other unsteady pressure sensors 22,24, located a distance X2 apart, each capable of measuring the unsteady pressure in the pipe 12. Signals from each pair of pressure sensors 18,20 and 22,24 are differenced by summers 44,54, respectively, to form spatial wavelength filters 33,35, respectively. Each spatial filter 33,35filters out acoustic pressure disturbances Pacoustic and other long wavelength pressure disturbances in the pipe 12 and passes short-wavelength low-frequency vortical pressure disturbances Pvortical associated with the vortical flow field 15. The spatial filters 33,35 provide signals Pas1,Pas2 to band pass filters 46,56 that filter out high frequency signals. The Pvortical-dominated filtered signals Pasf1,Pasf2 from the two regions 14,16 are cross-correlated by Cross-Correlation Logic 50 to determine a time delay τ between the two sensing locations 14,16 which is divided into the distance ΔX to obtain a convection velocity Uc(t) that is related to an average flow rate of the fluid (i.e., one or more liquids and / or gases) flowing in the pipe 12. The invention may also be configured to detect the velocity of any desired inhomogeneous pressure field in the flow. The invention may also be combined with an instrument, an opto-electronic converter and a controller in an industrial process control system.

Owner:EXPRO METERS

Apparatus and method for compensating a coriolis meter

ActiveUS7152460B2High densityAdd additional massMaterial analysis using microwave meansVolume/mass flow by dynamic fluid flow effectDischarge measurementsVolumetric Mass Density

A flow measuring system is provided that provides at least one of a compensated mass flow rate measurement and a compensated density measurement. The flow measuring system includes a gas volume fraction meter in combination with a coriolis meter. The GVF meter measures acoustic pressures propagating through the fluids to measure the speed of sound αmix propagating through the fluid to calculate at least gas volume fraction of the fluid and / or the reduced natural frequency. For determining an improved density for the coriolis meter, the calculated gas volume fraction and / or reduced frequency is provided to a processing unit. The improved density is determined using analytically derived or empirically derived density calibration models (or formulas derived therefore), which is a function of the measured natural frequency and at least one of the determined GVF, reduced frequency and speed of sound, or any combination thereof. The gas volume fraction (GVF) meter may include a sensing device having a plurality of strain-based or pressure sensors spaced axially along the pipe for measuring the acoustic pressures propagating through the flow.

Owner:EXPRO METERS

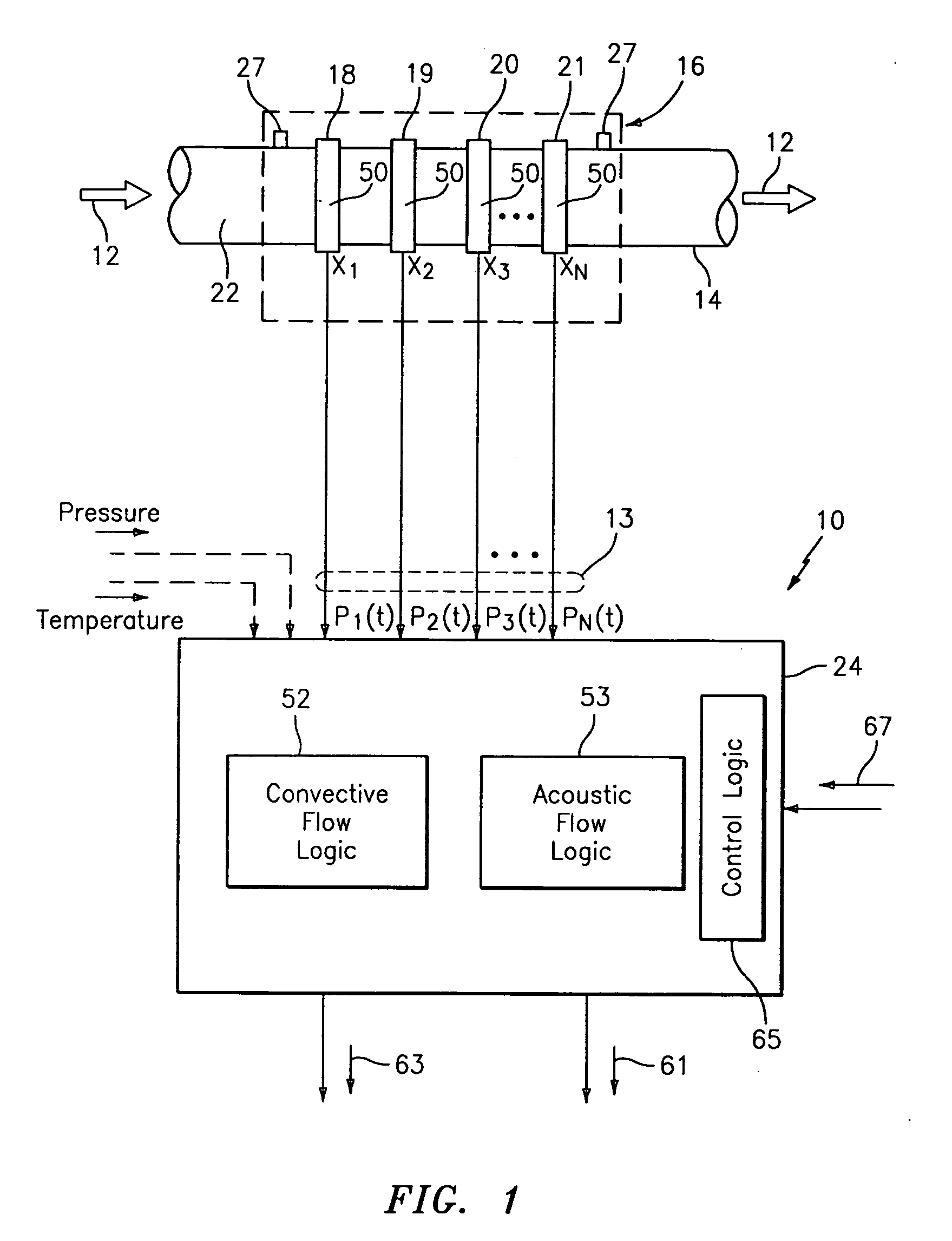

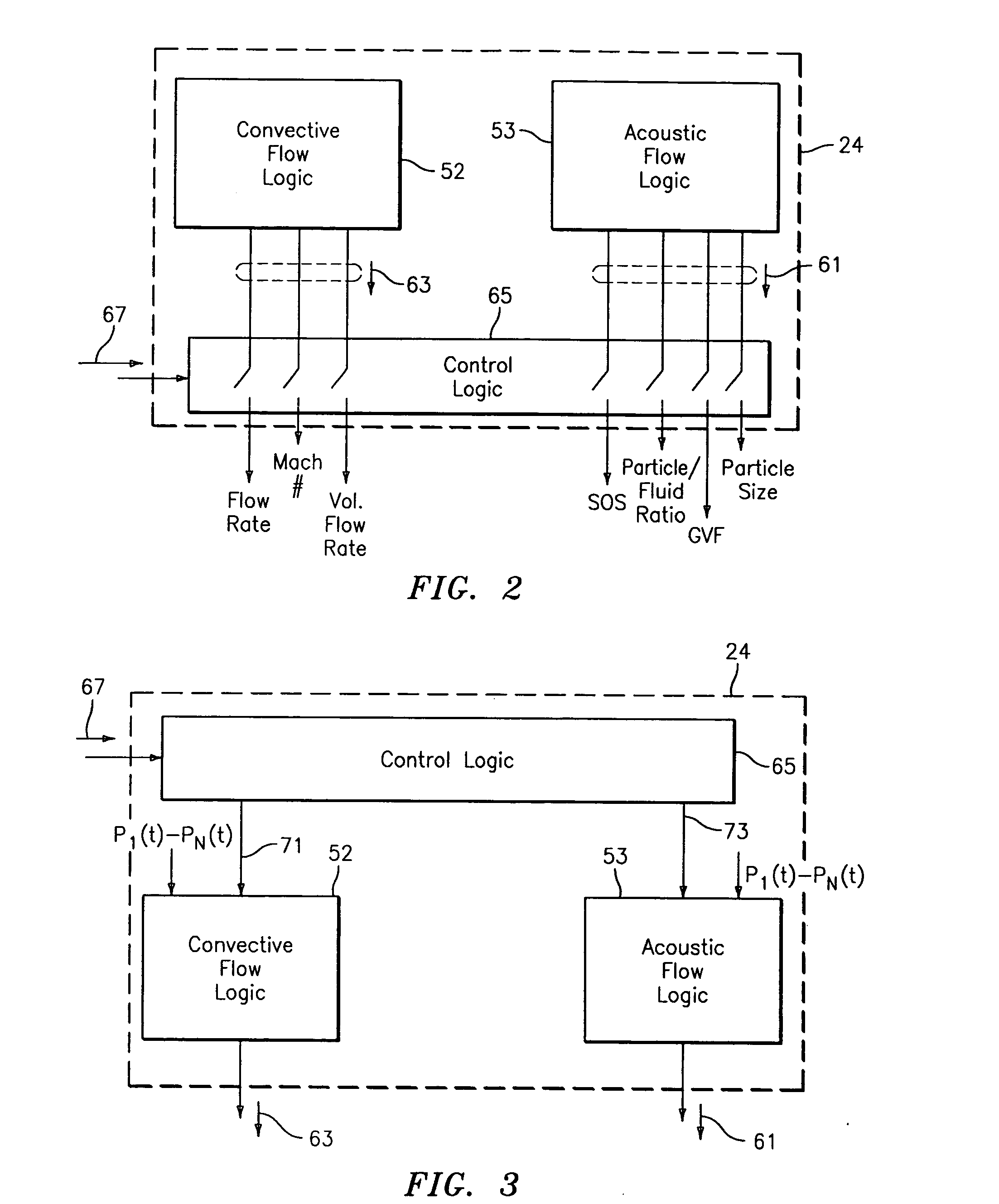

Configurable multi-function flow measurement apparatus having an array of sensors

ActiveUS20050011283A1Testing/calibration apparatusVolume/mass flow by thermal effectsSensor arrayMeasurement device

A configurable multi-function flow measurement apparatus is provided that can selectably function to measure the speed of sound propagating through a fluid flowing within a pipe and / or to measure pressures disturbances (e.g. vortical disturbances or eddies) moving with a fluid to determine respective parameters of the flow propagating through a pipe and detects the health of an industrial process. The configurable flow measurement device can also be selectable to function as a system diagnostic meter that provides a diagnostic signal indicative of the health of the industrial process, namely health of pumps, valves, motors and other devices in an industrial flow loop. The apparatus includes a sensing device that includes an array of strained-based or pressure sensors used to measure the acoustic and convective pressure variations in the flow to determine desired parameters. In response to a remote or local configuration signal, a control logic selects the desired function of the flow measurement apparatus.

Owner:EXPRO METERS

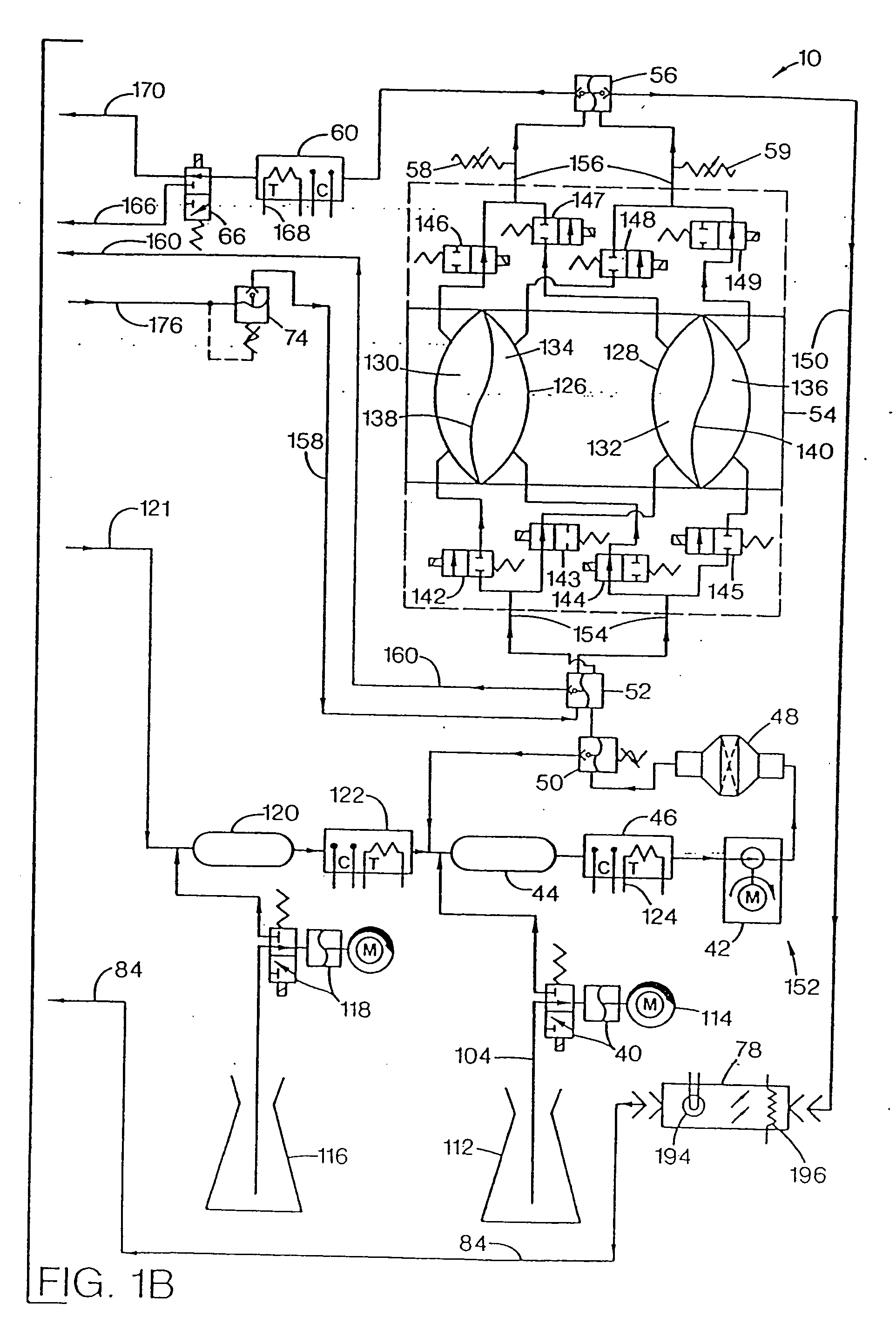

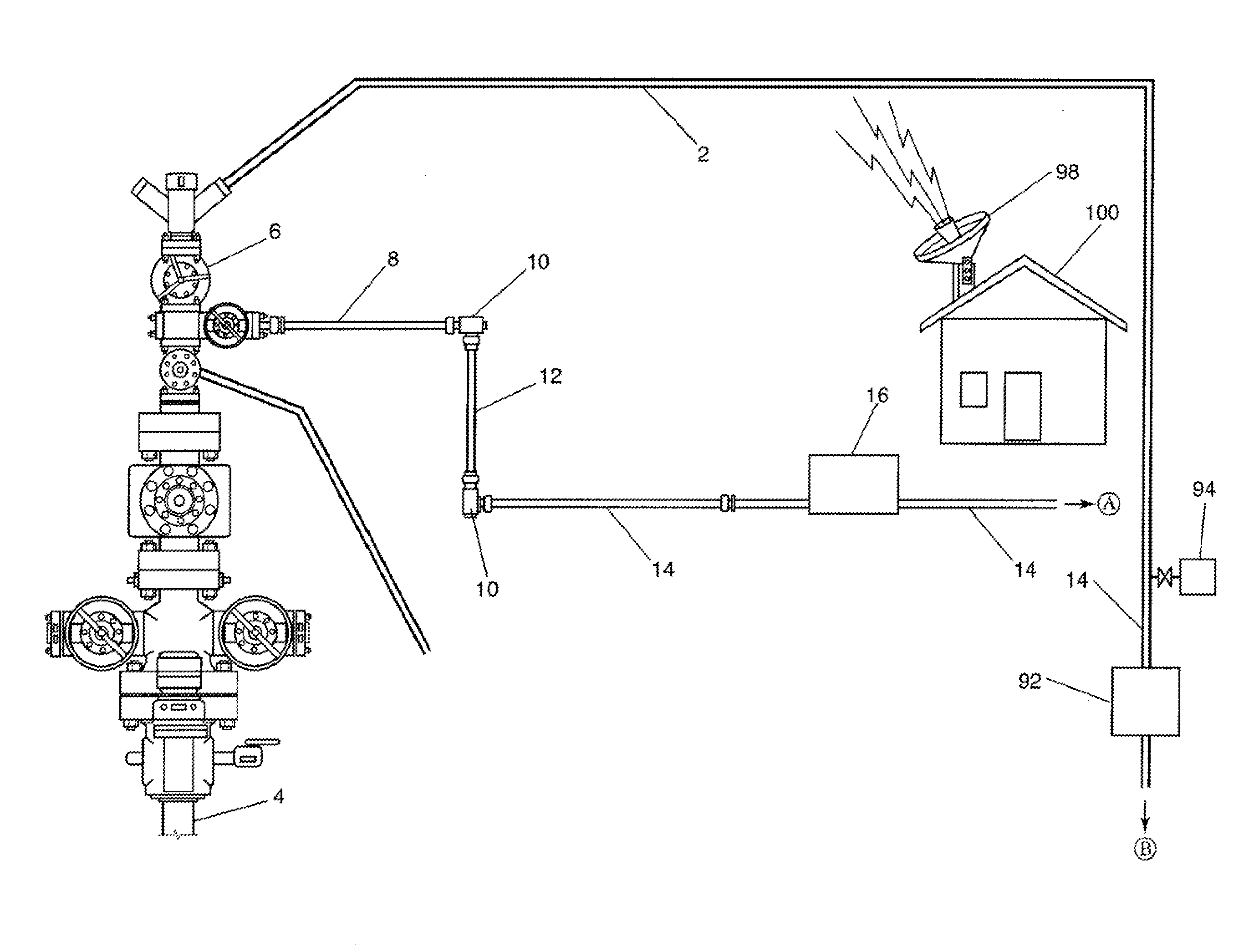

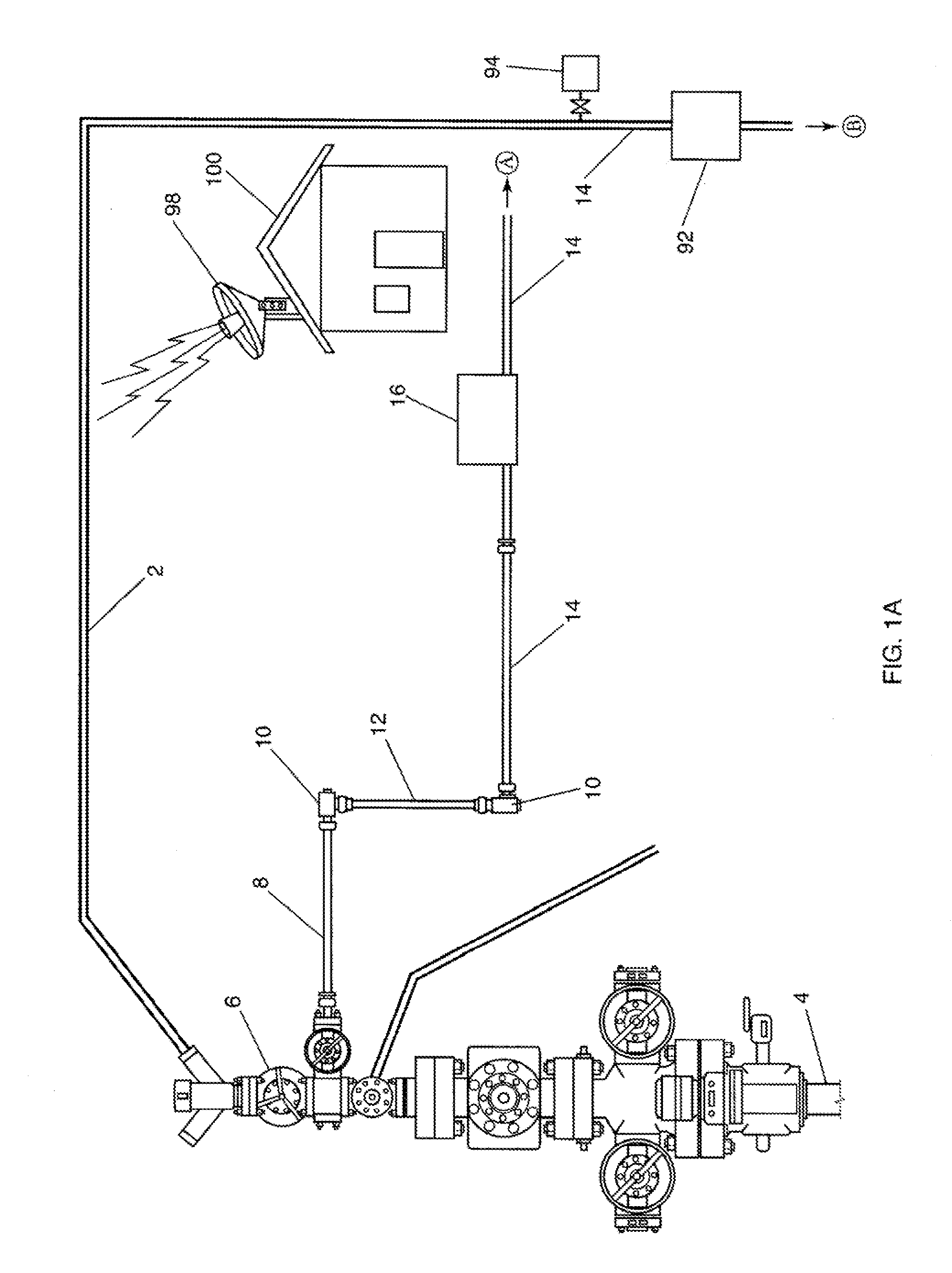

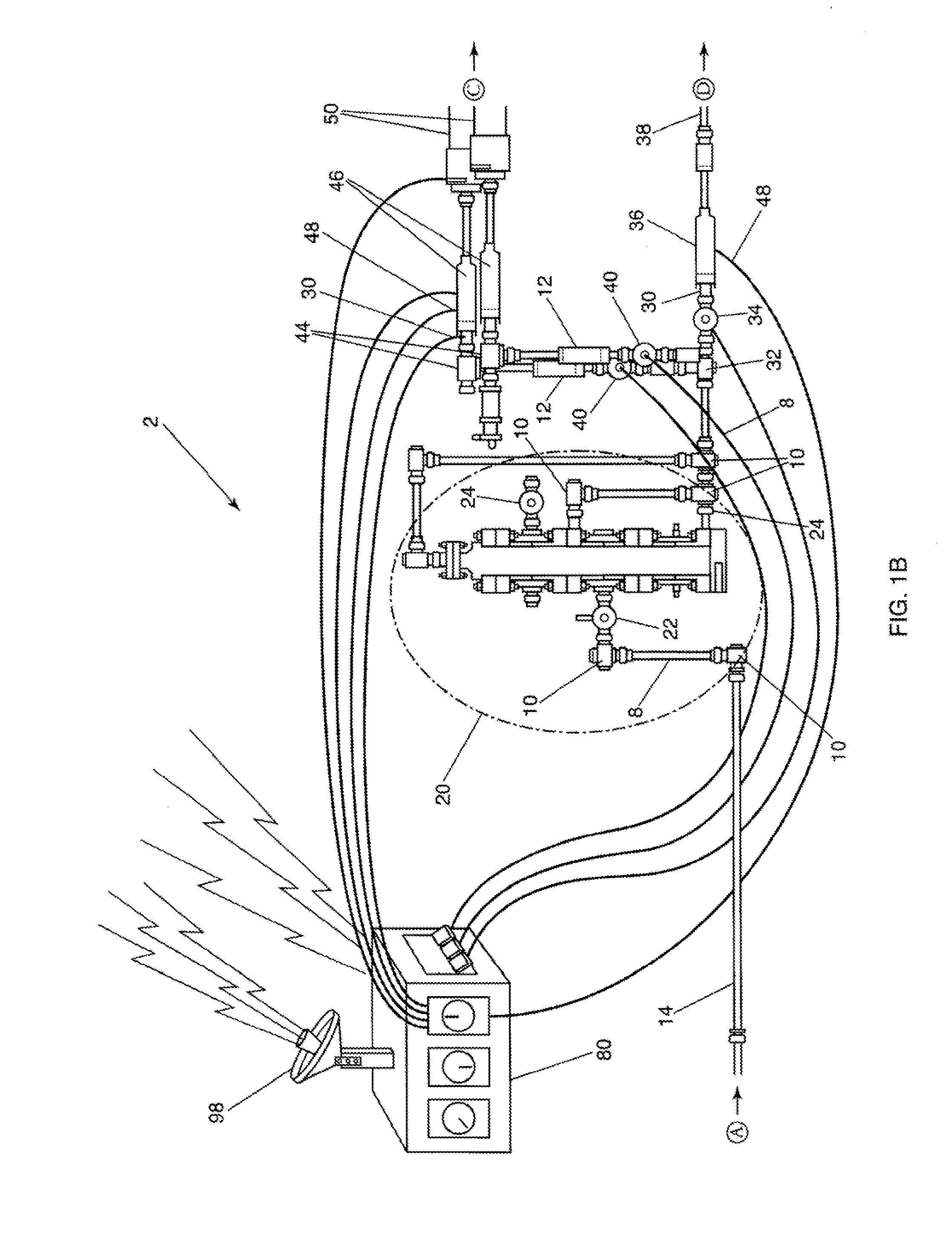

Automated closed loop flowback and separation system

InactiveUS20100206560A1Realize automatic adjustmentSurveyDrilling rodsAutomatic controlHuman–machine interface

An automated closed loop flowback and separation system that allows automated control and remote operation of a flowback operation from a safe distance without any fluid or gas release to the atmosphere. Four-phase separation tanks allow the transport gas, well bore cuttings, produced oil, and produced water to be automatically separated and transported through process piping for reuse or sale, eliminating the need for auxiliary equipment. Flow measurement instruments, pressure transmitters, and level transmitters work in conjunction with an automated blast choke to send data to a programmable logic controller for use in calculating the erosion status of the choke restriction and adjusting the choke to compensate. The programmable logic controller works with a touch-screen or similar human-machine interface to allow remote monitoring and control or automated control of the system. The automated blast choke can vary the choke restriction opening based on the pressure differential and flow rate conditions.

Owner:CANADIAN FRACMASTER

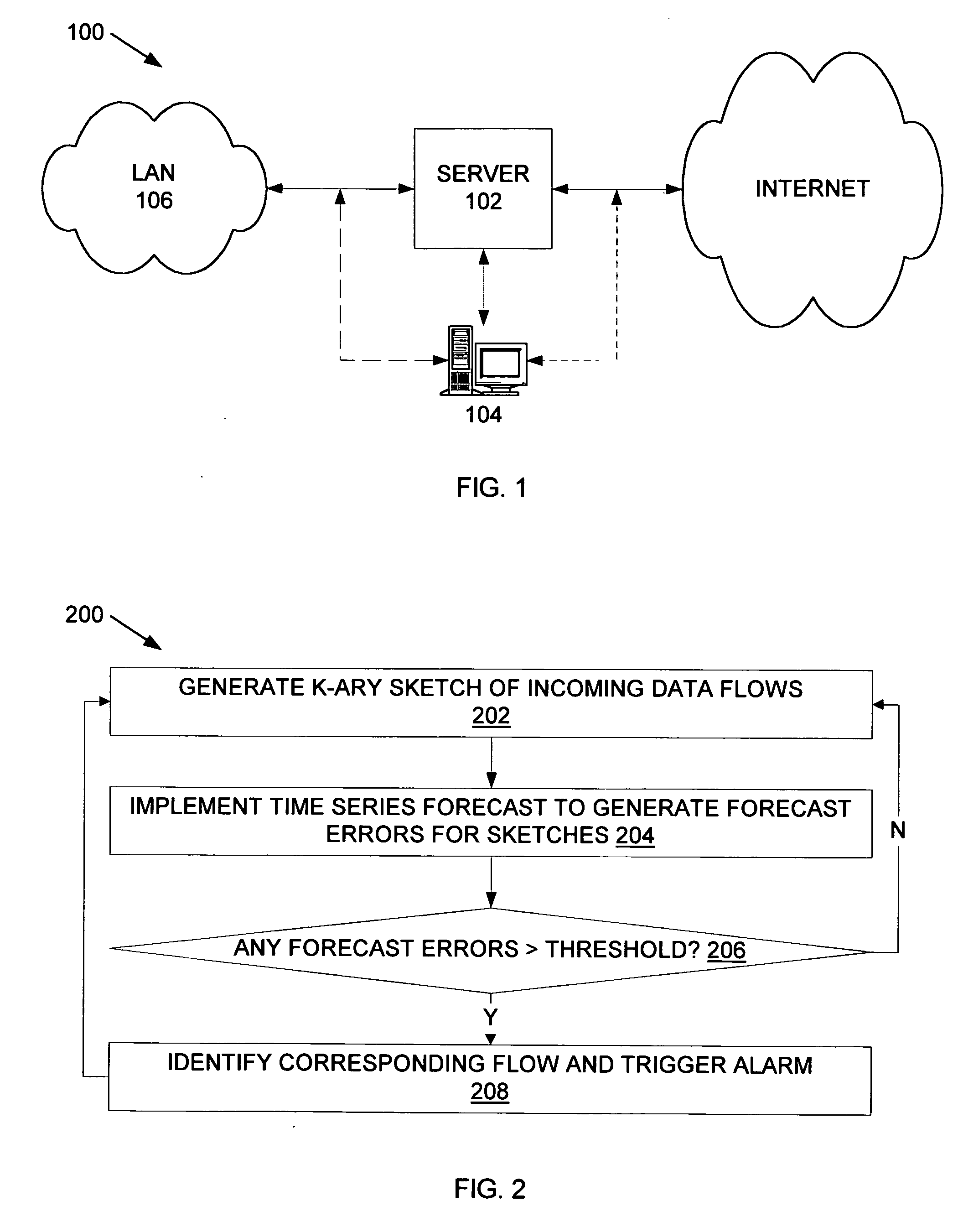

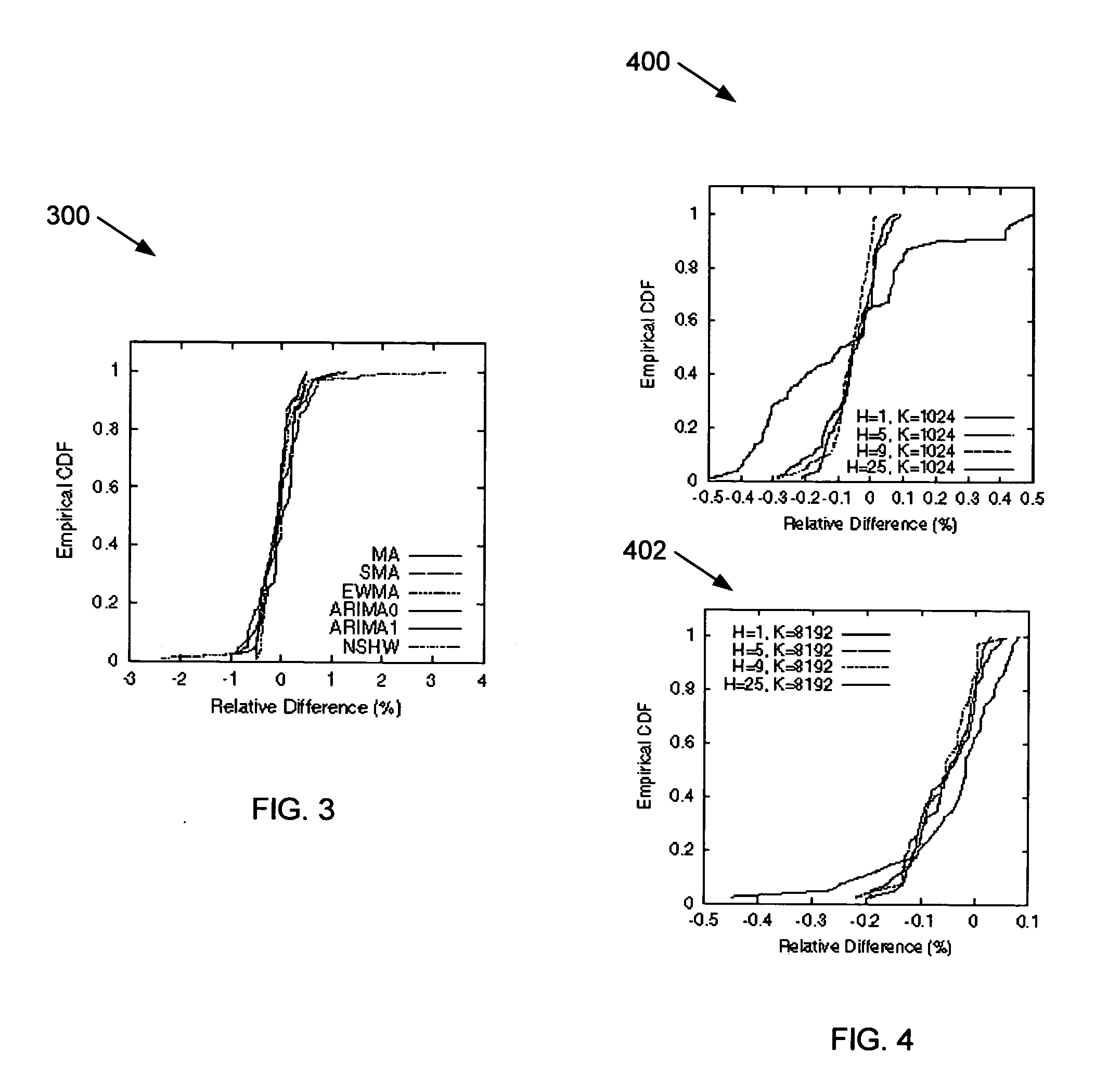

Method and apparatus for sketch-based detection of changes in network traffic

InactiveUS20050039086A1Easy to useImprove accuracyError preventionTransmission systemsData streamInternet traffic

A sketch-based change detection technique is introduced for anomaly detection and other applications that can benefit from having a quick and efficient change detection mechanism. The technique is capable of detecting significant changes in massive data streams with a large number of network time series. As part of the technique, we designed a variant of the sketch data structure, called k-ary sketch, uses a constant, small amount of memory, and has constant per-record update and reconstruction cost. A variety of time series forecast models are implemented on top of such summaries and detect significant changes by looking for flows with large forecast errors. Heuristics for automatically configuring the forecast model parameters are presented. Real Internet traffic data is used to demonstrate that the sketch-based change detection method is highly accurate when compared with per-flow analysis, and can be implemented at low computation and memory costs. The results validate using the technique as a building block for network anomaly detection and traffic measurement in large computer networks.

Owner:AT&T INTPROP I L P +1

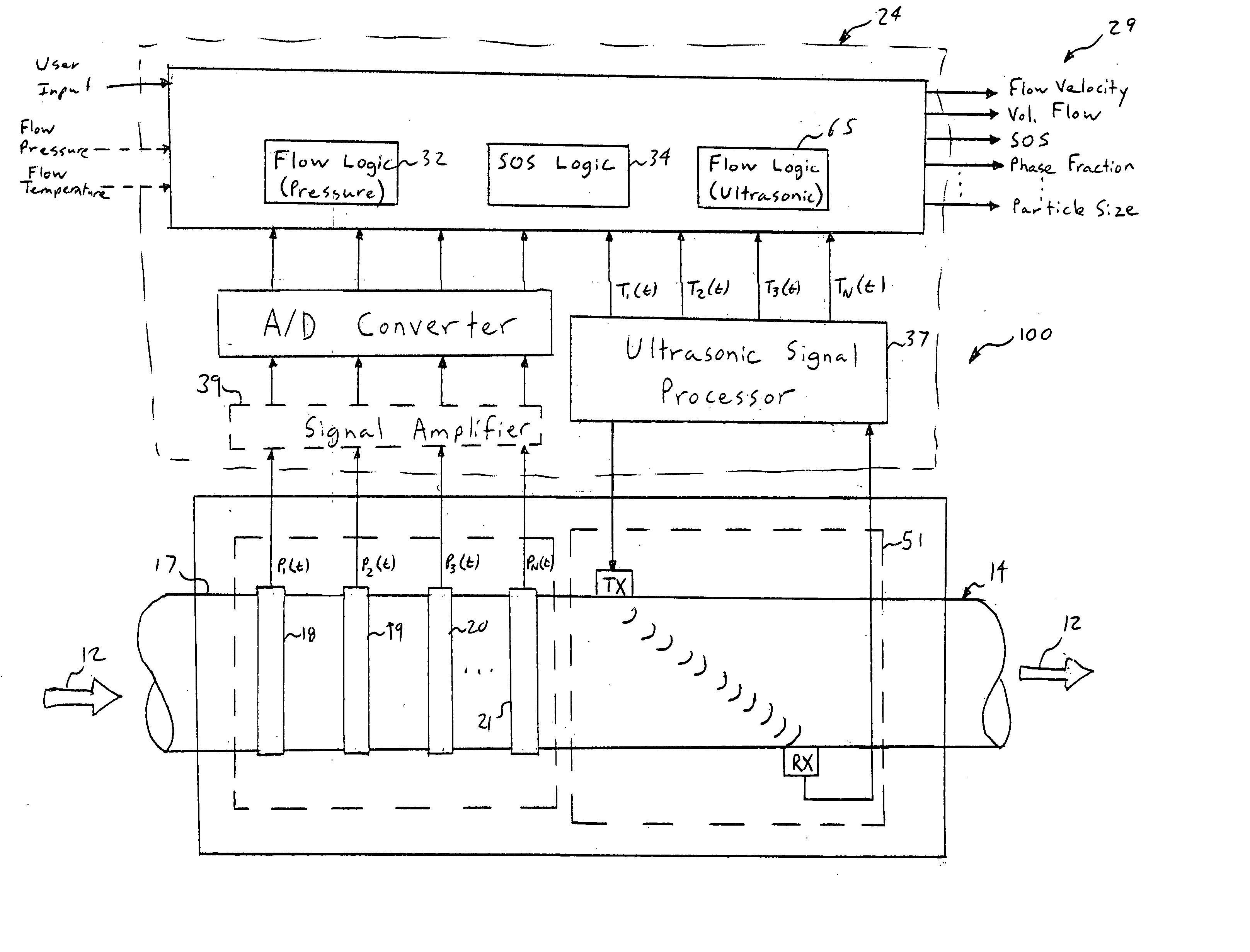

Flow measurement apparatus having strain-based sensors and ultrasonic sensors

ActiveUS20050125170A1More robustMaterial analysis using sonic/ultrasonic/infrasonic wavesVolume/mass flow measurementUltrasonic sensorMeasurement device

A flow measurement apparatus is provided that combines the functionality of an apparatus that uses strain-based sensors and ultrasonic sensors to measure the speed of sound propagating through a fluid flowing within a pipe, and measure pressures disturbances (e.g. vortical disturbances or eddies) moving with a fluid to determine respective parameters of the flow propagating through a pipe. The apparatus includes a sensing device that includes an array of pressure sensors used to measure the acoustic and convective pressure variations in the flow to determine desired parameters and an ultrasonic meter portion to measure the velocity and volumetric flow of the fluid. In response to an input signal or internal logic, the processor can manually or dynamically switch between the pressure sensors and ultrasonic sensors to measure the parameters of the flow. The flow measurement apparatus thereby provides a robust meter capable of measuring fluid flows having a wide range of different characteristics and flows exposed to different environmental conditions.

Owner:EXPRO METERS

Fuel consumption evaluation system

ActiveUS7454962B2Improve accuracyAnalogue computers for vehiclesAnalogue computers for trafficDriver/operatorIn vehicle

The present invention is intended to provide a fuel consumption evaluation system which obtains quantitative data to determine whether actual driving has consumed fuel more efficiently or less efficiently than average driving and gives the driver and / or manager concrete advice for fuel-efficient driving based on the obtained data, and also provide a fuel consumption evaluation system which decides, based on obtained fuel efficiency data, whether driving is more fuel-efficient than average driving and sets a target and gives the driver and / or manager concrete advice for fuel-efficient driving based on the obtained data in consideration of change in vehicle total mass without any influence of slopes and traffic flows and particularly encourages and instructs, in real time, the driver to do fuel-efficient driving. The system comprises: engine speed measuring means (2) which measures engine speed of a truck (1); accelerator opening degree measuring means (3) which measures an accelerator opening degree (α); vehicle velocity measuring means (4) which measures vehicle velocity (V); fuel flow rate measuring means (5) which measures a fuel flow rate (Fw); and control means (10) which evaluates fuel consumption of the truck from measured engine speed (N), accelerator opening degree (α), vehicle velocity (V) and fuel flow rate (Fw).

Owner:VOLVO LASTVAGNAR AB

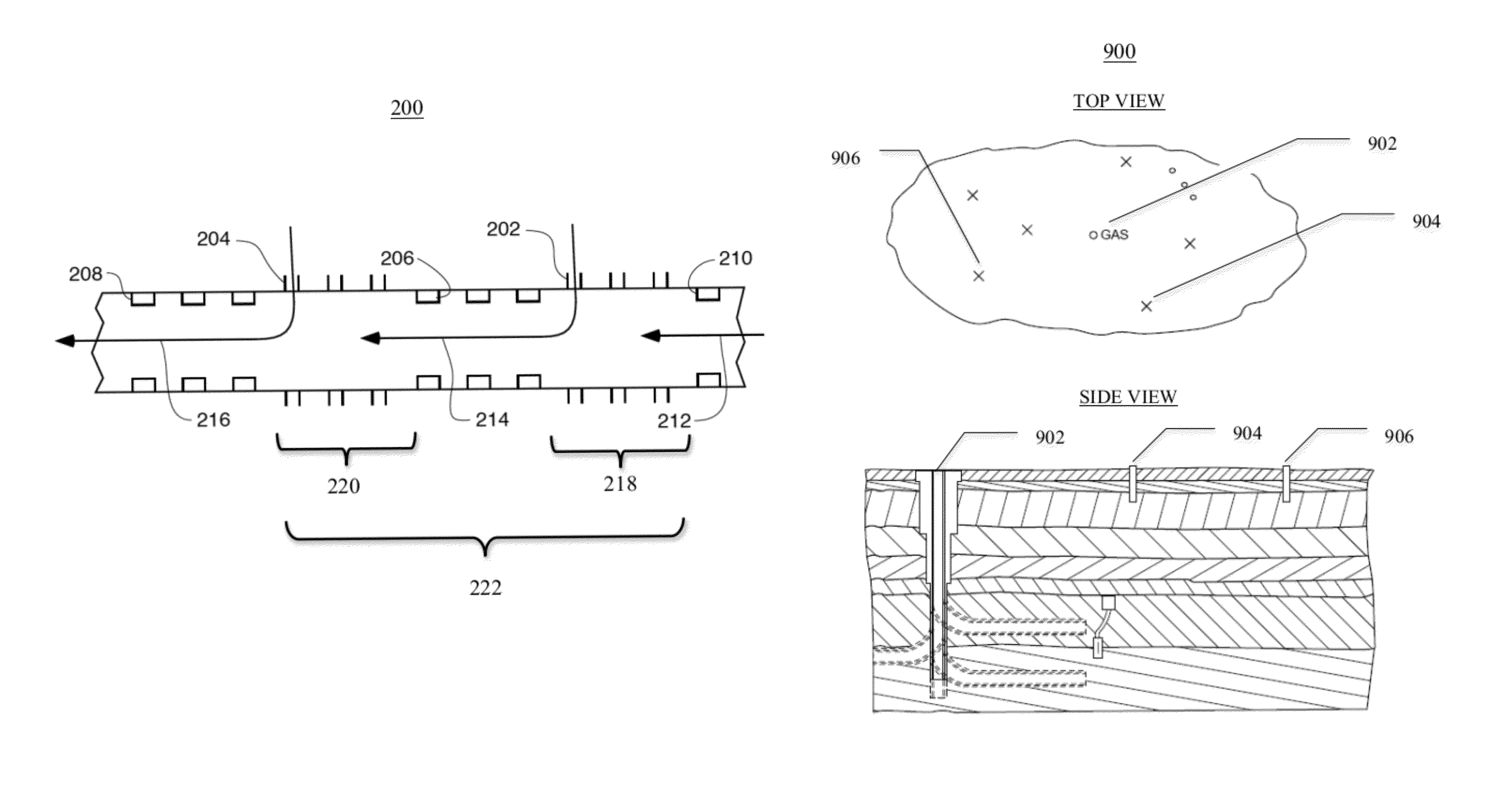

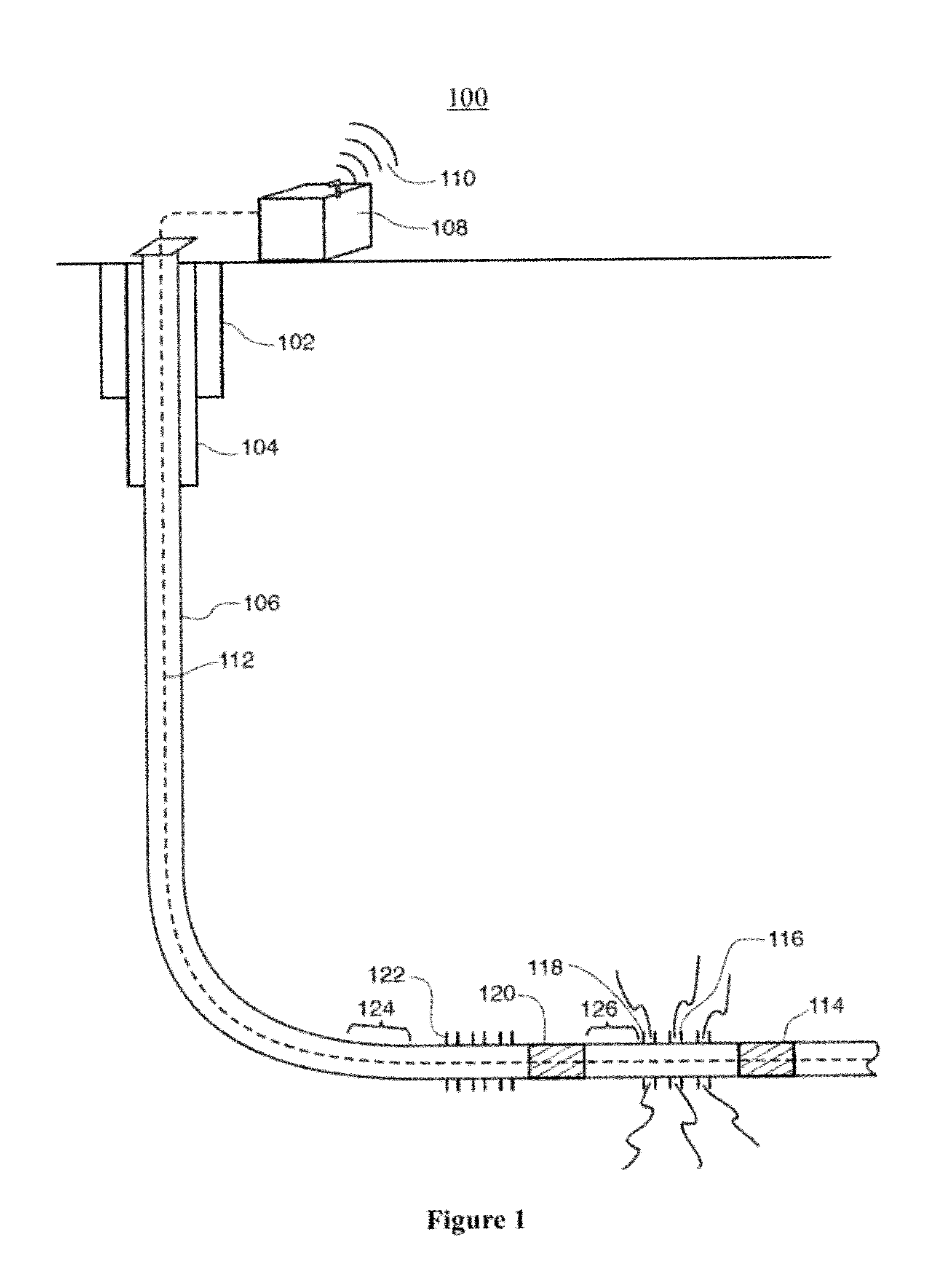

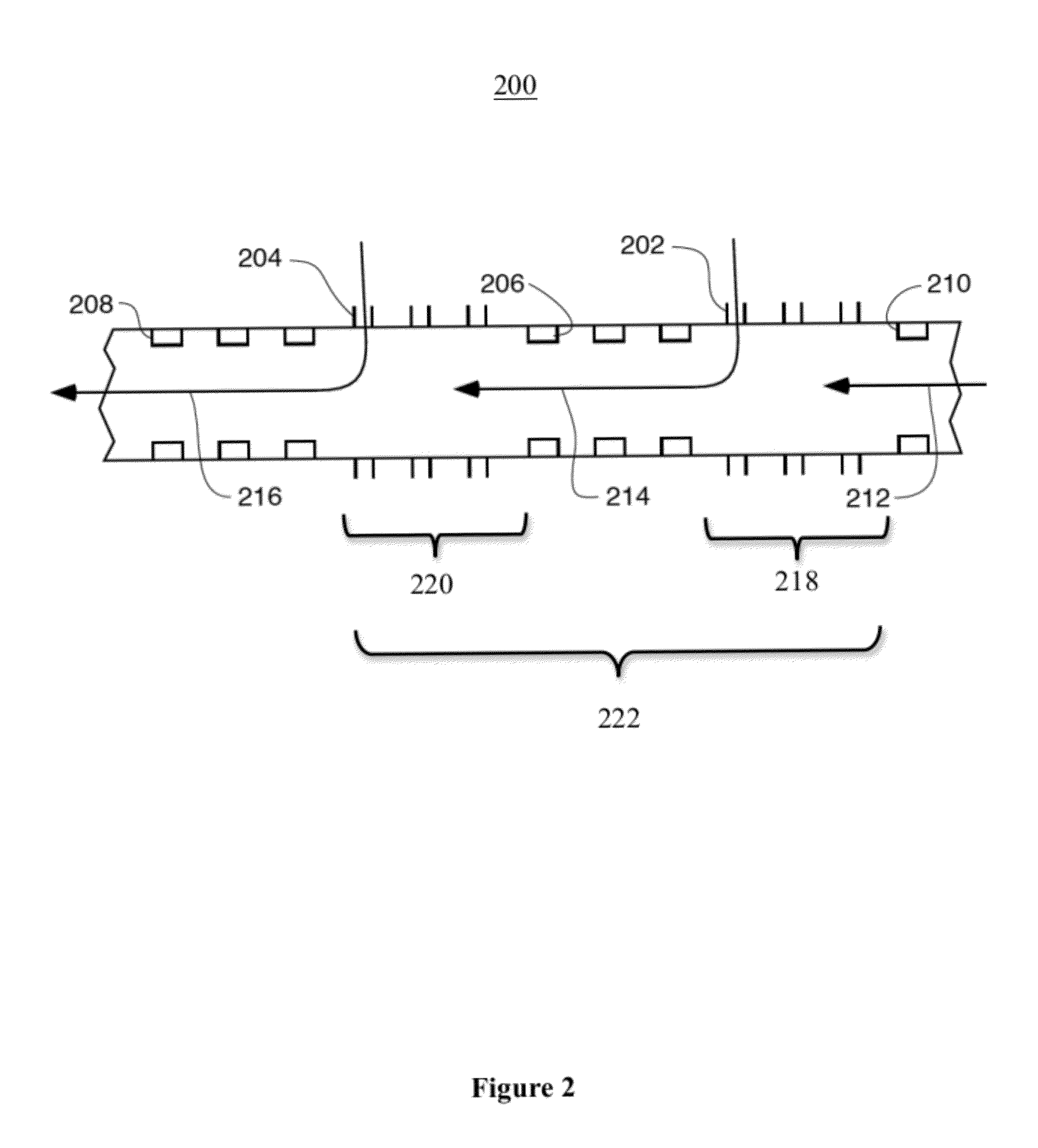

Systems and methods for monitoring groundwater, rock, and casing for production flow and leakage of hydrocarbon fluids

One embodiment of the present invention is a system comprising one or more subsystems, which can be practiced alone or in combination, which together allow for monitoring of groundwater, rock, and casing for production flow and leakage of hydrocarbon fluids. A flow measurement subsystem measures flow of hydrocarbons in the horizontal casing string. A well mechanical integrity monitoring subsystem monitors the mechanical integrity of the natural gas production well, including the junctures of a completed well. An aquifer monitoring subsystem directly monitors water aquifer(s) underneath and surrounding a natural gas production well or pad, including monitoring wells or existing water wells. A communication subsystem is used to communicate measurements taken downhole to the surface. The present invention may be used to enhance the production from a gas bearing shale formation, mitigate liability associated with hydrocarbon migration, and monitor for a loss of mechanical integrity of a well.

Owner:AMERICAN PIONEER VENTURES

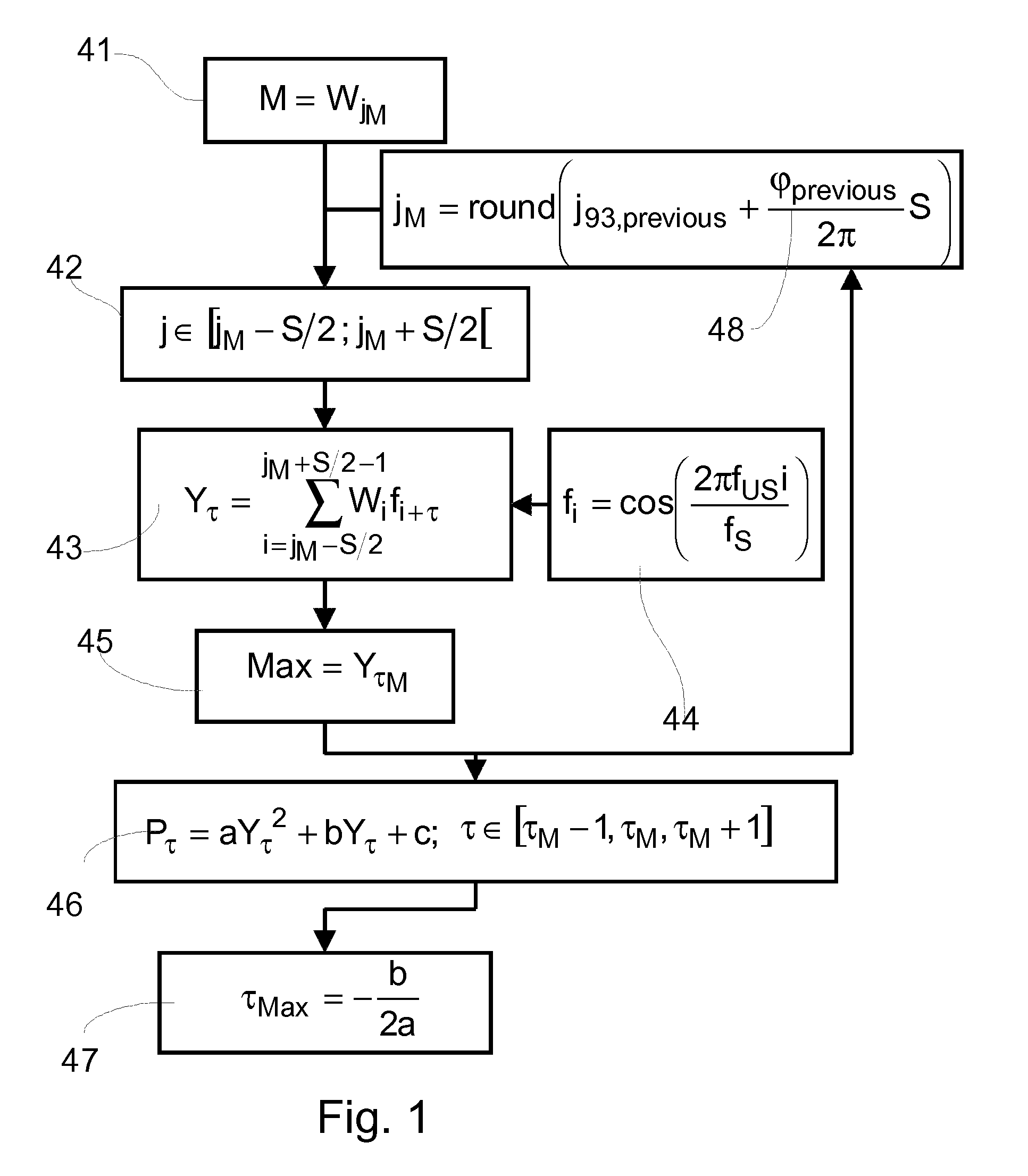

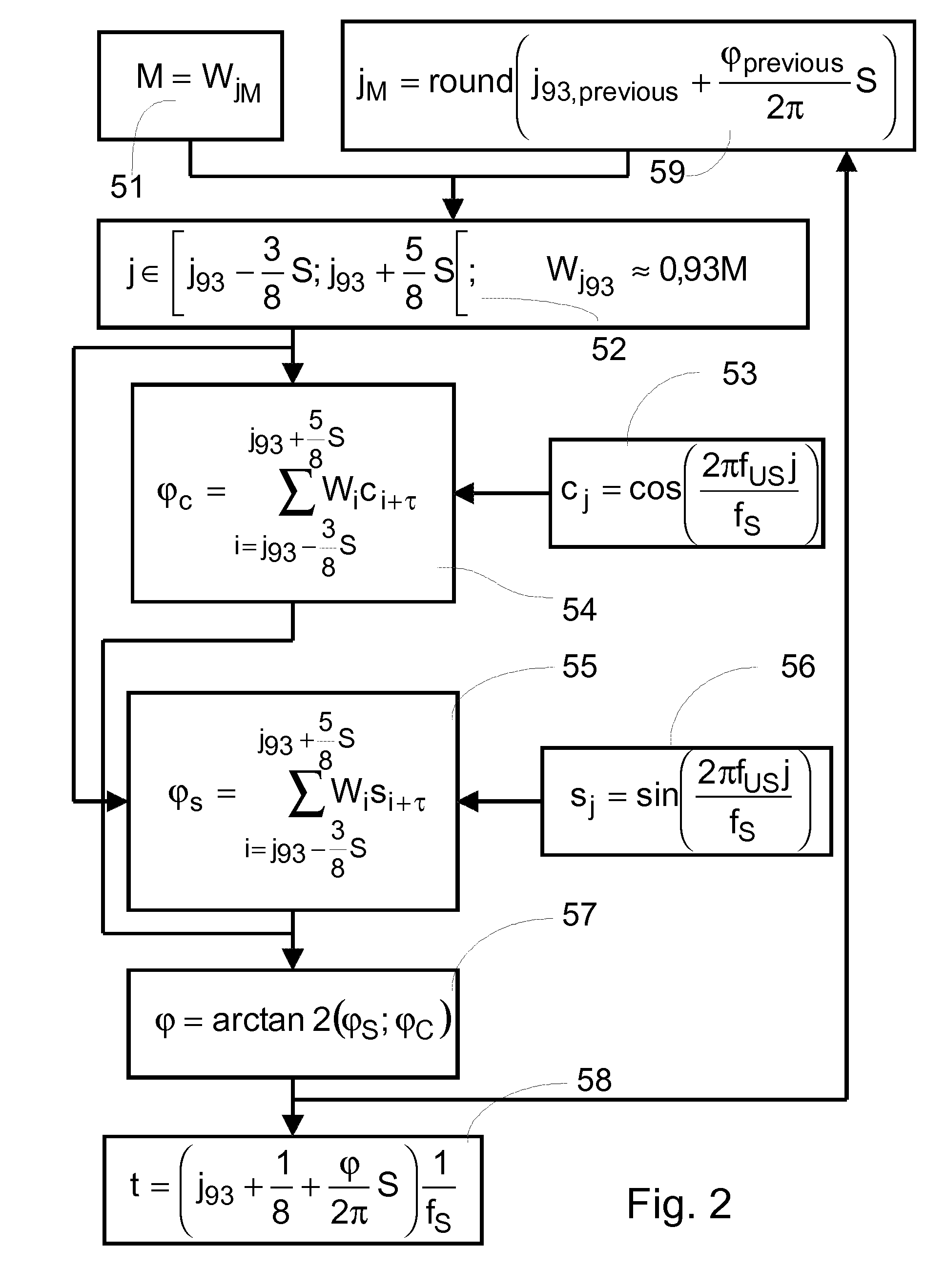

Method for determining the temporal position of a wave packet and flow measuring device

ActiveUS8103461B2Improve accuracyLess-expensive componentVolume/mass flow measurementDiagnostic recording/measuringDischarge measurementsComputer science

The invention relates to a method for determining the temporal position of a wave packet (31) in a flow measuring apparatus, and to a flow measuring apparatus. The method includes the sampling of the wave packet at a plurality of points in time, wherein a measured value is created at each point in time. Subsequently, a sum of products (43, 54, 55, 63, 64) is calculated, wherein each product is calculated for a determined point in time from a plurality of points in time and each product is the product of a value of a compare function (44, 53, 56, 61, 62) at the determined point in time and the measured value at the determined point in time. Finally, the temporal position of the wave packet is calculated from the sum of products.

Owner:VYAIRE MEDICAL GMBH

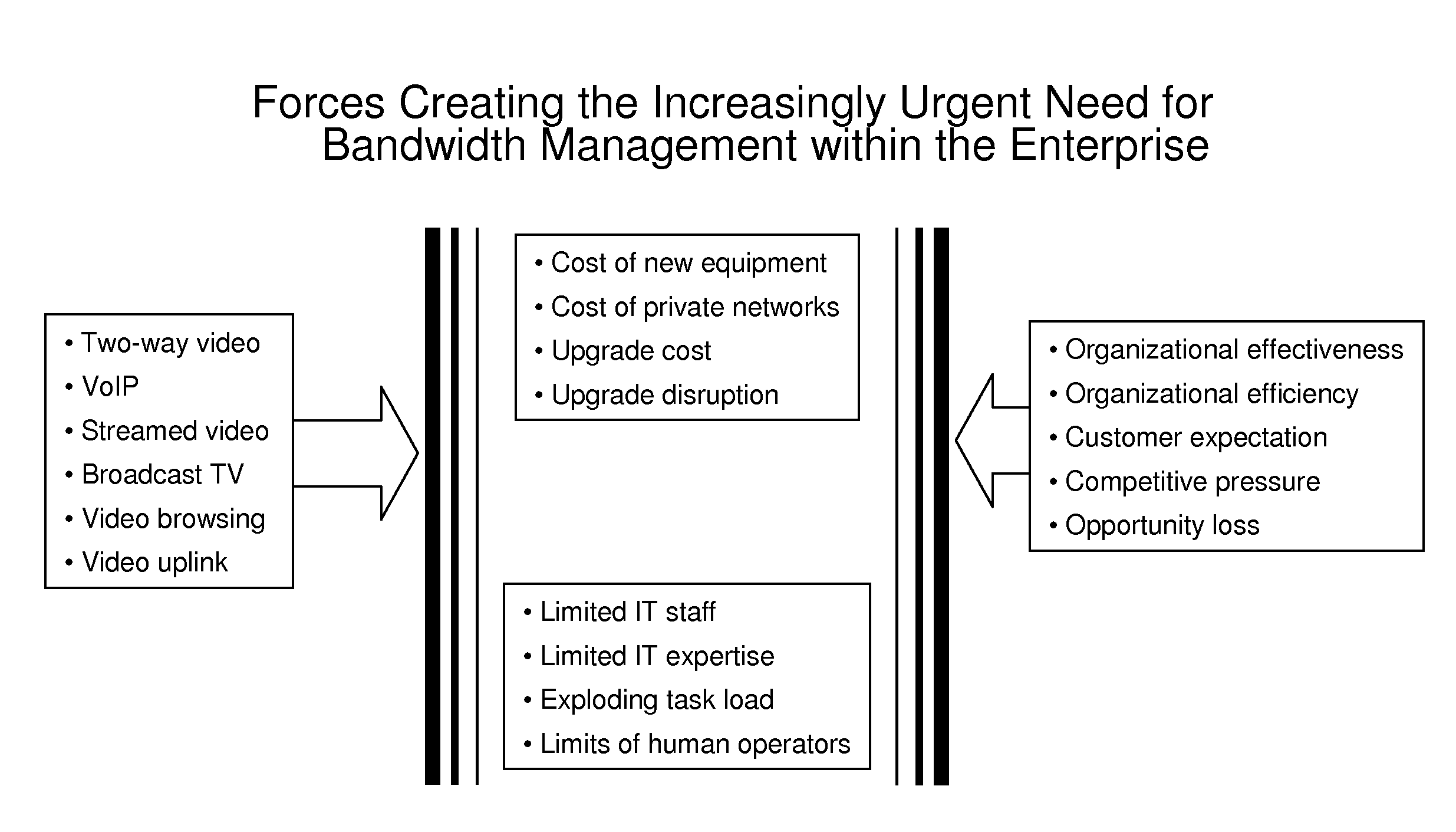

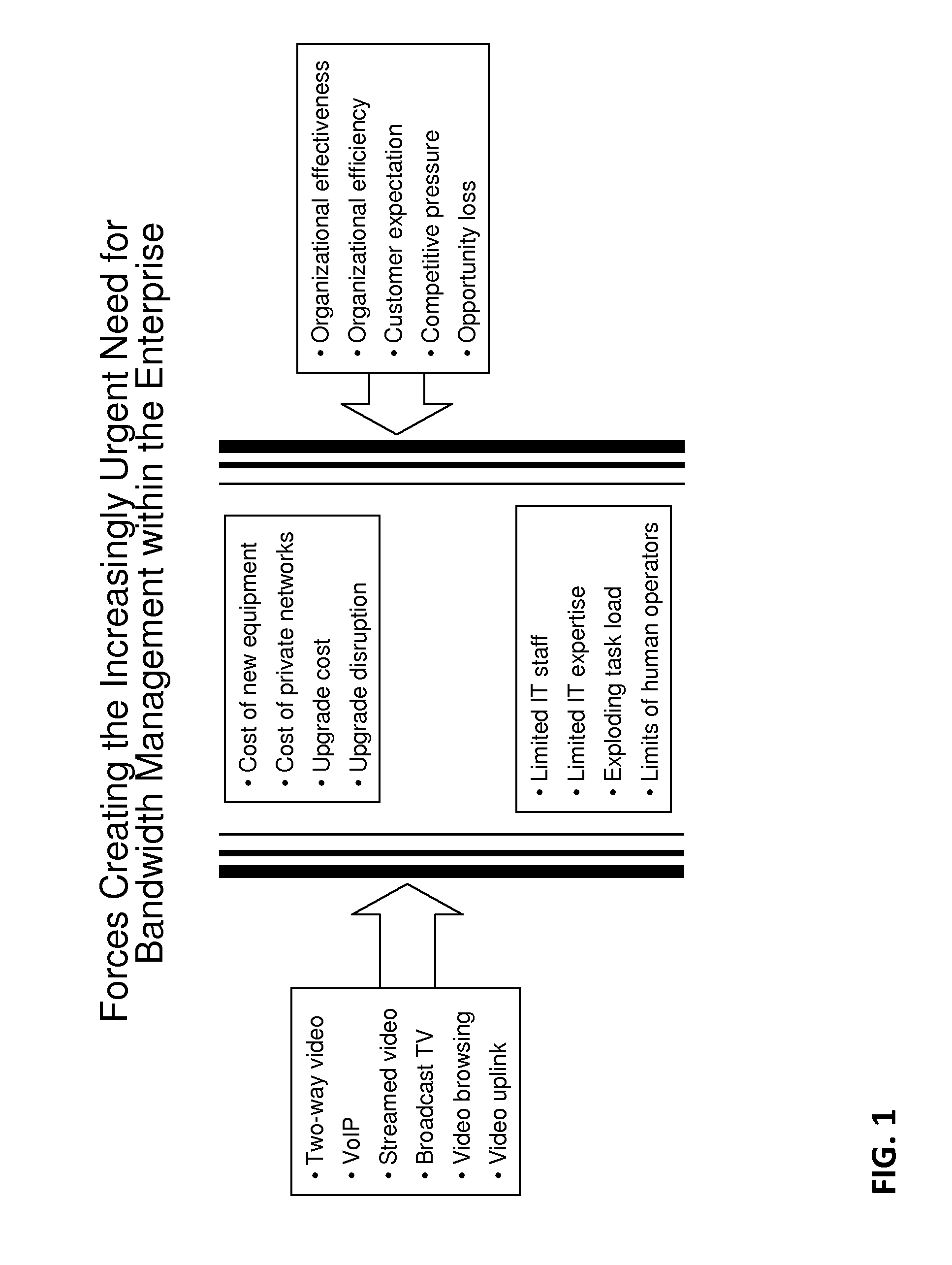

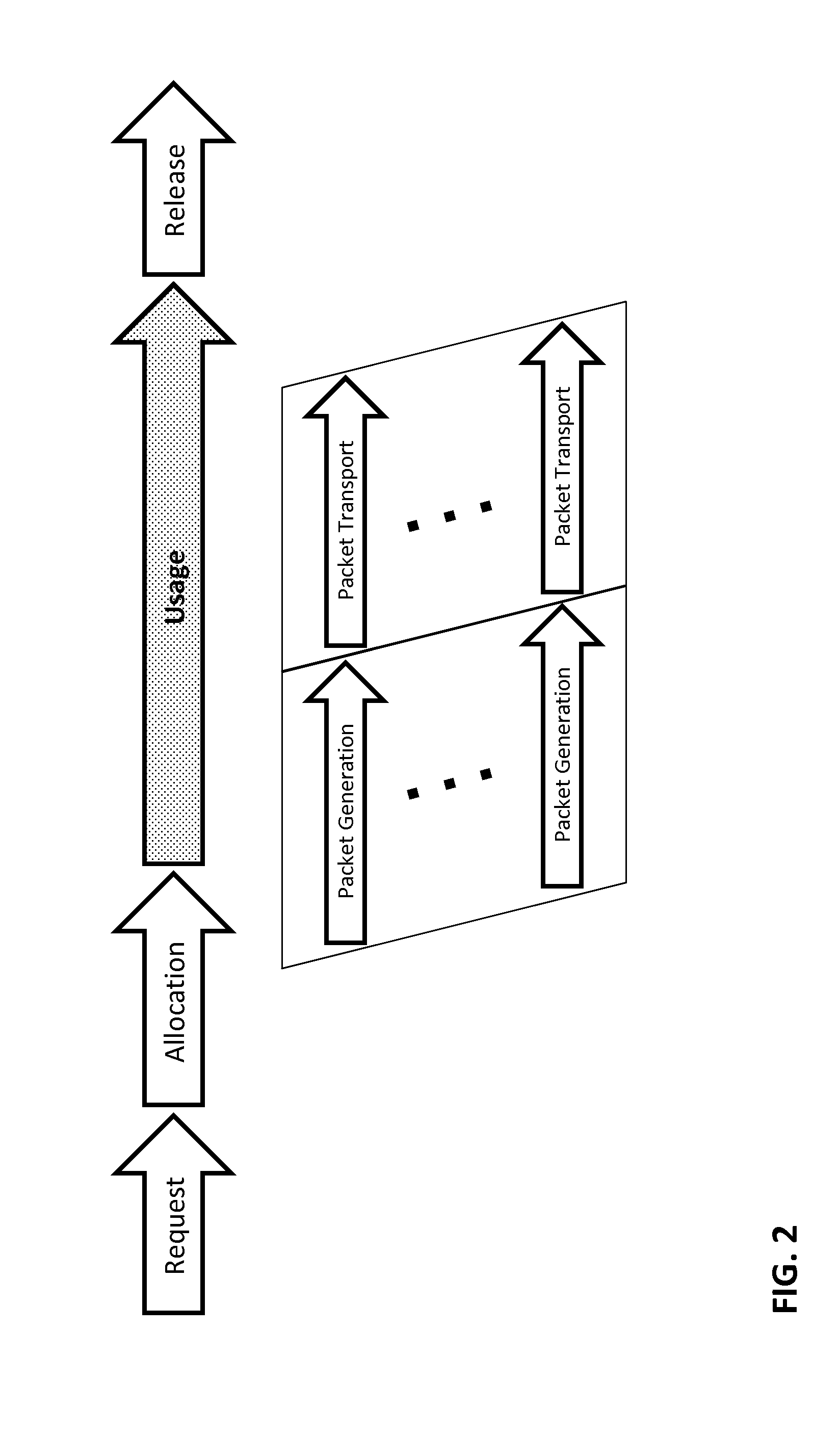

NEXT-GENERATION BANDWIDTH MANAGEMENT CONTROL SYSTEMS FOR MULTIPLE-SERVICE CALLS, SESSIONS, PACKET-LEVEL PROCESSES, AND QoS PARAMETERS - PART 1: STRUCTURAL AND FUNCTIONAL ARCHITECTURES

InactiveUS20130003543A1Easy to adaptError preventionFrequency-division multiplex detailsClosed loopStructure of Management Information

System and method for addressing immense, long-standing problem of bandwidth management, for example, in enterprise networks, VPNs, real-time and stored video services, mobile applications, wireless networks, and cloud computing applications. Described features include an automatic closed-loop control system infrastructure encompassing multiple time-scales and performing control actions optimized to the extent possible with respect to administrator-provided performance metrics. One aspect utilizes available or innovatively accessible means of session and QoS control (settings in configuration files, gateway APIs, QoS parameters, application bit-rate settings, etc.) within the context of practical multiple-vendor products in evolving multiple-service networks. Another aspect utilizes available or innovatively accessible means of session and QoS observations (values in reporting log files, gateway APIs, network monitoring, etc.) within the context of practical multiple-vendor products in evolving multiple-service networks. Traffic-measurement controlled adaptive reservations for distributed myopic single-service gatekeepers effectively shapes the permitted state-space boundary over a range of arbitrary curvatures.

Owner:AVISTAR COMM

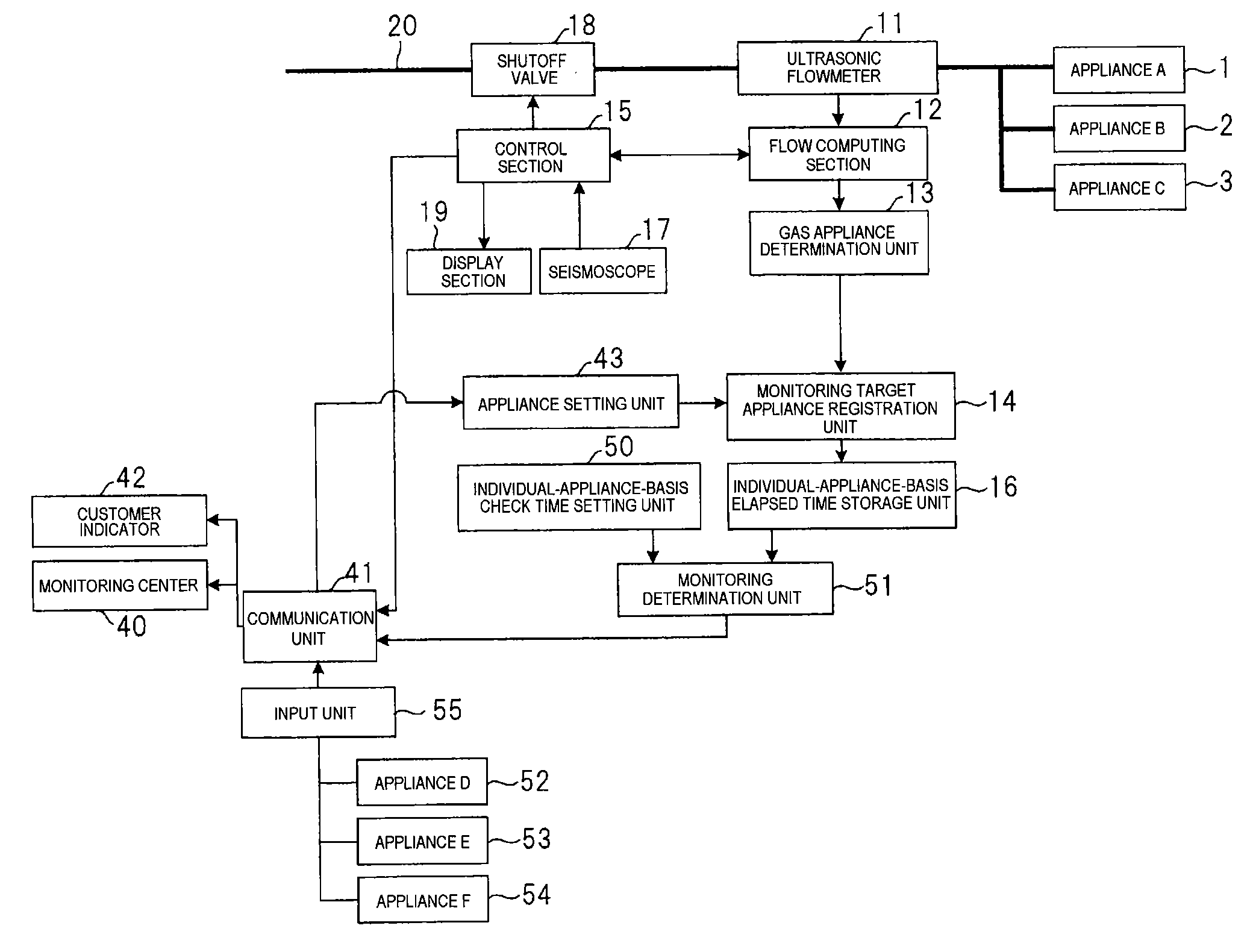

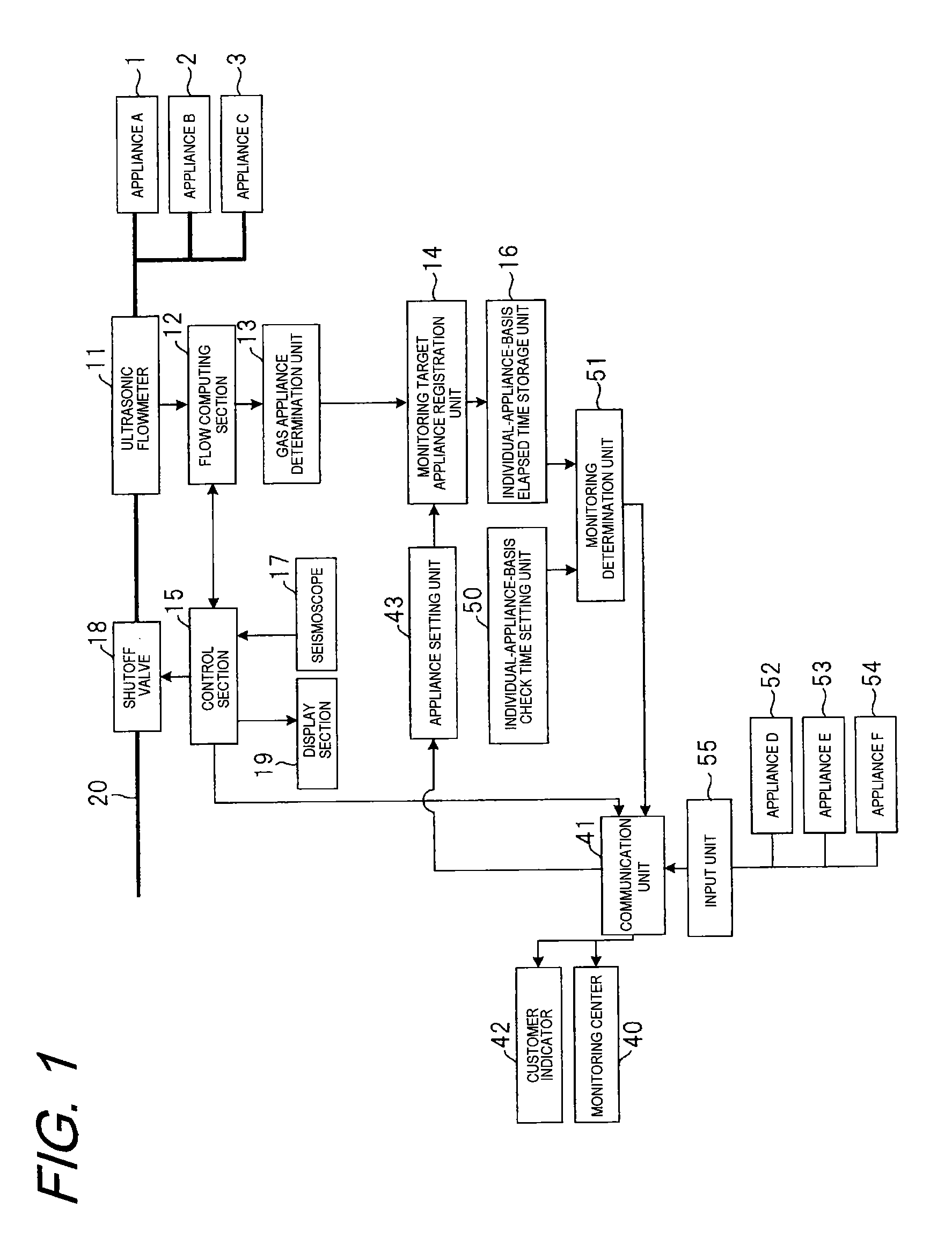

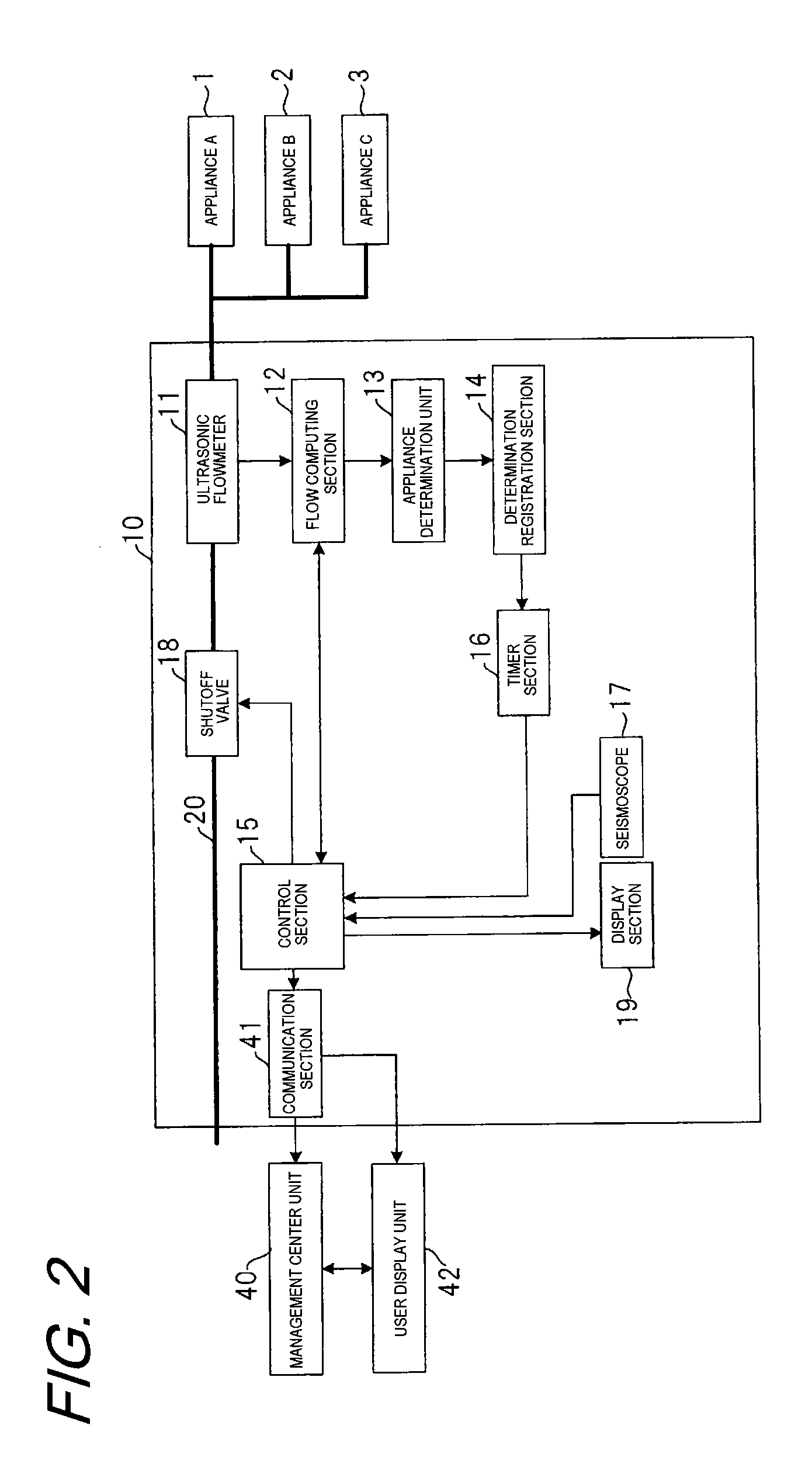

Appliance management system and gas supply system

InactiveUS20110012738A1Reduce in quantityAccelerate emissionsValve arrangementsTechnology managementTime informationEngineering

It is an object to acquire in real time information about the type of an appliance used at home, a cumulative time elapsed from installation of the appliance, and the like; preliminarily acquire inspection timing; and prevent occurrence of a problem in the appliance. There are provided an appliance determination section 13 that determines a gas appliance to be used from the quantity of momentary flow determined from a measured value of a flow measurement section 11 by predetermined arithmetic processing; an appliance setting section 43 capable of arbitrarily inputting appliance information about a monitoring target appliance; an appliance registration section 14 that registers a monitoring target appliance in accordance with a result of determination made by the appliance determination section 13 and an result of input performed with the appliance setting section 43; a timer section 16 that integrates and stores a time elapsed from a point in time when an appliance is registered as a monitoring target appliance in an appliance registration section 14 on a registered individual appliance basis; a communication section 41 that is connected to a monitoring center 40 with a communication line and that performs communication processing of flow information, appliance information, and the like; and a control section 15 that compares an integrated time of the timer section 16 with a preset monitoring time and outputs a signal for sending a report to a gas utility company or a user when the integrated time has exceeded the monitoring time.

Owner:PANASONIC CORP

Flow measuring device based on predetermine class of liquid

InactiveUS6609431B1Liquid dispensingVolume/mass flow by differential pressureVolumetric Mass DensityDischarge measurements

A flow meter and method for determining the corrected flow rate of a liquid falling into a predetermined class of liquids based on its viscosity and density is disclosed. The flow meter comprises a flow sensor for measuring an uncorrected flow rate of the liquid, a temperature sensor for measuring the temperature of the liquid, and a microprocessor for calculating the corrected flow rate based on the liquids predetermined class and the measured temperature. The flow sensor can include a restriction in the fluid flow path, first and second pressure sensors positioned one on each side of the restriction and a temperature sensor. The first and second pressure sensors measure the drop in fluid pressure created by the restriction and the temperature sensor measures the temperature of the liquid. By basing the corrected flow rate calculation on the predetermined class of the liquid, the calculation becomes a closed form solution that is deterministic providing for quick and accurate corrected flow rate calculation. A flow meter according to the present invention can be used in many applications such as, among others, liquid beverage dispensers and variable speed pumps.

Owner:SYS

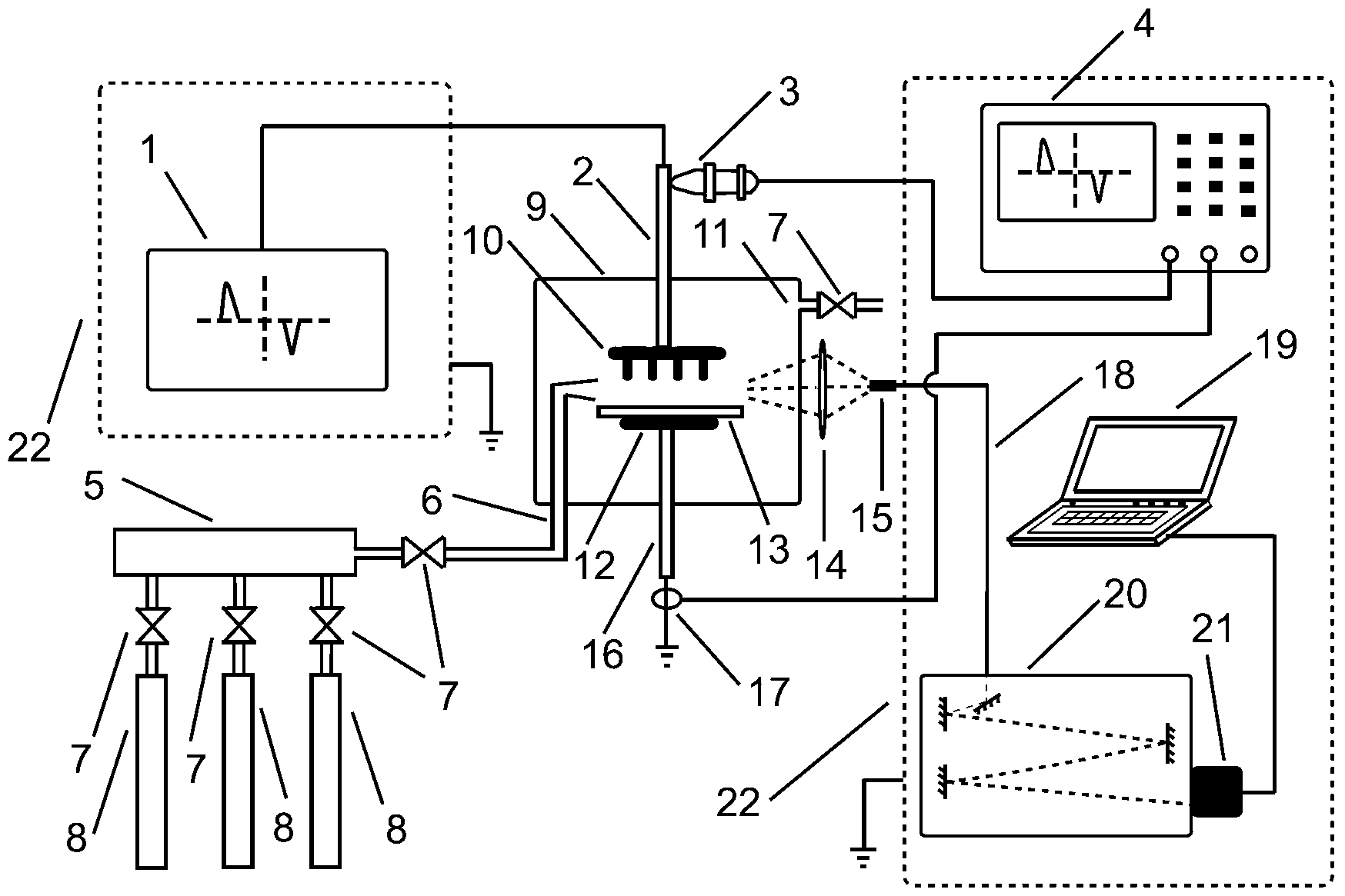

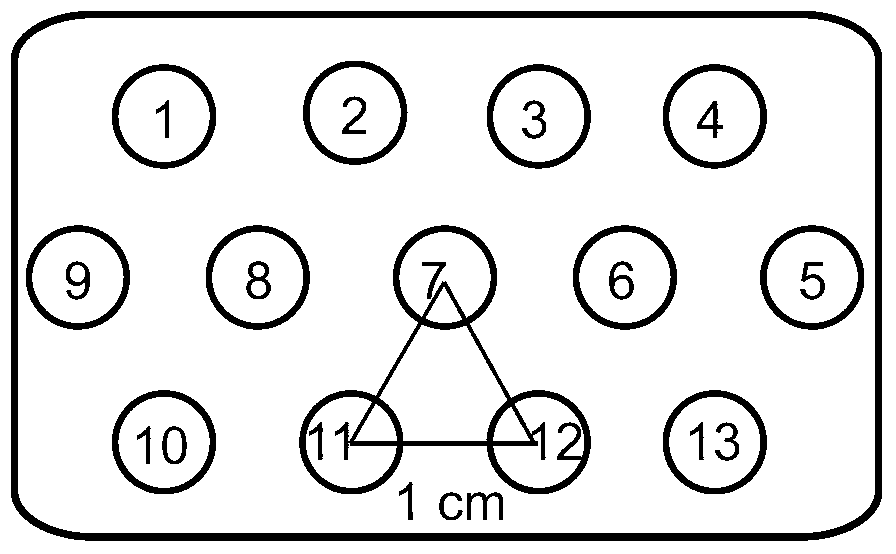

Experimental apparatus for acquiring large-area uniform discharge plasmas

InactiveCN103245655AIncrease electron densityImprove energy utilizationAnalysis by thermal excitationPlasma techniqueDischarge measurementsElectron density

The invention relates to an experimental apparatus for acquiring large-area uniform discharge plasmas, which belongs to the technical field of plasmas. The experimental apparatus comprises a bipolar nanosecond pulse power supply, a reactor, multi-needle-to-plate electrodes, a gas distribution system, a spectral measurement system and a discharge measurement system, wherein the bipolar nanosecond pulse power supply drives dielectric barrier discharge of air and other gas mixtures among the multi-needle-to-plate electrodes in the reactor, and the gas mixtures are input to the reactor through the gas distribution system; the spectral measurement system collects photonic information of plasma discharge in real time and inputs the photonic information to a computer for spectral analysis; and the discharge measurement system collects discharge voltage and current of the high-voltage nanosecond pulse power supply in real time, and the discharge voltage and current are displayed through a digital oscilloscope. By virtue of the bipolar nanosecond narrow-pulse power supply, the large-area discharge plasmas are generated without a magnetic field; and the generated plasmas are uniform, diffusive, high in electron density, high in energy utilization ratio, low in energy consumption and easy to control in a discharge process.

Owner:DALIAN UNIV OF TECH

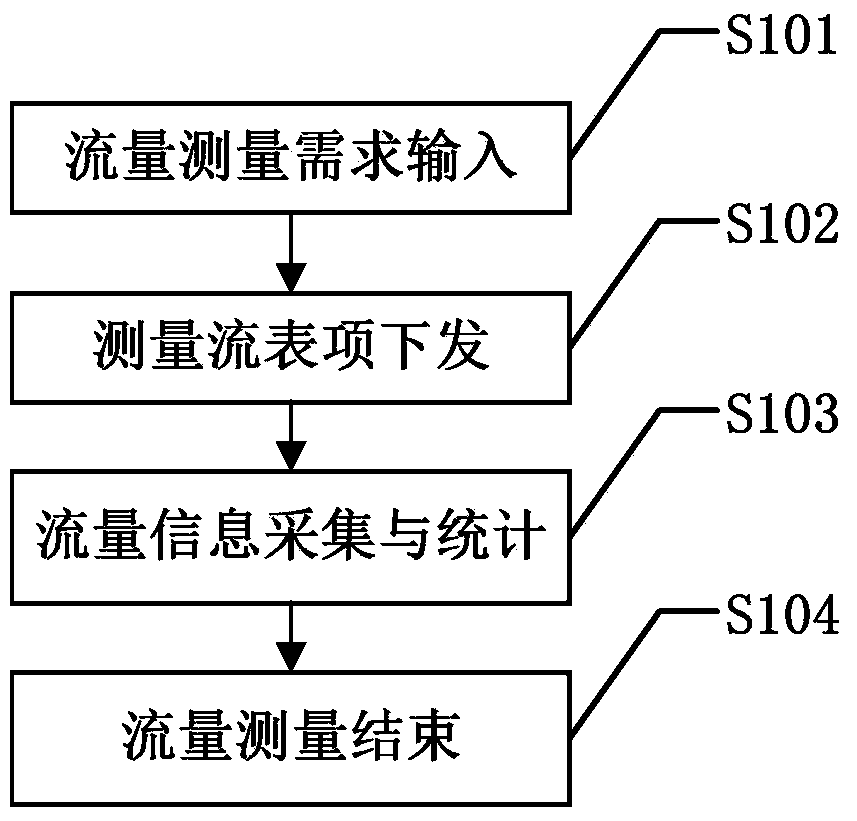

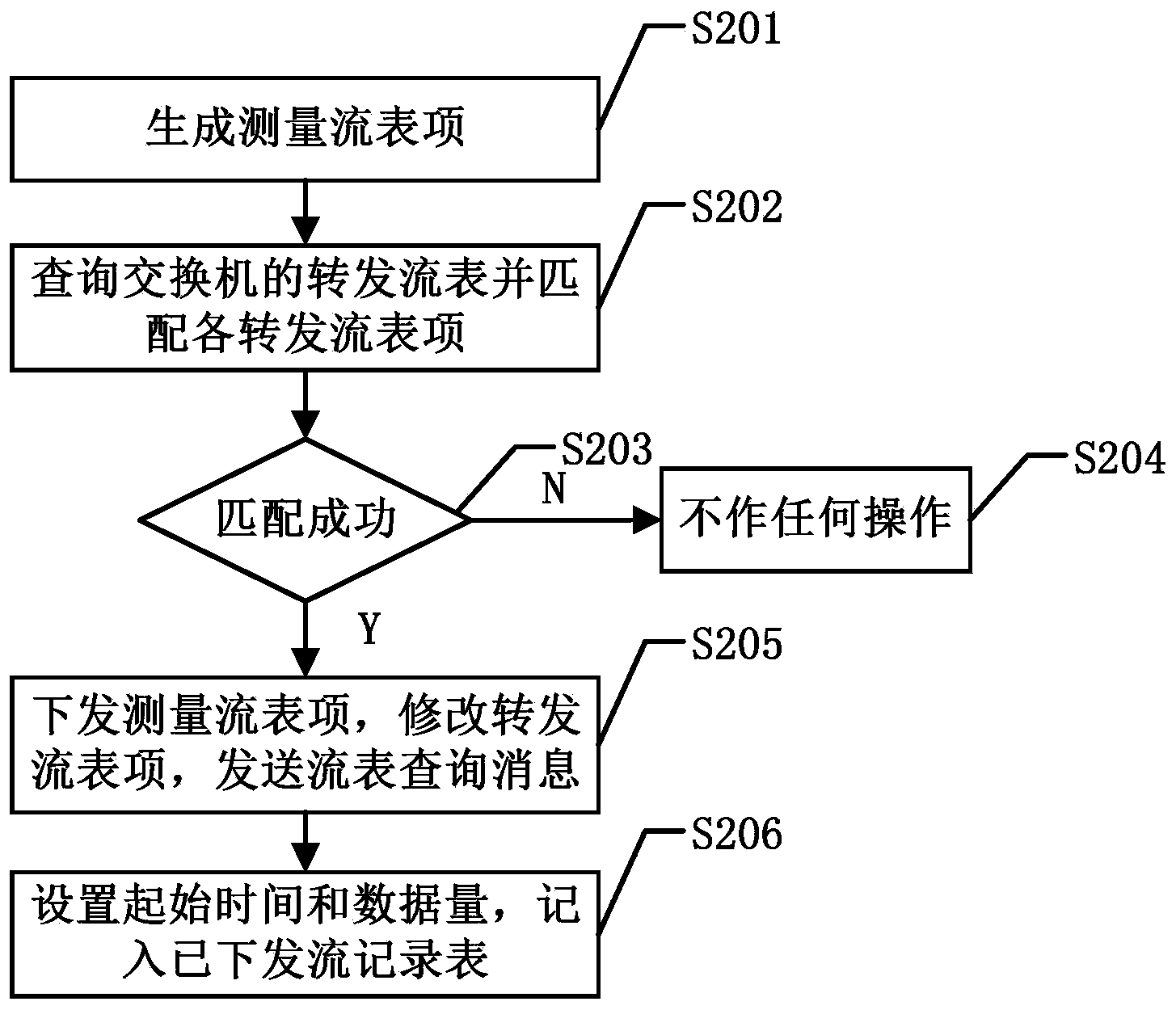

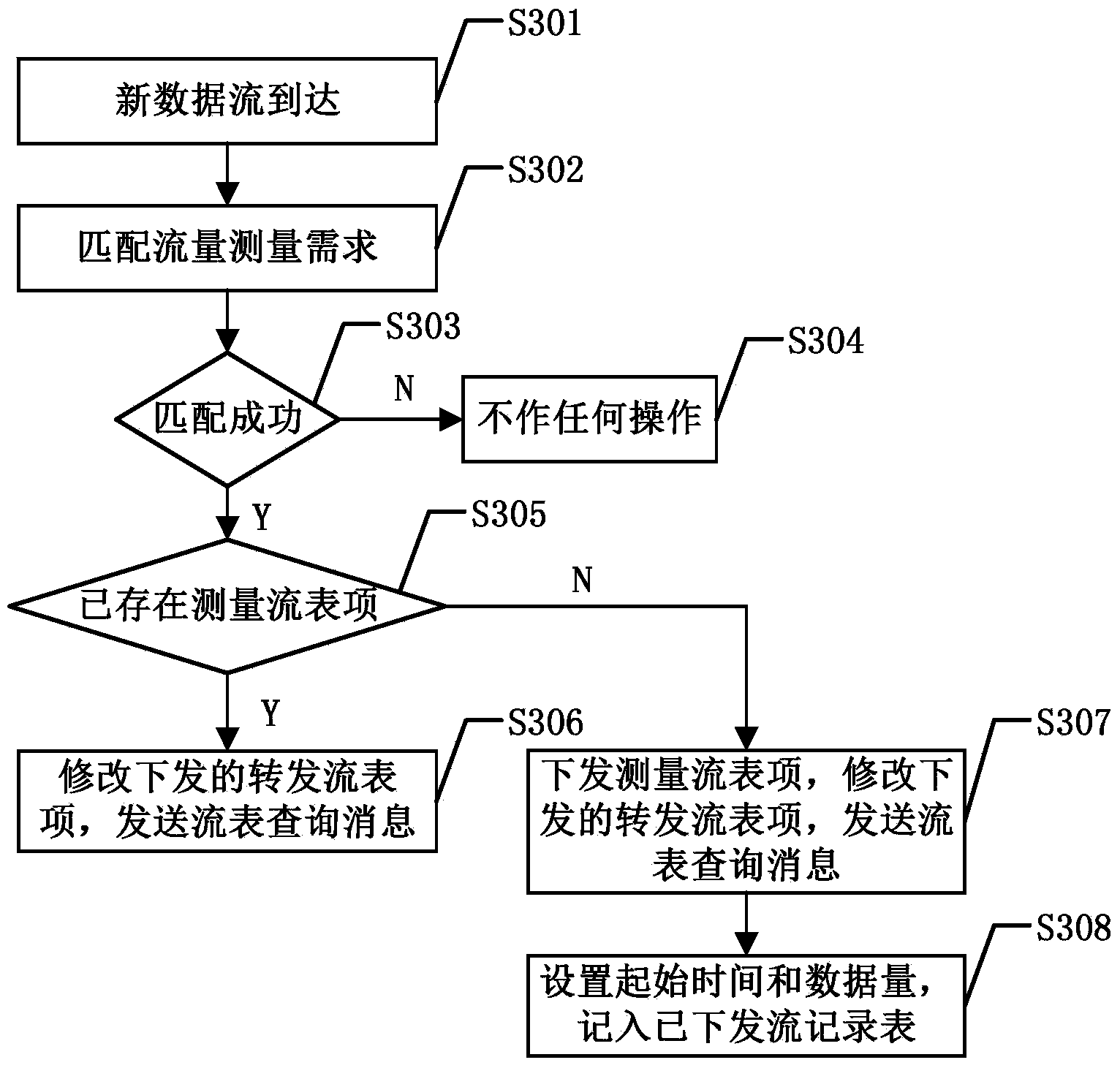

SDN (self-defending network) flow measuring method based on Open Flow

InactiveCN104243240AReduce overheadGuaranteed GranularityData switching networksData streamDischarge measurements

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

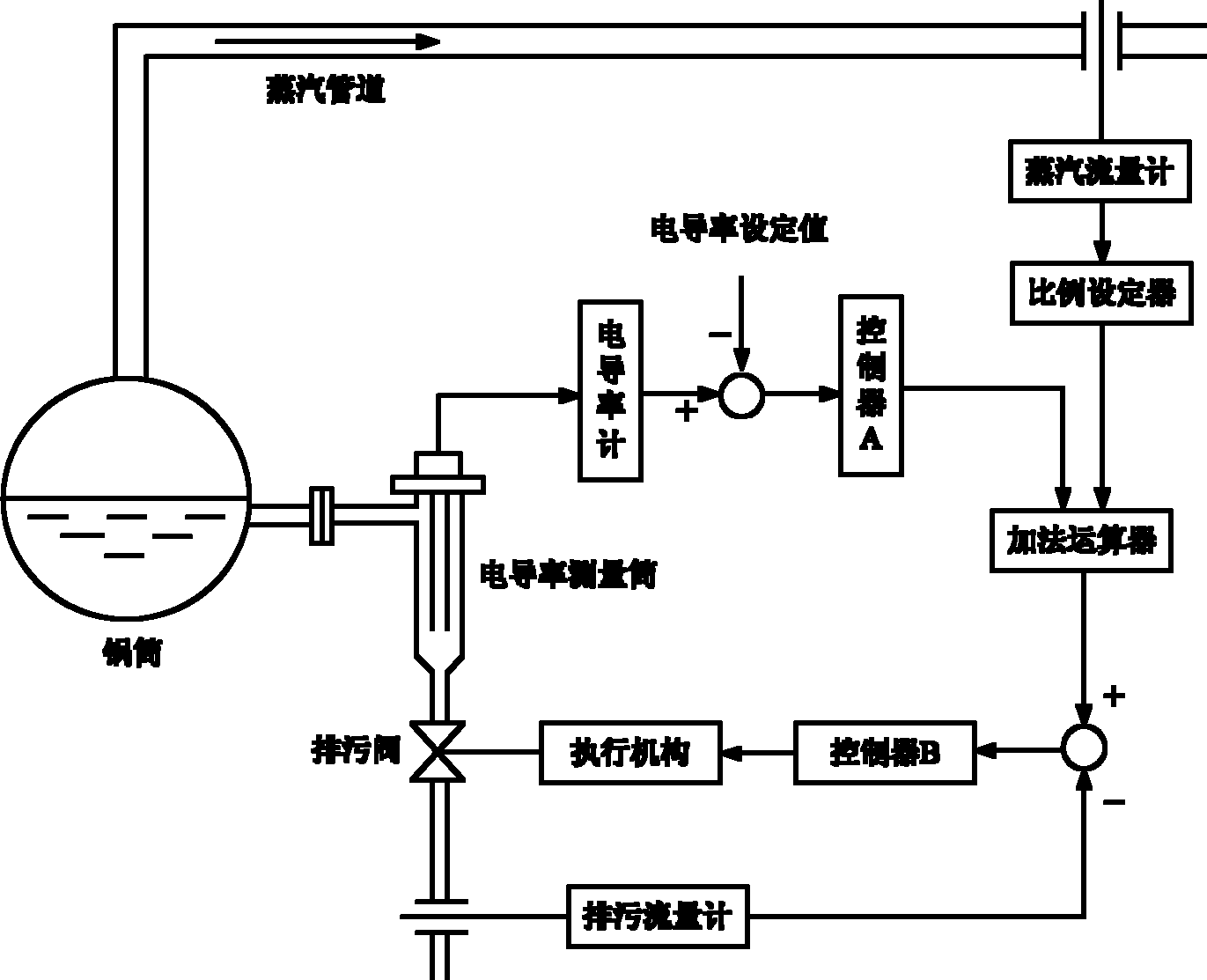

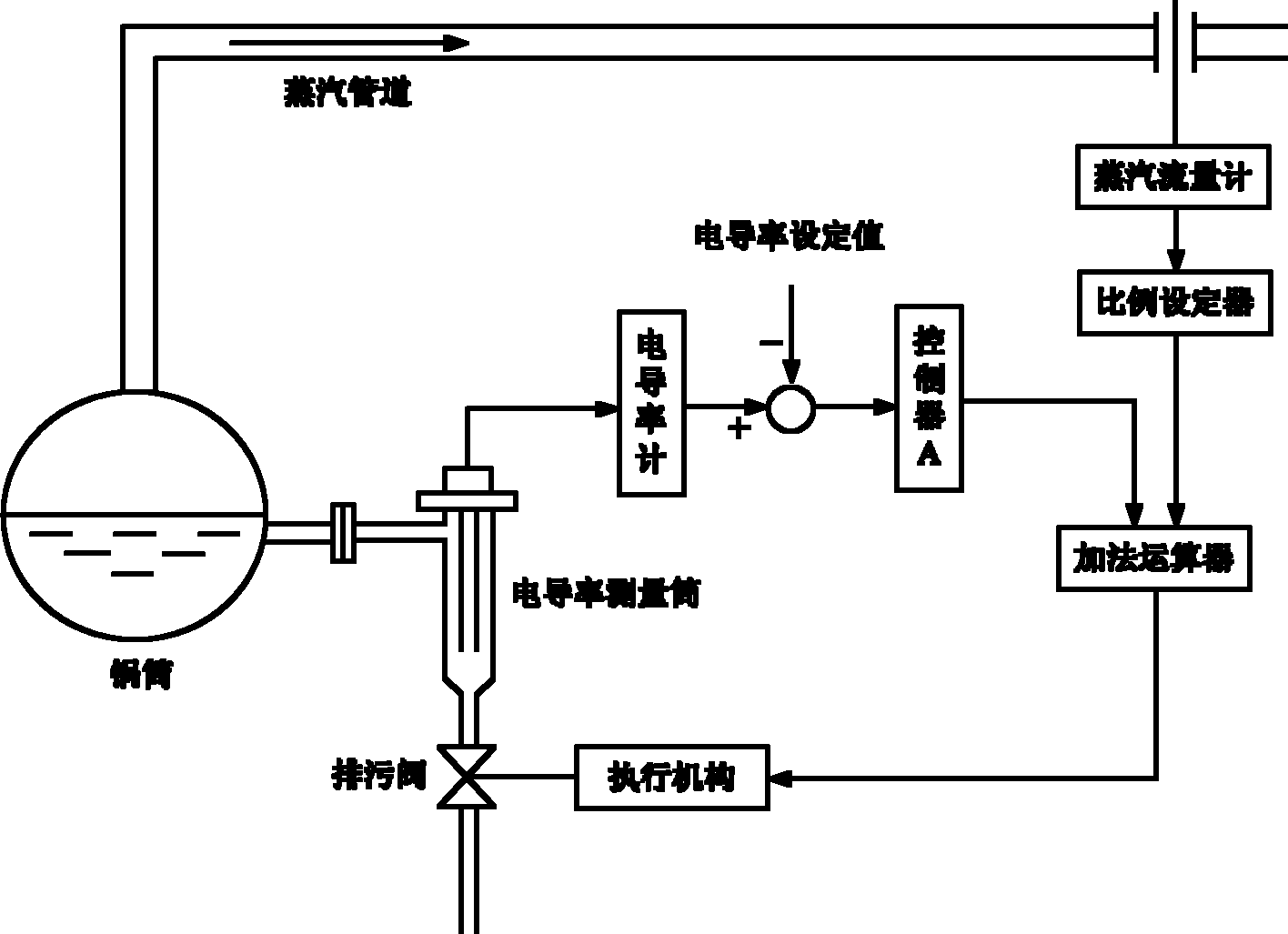

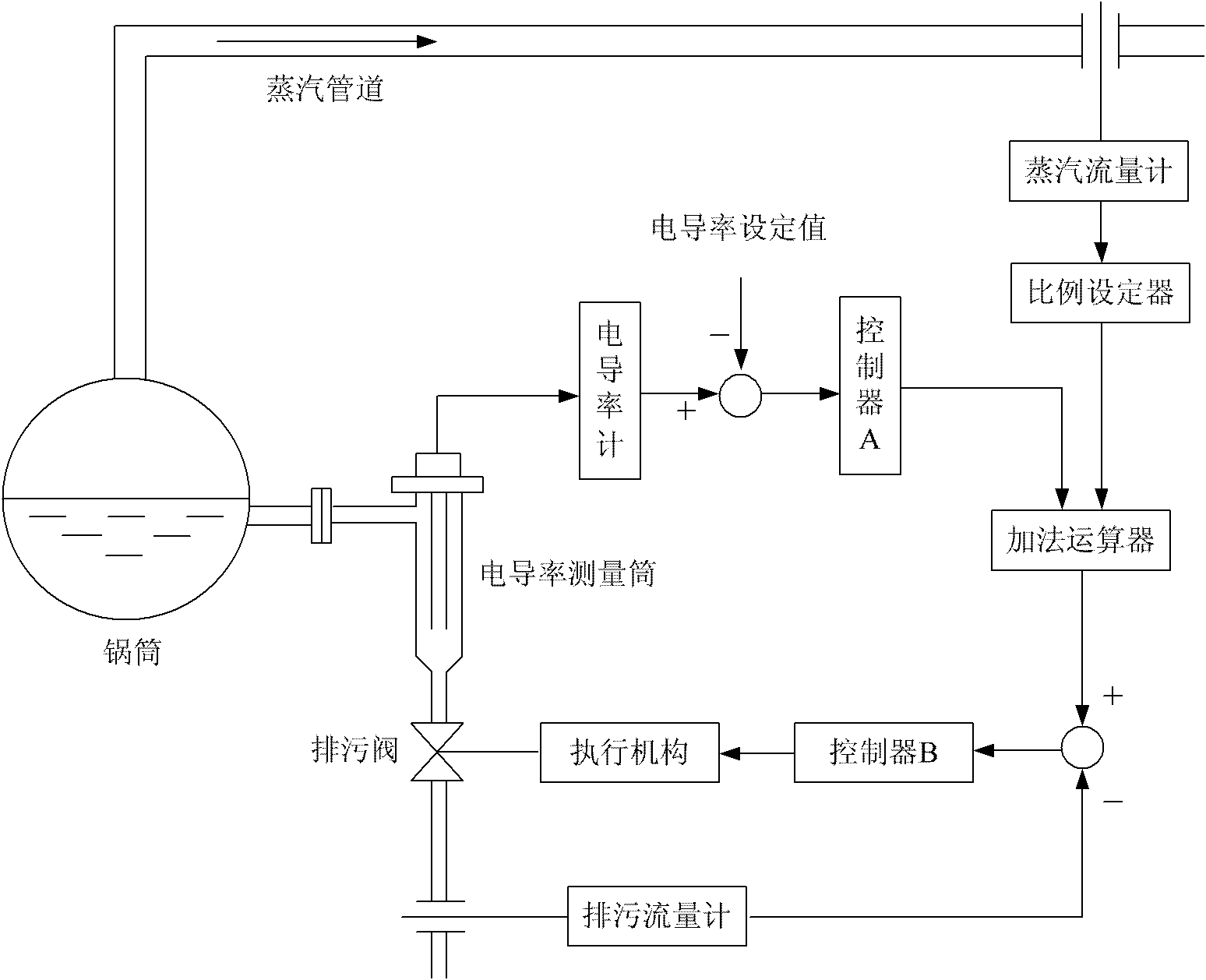

Optimal energy-saving method for controlling surface pollutant discharge of steam boiler

The invention discloses an optimal energy-saving method for controlling the surface pollutant discharge of a steam boiler. The method comprises the steps of firstly controlling the flow of pollutant discharge according to the steam flow proportionally, and continuously diluting water in the steam boiler as required; on this basis, configuring a conductivity close loop control circuit to prevent the influences, such as water supply salinity fluctuation, flow rate measurement error, boiler bottom periodic pollutant discharge and the like, and coupling the both by an addition logic unit so as to form a feedforward-feedback complex control system. The invention can prevent various interferences, stably keep the salinity of the water in the steam boiler above the desired level, and realize the optimal energy-saving and emission-reducing effects by the least pollutant discharge amount.

Owner:西安交大思源科技股份有限公司 +2

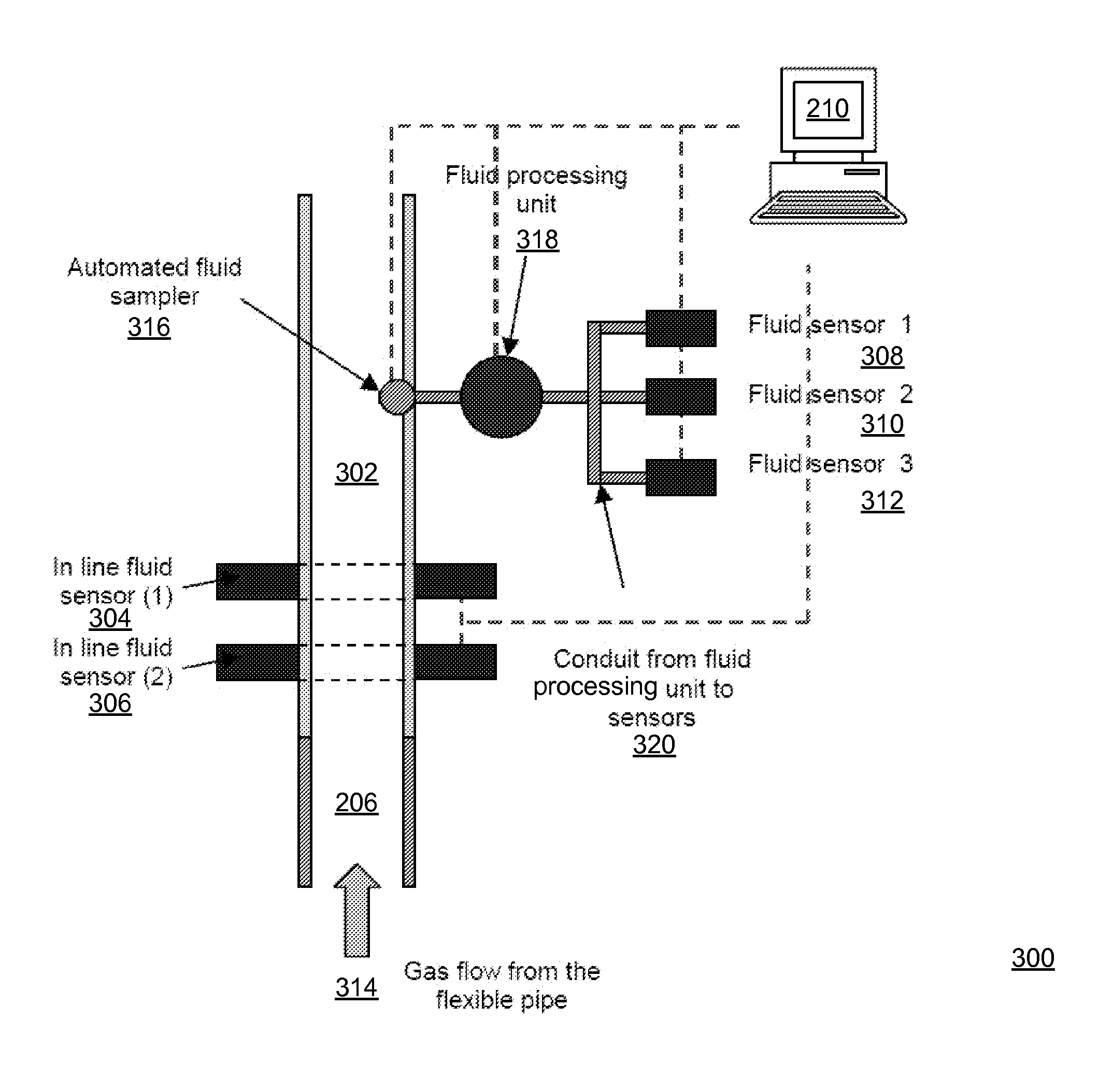

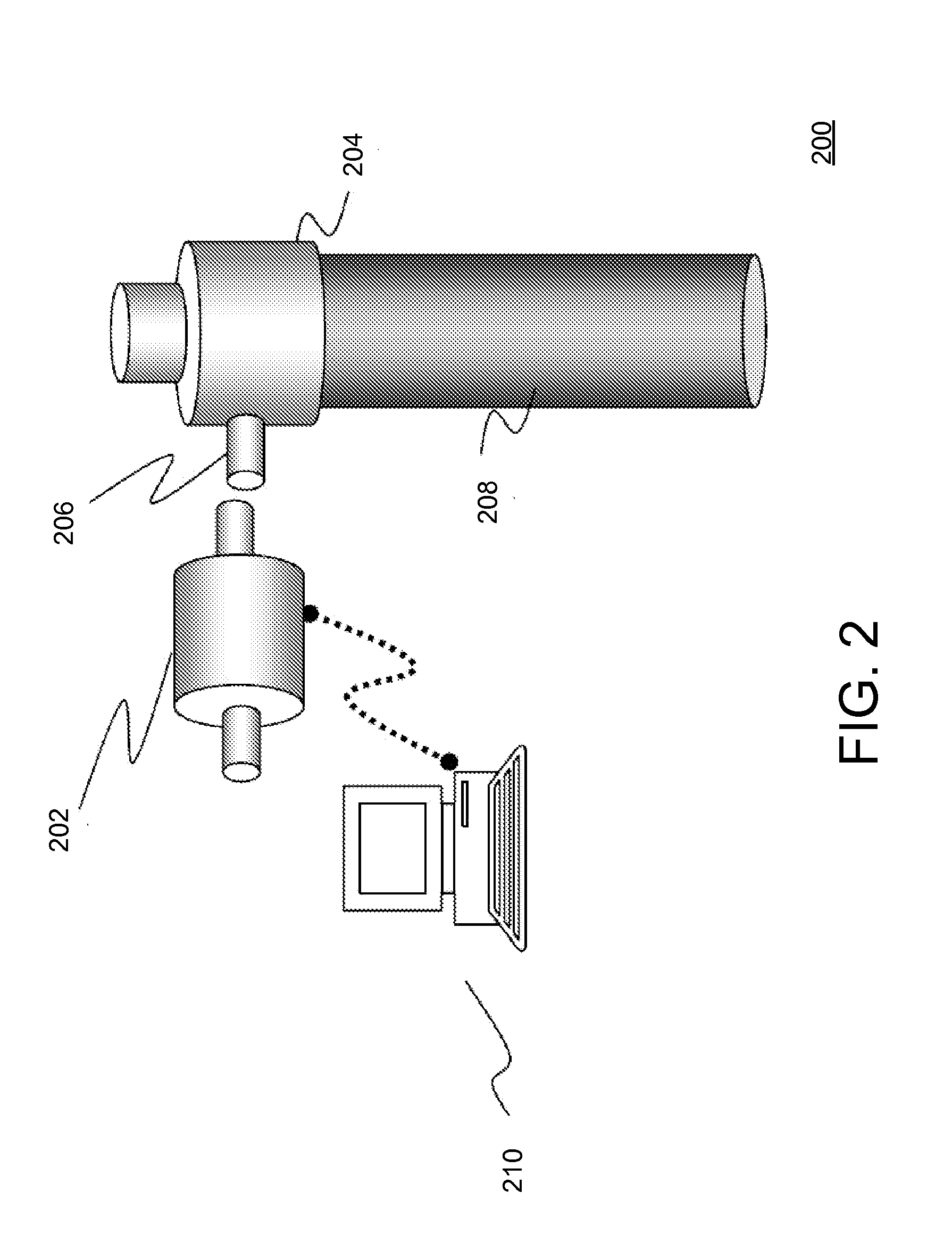

In-line composition and volumetric analysis of vent gases and flooding of the annular space of flexible pipe

InactiveUS20110153225A1High frequencyReduce in quantityPlug gaugesDrilling rodsExhaust valveVolume analysis

A method and system for monitoring a flexible pipe, including an inline sensor system coupled to the annulus of the flexible pipe to detect corrosion of the flexible pipe. Also disclosed are method and system for monitoring an amount of water being accumulated in an annulus of a flexible pipe, including locating a pressure measurement system proximate to the annulus for measuring pressure of gas inside the annulus; controlling a flow of vent gas with a vent gas valve; positioning a flow measurement system upstream or downstream of the vent gas valve for measuring the flow of the vent gas when the vent gas valve is opened; and collecting with a microprocessor pressure and flow measurement data from the pressure and the flow measurement systems for determining the amount of water accumulated in the annulus based on the collected pressure and flow measurement data.

Owner:SCHLUMBERGER TECH CORP

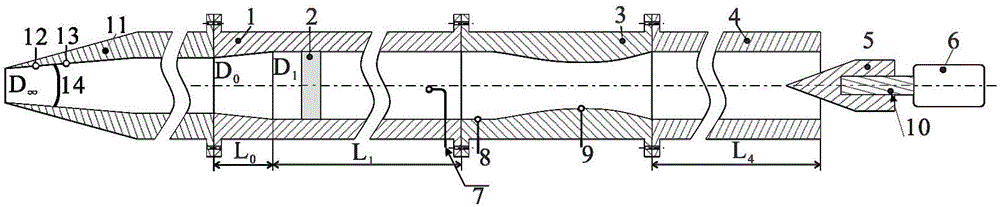

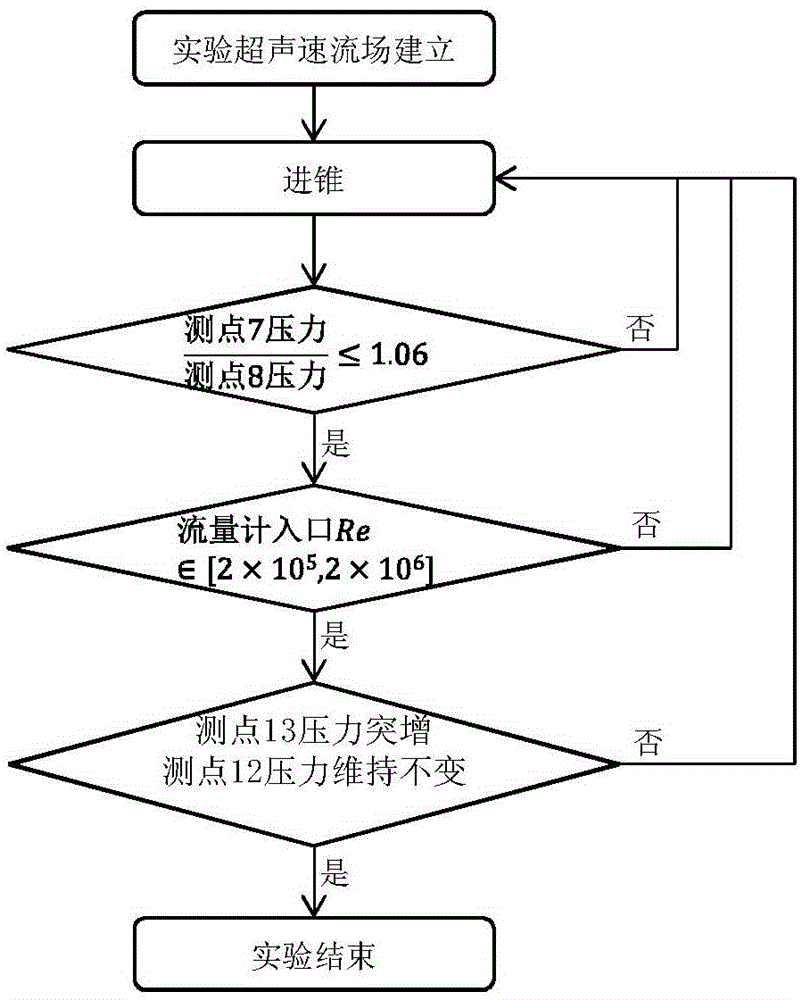

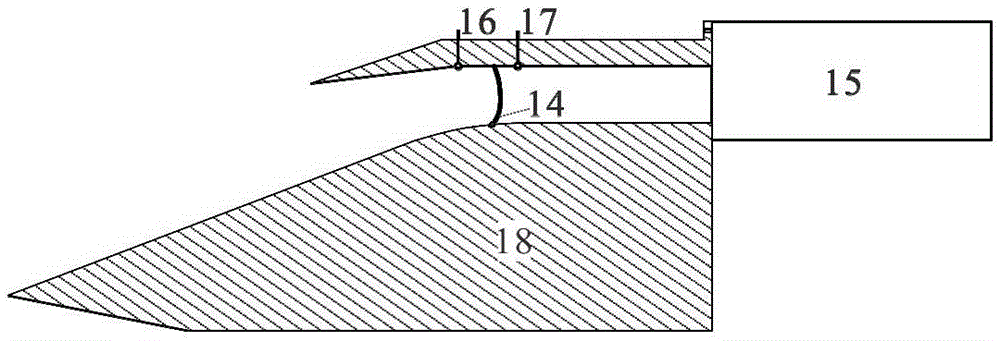

Flow test system suitable for supersonic/hypersonic channel and test method

ActiveCN105157948AGuaranteed response speedQuick responseAerodynamic testingVolume/mass flow by differential pressureShock waveEngineering

The invention discloses a flow test system suitable for supersonic / hypersonic channel, which mainly comprises a Venturi tube, a throttling module and a rectification module. By adjusting the outlet area of the throttling module, a shock wave structure inside the pipeline is formed; the shock wave and the designed diffuser are used to decelerate the supersonic / hypersonicin flow fully to a subsonic speed so as to satisfy the requirement of the Venturi tube to the inlet speed and Reynolds number. The system has the advantages of simple structure, small size, rapid response speed and high measurement precision; the throttling module adjusts the throttling degree according to pipe flow speed; the suitable Mach number scope is side; the demanded pressure measuring points are few; additional obstruction to the experiment channel is avoided compared to traditional flow test methods like * shaped rake; the throttling characteristic experiment of an air intake duct can be carried out at the same time; test cost is greatly saved; air-flow non-uniformity inside the channel is not sensitive; the system is particularly suitable for measuring flow of complex inner flow apparatuses like air intake ducts and diffusers whose inflow are supersonic / hypersonic.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com