Flow test system suitable for supersonic/hypersonic channel and test method

A flow test and hypersonic technology, which is applied in the testing of machines/structural components, volume/mass flow generated by mechanical effects, and detection of fluid flow by measuring differential pressure, can solve problems such as blockage of supersonic flow channels, and achieve pressure measurement Fewer points, wide Mach number range, and improved measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

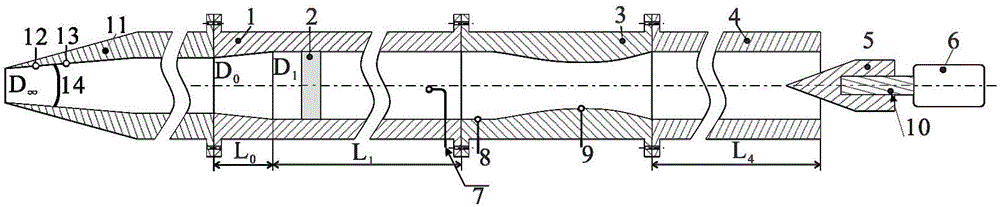

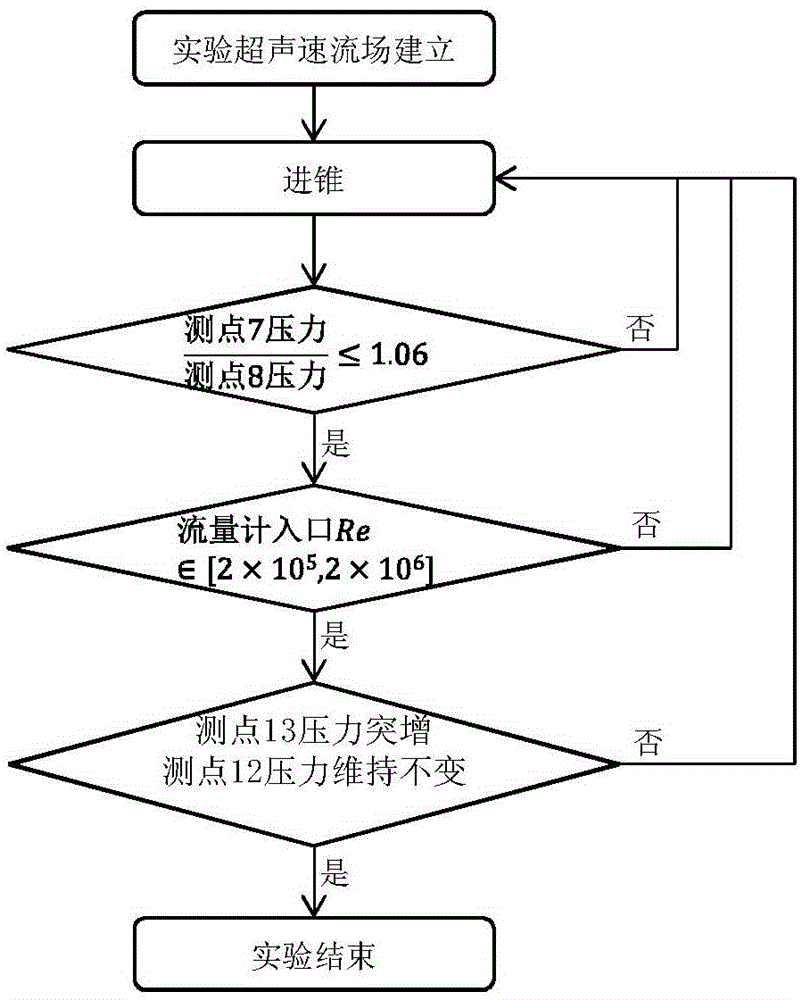

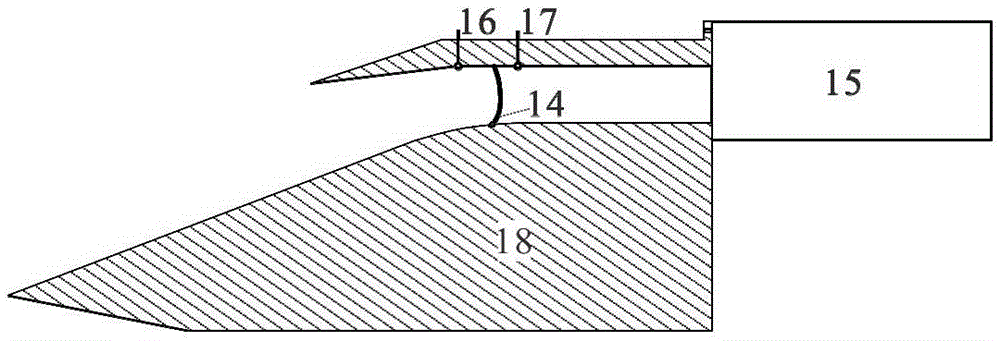

[0019] See figure 1 The invention discloses a flow measurement system suitable for supersonic / hypersonic flow channel. It is composed of Venturi flowmeter, throttling module and rectifier module. The Venturi flowmeter (3) is a standard part produced and calibrated according to the national standard GB / T2624-2006; the throttle module is composed of a plugging cone (5) and a linear stepping motor (6) The rectifier module is composed of the front rectifier section (1) and the rear equal straight rectifier section (4); the entire flow test system, in accordance with the front rectifier section (1), Venturi flowmeter (3), rear rectifier section (4) ), the throttling module is connected through the flange in turn, and is connected to the experimental model through the front rectification section (1); the front rectification section is composed of a diffuser and an equal straight pipeline, and a rectifier ( 2) To further break up the large-scale vortex formed by the upstream shock wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com